Mitsubishi Electric MELSERVO-J3W, MR-J3W-0303BN6, MR-J3W-1010B, MR-J3W-22B, MR-J3W-44B Instruction Manual

...

General-Purpose AC Servo

J3W Series

SSCNET interface 2-axis AC Servo Amplifier

MODEL

MR-J3W-0303BN6

MR-J3W- B

SERVO AMPLIFIER

INSTRUCTION MANUAL

The following servo motors will be available in the future. All specifications

of followings may be changed without notice.

HG-AK0136B

HG-AK0236B

HG-AK0336B

For situations of conformity with UL/CSA standard of the MR-J3W-0303BN6

servo amplifier, contact your local sales office.

C

Safety Instructions

Always read these instructions before using the equipment.

Do not attempt to install, operate, maintain or inspect the servo amplifier and servo motor until you have read

through this Instruction Manual, Installation guide, Servo motor Instruction Manual (Vol.2) and appended

documents carefully and can use the equipment correctly. Do not use the servo amplifier and servo motor until

you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

: Indicates what must not be done. For example, "No Fire" is indicated by

: Indicates what must be done. For example, grounding is indicated by

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so on

are classified into "POINT".

After reading this Instruction Manual, always keep it accessible to the operator.

.

.

A - 1

1. To prevent electric shock, note the following

WARNING

Before wiring or inspection, turn off the power and wait for 15 minutes or more until the charge lamp turns

off. Otherwise, an electric shock may occur. In addition, always confirm from the front of the servo amplifier,

whether the charge lamp is off or not.

Connect the servo amplifier and servo motor to ground.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, you

may get an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, you may get an electric

shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (terminal marked ) of the

servo amplifier with the protective earth (PE) of the control box.

When using an earth-leakage current breaker (RCD), select the type B.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor and regenerative resistor on incombustible material. Installing them

directly or close to combustibles will lead to a fire.

Always connect a magnetic contactor between the power supply and the main circuit power supply (L1, L2,

and L3) of the servo amplifier, in order to configure a circuit that shuts down the power supply on the side of

the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a large

current may cause a fire when the servo amplifier malfunctions.

Always connect a circuit protector between the power supply and power supply voltage input terminals (24,

0, and M) of the servo amplifier, in order to configure a circuit that shuts down the power supply on the side

of the servo amplifier's power supply. If a circuit protector is not connected, continuous flow of a large

current may cause a fire when the servo amplifier malfunctions.

When a regenerative resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative transistor fault or the like may overheat the regenerative resistor, causing a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

Always connect a molded-case circuit breaker to the power supply of the servo amplifier.

A - 2

3. To prevent injury, note the following

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal, Otherwise, a burst,

damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

Take safety measures, e.g. provide covers, to prevent accidental contact of hands and parts (cables, etc.)

with the servo amplifier heat sink, regenerative resistor, servo motor, etc. since they may be hot while

power is on or for some time after power-off. Their temperatures may be high and you may get burnt or a

parts may damaged.

During operation, never touch the rotating parts of the servo motor. Doing so can cause injury.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric shock,

etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of products is not allowed.

Do not carry the servo motor by the cables, shaft or encoder.

Install the servo amplifier in a load-bearing place in accordance with the Instruction Manual.

Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

The servo amplifier and servo motor must be installed in the specified direction.

Leave specified clearances between the servo amplifier and control enclosure walls or other equipment.

Do not install or operate the servo amplifier and servo motor which has been damaged or has any parts

missing.

Do not block the intake and exhaust areas of the servo amplifier. Doing so may cause faults.

Do not drop or strike servo amplifier or servo motor. Isolate from all impact loads.

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The geared servo motor must be installed in the specified direction to prevent oil leakage.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotating parts of the servo

motor during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When the equipment has been stored for an extended period of time, contact your local sales office.

When treating the servo amplifier be careful about the edged parts such as the corners of the servo

amplifier.

The servo amplifier must be installed in the metal cabinet.

A - 3

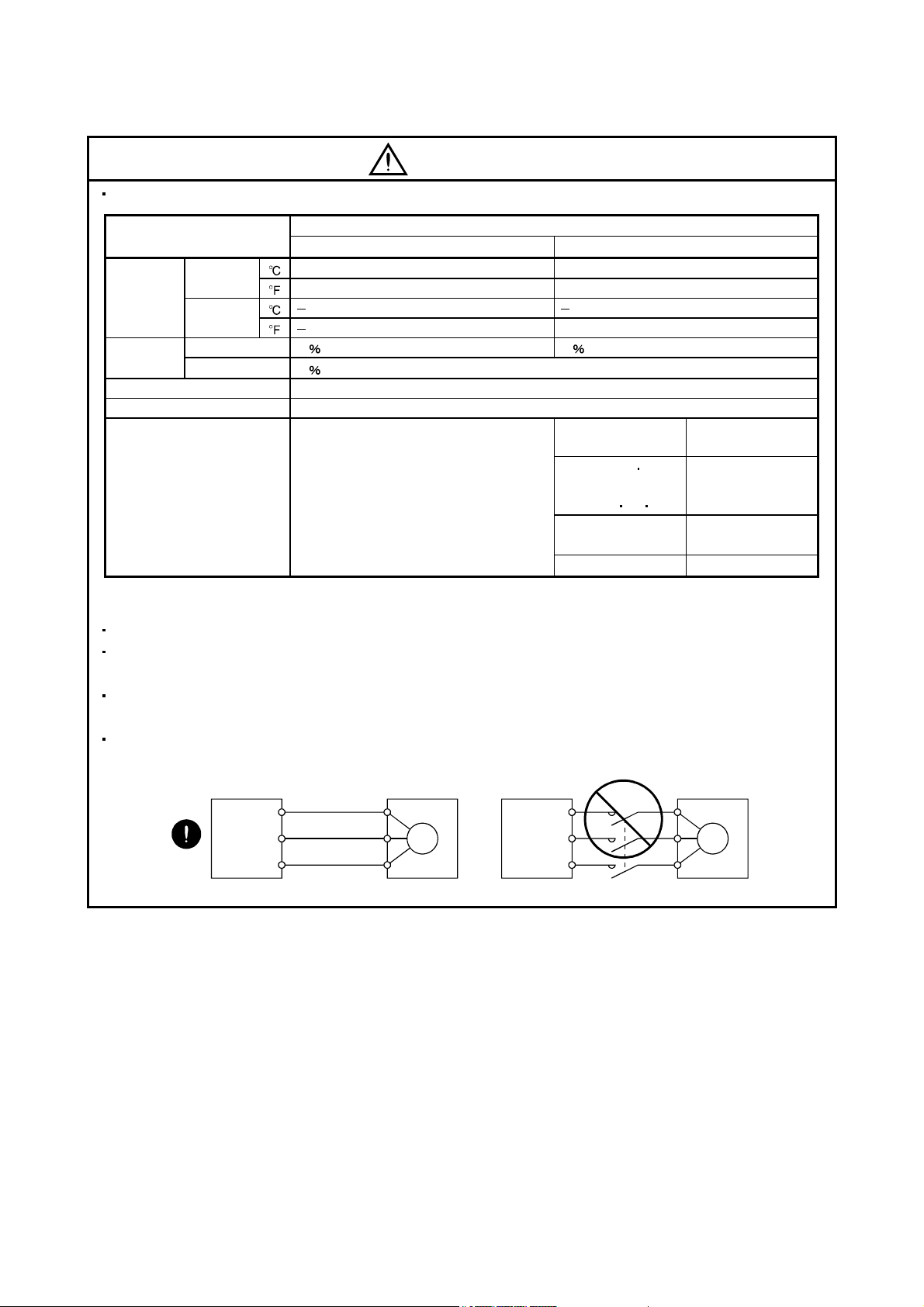

CAUTION

When you keep or use it, please fulfill the following environmental conditions.

Ambient

temperature

Ambient

humidity

Ambience Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m above sea level

(Note)

Vibration resistance

Note. Except the servo motor with a reduction gear.

Item

Operation

Storage

Operation 90 RH or less (non-condensing) 80 RH or less (non-condensing)

Storage 90

[ ] 0 to 55 (non-freezing) 0 to 40 (non-freezing)

[

] 32 to 131 (non-freezing) 32 to 104 (non-freezing)

[ ] 20 to 65 (non-freezing) 15 to 70 (non-freezing)

[

] 4 to 149 (non-freezing) 5 to 158 (non-freezing)

RH or less (non-condensing)

2

5.9 m/s

(directions of X, Y and Z axes)

Servo amplifier Servo motor

at 10 to 55Hz

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Do not install a power capacitor, surge killer or radio noise filter (FR-BIF option) between the servo motor

and servo amplifier.

Connect the wires to the correct phase terminals (U, V, W) of the servo amplifier and servo motor.

Not doing so may cause unexpected operation.

Connect the servo amplifier power output (U, V, and W) to the servo motor power input (U, V, and W)

directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Environment

HF-MP series

HF-KP series

HF-SP51 52

HC-UP72

HF-JP53

73 103

HC-LP52

HG-AK series X, Y: 49 m/s

X, Y: 49 m/s

X, Y: 24.5 m/s

X: 9.8 m/s

Y: 24.5 m/s

2

2

2

2

2

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

M

W

A - 4

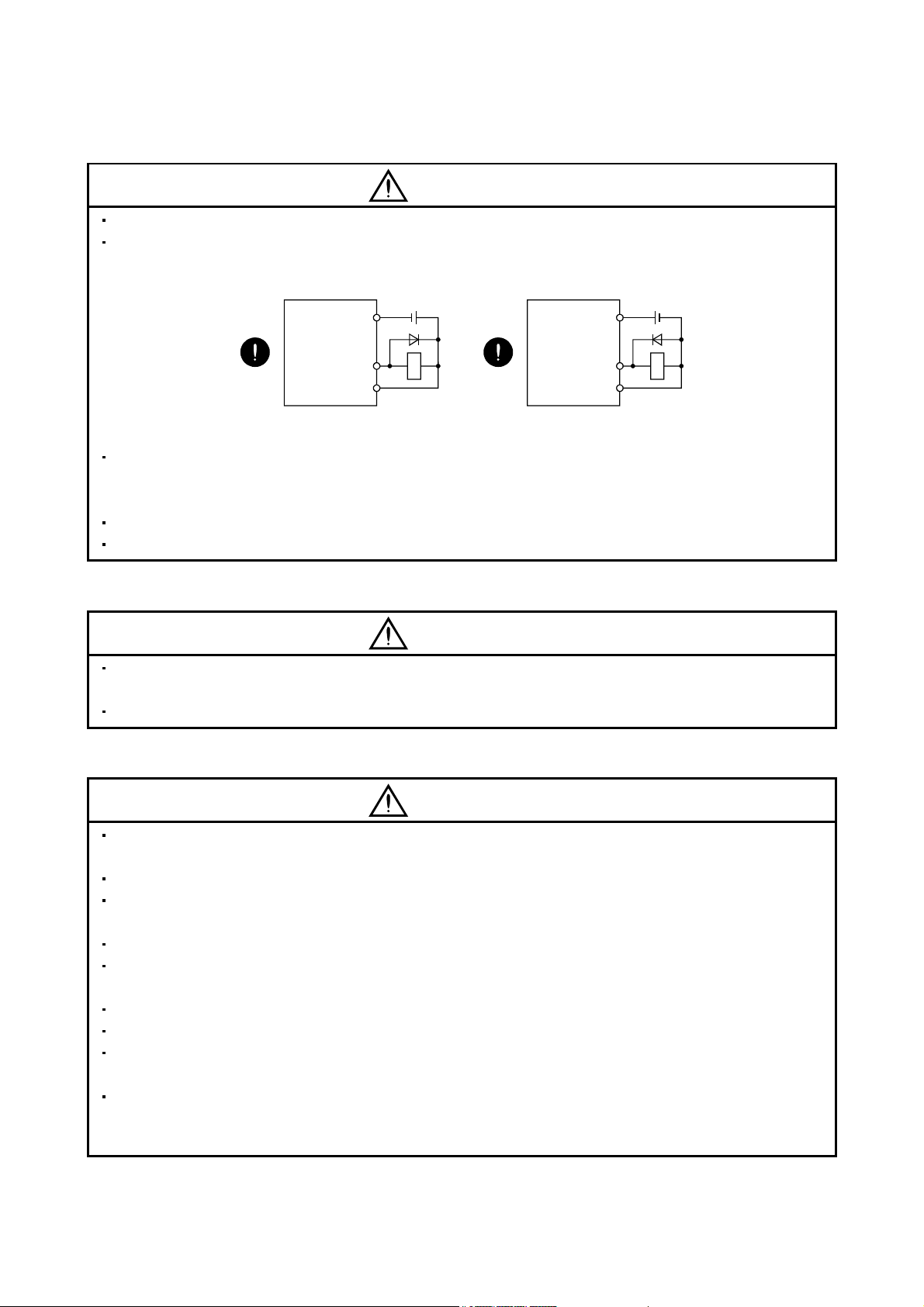

(2) Wiring

CAUTION

Do not connect AC power directly to the servo motor. Otherwise, a fault may occur.

