MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

LT2-250-M1ATW

-A1AT

-B1AT

(Auto-changer)

Double-Needle

Model

Class

o Thank you for

ing

Machine.

Before

booklet carefully together with

LT2-230/250.

the

your

purchase

useofyour

Lockstitch,

Automatic

Machine

of Mitsubishi Industrial

sewing

machine,

the

Instruction Manual of

Needle

Corner^Stitchlng

with

please

INSTRUCTION

Automatic

Undertrlmmer

Sew

, . .

read

this

Feed,

MANUAL

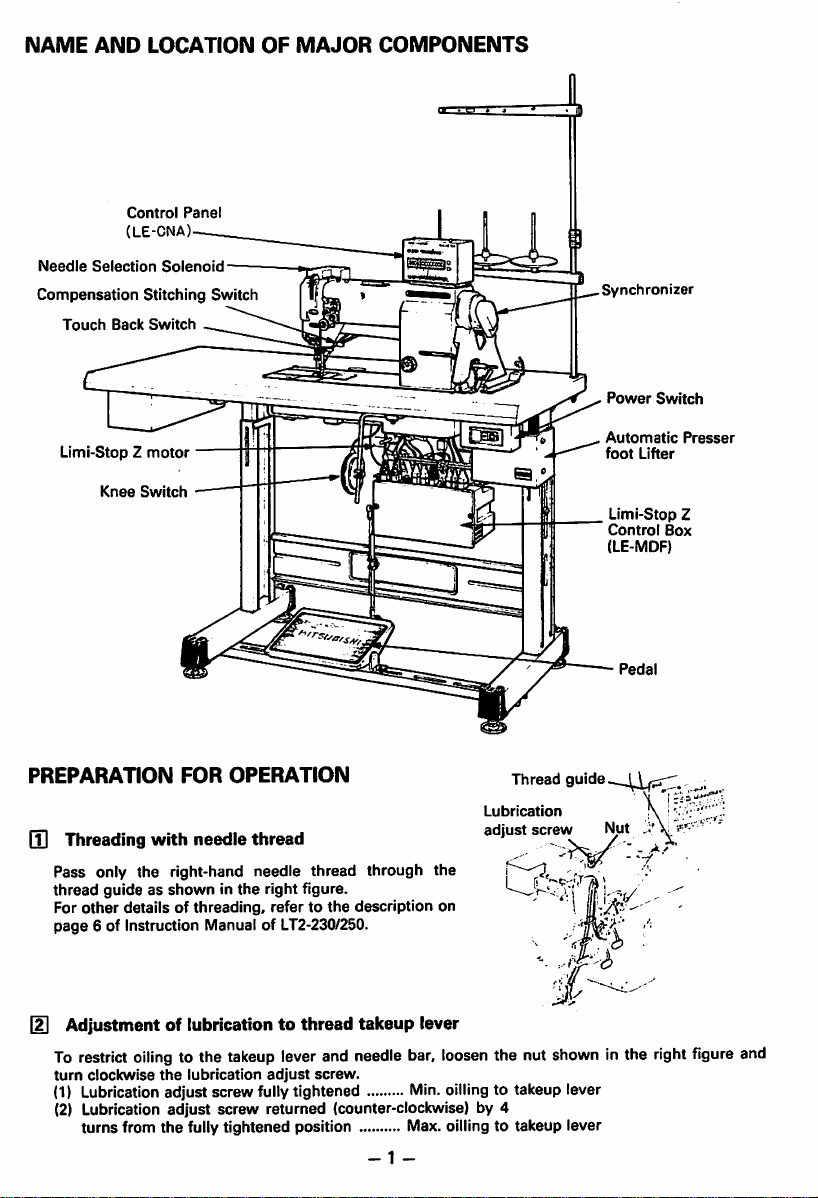

NAME

Needle

AND

Selection

Compensation

Touch

LOCATION

Control

(LE-CNA)

