MITSUBISHI 〈DIGITAL ASSP〉

MITSUBISHI 〈DIGIT AL ASSP〉

DESCRIPTION

The M66510 is a semiconductor laser diode driver that drives

a semiconductor laser of the type whose cathode and the

anode of monitor photodiode are connected to the stem.

Laser driving current of up to 120mA can be set by applying

constant voltage from outside to drive the laser diode.

It operates from a 5V single power supply , allowing switching

of laser driving current at a speed of 20M bits/sec.

*: Our semiconductor laser is of R type.

FEATURES

• Built-in two outputs for monitoring laser power (comparator

output and analog output)

• With laser driving current forced off pin

• High-speed switching (20M bits/s)

• High driving current (120mA max.)

• 5V single power supply

APPLICATION

Laser beam printer

M66510P/FP

LASER-DIODE DRIVER

LASER-DIODE DRIVER

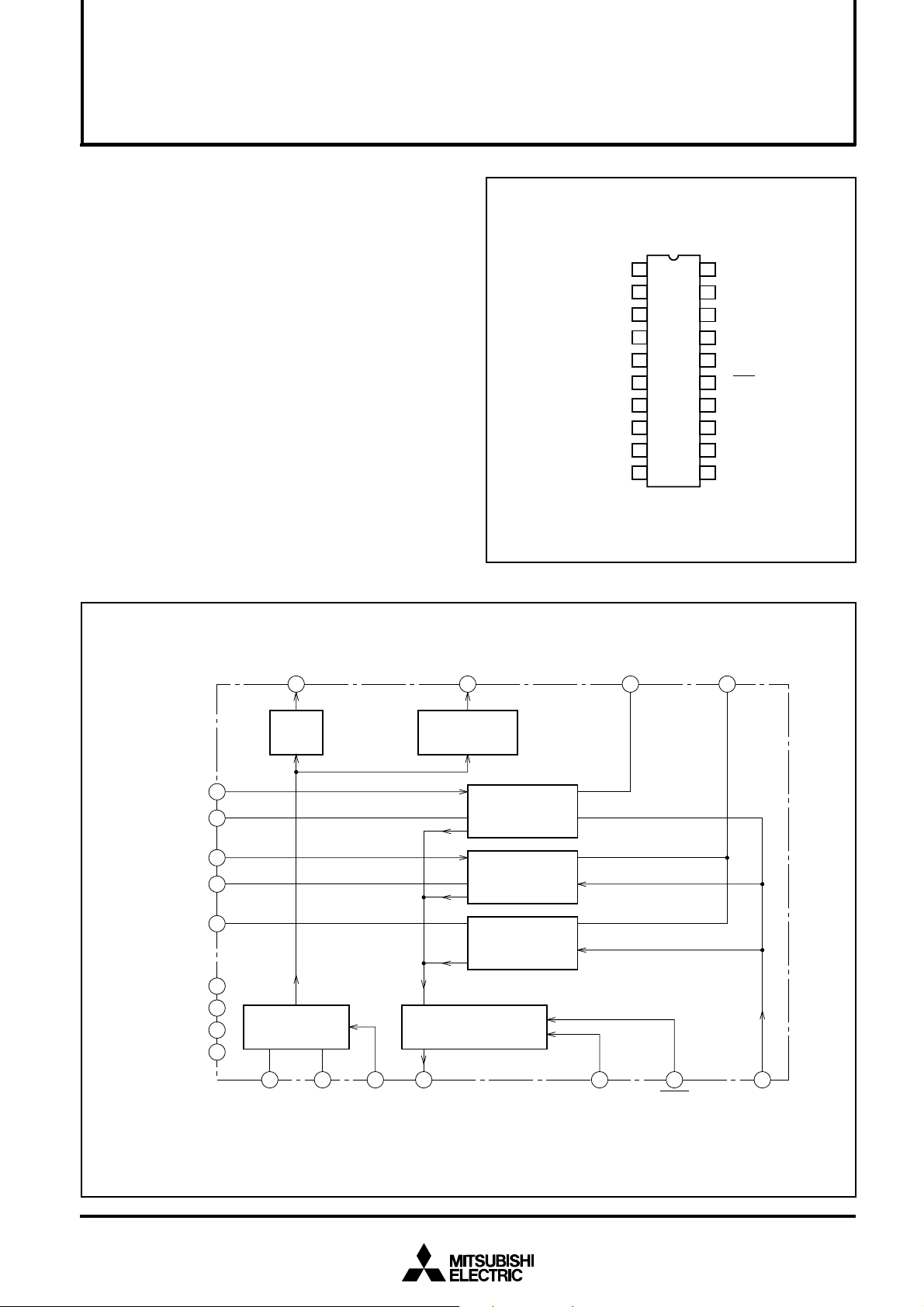

PIN CONFIGURATION (TOP VIEW)

