Page 1

INDUSTRIAL

LU2-4410-4430

A

MITSUBISHI

SEWING

MACHINE

MoHaI

Classes

Thank

Please

you

for

read.this

Single-Needle,

Automatic

choosing

instruction

Mitsubishi Industrial

carefully

Variable

before

INSTRUCTION

Double-Needle

Lockstitch

Compound-Feed

undertrimmer

speed

Sewing

operating

control

Machine.

the

machine.

MANUAL

Page 2

PRECAUTIONS

[T]

Safety Precautions

1.

When

turning

around/under

2.

Power

his/her

3. The

power

the

"V" belt,

4. Avoid placing fingers, hairs,

or

motor

the

the

needle

mustbeturned

seat.

mustbeturned

adjusting

when

the

machineisoperation.

power

and

off

the

BEFORE

on,

keep

your

the

area

around

when

the

machineisnot

off before tilting

machine, or

bars

etc.,

STARTING

hands

and

the

the

when

replacing.

near

the pulley, "V" belt, bobbin

Injury

could

fingers

pulley.

used,orwhen

machine head, installing or removing

result.

OPERATION

away

from

the

operator

winder

the

area

leaves

pulley,

5. Do not insert fingers into the thread take-up cover, under/round the needle, or pulley

when

the

machine

is in

operation.

6. Ifa belt cover, finger guard, and/or eye guard are installed, do not operate the machine

without

these

safety

devices.

[2]

Precaution before Starting Operation

1. if

the

the

2. If

lubricating.

3.

Whenanew

pulley

(The pulley

4. Verify

nameplate.

machine's oil pan

machineislubricated

sewing

with

the

should

the

voltage

power

has

machine

on.

rotate

counterclockwise

and

(singleorthree)

an oil

sump,

by a

is first

drop

turned

never

oiler,

when

phase

operate

never

on,

viewed

verify

with

the

machine before filling it.

operate

the

machine

the

rotational direction of

from

the

pulley.)

those

given on

the

before

the

motor

[U Precaution for Operating Conditions

1. Avoid using

temperature(5°C or lower). Otherwise, machine failure may result.

2. Avoid

3. Avoid using the

high-frequency

using

the

machine at

the

machineindusty

machineinareas

welder

and

abnormally

conditions.

others.Isgenerated.

high temperature(35°C or higher) or low

where

too

much

electrical noise,

resulted

from

the

Page 3

-

CONTENTS

-

PREPARATION

m

Power

I 2 I

Connectionofcontrol

r3~l

Adjustment of needle bar stop position 2

CAUTIONS

m Oiling(l) 3

I 2 I

Oiling(2)

I 3 I

Oiling

FOR

OPERATION

cable

ON

connection

USE

box 2

condition 4

I 4 I Adjustment of oiling to rotating hook 4

I 5 I Cautions on operation 4

OPERATION

m Installation of needles 5

m Winding of bobbin thread 5

I 3 I Selection of

thread

I 4 I Threading of needle threads 6

m Adjustment of feed

ri"!

Setting of bobbin 7

(stitch)

length and stitch reversing (touch-back) 7

I 7 I Threading of bobbin threads 8

r"8~l

Tension adjustment of bobbin threads 8

r"9~l Balance of thread tension 8

I101 Needle thread tension 8

rm

112I

nn

Adjustment

Timing

Adjustment

of presser foot pressure 8

between

rotating

hook

motion

and

needle

motion

of feed dog height 10

1141 Relationship between rotating hook motion and take-up lever motion 11

115 I Relationship between hook motion and opener motion 11

I161

Relationship

between needle motion and feed dog motion 12

117I Safety clutch device 13

1181 Upper feed adjustment (needle side) 14

I19 I Outside presser foot and inside presser vertical stroke adjustment 14

riol

Adjustment of forward/backward stitch length 15

rm

Installation of movable knife 15

Adjustment

Adjustmentofneedle

I

241

Adjustment

I25I

Sharpeningoffixed

I

261

Adjustment

of thread

trimmer

threads

cam 16

tension

of scissoring pressure of

knife

for change of

needletoneedle

release

assembly

movable

knife

and

fixed

knife

distance 19

17

18

18

1

3

6

9

ADJUSTMENT

I 1 I "1—2 POSITION" select switch operation

i 2 I Pedal operation

AND

OPERATION

OF

CONTROL

UNIT

20

20

I 3 I Adjusting the pedaling forces 20

I 4 I Adjusting the stitching speed 21

I 5 I Optional functions 22

Specifications 24

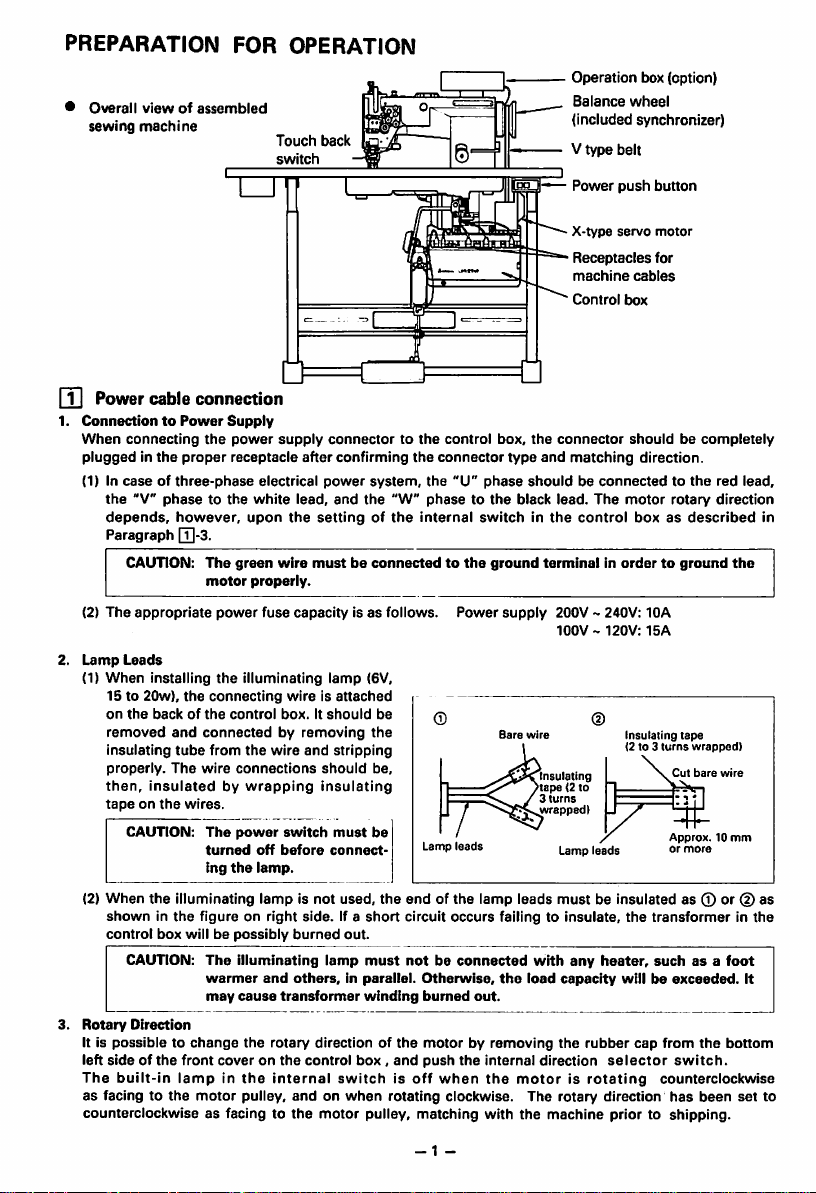

Page 4

PREPARATION

Overall

viewofassembled

sewing

machine

FOR

m Power cable connection

1.

ConnectiontoPower

When

connecting

pluggedinthe

(1) In

caseofthree-phase

the

"V"

phasetothe

depends,

Paragraph [T|-3.

CAUTION:

(2)

The

appropriate

Lamp

Leads

(1)

When

installing

15 to

20w),

on

the

backofthe

removed

insulating

properly.

then.

