Page 1

A

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

Model

LM2-4710.4730

1

I

'1

Thank

Sewing

Before

booklet

you

for

Machine.

the

useofyour

carefully'.

Single-Needle,

Automatic

Variable

your

purchase

sewing

of

machine,

Double-Needle

Lockstitch

Compound-Feed

undertrimmer

speed

Mitsubishi

please

Industrial

read

Classes

control

this

INSTRUCTION

MANUAL

Page 2

PRECAUTIONS

BEFORE

STARTING

OPERATION

[i]/Safetv

1. When

2.

Precautions

turning

around/under

Power

mustbeturned

his/her

seat.

the

the

power

needle

off

on, keep

and

when

the

area

the

your

hands

around

the

machineIsnot

and

fingers

pulley.

used,orwhen

away

the

from

operator

the

area

leaves

3. The power must be turned off before tilting the machine head. Installing or removing

the"Vbelt, adjusting

4. Avoid placing fingers, hairs, bars etc., near the pulley, "V" belt, bobbin

or

motor

when

5. Do not Insert'fingers Into the thread take-up cover, under/round the needle, or pulley

when

the

machine

6.Ifa

belt

cover,

without

these

(D

Precaution

1. If

the

2. If

the

lubricating.

3. When a new sewing machine Is first turned on, verify the rotational direction of the

pulley

(The pulley should rotate counterclockwisewhen viewed from the pulley.)

before

machine's

machineIslubricated

with

the

the

machine, or

the

machineIsoperation.

Is In

operation.

finger

guard,

safety

devices.

Starting

oil pan has an oil

power

on..

and/or

eye

Operation

sump,

by a

when

drop

Injury

guard

never

oiler,

replacing.

could

result.

are

installed,donot

operate

never

whder

operatejthe

the

machine before filling It.

operate

the

machine

pulley,

>

machine

|

before

4. Verify the voltage and (single or three) phase with those given on the motor

nameplate.

[3j Precaution for

1. Avoid

temperature(5°C'or lower). Otherwise,

2. Avoid

3. Avoid using the machine In

high-frequency

using

using

Operating

the

the

machineIndusty

welder

Conditions

machineatabnormally

and

others.Isgenerated.

high

machine

conditions.

areas

where too much electrical noise, resulted from the

temperature(35''C

failure may result.

or higher) or low

Page 3

SPECIFICATIONS

-

CONTENTS-

1

PREPERATION

I 1 I

Connecting

I 2 I

Settingupthe

I 3 I

Settingupthe

I 4 I

Adjustmentofneedle

CAUTIONS

ON

FOR

USE

OPERATION

the

electric

control

activating

cablestothe

panel

speedofthe

bar

stop

position

control

air

cylinder

box

I 1 I Oiling (1) 6

Oilihg (2) 6

I 3 I Oiling

I 4 I

I 5 I

HOW

I1I

I 2 I

dl

I 4 I

I S I

I 6 I

I 7 I

I 8 I

I 9 I

1101

ill!

112 I

113 I

1141

115 I

116 I

117 I

118 I

119 I

1201

I21 I

122 I

123 I

1241

I251

I261

127 I

I28 I

I29 I

130 I

I311

1321

1331

condition

Adjustmentofoilingtorotating

Cautionsonoperation

TO

Adjust

and

use

the

hook

machine

lnsta|llationofneedles

Windingofbobbin

Selectionofthread

Threadingofneedle

Adjustmentoffeed

Settingofbobbin

Adjustingofneedle

Threadingofbobbin

Tension

Balanceofthread

Needle

Adjustmentofpresser

Adjustmentofthread

AdjustmentofOutside

Instant

The

Installing

Adjustmentofthe

Timing

adjustmentofbobbin

thread

alternating

stopper

the

between

Adjustment of feed dog height 17

Relationship

Relationship

Relationship

Safety

clutch

Upper

feed

adjustment

Adjustmentofforward/backward

Installation

Positioningofthread

Adjustmentofthread

Adjustmentofneedle

of

Adjustmentofscissoring

Sharpeningoffixed

Adjustment

thread

threads

(stitch)

length

thread

guide

threads

threads

tention

tention

foot

pressure

screw

Feed

rotathing

between

between

between

device

movable

take-up

switch

for

regulator

alternating

trimmer

trimmer

threads

presser

adjusting

hook

rotating

hook

motion

needle

(Needle

knife

spring

foot

the

bracket

stroke

motion

nook

motion

side)

stitch

cam

cam

tention

pressureofmovable

knife

for

changeofneedle-to-needle

and

and

instant

motion

and

stitch

Inside

sensing

and

opener

and

length

release

reversing

presser

alternating

potentiometer

needle

and

take-up

motion

feed

dog

assembly

knife

distance

(touch

back)

foot

stroke

motion

lever

motion

motion

and

fixed knife 25

(LU2-4730) 26

2

3

4

5

7

7

7

8

8

9

9

10

10

10

11

11

11

11

11

12

12

14

14

15

15

16

18

18

19

20

21

21

22

23

23

24

25

Page 4

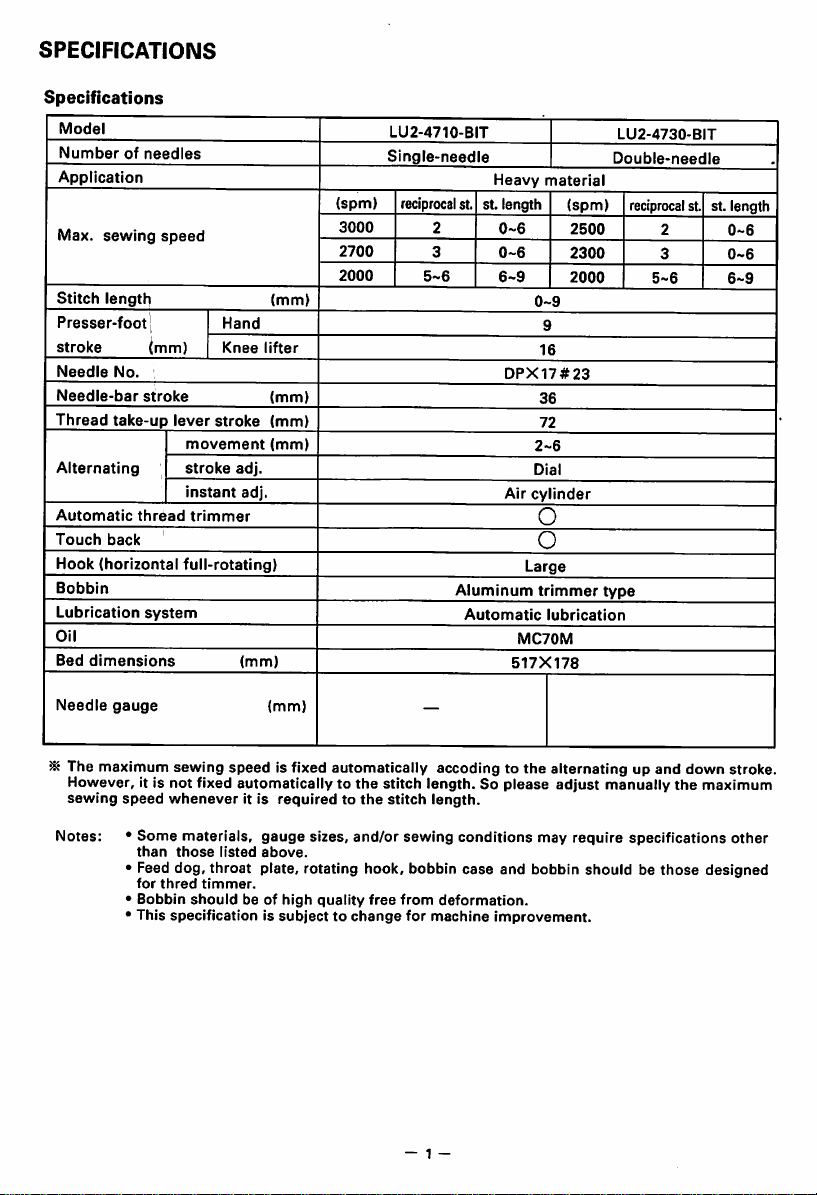

SPECIFICATIONS

Specifications

Model

Numberofneedles

Application

Max.

sewing

speed

Stitch

lengtli

Presser-footj

stroke

Needle

Needle-bar

Thread

Alternating

Automatic

Touch

Hook

Bobbin

Lubrication

Oil

Bed

No.

stroke

take-up

thread

back

(horizontal

dimensions

(mm)

lever

full-rotating)

system

Hand

Knee

stroke

movement

stroke

instant

trimmer

adj.

adj.

(mm)

(mm)

lifter

(mm)

(mm)

(mm)

(spm)

3000

2700

2000

LU2-4710-BIT

Single-needle

reciprocal

st. St. length

2

3

5-6

Aluminum

Heavy

0-6

0-6

6-9

DPX17#23

Air

Automatic

material

0-9

9

16

36

72

2-6

Dial

cylinder

o

o

Large

trimmer

lubrication

MC70M

517X178

(spm)

2500

2300

2000

LU2-4730-BIT

Double-needle

reciprocalst.

2

3

5-6

type

St. length

0-6

0-6

6-9

Needle

gauge

^ The maximum sewing

However, it is

sewing

Notes: *

not

speed

• Feed dog, throat plate, rotating hook, bobbin

•

•

fixed automatically to

whenever

Some

materials,

than

those

for

thred

Bobbin

This

timmer.

should

specificationissubjecttochange

(mm)

speed

is fixed automatically acceding to the alternating up and down stroke.

it is

requiredtothe

gauge

listed

above.

be of

high

the

sizes, and/or sewing conditions may require specifications

quality

free

stitch

stitch

from

for

- 1 -

—

length. So

length.

case

deformation.

machine

please

adjust

manually

and bobbin should be

improvement.

the

those

maximum

other

designed

Page 5

PREPARATION

m

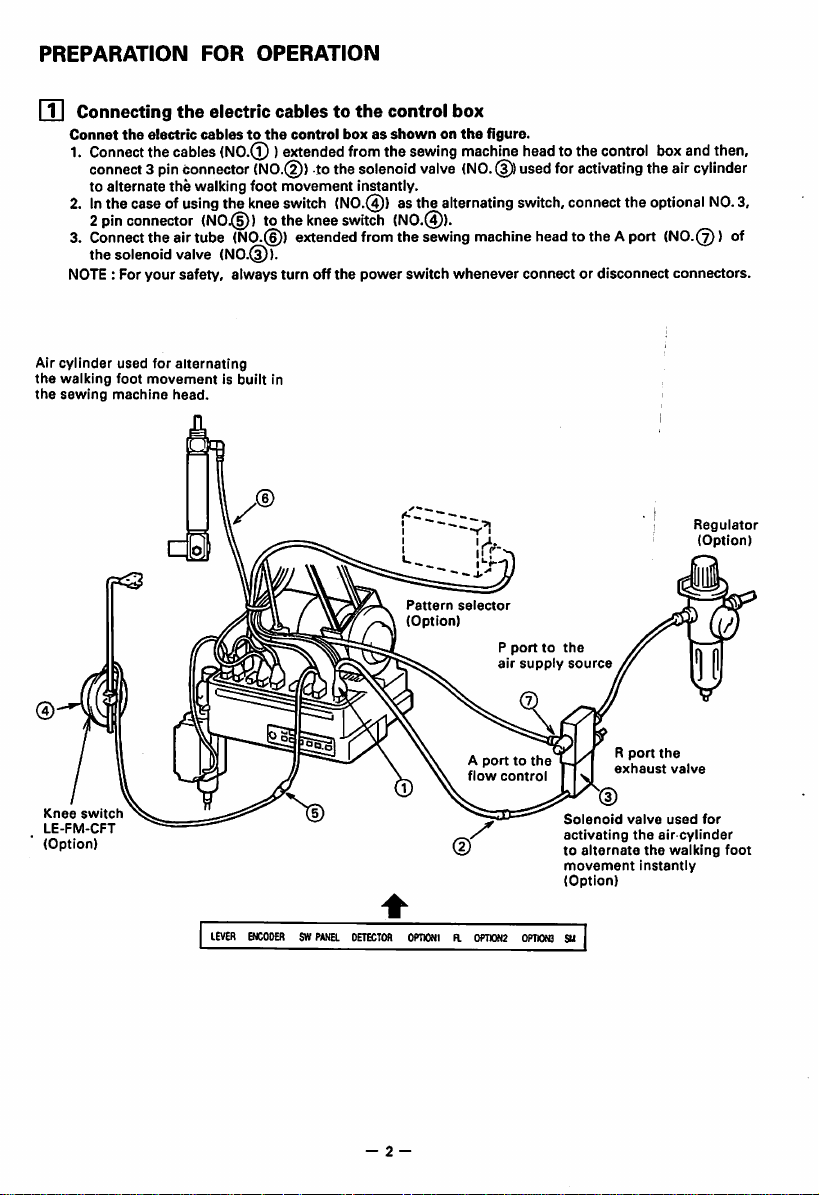

Connecting

Connet

the

1.

