Page 1

MELSEC iQ-R Series Energy Measuring Module

User’ s Manual

RE81WH

Details

(

)

Page 2

Mark

Meaning of the mark

Danger

Indicates that incorrect handling by ignoring this mark may result in death or severe

damage.

Title

Document number

IB63D82A

RE81WH

INTRODUCTION

(Read these precautions before using this product.)

This manual contains important instructions for MELSEC iQ-R series RE81W H.

Before using this module, please read this manual and the relevant manuals carefully and pay full attention to

safety to handle the product correctly.

The precautions given in this manual are concerned with this module only. For the safety precautions of the

programmable controller system, refer to the “MELSEC iQ-R Module Configuration Manual”.

Make sure that end users read this manual and then keep the manual in a safe place for future reference.

■Notations in this manual

Use the following marks in this manual.

injury.

Caution Indicates that incorrect handling by ignoring this mark may result in injury or property

Supplement Indicates precautions to avoid malfunction, to work the module properly.

Depending on circumstances, failure to follow the precautions given under “ Caution” may lead to further

serious consequences.

Please follow the precautions with full care because they are critical for personal and system safety.

The “n” used in this manual (for example: Xn0, Yn0, Un\G0, etc.) indicates the Start I/O No. of this module.

■Relevant manuals

The following manuals are also related to this module. You can download each manuals from the following

web site.

http://www.mitsubishielectric.com/fa/

MITSUBISHI Programmable Controller

MELSEC iQ-R Series Energy Measuring Module

Model RE81WH User’s Manual (Hardware)

MELSEC iQ-R Module Configuration Manual SH-081262ENG

GX Works3 Operating Manual SH-081215ENG

IB63D83

1

Page 3

Energy Measuring Module (RE81WH) x1

User’s Manual (Hardware) x1

RE81WH

■Checking package contents

This following items for this device and included in package. Check that no items are missing.

This module is not compliant for dealing / proving electric energy specified in a measurement law. Please use

the certified watt-hour meter to be used for deal and proof of electric energy measurement stipulated.

When considering to use this module for an atomic power, aerospace, medical fields or passenger use mobile,

please contact to a sales representative beforehand.

2

Page 4

RE81WH

FEATURES

(1) This Energy Measuring Module can measure various types of electric quantity just ONE module.

This Energy Measuring module can measure electric energy, reactive energy, current, voltage, electric

power, power factor, frequency, harmonic current and harmonic voltage.

Both consumption and regeneration of the electric energy can be measured.

(2) Extensive monitoring functions.

In addition to memorizing the maximum and minimum values, two types of alarm monitoring for upper

and lower limit can be performed.

Since the alarm setting is stored in the buffer memory, there is no need to complicated programs.

(3) It also can measure the electric energy for a certain period.

It can measure the electric energy for the duration of time for which the output device is on.

This feature enables to acquire the electric energy needed during device operation or energy per tact.

(4) It can acquire waveform data of current and voltage.

It can acquire waveform data of the measured current and voltage.

Thus, it is able to monitor / indicate using waveform data.

3

Page 5

Revision data

Manual number *

Revision

Mar, 2018

IB63D82

First edition

Nov, 2018

IB63D82A

Modification, addition for the description of the version

Revision history

RE81WH

* Manual Number is provided at the bottom of the cover page.

■

related to RE81WH

Section 2.2, 6.4

■Modification for the errors and other description

Section 4.2, 5.1, 5.5 and 8.1

This manual does not guarantee to protect or does not give permission to any industrial property and any related rights.

Also, our company shall not be held any responsible for any issues related to industrial properties due to product usage

described in this manual.

© 2018 MITSUBISHI ELECTRIC CORPORATION

4

Page 6

RE81WH

CONTENTS

INTRODUCTION ......................................................................................................................................... 1

FEATURES .............................................................................................................................................. 3

CONTENTS .............................................................................................................................................. 5

Section 1 SAFETY PRECAUTIONS ...................................................................................................... 7

1.1 Precautions for Operating Environment and Conditions .................................................................... 7

1.2 Matters concerning the preparation before use ................................................................................. 7

1.3 Installation and Wiring Precautions .................................................................................................... 8

1.4 Precautions for Start-up and Maintenance ....................................................................................... 10

1.5 Storage Precautions ......................................................................................................................... 10

1.6 Disposal Precautions ........................................................................................................................ 10

1.7 Packaging materials and this manual ............................................................................................... 10

Section 2 SYSTEM CONFIGURATION ................................................................................................ 11

2.1 Precautions for system configuration ............................................................................................... 11

2.2 Applicable system ............................................................................................................................. 11

Section 3 NAME AND FUNCTION OF EACH PART ............................................................................ 14

3.1 Name of each part ............................................................................................................................ 14

3.2 Indication and function of LEDs ........................................................................................................ 15

3.3 List of functions ................................................................................................................................. 16

3.4 Functions in detail ............................................................................................................................. 17

Section 4 I/O SIGNALS TO CPU MODULE ......................................................................................... 38

4.1 List of I/O signals .............................................................................................................................. 38

4.2 Details of I/O signals ......................................................................................................................... 39

Section 5 BUFFER MEMORY ............................................................................................................. 51

5.1 Buffer memory assignment .............................................................................................................. 51

5.2 Configurable sections (Un\G0 - Un\G99) ......................................................................................... 60

5.3 Measurement sections (Un\G100 - Un\G2999) ................................................................................ 70

5.4 Common sections (Un\G3000 - Un\G4999) ..................................................................................... 91

5.5 Waveform data sections (Un\G10000 - Un\G22013) ....................................................................... 94

Section 6 SETTING AND PROCEDURE FOR OPERATION ................................................................ 98

6.1 Procedure for operation .................................................................................................................... 98

6.2 Mounting and removing the module ................................................................................................. 99

6.3 Wiring.............................................................................................................................................. 101

6.4 Parameter setting ........................................................................................................................... 112

Section 7 PROGRAMMING ................................................................................................................ 126

7.1 Programming procedure ................................................................................................................. 126

7.2 System configuration and usage conditions for sample program .................................................. 127

7.3 Sample programming ..................................................................................................................... 129

Section 8 TROUBLESHOOTING ........................................................................................................ 135

8.1 List of error codes ........................................................................................................................... 135

8.2 Troubleshooting .............................................................................................................................. 137

8.3 Q&A ................................................................................................................................................ 140

5

Page 7

RE81WH

Section 9 REQUIREMENT FOR THE COMPLIANCE WITH EMC

AND LOW VOLTAGE DIRECTIVES .................................................................................. 143

Section 10 SPECIFICATION ................................................................................................................ 144

10.1 General specifications .................................................................................................................... 144

10.2 Electrical and mechanical specifications ........................................................................................ 146

10.3 External dimensions ....................................................................................................................... 147

10.4 Optional devices ............................................................................................................................. 148

APPENDIX ........................................................................................................................................... 153

INDEX ........................................................................................................................................... 154

WARRANTY ........................................................................................................................................... 156

6

Page 8

Section 1 SAFETY PRECAUTIONS

Places the ambient temperature exceeds the range 0 – 55ºC.

Places the relative humidity exceeds the range 5 – 95% or places with dewfall.

Places metal fragments or conductive substance are flying.

Dust, corrosive gas, saline and oil smoke exist.

Places in strong electromagnetic field or places large amounts of external noise exist.

Vibration and impact exceed the specifications.

RE81WH

Section 1 SAFETY PRECAUTIONS

1.1 Precautions for Operating Environment and Conditions

This module is premised on being used in pollution degree 2

degree, protect the module from the pollution on another device side to be incorporated.

Overvoltage category of measuring circuit in this module is CAT III

Do not use this product in the places listed below. Failure to follow the instruction may cause malfunctions and

a life decrease of product.

・

・Places the average daily temperature exceeds +35℃

・

・Altitude exceeds 2000 m.

・

・Places exposed to direct sunlight.

・

・Places exposed to rain or water drop.

・

・

・Installed places excluding the control panel.

This module is the open type device, which are designed to be housed within another device for prevention of

electric shock. House the module within the device such as the control panel before use. (Indoor use)

(Note 1) For the definition of the pollution degree and the over voltage category, refer to EN61010-1/2010.

1.2 Matters concerning the preparation before use

Use the module in the specified usage environment and conditions.

The setting of this module (phase wire system, primary voltage, primary current) is necessary before using it.

*Refer to "5.2 Configurable sections (Un\G0 - Un\G99)" about each setting method.

(Note1)

environment. When used in higher pollution

(Note 1)

.

Danger

● Do not write data into “System Area” in the buffer memory of the intelligent function module.

Also, do not output (turn ON) the “use prohibited” signal in the output signal sent from the sequencer

CPU to the intelligent function module.

Doing so may cause a malfunction to the sequencer system.

7

Page 9

Section 1 SAFETY PRECAUTIONS

Use the programmable controller in an environment that meets the general specifications in the

RE81WH

1.3 Installation and Wiring Precautions

Make sure to use the module by following cautions of this section. Improper use may impair protection provided

by this module.

Danger

● Shut off the external power supply for the module in all phases before installing or wiring. Failure to do

so may cause an electric shock or a damage of the module.

● Shut off the power supply for the module in all phases before installing or wiring. Failure to do so may

cause an electric shock or a damage, a fire on the module.

Caution

<Precautions for Electric work>

● Any person who is involved in the installation and the wiring of this Programmable Controller should be

fully competent to do the work.

●

“MELSEC iQ-R Module Configuration Manual”. Failure to do so may result in electric shock, fire,

malfunction, or damage to or deterioration of the product.

● After mounting the module, ensure that the module fixing hook is securely applied on the base unit and

the module is surely mounted. Incorrect mounting may cause malfunctions, a failure or a drop of the

module. When using the Programmable Controller in an environment of frequent vibrations, fix the

module with a screw.

● Tighten the screw within the specified torque range. Loose tightening can cause drop of the screw, short

circuit or malfunction. Over tightening can damage the screw and/or module, resulting in drop, short

circuit, or malfunction.

● Do not directly touch any conductive part of the module. Doing so can cause malfunctions or a failure of

the module.

● Take care not entering any foreign objects such as strips and wire pieces into the module. It may cause

a fire, a failure or a malfunction.

● In order to prevent the module from incoming foreign objects such as wire pieces during wiring work, a

foreign-object preventive label is placed on the module. While a wiring work is performed, keep the label

on the module. Before operating the system, peel off the label for heat release. If the foreign-object

preventive label is not peeled off and the system is in use, residual heat inside the module may reduce

the product life.

