The M66244FP is a high-speed digitally programmable pulse width modulator (PWM) which

uses high-performance silicon gate CMOS process technology.Output pulse width is

proportional to a 6-bit DATA input value. Two additional CONTROL inputs determine if the

pulse is placed at the beginning , middle ,or end of the clock period. Pulse width and

placement can be changed every clock cycle up to 72MHz.

FEATURES

• Frequency 45MHz to 72MHz

• 6 bit Resolution

• Center, Leading, Trailing Edge Modulation

• Single 3.3V Operation

• JTAG (IEEE Standard 1149.1Test Port)

PRELIMINARY DATA SHEET

DATA BUS

INPUT

PRELIMINARY DATA SHEET

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

High Speed Monolithic Pulse Width Modulator

NOTE:This is not final specification. Some parametric limits are subject to change

DESCRIPTION

APPLICATIONS

• Laser Printers

Gray Scale Capability

Resolution Enhancement

• Copiers

• Optical Disk Drives

• Precision Pulse Placement

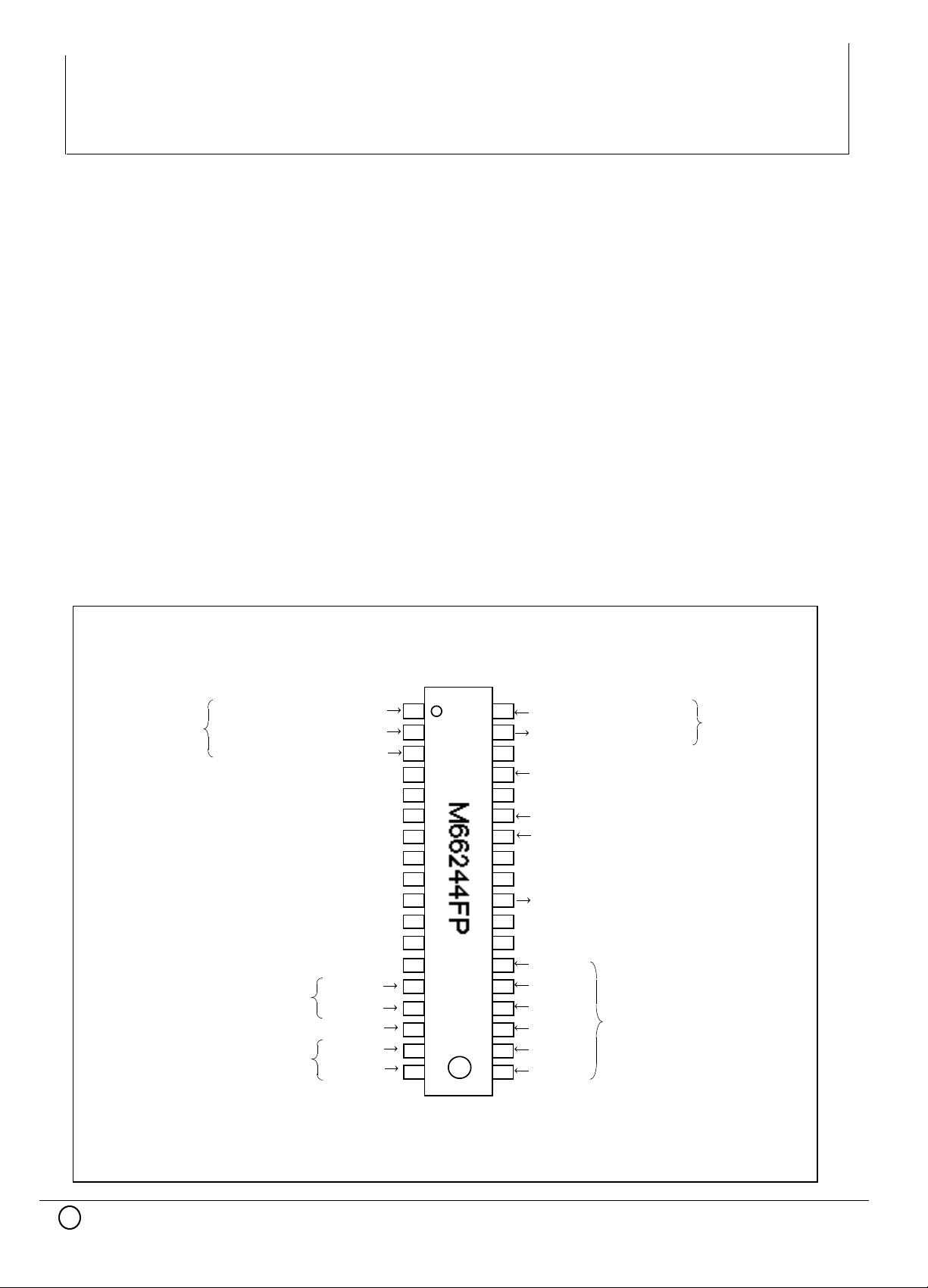

PIN CONFIGURATION (TOP VIEW)

TEST PIN

(JTAG)

TEST CLOCK INPUT

TEST MODE INPUT

FREQUENCY

RANGE SET INPUT

LINE SIGNAL INPUT

PULSE MODE

CONTROL

INPUT

TCK

TMS

TRSTTEST RESET INPUT

GND

VDD

GND

VDD

GND

VDD

GND

VDD

GND

VDD

FRANGE1

FRANGE2

LS

SEM/DEM

LEM/TEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

TDI

35

TDO

34

GND

33

CLK CLOCK INPUT

32

VDD

31

RESET

30

SET

29

VDD

28

GND

27

PWMOUT

VDD

26

GND

25

24

23

22

21

20

19

D0(LSB)

D1

D2

D3

D4

D5(MSB)

TEST DATA INPUT

TEST DATA OUTPUT

RESET INPUT

SET INPUT

TEST PIN

(JTAG)

C 1998 MITSUBISHI ELECTRIC CORPORATION

Outline 36P2R

(1/15)

FRANGE1 and FRANGE2 are set up correspond to

operation frequency range (refer to page 8)

