Mitsubishi Electronics MR-385R-ST-A, MR-385R-ST-A-NZ, MR-420R-W-A-NZ, MR-455R-W-A-NZ, MR-420R-ST-A-NZ User Manual

...

MITSUBISHI

HOME REFRIGERATORS

SERVICE MANUAL

Models

MR-385R-W-A

MR-385R-ST-A

MR-420R-W-A

MR-420R-ST-A

MR-455R-W-A

MR-455R-ST-A

MR-385R-W-A(NZ)

MR-385R-ST-A(NZ)

MR-420R-W-A(NZ)

MR-420R-ST-A(NZ)

MR-455R-W-A(NZ)

MR-455R-ST-A(NZ)

2005

NO.SM-RE-0502

A……......Australia

A(NZ) .....New Zealand

CONTENTS

1. SPECIFICATIONS....................................................

2. OUTLINES AND DIMENSIONS..................................

3. WIRING DIAGRAM....................................................

4. REFRIGERANT CIRCUIT...........................................

5. NAME OF THE PARTS...........................................

6. TROUBLE SHOOTING..............................................

6.1 TROUBLE CRITERION OF MAIN PARTS.......

6.2 HOW TO CHECK P.C.BOARDS......................

6.3 TEST POINT DIAGRAM OF

MAIN CONTROL BOARD..............................

6.4 MULFUNCTION DISPLAY AND CHECKING

POINT...........................................................