Solenoid

Stitching Switch

Back

Switch

Panel

OF

MAJOR

COMPONENTS

Synchronizer

Power

Switch

Limi-StopZmotor

Knee

PREPARATION

Switch

—

FOR

OPERATION

Q] Threading with needie thread

Pass only the right-hand needle thread through the

thread

guide as

other

For

page

6 of Instruction Manual of LT2-230/250.

showninthe

right figure.

details of threading, refer to the description on

Thread

Lubrication

adjust

screw

guide

Automatic

foot

Lifter

Limi-Stop Z

Control

Box

(LE-MDF)

Pedal

Presser

,

Adjustment of lubricationtothread

To

restrict

oiling

to the

takeup

turn

clockwise

the

lubrication

leverand needle bar,

adjust

screw.

takeup

lever

loosen

the nut shown in the right

(1) Lubrication adjust screw fullytightened Min.oillingto takeup lever

(2) Lubrication adjust

turns

from

screw

the

fully tightened position Max. oilling to takeup lever

returned (counter-clockwise) by 4

-1

-

figure

and

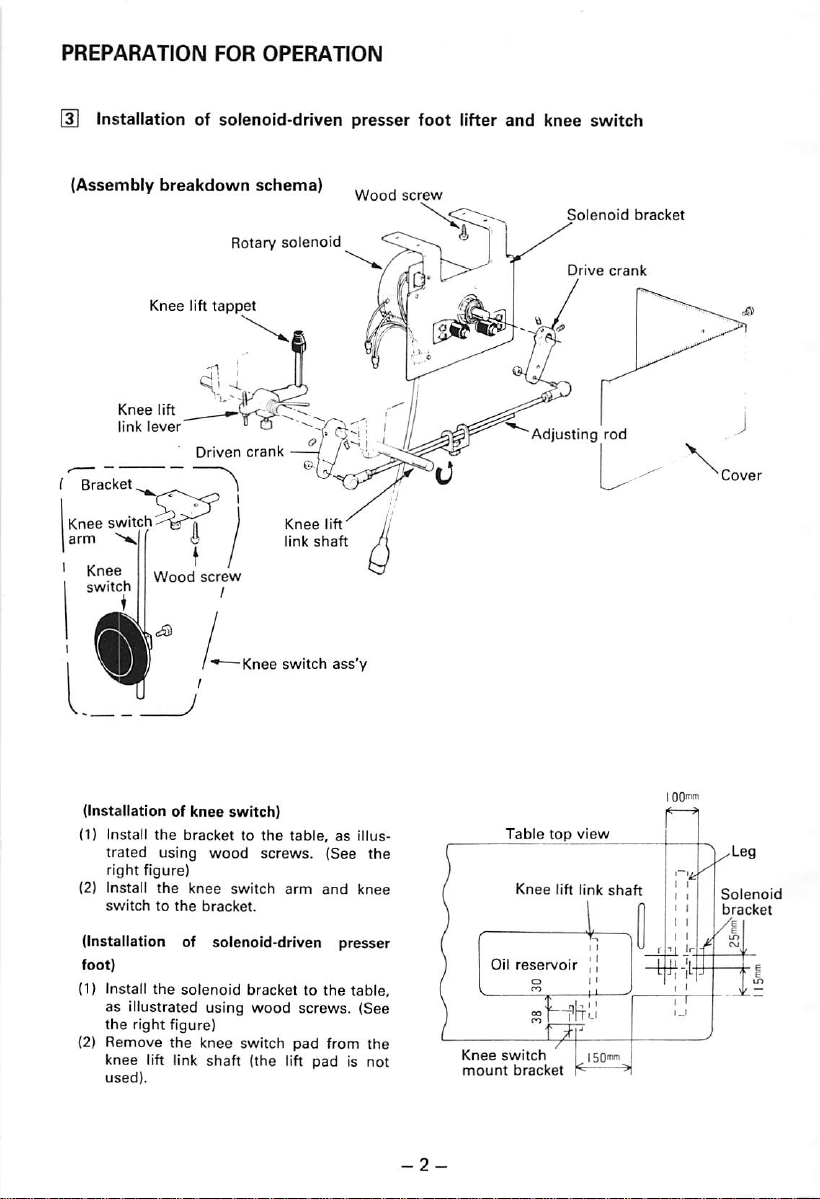

PREPARATION

FOR

OPERATION

Installationofsolenoid-driven

(Assembly

Knee

Iarm

Knee

link

switch

>*^1

breakdown

Knee

lift

lift

lever*

(

Wood

tappet

Driven

screw

schema)

