Page 1

MELSEC FX Series

Programmable Controllers

User's Manual

(Detailed Volume)

FX2N-64CL-M

CC-Link/LT Master Block

MITSUBISHI ELECTRIC

MITSUBISHI ELECTRIC

01 01 2003

JY997D08501

Version A

INDUSTRIAL AUTOMATION

Page 2

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of the FX

2N

-64CL-M CC-Link/LT Master Block. This

Manual should be read and understood before attempting to install or use the unit.

• Further information can be found in the FX

1N

Series Hardware Manual, FX2N Series

Hardware Manual, FX Series Programming Manual II, CL1PAD1 USER’S MANUAL

(Detailed Volume) and manual of CC-Link/LT Remote Stations.

• If the user is in any doubt at any stage of the installation of the FX

2N

-64CL-M CC-Link/LT

Master Block always consult a professional electrical engineer who is qualified and trained

to local and national standards that apply to the installation site.

• If the user is in any doubt about the operation or use of FX

2N

-64CL-M CC-Link/LT Master

Block please consult the nearest Mitsubishi Electric distributor.

• This manual is subject to change without notice.

FX2N-64CL-M CC-Link/LT Master Block

Page 3

i

FX2N-64CL-M CC-Link/LT Master Block

USER’S MANUAL (Detailed Volume)

Manual number : JY997D08501

Manual revision : A

Date : January 2003

FX2N-64CL-M CC-Link/LT Master Block

Page 4

FX2N-64CL-M CC-Link/LT Master Block

ii

Page 5

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing back

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However, to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you, the reader, to fill in your comments and fax them back to us. We look

forward to hearing from you.

Fax numbers: Your name: ...................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company: .............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location:................................................

Spain (34) 93-589-1579 .....................................................................

United Kingdom (01707) 278-695

Please tick the box of your choice

What condition did the manual arrive in?

!

Good

!

Minor damage

!

Unusable

Will you be using a folder to store the manual?

!

Ye s

!

No

What do you think to the manual presentation?

!

Tidy

!

Unfriendly

Are the explanations understandable?

!

Ye s

!

Not too bad

!

Unusable

Which explanation was most difficult to understand: ..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

!

Ye s

!

No

If so,which: ..................................................................................................................................

What do you think to the manual layout?

!

Good

!

Not too bad

!

Unhelpful

If there one thing you would like to see improved, what is it?.....................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Do you have any comments in general about the Mitsubishi manuals? .....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

FX2N-64CL-M CC-Link/LT Master Block

iii

Page 6

FX2N-64CL-M CC-Link/LT Master Block

iv

Page 7

FX2N-64CL-M CC-Link/LT Master Block

v

Safety guidelines for the User and Protection of the FX2N-64CL-M

This manual provides information for the use of the FX2N-64CL-M. The manual has been

written to be used by trained and competent personnel. The definition of such a person or

persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see Note) should be trained to use that

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the operation of the

completed equipment.

Note :

Note: the term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the Symbols Used in this Manual

At various times throughout out this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will now be listed with a brief description of

its meaning.

Hardware Warnings

1) Indicates that the identified danger

WILL

cause physical and property damage.

2) Indicates that the identified danger could

POSSIBLY

cause physical and property

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

Page 8

FX2N-64CL-M CC-Link/LT Master Block

vi

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Please contact a Mitsubishi distributor for more information concerning applications in life

critical situations or high reliability.

Page 9

vii

Table of Contents

Safty guidelines ....................................................................................v

Generic Names and Abbreviations...........................................................1

1. Outline ...................................................................................................1-1

1.1 Product Outline .................................................................................................... 1-1

1.2 Features .............................................................................................................. 1-1

1.3 Name and assignment of each part ....................................................................1-2

2. Specifications ........................................................................................2-1

2.1 General specifications .........................................................................................2-2

2.2 Network wiring specifications .............................................................................. 2-2

2.3 Performance specifications ................................................................................. 2-3

2.4 Outside Dimensions ............................................................................................ 2-4

3. System Startup Procedure ....................................................................3-1

4. System Configuration ............................................................................4-1

4.1 Total configuration ............................................................................................... 4-2

4.2 PLC connection ...................................................................................................4-3

4.2.1 Applicable PLC and number of connectable FX2N-64CL-M ...................................... 4-3

4.3 Power adapters installation concept.................................................................... 4-3

4.4 Power adapter installation condition....................................................................4-3

5. Handling Cautions .................................................................................5-1

5.1 Installation ........................................................................................................... 5-2

5.1.1 Installation direction................................................................................................... 5-2

5.1.2 DIN rail installation .................................................................................................... 5-2

5.1.3 Direct installation ....................................................................................................... 5-2

6. Connection of Cables, Connectors and Terminating Resistors.............6-1

6.1 Connection of units using flat cables dedicated to CC-Link/LT ........................... 6-2

6.2 How to attach connectors used for dedicated flat cable ...................................... 6-2

6.2.1 How to attach terminating resistor ............................................................................. 6-4

6.2.2 Wiring check.............................................................................................................. 6-5

7. Various Modes ......................................................................................7-1

7.1 ONLINE mode (DIP switch bit 6 = OFF, bit 7 = OFF).......................................... 7-1

7.2 CONFIG mode (DIP switch bit 6 = ON, bit 7 = OFF)...........................................7-1

7.3 TEST mode (self-loop-back test) (DIP switch bit 6 = OFF, bit 7 = ON)............... 7-1

FX2N-64CL-M CC-Link/LT Master Block

Page 10

FX2N-64CL-M CC-Link/LT Master Block

viii

8. Assignment of I/O Nos. .........................................................................8-1

8.1 Relationship between I/O No. and point mode.................................................... 8-1

8.2 Example of I/O No. assignment ........................................................................... 8-2

8.3 Automatic I/O No. assignment ............................................................................. 8-3

8.3.1 Automatic I/O No. assignment procedure ................................................................. 8-3

8.4 Specification of reserved station.......................................................................... 8-3

8.4.1 Reserved station setting method ............................................................................... 8-4

8.5 Editing the detailed remote station information ................................................... 8-5

8.5.1 How to edit detailed remote station information ........................................................ 8-5

9. Data Link Processing Time ...................................................................9-1

9.1 Link scan time...................................................................................................... 9-1

9.1.1 Link scan time calculation formula ............................................................................ 9-1

9.1.2 Transmission delay time............................................................................................ 9-2

10.Assignment of Buffer Memory ............................................................10-1

10.1 Buffer memory list.............................................................................................. 10-1

10.2 Details of buffer memory ................................................................................... 10-2

10.2.1 Remote station connection information [BFM #0 (0h) to #3 (3h)]............................ 10-2

10.2.2 Link error station information [BFM #4 (4h) to #7 (7h)]............................................ 10-2

10.2.3 Remote I/O error information [BFM #8 (8h) to #11 (Bh)] ......................................... 10-4

10.2.4 Reserved station information [BFM #16 (10h) to #19 (13h)] ................................... 10-4

10.2.5 Number of required input blocks [BFM #20 (14h)]................................................... 10-5

10.2.6 Number of required output blocks [BFM #21 (15h)] ................................................ 10-5

10.2.7 Data link final station information [BFM #22 (16h)].................................................. 10-5

10.2.8 External switch information [BFM #26 (1Ah)] .......................................................... 10-5

10.2.9 Command [BFM #27 (1Bh)] .................................................................................... 10-6

10.2.10Status information [BFM #28 (1Ch)] ....................................................................... 10-7

10.2.11Detailed error information [BFM #29 (1Dh)]............................................................ 10-8

10.2.12Model code [BFM #30 (1Eh)]................................................................................ 10-10

10.2.13Detailed remote station information [BFM #32 (20h) to #95 (5Fh)] ...................... 10-10

11.Program Example...............................................................................11-1

11.1 System Startup Procedure ................................................................................ 11-3

11.2 System configuration ......................................................................................... 11-4

11.3 Device assignment ............................................................................................ 11-5

11.4 Program example .............................................................................................. 11-6

12.Troubleshooting..................................................................................12-1

12.1 Status of each station during abnormal operation .............................................12-1

12.2 Confirmation of status based on status indicator LEDs and countermeasures . 12-2

12.2.1 ONLINE mode ......................................................................................................... 12-2

12.2.2 CONFIG mode ........................................................................................................ 12-3

12.2.3 TEST mode (self-loop-back test)............................................................................. 12-4

12.3 Countermeasures based on detailed error information .....................................12-5

12.4 Self-loop-back test ............................................................................................. 12-7

12.4.1 Operating procedure ............................................................................................... 12-7

12.5 Prevention of erroneous inputs to and outputs from remote I/O unit.................12-9

Page 11

Generic Names and Abbreviations

1

Generic Names and Abbreviations

The generic names and abbreviations shown below are used within explanation contained in

this manual.

Generic name/abbreviation Description

FX

2N

-64CL-M CC-Link/LT Master block FX2N-64CL-M

Master station

Station which controls the data link system.

One master station is required in one system.

Remote I/O station

Remote station which deals with bit information only

(to execute I/Os with external equipment)

(such as CL1XY2-DT1D5S and CL1X4-D1B2).

Remote station

General name for remote I/O station.

Controlled by the master station.

Power adapter

Supply of 24V DC to the CC-Link/LT system.

At least one power adapter is required per system.

FX2N-64CL-M CC-Link/LT Master Block

Page 12

FX2N-64CL-M CC-Link/LT Master Block Generic Names and Abbreviations

2

MEMO

Page 13

Outline 1

1-1

1. Outline

1.1 Product Outline

The CC-Link/LT master block FX2N-64CL-M can be connected to the FX Series PLC.

The CC-Link/LT system can be constructed with an FX Series PLC as the master station.

1.2 Features

The FX2N-64CL-M has the following features:

1) Reduced wiring time

The adoption of flat cabling for CC-Link/LT and special connector allow for reduced wiring

times.

2) Simplified programs

Link devices within CC-Link/LT are assigned to X/Y devices in the PLC, therefore, programs

can be prepared without recognizing the network.

