Page 1

Page 2

Page 3

SAFETY PRECAUTIONS •

•

(Be sure to read these instructions before using the product.)

Before using this product, read this manual and the relevant manuals introduced in this manual carefully

and handle the product correctly with full attention to safety.

The precautions given in this manual are concerned with this product. For the safety precautions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

CAUTION

Note that the failure to observe ! CAUTION level instructions may also lead to serious results

according to the circumstances.

Be sure to observe the precautions of both levels to ensure personal safety.

Please keep this manual in accessible place and be sure to forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

!

DANGER

• When a communication error has occurred in data link, data in the master module are

maintained.

Establish an interlock circuit in the sequence program using communication status information

so that the safety will be ensured.

!

CAUTION

• Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100mm (3.9inch) or more from each other.

Not doing so could result in noise that would cause erroneous operation.

• Do not write data to "Reserved area" of remote I/O areas or remote devices.

Doing so may cause malfunctions of the product.

A - 1 A - 1

Page 4

[Installation Precautions]

!

CAUTION

• Use each product in an environment as specified in the "general specification" in this manual.

Using the programmable controller outside the range of the general specifications may result in

electric shock, fire or malfunction, or may damage or degrade the product.

• Securely fix the product with DIN rails or module mounting screws.

Failure to do so may cause a fall or malfunctions of the product.

• Do not touch the conducted area or electric parts of the product.

Doing so may cause product malfunctioning or breakdowns.

[Wiring Precautions]

!

CAUTION

• For application to the CC-Link/LT, use cables specified by the CC-Link Partner Association.

Otherwise, performance of the CC-Link/LT cannot be guaranteed. Also, wire a network properly

in accordance with the specifications given in Chapter 3.

If not, normal data transmission cannot be guaranteed.

• Be sure to shut off all phases of the external power supply used by the system before installation

or wiring.

Not doing so can cause the product to be damaged or malfunction.

• Always ground the FG terminal to the protective ground conductor.

Not doing so can cause a malfunction.

• Make sure of the rated voltage and pin-outs of the product for proper wiring.

Connecting power source of improper rated voltage or faulty wiring may cause a fire or failure.

• Ensure that no foreign matter such as chips and wire-offcuts enter the product.

Foreign matter can cause a fire, failure or malfunction.

A - 2 A - 2

Page 5

[Wiring Precautions]

!

CAUTION

• Always secure the communication cable connected to the product by running it in a conduit or

clamping it.

Not doing so can cause damage to the product and/or cable due to the dangling, motion,

careless pulling, etc. of the cable or cause a malfunction due to a faulty connection of the cable.

• When disconnecting the communication cable connected to the product, do not pull it by holding

its cable part.

When disconnecting the cable with connector, hold the connector of the product's connection

part.

Disconnect the terminal block connection cable after loosening the terminal block screws.

Pulling the cable connected to the product can cause a malfunction or damage to the product

and/or cable.

[Starting and Maintenance Precautions]

!

CAUTION

• Do not touch pins while the product is energized. Doing so may cause malfunctions.

• Be sure to shut off all phases of the external power supply used by the system before cleaning.

• Do not disassemble or modify the product.

Doing so may cause failure, malfunctions, injury or fire.

• Do not drop the product or give it hard impact since its case is made of resin. Doing so can

damage the product.

• Be sure to shut off all phases of the external power supply used by the system before mounting

or dismounting the product to or from the panel.

Not doing so can cause the product to fail or malfunction.

• Mounting/removing the terminal block is limited to 50 times after using a product.

(IEC61131-2-compliant)

• Before handling the module, always touch grounded metal, etc. to discharge static electricity

from the human body.

Failure to do so can cause the module to fail or malfunction.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 3 A - 3

Page 6

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

Nov., 2002 SH(NA)-080362E-A First printing

Feb., 2003 SH(NA)-080362E-B

Addition

Section 2.2.1, 6.7

Correction

Section 2.1, 2.3, 3.3.2, 3.6.2, 4.1, 4.5.2

Jun., 2004 SH(NA)-080362E-C

Addition

Section 4.5.2, 4.5.3

Correction

Section 2.4, 3.2, 4.1, 4.5, 4.5.4, 4.7, 6.8

Jan., 2005 SH(NA)-080362E-D

Correction

SAFETY PRECAUTIONS, Generic Terms and Abbreviations,

Section 1.1, 1.2, 2.1, 2.2, 2.3, 3.2, 4.1, 4.2.1, 6.2, 6.6.4 to 6.6.8, 6.7, 6.8

Mar., 2006 SH(NA)-080362E-E

Correction

Compliance with the EMC Directive and Low Voltage Directive,

Section 2.3, 3.3.2, 3.4.5

May, 2008 SH(NA)-080362E-F

Correction

Manuals, Compliance with the EMC Directive and Low Voltage Directive,

Generic Terms and Abbreviations,

Section 2.2, 3.7.1, 3.8.1, 3.9, 4.5.2, 4.6, 4.7.1, 6.2, 6.6.6

Japanese Manual Version SH-080361-F

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2002 MITSUBISHI ELECTRIC CORPORATION

A - 4 A - 4

Page 7

INTRODUCTION

Thank you for purchasing the MELSEC-A series programmable controller. Before using the product, read

this manual carefully to fully understand the functions and the performance of the programmable controller.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS...............................................................................................................................A- 1

REVISIONS .....................................................................................................................................................A- 4

INTRODUCTION.............................................................................................................................................A- 5

Manuals ...........................................................................................................................................................A- 8

Compliance with the EMC Directive and Low Voltage Directive ...................................................................A- 8

Generic Terms and Abbreviations ..................................................................................................................A- 9

Product List......................................................................................................................................................A- 9

1. OVERVIEW 1- 1 to 1- 2

1.1 Overview................................................................................................................................................... 1- 1

1.2 Features ................................................................................................................................................... 1- 2

2. SYSTEM CONFIGURATION 2- 1 to 2- 8

2.1 Overall Configuration ...............................................................................................................................2- 1

2.2 Applicable System.................................................................................................................................... 2- 2

2.2.1 Applicable software package ............................................................................................................ 2- 2

2.3 Precautions for System Configuration..................................................................................................... 2- 3

2.4 Parts Sold Separately .............................................................................................................................. 2- 7

3. SPECIFICATIONS 3- 1 to 3-28

3.1 General Specifications ............................................................................................................................. 3- 1

3.2 Performance Specifications ..................................................................................................................... 3- 2

3.3 Network Wiring Specifications ................................................................................................................. 3- 3

3.3.1 CC-Link network wiring specifications .............................................................................................. 3- 3

3.3.2 CC-Link/LT network wiring specifications......................................................................................... 3- 3

3.4 Concept of Remote Input/Output............................................................................................................. 3- 5

3.5 Remote I/O Signals for CC-Link Master Module..................................................................................... 3- 6

3.5.1 Remote I/O signal list when 2 stations are occupied .......................................................................3- 6

3.5.2 Remote I/O signal list when 4 stations are occupied .......................................................................3- 7

3.5.3 Remote I/O signal list when 8 stations are occupied (4 occupied stations

3.5.4 Details of remote I/O signals............................................................................................................. 3- 9

3.6 Concept of the Number of Control Points (Point Mode Setting for CC-Link/LT and Number of Occupied

Stations Setting for CC-Link) ................................................................................................................... 3-15

3.6.1 Setting number of occupied stations ................................................................................................ 3-15

3.6.2 Setting point mode ............................................................................................................................ 3-15

3.7 Remote Registers .................................................................................................................................... 3-18

3.7.1 Assignment of remote registers ........................................................................................................ 3-18

2 modules)................ 3- 8

A - 5 A - 5

Page 8

3.7.2 Last station number setting (common to 2, 4 and 8 occupied stations (4 occupied stations

2 modules): Address RWwn)............................................................................................................ 3-20

3.7.3 Data link stop/restart instructions (common to 2, 4 and 8 occupied stations (4 occupied stations

2 modules): Address RWwn+1)........................................................................................................ 3-20

3.7.4 Error status flag clear (common to 2, 4 and 8 occupied stations (4 occupied stations

2 modules): Address RWwn+2)........................................................................................................ 3-20

3.7.5 Data of operating statuses (common to 2, 4 and 8 occupied stations (4 occupied stations

2 modules): Address RWrn) ............................................................................................................. 3-21

3.7.6 Data of faulty station (2 occupied stations: Address RWrn+1, common to 4 and 8 occupied stations

(4 occupied stations

3.7.7 Remote I/O error data (2 occupied stations: Address RWrn+2, common to 4 and 8 occupied stations

(4 occupied stations

3.7.8 Data of remote station connection (2 occupied stations: Address RWrn+3, common to 4 and

8 occupied stations (4 occupied stations

3.7.9 Setting data (2 occupied stations: Address RWrn+4, common to 4 and 8 occupied stations

(4 occupied stations

3.8 Data Link Processing Time...................................................................................................................... 3-26

3.8.1 CC-Link link scan time ...................................................................................................................... 3-26

3.8.2 CC-Link/LT link scan time ................................................................................................................. 3-26

3.9 Transmission Delay Time ........................................................................................................................ 3-27

2 modules): Address RWrn+1, RWrn+2) ..................................................... 3-22

2 modules): Address RWrn+3, RWrn+4) ..................................................... 3-23

2 modules): Address RWrn+5, RWrn+6) .................... 3-24

2 modules): Address RWrn+7) ..................................................................... 3-25

4. PROCEDURE UP TO DATA LINK 4- 1 to 4-23

4.1 Procedure Up to Data Link ...................................................................................................................... 4- 1

4.2 Mounting and Installation ......................................................................................................................... 4- 3

4.2.1 Handling precautions ........................................................................................................................ 4- 3

4.3 Part Names and Settings .........................................................................................................................4- 4

4.4 Facing Direction of the Module Installation ............................................................................................. 4- 7