● After inserting the electric wire or a bar terminal, make sure that no missing insertion is existing. Missing

insertion may cause a malfunction, a fire, or an electric shock on the device.

● Ensure the wiring to the module properly after checking the rated voltage and current of the product and

the terminal pin assignment. If the input voltage exceeds the rated voltage or the wiring is improper, it

may cause a fire or a breakage.

● The wires to be connected to the module shall be placed in a duct or fixed together by clamping. If the

electric wires are not placed in the duct or clamped together, loosen wires or their movement or careless

stretch may cause a breakage of the module or wire or a malfunction due to poor contact of electric wires.

● For protection against noise, transmission lines and input lines shall not be placed close to or bound

together with the power lines and high voltage lines. Keep distance as below between them. (Except for

the terminal block.)

Condition Distance

High-voltage line 600V or less 300mm or more

Other high-voltage line 600mm or more

8

Page 10

Section 1 SAFETY PRECAUTIONS

Cover the dangerous voltage part of the module.

RE81WH

Caution

<Connection of terminal block>

● In case using stranded wire, take measures so that the filament should not vary by using a bar terminal

or by processing the point twisted. Use the bar terminal appropriated for the size of electric wires. If

inappropriate bar terminal is used, a wire breakage or a contact failure may occur, which may cause a

device malfunction, a failure, a burnout or a fire.

● Use appropriate size of electric wires. If inappropriate size of electric wire is used, it may cause a fire due

to generated heat.

<Connection with the current sensor>

● When using this module, make sure to use it in combination with the dedicated current sensor. Do not

exceed the rating of the module for input of the current sensor. A secondary side (5A) of transformer

cannot directly input tot this module. For further details, refer the manuals for the current sensor to

maintain the functionalities and the accuracy of the module.

● The dedicated current sensor (excludes EMU2-CT5 and EMU-CT5-A) is used only for low voltage circuit.

It cannot be used for a high voltage circuit. EMU2-CT5 and EMU-CT5-A should be used with secondary

side (5A) of transformer transfixed. If it is connected with a high voltage circuit by mistake, it may cause

a burnout of the device and a fire. It is critically dangerous. For the allowance maximum voltage of current

sensor, refer to “10.4.1” in this manual.

● The dedicated current sensor has a polarity (directionality). Be careful about it when installing the module.

● If the wires connected to the module are strongly pulled off, it may cause a malfunction or a breakage to

the module or the wire.

<Connection of ground>

● Do not exceed the specified voltage when doing an insulation resistance test and a commercial frequency

withstand voltage test.

● To prevent persons with little knowledge about electric equipment from electric shock, panel must be

taken either following measure.

・ Lock the panel so that only those who get an education about electrical equipment and have

sufficient knowledge can unlock, or shut off power supply automatically upon opening the panel.

・

9

Page 11

Section 1 SAFETY PRECAUTIONS

Places the ambient temperature exceeds the range -25 - +75 ºC.

Places the relative humidity exceeds the range 5 - 95% or places with dewfall.

Places with metal fragments or conductive substance are flying.

Dust, corrosive gas, saline and oil smoke exist.

RE81WH

1.4 Precautions for Start-up and Maintenance

Caution

● Use the product within the ratings specified in this manual. If it is used outside the ratings, it may cause

not only a malfunction or a failure but also a fire or a burnout.

● Before operating the product, check that active bare wire etc. does not exist around the product. If any

bare wire is found, stop the operation immediately, and take an appropriate action such as isolation

protection.

● Do not disassemble or modify the module. It may cause a failure, a malfunction, an injury or a fire.

● Attaching and detaching the module must be performed after the power source is shut off for all outside

phases. If all phases are not shut off, it may cause an electric shock, a failure or a malfunction of the

module.

● Do not touch powered wires. It may cause a malfunction.

● Tightening mounting screws and cleaning module must be performed after the power source is shut off

for all outside phases. If all phases are not shut off, it may cause an electric shock, a failure or a

malfunction of the module.

● Use a soft dry cloth to clean off dirt of the module surface.

● Do not let a chemical cloth remain on the surface for an extended period of time nor wipe the surface

with thinner or benzene.

● Check for the following items to use this module properly for a long time.

<Daily maintenance>

(1) No damage on this module.

(2) No abnormality with LED indicators.

(3) No abnormal noise, smell or heat.

<Periodical maintenance (Once every 6 months to 1 year) >

(4) No looseness with installation, wire connection to terminal blocks, and connector connection.

(Check these items under the electric outage condition.)

1.5 Storage Precautions

To store the module, turn off the power and remove wires, and put it in a plastic bag.

For long-time storage, avoid the following places. Failure to follow the instruction may cause a failure and

reduced life of the module.

・

・Places the average daily temperature exceeds 35 ºC.

・

・Vibration and impact exceed the specifications.

・

・Places exposed to rain, water drops or direct sunlight.

・

1.6 Disposal Precautions

When disposing of this module, treat it as industrial waste.

1.7 Packaging materials and this manual

For reduction of environmental load, packaging materials are produced with cardboard, and this manual is

printed on recycled paper.

10

Page 12

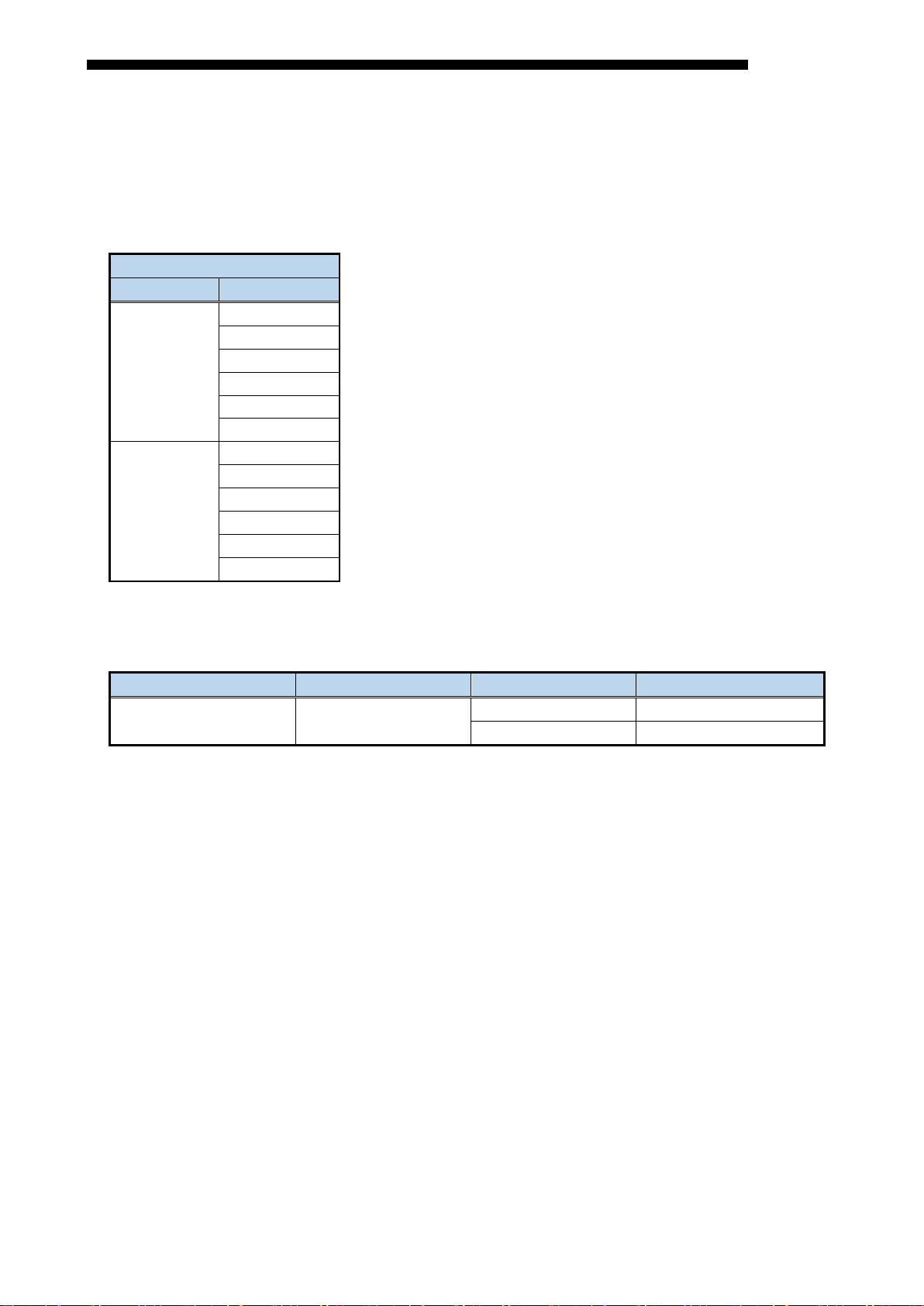

Section 2 SYSTEM CONFIGURATION

Attachable CPU Module

Attachable CPU Module

CPU Type

CPU Model

CPU Type

CPU Model

Programmable

R00CPU

Process CPU

R08PCPU

R01CPU

R16PCPU

R02CPU

R32PCPU

R120ENCPU

RE81WH

Section 2 SYSTEM CONFIGURATION

2.1 Precautions for system configuration

Attention to the following when configuring the system.

・Please install each modules so that the total number of occupied I/O points of these modules is equal to or less

than the number of I/O points of the CPU module used.

・Depending on the rated output current of the power supply used, mounting of the maximum number of

modules may not be possible. Consider the current consumption of each module to configure the system.

2.2 Applicable system

2.2.1 Applicable module

(1) CPU module

The CPU module that can install RE81WH is shown below.

For the number of mountable modules, refer to the "MELSEC iQ-R Module Configuration Manual".

RE81WH supports multiple CPU system.

controller CPU

R04CPU R120PCPU

R08CPU

R16CPU R16SFCPU

R32CPU R32SFCPU

R120CPU R120SFCPU

R04ENCPU C Controller module R12CCPU-V

R08ENCPU

R16ENCPU

R32ENCPU

Safety CPU R08SFCPU

11

Page 13

Section 2 SYSTEM CONFIGURATION

Type

Model

R35B

R38B

R312B

R310B

R310B-HT

R38RB-HT

Extension

R65B

R68B

R612B

R610RB

R610B-HT

RE81WH

(2) Base unit

The Base unit that can install RE81WH is shown below.

