Page 1

MITSUBISHI

INDUSTRIAL

MACHINE

TECHNICAL

Single,

Double-Needle

Lockstitch,

Thread,

Variable

SEWING

INFORMATION

Model

LU2-410.

Compound

Speed

feed.

-430

Automatic

ET-0I9A

MITSUBISI

MITSUBISHI

ELECTRIC

Page 2

CONTENTS

MACHINE

HEAD

SPECIFICATIONS

THREAD

TRIMMER

PREPARATIONS

1. POWER

2.

CONNECTION

3.

ADJUSTMENT

NOTE

ON

1.

OILING

2.

OILING

3.

LUBLICATION

4.

ADJUSTMENT

5.

HANDLING

CABLE

USE 6 ~ 7

(1) 6

(2) 6

CONSTRUCTION

DIAGRAM

FOR

OPERATION

WIRING

WITH

OF

CONTROL

NEEDLE

CONDITION

OF

LUBLICATION

INSTRUCTIONS

BOX 5

BAR

STOP

POSITION

TO

ROTATING

HOOK

2

3

4~5

4

5

7

7

7

HOW

TO

1.

INSTALLATION

2.

WINDING

3.

SELECTION

4.

THREADING

5.

ADJUSTMENT

6.

SETTING

7.

WINDING

8.

TENSION

9.

BALANCE

10.

TENSION

11.

ADJUSTMENT

12.

TIMING

13.

ADJUSTMENT

14.

RELATION

15.

RELATION

16.

RELATION

17.

SAFETY

18.

ADJUSTMENT

19.

ADJUSTMENT

USE

THE

OF

OF

OF

ADJUSTMENT

OF

OF

ADJUSTMENT

CLUTCH

SEWING

OF

BOBBIN

OF

THREAD

OF

NEEDLE

OF

STITCH

BOBBIN

BOBBIN

THREAD

NEEDLE

OF

PRESSER

OF

FEED

BETWEEN

BETWEEN

BETWEEN

(SAFETY

OF

UPPER

OF

OUTER

MACHINE

NEEDLES

THREAD

THREADS

LENGTH

THREADS

OF

TENSION

THREAD

FOR

DOG

ROTATING

ROTATING

NEEDLE

FEED

AND

BOBBIN

FOOT

ROTATING

PRESSURE

HEIGHT

HOOK

HOOK

AND

DEVICE)

(NEEDLE

INNER

AND

REVERSE

THREADS

HOOK

AND

AND

FEED

SIDE)

PRESSER

AND

TAKE-UP

OPENER

DOG

SEWING (TOUCH BACK)

NEEDLE

LEVER

MOTIONS

MOTIONS

STROKE

FOOT

8~17

8

8

9

9

10

10

1

1

1

1

1

12

13

14

14

15

16

16

17

Page 3

ADJUSTMENT

1.

INSTALLATION

2.

POSITIONING

3.

ADJUSTMENT

4.

ADJUSTMENT

5.

ADJUSTMENT

6.

SHARPENING

7.

ADJUSTMENT

8.

INSTALLATION

9.

REMOVAL

10.

FEED

11.

ADJUSTMENT

DOG,

OF

THREAD

OF

OF

OF

OF

THE

OF

OF

HOOK

THROAT

OF

OF

MOVABLE

THREAD

THREAD

THREAD

MOVABLE

FIXED

NEEDLE

OF

SOLENOID

BRACKET

PLATE,

NEEDLE

TRIMMER

TRIMMER

TRIMMER

TRIMMER

AND

KNIFE

GAUGE

HOOK,

UP

KNIFE

CRANK

STOP

CAM

CAM

FIXED

DISTANCE

KNIFE

MESHING

BOBBIN CASE, BOBBIN,

POSITION

PRESSURE

AND

BED

SLIDE

18~24

18

19

19

20

21

.21

22

23

23

23

24

ADJUSTMENT

1.

SELECTION

2.

PEDAL

3.

ADJUSTMENT

4.

ADJUSTMENT

5.

OPTIONAL

THREAD

TRIMMER

AND

APPLICATIONS

OF

POSITIONS1AND

OPERATION

OF

OF

FUNCTIONS

TROUBLESHOOTING

PEDAL

RUNNING

FOR

2

OPERATION

SPEED

CONTROL

PRESSURE

LIST

SYSTEM

25-27

25

25

25

25

26-27

28-29

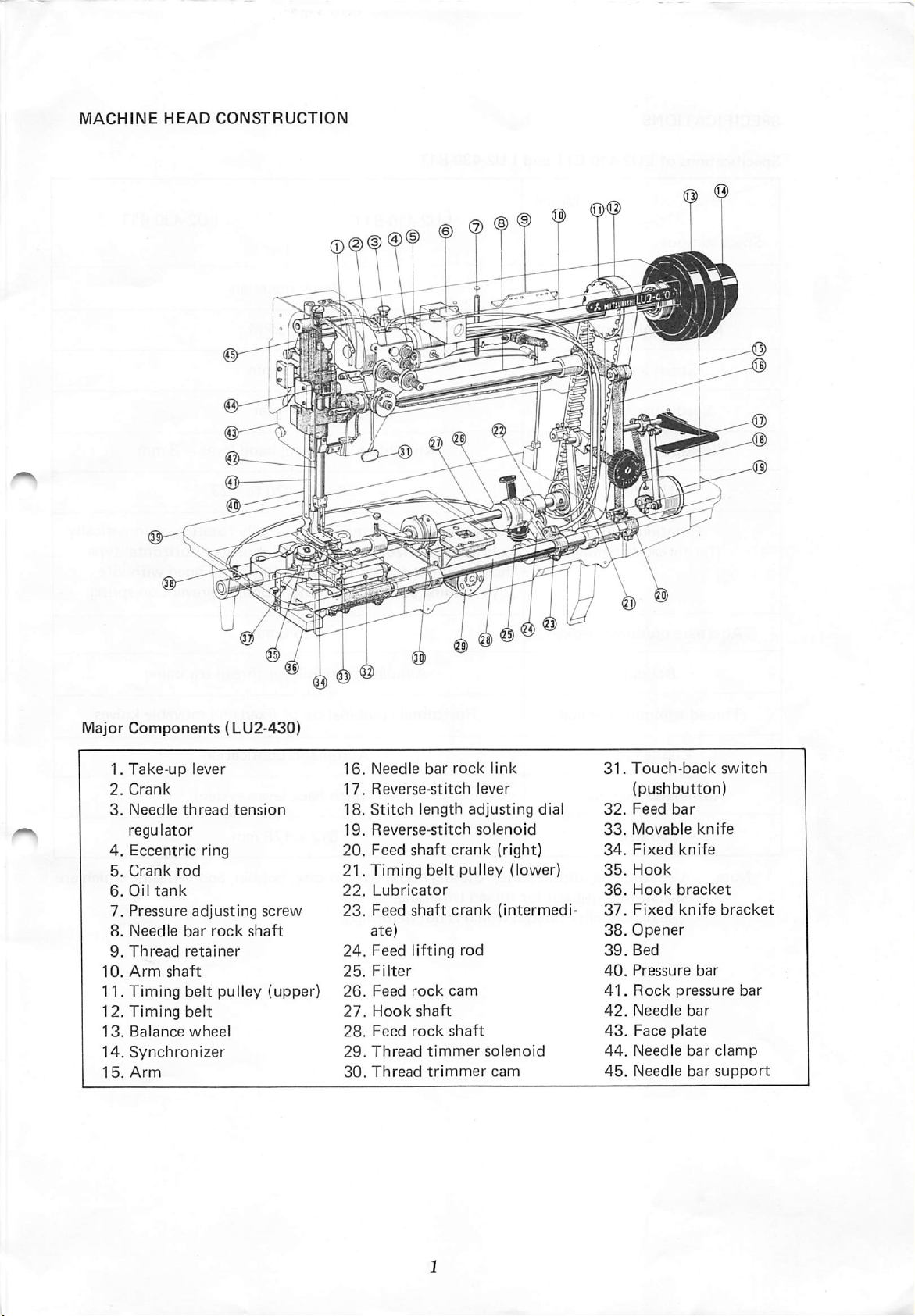

Page 4

1.

Take-up

2.

Crank

3.

Needle

regulator

4.

Eccentric

5.

Crank

6.

Oil

7.

Pressure

8.

Needle

9.

Thread

10.

Arm

11.

Timing

12.

Timing

13.

Balance

14.

Synchronizer

15.

Arm

tank

thread

rod

bar

retainer

shaft

belt

belt

lever

ring

adjusting

rock

pulley

wheel

tension

screw

shaft

(upper)

16.

Needle

17.

Reverse-stitch

18.

Stitch

19.

Reverse-stitch

20.

Feed

21.

Timing

22.

Lubricator

23.

Feed

ate)

24.

Feed

25.

Filter

26.

Feed

27.

Hook

28.

Feed

29.

Thread

30.

Thread

bar

length

shaft

belt

shaft

lifting

rock

shaft

rock

timmer

trimmer

rock

lever

adjusting

solenoid

crank

pulley

crank

rod

cam

shaft

link

(right)

(lower)

(intermedi

solenoid

cam

dial

31.

Touch-back

(pushbutton)

32.

Feed

33.

Movable

34.

Fixed

35.

Hook

36.

Hook

37.

Fixed

38.

Opener

39.

Bed

40.

Pressure

41.

Rock

42.

Needle

43.

Face

44.

Needle

45.