3) High speed refresh

High speed refresh (128 points/0.3 ms) is realized (as and when the transmission speed is

2.5 Mbps, 16-point mode is selected and eight stations are connected to the network).

4) Slave station disconnection function

Even if some units are down due to an abnormality, communication with the remaining

functional units is not affected.

However, if the trunk line cable is broken, data link is disabled for all stations.

5) Automatic return function

When a unit that was disconnected due to an abnormality is restored to it’s normal status,

the unit will return to the data link automatically and continue data transfer.

6) Data link stop/re-start

While data link is being executed, the user can stop and start the link again.

7) Remote station type information storage

In the CONFIG mode, the number of points occupied by remote stations, I/O types, etc. is

detected, and stored within the EEPROM.

8) Mode selection

The ONLINE, CONFIG and TEST modes are available.

ONLINE mode : Executes the data link for the CC-Link/LT system.

Select the ONLINE mode usually.

CONFIG mode: Allows automatic assignment of the I/O No.

When remote stations are planned to be added in the future, reserved

stations can be specified and detailed remote station information can be

edited.

After constructing the CC-Link/LT system, make sure to execute the

CONFIG mode once to assign the I/O No.

TEST mode : Executes self-diagnosis to judge whether the FX

2N

-64CL-M itself is in the

master station.

If the data link cannot be executed normally, the self-diagnosis function

analyses the FX

2N

-64CL-M itself.

FX2N-64CL-M CC-Link/LT Master Block

Page 14

FX2N-64CL-M CC-Link/LT Master Block Outline 1

1-2

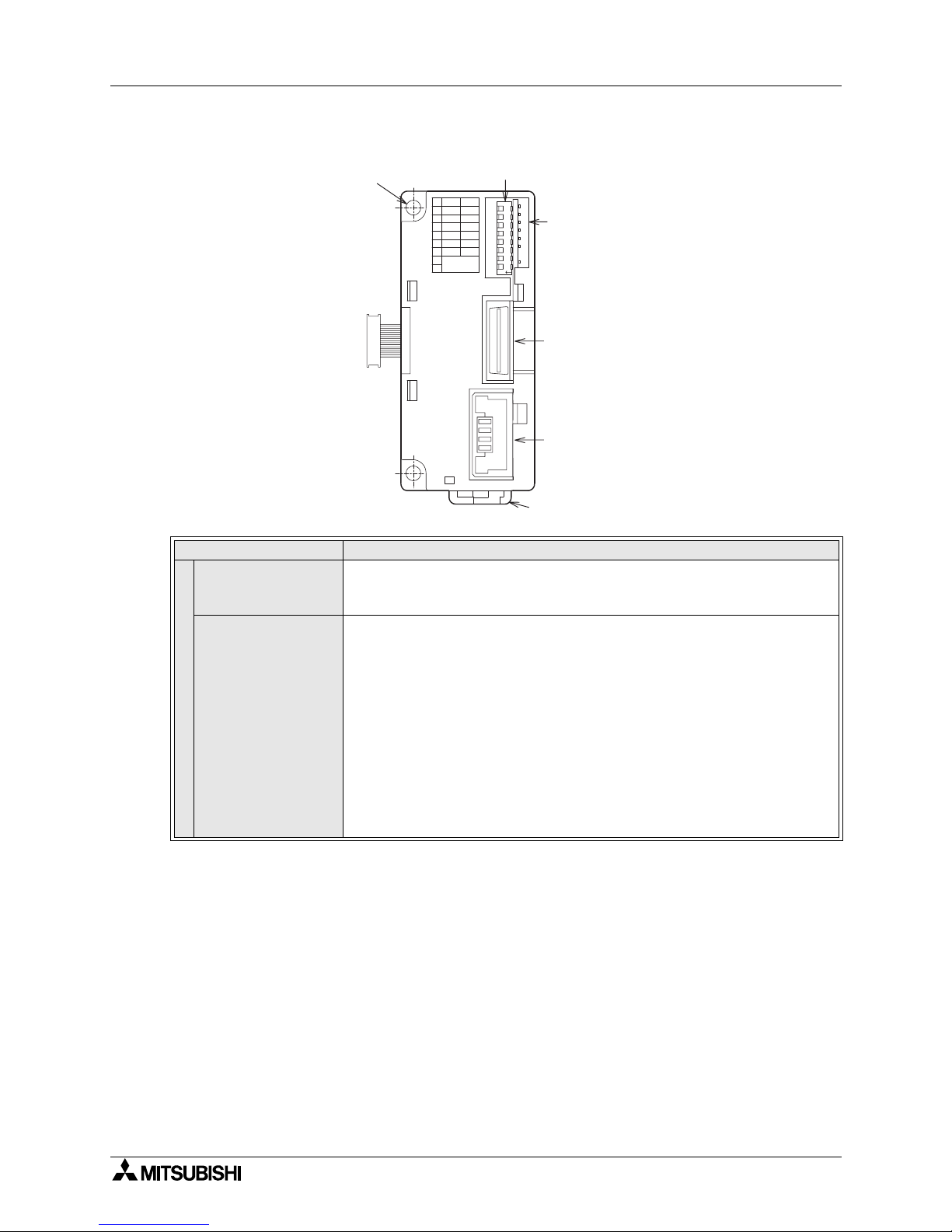

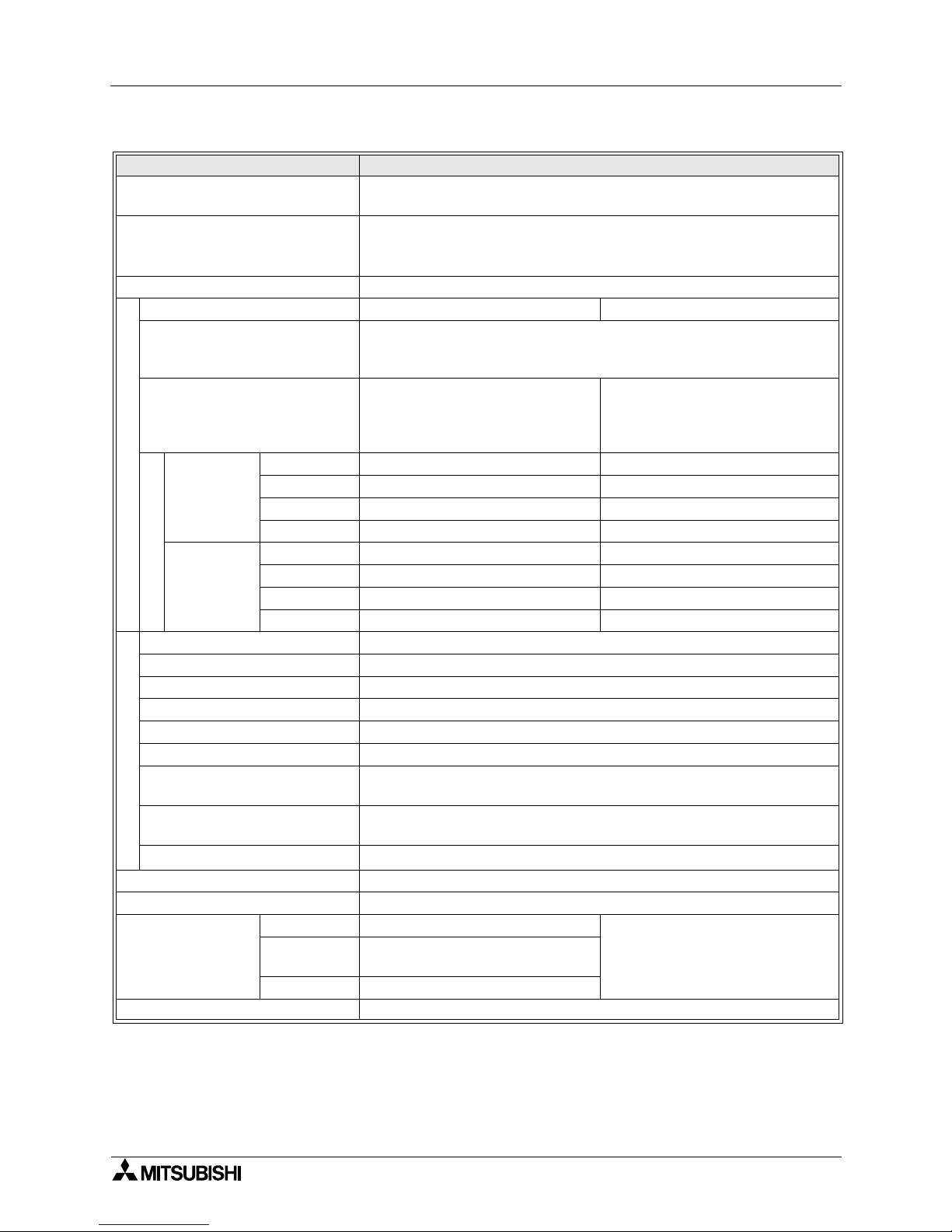

1.3 Name and assignment of each part

Name Description

Status indicator LEDs

POWER

<ONLINE mode/CONFIG mode/TEST mode>

Lit :Power is supplied

Extinguished :Power is not supplied

RUN

<ONLINE mode>

Lit :FX

2N

-64CL-M is operating normally

Extinguished :FX

2N

-64CL-M is abnormal

Power is interrupted

EEPROM read error (sum mismatch) occurred

<CONFIG mode>

Lit :FX

2N

-64CL-M is operating normally

Extinguished :FX

2N

-64CL-M is abnormal

Power is interrupted

<TEST mode>

Lit :FX

2N

-64CL-M is operating normally

Extinguished :FX

2N

-64CL-M is abnormal

Power is interrupted

DIP switch for operation setting

Extension cable

connected to PLC

123456

7

8

OFFON

B RATE

16pts. 4pts.