June 1998 Ver.8.0.0

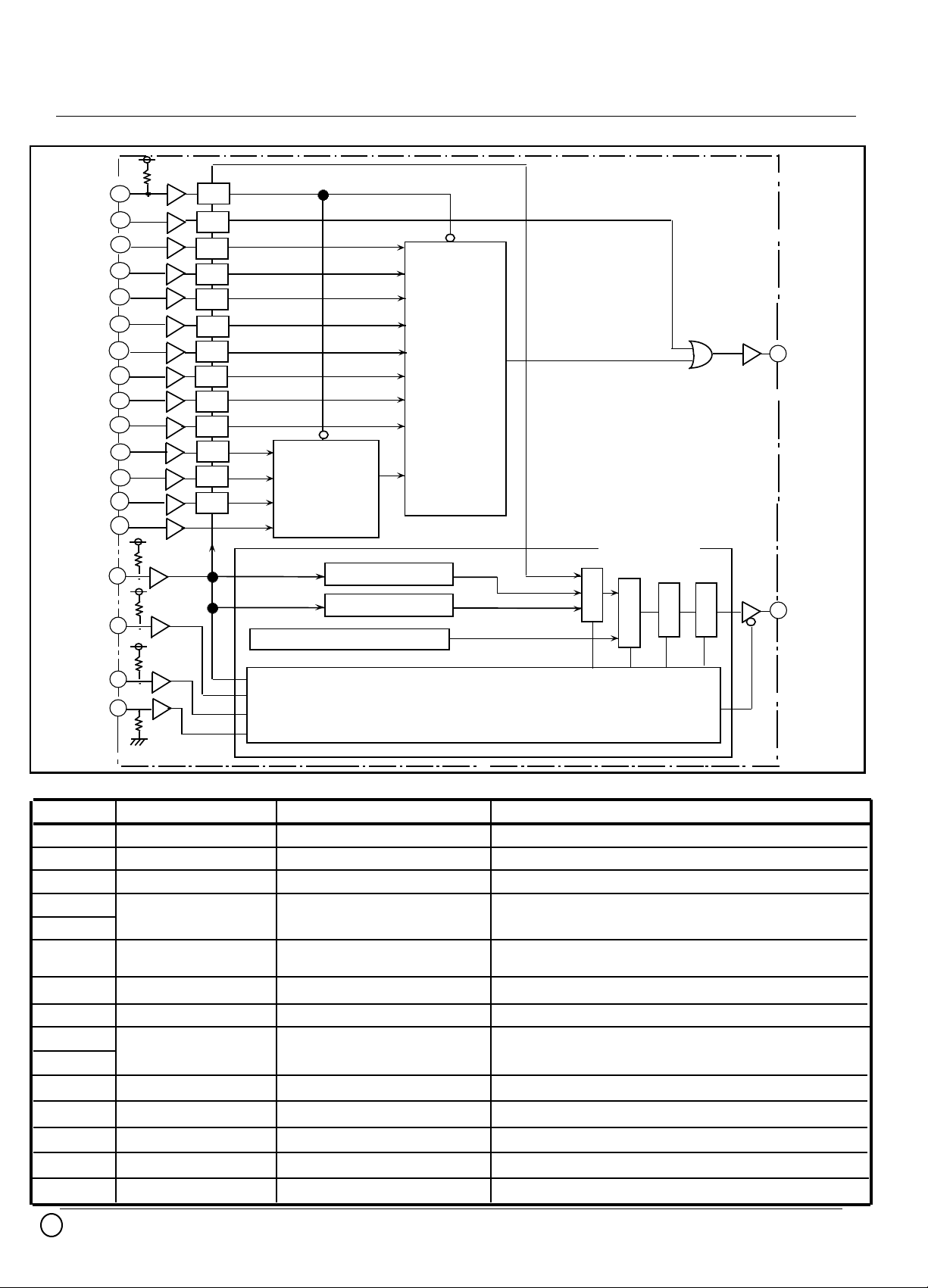

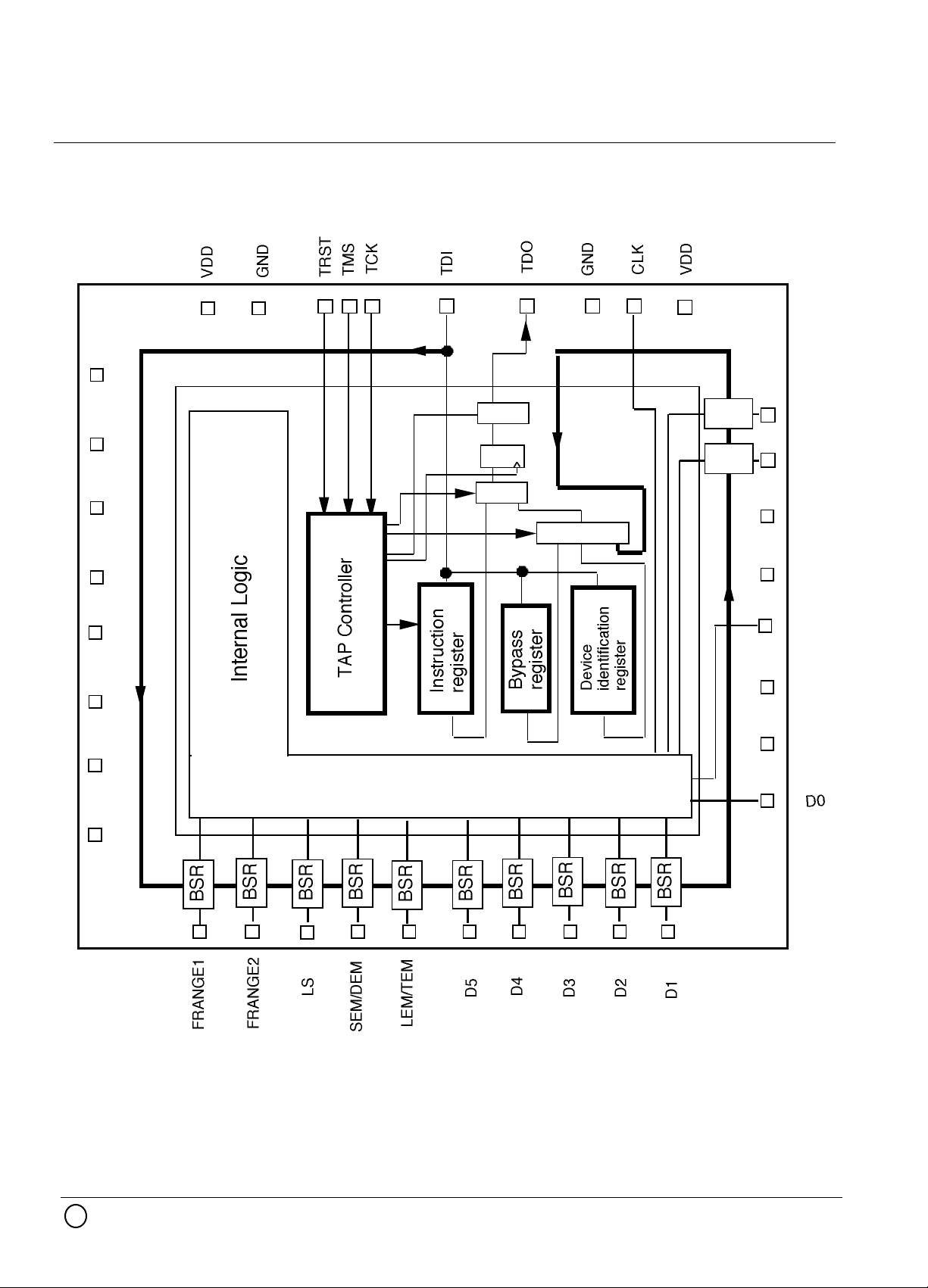

BLOCK DIAGRAM

MITSUBISHI <DIGITAL ASSP>

M66244FP

High Speed Monolithic Pulse Width Modulator

RESET

SET

D0(LSB)

D1

D2

D3

D4

D5(MSB)

LEM/TEM

SEM/DEM

LS

FRANGE2

FRANGE1

CLK

TDI

TRST

31

30

24

23

22

21

20

19

18

17

16

15

14

33

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

BSR

PULSE

GENERATE

CIRCUIT

PULSE WIDTH

and MODE

CONTROL

CIRCUIT

27

PWM OUT

JTAG Block

36

3

Instruction register

ID register

Bypass register

35

TDO

TMS

TCK

2

1

PIN DESCRIPTION

PIN NAME

D0-D5 Digital Data Bit

CLK

PWM OUT

SEM/DEM

LEM/TEM

SET

RESET

LS

FRANGE1

FRANGE2

TRST

TMS

TCK

TDI

TDO

NAME IN/OUT buffer type

Clock input

PWM output

Control output

pulse mode

Set input

Reset input

Line Signal input

Operation Frequency

range set up

Test Reset input

Test Mode Select input

Test Clock input

Test Data In input

Test Data Out output

TAP Contoroller

normal Input

normal Input

normal output

normal Input

normal Input

schmitt Input (Pull-up 50kΩ)

normal Input

normal Input

schmitt Input (Pull-up 50kΩ)

normal Input (Pull-up 50kΩ)

schmitt Input(Pull-down 50kΩ)

normal Input (Pull-up 50kΩ)

3-sate output

DESCRIPTION

6 bit Digital Data from MPU

Dot Clock input

PWM output

Control pin of output pulse mode (refer to page 3)

When SET is "H", PWM output is "H" (direct set )

