Page 1

MELSEC iQ-F

FX5 User's Manual (ASLINK)

Page 2

Page 3

COPYRIGHT

This document is protected by the law of copyright, whereby all rights established therein remain with the company Mitsubishi

Electric Corporation. Reproduction of this document or parts of this document is only permissible within the limits of the legal

determination of Copyright Law. Alteration or abridgement of the document is not permitted without the explicit written

approval of the company Mitsubishi Electric Corporation.

PRECAUTIONS REGARDING WARRANTY AND SPECIFICATIONS

The FX5-ASL-M is jointly developed and manufactured by Mitsubishi Electric and Anywire Corporation. Note that there are

differences in warranty.

•Warranty

Item FX5-ASL-M Other programmable controller products (e.g.

MELSEC iQ-F series)

Repair term after discontinuation of production 1 year 7 years

• Application of the EMC Directive

Item FX5-ASL-M Other programmable controller products (e.g.

MELSEC iQ-F series)

Applicable EMC standard EN61131-2 EN61131-2

• Application of the UL/cUL standards

Item FX5-ASL-ML Other programmable controller products (e.g.

MELSEC iQ-F series)

Applicable UL standard/cUL standard UL508 UL508

1

Page 4

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before use.)

Before using this product, please read this manual and the relevant manuals introduced in this manual carefully and pay full

attention to safety in order to handle the product correctly.

This manual classifies the safety precautions into two categories: [ WARNING] and [ CAUTION].

Depending on the circumstances, procedures indicated by [ CAUTION] may also cause severe injury.

It is important to follow all precautions for personal safety.

Store this manual in a safe place so that it can be read whenever necessary. Always forward it to the end user.

[DESIGN PRECAUTIONS]

WARNING

● An AnyWireASLINK system has no control function for ensuring safety.

● Make sure to set up the following safety circuits outside the PLC to ensure safe system operation

even during external power supply problems or PLC failure. Otherwise, malfunctions may cause

serious accidents.

- Most importantly, set up the following: an emergency stop circuit, a protection circuit, an interlock

circuit for opposite movements (such as normal vs. reverse rotation), and an interlock circuit to

prevent damage (to the equipment at the upper and lower positioning limits).

- Note that when the CPU module detects an error, such as a watchdog timer error, during selfdiagnosis, all outputs are turned off. Also, when an error that cannot be detected by the CPU

module occurs in an input/output control block, output control may be disabled. External circuits

and mechanisms should be designed to ensure safe machinery operation in such a case.

● Construct an interlock circuit in the program so that the whole system always operates on the safe

side before executing the control (for data change) of the PLC in operation.

Read the manual thoroughly and ensure complete safety before executing other controls (for program

change, parameter change, forcible output and operation status change) of the PLC in operation.

Otherwise, the machine may be damaged and accidents may occur due to erroneous operations.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

[DESIGN PRECAUTIONS]

CAUTION

● Configure safety circuits, such as an emergency stop circuit and interlock circuit, external to the

AnyWireASLINK system.

● Install module so that excessive force will not be applied to the terminal blocks.

Failure to do so may result in wire damage/breakage or PLC failure.

● Simultaneously turn on and off the power supplies of the CPU module and extension modules.

2

Page 5

[INSTALLATION PRECAUTIONS]

WARNING

● Make sure to cut off all phases of the power supply externally before attempting installation or wiring

work. Failure to do so may cause electric shock or damage to the product.

● Use the product within the generic environment specifications described in the User's Manual

(Hardware) of the CPU module used.

Never use the product in areas with excessive dust, oily smoke, conductive dusts, corrosive gas (salt

air, Cl

condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire, malfunctions, deterioration or damage

may occur.

, H2S, SO2 or NO2), flammable gas, vibration or impacts, or expose it to high temperature,

2

[INSTALLATION PRECAUTIONS]

CAUTION

● Do not touch the conductive parts of the product directly. Doing so may cause device failures or

malfunctions.

● When drilling screw holes or wiring, make sure that cutting and wiring debris do not enter the

ventilation slits of the PLC. Failure to do so may cause fire, equipment failures or malfunctions.

● For the product supplied together with a dust proof sheet, the sheet should be affixed to the ventilation

slits before the installation and wiring work to prevent foreign objects such as cutting and wiring

debris.

However, when the installation work is completed, make sure to remove the sheet to provide

adequate ventilation. Failure to do so may cause fire, equipment failures or malfunctions.

● Install the product on a flat surface. If the mounting surface is rough, undue force will be applied to the

PC board, thereby causing nonconformities.

● Install the product securely using a DIN rail or mounting screws.

● Work carefully when using a screwdriver such as installation of the product. Failure to do so may

cause damage to the product or accidents.

● Connect the extension cables, peripheral device cables, input/output cables and battery connecting

cable securely to their designated connectors. Loose connections may cause malfunctions.

● Turn off the power to the PLC before attaching or detaching the following devices. Failure to do so

may cause device failures or malfunctions.

- Peripheral devices, expansion board, expansion adapter, and connector conversion adapter

- Extension modules, bus conversion module, and connector conversion module

-Battery

3

Page 6

[WIRING PRECAUTIONS]

WARNING

● Make sure to cut off all phases of the power supply externally before attempting installation or wiring

work. Failure to do so may cause electric shock or damage to the product.

● Make sure to attach the terminal cover, provided as an accessory, before turning on the power or

initiating operation after installation or wiring work. Failure to do so may cause electric shock.

● The temperature rating of the cable should be 70 or more.

● Make sure to properly wire to the terminal block (European type) in accordance with the following

precautions. Failure to do so may cause electric shock, equipment failures, a short-circuit, wire

breakage, malfunctions, or damage to the product.

- The disposal size of the cable end should follow the dimensions described in the manual.

- Tightening torque should follow the specifications in the manual.

- Twist the ends of stranded wires and make sure that there are no loose wires.

- Do not solder-plate the electric wire ends.

- Do not connect more than the specified number of wires or electric wires of unspecified size.

- Affix the electric wires so that neither the terminal block nor the connected parts are directly

stressed.

[WIRING PRECAUTIONS]

CAUTION

● Connect the power supply wiring to the dedicated terminals described in this manual. If an AC power

supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will burn out.

● Do not apply the 24 V DC power before wiring the entire AnyWireASLINK system.

● Make sure to observe the following precautions in order to prevent any damage to the machinery or

accidents due to malfunction of the PLC caused by abnormal data written to the PLC due to the

effects of noise:

- Do not bundle the power line and control line together with or lay them close to the main circuit,

high-voltage line, load line or power line. As a guideline, lay the power line, control line and

communication cables at least 100 mm away from the main circuit, high-voltage line, load line or

power line.

- Ground the shield of the shielded wire or shielded cable at one point on the PLC. However, do not

use common grounding with heavy electrical systems.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

connected to the terminal block, loosen the terminal screw. Pulling the cable connected to the module

may result in malfunction or damage to the module or cable.

4

Page 7

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

● Do not touch any terminal while the PLC's power is on. Doing so may cause electric shock or

malfunctions.

● Before cleaning or retightening terminals, cut off all phases of the power supply externally. Failure to

do so in the power ON status may cause electric shock.

● Before modifying the program in operation, forcible output, running or stopping the PLC, read through

this manual carefully, and ensure complete safety. An operation error may damage the machinery or

cause accidents.

● Do not change the program in the PLC from two or more peripheral equipment devices at the same

time. (i. e. from an engineering tool and a GOT) Doing so may cause destruction or malfunction of the

PLC program.

[STARTUP AND MAINTENANCE PRECAUTIONS]

CAUTION

● Do not disassemble or modify the PLC. Doing so may cause fire, equipment failures, or malfunctions.

For repair, contact your local Mitsubishi Electric representative.

● Turn off the power to the PLC before connecting or disconnecting any extension cable. Failure to do

so may cause device failures or malfunctions.

● Turn off the power to the PLC before attaching or detaching the following devices. Failure to do so

may cause device failures or malfunctions.

- Peripheral devices, expansion board, expansion adapter, and connector conversion adapter

- Extension modules, bus conversion module, and connector conversion module

-Battery

● Do not drop the product or exert strong impact to it. Doing so may cause damage.

