SERVICE MANUAL

Models

MR-E55R-F-C

MR-E55R-PS-C

MR-E60R-F-C

MR-E60R-PS-C

CONTENTS

1. SPECIFICATIONS •••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2

2. WIRING DIAGRAM •••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5

3. OUTLINES AND DIMENSIONS •••••••••••••••••••••••••••••••••••••••••7

4. REFRIGERANT CIRCUIT ••••••••••••••••••••••••••••••••••••••••••••••••9

5. TROUBLESHOOTING••••••••••••••••••••••••••••••••••••••••••••••••••• 10

5-1 FUNCTION OF OPERATION PANEL ••••••••••••••••••••••••••• 10

5-2 FLOWCHART OF SELF-CHECK •••••••••••••••••••••••••••••••• 22

5-3 BLOCK DIAGRAM OF PRINTED CIRCUIT BOARD ••••••••26

5-4 AUTO ICE MAKER •••••••••••••••••••••••••••••••••••••••••••••••••26

5-5 FLOWCHART OF TROUBLE CRITERION •••••••••••••••••••• 28

5-6 TROUBLE CRITERION OF MAIN PARTS •••••••••••••••••••••35

5-7 TEST POINT DIAGRAM OF FILTER BOARD •••••••••••••••• 42

5-8 TEST POINT DIAGRAM OF CONTROL BOARD •••••••••••• 42

5-9

TROUBLESHOOTING FOR SUPERCOOL FREEZING OPERATION

•••• 43

6. NAMES OF THE PARTS ••••••••••••••••••••••••••••••••••••••••••••••• 47

7. DISASSEMBLY INSTRUCTIONS ••••••••••••••••••••••••••••••••••••• 48

HOME REFRIGERATOR

No. OAH110

NOTE:

• RoHS compliant products have <G> mark on the spec name plate.

C •••• Taiwan

PARTS CATALOG (OAB110)

Model name

indication

(Inside this door)

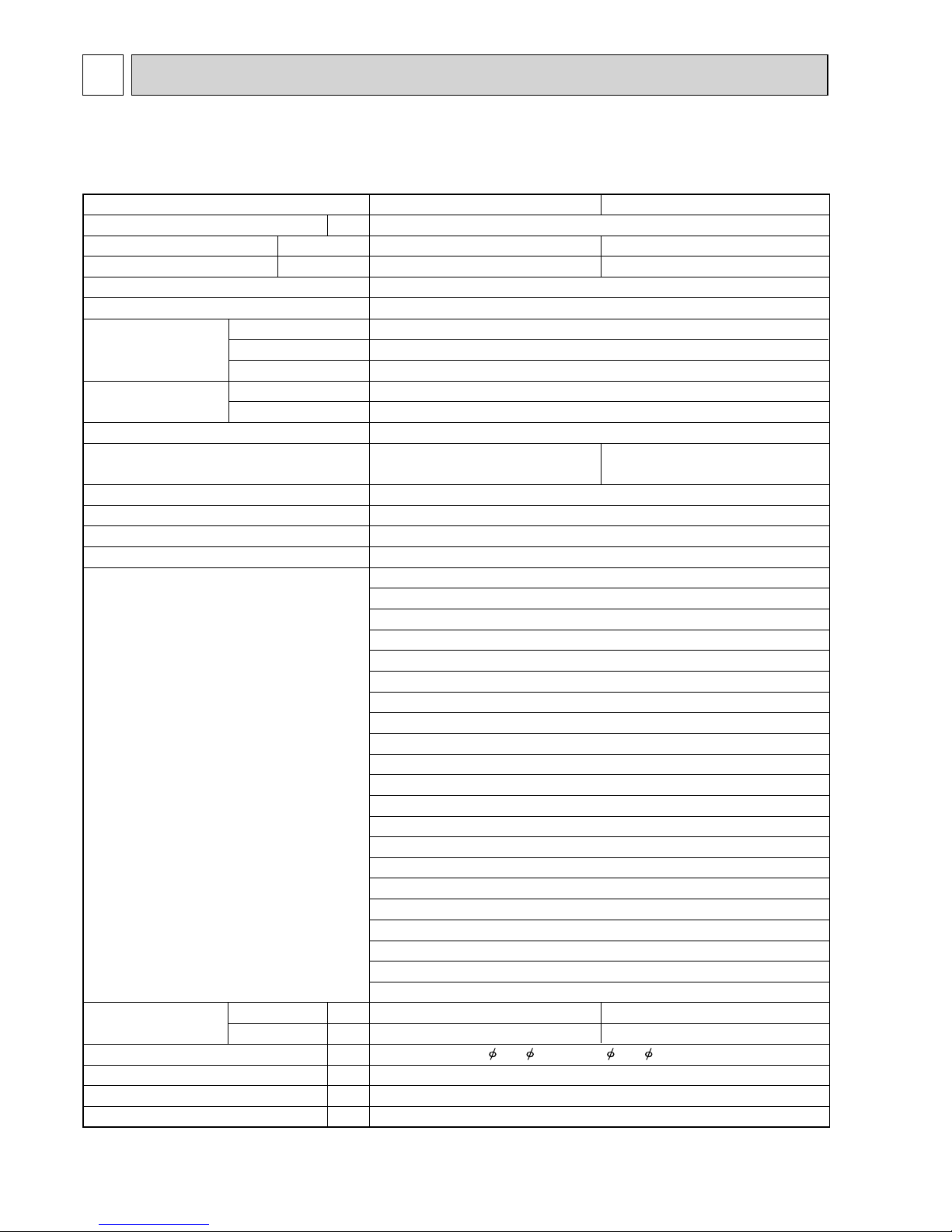

2

SPECIFICATIONS

1

SPECIFICATIONS

110 V, 60 Hz

E55R E60R

545 (gross) 601 (gross)

1821 × 685 × 728 1821 × 745 × 728

Cabinet, cabinet ceiling

,

sides,

back and front flange

Cabinet, cabinet ceiling, sides, back,

front flange and machine chamber condenser

103 108

109 115

Acrylic resin coated steel

ABS resin

Foamed polyurethane (Cyclopentane)

Foamed polyurethane (Cyclopentane)

Foamed polyurethane (Cyclopentane)

Forced air convection

Forced air convection

Fin and tube type

Automatic heater defrost

Automatic drainage, Forced evaporation method

Automatic control

LED

187 (FREOL S10)

9

kg

kg

mm

g

g

g

V,Hz

L

mm

Unit

Shipping

Weight

Accessories

Evaporator

Condenser

Defrost system

Drain

Temperature control system

Refrigerator compartment interior light

Power supply

Total capacity

Dimensions (H × W × D)

Cabinet

Food liner

Cabinet

Freezer door

Refrigerator door

Freezer

Refrigerator

Insulation

Cooling system

Capillary tube

Desiccant (molecular sieve)

Refrigerant filling capacity R600a

Refrigerating oil (model)

Change pocket (large)

Change pocket (small)

Bottle pocket (large)

Bottle pocket (small)

AUTO-shelf

Two-way flexishelf

Small item case

Free egg shelf

Slide chilled case

Lid of slide chilled case

Versa case

Aluminum tray (Versa case)

Water tank (with light-type bacteria removing filter with lead elimination function)

Freezing case (top)

Freezing case (bottom)

Ice server

Soundproof mat

Ice storage box

Vegetable case

Sliding case (Vegetable case)

Leg cover

2pcs.

2pcs.

1pc.

1pc.

2pcs.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1pc.

1.6 × 0.63 × 2740, 1.8 × 0.67 × 2740

94

MR-E55R-C

MR-E60R-C

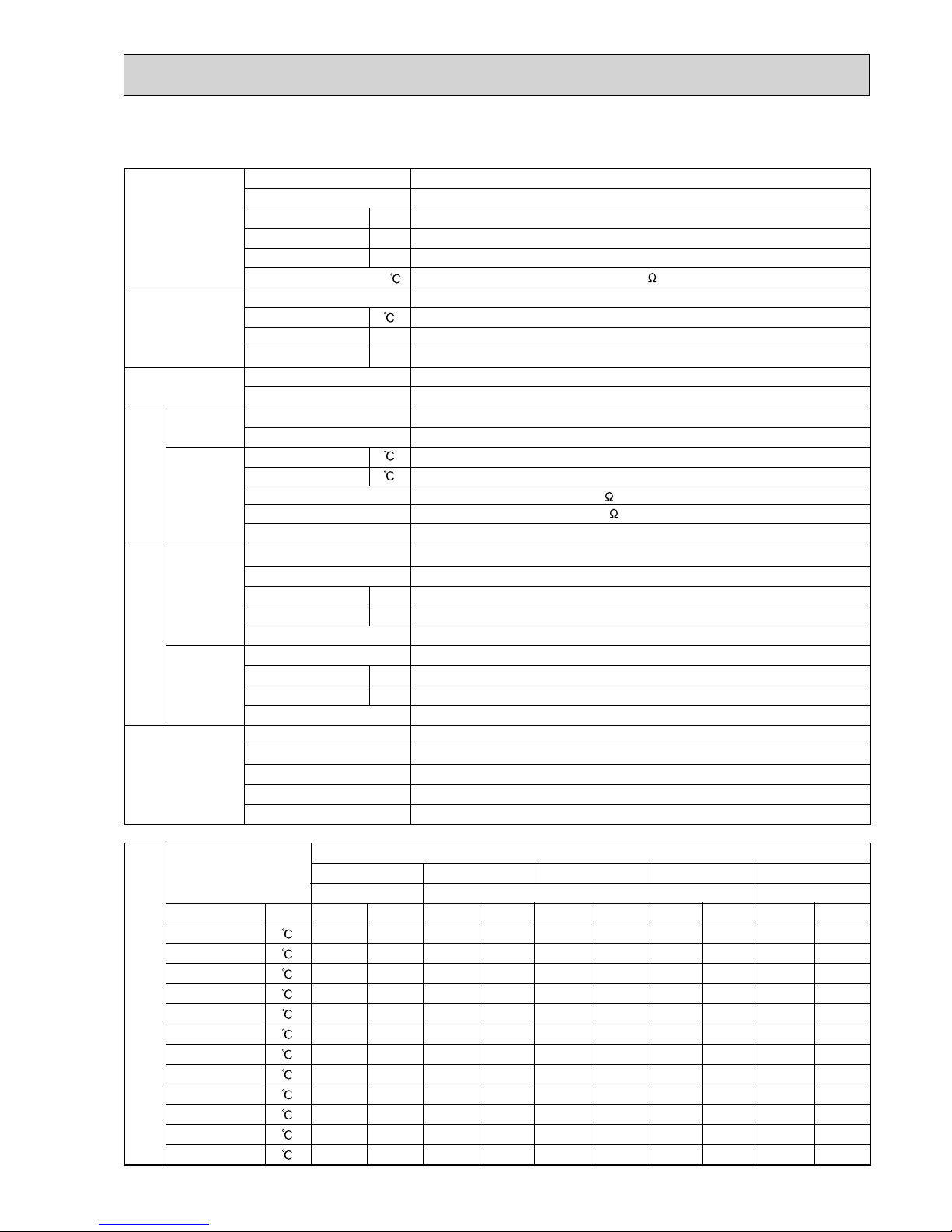

3

Temperature control

ON

−22.2

−18.9

−14.3

–

–

–

–

–

–

–

–

–

OFF

−23.8

−20.6

−16.0

–

–

–

–

–

–

–

–

–

OPEN

1.9

5.1

8.4

–

–

–

–

–

–

–

–

–

SHUT

0.1

3.2

6.4

–

–

–

–

–

–

–

–

–

Dial position

HI

MID

LOW

LOW (Soft freezing)

MID (Soft freezing)

HI

(Soft freezing)

FREEZER(LOW)

FREEZER(MID)

FREEZER(HI)

ICE MAKING

ICE MAKING STOP

CRYSTAL ICE MAKING

Model

NTC thermistor

Freezer

Compressor HeaterMotor damper

Refrigerator

OFF

4.2

6.1

7.7

–

–

–

–

–

–

–

–

–

ON

2.9

4.8

6.4

–

–

–

–

–

–

–

–

–

OPEN

–

–

–

−5.9

−9.8

−11.1

−12.0

−16.1

−17.7

–

–

–

SHUT

–

–

–

−7.1

−11.1

−12.3

−15.1

−19.4

−21.2

–

–

–

VegetableVersa

OPEN

–

–

–

–

–

–

–

–

–

−21.6

−21.6

−21.6

SHUT

–

–

–

–

–

–

–

–

–

−23.4

−23.4

−23.4

Ice making

W

A

A

Sec.

A

W

rpm

W

rpm

Compressor

Motor protector

Heater

(Rating)

Freezer

compartment

Refrigerator

Machine

chamber

Fan motor

Defrosting

control

Model

Power supply

Rated input

Starting current

Running current

Winding resistance (A.T.20 )

Model

Ambient temperature

Time

Current

Model

Type

Model

Specification

Defrost finish

Thermal fuse

Defrost heater 1

Defrost heater 2

Deodorizing function of defrost heater

Model

Type

Input

Revolution

Number of poles

Model

Input

Revolution

Number of poles

Water pipe heater

Rotational heater board

Vegetable compartment heater

Ice making tray heater

Water tank heater

EFI100E 13DHH

110 V, 60Hz

45 (1620rpm)

4 (Current limiter)

0.69 (1620rpm)

12.4

MM3-71CCV

25

16 or less

17.0

NSCE001DC1

4-phase stepping motor drive voltage DC12V

141 (110V,86W)

81 (110V,150W)

Control board

Microcomputer

Thermistor 14 ± 1.5

70 ± 2

Not equipped

UDQM002B3

DC brushless motor

2.4 (12V DC)

1520 (12V DC)

10P

4715JL04WS16G51

1.4 (12V DC)

1450 (12V DC)

