Mitsubishi Electric MELSERVO-J4, MR-CV, MR-J4-B(-RJ), MR-CR55K(4), MR-J4-B-RJ010 Instruction Manual

...

General-Purpose AC Servo

MELSERVO-J4 Servo amplifier

INSTRUCTION MANUAL (TROUBLE SHOOTING)

M

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 1

1. To prevent electric shock, note the following

WARNING

Before wiring or inspection, turn off the power and wait for 15 minutes or more (20 minutes or more for

converter unit) until the charge lamp turns off. Then, confirm that the voltage between P+ and N(between L+ and L- for converter unit) is safe with a voltage tester and others. Otherwise, an electric

shock may occur. In addition, always confirm whether the charge lamp is off or not from the front of the

servo amplifier (converter unit).

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

2. To prevent fire, note the following

CAUTION

When you use an MR-J4 multi-axis servo amplifier, connecting an encoder for wrong axis to the CN2A,

CN2B, or CN2C connector may cause a fire.

3. To prevent injury, note the following

CAUTION

The servo amplifier (drive unit), converter unit heat sink, regenerative resistor, servo motor, etc. may

become hot while power is on or for some time after power-off. Take safety measures, e.g. provide

covers, to avoid accidentally touching the parts (cables, etc.) by hand.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, etc.

(1) Wiring

CAUTION

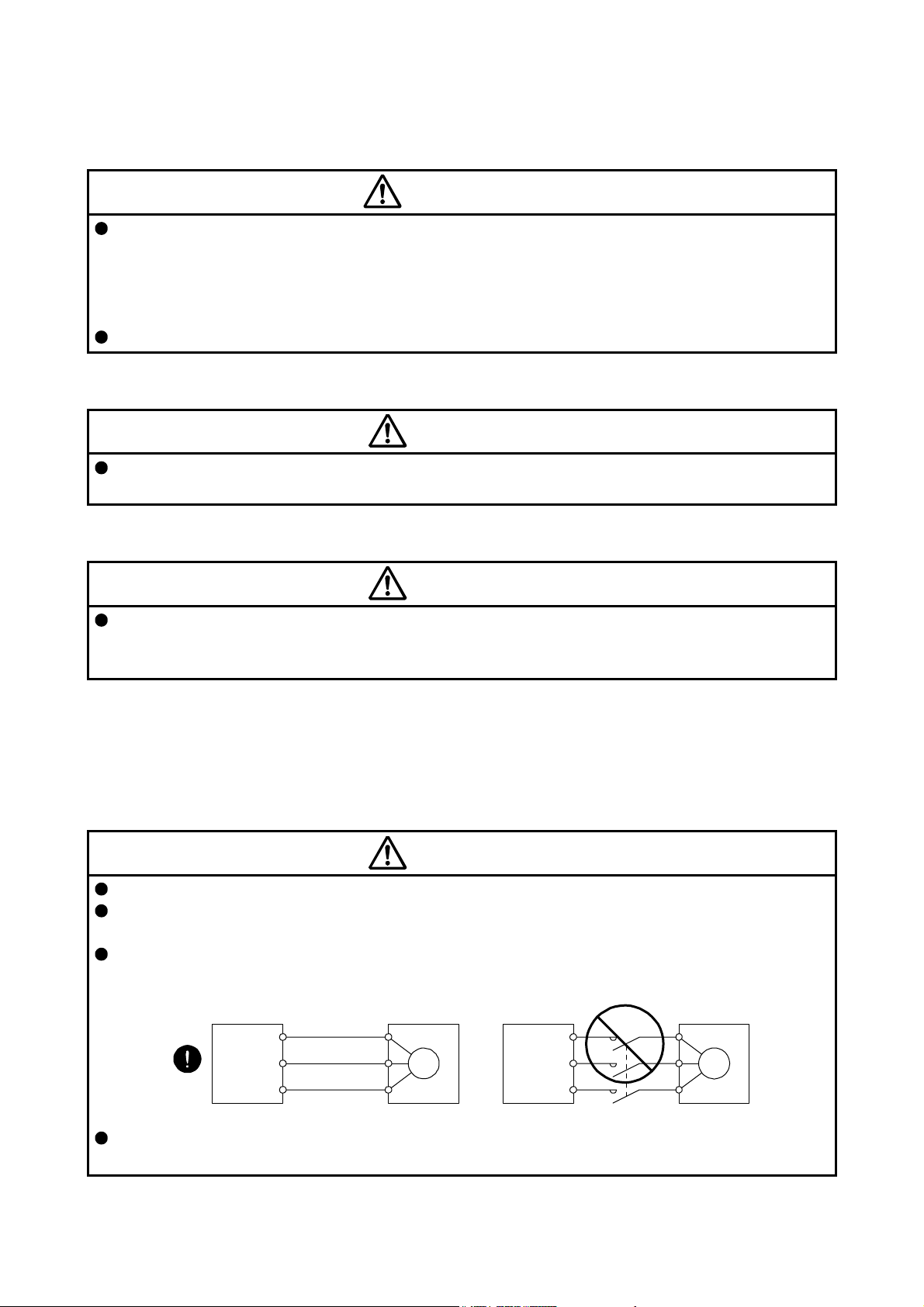

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

To avoid a malfunction of the servo motor, connect the wires to the correct phase terminals (U/V/W) of

the servo amplifier (drive unit) and the servo motor.

Connect the servo amplifier (drive unit) power output (U/V/W) to the servo motor power input (U/V/W)

directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

(drive unit)

U

V

W

Servo motor

U

V

W

M

Servo amplifier

(drive unit)

U

V

W

Servo motor

U

V

W

M

Configure a circuit to turn off EM2 or EM1 when the main circuit power is turned off to prevent an

unexpected restart of the servo amplifier (drive unit).

A - 2

(2) Usage

CAUTION

Before resetting an alarm, make sure that the run signal of the servo amplifier (drive unit) is off in order to

prevent a sudden restart. Otherwise, it may cause an accident.

Use the servo amplifier (drive unit) and converter unit with the specified servo motor.

(3) Corrective actions

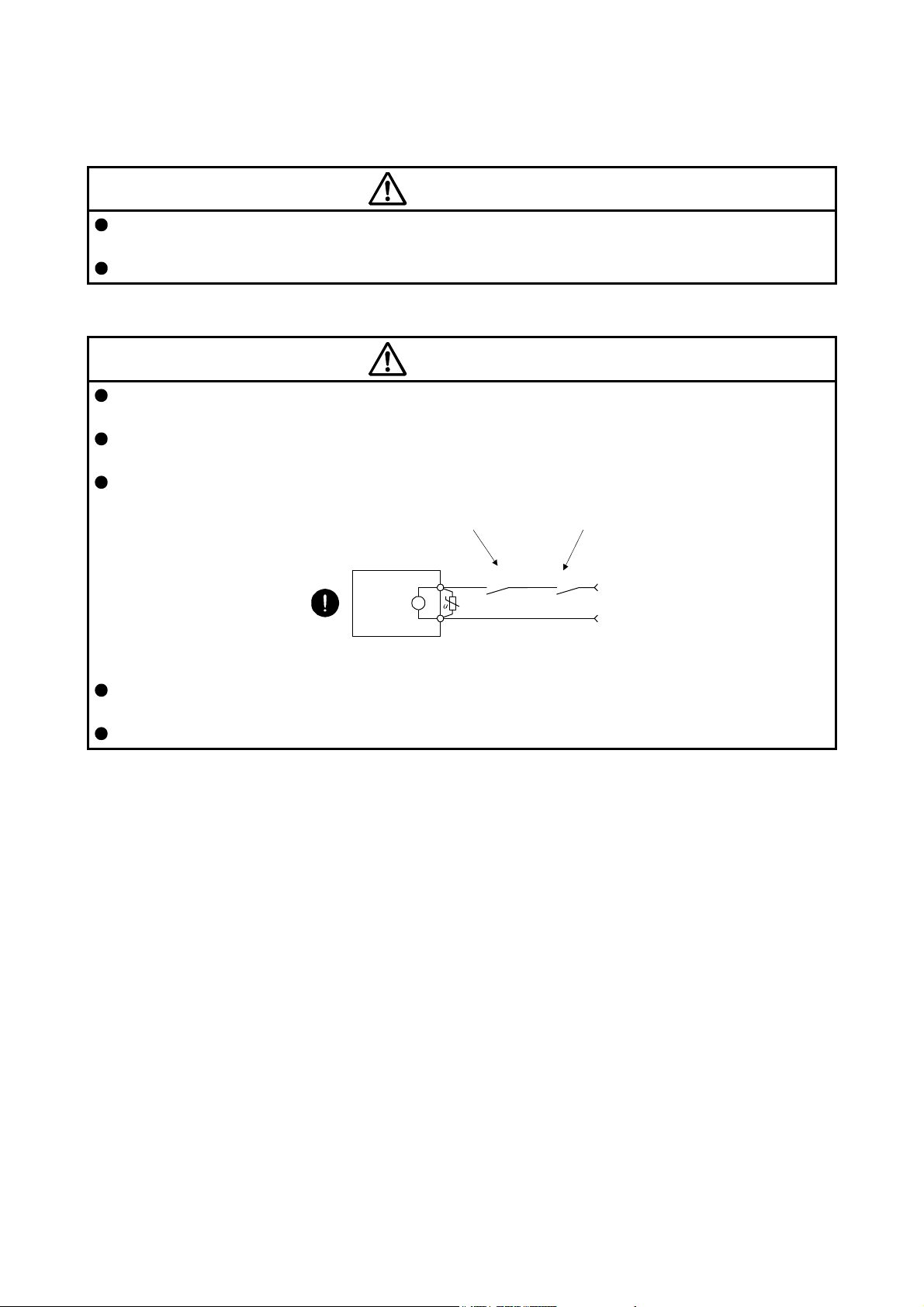

CAUTION

Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an electromagnetic brake or external brake to prevent the condition.

Configure an electromagnetic brake circuit which is interlocked with an external emergency stop switch.

Contacts must be opened when CALM (Common

malfunction) or MBR (Electromagnetic brake

interlock) turns off.

Contacts must be opened with

the emergency stop switch.

Servo motor

B

Electromagnetic brake

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

RA

24 V DC

A - 3

«About the manual»

This Instruction Manual covers the following models. These include servo amplifiers (drive units) which

have optional units.

MR-J4-_A/MR-J4-_A4/MR-J4-_A1/MR-J4-_A-RJ/MR-J4-_A4-RJ/MR-J4-_A1-RJ

MR-J4-_B/MR-J4-_B4/MR-J4-_B1/MR-J4-_B-RJ/MR-J4-_B4-RJ/MR-J4-_B1-RJ

MR-J4W_-_B

MR-J4-_B-RJ010/MR-J4-_B4-RJ010

MR-J4-03A6/MR-J4-03A6-RJ/MR-J4W2-0303B6

MR-J4-_GF/MR-J4-_GF4/MR-J4-_GF-RJ/MR-J4-_GF4-RJ

MR-J4-DU_A/MR-J4-DU_A4/MR-J4-DU_A-RJ/MR-J4-DU_A4-RJ

MR-J4-DU_B/MR-J4-DU_B4/MR-J4-DU_B-RJ/MR-J4-DU_B4-RJ

MR-CV_

MR-CR55K/MR-CR55K4

The symbols in the target column mean as follows.

[A]: MR-J4-_A/MR-J4-_A4/MR-J4-_A1/MR-J4-_A-RJ/MR-J4-_A4-RJ/MR-J4-_A1-RJ/MR-J4-DU_A/

MR-J4-DU_A4/MR-J4-DU_A-RJ/MR-J4-DU_A4-RJ/MR-J4-03A6/MR-J4-03A6-RJ

[B]: MR-J4-_B/MR-J4-_B4/MR-J4-_B1/MR-J4-_B-RJ/MR-J4-_B4-RJ/MR-J4-_B1-RJ/

MR-J4-DU_B/MR-J4-DU_B4/MR-J4-DU_B-RJ/MR-J4-DU_B4-RJ

[WB]: MR-J4W_-_B/MR-J4W2-0303B6

[RJ010]: MR-J4-_B-RJ010/MR-J4-_B4-RJ010

[GF]: MR-J4-_GF/MR-J4-_GF4/MR-J4-_GF-RJ/MR-J4-_GF4-RJ

[Other]: For manufacturer adjustment

A - 4

CONTENTS

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT) 1- 1 to 1-130

1.1 Explanation for the lists ..................................................................................................................... 1- 1

1.2 Alarm list ........................................................................................................................................... 1- 3

1.3 Warning list ...................................................................................................................................... 1-13

1.4 Remedies for alarms ........................................................................................................................ 1-16

1.5 Remedies for warnings .................................................................................................................... 1-92

1.6 Trouble which does not trigger alarm/warning .............................................................................. 1-116

1.7 Network module error codes.......................................................................................................... 1-129

2. TROUBLESHOOTING FOR MR-CV_POWER REGENERATION CONVERTER UNIT 2- 1 to 2- 8

2.1 Explanations of the lists .................................................................................................................... 2- 1

2.2 Alarm list ........................................................................................................................................... 2- 1

2.3 Warning list ....................................................................................................................................... 2- 2

2.4 Remedies for alarms ......................................................................................................................... 2- 2

2.5 Remedies for warnings ..................................................................................................................... 2- 7

3. TROUBLESHOOTING FOR MR-CR55K(4) RESISTANCE REGENERATION CONVERTER UNIT 3- 1 to 3-10

3.1 Explanation for the lists ..................................................................................................................... 3- 1

3.2 Alarm/warning list .............................................................................................................................. 3- 1

3.3 Remedies for alarms ......................................................................................................................... 3- 2

3.4 Remedies for warnings ..................................................................................................................... 3- 8

4. DRIVE RECORDER 4- 1 to 4-10

4.1 How to use drive recorder .................................................................................................................. 4- 1

4.2 How to display drive recorder information ........................................................................................ 4-10

APPENDIX App.- 1 to App.- 1

App. 1 Detection points of [AL. 25], [AL. 92], and [AL. 9F] ............................................................... App.- 1

1

MEMO

2

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

POINT

As soon as an alarm occurs, turn SON (Servo-on) off and interrupt the power.

[AL. 37 Parameter error] and warnings (except [AL. F0 Tough drive warning])

are not recorded in the alarm history.

[AL. 8D.1 CC-Link IE communication error 1] and [AL. 8D.2 CC-Link IE

communication error 2] are not recorded in the alarm history. For MR-J4-_GF_(RJ), these alarms are recorded by setting [Pr. PN06] to "_ _ _ 1".

When an error occurs during operation, the corresponding alarm or warning is displayed. When an alarm is

displayed, refer to section 1.4 and take the appropriate action. When an alarm occurs, ALM will turn off.

When an warning is displayed, refer to section 1.5 and take the appropriate action.

1.1 Explanation for the lists

(1) No./Name/Detail No./Detail name

Indicates each No./Name/Detail No./Detail name of alarms or warnings.

(2) Stop method

For the alarms and warnings in which "SD" is written in the stop method column, the servo motor stops

with the dynamic brake after forced stop deceleration. For the alarms and warnings in which "DB" or

"EDB" is written in the stop method column, the servo motor stops with the dynamic brake without forced

stop deceleration.

(3) Alarm deactivation

After its cause has been removed, the alarm can be deactivated in any of the methods marked

in the

alarm deactivation column. Warnings are automatically canceled after the cause of occurrence is

removed. Alarms are deactivated with alarm reset, CPU reset, or cycling the power.

(a) MR-J4-_A_(-RJ)/MR-J4-DU_A_(-RJ)

Alarm reset 1. Turning on RES (Reset) with input device

Cycling the power Turning the power off and then turning it on again.

Alarm deactivation Explanation

2. Pushing the "SET" button while the display of the servo amplifier is the current

alarm display status

3. Click "Occurring Alarm Reset" in the "Alarm Display" window of MR Configurator2

(b) MR-J4-_B_(-RJ010)/MR-J4W_-_B/MR-J4-DU_B_(-RJ)/MR-J4-_GF_(-RJ)

Alarm reset 1. Reset command from controller

CPU reset Resetting the controller itself

Cycling the power Turning the power off and then turning it on again.

Alarm deactivation Explanation

2. Click "Occurring Alarm Reset" in the "Alarm Display" window of MR Configurator2

(4) Processing system (only for MR-J4W_-_B_)

Processing system of alarms is as follows.