Connect

connect3pin

to

alternate

2.Inthecaseof

2

pin

connector

3.

Connect

the

solenoid

Air

the

the

NOTE : For

cylinder

walking

sewing

your

used

foot

machine

FOR

OPERATION

the electric cablesto the controlbox

electric

cablestothe

the

cables

(N0.(^ )

connector

the

walking

using

the

(N0.@)

theairtube

valve

(NO.©).

safety,

always

for

alternating

movementisbuilt

head.

(NO.d))

foot

knee

tothe

(NO.©)

control

extended

movement

switch

knee

extended

turn

off

in

boxasshownonthe

from

tothe

the

solenoid

instantly.

(N0.(^) asthe

switch

(N0.@).

from

the

the

power

switch

Pattern

(Option)

sewing

valve

alternating

sewing

figure.

machine

(NO.Cf))

machine

whenever

selector

P

air

head

tothe

used

switch,

head

connectordisconnect

porttothe

supply

control

for

activating

connect

the

totheAport (NO.©) of

source

box

theair

optional

connectors.

andthen,

cylinder

NO.

Regulator

(Option)

3,

Knee

switch

LE-FM-CFT

(Option)

LEVER

ENCODERSWPANEL

DETECTOR

- 2 -

A

porttothe

flow

OPIIONIH.0PTI0N2

control

OPT10N3

Solenoid

activating

to

alternate

movement

(Option)

SU

R

port

exhaust

valve

the

the

valve

used

air

the

walking

instantiy

for

cylinder

foot

Page 6

PREPARATION

FOR

OPERATION

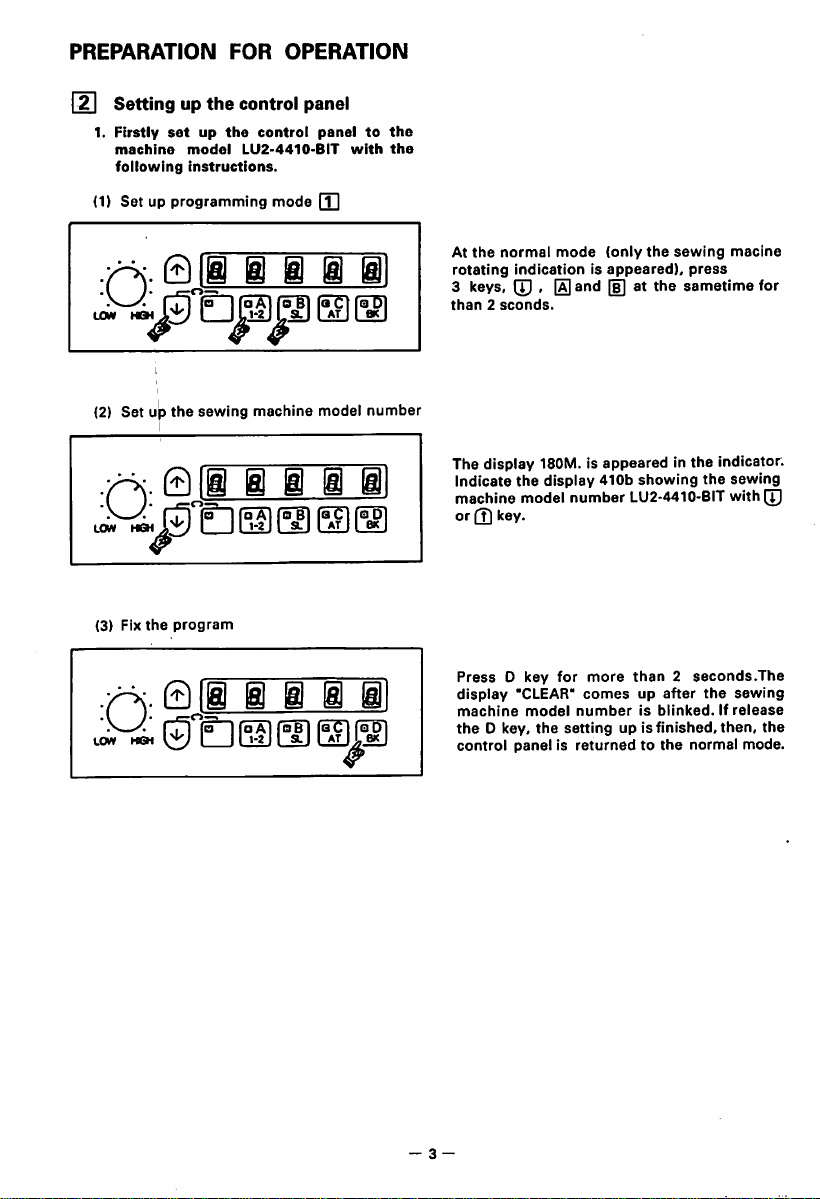

[2] Settingupthe

1.

Firstly

setupthe

machine

following

(1)

Set up programming mode (T]

.Q.

LOW

(2) Set up

HS

model

Instructions.

g)l§

the

sewing machine model

011

Q

LOW HGH

(3) Fix

the

program

.Q.

LOW

011

g

control

LU2-4410-BIT

control

panel

paneltothe

i i i

111

aC

AT

1 i 1 i

aC

AT

with

number

QD

1»

the

At

the

normal

mode

(only

the

sewing

rotating

3 keys,(p, and [i] at the sametime for

than2sconds.

The display 180M. is appeared in the indicator.

indicationisappeared),

Indicate

machine model

or (?) key.

the0key,

the

display 410b

PressDkey

display

'CLEAR*

machine

control

model

the

panelisreturnedtothe

number

for

setting

showing

LU2-4410-BIT with

more

than2seconds.The

comesupafter

numberisblinked.Ifrelease

up is

finished,

press

the

the

then,

normal

macine

sewing

[I]

sewing

the

mode.

3 —

Page 7

PREPARATION

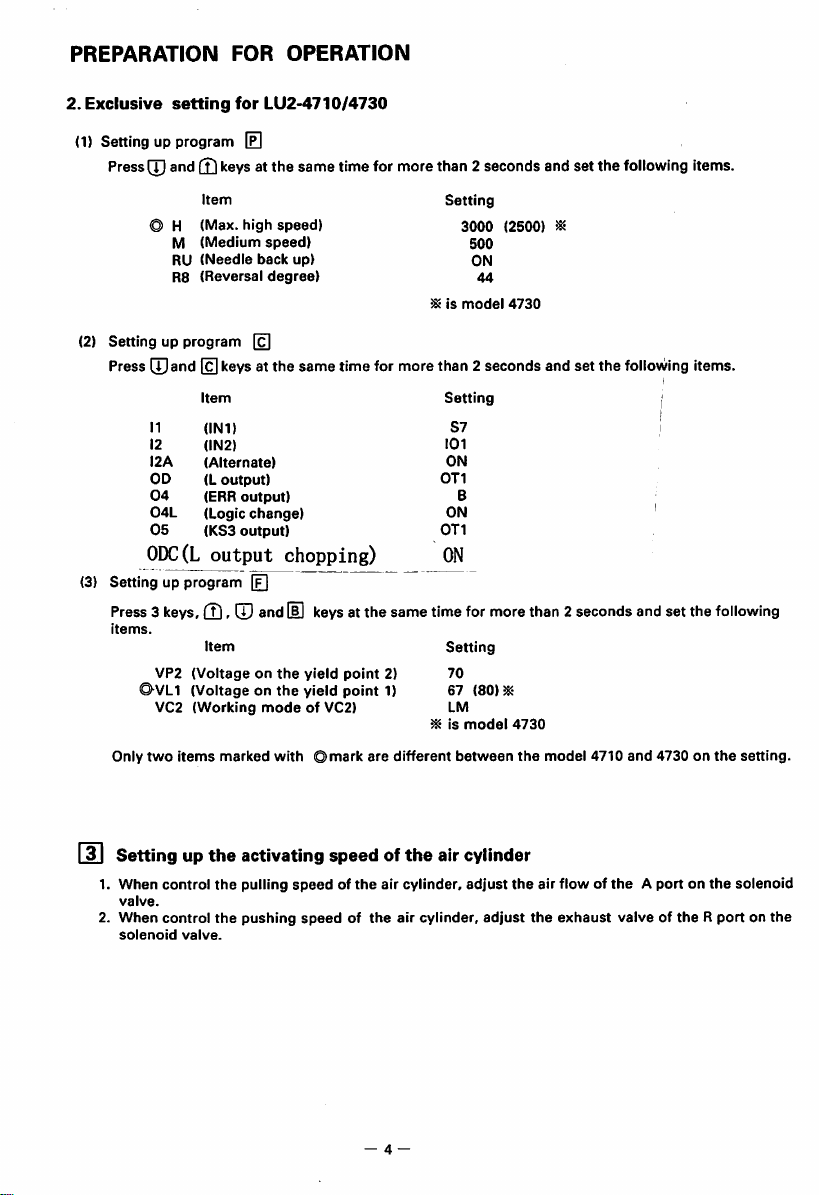

2.

Exclusive

(1)

Settingupprogram

Press

(2)

Settingupprogram

setting

[T]

and[£]keysat the same timefor morethan 2 seconds and set the

Item

(Max.

H

(Medium

M

(Needle

RU

(Reversal

R8

Press [T]and keys at the

Item

11

(IN1)

12

(IN2)

I2A

(Alternate)

CD

(L

04

04L

05

ODC(L

output)

(ERR

(Logic

(KS3

output chopping)

(3) Setting up program [f]

Press3keys,CD>CDend[H

items.

0VL1

Only

VP2

(Voltageonthe

(Voltage on

VC2

two

items

Item

(Working

marked

FOR

OPERATION

for

LU2-4710/4730

[p]

high

speed)

speed)

back

up)

degree)

same

time for more than 2 seconds and

output)

change)

output)

keys

atthe sametimeformorethan 2secondsandset the

yield

point

the

yield point 1) 67 (80)

modeofVC2) LM

with

©mark

2)

are

^ismodel

Mismodel

different

Setting

3000

Setting

S7

101

ON

0T1

B

ON

0T1

ON

Setting

70

between

500

ON

following

44

4730

set

the following items.

items.

following

4730

the

model

4710

and

4730onthe

setting.

m Settingupthe

1.

