Page 1

Transition from MELSEC-I/OLINK to

Feb. 2017 Edition

AnyWire DB A20 Handbook

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using products introduced in this handbook, please read relevant manuals and replacement

handbooks carefully and pay full attention to safety to handle the product correctly.

The precautions given in this handbook are concerned with products introduced in this handbook only. For

the safety precautions of the programmable controller system, refer to the user's manual for the CPU

module used.

In this handbook, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this handbook and then keep the handbook in a safe place for future

reference.

A - 1

Page 4

When the QJ51AW12D2 is used

[Design Precautions]

WARNING

● An AnyWire DB A20 system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or a personal computer with an intelligent

function module to modify data of a running programmable controller, configure an interlock circuit in

the sequence program to ensure that the entire system will always operate safely. For other forms of

control (such as program modification or operating status change) of a running programmable

controller, read the relevant manuals carefully and ensure that the operation is safe before

proceeding. Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the sequence program, and

determine corrective actions to be taken between the external device and CPU module in case of a

communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to each

module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Although an AnyWire DB A20 system features high noise immunity, keep a distance of 100mm or

more between the transmission cables or I/O cables and the high-voltage cables or power cables.

Failure to do so may cause malfunction.

● Configure safety circuits, such as an emergency stop circuit and interlock circuit, external to the

AnyWire DB A20 system.

A - 2

Page 5

[Installation Precautions]

WARNING

● Use the programmable controller in an environment that meets the general specifications in the user's

manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect interconnection may cause malfunction, failure, or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may result in damage to the product.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 3

Page 6

[Wiring Precautions]

CAUTION

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Incorrect wiring may damage modules and external devices.

Adjust a cable length and a module position to prevent disconnection of a connector type terminal

block or a cable.

● Do not solder stranded wires of a cable when connecting them to the terminal block. Doing so may

cause poor contact.

● The power supply voltage of remote slave modules may be insufficient due to a voltage drop in the

power supply line. Connect an external power supply so that the voltage of remote slave modules is

ensured.

● Do not apply the 24VDC power before wiring the entire AnyWire DB A20 system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Use 24VDC stabilized power supplies for devices in the AnyWire DB A20 system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

A - 4

Page 7

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may result in electric shock.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may cause the module to fail or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

● Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

A - 5

Page 8

When the LJ51AW12D2 is used

[Design Precautions]

WARNING

● An AnyWire DB A20 system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or a personal computer with an intelligent

function module to modify data of a running programmable controller, configure an interlock circuit in

the sequence program to ensure that the entire system will always operate safely. For other forms of

control (such as program modification or operating status change) of a running programmable

controller, read the relevant manuals carefully and ensure that the operation is safe before

proceeding. Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the sequence program, and

determine corrective actions to be taken between the external device and CPU module in case of a

communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to each

module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them. Failure to do so may result in malfunction due to

noise.

● Configure safety circuits, such as an emergency stop circuit and interlock circuit, external to the

AnyWire DB A20 system.

A - 6

Page 9

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines provided with the CPU module or head module. Failure to do so may result in electric

shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers.

Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 7

Page 10

[Wiring Precautions]

CAUTION

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Incorrect wiring may damage modules and external devices.

Adjust a cable length and a module position to prevent disconnection of a connector type terminal

block or a cable.

● Do not solder stranded wires of a cable when connecting them to the terminal block. Doing so may

cause poor contact.

● The power supply voltage of remote slave modules may be insufficient due to a voltage drop in the

power supply line. Connect an external power supply so that the voltage of remote slave modules is

ensured.

● Do not apply the 24VDC power before wiring the entire AnyWire DB A20 system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Use 24VDC stabilized power supplies for devices in the AnyWire DB A20 system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

A - 8

Page 11

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws. Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause drop

of the component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or

module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module, display unit, and terminal block), the number of connections/

disconnections is limited to 50 times (in accordance with IEC 61131-2).

Exceeding the limit may cause malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

A - 9

Page 12

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 10

Page 13

REVISIONS

* The handbook number is given on the bottom left of the back cover.

Print Date * Handbook Number Revision

Jan. 2013 L(NA)08263ENG-A First edition

May 2015 L(NA)08263ENG-B Change

Chapter 7 to Appendix 1, Appendix1 to Appendix 2

Partial correction

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS

Feb. 2016 L(NA)08263ENG-C Partial correction

Cover, WARRANTY

Feb. 2017 L(NA)08263ENG-D Addition of modules to be replaced

LJ51AW12D2

Partial correction

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS, Section

1.3, 2.1, 2.2.1, 3.2, 4.1, 5.1.2, Appendix 2.1

Japanese Handbook Version L08249-D

This handbook confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this handbook.

© 2013 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 14

CONTENTS

SAFETY PRECAUTIONS ................................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT ...............................................................................................A - 10

REVISIONS .................................................................................................................................................... A - 11

CONTENTS ...................................................................................................................................................A - 12

GENERIC TERMS AND ABBREVIATIONS ................................................................................................... A - 15

CHAPTER 1 INTRODUCTION 1 - 1 to 1 - 2

1.1 Replacement with AnyWire DB A20 ................................................................................................ 1 - 1

1.2 Precautions for Replacement .......................................................................................................... 1 - 2

1.3 Features of AnyWire DB A20 ........................................................................................................... 1 - 2

CHAPTER 2 PERFORMANCE SPECIFICATIONS COMPARISONS 2 - 1 to 2 - 4

2.1 Performance Specifications Comparison of MELSEC-I/OLINK and AnyWire DB A20 .................... 2 - 1

2.2 Wiring for AnyWire DB A20 ............................................................................................................. 2 - 3

2.2.1 Transmission distance .............................................................................................................. 2 - 3

2.2.2 Terminator connection .............................................................................................................. 2 - 3

2.2.3 Branch of transmission lines (transmission distance: 1km) ...................................................... 2 - 4

CHAPTER 3 FUNCTIONAL COMPARISONS 3 - 1 to 3 - 2

3.1 Functional Comparisons of MELSEC-I/OLINK and AnyWire DB A20 ............................................. 3 - 1

3.2 Master Module Switch Comparisons ............................................................................................... 3 - 2

CHAPTER 4 REPLACING THE MASTER MODULE 4 - 1 to 4 - 2

4.1 List of Alternative Master Module Models ........................................................................................ 4 - 1

CHAPTER 5 PROGRAMS COMPARISONS 5 - 1 to 5 - 6

5.1 I/O Signals ....................................................................................................................................... 5 - 1

5.1.1 MELSEC-I/OLINK ..................................................................................................................... 5 - 1

5.1.2 AnyWire DB A20 ....................................................................................................................... 5 - 3

CHAPTER 6 REPLACING THE I/O MODULES 6 - 1 to 6 - 40

6.1 List of Alternative I/O Module Models .............................................................................................. 6 - 1

6.2 I/O Module Specifications Comparisons .......................................................................................... 6 - 6

6.2.1 Input module specifications comparisons ................................................................................. 6 - 6

6.2.2 Output module specifications .................................................................................................. 6 - 12

6.2.3 I/O module specifications comparisons .................................................................................. 6 - 18

6.3 Applicable Crimping Terminal ........................................................................................................ 6 - 40

A - 12

Page 15

APPENDICES APPX- 1 to APPX - 3

Appendix 1 External Dimensions .......................................................................................................APPX - 1

Appendix 2 Relevant Manuals ...........................................................................................................APPX - 1

Appendix 2.1 Replacement handbooks .........................................................................................APPX - 1

Appendix 2.2 MELSEC-I/OLINK ....................................................................................................APPX - 2

Appendix 2.3 AnyWire DB A20 .....................................................................................................APPX - 2

A - 13

Page 16

● For the products shown in handbooks for transition, catalogues, and transition examples, refer to the

manuals for the relevant products and check the detailed specifications, precautions for use, and

restrictions before replacement.

For the products manufactured by Mitsubishi Electric Engineering Co., Ltd., Mitsubishi Electric System

& Service Co., Ltd., and other companies, refer to the catalogue for each product and check the

detailed specifications, precautions for use, and restrictions before use.

The manuals and catalogues for our products, products manufactured by Mitsubishi Electric

Engineering Co., Ltd., and Mitsubishi Electric System & Service Co., Ltd. are shown in Appendix of

each handbook for transition.

● Products shown in this handbook are subject to change without notice.