ONLINE

-

TEST

-

3

2

1

4

5

6

7

8

--

CONFIG ONLINE

FX2N-64CL-M

--

O

N

Extension connector

connected to an extension

block/unit or special

block/unit of the PLC

Connector for

CC-Link/LT interface

Hook for installation to DIN rail

2-φ4.5(0.18") mounting hole

(M4 mounting screw)

Status indicator LEDs

LINK

Page 15

FX2N-64CL-M CC-Link/LT Master Block Outline 1

1-3

Status indicator LEDs

ERR.

<ONLINE mode>

Lit :Communication speed setting error occurred

EEPROM read error (sum mismatch) occurred

Flickering :Power supplied for communication is abnormal

DIP switch for operation setting was changed during

operation

Extinguished :FX

2N

-64CL-M is operating normally

<CONFIG mode>

Lit :Communication speed setting error occurred

EEPROM write error occurred

Flickering :Power supplied for communication is abnormal

DIP switch for operation setting was changed during

operation

Extinguished :FX

2N

-64CL-M is operating normally

<TEST mode>

Lit :Communication speed setting error occurred

Flickering :Power supplied for communication is abnormal

DIP switch for operation setting was changed during

operation

Extinguished :FX

2N

-64CL-M is operating normally

L RUN

<ONLINE mode/CONFIG mode>

Lit :Data link is executed

Extinguished :Data link is stopped

<TEST mode>

Lit :Self-loop back Test was finished normally

Extinguished :Self-loop back Test was finished abnormally

(Extinguished while the self-loop back Test is executed)

L ERR.

<ONLINE mode>

Lit :Use station number discrepancy

(when BFM#32(20h) to #95(5Fh) is edited, the station

numbers are checked.)

Outside-control-range station error occurred

Flickering :Stations are abnormal

Extinguished :Data link is executed normally

<CONFIG mode>

Lit :Use station number discrepancy

(When the power is turned ON while a remote module is

attached and the following setting is made: number of

connected stations varies by editing BFM#32(20h) to

#95(5Fh))

Flickering :All stations are abnormal

(When power is turned ON while no remote module is

attached and then BFM#32(20h) to #95(5Fh) is edited)

Extinguished :Data link is executed normally

<TEST mode>

Lit :Self-loop back Test was finished abnormally

Extinguished :Self-loop back Test was finished normally

(Extinguished while the self-loop back Test is executed)

SD

<ONLINE mode/CONFIG mode/TEST mode>

Lit: Data is currently being sent

RD

<ONLINE mode/CONFIG mode/TEST mode>

Lit: Data is currently being received

Interface

Connector for the flat cable dedicated to the CC-Link/LT (24G/DB/DA/+24 V)

Name Description

Page 16

FX2N-64CL-M CC-Link/LT Master Block Outline 1

1-4

• Factory default, DIP switches are set OFF.

• The Test mode is selected when both the CONFIG and TEST modes are set ON

simultaneously.

• For each setting, the status at the time of power ON is valid.

(If a setting is changed after the power is set ON, such a change is invalid.)

CONFIGMODE

• Values held in BFM #32 (20h) to #95 (5Fh) that are changed online will cause a L ERR.

• No remote module attached during power ON will result in no L ERR.

• Remote module removed during operation will result in no L ERR.

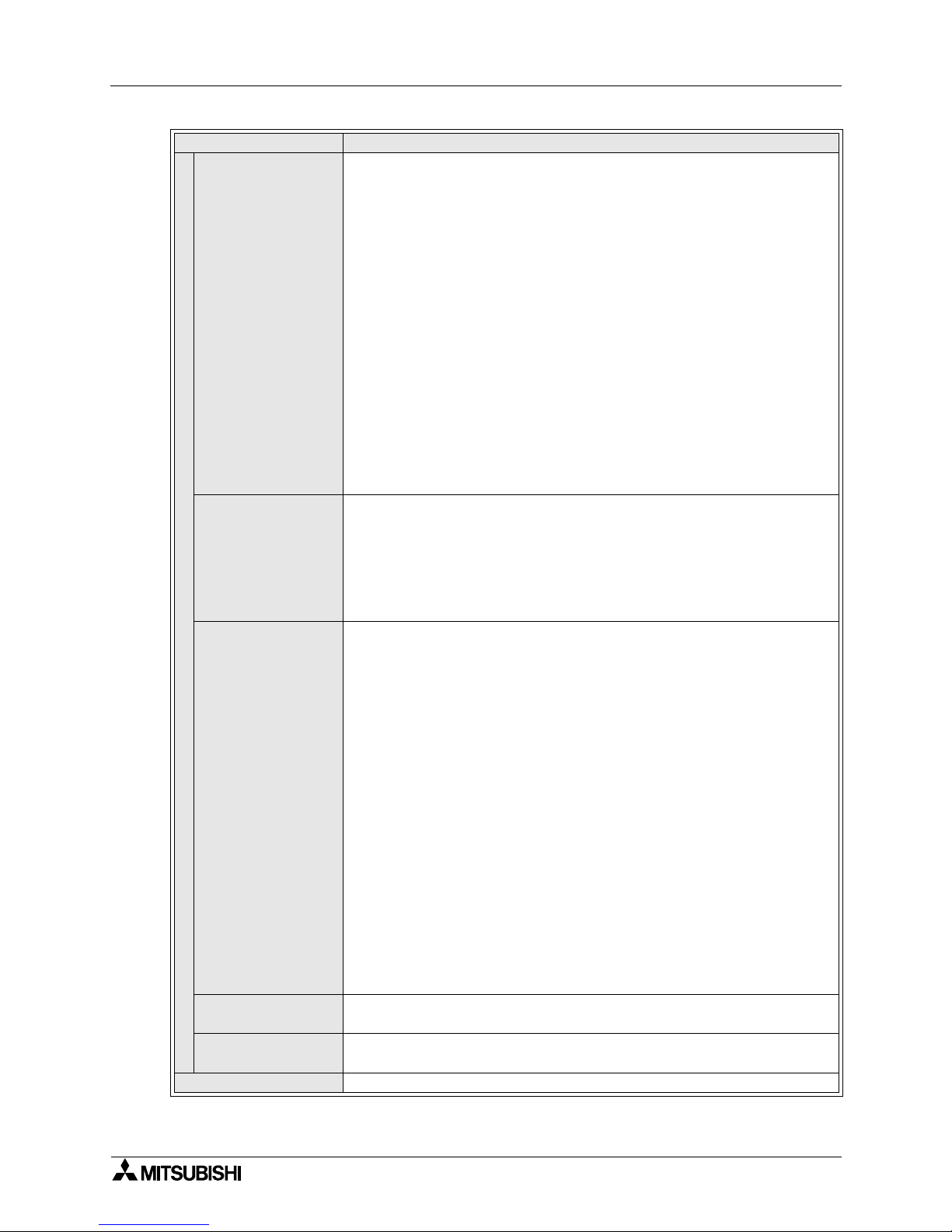

DIP switch for operation setting

1

B RATE

Communication speed setting

2

3 16pts/4pts

Point mode setting

(Select the number of I/O points per station.)

OFF:4-point mode (4 input points and 4 output points in each station)

ON :16-point mode (16 input points and 16 output points in each station)

4 --

Setting is disabled. (Make sure that it is OFF during operation.)

5 --

Setting is disabled. (Make sure that it is OFF during operation.)

6 CONFIG/ONLINE

CONFIG mode

OFF: ONLINE mode (normal operation)

ON : CONFIG mode (The information on the connected stations is saved to

the EEPROM.)

7 TEST/ONLINE

TEST mode

OFF: ONLINE mode (normal operation)

ON : TEST mode (Self-loop back Test)

8 --

Setting is disabled. (Make sure that it is OFF during operation.)

Name Description

Communication speed SW1 SW2

156 kbps OFF OFF

625 kbps ON OFF

2.5 Mbps OFF ON

Setting disabled ON ON

Page 17

Specifications 2

2-1

2. Specifications

This section explains the specifications of the FX2N-64CL-M.

DESIGN PRECAUTIONS

When a remote I/O unit fails, outputs may randomly set ON or OFF, therefore, build an

external monitoring circuit that will monitor any input signals that could cause a serious

accident.

DESIGN PRECAUTIONS

• Do not bind control and flat cables dedicated to CC-Link/LT together with power cables.

Keep control and flat cables dedicated to CC-Link/LT away from major circuits and power

cables by 100 mm (3.93") or more.

It may cause a malfunction due to noise interference.

• Use the FX

2N

-64CL-M in such status that any force is not applied on connectors for CCLink/LT interface and flat cables dedicated to CC-Link/LT.

If any force is applied, wire breakage and failure may be caused.

STARTING AND MAINTENANCE PRECAUTIONS

• Do not touch the terminals while the power is ON. It may cause an electric shock or

malfunction.

• Shut down all phases of the power supply outside the master block before starting any

cleaning procedures.

If the power is not disconnected from all sources, the FX

2N

-64CL-M may fail or

malfunction.

STARTING AND MAINTENANCE PRECAUTIONS

• Do not disassemble or modify the FX2N-64CL-M.

Doing so may cause failure, malfunction, injury, or fire.

• The case of the FX

2N

-64CL-M is made of resin.

Do not drop or apply strong impacts to the FX

2N

-64CL-M.

DISPOSAL PRECAUTIONS

• Treat the FX2N-64CL-M as industrial waste when disposing of the product.

