Mitsubishi MR-J2S-10CL, MR-J2S-40CL, MR-J2S-20CL, MR-J2S-60CL, MR-J2S-70CL Instruction Manual

...

General-Purpose AC Servo

MODEL

MR-J2S- CL

SERVO AMPLIFIER

INSTRUCTION MANUAL

Program Compatible

J2-Super Series

A - 1

Safety Instructions

(Always read these instructions before using the equipment.)

Do not attempt to install, oper ate, mainta in or inspect the s ervo amplif ier and servo m otor until you hav e read

through this I nstruction M anual, Insta llation guide, Servo motor Instruction Manual a nd appende d docum ents

carefully and can use the equipment corr ect l y. D o not use the ser vo amplifier and servo motor un ti l you have a

full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols:

: Indicates what must not be done. For example, "No Fire" is indicated by

.

: Indicates what must be do ne . Fo r exa mple , gr ou nd ing i s in di cat ed by

.

In this Instructi on Manual, instr uctions at a lower level t han the abo ve, instruc tions for other func tions, an d so

on are classified into "POINT".

After reading this installation guide, always keep it accessible to the operator.

A - 2

1. To prevent electric shock, note the following:

WARNING

Before wiring or inspection, switch power off and wait for more than 10 minutes. Then, confirm the voltage

is safe with voltage tester. Otherwise, you may get an electric shock.

Connect the serv o a mpl i fier and se rvo mot o r to grou nd .

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, you

may get an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, st ressed, loaded, or pin ched. Othe rwise, y ou may get an ele ctric shock.

2. To prevent fire, note the following:

CAUTION

Do not install the servo amplifier, servo motor and regenerative brake resistor on or near combustibles.

Otherwise a fire may cause.

When the servo amplifier has become faulty, switch off the main servo amplifier power side. Continuous

flow of a large current may cause a fire.

When a regenerative brake resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative brake transistor fault or the like may overheat the regenerative brake resistor, causing a fire.

3. To prevent injury, note the follow

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal, Otherwise, a

burst, damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

During power-on or for some time after power-off, do not touch or close a parts (cable etc.) to the servo

amplifier heat sink, regenerative brake resistor, servo motor, etc. Their temperatures may be high and you

may get burnt or a parts may damaged.

A - 3

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric

shock, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their weights.

Stacking in excess of the specified number of products is not allowed.

Do not carry the servo motor by the cables, shaft or encoder.

Do not hold the front cover to transport the controller. The controller may drop.

Install the servo amplifier in a load-bearing place in accordance with the Instruction Manual.

Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

The controller and servo motor must be installed in the specified direction.

Leave specified clearances between the servo amplifier and control enclosure walls or other equipment.

Do not install or operate the servo amplifier and servo motor which has been damaged or has any parts

missing.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier.

Do not drop or strike servo amplifier or servo motor. Isolate from all impact loads.

When you keep or use it, please fulfill the following environmental conditions.

Conditions

Environment

Servo amplifier Servo motor

[ ]0 to 55 (non-freezing) 0 to 40 (non-freezing)

Operation

[

] 32 to 131 (non-freezing) 32 to 104 (non-freezing)

[ ] 20 to 65 (non-freezing) 15 to 70 (non-freezing)

Ambient

temperature

Storage

[

] 4 to 149 (non-freezing) 5 to 158 (non-freezing)

Operation 90%RH or less (non-condensing) 80%RH or less (non-condensing)

Ambient

humidity

Storage 90%RH or less (non-condensing)

Ambience Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280 ft) above sea level

HC-KFS Series

HC-MFS Series

HC-UFS13 to 73

X

Y : 49

HC-SFS81

HC-SFS52 to 152

HC-SFS53 to 153

HC-RFS Series

HC-UFS 72

152

X

Y : 24.5

HC-SFS121 201

HC-SFS202

352

HC-SFS203

353

HC-UFS202

X : 24.5

Y : 49

[m/s2] 5.9 or less

HC-SFS301

X : 24.5

Y : 29.4

HC-KFS Series

HC-MFS Series

HC-UFS 13 to 73

X

Y : 161

HC-SFS81

HC-SFS52 to 152

HC-SFS53 to 153

HC-RFS Series

HC-UFS 72

152

X

Y : 80

HC-SFS121 201

HC-SFS202

352

HC-SFS203

353

HC-UFS202

X : 80

Y : 161

(Note)

Vibration

[ft/s

2

] 19.4 or less

HC-SFS301

X : 80

Y : 96

Note. Except the servo motor with reduction gear.

A - 4

CAUTION

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The servo motor with reduction gear must be installed in the specified direction to prevent oil leakage.

For safety of personnel, always cover rotating and moving parts.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When the equipment has been stored for an extended period of time, consult Mitsubishi.

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may misoperate.

Do not install a power capacitor, surge absorber or radio noise filter (FR-BIF option) between the servo

motor and servo amplifier.

Connect the output terminals (U, V, W) correctly. Otherwise, the servo motor will operate improperly.

Do not connect AC power directly to the servo motor. Otherwise, a fault may occur.

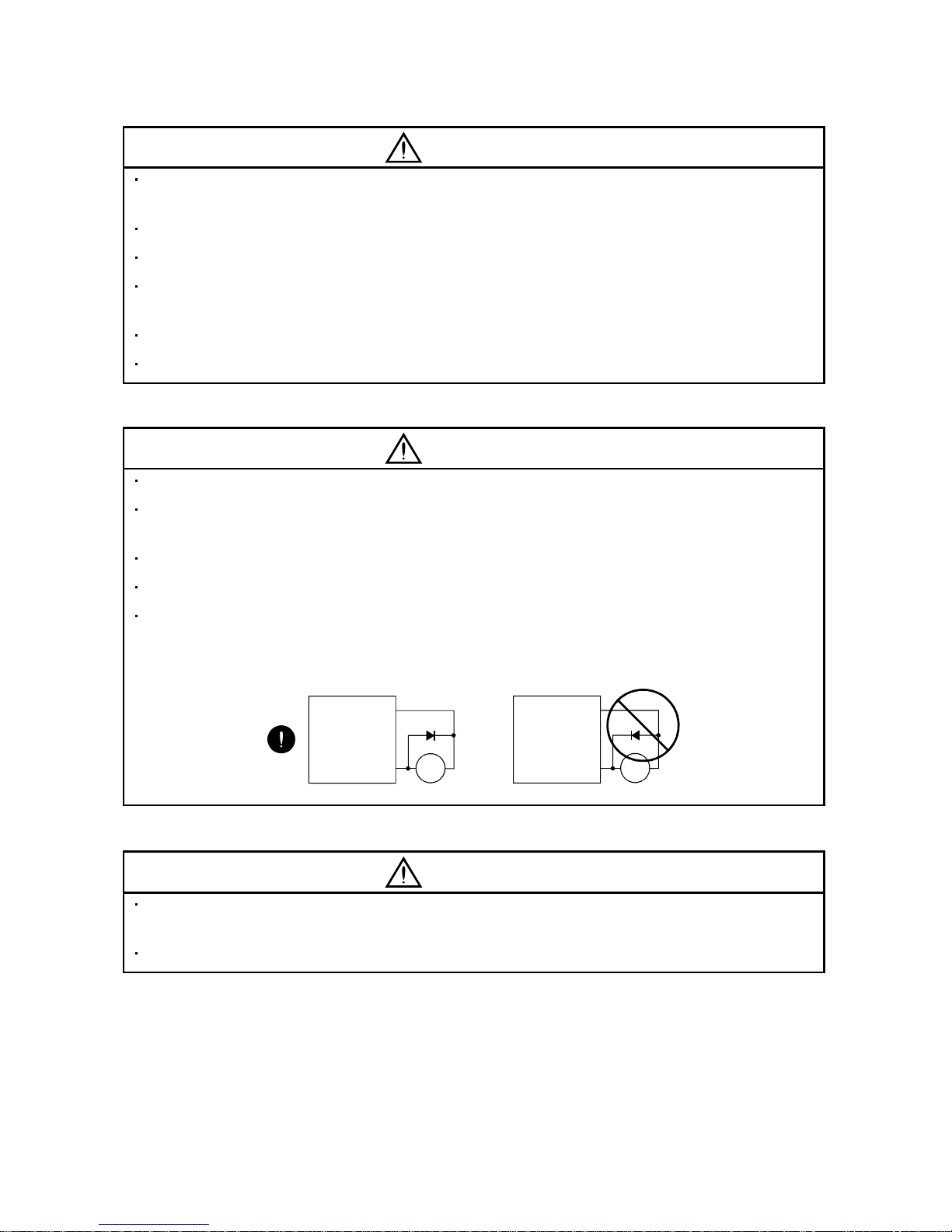

The surge absorbing dio de in stal le d on th e DC ou t put si gna l rel ay must be wired in the speci fie d di re ctio n .

Otherwise, the forced stop (EMG) and other protective circuits may not operate.

COM

(24VDC)

Servo

amplifier

RA

Control

output

signal

RA

Servo

amplifier

COM

(24VDC)

Control

output

signal

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be insatiable.

A - 5

(4) Usage

CAUTION

Provide an extern al emergenc y stop circuit to ens ure that operation c an be sto pped and po wer switch ed

off immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resett ing an alarm , mak e sure th at the r un s ignal is off to preve nt an ac cident . A sud den r estart is

made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise fi lter, etc. to m inim i ze th e inf lue nce of e lectrom ag netic int erf erenc e, which m a y b e c aus ed b y

electronic equipment used near the servo amplifier.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be used

for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ballscrew and the servo motor are

coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety,

install a stoppe r on the mach in e side .

(5) Corrective actions

CAUTION

When it is assum ed that a hazardous condi tion may take p lace at the occur due to a po wer failure or a

product fault, use a servo motor with electromagnetic brake or an external brake mechanism for the

purpose of prev en ti on .

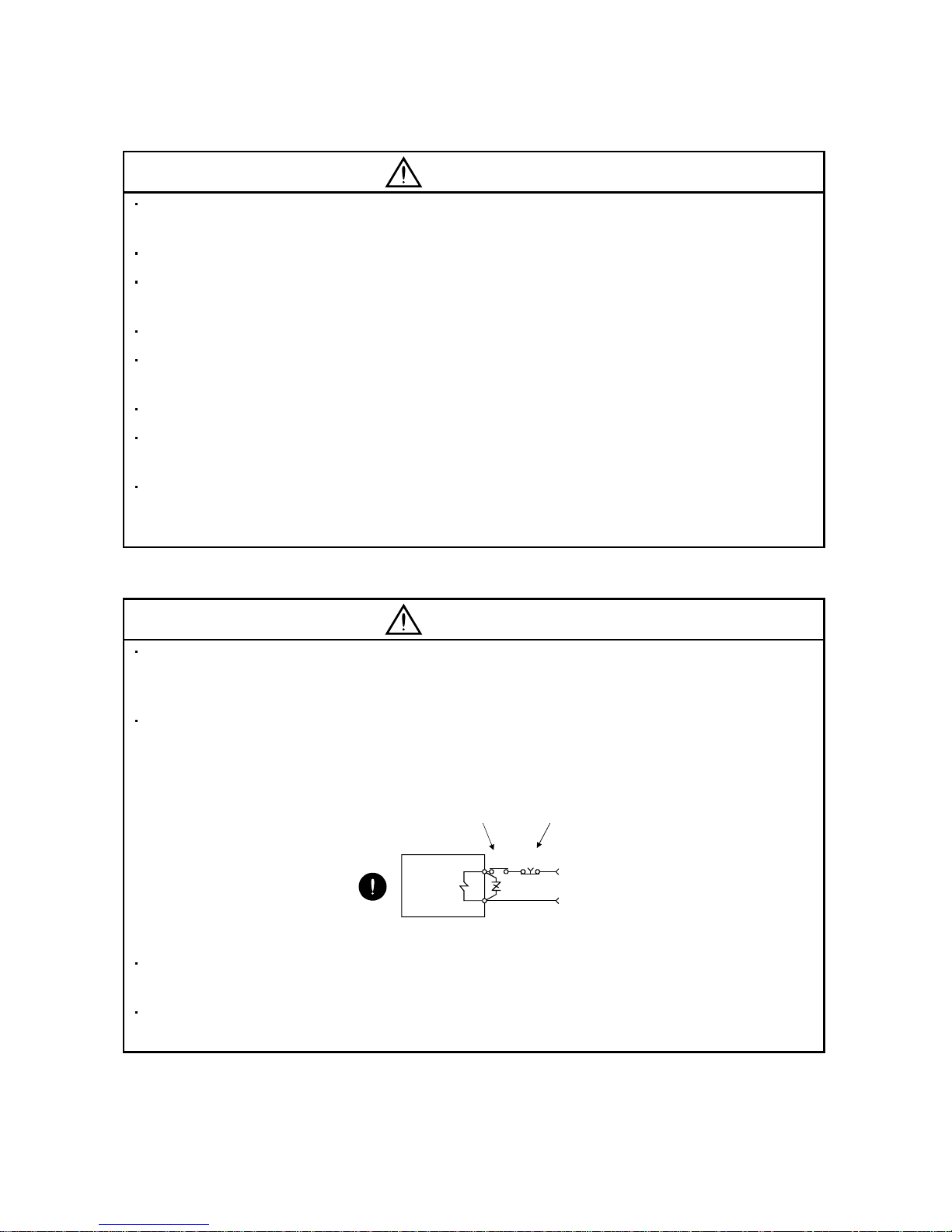

Configure the electromagnetic brake circuit so that it is activated not only by the servo amplifier signals but

also by an extern al fo rc ed stop (EM G) .

