MITSUBISHI

INDUSTRIAL

LT2-230.-250

Lockstitch,

Undertrimmer,

Variable

A

SEWING

MACHINE

Model

Class

Double-Needle

Automatic

Speed

INSTRUCTION

MANUAL

-CONTENTS-

PREPARATION

m Power cable

m

Connectionofcontrol

FOR

OPERATION

connection

box

m Adjustment of needle bar stop position 2

CAUTIONS

ON

USE

m Oiling (1) 3

S Oiling (2) 3

[31 Oilingcondition 4

[4] Adjustment of oilingto rotating hook 4

Cautions on operation 4

OPERATION

Installation of needles 5

Winding

Selection of

of bobbin thread 5

thread

Threading of needle threads 6

Adjustment of stitch length and stitch reversing (touch-back) 7

Setting of bobbin 7

Threadingof bobbin threads 8

Tension adjustment of bobbin threads 8

Balance of

Needle

10

Adjustment of presser foot pressure 8

11

Timing between rotating hook motion and needle motion

12

Adjustment of feed dog height 11

13

Relationship between rotating hook motion and take-up lever motion 12

14

Relationship between hook motion and opener motion 12

15

Relationship between needle motion and feed dog motion 13,14

16

Needle bar (left or right) stop operation {LT2-250) 15

17

Relationshipbetweenangle of corner stitching and stitch length 15

18

Installation

19

Adjustment of thread trimmer cam 17

20

Adjustmentofthread

21

Adjustmentofmeshing

22

Sharpening of fixed knife 19

23

Adjustment for change of needle gage 20

24

Wiper

25.

ADJUSTMENT

thread

thread

tension

tension

of movable knife 16

tension

regulator

pressureofmovable

knife

and

fixed

knife

adjustment

AND

OPERATION

OF

CONTROL

UNIT

9,10

1

2

6

8

8

18

19

21

m "1-2 POSITION" select switch operations 22

m

Pedal

m

m

operation 22

Adjusting

Adjusting

the

the

pedaling

stitching

forces

speed

22

23

fSl Optional functions 24, 25

CAUTION

26,

27

PREPARATION

• Overall

viewofassembled

sewing

machine

FOR

Touch

OPERATION

Faceplate

back

switch

Phase

reversing

2-type

LIMI-STOP

Balance

\/

_

plug

X

motor

wheel

Synchronizer

Power

Operation

With

this

box,

additional

as

automatic

used.

pushbutton

box

(option)

optional

functions

tackstitch

operation

can

such

be

m Power cable connection

1.

Connector

Each

connector

to

the

corresponding

the

mating

(DFor

installation

backofmotor.

Remove

from

the

wiresoflamp.

After the connection, be sure to protect the

connected

(3) When lamp is

two

lamp

3.

Power

cable

(The

power

(l)Whenathree-phase

direction.

the

the

leads.

cable

(plug)

shouldbecompletely

receptacle

of a

work

lamptothe

insulation

lamp

leads

wires

with

not

connectionissameasstand-

tape

and

connect

insulation

used, properly insulate

motorisused,

Control

after

and

tape.

box

set

checking

sew-

insulator

them

connect

Receptacles

machine

Rubber

to

for

cables

cushion

„

rMft

,

Sln%f9h

<btV''

«, .•

jCA

"GND"

terminal

ratingoflOA

and

20A

(3)

The

fuse

that

4.

having a

Directionofrotation

Direction of

end cover (remove the plug,

For single-phase

2

min.).

without

for

for

usedinthe

rotationofthe

three-phase

single-phase

control

ratingof8A.

motor,

operate

fail.

power

power

motor

turn

source,

source.

box

should

can

be reversed by inverting

it 180° and set to the plug socket again).

the

switch after

Besure to fully set the plug in the socket. _ 1 _

j

Lamp

leads

^

be

the

phase

the

motor

has completely

reversing plug in

stopped

the

(it will take

motor

about

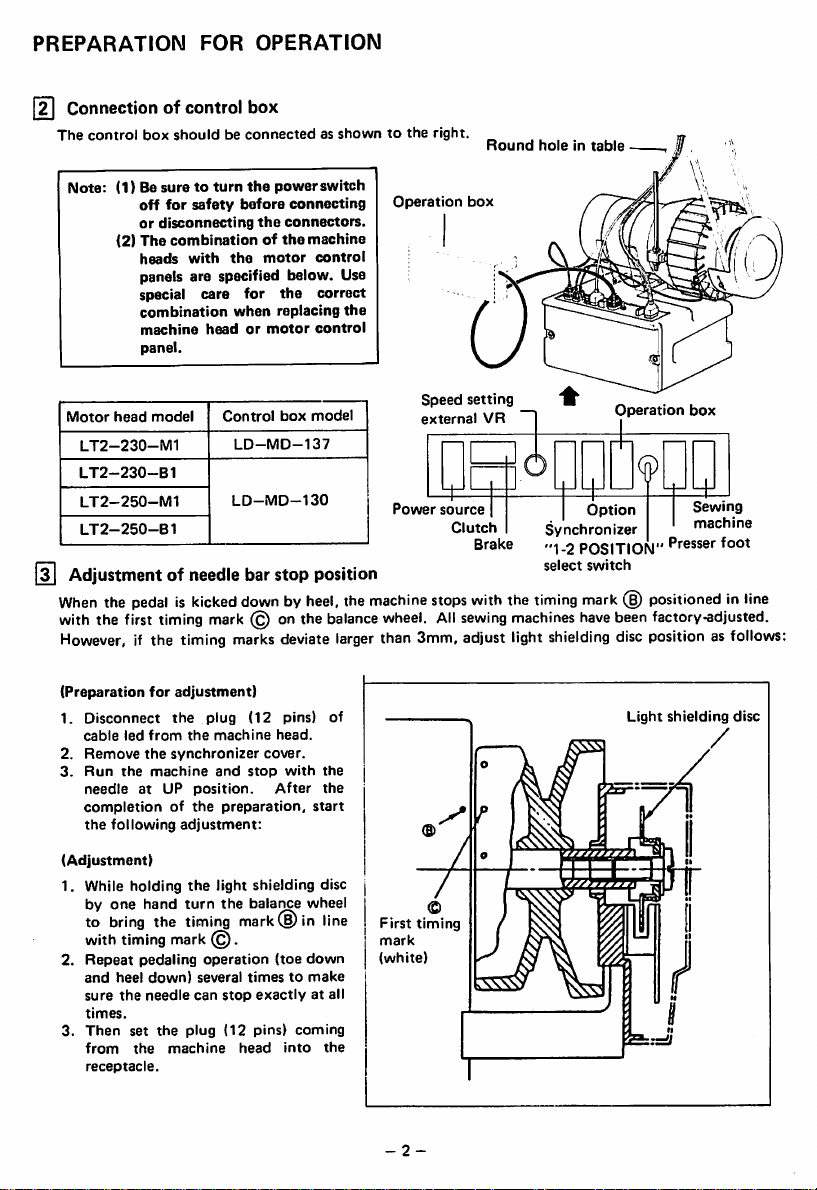

PREPARATION

[2I

Connection

The

control

box

Note:

(1) Be

off

or

disconnecting

(2)

The

heads

panels are specified below. Use

special

combination

machine

panel.

Motor

head

model

LT2-230-M1

LT2-230-B1

LT2-250-M1

LT2-250-B1

[3]

Adjustmentofneedle

When

the

with

However,

pedaliskicked

the

first

if the timing

timing

FOR

OPERATION

of controlbox

shouldbeconnectedasshowntothe

suretoturn

for

combinationofthe

with

the

safety

before

the

care

for

when

headormotor

Control

LD-MD-137

LD-MD-130

bar

downbyheel,

mark

@ onthe

marks

power

the

connectors.

motor

the

replacing

box

stop

deviate

switch

connecting

machine

control

correct

the

control

model

position

the

balance

larger

machine

wheel.

than 3mm, adjust light

right.

Operation

Speed

external

Power

stops

All

source

Clutch

Round

box

setting

VR

Brake

with

sewing

holeintable

Synchronizer

"1-2

select

the

timing

machines

shielding

Operation

Fh

9

Option

POSITION"

switch

mark

(§)

have

positionedinline

been

discposition as

box

Sewing

machine

Presser

foot

factory-adjusted.

follows:

(Preparation

1.