Rotary

crank

-Knee

solenoid

""^7r-i '

/

Knee

lift

link

shaft

switch

presser

ass'y

Wood

screw

foot

lifter

and

knee

Solenoid

Drive

Adjusting

switch

bracket

crank

rod

(Installationofknee

(1) Install

(2)

the

trated

using

right

figure)

Install

the

switchtothe

switch)

brackettothe

wood

screws.

knee

switch

bracket.

table,asillus

(See

arm

and

knee

the

(Installation of solenoid-driven presser

foot)

(1) Install

(2)

the

solenoid

as illustrated using

the

right

Remove

knee

used).

figure)

the

lift link

knee

shaft

bracket to

wood

switch

(the

lift

the

table,

screws. (See

pad

from

padisnot

the

Knee

mount

Oil

Table

Knee

reservoir

switch

bracket

top

view

lift

link

shaft

—'•

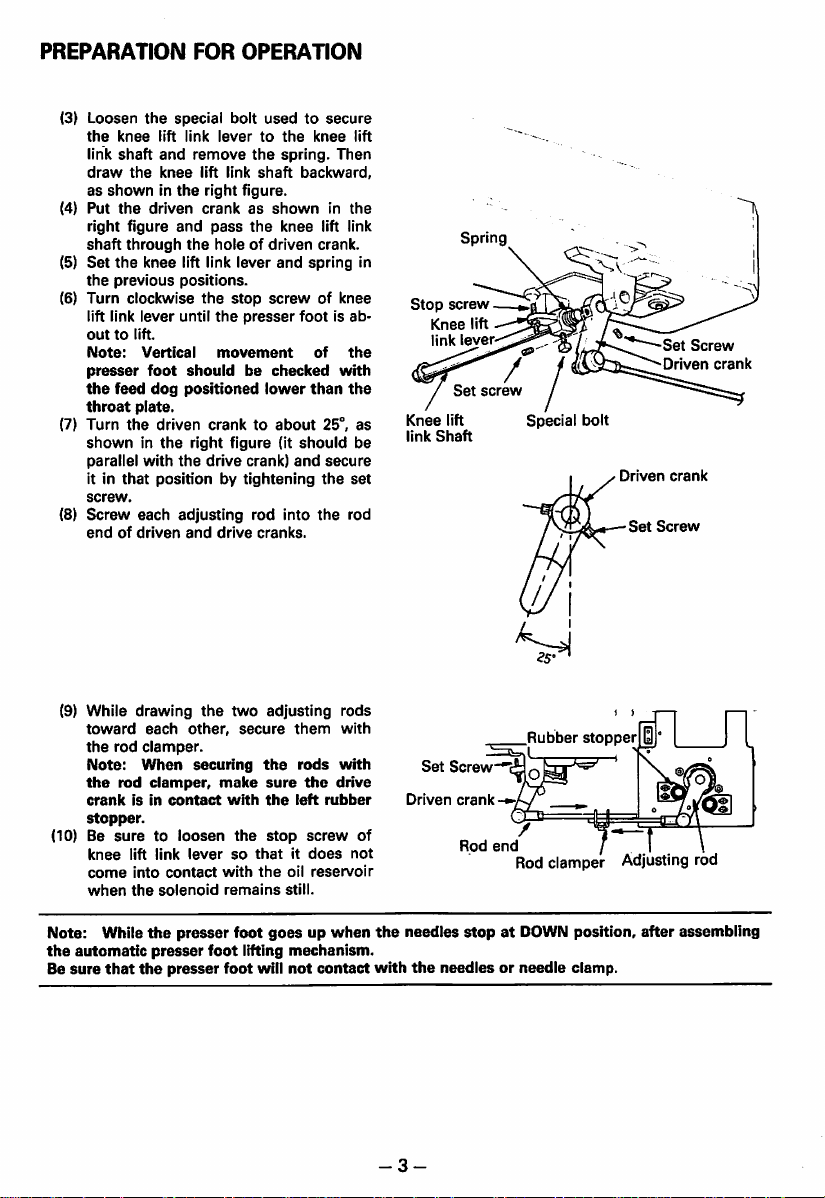

PREPARATION

FOR

OPERATION

(3) Loosen

the

knee

link

shaft

dravr

as

showninthe

(4)

