Page 1

General-Purpose AC Servo

J3 Series

Built-in Positioning Function

MODEL(SERVO AMPLIFIER)

MR-J3- _T

MODEL(CC-LINK IE FIELD NETWORK INTERFACE UNIT)

MR-J3-T10

SERVO AMPLIFIER

INSTRUCTION MANUAL

(CC-Link IE Field Network interface)

Page 2

Safety Instructions

Please read the instructions carefully before using the equipment.

Do not attempt to install, operate, maintain or inspect the equipment until you have read through this

Instruction Manual and appended documents carefully and can use the equipment correctly. Do not use the

servo amplifier and servo motor until you have a full knowledge of the equipment, safety information and

instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this installation guide, keep it accessible to the operator.

A - 1

Page 3

1. Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the limited number of product packages is not allowed.

Install the servo amplifier and servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the equipment.

Install the equipment in the specified direction.

Provide an adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the unit.

This unit is a precision instrument. Do not drop or strike the unit. Isolate it from all impact loads.

Store and use this unit in the environment conditions described in the section 1.3.

When the equipment has been stored for an extended period of time, contact your local sales office.

2. Wiring

CAUTION

Wire the equipment correctly and securely. After wiring, check again for incorrect wiring and tightening of

terminal screws, etc. Otherwise, the servo motor may operate unexpectedly.

3. Usage

CAUTION

Immediately shut off the power supply if smoke, abnormal noise, or odor arises from this unit.

Disassembly and repair must be performed by a qualified person.

Do not modify the equipment.

4. Corrective actions

CAUTION

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

5. Maintenance, inspection and parts replacement

CAUTION

Do not touch connector contacts and leads of the IC and other devices.

Do not place the unit on a metal object which is vulnerable to electric leakage, or on a wooden object

where static electricity may be charged. Do not place the unit on the object made of materials such as

plastic and vinyl.

Do not perform an insulation resistance test (megger test) at inspection.

A - 2

Page 4

6. General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

«About the manuals»

You must have this Instruction Manual and the following manuals to use this unit. Ensure to prepare them

to use the unit safely.

Relevant manuals

Manual name Manual number

MR-J3-_T Servo Amplifier Instruction Manual SH(NA)030058

MELSERVO Servo Motor Instruction Manual (Vol.2) SH(NA)030041

EMC Installation Guidelines IB(NA)67310

«Wiring»

Wires mentioned in this instruction manual are selected based on the ambient temperature of 40 °C

(104 °F).

A - 3

Page 5

MEMO

A - 4

Page 6

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1- 6

1.1 Summary........................................................................................................................................... 1- 1

1.2 System configuration ........................................................................................................................ 1- 1

1.3 Standard specifications..................................................................................................................... 1- 1

1.4 Rating plate....................................................................................................................................... 1- 2

1.5 Connector/interface .......................................................................................................................... 1- 2

1.6 Contents of the package................................................................................................................... 1- 2

1.7 Installation and removal of the unit ................................................................................................... 1- 3

2. I/O SIGNAL CONNECTION EXAMPLE 2- 1 to 2- 2

3. PARAMETERS 3- 1 to 3- 8

3.1 Basic setting parameters [Pr. PA_ _ ]............................................................................................... 3- 1

3.2 Gain/filter parameters [Pr. PB_ _ ].................................................................................................... 3- 2

3.3 Extension setting parameters [Pr. PC_ _ ] ....................................................................................... 3- 3

3.3.1 Parameter list ............................................................................................................................. 3- 3

3.3.2 Detail description........................................................................................................................ 3- 4

3.4 I/O setting parameters [Pr. PD_ _ ]................................................................................................... 3- 5

3.4.1 Parameter list ............................................................................................................................. 3- 5

3.4.2 Detail description........................................................................................................................ 3- 6

3.5 Option unit parameters [Pr. Po_ _ ] .................................................................................................. 3- 7

3.5.1 Parameter list ............................................................................................................................. 3- 7

3.5.2 Detail description........................................................................................................................ 3- 8

4. DISPLAY/OPERATING PARTS 4- 1 to 4- 4

4.1 MR-J3-_T servo amplifier ................................................................................................................. 4- 1

4.1.1 Explanation on the display/operating parts ................................................................................4- 1

4.1.2 Display details ............................................................................................................................ 4- 2

4.1.3 Unspecified station number ....................................................................................................... 4- 2

4.2 MR-J3-T10 IE Field Network interface unit....................................................................................... 4- 3

4.3 Selecting the station number and network number .......................................................................... 4- 4

5. TROUBLESHOOTING 5- 1 to 5- 4

5.1 Alarm and warning list ...................................................................................................................... 5- 2

5.2 Remedies for alarms......................................................................................................................... 5- 3

5.3 Remedies for warnings ..................................................................................................................... 5- 4

6. DIMENSIONS 6- 1 to 6- 2

1

Page 7

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION 7- 1 to 7- 12

7.1 System configuration ........................................................................................................................ 7- 1

7.2 Communication specifications .......................................................................................................... 7- 1

7.3 I/O device.......................................................................................................................................... 7- 2

7.3.1 I/O devices for a programmable controller CPU ........................................................................ 7- 2

7.3.2 I/O devices for a programmable controller CPU during indexer positioning operation ............. 7- 7

7.4 Restrictions on the CC-Link IE Field Network wiring ....................................................................... 7-12

2

Page 8

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

POINT

CC-Link IE Field Network communication function is available for the MR-J3-_T

servo amplifiers of which software version is B0 or above.

1.1 Summary

This instruction manual explains about MR-J3-T10 CC-Link IE Field Network interface unit. Refer to MR-J3_T Servo Amplifier Instruction Manual for the information not given in this manual.

Always use MR-J3-T10 with an MR-J3-_T. MR-J3-T10 enables an MR-J3-_T to connect to the CC-Link IE

Field Network by being attached to the MR-J3-_T.

The CC-Link IE Field Network communication function is exclusive of the CC-Link communication function. It

cannot be used with the CC-Link communication function at the same time.

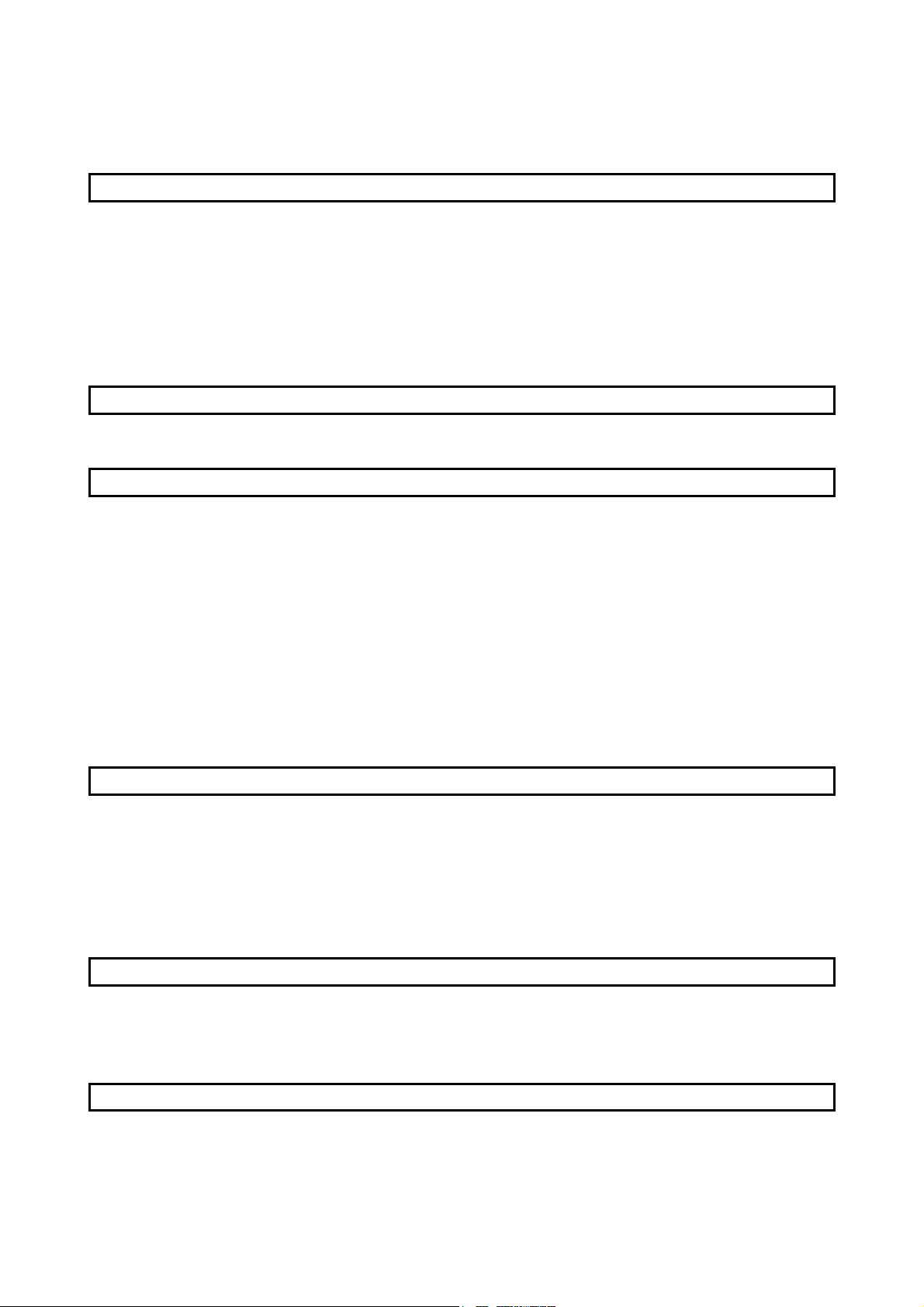

1.2 System configuration

Master

Controller

CN10A

Slave

MR-J3-_T

MR-J3-T10 MR-J3-_T MR-J3-T10MR-J3-_T MR-J3-T10

CN10A

CN10A

CNP3

CN2

CN10B

CNP3

CN2

CN10B

1.3 Standard specifications

Model MR-J3-T10

Control circuit

power supply

I/O interfaces CC-Link IE Field Network interface

Number of communication ports 2 (CN10A connector/CN10B connector)

Structure Natural-cooling, open (IP rating: IP 00)

Environment

Mass [g] 150

Voltage 5 V DC (supplied from the servo amplifier)

Rated current [A] 0.8

Ambient

temperature

Ambient

humidity

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude 1000 m or less above sea level

Vibration resistance 5.9 m/s

Operation

Storage

Operation

Storage

0 °C to 55 °C (non-freezing)

-20 °C to 65 °C (non-freezing)

90 %RH or less (non-condensing)

2

at 10 Hz to 55 Hz (X, Y and Z axes)