Each axis: Alarm is detected for each axis.

Common: Alarm is detected as the whole servo amplifier.

1 - 1

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

(5) Stop system (only for MR-J4W_-_B_)

This means target axis to stop when the alarm occurs.

Each axis: Only alarming axis will stop.

All axes: All axes will stop.

(6) Alarm code (only MR-J4-_A_(-RJ)/MR-J4-DU_A_(-RJ))

To output alarm codes, set [Pr. PD34] to "_ _ _ 1" when using an MR-J4-_A_(-RJ)/MR-J4-DU_A_(-RJ).

Alarm codes are outputted by on/off of bit 0 to bit 2. Warnings ([AL. 90] to [AL. F3]) do not have alarm

codes. The alarm codes in the following table will be outputted when they occur. The alarm codes will

not be outputted in normal condition.

When using an MR-D01 extension IO unit, you can output alarm codes by setting [Pr. Po12] to "_ _ _ 1".

Alarm codes are outputted by on/off of bit 0 to bit 3.

1 - 2

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

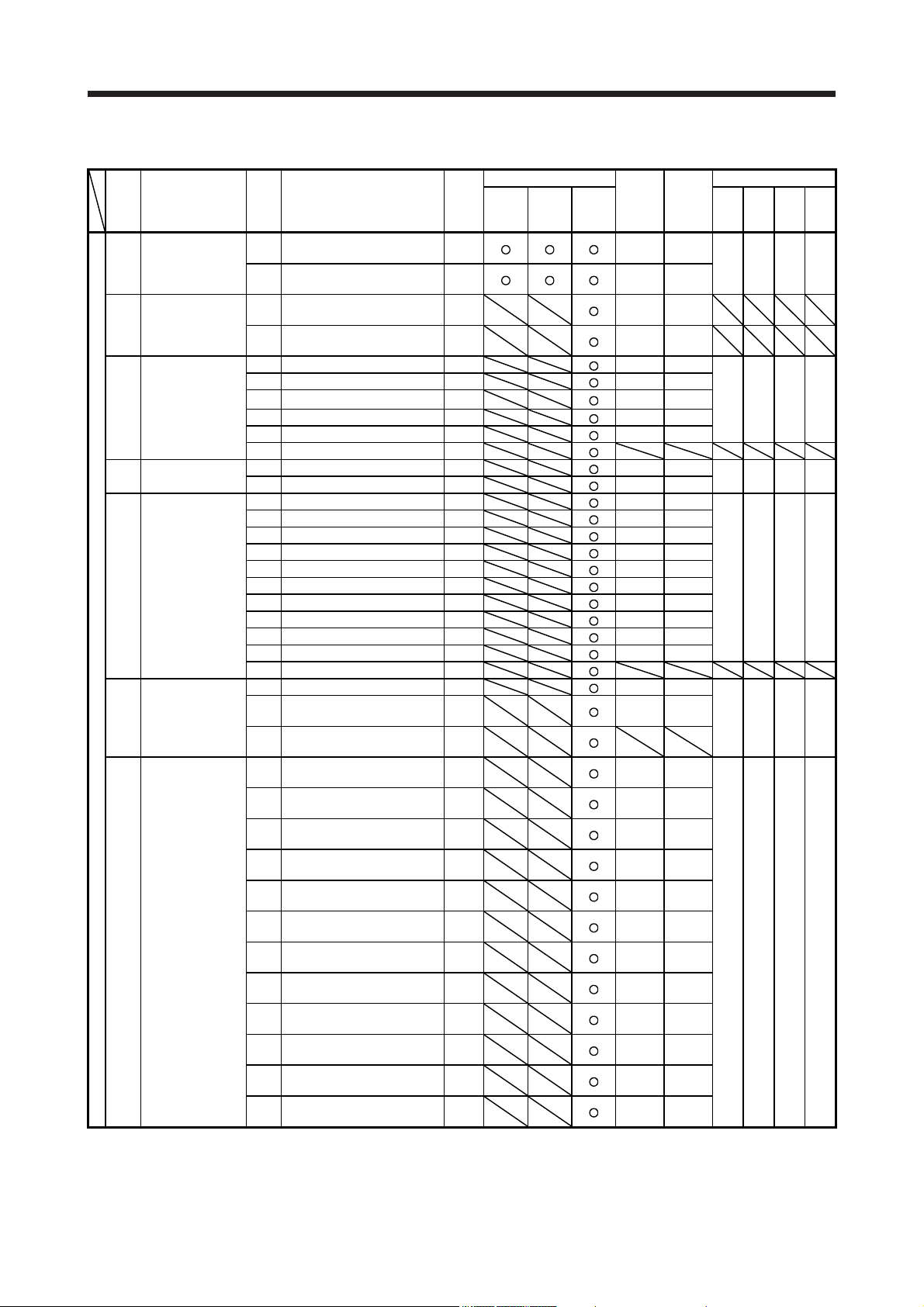

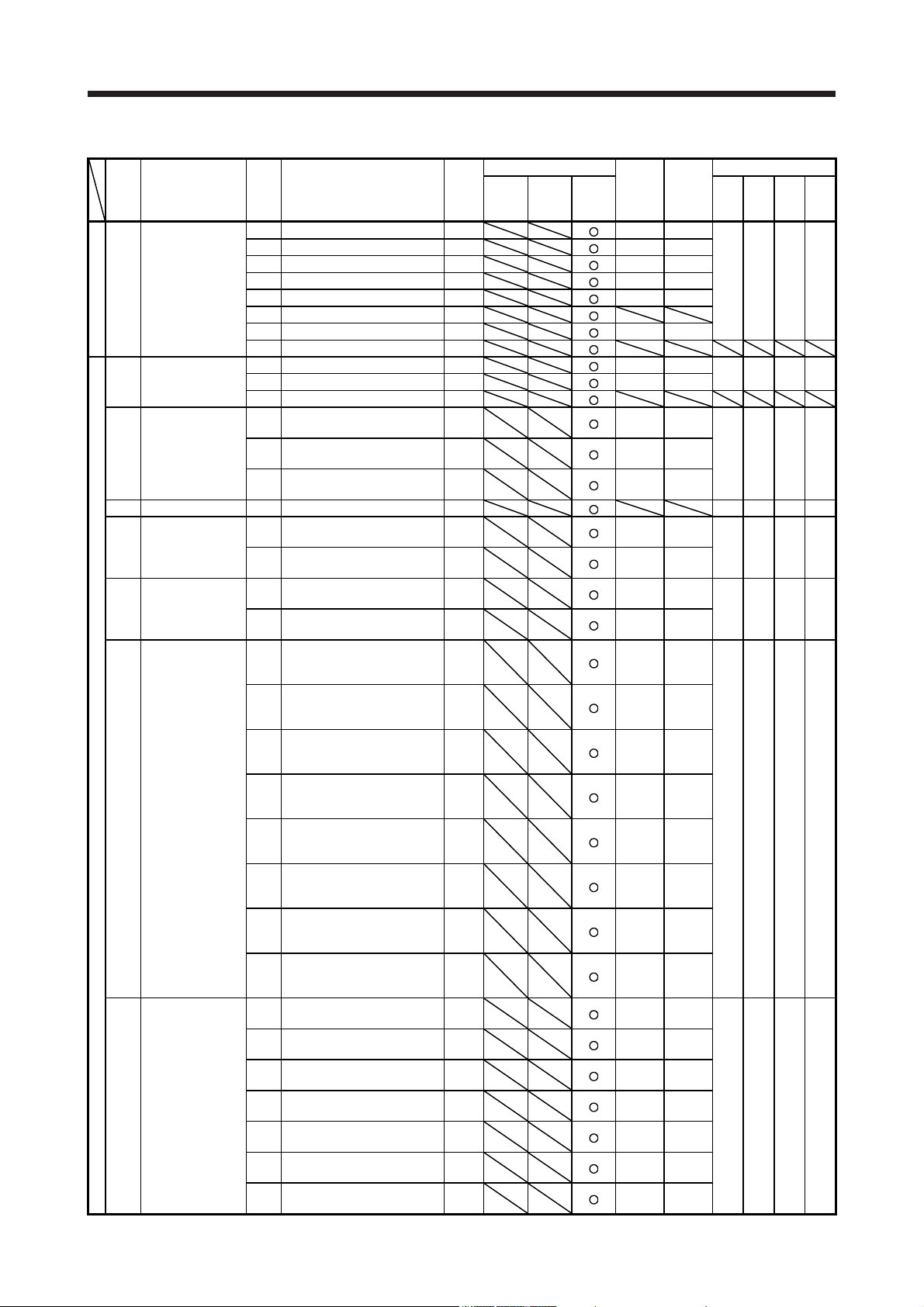

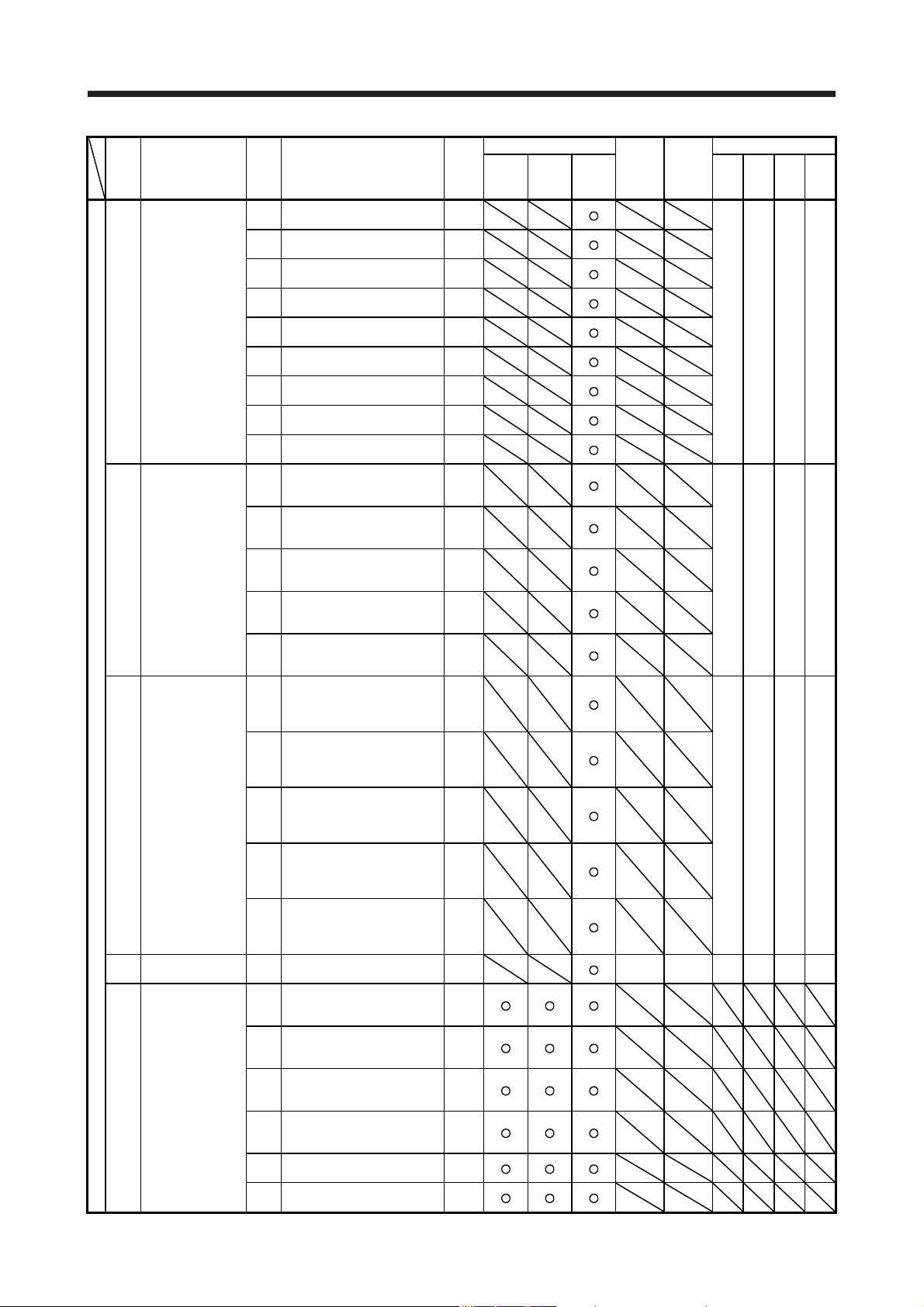

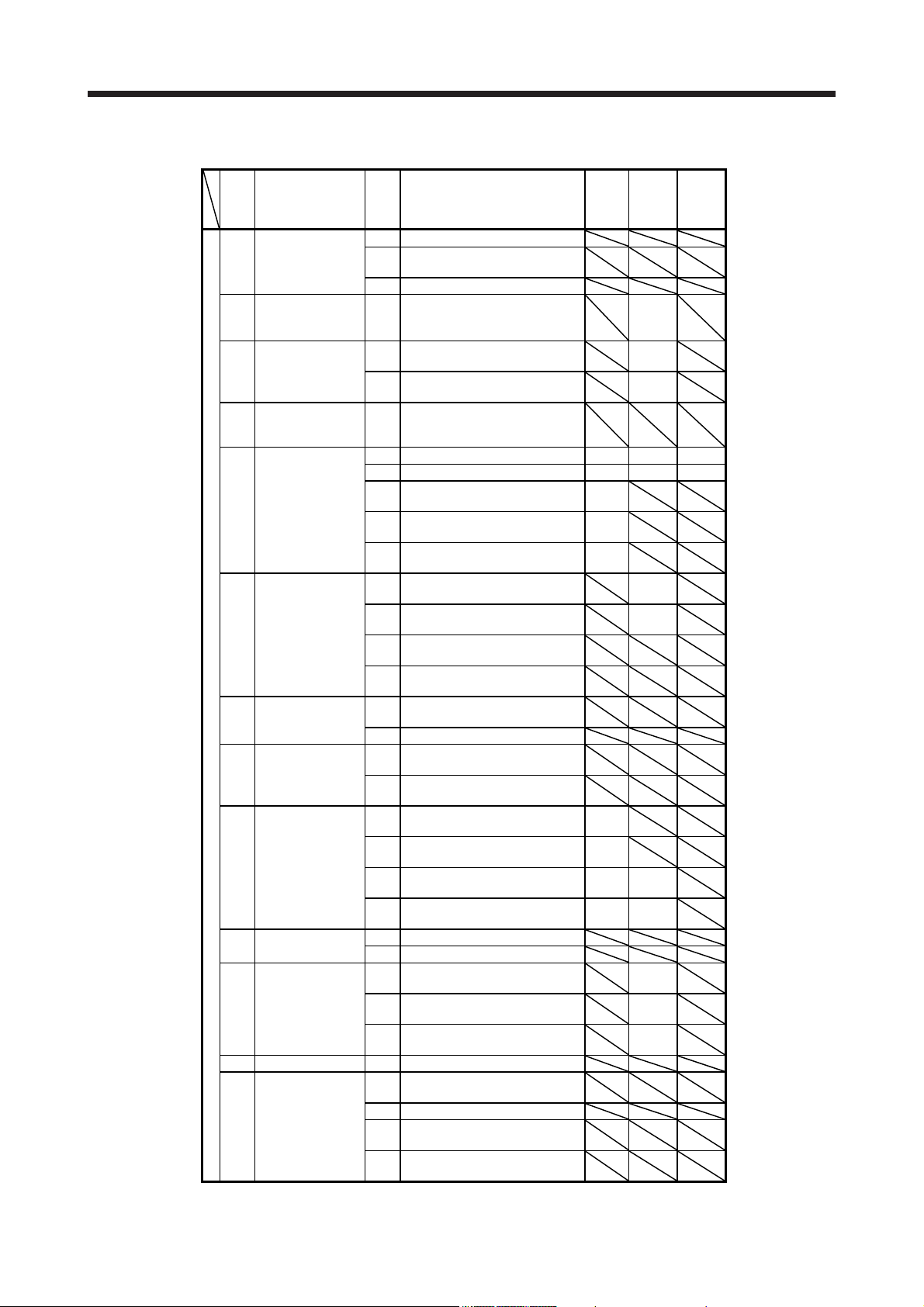

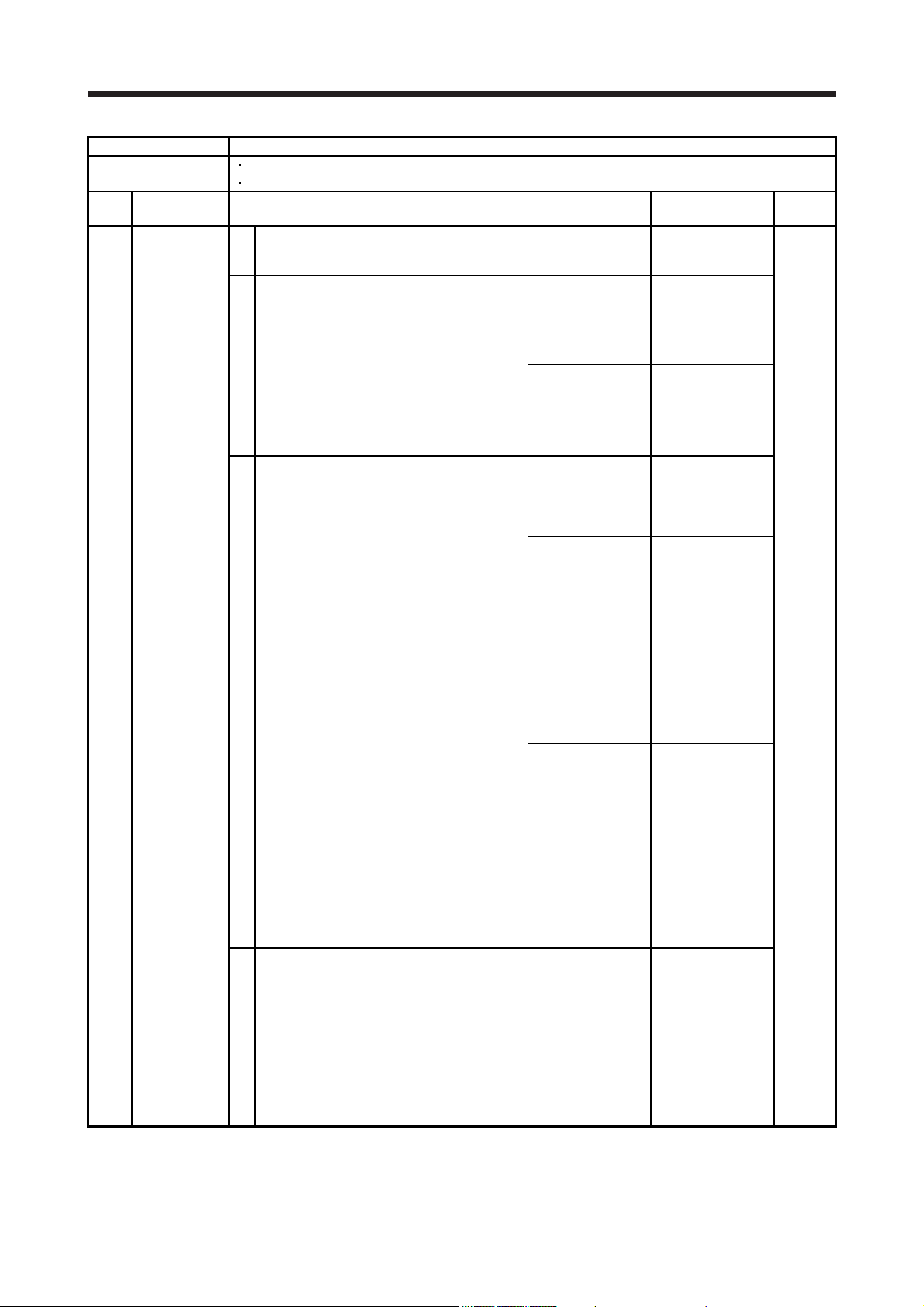

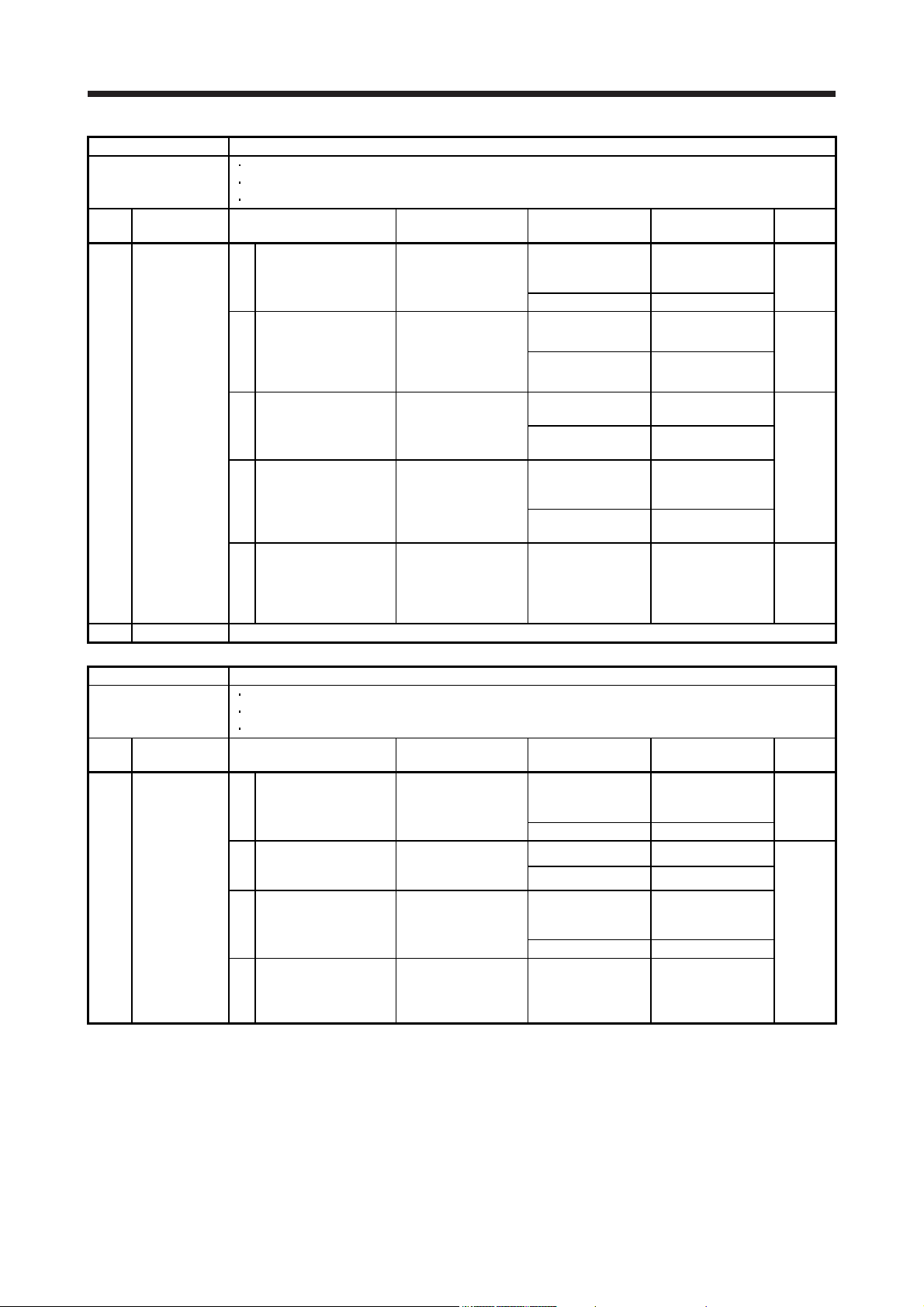

1.2 Alarm list

Stop

No. Name

Alarm

10 Undervoltage

11 Switch setting error

11.2

12.1 RAM error 1 DB

12.2 RAM error 2 DB

12.4 RAM error 4 DB

12.5 RAM error 5 DB

12.6 RAM error 6 DB

13.2 Clock error 2 DB

14.1 Control process error 1 DB

14.2 Control process error 2 DB

14.3 Control process error 3 DB

14.4 Control process error 4 DB

14 14.6 Control process error 6 DB

14.7 Control process error 7 DB

14.8 Control process error 8 DB

14.9 Control process error 9 DB

14.A Control process error 10 DB

14.B Control process error 11 DB

Memory error 1

12