When

control

2.

valve.

When

solenoid

control

valve.

the

the

activating

pulling

speedofthe

pushing

speedofthe

speedofthe air

air

cylinder,

air

cylinder,

4 —

cylinder

adjust

the

adjust

air flow of

the

exhaust

theAportonthe

solenoid

valveoftheRportonthe

Page 8

PREPARATION

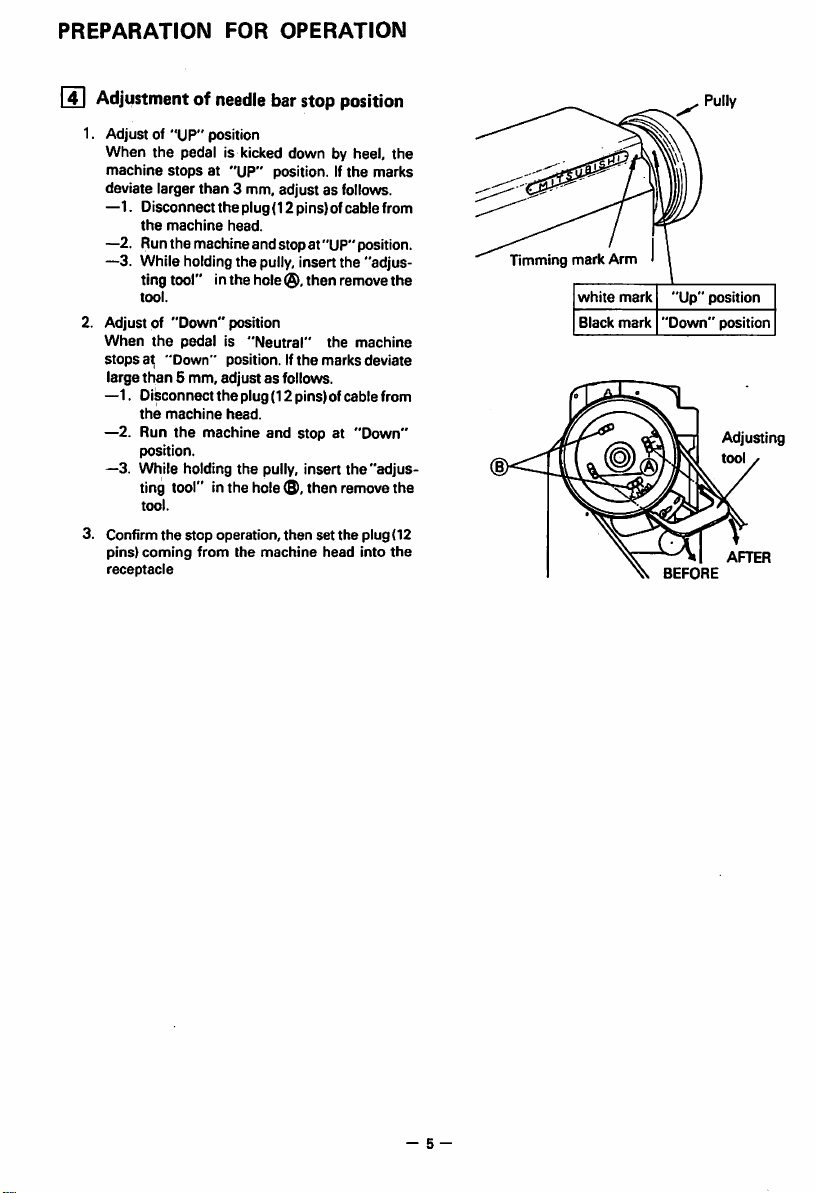

0

Adjustmentofneedle

FOR

OPERATION

bar

stop

position

1. Adjust of "UP" position

When

the

machine

pedal is kicked down by heel, the

stopsat"UP"

position. If

the

deviate larger than 3 mm, adjust as follows.

—1. Disconnect the plug (12 pins)ofcable from

the

—2. Run

machine

head.

the

machineand stop at "UP" position.

—3. While holdingthe pully,insert the "adjus

ting tool" in

tool.

2. Adjust of

When

the

stopsat"Down"

large

than

—1. Disconnect

the

machine

—2. Run

position.

—3.

While holdingthe pully,insert the "adjus

the

hole

then

"Down"

position

pedalis"Neutral"

position.Ifthe

the

marks

5 mm, adjustasfollows.

the

plug(12 pins) of cable from

head.

the

machine and stop at "Down"

remove

ting tool" inthe hole®,then removethe

tool.

3. Confirm the stop operation, then set the plug (12

pins)

coming

from

the

receptacle

machine

head

marks

the

machine

deviate

into

the

Timming

mark

white

Black

Arm

mark

mark

"Up"

"Down"

BEFORE

Pully

position

position

Adjusting

tool

AFTER

- 5 -

Page 9

CAUTIONS

ON

USE

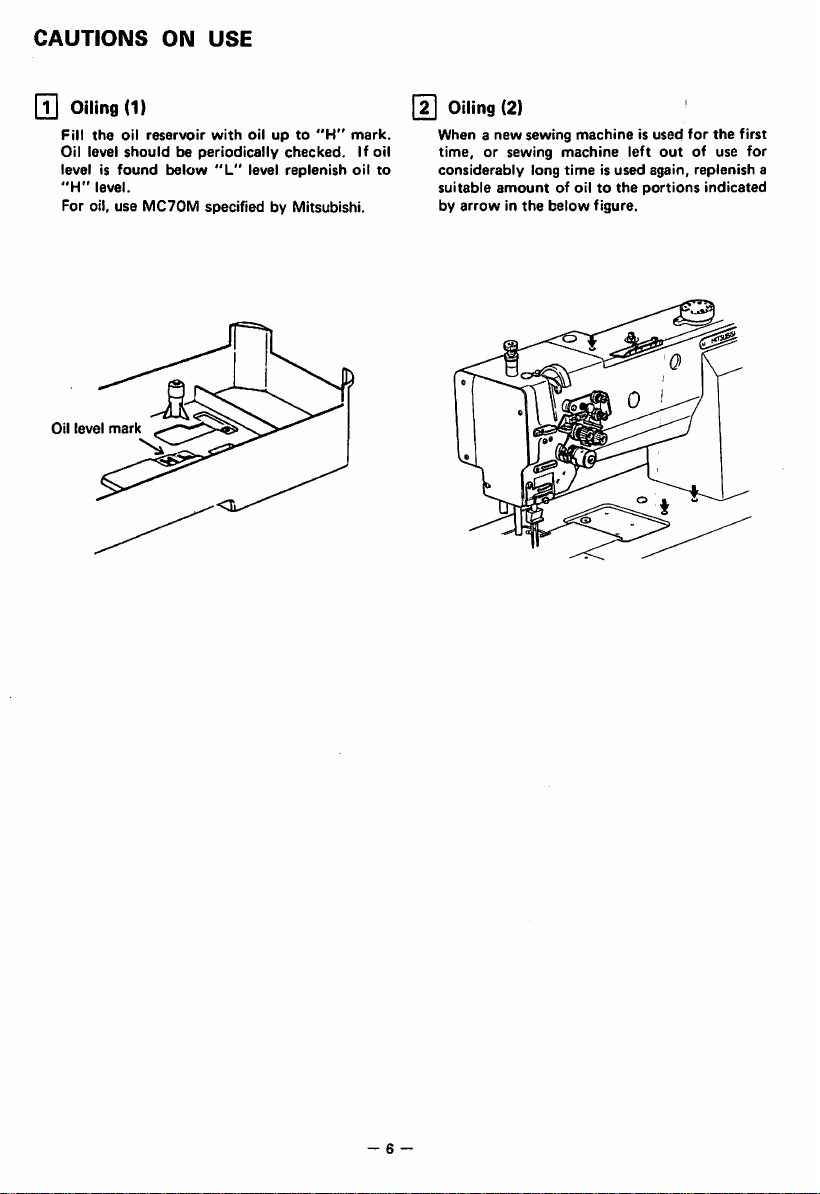

[T]

Oiling

(1)

Fill

the

oil

Oil level

level is

"H"

level.

reservoir

shouldbeperiodically

found

below

with

"L"

oilupto

checked.

level

replenish

For oil, use MC70M specified by Mitsubishi.

Oil

level

"H"

mark.

If oil

oil

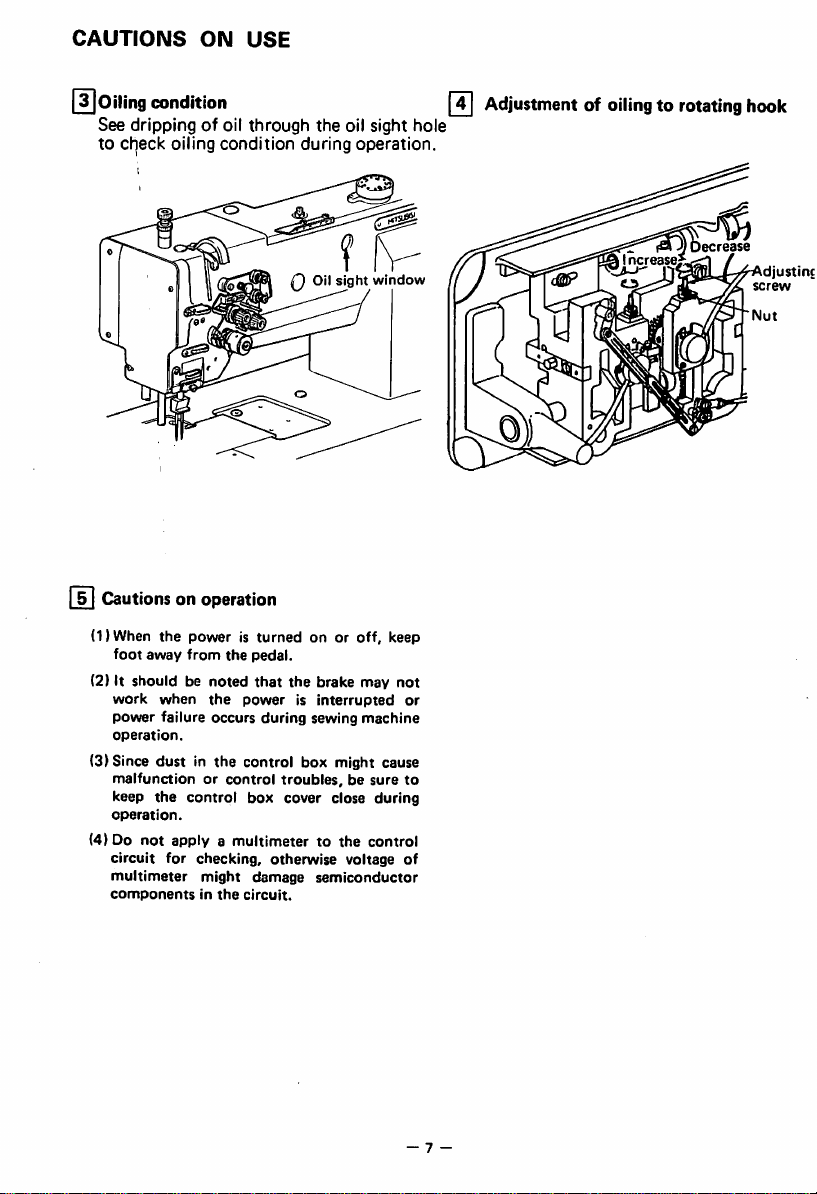

Oiling (2)

When a

new

sewing

to

time,orsewing

considerably

suitable

amount

by

arrowinthe

machineisused

machine

long

timeisused

of oiltothe

below

left

figure.

out

again,

portions

for

the

of use

replenish

indicated

first

for

a

- 6

Page 10

CAUTIONS

ON

USE

[^Oiling

condition

See dripping of oil through the oil sight hole

to

check

oiling

condition

i]

Cautionsonoperation

(DWhen

(2) It should be

foot

away

work

power

operation.

the

poweristurned

from

the

noted

when

the

failure occurs

(3) Since dust in the control box might cause

malfunctionorcontrol

keep

the

operation.