4P

110V-4.0W

110V-8.0W

110V-7.3W

110V -12.1W

110V-4.0W

Defrosting

timer

Three-way valve

ELECTRICAL PARTS SPECIFICATIONS

MR-E55R-C

4

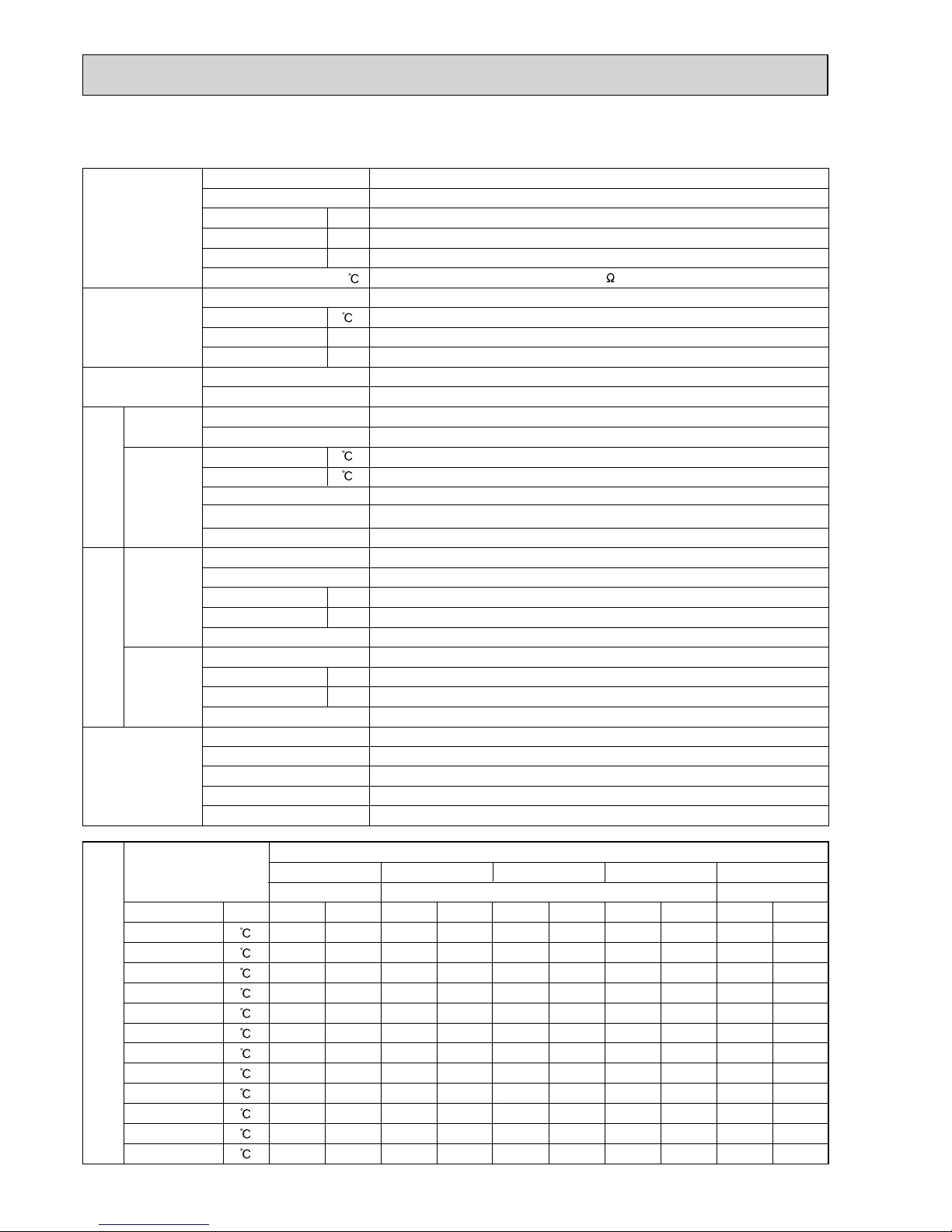

Temperature control

ON

−21.9

−19.2

−13.7

–

–

–

–

–

–

–

–

–

OFF

−23.5

−20.8

−15.4

–

–

–

–

–

–

–

–

–

OPEN

0.7

3.8

7.0

–

–

–

–

–

–

–

–

–

SHUT

−1.2

1.9

5.1

–

–

–

–

–

–

–

–

–

Dial position

HI

MID

LOW

LOW (Soft freezing)

MID (Soft freezing)

HI

(Soft freezing)

FREEZER (LOW)

FREEZER (MID)

FREEZER (HI)

ICE MAKING

ICE MAKING STOP

CRYSTAL ICE MAKING

Model

NTC thermistor

Freezer

Compressor HeaterMotor damper

Refrigerator

OFF

7.0

9.0

10.7

–

–

–

–

–

–

–

–

–

ON

5.1

7.0

8.7

–

–

–

–

–

–

–

–

–

OPEN

–

–

–

−7.1

−9.5

−10.7

−11.4

−16.5

−18.0

–

–

–

SHUT

–

–

–

−8.3

−10.7

−12.0

−14.5

−19.7

−21.5

–

–

–

VegetableVersa

OPEN

–

–

–

–

–

–

–

–

–

−17.9

−17.9

−17.9

SHUT

–

–

–

–

–

–

–

–

–

−20.8

−20.8

−20.8

Ice making

W

A

A

Sec.

A

W

rpm

W

rpm

Compressor

Motor protector

Heater

(Rating)

Freezer

compartment

Refrigerator

Machine

chamber

Fan motor

Defrosting

control

Model

Power supply

Rated input

Starting current

Running current

Winding resistance (A.T.20 )

Model

Ambient temperature

Time

Current

Model

Type

Model

Specification

Defrost finish

Thermal fuse

Defrost heater 1

Defrost heater 2

Deodorizing function of defrost heater

Model

Type

Input

Revolution

Number of poles

Model

Input

Revolution

Number of poles

Water pipe heater

Rotational heater board

Vegetable compartment heater

Ice making tray heater

Water tank heater

EFI100E 13DHH

110 V, 60Hz

45 (1620rpm)

4 (Current limiter)

0.69 (1620rpm)

12.4

MM3-71CCV

25

16 or less

17.0

NSCE001DC1

4-phase stepping motor drive voltage DC12V

110V-4.0W

110V-12.1W

81Ω (110V, 150W)

141Ω (110V, 86W)

Control board

Microcomputer

Thermistor 14 ± 1.5

70 ± 2

Not equipped

UDQM002B3

DC brushless motor

2.4 (12V DC)

1520 (12V DC)

10P

4715JL04WS16G51

1.4 (12V DC)

1450 (12V DC)

4P

110V-4.0W

110V-8.0W

110V-7.3W

Defrosting

timer

Three-way valve

ELECTRICAL PARTS SPECIFICATIONS

MR-E60R-C

5

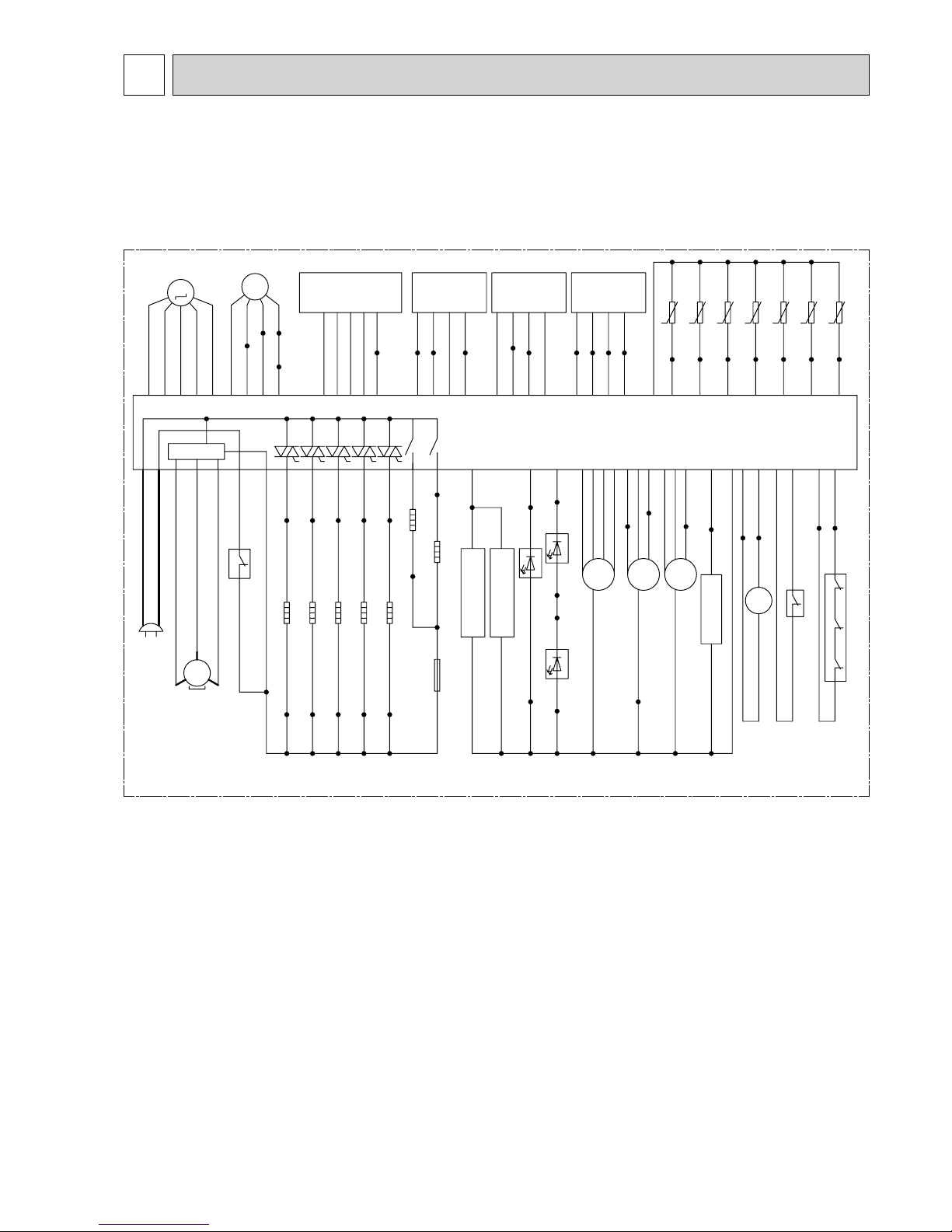

WIRING DIAGRAM

2

( SKELETON WIRING DIAGRAM )

MR-E55R-C

MR-E60R-C

I.THERMISTOR (Ice making compartment thermistor)

V.THERMISTOR (Vegetable compartment thermistor)

VERSA.THERMISTOR (Versa compartment thermistor)

DEF.THERMISTOR (Defrost thermistor)

ICE-TRAY THERMISTOR (Ice making tray thermistor)

F.THERMISTOR (Freezer compartment thermistor)

R.THERMISTOR (Refrigerator compartment thermistor)

TEMP. CONTROL BOARD: (Operation P.C. board)

COMPENSATIONAL HEATER FOR VEGETABLE ROOM: (Vegetable compartment heater)

DIVIDER HEATER: (Rotational heater board)

LED BOARD IN VEGETABLE ROOM: LEDs (Vegetable compartment)

TANK LED: (LED for bacteria removal from water tank)

LED BOARD IN REFRIGERATOR ROOM (R): Interior LED (right)

LED BOARD IN REFRIGERATOR ROOM (L): Interior LED (left)

S.LED: Versa compartment supercool freezing LED

R.LED(D): Refrigerator deodorization LED

DOOR SW. (FOR R-COMPARTMENT & ICE ROOM): Door switch (for refrigerator compartment, ice compartment)

DOOR SW. (FOR F-COMPARTMENT): Door switch (for freezer compartment)

FAN MOTOR (FOR COMPRESSOR): (BOX FAN)

VALVE MOTOR: Three-way valve

MOTOR DAMPER VS: Motor damper (for vegetable/versa compartment)

MOTOR DAMPER RI: Motor damper (for refrigerator/ice making compartment)

The wiring diagram in the dashed line is the

same as the one attached to the products.

Although the following parts are called in different names here,

they are identical with the parts shown in the service manual.

BLACKBLACK

WATER PIPE HEATER

GRAY GRAYGRAY BLUE

GRAY REDBLUEWHITE

THERMAL FUSE(73

°C

)

DEFROST

HEATER 1

BLACK

M

M

GRAY

RED

VIOLET

YELLOW

BLUE

VALVE MOTOR

WATER TANK HEATER

R.LED(D)

BLUEBLACK

S.LED

VIOLET

BLACK

PLUG

F1 : 10A FUSE

FUSE3

:

3A FUSE

ON THE BOARD

CONTROL BOARD,N/F BOARD

INVERTER

*

WHEN THE DOORS ARE CLOSED.

ICE GEAR BOX

(ON DISPLAY PANEL)

TEMP. CONTROL BOARD

MOTOR DAMPERRIMOTOR DAMPER

VS

THERMOPILE

WHITE

RED

YELLOW

SKY BLUE

LIGHT

BROWN

WHITE

WHITE/RED

BLUE

VIOLET

SKY BLUE

BLACK

GRAY

PINK RED

SKY BLUE

WHITE

GRAY

BLACK

BLACK

BLACK

BLACK

BLUE

WHITE

YELLOW

RED

ORANGE

BLUE

WHITE

YELLOW

RED

YELLOW

GREEN

PINK

GRAY

BROWN

SKY BLUE

WHITE/RED

LIGHT

BROWN

ORANGE

BLUE

PINK

BRIGHT

YELLOW

YELLOW

BROWN

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

R.THERMISTOR

F.THERMISTOR

ICE TRAY THERMISTOR

DEF.THERMISTOR

VERSA THERMISTOR

V.THERMISTOR

I.THERMISTOR

WHITE

BLACK

WHITE

RED

YELLOW

GRAY

WHITE

GRAY

GRAY

GRAY

GRAY

LIGHT

GREEN

YELLOW

WHITE

ORANGE

BLUE

WHITE

GRAY

GRAY

WHITE

BLUE

GRAY

GRAY

WHITE

WHITEWHITE

WHITE

DEFROST

HEATER 2

GRAY

DIVIDER HEATER

COMPENSATIONAL HEATER

FOR VEGETABLE ROOM

ICE TRAY HEATER

MOTOR PROTECTOR

COMPRESSOR

LIGHT

GREEN

BLACKREDVIOLET

WHITE/RED

WHITE/RED

TANK LED

LIGHT BROWN

BRIGHT YELLOW

RED

YELLOWVIOLET

MOVE EYE MOTOR

FAN MOTOR (FOR COMPRESSOR)

FAN MOTOR

LIGHT GREENWHITE

ORANGE

BLACK

BRIGHT YELLOW

YELLOW

BLACK

YELLOW

VIOLET

VIOLET

VIOLET

VIOLET

PINK

RED

LIGHT BROWNWHITE

WATER PUMP

YELLOW GREENWHITE

BROWNRED

DOOR SW.(FOR F-COMPARTMENT)

*

DOOR SW.(FOR R-COMPARTMENT & ICE ROOM)

*

LED BOARD IN

VEGETABLE ROOM

SKY BLUE

SKY BLUE

WHITE/RED

WHITE LIGHT BROWN

LED BOARD IN

REFRIGERATOR ROOM

(L)

WHITE

V

MS

3

˜

W

U

LED BOARD IN

REFRIGERATOR ROOM

(R)

LIGHT

BROWN

RED

LIGHT

GREEN

M

MMM

6

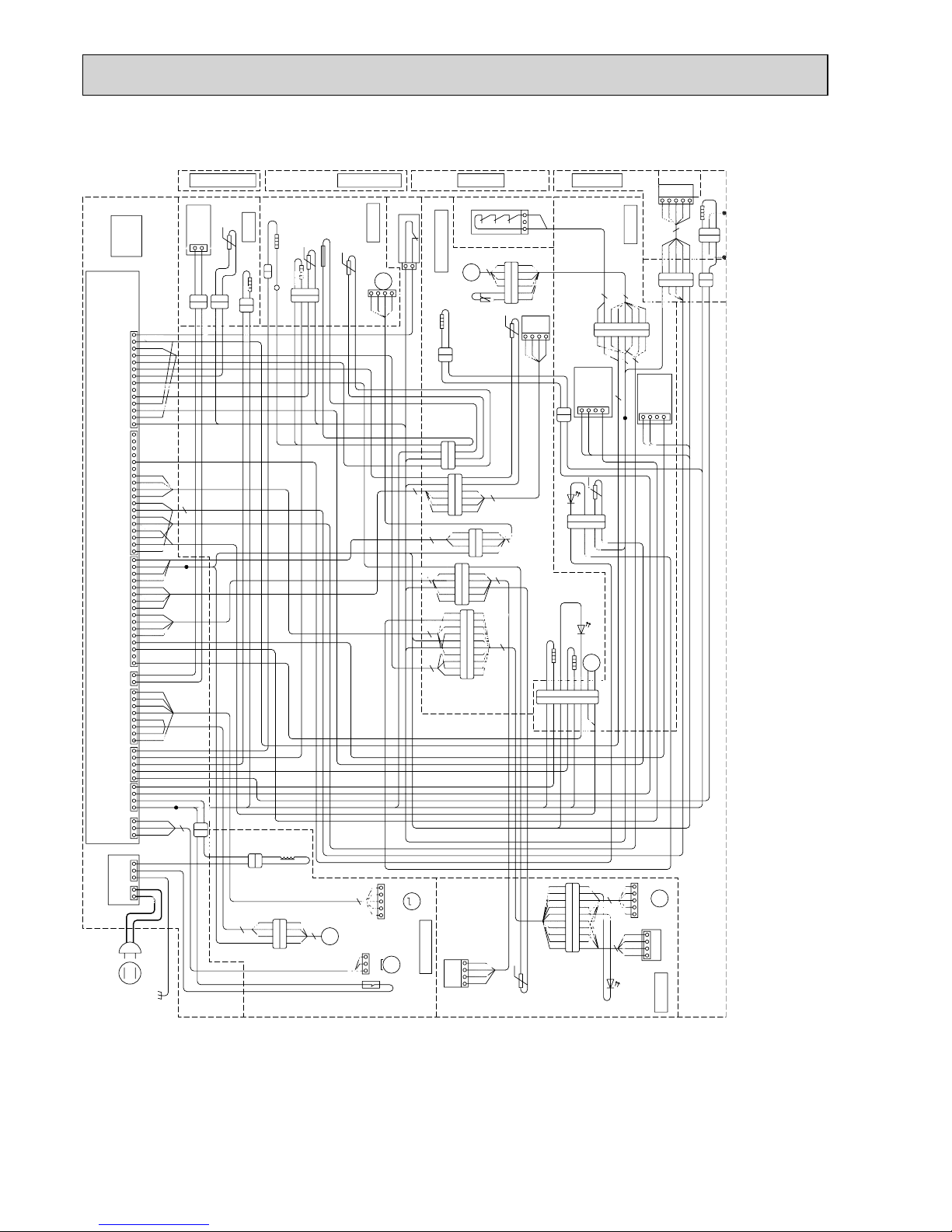

MR-E55R-C

MR-E60R-C

( ACTUAL WIRING DIAGRAM )