V

CC1

CURRENT SETTING

INPUT 1

CURRENT SETTING

LOAD OUTPUT 1

CURRENT SETTING

INPUT 2

CURRENT SETTING

LOAD OUTPUT 2

LASER CURRENT

FORCED OFF INPUT

CURRENT SETTING

LOAD OUTPUT 3

GND1

MONITOR

LOAD INPUT 1

MONITOR

LOAD INPUT 2

1

→

VL1

2

←

1RC

3

→

VL2

4

←

2RC

5

→

V

OFF

6

←

3RC

7

8

→

1RM

9

→

2RM

10

Outline 20P4K

20

19

18

M66510P/FP

17

16

15

14

13

12

11

M66510P/FP

→

→

→

←

←

→

→

←

LASER CURRENT

1RO

LOAD OUTPUT 1

LASER CURRENT

2RO

LOAD OUTPUT 2

LASER DIODE

LD

OUTPUT

GND2

MONITOR DIODE

PD

INPUT

DATA

DATA INPUT

V

CC2

MONITOR

COMPARATOR

CO

OUTPUT

MONITOR ANALOG

MO

OUTPUT

DUTY

CD

CONTROL INPUT

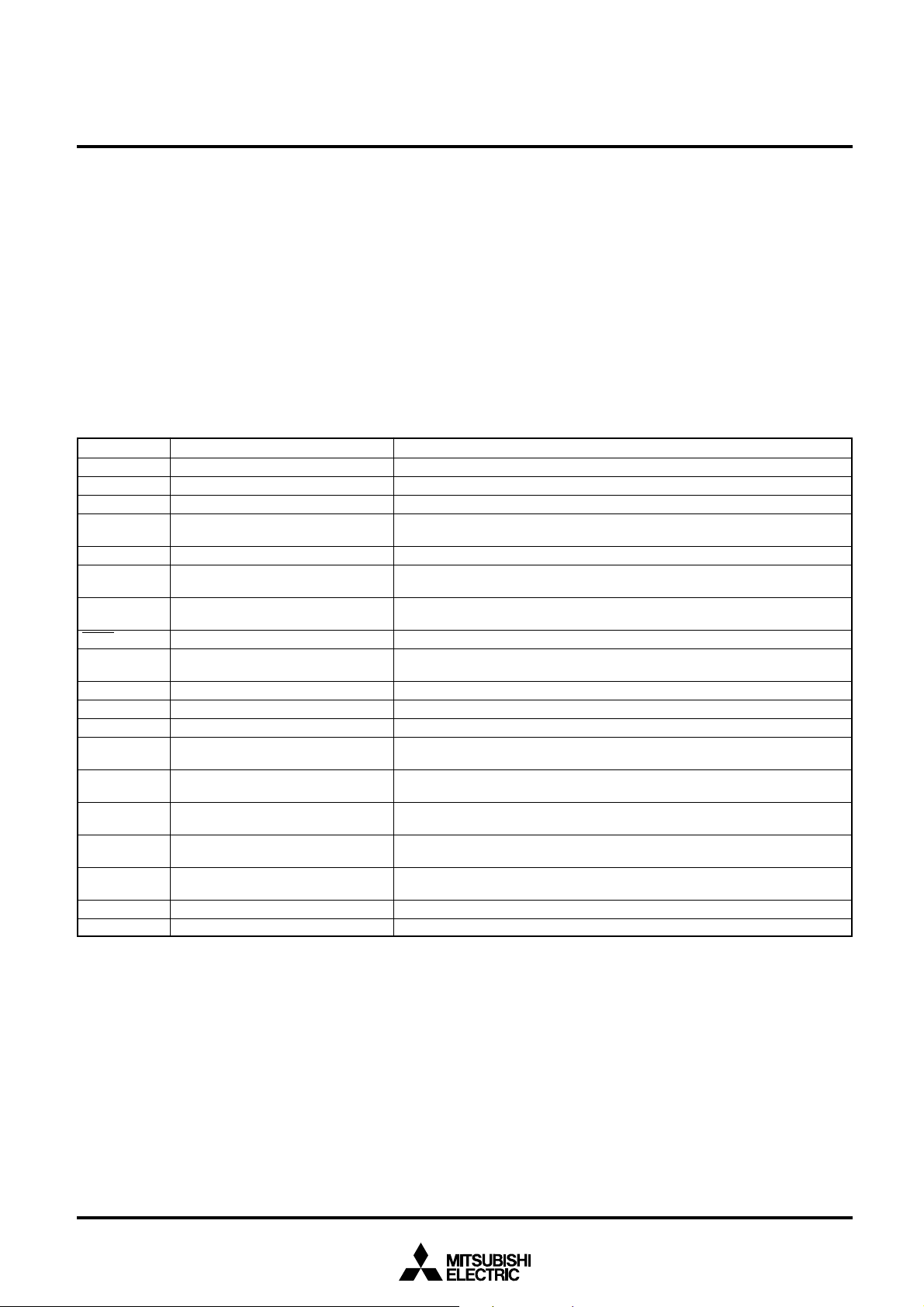

BLOCK DIAGRAM

CURRENT

SETTING

INPUT 1

CURRENT

SETTING

INPUT 2

V

CC1

CC2

L1

L2

MONITOR OUTPUT

MO

12

LINEAR

AMPLIFIER

2

31RC

4V

52RC

73RC

1V

14V

DIFFERENTIAL AMPLIFIER

17GND2

8GND1

9

1RM102RM

VL1, 1RC: LASER CURRENT (IL1) SETTING PIN

V

L2

, 2RC: LASER CURRENT (IL2) SETTING PIN

3RC: LASER CURRENT (I

MONITOR

DIODE INPUT

COMPARATOR OUTPUT

CURRENT SWITCHING CIRCUIT

16

PD

18

LD

LASER

DIODE OUTPUT

L3

) SETTING PIN

CO

13

COMPARATOR

(V

ref

= 1.2V)

CONSTANT CURRENT

SOURCE (I

CONSTANT CURRENT

SOURCE (I

CONSTANT CURRENT

SOURCE (I

I

L = IL1 + IL2 + IL3

CC1

V

V

CC2

1RO

20

L1

Max. 60mA

Max. 30mA

Max. 30mA

)

L2

)

L3

)

11

CD

DUTY

CONTROL INPUT

, GND1: IC INTERNAL ANALOG POWER SUPPLY PIN

, GND2: IC INTERNAL DIGITAL POWER SUPPLY PIN

15

DATA

DATA INPUT

2RO

19

LASER CURRENT

FORCED OFF

6

V

OFF

1

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

FUNCTION

The 66510 is a semiconductor laser diode driver that drives a

semiconductor laser of the type (our R type) whose cathode

