Mitsubishi Electric MR-C375C-W-A, MR-C375C-ST-A, MR-C375C-OB-A, MR-C375CL-W-A, MR-C375CL-ST-A Service Manual

...

Changes for the Better

Models

CONTENTS

A………….......Australia & New Zea land

1. SPECIFICATIONS....................................................

2. OUTLINES AND DIMENSIONS..................................

3. WIRING DIAGRAM....................................................

4. REFRIGERANT CIRCUIT...........................................

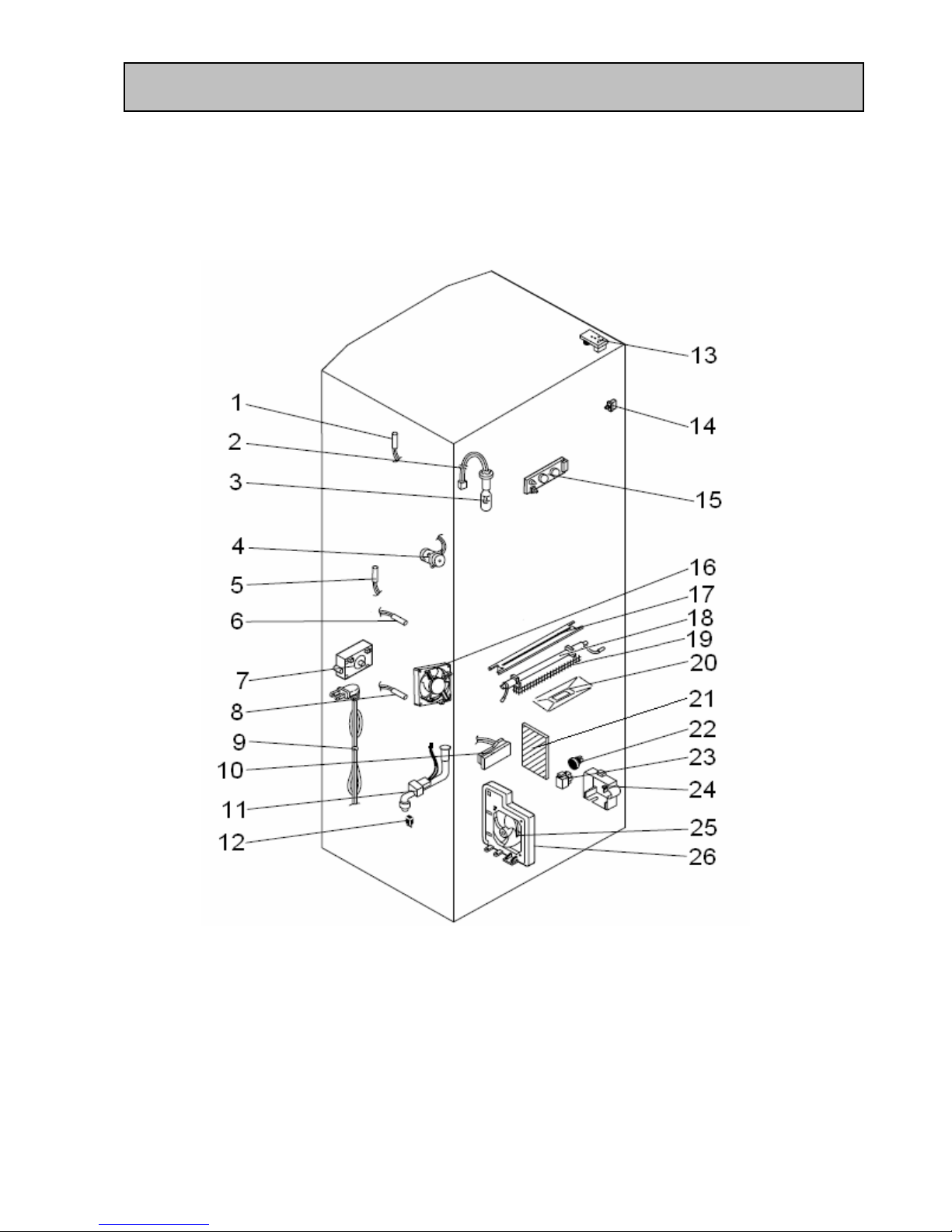

5. NAMES OF THE PARTS...........................................

6. TROUBLE SHOOTING..............................................

6.1 TROUBLE CRITERION OF MAIN PARTS.......

6.2 FUNCTION OF OPERATION PANEL..............

6.3 FLOW CHART OF SELF-CHECK....................

6.4 TEST POINT DIAGRAM OF MAIN CONTROL

BOARD........................................................

7. DISASSEMBLY INSTRUCTIONS...............................

8. PARTS LIST............................................................

1

3

5

7

9

11

11

14

15

18

19

24

MR-C375C-W-A

MR-C375C-ST-A

MR-C375C-OB-A

MR-C375CL-W-A

MR-C375CL-ST-A

MR-C405C-W-A

MR-C405C-ST-A

MR-C405CL-W-A

MR-C405CL-ST-A

2012

SERVICE MANUAL

NO.SM-RE-1206

MITSUBISHI

ELECTRIC

HOME REFRIGERATORS

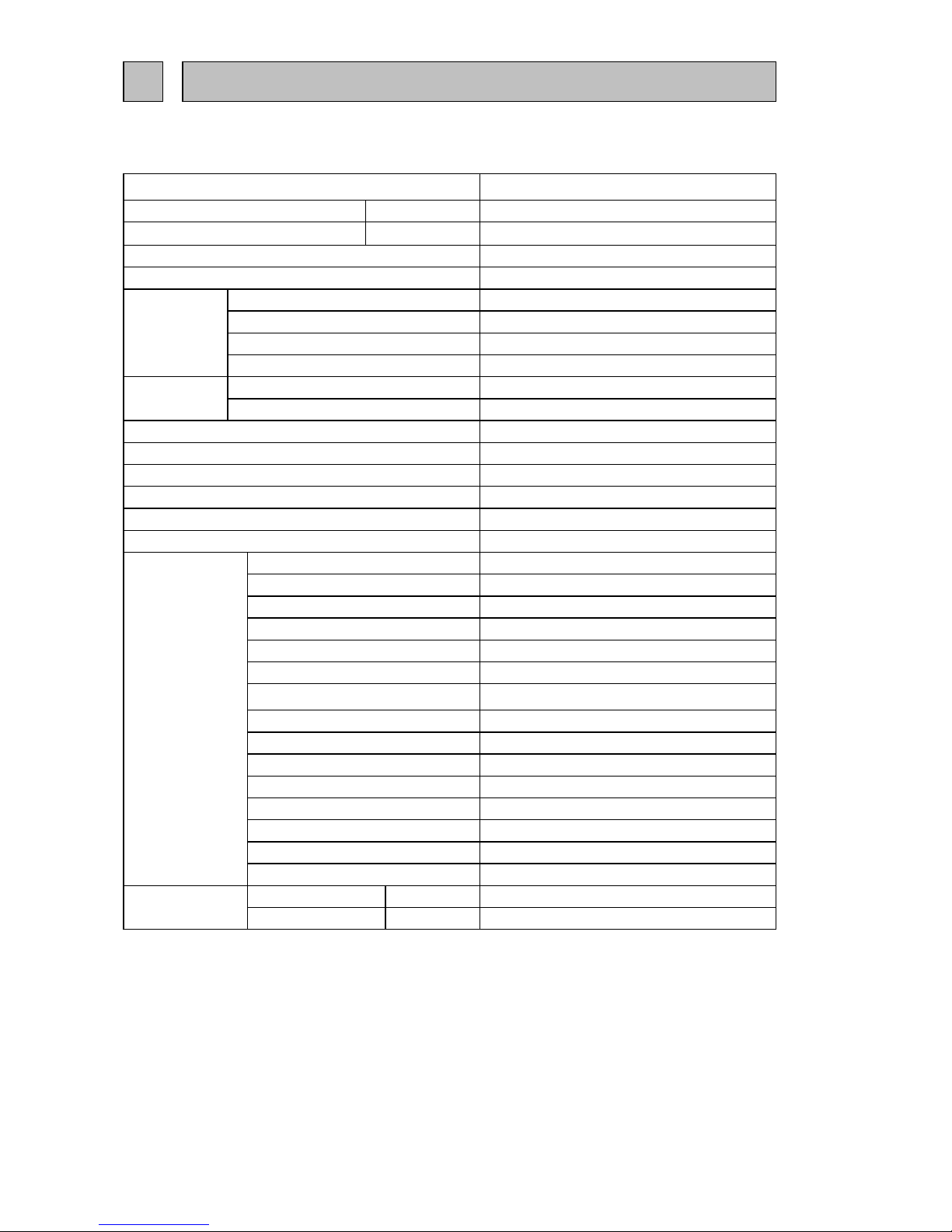

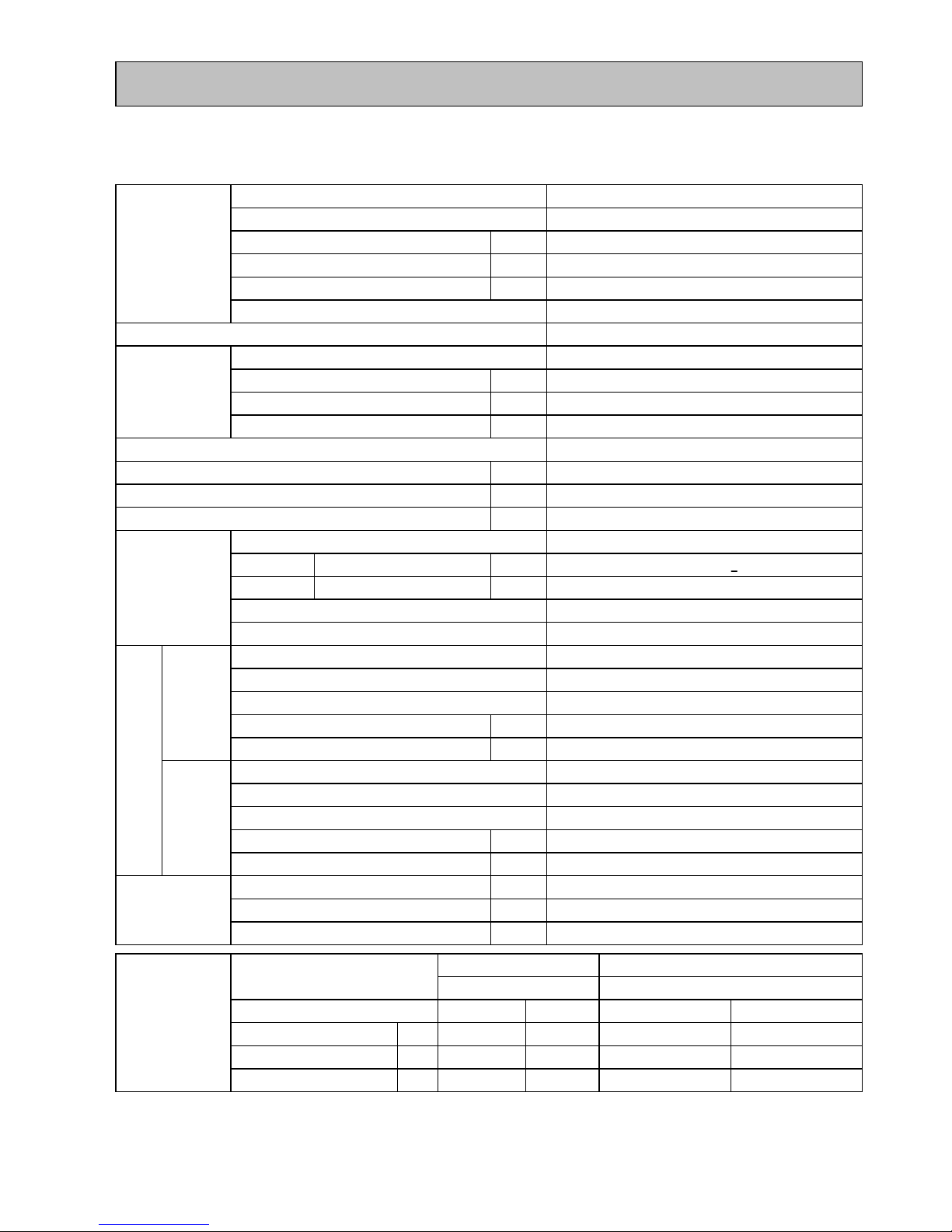

1-1 SPECIFICATIONS

MR-C375C-A, MR-C375CL-A

Power supply

Total capacity

L

Dimensions (HXWXD) mm. 1678 x 600 x 656

Cabinet

Acrylic resin coated steel

Food liner

ABS resin

Cabinet

Foamed cyclopenthane

Refrigerator door

Foamed cyclopenthane

Vegetable door

Foamed cyclopenthane

Freezer door

Foamed cyclopenthane

Cooling system

Freezer

Forced air convection

Refrigerator

3 way air flow

Evaporator

Fin and tube type

Condenser

Concealed type

Defrost system

Automatic (Defrost heater )