RE81WH can be installed to any I/O slot

*1 *2

.

*1 In case of Process CPU that operates in redundant mode, it can only be mounted with the extension

base unit. It is not allowed to be mounted with the main base unit.

*2 Limited within the range of I/O points for the CPU module.

Mountable Base unit

Main base

base

R68RB-HT

(3) Applicable software package

Software packages applicable to this module as follows.

Refer to the next page for the version of this module.

Product name Model name Remarks RE81WH version

GX Works3 Version1 SW1DND-GXW3-J

1.040S or later A

1.050C or later B

12

Page 14

Section 2 SYSTEM CONFIGURATION

Version

A

-

-

Version:A

Version:B

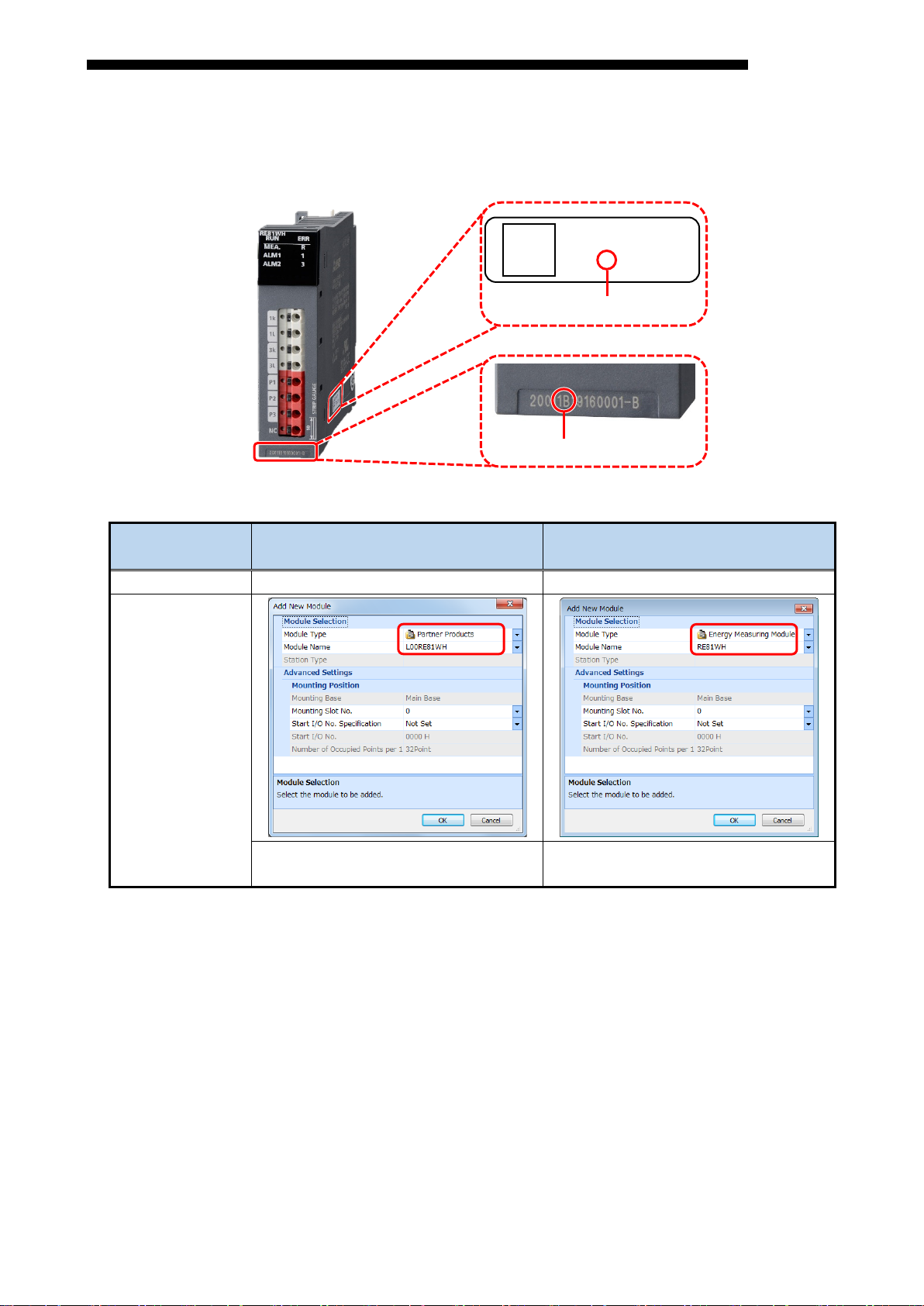

2.2.2 How to confirm the version of RE81WH

Confirm the version of RE81WH as below:

Refer to previous page for the software package corresponding to the each version.

○○○○○○

○○○B○○○○○

Version

Version

Changes for version of RE81WH

RE81WH

(Shipment start date)

Before After

B

(Nov, 2018)

Profile registration needed*

Profile registration unneeded

* When using version A on GX Works3, Profile (for MELSEC iQ-R series Energy Measuring Module

(RE81WH) profile) registration is needed

Refer to “GX Works3 operating manual” for registration of profile.

You can download the profile from the web site. (http://www.mitsubishielectric.com/fa/)

When using version B, Profile registration unneeded.

13

Page 15

Section 3 NAME AND FUNCTION OF EACH PART

(1) LED

Operating state of this

module is displayed.

(2) Current input terminals

Connect with the secondary

output of the dedicated

current sensor connected to

the current wire of the

measuring circuit.

(3) Voltage input terminals

Connect the voltage input

wire of the measuring circuit.

(6) Strip gauge

A gauge used for

checking the length of

stripped wire.

(5) Check hole

Use this for continuity

check to the terminal.

Use it with a tester

contact.

(4) Push button

Push this button to

insert a cable to the

terminal or remove it.

symbol

3L

3-phase current input terminal (load side)

P1

P3

1-phase voltage input terminal

3-phase voltage input terminal

NC

Unused

Section 3 NAME AND FUNCTION OF EACH PART

3.1 Name of each part

RE81WH

Figure 3.1-1 Appearance of the module

Table 3.1-1 The names and operations of terminal block

Terminal

1k

1L

3k

P2

1-phase current input terminal (power source side)

1-phase current input terminal (load side)

3-phase current input terminal (power source side)

2-phase voltage input terminal

Name of terminal

14

Page 16

Section 3 NAME AND FUNCTION OF EACH PART

Internal power supply is off, error is in

No measuring electric energy (no

In the case of alarm 1 reset method =

OFF: Alarm 2 not occurring

OFF: Normal operation

Displays the status of

measurement (regeneration)

of this module.

ON: Measuring electric energy (regeneration)

Displays the status of

measurement (regeneration)

ON: Measuring 1-phase electric energy

Displays the status of

measurement (regeneration)

phase electric energy

3.2 Indication and function of LEDs

The following describes names and functions of LEDs.

Table 3.2-1 Names and functions of LEDs

Name Color Role Indicator condition

RUN

LED

MEA.

LED

ALM1

LED

ALM2

LED

Displays the operation status

Green

of this module.

Displays measuring status of

Green

*2

this module.

Displays alarm 1 occurrence

status.

Red

Displays alarm 2 occurrence

status.

Red

ON: Normal operation

OFF:

occurrence in hardware. *1

ON: Measuring electric energy (consumption or

regeneration)

OFF:

measurement)

Flashing: Alarm 1 occurring

ON: Alarm 1 occurring → Not occurring

(

Self-retention)

OFF: Alarm 1 not occurring

Flashing: Alarm 2 occurring

ON: Alarm 2 occurring → Not occurring

(In the case of alarm 2 reset method = Self-

retention)

RE81WH

ERR

LED

R

LED

1

LED

3

LED

Displays error and the status

Red

Green

*2

Green

*2

Green

*2

of this module.

at side 1 of this module.

at side 3 of this module.

Flashing: Error in out of range of setting values

*1

ON: Error in occurrence in hardware

OFF: Other than the above

(regeneration)

OFF: Other than the above

ON: Measuring 3-

(regeneration)

OFF: Other than the above

*1: For details, refer to “8.1 List of error codes” in this manual.

*2: When calculated value is low, “MEA”LED, “R”LED, “1”LED and “3”LED are looked like flashing.

Comparing to the last value per measuring cycle, LEDs light while calculating, then LEDs light off upon

no changes.

Since measuring cycle is shortest as 10ms, short period setting seems like flashing.

*1

15

Page 17

Section 3 NAME AND FUNCTION OF EACH PART

(consumption, regeneration), reactive energy

), harmonic current, current harmonic

and sequentially stores the records into a buffer memory.

The electric energy only for a period of time when a

certain output signal is ON will be stored in the buffer

power factor, each maximum/minimum values and

date/time of occurrence are stored.

Upper/lower limit alarm

the specified input signal is turned on.

storage of the

Set the integrated value (electric energy (consumption,

regeneration), reactive energy (consumption lag)) to an

circuit into the buffer memory.