FX2N-64CL-M CC-Link/LT Master Block

Page 18

FX2N-64CL-M CC-Link/LT Master Block Specifications 2

2-2

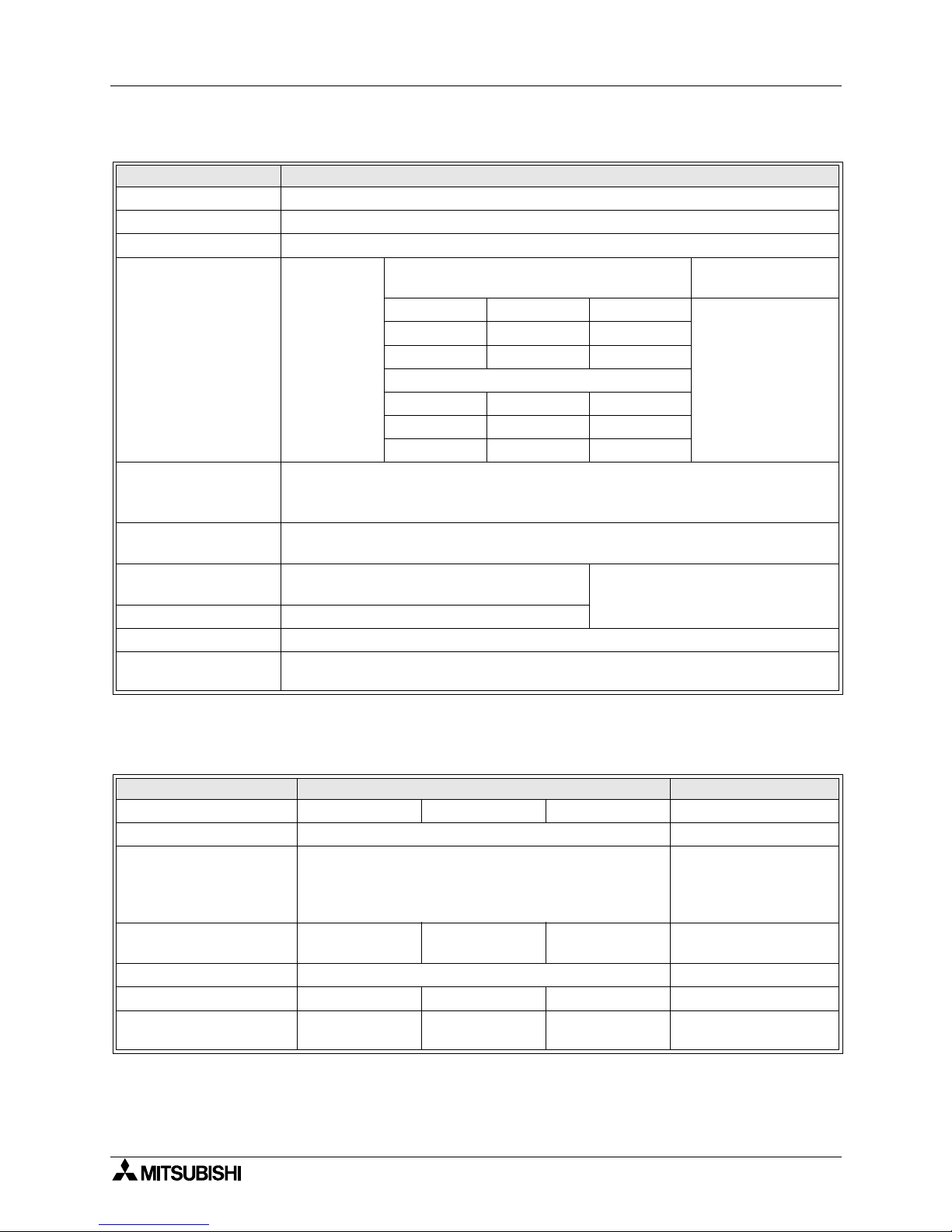

2.1 General specifications

2.2 Network wiring specifications

Item Specification

Operating temperature 0 to 55°C (32 to 131°F)

Storage temperature -20 to 70°C (-4 to 158°F)

Operating humidity 35 to 85%RH (Dew condensation should not be allowed.)

Vibration resistance

Conforming to

EN68-2-6

Direct mounting

Number of sweep

times

Frequency Acceleration Half amplitude

10 times in each of

the X, Y and Z

directions (for 80 min)

10 to 57Hz -- 0.075mm

57 to 150Hz 9.8m/s

2

--

DIN rail mounting

Frequency Acceleration Half amplitude

10 to 57Hz -- 0.035mm

57 to 150Hz 4.9m/s

2

--

Shock resistance

In conformance to EN 68-2-27

(147 m/s

2

, working time: 11 ms, half sine wave, three times in each of X, Y and Z

directions)

Noise immunity

By noise simulator of noise voltage = 1,000 Vp-p, noise width = 1 µs, rising = 1 ns,

cycle = 30 to 100 Hz

Dielectric withstand

voltage

500V AC for 1 min

In conformance to JEM-1021

Between case and PLC grounding

terminal

Isolation resistance 5 MW or more by 500V DC megger

Operating ambience Do not use in a corrosive gas, flammable gas or conductive dust environment.

Grounding

Grounding resistance 100W or less

(Common grounding with strong electrical systems.)

Item Specification Remarks

Communication speed 2.5Mbps 625kbps 156kbps --

Distance between stations No restriction --

Maximum number of

modules connected in 1

drop line

8 units

Maximum number of

remote I/O units

connected per branch in

a drop line

Maximum trunk length 35m (114' 9") 100m (328' 1") 500m (1640' 5")

Cable length between

terminating resistors

T-branch interval No restriction --

Maximum drop length 4m (13' 1") 16m (52' 5") 60m (196' 10") Cable length per branch

Cumulative drop line

length

15m (49' 2") 50m (164' 0") 200m (656' 2") Sum of all drop lines

Page 19

FX2N-64CL-M CC-Link/LT Master Block Specifications 2

2-3

2.3 Performance specifications

*1 When connected to an FX1N Series PLC, up to two FX2N-64CL-M can be connected to each of the

main and extension units.

*2 The FX

2N

-64CL-M draws 190mA from the 5V DC source.

The total 5V consumption of all special function blocks connected to a main unit or extension unit

must not exceed the 5V source capacity of the system.

(Refer to the Hardware manual of the applicable PLC)

Item Specification

Applicable PLC

FX

1N

/FX2N/FX

2NC

Series PLC (Section 4.3)

(FX

2NC

-CNV-IF is required when FX

2NC

Series PLC is connected.)

Number of connectable master

blocks

FX

1N

Series: Up to 4

*1

FX2N Series: Up to 8

*2

FX

2NC

Series: Up to 3

*2

Applicable point mode 4-point mode and 16-point mode (selectable by DIP switch)

Control specifications

4-point mode 16-point mode

Maximum number of link points

Connected to FX

1N

Series PLC: 128 points

Connected to FX

2N

/FX

2NC

Series PLC: 256 points

(including I/O points in PLC in each case)

Number of link points per station

( ) shows the number of link

points when composite I/O

module is used.

4 points (8 points) 16 points (32 points)

Link scan time

32 stations

Points 128 points 256 points

2.5Mbps 0.7ms 1.0ms

625kbps 2.2ms 3.8ms

156kbps 8.0ms 14.1ms

64 stations

Points 256 points 256 points

2.5Mbps 1.2ms 2.0ms

625kbps 4.3ms 7.4ms

156kbps 15.6ms 27.8ms

Communication specifications

Communication speed 2.5 Mbps, 625 kbps and 156 kbps (selectable by DIP switch)

Protocol BITR method (Broadcastpolling + Interval Timed Response)

Network topology T-branch

Error control method CRC

Number of connected stations 64 stations maximum

Remote station numbers 1 to 64

Master station connection

position

Connected at end of trunk line

RAS function

Communication error detection, automatic return to system, slave station

disconnection and internal loop back diagnosis

Connection cable

Dedicated flat cable (0.75 mm

2

× 4)

Number of occupied I/O points 8 points (fixed) + Number of connected remote I/O points

Current consumption inside 5V DC 190 mA (Supplied by PLC via extension connector)

24V DC power

supply

Voltage 20.4V to 28.8V DC

Supplied from power adapter via

connector for flat cable dedicated to

CC-Link/LT.

Current

consumption

25 mA

Initial current 35 mA

Mass (weight) 0.15 kg (0.33 lbs)

Page 20

FX2N-64CL-M CC-Link/LT Master Block Specifications 2

2-4

2.4 Outside Dimensions

FX2N-64CL-M

FX

2N

-64CL-M

RUN

ERR.

L RUN

L ERR.

SD

RD

POWER

43(1.70)

4(0.16)

2-φ4.5(0.18)

87(3.43)

90(3.55)

80(3.15)±0.5(0.02)(mounting size)

Unit: mm(inches)

