Page 1

USER’S MANUAL

FX2N-2LC Temperature Control Block

Page 2

FX2N-2LC Temperature Control Block

Foreword

• This manual contains te xt, diag rams and explanations which will guide the reader in the correct installation and operation of the communication facilities of FX series.

• Before attempting to install or use the communication facilities of FX series this manual

should be read and understood.

• If in doubt at an y stage of the installation of t he communication facilities of FX series always

consult a professional electrical engineer wh o is qualified and trained to the local and

national standards which apply to the installation site.

• If in doubt about the operation or use of the communication facilities of FX series please

consult the nearest Mitsubisi Electric dis tributor.

• This manual is subject to change without notice.

Page 3

FX2N-2LC Tempereture Control Block

FX

2N

-2LC

Temperature Control Block

USER’S MANUAL

Manual number : JY992D85801

Manual revision : A

Date : January 2000

i

Page 4

FX2N-2LC Tempereture Control Block

ii

Page 5

FX2N-2LC Tempereture Control Block

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing

back the frontiers of industrial automation. What is sometimes overlooked by the user is the

care and attention to detail that is taken with the documentation. However,to continue this process of improvement, the comments of the Mitsubishi users are always welcomed. This page

has been designed for you,the reader,to fill in your comments and fax them back to us. We

look forward to hearing from you.

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company..............................................

Australia (02) 638 -7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location:................................................

South Africa (0 27) 11 444-0223 .................... .................................................

United Kingdom (01707) 278-695

Please tick the box of your choice

What condition did the manual arrive in?

Will you be using a f o lder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand:..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which:..................................................................................................................................

What do you think to the manual layout?

If there one thing you would li ke to see improved,what is it?............ ............................. .............

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents,if possi-

ble please identify your experience:............................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

…

…

…

…

…

…

Good

Yes

Tidy

Yes

Yes

Good

…

Minor damage

…

No

…

Un-friendly

…

Not too bad

…

No

…

Not too bad

…

Unusable

…

Unusable

…

Un-helpful

Do you have any comments in general about the Mitsubishi manuals?.............................. .. .....

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

iii

Page 6

FX2N-2LC Tempereture Control Block

iv

Page 7

FX2N-2LC Tempereture Control Block

Guidelines for the Safety of the User and Protection of the Temperature control

block FX2N-2LC.

This manual provides information for the use of the Temperature control block FX2N-2LC. The

manual has been writte n to be use d by trained and compe tent personnel. T he definition of

such a person or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated w ith this manual should be of a com petent

nature, trained and qualified to the loc al and national sta ndards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to automated equipment.

b) Any commissioning or service engineer must be of a competent nature, tr ained and qual-

ified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely f amili ar with all ass ociated docume ntation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment should be trained to use that product in a safe

and coordinated manner in compliance to established safety practices. The operators

should also be familiar with documentation which is connected with the actual operation

of the completed equipment.

Note :

Note: the term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the Symbols Used in this Manual

At various times through out this manual cer tain s ymbols will be used to highlight p oints of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will no w be lis ted with a brief description of

its meaning.

Hardware Warnings

1) Indicates that the identified danger

2) Indicates that the identified danger could

WILL

cause physical and property damage.

POSSIBLY

cause physical and proper ty

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

v

Page 8

FX2N-2LC Tempereture Control Block

• Under no circumstances will Mitsubishi Electric be liable responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagr ams show n in this manual are int ended only as an aid to understanding the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for

actual use of the product based on these illustra tive examples.

• Owing to the very great variety in possible application of this equipment, you must satisfy

yourself as to its suitability for your specific application.

vi

Page 9

FX2N-2LC Temperature Control Block

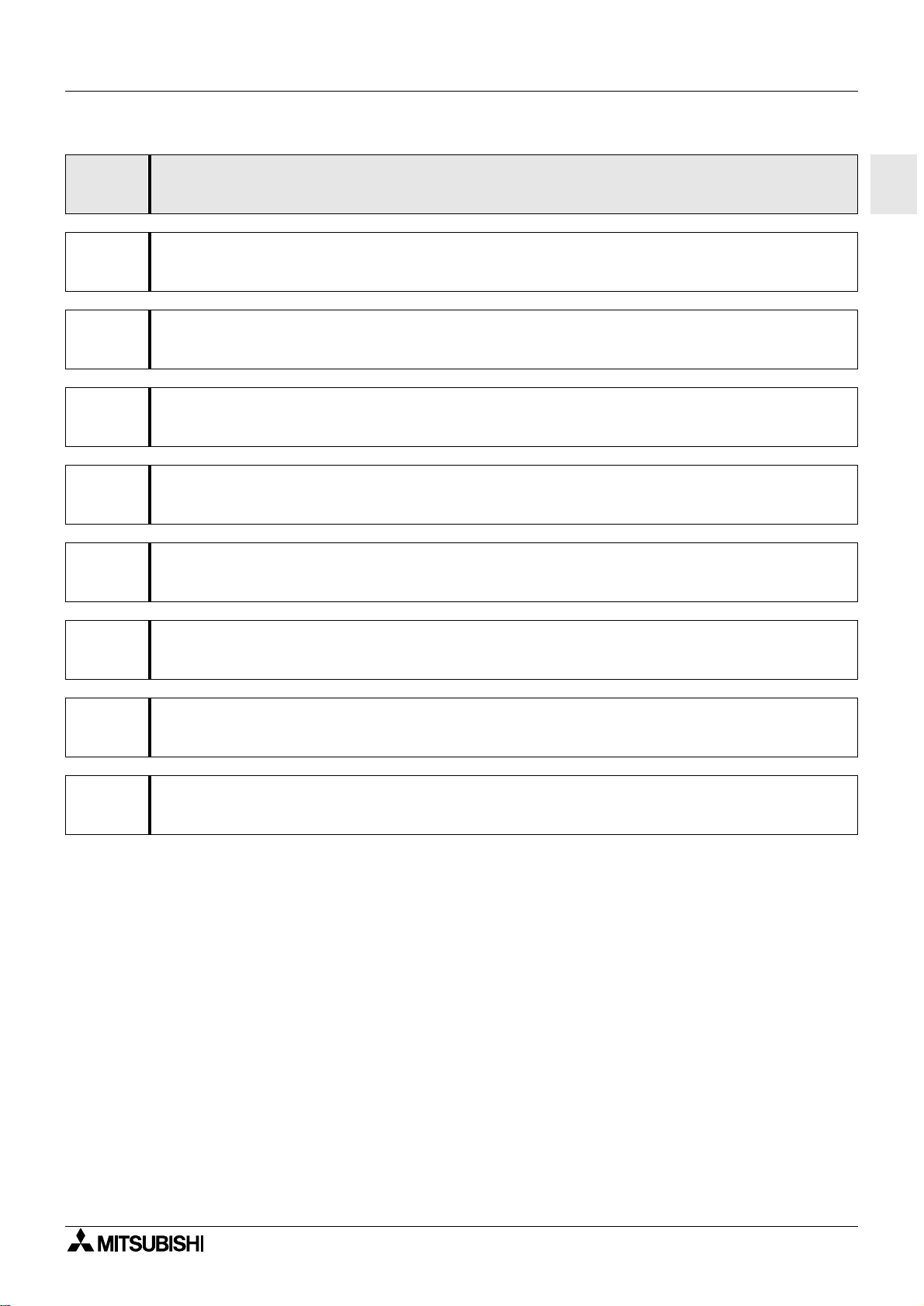

1. Introduction ...........................................................................................1-1

1.1 Outline of product ................................................................................................ 1-2

2. Product Configuration ...................................................... ............ .........2 -1

2.1 Outside d ime nsion........ .. ... ..................................................................................2-1

2.2 Name of each part...............................................................................................2-1

2.3 Status ind ic a t io n ..................................................................................................2-2

2.4 Installation method .............................................................................................. 2-3

2.5 Connection to PC Main Unit................ ........................................................ ........2-4

3. Specifications........................................................................................3-1

3.1 Environm en tal specifica tion s........ .. .. ................................................................... 3-1

3.2 Power supp ly specificati o n s .. .. ... .........................................................................3-1

3.3 Performance specifications .................................................................................3-2

3.4 Input specifications...................................................................... ...................... ..3-3

3.5 Input range............................................................ ..............................................3-4

3.6 Output specifications...........................................................................................3-5

Contents

4. Wiring....................................................................................................4-1

4.1 Wiring ..................................................................................................................4-2

5. Introduction of Functions.......................................................................5-1

5.1 PID control...........................................................................................................5-1

5.1.1 Easy PID control with two degrees of freedom..........................................................5-1

5.1.2 Overshoot prevention function.... ....... ...... ............................................. .....................5-2

5.2 Two-position control ............................................................................................ 5-3

5.3 Auto tuning fu n c tio n...................... .......................................................................5-4

5.3.1 AT (auto tuning)......................................................................................................... 5-4

5.3.2 AT bias ...................................................................................................................... 5-5

5.4 Auto / manual......................................................................................................5-6

5.4.1 Auto mode and manual mode ...................................................................................5-6

5.4.2 Balance-less, bump-less function..............................................................................5-7

5.5 Heater disconnection detection function...................................................... ........5-8

5.6 Loop breaking alarm function (LBA)....................................................................5-9

6. Alarm................................................................................ .....................6-1

7. Buffer Memory (BFM) ...........................................................................7-1

7.1 Buffer memo ry lis t ... ............................................................................................. 7-1

7.2 Details of buffer memories................................................................................... 7-4

7.2.1 BFM #0: Flag.............................................................................................................7-4

7.2.2 BFM #1 (CH1) and BFM #2 (CH2): Event.................................................................7-5

7.2.3 BFM #3 (CH1) and BFM #4 (CH2): Measured value (PV) ........................................7-7

7.2.4 BFM #5 (CH1) and BFM #6 (CH2): Control output value (MV) .................................7-7

7.2.5 BFM #7 (CH1) and BFM #8 (CH2): Heater current measured value.........................7-7

7.2.6 BFM #9: Default setting command............................................................................7-7

7.2.7 BFM #10: Error reset command ................................................................................7-7

7.2.8 BFM #11: Control start/stop changeover...................................................................7-7

7.2.9 BFM #12 (CH1) and BFM #21 (CH2) : Set value (SV)..............................................7-8

vii

Page 10

FX2N-2LC Temperature Control Block

7.2.10 BFM #13 to BFM #16 (CH1) and BFM #22 to BFM #25 (CH2):

Alarm 1/2/3/4 set value..............................................................................................7-8