Drain

Automatic (drainage)

Temperature control system

Automatic control

Refrigerator room light

240V, 15W (E12)

Glass shelf (R)

1 pc.

Slide shelf

1 pc.

Slide chilled case

1 pc.

Water tank

1 pc.

Free pocket (L)

2 pcs.

Egg case

1 pc.

Bottle pocket 1 pc.

Vegetable case

1 pc.

Fruit case

1 pc.

Freezing case (UP)

1 pc.

Freezing case (LOW)

1 pc.

Ice box sheet

1 pc.

Ice spoon

1 pc.

Ice box

1 pc.

Kick plate

1 pc.

Weight

Unit

kg

69

Shipping

kg

75

1

SPECIFICATIONS

Insulation

Accessories

GROSS (AS) 375 (R : 197 V : 75 F : 103)

230-240V 50Hz

1

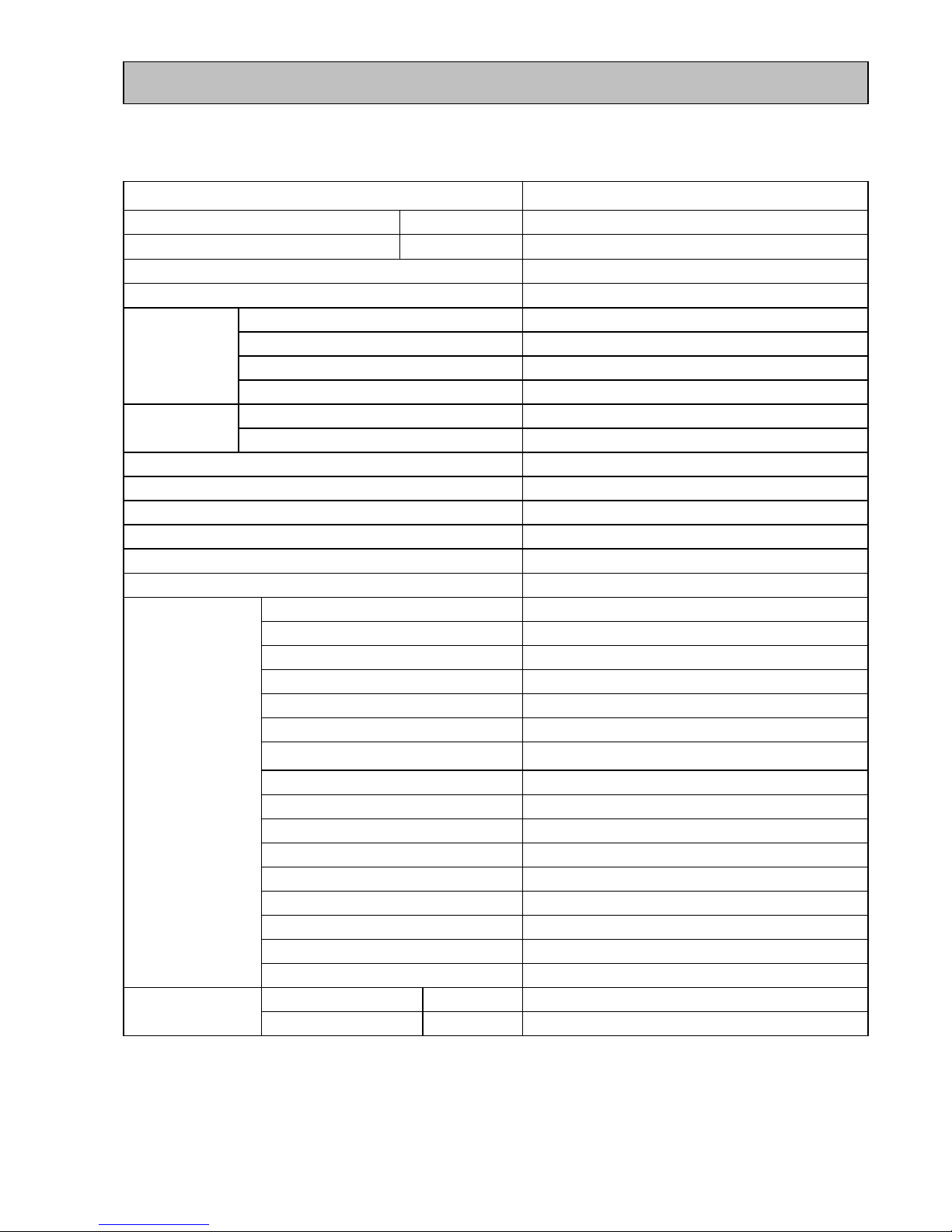

MR-C405C-A, MR-C405CL-A

Power supply

Total capacity L

Dimensions (HXWXD) mm. 1798 x 600 x 656

Cabinet Acrylic resin coated steel

Food liner ABS resin

Cabinet Foamed cyclopenthane

Refrigerator door Foamed cyclopenthane

Vegetable door Foamed cyclopenthane

Freezer door Foamed cyclopenthane

Cooling system Freezer Forced air convection

Refrigerator 3 way air flow

Evaporator Fin and tube type

Condenser Concealed type

Defrost system Automatic (Defrost heater )

Drain Automatic (drainage)

Temperature control system Automatic control

Refrigerator room light 240V, 15W (E12)

Glass shelf (R) 2 pcs.

Slide shelf 1 pc.

Slide chilled case 1 pc.

Water tank 1 pc.

Free pocket (L) 2 pcs.

Egg case 1 pc.

Free pocket (S) 1 pc.

Bottle pocket 1 pc.

Vegetable case 1 pc.

Fruit case 1 pc.

Freezing case (UP) 1 pc.

Freezing case (LOW) 1 pc.

Ice box sheet 1 pc.

Ice spoon 1 pc.

Ice box 1 pc.

Kick plate 1 pc.

Weight Unit kg 73

Shipping kg 80

230-240V 50Hz

Insulation

Accessories

GROSS (AS) 405 (R : 227 V : 75 F : 103)

2

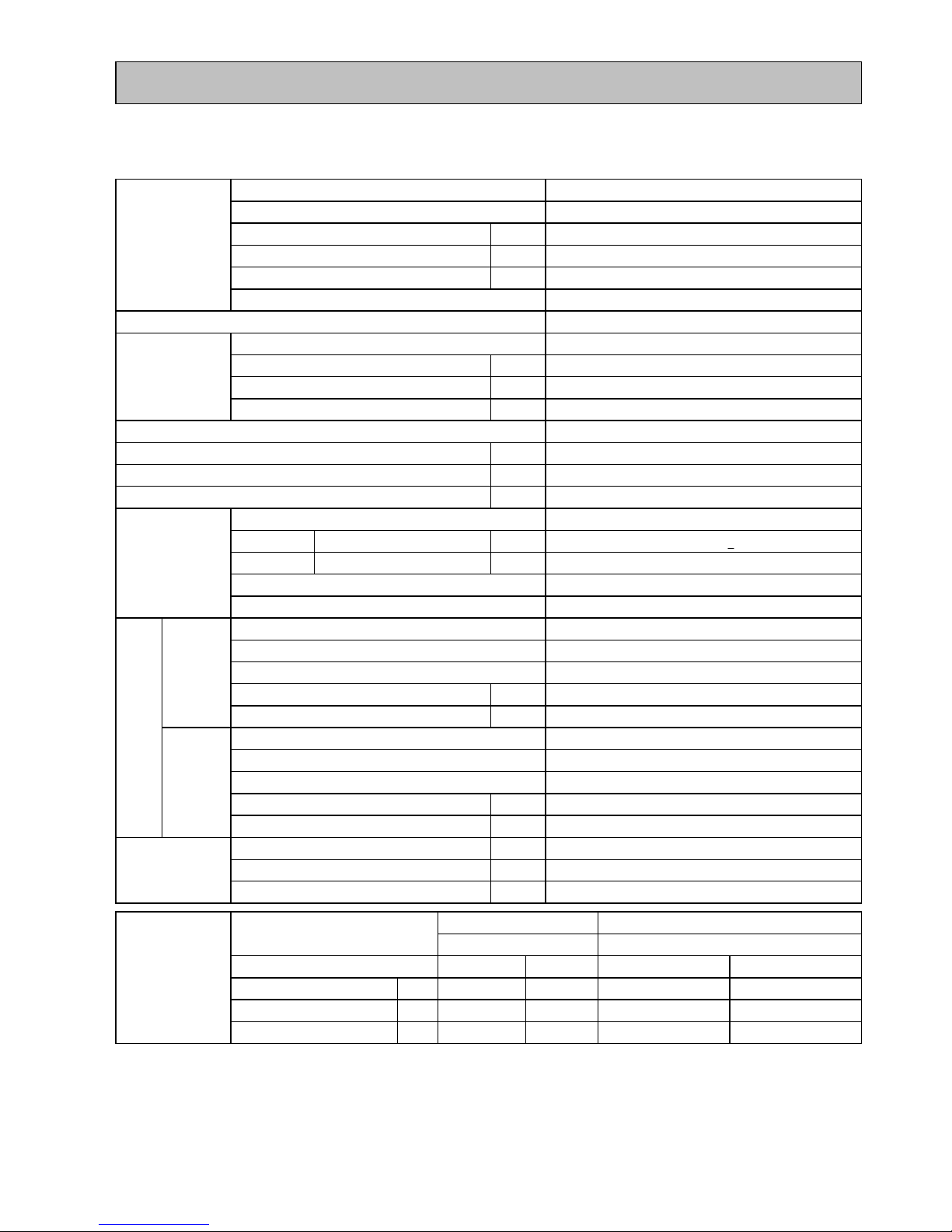

1-2 ELECTRICAL PARTS SPECIFICATION

MR-C375C-A , MR-C375CL-A

Model

DHS66C10RAW

Power supply

220-240V, 50Hz

Compressor

Rated input

W

Starting current

A

Rated current

A

Winding resistance

(A.T.