13 Clock error

15

16.1

16.2

16.3

16.5

16.6

16

16.B

16.C

16.D

16.E

16.F

(RAM)

Control process

error

Memory error 2

(EEP-ROM)

Encoder initial

communication

error 1

Detail

No.

Voltage drop in the control

10.1

circuit power

Voltage drop in the main circuit

10.2

power

Axis number setting error/

11.1

Station number setting error

Disabling control axis setting

error

12.3 RAM error 3 DB

13.1 Clock error 1 DB

14.5 Control process error 5 DB

15.1 EEP-ROM error at power on DB

EEP-ROM error during

15.2

operation

Home position information read

15.4

error

Encoder initial communication Receive data error 1

Encoder initial communication Receive data error 2

Encoder initial communication Receive data error 3

Encoder initial communication Transmission data error 1

Encoder initial communication Transmission data error 2

Encoder initial communication -

16.7

Transmission data error 3

Encoder initial communication -

16.A

Process error 1

Encoder initial communication Process error 2

Encoder initial communication Process error 3

Encoder initial communication Process error 4

Encoder initial communication Process error 5

Encoder initial communication Process error 6

Detail name

method

(Note

2, 3)

EDB

SD

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

Alarm deactivation

Alarm

reset

CPU

reset

Process-

Cycling

system

the

(Note 9)

power

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes 0 0 0 0

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Stop

ing

system

(Note 9)

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Alarm code (Note 8)

ACD3

(Bit 3)

0 0 1 0

0 0 0 0

0 0 0 0

0 0 0 0

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

0 1 1 0

ACD2

(Bit 2)

ACD1

(Bit 1)

ACD0

(Bit 0)