and the anode of monitor photodiode are connected to the

stem. Using the R type laser allows direct fixing the laser on

a device for easy installation, thus improving its radiation efficiency.

Laser driving current is set by applying voltage from outside.

The M66510 is equipped with two independent voltage applying pins to provide higher accuracy of setting the current

value.

PIN DESCRIPTIONS

Pin name

LD

PD

VL1

1RC

VL2

2RC

3RC

DATA

1RM,

2RM

MO

CO

VOFF

1RO

2RO

CD

VCC1

VCC2

GND1

GND2

Laser connecting pin

Monitor diode connecting pin

Voltage input pin for IL1 setting

Load resistor connecting pin for IL1

setting

Voltage input pin for IL2 setting

Load resistor connecting pin for IL2

setting

Load resistor connecting pin for IL3

setting

Switching data input pin

Monitor load resistor connecting pin

Monitor analog output pin

Monitor comparator output pin

Laser current forced off input pin

Load resistor connecting pin for laser

current IL1

Load resistor connecting pin for laser

current IL2/IL3

Duty compensating capacitor

connecting pin

Power supply pin 1

Power supply pin 2

GND pin 1

GND pin 2

Name

Connects the anode of semiconductor laser diode.

Connects the cathode of monitor photodiode.

Voltage input for setting the output current (IL1) of current source 1.

Connects IL1 setting load resistor between the pin and GND.

Voltage input for setting the output current (IL2) of current source 2.

Connects IL2 setting load resistor between the pin and GND.

Connects IL3 setting load resistor between the pin and GND. If IL3 is not used,

open the pin.

Turns on the laser in the “L” position, and off in the “H” position.

Connects between 1RM and 2RM the load resistor for converting monitor

photodiode current into voltage.

Analog output for monitoring laser power.

