Mitsubishi Electric Melservo-H, MR-H30KBN, MR-H30KAN, MR-H30KACN, MR-H30KDN Specifications

...

General-Purpose AC Servo

H Series

200VAC Large-Capacity Servo

MR-H30KAN

MR-H30KBN

MR-H30KACN

MR-H30KTN

MR-H30KDN

Specifications and Instruction Guide

Safety Instructions

(Always read these instructions before using the equipment.)

Do not attempt to install, ope rate, maint ain or inspect the servo amplif ier and servo m otor until you hav e read

through this Specifications and Instruction guide, Installation guide, Servo motor Instruction Manual and

appended docum ents c ar eful ly an d ca n us e th e eq uipm ent cor rec tl y. Do not us e t he s ervo am plif ier and ser v o

motor until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols:

: Indicates what must not be done. For example, "No Fire" is indicated by

: Indicates what must be done. For example, grounding is indicated by

In this Specific atio ns and Ins truct ion Manu al, instr uctio ns at a lo wer level than the above, ins truct ions for oth er

functions, and so on are classified into "POINT".

After reading this installation guide, always keep it accessible to the operator.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

.

.

A - 1

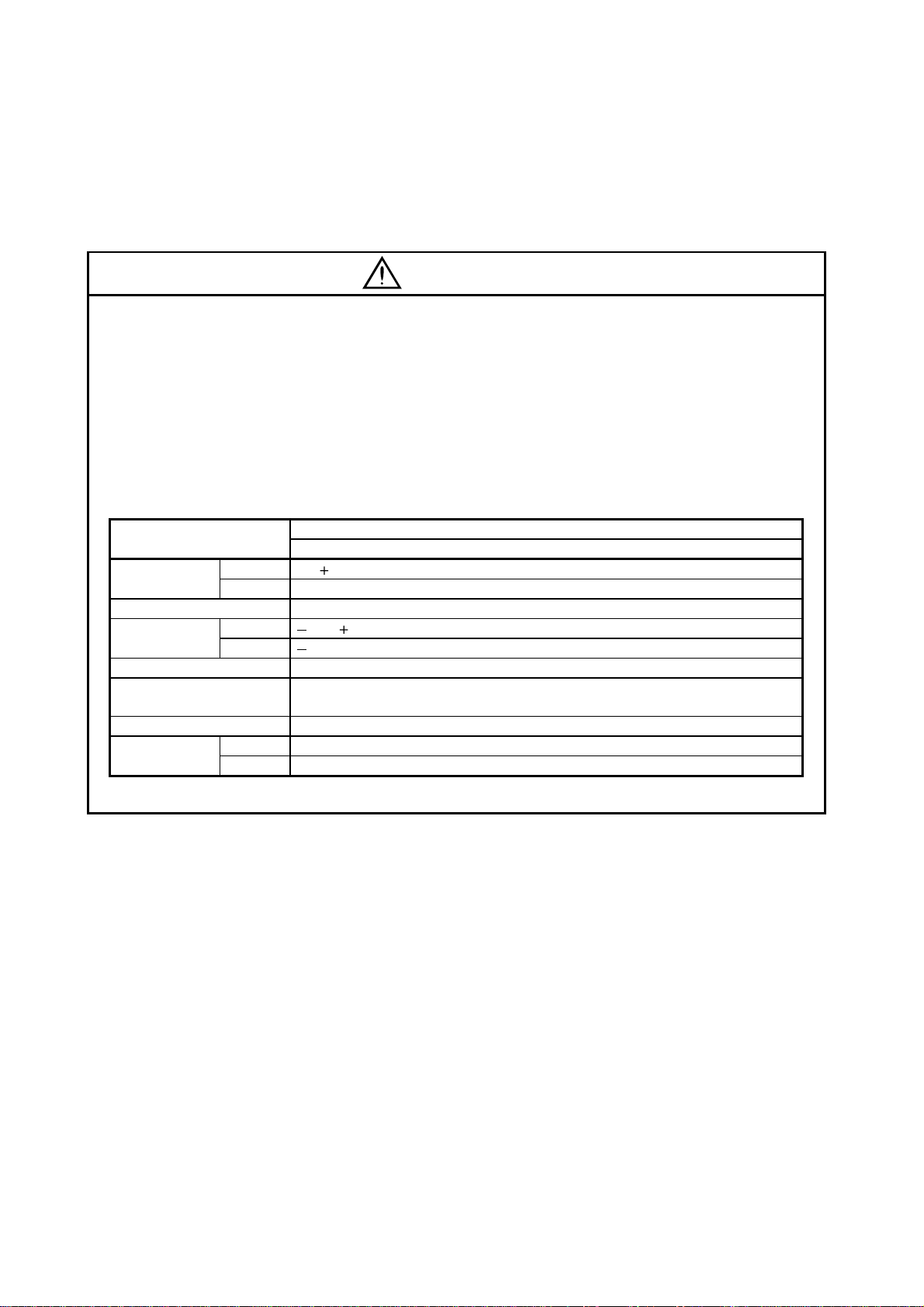

1. To prevent electric shock, note the following:

CAUTION

• Before wiring or inspec t i on, s witc h po wer off an d wa it for more than 1 0 minutes. Then, c o nfirm the volt ag e

is safe with voltage tester. Otherwise, you may get an electric shock.

• Connect the Converter unit to ground.

• Any person who is involved in wiring and inspection should be fully competent to do the work.

• Do not atte mpt to wi re th e C onv e rte r uni t un ti l th ey have been installed. Otherwise , you may get an elect ric

shock.

• Operate the switches with dry hand to prevent an electric shock.

• The cables should not be damaged, stressed loaded,, or pinched. Otherwise, you may get an electric

shock.

• During power-on or operation, do not open the front cover. You may get an electric shock.

• Do not operate the servo amplifier with the fr ont c o ver removed. H ig h-vo l t ag e t er minals and ch ar g ing area

are exposed and you may get an electric shock.

• Except for wiring or periodic inspection, do not remove the front cover even if the power is off.

The Converter unit is charged and you may get an electric shock.

2. To prevent fire, note the following:

CAUTION

• Do not install the Converter unit and regenerative brake resistor on or near combustibles.

Otherwise a fire may cause.

• When the Converter unit has become faulty, switch off the main Converter unit power side.

Continuous flow of a large current may cause a fire.

• When a regenerative brake resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative brake transistor fault or the like may overheat the regenerative brake resistor, causing a fire.

3. To prevent injury, note the follow

CAUTION

• Only the vo ltage specified in t he Instruction Man ual should be ap plied to each ter minal,, Otherwis e,, a

burst,, damage,, etc. may occur.

• Connect the terminals correctly to prevent a burst,, damage,, etc.

• Ensure th a t po l a rity (

• During power- on or f or some time after power-off, do no t t ouch the Conver ter unit fins , r e ge nerative brak e

resistor, servo motor, etc. Their temperatures may be high and you may get burnt.

, ) is correct. Otherwise, a burst, damage, etc. may occur.

A - 2

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric

shock, etc.

(1) Transportation and installation

CAUTION

• Transport the products correctly according to their weights.

• Stacking in excess of the specified number of products is not allowed.

• Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

• The Converter unit must be installed in the specified direction.

• Leave specified clearances between the Converter unit and control enclosure walls or other equipment.

• Do not install or operate the Converter unit which has been damaged or has any parts missing.

• Provide adequate pr otection to prevent screws and other co nductive matter, oil and other com bustible

matter from entering the Converter unit.

• Do not drop or strike converter unit or servo motor. Isolate from all impact loads.

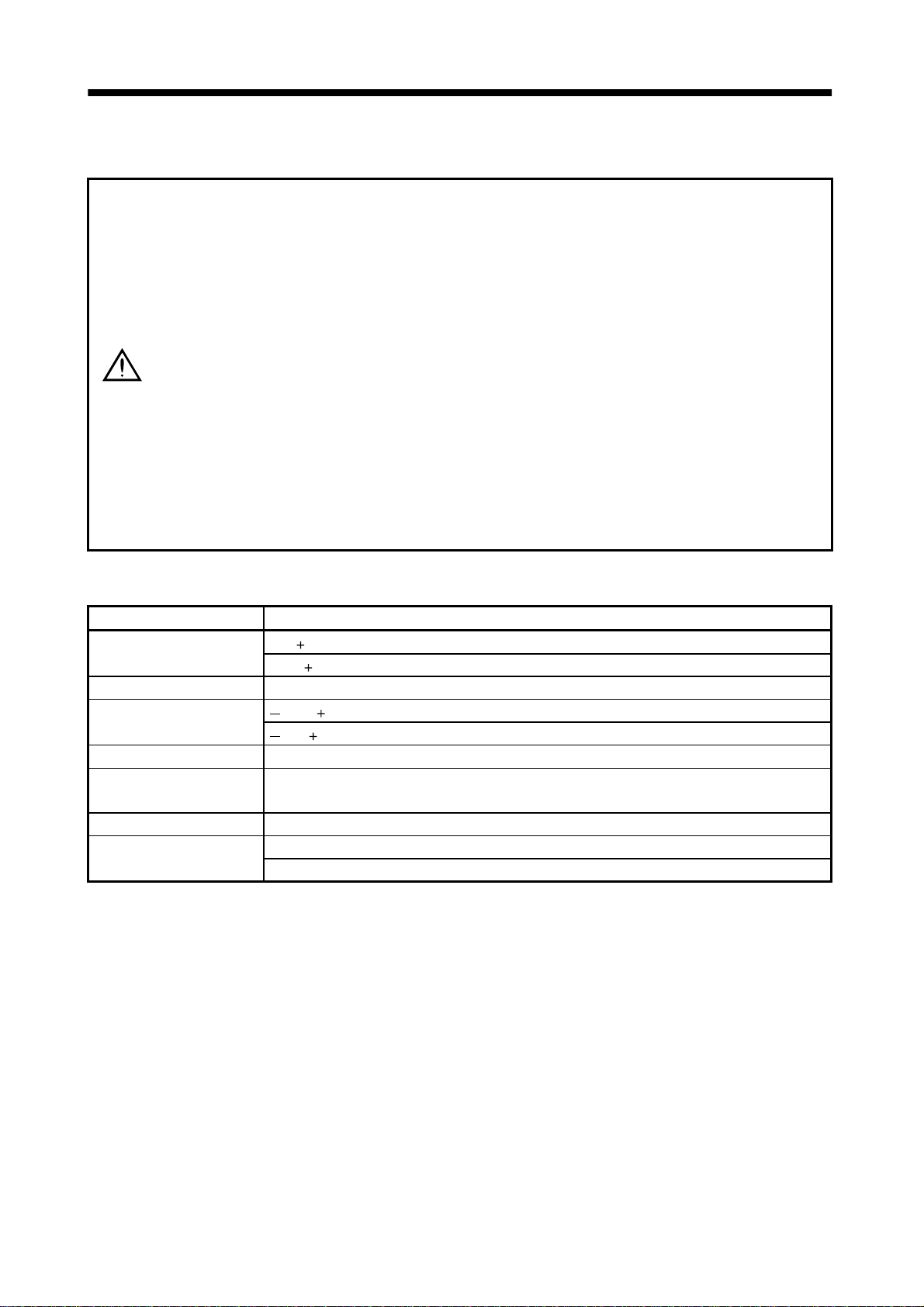

• Use the servo amplifier and servo motor under the following environmental conditions:

Environment

Ambient

temperature

Ambient humidity 90%RH or less (non-condensing)

Storage

temperature

Storage humi d i t y 90%RH or less (non-condensing)

Ambience

Altitude Max. 1000m (3280 ft) above sea level

Vibration

[°C] 0 to 55 (non-freezing)

[°F] 32 to 131 (non-freezing)

[°C] 20 to 65 (non-freezing)

[°F]

[m/s2] 5.9 or less

2

[ft/s

] 19.4 or less

4 to 149 (non-freezing)

Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and

dirt

Conditions

Servo amplifier

• When the equipment has been stored for an extended period of time, consult Mitsubishi.

A - 3

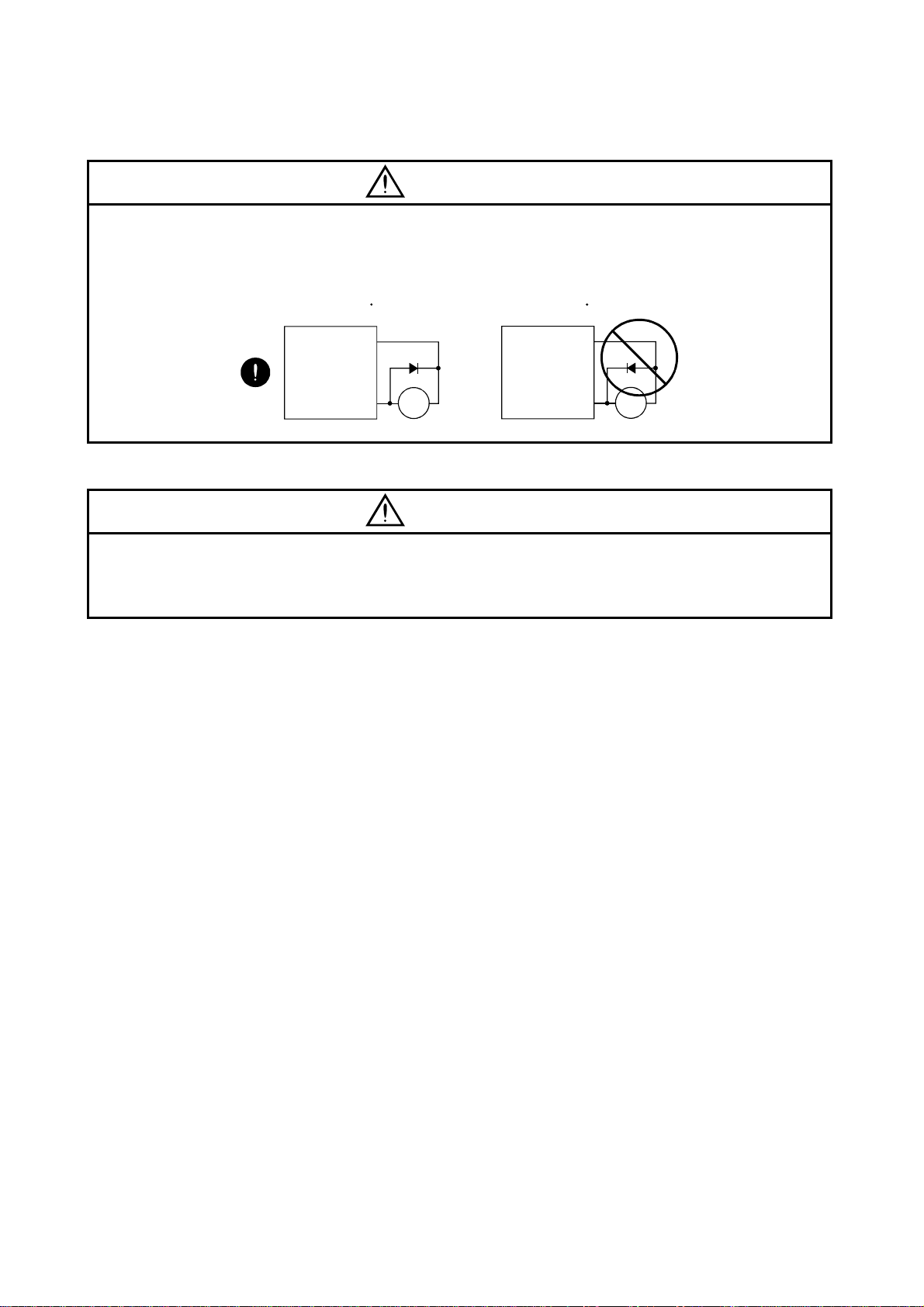

(2) Wiring

CAUTION

• Wire the equipment correctly and securely.

• The surge absorbing dio de i nst a l le d on the DC ou tp ut signal relay mus t b e wired in the specified direc t io n.

Otherwise, the emergency stop and other protective circuits may not operate.