20 oC

)

PTC RELAY

PTH7M330MD2

Model

5TM718MFBYY-53

Motor protector

Ambient temperature

oC

25

Time

Sec.

16 MAX

Current

A

4.2

Running capacitor

4µF

400

VAC

Capillary tube

mm.

∅

1.8 X ∅ 0.6 X

2350

Dehydrant Molecular sieve

g

10

Refrigerant HFC. 134a

g

170

Defrosting timer

Control board

Defrost finish

oC

Thermister

14 + 1.

5

Thermal fuse

oC

73

Defrost heater

Not equipped

Model

FBA12J12VXC

Type

DC brushless

Rate Voltage

12 VDC

Input

W

4.2 (12 VDC)

Revolution

r.p.m

2300 (12 VDC)

Model

4715JL04WS16G51

Type

DC brushless

Rate Voltage

12 VDC

Input W1.44 (12 VDC)

Revolution

r.p.m

1450 (12 VDC)

Vegetable case heater

W

6

Water pipe heater

W

0.9

Drain pipe heater

W

6

Freezer

Refrigerator

Dial position

ON

OFF

OPEN

SHUT

LOW

o

C

-9.2

-15.7

7.0

5.1

MID

o

C

-14.0

-20.0

4.2

2.3

HI

o

C

-16.0

-21.9

1.6

-0.2

Refrigerator

372 Ω (240V,

155W)

113/113.5(220/240V 50Hz)

7.78/8.55(220/240V 50Hz)

0.70/0.64(220/240V 50Hz)

18.4 Ω(

Main

) / 18.

5 Ω(

Aux

)

Defrosting control

Deodorizing function of defrost heater

Thermistor R

Thermistor F

Fan motor

Heater

Machine

Chamber

Temperature control

3

MR-C405C-A, MR-C405CL-A

Model

DHS66C10RAW

Power supply

220-240V, 50Hz

Compressor

Rated input

W

Starting current

A

Rated current

A

Winding resistance

(A.T.

20 oC

)

PTC RELAY

PTH7M330MD2

Model

5TM718MFBYY-53

Motor protector

Ambient temperature

oC

25

Time

Sec.

16 MAX

Current

A

4.2

Running capacitor

4µF

400

VAC

Capillary tube

mm.

∅

1.8 X ∅ 0.6 X

2350

Dehydrant Molecular sieve

g

10

Refrigerant HFC. 134a

g

170

Defrosting timer

Control board

Defrost finish

oC

Thermister

14 + 1.

5

Thermal fuse

oC

73

Defrost heater

Not equipped

Model

FBA12J12VXC

Type

DC brushless

Rate Voltage

12 VDC

Input

W

4.2 (12 VDC)

Revolution

r.p.m

2300 (12 VDC)

Model

4715JL04WS16G51

Type

DC brushless

Rate Voltage

12 VDC

Input

W

1.44 (12 VDC)

Revolution

r.p.m

1450 (12 VDC)

Vegetable case heater

W

6

Water pipe heater

W

0.9

Drain pipe heater

W

6

Freezer

Refrigerator

Dial position

ON

OFF

OPEN

SHUT

LOW

o

C

-9.2

-15.7

7.4

5.4

MID

o

C

-14.0

-20.0

4.5

2.6

HI

o

C

-16.0

-21.9

1.9

0.1

Thermistor R

Thermistor F

Fan motor

Heater

Machine

Chamber

Temperature control

Refrigerator

372 Ω (240V,

155W)

113/113.5(220/240V 50Hz)

7.78/8.55(220/240V 50Hz)

0.70/0.64(220/240V 50Hz)

18.4 Ω(

Main

) / 18.

5 Ω(

Aux

)