Needle

bar

knife

knife

bracket

knife

bar

pressure

bar

plate

bar

bar

switch

bracket

bar

clamp

support

Page 5

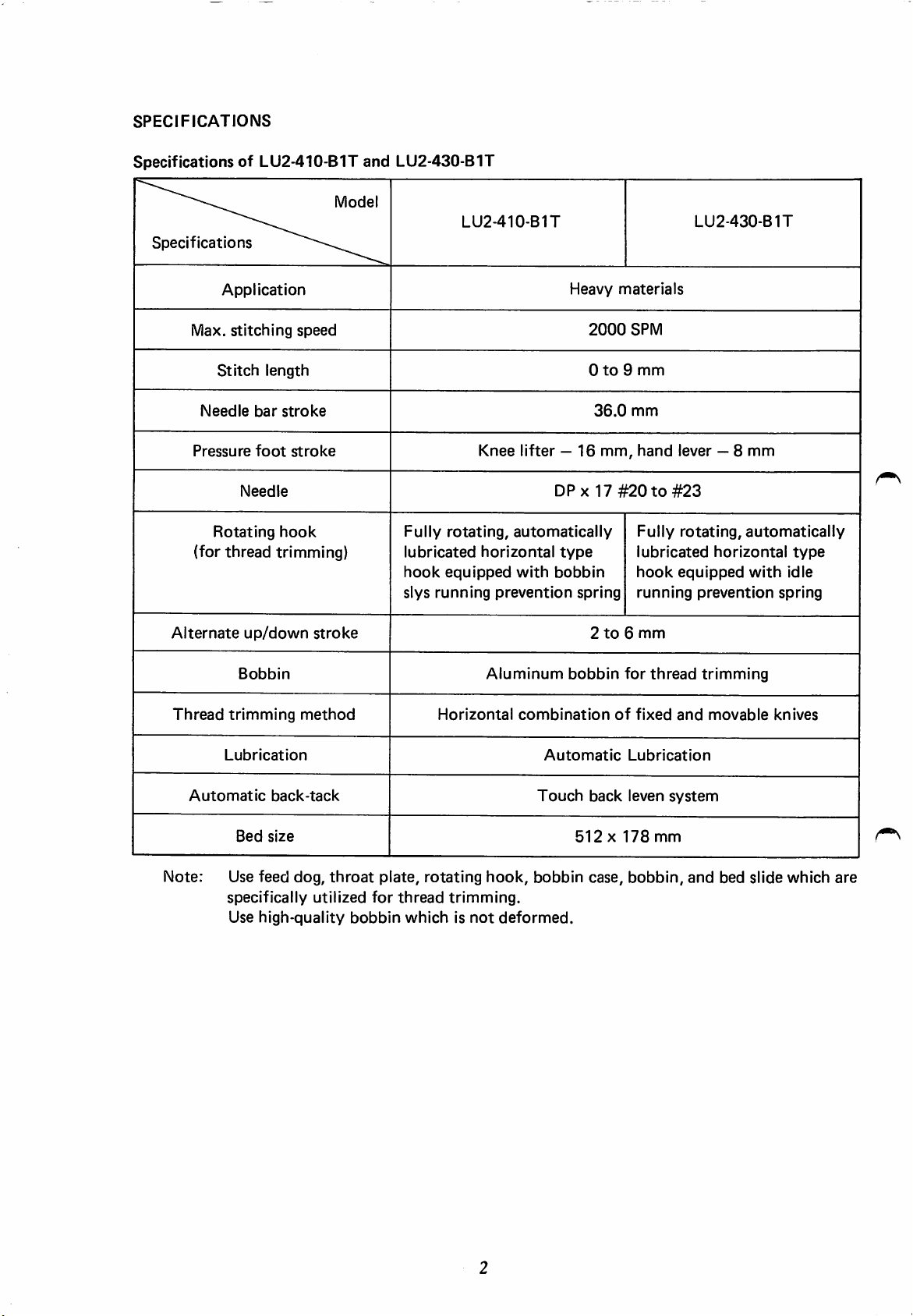

SPECIFICATIONS

SpecificationsofLU2-410-B1T

Model

Specifications

Application

Max.

Stitch

Needle

Pressure

Rotating

(for

thread

stitching

Needle

length

bar

stroke

foot

stroke

hook

trimming)

speed

and

LU2-430-B1T

Fully

lubricated

hook

slys

LU2-410-B1T

rotating,

equipped

running

Knee

lifter—16

automatically

horizontal

with

prevention

Heavy

2000

0to9

36.0

DPX17

type

bobbin

spring

materials

SPM

mm

mm

mm,

hand

#20to#23

Fully

lubricated

hook

running

LU2-430-B1T

lever —8

rotating,

horizontal

equipped

prevention

mm

automatically

type

with

idle

spring

Alternate

Thread

Automatic

up/down

Bobbin

trimming

Lubrication

back-tack

Bed

size

method

Note: Use feed dog,

specifically

Use

high-quality

stroke

throat

utilized

bobbin

plate,

for

thread

whichisnot

Horizontal

rotating

trimming.

Aluminum

combination

Automatic

Touch

hook,

bobbin

deformed.

2to6

bobbin

of

back

512X178

case,

mm

for

thread

fixed

Lubrication

leven

system

mm

bobbin,

trimming

and

movable

and

bed slide which

knives

are

Page 6

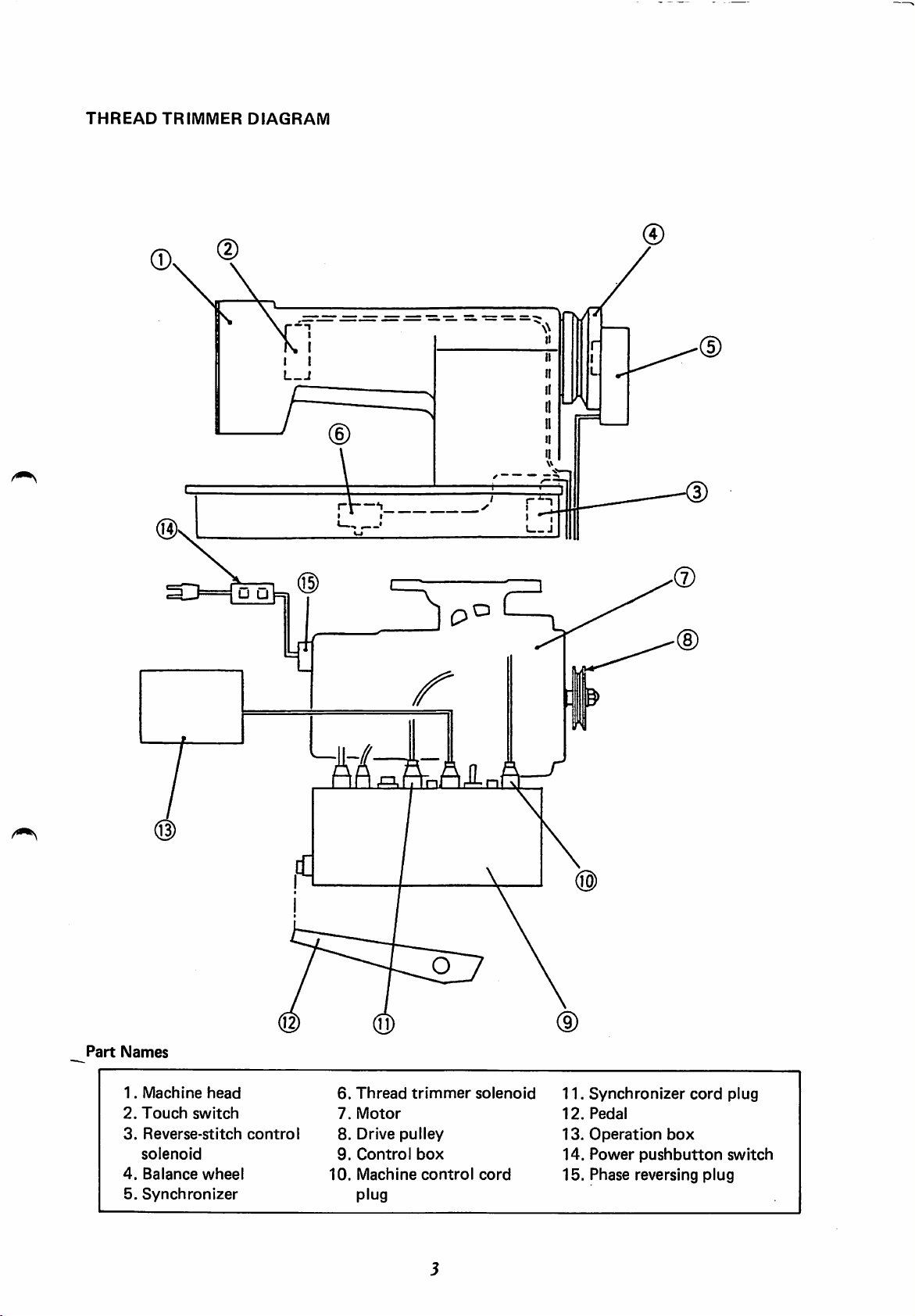

THREAD

TRIMMER

@

DIAGRAM

Part

Names

1.

Machine

2.

Touch

3.

Reverse-stitch

solenoid

4.

Balance

5.

Synchronizer

head

switch

wheel

control

Af(gl.A-rnAiLr.i

6.

7.

8.

9.

10.

Thread

Motor

Drive

Control

Machine

plug

trimmer

pulley

box

control

solenoid

cord

11.

12.

13.

14.