Put

the

right figure

shaft

(5)

Set

the

the

previous

(6)

Turn

lift link

outtolift.

Note;

presser

the

feed

throat

(7)

Turn

showninthe

parallel

it in

that

screw.

(8)

Screw

endofdriven

the

special bolt

lift

link

levertothe

and

knee

remove

lift

link

the

right figure.

driven

crankasshowninthe

and

through

knee

pass

the

holeofdriven

lift link

positions.

clockwise

lever

Vertical

foot

dog

the

until

the

movement

should

positioned

stop

plate.

the

driven

cranktoabout

right

the

figure

drive

with

positionbytightening

each

adjusting

and

drive

usedtosecure

the

spring.

shaft

the

knee

lever

and

screwofknee

presser

footisab

be

checked

lower

(it

should

crank)

and

rod

into

cranks.

knee

Then

backward,

lift link

crank.

spring

of

with

than

25°,

secure

the

the

the

the

set

rod

lift

be

Spring

in

Stop

screw

Knee

lift

link

lever-

screw

Knee

link

lift

Shaft

as

Special

bolt

Driven

Set

Set

Driven

crank

Screw

Screw

crank

(9) While

toward

the

rod

Note:

the

rod

crankisin

stopper.

(10) Be

suretoloosen

knee

come

when

Note: While

the

automatic

Be

sure

that

drawing

each

the

other,

clamper.

When

securing

clamper,

contact

lift

link

leversothatitdoes

into

contact

the

solenoid

the

presser

presser

the

presser

two

make

with

the

with

remains

foot

foot

foot

adjusting

secure

them

the

sure

the

stop

the

oil

still.

goesupwhen

lifting

mechanism.

will

not

rods

the

left

screw

reservoir

contact

rods

with

with

drive

rubber

not

Rubber

stopper

Set

Screw-^c

Driven

crank-»v

of

the

with

-3-

Rod

end

needles

stopatDOWN position,

the

needles

or needle clamp.

Rod

clamper

Adjusting

after

rod

assembling

PREPARATION

FOR

OPERATION

IS Installation of control panel

(1) Install

(2)

(3)

the

machine

control

head,

figure.

(To install,

control

to

slightly

en

Plug

into

videdinthe

Bind

panelonthe

screws.)

the

the

all

cords

while

compress

needle

correspoinding

control

with

der,asshowninthe

panel

as

shown

lightly

holding

topofmachine

the

rubber

selection

panel.

the

furnished

right

figure.

on

the

in

the

down

pads,

solenoid

receptacle

cord

top

right

head

tight

cord

pro

hol

the

Rubber

pad

of

Cord

holder

Plug (for

selection

Screw

needle

solenoid)

I External wiring

Connect

pensation

trol

right

(1)

(2)

(H Setting of

Set

the

figure.

the

automatic

stitch

paneltothe

switch,

control

figure.

The

compensation

shouldbeconnectedto2-pin

nector.

The

knee

pin

Note:

be

for

switch

white

connector.