6.5 IMPORTANCE DETAIL OF FAULT ANALYSIS.

7. DISASSEMBLY INSTRUCTIONS.................................

8. PARTS LIST...............................................................

1

7

10

11

13

14

14

16

17

18

19

20

23

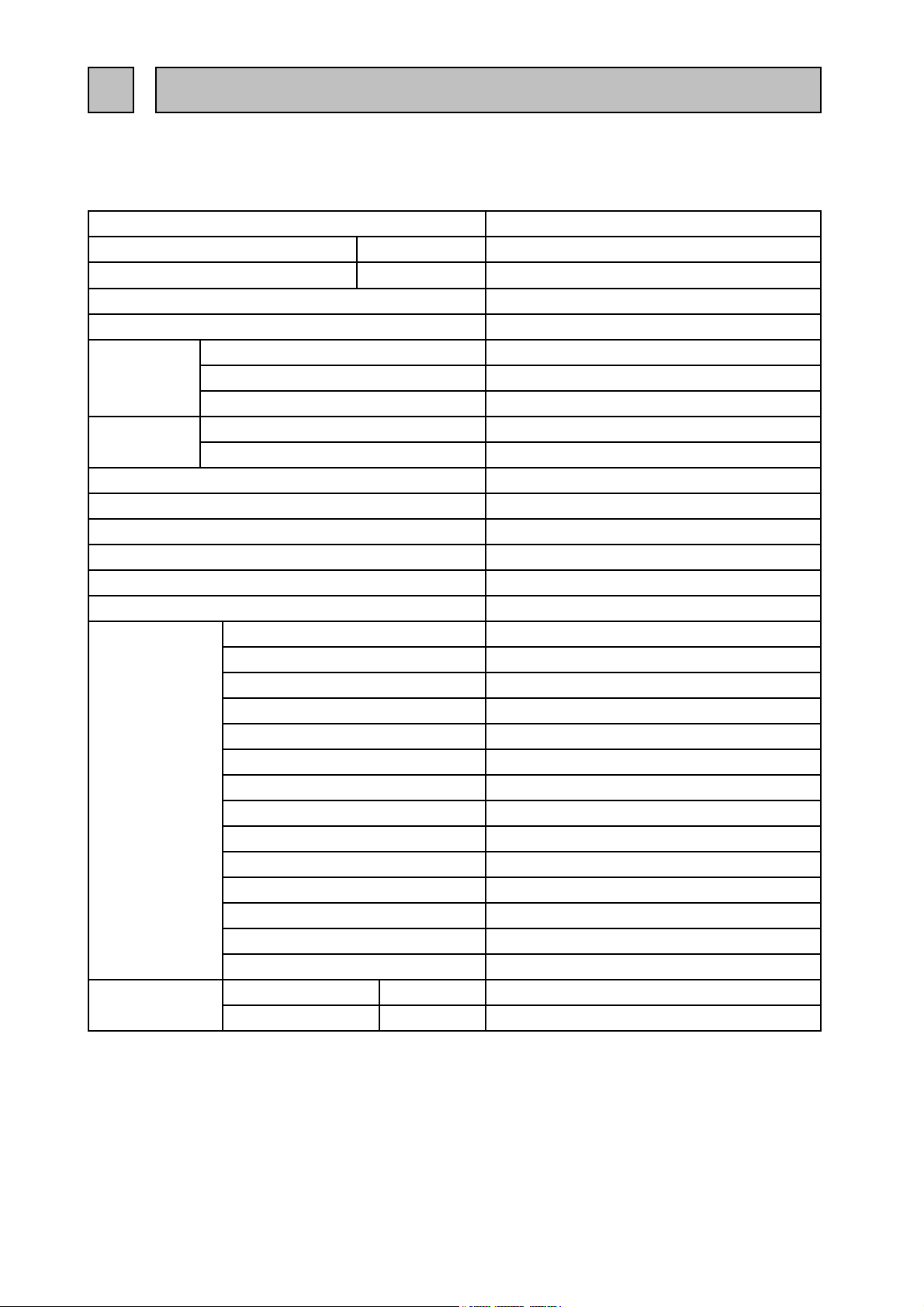

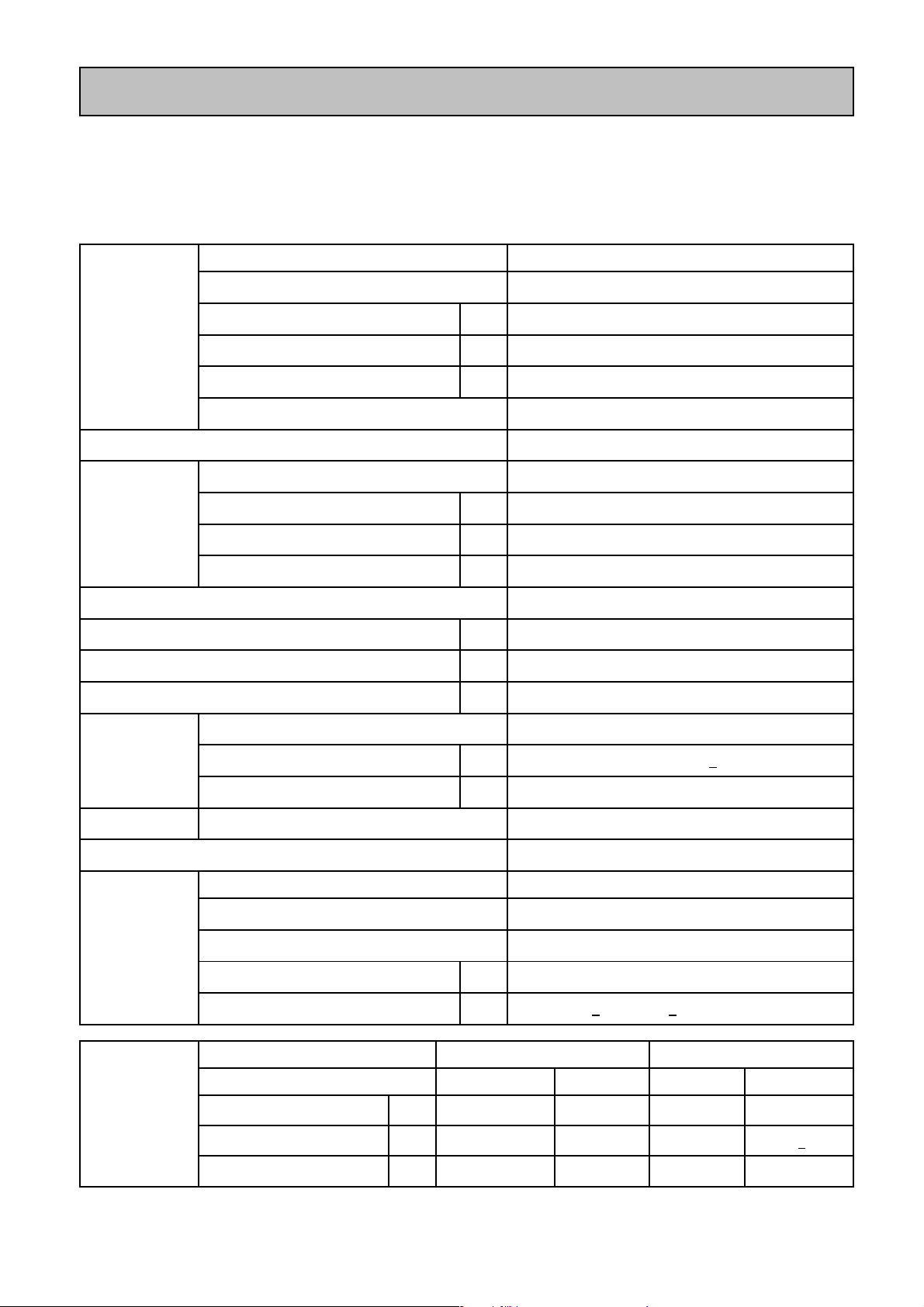

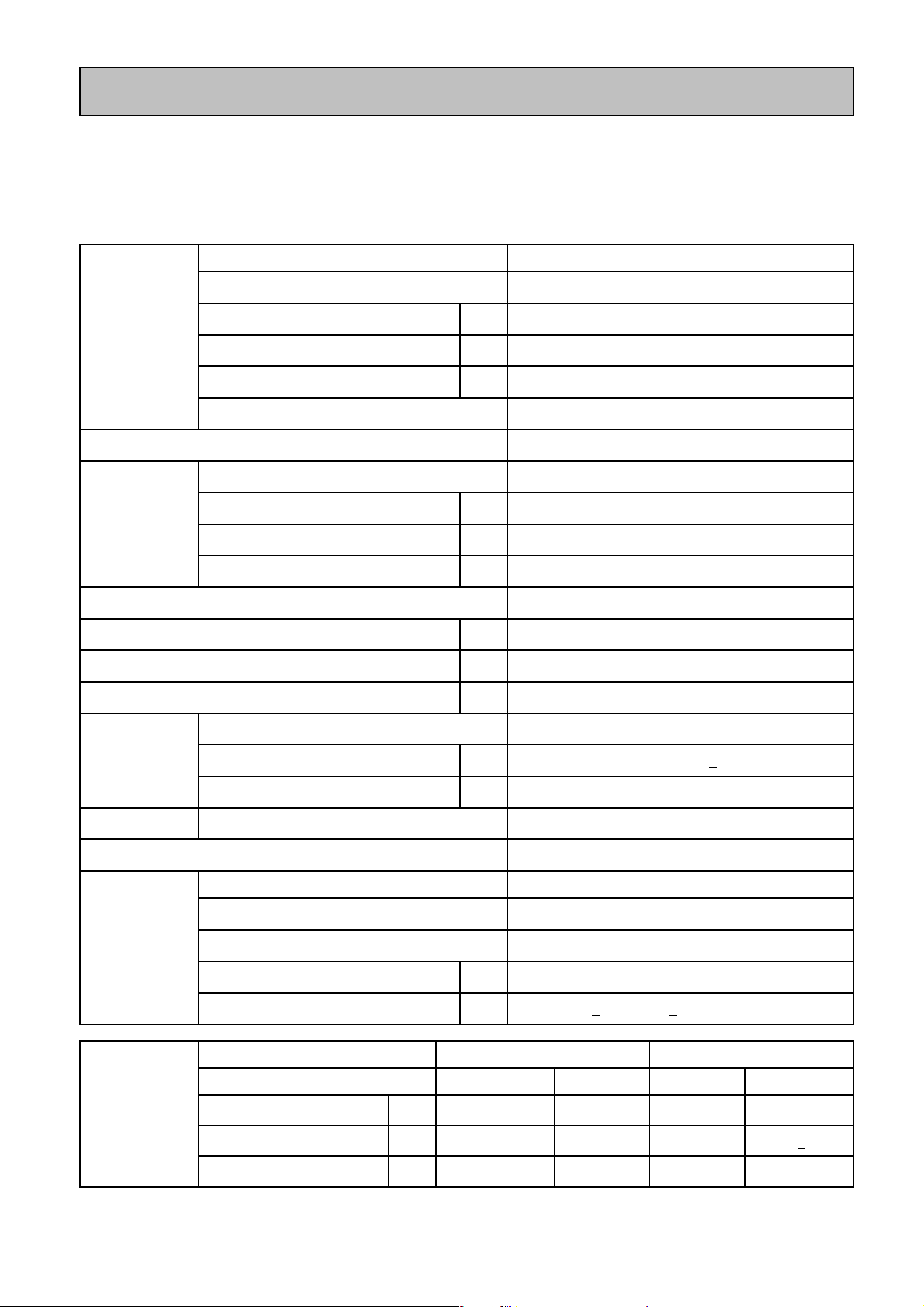

1 SPECIFICATION

1.1 SPECIFICATION

MR-385R-A

MR-385R-A(NZ)

Power supply 230/240V 50Hz

Total capacity (Gross (AS)) L

Dimensions (HXWXD) mm. 1591 x 685 x 700

Cabinet Acrylic resin coated steel

Food liner ABS resin

Cabinet Foamed cyclopenthane

Insulation

Cooling system

Evaporator Fin and tube type

Condenser Concealed type

Defrost system Automatic (Heater defrost)

Drain Automatic (drainage)

Temperature control system Automatic control

Refrigerator room light 240V 15W (E12)

Accessories

Weight

Freezer door Foamed cyclopenthane

Refrigerator door Foamed cyclopenthane

Freezer Forced air convection

Refrigerator Surround cooling,multi air flow,front air flow

Ice tray 1 pc.

Ice box 1 pc.

Freezer pocket 2 pcs.

Slide chilled case 1 pc.

Crystal shelf (F)

Crystal shelf (R)

Free pocket 1 pc.

Egg rack 2 pcs.

Adjust pocket 2 pcs.

Bottle pocket 2 pcs.

Vegetable case 1 pc.

Tray V 1 pc.

Drain pan 1 pc.

Bottle stopper 1 pc.

Unit kg 65

Shipping kg 72

385 (F : 130 R : 255)

1 pc.

3 pcs.

