MITSUBISHI 〈DIGITAL ASSP〉

MITSUBISHI 〈DIGITAL ASSP〉

DESCRIPTION

The M66516 is a semiconductor laser-diode driver/controller.

Its functions are the driving and laser power control of a specific type (Mitsubishi’s R type laser) of semiconductor laser

diode, in which the cathode of a semiconductor laser diode is

connected in stem structure to the anode of a monitoring

photodiode.

The IC has a laser drive current output pin of source type and

is capable of driving a laser diode on a maximum bias current

of 30mA and a maximum switching current of 120 mA, which

is switched at a rate of 20Mbits/sec.

Since the M66516 has a built in sample-hold circuit, it is pos-

∗

sible to realize an internal APC

system that requires no external device for laser power control.

∗: Automatic Power Control

FEATURES

• Built-in sample-hold circuit for APC function

• High speed switching (20Mbps)

• Large drive current (150mA max.)

• Capable of setting bias current (30mA max.)

• 5V single power supply

M66516FP

LASER-DIODE DRIVER/CONTROLLER

LASER-DIODE DRIVER/CONTROLLER

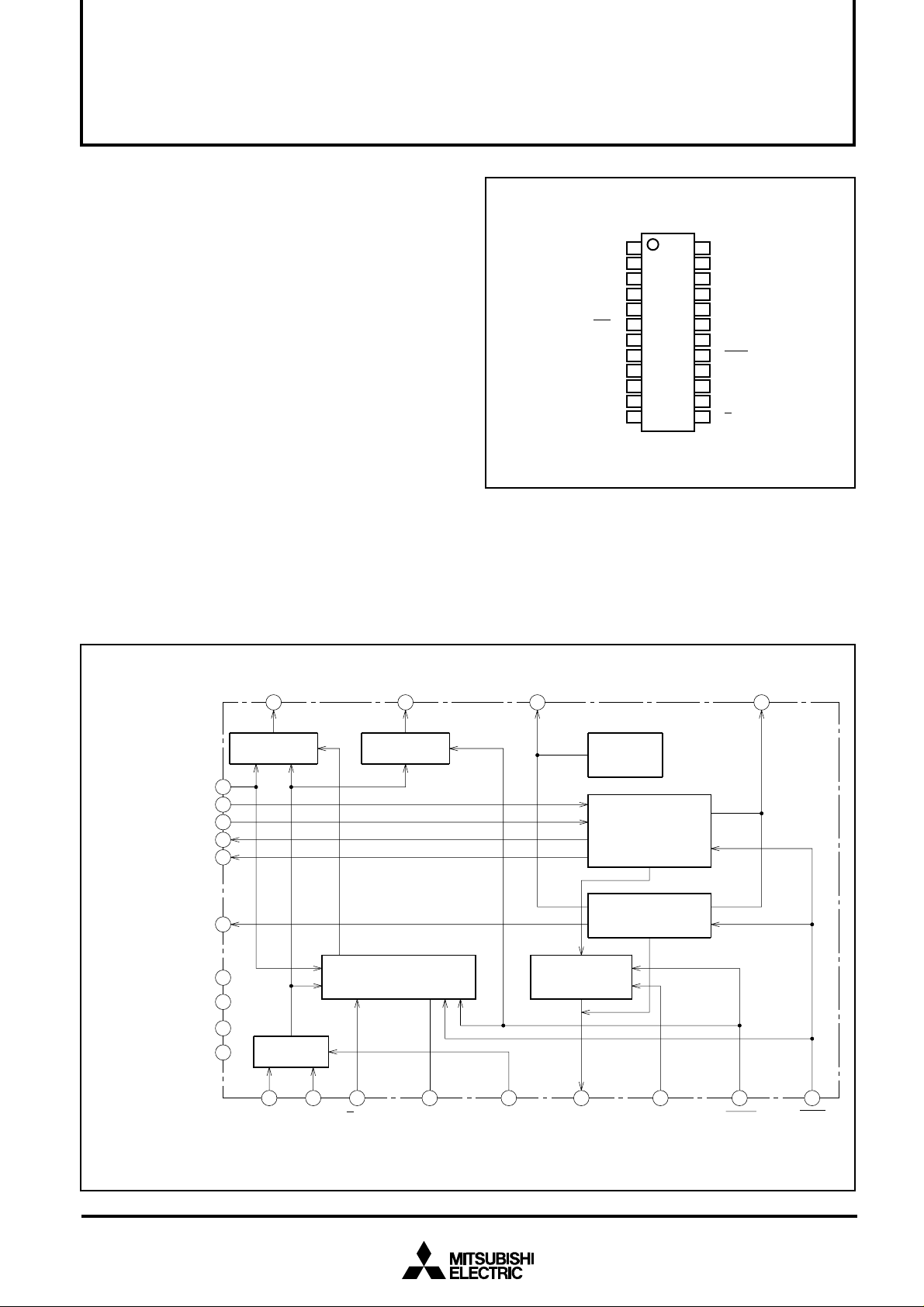

PIN CONFIGURATION (TOP VIEW)

