General-Purpose AC Servo

J2-Super Series

J2-Super Series MR-J2S- B-PY096 MR-J2S- B-S096(5.7kW) Instruction Manual

SSCNET Fully Closed Control Compatible

MODEL

MR-J2S- B-PY096

MR-J2S- B-S096(5.7kW)

INSTRUCTION MANUAL

B

B

A - 1

Safety Instructions

(Always read these instructions before using the equipment.)

Do not attempt to install, operate, maintain or inspect the servo amplifier and servo motor until you have read

through this Instruction Manual, Installation guide, Servo motor Instruction Manual and appended documents

carefully and can use the equipment correctly. Do not use the servo amplifier and servo motor until you have a

full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols:

: Indicates what must not be done. For example, "No Fire" is indicated by

.

: Indicates what must be done. For example, grounding is indicated by

.

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, always keep it accessible to the operator.

A - 2

1. To prevent electric shock, note the following:

WARNING

Before wiring or inspection, switch power off and wait for more than 15 minutes. Then, confirm the voltage

is safe with voltage tester. Otherwise, you may get an electric shock.

Connect the servo amplifier and servo motor to ground.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, you

may get an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, you may get an electric shock.

During power-on or operation, do not open the front cover. You may get an electric shock.

Do not operate the converter unit and servo amplifier with the front cover removed. High-voltage terminals

and charging area are exposed and you may get an electric shock.

Except for wiring or periodic inspection, do not remove the front cover even if the power is off. The servo

amplifier is charged and you may get an electric shock.

2. To prevent fire, note the following:

CAUTION

Install the converter unit and servo amplifier, servo motor and regenerative resistor on incombustible

material. Installing them directly or close to combustibles will lead to a fire.

When the servo amplifier has become faulty, switch off the main servo amplifier power side. Continuous

flow of a large current may cause a fire.

When a regenerative resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative transistor fault or the like may overheat the regenerative resistor, causing a fire.

3. To prevent injury, note the follow

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal. Otherwise, a burst,

damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

During power-on or for some time after power-off, do not touch or close a parts (cable etc.) to the servo

amplifier heat sink, regenerative resistor, servo motor, etc. Their temperatures may be high and you may

get burnt or a parts may damaged.

During operation, never touch the rotating parts of the servo motor. Doing so can cause injury.

A - 3

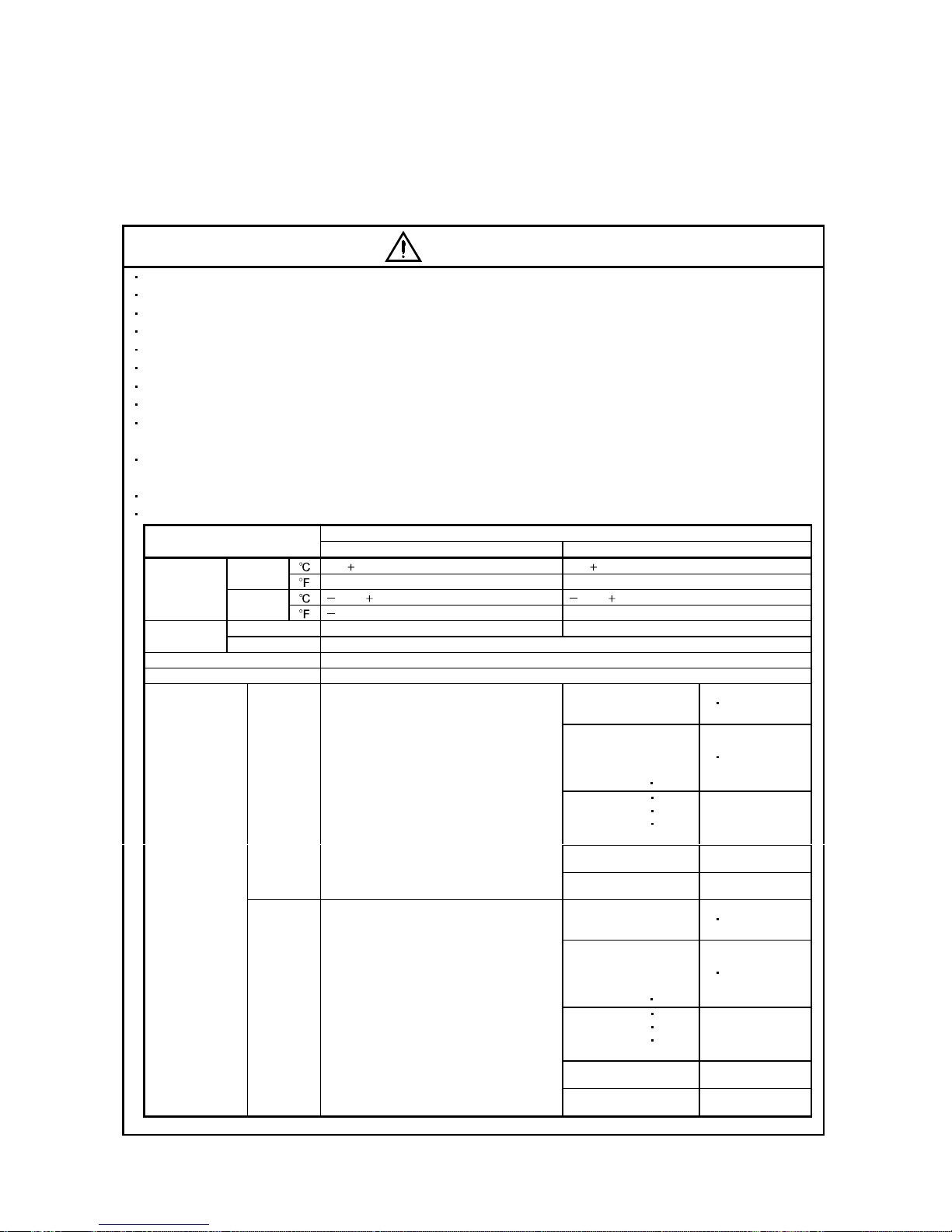

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric

shock, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their weights.

Stacking in excess of the specified number of products is not allowed.

Do not carry the servo motor by the cables, shaft or encoder.

Do not hold the front cover to transport the controller. The controller may drop.

Install the servo amplifier in a load-bearing place in accordance with the Instruction Manual.

Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

The controller and servo motor must be installed in the specified direction.

Leave specified clearances between the servo amplifier and control enclosure walls or other equipment.

Do not install or operate the servo amplifier and servo motor which has been damaged or has any parts

missing.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

Do not drop or strike servo amplifier or servo motor. Isolate from all impact loads.

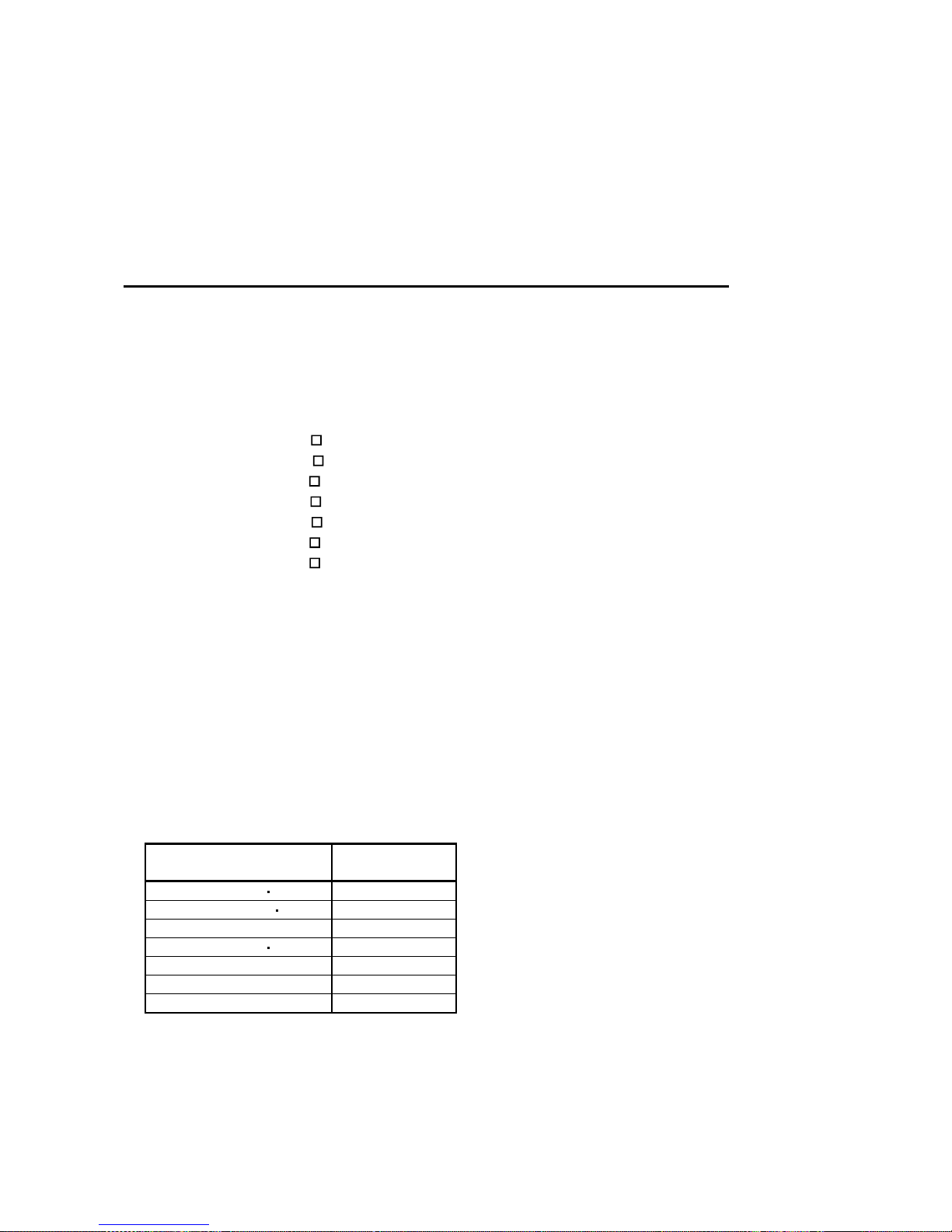

When you keep or use it, please fulfill the following environmental conditions.

Conditions

Environment

Servo amplifier Servo motor

[ ] 0 to 55 (non-freezing) 0 to 40 (non-freezing)

Operation

[

] 32 to 131 (non-freezing) 32 to 104 (non-freezing)

[ ] 20 to 65 (non-freezing) 15 to 70 (non-freezing)

Ambient

temperature

Storage

[

] 4 to 149 (non-freezing) 5 to 158 (non-freezing)

Operation 90%RH or less (non-condensing) 80%RH or less (non-condensing)

Ambient

humidity

Storage 90%RH or less (non-condensing)

Ambience Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280 ft) above sea level

HC-KFS Series

HC-MFS Series

HC-UFS13 to 73

X

Y : 49

HC-SFS81

HC-SFS52 to 152

HC-SFS53 to 153

HC-RFS Series

HC-UFS 72

152

X

Y : 24.5

HC-SFS121 201

HC-SFS202

352

HC-SFS203

353

HC-UFS202 to 502

X : 24.5

Y : 49

HC-SFS301

HC-SFS502 to 702

X : 24.5

Y : 29.4

[m/s2] 5.9 or less

HA-LFS11K2 to 22K2

X : 11.7

Y : 29.4

HC-KFS Series

HC-MFS Series

HC-UFS 13 to 73

X

Y : 161

HC-SFS81

HC-SFS52 to 152

HC-SFS53 to 153

HC-RFS Series

HC-UFS 72 152

X

Y : 80

HC-SFS121 201

HC-SFS202

352

HC-SFS203

353

HC-UFS202 to 502

X : 80

Y : 161

HC-SFS301

HC-SFS502 to 702

X : 80

Y : 96

(Note)

Vibration

[ft/s

2

] 19.4 or less

HA-LFS11K2 to 22K2

X : 38

Y : 96

Note. Except the servo motor with reduction gear.

A - 4

CAUTION

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The servo motor with reduction gear must be installed in the specified direction to prevent oil leakage.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotating parts of the servo

motor during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When the equipment has been stored for an extended period of time, consult Mitsubishi.

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may misoperate.

Do not install a power capacitor, surge absorber or radio noise filter (FR-BIF option) between the servo

motor and servo amplifier.

Connect the output terminals (U, V, W) correctly. Otherwise, the servo motor will operate improperly.

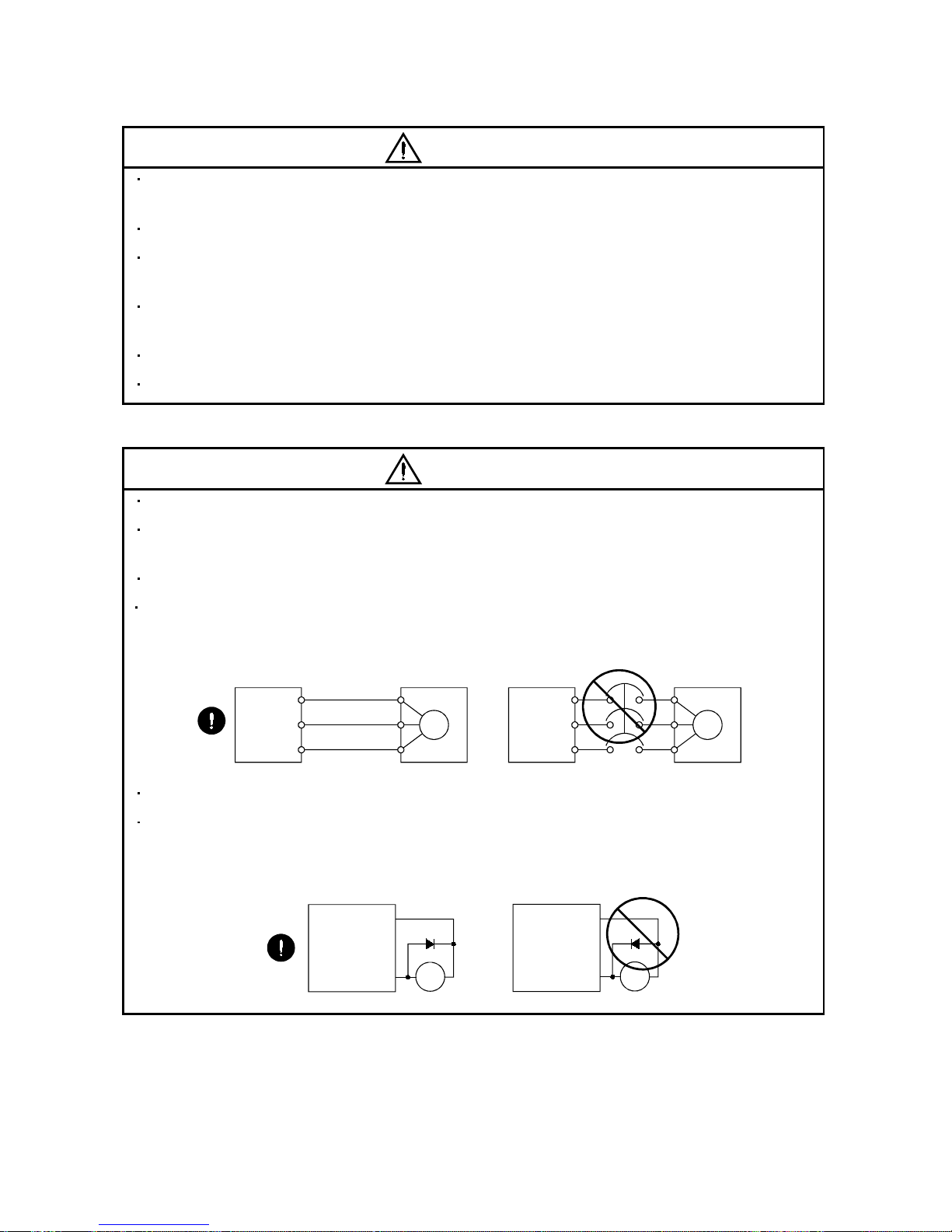

Connect the servo motor power terminal (U, V, W) to the servo motor power input terminal (U, V, W)

directly. Do not let a magnetic contactor, etc. intervene.

U

Servo Motor

M

V

W

U

V

W

U

M

V

W

U

V

W

Servo Amplifier

(drive unit)

Servo Motor

Servo Amplifier

(drive unit)

Do not connect AC power directly to the servo motor. Otherwise, a fault may occur.

