Changes for the Better

Models

MR-FT35EH-SW-C

MR-FT46EH-SW-C

MR-FT51EH-SW-C

CONTENTS

1. SPECIFICATIONS......................................................

2. OUTLINES AND DIMENSIONS...................................

3. WIRING DIAGRAM....................................................

4. REFRIGERANT CIRCUIT...........................................

5. NAME OF THE PARTS...............................................

6. TROUBLE SHOOTING................................................

6.1 TROUBLE CRITERION OF MAIN PARTS............

6.2 TEST POINT DIAGRAM OF MAIN CONTROL

BOARD..............................

6.3 LED TROUBLE DISPLAY AND CHECK

POINT.....................................................................

6.4 IMPORTANCE DETAIL OF FAULT ANALYSIS.....

7. DISASSEMBLY INSTRUCTIONS...............................

8. PARTS LIST...............................................................

2015

SERVICE MANUAL

NO.SM-RE-1508

MITSUBISHI

ELECTRIC

HOME REFRIGERATORS

C..............Taiwan

1

3

6

8

10

12

12

14

15

17

19

22

1.1 SPECIFICATIONS

MR-FT35EH-C MR-FT46EH-C MR-FT51EH-C

Egg rack

1 pc.

2 pcs.

2 pcs.

Forced air convection

Surround cooling,multi air flow,front air flow

2 pcs.

1 pc.

1 pc.

Automatic control

Shipping

Weight

kg

kg

Vegetable case

Drain pan

Unit

Adjust pocket

Bottle pocket

Acrylic resin coated steel

ABS resin

Foamed cyclopenthane

Fin and tube type

Concealed type

Crystal shelf (R)

Automatic (Heater defrost)

Freezer pocket

Slide chilled case

Crystal shelf (F)

Temperature control system

Refrigerator room light

Ice tray

Ice box

Accessories

Bottle stopper

Free pocket

Crystal shelf (RV)

Cabinet

Freezer door

Refrigerator door

Freezer

Refrigerator

Insulation

1

SPECIFICATIONS

110V 60HzPower supply

Total capacity

Dimensions (HXWXD) mm.

L

MR-FT35EH-C

MR-FT46EH-C

MR-FT51EH-C

352 (F : 106 R : 246) 460 (F : 150 R : 310) 510 (F : 150 R : 360)

Cabinet

Evaporator

Foamed cyclopenthane

Foamed cyclopenthane

Food liner

Cooling system

1 pc.

1 pc.

Condenser

1586 x 686 x 706 1652 x 751 x 795 1777 x 751 x 795

3 pcs.

Defrost system

Drain

3 pcs.

Automatic (drainage)

1 pc.

1 pc.

LED Light Board

2 pcs. 2 pcs.

2 pcs. 2 pcs.

1 pc.

1 pc.

67 80 85

73 89 94

1

1.2 ELECTRICAL PARTS SPECIFICATION

MR-FT35EH-C MR-FT46EH-C MR-FT51EH-C

Running capacitor

Capillary tube

Dehydrant Molecular sieve

Refrigerant R600a

Model

Type

Input

Revolution

Model

Type

Input

Revolution

Dial position ON OFF OPEN SHUT

Warmer

o

C

-13.1 -16.1 3.9 2.9

Normal

o

C

-18.8 -21.8 2.4 1.4

Colder

o

C

-23.6 -26.6 -3.0 -4.0

4(Current limiter)

Running current (A.T. : 30 ºC)

A

Heater Defrost heater

Defrosting control

mm.

g

g

Defrosting timer

Defrost finish

Thermal fuse

Current

Motor protector

Model

Ambient temperature

Time

0.78 0.81

0.83

1.8 X 0.65 X 2350

9

Compressor

Model

Power supply

Rated input W

o

C

Sec.

A

Starting current

Winding resistance (A.T. : 20 oC)

Control board

Thermister 14 +

1.5

73

A

12.4

W

MM3-71CCY

o

C

o

C

FBA12J12VXC

DC brushless

1.44 (12V DC)

1450

(12V DC)

25

16 MAX

17.0

4

m

F 400VAC

81 W

(110V 150W)

7

6

W

(110V 160W)

MR-FT35EH-C

MR-FT46EH-C

MR-FT51EH-C

109 108 112

EEI91E13DCH

110V 60Hz

Machine

Chamber

W

r.p.m

W

r.p.m

4.2 (12V DC)

2300

(12V DC)

