General-Purpose AC Servo

Functional safety unit

MODEL

MR-D30

INSTRUCTION MANUAL

E

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

CAUTION level may lead to a serious consequence according to conditions.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by

Indicates what must be done. For example, grounding is indicated by

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

.

.

A - 1

1. To prevent electric shock, note the following

WARNING

Before wiring or inspection, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and others.

Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp is off or

not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

During power-on or operation, do not open the front cover of the servo amplifier. Otherwise, it may cause

an electric shock.

Do not operate the servo amplifier with the front cover removed. High-voltage terminals and charging

area are exposed and you may get an electric shock.

Except for wiring and periodic inspection, do not remove the front cover of the servo amplifier even if the

power is off. The servo amplifier is charged and you may get an electric shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

Always connect a magnetic contactor between the power supply and the main circuit power supply

(L1/L2/L3) of the servo amplifier, in order to configure a circuit that shuts down the power supply on the

side of the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a

large current may cause smoke or a fire when the converter unit or servo amplifier malfunctions.

Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the main circuit power supply (L1/L2/L3) of the servo amplifier, in order to configure a circuit

that shuts down the power supply on the side of the servo amplifier’s power supply. If a molded-case

circuit breaker or fuse is not connected, continuous flow of a large current may cause smoke or a fire

when the servo amplifier malfunctions.

When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a regenerative

transistor malfunction or the like may overheat the regenerative resistor, causing smoke or a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier, servo motor, and MR-D30.

A - 2

3. To prevent injury, note the following

CAUTION

Only the power/signal specified in the Instruction Manual should be applied to each terminal. Otherwise,

it may cause an electric shock, fire, injury, etc.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, servo motor, etc., may be hot while the power is on

and for some time after power-off. Take safety measures such as providing covers to avoid accidentally

touching them by hands and parts such as cables.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the front cover, cables, or connectors when carrying the servo amplifier.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

The equipment must be installed in the specified direction.

Leave specified clearances between the servo amplifier and the cabinet walls or other equipment.

Do not install or operate the servo amplifier and MR-D30 which have been damaged or have any parts

missing.

Do not block the intake and exhaust areas of the servo amplifier and MR-D30. Otherwise, it may cause a

malfunction.

Do not drop or apply heavy impact on the servo amplifiers, servo motors, and MR-D30. Otherwise, it may

cause injury, malfunction, etc.

Do not strike the connector. Otherwise, it may cause a connection failure, malfunction, etc.

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Storage -20 °C to 65 °C (non-freezing)

Ambient

humidity

Storage

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude 2000 m or less above sea level

Vibration resistance 5.9 m/s2, at 10 Hz to 55 Hz (directions of X, Y and Z axes)

When the product has been stored for an extended period of time, contact your local sales office.

When handling the servo amplifier and MR-D30, be careful about the edged parts such as corners of

them.

Operation 0 °C to 55 °C (non-freezing)

Operation

5 %RH to 90 %RH (non-condensing)

A - 3

CAUTION

The servo amplifier and MR-D30 must be installed in a metal cabinet.

When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine are used

for disinfecting and protecting wooden packaging from insects, they cause malfunction when entering our

products. Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat method). Additionally,

disinfect and protect wood from insects before packing products.

To prevent a fire or injury in case of an earthquake or other natural disasters, securely install, mount, and

wire the servo motor in accordance with the Instruction Manual.

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Make sure to connect the cables and connectors by using the fixing screws and the locking mechanism.

Otherwise, the cables and connectors may be disconnected during operation.

Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF(-H)) on the servo

amplifier output side.

To avoid a malfunction, connect the wires to the correct phase terminals (U/V/W) of the servo amplifier

and servo motor.

Connect the servo amplifier power output (U/V/W) to the servo motor power input (U/V/W) directly. Do

not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

The surge absorbing diode installed to the DC relay for control output signals should be fitted in the

specified direction. Otherwise, the emergency stop and other protective circuits may not operate.

MR-D30

DO4NB

DO4PB

For sink output interface

24 V DC

RA

For source output interface

MR-D30

DO24VA/

DO24VB/

DO4PA

Control

output signal

24 V DC

RA

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo amplifier may cause a

malfunction.

Configure a circuit to turn off EM2 or EM1 when the main circuit power is turned off to prevent an

unexpected restart of the servo amplifier.

To prevent malfunction, avoid bundling power lines (input/output) and signal cables together or running

them in parallel to each other. Separate the power lines from the signal cables.

A - 4

(3) Test run and adjustment

CAUTION

When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it may

cause a malfunction, damage to the machine, or injury.

Before operation, check and adjust the parameter settings. Improper settings may cause some machines

to operate unexpectedly.

Never make a drastic adjustment or change to the parameter values as doing so will make the operation

unstable.

Do not get close to moving parts during the servo-on status.

(4) Usage

CAUTION

Provide an external emergency stop circuit to stop the operation and shut the power off immediately.

For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

Do not disassemble, repair, or modify the product. Otherwise, it may cause an electric shock, fire, injury,

etc. Disassembled, repaired, and/or modified products are not covered under warranty.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent a

sudden restart. Otherwise, it may cause an accident.

Use a noise filter, etc., to minimize the influence of electromagnetic interference. Electromagnetic

interference may affect the electronic equipment used near the servo amplifier.

Do not burn or destroy the servo amplifier. Doing so may generate a toxic gas.

Use the servo amplifier with the specified servo motor.

Wire options and peripheral equipment, etc. correctly in the specified combination. Otherwise, it may

cause an electric shock, fire, injury, etc.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as incorrect wiring, service life, and mechanical structure (e.g. where a ball screw and

the servo motor are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft.

To ensure safety, install a stopper on the machine side.

If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by an

external force. Otherwise, it may cause a fire.

A - 5

(5) Corrective actions

CAUTION

Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

If it is assumed that a power failure, machine stoppage, or product malfunction may result in a hazardous

situation, use a servo motor with an electromagnetic brake or provide an external brake system for

holding purpose to prevent such hazard.

Configure an electromagnetic brake circuit which is interlocked with an external emergency stop switch.

Use ALM (Malfunction) or SBCS

(SBC output) to open the contacts.

Contacts must be opened with

the emergency stop switch.

Servo motor

B

Electromagnetic brake

When an alarm occurs, eliminate its cause, ensure safety, and deactivate the alarm to restart operation.

If the molded-case circuit breaker or fuse is activated, be sure to remove the cause and secure safety

before switching the power on. If necessary, replace the servo amplifier and recheck the wiring.

Otherwise, it may cause smoke, fire, or an electric shock.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

After an earthquake or other natural disasters, ensure safety by checking the conditions of the

installation, mounting, wiring, and equipment before switching the power on to prevent an electric shock,

injury, or fire.

RA

24 V DC

(6) Maintenance, inspection and parts replacement

CAUTION

Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

It is recommended that the servo amplifier be replaced every 10 years when it is used in general

environment.

When using a servo amplifier whose power has not been turned on for a long time, contact your local

sales office.

Do not touch the lead sections such as ICs or the connector contacts.

Do not place the unit on metal that may cause a power leakage or wood, plastic or vinyl that may cause

static electricity buildup.

The parameters of MR-D30 are protected by passwords to prevent incorrect settings. The parameters of

MR-D30 which are returned for fixing/investigation will be initialized. The parameters and other settings

need to be set again.

A - 6

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

(8) Conditions of use for the product

MR-D30 complies with a safety standard, but this fact does not guarantee that MR-D30 will be free from

any malfunction or failure. The user of this product shall comply with any and all applicable safety

standard, regulation or law and take appropriate safety measures for the system in which the product is

installed or used and shall take the second or third safety measures other than the product. Our

company is not liable for damages that could have been prevented by compliance with any applicable

safety standard, regulation or law.

Our company prohibits the use of Products with or in any application involving, and we shall not be liable

for a default, a liability for defect warranty, a quality assurance, negligence or other tort and a product

liability in these applications.

(1) Power plants

(2) Trains, railway systems, airplanes, airline operations, and other transportation systems

(3) Hospitals, medical care, dialysis and life support facilities or equipment

(4) Amusement equipment

(5) Incineration and fuel devices

(6) Handling of nuclear or hazardous materials or chemicals

(7) Mining and drilling

(8) Other applications where the level of risk to human life, health or property are elevated.

A - 7

DISPOSAL OF WASTE

Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and

regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, MR-D30 may malfunction when the EEP-ROM

reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

«About the manual»

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare

them to use the servo safely.

Servo amplifiers and drive units are written as servo amplifiers in this Instruction Manual under certain

circumstances, unless otherwise stated.

Relevant manuals

Manual name Manual No.

MELSERVO MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual (Note 5) SH(NA)030106ENG

MELSERVO MR-J4-_A_(-RJ) Servo Amplifier Instruction Manual (Note 6) SH(NA)030107ENG

MELSERVO MR-J4-_GF_(-RJ) Servo Amplifier Instruction Manual (Motion Mode) (Note 8, 9) SH(NA)030218ENG

MELSERVO MR-J4-_GF_(-RJ) Servo Amplifier Instruction Manual (I/O Mode) (Note 9) SH(NA)030221ENG

MELSERVO MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Amplifier Instruction Manual (Note 7) SH(NA)030153ENG

MELSERVO MR-J4-DU_B4-RJ100 Drive Unit Instruction Manual (Note 10) SH(NA)030280ENG

MR-J4 Servo Amplifier Instruction Manual (Troubleshooting) SH(NA)030109ENG

MELSERVO Servo Motor Instruction Manual (Vol. 3) (Note 1) SH(NA)030113ENG

MELSERVO Linear Servo Motor Instruction Manual (Note 2) SH(NA)030110ENG

MELSERVO Direct Drive Motor Instruction Manual (Note 3) SH(NA)030112ENG

MELSERVO Linear Encoder Instruction Manual (Note 2, 4) SH(NA)030111ENG

MELSERVO EMC Installation Guidelines IB(NA)67310ENG

MELSEC iQ-R Safety Application Guide SH(NA)081538ENG

«Cables used for wiring»

Q173D(S)CPU/Q172D(S)CPU Motion Controller Programming Manual (Safety Observation) IB(NA)0300183

Note 1. It is necessary for using a rotary servo motor.

