MITSUBISHI 〈DIGITAL ASSP〉

MITSUBISHI 〈DIGITAL ASSP〉

DESCRIPTION

The M66332 is a facsimile image processing controller that

converts analog signals that are photoelectrically converted

by an image sensor into bi-level signals.

It has image processing functions such as peak detection,

uniformity correction, γ correction, MTF compensation, detector of background and object levels, dither control, separation of image data area, scale down, and area specification.

This controller has a built-in 5-bit flash type A-D converter

and interface circuits to image sensor, analog signal processing circuit, and CODEC (Coder & Decoder) to simplify control

of the readout mechanism.

FEATURES

0High Speed Scan (MAX. 2 ms/line, TYP. 5 ms/line)

0A3 (8 pixels/mm) Line Sensor Attachment

0Image sensor (CCD,CIS) control signal generation

CCD: SH, CK1, CK2, RS

Contact sensor (CIS): SH, CK1 (or CK2)

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

FACSIMILE IMAGE DATA PROCESSOR

M66332FP

0Analog signal processing circuit control signal generation

CLAMP, S/H, AGC, DSCH

0Built-in 5-bit Flash Type A-D Converter

0Bi-level data external input/output interface Serial output

(→M66330)

8-bit MPU bus output with external DMA control signal

0Image data processing

γ correction

Uniformity correction (block correction in units of 8 pixels)

MTF compensation (1 dimension)

Detector of background and object level (programmable)

Dithering control

• Dither method (16 levels using 4 × 4 matrix)

Separation of image data area (1 dimension)

Scale down A3 → B4, A3 → A4, B4 → A4

05V Single Power Supply

APPLICATION

Facsimiles

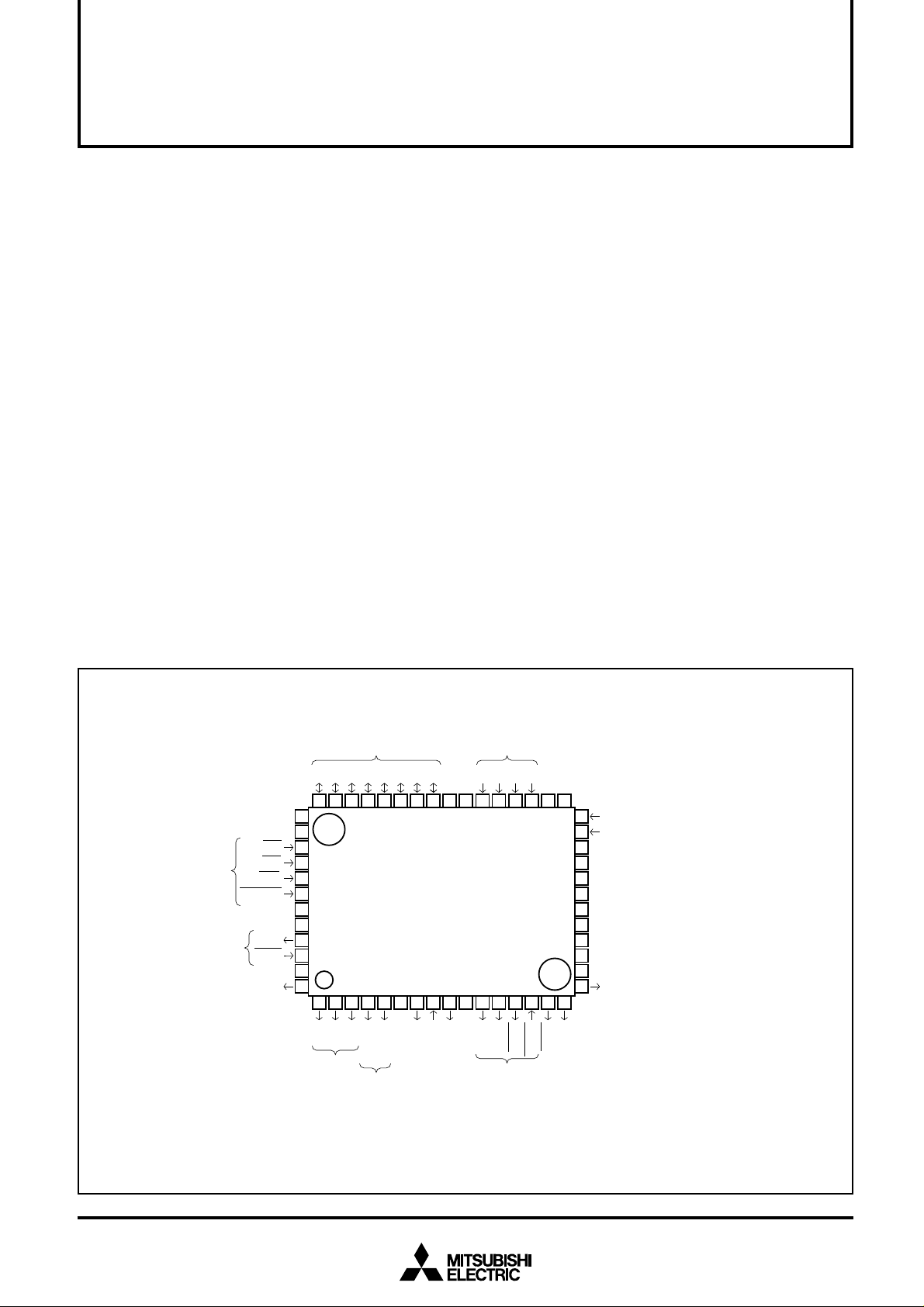

PIN CONFIGURATION (TOP VIEW)

45

GND

46

V

CC

CS

47

48

MPU Interface

DMA Interface

Sensor Interface

RD

WR

RESET

GND

GND

DRQ

DAK

V

CC

SH

49

50

51

52

53

54

55

56

MPU

Interface

(DATA)

D7D6D5D4D3D2D1

444342414039383736353433323130

D0

MPU

Interface

(ADDRESS)