SWITCHING CURRENT

SETTING INPUT 1

OUTPUT TO SWITCHING

CURRENT SETTING LOAD

SWITCHING CURRENT

SETTING INPUT 2

OUTPUT TO SWITCHING

CURRENT SETTING LOAD

LASER CURRENT

ENABLE INPUT

OUTPUT TO BIAS

CURRENT SETTING LOAD

MONITORING LOAD

MONITORING ANALOG

COMPARATOR OUTPUT

INPUTS

OUTPUT

MONITORING

1

VCC1

2

→

VL1

3

1RC

←

1

2

VL2

2RC

ENB

3RC

GND1

1RM

2RM

MO

CO

4

→

5

←

6

→

7

←

8

9

→

10

→

11

←

12

←

Outline 24P2N-B

24

23

22

21

M66516FP

20

19

18

17

16

15

14

13

M66516FP

OUTPUT TO LASER

RO

→

CURRENT LOAD

LASER CURRENT

LD

→

OUTPUT

NC

MONITORING DIODE

PD

←

INPUT

GND2

REFERENCE VOLTAGE

Vref

→

OUTPUT

REFERENCE VOLTAGE

Vr

←

INPUT

SWITCHING DATA

DATA

←

INPUT

DUTY CONTROL

CD

INPUT

VCC2

CONNECTION PIN FOR

CSH

SAMPLE-HOLD CAPACITOR

SAMPLE-HOLD

S/H

←

CONTROL INPUT

NC: No Connection

APPLICATION

Semiconductor laser-diode applied equipment

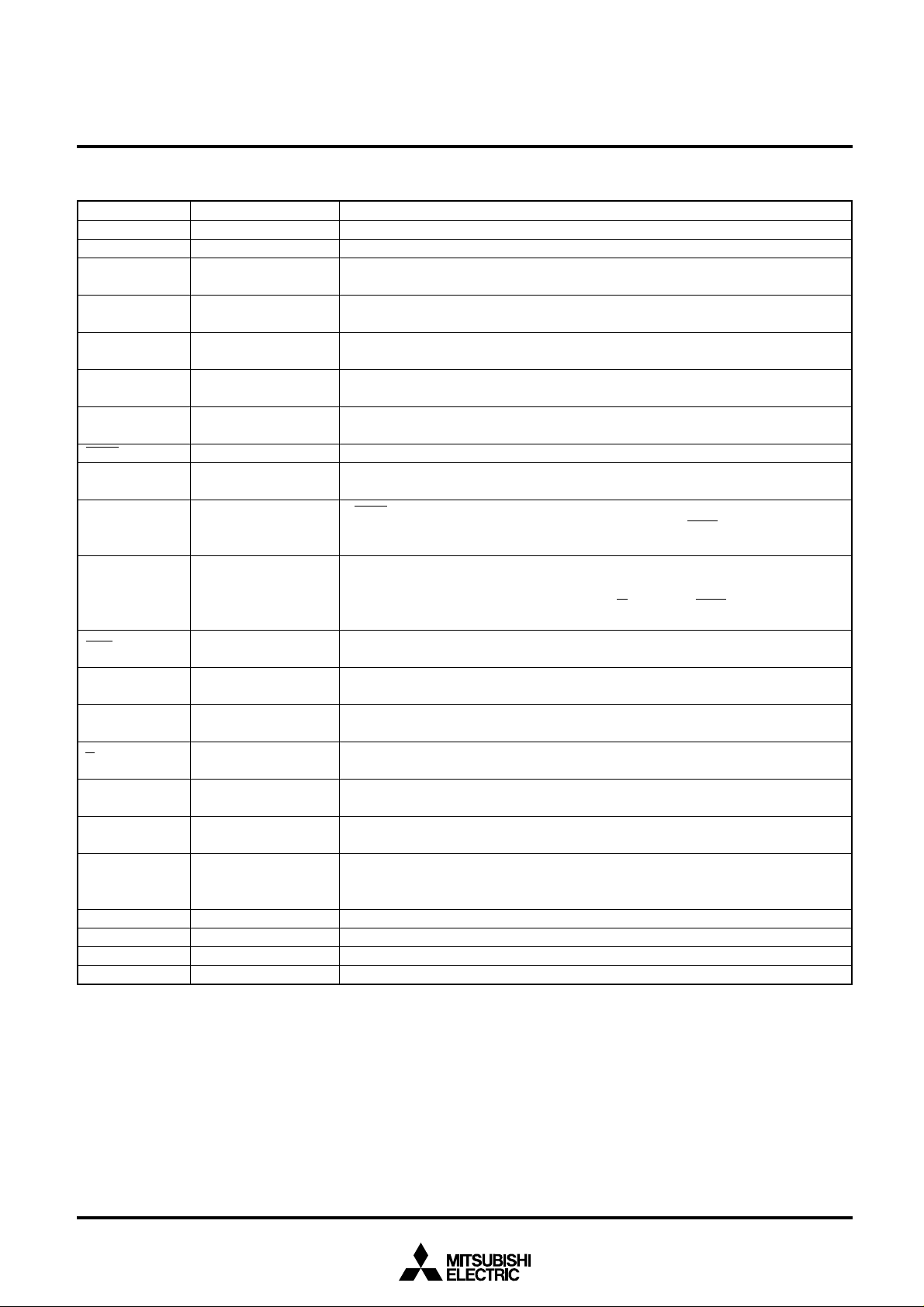

BLOCK DIAGRAM

V

SWITCHING CURRENT

SETTING INPUTS

V

1RC

2RC

3RC

V

GND

MONITORING

COMPARATOR OUTPUT

CO

COMPARATOR

V

r

18

2

L1

4

L2

3

5

7

1

CC

15

8

DIFFERENTIAL

20

AMP

ANALOG OUTPUT

MONITORING

MO

1112

LINEAR AMP

SAMPLE-HOLD

CIRCUIT

REFERENCE

VOLTAGE OUTPUT

V

ref

19

CURRENT

SWITCHING

CIRCUIT

RO

24

REFERENCE

VOLTAGE

SOURCE

SWITCHING

CURRENT

SOURCE

BIAS CURRENT

SOURCE

10

9

2RM PD LD

1RM

MONITORING

LOAD INPTUT

13

S/H

SAMPLE-HOLD

CONTROL INPUT

14

SH

C

CONNECTION

PIN FOR

DIODE INTPUT

MONITORING

SAMPLE-HOLD

CAPACITOR

21 23

OUTPUT TO

LASER

CURRENT LOAD

16

D

C

DUTY CONTROL

INPUT

17

DATA

SWITCHING

DATA INPUT

6

ENB

LASER CURRENT

ENABLE INPUT

1

PIN DESCRIPTIONS

Pin

LD

PD

VL1

1RC

VL2

2RC

3RC

DA T A

1RM, 2RM

MO

CO

ENB

RO

CD

S/H

CSH

Vref

Vr

VCC1

VCC2

GND1

GND2

Laser current output

Monitoring diode input

Switching current setting

input 1

Output to switching

current setting load 1

Switching current setting

input 2

Output to switching

current setting load 2

Output to bias current

setting load

Switching data input

Monitoring load input

Monitoring analog

output

Monitoring comparator

output

Laser current enable

input

Laser current load

output

Duty control input

Sample-hold control

input

Connection pin for

sample-hold capacitor

Reference voltage

output

Reference voltage input

Name

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

Description

Connect to anode on semiconductor laser diode.