The surge absorbing diode installed on the DC output signal of the servo amplifier relay must be wired in

the specified direction. Otherwise, the forced stop (EM1) and other protective circuits may not operate.

COM

(24VDC)

Servo

Amplifier

RA

Control

output

signal

RA

Servo

Amplifier

COM

(24VDC)

Control

output

signal

A - 5

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be insatiable.

(4) Usage

CAUTION

Provide a forced stop circuit to ensure that operation can be stopped and power switched off immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off to prevent an

accident. A sudden restart is made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise filter, etc. to minimize the influence of electromagnetic interference, which may be caused by

electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break a servo amplifier.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be used

for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ballscrew and the servo motor

are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety,

install a stopper on the machine side.

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may take place at the occur due to a power failure or a

product fault, use a servo motor with electromagnetic brake or an external brake mechanism for the

purpose of prevention.

Configure the electromagnetic brake circuit so that it is activated not only by the interface unit signals but

also by a forced stop (EM1).

EM1RA

24VDC

Contacts must be open when

servo-off, when an alarm occurrence

and when an electromagnetic brake

interlock (MBR).

Electromagnetic brake

Servo motor

Circuit must be

opened during

forced stop (EM1).

A - 6

CAUTION

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

When power is restored after an instantaneous power failure, keep away from the machine because the

machine may be restarted suddenly (design the machine so that it is secured against hazard if restarted).

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor of the servo amplifier will deteriorate. To prevent a secondary accident

due to a fault, it is recommended to replace the electrolytic capacitor every 10 years when used in general

environment. Please consult our sales representative.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

About processing of waste

When you discard servo amplifier, a battery (primary battery), and other option articles, please follow the law of

each country (area).

FOR MAXIMUM SAFETY

These products have been manufactured as a general-purpose part for general industries, and have not

been designed or manufactured to be incorporated in a device or system used in purposes related to

human life.

Before using the products for special purposes such as nuclear power, electric power, aerospace,

medicine, passenger movement vehicles or under water relays, contact Mitsubishi.

These products have been manufactured under strict quality control. However, when installing the product

where major accidents or losses could occur if the product fails, install appropriate backup or failsafe

functions in the system.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier and/or converter unit may

fail when the EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Precautions for Choosing the Products

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of Mitsubishi;

machine damage or lost profits caused by faults in the Mitsubishi products; damage, secondary damage,

accident compensation caused by special factors unpredictable by Mitsubishi; damages to products other

than Mitsubishi products; and to other duties.

A - 7

COMPLIANCE WITH EC DIRECTIVES

1. WHAT ARE EC DIRECTIVES?

The EC directives were issued to standardize the regulations of the EU countries and ensure smooth

distribution of safety-guaranteed products. In the EU countries, the machinery directive (effective in

January, 1995), EMC directive (effective in January, 1996) and low voltage directive (effective in January,

1997) of the EC directives require that products to be sold should meet their fundamental safety

requirements and carry the CE marks (CE marking). CE marking applies to machines and equipment

into which servo amplifiers have been installed.

(1) EMC directive

The EMC directive applies not to the servo units alone but to servo-incorporated machines and

equipment. This requires the EMC filters to be used with the servo-incorporated machines and

equipment to comply with the EMC directive. For specific EMC directive conforming methods, refer to

the EMC Installation Guidelines (IB(NA)67310).

(2) Low voltage directive

The low voltage directive applies also to servo units alone. Hence, they are designed to comply with

the low voltage directive.

This servo is certified by TUV, third-party assessment organization, to comply with the low voltage

directive.

(3) Machine directive

Not being machines, the servo amplifiers need not comply with this directive.

2. PRECAUTIONS FOR COMPLIANCE

(1) Servo amplifiers and servo motors used

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier :MR-J2S-10B-PY096 to MR-J2S-350B-PY096

MR-J2S-500B-S096 to MR-J2S-700B-S096

MR-J2S-10B1-PY096 to MR-J2S-40B1-PY096

Servo motor :HC-KFS

HC-MFS

HC-SFS

HC-RFS

HC-UFS

HA-LFS

HC-LFS

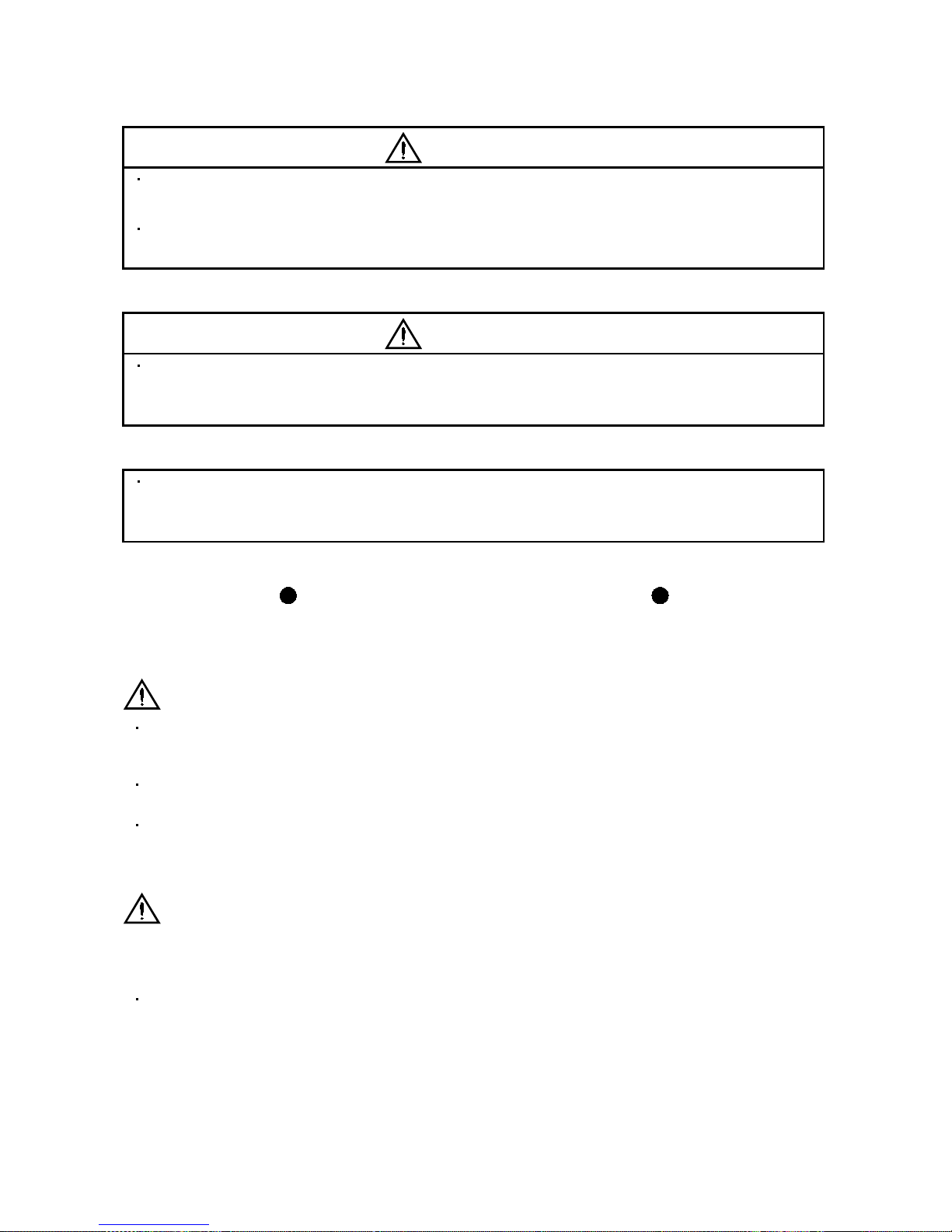

(2) Configuration

Reinforced

insulating

transformer

NFB

MC

SM

No-fuse

breaker

Magnetic

contactor

Reinforced

insulating type

24VDC

power

supply

Servo

amplifier

Servo

motor

Control box

(Note)

Note. The insulating transformer is not required for the 11kW or more servo amplifier.

(3) Environment

Operate the servo amplifier at or above the contamination level 2 set forth in IEC664. For this

purpose, install the servo amplifier in a control box which is protected against water, oil, carbon, dust,

dirt, etc. (IP54).

A - 8

(4) Power supply

(a) Operate the servo amplifier 7kW or less to meet the requirements of the overvoltage category II set

forth in IEC664. For this purpose, a reinforced insulating transformer conforming to the IEC or EN

standard should be used in the power input section.

Since the 11kW or more servo amplifier can be used under the conditions of the overvoltage

category III set forth in IE644, a reinforced insulating transformer is not required in the power

input section.

(b) When supplying interface power from external, use a 24VDC power supply which has been

insulation-reinforced in I/O.

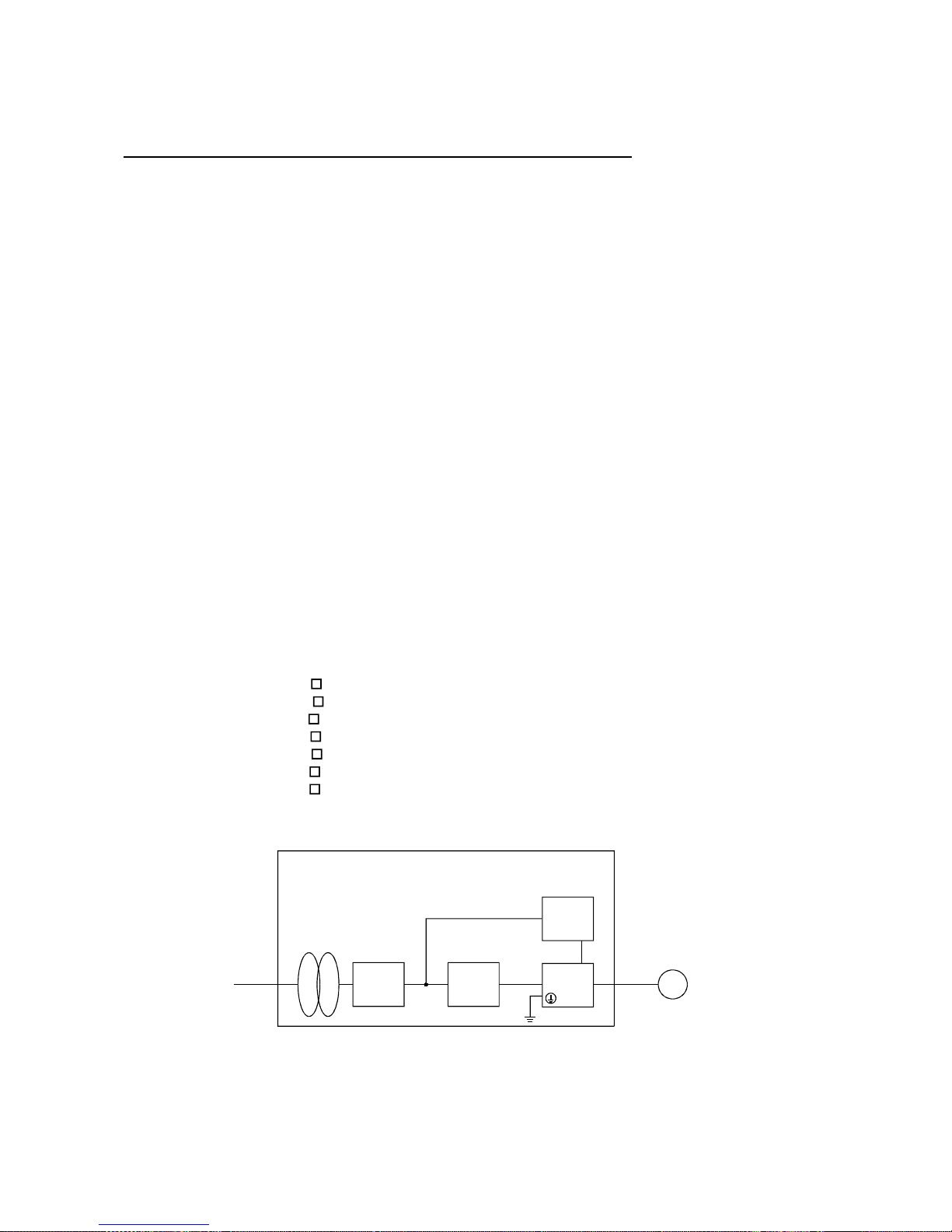

(5) Grounding

(a) To prevent an electric shock, always connect the protective earth (PE) terminals (marked

) of the

servo amplifier to the protective earth (PE) of the control box.

(b) Do not connect two ground cables to the same protective earth (PE) terminal Always connect the

cables to the terminals one-to-one.

PE terminals

PE terminals

(c) If a leakage current breaker is used to prevent an electric shock, the protective earth (PE)

terminals of the servo amplifier must be connected to the corresponding earth terminals.

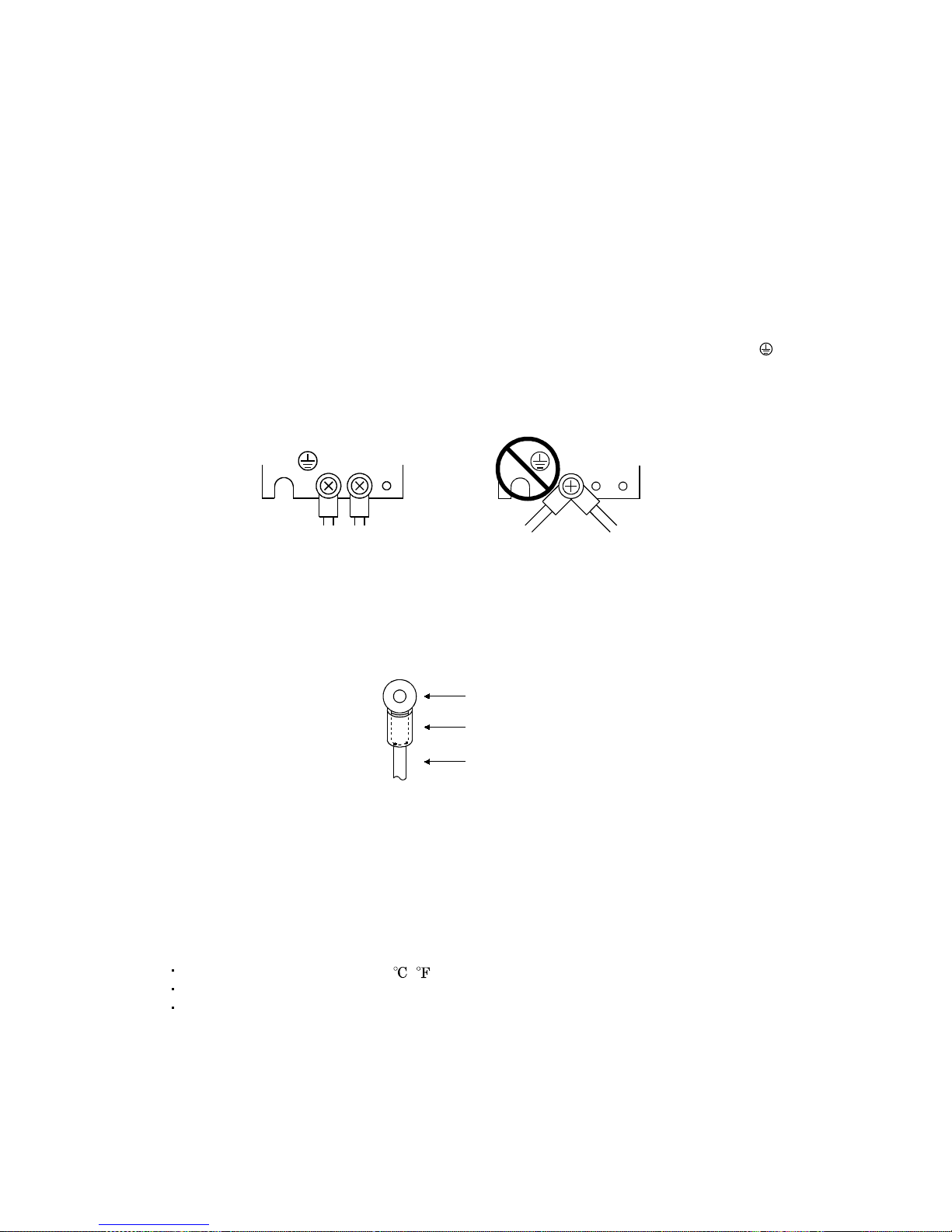

(6) Wiring

(a) The cables to be connected to the terminal block of the servo amplifier must have crimping

terminals provided with insulating tubes to prevent contact with adjacent terminals.