A - 14

Page 17

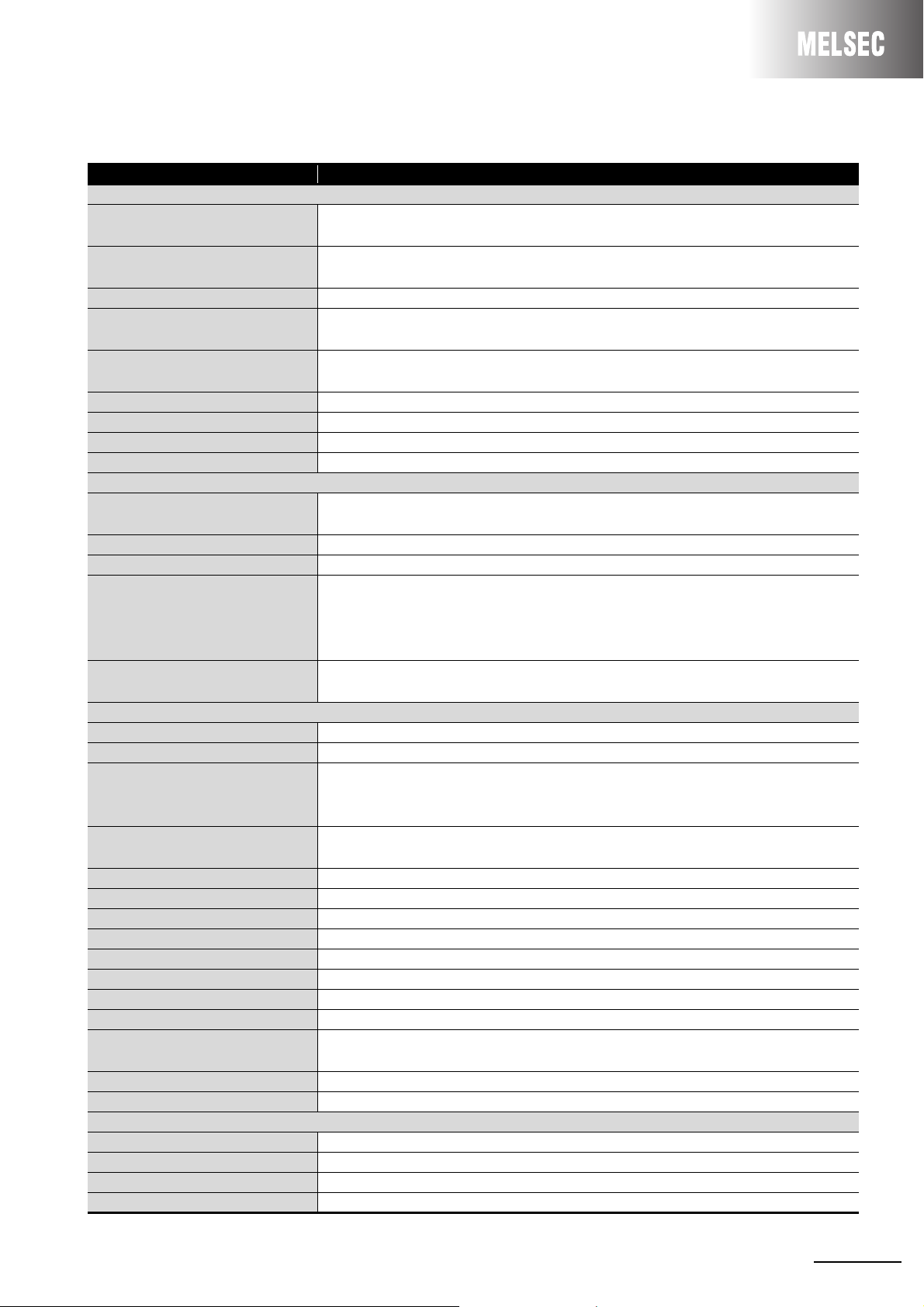

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this handbook uses the following generic terms and abbreviations.

Generic term/abbreviation Description

Series

A series

AnS series

A/AnS series A generic term for A series and AnS series

QnA series

QnAS series

QnA/QnAS series A generic term for QnA series and QnAS series

A/AnS/QnA/QnAS series A generic term for A series, AnS series, QnA series, and QnAS series

Q series The abbreviation for Mitsubishi Electric MELSEC-Q series programmable controllers

L series The abbreviation for Mitsubishi Electric MELSEC-L series programmable controllers

CPU module type

CPU module

Process CPU A generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU A generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

LCPU

CPU module model

ACPU A generic term for MELSEC-A series CPU modules

AnSCPU A generic term for MELSEC-AnS series CPU modules

AnNCPU

AnACPU

AnUCPU A generic term for the A2UCPU, A2UCPU-S1, A3UCPU, and A4UCPU

AnUS(H)CPU A generic term for the A2USCPU, A2USCPU-S1, and A2USHCPU-S1

A/AnSCPU A generic term for MELSEC-A series and -AnS series CPU modules

AnN/AnACPU A generic term for the AnNCPU and AnACPU

AnN/AnA/AnSCPU A generic term for the AnNCPU, AnACPU, and AnSCPU

QnACPU A generic term for MELSEC-QnA series CPU modules

QnASCPU A generic term for MELSEC-QnAS series CPU modules

QnA/QnASCPU A generic term for MELSEC-QnA series and -QnAS series CPU modules

A/AnS/QnA/QnASCPU

QCPU A generic term for MELSEC-Q series CPU modules

LCPU A generic term for MELSEC-L series CPU modules

Module model related to AnyWire DB A20

Master module A genetic term for the QJ51AW12D2 and LJ51AW12D2

QJ51AW12D2 The abbreviation for the AnyWire DB A20 master module, QJ51AW12D2

LJ51AW12D2 The abbreviation for the AnyWire DB A20 master module, LJ51AW12D2

AnyWire DB A20 An original transmission system provided by Anywire Corporation

The abbreviation for large types of Mitsubishi Electric MELSEC-A series programmable

controllers

The abbreviation for compact types of Mitsubishi Electric MELSEC-A series

programmable controllers

The abbreviation for large types of Mitsubishi Electric MELSEC-QnA series

programmable controllers

The abbreviation for compact types of Mitsubishi Electric MELSEC-QnA series

programmable controllers

A generic term for A series, AnS series, QnA series, QnAS series, Q series, and L

series CPU modules

A generic term for the Q00U(J)CPU, Q01UCPU, Q02UCPU, Q03UD(E)CPU,

Q03UDVCPU, Q04UD(E)HCPU, Q04UDVCPU, Q06UD(E)HCPU, Q06UDVCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU, Q13UDVCPU, Q20UD(E)HCPU,

Q26UD(E)HCPU, and Q26UDVCPU

A generic term for the L02SCPU, L02SCPU-P, L02CPU, L02CPU-P, L06CPU,

L06CPU-P, L26CPU, L26CPU-P, L26CPU-BT, and L26CPU-PBT

A generic term for the A1NCPU, A1NCPUP21/R21, A1NCPUP21-S3, A2NCPU,

A2NCPU-S1, A2NCPUP21/R21, A2NCPUP21/R21-S1, A2NCPUP21-S3(S4),

A3NCPU, A3NCPUP21/R21, and A3NCPUP21-S3

A generic term for the A2ACPU, A2ACPU-S1, A3ACPU, A2ACPUP21/R21,

A2ACPUP21/R21-S1, and A3ACPUP21/R21

A generic term for MELSEC-A series, -AnS series, -QnA series, and -QnAS series CPU

modules

A - 15

Page 18

1 INTRODUCTION

Point

1

INTRODUCTION

1

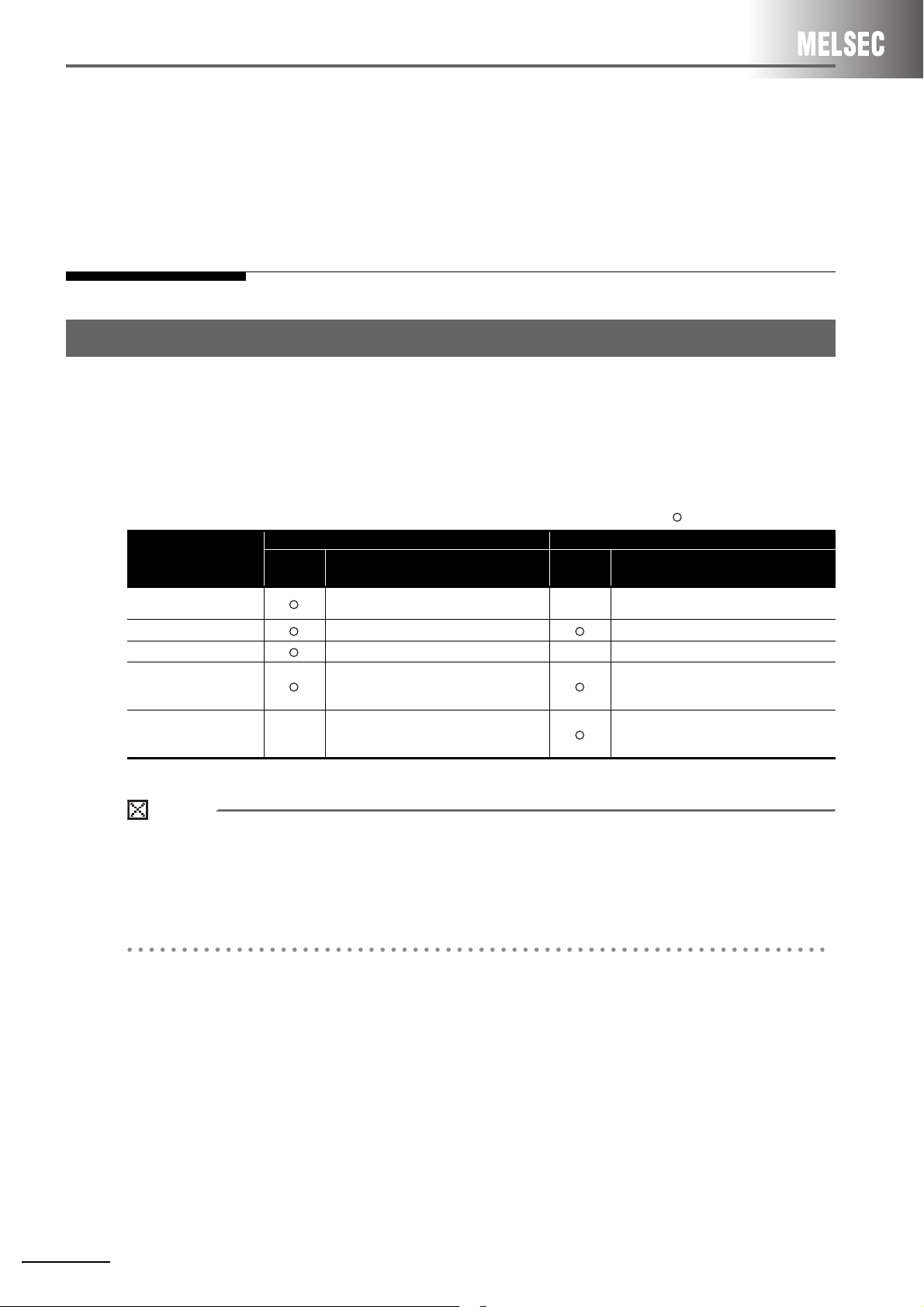

1.1 Replacement with AnyWire DB A20

The MELSEC-Q and L series do not have an MELSEC-I/OLINK master module. Therefore, the

alternatives are the AnyWire DB A20 or the CC-Link/LT. Features for replacement are listed in the

following table.