4715JL04WS16G51

DC brushless

Temperature control

Thermistor R

Freezer

Refrigerator

Thermistor F

73 82

85

Fan motor

Freezer

2

Unit : mm

MR-FT35EH-C

2

OUTLINES AND DIMENSIONS

PLUG CORD LENGTH

REQUIRED SPACE FOR INSTALLATION

3

Unit : mm

MR-FT46EH-C

PLUG CORD LENGTH

REQUIRED SPACE FOR INSTALLATION

629

795

4

Unit : mm

MR-FT51EH-C

PLUG CORD LENGTH

REQUIRED SPACE FOR INSTALLATION

629

795

5

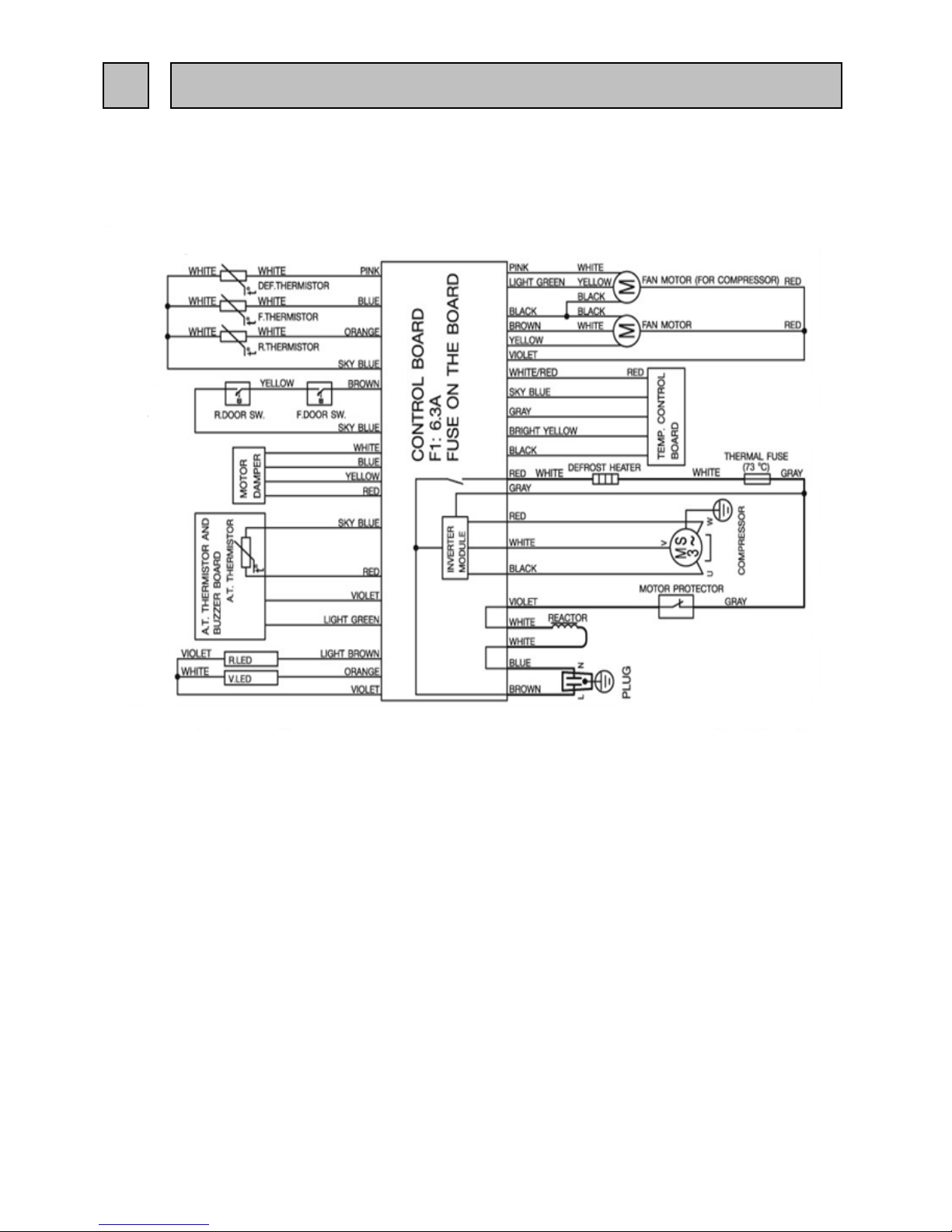

MR-FT35EH-C

MR-FT46EH-C (SKELETON WIRING DIAGRAM)

