Page 1

SERVICE MANUAL

HOME REFRIGERATOR

Model

MR-G50J-SS-NZ

No. OA090

Model name

indication

(Inside a door)

NZ············New Zealand

NOTE:

• RoHS compliant products have <G> mark on the spec name plate.

1. FEATURES ····················································································2

2. SPECIFICATIONS··········································································3

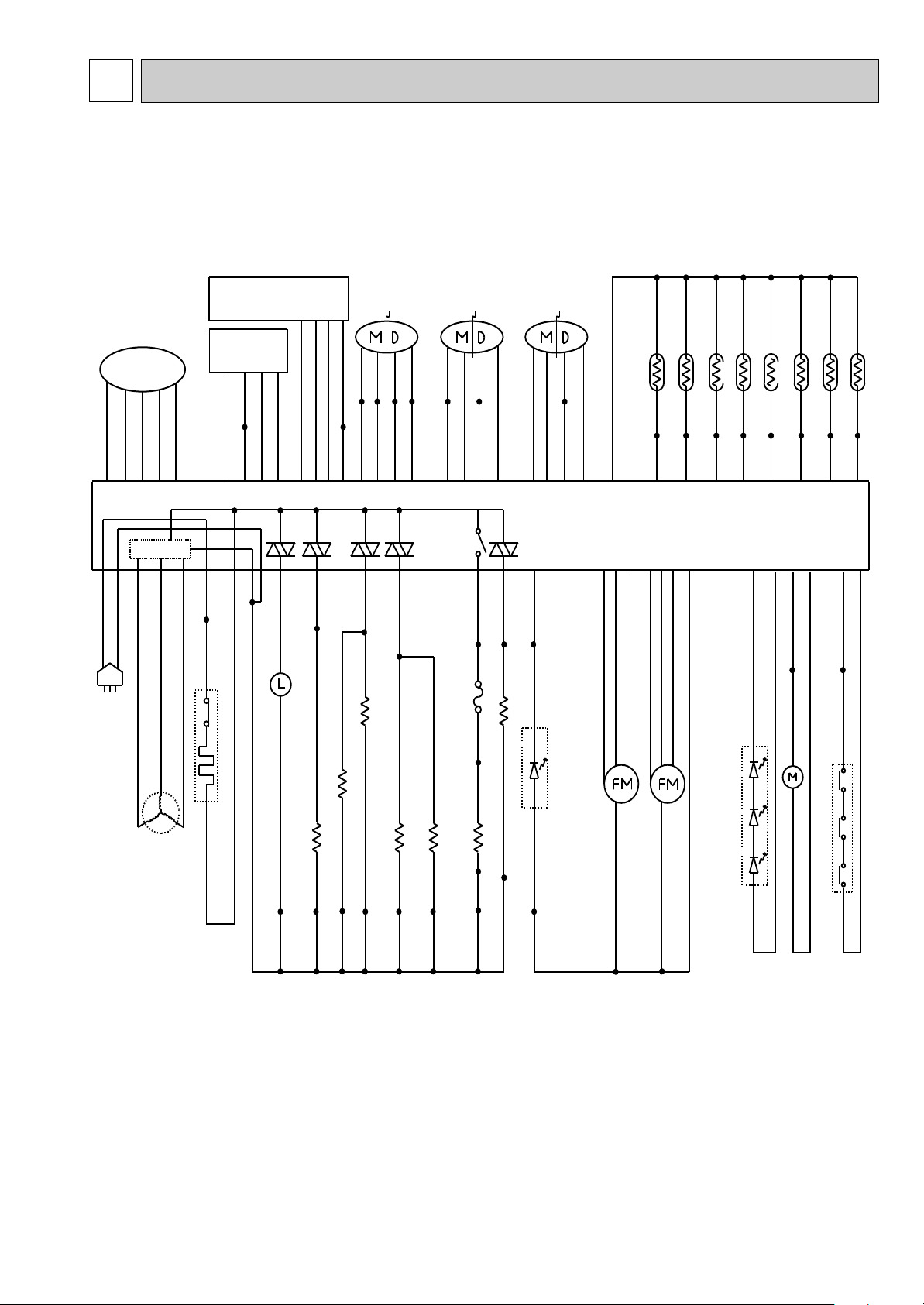

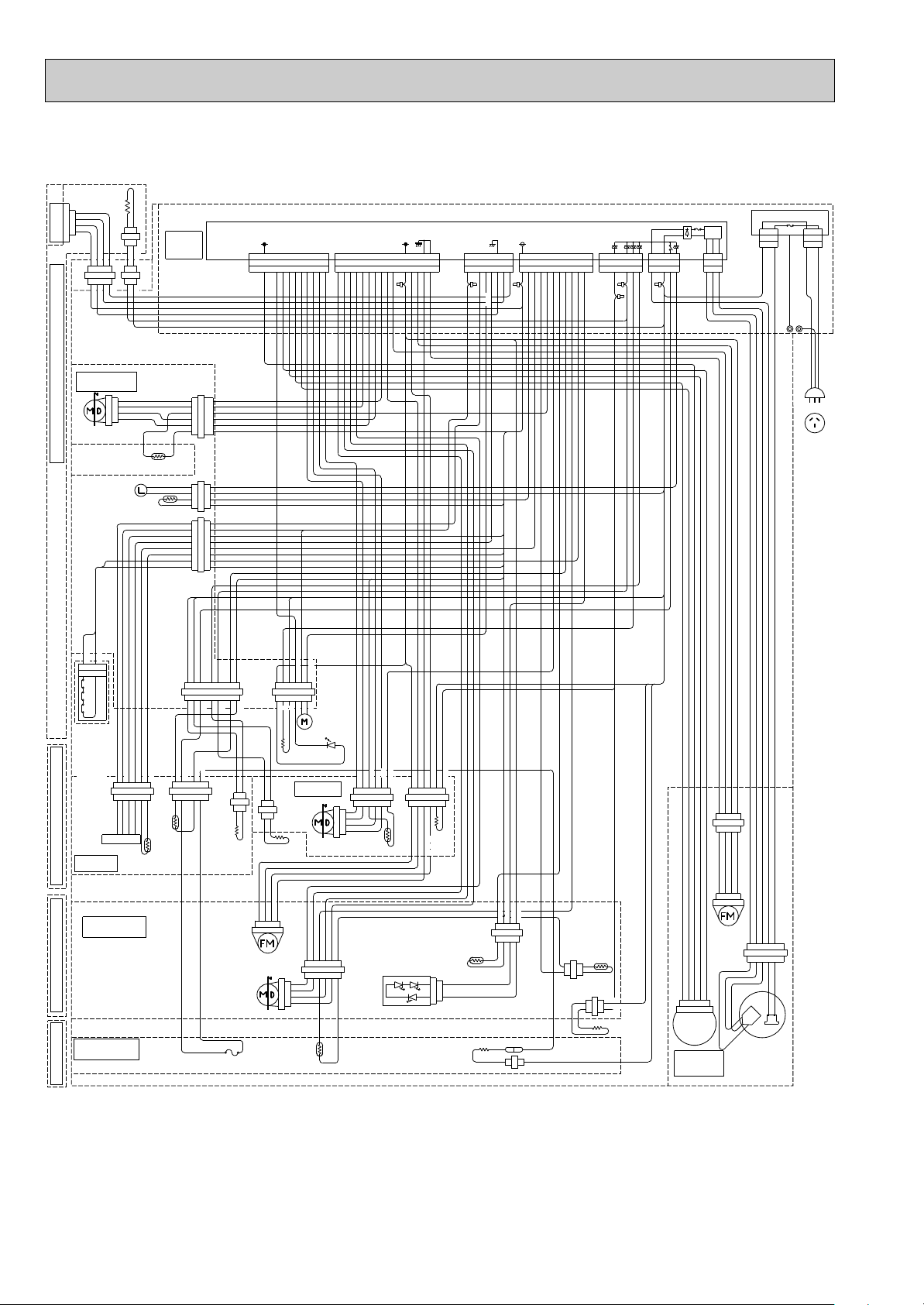

3. WIRING DIAGRAM ········································································5

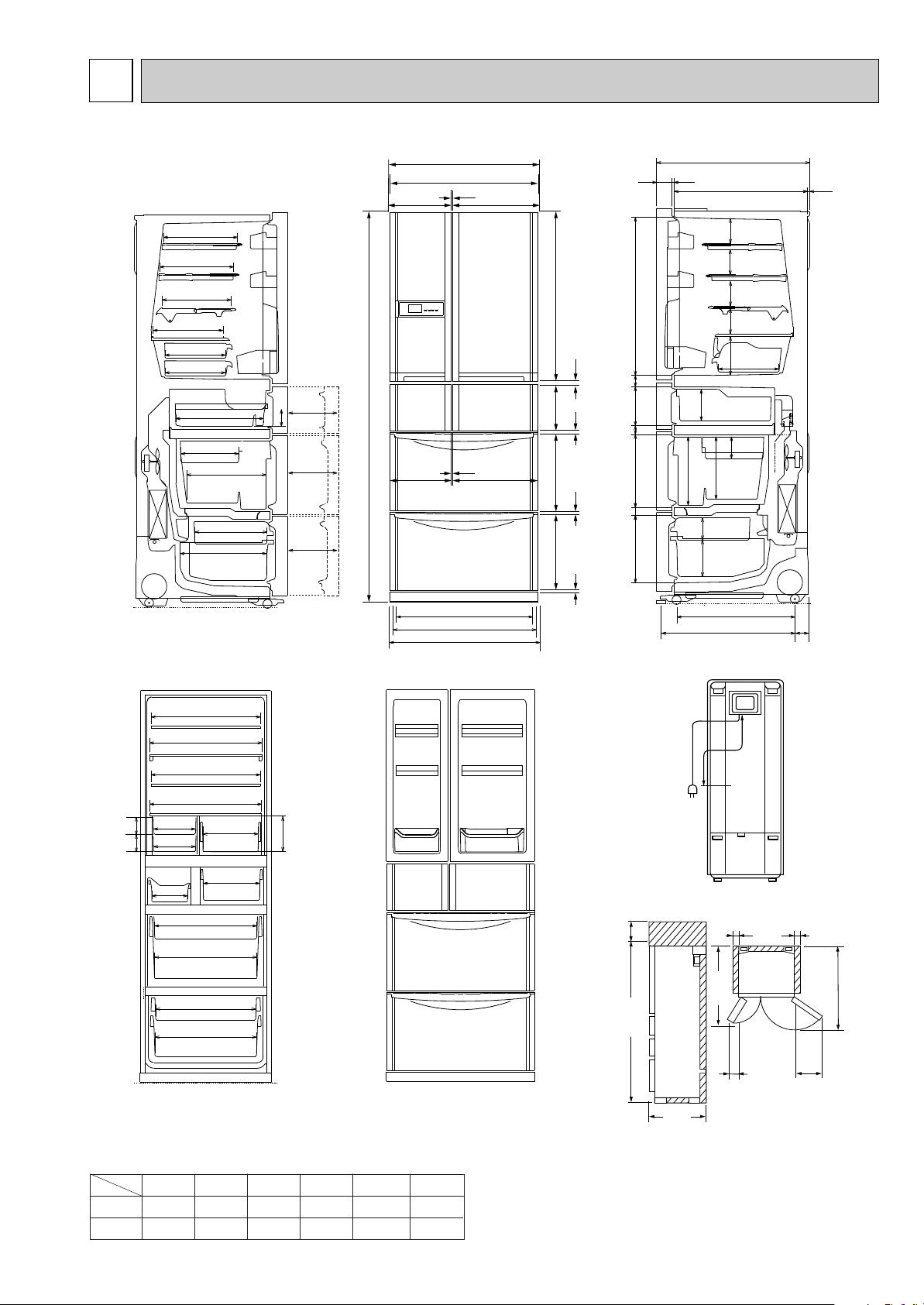

4. OUTLINES AND DIMENSIONS·····················································7

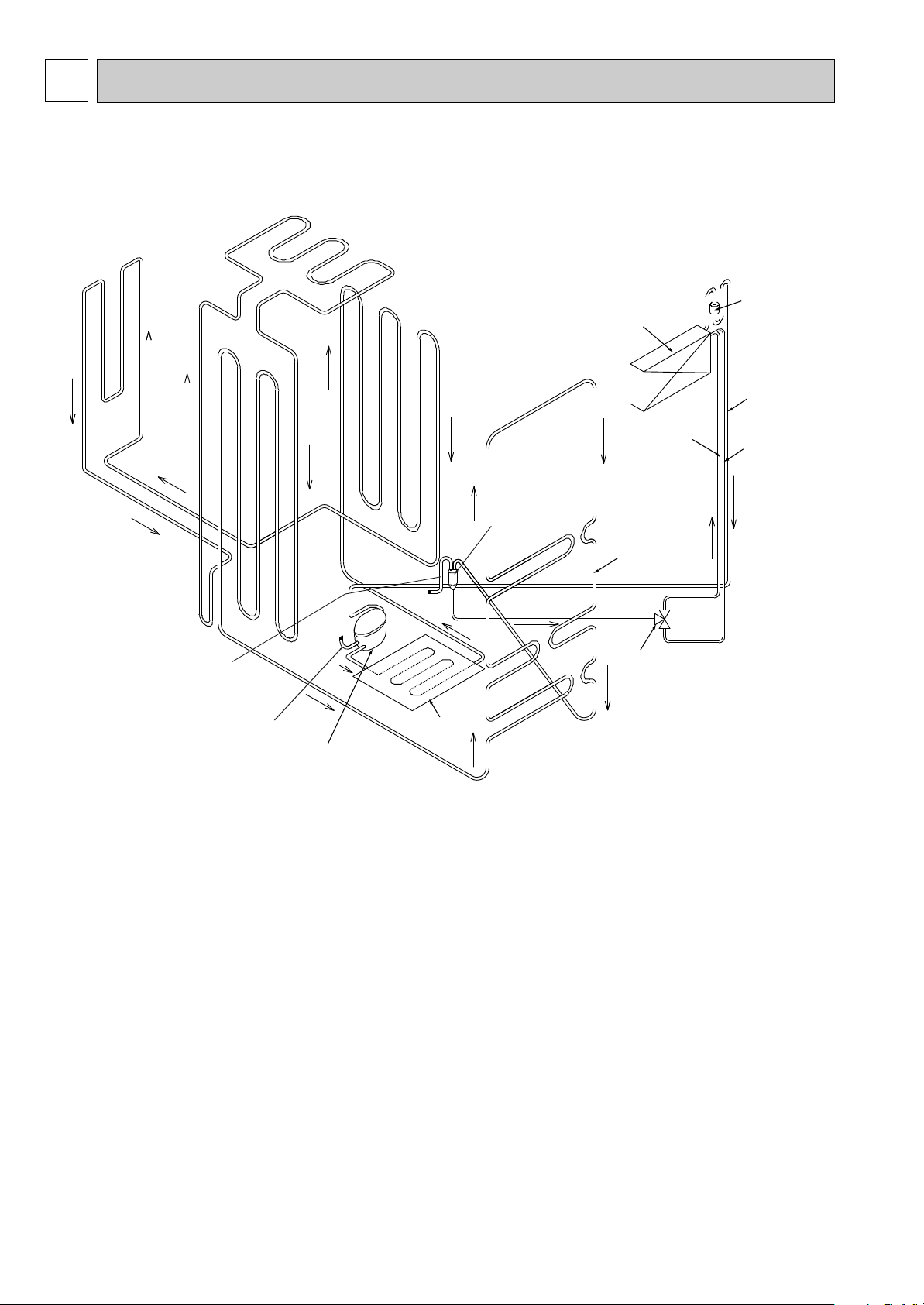

5. REFRIGERANT CIRCUIT ······························································8

6. TROUBLESHOOTING···································································9

6-1 FUNCTION OF OPERATION PANEL ···································9

6-2 FLOWCHART OF SELF-CHECK········································14

6-3 BLOCK DIAGRAM OF PRINTED CIRCUIT BOARD ·········17

6-4 AUTO ICE MAKER······························································17

6-5 FLOWCHART OF TROUBLE CRITERION ·························19

6-6 TROUBLE CRITERION OF MAIN PARTS··························26

6-7 TEST POINT DIAGRAM OF FILTER BOARD····················31

6-8 TEST POINT DIAGRAM OF CONTROL BOARD ···············32

7. NAMES OF THE PARTS·····························································33

8. DISASSEMBLY INSTRUCTIONS················································34

9. RoHS PARTS LIST ······································································41

CONTENTS

Page 2

1

FEATURES

MR-G50J-NZ

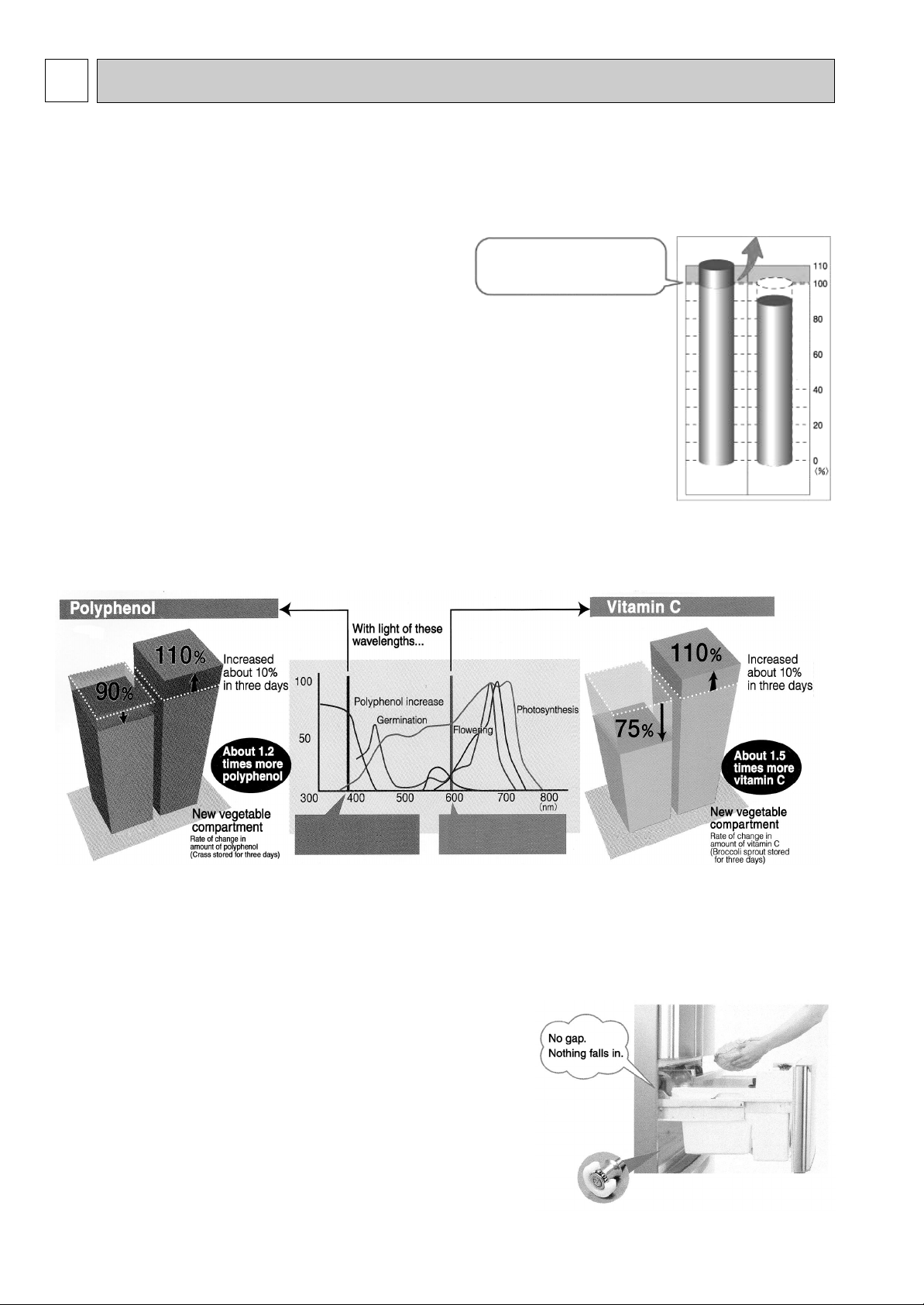

1. Vegetable compartment

(1)Mechanism

Two LED lights are mounted on the back and bottom

of the vegetable compartment. The LED (UV LED)

emits 375nm light, which is the effective wavelength

for biosynthesis of polyphenol. This revolutionary

vegetable compartment stimulates self-defense

function of vegetables and increases polyphenol by

irradiating ultraviolet light to vegetables for a certain

period of time.

* The lighting of LED is not controlled by opening or closing of the

vegetable compartment door. Thus, the LED may not be lighted

when the door is opened.

(2)Effect

Polyphenol in vegetables increased by 10% compared

to the time of purchase, and the amount of retained

polyphenol was 1.2 times more than that of the

vegetables preserved in prior refrigerators without light