Defrosting control

Deodorizing function of defrost heater

4

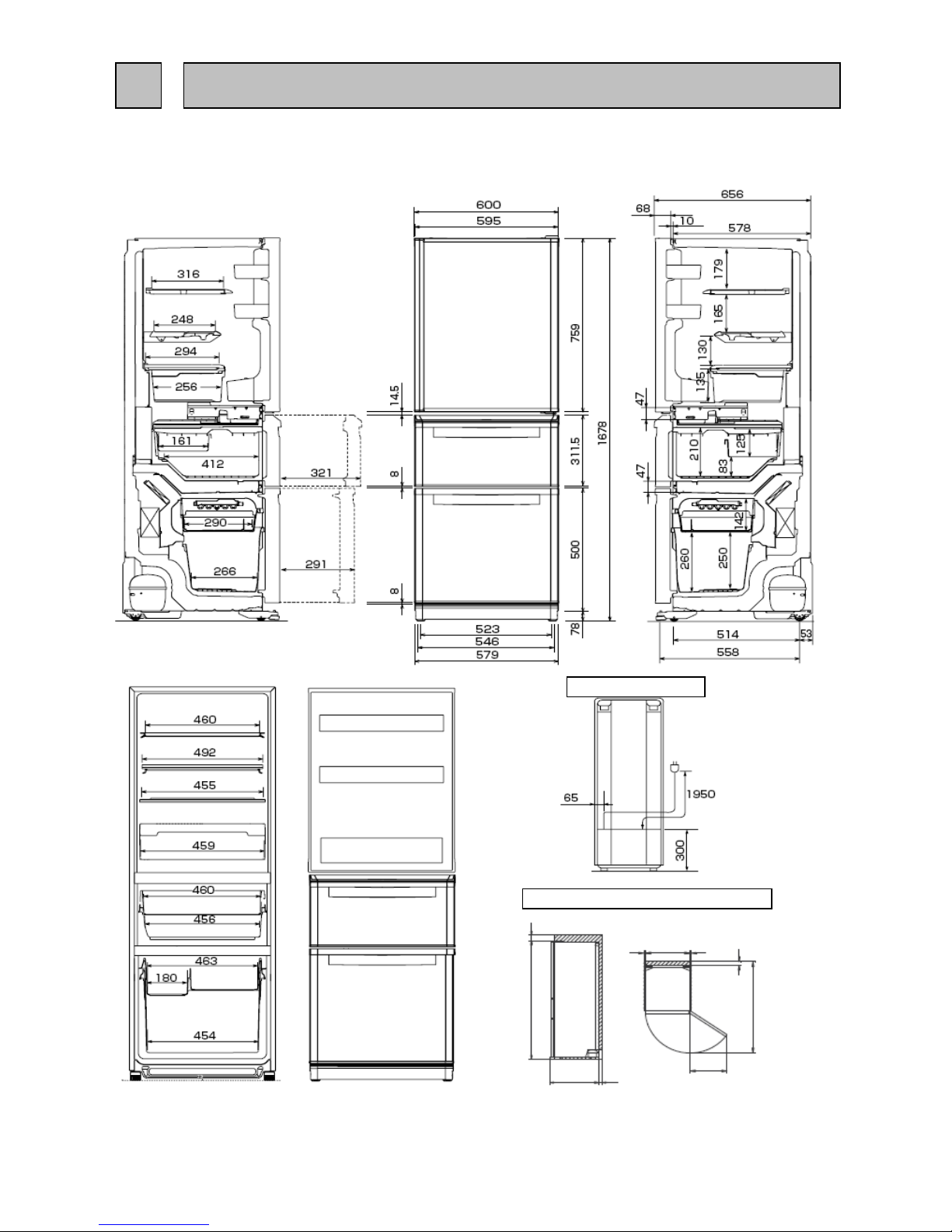

Unit : mm

MR-C375C-A, MR-C375CL-A

2

OUTLINES AND DIMENSIONS

PLUG CORD LENGTH

REQUIRED SPACE FOR INSTALLATION

100

1678

666

50

600

5

124

381

5

Unit : mm

MR-C405C-A, MR-C405CL-A

PLUG CORD LENGTH

REQUIRED SPACE FOR INSTALLATION

100

1798

666

50

20

600

20

5

1248

381

6

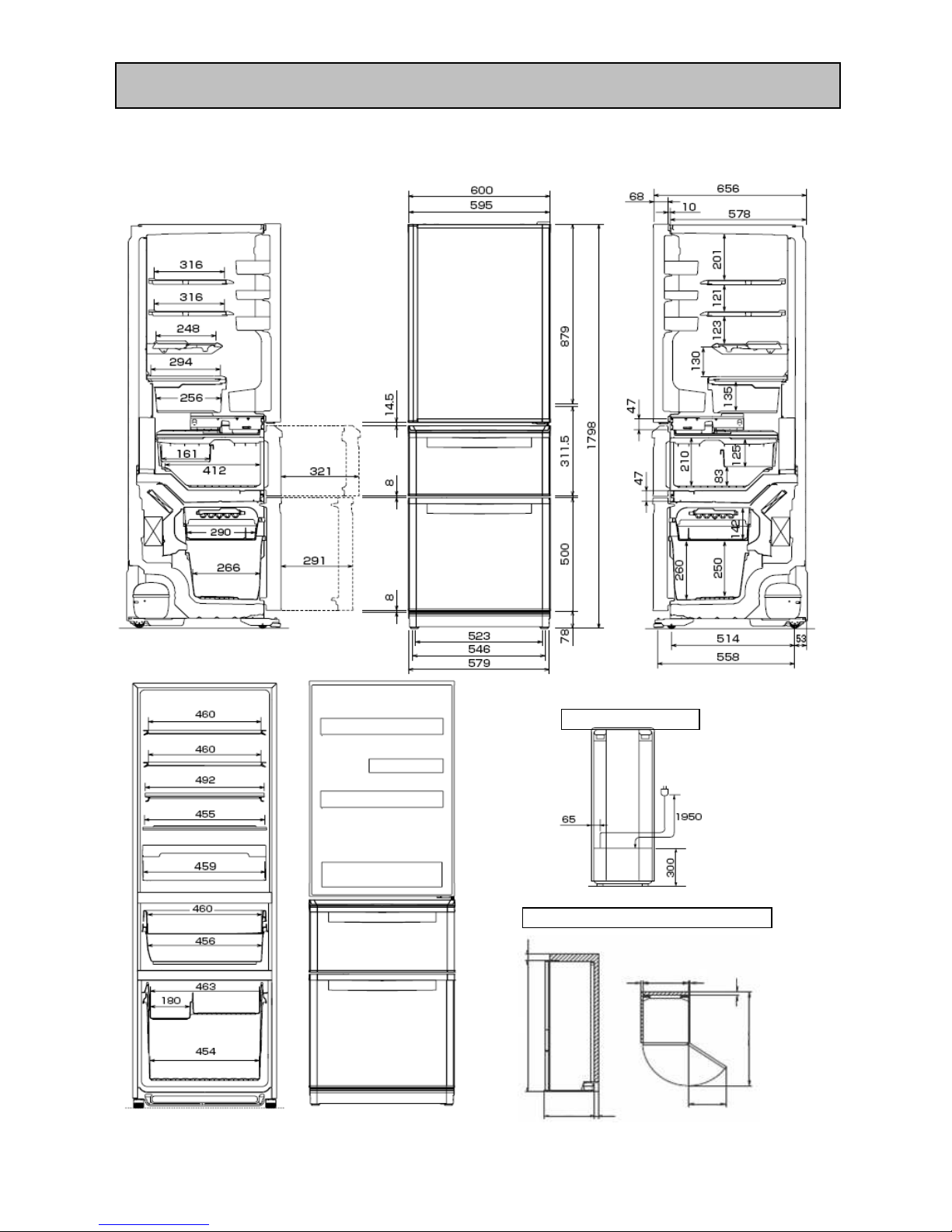

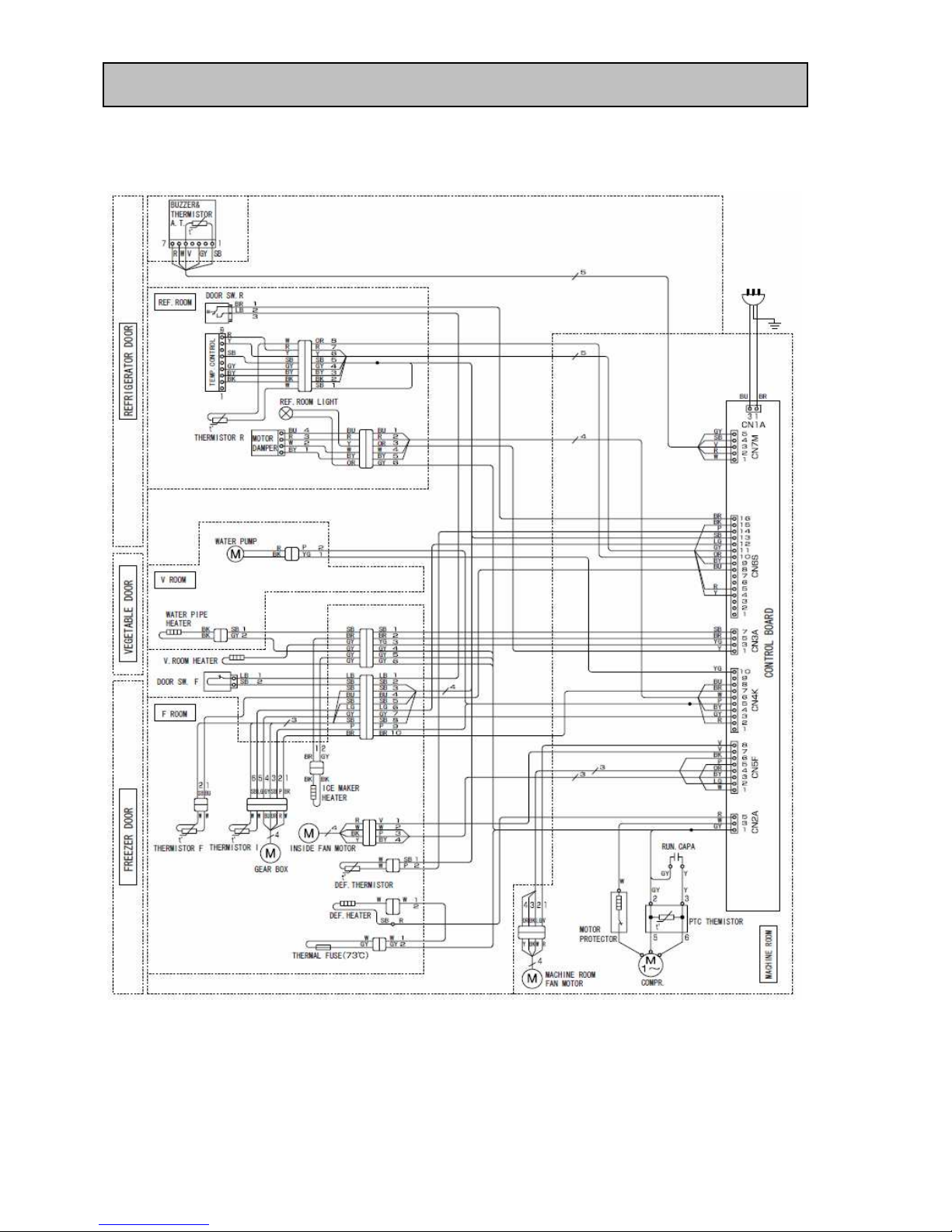

(SKELETON WIRING DIAGRAM)

MR-C375C-A, MR-C375CL-A

MR-C405C-A, MR-C405CL-A

3

WIRING DIAGRAM

7

(ACTUAL WIRING DIAGRAM)

MR-C375C-A, MR-C375CL-A

MR-C405C-A, MR-C405CL-A

Remark

GY=GRAY

BK=BLACK

BR=BROWN

W = WHITE OR = ORANGE

R = RED Y = YELLOW

SB = SKY BLUE YG = YELLOW/GREEN

P = PINK LG = LIGHT GREEN

LB = LIGHT BROWN BY = BRIGHT YELLOW

V = VIOLET BU = BLUE

8

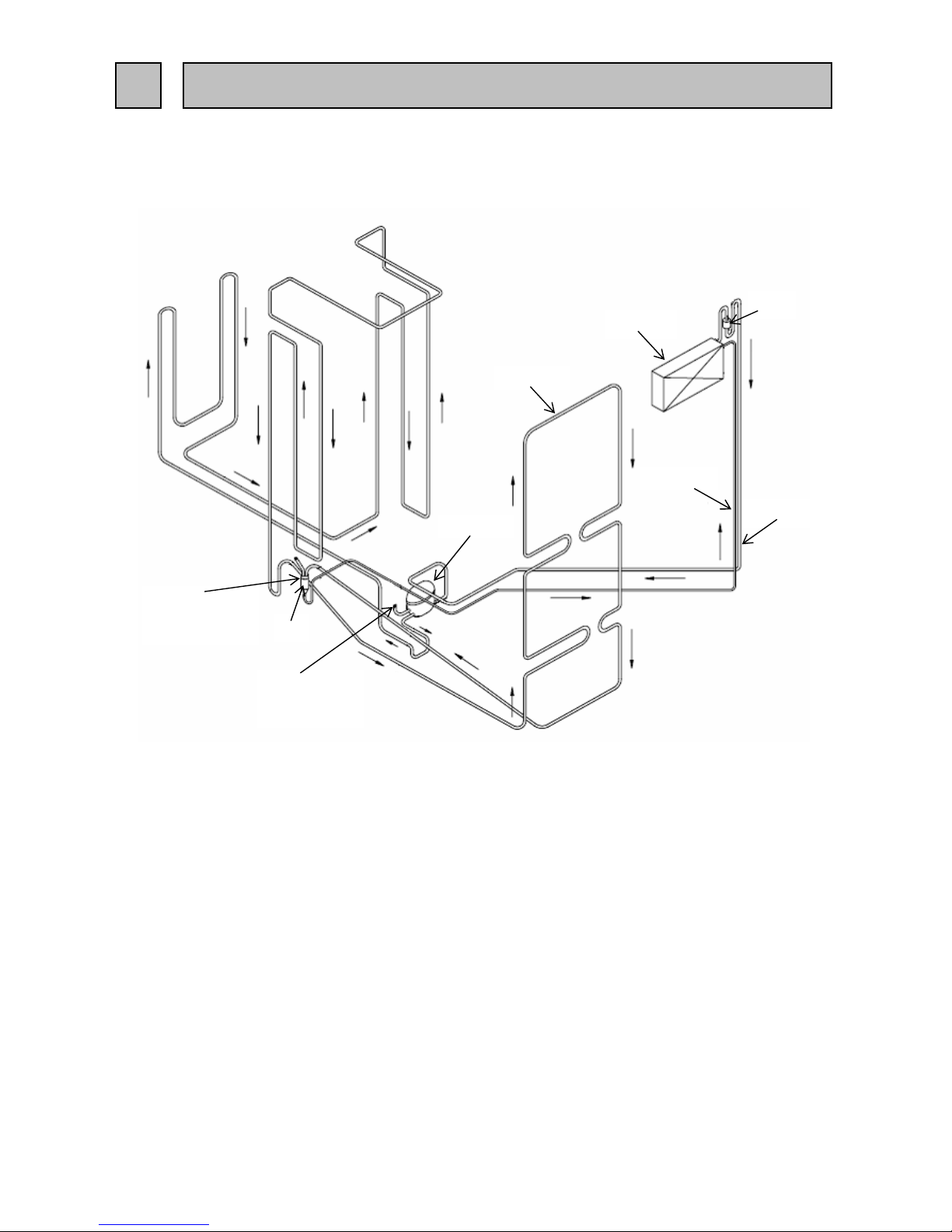

MR-C375C-A, MR-C375CL-A

MR-C405C-A, MR-C405CL-A

4

REFRIGERANT CIRCUIT

Muffler

Evaporator

Capillary tube

Suction pipe

Dryer

Cabinet pipe

Charge pipe

(High pressure side)

Charge pipe

(Low pressure side)

Compressor

9

MR-C375C-A MR-C375CL-A MR-C405C-A MR-C405CL-A

5

NAMES OF PARTS

10

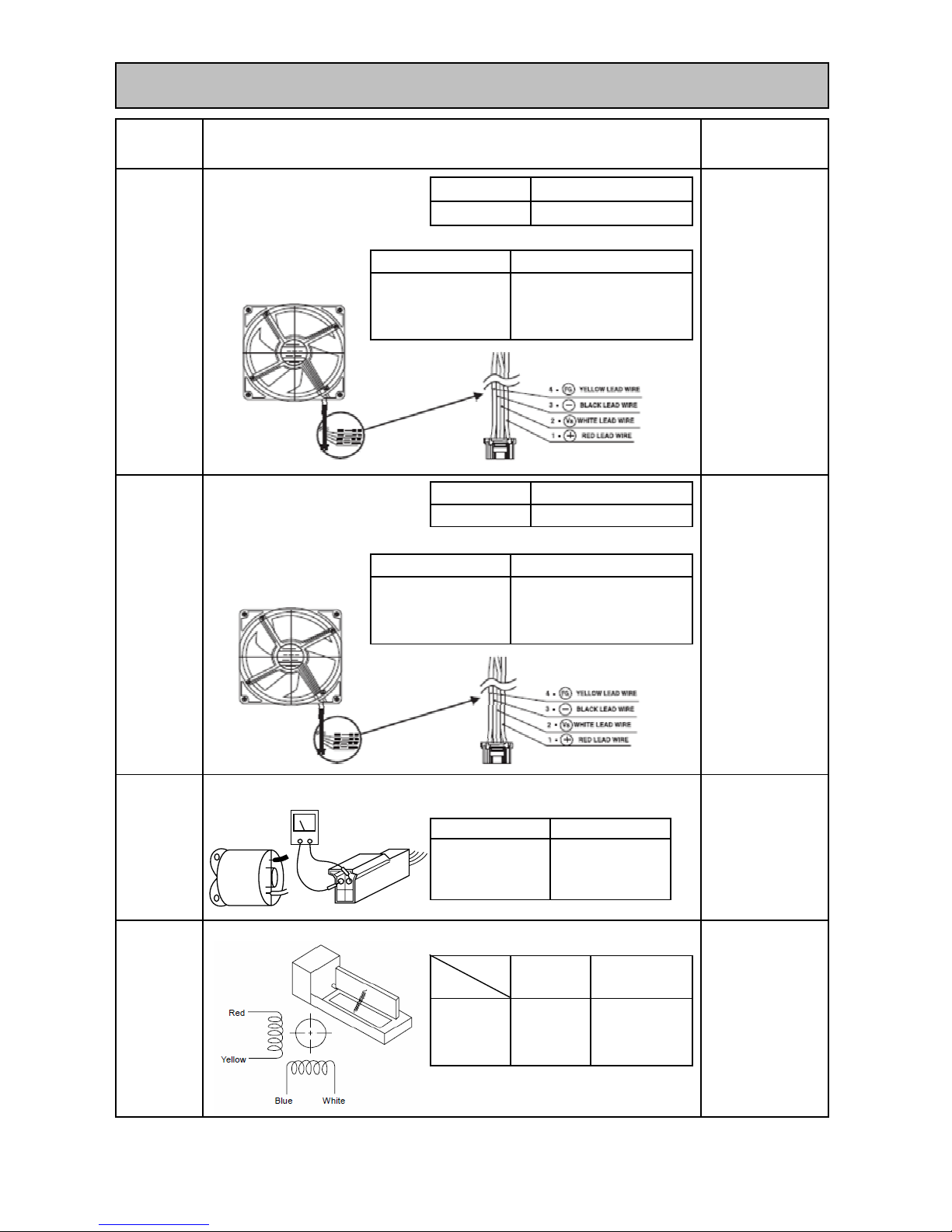

6.1 TROUBLE CRITERION OF MAIN PARTS

MR-C375CC-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

Compressor

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Measure the resistance with a tester.