[OPERATION PRECAUTIONS]

CAUTION

● Construct an interlock circuit in the program so that the whole system always operates on the safe

side before executing the control (for data change) of the PLC in operation. Read the manual

thoroughly and ensure complete safety before executing other controls (for program change,

parameter change, forcible output and operation status change) of the PLC in operation. Otherwise,

the machine may be damaged and accidents may occur by erroneous operations.

[DISPOSAL PRECAUTIONS]

CAUTION

● Please contact a certified electronic waste disposal company for the environmentally safe recycling

and disposal of your device.

5

Page 8

[TRANSPORTATION PRECAUTIONS]

CAUTION

● The PLC is a precision instrument. During transportation, avoid impacts larger than those specified in

the general specifications of the User's Manual (Hardware) of the CPU module used by using

dedicated packaging boxes and shock-absorbing palettes. Failure to do so may cause failures in the

PLC. After transportation, verify operation of the PLC and check for damage of the mounting part, etc.

6

Page 9

INTRODUCTION

This manual contains text, diagrams and explanations which will guide the reader in the correct installation, safe use and

operation of the AnyWireASLINK system master module of MELSEC iQ-F series and should be read and understood before

attempting to install or use the module.

Always forward it to the end user.

This module was jointly developed by Mitsubishi Electric and Anywire Corporation. The module allows the AnyWireASLINK

system to be connected to a MELSEC iQ-F series programmable controller system.

Regarding use of this product

• This product has been manufactured as a general-purpose part for general industries, and has not been designed or

manufactured to be incorporated in a device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power, aerospace, medicine or passenger

movement vehicles, consult Mitsubishi Electric.

• This product has been manufactured under strict quality control. However when installing the product where major

accidents or losses could occur if the product fails, install appropriate backup or failsafe functions in the system.

Note

• If in doubt at any stage during the installation of the product, always consult a professional electrical engineer who is

qualified and trained in the local and national standards. If in doubt about the operation or use, please consult the nearest

Mitsubishi Electric representative.

• Since the examples indicated by this manual, technical bulletin, catalog, etc. are used as a reference, please use it after

confirming the function and safety of the equipment and system. Mitsubishi Electric will accept no responsibility for actual

use of the product based on these illustrative examples.

• This manual content, specification etc. may be changed, without a notice, for improvement.

• The information in this manual has been carefully checked and is believed to be accurate; however, if you notice a doubtful

point, an error, etc., please contact the nearest Mitsubishi Electric representative. When doing so, please provide the

manual number given at the end of this manual.

7

Page 10

CONTENTS

COPYRIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

PRECAUTIONS REGARDING WARRANTY AND SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CHAPTER 1 OUTLINE 15

CHAPTER 2 SPECIFICATIONS 16

2.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CHAPTER 3 PROCEDURES BEFORE OPERATION 20

CHAPTER 4 FUNCTION 22

4.1 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 AnyWireASLINK Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Double Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Remote Address Change Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 Same ID Used Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Module with No ID Setting Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.7 Transmission Cable Short Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.8 Disconnected Transmission Cable Location Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.9 Transmission Cable Voltage Drop Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.10 Parameter Access Error Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.11 Error Status Automatic Recovery Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.12 Slave Information Acquisition at Start-up Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.13 Slave Module Parameter Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8

CHAPTER 5 SYSTEM CONFIGURATION 40

5.1 System Configuration of AnyWireASLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2 Power Supply to the AnyWireASLINK System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Method of supplying the power to the slave module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Scope of the power supply with transmission cables (DP and DN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CHAPTER 6 WIRING 45

6.1 Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2 Wiring Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.3 Wiring Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.4 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.5 Power Supply/grounding Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Power supply/grounding wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.6 Connecting Slave Module or Terminating Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 11

CHAPTER 7 PARAMETER SETTINGS 51

7.1 Parameter Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2 Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Transmission points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Startup operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Double verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Error status automatic recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3 Refresh Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 Slave Module Address Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5 Automatic Address Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Executing the automatic address detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Automatic address detection execution timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.6 Automatic Reading of the System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

CHAPTER 8 PROGRAMMING 59

8.1 Precautions on Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Communication of FX5-ASL-M with Slave Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

FX5-ASL-M setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Settings of the slave module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Checking the system status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Program example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

CHAPTER 9 TROUBLESHOOTING 65

9.1 Checking with LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.2 Checking Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Checking with the buffer memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.3 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.4 List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

APPENDICES 71

Appendix 1 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix 2 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Certification of UL, cUL standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Compliance with EC directive (CE Marking) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Requirement for compliance with EMC directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Caution for compliance with EC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Appendix 3 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Appendix 4 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Details of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendix 5 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Transmission cycle time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Update timing of I/O data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Response delay time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Parameter access response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

CONTENTS

9

Page 12

INDEX 88

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

10

Page 13

CONTENTS

11

Page 14

RELEVANT MANUALS

Manual name <manual number> Description

MELSEC iQ-F FX5 User's Manual (Startup)

<JY997D58201>

MELSEC iQ-F FX5U User's Manual (Hardware)

<JY997D55301>

MELSEC iQ-F FX5UC User's Manual (Hardware)

<JY997D61401>

MELSEC iQ-F FX5 User's Manual (Application)

<JY997D55401>

MELSEC iQ-F FX5 Programming Manual (Program Design)

<JY997D55701>

MELSEC iQ-F FX5 Programming Manual (Instructions, Standard

Functions/Function Blocks)

<JY997D55801>

MELSEC iQ-F FX5 User's Manual (Serial Communication)

<JY997D55901>

MELSEC iQ-F FX5 User's Manual (MELSEC Communication Protocol)

<JY997D60801>

MELSEC iQ-F FX5 User's Manual (MODBUS Communication)

<JY997D56101>

MELSEC iQ-F FX5 User's Manual (Ethernet Communication)

<JY997D56201>

MELSEC iQ-F FX5 User's Manual (SLMP)

<JY997D56001>

MELSEC iQ-F FX5 User's Manual (CC-Link IE)

<JY997D64201>

MELSEC iQ-F FX5 User's Manual (CC-Link)

<SH-081793ENG>

MELSEC iQ-F FX5 User's Manual (ASLINK)

<SH-081796ENG> (This manual)

MELSEC iQ-F FX5 User's Manual (Positioning Control - CPU module

built-in, High-speed pulse input/output module)

<JY997D56301>

MELSEC iQ-F FX5 User's Manual (Positioning Control - Intelligent

function module)

<SH-081805ENG>

MELSEC iQ-F FX5 Simple Motion Module User's Manual (Startup)

<IB0300251>

MELSEC iQ-F FX5 Simple Motion Module User's Manual (Application)

<IB0300253>

MELSEC iQ-F FX5 Simple Motion Module User's Manual (Advanced

Synchronous Control)

<IB0300255>

MELSEC iQ-F FX5 User's Manual (Analog Control - CPU module builtin, Expansion adapter)

<JY997D60501>

MELSEC iQ-F FX5 User's Manual (Analog Control - Intelligent function

module)

<SH-081802ENG>

MELSEC iQ-F FX5 User's Manual (Temperature Control)

<SH-081799ENG>

GX Works3 Operating Manual

<SH-081215ENG>

Transition from MELSEC FX3U, FX3UC Series to MELSEC iQ-F

Series Handbook

<JY997D66201>

Performance specifications, procedures before operation, and troubleshooting of the

CPU module.

Describes the details of hardware of the FX5U CPU module, including input/output

specifications, wiring, installation, and maintenance.

Describes the details of hardware of the FX5UC CPU module, including input/output

specifications, wiring, installation, and maintenance.

Describes basic knowledge required for program design, functions of the CPU

module, devices/labels, and parameters.

Describes specifications of ladders, ST, FBD/LD, and other programs and labels.

Describes specifications of instructions and functions that can be used in programs.

Describes N:N network, Parallel link, MELSEC Communication protocol, inverter

communication, non-protocol communication, and predefined protocol support.

Explains methods for the device that is communicating with the CPU module by MC

protocol to read and write the data of the CPU module.

Describes MODBUS serial communication and MODBUS/TCP communication.

Describes the functions of the built-in Ethernet port communication function.