CNP3

CN2

CN10B

1 - 1

Page 9

1. FUNCTIONS AND CONFIGURATION

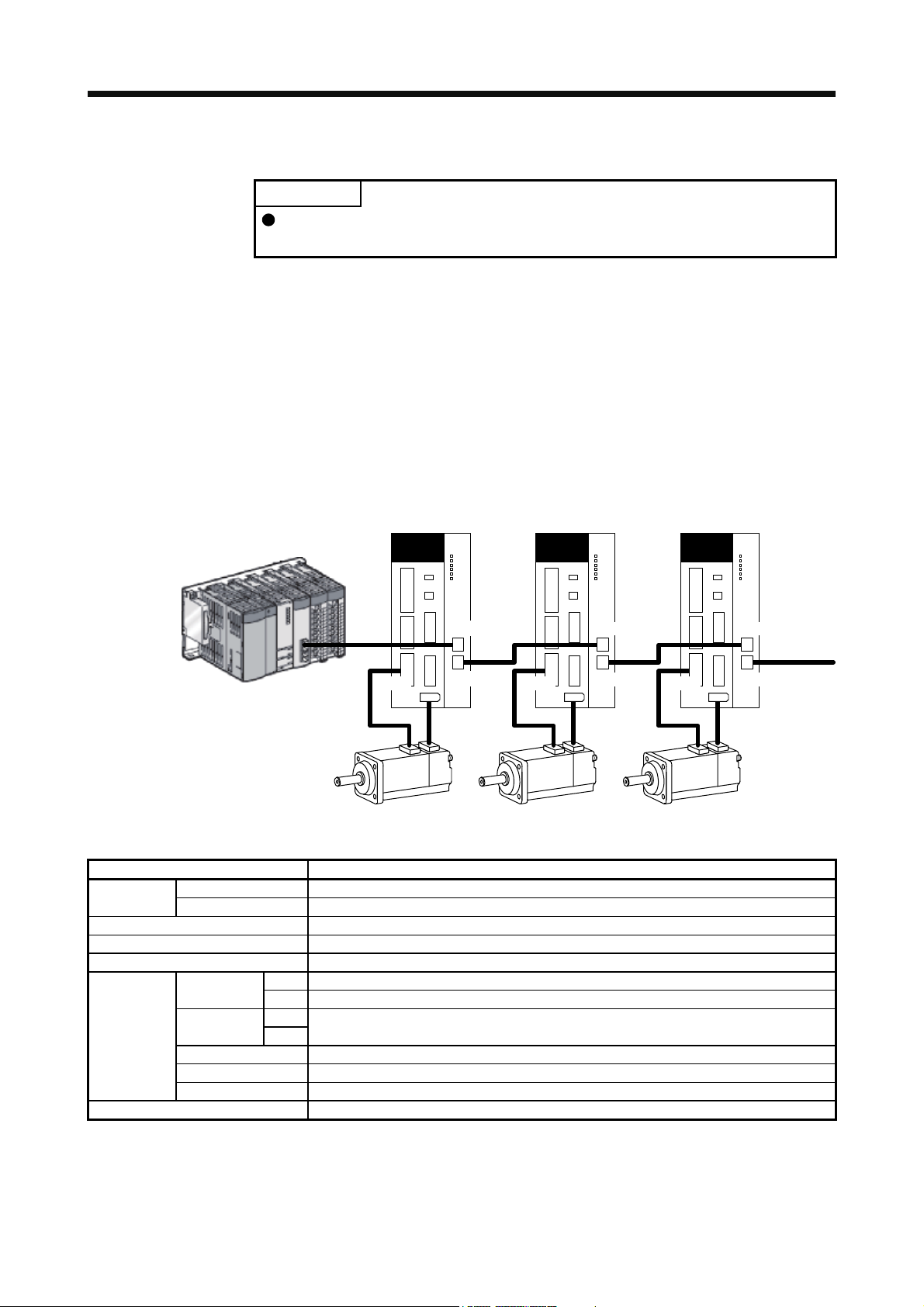

1.4 Rating plate

MODEL

POWER

INPUT

OUTPUT

SERIAL

1.5 Connector/interface

MR-J3-T10

RUN

ERR.

D LINK

SD

RD

L.ERR

CN10ACN10B

PUSH PUSH

CC-Link IE Field Network

communication connector (CN10A)

CC-Link IE Field Network

communication connector (CN10B)

1.6 Contents of the package

MR-J3-T10

:

IP00 MANUAL IB-0300171

1.5A 3PH+1PH

:

3PH+1PH200-230V

2.2A 1PH 200-230V

:

170V 0-360Hz 1.5A

:

For the wiring of CC-Link IE Field Network, use the following

wiring tools recommended by the CC-Link Partner Association.

Items Description

Cable type Shielded twisted pair cable (Category 5e)

Standard

Connector Category 5e or more RJ-45 plug

Commercially available products (as of April 2012)

Model Manufacturer Contact (Note)

SC-E5EW(-L)

(Note 1)

Note. The SC-E5EW cable is for in-enclosure and indoor uses. The SC-E5EW-

L cable is for outdoor use.

The CC-Link IE controller network cable cannot be used for the

CC-Link IE Field Network.

Model

IP rating Installation guide

Serial number

One of the following standards must be met.

IEEE802.3 1000BASE-T

ANSI/TIA/EIA-568-B (Category 5e)

Mitsubishi Electric System &

Service

email: oss-ip@melsc.jp

Contents Quantity

MR-J3-T10 CC-Link IE Field Network interface unit 1

MR-J3-T10 Installation Guide (IB(NA)0300159) 1

ZCAT1730-0730 data line filer (TDK) (Note 1) 2

Connector cover for CN10A/CN10B/CN3 (Note 2) 3

Note 1. Use the data line filters on the cables connected to the CN10A and CN10B connectors.

2. Two of the connector covers are already mounted on the CN10A and CN10B connectors when the

product is shipped from the factory. The other connector cover is for the CN3 connector of the MR-J3_T servo amplifier.

1 - 2

Page 10

1. FUNCTIONS AND CONFIGURATION

1.7 Installation and removal of the unit

Before installing or removing the unit, turn off the power and wait for 15 minutes

or more until the charge lamp turns off. Then, confirm that the voltage between P

WARNING

CAUTION

(+) and N (-) is safe with a voltage tester and others. Otherwise, an electric shock

may occur. In addition, when confirming whether the charge lamp is off or not,

always confirm it from the front of the servo amplifier.

Avoid installing and removing the unit repeatedly. Any contact failure of the

connector may be caused.

Avoid unsealing the unit to be free of dust and dirt against the connector except

installing. Make sure to use the pre-packing when storing.

Avoid using the unit of which the hook and knobs for fixing are damaged. Any

contact failure of the connector may be caused.

When installing and removing the unit to the MR-J3-500T or more, avoid dropping

out the installing screw inside it. Otherwise, it may cause a malfunction.

When installing and removing the unit to the MR-J3-500T or more, avoid

damaging the control board by the fixing plate. Otherwise, it may cause a

malfunction.

Make sure to tighten the unit with the enclosed installing screws when installing.

POINT

The internal circuits of the servo amplifier and the unit may be damaged by

static electricity. Always take the following precautions.

Ground human body and work bench.

Do not touch the conductive areas, such as connector pins and electrical

parts, directly by hand.

1 - 3

Page 11

1. FUNCTIONS AND CONFIGURATION

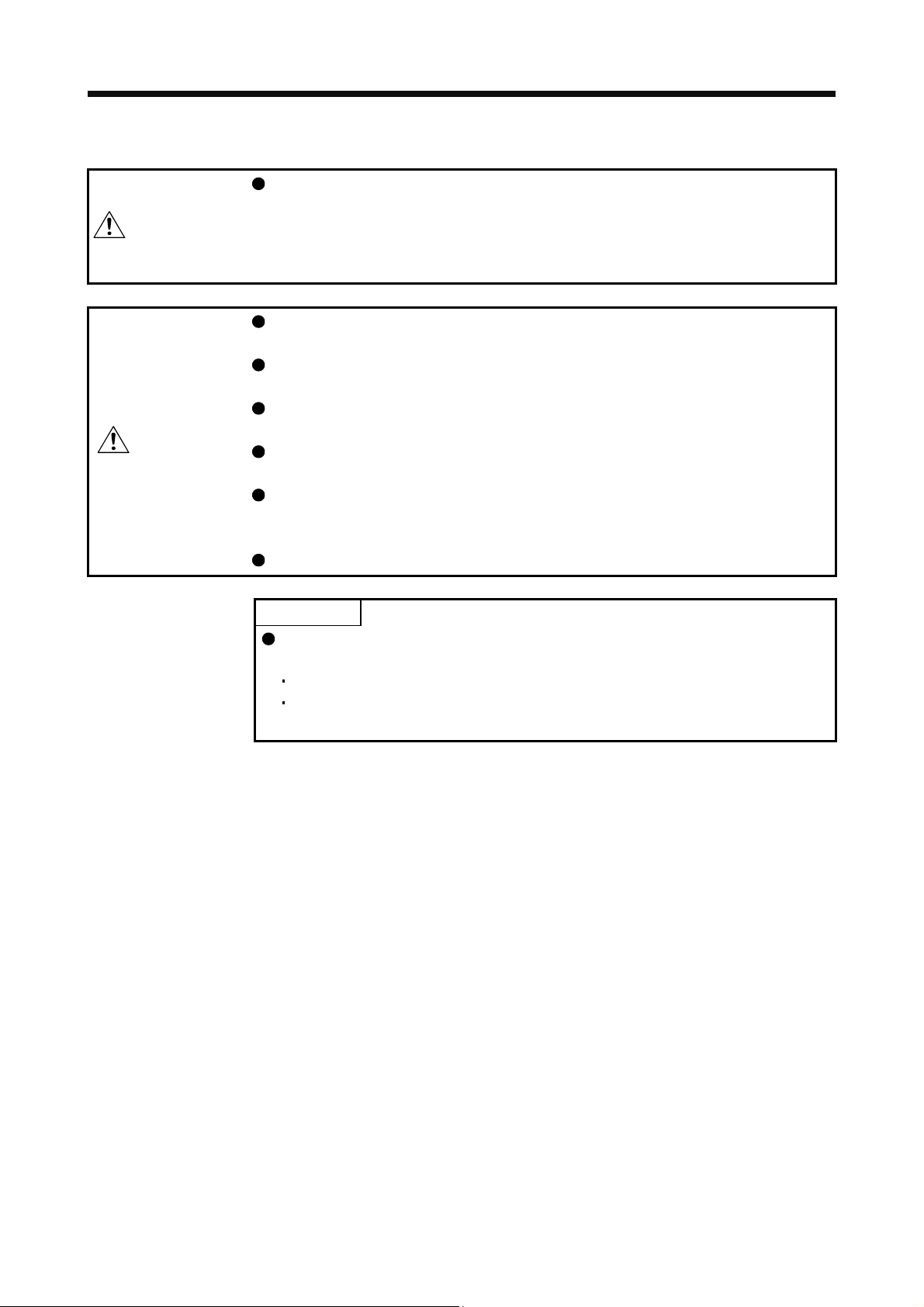

(1) MR-J3-350T or less/MR-J3-200T4 or less

(a) Installation of the unit

1)

Guide hole

2)

2)

Guide pins

Unit

(MR-J3-T10)

1) Remove the cover of connector for connecting

an option. Make sure to store the removed

cover.

2) Find the guide hole on the side of the servo

amplifier. To the guide hole, insert the unit's

guide pins.

Knobs

(b) Removal of the unit

a)

2)

3) Push the unit until the knobs click.

4) Tighten the unit with the enclosed installing

screw (M4).

4)

1) Remove the installing screw.

2) Keep pushing the knobs ( a) , b)) and pull out

the unit to the arrow direction. Avoid pulling out

the unit while it is tightened with the installation

1)

screw.

b)

When removing the unit, make sure to reinstall the

cover of connector for connecting an option to

avoid dust and dirt.