Crimping terminal

Insulating tube

Cable

(b) Use the servo motor side power connector which complies with the EN Standard. The EN Standard

compliant power connector sets are available from us as options.

(7) Auxiliary equipment and options

(a) The no-fuse breaker and magnetic contactor used should be the EN or IEC standard-compliant

products of the models described in Section 12.2.2.

(b) The sizes of the cables described in Section 12.2.1 meet the following requirements. To meet the

other requirements, follow Table 5 and Appendix C in EN60204-1.

Ambient temperature: 40 (104) [ ( )]

Sheath: PVC (polyvinyl chloride)

Installed on wall surface or open table tray

(c) Use the EMC filter for noise reduction.

A - 9

(8) Performing EMC tests

When EMC tests are run on a machine/device into which the servo amplifier has been installed, it

must conform to the electromagnetic compatibility (immunity/emission) standards after it has

satisfied the operating environment/electrical equipment specifications.

For the other EMC directive guidelines on the servo amplifier, refer to the EMC Installation

Guidelines(IB(NA)67310).

CONFORMANCE WITH UL/C-UL STANDARD

(1) Servo amplifiers and servo motors used

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier :MR-J2S-10B-PY096 to MR-J2S-350B-PY096

MR-J2S-500B-S096 to MR-J2S-700B-S096

MR-J2S-10B1-PY096 to MR-J2S-40B1-PY096

Servo motor :HC-KFS

HC-MFS

HC-SFS

HC-RFS

HC-UFS

HA-LFS

HC-LFS

(2) Installation

Install a cooling fan of 100CFM (2.8m

3

/min) air flow 4 in (10.16 cm) above the servo amplifier or

provide cooling of at least equivalent capability.

(3) Short circuit rating

This servo amplifier conforms to the circuit whose peak current is limited to 5000A or less. Having

been subjected to the short-circuit tests of the UL in the alternating-current circuit, the servo

amplifier conforms to the above circuit.

(4) Capacitor discharge time

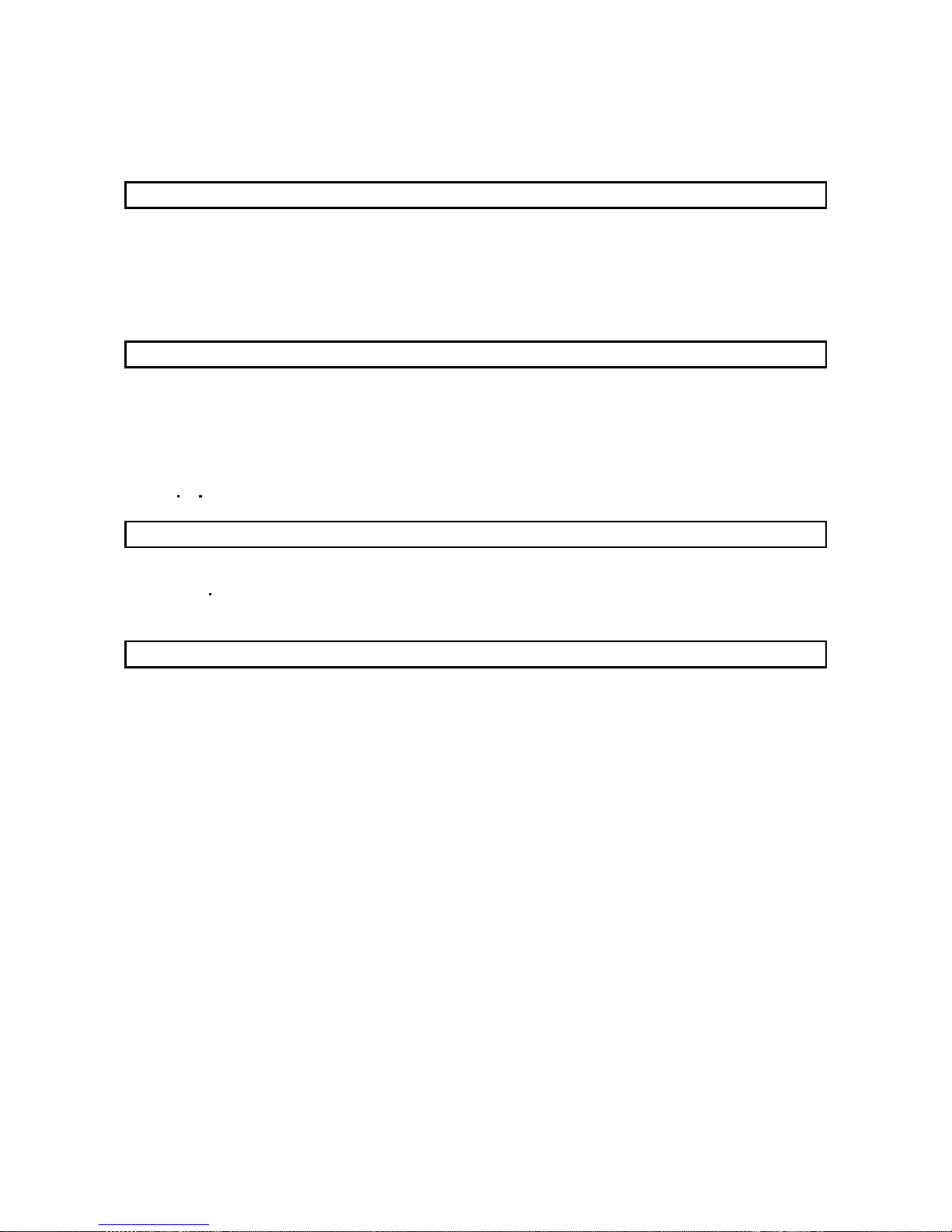

The capacitor discharge time is as listed below. To ensure safety, do not touch the charging section for

15 minutes after power-off.

Servo amplifier

Discharge time

[min]

MR-J2S-10B(1) 20B(1) 1

MR-J2S-40B(1) 60B 2

MR-J2S-70B to 350B 3

MR-J2S-500B 700B 5

MR-J2S-11KB 4

MR-J2S-15KB 6

MR-J2S-22KB 8

(5) Options and auxiliary equipment

Use UL/C-UL standard-compliant products.

A - 10

(6) Attachment of a servo motor

For the flange size of the machine side where the servo motor is installed, refer to "CONFORMANCE

WITH UL/C-UL STANDARD" in the Servo Motor Instruction Manual.

(7) About wiring protection

For installation in United States, branch circuit protection must be provided, in accordance with the

National Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided, in accordance with the Canada

Electrical Code and any applicable provincial codes.

1

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1- 6

1.1 Overview................................................................................................................................................... 1- 1

1.2 Control block diagram............................................................................................................................. 1- 2

1.3 Specification list....................................................................................................................................... 1- 3

1.4 Model name .............................................................................................................................................. 1- 3

1.5 System configuration............................................................................................................................... 1- 4

2. LINEAR SCALES 2- 1 to 2-30

2.1 Compatible linear scale list .................................................................................................................... 2- 1

2.1.1 Mitutoyo make linear scales (ABS type) ........................................................................................2- 2

2.1.2 Heidenhain make linear encoder (linear scale) (ABS type) ......................................................... 2- 9

2.1.3 Renishaw make linear encoders (linear scales) (INC type)......................................................... 2-15

2.1.4 Sony precision technology make linear encoders (linear scales) (INC type) .............................2-21

2.2 A

B Z-phase differential input Interface unit specifications.......................................................... 2-27

3. SIGNALS AND WIRING 3- 1 to 3- 6

3.1 Standard connection examples of full closed control servo amplifier control signals....................... 3- 1

3.2 Signal

t

erminal explanation ................................................................................................................. 3- 5

3.3 About power-on ........................................................................................................................................ 3- 6

4. OPERATION AND FUNCTIONS 4- 1 to 4-22

4.1 Startup...................................................................................................................................................... 4- 1

4.1.1 Startup procedure............................................................................................................................. 4- 1

4.1.2 Selection of full closed function ....................................................................................................... 4- 2

4.1.3 Selection of full closed encoder communication system................................................................ 4- 3

4.1.4 Setting of full closed encoder polarity............................................................................................. 4- 4

4.1.5 Setting of full closed encoder electronic gear ................................................................................. 4- 5

4.1.6 Confirmation of full closed encoder position data .........................................................................4- 6

4.1.7 Setting of dual feedback switching filter ........................................................................................ 4- 7

4.2 Home position return operation .............................................................................................................4- 8

4.2.1 General precautions ......................................................................................................................... 4- 8

4.2.2 Full closed encoder types and home position return methods ..................................................... 4- 8

4.3 Operation from controller ...................................................................................................................... 4-15

4.3.1 Operation from controller ...............................................................................................................4-15

4.3.2 Controller setting............................................................................................................................. 4-15

4.4 Functions .................................................................................................................................................4-17

4.4.1 Full closed control error detection.................................................................................................. 4-17

4.4.2 Auto tuning function ....................................................................................................................... 4-18

4.4.3 Machine analyzer function ............................................................................................................. 4-18

4.4.4 Test operation .................................................................................................................................. 4-18

4.5 Absolute position detection system....................................................................................................... 4-19

2

4.6 About the MR Configurator ................................................................................................................... 4-20

4.6.1 When current version of MR Configurator

(MRZJW3-SETUP121 to -SETUP151 S/W: E0 version) is used ................................................. 4-20

4.6.2 When full closed compatible MR Configurator

(MRZJW3-SETUP151 S/W: E1 version or later) is used .............................................................4-21

5. PARAMETERS 5- 1 to 5- 8

5.1 Parameter list ...................................................................................................................................... 5- 1

6. TROUBLESHOOTING 6- 1 to 6- 2

6.1 Alarm list.................................................................................................................................................. 6- 1

6.2 Scale error (AL. 2A) details classified by linear scale manufacturer .................................................6- 2

7. OPTIONS AND AUXILIARY EQUIPMENT 7- 1 to 7- 2

7.1 CN2 wiring option cable (MR-J2SCLCBL02M-P-H) ........................................................................... 7- 1

1 - 1

1. FUNCTIONS AND CONFIGURATION

1 FUNCTIONS AND CONFIGURATION

1.1 Overview

This Instruction Manual explains the product that imports a position F/B signal from a full closed

encoder, such as a linear scale, to the MR-J2S-B servo amplifier to perform full closed control.

For the items not described in this Instruction Manual, refer to the MELSERVO-J2S-B Specifications and

Installation Guide and Instruction Manual since they are the same as those of the standard model.

For the specifications of the A

B Z differential input I/F unit MR-J2S-CLP01, refer to the MR-J2S-

CLP01 Installation Guide.

[Items changed from those of the standard model]

1) The A

B Z differential input I/F unit MR-J2S-CLP01 or Mitsubishi serial interface compatible

linear scale is used to detect the position F/B signal of a full closed encoder such as a linear scale.

2) In addition to the full closed control that feeds back the position signal of the full closed encoder,

dual F/B control that feeds back a signal composed of the full closed encoder's position F/B signal

and the motor position F/B signal has been added as an extended function.

3) Function to switch pulse output between the full closed encoder and motor end encoder

4) Addition of restriction on the RS232C communication baud rate (enabled for 9600bps only)

[Functions deleted from the standard model]

1) Speed

torque control

2) Motor-less operation (test operation)

1 - 2

1. FUNCTIONS AND CONFIGURATION

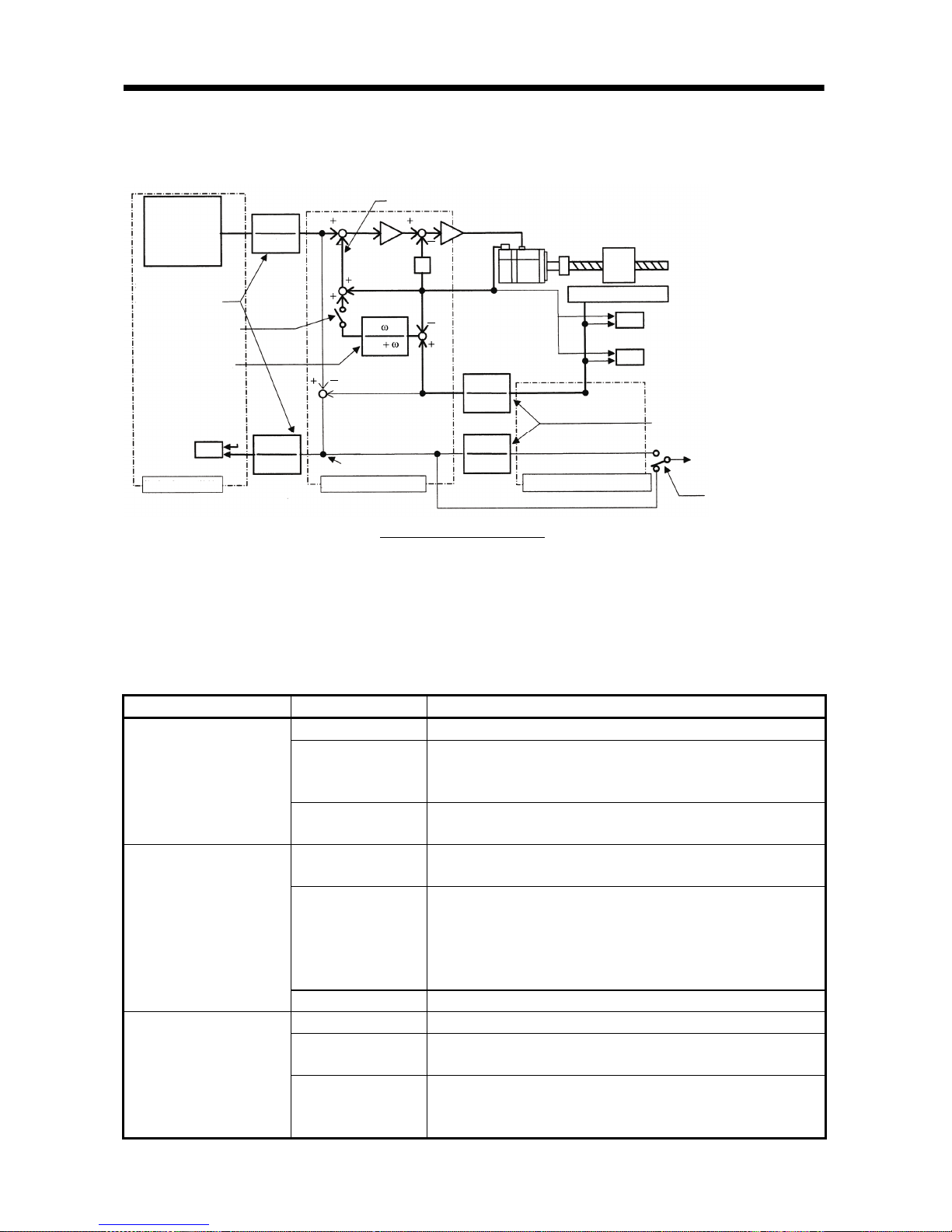

1.2 Control block diagram

A full closed control block diagram is shown below.

Controller

Command pulse

train electronic gear

Parameter No. 6

Full closed selection

Parameter No. 62

(Note 1, 2)

Dual F/B filter

Parameter No. 67

(Note 2)

In-position judgment

INP

Command pulse uni t

1

CMX

CMX

1

S

Dual f/b position signal

Position deviation

Encoder pulse unit

FCM

FCD

FCD

FCM

Servo motor

Linear scale

OP9

FCT

Closed end pulse unit

ABZ phase pulse

output selection

Parameter No. 68

Full closed control error

detection function selection

Parameter No. 62, 63, 64

Full closed electronic gear

Parameter No. 65, 66

Droop pulses (MR Configurator

display, analog monitor)

Droop pulse unit

selection

Parameter No. 68

Full closed control block diagram

S

Note 1. Switching between semi closed control and full closed control can be performed by changing the setting of parameter No. 62.

When semi closed control is selected, control is always performed on the basis of the position data of the motor end encoder

(independently of whether the motor is at a stop or running).

2. When parameter No. 62 "full closed function" is valid, dual F/B control in which the motor F/B signal and full closed encoder F/B

signal are combined by the dual F/B filter in parameter No. 67 is performed.

In this case, full closed control is performed when the motor is at a stop, and semi closed control is performed when the motor

is operating to improve control performance. When 1000 is set as the filter value of parameter No. 67, full closed control is

always performed.