Connect to cathode on monitoring photodiode.

Voltage input to set output current (IL1) of current source 1.

Connect load resistor between this pin and GND for IL1 setting.

Voltage input to set output current (IL2) of current source 2.

Connect a load resistor between this pin and GND for IL2 setting.

Connect a load resistor between this pin and GND for setting IB (bias current). Leave this

pin open if IB is not used.

If this pin is “L,” a current of IL1 + IL2 + IB flows through laser diode; if “H,” current IB flows.

Connect a load resistor between pins 1RM and 2RM for conversion of current generated by

monitoring photodiode into changes in voltage.

If DATA = “L” the potential difference generated on monitoring load resistor from photodiode

monitoring current is output as a voltage referenced to GND. If DATA = “H” the output at this

pin is fixed at “H” saturation level.

The potential difference generated on monitoring load resistor from photodiode monitoring

current is compared with the voltage on pin Vr. The result of the comparison is output in

TTL level.

This pin acts as comparator output pin only when S/H = “H” and DATA = “L.” In other states,

this output pin is fixed to “H.”

If this pin is “H,” all current supply circuits are turned off.

Connect a laser current load resistor between this pin and Vcc.

Connect a capacitor between this pin and GND for duty correction of light intensity

switching waveforms. If duty correction is not required, leave this pin open.

In internal APC mode, if this pin is “L,” sampling (APC) occurs, if “H,” holding (switching). In

external APC mode, connect this pin to Vcc.

Connect a capacitor for sample-hold function between this pin and GND.

Internal reference voltage (1.2V typ.) output pin of M66516

A reference voltage is applied to this pin to operate the comparator and the sample-hold

circuit. Connect this pin to the Vref pin if the internal reference voltage of the M66516 is

used.

Power supply for internal analog circuits. Connect to a positive power source (+5V).

Power supply for internal digital circuits. Connect to a positive power source (+5V).

GND for internal analog circuits.

GND for internal digital circuits.

2

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

OPERATION

1.Settings for Laser Drive Currents

The M66516 has built-in current sources for switching, IL1

and IL2, and a bias current source, IB. Each output current

can be controlled independently.

Approximate equations used for determining the current output from each of these current sources are as follows.

(1) IL1

IL1 is determined by the voltage on the VL1 pin and the resistor (RC 1) connected between the 1RC pin and GND.

The following equation is used for approximation.

IL1 [mA] = 12 ×

L2

(2) I

VL1 [V]

RC1 [kΩ]

IL2 is determined by the voltage on the VL2 pin and the resistor (RC 2) connected between the 2RC pin and GND.

The following equation is used for approximation.

IL2 [mA] = 12 ×

B

(3) I

VL2 [V]

RC2 [kΩ]

IB is determined by the internal reference voltage (Vref) and

the resistor (RC 3) connected between the 3RC pin and GND.

The following equation is used for approximation.

Buffer amp

LD

2RM

V

M

1RM

RM

+

−

Differential

amp

PD

V

r

−

+

+

−

Comparator

MO

CO

B [mA] = 10 ×

I

Vref [V]

RC3 [kΩ]

2.Laser Drive Current Switching Operation

If DA TA = “L,” laser drive current is I

I

B.

L1 + IL2 + IB; if DA TA = “H,”