EMGRA

24VDC

Contacts must be open when

servo-on (SON) is off, when a trouble (ALM)

is present and when an electromagnetic

brake interlock (MBR).

Electromagnetic brake

Servo motor

Circuit must be

opened during

forced stop (EMG).

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

When power is restor ed after an instant aneous power fail ure, keep awa y from the m achine becaus e the

machine may be restarted suddenly (design the machine so that it is secured against hazard if restarted).

A - 6

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor will deteriorate. To prevent a secondary accident due to a fault, it is

recommended to replace the electrolytic capacitor every 10 years when used in general environment.

Please consult our sales representative.

(7) General instructi o n

To illustrate de ta ils, the equipment in t he d ia gr ams of this Specificatio ns a nd Instruction Ma nu a l may have

been drawn without co vers and safety guards. W hen the equipment is operated, the covers and safety

guards must be installed as specified. Operation must be performed in accordance with this Specifications

and Instruction Manual.

About processing of waste

When you discard servo amplifier, a battery (primary battery), and other option articles, please follow the law of

each country (area).

FOR MAXIMUM SAFETY

This product is not designed or manufactured to be used in equipment or systems in situations that can

affect or enda nge r hu man li fe .

When considering this product for operation in special applications such as machinery or systems used in

passenger transportation, medical, aerospace, atomic power, electric power, or submarine repeating

applications, please contact your nearest Mitsubishi sales representative.

Although this product was manufactured under conditions of strict quality control, you are strongly advised

to install safety devices to forestall serious accidents when it is used in facilities where a breakdown in the

product is likely to cause a serious accident.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier and/or converter unit may

fail when the EEP-ROM reaches the end of its useful life.

Write to the EEP-R OM du e to par a mete r set tin g ch an ges

Home position setting in the absolute position detection system

Write to the EEP-ROM due to device changes

Write to the EEP-ROM due to program changes

A - 7

COMPLIANCE WITH EC DIRECTIVES

1. WHAT ARE EC DIRE CTI VES ?

The EC directives were issued to standardize the regulations of the EU countries and ensure smooth

distribution of safety-guaranteed products. In the EU countries, the machinery directive (effective in

January, 1995), EMC directive (effective in January, 1996) and low voltage dir ective (effective in January,

1997) of the EC directives require that products to be sold should meet their fundamental safety

requirements and carry the CE marks (CE mar king). CE marking applies to machines and equipment

into which servo amplifiers have been installed.

(1) EMC directive

The EMC directive applies not to the servo units alone but to servo-incorporated machines and

equipment. This requires the EMC filters to be used with the servo-incorporated machines and

equipment to comply with the EMC directive. For specific EMC directive conforming methods, refer to

the EMC Installation Guidelines (IB(NA)67310).

(2) Low voltage di re ctiv e

The low voltage directive applies also to servo units alone. Hence, they are designed to comply with

the low voltage directive.

This servo is certified by TUV, third-party assessment orga nization, to comply with th e low voltage

directive.

(3) Machine directive

Not being machines, the servo amplifiers need not comply with this directive.

2. PRECAUTIONS FOR COMPLIANCE

(1) Servo amplifiers and servo motors used

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier series :MR-J2S-10CL to MR-J2S-700CL

MR-J2S-10CL1 to MR-J2S40CL1

Servo motor series :HC-KFS

HC-MFS

HC-SFS

HC-RFS

HC-UFS

HA-LFS

HC-LFS

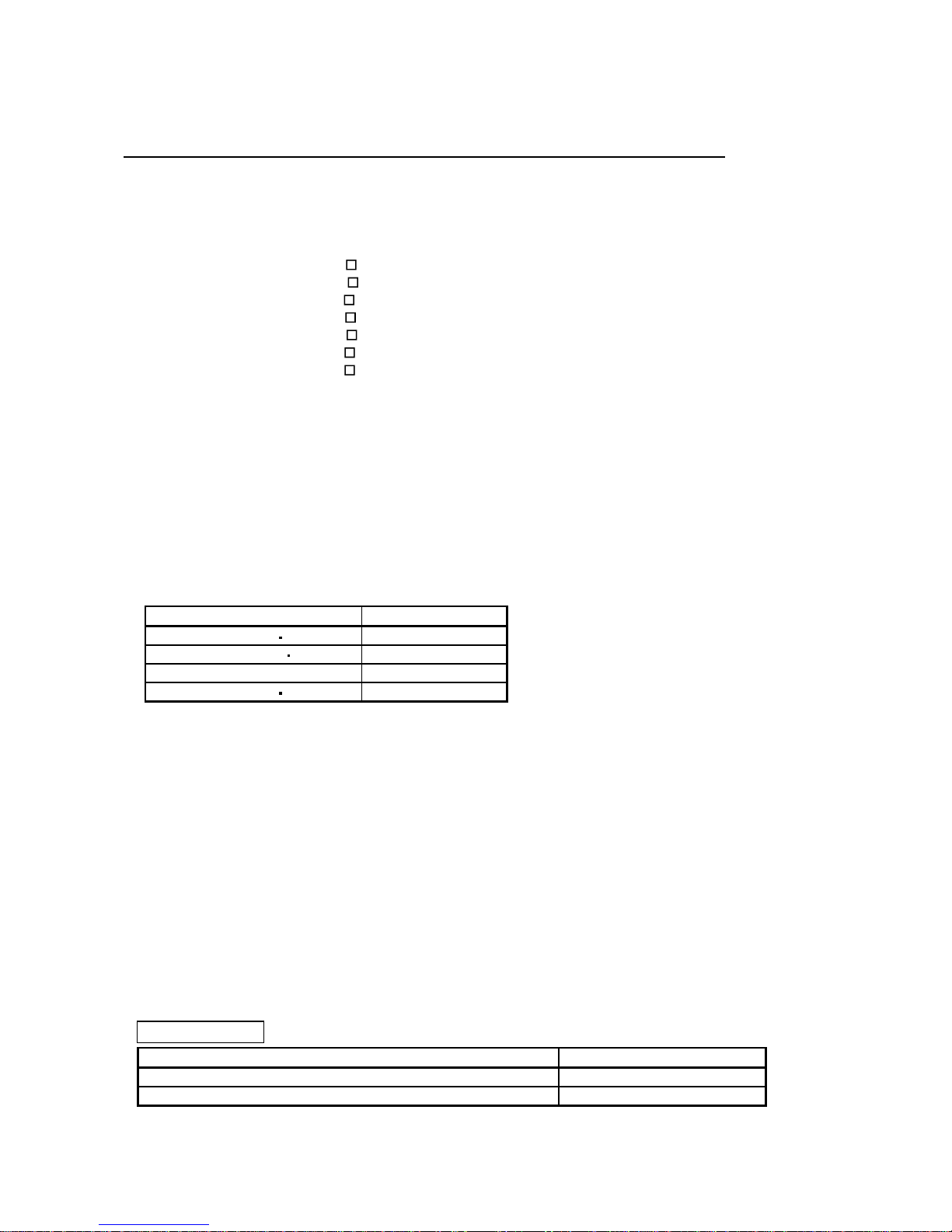

(2) Configuration

Reinforced

insulating

transformer

NFB

MC

SM

No-fuse

breaker

Magnetic

contactor

Reinforced

insulating type

24VDC

power

supply

Servo

amplifier

Servo

motor

Control box

(3) Environment

Operate the servo amplifier at or above the contamination level 2 set forth in IEC664. For this

purpose, install the servo amplifier in a control box which is protected against water, oil, carbon, dust,

dirt, etc. (IP54).

A - 8

(4) Power supply

(a) Operate the servo amplifier to meet the requirements of the overvoltage category II set forth in

IEC664. For this purpose, a reinforced insulating transformer conforming to the IEC or EN

Standard should be used in the power input section.

(b) When supplying interface power from external, use a 24VDC power supply which has been

insulation-reinforced in I/O.

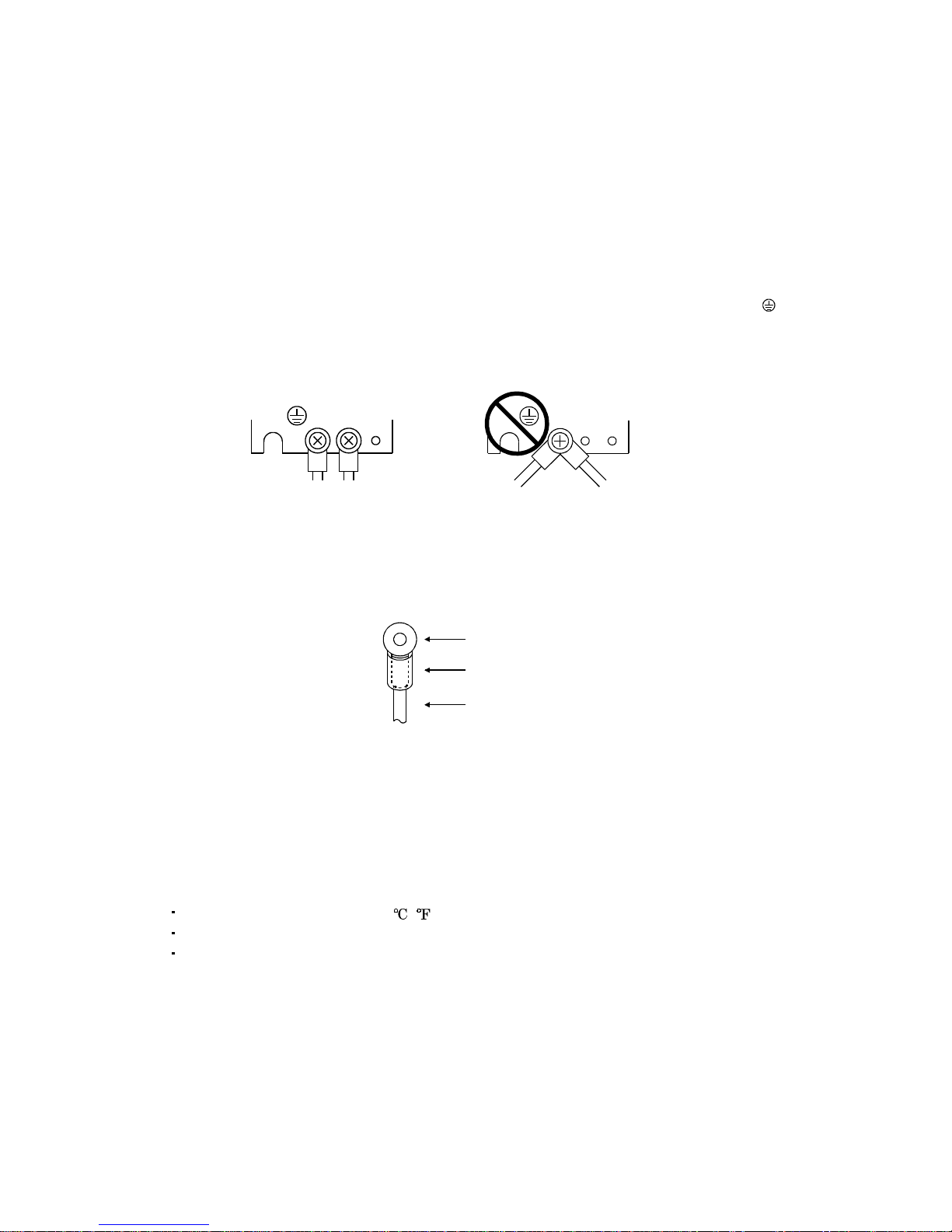

(5) Grounding

(a) To prevent an electric shock, always connect the protective earth (PE) terminals (marked

) of the

servo amplifier to the protective earth (PE) of the control box.

(b) Do not connect two ground cables to the same protective earth (PE) terminal. Always connect the

cables to the terminals one-to-one.

PE terminals

PE terminals

(c) If a leakage current breaker is used to prevent an electric shock, the protective earth (PE) terminals

of the servo ampli fi er mus t b e c onne ct ed t o t h e c orr es pondi n g eart h t ermi nal s.