Disconnect

cable

2.

Remove

3.

Run

needleatUP

completionofthe

the

(Adjustment)

1. While holding

by

to

with

2.

Repeat

and

sure

times.

3.

Then

from

receptacle.

for

led

from

the

the

machine

following

one

hand

bring

the

timing

pedaling

heel

down)

the

needle

set

the

the

adjustment)

the

plug

the

machine

synchronizer

and

position.

preparation,

adjustment:

the

light shielding disc

turn

the

timing

mark

(§).

operation

several

can

stop

plug

(12 pins)

machine

(12

pins) of

head.

cover.

stop

with

After

balance

mark® in

(toe

timestomake

exactlyatall

coming

head

into

the

the

start

wheel

line

down

the

First

mark

(white)

-2-

timing

Light

shielding

disc

/

CAUTIONS

m

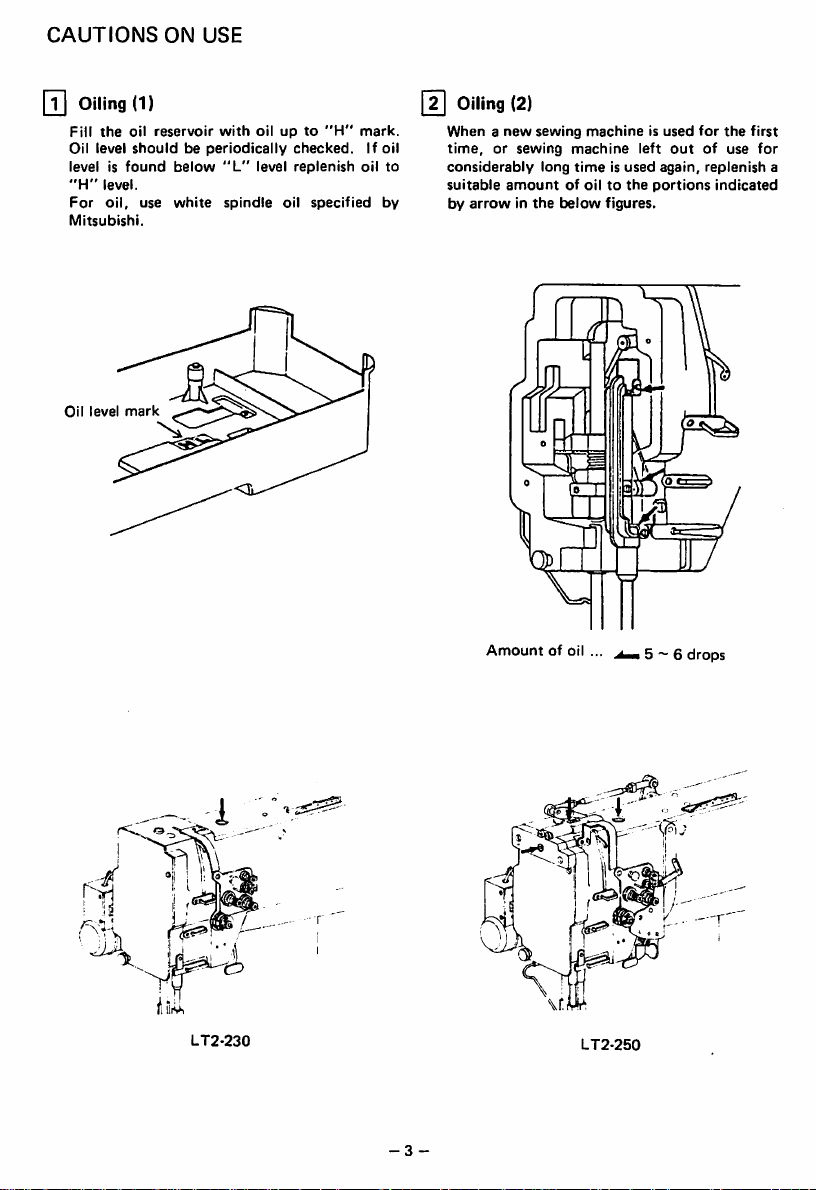

Oiling

Fill

the

Oil level

level is

"H"

level.

For

oil,

Mitsubishi.

Oil

level

ON

USE

(1)

oil

reservoir

shouldbeperiodically

found

use

mark

below

white

with

"L"

spindle

oilupto

checked.

level

replenish

oil

"H"

specified

mark.

If oil

oil

[2]

Oiling

(2)

Whenanew

to

by

time,orsewing

considerably

suitable

by

arrowinthe

sewing

machineisused

machine

long

amountofoiltothe

timeisused

below

figures.

left

again,

portions

for

the

outofuse

replenish

indicated

first

for

a

4

jIjL

:!

j '

LT2-230

Amountofoil

-3

-

..

LT2-250

5 ~ 6

drops

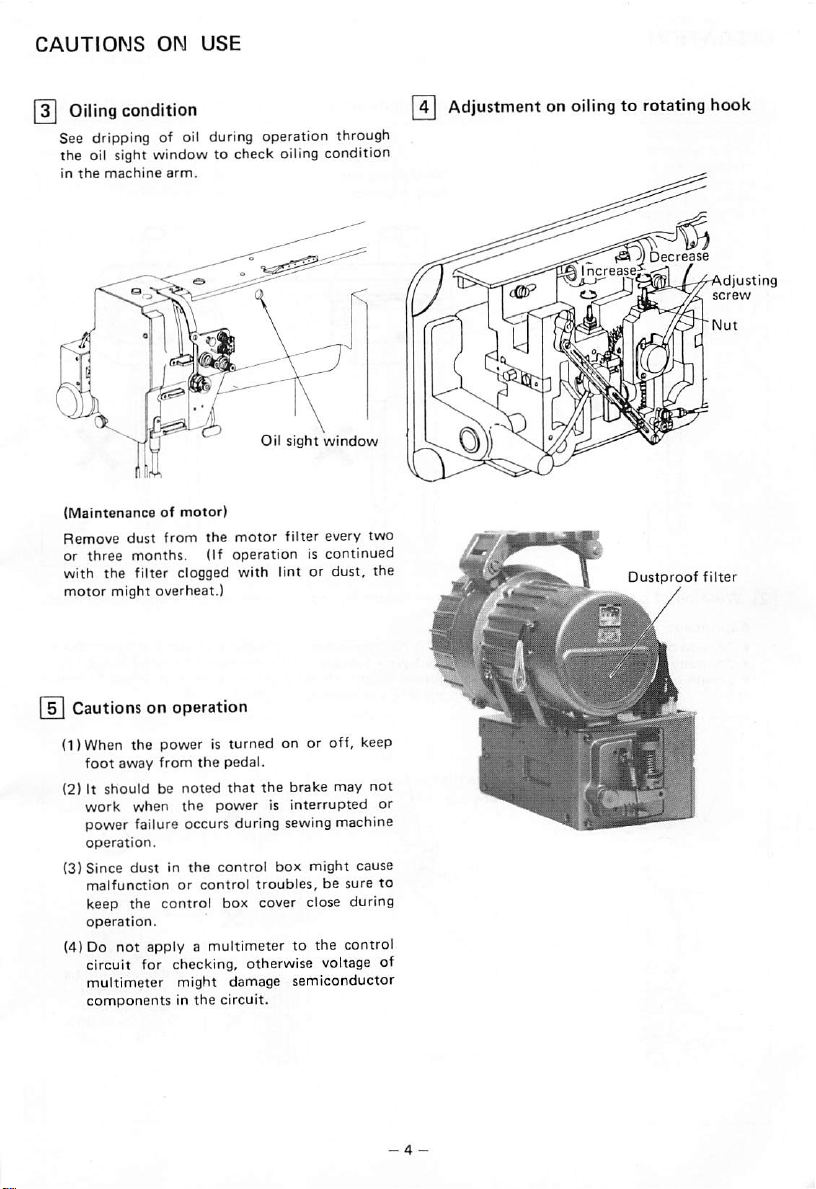

CAUTIONS

[y|

Oiling

ON

condition

USE

See dripping of oil during operation through

the oil sight window to check oiling condition

in

the

machine

(Maintenanceofmotor)

Remove

or

three

with

the

motor

dust

from

months.

filter clogged

might

overheat.)

arm.