4.5 Connecting Modules by CC-Link/LT Side Cables................................................................................... 4- 8

4.5.1 How to connect dedicated flat cable connector ............................................................................... 4- 9

4.5.2 How to connect VCTF or high flexible cable connector................................................................... 4-11

4.5.3 Mixture of different kinds of cables ...................................................................................................4-14

4.5.4 Mounting terminating resistors.......................................................................................................... 4-17

4.6 CC-Link Side Connection ........................................................................................................................ 4-18

4.6.1 Connection of the CC-Link dedicated cables ................................................................................... 4-19

4.7 Wiring the One-Touch Connector Plug ................................................................................................... 4-20

4.8 Wiring Check ............................................................................................................................................ 4-22

4.9 Maintenance and Inspection .................................................................................................................... 4-23

5. PROGRAMMING 5- 1 to 5-12

5.1 Conditions of Program Examples ............................................................................................................ 5- 1

5.2 Program Example for Use of QCPU (Q Mode)....................................................................................... 5- 4

5.3 Program Example for Use of QnACPU ................................................................................................... 5- 6

5.4 Program Example for Use of ACPU/QCPU (A Mode) (Dedicated Instructions).................................... 5- 8

5.5 Program Example for Use of ACPU/QCPU (A Mode) (FROM/TO Instructions) ...................................5-11

A - 6 A - 6

Page 9

6. TROUBLESHOOTING 6- 1 to 6-19

6.1 Station Status at Error Occurrence ......................................................................................................... 6- 1

6.2 Troubleshooting Flow............................................................................................................................... 6- 2

6.3 Troubleshooting when the "ERR" LED on the Master Station is Flashing............................................. 6- 3

6.4 Troubleshooting when the "PW" LED of the AJ65SBT-CLB has Turned Off ........................................6- 5

6.5 CC-Link Side Troubleshooting................................................................................................................. 6- 6

6.5.1 Troubleshooting when the CC-Link side "L RUN" LED of the AJ65SBT-CLB has turned off ........6- 6

6.5.2 Troubleshooting when the CC-Link side "L ERR." LED of the AJ65SBT-CLB is flickering............ 6- 7

6.6 CC-Link/LT Side Troubleshooting ...........................................................................................................6- 8

6.6.1 Troubleshooting when the CC-Link/LT side "L RUN" LED of the AJ65SBT-CLB has turned off... 6- 8

6.6.2 Troubleshooting when the CC-Link/LT side "L ERR." LED of the AJ65SBT-CLB has turned on/is

flickering............................................................................................................................................. 6- 9

6.6.3 Troubleshooting when the CC-Link/LT side "ERR." LED of the AJ65SBT-CLB has turned on/is

flickering............................................................................................................................................. 6-10

6.6.4 Troubleshooting when the "PW" LED of the CC-Link/LT remote I/O station has turned off .......... 6-11

6.6.5 Troubleshooting when the "L RUN" LED of the CC-Link/LT remote I/O station has turned off ..... 6-12

6.6.6 Troubleshooting when the "L ERR." LED of the CC-Link/LT remote I/O station has turned on/is

flickering............................................................................................................................................. 6-13

6.6.7 Troubleshooting when input cannot be imported from the CC-Link/LT remote I/O station ............6-14

6.6.8 Troubleshooting when output cannot be provided from the CC-Link/LT remote I/O station .......... 6-15

6.7 CC-Link / CC-Link/LT Diagnostics Using GX Developer ........................................................................ 6-16

6.8 Checking the Module Status (Self-loopback Test).................................................................................. 6-19

APPENDIX APP- 1 to APP- 4

Appx 1 External Dimensions.....................................................................................................................APP- 1

Appx 2 I/O Assignment Sheet...................................................................................................................APP- 2

Appx 2.1 I/O Assignment Sheet for 4-Point Mode Setting..................................................................APP- 2

Appx 2.2 I/O Assignment Sheet for 8-Point Mode Setting .................................................................. APP- 3

Appx 2.3 I/O Assignment Sheet for 16-Point Mode Setting................................................................ APP- 4

INDEX Index- 1 to Index- 2

A - 7 A - 7

Page 10

Manuals

The following manuals are also relevant to this product.

You can order them as necessary.

Relevant Manuals

Manual Name

Control & Communication System Master/Local Module User's Manual

type AJ61BT11/A1SJ61BT11

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61BT11 and A1SJ61BT11. (Sold separately)

Control & Communication System Master/Local Module User's Manual

type AJ61QBT11/A1SJ61QBT11

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61QBT11 and A1SJ61QBT11. (Sold separately)

Manual Number

(Model Code)

IB-66721

(13J872)

IB-66722

(13J873)

Control & Communication System Master/Local Module User's Manual type QJ61BT11N

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the QJ61BT11N. (Sold separately)

Type A80BDE-J61BT11 Control & Communication Link System Master/Local Interface

Board User's Manual (For SW4DNF-CCLINK-B)

Describes the system configuration, performance specifications, handling, wiring and troubleshooting of

the A80BDE-J61BT11. (Sold separately)

Type Q80BD-J61BT11N Control & Communication Link System Master/Local Interface

Board User's Manual (For SW1DNC-CCBD2-B)

Describes the system configuration, performance specifications, handling, wiring and troubleshooting of

the A80BDE-J61BT11. (Sold separately)

SH-080394E

(13JR64)

IB-0800175

(13JR28)

SH-080527ENG

(13JR77)

Compliance with the EMC Directive and Low Voltage Directive

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage

Directives when incorporating the Mitsubishi programmable controller (EMC and

Low Voltage Directives compliant) into other machinery or equipment, refer to the

"EMC AND LOW VOLTAGE DIRECTIVES" chapter of the User's Manual for the

CPU module used.

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is

printed on the rating plate of the programmable controller.

(2) For the product

For the compliance of this product with the EMC and Low Voltage Directives,

refer to the "CC-Link module" section in the "EMC AND LOW VOLTAGE

DIRECTIVES" chapter of the User's Manual for the CPU module used.

A - 8 A - 8

Page 11

Generic Terms and Abbreviations

Unless otherwise specified, this manual uses the following generic terms and abbreviations.

Generic Term/Abbreviation Description

AJ65SBT-CLB Abbreviation for AJ65SBT-CLB CC-Link - CC-Link/LT bridge module.

Generic product name for the product types SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

GX Developer

Master module

Remote I/O module

Remote device module

Remote module Generic term for remote I/O module and remote device module.

Remote I/O station

Remote device station

Remote station Generic term for remote I/O station and remote device station.

Intelligent device station

Dedicated power supply

Power supply adapter

RX

RY

RWw

RWr

SWnD5C-GPPW-EV and SWnD5C-GPPW-EVA.

(n indicates any of Versions 0 to 7)

Station that controls data link system.

One master station is required for each system.

Remote module that handles bit unit data only. (Performs input and output with external

devices.)

Remote module that handles bit unit and word unit data only. (Performs input and

output with external devices, and analog data conversion.)

Remote station that handles bit unit data only. (Performs input and output with external

devices.)

Remote station that handles bit unit and word unit data only. (Performs input and output

with external devices, and analog data conversion.)

Station that can perform transient transmission, such as the AJ65BT-R2N (including

local stations).

Module connected for power supply to CC-Link/LT system. At least one dedicated

power supply or power supply adapter is required for a system.

Remote input (for CC-Link)

Information input in bit unit from the remote station to the master station. (Represented

as RX)

Remote output (for CC-Link)

Information output in bit unit from the master station to the remote station.

(Represented as RY)

Remote register (Write area for CC-Link)

Information output in 16-bit unit from the master station to the remote device station.

(Represented as RWw)

Remote register (Read area for CC-Link)

Information input in 16-bit unit from the remote device station to the master station.

(Represented as RWr)

Product List

This product consists of the following.

Model name Product Name Quantity

AJ65SBT-CLB AJ65SBT-CLB CC-Link - CC-Link/LT Bridge Module 1

A - 9 A - 9

Page 12

1 OVERVIEW

1 OVERVIEW

MELSEC-A

1

1.1 Overview

This manual provides the specifications, part names, setting, etc. of the AJ65SBT-CLB

CC-Link - CC-Link/LT bridge module (hereafter referred to as the AJ65SBT-CLB) that

is designated to be used as a remote device station in a CC-Link system.

The AJ65SBT-CLB includes the bridge function to establish a connection between CCLink and CC-Link/LT.

Using the AJ65SBT-CLB connects the remote I/O of CC-Link/LT to a CC-Link system.

Any of the A series, QnA series and Q series can be used to configure a system,

realizing a compact wire-saving system.

AJ65SBT-CLB Remote I/O station Remote I/O station

Terminating resistor

Power supply adapter

CC-Link side

CC-Link/LT side

Partner company's

product

General power supply

24 V DC

Terminating resistor

Remote station

CL1Y4-T1B2

CL2AD4-B

Y0

Remote station

1 - 1 1 - 1

Page 13

1 OVERVIEW

MELSEC-A

1.2 Features

The AJ65SBT-CLB has the following features.

(1) Seamless connection of two networks

The AJ65SBT-CLB is a bridge module that can connect CC-Link and CC-Link/LT

seamlessly.

Using RX and RY (bit devices), one bridge module can control up to 224 points

(448 points when both inputs and outputs are used).

(2) Confirmation of communication status of CC-Link/LT remote

stations

The data link statuses and I/O errors of CC-Link/LT remote stations can be

confirmed from the PLC CPU of the CC-Link master station.

(3) Configuration of CC-Link/LT using A, QnA ser ies

A CC-Link/LT system can be configured using the MELSEC-A, QnA series via

CC-Link.

(4) Wire saving and easy installation

The one-touch connectors ensure easy installation by using as the CC-Link side

communication connectors.

(5) Compact size

The AJ65SBT-CLB has the same size as the AJ65SBTB1-8 compact remote

I/O module.