When SET is "L", PWM output depend on D<5:0>

When RESET is "L", M66244FP is reset to initial state.

refer to page 10

Test Reset input of JTAG test circuit

Test Mode Select input of JTAG test circuit

Test Clock input of JTAG test circuit

Test Data input of JTAG test circuit

Test Data output of JTAG test circuit

C 1998 MITSUBISHI ELECTRIC CORPORATION

(2/15)

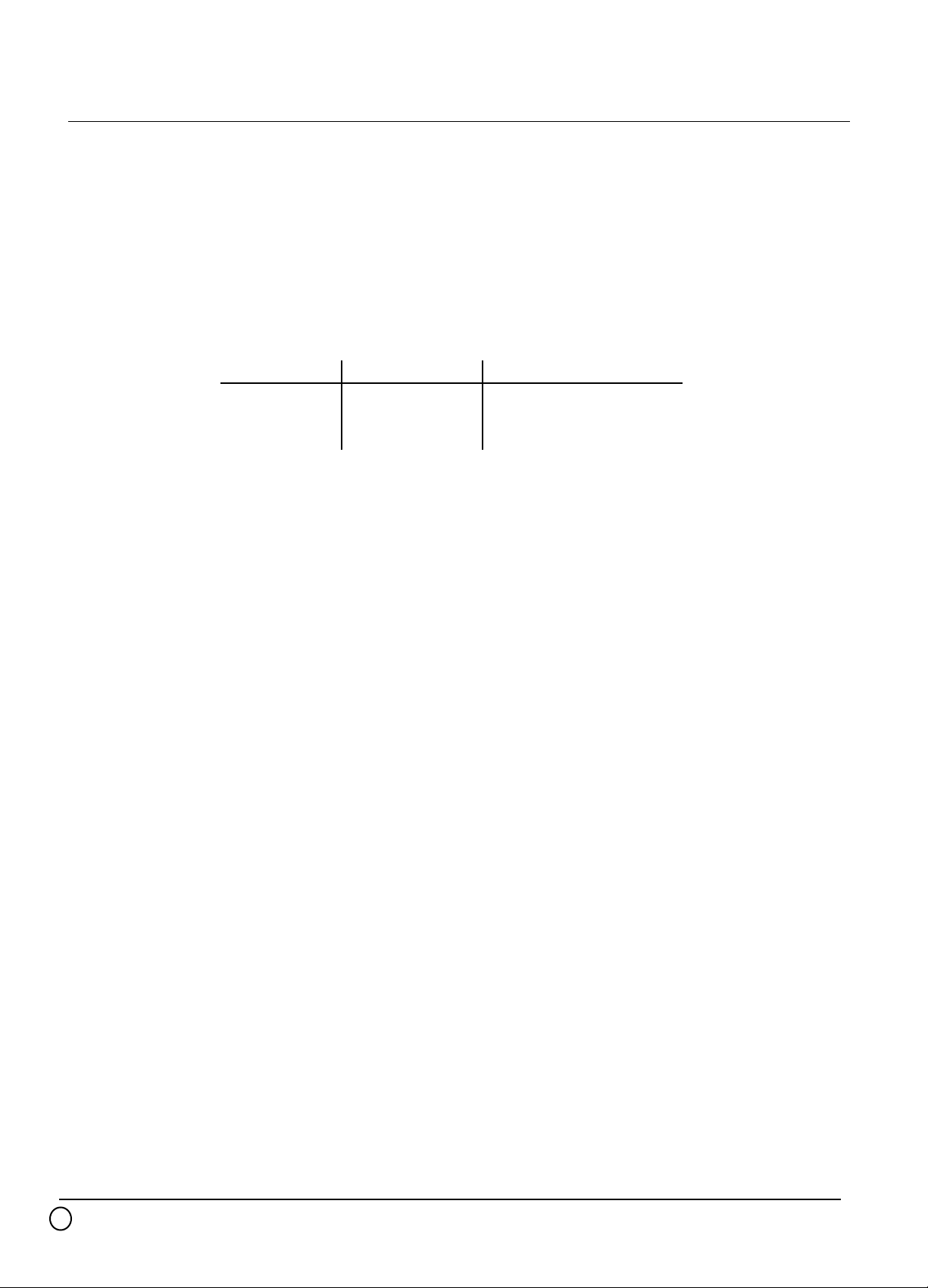

In the third cycle (N+2cycle) , DATA is 0F , SEM/DEM is "L" and LEM/TEM is "X". This means

PWMoutput width is 25% and positioning is center justify.

In the fourth cycle (N+3cycle) , DATA is 2F , SEM/DEM is "H" and LEM/TEM is "L". This

means PWMoutput width is 75% and positioning is left hand justify.

In the fifth cycle (N+4cycle) , DATA is 00 . So the CONTROL value is shown "X" . This means

the value is not important because a 0% pulse will be output for any CONTROL value.

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

FUNCTION

M66244 can control "H" width and positioning of PWM output by DATA pins (D<5:0> ) and

CONTROL pins (SEM/DEM,LEM/TEM) in each CLK period.

These inputs can be updated on the rising edge of the CLK.

Positioning the width-controlled pulse are begging , middle ,or end of the clock period.

This is accomplished through CONTROL pins (SEM/DEM,LEM/TEM)

Pulse positioning within the clock period is defined by the following CONTROL truth table.

SEM/DEM LEM/TEM Alignment

1 1 Right hand justify

1 0 Left hand justify

0 X Center justify

SEM/DEM : single edge modulation / dual edge modulation

LEM/TEM : leading edge modulation / trailing edge modulation

High Speed Monolithic Pulse Width Modulator

The diagram of page4 illustrates the output of the M66244FP with various DATA(D<5:0>) ,

CONTROL(SEM/DEM, LEM/TEM) inputs and PWM output.

This does not take into account any delays,which will explain later.

The rising edge is delayed from the leading edge of the clock, and the falling edge is delayed

from the center of the clock period.

Top line shows the clock; the second shows DATA inputs ; third shows CONTROL inputs

being updated on the rising edge of clock. The forth line shows the resulting PWM pulse with an

explanation of the second and third lines.

In the first cycle (Ncycle) , DATA is 3F . So the CONTROL value is shown as "X". This

means the value is not important because a 100% pulse will be output for any CONTROL value.

In the second cycle (N+1cycle) , DATA is 1F , SEM/DEM is "H" and LEM/TEM is "H". This

means PWMoutput width is 50% and positioning is right hand justify.

C 1998 MITSUBISHI ELECTRIC CORPORATION

(3/15)