Oil

sight

window

the

motor

(If

filter

operationiscontinued

with

lint or

every

dust,

two

the

Q

Adjustmentonoilingtorotating

Dustproof

hook

filter

Cautionsonoperation

(1)When

(2) It

the

foot

work

poweristurned

away

from

shouldbenoted

when

the

pedal.

that

the

the

powerisinterrupted

on or

brake

off,

power failure occurs during sewing machine

operation.

(3)

Since

malfunction

keep

operation.

(4) Do

dustinthe

the

not

applyamultimetertothe

or

control

control

control

box

box

might

troubles,besure

cover

close

circuit for checking, otherwise voltage of

multimeter

componentsinthe

might

damage

circuit.

semiconductor

may

during

control

keep

not

or

cause

to

OPERATION

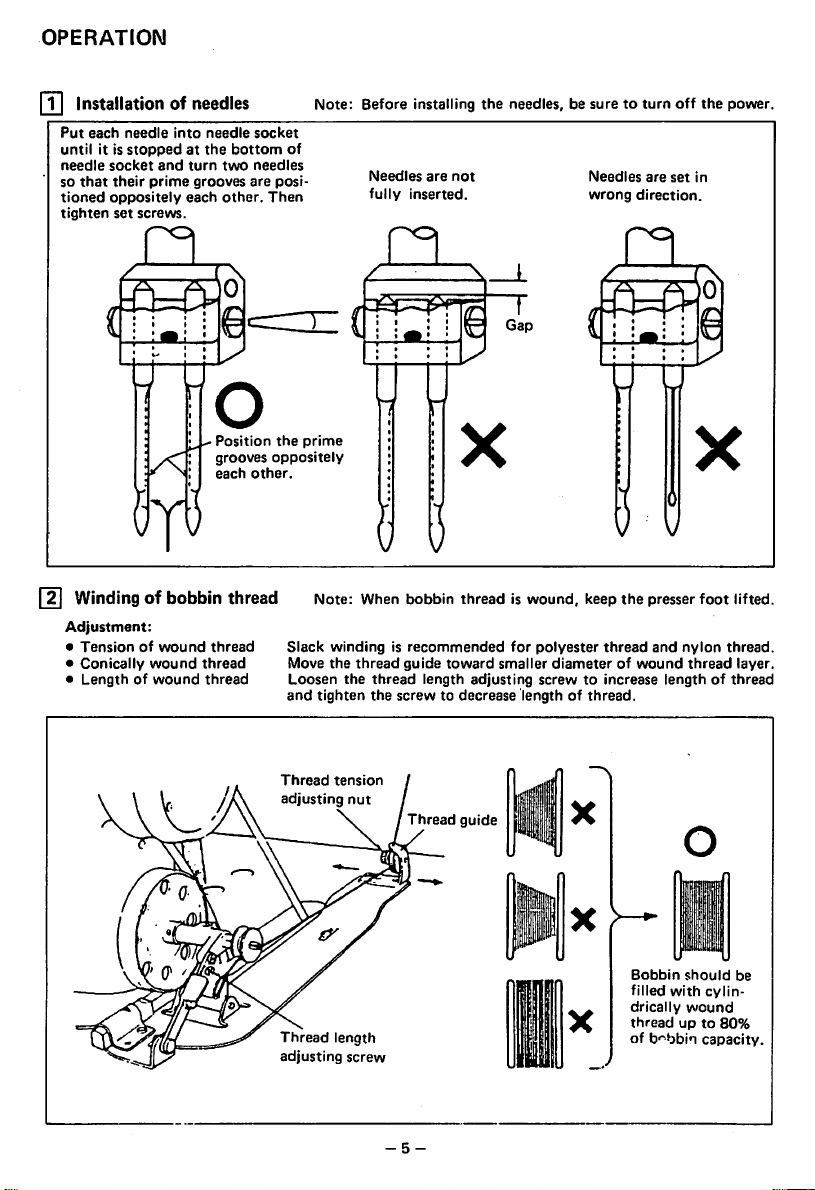

[T|

Installationofneedles

Put

each

that

it is

socket

oppositely

needle

stoppedatthe

and

their

prime

set

screws.

until

needle

so

tioned

tighten

into

each

needle

turn

grooves

bottom

two

other.

socket

needles

are

Then

posi

Note:

Before

installing

the

needles,besuretoturn

off

the

power.

of

Needles

are

fully

not

inserted.

Needles

wrong

are

set

direction.

in

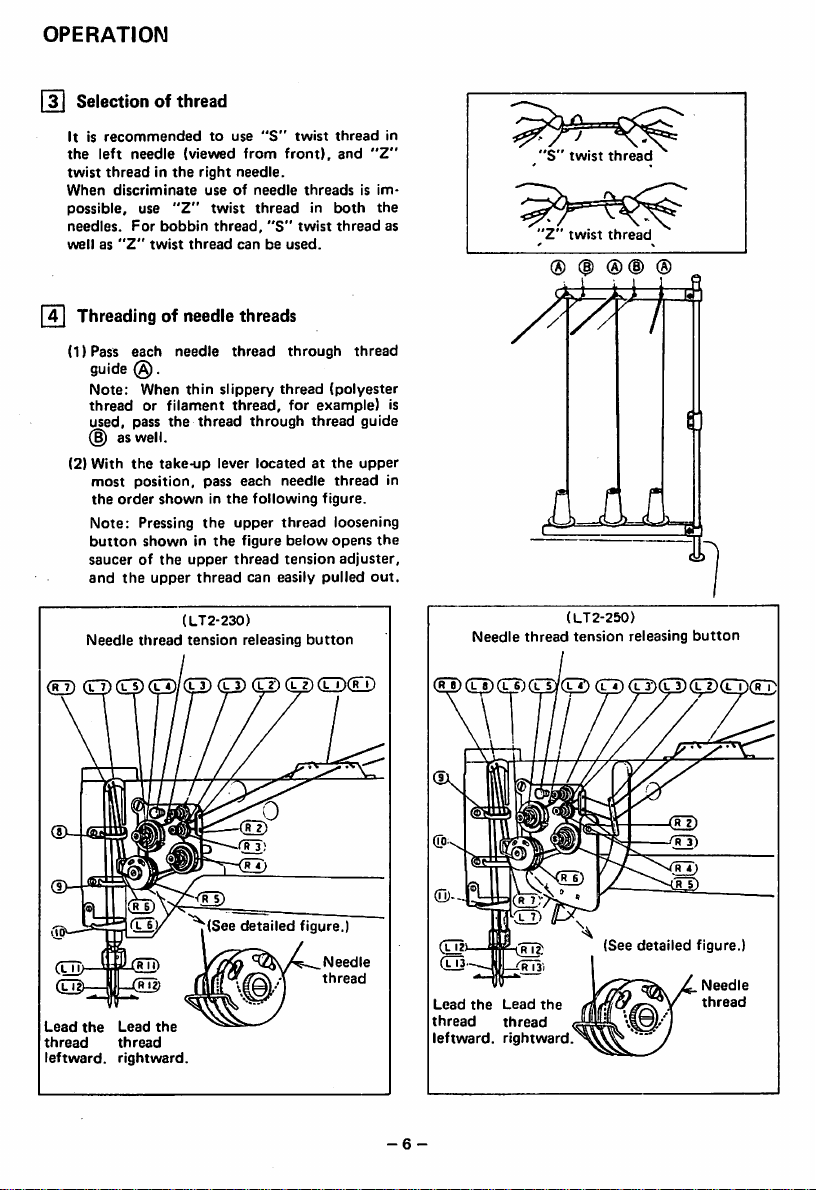

Windingofbobbin

Adjustment:

•

Tensionofwound

•

Conically

•

Lengthofwound

wound

Position

grooves

each

thread

thread

thread

other.

thread

the

prime

oppositely

• I

()

8

Note: When bobbin thread is wound, keep the presser foot lifted.