15.

e>

Synchronizer

Pedal

Operation

Power

Phase reversing

box

pushbutton

cord

plug

plug

switch

Page 7

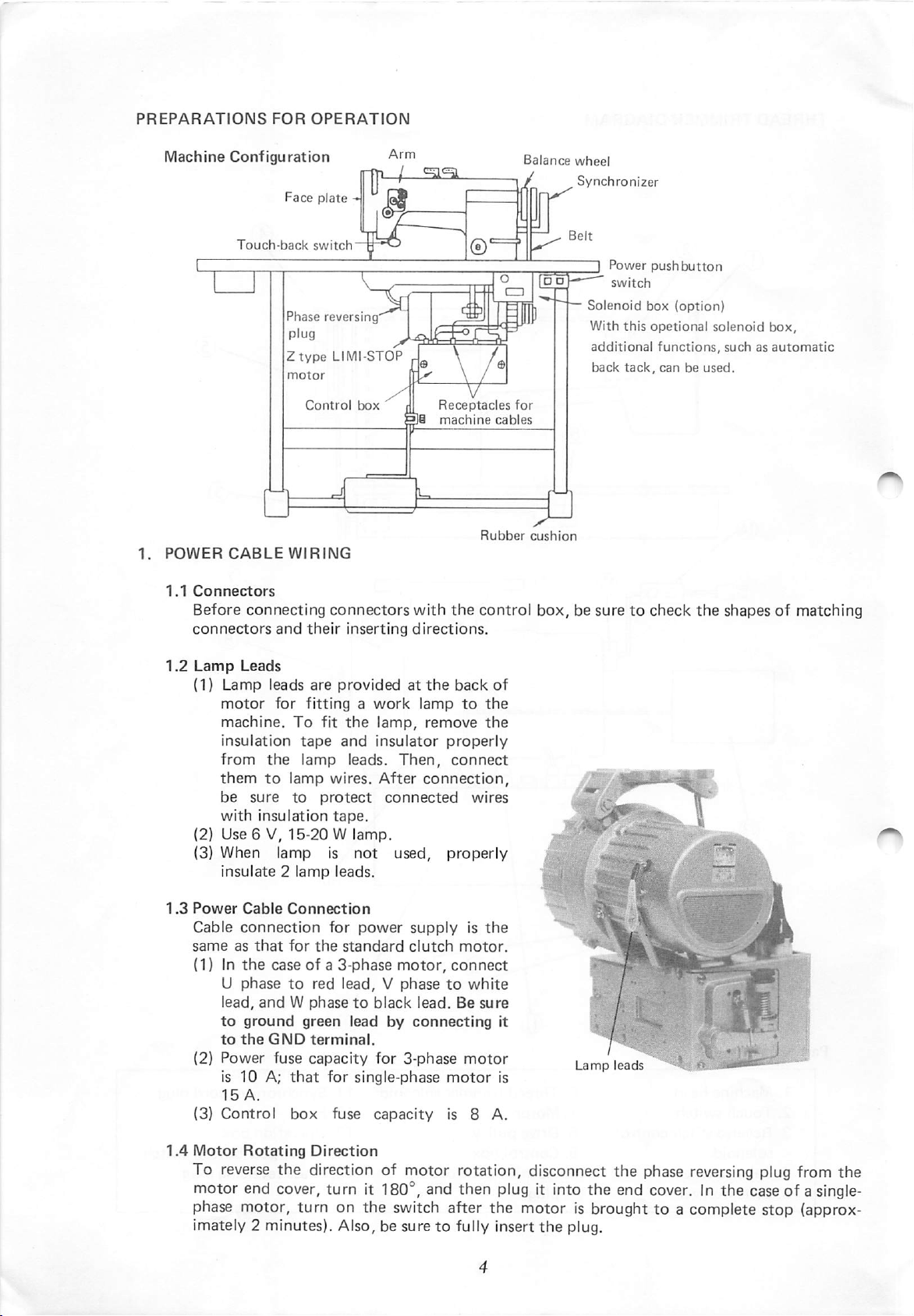

PREPARATIONS

FOR

OPERATION

1.

Machine

POWER

1.1

Connectors

Before

connectors

Configuration

Face plate

Touch-back

Phase

plug

Ztype

Control

CABLE

WIRING

connecting

and

switch'

reversing

LIMI-STOP

connectors

their

inserting

txDx

^

with

directions.

Receptacles

machine

Rubber

the

control

Balance

/

for

cables

wheel

Synchronizer

Solenoid

With

additional

back

cushion

box,besuretocheck

I Power

switch

this

tack,

pushbutton

box

(option)

opetional

functions,

canbeused.

the

solenoid

box,

suchasautomatic

shapesofmatching

1.2

1.3

Lamp

(1)

{2}

(3)

Power

Cable

same

(1) In

(2)

(3)

Leads

Lamp

motor

machine.

insulation

from

them

be

sure

with

insulation

Use6V,

When

insulate2lamp

Cable

connection

as

that

the

U

phasetored

lead,

andWphasetoblack

to

ground

Power

is 10 A;

15

A.

Control

leads

are

providedatthe

for

fittingawork

To

fit

tape

and

the

lamp

to

lamp

wires.

to

protect

tape.

15-20Wlamp.

lamp

caseofa

is

leads.

Connection

for

for

the

3-phase

lead,Vphasetowhite

green

fuse

capacity

that

for

box

fuse

back

lamp

to

the

lamp,

insulator

leads.

After

not

power

standard

remove

Then,

connection,

connected

used,

supplyisthe

clutch

motor,

properly

connect

wires

properly

motor.

connect

lead.Besure

leadbyconnecting

for

3-phase

single-phase

capacity

motor

motor

is 8 A.

of

the

the

w•

li

nilfc

JK'.j-

it

is

^

|

mniii

s-,

k

u

'$

I

JUBf

1.4

Motor

To

Rotating

reverse

Direction

the direction of motor rotation, disconnect the phase reversing plug from the

motor end cover, turn It 180°, and then plug it into the end cover. In the case of a

phase motor, turn on the switch after the motor is broughttoa complete stop (approx

imately 2 minutes). Also, be suretofully insert

the

plug.

single-

Page 8

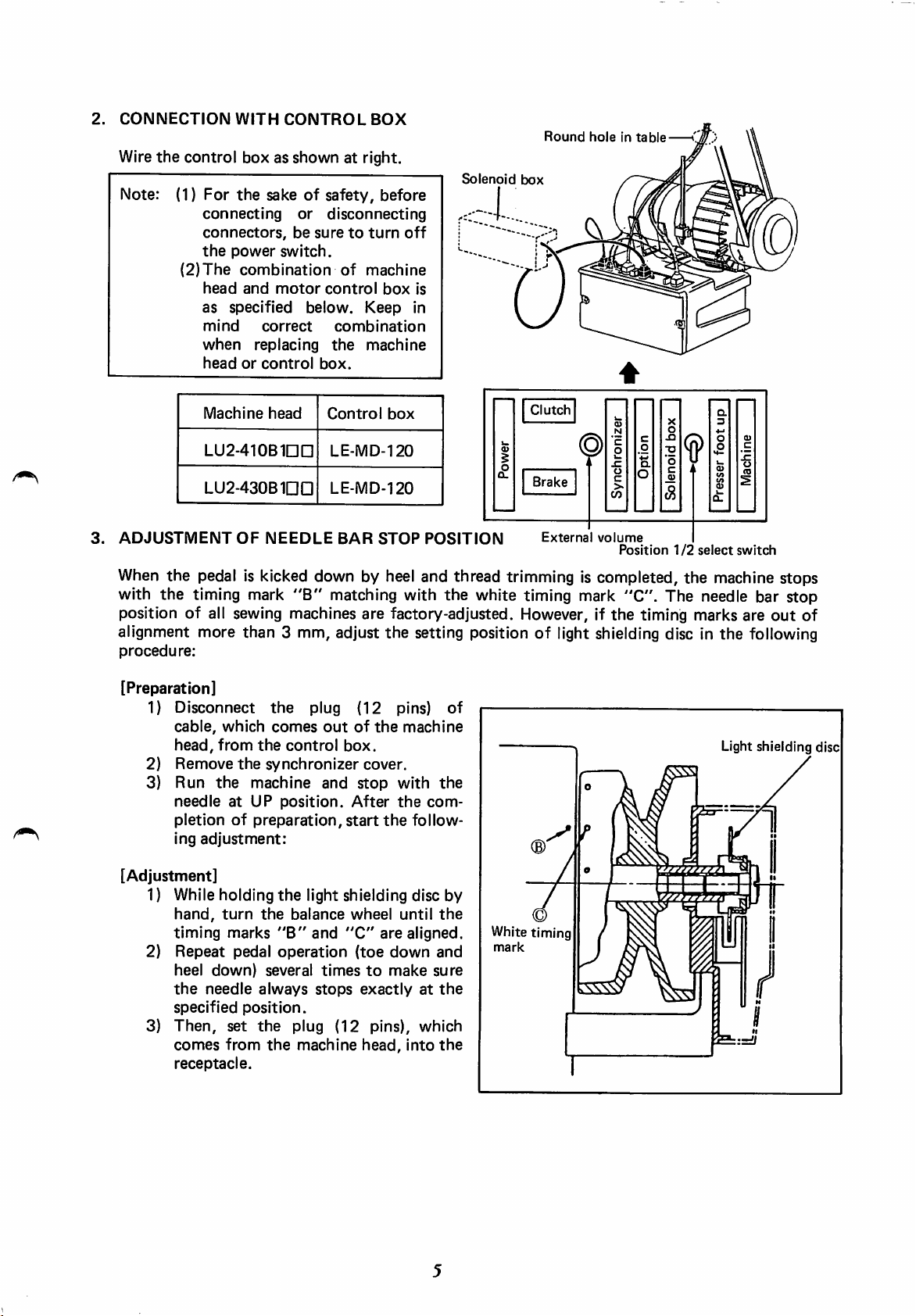

2.

CONNECTION

Wire

Note: (1)

the

WITH

control

boxasshownatright.

For

the

connecting

connectors,

the

power

(2)The

head

as

mind

specified

combination

and

when

headorcontrol

CONTROL

sakeofsafety,

or

disconnecting

be

suretoturn

switch.

motor

control

below.

correct

replacing

combination

the

box.

of

BOX

before

off

machine

box

Keep

machine

Round

holeintable

Solenoid

is

box

in

Clutch

Brake

External

volume

Position

the

timing marks are

1/2

select

switch

3.

ADJUSTMENT

When

with

Machine

LU2-410Binn

LU2-430BinD

the

pedal is kicked down by heel and thread trimming is completed, the machine stops

the

timing mark

OF

head

NEEDLE

"B"

Control

LE.MD-120

LE-MD-120

BAR

box

STOP

matching with

POSITION

the

white timing mark "C". The needle bar stop

position of all sewing machines are factory-adjusted. However, if

alignment more than 3 mm, adjust the setting position of light shielding disc in the following

procedure:

[Preparation]

1)

Disconnect

cable,

which

head,

from

2) Remove

3) Run

the

needle

pletionofpreparation,

ing

adjustment:

the

the

the

synchronizer

machine

at

UP

plug

comes

control

position.