Page 21

System Startup Procedure 3

3-1

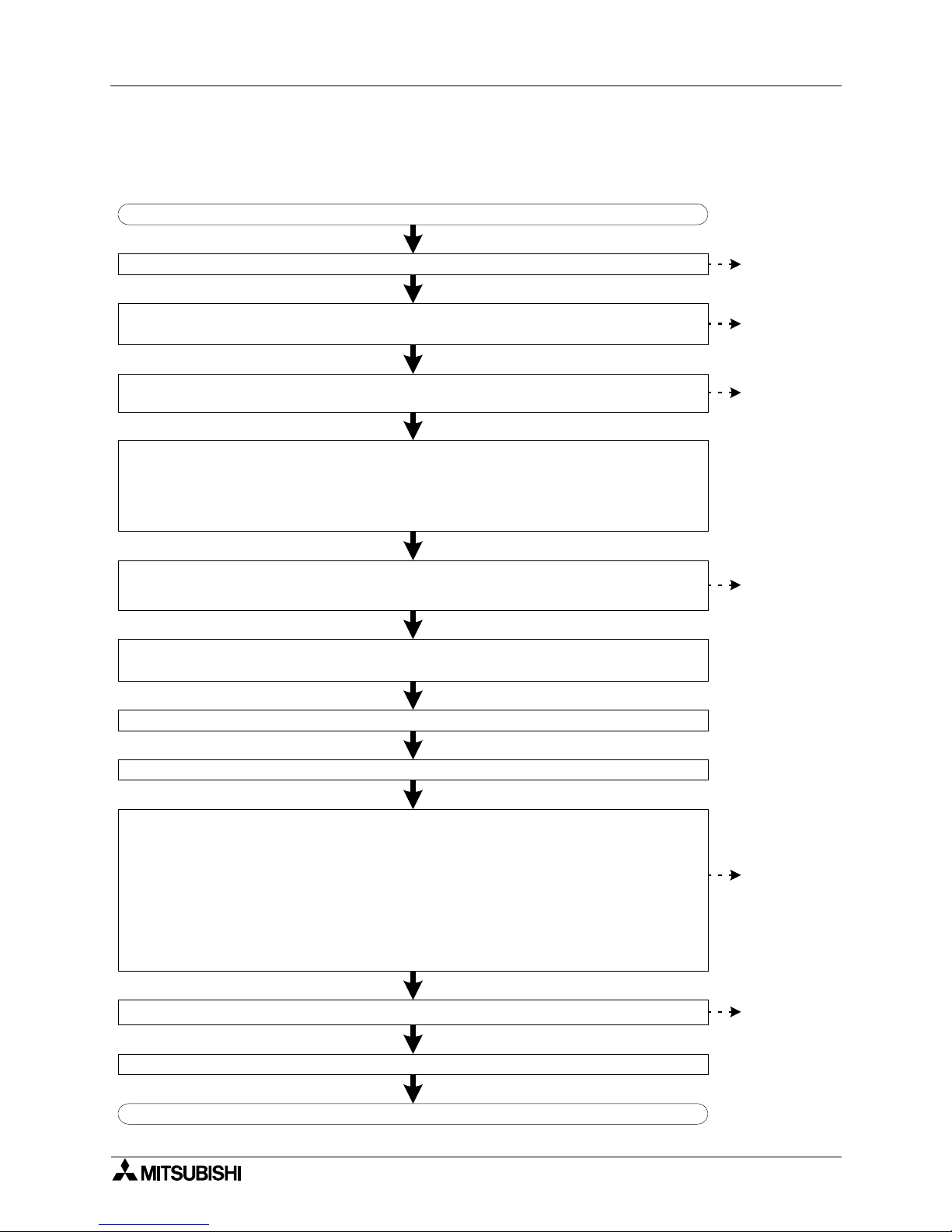

3. System Startup Procedure

Start up the CC-Link/LT system using the following procedure.

Start

Install the FX2N-64CL-M, remote I/O units and power adapter to the control panel and machine.

Connect the FX2N-64CL-M, remote I/O units and power adapter with the dedicated flat cables.

Connect terminating resistors at the both ends of the trunk line.

Terminating CONFIG mode

Turn OFF the power to the power adapter and main unit.

Set the DIP switch in the FX2N-64CL-M to the ONLINE mode.

Supply power to the power adapter before the main unit.

Confirming the operation based upon LEDs

FX

2N

-64CL-M

- Data link is normal: L RUN is lit.

- Data link is abnormal: L ERR. is lit or flickering.

- Setting is abnormal: The ERR. is lit.

Remote I/O unit

- Confirm remote station connection by checking buffer memory [BFM #0 (0h) to

#3 (3h)] in the FX

2N

-64CL-M.

- Confirm device operation using peripheral equipment for the PLC (with regard to monitorly and

forcing inputs + outputs ON and OFF).

Write a control program to the main unit.

Operate the system.

End

Set the transmission speed, point mode, station No., etc. of the FX2N-64CL-M and remote I/O units

using the DIP switches. (Set the FX2N-64CL-M to the CONFIG mode.)

Check the following items before turning the power ON.

- Confirm the installation status of the FX

2N

-64CL-M, remote I/O units and power adapter.

- Confirm the supply voltage for the power adapter.

- Confirm that the RUN/STOP switch for the main unit is set to STOP.

- Confirm that the same station No. is not used in two or more remote I/O units.

Executing CONFIG mode

Supply power to the power adapter before the main unit.

(Specify reserved stations and edit the detailed remote station information here if necessary.)

Refer to

Section 5.

Refer to

Section 6.

Refer to

Sections 1

and 7.

Refer to

Section 8.

Refer to

Sections 10

and 12.

Refer to

Section 11.

FX2N-64CL-M CC-Link/LT Master Block

Page 22

FX2N-64CL-M CC-Link/LT Master Block System Startup Procedure 3

3-2

MEMO

Page 23

System Configuration 4

4-1

4. System Configuration

This section explains the CC-Link/LT system configuration.

DESIGN PRECAUTIONS

When a remote I/O unit fails, outputs may randomly turn ON or OFF, therefore, build an

external monitoring circuit that will protect from any input signals that could cause a serious

accident.

DESIGN PRECAUTIONS

• Do not bind control cables and flat cables dedicated to CC-Link/LT together with power

cables.

Keep control cables and flat cables dedicated to CC-Link/LT away from major circuits and

power cables by 100 mm (3.93") or more.

It may cause a malfunction due to noise interference.

• Use the FX

2N

-64CL-M in anenvironment status that any force is not directly applied on

connectors for

CC-Link/LT interface and flat cables dedicated to CC-Link/LT.

If any force is applied, wire breakage and failure may occur.

FX2N-64CL-M CC-Link/LT Master Block

Page 24

FX2N-64CL-M CC-Link/LT Master Block System Configuration 4

4-2

4.1 Total configuration

This paragraph describes the system configuration and cautions for CC-Link/LT.

• Connect the master station, power adapter and remote stations using the flat cables

dedicated to CC-Link/LT and the connectors for dedicated flat cables.

• The connection order of remote stations has no relevance to the station No.

Even if the station No. of remote stations is not consecutive, no error will occur in the data

link.

• In the CC-Link/LT system, terminating resistors should be connected to both ends of the

trunk line.

Connect the terminating resistor on the FX

2N

-64CL-M side to a position within 200 mm

(7.87") from the FX

2N

-64CL-M.

• Make sure to lay out the master block on one side of the trunk line.

• Up to 64 remote stations can be connected to one FX

2N

-64CL-M as far as the condition

shown in the table below are satisfied.

• Equipment for CC-Link cannot be connected to the CC-Link/LT system.

On the contrary, equipment for CC-Link/LT cannot be connected to the CC-Link system.

• Refer to the respective instruction manuals when installing the power adapter or remote I/O

units.

• Refer to the homepage of the CC-Link Partner Association (CLPA) "http://www.cc-link.org/"

for details concerning flat cabling, terminating resistors and connector for CC-Link/LT.

Item Specification Remarks

Communication speed 2.5Mbps 625kbps 156kbps --

Distance between

stations

No restriction --

Maximum number of

modules connected in 1

drop line

8 units

Maximum number of

remote I/O units connected

per branch in a drop line

Maximum trunk length 35m (114' 9") 100m (328' 1") 500m (1640' 5")

Cable length between

terminating resistors

(excluding drop line length)

T-branch interval No restriction --

Maximum drop length 4m (13' 1") 16m (52' 5") 60m (196' 10") Cable length per branch

Cumulative drop line

length

15m (49' 2") 50m (164' 0") 200m (656' 2") Sum of all drop lines

PLC main unit

Terminating

resistor

T branch

connection

T-branch interval

Power

adapter

Remote

I/O station

Remote

I/O station

Drop length

(including branch)

Remote

I/O station

Remote

I/O station

Remote

I/O station

Remote

I/O station

Distance between

stations

Terminating

resistor

Trunk length (branch line length not included)

Trunk line

Drop line

Page 25

FX2N-64CL-M CC-Link/LT Master Block System Configuration 4

4-3

4.2 PLC connection

This paragraph explains which PLC series are connectable with the FX2N-64CL-M and

cautions on the number of connectable FX

2N

-64CL-M.

4.2.1 Applicable PLC and number of connectable FX

2N

-64CL-M

• Connect the FX

2N

-64CL-M to the right side of the PLC using an extension cable.

• The number of occupied I/O points is "8 (either input or output) points + Number of

connected remote I/O points".

The total number of I/O points including extended points must not exceed 128 points for the

FX

1N

Series or 256 points for the FX2N or FX

2NC

Series.

• The FX

2N

-64CL-M consumes 190 mA at 5V DC.

The total current consumption at 5V for special blocks connected to the PLC must not

exceed the 5 V power capacity of the main and extension units.

When connecting to the FX

1N

Series PLC, a maximum of two FX2N-64CL-M can be

connected to each of the main and extension units.

4.3 Power adapters installation concept

At least one power adapter is required per CC-Link/LT system.

When constructing a system using only one power adapter, the following three conditions

should be satisfied:

1) Total current consumption of remote I/O units, I/O equipment and master unit receiving

power from power adapter ≤ 5 A

2) To operate the system in a stable environment, the voltage drop should be equivalent to or

less than 3.6V.

3) Because the minimum operating voltage of each remote I/O unit connected to the power

adapter is 20.4 V, therefore, Supply voltage to power adapter - Voltage drop ≥ 20.4 V

If the total current consumption or voltage drop is large, the power adapter position should be

changed or additional power adapters should be installed.

For further details, refer to the "CL1PAD1 (Power Adapter) USER'S MANUAL (Detailed

Volume)" offered separately.

4.4 Power adapter installation condition

For further details on power adapter installation conditions, refer to the "CL1PAD1 (Power

Adapter) USER'S MANUAL (Detailed Volume)" offered separately.

The conditions for installing power adapters to the CC-Link/LT system depend on connected

equipment and wiring length.

Applicable PLC

FX

1N

/FX2N/FX

2NC

Series PLC

(FX

2NC

-CNV-IF is required when FX

2NC

Series PLC is connected.)

Number of connectable

master blocks

FX

1N

Series: Up to 4

FX

2N

Series: Up to 8

FX

2NC

Series: Up to 3

Page 26

FX2N-64CL-M CC-Link/LT Master Block System Configuration 4

4-4

MEMO

Page 27

Handling Cautions 5

5-1

5. Handling Cautions

INSTALLATION PRECAUTIONS

• Use the FX2N-64CL-M in an environment with the general specifications described in this

manual.

If the FX

2N

-64CL-M is used in any other environment, thus, electrical shock, fire,

malfunction, product damage or product deterioration may occur.

• Do not directly touch the conductive area of the FX

2N

-64CL-M, otherwise, the

FX

2N

-64CL-M may malfunction or fail.