( When the doors are closed. )

I.THERMISTOR (Ice making compartment thermistor) V.THERMISTOR (Vegetable compartment thermistor)

VERSA.THERMISTOR (Versa compartment thermistor) DEF.THERMISTOR (Defrost thermistor)

ICE-TRAY THERMISTOR (Ice making tray thermistor) F.THERMISTOR (Freezer compartment thermistor)

R.THERMISTOR (Refrigerator compartment thermistor) TEMP. CONTROL BOARD: (Operation P.C. board)

V.HEATER (Vegetable compartment heater) DIVIDER HEATER: (Rotational heater board)

VEGETABLE LED: LEDs (Vegetable compartment) TANK LED: (LED for bacteria removal from water tank)

R/I ROOM DOOR SWITCH: Door switch (for vegetable compartment, ice compartment)

FREEZER ROOM DOOR SWITCH: Door switch (for freezer compartment)

FAN MOTOR (FOR COMPRESSOR): (BOX FAN) R.LED(R): Interior LED (right)

R.LED(L): Interior LED (left) S.LED: Versa compartment supercool freezing LED

R.LED(D): Refrigerator deodorization LED VALVE MOTOR: Three-way valve

MOVE EYE MOTOR: i-see sensor

3

1

2

AC110V

60Hz

13

26

7

13

5

31

5

7

31

87 54 13

8 5

7

1

24

8

12

3

4

56

8791012 112134576910

5

1112

69

3

5

2

1

9101112131415

14 13

4

3

3

1

221

1

2

1

2

1

3

8765432

1

6

2

3

3

2

3

1

5

5

423

1

1

2

2

1

3421

145623

654321

4321

98 462753110

3

4

4

3

4

654321

4

1

4

4

2

1

2

1

1234567

8

4

4

10

3

4

4

5

3

131415161718

1

2

16

2

1

CN61L

5

31

1

2

4

4

4

3

2

2

GRAY

GRAY

GRAY

GRAY

GRAY

GRAY

GREEN

GREEN

WHITE

WHITE

GRAY

WHITE

RED

RED

PINK

BLACK

BLACK BLACK

SKY BLUE

SKY BLUE SKY BLUE

VAIOLET

VAIOLET

GRAY

VAIOLET

5

1

3

1

t°

t°

t°

t°

t°

t°

t°

TEMP.

CONTROL BOARD

DIVIDER

HEATER

REFRIGERATOR

COMPARTMENT

REFRIGERATOR

COMPARTMENT DOOR

WHITE

WHITE

RED

SKY BLUE

SKY BLUE

SKY BLUE

SKY BLUE

SKY BLUE

LIGHT BROWN

LIGHT GREEN

LIGHT GREEN

LIGHT BROWN

BLUE

BLUE

WHITE

WHITE/ RED

R, LED

(R):

WHITE

WHITE

WHITE/ RED

WHITE/ RED

WHITE/ RED

WHITE/ RED

R, LED

(L):

ICE/ VERSA

COMPARTMENT DOOR

WHITE

WHITE

2

R/ I ROOM

DOOR SWITCH

ICE COMPERTMENT

RED

SKY BLUE

SKY BLUE

LIGHT BROWN

LIGHT GREEN

BLUE

WHITE

WHITE

WHITE

RED

BLUE

YELLOW

M

MOTOR

DAMPER

ICE

GEAR

BOX

ICE TRY

THERMISTOR

ICE TRY HEATER

I. THERMISTOR

RED

BLUE

WHITE

YELLOW

WHITE

WHITE

FREEZR COMPARTMENT DOOR

VEGETABLE COMPRATMENT DOOR

FREEZER ROOM DOOR SWITCH

FREEZR

COMPARTMENT

M

FAN

MOTOR

WHITE/ RED

SKY BLUE

PINK

YELLOW

BRIGHT YELLOW

VAIOLET

THERMAL

FUZE (73ºC)

F. THERMISTOR

DEF. THERMISTOR

DEFROST

HEATER 2

DEFROST HEATER 1

WHITE

WHITE

BLACK

BLACK

PINK

SKY BLUE

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE WHITE

LIGHT BROWN

WHITE

BLUE

RED

VEGETABLE

COMPARTMENT

VEGETABLE

LEDS

BLUE

BLUE

VAIOLET

VAIOLET

VAIOLET

YELLOW

SKY BLUE

ELECTRIC

BOX

CONTROL

BOARD

GRAYGRAY

YELLOWYELLOW

GRAY

YELLOW

R. THERMISTOR

R. LED (D)

WHITE

WHITE

LIGHT GREEN

ORANGE

SKY BLUE

LIGHT GREEN

LIGHT BROWN

LIGHT BROWN

M

WATER PUMP MOTOR

TANK LED

WHITE

RED

RED

BLACK

GRAY GRAY

GRAY

BLUE

VIOLET

ORANGE

GRAY

GRAY

GRAY

WATER PIPE HEATER

YELLOW GREEN

LIGHT GREEN

BROWN

WHITE

GRAY

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

YELLOW

YELLOW

WHITE

RED

RED

RED

BLUE

BLUE

BLUE

WHITE

GRAY

SKY BULE

SKY BULE

ORANGE

BLUE

RED

WHITE/ RED

YELLOW

VIOLET

PINK

BRIGHT YELLOW

YELLOW

VIOLET

BLACK

BRIGHT YELLOW

BRIGHT YELLOW

BRIGHT YELLOWBRIGHT YELLOW

LIGHT GREENYELLOW GREEN

LIGHT BROWN

WHITE

LIGHT BROWN

WHITE

YELLOW GREEN

GRAY

SKY BULE

PINK

BROWN

SKY BULESKY BULE

VIOLETVIOLET

YELLOWYELLOW

GRAYGRAY

RED

BLACK

RED

BLACK

FILTER BOARD

WHITE/ RED

LIGHT BROWN

WHITE

BLACK

BLUE

RED

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

BRIGHT YELLOW

LIGHT GREEN

PINK

PINK

PINK

ORANGE

ORANGE

ORANGE

ORANGE

GRAY

GRAY

GRAY

GRAY

GRAY

SKY BULE

LIGHT BROWN

BROWN

BROWN

LIGHT BROWN

BRIGHT YELLOW

RED

RED

RED

RED

RED

WHITE

WHITE/ RED

WHITE/ RED

BLUE

BLUE

BLUE

BLUE

YELLOW GREEN

YELLOW GREEN

BRIGHT YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

VIOLET

VIOLET

VIOLET

VIOLET VIOLET

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

LIGHT GREEN

LIGHT GREEN

LIGHT GREEN

LIGHT BROWN

BLACK

WHITE

WHITE

BLACK

WHITE

WHITE

REACTOR

2

1

43

YELLOWORANGE

BLACK BLACK

VIOLET

LIGHT GREEN WHITE

RED

M

M

MS

3

˜

M

YELLOW

VIOLET

GRAY

RED

BLUE

25413

VALVE MOTOR

COMPRESSOR

(VIEW FROM REAR LEFT SIDE)

MACHINE CHAMBER

COMPARTMENT

213

WHITE

BLACK

RED

FAN MOTOR

(COMPRESSOR)

MOTOR

PROTECTOR

4

1

YELLOW

RED

BLUE

WHITE

MOTOR

DAMPER

VERSA

THERMISTOR

7

1

248563910

1

2453

2

3

LIGHT BROWN

LIGHT GREEN

LIGHT BROWN

LIGHT BROWN

BRIGHT YELLOW

BRIGHT

YELLOW

BRIGHT YELLOW

WHITE

SKY BLUE

YELLOW

YELLOW

YELLOW

GRAY

BLACK

RED

RED

BLACK

BLACK

BLACK

BLACK

BLACK

VIOLET /BLACKVIOLET

VIOLET

RED

BLACK

BLACK

BLACK

BLACK

4

1

2

3

VERSA

COMPARTMENT

THERMOPILE

MOVE EYE MOTOR

S.LED

TANK HEATER

432

1

V. HEATE R

LIGHT GREEN

GRAY

V. THERMISTOR

1

2

VIOLET

7

393

245

309

300

96

547

541

666(

Pitch between the front wheels

)

631(

Pitch between the adjust bolts

)

578(

Pitch between the rear wheels

)

363

8

363

8

128

8

5.5

2500

407

363

394.5

6

283.5

363 212 822

394.5283.5

6

1821

(Display)

685(Display)

680(Cabinet)

77

318

400

408

436

337

249

595

595

595

196

203

307

541

581

539

596

655

37

728(Display)

142

179

101

760

53

633

10

331

37

333

175

41

1075

204

314

86

104

358.5

358.8

348

255

REQUIRED SPACE FOR INSTALLATION

1821

20 685 20

211

290

950

728

100

1061

989

180.5

222

125

83.5

125

83.5

159.5

201

406

413

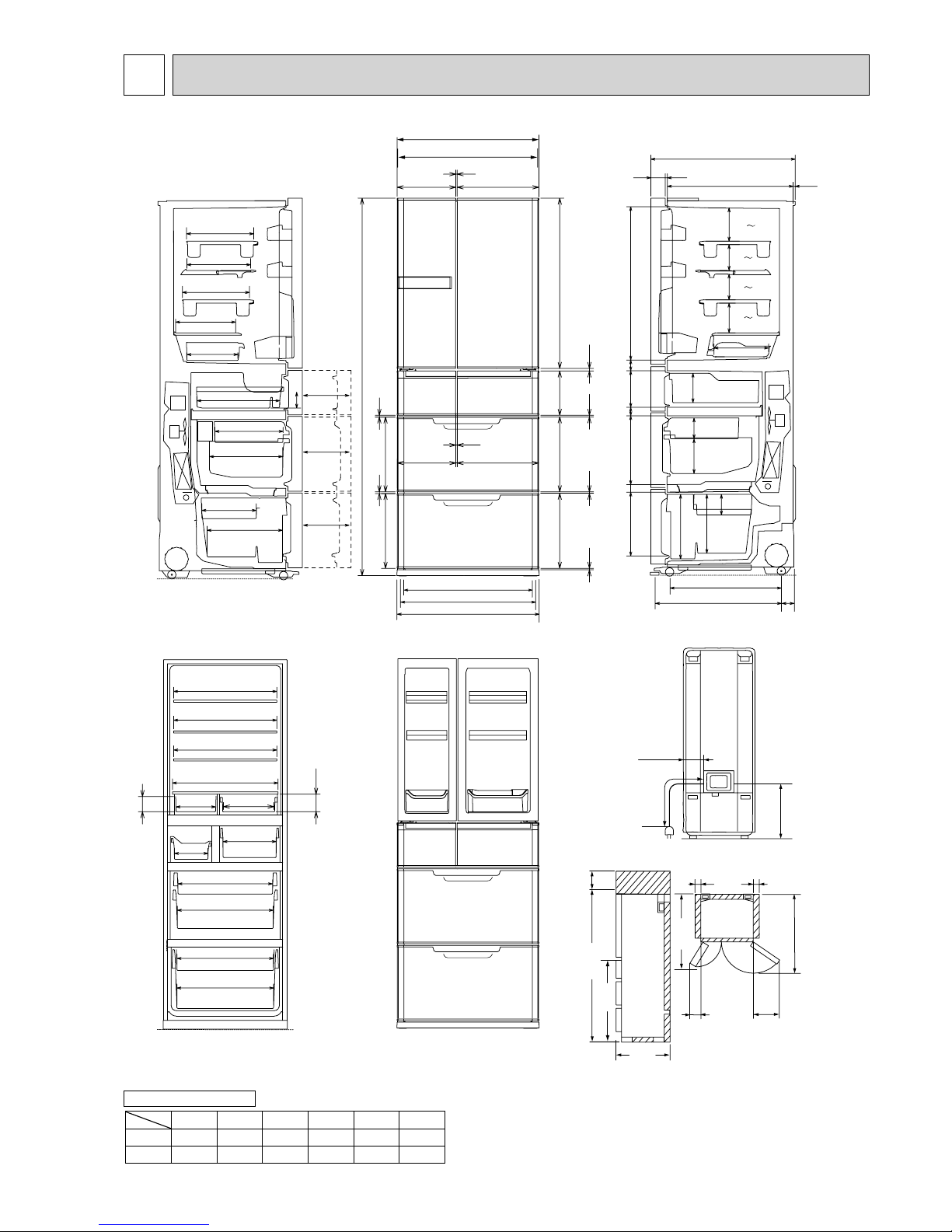

OUTLINES AND DIMENSIONS

3

MR-E55R-C

Unit : mm

R(L) : Refrigerator compartment (Left)

R(R) : Refrigerator compartment (Right)

I : Ice making compartment

S : Select compartment [Versa compartment]