Explains methods for the device that is communicating with the CPU module by

SLMP to read and write the data of the CPU module.

Describes CC-Link IE field network module.

Describes CC-Link system master/intelligent device module.

Describes AnyWireASLINK system master module.

Describes the positioning function of the CPU module built-in and the high-speed

pulse input/output module.

Describes the positioning module.

Specifications, procedures before operation, system configuration, wiring, and

operation examples of the Simple Motion module.

Functions, input/output signals, buffer memories, parameter settings, programming,

and troubleshooting of the Simple Motion module.

Functions and programming for the synchronous control of the Simple Motion

module.

Describes the analog function of the CPU module built-in and the analog adapter.

Describes the analog input module, analog output module, and multiple input

module.

Describes the temperature control module.

System configuration, parameter settings, and online operations of GX Works3.

Describes the transition from MELSEC FX3U/FX3UC series to MELSEC iQ-F series.

12

Page 15

TERMS

Unless otherwise specified, this manual uses the following terms.

For details on the FX3 devices that can be connected with the FX5, refer to the User’s Manual (Hardware) of the CPU module

to be used.

Term s Description

■Devices

FX5 Generic term for FX5U and FX5UC PLCs

FX3 Generic term for FX3S, FX3G, FX3GC, FX3U, and FX3UC PLCs

FX5 CPU module Generic term for FX5U CPU module and FX5UC CPU module

FX5U CPU module Generic term for FX5U-32MR/ES, FX5U-32MT/ES, FX5U-32MT/ESS, FX5U-64MR/ES, FX5U-64MT/ES,

FX5UC CPU module Generic term for FX5UC-32MT/D, FX5UC-32MT/DSS, FX5UC-64MT/D, FX5UC-64MT/DSS, FX5UC-96MT/D,

Extension module Generic term for FX5 extension modules and FX3 function modules

• FX5 extension module Generic term for I/O modules, FX5 extension power supply modules, and FX5 intelligent function modules

• FX3 extension module Generic term for FX3 extension power supply module and FX3 intelligent function module

• Extension module (extension cable type) Generic term for Input modules (extension cable type), Output modules (extension cable type), Input/output

• Extension module (extension connector

type)

I/O module Generic term for Input modules, Output modules, Input/output modules, Powered input/output modules, and

Input module Generic term for Input modules (extension cable type) and Input modules (extension connector type)

• Input module (extension cable type) Generic term for FX5-8EX/ES and FX5-16EX/ES

• Input module (extension connector type) Generic term for FX5-C16EX/D, FX5-C16EX/DS, FX5-C32EX/D, FX5-C32EX/DS, and FX5-C32EX/DS-TS

Output module Generic term for Output modules (extension cable type) and Output modules (extension connector type)

• Output module (extension cable type) Generic term for FX5-8EYR/ES, FX5-8EYT/ES, FX5-8EYT/ESS, FX5-16EYR/ES, FX5-16EYT/ES, and FX5-

• Output module (extension connector type) Generic term for FX5-C16EYT/D, FX5-C16EYT/DSS, FX5-C32EYT/D, FX5-C32EYT/DSS, FX5-C32EYT/D-TS,

Input/output module Generic term for Input/output modules (extension cable type) and Input/output modules (extension connector

• Input/output module (extension cable

type)

• Input/output module (extension connector

type)

Powered input/output module Generic term for FX5-32ER/ES, FX5-32ET/ES, FX5-32ET/ESS, FX5-32ER/DS, FX5-32ET/DS, and FX5-32ET/

High-speed pulse input/output module Generic term for FX5-16ET/ES-H and FX5-16ET/ESS-H

Extension power supply module Generic term for FX5 extension power supply module and FX3 extension power supply module

• FX5 extension power supply module Generic term for FX5 extension power supply module (extension cable type) and FX5 extension power supply

• FX5 extension power supply module

(extension cable type)

• FX5 extension power supply module

(extension connector type)

• FX3 extension power supply module Different name for FX3U-1PSU-5V

Intelligent module The abbreviation for intelligent function modules

Intelligent function module Generic term for FX5 intelligent function modules and FX3 intelligent function modules

• FX5 intelligent function module Generic term for FX5-4AD, FX5-4DA,FX5-8AD, FX5-4LC, FX5-20PG-P, FX5-40SSC-S, FX5-80SSC-S, FX5-

FX5U-64MT/ESS, FX5U-80MR/ES, FX5U-80MT/ES, FX5U-80MT/ESS, FX5U-32MR/DS, FX5U-32MT/DS,

FX5U-32MT/DSS, FX5U-64MR/DS, FX5U-64MT/DS, FX5U-64MT/DSS, FX5U-80MR/DS, FX5U-80MT/DS, and

FX5U-80MT/DSS

FX5UC-96MT/DSS, FX5UC-32MT/DS-TS, and FX5UC-32MT/DSS-TS

modules (extension cable type), Powered input/output module, High-speed pulse input/output module,

Extension power supply module (extension cable type), Connector conversion module (extension cable type),

Intelligent function modules, and Bus conversion module (extension cable type)

Generic term for Input modules (extension connector type), Output modules (extension connector type), Input/

output modules (extension connector type), Extension power supply module (extension connector type),

Connector conversion module (extension connector type), and Bus conversion module (extension connector

type)

High-speed pulse input/output modules

16EYT/ESS

and FX5-C32EYT/DSS-TS

type)

Generic term for FX5-16ER/ES, FX5-16ET/ES, and FX5-16ET/ESS

Generic term for FX5-C32ET/D, FX5-C32ET/DSS, FX5-C32ET/DS-TS, and FX5-C32ET/DSS-TS

DSS

module (extension connector type)

Different name for FX5-1PSU-5V

Different name for FX5-C1PS-5V

CCLIEF, FX5-CCL-MS, and FX5-ASL-M

13

Page 16

Ter ms Description

• FX3 intelligent function module Generic term for FX3U-4AD, FX3U-4DA, FX3U-4LC, FX3U-1PG, FX3U-2HC, FX3U-16CCL-M, FX3U-64CCL,

and FX3U-128ASL-M

Expansion board Generic term for board for FX5U CPU module

• Communication board Generic term for FX5-232-BD, FX5-485-BD, and FX5-422-BD-GOT

Expansion adapter Generic term for adapter for FX5 CPU module

• Communication adapter Generic term for FX5-232ADP and FX5-485ADP

• Analog adapter Generic term for FX5-4AD-ADP, FX5-4DA-ADP, FX5-4AD-PT-ADP, and FX5-4AD-TC-ADP

Bus conversion module Generic term for Bus conversion module (extension cable type) and Bus conversion module (extension

• Bus conversion module (extension cable

type)

• Bus conversion module (extension

connector type)

Connector conversion module Generic term for Connector conversion module (extension cable type) and Connector conversion module

• Connector conversion module (extension

cable type)

• Connector conversion module (extension

connector type)

Extended extension cable Generic term for FX5-30EC and FX5-65EC

Connector conversion adapter Different name for FX5-CNV-BC

Battery Different name for FX3U-32BL

Peripheral device Generic term for engineering tools and GOTs

GOT Generic term for Mitsubishi Electric Graphic Operation Terminal GOT1000 and GOT2000 series

■Software packages

Engineering tool The product name of the software package for the MELSEC programmable controllers

GX Works3 The product name of the software package, SWnDND-GXW3, for the MELSEC programmable controllers (The

■AnyWireASLINK

AnyWireASLINK A reduced wiring network where sensors at the end of a control system are connected to a programmable

ASLINKAMP A genetic term for sensor amplifiers that have an AnyWireASLINK interface

ASLINKER A genetic term for I/O devices that have an AnyWireASLINK interface

ID A parameter to identify whether the module is an input module or output module based on its address

RAS The abbreviation for Reliability, Availability, and Serviceability. This term refers to usability of automated

Address A parameter assigned to a slave module to identify each node on the AnyWireASLINK network

Address writer A hand-held device to read/write parameters (including addresses) from/to a slave module

Slave module A generic term for modules that communicate data with the FX5-ASL-M

Terminating unit A waveform shaper

Power cable (24V, 0V) A cable that connects a 24 V DC external power supply to the FX5-ASL-M.