Converter unit

Servo Amplifier

VIN

(24VDC)

Control

output

signal

RA

Converter unit

Servo Amplifier

VIN

(24VDC)

Control

output

signal

RA

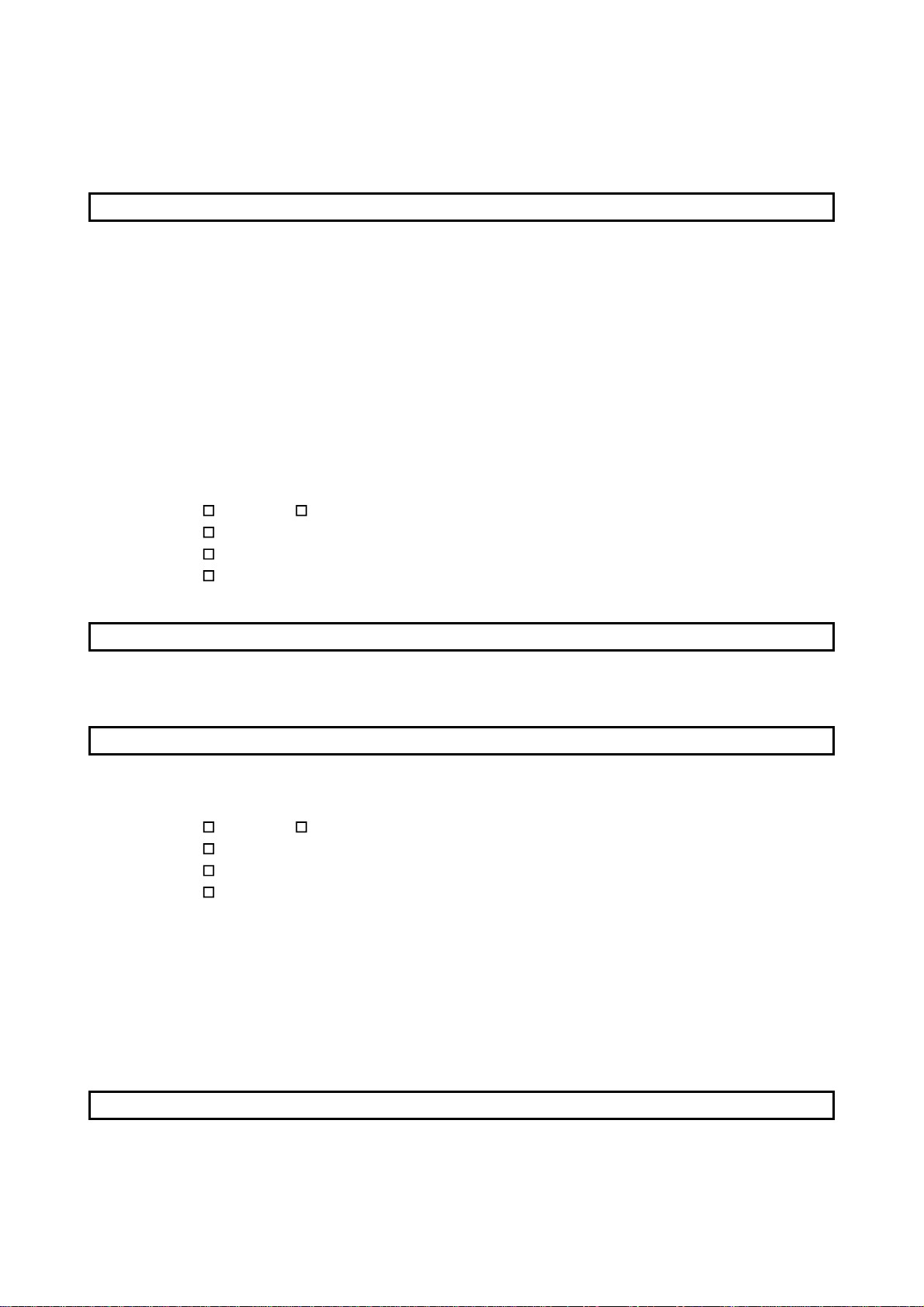

(3) Test run adjustment

CAUTION

• Before operat ion, c heck the param eter s ettings. Im proper set tings ma y cause s ome mac hines to p erform

unexpected operation.

• The parameter settings must not be changed excessively. Operation will be insatiable.

A - 4

(4) Usage

CAUTION

• Provide an external em ergency stop circ uit to ensur e that oper ation can b e stopped and power s witched

off immediately.

• Any person who is involved in disassembly and repair should be fully competent to do the work.

• Do not modify the equipment.

• Use a noise f ilter , etc . to m in im ize t he inf luenc e of el ectromagnetic inter fere nce , whic h m a y be c ause d by

electronic equipment used near the servo amplifier.

(5) Corrective actions

CAUTION

• When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

(6) Maintenance, inspection and parts replacement

CAUTION

• With age, the electrol ytic capacitor will deteriora te. To prevent a secondar y accident due to a fault, it is

recommended to replace the electrolytic capacitor every 10 years when used in general environment.

Please consult our sales representative.

(7) Disposal

CAUTION

• Dispose of the product as general industrial waste.

(8) General instruction

• To illustrate details , th e equ i pment in the d ia grams of this Specifications a nd Ins truction Manu al may have

been drawn withou t covers and safety guards. W hen the equipment is op erated, the covers and safety

guards must be installed as specified. Operation must be performed in accordance with this Specifications

and Instruction Manual.

A - 5

COMPLIANCE WITH EC DIRECTIVES

EN Standard-compliant models are scheduled for release.

CONFORMANCE WITH UL/C-UL STANDARD

UL/C-UL Standard-compliant models are scheduled for release.

<About the Manuals>

If it is the first time for you to use this servo, the optionally available Instruction Manual and Servo Motor

Instruction Manual are required in addition to this Specifications and Installation Guide. Always purchase them

and use the servo safely.

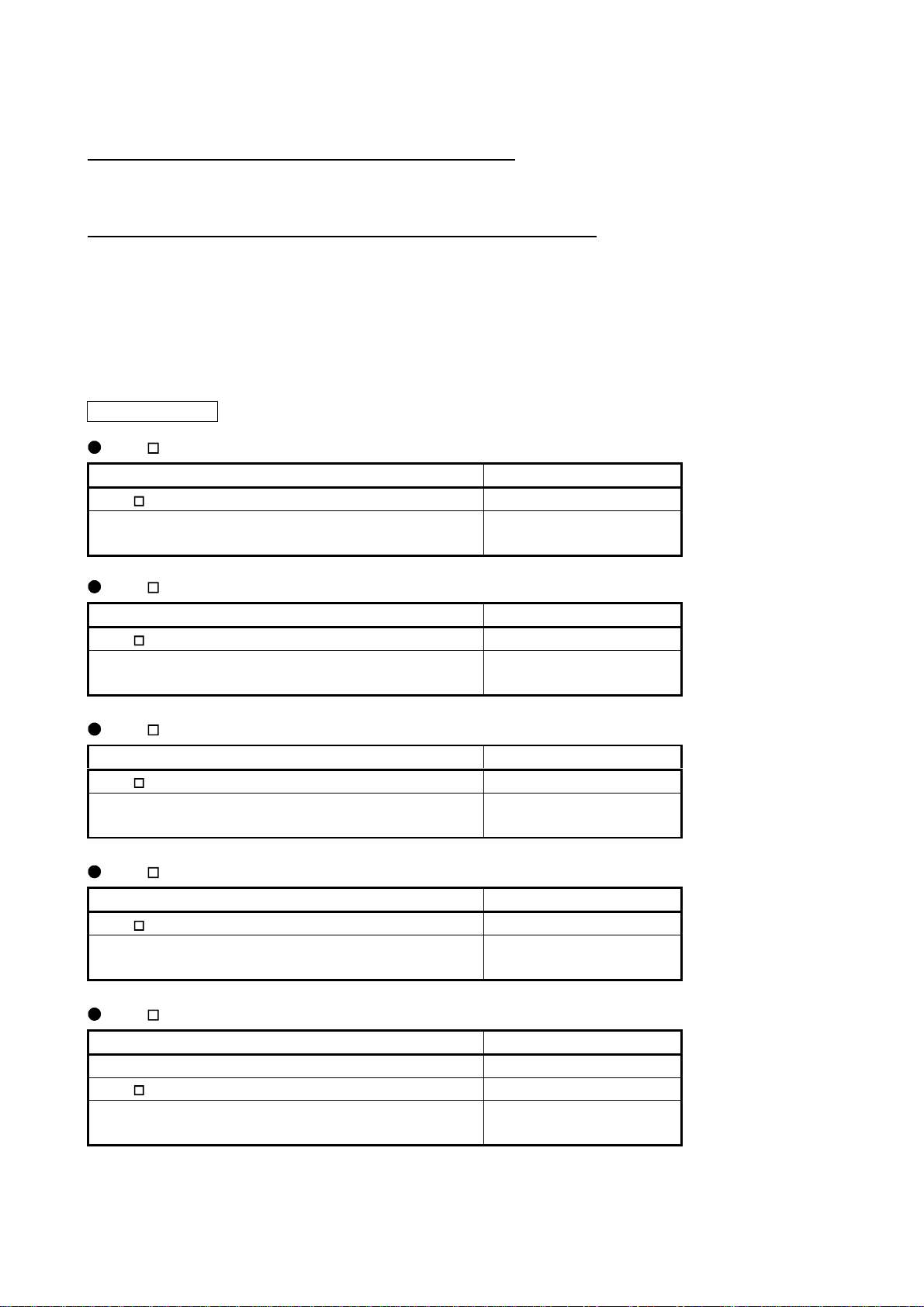

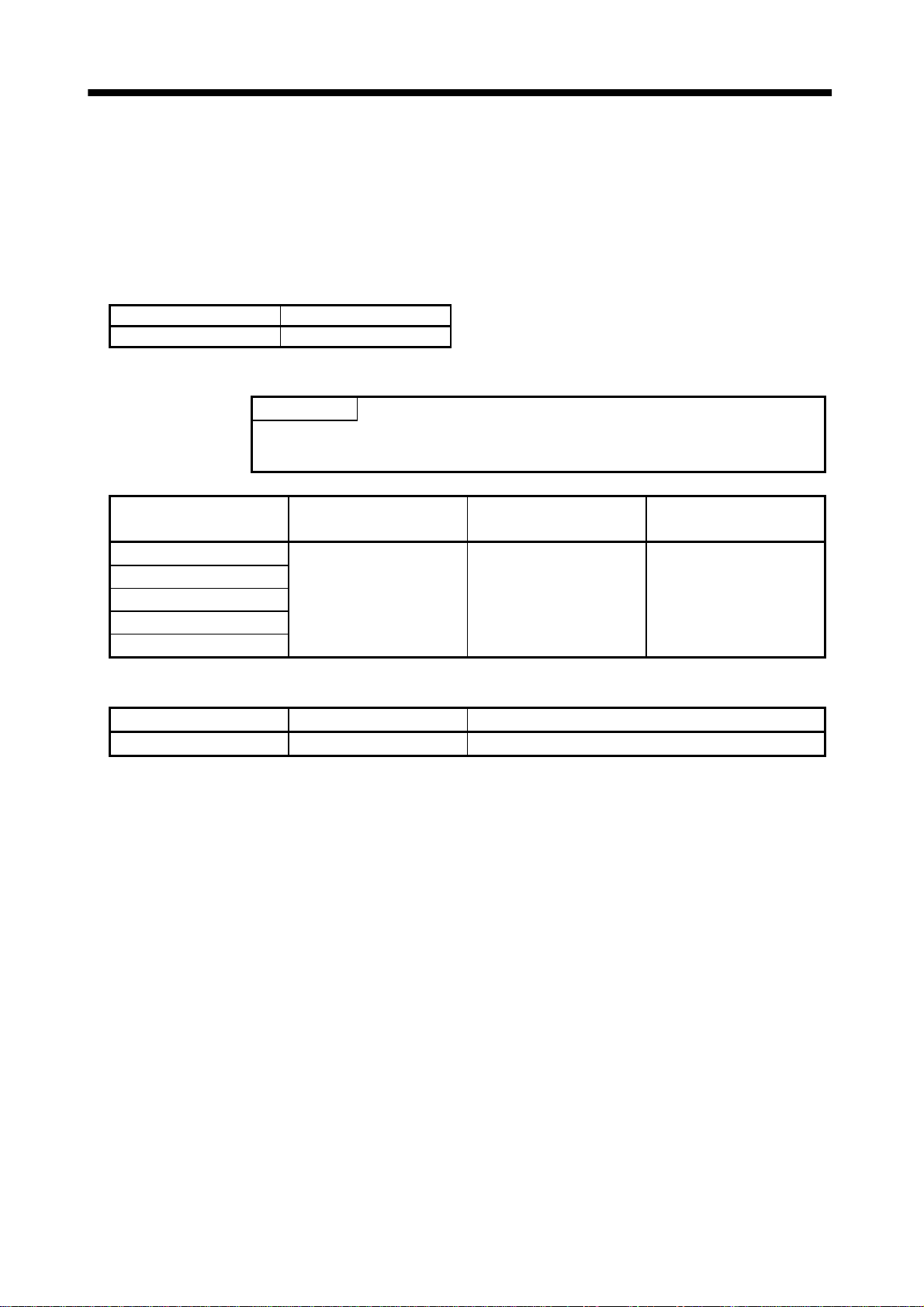

Relevant manuals

MR-H AN

Manual Name Manual No.

MR-H AN Servo Amplifier Instruction Manual SH(NA)3190

MELSERVO Servo Motor Instruction Manual

MR-H BN

SH(NA)3181

(Sub number B or later)

Manual Name Manual No.

MR-H BN Servo Amplifier Instruction Manual SH(NA)3192

MELSERVO Servo Motor Instruction Manual

SH(NA)3181

(Sub number B or later)

MR-H ACN

Manual Name Manual No.

MR-H ACN Servo Amplifier Instruction Manual SH(NA)3198

MELSERVO Servo Motor Instruction Manual

SH(NA)3181

(Sub number B or later)

MR-H TN

Manual Name Manual No.

MR-H TN Servo Amplifier Instruction Manual Scheduled for making

MELSERVO Servo Motor Instruction Manual

SH(NA)3181

(Sub number B or later)

MR-H DN

Manual Name Manual No.