Replacing MELSEC-I/OLINK with AnyWire DB A20 or CC-Link/LT

: Compatible, ×: Not compatible

Replacement with AnyWire DB A20 Replacement with CC-Link/LT

Item

External power supply

Connection type T-branch system, or tree branch system T-branch system

Connection cable The existing I/OLINK cables can be used. × New cables must be installed.

I/O module type

Programming ×

AnyWire products are not available in some countries. For details, please consult your local Mitsubishi

representative.

This transition handbook explains replacement of the MELSEC-I/OLINK with the AnyWire DB A20.

For replacement with the CC-Link/LT, refer to the following transition handbook.

Transition from MELSEC-I/OLINK to CC-Link/LT Handbook

Compati-

bility

Description

The existing I/OLINK external power supply

can be used.

4, 8, or 16 points

Input module/Output module/I/O combined

module

The master module occupies 32 points.

The I/O module address becomes the

specified device by the FROM/TO instruction.

Compati-

bility

× A power supply adapter is necessary.

2, 4, or 8 points

Input module/Output module/I/O combined

module

XY address of the master module becomes

XY address of the I/O module.

Needless to change address (up to 64 points)

Description

1 - 1

Page 19

1 INTRODUCTION

1.2 Precautions for Replacement

(1) Before replacing MELSEC-I/OLINK with AnyWire DB A20, refer to the manuals for each

AnyWire DB A20 module, and check the functions, specifications, and how to use the

modules.

(2) After replacing MELSEC-I/OLINK with AnyWire DB A20, check the operation of the entire

system before starting the actual operation.

1.3 Features of AnyWire DB A20

The transmission distance can be selected from 50m/200m/1km/3km using the DIP switch.

Up to 512 remote input points and 512 remote output points can be controlled by one QJ51AW12D2 or

LJ51AW12D2 (in the standard setting).

Disconnections can be detected even when the wiring is branched.