Slack

windingisrecommended

Move

the

the

tighten

tension

length

thread

screw

thread

the

Loosen

and

Thread

Thread

adjusting

guide

toward

length

screwtodecrease

Thread

adjusting

guide

for

polyester

smaller

diameterofwound

screwtoincrease

lengthofthread.

thread

Bobbin

filled

drically

threadupto

of

and

lengthofthread

with

b'-bbin

nylon

thread

should

cylin-

wound

capacity.

thread.

layer.

be

80%

-5-

OPERATION

]

Selectionofthread

Itisrecommended

the

left

twist

When

possible,

needles.

wellas"Z"

fT)

(1)Pass

needle

threadinthe

discriminate

use

For

Threadingofneedle

each

guide

(§).

Note:

When

threadorfilament

used,

pass

as

well.

(2)

With

the

most

position,

the

order

Note:

Pressing

button

showninthe

saucerofthe

and

the

Needle

thread

(0>

(U

to

(viewed

right

useofneedle

"Z"

bobbin

twist

thread

needle

thin

the

thread

take-up

pass

showninthe

the

upper

upper

thread

(LT2-230)

tension

use

from

needle.

twist

thread,

canbeused.

threads

thread

slippery

thread,

through

lever

each

upper

figure

thread

can

releasing

"S"

twist

front),

threadsisim

thread

in

"S"

twist

through

thread

for

example)

thread

locatedatthe

needle

following

figure.

thread

below

tension

easily

pulled

button

CTTXr

thread

and

"Z"

both

the

thread

thread

(polyester

guide

upper

thread

loosening

opens

the

adjuster,

out.

0

in

as

"S"

'Z"

® (|)

twist

twist

thread

thread

®(D

®

is

in

thread

(LT2-250)

tension

releasing

button

Needle

(^CpCEI)

(ljI)—

Lead

thread

leftward,

(TT)/ 7(See detailed figure.)

(rTT)

the

Lead

the

thread

rightward.

Needle

thread

(See

detailed

figure.)

Needle

Lead

the

Lead

thread

leftward,

-6-

the

thread

rightward.

thread

OPERATION

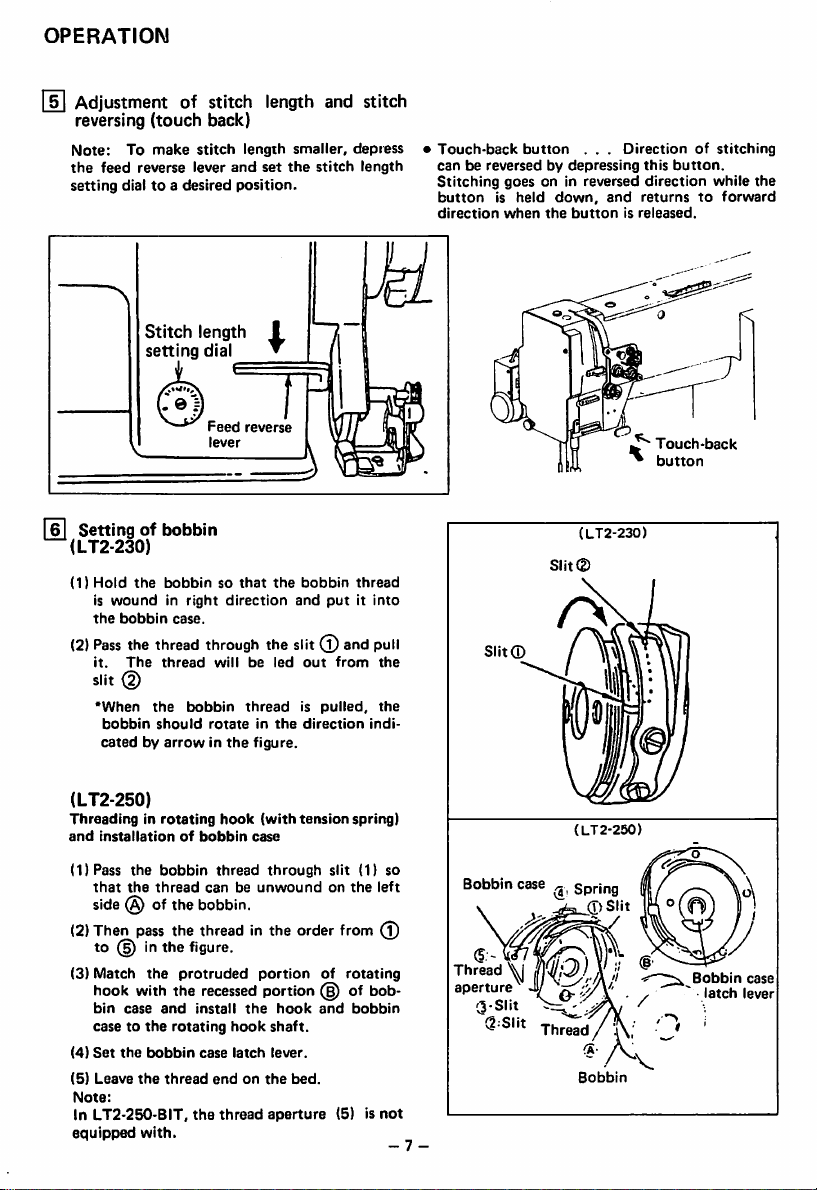

Adjustment

reversing

Note:

To

the

feed

setting

dialtoa

®

Settingofbobbin

(LT2-230)

(1)

Hold

is

woundinright

the

bobbin

(2)

Pass

the thread through the slit

it.

The

slit (2)

'When

bobbin

catedbyarrowinthe

of stitch length and stitch

(touch

back)

make

stitch

length

reverse

desired

Stitch

setting

the

bobbinsothat

case.

thread

the

should

lever

and

length

dial

Feed

lever

direction

willbeled

bobbin

rotateinthe

smaller,

set

the

position.

I

•

reverse

the

and

threadispulled,

figure.

stitch

bobbin

putitinto

(l)

out

direction

depress

length

thread

and pull

from

indi

•

Touch-back

canbereversedbydepressing

the

the

Stitching

buttonisheld

direction

goes

when

button

. . .

on in reversed

down,

the

buttonisreleased.

(LT2-230)

Directionofstitching

this

button.

direction

and

returnstoforward

while

Touch-back

button

the

(LT2-250)

Threadinginrotating

and

installationofbobbin

(1)Pass

the

that

side

(2)Then

bobbin

the

thread

(§) of the

pass

the thread in the order from

to (§) inthe figure.

(3)

Match

the

the

case

with

bobbin

the

with.

protruded

the

and

rotating

thread

the

hook

bin

casetothe

(4)

Set

(5)

Leave

Note:

In LT2-250-BIT,

equipped

hook

(with

case

thread

canbeunwound

through

bobbin.

portionofrotating

recessed

install

case

portion

the

hook

latch

endonthe

thread

aperture

shaft.

hook

lever.

tension

bed.

spring)

slit (1) so

on

the

of

and

bobbin

(5) is

bob

left

(T)

not

- 7 -

Bobbin

Thread

aperture

3-Slit

SSlit

(LT2-250)

case

Spring

0Slit

V

^

Thread

Bobbin

Bobbin

latch

case

lever

OPERATION

Ft]

Threadingofbobbin

il) Put

bobbin

the

(2) While holding the two needle threads by left

hand,

hand.

shownInthe

lifted.

shouldbealigned

thread

lugd)and

rotate

By

pullingupthe

Bothofbobbin

extenditbelow

Thread

the

figure,

threads

into the slit (j),

Opener

handwheel

and

the

thread

led

one

needle

bobbin

and

backward.

pass

the

bed.

Thread

turnbyright

threads,

threads

needle

under

will

thread

[9]

^

as

be

Balance

Needle

Needle

referencetobobbin

To

sion

Needle

special fabric and

and

of thread

AO

CX

threadtension

thread

adjust

needle

adjusting

strokeofthread

thread

nut.

tension

tension

Tight

bobbin

Loose

bobbin

tension

thread

thread

canbealso

thread

takeupspring.

Balanced

should

tension

needleorloose

tension

needleortight

tension

be

tension.

tension,

by changing intensity

adjusted

turn

adjusted

each

in

ten

for

81 Tension adjusmtnet of bobbin threads

Loosen

Tension

adjusting

screw

Tighten

[Til

Adjustmentofpresser

Pressuretofabric(s)

pressure

-8-

Loosen

adjusting

screw.