Before

suretoturn

safety.

pluggingorunplugging,

DIP

box

the

DIP

switches

control

boxto

"ON",asshown

presser

foot

lifter,

knee

switch

and

com

con

box,asshowninthe

stitching

shouldbeconnectedto2-

off

the

power

switch

black

switch

cable

con

switches in the control

S4L,

S2,

CKD

and

64P

inthe

right

Compensation

switch

Knee

switch

(LE-FM-CFT) •

Synchronizer ^ panel Sewingmachine

0} u

Clutch

n° §

iL

<A

Brake

External

volume

in

|

ON

la

SWI

_i

-j

tn

W

(n

PSU PSD

DELAY

M H

SPEED

^ ^

select

^ H

Control

stitching

^

Control

switch

i

ON

a Q a •

SW3

ON

BSBsasog

SW4

w

ON

HBEraangg

SW5

tEnjW

o — uJ +

panel

Automatic

Presser

(h

(55

o <

CNA)

(LE-

foot

II

— W (/) (D

CO

? 3 •-

—

_i_ia:

tOltO)

lifter

-4-

OPERATION

[T]

Setting of switches and counters on

FOR

AUTOMATIC

AUTO

fOMH

STAIR

tm

CORNER

the

control panel

STITCHING

3333KI23

23

3

232

Tl

(1)

Set the start

backward stitch "B" on

(2) Set the end backtacking "END" switch (2) to "ON" and

backward stitch "D" on

(3) Set the

Note:

(4)

Set

the

counter

o

The

When

(5) Set

number

Note:

single-needle

starts

backtacking

"CORNER

When

"NUMBER"

®-

numberofthe

all

When

without

SEWING"switch ® to "ON".

this

switchis"OFF",

(numberofcorner

preset

steps

of stitches to be

numberofsingle-needle

one

stitch and, after

signle-needle

"START"

counter®.

counter

next

corner

are

stitching.

switch(J)to "ON" and set number of

($).

usual

doudle-needle

stitching

completed,

completed

the

stitching

with single-needle stitching in

stitchesissetto"0",

(See

steps)

stepsisdisplayed

the

counterisreset

fabric is turned, double-needle stitching immediately

the

right

figure)

forward

set

number of forward stitch "C" and

stitchingispossible.

withinarange

by LED.

t0""1".

deep

from1step

each

pedal

heeling

steponcounter

stitch "A" and

to 8

steps

on

down

causes

Set

the

(6)

directionofturnateach

LEFT/RIGHT SELECTOR

The

directionofturnisdisplayed

switch.

For leftwardturn ( _11 i , set switch

For

rightward

—

turn(11—

endofcorner

(Maximum

i , set

by LED

switch

eight

colour

_Mi_

_HL

stitching

turns

•••

step

may

red

green

Single-needle

stitching

LED will light.

LED will light.

/ /

/ /

on

be

/ /

Double-needle

Stitchino

OPERATION

(D

Retracing

Every one depression of

are

retraced,besuretocheck

[3]

Continuous single-needle stitching

(1)

Set the

FOR

AUTOMATIC

of comer stitching step

the

"SUB" switch causes retracing of one corner stitching step. When steps

the

"SINGLE

NEEDLE"

switch ® to

CORNER

position by LED.

"ON".

STITCHING

(2) To'select the left needle or the right needle, set switch (]j).

*To

stop

the

•To

stop the right needle, depress

left needle,

depress

switch-BK.

switch_^L

red LED will flicker.

green

(3) Toe down the pedal to start continuous single-needle stitching.

(4)

Todisengage continuous single-needle

pedal.

[4]

Compensation stitching

Compensation stitching is

corner

stitching, or

corner

stitching.

(1) By

once

depressing

switch,

one

forward

stitch

direction.

(2) By depressing

switch while holding

switch,

one

backward

stitch

direction.

made

when

one

the

compensation stitch

can

the

compensation stitch

down

can

before starting

stitch is

be

added

the

be

added

stitching,

added

in

the

touchback

in

the

set the

in

LED

switch

will

@ to

flicker.

"OFF"

and toe downthe

Compensation

stitching

Touchback

switch

switch

Example of

Stitching

NUMBERofcorner

ing

Step

Numberofcorner

needle

Comer

pattern

steps

stitches

stitching direction

corner

stitch

single-

stitching

Needle

(6.4mm)

Stitch

(D (2)

LEFT

patterns

gauge

length:

LEFT

1/4"

3.2mm

LEFT

-6-

LEFT

®;'''

Needle

Stitch length:

RIGHT

LEFT

gauge

1/4" (6.4mm)

3.2mm

LEFT

RIGHT

LEFT

OPERATION FOR AUTOMATIC CORNER STITCHING

(D Stitching procedure

(Standard specification Pedal is deeply

heeled down for corner stitching.)