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Servo amplifier

24VDC

DOCOM

Servo amplifier

24VDC

DOCOM

Control output

signal

DICOM

For the sink output interface

RA

Control output

signal

DICOM

For the source output interface

RA

When the cable is not tightened enough to the terminal block (connector), the cable or terminal block

(connector) may generate heat because of the poor contact. Be sure to tighten the cable with specified

torque.

Connecting an encoder for different axis to the CN2A or CN2B connector may cause a malfunction.

Connecting a servo motor for different axis to the CNP3A or CNP3B connector may cause a malfunction.

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

Never adjust or change the parameter values extremely as it will make operation instable.

(4) Usage

CAUTION

Provide an external emergency stop circuit to ensure that operation can be stopped and power switched off

immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off to prevent an accident.

A sudden restart is made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise filter, etc. to minimize the influence of electromagnetic interference, which may be caused by

electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break a servo amplifier.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be used

for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor are

coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety, install

a stopper on the machine side.

A - 5

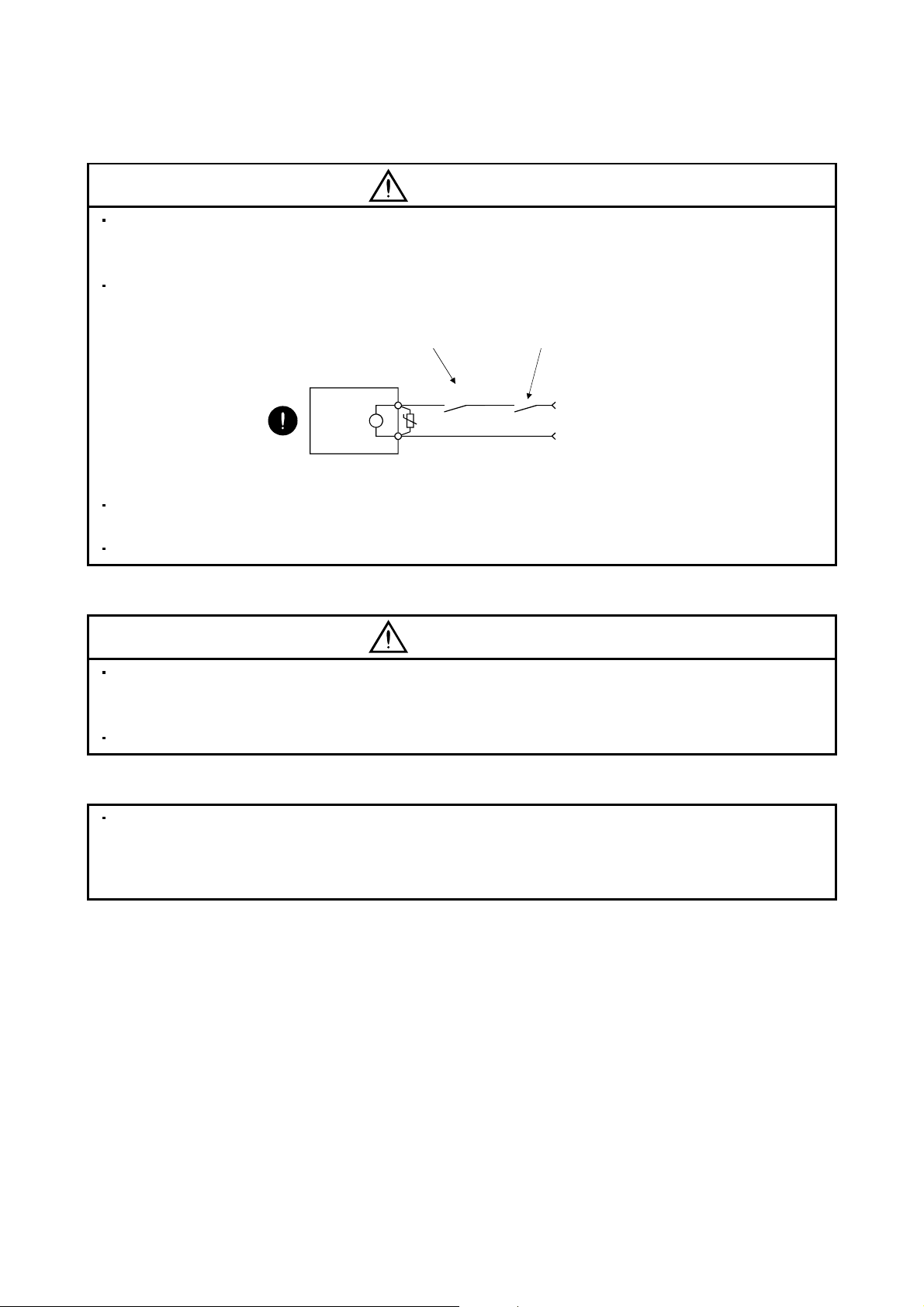

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may take place at the occur due to a power failure or a

product fault, use a servo motor with an electromagnetic brake or an external brake mechanism for the

purpose of prevention.

Configure a electromagnetic brake circuit so that it is activated also by an external emergency stop switch.

Contacts must be opened when a

malfunction (ALM-A/ALM-B) and when an

electromagnetic brake interlock (MBR-A/

MBR-B).

Servo motor

RA

Contacts must be opened with

the emergency stop switch.

B

U

Electromagnetic brake

24VDC

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor of the servo amplifier will deteriorate. To prevent a secondary accident

due to a fault, it is recommended to replace the electrolytic capacitor every 10 years when used in general

environment.

Please contact your local sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Specifications and Instruction Manual may have

been drawn without covers and safety guards. When the equipment is operated, the covers and safety

guards must be installed as specified. Operation must be performed in accordance with this Specifications

and Instruction Manual.

A - 6

DISPOSAL OF WASTE

Please dispose a converter unit, servo amplifier (drive unit), battery (primary battery) and other options according

to your local laws and regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the

total number of the following operations exceeds 100,000, the servo amplifier may fail when the EEP-ROM

reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

Precautions for Choosing the Products

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of Mitsubishi; machine

damage or lost profits caused by faults in the Mitsubishi products; damage, secondary damage, accident

compensation caused by special factors unpredictable by Mitsubishi; damages to products other than

Mitsubishi products; and to other duties.

A - 7

COMPLIANCE WITH CE MARKING

Refer to Appendix 3 for the compliance with CE marking.

COMPLIANCE WITH UL/CSA STANDARD

Refer to Appendix 4 for the compliance with UL/CSA standard.

<<About the manuals>>

This Instruction Manual and the following Servo Amplifier/Servo Motor Instruction Manuals (Vol.2) are

required if you use the General-Purpose AC servo MR-J3Wuse the MR-J3WRefer to chapter 15 for using MR-J3W-0303BN6.

Relevant manuals

MELSERVO-J3W Series Instructions and Cautions for Safe Use of AC Servos IB(NA)0300148

MELSERVO Servo Motor Instruction Manual (Vol.2)(Note 1) SH(NA)030041

EMC Installation Guidelines IB(NA)67310

SSCNET III Interface Linear Servo MR-J3- B-RJ004 INSTRUCTION MANUAL (Note 2) SH(NA)030054

SSCNET III Interface Direct drive servo MR-J3- B-RJ004 INSTRUCTION MANUAL (Note 3) In production

Note 1. Required to use the rotary servo motor.

2. Required to use the linear servo motor.

3. Required to use the direct drive motor.

<<Wiring>>

B safely.

Manual name Manual No.

B for the first time. Always purchase them and

Wires mentioned in this instruction manual are selected based on the ambient temperature of 40

A - 8

(104 ).

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1 - 1 to 1 - 10

1.1 Summary .................................................................................................................................................. 1 - 1

1.2 Function block diagram............................................................................................................................ 1 - 2

1.3 Servo amplifier standard specifications................................................................................................... 1 - 3

1.4 Function list .............................................................................................................................................. 1 - 5

1.5 Model code definition ............................................................................................................................... 1 - 6

1.6 Combination with servo motor .................................................................................................................1 - 7

1.7 Parts identification.................................................................................................................................... 1 - 8

1.8 Configuration including auxiliary equipment ........................................................................................... 1 - 9

2. INSTALLATION 2 - 1 to 2 - 6

2.1 Installation direction and clearances .......................................................................................................2 - 1

2.2 Keep out foreign materials ....................................................................................................................... 2 - 3

2.3 Cable stress ............................................................................................................................................. 2 - 3

2.4 SSCNET

2.5 Inspection items .......................................................................................................................................2 - 5

2.6 Parts having service lives ........................................................................................................................ 2 - 6

cable laying........................................................................................................................... 2 - 3

3. SIGNALS AND WIRING 3 - 1 to 3 -40

3.1 Input power supply circuit ........................................................................................................................ 3 - 2

3.2 I/O signal connection example ................................................................................................................ 3 - 4

3.3 Explanation of power supply system ....................................................................................................... 3 - 6

3.3.1 Signal explanations ........................................................................................................................... 3 - 6

3.3.2 Power-on sequence ..........................................................................................................................3 - 8

3.3.3 CNP1, CNP2, CNP3A, CNP3B wiring method ................................................................................ 3 - 9

3.4 Connectors and signal arrangements ....................................................................................................3 -12

3.5 Signal (device) explanations................................................................................................................... 3 -13

3.6 Alarm occurrence timing chart................................................................................................................ 3 -17

3.6.1 Timing chart...................................................................................................................................... 3 -17

3.6.2 Supplementary information.............................................................................................................. 3 -18

3.7 Interfaces ................................................................................................................................................. 3 -19

3.7.1 Internal connection diagram ............................................................................................................ 3 -19

3.7.2 Detailed description of interfaces..................................................................................................... 3 -20

3.7.3 Source I/O interfaces ....................................................................................................................... 3 -22

3.8 Treatment of cable shield external conductor ........................................................................................3 -23

3.9 SSCNET

3.10 Connection of servo amplifier and servo motor ................................................................................... 3 -26

3.10.1 Connection instructions.................................................................................................................. 3 -26

3.10.2 Power supply cable wiring diagrams ............................................................................................. 3 -27

3.11 Servo motor with an electromagnetic brake......................................................................................... 3 -31

3.11.1 Safety precautions ......................................................................................................................... 3 -31

3.11.2 Timing charts.................................................................................................................................. 3 -33

3.11.3 Wiring diagrams (HF-MP series

3.12 Grounding.............................................................................................................................................. 3 -38

cable connection .................................................................................................................3 -24

HF-KP series servo motor)..................................................... 3 -36

1

3.13 Control axis selection............................................................................................................................ 3 -39

3.14 Servo motor selection switch (SW3) .................................................................................................... 3 -40

4. STARTUP 4 - 1 to 4 -14

4.1 Switching power on for the first time ....................................................................................................... 4 - 2

4.1.1 Startup procedure.............................................................................................................................. 4 - 2

4.1.2 Wiring check ......................................................................................................................................4 - 3

4.1.3 Surrounding environment.................................................................................................................. 4 - 4

4.2 Startup ...................................................................................................................................................... 4 - 4

4.3 Servo amplifier display............................................................................................................................. 4 - 6

4.3.1 Scrolling display................................................................................................................................. 4 - 6

4.3.2 Status display of an axis ................................................................................................................... 4 - 7

4.4 Test operation ..........................................................................................................................................4 - 9

4.5 Test operation mode ............................................................................................................................... 4 -10

4.5.1 Test operation mode in MR Configurator ........................................................................................ 4 -10

4.5.2 Motor-less operation in controller .................................................................................................... 4 -12

5. PARAMETERS 5 - 1 to 5 -30

5.1 Basic setting parameters (No.PA ) ................................................................................................... 5 - 1

5.1.1 Parameter list ....................................................................................................................................5 - 2

5.1.2 Parameter write inhibit ......................................................................................................................5 - 3

5.1.3 Selection of control mode ................................................................................................................. 5 - 4

5.1.4 Selection of regenerative option .......................................................................................................5 - 4

5.1.5 Using absolute position detection system ........................................................................................5 - 5

5.1.6 Forced stop input selection ............................................................................................................... 5 - 5