radiation. (See graph)

Among different wavelength of light included in sunlight, lights of wavelength that "stimulates

photosynthesis" and "stimulates polyphenol increase" are used in the vegetable compartment.

Rate of change in amount of polyphenol

(Cress stored for three days)

About 1.2 times more

polyphenol retained

New vegetable

compartment

Amount of polyphenol at the time of purchase

2002 MITSUBISHI

refrigerator

MR-S46B

375nm LED effective for

biosynthesis of polyphenol

590 nm LED effective for

photosynthesis

2. " Auto Door Shut" function installed enable doors to be shut easily.

"Auto Door Shut" function automatically closes the door when its opened angle is less than 20 degrees.

3. Easy Access Vegetable room, Easy Access Freezer Room

The slide rollers enable smooth movement of vegetable

and freezer rooms.

Double rails allow the rooms to be pulled out completely,

providing easy access to even the back of the rooms.

2

▼Slide rollers

Page 3

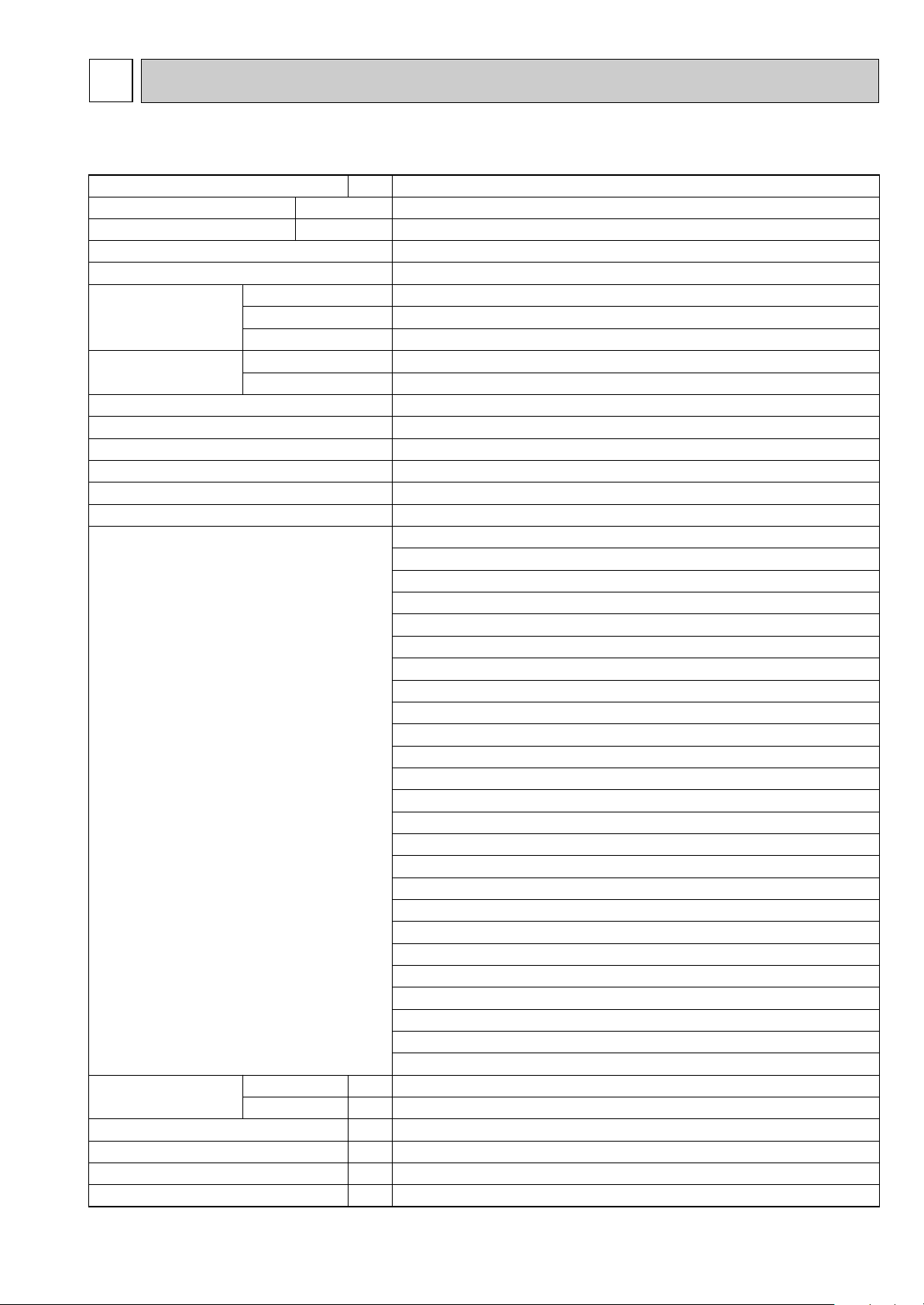

2

230V,50Hz

492 (R:264 F:82 V:97 I:12 S:37)

1798 x 745 x 699 (70-25/32 x 29-11/32 x 27-17/32)

Acrylic resin coated steel

ABS resin

Foamed polyurethane (Cyclopentane)

Foamed polyurethane (Cyclopentane)

Foamed polyurethane (Cyclopentane)

Forced air convection

Forced air convection

Fin and tube type

Cabinet, cabinet ceiling, sides, back and front flange

Automatic heater defrost

Automatic drainage, Forced evaporation method

Automatic control

240V,10W (E12)

99

110

{1.6 x {0.63 x 2680 / {1.8 x {0.67 x 2680

9

82

187 (FREOL S10)

kg

kg

mm

g

g

g

V,Hz

L

mm (inches)

Unit

Shipping

Weight

Accessories

Evaporator

Condenser

Defrost system

Drain

Temperature control system

Refrigerator compartment room light

Power supply

Total capacity

Dimensions (H x W x D)

Cabinet

Food liner

Cabinet

Freezer door

Refrigerator door

Freezer

Refrigerator

Insulation

Cooling system

Capillary tube

Desiccant (molecular sieve)

Refrigerant filling capacity R600a

Refrigerating oil (Model)

Free pocket (L)

Free pocket (S)

Bottle pocket (S)

Bottle pocket (L)

Tube stand

Height adjustable shelf

Three-way flexishelf

Two-way flexishelf

Small item case

Free egg shelf

Slide chilled case

Slide chilled case lid

Versa case

Aluminum tray (Versa case)

Water tank (With light-type bacteria removing filter)

Freezing case (upper)

Freezing case (lower)

Ice server

Sound proof mat

Ice storage bin

Vegetable case

Vegetable stand

Sliding case (Vegetable case)

Drain pan

Toe grille

2pcs.

2pcs.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

2pcs.