Open

Close

Opened (∞ Ω )

PTC Relay

PTH7M330MD2

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Normal

As PTC Relay has been heated while refrigerator is running be sure

to measure the resistance after the thermistor has got cool enough.

33 Ω (Approx.)

Abnormal(faulty)

Opened (∞ Ω ) or Short (0Ω)

Rated input W

113/113.5(220/240V 50Hz)

Short (0Ω )

18.5 Ω (Approx.)

Normal

Main wiring

A

Starting current

chamber at the

rear side of

0.70/0.64(220/240V 50Hz)

A

7.78./8.55(220/240V 50Hz)

Rated current

Measure the resistance with a tester.(Ambient

temperature:Room temperature 15oC ~ 25oC)

69 +

9o C

Abnormal

(faulty)

5TM718MFBYY-53

Opened

(∞ Ω )

or

Short (0Ω)

120 + 5o C

Connected

Point

Normal

18.4 Ω (Approx.)

Auxilliary wiring

Run capacitor

4

µF

Rated input

Motor

protector

400VAC

Abnormal(faulty)

Model

the frame

the frame

In the control

panel of the rear

side at

compressor

room

Compressor in

the machine

chamber at the

rear side of

the frame

Model

Normal

Abnormal(faulty)

Less than 1Ω

rear side of

chamber at the

the machine

Compressor in

6

Components

/ Part Name

TROUBLE SHOOTING

Model

Parts

Mounted

Position

Check Method and Criterion

DHS66C10RAW

Compressor in

the machine

Auxilialy

wiring

Main

wiring

6

356

3

1

3

Therminal check point

11

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC

~ 25oC)

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

Normal

Abnormal (faulty)

Me

asure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

In the fan grille of

the refrigerator

compartment.

Normal

Between 3 - 1 (GND

and Vcc): About 25kΩ

In the machine

chamber at the rear

side of the frame.

4715JL04WS16G51

Model

Type

DC brushless

Normal

415 Ω

(Approx.)

Type DC brushless

Under the water

tank holder in

refrigerator

compartment.

Open (∞ Ω )

or short

circuit (0Ω)

Abnormal

(faulty)

Winding

(Blue-White,

Red-Yellow)

Water pump

motor

(DC 5V)

16 Ω (Approx.)

Open (∞Ω) or

short circuit (0Ω)

Motor

damper for

refrigerator

compartment/

slide

compartment

In the fan grille of

the refrigerator

compartment.

Refrigerator

fan motor

FBA12J12VXCModel

Machine

chamber fan

motor

Normal

Abnormal (faulty)

Between 3 - 1 (GND

and Vcc): About 25kΩ

Between 3-1 : open( ∞ Ω )

or

between 2-1 : short ( 0 Ω)

Abnormal (faulty)

Between 3-1 : open( ∞ Ω )

or

between 2-1 : short ( 0 Ω)

Check Method and Criterion

Parts Mounted Position

Components/

Part Name

12

Measure the resistance with a tester.(Ambient temperature:Room temperature 15oC ~ 25oC)

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Measure the resistance with a tester according to the following graph.

(Thermistor resistance values against temperature)

Resistance measured under the ambient temperature from -50oC to +50 oC

1. 200 Ω to 500kΩ ............normal

2. Out of the above range ............abnormal

(kΩ)

Thermistor Check Procedure

Thermistor resistance will vary

with the change of temperature.

Take the temperature around the

thermistor, and then measure

thermistor resistance using a

tester.

The relation between resistance

and temperature is as shown on

the left side.

Trouble shooting with self-check

(1) If the self - check indicates the abnormality of thermistor right after the power is

turned on, measure the resistance of the thermistor.

If the circuit of thermistor is short , check the element of the thermistor and the

contact of the connector.

(2) When the self - check indicates the abnormality of thermistor a few seconds

after the power is turned on , check the contact of the connector.

Rated input 155 W

operation method

Power ON after defrosting

(14 + 1.5oC or more)

Thermistor

Opened ( ∞ Ω )

Defrost

Heater

(Outside air

thermistor) In the

buzzer board (check

board)

Check Method and Criterion

Parts Mounted

Position

Components/

Part Name

(Defrost thermistor)

Evaporator

(Freezer

compartment

thermistor and Ice

making tray

thermistor) In Ice

maker of freezer

compartment

Abnormal (faulty)

(Refrigerator

compartment

thermistor) In the

control panel of

refrigerator

compartment

372Ω (Approx.)

Normal

Water pipe

heater

Normal

The heater is turned on when the temperature of tray

for automatic ice making tray is about 10 oC or less

Operation method

In the drip tray

under the

evaporator of the

freezer

compartment

Abnormal (faulty)

1.3 kΩ (Approx.) Open (∞ Ω )

At the left

bottom of

vegetable

compartment

-20

20 30

-10

0

10

30

20

15

10

5

0

25

35

Thermistor resistance valves against

temperature

Temperature

Black

Black

Outside air thermistor

Refrigerator

compartment,

Freezer

compartment,

,Defrosting,

Ice making

Inner

thermistor

13

6.2 FUNCTION OF OPERATION PANEL

(1) Normal operation

(2) Ice making test / Self-check

2.1

Setting

Press the

switch for 5 seconds

2.2 Operation and display

During automatic ice making test,ice making stop LED blink.

When somthing is faulty

,

the trouble is indicated with blinking number of ice making stop LED

.(

See page

13,14

)

Self-check finishes automatically

.

LED trouble display is also automatically released

10

minutes later

.

However

,

the abnormal part has not been repair yet.

14

6.3 FLOW CHART OF SELF-CHECK

(1) Trouble shooting with self-check

This refrigerator has self-check feature to clarify and indicate where & what the trouble is. It can be checked that

there is something wrong with electronic circuit and electric parts.

Remark

(2) Timing of self-check

Defrost heater and related parts :

Self-check is conducted after defrosting.(Make sure to confirm the display before unplugging

because it is automatically reset once the power cord is pulled out.)

Ice maker and related parts :

To check the ice- making and then, check the blink amount of LED see the reference as (3)

Fan motor and related parts :

To check the blink amount of LED see the reference as (3)

Thermistor and related parts :

Self-check is continuously working.

Caution: The self-check will automatic start to begin power supply. But in the portion of the abnormality show the detail as (3) .

And the caution checking couldn't be summarized, please use self-check means by using operation panel.

Self-check

Press Ice making stop button

Was trouble

displayed?

Locate the trouble according to

LED indication.(See page

Disconnect power plug

Repair/replace defective part(s)

according to LED indication

Connect power plug

∗

Press Ice making stop button

Self-check ,Ice making stop LED

blink during the operational test

of automatic ice maker.

Check the parts whose

Abnormalities cannot be

detected by selfcheck.(Remark.1)

Is error no

longer

displayed?

Self-check is finished.

Slide room

Refrigerator room

Ice making

stop LED

Refrigerator

Freezer

Ice maker off

No

No

Yes

Yes

∗

Wait 10 minutes before

inserting the cord once it's

unplugged.(If the cord is

plugged in within 10

minutes,trouble may be

display.)

During the ice making test

mode,watch the operation of ice

maker gear box and water pump in

refrigerator.

Is trouble no longer

displayed?

No

1.) Self-check cannot detect abnormalities of the

following parts. See page 11~13 for trouble

criterion of main parts.

- Freezer & refrigerator door sw NG

- Thermo heater NG ( Water pipe / Vegetable

case heater etc.)

- Motor damper NG

- Water pump motor NG

2.) If the abnormality is found when power is

turned on, compressor and fan motor will be

suspended for 20 minutes.

15

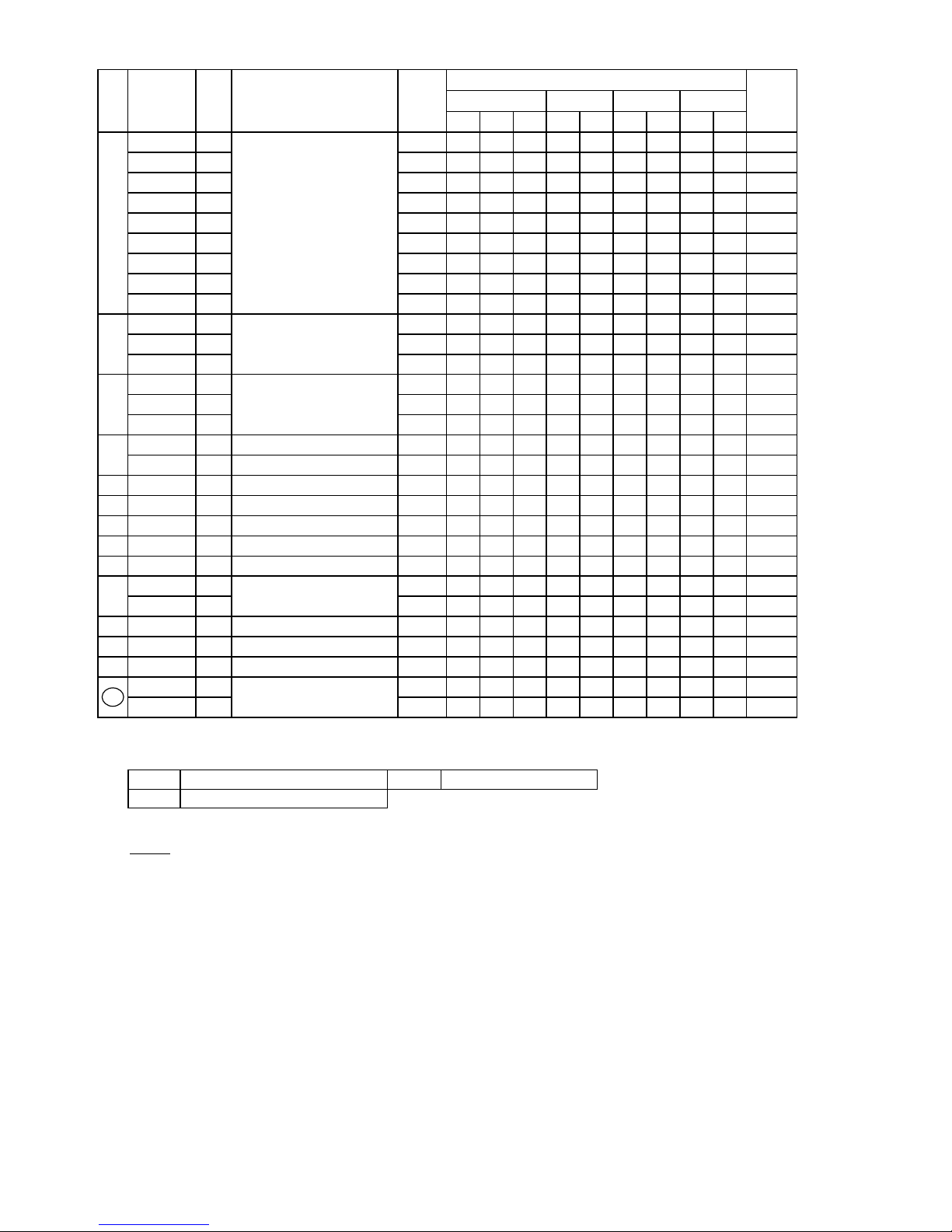

(3) LED trouble display and the check point

(3.1) LED trouble display : follow the procedure of "self check method

and its operation" at page 11. Trouble is indicated by the blinking number

of ice making stop LED.