1 - 3

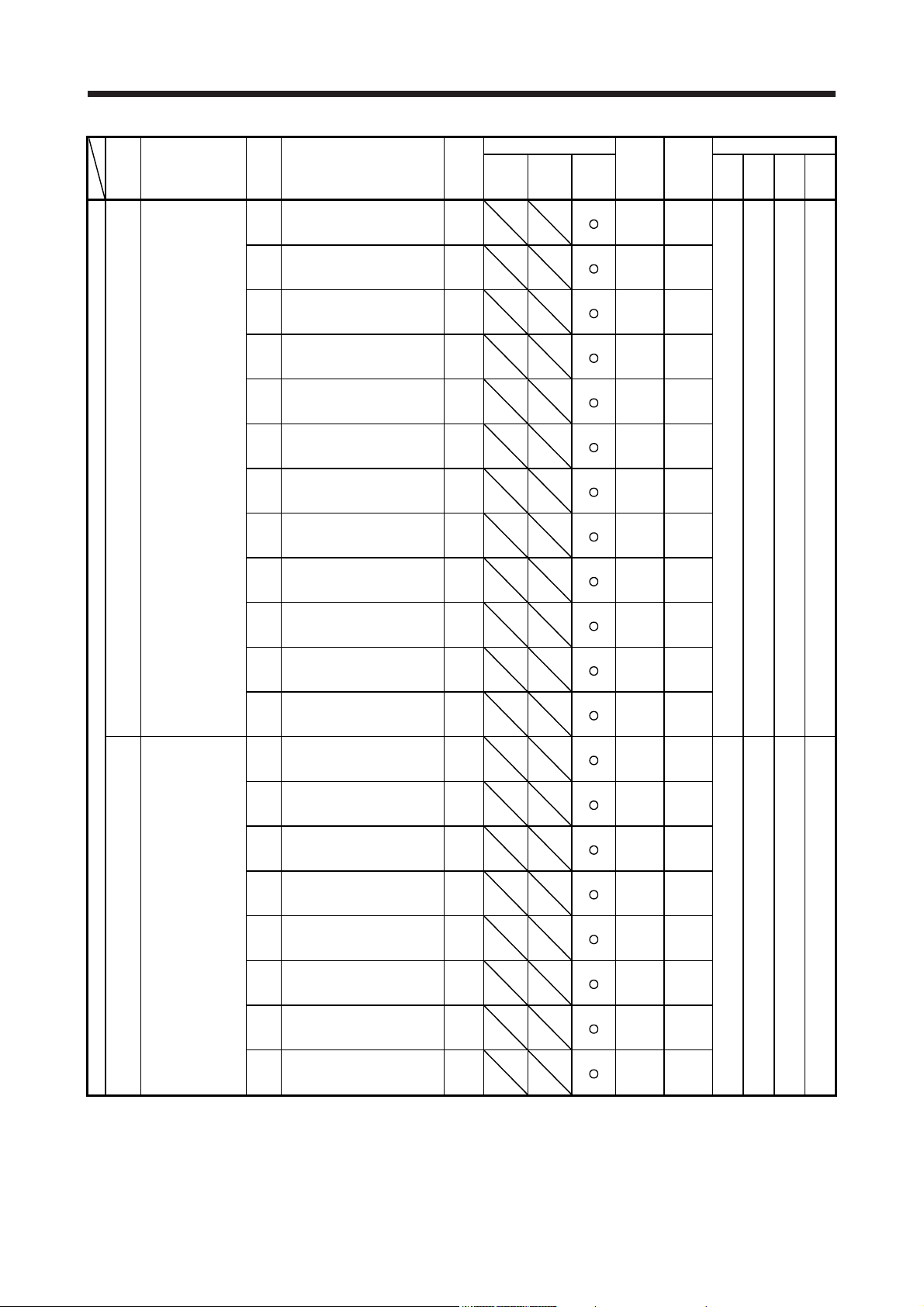

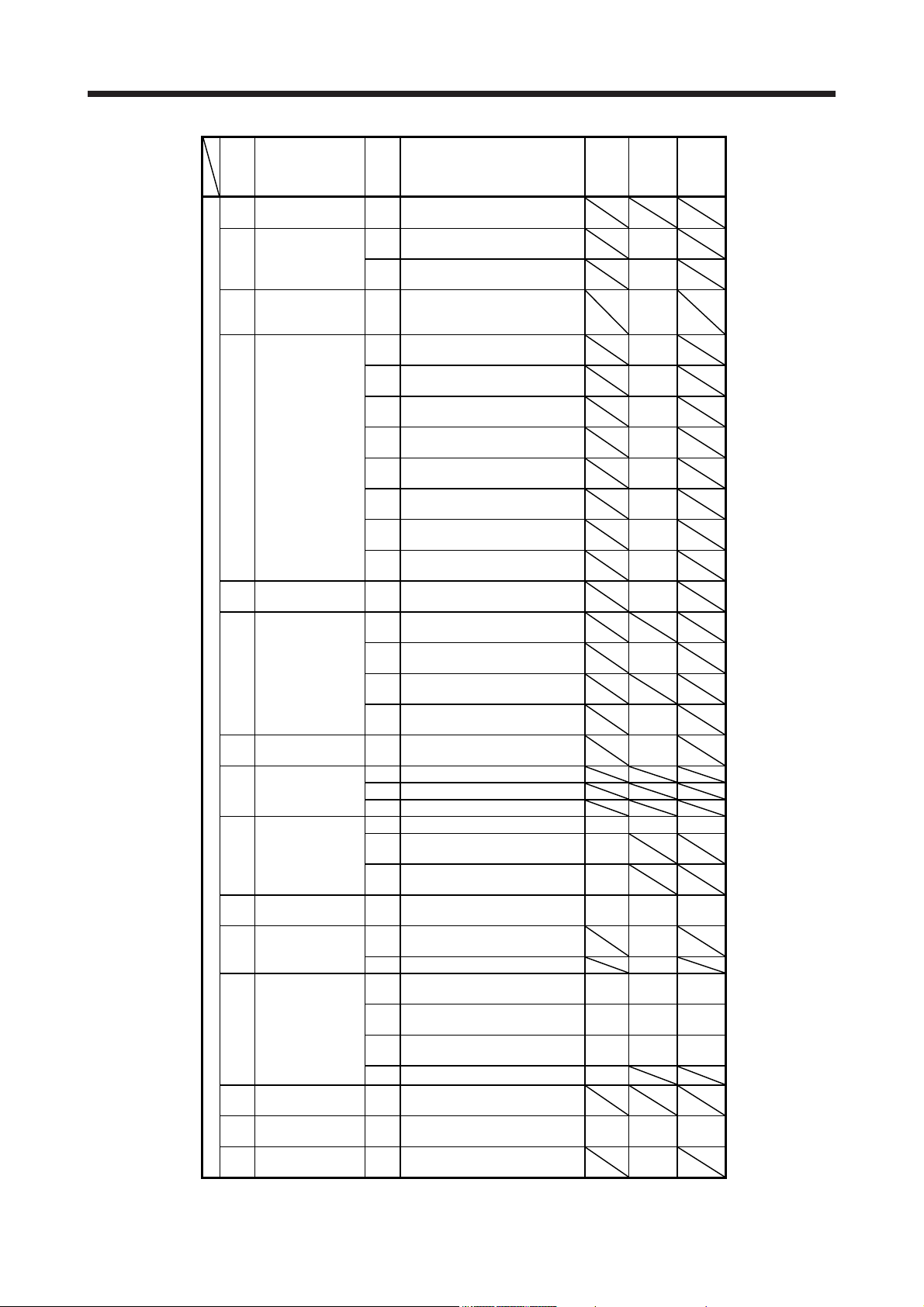

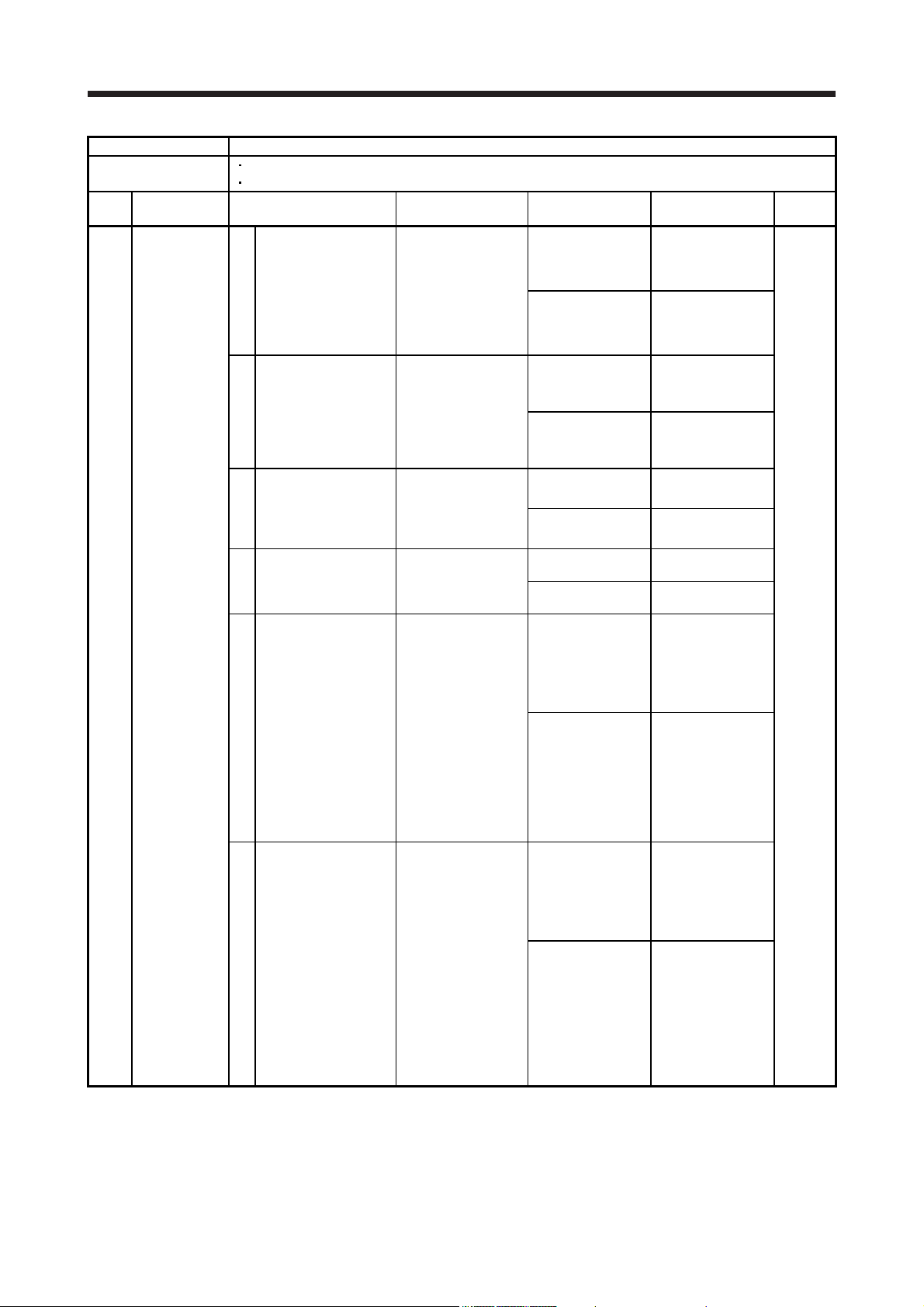

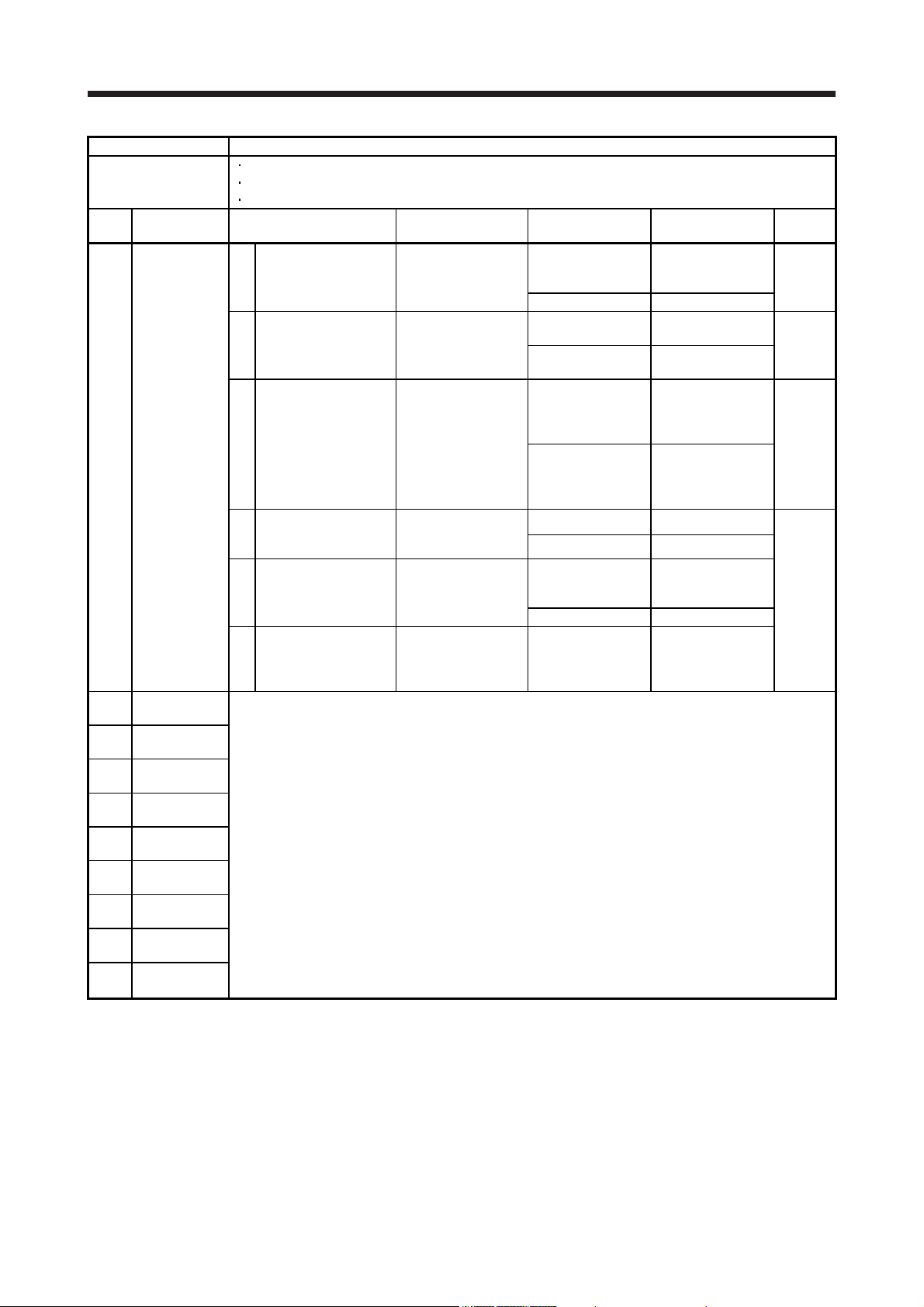

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

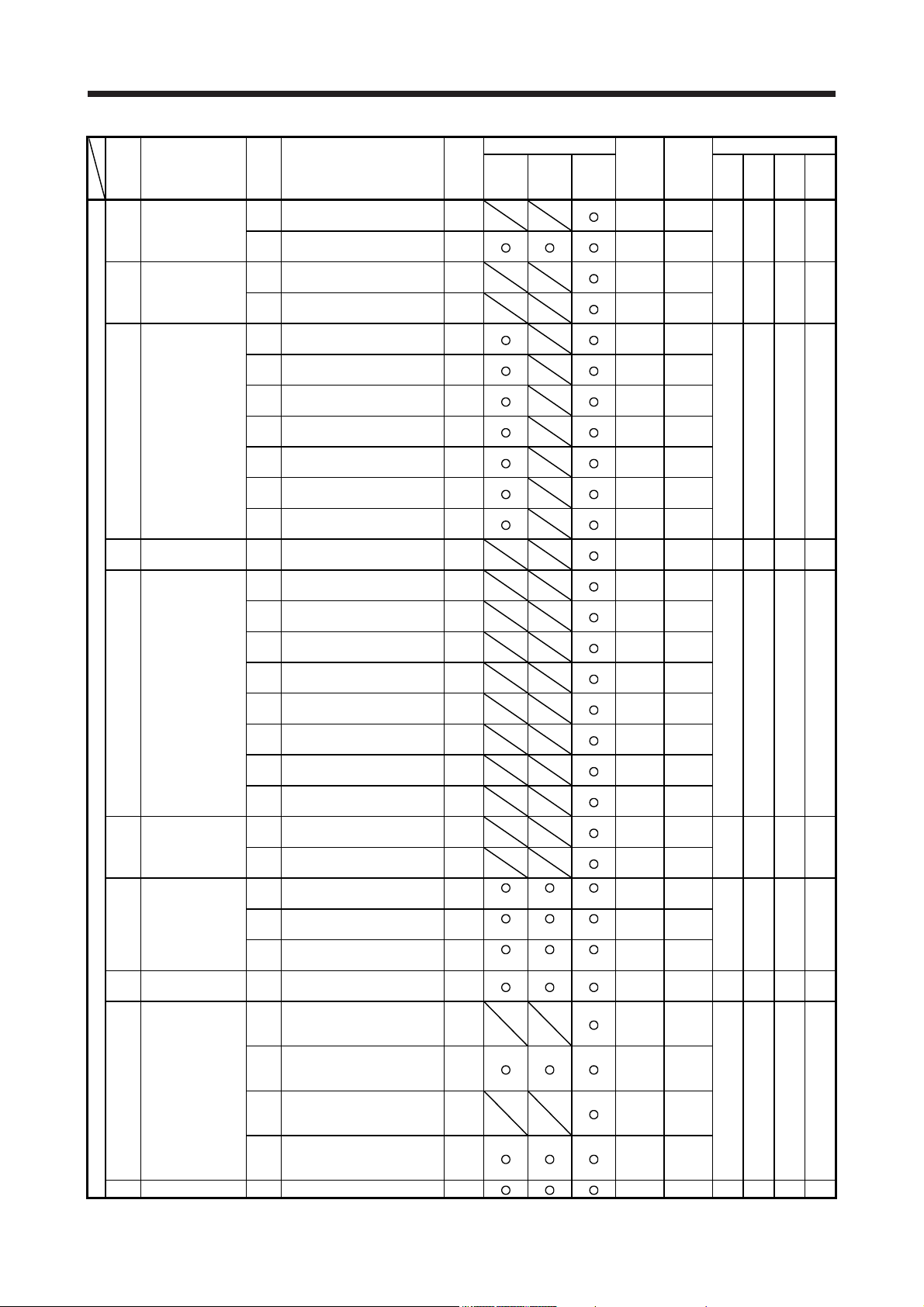

Stop

No. Name

17.1 Board error 1 DB

17.3 Board error 2 DB

Alarm

17.4 Board error 3 DB

17 Board error

17.6 Board error 5 DB

17.7 Board error 7 DB

17.8 Board error 6 (Note 6) EDB

17.9 Board error 8 DB

19 19.2 Flash-ROM error 2 DB

19.3 Flash-ROM error 3 DB

1B Converter error 1B.1 Converter unit error DB

Memory error 3

(Flash-ROM)

1A.1

1A

1E

1F

20

21 21.4 Encoder non-signal error EDB

Servo motor

combination error

1A.4

Encoder initial

communication

error 2

Encoder initial

communication

error 3

20.1

20.2

20.3

Encoder normal

communication

error 1

20.7

20.9

20.A

21.1 Encoder data error 1 EDB

21.2 Encoder data update error EDB

Encoder normal

communication

error 2

21.5 Encoder hardware error 1 EDB

21.6 Encoder hardware error 2 EDB

21.9 Encoder data error 2 EDB

Detail

No.

17.5 Board error 4 DB

19.1 Flash-ROM error 1 DB

Servo motor combination error

1

Servo motor control mode

1A.2

combination error

Servo motor combination error

2

1E.1 Encoder malfunction DB

1E.2 Load-side encoder malfunction DB

1F.1 Incompatible encoder DB

1F.2 Incompatible load-side encoder DB

Encoder normal

communication - Receive data

error 1

Encoder normal

communication - Receive data

error 2

Encoder normal

communication - Receive data

error 3

Encoder normal

20.5

communication - Transmission

data error 1

Encoder normal

20.6

communication - Transmission

data error 2

Encoder normal

communication - Transmission

data error 3

Encoder normal

communication - Receive data

error 4

Encoder normal

communication - Receive data

error 5

21.3 Encoder data waveform error EDB

Detail name

method

(Note

2, 3)

DB

DB

DB

EDB

EDB

EDB

EDB

EDB

EDB

EDB

EDB

Alarm deactivation

Alarm

reset

CPU

reset

Process-

Cycling

system

the

(Note 9)

power

Common All axes

Common All axes

Common All axes

Common All axes 0 0 0 0

Common All axes

Common All axes

Common All axes

Common All axes

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Stop

ing

system

(Note 9)