GND

VCCA3A2A1A0DGND

M66332FP

123456789

RS

CK2

CK1

Sensor

S/H

CLAMP

Interface

Prosessing

Analog Signal

GND

TEST

Test pin

Interface

10111213141516

CC

V

SVID

TEST

SYSCK

Test pin

System clock

STIM

SCLK

CODEC

Interface

SRDY

Outline 56P6N-A

CC

DV

29

28

TEST

27

ASIG

26

NC

25

VWL

24

VML3

23

ML2

V

22

GND

21

VML1

20

BL

V

19

AGND

18

CC

AV

17

DSCH

AGC

PTIM

Interface

Processing

Analog Signal

Sensor Interface

Test pin

Analog Signal

Processing Interface

White Basic Supply Voltage

Middle Basic Supply Voltage 3

Middle Basic Supply Voltage 2

Middle Basic Supply Voltage 1

Black Basic Supply Voltage

Analog Signal

Processing Interface

NC: No Connection

1

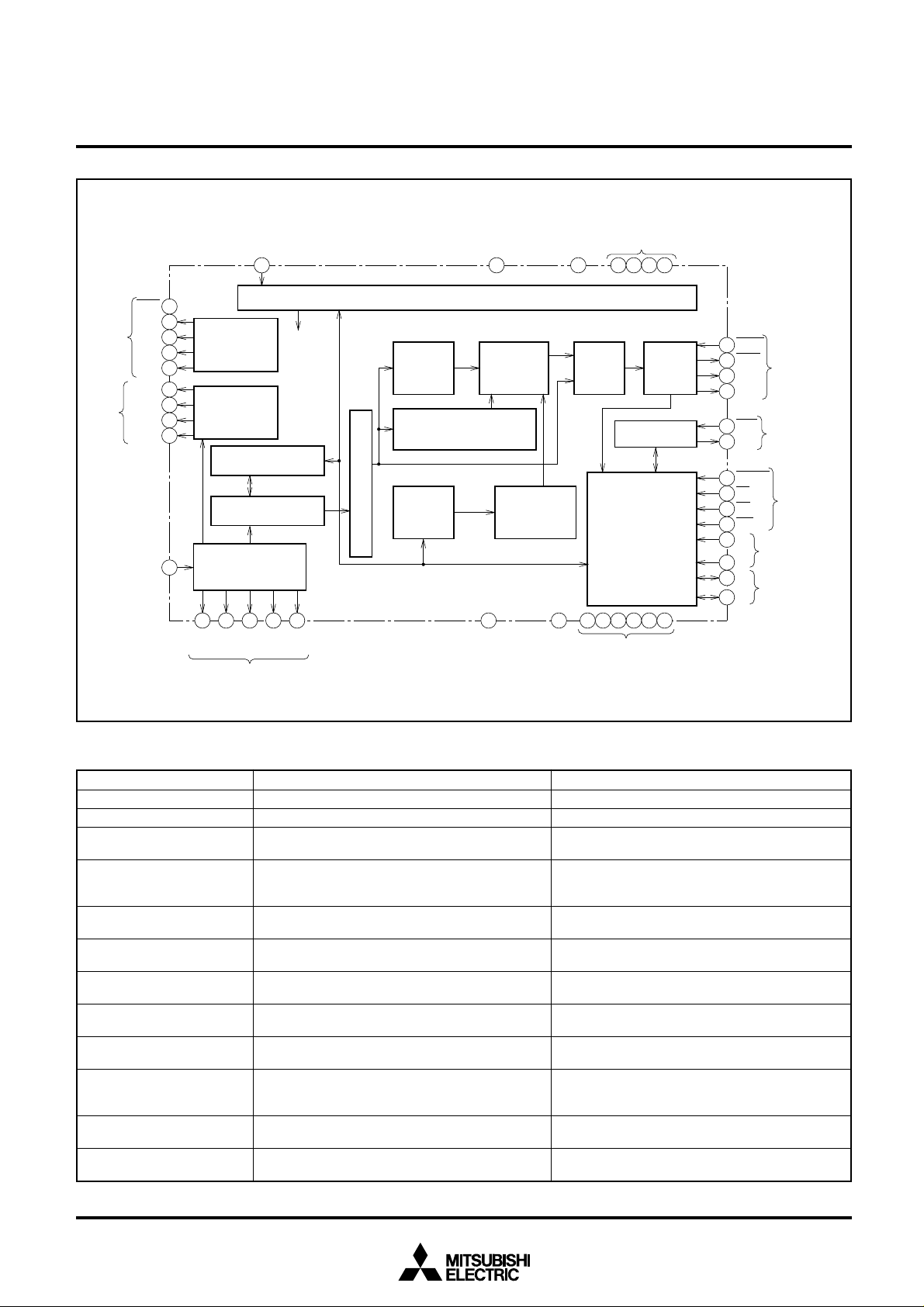

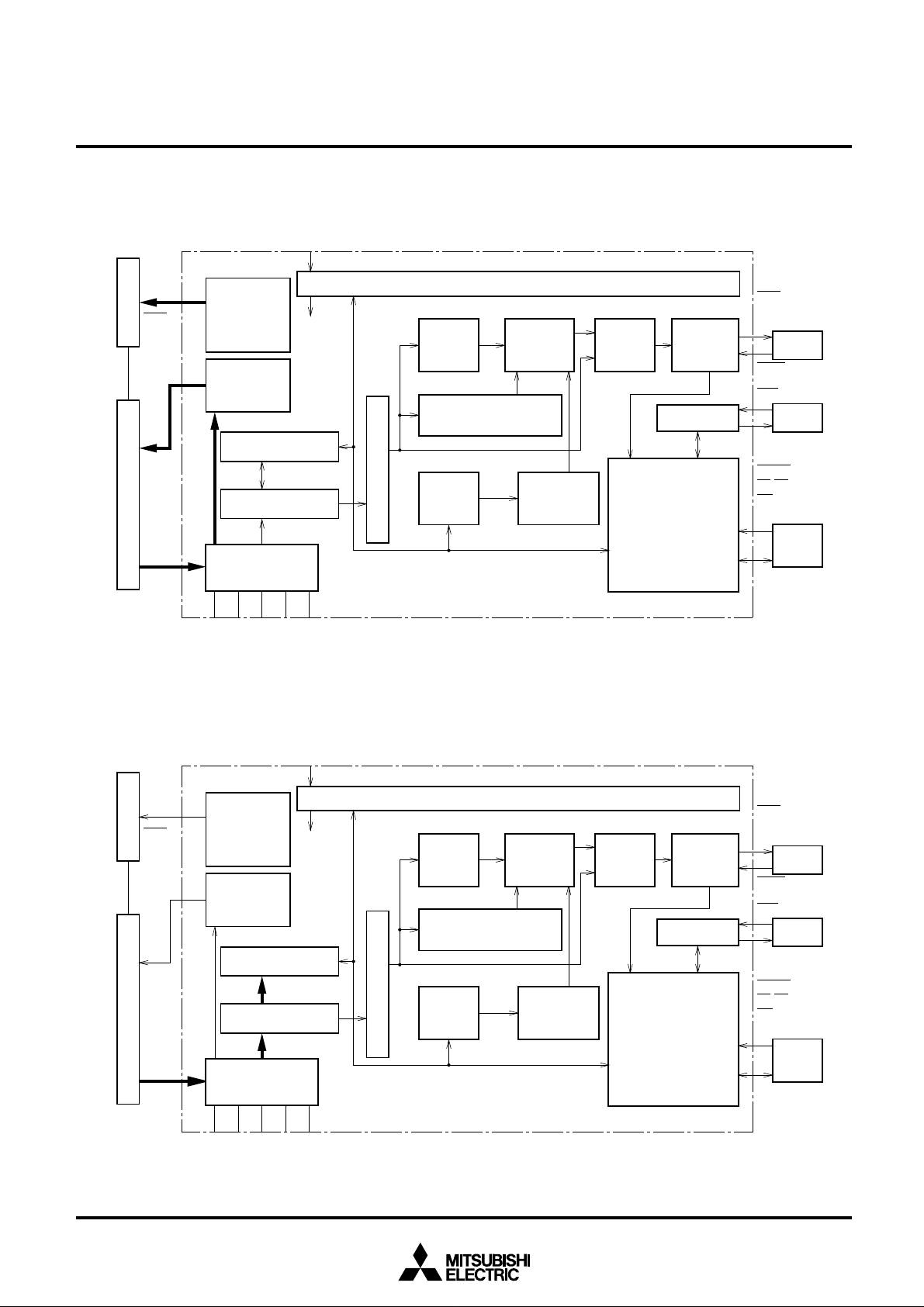

BLOCK DIAGRAM

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

Sensor

Interface

Analog

Signal

Interface

ASIG

System Clock ADC Analog

SYSCK

15PTIM

56SH

2CK1

Sensor Control

1CK2

3RS

4CLAMP

5S/H

Analog Control

16AGC

17DSCH

Correction memory

(304 words × 5bits)

Uniformity Correction

5bit A-D converter

27

(flash type)

20

21

23

V

BL

V

ML2

V

ML1

ADC Reference Voltage

8

24

V

ML3

To each

block

25

V

WL

Vcc

AV

CC

18

Image Processing Sequence Control Signal

Detection

of Image

Data Area

Simple Bi-level

Conversion/Background

and object Level Detection

SRAM 16

words

× 4bits

MTF compensation

Separation

of Image

Data Area

Collective

Dithering

(16 levels)

AGND

ADC

Analog GND

ADC Logic

DV

DGND

ADC

Logic GND

Vcc

CC

29

Convert

bi-level

V

CC

10 35 46 55

to

DMA Control

MPU Bus Interface

GND

Cur out/

Scale

down

525145362263019

14 SRDY

13 STIM

12 SCLK

11 SVID

54 DAK

53 DRQ

50 RESET

47 CS

48 RD

49 WR

MPU

31 A0

~~

Interface

34 A3

(Address)

37 D0

MPU

Interface

44 D7

(Data)

CODEC

Interface

DMA

Interface

MPU

Interface

Table 1 Image Processing Functions

Image Processing Function

Read Width

Resolution

Read speed

Uniformity Correction

MTF Compensation

Simple Bi-level Conversion

Pseudo half-tone

Separation of Image Data

Area

Scale down

γ Correction

Image Sensor Control Signal

Analog Signal Processing

• A4, B4, A3

• 8 pixels/mm (primary scanning direction)

• 5ms/line Typ. 2ms/line maximum

• White correction only

• Block correction in units of 8 pixels

• 50% Correction range

• Laplacian filter circuit for 3 × 1 pixels in current line

(1 dimension)

• Floating threshold method using background and

object level detection circuit

• Dither method: 16 levels (4 × 4matrix)

• Detection by brightness difference in 5 × 1 pixels

area in current line

• Selection method • Scale down: A3 → B4 set

to 13/15; B4 → A4, 9/11; A3 → A4, 12/17

• Logarithmic correction

• Control signal generation for contact sensor (CIS)

and scale down CCD

• Generate control signals for external CLAMP

circuit, sample/hold circuit, and AGC circuit

Specifications

Remarks

• Operated with system clock and PRE_DATA

(registers 2, 3)

• Built-in SRAM as correction memory (304 words ×

5bits) (read/write allowed from MPU)

• No need for compensation memory

• Built-in SRAM as dither memory (16 words × 4bits)

(read/write allowed from MPU)

• No need for processing memory

• Apply external voltage (resistor connection is also

allowed) to A-D converter middle basic supply

voltage pins.