MR-FT51EH-C

3

WIRING DIAGRAM

6

7

MR-FT35EH-C

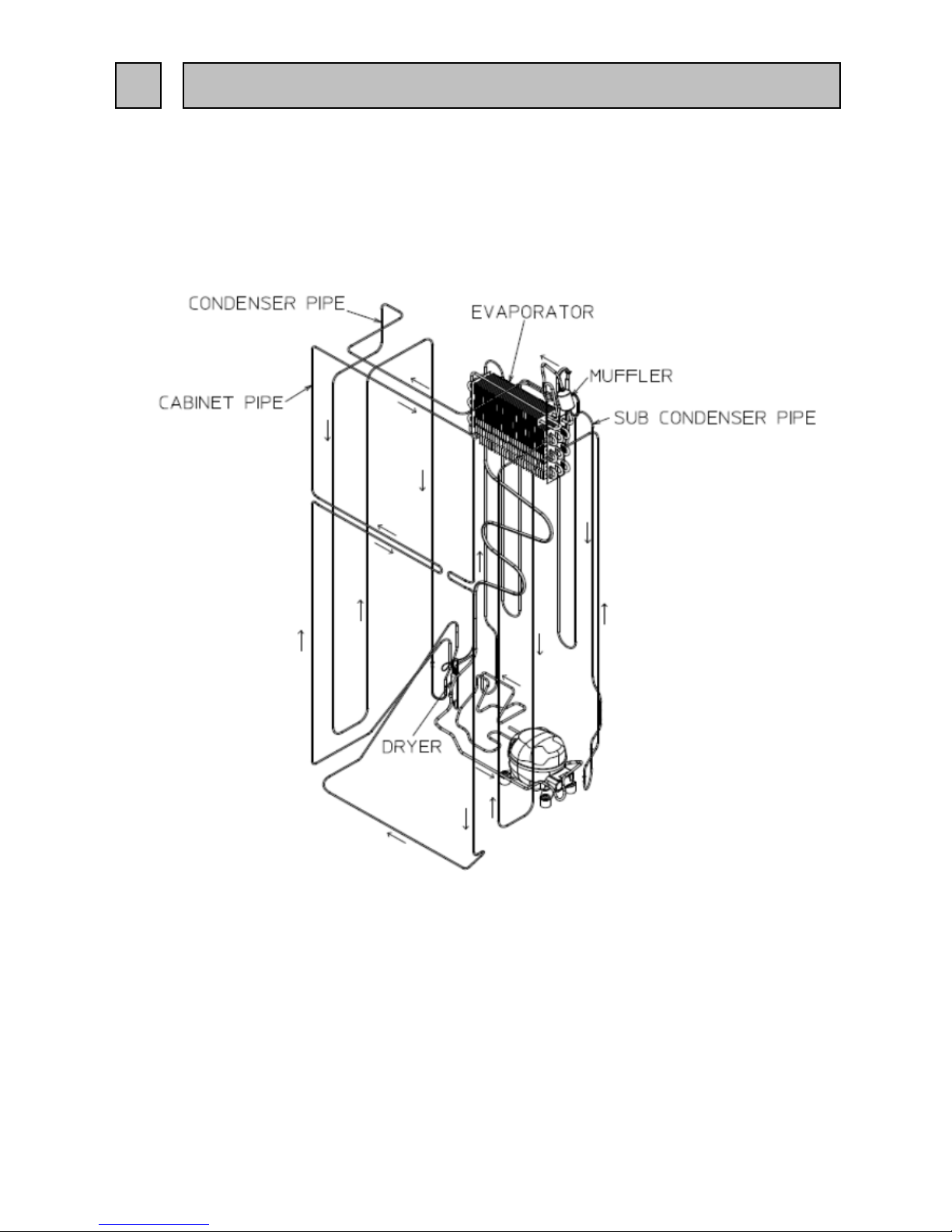

4

REFRIGERANT CIRCUIT

8

MR-FT46EH-C

MR-FT51EH-C

9

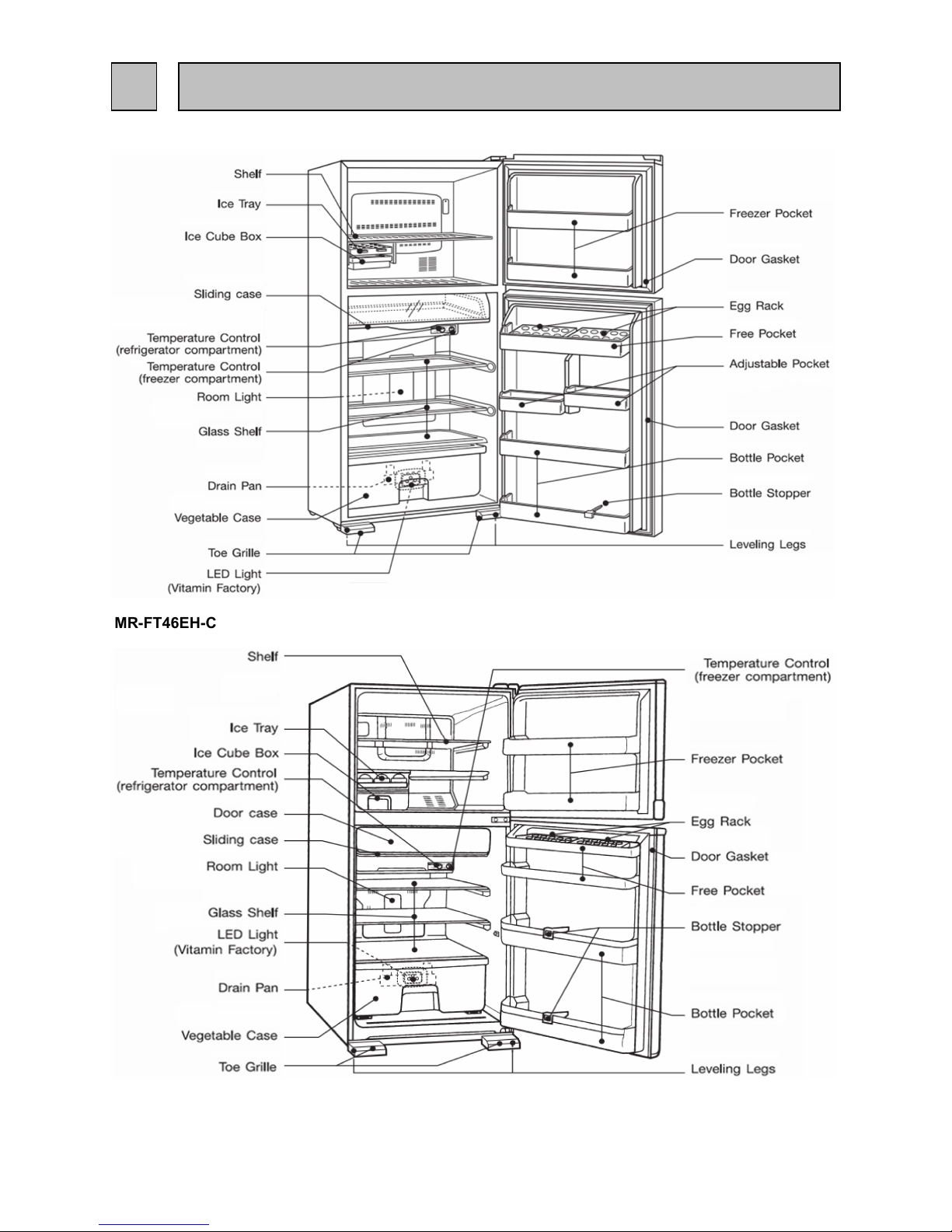

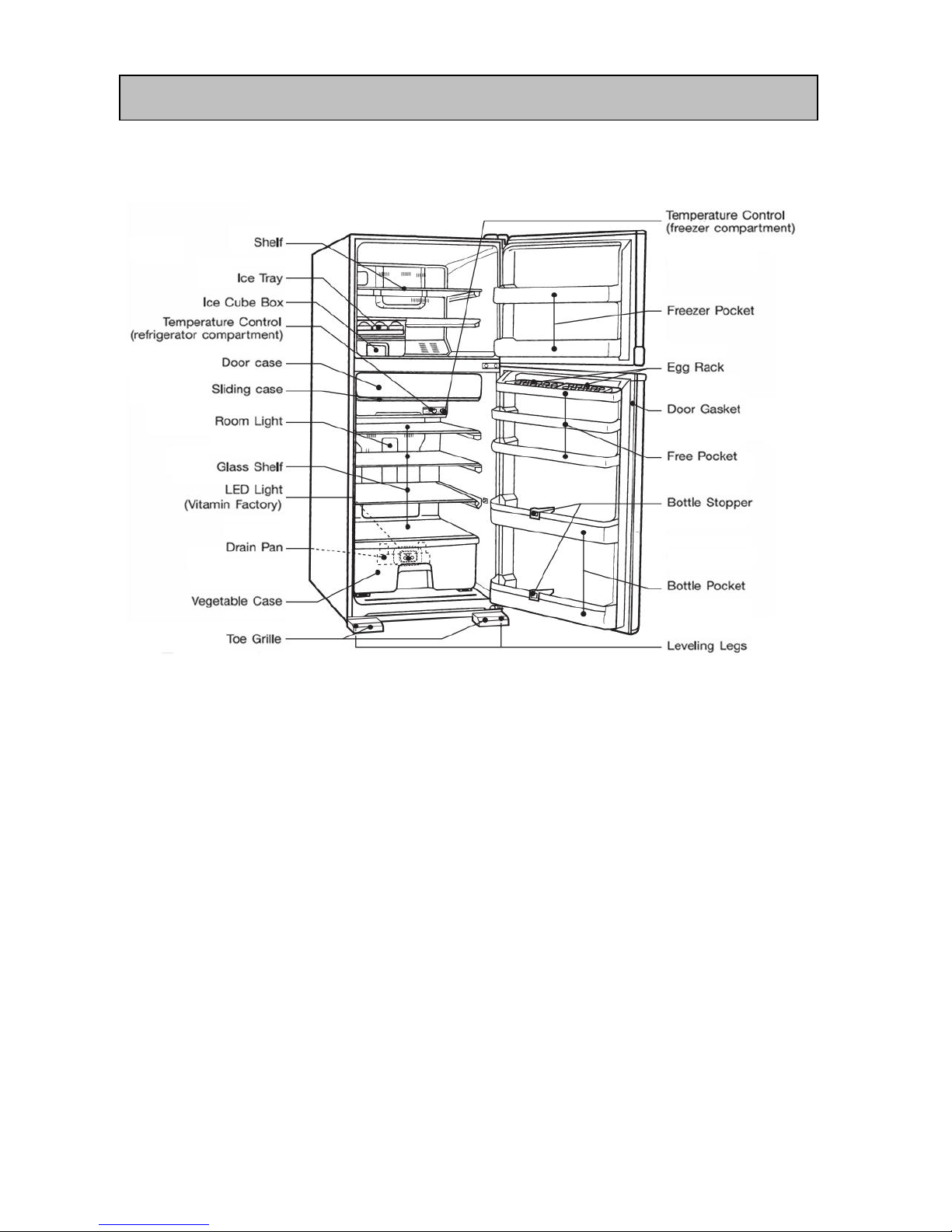

MR-FT35EH-C

MR-FT46EH-C

5

NAME OF PARTS

10

MR-FT51EH-C

11

6.1) TROUBLE CRITERION OF MAIN PARTS

MR-FT35EH-C MR-FT46EH-C MR-FT51EH-C

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Open

Close

Opened (

W

)