Comparator output for monitoring laser power.

Turns off all current source circuits in the “L” position.

Connects load resistor for laser current IL1 between 1RO pin and VCC.

Connects load resistor for laser current IL2 and IL3 between 2RO pin and VCC.

Connects duty compensating capacitor of optical output switch waveforms

between the pin and GND. If duty compensation is not required, open the pin.

Power supply for internal analog circuits. Connected to positive power supply

(+5V).

Power supply for internal digital circuits. Connected to positive power supply

(+5V).

GND for internal analog circuits.

GND for internal digital circuits.

It is also equipped with a laser current forced off pin to prevent overcurrent from flowing into the laser diode at the

power-ON time.

For detection of laser power, the monitor current of monitor

photodiode built in the laser is converted into voltage by an

external resistor to generate an analog output, and simultaneously the result of comparison with the internal reference

voltage is output as TTL-level logic information.

Function

2

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

DESCRIPTION OF OPERATION

1. Setting laser driving current

The M66510 is provided internally with three constant current

sources IL1, IL2 and IL3, allowing setting of each independent

output current.

The methods of setting IL1 to IL3 are given below in (1) to (3).

(1) Method of setting IL1

IL1 is approximated by the VL1 pin input voltage and the resistor (RC1) connected between 1RC pin and GND as follows:

L1[V]

IL1[mA] = 12 ×

V

RC1[kΩ]

However, 0≤ VL1 ≤ VCC – 1.8V, IL1(max.) = 60mA

(2) Method of setting I

L2

IL2 is approximated by the VL2 pin input voltage and the resistor (RC2) connected between 2RC pin and GND as follows:

L2[V]

IL2[mA] = 6 ×

However, 0≤ V

L2 ≤ Vcc – 1.8V, IL2(max.) = 30mA

V

RC2[kΩ]

(3) Method of setting IL3

IL3 is approximated by the internal reference voltage (Vref)

and the resistor (RC3) connected between 3RC pin and GND

as follows:

ref[V]

IL3[mA] = 10 ×

V

RC3[kΩ]

However, Vref=1.2V (standard), IL3(max.) = 30mA

Note: The expressions for setting IL1 to IL3 are typical. Actually, the set values

fluctuate several % depending on IC lot dispersion or operating ambient

temperature (See the ELECTRICAL CHARACTERISTICS).

