Mitsubishi Electric GENERAL PURPOSE AC SERVO MR-E- A/AG, MR-E-A, MR-E-AG Instruction Manual

General-Purpose AC Servo

MODEL

MR-E- A/AG

INSTRUCTION MANUAL

B

A - 1

Safety Instructions

(Always read these instructions before using the equipment.)

Do not attempt to install, oper ate, mainta in or inspect the s ervo amplif ier and servo m otor until you hav e read

through this I nstruction M anual, Insta llation guide, Servo motor Instruction Manual a nd appende d docum ents

carefully and can use the equipment corr ect l y. D o not use the ser vo amplifier and servo motor un ti l you have a

full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

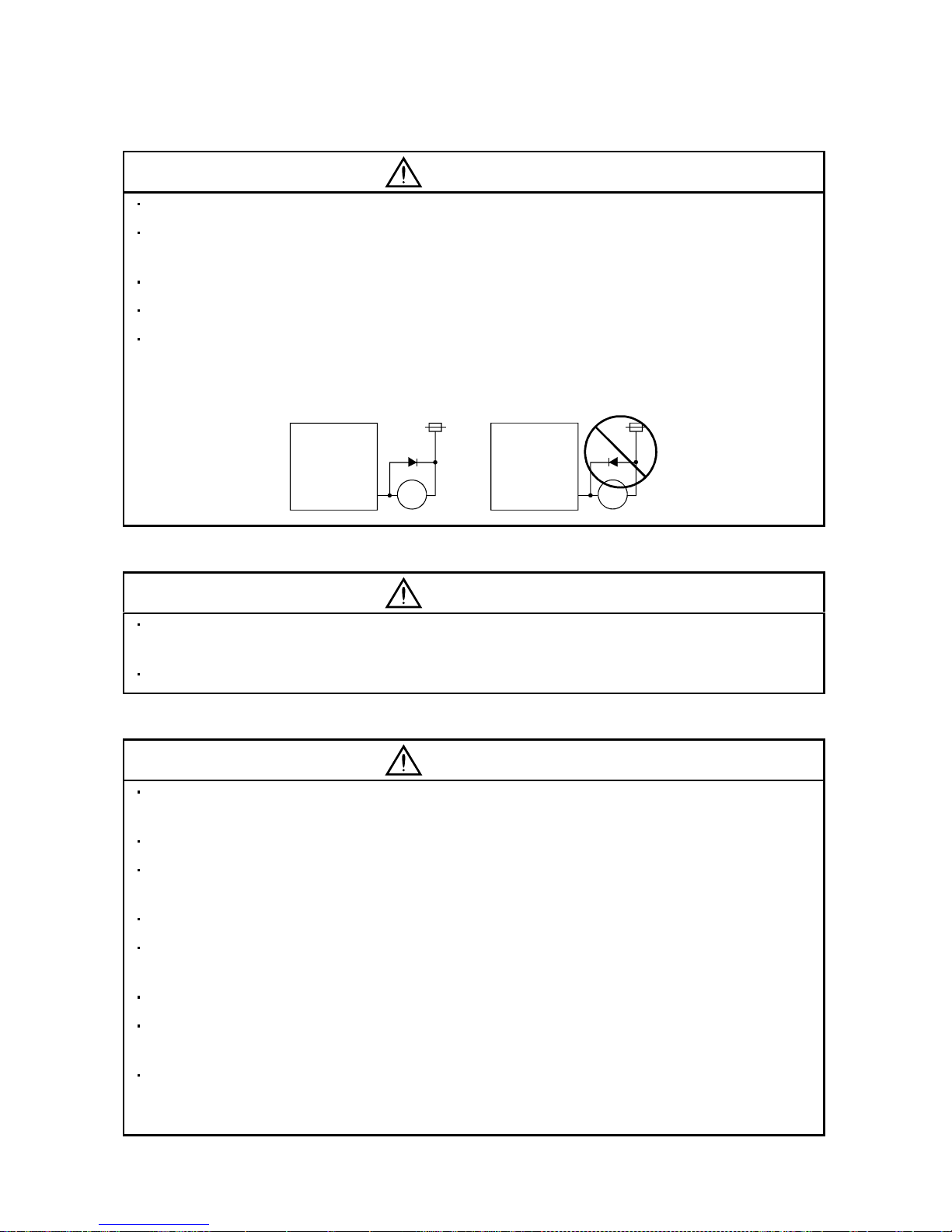

What must not be done and what must be done are indicated by the following diagrammatic symbols:

: Indicates what must not be done. For example, "No Fire" is indicated by

.

: Indicates what must be do ne . Fo r exa mple , gr ou nd ing i s in di cat ed by

.

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this installation guide, always keep it accessible to the operator.

A - 2

1. To prevent electric shock, note the following:

WARNING

Before wiring or inspection, switch power off and wait for more than 10 minutes. Then, confirm the voltage

is safe with voltage tester. Otherwise, you may get an electric shock.

Connect the serv o a mpl i fier and se rvo mot o r to grou nd .

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, you

may get an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, st ressed, loaded, or pin ched. Othe rwise, y ou may get an ele ctric shock.

2. To prevent fire, note the following:

CAUTION

Do not install the servo amplifier, servo motor and regenerative brake resistor on or near combustibles.

Otherwise a fire may cause.

When the servo amplifier has become faulty, switch off the main servo amplifier power side. Continuous

flow of a large current may cause a fire.

When a regenerative brake resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative brake transistor fault or the like may overheat the regenerative brake resistor, causing a fire.

3. To prevent injury, note the follow

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal, Otherwise, a

burst, damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

During power-on or for some time after power-off, do not touch or close a parts (cable etc.) to the servo

amplifier heat sink, regenerative brake resistor, servo motor, etc. Their temperatures may be high and you

may get burnt or a parts may damaged.

During operation, never touch the rotating parts of the servo motor. Doing so can cause injury.

A - 3

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric

shock, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their weights.

Stacking in excess of the specified number of products is not allowed.

Do not carry the servo motor by the cables, shaft or encoder.

Do not hold the front cover to transport the servo amplifier. The servo amplifier may drop.

Install the servo amplifier in a load-bearing place in accordance with the Instruction Manual.

Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

The servo amplifier and servo motor must be installed in the specified direction.

Leave specified clearances between the servo amplifier and control enclosure walls or other equipment.

Do not install or operate the servo amplifier and servo motor which has been damaged or has any parts

missing.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier.

Do not drop or strike servo amplifier or servo motor. Isolate from all impact loads.

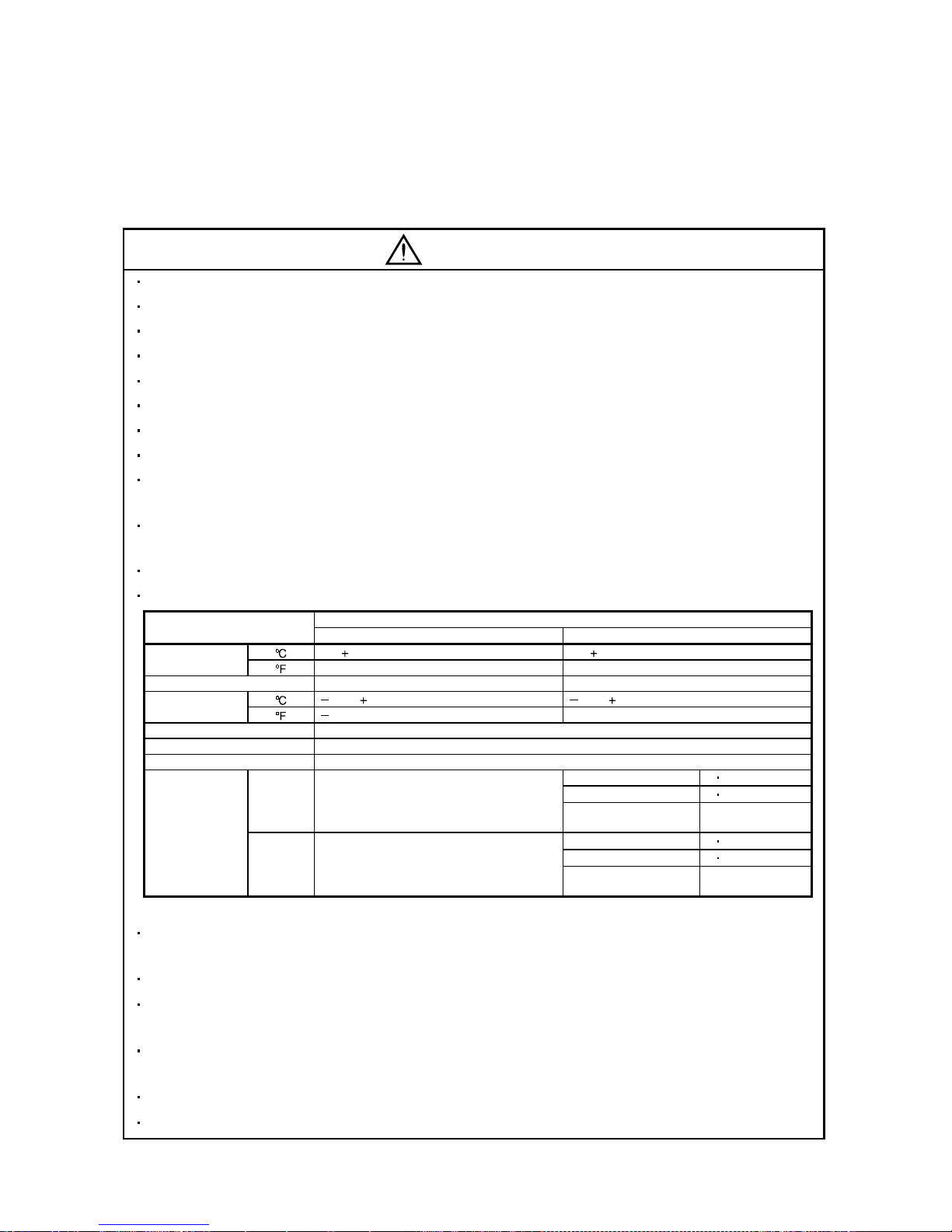

Use the servo amplifier and servo motor under the following environmental conditions:

Conditions

Environment

Servo amplifier Servo motor

[ ]0 to 55 (non-freezing) 0 to 40 (non-freezing)

Ambient

temperature

[

] 32 to 131 (non-freezing) 32 to 104 (non-freezing)

Ambient humidity 90%RH or less (non-condensing) 80%RH or less (non-condensing)

[ ] 20 to 65 (non-freezing) 15 to 70 (non-freezing)

Storage

temperature

[

] 4 to 149 (non-freezing) 5 to 158 (non-freezing)

Storage humidity 90%RH or less (non-condensing)

Ambience Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280 ft) above sea level

HC-KFE Series X Y : 49

HC-SFE52 to 152 X Y : 24.5

[m/s2] 5.9 or less

HC-SFE202

X : 24.5

Y : 49

HC-KFE Series X Y : 161

HC-SFE52 to 152 X Y : 80

(Note)

Vibration

[ft/s

2

] 19.4 or less

HC-SFE202

X : 80

Y : 161

Note: Except the servo motor with reduction gear.

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The servo motor with reduction gear must be installed in the specified direction to prevent oil leakage.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotating parts of the servo

motor during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When the equipment has been stored for an extended period of time, consult Mitsubishi.

A - 4

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may misoperate.

Do not install a power capacitor, surge absorber or radio noise filter (FR-BIF option) between the servo

motor and servo amplifier.

Connect the output terminals (U, V, W) correctly. Otherwise, the servo motor will operate improperly.

Do not connect AC power directly to the servo motor. Otherwise, a fault may occur.