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

Measure the resistance with a tester.(Ambient temperature:Room temperature 15

o

C ~ 25oC)

Machine

chamber fan

motor

In the machine

chamber at the

rear side of the

frame.

Less than 1W

Motor

damper for

refrigerator

compartment

In the control

panel

of the refrigerator

compartment.

Normal

Abnormal

(faulty)

Winding

(Blue-White,

Red-Yellow)

415 W (Approx.)

Open ( W ) or

short circuit

(0W)

chamber at the

61 + 8o C

rear side of

Measure the resistance with a tester.(Ambient temperature:Room

temperature 15

o

C ~ 25oC)

the frame

Normal

Abnormal(faulty)

Winding

(Black-White)

(White-Red)

(Red-Black)

12.4 W

(20 ºC)

Opened ( W ) or

short circuit (0W)

Motor

protector

Compressor in

Model

MM3-71CCY

the machine

Connected Point

100 + 5o C

Rated current

A

0.84/1.10 (27/37 rps) the frame

Normal

Abnormal

(faulty)

the machine

Rated input

W

35.1/48.7(27/37 rps) chamber at the

Starting current

A

4.0 rear side of

6

TROUBLE SHOOTING

Components

/ Part Name

Check Method and Criterion

Parts Mounted

Position

Compressor

Compressor in

Model

EEI91E13DCH

Model

4715JL04WS16G51

Type

DC brushless

Normal

Abnormal (faulty)

Between 3 - 1 (GND

and Vcc): About 25kW

Between 3-1 : open(

W ) or

between 2-1 : short ( 0

12

In fan grille of the

freezer compartment.

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

In the drip tray under

the evaporator of the

Measure the resistance with a tester.

freezer compartment

(Ambient temperature:Room temperature 15oC ~ 25oC)

Resistance measured under

Defrost thermistor

the ambient temperature from

(kW)

at the muffler

-50: to +50:

of evaporator

in freezer compartment.

1. 200" to 500k"

............normal

Freezer thermistor at

2. Out of the above range

fan grille of freezer

............abnormal

compartment.

Out air thermistor

under hinge cover

Thermistor Check Procedure

Thermistor resistance will vary

with the change of temperature.

Take the temperature around the thermistor,

and then measure resistance using a tester.

The relation of resistance and temperature is as shown on

the above graph.

Thermistor

MR-FT35EH

MR-FT46EH,FT51EH

331Ω (Approx.)

3

53Ω (Approx.)

Defrost

Heater

DC brushless

Model

Type

Model refrigerator

Rated input

Operation method

Abnormal (faulty)

Normal

Between 3 - 1 (GND

and Vcc): About 12kW

MR-FT35EH MR-FT46EH,FT51EH

Normal

Refrigerator

fan motor

Check Method and Criterion

Parts Mounted Position

Components/

Part Name

FBA12J12VXC

Between 3-1 : open( ¥ W )

or

between 3-4 : short ( 0 W)

150 W (110V) 160 W (110V)

Power ON after defrosting (14 ± 1.5ºC or more)

Abnormal (faulty)

Opened ( ∞ Ω )

Resistance

-20

20 30

-10

0

10

30

20

15

10

5

0

25

35

Thermistor resistance valves against

temperature

Temperature

Outside air thermistor

Freezer

thermistor,

Defrost

thermistor

Inner

thermistor

13

6.2 TEST POINT DIAGRAM OF MAIN CONTROL BOARD

14

MR-FT35EH,MR-FT46EH,MR-FT51EH

6.3 LED trouble display and check point.

1) Trouble is indicated by the blinking number of self-check LED(Red color) which locate

at near dial of control panel(The detail picture as shown in right side.)

The blinking number of self-check LED specifies the trouble which has occurred.

LED repeats to blinks as many times as the number specified for each trouble cycle.

Rule for convert error code from LED to numerical data as below :

- For ten's place, LED will light for 0.9s.(Long light period) - Time period while LED off inside its cycle was 0.3 s

- For ones' place, LED will light for 0.3s.(Short light period) - Time period while LED off between each cycle was 3 s

Example of error code 12 as shown in below timeline.

Table shown error code

Tens'

place

Ones'

place

0 2 Compressor turns OFF.

1 1

2. Check the resistance of thermistor.

>Replace.

1 2

2. Check the resistance of thermistor.

>Replace.

1 3

2. Check the resistance of thermistor.

>Replace.

1 8

3 1

>Replace.

3 2

2.Check BOX FAN operation. >Replace.

Trouble of BOX FAN When motor doesn’t rotate even though

power is on

1.Connector CN9S and CN5D

on control board, fan motor 4-pin

wire to wire connector

>Repair the

contact failure.

* 3 minutes later, the fan motor is

reactivated to be checked.

* Until the fan motor gets to operate

correctly, the buzzer sounds every time

the door is closed.

Trouble of freezer fan

motor

When motor doesn’t rotate even though

power is on

1.Connector CN9S and CN5D

on control board, fan motor 4-pin

wire to wire connector

2.Check fan motor operation.

>Repair the

contact failure.

* 3 minutes later, the fan motor is

reactivated to be checked.

* Until the fan motor gets to operate

correctly, the buzzer sounds every time

the door is closed.

Trouble of refrigerator

thermistor

When there is a short or open circuit in

the

F-room thermistor.

1. Connector CN9S on control board,

4-pin wire to wire connector

>Repair the

contact failure.

Synchronize the open/close status of R

damper with that of compressor

Trouble of outside air

thermistor

(NOTE 2)

When there is a short or open circuit in

the outside air thermistor.

>Replace

OPERATION

PCB

Control it by refering to outside temp at

25 ºC.