- 1 -

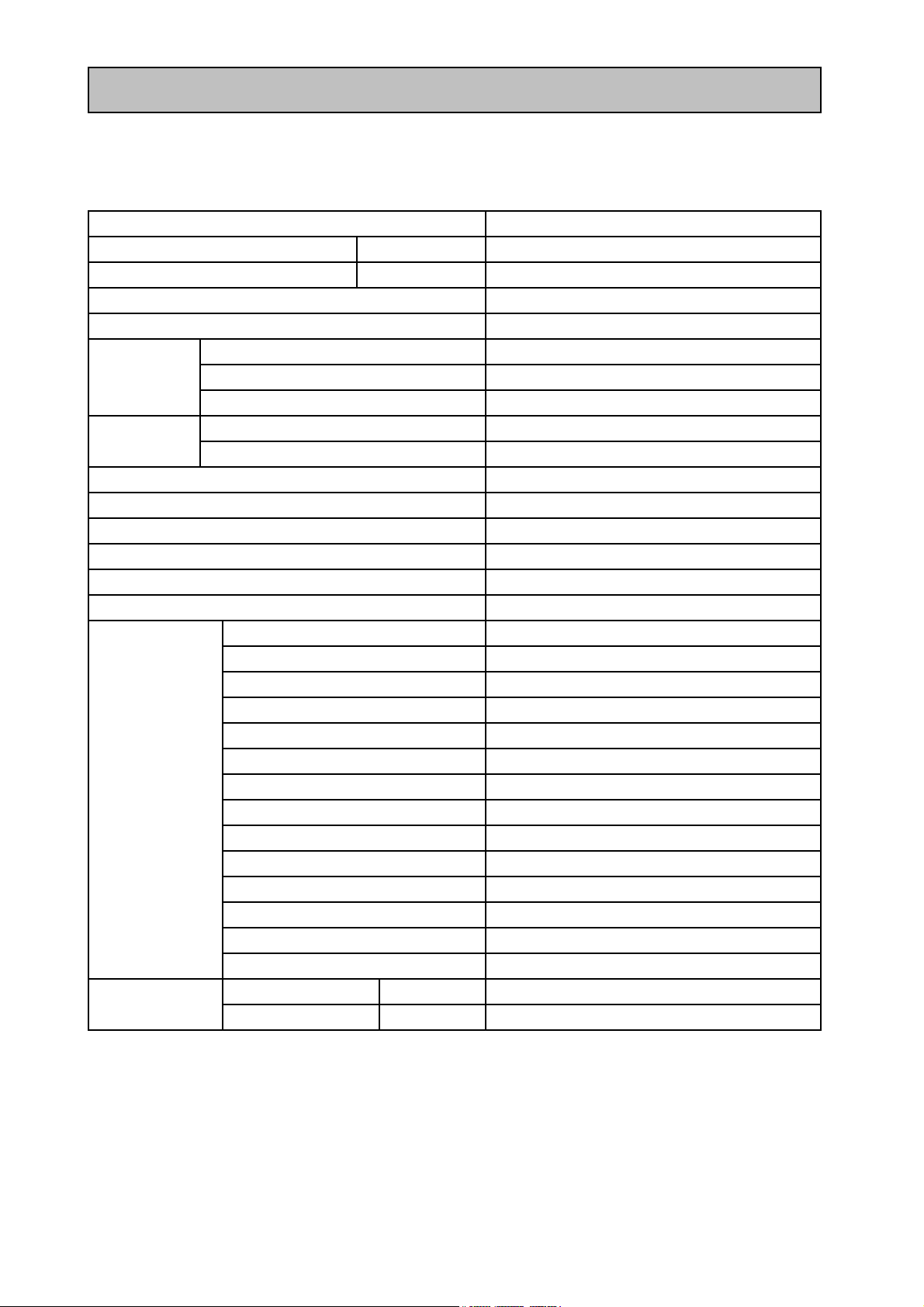

MR-420R-A

MR-420R-A(NZ)

Power supply 230/240V 50Hz

Total capacity (Gross (AS)) L

Dimensions (HXWXD) mm. 1696 x 685 x 700

Cabinet Acrylic resin coated steel

Food liner ABS resin

Cabinet Foamed cyclopenthane

Insulation

Cooling system

Evaporator Fin and tube type

Condenser Concealed type

Defrost system Automatic (Heater defrost)

Drain Automatic (drainage)

Temperature control system Automatic control

Refrigerator room light 240V 15W (E12)

Accessories

Weight

Freezer door Foamed cyclopenthane

Refrigerator door Foamed cyclopenthane

Freezer Forced air convection

Refrigerator Surround cooling,multi air flow,front air flow

Ice tray 1 pc.

Ice box 1 pc.

Freezer pocket 2 pcs.

Slide chilled case 1 pc.

Crystal shelf (F)

Crystal shelf (R)

Free pocket 1 pc.

Egg rack 2 pcs.

Adjust pocket 2 pcs.

Bottle pocket 2 pcs.

Vegetable case 1 pc.

Tray V 1 pc.

Drain pan 1 pc.

Bottle stopper 1 pc.

Unit kg 69

Shipping kg 73

420 (F : 130 R : 290)

1 pc.

3 pcs.

- 2 -

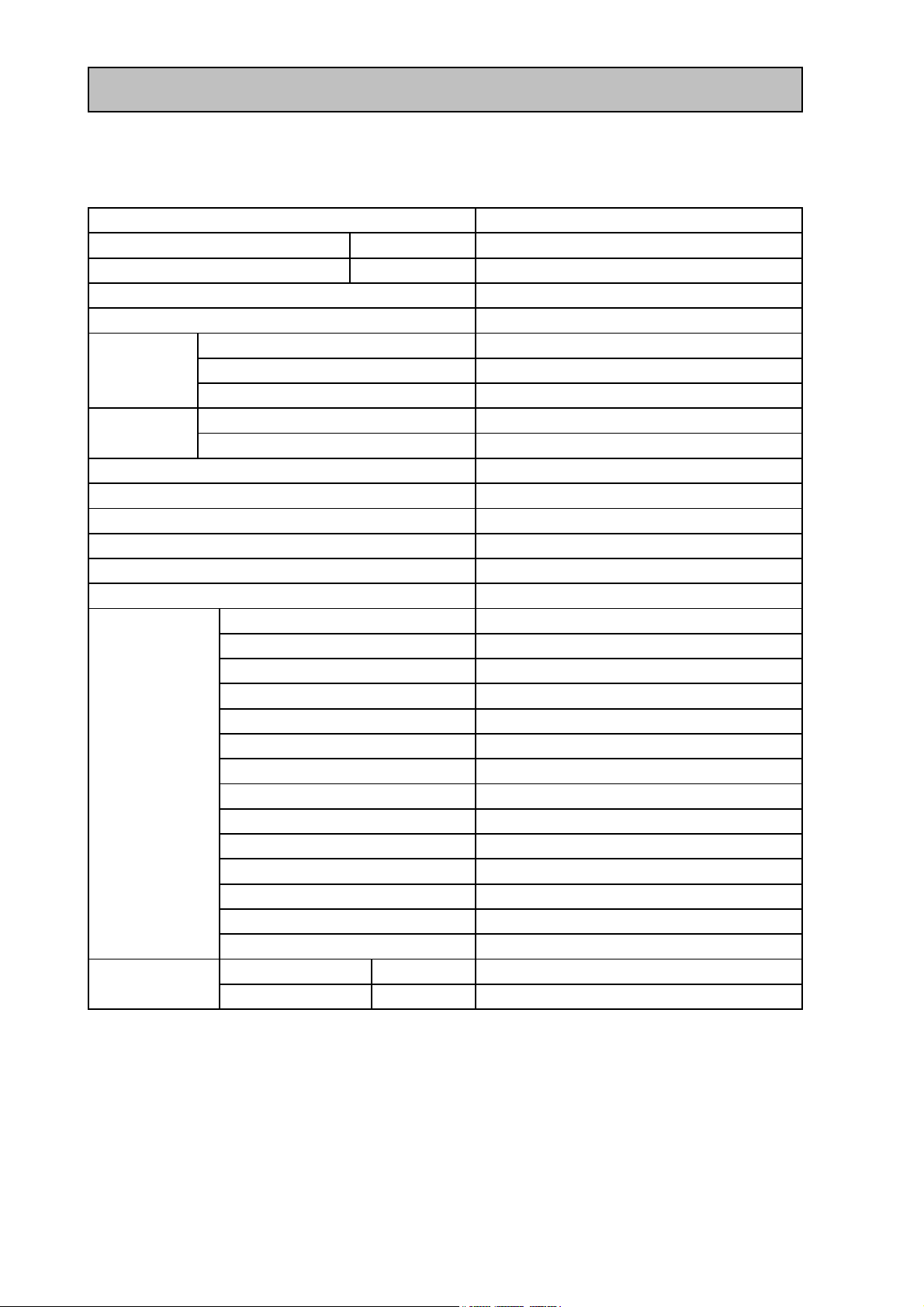

MR-455R-A

MR-455R-A(NZ)

Power supply 230/240V 50Hz

Total capacity (Gross (AS)) L

Dimensions (HXWXD) mm. 1806 x 685 x 700

Cabinet Acrylic resin coated steel

Food liner ABS resin

Cabinet Foamed cyclopenthane

Insulation

Cooling system

Evaporator Fin and tube type

Condenser Concealed type

Defrost system Automatic (Heater defrost)

Drain Automatic (drainage)

Temperature control system Automatic control

Refrigerator room light 240V 15W (E12)

Accessories

Weight

Freezer door Foamed cyclopenthane

Refrigerator door Foamed cyclopenthane

Freezer Forced air convection

Refrigerator Surround cooling,multi air flow,front air flow

Ice tray 2 pcs.

Ice box 1 pc.

Freezer pocket 2 pcs.

Slide chilled case 1 pc.

Crystal shelf (F)

Crystal shelf (R)

Free pocket 1 pc.

Egg rack 2 pcs.

Adjust pocket 3 pcs.

Bottle pocket 2 pcs.

Vegetable case 1 pc.

Tray V 1 pc.

Drain pan 1 pc.

Bottle stopper 1 pc.

Unit kg 73

Shipping kg 79

454 (F : 130 R : 324)

1 pc.

4 pcs.

- 3 -

1.2 ELECTRICAL PARTS SPECIFICATION

MR-385R-A

MR-385R-A(NZ)

Model

Power supply

Compressor Rated input W

Starting current A

Running current A

Winding resistance (T : 20

o

C)

PTC RELAY

Model

Motor protector Ambient temperature

o

C

Time Sec.

Current A

Running capacitor

Capillary tube mm.