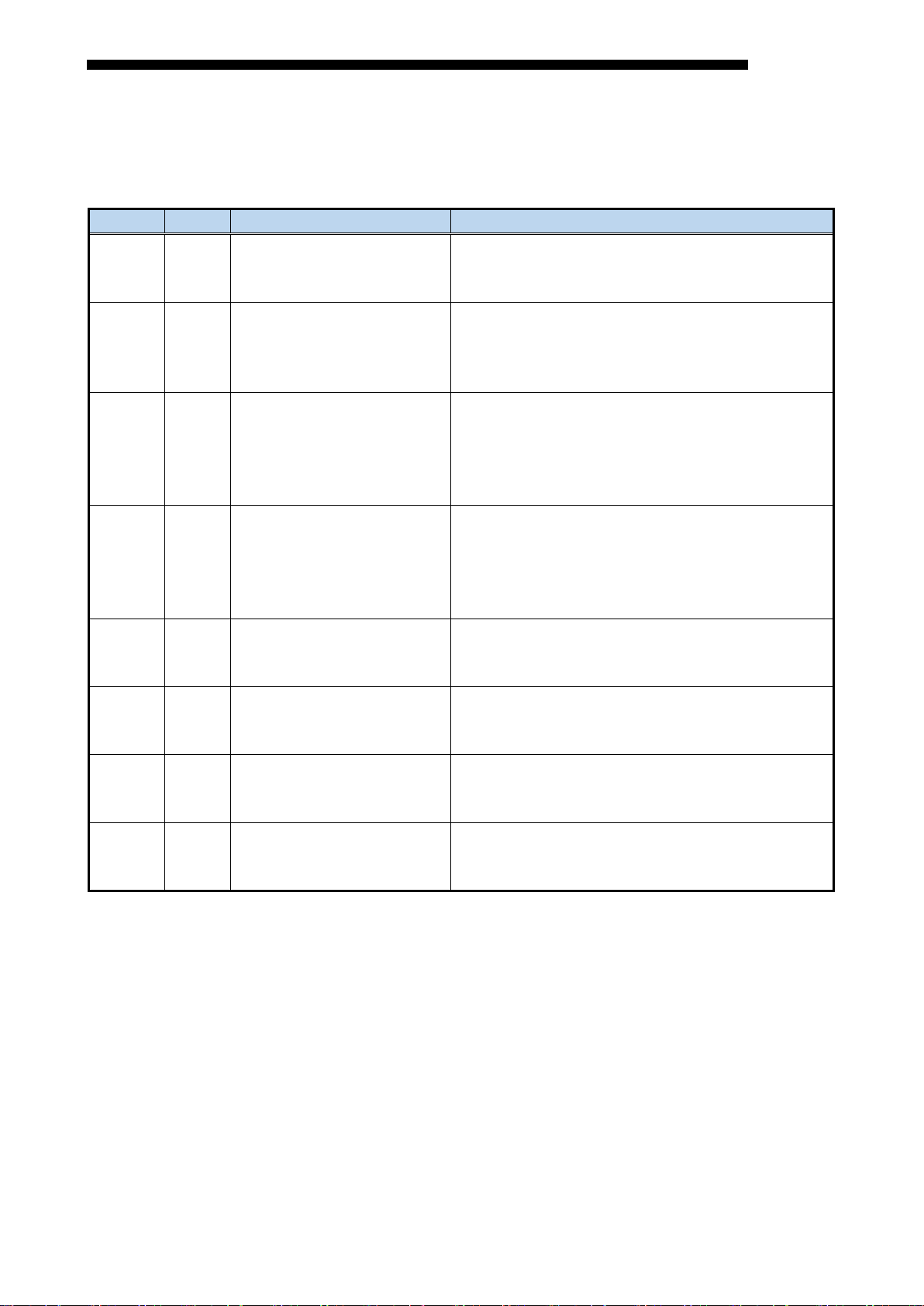

3.3 List of functions

Functions of RE81WH are provided in “Table 3.3-1 List of Functions”.

Table 3.3-1 List of Functions

No. Function Descriptions

It measures current, current demand, voltage, electric

power, electric power demand, Reactive power, apparent

power, power factor, frequency, effective energy

1 Measurement

(consumption lag

distortion, harmonic voltage, voltage harmonic distortion,

RE81WH

Reference

section

3.4.1

2 Periodic electric energy

3 Hold max./min. values

4

monitoring

5 Test

6 Integrated value set

7 Output of waveform data

memory.

Periodic energy 1 and 2 can be measured independently.

For current demand, voltage, electric power demand, and

Among current demand, voltage, electric power demand,

and power factor, you can select two measuring items for

which their upper/lower limit can be monitored.

If it exceeds the upper limit or goes below the lower limit,

Parameter setting enables pseudospecified value into the buffer memory, even with non-

existence of input from voltage and current (sensor).

Using this module, you can create a sequence, etc.

arbitrary value.

It is used to clear integrated value.

Stores waveform data of current / voltage of the measured

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

16

Page 18

Section 3 NAME AND FUNCTION OF EACH PART

Measured items

Details

period of current demand time is

Date of max. value occurrence

Date of min. value occurrence

Phase 1 harmonic current (n th)

Phase 1 harmonic current (Total)

Phase 3 harmonic current (n th) *1

Phase 3 harmonic current (Total) *1

Phase 1 current harmonic distortion (n th)

Phase 1 current harmonic distortion (Total)

Phase 3 current harmonic distortion (n th) *1

Phase 3 current harmonic distortion (Total) *1

RE81WH

3.4 Functions in detail

3.4.1 Measuring function

(1) Measured items

Measured items and measured ranges are described as follows.

Each measured item is stored in the buffer memory at every measuring cycle.

Refer to “5.2.12” for measuring cycle, and refer to “4.2.1(7)” for measuring cycle of harmonic current and

harmonic voltage.

Table 3.4.1-1 List of Measured items (1/2)

Current Phase 1 current

Phase 2 current*1

Phase 3 current*1

Average current

Current demand

* The average of fluctuation for the set

indicated.

Phase 1 current demand

Phase 2 current demand *1

Phase 3 current demand *1

Max. value

Min. value

Harmonic current *2

*1: If phase wire system is set to single-phase 2-wire, measurement will not be taken.

*2: The order of harmonic as follows.

RMS: 1st, 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th

Distortion: 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th

17

Page 19

Section 3 NAME AND FUNCTION OF EACH PART

Max. value

Min. value

Date/time of max. value occurrence

Date/time of min. value occurrence

1-2 harmonic voltage (n th)

1-2 harmonic voltage (Total)

2-3 harmonic voltage (n th) *1

2-3 harmonic voltage (Total) *1

1-2 voltage harmonic distortion (n th)

1-2 voltage harmonic distortion (Total)

2-3 voltage harmonic distortion (n th) *1

Apparent power

Apparent power

Max. value

Min. value

Date/time of max. value occurrence

Date/time of min. value occurrence

Frequency

Present value

Electric energy (consumption)

Electric energy (regeneration)

Reactive energy

Reactive energy (consumption lag)

Periodic electric energy

Periodic electric energy 1

Periodic electric energy 2

Table 3.4.1-1 List of Measured items (2/2)

Measured items

Details

Voltage 1-2 voltage (voltage V12)

2-3 voltage*1 (voltage V23)

3-1 voltage*1 (voltage V31)

Average voltage

Harmonic voltage *2

RE81WH

2-3 voltage harmonic distortion (Total) *1

Electric power Present value

Electric power demand

* The average of fluctuation for the set

period of electric power demand time

is indicated.

Reactive power Reactive power

Power factor Present value

Electric energy

Present value

Max. value

Min. value

Date/time of max. value occurrence

Date/time of min. value occurrence

*1: If phase wire system is set to single-phase 2-wire, measurement will not be taken.

*2: The order of harmonic as follows.

RMS: 1st, 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th

Distortion: 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th

18

Page 20

Section 3 NAME AND FUNCTION OF EACH PART

(The highest value after the max./min. value was reset.)

(The highest value after the max./min. value was reset.)

Highest value among 1-phase current demand, 2-phase current

(The highest value after the max./min. value was reset.)

Minimum

Minimum value of 1-phase current demand

(The lowest value after the max./min. value was reset.)

(The lowest value after the max./min. value was reset.)

phase current

(The lowest value after the max./min. value was reset.)

Maximum

Highest value of the 1 - 2 line voltage

(The highest value after the max./min. value was reset.)

(The highest value after the max./min. value was reset.)

(The lowest value after the max./min. value was reset.)

Lowest value of either the 1 - 2 line voltage or the 2 - 3 line voltage

(The lowest value after the max./min. value was reset.)

(2) Total, maximum, and minimum values

The following describes how to calculate the maximum, minimum, and total values.

Table 3.4.1-2 How to calculate the maximum, minimum and average values

Item Phase wire system Formula

Average

current

Average

voltage

Maximum

current

demand

single-phase 2-wire Average current = 1-phase current

single-phase 3-wire

three-phase 3-wire

single-phase 2-wire Average voltage = voltage V12

single-phase 3-wire

three-phase 3-wire

single-phase 2-wire

single-phase 3-wire

Average current = (1-phase current + 3-phase current) / 2

Average voltage = (voltage V12 + voltage V23) / 2

Maximum value of 1-phase current demand

Highest value of either 1-phase current demand or 3-phase current

demand

RE81WH

current

demand

voltage

Minimum

voltage

three-phase 3-wire

single-phase 2-wire

single-phase 3-wire

three-phase 3-wire

single-phase 2-wire

single-phase 3-wire

three-phase 3-wire

single-phase 2-wire

single-phase 3-wire

three-phase 3-wire

demand, or 3-phase current demand

Lowest value of either 1-phase current demand or 3-phase current

demand

Lowest value among 1-phase current demand, 2demand, or 3-phase current demand

Highest value of either the 1 - 2 line voltage or the 2 - 3 line voltage

Highest value among the 1 - 2 line voltage, the 2 - 3 line voltage, or

3 - 1 line voltage

(The highest value after the max./min. value was reset.)

Lowest value of the 1 - 2 line voltage

(The lowest value after the max./min. value was reset.)

Lowest value among the 1 - 2 line voltage, the 2 - 3 line voltage, or

3 - 1 line voltage

19

Page 21

Section 3 NAME AND FUNCTION OF EACH PART

decimal point

1 digit after the

decimal point

400 A ≤ PA < 4000 A

-3

Integer

1 A

4000 A ≤ PA

-3

x10

10 A

PV*1

factor

1 digit after the

3300 V ≤ PV

-3

x10

10 V

factor

decimal point

1 digit after the

decimal point

IV

1200 kW ≤ W < 12000 kW

-3

Integer

1 kW

V

12000 kW ≤ W < 120000 kW

-3

x10

10 kW

RE81WH

(3) Resolution of measured data

Resolution of measured data according to the rating (phase wire system, primary voltage setting, and

primary current setting) is described as follows.

(a) Current, current demand

Primary current setting

PA*1

PA < 40 A -3

Multiplying

factor

Resolution*2

2 digits after the

0.01 A

40 A ≤ PA < 400 A -3

0.1 A

*1: Case of setting value of the primary current (Un\G2) is “0”, the primary current (PA) is value of

primary current of CT (Un\G7).

In other cases, the primary current (PA) is the value of primary current (Un\G2).

*2: Digits lower than the resolution are fixed to 0.

(b) Voltage

Primary voltage setting

PV < 330 V -3

Multiplying

Resolution*2

decimal point

0.1 V

330 V ≤ PV < 3300 V -3 Integer 1 V

*1: Case of setting value of the primary voltage (Un\G1) is “0”, the primary voltage (PV) is value of

primary voltage of VT (Un\G5).