2. It is necessary for using a linear servo motor.

3. It is necessary for using a direct drive motor.

4. It is necessary for using a fully closed loop system.

5. It is necessary for using an MR-J4-_B_(-RJ) servo amplifier.

6. It is necessary for using an MR-J4-_A_(-RJ) servo amplifier.

7. It is necessary for using an MR-J4-DU_-RJ drive unit.

8. It is necessary for using an MR-J4-_GF_-RJ servo amplifier in the motion mode.

9. It is necessary for using an MR-J4-_GF_-RJ servo amplifier in the I/O mode.

10. It is necessary for using an MR-J4-DU_B4-RJ100 drive unit.

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 °C.

A - 8

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-28

1.1 Summary ........................................................................................................................................... 1- 1

1.2 Outline of safety observation function .............................................................................................. 1- 5

1.3 Function block diagram ..................................................................................................................... 1- 6

1.3.1 MR-J4-_GF_-RJ ......................................................................................................................... 1- 6

1.3.2 MR-J4-_B_-RJ ........................................................................................................................... 1- 8

1.3.3 MR-J4-_A_-RJ .......................................................................................................................... 1-10

1.3.4 MR-J4-DU_B_-RJ ..................................................................................................................... 1-11

1.3.5 MR-J4-DU_A_-RJ ..................................................................................................................... 1-13

1.4 System configuration ....................................................................................................................... 1-14

1.4.1 MR-J4-_GF_-RJ ........................................................................................................................ 1-14

1.4.2 MR-J4-_B_-RJ/MR-J4-DU_B-RJ .............................................................................................. 1-16

1.4.3 MR-J4-_A_-RJ/MR-J4-DU_A-RJ .............................................................................................. 1-18

1.5 Standard specifications .................................................................................................................... 1-19

1.6 Function list ...................................................................................................................................... 1-21

1.7 Combinations with servo amplifiers and servo motors .................................................................... 1-21

1.8 Rating plate ...................................................................................................................................... 1-26

1.9 Risk assessments ............................................................................................................................ 1-26

1.9.1 Common residual risks in each function ................................................................................... 1-26

1.9.2 Residual risks in each function ................................................................................................. 1-27

2. INSTALLATION 2- 1 to 2- 8

2.1 Installation direction and clearances ................................................................................................ 2- 2

2.2 Keep out foreign materials ................................................................................................................ 2- 4

2.3 Inspection items ................................................................................................................................ 2- 4

2.4 Parts having service life .................................................................................................................... 2- 4

2.5 Maintenance ..................................................................................................................................... 2- 4

2.6 Attachment and detachment of MR-D30 .......................................................................................... 2- 5

3. SIGNALS AND WIRING 3- 1 to 3-22

3.1 Connectors and pin assignment ....................................................................................................... 3- 3

3.2 I/O signal connection example .......................................................................................................... 3- 4

3.2.1 Input signal ................................................................................................................................. 3- 4

3.2.2 Output signal .............................................................................................................................. 3- 5

3.3 Connection of I/O interface ............................................................................................................... 3- 6

3.3.1 Source output ............................................................................................................................. 3- 6

3.3.2 Sink input .................................................................................................................................... 3- 7

3.3.3 DO1_ to DO3_ source output .................................................................................................... 3- 9

3.3.4 DO4NA source output and DO4NB sink output ......................................................................... 3- 9

3.4 Wiring for SBC output ...................................................................................................................... 3-10

3.5 Noise reduction techniques ............................................................................................................. 3-11

3.6 Signal explanations .......................................................................................................................... 3-13

3.6.1 Input device ............................................................................................................................... 3-13

3.6.2 Output device ............................................................................................................................ 3-14

3.6.3 Power supply ............................................................................................................................. 3-15

1

3.7 Wiring method of CN10A/CN10B connectors.................................................................................. 3-16

3.8 Connection example with other devices .......................................................................................... 3-17

3.8.1 MR-J4-_GF_-RJ ........................................................................................................................ 3-17

3.8.2 MR-J4-_B_-RJ/MR-J4-DU_B_-RJ ............................................................................................ 3-19

3.8.3 MR-J4-_A_-RJ/MR-J4-DU_A_-RJ ............................................................................................ 3-21

3.9 Power-on sequence ......................................................................................................................... 3-22

4. SAFETY OBSERVATION FUNCTION 4- 1 to 4-46

4.1 Achievable safety level ..................................................................................................................... 4- 2

4.2 Safety diagnosis function list ............................................................................................................ 4- 3

4.3 Startup .............................................................................................................................................. 4- 4

4.3.1 Switching power on for the first time .......................................................................................... 4- 4

4.3.2 Parameter ................................................................................................................................... 4- 6

4.3.3 Mandatory parameter setting ..................................................................................................... 4- 8

4.3.4 Test operation ............................................................................................................................ 4- 9

4.3.5 Unit replacement ........................................................................................................................ 4- 9

4.4 I/O function ........................................................................................................................................ 4- 9

4.4.1 Input device ................................................................................................................................ 4- 9

4.4.2 Output device ............................................................................................................................ 4-18

4.4.3 Safety observation function control by input device .................................................................. 4-21

4.4.4 Servo motor with functional safety ............................................................................................ 4-27

4.4.5 Position feedback fixing diagnosis function .............................................................................. 4-27

4.5 Safety observation function ............................................................................................................. 4-28

4.5.1 STO function ............................................................................................................................. 4-28

4.5.2 SS1 function .............................................................................................................................. 4-30

4.5.3 SS2/SOS function ..................................................................................................................... 4-34

4.5.4 SLS function .............................................................................................................................. 4-38

4.5.5 SSM function ............................................................................................................................. 4-41

4.5.6 SBC function ............................................................................................................................. 4-42

4.5.7 Status monitor (SM) function ..................................................................................................... 4-43

4.5.8 Multiple inputs of safety observation functional operation commands ..................................... 4-43

4.5.9 Simultaneous operation of STO and SS1 functions ................................................................. 4-44

4.5.10 At alarm occurrence ................................................................................................................ 4-44

5. PARAMETERS 5- 1 to 5-22

5.1 Parameter list .................................................................................................................................... 5- 1

5.1.1 Safety observation function parameters 1 ([Pr. PSA_ _ ]) ......................................................... 5- 2

5.1.2 Network parameters ([Pr. PSC_ _ ]) .......................................................................................... 5- 3

5.1.3 Safety I/O device parameters ([Pr. PSD_ _ ]) ............................................................................ 5- 5

5.2 Detailed list of parameters ................................................................................................................ 5- 7

5.2.1 Safety observation function parameters 1 ([Pr. PSA_ _ ]) ......................................................... 5- 7

5.2.2 Network parameters ([Pr. PSC_ _ ]) ......................................................................................... 5-10

5.2.3 Safety I/O device parameters ([Pr. PSD_ _ ]) ........................................................................... 5-13

6. DISPLAY 6- 1 to 6- 2

2

7. TROUBLESHOOTING 7- 1 to 7- 4

7.1 Alarm and warning list ...................................................................................................................... 7- 1

7.2 Combinations of the parameters that trigger [AL. 7A.3 Parameter combination error

(safety observation function)] ............................................................................................................ 7- 4

8. DIMENSIONS 8- 1 to 8- 2

8.1 MR-D30 functional safety unit ........................................................................................................... 8- 1

8.2 When an MR-D30 is attached to a servo amplifier ........................................................................... 8- 2

APPENDIX App. - 1 to App. - 1

App. 1 EC declaration of conformity ................................................................................................. App.- 1

3

MEMO

4

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

POINT

Servo amplifiers and drive units are written as servo amplifiers in this Instruction

Manual under certain circumstances, unless otherwise stated.

If the combination of MR-D30 and servo amplifier is wrong, "ERROR" will turn

on.

The simple cam function cannot be used with a servo amplifier on which MRD30 is mounted.

When replacing MR-D30 with one having a different software version, check that

the software version of MR-D30 supports the safety observation functions to

prevent them from operating unintentionally. As necessary, disable the safety

observation function.

This Instruction Manual only describes the functions of MR-D30. For servo amplifiers, refer to each servo

amplifier instruction manual.

You can extend the safety observation function by using MR-D30 with a compatible servo amplifier or drive

unit. However, which extension you can use depends on software version. The safety observation function

cannot be used other than the following combinations. "ERROR" on the MR-D30 display will turn on with

other combinations.

(1) Compatibility of servo amplifiers

(a) MR-J4-_GF_-RJ

1) Safety observation function control by input device

MR-D30

software version

A1 or later A3 or later

Servo amplifier

software version

2) Safety observation function control by network

MR-D30

software version

A2 or later A3 or later

Servo amplifier

software version

Safety observation function

STO/SS1/SBC/SLS/SSM/SOS/

SS2/SM

Safety observation function

STO/SS1/SBC/SLS/SSM/SOS/

SS2/SM

Servo motor

with functional

safety

HG-KR_W0C

HG-SR_W0C

HG-JR_W0C

Servo motor

with functional

safety

HG-KR_W0C

HG-SR_W0C

HG-JR_W0C

Servo amplifier

MR-J4-_GF_-RJ

Servo amplifier

MR-J4-_GF_-RJ

1 - 1

1. FUNCTIONS AND CONFIGURATION

(b) MR-J4-(DU)_B_-RJ/MR-J4-(DU)_A_-RJ

MR-D30

software version

A0 B3 or later STO/SS1/SBC/SLS/SSM/SM Not compatible MR-J4-_B_-RJ

A1 or later

Servo amplifier

software version

B3/B4 STO/SS1/SBC/SLS/SSM Not compatible MR-J4-_B_-RJ

B5 or later

Safety observation function

STO/SS1/SBC/SLS/SSM/SOS/

SS2/SM

Note. MR-J4-(DU)_A_-RJ manufactured in November, 2014 or later is supported.