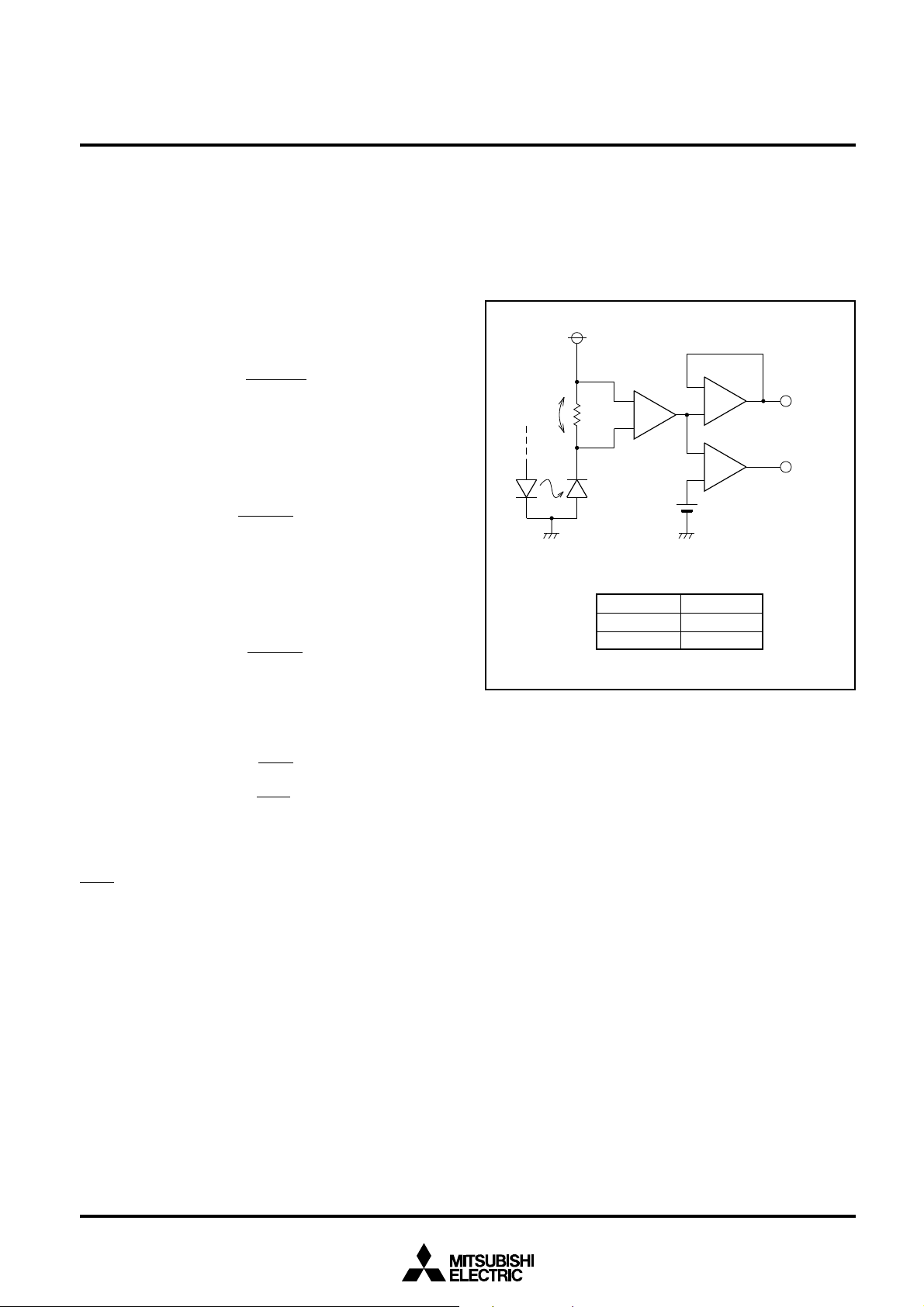

(2) The VM is output as an analog output from the MO pin

through the buffer amplifier and compared to the internal reference voltage Vref (1.2V standard) by the comparator. Then

the result of comparison is output from the CO pin on the TTL

level.

ref

–

+

Buffer

amplifier

+

–

Comparator

CO output

“L”

“H”

CO output

LD

V

M

RM

+ MO output

–

Differential

amplifier

PD

V

Condition

VM < Vref

VM > Vref

Monitor circuit schematic drawing

2. Switching operation

The laser is turned on when DATA= “L”. At this time, the laser driving current is I

L1 +IL2 +IL3.

The laser is turned off when DATA = “H”. At this time, the laser driving current becomes almost 0 regardless of IL1 to IL3.

3. Usage of VOFF input

The current which flows into the laser becomes 0 when

DATA= “H”. And the laser is turned off but the internal current sources are active.

Contrarily, the internal current sources are turned off when

OFF = “L”. It is therefore possible to prevent overcurrent from

V

flowing into the laser by setting V

OFF input to “L” until VCC

reaches 3.5V (standard) at the power-ON time, for example

(See 6. Internal reset).

4. Laser power monitor operation

The M66510 outputs the information on monitor photodiode

(PD) built in the laser from the MO and CO pins in the flow

given below.

(1) The current equal to the PD current produced through

emission of the laser flows into the resistor (RM) connected

between 1RM and 2RM. The potential difference (V

M) pro-

duced on RM is converted into a level from GND by the internal differential amplifier.

3

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

5. 1RO/2RO pin

The 1RO pin is used to connect the load resistor (RO1) for

current source 1 (I

load resistor (RO2) for current sources 2 (I

L1). The 2RO pin is used to connect the

L2) and 3 (IL3).

Connecting the load resistor between each pin and Vcc reduces IC internal power dissipation.

Set a resistance value so that each pin voltage does not go

down to 3.5V or less. In other words, set a value such as

meets the following expression:

RO1(RO2)[Ω] ≤

CC – 3.5[V]

V

Maximum load current [A] flowing into RO1(RO2)

Ex: When VCC = 5V and maximum load current of each source is 60mA, RO1

and RO2 will be 25Ω or less.

6. Internal reset operation

The M66510 is provided with an internal reset circuit to prevent overcurrent from flowing into the laser at the power-ON

time. The reset circuit operates within the range of V

CC <

3.5V (standard) to turn off all the current sources.

CC/GND pin

7. V

The power supply pins include V

CC1, VCC2, GND1 and

GND2, each of which is as follows in terms of internal circuit:

VCC1/GND1: Connected to an analog circuit.

CC2/GND2: Connected to a digital circuit.