0 0 1 0

ACD3

(Bit 3)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

0 0 0 0

0 1 1 0

0 1 1 0

0 1 1 0

0 1 1 0

0 1 1 0

1 - 4

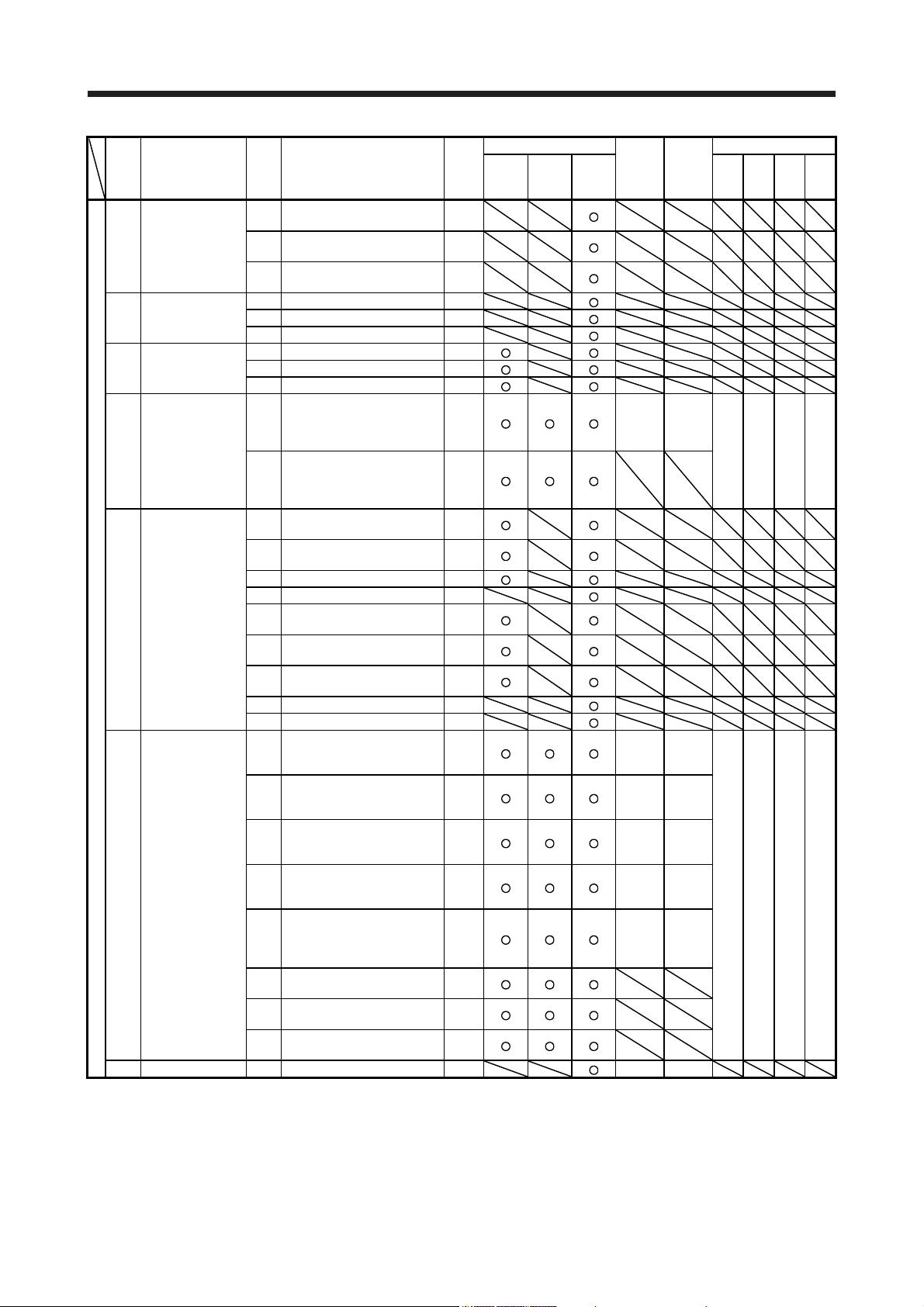

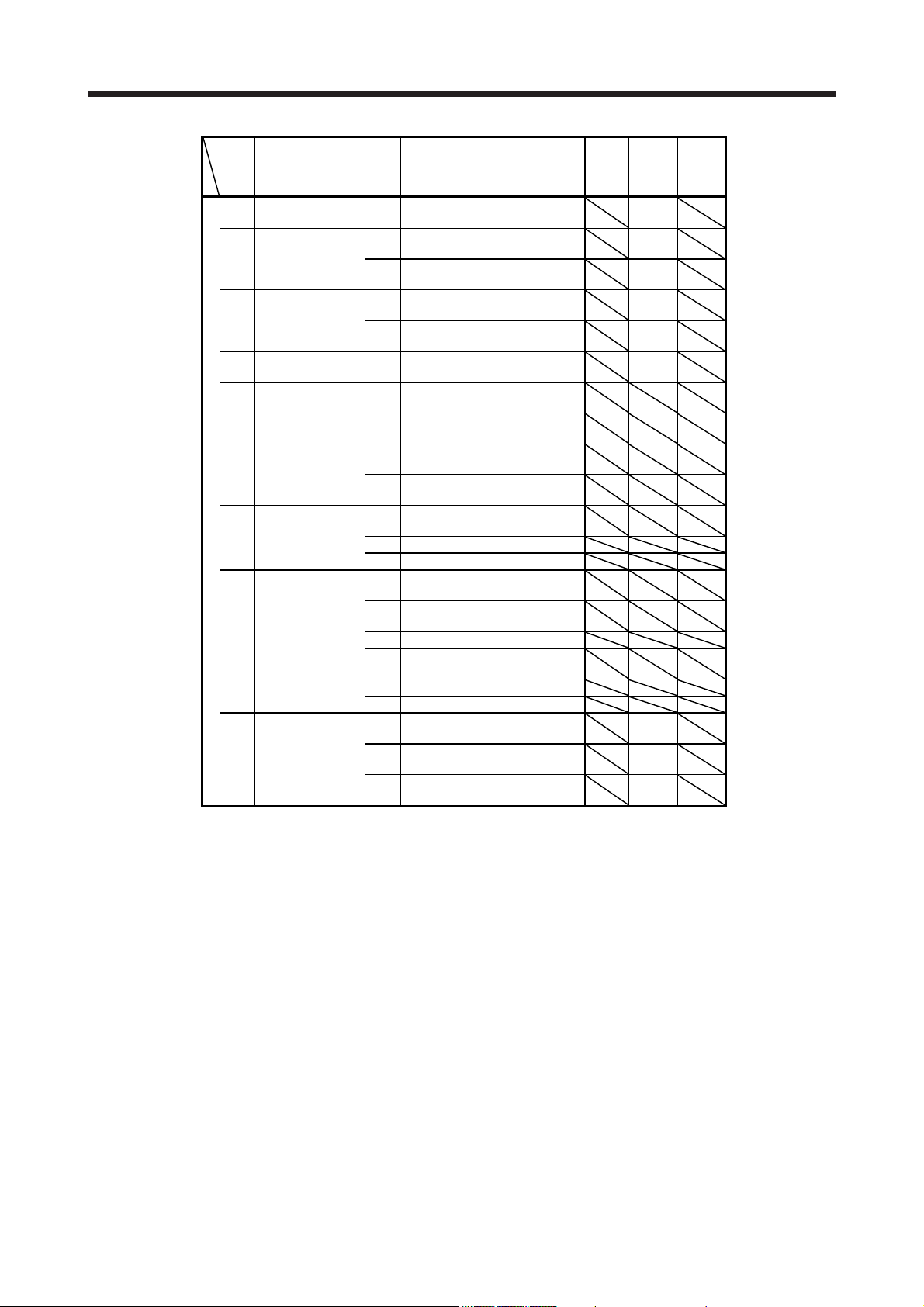

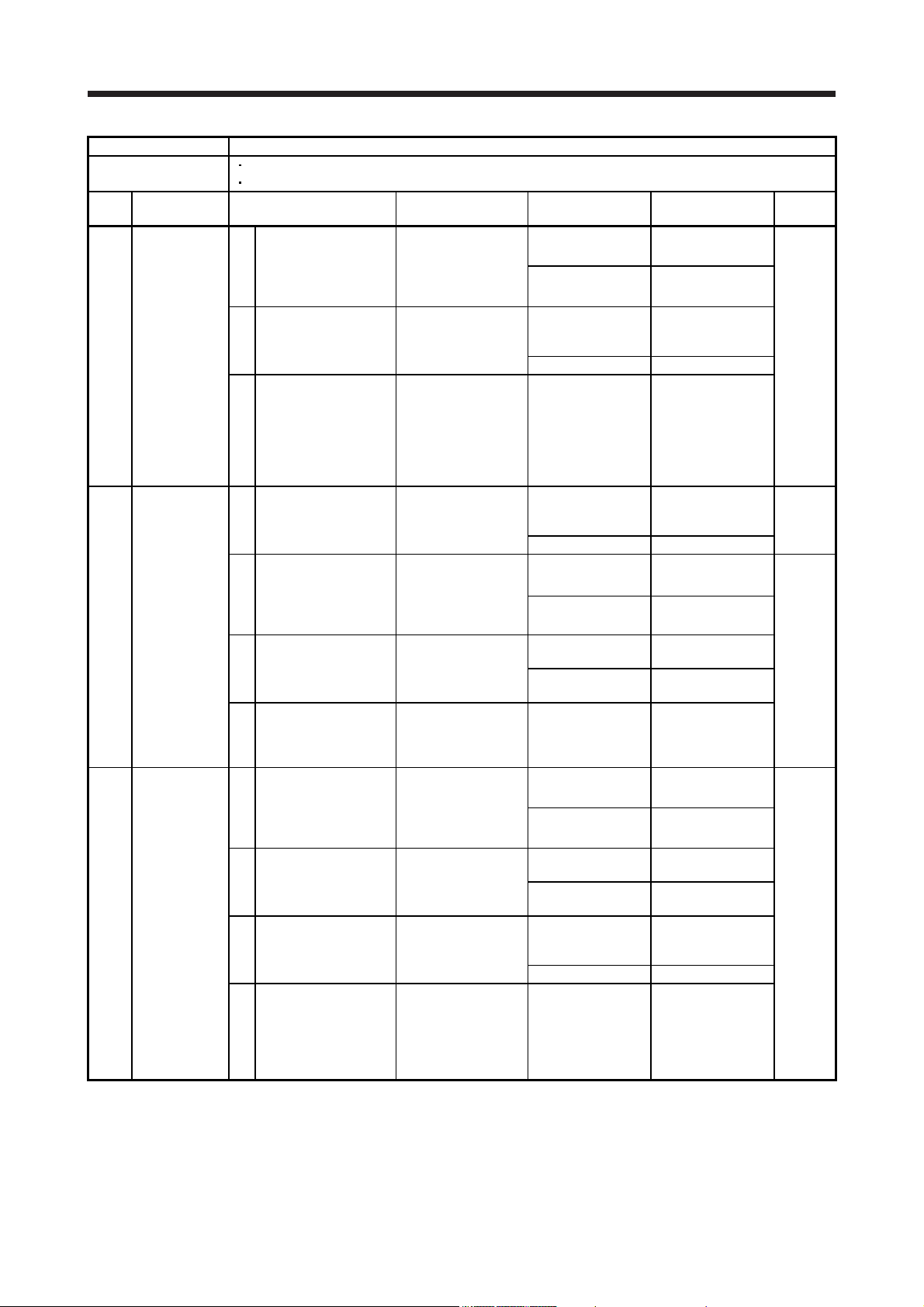

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

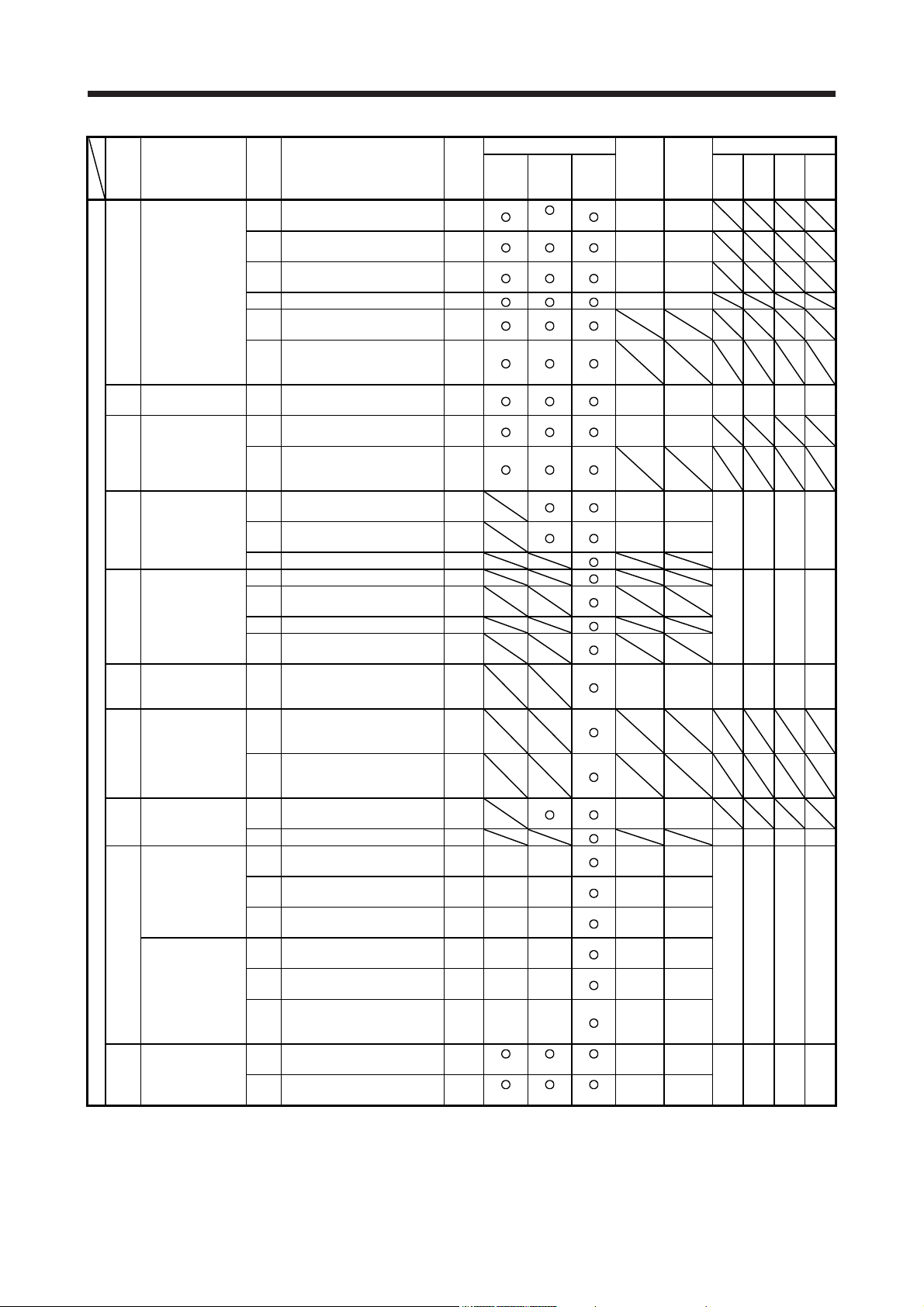

Stop

No. Name

Alarm

24 Main circuit error

33 Overvoltage 33.1 Main circuit voltage error EDB

Absolute position

25

27.1

27.2

27.3

27

27.5

27.6

27.7

28

2A.1 Linear encoder error 1-1 EDB

2A.2 Linear encoder error 1-2 EDB

2A.3 Linear encoder error 1-3 EDB

2A

2A.6 Linear encoder error 1-6 EDB

2A.7 Linear encoder error 1-7 EDB

2A.8 Linear encoder error 1-8 EDB

2B

30.1 Regeneration heat error DB

30 Regenerative error 30.2 Regeneration signal error DB

30.3

31 Overspeed 31.1 Abnormal motor speed SD

32.1

32 Overcurrent

32.4

erased

Initial magnetic

pole detection error

Linear encoder

error 2

Linear encoder

error 1

Encoder counter

error

Detail

No.