(12

outofthe

box.

cover.

and

stop

After

start

pins)

machine

with

the

the

of

Light shielding disc

the

com

follow

out

of

[Adjustment]

1) While holding

hand,

turn

timing

Repeat

2)

heel

the

specified

3)

Then,

comes

receptacle.

marks

down)

needle

set

from

the

pedal

several

always

position.

the

the

the

light shielding disc by

balance

"B"

operation

plug

machine

wheel

and

"C"

are

(toe

down

timestomake

stops

exactlyatthe

(12

pins), which

head,

until

aligned.

and

sure

into

the

Whitetiming

mark

the

Page 9

NOTE

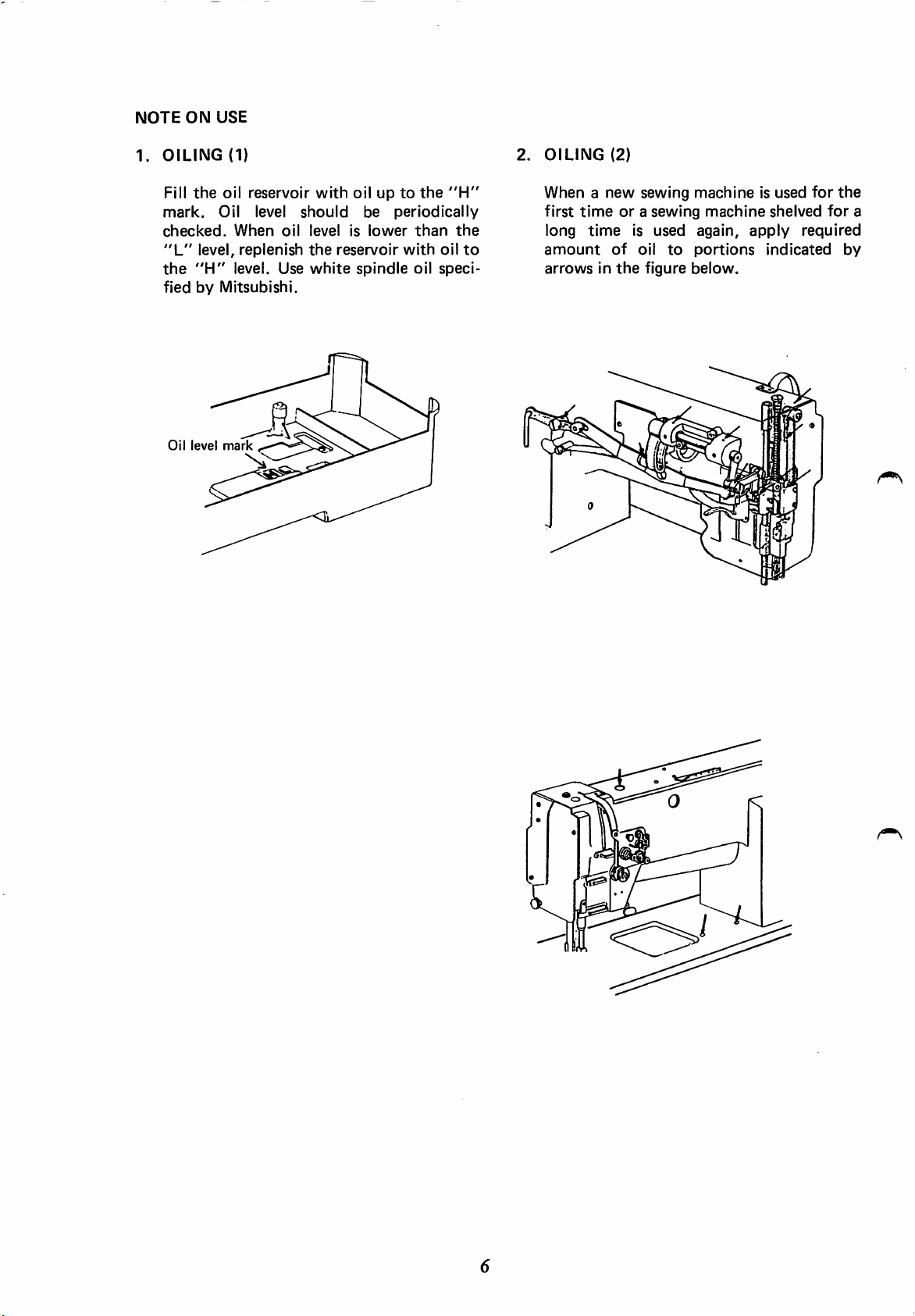

1.

ON

USE

OILING

Fill

mark.

checked.

"L"

the

fiedbyMitsubishi.

the

level,

"H"

(1)

oil

Oil level

reservoir

When

level. Use

oil

replenish

with

oilupto

should

levelislower

the

white

be

reservoir

spindle

the

"H"

periodically

than

the

with

oil

to

oil

speci

2.

OILING

When a

first

long

amount

arrowsinthe

(2)

new

timeora

time

is

of

sewing

sewing

used

oil

to

figure

machine

machine

again,

portions

below.

is used

shelved

apply

indicated

for

the

for

required

by

a

Oil

level

5

Page 10

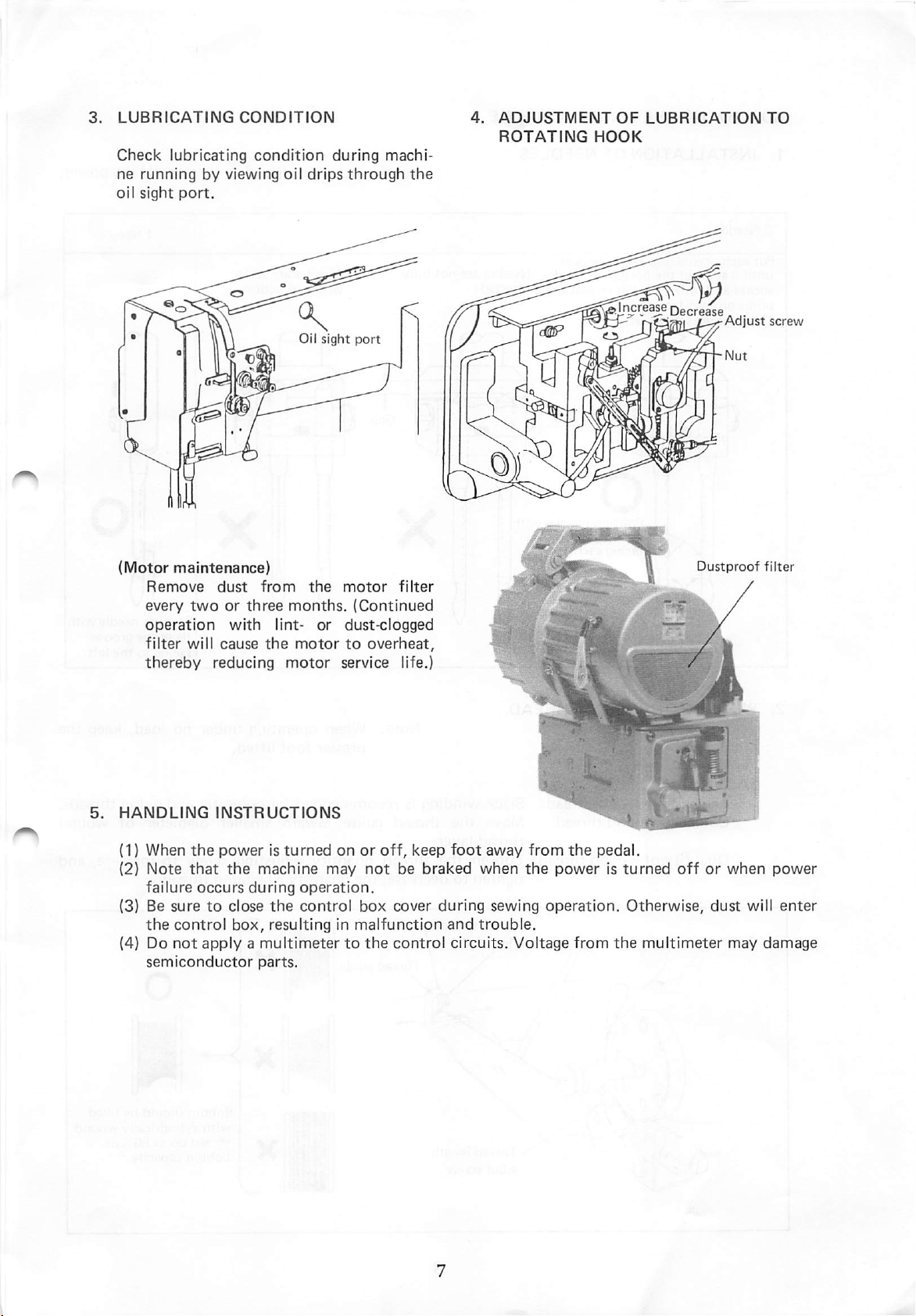

3.

LUBRICATING

Check

ne

oil

CONDITION

lubricating

runningbyviewing

sight

port.

condition

oil

drips

during

through

machi

the

4.

ADJUSTMENT

ROTATING

OF

HOOK

LUBRICATION

TO

(Motor

Remove

every

operation

filter

thereby

I

maintenance)

dust

two

or

three

with

will

cause

reducing

from

the

motor

months.

lint-

or

dust-clogged

the

motortooverheat,

motor

service life.)

filter

(Continued

I

[ncrease

Decrease

Dustproof

^

Adjust

screw

filter

5.

HANDLING

(1) When

(2)

(3) Be

(4) Do

INSTRUCTIONS

the

poweristurned

Note

that

the

failure

the

semiconductor

occurs

suretoclose

control

not

applyamultimetertothe

machine

during

box,

parts.

may

operation.

the

control

resulting in

onoroff,

not

box

malfunction

keep

be

braked

cover

control

foot

during

and

circuits.

away

when

sewing

trouble.

Voltage

from

the

the

poweristurned

operation.

from

pedal.