• Built-in 5-bit flash A-D converter

2

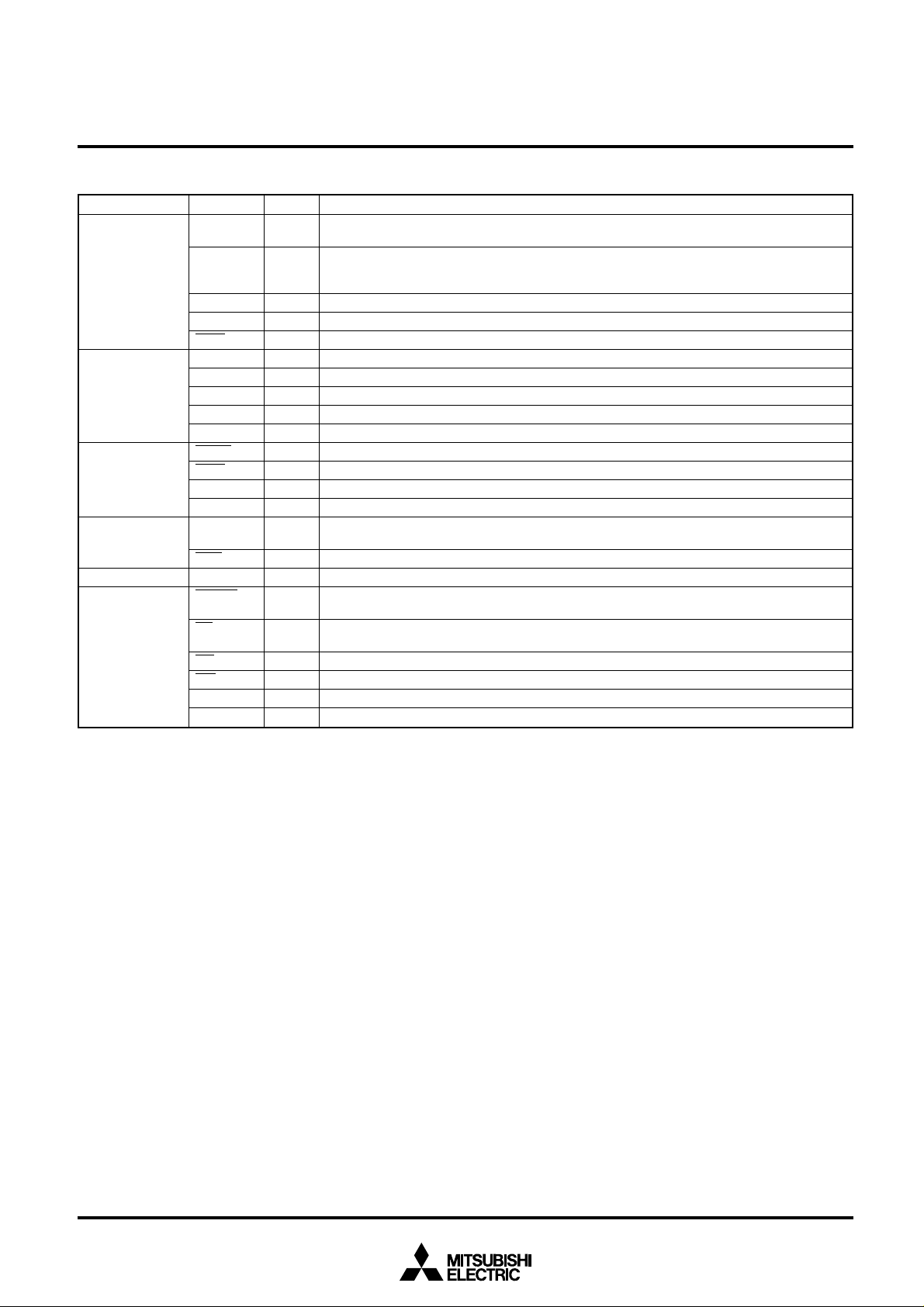

PIN DESCRIPTIONS

Block

Sensor Interface

Analog Circuit

Interface

CODEC Interface

DMA Interface

Clock

MPU Interface

Pin Names

SH

CK1

CK2

RS

PTIM

CLAMP

S/H

ASIG

AGC

DSCH

SRDY

STIM

SCLK

SVID

DRQ

DAK

SYSCK

RESET

CS

RD

WR

A0~A3

D0~D7

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

I/O

CCD: Shift pulse signal to transmit photo charges from the sensor to the transfer unit.

O

CIS: Start signal for the sensor read circuit.

CCD: Clock pulse signal for sequentially transmitting the transfer unit signal charge of the

O

sensor.

CIS: Clock pulse signal for the sensor read circuit shift register.

Reverse of CK1.

O

Pulse to reset the voltage of the CCD sensor floating capacitor to initial status.

O

Read roller pulse motor control signal.

O

CLAMP pulse to set the dark level of the sensor to reference voltage of the digital circuit.

O

Sample-hold signal to smooth out sensor image signal waveform.

O

Analog signals.

I

External AGC circuit gain down signal.

O

External AGC circuit gain up signal.

O

Data transmission ready signal from CODEC.

I

Data transmission bound signal for CODEC.

O

Clock signal for transmitting image data to CODEC.

O

Serial output of image data to CODEC. “H”: Black; “L”: White.

O

DMA request signal to external DMA controller for parallel output of image data through MPU

O

bus.

DMA acknowledge signal from external DMA controller for the above DRQ signal.

I

System clock input pin.

I

System reset signal. Resets counter, register, F/F, and latch, sets internal memory in standby

I

mode, and halts clock generation circuit.

Chip select signal used by MPU to access M66332. Set to “H” in operating mode (AGC, UNIF,

I

SCAN).

Control signal used by MPU to read data from M66332.

I

Control signal used by MPU to write data to M66332.

I

Address signals used to access M66332 internal registers.

I

8-bit bidirectional buffer.

I/O

Description

3

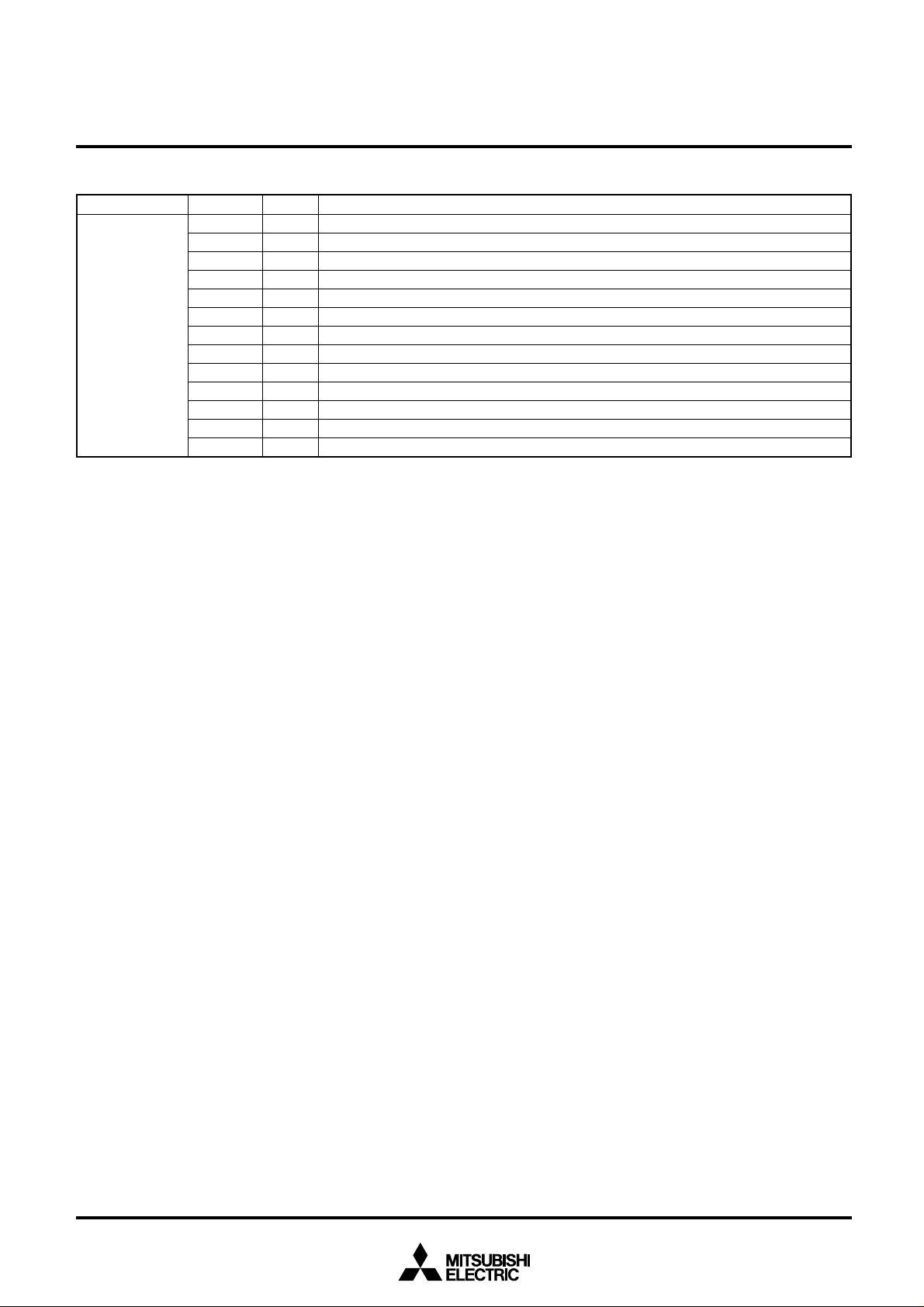

PIN DESCRIPTIONS (CONTINUED)