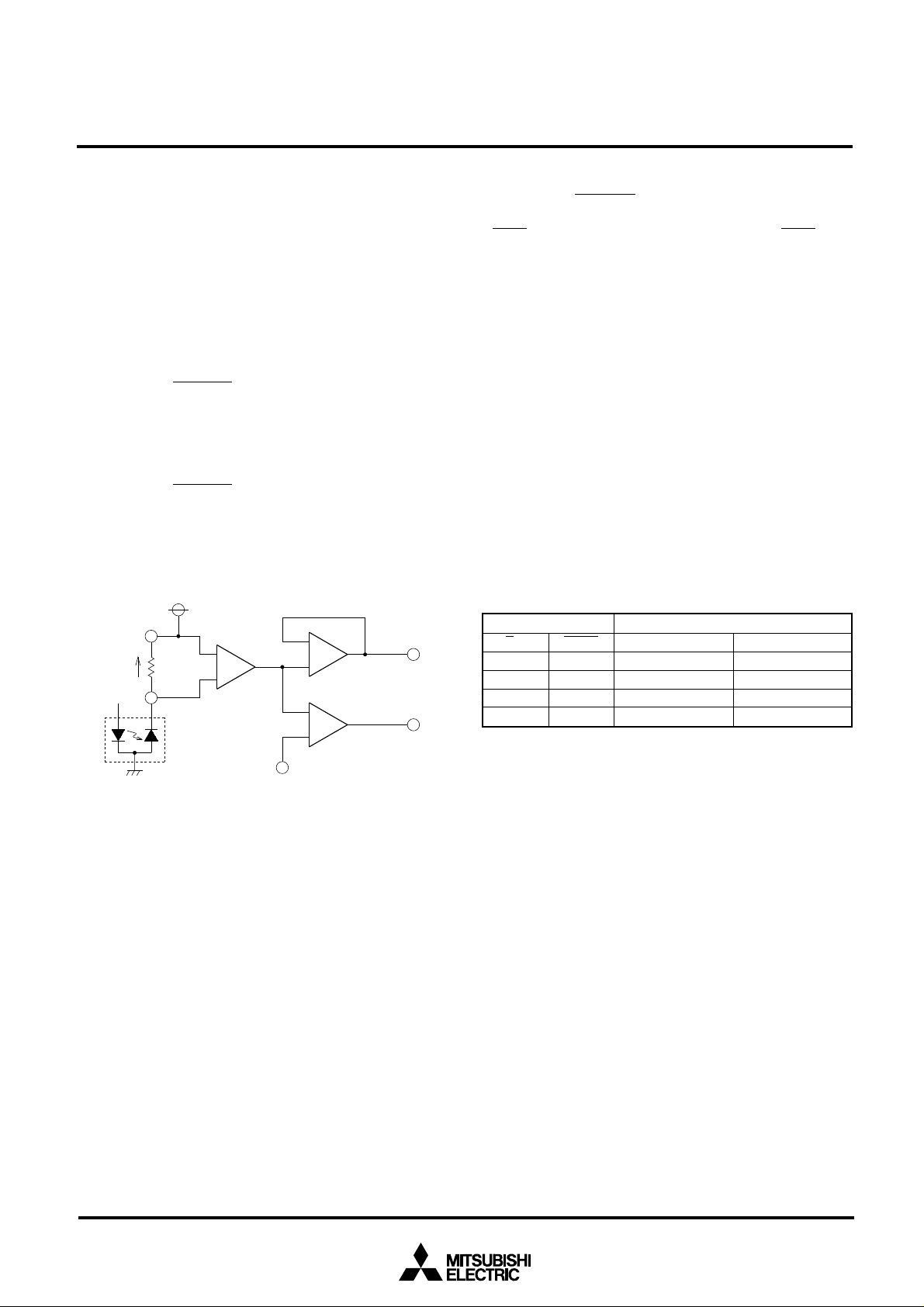

3.Laser Power Monitoring Operation

At the MO and CO pins, the M66516 outputs data obtained

by the monitoring photodiode (PD) contained in laser, in the

sequence explained below.

(1) A current equal to the PD current generated from laser

light flows through the resistor (RM) inserted between 1RM

and 2RM. Thence a potential difference (V

M) occurring on

RM is converted by the internal differential amp. to a level

from GND.

M is output at the MO pin as an analog signal through a

(2) V

buffer amp. At the same time, the comparator compares V

with the voltage applied to the Vr pin, then the result of the

comparison is output at the CO pin in TTL level.

M < Vr , CO output = “L”; and if V M > Vr, CO output = “H.”

If V

As the condition of the above operation, both the MO and CO

output circuits should be in monitoring operation. See the

table below.

Monitor Function Table

Input Output

S/H

L

L

H

H

DATA

L

H

L

H

MO output

Analog output

“H” saturation

Analog output

“H” saturation

CO output

Fixed to “H”

Fixed to “H”

Comparator output

Fixed to “H”

M

A Schematic Diagram of Monitor Circuits

3

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

4. RO Pin

A load resistor for laser drive current is connected to the RO

pin, through which a current almost equal to laser drive current flows in(when DATA = “H”). A load resistor is connected

between the RO pin and Vcc to reduce power dissipated in

the IC.

Due to reasons related to the operation of circuits, the voltage

at this pin should be 3.5V or higher.

Consequently, the maximum resistance, RO

(max.), of load

resistor RO is:

(max.) (Ω) =

RO

Vcc (min.) – 3.5 [V]

LD (max.) [A]

I

where ILD (max.) is the maximum of laser drive current. If, for

Reference voltage V

RM resistor voltage

difference

Switching data

Sample-hold control

input

V

DATA

S/H

r

M

Control circuit

Comparator

+ logic

example, Vcc

(min.) = 4.75 V and ILD(max.) = 150 mA, RO (max.)

= 8.3 Ω. Accordingly, if the resistances of RC 1 to RC 3 is selected so as to gain a maximum laser drive current of 150mA,

RO should be 8.3Ω at the maximum.

5. ENB Input

If laser current is controlled by the DATA input, the current

source circuit is in operation even with zero laser current. If

ENB input = “H”, all current source circuits go off including the

bias current source.