Otherwise,

the

off

multimeter

or

dust

when

will

may

power

enter

damage

Page 11

HOW

TO

USE

1.

INSTALLATIONOF

Put

each

until it

socket

prime

Then

needle

stopsatthe

and

grooves

tighten

THE

SEV\/ING

NEEDLES

into

needle

bottomofneedle

turn2needlessothat

face

each

set

screws.

socket

other.

O

.

Position

their

facing

needles

prime

each

MACHINE

Needles

Needles «

their

inserted.

with

grooves

other.

are

not

Note:

fully

X

Install

Needles

wrong

needles

are

direction.

set

after

in

X

turning

off

1

the

Needle

power.

2.

WINDING

[Adjustment]

OF

BOBBIN

Tensionofwound

Conically

wound

Quantityofwound

THREAD

thread:

thread:

thread:

Note:

Slack winding is

Move

thread

Loosen

the

layer.

the

thread

thread

tightentodecrease,

Thread

adjust

Thread

adjut

tension

nut

Thread

length

screw

When

operating

presser

recommended

guide

toward

quantity

the

quantityofwound

guide

under

foot

lifted.

for

polyester

smaller

adjusting screw

no

load,

and

nylon

diameter

to

thread.

keep

threads.

of

wound

increase,

the

and

Page 12

3.

SELECTION

It is

needle

the

depending

needles.

4.

THREADING

OF

recommended

(viewed

right

needle.

on

For

OF

THREAD

to

use

"8"

from

front)

When

needles, use

it is

"Z"

bobbin thread,-

NEEDLE

THREADS

twist

and

difficult

twist

either

"Z"

thread

twist

to

thread

thread

for

thread

use

for

the

threads

both

will

left

for

do.

. S

"Z"

twist

twist

A B

thread

thread

ABA

(1) Pass each needle thread through thread guide

Note: When

or

through

(2) With

the

position,

showninthe

Note: Pressing

button

tension

threadtobe

Needle thread tension regulator

(HD®®

thin

slippery

thread

(such as polyester

filament thread) is used, pass

thread

take-up lever located at

pass

each

figure

the

needle

below.

needle

guide

thread

"B"

thread

and

the

tension

(shown in figure below) will

disc,

thereby

allowing

picked up easily.

button

®(0

the

then

uppermost

in

the

regulator

open

the

"A".

thread

"A".

order

the

needle

iijLd

llMCiiD

Lead

thread

leftward. rightward.

Lead

thread

(Expanded

view)

Thread

Page 13

5.

ADJUSTMENT

OF

STITCH

LENGTH

AND

REVERSE

SEWING

(TOUCH

BACK)

To

make

stitch

length smaller, lower

stitch length adjust lever

length

adjust

Stitch

dial.

length

Stitch

adjust

length

and

turn

dial

adjust

the

lever

the

stitch

Touch-back

.... Direction

by pressing

oninreverse

is pressed,

direction

switch

of

when

stitching

this

direction

and

the

can

switch.

Stitching

while

*returns in forward

button

^

Touch-back

* switch

be reversed

goes

the

button

is

released.

6.

SETTING

(1)

Mount

the

(2)

Then

pull.

spring

* When

OF

bobbin

thread

pass

The

and

bobbin

indicated

BOBBIN

is

wound

the

thread

comes

the

should

by

thread

thread

into

clockwise.

through

passes

outofthe

bobbin

thread

rotate

arrowinthe

bobbin

the

under

slit

in

figure.

casesothat

slit

the

"2".

is

pulled,

the

direction

"1"

and

tension

the

Slit

SIt"2

"1

I

10

Page 14

7.

THREADING

(1)

Mount

set

the

the

bed.

the

latch

OF

bobbin

"1".

BOBBIN

caseinthe

Keep

THREADS

hook

thread

end

and

over

9.

BALANCE

OF

THREAD

TENSION

Thread

(2) Pick up 2 needle

and

rotate

right

threads

bobbin

and

and

led

hand.

as

threads

needle

backward.

the

balance

By pulling up

shown

threads

Opener

threads

are

—

wheel1turn

in

the

lifted.

Both

should

by

the

figure,

be

left

needle

bobbin

aligned

Thread

hand

by

the

10.

AO

BX

CX

TENSION

Needle

adjusted

tension.

To

each

needle

and

stroke

OF

adjust

tension

thread

thread

of

Balanced

Tight

bobbin

Loose

bobbin

NEEDLE

thread

with

tension

respecttobobbin

needle

adjusting

tension

by

changing

slack

thread

needleorloose

thread

needleortight

thread

THREAD

thread

nut.

for

take-up

tension

tension

tension

should

tension,

Also

special

force

be

thread

turn

adjust

fabric

and

spring.

8.

TENSION

THREADS

ADJUSTMENT

OF

BOBBIN

Loosen

11.

ADJUSTMENT

PRESSURE

Adjust

turning

Loosen^^^S

pressure

the

Thread

OF

PRESSER

depending

pressure

Tighten

adjusting

.

Pressure

tension

FOOT

on

adjust

fabrics

adjust

nut

by

screw.

screw

Tension

adjust

screw

Tighten

11

0

0

r»

A

Page 15

12.

TIMING

(1)

Set

(2) When

lowermost

the

locations:

ADJUSTMENT

stitch

length adjusting dialto"6".

the

needle is lifted

position,

needle

The

2.3

The

center

Gap

face

should

upper

mm

below

hook

of

between

of

needle

point

needle

FOR

the

be

locatedatthe

edgeofneedle

the

hook

should

axis.

the

hook

should

ROTATING

2.4

mm

rotating

eye

point.

be

locatedatthe

point

be

0.05

mm.

from

hook

following

should

and

the

HOOK

its

and

be

side

AND

NEEDLE

Hook

Upperedge

needle

Needle

2.4

Needle

lowest

Center of €

needle

2.3

mm

pointNy

l

of^

eye

lifted

at

position

0.05

' i n

mm

mm | l

(3) Needle

be

adjusted

* Easy

ing

dog

Positioning

(1)

With

mesh

with

located

driving

located

(2)

Tighten

of

(3)

Guideofrotating

When

position,

is

*

To

needle

gear (large)

(large) 1

and

rotating

in

adjustment

the

presser

before

the

hook

the

the

the

at

gear

at

adjutment.

needle

right

large

front,

(small) so

rear.

"8"

hook

shaft.

the

needle

the

nearlyinline

make

fine

motions,

to

2 mm in

hook

the

following

can

be

foot,

throat

point

at

lowermost

hand

driving gear (small)

gearsothat

and

mesh

screws

onto

hook

is

"C"

screwinrotating

with

the

adjustment

loosen

and

move

positions

made

plate,

that

the

position

at

its

needle.

screw

the

the

axial

procedure:

by

remov

and

position,

"8"

screw

the

left

hand

"8"

screw

set

contact

lowermost

hook

of

hook

in

driving

driving gear

direction.

can

feed

and

Hook

point

r(

) 5

is

is

X

X

X

X

X

X

1to2

mm

1to2

mm

Needleatlowest

position

12

Page 16

13.

ADJUSTMENT

The

foot

OF

heightoffeed

should

Light

be

fabric

positionistoo

ssureistoo

The

stitch

strong.

lengthofheavy fabric will

uniformifthe

the

presser

Measure

the

balance

feed dog

throat

Light

Normal

Heavy

foot

the

at

plate.

fabric

fabric

fabric

FEED

dog

adjusted

will be

DOG

and

the

depending

damagedifthe

highorthe

feed

dog

positionistoo

pressureistoo

height

wheel

the

of

feed

by

hand

highest position from

Approx.

...

throat

.Approx.

throat

plate

plate

Approx.

throat

plate

HEIGHT

pressureofpresser

on

fabrics.

feed

dog

presser

dog

and

weak.

locating

foot

by

pre

not

low

turning

the

be

or

the

0.8

mm

above

1.0

mm

above

1.2

mm

above

V///.

T~

;0.8

mm

mm

Adjusting

(1)

(2)

(3)

Procedure

Lean

Turn

it

when

mum

Loosen

the

the

height

(4) Vertically move

direction indicated by

to

locate

(5)

The

After

bar

feed

set

dog

height

screw.

machine

balance

the

feed

the

feed

the

feed dog

adjustment,

height is

head

wheel

dog rises

above

bar

set

the

factory-set

backward.

by

hand

and

to

the

the

throat

screw.

feed bar (in

arrowinthe

at

proper

tighten

at

1.2

maxi

plate.

figure)

height.

the

stop

the

feed

mm.

Feed

screw

bar

13

Page 17

14.

RELATION

When

the

the

relation

lever

motions

BETWEEN

ROTATING

HOOK

timing belt is removed for replacement,

between

shouldbeas

rotating

follows:

hook

and

(1) Turn the balance wheel and stop it when the

take-up lever is lifted

(2) Lean

sure

the

machine head backward and make

the

arrow

belt sprocket matches

bossofhook

(3) If

the

shaft

timing mark is

black line, remove

belttoobtain

(timing mark)

proper

to

the

bearing.

not

and

alignment.

its

top

on

the

black line on

aligned with the

reinstall

the

AND

take-up

position.

timing

the

timing

TAKE-UP

LEVER

MOTIONS

15.

RELATION

(1)

(2)

(3) If

BETWEEN

Turn

the

balance wheel by

when

the

opener

away

from

the

At

this

time,

the

bobbin

approximately

the

gap is

opener

of

opener.

set

screw

make

case

throat

holder

0.2

too

ROTATING

HOOK

hand

holderisthe

plate.

sure

mm.

that

"A"

longest

the

and

gap

the

largeorsmall, loosen

"B"

and

adjust

the

and

distance

between

opener

position

AND

stop

it

is

the

OPENER

Approx.

MOTIONS

0.2

mm

Timing

Black

Timing

Timing belt

sprocket

mark

(arrow)

belt

line

Opener

14

Screw

"B'

Opener

holder

Page 18

16.