(6) Wiring

(a) The cables to be connected to the terminal block of the servo amplifier must have crimping

terminals provided with insulating tubes to prevent contact with adjacent terminals.

Crimping terminal

Insulating tube

Cable

(b) Use the servo motor side power connector which complies with the EN Standard. The EN Standard

compliant power connector sets are available from us as options.

(7) Auxiliary equipment and options

(a) The no-fuse breaker and magnetic contactor used should be the EN or IEC standard-compliant

products of the models described in Section 14.2.2.

(b) The sizes of the cable s described in Section 14.2.1 mee t the following requ irements. To meet th e

other requirements, follow Table 5 and Appendix C in EN60204-1.

Ambient tempera t ur e: 40 (104 ) [ ( )]

Sheath: PVC (polyvinyl chloride)

Installed on wall surface or open table tray

(c) Use the EMC filter for noise reduction.

(8) Performing EMC tests

When EMC tests are run on a machine/device into which the servo amplifier has been installed, it

must conform to the electromagnetic compatibility (immunity/emission) standards after it has

satisfied the operating environment/electrical equipment specifications.

For the other EMC directive guidelines on the servo amplifier, refer to the EMC Installation

Guidelines(IB(NA)67310).

A - 9

CONFORMANCE WITH UL/C-UL STANDARD

(1) Servo amplifiers and servo motors used

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier series :MR-J2S-10CL to MR-J2S-700CL

MR-J2S-10CL1 to MR-J2S-40CL1

Servo motor series :HC-KFS

HC-MFS

HC-SFS

HC-RFS

HC-UFS

HA-LFS

HC-LFS

(2) Installation

Install a fan of 100C FM (2.8m

3

/min) air flo w 4 [in] (10.16 [ cm]) above the servo amplifier or p rovide

cooling of at least equivalent capability.

(3) Short circuit rating

This servo amplifier conforms to the circuit whose peak current is limited to 5000A or less. Having

been subjected to the short-circuit tests of the UL in the alternating-current circuit, the servo

amplifier conforms to the above circuit.

(4) Capacitor discharge time

The capacitor disch arg e time is as li sted below . To ensu re saf ety , do no t to uch the ch argin g sec tion f or

10 minutes after power-off.

Servo amplifier Discharge time [min]

MR-J2S-10CL(1) 20CL(1) 1

MR-J2S-40CL(1) 60CL 2

MR-J2S-70CL to 350CL 3

MR-J2S-500CL 700CL 5

(5) Options and auxiliary equipment

Use UL/C-UL standard-compliant products.

(6) Attachment of a servo motor

For the flange size of the machine side where the servo motor is installed, refer to “CONFORMANCE

WITH UL/C-UL STANDARD” in the Servo Motor Instruction Manual.

(7) About wiring protection

For installation in United States, branch circuit protection must be provided, in accordance with the

National Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided, in accordance with the Canada

Electrical Code and any applicable provincial codes.

<<About the manual s>>

This Instruction Manua l and the MELSER VO Serv o Moto r Ins truction M anual are requ ired if you use

the MR-J2S-CL for the first time. Always purchase them and use the MR-J2S-CL safely.

Relevant manuals

Manual name Manual No.

MELSERVO Servo Motor Instruction Manual SH(NA)3181

EMC Installation Guidelines IB(NA)67310

A - 10

MEMO

1

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-24

1.1 Introduction.............................................................................................................................................. 1- 1

1.1.1 Function block diagram....................................................................................................................1- 2

1.1.2 System configuration........................................................................................................................1- 3

1.1.3 I/O devices .........................................................................................................................................1- 8

1.2 Servo amplifier standard specifications................................................................................................1- 9

1.3 Function list ............................................................................................................................................1-11

1.4 Model code definition .............................................................................................................................1-12

1.5 Combination with servo motor............................................................................................... ...............1-13

1.6 Structure..................................................................................................................................................1-14

1.6.1 Part names .......................................................................................................................................1-14

1.6.2 Removal and reinstallation of the front cover ..............................................................................1-18

1.7 Servo system with auxiliary equipment...............................................................................................1-20

2. INSTALLATION 2- 1 to 2- 4

2.1 Environmental conditions.......................................................................................................................2- 1

2.2 Installation direction and clearances ....................................................................................................2- 2

2.3 Keep out foreign materials .....................................................................................................................2- 3

2.4 Cable stress ..............................................................................................................................................2- 4

3. SIGNALS AND WIRING 3- 1 to 3-36

3.1 Standard connection example ................................................................................................................3- 2

3.2 Internal connection diagram of servo amplifier ...................................................................................3- 4

3.3 I/O signals................................................................................................................................................. 3- 5

3.3.1 Connectors and signal arrangements............................................................................................. 3- 5

3.3.2 Signal (devices) explanations ..........................................................................................................3- 6

3.4 Detailed description of signals (devices)...............................................................................................3-13

3.4.1 Forward rotation start

Reverse rotation start Temporary stop/Restart................................ 3-13

3.4.2 Movement complete.........................................................................................................................3-14

3.4.3 Override............................................................................................................................................3-15

3.4.4 Torque limit......................................................................................................................................3-16

3.5 Alarm occurrence timing chart .............................................................................................................3-18

3.6 Interfaces.................................................................................................................................................3-19

3.6.1 Common line ....................................................................................................................................3-19

3.6.2 Detailed description of the interfaces............................................................................................3-20

3.7 Input power supply circuit.....................................................................................................................3-23

3.7.1 Connection example.........................................................................................................................3-23

3.7.2 Terminals..........................................................................................................................................3-25

3.7.3 Power-on sequence...........................................................................................................................3-26

3.8 Connection of servo amplifier and servo motor...................................................................................3-27

3.8.1 Connection instructions ..................................................................................................................3-27

3.8.2 Connection diagram.........................................................................................................................3-27

3.8.3 I/O terminals....................................................................................................................................3-29

2

3.9 Servo motor with electromagnetic brake .............................................................................................3-31

3.10 Grounding .............................................................................................................................................3-34

3.11 Servo amplifier terminal block (TE2) wiring method.......................................................................3-35

3.12 Instructions for the 3M connector.......................................................................................................3-36

4. OPERATION 4- 1 to 4-50

4.1 When switching power on for the first time..........................................................................................4- 1

4.1.1 Pre-operation checks ........................................................................................................................4- 1

4.1.2 Startup.................................................................................................................. .............................4- 2

4.2 Program operation mode.........................................................................................................................4- 5

4.2.1 What is program operation mode? ..................................................................................................4- 5

4.2.2 Programming language....................................................................................................................4- 6

4.2.3 Basic setting of signals and parameters........................................................................................4-25

4.2.4 Program operation timing chart ....................................................................................................4-26

4.3 Manual operation mode.........................................................................................................................4-27

4.3.1 Jog operation ....................................................................................................................................4-27

4.3.2 Manual pulse generator operation.................................................................................................4-29

4.4 Manual home position return mode .....................................................................................................4-31

4.4.1 Outline of home position return.....................................................................................................4-31

4.4.2 Dog type home position return............................................................................................ ...........4-33

4.4.3 Count type home position return ...................................................................................................4-35

4.4.4 Data setting type home position return ........................................................................................4-36

4.4.5 Stopper type home position return ................................................................................................4-37

4.4.6 Home position ignorance (servo-on position defined as home position).....................................4-38

4.4.7 Dog type rear end reference home position return....................................................................... 4-39

4.4.8 Count type front end reference home position return..................................................................4-40

4.4.9 Dog cradle type home position return ...........................................................................................4-41

4.4.10 Home position return automatic return function.......................................................................4-42

4.5 Absolute position detection system....................................................................................................... 4-43

4.6 Serial communication operation ...........................................................................................................4-46

4.6.1 Positioning operation in accordance with programs....................................................................4-46

4.6.2 Multidrop system.............................................................................................................................4-46

4.6.3 Group designation............................................................................................................................4-47

4.7 Incremental value command system........................................................................................... .........4-49

5. PARAMETERS 5- 1 to 5-26

5.1 Parameter list..........................................................................................................................................5- 1

5.1.1 Parameter write inhibit ...................................................................................................................5- 1

5.1.2 List ..................................................................................................................................................... 5- 2

5.2 Detailed explanation..............................................................................................................................5-21

5.2.1 Electronic gear .................................................................................................................................5-21

5.2.2 Changing the status display screen...............................................................................................5-22

5.2.3 S-pattern acceleration/deceleration...............................................................................................5-23

5.2.4 Analog output...................................................................................................................................5-23

5.2.5 Changing the stop pattern using a limit switch...........................................................................5-25

3

5.2.6 Alarm history clear..........................................................................................................................5-25

5.2.7 Software limit...................................................................................................................................5-25

6. SERVO CONFIGURATION SOFTWARE 6- 1 to 6-24

6.1 Specifications ...........................................................................................................................................6- 1

6.2 System configuration...............................................................................................................................6- 1

6.3 Station setting..........................................................................................................................................6- 3

6.4 Parameters...............................................................................................................................................6- 4

6.5 Simple Program.......................................................................................................................................6- 6

6.5.1 Program data.....................................................................................................................................6- 6

6.5.2 Indirect addressing...........................................................................................................................6- 9

6.6 Device assignment method....................................................................................................................6-11

6.7 Test operation.........................................................................................................................................6-15

6.7.1 Jog operation ....................................................................................................................................6-15

6.7.2 Positioning operation....................................................................................................................... 6-17

6.7.3 Motor-less operation........................................................................................................................6-19

6.7.4 Output signal (DO) forced output ..................................................................................................6-20

6.7.5 Program test operation ...................................................................................................................6-21

6.8 Alarm history ..........................................................................................................................................6-23

7. DISPLAY AND OPERATION 7- 1 to 7-20

7.1 Display flowchart..................................................................................................................................... 7- 1

7.2 Status display ..........................................................................................................................................7- 2

7.2.1 Display transition.............................................................................................................................7- 2

7.2.2 Display examples.............................................................................................................................. 7- 3

7.2.3 Status display list.............................................................................................................................7- 4

7.3 Diagnosis mode........................................................................................................................................7- 5

7.3.1 Display transition.............................................................................................................................7- 5

7.3.2 Diagnosis mode list...........................................................................................................................7- 6

7.4 Alarm mode................................................................................................................. .............................7- 8

7.4.1 Display transition.............................................................................................................................7- 8

7.4.2 Alarm mode list.................................................................................................................................7- 9

7.5 Parameter mode .....................................................................................................................................7-11

7.5.1 Parameter mode transition.............................................................................................................7-11

7.5.2 Operation example...........................................................................................................................7-12

7.6 External I/O signal display....................................................................................................................7-14

7.7 Output signal (DO) forced output .........................................................................................................7-15

7.8 Test operation mode........................................................................................................ .......................7-16

7.8.1 Mode change.....................................................................................................................................7-16

7.8.2 Jog operation ....................................................................................................................................7-17

7.8.3 Positioning operation....................................................................................................................... 7-18

7.8.4 Motor-less operation........................................................................................................................7-19

4

8. GENERAL GAIN ADJUSTMENT 8- 1 to 8-12

8.1 Different adjustment methods ...............................................................................................................8- 1

8.1.1 Adjustment on a single servo amplifier..........................................................................................8- 1

8.1.2 Adjustment using servo configuration software............................................................................8- 2

8.2 Auto tuning ..............................................................................................................................................8- 3

8.2.1 Auto tuning mode .............................................................................................................................8- 3

8.2.2 Auto tuning mode operation............................................................................................................8- 4

8.2.3 Adjustment procedure by auto tuning............................................................................................8- 5

8.2.4 Response level setting in auto tuning mode...................................................................................8- 6

8.3 Manual mode 1 (simple manual adjustment).......................................................................................8- 7

8.3.1 Operation of manual mode 1 ...........................................................................................................8- 7

8.3.2 Adjustment by manual mode 1 .......................................................................................................8- 7

8.4 Interpolation mode .................................................................................................................................8-10

8.5 Differences in auto tuning between MELSERVO-J2 and MELSERVO-J2-Super..........................8-11

8.5.1 Response level setting.....................................................................................................................8-11

8.5.2 Auto tuning selection....................................................................................................................... 8-11

9. SPECIAL ADJUSTMENT FUNCTIONS 9- 1 to 9-10

9.1 Function block diagram ..........................................................................................................................9- 1

9.2 Machine resonance suppression filter ...................................................................................................9- 1

9.3 Adaptive vibration suppression control.................................................................................................9- 3

9.4 Low-pass filter .........................................................................................................................................9- 4

9.5 Gain changing function...........................................................................................................................9- 5

9.5.1 Applications....................................................................................................................................... 9- 5

9.5.2 Function block diagram....................................................................................................................9- 5