MR-H-D-UE Installation Guide IB(NA)67327

MR-H AN Servo Amplifier Instruction Manual SH(NA)3190

MELSERVO Servo Motor Instruction Manual

SH(NA)3181

(Sub number B or later)

A - 6

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1 - 1 to 1 - 12

1.1 Packing list..............................................................................................................................................1 - 1

1.2 Overview..................................................................................................................................................1 - 1

1.3 Function block diagram .........................................................................................................................1 - 1

1.4 Standard specification............................................................................................................................1 - 4

1.4.1 Converter unit..................................................................................................................................1 - 4

1.4.2 Servo amplifier.................................................................................................................................1 - 4

1.5 Model definition......................................................................................................................................1 - 5

1.5.1 Rating plate......................................................................................................................................1 - 5

1.5.2 Model.................................................................................................................................................1 - 5

1.6 Combination with converter unit • servo motor .................................................................................1 - 5

1.7 Parts identification.................................................................................................................................1 - 6

1.7.1 MR-HP-30KA...................................................................................................................................1 - 6

1.7.2 MR-H

1.7.3 MR-H

1.7.4 MR-H

1.7.5 MR-H

1.8 Servo system with auxiliary equipment..............................................................................................1 -11

AN•MR-H DN................................................................................................................1 - 7

BN.......................................................................................................................................1 - 8

ACN....................................................................................................................................1 - 9

TN......................................................................................................................................1 -10

2. INSTALLATION 2 - 1 to 2 - 2

2.1 Environmental conditions......................................................................................................................2 - 1

2.2 Installation direction and clearances ...................................................................................................2 - 2

3. SIGNALS AND WIRING 3 - 1 to 3 - 16

3.1 Connectors and signal layouts ..............................................................................................................3 - 2

3.1.1 MR-HP30KA ....................................................................................................................................3 - 2

3.1.2 MR-H

3.1.3 MR-H

3.1.4 MR-H

3.1.5 MR-H

3.1.6 Explanation of signals.....................................................................................................................3 - 9

3.2 Power line circuit...................................................................................................................................3 -10

3.2.1 Connection example........................................................................................................................3 -11

3.2.2 Terminal ..........................................................................................................................................3 -12

3.2.3 How to use the connection bars.....................................................................................................3 -12

3.2.4 Power-on sequence..........................................................................................................................3 -13

3.3 Servo motor side details........................................................................................................................3 -14

3.4 Grounding...............................................................................................................................................3 -15

AN•MR-H DN................................................................................................................3 - 3

BN.......................................................................................................................................3 - 4

ACN....................................................................................................................................3 - 5

TN.......................................................................................................................................3 - 7

4. DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT 4 - 1 to 4 - 8

4.1 Display flowchart....................................................................................................................................4 - 1

4.2 Status display mode...............................................................................................................................4 - 2

- 1 -

4.2.1 Display exapmles.............................................................................................................................4 - 2

4.2.2 Status display list............................................................................................................................4 - 2

4.3 Diagnostic mode......................................................................................................................................4 - 3

4.3.1 Diagnostic list...................................................................................................................................4 - 3

4.3.2 External output signal indication..................................................................................................4 - 3

4.3.3 Output signal forced output............................................................................................................4 - 4

4.4 Alarm mode.............................................................................................................................................4 - 5

4.5 Parameter mode .....................................................................................................................................4 - 6

4.5.1 Operation example...........................................................................................................................4 - 6

4.5.2 Parameter list ..................................................................................................................................4 - 7

5. INSPECTION 5 - 1 to 5- 2

5.1 Inspection ................................................................................................................................................5 - 1

5.2 Life ...........................................................................................................................................................5 - 1

6. TROUBLESHOOTING 6 - 1 to 6 - 4

6.1 Servo amplifier........................................................................................................................................6 - 1

6.1.1 Alarm codes ......................................................................................................................................6 - 1

6.1.2 Alarm corrective actions .................................................................................................................6 - 1

6.2 Converter unit.........................................................................................................................................6 - 2

6.2.1 Alarms and warning list .................................................................................................................6 - 2

6.2.2 Remedies for alarms........................................................................................................................6 - 2

6.2.3 Remedies for warnings....................................................................................................................6 - 4

6.2.4. Cleaning the alarm history............................................................................................................6 - 4

7. OUTLINE DIMENSIONAL DRAWINGS 7 - 1 to 7 - 6

7.1 Converter unit (MR-HP30KA) ..............................................................................................................7 - 1

7.2 Servo amplifier........................................................................................................................................7 - 2

7.3 Connector.................................................................................................................................................7 - 4

8. CHARACTERISTICS 8 - 1 to 8 - 4

8.1 Overload protection characteristics......................................................................................................8 - 1

8.2 Power supply equipment capacity and generated loss .......................................................................8 - 2

8.3 Dynamic brake characteristics..............................................................................................................8 - 3

9. OPTIONS AND AUXILIARY EQUIPMENT 9 - 1 to 9 - 16

9.1 Option ......................................................................................................................................................9 - 1

9.1.1 Regenerative brake option..............................................................................................................9 - 1

9.1.2 External dynamic brake..................................................................................................................9 - 5

9.1.3 Cables and connecotors...................................................................................................................9 - 7

9.1.4 Heat sink outside mounting attachment (MR-ACN) ...................................................................9 - 9

9.1.5 MR-H-D01 option card ...................................................................................................................9 -10

- 2 -

9.2 Auxiliary equipment..............................................................................................................................9 -11

9.2.1 Recommended wires.......................................................................................................................9 -11

9.2.2 No-fuse breakers, magnetic contactors.........................................................................................9 -12

9.2.3 DC reactor........................................................................................................................................9 -12

9.2.4 Noise reduction products ...............................................................................................................9 -13

9.2.5 Leakage current breaker................................................................................................................9 -14

APPENDIX App - 1 to App - 10

APPENDIX 1. 200VAC 37kW SERVO (MR-H37K )......................................................................... App - 1

Appendix 1.1 Precautions for use.......................................................................................................App - 1

Appendix 1.2 Packing list....................................................................................................................App - 1

Appendix 1.3 Standard specifications................................................................................................App - 2

Appendix 1.4 Model code.....................................................................................................................App - 3

Appendix 1.5 Combination with converter unit................................................................................ App - 4

Appendix 1.6 Installation....................................................................................................................App - 4

Appendix 1.7 Outline dimensional drawing...................................................................................... App - 5

Appendix 1.8 Characteristics..............................................................................................................App - 7

Appendix 1.9 Option and auxiliary equipment................................................................................. App - 8

Appendix 1.10 Auxiliary equipment..................................................................................................App - 9

- 3 -

MEMO

- 4 -

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Packing list

After unpacking , check the name plate to m ake sure th at the Conv erter unit re ceived are as ordered by

the customer.

(1) Converter unit

Model Converter unit

MR-HP30KA 1

(2) Servo amplifier

POINT

• The regenerative brake resistor is not packed with the servo amplifier.

Always purchase the regenerati ve brake option. (Refer to Section 9.1.1.)

Model Servo Amplifier Connection conductors

MR-H-30KAN

MR-H30KBN

MR-H30KACN

MR-H30KTN

MR-H30KDN

121

Specification and Installtion

Guide

(3) Servo motor

Model Servo motor [pcs.] T O USE THE AC SERVO SAFELY

HA-LF30K2 1 1

1.2 Overview

The 30kW large-capacity type is newly available a s the Mitsubishi MELSER VO-H serie s general-purpo se

AC servo. This type is applicable to the fields where the same servo functions are used but a larger

capacity is necessary.

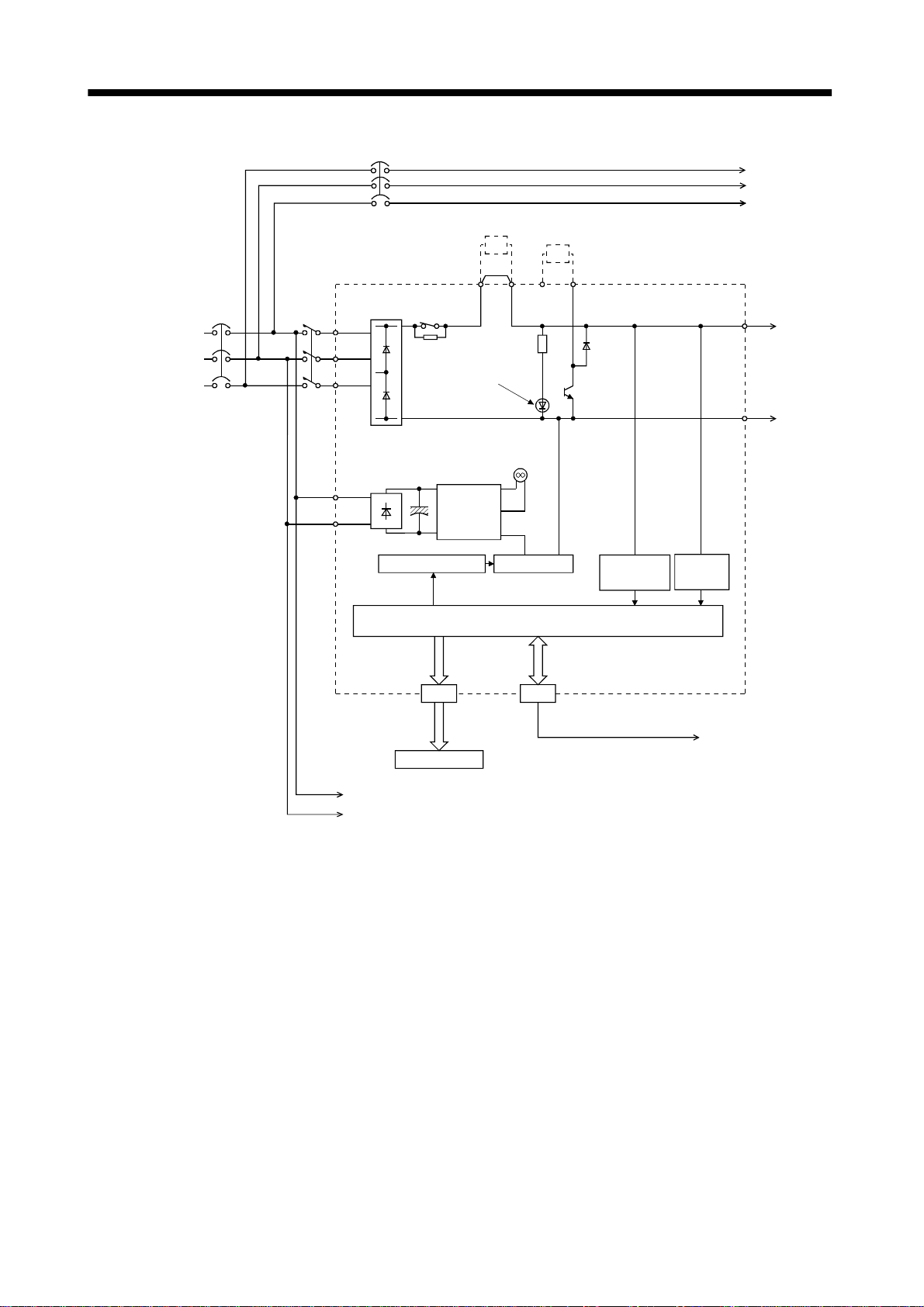

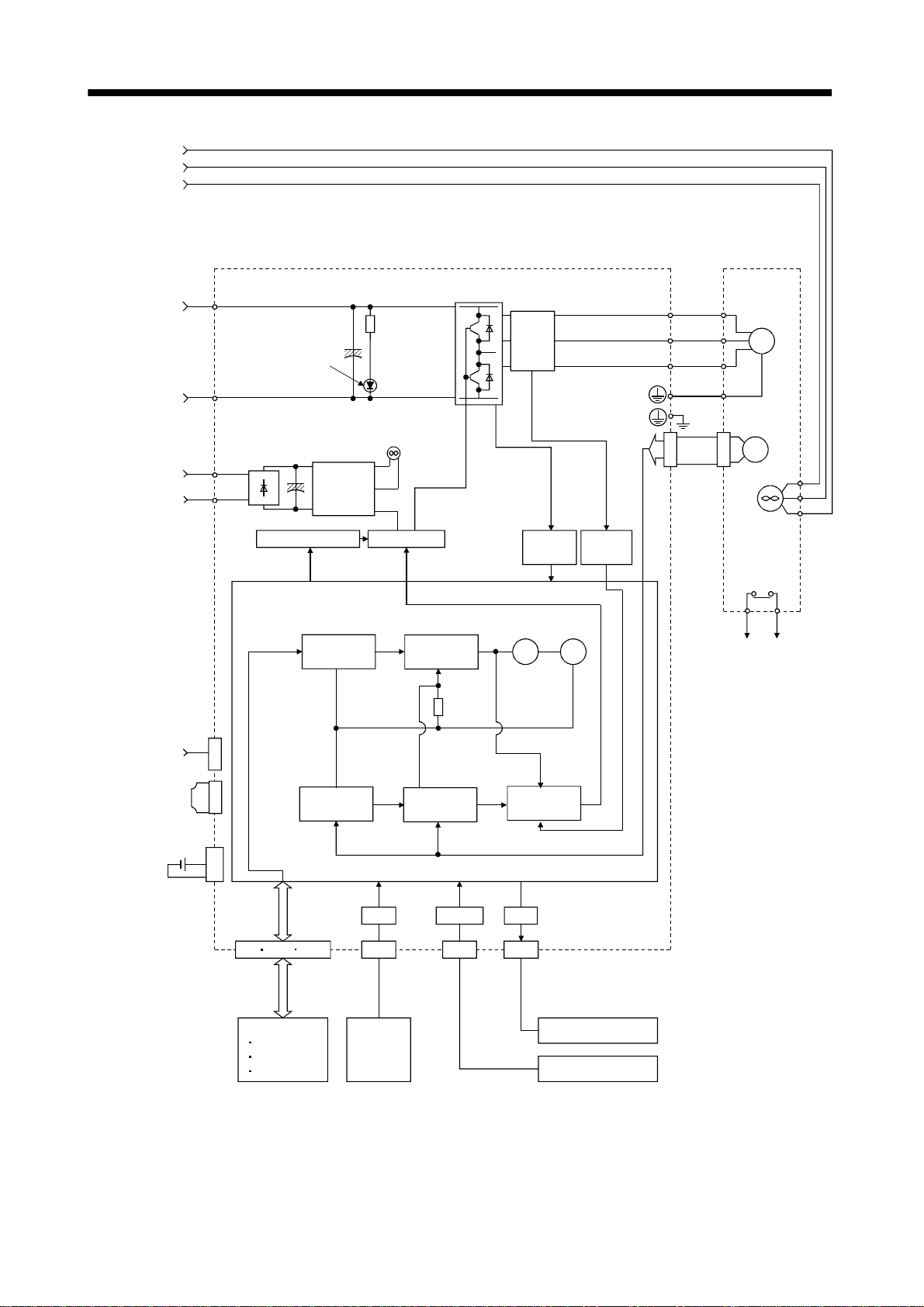

1.3 Function block diagram

The function block diagram of the Servo is shown on the next page.

1 - 1

1. FUNCTIONS AND CONFIGURATION

NFB

DCL

Regenerative brake option

BU

BV

BW

Power Suply

3-phase

200VAC

to 230VAC

NFB MC

Converter unit

DS RA

L1

L2

L3

L11

L21

Regenerative brake

P1 P2 P

CHARGE

lamp

Fan

Control

power

supply

Base amplifier

I/F

CN1 CN5

Trouble

C

Voltage

detection

CPU

Converter-servo amplifier

protection coordination

Overcurrent

protection

CN5A

P

P

N

N

L11

L12

1 - 2

1. FUNCTIONS AND CONFIGURATION

BU

BV

BW

L11

L12

Servo amplifier(Note)

P

P

N

N

L11

L12

CHARGE

lamp

Regenerative brake

(Note)

Pulse input

Control

power

supply

Model position

control

Fan

Base amplifier

Model speed

control

Current

detector

Overcurrent

protection

Virtual

motor

Virtual

encoder

Current

detection

Servo motor

U

U

V

V

SM

W

W

CN2

Encoder

BU

BV

BW

Fan

Thermal relay

OHS1

OHS2

CN5A

MR-A-TM

termination

connector

(Option)

MR-BAT

Optional battery

(for absolute posidtion)

Note: For MR-H-AN

CN5A

CN5B

CN5

CN1 CN11 CN12

(Note)

D I/O control

Servo on

Start

Failure,etc

Model position Model speed

Actual position

control

A/D

I/F

CN1 CN4 CN3

Analog

2ch

Actual speed

control

RS-232C

Model touque

Current control

D/A

Analog monitor 2CH

Parameter uni t

1 - 3

1. FUNCTIONS AND CONFIGURATION

1.4 Standard specificati on

1.4.1 Converter unit

Model

Item

Voltage/frequency 3-phase 200 to 230VAC, 50/60Hz

Main circuit

power supply

Control power

supply

Rated output 30kw

Regenerative power

(Using regenerative brake option)

Protective function

Structure Open(IP00)

Environment

Weight [Kg] [lb] 22 [48.502]

Permissible voltage

fluctuation

Permissible frequency

fluctuation

Voltage/frequency 1-phase 200 to 230VAC, 50/60Hz

Permissible voltage

fluctuation

Permissible frequency

fluctuation

Power consumption 50W

Ambient tempera ture

Ambient humidity 90%RH or less (non-condensing)

Storage temperture

Storage humi d i t y 90%RH or les s (non-condens i ng )

Ambient

Altitud Max. 1000m (3280 ft) above sea level

Vibration

3-phase 170 to 253VAC, 50/60Hz

Within

1-phase 170to 235VAC, 50/60Hz

Within

One MR-RB139: 1300W

Three MR-RB139s: 3900W

Regenerative overvoltage shutoff, overload shutoff (electronic thermal protector)

Regenerative alarm protection, undervoltage, instantaneous power failure protection

0 to 55 [°C] (non-freezing)

32 to

Indoors (no direct sunligh t )

Free from corrosive gas, flammable gas, oil mist, dust and dirt

5.9 [m/s2] or less

19.4 [ft/s

5%

5%

131 [°F] (non-freezing)

20 to 65 [°C] (non-freezing)

4 to 149 [°F] (non-freezing)

2

MP-HP30K

] or less

1.4.2 Servo amplifier

Servo amplifier

Item

Voltage/frequency Single-phase 200 to 230VAC, 50/60Hz

Permissible voltage

Control power

supply

Main circuit power supply The main circuit power of the servo amplifier is supplied by the converter unit.