(4) Do

circuit

multimeter

components

control

not

applyamultimetertothe

for

checking,

might

in

the

during

operation.

f fv-

Oil

slaht

on or

pedal.

that

the

powerisinterrupted

during

troubles,besure

box

cover close during

otherwise

damage

circuit.

off,

brake may

sewing

machine

control

voltage of

semiconductor

window

keep

not

Adjustmentofoilingtorotating

Increase

o

or

to

hook

Nut

7 -

Page 11

HOW

TO

ADJUST

pn

Installationofneedles

DoubeNeedle

Insert

the

of

screw

of

I

Adiustmant:

•

•

•

needle

needle

needle

clamp

keeping

facetoface

Windingofbobbin

Tensionofwound

Conically

Lengthofwound

wound

the

upto

and

long

thread

thread

thread

AND

the

tighten

groove

thread

USE

bottom

the

side

Slack

Move

Loosen

and

THE

MACHINE

Note:

Before

installing

nsufficient

Insertion

Note:

When

bobbin

windingisrecommended

the

thread

guide

the

thread

tighten

length

the

screwtodecrease

the

needles,besuretoturn

Needle

threadiswound,

for

toward

adjusting

polvester

smaller

screwtoincrease

lengthofthread.

distorted

X

/%i

keep

the

presser

thread

diameterofwound

and

off

the

power.

rs

Long

groove

left

side

foot

lifted.

nylon

thread.

thread

lengthofthread

layer.

i

Winding

adjusting

i

tension

screw

Page 12

HOW

[si

[4]

TO

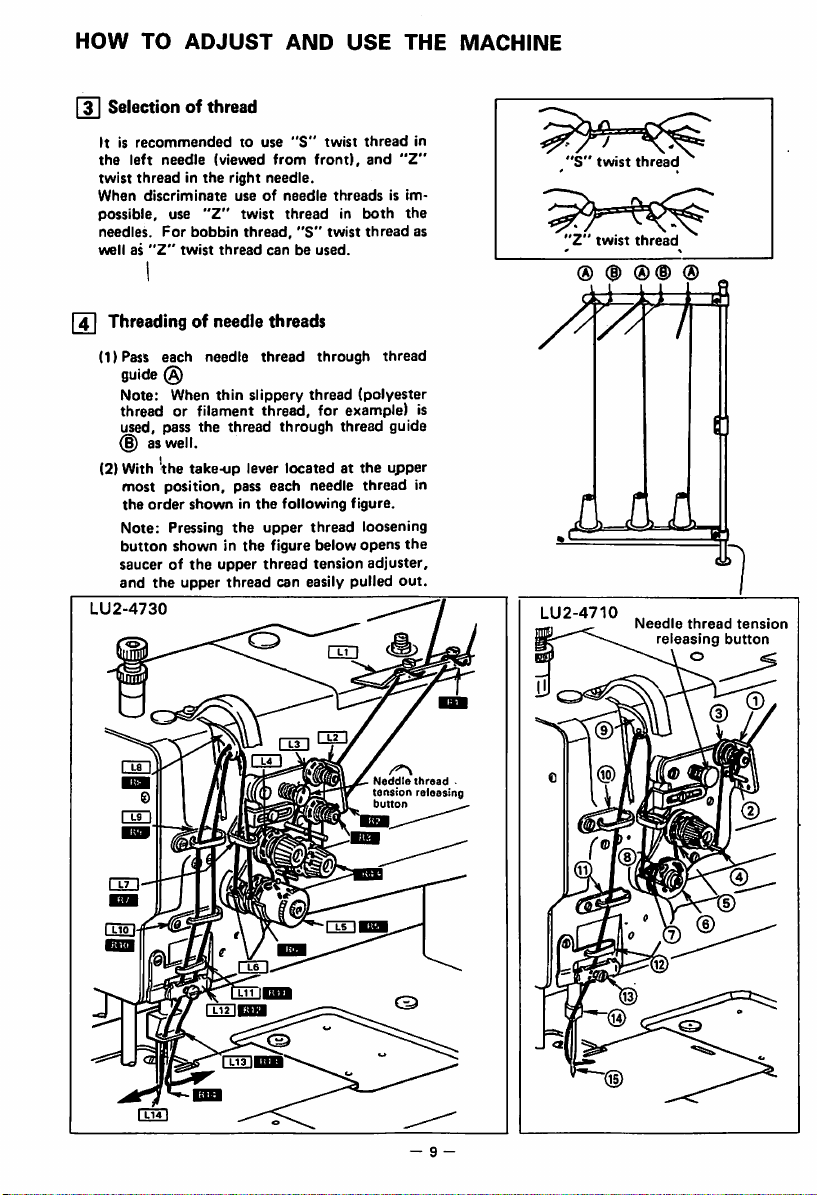

Selection of thread

It is

recommended

the

left

twist

When

possible,

needles.

wellas"Z"

needle

threadinthe

discriminate

use

For

Threadingofneedle

(1)Pass

(2)

each

guide

(g)

Note: When

thread or filament

used, pass

(§) as well.

With

Vhe

most

position, pass each needle

the

order

Note:

Pressing

button

showninthe

saucerofthe

and

the

LU2-4730

ADJUST

to

(viewed

right

useofneedle

"Z"

twist

bobbin

twist

thread

needle

thin

the

thread

take-up

showninthe

the

upper

upper

thread

AND

use

from

needle.

threadinboth

thread,

canbeused.

"S"

front),

"S"

USE

twist

thread

and

threadsisim

twist

thread

"Z"

threads

thread

through

slippery thread (polyester

thread,

for example) is

through

lever

located

following

upper

thread

figure below

thread

tension

can easily

thread

at the

thread

figure.

loosening

opens

adjuster,

pulled

thread

guide

upper

out.

THE

in

the

as

in

the

MACHINE

*S"

'Z"

® d)

AjIjI

LU

2-4710

twist

twist

thread

thread

®(D

Needle

®

1

thread

releasing

o

tension

button

Neddie

thread

tension

releasing

button

©

- 9 -

Page 13

HOW TO

]

Adjustmentoffeed

ADJUST

AND

(stitch)

USE

THE MACHINE

length

stitch reversing (touch back)

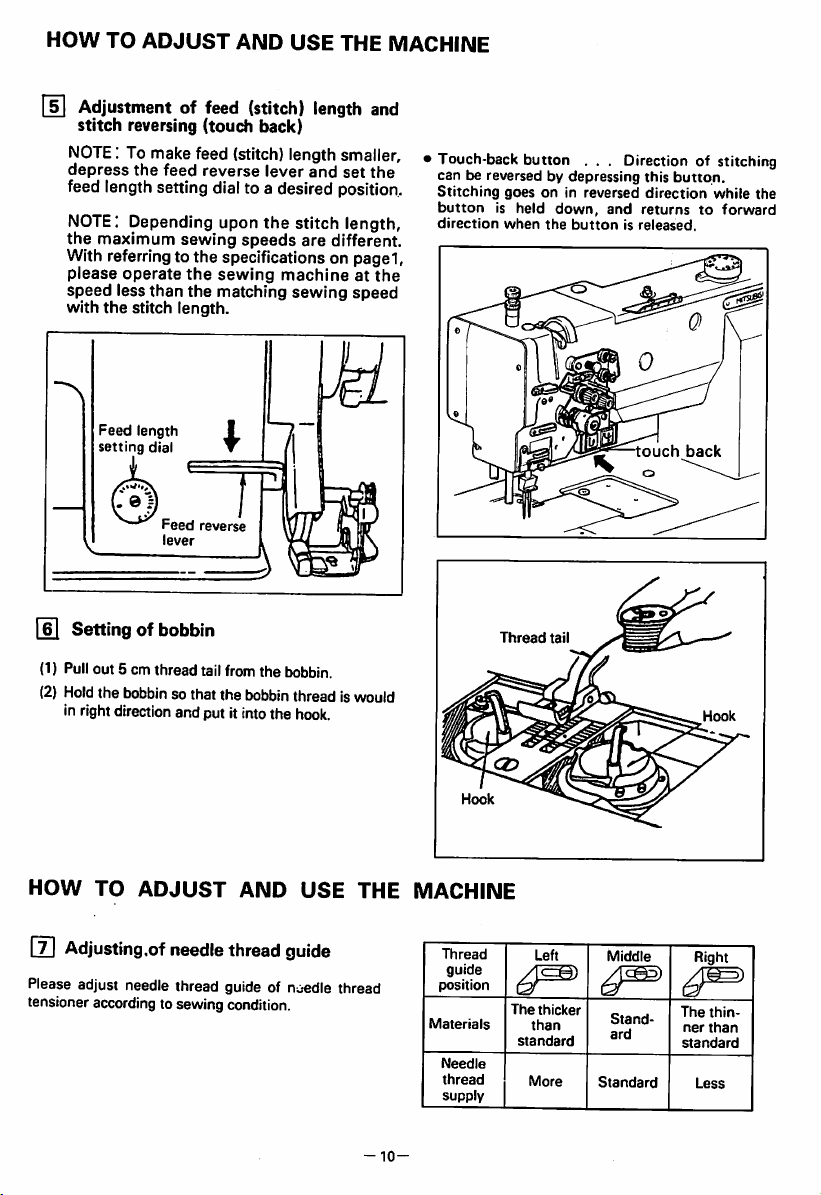

NOTE:

To make feed (stitch) length smaller,

depress

the

feed

reverse

lever

and

set

feed length setting dial to a desired position.

NOTE:

the

Depending upon

maximum

sewing

the

speeds

stitch length,

are

different.

With referringto the specifications on page1,

please

operate

speed

less than the matching

with

the

Feed

setting

the

stitch length.

length

dial

Feed

reverse

lever

sewing

I

machineatthe

sewing

and

the

speed

Touch-back button . . . Direction of stitching

can be reversed by depressing this

Stitching

button

direction

goesonin

is held

when

reversed

down,

the

and returnstoforward

buttonisreleased.

button.

direction

while

the

\

touch

back

Settingofbobbin

(1) Pullout 5 cm thread tailfromthe bobbin.

(2)

Hold

the

bobbin

Inrightdirectionand put it intothe

so thatthe

HOW

0

TO

ADJUST

Adjusting,of

needle

bobbin

AND

thread

thread iswould

hook.

USE

THE

guide

Please adjust needle thread guide of noedle thread

tensioner accordingto sewing condition.

-10-

MACHINE

Thread

guide

position

Materials

Needle

thread

supply

Thread

The

standard

Left

thicker

than

More

tail

Middle

Stand

ard

Standard

Right

The

ner

standard

Less

thin

than

Page 14

HOW

TO

ADJUST

AND

USE

THE

MACHINE

[S]

Threadingofbobbin

(l)Put

bobbin

thread

Into

the

lug(I)and extend itabove the bed.