1 - 4

Page 12

1. FUNCTIONS AND CONFIGURATION

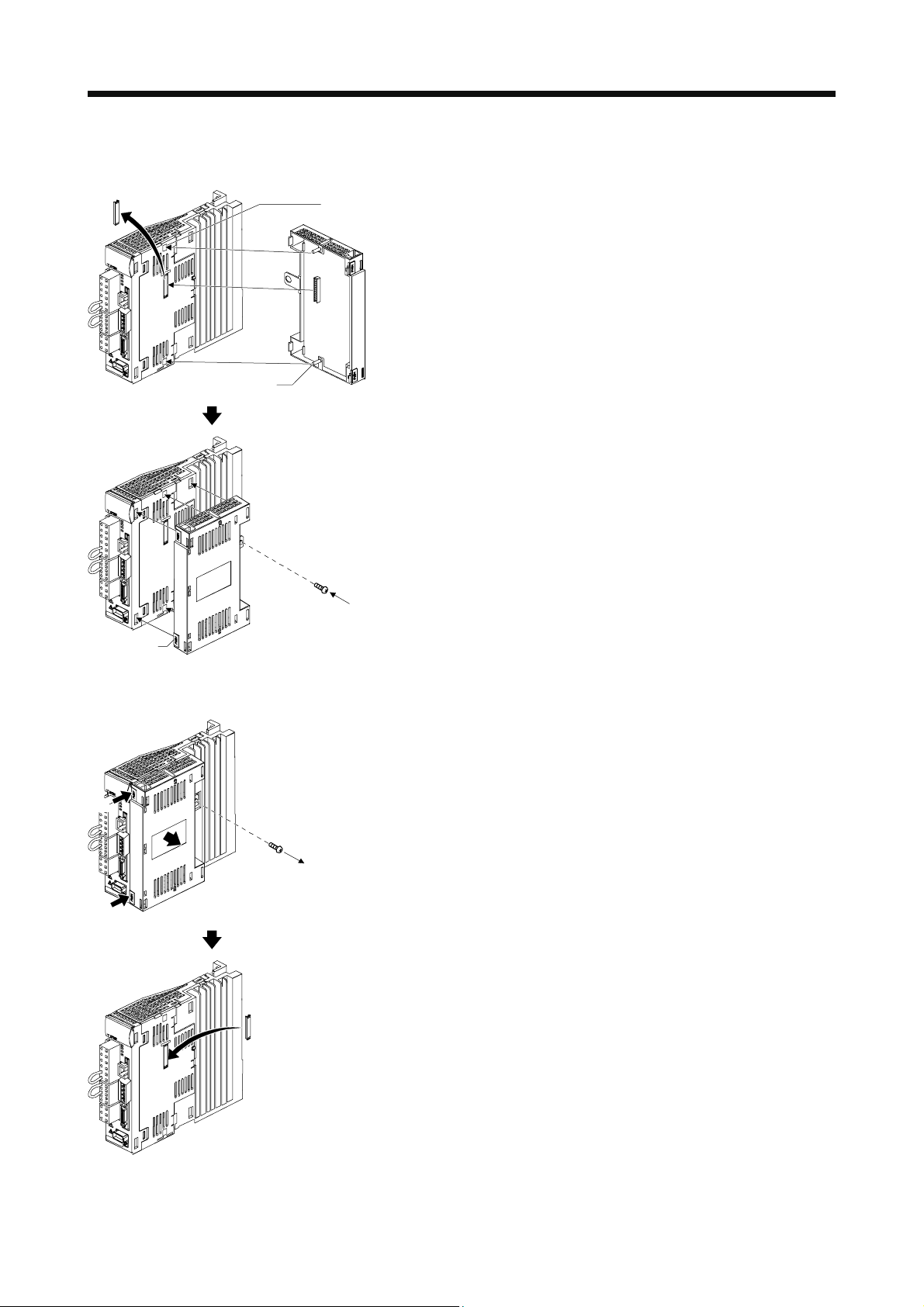

(2) MR-J3-350T4/MR-J3-500T(4)/MR-J3-700T(4)

(a) Removal of the side cover

a)

b)

(b) Installation of the unit

1)

Guide hole

1)

Keep pushing the knobs ( a) , b)) and pull out the

side cover to the arrow direction.

1) Find the guide hole on the side of the servo

amplifier. To the guide hole, insert the unit's

guide pins.

1)

Guide pins

2)

Knobs

(c) Removal of the unit

a)

2)

2) Push the unit until the knobs click.

3) Tighten the unit with the enclosed installing

screw (M4).

3)

1) Remove the installing screw.

2) Keep pushing the knobs ( a) , b)) and pull out

the unit to the arrow direction. Avoid pulling out

the unit while it is tightened with an installation

1)

screw.

b)

1 - 5

Page 13

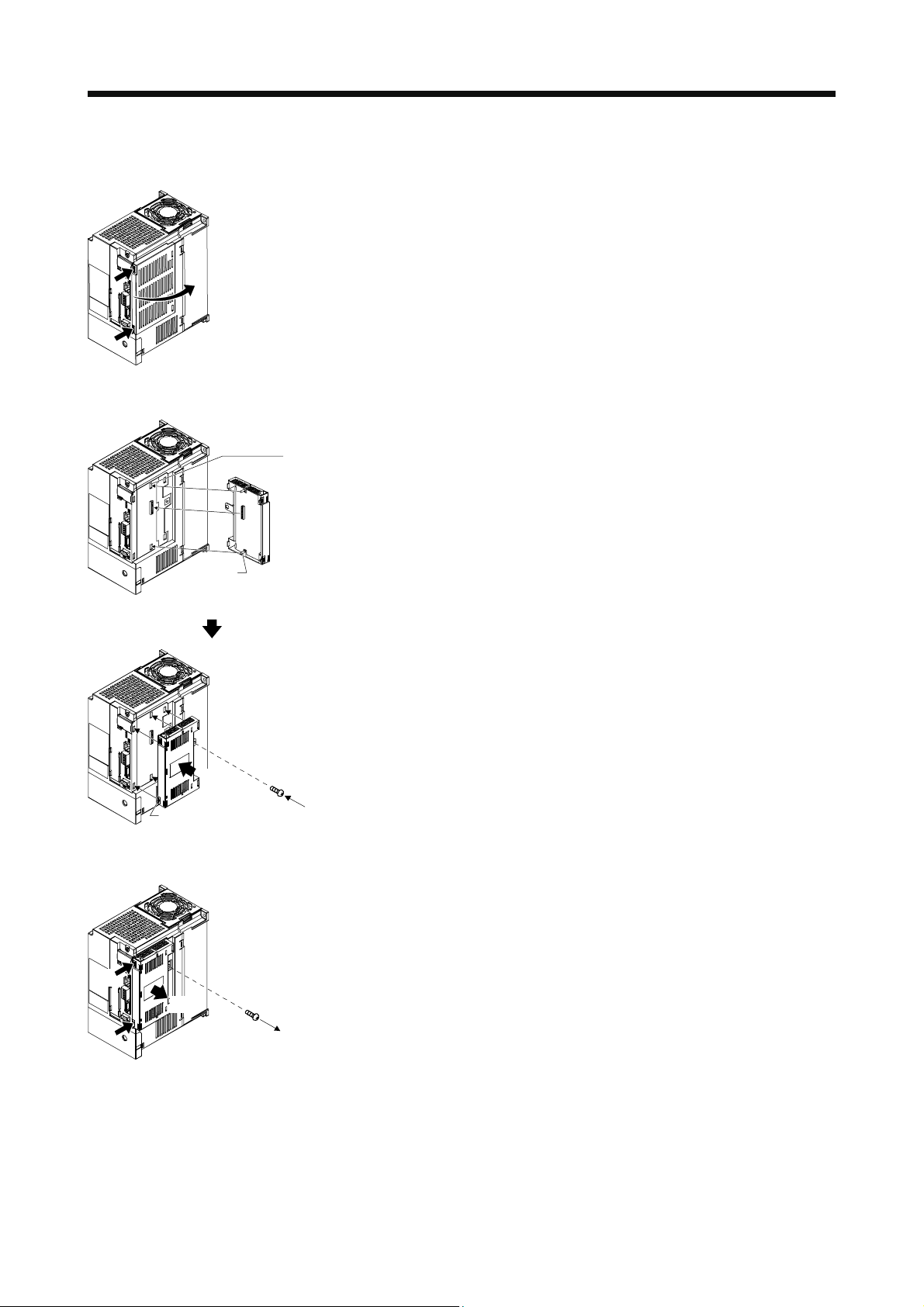

1. FUNCTIONS AND CONFIGURATION

(d) Installation of the side cover

a)

1)

1)

Hook of the side cover

1) Insert the side cover setting tabs into the

sockets a) of servo amplifier.

2) Push the side cover at the supporting point a)

until the knob clicks.

2)

Knob

(3) MR-J3-11KT(4) to MR-J3-22KT(4)

Avoid touching any remained burr after cutting off the part a) of the case.

CAUTION

Otherwise, injury may occur.

The installing screw holes for the MR-J3-11KT(4) to MR-J3-22KT(4) are covered at shipping. When

installing the unit for the first time, cut off the part a) of the case after removing the side cover.

When cutting off the part a), avoid damaging the case of the servo amplifier. After cutting off it, inside of

the servo amplifier has been exposed even though the side cover and the unit are installed. Avoid

unwanted parts from entering through the opened area into the servo amplifier. For installing or

removing the unit, refer to (2) in this section. The side cover structure is the same for MR-J3-11KT(4) to

MR-J3-22KT(4) and for this unit. Install or remove the side cover with the same way as for the unit.

However, the installing screw for the side cover is unnecessary.

a)

1 - 6

Page 14

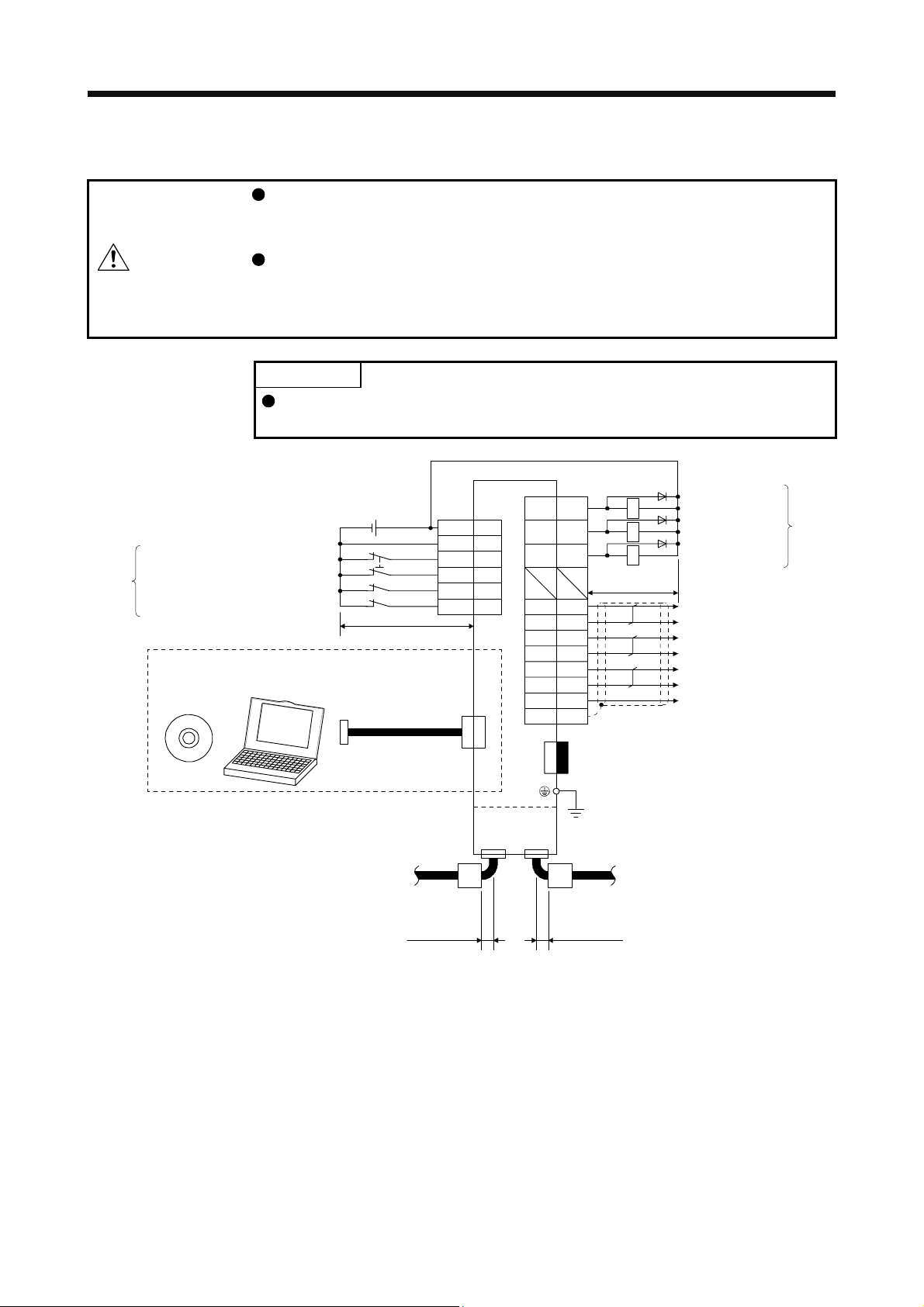

2. I/O SIGNAL CONNECTION EXAMPLE

2. I/O SIGNAL CONNECTION EXAMPLE

This chapter describes an example of connecting I/O signals. For details of MRJ3-_T signals and how to connect them, be sure to refer to the chapter 4 of MRJ3-_T Servo Amplifier Instruction Manual.