Insulatedbywrapping

tapeonthe

CAUTION:

(2)

When

the

showninthe

control

box

CAUTION:

Rotary

Direction

It is

possibletochange

left

sideofthe

The

built-in

as

facing to

counterclockwise

Supply

the

power

proper

receptacle

electrical

white

however,

the

and

tube

The

wires.

illuminating

upon

The

green

motor

properly.

power

fuse

the

illuminating

connecting

control

connectedbyremoving

from

the

wire

connections

The

power

turned

off

ing

the

lamp.

lampisnot

figureonright

willbepossibly

The

illuminating

warmer

and

may

cause

the

front

coveronthe

lampinthe

the

motor

pulley,

as facing to

OPERATION

Touch

back

switch

supply

connectortothe

after

confirming

power

lead,

the

wire

capacityisas

wireIsattached

box.Itshould

wire

and

switch

before

side.

burned

others,inparallel.

transformer

rotary

control

internal

andonwhen

the

system,

and

the

settingofthe

mustbeconnectedtothe

lamp

(GV,

be

the

stripping

should

be,

insulating

must

be

connect

used,

the

If a

short

out.

lamp

must

winding

directionofthe

box,

switchisoff

motor

pulley,

control

the

connector

the

"W"

"U"

phasetothe

internal

follows.

Lamp

Power

leads

endofthe

circuit

occurs

notbeconnected

Otherwise,

burned

motorbyremoving

and

push

the

when

rotating

clockwise. The

matching

Operation box (option}

Balance

(included

V

Power

X-type

Receptacles

machine

Control

box,

the

connector

type

and

matching

phase

shouldbeconnectedtothe

black

switchinthe

ground

lamp

lead.

control

terminalinordertoground

supply

200V

100V

Bare

wire

Insulating

tape<2to

3

turns

wrapped)

Lamp

leads

must

failing to

the

with

load

insulate,

any

capacity

out.

the

internal

direction

the

motorisrotating

rotary

with

the

machine

wheel

synchronizer)

type

belt

push

button

servo

motor

for

cables

box

shouldbecompletely

direction.

red

The

motor

rotary

direction

boxasdescribed

the

240V:

10A

120V:15A

@

Insulating

tape

(2to3

turns

wrapped)

Cut

bare

wire

Approx.10mm

or

leads

more

be insulated as 0 or (D as

the

transformerinthe

heater,

suchasa

foot

willbeexceeded.

rubber

cap

from

the

selector

bottom

switch.

counterclockwise

direction

prior to

has

been

shipping.

lead,

set

in

It

to

- 1 -

Page 5

PREPARATION

FOR

OPERATION

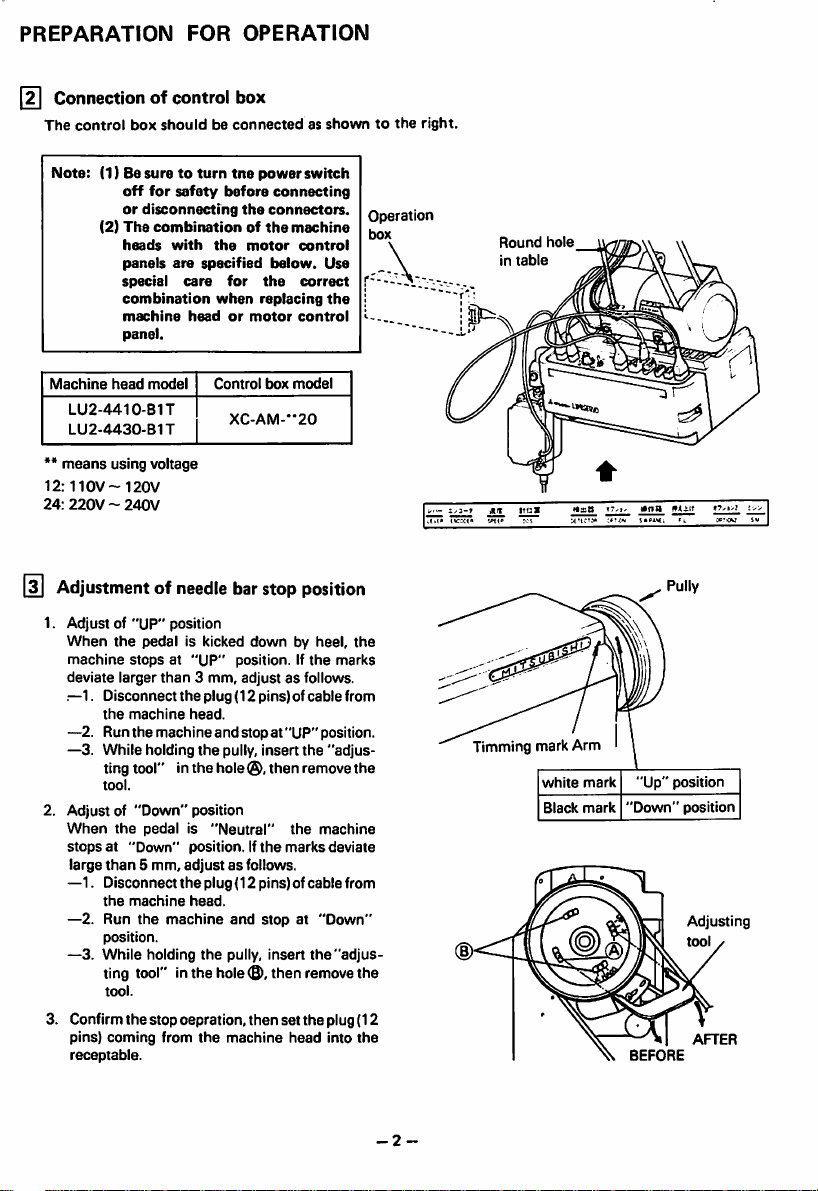

Connection

The

control

Note:

Machine

LU2-4410-BIT

LU2-4430-B1T

•*

means

12:110V~120V

24:

220V~240V

of

box

shouldbeconnectedasshowntothe

(1) Be

suretoturn

off

for

or

disconnecting

(2)

The

combinationofthe

heads

panels

special

combination

machine

panel.

head

model

using voltage

control

tne

safety

before

with

the

are

specified

care

for

when

headormotor

Control

XC-AM--20

box

the

Adjustmentofneedle bar

1. Adjust of "UP" position

When

the

pedal

machine

deviate larger

.—1.

Disconnect

the

—2. Run

—3. While holding

ting tool" in

tool.

2. Adjust of "Down" position

When

the

stopsat"Down"

large

than

Disconnect

—1.

the

—2. Run

position.

—3.

While

ting tool" in the hole0,then remove the

tool.

3. Confirm the stop oepration,

pins)

coming

receptable.

is kicked

stopsat"UP"

than

3 mm, adjustasfollows.

the

machine

the

pedalis"Neutral"

5 mm,

machine

the

plug (12 pins) of

head.

machine

the

the

position.Ifthe

adjustasfollows.

the

plug (12 pins) of

head.

machine

holding

the

from

the

and

pully, insert

hole®,

position. If

stopat"UP"

and

pully,

machine

power

switch

connecting

connectors.

machine

motor

control

below.

box

Use

correct

the

control

model

position

by heel,

the

the

replacing

stop

down

cable

position.

the

"adjus

then remove the

the

machine

marks

cable

stopat"Down"

insert

the

then

set

the

plug(12

head

into

the

marks

from

deviate

from

"adjus

the

Operation

box

right.