5.1.7 Auto tuning ........................................................................................................................................ 5 - 6

5.1.8 In-position range................................................................................................................................ 5 - 7

5.1.9 Selection of servo motor rotation direction ....................................................................................... 5 - 8

5.1.10 Encoder output pulse ......................................................................................................................5 - 8

5.2 Gain/filter parameters (No.PB

5.2.1 Parameter list ...................................................................................................................................5 -10

5.2.2 List of details..................................................................................................................................... 5 -11

5.3 Extension setting parameters (No.PC

5.3.1 Parameter list ...................................................................................................................................5 -17

5.3.2 List of details..................................................................................................................................... 5 -18

5.3.3 Analog monitor .................................................................................................................................5 -21

5.3.4 Alarm history clear............................................................................................................................ 5 -23

5.4 I/O setting parameters (No.PD

5.4.1 Parameter list ...................................................................................................................................5 -24

5.4.2 List of details..................................................................................................................................... 5 -25

5.5 Option setting parameters (No.Po

5.5.1 List of parameters............................................................................................................................. 5 -27

5.5.2 List of details.....................................................................................................................................5 -28

)........................................................................................................ 5 -10

) ...........................................................................................5 -17

) ......................................................................................................5 -24

) .................................................................................................5 -27

6. GENERAL GAIN ADJUSTMENT 6 - 1 to 6 -12

6.1 Different adjustment methods.................................................................................................................. 6 - 1

6.1.1 Adjustment on a single servo amplifier............................................................................................. 6 - 1

2

6.1.2 Adjustment using MR Configurator................................................................................................... 6 - 2

6.2 Auto tuning ............................................................................................................................................... 6 - 3

6.2.1 Auto tuning mode .............................................................................................................................. 6 - 3

6.2.2 Auto tuning mode basis .................................................................................................................... 6 - 4

6.2.3 Adjustment procedure by auto tuning............................................................................................... 6 - 5

6.2.4 Response level setting in auto tuning mode ....................................................................................6 - 6

6.3 Manual mode 1 (simple manual adjustment).......................................................................................... 6 - 7

6.4 Interpolation mode ..................................................................................................................................6 -11

7. SPECIAL ADJUSTMENT FUNCTIONS 7 - 1 to 7 -10

7.1 Function block diagram............................................................................................................................ 7 - 1

7.2 Machine resonance suppression filter..................................................................................................... 7 - 1

7.3 Vibration suppression control manual mode........................................................................................... 7 - 3

7.4 Low-pass filter .......................................................................................................................................... 7 - 5

7.5 Gain changing function ............................................................................................................................7 - 5

7.5.1 Applications .......................................................................................................................................7 - 5

7.5.2 Function block diagram .....................................................................................................................7 - 6

7.5.3 Parameters ........................................................................................................................................ 7 - 7

7.5.4 Gain changing procedure.................................................................................................................. 7 - 9

8. TROUBLESHOOTING 8 - 1 to 8 -34

8.1 Alarms and warning list............................................................................................................................ 8 - 1

8.2 Troubleshooting at power on ................................................................................................................... 8 - 3

8.3 Remedies for alarms................................................................................................................................ 8 - 4

8.4 Remedies for warnings ........................................................................................................................... 8 -29

9. OUTLINE DRAWINGS 9 - 1 to 9 - 4

9.1 Servo amplifier .........................................................................................................................................9 - 1

9.2 Connector ................................................................................................................................................. 9 - 3

10. CHARACTERISTICS 10- 1 to 10- 8

10.1 Overload protection characteristics ...................................................................................................... 10- 1

10.2 Power supply equipment capacity and generated loss .......................................................................10- 2

10.3 Dynamic brake characteristics.............................................................................................................. 10- 4

10.3.1 Dynamic brake operation............................................................................................................... 10- 4

10.3.2 The dynamic brake at the load inertia moment............................................................................. 10- 6

10.4 Cable bending life .................................................................................................................................10- 6

10.5 Inrush currents at power-on of main circuit and control circuit ............................................................10- 7

11. OPTIONS AND AUXILIARY EQUIPMENT 11- 1 to 11-56

11.1 Cable/connector sets ............................................................................................................................ 11- 1

11.1.1 Combinations of cable/connector sets ..........................................................................................11- 1

11.1.2 Encoder cable/connector sets .......................................................................................................11- 9

11.1.3 Motor power supply cables ...........................................................................................................11-20

11.1.4 Motor brake cables........................................................................................................................11-21

3

11.1.5 SSCNET

11.1.6 Battery cable..................................................................................................................................11-24

11.2 Regenerative options ...........................................................................................................................11-25

11.3 MR-BTCASE battery case and MR-BAT battery ................................................................................ 11-30

11.4 MR Configurator ...................................................................................................................................11-31

11.5 Selection example of wires ..................................................................................................................11-36

11.6 No-fuse breakers, fuses, magnetic contactors ...................................................................................11-40

11.7 Power factor improving AC reactors ................................................................................................... 11-41

11.8 Relays (recommended) .......................................................................................................................11-42

11.9 Noise reduction techniques ................................................................................................................. 11-42

11.10 Earth-leakage current breaker...........................................................................................................11-49

11.11 EMC filter (recommended) ................................................................................................................11-52

11.12 Junction terminal block MR-TB26A................................................................................................... 11-54

11.13 Surge absorbers (recommended) .....................................................................................................11-55

12. ABSOLUTE POSITION DETECTION SYSTEM 12- 1 to 12- 8

12.1 Features ............................................................................................................................................... 12-.1

12.2 Specifications ........................................................................................................................................ 12- 2

12.3 Assembling a battery unit ..................................................................................................................... 12- 5

12.3.1 Required items ...............................................................................................................................12- 5

12.3.2 Disassembly and assembly of the battery case MR-BTCASE..................................................... 12- 5

12.3.3 Battery transportation..................................................................................................................... 12- 7

12.4 Confirmation of absolute position detection data................................................................................. 12- 8

cable ..........................................................................................................................11-22

13. USING A LINEAR SERVO MOTOR 13- 1 to 13-84

13.1 Functions and configuration ................................................................................................................. 13- 1

13.1.1 Summary ........................................................................................................................................ 13- 1

13.1.2 Combinations of Servo Amplifiers and Linear Servo Motors........................................................ 13- 2

13.1.3 Configuration including auxiliary equipment.................................................................................. 13- 4

13.2 Connection of servo amplifier and linear servo motor .........................................................................13- 5

13.2.1 Connection instructions.................................................................................................................. 13- 5

13.2.2 Power supply cable wiring diagrams............................................................................................. 13- 6

13.3 Linear encoder ......................................................................................................................................13- 7

13.3.1 Compatible linear encoder list ....................................................................................................... 13- 7

13.3.2 Linear encoder and branch cable .................................................................................................. 13- 8

13.4 Signals and wiring ................................................................................................................................. 13- 9

13.4.1 Precautions on this chapter ..........................................................................................................13-10

13.4.2 Power supply system circuit connection example ....................................................................... 13-10

13.4.3 Internal connection diagram .........................................................................................................13-13

13.5 Operation and functions....................................................................................................................... 13-14

13.5.1 Startup ...........................................................................................................................................13-14

13.5.2 Magnetic pole detection ................................................................................................................ 13-17

13.5.3 Home position return.....................................................................................................................13-26

13.5.4 Test operation mode in MR Configurator .....................................................................................13-29

13.5.5 Operation from the controller ........................................................................................................13-30

13.5.6 Functions .......................................................................................................................................13-33

13.5.7 Absolute position detection system ..............................................................................................13-35

13.6 Parameters ........................................................................................................................................... 13-36

4

13.6.1 Parameter write inhibit (Parameter No.PA19).............................................................................. 13-37

13.6.2 Basic setting parameters (No.PA

13.6.3 Gain/Filter parameters (No.PB

13.6.4 Extension setting parameters (No.PC

13.6.5 I/O setting parameters (No.PD

13.6.6 Special setting parameters (No.PS

13.6.7 Option setting parameter .............................................................................................................. 13-57

13.7 Troubleshooting ...................................................................................................................................13-58

13.7.1 Alarms and warning list................................................................................................................. 13-58

13.7.2 Remedies for alarms ..................................................................................................................... 13-60

13.7.3 Remedies for warnings .................................................................................................................13-80

13.7.4 Detailed explanation of linear encoder error 1 (2A.

14. USING A DIRECT DRIVE MOTOR 14- 1 to 14-72

14.1 Functions and configuration ................................................................................................................. 14- 1

14.1.1 Summary ........................................................................................................................................ 14- 1

14.1.2 Combinations of servo amplifier and direct drive motor ............................................................... 14- 2

14.1.3 Configuration including peripheral equipment............................................................................... 14- 3

14.2 Connection of servo amplifier and direct drive motor ..........................................................................14- 4

14.3 Signals and wiring ................................................................................................................................. 14- 5

14.3.1 Notes of this chapter ......................................................................................................................14- 6

14.3.2 Input power supply circuit .............................................................................................................. 14- 7

14.3.3 Internal connection diagram ......................................................................................................... 14-10

14.4 Operation and functions....................................................................................................................... 14-11

14.4.1 Startup procedure ......................................................................................................................... 14-12

14.4.2 Magnetic pole detection ................................................................................................................14-13

14.4.3 Operation from controller .............................................................................................................. 14-20

14.4.4 Function ......................................................................................................................................... 14-25

14.5 Parameters ........................................................................................................................................... 14-27

14.5.1 Parameter writing inhibit (parameter No.PA19) ...........................................................................14-28

14.5.2 Basic setting parameters (No.PA

14.5.3 Gain/filter parameters (No.PB ).............................................................................................. 14-32

14.5.4 Extension setting parameters (No.PC

14.5.5 I/O setting parameters (No.PD

14.5.6 Special setting parameters (No.PS )...................................................................................... 14-36

14.5.7 Option setting parameters (No.Po

14.6 Troubleshooting ...................................................................................................................................14-41

14.6.1 Alarm and warning list................................................................................................................... 14-41

14.6.2 Remedies for alarms ..................................................................................................................... 14-43

14.6.3 Remedies for warnings .................................................................................................................14-56

14.7 Characteristics .....................................................................................................................................14-61

14.7.1 Overload protection characteristics ..............................................................................................14-61

14.7.2 Dynamic brake characteristics...................................................................................................... 14-62

14.8 Options for direct drive motor ..............................................................................................................14-64

14.8.1 Cable/connector sets ....................................................................................................................14-64

14.8.2 Absolute position storage unit MR-BTAS01................................................................................. 14-71

)......................................................................................... 13-38

)............................................................................................. 13-42

) ................................................................................. 13-45

)............................................................................................. 13-51

)...................................................................................... 13-52

) ................................................................13-84

)......................................................................................... 14-29

) ................................................................................. 14-34

)............................................................................................. 14-35

) ....................................................................................... 14-40

5

15. MR-J3W-0303BN6 SERVO AMPLIFIER 15- 1 to 15-72

15.1 Functions and configuration ................................................................................................................. 15- 1

15.1.1 Function block diagram ..................................................................................................................15- 2

15.1.2 Servo amplifier standard specifications ......................................................................................... 15- 3

15.1.3 Model designation .......................................................................................................................... 15- 5

15.1.4 Combination with servo motor ....................................................................................................... 15- 5

15.1.5 Parts identification ..........................................................................................................................15- 6

15.1.6 Configuration including peripheral equipment............................................................................... 15- 7

15.2 Installation (direction and clearances).................................................................................................. 15- 8

15.3 Signals and wiring ................................................................................................................................ 15-10

15.3.1 Input power supply circuit .............................................................................................................15-11

15.3.2 I/O signal connection example...................................................................................................... 15-13

15.3.3 Explanation of power supply system ............................................................................................ 15-15

15.3.4 Connectors and pin assignment ................................................................................................... 15-19

15.3.5 Alarm occurrence timing chart ......................................................................................................15-20

15.3.6 Connection of servo amplifier and HG-AK series servo motor.................................................... 15-23

15.3.7 Servo motor with an electromagnetic brake................................................................................. 15-26

15.3.8 Grounding...................................................................................................................................... 15-31

15.4 Startup .................................................................................................................................................. 15-32

15.4.1 Startup procedure ......................................................................................................................... 15-33

15.4.2 Troubleshooting during "24V ERROR" lamp on. .........................................................................15-33

15.4.3 Wiring check ..................................................................................................................................15-34

15.4.4 Surrounding environment .............................................................................................................15-35

15.5 Parameters ........................................................................................................................................... 15-36