In other cases, the primary voltage (PV) is the value of primary voltage (Un\G1).

*2: Digits lower than the resolution are fixed to 0.

(c) Electric power, electric power demand, Reactive power, Apparent power

Full load power W*1

Multiplying

Resolution

*2 *3

I W < 12 kW -3

II 12 kW ≤ W < 120 kW -3

III 120 kW ≤ W < 1200 kW -3

*1: Full load power (W) can be calculated by the following formula.

For calculating full load power W, refer to “Table 3.4.1-3 How to calculate full load power”.

Full load power W(kW) = α × Primary voltage (V) × Primary current (A) / 1000

Case of single-phase 2-wire: α = 1

Case of single-phase 3-wire: α = 2

Case of three-phase 3-wire: α = 3

*2: Digits lower than the resolution are fixed to 0.

*3: The module is kvar for reactive power and kVA for apparent power.

3 digits after the

decimal point

2 digits after the

0.001 kW

0.01 kW

0.1 kW

20

Page 22

Section 3 NAME AND FUNCTION OF EACH PART

decimal point

factor

decimal point

factor

5 digits after the

decimal point

3 digits after the

decimal point

decimal point

(d) Power factor

Power factor

All setting ranges -3

Multiplying

factor

Resolution*1

1 digit after the

*1: Digits lower than the resolution are fixed to 0.

(e) Frequency

Frequency

Multiplying

Resolution*1

RE81WH

0.1 %

All setting ranges -3

1 digit after the

0.1 Hz

*1: Digits lower than the resolution are fixed to 0.

(f) Electric energy, reactive energy, periodic electric energy

Full load power W*1

Multiplying

I W < 12 kW -5

II 12 kW ≤ W < 120 kW -4

III 120 kW ≤ W < 1200 kW -3

IV 1200 kW ≤ W < 12000 kW -2

V 12000 kW ≤ W < 120000 kW -1

Resolution

decimal point

4 digits after the

2 digits after the

decimal point

1 digit after the

*2 *3

0.00001 kWh

0.0001 kWh

0.001 kWh

0.01 kWh

0.1 kWh

*1: Refer to “(c) *1” about how to calculate Full load power (W).

For calculating full load power W, refer to “Table 3.4.1-3 How to calculate full load power”.

*2: Because the higher resolution than a typical watt-hour meter, the minimum digit values will change

more than 2 at once update in accordance with setting value of input voltage, primary current,

primary voltage of VT, secondary voltage of VT, primary current of CT and the condition of load.

*3: In the case of reactive energy, the unit will be kvarh.

21

Page 23

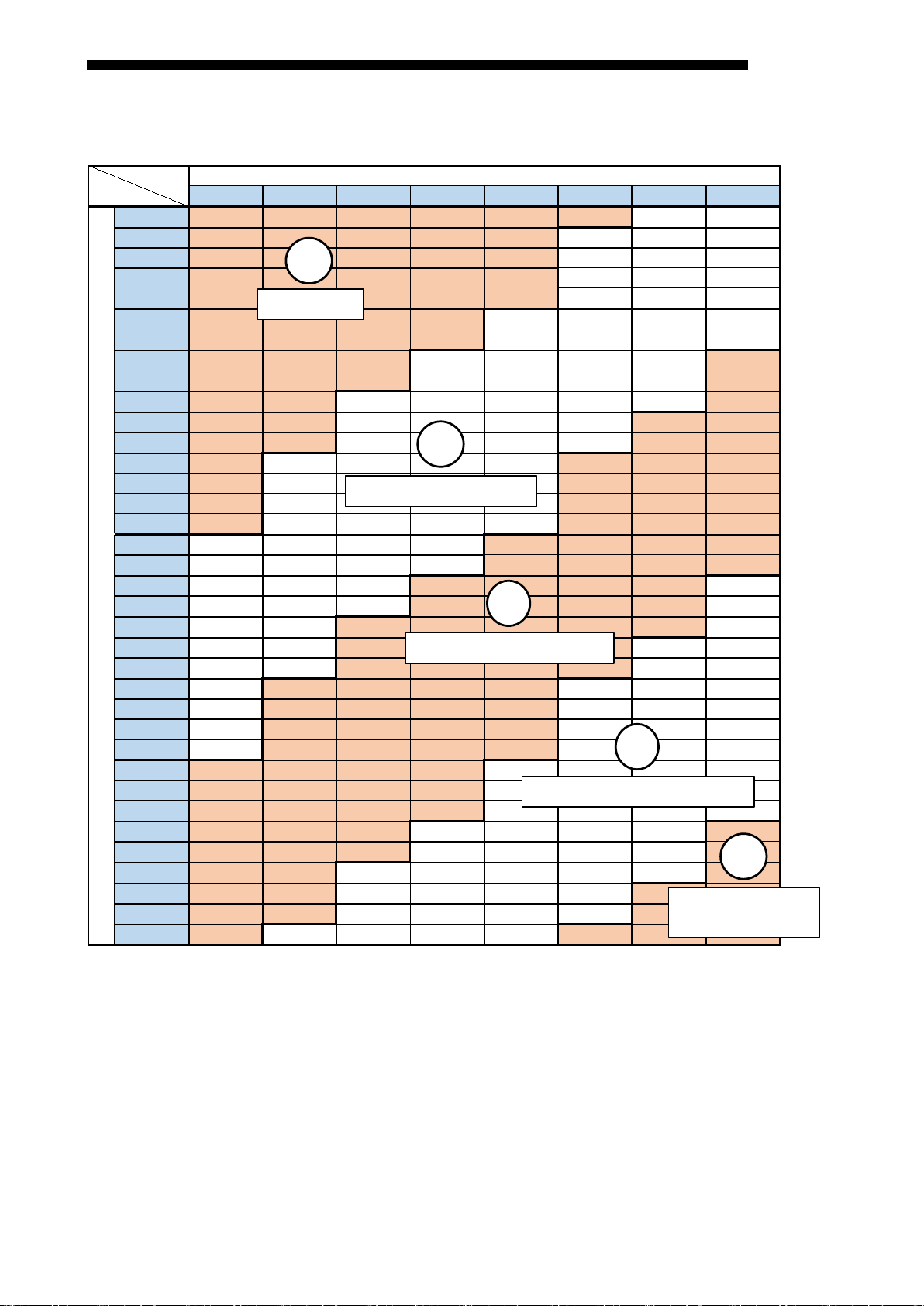

Section 3 NAME AND FUNCTION OF EACH PART

110 220 440 690 1100 2200 3300 6600

5

6

7.5

8

10

12

15

20

25

30

40

50

60

75

80

100

120

150

200

250

300

400

500

600

750

800

1000

1200

1500

1600

2000

2500

3000

4000

5000

6000

Primary current [A]

Primary voltage [V]

Ⅰ

Ⅱ

Ⅴ

W < 12 kW

12 kW ≤ W < 120 kW

120 kW ≤ W < 1200 kW

1200 kW ≤ W < 12000 kW

12000 kW ≤ W

< 120000 kW

Table 3.4.1-3 How to calculate full load power

Single-phase 2 wire system

RE81WH

22

Page 24

Primary voltage [V]

110

5

6

7.5

8

10

12

15

20

25

30

40

50

60

75

80

100

120

150

200

250

300

400

500

600

750

800

1000

1200

1500

1600

2000

2500

3000

4000

5000

6000

Primary current [A]

Ⅰ

W < 12 kW

Ⅱ

12 kW ≤ W < 120 kW

120 kW ≤ W < 1200 kW

1200 kW ≤ W < 12000 kW

Section 3 NAME AND FUNCTION OF EACH PART

Single-phase 3-wire system

RE81WH

23

Page 25

Section 3 NAME AND FUNCTION OF EACH PART

110 220 440 690 1100 2200 3300 6600

5

6

7.5

8

10

12

15

20

25

30

40

50

60

75

80

100

120

150

200

250

300

400

500

600

750

800

1000

1200

1500

1600

2000

2500

3000

4000

5000

6000

Primary current [A]

Primary voltage [V]

Ⅰ

W < 12 kW

Ⅱ

12 kW ≤ W < 120 kW

120 kW ≤ W < 1200 kW

1200 kW ≤ W < 12000 kW

Ⅴ

12000 kW ≤ W

< 120000 kW

Three-phase 3-wire system

RE81WH

24

Page 26

Section 3 NAME AND FUNCTION OF EACH PART

Measuring item

Behavior of the module

Current

When the input current is less than 0.4% of the rating current, it becomes 0A.

is 0A, current demand may not be 0A.

Indicate “0 A” if 1-2 line voltage is 0V.

Frequency condition:

Indicate “0 %” at each phase if harmonic current (Harmonic current (1st)) is 0A.

Indicate “0 %” if 1-2 line voltage is 0V.

When it is less than 44.5Hz, it becomes 0V.

When it is less than 44.5Hz, it becomes 0V.

Apparent power

* The unit is kvar for reactive power and kVA for apparent power.

Electric power

Electric power demand is obtained by electric power moving average. Therefore,

are 0V), it becomes 100%

When it is less than 44.5Hz, it is fixed to 44.5Hz.

RE81WH

(4) Restrictions for measuring data

・Measurement cannot be performed immediately after the power loading to the sequencer system

(Module ready signal is under the OFF condition).

After checking that Module ready (Xn0) is ON, obtain measuring data.

・Measurement cannot be performed immediately after operating conditions are set up to the module. After

checking that Operating condition setting completion flag (Xn9) becomes ON, obtain measuring data.

・Behaviors during operation are as follows.

Current demand Current demand is obtained by current moving average. Therefore, even if the current

Harmonic current Current condition:

Indicate “0 A” at each phase if current is 0A.

Voltage condition:

Indicate “0 A” at all phase if frequency is under 44.5Hz.

Current harmonic

distortion

Harmonic current condition:

Voltage condition:

Frequency condition:

Indicate “0 %” at all phase if frequency is under 44.5Hz.

Voltage Indicate “0 V” if RMS value is under 11V. (*1)

Harmonic voltage Voltage condition:

Indicate “0 V” at each inter-wire if voltage is 0V.

Indicate “0 V” if 1-2 line voltage is 0V.

Frequency condition:

Voltage harmonic

distortion

Electric power,

Reactive power,

demand

Electric energy The electric energy is measured with a load that is about 0.4% or more of all load

Power factor When current is 0A (at all phases are 0A) or when voltage is 0V (all in-between wires

Voltage condition:

Indicate “0 %” at each inter-wire if voltage is 0V.