Timming mark Arm

Round

in

table

hole

white

Black

mark

mark

"Up"

"Down"

Pully

position

position

Adjusting

tool

AFTER

-2

-

Page 6

CAUTIONS

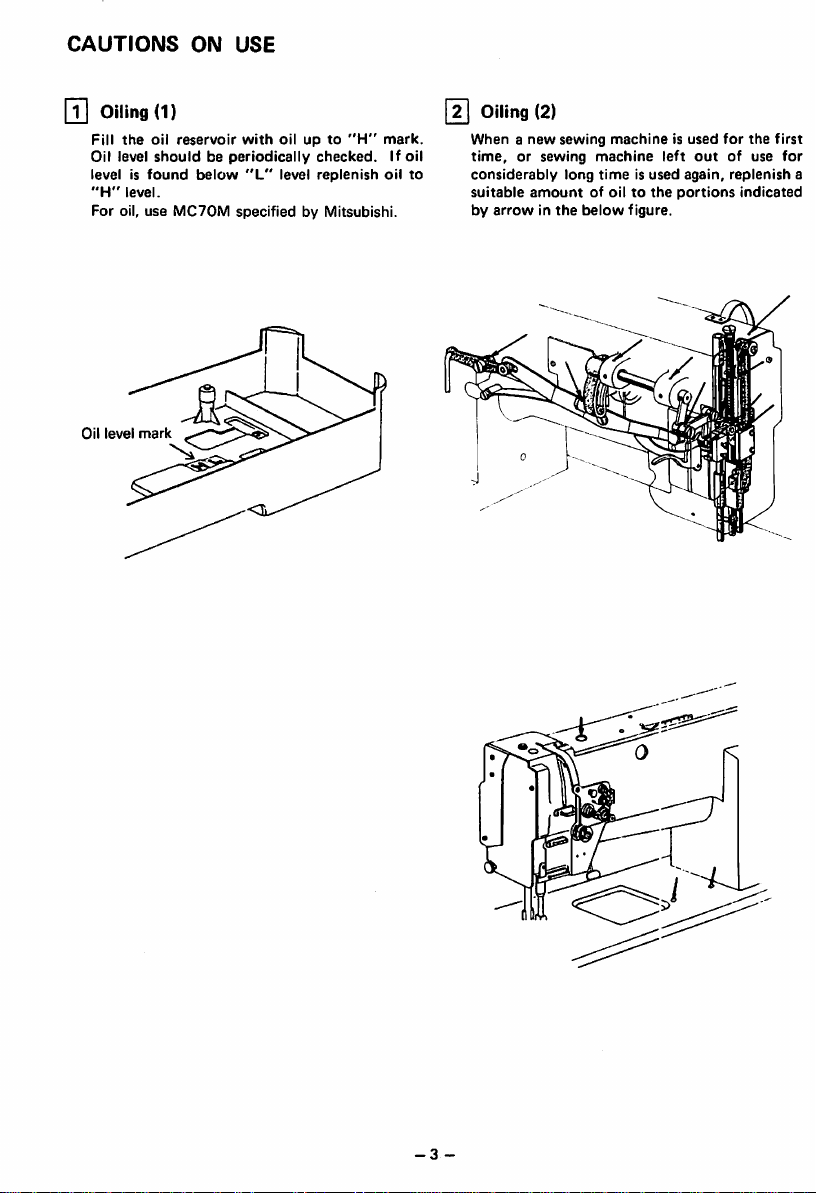

\T\

oiling

Fill

the

Oil level

level is

"H"

level.

For oil, use

Oil

level

ON

USE

(1)

oil

reservoir

shouldbeperiodically

found

MC70M

with

oilupto

below

"L"

level

specified by Mitsubishi.

"H"

checked.

replenish

mark.

If oil

oil

to

[2]

Oiling

Whenanew

time,

considerably

suitable

by

(2)

sewing

or sewing

long

amountofoiltothe

arrowinthe

machineisused

machine

timeisused

below

figure.

left

again,

portions

out

for

the

of use for

replenish

indicated

first

a

-3

-

Page 7

CAUTIONS

ON

USE

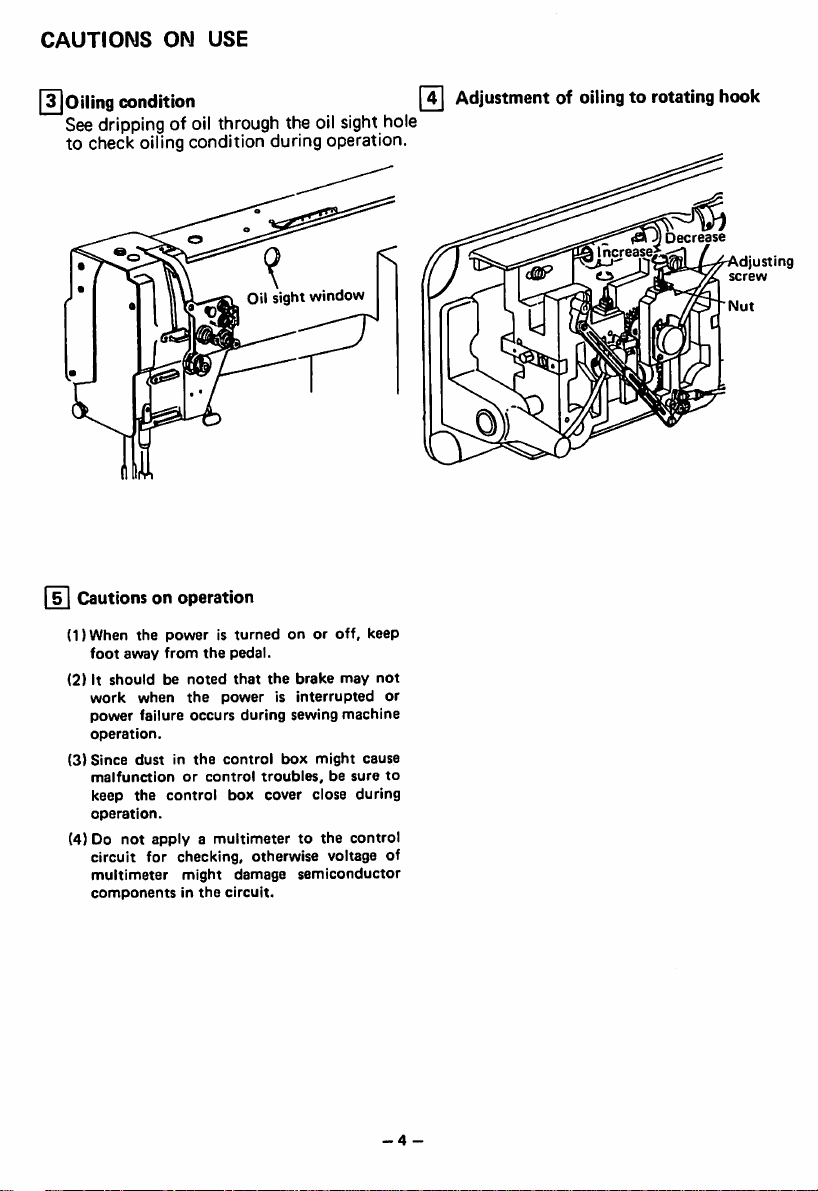

I^Oiling

condition

Seedrippingof oil through the oil sight hole

to check oiling condition during operation.

Oil sight window

j

Cautionsonoperation

11)

When

the

foot

(2)Itshouldbenoted

work

power

operation.

(3)

Since

malfunctionorcontrol

keep

operation.

(4) Do

poweristurnedonor

away

from

the

pedal.

that

when

the

failure

occurs

dustinthe

the

control

not

applyamultimetertothe

the

powerisinterrupted

during sewing

control

troubles,besure

box

cover close

circuit for checking, otherwise voltage of

multimeter

componentsinthe

might

damage

circuit.