7.2.11 BFM #17 (CH1) and BFM #26 (CH2): Heater disconnection alarm set value...........7-8

7.2.12 BFM #18 (CH1) and BFM #27 (CH2) : Auto/manual mode changeover ...................7-8

7.2.13 BFM #19 (CH1) and BFM #28 (CH2): Manual output set value................................7-9

7.2.14 BFM #20 (CH1) and BFM #29 (CH2): Auto tuning ex ecu tio n com man d..... ..............7-9

7.2.15 BCM#30: Unit type code............................................................................................7-9

7.2.16 BFM #32 (CH1) and BFM #51 (CH2): Operation mode ............................................7-9

7.2.17 BFM #33 (CH1) and BFM #52 (CH2): Proportional band (P)....................................7-9

7.2.18 BFM #34 (CH1) and BFM #53 (CH2): Integral time (I)............................................ 7-10

7.2.19 BFM #35 (CH1) and BFM #54 (CH2): Derivative time (D) ......................................7-10

7.2.20 BFM #36 (CH1) and BFM #55 (CH2): Control response parameter .......................7-11

7.2.21 BFM #37 (CH1) and BFM #56 (CH2): Output limiter upper limit

BFM #38 (CH1) and BFM #57 (CH2): Output limiter lower limit..............................7-12

7.2.22 BFM #39 (CH1) and BFM #58 (CH2): Output change ratio limiter..........................7-13

7.2.23 BFM #40 (CH1) and BFM #59 (CH2): Sensor correction value setting (PV bias)...7-14

7.2.24 BFM #41 (CH1) and BFM #60 (CH2): Adjustment sensitivity (dead zone) setting..7-15

7.2.25 BFM #42 (CH1) and BFM #61 (CH2): Control output cycle setting.........................7-15

7.2.26 BFM #43 (CH1) and BFM #62 (CH2): Primary delay digital filter setting ................7-16

7.2.27 BFM #44 (CH1) and BFM #63 (CH2): Setting change ratio limiter..........................7-17

7.2.28 BFM #45 (CH1) and BFM #64 (CH2): AT (auto tuning) bias...................................7-18

7.2.29 BFM #46 (CH1) and BFM #65 (CH2): Normal/reverse operation selection ............7-18

7.2.30 BFM #47 (CH1) and BFM #66 (CH2): Setting limiter upper limit

BFM #48 (CH1) and BFM #67 (CH2): Setting limiter lower limit .............................7-19

7.2.31 BFM #49 (CH1) and BFM #68 (CH2): Loop breaking alarm judgement time..........7-20

7.2.32 In BFM #50, set the loop breaking alarm dead zone of CH1.

In BFM #69, set the loop breaking alarm dead zone of CH2...................................7-21

7.2.33 BFM #70 (CH1) and BFM #71 (CH2): Input type selection .....................................7-22

7.2.34 BFM #72 to BFM #75: Alarm mode setting .............................................................7-23

7.2.35 BFM #76: Alarm 1/2/3/4 dead zone setting .............................................................7-25

7.2.36 BFM #77: Number of times of alarm 1/2/3/4 delay..................................................7-26

7.2.37 BFM #78: Number of times of heater disconnection alarm delay............................7-26

7.2.38 BFM #79: Temperature rise completion range setting ............................................ 7-27

7.2.39 BFM #80: Temperature rise completion soak time..................................................7-27

7.2.40 BFM #81: CT monitor method changeover .............................................................7-28

7.2.41 BFM #82: Set value range error address ................................................................7-28

7.2.42 BFM #83: Set value backup command....................................................................7-29

Contents

8. Program Example ........................................................................ .........8-1

8.1 Program example ................................................................................................ 8-2

9. Diagnostic .............................................................................................9-1

viii

Page 11

FX2N-2LC Temperature Control Block

Introduction 1

1 Introduction

2 Product Configuration

3 Specifications

4 Wiring

5 Introduction of Functions

6Alarm

1

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 12

FX2N-2LC Temperature Control Block

Introduction 1

Page 13

FX2N-2LC Temperature Control Block

1. Introduction

Cautions on design

• Install a saf et y circui t outs ide the PLC or the temper at ure cont rol block FX2N-2LC so that

the entire system conservatively operates even if an abnormality occurs in the external

power supply or a failure occurs in the PLC or the FX

If a safety circuit is installed inside the PLC, malfu nction and erroneous output may

cause accidents.

1) Make sure to const ruct an emergency stop circuit, protection circui t or interlock circuit to

prevent damages of a machine, etc. outside the PLC or the FX

2N

-2LC.

2N

Introduction 1

1

-2LC.

2) If the PLC or the FX

-2LC detects an abnormality such as a watch dog timer error or

2N

input value error by the self-diagnosis function or when an abnormality occurs in the I/O

control area, etc. which cannot be detected by the CPU in the PLC, output control may

be disabled.

Design external circuits and structure so that the entire system conservatively operates

in such cases.

3) If a failure occurs in a relay, transistor, TRIAC, etc. in an output unit of the FX

2N

the PLC, outputs may keep ON or OFF.

For output sig nals whic h ma y lead t o se v er e accidents , design e xt ernal circuits and structure so that the entire system conservatively operates.

Cautions on installation

• Use the unit in the environment for the general specifications described in the manual.

Nev er use the unit in a place with dusts , soot, conducti ve dusts , corrosive gas or flammable gas, place exposed to high temperature, dew condensation or rain and wi nd or place

exposed to vibration or impact.

If the unit is used in such a place, electrical shock, fire, malfunction, damages in the unit

or deterioration of the unit ma y be caused.

• Never drop cutting chips or electric wire chips into the ventilation window of the FX

2LC while drilling screw holes or wiring cables.

Such chips may cause fire, failure or malfunction.

-2LC or

-

2N

• After finishing installation, remove a dust preventing sheet adhered on the ventilation

window of the PC and the FX

2N

-2LC.

If the sheet remains attached, fire, failure or malfunction may be caused.

• Securely connect cables such as extension cables and memory cassettes to specified

connectors.

Imperfect contact may cause malfunction.

Caution on disposal

• When disposing of the unit, treat it as industrial waste.

1-1

Page 14

FX2N-2LC Temperature Control Block

1.1 Outline of product

The temperature control block FX2N-2LC (hereafter referred to as "temperature control block"

or "FX

output points is a special block to read temperature signals from thermocouples and platinum

resistance thermometer bulbs, and pe rform PID output control.

Connect the FX

1) As input sensors, two thermocouples, two platinum resistance thermometer bulbs or one

-2LC") equipped with two temperature input points and two transistor (open collector)

2N

-2LC to the FX

2N

thermocouple and one platinum resistance thermometer bulb are available.

2N/2NC

Introduction 1

Series PC.

2) Data can be written and read using FROM/TO instructions when the FX

to the FX

(The FX

2N

Series PC.

2N/2NC

-2LC performs arithmetic operation for PID control and output control. You do not

-2LC is connected

2N

have t o creat e sequence programs for PID operation.)

3) Disconnection of heaters can be detected by current detection (CT).

4) The proportional band, the integral time and the derivative time can be easily set by auto

tuning.

5) Channels are isolated against each other.