∗

When several troubles occur, smaller blinking number of LEDs has to be indicated first.

(3.2) Check point and treatment

Normal

1.

Normally display and the Auto ice-maker

system display.

*

If non-power supply, it'll show as same

the effect.

Auto ice maker NG

1.

The connector lead wire of Auto ice maker

1.

Check all points of the Auto ice maker

is not orderly.

connector lead wire. May be un-lock

and struck insert.

2.

2.

3.

3.

PCB plate ( Ref Con assy) NG

Thermistor(I) NG

1.

The connector thermistor (I) lead wire

1.

Check all points of the thermistor (I)

isn't orderly.

connector lead wire, may be unlock

and struck insert.

2.

Thermistor (I) NG (break or short)

2.

If the resistance of thermistor (I) is NG,

should be changed the thermistor and

re-check the resistance.

3.

PCB plate (Ref Con assay) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance).

Thermistor (F) NG

1.

The connector thermistor (F) lead wire

1.

Check all points of the thermistor (F)

isn't orderly.

connector lead wire, may be unlock

and struck insert.

2.

Thermistor (F) NG (break or short)

2.

If the resistance of thermistor (F) is

NG,should be changed the thermistor and

re-check the resistance.

3.

PCB plate (Ref Con assy) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

Thermistor (DEF) NG

1.

The connector DEF. thermistor lead wire

1.

Check all points of the thermistor

isn't orderly.

(DEF) connector lead wires, may be

unlock and struck insert.

2.

Thermistor (DEF) NG (break or short)

2.

If the resistance of thermistor (DEF) is

NG,should be changed the thermistor and

re-check the resistance.

3.

PCB plate (Ref Con assy) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

Defrost heater NG

1.

1.

2.

Defrost heater break or

2.

Thermal fuse break.

and thermal fuse.

3.

PCB plate (Ref Con assy) break.

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

isn't orderly.

maker.

Replace and re-check the PCB plate

and non-display)

connector lead wire, may be un-lock

Blink

Blink

Light

Light

Light

1 Blink

No Light

Display function of LED

Off

NO

Function Explanation

Light

No Light

Detecting method and corrective NG points

2 Blinks

Check the resistance of the defrost heater

and struck insert.

3 Blinks

Light

No Light

No Light

No Light

0.1 second

0.3 seconds

No Light

Replace and re-check the Auto ice

( Ref Con assy)

Auto ice maker (Motor's not rotate

The Defrost heater connector lead wire

Check all points of the defrost heater

Light

0.1 sec

5 sec

1

1

5 sec

1 2 1 2

5 sec

1 2 13

1 Cycle

0.1 sec

0.3 sec 0.3 sec

0.3 sec

1 Cycle

0.3 sec

1 Cycle

0.3 sec

Slide room

Refrigerator room

Ice making

stop LED

Refrigerator

Freezer

Ice maker off

16

Thermistor (R) NG

1.

The Thermistor (R) connector lead wire

1.

Check all points of Thermistor (R) connector

isn't orderly.

lead wire, may be unlock and struck insert.

2.

Thermistor (R) NG (break or short)

2.

If the resistance of Thermistor (R) is NG,

should be replaced the Thermistor (R) and

re-check the resistance.

3.

PCB plate (Ref Con assy) NG

3.

If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

Thermistor (A.T.) NG

1.

The Thermistor (A.T.) connector lead

1.

Check all points of the thermistor (A.T.)

wire isn't orderly.

connector lead wire, may be unlock and

struck insert.

2.

Thermistor (A.T.) NG (break or short)

2.

If the resistance of Thermistor (A.T) is NG,

3.

PCB plate (Ref Con assy) NG

should be replaced the Thermistor (R)

and re-check the resistance.

3.

If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

1.

DC motor is orderly connected.

1.

Check all points of DC motor connector

lead wire, may be unlock and struck insert.

2.

DC motor NG (Motor un-rotate and

2.

non-display)

re-check display.

3.

PCB plate (Ref Con assy) NG

3.

If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

1.

DC fan motor is orderly connected.

1.

Check all points of DC Fan motor connector

lead wire, may be unlock and struck insert.

2.

DC fan motor NG (Motor un-rotated,

2.

Replace DC fan motor (Outer motor assy)

and non-display.)

and check display.

3.

PCB plate (Ref Con assy) NG

3.

If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

PCB plate (Ref Con assy) NG

1.

PCB program (Ref Con assy) is NG

1.

Replace a new PCB plate (Ref Con assy)

Refrigerant circuit is NG.

1.

Pipe cracked (Welding joint)

1.

Check and corrective to each problem.

2.

Gas leak

3.

Compressor NG

Remark :

1.) For the refrigerator is NG more than one case, will show as the first symptoms before, such as Thermistor (F) NG (1 blink in 0.3 seconds) and

Thermistor (R) NG (4 blinks in 0.3 seconds). LED will blink 1 blink in 0.3 seconds until Thermistor (F) was corrected. Then change to 4 blinks in 0.3 seconds

and LED won't blink when Thermistor (R) was corrected.

2.) Ice making stop LED blink during the operational test for ice maker.

3.) Compressor won't work if the fridge have problem and LED blink.

4.) Characteristic value may be changed due to the product improvement.

6 Blinks

Display function of LED

Light

No Light

Light

Function Explanation Detecting method and corrective NG points

4 Blinks

10 Blinks

11 Blinks

Fan motor (Outer motor assy) NG

Replace DC motor (Fan grille assy) and

No Light

Light

No Light

Fan motor (Fan grille assy) NG

Light

No Light

19 Blinks

Light

16 Blinks

No Light

No Light

Light

5 sec

1

2

3

1 Cycle

4

1 2 6

1 Cycle

1 2

1 2 10

1

Cycle

1 2

1 2 11

1 Cycle

1 2

1 2 16

1 Cycle

1 2

1 2 19

1 Cycle

1 2

0.3 sec

0.3 sec

0.3 sec

0.3 sec

0.3 sec

0.3 sec

17

6.4 TEST POINT DIAGRAM OF MAIN CONTROL BOARD

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

CN4K

1

2

Red

Damper

3

Gray

Ice Maker Positon SW

4

Bright Yellow

Damper

5

Pink

Ice Maker & Water Pump Forward

6

White

Damper

7

Brown

Ice Maker Reverse

8

Blue

Damper

9

10

Yellow/Green

Water Pump

CN5F

8

Violet

12 VDC Common

7

Violet

12 VDC Common

6

Black

GND

5

Pink

GND

4

Orange

Outer Fan Motor FG

3

Bright Yellow

Inner Fan Motor FG

2

Light Green

Outer Fan Motor Vs

1

White

Inner Fan Motor Vs

CN6S

1

2

3

4

Yellow

Ice Maker Stop SW

CN1A

5

Red

Ice Maker Stop LED

1

Grey

6

3

Black

7

8

Blue

F Thermistor

CN2A

9

Bright Yellow

Temp Control Board

1

Grey

220 VAC Common

10

Orange

R Thermistor

3

White

Compressor

11

Gray

Temp Control Board

5

Red

Defrost Heater

12

Light Green

I Thermistor

13

Sky Blue

5 VDC Common

CN3A

14

Pink

DEF Thermistor

1

Yellow

Lamp

15

Black

GND

3

Yellow/Green

V Heater

16

Brown

Door SW

5

Brown

Ice Maker Heater

7

Sky Blue

Pipe Heater

Compulsory defrosting method

have

2

methods as below

1) Short circuit at 2-pin connector between no.6 (white wire) with no.7 (red wire)

CN7M

at Buzzer & Thermistor A.T. board.(Inside hinge cover)

1

White

12 VDC Common

2) Open door R and then adjust dial freezer at MID position. Use magnet touch

2

Red

Buzzer

door switch in order to simulate as door closing. (lamp must no light),then turn

3

Violet

A.T. Thermistor

the dial continuously as follow COLDER

→

LOW → MID

4 Sky Blue

5 VDC Common

5 Grey

Compulsion DEF

Parts Name

Lead color

Lead color

Parts Name

Lead color

Parts Name

Parts Name

Lead color

Parts Name

Lead color

Parts Name

Parts Name

Lead color

Lead color

220 VAC

12

VDC

5

VDC

18

DISASSEMBLY INSTRUCTIONS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

Plug out before work.

Check the automatic ice-maker by pressing ice making stop switch.

In assembling & disassembling parts use several kind of screws and rivets. Do not mistake to use them.

1. Detachment Control PCB parts Photo 1

Compressor cover

(1) Detach 7 pcs. of compressor cover screws behind the

refrigerator. (Photo 1)

Elect cover

(2) Detach 4 pcs. of Elect cover screws. (Photo 2)

Elect attach Photo 2

(3) Disconnect the connector and remove Elect attach. (Photo 3)

PCB (Refcon assy)

(4) Remove the catch of elect attach to release the PCB plate.

(Photo 3)

Photo 3

Caution on assembly

[1] Firmly connect the lead wire and the connector. Ensure the

wire are not pinched.

[2] Please use the new material of sealing insulation when

re-attach.

2. Detachment Lamp cover parts Photo 4

(1) Remove parts inside the refrigerator Shelf 1,2,3 shelf

Lamp cover inside the refrigerator

(1) Push up the lower catch, and pull the room light cover toward you.

(2) Detach two upper catches to take out the cover (Photo 4)

OPERATING PROCEDURE PHOTOS

7

Catch

Catch

4 x12

Stainless steel

4 x12 (Black)

With metal washer

Rivet

A B

D

C

Rivet

Lamp cover

7 fixing screws

Compressor

cover

4 fixing screws

Elect cover

Elect attach

PCB

Catch

Catch

19

3. Detachment the Vegetable case parts Ph

oto 5

(1) Detach parts inside vegetable compartment (Vegetable case, Fruit case).

(2) Detach the door of vegetable compartment.

(3) Detach rivet (C) at the right and unhooking 2 catches at front,

(center and left). (Photo 5)

Caution on assembly

[1] Be sure to put vegetable case cover on the catches at the rear of

vegetable compartment.

Water pump motor

(4) Remove two screws and cut the lead wire of water-pump motor to

detach it.

4. Detach the refrigerator room parts Photo 6

(1) Detach parts inside the refrigerator compartment.

(2) Detach parts inside the vegetable compartment.

(3) Detach a left screw of mirror hinge and pull out the lead wire.

(Photo 7)

(4) Detach the connector.

Control panel , Duct R, Temperature control panel Photo 7

(5) Remove the upper and lower rivets (C) of right side and left side,

then unhook 7 catches.(9 catches for C405B)

* Remove the right catch before push the control panel to the right

and detach it. (Photo 7)

Fan grille

(6) Remove the following; Screw (A) at the upper and right center,

2 screws (B) at the left and 2 screws (B) at the right. (Photo 6)

* Motor damper and thermal fuse are combined with fan grille.