After compressor off, the compressor

repeats 30-minute ON and 20-minute

OFF

Trouble of defrost

thermistor

When there is a short or open circuit in

the defrost thermistor.

1. Connector CN9S on control board,

4-pin wire to wire connector

>Repair the

contact failure.

The defrost heater won’t be turned ON.

Communication

error of inverter

A commutation error occurs between

refrigerator control circuit and inverter

control circuit in control board. (They

do not transmit and receive data for 10

seconds.)

>Replace the

control board

Trouble of freezer

thermistor

When there is a short or open circuit in

the

refrigerator compartment thermistor.

(NOTE2)

1. Connector CN9S on control

board,

>Repair the

contact failure.

ERROR CODE

Trouble Detecting method Check point How to fix Control

LED self

check

Tens' place Ones' place Tens' place Ones' place

0.9 s 0.3 s 0.3 s 0.3 s 0.3 s 3 s 0.9 s 0.3 s 0.3 s 0.3 s 0.3 s

1 CYCLE 1 CYCLE

LED ON

LED OFF

15

Tens'

place

Ones'

place

3 4

5 0

5 1

5 2

5 3

5 5

5 6

5 7

The setting of Self Mode Check will be displayed and blinks during or Self Mode Check operation.

SHORT or OPEN circuit of thermister.

When the resistance is ∞ Ω, the circuit is deemed open-circuited.

When the resistance is 0 Ω , the circuit is deemed short-circuited.

The error codes E50 to E55are not displayed even if those abnormalities occur when power is turned on.

Therefore, be sure to perform self check mode operation in order to check if any abnormality

indicated by these error codes occurs.

If those errors still continue for 1 minute after the restart, E56 will be displayed again.

(NOTE4)

(NOTE5)

(NOTE1)

(NOTE2)

Inverter drive module

abnormality

The overcurrent error is detected before

starting the compressor (failure of the IC

in the inverter drive module)

>Replace

the control board.

An attempt to restart the compressor is

repeated every 3 minutes

Trouble of control board

(EEPROM related trouble)

(NOTE4)

EEPROM (IC11M)

accumulates data necessary for control.

• The data are not input accurately.

• The microcomputer cannot read the

data.

>Replace the

control board.

If abnormality occurs when power is

turned on, the compressor is stopped

for 10 minutes.

When abnormality occurs during

normal operation, the compressor

keeps operating.

Defective wiring

connecting or trouble of

control board

The errors E50 to E53 keep occurring

over one and a half hour. (The situation,

which compressor cannot be operated,

continues.)

• The error display starts after

the error is determined as E56.

• The error display continues

until defrosting starts or cooling

operation gets back to normal. (The

error display does not disappear by

unplugging and plugging the power

cord.)

(Note5)

• An attempt to restart the compressor

is repeated every 3 minutes.

Trouble of bus-bar voltage

• The range of bus-bar voltage is not

approx. 50 ~ 340 VDC

Trouble of inverter

software reset function

• The inverter driving software

malfunctions.

Trouble of startup,

synchronization or

overcurrent detection

(NOTE4)

• There is no current at compressor

startup.

• The phase current exceeds 5.5 A at

compressor startup.

• The phase current exceeds 3.3 A

during compressor operation.

•A current of 5.3 A or more runs into the

bus-bar of control board.

The compressor is stopped and

reactivated 10 minutes later

Refer to “Compressor does not operate” topic

Refer to “Compressor does not operate” topic

Clogging of refrigerant

pipe or trouble relatedto

compressor.

(T0: Defrost thermistor temperature at

power input, T1: Defrost thermistor

temperature when 15 minutes have

passed from the power input)

• When the difference between T0 and

T1 is T0 ≦ T1

Check the compressor and the pipe. When cooling operation returns to

normal condition, the display of error

code disappears.

Trouble of inverter circuit

(NOTE4)

• There is any trouble in the circuit

which detects current of compressor

>Replace the

control board.

ERROR CODE

Trouble Detecting method Check point How to fix Control

16

6.4 Importance detail of fault analysis

6.4.1 Flow chart of self - check

1)Self - check monitor circuit

For show the fault condition of refrigerator and clarify point. Therefore, self - check monitor control is provided

that are able to monitor No. of blinking condition with electric circuit and electric part . Before disconnect power plug please

confirm LED self - check .

Caution

1.As the part list below couldn't analysis by self - check , then

please check by reference to trouble shooting page.

- Dilapidation of door switch ,refrigerator room and freezer room.

- Dilapidation of compressor and fan motor .

2.If have malfunction when supply the power . Compressor and

fan motor will not operate 20 minutes.

2)

Interval of self check analysis

- Troubles of thermistor : will check always.

- Trouble of defrost heater : will just analyse during defrost display only.

(The period checking will analyse the defrost circuit after connect the plug 2 hours )

Refrigerator plug

connect?

Connect power plug

Self - check

Mal Function Display

(No .of blinking)

No change on display

Normal operation

Check the fault point as

malfunction list

Disconnect power plug

Repair the macfunction cause

Connect power plug

No

Yes

Yes

No

17

6.4.2 LED for deodorition and bacteria eradication display

Install part point

Normal Use tester's diode range with swing meter during (-)-1 (+) of 2 PM connector by asking use

tester which have diode range ( )

Timing connect power

After compressor off 3 min. , after the defrost heater off 8 min during open the door ( max 5 min.)

Malfunction

LED will shine the violet

light with in timing hole

above.( right picture )

Use tester's diode range with swing meter during 2 (-)-1 (+) , and for make sure which change

poles and observe must be not swing of short resistance ( 0

W

)

LED

18

19

Defrost heater and Drip tray

(6)

Photo 6 Lift up Evaporator and remove the Defrost

heater out of base after remove Heater cover plate

and Drip tray

Caution on assembly

1. Insert the Fan into the base of Fan motor's shaft,

check if the Fan rotates with your finger.

2. When inserted Drip tray to effect to slacken the

lead wire of Defrost heater in order to prevent water

from entering the glass tube.

3. Attach Defrost thermistor with Muffler and tighten

the binder.

2. Remove parts inside the Refrigerator room

(1) Remove Chilled case door and Slide chilled case ,

remove Glass shelves of refrigerator room , remove

the Control panel

(2)

Remove Lamp cover R from Catch

(Photo 8)

(3) Remove Screw (Photo 8) and Rivet (Photo 7) , pull

the Control panel with to right refrigerator wall.

(4)

Remove S-tape lam, Detach connector between

control panel and refrigerator wall.