Block

Others

Pin Names

VCC

AVCC

DVCC

GND

AGND

DGND

VWL

VBL

VML1

VML2

VML3

TEST(IN)

TEST(OUT)

I/O

––

––

––

––

––

––

––

––

––

––

––

––

––

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

Description

Plus supply voltage.

Plus supply voltage for A-D converter analog units.

Plus supply voltage for A-D converter logic units.

GND pin.

Ground for A-D converter analog units.

Ground for A-D converter digital units.

A-D converter white basic supply voltage pin.

A-D converter black basic supply voltage pin.

Middle basic supply voltage pin. VML1 =(VWL – VBL) /4

Middle basic supply voltage pin. VML2 =2 ·(VWL – VBL) /4

Middle basic supply voltage pin. VML3 =3 ·(VWL – VBL) /4

Test input pin. Fix to “L”.

Test output pin. Keep open.

FUNCTIONAL DESCRIPTION

The following items which are necessary to use the image

processing functions of the M66332 are described.

(1)Operating mode

(2)Line period and read sequence

(3)Image processing function

(4)Sensor unit/analog signal processing unit interface

(5)CODEC interface

(6)Read/write to dither memory and uniformity correction

memory

(7) Reset

(8)Image quality control using registers

4

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

(1)Operating mode

The M66332 performs three basic operations.

• Peak value detection: The peak value of the analog signal

output from the analog signal processing circuits is

matched to the white reference voltage (V

M66332 internal A-D converter. (See also Figs. 19 to 22 in

the M66333FP document.)

• Uniformity correction data creation: White reference data is

created for sensor unit uniformity correction and written to

the correction memory (SRAM: 304 words × 5bits).

• Read operation: A document is read and the image is processed to output bi-level data as serial or parallel output.

These three basic operations are performed in the following

sequence depending on whether the sensor is CCD or CIS.

The sensor is selected with register 0 (SENS).

When the sensor is CCD:

UNIF mode Operation is started by setting the

UNIF command in register 0 to “H”.

If the sensor is CCD, peak detection

(16 line periods) and white uniformity correction data creation (8 line

periods) are performed consecutively.

To exit this operating mode, wait 30

line periods (at least 24 lines) from

the start and set the UNIF command

to “L”.

v

SCAN mode The read operation is started by set-

ting the SCAN command in register

0 to “H”.

Set the SCAN command to “L” to exit

this operation mode.

WL) of the

When the sensor is CIS:

(Creation and transmission of uniformity correction data)

UNIF mode This mode is started when the UNIF

command in register 0 is set to “H”.

When the sensor is CIS, if white correction is started with the UNIF command, peak detection (16 line

periods) and uniformity white correction data creation (8 line period) are

started.

To exit this operating mode, wait 30

line periods (at least 24 line periods)

from the start and set the UNIF command to “L”.

v

Data transfer The uniformity correction data per-

taining to white correction created in

UNIF mode are transferred to the

backup memory.

(Read operation)

AGC mode Peak detection is performed for 16

line periods when the AGC command in register 0 is set to “H”.

To exit this operating mode, wait 20

line periods (at least 16 lines) from

the start and set the AGC command

to “L”.

v

SCAN mode The read operation is started by set-

ting the SCAN command in register

0 to “H”.

Set the SCAN command to “L” to exit

this operating mode.

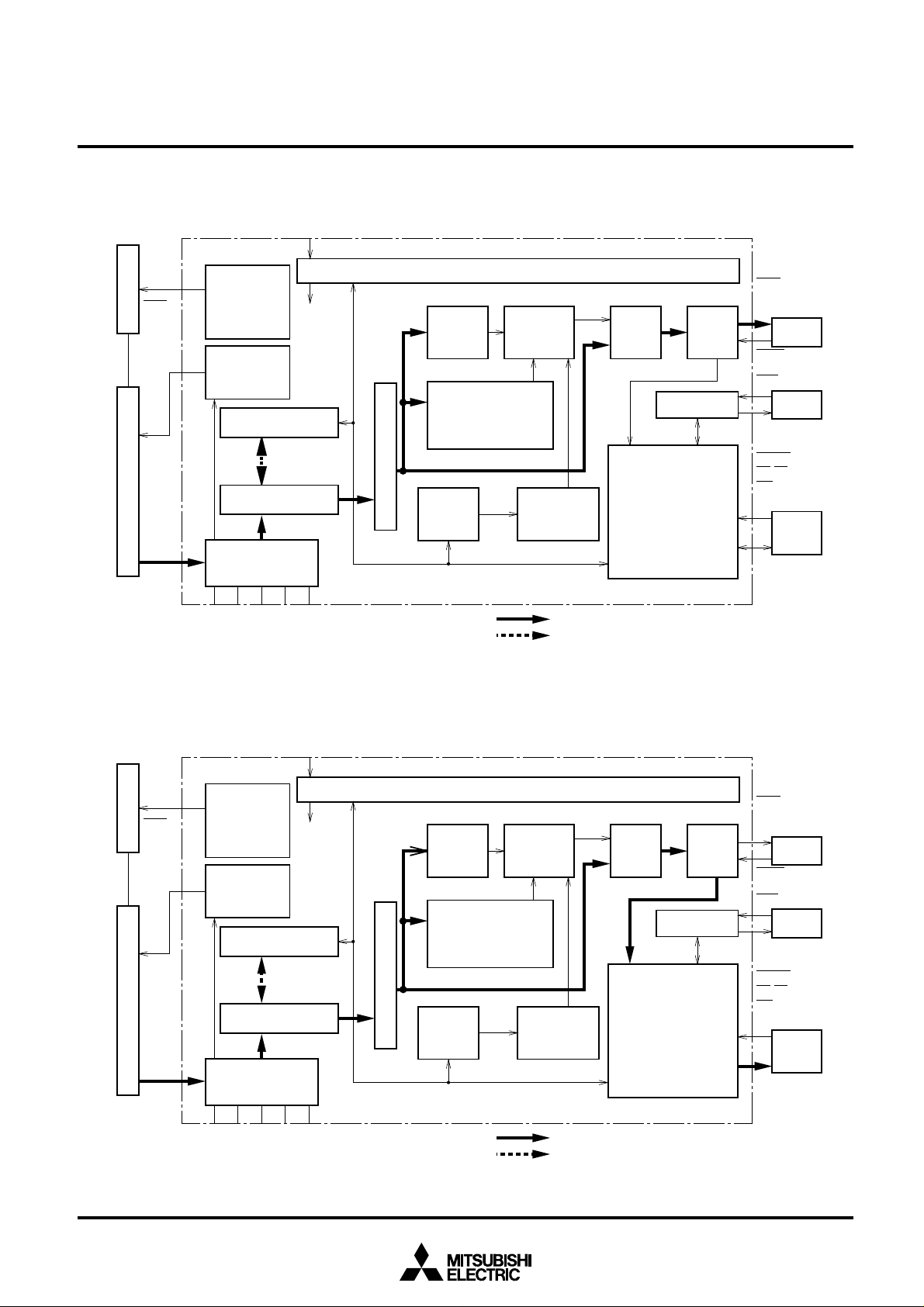

The signal functions and data flow in each mode are shown

on pages 4–123 and 4–124. Flowcharts are shown on pages

4-158 to 4–160.