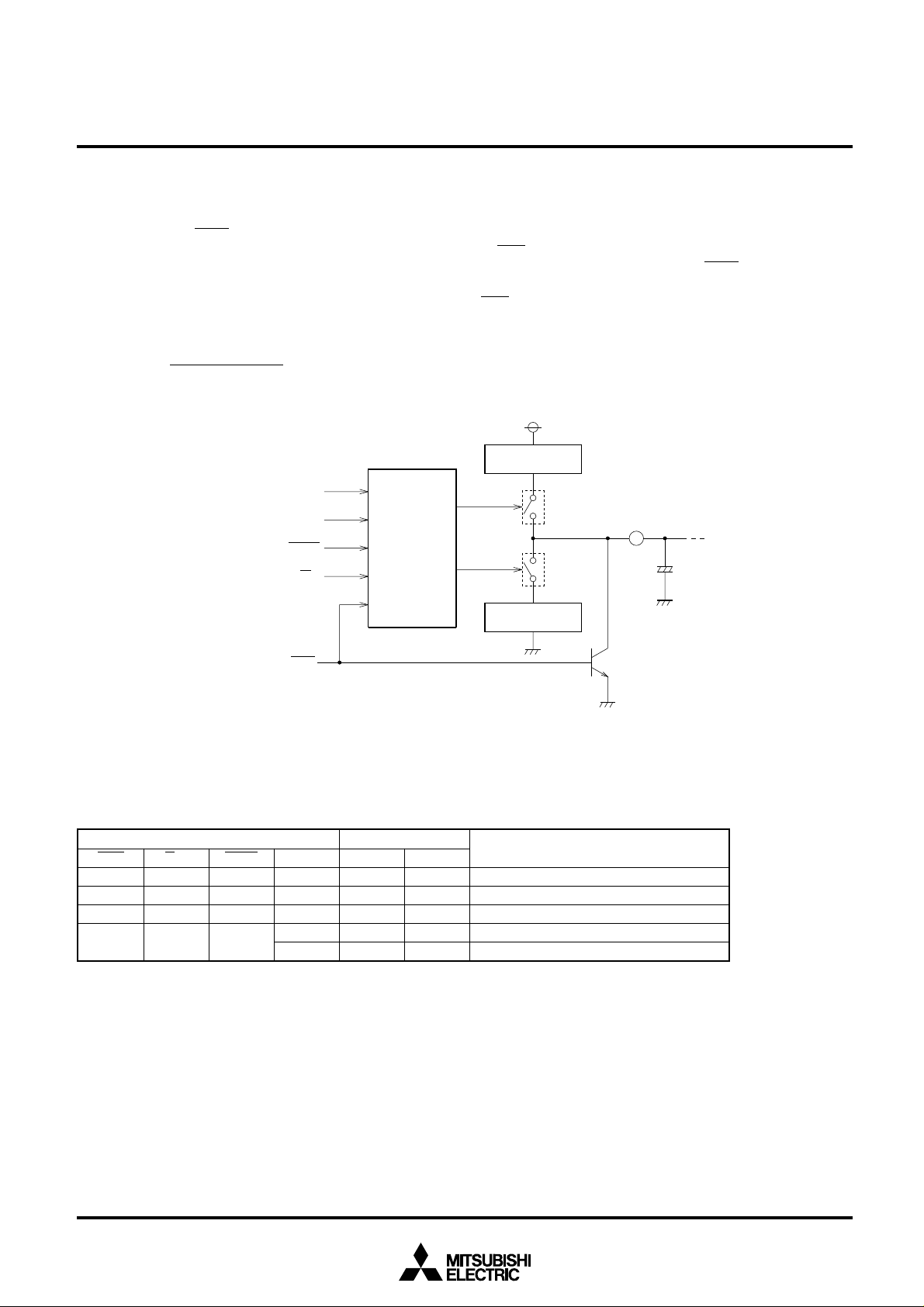

6. APC Operation

(1) Sample-hold circuit

The following are a conceptual diagram and function table of

the sample-hold circuit contained in the M66516.

Constant current

source for charging

SW1

Output

SW2

Constant current

source for discharging

SH

C

External capacitor

Function T able

ENB

H

L

L

L

×: Don’t care

S/H

×

H

L

L

Input

DATA

×

×

H

L

ENB

Conceptual Diagram: Sample-Hold Circuit

Switch condition

VM, Vr

×

×

×

VM < Vr

VM > Vr

SW1

OFF

OFF

OFF

ON

OFF

SW2

OFF

OFF

OFF

OFF

ON

Fixed to “L”

High impedance state (hold)

High impedance state (hold)

Constant current sourcing (sample)

Constant current sinking (sample)

Output

4

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

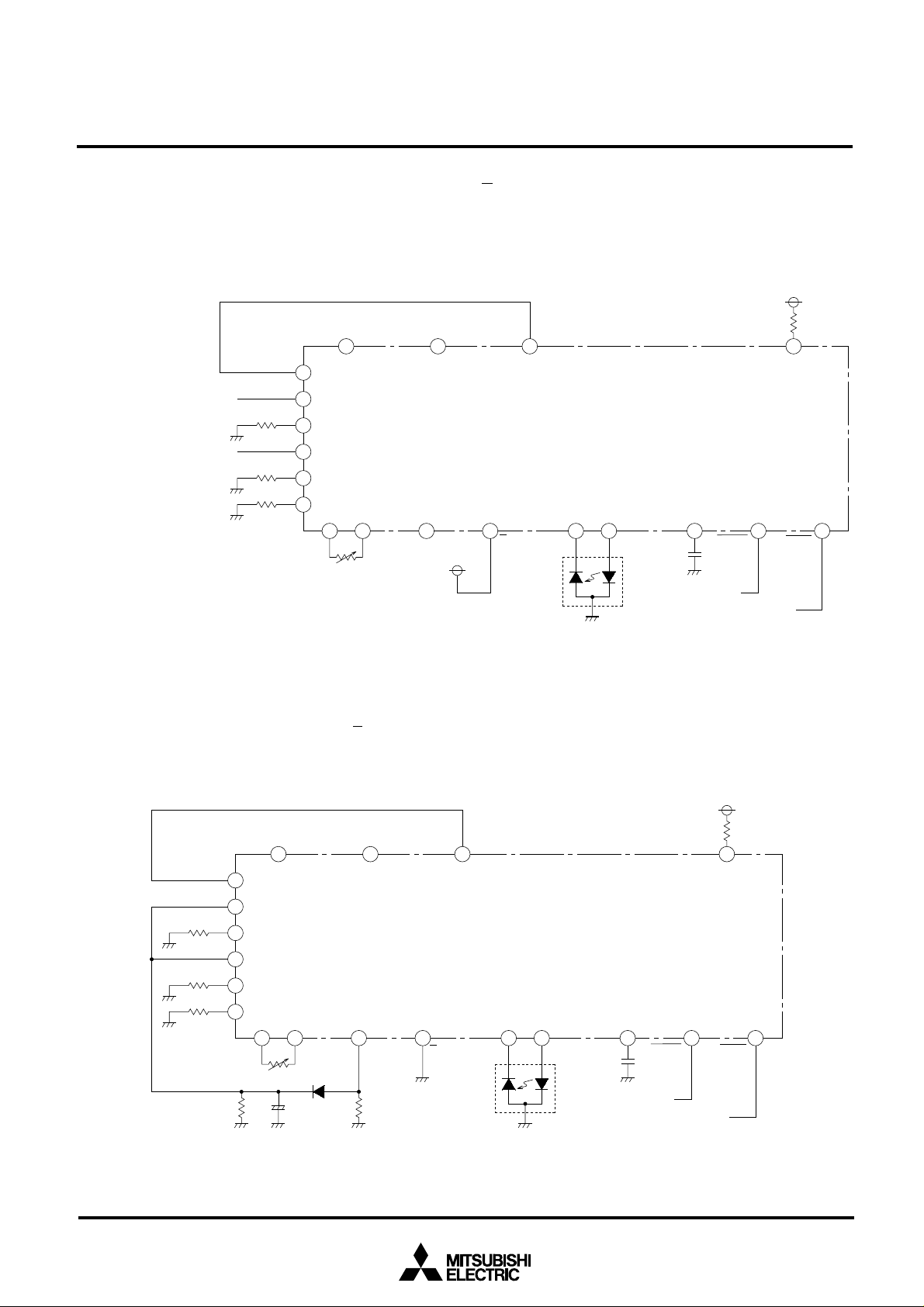

(2) External voltage-applied APC circuit

The following figure is an example of APC circuit configuration, in which voltages are applied from external sources to

L1 and VL2 input pins of the M66516. In this example, the

the V

14

MO

11

C

External control voltage 1

External control voltage 2

L1

V

1RC

VL2

2RC

3RC

Vr

18

2

3

4

5

7

1RM

CO

12

10

8

2RM

RM

S/H input pin is connected to Vcc and the C

SH pin is open.