AnyWire DB A20

AnyWire DB A20

terminating unit*

AnyWire DB A20 master module

QJ51AW12D2

or

AnyWire DB A20

remote I/O module (input)*

AnyWire DB A20

remote I/O module (output)*

*: Manufactured by Anywire Corporation

AnyWire DB A20 master module

LJ51AW12D2

1 - 2

Page 20

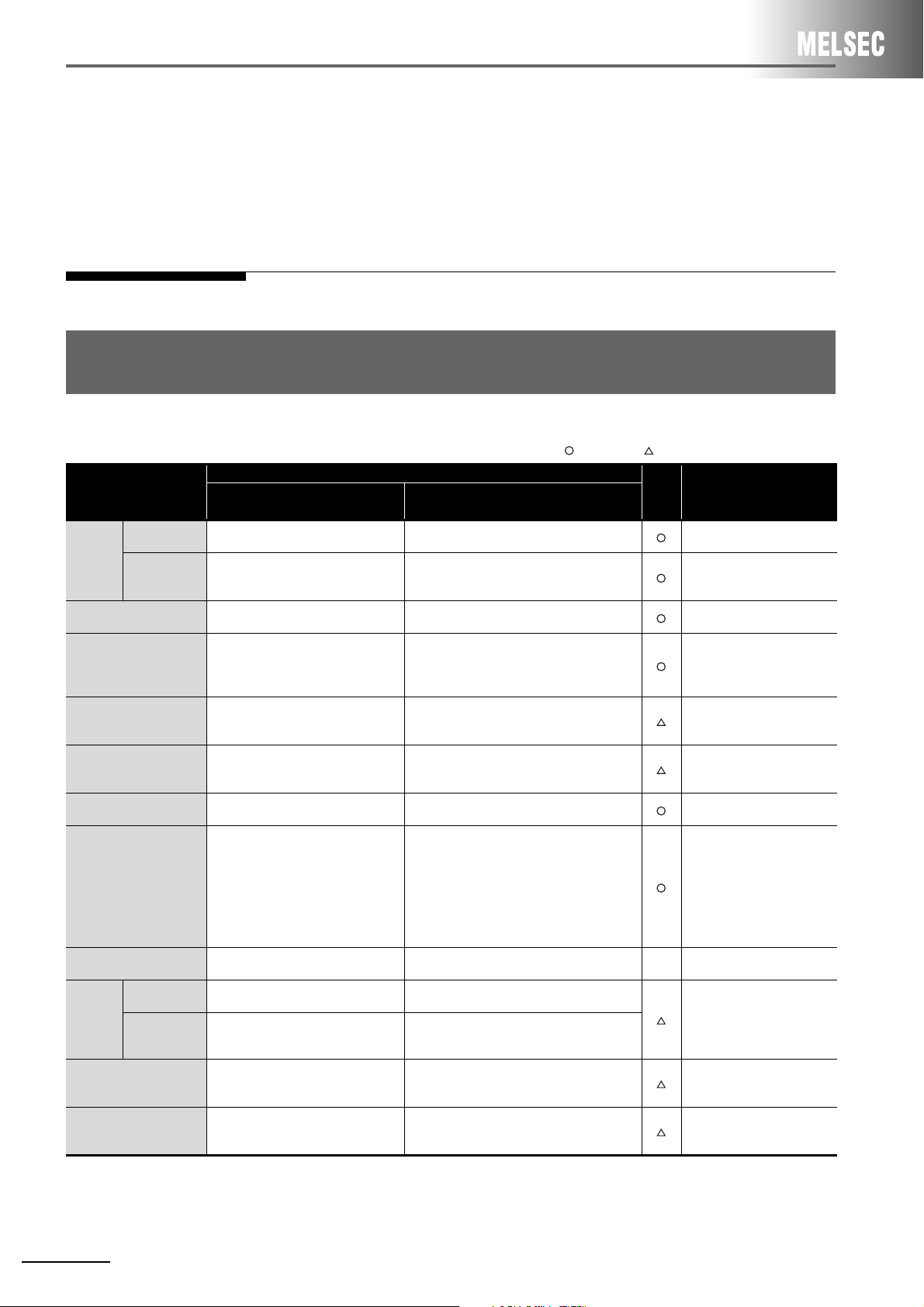

2 PERFORMANCE SPECIFICATIONS COMPARISONS

2

PERFORMANCE SPECIFICATIONS

2

COMPARISONS

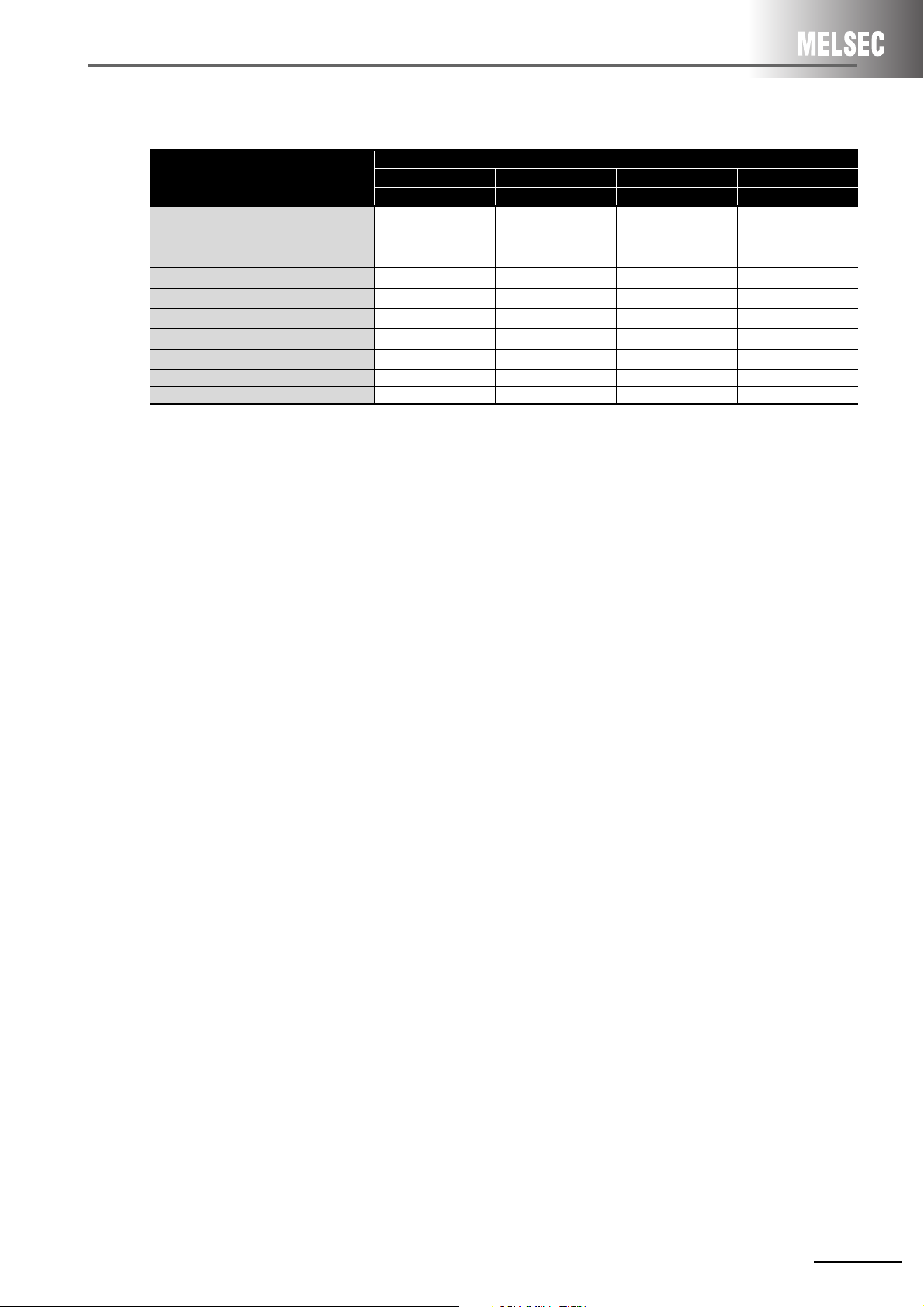

2.1 Performance Specifications Comparison of MELSEC-I/OLINK and AnyWire DB A20

: Compatible, : Partially changed, ×: Not compatible

Specifications Com-

Item

Max. number of

Per single

master

station

Link scan time

(Transmission cycle time)

Overall distance 200m

Communication speed 38.4kbps 125kHz/31.3kHz/7.8kHz/2kHz

Error control method Parity check Double-check system

Network Topology Bus (T-branch available)

Connection cable

Terminating resistor

(terminator)

External

power

supply to

master

module

Number of occupied I/O

points of master module

Internal current

consumption of master

module

link stations

Max. number of

control I/O

points

Voltage 21.6 to 27.6VDC

Current 0.09A

MELSEC-I/OLINK AnyWire DB A20

16 stations

(1 station 4 points)

(when the same number is used on X

Twisted pair cable (0.75mm

(I/O assignment: Output 16/32/64

128 points

and Y)

Approx. 5.4ms

2

2

Cabtire cable (0.75mm

Not required Required ×

16, 32, 48, or 64 points

points)

0.115A

)

(when the same number is used on X and Y)

2.7ms (for 128 points)

Bus (Multidrop system, T-branch system,

star system, or tree system)

General-purpose 2-/4-wire cable

(VCTF, VCF 0.75 to 1.25mm

),

General-purpose wire (0.75 to 1.25mm

Dedicated flat cable (0.75mm

(When the transmission distance exceeds

200m, use wires with a diameter of 0.9 to

24VDC +15 to -10% (21.6 to 27.6VDC)

Ripple voltage 0.5Vp-p or less

0.5A (When 128 slave modules are connected

and the load current is not included)

(I/O assignment: intelligent 32 points)

QJ51AW12D2: 0.5A

LJ51AW12D2: 0.2A

128 stations

1024 points

125kHz: 50m

31.3kHz: 200m

7.8kHz: 1km

2kHz: 3km

2

1.25mm

.)

32 points

*1

2

),

2

),

2

),

Precautions for replace-

pati-

bility

1kHz is equivalent to 1kbps.

Select the speed based on the

existing overall distance.

1kHz is equivalent to 1kbps.

The error control method is

different, but an error check

function is provided.

Crimping terminals can be

used. However, the

communication lines and

power lines connected to the

master module must be

processed to connect to

terminals.

A terminating resistor is

necessary.

Because the external power

supply current has increased,

the current capacity must be

reviewed.

The program and parameters

must be changed.

Internal current consumption of

5VDC must be recalculated.

ment

2 - 1

Page 21

2 PERFORMANCE SPECIFICATIONS COMPARISONS

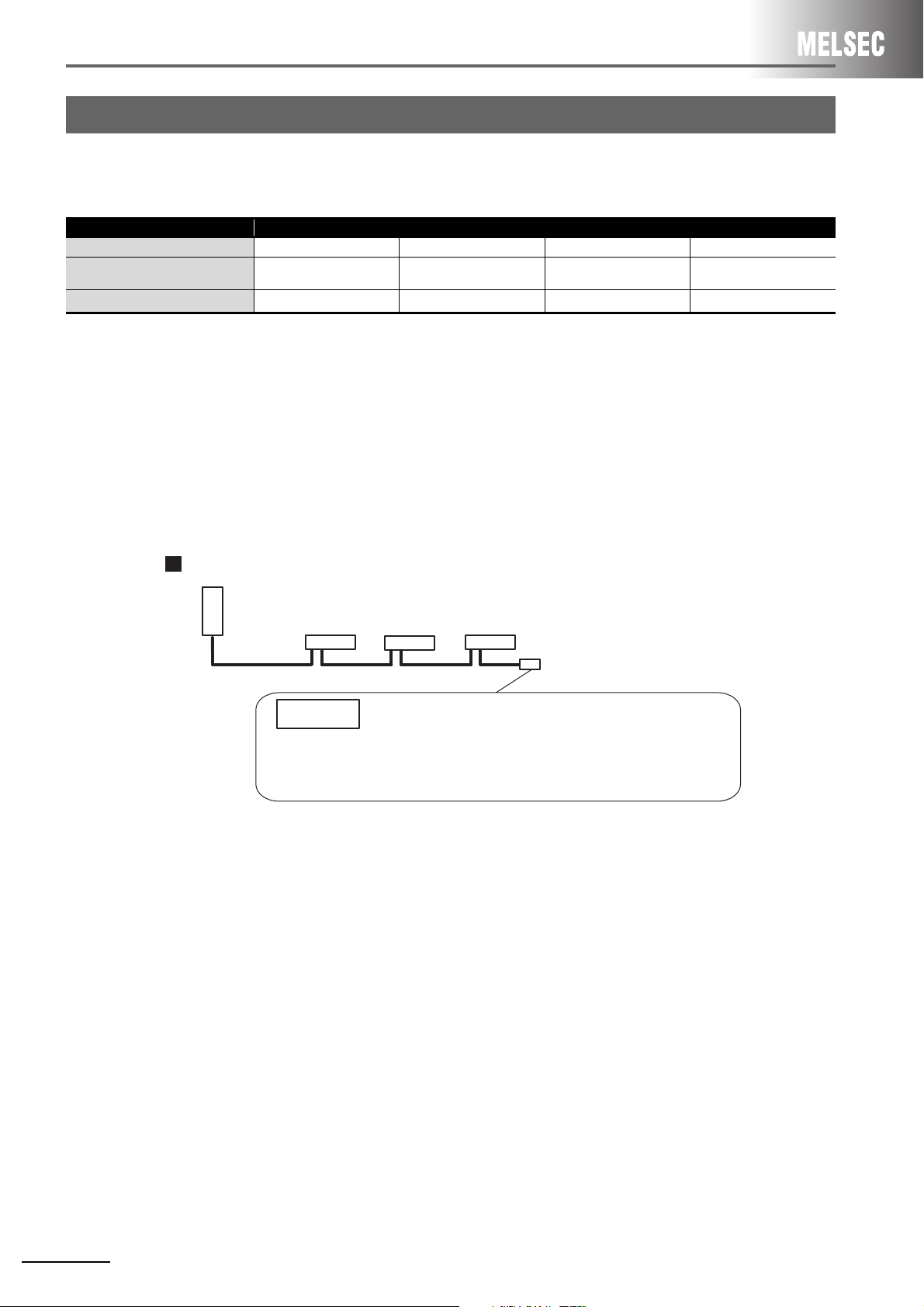

*1 The transmission cycle time of the AnyWire DB A20 master module differs depending on the number of transmission points

setting or the transmission clock. For details, refer to the following table.

Max. number of transmission

points setting

64 points (32 points × 2) 0.42 1.7 6.8 24.8

128 points (64 points × 2) 0.7 2.7 10.9 40.7

256 points (128 points × 2) 1.2 4.8 19.1 72.4

384 points (192 points × 2) 1.7 6.8 27.3 104.2

512 points (256 points × 2) 2.2 8.9 35.5 135.9

640 points (320 points × 2) 2.7 10.9 43.6 167.6

768 points (384 points × 2) 3.2 13.0 51.8 199.4

896 points (448 points × 2) 3.8 15.0 60.0 231.1

1024 points (512 points × 2) 4.3 17.1 68.2 262.9

2048 points (1024 points × 2) 8.4 33.4 133.8 516.8

125kHz 31.3kHz 7.8kHz 2kHz

(50m) (200m) (1km) (3km)

Transmission cycle time (ms)