off,

brake

may

machine

box

might

semiconductor

keep

not

or

cause

during

control

0

Adjustmentofoilingtorotating

to

hook

Decrease

"°"i ' ' *

djusting

screw

Nut

-4

-

Page 8

OPERATION

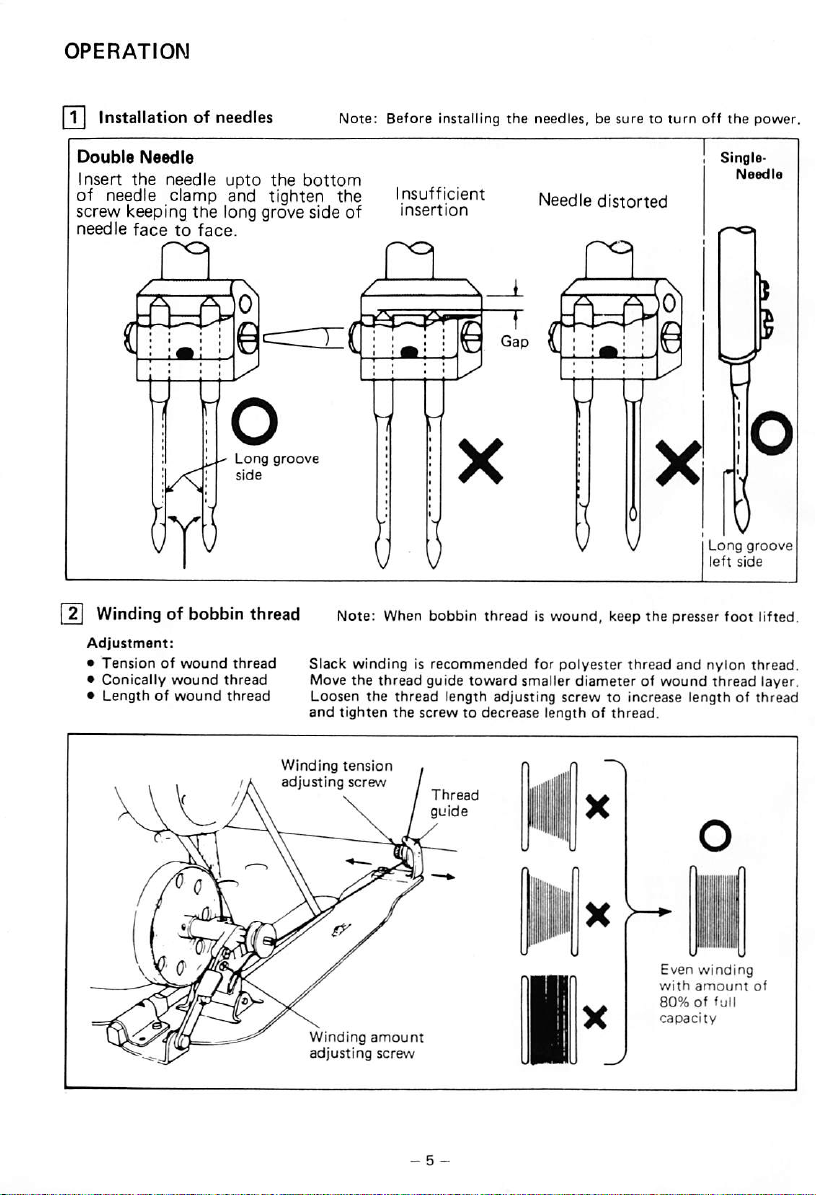

[T]

Installationofneedles

Note:

Before

installing

the

needles,besuretoturn

off

the

power.

Double

Insert

of needle clamp and tighten

screw keeping

needle

Needle

the

needle

the

facetoface.

I

Windingofbobbin

Adjustment:

•

Tensionofwound

• Conically

• Length

of

wound

wound

upto

the

bottom

long grove side of

Long

groove

side

thread

thread

thread

thread

the

Note:

Slack

Move

Loosen the

and

tighten

nsufficient

insertion

When

windingisrecommended

the

thread

thread

the

Needle

distorted

bobbin

threadiswound,

guide

toward

length adjusting screw to increase length of

screwtodecrease

for

smaller

lengthofthread.

keep

the

polyester

thread

diameterofwound

presser

and

Single-

Long

left

foot

nylon

thread

Needle

groove

side

thread.

lifted.

layer.

thread

i

/A

Winding

adjusting

I

tension

screw

Thread

guide

Even

winding

with

amount

80%offull

capacity

of

Page 9

OPERATION

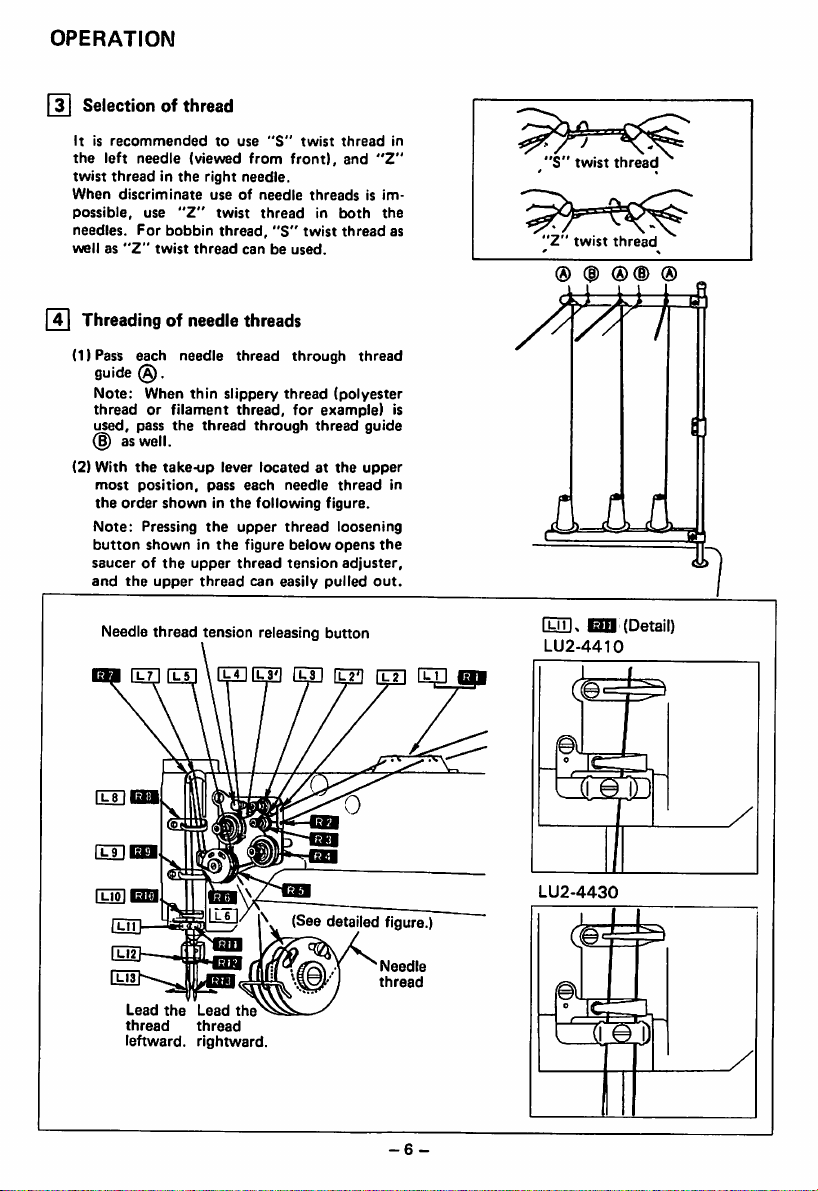

[y|

Selection of thread

Itisrecommended

the

left

twist

When

possible,

needles.

wellas"Z"

[41

(1)Pass

needle

threadinthe

discriminate

use

For

Threadingofneedle

each needle

guide

(§).

Note:

When

threadorfilament

used,

pass

(§) as well.

(2)

With

the

most

position,

the

order

Note:

Pressing

button

showninthe

saucerofthe

and

the

Needle

to

use

(viewed

from

right

needle.

useofneedle

"Z"

twist

bobbin

thread

thread,

canbeused.

twist

threads

thread

thin

slippery

the

take-up

showninthe

upper

thread

thread,

thread

through

lever

pass

each

the

upper

figure

upper

thread

thread

can

tension releasing button

"S"

twist

front),

threadsisim

thread

in

"S"

twist

through

thread

for

example)

thread

locatedatthe

needle

following

thread

below

tension

easily

figure.

pulled

thread

and

"Z"

both

the

thread

thread

(polyester

guide

upper

thread

loosening

opens

the

adjuster,

out.

in

"S"

twist

thread

as

"Z"

® ®

twist

thread

®(D

®

V

is

in

L

Iliik

I3D

LU2-4410

bil

(Detail)

Lead

the

thread

leftward,

Lead

the

thread

rightward.

(See detailed figure.)