* Fan and fan motor are combined with fan grille.

Caution on assembly

[1] Use new tapes and sealing materials for assembly.

[2] Putting some tape across joints, tape them securely so that they will

not leak the cool air.

[3] Attach a connector securely in order to prevent contact failure.

OPERATING PROCEDURE PHOTOS

Rivet

Catches

Catch

Catch

Vegetable

ca

se cover

Screw

Fan grille

F-room

Screw

Catch

CatchCatch

Catch

Catch

Catch

Screw

Lamp

Rivet

Control panel

Rivet

Rivet

Rivet

Mirror hinge

R-room

Catch

Catch

Catch

(only:C405B)

(only:C405B)

20

Defrost heater, Drip tray Photo 8

(7) Peel off the tape that fixes lead wires on the side wall

of the vegetable compartment. Then take out defrost heater

together with heater roof.

Detach heater roof and Heater cover from Defrost heater.

Detach the drip tray after removing the defrost heater.

Defrost thermistor

(8) Cut the binder and disconnect the connector. (Photo 9)

Caution on assembly

[1] Loosen the lead wire at the defrost heather to prevent

water from entering the glass tube and careful the

direction for the correct assembly.

[2] Attach the drip tray securely to the lower parts.

[3] Attach the defrost thermistor in the correct place. (If

they're attached out of place, thermal characteristics

will go wrong).

[4] Attach the lead wires to the fixture.

5 Detachment the parts in Freezer compartment

(1) Detach the parts inside the Freezer room (Ice spoon,

Freezing case [upper] and Freezing case [lower] ).

(2) Pull the door of Freezer compartment by pulling toward you.

Cover (upper)

(3) Detach 3 catches and remove it. (Photo 10)

(4) Disconnect the connector.

Automatic ice-maker

(5) push a catch to upper and pull the part to the right

and detach it. (Photo 10)

OPERATING PROCEDURE PHOTOS

Photo 9

P

hoto 10

Evaporator

Defrost heater

Cover (upper)

Ice corner

Catch

F-room

Rivet

Rivet

Catch

DEF thermistor

Aluminium

Heater

Defrost

heater

Tape

Drip tray

Tape

Heater roof

21

6 Detachment the vegetable compartment parts Photo 11

(1) Detach the door of the vegetable compartment.

Water pipe (lower)

(2) Detach a rivet (C), pipe cover and connector. Then

remove the water pipe lower.

Water tank tray

(3) Pull Tank tray to R-room upper and take it out together

with the water pipe. Photo 12

Caution on assembly

(1) Fit the water tank tray properly in order to prevent a

water leak.

Door Switch

(4) Insert a minus screwdriver between switch and body

to remove the door switch.

OPERATING PROCEDURE PHOTOS

R-room

Water pipe

Tank tray

Water pipe

Vegetable case room

Pipe cover

22

Compressor cover

(1) Remove 7 screws for compressor cover at the back of the refrigerator.

Fan motor of compressor compartment

(2) Detach the Elect cover

(3) Detach the Connector.

(4) Remove a screw that fixed bell mouth. Pull out the whole fan motor and disconnect the terminals.

(5) Pull out the fan from the fan motor.

(6) Detach the lid-fixing screw to take out the fan motor.

7 Detachment compressor.

(1) Collect gas from the charge pipe on the high pressure side.

(2) After collecting gas, cut the charge pipe on the low pressure side.

(3) Detach the welded section of the discharge pipe and suction pipe.

(4) Replace the compressor and the dryer at a time.

Caution on assembly

(1) After attaching the compressor, must to Vacuum and charge gas from charge pipe.

(2) Arrage the piping so that the pipe will not hit each other and compressor cover, (which causes loud noise). Then

attach the compressor cover.

(3) After all the work is complete, be sure to check the cooling preformance and the gas leak from the welded points.

OPERATING PROCEDURE

W

Attach U washer as the figure shown below

: This mark shown welded point

Fan motor (Machine room)

W

W

W

Dryer

W

W

W

W

Charge pipe(Low pressure side)

23

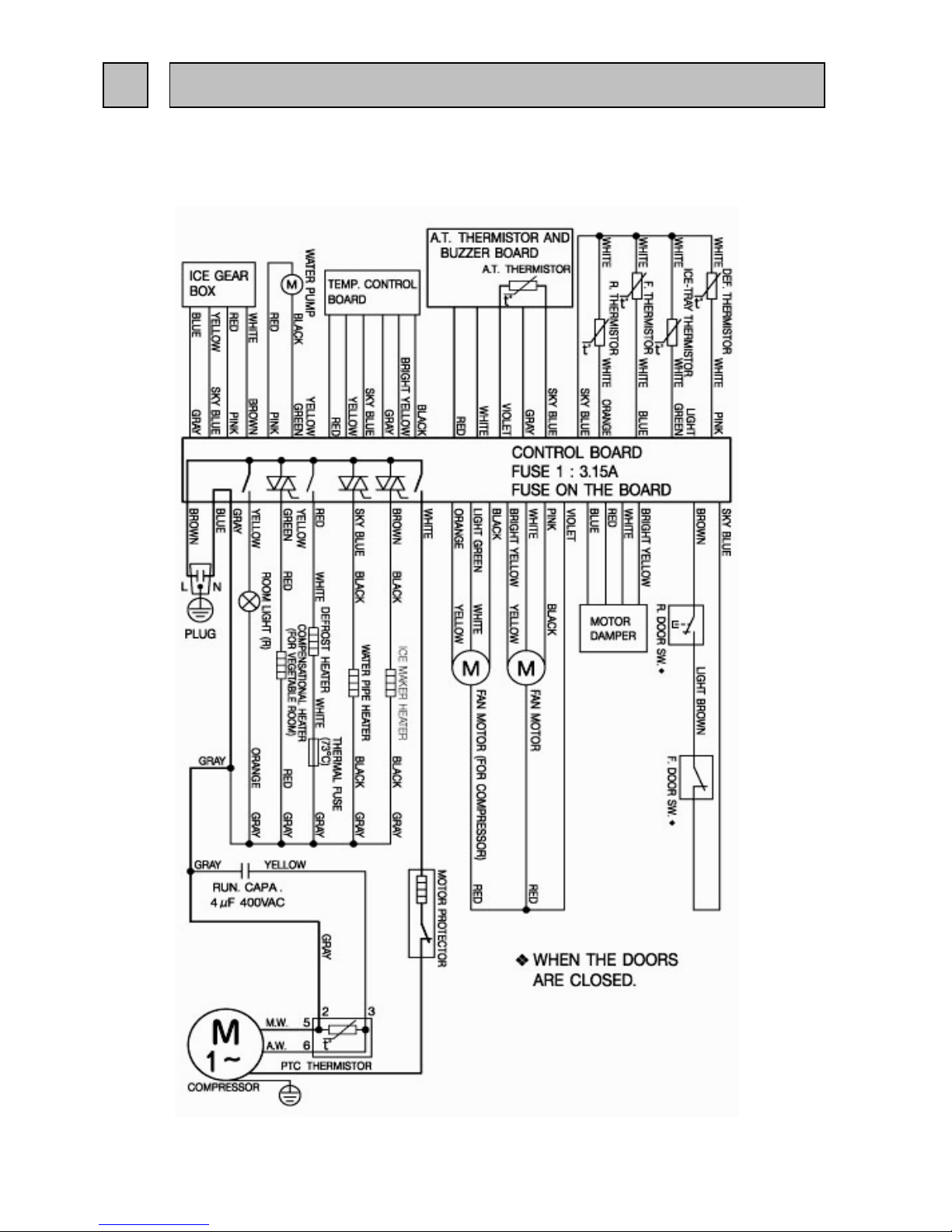

DOOR, BODY PARTS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

8 PARTS LIST

24

W ST OB W ST W ST W ST

KIERL6000

<G>

1

KIER66000

<G>

1

KIER63000

<G>

1

KIERN6000

<G>

1

KIERN7000

<G>

1

KIERL8000

<G>

1

KIER71000

<G>

1

KIERP0000

<G>

1

KIERP1000

<G>

1

KIEPE2002

<G>1111

KIEP90002

<G>

1

KIEP91002

<G>1111

KIEPE2001

<G>1111

KIEP90001

<G>

1

KIEP91001

<G>1111

KIEG05741

<G>

CATCHER RH

11111

KIEPE4741

<G>

CATCHER LH

111

1

5

KIEP89118

<G>

FREE POCKET L

222222222

6

KIEP89151

<G>

FRAME V ASSY

111111111

7

KIEP89157

<G>

FRAME F ASSY

111111111

8

KIEP89119

<G>

FREE POCKET S

111

1

9

KIEHJ3115

<G>

EGG CASE

111111111

KIEP89110

<G>1111

1

KIEP94110

<G>1111

11

KIEP89124

<G>

BOTTLE POCKET

111111111

12

KIEP89112

<G>

MAGNET GASKET ASSY ( V )

111111111

13

KIEP89111

<G>

MAGNET GASKET ASSY ( F )

111111111

KIERN0031

<G>1111

KIER72031

<G>1111

1

RECOMMEND PART NO. 1, 2, 3, 10, 12, 13

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

Remark

- Country code : A= Australia and New Zealand

- Colour code : W = White, ST = Stainless

PRICE/PIE

CE(US$-

FCA)

SPECPART NAME

Q'TY/UNIT

MR-C375CL-A

MR-C405CL-A

MR-C405C-A

MR-C375C-A

1

2

3

NO. PART NO.