1-2

Page 15

FX2N-2LC Temperature Control Block

Product Configuration 2

1 Introduction

2 Product Configuration 2

3 Specifications

4 Wiring

5 Introduction of Functions

6Alarm

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 16

FX2N-2LC Temperature Control Block

Product Configuration 2

Page 17

FX2N-2LC Temperature Control Block

2. Product Configuration

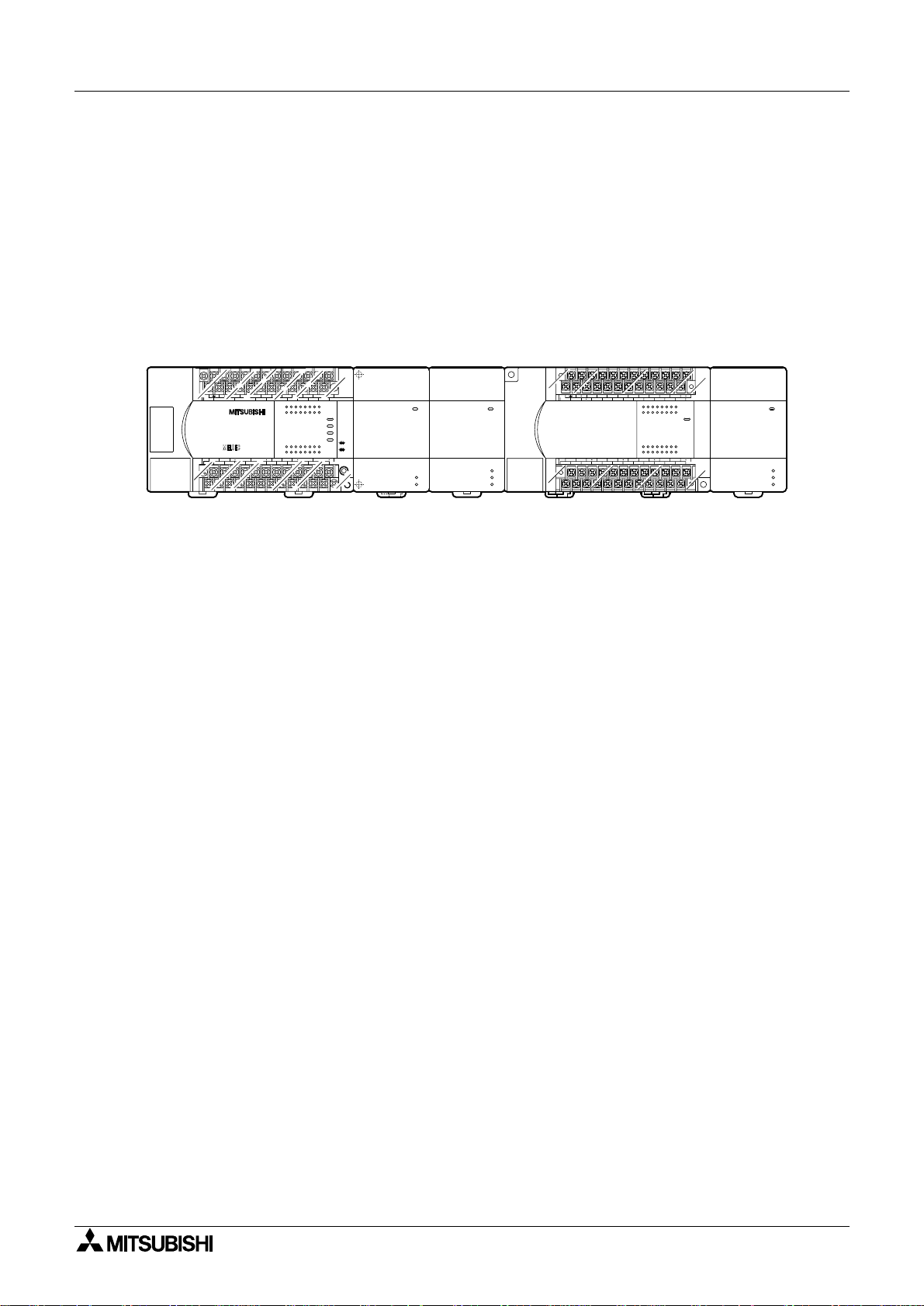

2.1 Outside dimension

4

Extension

cable

24+

24- O

Connector for next step

extension cable

Product Configuration 2

2

FX2N-2LC

Mounting

hole

φ

2-

45

55

2.2 Name of each part

➀

➁

24+

24- O

➂

POWER

24V

OUT1

OUT2

DIN rail

90

80 ±0.5

(mounting dimension)

Status indicator LED

DIN rail

(width:

35 mm)

mounting

groove

87

Unit: mm

Mass: kg

Outer color: Munsell 0.08GY / 7.64 / 0.81

Terminal block

24+ COM

24-

OUT1OUT2

POWER

FX2N-2LC

24V

OUT1

OUT2

➄

①

:PC connection cable

②

:Screw mounting hole

③

:Status indicator LED

④

:DIN rail mounting g roove (DIN rail width: 35 mm)

⑤

:DIN rail mounting hook

⑥

:Connector for next step ex tension cable

➅

➂

CT

➃

CH1 CH2

CT FG

PTA

PTB

TC+

PTB

TC-

➄

CT

CT FG

PTA

PTB

TC+

PTB

TC-

2-1

Page 18

FX2N-2LC Temperature Control Block

2.3 Status indication

Table 2.1:

LED name Indication Description

POWER

24V

OUT1

OUT2

Lit (green) 5 V power is supplied from PC main unit.

Extinguished 5 V power is not supplied from PC main unit.

Lit (red) 24 V power is supplied from outside.

Extinguished 24 V power is not supplied from outside.

Lit (red) OUT1 output is ON.

Extinguished OUT1 output is OFF.

Lit (red) OUT2 output is ON.

Extinguished OUT2 output is OFF.

Product Configuration 2

2-2

Page 19

FX2N-2LC Temperature Control Block

2.4 Installation method

Product Configuration 2

The FX2N-2LC can be installed on the right side of an FX2N/

Series extension unit or another extension block.

2NC

The FX

-2LC can be attached with a DIN rail DIN46277 ( wid th: 35 mm) or directl y attached to

2N

Series PLC ba sic unit, FX2N/

2NC

a panel surface with scr ews (M4).

• Installation on DIN rail

Align the upper side of the DIN rail mounting groove of the FX

DIN46277 (width: 35 mm) (①), and push the FX

When removing the FX

remove the FX

-2LC (④).

2N

-2LC, pull out downward the DIN rail mounting hook (③), then

2N

-2LC on the DIN rail (②).

2N

-2LC with a DIN rail

2N

When attaching to DIN rail When removing from DIN rail

➀

➃

2

➁

➂

• Direct installation on panel surface

Screw-tighten the FX

mounting holes provided on the left side of the FX

-2LC with M4 screws to a panel surface using two (upper and lower)

2N

-2LC.

2N

Assure the interval of 1 to 2 mm between a unit or block installed on the left side of the

FX

-2LC.

2N

Cautions on installation

• Use the unit in the environment for the general specifications described in the manual.

Nev er use the unit in a place with dusts , soot, conducti ve dusts , corrosive gas or flammable gas, place exposed to high temperature, dew condensation or rain and wi nd or place

exposed to vibration or impact.

If the unit is used in such a place, electrical shock, fire, malfunction, damages in the unit

or deterioration of the unit ma y be caused.

• Never drop cutting chips or electric wire chips into the ventilation window of the FX

2LC while drilling screw holes or wiring cables.

Such chips may cause fire, failure or malfunction.

• After finishing installation, remove a dust preventing sheet adhered on the ventilation

window of the PC and the FX

If the sheet remains attached, fire, failure or malfunction may be caused.

2N

-2LC.

2N

-

• Securely connect cables such as extension cables and memory cassettes to specified

connectors.

Imperfect contact may cause malfunction.

2-3

Page 20

FX2N-2LC Temperature Control Block

2.5 Connection to PC Main Unit

Connect the FX2N-2LC to the PC main unit with an extension cabl e.

FX

-2LC units are treated as special blocks of the PLC, and the special block No. 0 to 7 is

2N

automatically assigned to each FX

(These unit Nos. are used in FROM/TO instructions.)

One FX

For the details of I/O assignment in the PC, refer to the manual of the FX

-2LC unit occupies eight I/O points in the PC main unit.

2N

Product Configuration 2

-2LC unit from the one nearest to the PLC basic unit.

2N

Series PC.

2N/2NC

FX2N-32MR

(X000 to X017)

X3X2X1

FX2N-32MR

Y4Y5Y6

Y10

COM3

X10 X14 X16

X7

IN

OUT

Y12

Y11

Y13Y1Y2Y3

14 171510 12 13

Y14

COM X4

LX13X15

24+N

(Y000 to Y017)

72456130

1611

72456130

1611 1514 1710 12 13

Y15

FX2N-4AD

POWER

RUN

BATT.V

PROG.E

CPU.E

FX2N-4AD

Special

block

No. 0

POWER

A/D

24V

FX2N-2LC

POWER

FX2N-2LC

24V

OUT1

OUT2

Special

block

No. 1

(X020 to X037)

(Y020 to Y037)

( ) indicates the I/O No. assignment in the PC main unit.

• Up to eight FX

units can be connected to the FX

• When connecting the FX

-2LC units can be connected to the FX2N Series PC. Up to four FX2N-2LC

2N

Series PC.

2NC

-2LC unit to the FX

2N

Series PC, the interface FX

2NC

required.

(When connecting the FX

-2LC unit to the FX2N Series PC, the interface FX

2N

not required.)

FX2N-32MR

X0

X6 X0 X2 X4 X6

COM X4

24+N

X3X2X1

FX2N-32ER

X5

X7

IN

01234567

OUT

76543210

72456130

72456130

Y4Y5Y6

COM4COM2Y4Y5Y6Y7 COM3Y0Y1Y2Y3COM1Y0Y1Y2Y3

L X1X3X5X7

POWER

Y7

FX2N-2LC

POWER

FX2N-2LC

24V

OUT1

OUT2

Special

block

No.2

-CNV-IF is

2NC

-CNV-IF is

2NC

• For extension, an extension cable FX

rately are required.

Only one FX

-65EC can be used per system.