(Width 87.0 (3.43)

Either of screws or DIN rail can be used to mount the module to a control panel.

height 49.0 (1.93) depth 40.0 (1.57) mm (inch))

1

1 - 2 1 - 2

Page 14

A

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

2.1 Overall Configuration

MELSEC-

This section explains a system including the AJ65SBT-CLB.

For the transmission specifications, station-to-station distance, overall cable distance

2

(maximum transmission distance), etc. of CC-Link, refer to the user's manual of the

master module.

Refer to Section 3.3 for the wiring specifications.

Master

station

Remote I/O station

Intelligent

device station

CC-Link side

CC-Link/LT side

AJ65SBT-CLB

C

L

1

P

A

D

Remote stationRemote stationRemote station

C

L

2

8

Y

-

T

P

1

B

2

Y

0

C

L

2

8

Y

-

T

P

1

B

2

Y

0

1

Power

supply

adapter

General

power

supply

Item Specifications Remarks

Transmission speed 2.5 Mbps 625 kbps 156kbps

Station-to-station distance Not limited

Max. no. of modules per drop line 8 modules

Length of trunk line 35 m 100 m 500 m

T-branch interval Not limited

Max. length of drop line 4 m 16 m 60 m Max. cable length for one branch line

Overall length of drop lines 15 m 50 m 200 m Total length of all drop lines

T-branch

connection

Master station

Table 2.1 Network Wiring Specifications

Cable length between terminating resistors.

Length of

Length of trunk line (Drop line not included)

Interval length of T-branch

drop lines not included

*3

Terminating

resistor

Length

of

drop

Power

line

supply

adapter

Length of drop line

*2

*1

Remote

station

Remote

station

Distance

between stations

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Trunk line

Drop line

*3

Terminating

resistor

Remote

station

1: The length of the drop line includes the length of 2. (The max. length of drop line and overall

length of drop lines include the length of

2.)

3: Refer to Section 4.5.4 for the terminating resistor mounting method.

2 - 1 2 - 1

Page 15

A

2 SYSTEM CONFIGURATION

MELSEC-

POINT

(1) The connection order of remote stations is not relevant to the station numbers.

(2) The remote station numbers are not necessarily consecutive. (Empty station

number does not cause data link failure.)

2.2 Applicable System

This section explains the applicable master modules and the precautions for system

configuration.

(1) The following table indicates the applicable master modules.

Model Name

Q series QJ61BT11N, QJ61BT11

QnA series AJ61QBT11, A1SJ61QBT11

A series AJ61BT11, A1SJ61BT11

FX series FX2N-16CCL-M

PCI board Q80BD-J61BT11N, A80BD-J61BT11

Others CC-Link partner maker's master module

2.2.1 Applicable software package

The FX series can be used within the range of:

FX

1N, FX1NC 128 points

FX

2N, FX2NC 256 points

in the whole system.

2

To carry out CC-Link / CC-link/LT diagnostics, GX Developer of Version 8.00A or later

is required.

2 - 2 2 - 2

Page 16

A

2 SYSTEM CONFIGURATION

2.3 Precautions for System Configuration

(1) Arrangement of AJ65SBT-CLB

(a) CC-Link side

The AJ65SBT-CLB can be placed in any position as the remote device

station of the CC-Link system.

(b) CC-Link/LT side

Since T-branch connection can be made, the AJ65SBT-CLB can

apparently be placed midway through the trunk line. Note that the length of

Master

station

the trunk line is defined as the length between two terminating resistors.

Remote

I/O station

CC-Link side

CC-Link/LT side

AJ65SBT-CLB

Terminating resistor

Remote

device station

*3

MELSEC-

Remote

I/O station

Length of drop line

*2 *2 *2

Remote

station

Remote

station

Remote

station

Remote

station

*3

Terminating

resistor

Length of drop line

Length

of

drop

line

Length of trunk line

Power

supply

adapter

*2

*1

Remote

station

Remote

station

Distance

between stations

Remote

station

Remote

station

*1

Remote

station

Remote

station

Trunk line

Drop line

1 The length of drop line includes the length of 2. (The max. length of drop line and overall

length of drop lines include the length of 2.)

3 Refer to Section 4.5.4 for the terminating resistor mounting method.

(2) Number of CC-Link/LT side drop line branch stages

In the CC-Link/LT system, branch the drop line up to two stages.

The drop line cannot be branched to three or more stages.

Remote

station

Remote

station

Third drop line branch stage: cannot be wired.

Remote

station

Trunk line

Drop line

2 - 3 2 - 3

Page 17

A

2 SYSTEM CONFIGURATION

(3) Mounting condition for CC-Link/LT dedicated power supply or

power supply adaptor

The mounting conditions for a dedicated power supply or power supply adapter

for the CC-Link/LT vary depending on the devices to be connected and the wiring

length.

Refer to the User’s Manual of the dedicated power supply or power supply adapter for

the conditions.

POINT

Always connect the dedicated power supply or power supply adapter to the trunk

line. (Connection to branch lines is not allowed.)

(4) Prevention of incorrect input/output from remote I/O module of CC-

Link/LT

To prevent incorrect input/output from remote I/O modules, design the system

while paying full attention to the following.

(a) When power is ON or OFF

Power ON the remote I/O module (Power on the dedicated power supply or

power supply adapter) before starting the data link.

Also, stop the data link before powering OFF the remote I/O module

(Powering off the dedicated power supply or power supply adapter).

MELSEC-

Data link start

Data link stop

Master module

(Data link status)

Remote I/O module

(Power status)

Executed

Stopped

ON

OFF

2 - 4 2 - 4

Page 18

A

2 SYSTEM CONFIGURATION

(b) Instantaneous power failure of remote I/O module

When instantaneous power failure occurs in the power source (24V DC) for

the remote I/O module, incorrect data may be input.

1) Causes of incorrect input due to instantaneous power failure

Remote I/O module

(Power for module and

external power supply for input)

MELSEC-

The hardware of the remote I/O module converts the supplied power of

24V DC into 5V DC inside the module and uses it for its own operation.

When instantaneous power failure occurs in the remote I/O module,

the following,

(Time until 5V DC is turned OFF inside the remote I/O module)

>(Response time from ON to OFF of the input ), is established.

Therefore, when the devices are refreshed within the time shown as

(1), data will be incorrectly input. (Especially, when the input response

time is set to the high-speed response type)

1)

Remote I/O module

(Inside 5V DC)

Input (Xn)

Externally powering off for

input, turns input (Xn) OFF

after response time from ON to

OFF of Input unit.

Externally powering off for

input, turns input (Xn) ON

after response time from OFF

to ON of input module.

2 - 5 2 - 5

Page 19

A

2 SYSTEM CONFIGURATION

2) Preventive measure against incorrect input

MELSEC-

Install wiring so that the power is supplied from the same power

source to the power supply module, stabilized power supply and

external power supply for AC input.

Remote I/O module

Remote I/O module

External

supply

power

for input

External

supply

power

for input

DC input

AC input

AJ65SBT-CLB

Stabilized

power supply

Stabilized

power supply

AJ65SBT-CLB

Stabilized

power supply

24VDC

24VDC

24VDC

Power supply

adapter

Power supply

adapter

2 - 6 2 - 6

Page 20

A

2 SYSTEM CONFIGURATION

2.4 Parts Sold Separately

The plugs for AJ65SBT-CLB are sold separately.

One-touch

connector plug for

communication

1, 2

Online connector for

communication

One-touch connector

plug with terminating

resistor

(including 1)

3

Please purchase them as necessary.

Mitsubishi model

name

A6CON-L5P

A6CON-LJ5P

A6CON-TR11 ⎯

Part model name

(manufacturer)

35505-6000-

BOM GF (3M)

35720-L200-B00

AK (3M)

1 Mitsubishi's A6CON- 5P includes 10 plugs.

2 Once insulation-displaced, the one-touch connector plugs cannot be reused.

3 Mitsubishi's A6CON- J5P includes 5 plugs.

Specifications

communication line

0.5 (AWG#20)

shielded cable (drain wire)

0.5 (AWG#20)

⎯ ⎯ ⎯ ⎯

One-touch connector plug with

terminating resister attached

for communication (110Ω)

MELSEC-

2.2 to 3.0

Red

⎯ ⎯ ⎯

Color of

the cover

REMARK

• As following table indicates, the optional plugs/connectors are compatible with the

connectors for this module.

Connector for this Module Optional Parts

One-touch connector for

communication

• One-touch connector plug for communication

• Online connector for communication

• One-touch connector plug with terminating resistor

• Cables, connectors and terminating resistors on the CC-Link/LT side

For inquiries about the cables, connectors and/or terminating resistors on the CCLink/LT side, access the home page of the CC-Link Partner Association on the

Internet at http://www.cc-link.org/

.

2 - 7 2 - 7

Page 21

A

2 SYSTEM CONFIGURATION

MEMO

MELSEC-

2 - 8 2 - 8

Page 22

A

3 SPECIFICATIONS

3 SPECIFICATIONS

MELSEC-

3.1 General Specifications

Operating ambient

temperature

3

Storage ambient

temperature

Operating ambient

humidity

Storage ambient

humidity

Vibration resistance

Shock resistance

Operating ambience No corrosive gases

Operating altitude 2000m (6562ft.) max.

Installation location Inside control panel

Overvoltage

category 1

Pollution degree 2 2 max.

Item Specifications

This chapter provides the specifications of the AJ65SBT-CLB.

Table 3.1 General specifications

0 to 55°C

-25 to 75°C

5 to 95%RH, non-condensing

5 to 95%RH, non-condensing

Frequency Acceleration Amplitude Sweep count

Conforming

to

JIS B 3502,

IEC 61131-2

Conforming to JIS B 3502, IEC 61131-2 (147 m/s

Under

intermittent

vibration

Under

continuous

vibration

10 to 57Hz ———

57 to 150Hz

10 to 57Hz ———

57 to 150Hz

9.8m/s2

4.9m/s2

II max.