Indicate “0 %” if 1-2 line voltage is 0V.

Frequency condition:

When current is 0A (at all phases are 0A) or when voltage is 0V (all in-between wires

are 0V), it becomes 0kW.

even if electric power is 0kW, electric power demand may not be 0kW.

power. Even if the indicated value is “0”, measurement value will increase.

Frequency Voltage condition

Indicate “0 Hz” if 1-2 line voltage is 0 V.

Frequency condition

*1: In 1-phase three-wire system, indicate “0 V” if RMS value is under 22V.

25

Page 27

Section 3 NAME AND FUNCTION OF EACH PART

Periodic

RE81WH

3.4.2 Measuring function for periodic electric energy

This function is to measure electric energy (consumption) for a certain period, and stores it into the buffer

memory. It can be used to measure electric energy for a certain tact or energy (standby power) when the facility

or equipment is not in operation.

(1) Overview

(a) It can measure two periodic electric energy at maximum (periodic electric energy 1, periodic electric

energy 2). Each of these can be measured independently.

(b) While the time when Periodic electric energy 1 measurement flag (Yn1)/ Periodic electric energy 2

measurement flag (Yn2) is ON, periodic electric energy can be measured.

(c) Since Periodic electric energy is stored in the nonvolatile memory, it can be retained even when a power

source reset.

(d) I/O signals and buffer memory corresponding to each of periodic electric energy 1 and 2 are shown

below.

Periodic

electric energy

1

Periodic

electric energy

2

Supplement

Quantity survey of periodic electric energy is performed every measuring cycle. Therefore, if the

time for turning ON Periodic electric energy 1 measurement flag (Yn1) and Periodic electric energy

2 measurement flag (Yn2) is set to measuring cycle or less, measurement may not be performed.

For the measuring cycle, refer to “5.2.12”.

Buffer memory

(Double words)

Un\G114,115

Un\G116,117

electric

energy

measurement

flag

Yn1 Xn1 Yn3 Xn3

Yn2 Xn2 Yn4 Xn4

Periodic electric

energy data

completion flag

Periodic

electric

energy reset

request

Periodic electric

completion flag

energy reset

26

Page 28

Section 3 NAME AND FUNCTION OF EACH PART

Period ic ele ctric en ergy 1

OFF

Period ic ele ctric en ergy 1 reset reques t (Yn3)

Period ic ele ctric en ergy 1 reset com pletion flag (Xn3)

(i) (ii)

ON

ON

OFF

OFF

(iii)

Period ic ele ctric en ergy 1 me asuremen t flag (Yn1)

Period ic ele ctric en ergy 1 data co mple tio n flag (Xn1)

ON

OFF

ON

OFF

Period ic ele ctric en ergy 1

ON

OFF

(i) (ii)

(iii) (iv) (v)

RE81WH

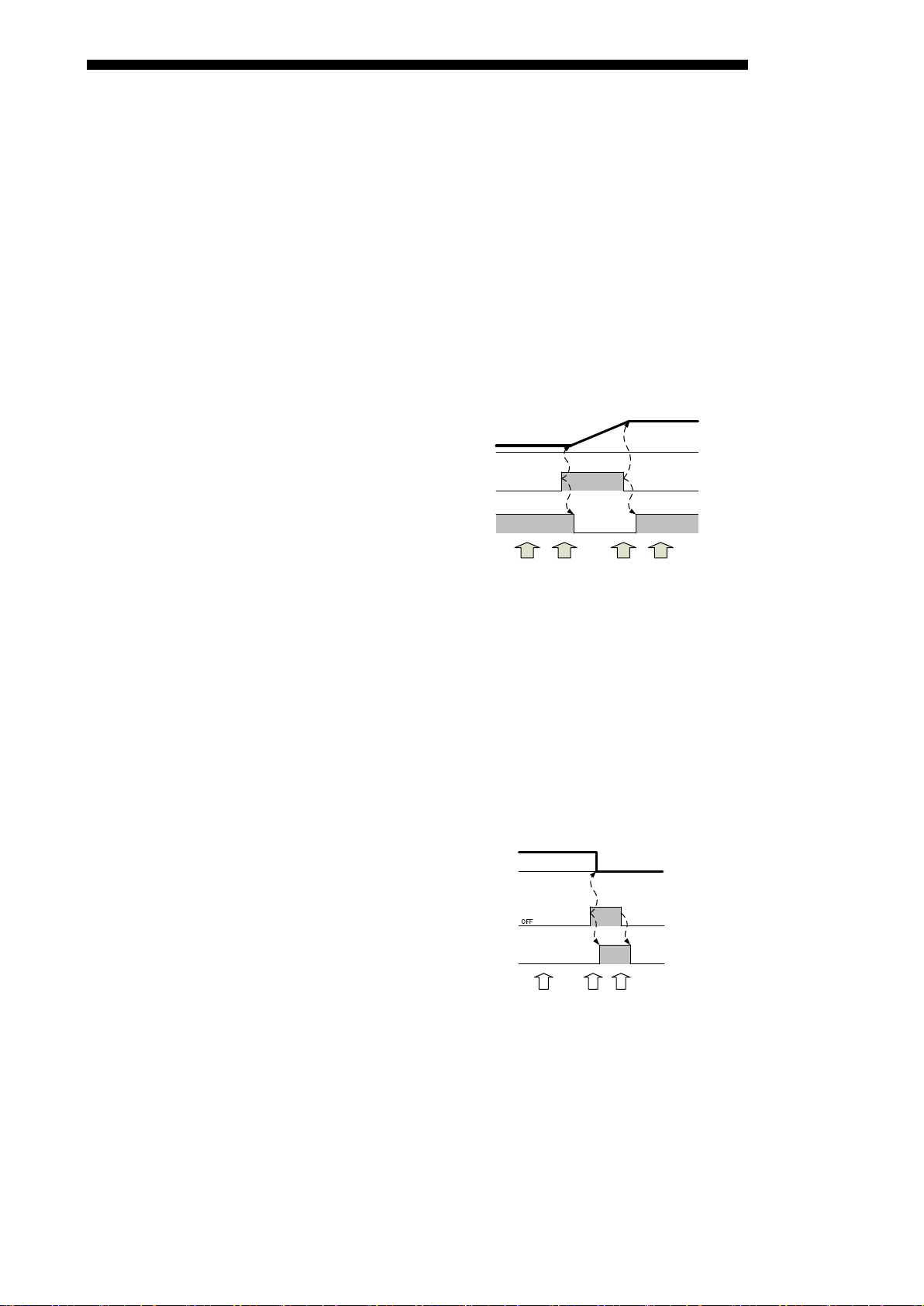

(2) Basic procedure

(a) Measuring periodic electric energy

(i) Check that Periodic electric energy measurement flag (Yn1/Yn2) i s O F F.

(ii) Check periodic electric energy (Un\G114, 115/Un\G116, 11 7).

(iii) When starting measurement, set Periodic electric energy measurement flag (Yn1/Yn2) to ON.

This module starts measuring specified periodic electric energy, and Periodic electric energy data

completion flag (Xn1/Xn2) will be turned OFF.

(iv) When stopping measurement, set Periodic electric energy measurement flag (Yn1/Yn2) to OFF.

This module stops measuring the specified periodic electric energy, and Periodic electric energy data

completion flag (Xn1/Xn2) will be turned ON.

(v) Check that Periodic electric energy data completion flag (Xn1/Xn2) becomes ON, and obtain the

value of periodic electric energy.

Figure 3.4.2-1 Basic procedure of measuring the periodic electric energy 1

(b) Resetting periodic electric power

(i) Check that Periodic electric energy measurement flag (Yn1/Yn2) is OFF and Periodic electric energy

reset request (Yn3/Yn4) is OFF.

(ii) Set Periodic electric energy reset request (Yn3/Yn4) to ON. The specified periodic electric energy is

reset to 0 kWh, and Periodic electric energy reset completion flag (Xn3/Xn4) will be turned to ON.

(iii) Check the Periodic electric energy reset completion flag (Xn3/Xn4) has become ON, then set Periodic

electric energy reset request (Yn3/Yn4) to OFF.

Periodic electric energy reset completion flag (Xn3/Xn4) will be turned OFF.

Figure 3.4.2-2 How to reset the periodic electric energy 1

27

Page 29

Section 3 NAME AND FUNCTION OF EACH PART

Periodic ele ctric energy 1 me asure ment f lag (Yn1)

Periodic ele ctric energy 1 dat a com ple tion flag (Xn1)

ON

OFF

OFF

OFF

Periodic ele ctric energy 1

ON

Period ic ele ctric energy 1 me asure ment f lag (Yn1)

Period ic ele ctric energy 1 data comple tio n flag (Xn1)

ON

OFF

ON

OFF

Period ic ele ctric energy 1

ON

OFF

Period ic ele ctric energy 1 res et request (Yn3)

Period ic ele ctric energy 1 res et com pletion fla g (Xn3)

(i) (ii)

ON

OFF

OFF

(iii) (iv) (v) (vi)

RE81WH

(3) Example of use

(a) Procedure for continuously measuring periodic electric energy

If you turn Periodic electric energy measurement flag (Yn1/Yn2) to ON only while measurement is

needed, this module accumulates the power starting at the previously measured amount. Usage

procedure is the same as (a) in (2).

An example is shown below.

Figure 3.4.2-3 Example of continuous measurement of periodic electric energy 1

(b) Procedure for measuring periodic electric energy at every reset

By the following usage procedure, this module accumulates electric energy every time after resetting

periodic electric energy.

(i) Check that Periodic electric energy measurement flag (Yn1/Yn2) is OFF and Periodic electric energy

reset request (Yn3/Yn4) is OFF.

(ii) Set Periodic electric energy reset request (Yn3/Yn4) to ON.

The specified periodic electric energy is reset to 0 kWh, and Periodic electric energy reset completion

flag (Xn3/Xn4) will be turned ON.

(iii) Check that Periodic electric energy reset completion flag (Xn3/Xn4) has become ON, and then set

Periodic electric energy reset request (Yn3/Yn4) to OFF.

Periodic electric energy reset completion flag (Xn3/Xn4) will be turned OFF.

(iv) When starting measurement, set Periodic electric energy measurement flag (Yn1/Yn2) to ON.