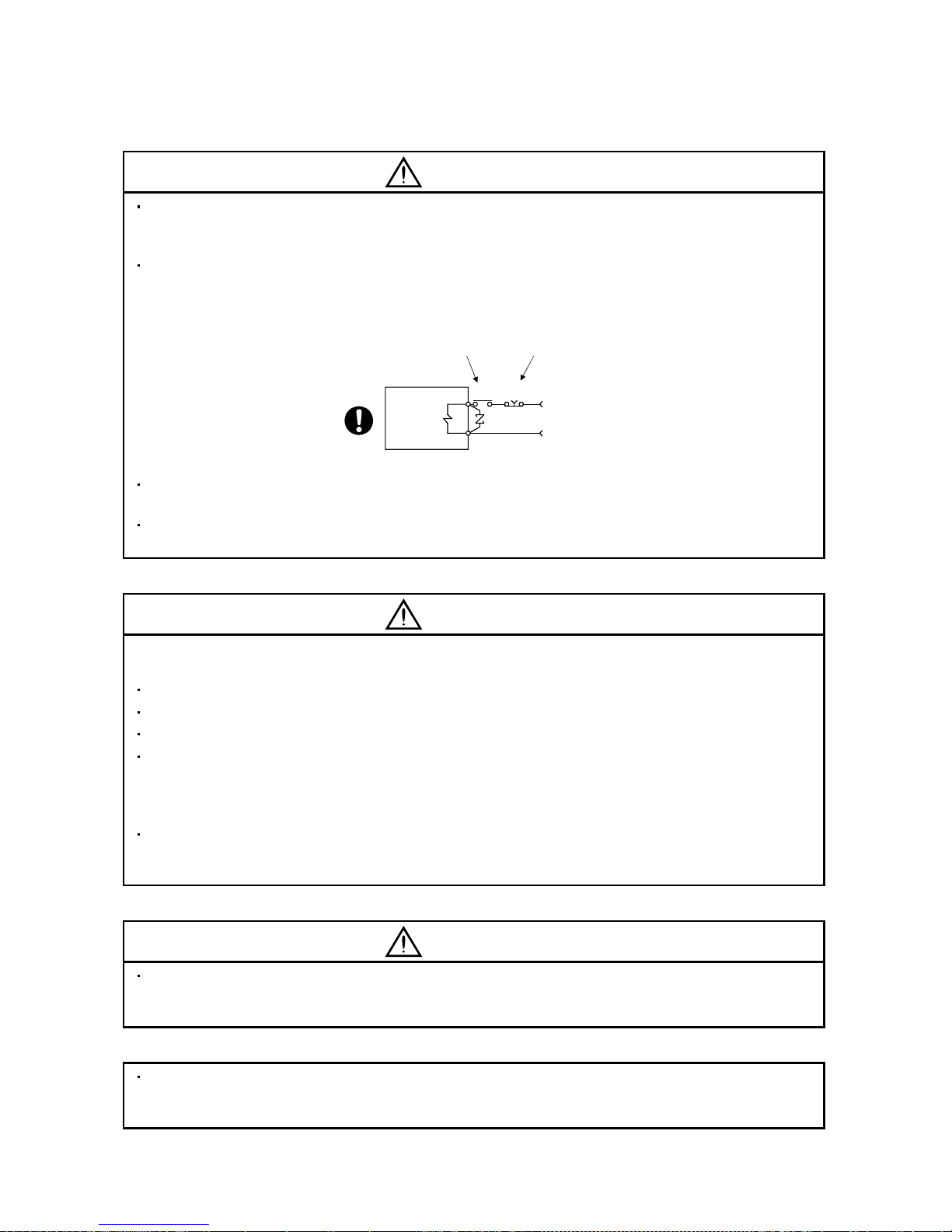

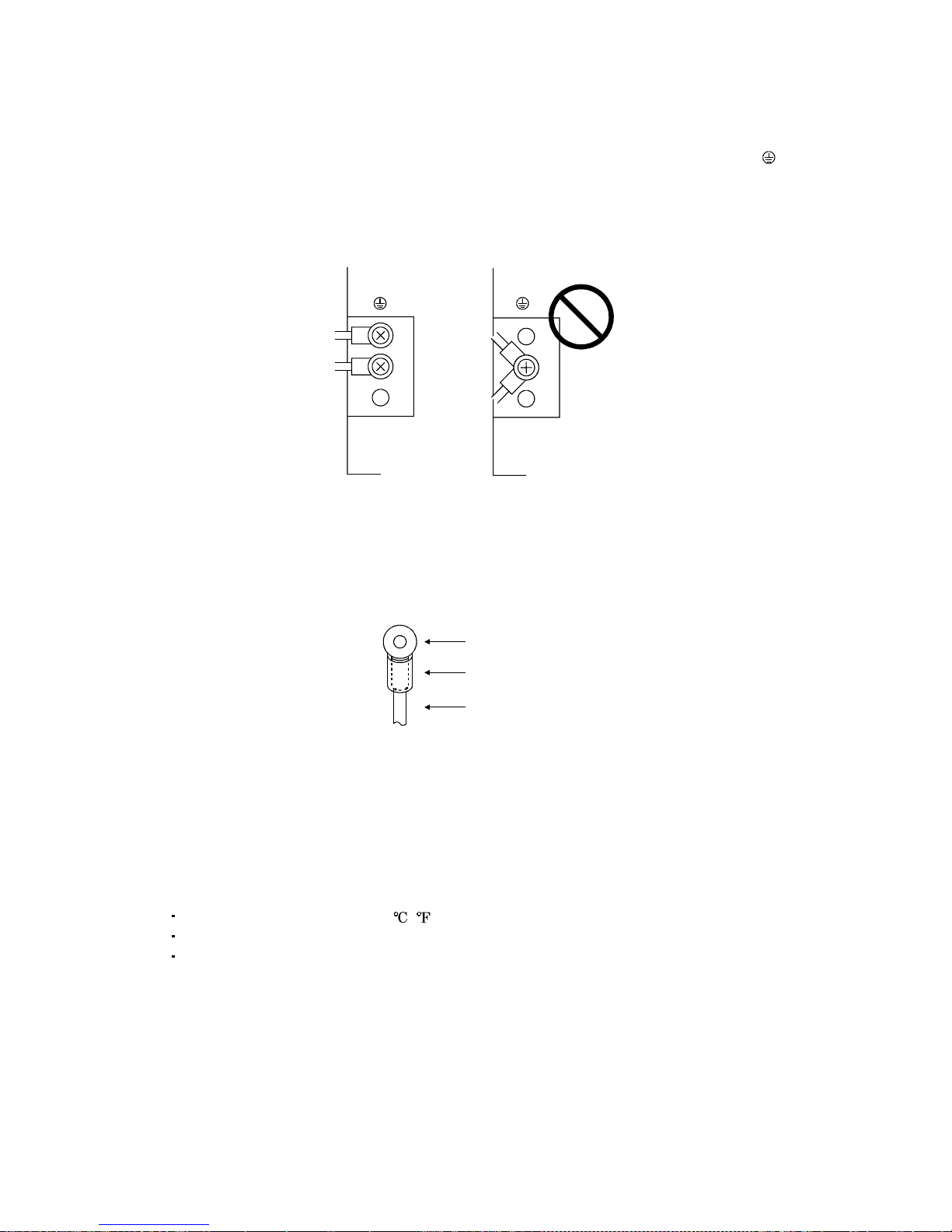

The surge absorbing dio de in stal le d on th e DC ou t put si gna l rel ay must be wired in the speci fie d di re ctio n .

Otherwise, the emergency stop and other protective circuits may not operate.

External

24VDC

RA

Servo

Amplifier

Control output

signal

Servo

Amplifier

RA

Control output

signal

External

24VDC

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be insatiable.

(4) Usage

CAUTION

Provide an extern al emergenc y stop c ircuit to ensure that oper ation ca n be sto pped and power s witched

off immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resettin g an alarm , make sure th at the run s ignal i s of f to pre vent an accid ent. A s udde n rest art is

made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise filter, etc. to minim i ze the inf lue nce of e lectromagnetic int erf erenc e, which m a y be c aus ed b y

electronic equipment used near the servo amplifier.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be used

for ordinary braking.

For such reas ons as servic e life and mec hanical struc ture (e.g. wher e a ballscrew and the s ervo motor

are coupled via a tim ing belt), the electrom agnetic brak e may not hol d the m otor shaf t. To ensur e safet y,

install a stoppe r on the mach in e side .

A - 5

(5) Corrective actions

CAUTION

When it is assu med that a ha zardous con dition ma y take place at t he occur due to a power f ailure or a

product fault, use a servo motor with electromagnetic brake or an external brake mechanism for the

purpose of prev en ti on .

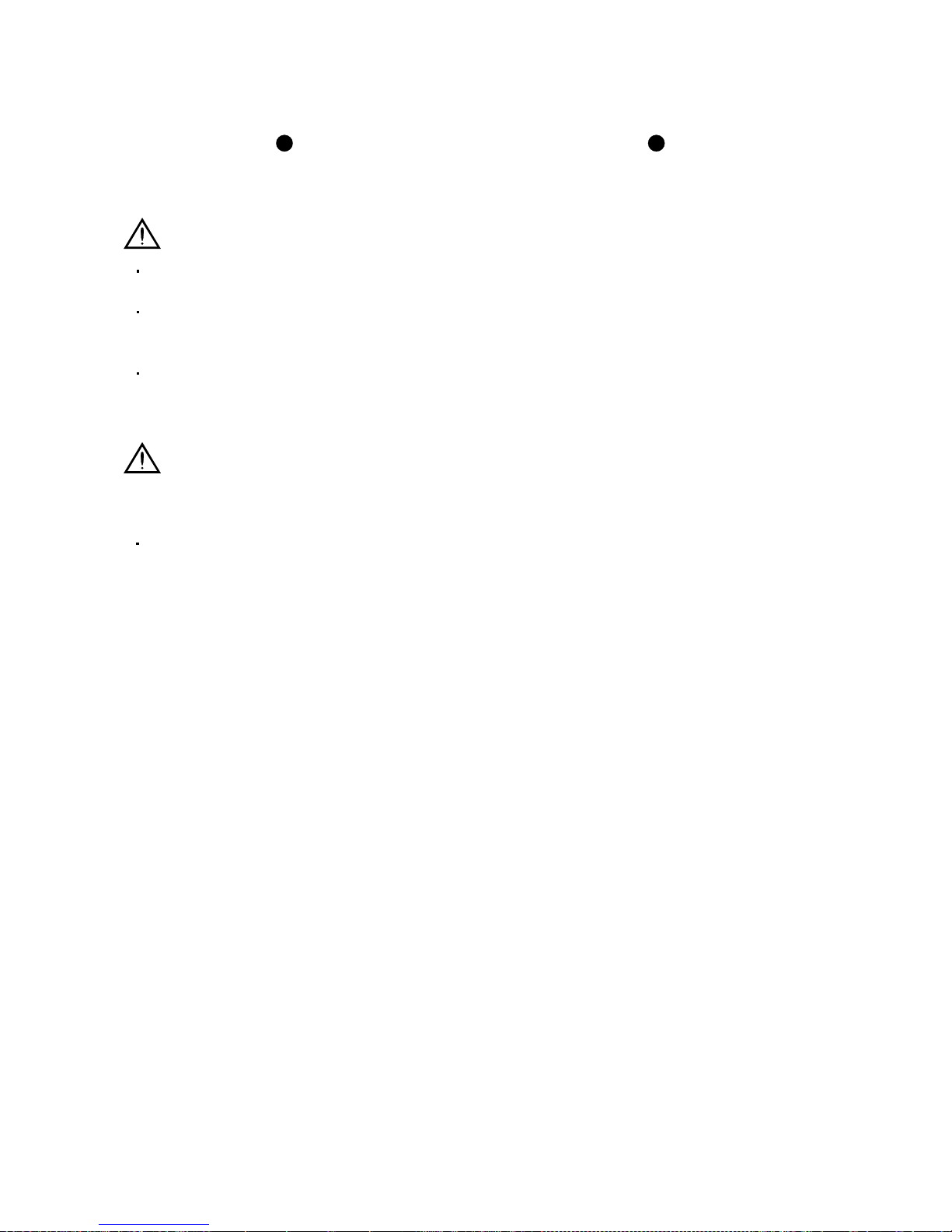

Configure the e lectromagnet ic brake circu it so that it is activated not only by the servo ampl ifier signa ls

but also by an external emergency stop signal (EMG).

EMGRA

24VDC

Contacts must be open when

servo-on signal is off, when an

alarm (trouble) is present and when

an electromagnetic brake signal.

Electromagnetic brake

Servo motor

Circuit must be

opened during

emergency stop signal.

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

When power is restor ed after an insta ntaneous po wer failure, keep awa y from the m achine beca use the

machine may be restarted suddenly (design the machine so that it is secured against hazard if restarted).

(6) Storage for serv o mo tor

CAUTION

Note the follow ing points whe n storing th e servo motor for an exten ded period of time (guide line: three or

more months).

Always store the servo motor indoors in a clean and dry place.

If it is stored in a dusty or damp place, make adequate provision, e.g. cover the whole product.

If the insulation resistance of the winding decreases, reexamine the storage method.

Though the servo m otor is rust-proofed befor e shipment using paint or rust preven tion oil, rust ma y be

produced depending on the storage conditions or storage period.

If the servo motor is to be stored for longer than six months, apply rust prevention oil again especially to

the machined surfaces of the shaft, etc.

Before using the prod uct after stor age for an extend ed pe ri od of tim e, h and-tur n the m otor out put sh aft t o

confirm that not hing is wrong with the ser vo motor. (When the servo m otor is equipped with a br ake,

make the above check after releasing the brake with the brake power supply.)

(7) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor will deteriorate. To prevent a secondary accident due to a fault, it is

recommended to replace the electrolytic capacitor every 10 years when used in general environment.

Please consult our sales representative.

(8) General instructi o n

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must be

installed as specified. Operation must be performed in accordance with this Instruction Manual.

A - 6

About processing of waste

When you discard servo amplifier, a battery (primary battery), and other option articles, please follow the law of

each country (area).

FOR MAXIMUM SAFETY

This product is not designed or manufactured to be used in equipment or systems in situations that can

affect or enda nge r hu man li fe .

When considering this product for operation in special applications such as machinery or systems used in

passenger transportation, medical, aerospace, atomic power, electric power, or submarine repeating

applications, please contact your nearest Mitsubishi sales representative.

Although this product was manufactured under conditions of strict quality control, you are strongly advised

to install safety devices to forestall serious accidents when it is used in facilities where a breakdown in the

product is likely to cause a serious accident.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier and/or converter unit may

fail when the EEP-ROM reaches the end of its useful life.

Write to the EEP-R OM du e to par a mete r set tin g ch an ges

A - 7

COMPLIANCE WITH EC DIRECTIVES

1. WHAT ARE EC DIRE CTI VES ?

The EC directives were issued to standardize the regulations of the EU countries and ensure smooth

distribution of safety-guaranteed products. In the EU countries, the machinery directive (effective in

January, 1995), EMC directive (effective in January, 1996) and low voltage dir ective (effective in January,

1997) of the EC directives require that products to be sold should meet their fundamental safety

requirements and carry the CE marks (CE mar king). CE marking applies to machines and equipment

into which servo amplifiers have been installed.

(1) EMC directive

The EMC directive applies not to the servo units alone but to servo-incorporated machines and

equipment. This requires the EMC filters to be used with the servo-incorporated machines and

equipment to comply with the EMC directive. For specific EMC directive conforming methods, refer to

the EMC Installation Guidelines (IB(NA)67310).

(2) Low voltage di re ctiv e

The low voltage directive applies also to servo units alone. Hence, they are designed to comply with

the low voltage directive.

(3) Machine directive

Not being machines, the servo amplifiers need not comply with this directive.