0N

-65EC (650 mm) and the FX

0N

-CNV-BC sold sepa-

2NC

2-4

Page 21

FX2N-2LC Temperature Control Block

Specifications 3

1 Introduction

2 Product Configur ation

3 Specifications 3

4 Wiring

5 Introduction of Functions

6Alarm

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 22

FX2N-2LC Temperature Control Block

Specifications 3

Page 23

FX2N-2LC Temperature Control Block

3. Specifications

3.1 Environmental specifications

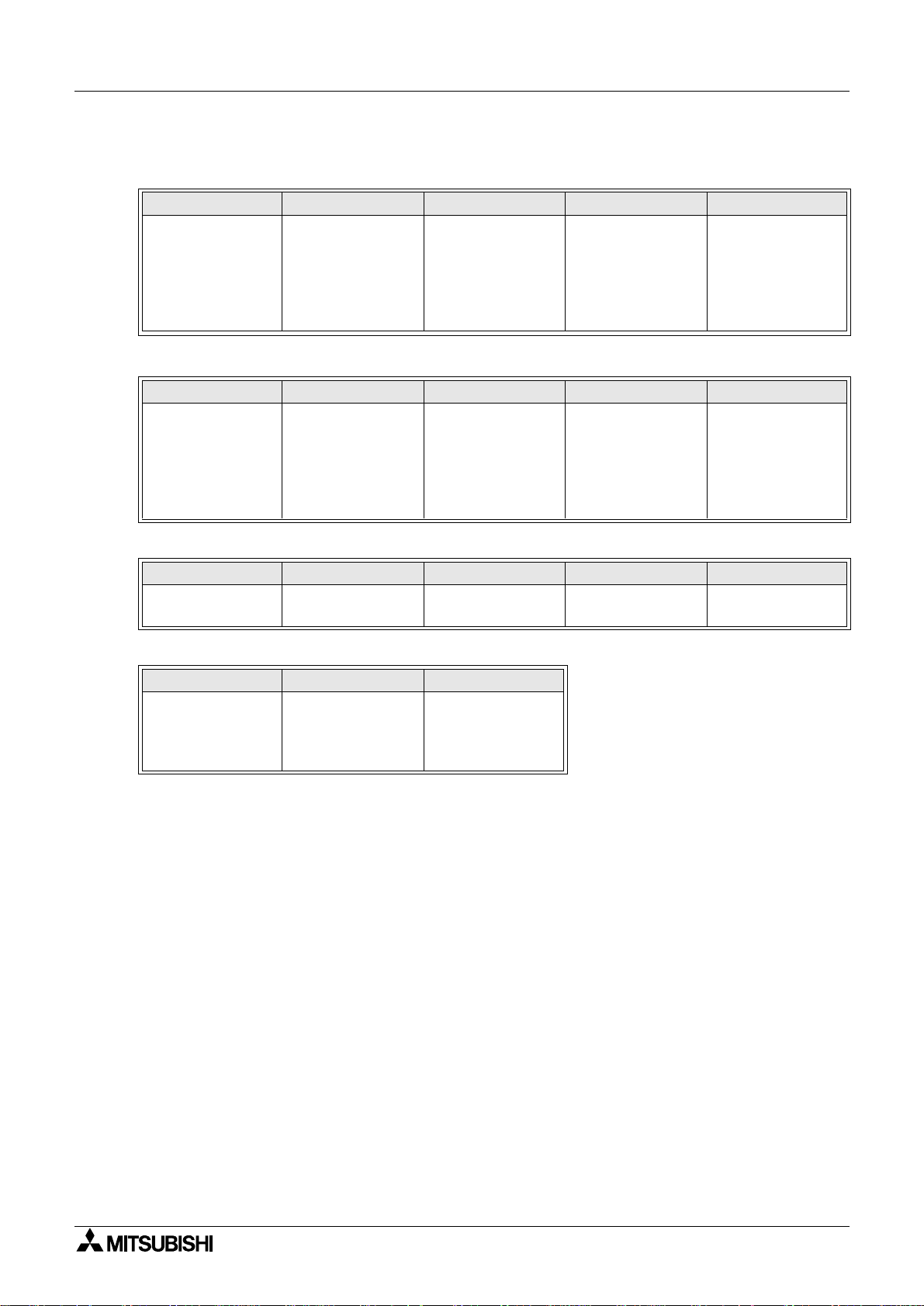

Table 3.1:

Item Specifications

Withstand voltage

500 VAC for 1 minute (between analog input terminal and grounding terminal)

Specifications 3

Other environmental specifications are equivalent to those for the PC main unit. (Refer to the

manual of the PC main unit.)

3.2 Power supply specifications

Table 3.2:

Item Specifications

Driving power supply 24 VDC (-15% to +10%), input from driving power supply terminal

Power supply for communi-

cation

Current consumption 24 VDC, 55 mA and 5 VDC, 70 mA

Insulation method

Number of occupied I/O

points

5 VDC (supplied from inside of PC main unit)

Analog input area and PC are insulated by photocoupler.

Power supply and analog input ar e insula ted by DC/DC converter.

(Channels are not insulated each other.)

8 points in total (including input points and output points)

3

3-1

Page 24

FX2N-2LC Temperature Control Block

3.3 Performance specifications

Table 3.3:

Item Description

Control method

Control operation period 500 ms

Set temperature range Equivalent to input range (Refer to 7.2.33)

Heater disconnection detection

Operation mode

Self-diagnosis function

Memory Built-in EEPROM (Number of times of overwrite: 100,000 times)

POWER

24V

Status

indication

OUT1

OUT2

Lit (green) 5 V power is supplied from PC main unit.

Extinguished 5 V power is not supplied from PC main unit.

Lit (red) 24 V power is supplied from outside.

Extinguished 24 V power is not supplied from outside.

Lit (red) OUT1 output is ON.

Extinguished OUT1 output is OFF.

Lit (red) OUT2 output is ON.

Extinguished OUT2 output is OFF.

Specifications 3

Two-position control, PID control (with auto tuning function), PI

control

Alarm is detected in accordance with setting of buffer memory.

(Variable within range from 0.0 to 100.0 A.).

0: Measured value monitor

1: Measured value monitor + Temperature alarm

2: Measured value monitor + Temperature alarm + Control

(Selected by buffer memory)

Adjustment data and input value are checked by watch dog timer.

When abnormality is detected, transistor output turns off.

3-2

Page 25

FX2N-2LC Temperature Control Block

3.4 Input specifications

Table 3.4:

Item Description

Number of input points 2 points

Input type

Measurement precision

Cold contact tempera-

Temperature

input

CT input

ture compensation error

Resolution

Sampling period 500 mS

Effect of external resistance

Input impedance

Sensor current Approx. 0.3 mA

Allowable input lead wire

resistance

Operation when input is

disconnected

Operation when input is

short-circuited

Number of input points 2 points

Current detector

Heater

current

measured

value

Measurement precision

Sampling period 1 second

Thermocou-

ple

Resistance

thermome-

ter bulb

When CTL-

12 is used

When CTL-

6 is used

Specifications 3

K, J, R, S, E, T, B, N, PLII, WRe5=26, U, L

Pt100, JPt100

± 0.7 % of range span ± 1 digit

(± 0.3 % of range span ± 1 digit when ambient temperature is

23 °C ± 5 °C)

However, 0 to 399 °C (0 to 799 °F) in B inputs as well as 0 to

32 °F in PLII and WRe5-26 inputs are outside precision guarantee range.

Within ± 1.0 °C

However, within ± 2.0 °C while input value is -100 to -150 °C

within ± 3.0 °C while input value is -150 to -200 °C

0.1 °C (0.1 °F) or 1 °C (1 °F)

(Varies depending on input range of used sensors.)

Approx. 0.35 µV/

1 Μ Ω

10 Ω or less

Upscale

Downscale

CTL-12-S36-8 or CTL-6-P-H

(manufactured by U.R.D. Co., Ltd.)

0.0 to 100.0 A

0.0 to 30.0 A

Larger one between ± 5 % of input value and 2 A

(excluding precision of current detector)

or more

Ω

3

3-3

Page 26

FX2N-2LC Temperature Control Block

3.5 Input range

Table 3.5:

Sensor type K J R S

-200.0 to 200.0 °C

-100.0 to 400.0 °C

Input range

Sensor type E T B N

Input range

-100 to 1300 °C

-100 to 2400 °F

-200.0 to 200.0 °C

-100 to 800 °F

0 to 1000 °C

0 to 1800 °F

-200.0 to 200.0 °C

-100.0 to 400.0 °C

-100.0 to 800.0 °C

-100 to 1200 °C

-100 to 1600 °F

-100 to 2100 °F

-200.0 to 200.0 °C

-200.0 to 400.0 °C

0 to 400.0 °C

-300.0 to 400.0 °F

-300.0 to 700.0 °F

0.0 to 700.0 °F

0 to 1700 °C

0 to 3200 °F

0 to 1800 °C

0 to 3000 °F

Specifications 3

0 to 1700 °C

0 to 3200 °F

0 to 1300 °C

0 to 2300 °F

Sensor type PL II WRe5-26 U L

Input range

Sensor type K J

Input range

0 to 1200 °C

0 to 2300 °F

-50.0 to 150.0 °C

-200.0 to 500.0 °C

-300.0 to 300.0°F

-300 to 900 °F

0 to 2300 °C

0 to 3000 °F

-50.0 to 150.0 °C

-200.0 to 600.0 °C

-300.0 to 300.0°F

-300 to 1100 °F

-200.0 to 600.0 °C

-300.0 to 700.0 °F

0.0 to 900.0 °C

0 to 1600 °F

• When B is used, 0 to 399 °C (0 to 799 °F) is outside the precision compensation range.

• When PLII is used, 0 to 32 °F is outside the precision compensation range.

• When WRe5 to WRe26 are used, 0 to 32 °F is outside the precision compensation range.

3-4

Page 27

FX2N-2LC Temperature Control Block

3.6 Output specifications

Table 3.6:

Item Description

Number of output points 2 points

Output method NPN open collector transistor output

Rated load voltage 5 to 24 VDC

Maximum load voltage 30 VDC or less

Maximum load current 100 mA

Leak current in OFF status 0.1 mA or less

Maximum voltage drop in ON status 2.5 V (maximum) or 1.0 V (typical) at 100 mA

Control output cycle 30 seconds (Variable within range from 1 to 100 seconds)

Specifications 3

3

3-5

Page 28

FX2N-2LC Temperature Control Block

Specifications 3

3-6

Page 29

FX2N-2LC Temperature Control Block

Wiring 4

1 Introduction

2 Product Configur ation

3 Specifications

4 Wiring 4

5 Introduction of Functions

6Alarm

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 30

FX2N-2LC Temperature Control Block

Wiring 4

Page 31

FX2N-2LC Temperature Control Block

4. Wiring

Cautions on Wiring

• Make sure to shut down the po wer supplies of all phases on the outside before starting

installation or wiring.

If the power supplies are not shut down, you may get electrical shock or the unit may be

damaged.

• As to loads which are dangerous when turning on at the same time, make sure to interlock them outside the PLC and the FX

gram in the PLC.

Wiring 4

-2LC in addition to interlocking of them in a pro-

2N

4

• Correctly connect the power cable of the FX

-2LC and the PLC as described in this

2N

manual.

If the AC po we r suppl y is connect ed to a DC I/O terminal or DC pow er terminal, the PLC

may be burnt.

• Never perform external wiring to unused terminals in the FX

-2LC and the PLC.

2N

Such wiring may damage the units.

• Per form Class 3 grounding with an electric wire of 2 mm

nal in the FX

-2LC and the PLC.

2N

2

or more to the ground ing termi-

However, never perform common grounding with a strong power system.

4-1

Page 32

FX2N-2LC Temperature Control Block

4.1 Wiring

When a temperature sensor is a thermocouple (TC)

FX2N-2LC

24+

24-

*1

OUT1

COM

OUT2

CT

CT

PTA / •

FG

PTB / TC+

PTB / TC-

CT

CT

Shielded cable

DC24V

+-

SSR

SSR

Thermocouple

Wiring 4

AC power supply

CT

Heater

CT

PTA / •

FG

PTB / TC+

PTB / TC-

Shielded cable

Thermocouple

Heater

When a temperature sensor is a resistance thermometer bulb (RTD)

Resistance

2N

FX

-2LC

PTA / •

FG

PTB / TC+

PTB / TC-

Shielded cable

*1 Connect the terminal in the FX

thermometer

bulb

-2LC to the terminal in the PLC to which Class

2N

3 grounding is performed.