CAUTION

(Note 3, 5)

(Note 9)

(Note 5)

(Note 8)

(Note 7)

MR Configurator/

MR Configurator2

Forced stop

Proximity dog

Forward rotation stroke end

Reverse rotation stroke end

Connecting the CC-Link IE Field Network cable to the CN3 connector on MR-J3_T causes malfunctions in network devices. Pay attention when connecting the

CC-Link IE Field Network cable because the CN3, CN10A, and CN10B

connectors have the same shape.

POINT

Use MR Configurator of MRZJW3-SETUP221E (software version C4 or above).

Use MR Configurator2 of SW1DNC-MRC2-E (software version 1.10L or above).

Servo amplifier

24 V DC (Note 4)

10 m or less

Personal

computer

MR-J3USBCBL3M

(Option)

+

CN6

DICOM

DOCOM

EMG

DOG

LSP

LSN

CN5

CN6

14 RD

5

17

1

2

3

4

15

16 ZP

13

26

11

24

12

25

23

Plate

CN3

ALM

LZ

LZR

LA

LAR

LB

LBR

LG

SD

(Note 1)

(Note 2)

RA1

RA3

RA4

10 m or less

(Note 12)

Connector cover

Ready

Malfunction (Note 6)

Home position

return completion

Encoder Z-phase pulse

(differential line driver)

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

Control common

(Note 9)

MR-J3-T10

(Note 10, 11)

CN10B

CN10A

CC-Link IE Field Network

Data line filter

ZCAT1730-0730 (TDK)

Data line filter

ZCAT1730-0730 (TDK)

80 mm or less 80 mm or less

CC-Link IE Field Network

2 - 1

Page 15

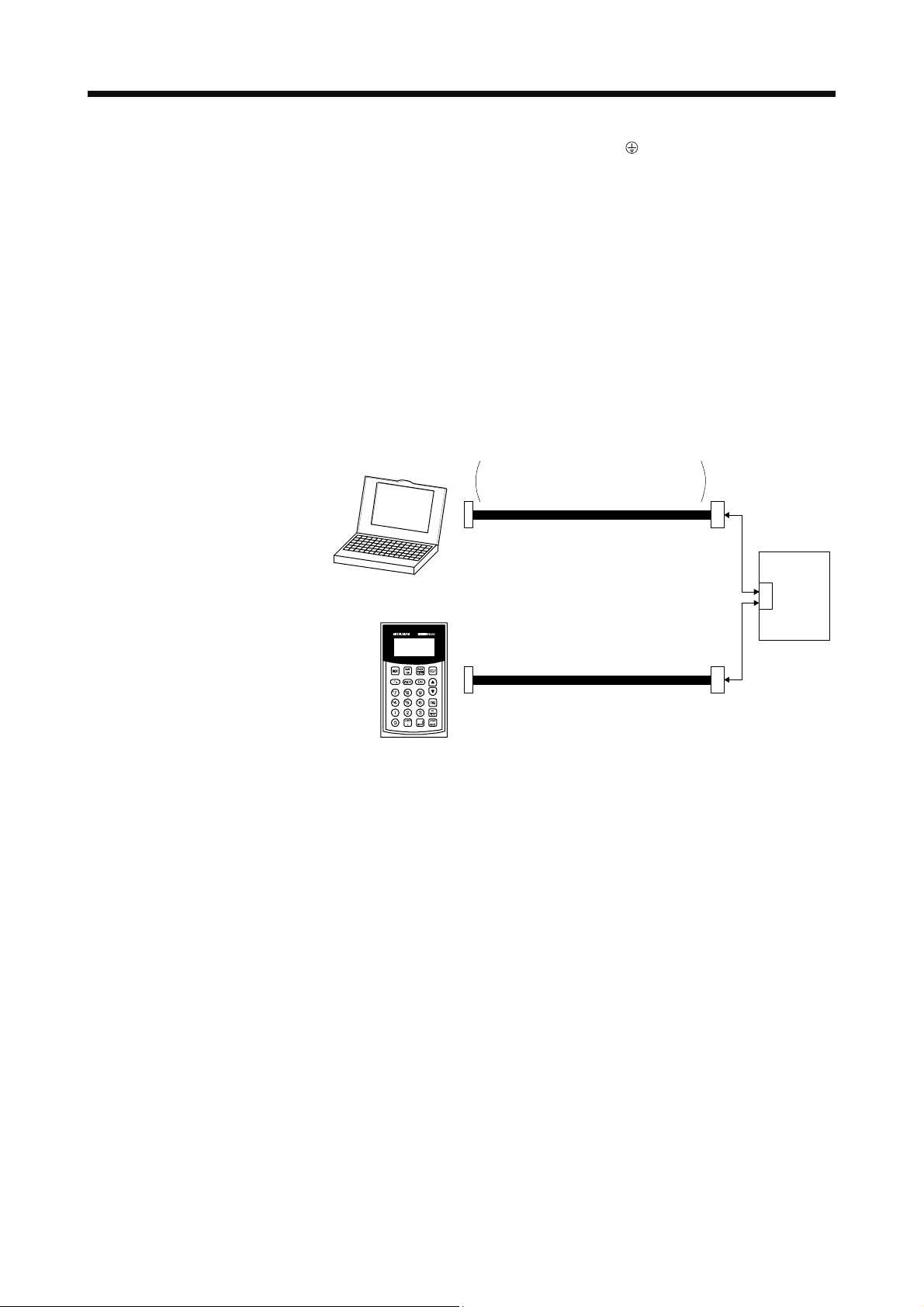

2. I/O SIGNAL CONNECTION EXAMPLE

r

Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the

protective earth (PE) of the cabinet.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will be faulty and will not output

signals, disabling EMG (Forced stop) and other protective circuits.

3. The forced stop switch (normally closed contact) must be installed.

4. Supply 24 V DC ± 10% 150 mA current for interfaces from the outside. 150 mA is the value applicable when all I/O signals are

used. The current capacity can be decreased by reducing the number of I/O points. Refer to section 4.8.2 (1) in MR-J3-_T

Servo Amplifier Instruction Manual that gives the current value necessary for the interface.

5. When starting operation, always turn on EMG (Forced stop) and LSP/LSN (Forward/Reverse rotation stroke end). (Normally

closed contact)

6. ALM (Malfunction) turns on in normal alarm-free condition.

7. Use MR Configurator of MRZJW3-SETUP221E (software version C4 or above). Use MR Configurator2 of SW1DNC-MRC2-E

(software version 1.10L or above).

8. Personal computers or parameter units can also be connected via the CN3 connector, enabling RS-422 communication. Note

that using the USB communication function (CN5 connector) prevents the RS-422 communication function (CN3 connector)

from being used, and vice versa. They cannot be used together.

Personal compute

RS-232C/RS-422 conversion cable

Recommended product: Interface cable

DSV-CABV

(Diatrend)

To RS-232C connector

or

MR-PRU03

parameter unit

EIA568-compliant cable (10BASE-T cable, etc.)

9. This diagram is for sink I/O interface. For source I/O interface, refer to section 4.8.3 in MR-J3-_T Servo Amplifier Instruction

Manual.

10. Note that using the CC-Link IE Field Network communication function prevents the CC-Link communication function from

being used, and vice versa. They cannot be used together.

11. Connecting the CC-Link IE Field Network cable to the CN3 connector of MR-J3-_T causes malfunctions in network devices.

Pay attention when connecting the CC-Link IE Field Network cable because the CN3, CN10A, and CN10B connectors have

the same shape. Connector covers are mounted on the CN10A and the CN10B connectors when the product is shipped from

the factory. Remove those connector covers to connect the CC-Link IE Field Network cables.

12. To avoid incorrect connection, set a connector cover, which is supplied with MR-J3-T10, to the CN3 connector of MR-J3-_T.

Servo amplifier

CN3

2 - 2

Page 16

3. PARAMETERS

3. PARAMETERS

The MR-J3-_T parameters during CC-Link IE Field Network communication are

CAUTION

3.1 Basic setting parameters [Pr. PA_ _ ]

the same with the parameters during CC-Link communication, except for [Pr.

Po34] and [Pr. Po35]. Refer to the chapter 6 of MR-J3-_T Servo Amplifier

Instruction Manual for the details of the parameters not listed in this chapter.

POINT

Parameter whose symbol is preceded by * is made valid with the following

conditions.

*: After setting the parameter, turn off the power and then on again.

No. Symbol Name

PA01 *STY Control mode 0000h

PA02 *REG Regenerative option 0000h

PA03 *ABS Absolute position detection system 0000h

PA04 *AOP1 Function selection A-1 0000h

PA05 *FTY Feeding function selection 0000h

PA06 *CMX Electronic gear numerator 1

PA07 *CDV Electronic gear denominator 1

PA08 ATU Auto tuning mode 0001h

PA09 RSP Auto tuning response 12

PA10 INP In-position range 100 µm

PA11 TLP Forward rotation torque limit 100.0 %

PA12 TLN Reverse rotation torque limit 100.0 %

PA13 This parameter is not used. Do not change this value by any means. 0002h

PA14 *POL Rotation direction selection 0

PA15 *ENR Encoder output pulses 4000 pulse/rev

PA16 This parameter is not used. Do not change this value by any means. 0

PA17 0000h

PA18

PA19 *BLK Parameter write inhibit 000Ch

0000h

Initial

value

Unit

3 - 1

Page 17

3. PARAMETERS

3.2 Gain/filter parameters [Pr. PB_ _ ]

No. Symbol Name

PB01 FILT Adaptive tuning mode (adaptive filter II) 0000h

PB02 VRFT

PB03 This parameter is not used. Do not change this value by any means. 0000h

PB04 FFC Feed forward gain 0 %

PB05 This parameter is not used. Do not change this value by any means. 500

PB06 GD2 Load to motor inertia ratio 7.0 Multiplier

PB07 PG1 Model loop gain 24 rad/s

PB08 PG2 Position loop gain 37 rad/s

PB09 VG2 Speed loop gain 823 rad/s

PB10 VIC Speed integral compensation 33.7 ms

PB11 VDC Speed differential compensation 980

PB12 This parameter is not used. Do not change this value by any means. 0

PB13 NH1 Machine resonance suppression filter 1 4500 Hz

PB14 NHQ1 Notch shape selection 1 0000h

PB15 NH2 Machine resonance suppression filter 2 4500 Hz

PB16 NHQ2 Notch shape selection 2 0000h

PB17 Automatic setting parameter

PB18 LPF Low-pass filter setting 3141 rad/s

PB19 VRF1 Vibration frequency for vibration suppression control 100.0 Hz

PB20 VRF2 Resonance frequency for vibration suppression control 100.0 Hz

PB21 This parameter is not used. Do not change this value by any means. 0.00

PB22

PB23 VFBF Low-pass filter selection 0000h

PB24 *MVS Slight vibration suppression control selection 0000h

PB25 This parameter is not used. Do not change this value by any means. 0000h

PB26 *CDP Gain switching selection 0000h

PB27 CDL Gain switching condition 10

PB28 CDT Gain switching time constant 1 ms

PB29 GD2B Load to motor inertia ratio after gain switching 7.0 Multiplier

PB30 PG2B Gain changing position loop gain 37 rad/s

PB31 VG2B Gain changing speed loop gain 823 rad/s

PB32 VICB Gain switching speed integral compensation 33.7 ms

PB33 VRF1B Vibration frequency for vibration suppression control after gain switching 100.0 Hz