Needle

thread

-6-

LU2-4430

<k

Page 10

OPERATION

I

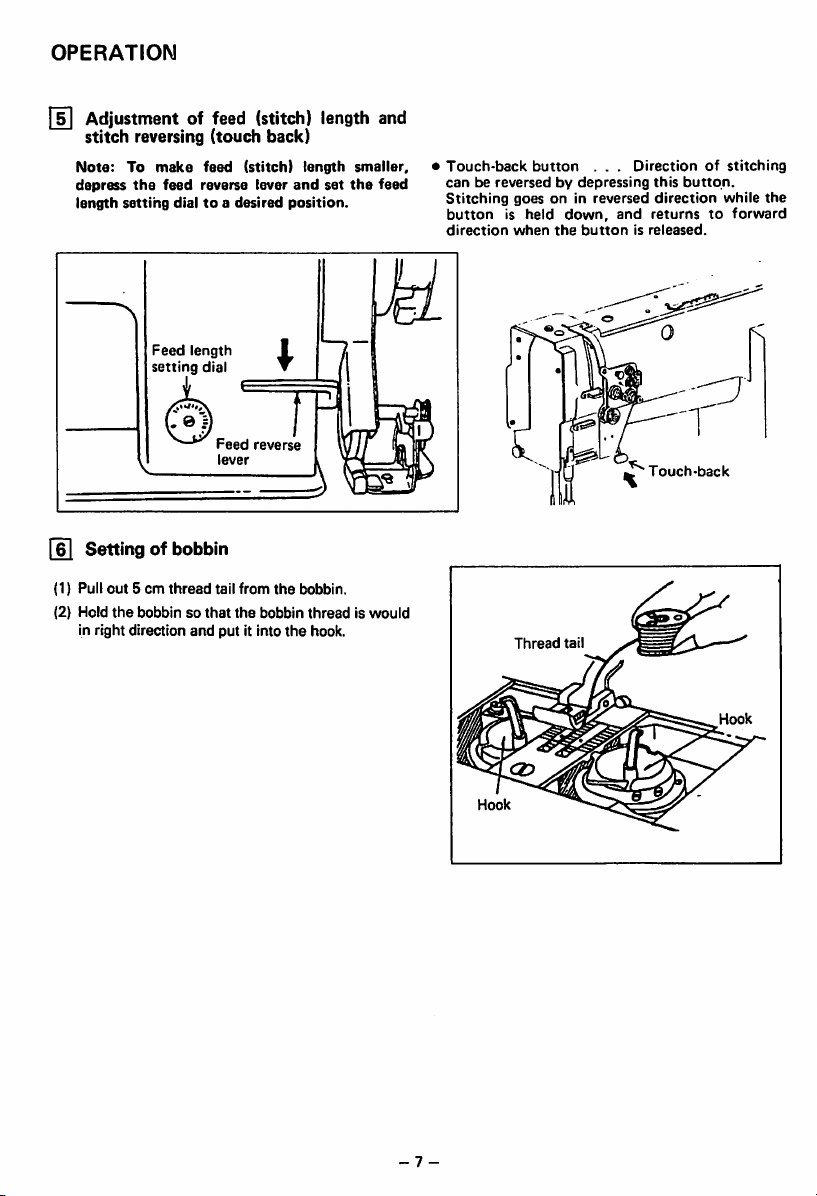

Adjustmentoffeed

stitch

reversing (touch back)

Note:

To

the

setting

make

feed

Feed

setting

depress

length

Settingofbobbin

(1) Pull

out5cm

(2) Hold

the

bobbinsothat

in right direction

reverse

dialtoa

length

thread

and

feed

dial

Feed

lever

tail

put it into

(stitch)

(stitch)

lever

desired

reverse

from

the

bobbin

length

length

and

position.

I

•

the

bobbin.

threadiswould

the

hook.

set

and

smaller,

the

feed

•

Touch-back

canbereversedbydepressing

Stitching

buttonisheld

direction

button

goesonin

down,

when

the

Thread

tail

. . .

reversed

buttonisreleased.

Directionofstitching

this

button.

direction

and

returnstoforward

Touch-back

while

the

- 7 -

Page 11

OPERATION

[7]

Threadingofbobbin

(1) Put the hook into the bobbin case and press

down

the

leftonthe

(2) While holding

hand,

hand.

showninthe

lifted.

needle

ward.

latch

bed.

Thread

the

rotate

the

By

pullingupthe

figure,

Each

combinationofbobbin

thread

should

threads

.

The

thread

end

should

Thread

Opener

two needle threads by left

handwheel

the

bobbin

be aligned

one

needle

turn

threads,

threads

thread

and

by right

will

led

and

back

be

(Tol

*

Needle

referencetobobbin

as

• To

be

sion

Needle

special

and

spring.

Balanceofthread

AO

8X

CX

Needle

threadtension

thread

tension

adjust

needle

adjusting

thread

fabric

movable

thread

nut.

tension can be also

and

range of slack

tension

Balanced

Tight

bobbin

Loose

bobbin

shouldbeadjusted

thread

threadbychanging

needleorloose

tension

needleortight

tension

tension.

tension,

thread

tension

turn

adjusted

each

ten

for

intensity

adjusting

in

[si

Tension

Tension

screw

adjusmtnetofbobbin

adjusting

threads

Loosen

Tighten

l\lfe

Loosen

&

|Tl|

Adjustmentofpresser

Pressuretofabric(s) can be

pressure

-8-

adjusting

screw.

Tighten

1

Thread

adjusting

foot

pressure

adjustedbyturning

Weak

Pressure

adjusting

screw

tension

nut

the

Page 12

OPERATION

12 Timing between rotating hook motion

and

needle

motion

(1) Set feed length (stitch length) to

feed

setting

(2) When

dead

dial.

needleislifted

point,

as shown in Figure, the follow

2.4mm

ing positional relationship should be main

tained.

—The

upper edge of needle eye should be

2.3mm

below

the

hook

—The hook point should be located at the

centerofneedle

—Gap

between the hook point and the side

faceofneedle

axis.

shouldbe0.05mm.

(3) Needle/rotating hook position can be ad

justedasfollows.

(For easy adjustment, it is recommended

that

the presser foot,

throat

dog assemblies are removed.)

•

Positioningofhook

(1)

When

the

smaller

side

and

crossed

left

larger wheel so

former

gear

thatofthe

(2)

Tighten

for

(3)

Approximate

"C"

the

position.

•Tofinely

motion

each

set

screw,onthe

screwofhook

needle

adjust

and

screwoflarger

wheel

in its

from1mmto2mm.

point

needleisat

herical

side

shouldbeengaged

that

the

comesonthe

latter

gearonthe

"S"

screw,

hook

positionofhook

shouldbefound

when

the

timing

hook

motion,

gear

wheel

axial

direction

DOWN

needleisat

between

"6"

on the

from

the

lower

point.

plate and feed

position,

gearsonthe

"S"

whereispunched

shaft.

and

with

screwofthe

front

side,

reverse

side.

close

DOWN

the

move

needle

the

the

loosen

withinarange

the

right

the

and

set

gear

Gap

between

and

upper

Needle

2.4mm from ^

needle lower ^

dead

point

Center

needle

hook

edgeofneedle

2.3mm

lift:

"An

of

axis'

Hook

point

eye

0.05mm

point

) ^

to

1 ~

2mm

1 ~

2mm

Needle

DOWN

position

-9

-

Page 13

OPERATION

13

Adjustmentoffeed

Height of feed dog and pressure of presser

shouldbeadjusted

following

♦

Fabric

too

♦

Even

dogistoo

small.

♦

Feed

point

cautions:

will be

high, or

stitch

damagedifthe

pressureofpresser

length

loworpressureofpresser

dog

height

where

the

dog

height

for

Individual

fabricis)

feed dog

with

extends

footistoo

cannotbeassuredifthe

footistoo

shouldbemeasuredatthe

needleisat

the

top

position.

foot

the

large.

feed

[0.8mm

1.0mm

For

light

fabrics

For

usual

fabrics

For

heavy

fabrics

Adjustment

(1)

Lean

(2)

Turn

the

(3)

Loosen

procedure

the

machine

the

handwheelbyhand

feed

dog

the

feed

(4) Vertically move

tion

indicatedbyarrowinthe

adjustitto

(5)

After

set

The

1.2

mm.

feed

screw.

the

adjustment,

dog

adequate

Approx.

throat

.

Approx.

throat

.

Approx.

throat

head

risestothe

bar

set

the

feed bar (in

plate

plate

plate

backward.

and

maximum

screw.