(c) MR-J4-DU_B4-RJ100

MR-D30

software version

A2 or later A3 or later

Servo amplifier

software version

Safety observation function

STO/SS1/SBC/SLS/SSM/SOS/SS2/

SM

(2) Characteristics of functions

(a) When using the safety observation function with wiring to the CN10_ connector of MR-D30 (Safety

observation function control by input device)

By combination of MR-D30 functional safety unit, servo amplifier compatible with MR-D30, and servo

motor with functional safety, the safety observation functions (STO/SS1/SBC/SLS/SSM/SOS/SS2)

compatible with Category 4, PL e, SIL 3 can be used. When a servo motor with functional safety is

not used, the SOS/SS2 functions are not available. The SLS/SSM functions are compatible with

Category 3, PL d, SIL 2.

Servo motor

with functional

safety

HG-KR_W0C

HG-SR_W0C

HG-JR_W0C

Servo motor

with functional

safety

HG-JR_W0C MR-J4-DU_B4-RJ100

Servo amplifier

MR-J4-_B_-RJ

MR-J4-_A_-RJ (Note)

MR-J4-DU_B_-RJ

MR-J4-DU_A_-RJ (Note)

Servo amplifier

1 - 2

1. FUNCTIONS AND CONFIGURATION

A

A

(b) When using the safety observation function through SSCNET III/H or CC-Link IE Field Network

(Safety observation function control by network)

The safety observation function is available by combining MR-D30 with MR-J4-B_-RJ through

SSCNET III/H, or with MR-J4-GF_-RJ through CC-Link IE Field Network. This ensures reduced

wiring. (Refer to table 1.1.)

Table 1.1 Compatibility of safety observation function

Safety observation function

(CC-Link IE Field Network) (Note 9)

Compatible controller

STO

SS1

SBC

SLS (Note 2)

SSM (Note 2)

SS2 (Note 2, 4)

SOS (Note 2, 4)

control by network

Safety Programmable Controller

R_SFCPU (Note 5)

+

Safety function module

R6SFM (Note 7)

+

Simple motion module

RD77GF_ (Note 6)

Category 4, PL e, SIL 3 (Note 1)

Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3)

Category 4, PL e, SIL 3 (Note 1) Category 4, PL e, SIL 3 (Note 1)

Note 1. To meet Category 4, PL e, SIL 3 for input signals, a diagnosis using test pulses is required. Refer to section 4.1 for detailed

conditions.

2. Linear servo system, direct drive servo system, and fully closed loop system are not compatible with SLS, SSM, SS2, and

SOS. Table 1.2 shows safety observation functions compatible with each system.

3. To meet Category 4, PL e, SIL 3, a servo motor with functional safety is required.

4. To enable SS2 and SOS, a servo motor with functional safety is required.

5.

6.

7. Safety function unit with Manufacturer Software Version 07 or later is required.

8. The combination of MR-D30 and MR-J4-_GF_-RJ is supported by MR Configurator2 with software version 1.60N or later. The

9. This is supported by GX Works3 with software version 1.035M or later and MR Configurator2 with software version 1.60N or

10. This is supported by MT Works2 with software version 1.100E or later.

safety programmable controller with software version 07 or later is necessary.

simple Motion module with software version 05 or later is necessary.

combination of MR-D30 and MR-J4-_B_-RJ is supported by MR Configurator2 with software version 1.25B or later. The

combination of MR-D30 and MR-J4-_A_-RJ is supported by MR Configurator2 with software version 1.34L or later.

later.

Safety observation function

control by network

(SSCNET III/H) (Note 10)

Drive safety integrated motion

controller

Q173DSCPU

Q172DSCPU

+

Safety signal module

Q173DSXY

Category 3, PL d, SIL 2

Safety observation function

control by input device (Note 8)

Category 4, PL e, SIL 3 (Note 1)

Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3)

1 - 3

1. FUNCTIONS AND CONFIGURATION

y

Table 1.2 Safety observation functions

compatible with each system.

System (Note)

Full.

Servo motor

functional safety

Servo motor with

STO

SS1

SBC

SLS

SSM

SS2

SOS

: Usable

Note. The systems indicate the following.

Servo motor with functional safety: Semi closed loop system using the servo motor

with functional safet

Servo motor: Semi closed loop system using the servo motor

Full.: Fully closed loop system using the servo motor or servo motor with functional

safety

Lin.: Linear servo motor system

DD: Direct drive motor system

Lin.

DD

1 - 4

1. FUNCTIONS AND CONFIGURATION

1.2 Outline of safety observation function

The following functions can be used by MR-D30 functional safety unit.

(1) STO (Safe torque off)

Shuts off servo motor drive energy electronically with based on an input signal from an external device

(secondary-side output shut-off). This corresponds to stop category 0 of IEC/EN 60204-1.

(2) SS1 (Safe stop 1)

Starts deceleration based on an input signal from an external device (EM2). After a specified time for the

check of stop, the STO function will be activated (SS1). This corresponds to stop category 1 of IEC/EN

60204-1.

(3) SS2 (Safe stop 2)

Starts deceleration based on an input signal from an external device (EM2). After a specified time for the

check of stop, the SOS function will be activated (SS2). This corresponds to stop category 2 of IEC/EN

60204-1.

(4) SOS (Safe operating stop)

Monitors whether the servo motor stops within the prescribed range for the stop position. The power is

supplied to the servo motor.

(5) SLS (Safely-limited speed)

Observes whether the speed is within a regulated speed limit value. When the speed is over a specified

speed, energy will be shut off by STO.

(6) SSM (Safe speed monitor)

Outputs a signal when the servo motor speed is within a regulated speed.

(7) SBC (Safe brake control)

Outputs a signal for an external brake control.

(8) Status monitor (SM: Status monitor)

Outputs a signal for the safety observation function status. This is an original function of the functional

safety unit, not the one defined in IEC/EN 61800-5-2.

1 - 5

1. FUNCTIONS AND CONFIGURATION

r

s

y

r

1.3 Function block diagram

1.3.1 MR-J4-_GF_-RJ

(1) Safety observation function control by input device

The following block diagram shows an operation of the safety observation function using input devices

assigned to pins of the CN10A and CN10B connectors. By diagnosis of input signals, the servo amplifier

complies with safety level Category 4, PL e, SIL 3.

Servo amplifie

Servo motor

MCCB MC L1

Powe

uppl

Not used

(Remove the short-circuit

connector.)

USB

CC-Link IE

Field Network

CC-Link IE

Field Network

Controller

or

CC-Link IE Field

Network device

Controller

or

CC-Link IE Field

Network device

Parameter setting

Input signal

(Note)

L2

L3

L11

L21

CN8CN1ACN1BCN5

Functional safety

unit

CN10ACN10B

Control circuit

power supply

Safety observation

function

Processing part 1

Input device

control

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output device

control

U

V

W

CN2

CN10ACN10B

24 V DC

RA

U

V

W

B1

B

B2

Encoder

Output signal

(Note)

M

Electromagnetic

brake

Safety observation

function

Processing part 2

Safety observation

function

Input device

control

Self-check

Parameter

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Output device

control

Note. Safety switch, safety relay, etc.

1 - 6

1. FUNCTIONS AND CONFIGURATION

(2) Safety observation function control by network

The following block diagram shows an operation of the safety observation function through CC-Link IE

Field Network. The electric wiring can be omitted.

Servo amplifier

Servo motor

MCCB MC L1

Power

supply

Not used

Controller

or

CC-Link IE

Field Network device

iQ-R series safety remote I/O module

input module

NZ2GFSS2-32D

iQ-R series safety CPU

RD77GF_

(Remove the short-circuit

connector.)

CC-Link IE Field

Network device

or cap

USB

Parameter setting

Main

Input signal

(Note)

Safety

function

module

R6SFM

CC-Link IE

Field Network

CC-Link IE

Field Network

Extension

output module

NZ2EXSS2-8TE

Output signal

(Note)

iQ-R

series

safety CPU

L2

L3

L11

L21

CN8

CN1ACN1BCN5

Functional safety

unit

Control circuit

power supply

Safety observation

function

Processing part 1

Self-check

Parameter

Safety observation

function

Processing part 2

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output device

control

Output device

control

24 V DC

RA

U

V

M

W

B1

Electromagnetic

B

B2

brake

Encoder

U

V

W

CN2

Output signal

CN10A

CN10B

(Note)

Note. Safety switch, safety relay, etc.

1 - 7

1. FUNCTIONS AND CONFIGURATION

1.3.2 MR-J4-_B_-RJ

(1) Safety observation function control by input device

The following block diagram shows an operation of the safety observation function using input devices

assigned to pins of the CN10A and CN10B connectors. By diagnosis of input signals, the servo amplifier

complies with safety level Category 4, PL e, SIL 3.

Servo amplifier Servo motor

MCCB MC

Power

supply

Not used

(Remove the short-circuit

connector.)

Controller

or servo

amplifier

Servo

amplifier

USB

Parameter setting

Input signal

(Note)

SSCNET III/H

SSCNET III/H

L1

L2

L3

L11

L21

CN8CN1ACN1BCN5

Functional safety

unit

CN10ACN10B

Control circuit

power supply

Safety observation

function

processing part 1

Input device

control

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output

device

control

U

V

W

CN2

CN10ACN10B

24 V DC

RA

U

V

W

B1

B

B2

Encoder

Output signal

(Note)

M

Electromagnetic

brake

Note. Safety switch, safety relay, etc.