PB34 VRF2B Resonance frequency for vibration suppression control after gain switching 100.0 Hz

PB35 This parameter is not used. Do not change this value by any means. 0.00

PB36 0.00

PB37 100

PB38 0

PB39 0

PB40 0

PB41 1125

PB42 1125

PB43 0004h

PB44 0000h

PB45

Vibration suppression control tuning mode (advanced vibration suppression

control)

0.00

0000h

Initial

value

0000h

Unit

3 - 2

Page 18

3. PARAMETERS

3.3 Extension setting parameters [Pr. PC_ _ ]

3.3.1 Parameter list

No. Symbol Name

Initial

value

Unit

PC01 This parameter is not used. Do not change this value by any means. 0000h

PC02 *ZTY Home position return type 0000h

PC03 *ZDIR Home position return direction 0001h

PC04 ZRF Home position return speed 500 r/min

PC05 CRF Creep speed 10 r/min

PC06 ZST Home position shift distance 0 µm

PC07 *ZPS Home position return data 0 × 10

PC08 DCT Moving distance after proximity dog 1000 × 10

STM

STM

µm

µm

PC09 ZTM Stopper type home position return stopper time 100 ms

PC10 ZTT Stopper type home position return torque limit value 15.0 %

PC11 CRP Rough match output range 0 × 10

STM

µm

PC12 JOG Jog speed 100 r/min

PC13 *STC S-shaped acceleration/deceleration time constant 0 ms

PC14 *BKC Backlash compensation 0 pulse

PC15 This parameter is not used. Do not change this value by any means. 0000h

PC16 MBR Electromagnetic brake sequence output 100 ms

PC17 ZSP Zero speed 50 r/min

PC18 *BPS Alarm history clear 0000h

PC19 *ENRS Encoder output pulses selection 0000h

PC20 *SNO Station number setting 0 station

PC21 *SOP RS-422 communication function selection 0000h

PC22 *COP1 Function selection C-1 0000h

PC23 This parameter is not used. Do not change this value by any means. 0000h

PC24 *COP3 Function selection C-3 0000h

PC25 This parameter is not used. Do not change this value by any means. 0000h

PC26 *COP5 Function Selection C-5 0000h

PC27 This parameter is not used. Do not change this value by any means. 0000h

PC28 *COP7 Function selection C-7 0000h

PC29 This parameter is not used. Do not change this value by any means. 0000h

PC30 *DSS Remote register-based position/speed specifying system selection 0000h

PC31 LMPL Software limit + 0 × 10

PC32 LMPH

PC33 LMNL Software limit - 0 × 10

STM

STM

µm

µm

PC34 LMNH

PC35 TL2 Internal torque limit 2 100.0 %

PC36 This parameter is not used. Do not change this value by any means. 0000h

PC37 *LPPL Position range output address + 0 × 10

PC38 *LPPH

PC39 *LNPL Position range output address - 0 × 10

STM

STM

µm

µm

PC40 *LNPH

PC41 This parameter is not used. Do not change this value by any means. 0000h

PC42 0000h

PC43 0000h

PC44 0000h

PC45 0000h

PC46 0000h

PC47 0000h

PC48 0000h

PC49

0000h

PC50 *COPA Function selection C-A 0000h

3 - 3

Page 19

3. PARAMETERS

3.3.2 Detail description

POINT

The parameter names of [Pr. PC50] is not displayed with the following versions

of MR Configurator/MR Configurator2. However, this setting value is

changeable. Follow the instructions in this Instruction Manual to set a value.

MRZJW3-SETUP221E: software version C3 or below

SW1DNC-MRC2-E: software version 1.09K or below

No. Symbol Name and function

PC50 *COPA Function selection C-A

000

[AL. 8D CC-Link IE communication error] extended

function selection

0: No extended function

1: Delayed [AL. 8D] detection

Use [Pr. PD25] to set how long to delay the

occurrence timing of [AL. 8D].

Initial

value

0000h Refer to

Setting

range

Name

and

function

column.

Unit

3 - 4

Page 20

3. PARAMETERS

3.4 I/O setting parameters [Pr. PD_ _ ]

3.4.1 Parameter list

No. Symbol Name

PD01 *DIA1 Input signal automatic on selection 1 0000h

PD02 This parameter is not used. Do not change this value by any means. 0000h

PD03 *DIA3 Input signal automatic on selection 3 0000h

PD04 *DIA4 Input signal automatic on selection 4 0000h

PD05 This parameter is not used. Do not change this value by any means. 0000h

PD06 *DI2 Input signal device selection 2 (CN6-2) 002Bh

PD07 *DI3 Input signal device selection 3 (CN6-3) 000Ah

PD08 *DI4 Input signal device selection 4 (CN6-4) 000Bh

PD09 *DO1 Output signal device selection 1 (CN6-14) 0002h

PD10 *DO2 Output signal device selection 2 (CN6-15) 0003h

PD11 *DO3 Output signal device selection 3 (CN6-16) 0024h

PD12 DIN1 External DI function selection 1 0C00h

PD13 This parameter is not used. Do not change this value by any means. 0000h

PD14 DIN3 External DI function selection 3 0800h

PD15 This parameter is not used. Do not change this value by any means. 0000h

PD16 *DIAB Input polarity selection 0000h

PD17 This parameter is not used. Do not change this value by any means. 0000h

PD18

PD19 *DIF Input filter setting 0002h

PD20 *DOP1 Function selection D-1 0010h

PD21 This parameter is not used. Do not change this value by any means. 0000h

PD22 *DOP3 Function selection D-3 0000h

PD23 This parameter is not used. Do not change this value by any means. 0000h

PD24 *DOP5 Function selection D-5 0000h

PD25 A8DT [AL. 8D CC-Link IE communication error] detection time 0000h ms

PD26 This parameter is not used. Do not change this value by any means. 0000h

PD27 0000h

PD28 0000h

PD29 0000h

PD30

0000h

0000h

Initial

value

Unit

3 - 5

Page 21

3. PARAMETERS

3.4.2 Detail description

POINT

The parameter names of [Pr. PD25] is not displayed with the following versions

of MR Configurator/MR Configurator2. However, this setting value is

changeable. Follow the instructions in this Instruction Manual to set a value.

MRZJW3-SETUP221E: software version C3 or below

SW1DNC-MRC2-E: software version 1.09K or below

No. Symbol Name and function

PD25 A8DT [AL. 8D CC-Link IE communication error] detection time

Selecting the [AL. 8D] detection time in [Pr. PC50] activates the time setting of

[AL. 8D].

It is 10 ms when [Pr. PC50] = "0".

Convert a decimal value to a hexadecimal value for input.

The setting range is up to 1000 ms. A set value is limited within the setting

range.

For example) If "03E8h" is set, the set value becomes 1000 ms.

The converted decimal value of "1388h" is 10000 ms, but it is

limited to 1000 ms, which is the upper limit of the setting range.

Initial

value

0000h 0000h

Setting

range

to

03E8h

Unit

ms

If [AL. 8D CC-Link IE

communication error] does not

have to be detected, use the

communication time-out setting in

the initial setting. When you

CAUTION

change the setting value, do not

set an unnecessarily long time

period. Doing so interferes swift

stop operation at an occurrence of

[AL. 8D CC-Link IE

communication error].

3 - 6

Page 22

3. PARAMETERS

3.5 Option unit parameters [Pr. Po_ _ ]

3.5.1 Parameter list

No. Symbol Name

Po01 This parameter is not used. Do not change this value by any means. 0000h

Po02 0302h

Po03 0905h

Po04 2524h

Po05 2026h

Po06 0427h

Po07 0807h

Po08 2726h

Po09 0423h

Po10 2101h

Po11 0000h

Po12 0000h

Po13 0000h

Po14 0001h

Po15 0

Po16 0

Po17 0

Po18 0

Po19 0

Po20 0

Po21 0

Po22 0

Po23 0000h

Po24 0050h

Po25 0200h

Po26 0

Po27 0

Po28 0

Po29 0000h

Po30 0000h

Po31 0000h

Po32 0000h

Po33

Po34 *STNO CC-Link IE communication station number selection 0000h

Po35 *NWNO CC-Link IE communication network number 0000h

0000h

Initial

value

Unit

3 - 7

Page 23

3. PARAMETERS

3.5.2 Detail description

POINT

The parameter names of [Pr. Po34] and [Pr. Po35] are not displayed with the

following versions of MR Configurator/MR Configurator2. However, their setting

values are changeable. Follow the instructions in this Instruction Manual to set a

value.

MRZJW3-SETUP221E: software version C3 or below

SW1DNC-MRC2-E: software version 1.09K or below

No. Symbol Name and function

Po34 *STNO CC-Link IE communication station number selection

Use this parameter to set the station number of the servo amplifier.

Convert a decimal value to a hexadecimal value for input.

If you are using an automatic station number, which is designated by the

master station, do not change the initial value "0000h".

If you are designating a station number, set a value in the range of 1 to 120

(0001h to 0078h). A value higher the maximum value will trigger [AL. 37

parameter error].

For example) The setting value "0078h" sets the station number of 120.

The setting value "0079h" or a higher will trigger [AL. 37

parameter error].

Po35 *NWNO CC-Link IE communication network number

Use this parameter to set the network number of the servo amplifier.

Convert a decimal value to a hexadecimal value for input.

The network number is 1 at the initial value of "0000h".

The maximum setting value for the network number is 239.

A value higher than the maximum value will trigger [AL. 37 parameter error].

For example) The setting value "00EFh" sets the station number of 239.

The setting value "012Ch" will trigger [AL. 37 parameter error].

If an automatic number has been selected with [Pr. Po34] and the rotary

switch on the MR-J3-_T, this parameter setting is ignored. Instead, the

network number transmitted from the master station is used.

Initial

value

0000h 0000h

0000h 0000h

Setting

range

to

0078h

to

00EFh

Unit

3 - 8

Page 24

4. DISPLAY/OPERATING PARTS

4. DISPLAY/OPERATING PARTS

4.1 MR-J3-_T servo amplifier

4.1.1 Explanation on the display/operating parts

5

6

4

7

3

8

2

9

1

0

5

5

6

4

3

2

6

4

7

7

3

8

8

2

9

1

9

1

0

0

Name/application

Display

The 3-digit, seven-segment LED shows the servo status and alarm

number.

Baud rate switch (MODE)

MODE

5

6

4

Do not change the initially set value (0).

7

3

8

2

9

1

0

Station number switches (STATION NO.)

For the setting method, refer to the section 4.3.

X10 STATION NO. X1

5

5

6

4

3

2

1

6

4

7

7

3

8

8

2

9

9

1

0

0

Set the ones place.

Set the tens place.

Occupied station count switch (SW1)

SW1

Do not change the initial setting (off).

4 - 1

Page 25

4. DISPLAY/OPERATING PARTS

4.1.2 Display details

On the servo amplifier display (three-digit, seven-segment display), check the status of communication with

the CC-Link IE controller at power-on, check the station number, and diagnose a fault at occurrence of an

alarm.

The table below shows the details.

Display Status Description

b## CC-Link IE communication

waiting

(Note 1) d## Ready Servo-on has been performed after initialization, and it is ready for operation. (The

(Note 1) C## Not ready Initialization is in progress, or an alarm has occurred.

(Note 2) $$$ Drive enabled The drive enabled condition has lasted for 2 s after turning on RYn1 (servo-on).

(Note 3) A** Alarm/Warning The alarm No./warning No. that occurred is displayed.