• When using a thermocouple, use specified compensating lead wires.

• When using a resistance thermometer bulb, use the three-wire type, and perform wiring

with lead wires having small resistance and no diffe rence in the resistance among the three

wires.

• Terminal tightening torque: 0.5 to 0.8 N·m

4-2

Page 33

FX2N-2LC Temperature Control Block

Introduction of Functions 5

1 Introduction

2 Product Configur ation

3 Specifications

4 Wiring

5 Introduction of Functions 5

6Alarm

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 34

FX2N-2LC Temperature Control Block

Introduction of Functions 5

Page 35

FX2N-2LC Temperature Control Block

5. Introduction of Functions

This section introduces the functions of the FX2N-2LC.

For setting of each function, refer to the description on buffer memories (BFM) later.

5.1 PID control

5.1.1 Easy PID control with two degrees of freedom

PID control is a control method to obtain stable control result by setting each of the constants

"P (proportional band)", "I (integral time)" and "D (derivative time)".

However, if each PID constant is so set that the "response to setting" becomes good, the

"response to disturbance" becomes deteri orated in PID control. On the c ontrar y, if each PID

constant is so set that the "response to disturbance" becomes good, the "response to setting"

becomes deteriorated.

Introduction of Functions 5

The FX

-2LC performs easy PID control with two degrees of freedom in which PID constants

2N

realizing good response to di sturbance are adopted and the shape of the "response to setting"

can be selected as either "fast", "medium" or "slow".

Setting of PID constants and selection of the "response to setting" can be p erformed using

buffer memories.

Conventional PID control

When PID constants are set so that the response to changes in set value becomes good

Response to changes in set value Response to disturbance

Set value

(SV)

When PID constants are so set that the response to disturbance becomes good

Response to changes in set value Response to disturbance

Set value

(SV)

Set value

(SV)

Set value

(SV)

5

Easy PID control with two degrees of freedom

Response to changes in set value Response to disturbance

Fast

Medium

Set value

(SV)

Slow

Set value

(SV)

5-1

Page 36

FX2N-2LC Temperature Control Block

5.1.2 Overshoot prevention function

Generally in PID control, when a deviation continues for a long time, the PID arithmetic operation result exceeds the effective range (from 0 to 100%) of the operation quantity. At this time,

even if the deviation becomes smaller, it takes some time until the output comes within the

effective range because of the integ ral oper ati on. As a result , executio n of an actual cor recti on

operation is delayed, and overshoot/undershoot occurs.

In order to prevent overshoot, the FX

function. The RFB limiter function feeds back the excessive quantity to the integral value and

makes the arithmetic operation result be held at the limit point when the PID arithmetic operation result exceeds the limit point (upper/lower limit of the output limiter) so that the PID arithmetic operation result al wa y s remains insi de the effective r ange . Accordingl y, when a deviatio n

becomes small, the correction operation is immediately performed.

Introduction of Functions 5

-2LC is equipped with the RFB (reset-feedback) limiter

2N

<When the RFB limiter function is not provided>

Operation

quantity (%)

Output limiter upper limit

Output limiter lower limit

Temperature

Target

value

Large overshoot

<When the RFB limiter function is provided>

The excessive quantity above the output limiter

upper limit is fed back to the integral value, and

the arithmetic operat ion result is held at the

upper limit value.

Operation

quantity (%)

Output limiter upper limit

Output limiter lower limit

Temperature

Target

value

5-2

Page 37

FX2N-2LC Temperature Control Block

5.2 Two-position control

When the proportional band (P) value is set to "0.0", the FX2N-2LC performs two-position control.

In two-position control, the control output (MV) is set to ON when the measured value (PV) is

larger than the temperature set value (SV) or OFF when the measured value (PV) is smaller

than the temperature set val ue (SV).

When the adjustment sen sitivity (dead zone) is set, repetitious tu r ning ON/OFF of the ou tput

around the temperature set value (SV) can be prevented.

However, if the adjustment sensitivity (dead zone) is set to a large value, upward/downward

fluctuation becomes large ac cordingly. If the adjustment sensitivity (dead zone ) is set to a

small value, chattering (drastic repetitious turning ON/OFF) may be caused by small oscillations of measured values.

Introduction of Functions 5

Temperature

set value (SV)

Operation output

value (MV)

ON OFF ON OFF

5

Adjustment sensitivity (dead zone)

* The adjustment sensitivity is equally given

to the upper portion and t he lower portion

of the temperature set value (SV).

Time

5-3

Page 38

FX2N-2LC Temperature Control Block

5.3 Auto tuning function

5.3.1 AT (auto tuning)

The AT (auto tuning) function automatically measures, calculates and sets optimal PID constants in accordance with the set temperature.

When the AT execution command (CH1: BFM #20, CH2: BFM #29) is set to "1", auto tuning is

performed. (Auto tuning can start from an arbitrary status at any time immediately after the

power is turned on, while the temperature is rising or while control is stable.)

When auto tuning starts, two-position control is p erformed using the set value (SV). B y twoposition control, the output is forcedly hunted and its amplitude and oscillation cycle are measured. PID constants are calculated based on the measured values, and stored in each

parameter. When auto tuning normally finishes, control continues with new calculated PID

constants.

While auto tuning is performed, b14 of the event (CH1: BFM #1, CH2: BFM #2) is set to "1".

For auto tuni ng, the AT bias can be set.

(In order to calculate proper PID constants by auto tuning, set the upper limit of the output limiter to 100%, the lower l imit of the output l imiter to 0%, and the output chang e r atio limi ter function to OFF.)

Introduction of Functions 5

1) Auto tuning can be performed when the following conditions are satisfied.

- The control start/stop status shall be set to "control start".

- The operation mode shall be set to the control "mode 2".

- The auto/manual mode shall be set to "auto".

- The input value (PV) shall be normal.

- The upper limit and the lower limit of the output limiter shall not be set to a same value.

- The proportional band shall not be set to "0 (two-position operation)".

5-4

Page 39

FX2N-2LC Temperature Control Block

2) When either of the following conditions are given during auto tuning, the operation is

aborted.

- When the input value (PV) becomes abnormal caused by disconnection, etc.

- When the set value (SV) is changed

- When control is stopped, when the operation mode is changed or when the auto/manual

mode is set to "manual"

- When the AT bias setting is changed

- When the PV bias setting is changed

- When the digital filter setting is changed

- When the output limiter setting is changed

- When the power is interrupted

- When the AT execution command (CH1: BFM #20, CH2: BFM #29) is set to "0 (AT stop)"

Measured value (PV)

Introduction of Functions 5

(Example: When AT is performed while the temperature is rising)

5

5.3.2 AT bias

Set the AT bias to perform auto tuning in which the measured v al ue (PV) should not exceed the

temperature set value (SV).

The auto tuning fu nction p erforms two-p osition co ntrol using the temperature set value (SV) ,

hunts the measured value (PV), then calculates and sets each PID constant. However, for

some control targets, overshoot caused by hunting is not desirable. Set the AT bias for such a

case. When the AT bias is set, the set value (SV) (AT point) with which auto tuning is performed can be changed.

Temperature

set value (SV)

Temperature

set value (SV)

Measured value (PV)

AT point

AT starts.

Example: When the AT bias is set to "-"

AT finishes.

Time

AT bias

AT starts.

AT finishes.

Time

5-5

Page 40

FX2N-2LC Temperature Control Block

5.4 Auto / manual

5.4.1 Auto mode and manual mode

The mode can be changed over between "auto" and "manual". In the auto mode, the control

output value (MV) is set to the output quantity automatically calculated in accordance with the

temperature set value (SV). In the manual mode, the control output value (MV) is set to the

output quantity set arbitrarily and manually.

In the manual mode, b13 (manual mode transition completion) of the event (CH1: BFM #1,

CH2: BFM #2) becomes "1" to notify the manual mode.

0.5 second is required to change over the mode. During changeover, the balance-less, bump-

less function is actuated.

Auto mode

In the auto mode, the measured value (PV) is compared with the temperature set value (SV),

and the control output (MV) is given by PID arithmetic operation.

This mode is selected when the FX

In the auto mode, the manual output value is always set to the output value (MV).

-2LC is shipped.

2N

Introduction of Functions 5

Manual mode

In the manual mode, the output (MV) value is fixed to a certain value.

By changing the manual output setting (BFM #19, BFM #28), the output value can be fixed to

an arbitrary value.

The manual output value can be changed while b13 of the e v ent (CH1: BFM #1, CH2: BFM #2)

is "1" (that is, when the manual mode is sel ected).

Even in the manual mode, the temperature alarm function is effective.

5-6

Page 41

FX2N-2LC Temperature Control Block

5.4.2 Balance-less, bump-less function

The balance-less, bump-less function prevents overload caused by drastic change in the control output value (MV) when the mode is changed over from auto to manual (or from manual to

auto).

Operation performed when the mode is changed o ver from auto to manual:

The control output value in the auto mode continues to be effective.

Operation performed when the mode is changed over from manual to auto:

The control output value is changed over to a value automatically calculated

based on the temperature set value (SV).

Operation output quantity

Auto Manual Auto

Introduction of Functions 5

5

Time

➀ ➁➂

➀

The mode is changed over from auto to manual. However, the operation output quantity

follows the operation output quantity in the auto mode.

➁

The operation output quantity is manually changed.

➂

The mode is changed over from manual to auto. The operation output quantity becomes

a value automatically calculated based on the temperature set value (SV).

5-7

Page 42

FX2N-2LC Temperature Control Block

5.5 Heater disconnection detection function

The heater disconnection detection function detects the current flowing in the load using a current detector (CT), it compares the detected value (heater current measured value) with the

current value set for heater disconnection alarm , and issues an alar m when the mea sured

value is more than or less than the current set value for the heater disconnection alarm.