2. PRECAUTIONS FOR COMPLIANCE

(1) Servo amplifiers and servo motors used (Acquisition schedule)

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier :MR-E-10A to MR-E-200A

Servo motor :HC-KFE

HC-SFE

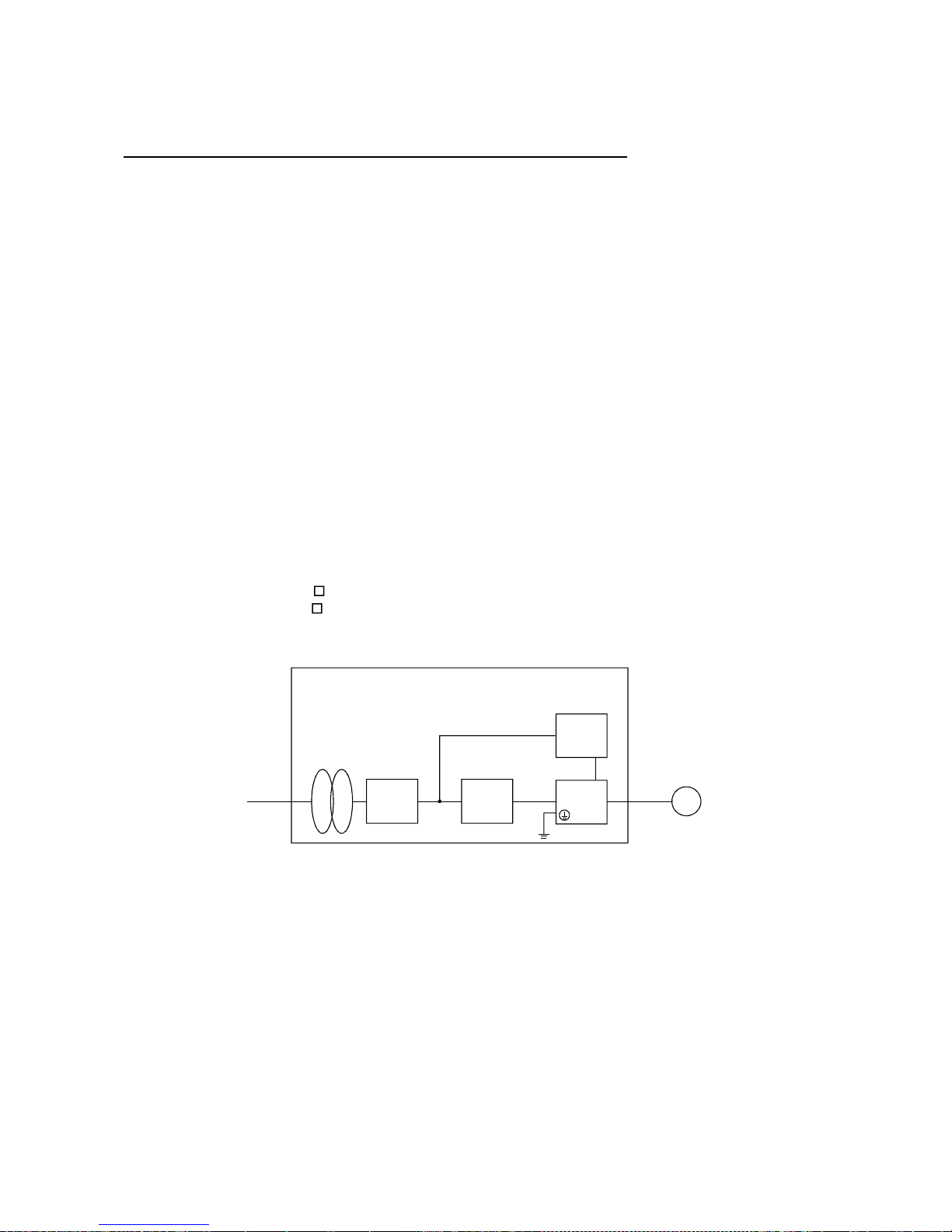

(2) Configuration

Reinforced

insulating

transformer

NFB

MC

SM

No-fuse

breaker

Magnetic

contactor

Reinforced

insulating type

24VDC

power

supply

Servo

amplifier

Servo

motor

Control box

Use the no-fuse breaker and magnetic contactor which conform to the EN or IEC Standard.

Design notice: Where residual-current-operated protective device (RCD) is used for protection case of

direvt or indirect contact, only RCD of type B is allowed on the supply side of this Electronic

Equipment(EE).

(3) Environment

Operate the servo amplifier at or above the contamination level 2 set forth in IEC664. For this

purpose, install the servo amplifier in a control box which is protected against water, oil, carbon, dust,

dirt, etc. (IP54).

(4) Power supply

(a) Operate the servo amplifier to meet the requirements of the overvoltage category II set forth in

IEC664. For this purpose, a reinforced insulating transformer conforming to the IEC or EN

Standard should be used in the power input section.

(b) As the external power supply for interface, use a 24VDC power supply that has been insulation-

reinforced in I/O.

A - 8

(5) Grounding

(a) To prevent an electric shock, always connect the protective earth (PE) terminals (marked

) of the

servo amplifier to the protective earth (PE) of the control box. Connect PE terminal of the control

box to the NEUTRAL of a power supply. Be sure to ground the NEUTRAL of a power supply.

(b) Do not con nect two g round cable s to the same pro tective e arth (PE) terminal. Always c onnect the

cables to the terminals one-to-one.

PE terminals PE terminals

(c) If a leakage current breaker is used to prevent an electric shock, the protective earth (PE) terminals

of the servo ampli fi er mus t b e c onne ct ed t o t h e c orr es pondi n g eart h t ermi nal s.

(6) Wiring

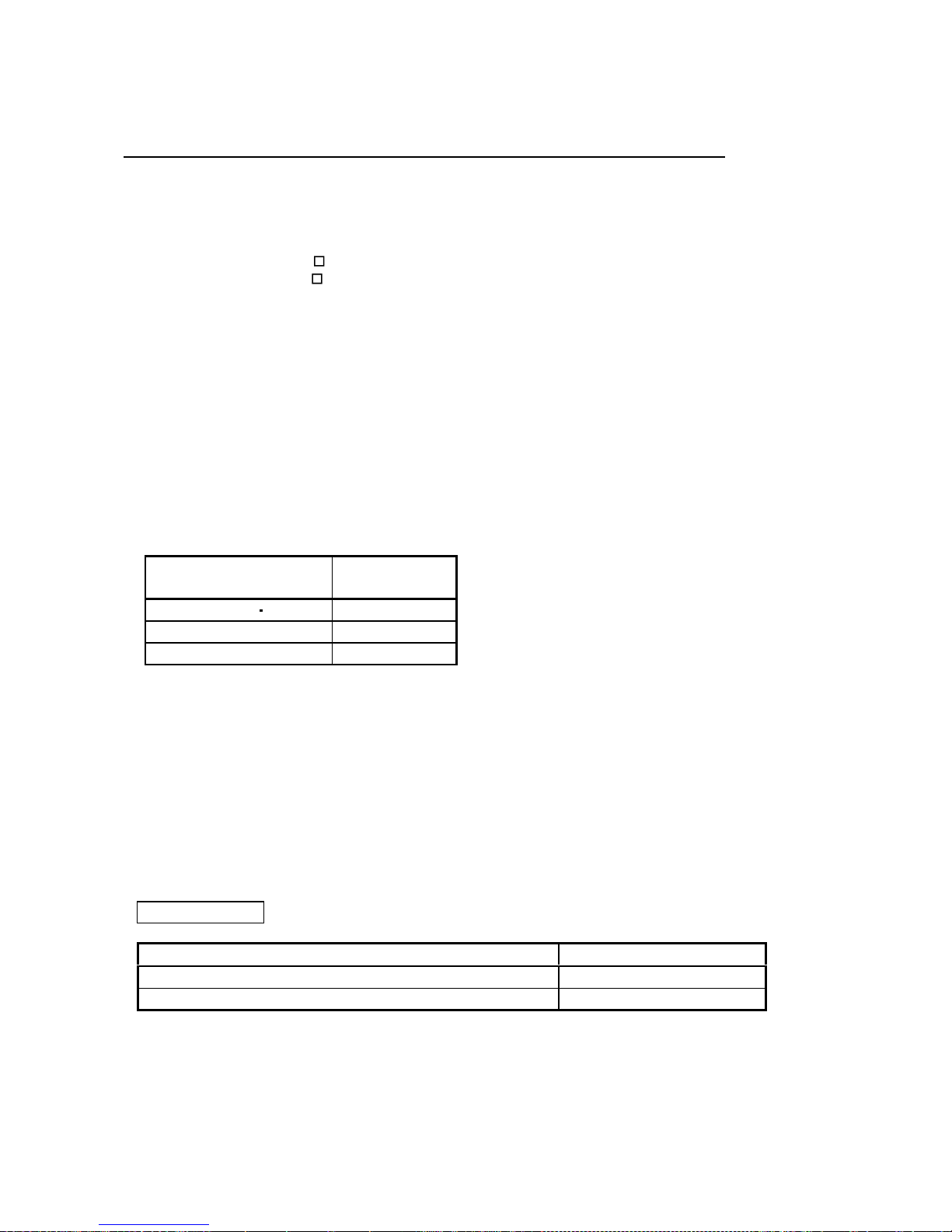

(a) The cables to be connected to the terminal block of the servo amplifier must have crimping

terminals provided with insulating tubes to prevent contact with adjacent terminals.

Crimping terminal

Insulating tube

Cable

(b) Use the servo motor side power connector which complies with the EN Standard. The EN

Standard-compliant power connector sets are available from us as options. (Refer to Section 13.1.2)

(7) Auxiliary equipment and options

(a) The no-fuse breaker and magnetic contactor used should be the EN or IEC standard-compliant

products of the models described in Section 13.2.2.

(b) The sizes of the cable s described in Section 13.2.1 mee t the following requ irements. To meet th e

other requirements, follow Table 5 and Appendix C in EN60204-1.

Ambient tempera t ur e: 40 (104 ) [ ( )]

Sheath: PVC (polyvinyl chloride)

Installed on wall surface or open table tray

(c) Use the EMC filter for noise reduction.

(8) Performing EMC tests

When EMC tests are run on a machine/device into which the servo amplifier has been installed, it

must conform to the electromagnetic compatibility (immunity/emission) standards after it has

satisfied the operating environment/electrical equipment specifications.

For the other EMC directive guidelines on the servo amplifier, refer to the EMC Installation

Guidelines(IB(NA)67310).

A - 9

CONFORMANCE WITH UL/C-UL STANDARD

(1) Servo amplifiers and servo motors used (Acquisition schedule)

Use the servo amplifiers and servo motors which comply with the standard model.

Servo amplifier :MR-E-10A to MR-E-200A

Servo motor :HC-KFE

HC-SFE

(2) Installation

Install a fan of 1 00CFM (2.8 m

3

/min) air flow 4 in (10.16 cm) above the servo amplifier or provide

cooling of at least equivalent capability.

(3) Short circuit rating

This servo amplifier conforms to the circuit whose peak current is limited to 5000A or less. Having

been subjected to the short-circuit tests of the UL in the alternating-current circuit, the servo

amplifier conforms to the above circuit.

(4) Capacitor discharge time

The capacitor disch arg e time is as li sted below . To ensu re saf ety , do no t to uch the ch argin g sec tion f or

10 minutes after power-off.

Servo amplifier

Discharge time

[min]

MR-E-10A 20A 1

MR-E-40A 2

MR-E-70A to 200A 3

(5) Options and auxiliary equipment

Use UL/C-UL standard-compliant products.

(6) About wiring protection

For installation in United States, branch circuit prot ecti on must be provided, in accordance with the

National Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided, in accordance with the Canada

Electrical Code and any applicable provincial codes.

<<About the manual s>>

Relevant manuals

Manual name Manual No.

MR-E Series To Use the AC Servo Safely IB(NA)0300057

EMC Installation Guidelines IB(NA)67310

A - 10

MEMO

1

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-10

1.1 Introduction.............................................................................................................................................. 1- 1

1.2 Function block diagram ..........................................................................................................................1- 2

1.3 Servo amplifier standard specifications................................................................................................1- 3

1.4 Function list .............................................................................................................................................1- 4

1.5 Model code definition ..............................................................................................................................1- 6

1.6 Combination with servo motor............................................................................................... ................1- 6

1.7 Parts identification..................................................................................................................................1- 7

1.8 Servo system with auxiliary equipment................................................................................................1- 9

2. INSTALLATION 2- 1 to 2- 4

2.1 Environmental conditions.......................................................................................................................2- 1

2.2 Installation direction and clearances ....................................................................................................2- 2

2.3 Keep out foreign materials .....................................................................................................................2- 3

2.4 Cable stress ..............................................................................................................................................2- 3

3. SIGNALS AND WIRING 3- 1 to 3- 48

3.1 Standard connection example ................................................................................................................3- 2

3.1.1 Position control mode .......................................................................................................................3- 2

3.1.2 Internal speed control mode ............................................................................................................3- 8

3.2 Internal connection diagram of servo amplifier ...................................................................................3- 9

3.3 I/O signals................................................................................................................................................3-10

3.3.1 Connectors and signal arrangements............................................................................................3-10

3.3.2 Signal explanations .........................................................................................................................3-13

3.4 Detailed description of the signals........................................................................................................3-19

3.4.1 Position control mode ......................................................................................................................3-19

3.4.2 Internal speed control mode ...........................................................................................................3-24

3.4.3 Position/internal speed control change mode................................................................................3-26

3.5 Alarm occurrence timing chart .............................................................................................................3-28

3.6 Interfaces.................................................................................................................................................3-29

3.6.1 Common line ....................................................................................................................................3-29

3.6.2 Detailed description of the interfaces............................................................................................3-30

3.7 Input power supply circuit.....................................................................................................................3-34

3.7.1 Connection example.........................................................................................................................3-34

3.7.2 Terminals..........................................................................................................................................3-35

3.7.3 Power-on sequence...........................................................................................................................3-36

3.8 Connection of servo amplifier and servo motor...................................................................................3-37

3.8.1 Connection instructions ..................................................................................................................3-37

3.8.2 Connection diagram.........................................................................................................................3-37

3.8.3 I/O terminals....................................................................................................................................3-39

3.9 Servo motor with electromagnetic brake .............................................................................................3-41

3.10 Grounding .............................................................................................................................................3-44

3.11 Servo amplifier connectors (CNP1, CNP2) wiring method

(When MR-ECPN1-B and MR-ECPN2-B of an option are used.)...................................................3-45

3.12 Instructions for the 3M connector.......................................................................................................3-48

2

4. OPERATION 4- 1 to 4- 6

4.1 When switching power on for the first time..........................................................................................4- 1

4.2 Startup......................................................................................................................................................4- 2

4.2.1 Selection of control mode..................................................................................................................4- 2

4.2.2 Position control mode .......................................................................................................................4- 2

4.2.3 Internal speed control mode ............................................................................................................4- 4

5. PARAMETERS 5- 1 to 5- 30

5.1 Parameter list..........................................................................................................................................5- 1