Dehydrant Molecular sieve g

Refrigerant HFC. 134a g

DG57C96RAW5

220/240V 50Hz

106/108(220/240V 50Hz)

7.38/8.01(220/240V 50Hz)

0.57/0.55(220/240V 50Hz)

18.2

Ω(Main) / 17.7 Ω(Aux)

PTH7M330MD2

5TM181NHBYY

25

16 MAX

5.4

4

µ

F 400VAC

∅ 1.8 X ∅ 0.7 X 2350

10

145

Defrosting control Defrosting timer

Defrost finish

Thermal fuse

Heater Defrost heater

Deodorition

Model

Type

Fan motor

Number of poles

Input W

Revolution r.p.m

Model Freezer

Dial position ON OFF OPEN SHUT

Temperature control

Warmer

Normal

Colder

Control board

o

C

o

C

Thermister 14 +

73

384

Ω

(240V 150W)

1.5

Filter

UDVH15MA1H

Single phase

2p

Less than 10.2/12 (220/240V 50Hz)

2520 +

200 / 2580+200 (220/240V 50Hz)

Refrigerator (MM1-6177)

o

C

o

C

o

C

-13.7 -19.0 - 3.5

-16.9 -22.9 MAX 5.0 -1.0 +

-20.4 -27.5 - -12.5

1.5

- 4 -

MR-420R-A

MR-420R-A(NZ)

Model

Power supply

Compressor Rated input W

Starting current A

Running current A

Winding resistance (T : 20

o

C)

PTC RELAY

Model

Motor protector Ambient temperature

o

C

Time Sec.

Current A

Running capacitor

Capillary tube mm.

Dehydrant Molecular sieve g

Refrigerant HFC. 134a g

DG66C11RAW5

220/240V 50Hz

117/118(220/240V 50Hz)

8.05/8.83(220/240V 50Hz)

0.71/0.66(220/240V 50Hz)

15.4

Ω(Main) / 17.7 Ω(Aux)

PTH7M330MD2

5TM205NHBYY

25

16 MAX

6.0

4

µ

F 400VAC

∅ 1.8 X ∅ 0.7 X 2350

10

145

Defrosting control Defrosting timer

Defrost finish

Thermal fuse

Heater Defrost heater

Deodorition

Model

Type

Fan motor

Number of poles

Input W

Revolution r.p.m

Model Freezer

Dial position ON OFF OPEN SHUT

Temperature control

Warmer

Normal

Colder

Control board

o

C

o

C

Thermister 14 +

73

384

Ω

(240V 150W)

1.5

Filter

UDVH15MA1H

Single phase

2p

Less than 10.2/12 (220/240V 50Hz)

2520 +

200 / 2580+200 (220/240V 50Hz)

Refrigerator (MM1-6177)

o

C

o

C

o

C

-13.7 -19.0 - 3.5

-16.9 -22.9 MAX 5.0 -1.0 +

-20.4 -27.5 - -12.5

1.5

- 5 -

MR-455R-A

MR-455R-A(NZ)

Model

Power supply

Compressor Rated input W

Starting current A

Running current A

Winding resistance (T : 20

o

C)

PTC RELAY

Model

Motor protector Ambient temperature

o

C

Time Sec.

Current A

Running capacitor

Capillary tube mm.

Dehydrant Molecular sieve g

Refrigerant HFC. 134a g

DD66C13RAW5

220/240V 50Hz

127/131(220/240V 50Hz)

8.3/9.1(220/240V 50Hz)

0.63/0.61(220/240V 50Hz)

12

Ω

(Main) / 28.7 Ω(Aux)

PTH7M330MD2

5TM205NHBYY

25

16 MAX

6.0

4

µ

F 400VAC

∅ 1.8 X ∅ 0.7 X 2350

10

145

Defrosting control Defrosting timer

Defrost finish

Thermal fuse

Heater Defrost heater

Deodorition

Model

Type

Fan motor

Number of poles

Input W

Revolution r.p.m

Model Freezer

Dial position ON OFF OPEN SHUT

Temperature control

Warmer

Normal

Colder

Control board

o

C

o

C

Thermister 14 +

73

384

Ω

(240V, 150W)

1.5

Filter

UDVH15MA1H

Single phase

2p

Less than 10.2/12 (220/240V 50Hz)

2520 +

200 / 2580+200 (220/240V 50Hz)

Refrigerator (MM1-6177)