The CO or MO output is used to monitor laser power for adjustment of external control voltage.

Vref

19

M66516FP

SH

13

S/H

PD

23

LD

1620

D

C

91pF

Data stream

17

DATA

Control signal

RO

24

ENB

6

(3) Peak-holding internal APC circuit

The following figure is a configuration example of peak-holding internal APC circuit. In this example, the S/H input pin is

connected to GND.

L1

V

1RC

V

L2

2RC

3RC

CO

12

V

r

18

2

3

4

5

7

10

9

1RM

R1

2RM

RM

C1

14

MO

11

C

R2

SH

13

S/H

If laser power is lower than preset value, C1 is charged with

the current from the C

SH output pin through D1. The charge

stored in C1 is discharged through R1 thereafter.

V

ref

19

M66516FP

PD

21 23

LD

16

C

D

91pF

Data stream

DATA

Control signal

RO

24

17

6

ENB

C1, R1: Time constant components

R2: Pull–down resistor

(Used for establishing C

SH

line voltage in case that CSH is in high impedance condition.)

5

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

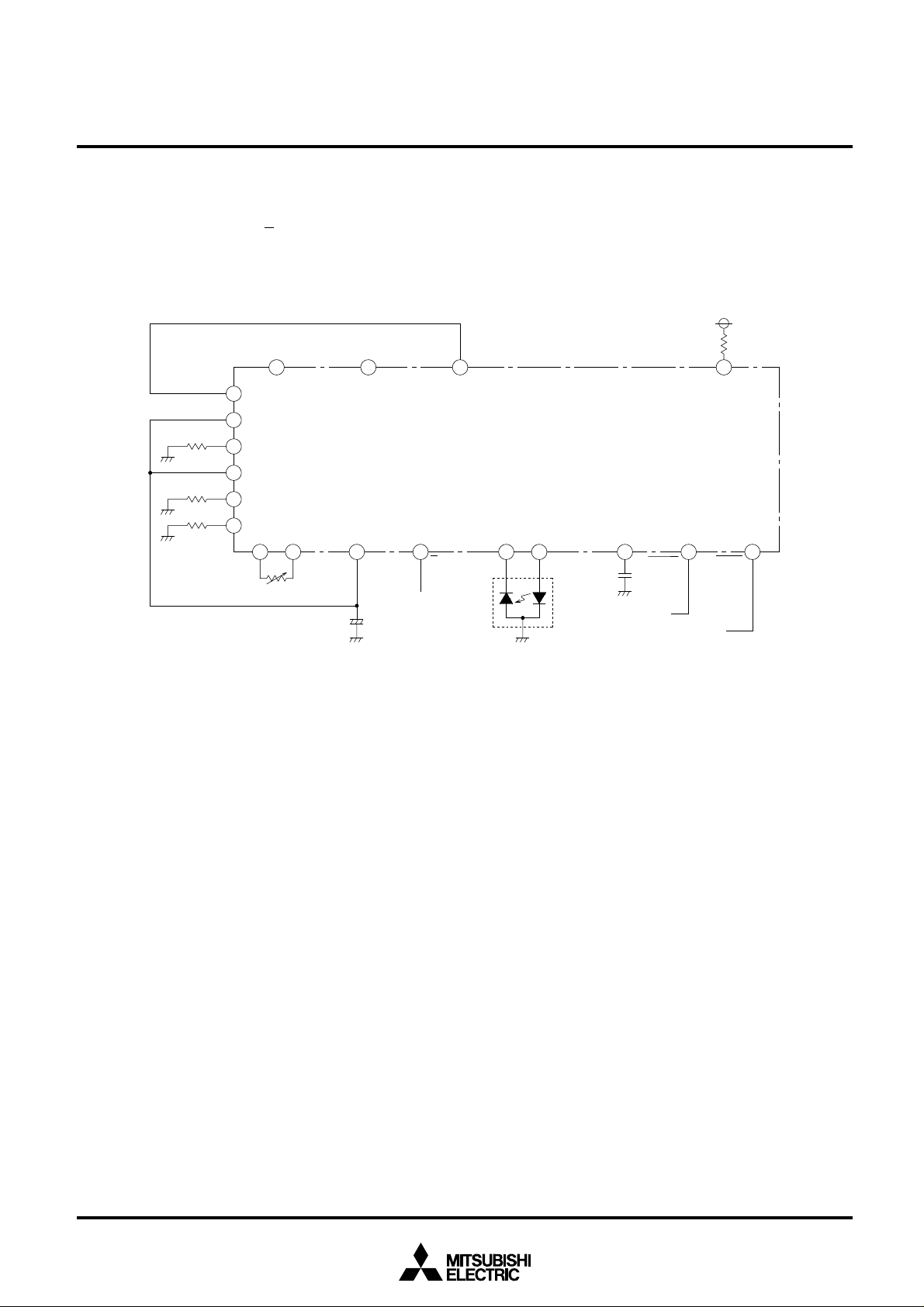

(4) Sample-hold type internal APC circuit

The following figure is a configuration example of samplehold type internal APC circuit. In this example, a sample-hold

control signal is applied to the S/H input pin.

In a sampling state, if laser power is lower than preset value,

14

MO

11

C

SH

C1

13

S/H

Control signal

V

r

18

2

V

L1

3

1RC

4

V

L2

5

2RC

7

3RC

1RM 2RM

CO

12

10

9

RM

C1 is charged by current from the C

SH output pin, while if it is

higher than preset value, C1 is discharged.

In a holding state, the CSH output is in high-impedance condition.