15.5.1 Basic setting parameters (No.PA

15.5.2 Extension setting parameters (No.PC

15.5.3 Manufacturer setting parameters (No.PE

15.5.4 Other function parameters (No.PF

15.5.5 Option setting parameters (No.Po

15.6 Troubleshooting ...................................................................................................................................15-44

15.7 Dimensions...........................................................................................................................................15-52

15.8 Characteristics .....................................................................................................................................15-53

15.8.1 Overload protection characteristics ..............................................................................................15-53

15.8.2 Power supply capacity and generated loss.................................................................................. 15-54

15.8.3 Dynamic brake characteristics...................................................................................................... 15-54

15.8.4 Inrush currents at power-on of main circuit and control circuit ....................................................15-56

15.9 Options and peripheral equipment ...................................................................................................... 15-57

15.9.1 Cable/connector sets .................................................................................................................... 15-57

15.9.2 Selection example of wires ........................................................................................................... 15-64

15.9.3 Circuit protector ............................................................................................................................. 15-65

15.10 Absolute position detection system ...................................................................................................15-66

15.10.1 Features ...................................................................................................................................... 15-66

15.10.2 Specifications ..............................................................................................................................15-67

15.10.3 Battery replacement procedure ..................................................................................................15-69

15.10.4 Battery mounting/removing procedure .......................................................................................15-70

15.10.5 Procedure to replace battery with the control circuit power off.................................................. 15-71

)......................................................................................... 15-36

) ................................................................................. 15-38

)............................................................................ 15-42

)....................................................................................... 15-43

) ....................................................................................... 15-43

6

APPENDIX App.- 1 to App.-17

App. 1 Difference between MR-J3-B and MR-J3W-B ..............................................................................App.- 1

App. 2 Signal layout recording paper ........................................................................................................App.- 5

App. 3 COMPLIANCE WITH CE MARKING.............................................................................................App.- 6

App. 4 COMPLIANCE WITH UL/CSA STANDARD .................................................................................App.- 9

App. 5 Handling of AC servo amplifier batteries for the United Nations

Recommendations on the Transport of Dangerous Goods.........................................................App.-14

App. 6 Symbol for the new EU Battery Directive .....................................................................................App.-15

App. 7 Recommended cable for servo amplifier power supply ...............................................................App.-16

7

MEMO

8

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

The Mitsubishi AC servo amplifier MELSERVO-J3W series is an AC servo that requires less space, less wiring,

and less energy while it maintains high performance, functionality and usability of MELSERVO-J3-B.

Two servo motors can be driven by this MR-J3W servo amplifier. Driving two servo motors by one MR-J3W

servo amplifier cuts down the installation area compared to the area required for two MR-J3 servo amplifiers.

Side-by-side installation is also available, making the system more compact.

Integrated 2-axis structure allows two axes to share the same SSCNET

main circuit power cable, cutting down the wiring area.

The capacitor in the MELSERVO-J3W series is re-charged, doubling the reusable energy compared to it of the

MELSERVO-J3 series. Regenerative energy is generated during deceleration of a servo motor. By reusing that

energy, much energy is saved. Depending on the operating condition, the regenerative option may be disabled.

The MR-J3W-77B servo amplifier has a 100W regenerative resistor built in, making the regenerative option

unnecessary even for a large regenerative load.

By simply shifting the switch, a rotary servo motor, a linear servo motor or a direct drive motor can be used for

each axis for the MR-J3W servo amplifier. A rotary servo motor, a linear servo motor and a direct drive motor

with different capacities can be connected to the MR-J3W-22B and MR-J3W-44B servo amplifier axes.

Using MELSERVO-J3W makes the linear servo motor and the direct drive motor structure simple and the

equipment compact with high performance. Using MELSERVO-J3W also saves the space.

As explained above, integrated 2-axis structure, multi-function, and improved regeneration efficiency reduce the

required parts for a servo system.

cable, control circuit power cable, and

1 - 1

1. FUNCTIONS AND CONFIGURATION

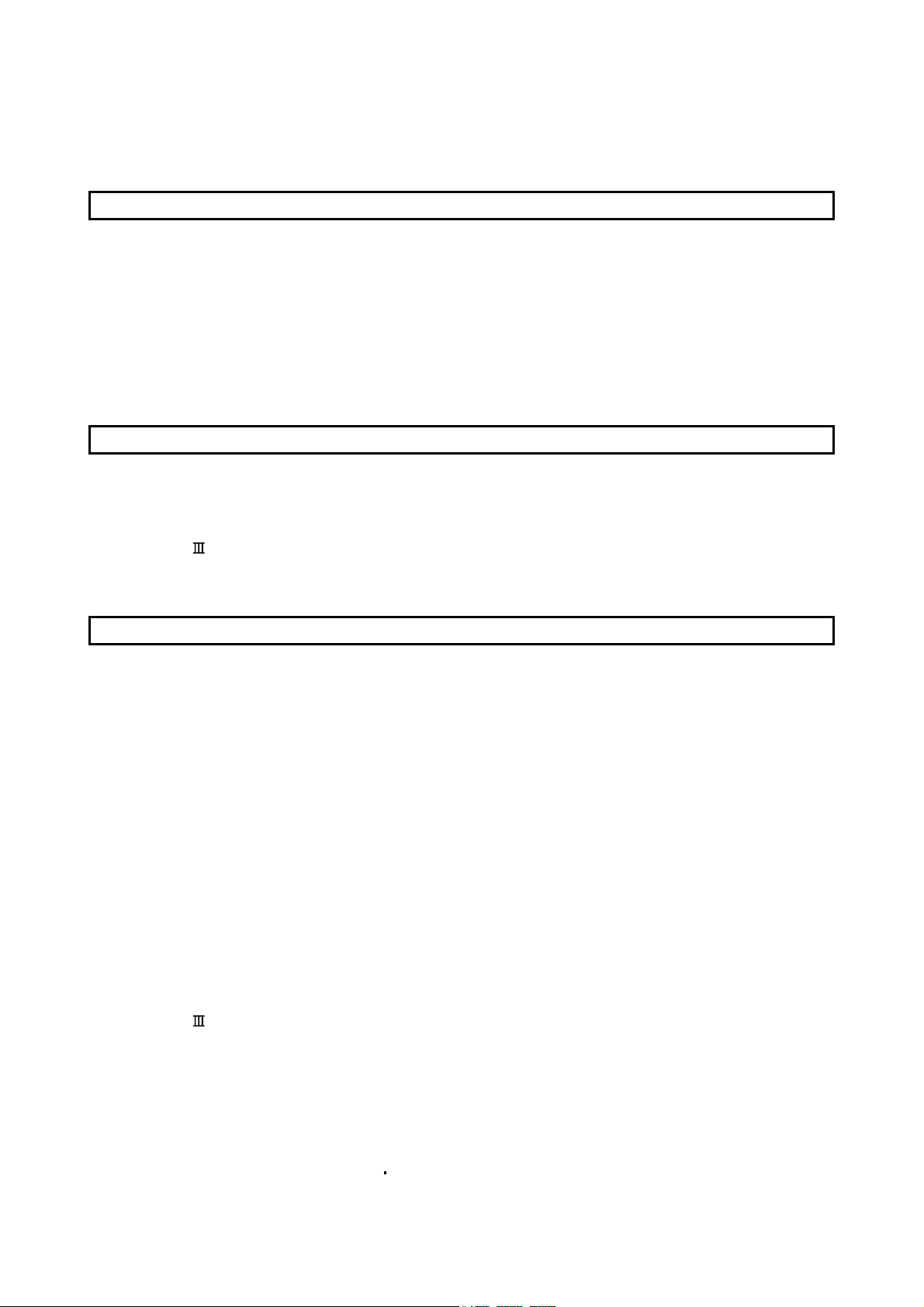

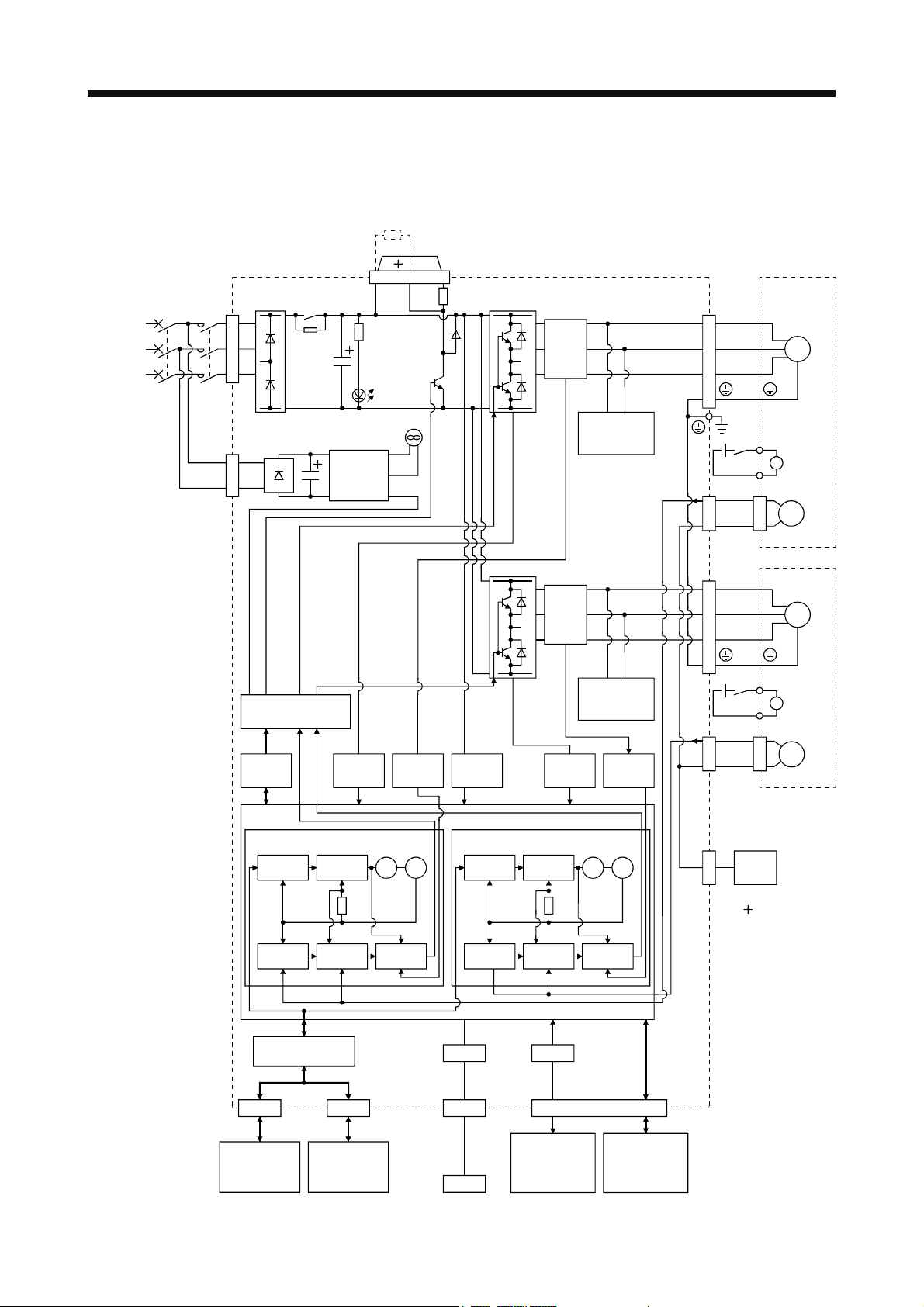

1.2 Function block diagram

The function block diagram of this servo is shown below.

Regenerative

option

(Note 2)

Power

supply

MCCB

Servo amplifier

MC

Diode

stack

L1

L2

CNP1CNP2

3

L

L11

L21

Base amplifier

Relay

CHARGE

(Note 1)

Control

circuit

power

supply

lamp

Cooling fan

PC D

CNP2

Regenerative

TR

Built-in regenerative resistor

TRM(A)

TRM(B)

Current

detector

Current

detector

Dynamic

brake circuit

(A)

Dynamic

brake circuit

(B)

A-axis Servo motor

U

U

V

V

W

W

CNP3ACN2A

B1

RA

24VDC

B

B2

Encoder

B-axis Servo motor

U

U

V

V

W

W

CNP3BCN2B

B1

RA

24VDC

B

B2

M

Electromagnetic

brake

M

Electromagnetic

brake

Virtual

motor

Current

detection

B

Virtual

encoder

Encoder

-

MR

BTCASE

CN4

Optional battery

Regenerative

brake

Control (A)

Model position

control (A)

Overcurrent

Model speed

control (A)

Current

detection

A

Virtual

encoder

Virtual

motor

A

Overvoltage

Control (B)

Model position

control (B)

Overcurrent

Model speed

control (B)

B

Case Battey

(for absolute position

detection system)

Actual position

control (A)

CN1A CN1B

Controller or

servo amplifier

Actual speed

control (A)

I/F

Control

Servo amplifier

or cap

Current

control (A)

Personal

computer

Actual position

control (B)

USB

CN5

USB

Actual speed

control (B)

D/A

Analog monitor

(2 channels)

Current

control (B)

CN3

Digital I/O

control

1 - 2

1. FUNCTIONS AND CONFIGURATION

Note 1. MR-J3W-22B dose not have a cooling fan.