Ground fault detected by

24.1

hardware detection circuit

Ground fault detected by

24.2

software detection function

Servo motor encoder -

25.1

Absolute position erased

Scale measurement encoder -

25.2

Absolute position erased

Initial magnetic pole detection Abnormal termination

Initial magnetic pole detection Time out error

Initial magnetic pole detection Limit switch error

Initial magnetic pole detection -

27.4

Estimated error

Initial magnetic pole detection Position deviation error

Initial magnetic pole detection Speed deviation error

Initial magnetic pole detection Current error

Linear encoder - Environment

28.1

error

2A.4 Linear encoder error 1-4 EDB

2A.5 Linear encoder error 1-5 EDB

2B.1 Encoder counter error 1 EDB

2B.2 Encoder counter error 2 EDB

Regeneration feedback signal

error

Overcurrent detected at

hardware detection circuit

(during operation)

Overcurrent detected at

32.2

software detection function

(during operation)

Overcurrent detected at

32.3

hardware detection circuit

(during a stop)

Overcurrent detected at

software detection function

(during a stop)

Detail name

method

(Note

2, 3)

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

EDB

DB

DB

DB

DB

DB

Alarm deactivation

Alarm

reset

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

CPU

reset

Cycling

the

power

Process-

system

(Note 9)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes

Common All axes 0 0 0 1

Common All axes

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes 1 0 0 1

Stop

ing

system

(Note 9)

All axes

All axes

All axes

All axes

All axes

All axes

ACD3

(Bit 3)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

1 1 0 0

1 1 1 0

1 1 1 0

0 1 1 0

0 1 1 0

1 1 1 0

0 1 0 1

0 1 0 0

1 - 5

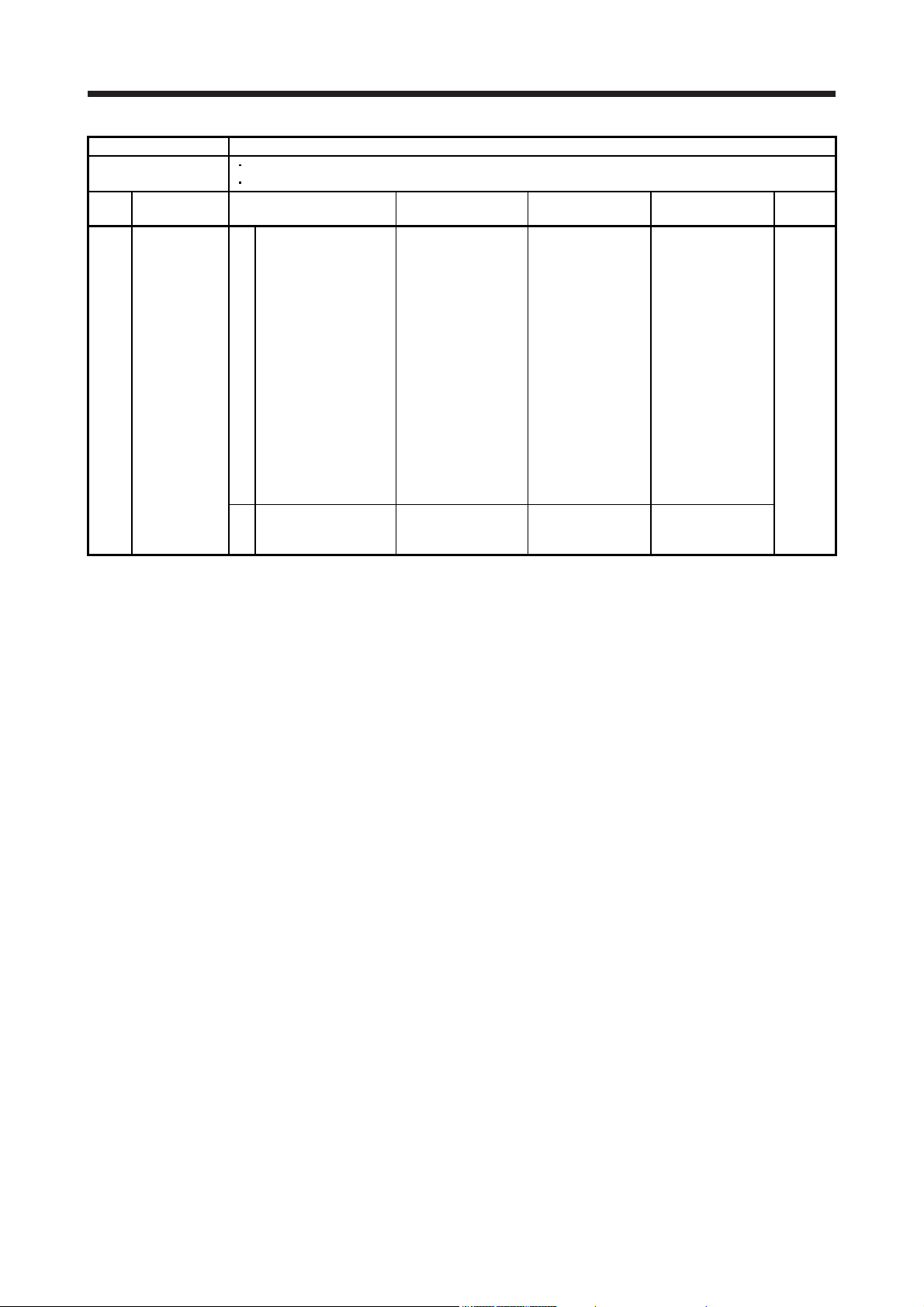

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

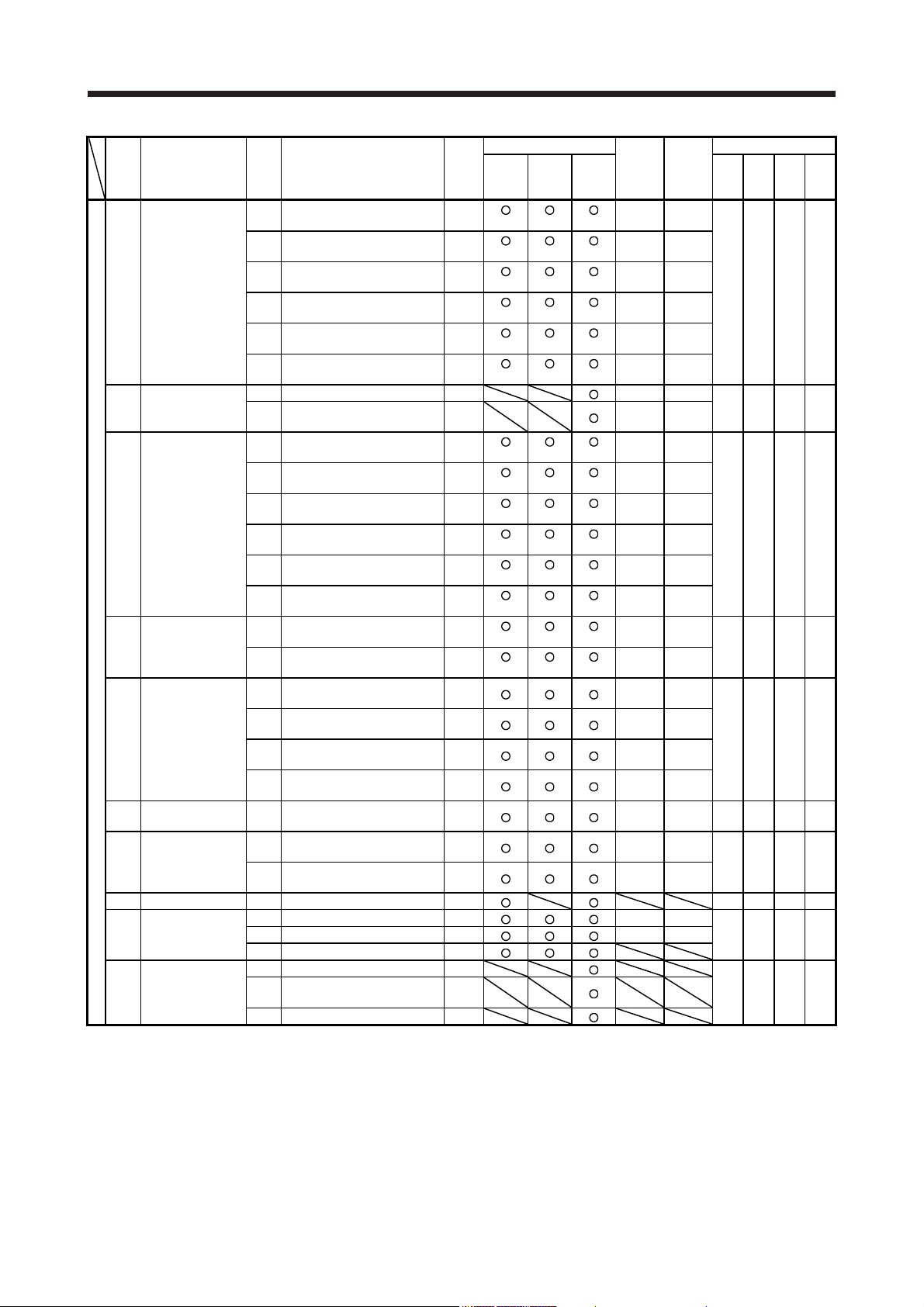

Stop

No. Name

Alarm

34.4 Hardware error signal detection SD

37.3 Point table setting error DB

39.3 Register No. error DB

3E.6 Operation mode switch error DB

SSCNET receive

34

35

36

37 Parameter error

39 Program error

3A

3D

3E

42

45

error 1

Command

frequency error

SSCNET receive

error 2

Inrush current

suppression circuit

error

Parameter setting

error for driver

communication

Operation mode

error

Servo control error

(for linear servo

motor and direct

drive motor)

Fully closed loop

control error

(for fully closed

loop control)

Main circuit device

overheat

Detail

No.

34.1 SSCNET receive data error SD

SSCNET connector connection

34.2

error

SSCNET communication data

34.3

error

SSCNET receive data error

34.5

(safety observation function)

SSCNET communication data

34.6

error (safety observation

function)

35.1 Command frequency error SD

Continuous communication

36.1

data error

Continuous communication

36.2

data error (safety observation

function)

37.1 Parameter setting range error DB

37.2 Parameter combination error DB

39.1 Program error DB

Instruction argument external

39.2

error

Non-correspondence instruction

39.4

error

Inrush current suppression

3A.1

circuit error

Parameter combination error

3D.1

for driver communication on

slave

Parameter combination error

3D.2

for driver communication on

master

3E.1 Operation mode error DB

Servo control error by position

42.1

deviation

Servo control error by speed

42.2

deviation

Servo control error by

42.3

torque/thrust deviation

Fully closed loop control error

42.8

by position deviation

Fully closed loop control error

42.9

by speed deviation

Fully closed loop control error

42.A

by position deviation during

command stop

Main circuit device overheat

45.1

error 1

Main circuit device overheat

45.2

error 2

Detail name

method

(Note

2, 3)

SD

SD

SD

SD

SD

SD

DB

DB

EDB

DB

DB

EDB (Note 4) (Note 4)

EDB (Note 4) (Note 4)

EDB (Note 4) (Note 4)

EDB (Note 4) (Note 4)

EDB (Note 4) (Note 4)

EDB (Note 4) (Note 4)

SD

SD

Alarm deactivation

Alarm

reset

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

CPU

reset

(Note 5)

Cycling

the

power

Process-

system

(Note 9)

Common All axes

Common All axes

Each

axis

Common All axes

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes 0 0 0 0

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes

Common All axes

Stop

ing

system

(Note 9)

1 0 0 0

ACD3

(Bit 3)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

1 1 0 1

1 0 0 0

0 0 0 0

0 1 1 0

0 0 1 1

1 - 6

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Stop

No. Name

46.1

Alarm

46.2

46

46.4 Thermistor circuit error SD

46.5

46.6

47 Cooling fan error

47.2

50.1

50.2

50 Overload 1

50.4

50.5

50.6

51 Overload 2

51.2

52.1 Excess droop pulse 1 SD

52 Error excessive

52.4

52.5 Excess droop pulse 3 EDB

54

56 Forced stop error

56.3

61 Operation error 61.1 Point table setting range error DB

63.1 STO1 off DB

63 STO timing error 63.2 STO2 off DB

63.5 STO by functional safety unit DB

64.1 STO input error DB

64

Servo motor

overheat

Oscillation

detection

Functional safety

unit setting error

64.3 Operation mode setting error DB

Detail

No.

Abnormal temperature of servo

motor 1

Abnormal temperature of servo

motor 2

46.3 Thermistor disconnected error SD

Abnormal temperature of servo

motor 3

Abnormal temperature of servo

motor 4

47.1 Cooling fan stop error SD

Cooling fan speed reduction

error

Thermal overload error 1

during operation

Thermal overload error 2

during operation

Thermal overload error 4

50.3

during operation

Thermal overload error 1

during a stop

Thermal overload error 2

during a stop

Thermal overload error 4

during a stop

Thermal overload error 3

51.1

during operation

Thermal overload error 3

during a stop

52.3 Excess droop pulse 2 SD

Error excessive during 0 torque

limit

54.1 Oscillation detection error EDB

56.2 Over speed during forced stop EDB

Estimated distance over during

forced stop

Compatibility mode setting

64.2

error

Detail name

method

(Note

2, 3)

SD

SD

DB

DB

SD

SD

SD

SD

SD

SD

SD

DB

DB

SD

EDB

DB

Alarm deactivation

Alarm

reset

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

(Note 1) (Note 1) (Note 1)

CPU

reset

Cycling

the

power

Process-

system

(Note 9)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes

Common All axes

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Common All axes

Common All axes 0 1 1 0

Stop

ing

system

(Note 9)

0 1 0 1

1 0 0 0

ACD3

(Bit 3)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

0 0 1 1

0 0 1 1

0 0 1 1

0 0 1 1

0 1 0 1

0 0 1 1

0 1 1 0

1 - 7

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

No. Name

65.1

Alarm

65.2

65.3

65 65.5

65.6

65.7

65.8

65.9

66.1

66 66.3

66.7

66.9

67.1

67 67.3

67.4

67.7

68

69.2

69.3

69.4

69.5

69.6

Functional safety

unit connection

error

Encoder initial

communication

error (safety

observation

function)

Encoder normal

communication

error 1

(safety observation

function)

STO diagnosis

error

69 Command error

Detail

No.

Functional safety unit

communication error 1

Functional safety unit

communication error 2

Functional safety unit

communication error 3

Functional safety unit

65.4

communication error 4

Functional safety unit

communication error 5

Functional safety unit

communication error 6

Functional safety unit

communication error 7

Functional safety unit shut-off

signal error 1

Functional safety unit shut-off

signal error 2

Encoder initial communication Receive data error 1 (safety

observation function)

Encoder initial communication -

66.2

Receive data error 2 (safety

observation function)

Encoder initial communication Receive data error 3 (safety

observation function)

Encoder initial communication Transmission data error 1

(safety observation function)

Encoder initial communication Process error 1 (safety

observation function)

Encoder normal

communication - Receive data

error 1 (safety observation

function)

Encoder normal

communication - Receive data

67.2

error 2 (safety observation

function)

Encoder normal

communication - Receive data

error 3 (safety observation

function)

Encoder normal

communication - Receive data

error 4 (safety observation

function)

Encoder normal

communication - Transmission

data error 1 (safety observation

function)

68.1 Mismatched STO signal error DB

Forward rotation-side software

69.1

limit detection - Command

excess error

Reverse rotation-side software

limit detection - Command

excess error

Forward rotation stroke end

detection - Command excess

error

Reverse rotation stroke end

detection - Command excess

error

Upper stroke limit detection Command excess error

Lower stroke limit detection Command excess error

Detail name

Stop

method

(Note

2, 3)

SD

SD

SD

SD

SD

SD

SD

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

DB

SD

SD

SD

SD

SD

SD

Alarm deactivation

Alarm

CPU

reset

reset

Process-

Cycling

system

the

(Note 9)

power

Common Common 0 0 0 0

Stop

ing

system

(Note 9)

0 0 0 0

0 1 1 0

0 1 1 0

ACD3

(Bit 3)

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

1 - 8

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

No. Name

70.1

Alarm

70.2

70.3

70.5

70.6

70.A

70.B

70.C

70.D

70.E

70.F

Load-side encoder

70

71.1

71.2

71.3

71

71.7

71.9

71.A

initial

communication

error 1

Load-side encoder

normal

communication

error 1

Detail

No.