5

Operation During Peak Detection

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

SYSCK

Image Processing Sequence Control Signal

PTIM

SH

Image sensorAnalog signal processing circuit

CK1

CK2

RS

CLAMP

S/H

AGC

DSCH

ASIG

Sensor Control

Analog Control

Correction memory

(304 words × 5bits)

Uniformity Correction

5bit A-D converter

(flash type)

VBL

VML2

VML1

VML3

To each

block

Resolution compensation

VWL

Data Flow in Creation of Uniformity Correction Data

Detection

of Image

Data Area

Simple Bi-level

Conversion/Background

and object level detection

SRAM 16

words

× 4bits

Separation

of Image

Data Area

Collective

Dithering

(16 levels)

Convert to

bi-level

DMA Control

MPU Bus Interface

Cut out/

Scale down

STIM

SCLK

SVID

CODEC

SRDY

DAK

DMA

DRQ

RESET

CS,RD

WR

A0~A3

MPU

D0~D7

SYSCK

PTIM

SH

Image sensorAnalog signal processing circuit

CK1

CK2

RS

CLAMP

S/H

AGC

DSCH

ASIG

Sensor Control

Analog Control

Correction memory

(304 words × 5bits)

Uniformity Correction

5bit A-D converter

(flash type)

VBL

VML2

VML1

VML3

To each

block

VWL

Image Processing Sequence Control Signal

Detection

of Image

Data Area

Simple Bi-level

Conversion/Background

and object level detection

SRAM 16

words

MTF Compensation

× 4bits

Separation

of Image

Data Area

Collective

Dithering

(16 levels)

Convert to

bi-level

DMA Control

MPU Bus Interface

Cut out/

Scale down

STIM

SCLK

SVID

CODEC

SRDY

DAK

DMA

DRQ

RESET

CS,RD

WR

A0~A3

MPU

D0~D7

6

Date Flow During Read Operation (for serial output)

SYSCK

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

Image Processing Sequence Control Signal

PTIM

SH

Image sensorAnalog signal processing circuit

CK1

Sensor Control

To each

block

CK2

RS

Analog Control

Correction memory

(304 words × 5bits)

CLAMP

S/H

AGC

DSCH

Uniformity Correction

SRAM 16

MTF Compensation

5bit A-D converter

V

BL

V

(flash type)

V

ML2

ML1

V

ML3

V

WL

ASIG

Date Flow During Read Operation (for parallel output)

Detection

of Image

Data Area

Simple Bi-level

Conversion/

Background

and object

level detection

words

× 4bits

Separation

Convert

of Image

Data Area

Collective

Dithering

bi-level

MPU Bus Interface

(16 levels)

: Image date

: Correction, Compensation date

to

Cut out/

Scale

down

DMA Control

STIM

SCLK

SVID

CODEC

SRDY

DAK

DMA

DRQ

RESET

CS,RD

WR

A0~A3

MPU

D0~D7

SYSCK

PTIM

SH

Image sensorAnalog signal processing circuit

CK1

Sensor Control

CK2

RS

Analog Control

Correction memory

(304 words × 5bits)

CLAMP

S/H

AGC

DSCH

Uniformity Correction

5bit A-D converter

V

BL

V

(flash type)

V

ML2

ML1

V

ML3

ASIG

To each

block

V

WL

Image Processing Sequence Control Signal

Detection

of Image

Data Area

Separation

of Image

Data Area

Simple Bi-level

Conversion/

Background

and object

level detection

SRAM 16

words

Resolution compensation

× 4bits

Collective

Dithering

(16 levels)