Safety observation

function

processing part 2

Input device

control

Self-check

Parameter

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

1 - 8

Output

device

control

1. FUNCTIONS AND CONFIGURATION

(2) Safety observation function control by network

The following block diagram shows an operation of the safety observation function through SSCNET

III/H. The electric wiring can be omitted.

Servo amplifier

Servo motor

MCCB MC L1

Power

supply

Not used

(Remove the short-circuit

Servo amplifier or

controller

connector.)

SSCNET III/H

Servo

amplifier

or cap

Parameter setting

CPU (iQ platform compatible)

Q17_DSCPU

Motion controller safety signal

unit Q173DSXY

Input signal

(Note 1)

USB

SSCNET III/H

Programmable

controller CPU

(iQ platform

compatible)

Output signal

(Note 2)

(Note 1)

L2

L3

L11

L21

CN8

CN1ACN1BCN5

Functional safety

unit

Control circuit

power supply

Safety observation

function

processing part 1

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output

device

control

U

V

W

CN2

CN10A

24 V DC

RA

U

V

W

B1

B2

Output signal

M

Electromagnetic

B

brake

Encoder

(Note 1)

Safety observation

function

processing part 2

Self-check

Parameter

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Output

device

control

CN10B

Note 1. Safety switch, safety relay, etc.

2. The safety observation function is certified by Certification Body only by combination of Q17_DSCPU/Q17_DSXY and

QnUD(E)(H)CPU programmable controller.

1 - 9

1. FUNCTIONS AND CONFIGURATION

r

1.3.3 MR-J4-_A_-RJ

The following block diagram shows an operation of the safety observation function using input devices

assigned to pins of the CN10A and CN10B connectors. By diagnosis of input signals, the servo amplifier

complies with safety level Category 4, PL e, SIL 3.

Servo amplifie

Servo motor

MCCB MC

Power

supply

Not used

(Remove the short-circuit

connector.)

DIO control

Controller

RS-422

USB

Parameter setting

Input signal

(Note)

L1

L2

L3

L11

L21

CN8CN5

CN1CN3

Functional safety

unit

CN10ACN10B

Control circuit

power supply

Safety observation

function

Processing part 1

Input device

control

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output device

control

U

V

W

CN2

CN10ACN10B

24 V DC

RA

U

V

W

B1

B

B2

Encoder

Output signal

(Note)

M

Electromagnetic

brake

Note. Safety switch, safety relay, etc.

Safety observation

function

Processing part 2

Input device

control

Self-check

Parameter

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

1 - 10

Output device

control

1. FUNCTIONS AND CONFIGURATION

T

T

1.3.4 MR-J4-DU_B_-RJ

(1) Safety observation function control by input device

The following block diagram shows an operation of the safety observation function using input devices

assigned to pins of the CN10A and CN10B connectors. By diagnosis of input signals, the servo amplifier

complies with safety level Category 4, PL e, SIL 3.

Drive unit

Servo motor

o L+ of converter unit

o L- of converter unit

Power

supply

Not used

(Remove the short-circuit

connector.)

Controller

or servo

amplifier

Servo

amplifier

USB

Parameter setting

Input signal

(Note)

SSCNET III/H

SSCNET III/H

L+

L-

L11

L21

CN8CN1ACN1BCN5

Functional safety

unit

CN10ACN10B

Control circuit

power supply

Safety observation

function

processing part 1

Input device

control

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output

device control

24 V DC

RA

U

V

M

W

B1

Electromagnetic

B

B2

brake

Encoder

U

V

W

CN2

CN10ACN10B

Output signal

(Note)

Safety observation

function

processing part 2

Safety observation

function

Input device

control

Self-check

Parameter

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Output

device control

Note. Safety switch, safety relay, etc.

1 - 11

1. FUNCTIONS AND CONFIGURATION

(2) Safety observation function control by network

The following block diagram shows an operation of the safety observation function through SSCNET

III/H. The electric wiring can be omitted.

Drive unit

Servo motor

To L+ of converter unit

To L- of converter unit

Power

supply

Not used

(Remove the short-circuit

Servo amplifier or

controller

connector.)

SSCNET III/H

Servo

amplifier

or cap

Parameter setting

CPU (iQ platform compatible)

Q17_DSCPU

Motion controller safety signal

unit Q173DSXY

Input signal

(Note)

USB

SSCNET III/H

Programmable

controller CPU

(iQ plat form

compatible)

Output signal

(Note 2)

(Note)

L+

L-

L11

L21

CN8

CN1ACN1BCN5

Functional safety

unit

Control circuit

power supply

Safety observation

function

processing part 1

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output

device control

U

V

W

CN2

CN10A

24 V DC

RA

U

V

W

B1

B2

Output signal

M

Electromagnetic

B

brake

Encoder

(Note 1)

Safety observation

function

processing part 2

Safety observation

function

STO function

SS1 function

Self-check

Parameter

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Output

device control

CN10B

Note 1. Safety switch, safety relay, etc.

2. The safety observation function is certified by Certification Body only by combination of Q17_DSCPU/Q17_DSXY and

QnUD(E)(H)CPU programmable controller.

1 - 12

1. FUNCTIONS AND CONFIGURATION

T

T

1.3.5 MR-J4-DU_A_-RJ

The following block diagram shows an operation of the safety observation function using input devices

assigned to pins of the CN10A and CN10B connectors. By diagnosis of input signals, the servo amplifier

complies with safety level Category 4, PL e, SIL 3.

Drive unit

Servo motor

o L+ of converter unit

o L- of converter unit

Power

supply

Not used

(Remove the short-circuit

connector.)

DIO control

Controller

RS-422

USB

Parameter setting

Input signal

(Note)

L+

L-

L11

L21

CN8CN5

CN1CN3

Functional safety

unit

CN10ACN10B

Control circuit

power supply

Safety observation

function

processing part 1

Input device

control

Self-check

Parameter

CN9

CN90

Safety observation

function

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Gate circuit

Control

CN7

CN70

Output

device control

U

V

W

CN2

CN10ACN10B

24 V DC

RA

U

V

W

B1

B

B2

Encoder

Output signal

(Note)

M

Electromagnetic

brake

Safety observation

function

processing part 2

Safety observation

function

Input device

control

Self-check

Parameter

STO function

SS1 function

SS2 function

SOS function

SLS function

SSM function

SBC function

SM function

Output

device control

Note. Safety switch, safety relay, etc.

1 - 13

1. FUNCTIONS AND CONFIGURATION

1.4 System configuration

For wirings other than in diagram, refer to each servo amplifier instruction manual.

1.4.1 MR-J4-_GF_-RJ

(1) Safety observation function control by input device

POINT

Remove the short-circuit connector on CN8.

Personal

MR Configurator2

computer

MR-J4-_GF_-RJ MR-D30

CN5

Junction terminal

block

CC-Link IE

Field Network

Field Network

Not used

(Remove the short-circuit

connector.)

CN1A

CN1BCC-Link IE

CN8

CN3

CN2

CN10A/CN10B

24 V DC power

supply for IO

Safety signal

U

V

W

Safety programmable

controller

Emergency stop

switch

Light curtain

1 - 14

1. FUNCTIONS AND CONFIGURATION

0

(2) Safety observation function control by network

POINT

Remove the short-circuit connector on CN8.

MR Configurator2

Personal

computer

MR-J4-_GF_-RJ MR-D3

Emergency stop

switch

Light curtain

R_SFCPU + R6SFM + RD77GF_

R_SFCPU + R6SFM + RD77GF_

Junction terminal

block

Safety signal

CC-Link IE

Field Network

CC-Link IE

Field Network

Not used

(Remove the short-circuit

connector.)

CN1A

CN1B

CN5

CN8

CN3

CN2

U

V

W

1 - 15

1. FUNCTIONS AND CONFIGURATION

1.4.2 MR-J4-_B_-RJ/MR-J4-DU_B-RJ

(1) Safety observation function control by input device

POINT

Remove the short-circuit connector on CN8.

Personal

MR Configurator2

computer

MR-J4-_B_-RJ MR-D30

CN5

Junction terminal

block

Not used

(Remove the short-circuit

connector.)

Servo system controller

or previous servo amplifier

CN1B

Next servo amplifier

CN1A or cap

CN1A

CN1B

CN3

CN8

CN2

CN10A/CN10B

24 V DC power

supply for IO

Safety signal

U

V

W

Safety programmable

controller

Emergency stop

switch

Light curtain

1 - 16

1. FUNCTIONS AND CONFIGURATION

0

(2) Safety observation function control by network

POINT

Remove the short-circuit connector on CN8.

MR Configurator2

Personal

computer

MR-J4-_B_-RJ MR-D3

Emergency stop

switch

Light curtain

Q17_DSCPU + Q173DSXY

Junction

terminal

block

Safety signal

Servo system controller

or previous servo amplifier

CN1B

Next servo amplifier

CN1A or cap

Not used

(Remove the short-circuit

connector.)

CN1A

CN2B

CN5

CN3

CN8

CN2

U

V

W

1 - 17

1. FUNCTIONS AND CONFIGURATION

1.4.3 MR-J4-_A_-RJ/MR-J4-DU_A-RJ

MR-J4-_A_-RJ MR-D30

CN5

CN6

CN3

CN8

CN1

U

V

W

MR Configurator2

Analog monitor

Personal computer, etc.

Junction terminal

block

POINT

Remove the short-circuit connector on CN8.

Personal

computer

Not used

(Remove the short-circuit

connector.)