Transmission cycle time A data sampling interval

Transmission cable (DP, DN) A signal cable that connects between a slave module and the FX5-ASL-M

connector type)

Different name for FX5-CNV-BUS

Different name for FX5-CNV-BUSC

(extension connector type)

Different name for FX5-CNV-IF

Different name for FX5-CNV-IFC

'n' represents a version.)

controller.

Output slave module ID: Address

ID of the input slave module or I/O combined slave module: Address + 200H

equipment.

This cable is also used when the isolation (4-line) type slave module and FX5-ASL-M are connected.

14

Page 17

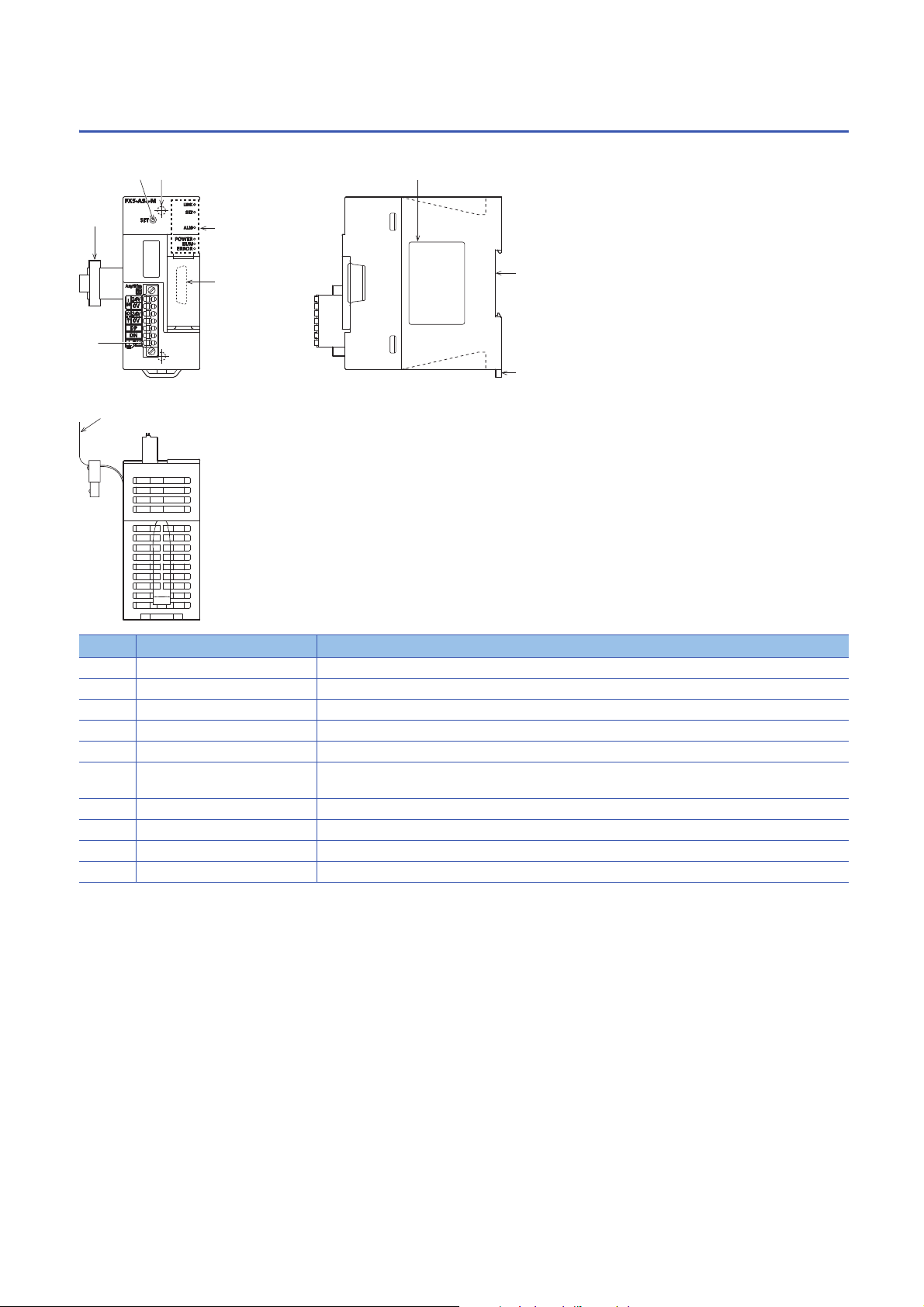

1 OUTLINE

(1)

(2)

(3)

(4)(7) (7)

(6)

(5)

The FX5-ASL-M type AnyWireASLINK system master module (hereinafter referred to as FX5-ASL-M) is an intelligent function

module for building an AnyWireASLINK system with FX5 CPU module.

The FX5-ASL-M is jointly developed and manufactured by Mitsubishi Electric and Anywire Corporation.

The AnyWireASLINK system is a sensor network system.

1

(1) FX5-ASL-M

(2) Slave module (ASLINKER)

(3) Slave module (ASLINKAMP)

(4) Terminating unit

(5) Cylinder, switch, or others

(6) Sensor head

(7) Link connector

1 OUTLINE

15

Page 18

2 SPECIFICATIONS

This chapter describes the FX5-ASL-M specifications.

2.1 General Specifications

The items other than the following are equivalent to those of the CPU module.

For the general specification, refer to the following manual.

MELSEC iQ-F FX5U User's Manual (Hardware)

MELSEC iQ-F FX5UC User's Manual (Hardware)

Items Specifications

Dielectric withstand voltage 500 V AC for 1 minute Between all terminals and ground terminal

Insulation resistance 10 M or higher by 500 V DC

2.2 Power Supply Specifications

The following table lists the power supply specifications.

Items Specifications

External power supply Power supply voltage 24 V DC +15%, -10%, ripple voltage 0.5 Vp-p or lower

Current consumption 100 mA

Transmission cable

supply current

Internal power supply Power supply voltage 5 V DC

Current consumption 200 mA

*1

insulation resistance tester

Recommended voltage: 26.4 V DC (24 V DC +10%)

Please use a UL Class 2 power supply

MAX 2 A

*1 Refer to the following for information about the relationship among the total length, the wire diameter of transmission cables (DP, DN),

and the transmission cable supply current.

On some slave modules with cables, the wire diameter of module-integrated transmission cables (DP, DN) may be smaller than 0.75

However, they can be used without any problem, provided that the wire diameter of transmission cables (DP, DN) meets the following

requirements.

Wire diameter of transmission

cables (DP, DN)

1.25 2 A maximum 1 A maximum 0.5 A maximum

0.75 1.2 A maximum 0.6 A maximum 0.3 A maximum

Transmission cable supply current

Total length of 50 m or less Total length of 50 to 100 m Total length of 100 to 200 m

.

16

2 SPECIFICATIONS

2.1 General Specifications

Page 19

2.3 Performance Specifications

The following table lists the performance specifications of the FX5-ASL-M.

Items Specifications

Transmission clock 27.0 kHz

Maximum transmission distance (total length) 200 m

Transmission system DC power superimposed total frame cyclic system

Connection type Bus topology (multidrop system, T-branch system, tree branch system)

Transmission protocol Dedicated protocol (AnyWireASLINK)

Error control Checksum, double-check system

Number of connected I/O points 384 points maximum

Number of connected slave modules 128 maximum (varies depending on the current consumption of each slave module)

External interface (power supply part/communication

part)

RAS function • Disconnected transmission cable location detection function

Transmission cable (DP, DN) • UL-listed general-purpose 2-wire cable (VCTF, VCT 1.25 , 0.75 , temperature rating 70 or

Power supply cable (24V, 0V) • UL-listed general-purpose 2-wire cable (VCTF, VCT 0.75 to 2.0 , temperature rating 70 or

Memory Built-in EEPROM (Number of times of overwrite : 100000 times)

Number of occupied I/O points 8 points

Applicable CPU module • FX5U CPU module (Ver. 1.050 or later)

Applicable engineering tool GX Works3 (Ver. 1.035M or later)

Number of connectable units 1 module

*1

*2

(input: maximum 256 points, output: maximum 256 points)

Push-in type 7-piece spring clamp terminal block

• Transmission cable short detection function

• Transmission cable voltage drop detection function

higher)

• UL-listed general-purpose wire (1.25 , 0.75 , temperature rating 70 or higher)

• Dedicated flat cable (1.25 , 0.75 , temperature rating 90)

higher)

• UL-listed general-purpose wire (0.75 to 2.0 , temperature rating 70 or higher)

• Dedicated flat cable (1.25 , 0.75 , temperature rating 90)

*3

• FX5UC CPU module

*4

(Ver. 1.050 or later)

2

*1 For slave modules with integrated transmission cables (DP, DN), the length of the transmission cables (DP, DN) is included in the total

length.