Control Mode Item Description

Feature Position is controlled according to the motor end data.

Advantage

Since this control is insusceptible to machine influence (such as

machine resonance), the gains of the servo amplifier can be

raised and the settling time shortened.

Semi closed control

Disadvantage

If the motor end is at a stop, the machine end may be vibrating

or the machine end accuracy not obtained.

Feature

Position is controlled according to the motor end data and

machine end data.

Advantage

Control is performed according to the motor end data during

operation, and according to the machine end data at a stop in

sequence to raise the gains during operation and shorten the

settling time.

A stop is made with the machine end accuracy.

Dual F/B control

Disadvantage No specific disadvantage.

Feature Position is controlled according to the machine end data.

Advantage

The machine end accuracy is obtained not only at a stop but also

during operation.

Full closed control

Disadvantage

Since this control is susceptible to machine influence (such as

machine resonance), the gains of the servo amplifier do not rise

and the settling time increases.

1 - 3

1. FUNCTIONS AND CONFIGURATION

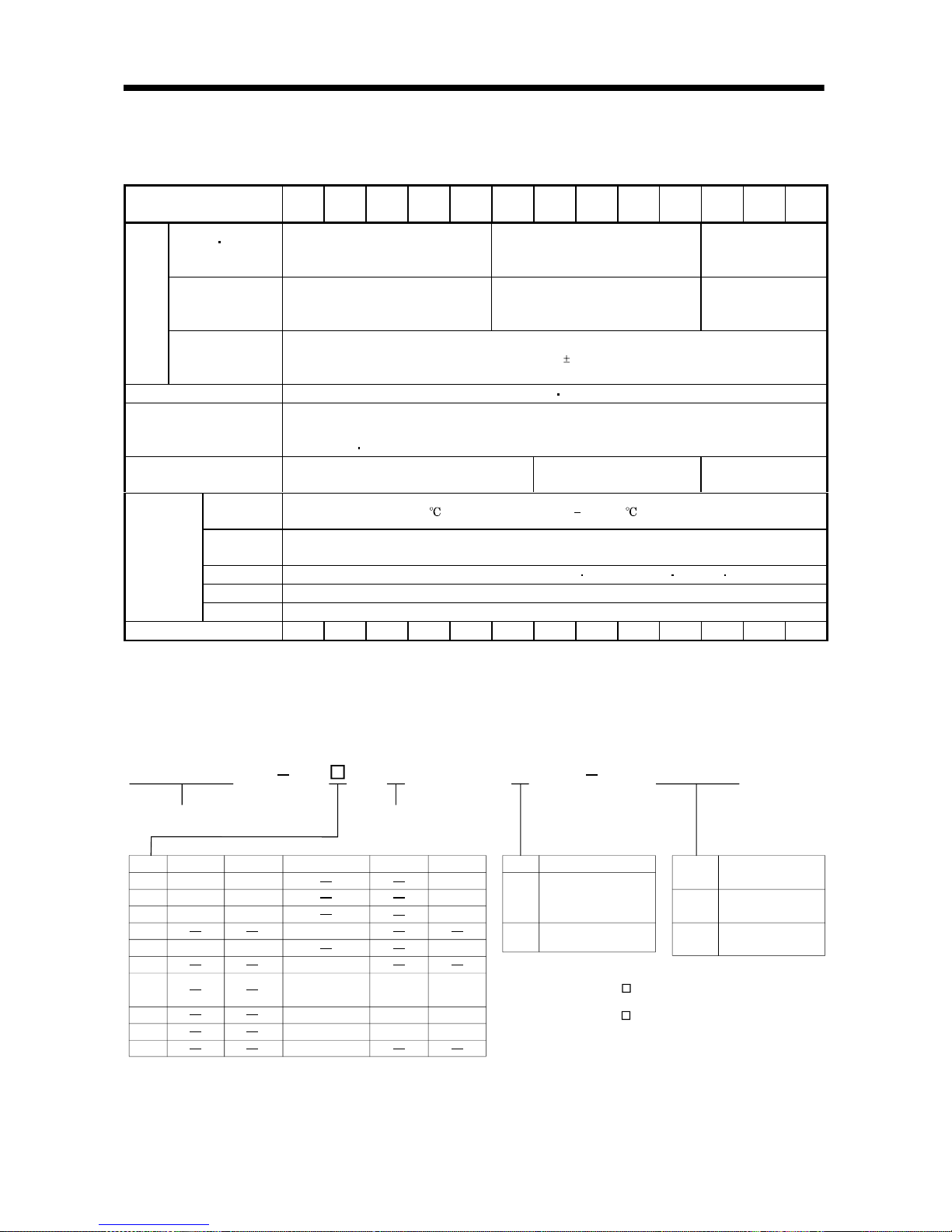

1.3 Specification list

(1) Servo amplifiers

Servo Amplifier Model

MR-J2S-

10B

-PY096

20B

-PY096

40B

-PY096

60B

-PY096

70B

-PY096

100B

-PY096

200B

-PY096

350B

-PY096

500B

-S096

700B

-S096

10B1

-PY096

20B1

-PY096

40B1

-PY096

Voltage frequency

(Note 1)

Three-phase 200 to 230VAC/50, 60Hz

or single-phase 230VAC/50, 60Hz

(Note 2)

Three-phase 200 to 230VAC/50, 60Hz

(Note 2)

Single-phase 100 to

120VAC/50, 60Hz

Permissible voltage

fluctuation

Three-phase 170 to 253VAC/50, 60Hz

or single-phase 207 to 253VAC/50,

60Hz

Three-phase 170 to 253VAC/50, 60Hz

Single-phase 85 to

127VAC/50, 60Hz

Power

supply

Permissible

frequency

fluctuation

Within

5%

Control system Sine-wave PWM control current control system

Protective functions

Overcurrent shutoff, regenerative overvoltage shutoff, overload shutoff (electronic thermal relay),

servo motor overheat protection, encoder error protection, regeneration error protection,

undervoltage

instantaneous power supply protection, overspeed protection, error excessive protection

Structure Self-cooling, open (IP00) Forced cooling, open (IP00)

Self-cooling,

open (IP00)

Ambient

temperature

0 to 55

(non-freezing), storage: 20 to 65 (non-freezing)

Ambient

humidity

90%RH or less (non-condensing), storage: 90%RH or less (non-condensing)

Ambience Indoors (no direct sunlight), without corrosive gas flammable gas oil mist dust and dirt

Altitude 1000m or less above sea level

Environment

Vibration 5.9m/s

2

or less

Weight (kg) 0.7 0.7 1.1 1.1 1.7 1.7 2.0 2.0 4.9 7.2 0.7 0.7 1.1

Note 1. The rated output capacity and rated speed of a servo motor used with the servo amplifier assumes that the power supply

voltage and frequency are as indicated. They cannot be guaranteed when a power supply voltage drop occurs.

2. The torque characteristic of the servo amplifier used with a servo motor assumes that the voltage is three-phase 200 to 230VAC

or single-phase 230VAC.

1.4 Model name

MR-J2S B1

10

20

40

60

70

100

200

350

500

700

053, 13

23

43

73 73

43

23

053, 13

52, 53

81, 102, 103

121, 201, 152,

202, 153, 203

301, 352, 353

502

702

353, 503

203 202

352, 502

103, 153

152

72, 73

13

23

43

HC-KFS HC-MFS HC-SFS HC-RFS HC-UFS

Mitsubishi general-purpose

AC servo amplifier series name

Compatible motor list

B: SSCNET compatibility

Symbol

Note. The standard specifications comply with the EN, UL and cUL Standards.

Symbol

Power supply

None

1

Three-phase 200VAC

or single-phase

230VAC (Note 1)

Single-phase 100VAC

(Note 2)

Note: 1. Single-phase 230VAC is

for only the servo amplifier

of MR-J2S-70 or less.

2. For only the servo amplifier

of MR-J2S-40 or less.

Symbol

PY096

S096

Full closed control

compatible amplifier

MR-J2S-B type

0.05 to 3.5kw

MR-J2S-B type

5.0, 7.0kw

PY096

1 - 4

1. FUNCTIONS AND CONFIGURATION

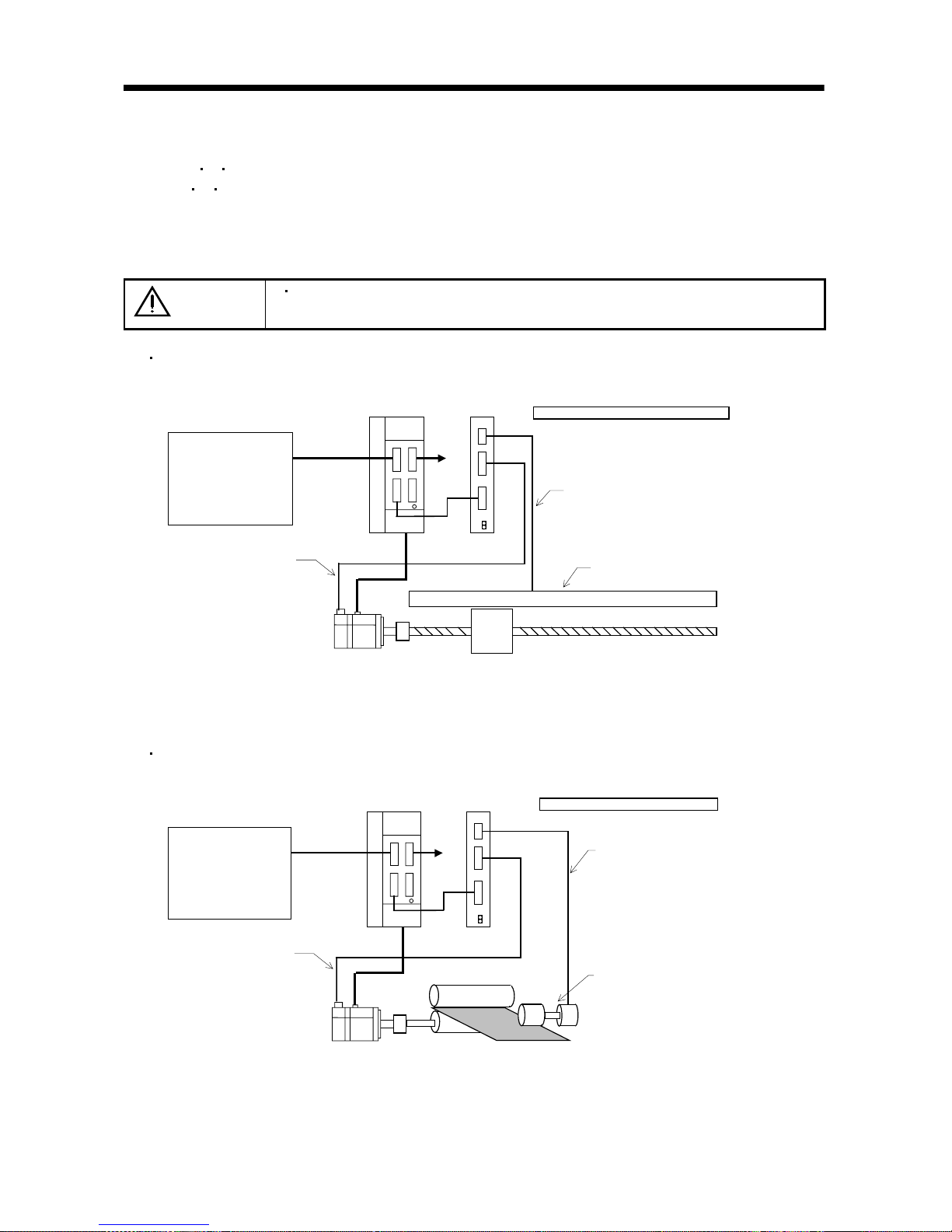

1.5 System configuration

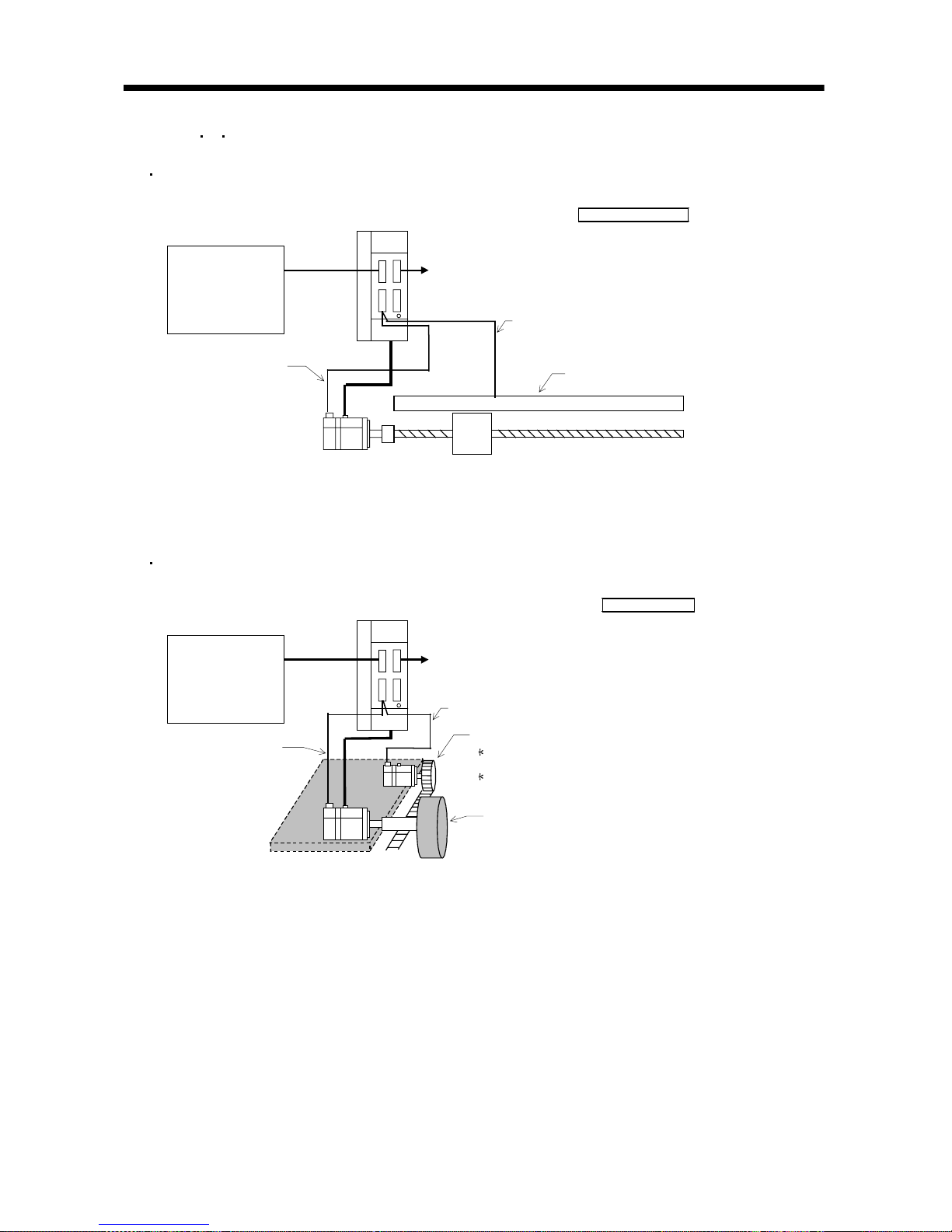

(1) When A

B Z differential input interface unit (MR-J2S-CLP01) is used

The A

B Z differential input interface unit (MR-J2S-CLP01) converts external ABZ phase pulses

into a position feedback signal that can be used for serial communication.

Full closed control is enabled by connecting the output of the MR-J2S-CLP01 to the servo amplifier

encoder connector.

CAUTION

When the MR-J2S-CLP01 is used, a linear scale without Z phase cannot be

connected. Use a linear scale that has the Z phase.