0.8mm

1.0mm

1.2mm

stop

height.

the

figure)

height.

tighten

the

feed

heightisfactory-adjusted

from

from

from

when-

direc

bar

1.2mm

zsn

to

Set

Feed

screw

bar

to

-

10

Page 14

OPERATION

14| Relationship between rotating

motion

When

moved

relationship

take-up

follows:

(1)Turn

(2)

(3) If

I

opener

and

take-up

the

timing

for

lever

the

take-up

Lean

the

sure

the

timing

the

bossoflower

the

black

line,

stallitagaintoadjust.

Relationship

belt

its

replacement,

between

motion

balance,

leverisliftedtoits

machine

arrow

belt

is in

timing

markisnotinline

remove

between

motion

lever

(toothed

rotating

should

wheel

head

(timing

line

shaft

the

backward

with

hook

motion

for

hook

be

and

upper

mark)

the

bearing.

timing

belt) was re

example,

motion

adjusted

stop

dead

putonthe

black

belt

motion

when

and

with

hook

point.

make

line

and

the

and

as

the

on

the

in

and

Black

lower

lineonboss

shaft

bearing

of

Timing

Timing

''^Timing

belt

sprocket

belt

mark

(1)Turn

when

remotely

(2)

Make

holder

0.2mm.

(3) If

opener

tionofthe

the

the

sure

the

balance

opener

from

gap

and

gapistoo

holder

opener.

wheelbyhand

holderislocated

the

throat

plate.

between

the

set

the

openerisapproximately

large or

screw

small,

(§) and

and

bobbin

loosen

adjust

stop

most

case

posi

the

-11-

Approx.

0.2mm

Opener Screw®

Opener

holder

Page 15

OPERATION

Relationship between needle

and

feed

dog

motion

(1)Set feed length to

dial.

(2)

Lean

the

machine

"0"

on the feed setting

head

backward.

motion

(3) Loosen the feed lifting rock shaft crank set

screws

(§) and (§) .

(4) Set the needle at the lowest position.

(5) Adjust

vibration

the

distance between presser rod

prevention

rod

to

9mm

and

and

temporarily tighten the feed lifting rock

shaft

crank

set

screws@and

(§) .

(6j Check that the right feed lifting rock shaft

crank is connected with the link at right

(71

angle, as

If the

move

move

shown

connection

the

back

the

right link to

in Figure.

is not at

cover,

connect

loosen

right

screw

the

angle,

@ and

right feed

re

lifting rock shaft with the link at right angle.

(8)After the completion of adjustment, fully

tighten

the

screws

@ , (§) and © .

At

this

time

make

certain

that

needle

enter

of

the

the

hole.

feed

dog

needle

holeatthe

can

center

Screw

Screw

(g)

Feed

shaft

lifting

crank

rock

(middle)

.Feed

shaft

lifting

crank

rock

(right)

Link

9mm

Needle

—Vibration

prevention

rod

rod

Feed

shaft

-12-

lifting

crank

rock

(right)

Screw©

kvx

Screw©

J

•aij.

Page 16

OPERATION

(ITI

1)

FUNCTION

safety

Safety

the

the

machine is

ation.

clutch

clutch

hook

threadiscaught

device is installed to

and

cog

loaded

OF

SAFETY

DEVICE:

belt

from

into

the

abnormally

damage in case

hook

during

CLUTCH.

1) When the safety clutch acts, the cog belt

pulley

will be

hook

rotate.

shaft will

Stop

unloaded,

stop.

the

then

the

arm

rotation

shaft

The

operationofmachine.

2) Clean the thread thoroughly which iscaught

into

the

hook.

3) Turn the cog belt hub by hand, and check

whether

properly,

the

place

hook

the

shaft

rotates

clutch

deviceasfollows.

lightly

prevent

when

oper

only will

and

the

Safety

clutch

belt

pulley

belt

hub

of

Balance

wheel

2) HOW TO

1) While pressing

opposite

balance wheel slowly by right

from

SET

THE

SAFETY

down

sideofbedbyleft

youasshowninthe

the

push

buttononthe

hand,

figure.

hand

2) The balance wheel will stop by the gear

plate,

but

turn

the

firmly.

3) Release

the

push

balance

button.

wheel

4) As shown in the Figure, the safety clutch

deviceisset.

3)

FORCE

CLUTCH.

1)

2) To adjust

3)

The

smallest

tric

The

white

loosen

pin.

After

the

APPLIED

force

when

pin

faces

force

mark

the

the

set

screw.

TO

THE

appliedtothe

the

the

proportionally

faces

the

force, slide the timing belt,

set

screw,

adjustment,

safety

white

markofthe

centerofthe

the

outside.

and

make

increasesasthe

turn

clutch is

the

suretofasten

SEFETY

lower

CLUTCH.

turn

the

away

more

the

eccen

shaft.

eccentric

White

Mark

Strengthen

Eccentric

I-—

Push

button

Gear

Timing

Pin

Screw

plate

Belt

-13-

Weaken

Lower

Shaft

Eccentric

Pin

Page 17

OPERATION

1}

UPPER FEED ADJUSTMENT

(NEEDLE

If

the

to

the

horizontal feed

the

upper

(Howtoadjust)

1) Loosen

2) Move the special bolt upward to decrease

upper

3) Move

the

upper

lower feed theoretically becomes equal

the

reference

shaft

4) Securely tighten the special bolt after adjust

ment.

SIDE)

uneven feeding occurs according to

fabric,

adjust

the

long hole of

crank

(right)toadjust

bolt.

downwardtoincrease

upper

feed

and

horizontal

feed.

the

crank.

the

feed

special

special

feed.

shaft

length.

bolt

The

lineonthe

the

the

feed

Push

mating

button

notch

Horizontal

Reference//^^~Upper

shaft

crank,

feed

right

decreases

v<;;^line

^

Link

(Needle

Special-..-^

bolt-Upper

feed

-/•

increases

at

rock

bar

link)

h9| Outside

vertical

When

when

stroke

shouldbeadjustedasfollows:

presser

stroke

fabric

thicknessoffabric

(movable range) of

Adjustment

1)

Loosen

the

special

2) Teh vertical

come

maximum

upward

and

set.

3)

The

vertical

when

the

nutismoved

4) After

•

special

The

be

adjusted

mm.

the

bolt.

vertical

adjustment,

withinarange

foot and

adjustment

with

large

elasticityissewn,

changes,

bolt.

strokesofthe

when

the

strokes

strokesofthe

becomes

inside

presser

the

the

vertical

presser feet

presser feet be

crank

rodismoved

downward

minimum

and

fully tighten the

presser

feet

from6mm

set.

can

to 2

or

Special

bolt

Crank

-Increase

Decrease

Crank

rod

-14-

Page 18

OPERATION

Adjsutmentofforward/backward

20

stitch

length

Forward/backward

by

moving

figure,asfollows:

(1)

Remove

(2)

Set

the

Position

feed

adjusting

stitch

length

length

(3)

Loosen

(One

screw

iver

passed

openedbyremoving

(4)Toincrease

eccentric

To

increase

eccentric

21

Installationofmovable

1.

Initial

positionofmovable

(1) Turn

the

stitch

length

the

eccentric

the

arm

stitch

and

regulatar

two

back

length

make

surenoplay

cam

(If play exists,

adjusting

screw

screwsoffeed

shouldbeloosenedbyscrewdr

through

forward

shaft

counterclock-wise.

backward

shaft

clock-wise.

canbeadjusted

shaft

cover.

adjustment

dial

and

again.)

the

hole

rod

and

stitch

length,

stitch

length,

showninthe

dialto"0"

existsinthe

adjust

the

stitch

adjusting

rubber

that

cam.

can

plug.)

turn

turn

the

be

the

the

knife

knife

balance wheel and lower the needle bar to

To

backward i|^

stitch length

Eccentric

shaft

Connecting

the

lowest position.

lessen

rod

To

lessen

forward

stitch

Screw

' I

length

(2)Pushthe cam followercrank so that the cam roller enters into the thread trimmer cam groove.

(3)Turn the balance wheel until the black mark point on the arm meets the white mark point on the

balance

wheel.

Set the cam follower crank at this position with a screwdriver temporarily preventing

roller

coming

out

from

the

cam

groove.