2

, 3 times in each of 3 directions X, Y, Z)

0.075mm

(0.003inch)

———

0.035mm

(0.001inch)

———

10 times each in

X, Y, Z directions

(for 80 min.)

1 : This indicates the section of the power supply to which the equipment is assumed to be connected

between the public electrical power distribution network and the machinery within premises. Category II

applies to equipment for which electrical power is supplied from fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

2 : This index indicates the degree to which conductive material is generated in terms of the environment

where the equipment is used.

Pollution level 2 is when only non-conductive pollution occurs but temporary conductivity may be produced

due to condensation.

3 : Do not use or store the programmable controller under pressure higher than the atmospheric pressure of

altitude 0m.

Doing so can cause a malfunction.

When using the programmable controller under pressure, please contact your sales representative.

3 - 1 3 - 1

Page 23

A

3 SPECIFICATIONS

MELSEC-

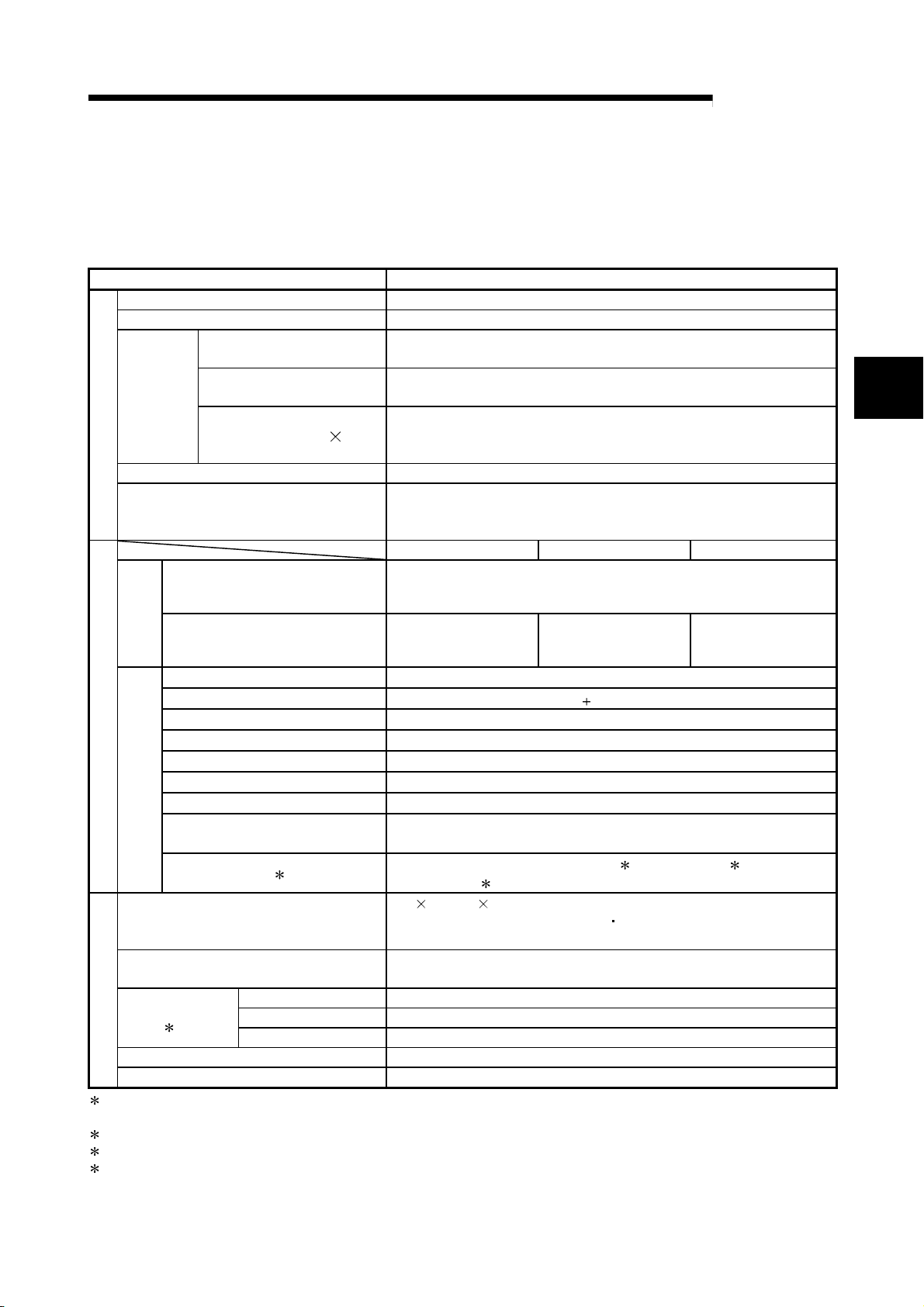

3.2 Performance Specifications

The following table provides the performance specifications of the AJ65SBT-CLB.

Table

3.2 Performance specifications

Item Specifications

Station type Remote device station

CC-Link Version Ver.1.10

2 stations

Number of

occupied

stations

CC-Link side

AJ65SBT-CLB connection position No restrictions

External connection system

4-point mode 8-point mode 16-point mode

Control

CC-Link/LT side

Communication specifications

Module mounting screw

Module mounting direction

24V DC power

Common

supply

Level of protection IP2X

Weight 0.09kg

1 Performance of the CC-Link/LT cannot be guaranteed for use of cables other than the dedicated flat cables, VCTF

cables and high flexible cables.

2 Supplied by the dedicated power supply or power supply adaptor of CC-Link/LT.

3 For VCTF cable specifications, see Table 3.3.

4 Use the dedicated flat cables and high flexible cables accredited by the CC-Link Partner Association. (Refer to Section

2.4.)

4 stations

8 stations

(4 occupied stations

modules)

Maximum number of link points

Number in parentheses assumes

use of the same I/O addresses

Number of link points per station

Number in parentheses assumes

specifications

use of the same I/O addresses

Transmission speed 2.5Mbps/625kbps/156kbps

Communication system BITR system (Broadcastpolling Interval Timed Response)

Transmission path format T-branch system

Error control system CRC

Number of connected modules 56 modules

Remote station number 1 to 56

AJ65SBT-CLB connection position Connected at the end of the trunk line

RAS functions

Connection cable 1

Voltage 24V DC externally supplied (20.4V DC to 26.4V DC, ripples within 5%)

2

Current consumption 0.075A (When 24V DC)

Start-time current 0.165A (When 24V DC)

2

64 points each for RX and RY (16 points are used in the system)

8 points each for RWr and RWw

128 points each for RX and RY (16 points are used in the system)

16 points each for RWr and RWw

256 points each for RX and RY (32 points are used in the system)

32 points each for RWr and RWw

One-touch connector for communication [transmission circuit] (5-pin,

insulation displacement type connector plug is sold separately)

<Sold separately> Online connector for communication: A6CON-LJ5P

224 points (448 points)

4 points

(8 points)

Network diagnostics, internal loopback diagnostics, slave station

separation, automatic return to system

8 points

(16 points)

16 points

(32 points)

Dedicated flat cable (0.75mm2X4) 4, VCTF cable 3, high

flexible cable

0.7mm 16mm or more screw

M4

Tightening torque range 78 to 108N

DIN rail can also be used for mounting.

Can be mounted in any of six orientations.

(No restrictions on mounting directions)

4

cm

3

3 - 2 3 - 2

Page 24

A

3 SPECIFICATIONS

Table 3.3 VCTF cable specifications (Extract from JIS C 3306)