This module starts measuring the specified periodic electric energy, and Periodic electric energy data

completion flag (Xn1/Xn2) will be turned OFF.

(v) When stopping measurement, set Periodic electric energy measurement flag (Yn1/Yn2) to OFF.

This module stops measuring the specified periodic electric energy, and Periodic electric energy data

completion flag (Xn1/Xn2) will be turned ON.

(vi) Check that Periodic electric energy data completion flag (Xn1/Xn2) becomes ON, and obtain the

value of periodic electric energy.

Figure 3.4.2-4 Example of measurement of periodic electric energy 1 every time after resetting

28

Page 30

Section 3 NAME AND FUNCTION OF EACH PART

Setting value

Description

11

Current demand

12

Voltage

Max./min. value s clea r re qu es t (YnD)

Max./min. value s clea r completion flag (XnD)

ON

ON

OFF

OFF

RE81WH

3.4.3 Max./min. value hold function

It memorizes the max./min. value for each measuring item, and retains them until the max./min. value clear

are performed.

(1) Max./min. value memory

It memorizes the max. and min. values, and the time of occurrence (year/month/day/hour/minute/second/day

of the week/millisecond) values for the following measuring item.

* The max. and min. values and the date of occurrence are stored in the nonvolatile memory, so that these

values can be retained even when a power source reset.

・Current demand

・Voltage

・Electric power demand

・Power factor

(2) How to clear the max. and min. values

You can use the I/O signal to clear the max. and min. values that specified by max./min. values clear target

(Un\G56).

The max. and min. values immediately after the clear becomes the present values and the date of

occurrence will be the present date and time.

The following describes how to clear the max. and min. values.

(a) Check that Max./min. values clear request (YnD) is O F F.

(b) Set the max./min. values clear target(Un\G56).

The setting range is shown below.

13 Electric power demand

14 Power factor

19 All of the above

Others Do not clear

(c) Set Max./min. values clear request (YnD) to ON.

This module clears the max./min. values set by (b), and the date of occurrence, and set Max./min.

values clear completion flag (XnD) to ON.

(d) Check that Max./min. values clear completion flag (XnD) is ON, and then set Max./min. values clear

request (YnD) t o O F F.

Max./min. values clear completion flag (XnD) will be turned OFF.

Figure 3.4.3-1 Procedure for clearing max./min. value

29

Page 31

Section 3 NAME AND FUNCTION OF EACH PART

(Alarm 1 / Alarm 2)

8: Power factor lower limit

For respective alarm 1 and

Alarm monitoring

-2147483648 – 2147483647

Power factor :×10-3 %

The value to be monitored for

the alarm. Set the value

according to the unit of the

(Double words)

Alarm reset method

0: Self-retention

Set whether or not the alarm-

the upper limit alarm value or

Only when the state that it

exceeds the upper limit alarm

monitoring value or it goes

below the lower limit alarm

monitoring value continues for

it is considered as an alarm

occurrence.

RE81WH

3.4.4 Upper/lower limit alarm monitoring function

You can set an upper and lower limit alarm for maximum two points and implement a monitoring function for

them.

During the alarm monitoring, you can check the alarm occurrence by the input signal.

(1) Setting items of the upper/lower limit alarm monitoring

Setting items and setting range for the alarm monitoring are described below.

Items set in the

buffer memory

Setting range Description

Alarm monitoring

factor

(Un\G11 / Un\G21)

value

(Un\G12,13

/ Un\G22,23)

(Un\G14 / Un\G24)

Alarm delay time

(Un\G15 / Un\G25)

0: No monitoring

1: Current demand upper limit

2: Current demand lower limit

3: Voltage upper limit

4: Voltage lower limit

5: Power demand upper limit

6: Power demand lower limit

7: Power factor upper limit

[Unit]

Current demand :×10

Voltage :×10

Electric Power demand :×10

1: Self-reset

0 – 300

[Unit] second

-3

A

-3

V

-3

kW

alarm 2, set the monitoring item

either the upper / lower limit or

measuring factor.

measuring item that is set as an

alarm monitoring factor.

occurrence condition should be

retained if the value goes below

goes over the lower limit alarm

value after the upper/lower limit

alarm occurred.

* Each item of the alarm monitoring is stored in the nonvolatile memory, so that values can be retained even

when a power source reset.

the period of alarm delay time,

30

Page 32

Section 3 NAME AND FUNCTION OF EACH PART

ON

OFF

OFF

ON

OFF

OFF

Operating condition setting completion flag (Xn9)

Operating condition setting request (Yn9)

Alar m 1 flag (XnA )

OFF

ON

Ala rm

del ay t ime

ON

Alar m 1 res et r equest (YnA)

OFF

ALM1 LED

OFF Flashing OFFON

(i)

(ii)

(iii) (iv)

Upper limit

RE81WH

(2) How to set the upper/lower limit alarm monitoring

Setting procedures are as following.

(a) Check that Operating condition setting request (Yn9) is OFF.

(b) Set the alarm item in the buffer memory (Un\G11 / Un \G21), alarm value (Un\G12, 13 / Un\G22, 23),

alarm reset method (Un\G14 / Un\G24), and alarm delay time (Un\G15 / Un\G25).

(c) Set Operating condition setting request (Yn9) to ON.

Operation starts at each set value, and then, Operating condition setting completion flag (Xn9) is turned

ON.

(d) Check that Operating condition setting completion flag (Xn9) becomes ON, and then set Operating

condition setting request (Yn9) to OFF.

Operating condition setting completion flag (Xn9) will be turned OFF.

Figure 3.4.4-1 Time chart of alarm monitoring setting

(3) Behavior of the upper/lower limit alarm

(a) When the alarm reset method is in the “0: Self-retention” setting (example of an upper limit monitoring

at alarm 1)

(i) If the measured value that was set with the alarm 1 monitoring item exceeds the upper limit and the

situation continues and remains for the alarm 1 delay time, Alarm 1 flag (XnA) will be turned ON.

At the same time, ALM1 LED flashes.

(ii) Even if the measured value goes below the upper limit, Alarm 1 flag (XnA) retains an ON status (Self-

retention).

During the self-retention, ALM1 LED is turned on.

(iii) By turning Alarm 1 reset request (YnA) to ON, Alarm 1 flag (XnA) will be turned OFF.

At this time, ALM1 LED is turned off.

(iv) Check that Alarm 1 flag (XnA) becomes OFF, and then set Alarm 1 reset request (YnA) to OFF.

Figure 3.4.4-2 Time chart of the upper/lower limit alarm (alarm reset method = “Self-retention”)

31

Page 33

Section 3 NAME AND FUNCTION OF EACH PART

Alar m 1 flag (XnA )

ON

Ala rm

del ay t ime

Ala rm

del ay t ime

ALM1 LED

OFF Flashing OFF

(i)

(ii)

(iii)

Upper limit

Alar m 2 flag (XnB )

OFF

ON

Ala rm

del ay t ime

Ala rm

del ay t ime

ALM2 LED

OFF Flashing OFF

(i)

(ii)

(iii)

Lower limit

RE81WH

(b) When the alarm reset method is in the “1: Self-reset” setting (example of an upper limit monitoring at

alarm 1)

(i) If the measured value that was set with the alarm 1 monitoring factor exceeds the upper limit and the

situation continues and remains for the alarm 1 delay time, Alarm 1 flag (XnA) will be turned ON.

At the same time, ALM1 LED flashes.

(ii) If the measured value goes below the upper limit, Alarm 1 flag (XnA) will be turned OFF. At this time,

ALM1 LED is turned off.

(iii) When the measured value that was set with the alarm 1 monitoring item goes below the upper limit

within the alarm 1 delay time even though the measured value exceeds the upper limit, the alarm 1

flag (XnA) will remain in OFF status.

Figure 3.4.4-3 Time chart of the upper/lower limit alarm (alarm reset method = “Self-reset”)

(c) When the alarm reset method is in the “Self-reset” setting (Example of a lower limit monitoring at alarm

2)

(i) If the measured value that was set with the alarm 2 monitoring factor goes below the lower limit and

the situation continues and remains for the alarm 2 delay time, Alarm 2 flag (XnB) will turn ON.

At the same time, ALM2 LED flashes.

(ii) If the measured value exceeds the lower limit, Alarm 2 flag (XnB) will turn OFF. At this time, ALM2

LED is turned off.

(iii) When the measured value that was set with the alarm 2 monitoring item exceeds the lower limit within

the alarm 2 delay time even though the measured value goes below the lower limit, the Alarm 2 flag

(XnB) will remain in OFF status.

Figure 3.4.4-4 Time chart of the upper/lower limit alarm (alarm reset method = “Self-reset”)

32

Page 34

Section 3 NAME AND FUNCTION OF EACH PART

Alar m 1 flag (XnA )

ON

ON

OFF

Alar m 1 res et request (YnA)

ALM1 LED

OFF Flashing OFF

(ii) (iii) (iv)(i) (v)

ON

Upper limit

Flashing

Ala rm

del ay t ime

Ala rm

del ay t ime

RE81WH

(4) How to reset Alarm flag

When Alarm flag is ON during the alarm occurrence or the self-retention (in the case of the alarm reset

method = “Self-retention“), Alarm flag can be reset (turned OFF) using Alarm reset request.

(a) How to reset Alarm flag during alarm occurrence (example of the upper limit alarm monitoring with the

alarm 1)

(i) If the measured value that was set with the alarm 1 monitoring factor exceeds the upper limit, Alarm

1 flag (XnA) will turn ON.

At the same time, ALM1 LED flashes.

(ii) By turning Alarm 1 reset request (YnA) to ON, Alarm 1 flag (XnA) will turn OFF.

At this time, ALM1 LED will remain flashing (because ALM1 LED is synchronized with the alarm

status, it will not turn off).

(iii) Check that Alarm 1 flag (XnA) becomes OFF, and then set Alarm 1 reset request (YnA) to OFF.

(iv) If the measured value goes below the upper limit, ALM1 LED will turn off.

(v) After that, if the measured value exceeds the upper limit, Alarm 1 flag (XnA) will turn ON again. At

the same time, ALM1 LED flashes.

(b) How to reset Alarm flag during self-retention (only in the case the alarm reset method = “Self-retention”)

Refer to the procedure described in (3)(a).

(5) Precautions during the alarm monitoring

When current demand time and electric power demand time are set to anytime other than 0 second, current

demand value and electric power demand value become lower than the actual values (closer to 0)

immediately after the power source ON and the CPU reset.