(4)

Loosen

the

thread

(5) Adjust

the

fixed

trimmer

the

movable knife so

knife,asshowninFigure

rocking

crank

clamp

bolts

@ and(^.

that

the movable knife end slant portion protrudes 0 —0.5 mm from

and

tighten

the

bolts

@ and .

the

cam

Bolt@

Thread

rocking

Thread

rocking

trimmer

crank

trimmer

crank

Bolt(B)

-15-

0.5mm

Movable

knife

Fixed

knife

Page 19

OPERATION

2.

Gap

between

holder

(1)

Turn

reaches

(2)

With

press

wheel

extremityofits

stopper

the

the

cam

until

movable

balance

the

lowest

needleatthe

follower

the

stroke.

knife

wheelbyhand

position.

lowest

crank,

movable

knife

(3) Manually rotate the inner hook in

tion

indicated by

arrow

in Figure

gap between the movable knife and the in

ner hook stopper to about 0.5 mm (the

^

Adjustment

(1)

(2)

(3)

screws

for

@

and

this adjustment).

of thread

Turn

the

balance wheel by

Maintaining

grooveofthread

Turning

starts

pointonthe

To

adjust,

the

the

moving

loosen

(@)

needle

trimmer

balance

when

arm.

shouldbeloosened

trimmer

position,

wheel by

the

green

two

thread

and

turn

hand

cam.

bobbin

until

position,

the

balance

reaches

the

and

cam

until

depress

hand,

mark

trimmer

case

needle

de*

the

direc-

adjust

the

needles reach

the

cam

adjust

the

pointonthe

cam

clamp

Movable

knife-

Hook positioner

Approx.

0.2

mm

the

lowest position.

follower

thread

crank

trimmer

and

put

the

camsothat

cam

the

balance wheel comes in line with

screws

@ .

Screw

Screw

Inner

roller

movable

the

black

hook

into

the

knife

mark

Cam

groove

Thread

^

Screw

trimmer

Cam

crank

Cam

follower

roller

@

cam

-16-

Green

mark

Black

point

point

mark

Balance

wheel

Page 20

OPERATION

2^

Adjustmentofneedle

threads

tension

release

assembly

(1) Turn the balance

(2)

Maintaining

grooveofthread

(3) Turning the balance wheel by hand, adjust the thread tension releasecam so that the tension disc

close

when

on

the

arm.

To

adjust,

(4)

Opening

the convexed portion of thread release cam, as shown in Fig.

To adjust, loosen the screws (g) and draw the wire.

(5)

Make

fine

(6)

Loosen

the

Thread

tension

release

lever

Screw(M

Roller

(g)

Thread

release

cam

Thread

trimmer

cam

wheel

by hand until the needlesreach the lowestposition.

the

needle

position,

trimmer

the

white

loosen

degreeoftension

two

cam.

mark

tension

pointon the

release

disc

adjustmentbyloosening

nut

(5)

and

make

(D

Screw

©

depress

the cam follower crank and put the cam rollerinto the

balance

cam

clamp

shouldbeadjusted

thenut{§),

the

outer

casing

approach

Cam

follower

crank

Cam

roller

Outer

wheel

screws

with

Arm

comesinline

@.

the

tension

release

rightwardtoincrease

White

Black

point

casing

withthe

roller

mark

point

mark

black

(g)

the

Balance

mark

mounted

opening

point

on

value.

wheel

-17-

Page 21

OPERATION

24] Adjustmentof

(1)

Loosen

(2)

Turn

socket

Note: Since excess pressure causes large

(3) Move

Fixed

bracket

Hexagonsocket head

cap

screw

scissoring

the

fixed

knife

bracket

the

vertical

head

the

position

cap

screw

@.

ming failure, adjust it so

movable knife

knife

@

pressure of

clamp

adjusting

and

screw

that

check

movable

knifeandfixed knife

bolt (§).

(§)to

adjust

meshing

torque

thread can be trimmed with minimum pressure.

that

the

to the thread trimming mechanism and trim

thread

can be sharply trimmed.

pressure

and

thenrighten

the

hexagon

25

Sharpeningoffixed

When

the

it is

knives

very

Since

Vertical

knife

dull,

the

difficulttosharpen

fixed

Fixed

position

adjusting

knife

shouldbesharpenedasillustrated

the

movable

knife

-18-

screw

knife,

replaceitwithanew

Oil

(§)

stone

in Fig.

one

whenitdulls.

Page 22

OPERATION

26 Adjustment fot

changeofneedle-to-needle

distance

(LU2-4430)

(1) Replace the throat plate, feed dog and needle clamp.

(Sincethe throat plate and feed dog are special parts

suretouse

(2) Lean

(3)

Loosen

(4)

Remove

(5)

Loosen

hook.

(6) When

(7)

Contact

link

(8)

Turn

(9)

Loosen

(10)

Depress

smoothly

(11) Adjustment of the cam groove and the cam roller

(a) Push

those

specified by us.)

the

machine

two

the

the

the

the

clamp

the

balance wheel by

the

the

the

head

connecting

spring

hook

bracket

needles

and

rocking

bolt(^.

nuts

(§)

cam

follower

enter

the

grooveofthread

cam follower crank so

backward.

link

clamp

.

clamp

hooks

have been

cranks@and

hand

until

and

(§).

crank

(E)

bolts(j).

screws

adjusted,

(§)tothe

the

and

trimmer

that

(§)

needles reach

adjust

cam.

the cam roller enters into

and

(§)

install

stopper

the

designed

and

adjust

the

spring

pins

(1)

the

lowest

connecting

for thread trimmingmachine, be

gap

between

and

and

tighten

position.

rod(Qso

that

the

cam groove.

(b)Turn the connecting rod (L)and adjust the clearance between the cam roller and the cam

groove

surface

N as

smallaspossible,

and

tighten

the

nuts

(g)

and

(H)

.

(c) Push the cam follower crank again and check that the cam roller enters into the

thread

trimmer

Thread

rocking

Connecting link

Hook

trimmer

crank

bracket

cam

©

groove

Screw

smoothly.

6$

Stopper

pin©

Screw

Hook

Cam

@

bracket

Spring'

Cam

roller

groove

w

N-phase

,C3in

crank

.

Thread

cam

follower

.

Lower

1Shalt

Cam

crank (1^

Cam

each

the

trimmer

follower

roller

the

cam

needle

roller

and

connecting

can

Bolt

(XI

Stopper

Thread

pin©

\ \

trimmer

rocking crank {jjl

-19-

Nut 'H '.QT

Connectirtgrod^'Lj

^ut

>5)

Thread

t.immor

cam

Page 23

ADJUSTMENT

AND

OPERATION

OF

CONTROL

UNIT

Setting

Thestop

-5 2-

the

position

mark

mark

1-2

ofthe

When the switch is set to 1

and

trim

the

thread.

I2 I

Pedal

Operation

The

two-step

go

up.

\^Pedal

12

POSITION

Pedal

1

POSITION

2

POSITION

operation

pedal

Position

Settin^\

POSITION

sewing

2

POSITION

1

POSITION

heeling

Switch

machine

POSITION,

mechanism

Toe

Stopatneedle

UP position

Stopatneedle

DOWN position

down

Neutral

fully

allows

canbe

determined

bytheselect

switch

onthe

panel.

heelingthe pedalcauses the sewing machineto rotateoneturn

the

thread

tobe

trimmed

—

Neutral

Presser

goes

Presser

goes

up.

up.

—

foot

foot

Light Heeling

andthe

presser

foottoautomatically

Neutral —Full Heeling

Sewing

machine

and

trims

goes

up.

Sewing

machine

from DOWN to UP position

trims

thread,

goes

up.

thread,

then

rotates

then

rotates

presser

presser

/ //'

Neutral (stitching

start)

^^•^I^Heeiing

Neutral

one

half

turn

foot

turn

and

foot

Note: 1. Thestitching speed can be variedby changing the pedal toeing degree.