June 1998 Ver.8.0.0

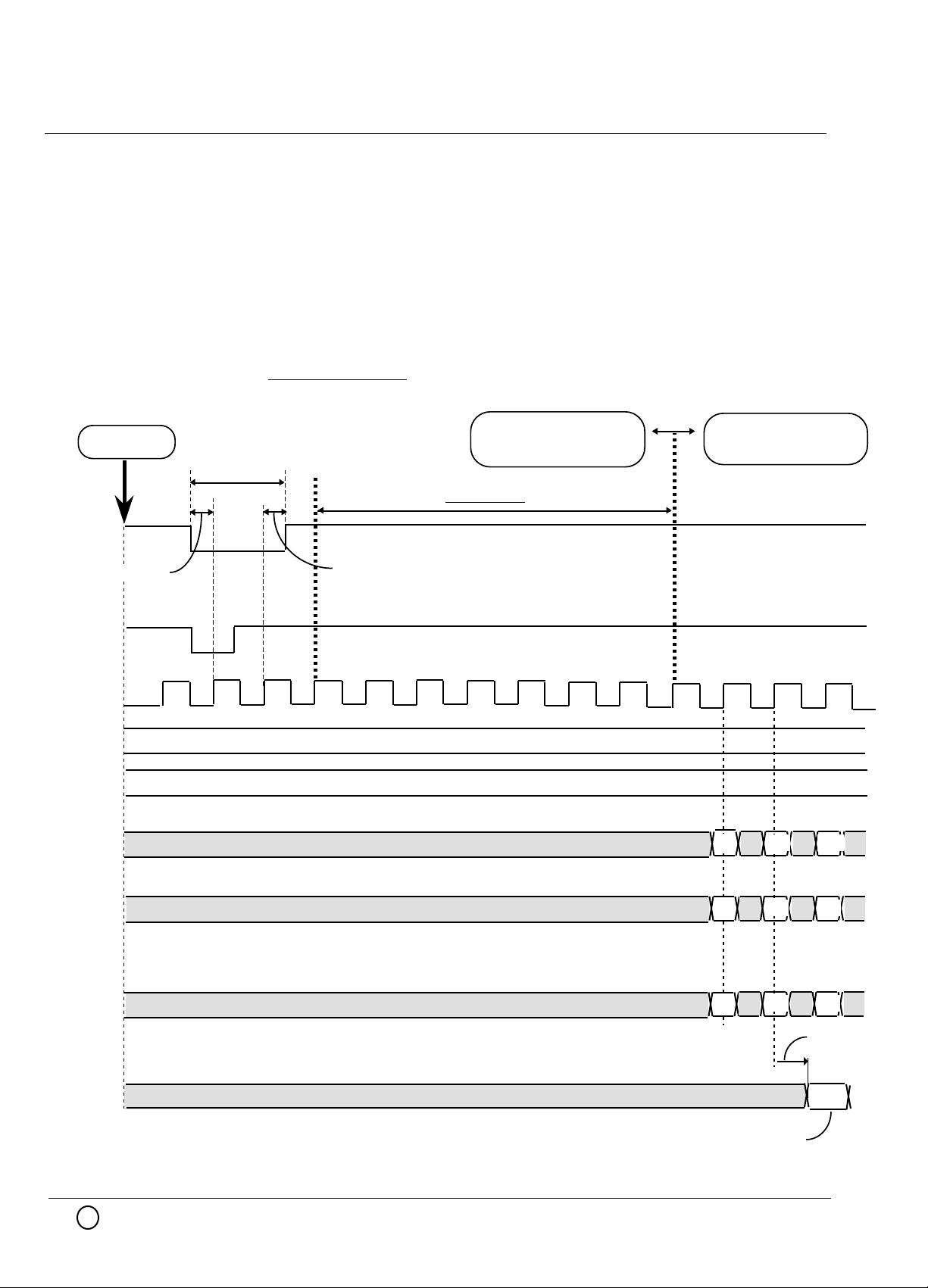

PWM OUTPUT EXAMPLE

MITSUBISHI <DIGITAL ASSP>

M66244FP

High Speed Monolithic Pulse Width Modulator

N N+1

CLK

D<0:5>

SEMDEM

LEM/TEM

PWMOUT

Right hand justify Left hand justify

PWM Pulse linearity (image figure)

N+2

N

100% 50% 25% 75% 0%

N+1 N+2

N+3

2F3F 1F 0F 00 3F

N+4

N+3

Center hand justify

Minimum

"L" Pulse

Width

Minimum

"H" Pulse

Width

CLK

PWMOUT

100

0

(1) In case of next pulse is "H" (2) In case of next pulse is "L"

100

Liner region

Change of linearity

Minimum

"H" Pulse

Width

Liner region

Change of linearity

0

0

"L"

Code (Dec)

"H"

Next Pulse

63

0

"L"

Code (Dec)

Next Pulse

63

"L"

Minimum

"H" Pulse

Width

C 1998 MITSUBISHI ELECTRIC CORPORATION

Minimum

"L" Pulse

Width

Minimum

"H" Pulse

Width

(4/15)

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

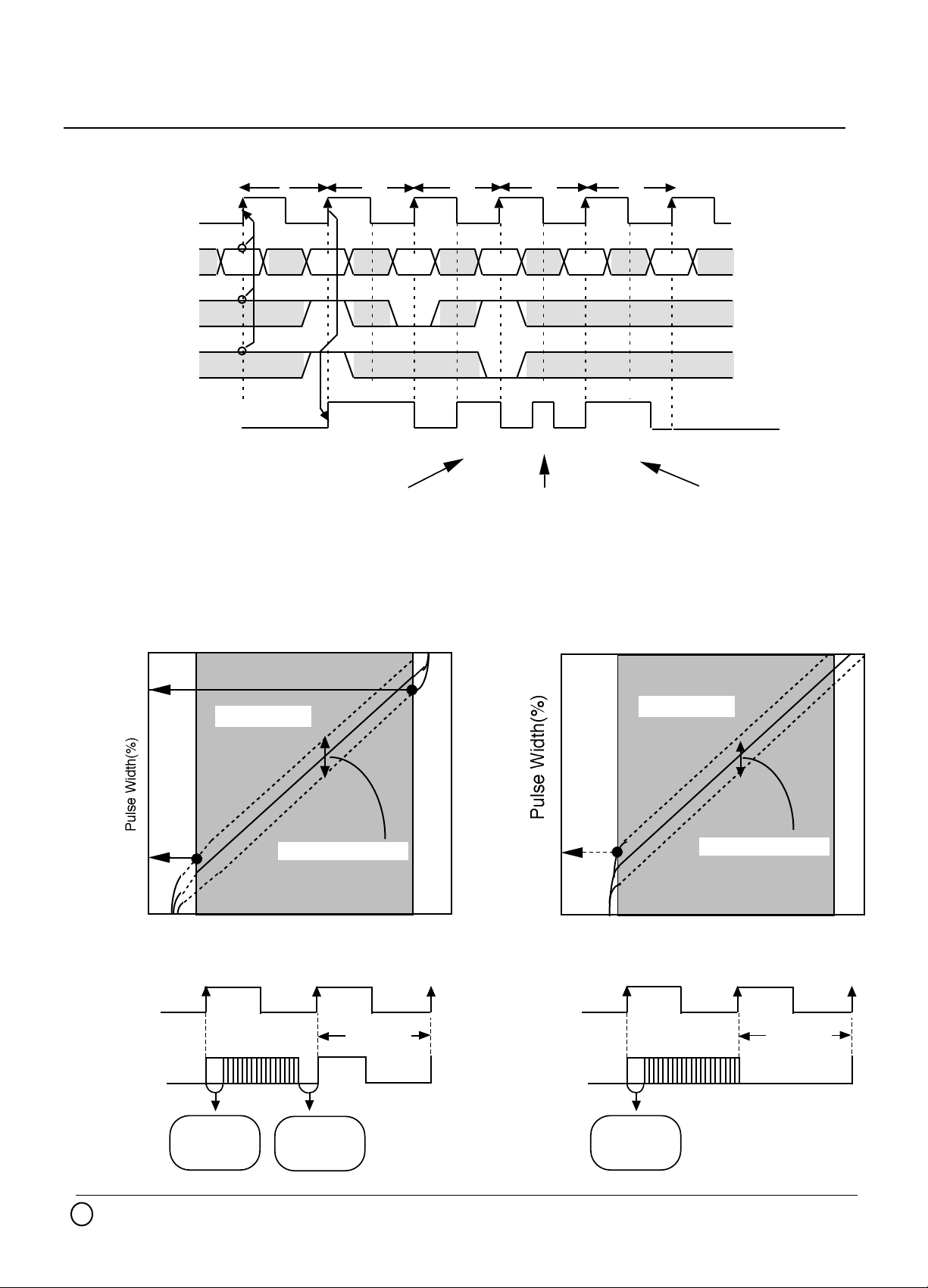

OPERATING TIMING BETWEEN POWER ON TO NORMAL OPERATION

After Power on, it needs following oerations before start normal operation.