2pcs.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

SPECIFICATIONS

SPECIFICATIONS

MR-G50J-NZ

3

Page 4

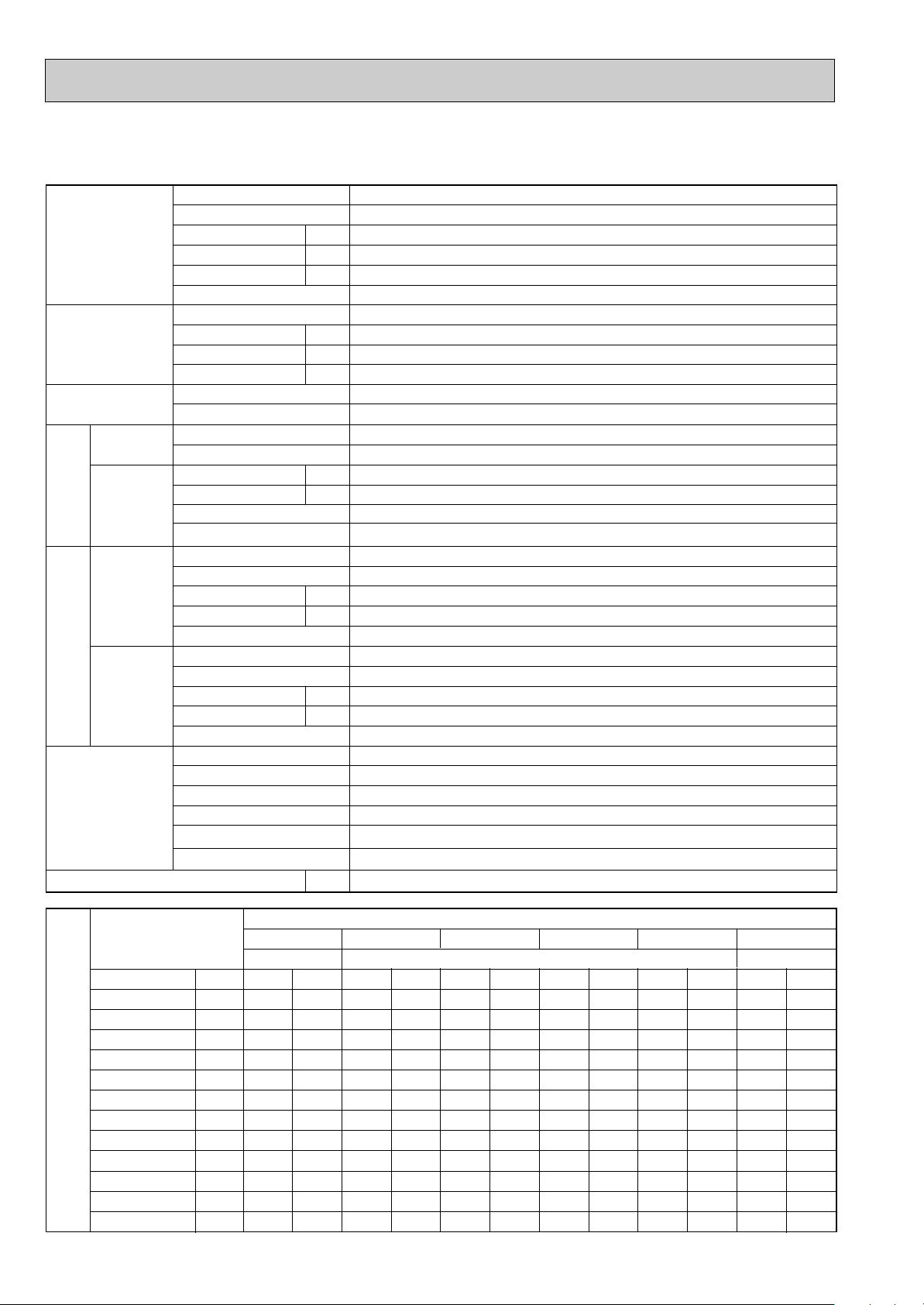

W

A

A

°C

Sec.

A

°C

°C

W

rpm

W

rpm

°C

Compressor

Motor protector

Heater

(Rating)

Freezer

compartment

Refrigerator

Machine

Chamber

Fan motor

Defrosting

control

Ice maker temperature

Model

Power supply

Rated input

Starting current

Running current

Winding resistance (A.T.20°C)

Model

Ambient temperature

Time

Current

Model

Type

Model

Specification

Defrost finish

Thermal fuse

Defrost heater

Deodorizing function of defrost heater

Model

Type

Input

Revolution

Number of poles

Model

Type

Input

Revolution

Number of poles

Water pipe heater

Rotational heater board

Divider heater (I/S)

Vegetable compartment heater 1

Vegetable compartment heater 2

Ice making tray heater

ETI100E 13DAH

230V,50Hz

45/159 (1620/4800rps)

2.0 (Current limiter)

0.63/2.19 (1620/4800rps)

9.27"

MM3-71CCV

25

16 or less

17.0

NSCE001DC1

4-phase stepping motor drive voltage DC12V

325" (230V,163W)

Control board

Microcomputer

Thermistor 14±1.5

70±2

Not Equipped

UDQM002B3

DC brushless motor

2.4 (12V DC)

1520 (12V DC)

10P

UDQM004B3

DC brushless motor

1 (12V DC)

1200 (12V DC)

10P

230V-8.0W

230V-8.0W

230V-5.5W

230V-9.0W

230V-9.0W

220V-10.0W

-11.6

Defrosting

timer

Three-way valve

:

:

:

:

:

:

:

:

:

:

:

:

Temperature control

ON

-20.3

-17.6

-14.9

–

–

–

–

–

–

–

–

–

OFF

-24.1

-21.4

-18.7

–

–

–

–

–

–

–

–

–

OPEN

-0.6

1.6

4.8

–

–

–

–

–

–

–

–

–

SHUT

-1.8

0.4

3.5

–

–

–

–

–

–

–

–

–

Dial position

HI

MID

LOW

REFRIGERATOR

CHILLED

LOW (Soft freezing)

MID (Soft freezing)

HI

(Soft freezing)

FREEZER

ICE MAKING

ICE MAKING STOP

CRYSTAL ICE MAKING

Model

NTC thermistor

Freezer

Compressor HeaterMotor damper

Refrigerator

ON

2.3

3.2

4.2

–

–

–

–

–

–

–

–

–

OFF

3.5

4.5

5.4

–

–

–

–

–

–

–

–

–

OPEN

–

–

–

4.4

1.8

-2.3

-4.0

-5.9

-17.1

–

–

–

SHUT

–

–

–

2.4

-0.1

-4.0

-5.9

-7.7

-20.4

–

–

–

VegetableVersa

OPEN

–

–

–

–

-1.0

–

–

–

–

–

–

–

SHUT

–

–

–

–

-2.3

–

–

–

–

–

–

–

OPEN

–

–

–

1.2

–

–

–

–

–

-20.2

-20.2

-20.2

SHUT

–

–

–

-0.1

–

–

–

–

–

-23.1

-23.1

-23.1

Slide chilled Ice making

ELECTRICAL PARTS SPECIFICATIONS

MR-G50J-NZ

4

Page 5

3

ICE MAKING TRAY HEATER

Vegetable compartment heater 2

Vegetable compartment heater 1

CONTROL BOARD, N/F BOARD

INVERTER

GRAY

GRAYREDRED

GRAYREDRED

DEFROST HEATER

WHITE WHITE

RED

RED GRAY

GRAY

WHITEWHITE

WATER PIPE HEATER

YELLOW

BLACK

FAN MOTOR (FOR COMPRESSOR)

LIGHT GREEN

BLACK

ORANGE

BRIGHT YELLOW

FAN MOTOR

LED

THERMAL FUSE (73:)

VIOLET

RED

BLACK

LIGHT GREEN

DIVIDER HEATER (I/S)

YELLOW

GREEN

YELLOW GREEN

WHITE

ROTATIONAL HEATER BOARD

COMPRESSOR

ORANGE

GRAY

V

WU

WHITEWHITE

GRAY

GRAY

GRAY

GRAYRED

REDRED

BLUE

BLACK

WHITE

RED

YELLOW

VIOLET

GRAY

R-COMPARTMENT ROOM LIGHT

YELLOW

YELLOW

VIOLET

MOTOR PROTECTOR

L N

PLUG

Vegetable compartment LED board

BLACK

WATER PUMP

VIOLET

VIOLET

WHITE

THREE-WAY

VALVE

WHITE

WHITE

RED

LIGHT BROWN

SKY BLUE

VERSA.THERMISTOR

I.THERMISTOR

YELLOW

GREEN

BLUE

LIGHT

GREEN

PINK

BRIGHT

YELLOW

YELLOW

BROWN

F.THERMISTOR

C.THERMISTOR

R.THERMISTOR

WHITE

WHITE

ORANGE

WHITE

WHITE

ICE-TRAY THERMISTOR

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

SKY BLUE

WHITE

WHITE

WHITE

WHITE

V.THERMISTOR

WHITE

WHITE

DEF.THERMISTOR

YELLOW

BLUE

ORANGE

BLACK

VIOLET

YELLOW

RED

BLUE

SKY BLUE

RED

WHITE

SKY BLUE

BLACK

GRAY

PINK

PINK

LIGHT BROWN

YELLOW GREEN

BROWN

RED

YELLOW

WHITE

BLUE

BLUE

WHITE

YELLOW

RED

WHITE / RED

BROWN

MOTOR DAMPER MOTOR DAMPER MOTOR DAMPER

BLUE

WHITE

RED

YELLOW WHITE / RED

(LIQUID CRYSTAL DISPLAY)

TEMP. CONTROL BOARD

DOOR SWITCH.(FOR R-COMPARTMENT & ICE MAKING COMPARTMENT)

ICE GEAR BOX

F1 :10A FUSE

FUSE1

: 3A FUSE

ON THE BOARD

W

WHEN THE DOORS ARE CLOSED.

WIRING DIAGRAM

MR-G50J-NZ

( SKELTON WIRING DIAGRAM )

I.THERMISTOR (Ice making compartment thermistor)

V.THERMISTOR (Vegetable compartment thermistor)

VERSA.THERMISTOR (Versa compartment thermistor)

DEF.THERMISTOR (Defrost thermistor)

ICE-TRAYTHERMISTOR (Ice making tray thermistor)

F.THERMISTOR (Freezer compartment thermistor)

C.THERMISTOR (Slide chilled compartment thermistor)

R.THERMISTOR (Refrigerator compartment thermistor)

5

Page 6

MR-G50J-NZ

SSR4 SSR3SSR5

FUSE1

X1SSR1

SSR2

F1

L

N

N

L

AC230V

Power

Plug

50Hz

N/F BOARD

CN1

1

3

3

1

CN12

8

2

3

4

1

4321

Electric

box

1

2

3

5

6

2

3

4

1

4 3 12

4 23

21

87652 3 41

6541 2 3

6

5

4

3

2

1

7

8

4

MOTOR DAMPER

F.THERMISTOR

THERMAL

FUSE (73:)

CN9D

4

3

2

1

2

4

1

3

56

57 692110

12

21

1112

9

2 3 4

1

1

2

2

1

4 3 12 16151413 1112 10 9 78

6 5

4

3

2

1

CN4D

8

1

2

3

4

1

WATER PIPE

HEATER

S.THERMISTOR

DIVIDER HEATER

(I/S)

FAN MOTOR

ICE-TRAY

HEATER

ICE-TRAY

THERMISTOR

ICE-GEAR BOX

I.THERMISTOR

MOTOR

DAMPER

Versa

Compartment

WATER PUMP

LED

652 3 4

1

6542 3

1

652 3 4

1

V. THERMISTOR

Vegetable compartment

LED board

CN8K

CONTROL BOARD

Refrigerator compartment door

Refrigerator

Compartment

Vegetable

compartment

Vegetable compartment door

Freezer compartment door

Ice compartment / versa compartment door

Freezer

Compartment

C. THERMISTOR

R. THERMISTOR

R-COMPARTMENT

ROOM LIGHT

MOTOR DAMPER

Slide

Compartment

26

9

7 13

5

CN50G

3 1

CN2A

57 3 1

CN3A

8 7 5 4 13

CN7S

1110

1

432

1

2

DEF.THERMISTOR

4

2 3 41

Machine

chamber

fan motor

3

2

1

MOTOR

PROTECTOR

Machine

chamber

compartment

COMPRESSOR

(View from rear

left side)

3

2

1

1 2 3 4 65

VEGETABLE

COMPARTMENT

HEATER 2

DEFROST HEATER

2

1

5

7

Three-way

valve

14

91

24

1

1 2 3

4

5

56

11

Brown

Blue

Violet

Gray

INVERTER

White

Black

Red

Yellow

Yellow

Blue

Black

Light brown

Blue

Brown

Yellow

Yellow green

Pink

Gray

Pink

Black

Black

Black

Violet

Yellow

Blue

White

Red / White

Red

Brown

Pink

Brown

White

Red

Yellow

Blue

Black

Blue

Red

Blue Blue

Red Red

Yellow green

White

Red / White

Sky blue

White White

White

White

Yellow

White

Red

Orange

White

White

Yellow

Gray

Orange

White

White

White

Light brown

Red

Sky blue

Sky blue

Sky blue

Sky blue

Sky blue

Blue

Blue

Light green

Light green

Sky blue

Yellow

Yellow

Red

Red

Rotational heater board

Violet

Light green

Orange

Red / White

Light green

Yellow green

Orange

Light green

Bright yellow

Blue

White

Red

Light green

Orange

Sky blue

Bright yellow

White

Yellow green

Red

Gray

Gray

Gray

Gray

Red

Yellow

White

Brown

Violet

Blue

Gray

Red

Sky blue

Ice

compartment

Red

Violet

Violet

Light green

Orange

Black

Violet

Light green

Orange

Black

Violet

Violet

Gray

Black

White

Red

Yellow

Yellow

Violet

Violet

Black

Black

Orange

Violet

Yellow

Blue

White

Red

Light green

Orange

Black

Pink

Red

Blue

WhiteWhite

Red

Sky blue

Black

White

White

Black

Violet

Red

Pink

Yellow

Violet

Bright yellow

Yellow

White

White

White

Red

Blue

Blue

Red

White

Yellow

Gray

Gray

Yellow

White

White

White

White

White

Gray

White

Red

Sky blue

Light brown

Yellow green

Blue

Pink

Pink

Yellow

Violet

Brown

White

Yellow

White

White

Red

Blue

Yellow

White

Red

Blue

Red

Vegetable

compartment

heater 1

White

White

Blue

Yellow

Red

White

Yellow

Black

Violet

White

White

Gray

Yellow green

Yellow green

Gray

Bright yellow

Black

Yellow

Violet

White

Sky blue

Red / white

Bright yellow

Red

Brown

Sky blue

Gray

Brown

White

Sky blue

Light green

Blue

Sky blue

Red

White

DOOR SWITCH

(FOR R-COMPARTMENT

& ICE COMPARTMENT)