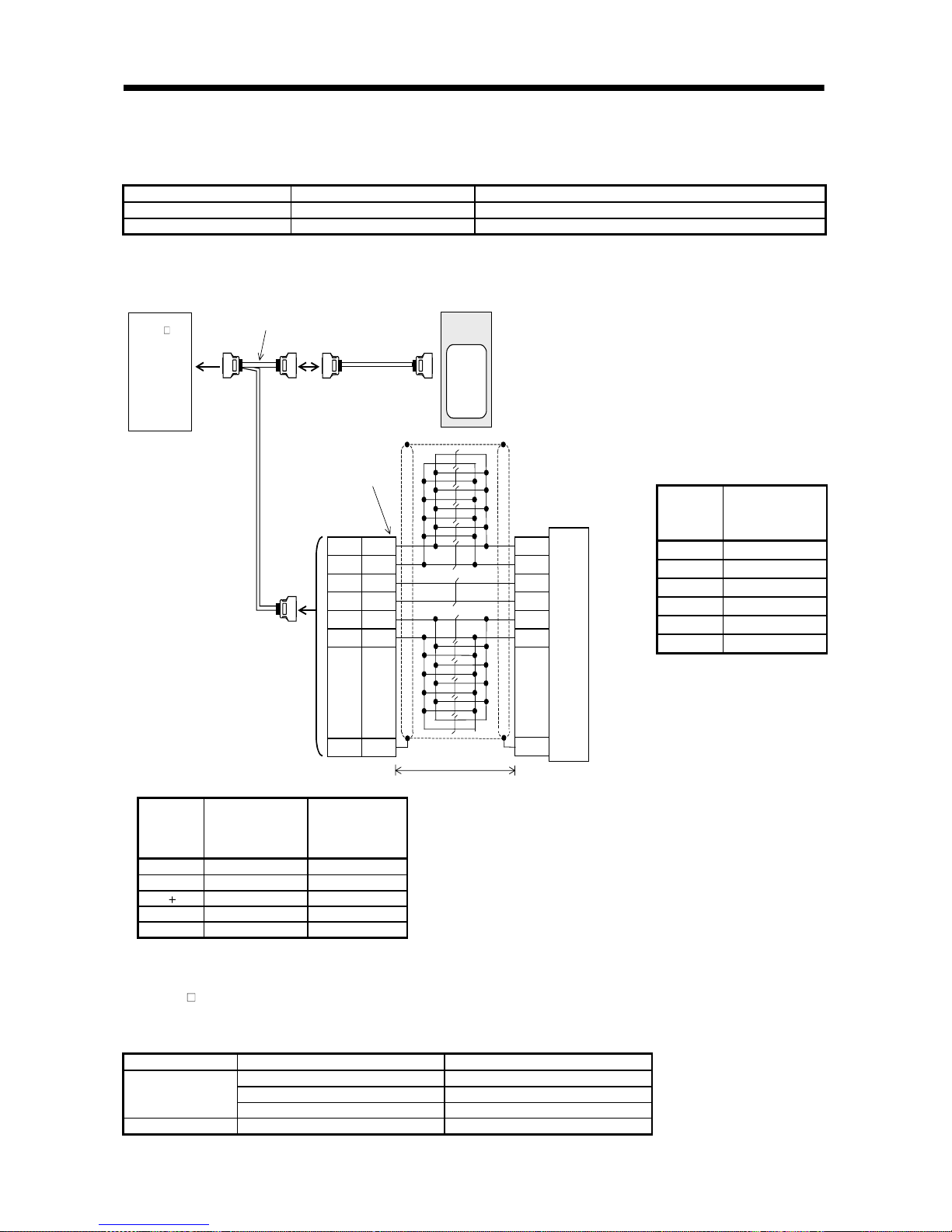

System configuration example 1 (when ABZ pulse train-specified linear scale is used)

SSCNET controller

Servo amplifier

Position

command

control signal

CN1A

CN1B

CN2

CN2

SSCNET

Encoder signal

Linear scale

A, B, Z phase output (ALM output)

ABZ differential input I/F unit

Servo motor

To other

axis

General-purpose pulse output linear scale

MR-J2S-CLP01

Note 1. A linear scale without Z phase cannot be connected.

2. No compatibility with an absolute position detection system.

System configuration example 2 (when ABZ phase pulse train-specified rotary encoder is used)

SSCNET controller

Servo amplifier

Position

command

control signal

CN1A

CN1B

CN2

CN2

SSCNET

Encoder signal

Rotary encoder

A, B, Z phase output

(ALM output)

ABZ differential input I/F unit

Servo motor

To other

axis

General-purpose pulse output encoder

MR-J2S-CLP01

Note 1. A rotary without Z phase cannot be connected.

2. No compatibility with an absolute position detection system.

3. In this example, full closed control cannot be performed if there is no stock (work).

1 - 5

1. FUNCTIONS AND CONFIGURATION

(2) When A B Z differential input interface unit (MR-J2S-CLP01) is not used

System configuration example 3 (when serial communication-specified linear scale is used)

SSCNET controller

Servo amplifier

Position

command

control

signal

CN2

SSCNET

Encoder signal

Linear scale

Serial communication signal cable

Servo motor

To other axis

Serial I/F linear scale

Note 1. When an ABS type linear scale is used, this example is compatible with an absolute position detection system. Note that

the battery (MR-BAT) is not needed.

System configuration example 4 (when serial communication-specified servo motor is used)

SSCNET controller

Servo amplifier

Position

command

control

signal

CN2

SSCNET

Encoder signal

Drive section

Serial communication signal cable

Driving servo

motor

To other axis

Serial I/F encoder

Position detection section (detecting servo

motor and pulley)

Use the HC-MFS/KFS series servo motor.

(131072p/rev resolution)

No compatibility with absolute position

detection.

Note 1. Use the HC-KFS series or HC-MFS series servo motor in the position detection section.

2. No compatibility with an absolute position detection system.

1 - 6

1. FUNCTIONS AND CONFIGURATION

MEMO

2 - 1

2. LINEAR SCALES

2 LINEAR SCALES

Contact the linear scale manufacturer for details of the linear scales such as the specifications,

performance and warranties.

2.1 Compatible linear scale list

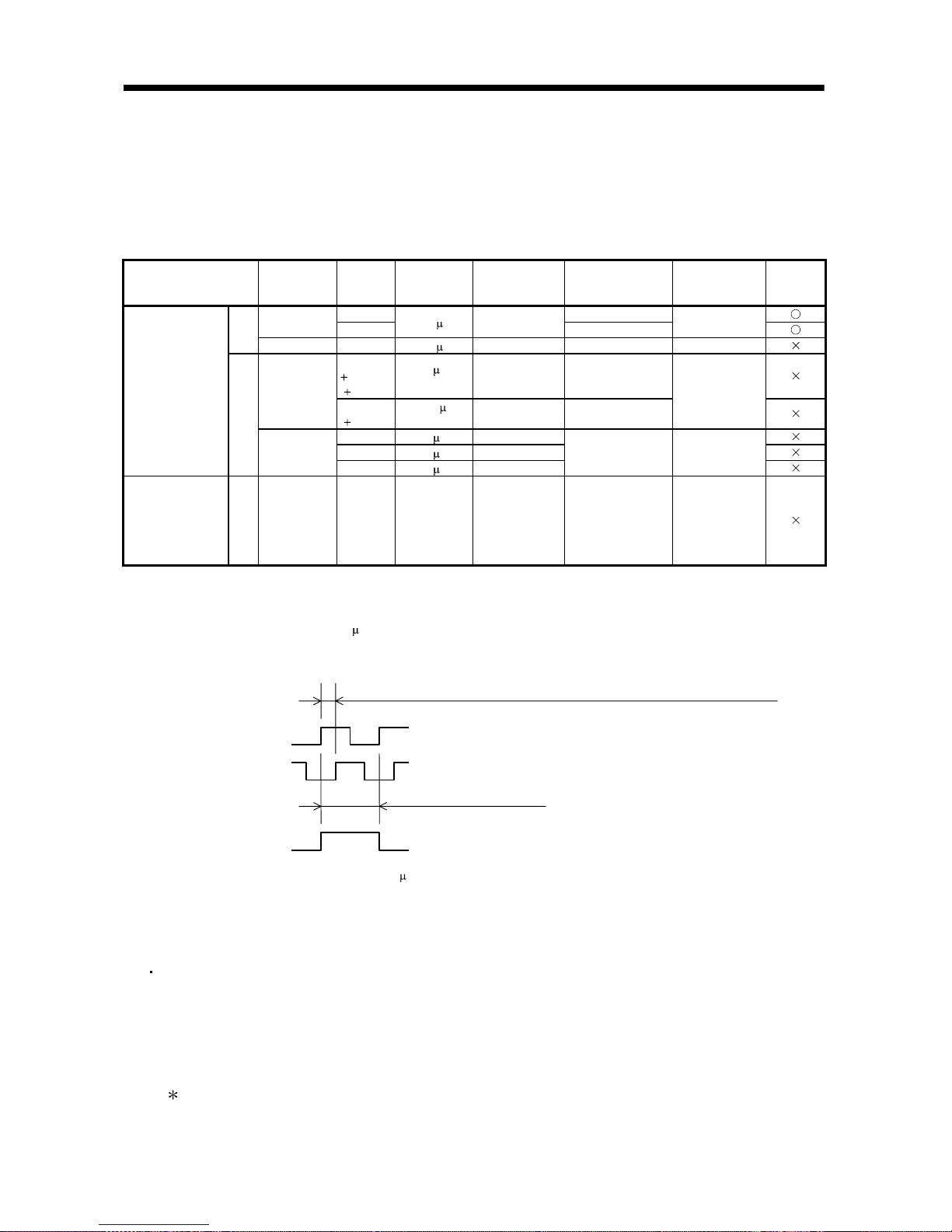

Scale Type Manufacturer Model Resolution

Rated Speed

(Note 1)

Effective

Measurement

Length (Maximum)

Communication

System

Absolute

Position

System

AT343A 3000mm

Mitutoyo

AT543A

0.05 m2.0m/s

1500mm

2 wire type

ABS

type

Heidenhain LC491M 0.05

m 2.0m/s 2040mm 4 wire type

SL710

PL101R

MJ830

0.2

m

(Note 2)

6.4m/s 3000mm

Sony

Precision

Technology

SH13

MJ830

0.005

m

(Note 2)

1.4m/s 1240mm

2 wire type

RGH26P 5.0 m4.0m/s

RGH26Q 1.0 m3.2m/s

Mitsubishi serial

interface

compatibility

INC

type

Renishaw

RGH26R 0.5

m1.6m/s

70000mm 2 wire type

A/B/Z phase

differential output

(MR-CLP01 used)

A/B/Z signal

required

(Note 3)

INC

type

Not specified (Note 3)

Scale

dependent

(Note 4)

Scale

dependent

Scale dependent 2 wire type

Note 1. The upper limit value of the linear servo motor speed is the lower value of the maximum speed of the linear servo motor and the

rated speed of the linear scale.

2. Changes depending on the setting of the interpolator (MJ830: Sony Precision Technology make). Set the resolution within the

range of the minimum resolution to 5

m.

3. The phase difference between the A-phase pulse and B-phase pulse must be 500ns or more, and the Z-phase pulse width be

equivalent to one cycle of the A-phase pulse. Also, the Z phase must be synchronized with the A phase/B phase.

4. The permissible resolution range is 0.005 to 5

m. Select the linear scale within this range.

[About handling of the linear scale]

If the linear scale is mounted improperly, for example, an alarm, position shift, etc. may occur.

In such cases, also check the mounting of the linear scale.

General check items of the linear scale

(a) Check that the gap between the head and scale is proper.

(b) Check the scale head for rolling and yawing (looseness of scale head section).

(c) Check the scale surface for contamination and scratches.

(d) Check that the vibration and temperature are within the operating range.

(e) Check that the speed is within the permissible range without overshooting.

For detailed check items, contact the linear scale manufacturer.

A phase

B phase

Phase difference between A phase and B phase: 500ns or more

Z phase

One cycle of A phase

2 - 2

2. LINEAR SCALES

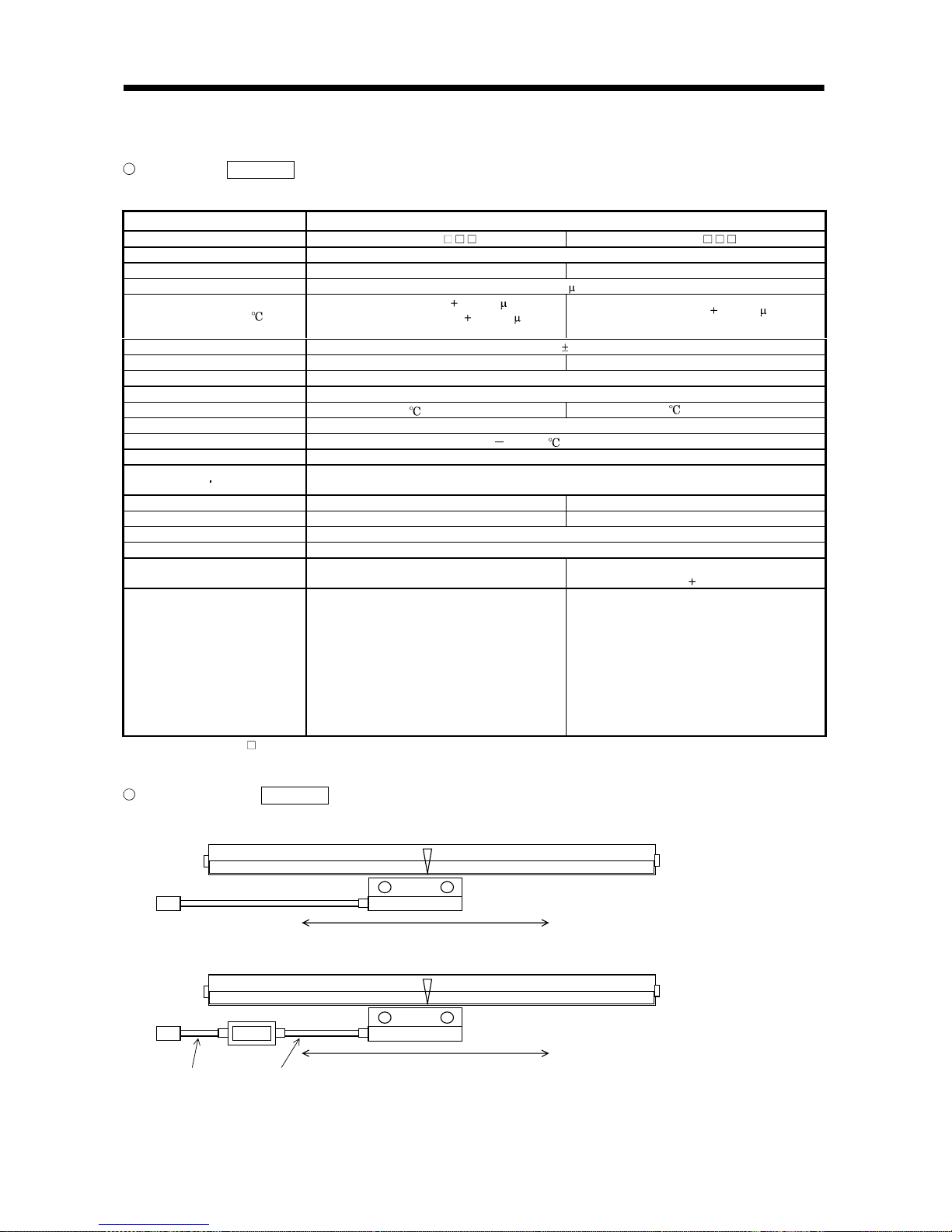

2.1.1 Mitutoyo make linear scales (ABS type)

Specifications Reference

Contact Mitutoyo for the specifications of these linear scales.