V

In actual wiring, pay attention to the following:

(1) Make wiring width as wide as possible. Avoid redundant

wiring.

(2) Lay out an electrolytic capacitor for stabilizing voltage as

close to V

(3) Lay out a bypass capacitor as close to V

CC1/GND1 as possible.

CC2/GND2 as

possible.

Method of calculating power dissipation

The power dissipation P of M66510 is given by the expression given below.

CC × VCC +I(1RO) × (V(1RO) –V(LD))+I(2RO)× (V(2RO) –

P=I

V

(LD))+IOL(CO) × VOL(CO)

where, V(1RO) : 1RO pin voltage

(2RO) : 2RO pin voltage

V

I

(1RO) : 1RO pin load current

(2RO) : 2RO pin load current

I

(LD) : LD pin voltage

V

I

OL(CO) : CO pin “L” output current

OL(CO) : CO pin “L” output voltage

V

For example, when V

I

(1RO) =I(2RO) = 60mA, V(LD) = 2.5V, IOL(CO) = 8mA and

OL(CO) = 0.5V, the power dissipation at the laser-ON/OFF

V

CC = 5.25V, V(1RO) =V(2RO) = 3.5V,

time is as follows:

(1) Laser-ON time (DA TA = “L”, I

ON = 26 × 5.25 + 60 × (3.5 – 2.5) + 60 × (3.5 – 2.5) + 8 × 0.5

P

CC=26mA)

= 260.5(mW)

(2) Laser-OFF time (DATA = “H”, ICC = 44mA)

OFF = 44 × 5.25 + 0 + 0 + 8 × 0.5 = 235(mW)

P

Precaution for peripheral element wiring

Lay out the peripheral elements required for M66510 operation as close to M66510 as possible.

4

OPERATING WAVEFORM

P0

Laser output P

lL3

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

Laser output

Laser current lL

lL1

L2

l

Driving current pulse

lL1 : 0 ~ 60mA

l

L2 : 0 ~ 30mA

l

L3 : 0 ~ 30mA

ABSOLUTE MAXIMUM RATINGS

Symbol

VCC

VI

VO

IL1

IL2

IL3

Pd

Tstg

Note 1: When Ta ≥ 25°C, do derating of 10.4mW/°C.

2: When T

Supply voltage

Input voltage

Output current

Output current 1

Output current 2

Output current 3

Power dissipation

Storage temperature

a ≥ 25°C, do derating of 6.4mW/°C.

Parameter

VL1, VL2

DATA, VOFF

CO

1RO, 2RO

DIP

SOP

RECOMMENDED OPERATINIG CONDITIONS

Parameter

VCC

IL1

IL2

IL3

Topr

Symbol

Supply voltage

Output current 1

Output current 2

Output current 3

Operating ambient temperature

Conditions

When output is “H”

IC unit, when Ta=25°C (Note 1)

IC unit, when Ta=25°C (Note 2)

Conditions

Min.

4.75

–20

Ratings

–0.5 ~ +7.0

–0.3 ~ VCC

–0.3 ~ + 7

–0.3 ~ + 5.5

–0.3 ~ + 7

–90

–45

–45

1300

800

–65 ~ 150

Limits

Typ.

5

Max.

5.25

–60

–30

–30

75

Unit

V

V

V

mA

mA

mA

mW

°C

Unit

V

mA

mA

mA

°C

5

MITSUBISHI 〈DIGITAL ASSP〉

ELECTRICAL CHARACTERISTICS (VCC = 5V ± 5%, Ta = –20 ~ 75°C, unless otherwise noted)

Parameter

DAT A, VOFF

DAT A, VOFF

VL1, VL2

CO

CO

LD

MO

MO

Temperature coefficient

DAT A, VOFF

VIH

VIL

VI

VOH

VOL

VLD

VOS

∆VM

II

Symbol

“H” input voltage

“L” input voltage

Upper limit of effective input voltage

“H” output voltage

“L” output voltage

Operating supply voltage

Output offset voltage

Output voltage variance

width

Input current

VL1, VL2

Vref

IL1

IL2

IL3

IOFF

ICC

Note 3: IMO: MO pin output current. IPD: PD pin input current

4: RM: Resistance connected between 1RM and 2RM pins.

5: This indicates the input voltage – output current conversion characteristic. Use I

tions.

*: The standard value is given on VCC = 5V and at Ta = 25°C. The items with Ta specified under test conditions are given on VCC = 5V.