Gray

Red

White

Gray

Sky blue

black

Pink

Gray

Red

Black

White

White

Red

White

Gray

Gray

Gray

Yellow

White

Brown

Sky blue

White

White

Sky blue

White

Gray

White

Gray

BOARD

TEMP. CONTROL

Black

Yellow green

Light green

Yellow green

Bright yellow

Sky blue

( ACTUAL WIRING DIAGRAM )

I.THERMISTOR (Ice making compartment thermistor)

V.THERMISTOR (Vegetable compartment thermistor)

S.THERMISTOR (Versa compartment thermistor)

DEF.THERMISTOR (Defrost thermistor)

ICE-TRAY THERMISTOR (Ice making tray thermistor)

F.THERMISTOR (Freezer compartment thermistor)

C.THERMISTOR (Slide chilled compartment thermistor)

R.THERMISTOR (Refrigerator compartment thermistor)

( When the doors are closed. )

6

Page 7

4

2500

100

930

1809

1100

745

20

REQUIRED SPACE FOR INSTALLATION

20

699

247

338

77

324

324

318

313

400

351

392

440

337

363

329

262

249

249

534

600

67

782214361

5

740 (Cabinet)

745 (Display)

361

1798 (Display)

1287 8

727(Pitch between the front wheels)

691(Pitch between the adjust bolts)

669(Pitch between the rear wheels)

162

7676

275

284

456

5

284

456

699

124

162

124

142

312

284

99

168

101

123

124

720

52

607

10

307

37

332 176

41

1072

(Display)

642

654

374

655

196

203

203

367

610

612

601

654

607

OUTLINES AND DIMENSIONS

MR-G50J-NZ

Unit : mm

H

W

R(L)

782

284

R(R)

782

456

I

214

284

S

214

456

V

361

745

F

361

745

R(L) : Refrigerator compartment (Left)

R(R) : Refrigerator compartment (Right)

I : Ice making compartment

S : Select compartment [Versa compartment]

V : Vegetable compartment

F : Freezer compartment

7

Page 8

5

REFRIGERANT CIRCUIT

MR-G50J-NZ

Muffler

Evaporator

Suction pipe

Charge pipe

(Low pressure side)

{6.35

Charge pipe

(High pressure side)

{4

Compressor

Radiator

plate

Dryer

#150

Capillary tube

{1.8✕{0.63✕2680(mm)

Cabinet pipe

Three-way

valve

Capillary tube

{

1.6✕{0.67✕2680(mm)

8

Page 9

6

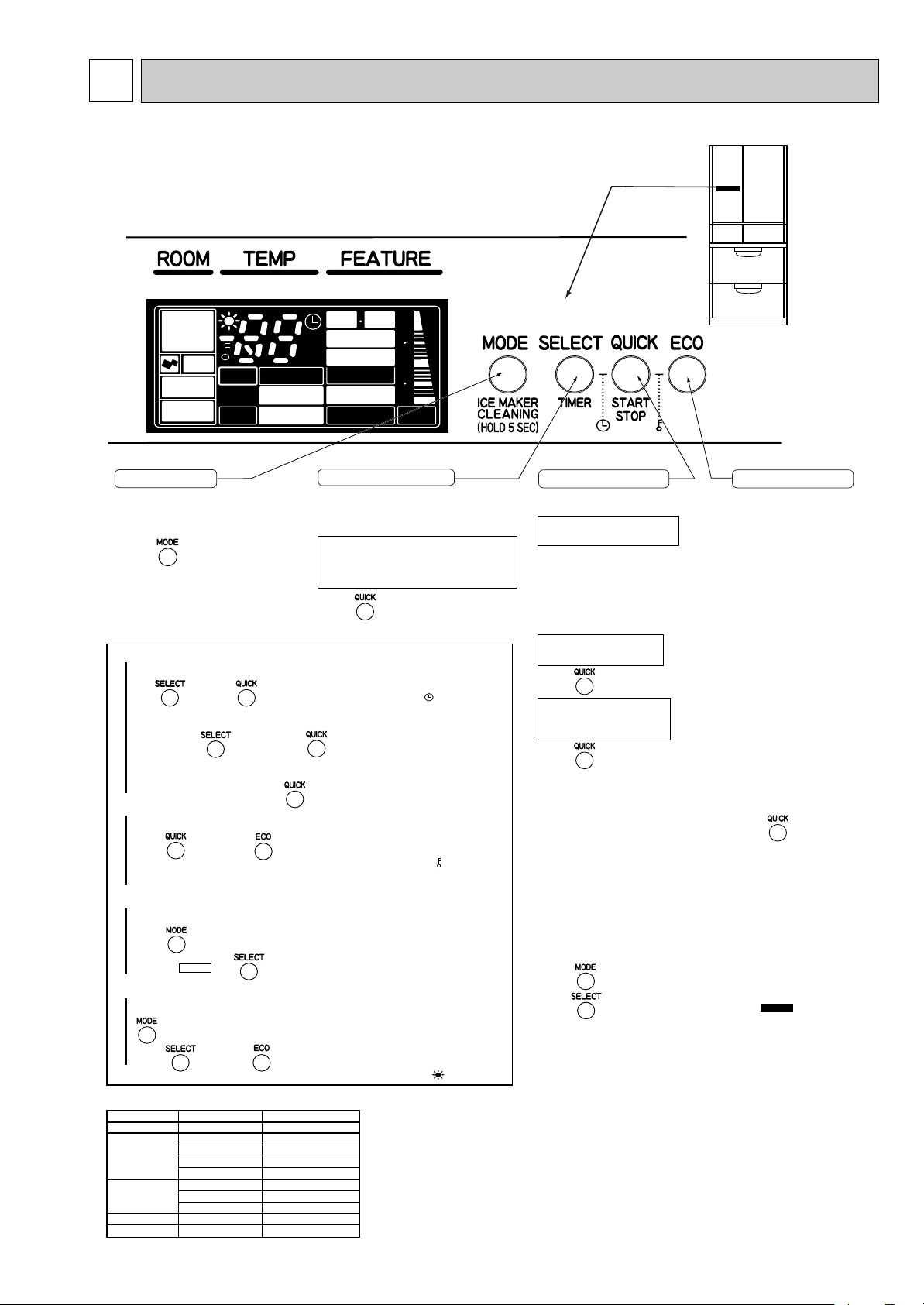

ECO MODE switch

:

Min

REF

VEG

FZR

QCK

REF

CHILL

SOFTF

F Z R

ICE

(

STOP

)

DEO

L M H

VEG

QCK ICE

REG ICE

ECO

CRL ICE

VR

D

L

M

H

MODE switch

●The switch functions to

select the required

compartment.

Press switch and display the

required compartment to apply the

function of temperature adjustment

or quick mode.

SELECTION switch

When setting the operation mode

of refrigerator, vegetable, and

freezer compartment to "Middle" at

the same time.

Press switch for about 3 seconds

until a "beep" sound is heard.

●The switch functions to set the

operation mode or temperature

of compartments individually.

QUICK MODE switch

Quick mode is finished

automatically.

It automatically

finishes about 2 hours later.

●Each compartment can

be cooled rapidly.

When stopping

quick mode halfway

When stopping

quick mode of all

compartments at once

Press switch again.

Press switch for about

3 seconds against one of the

compartments which is in

QUICK MODE.

w

●Each compartment

can be operated with

energy saved.

Convenient function

1

Cooking timer

Press switch and switch for 1 second at the same time. ( is displayed.)

(Cooking timer can be released in the same way.)

Cooking timer mode is set and "0" blinks.

Set the time with switch. ➝ Press to start ➝ Alarm sound will annonce the

completion of cooking period.

(1~99 minutes) (To stop the timer halfway through the operation, press

again).

2

Child lock

Press switch and switch for 3 seconds at the same time.

( is displayed.)

(Child lock can be released in the same way.)

3

Ice making stop

Press to select "ice making compartment".

➝ Select with switch.

ICE(STOP)

4

ON/OFF of LED for bacteria removal from water tank

to select "vegetable compartment".

Press switch and switch for 3 seconds at the same time.

Approx.

0 to 6

:

Approx. 0 to 6

:

Approx.

-2 to 2

:

Approx.

-9 to -5

:

Approx.

-18 to -16

:

Approx.

0 to 6

:

Approx.

-21 to -17

:

Approx.

-21 to -17

:

Approx.

3 to 9

:

Approx.

-21 to -17

:

Operating mode and Temperature range

Compartment

Refrigeratorcompartment

Middle

Refrigerator

Chilled

Soft freezing (Middle)

Freezer

Refrigerator

Ice making

Ice making stop

Middle

Middle

Versa

compartment

Ice making

compartment

Vegetable compartment

Freezer compartment

Mode Temp range

wThe temp range above is based on the data measured at the center of each

compartment with the door closed and with no food inside under the condition of

ambient temperature 30:. The range varies depending on circumstances.

To reset the unit to the initial setting, press

for 3 seconds. The setting of the refrigerator

compartment, vegetable compartment, and

the freezer compartment will be set to "Middle",

and fast cooling operation, energy-saving

operation, and cooking timer setting for all

compartments will be canceled.

w

To use "ice making compartment" as "refrigerator

compartment"

1Press to select "ice making compartment."

2Press for about 3 seconds and let flash.

4To get back to "ice making", just change the temperature

setting.

3After ice-making compartment is set to function as refrigerator,

take ice or water out of the ice tray which are automatically

dropped into ice storage bin. When ice-making function

will not be used for a while, wash the water tank well with

water and place it back after drying thoroughly.

R E FR E F

( is displayed.)

TROUBLESHOOTING

6-1 FUNCTION OF OPERATION PANEL

MR-G50J-NZ

(1) Function of normal operation

9

Page 10

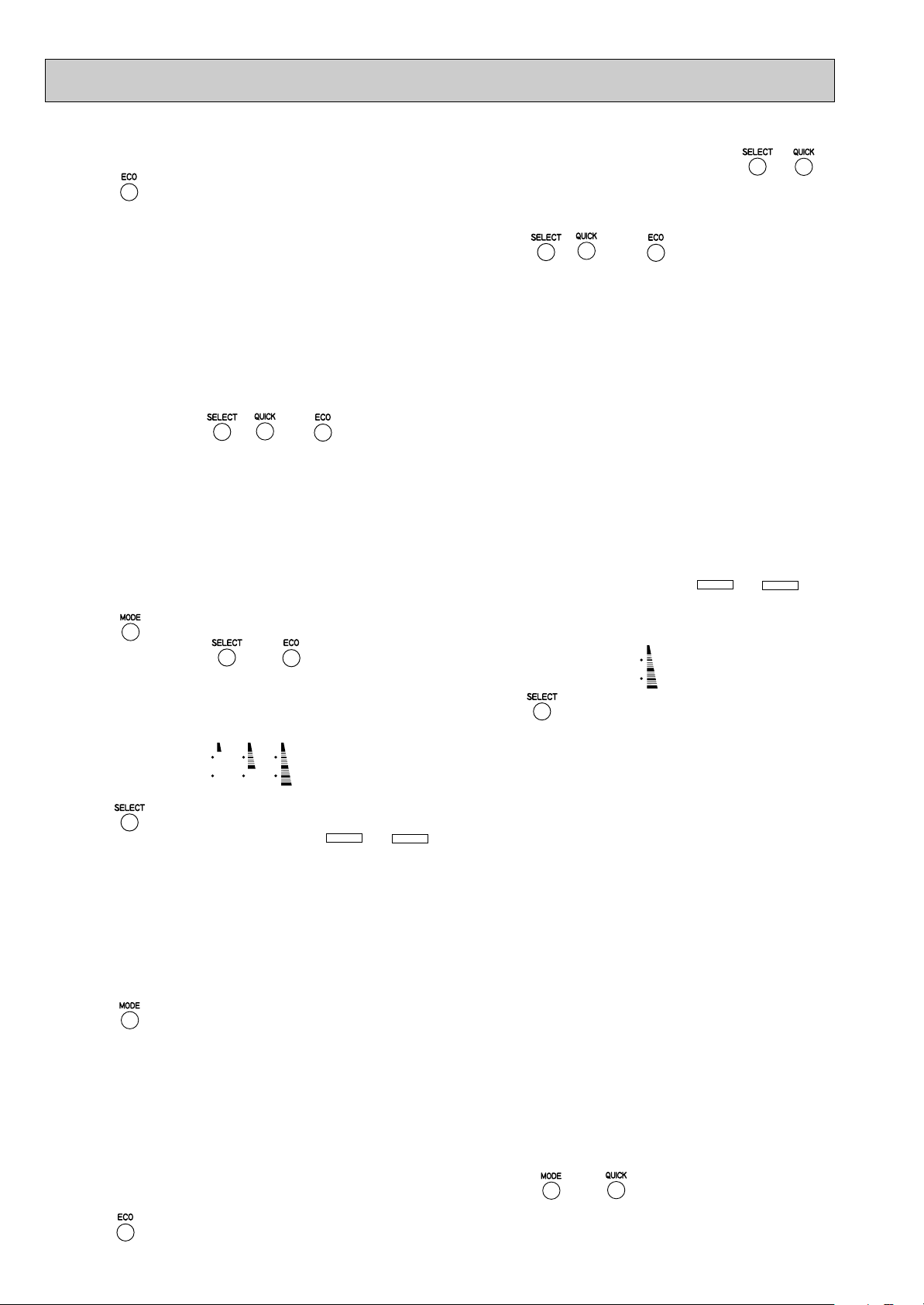

(2) Demonstration mode for shop display

L

M

H

L

M

H

L

M

H

R E F

F Z R

L

M

H

R E F

F Z R

Demonstration mode is not available when the temperature of freezer compartment is -7: or less even if ,

and are simultaneously pressed for about 5 seconds and a “beep” sound is heard. Cooling operation starts

instead.

11

Setting

●Within one minute after power supply is turned on, simultaneously press , , and switch for about

5 seconds with the door of ice making compartment left open. When the setting is complete, a “beep” sound is heard

and “D” is displayed.

22

Panel operation mode during demonstration mode

The panel operation mode changes to “manual” if any of the switches is pressed and it changes to “auto” if none of the

switches is pressed within 3 minutes after demonstration mode is set.

Manual mode: Panel indication changes according to switch operation.

Auto mode: Panel indication is automatically changed.

33

Release

●Simultaneously press , and switch for about 5 seconds with the door of ice making compartment left open.