Thread

Opener

<2)

While holding

rotate

By pulling up

figure,

bobbin

and

led

the

handwheel

the

thread

backward.

the

two needle threads by left hand,

one

the

needle

bobbin

and

threads,asshowninthe

threads

needle

thread

threads

slit^l>,pass

turn

willbelifted. Both of

under

Thread

by right

hand.

shouldbealigned

the

Balanceofthread

AO

B X

C X

ITl]

Needle

Turn

the

thread

edle

thread

thread

tension.

tension

tension

Balanced

Tight needle or

bobbin

Loose

bobbin

tension

adjust

nutstoadjust

tension

loose

tension

needleortight

tension

Pretension

Tighten

Loosen

Tighten

the

ne

^

Tension

screw

Tension

adjusting

adjusmtnetof bobbinthreads

Loosen

Tighten

[ia

Adjustment of presser foot pressure

Pressuretofabric(s)

pressure

-11

adjusting

Weaken

Loosen

Thread

tension

adjust

nut

canbeadjustedbyturning

screw.

^

Tighten

C

the

Page 15

HOW

TO

ADJUST

|j3|

Adjustmentofthread

AND

USE

take>up

THE

spring

1) Adjustment of thread take-up spring length

•To

adjust the thread take-up spring (D for the

left-hand

thread,

loosen

the

stopper

stop

screw (D and move the stopper (I).

•To

adjust the thread take-up spring ® for the

right-hand thread, loosen

the

stopper

stop

screw © and move the stopper ®.

2) Adjustment of thread take-up spring strength

•When

adjusting

loosen

the

Arm and turn next

Tighten

the

the

adjustment.

•When

adjusting

lock

lock

the

left-hand

nut

(2)

and

the

nut®and

the

right-hand

thread

screw

screw

thread

spring,

® in

(Q)

spring,

the

adjusting shaft

the

the

®.

after

loosen the screw ® and turn next the adjust

nut Tighten the screwi ® after the

adjustment.

MACHINE

decrease

ncrease

w

-

Right

side

-

Right

side

Loosen

Tighten

-

Left

side

ll^

AdjustmentofOutside

and

Inside

presser

1. Adjustment of alternating movement

(1)

The

alternating

pressre

be adjusted by using the adjusting dial

located on

foot

the

and

top

movement

inside

foot

presser

cover.

presserfoot

onthe

(2) Face the desired number printed on the

d|al to

the

top

(3) Thenumber printed onthe dialrepresents

the

presser

matching

cover.

possible

foot and inside presser foot from

mark

locatedonthe

protrusionofthe

the throat piate when the aiternating

movementsonthese

(4)

If the

alternating

set,

they can be readjusted up to 2.0-

6.0mm

are

evenly

movements

are

putside

foot

outside

set.

evenly

can

Alternating

adjusting

Matching

—

12—

mark

Rubber

dial

' ^

plug

stroke

Page 16

HOW TO

2. To

movements

and

(1) For

ADJUST

change

the

between

Inside

presser

example,toincrease

inside

presser

of

the

outside

(l)

Remove

top

throat

(3)

Loosen

(right)

(4)The

side

with

the rubber pluglocatedonthe

cover.

Rotate

the

presser

footisslightly

plate.

set

upper

feed

built-in

presser

the

throat

AND USE THE MACHINE

balanceofthe

the

outside

foot.

and

decrease

foot:

until

raised

(§)

located

rock

untilitmakes

plate.

Then,

the

foot,

presser

pulley

screw

lifting

spring pullsdown the out

foot

screw@.

(5) Thiscompletesthe adjustment,i.e.,the

protrusionofthe

has

been

And,

presser

same

(2) As a

contrary

riseofinside

the

riseofthe

First,

rotate

presserisslightly

the

foot

distance.

decreased

vertical

has

been

case

presser

outside

the

pulley

raised

outside

by a

motionofthe

increasedbythat

(1),todecrease

foot,

presser

until

from

plate. Next, loosen screw(§).

tightenscrew@.This decreases the rise

of

the

inside

presser

foot.

alternating

presser

riseofthe

the

the

outside

from

on the

shaft

contact

tighten

presser

set

distance.

and

increase

foot:

the

the

Finally,

foot

rise

the

crank,

set

foot

inside

the

inside

throat

Outside

presser

foot

Inside

Rubber plug

Upper

shaft

presser

2.0-6.0mm

feed

crank

foot.

lifting rock

(right)

Mounting

Turn

(1)

the

position.

(2) In

this

locatedonthe

in

the

showninthe

the

the

thread

st^te,

upper

Upper

balance

take-up

eccentric

figure.

eccentric

wheelbyhand

leveratthe

remove

the

arm.

Locate

feed

And

feed

rubber

No.2

lifting

tighten

lifting cam

to bring

lowest

plug

screw'A"

cam

it.

as

—13—

No,1

No,2

screw'A"

Upper

eccentric

liltingcam

screw

feed

Page 17

HOW

TO

ADJUST

AND

^ Instantalternatingswitch

During

the

sewing

hasastep,

the

alternating

ly

becomes

Hit

once,

(Blinking

Hit

twice,

ON

LED

OFF

T

hit

the

strokeofthe

much

lamp)

operation, ifa

instant

alternating

biggertoget

The

down

highest

Is

the

ewing

from

The

down

the

ed

stroke

USE

THE

sewing

switch,

walking

foot

over

the

alternating

movement

(It is

highest

machineisshipped

the

alternating

movement

normal

with

adjusting

adjusted

when

factory.)

stroke

the

becomes

becomes

alternating

dial.

material

then

instant

step.

up

and

6mm

the

up

and

controll

MACHINE

s-

Stopper

.Alternating

.adjusting

screw

Instant

alternating

stroke

dial

switch

NOTE1:The

2: It

Tfl The

instant

The

maximum

the

instant

be

adjusted

right

figure.

©The

maximum

when

factory.

If

the

to

make

procedures.

1.

2.

3.

4.

knee

the

instant

also

and

down

only

nating

stopper

alternating

alternating

with

the

sewing

maximum

smaller

Set

the

dialtothe

Loosen

Tighten

with

Tighten

switch

alternating

canbeset

movement

while

pressing

switch.

screw

alternating

functionisactivated

the

stopper

alternating

machineisshipped

alternating

somehow,

alternating

desired

the

nut

shownonthe

the

stopper

the

pin.

the

nut.

also

canbeused

switch.

the

alternating

most

the

instant

for adjusting

stroke.

stroke

the

time

screw

showonthe

stroke

is fixed at

strokeisrequired

take

the

following

stroke

screw

adjusting

right

untilithits

numberofthe

highest

alter

when

6mm

from

stroke.

figure.

the

can

the

as

up

Stopper

Screw

"V

E3

r

Nut

.

red

mark

.(position

6mm)

at

E

-14-

Page 18

HOW

TO

ADJUST

5^

Installing

Should

it be

regulator

procedure

CAUTION;Ifthe

positioned,

maybetoo

machine

(1)

Set the

wall

illustrated to

between

operation.)

necessarytodismount

bracket and its related

explained

the

operation.

clearance

locatedonthe

of

the

feed regulator bracket is poorly

resultant

short

the

the

these

Feed

below.

or long,

between

regulator

machine

left. (Use a

parts.

AND

regulator

alternating

causing

special

shaft

armto42.6mm

42.6mm

This

facilitates

USE

THE MACHINE

bracket

and

the

parts,

use

movements

defective

screw

and

the

spacer

(2)Withthe feed regulator stud held-as explained

step

(1)

above,

adjust

the

feed

in

bracket.

clearance of

pin(D

and

the

IISJ

Adjustment

sensing

(1)

(2) Remove all

1

(3)

set

(4) Turn ON

tion

lay VCat

(5) Loosen the slotted head bolt(0)of the potenti

ometer

At

any

(6) Fix

aft special

sewing

(Itisrecommendedtouse

42.6mm

(7)

Turn

displayVCindicates

(8) Tighten the slotted head bolt(Q)of

ometer

At

any

(9) Make

icates

If

from

again.

(10)Turn OFF

(11)Put

(12)Connectallthe

condition.

This

adjustment

2.3mm

the

arm.

located

top

Tighten

onthe

cover

ofthe

between

feed

mounting

screws

alternating

potentiometer

(Please

refertothe

Limi-servoX

Please

note

proper

Turn

connector.

Remove

the

this

the

this

the

set

thatiffault

sewing

OFF

the

the

the

alternating

the

panelofthe

the

crank.

time,

bending

torquetothe

distance between the feed adjusting

screw®

machine

for

quick

the

potentiometer

crank.

time,

bending

torquetothe

sure

again

280-289.

display

280-289,

the

the

top

cover

the

alternating

instruction

BMFY

also.)

speed

can

power

switch.

connectors

top

coverinthe

dial for

power

switch

control box to

programming

please

pay

and

arm

42.6mm.

fixing.)

280~289.

please

pay

that

the

indicates

adjust

the

power

switch.

backinthe

dial

for

connectors

the

scale

attention

potentiometer

the

shaftsothat

attention

potentiometer

input

the

potentiometer

except

then,

scale

back to

should

the

periphery of

regulator

face

located

manual

adjustment,

not

obtained.

the

condition

2.

set

the

the

input

mode

E.

nottogive

inner

wall of

the

spacer

the

nottogive

display VC ind

different

condition

2.

the

regulator

insure

bracket

stroke

optional

which

opera

shaft.

sized

the

input

potenti

shaft.

number

shaft

which

original

feed

side

the

the

disp

the

for

sh

the

@

as

on

-15-

Feed

n.

2.3mm

Feed regulator bracket

/

regulator

shaft

k

42.6mm

(A)

m

a

f

Potentiometer

©

42.6mm

Page 19

HOW TO ADJUST AND USE THE MACHINE

H

Timing

and

(1) Set feed length (stitch length) to

feed

needle

setting

between

motion

dial.

rotating

hook

motion

"6"

on the

(2)When needle is lifted 2.4mm from the lower

dead point, as shown in Figure, the follow

ing

positional relationship should be main

tained.

—The

upper edge of needle eye should be

2.3mm

below

the

hook

—The

hook point should be located at the

centerofneedle

—Gap

between the hook point and the side

faceofneedle

shouldbe0.05mm.

point.

axis.

(3) Needle/rotating hook position can be ad

justedasfollows.

(For easy adjustment, it is recommended

that the presser foot, throat plate and feed

dog assembliesare removed.)