The heater current can be measured using buffer memories (BFM #7, BFM #8).

Connection example

Power supply

Temperature

control block

-2LC

FX

2N

Control output

Current detector

Operating

machine SSR

Introduction of Functions 5

Current detector input

Heater

Measured

value (PV)

Sensor

Control target

Alarm operation

The heater disconnection detection function issues an alarm in the following cases.

When the heater current does not flow

1)

... Caused by heater disconnecti on, error in operating machine, etc.

When the reference heater current value is equivalent to or less than the current set value

for the heater disconnection alarm while the control output is ON, an alarm is issued.

However, if the control output ON time is 0.5 sec or less, heater disconnection alarm is not

issued.

When the heater current does not turn off

2)

... Caused by a molten relay, etc.

When the reference heater curr ent value is m ore th an th e curre nt set value for the hea ter

disconnection alarm while the control output is OFF, an alarm is issued.

However, if the control output OFF time is 0.5 sec or less, heater disconnection alarm is not

issued.

Current detector

CTL-12-S36-8 (Applicable current range: 0.0 to 100.0 A)

CTL-6-P-H (Applicable current range: 0.0 to 30.0 A)

Manufacturer: U.R.D. Co., Ltd.

5-8

Page 43

FX2N-2LC Temperature Control Block

5.6 Loop breaking alarm function (LBA)

The loop breaking alarm function starts to detect the variation of the measured value (PV), at

every loop breaking alar m judgment time w hen the output be comes more tha n 100% (or the

output limiter upper limit) or less than 0% (or the output limiter lower limit), then sets to ON the

loop breaking alarm (CH1: BFM #1 b8, CH2: BFM #2 b8) when judging that there is an abnormality in the control loop.

Abnormality judgment criteria

Table 5.1: Heating control (rever se operation)

When output is less than 0% or

output li miter lower limit

When output is more than 100%

or output limiter upper limit

When measured value (PV) does not decrease at least by loop

breaking change criteria (2 °C) within loop breaking set time, an

alarm is issued.

When measured value (PV) does not increase at least by loop breaking change criteria (2 °C) within loop breaking set time, an alarm is

issued.

Introduction of Functions 5

Table 5.2: Cooling control (normal operation)

When output is less than 0% or

output li miter lower limit

When output is more than 100%

or output limiter upper limit

When measured value (PV) does not decrease at leas by loop breaking change criteria (2 °C) within loop breaking set time, an alarm is

issued.

When measured value (PV) does not increase at least by loop breaking change criteria (2 °C) within loop breaking set time, an alarm is

issued.

Abnormality targets

1) Abnormality in control target: Heater disconnection, lack of power supply, wiring mistake,

etc.

2) Abnormality in sensor: Sensor disconnection, short-circuit, etc.

3) Abnormality in operating machine: Molten relay, wiring mistake, etc.

4) Abnormality in output circuit: Molten relay inside instrument, etc.

5) Abnormality in input circuit: No change in the measured value (PV) even after input has

changed

Note:

- When the auto tuning function is used, the LBA set time is automatically set to the inte-

gral time result multiplied by 2.

The LBA set time does not change even if the integral v alue changes.

5

- While auto tuning is performed, the loop breaking alarm function is disabled.

- If the LBA set time is too short or is not suitable to control targets, the loop breaking

alarm may repeatedly turn on and off or may not turn on.

In such a case, change the LBA set time in accordance with the situation.

- The loop breaking alarm function judges abnormalities in the control loop, but cannot

detect positions in which abnormalities occur.

Check each part of the control system in turn.

5-9

Page 44

FX2N-2LC Temperature Control Block

Introduction of Functions 5

5-10

Page 45

FX2N-2LC Temperature Control Block

1 Introduction

2 Product Configur ation

3 Specifications

4 Wiring

5 Introduction of Functions

Alarm 6

6 Alarm 6

7 Buffer Memory (BFM)

8 Program Example

9 Diagnostic

Page 46

FX2N-2LC Temperature Control Block

Alarm 6

Page 47

FX2N-2LC Temperature Control Block

6. Alarm

The FX2N-2LC is equipped with 14 types of alarms. Among them, up to 4 ty pes can b e used in

accordance with the application.

The alarm types to be used can be selected using buffer memories. The result of each alarm

is written to BFM #1 and BFM #2, and can be read in the PLC main unit.

When the measured value (PV) is near th e alar m set value of an use d alar m typ e, the alar m

status and the non-alarm status may be repeated by fluctuation in inputs. In or der to c ope with

such a case, the alarm dead zone can be set to prevent repeating of the alarm status and the

non-alarm status. (The dead zone of alarms 1 to 4 can be set using BFM #76.)

Table 6.1:

Alarm

No.

0 Alarm function OFF Alarm function is disabled. --1 Upper limit input value alarm

2 Lower limit input value alarm

3 Upper limit deviation alarm

4 Lower limit deviation alarm

5 Upper/lower limit deviation

6 Range alarm

Upper limit input value alarm

7

with wait

Lower limit input value alarm

8

with wait

Upper limit deviation value

9

alarm with wait

Lower limit deviation val ue

10

alarm with wait

Upper/lower limit deviation

11

value alarm with wait

Alarm type Description

When measured value (PV) is more than alarm set

value, an alarm is issued.

When measured value (PV) is less than alarm set

value, an alarm is issued.

When deviation (= Measured value (PV) - Set

value (SV)) is more than alarm set value, an alarm

is issued.

When deviation (= Measured value (PV) - Set

value (SV)) is less than alarm set value, an alarm

is issued.

When absolute deviation (= Measured value (PV)

- Set value (SV)) is more than alarm set value, an

alarm is issued.

When absolute deviation (= Measured value (PV)

- Set value (SV)) is less than alarm set value, an

alarm is issued.

When measured value (PV) is more than alarm set

value , an alarm is issued . How ev er, when power is

turned on, measured value is ignored.

When measured value (PV) is less than alarm set

value , an alarm is issued . How ev er, when power is

turned on, measured value is ignored.

When deviation (= Measured value (PV) - Set

value (SV)) is more than alarm set value, an alarm

is issued. However, when power is turned on,

measured value is ignored.

When deviation (= Measured value (PV) - Set

value (SV)) is less than alarm set value, an alarm

is issued. However, when power is turned on,

measured value ignored.

When absolute deviation (= Measured value (PV)

- Set value (SV)) is more than alarm set value, an

alarm is issued. However, when power is turned

on, measured value is ignored.

Alarm 6

Set

range

Input

range

Input

range

±Input

width

±Input

width

+Input

width

+Input

width

Input

range

Input

range

±Input

width

±Input

width

+Input

width

6

6-1

Page 48

FX2N-2LC Temperature Control Block

Table 6.1:

Alarm

No.

12

13

14

Upper limit deviation value

alarm with re-wait

Lower limit deviation val ue

alarm with re-wait

Upper/lower limit deviation

value alarm with re-wait

Alarm type Description

Input range:Numeric value from the lower limit to the upper limit of input value

When deviation (= Measured value (PV) - Set

value (SV)) is more than alarm set value, an alarm

is issued. However, when power is turned on and

when set value is changed, measured value is

ignored.

When deviation (= Measured value (PV) - Set

value (SV)) is less than alarm set value, an alarm

is issued. However, when power is turned on and

when set value is changed, measured value is

ignored.

When absolute deviation (= Measured value (PV)

- Set value (SV)) is more than alarm set value, an

alarm is issued. However, when power is turned

on and when set value is changed, measured

value is ignored.

Alarm 6

Set

range

±Input

width

±Input

width

+Input

width

Input width:Width from the lo wer limit to the upper limit of input value (Input width = Upper limit

value - Low er limit value)

± Input width ...Both a positive and negative numeric values can be set.

+ Input width ...Only a positive numeric value can be set.

6-2

Page 49

FX2N-2LC Temperature Control Block

Upper limit input value alarm

When the measured value (PV) is more than the alarm set value, an alarm is issued.

Alarm 6

Measured value (PV)

Alarm set value

Alarm status

Measured value (PV)

Time

Non-alarm status

Alarm status

Lower limit input value alarm

When the measured value (PV) is less than th e alarm set va lue, an alarm is issued.

Measured value (PV)

Measured value (PV)

Alarm set value

Time

Alarm status

Non-alarm status

Alarm status

6

Upper limit deviation alarm

When the deviation ( = Measured value (PV) - Set value (SV)) i s more than the al arm set val ue ,

an alarm is issued.

Measured value

Alarm set

value

Temperature

set value (SV)

Alarm status

< When the deviation is positive >

(PV)

Measured value

(PV)

Devia

tion

Time

Temperature

set value (SV)

Alarm status

< When the deviation is negative >

Measured value

(PV)

Alarm set

value

Measured value

Non-alarm

status

(PV)

Devia

tion

Time

Alarm

status

6-3

Page 50

FX2N-2LC Temperature Control Block

Lower limit deviation alarm

When the deviation (= Measured value (PV) - Set value (SV)) is less than the alarm set value,

an alarm is issued.

Alarm 6

< When the deviation is positive >

Measured value

(PV)

Alarm set

value

Temperature

set value (SV)

Alarm status

Measured value

(PV)

Devia

tion

Time

Temperature

set value (SV)

Alarm set value

Alarm status

Upper/lower limit deviation alarm

When the absolute deviation (=

Measured value (PV) - Set value (SV)) is more than the

alarm set value, an alarm is issued.

For example, if the alarm set value is "+10

°

C", an alarm is issued when the measured value

(PV) is outside the range from "set value (SV) + 10

Measured value (PV)

Alarm set

value

Temperature

set value (SV)

Alarm set

value

Measured value (PV)

< When the deviation is negative >

Measured value

(PV)

°

C" to "set value (SV) - 10 °C".

Deviation

Deviation

Measured value

(PV)

Non-alarm

status

Devia

tion

Time

Alarm

status

Alarm status

Range alarm

When the absolute deviat ion (=

Measured value (PV) - Set value (SV)) is less than the alarm

set value, an alarm is issued.