I3 I

Adjusting

Pressures

The lever unit spring

stepsbychanging

ponding

spring

For automatic

the

pressure

Pedal

pressure

the

adjust

presser

Toeing

is adjustable in

position of

knob.

fool lifting,

and

Heeling

the

use

three

corres

the

optional LE-FAlifter or a

Heeling

adjust

Toeing

adjust

spring

knob

spring

knob

solenoid

pressure

pressure

valve (24V DC).

| It

H

Page 24

ADJUSTMENT

I 4 I

Adjusting

AND

the

Operating

OPERATION

Speeds

OF

CONTROL

UNIT

1 Adjusting

Two variable resistors are available for adjustment ofthe maximum speed;

and

low

Is

To

2. Adjusting

The low

and

to

Speed

the

maximum

the

other

speed

factory-setasfollows:

settoany

CAUTION

The

motor

counterclockwise

250spm).

rt

on the control box panel. The external variable resistor (knob) allows

and

the

maximum

Internal

Variable

speed

speed

setbythe

pulley is used.

the

low

speed

speed

Is adjustable with

setting

Internal variable

L P T H M

iwii^iwiraiw

speed

2000spm

outside

internal

(speed

turn

(speed available with the pedal fully toed)

speed

set by the Internal variable resistor H. The internal variable resistor H

ResistorHSetting

the

above

range,

adjust

the

Internal variable

variable

available

the

decreases.

resistors

resistorHand

with

the

internal variable resistor L.Clockwise

The

speed

external

pedal slightly toed)

Is adjustable

one

Islocated In

adjustment

External Knob Adjustable

Low

speedtomaximum

resistor

H, using a

knob

cannotbeexceeded

turn

between160

Control box

Increases the low speed

and

320spm

panel

the

control box

Range

speed.

speed

if a larger

factory-set

between

I

meter.

I

L (Low

speed)

P (Positioning

T (Thread trimming

H (High

speed)

M

(Medium

3.

Positioning

The

clockwise to

4. Adjusting

The

and

sewing

contact

5.

Adjusting

When

speed)Isadjustable

speed

positioning

Increase

the

thread

thread

trimming

counterclockwisetodecrease,

machine

the

service

the

backtacking

anyonthe

speed)

speed)

speed)

speed

canbeadjustedbythe

and

counterclockwisetodecrease,

trimming

speed

canbeadjustedbythe

used.

When

agency.

speed

control

switch

with

the

internal

speed

the

adjusting

panels

trimming

this

(option) Is

variable

External

knob

internal

variable

the

internal

speedIsfactory-set

speed,

refertothe

used

resistor

for

M.

resistor

adjustable

variable

backtacking,

1-2POSITION

P (factory-set to

rangeis160to320spm.

resistorT.Turn

to 1

sewing

75spm

machine

the

backtacking

select

Itclockwise to

and

switch

250spm).

may

dependonthe

adjusting

speed

Turn

increase

manual

(medium

it

of

Page 25

ADJUSTMENT

I5 I

Optional

AND

Functions

OPERATION

OF

CONTROL

UNIT

Bysetting

control box

machinetobe

service

1.

the

internal switchesand connecting external switches to

can

usedasa

agency.

Internal

switches

SW1

G1: Gain

A;

SL, +1:

US:

PCS:

TB:

Standing-work

high-speed

(Not required for

Slow

NeedleUPcontrol

switch

1-2

Back

be used with various sewing

standing-work

machineoran

ssssSsoci

tu

swzumuH

XC-AM

switch

(to be

setat"ON")

switch

start

switch

POSITION

tack

solenoidatthread

sewing

the

switch

machine

external knob)

by back

trimmer

machines

tack

with underbed trimmer and allows

automatic

cf+SsSo-fie

swHnmn

Internal

Switches

SL

+1

S3L: Presser foot liftingcancel switch by light heeling

RU: Reverser needle liftingswitch

Usedto stopthe sewing machine near the needle bar topdead center byreversing the motor

after

thread

trimming.

S6/TL: Thread trimming safety/thread trimming cancel select switch

Usedto switchthe sewing machineconnector 5 - 6 signal betweenthe thread

IL:

safety S6 and thread trimming cancel TLfunctions.

Thread

trimmer

interlock

cancel

switch

Usedto cancelthe operation restartdisablecommandat the timeofthread

BM: Backtacking stitch

to restart operation after interlock

change

switch

time

has

passed.

Usedto set the backtack solenoidoperation timingto match the lengthofbacktacking stitch.

the

option connectorsasrequired,

machine.

For

further

details,

s»4

0

1

stitch

OFF

OFF

ON

OFF

trimming.

2

stitches

the

contact

aa

ON

ON

trimming

Set toON

each

sewing

the

BM

OFF

ON

UP

DN-

N-2

~LJ

N-1

T_r

T_r

Backtack solenoid operation timing ON or OFF

ON

i \0\-\-

-22-

On

N

i_r

i_r

OFF

Page 26

ADJUSTMENT

AND

OPERATION

OF

CONTROL

UNIT

UDS: Needle UP/DOWN control by back tack switch

Allows a half stitch to be sewn by turning on the back tack switch S7 when the sewing

machine

has

D:

Start

stoped.

backtacking

speed

varying switch

Allows start backtacking speed to be changed (between low and backtacking speeds) in

2.

Option

accordance

connectors

with

the

pedal

toeing

Position

degree.

0

/ \

LOW

HIGH

Lever

Option

1

Run (high

Run

(low

+12V

Correction stitching 6

UP/DOWN

Variable-speed

Thread

Run

(medium

Option 2

One-shot

UP

position

DOWN position priority

Power

UP

position

priority

stop/emergency

Encoder

speed)

speed)

control

signal 4

trimmer

speed)

OV 1

signal

stop

supply

stop

OV

signal

9

8

7

5

3

2

6

5

4

3

2

1

VC1

VC2

nIE

—

OV

—CK

+12V

—40mA

OV

Detector

1

^ 1

,

-SH

Option

External

(D (g) ®

0 (5)(I)

0 0 0

knob

A

AAA

0

Presser

toot

up

Option2Sewing

mashine

Control

switch

1

panel

10k

n

Presser

foot

UP

OV 1

Presser foot UP signal

Presser

foot

UPoutput

PresserfootUPoutput — 4 Back

2

♦

3

Sewing

Thread

machine

trimming

Thread

Back

safety/thread

Wiper

-

23

tack

+30V

OV

tack

+30V

—

OV

trimmer

+30V

output

Ground

output

signal

output

trimming

cancel

12

11

10

9

8

7

6

5

4

3

2

1

SG/TL

Sewing

machine

Page 27

SPECIFICATIONS

Specifications

Model

Number

of

needles

Application

Max.

sewing

speed

Sticch

length

Presser-foot

stroke

Needle

No.

Needle-bar

Thread

Vertical

Automatic

Touch

Hook

Bobbin

Lubrication

Oil

Bed

Needle

stroke

take-up

strokeofupper

Thread

back

(horizontal full-rotating)

system

dimensions

gauge

(mm)

lever

stroke

trimmer

Knee

Hand

feed

lifter

(spm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

LU2-4410-BIT

.

LU2-4410-B1T-CS

Single-needle

Heavy

material

2000

0~9

8

16

DPX17

#23

36

74.5

2~6

O o O

O

Automotive

DPX17

seat

2000 2000

(D

8 8

I

CM

16

#23

35

70

o O

Large

Automatic

517X178

0

trimmer

1

MC70M

(O

lubrication

Aluminum

LU2-4430-B1T

Double-needle

Heavy

0~9

DPX17

74.5

2~6

type

Standard:

Special:

3.2,4,4.8,8.9.5,

12.7,

16, 19.

material

16

#23

36

6.4

25.4

Notes: •

Some

materials,

than

those

• Feed dog,

timmer.

• Bobbin

•

should

This

specificationissubjecttochange

gauge

listed

above.

throat

plate, rotating hook, bobbin

be of

high

sizes,

quality

and/or

free

from

-24-

sewing

conditions

case

and bobbin should be

deformation.

for

machine

may

improvement.

require

specifications

those

designed for

other

thread

Page 28

A

MITSUBISHI

"EAO

0"IC£

MITSUBISHI

0£H<I

ELECTRIC

SLOG

m*RukouCki

TOKYO

CORPORATION

lao

TCiEK

j2«53J

CABiE

MElCO

TQKyO

A180E271P01

PrintedinJapan

Loading...

Loading...