MELSEC-

Type No. of cores

Vinyl cabtyre,

Round cord

Nominal cross-

sectional area

4 0.75mm

Conductor

Composition

No. of wires/wire diameter

2

30/0.18mm 1.1mm

Outside

diameter

Insulator

thickness

0.6mm 1.0mm

Sheath

thickness

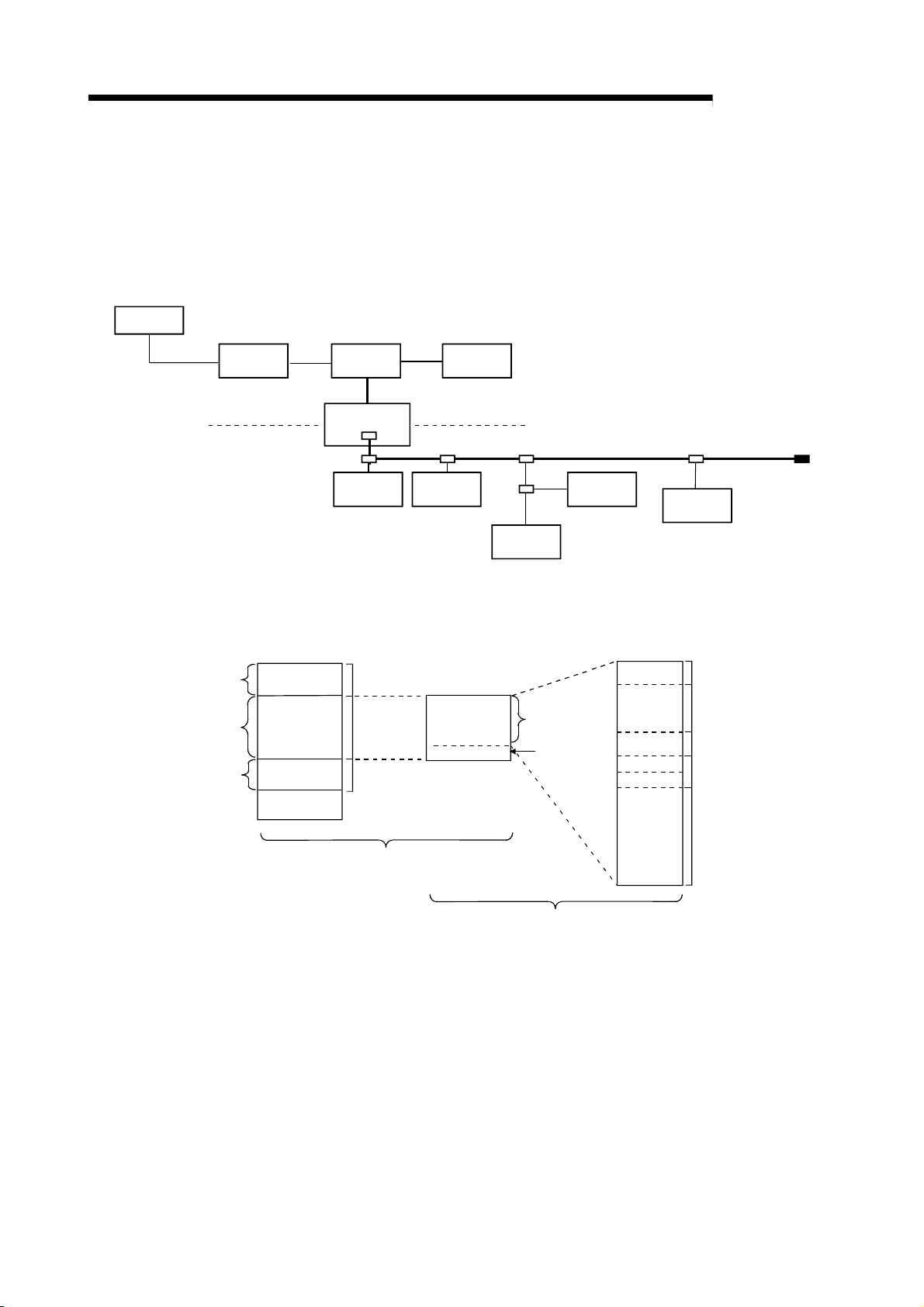

3.3 Network Wiring Specifications

3.3.1 CC-Link network wiring specifications

For the network wiring specifications of CC-Link, refer to the user's manual of the

master module.

3.3.2 CC-Link/LT network wiring specifications

Master

station

CC-Link side

CC-Link/LT side

T-branch

connection

Terminating

1 The length of drop line includes the length of 2. (The max. length of drop line and overall

length of drop lines include the length of

3 Refer to Section 4.5.4 for the terminating resistor mounting method.

3 - 3 3 - 3

The following indicates the network wiring specifications of CC-Link/LT.

Item Specifications Remarks

Transmission speed 2.5 Mbps 625 kbps 156 kbps

Distance between stations Not limited

Max. no. of connectable

modules per drop line

8 modules

Cable length between

Length of trunk line 35 m 100 m 500 m

terminating resistors. Length

of drop lines not included

T-branch interval Not limited

Max. length of drop line 4 m 16 m 60 m

Max. cable length per branch

line

Overall length of drop lines 15 m 50 m 200 m Total length of all drop lines

device station

*1

Length

of

drop

line

Remote

Length of trunk line (Drop line not included)

*2

Distance

between stations

Remote

station

Remote

Remote

station

Remote

I/O station

station

Interval length of T-branch

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Trunk line

Drop line

AJ65SBT-CLB

resistor

Remote

I/O station

Length

of

drop

*3

line

Power

supply

adapter

2.)

Terminating

resistor

Conductor

resistance

(20

)

25.1

Ω/km

*3

Page 25

A

3 SPECIFICATIONS

MELSEC-

POINT

When connecting multiple lines with dedicated connectors to form one trunk line,

the number of connections must be 10 or less.

Line

Master station

connection

Terminating

resistor

Power

supply

adapter

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Remote

station

Terminating

resistor

3 - 4 3 - 4

Page 26

A

3 SPECIFICATIONS

3.4 Concept of Remote Input/Output

This section explains the I/O signals for the AJ65SBT-CLB module.

Example: The following provides an example of setting the AJ65SBT-CLB to 2

occupied stations and 4-point mode.

Master

station

Station 1

1 station

occupied

Station 2

2 stations

occupied

Station 3

1 station

occupied

MELSEC-

CC-Link side

CC-Link/LT side

CC-Link master station

Station 1

Station 2

Station 3

AJ65SBT-CLB

Remote input

RX0F to RX00

RX1F to RX10

RX2F to RX20

RX3F to RX30

RX4F to RX40

RX5F to RX50

RX6F to RX60

RX7F to RX70

to

RX7FF to RX7F0

Section 3.5.1 to Section 3.5.3

Station 1

4 input

points

CL1X4-D1B2 CL2X8-D1B2

1 station

2 station

1 station

Station 2

8 input

points

AJ65SBT-CLB

RX2F to RX20

RX3F to RX30

RX4F to RX40

RX5F to RX50

Station 4

2 output

points

CL1Y2-T1D2S

48 points

System area,

16 points

Station 3

4 output

points

CL1Y4-T1B2

CC-Link/LT side

1) 4 points

2) 8 points

3) 4 points

4) 2 points

Empty,2 points

5) 16 points

Station 5

16 input

points

CL2X16-D1M1V

1 station

2 stations

1 station

1 station

4 stations

Section 3.5.4

3 - 5 3 - 5

Page 27

A

3 SPECIFICATIONS

3.5 Remote I/O Signals for CC-Link Master Module

This section explains the I/O signals of the AJ65SBT-CLB for the CC-Link master

module.

3.5.1 Remote I/O signal list when 2 stations are occupied

MELSEC-

Signal Direction: AJ65SBT-CLB master module Signal Direction: Master module AJ65SBT-CLB

Remote input (RX) Name Remote output (RY) Name

RXn0

to

RX(n 2)F

RX(n+3)0

to

3)9

RX(n

RX(n 3)A Error status flag

RX(n 3)B Remote READY

RX(n 3)C

RX(n 3)D

RX(n 3)E

RX(n 3)F

Out of 64 points, 16 points are used as a system area.

RYn0

Used by CC-Link/LT remote

Use prohibited

Use prohibited

to

RY(n 2)F

3)0

RY(n

to

3)F

RY(n

Used by CC-Link/LT remote

Use prohibited

POINT

The prohibited devices are used by the system and therefore cannot be used by

the user.

If data is written to the buffer memory area corresponding to the prohibited device

or to the device specified for auto refresh, the functions of the AJ65SBT-CLB

cannot be guaranteed.

3 - 6 3 - 6

Page 28

A

3 SPECIFICATIONS

3.5.2 Remote I/O signal list when 4 stations are occupied

MELSEC-

Signal Direction: AJ65SBT-CLB Master module Signal Direction: Master module AJ65SBT-CLB

Remote input (RX) Name Remote output (RY) Name

RXn0

to

6)F

RX(n

RX(n 7)0

to

RX(n 7)9

RX(n 7)A Error status flag

RX(n 7)B Remote READY

RX(n 7)C

RX(n 7)D

RX(n 7)E

RX(n 7)F

Out of 128 points, 16 points are used as a system area.

RYn0

Used by CC-Link/LT remote

Use prohibited

Use prohibited

to

RY(n 6)F

RY(n

7)0

to

RY(n 7)F

Used by CC-Link/LT remote

Use prohibited

POINT

The prohibited devices are used by the system and therefore cannot be used by

the user.

If data is written to the buffer memory area corresponding to the prohibited device

or to the device specified for auto refresh, the functions of the AJ65SBT-CLB

cannot be guaranteed.

3 - 7 3 - 7

Page 29

A

3 SPECIFICATIONS

MELSEC-

3.5.3 Remote I/O signal list when 8 stations are occupied (4 occupied stations 2 modules)

Out of 256 points, 32 points are used as a system area.

When 8 stations (4 occupied stations

Signal Direction: AJ65SBT-CLB Master module Signal Direction: Master module AJ65SBT-CLB

Remote input (RX) Name Remote output (RY) Name

RXn0

to

RX(n 6)F

RX(n 7)0

to

7)9

RX(n

RX(n 7)A Error status flag

RX(n 7)B Remote READY

RX(n 7)C

RX(n 7)D

RX(n 7)E

RX(n 7)F

RX(n 8)0

to

RX(n E)F

RX(n F)0

to

F)9

RX(n

RX(n F)A Error status flag

RX(n F)B Remote READY

RX(n F)C

RX(n F)D

RX(n F)E

RX(n F)F

occupying modules are placed in series.

Used by CC-Link/LT remote

Use prohibited

Use prohibited

Used by CC-Link/LT remote

Use prohibited

Use prohibited

POINT

• The prohibited devices are used by the system and therefore cannot be used by

the user.

If data is written to the buffer memory area corresponding to the prohibited device

or to the device specified for auto refresh, the functions of the AJ65SBT-CLB

cannot be guaranteed.

• Set the station data as two modules that occupy four remote device stations.

• The same data is stored into "RXn

2 modules) are occupied, two 4-station

RYn0

to

RY(n 6)F

7)0

RY(n

to

7)F

RY(n

RY(n 8)0

to

RY(n E)F

F)0

RY(n

to

F)F

RY(n

Used by CC-Link/LT remote

Use prohibited

Used by CC-Link/LT remote

Use prohibited

7A, RXn 7B" and "RXn FA, RXn FB".

3 - 8 3 - 8

Page 30

A

3 SPECIFICATIONS

3.5.4 Details of remote I/O signals

This section explains the assignment and functions of the CC/Link remote

inputs/outputs.