o

C

o

C

o

C

-13.7 -19.0 - 3.5

-16.9 -22.9 MAX 5.0 -1.0 +

-20.4 -27.5 - -12.5

1.5

- 6 -

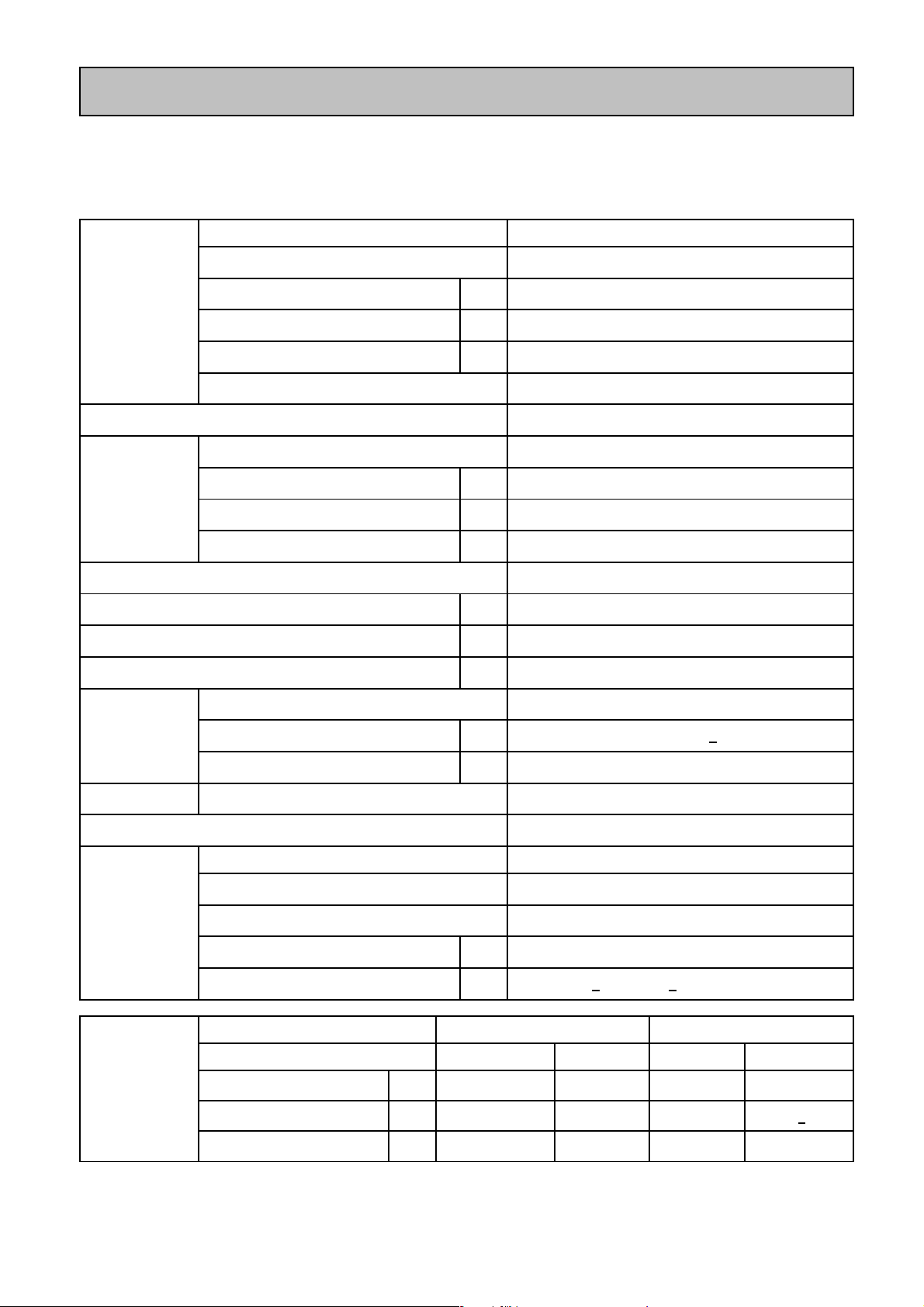

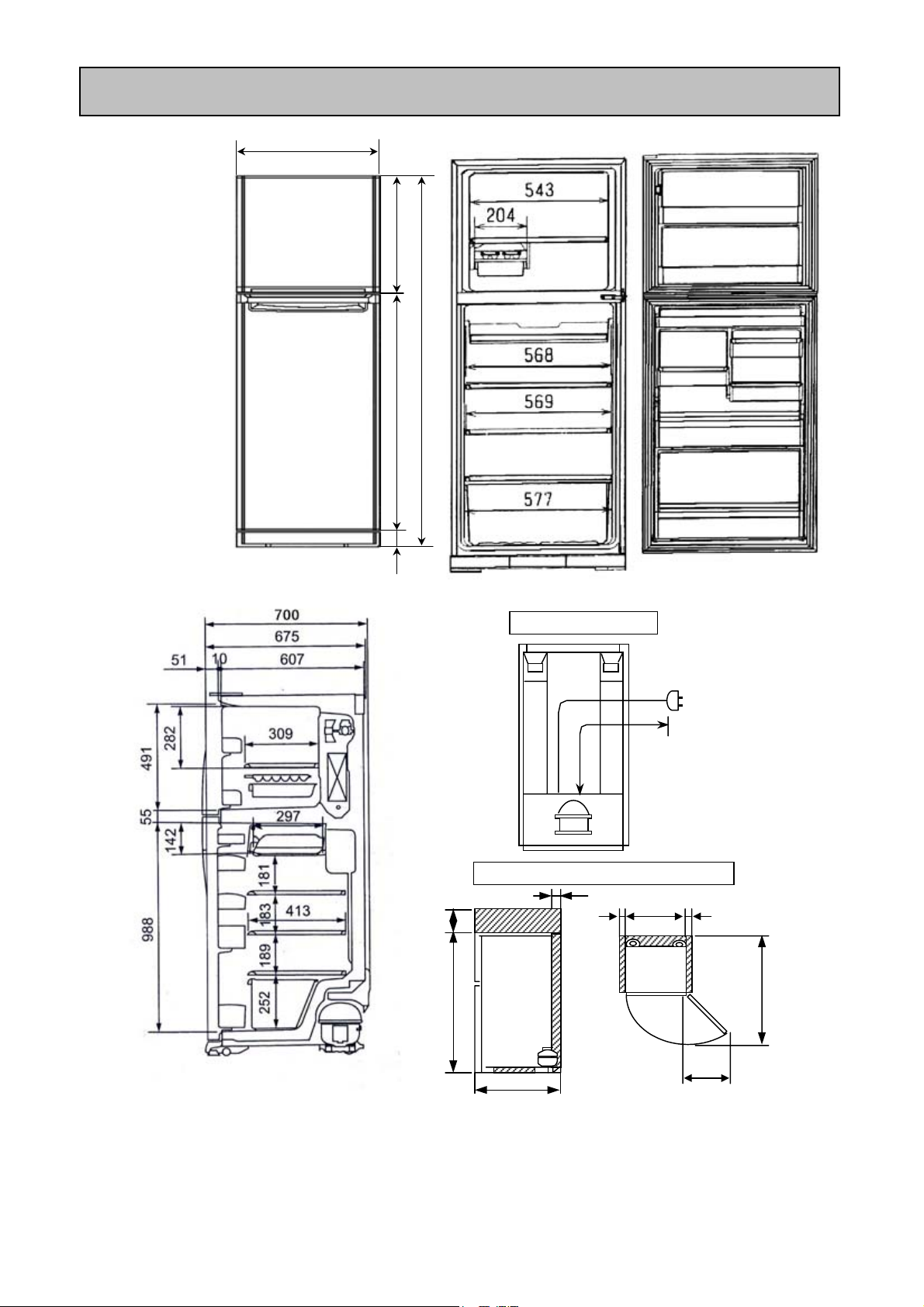

2 OUTLINES AND DIMENSIONS

MR-385R-A

MR-385R-A(NZ)

685

Unit : mm

568

81591

942

73

PLUG CORD LENGTH

1950

REQUIRED SPACE FOR INSTALLATION

40

20

100

1591

685

20

1334

- 7 -

454

700

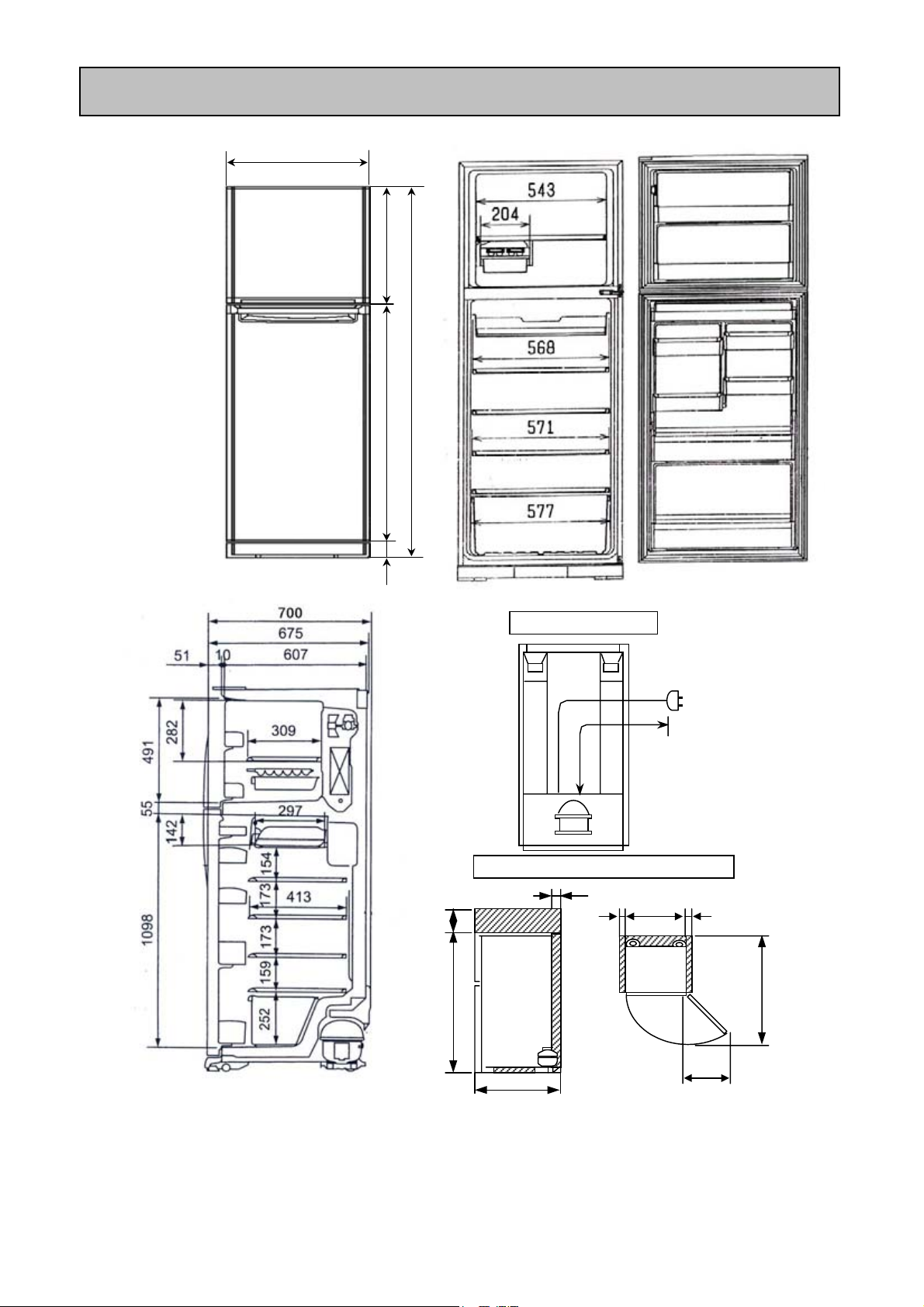

MR-420R-A

MR-420R-A(NZ)

Unit : mm

685

568

81696

1047

73

PLUG CORD LENGTH

1950

REQUIRED SPACE FOR INSTALLATION

40

20

100

1696

700

20685

1334

454

- 8 -

MR-455R-A

MR-455R-A(NZ)

Unit : mm

685

568

81806

1157

73

PLUG CORD LENGTH

1950

REQUIRED SPACE FOR INSTALLATION

40

20

100

1806

700

20685

1334

454

- 9 -

3 WIRING DIAGRAM

(SKELETON WIRING DIAGRAM)

MR-385R-A

MR-385R-A(NZ)

MR-420R-A

MR-420R-A(NZ)

MR-455R-A

MR-455R-A(NZ)

(ACTUAL WIRING DIAGRAM)

- 10 -

4 REFRIGERANT CIRCUIT

MR-385R-A MR-420R-A

MR-385R-A(NZ) MR-420R-A(NZ)

- 11 -

MR-455R-A

MR-455R-A(NZ)

- 12 -

5 NAME OF PARTS

MR-385R-A

MR-385R-A(NZ)

MR-420R-A

MR-420R-A(NZ)

MR-455R-A

MR-455R-A(NZ)

- 13 -

6 TROUBLE SHOOTING

6.1 TROUBLE CRITERION OF MAIN PARTS

MR-385R-A MR-420R-A MR-455R-A

MR-385R-A(NZ) MR-420R-A(NZ) MR-455R-A(NZ)

Components/

Part Name

Compressor

Run capacitor

Check Method and Criterion

Model

Rated input

Starting current

Running current

Auxilialy

wiring

W

A

A

Main

wiring

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

DG57C96RAW5

106/108(220/240V 50Hz)

7.38/8.01(220/240V 50Hz)

0.57/0.55(220/240V 50Hz)

Main wiring

Auxilliary wiring

18.2Ω (Approx.)