5.1.1 Parameter write inhibit ...................................................................................................................5- 1

5.1.2 Lists....................................................................................................................................................5- 2

5.2 Detailed description ...............................................................................................................................5-25

5.2.1 Electronic gear .................................................................................................................................5-25

5.2.2 Analog monitor.................................................................................................................................5-26

5.2.3 Using forward/reverse rotation stroke end to change the stopping pattern..............................5-29

5.2.4 Alarm history clear..........................................................................................................................5-29

5.2.5 Position smoothing ..........................................................................................................................5-30

6. DISPLAY AND OPERATION 6- 1 to 6-14

6.1 Display flowchart..................................................................................................................................... 6- 1

6.2 Status display ..........................................................................................................................................6- 2

6.2.1 Display examples.............................................................................................................................. 6- 2

6.2.2 Status display list.............................................................................................................................6- 3

6.2.3 Changing the status display screen................................................................................................6- 4

6.3 Diagnostic mode.......................................................................................................................................6- 5

6.4 Alarm mode................................................................................................................. .............................6- 6

6.5 Parameter mode ......................................................................................................................................6- 7

6.6 External I/O signal display.....................................................................................................................6- 8

6.7 Output signal (DO) forced output .........................................................................................................6-10

6.8 Test operation mode........................................................................................................ .......................6-11

6.8.1 Mode change.....................................................................................................................................6-11

6.8.2 Jog operation ....................................................................................................................................6-12

6.8.3 Positioning operation....................................................................................................................... 6-13

6.8.4 Motor-less operation........................................................................................................................6-14

7. GENERAL GAIN ADJUSTMENT 7- 1 to 7-10

7.1 Different adjustment methods ...............................................................................................................7- 1

7.1.1 Adjustment on a single servo amplifier..........................................................................................7- 1

7.1.2 Adjustment using servo configuration software............................................................................7- 2

7.2 Auto tuning ..............................................................................................................................................7- 3

7.2.1 Auto tuning mode .............................................................................................................................7- 3

7.2.2 Auto tuning mode operation............................................................................................................7- 4

7.2.3 Adjustment procedure by auto tuning............................................................................................7- 5

7.2.4 Response level setting in auto tuning mode...................................................................................7- 6

3

7.3 Manual mode 1 (simple manual adjustment).......................................................................................7- 7

7.3.1 Operation of manual mode 1 ...........................................................................................................7- 7

7.3.2 Adjustment by manual mode 1 .......................................................................................................7- 7

7.4 Interpolation mode .................................................................................................................................7-10

8. SPECIAL ADJUSTMENT FUNCTIONS 8- 1 to 8-10

8.1 Function block diagram ..........................................................................................................................8- 1

8.2 Machine resonance suppression filter ...................................................................................................8- 1

8.3 Adaptive vibration suppression control.................................................................................................8- 3

8.4 Low-pass filter .........................................................................................................................................8- 4

8.5 Gain changing function...........................................................................................................................8- 5

8.5.1 Applications....................................................................................................................................... 8- 5

8.5.2 Function block diagram....................................................................................................................8- 5

8.5.3 Parameters ........................................................................................................................................8- 6

8.5.4 Gain changing operation..................................................................................................................8- 8

9. INSPECTION 9- 1 to 9- 2

10. TROUBLESHOOTING 10- 1 to 10-12

10.1 Trouble at start-up ..............................................................................................................................10- 1

10.1.1 Position control mode...................................................................................................................10- 1

10.1.2 Internal speed control mode ........................................................................................................10- 4

10.2 When alarm or warning has occurred...............................................................................................10- 5

10.2.1 Alarms and warning list ..............................................................................................................10- 5

10.2.2 Remedies for alarms.....................................................................................................................10- 6

10.2.3 Remedies for warnings................................................................................................................10-11

11. OUTLINE DIMENSION DRAWINGS 11- 1 to 11- 8

11.1 Servo amplifiers...................................................................................................................................11- 1

11.2 Connectors............................................................................................................................................11- 5

12. CHARACTERISTICS 12- 1 to 12- 4

12.1 Overload protection characteristics...................................................................................................12- 1

12.2 Power supply equipment capacity and generated loss ....................................................................12- 1

12.3 Dynamic brake characteristics...........................................................................................................12- 3

12.4 Encoder cable flexing life................................................................................................ ....................12- 4

13. OPTIONS AND AUXILIARY EQUIPMENT 13- 1 to 13-32

13.1 Options..................................................................................................................................................13- 1

13.1.1 Regenerative brake options.........................................................................................................13- 1

13.1.2 Cables and connectors..................................................................................................................13- 6

13.1.3 Analog monitor, RS-232C branch cable (MR-E3CBL15-P).....................................................13-19

13.1.4 Servo configurations software....................................................................................................13-20

4

13.2 Auxiliary equipment ..........................................................................................................................13-21

13.2.1 Recommended wires....................................................................................................................13-21

13.2.2 No-fuse breakers, fuses, magnetic contactors...........................................................................13-23

13.2.3 Power factor improving reactors................................................................................................13-23

13.2.4 Relays............................................................................................................................................13-24

13.2.5 Surge absorbers ...........................................................................................................................13-24

13.2.6 Noise reduction techniques.........................................................................................................13-24

13.2.7 Leakage current breaker.............................................................................................................13-30

13.2.8 EMC filter.....................................................................................................................................13-32

14. SERVO MOTOR 14- 1 to 14- 38

14.1 Compliance with the overseas standards..........................................................................................14- 1

14.1.1 Compliance with EC directives...................................................................................................14- 1

14.1.2 Conformance with UL/C-UL standard.......................................................................................14- 1

14.2 Model name make-up..........................................................................................................................14- 2

14.3 Parts identification..............................................................................................................................14- 4

14.4 Installation...........................................................................................................................................14- 5

14.4.1 Environmental conditions............................................................................................................14- 6

14.4.2 Installation orientation................................................................................................................14- 6

14.4.3 Load mounting precautions.........................................................................................................14- 7

14.4.4 Permissible load for the shaft......................................................................................................14- 8

14.4.5 Protection from oil and water.....................................................................................................14-11

14.4.6 Cable .............................................................................................................................................14-12

14.5 Connectors used for servo motor wiring...........................................................................................14-13

14.5.1 HC-KFE series.............................................................................................................................14-13

14.5.2 HC-SFE series..............................................................................................................................14-13

14.6 Specifications ......................................................................................................................................14-19

14.6.1 Standard specifications...............................................................................................................14-19

14.6.2 Torque characteristics.................................................................................................................14-21

14.6.3 Servo motors with reduction gears............................................................................................14-22

14.6.4 Servo motors with special shafts................................................................................................14-25

14.6.5 D cut..............................................................................................................................................14-25

14.7 Characteristics....................................................................................................................................14-26

14.7.1 Electromagnetic brake characteristics......................................................................................14-26

14.7.2 Vibration rank..............................................................................................................................14-28

14.7.3 Machine Accuracies.....................................................................................................................14-28

14.8 Outline dimension drawing...............................................................................................................14-29

14.8.1 HC-KFE series.............................................................................................................................14-29

14.8.2 HC-SFE series..............................................................................................................................14-32

14.9 Outline dimension drawing (in inches) ............................................................................................14-34

14.9.1 HC-KFE series.............................................................................................................................14-34

14.9.2 HC-SFE series..............................................................................................................................14-37

5

15. MR-E-

AG SERVO AMPLIFIER COMPATIBLE WITH ANALOG INPUT 15- 1 to 15- 62

15.1. Functions and configuration..............................................................................................................15- 1

15.1.1 Introduction...................................................................................................................................15- 1

15.1.2 Function block diagram ...............................................................................................................15- 2

15.1.3 Servo amplifier standard specifications .....................................................................................15- 3

15.1.4 Model code definition....................................................................................................................15- 4

15.1.5 Parts identification.......................................................................................................................15- 4

15.1.6 Servo system with auxiliary equipment.....................................................................................15- 6

15.2. Signals and wiring..............................................................................................................................15- 8

15.2.1 Standard connection example .....................................................................................................15- 8

15.2.2 Internal connection diagram of servo amplifier .......................................................................15-11

15.2.3 Connectors and signal arrangements........................................................................................15-12

15.2.4 Signal explanations.....................................................................................................................15-14

15.2.5 Detailed description of the signals.............................................................................................15-18

15.3 Startup.................................................................................................................................................15-25

15.3.1 Speed control mode......................................................................................................................15-25

15.3.2 Torque control mode....................................................................................................................15-27

15.4 Parameters..........................................................................................................................................15-29

15.4.1 Item list.........................................................................................................................................15-29

15.4.2 Details list ....................................................................................................................................15-32

15.5 Display and operation........................................................................................................................15-51

15.5.1 Display flowchart.........................................................................................................................15-51

15.5.2 Status display...............................................................................................................................15-53

15.5.3 Diagnostic mode...........................................................................................................................15-55

15.5.4 External I/O signal display.........................................................................................................15-57

15.6. Troubleshooting.................................................................................................................................15-59

15.6.1 Trouble at start-up ......................................................................................................................15-59

15.6.2 Alarms and warning list .............................................................................................................15-61

6

MEMO

1 - 1

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Introduction

The Mitsubishi MR-E series general-purpose AC servo is based on the MR-J2-Super series, and has the

same high performance and limited functions.

It has position control and internal speed control modes. Further, it can perform operation with the

control modes changed, e.g. position/internal speed control. Hence, it is applicable to a wide range of

fields, precision positioning and smooth speed control of machine tools and general industrial machines.

As this new series has the RS-232C or RS-422 serial communication function, a servo configuration

software-installed personal computer or the like can be used to perform parameter setting, test operation,

status display monitoring, gain adjustment, etc.

With real-time auto tuning, you can automatically adjust the servo gains according to the machine.

The MR-E series servo motor is equipped with an incremental position encoder that has the resolution of

10000 pulses/rev to ensure high precision positioning.

(1) Position control mode

An up to 500kpps high-speed pulse train is used to control the speed and direction of a motor and

execute precision positioning of 10000 pulses/rev resolution.

The position smoothing function provides a choice of two different modes appropriate for a machine, so

a smoother start/stop can be made in response to a sudden position command.

A torque lim it i s i m po se d o n the servo am plifier by the c lam p circuit to pr o tect the po w e r transistor in

the main circuit from overcurrent due to sudden acceleration/deceleration or overload. This torque

limit value can be changed to any value with the parameter.

(2) Internal spee d co nt rol mod e

The parameter-driven internal speed command (max. 7 speeds) is used to control the speed and

direction of a servo motor smoothly.

There are also the acceleration/deceleration time constant setting in response to speed command, the

servo lock function at a stop time.

1 - 2

1. FUNCTIONS AND CONFIGURATION

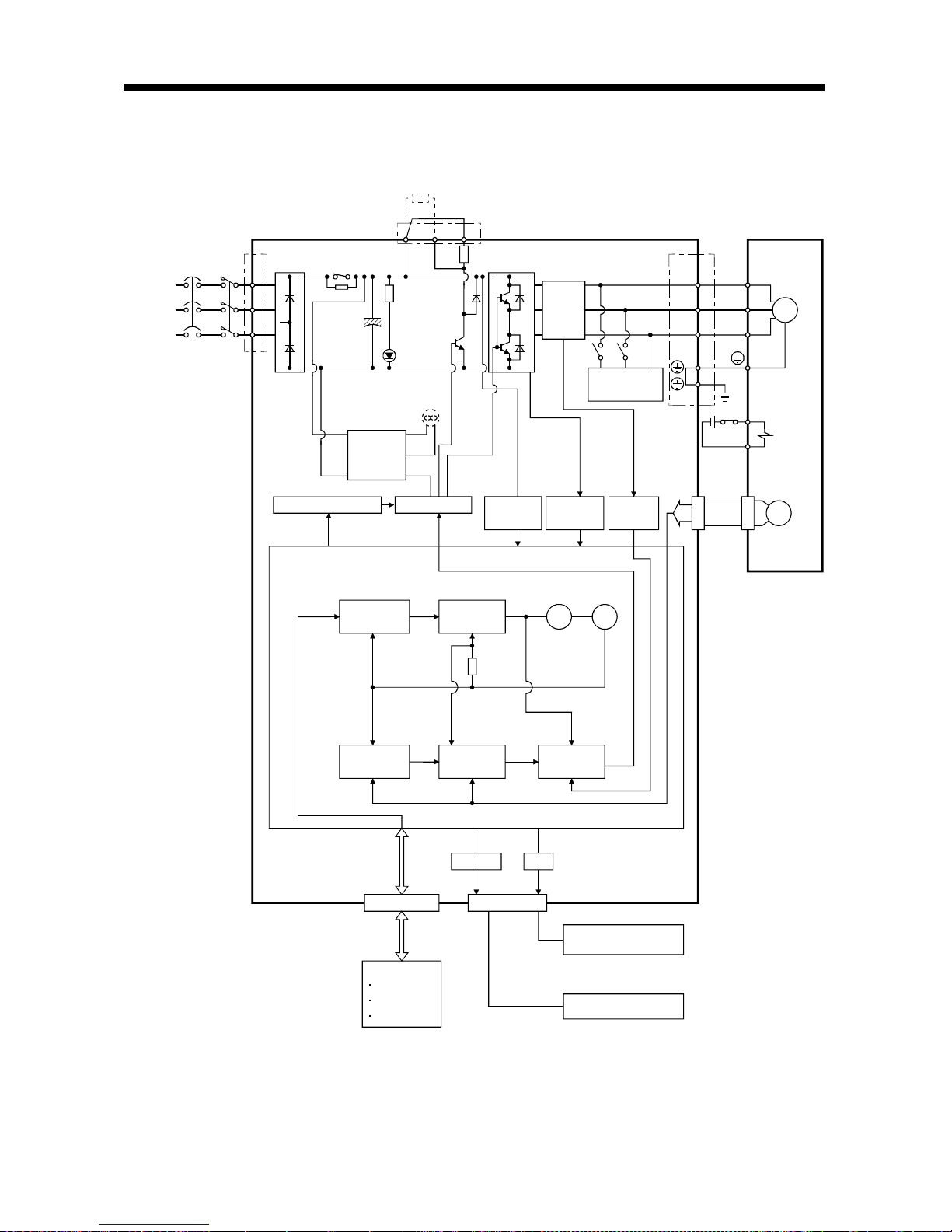

1.2 Function block diagram

The function block diagram of this servo is shown below.