(1) Shallowly

presser

(2) Put fabrics in position.

(3) For start bacldacking and double-needle

stitching,

(4) Corner stitching is accomplished in

order

repeated for

toe

foot.

toe

(2)*~(§)

down the pedal to lift

down

the

pedal.

shown

below

the

preset

(stitching

number

the

the

is

of steps).

Note: When

is

completed,

(5)

When

backtacking is

trimmed.

the

the

knee switch is

present

the

numnberofsteps

counterisresetto"1".

set

done

and

the

(6) When the knee switch is held at "ON",

presser

foot

goes

(7)

Operation

Stitching

Pedal

opera

tion

Stitching

tern

Remove

pat

the

0

Start

tacking

ble

reedle

stitching

Pedal

fabrics.

back

and

toe

dou

down

up.

Single-

needle

with

fixed

berofstitches-*

Presser

goes

up.

Pedal

deeply

heel

down

stitching

foot

to "ON",

threads are

turned-♦Press

num

er foot

down.

Continued

—

Neutral

end

the

Fabrics

goes

(1)

Neutral

(2)Shallow toe down (inching)

(3) Deep

toe

down

(4)Shallow heeldown (presser footgoes

up)

(5)Deep heel down (corner stitching)

are

-

Note: For

ing force, refertothe

page22of

LT2-230/250.

Single-

needle

stitching

with

fixed

berofstitches

adjustmentofthe

the

(§)

needlestitching

num

Pedal

toe

down

description on

Instruction

Oouble-

pedal

Manual

(§)

End

ing

and

trimming

Knee

-ON-

of

backtack

thread

switch

Note:

Do

not

If

the

toeing

turn

poweristurned

down

the

stitching as in (U on

off

the

off

pedal. If

the

power

during

corner

during

corner

the

powerisinterrupted

stitching,

stitching.

double-needle

by mistake,

stitching

start

may

and

notberesumed

continue

previous page described to resume double-needle stitching.

-7-

single-needle

by

AUTOMATIC CORNER STITCHING .... SPECIAL OPERATION PROCEDURE

*Besides the previously described standard operation procedure, automatic corner stitching may be

madeinthe

[T]

Cornerstitching... Knee switchoperation

(1) For

foot

switch

showninthe

Set

(2)

in

(3) For

^

Stitch

tacking

ing

double

stitching

Pedal

Pedal

down

opera

tion

Stitch

ing

pat

tern

following

this

operation,

lifter,

compensation

and

control

the

DIP

"64P"inthe

the

corner

switches

control

right figure.

stitching, perform

operationinthe

Corner

stitching Knee

Thread

trimming

Presser

lifter UP

Start

back-

(^Single-

and

needle

ing with fixed

needle

number

stitches-.

Presser

goes

up.

toe

Knee

ON

—

way:

the

automatic

stitch switch,

panel

right

shouldbewires

figure.

"S4L",

boxto"ON"asshown

following

tion

...

Deep

down

Shallow

ing

stitch

foot

switch

Fabrics

turned-.

Presser

foot

goes

of

down.

Continued

Neutral

the

order:

switch

pedal

down

are

-

presser

"CKD"

following

opera

heeling

pedal

(^Single-

needle

ing with fixed

numt>er

stitches

knee

heel

stitch

of

Pedal

as

and

toe

switch-^

(^Double-

needle

stitching

down

i

(^

tacking

thread

ming

Pedal

heel

End

deeply

down

back-

and

trim

Compensation

stitching switch

whittt

ON

QD

SWI

Automatic

foot

lifter

ON

SW3

Control

panel

presser

CM(O§

(OCOO S

oonn

05

CO(0to

Q.

m Corner stitching ... Shallow pedal heel

ing

operation

(1) The wiring

standard

(2)

The

"CKD"

be

setto"ON",asshowninthe

(3) Install

the

next figure. The foot switch is used to lift

the

does

corner

DIP

and

the

presser

not differ from

stitching.

switches

"64P"inthe

foot

"S4L",

switch

(option),asshown

control

foot in the middle of stitching.