Strong

Tighten

foot

canbe

adjustedbyturning

L

Weak

Thread

adjusting

pressure

Pressure

screw

tension

nut

the

adjusting

OPERATION

12

Timing

* m *1 /Among Jhe followingeKplanotionsA

and

(DSet

(2)

(3)

•

Position

Adjust

centerofneedle

(1)

(2)

(3)

(4)

Note:Inthe

loosen

ingofhook

between

ncedla

motionrthosizoinuppeninetsforMITW

stitch

length

When

position,asshown

relationship

—The

1.6mmbelow

—The

centerofneedle

—Gap

faceofneedle

Needle/rotating

justedasfollows.

(For

that

dog assemblies

Lean

three

Turn

needleislifted

position.

Rotate

hook

Move

ward

hook

mm.

and

length

setting

dial.

needleislifted

shouldbemaintained.

upper

edgeofneedle

hook

point

between

easy

the

the

shouldbe0.05mm.

adjustment,

presser

are

adjustmentofhook

the

hook

pointsothatitcomestothe

axis.

the

machine

set screws of

the

balance

the

hookbyhandtoposition

pointtothe

the

hook

and

position

point

and

For

this

twoofC

adjustment,

shouldbeloosened.

adjustment,

set

screwsCand

shaft

gear

rotatinq

\and

to

the

hook

hook

the

iize

beneath

2.2mmfrom

the

following

point.

on

eye

It II

the

the

positional

should

shouldbelocatedatthe

axis.

hook

point

and

hook

foot,

position

throat

it is

plate

can

recommended

and

removed.)

point

head

backward

hook

wheel

2.2

mm

centerofneedle

bracket

it so

that

side

faceofneedleis0.05

do

always

and

lower

and

shaft

gear (small).

and

stop

when

from

the

axis.

leftwardorright-

gap

between

each

screws

not

excessively

maintain

shaft

gear.

motion

for

BIT.

stitch

lowest

the

side

be ad

feed

loosen

the

lowest

the

the

A,B

mesh

Gap

]

/

and

Needle

2.2

between

upper

mm

needle lowest ^

be

position

Center

needle

Set

screwofhook

shaft

gear

edgeofneedle

lift:

from

of

axis

Hook

(small)

0)

hook

point

point

0.05mm

eye

Set

screwoflower

shaft

gear

(large)

Set screw (A)

Set screw (A)

(5)

Tighten

(l)

While

against

tighten

After

and

Q)

Then

the

set

pressing

the

the

checking

the

tighten

screws in

the lowershaft gear

side

faceofhook

set

screwsCfirst.

gap

hook,

tighten

theset

the

following

between

the

screws

set

B.

bracket,

the

screws

order:

(large)

needle

A.

screw

Set screw (B)

9 -

Set

screw

OPERATION

•

Position

adjustmentofneedle

Adjust

needle

upper

edgeofneedle

1,6mmwhen

its

lowest

(1)

Remove

of

needle

bartoadjust.

(2)

After

positionsothat

eye

the

position.

the

bar

the

adjustment,

face

bracket

and

needleisliftedby2.2mmfrom

plate,

loosen

and

tighten

point

gap

the

hook

the

vertically

the

between

point

set

move

set screw.

the

screw

the

is

Needle

bar

(LT2-250)

•

Needle

vertical

Adjust

vertical

needle

barislocatedatits

II)

Remove

(2)

Rotate

needle

lequaltopitchofneedle

The

needle

turned

counterclockwise.

(3)

Return

before

the

screw

@ .

position

theset

one

position

clockwise,

the

adjustment

adjustment

position

turn

lifts

needle

of

needle

top

position.

screw

(§).

the

needle clamp,

canbechangedby0.6mm

bar

and

the

lowers

screw).

needle

when

when

clamptothe

and

retighten

after

thereby

clamp

position

the

one

turned

set

/Needle

bracket

Set

ILT2-230)

•

Needle

bar

_Set

screw

i

Needle

clamp

is

Lowers

Lifts

bar

screw

-•§

o

0

T

(LT2-250)

-

10

OPERATION

13| Adjustment of feed dog height

Height of feed dog and pressure of presser foot

should

be adjusted for individual fabric(s)

following

cautions:

♦

Fabric will be damaged if

too

high, or pressure of presser

♦

Even stitch length

cannot

the

be assured if the feed

dog is too low or pressure of presser foot is

small.

♦

Feed

point

dog height

where

the

needleisat

should

be measured at

feed dog

footistoo

the

top

with

extends

large.

too

position.

the

the

!

0.8mm

1.0mm

For

light

For

usual

For

heavy

Adjustment

(1)

Lean

(2)

Turn

the

feed

(3)

Loosen

(4)

Vertically

tion

adjustitto

(5)

After

set

screw.

The

feed

1

mm.

fabrics

fabrics

fabrics

procedure

the

machine

the

handwheelbyhand

dog

risestothe

the

feed

bar

move

the

Apprdx.

throat

Approx.

throat

Approx.

throat

head

set

feed

0.8mm

plate

1.0mm

plate

1.2mm

plate

backward.

and

maximum

screw.

bar

indicatedbyarrowinthe

the

adjustment,

dog

adequate

height.

tighten

heightisfactory-adjusted

(in

the

stop

the

figure)

feed

from

from

from

when

height.

direc

bar

2mm

to

Set

Feed

screw

bar

to

-11-

OPERATION

|l^

Relationship

motion

and

between

take-up

lever

rotating

motion

When the timing belt (cog belt) was removed for

its replacement, for example,

between

motion

rotating

shouldbeadjustedasfollows:

hook

motion

the

and

relationship

take-up

hook

lever

(1)Turn

take-up

(2)

Lean

sure

the

timing

the

bossofhook

(3) If

the

black

stallitagaintoadjust.

Relationship

15

opener

(1)Turn

when

remotely

(2)

Make

and

the

(3) If

the

opener

the

opener.

the

the

belt

timing

line,

balance

lever is

machine

arrow

lifted

head

(timing

is in line

shaft

markisnot

remove

wheel

to its

with

bearing.

the

between

motion

the

balance

the

from

sure

openerisapproximately

gap is

set

wheelbyhand

opener

holderislocated

the

throat

gap

between

too

large or small, loosen

screw@and

and

top

backward

mark)

the

in line

timing

hook

plate.

the

bobbin

adjust

stop

when

postion.

and

putonthe

black

line

with

belt

and

motion

and

case

0.2

mm.

position

make

and

stop

most

the

the

the

on

Timing

belt

in

Black

hook

Approx.

lineonboss

shaft

0.2mm

of

bearing

Timing

ng

belt

mark

sprocket

of

-12-

'

Opener

Screw(6*^

Opener

holder

OPERATION

Relationship

feed

dog

oThe

needle

at

the

(1)

Set

setting

(2)

Lean

(3)

Loosen

between

motion

feed

dog

can

plunge

centerofthe

stitch

dial.

the

machine

the

lengthto"0"onthe

and(^.

(4) Lower

(5)

(6)

(7) If the connection is

(8)

the

needletothe

Adjust

the

bar

and

the

tentatively

of

the

feed

shaft

Check

that

nected

with

in

Figure.

move

the

and

arrow

After

tighten

back

move

the

directiontoadjust.

the'completionofadjustment,

the

screws@,(§)and

needle

motion

(LT2-230)

shouldbeadjustedsothat

into

the

feed

dog

stitch

set

needle

screw

feed

hole.

shaft

head

backward.

crank

lowest position.

distance

tighten

the

the

needle

the

crank.

right

feed

linkatright

cover,

needle

between

bartobe

the

screws@and

shaft

crankiscon

angle,asshown

not

at right angle, re

loosen

the

bar

rocking

13.5,

screw

rodinthe

©.

and

the

hole

length

pressure

and

@

fully

Screw

Screw

Feed

crank

/

shaft

(middle)

Feed

crank

shaft

(right)

Needle

rocking

bar

rod

Needle

bar

Pressure

bar.