CN10A/CN10B

24 V DC power

supply for IO

Safety signal

Safety programmable

controller

CN2

Emergency stop

switch

Light curtain

1 - 18

1. FUNCTIONS AND CONFIGURATION

1.5 Standard specifications

Model MR-D30

Output

Interface power

supply

Safety

performance

Safety

observation

function

(IEC/EN 618005-2)

Compliance with

global standards

Structure (IP rating) Natural cooling, open (mounted on a servo amplifier: IP20, MR-D30 (single): IP00)

Environment

Mass [g] 150

Rated voltage 24 V DC

Rated current [A] 0.3

Voltage 24 V DC ± 10%

Power supply

capacity [A]

EN ISO 13849-1 Category 4, PL e and Category 3, PL d

Standards certified by

CB

Mean time to

dangerous failure

Effectiveness of fault

monitoring of a

system or subsystem

Average probability of

dangerous failures per

hour

Mission time TM = 20 [years]

Response

performance (Note 2)

Speed observation

resolution

Position observation

resolution

Safety position data

resolution

Input device 6 points × 2 systems (source/sink)

Output device

Safe torque off (STO) Category 4, PL e, SIL 3 (Note 3)/Category 3, PL d, SIL 2

Safe stop 1 (SS1) Category 4, PL e, SIL 3 (Note 3)/Category 3, PL d, SIL 2

Safely-limited speed

(SLS) (Note 7)

Safe speed monitor

(SSM) (Note 7)

Safe brake control

(SBC)

Safe operating stop

(SOS) (Note 5, 7)

Safe stop 2 (SS2)

(Note 5, 7)

Status monitor

(Note 6)

CE marking

Ambient temperature Operation: 0 °C to 55 °C (non-freezing), storage: -20 °C to 65 °C (non-freezing)

Ambient humidity

Ambience Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust

Altitude 2000 m or less above sea level

Vibration resistance 5.9 m/s2, 10 Hz to 57 Hz

Depends on a command resolution (22 bit position command: 0.1 r/min or less)

Using drive safety integrated motion controller: 60 ms or less

Using drive safety integrated programmable controller: 65 ms or less

Source: 3 points × 2 systems and 1 point × 1 system

Category 4, PL e, SIL 3 (Note 3, 4)/Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3, 4)/Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3)/Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3)/Category 3, PL d, SIL 2

Category 4, PL e, SIL 3 (Note 3)/Category 3, PL d, SIL 2

EN 62061 SIL CL 2 and SIL CL 3

Using input device: 15 ms or less

Category 4, PL e, SIL 3/Category 3 PL d, SIL 2

MD: EN ISO 13849-1, EN 61800-5-2, EN 62061

Operation: 5 %RH to 90 %RH (non-condensing),

storage: 5 %RH to 90 %RH (non-condensing)

0.8 (Note 1)

IEC 61508 SIL 2 and SIL 3

EN 61800-5-2

MTTFd ≥ 100 [years] (313a)

DC = High, 97.6 [%]

PFH = 6.57 × 10

1/32 rev

32 pulses/rev (5 bits)

Sink: 1 point × 1 system

EMC: EN 61800-3

-9

[1/h]

1 - 19

1. FUNCTIONS AND CONFIGURATION

Note 1. This is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of

I/O points.

2. Time from STO input off to energy shut off

3. To meet Category 4, PL e, SIL 3 for input signals, a diagnosis using test pulses is required.

4. To meet Category 4, PL e, SIL 3, using with an HG-KR_W0C, HG-SR_W0C, or HG-JR_W0C servo motor is required.

5. To enable SS2 and SOS, using with an HG-KR_W0C, HG-SR_W0C, or HG-JR_W0C servo motor is required.

6. Status monitor is a Mitsubishi Electric original function. For the observation functions and the safety levels which can be

displayed on the monitor, refer to the items of “Safety observation function (IEC/EN 61800-5-2)”.

7. Linear servo system, direct drive servo system, and fully closed loop system are not compatible with SLS, SSM, SS2, and

SOS.

1 - 20

1. FUNCTIONS AND CONFIGURATION

1.6 Function list

Function Description

15 ms or less (using input device)

STO Shut-off response time

SS1 Deceleration delay time 0 ms to 60000 ms (parameter setting)

Safety

observation

function

Input/output

function

Parameter setting

Safety communication function

SBC Shut-off response time

SLS1/SLS2/SLS3/SLS4 Observation speed 0 r/min to 10000 r/min (parameter setting) (Note 3)

SSM Observation speed 0 r/min to 10000 r/min (parameter setting)

SS2 Deceleration delay time 0 ms to 60000 ms (parameter setting)

SOS Observation position 0 rev to 100 rev (parameter setting)

Status monitor (SM) Response time 200 μs

Number of inputs 6 points × 2 systems

Mismatch permissible

time of duplication input

Input device

Number of outputs 4 points × 2 systems (Note 4)

Output device Test pulse off time 0.444 ms to 1.77 ms (parameter setting)

Test pulse interval 1 s or less

mismatch detection

Test pulse off time 0.444 ms to 1.77 ms (parameter setting)

Test pulse interval 1 s or less

Noise rejection filter 0.888 ms to 28.4 ms (parameter setting)

Safety communication

cycle

Safety communication

delay time

Note 1. This is when the safety communication cycle is 14.2 ms.

2. This is when the safety communication cycle is 16.0 ms. For details on how to calculate the response time, refer to the

MELSEC iQ-R Safety Application Guide.

3. Each observation speed can be set separately.

4. MR-D30 manufactured in September, 2014 or earlier has three output points. Connecting a circuit to DO4NA or DO4PB of MR-

D30 manufactured in September, 2014 or earlier may cause a malfunction of MR-D30. Connecting MR-D30 manufactured in

September, 2014 or earlier to the servo amplifier will deactivate displays about DO4_ of MR Configurator2.

1.7 Combinations with servo amplifiers and servo motors

POINT

MR-D30 supported by with MR-J4-(DU)_A_-RJ with software version B5 or

later, MR-J4-(DU)_B_-RJ with software version B5 or later, or MR-J4-_GF_-RJ

with software version A3 or later.

When you use a servo motor with functional safety, MR-BT6VCASE battery

case cannot be used.

60 ms or less (using SSCNET III/H) (Note 1)

65 ms or less (Using CC-Link IE Field Network) (Note 2)

15 ms or less (using input device)

60 ms or less (using SSCNET III/H) (Note 1)

65 ms or less (Using CC-Link IE Field Network) (Note 2)

1 ms to 60000 ms (parameter setting)

Failure diagnosis by duplication parameter, writing protection by

password

14.2 ms to 28.4 ms (parameter setting) (Using SSCNET III/H)

16.0 ms to 32.0 ms (parameter setting) (Using CC-Link IE Field

Network)

60 ms or less (Using SSCNET III/H) (Note 1)

65 ms or less (Using CC-Link IE Field Network) (Note 2)

Servo amplifiers and servo motors that can be used with MR-D30 are listed as follows. The usable safety

observation function and achievable safety performance level vary depending on each servo motor to be

used. Refer to section 4.1 for details.

1 - 21

1. FUNCTIONS AND CONFIGURATION

(1) 200 V class

(a) Combinations with MR-J4-_ servo amplifiers

Servo amplifier

MR-J4-10B-RJ

MR-J4-10A-RJ

MR-J4-10GF-RJ

MR-J4-20B-RJ

MR-J4-20A-RJ

MR-J4-20GF-RJ

MR-J4-40B-RJ

MR-J4-40A-RJ

MR-J4-40GF-RJ

MR-J4-60B-RJ

MR-J4-60A-RJ

MR-J4-60GF-RJ

MR-J4-70B-RJ

MR-J4-70A-RJ

MR-J4-70GF-RJ

MR-J4-100B-RJ

MR-J4-100A-RJ

MR-J4-100GF-RJ

MR-J4-200B-RJ

MR-J4-200A-RJ

MR-J4-200GF-RJ

MR-J4-350B-RJ

MR-J4-350A-RJ

MR-J4-350GF-RJ

MR-J4-500B-RJ

MR-J4-500A-RJ

MR-J4-500GF-RJ

Servo motor

HG-KR053

HG-KR13

HG-MR053

HG-MR13

HG-KR23

HG-MR23

HG-KR43

HG-MR43

HG-SR51

HG-SR52

HG-JR53

HG-KR73

HG-MR73

HG-JR73

HG-UR72

HG-SR81

HG-SR102

HG-JR53 (Note)

HG-JR103

HG-SR121

HG-SR201

HG-SR152

HG-SR202

HG-JR73 (Note)

HG-JR103 (Note)

HG-JR153

HG-JR203

HG-RR103

HG-RR153

HG-UR152

HG-SR301

HG-SR352

HG-JR153 (Note)

HG-JR203 (Note)

HG-JR353

HG-RR203

HG-UR202

HG-SR421

HG-SR502

HG-JR353 (Note)

HG-JR503

HG-RR353

HG-RR503

HG-UR352

HG-UR502

Rotary servo motor

Servo motor with functional

safety

HG-KR053W0C

HG-KR13W0C

HG-KR23W0C LM-U2PAB-05M-0SS0

HG-KR43W0C LM-H3P2A-07P-BSS0

HG-SR51W0C

HG-SR52W0C

HG-JR53W0C

HG-KR73W0C

HG-JR73W0C

HG-SR81W0C

HG-SR102W0C

HG-JR53W0C (Note)

HG-JR103W0C

HG-SR121W0C

HG-SR201W0C

HG-SR152W0C

HG-SR202W0C

HG-JR73W0C (Note)

HG-JR103W0C (Note)

HG-JR153W0C

HG-JR203W0C

HG-SR301W0C

HG-SR352W0C

HG-JR153W0C (Note)

HG-JR203W0C (Note)