•

Positioningofhook

(1)

When

the

smaller

crossed

side

and

left

larger wheel so

former

gear

thatofthe

(2) Tighten each

for

set

(3)

*Tofinely

screw,onthe

Approximate

"C"

screwofhook

the

needle

position.

motion

screwoflarger

wheelinits

from

adjust

and

1mmto2mm.

point

needleisat

side

DOWN

herical gearsonthe

shouldbeengaged

that

the

comesonthe

latter

gear on

"S"

positionofhook

when

hook

gear

axial

the

screw, where is punched

hook

shouldbefound

the

needleisat

timing

between

motion,

wheel

direction

position,

"S"

screw of the

front

side,

reverse side.

shaft.

the

loosen

and

move

withinarange

with

close

DOWN

needle

the

the

the

right

the

and

to

set

gear

Gap

and

Needle

2.4mm

needle lower ^

dead

Center

needle

between

upper

2.3mm

lift:

from

point

of

axis'

Hook

)

1 ~

hook

2mm

*

point

point

0.05mm

edgeofneedle

eye

1 ~

I

2mm

16—

Needle

position

DOWN

Page 20

OPERATION

gOl

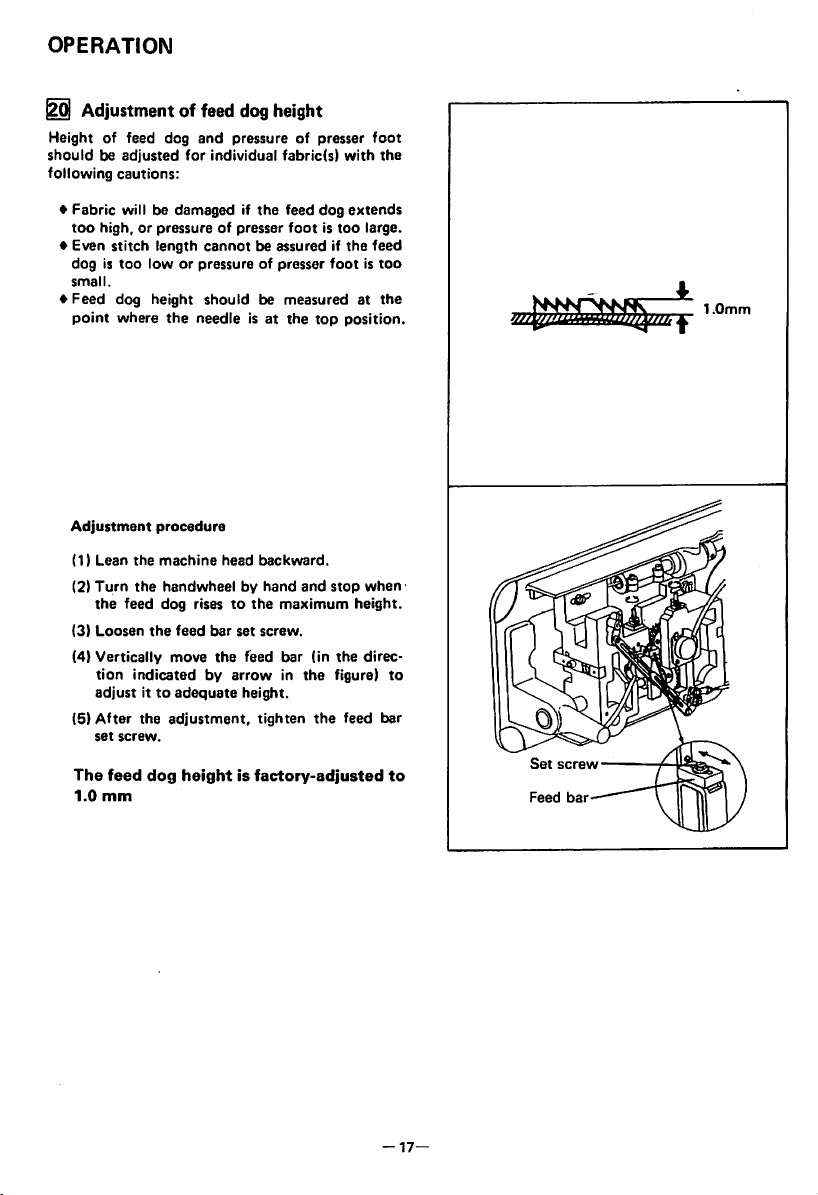

Adjustmentof feed dogheight

Height

of feed dog

shouldbeadjusted

following

cautions:

♦

Fabric

will be

too

high,orpressureofpresser

♦

Even

stitch

dogistoo

small.

♦

Feed

dog

point

where

and

pressure

for

individual

damagedifthe

length

cannotbeassuredifthe

loworpressureofpresser

height

shouldbemeasuredatthe

the

needleisat

of presser

fabric(s)

feed

dog

footistoo

the

top

foot

with

the

extends

large.

feed

footistoo

position.

mr-

I.Omm

Adjustment

(1)

Lean

(2)

Turn

the

feed

(3)

Loosen

(4)

Vertically

tion

adjustitto

(5)

After

set

screw.

The

feed

1.0

mm

procedure

the

machine

the

the

head

backward.

handwheelbyhand

dog

risestothe

feed

bar

set

screw.

move

the

feed

and

maximum

bar

indicatedbyarrowinthe

adequate

the

adjustment,

dog

heightisfactory-adjusted

height.

tighten

(in

the

stop

the

figure)

feed

when

height.

direc

bar

to

Set

Feed

screw

bar

to

—

17—

Page 21

HOW

TO

ADJUST

AND

USE

THE

] Relationship between rotating hook

motion

When the

moved

relationship

take-up

follows:

for

lever

and

timing

its

between

take-up

belt

replacement,

rotating

motion

lever

(toothed

should

motion

belt) was re

for

example,

hook

be

motion

adjusted

MACHINE

the

and

as

(DTurn

(2)

(3) If

]

(1)Turn

(2)

(3) If

the

take-up

Lean

sure

timing

the

black

stallitagaintoadjust.

balance,

leverisliftedtoits

the

machine

the

arrow

belt

bossoflower

the

timing

line,

Relationship

opener

motion

the

the

sure

@ and the

the

gapistoo

holder

balance

from

when

remotely

Make

holder

0.2mm.

opener

tionofthe

wheel

and

head

backward

(timing

is in

markisnotinline

remove

between

opener

the

gap

mark)

line

with

shaft

bearing.

the

timing

hook

wheelbyhand

holderislocated

throat

between

openerisapproximately

largeorsmall,

set

screw

opener.

@ and

upper

the

plate.

the

stop

when

dead

and

putonthe

black

belt

motion

and

bobbin

loosen

adjust

line

with

and

the

point.

make

the

and

stop

most

case

posi

on

in

the

Black

lower

Approx.

lineonboss

shaft

bearing

0.2mm

Timing

belt

-Timing

belt

Timing

mark

sprocket

-18-

Opener Screw (gi

Opener

holder

Page 22

HOW

TO

ADJUST

AND

USE

THE MACHINE

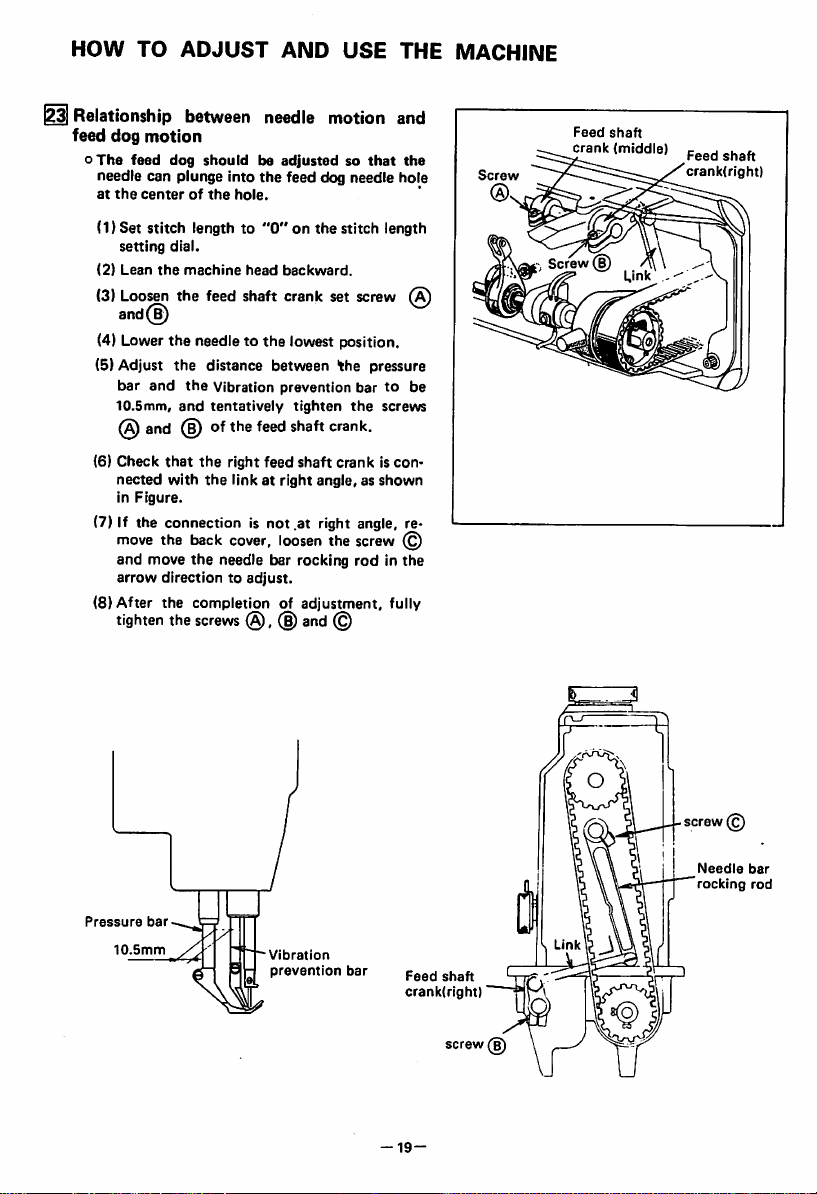

IRelationship between

feed

dog

motion

oThe

feed

dog

needle can plunge into

at

the

centerofthe

(1) Set stitch length to

setting

(2)

Lean

(3)

Loosen

shouldbeadjustedsothat

dial.

the

machine

the

feed

needle

the

feed dog needle hole

hole.

"0"

on the stitch length

head

backward.

shaft

crank

motion and

set

and(^

(4) Lower the needle to the lowest position.

(5) Adjust

(6) Check

(7) If the connection is not .at right angle, re

(8) After the completion of adjustment, fully

the

bar

and

10.5mm,

@

and

nected

in

Figure.

distance between

the

Vibration prevention bartobe

and

tentatively

@ of

the

feed

that

the

with

right feed

the

linkatright

the

tighten

shaft

crank.

shaft

crank is con

angle,asshown

move the back cover, loosen the screw (£)

and

move

the

needle

arrow

directiontoadjust.

tighten

the

screws@,(§)

bar rocking

and

©

screw

pressure

the

screws

rodinthe

the

Screw

(A)

Feed

crank

Screw

®

shaft

(middle)

Feed

shaft

crank(right)

Pressure

10.5mm

'©

Needle

bar

rocking

rod

bar

Vibration

prevention

bar

Feed

crank(right)"rpi

shaft

screw(D

-19-

Page 23

HOW

TO

ADJUST

AND

USE

THE

MACHINE

M SAFETY

Safety

the

the

CLUTCH

clutch

hook

and

threadiscaught

machineisloaded

ation.

1)

FUNCTION

1) When

pulley

hook

rotate.

2) Clean

into

3)

Turn

whether

properly,

2) HOW

1) While

opposite

balance

from

OF

the

safety clutch acts,

willbeunloaded,

shaft

will

Stop

the

the

thread

the

hook.

the

cog

the

hook

place

TO

SET

pressing

sideofbedbyleft

wheel

youasshowninthe

2) The balance wheel will

plate,

but

3) Release

4) As

3)

FORCE

CLUTCH.

1)

2) To

3)

firmly.

showninthe

deviceIsset.

The

smallest

tric

pin

The

white

adjust

loosen

pin.

After

the

set

the

APPLIED

force

appliedtothe

when

faces

force

mark

the

the

adjustment,

screw.

turn

push

the

proportionally

faces

the

set

DEVICE:

deviceisinstalledtoprevent

cog

belt

from

damageincase

into

the

hook

when

abnormally

SAFETY

stop.

operationofmachine.

thoroughly

belt

hubbyhand,

shaft

the

clutch

THE

down

slowly

CLUTCH.

then

the

The

arm

shaft

which is

rotates

deviceasfollows.