(1) Set the value of FRANGE1 and FRANGE2 depends on operation ferequency. (Refer to page 9)

(2) Input CLK same as normal operarion frequency.

(3) Reset operarion using RESET (31pin) and TRST (3pin) .

(reset to initial state of internal logic and BSR)

(4) CLK continue to input during 100msec.

High Speed Monolithic Pulse Width Modulator

Power ON

RESET

tsu(RESET)

TRST

CLK

FRANGE1

FRANGE2

D<5:0>

reset cycle

set up period

of internal circuit

100msec

th(RESET)

Fixed value determined page9

Fixed value determined page9

normal operation

period

n

n+2n+1

SEM/DEM

LEM/TEM

PWMOUT

Note: The reset cycle requires a minimum of two cycles.

C 1998 MITSUBISHI ELECTRIC CORPORATION

(5/15)

n

n

N cycle

output

n+1

n+2n+1

n+2

td(PWM)

n

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

OPERATING TIMING EXAMPLE

DATA(D<0:5>) and CONTROL(SEM/DEM,LEM/TEM) are written to the latching circuit at the

first rise edge of CLK. PWMOUT is outputted at the next edge of CLK. A propagation delay

exists between the CLK and PWMOUT pulse. The minimum propagation delay can be observed

when alternating between codes 00(H) and 3F(H).

In the following diagram, when SET is "H" , PWM output is "H" , when SET is "L" , PWMOUT is

determined correspond to D<5:0>. The function of SET is direct set, so when the rise edge of

CLK and SET are entered at the same time PWMOUT will be "H" .

SET

High Speed Monolithic Pulse Width Modulator

tw(SET)

CLK

D<5:0>

SEM/DEM

LEM/TEM

tw(CLK)

N cycle

tsu(D) th(D)

tsu(SD)

tsu(LT) th(LT)

th(SD)

N+1 cycle

td(PWM)

N+2 cycle

n+2n+1n

n+2n+1n

n+2n+1n

td(SET)

N+3 cycle

n+3

n+3

n+3

N+4 cycle

n+3

n+3

n+3

td(PWM)

td(SET)

PWMOUT

C 1998 MITSUBISHI ELECTRIC CORPORATION

n

N

cycle output

(6/15)

"H"

n+3

N+3

cycle output

MITSUBISHI <DIGITAL ASSP>

June 1998 Ver.8.0.0

High Speed Monolithic Pulse Width Modulator

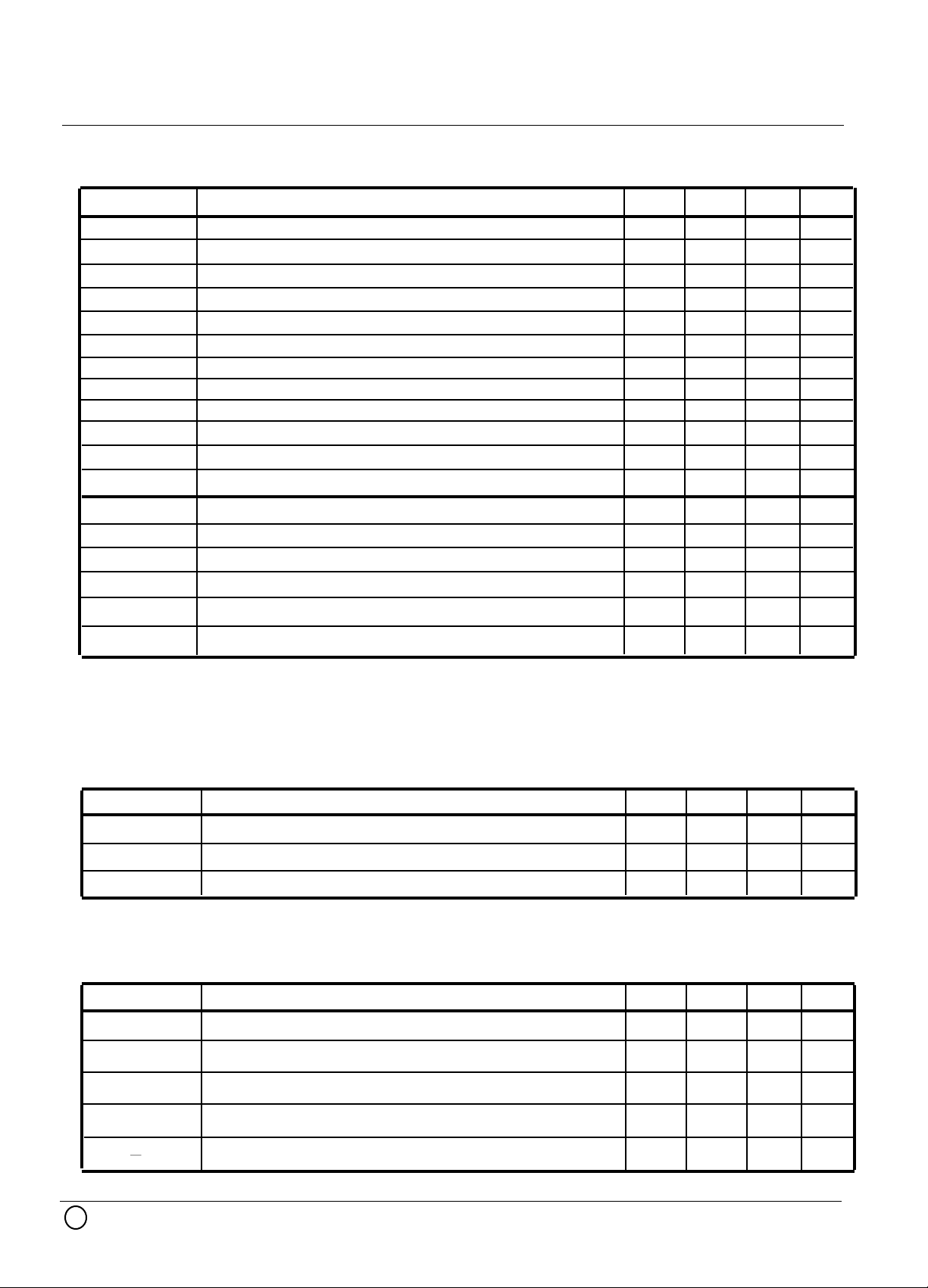

TIMING CONDITIONS (Ta=0~ 70˚C,Vcc=3.3V±5%, GND=0V)

M66244FP

Symbol Parameter

tw(CLK)

duty(CLK)

tsu(RESET)

th(RESET)

tw(SET)

tsu(D)

th(D)

tsu(SD)

th(SD)

tsu(LT)

th(LT)

tr / tf Input pulse rise / fall time

tw(TCK)

tsu(TDI)

th(TDI)

tsu(TMS)

th(TMS)

tw(TRST)

Clock cycle

Clock duty

RESET setup time to CLK

RESET hold time to CLK

SET pulse width

Input data setup time to CLK

Input data hold time to CLK

SEM/DEM setup time to CLK

SEM/DEM hold time to CLK

LEM/TEM setup time to CLK

LEM/TEM hold time to CLK

TCK cycle

TDI setup time to CLK

TDI hold time to CLK

TMS setup time to CLK

TMS hold time to CLK

TRST pulse width

14

14

50

10

10

10

10

20

Typ.

6

6

6

6

6

6

6

6

Max.

±7

22

2

UnitMin.

ns

%

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

SWITCHING CHARACTERISTICS (Ta=0~ 70˚C,Vcc=3.3V±5%, GND=0V)

Symbol Parameter

td (PWM) PWM output access time ns

td (SET)

td (TDO)

TDO access time

Typ.

Max.