System Sine-wave PWM control, current control system

Structure Open (IP00)

Environment

Weight Kg [lb] 47 [103.617]

Function Refer to the corresponding Servo Amplifier Instruction Manual of 22kW or less.

fluctuaion

Permissible frequency

fluctuation

Power consumption 50W

Ambient tempera ture 0 to 55 [°C] (non-freezing), storage: 20 to 65 [°C] (no n -free zin g )

Humidity 90%RH or less (non-condensing), storage: 90%RH or less (non-condensing)

Ambience

Altitude Max. 1000m (3280ft) above sea level

Vibration 5.9 [m/s

Single-phase 170 to 253VAC, 50/60Hz

Within

Indoors (no direct sunligh t )

Free from corrosive gas, flammable gas, oil mist, dust and dirt

5%

2

] or less

MR-H30K

1 - 4

1. FUNCTIONS AND CONFIGURATION

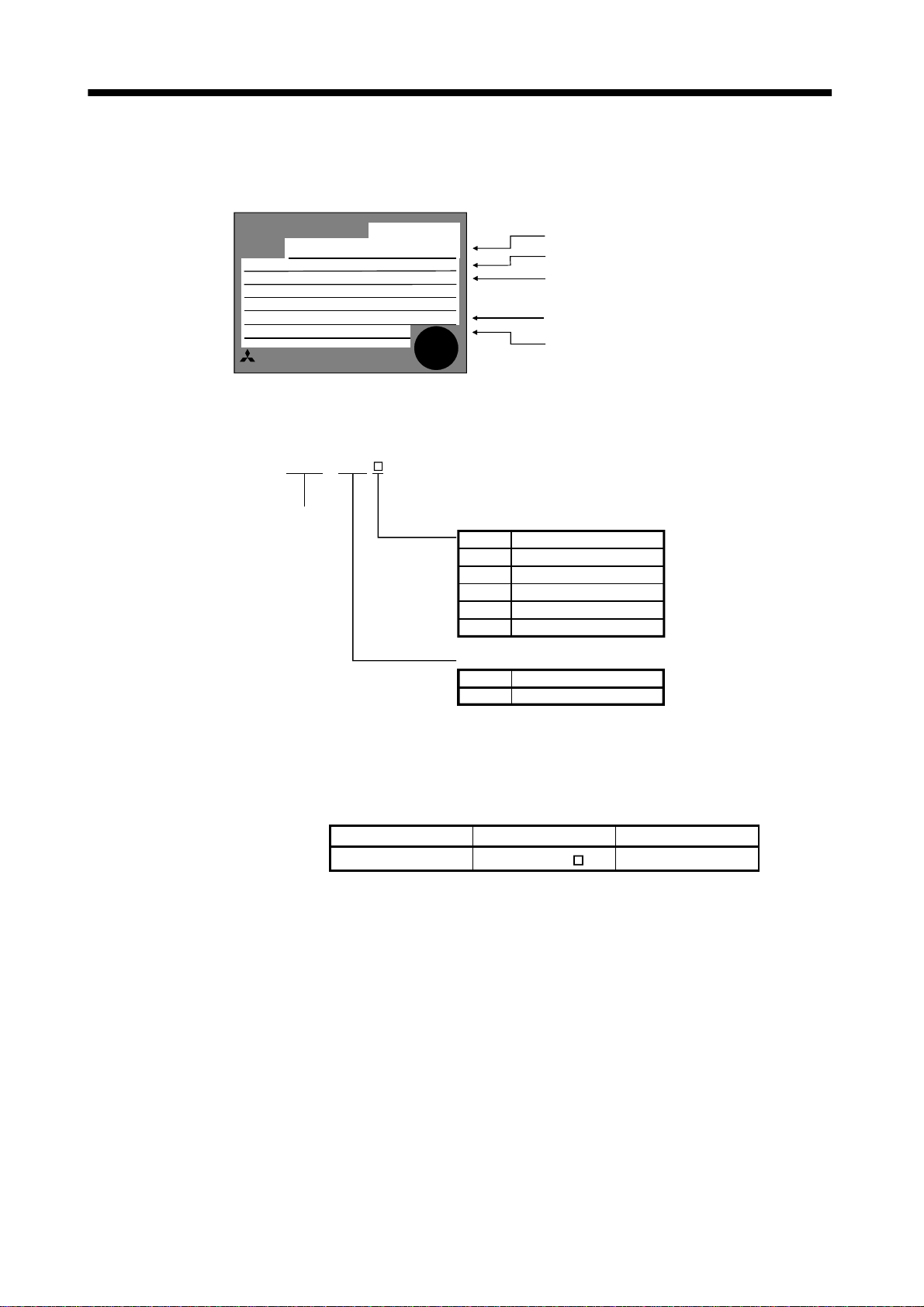

1.5 Model definition

1.5.1 Rating plate

1.5.2 Model

MITSUBISHI

MODEL

POWER

MR-H30KA

POWER :

INPUT :

OUTPUT :

SERIAL :

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

30kW

AC200V-230V 50/60Hz

A

TC300A156G54

MR-H

30

Series name

AC SERVO

AC SERVO

PASSED

Symbol

AN

General-Purpose Interface

BN

Positioning function built-in

ACN

TN

DN

Rated output

Symbol

30K

Model

Capacity

Applicable power supply

Rated output current

Serial number

Servo Type

SCCNET-compatible

CC-Link-compatible

Source I/O

Output [kW]

30

1.6 Combination with converter unit • servo motor

The following table table lists combinations of Convert er unit • servo amplifi ers and s ervo motors.

Converter unit Servo amplifier Servo motor

MR-HP30KA MR-H30K HA-LF30K2

1 - 5

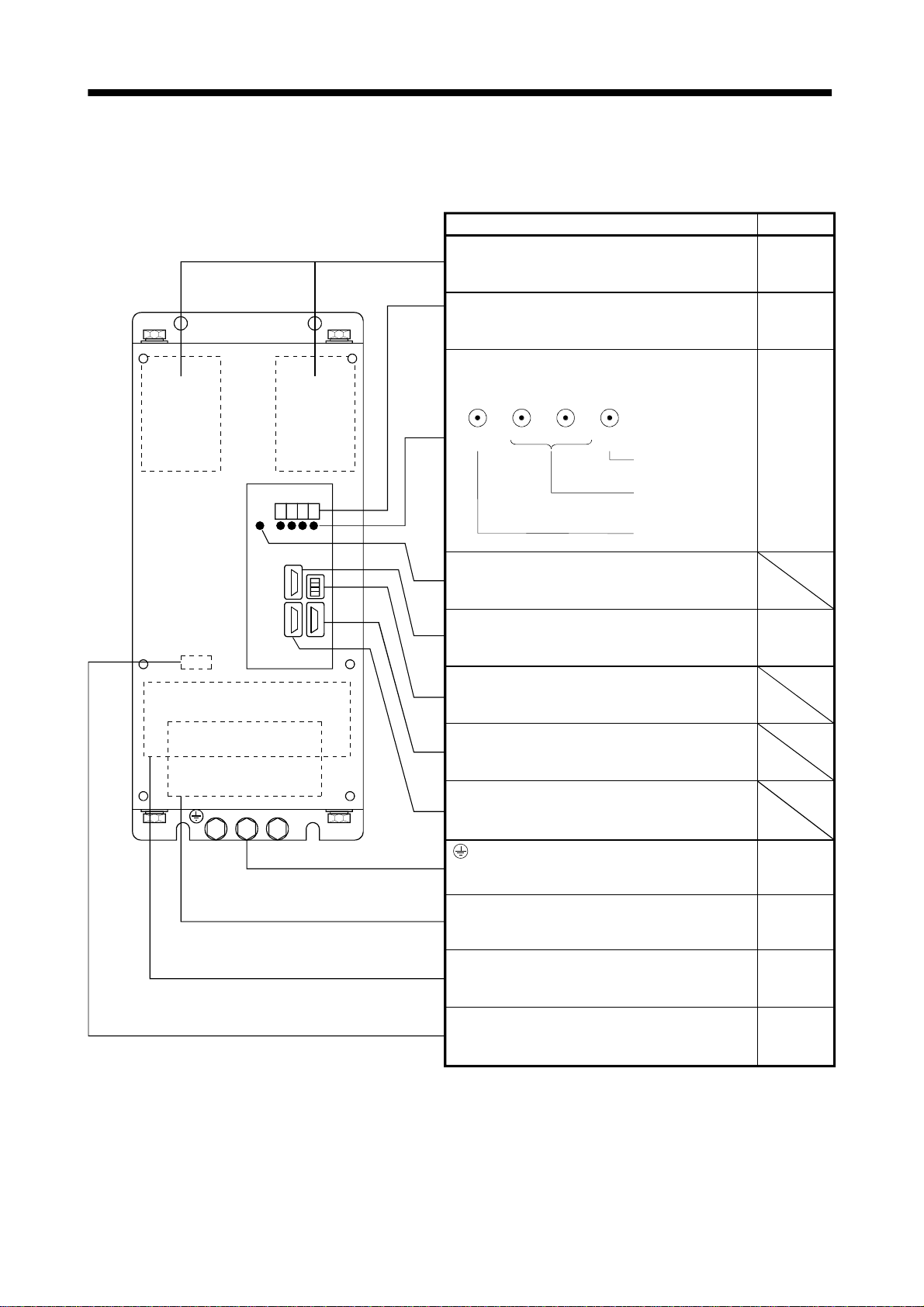

1. FUNCTIONS AND CONFIGURATION

1.7 Parts identification

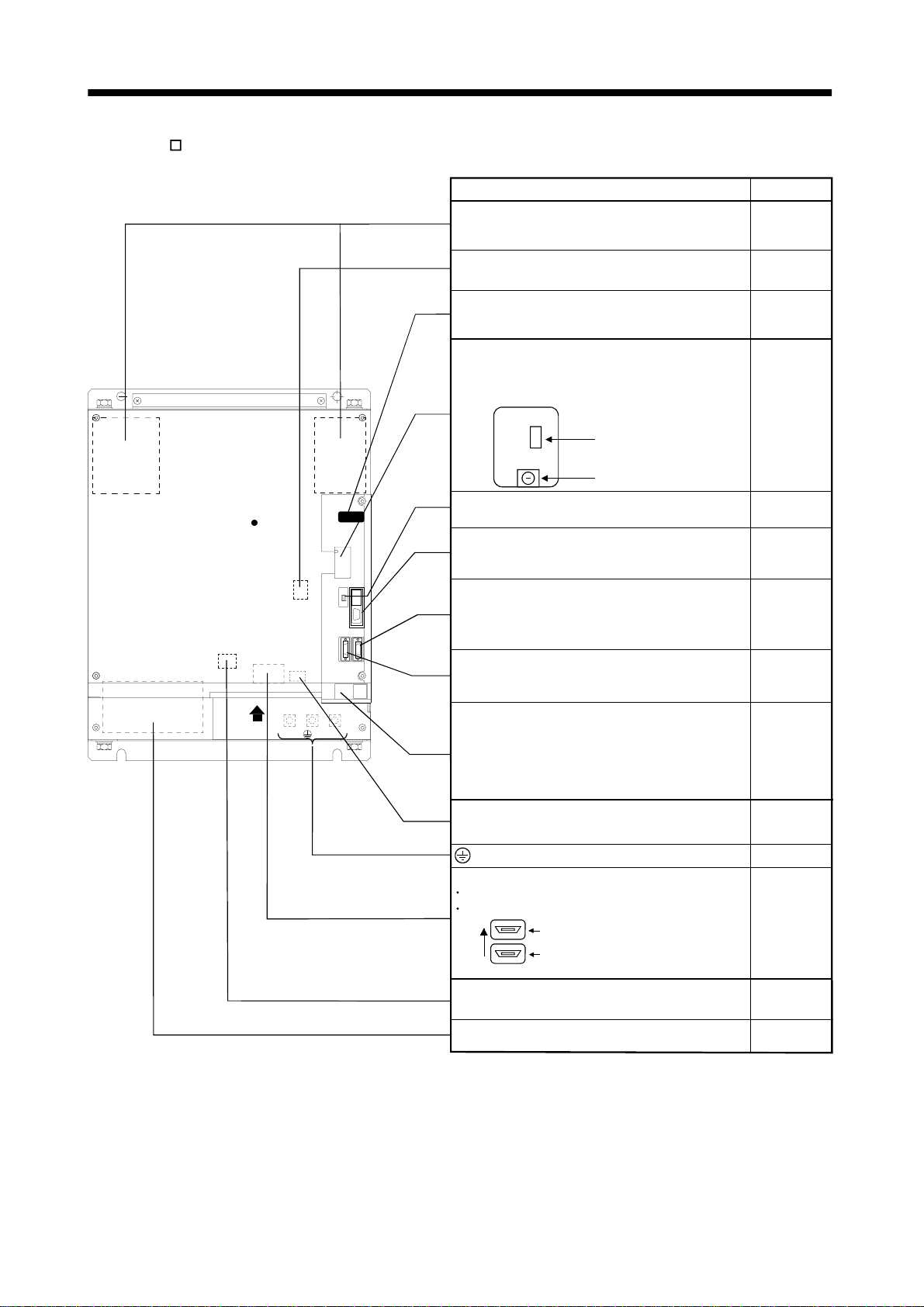

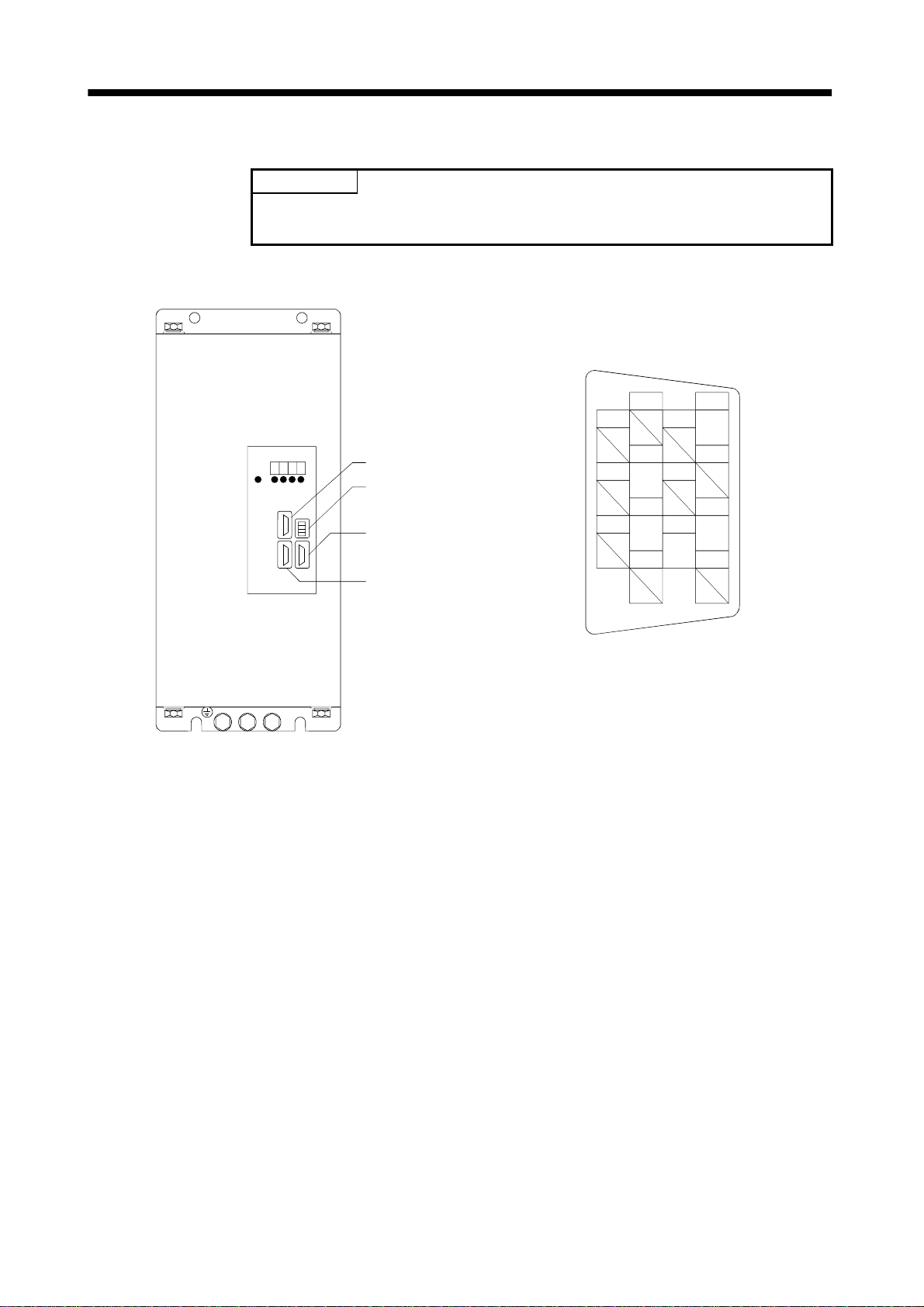

1.7.1 MR-HP-30KA

TE2-1 TE2-2

TE3

TE1-1

Name/Application

TE2-1, TE2-2 (PN terminals)

Connect to the servo amplifier using the connection

conductors supplied to the servo amplifier.