F : Freezer compartment

V : Vegetable compartment

R(L) R(R) I S F V

Hight 822 822 212 212 363 363

Width 283.5 394.5 283.5 394.5 684 684

DOOR DIMENSION

8

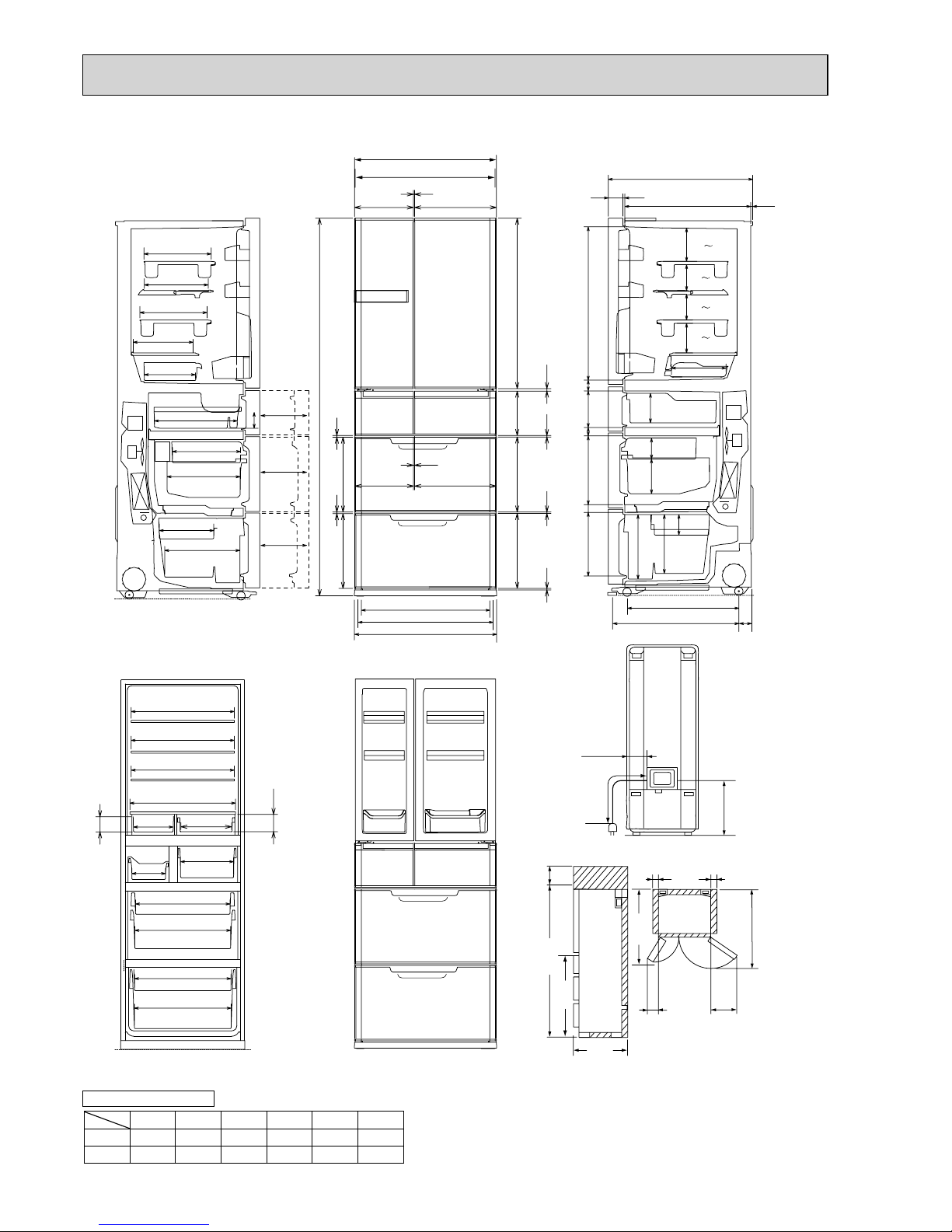

MR-E60R-C

393

245

309

300

96

607

601

REQUIRED SPACE FOR INSTALLATION

726(

Pitch between the front wheels

)

691(

Pitch between the adjust bolts

)

638(

Pitch between the rear wheels

)

363

8

363

8

12

8

8

5.5

2500

407

363

454.5

6

283.5

363 212 822

454.5283.5

6

1821

(Display)

745(Display)

740(Cabinet)

77

318

400

408

436

337

249

655

655

655

196

203

367

601

641

599

596

655

37

728(Display)

142

179

101

760

53

633

10

331

37

333

175

41

1075

204

374

86

104

358.5

358.5

348

255

1821

20 745 20

211

335

950

728

100

1121

180.5

222

125

83.5

125

83.5

159.5

201

989

406

413

R(L) : Refrigerator compartment (Left)

R(R) : Refrigerator compartment (Right)

I : Ice making compartment

S : Select compartment [Versa compartment]

F : Freezer compartment

V : Vegetable compartment

R(L) R(R) I S F V

Hight 822 822 212 212 363 363

Width 283.5 454.4 283.5 454.5 744 744

DOOR DIMENSION

9

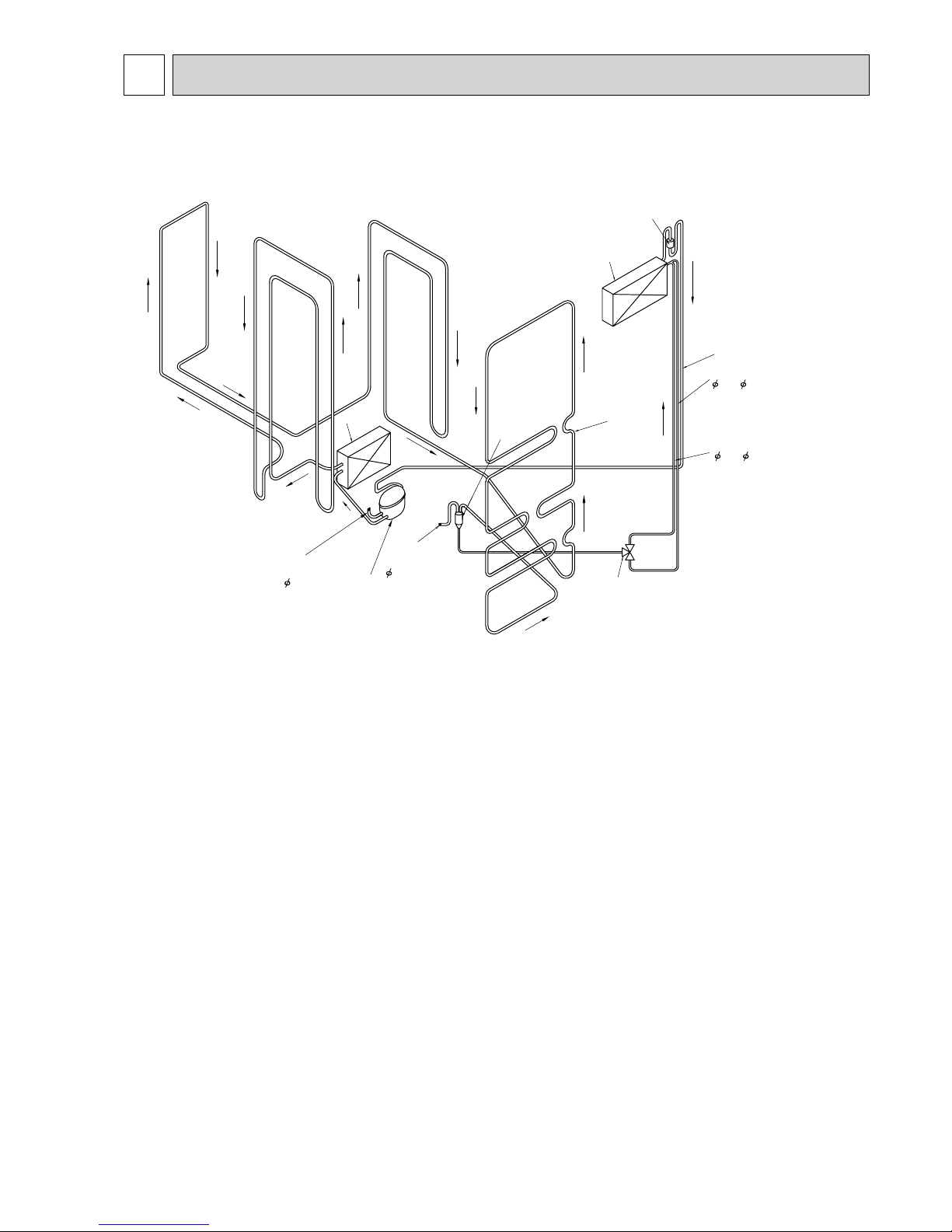

REFRIGERANT CIRCUIT

4

Capillary tube

1.8× 0.67×2740 (mm)

1.6× 0.63×2740(mm)

Suction pipe

Muffler

Evaporator

Dryer

Cabinet

pipe

#150

Compressor

Charge pipe

(Low pressure

side) 6.35

Charge pipe

(High pressure side)