Load-side encoder initial

communication - Receive data

error 1

Load-side encoder initial

communication - Receive data

error 2

Load-side encoder initial

communication - Receive data

error 3

Load-side encoder initial

communication - Transmission

data error 1

Load-side encoder initial

communication - Transmission

data error 2

Load-side encoder initial

70.7

communication - Transmission

data error 3

Load-side encoder initial

communication - Process error 1 DB

Load-side encoder initial

communication - Process error 2 DB

Load-side encoder initial

communication - Process error 3 DB

Load-side encoder initial

communication - Process error 4 DB

Load-side encoder initial

communication - Process error 5 DB

Load-side encoder initial

communication - Process error 6 DB

Load-side encoder normal

communication - Receive data

error 1

Load-side encoder normal

communication - Receive data

error 2

Load-side encoder normal

communication - Receive data

error 3

Load-side encoder normal

71.5

communication - Transmission

data error 1

Load-side encoder normal

71.6

communication - Transmission

data error 2

Load-side encoder normal

communication - Transmission

data error 3

Load-side encoder normal

communication - Receive data

error 4

Load-side encoder normal

communication - Receive data

error 5

Detail name

Stop

method

(Note

2, 3)

DB

DB

DB

DB

DB

DB

EDB

EDB

EDB

EDB

EDB

EDB

EDB

EDB

Alarm deactivation

Alarm

reset

CPU

reset

Cycling

the

power

Process-

ing

system

(Note 9)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Stop

system

(Note 9)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

ACD3

(Bit 3)

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

0 1 1 0

0 1 1 0

1 - 9

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Stop

No. Name

72.1 Load-side encoder data error 1 EDB

Alarm

72.2

Load-side encoder

72 72.4

72.5

72.6

72.9 Load-side encoder data error 2 EDB

74.1 Option card error 1 DB

74.2 Option card error 2 DB

74 Option card error 1 74.3 Option card error 3 DB

74.4 Option card error 4 DB

74.5 Option card error 5 DB

75 Option card error 2

75.4 Option card disconnected DB

79.1

79.2

79

79.4 Servo amplifier error SD

79.5 Input device error SD

79.6 Output device error SD

79.7 Mismatched input signal error SD

79.8 Position feedback fixing error DB

7A.2

7A

7A.3

7A.4

7B.1

7B

7B.3

7B.4

7C

7C.2

7D

7D.2 Speed observation error DB

82

normal

communication

error 2

Functional safety

unit diagnosis error

Parameter setting

error

(safety observation

function)

Encoder diagnosis

error

(safety observation

function)

Functional safety

unit communication

diagnosis error

(safety observation

function)

Safety observation

error

Master-slave

operation error 1

Detail

No.

Load-side encoder data update

error

Load-side encoder data

72.3

waveform error

Load-side encoder non-signal

error

Load-side encoder hardware

error 1

Load-side encoder hardware

error 2

75.3 Option card connection error EDB

Functional safety unit power

voltage error

Functional safety unit internal

error

Abnormal temperature of

79.3

functional safety unit

Parameter verification error

7A.1

(safety observation function)

Parameter setting range error

(safety observation function)

Parameter combination error

(safety observation function)

Functional safety unit

combination error (safety

observation function)

Encoder diagnosis error 1

(safety observation function)

Encoder diagnosis error 2

7B.2

(safety observation function)

Encoder diagnosis error 3

(safety observation function)

Encoder diagnosis error 4

(safety observation function)

Functional safety unit

7C.1

communication setting error

(safety observation function)

Functional safety unit

communication data error

(safety observation function)

7D.1 Stop observation error DB

82.1 Master-slave operation error 1 EDB

Detail name

method

(Note

2, 3)

EDB

EDB

EDB

EDB

EDB

DB

DB

SD

DB

DB

DB

DB

DB

DB

DB

DB

SD

SD

Alarm deactivation

Alarm

(Note 7)

(Note 7)

(Note 7)

(Note 7)

(Note 3)

(Note 7)

CPU

reset

reset

Cycling

power

the

Process-

system

(Note 9)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Stop

ing

system

(Note 9)

ACD3

(Bit 3)

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Each

axis

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

0 1 1 0

1 1 1 1

1 0 0 0

0 1 1 0

0 0 0 0

1 1 1 1

1 - 10

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Stop

No. Name

Alarm

8D.1

8D.2

8D.5 Master station setting error 2 DB

8D 8D.6

8D.7

8D.8

8D.9 Synchronization error 1 SD

8D.A Synchronization error 2 SD

8E.1

88888 Watchdog 8888._ Watchdog DB

Network module

84

initialization error

Network module

85

86

8A

8E.2

8E

8E.6

8E.7

8E.8

error

Network

communication

error

USB

communication

time-out error/serial

communication

time-out

error/Modbus-RTU

communication

time-out error

CC-Link IE

communication

error

USB

communication

error/serial

communication

error/Modbus-RTU

communication

error

Detail

No.

Network module undetected

84.1

error

Network module initialization

84.2

error 1

Network module initialization

84.3

error 2

85.1 Network module error 1 SD

85.2 Network module error 2 SD

85.3 Network module error 3 SD

86.1 Network communication error 1 SD

86.2 Network communication error 2 SD

86.3 Network communication error 3 SD

USB communication time-out

8A.1

error/serial communication

time-out error

Modbus-RTU communication

8A.2

time-out error

CC-Link IE communication

error 1

CC-Link IE communication

error 2

8D.3 Master station setting error 1 DB

CC-Link IE communication

error 3

CC-Link IE communication

error 4

CC-Link IE communication

error 5

USB communication receive

error/serial communication

receive error

USB communication checksum

error/serial communication

checksum error

USB communication character

8E.3

error/serial communication

character error

USB communication command

8E.4

error/serial communication

command error

USB communication data

number error/serial

8E.5

communication data number

error

Modbus-RTU communication

receive error

Modbus-RTU communication

message frame error

Modbus-RTU communication

CRC error

Detail name

method

(Note

2, 3)

DB

DB

DB

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

Alarm deactivation

Alarm

CPU

reset

reset

Process-

Cycling

system

the

(Note 9)

power

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Common All axes

Stop

ing

system

(Note 9)

ACD3

(Bit 3)

Alarm code (Note 8)

ACD2

ACD1

ACD0

(Bit 2)

(Bit 1)

(Bit 0)

0 0 0 0

0 0 0 0

1 - 11

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

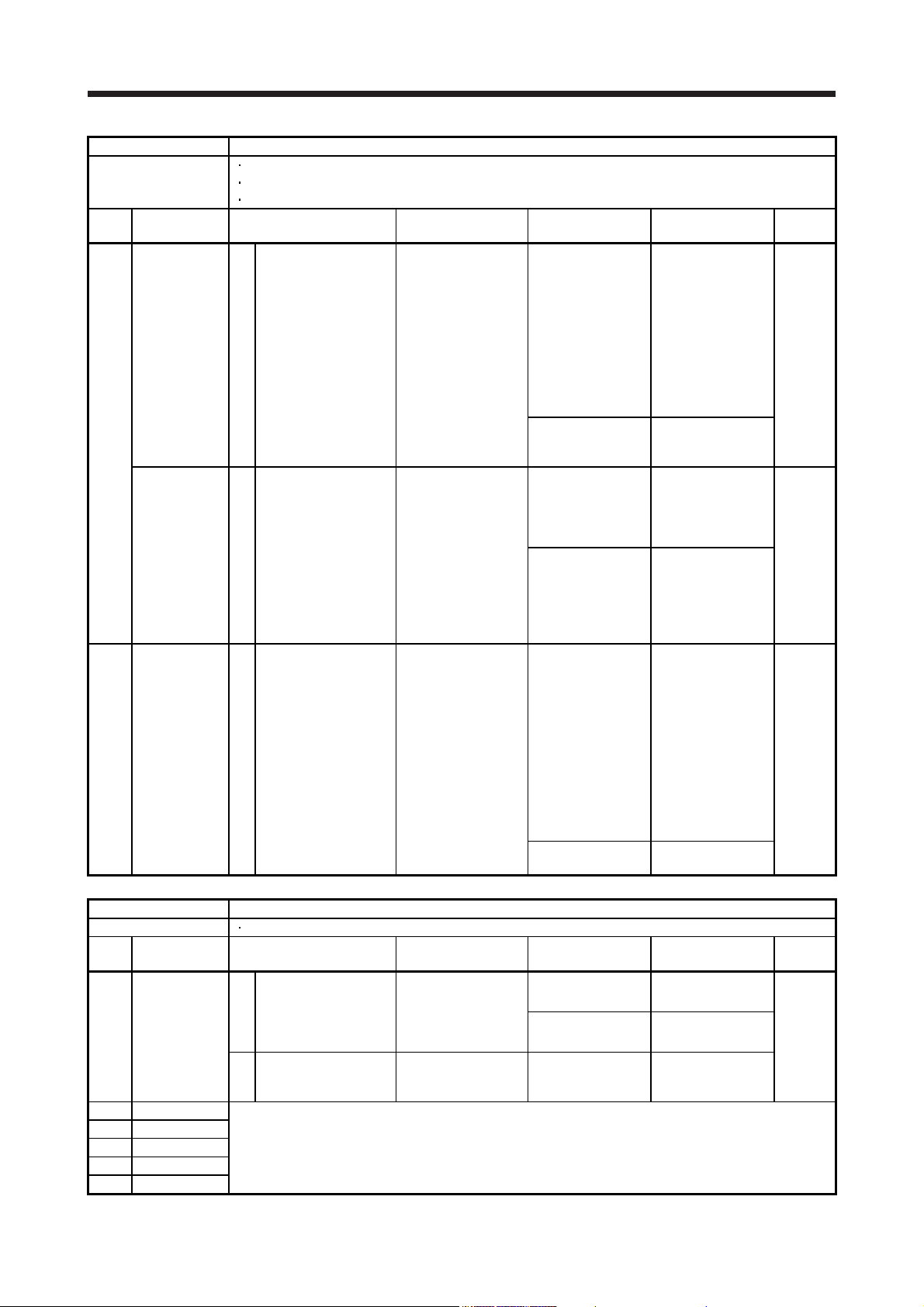

A

Note 1. After resolving the source of trouble, cool the equipment for approximately 30 minutes.

2. The following shows three stop methods of DB, EDB, and SD.

DB: Stops with dynamic brake. (Coasts for the servo amplifier without dynamic brake.)

Coasts for MR-J4-03A6(-RJ) and MR-J4W2-0303B6. Note that EDB is applied when an alarm below occurs;

[AL. 30.1], [AL. 32.2], [AL. 32.4], [AL. 51.1], [AL. 51.2], [AL. 888]

EDB: Electronic dynamic brake stop (available with specified servo motors)

Refer to the following table for the specified servo motors. The stop method for other than the specified servo motors will

be DB.

3. This is applicable when [Pr. PA04] is set to the initial value. The stop system of SD can be changed to DB using [Pr. PA04].

4. The alarm can be canceled by setting as follows:

5. In some controller communication status, the alarm factor may not be removed.

6. This alarm will occur only in the J3 compatibility mode.

7. Reset this while all the safety observation functions are stopped.

8.

9. The processing and stop systems are applicable only for the multi-axis servo amplifiers (MR-J4W_-_B_). Refer to section 1.1

SD: Forced stop deceleration

For the fully closed loop control: set [Pr. PE03] to "1 _ _ _".

When a linear servo motor or direct drive motor is used: set [Pr. PL04] to "1 _ _ _".

larm codes are outputted only from MR-J4-_A_(-RJ)/MR-J4-DU_A_(-RJ). Refer to section 1.1 for details.

for details.

Series Servo motor

HG-KR HG-KR053/HG-KR13/HG-KR23/HG-KR43

HG-MR HG-MR053/HG-MR13/HG-MR23/HG-MR43

HG-SR HG-SR51/HG-SR52

HG-AK HG-AK0136/HG-AK0236/HG-AK0336

1 - 12

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

1.3 Warning list

Stop

No. Name

Home position

return incomplete

90 90.2

Warning

90.5 Z-phase unpassed

91

92

92.3 Battery degradation

93

95.1 STO1 off detection DB Common All axes

95.2 STO2 off detection DB Common All axes

95 STO warning

95.4

95.5

96.1

96

96.3

96.4

97

97.2 Next station position warning

98

98.2

99.1 Forward rotation stroke end off

99 Stroke limit warning

99.4 Upper stroke limit off (Note 7)

99.5 Lower stroke limit off (Note 7)

9A

9A.2 Optional unit BCD input data error

9B

9B.3 Excess droop pulse 2 warning

9B.4

9C Converter error 9C.1 Converter unit error

9D.1

9D

9D.3

9D.4

warning

Servo amplifier

overheat warning

(Note 1)

Battery cable

disconnection

warning

ABS data transfer

warning

Home position

setting warning

Positioning

specification

warning

Software limit

warning

Optional unit input

data error warning

Error excessive

warning

CC-Link IE warning

1

Detail

No.

90.1 Home position return incomplete

Home position return abnormal

termination

Main circuit device overheat

91.1

warning

Encoder battery cable

92.1

disconnection warning

ABS data transfer requirement

93.1

warning during magnetic pole

detection

STO warning 1 (safety observation

95.3

function)

STO warning 2 (safety observation

function)

STO warning 3 (safety observation

function)

In-position warning at home

positioning

Command input warning at home

96.2

positioning

Servo off warning at home

positioning

Home positioning warning during

magnetic pole detection

Program operation disabled

97.1

warning

Forward rotation-side software

98.1

stroke limit reached

Reverse rotation-side software

stroke limit reached

99.2 Reverse rotation stroke end off

9A.1 Optional unit input data sign error

9B.1 Excess droop pulse 1 warning

Error excessive warning during 0

torque limit

Station number switch change

warning

9D.2 Master station setting warning

Overlapping station number

warning

Mismatched station number

warning

Detail name

Process-

method

(Note 2,

system

3)

(Note 5)

Common

Each

Each

DB

DB

DB

Each

Each

(Note

4, 7)

(Note

4, 7)

Each

Each

Each

Each

Each

Stop

ing

system

(Note 5)

axis

axis

axis

axis

axis

axis

axis

axis

axis

1 - 13

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Stop

No. Name

CC-Link IE warning

9E

Warning

9F Battery warning

9F.2 Battery degradation warning

E0

E1.1

E1.2

E1.3

E1 Overload warning 1

E1.5

E1.6

E1.7

E1.8

E2

E3.1

E3

E3.4

E3.5

E4 Parameter warning E4.1

E5

E5.2 ABSM off during ABS data transfer

E5.3 SON off during ABS data transfer

E6.2

E6

E6.3

Controller forced stop

E7

E8

E8.2 Cooling fan stop Common

E9.2

E9

E9.3

E9.4 Converter unit forced stop DB

EA

EB

EC Overload warning 2 EC.1 Overload warning 2

2

Excessive

regeneration

warning

Servo motor

overheat warning

Absolute position

counter warning

ABS time-out

warning

Servo forced stop

warning

warning

Cooling fan speed

reduction warning

Main circuit off

warning

ABS servo-on

warning

The other axis error

warning

Detail

No.

9E.1 CC-Link IE communication warning

9F.1 Low battery

E0.1 Excessive regeneration warning Common

Thermal overload warning 1 during

operation

Thermal overload warning 2 during

operation

Thermal overload warning 3 during

operation

Thermal overload warning 4 during

E1.4

operation

Thermal overload error 1 during a

stop

Thermal overload error 2 during a

stop

Thermal overload error 3 during a

stop

Thermal overload error 4 during a

stop

E2.1 Servo motor temperature warning

Multi-revolution counter travel

distance excess warning

E3.2 Absolute position counter warning

Absolute positioning counter EEPROM writing frequency warning

Encoder absolute positioning

counter warning

Parameter setting range error

warning

E5.1 Time-out during ABS data transfer

E6.1 Forced stop warning SD Common All axes

SS1 forced stop warning 1 (safety

observation function)

SS1 forced stop warning 2 (safety

observation function)

E7.1 Controller forced stop warning SD Common All axes

Decreased cooling fan speed

E8.1

warning

Servo-on signal on during main

E9.1

circuit off

Bus voltage drop during low speed

operation

Ready-on signal on during main

circuit off

EA.1 ABS servo-on warning

EB.1 The other axis error warning DB

Detail name

Process-

method

(Note 2,

system

3)

(Note 5)

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

SD

SD

Common

DB Common All axes

DB Common All axes

DB Common All axes

Each

Each

Stop

ing

system

(Note 5)

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

axis

(Note 6)

axis

axis

1 - 14

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

A

Stop

No. Name

Output watt excess

ED

Warning

F0 Tough drive warning

F2

F2.2

F3

F4.6

F4 Positioning warning

F4.7

F4.9

F5

F5.2 Cam data - Area miswriting warning

F5.3 Cam data checksum error

F6.1

F6

F6.3 Cam unregistered error

F6.4

F6.5 Cam No. external error

F6.6 Cam control inactive

F7

F7.2 Friction failure prediction warning

F7.3

Note 1. After resolving the source of trouble, cool the equipment for approximately 30 minutes.

warning

Drive recorder -

Miswriting warning

Oscillation detection

warning

Simple cam

function - Cam data

miswriting warning

Simple cam

function - Cam

control warning

Machine diagnosis

warning

Detail

No.