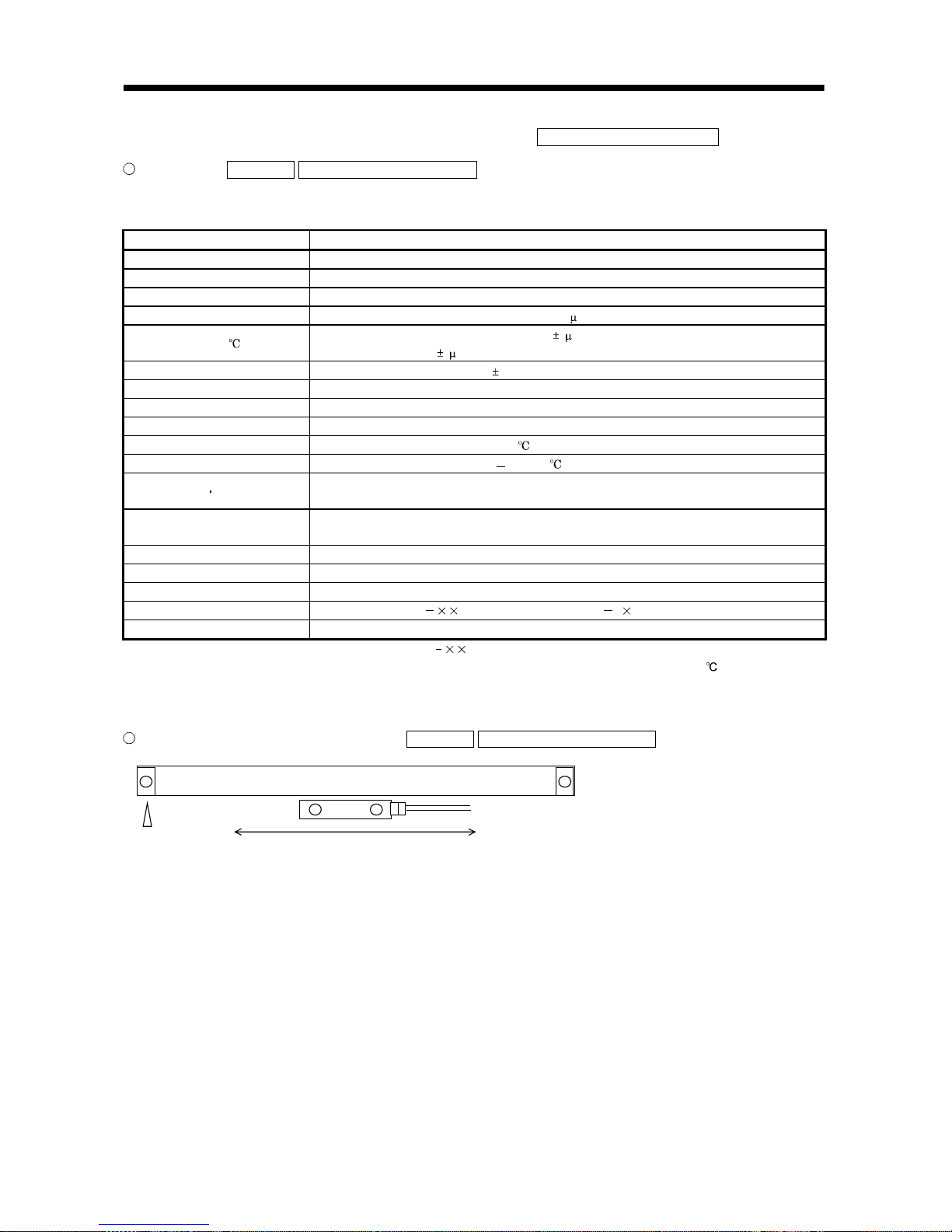

Item Specifications

Model AT343A- AT543ASystem Capacitive, photoelectric, combined type

Effective measurement length 100 to 3000mm 100 to 1500mm

Resolution 0.05 m

Indication accuracy (20 )

100 to 1500mm: 3

3L/1000 m

1600mm to 3000mm: 5

5L/1000 m

L: Effective measurement length

100 to 1500mm: 3

3L/1000 m

L: Effective measurement length

Supply power voltage 5V 5%

Current consumption Max.250mA Max.270mA

Rated response speed 2.0m/s

Maximum response speed 2.0m/s

Operating temperature range 0 to 45 (non-freezing) 0 to 50 (non-freezing)

Operating humidity range 20 to 80%RH (non-condensing)

Storage temperature range 20 to 70 (non-freezing)

Storage humidity range 20 to 80%RH (non-condensing)

Dust tightness water tightness

IP53 or equivalent

(in the indication method given in the instruction manual of the Mitutoyo make linear scale)

Vibration resistance 100m/s2 (55 to 2000Hz) 150m/s2 (55 to 2000Hz)

Shock resistance 150m/s2 (1/2sin, 11ms) 200m/s2 (1/2sin, 11ms)

Sliding force 5N or less

Output signal Serial communication compatibility

Output cable

Mitutoyo make option

Part No. 09BAA598A to C:0.2, 2, 3m

Supplied as standard

Head cable 5m

output cable 1m

Connection cable

(Mitsubishi option)

Refer to the standard connection example in

Chapter 3 and fabricate the cable.

When the MR-J2SCLCBL02M-P-H is used,

any of the following Mitsubishi cables can also

be used (Note 1).

Output cable length 0.2m: MR-JCCBL2, 5,

10M-H

2m: MR-JCCBL2, 5M-H

3m: MR-JCCBL2M-H

Refer to the standard connection example in

Chapter 3 and fabricate the cable.

When the MR-J2SCLCBL02M-P-H is used,

any of the following Mitsubishi cables can also

be used (Note 1).

MR-JCCBL2, 5, 10M-H

Note 1. The MR-JCCBL M-L and MR-JCCBL20M-H and more (20m and more) cannot be used.

2. The battery (MR-BAT) is not required to configure an absolute position detection system.

Scale unit structure Reference

Home position

Decreasing direction

Mitutoyo

AT343A

Output cable

Home position

Mitutoyo

AT543A

Output cable Head cable

Increasing direction

Decreasing direction Increasing direction

2 - 3

2. LINEAR SCALES

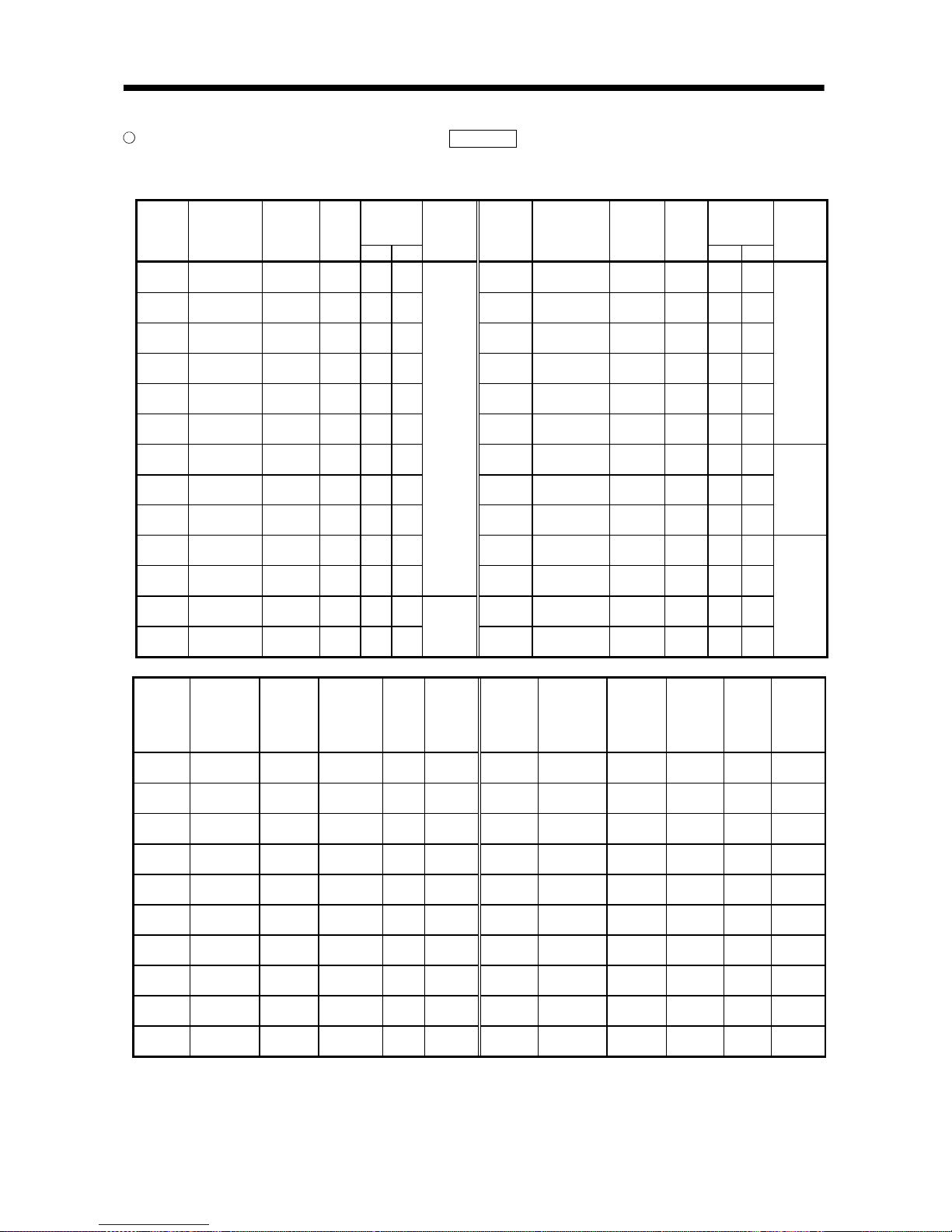

AT343A and AT543A mounting dimension tables Reference (Dimension unit: mm)

The following tables indicate L0 to L4 and number of mounting blocks or number of fixing holes in the

outline drawings shown on the next page.

Mounting

Block Fixing

Pitch

Mounting

Block Fixing

Pitch

Model

Effective

Measurement

Length

L0

Maximum

Moving

Length

L1

Full

Length

L2

L3 L4

Number of

Mounting

Blocks

(pcs.)

Model

Effective

Measurement

Length

L0

Maximum

Moving

Length

L1

Full

Length

L2

L3 L4

Number of

Mounting

Blocks

(pcs.)

AT343A-

300

300 330 440 220 150

AT343A-

1300

1300 1360 1470 735 325

AT343A-

350

350 380 490 245 175

AT343A-

1400

1400 1460 1570 785 350

AT343A-

400

400 430 540 270 200

AT343A-

1500

1500 1560 1670 835 375

AT343A-

450

450 480 590 295 225

AT343A-

1600

1600 1690 1800 900 400

AT343A-

500

500 540 650 325 250

AT343A-

1700

1700 1790 1900 950 425

AT343A-

600

600 650 760 380 300

AT343A-

1800

1800 1890 2000 1000 450

5

AT343A-

700

700 760 870 435 350

AT343A-

2000

2000 2100 2210 1105 335

AT343A-

750

750 810 920 460 375

AT343A-

2200

2200 2300 2410 1205 370

AT343A-

800

800 860 970 485 400

AT343A-

2400

2400 2500 2610 1305 400

7

AT343A-

900

900 960 1070 535 450

AT343A-

2500

2500 2600 2710 1355 315

AT343A-

1000

1000 1060 1170 585 500

3

AT343A-

2600

2600 2700 2810 1405 325

AT343A-

1100

1100 1160 1270 635 275

AT343A-

2800

2800 2900 3010 1505 350

AT343A-

1200

1200 1260 1370 685 300

5

AT343A-

3000

3000 3050 3210 1605 375

9

Model

Effective

Measurement

Length

L0

Maximum

Moving

Length

L1

Mounting

Hole Position

L2

Full

Length

L3

Number of

Fixing

Holes

(n) (pcs.)

Model

Effective

Measurement

Length

L0

Maximum

Moving

Length

L1

Mounting

Hole

Position

L2

Full

Length

L3

Number of

Fixing

Holes

(n)

(pcs.)

AT543A-

100

100 120 12.5 225 3

AT543A-

700

700 720 12.5 825 9

AT543A-

150

150 170 37.5 275 3

AT543A-

750

750 770 37.5 875 9

AT543A-

200

200 220 12.5 325 4

AT543A-

800

800 820 12.5 925 10

AT543A-

250

250 270 37.5 375 4

AT543A-

900

900 920 12.5 1025 11

AT543A-

300

300 320 12.5 425 5

AT543A-

1000

1000 1020 12.5 1125 12

AT543A-

350

350 370 37.5 475 5

AT543A-

1100

1100 1120 12.5 1225 13

AT543A-

400

400 420 12.5 525 6

AT543A-

1200

1200 1220 12.5 1325 14

AT543A-

450

450 470 37.5 575 6

AT543A-

1300

1300 1320 12.5 1425 15

AT543A-

500

500 520 12.5 625 7

AT543A-

1400

1400 1420 12.5 1525 16

AT543A-

600

600 620 12.5 725 8

AT543A-

1500

1500 1520 12.5 1625 17

2 - 4

2. LINEAR SCALES

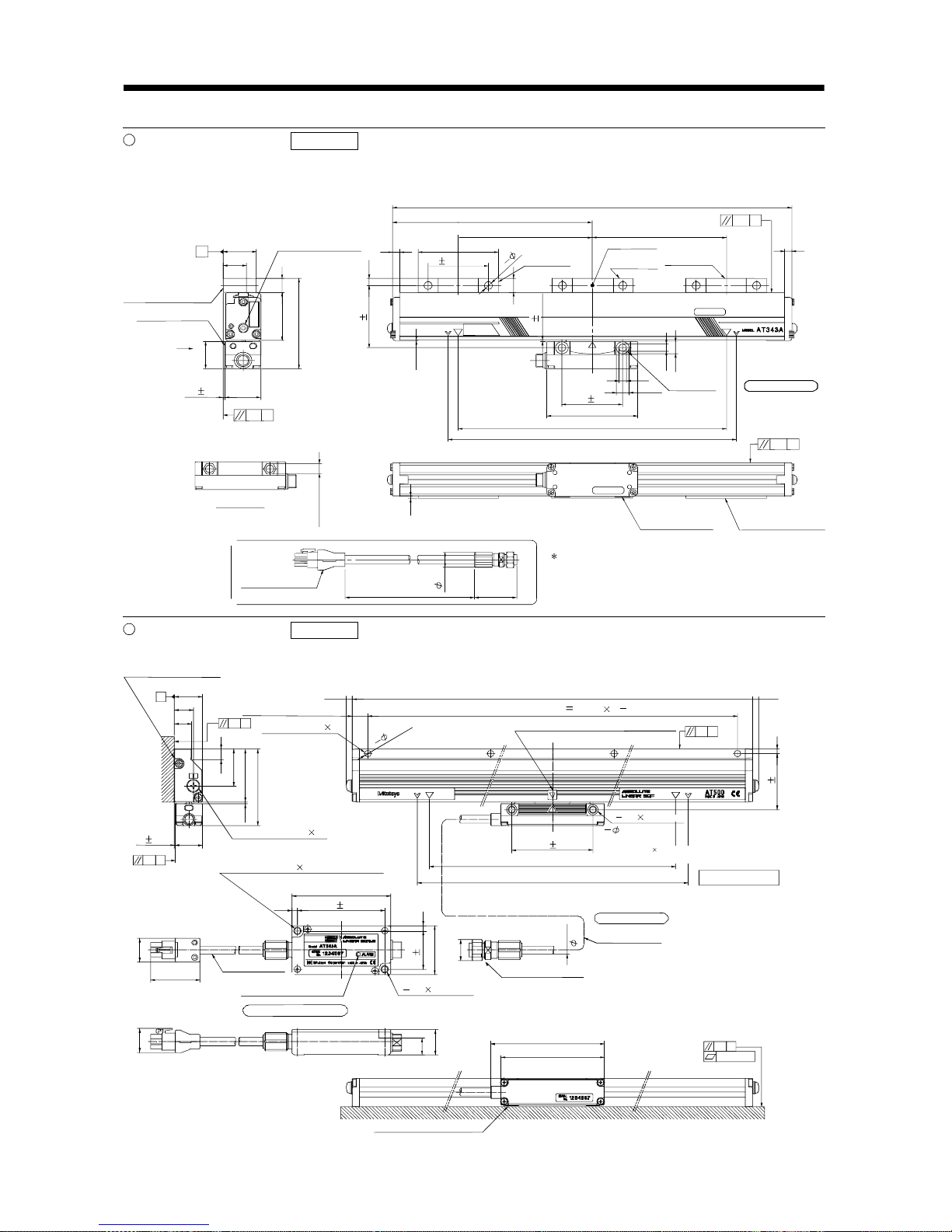

AT343A outline drawing Reference (Dimension unit: mm)

Effective measurement length 300mm to 3000mm

This outline drawing is based on the data from Mitutoyo. Contact Mitutoyo for this outline drawing.

Spot facing

depth 5

7

7

11.6

A

32.5

23

X

36

29

50.5 15

95.5

0.1

A

2.5

7.5

807

1

5

0.2

G

(42)

8

12.6

L

(

0.5

)

Scale body mounting

surface

Detection head

mounting surface

Air supply port (M5)

(Provided at both ends)

Full length L2

Mounting block fixing pitch L3

Mounting block fixing pitch L4 Mounting block fixing pitch L4

Elastical ly fixing

area

Mounting block

Completely

fixing area

Elastically

fixing area

Spot facing

depth 6.5

G: Machine guide

Effective measurement length L0

Maximum moving lengt h L1

View X

11 (hexagon)

Detection head

mounting surface

Scale body mounting

surface

Option (L = any of three different len gths, 0.2m, 2m, 3m)

Signal cable

(Vinyl sheathed)

( 16)

1.5 0.2

66 0.3

60 0.2

60 0.2

90

2

8

The signal cable is optional.