Regenerative brake option

Servo amplifier

Current

detector

CHARGE

lamp

Servo motor

Regenerative

TR

(Note 1)

Regene rative brake

Base amplifier

Voltage

detection

Overcurrent

protection

Encoder

Dynamic

brake

Control

power

supply

Fan

(MR-E-200A only)

Electromagnetic

brake

Current

detection

Model position

control

Model speed

control

Pulse

input

Model

position

Actual position

control

Actual speed

control

Current

control

Model torque

Virtual

motor

Virtual

encoder

Model

speed

D I/O control

Servo on

Start

Failure, etc.

Controller

Analog monitor

(2 channels)

RADS

D

C

P

NFB MC

L

1

L

2

L

3

CN1

CN3

RS-232C

E2

I/F

CN2

U

V

W

U

V

W

SM

E1

RS-232C D/A

Power

supply

3-phase

200 to

230VAC,

1-phase

230VAC

(Note 2)

(Note 3)

(Note 3)

(Note 3)

(Note 3)

(Note 3)(Note 3)

Note:1. The built-in regenerative brake resistor is not provided for the MR-E-10A/20A.

2. The single-phase 230VAC can be used for MR-E-70A or smaller servo amplifier.

Connect the power supply cables to L

1

and L2 while leaving L3 open.

3. The control circuit connectors (CN1, CN2 and CN3) are safely isolated from main circuit terminals

(L

1

, L2, L3, U, V, W, P, C and D).

1 - 3

1. FUNCTIONS AND CONFIGURATION

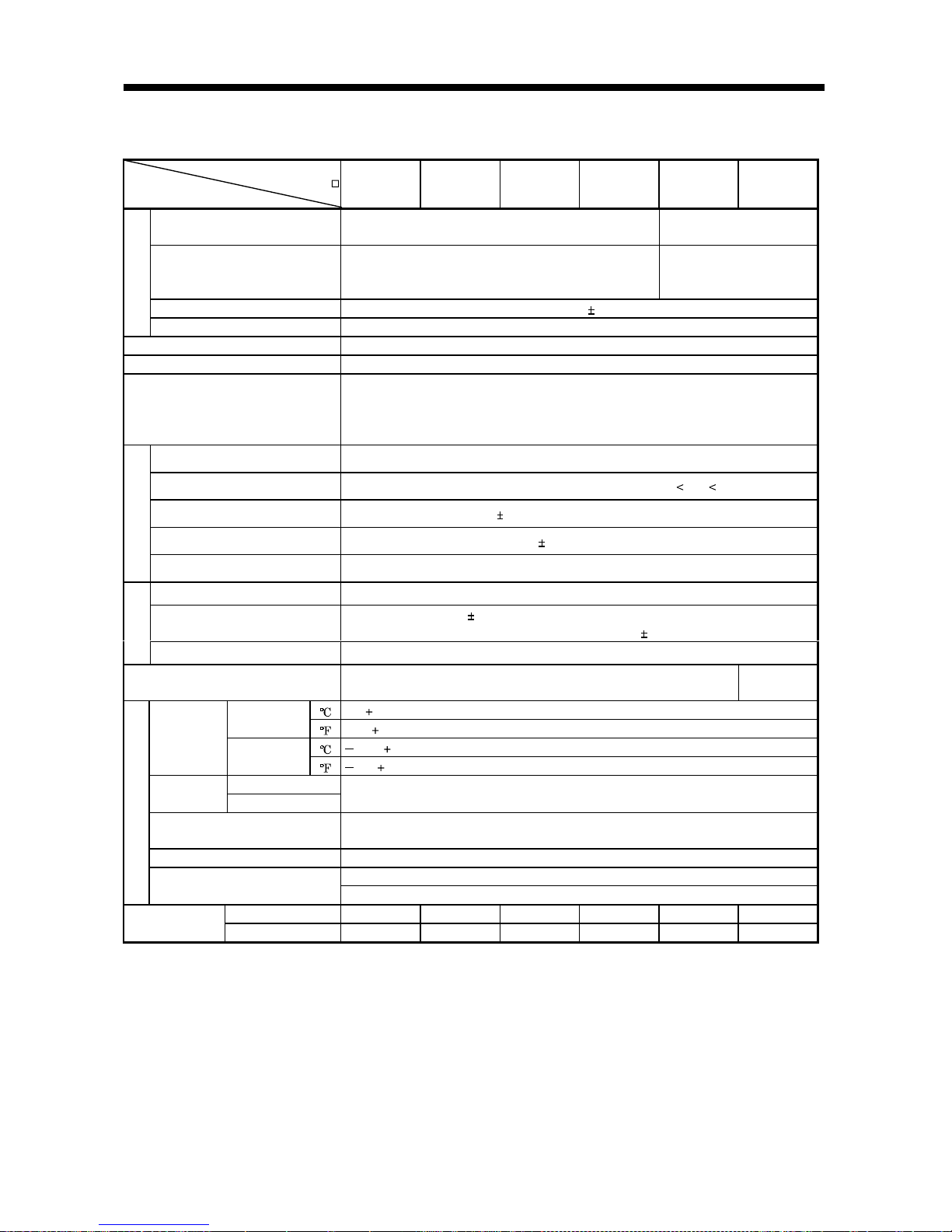

1.3 Servo amplifier standard specifications

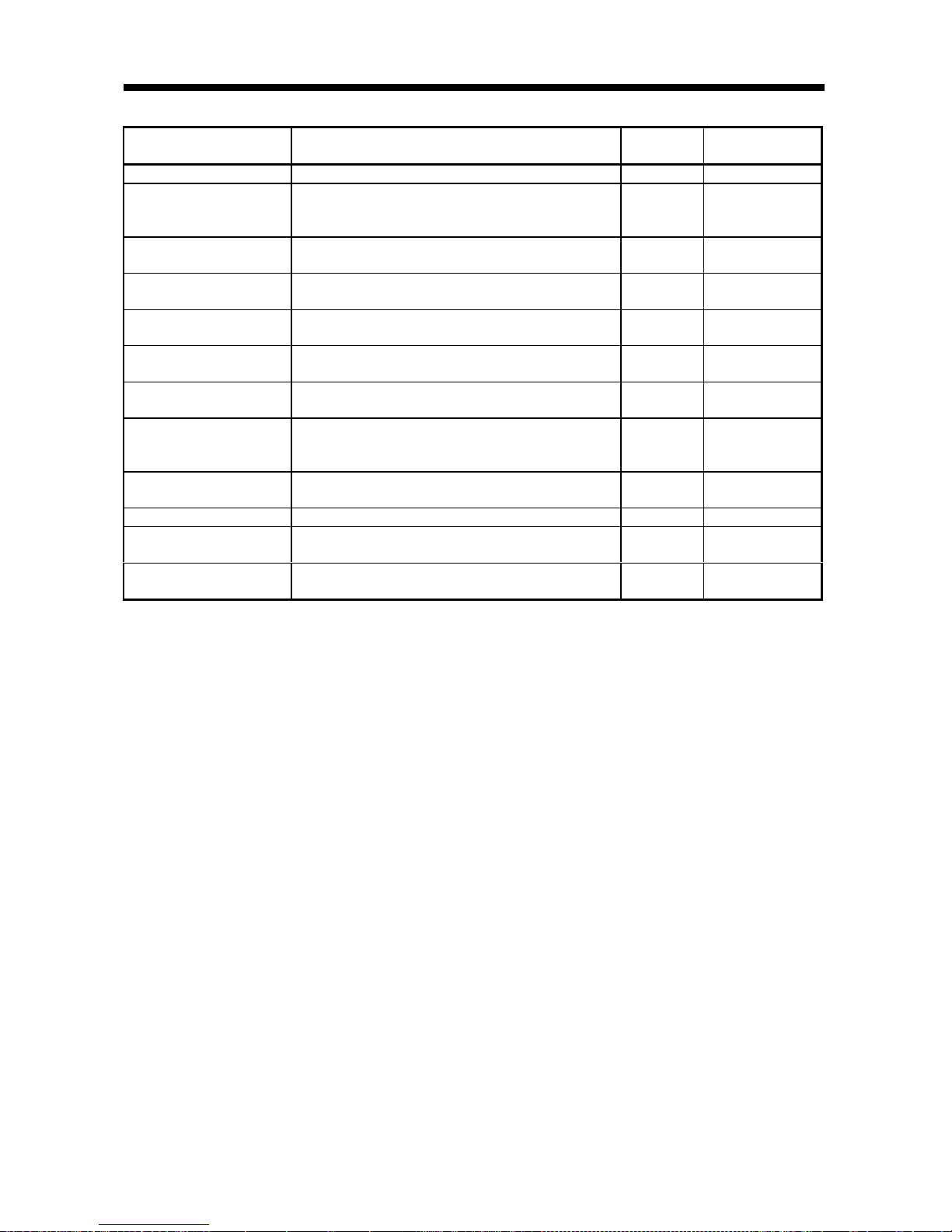

Servo Amplifier

MR-E-

Item

10A 20A 40A 70A 100A 200A

Voltage/frequency

3-phase 200 to 230VAC, 50/60Hz or 1-phase 230VAC,

50/60Hz

3-phase 200 to 230VAC,

50/60Hz

Permissible voltage fluctuation

3-phase 200 to 230VAC:

170 to 253VAC

1-phase 230VAC: 207 to 253VAC

3-phase 170 to 253VAC

Permissible frequency fluctuation Within 5%

Power supply

Power supply capacity Refer to Section12.2

System Sine-wave PWM control, curr ent c ontr ol syste m

Dynamic brake Built-in

Protective functions

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic

thermal relay), encoder error protection, regenerative brake error protection,

undervoltage, instantaneous power failure protection, overspeed protection, excessive

error protection

Max. input pulse frequency 500kpps (for differential receiver), 200kpps (for open collector)

Command pulse multiplying factor Electronic gear A:1 to 65535 B:1 to 65535, 1/50 A/B 50

In-position range setting 0 to 10000 pulse (command pulse unit)

Error excessive 10 revolutions

Position control mode

Torque limit Set by parameter setting

Speed control range Internal speed command 1: 5000

Speed fluctuation ratio

0.01% or less (load fluctuation 0 to 100%)

0% or less (power fluctuation

10%)

Internal speed

control mode

Torque limit Set by parameter setting

Structure Self-cooled, open (IP0 0)

Force-cooling,

open (IP00)

[ ]0 to 55 (non-freezing)

Operation

[

] 32 to 131 (non-freezing)

[ ] 20 to 65 (non-freezing)

Ambient

temperature

Storage

[

] 4 to 149 (non-freezing)

Operation

Ambient

humidity

Storage

90%RH or less (n on- c o n d en si n g)

Ambient

Indoors (no direct s un li g ht )

Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280ft) above sea level

5.9 [m/s2] or less

Environment

Vibration

19.4 [ft/s

2

] or less

[kg] 0.8 0.8 1.2 1.8 1.8 2.0

Weight

[lb] 1.8 1.8 2.6 4.0 4.0 4.4

1 - 4

1. FUNCTIONS AND CONFIGURATION

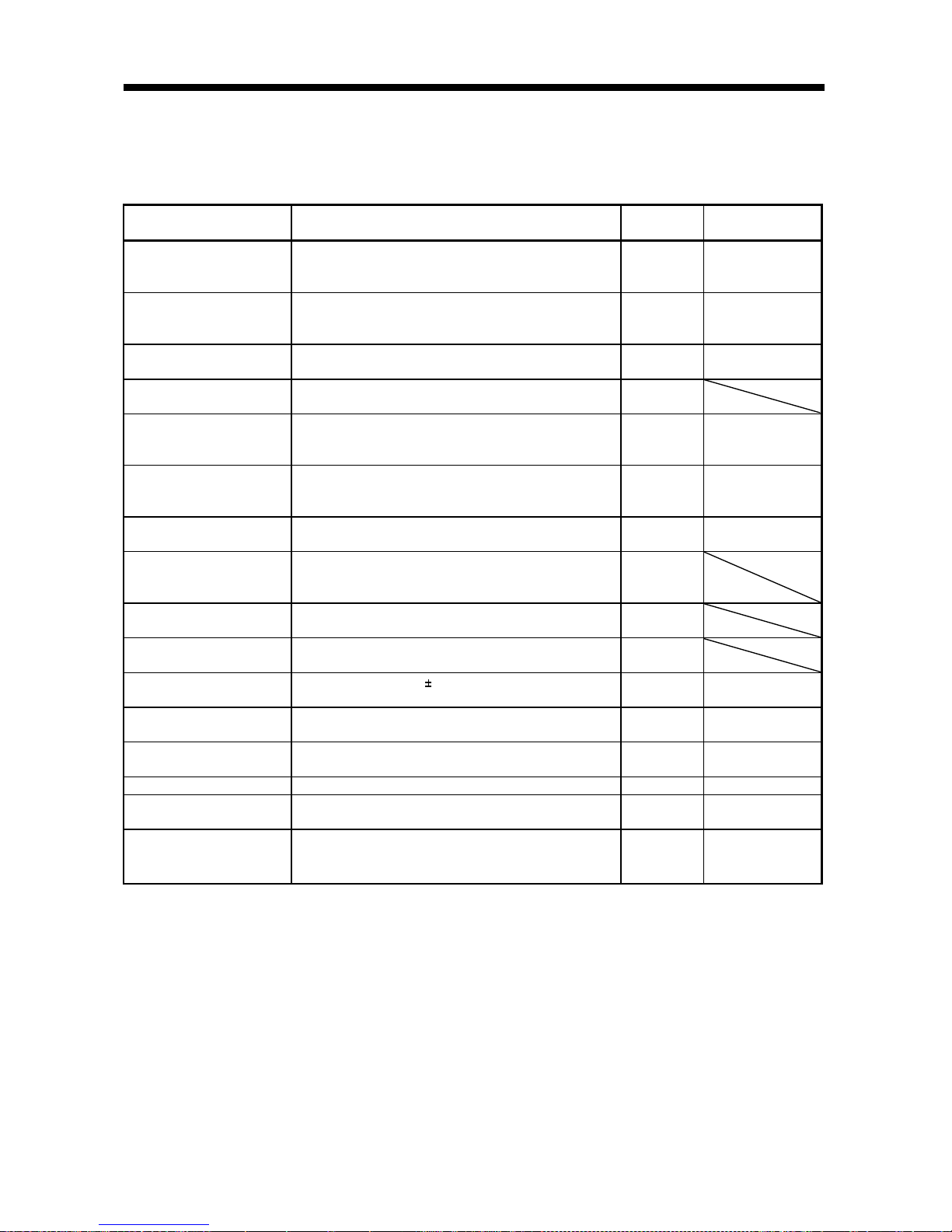

1.4 Function list

The following table lists the functions of this servo. For details of the functions, refer to the corresponding

chapters and sections.