• Shut down all power supplies before attaching/removing the FX

2N

-64CL-M to/from the

panel, otherwise, the FX

2N

-64CL-M may fail or malfunction.

• Securely fix the FX

2N

-64CL-M with DIN rail or mounting screws. When using mounting

screws, securely tighten them within the specified torque range.

If the screws are too loose, the module may detach from its installed position, short

circuit, or malfunction. If the screws are too tight, the screws may be damaged, which

may cause the module to detach from its installed position or short circuit.

• Install the FX

2N

-64CL-M on to a flat surface.

If the installation surface is not flat, an excessive force may be applied on the PCBs,

leading to nonconformity.

FX2N-64CL-M CC-Link/LT Master Block

Page 28

FX2N-64CL-M CC-Link/LT Master Block Handling Cautions 5

5-2

5.1 Installation

The FX2N-64CL-M can be attached via DIN rail or attached directly with screws.

The installation procedure in each case is described below.

5.1.1 Installation direction

• Do not install the master block on floor surfaces, ceiling surfaces or in a horizontal direction.

If the master block is installed in such a way, its temperature may rise.

Install the master block vertically on wall surfaces as shown in the figure below.

• Secure a space of 50 mm (1.96") or more between the master block and other equipment or

structures. Keep the master block off high voltage cables, high voltage equipment and

power equipment as much as possible.

5.1.2 DIN rail installation

Align the upper DIN rail installation groove in the module with the DIN rail 1), and press the

module in that position 2).

When removing the module, pull the installation hook downwards 3), then remove the module

4).

5.1.3 Direct installation

Fix the FX

2N

-64CL-M on to the panel surface by tightening M4 screws inserted in two (upper

and lower) mounting holes provided on the master block.

Install the FX

2N

-64CL-M and other units so that a clearance of 1 to 2 mm is assured among

each unit.

Applicable DIN rail TH35-7.5Fe and TH35-7.5AI (conforming to JIS C2812)

Applicable screw M4 height: 16mm(0.63") or more (Tightening torque range: 78 to 108 N

⋅⋅⋅⋅

cm)

1)

Installation Removal

2)

3)

4)

Page 29

Connection of Cables, Connectors and Terminating Resistors 6

6-1

6. Connection of Cables, Connectors and Terminating Resistors

Connect the master station, power adapter and remote stations with flat cables dedicated to

CC-Link/LT and connectors for dedicated flat cables.

Lay out the master block on one side of the trunk line.

WIRING PRECAUTIONS

• Shut down all power supplies before starting installation or wiring work.

If the power is not disconnected from all sources an electric shock or serious product

damage may occur.

WIRING PRECAUTIONS

• Correctly wire the master block while confirming the rated voltage and terminal

arrangement of the FX

2N

-64CL-M.

If a power supply different from the rated supply is connected or wiring is performed

incorrectly, fire or failure may be caused.

• Correctly wire the master block while confirming the rated voltage and terminal

arrangement of the FX

2N

-64CL-M.

If a power supply different from the rated supply is connected or wiring is performed

incorrectly, fire or failure may occur.

• Pay attention to foreign objects such as cuttings or wiring chips do not enter the

FX

2N

-64CL-M, otherwise, fire, product failure or malfunction may occur.

FX2N-64CL-M CC-Link/LT Master Block

Page 30

FX2N-64CL-M CC-Link/LT Master Block Connection of Cables, Connectors and Terminating Resistors 6

6-2

6.1 Connection of units using flat cables dedicated to CC-Link/LT

This paragraph explains the connection method using flat cables dedicated to CC-Link/LT.

1) The connection order of dedicated flat cables has no relevance to the station No.

2) Lay out the FX

2N

-64CL-M at either end of the trunk line.

Connect a terminating resistor on the FX

2N

-64CL-M side in a position that is within 20 cm

from the FX

2N

-64CL-M.

3) Make sure to connect a terminating resistor to each end of the trunk line the CC-Link/LT.

Connect T-branches and remote I/O units using the connectors for dedicated flat cable.

6.2 How to attach connectors used for dedicated flat cable

This paragraph explains how to attach connectors used for the dedicated flat cable.

1) Components

The components are as shown below.

T-branch area

Master station/remote station/power adapter connection area

Trunk line

Drop line

Connector for dedicated

flat cable

Connector for

dedicated

flat cable

Connector for dedicated

flat cable

-Master station (FX

2N

-64CL-M)

-Power adapter (CL1PAD1)

-Terminal block type remote

I/O unit

-Sensor connector type remote

I/O unit

-MIL collector type remote I/O unit

Connector for

dedicated

flat cable

Cable type

remote I/O unit

Connector for dedicated

flat cable

C o m p o n e n t 1 : C o v e r C o m p o n e n t 2 : B o d y

C o m p o n e n t 3 : D e d i c a t e d f l a t

c a b l e

O r a n g e c o l o r

Page 31

FX2N-64CL-M CC-Link/LT Master Block Connection of Cables, Connectors and Terminating Resistors 6

6-3

2) Attachment procedure

The procedure is shown below.

a) Terminal processing procedure

b) T-branch processing procedure

1 ) C o r r e c t l y s e t t h e d e d i c a t e d f l a t

c a b l e o n t h e c o v e r . ( P a y a t t e n t i o n

t o t h e o r a n g e c o l o r l o c a t i o n o f t h e

d e d i c a t e d f l a t c a b l e . )

N o t e 1 : T h i s d i r e c t i o n i s w r o n g .

O r a n g e c o l o r

O r a n g e c o l o r

O r a n g e c o l o r

2 ) C l o s e t h e c o v e r t o f i r m l y h o l d t h e

d e d i c a t e d f l a t c a b l e .

3 ) C o m b i n e t h e b o d y w i t h t h e c o v e r ,

a n d p r e s s - f i t t h e m w i t h p l i e r s , e t c .

4 ) C o n f i r m t h a t t h e l a t c h i s e n g a g e d

i n f o u r p o s i t i o n s .

N o w , p r e s s - f i t t i n g i s f i n i s h e d .

O r a n g e c o l o r

N o t e 2 :

O r a n g e c o l o r

O r a n g e c o l o r

I f t h e o r a n g e d e d i c a t e d f l a t

c o v e r c a n b e s e e n f r o m t h e

n o t c h e d w i n d o w i n t h e f r o n t ,

t h e w i r i n g i s w r o n g . O p e n t h e

c o v e r , a n d c o r r e c t l y s e t t h e

d e d i c a t e d f l a t c o v e r .

5 ) C u t o f f t w o p o s i t i o n s a t t h e r o o t o f

t h e t i p o f t h e c o v e r w i t h n i p p e r s ,

e t c . , a n d r e m o v e t h e t i p .

O r a n g e c o l o r

6 ) S e t t h e c o v e r t o t h e p o s i t i o n i n

w h i c h T - b r a n c h w i l l b e s e t .

7 ) E x e c u t e p r e s s - f i t t i n g i n t h e s a m e

w a y a s i n s t e p s 3 ) a n d 4 ) a b o v e .

C u t o f f h e r e .

O r a n g e c o l o r

Page 32

FX2N-64CL-M CC-Link/LT Master Block Connection of Cables, Connectors and Terminating Resistors 6

6-4

6.2.1 How to attach terminating resistor

This paragraph explains how to attach terminating resistors to either end of the CC-Link/LT

system.

Attach terminating resistors to the connectors placed to flat cables dedicated to CC-Link/LT.

1) How to attach a terminating resistor on the FX

2N

-64CL-M side

The method to attach a terminating resistor on the FX

2N

-64CL-M side is shown below.

Connect a terminating resistor in a position within 200mm (7.87") from the FX

2N

-64CL-M.

2) How to attach a terminating resistor on the trunk line side

The method to attach a terminating resistor on the opposite side of the FX

2N

-64CL-M is

shown below.

Terminating resisto

r

Connector for dedicated

flat cable

FX2N-64CL-M

Terminating

resistor

FX2N-64CL-M

Connector for

dedicated flat

cable

Within 200mm (7.87")

from the FX

2N-64CL-M

Terminating

resistor

Connector for

dedicated flat cable

Page 33

FX2N-64CL-M CC-Link/LT Master Block Connection of Cables, Connectors and Terminating Resistors 6

6-5

6.2.2 Wiring check

Confirm the wiring between remote I/O units and external equipment.

Example of wiring check

The figure below shows an example in which the head I/O No. in the FX

2N

-64CL-M is X020/

Y020 and 4-point mode is selected.

Operating procedure

1) Connect the FX

2N

-64CL-M, power adapter and remote I/O units using the dedicated cables.

Set the transmission speed, point mode, station No., etc. using the DIP switches in the

FX

2N

-64CL-M and remote I/O units.

At this time, select the CONFIG mode in the FX

2N

-64CL-M (by setting bit 6 ON and setting

bit 7 OFF).

2) Supply power to the power adapter before the PLC unit.

3) When the acquisition of remote I/O unit information is completed in the CONFIG mode (that

is, when b4 of the BFM #28 (1Ch) turns ON), turn the power OFF.

4) Set the FX

2N

-64CL-M to ONLINE mode (by setting bit 6 OFF and bit 7 OFF). Supply power

to the power adapter before the FX

2N

-64CL-M. Then, execute step a) or b) below.

a) Checking the wiring between the input unit and external equipment

- Turn ON the switch corresponding to "X020" of the external equipment connected to

the input unit with station No. is 1.

- Monitor X020 from peripheral equipment.

- If X020 is ON, connection between the input unit and external equipment is normal.

b) Check the wiring between the output unit and external equipment

- Turn Y020 ON/OFF from peripheral equipment using the forced ON/OFF operation.

- If the connection between the output unit and external equipment is normal, a lamp

corresponding to "Y020" in the external equipment will light.