: Image date

: Correction, compensation date

Convert

to

bi-level

Cut out/

Scale

down

DMA Control

MPU Bus Interface

STIM

SCLK

SVID

CODEC

SRDY

DAK

DMA

DRQ

RESET

CS,RD

WR

A0~A3

MPU

D0~D7

7

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

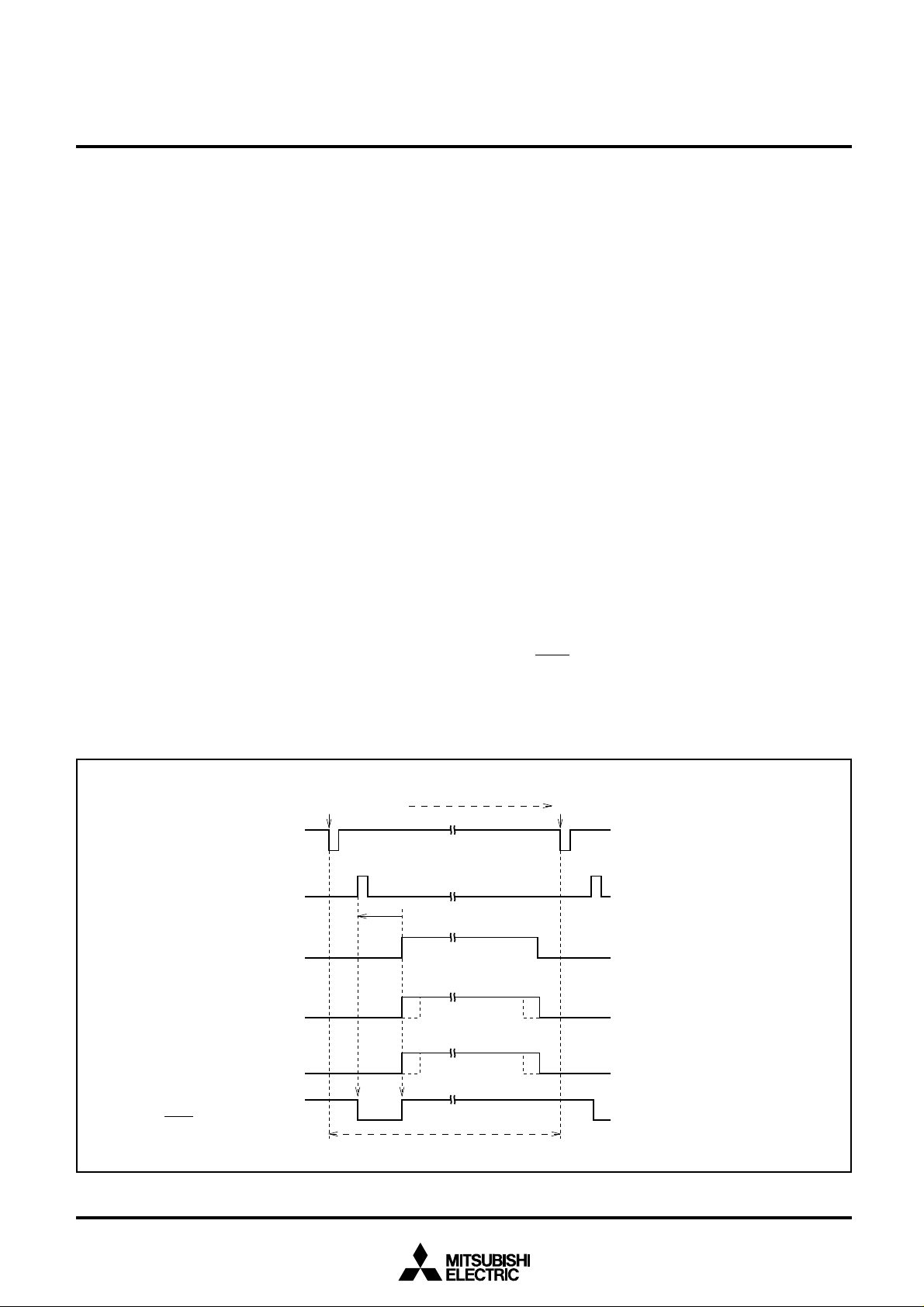

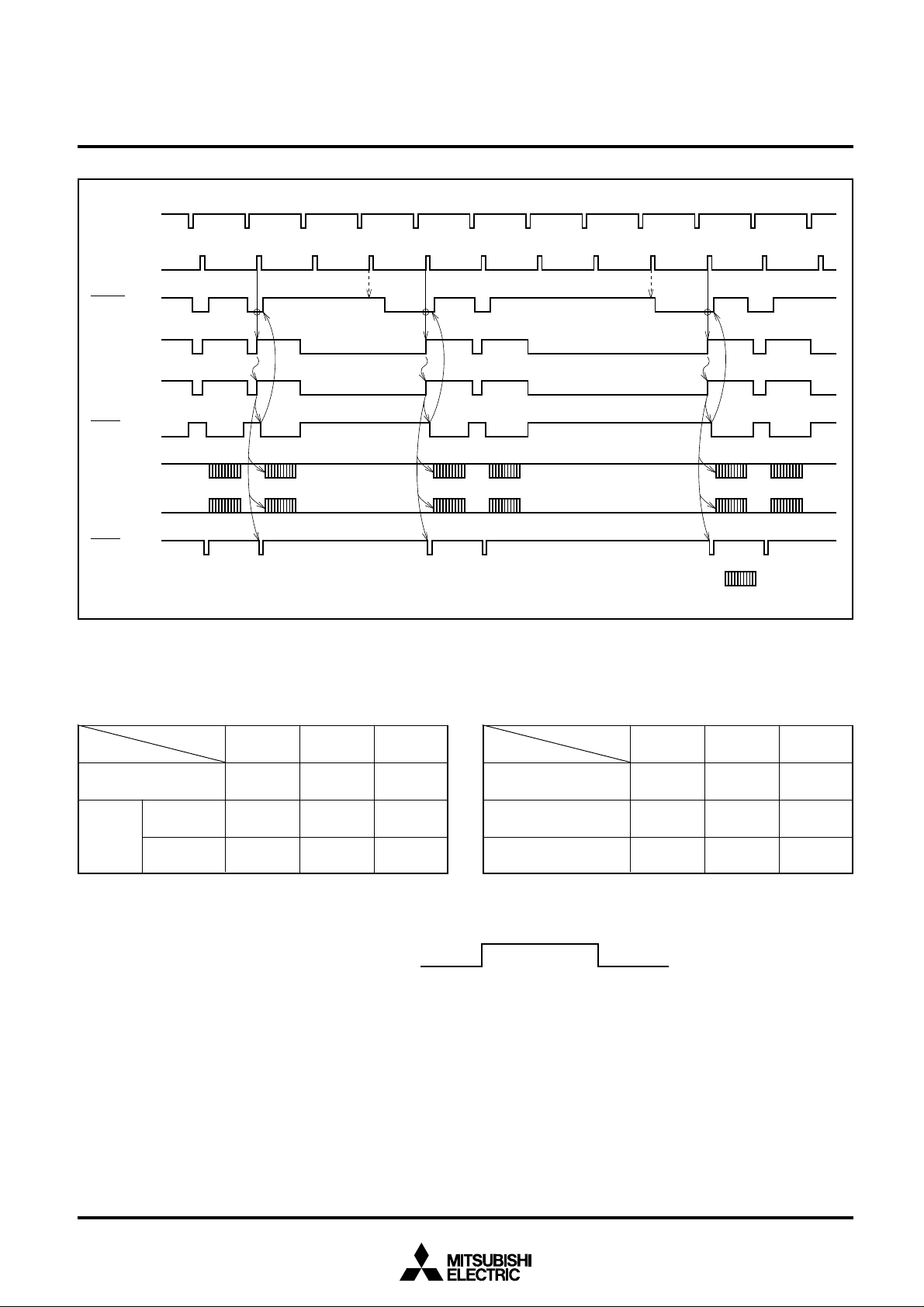

(2)Line period and read sequence

Figure 1 shows the relationship between the M66332 line

period and the read sequence.

• 1 line period (1/ACCK): Defines the processing time per

line for M66332. The line period is

determined from the line period

counter registers 2 and 3

(PRE_DATA) and pixel transmission clock (ADCK). ADCK is 1/

16th of SYSCK.

1 line period (1/ACCK) [NS]

= line period counter × pixel transmission clock period [NS]

= (PRE_DATA + 1) × 1/ADCK [NS]

= (PRE_DATA + 1) × 16/SYSCK [NS]

The line period counter is

counted down with the pixel

transmission clock after loading

the PRE_DATA value and generates the following addresses.

• Sensor start pulse (SH): Image sensor start pulse. The position of the start pulse is determined by the value in register 4

(ST_PL) which is the offset from

the uniformity correction range

(UNIFG).

Set ST_PL to the following values

according to the type of image

sensor.

CCD: ST_PL = sensor dummy

pixel + 2

CIS: ST_PL =2

• Uniformity correction

range (UNIFG):

• AGC range (AGCG):

• Source document read

width:

• Pulse motor control

signal (PTIM):

Defines the uniformity correction

range. This range corresponds to

the sensor width (A3 to A4).

Refer to Table 2 for the relationship between sensor width and

uniformity correction range.

Defines the peak detection range.

This range corresponds to the

sensor width (A3 to A4).

Auto gain control is performed for

the entire width (solid line) of the

sensor in AGC mode and for the

range inside the sensor width

(dotted line) in SCAN mode.

Refer to Table 2 for the relationship between sensor width and

AGC range.

Defines the source document

read width.

If the document width is less than

the sensor width, the document

should be centered on the sensor

because the read range is set

from the center of the sensor.

Refer to Table 3 for the relationship between sensor width and

source document read width.

Generates the pulse motor control signals for the read roller.

PRE_DATA load 0

Line period

(ACCK)

Sensor start

pulse

(SH)

Uniformity correction

range

(UNIFG)

AGC range

(AGCG)

Source document

read width

Pulse motor

control

(PTIM)

Fig. 1 Line period and read sequence

ST_PL

Down count

1 line period

Relationship with registers

Registers 2, 3

(PRE_DATA)

Register 0 (SENS_W)

Register 4 (ST_PL)

Register 0 (SENS_W)

Register 0 (SENS_W)

Register 1 (SOURCE)

Register 1

(SOURCE, DEST , REDU)

8

1 line period

(ACCK)

Sensor start

pulse (SH)

SRDY

(SSCAN)

(BCSCAN)

STIM

SCLK

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

SVID

PTIM

Fig. 2 CODEC Interface and read sequence

Table 2 Sensor width and gate signal range

Sensor width

Gate signal

Uniformity correction

range (UNIFG)

AGC

range

(AGCG)

AGC mode

SCAN mode

A3

2487/55

2487/55

2370/162

2279/231

2279/231

2194/306

X : Left end address

Y : Right end address

B4

A4

2119/391

2119/391

1760/740

: Output bound(SSCAN), (BCSCAN) : Internal signals

Table 3 Source document read width according to

sensor width and source document size

Sensor width

Source document size

A3

B4

A4

XYX / Y

A3

2487/55

2278/230

2118/390

B4

––

2278/230

2118/390

2118/390

A4

––

––

9

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

(3)Image processing function

The M66332 converts image signals from the image sensor

to bi-level signals. Bi-level conversion can be either simple bilevel conversion or pseudo half-tone conversion which converts image shades into bi-levels.

The signal output from the image sensor must be corrected

and compensated to reduce distortion and degradation before it can be converted to bi-level signals.

Furthermore, for reduction in transmission time, separation of

image data area and optimum bi-level conversion must be

performed.

The functions necessary for image processing are described

below.

• Peak detection

• Uniformity correction

• MTF compensation

• Background and object level detection (simple bi-level conversion)