When the function is released, a “beep” sound is heard. “D” disappears and the panel indication gets back to normal.

Note: Follow the procedure above to release demonstration mode as it cannot be released by simply turning

on/off the power supply.

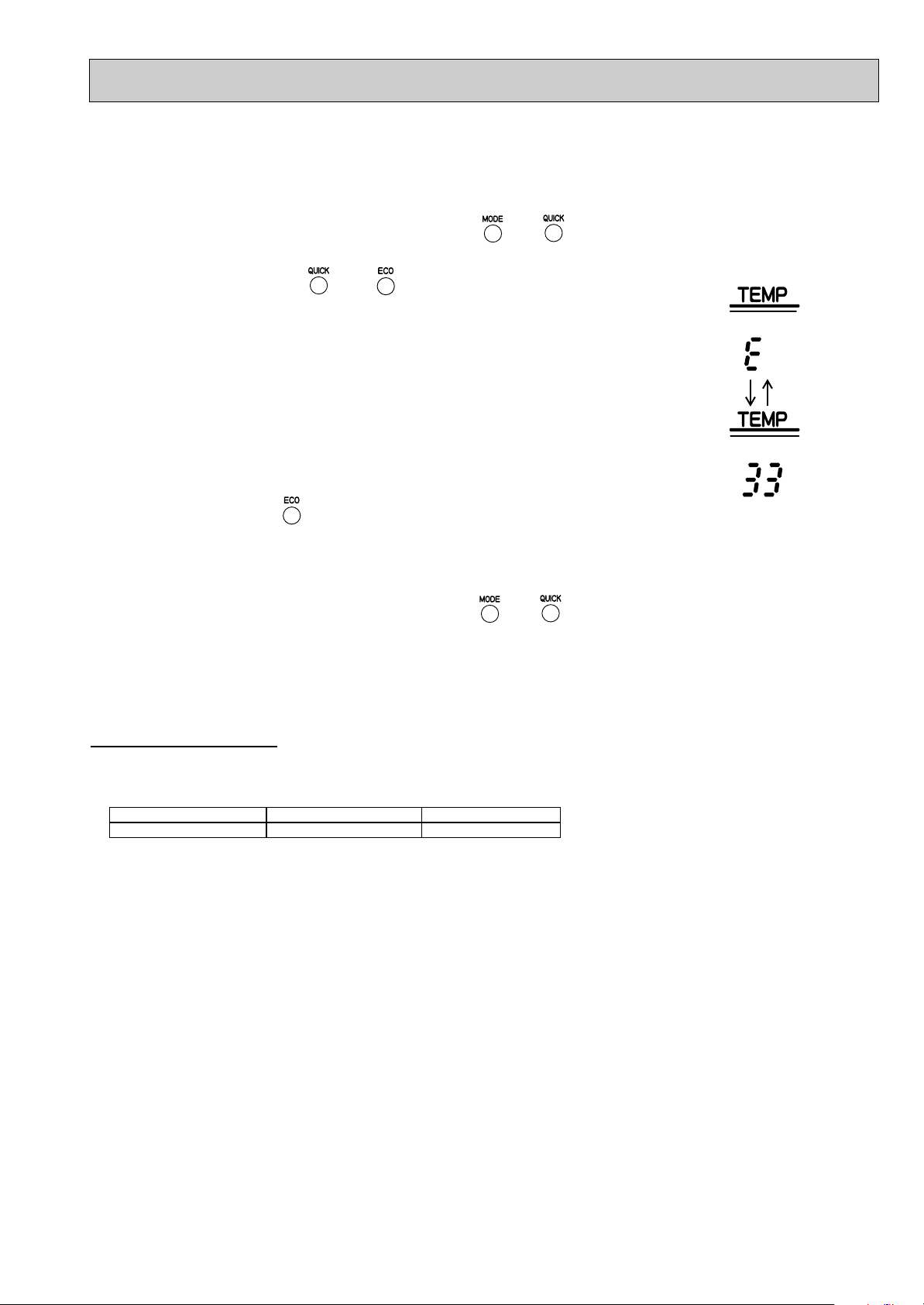

(3) Fine adjustment of temperature

Fine adjustment of temperature is available for refrigerator compartment, freezer compartment and versa

compartment.

As for versa compartment, however, it is only available when the compartment is set to or .

11

Setting

●Press switch to select refrigerator compartment, freezer compartment or versa compartment.

●Simultaneously press and for about 3 seconds until a “beep” sound is heard.

●The indication changes as show in the right.

22

Fine adjustments of temperature

Temperature adjustment is made by approximately 0.3-0.5: by pressing and it is indicated with 15-steps bars

on the panel. The temperature displayed on the panel, however, changes by 1: and might not change according to

fine adjustment.

Example of display:

In case of versa compartment

●Press to make versa compartment function as refrigerator or freezer .

When the blinking marks on the display, or , are lit in 3 seconds, apply fine adjustment of temperature.

33

Release

Follow the same procedure as setting and the finely-adjusted temperatures are reset for refrigerator compartment, freezer

compartment and versa compartment at once.

(4) Ice making test / Self-check

This function is not available during the following modes: Child lock, Demonstration, Cooking timer, Changing the

rotational speed of compressor, and Error code display.

11

Setting

●Press for about five seconds.

22

Operation and its display

●While automatic ice making is testing, the indication of ice making compartment setting blinks on LCD.

●When something is faulty, the error code is indicated.

33

Release

The test automatically finishes in 10 minutes and the error code changes to temperature display.

(5) Thermistor temperature check mode

11

Setting

●With the door of ice making compartment left open, simultaneously press and for about 3 seconds until a

“beep” sound is heard and “88” blinks.

●Press with the door left open.

10

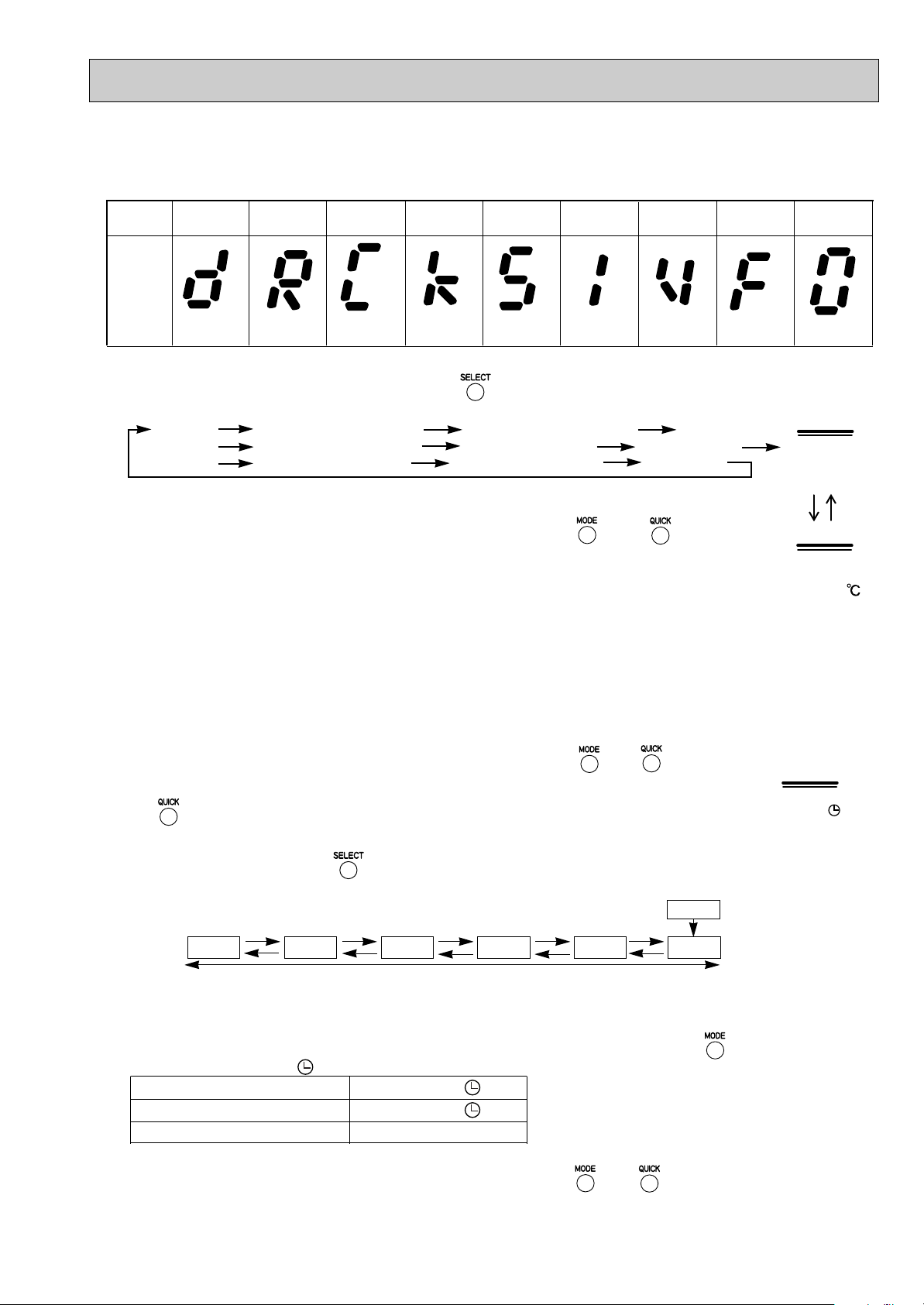

Page 11

22

d

-28

TEMP

TEMP

52

TEMP

Display

After the setting is complete, the kinds of thermistor and its temperature are alternately shown on the panel.

In case of abnormality, the display returns to current temperature. Please note that the temperature detected

by thermistor may be a little different from the real one due to the influence of refrigerator temperature.

Kind of

thermistor

Display

Defrosting

Refrigerator

compartment

Slide chilled

compartment

Ice making

compartment

Versa

compartment

Ice making

tray

Vegetable

compartment

(d) (R) (C) (K) (S) (I) (V) (F) (O)

Freezer

compartment

Outside air

33

Change of display

●While thermistor temperature check mode is set, press . Ashort beep sound is heard at each press

and the thermistor is changed in the order below.

Defrosting Refrigerator compartment Slide chilled compartment

Ice making compartment Versa compartment Ice making tray

Vegetable compartment Freezer compartment Outside air

W The defrosting thermistor is always selected first at the beginning of the setting.

44

Release

●With the door of ice making compartment left open, simultaneously press and

for about 3 seconds until a beep sound is heard. The temperature of thermistor disappears

and the display gets back to current temperature.

●The function is automatically released one-hour later.

●Follow the procedure above to release this mode. For the prevention of the compressor, avoid releasing

it by plugging and unplugging the power cord.

(Ex.) When defrost

thermistor

reads -28:.

(6) Change mode of compressor rotational speed

Operation sound can be checked by changing the rotational speed of compressor. Always conduct a check while the

compressor is operating and the “-” mark is not on the display, which shows the compressor stops. If the “-” mark is on the

display, unplug the power cord and then plug it in a few seconds to operate the compressor. Also, this function is not

available during the following modes: Child lock, Demonstration, Cooking timer, Thermistor temperature check and error

code display.

11

Setting

●With the door of ice making compartment left open, simultaneously press and

for about 3 seconds until a “beep” sound is heard, and “88” blinks.

●Press with the door left open.

(Ex.) When the rotational

speed is 52 rps

22

Changing the rotational speed

●After the setting is complete, press and the rotational speed of compressor alternately changes in 6 steps.

The rotational speed (rps) is shown on the panel. Basically the compressor starts operating at level 5, however, it depends

on model or specification change.

Level 0 Level 1 Level 2 Level 3 Level 4 Level 5

Low speed

W Note: Operation sound may get increased in the process of changing the speed, but that does not mean any

33

ON and OFF of machine chamber fan motor

Under this function, fan motor in machine chamber can be switched on and off at each press of switch.

The on/off state is shown with mark on the panel.

44

Release

●With the door of ice making compartment left open, simultaneously press and for about 3 seconds until a

“beep” sound is heard. The screen returns to the temperature display.

●The function is automatically released one-hour later.

●Follow the procedure above to release this function. For the prevention of the compressor, avoid releasing it by plugging

and unplugging the power cord.

problem. Check the operation sound when the rotation is stabilized.