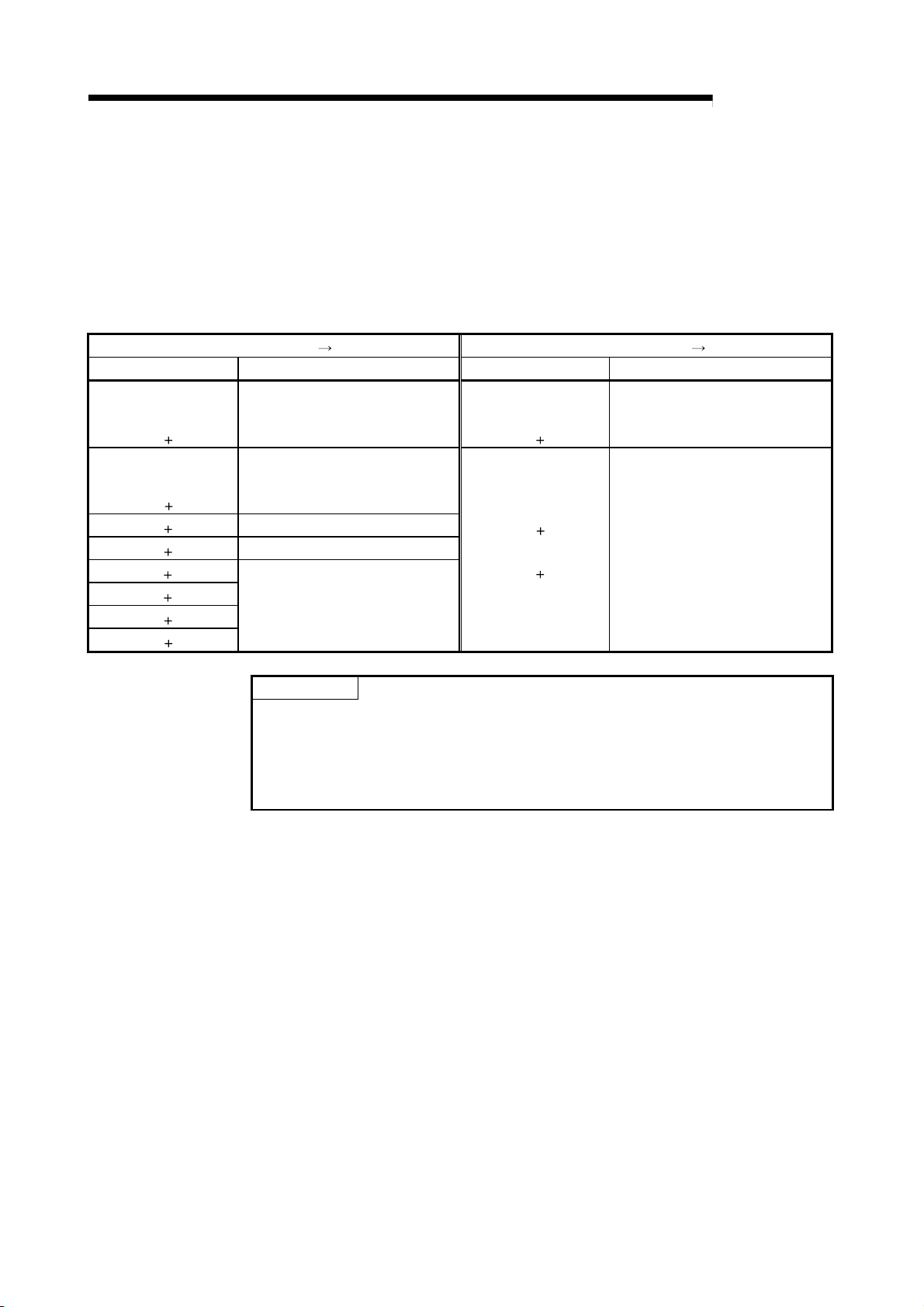

(1) Remote I/O signal list for 4-point mode setting

CC-Link

RXnF to RXn0 Station number 4 Station number 3 Station number 2 Station number 1

RX(n 2)F to RX(n 2)0 Station number 12 Station number 11 Station number 10 Station number 9

RX(n 3)F to RX(n 3)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 4 Station number 3 Station number 2 Station number 1

RY(n 2)F to RY(n 2)0 Station number 12 Station number 11 Station number 10 Station number 9

RY(n 3)F to RY(n 3)0 Use prohibited

CC-Link

RXnF to RXn0 Station number 4 Station number 3 Station number 2 Station number 1

RX(n 6)F to RX(n 6)0 Station number 28 Station number 27 Station number 26 Station number 25

RX(n 7)F to RX(n 7)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 4 Station number 3 Station number 2 Station number 1

RY(n 6)F to RY(n 6)0 Station number 28 Station number 27 Station number 26 Station number 25

RY(n 7)F to RY(n 7)0 Use prohibited

(a) The following table lists the I/O signals for 2 occupied station setting

F E D C B A 9 8 7 6 5 4 3 2 1 0

to to

F E D C B A 9 8 7 6 5 4 3 2 1 0

to to

(b) The following table lists the I/O signals for 4 occupied station setting

F E D C B A 9 8 7 6 5 4 3 2 1 0

to to

F E D C B A 9 8 7 6 5 4 3 2 1 0

to to

MELSEC-

Remote input (X) of CC-Link/LT Remote input (RX) of

Remote output (Y) of CC-Link/LT Remote output (RY) of

Remote input (X) of CC-Link/LT Remote input (RX) of

Remote output (Y) of CC-Link/LT Remote output (RY) of

3 - 9 3 - 9

Page 31

A

3 SPECIFICATIONS

CC-Link

RXnF to RXn0 Station number 4 Station number 3 Station number 2 Station number 1

to to

RX(n 6)F to RX(n 6)0 Station number 28 Station number 27 Station number 26 Station number 25

RX(n 7)F to RX(n 7)0 Use prohibited

RX(n 8)F to RX(n 8)0 Station number 32 Station number 31 Station number 30 Station number 29

to to

RX(n E)F to RX(n E)0 Station number 56 Station number 55 Station number 54 Station number 53

RX(n F)F to RX(n F)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 4 Station number 3 Station number 2 Station number 1

to to

RY(n 6)F to RY(n 6)0 Station number 28 Station number 27 Station number 26 Station number 25

RY(n 7)F to RY(n 7)0 Use prohibited

RY(n 8)F to RY(n 8)0 Station number 32 Station number 31 Station number 30 Station number 29

to to

RY(n E)F to RY(n E)0 Station number 56 Station number 55 Station number 54 Station number 53

RY(n F)F to RY(n F)0 Use prohibited

MELSEC-

(c) The following table lists the I/O signals for 8 occupied station (4 occupied

stations

2 modules) setting

Remote input (X) of CC-Link/LT Remote input (RX) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

Remote output (Y) of CC-Link/LT Remote output (RY) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

3 - 10 3 - 10

Page 32

A

3 SPECIFICATIONS

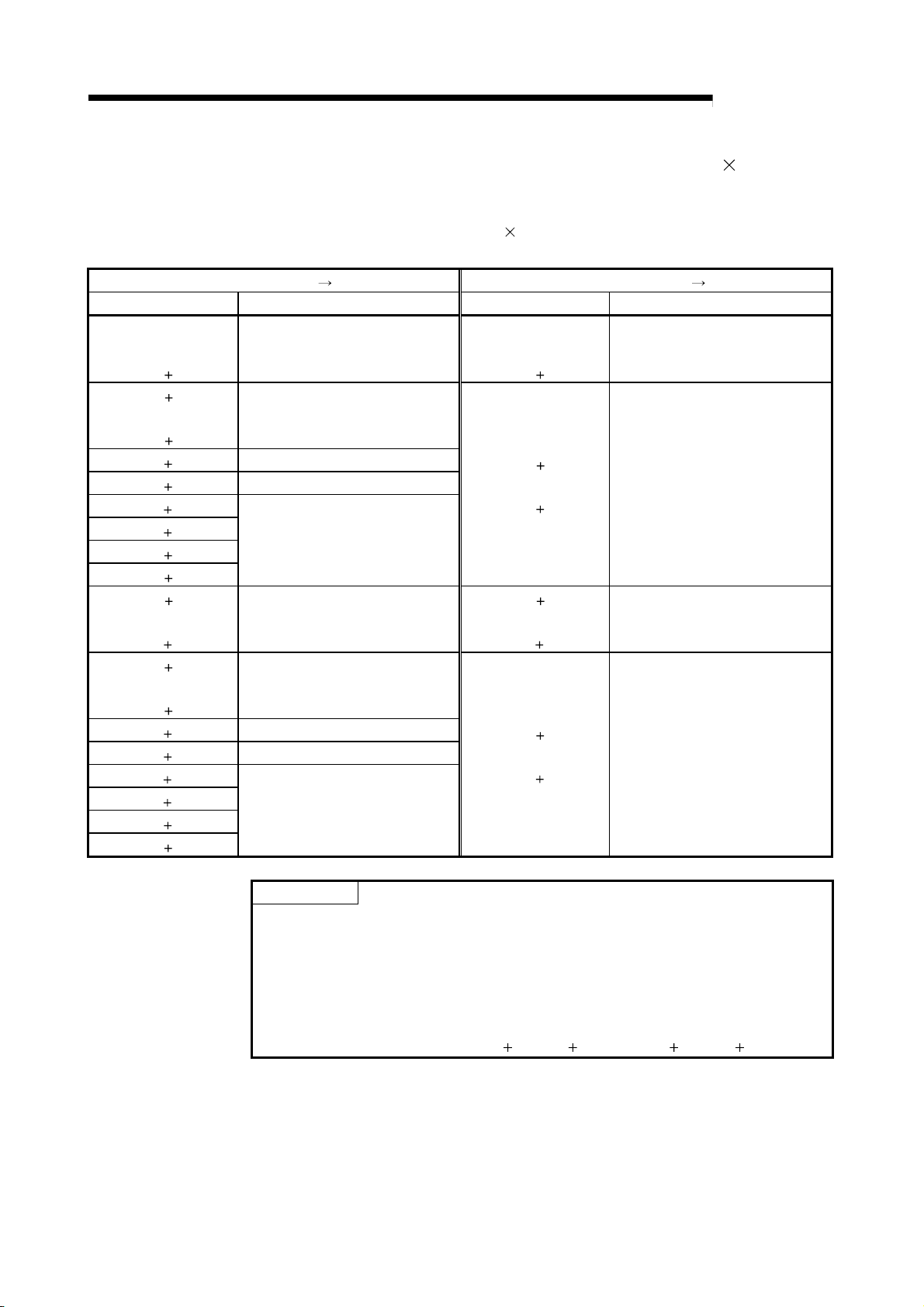

(2) Remote I/O signal list for 8-point mode setting

CC-Link

RXnF to RXn0 Station number 2 Station number 1

to to

RX(n 2)F to RX(n 2)0 Station number 6 Station number 5

RX(n 3)F to RX(n 3)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 2 Station number 1