9.5.3 Parameters ........................................................................................................................................9- 6

9.5.4 Gain changing operation..................................................................................................................9- 8

10. INSPECTION 10- 1 to 10- 2

11. TROUBLESHOOTING 11- 1 to 11-10

11.1 Trouble at start-up ..............................................................................................................................11- 1

11.1.1 Position control mode...................................................................................................................11- 1

11.2 When alarm or warning has occurred...............................................................................................11- 2

11.2.1 Alarms and warning list ..............................................................................................................11- 2

11.2.2 Remedies for alarms.....................................................................................................................11- 3

11.2.3 Remedies for warnings.................................................................................................................11- 9

12. OUTLINE DIMENSION DRAWINGS 12- 1 to 12- 8

12.1 Servo amplifiers...................................................................................................................................12- 1

12.2 Connectors............................................................................................................................................12- 6

5

13. CHARACTERISTICS 13- 1 to 13- 8

13.1 Overload protection characteristics...................................................................................................13- 1

13.2 Power supply equipment capacity and generated loss ....................................................................13- 2

13.3 Dynamic brake characteristics...........................................................................................................13- 4

13.4 Encoder cable flexing life................................................................................................ ....................13- 6

13.5 Inrush Currents at Power-On of Main Circuit and Control Circuit .............................................. 13- 7

14. OPTIONS AND AUXILIARY EQUIPMENT 14- 1 to 14-44

14.1 Options..................................................................................................................................................14- 1

14.1.1 Regenerative brake options.........................................................................................................14- 1

14.1.2 Brake unit......................................................................................................................................14- 9

14.1.3 Power return converter...............................................................................................................14-11

14.1.4 Cables and connectors.................................................................................................................14-14

14.1.5 Junction terminal block (MR-TB20)..........................................................................................14-22

14.1.6 Maintenance junction card (MR-J2CN3TM) ............................................................................14-24

14.1.7 External digital display (MR-DP60)..........................................................................................14-26

14.1.8 Manual pulse generator (MR-HDP01) ......................................................................................14-28

14.1.9 Battery (MR-BAT, A6BAT).........................................................................................................14-29

14.2 Auxiliary equipment ..........................................................................................................................14-30

14.2.1 Recommended wires....................................................................................................................14-30

14.2.2 No-fuse breakers, fuses, magnetic contactors...........................................................................14-32

14.2.3 Power factor improving reactors................................................................................................14-32

14.2.4 Relays............................................................................................................................................14-33

14.2.5 Surge absorbers ...........................................................................................................................14-33

14.2.6 Noise reduction techniques.........................................................................................................14-33

14.2.7 Leakage current breaker.............................................................................................................14-39

14.2.8 EMC filter.....................................................................................................................................14-41

14.2.9 Setting potentiometers for analog inputs..................................................................................14-43

15. COMMUNICATION FUNCTIONS 15- 1 to 15-36

15.1 Configuration.......................................................................................................................................15- 1

15.1.1 RS-422 configuration....................................................................................................................15- 1

15.1.2 RS-232C configuration.................................................................................................................15- 2

15.2 Communication specifications............................................................................................................15- 3

15.2.1 Communication overview.............................................................................................................15- 3

15.2.2 Parameter setting.........................................................................................................................15- 4

15.3 Protocol.................................................................................................................................................15- 5

15.4 Character codes ...................................................................................................................................15- 7

15.5 Error codes ...........................................................................................................................................15- 8

15.6 Checksum.............................................................................................................................................15- 8

15.7 Time-out operation..............................................................................................................................15- 9

15.8 Retry operation....................................................................................................................................15- 9

15.9 Initialization........................................................................................................................................15-10

15.10 Communication procedure example ...............................................................................................15-10

6

15.11 Command and data No. list.............................................................................................................15-11

15.11.1 Read commands.........................................................................................................................15-11

15.11.2 Write commands........................................................................................................................15-14

15.12 Detailed explanations of commands...............................................................................................15-16

15.12.1 Data processing..........................................................................................................................15-16

15.12.2 Status display ............................................................................................................................15-18

15.12.3 Parameter...................................................................................................................................15-19

15.12.4 External I/O signal statuses.....................................................................................................15-21

15.12.5 Device ON/OFF..........................................................................................................................15-23

15.12.6 Disable/enable of I/O devices (DIO) .........................................................................................15-24

15.12.7 Input devices ON/OFF (test operation)...................................................................................15-25

15.12.8 Test operation mode..................................................................................................................15-26

15.12.9 Output signal pin ON/OFF output signal (DO) forced output..............................................15-29

15.12.10 Alarm history...........................................................................................................................15-30

15.12.11 Current alarm..........................................................................................................................15-31

15.12.12 Current position latch data ....................................................................................................15-32

15.12.13 General-purpose register ........................................................................................................15-33

15.12.14 Servo amplifier group designation.........................................................................................15-35

15.12.15 Software version......................................................................................................................15-36

Appendix App- 1 to App- 2

App 1. Status indication block diagram .................................................................................................App- 1

App 2. Junction terminal block (MR-TB20) terminal block labels......................................................App- 2

7

Optional Servo Motor Instruction Manual CONTENTS

The rough table of contents of the optional MELSERVO Servo Motor Instruction Manual is intro duced

here for your reference. Note that the contents of the Servo Motor Instruction Manual are not included in

the Servo Amplifier Instruction Manual.

1. INTRODUCTION

2. INSTALLATION

3. CONNECTORS USED FOR SERVO MOTOR WIRING

4. INSPECTION

5. SPECIFICATIONS

6. CHARACTERISTICS

7. OUTLINE DIMENSION DRAWINGS

8. CALCULA TIO N ME TH ODS FOR DESIGNIN G

8

MEMO

1 - 1

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Introduction

The MR-J2S-CL progr am-compatible AC servo amplifie r is based on the MR-J2S-CP AC servo amp lifier

with built-in positioning functions and incorporates program-driven, single-axis positioning functions.

These functions perform positioning operation by creating the position data (target positions), servo motor

speeds, acceleration and deceleration time constants, etc. as a program and executing the program. The

servo amplifier is the mos t appropriate to configu re a simple positioning system or to simp lify a system,

for example.

Up to 16 programs can be created. The program capacity is 120 steps as a total of all programs.

All servo motors are equipped with an absolute position encoder as standard. An absolute position

detection system can be configured by merely adding a battery to the servo amplifier. Once the home

position has been set, home position return is not required at power on, alarm occurrence, etc.

1 - 2

1. FUNCTIONS AND CONFIGURATION

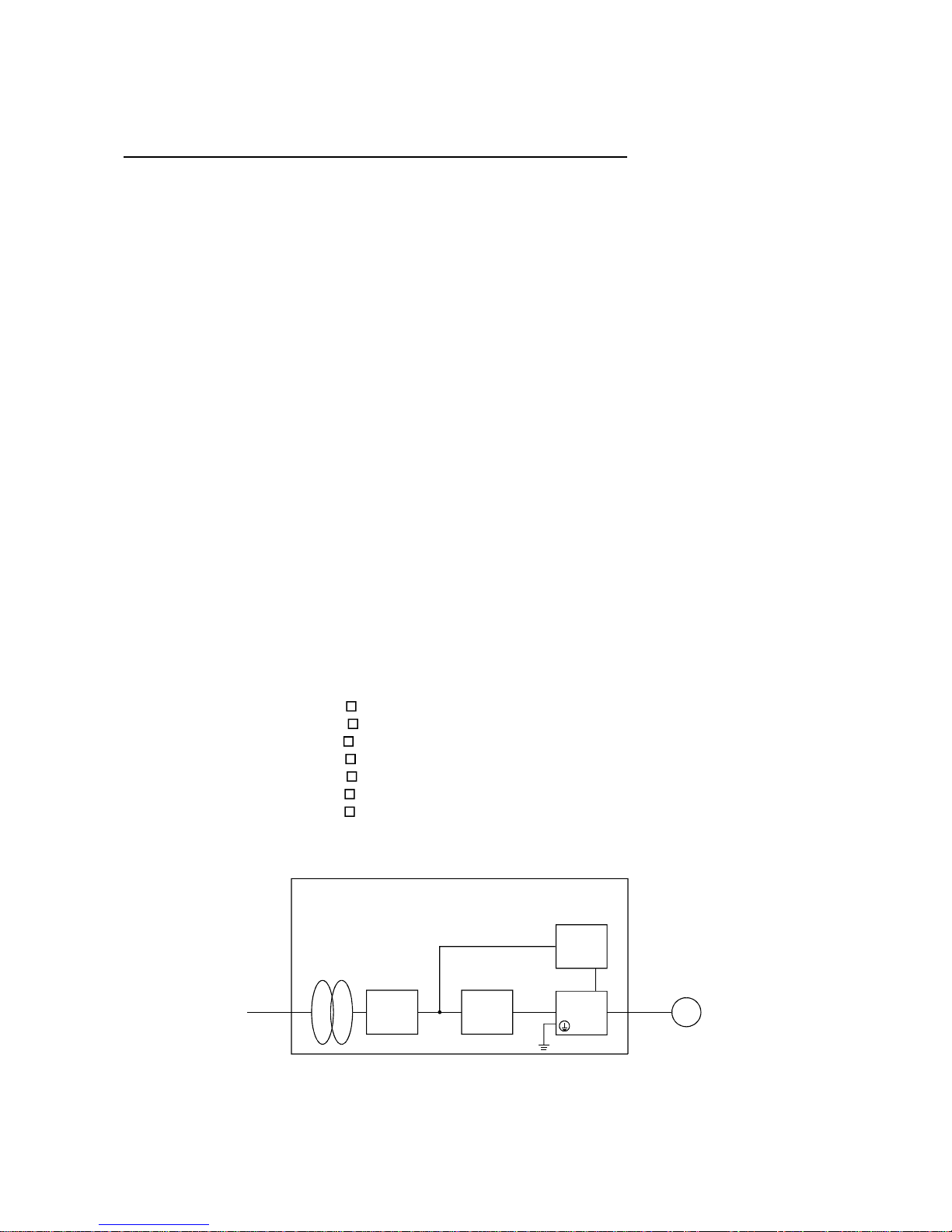

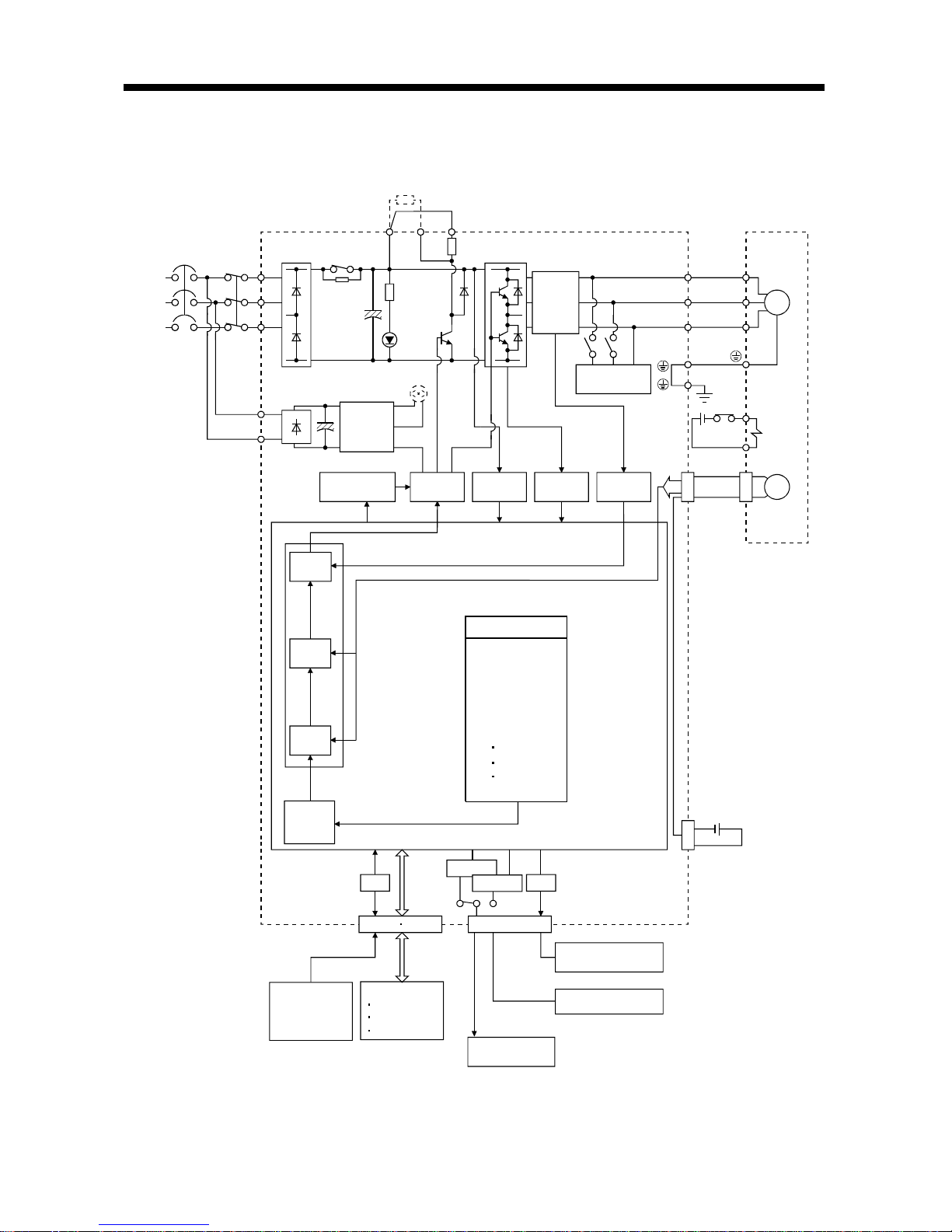

1.1.1 Function block diagram

The function block diagram of this servo is shown below.