888 CPU Error CPU watchdog error has occurred.

(Note 4) b00 JOG operation, positioning operation, program operation, DO forced output, and 1

(Note 1) d##.

C##.

(Note 4)

Test operation mode

Note 1. ## denotes any of symbols or numerals of -- or 00 to C0 and what it means is listed below.

2. $$$ indicates the number of the point table No. being executed. $$$ is a number between 0 and 255.

3. ** indicates the warning/alarm No.

4. MR Configurator/MR Configurator2 or an MR-PRU03 parameter unit is required.

4.1.3 Unspecified station number

Power of the servo amplifier was switched on at the condition that the power of the

CC-Link IE master module is off.

CC-Link IE master module is faulty.

display appears for 2 s.)

step feed

Motor-less operation

## Description

00 Set to the test operation mode.

-- For the station No. 0 (unset), refer to section 4.1.3.

01 Station No. 1

02 Station No. 2

: :

: :

99 Station No. 99

A0 Station No. 100

: :

: :

A9 Station No. 109

b0 Station No. 110

: :

: :

b9 Station No. 119

c0 Station No. 120

If 0 (unspecified) is set as the station number, the communication is performed with the station number set

by the master station.

Display

Servo amplifier

power on

b- - cAO

CC-Link IE communication starts

Station No.100 designated by the master station

4 - 2

Page 26

4. DISPLAY/OPERATING PARTS

4.2 MR-J3-T10 IE Field Network interface unit

The table below shows the detailed description of the communication alarm display area. MR-J3-T10 has

eight LEDs.

Table 4.1 LED display description

MR-J3-T10

No. LED Name

1 RUN Operating status Lit Operating normally (RUN status)

RUN

ERR.

D LINK

SD

RD

L.ERR

Red

Red

Green

2 D LINK Cyclic communication

status

Flashing Data not linked (after parameter frame

3 SD Network transmission

CN10ACN10B

Green (LINK)

Red (L.ER)

Green (LINK)

Red (L.ER)

4 RD Network reception

5 ERR. Unit error status Lit Unit error

6 L ERR. Communication error

status

status

status

7 L ER

PUSH PUSH

(port 1/2)

8 LINK

Communication error

status

Link status Lit Linking up

(port 1/2)

The table below shows display pattens for different statuses.

No. Status RUN D LINK ERR. L ERR.

1 Failure at start

2 Normal (condition before communication connection)

3 Normal (condition before cyclic commutation established)

4 Normal (during cyclic communication)

5 Failure occurred (communication disabled due to faulty MR-

J3-T10)

6 Failure occurred (cyclic communication stopped due to faulty

MR-J3-T10)

7 Failure occurred (WDT error)

8 Failure occurred (option card come off)

9 Failure occurred (cyclic communication stopped due to

incorrect setting)

10 Failure occurred (abnormal data received, data looped back)

11 Failure occurred (disconnection due to twisted pair cable

came off)

12 Failure occurred (cyclic data not received)

13 Failure occurred (abnormal station/network number

designated by the master)

14 Reserved station specification

LED

status

Extinguished

Hardware fault (WDT error)

Description

Lit Linking data (cyclic transmitting)

received)

Extinguished

Data not linked (disconnecting)

Lit Data transmitting

Lit Data receiving

Extinguished

Nothing abnormal

Lit Receiving abnormal data. Or, data is looped

back to its own station.

Lit Receiving abnormal data. Or, data is looped

back to its own station.

L ER

(port)

- - - A74

- - - A74

LINK

(port)

- b**

- b**

- c**

- A74

- A74

-

-

- - A9E

- A9d

- A8d

- A8d

- A8d

- A8d

( : lit, : extinguished, : flashing, -: refer to Table 4.1.)

Servo

amplifier

display

A37

A8d

A75

4 - 3

Page 27

4. DISPLAY/OPERATING PARTS

4.3 Selecting the station number and network number

(1) How to number the stations

Set the servo station numbers before powering on the servo amplifiers. Station numbers may be set

within the range 1 to 120.

(2) Station number setting method

(a) Use the station number switches (RSW1, RSW2) on the front face of the MR-J3-_T to select a

station number between 1 to 64. In the initial status, the station number is set to station 1. When the

station number is set to 0, communication is performed with the station number designated by the

master station.

X10 STATION NO. X1

5

5

6

4

3

2

1

(b) Use [Pr. Po34] to select the station number 65 or above. In this case, the setting made by the station

number switches is ignored.

(c) A station number command from a master module through CC-Link IE Field Network has a priority

over the command sources (a) and (b). For how to use the master station to designate a station

number to a servo amplifier, refer to the user's manual of the CC-Link IE Field Network master/local

module.

(3) Network number setting

Use [Pr. Po35] to set a network number to a servo amplifier. The network number can be set between 1

and 239. When the station number is set to 0, communication is performed with the station number

designated by the master station. In the initial status, 0 is set. For how to use the master station to

designate a network number, refer to the user's manual of the CC-Link IE Field Network master/local

module.

6

4

7

7

3

8

8

2

9

9

1

0

0

Set the ones place.

Set the tens place.

4 - 4

Page 28

5. TROUBLESHOOTING

5. TROUBLESHOOTING

POINT

This chapter describes about the alarms and warnings, which are different from

the ones displayed in the CC-Link communication operation. Refer to the

chapter 11 of MR-J3-_T Servo Amplifier Instruction Manual for the alarms and

warnings not listed in this chapter.

The alarm names of [AL. 74] and [AL. 75] are not displayed with the following

versions of MR Configurator/MR Configurator2, and the alarms of CC-Link

communication are displayed for [AL. 8D], [AL. 97], [AL. 9D], and [AL. 9E].

Replace the alarm cause, etc. to the ones listed in this instruction manual.

MRZJW3-SETUP221E: software version C3 or below

SW1DNC-MRC2-E: software version 1.09K or below

5 - 1

Page 29

5. TROUBLESHOOTING

5.1 Alarm and warning list

After its cause has been removed, the alarm can be deactivated in any of the methods marked

in the

alarm deactivation column. The alarm is automatically canceled after removing the cause of occurrence.

Alarm deactivation No. Name

No. Name

10 Undervoltage

12 Memory error 1 (RAM)

Alarm

13 Clock error

15 Memory error 2 (EEP-ROM)

16 Encoder error 1 (at power-on)

17 Board error

19 Memory error 3 (Flash-ROM)

1A Motor combination error

20 Encoder error 2

24 Main circuit error

25 Absolute position erased

30 Regenerative error (Note 1) (Note 1) (Note 1)

31 Overspeed

32 Overcurrent

33 Overvoltage

35 Command pulse frequency error

37 Parameter error

45 Main circuit device overheat (Note 1) (Note 1) (Note 1)

46 Servo motor overheat (Note 1) (Note 1) (Note 1)

47 Cooling fan error

50 Overload 1 (Note 1) (Note 1) (Note 1)

51 Overload 2 (Note 1) (Note 1) (Note 1)

52 Error excessive

61 Operation alarm

74 Option card error

75 Option card error 2

8A

8D CC-Link IE communication error

8E Serial communication error

888 Watchdog

Serial communication time-out

error

Power

off to on

(Note 3)

MR Configurator/

MR Configurator2

Parameter unit

97 Next station warning

99 Stroke limit warning

9D CC-Link IE warning 1

9E CC-Link IE warning 2

9F Battery warning

E0 Excessive regeneration warning

E1 Overload warning 1

ED Output watt excess warning

(Note 4)

(Note 2)

Alarm

reset

(Note 4)

Warning

E9 Main circuit off warning

EC Overload warning 2

Home position return

90

incomplete warning

Battery cable disconnection

92

warning

96 Home position setting warning

98 Software limit warning

Absolute position counter

E3

warning

E6 Servo forced stop warning

Cooling fan speed reduction

E8

warning

Note 1. Wait for about 30 minutes as cooling time after removing the cause of occurrence, then deactivate the alarm.

2. Turns on RY (n + 1) A or RY (n + 3) A.

3. Clicking the "Alarm reset" button on the "Alarm display" screen of MR Configurator/MR Configurator2 allows an alarm to be

deactivated.

Pressing the "STOP RESET" key of the parameter unit allows an alarm to be deactivated.

4. Deactivation of the alarm may not be possible. Refer to the section 5.2 for details.

5 - 2

Page 30

5. TROUBLESHOOTING

5.2 Remedies for alarms

When an alarm occurs, ALM (Malfunction) switches on and the dynamic brake is operated to stop the servo

motor. At this time, the display indicates the alarm No.

Remove the cause of the alarm in accordance with this section. MR Configurator/MR Configurator2 may be

used to refer to the cause.

No. Name Description Cause Action

74 Option card error MR-J3-T10 is not properly

recognized.

75 Option card error 2 MR-J3-T10 is not properly

recognized.

8D 1. The station number is set to 65 or

CC-Link IE

communication

error

3. The network number is set to a

4. The transmission status is

5. CC-Link IE Field Network

6. CC-Link IE Field Network cable

7. CC-Link IE Field Network cable

8. Noise entered the CC-Link IE Field

9. A reserved station has been

Normal communication with

the master station cannot be

made.

MR-J3-T10 faulty. Replace the MR-J3-T10.

Connection failure of MR-J3-T10. Check the connection between

MR-J3-T10 and a servo

amplifier.

Set the station within the range 1

higher.

2. The station number is set to a

value other than 1 to 120 with the

master station.

value other than 1 to 239 with the

master station.

abnormal.

connector has come off.

wiring incorrect.

faulty.

Network cable.

selected by the master station, and

the cyclic communication has

stopped.

to 64, and turn the power on.

Set a value in the range 1 to 120

with the master station. After the

cause has been removed, the

alarm can be deactivated with a

reset.

Set a value in the range 1 to 239

with the master station. After the

cause has been removed, the

alarm can be deactivated with a

reset .

Review the wiring. After the

cause has been removed, the

alarm can be deactivated with a

reset.

1. Connect the cable or

connector correctly.

2. Repair or change the CC-Link

IE Field Network cable.

After the cause has been

removed, the alarm can be

deactivated with a reset.

Take the noise reduction

measures. After the cause has

been removed, the alarm can be

deactivated with a reset.

Deselect the reserved station

with the master station.

5 - 3

Page 31

5. TROUBLESHOOTING

5.3 Remedies for warnings

If [AL. 98 Software limit warning] and [AL. E6 Servo forced stop warning] occur, the servo off status is

established. If any other warning occurs, operation can be continued but an alarm may take place or proper

operation may not be performed.

Remove the cause of warning according to this section. Use MR Configurator/MR Configurator2 to refer to a

factor of warning occurrence.

No. Name Description Cause Action

97 Next station

warning (out of

setting range

warning)

9D CC-Link IE

warning 1

9E CC-Link IE

warning 2

2. CC-Link IE Field Network

3. CC-Link IE Field Network cable

4. CC-Link IE Field Network cable

5. Communication with the master

6. Data is looped back to its own

Setting error of point

table/next station/speed

selection

The station number switch or

baud rate switch setting has

been changed after power-on.

Communication error with the

cable.

A number for point table/next

station/speed selection has been set

with the master station.

1. The station number switch setting

has been changed after power-on.

2. The setting at the master station

side is incorrect.

1. The transmission status is

abnormal.

connector has come off.

wiring incorrect.

faulty.

station is abnormal.

station in a ring connection.

For the point table/next

station/speed selection, set a

number within the setting range

with the master station.

Return to the setting at poweron.

Review the setting on the master

station side.

Take the noise reduction

measures.

1. Connect the cable or

connector correctly.

2. Change the CC-Link IE Field

Network cable.

Review the communication

setting on the master station

side.

1. Connect the cable or

connector correctly.

2. Change the CC-Link IE Field

Network cable.