Reference voltage

Output current 1 (Note 5)

Output current 2 (Note 5)

Output current 3 (Note 5)

Off-state output current

Supply current

Temperature coefficient

LD

Temperature coefficient

LD

Temperature coefficient

LD

LD

Test conditions

IOH=–400mA

IOL=4mA

IOL=8mA

IMO=±20mA, IPD=0mA (Note 3)

IPD=–0.2~2.0mA, IMO=±20mA,

RM=1kΩ (Note 4)

RM=1kΩ, IPD=–1.2mA

VI=2.7V

VI=0.4V

VI=0~VCC

Ta=–20~75°C

Ta=25~75°C

VL1=3V, RC1=560 Ω, VLD=2V

VL2=3V, RC2=560 Ω, VLD=2V

RC3=360Ω, VLD=2V

VOFF=DATA=2V

VOFF=DATA=0.8V

VCC=5.25V, V

VL1=VL2=3.0V ,

OFF

=4.5V ,

DATA=0V

RC1=RC2=560Ω,

RC3=360Ω,

1RO, 2RO, LD open

L1 to IL3 within the range of limits of the recommended operating condi-

DATA=4.5V

Min.

2

VCC–1.8

2.7

0

VCC–1.4

M66510P/FP

LASER-DIODE DRIVER

Limits

Typ.*

30

20

0.05

1.2

–1.1

–0.7

–62

0.037

–31

0.017

–31

–0.2

–1

17

30

Max.

0.8

0.4

0.5

2.5

–0.2

–20

20

±1

–1

26

44

Unit

mV

mV

mV/°C

mA

mA

mA

mV/°C

mA

mA/°C

mA

mA/°C

mA

mA

mA

mA

V

V

V

V

V

V

V

ELECTRICAL CHARACTERISTICS (VCC = 5V, Ta = 25°C)

Test pin

Input

VL1/VL2

voltage

PD current

PD current

V

OFF

voltage

V

OFF

voltage

Output

current

voltage

voltage

LD current

LD current

6

fOP

tRP1

tRP2

tRP3

tON

tOFF

Symbol

Parameter

Operating frequency

Circuit response time 1

Circuit response time 2

Circuit response time 3

Circuit ON time

Circuit OFF time

LD

MO

CO

Test conditions

ILD(L)=0mA, ILD(H)=–60mA

(Note 6)

ILD(L)=–55mA,

ILD(H)=–65mA (Note 6)

IPD(L)=0mA, IPD(H)=–2mA,

RM=1kΩ (Note 7)

|∆IPD|=0.2mA, RM=1kΩ

(Note 7)

|∆IPD|=1mA (Note 7)

|∆IPD|=0.2mA (Note 7)

ILD(H)=–60mA (Note 8)

ILD(H)=–60mA (Note 8)

Min.

Limits

Typ.

20

4.5

0.5

7

1

7

0.5

3

0.5

Max.

7

2

10

3

10

2

5

2

Unit

Mbps

ms

ms

ms

ms

ms

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

NOTE 6: TEST CIRCUIT

NOTE 7: TEST CIRCUIT

5V

P.G.

t

r

= tf = 6ns

Oscilloscope

(input)

560Ω

50Ω

560Ω

L1

V

V

L2

1RC

2RC

1RM

V

CC

DATA

1RO

2RO

LD

PD

20Ω

20Ω

l

LD

Current probe

Oscilloscope

(output)

560Ω

560Ω

RM

2RM

GND

Other pins are open.

TIMING CHART TIMING CHART

V

IH

V

L1, VL2

I

LD

t

RP1

50%

10%

90%

t

RP1

50%

V

IL

I

LD(H)

I

LD(L)

IPD

MO, CO

V

V

1RC

2RC

1RM

2RM

50%

t

RP2,

tRP3

V

L1

L2

GND

MO=10%

CO=1.5V

CC

1RO

2RO

DATA

PD

CO

MO

20Ω

20Ω

l

PD

Oscilloscope

(output)

50%

MO=90%

CO=1.5V

5V

Oscilloscope (input)

Current probe

50Ω

Other pins are open.

PD

I

|

I

||

PD

t

RP2,

tRP3

P.G.

tr = tf = 6ns

IPD(H)

|

IPD(T)( ✽)

IPD(L)

V

OH

VOL

NOTE 8: TEST CIRCUIT

560Ω

560Ω

Oscilloscope (input)

P.G.

t

r

= tf = 6ns

50Ω

TIMING CHART

V

OFF

I

LD

1.5V

OFF

t

V

V

1RC

2RC

1RM

2RM

V

10%

L1

L2

OFF

V

CC

GND

1RO

2RO

LD

PD

DATA

20Ω

1.5V

20Ω

LD

I

Current probe

Other pins are open.