For wiring of 50 m or more with 4 wires (DP, DN, 24V, 0V), insert the noise filter for power supply cables between the power supply and

cables. For details, refer to the manual for the ASLINK FILTER (ANF-01) manufactured by Anywire Corporation.

*2 The number of available remote I/O points per CPU module varies depending on the number of I/O points of the extension devices. For

the limit of I/O points, refer to the following manual.

MELSEC iQ-F FX5U User's Manual (Hardware)

MELSEC iQ-F FX5UC User's Manual (Hardware)

*3 FX5-CNV-IFC or FX5-C1PS-5V is necessary to connect FX5-ASL-M to the FX5UC CPU module.

*4 FX5-ASL-M and FX3U-128ASL-M cannot be used together.

2 SPECIFICATIONS

2.3 Performance Specifications

17

Page 20

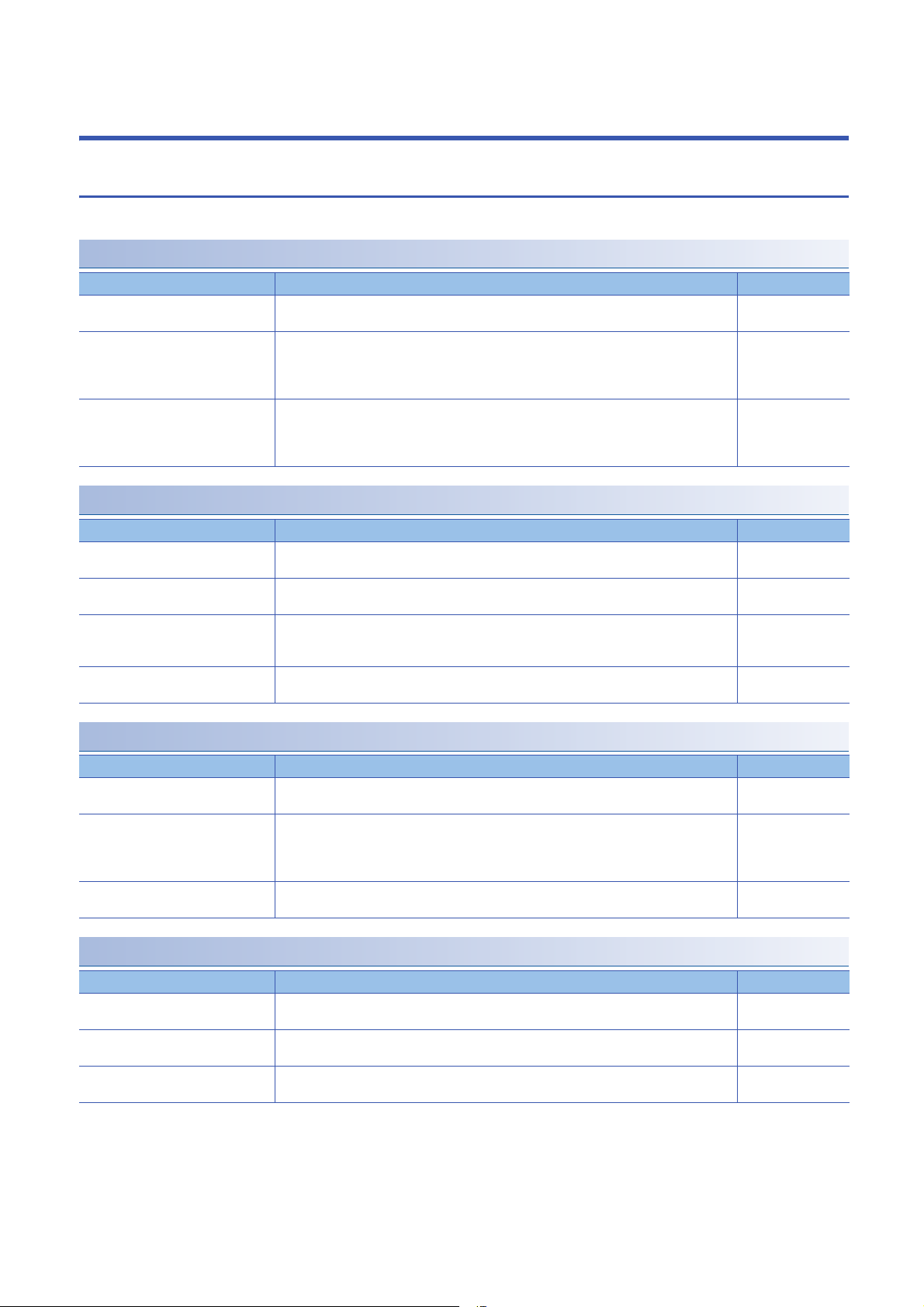

2.4 Part Names

[1]

[10]

[2]

[4][3]

[8]

[7]

[9]

[5]

[6]

This chapter describes the names of each part of the FX5-ASL-M.

No. Name Description

[1] Transmission cable terminal block A terminal block of the AnyWireASLINK

[2] Extension cable Cable for connecting the module when adding the FX5-ASL-M

[3] SET switch Switch for automatic detection of the slave module ID (address)

[4] Direct mounting hole Screw holes (2-4.5, mounting screw: M4 screw) for direct installation

[5] Operation status display LEDs Indicates the operating status of the module. (Page 19 LED display)

[6] Extension connector (for next

[7] Name plate The product model name, manufacturer's serial number etc. are shown.

[8] DIN rail mounting groove The module can be installed on DIN46277 rail (35 mm wide).

[9] DIN rail mounting hook Hook for mounting the module on a DIN rail of DIN46277 (35 mm wide).

[10] Pullout tab They are used when drawing out an extension cable.

module)

Connector for connecting the extension cable of an extension module.

18

2 SPECIFICATIONS

2.4 Part Names

Page 21

LED display

The following table lists the LED display.

LED display LED color Description

POWER Green Indicates the operating status.

On: Power on

Off: Power off or module failure

RUN Green Indicates the operating status.

On: Normal operation

Off: Error

ERROR Red Indicates the error status.

On: Minor error or major error

Flashing: Moderate error or major error

Off: Normal operation

LINK Green Indicates the link status.

Flashing: Normal operation

Off: 5 V DC power off or module failure

SET Green Indicates the address detection status.

On: Automatic address detection in progress

Flashing: Writing in the EEPROM

Off: Normal operation

ALM Red Indicates the warning status.

On: DP/DN disconnection, no response from the slave module

Flashing (1-second intervals): DP-DN short circuit, 24V-DP short circuit

Flashing (0.2-second intervals): A 24 V DC power supply is not being supplied or the voltage is low.

Off: Normal operation

2

2 SPECIFICATIONS

2.4 Part Names

19

Page 22

3 PROCEDURES BEFORE OPERATION

This chapter describes the procedures before operation.

1. Checking the specifications of the FX5-ASL-M

Check the specifications of the FX5-ASL-M. (Page 16 SPECIFICATIONS)

2. Installation of the FX5-ASL-M

Connect the FX5-ASL-M to the CPU module. For details, refer to the following.

MELSEC iQ-F FX5U User's Manual (Hardware)

MELSEC iQ-F FX5UC User's Manual (Hardware)

3. Configuring a system

Configure an AnyWireASLINK system and set parameters which are required for start-up.

• Wiring (Page 45 WIRING)

• Parameter setting (Page 51 PARAMETER SETTINGS)

• Address setting of slave modules (Page 54 Slave Module Address Setting)

• Automatic address detection function (Page 55 Automatic Address Detection Function)

4. Powering on the system

Power on and start the system in the order shown below.