5 - 4

Page 32

6. DIMENSIONS

6. DIMENSIONS

(1) MR-J3-T10

[Unit: mm]

28

20

MR-J3-T10

103

98

94

5 × 6 mounting hole for grounding

161

114.5

97

Rating plate

24.5

Mass: 0.15 kg

6 - 1

Page 33

6. DIMENSIONS

r

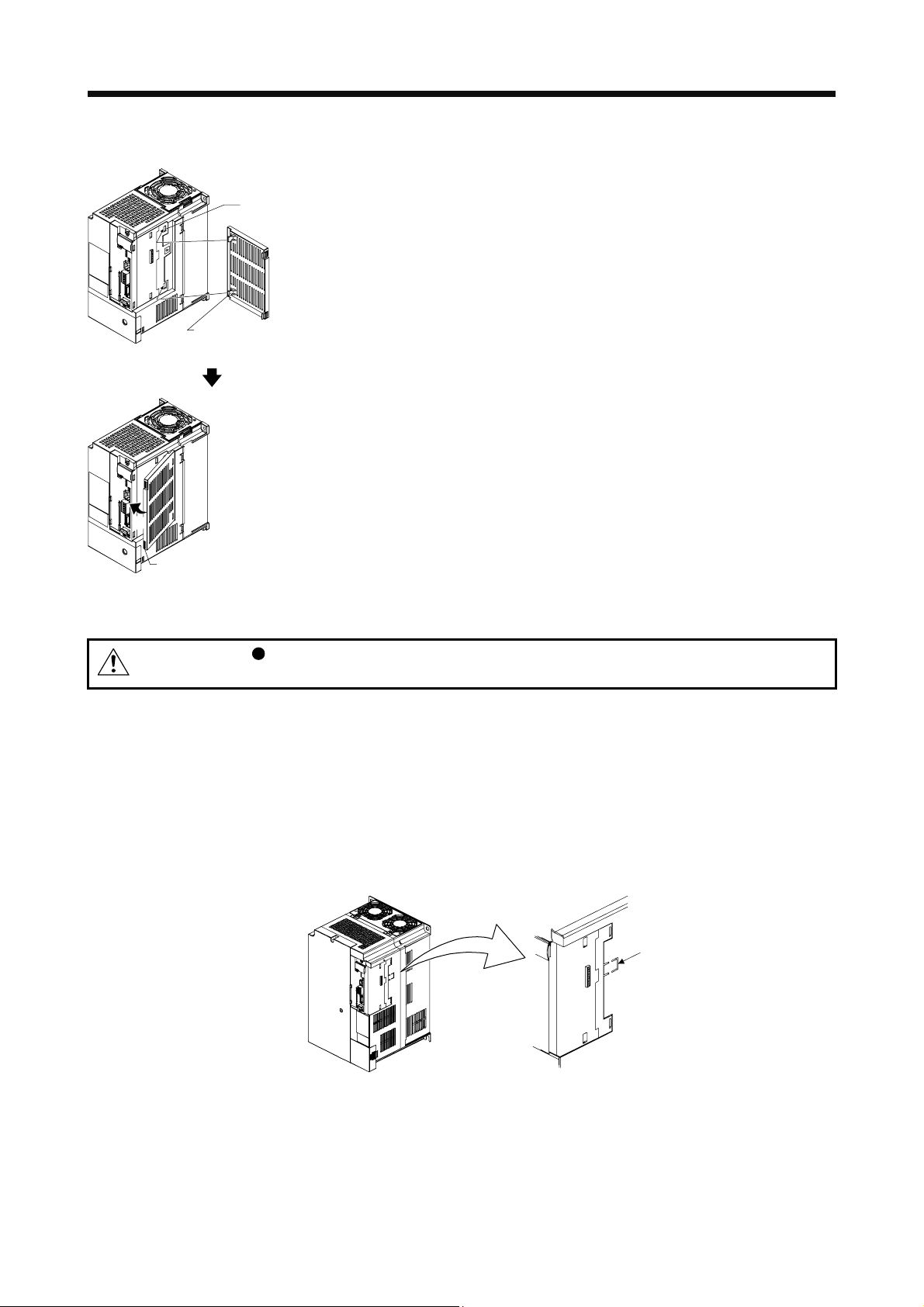

(2) When the unit is mounted on a servo amplifier

100 V/200 V 0.1 kW to 3.5 kW

400 V 0.6 kW to 2 kW

MR-J3-T10 MR-J3-T10

CN5

CNP1

CN3

CN1

CNP2

CN10A

CN6

CNP3

CN10B

CN2

CN4

L

200 V 5 kW/7 kW

400 V 3.5 kW to 7 kW

Servo amplifierServo amplifie

CN5

CN3

CN1

CN10A

CN6

CN10B

CN2

CN4

L

Servo amplifier L [mm]

MR-J3-10T1 to MR-J3-401

20

MR-J3-10T to MR-J3-100T

MR-J3-60T4 to MR-J3-100T4

MR-J3-200TN/MR-J3-350T

15

MR-J3-200T4

MR-J3-500T/MR-J3-700T

10

MR-J3-350T4 to MR-J3-700T4

MR-J3-11KT to MR-J3-22KT

0

MR-J3-11KT4 to MR-J3-22KT4

6 - 2

Page 34

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

7.1 System configuration

Item CC-Link IE Field Network

Network topology Line/start/ring

Variable communication speed 1 Gbps

Transmission speed between stations 100 m

Number of connected units Max. 120

7.2 Communication specifications

Item Description

Device type CC-Link IE Field Network intelligent device station

Number of communication ports 2 ports (RJ45-1000BASE-T)

Cyclic communication

Receiving control signal (RY) 128 points, control data (RWw) 16 points

Transmitting control signal (RY) 128 points, control data (RWr) 16 points

7 - 1

Page 35

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

7.3 I/O device

Most devices used in CC-Link IE Field Network communication are the same with the devices used in CCLink communication with two occupied stations. However, some device numbers have been changed. The

devices, of which device numbers are different from the numbers in CC-Link communication, are shaded.

7.3.1 I/O devices for a programmable controller CPU

(1) Bit device (master station → servo amplifier RY)

(Note 1)

Device No.

RYn0 Servo-on Servo-on Servo-on

1 Forward rotation start Forward rotation start Forward rotation start

2 Reverse rotation start Reverse rotation start Reverse rotation start

3 Proximity dog Proximity dog Proximity dog

4 Forward rotation stroke end Forward rotation stroke end Forward rotation stroke end

5 Reverse rotation stroke end Reverse rotation stroke end Reverse rotation stroke end

6 Automatic/manual selection Automatic/manual selection Automatic/manual selection

7 Temporary stop/restart Temporary stop/restart Temporary stop/restart

8 Monitor output execution demand Monitor output execution demand Monitor output execution demand

9 Instruction code execution demand Instruction code execution demand Instruction code execution demand

A Point table No. selection 1 Point table No. selection 1 Reserved

B Point table No. selection 2 Point table No. selection 2 Reserved

C Point table No. selection 3 Point table No. selection 3 Reserved

D Point table No. selection 4 Point table No. selection 4 Reserved

E Point table No. selection 5 Point table No. selection 5 Reserved

F Clear Clear Clear

RY (n + 1) 0 Reserved Reserved Reserved

1 Reserved Reserved Reserved

2 Reserved Reserved Reserved

3 Reserved Reserved Reserved

4 Reserved Reserved Reserved

5 Reserved Reserved Reserved

6 Reserved Reserved Reserved

7 Reserved Reserved Reserved

8 Reserved Reserved Reserved

9 Reserved Reserved Reserved

A Reset Reserved Reserved

B Reserved Reserved Reserved

C Reserved Reserved Reserved

D Reserved Reserved Reserved

E Reserved Reserved Reserved

F Reserved Reserved Reserved

CC-Link (1 station)

RY (32 points)

CC-Link (2 stations)

RY (64 points)

CC-Link IE Field

RY (128 points) (Note 2)

7 - 2

Page 36

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(Note 1)

Device No.

RY (n + 2) 0 Position command execution demand Position command execution demand

1 Speed command execution demand Speed command execution demand

2 Reserved Reserved

3 Point table No. selection 6 Reserved

4 Point table No. selection 7 Reserved

5 Point table No. selection 8 Reserved

6 Internal torque limit selection Internal torque limit selection

7 Proportional control Proportional control

8 Gain switching Gain switching

9 Reserved Reserved

A

B

C Reserved Reserved

D Reserved Reserved

E Reserved Reserved

F Reserved Reserved

RY (n + 3) 0 Reserved Reserved

1 Reserved Reserved

2 Reserved Reserved

3 Reserved Reserved

4 Reserved Reserved

5 Reserved Reserved

6 Reserved Reserved

7 Reserved Reserved

8 Reserved Reserved

9 Reserved Reserved

A Reset Reset

B Reserved Reserved

C Reserved Reserved

D Reserved Reserved

E Reserved Reserved

F Reserved Reserved

Note 1. "n" depends on the station number setting.

2. The number of bit device points is fixed to 128. If a point other than 128 is set, [AL. 9D] will occur. Device No. RY (n + 4) to RY

(n + 7) are reserved.

CC-Link (1 station)

RY (32 points)

CC-Link (2 stations)

RY (64 points)

Position/speed specifying system

selection

Absolute value/incremental value

selection

CC-Link IE Field

RY (128 points) (Note 2)

Position/speed specifying system

selection

Absolute value/incremental value

selection

7 - 3

Page 37

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(2) Bit device (servo amplifier → master station RX)

(Note 1)

Device No.

RXn0 Ready Ready Ready

1 In-position In-position In-position

2 Rough match Rough match Rough match

3 Home position return completion Home position return completion Home position return completion

4 Limiting torque Limiting torque Limiting torque

5 Reserved Reserved Reserved

6 Electromagnetic brake interlock Electromagnetic brake interlock Electromagnetic brake interlock

7 Temporary stop Temporary stop Temporary stop

8 Monitoring Monitoring Monitoring

9 Instruction code execution completion Instruction code execution completion Instruction code execution completion

A Warning Warning Warning

B Battery warning Battery warning Battery warning

C Travel completion Travel completion Travel completion

D Dynamic brake interlock Dynamic brake interlock Dynamic brake interlock

E Position range output Position range output Position range output

F Reserved Reserved Reserved

RX (n + 1) 0 Reserved Reserved Reserved

1 Reserved Reserved Reserved

2 Reserved Reserved Reserved

3 Reserved Reserved Reserved

4 Reserved Reserved Reserved

5 Reserved Reserved Reserved

6 Reserved Reserved Reserved

7 Reserved Reserved Reserved

8 Reserved Reserved Reserved

9 Reserved Reserved Reserved

A Malfunction Reserved Reserved

B Remote station communication ready Reserved Reserved

C Reserved Reserved Reserved

D Reserved Reserved Reserved

E Reserved Reserved Reserved

F Reserved Reserved Reserved

RX (n + 2) 0

1

2 Point table No. output 1 Reserved

3 Point table No. output 2 Reserved

4 Point table No. output 3 Reserved

5 Point table No. output 4 Reserved

6 Point table No. output 5 Reserved

7 Point table No. output 6 Reserved

8 Point table No. output 7 Reserved

9 Point table No. output 8 Reserved

A Reserved Reserved

B Reserved Reserved

C Reserved Reserved

D Reserved Reserved

E Reserved Reserved

F Reserved Reserved

CC-Link (1 station)

RX (32 points)

CC-Link (2 stations)

RX (64 points)

Position command execution

completion

Speed command execution

completion

CC-Link IE Field

RX (128 points) (Note 2)

Position command execution

completion

Speed command execution

completion

7 - 4

Page 38

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(Note 1)

Device No.

RX (n + 3) 0 Reserved Reserved

1 Reserved Reserved

2 Reserved Reserved

3 Reserved Reserved

4 Reserved Reserved

5 Reserved Reserved

6 Reserved Reserved

7 Reserved Reserved

8 Reserved Reserved

9 Reserved Reserved

A Malfunction Malfunction

B Remote station communication ready Remote station communication ready

C Reserved Reserved

D Reserved Reserved

E Reserved Reserved

F Reserved Reserved

Note 1. "n" depends on the station number setting.