ON

t

90%

5V

Oscilloscope

(output)

3V

0V

I

LD(H)

I

LD(L)

PD when CO output is inverted.

: I

✽

7

APPLICATION EXAMPLE

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

5V

0.1mF 0.22mF

RC1

560Ω

RC2

560Ω

RC3

360Ω

M66510

L1

V

1RC

L2

V

2RC

3RC

V

CC1

V

CC2

GND2

GND1

12

Linear

amplifier

2

3

4

5

7

1

14

Differential amplifier

17

8

9

1RM102RM

RM

3kΩ

Control circuit

MO

16

CO

13

Comparator

(V

ref

= 1.2V)

Constant current source

(IL1)

Max. 60mA

Constant current source

L2

)

(I

Max. 30mA

Constant current source

L3

)

(I

Max. 30mA

Power supply switching

circuit

L

= I

L1

+ I

L2

I

18

PD

LD

ML4403R

5V

RO1

20Ω

1RO

20

+ I

L3

11

15

CD

91pF

Data stream Control signal

20Ω

DATA

RO2

2RO

19

6

V

OFF

8

STANDARD CHARACTERISTICS (VCC = 5V, Ta = 25°C)

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

LASER CURRENT - CURRENT SETTING VOLTAGE CHARACTERISTIC

–100

I

L1

+ l

L2

(mA)

L2

, I

L1

–80

–60

IL1(RC1=560Ω)

IL2(RC2=560Ω)

–40

LASER CURRENT I

–20

0

012

CURRENT SETTING INPUT VOLTAGE VL1, V

345

L2

(V)

MO OUTPUT - MONITOR CURRENT CHARACTERISTIC

LASER CURRENT - RC3 RESISTANCE CHARACTERISTIC

–50

–40

(mA)

L3

–30

–20

LASER CURRENT I

–10

0

0.2 0.4 0.6

RC3 RESISTANCE (kΩ)

0.8 1.0 1.2

CO OUTPUT - MONITOR CURRENT CHARACTERISTIC

5

(V)

MO

4

3

2

1

MONITOR ANALOG OUTPUT V

0

0–1–2

MONITOR CURRENT I

V

MO

RM=1kΩ

–3 –4 –5

PD

(mA)

(V)

5

CO

4

3

2

1

MONITOR COMPARATOR OUTPUT V

0

–0.8 –1.0 –1.2

MONITOR CURRENT I

–1.4 –1.6 –1.8

RM=1kΩ

PD

(mA)

9

EVALUATION OF SWITCHING OPERATION WAVEFORM

Connector

0.1mF

1

VCC 1VCC1

2GND

3VL1

4VL2

5VOFF

6GND

7CO

8MO

9DATA

10PD

22mF

JP

(Open)

RM

3kΩ

RC1

680Ω

RC2

680Ω

RC3

390Ω

2VL1

3 1RC

4V

L2

5 2RC

OFF

6V

7 3RC

8 GND1

9 1RM

10 2RM

CC2

MITSUBISHI 〈DIGITAL ASSP〉

M66510P/FP

LASER-DIODE DRIVER

RO

12Ω

201RO

192RO

18LD

17GND

16PD

15DATA

14V

13CO

12MO

D

11C

91pF

0.1

mF

( ✽ )

R

LD

500Ω

( ✽ )

CLD

75pF

Directly mounted on

PC board

Laser beam

output

ML4403R

V

CC = 5V

T

a = 25°C

Laser power

meter

50Ω

Oscilloscope

(laser beam output)

Oscilloscope (data input)

P.G.

(Note 9)

Note 9: tr =tf= 6ns, VO =3Vp-p, duty = 50%

50Ω

SWITCHING OPERATION WAVEFORM

DATA input

(2V/div)

Laser beam output

(1mW/div)

3V

0V

3mW

0mW

✽ : The R

LD and CLD optimum values depend on

a type of laser used and a PCB pattern.

EVALUATION CIRCUIT

2Mbit/s (t: 200ns/div)

10Mbit/s (t: 50ns/div) 20Mbit/s (t: 20ns/div)

5Mbit/s (t: 100ns/div)

10

Note: The delay from DATA input to laser beam output includes a measurement delay.

Loading...

Loading...