Condenser

Capillary tube

Three-way

valve

4.0

MR-E55R-C

MR-E60R-C

10

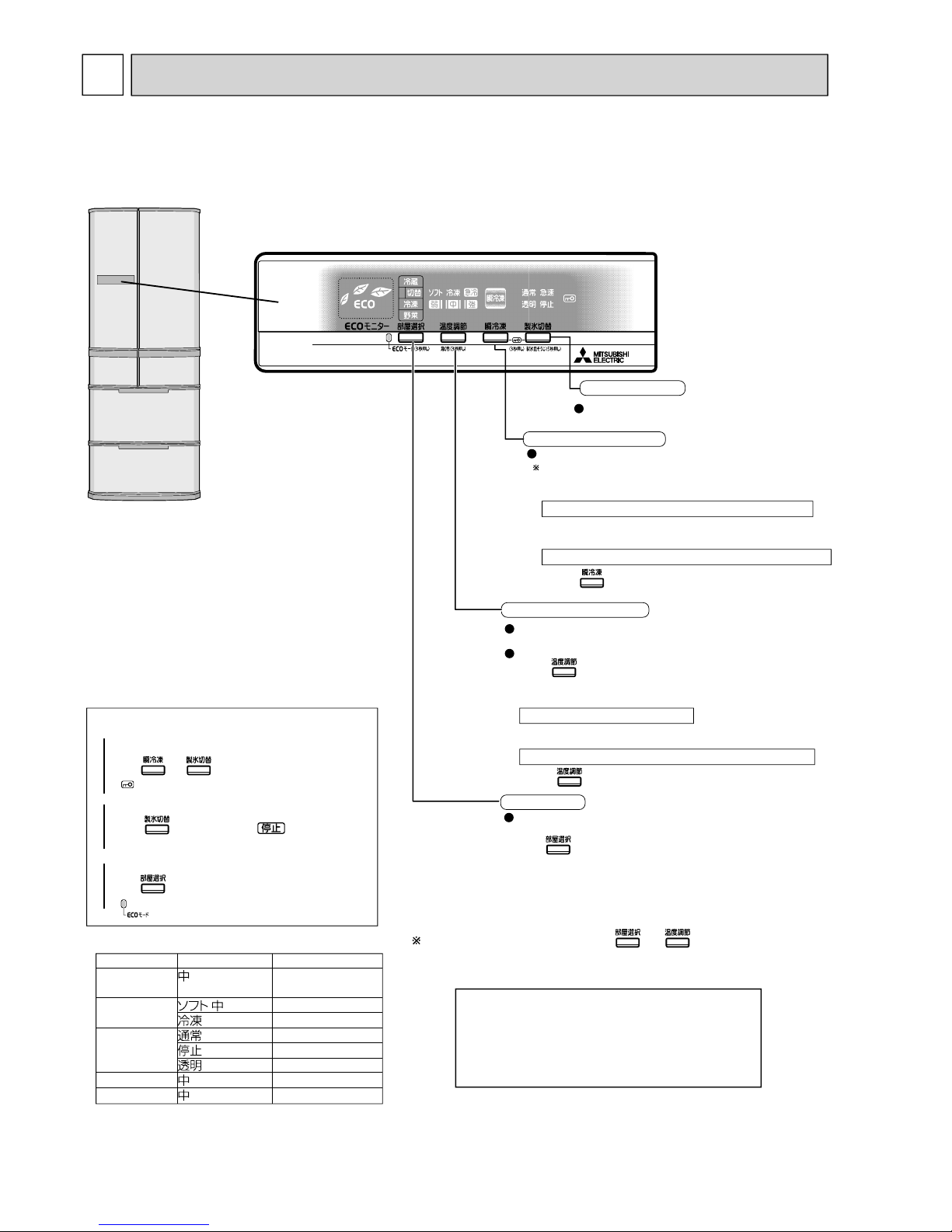

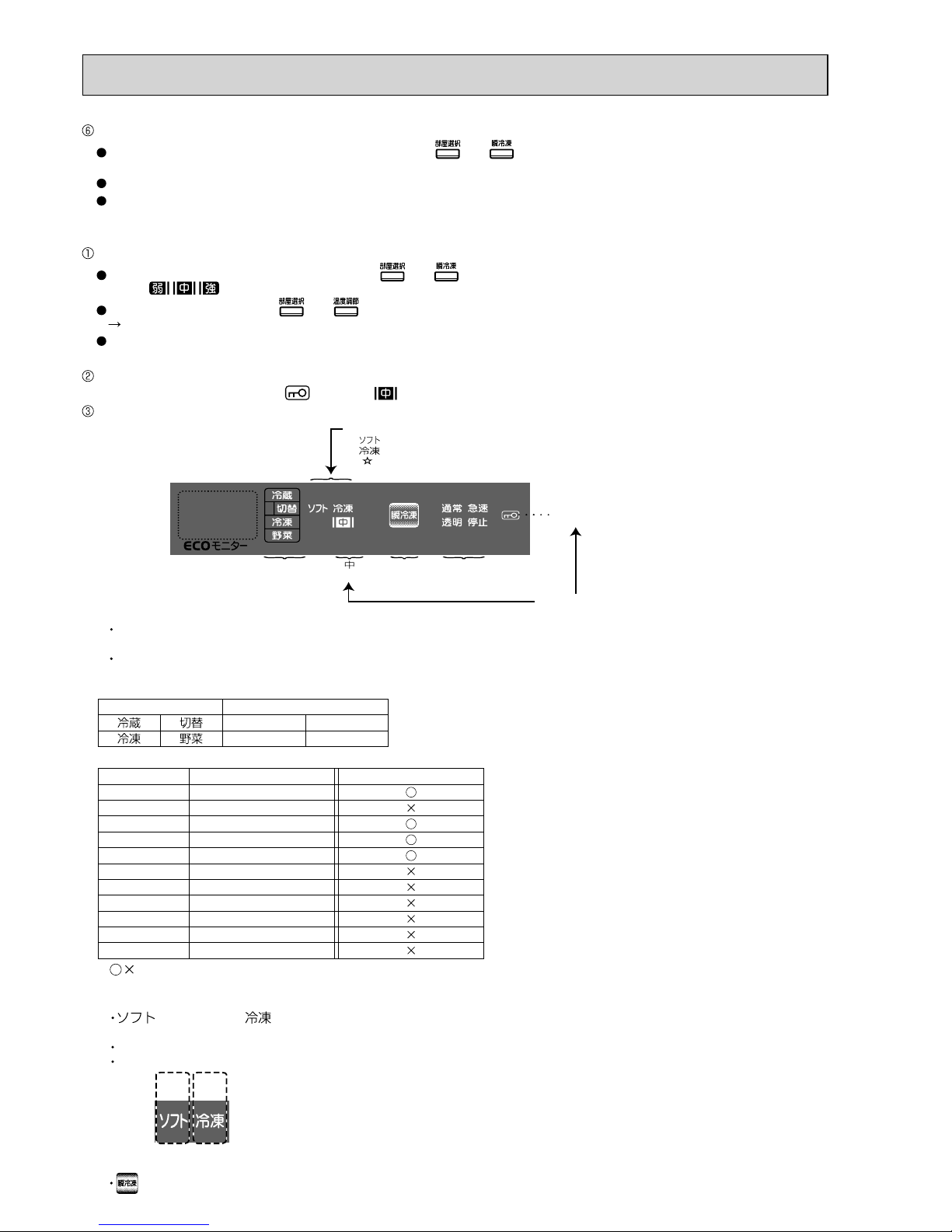

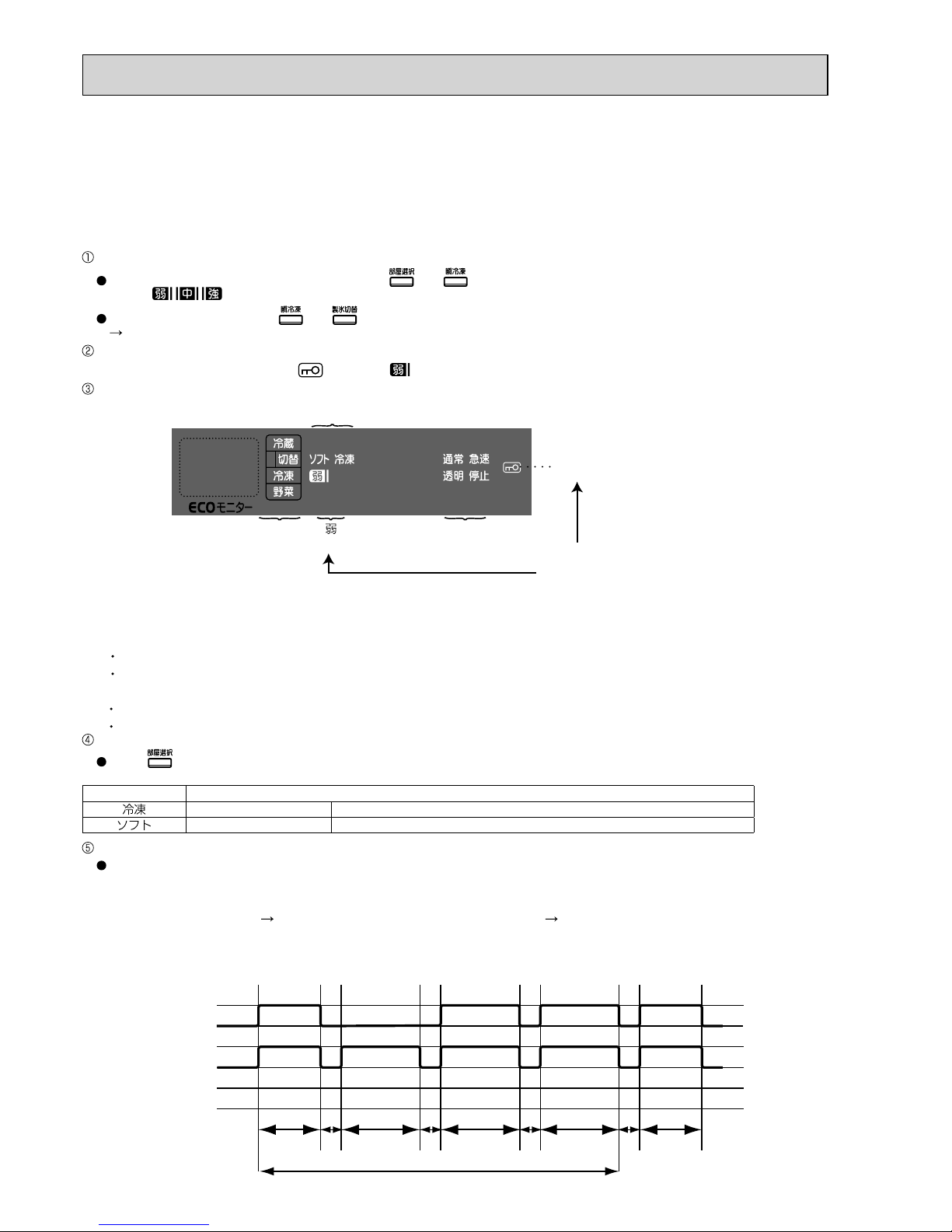

ROOM button

Pressing this button selects the

compartment to be displayed.

Press to select the compartment before adjusting

the temperature or cooling fast.

When the versa compartment is set at soft freezing

mode, fast cooling cannot be selected.

SELECT / QUICK button

Pressing this button sets each compartment’s temperature.

In order to cool fast:

QUICK mode stops automatically

• QUICK mode automatically stops in 2 hours.

When stopping QUICK mode before it automatically ends

Press for 3 seconds.

This operation starts only when the room selection is set to

the versa compartment, and also the versa compartment is

set to soft freezing mode.

• Press once.

The supercool freezing operation ends automatically

• The superc ool freezing operation automatically ends

after 6 to 8 hours.

When stopping the supercool freezing operation before it automatically ends

• Press once.

ICE SELECT button

Supercool freezing button

Pressing this button selects the setting

of the ice making compartment.

The supercool freezing operation starts.

To reset the settings when initialled, press and simultaneously

for 3 seconds. The temperatures of the refrigerator, vegetable, and freezer compartments

will be set to “Middle” .The Fast Cooling operations in all the compartments will stop.

USEFUL FUNCTIONS

Press and simultaneously for 3 seconds.

Child lock

( lamp turns on)

1

2

Press several times until is displayed.

Stop ice making

3

Press button for 3 seconds.

( lamp turns on)

ECO mode (To start and cancel)

Operating mode and Temperature range

Compartment

Mode

Temp. range

Approx.

0 to 6

°C

Approx.

−9 to −5°C

Approx.

−

18 to −12

°C

Approx.

−

21 to −17

°C

Approx.

−

21 to −17

°C

Approx.

−21 to −17°C

Approx.

3 to 9°C

Approx.

−21 to −17°C

Refrigerator

compartment

Versa

compartment

Ice making

compartment

Vegetable compartment

Freezer compartment

The temp. range is based on the data measured at the center of each compartment with the door closed and with no

food inside under the condition of ambient temperature 30°C.

TROUBLESHOOTING

5

MR-E55R-C

MR-E60R-C

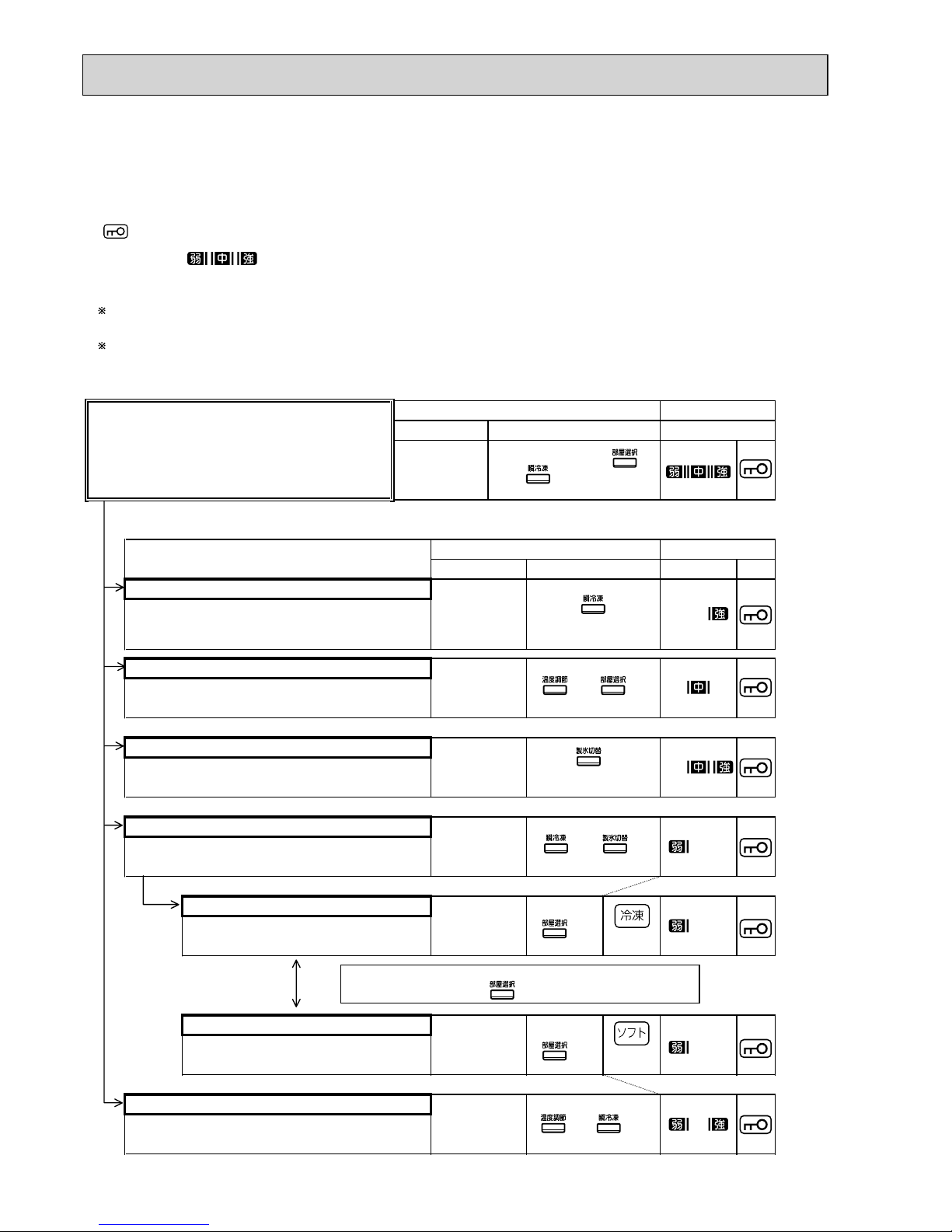

(1) Function of normal operation

5-1 FUNCTION OF OPERATION PANEL

· The display extinguishes in 30 seconds

after the last button is pressed.

(No failure in refrigerator)

· Pushing any button turns on the display

again.

11

(2) Demonstration mode for shop display

Setting

Within 1 minute after power supply turns on, press the , , and simultaneously for 5 seconds

with the door of the ice making compartment opened.

When the setting is complete, a “beep” sound is heard and “Auto Demo Mode” is displayed.

Demonstration mode is not available when the temperature of freezer compartment is –7°C or lower.

Panel operation mode during demonstration mode

The panel operation mode changes to “manual” if any of the switches is pressed. It changes to "auto" if none of the switches

is pressed for 45 seconds since the last time any of the switches was pressed.

Manual mode: Panel indication changes according to switch operation.

Auto mode: Panel indication is automatically changed.

Release

1) Open the ice making compartment’s door during demonstration mode, and leave it open.

2) Press

button twice.

3) Simultaneously press

, , and for 5 seconds. (A “beep” sound is heard in about 5 seconds.)

Verify that the room display and the temperature adjustment display on the operation panel do not light by turns a minute

after the 3 steps above are performed.

Note: Follow the procedure above to release demonstration mode as it cannot be released by simply turning

on/off the power supply.

(3) Fine adjustment of temperature

Fine adjustment of temperature is available for refrigerator compartment, freezer compartment and versa

compartment.

As for versa compartment, however, it is only available when the compartment is set to

.

Setting

Simultaneously press and for about 3 seconds until a “beep” sound is heard.

Room display blinks every 10 seconds in fine adjustment mode.

Fine adjustments of temperature

Follow the same operation procedure for temperature adjustment.

Release

Follow the same procedure as Setting and the finely-adjusted

temperatures are reset for refrigerator compartment, freezer

compartment and versa compartment at once.

Temperature is adjusted in approximately 0.3 to 0.6°C

increments.

(4) Ice making test/Self-check

Setting

Press for about 5 seconds.

Operation and its display

While automatic ice making is testing, the indication of ice

making compartment setting blinks on display.

When something is faulty, the error code is indicated.

Release

The test automatically finishes in 10 minutes.

Fine adjustment of temperature

Normal mode

Fine adjustment mode

Note: -25 °C freezing.

Select the maximum setting of the

temperature adjustment function for the

freezer compartment.

There is no particular display when the

setting is selected.

(5)

“LOW” setting on the anti-condensation heater

Outline

This setting lowers energy on the anti-condensation heater,

allowing for lower power consumption.

If, however, the condensation forms on the partitions, cancel

the setting.

Setting

Press and buttons simultaneously for 3 seconds

(until 1 beep sound is heard ).

Cancellation

Go through the same procedure as that of Setting (2 beep

sounds are heard when cancelled).

When the settings are reset, this setting is also cancelled.

Display/indication of the setting status

No display is available to show the low setting state on the

anti-condensation heater.

The number of beep sounds indicates the setting state.

Beep (1 time) Set to Low

Beep beep (2 times)

Low setting is canceled and returned to normal state.