Function Description

(Note)

Control mode

Refer to

Position control mode This servo is used as position control servo. P

Section 3.1.1

Section 3.4.1

Section 4.2.2

Internal speed control mode This servo is used as internal spe ed control servo. S

Section 3.1.2

Section 3.4.2

Section 4.2.3

Position/internal speed

control change mode

Using external input signal, control can be switched

between position control and internal speed control.

P/S Section 3.4.4

High-resolut ion encoder

High-resolution encoder of 131072 pulses/rev is used as a

servo motor e ncoder.

P, S, T

Gain changing function

You can switch between gains during rotation and gains

during stop or use an external input signal to change gains

during operation.

P, S Section 8.5

Adaptive vibration

suppression control

Servo amplifier detects mechanical resonance and sets filter

characteristics automatically to suppress mechanical

vibration.

P, S Section 8.3

Low-pass filter

Suppresses high-frequency resonance which occurs as servo

system response is increased.

P, S Section 8.4

Machine analyzer function

Analyzes the frequency characteristic of the mechanical

system by simply connecting a servo configuration softwareinstalled personal computer and servo amplifier.

P

Machine simulation

Can simulate machine motions on a personal computer

screen on the basis of the machine analyzer results.

P

Gain search function

Personal computer changes gains automatically and

searches for overshoot-free gains in a short time.

P

Slight vibration suppression

control

Suppresses vibration of 1 pulse produced at a servo motor

stop.

P Parameter No. 20

Electronic gear Input pulses can be multiplied by 1/50 to 50. P

Parameters No. 3, 4,

69 to 71

Auto tuning

Automatically adjusts the gain to optimum value if load

applied to the servo motor shaft varies.

P, S Chapter 7

Position smoothing Speed can be increased smoothly in response to input pulse. P Parameter No. 7

S-pattern acceleration/

deceleration time constant

Speed can be increased and decreased smoothly. S Parameter No. 13

Regenerative brake option

Used when the built-in regenerative brake resistor of the

servo amplifier does not have sufficient regenerative

capability for the regenerative power generated.

P, S Section 13.1.1

1 - 5

1. FUNCTIONS AND CONFIGURATION

Function Description

(Note)

Control mode

Refer to

Alarm history cl ea r Alarm history is cleared. P, S Parameter No. 16

Restart after instantaneous

power failure

If the input power supply volt age had reduced to cause an

alarm but has returned to normal, the servo motor can be

restarted by merely switching on the start signal.

S Parameter No. 20

Command pulse selection

Command pulse train form can be selected from among four

different types.

P Parameter No. 21

Input signal selection

Forward rotation start, reverse rotation start, servo-on and

other input signals can be assigned to any pins.

P, S

Parameters

No. 43 to 48

Torque limit Servo motor torque can be limited to any value. P, S

Section 3.4.1 (5)

Parameter No. 28

Status display

Servo status is shown on the 5-digit, 7-segment LED

display

P, S Section 6.2

External I/O signal display

ON/OFF statuses of external I/O signals are shown on the

display.

P, S Section 6.6

Output signal (DO)

forced output

Output signal can be forced on/off independently of the

servo status.

Use this function for output signal wiring check, etc.

P, S Section 6.7

Test operation mode

Servo motor can be run from the operation section of the

servo amplifier without the star t signal entered.

P, S Section 6.8

Analog monitor output Servo status is output in terms of voltage in real time. P, S Parameter No. 17

Servo configuration s oft w are

Using a personal computer, parameter setting, test

operation, status display, etc. can be performed.

P, S Section 13.1.8

Alarm code output

If an alarm has occurred, the corresponding alarm number

is output in 3-bit code.

P, S Section 10.2.1

Note:P: Position control mode, S: Internal speed control mode

P/S: Position/internal speed control change mode

1 - 6

1. FUNCTIONS AND CONFIGURATION

1.5 Model code definition

(1) Rating plate

MR-E-40A

MITSUBISHI

AC SERVO

MADE IN JAPAN

MODEL

MITSUBISHI ELECTRIC CORPORATION

AC SERVO

PASSED

POWER

INPUT

OUTPUT

SERIAL

:400W

:2.6A 3PH200-230V 50Hz

:2.6A3PH200-230V 60Hz

:170V 0-360Hz 2.8A

:XXXXYYYYY

:TCXXXAYYYGZZ

:

Model

Capacity

Applicable power supply

Rated output current

Serial number

(2) Model

70

750

40 400

10

100

20

100

200

1000

200 2000

MR-E-200AMR-E-40A or less MR-E -70A, 100A

Rating plate Rating plate

Rating plate

Series

Rated output

General-purpose interface

Symbol

Rated output [W]

Symbol

Rated output [W]

- AMR - E

1.6 Combination with servo motor

The following table li st s combin a tions of servo amplifiers and servo mo to rs. T he sa me co mb ina t io ns ap ply

to the models with electromagnetic brakes and the models with reduction gears.

Servo motors

Servo amplifier

HC-KFE

HC-SFE

2000r/min

MR-E-10A 13

MR-E-20A 23

MR-E-40A 43

MR-E-70A 73 52

MR-E-100A 102

MR-E-200A 152 202

1 - 7

1. FUNCTIONS AND CONFIGURATION

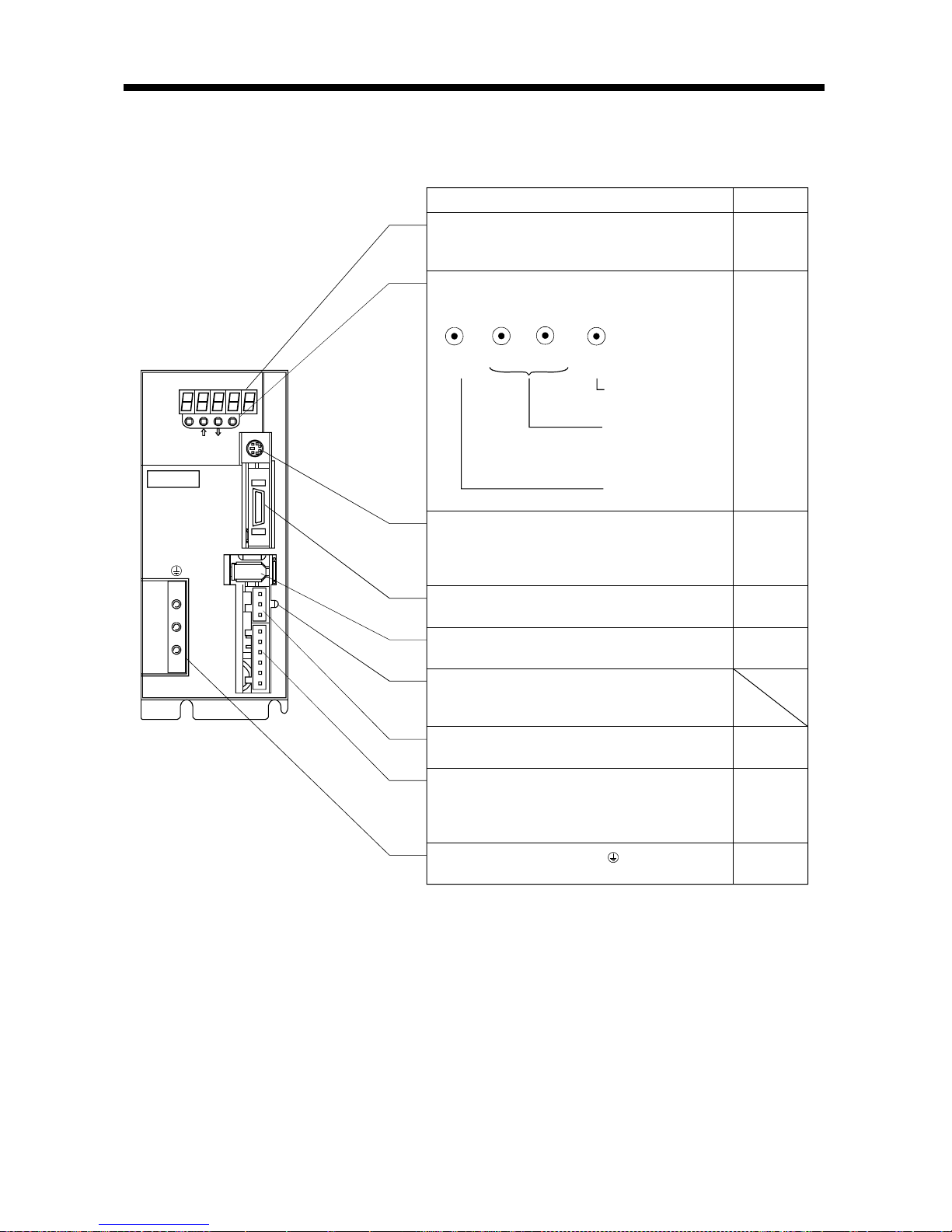

1.7 Parts identification

(1) MR-E-100A or less

MODE

CN3

SET

CN1

CN2

CNP2

CNP1

L3L2 L1 D C P W V U

CHARGE

MITSUBISHI

MR-

Chapter6

Display

The 5-digit, seven-segment LED shows the servo

status and alarm number.

Used to set data.

Used to change the

display or data in each

mode.

Used to change the

mode.

MODE

UP

DOWN

SET

Operation section

Used to perform status display, diagnostic, alarm and

parameter setting operations.

Chapter6

Communication connector (CN3)

Used to connect a command device (RS-232C)

and output analog monitor data.

I/O signal conn e ct or (CN1)

Used to connect digital I/O signal s.

Section3.3

Encoder connector ( C N2 )

Connector for connection of the servo motor encoder.

Section3.3

Section13.1.2

Charge lamp

Lit to indicate that the main circuit is charged. While

this lamp is lit, do not reconnect the cables.

Protective earth (PE) terminal ( )

Ground terminal.

Section3.10

Section11.1

Section3.3

Section13.1.2

Chapter14

Section3.7

Section11.1

Section3.7

Section11.1

Section13.1.1

Refer to

Name/Application

Motor power supply conn e ctor (CNP2)

Used to connect the servo mo tor.

Power supply/regenerative connector (CNP1)

Used to connect the input power supply and

regenerative brake option.

1 - 8

1. FUNCTIONS AND CONFIGURATION

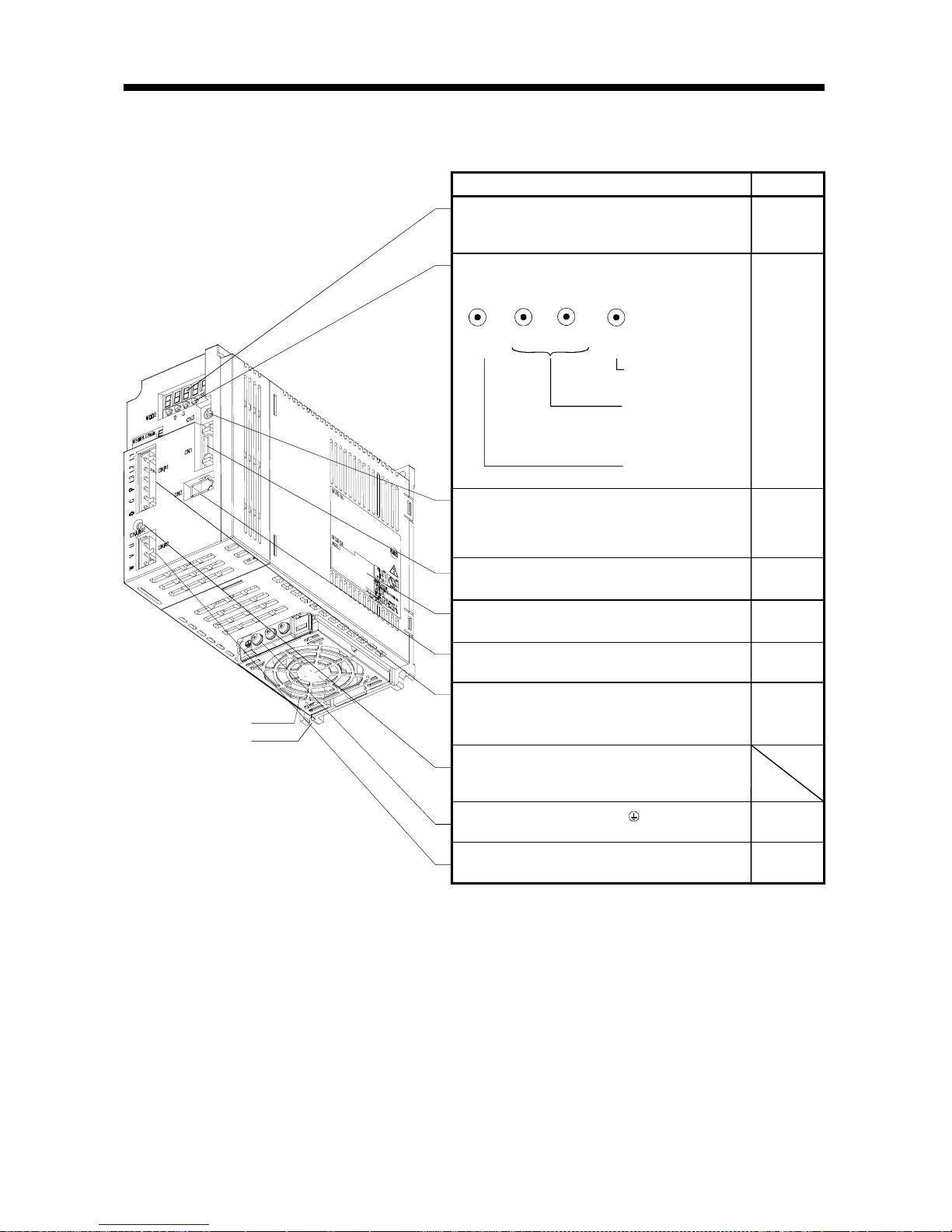

(2) MR-E-200A

Refer to

Name/Application

Chapter6

Display

The 5-digit, seven-segment LED shows the servo

status and alarm number.