Display

The four-digit, seven-segment LED shows the servo

status and alarm number.

Operation section

Used to perform status display, diagnostic, alarm and

parameter point table operations.

MOVE UP

Charge lamp

Lit to indicate that the main circuit is charged. While

this lamp is lit, do not reconnect the cables.

CN1

Outputs an alarm signal.

CN3

For maker adjustment. Leave this open.

DOWN

SET

Used to set data.

Used to change the

display data in each

mode.

Used to change the

mode.

Refer To

Section

3.2.2(1)

Chapter 4

Chapter 4

Section 3.1.2

TE1-2

CN6

For maker adjustment. Leave this open.

CN5

Connect to CN5A of the servo amplifier.

(Ground terminal)

TE1-2

Supply main circuit power.

TE1-1

Connect the regenerative brake option or DC reactor.

TE3

Supply control circuit power.

Section 3.2.2

Section 3.2.2

Section 3.2.2

Section 3.2.2

1 - 6

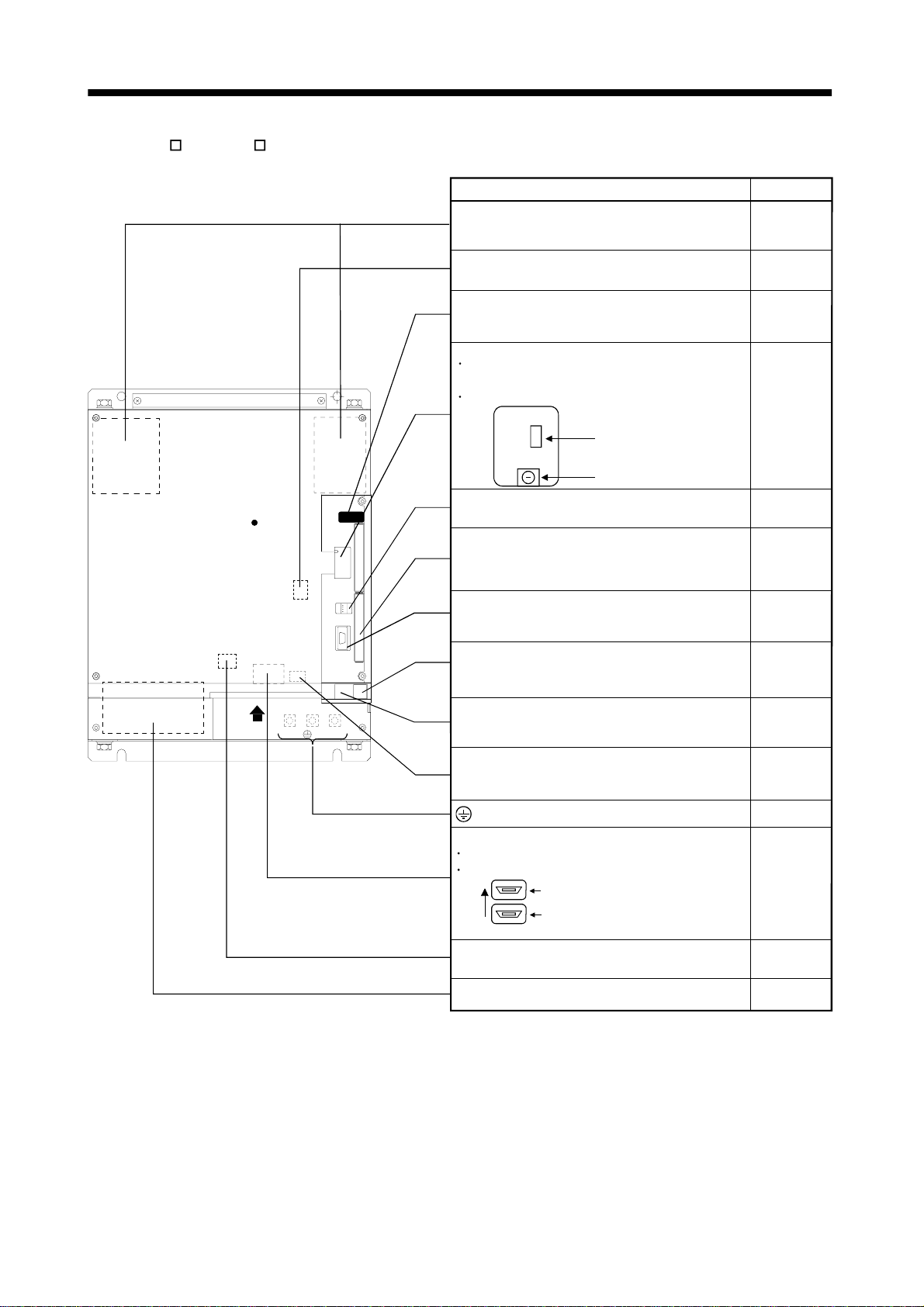

1. FUNCTIONS AND CONFIGURATION

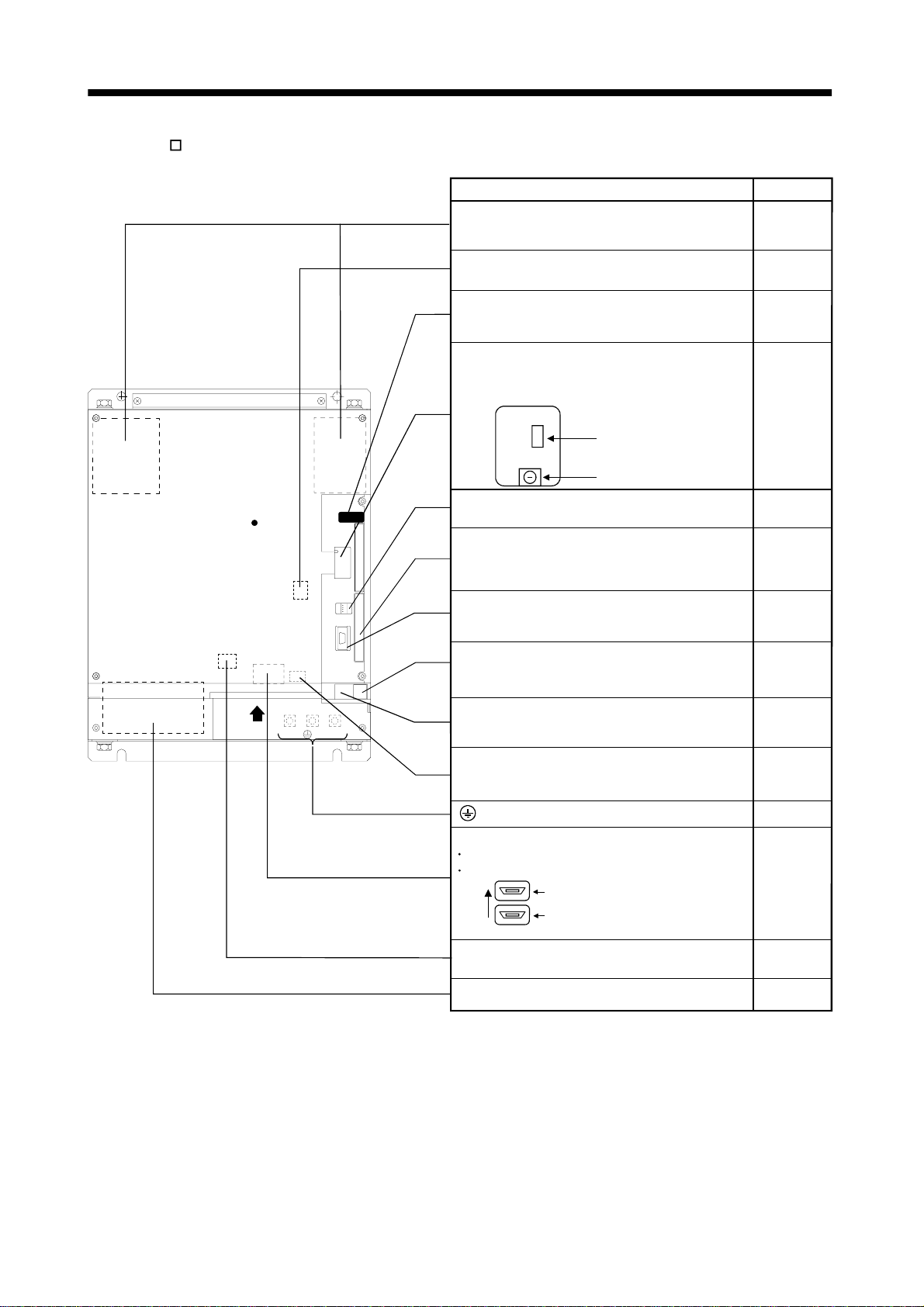

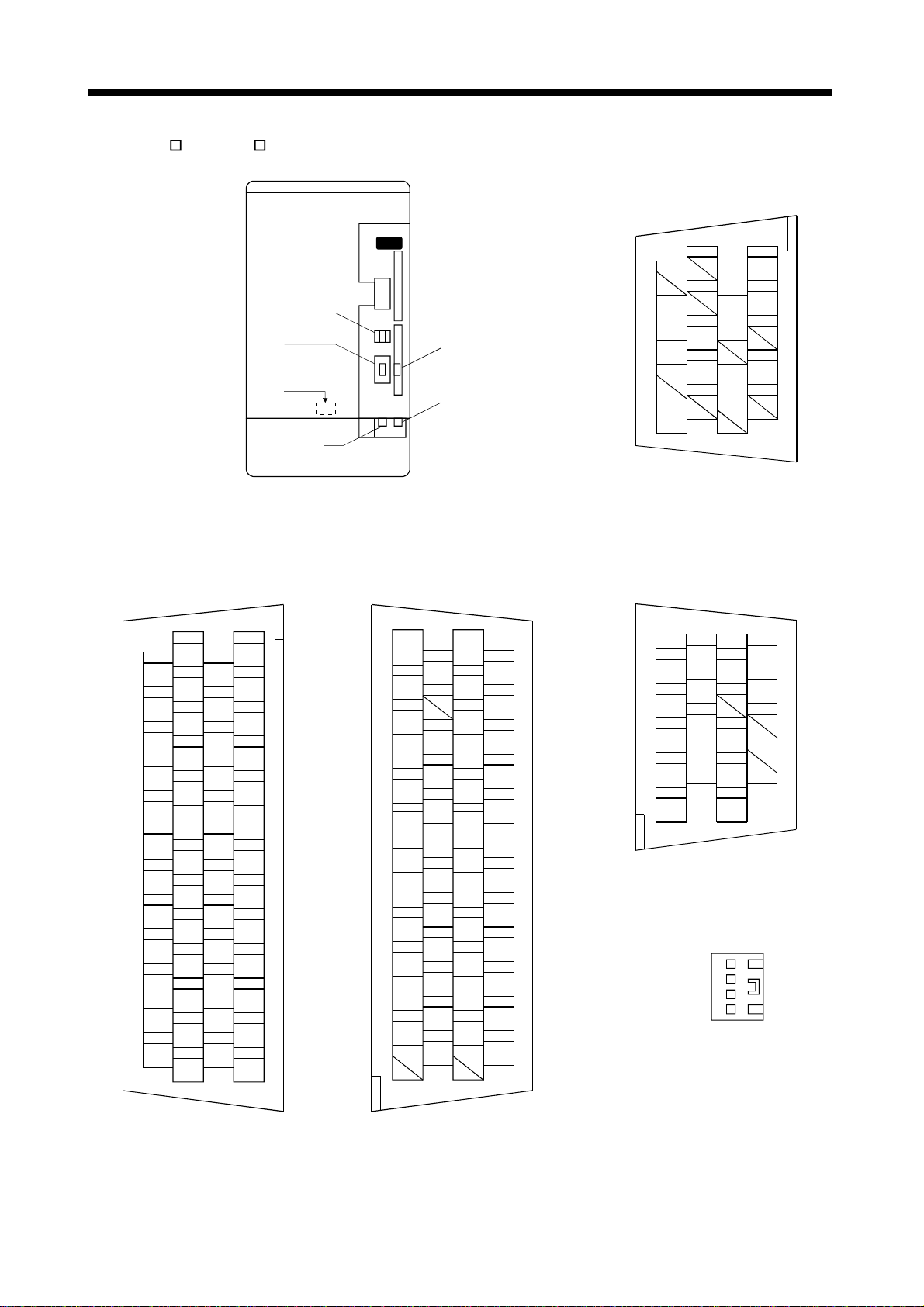

1.7.2 MR-H AN•MR-H DN

TE2-1

TE1

Charge lamp

a

TE2-2

CN3

CN4

CN1

Name/Application

TE2-1, TE2-2 (PN terminals)

Connect to the PN terminals of the converter unit

using the connection conductors supplied.

Battery holder

Contains the battery for absolute position data backup.

Display

The four-digit, seven-segment LED shows the servo

status and alarm number.

Switch window

CN5 : Connector for connection of the battery for

absolute position detection

CS1 : Status indication select switch

CN5

CS1

CN3 (Analog monitor output connector)

Used to output an analog monitor signal.

CN12 (MR-H-D01 option card)

Used to input an auxiliary pulse train when the

MR-H-D01 option card is loaded.

CN4 (Communication connector)

Used for connection with the MR-PRU01A/personal

computer.

CN11 (MR-H-D01 option card)

Used to connect extra digital I/O signals when the

MR-H-D01 option card is loaded.

CN1 (I/O signal connector)

Used to connect digital I/O signals.

CN2 (Encoder connector)

Connector for connection of the servo motor encoder.

(Ground terminal)

CN5A, CN5B (Converter unit connectors)

CN5A: Connect to CN5 of the converter unit.

CN5B: Connect the termination connector (MR-A-TM).

CN5A

Front

CN5B

View a

TE3 (Control circuit terminal)

Supply control circuit power.

TE1

Connect to U, V, W of the servo motor.

Refer To

Section 3.2.2

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 3.1.2

Section 9.1.5

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 3.1.2

Section 9.1.5

Servo Amplifier

Instruction

Manual

Section 3.1.2

Servo Amplifier

Instruction

Manual

Section 3.1.2

Servo Amplifier

Instruction

Manual

Section 3.2.2

Section 3.2.1

Section 3.2.2

Section 3.2.2

1 - 7

1. FUNCTIONS AND CONFIGURATION

1.7.3 MR-H BN

TE2-1

TE1

Charge lamp

a

TE2-2

CN3

CN6

CN4

CN1BCN1A

Name/Application

TE2-1, TE2-2 (PN terminals)

Connect to the PN terminals of the converter unit

using the connection conductors supplied.

Battery holder

Contains the battery for absolute position data backup.

Display

The four-digit, seven-segment LED shows the servo

status and alarm number.

Switch window

· CN5: Connector for connection of the battery for

absolute position detection

· CN1: Axis select switch

CN5

CS1

CN3 (Analog monitor output connector)

Used to output an analog monitor signal.

CN4 (Communication connector)

Used for connection with the MR-PRU01A/personal

computer.

CN1B (Bus cable connector)

Used to connect a bus cable which links with a

subsequent axis servo amplifier or termination

controller.

CN1A (Bus cable connector)

Used to connect a bus cable which links with a

controller or preceding-axis servo amplifier.

CN6 (I/O signal connector)

Connect the CN6 connector which comes standard.

The CN6 connector is shorted between EM1-EM2.

When making up an emergency stop circuit externally,

open EM1-EM2 and connect an external emergency

stop switch across them.

CN2 (Encoder connector)

Connector for connection of the servo motor encoder.