(5) Remove Catch in left side (Photo 9) and right side of

Duct R assy, Remove Duct R assy (Photo 9)

(Duct damper setting inside Duct R assy)

(6)

Remove S-tape lam, Detach Temp control board

from Catch before Remove Temp control board from

lock socket, Remove Connector from Temp control

board

Remove LED attach assy after remove Lamp cover

(Photo 11,12)

(7) Remove Screw between LED attach assy and Control

panel (Sub) and unlock Catch before remove LED

board from LED attach socket.

(*Remark : LED attach assy is assembling between

LED board attach and LED light board)

OPERATING PROCEDURE

PHOTOS

Photo 7

Photo 6

Defrost heater

Heater roof

Drip tray

Evaporator Def thermistor

Rivet

Catch

Screw

Control panel

Lamp cover R

Control panel (Sub)

Catch

Photo 8

Duct R assy

Control panel

Temp control board

Photo 11

S-tape lam

S-tape lam

Catch (Left)

Connector

(สําหร ับรุ่น

MR-

Screw

Screw

LED attach

assy(Back)

LED attach

assy(ด้านหลัง)

Catch

Connector

Catch

LED attach

assy(Front)

(For model

MR-FT35EH)

LED attach

assy(Front)

LED light

board

Catch

Connector

Photo 12

LED light

board

Photo 9

Photo 10

(For model MRFT46EH,FT51EH)

LED attach

assy(Back)

20

Removing vitamin up assy

(8)

Remove the Vitamin up attach.

(Photo 13)

(9)

Remove the 2 screw and remove the vitamin up.

(Photo 14)

Remove the Elect cover

(10)

Take out screw (2 points)

(Photo 15)

(11) Take out screw (2 points)at left side and right side

of electric box cover ,then pull the electric box cover

(Photo 16)

OPERATING PROCEDURE PHOTOS

Welding point at back side of refrigerator

(For model MR-FT46EH,FT51EH)

CHARGE PIPE

DRYER

DISCHARGE PIPE

COMPRESSOR

B

B

BINDER

(For model MR-FT35EH)

SUCTION PIPE

Screws

Photo 14

Photo 13

Vitamin up

Vitamin up

attach

Screw

Screw

Photo 15

Photo 16

Connector

Connector

Catch

Elect cover

Refcon assy

Elect attach

Catch

21

DOOR, BODY PARTS

MR-FT35EH-C

8 PARTS LIST

2

3

4

5

6

8

12

11

13

9

10

1

7

22

DOOR , BODY PARTS

Q'TY/UNIT

MR-FT35EH-C

sw

1 KIEL76131 <G> FREEZER POCKET

1

2 KIEL76131 <G> FREEZER POCKET

1

3 KIE401115 <G> EGG RACK

2

4 KIEL75118 <G> FREE POCKET

1

5 KIEL75159 <G> ADJUST POCKET

2

6 KIEL76124 <G> BOTTLE POCKET

1

7 KIEL76124 <G> BOTTLE POCKET

1

8 KIEH88143 <G> BOTTLE STOPPER

1

9 KIEYE1001 <G> DOOR F

1

10 KIEH79111 <G> MAGNET GASKET ASSY (F)

1

11 KIEYE1000 <G> DOOR R

1

12 KIEH79110 <G> MAGNET GASKET ASSY (R)

1

13 KIEG05741 <G> CATCHER

2

14 KIEY82031 <G> BADGE ASSY

1

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

Remark

- Country code : C = TAIWAN

- Color code : SW = SNOWY WHITE

PRICE/PIECE

(US$-FCA)

NO. PART NO. PART NAMESRoHS SPEC

F

R

FREEZER ROOM

REFRIGERATOR ROOM

23

ACCESSORY PARTS

MR-FT35EH-C

24

ACCESSORY PARTS

Q'TY/UNIT

MR-FT35EH-C

sw

1 KIEWD0662 <G> BELL MOUTH 1

2 KIET73663 <G> FAN GRILLE

PLASTIC PART ONLY

1

3 KIEWD0450 <G> ICE CORNER ASSY 1

4 KIEWD0665 <G> DUCT R ASSY 1

5 KIEL75411 <G> SLIDE CHILLED CASE 1

6 KIEWD0850 <G> CONTROL PANEL

PLASTIC PART ONLY

1

7 KIEHJ3305 <G> THERMO DIAL (R) 2

8 KIEY54853 <G> CONTROL PANEL (SUB) 1

9 KIEL75470 <G> LAMP COVER (R) 1

10 KIEK66430 <G> GLASS SHELF ( R ) 3

11 KIEV68405 <G> VEGETABLE CASE 1

12 KIEWD0435 <G> DRAIN PAN 1

13 KIE805794 <G> CASTER SET 2

14 KIEH79326 <G> LEAD COVER F 1

15 KIER65705 <G> HINGE COVER 1

16 KIEP89701 <G> HINGE ASSY (UPPER) 1

17 KIEH79431 <G> CRYSTAL SHELF (F) 1

18 KIEL55440 <G> ICE TRAY 1

19 KIEG63487 <G> ICE BOX 1

20 KIEWD0746 <G> STOPPER HINGE 2

21 KIEMQ4703 <G> HINGE ASSY (MIDDLE) 1

22 KIEV91418 <G> CHILLED CASE DOOR 1

23 KIEWD1795 <G> CASTER ASSY RH 1

24 KIEWD0795 <G> CASTER ASSY LH 1

25 KIEWD1460 <G> ADJUST FOOT RH 1

26 KIEWD0460 <G> ADJUST FOOT LH 1

27

KIEY86730 <G> KICK PLATE RH 1

28 KIEY82730 <G> KICK PLATE LH 1

29

KIEWD0652 <G> COMP COVER ASSY

ATTACH AT LOWER SIDE OF

BEHIND REF

1

30

KIEYE1663 <G> FAN GRILLE ASSY

INCLUDE ALL OF ELECTRICAL PART

& PLASTIC PART

1

31

KIEWD0449 <G> ICE CORNER SUPPORT

ATTACH AT BETWEEN ICE

CORNER LH & RH

1

32 KIEYE1858 <G> CONTROL PANEL ASSY

INCLUDE ALL OF ELECTRICAL PART

& PLASTIC PART

1

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

NO. PART NO. RoHS PART NAMES SPEC

PRICE/PIECE

(US$-FCA)