• Turn on the 24 V DC external power supply for the AnyWireASLINK system.

• Turn on the power supply of the programmable controller.

5. Checking operations with the LEDs

Check whether communications are established normally.

When the communications are established normally, the following LED on/off statuses are as follows.

• POWER LED: On

• RUN LED: On

• ERROR LED: Off

• LINK LED: Flashing

• SET LED: Off

• ALM LED: Off

6. Programming

Create a program. For details, refer to the following.

Page 59 PROGRAMMING

• If the programmable controller is powered on before the 24 V DC external power supply in the

AnyWireASLINK system, a transmission cable voltage drop detection error may occur.

• To power off the system, power off the programmable controller, and turn off the 24 V DC external power

supply in the AnyWireASLINK system.

20

3 PROCEDURES BEFORE OPERATION

Page 23

MEMO

3

3 PROCEDURES BEFORE OPERATION

21

Page 24

4 FUNCTION

4.1 Function List

The following table lists the function available for the FX5-ASL-M.

AnyWireASLINK transmission

Function Description Reference

Bit transmission Exchanges I/O data of up to 384 points (input max. 256 points, output max. 256 points)

between the FX5-ASL-M and a slave module.

Double check A double check is an error control system. In this system, cycle data in AnyWireASLINK

Slave module parameter read/write In AnyWireASLINK, parameter information of a slave module and the AnyWireASLINK system

transmission is recognized as valid data if the data matches with the data of the last

transmission or is ignored as invalid data if the data does not match with the last data.

A double check ensures reliability of communication.

in addition to I/O information are sent and received between the FX5-ASL-M and a slave

module.

Execute this function to check or change parameter information of a slave module.

Address setting

Function Description Reference

Automatic address detection function Enables the FX5-ASL-M to detect and store the ID (address) of the connected slave module

when the SET switch on the FX5-ASL-M is pressed.

Remote address change function Changes an ID (address) of a slave module using the buffer memory area without an address

Same ID used detection function Checks whether the same ID is used for multiple slave modules through automatic address

Module with no ID setting detection

function

writer.

detection or same address used check. The LEDs of the relevant slave modules are forcibly

turned on.

Detects slave modules with no ID assigned (default ID) through automatic address detection

or same address used check.

Page 23

Page 24

Page 35

Page 55

Page 25

Page 26

Page 28

RAS

Function Description Reference

Transmission cable short detection

function

Disconnected transmission cable

location detection function

Transmission cable voltage drop

detection function

Protects the system by detecting the current out of the specifications of the AnyWireASLINK

system across DP-DN or 24V-DP and stopping the transmission.

Notifies the ID of a slave module that has been separated from the FX5-ASL-M because of

disconnection in the transmission cables (DP, DN) between the FX5-ASL-M and the slave

module, to locate the disconnection in the transmission cables (DP, DN) from the upper

system.

Detects a voltage drop in the 24 V DC external power supply, enabling the FX5-ASL-M to

detect a failure in the 24 V DC external power supply or a wiring error from the upper system.

Page 29

Page 30

Page 31

Others

Function Description Reference

Parameter access error detection

function

Error status automatic recovery

function

Slave information acquisition at startup function

Allows parameter access errors to be detected. Page 32

Allows for automatic error reset for DP/DN disconnection errors and parameter errors after the

error status is cleared.

Allows for automatic acquisition of information of slave modules when the CPU module is

reset or power off and on the system.

Page 34

Page 34

22

4 FUNCTION

4.1 Function List

Page 25

4.2 AnyWireASLINK Transmission

(1) (2)

(5)

M2000

M2001

M2002

M2255

M3000

M3001

M3002

M3255

(3)

ID: 200H

IN 1

IN 0

(4)

(6)

(7)

ID: 0H

OUT 1

OUT 0

U1\G0.0

U1\G0.1

U1\G0.2

U1\G15.F

U1\G4096.0

U1\G4096.1

U1\G4096.2

U1\G4111.F

The AnyWireASLINK is a high-speed and highly reliable system which releases the work site from complicated and incorrect

wiring.

In AnyWireASLINK, the FX5-ASL-M communicates with slave modules using IDs (addresses) of the slave modules.

The IDs (addresses) of the slave modules are stored in the buffer memory of the FX5-ASL-M.

4

(1) CPU module

(2) FX5-ASL-M

(3) Input slave module (ASLINKER): Address 0

(4) Output slave module (ASLINKER): Address 0

(5) Buffer memory

(6) Sensor switch

(7) LED

Bit transmission

A maximum of 384 I/O data points (input max. 256 points, output max. 256 points) can be exchanged between the FX5-ASL-

M and a slave module.

4 FUNCTION

4.2 AnyWireASLINK Transmission

23

Page 26

4.3 Double Verification

bit bit

·

bit bit

·

(1)

·

·

(4)

(2)

(3)(3)

word word

·

word word

·

(1)

·

·

(4)

(2)

(3)(3)

A double check is an error control system. In this system, cycle data in AnyWireASLINK transmission is recognized as valid

data if the data matches with the data of the last transmission or is ignored as invalid data if the data does not match with the

last data. The double verification ensures reliability of communication.

The double verification is classified into a bit double verification and word double verification.

Overview

■Bit double verification

If one bit of data is the same between two successive transmission cycles, the data is valid and I/O data is communicated.

(1) Transmission cycle (last)

(2) Transmission cycle (current)

(3) I/O data

(4) This data is compared with the verification data (one bit) of the last transmission cycle.

■Word double verification

If one word (16 bits) of data is the same between two successive transmission cycles, the data is valid and I/O data is

communicated.

(1) Transmission cycle (last)

(2) Transmission cycle (current)

(3) I/O data

(4) The data is compared with the verification data (one word) of the last transmission cycle.

The bit double verification is suitable for digital I/O type slave modules, which use information in units of bits.

The word double verification is suitable for analog I/O type slave modules, which use information in units of

words.

Setting method

Set the double verification in "Double verification" of "Basic setting". (Page 52 Double verification)

24

4 FUNCTION

4.3 Double Verification

Page 27

4.4 Remote Address Change Function

ID

0200H 0210H

With this function, an ID (address) of a slave module can be changed using the buffer memory area without an address writer.

Applicable slave module

For the slave modules that support the remote address change function, contact Anywire Corporation.

Operating procedure

1. Execute automatic address detection to check that no error has occurred in the AnyWireASLINK system. (Page 55

Automatic Address Detection Function)

2. Specify an access method to a slave module.

Store 0002H (address change) in 'Parameter access setting' (Un\G10320).

4

3. Specify an ID of the slave module to be accessed.

Store the ID to be changed (old ID) in 'Parameter access target module ID specification' (Un\G10321).

ID Description

0000H to 00FFH ID of the output slave module

0200H to 02FFH ID of the input slave module or I/O combined slave module

4. Specify a new ID of the slave module.

Store the new ID in 'Change ID specification' (Un\G10323).

ID Description

0000H to 00FFH ID of the output slave module

0200H to 02FFH ID of the input slave module or I/O combined slave module

If the specified ID has already been used or is out of the allowable specification range, an error occurs.

5. Turn on and off 'Parameter access request command for the slave module' (Un\G27 b8).

At this time, 'Parameter access completion flag' (Un\G28 b9) turns off. When the parameter access is completed, 'Parameter

access completion flag' (Un\G28 b9) automatically turns on.

6. After changing the IDs of all the target slave modules, execute automatic address detection. (Page 55 Automatic

Address Detection Function)

Precautions

• Before executing this function, make sure to execute automatic address detection to check that no error has occurred in the

AnyWireASLINK system. (Page 55 Automatic Address Detection Function)

• This function cannot be executed for slave modules separated from the FX5-ASL-M because of disconnection or slave

modules having the same ID. Use an address writer to change the IDs of such slave modules.

• This function can be executed if only one slave module having no ID exists within one AnyWireASLINK line. If IDs of

multiple slave modules are not set, it is recognized as an ID duplication. Thus, the IDs cannot be changed.