(Ground terminal)

CN5A, CN5B (Converter unit connectors)

CN5A: Connect to CN5 of the converter unit.

CN5B: Connect the termination connector (MR-A-TM).

CN5A

Front

CN5B

View a

TE3 (Control circuit terminal)

Supply control circuit power.

TE1

Connect to U, V, W of the servo motor.

Refer To

Section 3.2.2

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 3.1.3

Servo Amplifier

Instruction

Manual

Section 3.1.3

Servo Amplifier

Instruction

Manual

Section 3.2.2

Section 3.2.1

Section 3.2.2

Section 3.2.2

1 - 8

1. FUNCTIONS AND CONFIGURATION

1.7.4 MR-H ACN

TE2-1

TE1

Charge lamp

a

TE2-2

CN3

CN4

CN1

Name/Application

TE2-1, TE2-2 (PN terminals)

Connect to the PN terminals of the converter unit

using the connection conductors supplied.

Battery holder

Contains the battery for absolute position data backup.

Display

The four-digit, seven-segment LED shows the servo

status and alarm number.

Switch window

CN5 : Connector for connection of the battery for

x

absolute position detection

CS1 : Status indication select switch

x

CN5

CS1

CN3 (Analog monitor output connector)

Used to output an analog monitor signal.

CN12 (MR-H-D01 option card)

Used to input an auxiliary pulse train when the

MR-H-D01 option card is loaded.

CN4 (Communication connector)

Used for connection with the MR-PRU01A/personal

computer.

CN11 (MR-H-D01 option card)

Used to connect extra digital I/O signals when the

MR-H-D01 option card is loaded.

CN1 (I/O signal connector)

Used to connect digital I/O signals.

CN2 (Encoder connector)

Connector for connection of the servo motor encoder.

(Ground terminal)

CN5A, CN5B (Converter unit connectors)

CN5A: Connect to CN5 of the converter unit.

CN5B: Connect the termination connector (MR-A-TM).

CN5A

Front

CN5B

View a

TE3 (Control circuit terminal)

Supply control circuit power.

TE1

Connect to U, V, W of the servo motor.

Refer To

Section 3.2.2

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 9.1.5

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 9.1.5

Servo Amplifier

Instruction

Manual

Section 3.1.4

Servo Amplifier

Instruction

Manual

Section 3.1.4

Servo Amplifier

Instruction

Manual

Section 3.2.2

Section 3.2.1

Section 3.2.2

Section 3.2.2

1 - 9

1. FUNCTIONS AND CONFIGURATION

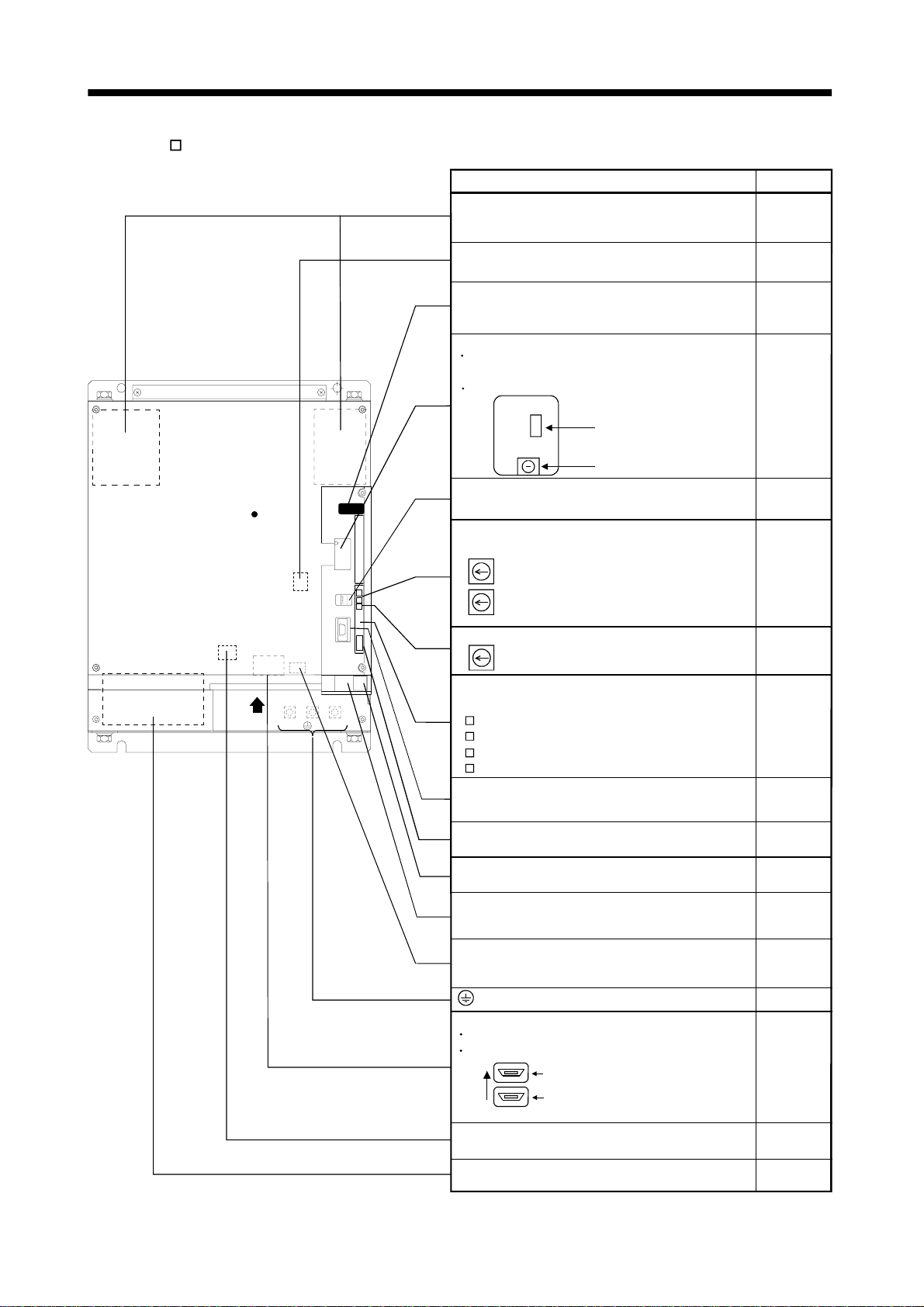

1.7.5 MR-H TN

TE2-1

TE1

Charge lamp

a

TE2-2

CN3

CN4

CN1

Name/Application

TE2-1, TE2-2 (PN terminals)

Connect to the PN terminals of the converter unit

using the connection conductors supplied.

Battery holder

Contains the battery for absolute position data backup.

Display

The four-digit, seven-segment LED shows the servo

status and alarm number.

Switch window

CN5 : Connector for connection of the battery for

absolute position detection

CS1 : Status indication select switch

CN5

CS1

CN3 (Analog monitor output connector)

Used to output an analog monitor signal.

Station number switches

Used to set the station number of the servo amplifier.

SW4: Used to set the second digit. (X10)

SW3: Used to set the first digit. (X1)

SW2 (Baudrate switch)

Used to choose the CC-Link communication

baudrate.

Communication alarm display

Shows the alarm in CC-Link communication.

RD

SD

L.ERR

L.RUN

CN4 (Communication connector)

Used for connection with the MR-PRU01A/personal

computer.

SW1 (Occupied station count switch)

Use to set the number of stations occupied.

CC-Link terminal block

Used to wire the CC-Link cables.

CN1 (I/O signal connector)

Used to connect digital I/O signals.

CN2 (Encoder connector)

Connector for connection of the servo motor encoder.

(Ground terminal)

CN5A, CN5B (Converter unit connectors)

CN5A: Connect to CN5 of the converter unit.

CN5B: Connect the termination connector (MR-A-TM).

CN5A

Front

CN5B

View a

TE3 (Control circuit terminal)

Supply control circuit power.

TE1

Connect to U, V, W of the servo motor.

Refer To

Section 3.2.2

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Servo Amplifier

Instruction

Manual

Section 3.1.5

Servo Amplifier

Instruction

Manual

Section 3.1.5

Servo Amplifier

Instruction

Manual

Section 3.2.2

Section 3.2.1

Section 3.2.2

Section 3.2.2

1 - 10

1. FUNCTIONS AND CONFIGURATION

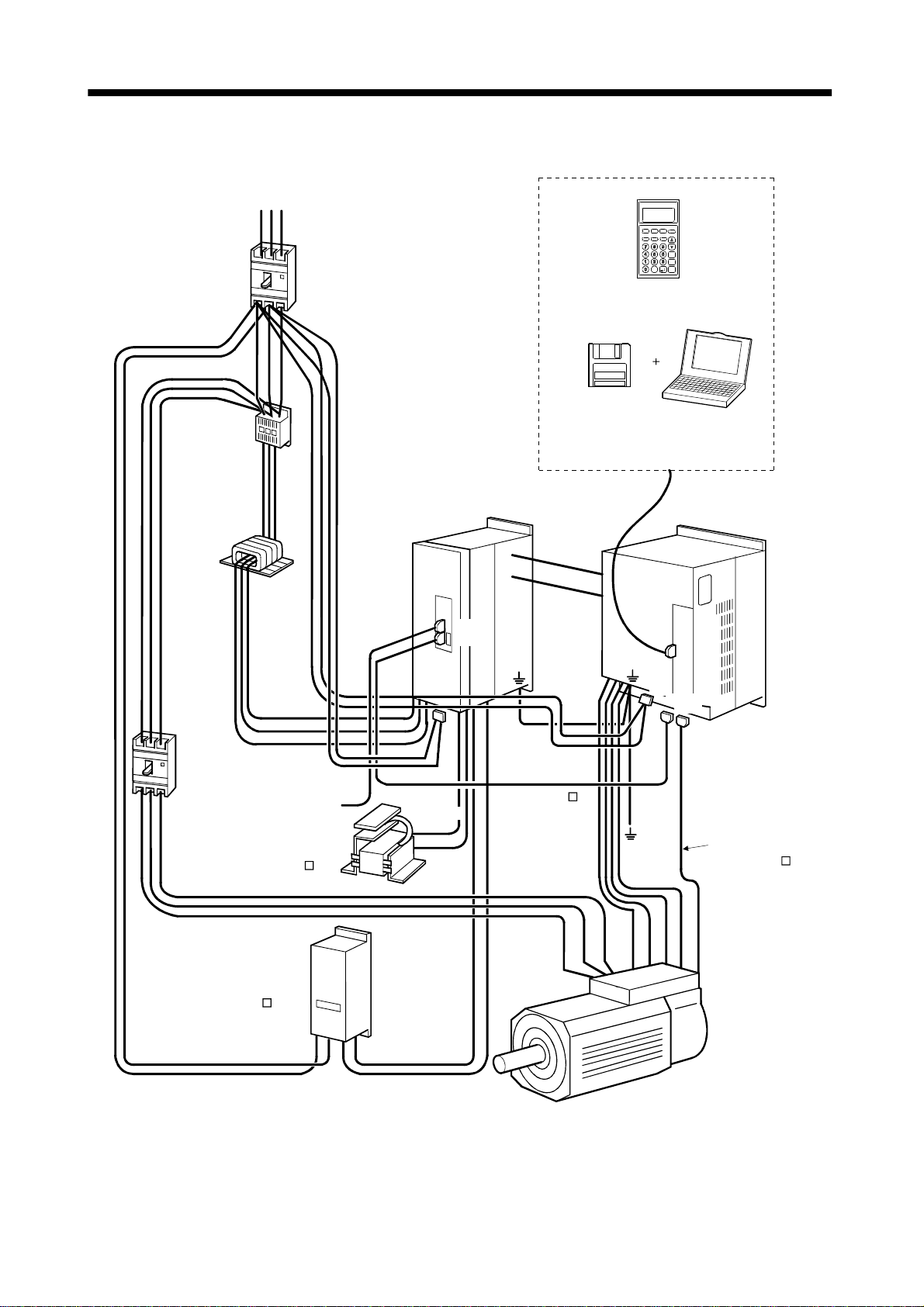

1.8 Servo system with auxiliar y equipm ent

No-fuse

breaker

Magnetic

contactor

Line noise

filter

3-phas e, 200 to 230VAC

RS T

(NFB)

(MC)

(FR-BLF)

(Note3)

Converter unit

CN1

CN5

Servo Configuration

software

The parameter unit or Servo

Configuration software is required

for parameter setting .

Parameter unit cable

communication cable

P

N

or

(Note 1)

P

N

Parameter unit

or

Servo amplifier

CN4

Personal

computer

No-fuse

breaker

(NFB)

(Control signal)

Power factor improving

DC reactor

(MR-DCL K)

Regenerative

brake option

(MR-RB )

(Note 2)

R1

U

V

W

L11

L21

CN5A

L1

L2

L3

L11

L21

P1

PC

(MR-J2HBUS M)

P2

CN2

CN1

Encoder cable

(MR-HSCBL M)

U

BU

BV

BW

VWE

P

S1

C

Servo motor

HA-LF series

1 - 11

1. FUNCTIONS AND CONFIGURATION

MEMO

1 - 12

2. INSTALLATION

2. INSTALLATION

• Stacking in excess of the limited number of products is not allowed.

• Install the equipment to incombustibles. Installing them directly or close to

• Install the equipment in a load-bearing place in accordance with this Instruction

• Do not get on or put heavy load on the equipment to prevent injury.

• Use the equipment within the specified environmental condition range.

• Provide an adequ a te prot e cti on to preve nt scr ew s, meta lli c de t rit u s and ot he r

CAUTION

• Do not block the intake/exhaust ports of the Converter unit and servo amplifier.

• Do not subject the Converter unit and servo amplifier to drop impact or shock loads

• Do not install or operate a faulty Converter unit and servo amplifier.

• When the product has been stored for an extended period of time, consult

combustibles will led to a fire.

Manual.

conductive matter or oil and other combustible matter from entering the Converter

unit and servo amplifier.

Otherwise, a fault may occur.

as they are precision equipment.

Mitsubishi.

2.1 Environmental con dit ions

Environment Conditions

Ambient temperature

Ambient humidity 90%RH or less (non-condensing)

Storage temperature

Storage humidity 90%RH or less (non-condensing)

Ambient

Altitude Max. 1000m (3280 ft) above sea level

Vibration

0 to 55 [°C] (non-freezing)

32 to

131 [°F] (non-freezing)

20 to 65 [°C] (non-freezing)

4 to 149 [°F] (non-freezing)

Indoors (no direct sunlight)

Free from corrosive gas, flammable gas, oil mist, dust and dirt

5.9 [m/s2] or less

2

19.4 [ft/s

] or less

2 - 1

2. INSTALLATION

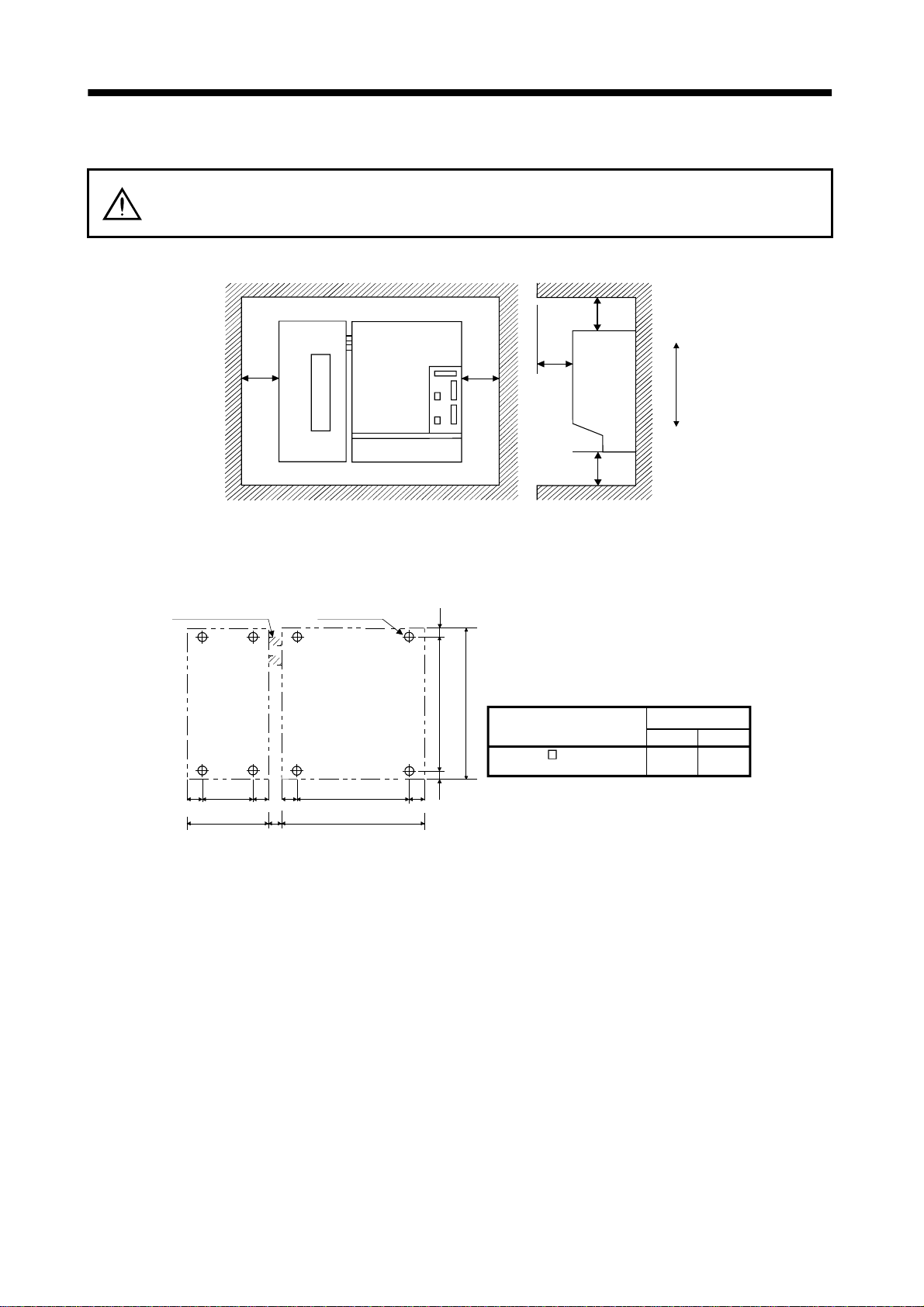

2.2 Installation direction and clearances

• Install the equipment in the specified direction. Not doing so can cause a failure.