Machine chamber fan motor

ON

OFF

Display of

Displayed

Not displayed

11

Normal

High speed

Page 12

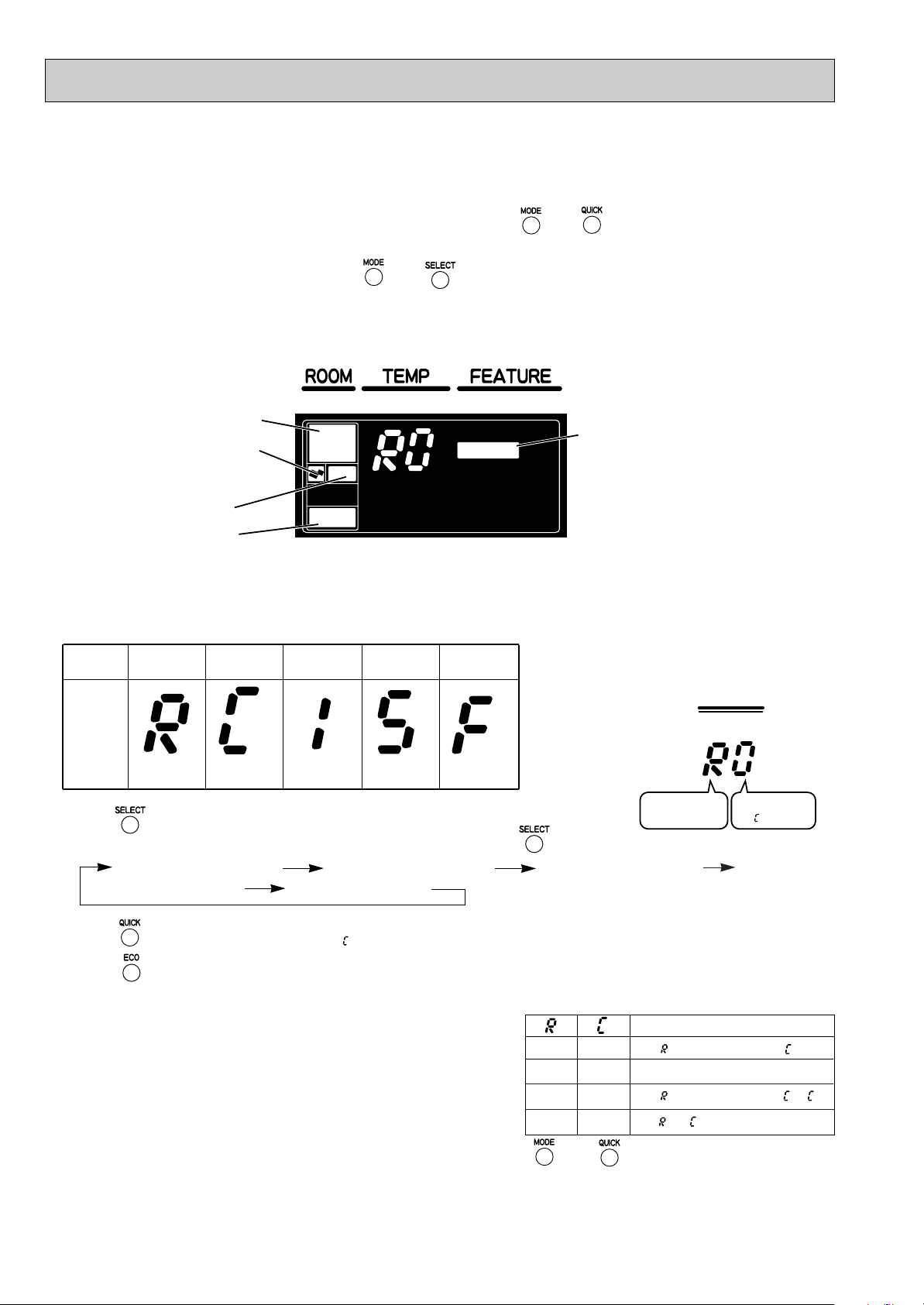

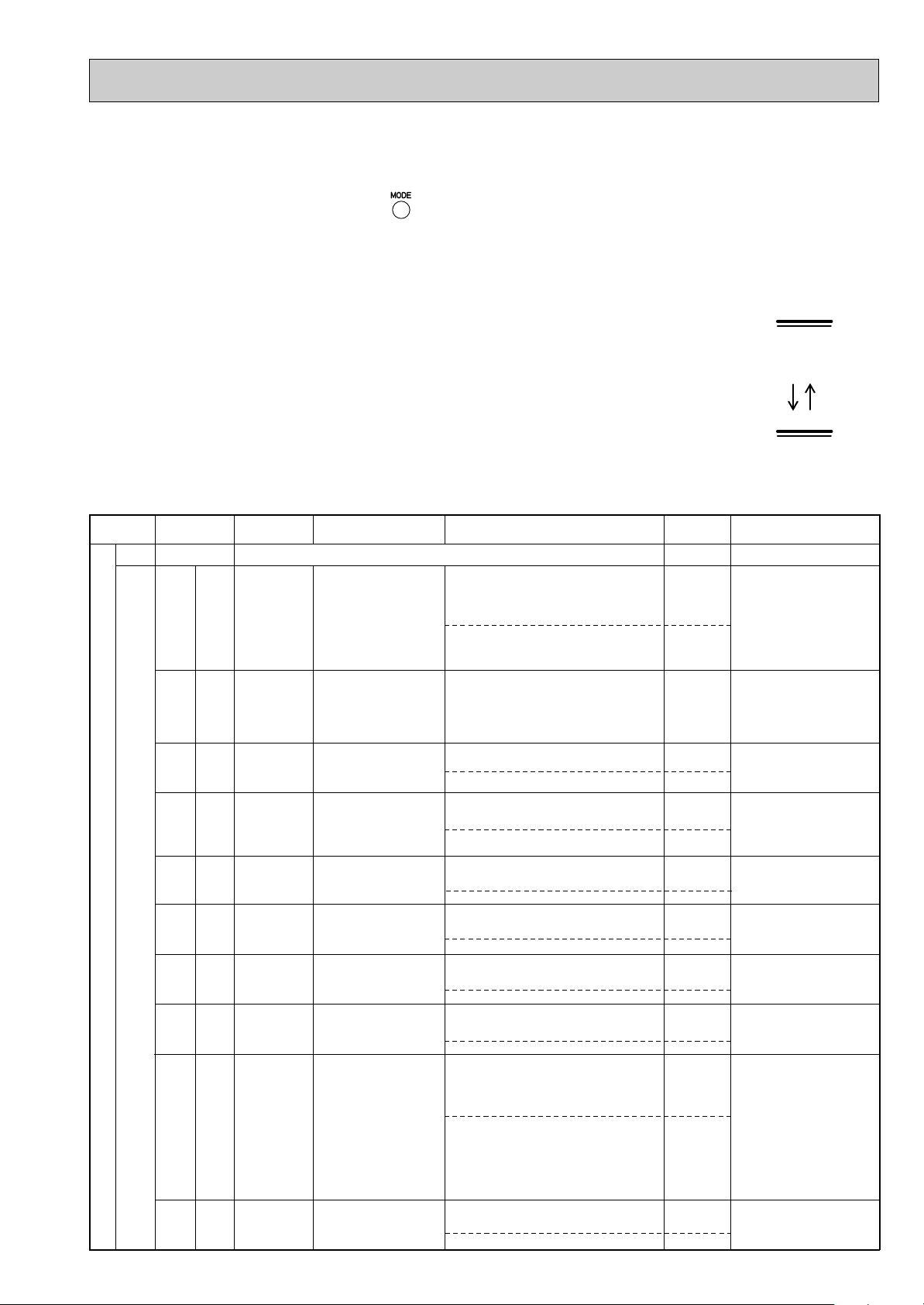

(7) Damper Operation Mode

(1)Damper to

be set up

(2)" " to open,

" " to close

0

TEMP

Ice making compartment

Freezer compartment

Slide chilled compartment

Refrigerator compartment

REF

FZR

CHILL

VR

Versa compartment

During damper operation mode, the damper is forcibly opened and closed and the state of

damper is shown on the panel.

11

Setting

●With the ice making compartment door left open, simultaneously press and for about 3 seconds until a

“beep” sound is heard, and “88” blinks.

●With the door left open, simultaneously press and for about 3 seconds until a “beep” sound is heard.

22

Status display of each damper

Each compartment display turns on when each damper is open and turns off when each damper is closed.

Ex.) When all dampers are open;

33

How to make each damper open or close

Although the state is shown on the panel, check airflow and confirm the damper is really opened or closed. However, air

does not come out when the door is closed, so put a magnet on the door switch to simulate the condition of the door closed.

●Change of display

Kind of

damper

Refrigerator

compartment

Slide chilled

compartment

Ice making

compartment

Versa

compartment

Freezer

compartment

(Ex.) When making the damper of

refrigerator compartment

open

Display

(R) (C) (I) (S) (F)

(1)Press to select the damper to be set up.

A “beep” sound is heard and the kind of damper is changed every time is pressed.

Refrigerator compartment Slide chilled compartment Ice making compartment

Versa compartment Freezer compartment

(2)Press to “0” to open the damper or “ ” to close the damper.

(3)Press for about 3 seconds to convey the setting to the damper.

A“beep”sound is heard if the setting has been conveyed.

After the setting is conveyed, the damper starts operating

and the display blinks. It stops blinking and starts to light

when the operation stops automatically. Please note that the

setting cannot be changed when the damper is operating.

44

Release

●With the door of ice making compartment left open, simultaneously press and for about 3 seconds until a

“beep” sound is heard. The screen returns to the temperature display.

●This function is not automatically released.

●Follow the procedure above to release this function. For the prevention of the compressor, avoid releasing it by plugging

and unplugging the power cord.

As the damper of slide chilled compartment opens and

closes in conjunction with the damper of refrigerator

compartment, it is necessary to set them to the either

of the following.

How to set

Open

Close

Open Close

Close Close

Open

Open

00

Set to

and then set to 00.

Not available

Set to 00and then set to .

Set to .

12

Page 13

(8) Error history display mode

Error history can be observed in the error history display mode.

Use this mode when the actual problem of the refrigerator is different from the error which

was displayed at the service-call received.

11

Setting

●Open the door of the ice making compartment, and press and together

for 3 seconds until a “beep” is heard and and “88” blinks.

●With the door left open, press and together for 3 seconds until a “beep” is heard.

22

Display details

●Same as the error display and trouble locating. (Refer to 6.2(3))

●When there is no recorded error, “ — ” will be displayed.

●When several errors have occurred, error will be displayed in the increasing numerical

order, as in the error display and trouble locating.

(Ex.) In case errors in the ice tray thermistor (e10), refrigerator thermistor (e13) and

refrigerator fan motor (e31) have occurred:

ee➝1100➝1133➝3311➝ee➝1100➝1133➝3311

33

Check points and resetting the error history

●Follow the treatment procedures shown in the self-check.

●After the treatment, press for 3 seconds to reset the error history.

“ — ” will be displayed when the data is reset successfully.

●Perform the self-check again (Refer to 6.2) to confirm there are no dysfunctions.

44

Release

●Open the door of the ice making compartment, and press and together

for 3 seconds until a “beep” is heard.

The display will return to the normal temperature display.

●Function is automatically released in an hour.

●Follow the procedure above to release this function. For the prevention of the compressor, avoid releasing it by plugging

and unplugging the power cord.

·····

(Ex.) When there is problem

with the ice maker gear box.

Door Buzzer System :

Door buzzer has been installed so that one will not forget to close the door.

When the door of refrigerator compartment or ice making compartment is left open for a minute, the buzzer starts ringing and

informs that the door needs to be closed.

When door is left open for:

Buzzer

1 minute- 4 minutes

Buzzer rings every 1 minute

More than 5 minutes

Keeps ringing

The buzzer will stop ringing as soon as the door is closed.

However, this buzzer system does not work when the door is not widely open like when something is pinched between the

door and refrigerator.

If the door is not closed completely, the temperature inside the refrigerator will rise and it will be a cause of spoiling the food

inside.

When the buzzer does not stop even if all the doors are closed, abnormality may occur in door switch.

If the buzzer keeps ringing and annoying, it can be stopped by the following operations.

1 Perform the ice making test operation.

(Note: If the test is conducted with water in the ice tray, water may fall into the ice storage bin because the tray is rolled over

in the ice making operation.)

Buzzer sounds when a trouble is found in refrigerator fan motor or in machine chamber fan motor. The buzzer sounds every

time the door is closed until the fan motor gets to operate correctly.

(Check the error code by following the steps in Specification of display in self-check result on page 14.)

13

Page 14

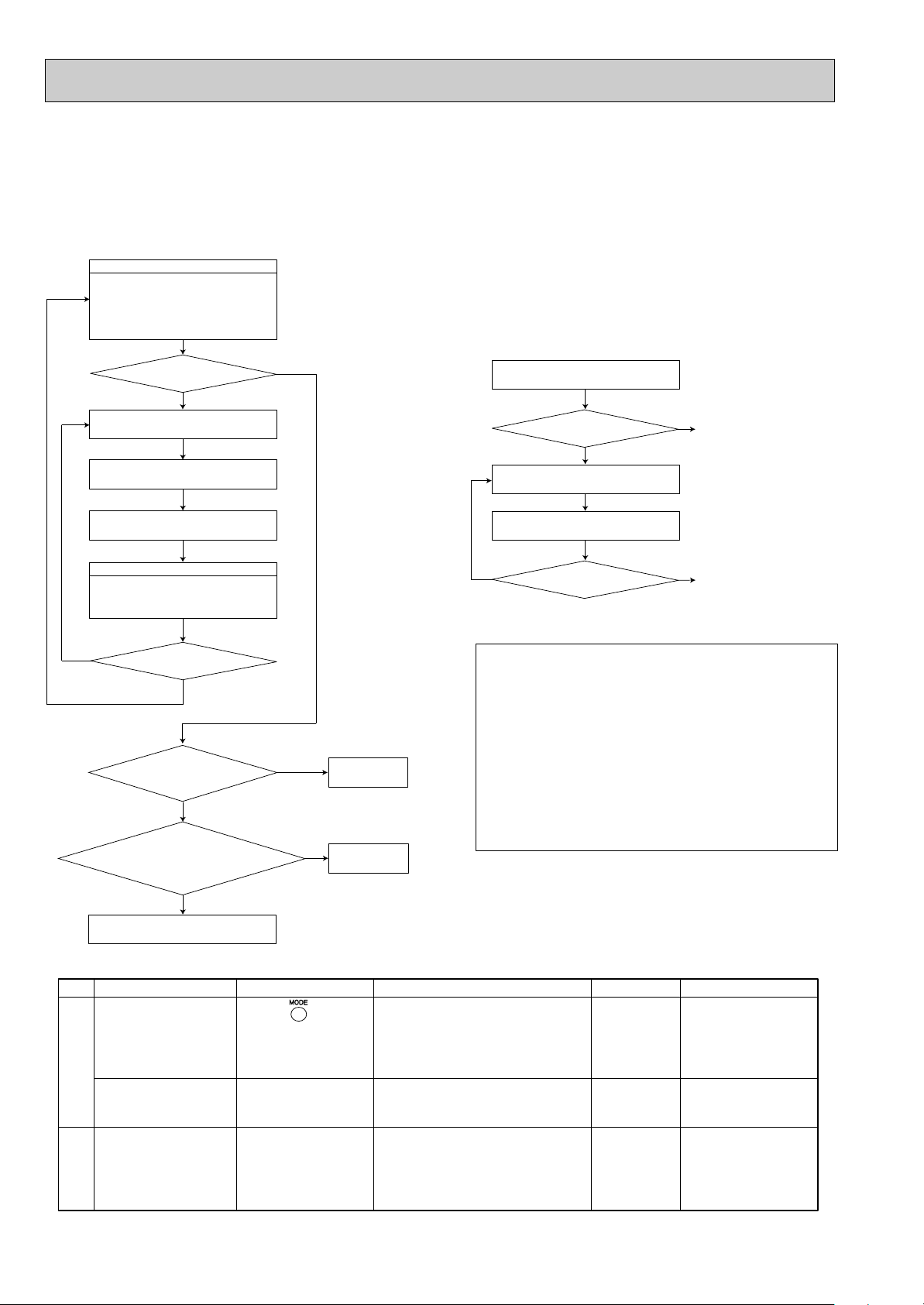

6-2 FLOWCHART OF SELF-CHECK

A

Self-check

Error history mode (Refer to 6.1(8))

Problem may recover automatically.