SAFETY

the

push

hand,

by

right

buttononthe

figure.

stop

the

balance

button.

Figure,

the

safety

TO

THE

safety

the.white

clutchIsthe

markofthe

centerofthe

increasesasthe

the

outside.

force,

slide

and

make

turn

the

the

suretofasten

screw,

during

the

by the gear

wheel

lower

timing belt,

the

oper

cog belt

rotation

only

will

caught

and

check

lightly

and

CLUTCH.

turn

the

hand

away

more

clutch

SEFETY

eccen

shaft.

eccentric

Safety

clutch

belt

pulley

belt

hub

of

Balance

wheel

Push

button

Gear

plate

White

Strengtheni^Screw

Weaken

Lower

-20-

Mark

Shaft

Eccentric

Timing

Pin

Eccentric

Belt

Pin

Page 24

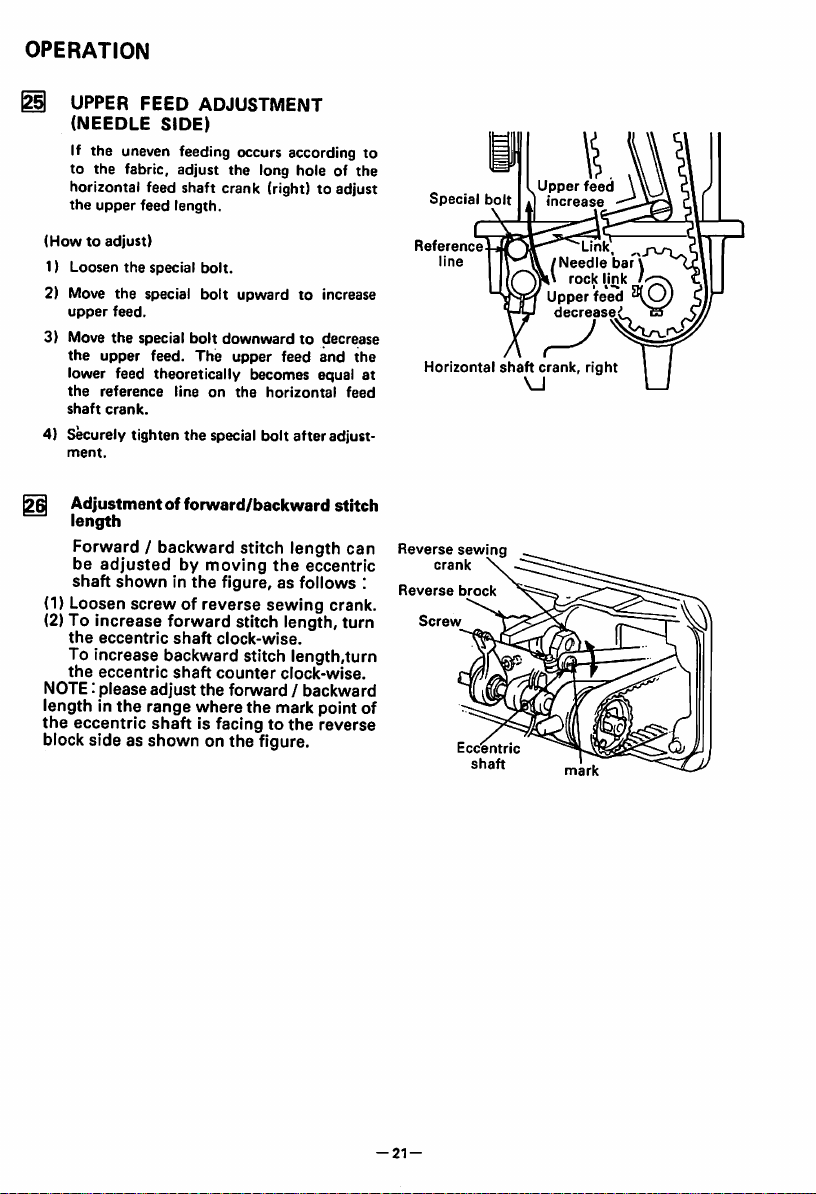

OPERATION

I

UPPER

(NEEDLE

If the uneven feeding occurs according to

to the fabric, adjust the long hole of

horizontal feed shaft crank (right) to adjust

the

upper

FEED

SIDE)

feed

length.

ADJUSTMENT

the

Special

bolt

.Upperfeed

»|

increase

\

(Howtoadjust)

1) Loosen

the

special

bolt.

2) Move the special bolt upward to increase

upper

feed.

3) Move

the

special

bolt

the

upper

lower feed theoretically becomes equal at

the

shaft

feed.

reference

crank.

downward to decrease

The

upper

lineonthe

horizontal

feed

and

4) Securely tighten the special bolt afteradjust

ment.

^

Adjustmentofforward/backward

stitch

length

Forward / backward stitch length

be

adjustedbymoving

shaft

showninthe

(1) Loosen

(2) To

the

screwofreverse

increase

eccentric

forward

shaft

the

eccentric

figure, as follows :

sewing

crank.

stitch length,

clock-wise.

To increase backward stitch length,turn

the

eccentric

NOTE: please

length in

the

eccentric

shaft

adjust

the

range where the mark point of

shaft

counter

the

is facingtothe

clock-wise.

forward / backward

reverse

block side as shown on the figure.

the

feed

can

turn

Reference

Horizontal

Reverse

crank

Reverse

Screw

sewing

brock

Eccentric

shaft

shaft

VJ

/Needle

Upper

decrease

crank,

rock

mark

Link

right

Mnk

feed

ba^V

*

-21-

Page 25

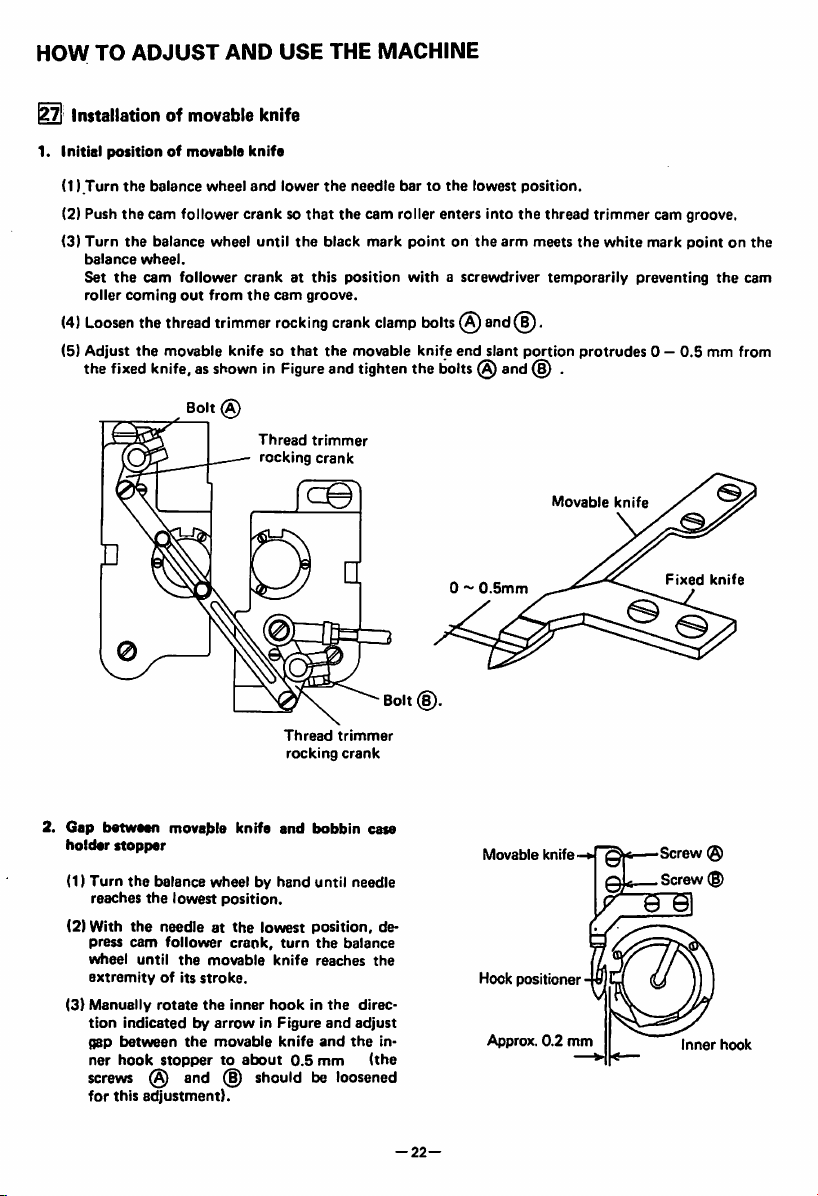

HOVyTOADJUST

13

Installationofmovable

1. Initial positionofmovable

(1)

Turn

the

balance

wheel

(2) Push

(3)

(4)

(5) Adjust

the

Turn

the

balance

Set

the

roller

coming

Loosen

the

fixed

cam follower

balance

wheel.

cam

the

the

wheel

follower

out

from

thread

trimmer

movable knife so

knife,asshowninFigure

Bolt

<g)

AND USE THE MACHINE

knife

knife

and

lower

the

needle

bartothe

cranksothat

until

crankatthis

the

cam

rocking

Thread

rocking

the

groove.

that

the

cam roller enters into

black

mark

position

crank

ciamp

the

movable knife

and

tighten

trimmer

crank

pointonthe

withascrewdriver

bolts

@ and(^.

end

the

bolts@and

lowest

slant

position.

the

arm

portion

thread

meets

the

temporarily

(§) .

trimmer

white

protrudes

cam groove.

mark

pointonthe

preventing

0 —

0.5

the

cam

mm from

2.

Gap

holder

(1)

(2) With

(3)

between

Turn

reaches

press

wheel

extremityofits

Manually

tion

gap

ner

screws

for

movable

stopper

the

balance wheel by

the

lowest

position.

the

needleatthe

cam

follower

until

rotate

indicatedbyarrowinFigure

between

hook

stoppertoabout

@

this

adjustment).

the

the

and

movable

stroke.

the

movable

(|)

crank,

inner

Thread

trimmer

rocking

crank

knife

and

bobbin

hand

until needle

lowest

position,

turn

the

0.5

balance

reaches

and

and

mm

knife

hookinthe

knife

shouldbeloosened

case

direc

adjust

the

(the

Bolt(B).

de

the

in

0 ~

0.5mm

Movable

Hookpositioner

Approx.