CAUTION

(1) Installation of one servo amplifier

• Leave the specified clearances between the converter unit/servo amplifier and the

control box inside walls or other equipment. Not doing so can cause a failure.

Converter unit

50mm

(1.969in)

or more

Servo Amplifier

50mm

(1.969in)

or more

100mm

100mm

(3.937in)

or more

(3.937in)

or more

Top

Bottom

120mm

(4.724in)

or more

Front view

Side view

(2) Mounting dimensional diagram

Exclusive

connection co nductor

Converter

unit

110

(4.33)

200

(4.66)

45

(1.77)

(0.47)

45

(1.77)

(1.77)

20

8-M10 screw

Servo amplifier

45

W2

W1

45

(1.77)

10(0.39)10

480(18.9)

(0.39)

500(19.69)

Servo Amplifier Model

MR-H30K

[Unit: mm]

([Unit: in])

Dimension

W1

450

(17.717)

W2

360

(14.173)

(3) Others

When using heat generating equipment such as the regenerative brake option, install them with full

consideration of heat generation so that the Converter unit and servo amplifier is not affected.

Install the Converter unit and servo amplifier on a perpendicular wall in the correct vertical direction.

2 - 2

3. SIGNALS AND WIRING

3. SIGNALS AND WIRING

• Any person who is involved in wiring should be fully competent to do the work.

• Before starting wiring, make sure that the charge lamp is off and the voltage is safe

in the tester or the like more than 10 minutes after power-off. Otherwise, you may

get an electric shock.

WARNING

CAUTION

• Ground the Conv e rte r uni t an d se rvo a mpl i fie r and th e se rvo mot o r se cur ely .

• Do not attempt to wire the Converter unit and servo amplifier and servo motor until

they have been installed. Otherwise, you may get an electric shock.

• The cables should not be damaged, stressed excessively, loaded heavily, or

pinched. Otherwise, you may get an electric shock.

• Wire the equipment correctly and securely. Otherwise, the servo motor may

misoperate resulting in injury.

• Connect cables to correct terminals to prevent a burst, fault, etc.

• Ensure th a t po l a rity (

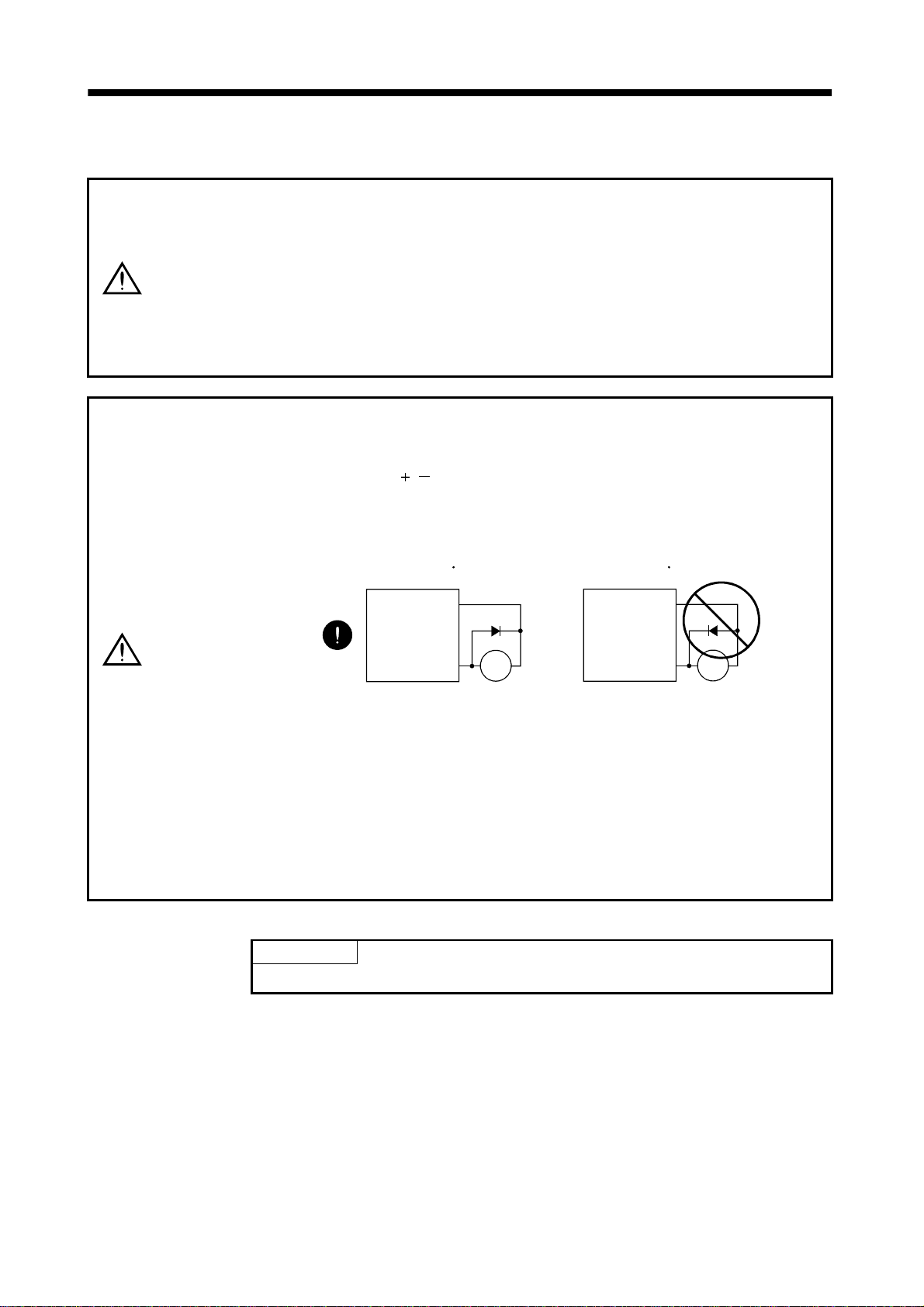

• The surge absorbing diode installed to the DC relay designed for control output

should be fitted in the specified direction. Otherwise, the signal is not output due to

a fault, disabling the emergency stop and other protective circuits.

, ) is correct. Otherwise, a burst, damage, etc. may occur.

Converter unit

Servo Amplifier

VIN

(24VDC)

Control

output

signal

RA

Converter unit

Servo Amplifier

VIN

(24VDC)

Control

output

signal

RA

• Use a noise filter, etc. to minimize the influence of electromagnetic interference,

which may be given to electronic equipment used near the Converter unit and

servo amplifier.

• Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF

option) with the power line of the servo motor.

• When using the regenerative brake resistor, switch power off with the alarm signal.

Otherwise, a transistor fault or the like may overheat the regenerative brake

resistor, causing a fire.

• Do not modify the equipment.

POINT

• The pin with the same signal name are connected in the servo amplif ier.

3 - 1

3. SIGNALS AND WIRING

3.1 Connectors and signal layouts POINT

• The signal layouts of the connectors are views from the wiring section of

the cable connectors.

3.1.1 MR-HP30KA

CN1 (alarm output connector)

Model: 10114-3000VE(3M make)

Converter unit

CN1

CN3

Leave this open.

CN6

Leave this open.

CN5

Connect to CN5A of the servo

amplifier.

1

2

3

4

SE

5

6

SG

7

9

11

13

COM

8

ALM

10

12

VDD

14

3 - 2

3. SIGNALS AND WIRING

3.1.2 MR-H AN•MR-H DN

Servo amplifier

CN2 (for encoder signals)

Model PCR-S20FS (Honda Tsushin make)

CN4

(For parameter unit)

CN2

CN1

CN1 (for I/O signals)

Model PCR-S50FS (Honda Tsushin make)

27

TLAP

29

TLAN

31

FPA

33

OP

35

NP

37

CR

39

LSN

41

DI0

43

DI2

45

DI4

47

SG

49

RD

26

N15R

28

LG

30

LG

32

FPB

34

LG

36

NPR

38

LSP

40

SG

42

DI1

44

DI3

46

EMG

48

ALM

50

SD

2

VC

4

LA

6

LB

8

LZ

10

PP

12

SON

14

PC

16

SG

18

PPO

20

VIN

22

VDD

24

PF

1

P15R

3

LG

5

LAR

7

LBR

9

LZR

11

PPR

13

TL

15

RES

17

SG

19

NPO

21

VDD

23

ZSP

25

TLC

CN3

(Note)

CN12

(MR-H-D01)

(Note)

CN11

(MR-H-D01)

Note: Used when the MR-H-D01

option card is loaded.

CN11 (for MR-H-D01 I/O signals)

Model PCR-S50FS (Honda Tsushin make)

25

DO13

23

DO11

21

VDD

19

DI19

17

SG

15

DI05

13

DI03

11

DI01

9

DO05

7

DO03

5

DO01

3

DI21

1

24

DO12

22

20

VIND

18

DI18

16

SG

14

DI04

12

DI02

10

DI10

8

DO04

6

DO02

4

DO00

2

DI20

50

SD

48

DO14

46

DI17

44

DI15

42

DI13

40

SG

38

DI10

36

DI08

34

DI06

32

DO09

30

DI23

28

DI22

26

DO15

SG

DI16

DI14

DI12

DI11

DI09

DI07

DO10

DO08

DO07

DO06

12

14

BAT

16

P5

18

20

SD

11

13

15

LG

17

LG

19

MR

1

2

LG

LG

3

4

MRR

5

6

7

8

P5

P5

9

10

CN12 (for MR-H-D01 input signals)

Model PCR-S20FS (Honda Tsushin make)

10

49

47

45

43

41

39

37

35

33

31

9

OP24

OP5

8

7

P5

P5

6

5

NP1D

PP1D

4

3

NPD

NPRD

2

1

LG

NTR

CN3 (for analog monitor)

Model 171822-4 (AMP mak e)

(M01) 1

19

SG

17

15

PTR

13

PPRD

11

LG

20

SD

18

P24

16

14

12

PPD

(M02) 2

29

27

(M0G) 4

3 - 3

3. SIGNALS AND WIRING

3.1.3 MR-H BN

Servo amplifier

CN2 (for encoder signals)

Model PCR-S20FS (Honda Tsushin make)

CN3

CN4

(

For parameter unit

CN1A

(For connection

of preceding axis)

CN2

CN1B

(

For connection of

subsequent axis

CN6

(For electromagnetic brake/

emergency stop signal)

CN1A (For connection of preceding axis)

Model PCR-S20FS (Honda Tsushin make)

12

RD*

14

TD*

16

EMG*

18

20

SD

11

LG

13

15

LG

17

19

2

RD

4

TD

6

EMG

8

10

1

LG

3

5

LG

7

9

BT

11

12

13

14

BAT

SD

15

16

LG

P5

17

18

LG

19

20

)

)

CN1B (For connection of subsequent axis)

Model PCR-S20FS (Honda Tsushin make)

11

12

LG

RD*

13

14

TD*

15

16

LG

EMG*

18

20

SD

EMG

17

19

RD

TD

1

2

LG

LG

3

4

MRR

MR

5

6

7

8

P5

P5

9

10

1

2

LG

3

4

5

6

LG

7

8

9

10

BT

CN6 (For connection of electromagnetic

brake/emergency stop signal)

Model FCN-3610P008 (Fujitsu make)

4B

4A

DB

3B

MBR3ACOM

2A 2B

1B

EM11AEM2

CN6 connector (EM1-EM2 shorted) supplied as standard

3 - 4

CN3 (For analog monitor)

Model 171822-4 (AMP make)

(M01) 1

(M02) 2

(M0G) 4

3. SIGNALS AND WIRING

3.1.4 MR-H ACN

(1) Positioning system

Servo amplifier

Model PCR-S20FS (Honda Tsushin make)

CN2 (for encoder signals)

CN3

CN4

(For parameter unit)

CN2

CN1

CN1 (For input signals)

Model PCR-S50FS (Honda Tsushin make)

27

TLAP

29

31

FPA

33

OP

35

37

CR

39

LSN

41

DI0

43

DI2

45

ST2

47

SG

49

RD

26

N15R

28

LG

30

LG

32

FPB

34

LG

36

38

LSP

40

SG

42

DI1

44

ST1

46

EMG

48

ALM

50

SD

2

OVR

4

LA

6

LB

8

LZ

10

12

SON

14

JFS

16

SG

18

PPO

20

VIN

22

VDD

24

PF

1

P15R

3

LG

5

LAR

7

LBR

9

LZR

11

13

DEC

15

STP

17

SG

19

NPO

21

VDD

23

CPO

25

ZP

(Note)

CN12

(MR-H-D01)

(Note)

CN11

(MR-H-D01)

Note: Used when the MR-H-D01

option card is loaded.

CN11 (MR-H-D01 option card)

Model PCR-S50FS (Honda Tsushin make)

25

DO13

23

DO11

21

VDD

19

DI19

17

SG

15

DI05

13

DI03

11

DI01

9

DO05

7

DO03

5

DO01

3

DI21

1

24

DO12

22

20

VIND

18

DI18

16

SG

14

DI04

12

DI02

10

DI10

8

DO04

6

DO02

4

DO00

2

DI20

50

SD

48

DO14

46

DI17

44

DI15

42

DI13

40

SG

38

DI10

36

DI08

34

DI06

32

DO09

30

DI23

28

DI22

26

49

DO15

47

SG

45

DI16

43

DI14

41

DI12

39

DI11

37

DI09

35

DI07

33

DO10

31

DO08

29

DO07

27

DO06

12

14

BAT

16

P5

18

20

SD

11

13

15

LG

17

LG

19

MR

1

2

LG

LG

3

4

MRR

5

6

7

8

P5

P5

9

10

CN12 (MR-H-D01 option card)

Model PCR-S20FS (Honda Tsushin make)

9

OP5

7

P5

5

PP1D

3

NPRD

1

NTR

10

OP24

8

P5

6

NP1D

4

NPD

2

LG

19

SG

17

15

PTR

13

PPRD

11

LG

20

SD

18

P24

16

14

12

PPD

CN3 (For analog monitor)

Model 171822-4 (AMP make)

(M01) 1

(M02) 2

(M0G) 4

3 - 5

3. SIGNALS AND WIRING

(2) Roll feed system

Servo amplifier

Model PCR-S20FS (Honda Tsushin make)

CN2 (for encoder signals)

CN3

CN4

(For parameter unit)

CN2

CN1

CN1 (For input signals)

Model PCR-S50FS (Honda Tsushin make)

27

TLAP

29

31

FPA

33

OP

35

37

CR

39

LSN

41

DI0

43

DI2

45

ST2

47

SG

49

RD

26

N15R

28

LG

30

LG

32

FPB

34

LG

36

38

LSP

40

SG

42

DI1

44

ST1

46

EMG

48

ALM

50

SD

2

OVR

4

LA

6

LB

8

LZ

10

12

SON

14

JFS

16

SG

18

PPO

20

VIN

22

VDD

24

PF

1

P15R

3

LG

5

LAR

7

LBR

9

LZR

11

13

DEC

15

STP

17

SG

19

NPO

21

VDD

23

CPO

25

ZP

(Note)

CN12

(MR-H-D01)

(Note)

CN11

(MR-H-D01)

Note: Used when the MR-H-D01

option card is loaded.