2 - 2

Page 22

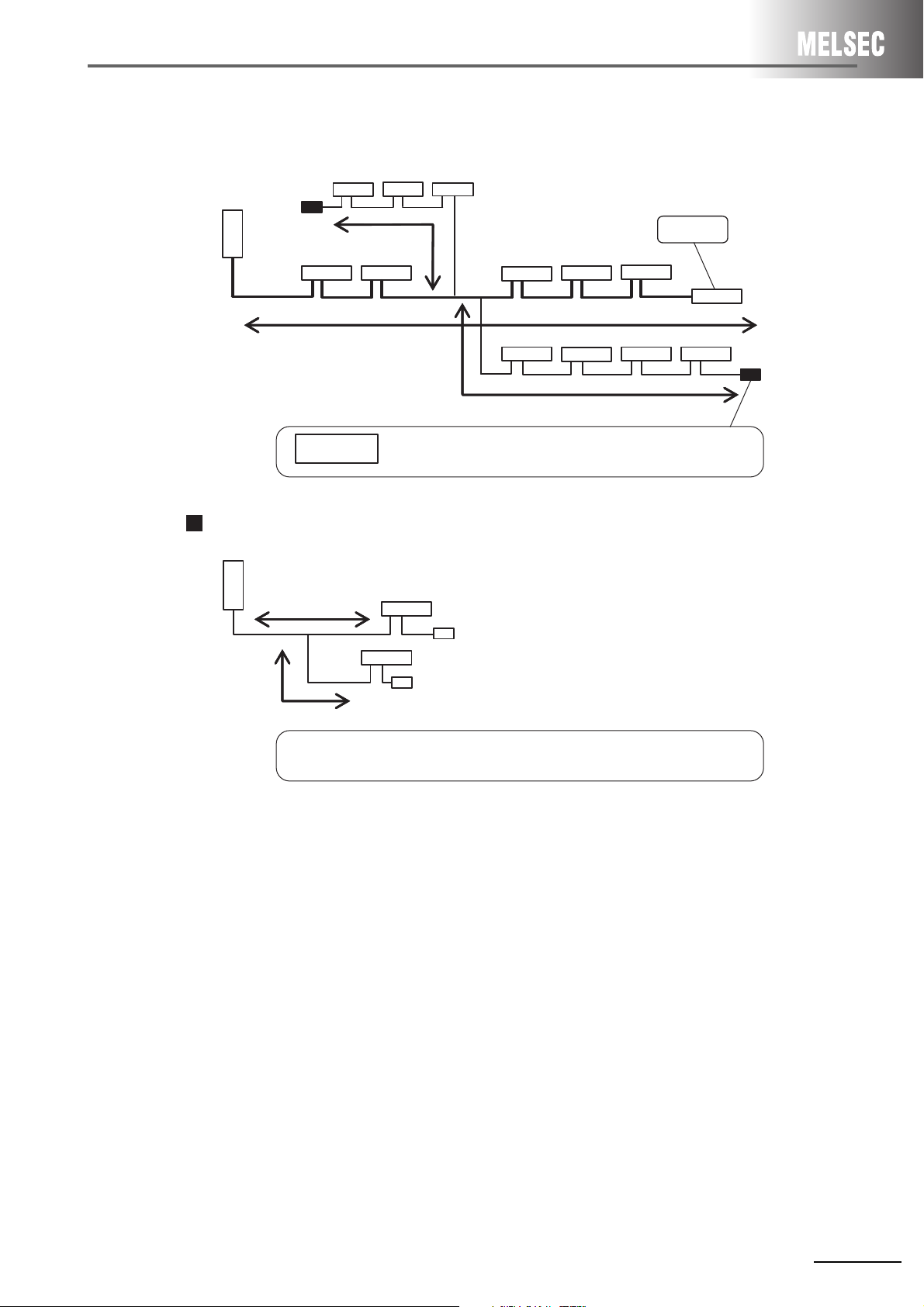

2 PERFORMANCE SPECIFICATIONS COMPARISONS

Important

Terminating unit

Basic

Connect a terminating unit at the end of a line for one master

module.

Transmission distance 50m (total length)

200m (total length)

1km (total length)

3km (total length)

The setting applies to all the transmission speeds.

2.2 Wiring for AnyWire DB A20

2.2.1 Transmission distance

Item Specifications

Transmission clock

Max. transmission distance

(total length)

Number of connectable modules Up to 128 Up to 128 Up to 128

*1 When setting the transmission clock at 125kHz using the QJ51AW12D2 with a serial number (sixth digit) 5 or earlier, use

the product under the following conditions.

• External power supply voltage range: 21.6VDC to 25.2VDC

• Operating ambient temperature: 0 to 50°C

*2 Up to 64 modules can be connected within 2km.

2.2.2 Terminator connection

To ensure more stable transmission, connect the terminating resistor (AT2 manufactured by Anywire

Corporation) at the end of the transmission line.

*1

125kHz

50m 200m 1km 3km

31.3kHz 7.8kHz 2kHz

Up to 32

*2

2 - 3

Page 23

2 PERFORMANCE SPECIFICATIONS COMPARISONS

A

B

Basic

Branch line:

200m

Main line: 500m

AnyWire

at the end

Branch line: 300m

Connect one terminating unit at the end of a branch line that is

200m or longer.

Contact us if more than two branch lines are 200m or longer.

Total length

The total length of the transmission distance for the AnyWire DB A20 can be

calculated from A + B. Note that the total length should not exceed the maximum

transmission distance set for the system to branch lines.

Important

2.2.3 Branch of transmission lines (transmission distance: 1km)

2 - 4

Page 24

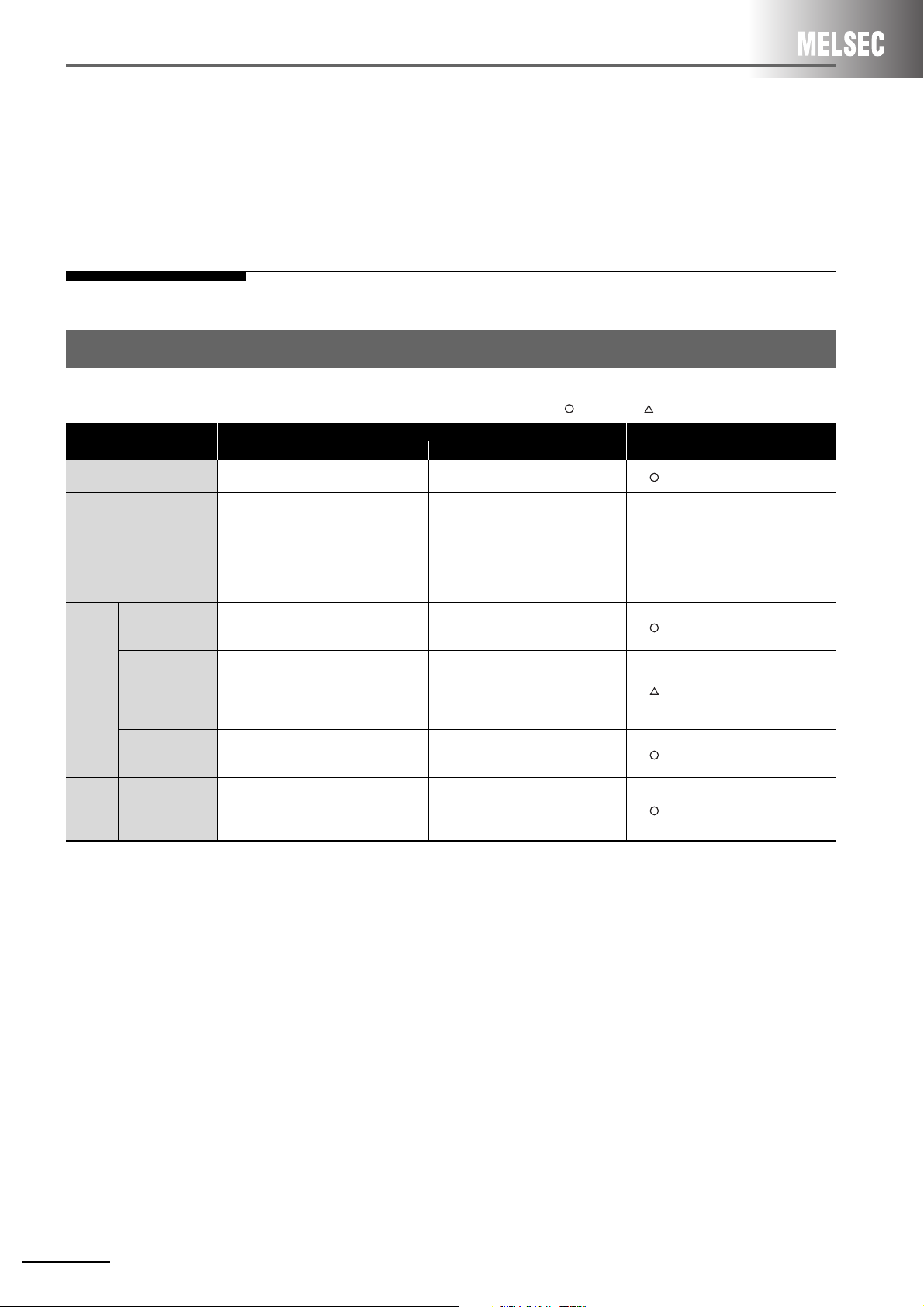

3 FUNCTIONAL COMPARISONS

3

FUNCTIONAL COMPARISONS

3

3.1 Functional Comparisons of MELSEC-I/OLINK and AnyWire DB A20

: Compatible, : Partially changed, ×: Not compatible

Item

Remote station

communication

Remote station address

Detection of faulty

station (display)

Notification method

RAS

function

Others

of the error

detection to the

CPU module

Line check

Error check of

disconnected

station enabled/

disabled setting

Specifications Compat-

MELSEC-I/OLINK AnyWire DB A20

Communication with up to 16 slave

stations is possible.

XY address of the master station becomes

the XY address of the remote station

module.

The LED display (ERROR STATION) on

the master station notifies a user of faulty

stations.

When an error is detected, the CPU

module is notified by Fuse blown detection

(M 9000). External output is also

performed from the RUN A/B terminals on

the MELSEC-I/OLINK master module.