HG-JR353W0C

HG-SR421W0C

HG-SR502W0C

HG-JR353W0C (Note)

HG-JR503W0C

Linear servo motor

(primary side)

LM-U2PBB-07M-1SS0

LM-H3P3A-12P-CSS0

LM-K2P1A-01M-2SS1

LM-U2PAD-10M-0SS0

LM-U2PAF-15M-0SS0

LM-U2PBD-15M-1SS0 TM-RFM006C20

LM-H3P3B-24P-CSS0

LM-H3P3C-36P-CSS0

LM-H3P7A-24P-ASS0

LM-K2P2A-02M-1SS1

LM-U2PBF-22M-1SS0

TM-RFM018E20

LM-H3P3D-48P-CSS0

LM-H3P7B-48P-ASS0

LM-H3P7C-72P-ASS0

LM-FP2B-06M-1SS0

LM-K2P1C-03M-2SS1

LM-U2P2B-40M-2SS0

LM-H3P7D-96P-ASS0

LM-K2P2C-07M-1SS1

LM-K2P3C-14M-1SS1

LM-U2P2C-60M-2SS0

LM-FP2D-12M-1SS0

LM-FP4B-12M-1SS0

LM-K2P2E-12M-1SS1

LM-K2P3E-24M-1SS1

LM-U2P2D-80M-2SS0

Direct drive motor

TM-RG2M002C30

TM-RU2M002C30

TM-RG2M004E30

TM-RU2M004E30

TM-RFM002C20

TM-RG2M004E30

TM-RU2M004E30

TM-RG2M009G30

TM-RU2M009G30

TM-RFM004C20

TM-RFM006E20

TM-RFM012E20

TM-RFM012G20

TM-RFM040J10

TM-RFM048G20

TM-RFM072G20

TM-RFM120J10

TM-RFM240J10

1 - 22

1. FUNCTIONS AND CONFIGURATION

Rotary servo motor

Servo amplifier

MR-J4-700B-RJ

MR-J4-700A-RJ

MR-J4-700GF-RJ

MR-J4-11KB-RJ

MR-J4-11KA-RJ

MR-J4-11KGF-RJ

MR-J4-15KB-RJ

MR-J4-15KA-RJ

MR-J4-15KGF-RJ

MR-J4-22KB-RJ

MR-J4-22KA-RJ

MR-J4-22KGF-RJ

Servo motor

HG-SR702

HG-JR703

HG-JR503 (Note)

HG-JR601

HG-JR701M

HG-JR903

HG-JR801

HG-JR12K1

HG-JR11K1M

HG-JR15K1

HG-JR15K1M

HG-JR20K1

HG-JR25K1

HG-JR22K1M

Note. The maximum torque can be increased to 400% of the rated torque.

(b) Combinations with MR-J4-DU_ drive units

Drive unit

MR-J4-DU900B-RJ HG-SR702 (Note 2)

MR-J4-DU11KB-RJ HG-JR12K1

MR-J4-DU15KB-RJ HG-JR15K1

MR-J4-DU22KB-RJ HG-JR20K1

MR-J4-DU30KB-RJ

MR-J4-DU30KA-RJ

MR-J4-DU37KB-RJ

MR-J4-DU37KA-RJ

Servo motor

HG-JR601

HG-JR801

HG-JR701M (Note 2)

HG-JR503 (Note 1)

HG-JR703 (Note 2)

HG-JR903

HG-JR11K1M

HG-JR15K1M

HG-JR25K1

HG-JR22K1M

HG-JR30K1

HG-JR30K1M

HG-JR37K1

HG-JR37K1M

Note 1. The maximum torque can be increased to 400% of the rated torque.

2. By enabling the maximally increased torque function when drive unit is connected, the maximum

torque can be increased.

Servo motor with functional

safety

HG-SR702W0C

HG-JR703W0C

HG-JR503W0C (Note)

HG-JR701MW0C

HG-JR903W0C

HG-JR11K1MW0C

HG-JR15K1MW0C LM-FP4F-48M-1SS0

HG-JR22K1MW0C

Rotary servo motor

Servo motor with functional

HG-SR702W0C (Note 2)

HG-JR701MW0C (Note 2)

HG-JR503W0C (Note 1)

HG-JR703W0C (Note 2)

HG-JR903W0C

HG-JR11K1MW0C LM-FP4F-36M-1SS0

HG-JR15K1MW0C LM-FP4H-48M-1SS0

HG-JR22K1MW0C

safety

Linear servo motor

(primary side)

LM-FP2F-18M-1SS0

LM-FP4D-24M-1SS0

LM-FP4F-36M-1SS0

Linear servo motor

(primary side)

LM-FP2F-18M-1SS0

LM-FP4D-24M-1SS0

Direct drive motor

1 - 23

1. FUNCTIONS AND CONFIGURATION

(2) 400 V class

(a) Combinations with MR-J4-_ servo amplifiers

Servo amplifier

MR-J4-60B4-RJ

MR-J4-60A4-RJ

MR-J4-60GF4-RJ

MR-J4-100B4-RJ

MR-J4-100A4-RJ

MR-J4-100GF4-RJ

MR-J4-200B4-RJ

MR-J4-200A4-RJ

MR-J4-200GF4-RJ

MR-J4-350B4-RJ

MR-J4-350A4-RJ

MR-J4-350GF4-RJ

MR-J4-500B4-RJ

MR-J4-500A4-RJ

MR-J4-500GF4-RJ

MR-J4-700B4-RJ

MR-J4-700A4-RJ

MR-J4-700GF4-RJ

MR-J4-11KB4-RJ

MR-J4-11KA4-RJ

MR-J4-11KGF4-RJ

MR-J4-15KB4-RJ

MR-J4-15KA4-RJ

MR-J4-15KGF4-RJ

MR-J4-22KB4-RJ

MR-J4-22KA4-RJ

MR-J4-22KGF4-RJ

Servo motor

HG-SR524

HG-JR534

HG-SR1024

HG-JR534 (Note)

HG-JR734

HG-JR1034

HG-SR1524

HG-SR2024

HG-JR734 (Note)

HG-JR1034 (Note)

HG-JR1534

HG-JR2034

HG-SR3524

HG-JR1534 (Note)

HG-JR2034 (Note)

HG-JR3534

HG-SR5024

HG-JR3534 (Note)

HG-JR5034

HG-SR7024

HG-JR5034 (Note)

HG-JR6014

HG-JR701M4

HG-JR7034

HG-JR8014

HG-JR12K14

HG-JR11K1M4

HG-JR9034

HG-JR15K14

HG-JR15K1M4

HG-JR20K14

HG-JR25K14

HG-JR22K1M4

Note. The maximum torque can be increased to 400% of the rated torque.

Rotary servo motor

Servo motor with functional

HG-SR524W0C

HG-JR534W0C

HG-SR1024W0C

HG-JR534W0C (Note)

HG-JR734W0C

HG-JR1034W0C

HG-SR1524W0C

HG-SR2024W0C

HG-JR734W0C (Note)

HG-JR1034W0C (Note)

HG-JR1534W0C

HG-JR2034W0C

HG-SR3524W0C

HG-JR1534W0C (Note)

HG-JR2034W0C (Note)

HG-JR3534W0C

HG-SR5024W0C

HG-JR3534W0C (Note)

HG-JR5034W0C

HG-SR7024W0C

HG-JR5034W0C (Note)

HG-JR7034W0C

HG-JR701M4W0C

HG-JR11K1M4W0C

HG-JR9034W0C

HG-JR15K1M4W0C

HG-JR22K1M4W0C LM-FP5H-60M-1SS0

safety

Linear servo motor

(primary side)

1 - 24

1. FUNCTIONS AND CONFIGURATION

(b) Combinations with MR-J4-DU_ drive units

MR-J4-DU900B4-RJ HG-SR7024 (Note 2)

MR-J4-DU11KB4-RJ HG-JR12K14

MR-J4-DU15KB4-RJ HG-JR15K14

MR-J4-DU22KB4-RJ HG-JR20K14

MR-J4-DU30KB4-RJ

MR-J4-DU30KA4-RJ

MR-J4-DU37KB4-RJ

MR-J4-DU37KA4-RJ

MR-J4-DU45KB4-RJ

MR-J4-DU45KA4-RJ

MR-J4-DU55KB4-RJ

MR-J4-DU55KA4-RJ

Two units of MR-J4DU55KB4-RJ100

Four units of MR-J4DU45KB4-RJ100

Four units of MR-J4DU55KB4-RJ100

Note 1. The maximum torque can be increased to 400% of the rated torque.

2. By enabling the maximally increased torque function when drive unit is connected, the maximum

(3) 100 V class

Servo amplifier

MR-J4-10B1-RJ

MR-J4-10A1-RJ

MR-J4-10GF1-RJ

MR-J4-20B1-RJ

MR-J4-20A1-RJ

MR-J4-20GF1-RJ

MR-J4-40B1-RJ

MR-J4-40A1-RJ

MR-J4-40GF1-RJ

Drive unit

HG-JR6014

HG-JR8014

HG-JR701M4 (Note 2)

HG-JR5034 (Note 1)

HG-JR7034 (Note 2)

HG-JR9034

HG-JR11K1M4

HG-JR15K1M4

HG-JR22K1M4

HG-JR25K14

HG-JR30K14

HG-JR30K1M4

HG-JR37K14

HG-JR37K1M4

HG-JR45K1M4

HG-JR55K1M4

torque can be increased.