• Pseudo half-tone

dither method

• Separation of image data area

• Image scale down/area specification

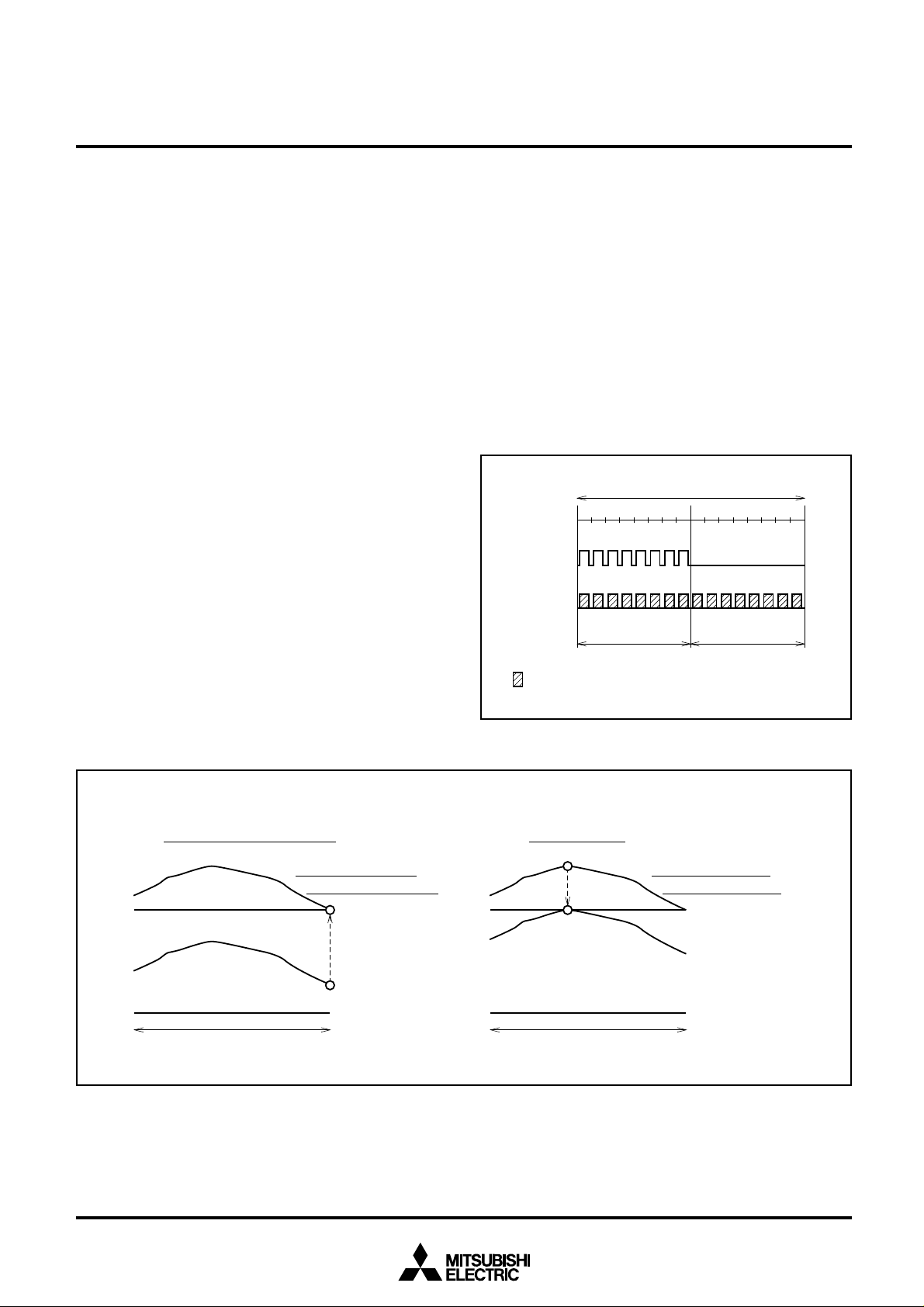

• Peak detection

The A-D converter of the M66332 is used with its reference

voltages (V

BL, is set to 0V to keep the dynamic range of the A-D con-

V

WL, VBL) fixed. Normallly, VWL is set to VCC and

verter wide. Peak detection must be performed for analog signals to match them with the full scale value of the A-D

converter before they are input to the A-D converter.

Peak detection is performed by reading white data in AGC

mode, one of the three M66332 operating modes (AGC,

UNIF, SCAN).

In AGC mode, 8-line period worth of DSCH signal to raise

gain—for gain control—and 16-line period worth of AGC signal to lower gain—for the overflowing of the A-D converter—

are generated after AGC command start (register 0: AGC) as

shown in Fig. 3.

This changes the gain as shown in Fig. 4.

Peak detection

Line period

DSCH

(raise gain)

AGC

A-D converter

overflow

(lower gain)

12345678910111213141516

Peak detection

preprocessing

Peak gain control

Peak detection (preprocessing)

After completing peak

detection preprocessing

V

WL

White data

V

BL

1 line

Match the output

level of the last pixel

of a line to V

Fig. 4 Changes in gain during peak detection

WL

: Generated in pixel units only when the A-D converter overflows.