RELATION

(1)

Set

(2)

Lean

(3) Loosen

and

(4) Lower

BETWEEN

the

stitch length adjust dial

the

machine

the

feed

"B".

the

needle

(5) Allow 9-mm gap between

the

rock

pressure bar (10.1 mm

and

420).

Then

crank

(6) Check

is

connected

as

showninthe

(7) If

the

remove

to

obtain

(8) After

tighten

xrews

"A"

to

see if

with

connection

the

back

the

right angles.

the

completion of adjustment, fully

the

screws

NEEDLE

head

backward.

shaft

crank

to

its lowest

the

finger-tighten

and

"B".

the

right feed

the

link at right angles

figure.

is

not

cover

and

"A",

AND

FEED

to

"0".

set

screws

"A"

position.

pressure bar

for

the

shaft

LU2-400

feed

shaft

crank

and

at right angles,

loosen

"B",

"C"

and

screw

"C".

DOG

MOTIONS

Screw

Screw

"A"

"B

Feed

shaft

crank

Feed

(intermediate)

shaft

crank (right)

Link

LU2-410and

LU2-400

and

430

420

-

Needle

Rock

bar

pressure

Feed

Dimension

9.0

mm

10.1

mm

bar

shaft

A

crank

Screw

(right)

"8

Link

Screw

"C

15

Page 19

17.

SAFETY

The

belt

runs

by

the

(1)

Function

1)

2)

3)

(2)

Setting

1)

2)

3) Release

4)

CLUTCH

safety

from

under

hook

When

(SAFETY

clutch

prevents

being damaged

excessive

load

caughtinthreads.

the

safety

DEVICE)

hook

when

which

clutch

the

is

timing belt pulley races, causing

shaft

to

stop

and

only

the

arm

keep

turning.

the

machine.

Remove

from

the

Turn

hand

hook

nism

back

the

to

shaft.

Therefore,

threads

hook.

timing

check

Then

again.

and

belt

for

other

set

pulley

smooth

the

immediately

foreign

clutch

Procedure

While

button,

of

balance

tion

Now

intermeshing

mechanism.

again

kept

The

showninthe

simultaneously

whichislocatedonthe

bed,

by

left

hand,

wheel

by

right

shownbyarrowinthe

the

with

balance

further

the

wheelisstopped

plate

providedinthe

Then

turn

greater

pushbutton

pressed.

clutch

mechanism

figure.

pressing

slowly

handinthe

figure.

the

balance

force.

which

is

now

and

timing

machine

is

caused

actuated,

the

shaft

matter

bushing

rotation

mecha

the

other

turn

by

clutch

wheel

has

set

hook

stop

by

push

side

the

direc

the

been

to

of

Safety

switch

Timing belt pulley

Bushing

Balance

as

wheel

Pushbutton

18.

ADJUSTMENT

SIDE)

When

on

of

STROKE

stitchingisnot

fabrics,

slot

adjust

in feed

[Adjusting Procedure]

1)

Loosen

2) When

the

upper

3) When

stroke

feeds

point

rock

of

special

4)

After

OF

the

rock

the

special

this

bolt

feed

this

boltisset

decreases.

are

theoretically

where

shaft

the

crankisaligned

bolt.)

adjustment,

UPPER

made

upper

bolt.

is

stroke

(The

reference

tighten

FEED

uniformly

feed

shaft

set

at

increases.

at

upper

equivalent

stroke

crank

upper

lower

line

with

the

special

(NEEDLE

depending

by

range

(right).

position,

position,

and

lower

at

the

for

feed

the

center

bolt.

Pushbutton

joint

portion

Intermeshing

F^ed rock shaft crank (right)

Upper

Reference

Special

[(needle bar rock link)

Upper

bolt.

feed

feed

plate

stroke

stroke

16

Page 20

19.

ADJUSTMENT

(1)

(2)

(3)

OF

Operating

Height

OUTER

Adjustment

AND

INNER

PRESSER

When springy material is sewnorwhen

thickness

heightofpresser

changes

greatly,

foot.

adjust

the

operating

[Adjusting Procedure]

1) Loosen

2)

3)

4)

Alternate

The

best

changing

outer

fabrics.

Example:

and

When

vertical

increase

prevents

Setting

upper

heightofinner

Setting

decreases

After

bolt.

The

between

the

special

the

crank

position

the

bolt

the

height.

adjustment,

heightofpresser

2

mm

Up/Down

feed

the

inner

slippery

stroke

that

Strokes

condition

alternate

presser

fabric

of

of

inner

slipping.

bolt.

rod

special

increases

and

outer

at

lower

tighten

feetisadjustable

and6mm.

can

be

up/down

feet

is

outer

presser

presser

bolt

the

operating

presser feet.

position

the

special

obtained

strokes of

depending

sewn,

reduce

foot

foot.

[Adjusting Procedure]

1)

Turn

the

2)

3)

4)

5)

6)

Mounting

Turn

1)

the

2) In

this

eccentric

tighten

balance

when

lowest

Lower

Loosen

feed

Moving

increases

presser

outer

the

position.

the

the

lifting

the

foot

presser

take-up

presser

rock

the

Reversely, moving it

reduces

presser

presser.

After

screw

presser

thatofouterat3.2

the

needle

the

and

adjustment,

"A".

footisfactory-setat2

the

Eccentric

balance

bar

state,

locate

ring as

it.

wheel

lever

bar

lifter.

screw

shaft

crank

vertical

"A"

crank.

"B"

stroke

and decreases

foot.

vertical

increases

motion

that

securely

(Vertical

stroke

mm.)

Ring

wheel

at

the

by

highest

No. 1

showninthe

and

reaches

in

to

to

tighten

hand

screw

stop

the

the

of

that

the

of

of

of

mm

to

position.

"C"

figure

the

by

on

and

This

upper

left

inner

right

inner

outer

the

inner

and

bring

and

FEET

Upper feed lifting rock shaft crank

Special

bolt/O

Screw

at

Lower

Crank

Uniform

Non-uniform

Arm

rod

vertical

motion

vertical

it

its

of

Eccentric

No.1screw

in

No.2screw

"O

Crank

"B

ring

"A

Uniform

(Higher)

Inner

presser

Outer

presser

motion

(Lower)

b)—

Upper feed lifting

rodshaft

foot

foot

Arm

crank

"8'

\

17

Page 21

ADJUSTMENT

1.

INSTALLATION

1.1

Initial

(1)

(2) With

(3) In

(4)

(5) Adjust

Thread

trimmer

rocking

crank

OF

THREAD

OF

MOVABLE

Position

Turn

onto

this

on

the

necessary

roller

Loosen

knife

of

Movable

the

balance wheel by hand until

the

needles at this position, push

the

thread

state,

trimmer

turn

arm is aligned with

work

on

from

slipping

the

bolts

the

movable knife so

bladeasillustratedinthe

Bolt

"A

TRIMMER

KNIFE

Knife

cam

the

balance wheel and

the

cam follower crank using screw

outofthe

"A"

and

"B"

the

groove.

the

white point on

cam

groove.

on

the

that

its slant

figure.

needles reach

the

cam follower cranktolocate

stop

their

it at

the

point

the

balance wheel. At this time, make

and

thread

Then

trimmer

portion

tighten

rocking

protrudes0to

the

bolts

lowest position.

the

cam roller

where

the

black

screwdriver to prevent

crank.

0.5

"A"

Movable

mm from

and

"B".

knife

the

point

the

fixed

1.2

GAP

BETWEEN

(1)

Turn

needles

(2) With

cam

ance

knife

(3)

Turn

the

the

the

holder

by

the

balance

reach

the

needlesatthis

follower

wheel

reaches

the

bobbin

direction

figure.

movable

stopper

loosening

MOVABLE

wheel

their

crank.

by

hand

the

endofits

case

indicated

Then

adjust

knife

to

approximately

the

0

Thread trimmer rocking crank

Then

until

holder

and

screws

KNIFE

by

lowest

position,

by

the

the

hand

turn

the

stroke.

the

gap

bobbin

"A"

AND

until

position.

push

the

movable

by

arrow

between

0.5

and

hand

Bolt

BOBBIN

the

the

bal

in

in

case

mm

"B".

0~

"B"

Bobbin

stopper

0.

CASE

Movable

case

Approx,

HOLDER

knife->

holder

0.5

mm

STOPPER

Screw

Screw

Bobbin

Fixed

"A'

"B"

case

knife

holder

18

Page 22

2.

POSITIONING

(1)

(2)

Adjust

bushing

shaft

After

contact

release

(i.e.

after

OF

the

gap

between

to

17.3

set

screw

"A".

bringing

with

cam

the

the

with

eliminating gap),

THREAD

mm

and

thread

bushing,

the

the

trimmer

thread

tighten

TRIMMER

feed

cam

tighten

and

the

trimmer

the

cam

set

CAM

and

the

hook

into

tension

cam

screws.

Bracket

3.

ADJUSTMENT

(1)

(2) With

(3) By

OF

Turn

cam

onto

the

needles

turning

thread

knife

the

balance

point

the

reach

the

follower

the

starts

on

the

balance

needles

groove

the

trimmer

moving

wheel is aligned

loosen2thread

"A".

THREAD

their

crank

wheel

lowest

at

of

this

to

by

position.

position,

locate

thread

balance wheel by

cam

so

when

the

arm.

To

make

trimmer

cam

TRIMMER

hand

the

cam

trimmer

hand,

that

the

green

with

this

adjustment,

clamp

until

push

movable

point

the

screws

•Tension

CAM

the

the

roller

cam.

adjust

on

black

release

1

Arm

cam

cam

Thread

Bushing

0

trimmer

Black

Screw

i

point

cam

Green

"

point

I

Feed

Feed

cam

Balance

rod

wheel

Cam

c_

Cam

follower

roller

crank

0

Screw

"A"

Cam

groove

Thread

trimmer

cam

19

J

Page 23

4.

ADJUSTMENT

(1)

Turn

the

(2) With

(3) By

the

the

grooveofthread

turning

tension

point

(4)

Adjust

mounted on

adjustment,

(5)

For

fine

(6) When the nuts

degree

OF

balance

needlesatthis

the

disc closes

on

the

arm.

the

opening

the

loosen

adjustment,

increases.