2. For 1-phase 200 to 230VAC, connect the power supply to L

specification.

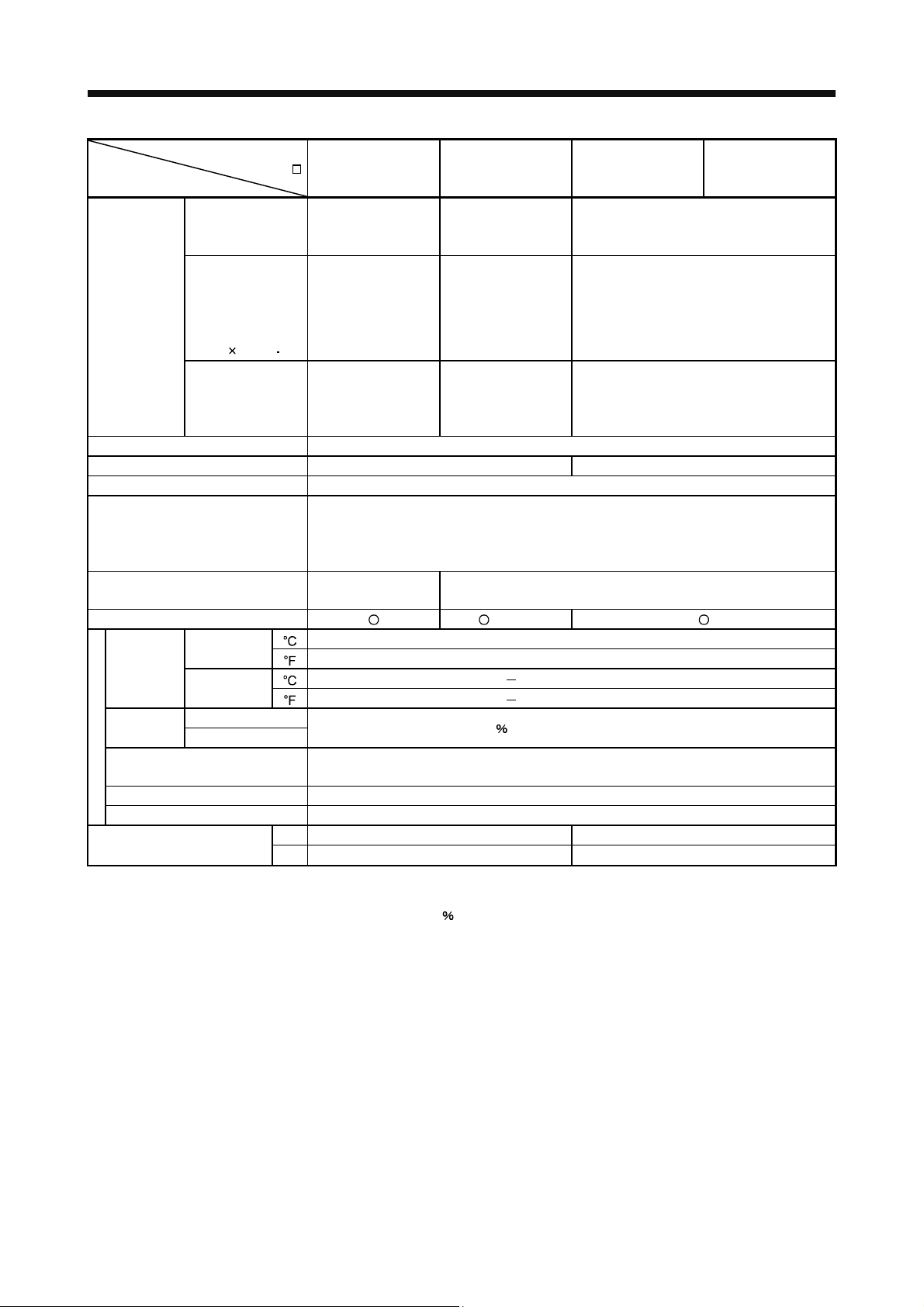

1.3 Servo amplifier standard specifications

Servo amplifier

MR-J3W-

Item

Rated output capacity

Rated voltage 3-phase 170VAC

Output

Rated current [A] 1.5 1.5 2.8 2.8 5.8 5.8 6.0 6.0

Voltage, frequency 3-phase or 1-phase 200 to 230VAC, 50/60Hz 3-phase 200 to 230VAC, 50/60Hz

Rated current [A] 3.5 6.1 10.4 13.9

Permissible voltage fluctuation

Permissible frequency fluctuation Within 5

Power supply capacity Refer to section 10.2

Main circuit power supply

Inrush current Refer to section 10.5

Voltage, frequency 1-phase 200 to 230VAC, 50/60Hz

Rated current [A] 0.4

Permissible voltage

Control circuit

power supply

Interface power

supply

fluctuation

Permissible

frequency fluctuation

Power

consumption

Inrush current Refer to section 10.5

Voltage 24VDC 10

Power supply

capacity

[W] 55

[A] (Note 1) 0.25

22B 44B 77B 1010B

A-axis

200W

3-phase or 1-phase 200 to 230VAC:

1-phase 170 to 253VAC

Within

B-axis

200W

170 to 253VAC

1, L2 and leave L3 open. Refer to section 1.3 for the power supply

A-axis

400W

B-axis

400W

A-axis

750W

5

B-axis

750W

3-phase 170 to 253VAC

A-axis

1kW

B-axis

1kW

1 - 3

1. FUNCTIONS AND CONFIGURATION

Servo amplifier

MR-J3W-

Item

Reusable

regenerative energy

(Note 3) [J]

Rotary servo motor’s

inertia moment

Capacitor

regenerative

Control system Sine-wave PWM control, current control system

Built-in regenerative resistor [W] 10 100

Dynamic brake Built-in

Protective functions

Structure

Side-by-side installation (Note 2)

Ambient

temperature

humidity

Ambient

Environmental conditions

Altitude Max. 1000m above sea level

Vibration resistance 5.9 m/s2 at 10 to 55Hz (X, Y and Z directions)

Mass

Note 1. 0.25A is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of I/O

points.

2. When closely mounting MR-J3W-44B, operate them at 90

3. The regenerative energy is generated under the following conditions.

Rotary servo motor: The energy is generated when a machine with the inertia moment equivalent to permissible charging amount

Linear servo motor: The energy is generated when a machine with the mass equivalent to permissible charging amount decelerates

Direct drive motor: The energy is generated when a machine with the inertia moment equivalent to permissible charging amount

4. This value is inertia moment when decelerating rotary servo motor from the rated speed to a stop. When decelerating two axes

simultaneously, the inertia moment is a total of two axes. When not decelerating two axes simultaneously, the inertia moment is for

one axis. This note also applies to the direct drive motor.

5. This value is mass when decelerating linear servo motor from the rated speed to a stop. The mass includes a mass of primary side

(coil). When decelerating two axes simultaneously, the mass is a total of two axes. When not decelerating two axes simultaneously,

the mass is for one axis.

equivalent to

permissible charging

amount (Note 4)

[

10-4kg m2]

Linear servo motor’s

mass equivalent to

permissible charging

amount (Note 5) [kg]

Self-cooled, open

Operation

Storage

Operation Ambient

Storage

[kg] 1.4 2.3

[lb] 3.09 5.07

decelerates from the rated speed to stop.

from the maximum speed to stop.

decelerates from the rated speed to stop.

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic thermal

[ ] 0 to 55 (non-freezing)

[

] 32 to 131 (non-freezing)

[ ] 20 to 65 (non-freezing)

[

] 4 to 149 (non-freezing)

22B 44B 77B 1010B

17 22 46

3.45 4.46 9.32

8.5 11.0 23.0

relay), servo motor overheat protection, encoder error protection, regenerative error protection,

undervoltage, instantaneous power failure protection, overspeed protection, excessive error

protection, magnetic pole detection protection, Linear servo control error detection protection

(IP rating: IP00)

Free from corrosive gas, flammable gas, oil mist, dust and dirt

Force-cooling, open (IP rating: IP00)

90

RH or less (non-condensing)

Indoors (no direct sunlight)

or smaller effective load ratio.

1 - 4

1. FUNCTIONS AND CONFIGURATION

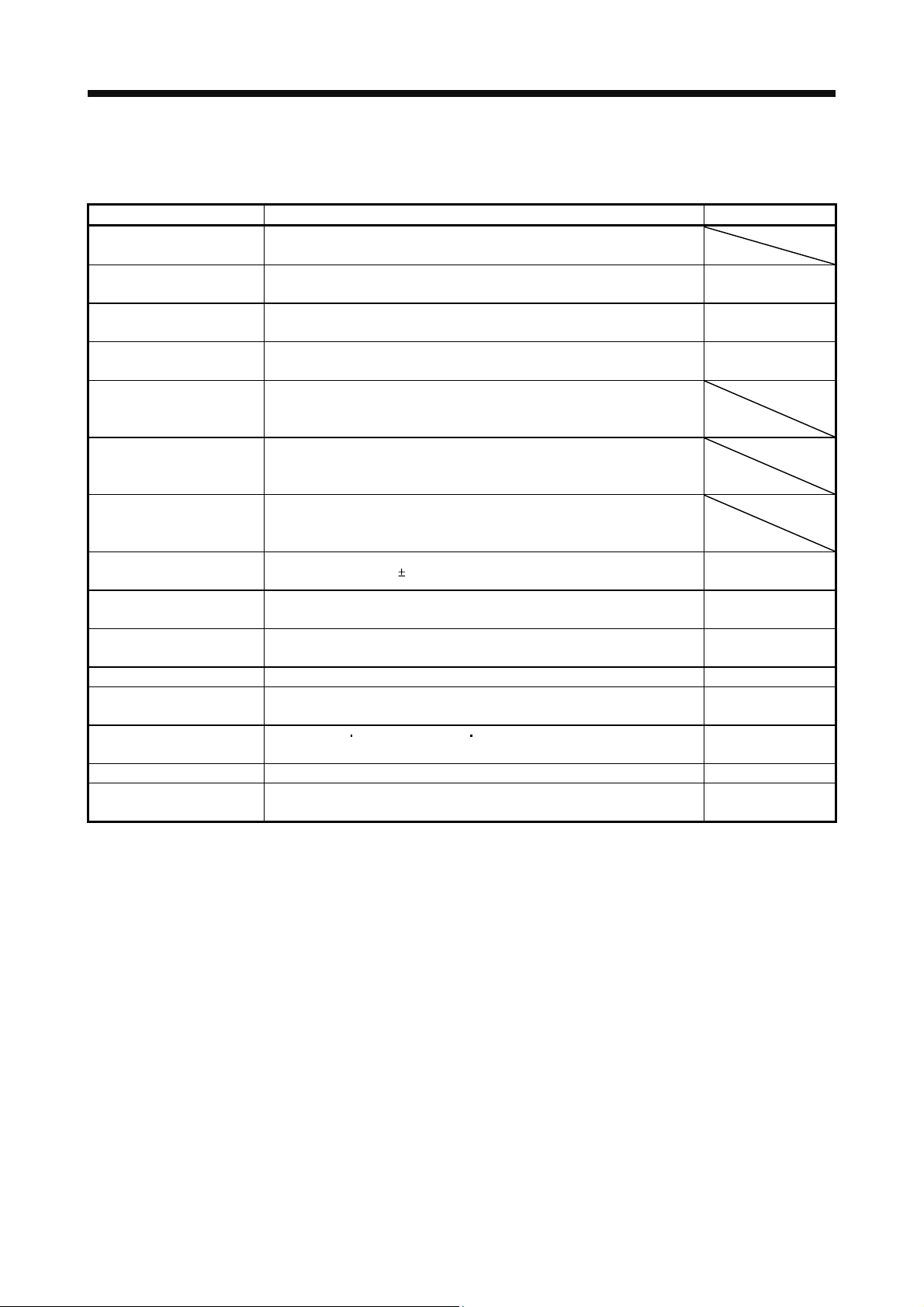

1.4 Function list

The following table lists the functions of this servo. For details of the functions, refer to the reference field.