Perform the following if error is not displayed

before treatment or the error which was displayed

at the time power of the unit was turned on is not displayed.

Operate the ice-making test.

(Current displayed error: Refer to 1

in the table below.)

The display of ice making compartment setting will blink during the test.

c

D

D

Self-check

Plug the power cord into outlet.

(Current displayed error:

Refer to 2 in the table below.)

Locate the trouble according to LED

indication. (See page 15,16)

Is error displayed?

Is error displayed?

Is error displayed?

Release error displayed

mode, and the self-check

is finished.

Release error display

mode and perform the

self-check again.

(go to A)

Note1: Self-check cannot detect abnormalities in the following parts.

See page 19-31 for troubleshooting.

Door switch

Motor damper

Heater (Water pipe / Vegetable compartment heater, etc.)

Water pump motor

Note2: If any abnormality is found when switch is turned on, compressor

and fan motor are suspended for 10 minutes.

Note3: The alarm beeps when some abnormalities (motor-locked) have

occurred at the refrigerator fan motor restarts its normal operation.

Note4: If any abnormality occurs in compressor's inverter circuit,

the compressor and the refrigerator fan motor stop for 10 minutes

(not only when plugging the power cord).

Yes

No

Is error displayed?

Was more than one error

displayed during repair?

No

Yes

No

Yes

NoYes

Yes

Yes

During the ice-making

test mode, watch the

operation ice-maker

gear box and water

pump in refrigerator.

*Wait 10 minutes

before inserting

the cord once

it's unplugged.

(if the cord is

plugged in within

10 minutes, error

may be displayed.)

B

Unplug the power cord from outlet.

Repair /replace defective part(s)

according to LCD indication.

Self-check is finished.

Set the error display mode.

Reset the error history.

(Refer to 6.1(8))

Perform self-check

procedures B through C.

Perform error

history mode.

No

No

Was the error which was

displayed at the service-call received

was turned on displayed?

Was treatment performed?

Perform error

history mode.

D

Operation method Display or self-check operation Display time OthersItem

1Ice making test operation.

All items except (*6) listed

up on the table at page

17 will be checked.

1.Conduct the automatic ice making test.

(The display of ice making compartment

setting is blinked)

2.When trouble is found, all error codes

except e50-e55 are displayed.

3.When error is not found, nothing is

displayed.

For 10 minutes

after setting.

Self-check is not available

during child lock, cooking

timer, changing the rotational speed of compressor,

checking the temperature

of thermistor, damper operation and demonstration

modes.

Self-check is not available

during child lock, cooking

timer, changing the rotational speed of compressor,

checking the temperature

of thermistor, damper operation and demonstration

modes.

Self-check is not available

during demonstration

mode.

For 10 minutes

after power is

supplied.

For one hour

after setting,

or until mode

is released.

1.When trouble is found, all trouble except

e50-e55 and displayed.

2.When error is not found, nothing is

displayed.

1.When trouble is found, all trouble except

e50-e55 and displayed.

2.When error is not found, nothing is

displayed.

Press the switch.

for 5 seconds.

Plug the power

cord into outlet.

Refer to 6.2(3)

Error history

display mode.

2Power input.

All items except (*6) listed

up on the table at page

17 will be checked.

3Error history

(current displayed error)

Self-check

Display error

history.

MR-G50J-NZ

(1) Troubleshooting with self-check

This refrigerator has self-check feature to clarify and indicate where & what the trouble is.

You can perform operation checks and identify malfunction of electric or electronic parts.

Error history is recorded and can be displayed by the refrigerator.

●Self-check and error display method and operation

●Release of self-check display mode

self-check finishes automatically. Error cord display is automatically released 10 minutes later.

14

Page 15

(2) Timing in self-check

e

33

TEMP

TEMP

Trouble of Defrost heater : Self-check is conducted after defrosting.

Trouble of Ice maker : Press the switch on the panel for 5 seconds. (Ice making test mode.)

Trouble of Fan motor : Open the door and then closed it.

Trouble of Inverter : Check the error when compressor starts up or is operating.

Trouble of Thermistor : Self-check is continuously working

(Make sure to confirm the display before unplugging the power cord

because it is automatically reset once the power cord is pulled out.)

The setting of ice making compartment blinks on LCD during the test operation.

When abnormality is found in fan motor, buzzer sound is heard every time the door

is closed.

(3) Error display and trouble locating

1. Display details

After conducting the self-check by referring to 6-2(1), error codes are displayed in the temperature display section. ”

When several errors occur, they are displayed alternately. However, the error whose code has

a smaller number has priority to be displayed first.

(Ex.) In case the errors of ice tray thermistor (

fan motor (

✻ For 2 minutes in self-check, a high-tone sound is heard due to the operation check of damper .

ee

” and two digit error code flashes alternately as shown in the right figure.

ee1100

ee3311

) are happening simultaneously;

), refrigerator thermistor (

ee➝1100➝1133➝3311➝ee➝1100➝1133➝3311

ee1133

) and refrigerator

·····

2. Check point and treatment

Display Error code

Testing

(*1)

e

02

e

e 03

e 10

e

LCD

Self-check

e

e

e

e

e

01

(*5)

Communication

error of

operation panel

Communication

error of inverter

Trouble of

model judgement

Trouble of ice

making tray

thermistor

Trouble of

freezer com-

11

partment

thermistor

Trouble of

defrost

12

thermistor

Trouble of

refrigerator

13

thermistor

Trouble of

chilled compart-

14

ment thermistor

Trouble of

versa compartment thermistor

15

Trouble of vegetable compart-

16

ment thermistor

Trouble

Detecting method

(*3)

Ice maker is under testing

When the following communication errors occur

between control board and

operation P.C. board:

•They transmit and receive

data that has nothing to do

with settings.

•They cannot transmit and

receive data each other

for about two seconds.

When abnormality is found in

the communication between

refrigerator control circuit and

inverter control circuit in control board. (When they do not

transmit and receive data for

10 seconds.)

When the model of control board is different from

the one of operation P.C.

board.

When there is a short or

open circuit in the ice

making tray thermistor.

When there is a short or

open circuit in the freezer

compartment thermistor.

When there is a short or

open circuit in the defrost

thermistor.

When there is a short or

open circuit in the refrigerator compartment thermistor.

When there is a short or

open circuit in the chilled

compartment thermistor.

When there is a short or

open circuit in the versa

compartment thermistor.

When there is a short or

open circuit in the vegetable compartment thermistor .

Check point Treatment

1. Connector CN8K, CN7S on control board

4-pin relay connector (hinge)

4-pin connector on operation P.C. board

2. Trouble of control board and operation

P.C. board

1. Check the model name of control board

2. Check the operation p.c. board.

1. Connector CN7S on control board, Ice gear

box 6-pin relay connector, 8-pin relay

connector

2. Check the resistance of thermistor.

1. Connector CN7S on control board. 6-pin

relay connector

2. Check the resistance of thermistor.

1. Connector CN7S on control board. 2-pin

relay connector

2. Check the resistance of thermistor.

1. Connector CN7S on control board, 4-pin

relay connector

2. Check the resistance of thermistor.

1. Connector CN7S, on control board, 6-pin

relay connector

2. Check the resistance of thermistor.

1. Connector CN7S on control board, 6-pin

relay connector

2. Check the resistance of thermistor.

1.

Connector CN7S on control board, 4-pin

relay connector

2. Check the resistance of thermistor.

Repair the

contact failure.

Replace

Replace the

control

board.

Replace

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

(Ex.) When ice maker gear

box is defective.

Control

Keep the same operation as

the one before the communication error has occurred.

Compressor OFF.

Keep operating the unit, and

conduct error code indication

only.

When the compartment door

has been closed for 3 hours

and when freezer compartment

thermistor is -10: or less, icedetecting operation starts.

After 10 minutes off, the

compressor repeats 30minute ON and 20-minute

OFF.

The defrost heater won’t be

turned ON.

Synchronize the open/close

status of R damper with that

of C damper.

Synchronize the open/close

status of C damper with that

of R damper.

•When S-compartment is

used as “freezer”: S-damper

is open when compressor is

turned on, S-damper is

closed when compressor is

turned off.

•When S-compartment is

used other than “freezer”: Sdamper remains open for

the first 3 minutes and then

closed for the rest of time.

S-compartment:

Versa(select) compartment.

•When R-damper is open,

V-heater is turned on.

•When R-damper is closed,

V-heater is turned off.

15

Page 16

Display Error code

e

e

e

30

e

32

e

e

e

LCD

Self-check

e

e

e

e

e

e

54

Trouble of ice

making compartment

thermistor

17

Trouble of outside air ther-

18

mistor

Trouble of

defrost heater

(*6)

Trouble of refrigerator fan motor

31

Trouble of

machine chamber fan motor

Trouble of ice

maker gear box

33

Clogging of

refrigerant

pipe or trouble

34

related to

compressor

Trouble of electromagnetic

41

three-way valve

Trouble of invert-

er circuit

50

Trouble of bus-

51

bar voltage

Trouble of inverter

software reset

52

function

Trouble of startup

, synchronization

or overcurrent

53

detection

Trouble of power

supply voltage

Trouble

Detecting method

(*3)

When there is a short or

open circuit in the ice

making compartment

thermistor.

When there is a short or

open circuit in the outside air thermistor.

When defrosting is not

finished in 2 hours.

•When motor doesn’t

rotate even though

power is on.

•When the waveform,

which indicates the rotation times of motor, cannot be detected.

•When motor doesn’t

rotate even though

power is on.

•When the waveform,

which indicates the rotation times of motor, cannot be detected.

When the gear box operation

is not finished in 30 seconds.

(T0: Defrost thermistor temperature at power input, T1:

Defrost thermistor temperature when 15 minutes have

passed from the power input)

•When the difference

between T0 and T1 is

T0[T1. (*5)

When defrost thermistor reads

-10:or above in five minutes

after the compressor’s

startup.(*5)

•When there is any trouble in

the circuit which detects cur-

(*6)

rent of compressor.

•When the range of bus-bar

voltage is not approx. DC

(*6)

260-390V.

•When the inverter driving

software malfunctions.

•When there is no current at

compressor startup.

•When phase current exceeds

5.5A at compressor startup.

•When phase current exceeds

3.3A during compressor operation.

•When current of 5.3A or more

(*6)

runs into the bus-bar of

control board.

When bus-bar voltage (full

wave voltage) is DC 390V or

(*6)

above in power input.

Check point

1. Connector CN7S on control board, 6-pin,

9-pin relay connector

2. Check the resistance of thermistor.

1. Connector CN2A on control board

Defrost heater plug and receptacle, 1-pin

relay connector

Thermal fuse 4-pin, 8-pin relay connector

2. Check the resistance of defrost heater.

3. Check the continuity of thermal fuse.

1. Connector CN4D on control board,

Refrigerator fan motor 6-pin relay connector

2. Check refrigerator fan motor operation.

1. Connector CN4D on control board,

4-pin connector, 4-pin relay connector

2. Check machine chamber fan motor operation.

1. Connector CN8K on control board,

Ice gear box 6-pin relay connector, 8-pin relay connector

2. Ice gear box frozen point

3. Check the trouble of the ice gear box with the

ice making test operation.

Check the compressor and the pipe.

Connector CN9D on control board

5-pin connector in machine chamber

Refer to “Compressor does not operate” at page 21.

1. Different voltage of power supply outlet

2. Trouble of relay in the circuit on the control board

Treatment

Repair the

contact failure.

Replace

Replace the

operation

P.C. board.

Repair the

contact failure.

Replace

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Repair the

contact failure.

Replace

Replace

Repair the

contact failure.

Replace

the control

board.

Control

•When ice making compart-

ment is used as “refrigerator”, synchronize I-damper

with R-damper.

•When ice making compart-

ment is used as “ice making”, synchronize I-damper

with F-damper.

Compressor is activated at

“Speed-level 2.”

The defrost heater is

stopped and if the next

defrosting finishes in 2

hours, the error code will

disappear .

•3 minutes later, the refrigerator

fan motor is reactivated to be

checked.

•Until the fan motor gets to operate correctly, the buzzer sounds

every time the door is closed.

•3 minutes later, the machine

chamber fan motor is reactivated

to be checked.

•Until the fan motor gets to oper-

ate correctly, the buzzer sounds

every time the door is closed.

100 minutes later, the gear box is

reactivated to be checked again.

When cooling operation returns to

normal condition, the display of

error code disappears.

Check the operation of electromagnetic three-way valve and

then open the valve.

The compressor is suspended and reactivated 10 minutes later.

Refrigerator compartment room

light OFF

Heaters. OFF

Trouble of control board

(EEPROM

55

e

e

*1 : The setting of ice making compartment will be displayed and blinks during or after ice making test operation.

*2 : This operation is called the recovery operation:

If the damper has not operated ever once during the compressor operation, make the damper operate when the compressor stops.

*3 : When the resistance is ∞', the circuit is deemed open-circuitted.

When the resistance is 0', the circuit is deemed short-circuitted.

e01

*4 : Once

*5 : Characteristic value may change in order to improve the product.

*6 : The error codes

*7 : If those errors still continue for 1minute after the restart,

is detected, other errors would be ignored and not displayed on the panel.

e50

Therefore, be sure to perform ice making test operation in order to check if any abnormality indicated by these error codes occurs. (See page 14.)

related trouble)

Defective wiring

continuity or

trouble of control

board

56

e55

to

are not displayed even if those abnormalities occur at power input.

EEPROM (IC11M)

accumulates data necessary

(*6)

for control.

•When the data are not input

accurately.

•When microcomputer cannot

read the data.

The errors 50 to 53 keep

occurring over one and a half

hour.

(the situation, which compressor cannot be operated,

continues.)

Overcurrent detection error

occurred before the

compressor is activated.

e56

Refer to “Compressor does not operate” at page.22.

will be displayed again.

Replace

the control

board.

16

When abnormality occurs in

power input, the compressor

is suspended for 10 minutes.

When abnormality occurs in

normal operation, the compressor keeps operating.