FX2N-64CL-M

(X020/Y020, 4-point mode)

4-point input unit

CL1X4-D1B2

(station No. = 1,

number of occupied

stations = 1)

X020

ON

ON

Y020

Power

adapter

4-point output unit

CL1Y4-T1B2

(station No. = 2,

number of occupied

stations = 1)

PLC main

unit

Terminating

resistor

Terminating

resistor

Page 34

FX2N-64CL-M CC-Link/LT Master Block Connection of Cables, Connectors and Terminating Resistors 6

6-6

MEMO

Page 35

Various Modes 7

7-1

7. Various Modes

The FX2N-64CL-M has ONLINE, CONFIG and TEST modes.

Each mode can be selected using the appropriate DIP switch.

(Turn OFF the power to the PLC before setting the DIP switches.)

7.1 ONLINE mode (DIP switch bit 6 = OFF, bit 7 = OFF)

In ONLINE mode, the FX2N-64CL-M will execute the data link in the CC-Link/LT system.

Select this mode for normal use.

7.2 CONFIG mode (DIP switch bit 6 = ON, bit 7 = OFF)

In CONFIG mode, the FX2N-64CL-M assigns the station No. and I/O Nos. for remote stations.

The FX

2N

-64CL-M acquires the information (I/O type and number of points) on the connected

remote stations, then stores it to the buffer memory [BFM #32 (20h) to #95 (5Fh)] and built-in

memory (EEPROM).

After constructing the CC-Link/LT system, execute the CONFIG mode to automatically assign

the I/O Nos.

(After constructing the CC-Link/LT system, assign the I/O Nos. by executing the CONFIG

mode.)

If remote stations are to be extended in the future, the I/O Nos. can be assigned while skipping

some I/O Nos.

For the details of assignment of the I/O Nos., refer to "8. Assignment of I/O Nos."

7.3 TEST mode (self-loop-back test) (DIP switch bit 6 = OFF, bit 7 = ON)

In TEST mode (for the self-loop-back test), the FX2N-64CL-M checks whether it is fully

functional by receiving data sent by itself.

In this test, it is not necessary to connect remote stations.

(Connect the FX

2N

-64CL-M to the power adapter, then turn ON the communication power.)

For details on the self-loop-back test, refer to "12.4 Self-loop-back test".

• When the FX

2N

-64CL-M is set to the TEST mode while it is connected to a FX1N Series

PLC, the PLC is stopped.

(The self-loop-back test will be executed normally, and the test result will be indicated by the

status indicator LEDs.)

FX2N-64CL-M CC-Link/LT Master Block

Page 36

FX2N-64CL-M CC-Link/LT Master Block Various Modes 7

7-2

MEMO

Page 37

Assignment of I/O Nos. 8

8-1

8. Assignment of I/O Nos.

The FX2N-64CL-M assigns I/O information for remote I/O units to devices X (input) and Y

(output) in the PLC.

The I/O Nos. are assigned in CONFIG mode.

At this time, the I/O Nos. are assigned in octal serial Nos. following the I/O No. occupied by the

PLC while eight points are handled as one block.

(For further details, refer to "8.2 Example of I/O No. assignment")

For a station No. to which a remote I/O unit will be connected to in the future, the I/O No. can

be secured by "specifying it as a reserved station" and "editing the detailed remote station

information on it".

8.1 Relationship between I/O No. and point mode

The I/O No. is equivalent between the 4-point mode and 16-point mode, but the station No. of

each remote station is different between 4-point mode and 16-point mode.

When using remote I/O units of more than 4 I/O points, more I/O points can be used if the 16point mode is selected due to the restriction in the number of connected stations

(64 stations maximum).

Example:When sixty-three CL1XY2-DT1D5S units (cable type remote unit having 1 input point

and 1 output point) (station No.: 1 to 63) and one CL2X8-D1B2 unit (terminal block

type remote I/O unit having 8 input points) are to be connected to the FX

2N

-16MR, a

system can be constructed in the 16-point mode, but cannot be constructed in the 4point mode due to the CL2X8-D1B2 unit occupying two stations and the number of

remote stations exceeds 64.

However, if the number of stations is equivalent, the link scan time is longer in the 16-point

mode than in the 4-point mode.

(For further details of the link scan, refer to "9. Data Link Processing Time".)

1) When connecting all remote I/O units and assigning their I/O Nos., refer to "8.3 Automatic

I/O No. assignment".

2) When assigning the I/O Nos. without connecting remote I/O units and preparing a sequence

program or connecting additional remote I/O units in the future, refer to "8.3 Automatic I/O

No. assignment" and "8.4 Specification of reserved station" and "8.5 Edition of detailed

remote station information".

• In CONFIG mode, the FX

2N

-64CL-M does not occupy I/O points for remote stations.

(It occupies only 8 points as a special block.)

I/O extension blocks/units of the PLC connected after the FX

2N

-64CL-M do not operate.

FX2N-64CL-M CC-Link/LT Master Block

Page 38

FX2N-64CL-M CC-Link/LT Master Block Assignment of I/O Nos. 8

8-2

8.2 Example of I/O No. assignment

This paragraph describes I/O No. assignment in the configuration example shown below.

When the FX

2N

-64CL-M is set to the CONFIG mode and the PLC is powered ON, the FX2N64CL-M checks for connected remote stations, and assigns the I/O No. to each remote station.

Though the I/O No. is equivalent between the 4-point mode and 16-point mode, the station No.

of each remote station is different between the 4-point mode and 16-point mode.

In the configuration example above, the link scan time is longer in the 16-point mode than in

the 4-point mode.

(For the details of the link scan, refer to "9. Data Link Processing Time".)

*1 With regard to X and Y, 8 points are occupied as 1 block. As a result, if the number of I/O

points occupied by a station is a number which cannot be divided by "8", unused Nos. are

generated.

In the configuration example above, the I/O Nos. are assigned as shown below.

Station No.

Number of points I/O assignment (X) I/O assignment (Y)

4-point mode 16-point mode

Station No.1 Station No.1 4 input points X040 to X043 --

Station No.2 Station No.2 2 output points -- Y020 to Y021

Station No.3 Station No.3 16 input points X044 to X063 --

Station No.7 Station No.4

2 input points/

2 output points

X064 to X065 Y022 to Y023

Station No.8 Station No.5 4 input points X066 to X071 --

Unused I/O

*1

X072 to X077 Y024 to Y027

PLC

FX2N-32MT

I/O extension

block

FX2N-16EX

Master block

FX2N-64CL-M

Station No. when the 16-point mode is selected

4 input

points

2 output

points

16 input

points

2 I/O

points

4 input

points

PLC

FX2N-32MT

I/O extension

block

FX2N-16EX

Master block

FX2N-64CL-M

Station

No.1

4 input

points

Station

No. 2

2 output

points

Station

No.3

16 input

points

Station

No. 4

2 I/O

points

Station

No.5

4 input

points

Station No. when the 16-point mode is selectedY000 to Y017 (octal)

X040 to X043 Y020 to Y021 X044 to X063 X064 to X065

Y022 to Y023

X066 to X071

X000 to X037 (octal)

Page 39

FX2N-64CL-M CC-Link/LT Master Block Assignment of I/O Nos. 8

8-3

8.3 Automatic I/O No. assignment

The I/O Nos. can be assigned automatically in the CONFIG mode.

Parameter settings and sequence programs are not necessary for this assignment.

8.3.1 Automatic I/O No. assignment procedure

Execute the steps 1) to 3) below to automatically assign the I/O Nos.

1) Connect each remote I/O unit to the FX

2N

-64CL-M. In the FX2N-64CL-M, set bit 6 of the DIP

switch to ON, and set bit 7 (to select the CONFIG mode) to OFF. Power up, first, the power

adapter, then, the PLC.

The FX

2N

-64CL-M acquires the information (I/O type and number of points) on connected

remote stations, and stores it to the buffer memory [BFM #32 (20h) to #95 (5Fh)] and builtin memory (EEPROM).

2) Confirm that the contents of the buffer memory [BFM #32 (20h) to #95 (5Fh)] are consistent

with the actual system configuration.

3) Set bit 6 of the DIP switch in the FX

2N

-64CL-M to OFF. Reset the power to the PLC.

The FX

2N

-64CL-M reads the information on connected remote stations from the built-in

memory (EEPROM), and assigns the I/O No.

8.4 Specification of reserved station

The FX2N-64CL-M assigns the I/O No. in the CONFIG mode. If remote stations will be added in

the future, temporary I/O Nos. can be assigned (specification of reserved stations).

By this function, even if remote stations are added, it is not necessary to change the I/O Nos.

assigned to other remote stations and extension blocks/units connected to the PLC.

If remote stations are connected in places for reserved station, the connected remote stations

can operate with the existing setting, but errors such as wire breakage cannot be detected.

After connecting remote additional stations, execute automatic I/O No. assignment in the

CONFIG mode again. The system will update the detailed remote station information, and the

new remote stations will be able to be used normally (errors will be detected).

Page 40

FX2N-64CL-M CC-Link/LT Master Block Assignment of I/O Nos. 8

8-4

8.4.1 Reserved station setting method

Set reserved stations using the steps 1) to 4) below.

1) Set the FX

2N

-64CL-M to the CONFIG Mode (by setting bit 6 of the DIP switch to ON and

setting bit 7 to OFF). Power up the FX

2N

-64CL-M.

(The FX

2N

-64CL-M will assign the I/O Nos.)

2) Write the information (station type and number of I/O points) for the station to be added in

the detailed remote station information buffers [BFM #32 (20h) to #95 (5Fh)]. Set the

reserved station flag (bit 15) to ON in the appropriate BFM.

(If the bit for reserved station is set to OFF, errors such as wire breakage are detected while

a remote station is not connected.)

3) Give the instruction to write to the EEPROM [by setting from OFF to ON b4 of the BFM #27

(1Bh)].

4) After setting reserved stations, confirm that write to the EEPROM is completed by checking

b4 of the BFM #28 (1Ch). Then, set the power of the FX

2N

-64CL-M ON using the normal

procedure (setting the bit 6 of the DIP switch to OFF), and confirm that the detailed remote

station information [BFM #32 (20h) to #95 (5Fh)] is updated.

Configuration of detailed remote station information

Buffer memory No. Description

BFM #32(20h) Remote station information area for the station No.1

BFM #33(21h) Remote station information area for the station No.2

.