For example, if the alarm set value is "+10

°

C", an alarm is issued when the measured value

(PV) is inside the range from "s et value (SV) + 10

Measured value (PV)

Measured value (PV)

Alarm set

value

Temperature

set value (SV)

Alarm set

value

Alarm status

Time

°

C" to "set value (SV) - 10 °C".

Deviation

Deviation

Time

Non-alarm status

Alarm status

Non-alarm status

Alarm status

6-4

Page 51

FX2N-2LC Temperature Control Block

Alarm wait operation

The wait operation ignores the alarm status of the measured value (PV) occurred when the

power is turned on, and disables the alarm function until the measured value (PV) goes out of

the alarm status once.

When control starts, the wait operation is performed also.

Alarm 6

< When the wait operation is performed >

Measured value (PV)

Temperature

set value (SV)

Alarm set

value

Wait operation region

Alarm status

Measured value

(PV)

Devia

tion

Time

< When the wait operation is not performed >

Measured value (PV)

Temperature

set value (SV)

Alarm set

value

Alarm status

Non-alarm

status

Measured value

(PV)

Devia

tion

Time

Alarm

status

Alarm re-wait operation

The alarm re-wait operation ignores the alar m status of the mea sured value (PV) occurred

when the power is turned on, and disables the alarm function until the measured value (PV)

goes out of the alarm status once.

When the temperature set value (SV) is changed, the measured value (PV) for deviation alarm

changes accordingly. At this time, even if the measured value (PV) becomes the alarm status,

the alarm re-wait function ignores it again and disables the alarm function until the measured

value (PV) goes out of the alarm status again.

6

Re-wait operation

Measured value (PV)

Temperature set

value (SV)

Alarm set value

Temperature set

value (SV1)

Alarm set value

Alarm status

Set value is changed.

Wait operation region

Measured value (PV)

Wait operation region

Deviation

Deviation

Time

Non-alarm

status

Alarm status

6-5

Page 52

FX2N-2LC Temperature Control Block

Alarm 6

6-6

Page 53

FX2N-2LC Temperature Control Block

1 Introduction

2 Product Configuration

3 Specifications

4 Wiring

5 Introduction of Functions

Buffer Memory (BFM) 7

6Alarm

7 Buffer Memory (BFM) 7

8 Program Example

9 Diagnostic

Page 54

FX2N-2LC Temperature Control Block

Buffer Memory (BFM) 7

Page 55

FX2N-2LC Temperature Control Block

7. Buffer Memory (BFM)

Each setting and alarm in the FX2N-2LC is written from or read to the PLC main unit through

buffer memories (hereafter referred to as "BFM").

Each BFM consists of 16 bits. Use FROM/TO instructions in the 16-bit format.

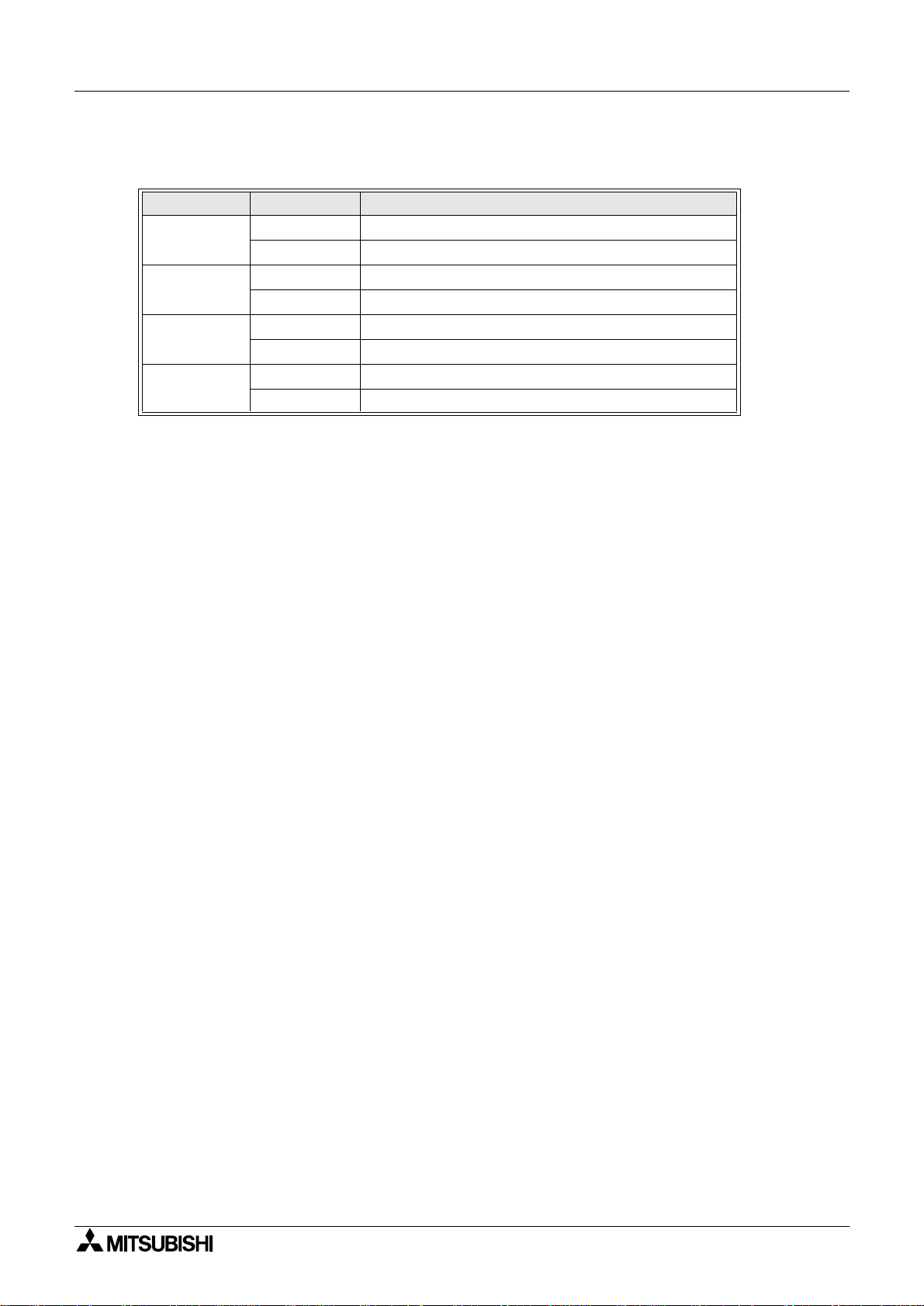

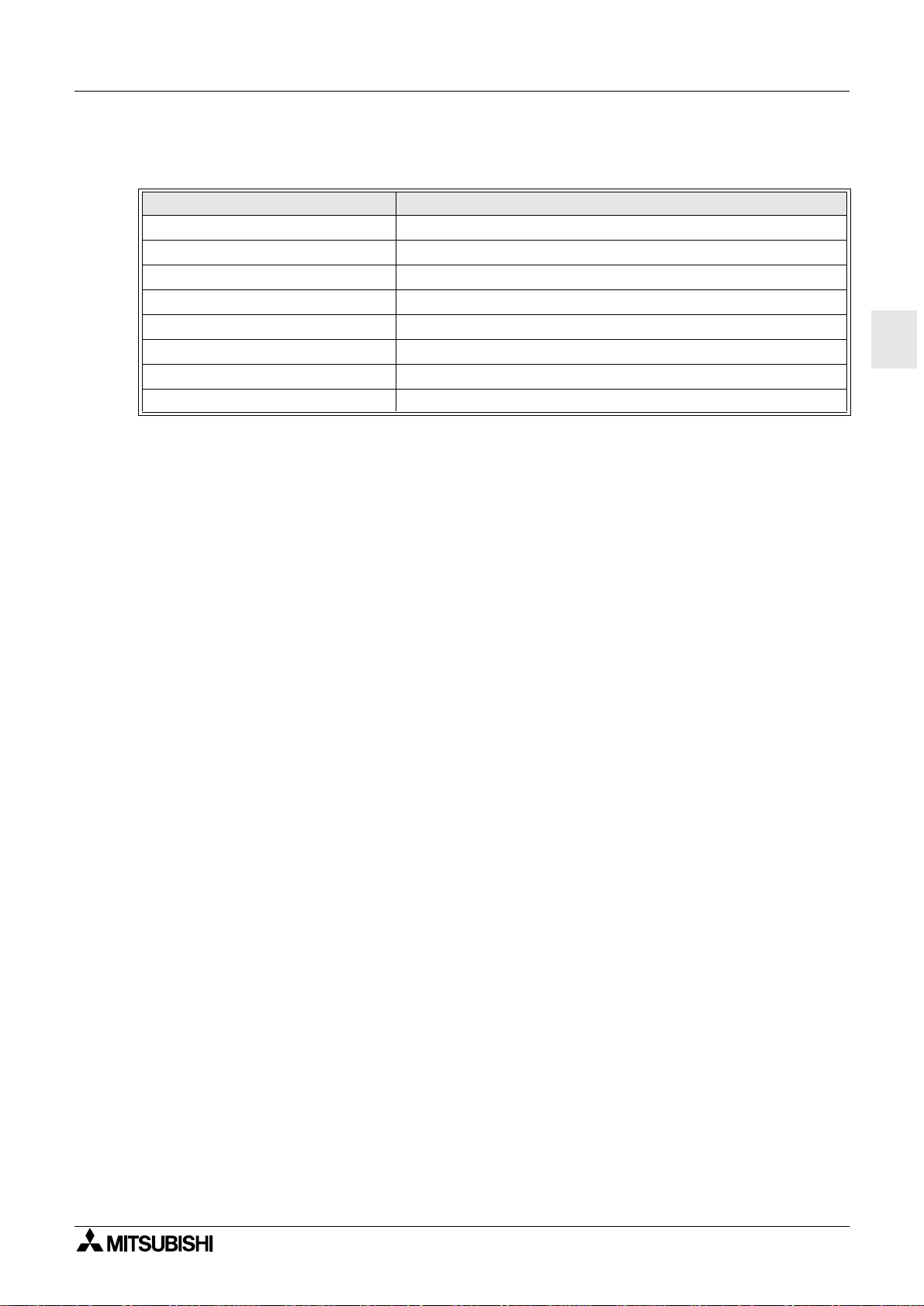

7.1 Buffer memory list

Table 7.1:

BFM No.