17.7 Ω

MR-385R MR-420R,455R

Rated input

Parts Mounted

Position

MR-420R,455RMR-385R

DG66C11RAW5

117/118(220/240V 50Hz)

8.05/8.83(220/240V 50Hz)

0.71/0.66(220/240V 50Hz)

Normal

15.4Ω (Approx.)

(Approx.)

17.7 Ω (Approx.)

Abnormal

(faulty)

Opened(∞ Ω )

RU

Short (0Ω)

Compressor in

the machine

chamber at the

rear side of

the frame

In the control

400VAC

Measure the resistance with a tester. refrigerator

panel of the

Motor

protector

PTC RELAY

abnormal(faulty)

Short (0

MR-420R,455RMR-385R

120 + 5o C

69 + 9o C

Model

Connected

Point

Open

Close

Normal

Opened (∞Ω )

5TM181NHBYY 5TM205NHBYY

120 + 5o C

69 + 9o C

Measure the resistance with a tester.(Ambient temperature:Room temperature 15

Normal abnormal(faulty)

Less than 1

5

6

2

3

6

2

3

Model

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Normal abnormal(faulty)

5

33Ω (Approx.)

As PTC Relay has been heated while refrigerator is running be sure

to measure the resistance after the thermistor has got cool enough.

Ω

Opened (∞Ω )

PTH7M330MD2

Opened

Ω

(∞Ω )

)

o

C ~ 25oC)

or Short (0Ω)

compartment

Compressor in

the machine

chamber at the

rear side of

the frame

Compressor in

the machine

chamber at the

rear side of

the frame

- 14 -

Components/

Part Name

Refrigerator

fan motor

Check Method and Criterion

Model

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Parts Mounted Position

Fan grill of the

freezer compartment.

UDVH15MA1H

Defrost

Heater

Thermistor

Normal

560+ 10% ( Ω )

Rated input 150 W

operation method

abnormal(faulty)

Short (0Ω)

Power ON after defrosting

1.5oC or more)

(14 +

In the drip tray under

the evaporator of the

freezer compartment

Measure the resistance with a tester.

(Ambient temperature:Room temperature 15oC ~ 25oC)

Abnormal (faulty)Normal

384

(Approx.)

Ω

Resistance measured under Defrost thermistors

the ambient temperature from Thermistor resistance radiator

-50: to +50:

1. 200" to 500k" F-thermistor, control

............normal

2. Out of the above range

............abnormal

Thermistor Check Procedure

(kΩ)

30

25

20

15

Resistance

10

5

Thermistor resistance will vary

with the change of temperature.

-20 -10 0 20

Take the temperature around the thermistor, Temperature

and then measure resistance using a tester.

The relation of resistance and temperature is as shown on the above graph.

against temperature of the freezer

10

Opened

( ∞ Ω )

30

compartment.

panel of the refrigerator

compartment.

(oC)

- 15 -

6.2 HOW TO CHECK P.C BOARDS

MR-385R-A MR-420R-A MR-455R-A

MR-385R-A(NZ) MR-420R-A(NZ) MR-455R-A(NZ)

(1) Precautions

Unplug unit before checking

If the controller P.C. board box is opened with the refrigerator inside

cooled, dew will form on the control board, causing trouble such as

poor insulation.

The following cares must be taken when servicing.

1. Be sure to unplug the power cord before servicing.

2. Wipe away droplets on the control board box with dry cloth,

and dry it up before setting a new controller P.C board.

(2) How to check the controller P.C board and vicinity.

The control board box can be checked without opening the box.

Measure the voltage and resistance using 8 connectors outside

the box. How to check with connectors

1. Check for 230/240V output during power on. POWER ON

Make the pin No.7,9 of the 9 pins white connector as a common pin,

and measure the voltage between the common pin and

another pin.

Make sure that 230/240V is output

Note: The room light always has 230/240V.

2. Check for "thermistor" output during power on.

5 pins white connector

Make the pin No.1 of the 5 pin white connector as a

common pin, and measure the voltage between the common

pin and another pin.

Make sure that 2-3 VDC is output.

3.Check for weak current wiring during power off

5 pins white connector

Remove the connector, and measure the resistance across

-No.1 pin and No.2 pin to confirm the continuity for DEF

thermistor.

-No.1 pin and No.3 pin to confirm the continuity for the

Freezer thermistor.

POWER OFF

- 16 -

6.3 TEST POINT DIAGRAM OF MAIN CONTROL BOARD

MR-385R-A MR-420R-A MR-455R-A

MR-385R-A(NZ) MR-420R-A(NZ) MR-455R-A(NZ)

- 17 -

2 times1 time

5 Sec.

Cycle

1

Improve in contact

2

Improve in contact

3

Change part

Improve in contact

Change part

5 Sec.

2 times

1 time

5 Sec.

1 time1 time

5 Sec.

Cycle

Cycle

1. Check connector of control PCB CN5 , relay

connector 6 pin

Open circuit or short

circuit case

1. Check connector of control PCB CN5 ,

2. Check the resistance of thermistor Change part

relay connector 2 pin

2. Check the resistance of thermistor Change part

1. Check connector of control PCB CN1 ,

Open circuit or short

circuit case

relay connector temp. fuse

Defrost unfinished

0 Ω

2. Check the resistance of defrost heater

3. Check the resistance of temp. fuse

, resistance of short circuit is

Ω

with in 2 hours

Cycle

2 times 2 times

ON

OFF

6.4 Malfunction Display and Checking points.

6.4.1 ) Malfunction display will use LED for show self-check

6.4.2 ) Fucntion display

6.4.3 ) Repairing and check point

* A the case below , if the analysis result has malfunction over 2 points and will express in the list has more importance.

Fault trouble of freezer thermistor

1 time

Function display Cause Analysis result Check point Corrective Priority Repairing

- 18 -

Fault trouble of defrost thermistor

2 times

Lighting mode

Malfunction display

Fault trouble of defrost heater

3 times

LED display self - check

Caution

1. Before plug in the AC power , Be ensure the comp had been off more than 20 min.

2. The consider short circuit or open circuit of thermistor , resistance of open circuit is ∞

6.5 Importance detail of fault analysis

6.5.1 Flow chart of self - check

1) Self - check monitor circuit

For show the fault condition of refrigerator and clarify point. Therefore, self - check monitor control is provided

that are able to monitor No. of blinking condition with electric circuit and electric part . Before disconnect power plug please

confirm LED self - check .

"CONTROL PANEL"

Refrigerator plug

connect?

No

Yes

Self - check

Mal Function Display

(No .of blinking)

Yes

Check the fault point as

malfunction list

Connect power plug

No

No change on display

Caution

LED show shelf - check

Normal operation

1. As the part list below couldn't analysis by self - check , then

please check by reference to trouble shooting page.

- Dilapidation of door switch ,refrigerator room and freezer room.

- Dilapidation of compressor and fan motor .

2. If have malfunction when supply the power . Compressor and

Disconnect power plug

Repair the macfunction cause

Connect power plug

2) Interval of self check analysis

- Troubles of thermistor : will check always.

- Trouble of defrost heater : will just analyse during defrost display only.

(The period checking will analyse the defrost circuit after connect the plug 2 hours )

fan motor will not operate 20 minutes.

- 19 -

7

DISASSEMBLY INSTRUCTIONS

MR-385R-A MR-420R-A MR-455R-A

MR-385R-A(NZ) MR-420R-A(NZ) MR-455R-A(NZ)

Unplug the power cord before prepairing and servicing

OPERATION PROCEDURE

1. Remove parts insider the Freezer room

(1) Photo 1st Remove Crystal shelf Freezer,

Ice corner tray assy, Ice tray, Ice box

Fan Grille

(2) Photo 2nd Remove scews for closing Lead cover F,

Remove 2 Rivets From Fan grille

(3) Photo 3rd Cut binder, remove poly bag, Take off

connector lead wire.