Fig. 3 Peak detection

Peak gain control

V

WL

V

BL

1 line

After completing gain

control for peak value

Match the peak sensor

output within a line toV

WL

10

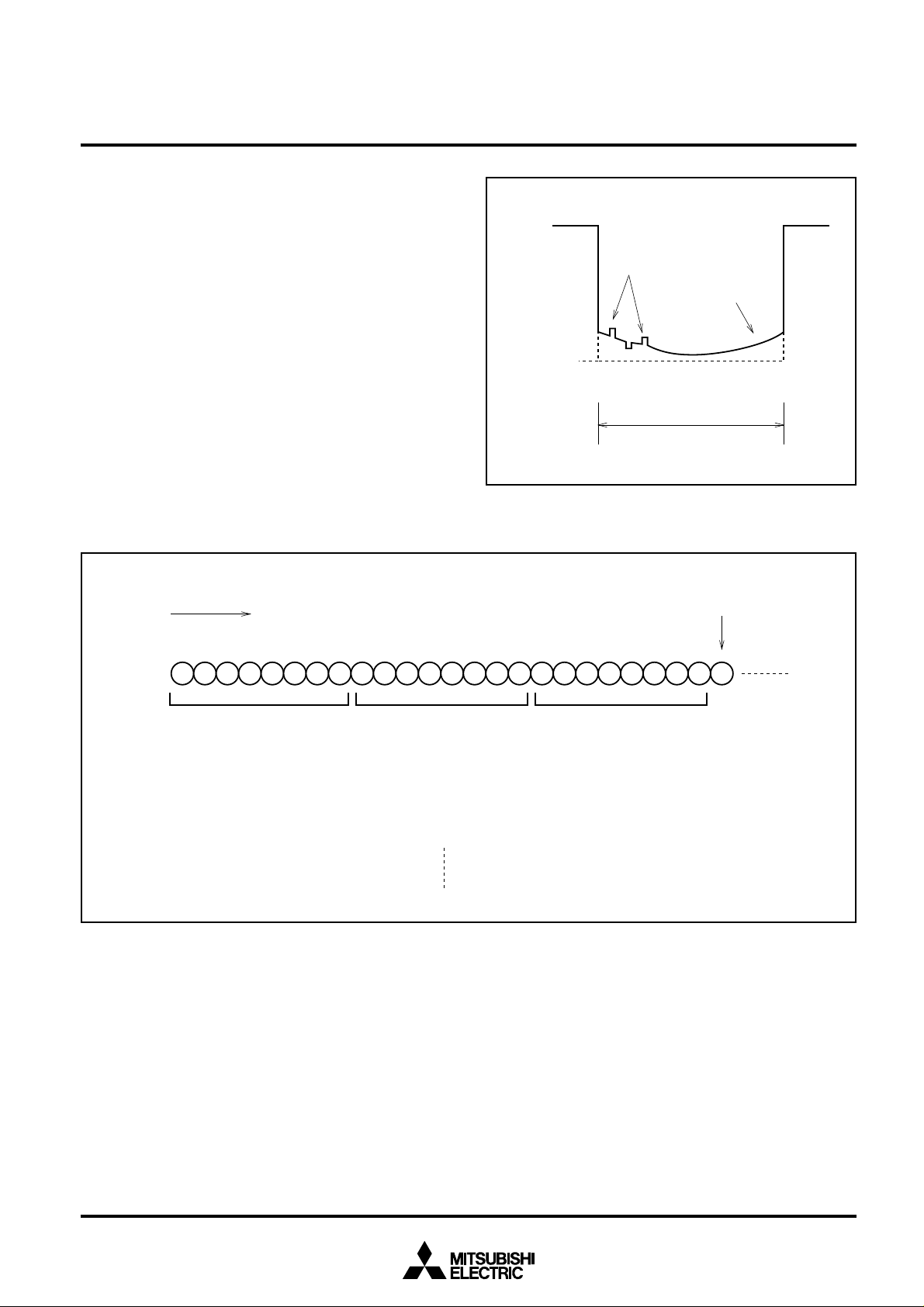

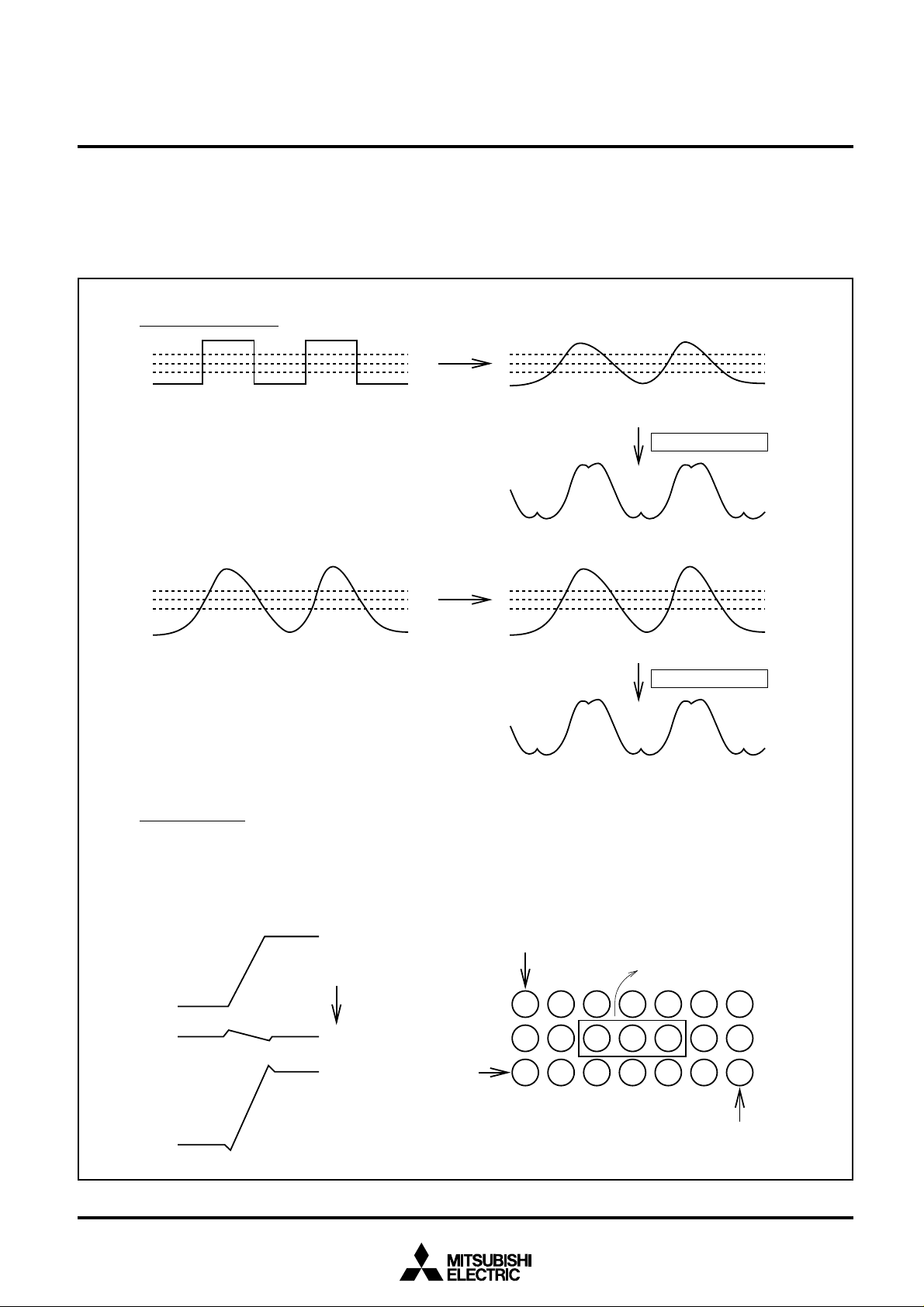

• Uniformity correction

Uniformity correction corrects the drop in lighting level at

both ends of the light source, shading distortion due to drop

in lighting level at the rim of the lens, and high frequency distortion caused by the scattering of pixel-unit image sensor

characteristic (see Fig. 5).

The M66332 creates uniformity correction data in UNIF

mode, one of the three operating modes (AGC, UNIF, SCAN),

handling 8 pixels as a unit as shown in Fig. 6. The created

data is written to the internal correction memory (SRAM: 304

words × 5 bits).

In SCAN mode, the correction data is read from the internal

correction memory to successively correct the input image

data in pixel units.

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

Black level

High frequency

distortion

Shading distortion

White level

1 line

Primary scanning direction

189161724

For pixels from 1 to 8, uniformity correction is carried out by correction data 1.

For pixels from 9 to 16, uniformity correction is carried out by correction data 2.

For pixels from 17 to 24, uniformity correction is carried out by correction data 3.

Fig. 6 Creation of uniformity correction data

Fig. 5 Image sensor white data output waveform

Pixels

Correction data 3Correction data 2Correction data 1

11

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

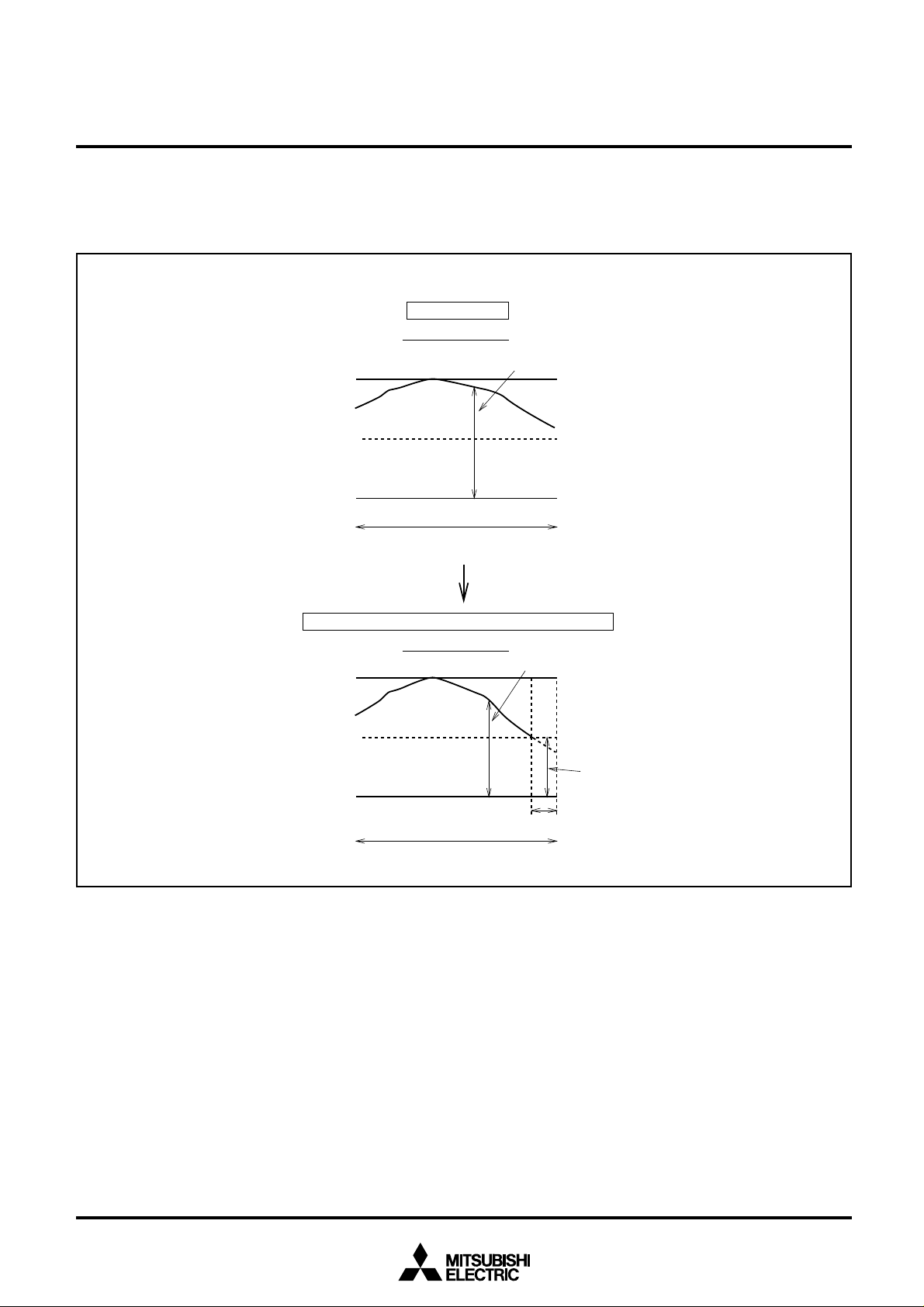

• Correction

The M66332 performs entire pixel correction for 50% correction range as shown in Fig. 7.

White Correction

Analog signal input

V

WL

50%

V

BL

1 line

If correction range is exceeded (during white correction)

Analog signal input

V

WL

Correction is not possible if the white correction data exceeds

the 50% correction range as shown in Fig. 7. Therefore, be

sure to keep the input signal within the correction range.

White data

White data

5

2

-1

4

-1

2

0

5

2

-1

Fig. 7 Uniformity correction

50%

V

BL

1 line

4

-1

2

White data exceeding

correction range

0

Portion exceeding correction range

12

MITSUBISHI 〈DIGITAL ASSP〉

M66332FP

FACSIMILE IMAGE DATA PROCESSOR

• MTF compensation

As shown in Fig. 8, characters and photos that have been

photoelectrically converted by the sensor unit are characterized by a drop in resolution. The MTF compensation per-

Photoelectric conversion

Source document (characters)

formed by the M66332 enhances the high frequency components with a Laplacian filter to maintain the resolution of the

image data and creates a perception of increased dynamic

range.

Photoelectric

conversion

Image signal

MTF compensation

Compensated data

Photoelectric

conversion

Source document (photo)

MTF compensation

Image signal

Compensated data

X’ = X + α ((X – A) + (X – B))

α = Primary scanning compensation coefficient, register 5 (MTF)

Secondary scanning direction

F

G

Primary scanning

direction

Window 3 × 1

AXB

MTF compensation

Fig. 8 MTF Compensation

F–G

Pixel

13

Loading...

Loading...