40

20

40

OUTPUT PULSE LINEARITY (Ta=0~ 70˚C,Vcc=3.3V±5%, GND=0V)

Symbol

DLV

DLT

DLW

Pw+(min)

Pw (max)

Parameter

Differential linearity by voltage change

Differential linearity by temperature change

Differential linearity by wafer lot change

Minimum "H" pulse width

Minimum "L" pulse width

(@CL=10pF)

(@CL=10pF)

4

4

Typ.

Max.

4

4

4

UnitMin.

ns"H" output access time

ns

UnitMin.

%

%

%

ns

ns

C 1998 MITSUBISHI ELECTRIC CORPORATION

(7/15)

positive going threshold voltage

for schmitt type input

June 1998 Ver.8.0.0

High Speed Monolithic Pulse Width Modulator

ABSOLUTE MAXIMUM RATINGS (Ta=0~70˚C unless otherwise noted)

MITSUBISHI <DIGITAL ASSP>

M66244FP

Symbol

Vcc

VI

Vo

Pd

Tstg

Parameter

Supply voltage

Input voltage

Output voltage

Maximum power dissipation

Storage temperature

Conditions

A value based GND pin

Ta = 70 ˚C

Ratings

-0.3~+4.6

-0.3~VCC+0.3

-0.3~VCC+0.3

414

-55~150

Unit

V

V

V

mW

˚C

RECOMMENDED OPERATING CONDITIONS

Symbol

Vcc

GND

Topr

Parameter

Supply voltage

Supply voltage

Operating ambient temperature

Min. Typ. Max.

3.15 3.45

Limits

3.3

0

0~70

Unit

V

V

˚C

ELECTRICAL CHARACTERISTICS (Ta=0~70˚C, Vcc=3.3V±5%,GND=0V unless otherwise noted)

0.5

2.0

Limits

Typ.

0.75

Max.

1.65

2.41.4

Symbol Parameter

VIH

VIL

VT-

VT+

VH

VOH

"H" Input voltage

for normal type input

"L" Input voltage

for normal type input

Negative going threshold voltage

for schmitt type input

Hysteresis

for schmitt type input

"H" Output voltage

Conditions

D0~D5, LEM/TEM ,LS

SEM//DEM, CLK, SET,

FRANGE1, FRANGE2

TCK, TRST, RESET

Vcc=3.3V

IOH=-2mA

Min.

Vcc x 0.8

0.8

Unit

V

V

V

V

V

V

VOL

IIH

IIL

IOZH

IOZL

Icc

CI Input capacitance

CO

"L" Output voltage

"H" Input current

"L" Input current

Off state "H" output current

Off state "L" output current

Operating mean

current dissipation

Off state output capacitance

Note 1 : under consideration

C 1998 MITSUBISHI ELECTRIC CORPORATION

IOL=2mA

VI=Vcc

VI=GND

Vo=Vcc

Vo=GND

f=72MHz , CL=10pF

f=1MHz

f=1MHz

(8/15)

TDO

TDO

0.55

10

-10

10

-10

120

10

15

V

µA

µA

µA

µA

mA

pF

pF

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

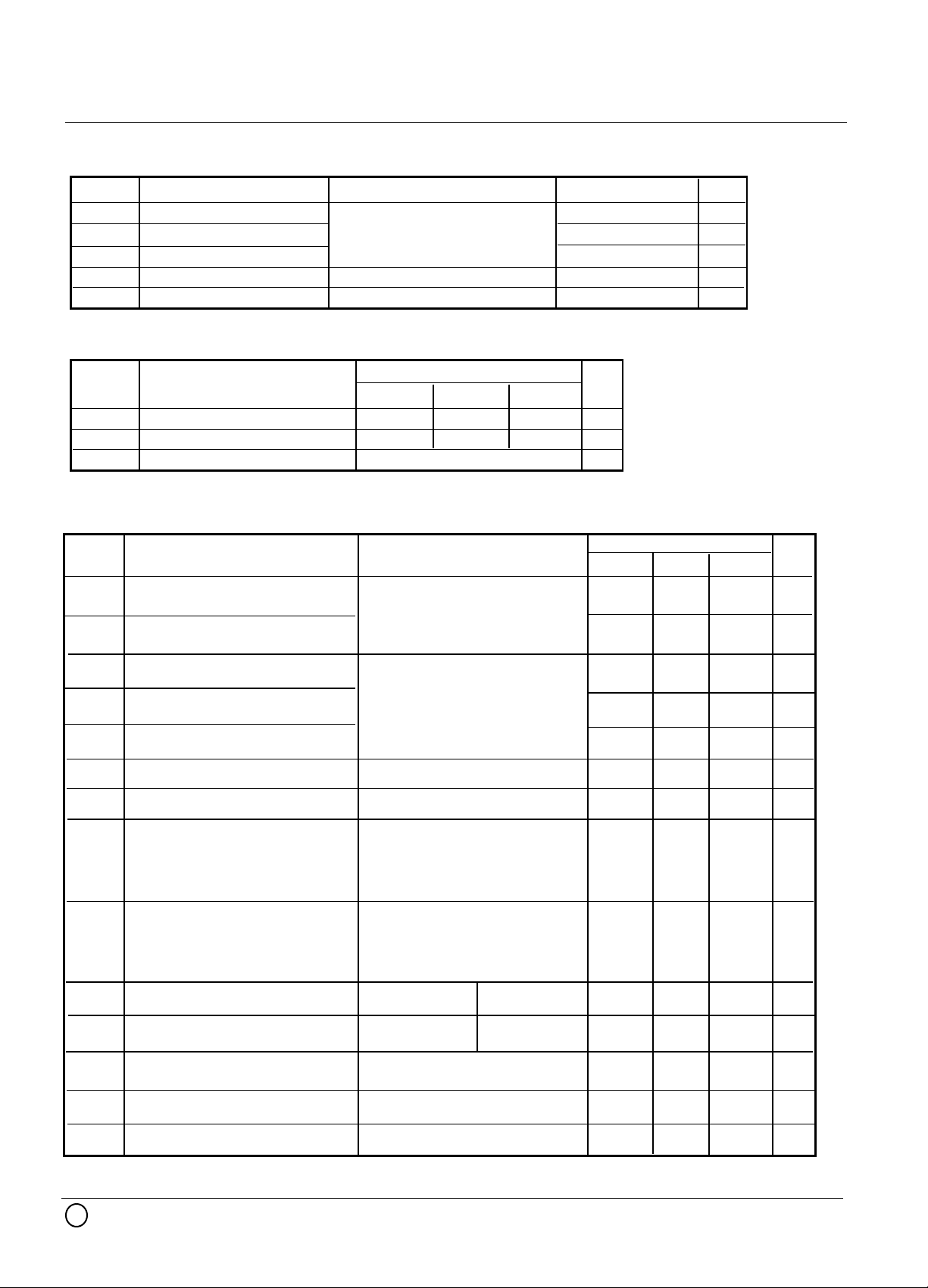

SETTING OF OPERATING FREQUENCY RANGE

M66244FP can operate between 45MHz to 72MHz of clock frequency, it needs to set the value

of the FRANGE1 and FRANGE2 correspond to operating frequency.