Servo motor

HG-KR053

HG-KR13

HG-MR053

HG-MR13

HG-KR23

HG-MR23

HG-KR43

HG-MR43

Servo motor

Rotary servo motor

Rotary servo motor

Servo motor with functional

HG-SR7024W0C (Note 2)

HG-JR701M4W0C (Note 2)

HG-JR5034W0C (Note 1)

HG-JR7034W0C (Note 2)

HG-JR9034W0C

HG-JR11K1M4W0C

HG-JR15K1M4W0C

HG-JR22K1M4W0C LM-FP5H-60M-1SS0

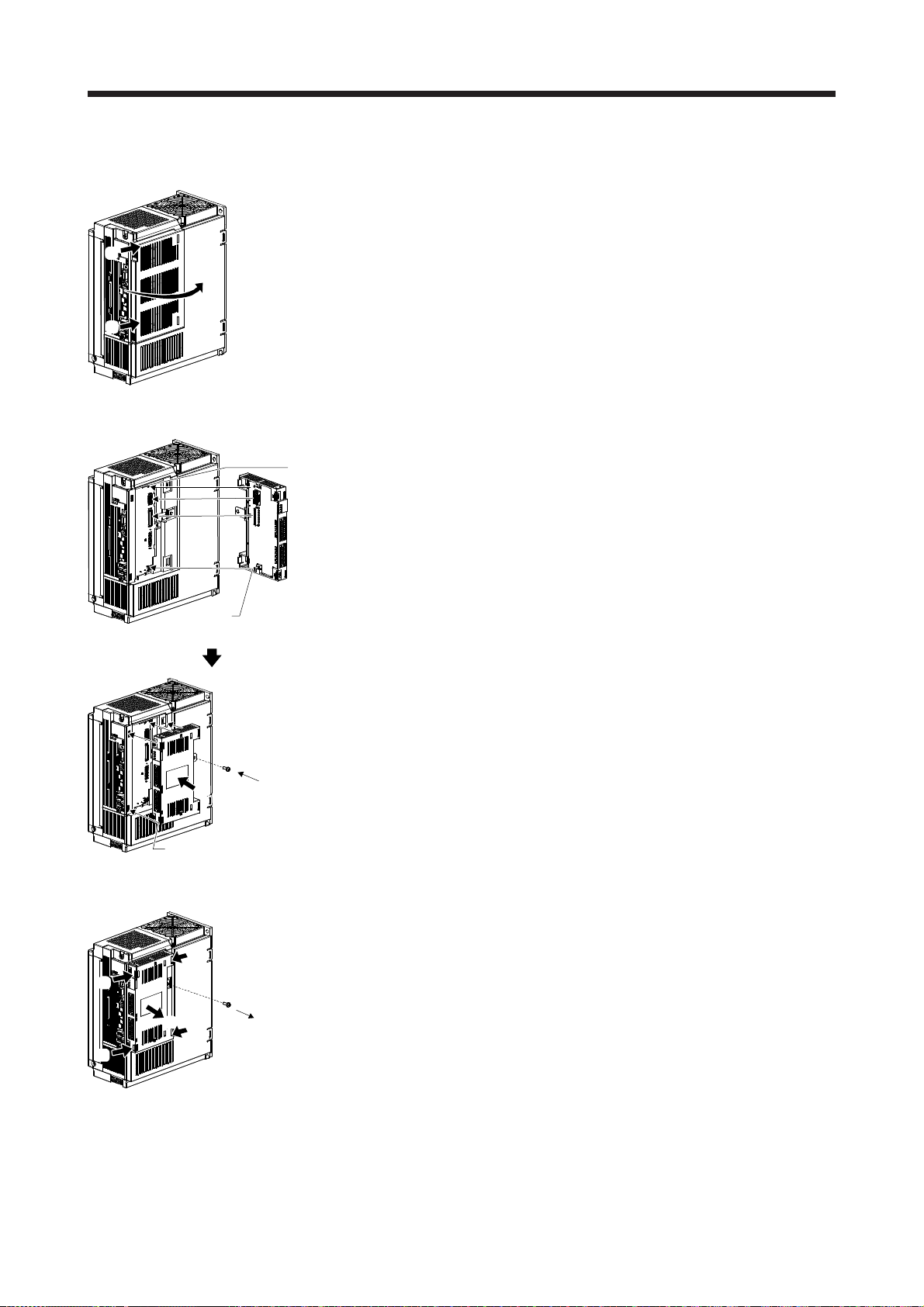

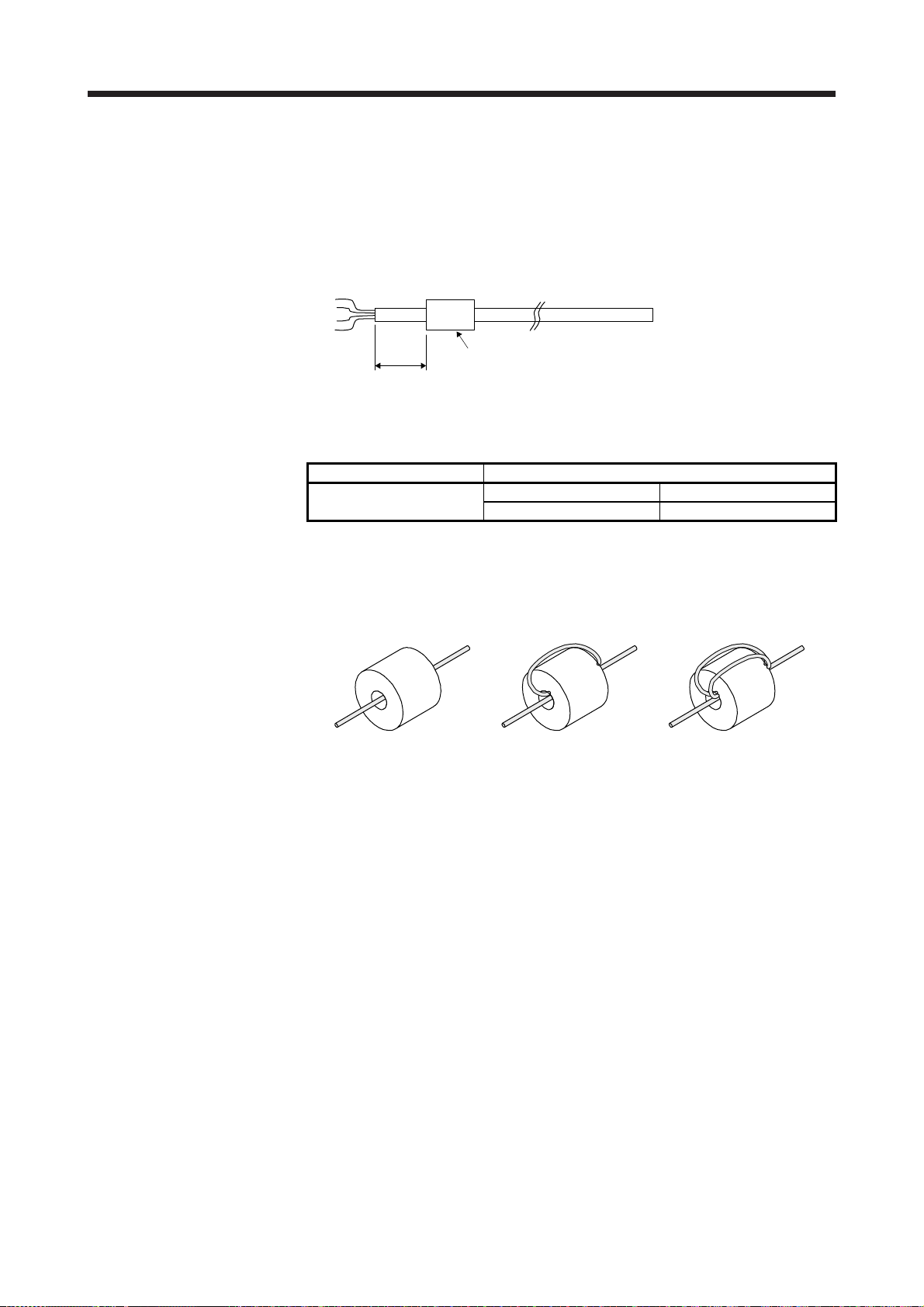

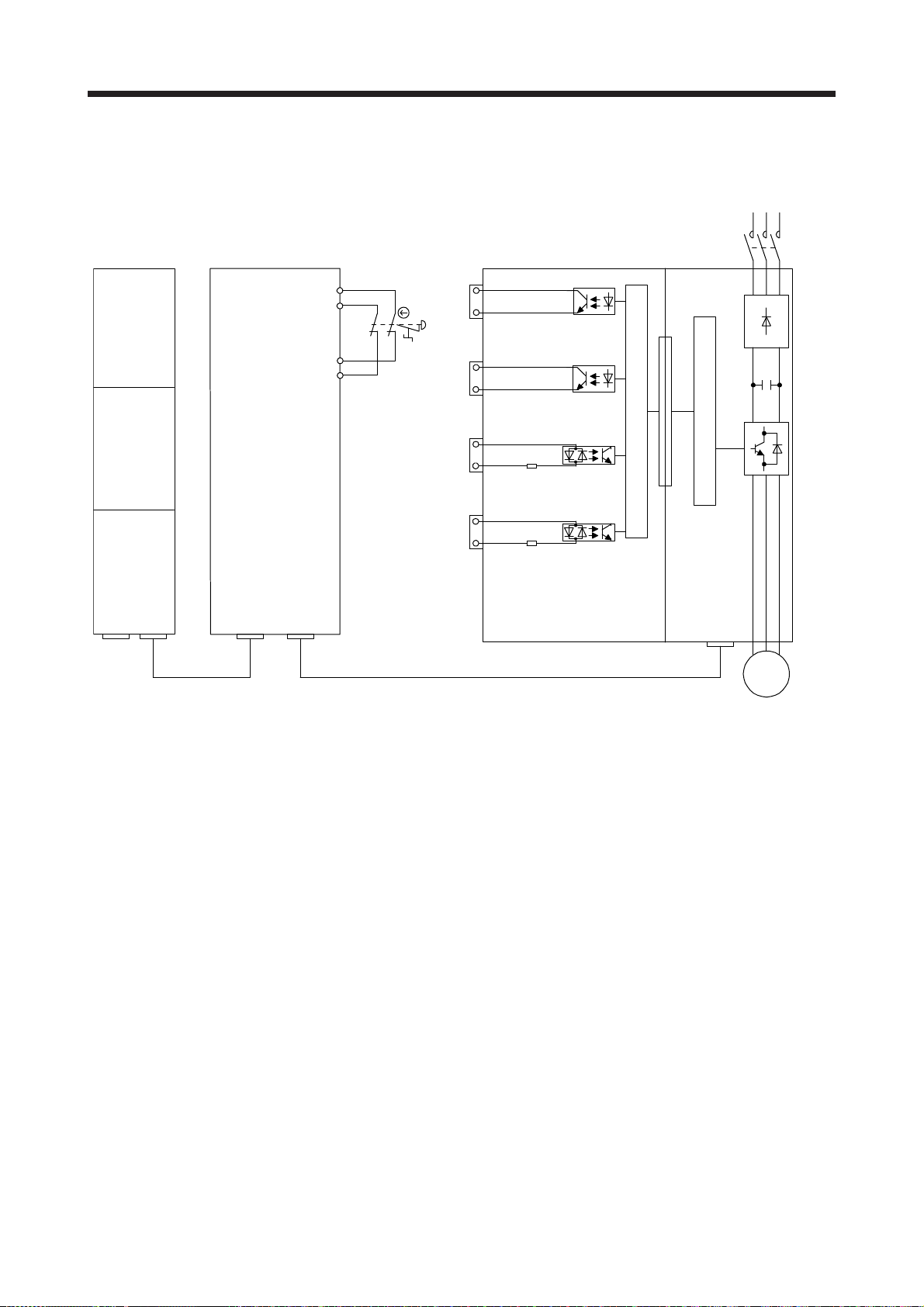

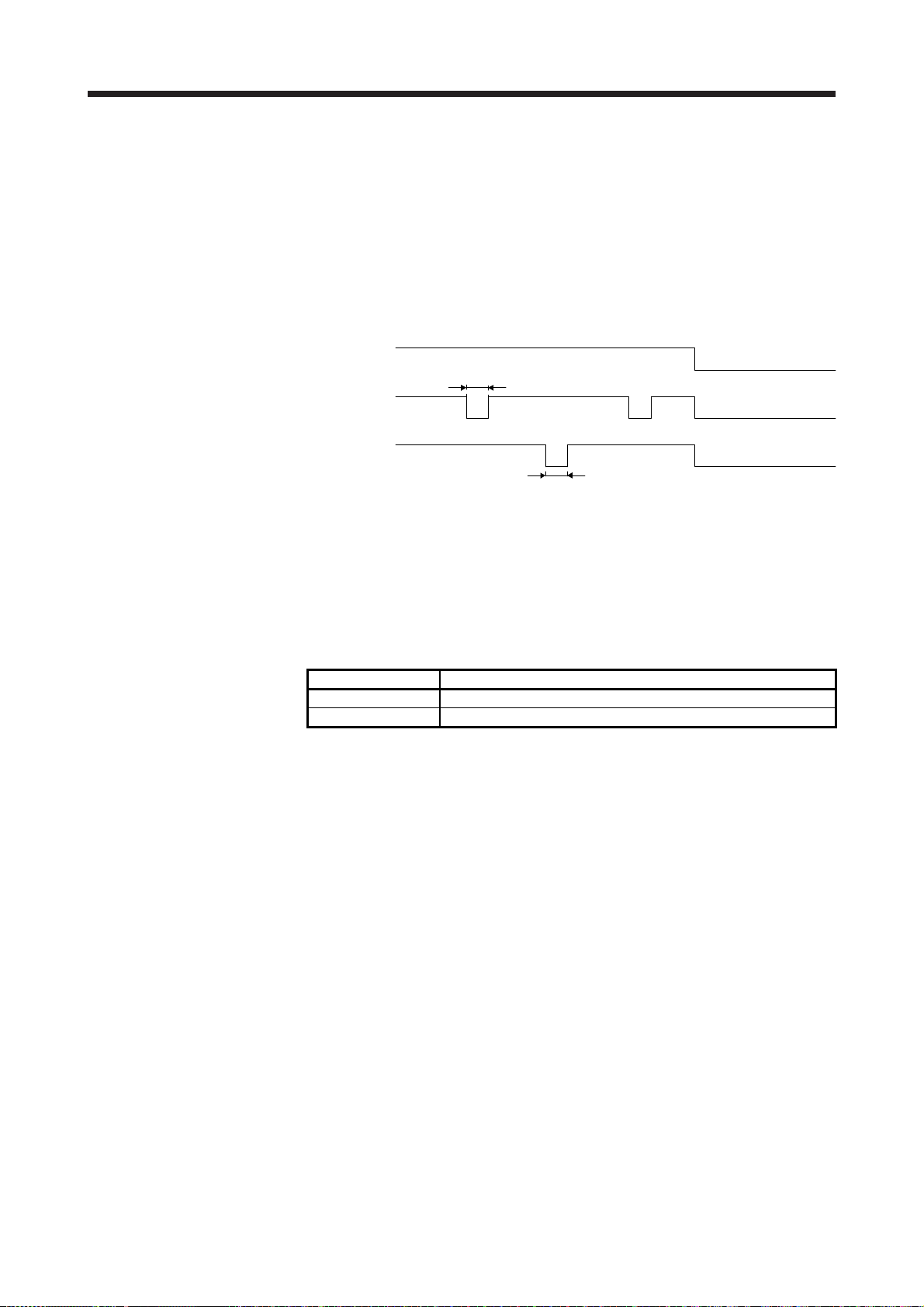

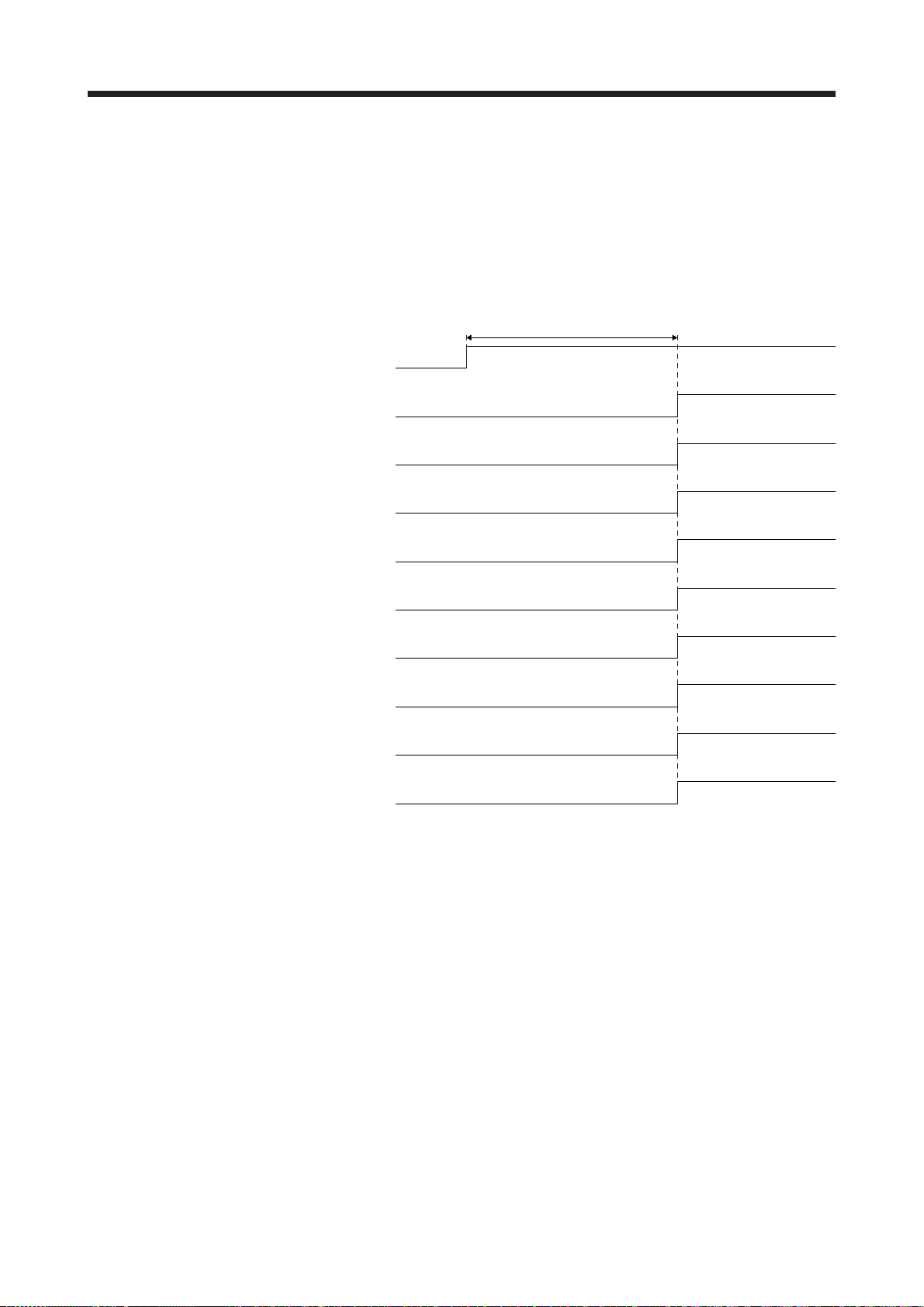

HG-JR110K24W0C