Used to set data.

Used to change the

display or data in each

mode.

Used to change the

mode.

MODE

UP

DOWN

SET

Operation section

Used to perform status display, diagnostic, alarm and

parameter setting operations.

Chapter6

Communication connector (CN3)

Used to connect a command device (RS232C)

and output analog monitor data.

Section3.3

Section13.1.2

Chapter14

I/O signal connector (CN1)

Used to connect digital I/O signals.

Section3.3

Name plate

Charge lamp

Lit to indicate that the main circuit is charged. While

this lamp is lit, do not reconnect the cables.

Encoder co nnector (C N2 )

Connector for connection of the servo motor enc oder.

Section1.5

Section3.3

Section13.1.2

Motor power supply connector (CNP2)

Used to connect the servo motor.

Protective earth (PE) terminal ( )

Ground terminal.

Power supply/regenerative connector (CNP1)

Used to connect the input power supply and

regenerative brake option.

Section3.7

Section11.1

Section3.7

Section11.1

Section13.1.1

Section3.10

Section11.1

Cooling fan

Installation notch

(4 places)

1 - 9

1. FUNCTIONS AND CONFIGURATION

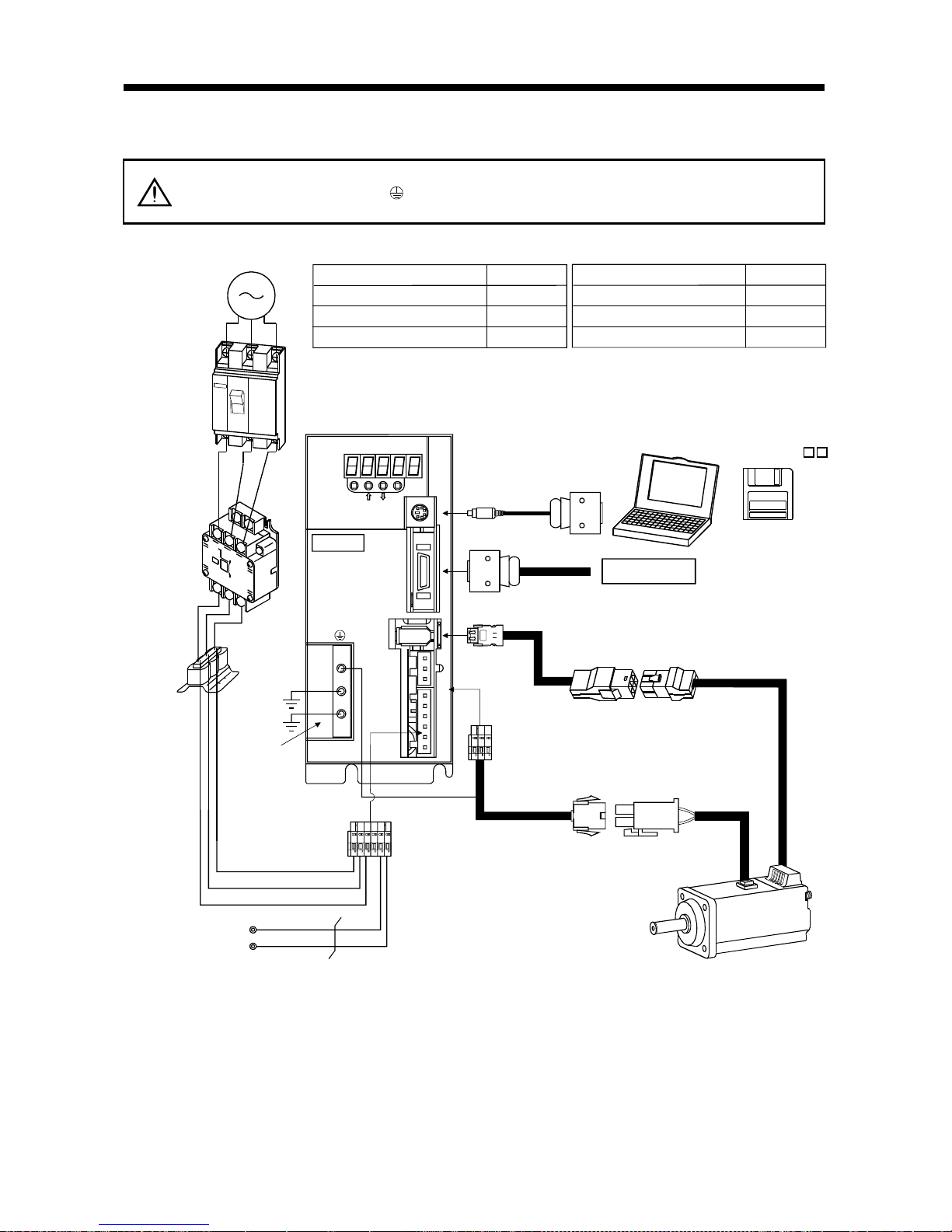

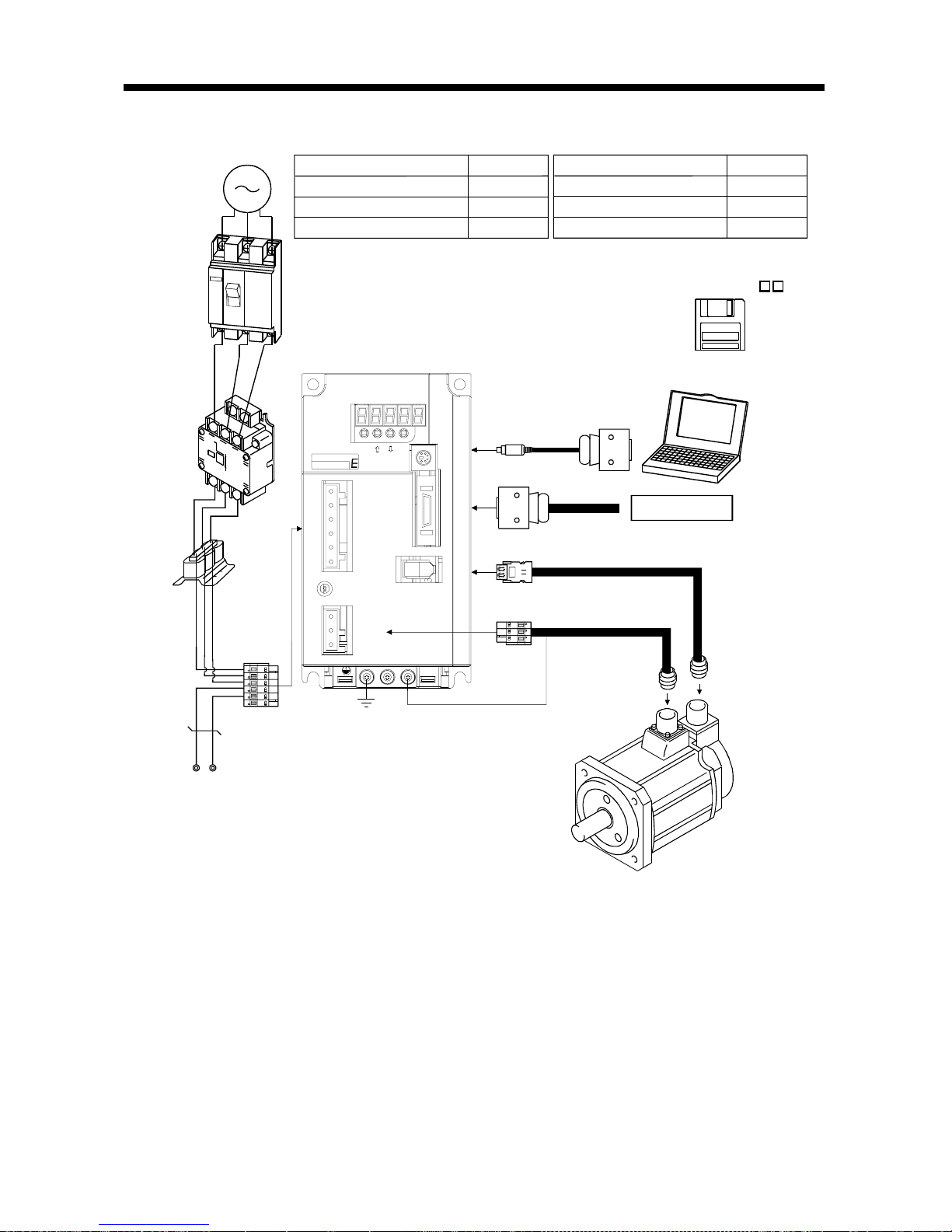

1.8 Servo system with auxiliary equipment

WARNING

To prevent an electric shock, always connect the protective earth (PE) terminal

(terminal m ar k ed

) of the servo amplifier to the prot ective ear th (PE) of the contr ol

box.

(1) MR-E-100A or less

MODE

CN3

SET

CN1

CN2

CNP2

CNP1

L3L2 L1 D C P W V U

CHARGE

MITSUBISHI

MR-E-

P

C

L

3

L

2

L

1

(Note 2)

3-phase 200V

to 230VAC power

supply or

1-phase 230VAC

power supply

No-fuse breaker

(NFB) or fuse

Magnetic

contactor

(MC)

To CN2

To CN1

To CN3

Protective earth

(PE) terminal

Servo motor

Personal

computer

Servo amplifier

Regenerative option

Options and auxiliary equipment

No-fuse breaker

Magnetic contactor

Servo configuration software

Regenera tive option

Refer to

Section 13.2.2

Section 13.2.2

Section 13.1.4

Section 13.1.1

(Note 1)

Encoder cable

Options and auxiliary equipment

Refer to

Cables

Section 13.2.1

Command device

(Note 1)

Power supply lead

Power

factor

improving

reactor

(FR-BAL)

Power factor improving reactor

Section 13.2.3

Servo configuration

software

MRZJW3-SETUP1

Note: 1. The HC-SFE series have cannon connectors.

2. A 1-phase 230VAC power supply may be used with the servo amplifier of MR-E-70A or less. Connect the power supply to

L

1

and L2 terminals and leave L3 open.

1 - 10

1. FUNCTIONS AND CONFIGURATION

(2) MR-E-200A

L

3

L

2

L

1

DC L3PL1L2

CHARGE

CNP2

CNP1

CN1

CN2

UVW

CN3

MODE

SET

MITSUBIS HI

EZMotion

P

C

Options and auxiliary equipment

No-fuse breaker

Magnetic contactor

Servo configuration software

Regene rative op ti on

Refer to

Section 13.2.2

Section 13.2.2

Section 13.1.4

Section 13.1.1

Options and auxiliary equipment

Refer to

Cables Section 13.2.1

Power factor improving reactor

Section 13.2.3

Power

f

actor

improving

reactor

(FR-BAL)

3-phase 200V

to 230VAC

power supply

No-fuse

breaker

(NFB) or

fuse

Magnetic

contactor

(MC)

To CN2

To CN1

To CN3

Servo amplifier

Regene rative op ti on

Personal

computer

Command device

Servo configuration

software

MRZJW3-SETUP1

To CNP2

2 - 1

2. INSTALLATION

2. INSTALLATION

CAUTION

Stacking in excess of the limited number of products is not allowed.

Install the equipment to incombustibles. Installing them directly or close to

combustibles will led to a fire.

Install the equipment in a load-bearing place in accordance with this Instruction

Manual.

Do not get on or put heavy load on the equipment to prevent injury.

Use the equipment within the specified environmental condition range.

Provide an adequate protection to prevent screws, metallic detritus and other

conductive matter or oil and other combustible matter from entering the servo

amplifier.

Do not block the intake/exhaust ports of the servo amplifier. Otherwise, a fault may

occur.

Do not subject the servo amplifier to drop impact or shock loads as they are

precision equipment.

Do not install or operate a faulty servo amplifier.

When the product has been stored for an extended period of time, consult

Mitsubishi.