High Speed Monolithic Pulse Width Modulator

Frequency range

45MHz~50MHz

50MHz~60MHz

60MHz~72MHz

FRANGE1 FRANGE2

L

H

H

H

L

H

TIMING of PROPAGATION DELAY and THRESHOLD VOLTAGE of PULSE WIDTH

3.0V

0V

VOH

VOL

CLK

PWMOUT

1.3V

td(PWM)

1.3V

tw(PWM)

SET

PWMOUT

NOTE : OUTPUT LOAD 10pF

C 1998 MITSUBISHI ELECTRIC CORPORATION

1.3V

td(SET)

1.3V

(9/15)

"H"

3.0V

0V

VOH

VOL

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

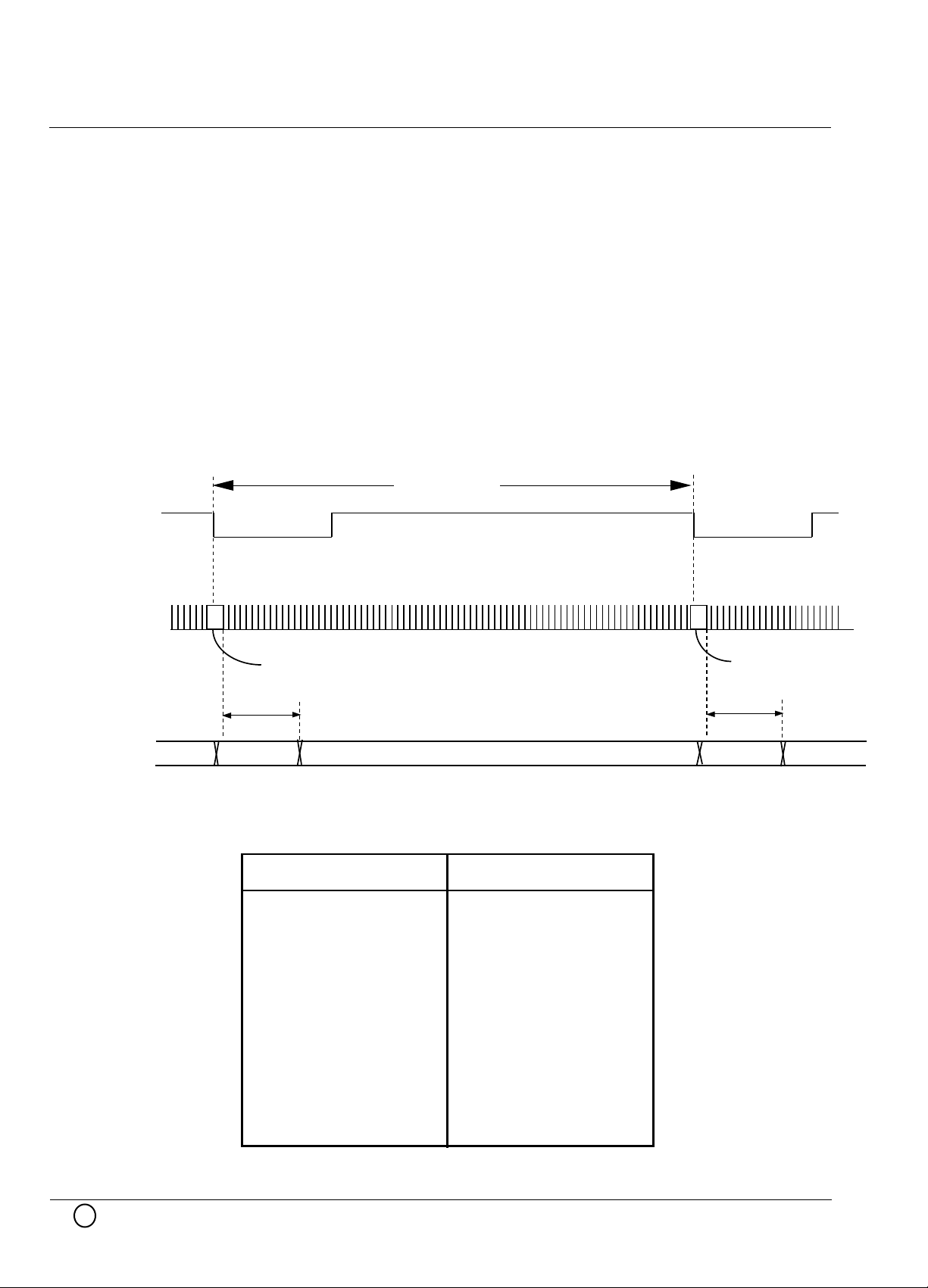

Solution for clock period is shifted

In the printer or copier system, there are some possibility that clock period is shifted because

beam detect signal generates at the beginning of each pass across the paper.

If clock period is shifted one time, PWMOUT will be invalid. It needs long time to recover valid

PWMOUT after previous clock period inputted.

To settle above problem, beam detect signal take in to LS (16 pin) of M66244FP.

For this, It can recover valid PWMOUT within 4usec after previous clock period inputted.

1 line sequence

High Speed Monolithic Pulse Width Modulator

Beam-detect

PWM clock

PWMOUT

4 usec

valid invalid

clock stopped time (ns)

Phase shifted clock

valid

Example of operating timing using LS function

recovery time(ns)

20

40

60

80

100

200

400

600

800

1000

2000

4000

1000

1000

2000

4000

7000

10000

14000

17000

20000

23000

30000

40000

Phase shifted clock

4 usec

invalid

valid

recovery time that not using LS function

C 1998 MITSUBISHI ELECTRIC CORPORATION

(10/15)

MITSUBISHI <DIGITAL ASSP>

June 1998 Ver.8.0.0

M66244FP

High Speed Monolithic Pulse Width Modulator

TEST CIRCUIT DESCRIPTION (JTAG)

GENERAL DESCRIPTION

The Test Access Port conforms with the IEEE standard 1149.1.

This standard defines a test access port and boundary-scan architecture for digital integrated

circuits.

The facilities defined by the standard seek to provide a solution to the problem of testing

assembled printed circuit boards and other products based on highly complex digital

integrated circuits and high-density surface-mounting assembly techniques. They also

provide a means of accessing and controlling design-for-test features build into digital

integrated circuits themselves.

PIN DESCRIPTION

TCK,TMS,TDI,TRST,TDO are used in this test operation.

•Test Clock Input (TCK)

TCK provides the clock for the test logic defined by this standard. Stored-state devices

contained in the test logic retain their state indefinitely when the signal applied to TCK is

stopped at 0.

•Test Mode Select Input (TMS)

The signal received at TMS is decoded by the TAP controlled to control test operation.

The signal presented at TMS is sampled by the test logic on the rising edge of TCK.

•Test Data Input (TDI)

Serial test instructions and data are received by the test logic at TDI.

The signal presented at TDI is sampled by the test logic on the rising edge of TCK.

•Test Reset Input (TRST)

The TRST input provides for asynchronous initialization of the TAP controller.

If TRST is included in the TAP, then the TAPcontroller is asynchronously reset to the TestLogic-Reset controller state when a logic 0 is applied to TRST.

•Test Data Input (TDO)

TDO is a serial output for test instructions and data from the test logic defined in this

standard.

Changes in the state of the signal driven through TDO occur only on the falling edge of

TCK. The TDO driver is set to its inactive drive state except when the scanning of data is in

progress.