Function Description Reference

High-resolution encoder

Absolute position detection

system

Gain changing function

Low-pass filter

Machine analyzer function

Machine simulation

Gain search function

Slight vibration suppression

control

Auto tuning

Regenerative option

Alarm history clear Alarm history is cleared. Parameter No.PC21

Output signal (DO)

forced output

Test operation mode

Analog monitor output Servo status is output in terms of voltage in real time. Parameter No.PC09

MR Configurator

High-resolution encoder of 262144 pulses/rev is used as a rotary servo motor

encoder.

Merely setting a home position once makes home position return unnecessary

at every power-on.

Switches gains by using input devices or gain switching conditions (including the

servo motor speed).

Suppresses high-frequency resonance which occurs as servo system response

is increased.

Analyzes the frequency characteristic of the mechanical system by simply

connecting an MR Configurator installed personal computer and servo amplifier.

MR Configurator is necessary for this function.

Can simulate machine motions on a personal computer screen on the basis of

the machine analyzer results.

MR Configurator is necessary for this function.

Personal computer with MR Configurator changes gains automatically and

searches for overshoot-free gains in a short time.

MR Configurator is necessary for this function.

Suppresses vibration of

Automatically adjusts the gain to optimum value if load applied to the servo

motor shaft varies.

Used when the built-in regenerative resistor of the servo amplifier does not have

sufficient regenerative capability for the regenerative power generated.

Output signal can be forced on/off independently of the servo status.

Use this function for output signal wiring check, etc.

JOG operation

However, MR Configurator is necessary for positioning operation.

Using a personal computer, parameter setting, test operation, status display,

etc. can be performed.

positioning operation DO forced output

1 pulse produced at a servo motor stop. Parameters No.PB24

Chapter 12

Section 7.5

Section 7.4

Chapter 6

Section 11.2

Section 4.5.1 (1) (d)

Section 4.5

Section 11.4

1 - 5

1. FUNCTIONS AND CONFIGURATION

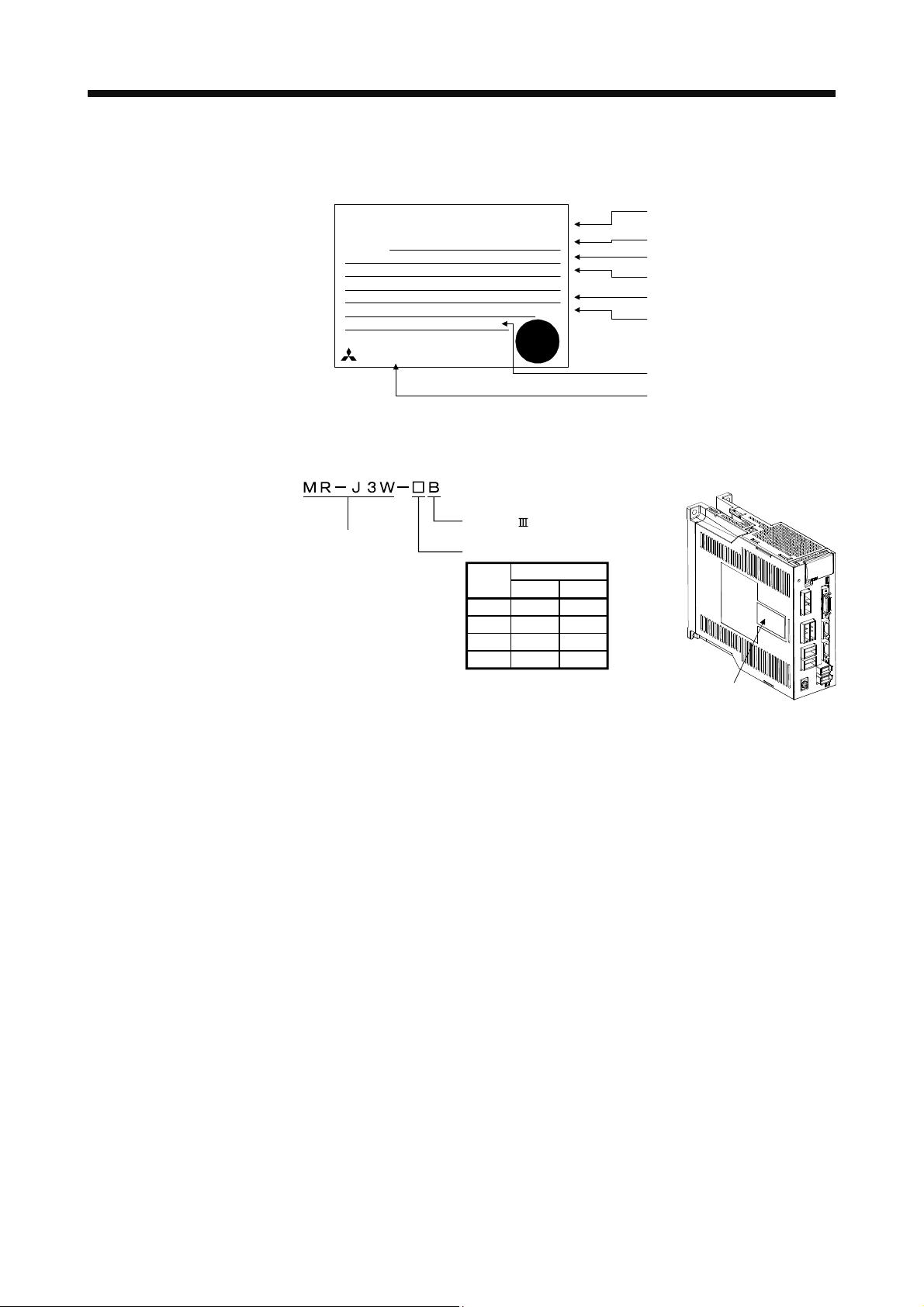

1.5 Model code definition

(1) Rating plate

MITSUBISHI

(2) Model

MODEL

POWER:

INPUT:

OUTPUT:

SERIAL: A99001050

KCC-REI-MEK-TC300A***G51

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

Series

MR-J3W-44B

400W(A)+400W(B)

6.1A 3PH+1PH200-230V 50Hz

170V 0-360Hz 2.8A(A)+2.8A(B)

AC SERVO

DATE 2011-08

3PH+1PH200-230V 60Hz

PASSED

SSCNET interface

Rated output

Rated outpur[W]

Symbol

A-axis

22 200 200

44 400 400

77 750 750

1010 1k 1k

B-axis

The year and month

of manufacture

Model

Capacity

Applicable power supply

Rated output current

Serial number

KC mark number

Country of origin

Rating plate

1 - 6

1. FUNCTIONS AND CONFIGURATION

1.6 Combination with servo motor

POINT

Refer to section 13.1.2 for the combinations with linear servo motors.

Refer to section 14.1.2 for the combinations with direct drive motors.

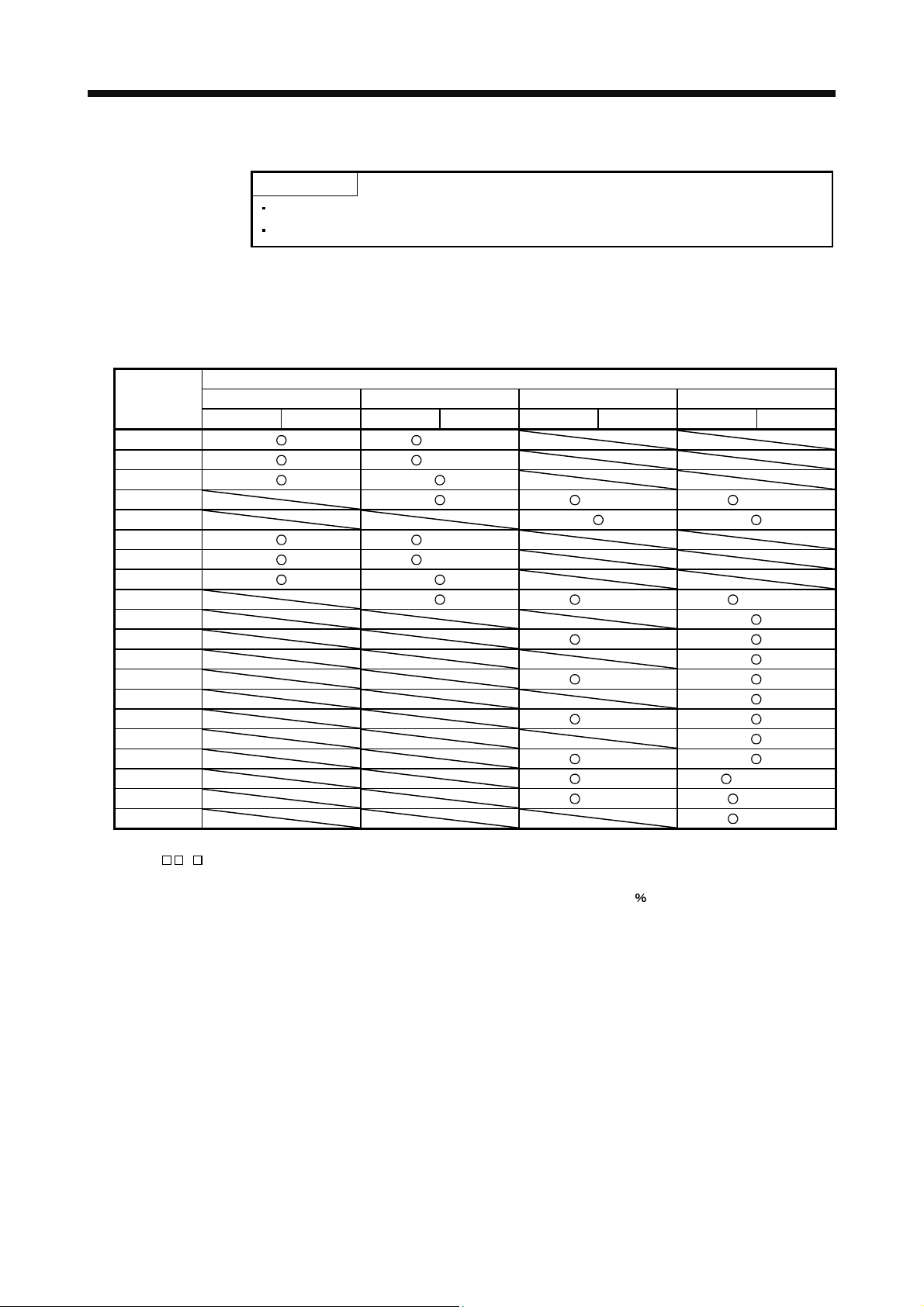

The following table lists combinations of servo amplifiers and servo motors. The same combinations apply to the

models with an electromagnetic brake and the models with a reduction gear.

With the servo amplifier whose software version is B3 or later, the following servo motors can be used without

parameter change.

Servo amplifier

Servo motor MR-J3W-22B MR-J3W-44B MR-J3W-77B MR-J3W-1010B

A-axis B-axis A-axis B-axis A-axis B-axis A-axis B-axis

HF-MP053 (Note 1)

HF-MP13 (Note 1)

HF-MP23

HF-MP43 (Note 1) (Note 1)

HF-MP73

HF-KP053 (Note 1)

HF-KP13 (Note 1)

HF-KP23

HF-KP43 (Note 1) (Note 1)

HF-KP73

HF-SP51 (Note 1)

HF-SP81

HF-SP52 (Note 1)

HF-SP102

HC-LP52 (Note 1)

HC-LP102

HC-UP72 (Note 1)

HF-JP53 (Note 2) (Note 2, 3)

HF-JP73 (Note 2) (Note 2)

HF-JP103 (Note 2)

Note 1. With the servo amplifier whose software version is B2 or earlier, this servo motor can be used by setting parameter No.Po04 to

"

1 ". With the servo amplifier whose software version is B3 or later, no parameter setting is required.

2. This servo motor can be used with the servo amplifier whose software version is B3 or later.

3. With this combination, the maximum torque of the HF-JP53 servo motor increases to 400

of the rated torque.