Cable disconnection can be checked by

the ON status of the LEDs on the master

station and slave stations.

If there is a station that is not connected,

the error check can be disabled by setting

the ON LINE STATION switch of the

master station to off.

Communication with up to 128 slave

stations is possible.

I/O information is stored in the buffer

memory.

The device that data are read from and

written to the buffer memory by the

FROM/TO instruction will be assigned

to the remote station module address in

the program.

The LED display (ALM) on the master

station notifies a user of faulty stations.

An error is notified by the I/O signal

(Xn4: Disconnection detected) from the

AnyWire DB A20 master module. Note,

however, an external output is not

performed from terminals.

Cable disconnection can be checked by

the ON status of the LEDs on the

master station and slave stations.

The master station is provided with a

function to automatically recognize the

number of occupied points and the set

address of the connected station.

ibility

×

Precautions for

replacement

Program change or different

remote station module line

numbers are required

because the concept of the

addresses is different.

Change of the sequence

program is required because

the notifying device differs. If

an external output is required,

an output signal is necessary.

Though the setting method

differs, a station that is not

connected can be detected.

3 - 1

Page 25

3 FUNCTIONAL COMPARISONS

3.2 Master Module Switch Comparisons

Item

Number of transmission

points

Transmission speed

Double check mode -

Waveform output

*2

method

ON LINE STATION

Automatic address

detection

MELSEC-I/OLINK AnyWire DB A20

Set the number of occupied points of

the master module to 16, 32, 48, or 64

points in the I/O assignment of the

parameter.

The number of occupied points of the

master module becomes the maximum

number of connected points.

Setting is not required.

(The communication speed and

transmission distance are fixed.)

Setting is not required.

The transmission waveform is

automatically output by switching the

operating status of the CPU module to

RUN.

(The module always receives input

signals.)

ON LINE STATION is a switch for

determining whether to use the remote

I/O module or not.

*1 Set the transmission speed with the operation mode selector for the QJ51AW12D2. For the LJ51AW12D2, set it on the

"Switch Setting for I/O and Intelligent Function Module" window.

*2 The waveform output method can be set in the LJ51AW12D2 and the QJ51AW12D2 with a serial number (sixth digit) 6 or

later.

-

Specifications Compat-

Set the number of transmission points

of the slave module.

Select the transmission speed.

Transmission distance is determined

depending on the transmission speed.

Double check mode is an error control

system that compares the current cycle

data and the previous cycle data. The

data is valid when the comparison

result matches.

Based on the setting, the transmission

waveform is output by turning on of

Module READY (Xn0) or Transmission

waveform output command (Yn2).

This function allows the master module

to automatically recognize an ID

(address) of a slave module.

: Compatible, : Partially changed, ×: Not compatible

Precautions for

ibility

Setting method is cha nged from setting

of the I/O assignment of parameter to

intelligent function switch setting.

The transmission speed must be set in

accordance with the number of slave

modules to be connected and the total

length of the transmission distance.

Double check mode is a new function

of AnyWire DB A20.

The function of the alternative module

becomes equivalent to the one of the

former module by turning on of Module

READY (Xn0) to output the

transmission waveform.

-

Stations to be used (remote I/O module

or slave module) can be determined by

these functions.

The setting method differs between

former and alternative modules.

replacement

*1

3 - 2

Page 26

4 REPLACING THE MASTER MODULE

4

REPLACING THE MASTER MODULE

4

4.1 List of Alternative Master Module Models

MELSEC-I/OLINK Alternative model for AnyWire DB A20

Product Model Model Remarks (restrictions)

Master module

AJ51T64

A1SJ51T64

QJ51AW12D2

LJ51AW12D2

It is recommended to replace the module with the AnyWire DB

A20. For details, refer to the user's manual for each module.

4 - 1

Page 27

4 REPLACING THE MASTER MODULE

Memo

4 - 2

Page 28

5 PROGRAMS COMPARISONS

A1S

J51

T64

X/YC0

X/YFF

A1S

Y41P

YA0

YBF

A1S

Y41P

Y80

Y9F

A1S

Y41P

Y60

Y7F

A1S

X41

X40

X5F

A1S

Y41P

X20

X3F

A1S

X41

X0

X1F

CPU

AJ55TB3-4D

(input module

occupied one station)

Station

No.0

AJ55TB2-8T

(output module

occupied two stations)

Station

No.1

AJ55TB32-4DT

(I/O module

occupied one station)

Station

No.3

AJ55TB3-8D

(input module

occupied two stations)

Station

No.5

AJ55TB32-8DT

(I/O module

occupied one station)

Station

No.4

ON LINE STATION

setting switches

ON: 0 to 6

OFF: 7 to F

Address C0 to C3

Address D4 to DB Address D0 to D3

Address C4 to CB Address CC to CF

5

PROGRAMS COMPARISONS

5

5.1 I/O Signals

5.1.1 MELSEC-I/OLINK

I/O signals of the MELSEC-I/OLINK will be assigned to the addresses of the connected remote I/O

module.

5 - 1

Page 29

5 PROGRAMS COMPARISONS

0

AJ55TB3-4D (input 4-point module)

AJ55TB2-8T (output 8-point module)

AJ55TB32-8DT (input 4-point/output 4-point module)

AJ55TB3-8D (input 8-point module)

AJ55TB32-4DT (input 2-point/output 2-point module)

(A 4-point I/O combined module can be used the first half 2 points

of both of X and Y. The module cannot be used the second half 2 points.

C0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

D0

1

2

3

4

5

6

7

8

9

A

B

C

1

2

3

4

5

6

Station No.

of remote

I/O module

Addresses

(Hexadecimal)

Device

XY

Remarks

The device used is indicated by .

The following table listed addresses for each remote I/O module.

5 - 2

Page 30

5 PROGRAMS COMPARISONS

Point

X/YC0

X/YDF

QY41P

QJ51

AW12D2

YA0

YBF

QY41P

Y80

Y9F

QY41P

Y60

Y7F

QX41

X40

X5F

QY41P

X20

X3F

QX41

X0

X1F

CPU

A20SB-04U

(input module)

A20PB-08U

(output module)

A20XB-16UD

(I/O module)

A20SB-08UD

(input module)

A20XB-16UD

(I/O module)

Buffer memory address:

100

H (bit 0 to bit 3)

Switch setting: 0

Buffer memory address:

102

H (bit 0 to bit 3)

Switch setting: 32

Buffer memory address:

1100

H (bit 4 to bit 11)

Switch setting: 4

Input:

Buffer memory address: 101

H (bit 0 to bit 7)

Switch setting: 16

Output:

Buffer memory address: 1101

H (bit 0 to bit 7)

Switch setting: 16

Input:

Buffer memory address: 101

H (bit 8 to bit 15)

Switch setting: 24

Output:

Buffer memory address: 1101

H (bit 8 to bit 15)

Switch setting: 24

5.1.2 AnyWire DB A20

Details on the addresses when replacing the I/OLINK are explained by using the module configuration

example described in Section 5.1.1.

I/O information of the AnyWire DB A20 are stored in the buffer memory. The device that data are read

from and written to the buffer memory by the FROM/TO instruction will be assigned to the remote station

module address in the program. The program that controls input and output of the I/OLINK remote

station must be changed.

[System configuration example]

In this example, settings are made to match the addresses of the existing I/OLINK. Since the number of

occupied points differ between the existing module and the replacement module, their addresses cannot

be assigned in the same way. The addresses in this replacement module is example. They can be

assigned as desired according to the system configuration.

5 - 3

Page 31

5 PROGRAMS COMPARISONS

Bit15Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit

0

Unused due to

fractional points

Unused

(used area for the existing output module AJ55TB2-8T)

A20SB-04U

(replacement area for AJ55TB3-4D)

(input: 4 points)

Buffer memory

address

100

H

101H

102H

Buffer memory

address

110 0

H

110 1H

110 2H

A20XB-16UD (replacement area for AJ55TB32-8DT)

(input: 8 points)

Unused

Unused due to

fractional points

A20XB-16UD (replacement area for AJ55TB32-4DT)

(input: 8 points)

A20XB-08UD (replacement area for AJ55TB32-8D)

(input: 8 points)

Unused (used area for the

existing input module

AJ55TB3-40)

A20PB-08U (replacement area for AJ55TB2-8T)

(output: 8 points)

A20XB-16UD (replacement area for AJ55TB32-8DT)

(output: 8 points)

Unused

A20XB-16UD (replacement area for AJ55TB32-4DT)

(output: 8 points)

Unused

(used area for the existing input module AJ55TB32-8D)

Existing address

Existing module

(Refer to configura-

tion in Section 5.1.1.)

AJ55TB3-4D (input 4 points) XC0 to XC3

AJ55TB2-8T (input 8 points) XC4 to XCB

XCC to XCD

AJ55TB32-4DT

(input 2 points/output 2 points)

Number of occupied points is 4.

AJ55TB32-8DT

(input 4 points/output 4 points)

Number of occupied points is 4.

AJ55TB3-8D (input 8 points) XD4 to XDB

(XCC to XCF are

occupied.)

YCC to YCD

(YCC to YCF are

occupied.)

XD0 to XD3

YD0 to YD3

(YCC to YCF are

occupied.)