(Part No.09BAA598A to C: 0.2m, 2m, 3m)

1.5 0.2

0.2 G

AT543A outline drawing Reference (Dimension unit: mm)

This outline drawing is based on the data from Mitutoyo. Contact Mitutoyo for this outline drawing.

Air supply port (M5 0.8)

A

0.1

G

8.5

30

43

62

(1.5)

0.1

G

4

(17)

40

4.5

80

4.5

(40)

(

19.2

)

(19.6)

20

13.4

92

84

0.1

G

0.03/100

AR

Scale unit mounting surface

(Provided on both sides)

Mounting hole position: L2

(4.8)

Fixing screw: M4 0.8

(L = 18mm or more)

Full length: L3

(4.8)

Mounting hole pitch P 100mm (n 1)

Position where absolute value data is zero

(Nearly at scale center)

2 8 spot facing

depth 5(One side only)

2 M6 1

(through)

60 0.2

Fixing screw: M4 0.8L = 20mm or more,

or can be fixed with M6 screw from rear side.

Effective measurement length: L0

Maximum moving length: L1

G: Machine guide

Fixing screw: M4 0.8L = 18mm or more,

or can be fixed with M6 screw from rear side.

Output cable

(Vinyl sheath)

Alarm display LED window

Waterproof connector

2 M6 1

(through)

Scale uni t

Head cable

(Vinyl sheath)

Interface unit

Scale unit mounting surface

22

0.1

A

1 0.1

n

5

(

H

ol

e)

45.2 0.2

23

14

15.5

71 0.2

31 0.2

6.5

2 - 5

2. LINEAR SCALES

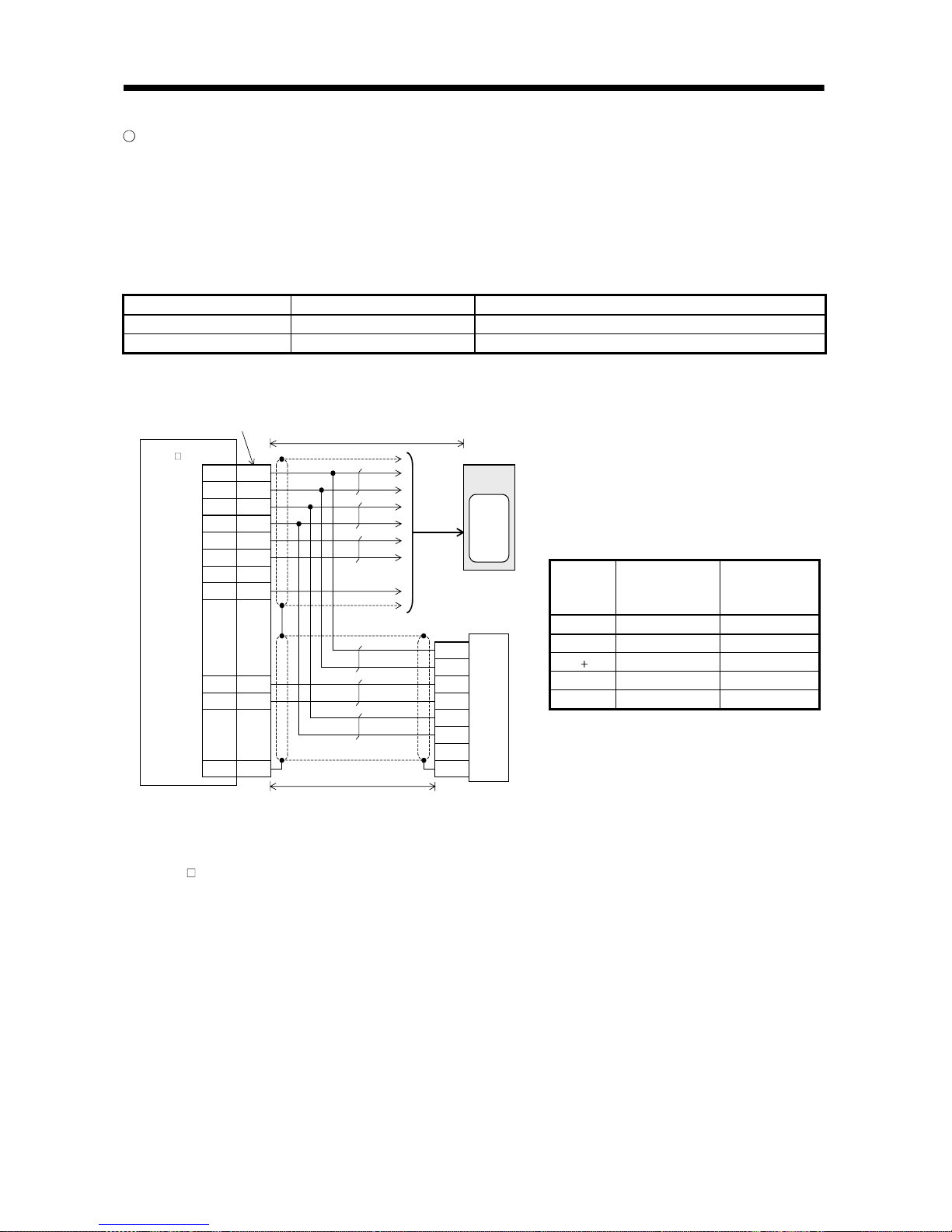

Connection cable connection examples (1)

The following cable wiring examples assume that the linear scale is connected directly to CN2 of the servo

amplifier.

(1) Connection example of up to 5m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Scale Model Scale Side Output Cable Specifications

AWG24 AT343A Mitutoyo make output cable 2m

AWG24 AT543A Mitutoyo make output cable 1m

[Connection example]

10120-3000PE, 10320-52F0- 008

(3M make or equi valent )

(Note 1)

Mitutoyo make linear scale

19

12

20

11

7

17

1

P5

LG

P5

LG

M

R

MR

R

LG

6

16

Plate

M

D

MD

R

S

D

P5

LG

R

Q

/

RQ

P5

LG

F

G

(Note 2)

CN2

Servo motor

Encoder

(Note 3)

Servo ampli fier

MR-J2S -

B

-PY096/S096

50m or less (2 wire type)

5m or less

Note 1. Do not connect the linear scale that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MR-

J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear scale side

output cable and connector.

[Linear scale side connector] (Note 4)

Applicable

Housing

172161-9

(Tyco Electronics

or equivalent)

RDAD-15S-LNA

(Hirose Electric

or equivalent)

RQ 1 7

/RQ 2 8

P5 ( 5V) 7 3, 4

LG (0V) 8 1, 2

FG 9 15

2 - 6

2. LINEAR SCALES

(2) Connection example of 5m to 30m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Scale Model Scale Side Output Cable Specifications

AWG24 AT343A Mitutoyo make output cable 0.2m

AWG22 AT543A Mitutoyo make output cable 1m

[Connection example]

The wiring length is up to 30m. Depending on the wiring length, however, the number of LG and P5

connections must be changed according to the following table.

(Note 1)

Mitutoyo make linear scale

19

12

20

11

7

17

1

P5

LG

P5

LG

M

RMRR

LG

6

16

Plate

MD

MD

R

SD

P5

LG

RQ

/RQ

P5

LG

FG

(Note 2)

CN2

Servo motor

Encoder

(Note 3)

Servo amplifier

MR-J2S -

B

-PY096/S096

10120-3000PE, 10320-52F0-0 08

(3M make or equivalent )

50m or less (2 wire type)

30m or less

Note 1. Do not connect the linear scale that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MR-

J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear scale side

output cable and connector.

Wiring

Length

Number of LG and

P5 Connections

to 5m 2 parallel

to 10m 4 parallel

to 15m 6 parallel

to 20m 8 parallel

to 25m 10 parallel

to 30m 12 parallel

[Linear scale side connector] (Note 4)

Applicable

Housing

172161-9

(Tyco Electronics

or equivalent)

RDAD-15S-LNA

(Hirose Electric or

equivalent)

RQ 1 7

/RQ 2 8

P5 ( 5V) 7 3, 4

LG (0V) 8 1, 2

FG 9 15

2 - 7

2. LINEAR SCALES

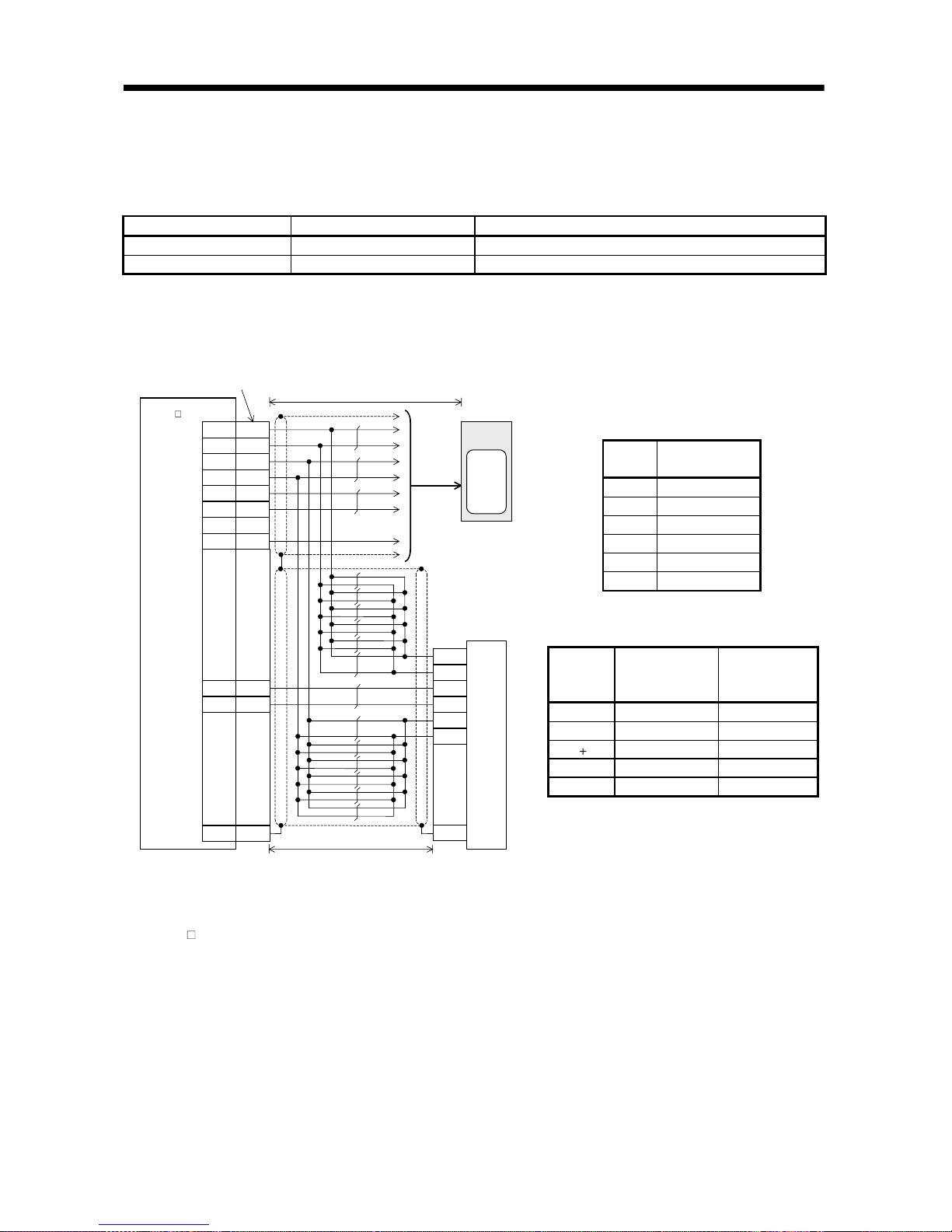

Connection cable connection examples (2)

The following cable wiring examples assume that the linear scale is connected to CN2 of the servo

amplifier using the option cable MR-J2SCLCBL02M-P-H.

(1) Connection example of up to 5m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Scale Model Scale Side Output Cable Specifications

AWG24 AT343A Mitutoyo make output cable 2m

AWG24 AT543A Mitutoyo make output cable 1m

[Connection example]

10120-3000PE, 10320-52F0- 008

(3M or equivalent)

To CN2

Servo motor

Encoder

(Note 1)

Mitutoyo make linear scale

1912P5

LG

7

17

20

11

Plate

M

R

MR

R

P5

LG

S

D

P5

LG

R

Q

/RQ

P5

LG

FG

(Note 2)

(Note 3)

Servo amplifier

MR-J 2S-

B

-PY096/S096

Linear

scale

connector

Option cable

(MR-J2SCLCBL02M-P-H)

5m or less

Note 1. Do not connect the linear scale that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MR-

J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear scale side

output cable and connector.

5. When the MR-J2SCLCBL02M-P-H is used, the Mitsubishi option cable can be used as the linear scale connection cable.

Scale Model

Scale Side Output

Cable Length

Mitsubishi Option Cable

Model

0.2m MR-JCCBL2, 5, 10M-H

2m MR-JCCBL2, 5M-H

AT343A

3m MR-JCCBL2M-H

AT543A 1m MR-JCCBL2, 5, 10M-H

[Linear scale side connector] (Note 4)

Applicable

Housing

172161-9

(Tyco Electronics

or equivalent)

(Note 5)

RDAD-15S-LNA

(Hirose Electric or

equivalent)

RQ 1 7

/RQ 2 8

P5 ( 5V) 7 3, 4

LG (0V) 8 1, 2

FG 9 15

2 - 8

2. LINEAR SCALES

(2) Connection example of 5m to 30m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Scale Model Scale Side Output Cable Specifications

AWG24 AT343A Mitutoyo make output cable 0.2m

AWG22 AT543A Mitutoyo make output cable 1m

[Connection example]

The wiring length is up to 30m. Depending on the wiring length, however, the number of LG and P5

connections must be changed according to the following table.

10120-3000PE, 10320-52F0-008

(3M or equi valent)

To CN2

Servo mot or

Encoder

(Note 1)

Mitutoyo make linear scale

1912P

5LG7

17

20

11

Plat e

M

RMRRP5

LG

SD

P

5

LG

R

Q

/

RQ

P

5

LG

FG

(Note 2)

(Note 3)

Servo ampli fier

MR- J2 S-

B

-PY096/ S096

Linear

scale

connect or

Opti on cabl e

(MR-J2SCLCBL02M-P-H)

30m or less

Note 1. Do not connect the linear scale that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MRJ2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear scale side

output cable and connector.

5. When the MR-J2SCLCBL02M-P-H is used, the Mitsubishi option cable can be used as the linear scale connection cable.

Scale Model Scale Side Output Cable Length Mitsubishi Option Cable Model

0.2m MR-JCCBL2, 5, 10M-H

2m MR-JCCBL2, 5M-H

AT343A

3m MR-JCCBL2M-H

AT543A 1m MR-JCCBL2, 5, 10M-H

[Linear scale side connector] (Note 4)

Applicable

Housing

172161-9

(Tyco Electronics

or equivalent)

(Note 5)

RDAD-15S-LNA

(Hirose Electric or

equivalent)

RQ 1 7

/RQ 2 8

P5 ( 5V) 7 3, 4

LG (0V) 8 1, 2

FG 9 15

Wiring

Length

Number of LG

and P5

Connections

to 5m

2 parallel

to 10m

4 parallel

to 15m

6 parallel

to 20m

8 parallel

to 25m

10 parallel

to 30m

12 parallel

2 - 9

2. LINEAR SCALES

2.1.2 Heidenhain make linear encoder (linear scale) (ABS type) Scheduled to be compatible

Specifications Reference Scheduled to be compatible

Contact Heidenhain for the specifications of this linear encoder (linear scale).