(Note2)

Power

supply

3-phase

200 to

230VAC,

or

1-phase

100 to

120VAC

NFB

MC

Servo amplifier

Regenerative brake option

(Note1)

(Note3)

PDC

DS

RA

L

1

L

2

L

3

CHARGE

lamp

Regenerative

brake

transistor

Dynamic

brake

Current

detector

Servo motor

SM

U

V

W

U

V

W

E2

E1

Encoder

Electromagnetic

brake

CN2

L

11

L

21

Fan

(MR-J2S-200CP or more)

Regenerative

brake

Base

amplifier

Voltage

detection

Overcurrent

protection

Control

power

supply

Current

detection

I/F

A/D

CN1A CN1B

RS-232C

RS-422

D/A

CN3

CON1

MR-BAT

Optional battery

(for absolute position

detection system)

D I/O control

Servo on

Start

Failure, etc.

Analog

(2 channels)

To other servo

amplifier

RS-422/RS-232C

Controller

Analog monitor

(2 channels)

Model adaptive control

Current

control

Position

control

Speed

control

Position

command

creation

Note:1. The built-in regenerative brake resistor is not provided for the MR-J2S-10CL (1).

2. For 1-phase 230VAC, connect the power supply to L

1,L2

and leave L3 open.

L

3

is not provided for a 1-phase 100 to120VAC power supply.

3. For MR-J2S-350CL or less.

Program

SPN (1000)

STA (200)

STB (300)

MOV (500)

SPN (1000)

MOVA (1000)

MOVA (0)

STOP

1 - 3

1. FUNCTIONS AND CONFIGURATION

1.1.2 System configuration

This section describes operations using this servo.

You can arrange any configurations from a single-axis to max. 32-axis systems. Further, the connector

pins in the interface section allow you to assign the optimum signals to respective systems. (Refer to

Sections 1.1.3 and 3.3 .3.) The Servo configur ation Software (refer to Chapter 6) and per sonal computer

are required to change or assign devices.

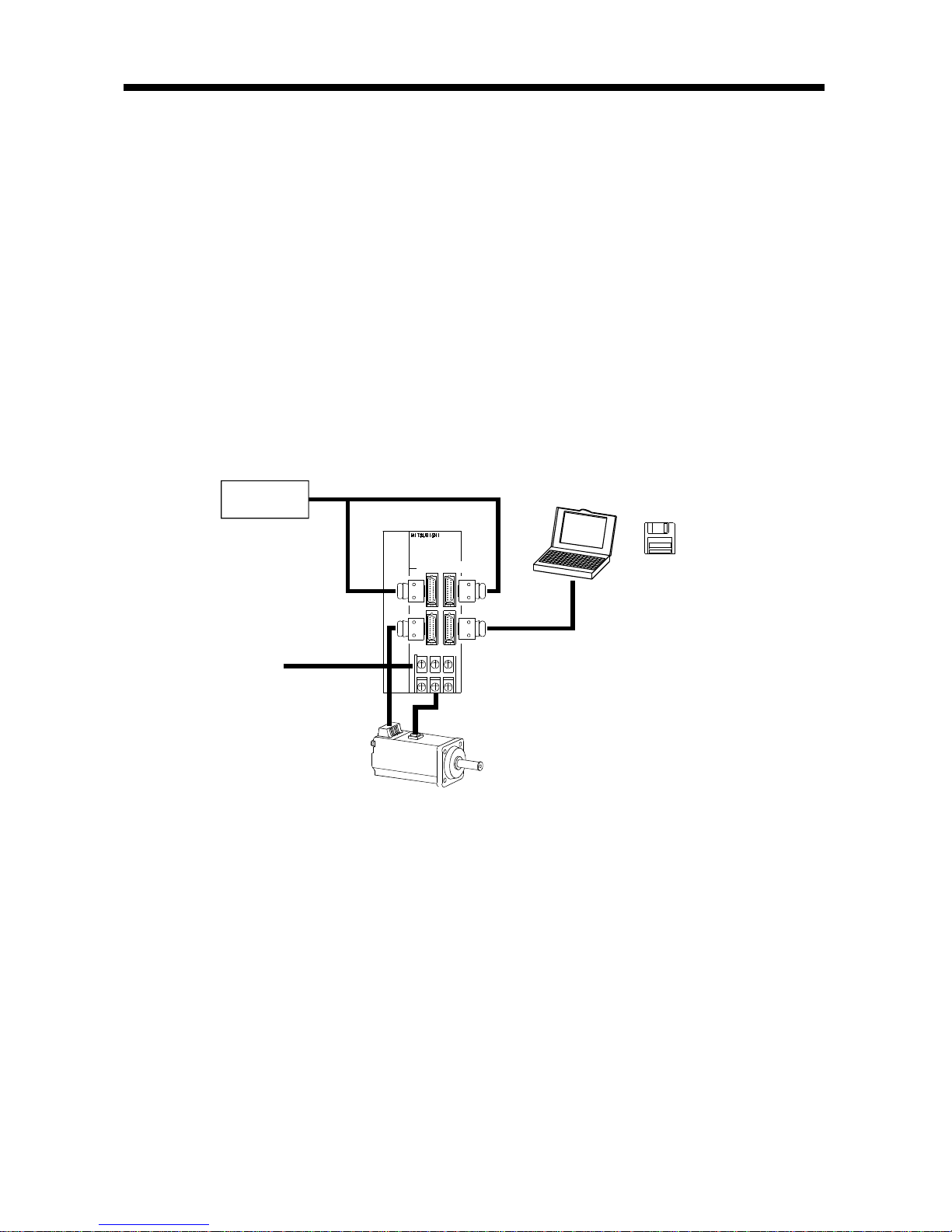

(1) Operation using external input signals

(a) Description

The following configuration example assumes that external input signals are used to control all

signals (devices).

The I/O signals are as fac t ory- set.

(b) Configuration

The following configuration uses external I/O signals. The personal computer is used with Servo

configuration Software to set creation of a program, change and monitor the parameters.

Servo amplifier

External I/O

signals

Power supply

Servo motor

RS–232C

Servo configuration

Software

Personal

computer

CN1A CN1B

CN2 CN3

1 - 4

1. FUNCTIONS AND CONFIGURATION

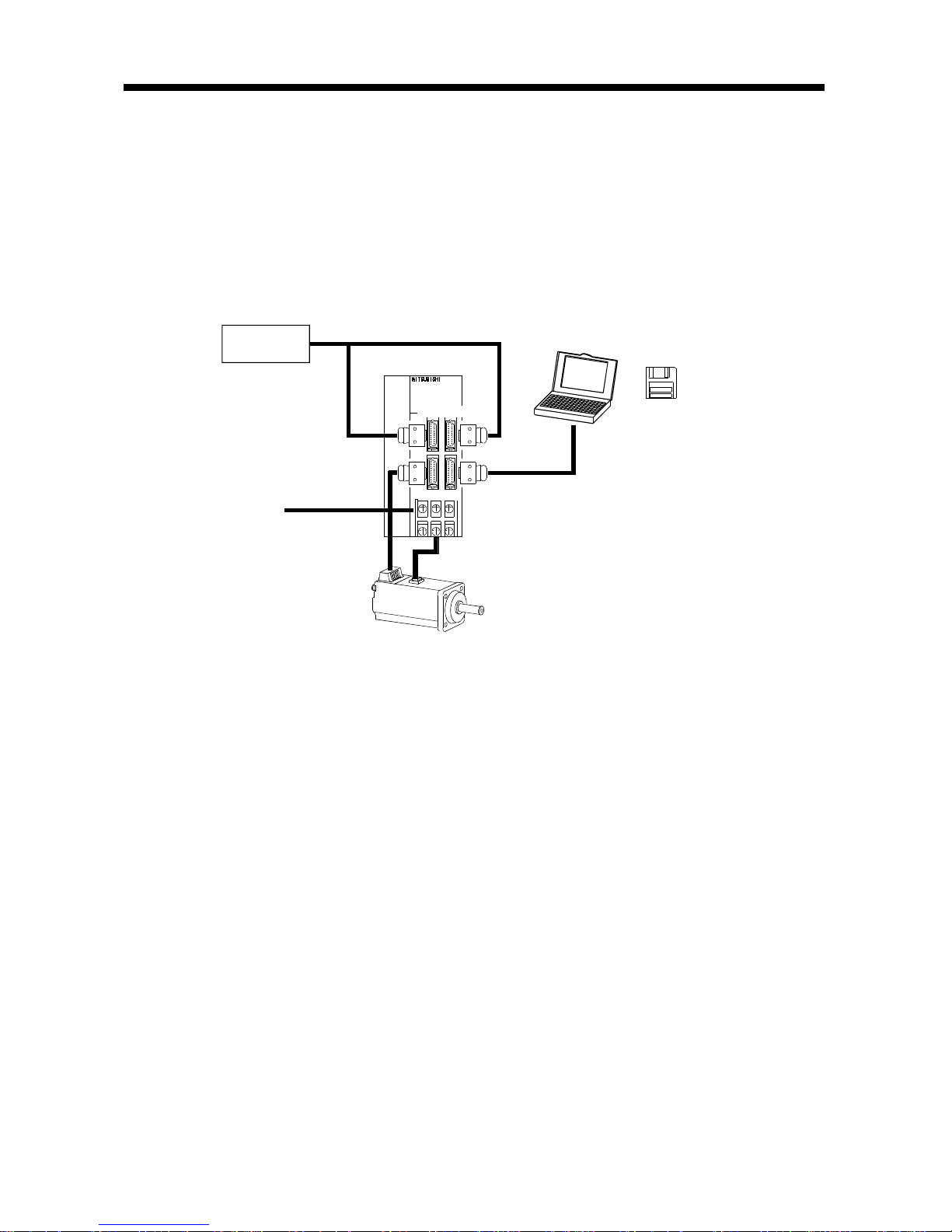

(2) Operation using external input signals and communication

(a) Description

Communication can be used to Selection of the program, change parameter values, and confirm

monitor data, for example. Enter a forward rotation start (ST1) or reverse rotation start (ST2)

through the external I/O. Use this system when position data/speed setting or the host personal

computer or the like is used to change the parameter values, for example.

(b) Configuration

1) One servo amplifier is connected with the personal computer by RS-232C.