Feed

shaft

crank (right)

-13-

Screw®

Screw

Needle

rocking

©

bar

rod

OPERATION

Relationship

and

feed

•

The

feed

needle

can

at

the

centerofthe

(1)

Set

stitch lengthto"0"onthe

setting

(2)

Lean

the

(3)

Loosen

between

dog

motion

dog

shouldbeadjustedsothat

plunge

dial.

machine

the

feed

into

hole.

head

shaft

(LT2-250)

the

backward.

crank

needle

feed

dog

stitch

set

and@.

(4)

Lower

the

needletothe

(5) Adjust

(6)

(7) If

(8)

the

bar

tentatively

of

the

Check

nected

in

Figure.

the

move the back cover, loosen the screw (£}

and

the

figuretoadjust.

After

tighten

distance

and

the

needle

tighten

feed

shaft

that

the

right

with

the

connectionisnotatright

move

the

Linkinthe

the

completionofadjustment,

the

screws

lowest

between

bartobe

the

screws

crank.

feed

linkatright

(§),(§)

position.

the

14.1,

shaft

crankiscon

angle,asshown

angle, re

arrow

direction

and

(6).

motion

needle

length

screw

pressure

and

fully

the

and

hole

of

Screv

Screw

Feed

crank

shaft

(middle)

Feed

shaft

Srank (right)

Link

Pressure

bar

Needle

bar

„ [

Feed

shaft

crank (right)

Screw

-

14

Screw©

Link

S i

(D-lr™7

OPERATION

17

Needle bar (left or right)

(LT2-250)

• The stop lever should be set to

tion.

stop

operation

"L"or"R"

posi

Note: Although the

stop

lever can be operated

during sewing operation, it is recommended for

safe operation

that

the sewing machine is

stoppped with the take-up lever at nearly its

top

(1)

(2)

(3)

position

Left

Move

the

Right

Move

the

Two

needle

the

left

needle

needle bar

the

right

needle

and

bar

stop

stop

needle

bar

the

lever is set.

stop

lever to

bar.

stop

lever to

bar.

operation

operation

"L"

operation

"R"

positiontostop

positiontostop

To change single-needle (left or right) ope

rationtodouble-needle

the push lever backward. The

automatically

double-needle

]

Relationship

returnto"0"

operation

between

operation,

becomes

stop

position

depress

lever will

and

possible.

angleofcorner

stitching and stitch length

(Din

order

to

assure

neat

corner

stitch

length

ference to angle of

shouldbedetermined

corner

stitching

following table (applicable only to 1/4

needle

(2) By

width).

determining

stitch

ing for a given angle of

numberofoutside

identified

from

the

corner

table.

length

corner

(3) Ex.: When stitch length of 40° corner stitch

ing is

determined

numberofstitchesis"6".

Relationship

between

stitch

length

onlyto1'4

46

3 7

30

2 5

2 1

1 8 1 3

1 5

1 2

and

needle

4

4 4

3 4 2 7

2.8

2 3 1 8 1 5

1 9

1 6

Angle of

corner

stitching

100

120

130^

140-

Number

30

40*

50'

60'

70'

BO"

90'

(applicable

stitches

ol

2 3

55

46

38

32

2 /

22

18

t 5

1 1

stitching,

from

of inside

stitching, the

stitches

to

2.9mm,

numberofstitches

width)

5

6

4 3 7

4.3

35

111]

23

2 2

1 9 1 6

1.5

1 3

1 3

in re

stitch

can

7 8

2 5

20

the

be

the

30

22

1 7

-15-

Number

of

stitches

Push

Angle

corner

(6)\

Stop

lever

lever

of

^

,

OPERATION

BD

Installationofmovable

1.

initial

positionofmovable

(1)

Turn

the

balance

(2)

Push

the

cam

(3)

Turn

the

balance

wheel.

the

cam

coming

the

thread

the

movable

fixed

knife,asshowninFigure

(4)

(5)

balance

Set

roller

Loosen

Adjust

the

wheel

follower

wheel

follower

out

from

trimmer

Bolt(g)

knife

knife

and

lower

cranksothat

until

the

crankatthis

the

cam

rocking

knifesothat

Thread

rocking

the

the

black

groove.

crank

the

and

trimmer

crank

needle

cam

mark

position

clamp

movable

tighten

bartothe

roller

pointonthe

withascrewdriver

the

enters

bolts

(A)

knife

end

bolts@and

lowest

into

arm

and(^.

slant

position.

the

thread

meets

temporarily

portion

(§)

the

protrudes

.

trimmer

white

cam

groove.

mark

pointonthe

preventing

0 —

0.5mmfrom

the

cam

2.

Gap

between

holder

stopper

(1)

Turn

reaches

(2)

With

press

wheel

extrernityofits

(3) Manually

tion

gap between

ner hook stopper to

screws

for this adjustment).

movable

the

balance

the

lowest

the

needleatthe

cam

follower

until

the

rotate

indicated by

the

(§)

and

Thread

trimmer

rocking

knife

and

bobbin

wheelbyhand

position.

crank,

movable

stroke.

the

inner

arrow

lowest

turn

knife

hookinthe

in Figure

until

position,

the

balance

reaches

and

movable knife and the in

about

0.2

(§)

shouldbeloosened

mm (the

crank

case

needle

direc

adjust

Boltd)

de

the

0 ~

Hook

0.5mm

Movable

positioner

Approx

Movable

knife

0.2mm

knife

Fixed

Screw®

Screw®

Inner

knife

hook

-16-

OPERATION

20| Adjustment of thread trimmer cam

(1) Turn the balance wheel by

(2) Maintaining

grooveofthread

(3) Turning

starts moving when

pointonthe

To

adjust,

Cam

groove

the

needle

trimmer

the

balance wheel by

arm.

loosen

two

position,

the

thread

Thread

hand

until the needles reach

depress

cam.

hand,

green mark

trimmer

Cam

crank

Screw

trimmer

the

cam

adjust the

pointonthe

cam

clamp

follower

Cam

roller

®

cam

the

lowest position.

follower

thread

balance wheel comes in line with

screws

Arm

crank

trimmer

® .

Black

point

and

cam so

mark

put

Green

that

point

the

cam

the

mark

u

roller

movable knife

the

black mark

Balance

J-

Li

into

wheel

the

-17-

OPERATION

Adjustmentofthead

(1)

Turn

the

balance wheel by

(2) Maintaining

grooveofthread

(3)

Turning

the

the

needle

trimmer

balance

tension

hand

position,

cam.

wheel by

regulator

until

the

depress

hand,

adjust

needles

the

cam follower

the

thread

reach

the

tension

lowest

crank

release

position.

and

put

camsothat

the

cam roller

close when the white mark point on the balance wheel comes in line with the black mark point

on

the

arm.

To

adjust,

loosen

two

tension

release

cam

clamp

screws

@.

(4)

Opening

the

To adjust, loosenthe

(5)

Make

Thread

tension

release

lever

Screw (A)

degreeoftension

convexed

portionofthread

fine

adjustmentbyloosening

discshouldbe adjusted with the

release

screws

(g) and draw the wire.

cam,asshowninFig.

thenut© .

Cam

follower

crank

Cam

roller

Arm

tension

Black

point

release

roller(§)mountedon

mark

white

point

(D

Roller(b)

Thread

release

cam

Thread

trimmer

cam Screw©

Nut©

mark

the

Balance

y

into

tension

Lf

the

disc

wheel

-18-

OPERATION

22 Adjustment of meshing pressure of movable knife and fixed knife

(11

Loosen

the

fixed

knife

bracket

clamp

bolt

@.

(2) Turn the

bolt®

Note: Since excess pressure causes large

(3) Move

Fixed

bracket

vertical

position

.

ming failure, adjust it so

the

movable knife

knife

and

adjusting

that

check

flISF

screw (§) to adjust

torque

meshing

to the thread trimming mechanism and trim

pressure

thread can be trimmed with minimum pressure.

that

the

thread

can be sharply

trimmed.

and thenrighten the

23

Sharpeningoffixed

When

the

it is

knives

very

Since

0))

Vertical

knife

dull,

the

difficulttosharpen

fixed

Fixed

position

knife

shouldbesharpenedasillustrated

the

knife

movable

adjusting

knife,

-19-

screw®

replaceitwithanew

Oil

stone

in Fig.

one

whenitdulls.