Heidenhain Sales Section No. 2: TEL. (03) 3234-7781

Item Specifications

Model LC491M

System Photoelectric scanning system

Effective measurement length 70 to 2040mm

Resolution 0.05 m

Accuracy grade (20 )

5 m

3 m (up to effective measurement length 1240)

Supply power voltage 5V 5% on the linear encoder side

Current consumption Max.300mA

Rated response speed 2.0m/s

Maximum response speed 2.0m/s

Operating temperature range 0 to 50 (non-freezing) (Note 2)

Storage temperature range 20 to 70

(non-freezing)

Dust tightness water tightness

IP53 (when mounted according to the manual of the Heidenhain make linear encoder)

IP64 (when filled with compressed air)

Vibration resistance

100m/s

2

(DINIEC 68-2-6) without mounting spur

150m/s

2

(DINIEC 68-2-6) with mounting spur

Shock resistance 150m/s2 (DINIEC 68-2-6) (11ms)

Required feeding force 5N or less

Output signal Serial communication compatibility

Output cable 337 439 (17 pin coupling), 367 425 0 (20 pins), etc. (Note 1)

Connection cable Refer to the standard connection example in Chapter 3 and fabricate the cable.

Note 1. When the MR-J2SCLCBL02M-P-H is used, 367 425 (5m or less) can be connected directly.

2. The linear encoder (linear scale) is extremely sensitive to the operating temperature. When it exceeds 50

, an alarm may

occur. It is recommended to pay special attention to the operating temperature and secure the temperature change margins.

3. The battery (MR-BAT) is not required to configure an absolute position detection system.

Linear encoder (linear scale) unit structure Reference Scheduled to be compatible

Decreasing direction Increasing direction

(With the housing section fixed)

Home position

2 - 10

2. LINEAR SCALES

LC491M outline drawing Reference Scheduled to be compatible (Dimension unit: mm)

This outline drawing is based on the data from Heidenhain. Contact Heidenhain for this outline drawing.

DIN ISO 8015

ISO 2768-m H

2

Without mounting spur

With mounting spur

Machine gu ide

Measurement point for adjustment

Dimensional tolerance for machine installation

Compressed air filling port

Measurement length starting point (pos. 20mm)

Mounting s pur

2 - 11

2. LINEAR SCALES

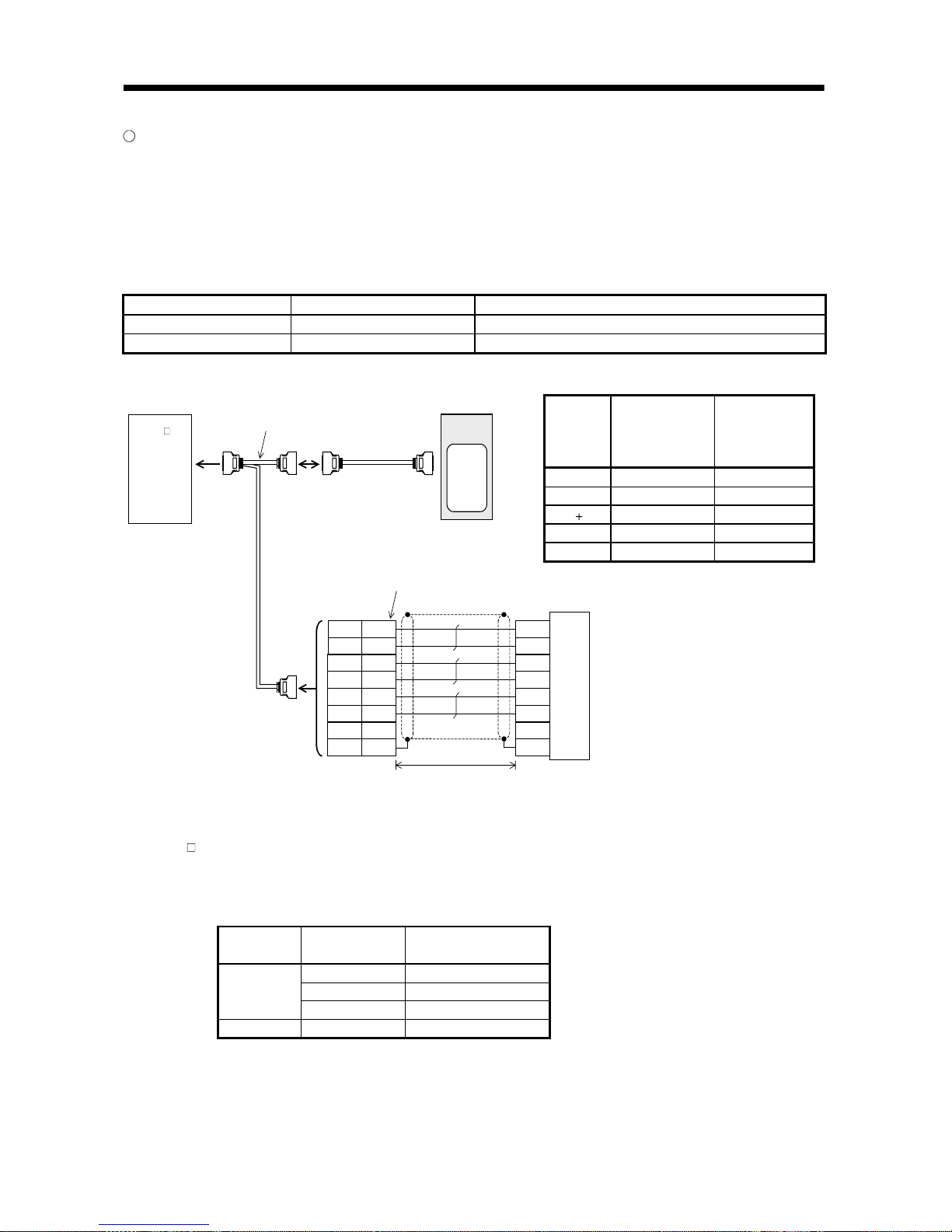

Connection cable connection examples (1)

The following cable wiring examples assume that the linear encoder (linear scale) is connected directly to

CN2 of the servo amplifier.

CAUTION

When the Heidenhain linear encoder (linear scale) is used, the

communication system is of 4 wire type.

Change the setting of serial encoder cable selection (parameter No. 23) as

indicated below. If a wrong value is set, a servo alarm (alarm 70) occurs.

Pr.23

2 (4 wire type setting is made valid.)

(1) Connection example of up to 5m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Encoder (Scale) Model Encoder (Scale) Side Output Cable Specifications

AWG22 LC491M Heidenhain make output cable 0.5m

[Connection example]

(Note 1)

Heidenhain make linear encoder

(linear scale)

(Linear encoder head section)

19

12

20

11

7

17

1

P

5

LG

P

5

LG

M

RMRR

LG

4

14

6

16

Pla te

MD

2

MDR

2

MD

MD

R

SD

P5

LG

SD

/

SD

R

Q

/RQ

F

G

(Note 2)

CN2

Servo mot or

Encoder

(Note 3)

Servo ampli fier

MR- J 2S -

B

-PY096/ S096

5V/sensor

0V/sensor

10120-3000PE, 10320-52F0-008

(3M make or equi valent)

50m or less (2 wire type)

5m or less

Note 1. Do not connect the linear encoder (linear scale) that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of

the MR-J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear

encoder (linear scale) side output cable and connector.

[Linear scale side connector] (Note 4)

Applicable

Housing

17 Pin Coupling

291697-26 (Female)

(Heidenhain make)

20 Pin Connector

(3M or equivalent)

SD 14 6

/SD 17 16

RQ 8 7

/RQ 9 17

5V 7 20

0V 10 1

5V/sensor 1 19

0V/sensor 4 11

2 - 12

2. LINEAR SCALES

(2) Connection example of 5m to 30m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Encoder (Scale) Model Encoder (Scale) Side Output Cable Specifications

AWG22 LC491M Heidenhain make output cable 0.5m

[Connection example]

The wiring length is up to 30m. Depending on the wiring length, however, the number of LG and P5

connections must be changed according to the following table.

19

12

20

11

7

17

1

P5

LG

P5

LG

M

RMRR

LG

Plate

SD

(Note 2)

CN2

Servo motor

Encoder

(Note 3)

Servo amplifier

MR-J 2S-

B

-PY096/S096

(Note 1)

Heidenhain make li near encoder (linear scale)

(Linear encoder head section)

P5

LG

SD

/

SD

R

Q

/RQ

5V/sensor

0V/sensor

FG

4

14

6

16

MD2

MDR2

MD

MD

R

10120-3000PE, 10320-52F0-008

(3M make or equivalent )

50m or less (2 wire type)

30m or less

Note 1. Do not connect the linear encoder (linear scale) that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MR-

J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear encoder

(linear scale) side output cable and connector.

Wiring

Length

Number of LG and

P5 Connections

to 5m 2 parallel

to 10m 4 parallel

to 15m 6 parallel

to 20m 8 parallel

to 25m 10 parallel

to 30m 12 parallel

[Linear scale side connector] (Note 4)

Applicable

Housing

17 Pin Coupling

291697-26 (Female)

(Heidenhain make)

20 Pin Connector

(3M or equivalent)

SD 14 6

/SD

17 16

RQ 8 7

/RQ 9 17

5V 7 20

0V 10 1

5V/sensor 1 19

0V/sensor 4 11

2 - 13

2. LINEAR SCALES

Connection cable connection examples (2)

The following cable wiring examples assume that the linear encoder (linear scale) is connected to CN2 of

the servo amplifier using the option cable MR-J2SCLCBL02M-P-H.

(1) Connection example of up to 5m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Encoder (Scale) Model Encoder (Scale) Side Output Cable Specifications

AWG22 LC491M Heidenhain make output cable 0.5m

[Connection example]

10120-3000PE, 10320-52F0- 52F0-008

(3M or equivalent)

To CN2

Servo motor

Encoder

1912P5

LG

6

16

20

11

Plate

M

D

MD

R

P5

LG

S

D

(Note 2)

(Note 3)

Servo amplifier

MR-J2 S-

B

-PY096/S096

Linear

scale

connector

Option ca ble

(MR-J2SCLCBL02M-P-H)

(Note 1)

Heidenhain make linear encoder

(linear scale)

(Linear encoder head section)

P5

L

G

S

D

/

SD

R

Q

/

RQ

FG

5V/sensor

0V/sensor

717M

RMRR

5m or less

Note 1. Do not connect the linear encoder (linear scale) that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MR-

J2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear encoder

(linear scale) side output cable and connector.

5. Can be connected directly when the MR-J2SCLCBL02M-P-H is used.

[Linear scale side connector] (Note 4)

Applicable

Housing

17 Pin Coupling

291697-26 (Female)

(Heidenhain make)

20 Pin Connector

(Note 5)

(3M or equivalent)

SD 14 6

/SD 17 16

RQ 8 7

/RQ 9 17

5V 7 20

0V 10 1

5V/sensor 1 19

0V/sensor 4 11

2 - 14

2. LINEAR SCALES

(2) Connection example of 5m to 30m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Encoder (Scale) Model Encoder (Scale) Side Output Cable Specifications

AWG22 LC491M Heidenhain make output cable 0.5m

[Connection example]

The wiring length is up to 30m. Depending on the wiring length, however, the number of LG and P5

connections must be changed according to the following table.

10120-3000PE, 10320-52F0-008

(3M or equi valent)

To CN2

Servo motor

Encoder

1912P

5LG6

16

20

11

Pla te

MD

MD

R

P

5

LG

SD

(Note 2)

(Note 3)

Servo ampli fier

MR- J2 S-

B

-PY096/ S096

Linear

scale

connector

Opti on cabl e

(MR-J2SCLCBL02M-P-H)

(Note 1)

Heidenhain make linear encoder (linear sc ale)

(Linear encoder head section)

P

5

LG

SD

/

SD

R

Q

/

RQ

5V/sensor

0V/sensor

7

17

M

RMRR

FG

30m or less

Note 1. Do not connect the linear encoder (linear scale) that is not indicated in this specification.

2. Connect the shield wire to the plate (ground plate) in the connector securely.

3. For the wiring to the servo motor, refer to the standard connection examples in Chapter 3 and the Instruction Manual of the MRJ2S-

B standard model.

4. Contact the scale manufacturer for detailed specifications such as the combinations, models, types, etc. of the linear encoder

(linear scale) side output cable and connector.

5. Can be connected directly when the MR-J2SCLCBL02M-P-H is used.

Wiring

Length

Number of LG and

P5 Connections

to 5m 2 parallel

to 10m 4 parallel

to 15m 6 parallel

to 20m 8 parallel

to 25m 10 parallel

to 30m 12 parallel

[Linear scale side connector] (Note 4)

Applicable

Housing

17 Pin Coupling

291697-26 (Female)

(Heidenhain make)

20 Pin Connector

(Note 5)

(3M or equivalent)

SD 14 6

/SD

17 16

RQ 8 7

/RQ 9 17

5V 7 20

0V 10 1

5V/sensor 1 19

0V/sensor 4 11

2 - 15

2. LINEAR SCALES

2.1.3 Renishaw make linear encoders (linear scales) (INC type)

Specifications Reference

Contact Renishaw for the specifications of these linear encoders (linear scales).

Renishaw Encoder Section: TEL. (03) 5332-6023

Item Specifications

Model RGH26P RGH26Q RGH26R

System Optical system

Effective measurement length Maximum length 70000mm

Resolution 5 m1m0.5m

Accuracy (20 ) 3 m/m (when compensation is made between two points)

Supply power voltage 5V 5%

Current consumption Max.230mA

Rated response speed (Note 1) 4.0m/s 3.2m/s 1.6m/s

Maximum response speed 5.0m/s 4.0m/s 2.0m/s

Operating temperature range 0 to 55 (non-freezing)

Operating humidity range 10 to 90%RH (non-condensing)

Storage temperature range 20 to 70 (non-freezing)

Dust tightness water tightness IP50

Vibration resistance 100m/s2 (55 to 2000HZ)

Shock resistance 1000m/s2 (1/2sin, 11ms)

Output signal

Serial communication compatibility

(Z phase data included, serial communication of reference mark data is also is made) (Note 3)

Output cable Renishaw make N-15 PIN Dtype Dtype plug (0.5m)

Connection cable Refer to the standard connection example in Chapter 3 and fabricate the cable.

Note 1. Use at the rated speed or less.

2. A limit switch signal cannot be imported directly to the servo amplifier. When using a limit switch, use a photocoupler for

isolation.

3. A home position return cannot be made if there is no encoder (scale) home position (reference mark). Always provide an

encoder (scale) home position (reference mark).

Linear encoder (linear scale) unit structure Reference

RENISHAW

RGH26

Increasing direction Decreasing direction

Note 1. Always set an encoder (scale) home position (reference mark).

2 - 16

2. LINEAR SCALES

RGH26P, RGH26Q, RGH26R outline drawing Reference (Dimension unit: mm)

This outline drawing is based on the data from Renishaw. Contact Renishaw for this outline drawing.

Reference mark actuator

Dynamic bending radius R50

Static bending radius R10

6 minimum

Reference mark sensor position

Optical center

M3 0.5, two 9.5 deep holes

14

(Yaw tolerance 0.5 )

0.38

Mounting

surface

Setup

LED

(Roll tolerance 1.0 )

0.13

Mounting surface

range

Selectable mounting

surface

Q limit sensor position

M3 0.5, two 7.5

deep holes

Mount the Q

limit switch with

the white point up.

P limit sensor position

P limit switch

Mount it with the white point

directed toward the machine

stock side.

(Size is the same as that of

the Q limit switch.)

The arrow indicates the

forward moving direction

of the read head relative

to the scale.

Scale mounting surface

Clearance detail

(Pitch tolerance 1.0 )

0.8

0.8 0.1

7.6

27

13

9

3

11.6

16

17

15.5

6

10.5

10

3

23.5

14.614.6

44

38

10.6

5

2.2

4.7

7

14.5

22

4

2

3

2 - 17

2. LINEAR SCALES

Connection cable connection examples (1)

The following cable wiring examples assume that the linear encoder (linear scale) is connected directly to

CN2 of the servo amplifier.

(1) Connection example of up to 5m wiring length (This connection example assumes that the following

operating combination is satisfied.)

[Operating combination]

Used Wire Size Encoder (Scale) Model Encoder (Scale) Side Output Cable Specifications

AWG22 RGH26 Renishaw make output cable 0.5m

[Connection example]

(Note 1)

Renishaw make linear encoder

(linear scale)

19

12

20

11

7

17

1

P5

LG

P5

LG

M

RMRR

LG

6

16

Plate

M

DMDR

S

D

P5

LG

M

RMRR

P5

LG

Inner

S

D

(Note 2)

CN2

Servo motor

Encoder

(Note 3)

Servo ampli fier

MR-J2S -

B

-PY096/S096

/P

/Q

Limit s witch out put (Note 4)

(Note 5)