Servo amplifier

External I/O

signals

Power supply

Servo motor

RS–232C

Servo configuration

Software

Personal

computer

CN1A CN1B

CN2 CN3

1 - 5

1. FUNCTIONS AND CONFIGURATION

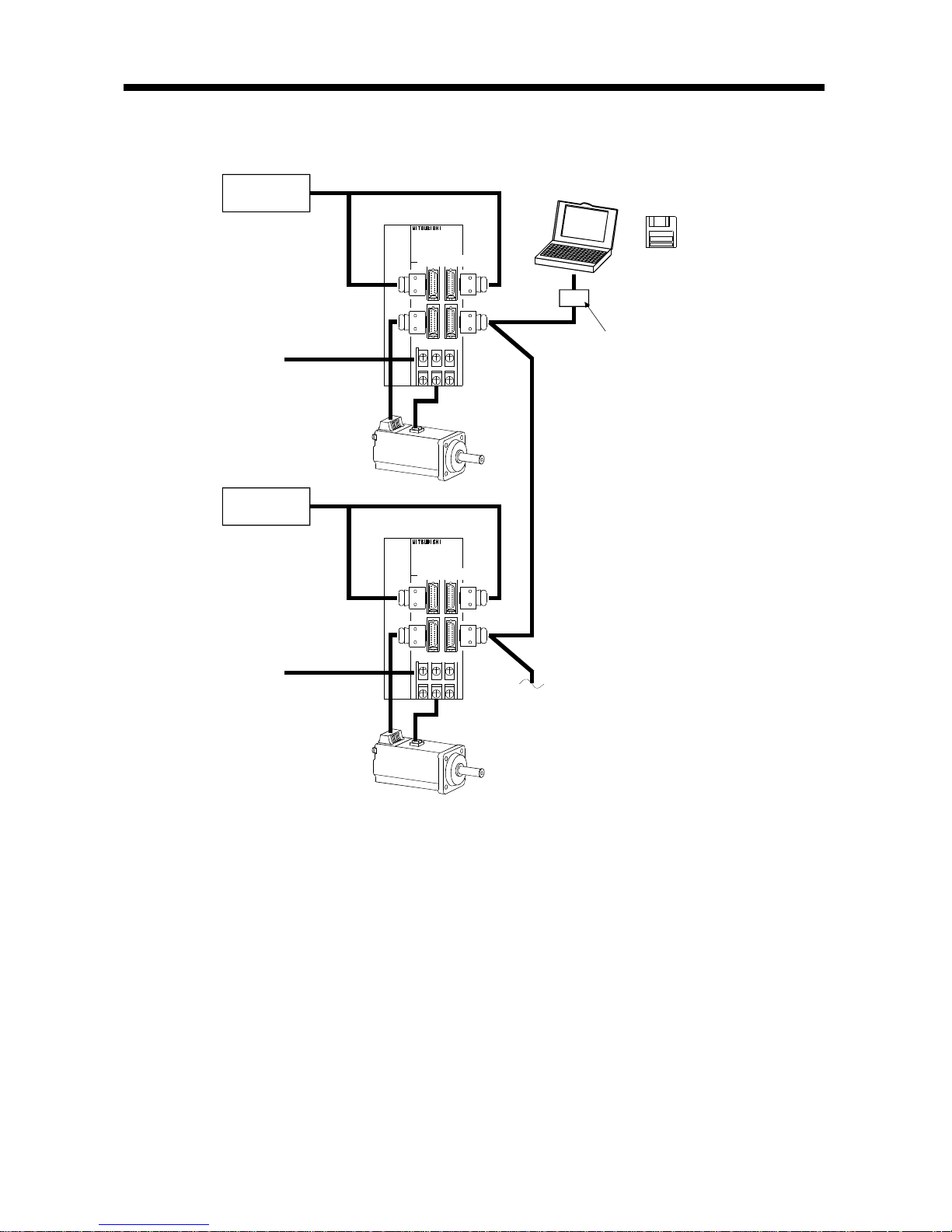

2) Several (up to 32) servo amplifiers are connected with the personal computer by RS-422.

Use parameter No. 16 to change the communication system.

Servo amplifier (axis 1)

External I/O

signals

Power supply

Servo motor

RS–422

Servo configuration

Software

Personal

computer

CN1A CN1B

CN2 CN3

Servo amplifier (axis 2)

External I/O

signals

Servo motor

CN1A CN1B

CN2 CN3

RS–232C

RS–232C/RS-422 converter

(to be prepared by the customer)

To the next axis

RS–422

Power supply

1 - 6

1. FUNCTIONS AND CONFIGURATION

(3) Operation using communication

(a) Description

Analog input, forced sto p (EMG) and other signals are controlled by exte rnal I/O signals an d the

other devices controlled through communication. Also, you can set each program, selection of the

program, and change or set parameter values, for example. Up to 32 axes may be controlled.

(b) Configuration

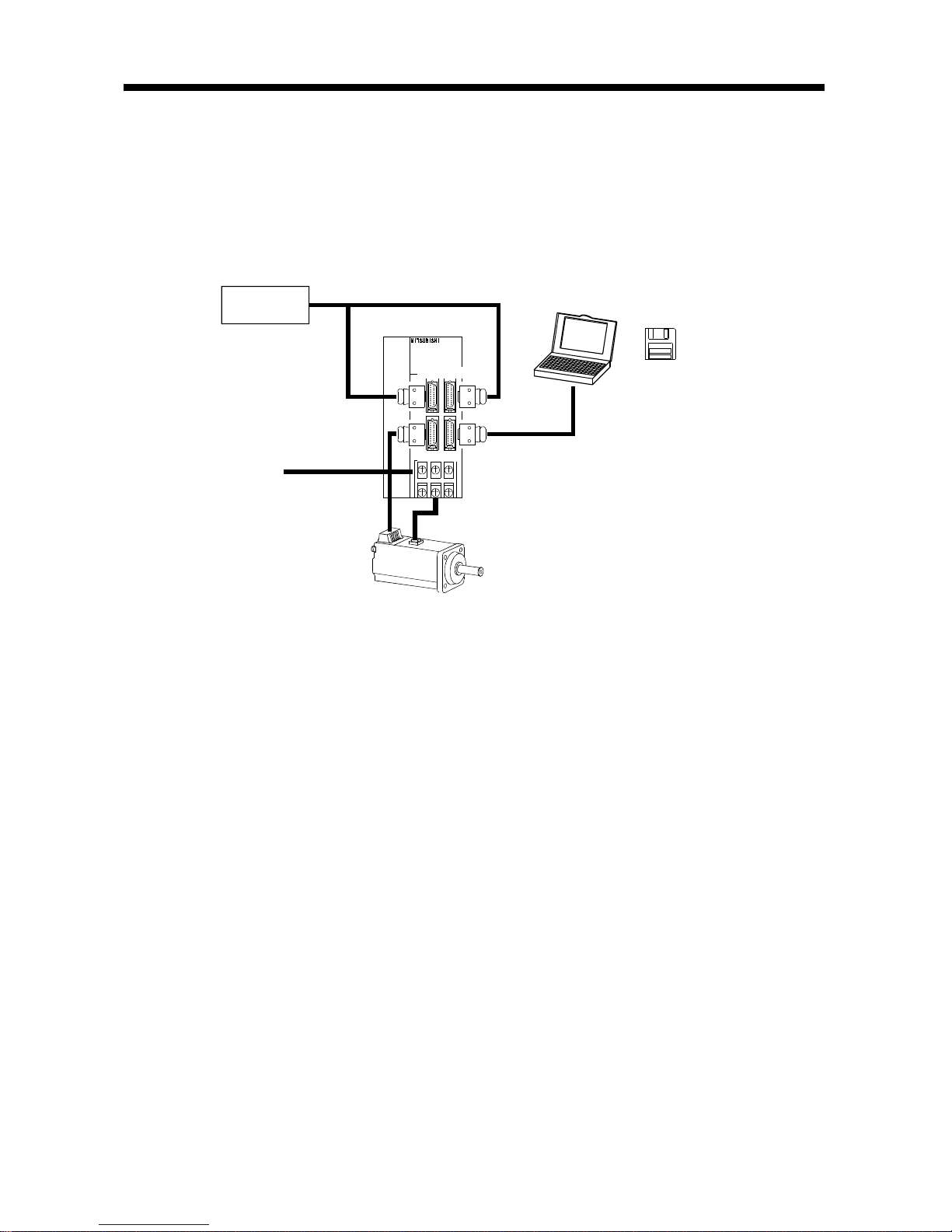

1) One servo amplifier is connected with the personal computer by RS-232C.

Servo amplifier

External I/O

signals

Power supply

Servo motor

RS–232C

Servo configuration

Software

Personal

computer

CN1A CN1B

CN2 CN3

1 - 7

1. FUNCTIONS AND CONFIGURATION

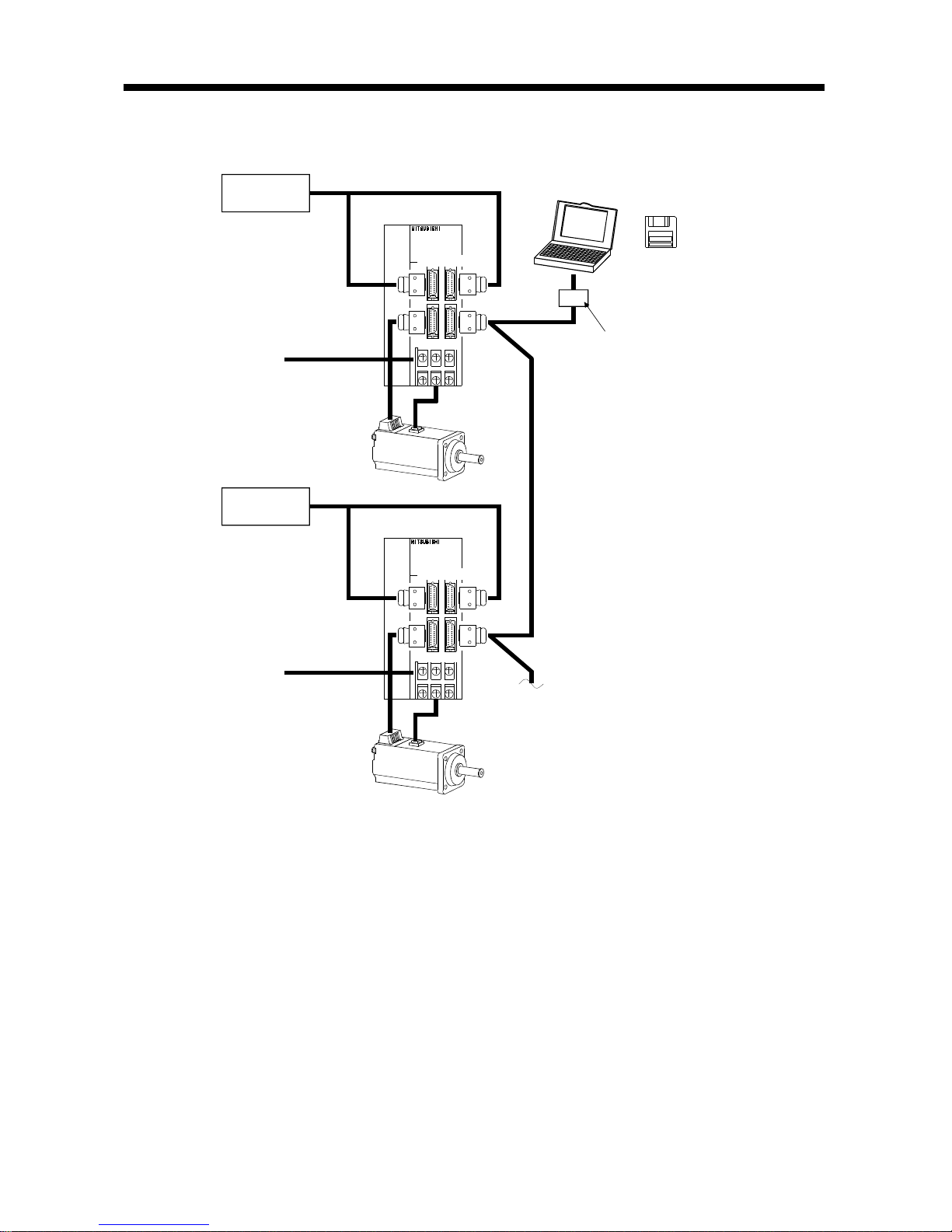

2) Several (up to 32) servo amplifiers are connected with the personal computer by RS-422.

Use parameter No. 16 to change the communication system.