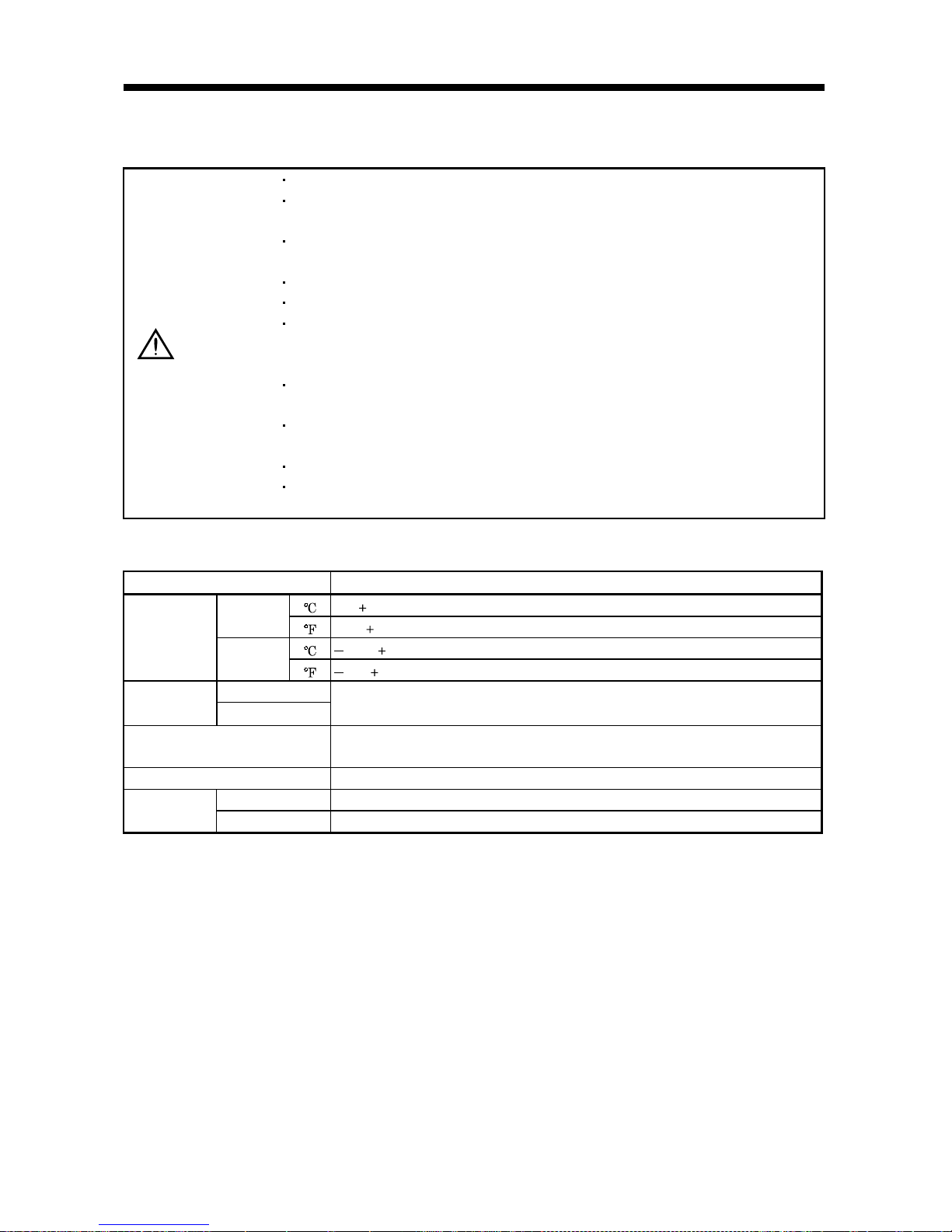

2.1 Environmental conditions

Environment Conditions

[ ]0 to 55 (non-freezing)

Operation

[

] 32 to 131 (non-freezing)

[ ] 20 to 65 (non-freezing)

Ambient

temperature

Storage

[

] 4 to 149 (non-freezing)

Operation

Ambient

humidity

Storage

90%RH or less (non-condensing)

Ambience

Indoors (no direct sunlight)

Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m (3280 ft) above sea level

[m/s2] 5.9 [m/s2] or less

Vibration

[ft/s

2

] 19.4 [ft/s2] or less

2 - 2

2. INSTALLATION

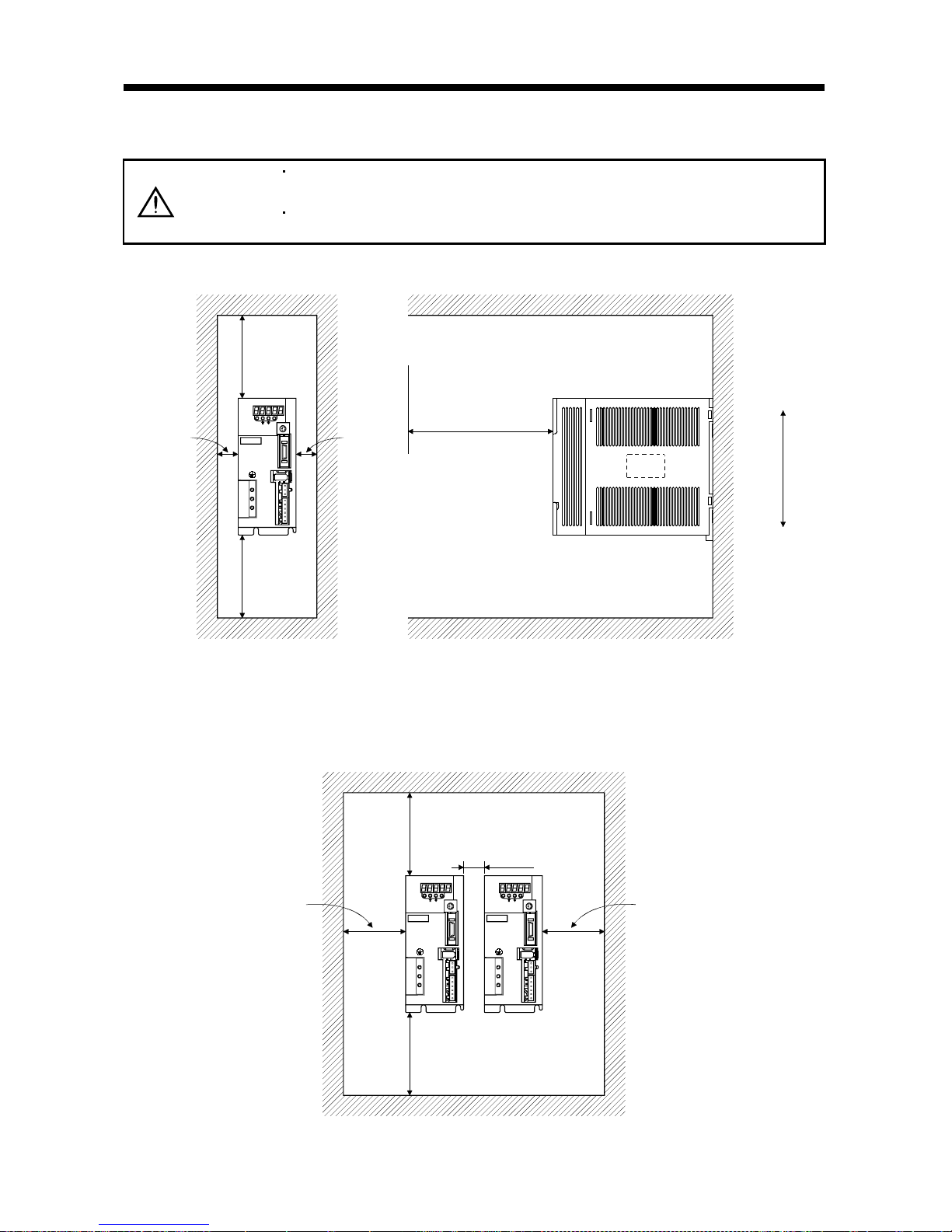

2.2 Installation direction and clearances

CAUTION

The equipment mus t be installe d in the specif ied direct ion. Other wise, a fau lt may

occur.

Leave specified clearances between the servo amplifier and control box inside

walls or other equipment.

(1) Installation of one servo amplifier

MODE

CN3

SET

CN1

CN2

CNP2

CNP1

L3L2 L1 D C P W V U

CHARGE

MITSUBISHI

MR-

Control box Control box

10mm

(0.4 in.)

or more

10mm

(0.4 in.)

or more

40mm

(1.6 in.)

or more

Servo

amplifier

40mm

(1.6 in.)

or more

Wiring clearance

Top

Bottom

(2.8 in.)

70mm

(2) Installation of two or more servo amplifiers

Leave a large clearance between the top of the servo amplifier and the internal surface of the control

box, and install a fan to prevent the internal temperature of the control box from exceeding the

environmental conditions.

MODE

CN3

SET

CN1

CN2

CNP2

CNP1

L3L2 L1 D C P W V U

CHARGE

MITSUBISHI

MR-

MODE

CN3

CN1

CN2

CNP2

CNP1

L3L2 L1 D C P W V U

CHARGE

MITSUBISHI

MR-

SET

Control box

30mm

(1.2 in.)

or more

30mm

(1.2 in.)

or more

10mm

(0.4 in.)

or more

40mm

(1.6 in.)

or more

100mm

(4.0 in.)

or more

2 - 3

2. INSTALLATION

(3) Others

When using heat generating equipment such as the regenerative brake option, install them with full

consideration of heat generation so that the servo amplifier is not affected.

Install the servo amplifier on a perpendicular wall in the correct vertical direction.

2.3 Keep out foreign materials

(1) When installing the unit in a control box, prevent drill chip s and wire fragmen ts from entering th e

servo amplifier.

(2) Prevent oil, water, metallic dust, etc. from entering the servo amplifier through openings in the control

box or a fan installed on the ceiling.

(3) When insta lling the con trol box in a place wher e there are much toxic g as, dirt and dust, co nduct an

air purge (force clean air into the control box from outside to make the internal pressure higher than

the external pressure) to prevent such materials from entering the control box.

2.4 Cable stress

(1) The way of clamping the cable must be fully examined so that flexing stress and cable's own weight

stress are not applied to the cable connection.

(2) For use in any application where the servo motor moves, fix the cables (encoder, power supply, brake)

supplied with the servo motor, and flex the optional encoder cable or the power supply and brake

wiring cables. Use the optional encoder cable within the flexing life range. Use the power supply and

brake wiring cables within the flexi ng lif e of the cabl es.

(3) Avoid any probability that the cable sheath might be cut by sharp chips, rubbed by a machine corner

or stamped by workers or vehicles.

(4) For installation on a machine where the servo motor will move, the flexing radius should be made as

large as possible. Refer to section 12.4 for the flexing life.

2 - 4

2. INSTALLATION

MEMO

3 - 1

3. SIGNALS AND WIRING

3. SIGNALS AND WIRING

WARNING

Any person who is involved in wiring should be fully competent to do the work.

Before starting wiring, switch power off, then wait for more than 10 minutes, and

after the charge lamp has gone off, make sure that the voltage is safe in the tester

or like. Otherwise, you may get an electric shock.

Ground the servo amplifier and the servo motor securely.

Do not attempt to wire the servo amplifier and servo motor until they have been

installed. Otherwise, you may get an electric shock.

The cables should not be damaged, stressed excessively, loaded heavily, or

pinched. Otherwise, you may get an electric shock.

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may

misoperate, resulting in injury.

Connect cables to correct terminals to prevent a burst, fault, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

The surge absorbing diode installed to the DC relay designed for control output

should be fitted in the specified direction. Otherwise, the signal is not output due to

a fault, disabling the emergency stop and other protective circuits.

RA

RA

Servo

Amplifier

Control output

signal

External

24VDC

External

24VDC

Servo

Amplifier

Control output

signal

Use a noise filter, etc. to minimize the influence of electromagnetic interference,

which may be given to electronic equipment used near the servo amplifier.

Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF

option) with the power line of the servo motor.

When using the regenerative brake resistor, switch power off with the alarm signal.

Otherwise, a transistor fault or the like may overheat the regenerative brake

resistor, causing a fire.

Do not modify the equipment.

3 - 2

3. SIGNALS AND WIRING

3.1 Standard connection example

POINT

Refer to Section 3.7.1 for the connection of the power supply system and to

Section 3.8 for connection with the servo motor.

3.1.1 Position control mode

(1) FX-10GM

9,19

9

12

INP

RD

RA1

RA2

ALM

ZSP

17

16

18

LA

LAR

LB

LBR

SD

15

4

3

SD

6

MO1

LG

MO2

A

A

VIN

VIN

OP

LG

OPC

VIN

PP

SG

NP

CR

SG

SD

10

11

1

1

21

14

2

1

23

13

25

5

13

12

1

2

14

13

7,17

8,18

6

9,19

16

3

4

11

5

15

1

2

4

5

6

8

3

7

START

STOP

FWD

RVS

DOG

LSR

COM1

ZRN

LSF

FX-10GM

CN3

20

19

LZ

LZR

8

4

3

6

7

13

EMG

SON

RES

LSP

LSN

SG

1VIN

CN1

13 SG

SVRDY

COM2

COM2

SVEND

COM4

PGO

VC

FPO

FP

COM5

RP

RPO

CLR

COM3

24

Positionin g mo du l e

(Note 9) 2m(6.5ft) max.

Servo amplifier

(Note 8)

(Note 8)

CN1

CN1

(Note2, 4)

(Note 6)

Trouble

Zero speed

Plate

(Note 8)

Plate

(Note 3, 5) Emergency stop

Servo-on

Reset

(Note 5) Forward rotation stroke end

Reverse rotation stroke end

(Note 10)

Servo configuration

software

Personal

computer

10m(32ft) max.

(Note 7)

Communic ation cable

(Note 7)

Monitor output

Max. 1mA

Reading in both

directions

(Note 8)

(Note 1)

CN1

(Note 8)

CN3

(Note 8)

10k

10k

2m (6.5ft) max.

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

Encoder Z-phase pulse

(differential line driver)

External

power

supply

24VDC

Plate

(Note 11)

3 - 3

3. SIGNALS AND WIRING

Note: 1. To prevent an electric shock, always connect the protective earth (PE) terminal (t erminal mark ed ) of the servo amplifier to

the protective earth (PE) of the control box.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will be faulty and will not output

signals, disabling the emergency stop and other protective circ uit s.

3. The emergency stop switch (normally closed contact) must be installed.

4. The sum of currents that flow in the external relays should be 80mA max. If it exceeds 80mA, supply interface power from

external. (Refer to Section 3.6.2)

5. When starting operation, always connect the emergency stop signal (EMG) and forward/ reverse rotation st roke end signal

(LSN/LSP) with SG. (Normally closed contacts)

6. Trouble (ALM) is connected with COM in normal alarm-free condition. When this signal is switched off (at occurrence of an

alarm), the output of the controller should be stopped by the sequence program.

7. When connecting the personal computer together with monitor outputs 1, 2, use the branch cable (MR-E3CBL15-P). (Refer to

Section 13.1.3)

8. The pins with the same signal name are connected in the servo amplifier.

9. This length applies to the command pulse train input in the opencollector system. It is 10m (32ft) or less in the differential line

driver system.

10. Use MRZJW3-SETUP 154E.

11. Connect the external 24VDC power supply if the output signals are not used.

3 - 4

3. SIGNALS AND WIRING

(2) AD75P (A 1SD75P )

26

8

24

5

21

4

22

7

23

3

25

6

1

20

12

14

35

16

13

15

11

2

36

19

VIN

INP

LZ

CR

PG

NP

NG

RD

SG

PP

LZR

SD

LG

DOG

COM

RLS

START

CHG

FLS

STOP

COM

READY

COM

INPS

CLEAR

PGO(24V)

PGO(5V)

PGO COM

CLEAR COM

PULSE FPULSE F+

PULSE R-

PULSE R+

PULSE F

PULSE COM

PULSE R

PULSE COM

17

16

18

LA

LAR

LB

LBR

SD