Movable

knife-

0.2

mm

knife

Fixed

Screw

Screw

Inner

knife

hook

—

22—

Page 26

HOW

TO

ADJUST

AND

USE

THE

MACHINE

Bracket

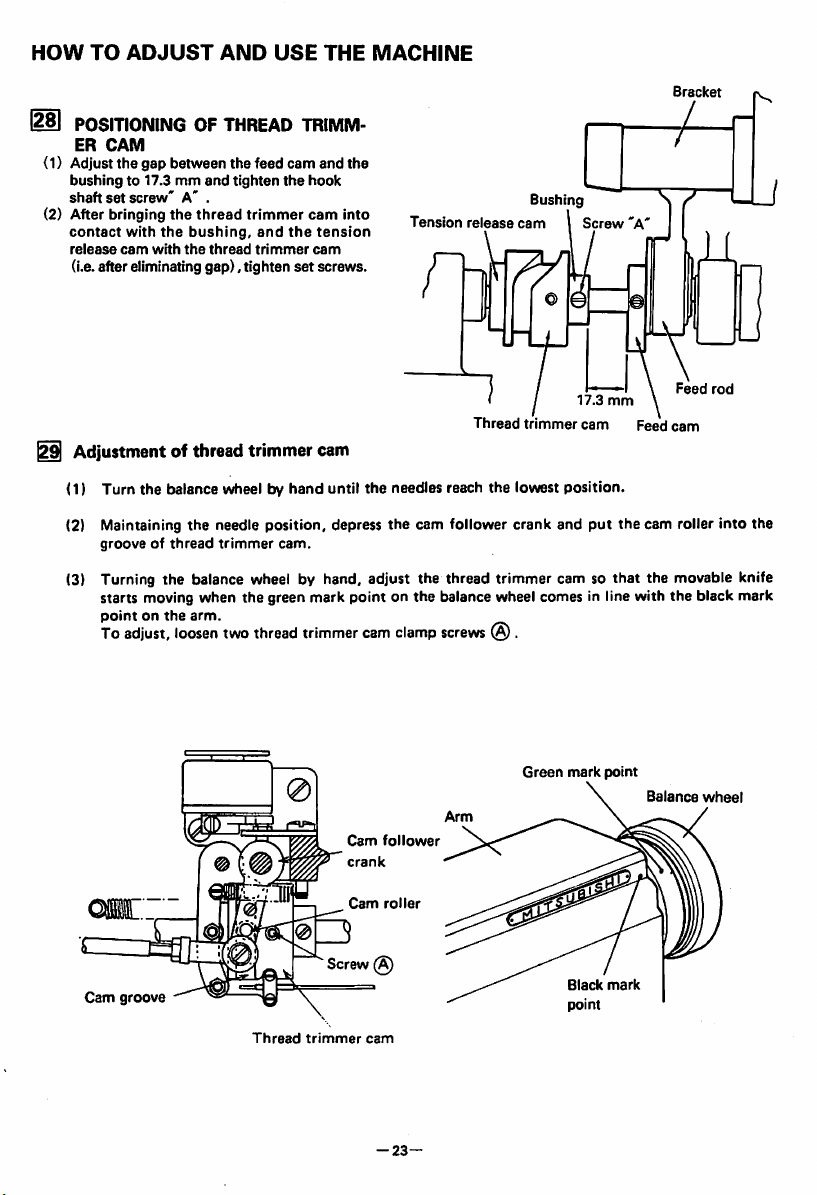

POSITIONING

ER

bushing

shaft

CAM

the

to 17.3mmand

set

screw'A'.

(1) Adjust

(2) After bringing

contact

with

release

cam

(i.e.after eliminating

OF

THREAD

TRIMM

gap between the feed cam and the

tighten

the

hook

the

thread

with

the

bushing,

the

thread

gap).

trimmer

tighten

and

trimmer

the

set

cam

tension

cam

screws.

into

Tension

Bushing

release

cam

t / 17.3

Thread

trimmer

Screw

cam

'A'

mm

Feed

I Adjustment of thread trimmercam

<1)

Turn the balance wheel by hand until the needles reach the lowest position.

(2) Maintaining the needle position, depress the cam follower crank and

grooveofthread

trimmer

cam.

(3) Turning the balance wheel by hand, adjust the thread trimmer cam so

starts moving when the green mark point on the balance wheel comes in line with the black mark

pointonthe

To

adjust,

arm.

loosen

two

thread

trimmer

cam

clamp

screws

® .

put

the cam roller into the

that

Feed

\

rod

cam

the movable knife

Cam

groove

Thread

Screw (A)

trimmer

Cam

crank

Cam

cam

-23—

follower

roller

Green

mark

Black

point

point

mark

Balance

wheel

Page 27

HOW

TO

ADJUST

5ol

Adjustmentofneedle

(1)

Turn

the

AND

threads

balance wheel by

USE

hand

THE

tension

until

MACHINE

release

the

needles reach

assembly

the

lowest position.

(2) Maintaining the needle position, depress

grooveofthread

(3) Turning the balance wheel by hand, adjust

close when the white mark point on the balance wheel comes inline with the black mark point

on

the

arm.

To

adjust,

(4)

Opening

the

convexed

To

adjust,

(5)

Make

fine

(6)

Loosen

thenut(§)

trimmer

loosen

degreeoftension

portionofthread

loosen

two

the

cam.

tension

screws

release

disc

© and

adjustmentbyloosening

and

make

the

N

shouldbeadjusted

release

the

the

cam

clamp

cam,

as shown in Fig.

draw

the

thenut{§).

outer

casing

cam follower crank and

thread

tension release cam so

screws

@.

withthe

tension

wire.

approach

rightwardtoincrease

White

put

release

mark

the

that

roller

point

(D|

Cam

Thread

release

Screw

Roller

Thread

release

tension

lever

(§)

(D

cam

Thread

cam

trimmer

(D

_

Screw©

crank

Cam

follower

roller

Outer

casing

Black

point

mark

cam roller into the

the

tension disc

(g)

mounted

the

opening

value.

Balance

wheel

on

-24—

Page 28

HOW

TO

ADJUST

AND

USE

THE

MACHINE

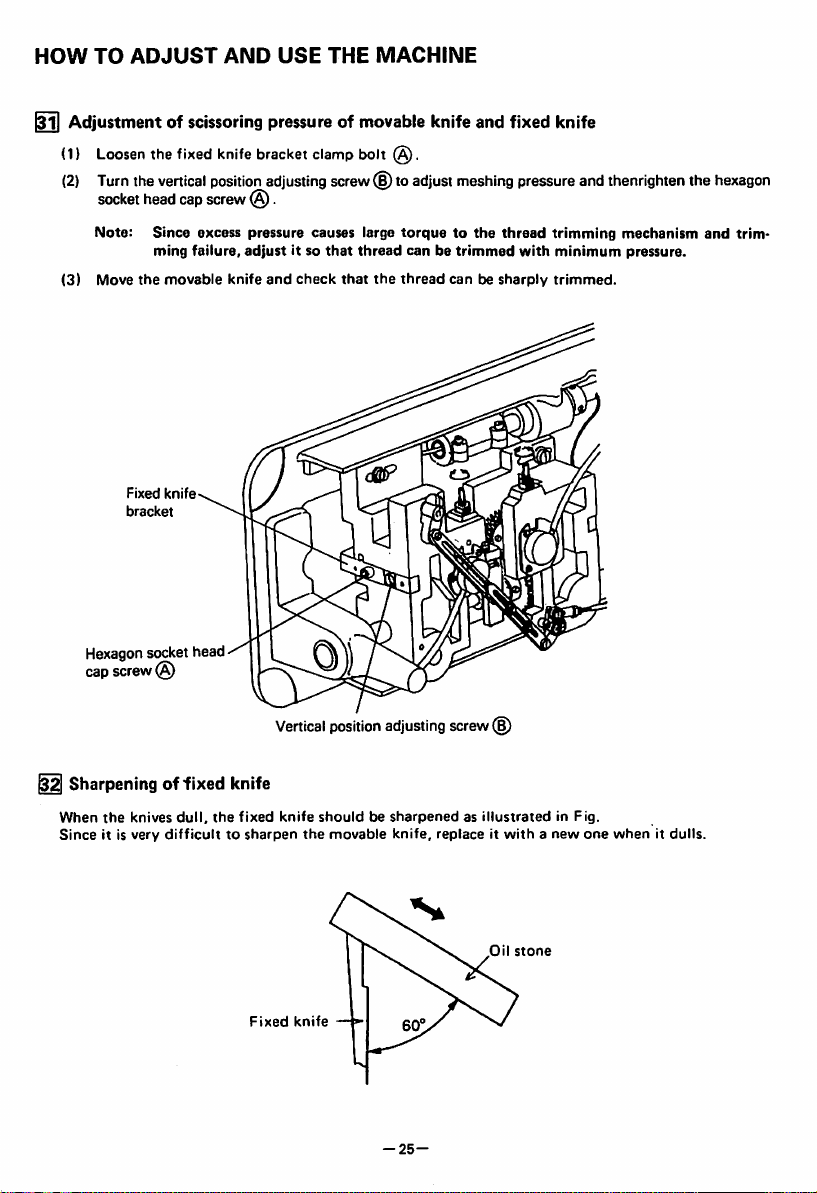

^ Adjustment of

(1)

Loosen

the

(2)

Turn

the

vertical

socket

head

Note:

Since

ming

(3)

Move

the

movable

Fixed

knife

bracket

Hexagon

cap

screw

sockethead

@

scissoring

fixed

knife

position

cap

screw

excess

failure,

bracket

(§).

pressure

adjust

knife

pressure of

clamp

adjusting

and

it so

check

screw

causes

that

movable

bolt

large

thread

that

knifeand fixed knife

(S)to

adjust

meshing

torquetothe

canbetrimmed

the

thread

canbesharply

pressure

thread

with

and

trimming

minimum

trimmed.

thenrighten

mechanism

pressure.

the

and

hexagon

trim

^

Sharpeningoffixed

When

the

knives

Since

it is

dull,

very

difficulttosharpen

the

knife

fixed

Fixed

Vertical

position

adjusting

knife

shouldbesharpenedasillustratedinFig.

the

movable

knife

-25-

screw(§)

knife,

replaceitwithanew

Oil

stone

one

whenitdulls.

Page 29

OPERATION

Adjustment forchangeofneedle-to-needle distance

(1)

Replace

thethroat

(Sincethe throat plate and feed dog are

suretouse

(2) Lean

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11) Adjustment of

the

Loosen

Remove

Loosen

hook.

When

the

Contact

link

clamp

Turn

the

Loosen

Depress

smoothly

(a) Push

machine

two

the

the

needles

the

balance

the

the

enter

the

plate,

feeddog,presser

those

specified

connecting

spring

hook

and

rocking

head

backward.

.

bracket

hooks

cranks

link

by us.)

clamp

clamp

have

(c)

and

bolt(^.

wheel by

nuts

(§)

cam

follower

the

the

cam follower crank so

hand

and

(0).

crank®and

grooveofthread

cam groove and

until

foot,

special

bolts

Q).

screws®and(Dand

been

adjusted,

(5) to

the

the

needles reach

adjust

trimmer

the

cam.

cam roller

that

the

(LU2-4730)

and

needle

the

the

pins

clamp.

adjust

spring

(§)

lowest

gap

between

@.

and

position.

rod©so

the

each

and

tighten

that

the

cam groove.

parts designed for thread trimming machine,be

install

stopper

the

connecting

cam roller enters into

(b)Turn the connecting rod (L)and adjust the clearance between the cam roller and the cam

groove

(c) Push

thread

surfaceNas

the

cam follower crank again and check

trimmer

Thread

trimmer

rocking

crank(£)

Connecting link

Hook

bracktt

smallaspossible,

cam

groove

Screw

smoothly.

^

Stopper pin ©

and

tighten

Screw

Hook

the

Cam

bracket

Spring

C0

Cam

nuts

that

roller

groove

'IW

(§)

and

(§).

the

cam roller enters into

,Cam

follower

crank

.

Thread

cam

.

Lower

i

(haft

N-phase

Cam

crank

trimmer

follower

needle

the

cam

and

connecting

roller

can

the

Bolt

Stopper

pin®

Thread

trimmer

rocktrtgcrank(Ql

-26-

!

Nut

Connecting rod I'D

NutThread

Screw

I'd!

(H

liimincr

cam

Page 30

Amitsubishi

HEAD OEFICE MITSUBISHI DENKI

BlOC

electric

MAAUNOUCHI TOKYO

corporation

100

TELEX

J2AS32

CABLE MELCOTOKYO

A180E363P02

PrintedinJapan

Loading...

Loading...