THREAD

wheelbyhand

balance wheel by

when

For

degreeoftension

convexed portionofthread

the

"D"

RELEASER

until

the

position,

trimmer

the

this

nut

loosen

push

cam.

hand,

white

adjustment,

"C"

and

the

nuts

needles reach

the

cam

follower

adjust

point

on

the

the

loosen 2 tension release cam clamp screws

disc

with

the

release cam as shown in

draw

the

wire.

"D"

(0.5to0.7

the

lowest

cranktolocate

thread

position.

the

tension release cam so

balance wheel is aligned

tension

release lever

roller

the

mm).

cam roller

with

figure.

are loosened and the outer casing is shifted rightward, the opening

White

Arm Black

point

point

/ Balance wheel

"B"

that

the

which

For

onto

the

black

"A".

is

this

Tension

Roller

Thread

release

Screw

"A

"B

release

Thread

lever

cam

trimmer

cam

Screw

(dI

(D

"C"

Cam

Cam

follower

roller

crank

Outer

' Largeropening degree

J

casing

20

Page 24

5.

ADJUSTMENT

OF

MOVABLE

AND

FIXED

KNIFE

MESHING

PRESSURE

(1) Loosen

the

fixed knife bracket clamp

bolt

"A".

(2) Turn the vertical position adjust screw "B" to adjust the

the

bolt

"A".

Note; Since excess scissoring pressure causes large

nism

and

(3) Move

results in

minimum

the

movable knifetocheckifthe

pressure.

trimming

failure,

thread

C0P

Fixed

knife

bracket

Bo

t "

adjust

is sharply

torquetothe

it so

meshing

that

the

trimmed.

pressureand then tighten

thread trimming mecha

thread

canbetrimmed

with

6.

SHARPENING

When

movable

the

Vertical

cutting

THE

position

FIXED

adjust

KNIFE

edgeofknive is dull,

knifeisdifficulttosharpen,

Fixed

screw

"B'

sharpen

replaceitwithanew

knife

the

fixed knife as

Oilstone

one.

showninthe

figure. Since

the

21

Page 25

7.

ADJUSTMENT

Rocking crank

Connecting

"C

link-

Screw

OF

"A"

\

NEEDLE

Stopper

GAUGE

pin

DISTANCE

"E"

Screw

"A

Hook

(right)

bracket

Hook

bracket

(left)-

Screw

(1)

Lean

the

(2)

Loosen2connecting

(3) Replace

needle

(4)

Remove

(5)

Loosen

and

"B"toadjust

and

hooks.

(6)

When

adjusted,

(7) Make

tact

the

with

tighten

(8)

Turn

the

(9)

Loosen

(10) Push

(11)

the

is

smoothly

Adjustmentofcam

a) Push

b) By

turning

plane

c) Push

thread

0

Bolt

"J"

Stopper

machine

the

clamp.

the

spring

the

hook

the

needles

install

rocking

the

the

connecting

balance wheelbyhand

the

nuts

cam

placed

the

cam follower cranktoplace

"N"asshowninthe

the

cam follower

trimmer

pin

head

throat

"M".

bracket

the

the

spring

cranks

stopper

"G"

follower

onto

groove

the

connecting

cam

"F

backward.

link

plate,

gaps

and

pins

link

and

crank

the

crank

groove.

clamp

clamp

hooks

"M".

"C"

"E"

"H".

grooveofthread

and

Screw

Thread

crank

bolts

trimmer

"D"

feed dog,

screws

between

and

clamp

"K"

and

until

cam

have

"D"

"F",

bolt

and

roller

needles

been

the

adjust

the

rod

"L",

figure (within

againtocheck if

Spring "M

\

I

Connecting

rod

"L"

Nut"G"

"B"

rocking

"J".

and

"A"

Cam

con

and

"J".

needles reach

the

connecting

trimmer

cam roller

minimize

0.2

mm).

the

Cam

roller

groove

the

cam.

onto

the

gap

between

Then

cam roller is

tu

j •

thread

Plane

lowest

rod

"L"sothat

the

cam groove.

tighten

smoothly

—Cam

Cam

trimmer

Cam

follower

Thread

"N'

position.

the

cam roller

the

nuts

follower

cam

Hook

placed

roller

crank

trimmer

shaft

the

"G"

cam

and

onto

crank

"K'

cam

and

"K'

roller

the

"H".

the

Note:

When needle

width

exceeds

22

3/4",

change

the

connecting

rod

"L".

Page 26

8.

INSTALLATION

(1) Install

0.5—mm

the

9.

REMOVAL

(1)

Removal

The

without

unit.

(2) Remove

following

1)

2)

3)

•4)

6) With

6) Remove

7)

OF

SOLENOID

the

solenoid crank, providing a 0—

gap

between

solenoid

* Larger

into

during

malfunction

hook

crank.

gap

contact

solenoid

OF

HOOK

of

bracket

will

hook

cause

with

rotation,

of

BRACKET

bracket

(left)

disassembling

the

hook

procedure;

Remove

Remove

Remove

Remove

bracket

the

opener.

the

fixed

the

hook.

the

movable

the

lever raised, remove

by

shifting

indicatedbyarrowinthe

the

bobbin

spring.

Shift

the

leverinthe

remove

the

hook

bracket

CRANK

the

the

rotary

the

cam

solenoid

rollertocome

follower

resultinginthe "

thread

bracket (right) in

knife.

the

knife.

it in

arrow

trimmer

(left)

can

thread

figure.

thread

(right).

(LU2-430)

be

the

the

direction

direction

removed

trimmer

retaining

to

and

0--0.5»»

crank

unit.

Solenoid

the

knife

to

i

msi

crank

Knife

bracket

Movable

Bobbin

retaining

Fixed

Rotating

knife

thread

spring^

knife

hook

lE^

0

V

ssssw

Opener

Rotary

Cam

0

solenoid

Roller

follower

crank

Lever

10.

FEED

DOG,

(1) Since

used

(2) Slip

A

conical

to

during

(3)

Bobbin

Use

machine.

num,

the

*

Reassemble

reverse

the

for

thread

running

prevent

thead

the

it easily

THROAT

feed dog,

prevention

spring is

the

trimming.

bobbin

Since

deforms.

the

hook

procedure.

PLATE,

throat

HOOK, BOBBIN

plate,

trimming,besuretouse

spring

loadedinthe

bobbin

which

the

bobbin

To

from

is

attached

is

prevent

threadaslightlyaspossible.

brakcet

hook,

rotating

slip

made

bobbin case,

ones

hook

running

to

of

alumi

this,

wind

in

CASE,

specified

the

BOBBIN,

bobbin,

AND

and

by Mitsubishi.

BED

SLIDE

bed slide are specifically

Idle

running

spring

Rotating

prevention

hook

23

Page 27

11.

ADJUSTMENT

OF

NEEDLE

UP

STOP

POSITION

(LU2-410-B1T,

LU2-430-B1T)

The needle UP

thicknesses

stop

and

materialsofthreads

[Adjusting Procedure]

Perform stitching

point

on

the

1)

Advanced

and

balance wheel

needle

position,

thread

UP

stop

after

trimming

and

the

timing

and

thread

fabrics.

on

black

trimming, should be adjusted depending on

For

adjustment,

a sample

point

When deviation

trimming knife failstooperate, resulting in trimming

failure of both needle and bobbin threads at left and right.

on

and

the

proceedasfollows;

check

arm

"A"

deviation

when

is more than 2 mm, thread

needle

between

UP

motion

the

white

stops.

the

2)

Delayed

3)

Adjustment

If deviations are present as shown above, adjust

nizer until

needle

the

UP

stop

timing

•

specified dimensions

"A"

When

between

and

deviation

the

"B"

needle

"B"ismore

edge

and

than5mm,

throat

plate

light shielding disc portion of synchro

are obtained. For adjusting procedure, see

Section 3 "ADJUSTMENT OF NEEDLE BAR STOP POSITION" in page 5ofthe

tion Manual. When making

and

thread

trimming.

the

adjustment, check

the

stop position through actual stitching

clearance

reduces.

Instruc

24

Page 28

ADJUSTMENT

1.

SELECTION

AND

OF

USE

OF

POSITIONS

CONTROL

1

AND

SYSTEM

2

Select

When position 1 is selected,

the

2.

The 2-step pedal operation feature allows

riseofpresser

the

machine

• • :

stop

Position

Position

position by useofthe

2

1

the

thread is trimmed following a

select switch on

the

panel.

turn

by a heel-down operation on

pedal.

PEDAL

OPERATION

the

operation of run, thread trimming, and automatic

foot.

Pedal

Operation

Position

Pedal

Note 1: Variable speed run from lowtohigh speeds is available depending on pedaling strokes.

Note 2: Since presser

Note 3: Use optionally available Type LD-C2,

Position

Position

Operation

Setting

1

2

TOE

Needle

Needle

foot

rise is

DOWN

NEUTRAL

position.

stopsatDOWN

position.

to

stops

at UP

' ' ' /

/'

Neutral

outputtothe

11/

NEUTRAL

Pressure

Pressure

^

Toe

(machine

presser

04,or06

TO

foot

foot

Step

Step

SLIGHT

DOWN

goes up.

goes

2

1

up.

One

then

Needle

half

then

HEEL

down

start)

footupconnector,

solenoid box for tack-stitching.

Neutral

use solenoid valve (DC 24 V).

turn

turn

NEUTRAL

HEEL

and

thread

presser

fromUPto

and

thread

presser

foot

Heel

down

DOWN

foot

TO

trimming,

goes

up.

DOWN,

trimming,

goes

up.

3.

ADJUSTMENT

3.1

3.2

4.

ADJUSTMENT

(1)

OF

PEDAL

Adjustment

Pedal

changing

spring

pressure

unstable

Adjustment

After

"B"

to

ment,

of

tow-down

the

hooking

on

the

may

lever

of

loosening

adjust

tighten

OF

Pedal

pressure

lever.

cause

stop

Pedal

the

spring

and

secure

RUNNING

Tow-down

position.