12

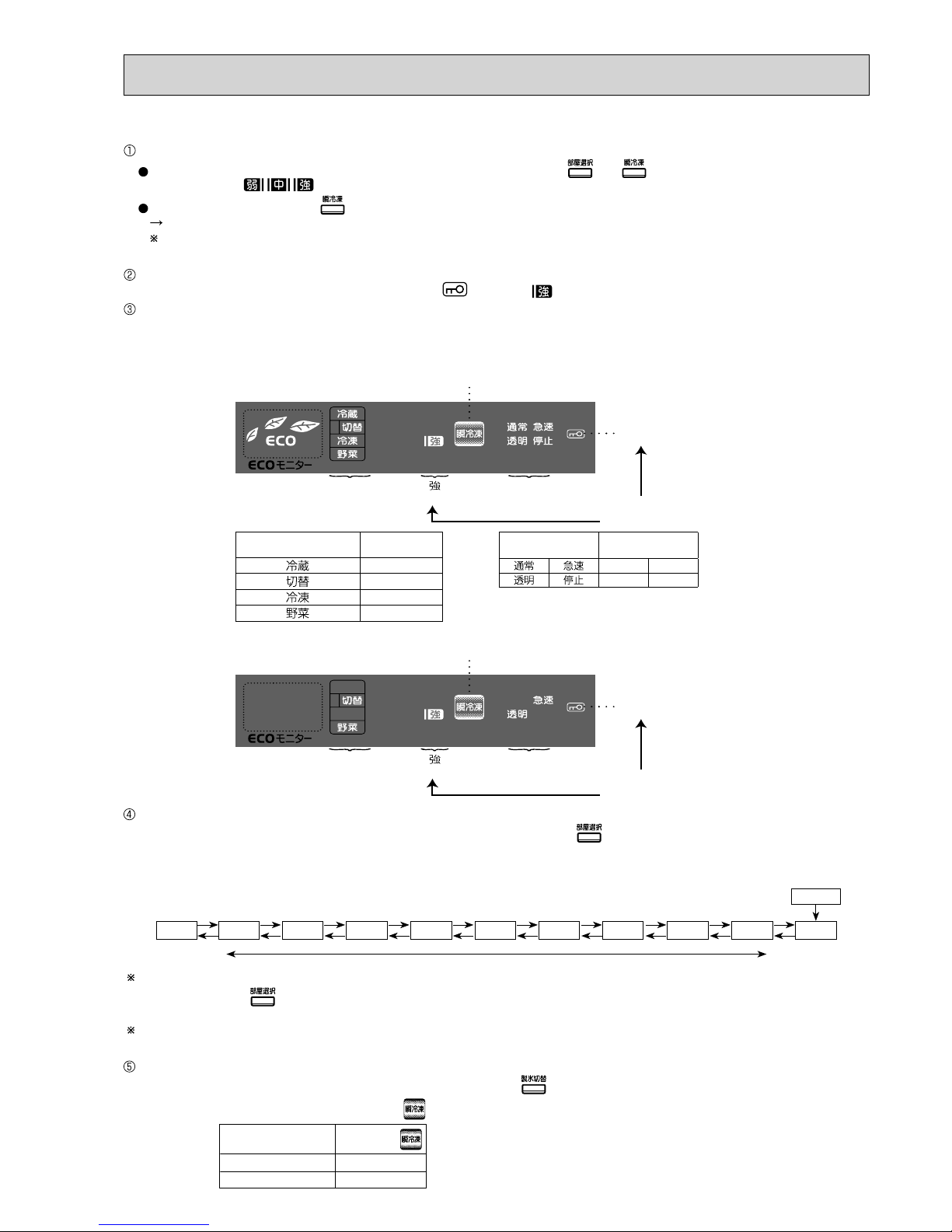

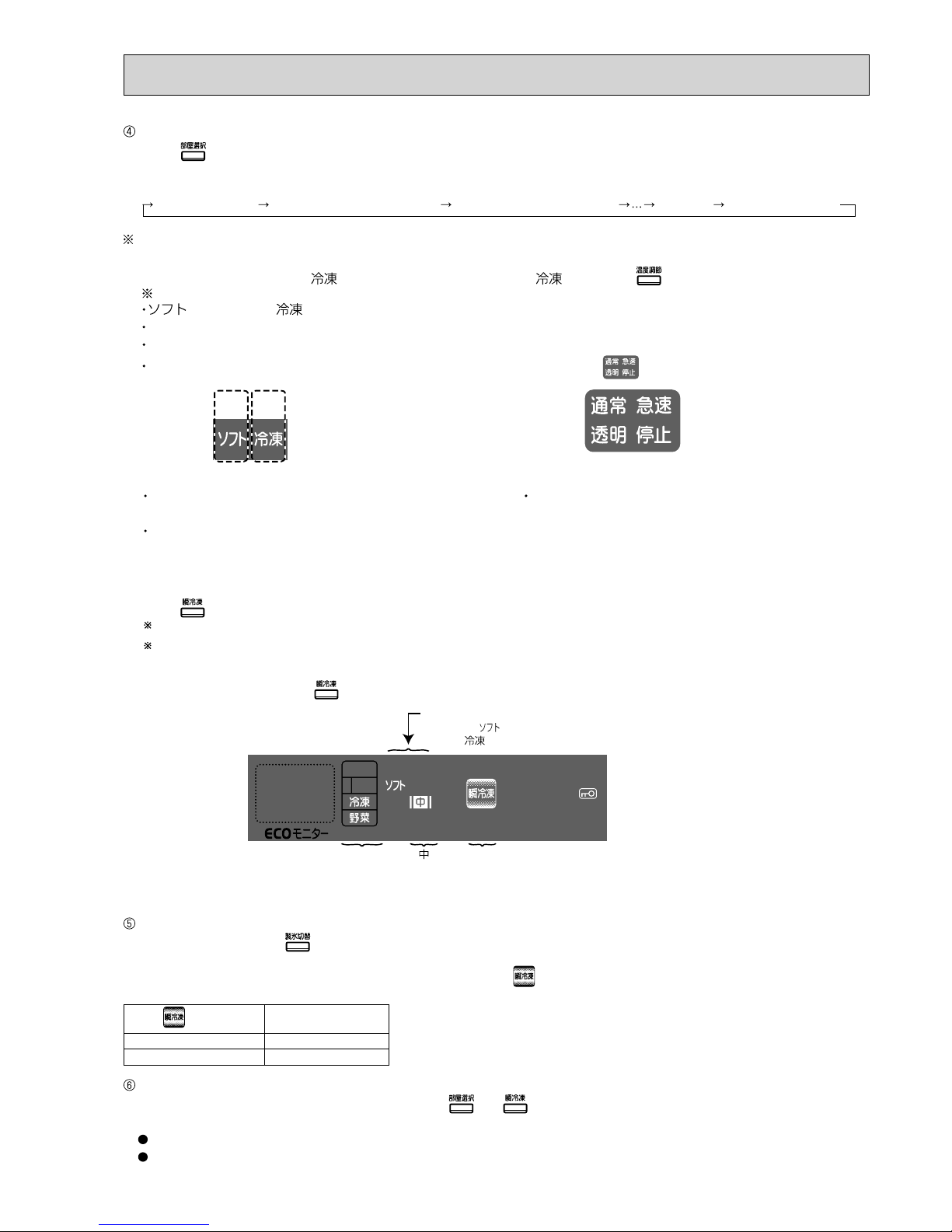

(6) Service Check Function

1) Outline

• The chart below shows the outline of service check function.

• “Service check entry” needs to be set in order to perform each check mode. After setting “service check entry,” start the

setting operation of the check mode to be displayed.

• blinks while service check function is performed.

• The display of

indicates which mode is in operation.

• When one of the check modes is in operation, other modes cannot be set. The mode in operation needs to be cancelled

before setting another mode.

Once each check mode starts, it continues operating even if the door gets closed.

(Open the door when releasing each mode.)

Refer to the next sections about the operation procedure and display of each check mode.

• In order to release “service check function entry,” follow the same procedure as setting operation during “service check

function entry” or each check mode.

Setting / releasing method Display

Door Button operation Blinking

(1)

(2)

(3)

(4)

(4)(1)

(4)(2)

(5)

Open the

ice making com-

partment’s door

Leave the

ice making

compartment’s

door open

Leave the

ice making

compartment’s

door open

Leave the

ice making

compartment’s

door open

Leave the

ice making

compartment’s

door open

Leave the

ice making

compartment’s

door open

Simultaneously press

and for 3 seconds

Simultaneously press

and for

3 seconds

Simultaneously press

and for

3 seconds

Simultaneously press

and for

3 seconds

Press

Press

Press for

3 seconds

Press for

3 seconds

DisplaySetting method

Mode

Door Button operation Lighting

Blinking

1) Compressor’s rotational speed change mode

…The rotational speed of the compressor can be

changed; The fan motor in machine chamber

can be switched on and off.

2) Damper Operation mode

…Each damper can be opened and closed; Refrigerator

fan can be switched on/off.

3) Thermistor temperature check mode

…The detected temperature of each thermistor can

be checked.

4) Error history display mode

…The error occurred in the past can be checked.

(1) History display mode

…All the errors occurred in the past can be

checked in numeric order.

-

(2) Order of occurrence mode

…The newest 5 errors (at the maximum) are

displayed from the newest to the older.

-

5) Set temperature adjustment mode

…The set temperature in each compartment can be

adjusted.

Service check function entry

“History display mode” and “Order of occurrence mode” are

switched over each time is pressed.

13

e.g.) Compressor’s rotational speed 56rps, Fan box fan ON

Blinking

“ ”

Lighting

Fan in box fan ON/OFF

Compressor’s

rotational speed

Tens’ place

Compressor’s

rotational speed

Ones’ place

Display during Compressor’s

rotational speed change mode

Room display

Corresponding

values

8

4

2

1

Ice making mode

display

Corresponding

values

84

21

Blinking

“ ”

Lighting

Fan in box fan ON

Tens’ place "5"

(=4+1)

Ones’ place "6"

(=4+2)

Display during Compressor’ s

rotational speed change mode

Changing the rotational speed

After setting this mode, compressor’s rotational speed changes every time button is pressed.

Rotational speed (rps) is divided into ones’ place and tens’ place when it is displayed.

(Basically the compressor starts operation at level 10, however, it may be different depending on models, or as a result of

specification change.)

<Change of rotational speed>

Rotational speed can be changed only when the compressor is in operation. While the compressor stops, rotational speed is

not displayed, and

button operation is not effective. When the compressor stops, unplug the power code, and wait for

a several minutes, then plug it again.

Operation sound may get increase in the process of changing rotational speed, but that is not dysfunction. Check the sound

level when rotational speed is stabilized.

Switching ON/OFF the box fan

In this mode, box fan can be switched on and off at each press of .

Box fan

The ON/OFF state is displayed with on the display panel.

ON

OFF

Display of

Lighting

Not lighting

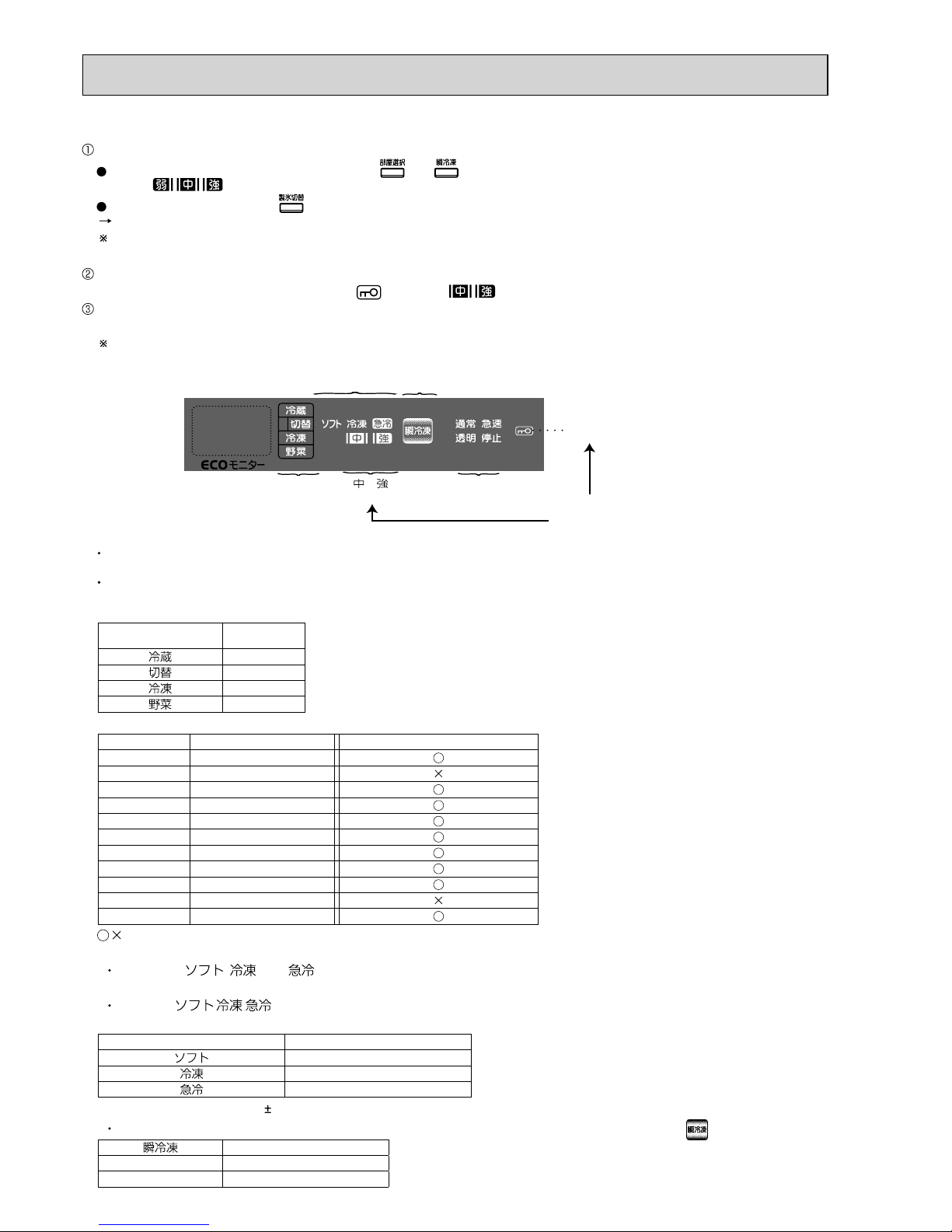

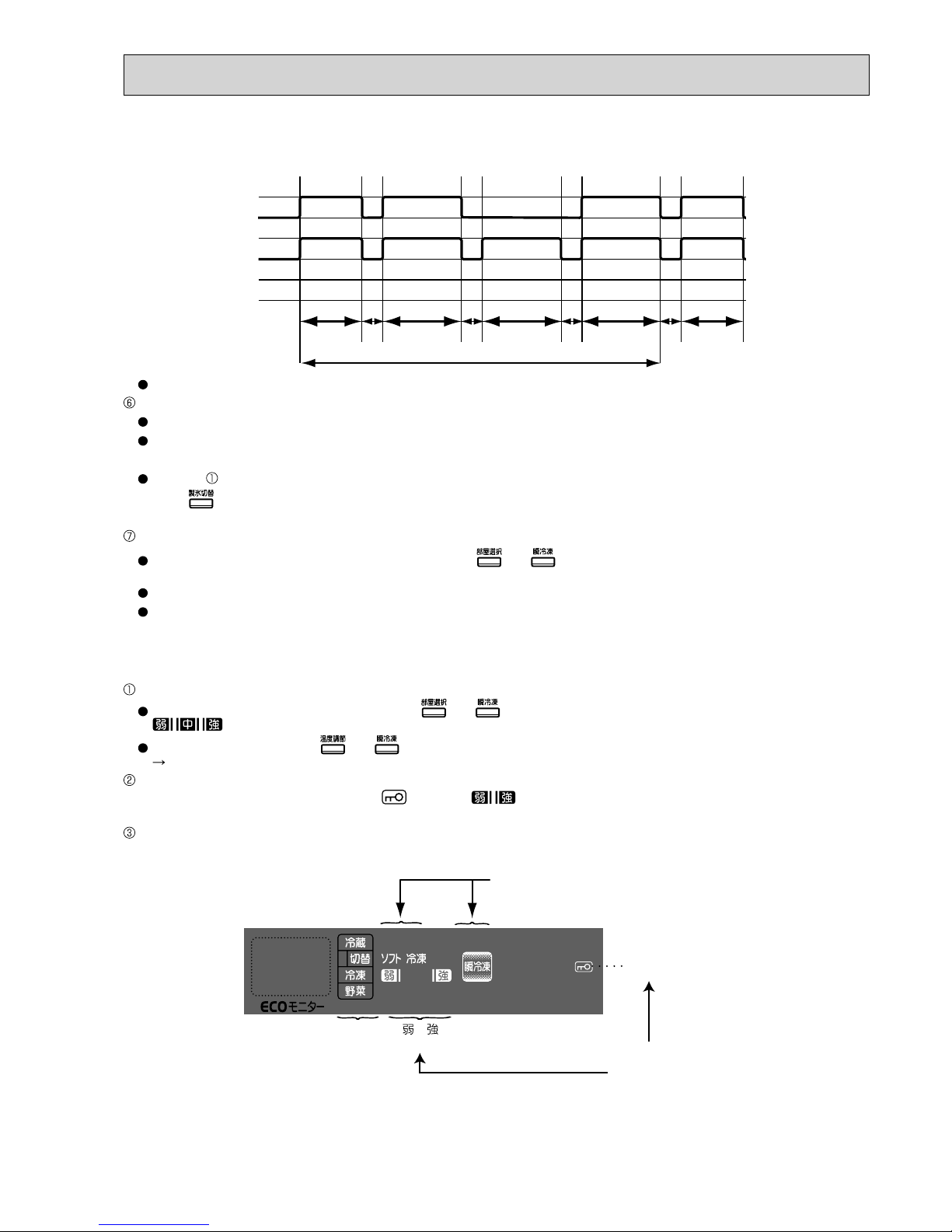

2) Compressor’s rotational speed change mode

Setting

With the ice making compartment’s door opened, simultaneously press and for 3 seconds until a “beep”

sound is heard. starts to blink.

With the door opened, press for 3 seconds to start compressor’s rotational speed change mode.

Once this mode starts, it continues operating even if the door is closed.

Compressor’s rotational speed change mode is not available during demonstration mode, thermistor temperature check

mode, set temperature adjustment mode, error history display mode, or when child lock is effective.

Display during compressor’s rotational speed change mode

During compressor’s rotational speed change mode, blinks and lights up.

Display of rotational speed

• Compressor’s rotational speed is divided into ones’ place and tens’ place when it is displayed.

• One of the values (8/4/2/1) is assigned to each indicator of both tens’ place and one’ place on the display panel. The sum of

the corresponding values of the lighting indicators is the compressor’s rotational speed.

Level 0 Level 1 Level 2 Level 3 Level 4 Level 5

Normal

Low speed

High speed

Level 6 Level 7 Level 8 Level 9

Level 10

14

3) Damper Operation Mode

Setting

With the ice compartment door opened, press and simultaneously for 3 seconds until a “beep” sound is

heard. blinks.

With the door opened, press and simultaneously for 3 seconds until a “beep” sound is heard.

Damper operation mode starts. Once this mode starts, it continues operating even if the door gets closed.

Damper operation mode is not available during demonstration mode, thermistor temperature check mode, compressor’s

rotational speed change mode, temperature adjustment mode, error history display mode, or when child lock is effective.

Display during damper operation mode

During damper operation mode, blinks and lights up.