4.4 Remote Address Change Function

4 FUNCTION

25

Page 28

4.5 Same ID Used Detection Function

This function checks whether the same ID is used for multiple slave modules through automatic address detection or same

address used check. The LEDs of the relevant slave modules are forcibly turned on.

• ID duplications are detected through automatic address detection or same address used check. If the CPU

module is reset or the power is turned off after ID duplication detection, the same ID used status cannot be

checked until automatic address detection or same address used check is executed again.

• Even if an ID is assigned to multiple modules, a single ID is stored in 'Number of the alarm IDs' (Un\G9984)

and 'Alarm ID information storage area' (Un\G9985 to Un\G10112). For example, even when multiple

modules have an ID 10, "1" is stored in 'Number of the alarm IDs' (Un\G9984) and "10" is stored in 'Alarm ID

information storage area' (Un\G9985 to Un\G10112).

How to execute automatic address detection

For details on automatic address detection, refer to the following.

Page 55 Automatic Address Detection Function

How to execute same address used check

Turn off and on 'Overlap address inspection command' (Un\G27 b2). If 'Overlap address inspection flag' (Un\G28 b12) turns

on and off, it indicates that the same address used check is completed.

The same address used check cannot be executed under any of the following conditions.

• When an error occurs in the AnyWireASLINK system (Example: Short circuit, 24 V DC external power supply voltage drop)

• Within approximately five seconds after the AnyWireASLINK system is powered on or system is reset

• When automatic address detection is in progress (While 'Automatic address detection flag' (Un\G28 b11) is on)

• When the same address used check is in progress (While 'Overlap address inspection flag' (Un\G28 b12) is on)

• When the parameter access is in progress (While 'Parameter access request command for the slave module' (Un\G27 b8),

'Parameter batch read command for the slave module' (Un\G27 b9), or 'Parameter batch write command for the slave

module' (Un\G27 b10) is on)

• When any of the following errors has occurred

Error code Error description

0CC8H Transmission cable voltage drop error

0CC9H DP/DN short error

0CCBH 24V/DP short error

1867H FX5-ASL-M hardware failure

3064H

3065H

3066H

How to check the same ID used status

When the AnyWireASLINK system is in the following status, the same ID is used for multiple modules.

Even in the same ID used status, the AnyWireASLINK bit transmission does not stop.

• 'Slave module alarm signal' (Un\G28 b8) turns on.

• Same ID used error (error code: 0D90H) is stored in 'Latest error code storage area' (Un\G10256) and the duplicate ID is

stored in 'Latest error ID storage area' (Un\G10257).

• The relevant ID is stored in 'Alarm ID information storage area' (Un\G9985 to Un\G10112).

*1 If multiple errors occur simultaneously, the latest error is displayed.

26

4 FUNCTION

4.5 Same ID Used Detection Function

*1

Page 29

How to recover from same ID used status

Check 'Number of the alarm IDs' (Un\G9984) and 'Alarm ID information storage area' (Un\G9985 to Un\G10112). Then set a

unique ID (address) in all the slave modules. (Page 78 Number of the alarm IDs, Page 78 Alarm ID information storage

area)

Set IDs (addresses) of slave modules and execute automatic address detection of the FX5-ASL-M. Then, the IDs of the slave

modules are stored in the FX5-ASL-M and the error is cleared. (Page 55 Automatic Address Detection Function)

Precautions

While an ID (address) is used for multiple slave modules, executing either of the following can eliminate the same ID used

error. However, the address is still used for the multiple slave modules.

• Powering off and on the AnyWireASLINK system

• Turning off and on 'Error flag clear command' (Un\G27 b0)

4

4 FUNCTION

4.5 Same ID Used Detection Function

27

Page 30

4.6 Module with No ID Setting Detection Function

This function detects slave modules with no ID assigned (default ID) through automatic address detection or same address

used check.

Module Default ID

Input slave module, I/O combined slave module 767

Output slave module 255

• Modules with no ID set are detected through automatic address detection or same address used check. If

the CPU module is reset or the power is turned off after a module with no ID set is detected, the no ID

number setting status cannot be checked until automatic address detection or same address used check is

executed again.

• Even if no ID is assigned to modules, a single ID is stored in 'Number of the alarm IDs' (Un\G9984) and

'Alarm ID information storage area' (Un\G9985 to Un\G10112). For example, even when multiple modules

have an ID 255, "1" is stored in 'Number of the alarm IDs' (Un\G9984) and "255" is stored in 'Alarm ID

information storage area' (Un\G9985 to Un\G10112).

How to execute automatic address detection

For details on automatic address detection, refer to the following.

Page 55 Automatic Address Detection Function

How to execute same address used check

Turn off and on 'Overlap address inspection command' (Un\G27 b2). If 'Overlap address inspection flag' (Un\G28 b12) turns

on and off, it indicates that the same address used check is completed.

The same address used check cannot be executed under any of the following conditions.

• When an error occurs in the AnyWireASLINK system (Example: Short circuit, 24 V DC external power supply voltage drop)

• Within approximately five seconds after the AnyWireASLINK system is powered on or system is reset

• When automatic address detection is in progress (While 'Automatic address detection flag' (Un\G28 b11) is on)

• When the same address used check is in progress (While 'Overlap address inspection flag' (Un\G28 b12) is on)

• When the parameter access is in progress (While 'Parameter access request command for the slave module' (Un\G27 b8),

'Parameter batch read command for the slave module' (Un\G27 b9), or 'Parameter batch write command for the slave

module' (Un\G27 b10) is on)

• When any of the following errors has occurred

Error code Error description

0CC8H Transmission cable voltage drop error

0CC9H DP/DN short error

0CCBH 24V/DP short error

1867H FX5-ASL-M hardware failure

3064H

3065H

3066H

28

4 FUNCTION

4.6 Module with No ID Setting Detection Function

Page 31

How to check the no ID number setting status

When the AnyWireASLINK system is in the following status, no ID number setting status is detected.

Even in the no ID number setting status, the AnyWireASLINK bit transmission does not stop.

• 'Slave module alarm signal' (Un\G28 b8) turns on.

• No ID setting error (error code: 0D91H) is stored in 'Latest error code storage area' (Un\G10256) and unset ID is stored in

'Latest error ID storage area' (Un\G10257).

• Unset IDs are stored in 'Alarm ID information storage area' (Un\G9985 to Un\G10112).

*1 If multiple errors occur simultaneously, the latest error is displayed.

*1

How to recover from the no ID number setting status

Check 'Number of the alarm IDs' (Un\G9984) and 'Alarm ID information storage area' (Un\G9985 to Un\G10112). Then set

addresses to slave modules. (Page 78 Number of the alarm IDs, Page 78 Alarm ID information storage area)

Check that "255" is not set as the address of the slave module.

Set IDs (addresses) of slave modules and execute automatic address detection of the FX5-ASL-M. Then, the IDs of the slave

modules are stored in the FX5-ASL-M and the error is cleared. (Page 55 Automatic Address Detection Function)

Precautions

While an ID (address) of a slave module is not set, executing either of the following can eliminate the no ID setting error.

However the address of the slave module is still not set.

• Powering off and on the AnyWireASLINK system

• Turning off and on 'Error flag clear command' (Un\G27 b0)

4

4.7 Transmission Cable Short Detection Function

This function protects the system by detecting the current out of the specifications of the AnyWireASLINK system across DP-

DN or 24V-DP and stopping the transmission.

How to check the transmission cable short status

When the AnyWireASLINK system is in the following status, a transmission cable short has occurred.

• The LINK LED turns off and the ALM LED flashes repeatedly at one second intervals.

• When any of the transmission cables (DP, DN) is short-circuited, 'DP/DN short error' (Un\G28 b1) turns on.

• When any of the transmission cables (24V, DP) is short-circuited, '24V/DP short error' (Un\G28 b2) turns on.

• A DP/DN short error (error code: 0CC9H) or 24V/DP short error (error code: 0CCBH) is stored in 'Latest error code storage

area' (Un\G10256) and 0FFFH is stored in 'Latest error ID storage area' (Un\G10257).

• The AnyWireASLINK bit transmission stops.

*1 If multiple errors occur simultaneously, the latest error is displayed.