4

BADGE ASSY

MAGNET GASKET ASSY ( R )10

14

DOOR R

DOOR V

DOOR F

RoHS

FRFREEZER ROOM

REFRIGERATOR ROOM

V

VEGETABLE ROOM

25

BODY PARTS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

26

WSTOBWSTWSTWST

KIEP89858 <G> 1 1 1 1 1

KIEP94858 <G> 1 1 1 1

2 KIEHJ3305 <G> THERMO DIAL (R) 2 2 2 2 2 2 2 2 2

3 KIEP89802 <G> DUCT V ASSY 1 1 1 1 1 1 1 1 1

4 KIEP89818 <G> COVER DUCT V 1 1 1 1 1 1 1 1 1

5 KIEP89503 <G> WATER TRAY ASSY 1 1 1 1 1 1 1 1 1

6 KIEP89808 <G> CONNECTOR COVER 1 1 1 1 1 1 1 1 1

7 KIEPE2663 <G> FAN GRILLE ASSY 1 1 1 1 1 1 1 1 1

KIEHJ3708 <G> 1 1 1 1

KIEP91708 <G> 1 1 1 1

KIEP90708 <G> 1

9 KIEP89442 <G> PIPE COVER 1 1 1 1 1 1 1 1 1

10 KIEPE2350 <G> AUTO ICE MAKER 1 1 1 1 1 1 1 1 1

11 KIEP89652 <G> COMP COVER ASSY 1 1 1 1 1 1 1 1 1

12 KIE805794 <G> CASTER SET 2 2 2 2 2 2 2 2 2

13 KIEHJ3709 <G> SCREW LABEL (F) 2 2 2 2 2 2 2 2 2

14 KIEH79795 <G> CASTER ASSY 2 2 2 2 2 2 2 2 2

15 KIEC02460 <G> ADJUST BOLT 2 2 2 2 2 2 2 2 2

KIER65705 <G> 1 1

KIEP91705 <G> 1 1

KIEP90705 <G> 1

KIERN6705 <G> 1 1

KIEPE5705 <G> 1 1

KIEP89701 <G> 1 1 1 1 1

KIEPE4701 <G> 1 1 1 1

18 KIEP89470 <G> LAMP COVER 1 1 1 1 1 1 1 1 1

19 KIEHJ4503 <G> JOINT PIPE (TANK) 1 1 1 1 1 1 1 1 1

20 KIEHJ3531 <G> WATER TANK CAP 1 1 1 1 1 1 1 1 1

21 KIEHJ3519 <G> WATER PUMP 1 1 1 1 1 1 1 1 1

22 KIEK96527 <G> WATER TANK COVER ASSY 1 1 1 1 1 1 1 1 1

KIEMT0702 <G> 1 1 1 1 1

KIEHJ2702 <G> 1 1 1 1

24 KIEHJ3798 <G> ROLLER 4 4 4 4 4 4 4 4 4

25 KIEHJ3520 <G> WATER TANK 1 1 1 1 1 1 1 1 1

26 KIEHJ3526 <G> FILTER (TANK) 1 1 1 1 1 1 1 1 1

27 KIEP89328 <G> ELECT BOX COVER ASSY 1 1 1 1 1 1 1 1 1

28 KIEMQ4326 <G> ELECT BOX SUB ASSY 1 1 1 1 1 1 1 1 1

29 KIEHJ4442 <G> COVER (IM) 1 1 1 1 1 1 1 1 1

KIEPE2730 <G> 1 1 1 1

KIEP91730 <G> 1 1 1 1

KIEP90730 <G> 1

31 KIEPJ5663 <G> FAN GRILLE 1 1 1 1 1 1 1 1 1

32 KIEP94662 <G> BELL MOUTH 1 1 1 1 1 1 1 1 1

33 KIEHJ4682 <G> DUCT DAMPER 1 1 1 1 1 1 1 1 1

34 KIEP89336 <G> THERMAL FUSE ASSY 1 1 1 1 1 1 1 1 1

RECOMMEND PART NO. 7, 20, 22, 34

ABBREVIATION

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

30 KICK PLATE

MR-C375C-A

23

1 CONTROL PANEL

16 HINGE COVER

HINGE ASSY (LOW)

RoHS

PRICE/PIECE

(US$-FCA)

SPECPART NAME

Q'TY/UNIT

MR-C405C-A

MR-C405CL-A

MR-C375CL-A

HINGE ASSY (UP) 17

PART NO.NO.

8 LABEL FC

FRFREEZER ROOM

REFRIGERATOR ROOM

IMVICE MAKER

VEGETABLE ROOM

27

ELECTRICIAL PARTS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

28

WSTOBWSTWSTWST

1

KIEHJ3313

<G>

THERMISTOR (R)

111111111

KIEP89386

<G> 1 1 1 1 1

KIEP94386

<G> 1 1 1 1

3 KIE402360

<G> LAMP 240V 15W E12 1 1 1 1 1 1 1 1 1

4 KIEHJ3365

<G> WATER PUMP 1 1 1 1 1 1 1 1 1

5 KIEP89312

<G> THERMISTOR (DEF) 1 1 1 1 1 1 1 1 1

6 KIEHJ3378

<G> THERMISTOR (F) 1 1 1 1 1 1 1 1 1

7 KIEHJ3469

<G> GEAR BOX (IM) 1

1 1 1 1 1 1 1 1

8 KIEHJ3316

<G> THERMISTOR (I) 1 1 1 1 1 1 1 1 1

9 KIEPE2354

<G> PLUG CORD ASSY 1 1 1 1 1 1 1 1 1

10 KIEHJ3362

<G> REED SWITCH 1 1 1 1 1 1 1 1 1

11 KIEP89364

<G> WATER PIPE ASSY 1 1 1 1 1 1 1 1 1

12 KIELR4346

<G> RUNNING CAPACITOR 4µF 400VAC 1 1 1 1 1 1 1 1 1

13 KIEKA0374

<G>

BUZZER BOARD &

THERMISTOR (A.T.)

1 1 1 1 1 1 1 1 1

14 KIEMQ4363

<G> LAMP SWITCH (R) 1 1 1 1 1 1 1 1 1

15 KIEKA0382

<G> TEMP CONTROL PANEL 1 1 1 1 1 1 1 1 1

16 KIEMQ4320

<G> FAN MOTOR ASSY 1 1 1 1 1 1 1 1 1

17 KIEP89537

<G> HEATER ROOF 1 1 1 1 1 1 1 1 1

18 KIEP89392

<G> DEFROST HEATER 1 1 1 1 1 1 1 1 1

19 KIEP89397

<G> HEATER COVER 1 1 1 1 1 1 1 1 1

20 KIEP89538

<G> DRIP TRAY 1 1 1 1 1 1 1 1 1

KIERN4339

<G> 1

1 1 1 1

KIERN8339

<G> 1 1 1 1

22 KIEP89340

<G> MOTOR PROTECTOR 5TM718MFBYY53 1 1 1 1 1 1 1 1 1

23 KIEE76330

<G> PTC RELAY PTH7M330MD2 1 1 1 1 1 1 1 1 1

24 KIEG05341

<G> PROTECTOR COVER 1 1 1 1 1 1 1 1 1

25 KIEP89325

<G> OUT FAN MOTOR ASSY 1 1 1 1 1 1 1 1 1

26 KIEP89662

<G> BELL MOUTH M ASSY 1 1 1 1 1 1 1 1 1

RECOMMEND PART NO. 1, 3, 5, 6, 8, 13, 15, 18, 21, 22, 23

REFCON ASSY

21

2

LAMP SOCKET

MR-C405CL-A

RoHS

PRICE/PIE

CE(US$-

FCA)

SPECPART NAME

Q'TY/UNIT

MR-C375C-A

PART NO.NO.

MR-C375CL-A

MR-C405C-A

29

ACCESSORY AND UNIT PARTS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

30

WSTOBWSTWSTWST

1

KIEP89420

<G>

GLASS SHELF R ASSY

111112222

2 KIEHJ3427

<G> SLIDE SHELF (REAR) 1 1 1 1 1 1 1 1 1

3 KIEHJ3428

<G> SLIDE SHELF (FRONT) 1 1 1 1 1 1 1 1 1

4 KIEP89413

<G> SLIDE CHILLED CASE 1 1 1 1 1 1 1 1 1

5 KIEP89409

<G> VEGEATABLE CASE COVER 1 1 1 1 1 1 1 1 1

6 KIEP89406

<G> FRUIT CASE 1 1 1 1 1 1 1 1 1

7 KIEP89468

<G> ICE BOX SHEET 1 1 1 1 1 1 1 1 1

8 KIEP89487

<G> ICE BOX 1 1 1 1 1 1 1 1 1

9 KIEP89474

<G> FREEZING CASE (UP) 1

1 1 1 1 1 1 1 1

10 KIEHJ3477

<G> ICE SPOON 1 1 1 1 1 1 1 1 1

11 KIEP89475

<G> F CASE (LOW) 1 1 1 1 1 1 1 1 1

12 KIEP89420

<G> GLASS SHELF R ASSY 1 1 1 1 1 1 1 1 1

13 KIEP89405

<G> VEGEATABLE CASE 1 1 1 1 1 1 1 1 1

14 KIEP89995

<G> EVAPORATOR 1 1 1 1 1 1 1 1 1

15 KIEP89504

<G> ELBOW 1 1 1 1 1 1 1 1 1

16 KIEAA1980

<G> DRYER XH-9,10GR 1 1 1 1 1 1 1 1 1

17 KIEP89435

<G> DRAIN PAN 1 1 1 1 1 1 1 1 1

18 KIEPE2277

<G> COMPRESSOR DHS66C10RAW 1 1 1 1 1 1 1 1 1

19 KIEHJ3735

<G> U WASHER 4 4 4 4 4 4 4 4 4

20 KIEE76797

<G> RUBBER MOUTH 4 4 4 4 4 4 4 4 4

RECOMMEND PART NO. 1, 2, 3, 4, 14, 16, 18

PRICE/PIE

CE(US$-

FCA)

RoHSPART NO.NO.

MR-C375CL-A

SPECPART NAME

Q'TY/UNIT

MR-C405CL-AMR-C375C-A

MR-C405C-A

31

PACKING PARTS

MR-C375C-A

MR-C375CL-A

MR-C405C-A

MR-C405CL-A

NO STEP ON

1

C.F.B BOX ASSY

6

C.F.B TOP COVER

3

PACKING COVER

5

C.F.B PALLET

4

BOTTOM CUSHION

L

R

2

TOP CUSHION

32

WSTOBWSTWSTWST

KIERN4970

<G>

1

KIERN5970

<G>

1

KIETY7970

<G>

1

KIERN6970

<G>

1

KIERN7970

<G>

1

KIERN8970

<G>

1

KIERN9970

<G>

1

KIERP0970

<G>

1

KIERP1970

<G>

1

2

KIEP89979

<G>

TOP CUSHION 1 1 1 1 1 1 1 1 1

3 KIEHN8973

<G>

PACKING COVER 1 1 1 1 1 1 1 1 1

4 KIEP89978

<G>

BOTTOM CUSHION 1 1 1 1 1 1 1 1 1

5 KIEP89974

<G>

C.F.B PALLET 1 1 1 1 1 1 1 1 1

6 KIEP89975

<G>

C.F.B TOP COVER 1 1 1 1 1 1 1 1 1

PRICE/PIE

CE(US$-

FCA)

Q'TY/UNIT

MR-C405CL-A

MR-C375CL-A

SPEC

MR-C405C-A

C.F.B BOX ASSY

PART NAME

MR-C375C-A

1

RoHS

PART NO.NO.

33

MITSUBISHI ELECTRIC CORPORATATION

HEAD OFFICE : MITSUBISHI DENKI BLDG., MARUNOUCHI,TOKYO 100. TELEX : J24532 CABLE MELCO TOKYO

Distributed by

MITSUBISHI ELECTRIC AUSTRALIA PTY LTD.

(Incorporated in New South Wales) ABN 58 001 215 792

New South Wales :

Queensland:

South Australia /

348 Victoria Road,

Unit 12, 469

Northern territory :

Rydalmere NSW 2116

Nudgee Road,

Suite 1, 224 Glen Osmond Road

Ph : (02) 9684 7777

Hendra QLD , 4011

FULLARTON SA 5063

Fax : (02) 9898 1043

Ph : (07) 3263 2000

Ph: (08) 8338 1001

Fax : (07) 3630 1888 Fax : (08) 8338 0501

Western Australia :

Victoria / Tasmania :

Far North

329 Collier Road,

Building 28, Omnico bus. Park

Queensland:

Bassendean WA 6054

270 Ferntree Gully Road,

Capricorn Air,

Ph : (08) 9377 3400

Notting Hill 3168

13 Mackley St,

Fax : (08) 9377 3499

Ph : (03) 9535 7800

Garbutt 4814

Fax : (03) 9535 7801 Ph: (07) 4775 5222

Fax : (07) 4775 5303

Distributed by

BLACK DIAMOND TECHNOLOGIES LIMITED (BDT)

Wellington Office (Head Office)

Auckland Office

Christchurch Office

1 Parliament Street

Unit1, 4 Walls Road

Suite 2, Level 1

PO Box 30-772

Penrose

37 Manderville Street

Lower Hutt

Auckland PO Box 12-726

Christchurch PO Box 1604

Ph : (04) 560 9100

Ph: (09) 526 9340

Ph : (03) 341 7052

Fax : (04) 560 9133

Fax : (09) 526 9369

Fax : (03) 341 7054

Loading...

Loading...