2. The number of bit device points is fixed to 128. If a point other than 128 is set, [AL. 9D] will occur. Device No. RX (n + 4) to RX

(n + 7) are reserved.

(3) Word device (master station → servo amplifier RWw)

(Note 1)

Device No.

RWwn0 Monitor 1 Monitor 1 Monitor 1

1 Monitor 2 Monitor 2 Reserved

2 Instruction code Instruction code Monitor 2

3 Writing data Writing data Reserved

4

5

6

7

8

9

A

B

C

D

E

F

Note 1. "n" depends on the station number setting.

2. If an out-of-range value is set to Point table No. selection, [AL. 97] will occur.

3. The number of word device points is fixed to 16. If a point other than 16 is set, [AL. 9D] will occur.

CC-Link (1 station)

RX (32 points)

CC-Link (1 station)

RWw (4 points)

CC-Link (2 stations)

RX (64 points)

CC-Link (2 stations)

RWw (8 points)

Position command data lower 16 bits

/Point table No.

Position command data upper 16 bits Writing data

Speed command data/Point table No. Point table No. selection (Note 2)

Reserved Reserved

Instruction code

Position command data lower 16 bits

/Point table No.

Position command data upper 16 bits

Speed command data/Point table No.

Reserved

Reserved

Reserved

Reserved

Reserved

CC-Link IE Field

RX (128 points) (Note 2)

CC-Link IE Field

RWw (16 points) (Note 3)

7 - 5

Page 39

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(4) Word device (servo amplifier → master station RWr)

(Note 1)

Device No.

RWrn0 Monitor 1 data Monitor 1 data lower 16 bits Monitor 1 data lower 16 bits

1 Monitor 2 data Monitor 1 data upper 16 bits Monitor 1 data upper 16 bits

2 Respond code Respond code Monitor 2 data lower 16 bits

3 Reading data Reading data Monitor 2 data upper 16 bits

4

5

6

7

8

9

A

B

C

D

E

F

Note 1. "n" depends on the station number setting.

2. The number of word device points is fixed to 16. If a point other than 16 is set, [AL. 9D] will occur.

CC-Link (1 station)

RWr (4 points)

CC-Link (2 stations)

RWr (8 points)

Reserved Respond code

Monitor 2 data lower 16 bits Reading data

Monitor 2 data upper 16 bits Point table No. output

Reserved Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

CC-Link IE Field

RWr (16 points) (Note 2)

7 - 6

Page 40

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

7.3.2 I/O devices for a programmable controller CPU during indexer positioning operation

(1) Bit device (master station → servo amplifier RY)

(Note 1)

Device No.

RYn0 Servo-on Servo-on Servo-on

1 Start Start Start

2 Rotation direction specifying Rotation direction specifying Rotation direction specifying

3 Reserved Reserved Reserved

4 Reserved Reserved Reserved

5 Reserved Reserved Reserved

6 Operation mode selection 1 Operation mode selection 1 Operation mode selection 1

7 Operation mode selection 2 Operation mode selection 2 Operation mode selection 2

8 Monitor output execution demand Monitor output execution demand Monitor output execution demand

9 Instruction code execution demand Instruction code execution demand Instruction code execution demand

A Next station selection 1 Next station selection 1 Reserved

B Next station selection 2 Next station selection 2 Reserved

C Next station selection 3 Next station selection 3 Reserved

D Next station selection 4 Next station selection 4 Reserved

E Next station selection 5 Next station selection 5 Reserved

F Reserved Reserved Reserved

RY (n + 1) 0 Reserved Reserved Reserved

1 Reserved Reserved Reserved

2 Reserved Reserved Reserved

3 Reserved Reserved Reserved

4 Reserved Reserved Reserved

5 Reserved Reserved Reserved

6 Reserved Reserved Reserved

7 Reserved Reserved Reserved

8 Reserved Reserved Reserved

9 Reserved Reserved Reserved

A Reset Reserved Reserved

B Reserved Reserved Reserved

C Reserved Reserved Reserved

D Reserved Reserved Reserved

E Reserved Reserved Reserved

F Reserved Reserved Reserved

CC-Link (1 station)

RY (32 points)

CC-Link (2 stations)

RY (64 points)

CC-Link IE Field

RY (128 points) (Note 2)

7 - 7

Page 41

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(Note 1)

Device No.

RY (n + 2) 0 Position command execution demand Position command execution demand

1 Speed command execution demand Speed command execution demand

2 Reserved Reserved

3 Next station selection 6 Reserved

4 Next station selection 7 Reserved

5 Next station selection 8 Reserved

6 Internal torque limit selection Internal torque limit selection

7 Proportional control Proportional control

8 Gain switching Gain switching

9 Reserved Reserved

A

B Reserved Reserved

C Speed selection 1 Speed selection 1

D Speed selection 2 Speed selection 2

E Speed selection 3 Speed selection 3

F Reserved Reserved

RY (n + 3) 0 Reserved Reserved

1 Reserved Reserved

2 Reserved Reserved

3 Reserved Reserved

4 Reserved Reserved

5 Reserved Reserved

6 Reserved Reserved

7 Reserved Reserved

8 Reserved Reserved

9 Reserved Reserved

A Reset Reset

B Reserved Reserved

C Reserved Reserved

D Reserved Reserved

E Reserved Reserved

F Reserved Reserved

Position/speed specifying system

Note 1. "n" depends on the station number setting.

2. The number of bit device points is fixed to 128. If a point other than 128 is set, [AL. 9D] will occur. Device No. RY (n + 4) to RY

(n + 7) are reserved.

CC-Link (1 station)

RY (32 points)

selection

CC-Link (2 stations)

RY (64 points)

CC-Link IE Field

RY (128 points) (Note 2)

Position/speed specifying system

selection

7 - 8

Page 42

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(2) Bit device (servo amplifier → master station RX)

(Note 1)

Device No.

RXn0 Ready Ready Ready

1 In-position In-position In-position

2 Rough match Rough match Rough match

3 Home position return completion Home position return completion Home position return completion

4 Limiting torque Limiting torque Limiting torque

5 Reserved Reserved Reserved

6 Electromagnetic brake interlock Electromagnetic brake interlock Electromagnetic brake interlock

7 Temporary stop Temporary stop Temporary stop

8 Monitoring Monitoring Monitoring

9 Instruction code execution completion Instruction code execution completion Instruction code execution completion

A Warning Warning Warning

B Battery warning Battery warning Battery warning

C Travel completion Travel completion Travel completion

D Dynamic brake interlock Dynamic brake interlock Dynamic brake interlock

E Reserved Reserved Reserved

F Reserved Reserved Reserved

RX (n + 1) 0 Reserved Reserved Reserved

1 Reserved Reserved Reserved

2 Reserved Reserved Reserved

3 Reserved Reserved Reserved

4 Reserved Reserved Reserved

5 Reserved Reserved Reserved

6 Reserved Reserved Reserved

7 Reserved Reserved Reserved

8 Reserved Reserved Reserved

9 Reserved Reserved Reserved

A Malfunction Reserved Reserved

B Remote station communication ready Reserved Reserved

C Reserved Reserved Reserved

D Reserved Reserved Reserved

E Reserved Reserved Reserved

F Reserved Reserved Reserved

RX (n + 2) 0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

CC-Link (1 station)

RX (32 points)

CC-Link (2 stations)

RX (64 points)

Position command execution

completion

Speed command execution

completion

Station output 1 Reserved

Station output 2 Reserved

Station output 3 Reserved

Station output 4 Reserved

Station output 5 Reserved

Station output 6 Reserved

Station output 7 Reserved

Station output 8 Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Position command execution

completion

Speed command execution

completion

CC-Link IE Field

RX (128 points) (Note 2)

7 - 9

Page 43

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(Note 1)

Device No.

RX (n + 3) 0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Note 1. "n" depends on the station number setting.

2. The number of bit device points is fixed to 128. If a point other than 128 is set, [AL. 9D] will occur. Device No. RX (n + 4) to RX

(n + 7) are reserved.

(3) Word device (master station → servo amplifier RWw)

(Note 1)

Device No.

RWwn0 Monitor 1 Monitor 1 Monitor 1

1 Monitor 2 Monitor 2 Reserved

2 Instruction code Instruction code Monitor 2

3 Writing data Writing data Reserved

4

5

6

7

8

9

A

B

C

D

E

F

Note 1. "n" depends on the station number setting.

2. This device is used to select the remote register-based position/speed specifying method.

3. If an out-of-range value is set to the next station No. selection, [AL. 97] will occur.

4. The number of word device points is fixed to 16. If a point other than 16 is set, [AL. 9D] will occur.

CC-Link (1 station)

RX (32 points)

CC-Link (1 station)

RWw (4 points)

CC-Link (2 stations)

RX (64 points)

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

Malfunction Malfunction

Remote station communication ready Remote station communication ready

Reserved Reserved

Reserved Reserved

Reserved Reserved

Reserved Reserved

CC-Link (2 stations)

RWw (8 points)

Next station No. (Note 2) Instruction code

Reserved Writing data

Speed command data/next station

No.

Reserved Reserved

Next station No. selection (Note 3)

Next station No. (Note 2)

Reserved

Speed command data/next station

No.

Reserved

Reserved

Reserved

Reserved

Reserved

CC-Link IE Field

RX (128 points) (Note 2)

CC-Link IE Field

RWw (16 points) (Note 4)

7 - 10

Page 44

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

(4) Word device (servo amplifier → master station RWr)

(Note 1)

Device No.

RWrn0 Monitor 1 data Monitor 1 data lower 16 bits Monitor 1 data lower 16 bits

1 Monitor 2 data Monitor 1 data upper 16 bits Monitor 1 data upper 16 bits

2 Respond code Respond code Monitor 2 data lower 16 bits

3 Reading data Reading data Monitor 2 data upper 16 bits

4

5

6

7

8

9

A

B

C

D

E

F

Note 1. "n" depends on the station number setting.

2. The number of word device points is fixed to 16. If a point other than 16 is set, [AL. 9D] will occur.

CC-Link (1 station)

RWr (4 points)

CC-Link (2 stations)

RWr (8 points)

Reserved Respond code

Monitor 2 data lower 16 bits Reading data

Monitor 2 data upper 16 bits Next station No. output

Reserved Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

CC-Link IE Field

RWr (16 points) (Note 2)

7 - 11

Page 45

7. CC-LINK IE FIELD NETWORK COMMUNICATION FUNCTION

7.4 Restrictions on the CC-Link IE Field Network wiring

POINT

This chapter explains about the restrictions that apply to a network change

during cyclic communication.

If communication is disconnected in a line of a network where several servo amplifiers are connected, [AL.

8D CC-Link IE communication error] may occur in the servo amplifiers that are not on the disconnected line.

(Refer to figures 7.1 and 7.2.)

Master

station

Servo

amplifier

01 station

Master

station

Network HUB

Servo

amplifier

02 station

Servo

amplifier

03 station

[AL. 8D] occurs at all stations.

A line is disconnected.

Network HUB

Servo

amplifier

04 station

Servo

amplifier

05 station

Servo

amplifier

06 station

Servo

amplifier

01 station

[AL. 8D] occurs at all stations.

Network HUB

Servo

amplifier

02 station

New line is added.

Servo

amplifier

03 station

Figure 7.1 When communication is disconnected in a line

Figure 7.2 When a line is newly added

[AL. 8D CC-Link IE communication error] is detected when cyclic transmission stops for a time period longer

than the communication time-out detection time of the servo amplifier. Such cyclic transmission stop occurs

because of a disconnected/reconnected station due to a shut-off/reconnected network path.

An initial value is set for the communication time-out detection time in consideration of applications that

require real-time operation. Therefore, the initial value is shorter than the general time-out detection time for

CC-Link IE Field Network devices. (10 ms detection time in the initial value)

If the above initial setting creates inconvenience for an application requiring frequent communication path