Servo amplifier (axis 1)

External I/O

signals

Power supply

Servo motor

RS–422

Servo configuration

Software

Personal

computer

CN1A CN1B

CN2 CN3

Servo amplifier (axis 2)

External I/O

signals

Servo motor

CN1A CN1B

CN2 CN3

RS–232C

RS–232C/RS-422 converter

(to be prepared by the customer)

To the next axis

RS–422

Power supply

1 - 8

1. FUNCTIONS AND CONFIGURATION

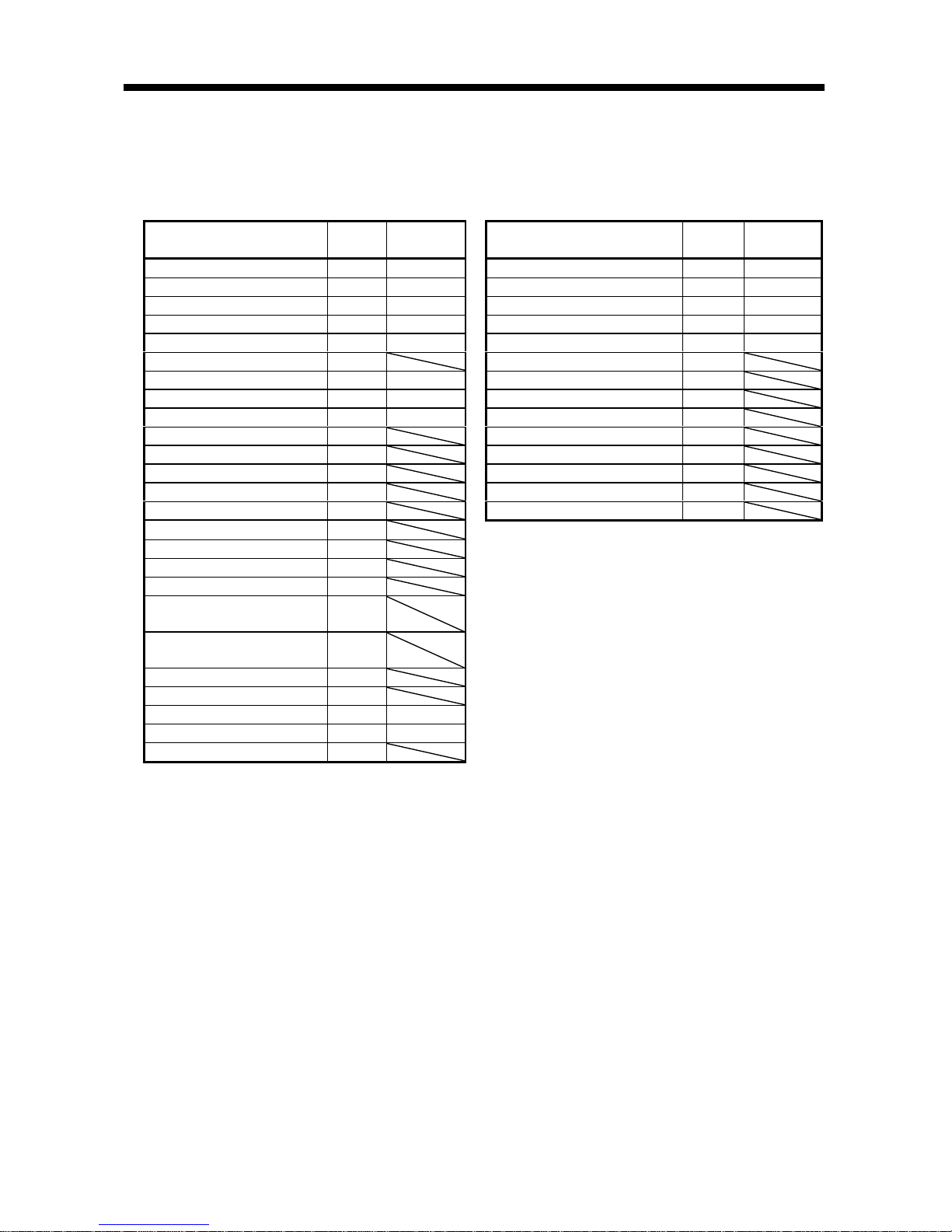

1.1.3 I/O devices

This servo amplifier allows devices to be al located to the pins of connector CN1A/CN1B a s desired. The

following devices can be allocated. For device details, refer to Section 3.3.2.

Input device Symbol

Factory-

allocated pin

Output device Symbol

Factory-

allocated pin

Servo-on SON CN1A-19 Trouble ALM CN1B-18

Reset RES CN1B-15 Ready RD CN1B-19

Forward rotation stroke end LSP CN1B-16 Movement complete PED CN1B-6

Reverse rotation stroke end LSN CN1B-17 Zeroing completion ZP CN1A-18

Forward rotation start ST1 CN1B-7 Program output 1 OUT1 CN1B-4

Reverse rotation start ST2 Program output 2 OUT2

Proximity dog DOG CN1A-8 Program output 3 OUT3

Program No. selection 1 DI0 CN1B-5 Electromagnetic brake interlock MBR

Program No . selection 2 DI1 CN1B-14 Position range POT

Program No. selecti on 3 DI2 Warning WNG

Program No. selection 4 DI3 Battery warning BWNG

Forced stop EMG Limiting torque TLC

Automatic/manual selection MD0 Temporary stop PUS

Override selection OVR SYNC synchronous output SOUT

External torque limit selection TL

Internal torque l imit selection TL2

Proportion control PC

Temporary stop/restart STP

Manual pulse generator

multiplication 1

TP0

Manual pulse generator

multiplication 2

TP1

Gain switch CDP

Current position latch input LPS

Program input 1 PI1 CN1B-8

Program input 2 PI2 CN1B-9

Program input 3 PI3

1 - 9

1. FUNCTIONS AND CONFIGURATION

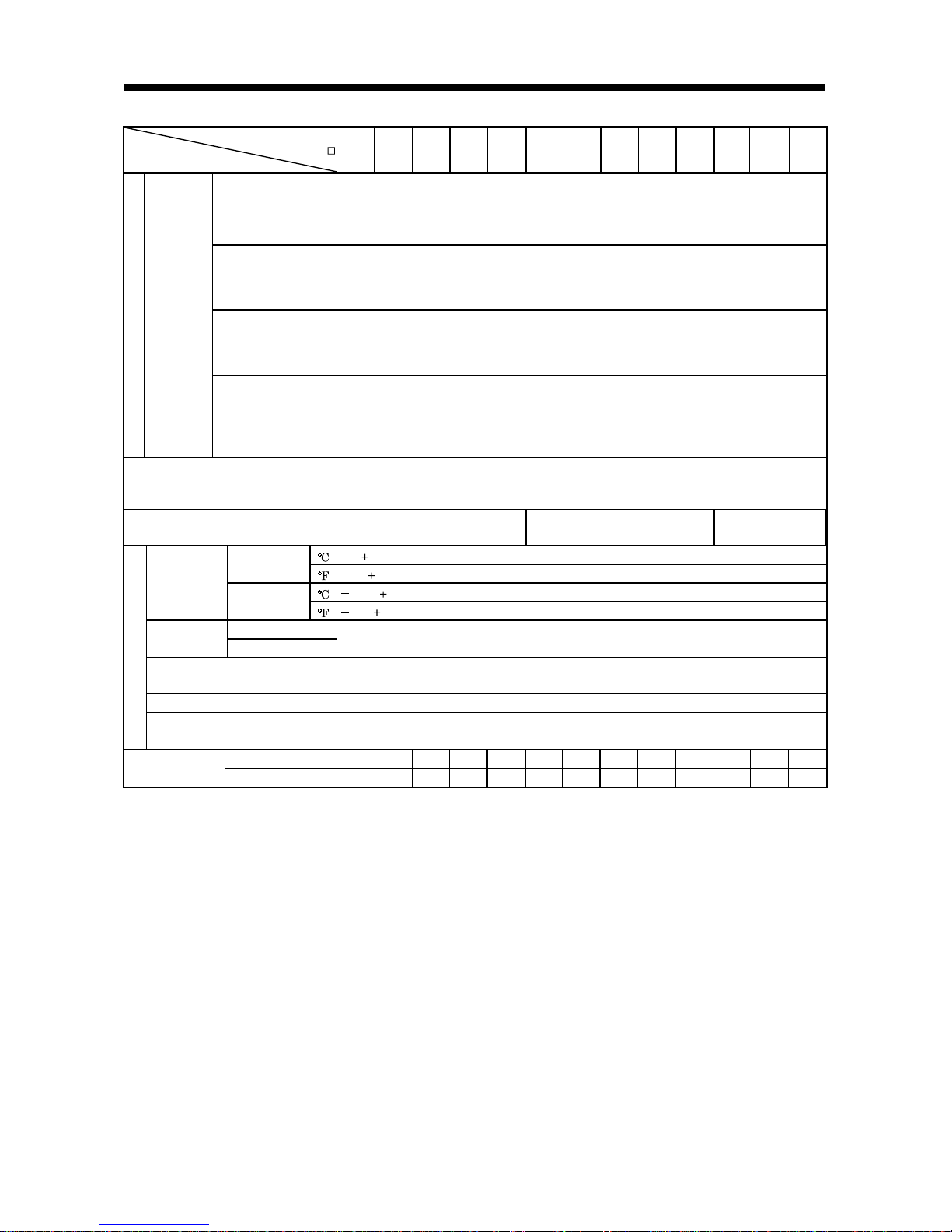

1.2 Servo amplifier standard specifications

Servo amplifier

MR-J2S-

Item

10CL 20CL 40CL 60CL 70CL 100CL 200CL 350CL 500CL 700CL 10CL1 20CL1 40CL1

Voltage/frequency

3-phase 200 to 230VAC, 50/60Hz

or 1-phase 230VAC, 50/60Hz

3-phase 200 to 230VAC, 50/60Hz

1-phase 100 to

120VAC 50/60Hz

Permissible voltage fluctuation

3-phase 200 to 230VAC:

170 to 253VAC

1-phase 230VAC: 207 to 253VAC

3-phase 170 to 253VAC

1-phase

85 to 127VAC

Permissible frequency fluctuation Within 5%

Power supply

Power supply capacity Refer to Section13.2

System Sine-wave PWM control, curr ent c ontr ol syste m

Dynamic brake Built-in

Protective functions

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic

thermal relay), se rv o motor overheat protection, encode r e rro r protection, regen era t i ve

brake error prot ecti on , u ndervoltage, instan t a neous power failure protection, ove rs p eed

protection, exces si v e error protecti on

Operational

specifications

Programming language (Programming with Servo-configuration software).

Programming capacity: 120 steps

Position

command input

Setting by programming language.

Movement setting range at 1 point:

1[ m] to 999.999[mm]

Speed command

input

Servo motor speed , a cceleration/decelera t i on time constant and S - pattern

acceleration/decel era t i on t ime constant by programming langua ge.

S-pattern acceleration/decel erat ion time constant can set by parameter N o.1 4 or by

programming.

Command system

Programming

System

Signed absolut e va l u e command (signed in cremental value c o mma n d s y st em can be

specified), signed incremental value command system

Program operation mode

Setting by programming language

Jog

Jog operation is perform ed in accordance with the paramet er-set sp eed command by

contact input or through RS-422 (232C) communication.

Manual

operation

mode

Manual pulse

generator

Manual feed is made by manual pulse generator.

Command pulse multiplication:

1, 10 or 100 is selected using parameter.

Dog type

Home position return is made starting with Z-phase pulse after passage of proximity dog.

Home position address may be set. Home position shift distance may be set. Home position

return direction may be selected .

Automatic at-dog home position return, Automatic stroke return function

Count type

Home position return is made by counting encoder pulses after contact with proximity dog.

Home position address may be set. Home position shift value may be set. Home position

return direction may be set.

Automatic at-dog home position return, Automatic stroke return function

Data setting type

Home position return is made without dog.

Home position may be set at any p osi t i on b y manual operatio n, etc. Home posit i on a ddress

may be set.

Operation mode

Manual

home

position

return

mode

Stopper type

Home position return is mad e b y p ressi ng ma chine part against stroke end.

Home position address may be set. Home position return direction may be set.

1 - 10

1. FUNCTIONS AND CONFIGURATION

Servo amplifier

MR-J2S-

Item

10CL 20CL 40CL 60CL 70CL 100CL 200CL 350CL 500CL 700CL 10CL1 20CL1 40CL1

Home position

ignorance

(Servo-on position as

home position)

Position where servo-on (SON) is s w it ch ed on is defined as home position.

Home position address may be set.

Dog type rear end

reference

Home position return is made with respect to the rear end of a proximity dog.

Home position address may be set. Home position shift value may be set. Home position

return direction may be set.

Automatic at-dog home position return, Automatic stroke return function

Count type front end

reference

Home position return is made with respect to the front end of a proximity dog.

Home position address may be set. Home position shift value may be set. Home position

return direction may be set.

Automatic at-dog home position return, Automatic stroke return function

Operation mode

Manual

home

position

return

mode

Dog cradle type

Home position return is made with respect to the front end of a proximity dog by the first

Z-phase pulse.

Home position address may be set. Home position shift value may be set. Home position

return direction may be set.