V

ref

19

M66516FP

PD

21 23

LD

16

D

C

91pF

Data stream

17

DATA

Control signal

RO

24

ENB

6

C1: Capacitor for sample–hold function

6

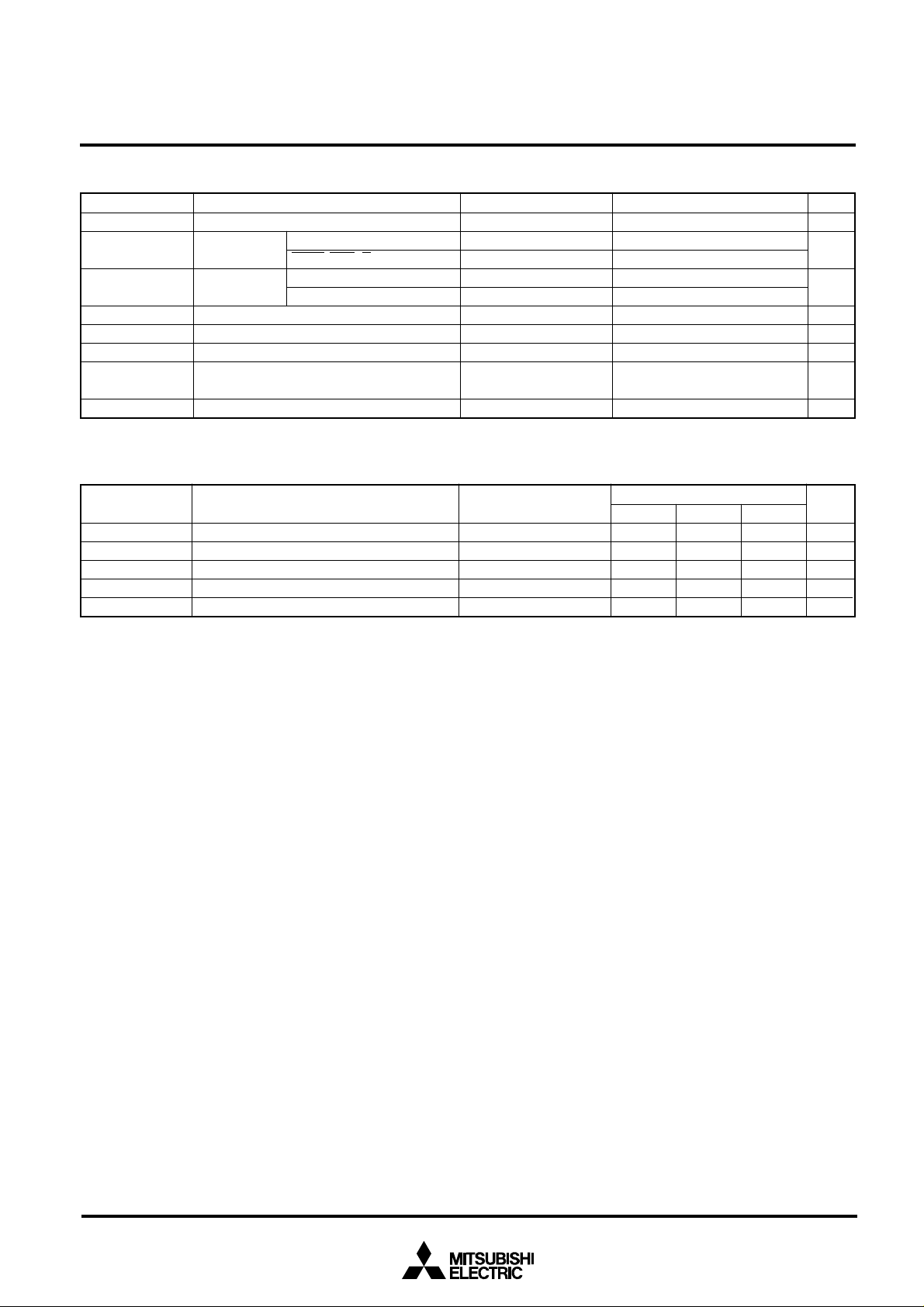

ABSOLUTE MAXIMUM RATINGS (Ta = –20 ~ 75°C, unless otherwise noted)

Parameter

VL1, VL2, Vr

DATE, ENB, S/H

CO

RO

“H” Output

“H” Output

Measured being mounted

Ta = 25°C (Note 1)

VCC

VI

VO

IL1

IL2

IB

Pd

Tstg

Symbol

Supply voltage

Input voltage

Output voltage

Output current 1

Output current 2

Bias current

Power dissipation

Storage temperature

SWITCHING CHARACTERISTICS (Ta = –20 ~ 75°C, unless otherwise noted)

Symbol

VCC

IL1

IL2

IB

Topr

Note 1: When Ta ≥ 25°C, derate by 7.1mW/°C

Supply voltage

Output current 1

Output current 2

Bias current

Operational ambient temperature

Parameter

Conditions

Conditions

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

Min.

4.75

–20

Ratings

–0.5 ~ +7.0

–0.3 ~ VCC

–0.3 ~ +7.0

–0.3 ~ +5.5

–0.3 ~ +7.0

–90

–90

–45

890

–60 ~ 150

Limits

Typ.

5.0

Max.

5.25

–60

–60

–30

75

Unit

V

V

V

mA

mA

mA

mW

°C

Unit

V

mA

mA

mA

°C

7

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

ELECTRICAL CHARACTERISTICS (Ta = –20 ~ 75°C, VCC = 5V±5%, unless otherwise noted)

Symbol

VIH

VIL

VI

VOH

VOL

VOH

VOL

VLD

VOS

∆VM

II

Vref

Vr

IL1

IL2

IB

IOFF

Icg

Idg

Ioz

ICC

Note 2: Typical values are gained under conditions of Vcc = 5V and Ta = 25°C. Regarding parameters that Ta is specified as test condition, however, typical

“H” Input voltage

“L” Input voltage

Maximum effective Input voltage

“H” Output voltage

“L” Output voltage

“H” Output voltage

“L” Output voltage

Ambient tempererature

Output offset voltage

Output voltage fluctuation

Input current

Reference voltage

output

Reference voltage input

Output current 1 (5)

Output current 2 (5)

Bias current (5)

OFF state output current

Charge current

Discharge current

Output leak current

Supply current

values are gained under the condition Vcc = 5V.

3: IMO: Output current at MO pin; IPD: Input current at PD pin

4: RM: Resistor inserted between 1RM and 2RM.

5: These parameters indicate the conversion characteristics of the input voltage and output current. In actual use, I

specified as limits in the recommended operating conditions.