How to recover from the transmission cable short status

How to recover from the transmission cable short status is as follows.

1. Eliminate the short circuit in the AnyWireASLINK system.

When the short status is exited, AnyWireASLINK bit transmission resumes automatically.

If the status does not change, the short circuit has not been eliminated. Check it again.

2. Power off and on the AnyWireASLINK system or turn on and off 'Error flag clear command' (Un\G27 b0).

The following status is resulted:

• 'DP/DN short error' (Un\G28 b1) and '24V/DP short error' (Un\G28 b2) turn off.

• The ALM LED turns off.

• The data in 'Latest error code storage area' (Un\G10256) and 'Latest error ID storage area' (Un\G10257) are cleared.

*1

*1

4 FUNCTION

4.7 Transmission Cable Short Detection Function

29

Page 32

4.8 Disconnected Transmission Cable Location

Detection Function

This function notifies the ID of a slave module that has been separated from the FX5-ASL-M because of disconnection in the

transmission cables (DP, DN) between the FX5-ASL-M and the slave module, to locate the disconnection in the transmission

cables (DP, DN) from the upper system.

• To enable the disconnected transmission cable location detection function, execute automatic address

detection when configuring, modifying, or expanding the system. (Page 55 Automatic Address

Detection Function)

• After a system is configured, the disconnection detection may still work when a slave module is

disconnected from the system. Execute automatic address detection after modifying the system.

• Even if disconnection in the transmission cable (DP, DN) is detected, the AnyWireASLINK bit transmission

does not stop.

How to check the transmission cable disconnection status

When the AnyWireASLINK system is in the following status, the transmission cable (DP, DN) have been disconnected or a

slave module error has occurred.

• The ALM LED turns on.

• 'DP/DN disconnection error' (Un\G28 b4) turns on.

• The number of error IDs is stored in 'Number of the error IDs' (Un\G8192).

• The disconnected ID (address) is stored in 'Error ID information storage area' (Un\G8193 to Un\G8320).

• The bits of 'Error ID information bit area (output)' (Un\G8704 to Un\G8719) and 'Error ID information bit area (input)'

(Un\G8736 to Un\G8751) corresponding to the disconnected ID (address) turn on.

• DP/DN disconnection error (error code: 0CCAH) is stored in 'Latest error code storage area' (Un\G10256) and the

disconnected ID is stored in 'Latest error ID storage area' (Un\G10257).

*1 If multiple errors occur simultaneously, the latest error is displayed.

*1

*1

How to recover from the transmission cable disconnection status

How to recover from the transmission cable disconnection status is as follows.

1. Eliminate the disconnection in the AnyWireASLINK system.

When the disconnection status is exited, AnyWireASLINK bit transmission resumes automatically.

When the slave module has been disconnected from the system, execute automatic address detection. (Page 55

Automatic Address Detection Function)

2. Power off and on the AnyWireASLINK system or turn on and off 'Error flag clear command' (Un\G27 b0).

The following status is resulted:

• 'DP/DN disconnection error' (Un\G28 b4) turns off.

• The ALM LED turns off.

• The data in 'Latest error code storage area' (Un\G10256) and 'Latest error ID storage area' (Un\G10257) are cleared.

• When the automatic address detection is executed in step 1, the operation in step 2 is not necessary.

• If the error status automatic recovery mode is set in "Error status automatic recovery" of "Basic setting", the

error status is automatically cleared after the disconnection status is exited.

30

4 FUNCTION

4.8 Disconnected Transmission Cable Location Detection Function

Page 33

4.9 Transmission Cable Voltage Drop Detection

Function

This function detects a voltage drop in the 24 V DC external power supply, enabling the FX5-ASL-M to detect a failure in the

24 V DC external power supply or a wiring error from the upper system.

For the specifications of the 24 V DC external power supply to the FX5-ASL-M, refer to the Page 16

Power Supply Specifications.

How to check the transmission cable voltage drop status

When the AnyWireASLINK system is in the following status, a voltage drop in the 24 V DC external power supply has been

detected.

• The ALM LED flashes at 0.2 second intervals.

• 'Transmission cable voltage drop error' (Un\G28 b3) turns on.

• Transmission cable voltage drop error (error code: 0CC8H) is stored in 'Latest error code storage area' (Un\G10256) and

0FFFH is stored in 'Latest error ID storage area' (Un\G10257).

• The AnyWireASLINK bit transmission stops.

*1 If multiple errors occur simultaneously, the latest error is displayed.

*1

*1

How to recover from the transmission cable voltage drop status

How to recover from the transmission cable voltage drop status is as follows.

1. Check the voltage of the 24 V DC external power supply and replace the power supply or check the wiring, as necessary.

When the transmission cable voltage drop is corrected, AnyWireASLINK bit transmission resumes automatically.

2. Power off and on the AnyWireASLINK system or turn on and off 'Error flag clear command' (Un\G27 b0).

The following status is resulted:

• 'Transmission cable voltage drop error' (Un\G28 b3) turns off.

• The ALM LED turns off.

• The data in 'Latest error code storage area' (Un\G10256) and 'Latest error ID storage area' (Un\G10257) are cleared.

4

4 FUNCTION

4.9 Transmission Cable Voltage Drop Detection Function

31

Page 34

4.10 Parameter Access Error Detection Function

This function allows parameter access errors to be detected.

• Slave module hardware error (error code: 0D2CH, 0D2DH)

• Parameter access target module ID error (error code: 0D2EH)

• Parameter value error (error code: 0D2FH)

• Parameter access error (error code: 0D30H)

• Slave module status error (error code: 0D31H)

• Same ID used error (error code: 0D90H)

• No ID setting error (error code: 0D91H)

• New ID error (error code: 0D92H)

How to check the parameter access error status

The following table lists parameter access error statuses.

Error description Status when an error occurred

Status information Buffer memory

Slave module hardware error 'Slave module alarm signal' (Un\G28 b8) turns on. ■'Latest error code storage area' (Un\G10256)

Parameter access target module ID

error

Parameter value error

Parameter access error 'Parameter access error' (Un\G28 b10) turns on.

Slave module status error 'Slave module alarm signal' (Un\G28 b8) turns on.

Same ID used error

No ID setting error

New ID error

The error code is stored.

■'Latest error ID storage area' (Un\G10257)

The IDs corresponding to the error codes are stored.

■'Number of the alarm IDs' (Un\G9984)

The number of IDs relevant to alarm occurrence is stored.

■'Alarm ID information storage area' (Un\G9985 to

Un\G10112)

The IDs relevant to alarm occurrence are stored.

*2

*1

*2

*1 If multiple errors occur simultaneously, the latest error is displayed.

*2 If an error occurs in parameter access, data are stored in 'Number of the error IDs' (Un\G8192) and 'Error ID information storage area

(Un\G8193 to Un\G8320)'.

How to recover from the parameter access error status

How to recover from the parameter access error status is as follows.

■Slave module hardware error

Take measures such as those against noise to remove factors causing errors. Then power off and on the AnyWireASLINK

system or turn on and off 'Error flag clear command' (Un\G27 b0).

■Parameter access target module ID error, parameter value error

Remove factors causing errors (for example, parameter access program). Then power off and on the AnyWireASLINK system

or turn on and off 'Error flag clear command' (Un\G27 b0).

32

4 FUNCTION

4.10 Parameter Access Error Detection Function

Page 35

■Parameter access error

If any of the following errors has occurred, eliminate the error cause.

• Slave module hardware error (error code: 0D2CH, 0D2DH)

• Slave module status error (error code: 0D31H)

• Same ID used error (error code: 0D90H)

When an error occurs in a parameter access due to a cause other than the above errors, the possible cause is noise. Take

measures such as those against noise to remove factors causing errors. Then power off and on the AnyWireASLINK system

or turn on and off 'Error flag clear command' (Un\G27 b0).

If the error status automatic recovery mode is set in "Error status automatic recovery" of "Basic setting", the

error is automatically cleared after recovery from the parameter access error status.

■Slave module status error

Check the status details of the target slave module to remove factors causing errors. Then power off and on the

AnyWireASLINK system or turn on and off 'Error flag clear command' (Un\G27 b0).