ED.1 Output watt excess warning

Instantaneous power failure tough

F0.1

drive warning

F0.3 Vibration tough drive warning

Drive recorder - Area writing time-

F2.1

out warning

Drive recorder - Data miswriting

warning

F3.1 Oscillation detection warning

Target position setting range error

F4.4

warning

Acceleration time constant setting

range error warning

Deceleration time constant setting

range error warning

Home position return type error

warning

Cam data - Area writing time-out

F5.1

warning

Cam axis one cycle current value

restoration failed

Cam axis feed current value

F6.2

restoration failed

Cam control data setting range

error

F7.1 Vibration failure prediction warning

Total travel distance failure

prediction warning

Detail name

Process-

method

(Note 2,

system

3)

(Note 5)

Each

Each

Each

Common

Common

Each

Each

Each

Each

2. The following shows two stop methods of DB and SD.

DB: Stops with dynamic brake. (Coasts for the servo amplifier without dynamic brake.)

Coasts for MR-J4-03A6(-RJ) and MR-J4W2-0303B6.

SD: Forced stop deceleration

3. This is applicable when [Pr. PA04] is set to the initial value. The stop system of SD can be changed to DB

using [Pr. PA04].

4. For MR-J4-_A_ servo amplifier, quick stop or slow stop can be selected using [Pr. PD30].

5. The processing and stop systems are applicable only for the multi-axis servo amplifiers (MR-J4W_-_B_).

Refer to section 1.1 for details.

6.

s the initial value, it is applicable only for [AL. 24] and [AL. 32]. All-axis stop can be selected using [Pr.

PF02].

7. For MR-J4-_GF_ servo amplifier, quick stop or slow stop can be selected using [Pr. PD12]. (I/O mode

only)

ing

axis

axis

axis

axis

axis

axis

axis

Stop

system

(Note 5)

1 - 15

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

1.4 Remedies for alarms

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate

the alarm before restarting operation. Otherwise, it may cause injury.

CAUTION

If [AL. 25 Absolute position erased] occurs, always make home position setting

again. Otherwise, it may cause an unexpected operation.

As soon as an alarm occurs, make the Servo-off status and interrupt the main

circuit power.

POINT

When any of the following alarms has occurred, do not cycle the power

repeatedly to restart. Doing so will cause a malfunction of the servo amplifier

and servo motor. Remove its cause and allow about 30 minutes for cooling

before resuming the operation.

[AL. 30 Regenerative error] [AL. 45 Main circuit device overheat]

[AL. 46 Servo motor overheat] [AL. 50 Overload 1]

[AL. 51 Overload 2]

[AL. 37 Parameter error] is not recorded in the alarm history.

Remove the cause of the alarm in accordance with this section. Use MR Configurator2 to refer to the cause

of alarm occurrence.

1 - 16

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 10 Name: Undervoltage

Alarm content

Detail

No.

10.1 Voltage drop in

Detail name Cause Check method Check result Action Target

the control

It has no failure. Check (2).

circuit power

(2) The voltage of the

The voltage is

(3) The power was cycled

It has no problem. Check (4).

(4) An instantaneous

It has no problem. Check (5).

(5) When a power

The voltage of the control circuit power supply has dropped.

The voltage of the main circuit power supply has dropped.

(1) The control circuit

power supply

connection is incorrect.

control circuit power

supply is low.

before the internal

control circuit power

supply stopped.

power failure has

occurred for longer

time than the specified

time.

The time will be 60 ms

when [Pr. PA20] is "_ 0

_ _".

The time will be the

value set in [Pr. PF25]

when [Pr. PA20] is "_ 1

_ _".

The time will be 60 ms

when [Pr. PX25] is "_ 0

_ _" and the J3

extension function is

used. The time will be

the value set in [Pr.

PX28] when [Pr. PX25]

is "_ 1 _ _".

An instantaneous power

failure of 15 ms or

longer has occurred on

MR-J4-03A6(-RJ) or

MR-J4W2-0303B6.

regeneration converter

is used, the voltage of

the control circuit power

supply is distorted.

Check the connection

of the control circuit

power supply.

Check if the voltage of

the control circuit

power supply is lower

than prescribed value.

200 V class: 160 V

AC

400 V class: 280 V

AC

100 V class: 83 V AC

24 V DC input: 17 V

DC

Check the power-on

method if it has a

problem.

Check if the power

has a problem.

Check if the power

has a problem.

When power supply

impedance is high,

power supply voltage

will be distorted due to

current at power

regeneration, and it

may be recognized as

undervoltage.

It has a failure. Connect it correctly. [A]

The voltage is the

prescribed value or

lower.

higher than the

prescribed value.

It has a problem. Cycle the power

It has a problem. Review the power.

It has a problem. Review the setting

Review the voltage

of the control circuit

power supply.

Check (3).

after the sevensegment LED of the

servo amplifier is

turned off.

of "[AL. 10

Undervoltage]

detection method

selection" with the

following

parameters.

[A]: [Pr. PC27]

[B] [WB] [RJ010]

[GF]: [Pr. PC20]

Review the power.

[B]

[WB]

[RJ010]

[GF]

1 - 17

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 10 Name: Undervoltage

Alarm content

Detail

No.

10.2 Voltage drop in

Detail name Cause Check method Check result Action Target

the main circuit

power

It is connected. Check (2).

(2) The wiring between P3

It is connected. Check (3).

(3) For the drive unit, the

It has no failure. Check (4).

(4) For the drive unit, the

It has no failure. Check (5).

(5) The voltage of the main

The voltage is

(6) The alarm has

The voltage is equal

The voltage of the control circuit power supply has dropped.

The voltage of the main circuit power supply has dropped.

(1) The main circuit power

supply wiring was

disconnected.

For the drive unit, the

main circuit power

supply wiring of the

converter unit was

disconnected.

and P4 was

disconnected.

For the drive unit, the

wiring between P1 and

P2 of the converter unit

was disconnected.

magnetic contactor

control connector of the

converter unit was

disconnected.

bus bar between the

converter unit and drive

unit was disconnected.

circuit power supply is

low.

occurred during

acceleration.

Check the main circuit

power supply wiring.

Check the main circuit

power supply wiring of

the converter unit.

Check the wiring

between P3 and P4.

Check the wiring

between P1 and P2 of

the converter unit.

Check the magnetic

contactor control

connector of the

converter unit.

Check the bus bar

between the converter

unit and drive unit.

Check if the voltage of

the main circuit power

supply is the

prescribed value or

lower.

200 V class: 160 V

AC

400 V class: 280 V

AC

100 V class: 83 V AC

48 V DC setting: 35 V

DC

24 V DC setting: 15 V

DC

Check if the bus

voltage during

acceleration is lower

than the prescribed

value.

200 V class: 200 V

DC

400 V class: 380 V

DC

100 V class: 158 V

DC

48 V DC setting: 35 V

DC

24 V DC setting: 15 V

DC

It is disconnected. Connect it correctly. [A]

It is disconnected. Connect it correctly.

It is disconnected. Connect it correctly.

It is disconnected. Connect it correctly.

The voltage is the

prescribed value or

lower.

higher than the

prescribed value.

The voltage is lower

than the prescribed

value.

to or higher than the

prescribed value.

Increase the voltage

of the main circuit

power supply.

Check (6).

Increase the

acceleration time

constant. Or

increase the power

supply capacity.

Check (7).

[B]

[WB]

[RJ010]

[GF]

1 - 18

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 10 Name: Undervoltage

Alarm content

Detail

No.

10.2 Voltage drop in

Detail name Cause Check method Check result Action Target

the main circuit

power

(8) For the drive unit, the

The voltage of the control circuit power supply has dropped.

The voltage of the main circuit power supply has dropped.

(7) The servo amplifier is

malfunctioning.

converter unit is

malfunctioning.

Check the bus

voltage value.

Replace the converter

unit, and then check

the repeatability.

The bus voltage is

less than the

prescribed value

although the voltage

of the main circuit

power supply is

within specifications.

200 V class: 200 V

DC

400 V class: 380 V

DC

100 V class: 158 V

DC

48 V DC setting:

24 V DC setting:

It is not repeatable. Replace the

Replace the servo

amplifier.

35 V DC

15 V DC

converter unit.

[A]

[B]

[WB]

[RJ010]

1 - 19

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 11 Name: Switch setting error

The setting of the axis selection rotary switch or auxiliary axis number setting switch is incorrect.

Alarm content

Detail

No.

11.1 Axis number

11.2 Disabling

The setting is other

Detail name Cause Check method Check result Action Target

setting error

Both of the auxiliary

Station number

setting error

The station number

control axis

setting error

Alarm No.: 12 Name: Memory error 1 (RAM)

Alarm content A part (RAM) in the servo amplifier is failure.

Detail

No.

12.1 RAM error 1 (1) A part in the servo

12.2 RAM error 2 Check it with the check method for [AL. 12.1].

12.3 RAM error 3

12.4 RAM error 4

12.5 RAM error 5

12.6 RAM error 6

Detail name Cause Check method Check result Action Target

It is not repeatable. Check (2).

(2) Something near the

The setting of the disabling control axis switch is incorrect.

The setting of the station number selection rotary switch is incorrect.

(1) The setting of the axis

No. is incorrect.

(2) The station number is

set to a value other

than "1" to "120" with

the station number

selection rotary switch.

(1) The setting of the

disabling control axis

switch is incorrect.

amplifier is failure.

device caused it.

Check the settings of

the auxiliary axis

number setting

switches (SW25/SW2-6) and axis

selection rotary switch

(SW1).

Check the settings of

the station number

selection rotary

switches (SW2/SW3).

Check the setting of

the disabling control

axis switch.

Disconnect the cables

except for the control

circuit power supply,

and then check the

repeatability.

Check the power

supply for noise.

When both of the

auxiliary axis

number setting

switches are on,

check the axis

selection rotary

switch if "F" is

selected for MRJ4W2, ("E" or "F" is

selected for MRJ4W3).

axis number setting

switches are off.

The setting of the

station number

selection rotary

switch is set to "0"

or "121" or more.

is set to a value from

"1" to "120" with the

station number

selection rotary

switch.

Check if the setting

is as follows.

1) Only A-axis is

disabled.

2) Only B-axis is

disabled.

3) A-axis and B-axis

are disabled.

4) A-axis and C-axis

are disabled.

5) All axes are

disabled.

than above.

It is repeatable. Replace the servo

It has a failure. Take

Set the axis No.

correctly.

Replace the servo

amplifier.

Set the station

number correctly.

Replace the servo

amplifier.

Set it correctly. [WB]

Replace the servo

amplifier.

amplifier.

countermeasures

against its cause.

[WB]

[GF]

[A]

[B]

[WB]

[RJ010]

[GF]

1 - 20

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 13 Name: Clock error

A part in the servo amplifier is failure.

Alarm content

Detail

No.

13.1 Clock error 1 (1) The MR-J3-T10 came

13.2 Clock error 2 Check it with the check method for [AL. 13.1].

Detail name Cause Check method Check result Action Target

It did not occur. Check (2).

(2) A part in the servo

It is not repeatable. Check (3).

(3) A clock error

It does not occur. Check (4).

(4) The servo amplifier of

It is not

(5) Something near the

Alarm No.: 14 Name: Control process error

Alarm content

Detail

No.

14.1 Control

Detail name Cause Check method Check result Action Target

process error 1

It did not occur. Check (2).

(2) The parameter setting

It is correct. Check (3).

(3) Something near the

It has no failure. Check (4).

(4) The servo amplifier is

A clock error transmitted from the controller occurred.

[RJ010]: MR-J3-T10 came off.

Check if [AL. 74

off during the CC-Link

IE communication.

amplifier is failure.

transmitted from the

controller occurred.

the next axis is

malfunctioning.

device caused it.

The process did not complete within the specified time.

[RJ010]: MR-J3-T10 came off.

[GF]: A part (communication IC) in the servo amplifier is failure.

(1) The MR-J3-T10 came

off during the CC-Link

IE communication.

is incorrect.

device caused it.

malfunctioning.

Option card error 1]

occurred with alarm

history.

Disconnect the cables

except for the control

circuit power supply,

and then check the

repeatability.

Check if the alarm

occurs when you

connect the amplifier

to the controller.

Check if the servo

amplifier of the next

axis is malfunctioning.

Check the power

supply for noise.

Check if the connector

is shorted.

Check if [AL. 74

Option card error 1]

occurred with alarm

history.

Check if the

parameter setting is

incorrect.

Check the power

supply for noise.

Check if the connector

is shorted.

Replace the servo

amplifier, and then

check the

repeatability.

It is occurring. Check it with the

It is repeatable. Replace the servo

It occurs. Replace the

It is malfunctioning. Replace the servo

malfunctioning.

It has a failure. Take

It is occurring. Check it with the

It is incorrect. Set it correctly. [A]

It has a failure. Take

It is not repeatable. Replace the servo

check method for

[AL. 74].

amplifier.

controller.

amplifier of the next

axis.

Check (5).

countermeasures

against its cause.

check method for

[AL. 74].

countermeasures

against its cause.

amplifier.

[RJ010]

[A]

[B]

[WB]

[RJ010]

[GF]

[B]

[WB]

[A]

[B]

[WB]

[RJ010]

[GF]

[RJ010]

[B]

[WB]

[RJ010]

[GF]

1 - 21

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 14 Name: Control process error

The process did not complete within the specified time.

Alarm content

Detail

No.

14.2 Control

14.3 Control

14.4 Control

14.5 Control

14.6 Control

14.7 Control

14.8 Control

14.9 Control

14.A Control

14.B Control

Detail name Cause Check method Check result Action Target

process error 2

It did not occur. Check (2).

(2) A synchronous signal

It is not repeatable. Check (3).

(3) Adaptive tuning mode

It has not been

(4) The parameter setting

It is correct. Check (5).

(5) Something near the

It has no failure. Check (6).

(6) The servo amplifier is

process error 3

process error 4

process error 5

process error 6

process error 7

process error 8

process error 9

process error 10

process error 11

[RJ010]: MR-J3-T10 came off.

[GF]: A part (communication IC) in the servo amplifier is failure.

(1) The MR-J3-T10 came

off during the CC-Link

IE communication.

error transmitted from

the controller occurred.

or vibration

suppression control

tuning mode has been

executed for multiple

axes simultaneously.

is incorrect.

device caused it.

malfunctioning.

Check it with the check method for [AL. 14.1].

Check if [AL. 74

Option card error 1]

occurred with alarm

history.

Replace the

controller, and then

check the

repeatability.

Check the setting of

[Pr. PB01] or [Pr.

PB02].

With the J3 extension

function, Check the

setting of [Pr. PB01],

[Pr. PB02], or [Pr.

PX03].

Check if the

parameter setting is

incorrect.

Check the power

supply for noise.

Check if the

connector is shorted.

Replace the servo

amplifier, and then

check the

repeatability.

It is occurring. Check it with the

check method for

[AL. 74].

It is repeatable. Replace the servo

amplifier.

It has been

executed for

multiple axes

simultaneously.

executed for

multiple axes

simultaneously.

It is incorrect. Set it correctly. [A]

It has a failure. Take

It is not repeatable. Replace the servo

Execute it for each

axis.

Check (4).

countermeasures

against its cause.

amplifier.

[RJ010]

[B]

[WB]

[WB]

[B]

[WB]

[RJ010]

[GF]

1 - 22

1. TROUBLESHOOTING FOR SERVO AMPLIFIER (DRIVE UNIT)

Alarm No.: 15 Name: Memory error 2 (EEP-ROM)

Alarm content

Detail

No.

15.1 EEP-ROM error

15.2 EEP-ROM error

15.4 Home position

Detail name Cause Check method Check result Action Target

at power on

It is not repeatable. Check (2).

(2) Something near the

It has no failure. Check (3).

(3) The number of write

during operation

It did not occur. Check (2).

(2) EEP-ROM is

It does not occur. Check (3).

(3) A write error occurred

It takes less than an

(4) Something near the

information read

error

It is not repeatable. Check (2).

(2) Multiple rotation data

It has no failure. Check (3).

(3) Something near the

It has no failure. Check (4).

(4) The number of write

A part (EEP-ROM) in the servo amplifier is failure.

[RJ010]: MR-J3-T10 came off.

(1) EEP-ROM is

malfunctioning at power

on.

device caused it.

times exceeded

100,000.

(1) The MR-J3-T10 came

off during the CC-Link

IE communication.

malfunctioning during

normal operation.

while adjustment results

were processed.