.

.

.

.

.

BFM #95(5Fh) Remote station information area for the station No.64

Bit Function 1(ON) 0(OFF)

b0

Number of I/O points

00001:1point 00101:5points 01001: 9points

01101:13points 00010:2points 00110:6points

01010:10points 01110:14points 00011:3points

00111:7points 01011:11points 01111:15points

00100:4points 01000:8points 01100:12points

10000:16points

The bits above are in the order "b4, b3, b2, b1, b0".

b1

b2

b3

b4

b5 to b7 (Setting prohibited) Set these bits to 0.

b8 Input flag Input is given. Input is not given.

b9 Output flag Output is given. Output is not given.

b10 (Setting prohibited) Set these bits to 0.

b11 Head station flag This is the head station. This is not the head station.

b12 Input filter setting High-speed input General-purpose input

b13 Output hold/clear setting HOLD CLEAR

b14 (Setting prohibited) Set these bits to 0.

b15 Reserved station flag

This is specified as reserved

station.

This is not specified as

reserved station.

Page 41

FX2N-64CL-M CC-Link/LT Master Block Assignment of I/O Nos. 8

8-5

8.5 Editing the detailed remote station information

After assigning the I/O Nos. in the CONFIG mode, the I/O No. assignment in each station No.

can be edited.

With this function, the number of I/O points can be changed, and the I/O Nos. can be assigned

to unconnected station Nos. for future use. If remote stations are added in the future, it is not

necessary to change the I/O Nos. in other remote stations and extension blocks/units

connected to the PLC.

If a remote station is not connected to an edited station No., errors such as wire breakage error

will occur.

If a remote station is connected to an edited station No. the remote station will operate with the

existing setting.

8.5.1 How to edit detailed remote station information

Edit the detailed remote station information using the steps 1) to 4) below.

1) Set the FX

2N

-64CL-M to the CONFIG Mode (by setting bit 6 of the DIP switch to ON and

setting bit 7 to OFF). Set the power of the FX

2N

-64CL-M to ON.

(The FX

2N

-64CL-M will assign the I/O Nos.)

2) Write the information (station type and number of I/O points) for the station to be added in

the detailed remote station information buffers [BFM #32 (20h) to #95 (5Fh)]. Set the

reserved station flag (bit 15) to OFF in the appropriate BFM.

(If the bit for reserved station is set to ON, the station is regarded as a reserved one, and

errors such as wire breakage error cannot be detected.)

3) To the detailed remote station information on every remote station to be edited, write the

information on the remote station. Then, give the instruction for write to the EEPROM [by

setting b4 of the BFM #27 (1Bh) from OFF to ON].

4) After editing the remote station information, confirm that write to the EEPROM is completed

by checking b4 of the BFM #28 (1Ch). Then, set the power of the FX

2N

-64CL-M to ON using

the normal procedure (by setting bit 6 of the DIP switch to OFF), and confirm that the

detailed remote station information [BFM #32 (20h) to BFM #95 (5Fh)] is updated.

Buffer memory No. Description

BFM #32(20h) Remote station information area for the station No.1

BFM #33(21h) Remote station information area for the station No.2

.

.

.

.

.

.

BFM #95(5Fh) Remote station information area for the station No.64

Page 42

FX2N-64CL-M CC-Link/LT Master Block Assignment of I/O Nos. 8

8-6

Configuration of detailed remote station information

Bit Function 1(ON) 0(OFF)

b0

Number of I/O points

00001:1point 00101:5points 01001: 9points

01101:13points 00010:2points 00110:6points

01010:10points 01110:14points 00011:3points

00111:7points 01011:11points 01111:15points

00100:4points 01000:8points 01100:12points

10000:16points

The bits above are in the order "b4, b3, b2, b1, b0".

b1

b2

b3

b4

b5 to b7 (Setting prohibited) Set these bits to 0.

b8 Input flag Input is given. Input is not given.

b9 Output flag Output is given. Output is not given.

b10 (Setting prohibited) Set these bits to 0.

b11 Head station flag This is the head station. This is not the head station.

b12 Input filter setting High-speed input General-purpose input

b13 Output hold/clear setting HOLD CLEAR

b14 (Setting prohibited) Set these bits to 0.

b15 Reserved station flag

This is specified as reserved

station.

This is not specified as

reserved station.

Page 43

Data Link Processing Time 9

9-1

9. Data Link Processing Time

This section explains the link scan time and transmission delay time.

9.1 Link scan time

This paragraph explains the link scan time for the CC-Link/LT network.

9.1.1 Link scan time calculation formula

Link scan time = a + ( b × N ) × c [µs]

a: Constant (depends on the transmission speed)

b: Constant (depends on the transmission speed and point mode)

c: Constant (depends on the transmission speed)

N: Final station No.

As shown in the formula above, if the number of stations is held constant, the link scan time is

shorter in the 4-point mode than in the 16-point mode.

Transmission speed 2.5Mbps 625kbps 156kbps

Value a 22 88 353

Transmission speed 2.5Mbps 625kbps 156kbps

Value b

4-point mode 46 41 37

16-point mode 76 71 67

Transmission speed 2.5Mbps 625kbps 156kbps

Value c 0.4 1.6 6.4

0204060

Number of

stations

0

0.5

1.0

1.5

2.0

2.5

16-point mode

4-point mode

Link scan time (ms)

Link scan time (at 2.5 Mbps)

FX2N-64CL-M CC-Link/LT Master Block

Page 44

FX2N-64CL-M CC-Link/LT Master Block Data Link Processing Time 9

9-2

9.1.2 Transmission delay time

The transmission delay time (the time until data is received) (including the time for

communication between the main unit and FX

2N

-64CL-M) can be calculated by the following

formula.

1) Master station ← Remote station (input)

Time until a device (X) in the main unit turns ON or OFF after a signal is input to the remote

station

Calculation formula

SM

×

2 + (2 - n)*1 × LS + Remote station input response time [ms]

SM: Scan time of master station PLC

LS: Link scan time

n: SM/LS (whose decimals are omitted)

*1: 0 if the value "2-n" is 0 or less

Example:

The scan time of the master station PLC is 5 ms, the link scan time is 1.2 ms, and the input

response time of the remote I/O station is 1.5 ms

SM

×

2 + (2 - n)*1 × LS + Remote station input response time [ms]

= 5

×

2 + (2 - 4)

×

1.2 + 1.5 [n = 4 (5/1.2 = 4.16..., then decimals are omitted)]

= 11.5 [ms]

2) Master station → Remote station (output)

Time until an output in the remote station turns ON or OFF after a device (Y) in the main

unit is set to ON or OFF

Calculation formula

SM + LS × 2 + Remote station output response time [ms]

SM: Scan time of master station PLC

LS: Link scan time

Example:

The scan time of the master station PLC is 5 ms, the link scan time is 1.2 ms, and the output

response time of the remote I/O station is 0.5 ms

SM + LS × 2 + Remote station output response time [ms]

= 5 + 1.2 × 2 + 0.5

= 7.9 [ms]

Page 45

Assignment of Buffer Memory 10

10-1

10. Assignment of Buffer Memory

Data transfer between the PLC main unit and FX2N-64CL-M is executed by a program in the

PLC.

Use the FROM instruction to read data saved in the FX

2N

-64CL-M to the main unit.

The FROM instruction reads the data saved in the buffer memory (BFM) in the FX

2N

-64CL-M

to devices (such as D and M) in the main unit.

Use the TO instruction to write data from the main unit to the FX

2N

-64CL-M.

The TO instruction writes data from devices (such as D and M) in the main unit to the buffer

memory (BFM) in the FX

2N

-64CL-M.

10.1 Buffer memory list

*1 "W" is enabled only in the CONFIG mode.

Buffer memory No.

Name Description

R: Read

W: Write

DEC HEX

0 to 3 0h to 3h

Remote station connection

information

Stores the connection status of each remote

station. (When a remote station is connected, a

corresponding bit is ON.)

R

4 to 7 4h to 7h

Link error station

information

Stores the data link status of each remote

station.

R

8 to 11 8h to Bh

Remote I/O error

information

Stores the I/O error occurrence status of each

remote station. For the contents of error, refer to

the instruction manual of each remote station.

R

12 to 15 Ch to Fh (Prohibited to use) -- --

16 to 19 10h to 13h

Reserved station

information

Stores the reserved station setting status. R

20 14h

Number of required input

blocks

Stores the number of input blocks (in the unit of

8 points) required to assign the I/O Nos.

R

21 15h

Number of required of

output blocks

Stores the number of output blocks (in the unit

of 8 points) required to assign the I/O Nos.

R

22 16h

Data link final station

information

Stores the final station No. available in the data

link. (This information is set according to the

station information stored in the EEPROM.)

R

23 to 25 17h to 19h (Prohibited to use) -- --

26 1Ah External switch information Stores the DIP switch setting status. R

27 1Bh Command

Gives instructions to the FX

2N

-64CL-M for

stopping or starting up again the data link and

writing data to the EEPROM.

R/W

28 1Ch Status information

Stores the status information such as RUN and

data link.

R

29 1Dh Detailed error information

Stores the detailed information on errors

detected by the FX

2N

-64CL-M.

R

30 1Eh Model code K7120 R

31 1Fh (Prohibited to use) -- --

32 20h

Detailed remote station

information (station No.1)

Stores the information (I/O type and number of

points) on the remote station No.1. The

information can be edited in the CONFIG mode.

R/W

*1

...

...

...

...

...

95 5Fh

Detailed remote station

information (station No.64)

Stores the information (I/O type and number of

points) on the remote station No.64. The

information can be edited in the CONFIG mode.

R/W

*1

FX2N-64CL-M CC-Link/LT Master Block Model

Page 46

FX2N-64CL-M CC-Link/LT Master Block Model Assignment of Buffer Memory 10

10-2

10.2 Details of buffer memory

10.2.1 Remote station connection information [BFM #0 (0h) to #3 (3h)]