Replaced module

A20SB-04U

(input 4 points)

A20PB-08U

(input 8 points)

A20XB-16UD

(input 8 points/output 8

points)

A20XB-16UD

(input 8 points/output 8

points)

A20SB-08UD

(input 4 points)

Input side address Output side address

Switch

setting

0

16

24

32

Buffer

memory

address

100

bit 0 to bit 3

–4

101

bit 0 to bit 7

–16

101

bit 8 to bit 15

–24

102

bit 0 to bit 7

Switch

setting

H

H

H

H

Buffer

memory

address

–

110 0

bit 4 to bit 11

–

110 1

bit 0 to bit 7

–

110 1

bit 8 to bit 15

–

H

H

H

5 - 4

Page 32

5 PROGRAMS COMPARISONS

Remarks

Unused due to

fractional points

Unused

(used area for the existing output module AJ55TB2-8T)

A20SB-04U (input: 4 points)

X1000 to X1003

Buffer memory

address

100

H

101H

102H

Buffer memory

address

110 0

H

110 1H

110 2H

A20XB-16UD (input: 8 points)

X1018 to X101F

Unused

Unused due to

fractional points

A20XB-16UD (input: 8 points)

X1010 to X1017

A20XB-08UD (input: 8 points)

X1020 to X1027

Unused (used area for the

existing input module

AJ55TB3-40)

A20PB-08U (output: 8 points)

Y1004 to Y101B

A20XB-16UD (output: 8 points)

Y1018 to Y101F

Unused

A20XB-16UD (output: 8 points)

Y1010 to Y1017

Unused

(used area for the existing input module AJ55TB32-8D)

FROM

TO

H0C

H0C

H1100

H100

K4X1000

K4Y1000

K3

K3

Ex.

* The XY address specified by the buffer memory read/write instruction "FROM/TO" becomes the XY address in the program.

The following shows the XY address of each module when the FROM/TO instruction is programmed.

(1) I/O signals of the AnyWire DB A20 master module

I/O signals of the master module indicate the state of the module, and are used as command

output. This is different from using as ON/OFF signals of the remote station for MELSEC-I/OLINK.

The "n" in the table is the start I/O number of the master module which is determined according to

the mounted position and modules mounted before the master module.

Input number Signal name Output number Signal name

Xn0 Module READY Yn0 Disconnection flag reset command output

Xn1 Short between D and G terminals Yn1

Xn2 Short between D and 24V terminals

Xn3 24V not applied

Xn4 D/G line disconnection

Xn5 to Xn7 Use prohibited

Xn8 to XnB

XnC to XnF Use prohibited

X(n+1)0 to

X(n+1)3

X(n+1)4

X(n+1)5 to

X(n+1)F

*1 Use prohibited for the LJ51AW12D2.

5 - 5

*2 When 8 is set for "Switch 1", the settings are as follows.

*3 Use prohibited for the QJ51AW12D2.

*4 The QJ51AW12D2 with a serial number where the sixth digit is "6" or later can be used.

*1

*3

Xn8: OFF, Xn9: OFF, XnA: OFF, XnB: O

When the start I/O number of the master module is "X/Y10"

Xn0 to X(n+1)F X10 to X2F

Yn0 to X(n+1)F Y10 to Y2F

*4

Yn2

"Switch Setting for I/O and Intelligent

Function Module"

Switch 1 setting value

*2

Use prohibited

Automatic address detection flag

Use prohibited

Yn3 to YnF Use prohibited

Y(n+1)0 to

Y(n+1)F

Automatic address detection command

output

Transmission waveform output command

Use prohibited

Page 33

5 PROGRAMS COMPARISONS

Ex.

Buffer memory address

Bit No.

15141312111098 76543210

1514131211109876543210

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

100

H

101

H

AnyWire input address: 0

(2) Buffer memory of the AnyWire DB A20

In the MELSEC-I/OLINK, the occupied XY address of the master module becomes the XY

address of the remote station module, while in the AnyWire DB A20, the ON/OFF information of a

slave module is stored in the buffer memory. Therefore, the address of the slave module in the

program will be the device or the device number used the FROM/TO instruction which data are

read from and written to the buffer memory.

This area is for data communication between the master module and CPU module.

Buffer memory address Description

100H to 13F

1100H to 113F

2000

2001H to 2080

2400

2401H to 2480

2810

2811

*1

H

*1

H

H

H

*2

H

H

H

*2

H

*2

*2

*1 The buffer memory address occupies a 64-word sized area, irrespective of the number of I/O points.

*2 The QJ51AW12D2 with a serial number where the sixth digit is "6" or later can be used.

Input (1024 points): The least significant bit of 100H is the 0th data, and the most significant bit of 13FH is the 1023rd

data.

Output (1024 points): The least significant bit of 1100H is the 0th data, and the most significant bit of 113FH is the

1023rd data.

Number of error IDs (1 word)

Error ID information

Number of connection IDs (1 word)

Connection ID information

Latest error code storage area

Latest error ID storage area

Correspondence between the buffer memory address and AnyWire DB A20 input address

For details, refer to the following manual.

MELSEC-Q/L AnyWire DB A20 Master Module User's Manual SH(NA)-080968ENG

5 - 6

Page 34

6 REPLACING THE I/O MODULES

6

REPLACING THE I/O MODULES

6

6.1 List of Alternative I/O Module Models

I/OLINK series model AnyWire DB A20 series alternative model

Product Model name Model name Remarks (restrictions)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (wiring: 3-wire 2-wire) (A negative common type cannot

be used.)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (wiring: 3-wire 2-wire) (A positive common type cannot

be used.)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (A negative common type cannot be used.)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (A positive common type cannot be used.)

Input module

AJ55TB3-4D

(when positive common

type is used)

AJ55TB3-4D

(when negative common

type is used)

AJ55TB3-8D

(when positive common

type is used)

AJ55TB3-8D

(when negative common

type is used)

A20SB-04U

A20SB-04US

A20SB-08UD

A20SB-08USD-1

6 - 1

Page 35

6 REPLACING THE I/O MODULES

I/OLINK series model AnyWire DB A20 series alternative model

Product Model name Model name Remarks (restrictions)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (A negative common type cannot be used.)(8 points/

common 16 points/common)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(5) Functions: Changed (A positive common type cannot be used.)(8 points/

common 16 points/common)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency: Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed (4 points/common All points independent)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program:

(4) Specifications:

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency: Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed (8 points/common All points independent)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency: Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed (8 points/common All points independent)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated load voltage: Changed (12VDC is not applicable.)

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed (Surge suppressor: Supported Not supported)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated load voltage: Changed (12VDC is not applicable.)

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed (Surge suppressor: Supported Not supported)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

Rated load voltage: Changed (12VDC is not applicable.)

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed (Surge suppressor: Supported Not supported)

Input module

Output module

AJ55TB3-16D

(when positive common

type is used)

AJ55TB3-16D

(when negative common

type is used)

AJ55TB2-4R A20PB-04RS

AJ55TB2-8R A20PB-08RS

AJ55TB2-16R A20PB-16RS

AJ55TB2-4T A20PB-04U

AJ55TB2-8T A20PB-08U

AJ55TB2-16T A20PB-16U

A20SB-16UD

A20SB-16USD

6 - 2

Page 36

6 REPLACING THE I/O MODULES

I/OLINK series model AnyWire DB A20 series alternative model

Product Model name Model name Remarks (restrictions)

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

Number of input points: 2 4

Wiring: 3-wire 2-wire

A negative common type cannot be used.

(Output part)

Number of output points: 2 4

2 points/common All points independent

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

Number of input points: 2 4

Wiring: 3-wire 2-wire

A positive common type cannot be used.

(Output part)

Number of output points: 2 4

2 points/common All points independent

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

Wiring: 3-wire 2-wire

A negative common type cannot be used.

(Output part)

4 points/common All points independent

I/O module

AJ55TB32-4DR

(when positive common

type is used)

AJ55TB32-4DR

(when negative common

type is used)

AJ55TB32-8DR

(when positive common

type is used)

A20SB-04U

+ A20PB-04RS

A20SB-04US

+ A20PB-04RS

A20SB-04U

+ A20PB-04RS

6 - 3

Page 37

6 REPLACING THE I/O MODULES

I/OLINK series model AnyWire DB A20 series alternative model

Product Model name Model name Remarks (restrictions)

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

Wiring: 3-wire 2-wire

A positive common type cannot be used.

(Output part)

4 points/common All points independent

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

A negative common type cannot be used.

(Output part)

8 points/common All points independent

(1) External wiring: Changed

(2) Number of modules: Changed (Two modules are required.)

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Changed (The voltage that can be used is equivalent.)

Rated load current: Not changed

Maximum switching frequency:

Changed (3600 times/hour 20 times/minute)

(5) Functions: Changed

(Input part)

A positive common type cannot be used.