Fan motor

(4) Photo 4th Remove Fan motor after remove fan and

remove screw out of fan motor base.

Photo 1

Ice tray

Ice box

Photo 2

Photo 3

PHOTO

Crystal shelf F

Ice corner tray assy

Screw

Rivets

Lead cover F

Fan grille

Bag

Defrost thermal fuse and Freezer thermistor

(5)

Photo 4th Remove fan grille out of bell mouth, remove

the connector and plug to take out the thermal fuse and

thermistor freezer.

Defrost heater and Drip tray

(6)

Photo 5th Lift up evaporator and remove the defrost heater

out of base after remove heater cover plate and drip tray

Caution on assembly

(7) 1. Insert the fan into the base of fan motor's shaft, check

if the fan rotates with your finger.

2. When inserted drip tray to effect to slacken the lead

wire of defrost heater in order to prevent water from

entering the glass tube.

3. Attach defrost thermistor with muffler and lighten the

binder.

Binder

Connector lead wire

Photo 4

Screw

Thermal fuse

Fan motor

Bell mouth

Photo 5

Evaporator

Def thermistor

Drip tray

Defrost heater

Heater cover

- 20 -

OPERATION PROCEDURE PHOTO

2. Remove parts inside the refrigerator

(1) Remove chilled case door and slide chilled case ,

remove crystal shelf of refrigerator room , remove the

control panel

(Photo 6)

(2) Remove lamp cover R

(Photo 6)

(3) Remove screw and rivet , pull the control panel with

to right refrigerator wall.

(Photo 6)

(4) Pick the aluminium tape and sealing tape, remove

PC Board

(Photo 7)

(5) Remove duct R assy, damper thermo is installed

within it.

Photo 6

Control panel

Photo 7

Sealing tape

Thermo dial R

Lamp cover R

PC Board

Rivets

Thermo dial F

Screws

Duct R assy

(Photo 7)

Remove the screw of damper thermo

Caution on assembly

1. Be sure to use new sealing materials and tape for

assembly.

2. Attach the sealing material of refcon assy and attach

the aluminium tape everytimes for protective moisture.

Aluminium tape

- 21 -

OPERATING PROCEDURE

y

gepip

3. Removing the compressor

(1) Detach the drain pan.

Compressor

(2) Collect gas from the charge pipe on the high pressure side.

(3) After collecting gas, cut the charge pipe on the low pressure side.

(4) Detach the welded section of the discharge pipe and suction pipe

(5) Replace the compressor and the dryer at a time. (The dryer should be the one packed with the compressor.)

CAUTION ON ASSEMBLY

After replacement check cooling operation and check the weld for gas leaking.

Fig<MR-385R,420R,455R>

Suction pipe

w

w

Binder

Dr

er

Char

e

U Washer

w

Discharge pipe

(High pressure side)

: This mark shows welding point.

w

- 22 -

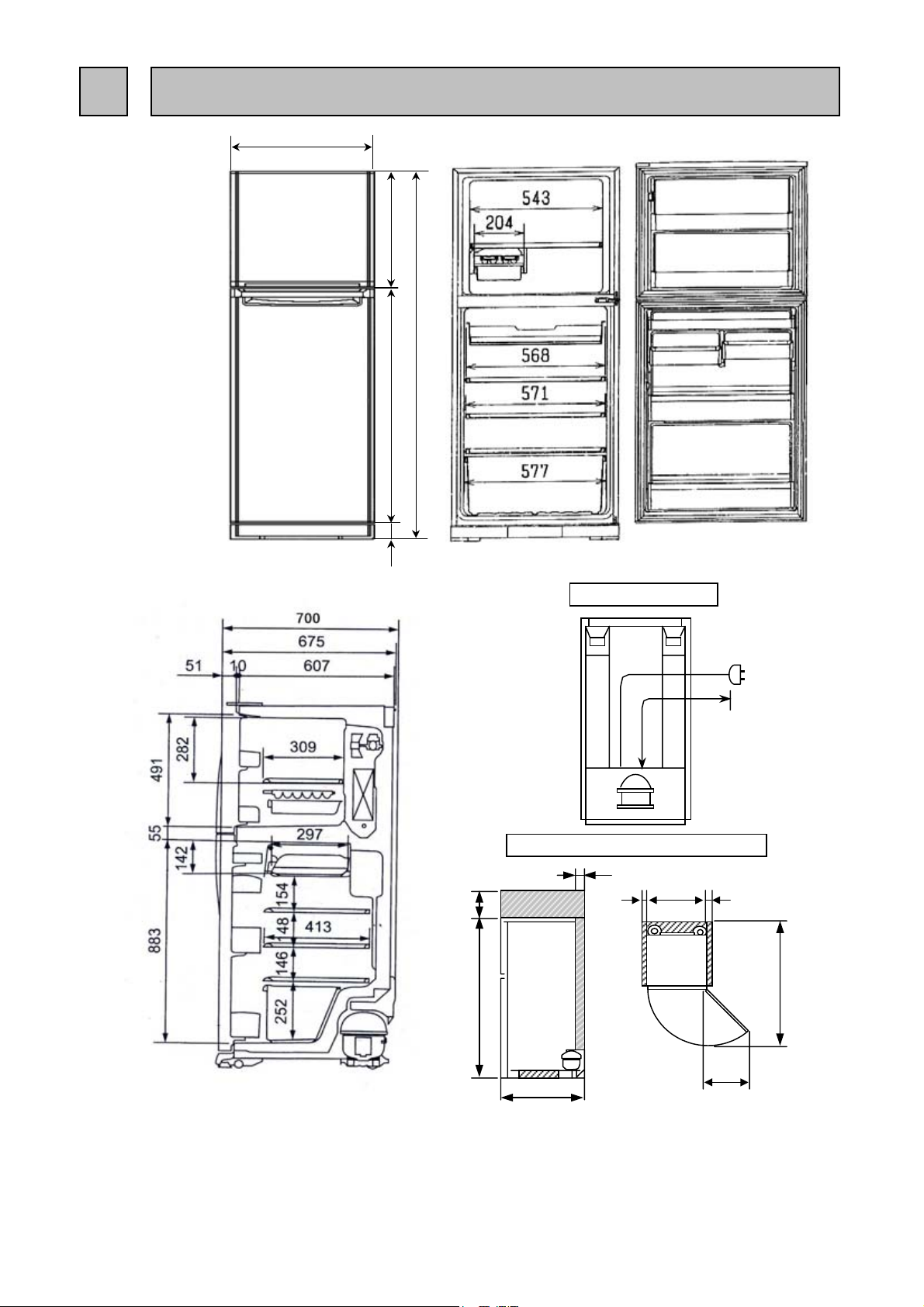

8 PARTS LIST

DOOR, BODY PARTS

MR-385R-A

MR-385R-A(NZ)

MR-420R-A

MR-420R-A(NZ)

7

8

1

11

2

3

4

9

5

6

10

MR-455R-A

MR-455R-A(NZ)

7

8

1

2

3

4

5

11

9

10

6

- 23 -

Q'TY/UNIT

385R

420R

455R

PART NO. PART NAMENO.

A A(NZ)

A A(NZ) A A(NZ)

WSTWSTWSTWSTWSTWST

1 KIEJ62131 FREEZER POCKET 222222222222

2 KIE401115 EGG RACK 222222222222

3 KIEJ62118 FREE POCKET 111111111111

4 KIEJ62159 ADJUST POCKET 222222223333

5 KIEJ62124 BOTTLE POCKET 222222222222

6 KIEH88143 BOTTLE STOPPER 111111111111

KIEJ81001 111111

7 DOOR F

KIEJ82001 111111

8 KIEH79111 MAGNET GASKET ASSY (F) 111111111111

KIEJ81000 1 1

KIEJ82000 1 1

KIEJ83000 1 1

9

DOOR R

KIEJ84000 1 1

PRICESPEC

KIEJ85000 1 1

KIEJ86000 1 1

KIEH79110 1111

10

KIEH82110 1111

MAGNET GASKET ASSY (R)

KIEH85110 1111

11 KIEG05741 CATCHER 111111111111

KIEJ81011 111111

12

HANDLE COVER R

KIEJ82011 111111

KIEJ81010 111111

13

HANDLE BODY

KIEJ82010 111111

14 KIEJ79031 BADGE ASSY 111111111111

RECOMMEND PART NO. 7, 8, 9, 10

ABBREVIATION

FRFREEZER ROOM

REFRIGERATOR ROOM

ENCIRCLED PART NUMBER ARE NOT SHOWN IN THE FIGURES.