CH1 CH2

#0 Flag Error flag, ready flag, etc. 0

#1 #2 Event

#3 #4 Measured value (PV) ±5% of input range (°C/°F) 0.0

#5 #6 Control output value (MV) -5.0 to 105.0 (%) -5.0

#7 #8 Heater current measured value 0.0 to 105.0 (A) 0.0

#9 Initialization command

#10 Error reset command

#11 Control start/stop changeover

#12 #21 Set value (SV) Within set range limiter 0.0

#13 #22 Alarm 1 set value

#14 #23 Alarm 2 set value 0.0

#15 #24 Alarm 3 set value 0.0

#16 #25 Alarm 4 set value 0.0

#17 #26

#18 #27 Auto/manual mode changeover 0:AUTO 1:MAN 0

#19 #28 Manual output set value -5.0 to 105.0 (%) *1 0.0

#20 #29 Auto tuning execution command

#30 Unit type code 2060 R

#31 Prohibited --- --- ---

#32 #51 Operation mode

#33 #52 Proportional band

#34 #53 Integral time 1 to 3,600 sec 240

#35 #54 Derivative time 0 to 3,600 sec 60

Heater disconnection alarm set

value

Name Description/set range

Buffer Memory (BFM) 7

Alarm status, temperature rise

completed status, etc.

0: Performs nothing

1: Initializes all data

2: Initializes BFM #10 to BFM #69

0: Performs nothing

1: Resets errors

0: Stops control

1: Starts control

Unit: °C or °F

Allowable set range varies

depending on alarm mode setting.

0.0 to 100.0 A

(When "0.0" is set, alarm function

is disabled.)

0: Stops auto tuning

1: Performs auto tuning

0: Monitor

1: Monitor + Temperature alarm

2: Monitor + Temperature alarm +

Control

0.0 to 1,000.0 %/span

(When "0.0" is set, two-position

control is performed.)

Initial

value

0.0

0.0

3.0

Remarks

0

0

0

0

R/W

0

2

R/W

R

---

7

✩

---

✩

7-1

Page 56

FX2N-2LC Temperature Control Block

Table 7.1:

BFM No.

CH1 CH2

#36 #55 Control response parameter 0: Slow 1: Medium 2: Fast 0

#37 #56 Output limiter upper limit

#38 #57 Output limiter lower limit -5.0% to output limiter upper limit 0.0

#39 #58 Output change ratio limiter

#40 #59

#41 #60

#42 #61 Control output cycle setting 1 to 100 sec 30

#43 #62 Primary delay digital filter setting

#44 #63 Setting change ratio limiter

#45 #64 AT (auto tuning) bias ±Input span (°C/°F) 0.0

#46 #65

#47 #66 Setting limiter upper limit

#48 #67 Setting limiter lower limit

#49 #68

#50 #69 Loop breaking alarm dead zone 0.0 or 0 to input span (°C/°F) 0.0

#70 #71 Input type selection 0 to 43 2

#72 Alarm 1 mode setting

#73 Alarm 2 mode setting 0

#74 Alarm 3 mode setting 0

#75 Alarm 4 mode setting 0

#76 Alarm 1/2/3/4 dead zone setting 0.0 to 10.0 (% / span) 1.0

#77

#78

#79

#80

Sensor correction value setting

(PV bias)

Adjustment sensitivity (dead

zone) setting

Normal/reverse operation selection

Loop breaking alarm judgement

time

Number of times of alarm 1/2/3/4

delay

Number of times of heater disconnection alarm delay

Temperature rise completion

range setting

Temperature rise completion

soak time

Name Description/set range

Output limiter lower limit to 105.0

(%)

0.0 to 100.0 %/sec

(When "0.0" is set, function is disabled.)

±50.00 (% / span) 0.00

0.0 to 10.0 (% / span) 1.0

0 to 100 sec

(When "0" is set, function is disabled.)

0.0 to 100.0 %/min

(When "0.0" is set, function is disabled.)

0: Normal operation

1: Reverse operation

Setting limiter lower limit to input

range upper limit

Input range lower limit to setting

limiter upper limit

0 to 7,200 sec

(When "0" is set, alarm function is

disabled.)

0 to 14

0 to 255 times 0

3 to 255 times 3

1 to 10 (°C/°F) 1.0

0 to 3600 (sec) 0

Buffer Memory (BFM) 7

Initial

value

100.0

1300

0.0

0.0

-100

480

Remarks

0

1

R/W

0

✩

7-2

Page 57

FX2N-2LC Temperature Control Block

Table 7.1:

BFM No.

CH1 CH2

#81 CT monitor method changeover

#82 Set value range error address

#83 Set value backup command

R : Only read is enabled.

R/W: Both read and write are enabled.

: Setting data can be backed up by EEPROM in accor dance wit h the setting of BFM #83.

✩

*1 : Write is enabled when the manual mode transition completion flag is ON.

Name Description/set range

0: Monitors both ON current and

OFF current.

1: Monitors only ON current.

0: Normal

1 or another numeric value : Setting error address

0: Normal

1: Starts to write EEPROM.

Buffer Memory (BFM) 7

Initial

value

Remarks

0R/W

0R

0R/W

✩

- As to a numeric value containing a decima l point and n umber s af ter tha t, set it as a value

multiplied by 10.

Example: 100.0 (actual value)

→→→→

1000 (set value)

- If a value is written by mistake to a buffer memory used only for read, the written value is

ignored. And 500 ms later, the buffer me mory is overwritten with a correct value.

- If a value outside the allowable set rang e is written to a buffer memory used both f or read

and write, the set value range error (b1) of the flag (BFM #0) turns on.

And the buff er memory in which the set v alu e range er ror has occu rred is control led wit h

the upper limit or the low er limit of the allowable set range.

7

7-3

Page 58

FX2N-2LC Temperature Control Block

7.2 Details of buffer memories

7.2.1 BFM #0: Flag

Table 7.2:

Bit No. Description Operation

b0 Error present

b1 Set value range error Turns on when data outside set range is written.

b2 24 VDC power supply error

b3 Set value backup error

b4 Not used --b5 Not used --b6 Not used --b7 Not used ---

Sum check error for adjustment

b8

data error

Cold contact temperature com-

b9

pensation data error

b10 A/D converted value error

b11 Not used --b12 Controlling flag Turns on when FX

b13 Set value being backed up

b14 Initialization completion flag Turns on when initialization is completed.

b15 Temperature control ready flag Turns on when FX

Buffer Memory (BFM) 7

Turns on when an error among b1 to b10 below has

occurred.

Turns on when driving power supply (24 VDC) is not supplied.

Turns on when an error has been caused by noise or when

a failure has occurred in FX

2N

-2LC.

If contents of error are not eliminated even after power is

turned off once then on again, contact Mitsubishi Electric

System Service.

Turns on when an error has been caused by noise or when

a failure has occurred in FX

2N

-2LC.

If contents of error are not eliminated even after power is

turned off once then on again, contact Mitsubishi Electric

System Service.

-2LC is performing control.

2N

Remains ON while set values are being backed up.

Refer to 7.2.42.

-2LC becomes ready for operation.

2N

Operation of b15 (Temperature control ready flag)

Temperature control ready flag

Power is turned on.

It takes 500 ms

maximum.

Initialization of temperature

control CPU is completed.

Description on operation

1) When the power is turned on and initialization of the te mperature control CPU is completed, the temperature control ready flag turns on.

2) While the temperature control ready flag is ON, the FX

-2LC accepts TO inst ructions.

2N

7-4

Page 59

FX2N-2LC Temperature Control Block

7.2.2 BFM #1 (CH1) and BFM #2 (CH2): Event

BFM #1 corresponds to CH1. BFM #2 corresponds to CH2. Assignment is equivalent

between BFM #1 and BFM #2.

Table 7.3:

Bit No. Assignment Description

b0 Input error (upper limit) Turns on when input value is over scale.

b1 Input error (lower limit) Turns on when input value is under scale.

Cold contact temperature com-

b2

pensation data error

b3 A/D converted value error

b4 Alarm 1 Turns on when an alarm has occurred.

b5 Alarm 2 Turns on when an alarm has occurred.

b6 Alarm 3 Turns on when an alarm has occurred.

b7 Alarm 4 Turns on when an alarm has occurred.

b8 Loop breaking alarm Turns on when a loop breaking alarm has occurred

b9 Heater disconnection alarm Turns on when a heater disconnection alarm has occurred.

b10 Heater meltdown alarm Turns on when a heater meltdown alarm has occurred.

b11 Not used ---

Decimal point position

b12

b13

b14

b15

(0: Unit = 1°C/°F, 1: Unit = 0.

1°C/°F)

Manual mode transition completed

AT (auto tuning) being performed

Temperature rise completed

status

Turns on when an error has been caused by noise or when

a failure has occurred in FX

If contents of error are not eliminated even after power is

turned off once then on again, contact Mitsubishi Electric

System Service.

Turns on when input range is set to "0. 1°C/°F".

Turns on when transition to manual mode is completed.

Only while b13 is ON, manual output set value can be written.

Remains ON while auto tuning is being performed.

Turns on after soak time (BFM #80) is finished within tem-

perature rise completion range (BFM #79).

2N

Buffer Memory (BFM) 7

-2LC.

7

7-5

Page 60

FX2N-2LC Temperature Control Block

Operation of b15 (temperature rise completed status)

Example 1: When the soak time is set to "0"

Set value (SV)

Temperature

rise completed

Example 2: When the soak time is set to any positive value

Set value (SV)

Buffer Memory (BFM) 7

Temperature rise

completion range

Temperature rise

completion range

Temperature

rise completed

Soak

time

Soak

time

This bit notifies that the measured value (BFM #3, BFM #4) reaches near the set value (BFM

#12, BFM #21).