OPERATION

24

Adjustment

(1)

Replace

(Since

suretouse

(2)

Lean

(3)

Loosen

(4)

Remove

(5)

Loosen

hook.

(6)

When

(7)

Contact

link

(8)

Turn

(9)

Loosen

(10)

Depress

smoothly

(11)

Adjustmentofthe

(a)

Push

(b)

Turn

groove

(c) Push

trimmer

for

changeofneedle gage

the

throat

plate,

feed

dog

feed

and

dog

the

the

machine

throat

plate

those

specifiedbyus.)

head

and

backward.

two connecting link clampbolts(j).

the

spring

@ .

the

hook

the

needles

the

rocking

clamp

bolt(j).

the

balance wheel by

thenuts (§)and

the

cam

enter

the

cam

the

connecting

surface

the

cam

cam

Thread

trimmer

rockingcrank (©

Connecting

Hook

bracket

(left)

Screw®

bracket

and

follower

the

follower

(n)as

groove

link

clamp

hooks

have

cranks

(c)

and

hand

until

(H)

.

crank

® and

grooveofthread

cam

groove

and

cranksothat

rod

and

smallaspossible,

follower

crank

smoothly.

Screw

Bolt®

W

Stopper

screws

been

needle

are

adjusted,

@ to

the

trimmer

the

cam

the

adjust

again

Stopper

pin© ,

Thread

rocking

clamp.

special

parts

(§)

and

(g) and

install

the

stopper

needles reach

adjust

the

cam.

Then

roller

cam

roller

the

clearance

and

tighten

and

check

pin

Screw®

Hook

Connecting

Nut®

trimmer

crank®

designed

for

adjust

the

spring

pins

(§)

the

lowest

connecting

rod© sothatthe

tighten

enters

into

between

the nuts(g)and

that

the

cam

Cam

roller

Cam

groove

bracket

(right)

Spring

Nut®

rod(0

®

thread

gap

.

and

position.

the

nuts

the

the

roller

Thread

between

and

(G)

cam

groove.

cam

(H)

.

,Cam

crank

,

33

trimmer

trimming

each

tighten

and

roller

enters

follower

Thread

trimmer

cam

-

Lower

'f"®"

Cam

follower

crank

®

cam

cam

(0).

and

into

machine,

needle

the

connecint

roller

the

the

thread

be

and

can

cam

-20-

]

Wiper

adjustment

(1)

Set

stitch

length dialto"5"

sewing

machine

position.

(2)

Loosen

the

to

be

parallel

showninFig.

(3)

Loosen

the screw (§) and turn the wiper

shafttoadjustsothat

tipofwire

range

from

1.5mmto2mm.

(4)

Loosen

the

to adjust

point

2

shown

(5) Pass

(6)

Loosen

0.5

that

wiper.

mm

mm

nut

the

and

the

when

each

needle

the

screw

leftwardorrightwardtoadjust

thread

canbesecurely

and

with

the

needleatUP

screw@and

with

and

needle

(e)and

clearance

presser

the

linkispushedbyfinger as

thread

© and

adjust

the

bed

surface,

gap

between

pointiswithin

turn the screw®

between

foot

becomes

through

needle

move

hopkedbythe

the

the

stop

the

the

link

the

wiper

about

eye.

wiper

so

Screw®

as

a

Screw®

Wiper

shaft

Needle

Caution: For a gauge size over

replace

with

the

Approx.

separate

Screw©

Wiper

0.5mm

wiper

Screw

——Approx.

5/8"

shaft.

(16 mm),

Approx.

2

0.5mm

Needle

mm

Presser

-21

foot

Wiper

1.5~2.0

mm

Nut(D

Set

screw

0

Wiper

Link

-

ADJUSTMENT

I 1 I

"1—2

Needlestop position can be selected between "1—POSITION" and "2-POSITION".

AND

POSITION"

OPERATION

select

switch

OF

CONTROL

UNIT

_•

—1

When

the

pedal is kicked

I2 I

Pedal

operation

The

pedal

follows;

\

\

•T-2 POSITION"'

switch

setting

1

POSITION

2

POSITION

Pedal

operation

Notes; 1. Stitching speed can be changed by changingdegree of pressingdown of the pedal.

2. For automatic presser foot lift, use optional unit.

3.

I 3 I

Adjusting

1.

Adjusting

The

pedal

justed by

the coil spring to the lever. ^ ^

It should be noted that the lever may f

notbestoppedatpositionifthe

mark

t_mark

switch

setat "1

back

operation and

Pedal

operation

by heel.

Stop

"UP"

Stop

"DOWN"

"2-POSITION"

"1-POSITION"

POSITION",

resultant

Toe

with

position

with

motion

down

Neutral

needle

needle

position

thread is

at

at

trimmed

(stitching,

Light

Presser foot goes Presserfoot goes UPafter one

up

Presser foot goes Presser

up

inone turnof the

thread

Neutral

I

heeling

trimming

turn

(needle

trimming

and

and

foot

DOWNtoUP)

' 1 '

.J-i

Neutral (stitching

(DC

24V).

For

tackstitching.

the

pedaling

the

pedal

toe

use

forces

down

optional

force

control

toe down force can be ad- ^

changing

hooking

position

force

of ®

is

start

bn-..

LD-C2, C4or06.

position)

LE-FM-1

Neutral

or LE-FM-2. or solenoid valve

» ^

sewing

needle

Neutral

Full

thread

goes UP

machine

motion)

4

heeling

trimming

after

B A

and

when

holf

thread

the

are as

2.

Adjusting

To adjust,

.,g„_

After

(see

Fig.

the

pedal

loosen

the

adjustment,

6).

heeling

force

nut "A" and turn bolt ^

tighten

nut

"A"

Coil

/ " \

/DECREASE—INCREAS^

spring

Fig. 6

Adjusting

x "

the

pedal pressing

Lever

down

force

ADJUSTMENT

I 4 I

Adjusting

1,

Adjusting

AND

OPERATION

the stitching speed

the

maximum

stitching

speed

OF

CONTROL

UNIT

(1) Adjusting the maximum speed (Maximum speed isthe speed achieved when the pedal is fully

pressed

down)

Two

variable resistors are available

the

control

variable

the

internal

setting

resistor

box

range from

resistor

Internal

3700

3000

"H"

The

within

Pole

2

pole

For

speed

variable

variable

The

Marks are put on

showninFig.7,for

For

fine

speed

adjustment,

•CAUTION*

(1)

Speed

faster

motor

pulley

S

eedsettin

inte^arVR^

and

the

resistoronthe

otherisone

the

"H".

variable

resistor

variable

resistor

rpm (LT2-230 MITW)

rpm

(LT2-250,

outofthe

the

than

diameter

adjustable

mustbechanged.

internal variable resistor

reference.

use a

that

setonthe

overacertain

2500spm

4500spm

for

adjustmentofthe

the

control

box

control

box

front

front

(external

low (minimum) speedtothe

"H"issetbyus

"H"

LT2.230

range of

setting

BIT)

the

when

external

the

External

"H"attwo

speed

meter

two

variable

diameter.

Speed

resistors

setting

external

maximum

panel.

VR)

permits

speed;

oneislocated

adjustmentofspeed

maximum speed set by

motorisshippedasfollows:

variable

resistor

adjustabe

Maximum

variable

speed~250

resistor,

the

settingofinternal

points (2,500 rpm and

cannotbeachievedbyincreasing

"1—2

POSITION"

variable

resistor

the

rpm

4,500

select

\

in

internal

range

rpm), as

switch

'M"

(Medium)]

I

(2) Adjusting

slightly)

The

positioning

Speed

when

turned

The

positioning

by

us).

(3)

Adjusting

The

internal

The

speed

turned

Since

thread

manualofthe

ming

speed.