Heel-down

nut

Adjustmentofmaximum

Two

volumes

exterior

maximum

volume

No.ofPoles

2

poles

To

select

"H".

Since

as

showninthe

tachometer,

for

changing

panel

to

of

low

control

speeds

"H"isfactory-setatthe

Internal

speeds

the

which

internal

following page, use

etc.

OPERATION

Force

canbeadjusted

positionofthe

Note

that

malfunction

Force

"A",

turn

pressure.

the

nut

SPEED

After

"A".

speed (speed

maximum

box.

The

which

have

following

Volume

2000

spm

are

outside

volume

"H"Ismarkedat2

PRESSURE

tension

too

weak

due

the

bolt

adjust

obtained

speed

external

been

speeds.

"H"

Setting

the

aforementioned

these

by

to

are

set

marks

Tension

when

provided

volume

by

the

locations

as guides.

spring

pedal is fully

inside

the

allows

adjustment

internal

Adjustable

Max.

range,

(with

For

stamped)

control

box

in

volume

RangebyExternal

adjust

2500

finer

"H".

speedto200

the

internal

spm

speed

and

B A

Lever

andonthe

the

The

Volume

spm

4500

setting,

range

internal

volume

spm)

use a

of

Page 29

Note:

Even if

internal

Speed

internal

the

volume

setting

volume

motor

jgOO

/ ,

"H"

spm

pulley

and

4500

diameterismade

external

volume

spm

larger,

cannot

External

speed

be

volume

obtained.

higher

Position

than

1/2

the

select

settings

switch

of

5.

M (Medium) (High) (Low) (Thread)

(W

(2)

H /

Adjustment

The

positioning

wise

increases

(This

volumeIsfactory-setat200

(3)

Adjustment

The

thread

increases

the

adjustment

dealer.

(4)

Adjustmentoftack-stitching

When

stitching

OPTIONAL

By

the

be

applied

details,

(1)

tack-stitchingismade

connections

consult

Internal

COR:

Correction

G:

Gain

A: High-speed

machine

volume

SH:

One-shot

POS:

Positons1and2(thread

of

of

trimming

speed

speed

FUNCTIONS

toavertical

your

switch

switch

LX

M

positioning

(low)

speed

thread

and

counterclockwise

of

trimming

canbeadjusted

of

internal

dealer.

sewing (high speed) IL:

(Keep

switch

(Not

is provided)

function

motion) _S

US:

TB:

Needle

Back

thread

UPbytouch-back

solenoid

trimming

T

speed

can be

and

counterclockwise

trimming

speed

work

required

activated

can

speed

by useofType

switch

sewing

this

switch

for

vertical

when

switch

speed

spm.)

speed

be

speed,

by

the

and

machine

external

trimming

switch

at

time

(speed

adjusted

adjusted

decreases.

consult

internal

external

on.)

sewing

I—

—

of

~

I

obtained

by

the

decreases.

by

This

the

LD-C2,

volume

optional

and

various

IL:

-1-21Slow

-1-1

SL

+

when

internal

Adjustable

the

internal

volumeisfactory-setat175

Adjustment

04or06

"M".

Thread

Thread

Start

Switch

pedal is slightly

volume

rangeis160to320

volume

Instruction

solenoid

connector,

types

of

trimming

trimming

1

needle

ON

OFF

OFF

automatic

needles

"L".

"T".

this

interlock

interlock

2

ON

ON

OFF

stamped)

Turningitclock

Clockwise

spm.

Manual

box

sewng

or

(option),

machine

machines.

reset

switch

reset

switch

3

needles

ON

OFF

ON

needles

spm.

turn

For

your

tack-

can

For

4

ON

ON

ON

FL:

Internal

switch

mimij'

_ -I-

-f

Automatic

rrm

presser

foot

rise reset by S2

Page 30

(2)

Automatic

Set

and

thread

adjust

trimming

thread

trimming

timing

withP5and

P24.

Needle DOWN

Needle UP position

Standard

(3)

Optional

Various

For

input

© ®

® @

Power

Run (high

Run

(low

Variable

Correction

Needle

UP

Variable

Thread

Run

0 V

trimming

(medium

Thread

connectors

operations

© @ @

speed)

speed)

voltage

sewing

speed

speed)

position'

trimming

Wiper

W

signals, use

Clutch

© ®

Brake

Option

command

1

T

are

possible by

contacts

Speed

LOW

9

8

7

6

5

4

3

2

1

O

Q

_Q)

T> a

® o

ni

V

which

<6^

:<3)®

HIGH

Synchronizer

applying

are

signals

highly reliable in

(2)®®

Option

External

volume

10

kfi

0X2)(a)

Solenoid

a

o

*•>

v>

Q.

z>

•a

a>

a>

Z

from

exteriortooptional

contacting

Position

box

+30

V

Presser

Presser

footUPoutput

performance.

1/2

foot

Presser

Presserfoot UPsignal

0 V

Touch-back

+30

V

0 V

Touch-back

Trimming

0 V

Trimming

+30

V

Thread

Grounding

output

signal

safety

output

removal

output

®(D®

(2)

(2)®®

UP Machine

foot

Machin

switch

connectors.

UP

4

—©—1

3

2

-W-|

1

e

12

-<S>-|

11

10

9

8

7

6

5

4

-0-1

3

2

1

—e+n

(4)

Reverse

sewing

bytouch-back

The operation by use of touch-back switch (S?) is actuated only during machine operation.

27

Machine

main

unit

Page 31

THREAD

TRIMMER

TROUBLESHOOTING

LIST

Trouble

Threadisnot

mmed.

Cause

1.

Roller

does

not

rest

tri

cam

groove

at

the

lowest

when

position.

onto

needle is

Corrective

Adjust

crank

Check

noid

2.

Fixed

tive

ble

3.

Movable

located.

4.

Machine

ing is

5.

Thread

improperly

6.

Needle

lease

knifeisnotinposi

engagement

knife.

with

knifeisimproperly

stop

position

too

advanced.

trimmer

adjusted.

thread

tension

timingistoo

mova

tim

cam

re

advanced.

Adjust

ssure

and

fixed

Check

knife.

Adjust

Adjust

is

cam.

Adjust

sion

regulator.

Action

cam

follower

position.

settingofsole

crank.

intermeshing

between

knives.

pre

movable

settingofmovable

synchronizer.

thread

needle

trimmer

thread

ten

Reference

Sec.7(10)inP.

Sec.8inP.23

Sec.5inP.21

Sec,

1 in P.

P24

Sec.3inP.19

Sec.

4 in P.

22

18

20

After

mming,

thread

of

needle.

After

needle

too

long.

thread

needle

slips

trimming,

thread

tri

out

Sec.

4 in P.

1.

Needle

failstoopen.

2.

Thread

retainer.

3.

Thread

passed

ling

4.

Needle

leasing

1.

Bobbin

is

spring

2.

Pretension

3.

Needle

leasing

vanced.

thread

catches

is

not

through

parts.

thread

timingistoo

thread

pressureistoo

is

thread

timing

tension

in

smoothly

thread

tension

delayed.

retaining

insufficient.

tension

is

too

disc

thread

hand

re

high.

re

ad

Adjust

sion

dle

needle

regulator.

Check

threadingofnee

thread.

Polish

parts

such

retainer,

tension

needle

clamp.

Adjust

sion

regulator.

Reduce

Increase

Adjust

sion

regulator.

thread

needle

regulator,

needle

spring

spring

needle

thread

handling

as

thread

pressure.

pressure.

thread

ten

thread

thread

and

ten

ten

Sec.4inP.9

Sec.4inP.20

Sec.4inP.20

20

28

Page 32

Trouble

Cause

Corrective

Action

Reference

After

needle

too

short.

trimming,

thread

1.

Working

is

thread

large.

2.

Thread

passed

ling

3.

Opening

thread

sufficient.

4.

Threadiscaughtinthread

retainer.

5.

Pretensionistoo

6.

Threadisbroken

ble

retaining

7.

Needle

leasing

stroke

take-up

through

is

springistoo

not

thread

parts.

degree

tension

disc

high.

knife

and

bobbin

spring.

thread

tension

timingisimproper.

of

slack

smoothly

hand

of

needle

is in

by

mova

thread

Reduce

to

performance

versely

the

working

degree

affected.

that

is

stroke

sewing

not

ad

Polish thread handling

parts

such

as

thread

retainer,

tension

needle

Adjust

sion

Check

dle

Decrease

Buff

thread

re

Adjust

thread

cam.

needle

regulator,

clamp.

needle

regulator.

threading

thread.

pretension.

end

retaining spring.

cam

tension

thread

of

of

regulator

thread

and

ten

of nee

bobbin

needle

Sec.4inP.20

Sec.4inP.9

Sec.4inP.20

Stitches

start

5

to

after

sewing,

thread

of

6

skip

start

is

sewing.

stitches

bobbin

broken.

at

1.

2.

3.

Bobbin

bobbin

spring.

After

dle

Bobbin

thread

thread

thread

thread

thread

trimming,

is

is

out

retaining

nee

too

short.

tensionistoo

of

1. Correct spring pressu

re

and

also

movable

knife

contact

surface.

high.

4.

Slow

start

switchisturned

on.

5.

Thread

around

1.

Bobbin

of

2.

high.

Bobbin

due

bobbin.

3.

Thread

passed

eye

is

wound

needle.

thread

tensionistoo

threadisentangled

to

idle

running

is

not

through

and

throat

feed

plate,oris

1

turn

smoothly

needle

Check if idle running

of

prevention

side

rotating

Polish

throat

plate.

needle

spring

hook.

eye

is in

and

P.

23

damaged.

29

Page 33

o

o

(8403)

REG

PrintedinJapan

A

MITSUBISHI

HEAD

OFFICE

MITSUBISHI

ELECTRIC

OEHKI

BLOC

MARUNOUCHI

CORPORATION

TOKYO

100

TELEX

J24S32

CABLE

MELCO

TOKYO

Loading...

Loading...