Control state display of each damper

Blinking

“ ”

Lighting

a) Damper

serial number

b) State of damper

: present state

: next state

( The damper of the selected compartment is in operation, the indicator

in the present state blinks.)

During damper operation mode

c) Refrigerator

fan ON/OFF

d) Display during damper

operation “Blinks”

a) Damper serial number

The room display on the display panel corresponds to the values representing damper types. The room display indicators

and their corresponding values (8/4/2/1) are shown in the tables below.

Each serial number is assigned to each compartment (thermistor), which is used in thermistor temperature mode and

set temperature adjustment mode besides damper operation mode. The sum of the corresponding values of the lighting

indicators is the damper’s serial number.

Room Display Corresponding values

84

21

Serial number Assigned compartment Damper operation mode

1 Refrigerator compartment

2 Slide chilled compartment

3 Ice making compartment

4 Versa compartment

5 Vegetable compartment

6 Freezer compartment

7 Defrosting

8 Ice tray

9 Outdoor air

10 Deodorization

11 Thermopile

/ : SW operation is effective/ineffective

b) State of damper

on the left and on the right represent respectively the present state and the next state of the damper

operation.

When the right and left indicators are ON, it indicates that the damper is open.

When the right and left indicators are OFF, it indicates that the damper is close.

c) ON/OFF state of refrigerator fan motor

indicates the ON/OFF state of refrigerator fan motor.

Next

Present

Release

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”

sound is heard. The screen returns to the normal temperature display.

The function is automatically released in one hour.

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure

above for protection of the compressor.

15

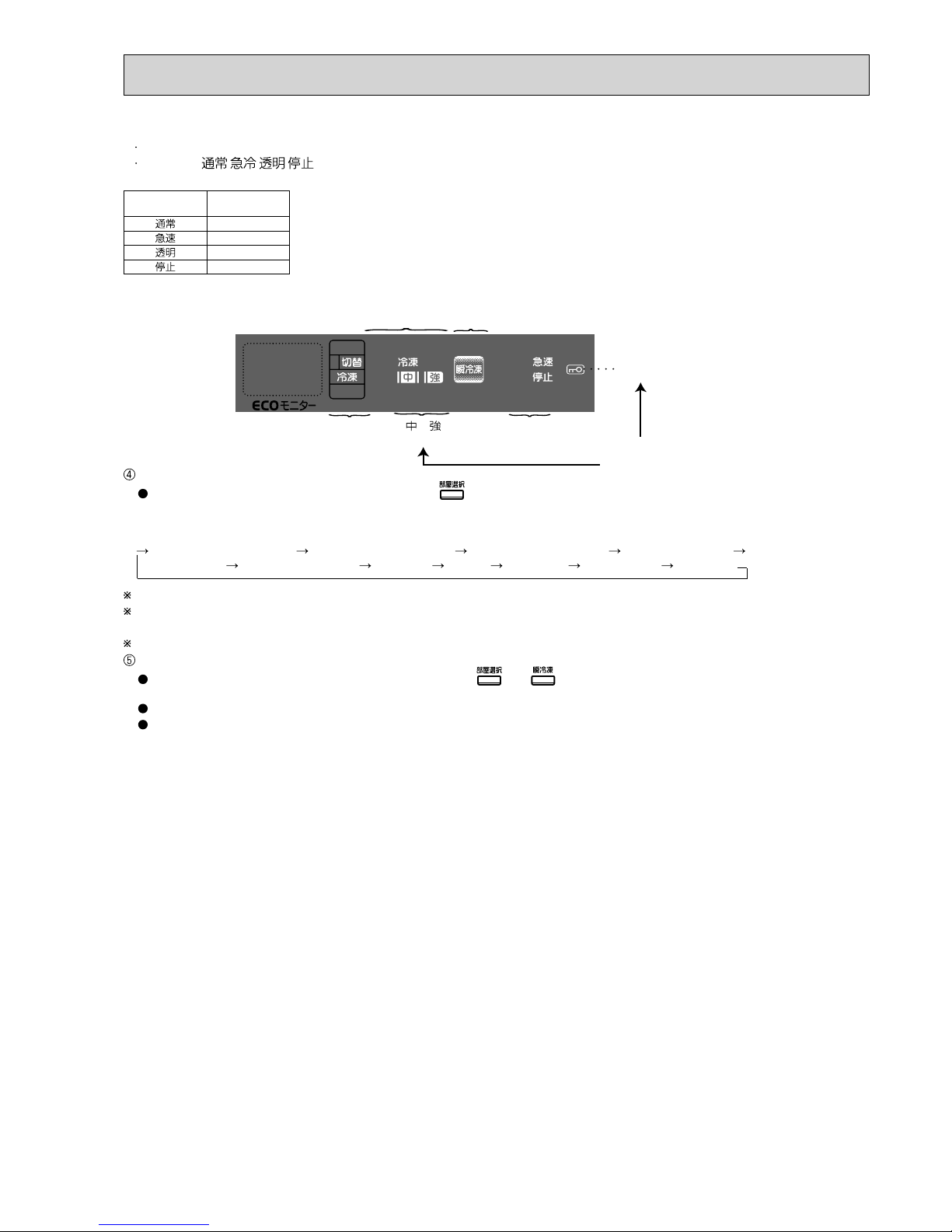

Opening and closing dampers

(1) Press to select the damper to be set. Each press of the button makes a “beep” sound and changes the kind of

dampers. The serial number described in a) indicates the selected damper.

The selected damper is displayed using the serial number (1: refrigerator ~ 10: deodorization) in numeric order repeatedly.

Refrigerator damper slide chilled compartment damper ice making compartment damper outdoor air deodorization damper

Slide chilled compartment, defrosting, ice tray, outdoor air, and deodorization can be selected;

however, it is ineffective in damper operation mode.

(2) To open the damper, turn on , and to close the damper, turn off by pressing

button.

Damper operation indicators

on the left and on the right represent respectively the present state and the next state of the damper operation.

The on and off of the right and left indicators indicate respectively the opening and closing of the damper.

The damper operation of the indicator blinking in the “present state” is in operation.

When any of the damper operations including those not selected is in operation, blinks.

Next

Present

Switching ON/OFF the refrigerator fan motor in the unit

In this mode, each press of switches on and off the refrigerator fan motor.

The ON/OFF state of the refrigerator fan motor is represented with .

display Fan motor in the unit

Lighting ON

Not lighting OFF

Release

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep” sound is

heard. The screen returns to the normal temperature display.

The function is automatically released in one hour.

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure

above for protection of the compressor.

“ ”

Lighting

a) Serial

number

“3” : Ice making

compartment

b) State of damper

Present: “ ”

Next: “ ”

c) Refrigerator fan

Lighting: ON

Blinking

(3) Press

for 3 seconds to operate the damper. (A “beep” sound is heard when the setting has been conveyed.)

Setting of the operating damper cannot be changed.

Damper operation stops automatically. (Blinking changes to lighting.)

e.g.) When changing the damper of ice making compartment from “CLOSE” state to “OPEN” state, select the indicators as

shown below and press

for 3 seconds.

The present and next damper operations of the selected

compartment illuminate.

When the damper of the selected compartment is in

operation, the indicator in the present state blinks.

<Present and next states of the damper of the selected

compartment>

< The damper of any compartment is in operation>

}

}

16

4) Thermistor temperature check mode

Setting

With the ice compartment door opened, press and simultaneously for 3 seconds until a “beep” sound is

heard. blinks.

With the door opened, press for 3 seconds.

Thermistor temperature check mode starts. Once this mode starts, it continues operating even if the door gets closed.

Thermistor temperature check mode is not available during demonstration mode, compressor's rotational speed change

mode, set temperature adjustment mode, error history display mode, or when child lock is effective.

Display during thermistor temperature check mode

During thermistor temperature check mode, blinks and lights up.

Displaying the thermistor temperature

The kind and temperature of thermistor is displayed on the operation panel.

The ambient temperature detected by thermistor may be a little different from the actual one due to the influence of the

temperature in the refrigerator.

a) Thermistor serial number

The room display on the display panel corresponds to the values representing thermistor types. The room display indicators

and their corresponding values (8/4/2/1) are shown in the tables below.

Each serial number is assigned to each compartment (thermistor), which is used in damper operation mode and

set temperature adjustment mode besides thermistor temperature mode. The sum of the corresponding values of the

lighting indicators is the thermistor’s serial number.

Room display

Corresponding

values

8

4

2

1

Serial number Assigned compartment Thermistor temperature check mode

1 Refrigerator compartment

2 Slide chilled compartment

3 Ice making compartment

4 Versa compartment

5 Vegetable compartment

6 Freezer compartment

7 Defrosting

8 Ice tray

9 Outdoor air

10 Deodorization

11 Thermopile

/ : SW operation is effective/ineffective

b) Thermistor temperature tens’ place

Usually, the , , and indicators that are used for temprature adjustment in the versa compartment represent

tens' place of the thermistor temprature.

Display of

// corresponds to the values, 4/2/1. The sum of the corresponding values of the blinking

indicators is the tens’ place of thermistor temperature.

Room display Corresponding values

4

2

1

c) Thermistor temperature signs

Plus and minus signs of thermistor temperature are indicated on the display which is usually used for mode.

Thermistor temperature signs

Lighting

-

Not lighting +

a) Thermistor

Serial number

b) Thermistor temperature

tens’ place

c) Thermistor temperature

± signs

d) Thermistor

temperature

ones’ place

“ ” “ ”

Lighting

Blinking

Display during

thermistor temperature

check mode

17

d) Thermistor temperature ones’ place

Ones’ place of thermistor temperature is indicated on the display part which is usually used for ice making setting.

Display of

/ / / corresponds to the values, 8/4/2/1. The sum of the corresponding values of lighting

indicators is the ones’ place of thermistor temperature.

Room display

Corresponding

values

8

4

2

1

e.g.) When freezer compartment thermistor is –25 ºC.

“ ” “ ”

Lighting

Blinking

Display during

thermistor temperature

check mode

a) Serial number

“6” : Freezer

b) Tens’ place

“2”

c) Sign

“-”

d) Ones’ place

“5” (=4+1)

Changing the thermistor on display

While thermistor temperature is on display, press .

Each press of the button makes a “beep” sound and changes the kind of thermistor.

Each thermistor is displayed using the serial numbers described in a) in numeric order repeatedly (1: refrigerator

compartment ~ 11: thermopile).

Refrigerator compartment slide chilled compartment ice making compartment versa compartment vegetable

compartment

freezer compartment defrosting ice tray outdoor air deodorization thermopile

When this mode is set, the display always starts from the refrigerator thermistor.

Slide chilled compartment thermistor can be selected; however, it is ineffective because slide chilled compartment thermistor

is not installed.

Deodorization can be selected; however, it is ineffective in thermistor temperature check mode.

Release

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”

sound is heard. The screen returns to the normal temperature display.

The function is automatically released in one hour.

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure

above for protection of the compressor.

18

5) Error history display mode

The errors occurred in the past can be observed as an error history. Use this mode when the actual problem of

the refrigerator is different from the error that was displayed at the service-call received.

Error history display mode offers two ways of display. One of the two is “history display mode,” which shows all

errors occurred in the past in numeric order of the error code; the other is “order of occurrence mode,” which

shows the newest 5 errors (at the maximum) from the newest to the older.

Error history display mode starts with “history display mode.”

Setting

With the ice compartment’s door opened, press and simultaneously for 3 seconds until a “beep” sound is

heard. blinks.

With the door opened, press

and simultaneously for 3 seconds until a “beep” sound is heard.

History error mode starts. Once this mode starts, it continues operating even if a door gets opened.

Display during error history display mode

During error history display mode, blinks and lights up.

Display of error history information.

a)

Mode display

b) Error code

Tens’ place

c) Error code

Ones’ place

“ ”

Lighting

Display during error

history display mode

Blinking

a) Mode display

Display the selected mode between “history display mode” and “order of occurrence mode.”

b) Error code tens’ place

It displays the tens’ place of error code.

It applies the same representative method as the error display of self-check.

c) Error code ones’ place

It displays the ones’ place of error code.

It applies the same representative method as the error display of self-check.

Switching over the mode

Press to select one of the error history display modes. Each press of the button makes a “beep” sound and

switches over between “history display mode” and “order of occurrence mode.”

Compartment Error history display mode

History display mode Display all errors occurred in the past in numeric order of the error code

Order of occurrence mode Display the newest 5 errors (at the maximum) from the newest to the older.

Tens’ place

Ones’ place

Error code

Pre-display

3sec.

0.5

sec.

Repetition

0.5

sec.

0.5

sec.

0.5

sec.

5sec. 5sec. 5sec.

E01 E13 E31

3sec.

Pre-display

Display method

Display method of the error code is the same as self check error display. (Refer to 5-2(3)); however, all indicators used for

the display of error code light up simultaneously for 3 seconds before the first error code is displayed (“pre-display”).

e.g.) When errors occurred in the following order:

fan motor error (E31) communication error of operation panel (E01) refrigerator thermistor error (E13)

• Display during history display mode

Errors are displayed in numeric order.

19

•Display during order of occurrence mode

Errors are displayed from the newest to the older.

Tens’ place

Ones’ place

Error code

Pre-display E13 E01 E31

3sec.

0.5

sec.

Repetition

0.5

sec.

0.5

sec.

0.5

sec.

5sec. 5sec. 5sec. 3sec.

Pre-display

When no error occurred in the past, error code is not displayed.

Check points and resetting the error history

Check and take appropriate measures according to the procedures as stated in 5-2(1).

Conduct self-check again to confirm there is no malfunction. (Make sure all connectors are connected properly and there is

no loose connection.)

Refer to “ Setting” above and activate the error history mode again. With the ice making compartment’s door opend,

press

for 3 seconds to reset error history. (Resetting the error history is completed.) If it is completed correctly,

no error code would be displayed.

Release

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”

sound is heard. The screen returns to the normal temperature display.

The function is automatically released in one hour.

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure

above for protection of the compressor.

a) Compartment

serial number

b) Set temperature

adjustment level

“ ” “ ”

Lighting

Display during set

temperature

adjustment mode

Blinking

6) Set temperature adjustment mode

Switch operation on the operation panel changes the set temperature in each compartment.

Setting

With the ice compartment door opened, press and simultaneously for 3 seconds until a “beep” sound is heard.

blinks.

With the door opened, press

and simultaneously for 3 seconds until a “beep” sound is heard.

Set temperature adjustment mode starts. Once this mode starts, it continues operating even if the door gets closed.

Display during set temperature adjustment mode

During set temperature adjustment mode, blinks and lights up.

Control state display of each compartment

20

a) Compartment serial number

Serial number of the selected compartment for set temperature adjustment is displayed on the part that are usually used

for room display.

Each serial number is assigned to each compartment that will be used in set temperature adjustment mode besides damper

operation mode and thermistor temperature check mode.

The sum of the corresponding values of the lighting indicators is the compartment serial number.

Room display

Corresponding

values

8

4

2

1

Serial number Assigned compartment Set temperature adjustment mode

1 Refrigerator compartment

2 Slide chilled compartment

3 Ice making compartment

4 Versa compartment

5 Vegetable compartment

6 Freezer compartment

7 Defrosting

8 Ice tray

9 Outdoor air

10 Deodorization

11 Thermopile

/ : SW operation is effective/ineffective

b) Set temperature adjustment level

Adjusting the set temperature

(1) Select the compartment with button.

(2) Each press of the button makes a “beep” sound and changes the compartment to adjust the set temperature.

Each compartment will be displayed using the serial numbers (1: Refrigerator compartment~ 6: Freezer

compartment) in numeric order repeatedly.