When current demand value and electric power demand value are being monitored for their lower limit alarm,

the alarm occurrence flag may turn ON. Thus, to avoid this, follow the procedure below.

(a) Set the alarm monitoring target to “no monitoring” immediately after the power source ON and the CPU

reset.

(b) After passing for a 3-times longer period than the demand time, set the alarm monitoring target again,

and start the alarm monitoring.

Figure 3.4.4-5 Procedure for resetting Alarm 1 flag (alarm reset method = “Self-reset”)

33

Page 35

Section 3 NAME AND FUNCTION OF EACH PART

operation before running the sequence program.

RE81WH

3.4.5 Tes t function

This function is to output pseudo-fixed value to a buffer memory for debugging sequence program. The value

can be output to the buffer memory without input of voltage and current.

Caution

● Because fixed-value is output to the buffer memory, separate the actual device to avoid unexpected

(1) How to use the test function

Using the parameter setting, you can start the test mode to output the fixed value.

Refer to “6.4.2” for procedure of the parameter setting, refer to “6.4.5” for start or end the test mode.

(2) Content of pseudo-output

For the value to be output to the buffer memory, refer to Table 5.1-1 to 5.1-3 in “5.1 Buffer memory

assignment”.

(3) LED display when using the test function

All LED ON.

(4) I/O signals when using the test function

Unit READY (Xn0) only ON.

Other input and output signals are all OFF.

34

Page 36

Section 3 NAME AND FUNCTION OF EACH PART

1

Electric energy (consumption)

2

Electric energy (regeneration)

3

Reactive energy (consumption lag)

積算値

セット

要求(Y3)

積算値セット完了 フラグ(X3)

ON

OFF

OFF

ON

OFF

OFF

RE81WH

3.4.6 Integrated value set function

This is a function that can set the integrated value (electric energy (consumption, regeneration), reactive

energy (consumption lag)) to an arbitrary value.

It is used to clear integrated value.

(1) Setting procedure

Setting procedures are as follows.

(a) Set the integrated value setting target (Un\G51) in the buffer memory.

Setting range is as follows.

Setting value Description

0 No set

(b) Set the integrated value setting value (Un\G52, 53) in the buffer memory.

・Configurable range: 0 to 999999999

・The unit used for the setting value is the same as that used for the electric energy and reactive

energy output to the buffer memory.

For details, refer to “5.3.2”.

(c) Turn Integrated value set request (YnC) from OFF to ON to enable the setting.

Integrated value set completion flag (XnC) turns ON after Integrated value set request (YnC) is set OFF

to ON.

(d) After checking that integrated value set completion flag (XnC) turns ON and setting is completed, set

the integrated value set request (YnC) t o OF F.

After detected that the integrated value set request (YnC) turns OFF, the integrated value set completion

flag (XnC) turns OFF.

Integrated value set request (YnC )

Integrated value set completion flag (XnC)

Figure 3.4.6 Integrated value setting procedure

(2) Default value

Integrated value setting target (Un\G51) is set to 0 (No set).

Integrated value setting value (Un\G52, 53) is set to 0.

35

Page 37

Section 3 NAME AND FUNCTION OF EACH PART

Measured items

Details

waveform data of 1-2 line voltage

waveform data of 2-3 line voltage*1

waveform data of 1-phase current

waveform data of 3-phase current*1

RE81WH

3.4.7 Waveform data output function

Waveform data is sampling data of current / voltage waveform of the measured circuit. Using this data, it is

possible to display the waveform, obtain changes of waveform. (Each data is converted value as unit V, A)

Waveform data is stored into the buffer memory in two methods as below.

* Waveform data to be measured is same, whereas buffer memory for storing data different.

(1) Waveform data sampled during period of measured data acquisition clock is stored into the buffer

memory.

The waveform data is stored into the buffer memory per period of measured data acquisition clock.

The buffer memory for storing multiple waveform data is secured. Waveform data sampled per sampling

period (254μs) during period of measured data acquisition clock is collectively stored into the buffer memory.

This method is used for acquiring waveform data synchronized with period of measured data acquisition

clock.

Refer to “4.2.1(8)” for synchronizing method.

(a) Measuring items

waveform data of voltage

waveform data of current

(b) Number of waveform data

The number of each waveform data to be stored is the number of sampling during period of measured

data acquisition clock.

Since the sampling period is not synchronized with the period of measured data acquisition clock, the

number of waveform data may be different even in the same period of measured data acquisition clock.

Thus, the number of each waveform data is stored into the buffer memory separately from the waveform

data.

(c) Restrictions for waveform data:

・It is impossible to obtain waveform data immediately after applying power to programmable controller

system. (Module ready OFF state)

Obtain waveform data after confirming “Module ready ON state”.

・It is impossible to obtain waveform data immediately after setting operating condition of this device.

Obtain waveform data after confirming “operating condition setting completed flag” is ON.

・Set the period of measured data acquisition clock below 50ms.

Where the period is larger than 50ms, waveform data is not stored into the buffer memory.

・It is possible to occur communication error inside the RE81WH due to disturbance noise (parallel noise

to CT line). When a communication error is occurred (when a communication error flag indicates error),

waveform data during the period of measured data acquisition clock is not stored into the buffer memory.

Instead “0” is stored into the buffer memory.

36

Page 38

Section 3 NAME AND FUNCTION OF EACH PART

ontinuous waveform

data of voltage and

RE81WH

(2) The waveform data is stored into the buffer memory per sampling period.

The waveform data is stored into the buffer memory per sampling period (μs) of the waveform data.

This method is used for acquiring the waveform data synchronized with sampling period.

Refer to “4.2.1(6)” for synchronizing method.

(a) Measured items

Measured items

Details

C

current

*1: When setting single phase 2-wire system for phase wire system, no measuring is performed.

(b) Number of waveform data

The number of each waveform data to be stored into buffer memory at once is one.

(c) Restrictions for waveform data

・It is impossible to obtain waveform data immediately after applying power to programmable controller

system. (Module ready OFF state)

Obtain waveform data after confirming “Module ready ON state”.

・It is impossible to obtain waveform data immediately after setting operating condition of this device.

Obtain waveform data after confirming “operating condition setting completed flag” is ON.

・It is possible to occur communication error inside the RE81WH due to disturbance noise (parallel noise

to CT line). When a communication error is occurred (when a communication error flag indicates error),

waveform data during the period of measured data acquisition clock is not stored into the buffer memory.

(In this case, the last waveform data is stored into the buffer memory)

waveform data of 1-2 line voltage

waveform data of 2-3 line voltage*1

waveform data of 1-phase current

waveform data of 3-phase current*1

37

Page 39

Section 4 I/O SIGNALS TO CPU MODULE

Input signal

(signal direction from RE81WH to CPU module)

Output signal

(signal direction from CPU module to RE81WH)

Device

No.

Device

No.

Periodic electric energy 1 data

completion flag

Periodic electric energy 1 measurement

flag

Periodic electric energy 2 data

completion flag

Periodic electric energy 2 measurement

flag

Periodic electric energy 1 reset

completion flag

Periodic electric energy 2 reset

completion flag

Xn6

Waveform data acquisition clock

Yn6

Use prohibited *1

Measured harmonics data acquisition

clock

Xn8

Measured data acquisition clock

Yn8

Use prohibited *1

Operating condition setting completion

flag

XnA

Alarm 1 flag

YnA

Alarm 1 reset request

XnB

Alarm 2 flag

YnB

Alarm 2 reset request

XnC

Integrated value set completion flag

YnC

Integrated value set request

XnD

Max./min. values clear completion flag

YnD

Max./min. values clear request

XnE

Use prohibited *1

YnE

Use prohibited *1

XnF

Error flag

YnF

Error clear request

Xn10

Use prohibited *1

Yn10

Use prohibited *1

Xn11

Use prohibited *1

Yn11

Use prohibited *1

Xn12

Use prohibited *1

Yn12

Use prohibited *1

Xn13

Use prohibited *1

Yn13

Use prohibited *1

Use prohibited *1

Use prohibited *1

Xn1C

Use prohibited *1

Yn1C

Use prohibited *1

Xn1D

Use prohibited *1

Yn1D

Use prohibited *1

Xn1E

Use prohibited *1

Yn1E

Use prohibited *1

Xn1F

Use prohibited *1

Yn1F

Use prohibited *1

Section 4 I/O SIGNALS TO CPU MODULE

4.1 List of I/O signals

I/O signals of RE81WH are listed in Table 4.1-1.

Table 4.1-1 List of I/O signals

RE81WH

Signal name

Signal name

Xn0 Module ready Yn0 Use prohibited *1

Xn1

Xn2

Xn3

Xn4

Xn5

Xn7

Xn9

Use prohibited

*1

Yn1

Yn2

Yn3 Periodic electric energy 1 reset request

Yn4 Periodic electric energy 2 reset request

Yn5

Yn7

Use prohibited *1

Use prohibited

*1

Yn9 Operating condition setting request

Xn14

Xn15 Use prohibited *1 Yn15 Use prohibited *1

Xn16 Use prohibited *1 Yn16 Use prohibited *1

Xn17 Use prohibited *1 Yn17 Use prohibited *1

Xn18 Use prohibited *1 Yn18 Use prohibited *1

Xn19

Use prohibited

*1

Xn1A Use prohibited *1 Yn1A Use prohibited *1

Xn1B

Use prohibited

*1

*1: These signals cannot be used by the user since they are for system use only.

38

Yn14

Yn19

Yn1B

Use prohibited *1

Use prohibited *1

Page 40

Section 4 I/O SIGNALS TO CPU MODULE

RE81WH

4.2 Details of I/O signals

Detailed explanation about I/O signals of RE81WH is shown as follows

4.2.1 Input signals

(1) Module ready (Xn0)

After the power of CPU module is turned on or the CPU module reset is performed, it will turn ON upon the

measurement is ready.

This signal (Xn0) is turned OFF when energy measuring module displays a hardware error, then RUN LED

is turned off.

(2) Periodic electric energy 1 data completion flag (Xn1)

When Periodic electric energy 1 measurement flag (Yn1) is turned OFF and measuring of the periodic

electric energy 1 is stopped, then this signal (Xn1) turns ON.

When Periodic electric energy 1 (Yn1) is turned ON and measuring of the periodic electric energy 1 is started,

then this signal (Xn1) turns OFF.