"SSL",

box

right

that

"82",

should

figure.

for

in

-8-

nn

ON

SWI

ON

SW3

CMCO§

<0 O) o S

a 8

no

05

COyjM

CL

(4) For corner stitching, perform the following

operation in

the

following order:

Cornerstitching Shallow pedai heel

ing

Threadtrimming...

down

Knee

switch opera

tion

Presser foot

lifting

at start of stitching

Knee switch opera

tionorshallow

al

Presser

foot lifting in

heeling

the

middle of shal

low stitching

Foot

switch

operation

Stitch

^

Start

back

ing

Pedal

opera

tion

Stitch

ing

pat

tern

tawing

double

stitching

Pedal

down

toe

and

needle

(^Single-

needle

ing with fixed

number

stitches-*

Presser

goes

Pedal

heel

up.

shallow

down

stitch

foot

of

—

(^Fabrics

turned-*

Presser

foot

goes

down.

Continued

Neutral

ere

-*

(^Single-

needle

ing with fixed

number

stitches

stitch

Pedal

of

ped

(^Double-

needle

stitching

toe

down

Foot

(g)

tacking

thread

ming

Knee

-ON-

End

switch

and

trim

switch

back-

Note: Foot switch

(LE-CFT-3)

is optionally available.

-9-

SPECIFICATIONS

*Sewing

machine

Model

Application

Max.

speed

spm

Stitch length mm (inch)

Presser

foot

thread

stroke

trimmer

system

Automatic/manual

Needle

Hook

(for

Bobbin

Lubrication

Compensation sewing

Touchback

Wiper

Needle

gaugemm(inch)

Note:

Forfeed dog, throat plate, slider plate, bobbin

Bobbin

•Applicable

Motor

Control

Equipment

box

•Auto-Changer

Model

Automatic

presser foot

lifter

Control

panel

Knee

switch

head

mm

(inch)

use)

should

be of

good

quality

CA-Z402E

Kit

LE-CNA-KM

(Standard)

LE-FM.2

(Electromagnetic type)

LE-FM-CFT

LE-MDF

LE-CNA

LT2-250-M1ATW

Light to

3,500

4 (5/32)

DP X 5

135

134Nm90

Horizontal

hook

with

(with

thread

vention

Standard-6.4

that

is not

CB-Z402E

LE-CNA-KA

(Option)

LE-FA

(Pneumatic

LT2-250-A1AT

medium-heavy

3,000

5 (3/16) 5 (3/16)

#14,

X 5

#14,

type

standard

bobbincase

slack

pre

spring)

Aluminum

Provided

(1/4),

case

and bobbin, use those for thread trimmer application.

deformed.

•Control

Medium-heavy

9/7

135

Horizontal

(with

bobbin

Automatic

Optional-3.2,

Panel

Model

3,000

(11/32/9/32)

DP X 5

#16,

X 5

#16,

134Nm100

type

for

Provided

Provided

large-sized

slack

thread

lubrication

thread

4.8, 8, 9.5, 12.7 (1/8, 3/16, 5/16,

Backtacking

Number

of

type)

corner-stitching

Number

comer

Process

Continuous

single-needle

stitching

of

stitches

return

steps

prevention

trimmer

Not

provided

4-dial

Possible

LT2-250-B1AT

Medium-heavy

3,000

(15/64)

6

DP X 5

135

134Nm110

hook

with

spring)

use

LE-CNA

system

(0 to 9 stitches),

start

and

Max.

0to9

stitches

Possible

for right

#18,

X 5

bobbincase

3«,

end

8

and

left

to

heavy

2,500

7 (9/32)

#18.

1/2)

needles

Amitsubishi

HEAD OFFICE

MITSUBISHI

OEMCI BLOG

electric

MARUNOUCHI

TOKYO

corporation

100

TELEX

J2A532

CABLE MELCO TOKYO

A180E066P01

Loading...

Loading...