Refrigerator compartment slide chilled compartment ice making compartment versa compartment

vegetable compartment freezer compartment

Set temperature adjustment operation of slide chilled compartment is possible; however, it is ineffective because slide chilled

compartment thermistor is not installed.

(3) Select the adjustment level of set temperature with .

Each press of the button makes a “beep” sound and changes the adjustment level of set temperature.

There are 5 adjustment levels of set temperature (

2 & 0), and the selected level is displayed.

The indicator that lights up represents minus (−).

Adjustment level Temperature adjustment display

Change of the set

temperature

+2

About +2 ºC

+1 About +1 ºC

±0 No change

−1 About −1 ºC

−2

About −2 ºC

The changed adjustment levels are stored on the control board. If the control board is replaced, the updated information will be lost.

Release

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”

sound is heard. The screen returns to the normal temperature display.

The function is automatically released in one hour.

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure

above for protection of the compressor.

21

Door Buzzer System :

Door buzzer has been installed so that one will not forget to close the door.

• The buzzer rings in the following conditions:

1. When door is left open.

2. When refrigerator fan motor or box fan is abnormal.

1. The buzzer rings to inform the open door when the door of ice making compartment, refrigerator compartment, or freezer

compartment is left open for more than 1 minute.

• The buzzer rings every minute. After 5 minutes, the buzzer rings continuously.

• The buzzer will stop ringing as soon as the door is closed.

• When the buzzer does not stop even if all the doors are closed, the door switch may be abnormal.

The buzzer can be stopped by the following operations.

Perform the ice making test operation. (Refer to 5-2(1).)

(Note: If the test is conducted with water in the ice tray, water may fall into the ice storage box

because the tray is rolled over in the ice making operation.)

Synchronizing the buzzer sound, the indicator(s) of the compartment(s) with door(s) that are(is) left

open blink(s) to alert.

2. Buzzer sounds when a trouble is found in refrigerator fan motor or in box fan. The buzzer sounds

every time the door is closed until normal operation is obtained.

(Check the error code by following the steps in Specification of display in self-check result on page 22.)

Buzzer

1. When door is left open

Every 1 minute, for 4 minutes "Beep beep" 4 times

After 5 minutes “"Beep beep" continuously

2. Refrigerator fan motor or box fan is abnormal "Beep beep" 2 times

Interior LED :

• Interior LED inside the refrigerator compartment lights when the door of refrigerator compartment or ice making compart ment is open.

• When interior LED is lighted continuously for more than 60 minutes, it is turned off to prevent heating.

• The protection is released when doors of refrigerator compartment and ice making compartment are closed. Then, interior

LED will be lighted the next time at normal timing.

Blinks while

interlocking

with “beep, beep”

tone.

22

MR-E55R-C

MR-E60R-C

(1) Troubleshooting with self-check

This refrigerator has self-check feature to clarify and indicate where & what the trouble is.

You can perform operation checks and identify malfunction of electric or electronic parts.

Error history is recorded and can be displayed by the refrigerator.

5-2 FLOWCHART OF SELF-CHECK

Self-check

Error history mode (Refer to 5-1.(6)5))

Problem may recover automatically.

Perform the following if error is not displayed

before taking measures or the error which was informed

from user by telephone is not displayed.

Operate the ice-making test.

(Current displayed error: Refer to

in the table below.)

The display of ice making compartment setting will blink during the test.

Self-check

Plug the power cord into outlet.

(Current displayed error:

Refer to in the table below.)

Locate the trouble according to error

display. (See page 23-25)

Is error displayed?

Is error displayed?

Is error displayed?

Release error displayed

mode, and the self-check

is finished.

Release error display

mode and perform the

self-check again.

(go to )

Yes

No

Is error displayed?

Was more than one error

displayed during repair?

No

Yes

No

Yes

NoYes

Yes

Yes

During the ice-making

test mode, watch the

operation ice-maker

gear box and water

pump in refrigerator.

*Wait 10 minutes

before plugging

the cord once

it's unplugged.

(If the cord is

plugged in within

10 minutes, error

may be displayed.)

Unplug the power cord from outlet.

Repair /replace defective part(s)

according to error display.

Self-check is finished.

Set the error display mode.

Reset the error history.

(Refer to 5-1.(6)5))

Perform self-check

procedures through .

Perform error

history mode.

No

No

Was the error which was informed

from user by telephone displayed?

And were measures taken?

Perform error

history mode.

Note1: Self-check cannot detect abnormalities in the following parts.

See page 28-41 for troubleshooting.

Door switch

Motor damper

Heater (Water pipe/Vegetable compartment heater, etc.)

Water pump motor

Note2: If any abnormality is found when plugging the power cord,

compressor and fan motor are suspended for 10 minutes.

Note3: The alarm beeps when some abnormalities (motor-locked) have

occurred at the refrigerator fan motor or box fan restarts its normal

operation.

Note4: If any abnormality occurs in compressor's inverter circuit,

the compressor and the refrigerator fan motor stop for 10 minutes

(not only when plugging the power cord).

Self-check and error display method and operation

Release of self-check display mode

Self-check finishes automatically. Error cord display is automatically released 10 minutes later.

Operation method Display or self-check operation Display period OthersItem

Ice making test operation.

All items except (*6) listed

up on the table at page

25 will be checked.

1.Conduct the automatic ice making test.

(The display of ice making compartment

setting blinks)

2.When trouble is found, all error codes

are displayed.

3.When error is not found, nothing is

displayed.

For 10 minutes

after setting.

Self-check is not available

during child lock, cooking

timer, changing the rotational speed of compressor,

checking the temperature

of thermistor, damper operation and demonstration

modes.

Self-check is not available

during child lock, cooking

timer, changing the rotational speed of compressor,

checking the temperature

of thermistor, damper operation and demonstration

modes.

Self-check is not available

during demonstration

mode.

For 10 minutes

after power is

supplied.

For 1 hour after

setting, or until

mode is released.

1.When trouble is found, all troubles except

E50 ~ E55 are displayed.

2.When error is not found, nothing is

displayed.

1.When trouble is found, all troubles except

E50 ~ E57 are displayed.

2.When error is not found, nothing is

displayed.

Press the switch.

for 5 seconds.

(“Beep” is heard)

Plug the power

cord into outlet.

Refer to 5-1.(6)5)

Error history

display mode.

Power input.

All items except (*6) listed

up on the table at page

25 will be checked.

Error history

Self-check

(current displayed error)

Display error

history.

23

(3) Error display and trouble locating

1. Display details

After conducting the self-check referring to 5-2(1), flashes repetitively and the error code will be displayed and divided

into tens’ place and ones’ place if any.

When two or more errors occur, they are displayed alternately. The error whose code has smaller number has priority to be

displayed first. There are 0.5 seconds intervals between the error codes

(2) Timing in self-check

Trouble of Defrost heater : Self-check is conducted after defrosting.

(Make sure to confirm the display before unplugging the power cord

because it is automatically reset once the power cord is unplugged.)

Trouble of Ice maker : Press the switch on the panel for 5 seconds. (Ice making test mode)

The setting of ice making compartment blinks on display during the test operation.

Trouble of Fan motor : Open the door and then close it.

When abnormality is found in fan motor, buzzer sound is heard every time the door is closed.

Trouble of Inverter : Check the error when compressor starts up or is operating.

Trouble of Thermistor : Self-check is continuously working

For 2 minutes in self-check, a high-tone sound is heard due to the operation check of damper.

2. Check point and measures

b) Error code

Tens’ place

…

c) Error code

Ones’ place

…

Flashing

Room display

Corresponding

values

8

4

2

1

Ice making mode display Corresponding values

84

21

e.g.) In case the errors of refrigerator thermistor (E13) and ice maker gear box (E33) are occuring simultaneously.

Tens’ place

Ones’ place

Error code

0.5

sec.

0.5

sec.

0.5

sec.

5sec.

E13 E33 E13 E33

5sec. 5sec. 5sec.

Display

Error

code

Display

Trouble

Detecting method

(*3)

Check point Measures Control

Tens' place

Ones' place

Self-check

Testing

(*1) Ice maker is under testing

Error display

E

01

(*4)

Communication

error of

operation panel

When the following communication errors occur

between control board and

operation P.C. board:

• They transmit and receive

data that has nothing to

do with settings.

•

They cannot transmit

and

receive data each

other for about 2 seconds.

1. Connector CN10K, CN9S, CN5D on control board

5-pin wire to wire connector (hinge)

5-pin connector on operation P.C. board

Repair the

contact failure.

Keep the same operation

as the one before the

communication error has

occurred.

2. Trouble of control board and operation

P.C. board

Replace.

E

02

Communication

error of inverter

When abnormality is found in the

communication between refrigerator control circuit and inverter

control circuit in control board.

(When they do not transmit and

receive data for 10 seconds.)

Replace the

control board.

Compressor OFF.

E03

Trouble of

model judgement

When the model of

control board is different

from that of operation

P.C. board.

1. Check the model name of control board. Replace. Keep operating the unit,

and conduct error code

indication only.

2. Check the operation P.C. board. Replace.

E10

Trouble of ice

making tray

thermistor

When there is a short

or open circuit in the ice

making tray thermistor.

1. Connector CN9S on control board, ice gear

box 6-pin wire to wire connector, 8-pin wire

to wire connector

Repair the

contact failure.

When the compartment door

has been closed for 3 hours

and when freezer compartment thermistor is -10 or

less, ice-detecting operation

starts.

2. Check the resistance of thermistor. Replace.

E11

Trouble of

freezer compartment

thermistor

When there is a short

or open circuit in the

freezer compartment

thermistor.

1. Connector CN9S on control board,

4-pin wire to wire connector

Repair the

contact failure.

After 10 minutes off, the

compressor repeats 30minute ON and 20-minute

OFF.

2. Check the resistance of thermistor. Replace.

E12

Trouble of

defrost

thermistor

When there is a short

or open circuit in the

defrost thermistor.

1. Connector CN9S on control board,

2-pin wire to wire connector

Repair the

contact failure.

The defrost heater won’t

be turned ON.

2. Check the resistance of thermistor. Replace.

24

Display

Error

code

Display

Trouble

Detecting method

(*3)

Check point Measures Control

Tens' place

Ones' place

Self-check

Error display

E13

Trouble of

refrigerator

thermistor

When there is a short

or open circuit in the

refrigerator compartment

thermistor.

1. Connector CN9S on control board,

4-pin wire to wire connector

Repair the

contact failure.

Synchronize the open/

close status of R damper

with that of compressor

ON/OFF.

2. Check the resistance of thermistor. Replace.

E15

Trouble of

versa compartment thermistor

When there is a short or

open circuit in the versa

compartment thermistor.

1. Connector CN9S on control board,

6-pin wire to wire connector

Repair the

contact failure.

• When S-compartment

is used as “freezer”:

S-damper is open when

compressor is turned

on, S-damper is closed

when compressor is

turned off.

•

When S-compartment

is used as other than

“freezer”: S-damper

remains open for the

first 3 minutes and then

closed for the rest of

time.

S-compartment: Versa

(select) compartment.

2. Check the resistance of thermistor. Replace.

E16

Trouble of vegetable compartment thermistor

When there is a short

or open circuit in the

vegetable compartment

thermistor .

1. Connector CN9S on control board, 2-pin

wire to wire connector

Repair the

contact failure.

•

When R-damper is open,

V-heater is turned on.

• When R-damper is

closed, V-heater is

turned off.

2. Check the resistance of thermistor. Replace.

E17

Trouble of ice

making compartment

thermistor

When there is a short

or open circuit in the ice

making compartment

thermistor.

1. Connector CN9S on control board, 6-pin

wire to wire connector

Repair the

contact failure.

• When ice making compartment is used as

“refrigerator”, synchronize

I-damper with R-damper.

• When ice making compartment is used as “ice

making”, synchronize

I-damper with F-damper.

2. Check the resistance of thermistor. Replace.

E18

Trouble of

outside air

thermistor

When there is a short or

open circuit in the outside air thermistor.

Replace the

operation

P.C. board.

Compressor is activated

at “Speed-level 2.”

E23

Trouble of

thermopile

When there is a short or

open circuit in the outside air thermistor.

Relay connector 10 pin 2 positions.

Refer to "5-9.3 Failure diagnosis for the

thermopile (HIKARI i-see Sensor)".

Perform supercool freezing control in emergency

operation mode.

E30

Trouble of

defrost heater 1

(*6)

When defrosting is not

finished in 2 hours.

1. Connector CN2A on control board,

Defrost heater plug and receptacle,

1-pin wire to wire connector,

Thermal fuse 4-pin wire to wire connec-

tor

Repair the

contact failure.

The defrost heater is

stopped and if the next

defrosting finishes in 2

hours, the error code will

disappear.

2. Check the resistance of defrost heater. Replace.

3. Check the continuity of thermal fuse. Replace.

E31

Trouble of

refrigerator

fan motor

• When motor doesn’

t rotate even though

power is on.

• When the waveform,

which indicates the

rotation times of motor,

cannot be detected.

1. Connector CN5D on control board,

Refrigerator fan motor 4-pin wire to wire

connector

Repair the

contact failure.

•

3 minutes later, the refrig-

erator fan motor is reactivated to be checked.

• Until the fan motor gets

to operate correctly, the

buzzer sounds every

time the door is closed.

2. Check refrigerator fan motor operation. Replace.

E32

Trouble of box

fan

• When motor doesn’

t rotate even though

power is on.

• When the waveform,

which indicates the

rotation times of motor,

cannot be detected.

1. Connector CN4D, CN5D on control

board,

Box fan, 4-pin wire to wire con-

nector

Repair the

contact failure.

• 3 minutes later, the box

fan is reactivated to be

checked.

• Until the fan motor gets

to operate correctly, the

buzzer sounds every

time the door is closed.

2. Check box fan operation.

Replace.

E33

Trouble of ice

maker gear

box

When the gear box

operation is not finished

in 30 seconds.

1. Connector CN8K, CN10K on control board, ice gear box

6-pin wire to wire connector, 8-pin wire to wire connector

Repair the

contact failure.

100 minutes later, the

gear box is reactivated to

be checked again.

2. Ice gear box frozen point Replace.

3. Check the trouble of the ice gear box

with the ice making test operation.

Replace.

E34

Clogging of

refrigerant

pipe or trouble related to

compressor

(T0: Defrost thermistor

temperature at power

input, T1: Defrost thermistor temperature when

15 minutes have passed

from the power input)

•When the difference

between

T0 and T1 is T0

T1. (*5)

Check the compressor and the pipe. When cooling operation

returns to normal condition, the display of error

code disappears.

E41

Trouble of

solenoid

three-way

valve

When defrost thermistor

reads -10 or above in five

minutes after the compressor’s startup. (*5)

Connector CN4D on control board,

5-pin connector to three-way valve

Repair the

contact failure.

Check the operation of

solenoid three-way valve

and then open the valve.

25

*1 : The setting of ice making compartment will be displayed and blinks during or after ice making test operation.

*2 : This operation is called the recovery operation:

If the damper has not operated ever once during the compressor operation, make the damper operate when the compressor stops.

*3 : When the resistance is

, the circuit is deemed open-circuited.

When the resistance is 0 , the circuit is deemed short-circuited.

*4 : Once E01 is detected, other errors would be ignored and not displayed on the panel.

*5 : Characteristic value may change in order to improve the product.

*6 : The error codes E50 to E55 are not displayed even if those abnormalities occur at power input.

Therefore, be sure to perform ice making test operation in order to check if any abnormality indicated by these error codes occurs. (See page 22.)

*7 : If those errors still continue for 1 minute after the restart, E56 will be displayed again.

Display

Error

code

Display

Trouble

Detecting method

(*3)

Check point Measures Control

Tens' place

Ones' place

Self-check

Error display

E50

Trouble of

inverter circuit

• When there is any

trouble in the circuit