C 1998 MITSUBISHI ELECTRIC CORPORATION

(11/15)

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

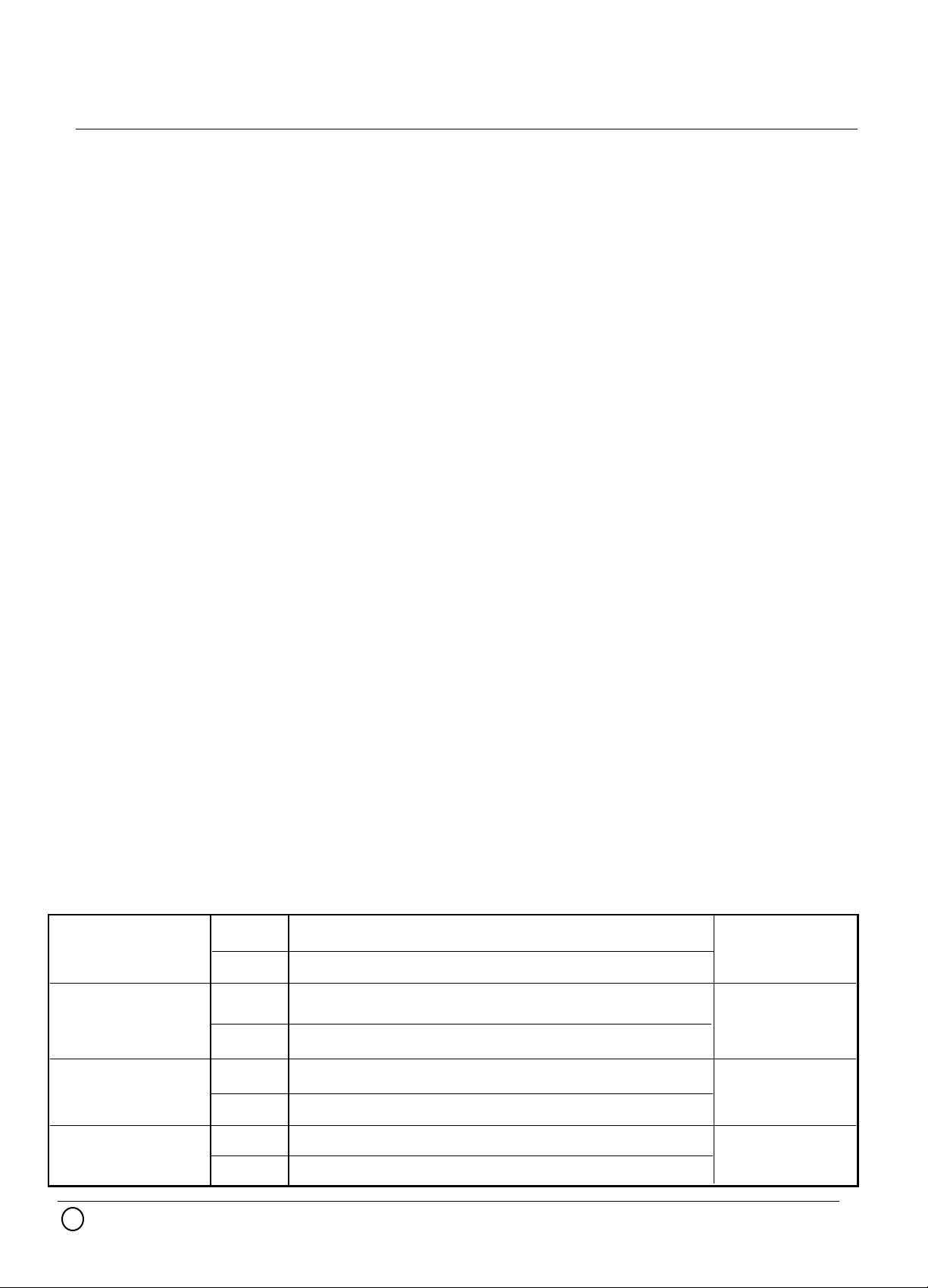

BLOCK DIAGRAM OF TEST CIRCUIT

3

GND

VDD

GND

5

6

7

8

4

High Speed Monolithic Pulse Width Modulator

2

361

33

3435

32

BSR

BSR

29

31

30

RESET

SET

VDD

VDD

GND

VDD

GND

VDD

10

11

12

13

9

14 15

16

17

18 19 20 21 22

23

28

27

26

25

24

GND

PWMOUT

VDD

GND

NOTE1 : BSR routing order = FRANGE1→FRANGE2→LS →SEMDEM→

LEMTEM→D5→D4→D3→D2→D1→D0 →SET →RESET

NOTE2 : CLK(33pin) and PWMOUT(27pin) do not have BSR.

C 1998 MITSUBISHI ELECTRIC CORPORATION

(12/15)

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

TAP CONTROLLER DESCRIPTION

The TAP controller is a synchronous finite state machine that responds to change at the

TMS and TCK signals of the TAP and controls the sequence of operations of the circuitry

defined by this standard.

The state diagram for the TAP controller is shown in following figure.

All state transitions of the TAP controller occur on the value of TMS at the time of a rising

edge of TCK.

High Speed Monolithic Pulse Width Modulator

C 1998 MITSUBISHI ELECTRIC CORPORATION

(13/15)

MITSUBISHI <DIGITAL ASSP>

length serial path between the TDI and the TDO pins of a M66244FP when no test operation of

M66244FP is required.

This allows more rapid movement of test data to and from other components on a board that

are required to perform test operations.

The BYPASS instruction select the bypass register to be connected for serial access between

TDI and TDO in the Shift-DR controller state.

M66244FP

June 1998 Ver.8.0.0

INSTRUCTION DESCRIPTION

INSTRUCTION SET

Instruction Code (Binary)

EXTEST

IDCODE

SAMPLE/PRELAOD

BYPASS

000

001

010

111

High Speed Monolithic Pulse Width Modulator

Selected TDR

BSR (Boundary Scan Register)

DIR (Device Identification Register)

BSR

BPR (Bypass Register)

EXTEST INSTRUCTION

EXTEST instruction allows testing of off-cihp circuitry and board level interconnections. Data

would typically be loaded onto the latched parallel outputs of boundary-scan shift-register

stages using the SAMPLE/PRELOAD instruction prior to selection of the EXTEST instruction.

The EXTEST instruction select only the BSR(Boundary-scan register) to be connected for

serial access between TDI and TDO in the Shift-DR controller state.

When the EXTEST instruction is selected, the state of all signals received at system input

pins are loaded into the boundary-scan register on the rising edge of TCK in the Capture-DR

controller state.

PWMOUT pin does not have BSR, so PWMOUT pin can not test interconnection to board

using the EXTEST instruction.

BYPASS INSTRUCTION

The bypass register contains a single shift-register stage and is used to provided a minimum-

C 1998 MITSUBISHI ELECTRIC CORPORATION

(14/15)

MITSUBISHI <DIGITAL ASSP>

M66244FP

June 1998 Ver.8.0.0

SAMPLE/PRELOAD INSTRUCTION

The SAMPLE/PRELOAD instruction allows a snapshot of normal operation of the component

to the taken and examined. It also allows data values to be loaded onto the latched parallel

outputs of the boundary-scan shift register prior to selection of the other boundary-scan test

instruction.

The SAMPLE/PRELOAD instruction select only the boundary-scan register to be connected

for serial access between TDI and TDO in the Shift-DR controller state.

When SAMPLE/PRELOAD instruction is selected, the state of all signals flowing through

system pins are loaded into the register on the rising edge of TCK in the Capture-DR controller

state.

When SAMPLE/PRELOAD instruction is selected, parallel output registers/latches included in

boundary-scan register cells load the data held associated shift-register stage on the falling

edge of TCK in the Update-DR controller state.

High Speed Monolithic Pulse Width Modulator

IDCOAD INSTRUCTION

Use of the device identification register allows a code to be serially read from the component

that shows:

(1)The version number for the part

(2)The part number

(3)The manufacturer's identity

The IDCODE instruction select only the device identification register to be connected for serial

access between TDI and TDO in the Shift-DR controller state.

When the IDCODE instruction is selected, the vendor identification code is loaded into the

device identification register on the rising edge of TCK following entry into Capture-DR

controller state.

ID code of M66244FP is as follow;

Version

(4bit)

Part num.

(16bit)

bit num.

code

bit num.

code

31 30 29 28

0 0 0 0

27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12

0 0 0 1 1 0 0 0 0 1 1 0 0 1 0 0

binary code

of "6244"

Manufacture num.

(11bit)

LSB

(4bit)

C 1998 MITSUBISHI ELECTRIC CORPORATION

bit num.

code

bit num.

code

11 10 9 8 7 6 5 4 3 2 1

0 0 0 0 0 0 1 1 1 0 0

0

1

JEDEC code

of MITSUBISHI

fixed value

(15/15)

Loading...

Loading...