Automatic at-dog home position return, Automatic stroke return function

Other functions

Absolute position detection, backlash function

Overtravel prevention using external limit switch

Software stroke limit, override using external analog signal

Structure Self-cooled, open (IP0 0) Force-cooling, open (I P00 )

Self-cooled,

open (IP00)

[ ]0 to 55 (non-freezing)

Operation

[

] 32 to 131 (non-freezing)

[ ] 20 to 65 (non-freezing)

Ambient

temperature

Storage

[

] 4 to 149 (non-freezing)

Operation

Ambient

humidity

Storage

90%RH or less (n on- c o n d en si n g)

Ambient

Indoors (no direct s un li g ht )

Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280ft) above sea level

5.9 [m/s2] or less

Environment

Vibration

19.4 [ft/s

2

] or less

[kg] 0.7 0.7 1.1 1.1 1.7 1.7 2.0 2.0 4.9 7.2 0.7 0.7 1.1

Weight

[lb] 1.5 1.5 2.4 2.4 3.75 3.75 4.4 4.4 10.8 15.87 1.5 1.5 2.4

1 - 11

1. FUNCTIONS AND CONFIGURATION

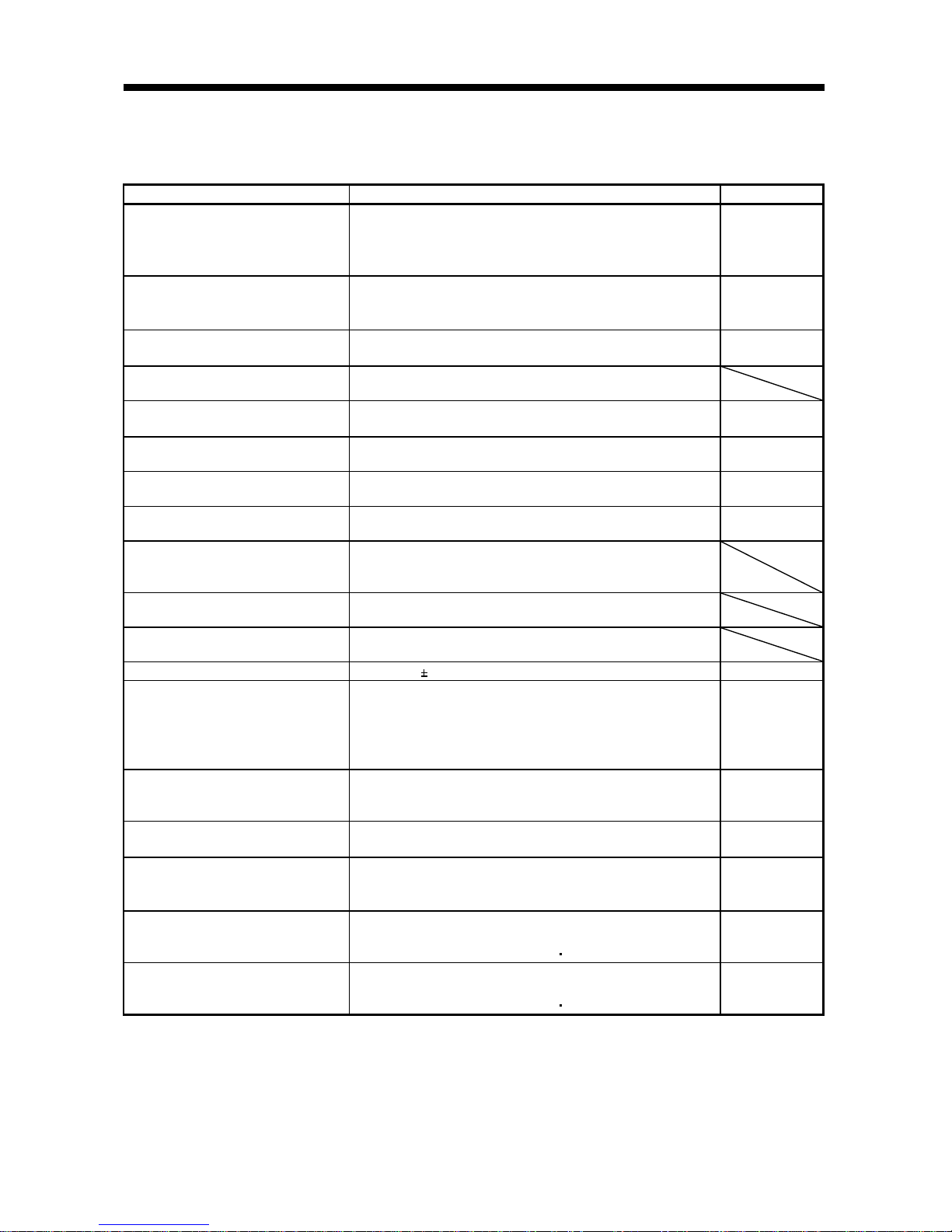

1.3 Function list

The following table lists the functions of this servo. For details of the functions, refer to the reference field.

Function Description Reference

Positioning by program operation

Operation is performed in accordance with the contents of any

program selected from among pre-created 16 programs.

Use the external input signal or communication function to choose

the program.

Section 4.2

Manual home position return

Dog type, count type, data setting type, stopper type, home

position ignoran ce, dog type rear end reference, count type front

end reference, dog cradle type

Section 4.4

Multidrop communicatio n

Up to 32 axes of MR-J2S-CL are controllable simultaneously by

RS-422 communication.

Section 4.6.3

Chapter 15

High-resolut ion encoder

High-resolution encoder of 131072 pulses/rev is used as a servo

motor encoder.

Absolute position detection system

By merely setting the home position once, home position return

need not be done at each power on.

Section 4.5

Gain changing function

You can switch between gains during rotation and gains during

stop or use an external signal to change gains during operation.

Section 9.5

Adaptive vibration suppression control

Servo amplifier detects mechanical resonance and sets filter

characteristics automatically to suppress mechanical vibration.

Section 9.3

Low-pass filter

Suppresses high-frequency resonance which occurs as servo

system response is increased.

Section 9.4

Machine analyzer function

Analyzes the frequency characteristic of the mechanical system by

simply connecting a servo configuration software-installed

personal computer and servo amplifier.

Machine simulation

Can simulate machine motions on a personal computer screen on

the basis of the machine analyzer results.

Gain search function

Personal computer changes gains automatically and searches for

overshoot-free gains in a short time.

Slight vibration suppression control Vibration of 1 pulse at servo motor stop is suppressed. Parameter No. 20

Electronic gear

The electronic gear is used to make adjustment so that the servo

amplifier setting matches the machine moving distance. Also,

changing the electronic gear value allows the machine to be moved

at any multiplication ratio to the moving distance using the servo

amplifier.

Section 5.2.1

Auto tuning

Automatically adjusts the gain to optimum value if load applied to

the servo motor shaft varies. Higher in performance than MR-J2

series servo amplifier.

Chapter 8

S-pattern acceleration/deceleration time

constant

Acceleration/deceleration can be made smoothly.

Section 4.2.1 (2) 2)

Section 5.2.3

Regenerative brake option

Used when the buil t - i n regenerative b ra ke resistor of the servo

amplifier does not have sufficient regenerative capability for the

regenerative power generat ed.

Section 14.1.1

Brake unit

Used when the regenerative bra ke option cann ot pr ov i de enough

regenerative power.

Can be used with the MR-J2S-500CL

MR-J2S-700CL.

Section 14.1.2

Return converter

Used when the regenerative brake option cannot provide enough

regenerative power.

Can be used with the MR-J2S-500CL

MR-J2S-700CL.

Section 14.1.3

1 - 12

1. FUNCTIONS AND CONFIGURATION

Function Description Reference

Analog monitor The servo status is output in terms of voltage in real time. Section 5.2.4

Alarm history

By using the Se rvo configuration Software, the current alarm an d

five past alarm numbers are stor ed and dis pl a y ed.

Section 6.8

I/O signal selection (Device setting)

By using the Servo configuration Software, any devices can be

assigned to 9 input, 5 output and 1 I/O pins.

Section 6.6

Torque limit

Servo motor-torque is limited.

Parameter 2 limit value

Analog input

1 limit value

Section 3.2.5

Override (speed limit)

The servo motor speed is limited by analog input.

The ratio of override to the set speed can be changed between 0 to

200%.

Section 3.2.4

Status display The servo status is displayed. Section 7.2

Test operation mode

Jog, Positioning, Operation w/ o motor, Forced outp ut , P ro g ram

test

Section 6.7

Limit switch

The servo motor travel region can be limited using the forward

rotation stroke end (LSP)/reverse rotation stroke end (LSN).

Section 5.2.5

Software limit

The travel region is limited using parameters in terms of address.

The function similar to that of a limit switch is limited by

parameter.

Section 5.2.9

1.4 Model code definition

(1) Rating plate

POWER

MITSUBISHI

AC SERVO

MADE IN JAPAN

MODEL

MR-J2S-60CL

MITSUBISHI ELECTRIC CORPORATION

600W

3.2A 3PH 1PH200-230V 50Hz

170V 0-360Hz 3.6A

POWER :

INPUT :

OUTPUT :

SERIAL :

AC SERVO

A5

PASSED

Model

Capacity

Applicable power supply

Rated output current

Serial number

3PH 1PH200-230V 60Hz

5.5A 1PH 230V 50/60Hz

TC3 AAAAG52

1 - 13

1. FUNCTIONS AND CONFIGURATION

(2) Model

MR–J2S–100CL or less

MR–J2S–200CL 350CL

Program compatibility operation function

Rated output

Rating plate

Rating plate

MR–J2S–

Series

CL

Note:1. Not supplied to the servo amplifier of

MR-J2S-60CL or more.

2. Not supplied to the servo amplifier of

MR-J2S-100CL or more.

Power Supply

Power supply

None

3-phase 200 to 230VAC

(Note2)

1-phase 230VAC

(Note1)

1

1-phase 100V to 120VAC

Symbol

Rated

output [W]

100

10

Symbol

200

20

400

40

600

60

750

70

1000100

2000200

3500350

Rated

output [W]

Symbol

5000500

7000700

MR-J2S-500CL

MR-J2S-700CL

Rating plate Rating plate

1.5 Combination with servo motor

The following table lists combinatio ns of servo ampl ifier s and se rvo moto rs. The same comb inat ions app ly

to the models with electromagnetic brakes and the models with reduction gears.

Servo motors

HC-SFS HC-UFS

Servo amplifier

HC-KFS

HC-MFS

1000r/min 2000r/min 3000r/min

HC-RFS

2000r/min 3000r/min

MR-J2S-10CL (1) 053 13 053 13 13

MR-J2S-20CL (1) 23 23 23

MR-J2S-40CL (1) 43 43 43

MR-J2S-60CL 52 53

MR-J2S-70CL 73 73 72 73

MR-J2S-100CL 81 102 103

MR-J2S-200CL 121 201 152 202 153 203 103 153 152

MR-J2S-350CL 301 352 353 203 202

MR-J2S-500CL 502 353 503 352 502

MR-J2S-700CL 702

Servo motors

HA-LFS

Servo amplifier

(Note)

1000r/min

(Note)

1500r/min

2000r/min

(Note)

HC-LFS

MR-J2S-60CL 52

MR-J2S-100CL 102

MR-J2S-200CL 152

MR-J2S-350CL 202

MR-J2S-500CL

(Note)

502 302

MR-J2S-700CL 601 701M

(Note)

702

Note: Consult us since the servo amplifier to be used with any of these servo motors is optional.

1 - 14

1. FUNCTIONS AND CONFIGURATION

1.6 Structure

1.6.1 Part names

(1) MR-J2S-100CL or less

MODE

UP DOWN SET

Used to set data.

Used to change the

display or data in each

mode.

Used to change the

mode.

Reference

Section4.5

Chapter7

Name/Application

Battery holder

Contains the battery for absolute position data ba ck up .

Battery connector (CON1)

Used to connect the battery for absolute position data

backup.

Display

The 5-digit, seven-segment LED shows the ser v o

status and alarm number.

MODE

UP DOWN

SET

I/O signal connector (CN1A)

Used to connect digital I/O signals.

Communication connector (CN3)

Used to connect a command device (RS-422/RS-232C)

and output analog monitor data.

Name plate

Charge lamp

Lit to indicate that the main circuit is charged. While

this lamp is lit, do not reconnect the cables.

Encoder connector (CN2 )

Connector for connection of the servo motor encoder.

Main circuit terminal block (TE1)

Used to connect the input power supply and servo

motor.

Protective earth (PE) terminal ( )

Ground terminal.

Section4.5

Operation section

Used to perform status display, diagnostic, alarm and

parameter setti ng op e rat io ns.

Chapter7

Section3.3

I/O signal connector (CN1B)

Used to connect digital I/O signals.

Section3.3

Chapter6

Chapter15

Section14.1.4

Section1.4

Section3.3

Section14.1.4

Control circuit terminal block (TE2)

Used to connect the contr ol circuit power supply and

regenerative brake option.

Section3.7.2

Section3.7.2

Section14.1.1

Section3.10

1 - 15

1. FUNCTIONS AND CONFIGURATION

(2) MR-J2S-200CL MR-J2S-350CL

POINT

This servo amplifier is shown without the front cover. For removal of the

front cover, refer to Section 1.6.2.

MODE UP DOWN

SET

Cooling fan

Mounting hole (4 places)

Used to set data.

Used to change the

display or data in each

mode.

Used to change the

mode.

Reference

Section4.5

Chapter7

Name/Application

Battery holder

Contains the battery for absolute position data backup.

Battery connector (CON1)

Used to connect the battery for absolute position data

backup.

Display

The 5-digit, seven-segment LED shows the servo

status and alarm number.

MODE

UP

DOWN

SET

I/O signal connector (C N 1A)

Used to connect digital I/O signals.

Communication connector (CN3)

Used to connect a command device (RS-422/RS232C)

and output analog monitor data.

Name plate

Charge lamp