F

R REFRIGERATOR ROOM

FREEZER ROOM

25

ELECTRICIAL PARTS AND UNIT PARTS

MR-FT35EH-C

26

ELECTRICIAL PARTS AND UNIT PARTS

Q'TY/UNIT

MR-FT35EH-C

sw

1 KIEY82326 <G> ELECT COVER ASSY 1

2 KIEWD0367 <G> REACTOR 1

3 KIEYE1339 <G> REFCON ASSY 1

4 KIEYE1336 <G> THERMISTOR & FUSE ASSY 1

5 KIEYE1354 <G> PLUG CORD ASSY 1

6 KIEMQ4995 <G> EVAPORATOR 1

7 KIEWD0537 <G> HEATER ROOF 1

8 KIEYE1392 <G> DEFROST HEATER ASSY 110V 150W 1

9 KIEHJ4682 <G> DUCT DAMPER 1

10 KIEWD0313 <G> THERMITOR ( R ) ASSY 1

11 KIEH61399 <G> FILTER 1

12 KIEWD0980 <G> DRYER XH-9,9GR 1

13 KIEK48369 <G> VITAMIN UP ATTACH 1

14 KIEK48379 <G> VITAMIN UP 1

15 KIEWD1662 <G> FAN ATTACH 1

16 KIEP89325 <G> OUT FAN MOTOR ASSY 4715JL04WS16G51 1

17 KIEB66378 <G> THERMISTOR (F) 1

18 KIEMQ4312 <G> THERMISTOR (DEF) 1

19 KIEV61374 <G>

BUZZER BOARD & THERMISTOR (A.T.)

1

20 KIEMQ4320 <G> FAN MOTOR FBA12J12VXC 1

21 KIEWD0538 <G> DRIP TRAY 1

22 KIEMQ4363 <G> LAMP SWITCH 2

23 KIEP64382 <G> TEMP CONTROL BOARD 1

24 KIEWD0360 <G> LED LIGHT BOARD ASSY 1

25 KIEWD0361 <G> LED BOARD ATTACH 1

26 KIEWD0341 <G> PROTECTOR COVER 1

27 KIEWD0340 <G> MOTOR PROTECTOR MM3-71CCY 1

28 KIEWD0277 <G> COMPRESSOR EEI91E13DCH 1

29 KIE902735 <G> U WASHER 3

30 KIEHJ3797 <G> RUBBER MOUNT 4

31 KIEN43919 <G> MINUS ION 1

32 KIEWD0327 <G> ELECT ATTACH

PLASTIC PART ONLY

(ATTACH WITH REFCON

ASSY)

1

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

NO. PART NO. RoHS PART NAMES SPEC

PRICE/PIECE

(US$-FCA)

FRFREEZER ROOM

REFRIGERATOR ROOM

DEF DEFROST

27

PACKING PARTS

MR-FT35EH-C

NO STEP ON

1

C.F.B B OX ASSY

9

C.F.B TOP COVER

6

DF CORUGATED BOARD

5

PACKING COVER

8

C.F.B PALL ET

7

BOTTOM CUSHION

4

INSU TOP CUSHION (S)

3

INSU TOP CUSHION

(L)

2

TOP CUSHION

28

PACKING PARTS

Q'TY/UNIT

MR-FT35EH-C

sw

1 KIEYE1970

<G>

C.F.B BOX ASSY 1

2 KIEWD0979 <G> TOP CUSHION 1

3 KIEWD0972 <G> INSU TOP CUSHION (L) 1

4 KIEWD1972 <G> INSU TOP CUSHION (S) 2

5 KIEG55973 <G> PACKING COVER 1

6 KIEH79971 <G> DF CORUGATED BOARD 1

7 KIEWD0978 <G> BOTTOM CUSHION 1

8 KIEWD0974 <G> C.F.B PALLET 1

9 KIEH79975 <G> C.F.B TOP COVER 1

NO. PART NO. RoHS PART NAMES SPEC

PRICE/PIECE

(US$-FCA)

29

DOOR , BODY PARTS

MR-FT46EH-C

MR-F51EH-C

30

DOOR , BODY PARTS

MR-FT46EH-C MR-FT51EH-C

SW SW

1

KIEV80131 <G> FREEZER POCKET 2 2

2

KIE401115 <G> EGG RACK 2 2

3

KIEV80118 <G> FREE POCKET ( S ) 1 1

4

KIEV80119 <G> FREE POCKET ( L ) 1 2

5

KIEV80124 <G> BOTTLE POCKET 2 2

6

KIEH88143 <G> BOTTLE STOPPER 2 2

7

KIEY82001 <G> DOOR F 1 1

8

KIEV80111 <G> MAGNET GASKET ASSY ( F ) 1 1

KIEY82000 <G> 1

KIEY86000 <G> 1

KIEV80110 <G> 1

KIEV82110 <G> 1

11

KIEY82031 <G> BADGE ASSY 1 1

RECOMMED PART NO. 7, 8, 9, 10

PART NO. THAT ARE CIRCLED ARE NOT SHOWN IN THE FIGURES

ABBREVIATION

Remark

- Country code : C = TAIWAN

- Color code : SW = SNOWY WHITE

PRICE/PIECE

(US$-FCA)

9

DOOR R

10

MAGNET GASKET ASSY ( R )

NO. PART NO.

RoHS

PART NAME SPEC

Q'TY/UNIT

FRFREEZER ROOM

REFRIGERATOR ROOM

31

ACCESSORY PARTS

MR-FT46EH-C

MR-FT51EH-C

32

ACCESSORY PARTS

MR-FT46EH-C MR-FT51EH-C

SW SW

1

KIEWD6662 <G> BELL MOUTH

1 1

2

KIEMR7492 <G> COVER GRILLE

1 1

3

KIEPM7663 <G> FAN GRILLE

1 1

4

KIEG05450 <G> ICE CORNER

1 1

KIEWD6665 <G>

1

KIEWD9665 <G>

1

6

KIEWD6850 <G> CONTROL PANEL

1 1

7

KIEHJ3305 <G> THREMO DIAL ( R )

2 2

8

KIEC02411 <G> SLIDE CHILLED CASE

1 1

KIEWD6853 <G>

1

KIEWD9853 <G>

1

KIEL85470 <G>

1 1

KIEL87470 <G>

11

KIEL85430 <G> GLASS SHELF ASSY ( R )

1 1

KIEC02685 <G>

1

KIEC08685 <G>

1

13

KIEL85430 <G> GLASS SHELF ASSY ( R )

1 2

14

KIE805794 <G> CASTER SET

2 2

15

KIEWD0435 <G> DRAIN PAN

1 1

16

KIEC02789 <G> SHAFT ROLLER

2 2

17

KIEG05326 <G> COVER F

1 1

18

KIER65705 <G> HINGE COVER (RH)

1 1

19

KIEP89701 <G> HINGE ASSY (UPPER) RH

1 1

20

KIEWD6431 <G> CRYSTAL SHELF ( F )