CN11 (MR-H-D01 option card)

Model PCR-S50FS (Honda Tsushin make)

25

DO13

23

DO11

21

VDD

19

DI19

17

SG

15

DI05

13

DI03

11

DI01

9

DO05

7

DO03

5

DO01

3

DI21

1

24

DO12

22

20

VIND

18

DI18

16

SG

14

DI04

12

DI02

10

DI10

8

DO04

6

DO02

4

DO00

2

DI20

50

SD

48

DO14

46

DI17

44

DI15

42

DI13

40

SG

38

DI10

36

DI08

34

DI06

32

DO09

30

DI23

28

DI22

26

49

DO15

47

SG

45

DI16

43

DI14

41

DI12

39

DI11

37

DI09

35

DI07

33

DO10

31

DO08

29

DO07

27

DO06

12

14

BAT

16

P5

18

20

SD

11

13

15

LG

17

LG

19

LG

MR

P5

10

1

2

LG

3

4

MRR

5

6

7

8

P5

9

CN12 (MR-H-D01 option card)

Model PCR-S20FS (Honda Tsushin make)

9

OP5

7

P5

5

PP1D

3

NPRD

1

NTR

10

OP24

8

P5

6

NP1D

4

NPD

2

LG

19

SG

17

15

PTR

13

PPRD

11

LG

20

SD

18

P24

16

14

12

PPD

CN3 (For analog monitor)

Model 171822-4 (AMP make)

(M01) 1

(M02) 2

(M0G) 4

3 - 6

3. SIGNALS AND WIRING

3.1.5 MR-H TN

(1) Positioning system

Servo amplif ier

CN3

CN4

(For parameter unit)

CN2

CN1

CN1

Model PCR-S50FS (Honda Tsushin make)

Model PCR-S20FS (Honda Tsushin make)

CN2 (for encoder signals)

12

14

BAT

16

P5

18

20

SD

11

13

15

LG

17

LG

19

LG

MR

P5

1

2

LG

3

4

MRR

5

6

7

8

P5

9

10

27

TLAP

29

31

FPA

33

OP

35

37

CR

39

LSN

41

DI0

43

DI2

45

ST2

47

SG

49

RD

26

N15R

28

LG

30

LG

32

FPB

34

LG

36

38

LSP

40

SG

42

DI1

44

ST1

46

EMG

48

ALM

50

SD

OVR

LA

LB

LZ

10

12

SON

14

JFS

16

SG

18

PPO

20

VIN

22

VDD

24

PF

1

P15R

2

3

LG

4

5

LAR

6

7

LBR

8

9

LZR

11

13

DEC

15

STP

17

SG

19

NPO

21

VDD

23

CPO

25

ZP

CN3 (For analog monitor)

Model 171822-4 (AMP make)

(M01) 1

(M02) 2

(M0G) 4

3 - 7

3. SIGNALS AND WIRING

)

(2) Roll feed system

Servo amplifier

CN2 (for encoder signals)

Model PCR-S20FS (Honda Tsushin make

CN3

CN4

(For parameter unit)

CN2

CN1

CN1

Model PCR-S50FS (Honda Tsushin make)

27

TLAP

29

31

FPA

33

OP

35

37

CR

39

PS2

41

MO0

43

MO2

45

ST2

47

SG

49

RD

26

N15R

28

LG

30

LG

32

FPB

34

LG

36

38

TL

40

SG

42

MD1

44

ST1

46

EMG

48

ALM

50

SD

2

OVR

4

LA

6

LB

8

LZ

10

12

SON

14

JFS

16

SG

18

PPO

20

VIN

22

VDD

24

INP

1

P15R

3

LG

5

LAR

7

LBR

9

LZR

11

13

DEC

15

STP

17

SG

19

NPO

21

VDD

23

CPO

25

11

12

13

14

BAT

15

16

LG

P5

17

18

LG

19

20

SD

CN3 (For analog monitor)

Model 171822-4 (AMP make)

(M01) 1

(M02) 2

(M0G) 4

LG

MR

P5

1

2

LG

3

4

MRR

5

6

7

8

P5

9

10

3 - 8

3. SIGNALS AND WIRING

3.1.6 Explanation of signals

For the servo amplifier signals, refer to the Servo Amplifier Instruction Manual of 22kW or less. This

section provides the converter unit signals.

For the I/O interfaces (symbols in I/O column in the table), refer to this section(2)

(1) Signals

Signal Name Pin Code Pin No. Function/Application I/O Category

24V 10% is output across VDD-SG.

Driver power supply VDD 12

Digital I/F power

supply input

24V common SG 5 Common terminal for VDD. Isolated from LG.

Signal common SE 3

Shield SD Plate Connect one end of the shield cable.

Trouble ALM 8

COM 13

Connect with COM when using this power supply for the digital

interface.

Permissible current: 80mA

Enter 24VDC

Digital interface driver power supply input terminal.

Connect to VDD when using VDD as an interface power supply.

Connect a 24VDC, 80mA or more power supply here when using an

external powe r supply.

Common for open collector output.

Connect to SG.

ALM-SG are disconnected when the protective circuit is activated

to shut off the base circuit at po wer-off.

They are connected when the st at u s is normal at power-off.

10% for digital interface.

DO-1

(2) Interface

Here are give n the details of the o utput signal interface ( DO-1: Refer to I/O Ca tegory in the above

table) given in (1) of this sectio n. Refer to this section and conn ect the interfaces w ith the external

equipment.

A lamp, relay or photocoupler can be driven. (Permissible current: 40mA or less, inrush current:

100mA or less)

For use of internal power supply For use of external power supply

Converter unit

24VDC

VDD

COM

ALM

SG

Load

If the diode is not

connected as shoun,

the converter unit

willl be damaged.

Converter unit

24VDC

VDD

COM

ALM

SG

Do not connect

VDD-COM.

24VDC

Load

If the diode is not

connected as shoun,

the converter unit

willl be damaged.

10%

3 - 9

3. SIGNALS AND WIRING

3.2 Power line circuit

• Insulate the connections of the power supply terminals. Not doing so can cause an

WARNING

CAUTION

electric shock.

• When the servo amplifier has become faulty, switch power off on the Converter unit

power side. Continuous flow of a large current may cause a fire.

• Use the trouble signal to switch power off. Otherwise, a regenerative brake

transistor fault or the like may overheat the regenerative brake resistor, causing a

fire.

• Connect the power supply phases (U, V, W) of the servo amplifier and servo motor

correctly. Not doing so can cause the servo motor to run abnormally.

• Do not connect a three-phase 200V power supply directly to the servo motor. Doing

so can cause a failure.

3 - 10

3. SIGNALS AND WIRING

3.2.1 Connection example

3-phase

200 to

230VAC

50/60Hz

MCNFB

DC reactor

(Option)

P

N

N

CN5

MR-J2HBUS

M cable

MR-A-TM

termination

connector

(Option)

L1

L2

Converter

L3

unit

L11

L21

P1

P2

(Note2)

PC

CN

13

12

COM

VDD

RA3

ALM

8

SE

3

SG

5

PP

N

CN5

CN5

Servo

amplifier

CN2

U

V

W

P

N

(Note3)

External

dynamic

brake

MR-HSCBL

M cable

24VDC

power

supply

U

V

W

OHS1

RA2

Servo motor

HA-LFseries

SM

Encoder

Fan

OHS2

BU

BV

BW

Servo

motor

thermal

relay

PC PC PC

Servo

RA1

Convert

RA3

G3 G4 G3 G4 G3 G4

(Note1)

Regenerative

brake option

Fan Fan

R

S

(Note1)

Regenerative

brake option

Fan

R

S

Motor thermal relay

EMG OFF ON

RA2

(Note1)

Regenerative

brake option

R

S

Operation-ready

MC

L11

L21

CN1

22

20

48

48

VDD

VIN

ALM

RA1

(Note4)

MC

SK

Note: 1. For the MR-RB 139. For the MR-RB1 37, three units are use d as one set (permis sible wattage:

3900W).

2. When using the DC reactor, disconnect the short bar across P1-P2.

3. When using the external dynamic, Refer to Section 9.1.2.

4. Not provided for the MR-H

BN.

3 - 11

3. SIGNALS AND WIRING

3.2.2 Terminal

Refer to Section 7.2 for the terminal block arrangement and signal layout.

(1) Converter unit

Signal Name Abbreviati on Terminal Block Description

Main circuit power supply L1•L2•L3 TE1-2 Connect three-phase 200 to 230VAC, 50/60Hz to L1, L2, L3.

Control circuit power supply L11•L21 TE3 Connect single-phase 200 to 230VAC, 50/60Hz.

DC reactor P1•P2 TE1-1

Regenerative brake P•C TE1-1

PN power output P•N

Grounding PE

TE2-1

TE2-2

(2) Servo amplifier

Signal Name Abbreviati on Terminal Block Description

Servo motor output U•V•W TE1A Connect to the servo motor power supply terminals (U, V, W).

Control circuit power supply L11•L21 Connect single-phase 200 to 230VAC, 50/60Hz.

PN power supply P•N

Grounding PE

TE2-1

TE2-2

When using the DC reactor, connect it after removing the

connection plate across P1-P2.

Connect to the P and C terminals of the regenerative brake

option.

Connect to the P and N terminals of the converter unit.

Use the accessory connection bars to make connection.

Connec t this term inal to the pro tective e arth (PE) terminals of

the servo motor and control box for grounding

Connect to the P and N terminals of the converter unit.

Use the accessory connection bars to make connection.

Connec t this term inal to the pro tective e arth (PE) terminals of

the servo motor and control box for grounding

3.2.3 How to use the connection bars

Connect P and N of the servo amplifier and P and N of the converter unit using the connection conductors

as shown below.

Connection conductors

Converter unit

Servo amplifier

3 - 12

3. SIGNALS AND WIRING

3.2.4 Power-on sequence

1) Always wire the pow er supply as shown in above Section 3.7.1 using the magnetic co ntactor with the

main circuit power supply. Configure up an external sequence to switch off the magnetic contac tor as

soon as an alarm occurs.

2) Switch on the control circuit power supply L

, L21 simultaneously with the main circuit power supp ly

11

or before switch ing on the main c ircuit power supply. If the main circuit powe r supply is not on, the

display shows the corresponding warning. However, by switching on the main circuit power supply, the

warning disappears and the servo amplifier will operate properly.

3) The servo amplifier can accept the servo-on signal (SON) about 1 second after the main circuit power

supply is switched on. Therefore, when SON is switched on simultaneously with the three-phase power

supply, the b ase circuit will switch on in a bout 1 second, and the ready sign al (RD) will switch on in

further about 20ms, making the servo amplifier ready to operate.

• To stop operation and switch power off immediately, provide an external emergency

CAUTION

stop circuit.

Make up a circuit which shuts off main circuit power as soon as EMG-SG are opened at an emergency

stop. Opening EMG-SG coasts the servo motor. When the optional dynamic brake is used, the servo motor

comes to a sudden stop.At this time, the display shows the servo emergency stop warning (ALE6).

During ordinary operation, do not use the external emergency stop signal to alternate stop and run. If the

start signal is on or a pulse train is input during an emergency stop, the servo motor will rotate as soon as

the warning is reset. During an emergency stop, always shut off the run command.

Servo amplifier

VDD

VIN

EMG

SG

3 - 13

3. SIGNALS AND WIRING

3.3 Servo motor side details

Terminal box

Terminal box inside

Portion a

Portion b

Motor power supply terminal block

Cooling fan terminal block M 4 screw

Note: 1. The encoder connector may also be fitted to portion a.

2. Wiring may also be carried out from portion b.

Encoder connector

MS3102A20-29P

Encoder connector

MS3102A20-29P

(Note1)

(Note2)

Earth terminal M5 screw

Thermal protector termi nal block M4 screw

Encoder connector

signal arrangement

MS3102A-29P

Key

T

S R

B

A

N

P

G

M

L

K

J

HF

Pin Signal Pin Signal

AMD K

BMDR L

CMR M

DMRR NSHD

C

EP

D

FBAT R LG

E

GLG SP5

HT

J

Power supply connection screw size

Servo Motor Power Supply Connection

Screw Size

HA-LF30K2 M10

Signal Name Abbreviati on Description

Power supply U•V•W Connect to the motor output terminals (U, V, W) of the servo amplifier.

Supply power which satisfies the following specifications.

Item Description

Cooling fan BU•BV•BW

Voltage/frequency Three-phase 200 to 230VAC, 50/60Hz

Power consumption [W] 45(50Hz)/63(60Hz)

Rated voltage [V] 0.32(50Hz)/0.35(60Hz)

Motor thermal relay OHS1•OHS2 OHS1-OHS2 are opened when heat is generated to an abnormal temperature.

Earth terminal

For grounding, connect to the earth of the control box via the earth terminal of the servo

amplifier.

3 - 14

3. SIGNALS AND WIRING

2

2

3.4 Grounding

WARNING

• Gorund the servo amplifier and servo motor securely

The servo amplifier switches the power transistor on-off to supply power to the servo motor. Depending on

the wiring and ground cablerouting, the servo amplifier may be affected by the switching noise (due to

di/dt and dv/dt) of the transistor. To prevent such a fault, refer to the following diagram and always

ground.

Control box

Servo motor

Encoder

U

V

SM

W

3-phase

00 to

30VAC

NFB

Converter

unit

11

L

21

MC

Line filter

L

P

1

L

N

2

L

3

L

Servo amplifier

11

L

21

L

P

N

CN2

U

V

W

Must be grounded

by cable

Earth plate

Programmable

controller

Outer

box

3 - 15

3. SIGNALS AND WIRING

MEMO

3 - 16

4. DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT

4. DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT

4.1 Display flowchart

Use the display (4-dignht, 7-segment LED) on the front panel of theConverter unit for stat us dis play,

parameter setting, etc. Set the parameters before operation, diagnose an alarm, confirm external

sequences, and/or confirm the operation status.

Press the MODE, UP or DOWN button once to move the next screen.

button

MODE

Status display Diagnosis Alarm

Basic parameters

Bus voltage

Effective load ratio

Peak load ratio

Within one-revolution po sit i on

[%]

Sequence

External I/O siglal

Output signal

forcded output

Sorftware

version L

Sorftware

version H

Current alarm

Last alarm

Tenth alarminpast

Parameter

errorNo.

ParameterNo.0

ParameterNo.1

UP

DOWN

ParameterNo.8

ParameterNo.9

4 - 1

4. DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT

4.2 Status display mode

The servo status during operation is shown on the 4-digit, 7-segment LED display. Press the "UP" or

"DOWN" button to change display data as desired.

When the required data is selected, the corresponding symbol is displayed. Press the "SET" button to

display that data.

The converter unit display section can show four items of data such as the effective load factor.

4.2.1 Display examples

The following table shows the display exam ples.

Item Status Display

Bus voltage 225[V]

Effective load factor 67[%]

Peak load factor 95[%]

Regenerative load factor 90[%]

4.2.2 Status display list

The following table lists the servo statuses that may be displayed.

Status Display Symbol Unit Description Indication Range

Bus voltage d V The converter unit voltage is displayed. 150 to 500

Continuous effective load torque is displayed. (Note)

Effective load factor J %

Peak load factor b %

Regenerative load

factor

L%

The effective value is displayed relative to the rated

torque of 100%.

The peak output is displayed. (Note)