Parameter

DATA, ENB, S/H

DATA, ENB, S/H

VL1, VL2

CO

CO

CSH

CSH

LD

MO

MO

Temperature coefficient

DATA, ENB

VL1, VL2, Vr

Temperature

coefficient

LD

Temperature coefficient

LD

Temperature coefficient

LD

LD

CSH

CSH

CSH

DATA = 0V

DATA = 4.5V

IOH = –400µA

IOL = 4mA

IOL = 8mA

ENB = 0.8V, IOH = –2mA

ENB = 0.8V, IOH = 2mA

IMO = ±20µA (3)

IPD = –0.2 ~ 2.0mA

IMO = ±20µA, RM = 1kΩ (4)

IPD = –1.2mA

VI = 2.7V

VI = 0.4V

VI = 0 ~ VCC

IO = –10µA

Ta = –20 ~ 25°C

Ta = 25 ~ 75°C

VL1 = 3V, VL2 = 0V, VLD = 2V,

RC1 = RC2 = 560Ω, RC3 open

VL1 = 0V, VL2 = 3V, VLD = 2V,

RC1 = RC2 = 560Ω, RC3 open

RC3 = 360Ω, VLD = 2V

ENB = 0.8V, DATA = 2V

ENB = 2V, DATA = 0.8V

VO = 0.6 ~ 4.0V

VO = 0.6 ~ 4.0V

VO = 0 ~ VCC, Hold condition

VCC = 5.25V , ENB = 0V,

VL1 = VL2 = 3V,

RC1 = RC2 = 560Ω, RC3 = 360

output open

Test conditions

Min.

2.0

VCC – 1.8

2.7

4.0

0.4

–0.66

0.66

Ω

Limits

(2)

Typ.

VCC – 1.4

30

20

0.05

1.2

–1.5

–0.7

–62

0.037

–62

0.037

–31

L1, IL2, and IB shall be within the range

Max.

0.8

0.4

0.5

0.6

2.5

mV/°C

20

–0.2

±1

mV/°C

2.0

mA/°C

mA/°C

–1

–20

–2.0

2.0

±8

36

54

Unit

V

V

V

V

V

V

V

V

mV

mV

µA

mA

µA

V

V

mA

mA

mA

mA

µA

mA

mA

µA

mA

8

SWITCHING CHARACTERISTICS (Ta = –25°C, VCC = 5V)

Symbol

fop

tRP1

tRP2

tRP3

tRP4

tON

tOFF

Parameter

Operating frequency

Circuit response time 1

Circuit response time 2

Circuit response time 3

Circuit response time 4

Circuit ON time

Circuit OFF time

VL1, VL2

voltage

PD current

PD current

DATA

voltage

ENB voltage

ENB voltage

Input

Test pin

Output

LD current

MO voltage

CO voltage

CSH voltage

LD current

LD current

Test condition

ILD(L) = 0mA

ILD(H) = –60mA(Note 6)

ILD(L) = –55mA

ILD(H) = –65mA(Note 6)

IPD(L) = 0mA

IPD(H) = –2mA

RM = 1kΩ (Note 7)

|∆IPD| = 0.2mA

RM = 1kΩ (Note 7)

|∆IPD| = 1mA (Note 7)

|∆IPD| = 0.2mA (Note 7)

IPD = 0mA, –2mA,

RM = 1kΩ , Vr = 1.2V

(Note 8)

ILD(H) = –60mA(Note 9)

ILD(H) = –60mA(Note 9)

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

Limits

Min. Typ.

20

Max.

10

10

Unit

Mbps

7

2

µs

µs

µs

3

2

8

5

2

µs

µs

µs

µs

µs

NOTE 6: TEST CRICUTS

V

CC

NOTE 7: TEST CRICUTS

Oscilloscope(input)

RO

LD

PD

PD

8.2Ω

LD

I

Oscilloscope(output)

Current probe

LD

V

L1

V

L2

560Ω

1RC

560Ω

2RC

1RM

RM

2RM

Other pins are opened

P.G.

tr=tf=6

V

560Ω

V

1RC

50Ω

ns

2RC

1RM

2RM

Other pins are opened

L2

L1

V

CC

GND

DATA

ENB

TIMING CHARTS TIMING CHARTS

IH

V

V

L1

V

L2

50%

RP1

t

I

LD

10%

50%

t

RP1

90%

V

IL

I

LD(H)

I

LD(L)

I

PD

MO,

CO

50%

t

RP2,

RP3

t

CC

V

CC

V

RO

PD

DATA

S/H

CO

MO

GND

MO =10%,

CO =1.5V

8.2Ω

Oscilloscope(input)

Current probe

I

LD

50Ω

Oscilloscope(output)

50%

t

t

MO =90%,

CO =1.5V

RP2,

RP3

P.G.

r=tf=6ns

t

∆I

PD

∆I

PD

I

PD(H)

I

PD0

I

PD(L)

V

OH

OL

V

(∗)

PD

gained at the moment CH output is inverted.

: I

(∗)

9

MITSUBISHI 〈DIGITAL ASSP〉

M66516FP

LASER-DIODE DRIVER/CONTROLLER

NOTE 8: TEST CIRCUTS

V

CC

V

CC

V

L1

V

L2

560Ω

560Ω

1RC

2RC

DATA

ENB

RO

PD

8.2Ω

Oscilloscope(input)

I

LD

P.G.

V

r

1.2V

50Ω

t

r=tf=6ns

NOTE 9: TEST CIRCUTS

560Ω

Oscilloscope

(input)

560Ω

S/H

1RM

RM

2RM

GND

Other pins are opened

C

SH

Oscilloscope(output)

P.G.

r=tf=6ns

t

50Ω

Other pins are opened

TIMING CHARTS TIMING CHARTS

3V

ENB

I

LD(L)

1.5V

t

ON

DATA

C

SH

1.5V

t

RP4

3.0V

0.4V

0V

V

V

OH

OL

V

V

1RC

2RC

1RM

2RM

ENB

90%

L1

L2

V

CC

CC

V

GND

RO

LD

PD

DATA

8.2Ω

PD

1.5V

I

LD

Oscilloscope

(output)

Current probe

LD

3V

0V

t

OFF

I

LD(H)

10%

I

LD(L)

10

Loading...

Loading...