•Error display starts after it is

regarded as e56.

•Error display continues until

defrosting starts or cooling oper

ation gets back to normal. (Error

display doesn’t disappear by

unplugging and plugging the

power cord.*7)

•Try to restart compressor every 3

minutes.

Page 17

6-3 BLOCK DIAGRAM OF PRINTED CIRCUIT BOARD

CN3A

CN4D

Control board

CN9D

CN8K

CN7S

Water pump motor

LED for bacteria

removal from water

tank

6-pin connector

6-pin connector8-pin connector

6-pin connector

Ice tray thermistor

Ice making

gear box

M

0

5

4

6

5

4

3

2

1

6

5

4

3

2

1

3

1

898

9

3

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

3 3

5 5

6 6

9 9

6

5

8

7

6

5

8

7

0

5

4

M

Ice making

compartment

thermistor

Water pipe heater

CN2A

9-pin connector

MR-G50J-NZ

Parts outside/inside of Refrigerator

For 325V system

•Compressor

For 230V system

•Defrost heater

•Vegetable compartment heater

1&2

•Rotational heater board

•Divider heater (I/S)

•Water pipe heater

•

Refrigerator compartment room light

•Ice making tray heater

•Setting up temperature, feature, quick mode and eco mode for each

compartment

•Display of self-check

•Outside air thermistor

•Buzzer

Control circuit of refrigerator

•Read/control each compartment temperature (Neuro-fuzzy)

•Control on timers

•Operation control of the parts such as fan

motor or heater, etc. equipped inside/

outside

Operation P.C. board

Control board

Inverter control circuit of compressor

•Inverter control of compressor

•Inverter-drive power module

•Detection of bus-bar voltage

For 12V DC system

•Refrigerator fan motor

•Machine chamber fan motor

•Motor damper

•Ice maker gear box

•Three-way valve

•LED for vegetable compart

ment.

•LED for bacteria removal from

water tank

For 5V DC system

•Freezer compartment thermistor

•Refrigerator compartment thermistor

•Defrost thermistor

•Slide chilled compartment thermistor

•Door switch (For refrigerator com

partment & ice compartment)

•Ice tray thermistor

•Ice making compartment thermistor

•Vegetable compartment thermistor

•Position-specifying switch in ice

maker gear box

•Versa compartment thermistor

6-4 AUTO ICE MAKER

MR-G50J-NZ

(1) Ice making cycle

Water supply

The ice tray is filled with water

from the water tank.

(2) Automatic ice maker circuit

Ice ejection

After the detection lever

checks the amount of ice, the

ice tray is rolled over for ice

ejection.

17

Ice making

Ice tray thermistor watches

and controls the ice making

operation.

Ice stock

Ice is stocked in the ice server.

Ice making capacity is about

100 - 120 cubes a day.

Stock capacity of Ice cubes is

about 100 cubes.

Page 18

(3) Operation by ice making test

Ice stock detective

lever detects the

Press the switch

for 5 seconds or

more.

(See “• Self check

and error display

method and opera-

amount of ice.

Detective lever once

come down to detection

point then return to the

original position.

tion, 1 Ice making

test operation” at

page 14.)

Ice making test completes

about 20 seconds later.

Ice tray

(Upper freezer compartment)

[Check point of automatic ice maker operation]

*Never touch the automatic ice maker while it is operating.

After the operational test, a popping sound is heard several times because the operation of three-way valve is checked automatically. During the operation, do not insert a hand into the automatic ice maker.

The ice tray is

rolled over and the

system is reset.

The ice tray rolls

over once to drop

the ice, then return

to the original position.

Detection lever

Water pump motor

is operates.

Remove the lid of

the water tank then

check the sounds

of water running.

Completion

When abnormality

occurs, the error code

is displayed on the

panel.

Inspect the abnormal

points by referring to

page 15, 16.

Check here.

(Lower-left part of refrigerator compartment)

(4) Maintenance for water pump and water pipe

Water pump & Light-type bacteria removing filter

1. Pull out the pipe.

Water

tank

Water pipe · Tank holder

1. Pull out water supply

pipe. Wipe the tank

holder with clean cloth.

•Do not let water flow into

the tank holder.

2. Turn the tank

pump to detach.

Tank

pipe

Water pump

Water

supply

pipe

3. Pull out the tank pipe, turn the cap

to remove, and then wash

the propeller with water.

•The propeller is

made of the magnet.

Wash it well with water

so that no alien substance remains on it.

Light-type bacteria removing filter

Tank holder

(5) Troubleshooting for automatic ice-maker

The ice-maker gear box may be defective, cooling may be poor or ice cubes may be full in the server.

1.Check inside of the ice server.

2.Measure the resistance of ice tray thermistor

circuit.

on the ice tray

Water or ice is

3.Check if the temperature of the freezer compartment is cool enough.

come out from

the tray

The ice does not

(It takes longer to make ice during summer

time or if the door is frequently opened.)

The water saucer may be defective, or the ice tray may get cracked.

4. Check the water pipe between the refrigerator

compartment and freezer compartment for dirt,

and foreign objects.

water

saucer

Water in

5.Check the condition of ice tray.

Tank pipe

Propeller

Cap

2. Separate pieces and wash with water.

packing

Aluminum pipe

4. Remove the light-type bacteria removing filter

and wash it in water.

Normally the filter need not be replaced. However, replace it

in the following condition:

•When the filter is clogged by passing something other than

water through the filter.

•When the filter is broken.

Cover

In such a case, contact the dealer that you purchased this

refrigerator.

5. Put the parts back in the reverse order of disassembly.

3. Reverse steps to replace the pipe.

•Twist the

aluminum

pipe to

replace it.

Side A

Side B

•Ice cubes are not stored flatly

and the amount is detected as

full.

➔Inspection

Water pipe

•Replace the water

pipe.

Be sure that sides A

and B fit flush to

each other.

•Food inside the ice server

•Open circuit (∞') or

short circuit (0')

•Not enough

•Clogging

•Freezing (For freezing, check

the pipe heater resistance.

•Broken or cracked

•Not placed properly

➔Replace the ice tray

thermistor.

➔Poor cooling

➔Clean the water pipe.

➔Defrost

➔Replace the tray.

➔Reinstall it properly.

Trouble with ice-making

in the ice tray

No water or ice

No waterdrops in water saucer

Water in the tank

holder

Chained ice,

Water leaking from

the ice server

6.Disassemble the water pump and check the

inside of the pipe.

•Dirt or foreign objects

➔Repair and explain to

the user for proper

usage.

7.Tank pipe is clogged , has a hole or is not

properly installed.

8.Check the motor coil resistance.

9.Check if there are any dirt or foreign object

which are difficult to remove in the water tank.

Also, check if there is any crack or deformation

•Clogging, disconnecting

•Hole or crack

•Open or short circuit

•Crack or deformation

➔

Clean / Reinstall it properly.

➔Change the tank pipe.

➔Check the water

pump.

➔Change the water

tank.

on the tank.

10.

Check the water pipe for dirt, and foreign

objects. Also, check the water pipe position and

connection.

11.

Check the water pipe (between F.compartment

and R.compartment) for clogging.

12.

Check the water pump operation by the icemaking test.

13.

Water spill at the installation of water tank or more water over the full water level may cause to from

•Clogging, disconnecting

•Hole or crack

➔Clean / Reinstall it

properly.

➔Replace the pipe.

•Clogging ➔Clean / Remove the

dirt.

•Water filling time is longer

than 9 seconds.

➔Replace the control

board.

chained ice.

14.

Measure the water pump coil resistance.

•Open or short circuit ➔Change the water

pump motor.

18

Page 19

6-5 FLOWCHART OF TROUBLE CRITERION

Weak

Low

High Chilled

Chilled

Middle

Refrigerator

Refrigerator

compartment

Slide chilled

compartment

Cooling Strong

Control board

CN2A

CN4D

CN7S

4-pin

connector

6-pin

connector

Refrigerator compartment room light

Refrigerator compartment

thermistor

Slide chilled compartment

thermistor

Motor damper

(for refrigerator compartment/

slide compartment)

9

0

1

2

9

0

1

2

6

5

4

3

2

1

6

5

4

3

2

1

1

2

3

4

1

2

3

4

4

55

8

1

4

11

8

1

L

M

Jumper to be cut

JP1

1; lowers

1; lowers

1; highers

1; lowers2; lowers

JP2 JP3 JP6JP4

Temperature change

Freezer

compartment

Refrigerator

compartment

Slide chilled

compartment

1; lowers

JP5

Versa

compartment

Ice making

compartment

Slide chilled

compartment

Refrigerator

compartment

Versa

compartment

Ice

making

compartment

Attach a

magnet bar

here.

Jumper

Operation P.C. board

MR-G50J-NZ

Excessive cooling

Are the temperatures of

refrigerator compartment/ set to “Low”?

Yes

Only food around the

air blowing part get

frozen

No

Expose the damper (for refrigerator compartment/ slide compartment) so that its operation can be visibly checked and

conduct an ice-making test. Does the baffle open/close ?

(Wait 1 minute for self-check).

(See “Self check method and its operation,1 Ice making

test operation” at page 14.)

Normal

Is the motor damper (for refrigerator compartment/ slide

Refrigerator compartment/ Slide chilled compartment

[1]

compartment) covered with frost?

No

Check the refrigerator compartment thermistor

Put refrigerator compartment thermistor into ice water (0:), dis-

connect the 4-pin connector, and measure resistance between

3 (white) and 4 (white).

No

Yes

•Resistance at 0: :approx. 6-7k".

Set the temperatures

to “Low”.

Keep the food away

from the blowing part

No cooling, poor cooling

Are the temperature of

refrigerator compartment/ set to “High”?

Yes

Open the refrigerator

compartment door with

a magnet on the door

switch to check that

cold air blows from the

outlet.

The baffle does not operate

Yes

Refrigerator compartment

thermistor abnormal

Yes

No

No

Replace the motor damper (for refrigerator compartment/ slide chilled

compartment)

❈Motor damper is combined with

control panel assembly.

Repair the frosted part.

Replace the refrigerator

compartment thermistor

Set the temperatures

to “High”.

Proceed to [5] at page

23.

Check the chilled compartment thermistor

Put chilled compartment thermistor into ice water (0:), dis-

connect the 6-pin connector, and measure resistance between

3 (white) and 6 (white).

Cutting jumper wires on operation P.C. board can

change the set temperature of each compartment.

Unscrew the back of operation p.c. board and remove

decoration panel to cut the jumper wires.

•Resistance at 0: :approx. 6-7k".

Chilled compartment

thermistor abnormal

w1

19

Replace the slide chilled

compartment thermistor

Page 20

Poor cooling

Control board

CN7S

CN4D

M

6-pin connector

Freezer

compartment

thermistor

Motor damper

(for freezer

compartment)

6

5

4

3

2

1

6

5

4

3

2

1

4

4

5

6

3

4

5

6

3

444

Filter board

Control board

Noise filter

CN1

CN2

CN2A CN50G

Compressor

M

Motor

protector

6-pin connector in machine chamber

1

3

3

1

1

3

1

3

1

3

5

1

3

5

5

7

5

7

1

2

3

4

5

1

2

3

4

5

M

1

Is the set temperature of freezer compartment set to “High”?

2

Does cool air come out of air outlet?

Operate the ice-making test at the place where the operation of

3

dampers (Refrigerator compartment and slide compartment ther-

Freezer compartment

[2]

mistor) is visible. Does the baffle open / close? (Wait 1 minute for

self-check).

(See “Serf-check and error display method and operation, 1 Ice

making test operation” at page 14.)

Check freezer compartment thermistor.

4

Yes

Yes

Normal

No

No

The baffles

do not

function.

Normal

Set the temperature to “High”.

Proceed to “The refrigerator fan motor does not work.”

Replace the motor damper (for freezer compartment ).

ww

Replace the fan grille as well as the motor

damper since they are combined together.

When compressor

operates, LCD indicates e41 as a

Exchange

the unit

result of self-check.

Dip freezer compartment thermistor into ice water (0:), and

measure the resistance between terminal 3 (white) and 6

(white) by detaching 6-pin connector at the left-back bottom of

vegetable compartment.

•Resistance at 0: :approx. 6~7k".

Defective thermistor

Replace freezer compartment thermistor

Not cooling at all(In case any error codes doesn’t appear as shown in page 21,22 even though mode switch is pressed for 5 seconds)

Yes

Is refrigerator in the demonstration mode?

No

Does AC 230V run between 1 and 3, terminals of CN1 on filter board?

Yes

Does AC 230V run between 3 and 5, terminals of CN2 on filter board?

Release the demonstration mode. (See page 10.)

No

Inspect power-supply wiring such as power cord and

breaker etc.

No

Replace the filter board.

Compressor does not operate

Detach each connector CN2A on

control board check the continuity

between terminals 5 and 7

[3]

respectively.

(Check if there is a short or open

circuit in the motor protector.)

Detach connector CN50G on control board and check the resistance respectively between terminals of 1,3 and 5:approx.9.3"

Check the error display of selfcheck after turning on and off the

power supply.

wWith all the connectors connected.

Inverter-related parts may be

defective. Conduct ice making

test operation. (see page 21 for

error codes.)

Yes

Continuity detected

Continuity detected

No

continuity

Motor protector (open circuit)

wBy measuring the resistance,

ensure that the circuit is open.

No

continuity

Disconnect 6-pin connector in

machine chamber to check resistance between terminals of 1, 2

and 3: approx.9.3"

Measure the resistance of compressor’s winding between terminals of black, white, and red :

approx.9.3"

Abnormal

Normal

Check connector contact.

Abnormal

Abnormal

Exchange the unit

Normal

Replace the lead wire

assembly (Lead wire of

compressor)

20

Page 21

Inverter-related indication “Compressor does not operate”

Error

code

e50

e51

Abnormality

Trouble of

inverter circuit

Bus-bar

voltage is

abnormal.

Possible cause Symptom Treatment

•When there is

any trouble in the

circuit which

detects phase

current of compressor.

•Power supply

voltage is

abnormal.

•Defective reactor

on the N/F board

Compressor

does not

rotate.

Compressor

does not

rotate.

Replace the control board.

Start

Measure the voltage of

power supply.

Arrange power supply to make the voltage

within 180-280V and conduct the following

checks.

160V or

280V or more

more

Arrange