(4)

Adjusting

When an

(medium

"H"

(Hjghl

"L"(Low)|

SPEED

the

low speed (Positioning speed is

increases

counter-clockwise,

speed

when

counter-clockwise.

speedisadjustable

the

thread

variable

increases

trimming

sewing

the

barracking

operation

speed)

can be

(Thread

trimming)

1

(low

the

internal

trimming

resistor

"T"

when

the

(setto200

speed

machineorconsult

speed

box,

LD-C2, C4orC6

adjustedbythe

speed)

canbeadjustedbythe

variable

withinarange

speed

permits

variable

may

adjustmentofthread

resistor

rpmbyus).

differ

from

our

internal

the

speed when the pedal is pressed

resistor

"L"isturned

from

160

"T"isturned

machinetomachine,

service

agency

(option)

is used

variable resistor

internal

rpmto320

trimming

clockwise,

for

for

variable resistor

clockwise,

rpm

speed.

and

refertothe

readjustmentofthread

barracking,

"M".

barracking

end

decreases

(setto250

decreases

instruction

down

"L".

rpm

when

trim

speed

ADJUSTMENT

AND

OPERATION

OF

CONTROL

UNIT

15 I Optionalfunctions

By connecting external (optional) control signal to the option connector, and setting the correspond

internal

DIP

switch,

various

For

details,

consult

with

optional

our

service

functions

agency.

canbeused.

Internal

(1)

Internal

COR :

+ 2

+ 1

S L

DIP

switch

DIP

switch

Correction

stitching

G :

Gain

switch

A : High-speed

stand

working

machine

external

available)

SH:One-shot

Slow

start

S L

+ 1

+ 2

ON.

ojllllllli

OFF

DC

8^-

+ +wii.^

stitching (high-speed

switch)

(tobesetat"ON")

stitching

(not

variable

function

control

switch

type

sewing

necessary

resistor

switch

switch

0

OFF

OFF

OFF

for

when

is

ON

OFF

X en CO m

O

to

CL D H

IL:Thread

switch

trimmer

interlock

release

POS : "1—2 POSITION" (thread trimming)

US : Needle

TB ;

FL : Automatic presser

1

stitch

ON

OFF

OFF

2

stitches

ON

ON

OFF

back

switch

Back

solenoid

trimming

"UP"

position

operationatthread

3

stitches

ON

OFF

ON

stopbytouch-

foot

lift (by

4

stitches

ON

ON

ON

Sj)

(2)

Automaitc

The

timingofautomatic

struction

Standard

timing

Needle

Needle

writteninthe

The

timing

"DOWN'

"UP"

Thread

wiper

thread

trimming

chart

trimmer'

sewing

is as

i ' •

i < I

I ' I

I I i

1

timing

thread

follows:

I I

!-+•

I I

-t-T

Needle

'DOWN"

chart

trimmer

machine

operation

settingupprocedure.

-24-

shouldbeadjustedinaccordance

—n

Needle

"UP"

with

the

in

r

ADJUSTMENT

(3)

Option

Various

For

contacts

AND

connector

external

necessary

OPERATION

controls

can be used by

for

input

OF

CONTROL

connecting

signal, use reliable

external

one.

UNIT

signaltothe

option

connector.

Speed

LOW

HIGH

•0

ov

Power

® (D

(5) (D

(§) (D

source

Option

HIglvspecd

opentMn

Low-speM

opeistnn

VeiiaMevoltage

Correction

sMcliinR

Needle

Speed control

cotivnand

Tlvead trimming

MediuiThSpeed

oneratton

OV

lifting

® (D

Clutch

© (D

Brake

1

9

8

7

6

S

4

3

2

1

(4) Reverse stitching by touchback switch

Touchback switch (S7) is operative only while the sewing machine is in operation.

f®®)

Synchr

onizer

Presser

OV

Pres^footUt

+ 30 V

Prespr loot tit

out^

External

resistor

Option

®{D(D

@®(D

®(D(D

Option

foot

variable

10kf2

1

1

2

3

4

~©

@®(D

®(0)®

Operation

POSITION"

•&

box

1

®®@

®

(g)(Q)®

Presser

Sewing

foot

machine

Sewing

machine

Toudiliackoutput

+

30

V

OV

Touchback

itgnil

—

—

Thgid^uijigiiog

OV

Thread

trimming

output

+

30

Wiparoutput

GND

12

II

10

9

8

7

6

5

4

3

V

2

1

Sewing

machine

body

-25

-

CAUTION;

Whenaneedleofsmall

Threading

for

light fabric stitching

gauge

(below

#11) is used,each

needle

thread shouldbe wound about 3/4 turn

around needle and then passed through needle eye, as shown below, to assure neat stitches. It is re

commendedtouse

stepped

needle.

-26-

(Caution)

AdjustmentofNeedle

Stop

Position

(LT2-230-B1T, LT2-250-B1T)

The machines, LT2-230-B1T and LT2-250-B1T, are shipped out after completion of the

sewing

and thread

bobbinonthree-folded

Itis necessary to adjust the needle

the

thickness

fabrictobe

Adjustment

Check

the

arm

when

the

1.

When

the

2.

When

the

and

sewn.

distance

needle

needle

needle

trimming

materialofthe

Follow

between

tests with the thread of

denim

(0.8mminthickness).

the

the

stops

at UP

stop

early;

4

stop

late;

stop

used

adjusting

white

position

vinyion

No.B

for both the

position after the thread is trimmed according to

sewing

thread,

and

the

procedure

markonthe

after

the

If

the

the

needle

left

mentioned

balance

fabric is

distanceAshown

malfunctionofthe

threads

and

right

thickness

wheel

sewn

and

sides)

below.

and

and

the

are

and

the

the

thread

left

knives

bobbin

not

trimmed

materialofthe

black

markonthe

is trimmed.

is 2mmor

occur,

threads

needle

properly.

and

more,

(at

and

the

the

3.

Adjusting

If

the

needle

synchronizer

within 5 mm

of Needle Bar

sureofthe

stop

Method

stop

position is deviated as

detector

according

Stop

discsothat

to the adjusting

Position, on the

position after

the

£\

the

sewing

distance

page

If

the

the

throat

shown

A may be within 2 mm

procedure

2of

the

and

the

-27

-

distanceBshown

clearance

plate

between

becomes

above, adjust

mentioned in the secion

the

left

the

narrow.

setting

and

is 5mmor

needle

location of

the

distance

[T],

Adjustment

and

more,

the

the

Instruction Manual. In adjusting, make

thread

trimming is actually completed.

8

SPECIFICATIONS

SpecificationsofLT2-230

Model

Spec.

Application

Stitching

speed

(Max.)

Stitch

length

Needle

bar

stroke

Presser

foot

storke

Needle

Rotating

hook

(for

thread

trimmer

use)

Bobbin

case

Bobbin

Thread

trimming

method

Lubrication

Automatic

Bed

Notes;•Feed

size

back

designed

•

Bobbin

dog,

throat

for

shouldbeof

and

LT2-230-M1TW

Medium-heavy

4000

spm

0~4

mm

33.4

DP X 5

Full-rotation,

lubrication,

hook,

prevention

Aluminum

trimmer

plate,

thread

LT2-250

3500

spm

5

mm

mm

Knee

Hand

equipped

spring

bobbin

use

timmer.

high

LT2-250-M1TW

fabric

3500

spm

0~-4

mnr

32.0

lifter:9mm

lever:7mm

#14

(#11~#18)

automatic

horizontal

with

racing

Fquipped

spring

for

Combinationoffixed

rotating

quality

mm

type

thread

hook,

free

5

3000

spm

mm

with

Automatic

bobbin

from

LT2-230.B1T

3000

spm

0-6

mrr

35.0

mm

DP X 5

knife

Touch-back

517X178

deformation.

Medimu-heavy

2500

spm

7

mm

#18

full-rotation,

lubrication,

hook,

prevention

Aluminum

trimmer

and

lubrication

mm

case

and

LT2-250-B1T

3000

spm

0~6

mm

Knee

lifter:13mm

hand

lever:7mm

(#14~#21)

equipped

bobbin

use

movable

bobbin

2500

spm

7

mm

automatic

horizontal

with

spring

Equipped

spring

knife

fabric

32.0

for

LT2-250:A1T

3000

spm

5

mm

mm

type

raching

with

thread

shouldbethose

A

MITSUBISHI

MEAD

0*FiCt

MITSUBISHI

OENICI

ELECTRIC

BLOC

MARUNOUChi

TOKYO

CORPORATION

iOO

TELEX

J24$32

CABLE

MElCO

TOKrO

A180E016P05

PrintedinPapan

Loading...

Loading...