1 1

21

KIEME5438 <G> ICE CORNER TRAY

1 1

22

KIEL85440 <G> ICE TRAY

1 1

23

KIEC02467 <G> ICE BOX

1 1

24

KIEMQ4703 <G> HINGE ASSY (MIDDLE) RH

1 1

25

KIEWD0746 <G> DOOR STOPPER (F/R) RH

2 2

26

KIEV80418 <G> CHILLED CASE DOOR

1 1

27

KIEH88429 <G> GLASS SHELF ( RV )

1 1

28

KIEV80405 <G> VEGETABLE CASE

1 1

29

KIEG05788 <G> ROLLER BOX

2 2

30

KIEG05798 <G> ROLLER

2 2

31

KIEWD1795 <G> CASTER ASSY RH

1 1

32

KIEWD0795 <G> CASTER ASSY LH

1 1

33

KIEWD1460 <G> ADJUST FOOT RH

1 1

34

KIEWD0460 <G> ADJUST FOOT LH

1 1

35

KIEY86730 <G> KICK PLATE RH

1 1

36

KIEY82730 <G> KICK PLATE LH

1 1

37

KIEWD6652 <G>

COMP COVER ASSY

Attach at lower side of behind ref 1 1

38

KIEYE2663 <G>

FAN GRILLE ASSY

Include all of electrical part & plastic part 1 1

KIEYE2858 <G>

1

KIEYE3858 <G>

1

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

Include all of electrical part & plastic part

10

LAMP COVER ( R )

12

DUCT R (SUB)

39

CONTROL PANEL ASSY

PRICE/PIECE

(US$-FCA)

5

DUCT R ASSY

9

CONTROL PANEL ( SUB )

NO. PART NO.

RoHS

PART NAME SPEC

Q'TY/UNIT

FRFREEZER ROOM

REFRIGERATOR ROOM

R.V. BETWEEN REFRIGERATOR ROOM AND VEGETABLE ROOM

33

ELECTRICIAL PARTS AND UNIT PARTS

MR-FT46EH-C

MR-FT51EH-C

34

ELECTRICIAL PARTS AND UNIT PARTS

MR-FT46EH-C MR-FT51EH-C

SW SW

1 KIEY82326

<G> ELECT COVER ASSY

1 1

2 KIEWD0367

<G> REACTOR

1 1

3 KIEYE2339

<G> REFCON ASSY

1 1

4 KIEYE2336

<G> THERMAL FUSE ASSY ( DEF )

1 1

5 KIEYE1354

<G> PLUG CORD ASSY

1 1

6 KIENB1995

<G> EVAPORATOR

1 1

7 KIEWD6537

<G> HEATER ROOF

1 1

8 KIEYE2392

<G> DEFROST HEATER ASSY

1 1

9 KIEHJ4682

<G> DUCT DAMPER

1 1

10 KIEWD6313

<G> THERMITOR ( R ) ASSY

1 1

11 KIEH61399

<G> FILTER

1 1

12 KIEN43919

<G> MINUS ION

1 1

13 KIEWD0980

<G> DRYER XH-9,9GR

1 1

14 KIEK48369

<G> VITAMIN UP ATTACH

1 1

15 KIEK48379

<G> VITAMIN UP

1 1

16 KIEWD7662

<G> FAN ATTACH

1 1

17 KIEP89325

<G> OUT FAN MOTOR ASSY 4715JL04WS16G51

1 1

18 KIEB66378

<G> THERMISTOR ( F )

1 1

19 KIEMQ4312

<G> THERMISTOR ( DEF )

1 1

20 KIEV61374

<G> BUZZER BOARD & THERMISTOR (A.T.)

1 1

21 KIEMQ4320

<G> FAN MOTOR FBA12J12VXC

1 1

22 KIEB66538

<G> DRIP TRAY

1 1

23 KIEMQ4363

<G> LAMP SWITCH

2 2

24 KIEP64382

<G> TEMP CONTROL BOARD

1 1

25 KIEW73360

<G> LED LIGHT BOARD ASSY

1 1

26 KIEWD6361

<G> LED BOARD ATTACH

1 1

27 KIEWD0341

<G> PROTECTOR COVER

1 1

28 KIEWD0340

<G> MOTOR PROTECTOR MM3-71CCY

1 1

29 KIEWD0277

<G> COMPRESSOR EEI91E13DCH

1 1

30 KIE902735

<G> U WASHER

4 4

31 KIEHJ3797

<G> RUBBER MOUNT

4 4

32 KIEWD6990

<G> CONDENSER

1 1

33 KIEWD0327

<G> ELECT ATTACH

PLASTIC PART ONLY

(ATTACH WITH REFCON

ASSY)

1 1

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

PRICE/PIECE

(US$-FCA)

NO. PART NO.

RoHS

PART NAME SPEC

Q'TY/UNIT

F

DEF

FREEZER ROOM

DEFROST

35

110V 160W

PACKING PARTS

MR-FT46EH-C

MR-FT51EH-C

NO STEP ON

1

C.F.B B OX ASSY

9

C.F.B TOP COVER

6

SIDE CUSHION

5

PACKING COVER

8

C.F.B PALL ET

7

BOTTOM CUSHION

4

INSU TOP CUSHION (S)

3

INSU TOP CUSHION (L)

2

TOP CUSHION

36

PACKING PARTS

MR-FT46EH-C MR-FT51EH-C

SW SW

KIEYE2970 <G> 1

KIEYE3970 <G> 1

2

KIEWD6979 <G> TOP CUSHION 1 1

3

KIEWD6972 <G> INSU TOP CUSHION (L) 1 1

4

KIEWD7972 <G> INSU TOP CUSHION (S) 2 2

5

KIEG55973 <G> PACKING COVER 1 1

6

KIEG55971 <G> SIDE CUSHION 1 1

7

KIEWD6978 <G> BOTTOM CUSHION 1 1

8

KIEWD6974 <G> C.F.B PALLET 1 1

9

KIEWD6975 <G> C.F.B TOP COVER 1 1

PRICE/PIECE

(US$-FCA)

1

C.F.B BOX ASSY

NO. PART NO.

RoHS

PART NAME SPEC

Q'TY/UNIT

37

KANG YONG ELECTRIC PUBLIC COMPANY LIMITED.

67 Moo 11, Bangna-Trad Road Km.20, Bangplee, Samutprakarn 10540 Thailand.

TEL : 0-2337-2900 FAX : 0-2337-2954

http:www.mitsubishi-kye.com

Printing Date : September 2015

e-mail: information@kye.meap.com

Loading...

Loading...