1 - 7

1. FUNCTIONS AND CONFIGURATION

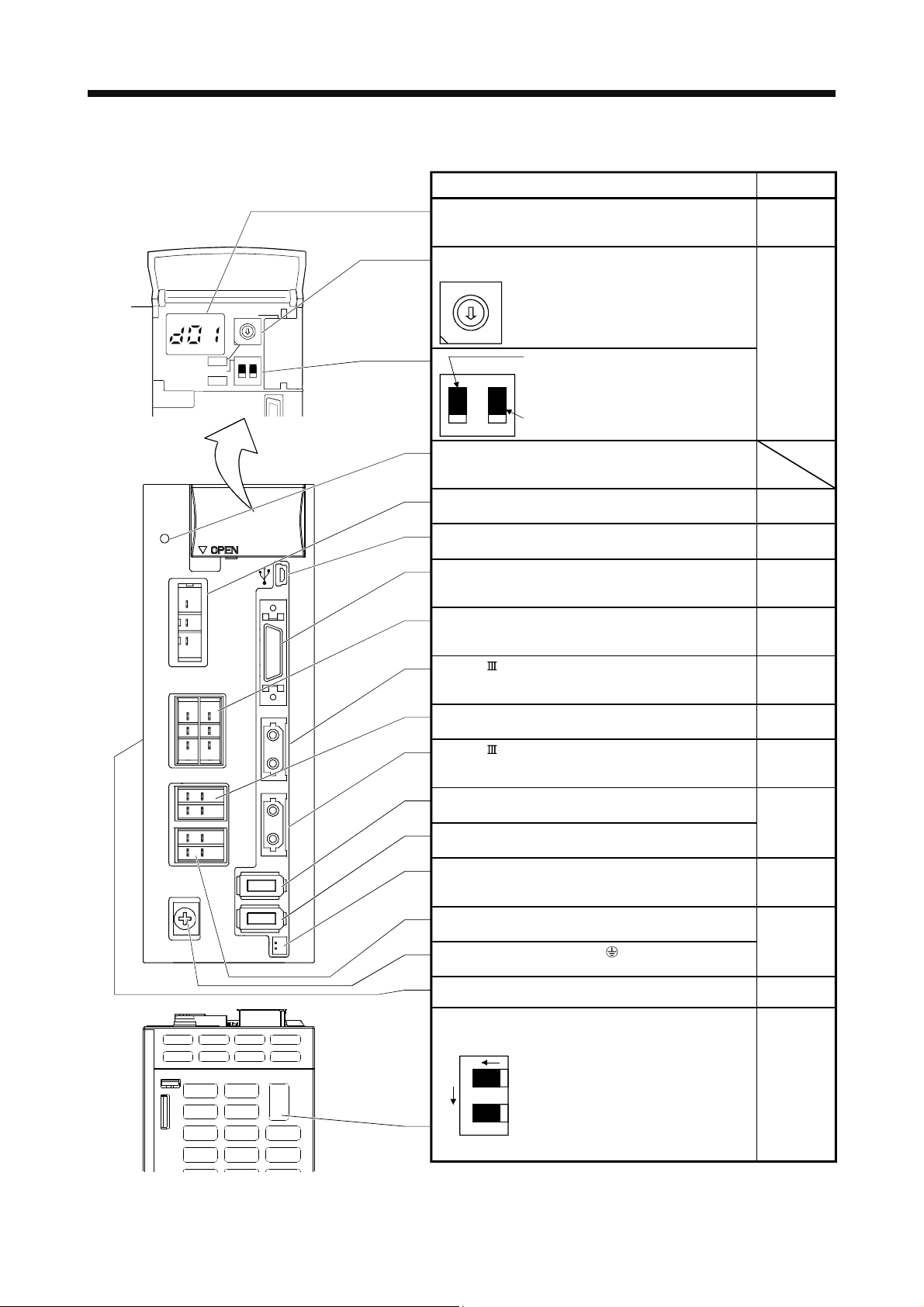

1.7 Parts identification

Side view

SW1

TEST

SW2

7

6

5

4

3

2

ON 4E

12

Name/Application

Detailed

explanation

Display

The 3-digit, seven-segment LED shows the servo status

Section 4.3

and alarm number.

Rotary axis setting switch (SW1)

SW1

8

7

6

5

4

8

9

A

B

C

D

E

F

1

0

3

2

1

0

SW2

Used to set the axis No. of servo amplifier.

9

A

B

C

D

E

F

Test operation select switch (SW2-1)

Used to perform the test operation

Section 3.13

mode by using MR Configurator.

1

to the "Down" position).

For manufacturer setting (Be sure to set

2

Charge lamp

Lit to indicate that the main circuit is charged. While this

lamp is lit, do not reconnect the cables.

Main circuit power supply connector (CNP1)

Connect the input power supply.

USB communication connector (CN5)

Connect the personal computer.

I/O signal connector (CN3)

Used to connect digital I/O signals.

More over an analog monitor is output.

Control circuit connector (CNP2)

Connect the control circuit power supply/regenerative

option.

Section 3.1

Section 3.3

Section 11.4

Section 3.2

Section 3.4

Section 3.1

Section 3.3

SSCNET cable connector (CN1A)

Used to connect the servo system controller or the front

Section 3.9

axis servo amplifier.

A-axis servo motor power output connector (CNP3A)

Connect the A-axis servo motor.

Section 3.1

Section 3.3

SSCNET cable connector (CN1B)

Used to connect the rear axis servo amplifier. For the final

Section 3.9

axis, puts a cap.

A-axis servo motor encoder connector (CN2A)

Used to connect the A-axis servo motor encoder.

B-axis servo motor encoder connector (CN2B)

Section 3.4

Section 11.1

Used to connect the B-axis servo motor encoder.

Battery connector (CN4)

Used to connect the battery for absolute position data

backup. Battery is not required in fully closed control.

Section 11.3

Chapter 12

B-axis servo motor power output connector (CNP3B)

Connect the B-axis servo motor.

Protective earth (PE) terminal ( )

Section 3.1

Section 3.3

Ground terminal.

Rating plate

Section 1.5

Servo motor selection switch (SW3)

NO

A-axis

SW3

Bottom

21

Front side

B-axis

Used to select the servo motor to

be used.

Section 3.14

OFF: Rotary servo motor

ON : Linear servo motor and

direct drive motor

1 - 8

1. FUNCTIONS AND CONFIGURATION

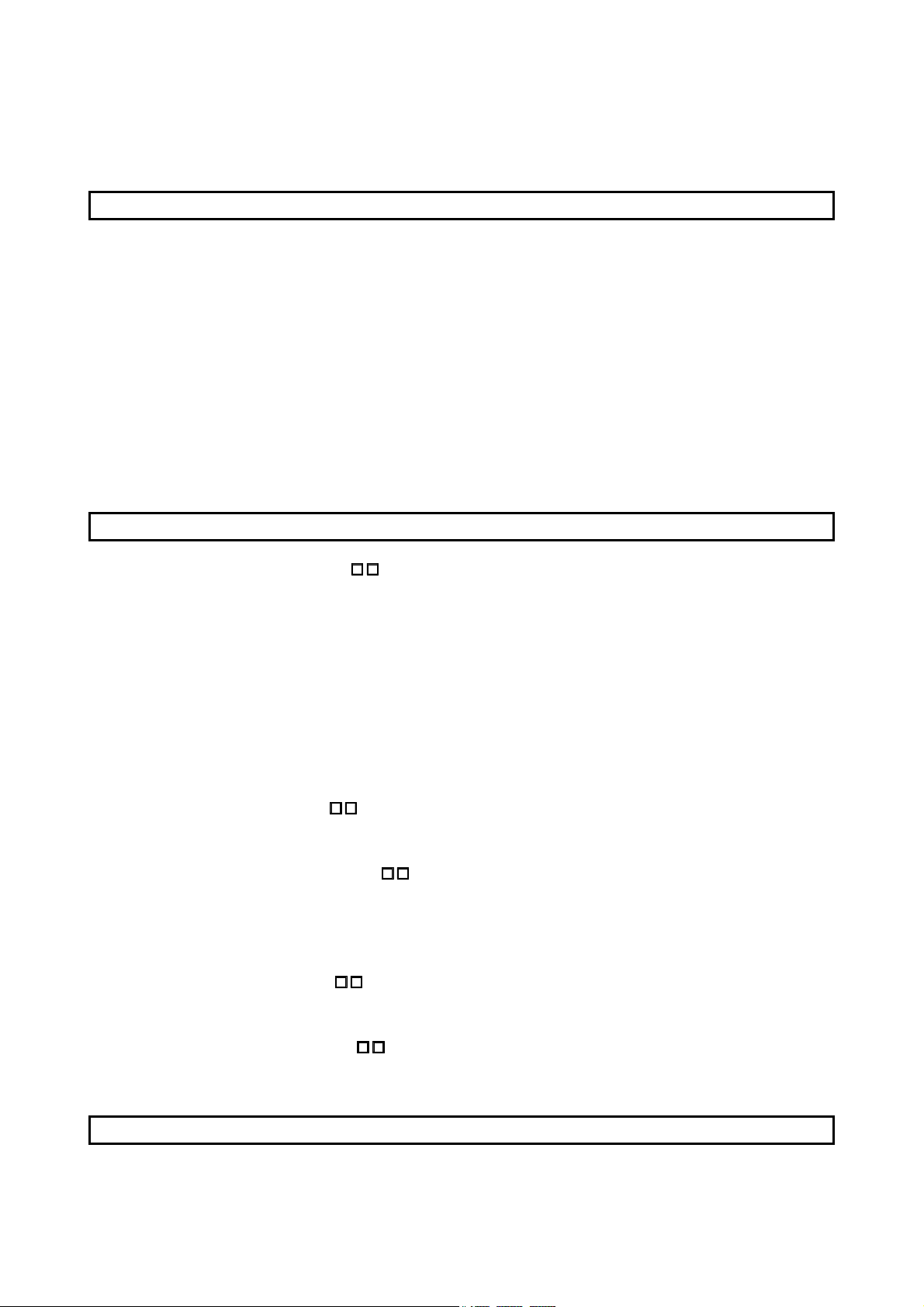

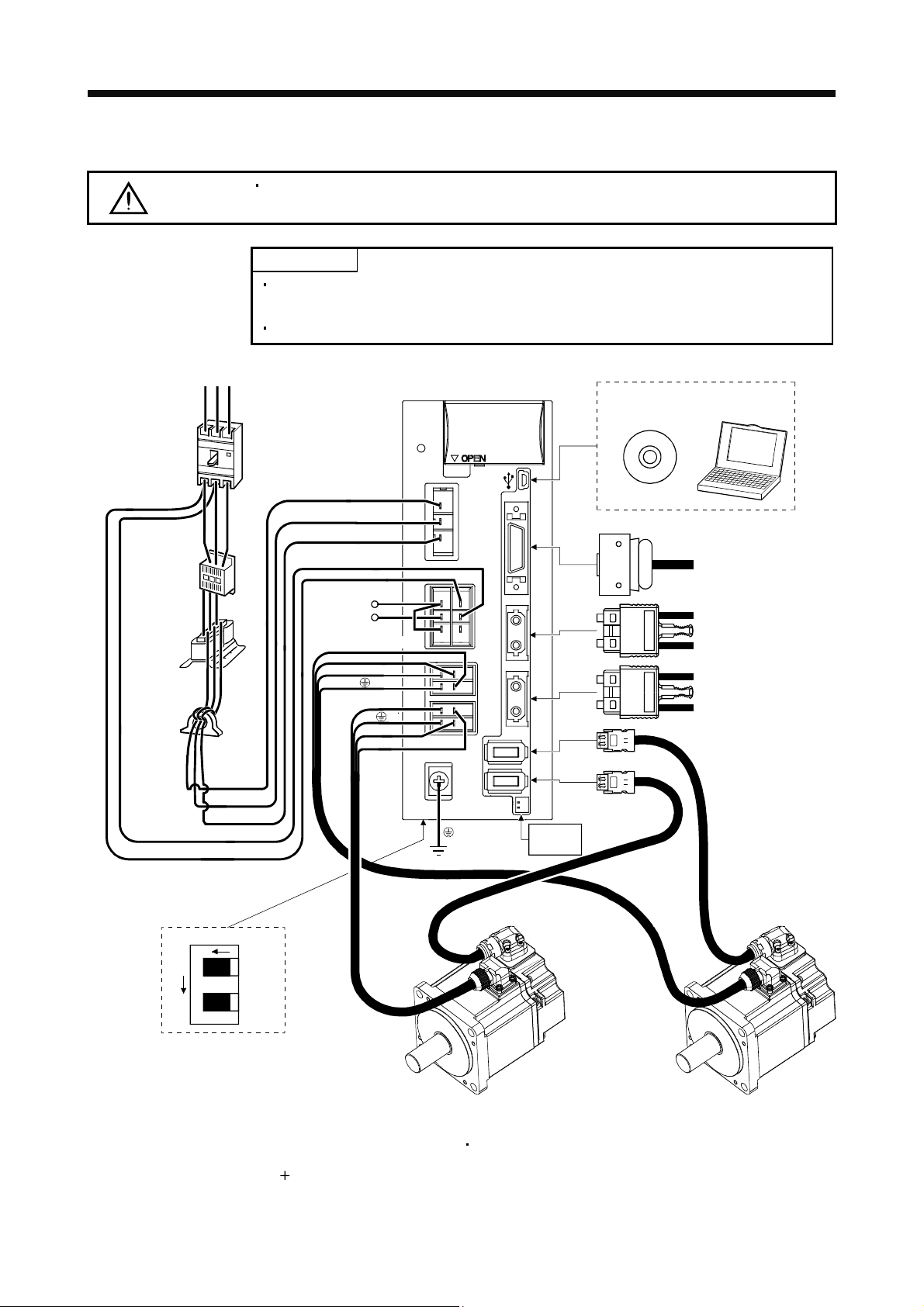

1.8 Configuration including auxiliary equipment

CAUTION

(Note 2)

Power supply

Molded-case

circuit breaker

(MCCB) or fuse

Magnetic

contactor

(MC)

Power factor

improving AC

reactor

(FR-BAL)

Line noise

filter

(FR-BSF01)

RST

(Note 2)

Connecting a servo motor for different axis to the CNP3A or CNP3B connector may

cause a malfunction.