- 24 -

ACCESSORY PARTS

MR-385R-A

MR-385R-A(NZ)

MR-420R-A

MR-420R-A(NZ)

16

17

1

2

3

4

18

19

20

21

22

MR-455R-A

MR-455R-A(NZ)

13

14

10

11

12

15

1

2

10

5

6

7

8

9

29

3

4

5

6

7

8

9

30

16

23

24

25

26

27

22

28

31

17

18

19

20

21

22

23

24

25

26

15

11

14

12

13

- 25 -

29

27

22

28

31

30

Q'TY/UNIT

NO. PART NAMEPART NO.

SPEC

385R 420R

A A(NZ) A A(NZ) A A(NZ)

455R

WSTWSTWSTWSTWSTWST

1 KIEH79662 BELL MOUTH 111111111111

2 KIEJ81473 LAMP COVER (F) 111111111111

3 KIEH79663 FAN GRILLE 111111111111

4 KIEH79450 ICE CORNER ASSY 111111111111

KIEH79665 1111

5

KIEH82665 1111

KIEH85665 1111

6 KIEH79411 SLIDE CHILLED CASE 111111111111

7 KIEJ81850 CONTROL PANEL 111111111111

KIEH79305 11111111

8

KIEHK4305 1111

KIEH79853 1111

9

KIEH82853 1111

KIEH85853 1111

KIEJ62470 1111

10

KIEJ65470 11111111

11 KIEH79420 CRYSTAL SHELF (R) 333333334444

12 KIEJ81468 TRAY V 111111111111

13 KIEJ62405 VEGETABLE CASE 111111111111

14 KIEH79435 DRAIN PAN 111111111111

15 KIE805794 CASTER SET 222222222222

16 KIEH79326 LEAD COVER F 111111111111

KIEJ81705 1 1 1 1 1

17 HINGE COVER

KIEJ82705 111111

18 KIEJ81701 HINGE ASSY (UPPER) 111111111111

19 KIEH79431 CRYSTAL SHELF (F) 111111111111

20 KIEH79440 ICE TRAY 111111111111

21 KIEH79467 ICE BOX 111111111111

22 KIEB66746 STOPPER HINGE 222222222222

23 KIEE94703 HINGE ASSY (MIDDLE) 111111111111

24 KIEJ62418 CHILLED CASE DOOR 111111111111

25 KIEH79416 TRAY C 111111111111

26 KIEH79315 THERMO DIAL (F) 111111111111

27 KIEH79474 VITAMIN GUARD 111111111111

28 KIEE94702 HINGE ASSY (LOWER) 111111111111

29 KIEH79795 CASTER ASSY 222222222222

30 KIEC02460 ADJUST BOLT 222222222222

KIEJ81730 1 1 1 1 1

KIEJ82730 111111

DUCT R ASSY

THERMO DIAL (R)

CONTROL PANEL (SUB)

LAMP COVER (R)

KICK PLATE31

PRICE

RECOMMEND PART NO. 2, 3, 4, 5, 6, 11, 13, 19, 20, 21, 24, 25

ABBREVIATION

F

FREEZER ROOM V BETWEEN REFRIGERATOR ROOM AND VEGETABLE ROOM

R REFRIGERATOR ROOM

- 26 -

ELECTRICIAL PARTS AND UNIT PARTS

MR-385R-A

MR-385R-A(NZ)

MR-420R-A

MR-420R-A(NZ)

MR-455R-A

MR-455R-A(NZ)

1

2

3

4

5

6

7

12

31

13

14

15

16

17

15

18

19

20

21

22

23

24

10

8

9

11

25

30

26

27

28

29

- 27 -

Q'TY/UNIT

NO. PART NO. PRICESPEC

PART NAME

385R

A A(NZ)

420R

A A(NZ)

455R

A A(NZ)

WSTWSTWSTWSTWSTWST

1 KIEH79336 THERMAL FUSE ( DEF ) 111111111111

2 KIEH85995 EVAPORATOR 111111111111

3 KIEH79537 HEATER ROOF 111111111111

4 KIEHM2392 DEFROST HEATER ASSY

5 KIEB66397 HEATER COVER 111111111111

6 KIE402360 LAMP E17 240V I5W 111111111111

7 KIEH79538 DRIP TRAY 111111111111

8 KIEH79301 DAMPER THERMO MM1-6177 111111111111

KIEJ81277

9 COMPRESSOR

KIEJ82277

10 KIE902735 U WASHER 333333333333

11 KIEE76797 RUBBER MOUNT 444444444444

12 KIEH79312 THERMISTOR (DEF) 111111111111

13 KIEH79378 THERMISTOR (F) 111111111111

14 KIEH79323 MOTOR ATTACH 111111111111

15 KIE401329 FAN MOTOR BUSH 222222222222

16 KIEC02320 FAN MOTOR UDVH15MA1H 111111111111

17 KIECD4362 FAN SWITCH 111111111111

18 KIEHD2386 LAMP SOCKET(R) 111111111111

19 KIEG01321 FAN 111111111111

20 KIEA53346 RUNNING CAPACITOR

21 KIEJ81339 REFCON ASSY 111111111111

22 KIEH82336 THERMAL FUSE 111111111111

23 KIEH79363 LAMP SWITCH ( R ) 111111111111

24 KIEJ81354 PLUG CORD ASSY 111111111111

25 KIEJ81807 CONNECTOR BOX 111111111111

26 KIEAA1980 DRYER 4AXH-9,10GR 111111111111

27 KIEG05341 PROTECTOR COVER 111111111111

KIEJ62340 5TM181NHBYY 1111

28 MOTOR PROTECTOR

KIEJ83340 5TM205NHBYY 11111111

29 KIEE76330 PTC RELAY

30 KIEH61399 FILTER 111111111111

31 KIEHJ3311 THERMITOR (A.T.) 111111111111

240V, 150W NOT

DEODORIZER

DG57C96RAW5

DG66C11RAW5

4

µF, 400VAC

PTH7MM330MD2

111111111111

1111

11111111

111111111111

111111111111

RECOMMEND PART NO. 1, 6, 9, 10, 13, 14, 22, 23, 27, 29, 30

ABBREVIATION

FRFREEZER ROOM

REFRIGERATOR ROOM

DEF DEFROST

- 28 -

PACKING PART

MR-385R-A MR-385R-A(NZ)

MR-420R-A MR-420R-A(NZ)

MR-455R-A MR-455R-A(NZ)

3

TOP CUSHION MID

3

2

1

L

TOP CUSHION

R

2

REFRIGERATOR

NO STEP ON

C.F.B BOX ASSY

8

C.F.B TOP COVER

1

5

SIDE CUSHION ASSY

6

BOTTOM CUSHION

4

PACKING COVER

7

C.F.B PALLET

- 29 -

Q'TY/UNIT

NO. PART NO. PART NAME

KIEJ81970 1

KIEJ82970 1

KIEJ83970 1

KIEJ84970 1

KIEJ85970 1

KIEJ86970 1

1

KIEJL4970 1

KIEJL5970 1

KIEJL6970 1

KIEJL7970 1

KIEJL8970 1

C.F.B BOX ASSY

SPEC

385R 420R

A A(NZ) A A(NZ)

WSTWSTWSTWSTWSTWST

455R

A(NZ)

A

PRICE

KIEJL9970 1

2 KIEJ81979 TOP CUSHION 111111111111

3 KIEH79972 TOP CUSHION MID 111111111111

4 KIEG55973 PACKING COVER 111111111111

5 KIEJ81971 SIDE CUSHION ASSY 111111111111

6 KIEH79978 BOTTOM CUSHION 111111111111

7 KIEH79974 C.F.B PALLET 111111111111

8 KIEH79975 C.F.B TOP COVER 111111111111

- 30 -

MITSUBISHI ELECTRIC CORPORATATION

HEAD OFFICE : MITSUBISHI DENKI BLDG., MARUNOUCHI,TOKYO 100. TELEX : J24532 CABLE MELCO TOKYO

Distributed by

BLACK DIAMOND TECHNOLOGIES LIMITED (BDT)

Wellington Office (Head Office) Auckland Office Christchurch Office

1 Parliament Street Unit1, 4 Walls Road Suite 2, Level 1

PO Box 30-772 Penrose 37 Manderville Street

Lower Hutt Auckland PO Box 12-726 Chistchurch PO Box 1604

Ph : (04) 560 9100 Ph: (09) 526 9340 Ph : (03) 341 7052

Fax : (04) 560 9133 Fax : (09) 526 9369 Fax : (03) 341 7054

Loading...

Loading...