to to

RY(n 2)F to RY(n 2)0 Station number 6 Station number 5

RY(n 3)F to RY(n 3)0 Use prohibited

CC-Link

RXnF to RXn0 Station number 2 Station number 1

to to

RX(n 6)F to RX(n 6)0 Station number 14 Station number 13

RX(n 7)F to RX(n 7)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 2 Station number 1

to to

RY(n 6)F to RY(n 6)0 Station number 14 Station number 13

RY(n 7)F to RY(n 7)0 Use prohibited

MELSEC-

(a) The following table lists the I/O signals for 2 occupied station setting

Remote input (X) of CC-Link/LT Remote input (RX) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

Remote output (Y) of CC-Link/LT Remote output (RY) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

(b) The following table lists the I/O signals for 4 occupied station setting

Remote input (X) of CC-Link/LT Remote input (RX) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

Remote output (Y) of CC-Link/LT Remote output (RY) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

3 - 11 3 - 11

Page 33

A

3 SPECIFICATIONS

CC-Link

RXnF to RXn0 Station number 2 Station number 1

to to

RX(n 6)F to RX(n 6)0 Station number 14 Station number 13

RX(n 7)F to RX(n 7)0 Use prohibited

RX(n 8)F to RX(n 8)0 Station number 16 Station number 15

to to

RX(n E)F to RX(n E)0 Station number 28 Station number 27

RX(n F)F to RX(n F)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 2 Station number 1

to to

RY(n 6)F to RY(n 6)0 Station number 14 Station number 13

RY(n 7)F to RY(n 7)0 Use prohibited

RY(n 8)F to RY(n 8)0 Station number 16 Station number 15

to to

RY(n E)F to RY(n E)0 Station number 28 Station number 27

RY(n F)F to RY(n F)0 Use prohibited

MELSEC-

(c) The following table lists the I/O signals for 8 occupied station (4 occupied

stations

F E D C B A 9 8 7 6 5 4 3 2 1 0

F E D C B A 9 8 7 6 5 4 3 2 1 0

2 modules) setting

Remote input (X) of CC-Link/LT Remote input (RX) of

Remote output (Y) of CC-Link/LT Remote output (RY) of

3 - 12 3 - 12

Page 34

A

3 SPECIFICATIONS

(3) Remote I/O signal list for 16-point mode setting

CC-Link

RXnF to RXn0 Station number 1

to to

RX(n 2)F to RX(n 2)0 Station number 3

RX(n 3)F to RX(n 3)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 1

to to

RY(n 2)F to RY(n 2)0 Station number 3

RY(n 3)F to RY(n 3)0 Use prohibited

CC-Link

RXnF to RXn0 Station number 1

to to

RX(n 6)F to RX(n 6)0 Station number 7

RX(n 7)F to RX(n 7)0 Use prohibited

CC-Link

RYnF to RYn0 Station number 1

to to

RY(n 6)F to RY(n 6)0 Station number 7

RY(n 7)F to RY(n 7)0 Use prohibited

MELSEC-

(a) The following table lists the I/O signals for 2 occupied station setting

Remote input (X) of CC-Link/LT Remote input (RX) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

Remote output (Y) of CC-Link/LT Remote output (RY) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

(b) The following table lists the I/O signals for 4 occupied station setting

Remote input (X) of CC-Link/LT Remote input (RX) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

Remote output (Y) of CC-Link/LT Remote output (RY) of

F E D C B A 9 8 7 6 5 4 3 2 1 0

3 - 13 3 - 13

Page 35

A

3 SPECIFICATIONS

(c) The following table lists the I/O signals for 8 occupied station (4 occupied

CC-Link

RXnFRXn0

to to

RX(n6)FRX(n6)0

RX(n7)FRX(n7)0

RX(n8)FRX(n8)0

to to

RX(nE)FRX(nE)0

RX(nF)FRX(nF)0

CC-Link

RYnFRYn0

to to

RY(n6)FRY(n6)0

RY(n7)FRY(n7)0

RY(n8)FRY(n8)0

to to

RY(nE)FRY(nE)0

RY(nF)FRY(nF)0

stations

F E D C B A 9 8 7 6 5 4 3 2 1 0

F E D C B A 9 8 7 6 5 4 3 2 1 0

2 modules) setting

Remote input (X) of CC-Link/LT Remote input (RX) of

Station number 1

Station number 7

Use prohibited

Station number 8

Station number 14

Use prohibited

Remote input (Y) of CC-Link/LT Remote input (RY) of

Station number 1

Station number 7

Use prohibited

Station number 8

Station number 14

Use prohibited

Device No. Signal Name Description

RX(n 3)A 1 Error status flag

RX(n 3)B 2 Remote READY

(4) Functions of remote I/O signals

Turns on when a remote I/O error occurs on CC-Link/LT side or when all

stations or remote stations become faulty. Automatically turns off upon

recovery from the error.

Turns on during normal operation.

Turns off in the CC-Link/LT side self-loopback test mode or when a switch

error occurs on a CC-Link/LT side.

1: When 4 stations are occupied RX(n 7)A

When 8 stations are occupied RX(n 7)A, RX(n F)A

2: When 4 stations are occupied RX(n 7)B

When 8 stations are occupied RX(n

7)B, RX(n F)B

MELSEC-

3 - 14 3 - 14

Page 36

A

3 SPECIFICATIONS

MELSEC-

3.6 Concept of the Number of Control Points (Point Mode Setting for CC-Link/LT and

Number of Occupied Stations Setting for CC-Link)

This section explains the concept of the settings required for system configuration, i.e.,

point mode setting and number of occupied stations setting.

The point mode setting sets the number of points that can be controlled for each

occupied remote station in the CC-Link/LT.

The point mode has three different modes: 4-point mode, 8-point mode, and 16-point

mode. If the number of occupied stations is the same, the number of remote stations that

can be controlled in the CC-Link/LT changes depending on the setting of the point mode.

Note that, when connecting a remote device station to the CC-Link/LT system, set the

16-point mode in the point mode setting for the CC-Link/LT.

3.6.1 Setting number of occupied stations

This section explains a simple setting method of the point mode setting and number of

occupied stations setting.

As the point mode, use the 4-point mode. According to the number of I/O points of the

Number of Remote

Station I/O Points

48 points or less 2 stations

49 to 112 points 4 stations

113 to 224 points

remote station, refer to the following table and set the number of occupied stations.

POINT

Number of Occupied Stations Setting

of AJ65SBT-CLB

8 stations

(4 occupied stations

2 modules)

Point Mode Setting of

AJ65SBT-CLB

4-point mode

Since the default setting is the 8-point mode, change it to the 4-point mode.

3.6.2 Setting point mode

This section explains the point mode setting and the application method for number of

occupied stations setting.

(1) If the number of occupied stations is set the same, the number of controllable remote

Number of Occupied

Stations Setting

Point mode

setting

4-point mode 12 stations 28 stations 56 stations

8-point mode 6 stations 14 stations 28 stations

16-point mode 3 stations 7 stations 14 stations

3 - 15 3 - 15

stations changes depending on the point mode setting, as the following table shows.

2 Occupied

Stations

4 Occupied

Stations

(4 occupied stations 2 modules)

8 Occupied Stations

(2) If the remote module is the same, the number of occupied stations changes due

to the point mode.

For example, if a 16-point module is used, the occupied station number changes

from 4 occupied stations to 2 occupied stations to 1 occupied station when the point

mode changes from the 4-point mode to the 8-point mode to the 16-point mode.

Page 37

A

3 SPECIFICATIONS

(3) As the point mode, it is recommended to use the 4-point mode that has the least

Master

station

Station 1

2 stations

occupied

MELSEC-

number of empty points.