POINT

Equipment other than the servo amplifier and the servo motor are optional or

recommended products.

To use a rotary servo motor, turn SW3 off (factory setting).

Servo amplifier

MR Configurator

CN5

L

1

L2

L

3

CNP1

CN3

(Note 3)

V

U

W

P

C

D

W

V

U

CNP2

CNP3A

CNP3B

CN1A

CN1B

CN2A

Regenerative

option

Personal

computer

I/O signal

Servo system

controller or Front axis

servo amplifier CN1B

Rear servo amplifier

CN1A or Cap

CN2B

(Note 1)

L

L11

21

CN4

Battery

unit

A-axis servo motorB-axis servo motor

SW3

ON

12

Front side

A-axis

B-axis

Note 1. A battery unit consists of one MR-BTCASE battery case and eight MR-BAT batteries. Use the battery unit in the absolute position

detection system of the position control mode. (Refer to section 12.3.)

2. For 1-phase 200V to 230VAC, connect the power supply to L

1 L2 and leave L3 open. Refer to section 1.3 for the power supply

specification.

3. Make sure to connect the P

terminal to the D terminal. When using the regenerative option, refer to section 11.2.

1 - 9

1. FUNCTIONS AND CONFIGURATION

MEMO

1 - 10

2. INSTALLATION

2. INSTALLATION

WARNING

CAUTION

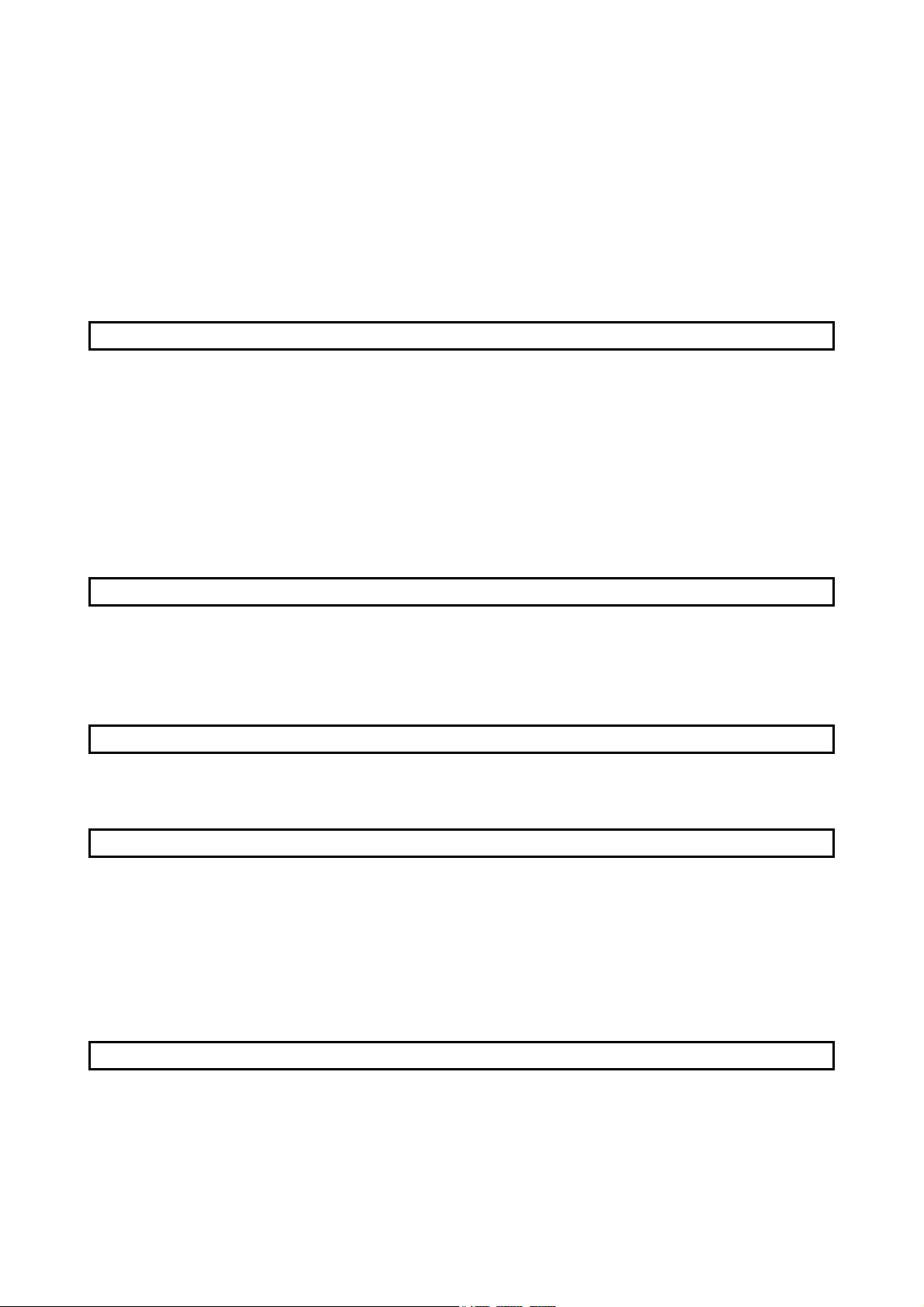

2.1 Installation direction and clearances

To prevent electric shock, ground each equipment securely.

Stacking in excess of the limited number of products is not allowed.

Install the equipment on incombustible material. Installing it directly or close to

combustibles will lead to a fire.

Install the equipment in a load-bearing place in accordance with this Instruction

Manual.

Do not get on or put heavy load on the equipment to prevent injury.

Use the equipment within the specified environmental condition range. (For the

environmental conditions, refer to section 1.3.)

Provide an adequate protection to prevent screws and other conductive matter, oil

and other combustible matter from entering the servo amplifier.

Do not block the intake and exhaust areas of the servo amplifier. Doing so may

cause faults.

Do not drop or strike the servo amplifier. Isolate from all impact loads.

Do not install or operate the servo amplifier which has been damaged or has any

parts missing.

Do not install or operate a faulty servo amplifier.

When the product has been stored for an extended period of time, contact your local

sales office.

When treating the servo amplifier, be careful about the edged parts such as the

corners of the servo amplifier.

The servo amplifier must be installed in the metal cabinet.

The equipment must be installed in the specified direction. Otherwise, a fault may

CAUTION

When using heat generating equipment such as the regenerative option, install them with full consideration of

heat generation so that the servo amplifier is not affected.

Install the servo amplifier on a perpendicular wall in the correct vertical direction.

occur.

Leave specified clearances between the servo amplifier and control box inside walls

or other equipment. Doing so may cause faults.

2 - 1

2. INSTALLATION

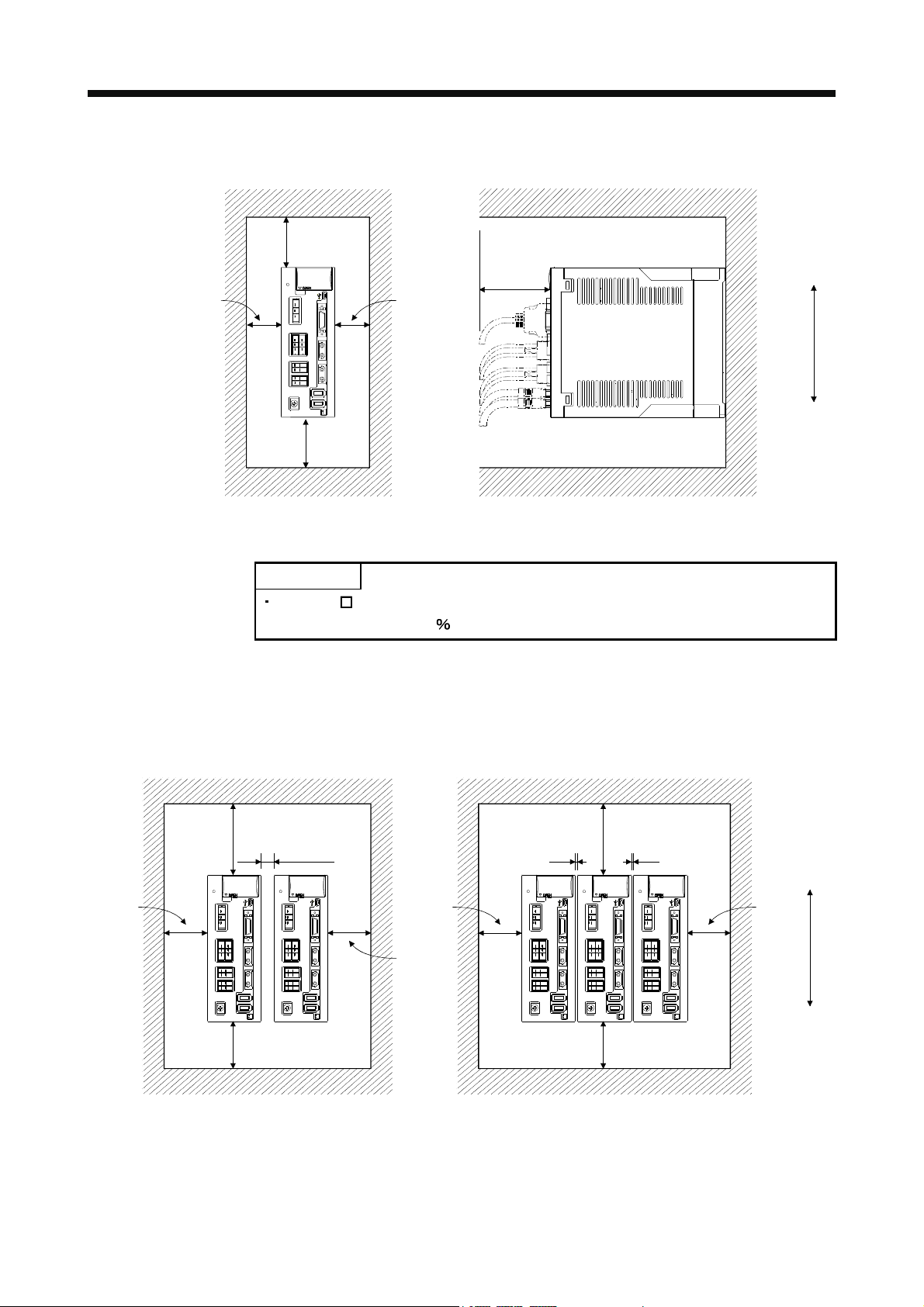

(1) Installation of one servo amplifier

40mm

or more

Servo amplifier

10mm

or more

40mm

or more

10mm

or more

Wiring

allowance

80mm

Control boxControl box

Top

Bottom

(2) Installation of two or more servo amplifiers

POINT

MR-J3W- B can be installed side-by-side. However, use MR-J3W-44B with the

effective load ratio of 90

or less.

Leave a large clearance between the inner surface of a control box and the servo amplifier to circulate air above

and below the servo amplifier.

When installing the servo amplifiers closely, leave a clearance of 1mm between the adjacent servo amplifiers in

consideration of mounting tolerances.

1mm

Control box

100mm

or more

1mm

Top

30mm

or more

30mm

or more

Control box

100mm

or more

10mm

or more

30mm

or more

30mm

or more

Bottom

40mm

or more

Leaving clearance Mounting closely

40mm

or more

2 - 2

2. INSTALLATION

2.2 Keep out foreign materials