(Output part)

8 points/common All points independent

I/O module

AJ55TB32-8DR

(when negative common

type is used)

AJ55TB32-16DR

(when positive common

type is used)

AJ55TB32-16DR

(when negative common

type is used)

A20SB-04US

+ A20PB-04RS

A20SB-08UD

+ A20PB-08RS

A20SB-08USD-1

+ A20PB-08RS

6 - 4

Page 38

6 REPLACING THE I/O MODULES

I/OLINK series model AnyWire DB A20 series alternative model

Product Model name Model name Remarks (restrictions)

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Not changed

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed

(Input part)

Number of input points: 2 8

(Output part)

Number of output points: 2 8

Surge suppressor: Supported Not supported

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Not changed

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed

(Input part)

Number of input points: 4 8

(Output part)

Number of output points: 4 8

Surge suppressor: Supported Not supported

(1) External wiring: Changed

(2) Number of modules: Not changed

(3) Program: Changed

(4) Specifications:

(Input part)

Rated input voltage: Not changed

Rated input current: Not changed

ON voltage/ON current: Changed

OFF voltage/OFF current: Changed

Input resistance: Not changed

(Output part)

Rated load voltage: Not changed

Rated load current: Changed (0.5A/point 0.2A/point)

(5) Functions: Changed

(Input part)

None

(Output part)

Surge suppressor: Supported Not supported

I/O module

AJ55TB32-4DT A20XB-16UD

AJ55TB32-8DT A20XB-16UD

AJ55TB32-16DT A20XB-16UD

6 - 5

Page 39

6 REPLACING THE I/O MODULES

6.2 I/O Module Specifications Comparisons

6.2.1 Input module specifications comparisons

(1) Comparisons between AJ55TB3-4D and A20SB-04U

: Compatible, : Partially changed, ×: Not compatible

Specifications AJ55TB3-4D A20SB-04U

Number of input points 4 points 4 points

External input ↔ Internal circuit:

Insulation method

Input type Positive/negative common shared type Positive common type

Rated input voltage 24VDC 24VDC

Rated input current Approx. 7mA Approx. 7mA

Operating voltage range

Maximum simultaneous on

input point

ON voltage/ON current 14VDC or higher/3.5mA or higher 16VDC or higher/5.5mA or higher

OFF voltage/OFF current 6VDC or lower/1.7mA or lower 8VDC or lower/2mA or lower

Input resistance Approx. 3.3k Approx. 3.3k

Response

time

Common terminal

arrangement

Operation indicator ON indication (LED) ON indication (LED)

External wiring method

Applicable wire size

Applicable crimping

terminal

I/O module

power

supply

External dimensions 50(H) × 82(W) × 66(D) mm 40(H) × 65(W) × 60(D) mm The shape is different.

Installation method

Weight 0.2kg 0.09kg

OFF ON 10ms or less 1ms or less

ON OFF 10ms or less 1ms or less

Voltage 15.6 to 27.6VDC

Current 35mA 50mA

Internal circuit ↔ Transmission circuit:

16-point terminal block (M3 screw)

Photocoupler

Not insulated

19.2 to 26.4VDC

(ripple ratio within 5%)

100% 100%

4 points per common

(3-wire type terminal block)

Transmission circuit included

0.75 to 2mm

1.25-3, 1.25-YS3A,

2-S3, 2-YS3A

V1.25-3, V1.25-YS3A,

V2-S3, V2-YS3A

Screw mounted Screw mounted ×

Mounted to DIN rail Mounted to DIN rail

2

External input ↔ Internal circuit: Not insulated

Internal circuit ↔ Transmission circuit:

Photocoupler

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

4 points per common

(2-wire type terminal block)

10-point terminal block (M3 screw)

Transmission circuit included

(when the following applicable crimping

0.3 to 1.25mm

terminals are used: 0.75 to 2mm

For wire sizes 0.75 to 2mm

R2-3SL, RAV2-3SL, RAP2-3SL,

VD2-3S, VD2-3.5SS, VD2-3.5S,

VDAV2-3.5SS, VDAV2-3.5S

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

2

2

Compat-

ibility

2

)

*1 For the negative common type, use A20SB-04US.

*2 Check the specifications of the sensors or switches to be connected to the A20SB-04U.

Precautions for

replacement

The insulated locations are

different.

A negative common type

cannot be used.

Operating voltage range is

different.

ON voltage and ON current

are increased.

OFF voltage and OFF current

are increased.

To connect an item such as a

3-wire type sensor, an

external common terminal

block is required.

Wiring must be changed.

Existing wires can be used but

applicable crimping terminals

are different.

For details, refer to Section

6.3.

Operating voltage range is

different.

Because the current

consumption has increased,

the current capacity must be

reviewed.

Because mounting hole size is

different, reworking is

required.

The A20SB-04U can be

mounted to the existing DIN

rail.

*1

*2

*2

6 - 6

Page 40

6 REPLACING THE I/O MODULES

(2) Comparisons between AJ55TB3-4D and A20SB-04US

: Compatible, : Partially changed, ×: Not compatible

Specifications AJ55TB3-4D A20SB-04US

Number of input points 4 points 4 points

External input ↔ Internal circuit:

Insulation method

Input type Positive/negative common shared type Negative common type

Rated input voltage 24VDC 24VDC

Rated input current Approx. 7mA Approx. 7mA

Operating voltage range

Maximum simultaneous on

input point

ON voltage/ON current 14VDC or higher/3.5mA or higher 16VDC or higher/5.5mA or higher

OFF voltage/OFF current 6VDC or lower/1.7mA or lower 8VDC or lower/2mA or lower

Input resistance Approx. 3.3k Approx. 3.3k

Response

time

Common terminal

arrangement

Operation indicator ON indication (LED) ON indication (LED)

External wiring method

Applicable wire size

Applicable crimping

terminal

I/O module

power

supply

External dimensions 50(H) × 82(W) × 66(D) mm 40(H) × 65(W) × 60(D) mm The shape is different.

Installation method

Weight 0.2kg 0.09kg

OFF ON 10ms or less 1ms or less

ON OFF 10ms or less 1ms or less

Voltage 15.6 to 27.6VDC

Current 35mA 43mA

Internal circuit ↔ Transmission circuit:

16-point terminal block (M3 screw)

Photocouplerd

Not insulated

19.2 to 26.4VDC

(ripple ratio within 5%)

100% 100%

4 points per common

(3-wire type terminal block)

Transmission circuit included

0.75 to 2mm

1.25-3, 1.25-YS3A,

2-S3, 2-YS3A

V1.25-3, V1.25-YS3A,

V2-S3, V2-YS3A

Screw mounted Screw mounted ×

Mounted to DIN rail Mounted to DIN rail

2

External input ↔ Internal circuit: Not insulated

Internal circuit ↔ Transmission circuit:

10-point terminal block (M3 screw)

(when the following applicable crimping

terminals are used: 0.75 to 2mm

Photocoupler

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

4 points per common

(2-wire type terminal block)

Transmission circuit included

0.3 to 1.25mm

For wire sizes 0.75 to 2mm

R2-3SL, RAV2-3SL, RAP2-3SL,

VD2-3S, VD2-3.5SS, VD2-3.5S,

VDAV2-3.5SS, VDAV2-3.5S

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

2

2

Compat-

ibility

2

)

Precautions for

replacement

The insulated locations are

different.

A negative common type

cannot be used.

Operating voltage range is

different.

ON voltage and ON current

are increased.

OFF voltage and OFF current

are increased.

To connect an item such as a

3-wire type sensor, an

external common terminal

block is required.

Wiring must be changed.

Existing wires can be used but

applicable crimping terminals

are different.

For details, refer to Section

6.3.

Operating voltage range is

different.

Because the current

consumption has increased,

the current capacity must be

reviewed.

Because mounting hole size is

different, reworking is

required.

The A20SB-04US can be

mounted to the existing DIN

rail.

*1

*2

*2

6 - 7

*1 For the positive common type, use A20SB-04U.

*2 Check the specifications of the sensors or switches to be connected to the A20SB-04US.

Page 41

6 REPLACING THE I/O MODULES

(3) Comparisons between AJ55TB3-8D and A20SB-08UD

: Compatible, : Partially changed, ×: Not compatible

Specifications AJ55TB3-8D A20SB-08UD

Number of input points 8 points 8 points

External input ↔ Internal circuit:

Insulation method

Input type Positive/negative common shared type Positive common type

Rated input voltage 24VDC 24VDC

Rated input current Approx. 7mA Approx. 7mA

Operating voltage range

Maximum simultaneous on

input point

ON voltage/ON current 14VDC or higher/3.5mA or higher 16VDC or higher/5.5mA or higher

OFF voltage/OFF current 6VDC or lower/1.7mA or lower 8VDC or lower/2mA or lower

Input resistance Approx. 3.3k Approx. 3.3k

Response

time

Common terminal

arrangement

Operation indicator ON indication (LED) ON indication (LED)

External wiring method

Applicable wire size

Applicable crimping

terminal

I/O module

power

supply

External dimensions 50(H) × 114(W) × 66(D) mm 40(H) × 140(W) × 60(D) mm The shape is different.

Installation method

Weight 0.3kg 0.18kg

OFF ON 10ms or less 1ms or less

ON OFF 10ms or less 1ms or less

Voltage 15.6 to 27.6VDC

Current 45mA 117mA

Internal circuit ↔ Transmission circuit:

24-point terminal block (M3 screw)

Photocoupler

Not insulated

19.2 to 26.4VDC

(ripple ratio within 5%)

100% 100%

8 points per common

(3-wire type terminal block)

Transmission circuit included

0.75 to 2mm

1.25-3, 1.25-YS3A,

2-S3, 2-YS3A

V1.25-3, V1.25-YS3A,

V2-S3, V2-YS3A

Screw mounted Screw mounted ×

Mounted to DIN rail Mounted to DIN rail

2

External input ↔ Internal circuit: Not insulated

Internal circuit ↔ Transmission circuit:

30-point terminal block (M3 screw)

(when the following applicable crimping

terminals are used: 0.75 to 2mm

Photocoupler

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

8 points per common

(3-wire type terminal block)

Transmission circuit included

0.3 to 1.25mm

For wire sizes 0.75 to 2mm

R2-3SL, RAV2-3SL, RAP2-3SL,

VD2-3S, VD2-3.5SS, VD2-3.5S,

VDAV2-3.5SS, VDAV2-3.5S

21.6 to 27.6VDC

(ripple voltage 0.5Vp-p or less)

2

2

Compat-

ibility

2

)