Example: In the case of one 2-point remote station, five 4-point remote stations,

one 8-point remote station and one 16-point remote station

Station 2

1 station

occupied

Station 3

1 station

occupied

CC-Link side

CC-Link/LT side

4-point mode

(4 points/station)

Number of occupied

stations: 2 stations

(maximum 48 points)

Total number of

stations: 12 stations

X/Y0

1) 4 points

2) 8 points

3) 4 points

X/Y10

4) 2 points

Empty, 2 points

5) 16 points

X/Y20

X/Y23

6) 4 points

7) 4 points

8) 4 points

Use

prohibited

16 points

AJ65SBT-CLB

Station 1

4 input

points

Station 2

8 input

points

Station 3

4 output

points

CL1X4-D1B2 CL2X8-D1B2 CL1Y4-T1B2

Station 4

2 output

points

CL1Y2-T1D2S CL1XY8-DT1B2 CL1Y4-T1B2

8-point mode

(8 points/station)

Number of occupied

stations: 4 stations

(maximum 112 points)

Total number of

stations: 9 stations

1 station

X/Y0

2 station

1 station

X/Y10

1 station

4 station

X/Y20

1 station

1 station

1 station

X/Y30

1) 4 points

Empty, 4 points

2) 8 points

3) 4 points

Empty, 4 points

4) 2 points

Empty, 6 points

5)

16 points

6) 4 points

Empty, 4 points

7) 4 points

Empty, 4 points

8) 4 points

Empty, 4 points

1 station

1 station

1 station

1 station

2 station

1 station

1 station

1 station

16-point mode

(16 points/station)

Number of occupied

stations: 4 stations

(maximum 112 points)

Total number of

stations: 8 stations

X/Y0

1) 4 points

Empty,12points

X/Y10

2) 8 points

Empty, 8 points

X/Y20

3) 4 points

Empty,12points

X/Y30

4) 2 points

Empty,14points

X/Y40

5)

16 points

Station 6

4 input/output

1 station

1 station

1 station

1 station

1 station

Station 5

16 input

points

CL2X16-D1M1V CL1Y4-T1B2

Station 8

4 output

points

points

16-point mode (4 points/station)

Number of occupied stations: 8 stations

(4 occupied stations 2 stations)

(maximum 224 points)

Total number of stations: 8 stations

X/Y0

X/Y10

1) 4 points

Empty,12points

X/Y80

1 station

X/Y90

1) 4 points

Empty,12points

2) 8 points

1 station

Empty, 8 points

X/Y20

3) 4 points

1 station

1 station

Empty,96points

1 station

X/Y30

X/Y40

Empty,12points

4) 2 points

Empty,14points

5)

16 points

Station 7

4 output

points

1 station

X/Y50

X/Y60

X/Y70

6) 4 points

Empty,12points

7) 4 points

Empty,12points

Use

prohibited

16 points

First module

1 station

1 station

Use

prohibited

16 points

Second module

Empty,48points

Use

prohibited

16 points

X/Y50

X/Y60

X/Y70

6) 4 points

Empty,12points

7) 4 points

Empty,12points

8) 4 points

Empty,12points

1 station

1 station

1station

When 4 occupied stations and 16-point mode are selected in

the above system, Station 8 cannot be set. (When the 16-point

mode has been set for 4 occupied stations, only up to 7 stations can be set.)

Set 8 occupied stations (4 occupied stations 2 modules) as shown above,

or change the point mode setting to the 4-point mode or 8-point mode.

3 - 16 3 - 16

Page 38

A

3 SPECIFICATIONS

(4) The assignment of the I/O numbers is explained below using the assignment

Station

No.

Model Name Input Output

(2 stations occupied)

MELSEC-

sheet in the Appendices. It is an example where the number of occupied stations

is 2 and the point mode setting is the 4-point mode as shown in the configuration

of the Section (3).

Station

No.

Model Name Input Output

(4 stations occupied)

3 - 17 3 - 17

Page 39

A

3 SPECIFICATIONS

3.7 Remote Registers

The AJ65SBT-CLB has the remote registers to make data communication with the

master module.

This section explains the assignment and data structure of the remote registers of the

AJ65SBT-CLB.

3.7.1 Assignment of remote registers

MELSEC-

The following tables indicate the assignment of the remote registers.

(1) RWw

Address Remote Register Definition Initial value Reference

RWwn Last station number setting 0 Sec. 3.7.2

RWwn 1 Data link stop/restart instructions 0 Sec. 3.7.3

RWwn 2 Error status flag clear 0 Sec. 3.7.4

RWwn 3

to

RWwn

F

n: Address assigned to the master station in station number setting.

Use prohibited

(2) RWr

(a) When 2 stations are occupied

Address Remote Register Definition Reference

RWrn Data of operating statuses Sec. 3.7.5

RWrn 1 Data of faulty station : Station number 1 to 12 Sec. 3.7.6

RWrn 2 Remote I/O error data :Station number 1 to 12 Sec. 3.7.7

RWrn 3 Data of remote station connection Sec. 3.7.8

RWrn 4 Setting data Sec. 3.7.9

RWrn 5

to

RWrn

7

n: Address assigned to the master station in station number setting.

Use prohibited

(b) When 4 stations are occupied

Address Remote Register Definition Reference

RWrn Data of operating states Sec. 3.7.5

RWrn 1

RWrn 2

RWrn 3

RWrn 4

RWrn 5

RWrn 6

RWrn 7 Setting data Sec. 3.7.9

RWrn 8

to

RWrn

F

Data of faulty station : Station number 1 to 28 Sec. 3.7.6

Remote I/O error data :Station number 1 to 28 Sec. 3.7.7

Data of remote station connection Sec. 3.7.8

Use prohibited

n: Address assigned to the master station in station number setting.

3 - 18 3 - 18

Page 40

A

3 SPECIFICATIONS

MELSEC-

(c) When 8 stations (4 occupied stations 2 modules) are

occupied

First module

Address Remote Register Definition Reference

RWrn Data of operating statuses Sec. 3.7.5

RWrn 1

RWrn 2

RWrn 3

4

RWrn

RWrn 5

RWrn 6

RWrn 7 Setting data Sec. 3.7.9

RWrn 8

to

F

RWrn

Second module

Address Remote Register Definition Reference

RWr(n 1) Data of operating states Sec. 3.7.5

RWr(n 1) 1

RWr(n 1) 2

RWr(n 1) 3

RWr(n 1) 4

RWr(n 1) 5

RWr(n 1) 6

RWr(n 1) 7 Setting data Sec. 3.7.9

RWr(n 1) 8

to

RWr(n

POINT

1) F

The prohibited remote register areas are used by the system and therefore cannot

be used by the user.

If data is written to the buffer memory area corresponding to the prohibited remote

register area or to the device specified for auto refresh, the functions of the

AJ65SBT-CLB cannot be guaranteed.

Data of faulty station : Station number 1 to 32 Sec. 3.7.6

Remote I/O error data : Station number 1 to 32 Sec. 3.7.7

Data of remote station connection Sec. 3.7.8

Use prohibited

Data of faulty station : Station number 33 to 56 Sec. 3.7.6

Remote I/O error data : Station number 33 to 56 Sec. 3.7.7

Data of remote station connection Sec. 3.7.8

Use prohibited

n: Address assigned to the master station in station number setting.

3 - 19 3 - 19

Page 41

A

3 SPECIFICATIONS

MELSEC-

3.7.2 Last station number setting (common to 2, 4 and 8 occupied stations (4 occupied

stations 2 modules): Address RWwn)

The setting status of the last station number is stored.

Bit Name Description Initial value

b0 to b7 Empty Fixed at 0

Set the last station number for a data link.

This eliminates the processing of data link

to the non-connected stations, reducing the

link refresh time.

If the value is set beyond the number of

connectable stations (refer to Section

b8 to b13

b14, b15 Empty Fixed at 0

Last station number

setting

3.6.2), the setting will be ignored.

<Setting range>

2 occupied stations: Station 1 to 12

4 occupied stations: Station 1 to 28

8 occupied stations (4 occupied stations

If the value of 0 or more than 56 is set, a

data link is performed with the number of

stations within the setting range.

2 modules): Station 1 to 56

0

3.7.3 Data link stop/restart instructions (common to 2, 4 and 8 occupied stations (4 occupied

stations 2 modules): Address RWwn+1)

Data link stop and restart are controlled. When a data link stop and a data link restart

are requested simultaneously, the data link stop has higher priority.

Bit Name Description Initial value

b0 Data link stop

b1 to b14 Empty Fixed at 0

b15 Data link restart

0 : Data link stop not requested

1 : Data link stop requested

0 : Data link restart not requested

1 : Data link restart requested

0

0

3.7.4 Error status flag clear (common to 2, 4 and 8 occupied stations (4 occupied stations

2 modules): Address RWwn+2)

Error of station outside control range is cleared.

Bit Name Description Initial value

b0 to b2 Empty Fixed at 0

Error of station

b3

b4 to b15 Empty Fixed at 0

outside control range

clear

0 : Clear not requested

1 : Clear requested

0

3 - 20 3 - 20

Page 42

A

3 SPECIFICATIONS

MELSEC-

3.7.5 Data of operating statuses (common to 2, 4 and 8 occupied stations (4 occupied

stations 2 modules): Address RWrn)

Bit Name Description

b0 Data link status

b1 Initial communication status

b2 to b7 Empty Fixed at 0

b8 Data link failure

b9 All stations failed

b10 Remote I/O error

b11 Error of station outside control range

b12 Point mode setting error

b13 Transmission speed setting error

b14 Switching during operation

b15 Hardware failure

The CC-Link/LT side operating status is stored.

0: Data link stopped

1: Data link being executed

0: Initial communication not completed

1: Initial communication completed

0: Data link normal

1: One or more faulty station in data link identified

0: One or more normal data link station identified

1: All stations are faulty

0: No remote I/O error

1: One or more faulty remote I/O station

0: No error

1: Remote station(s) set to the station number higher than the last

of refresh range

0: Normal

1: Point mode switch set outside valid range

0: Normal

1: Transmission rate setting switch set outside valid range

0: No switching

1: Switching identified

0: Normal

1: Failure identified by self-loopback test

3 - 21 3 - 21

Page 43

A

3 SPECIFICATIONS

MELSEC-

3.7.6 Data of faulty station (2 occupied stations: Address RWrn 1, common to 4 and 8

occupied stations (4 occupied stations 2 modules): Address RWrn 1, RWrn 2)

The data link statuses of the CC-Link/LT remote stations are stored.

• When 2 stations are occupied, the data of faulty stations in the CC-Link/LT is stored

into RWrn+1.

• When 4 or 8 stations (4 occupied stations

faulty stations in the CC-Link/LT is stored into RWrn

Number of Occupied Stations Number of Stations

When 2 stations are occupied 1 to 12 stations

When 4 stations are occupied 1 to 28 stations

First module 1 to 32 stations When 8 stations (4

occupied stations

modules) are occupied

2

Second module 33 to 56 stations

2 modules) are occupied, the data of

1, RWrn 2.

Address b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

RWrn 1

(1) When 2 stations are occupied

Station

Station

Station