Page 1

MITSUBISHI

INDUSTRIAI.

MACHINE

LT2-2230

Double-Needle

Needle

Lockstitch,

Undertrimmer,

A

SEWING

Model

Classes

feed

Automatic

Variable

INSTRUCTION

Speed

MANUAL

Page 2

PRECAUTIONS

(1)

Safety

1. Keep your

area

2.

Power

operator

Precautions

hands

around

the

mustbeturned

leaves

and

pulley

his/her

BEFORE

fingers

when

off

when

seat.

STARTING

away

from

turning

the

the

area

the

power

machine

TO

around

on.

is not in

OPERATE

the

needle

use,orwhen

3. Power must be turned off before tilting the machine head, installing or

removing

4. Avoid placing fingers, hair, bars etc.,

winder, or motor

5. Do

needle, or pulley

6. Ifa belt cover, finger guard,

the

(2)

Precautions

1. If

the

filling it.

2. If

the

lubricating.

3. When a

direction of

.(Thepulleyshould rotate counterclockwise

4. Verify

machine

(3)

Precautions

the

not

insert

machine

before

machine's

"V" belt, adjusting

when

the

fingers

without

when

Starting

oil

pan

into

the

these

has

the

machine, or replacing its parts.

near

the

pulley, "V" belt, bobbin

machine

the

machine

and/or

safety

Operation

is operating.

thread

is operating.

eye guard

devices.

take-up

cover,

are

an oil sump, never operate

machineis lubricatedbya drop oiler, never operate

new

sewing machine is first turned on, verify

the

pulley

with

the

power

on.

when

viewed from the pulley.)

the

voltage

nameplate.

for

and

Operating

(single or three)

Conditions

phase

with

under/around

installed, do not operate

the

machine before

the

machinebefore

the

those

given on

1. Avoidusing the machine at abnormally hightemperatures (35°C or higher)

or low

temperatures

2. Avoid using

the

(5°C or lower). Otherwise, machine failure may result.

machine in dusty conditions.

and

the

the

the

rotational

the

Page 3

-CONTENTS-

PREPARATION

m

Power

[2

Connectionofcontrol

cable

FOR

OPERATION

connection

box

[Tl Adjustment of needlebar stop position 3

CAUTIONS

m Oiling (2) 4

r2l Oiling condition and adjustment on oiling to

m

ON

USE

Adjustmentofoilingtorotating

hook

thread

take-up lever 5

IT] Cautions on operation 5

OPERATION

Installationofneedles

Winding of

Selectionofthread

Threadingofneedle

bobbin

thread

threads

Adjustment of stitch length and stitch reversing (touch-back) 8

Settingofbobbin

Adjustment of needlethread guide 8

Threadingof bobbin threads 9

Tension adjustment of bobbin threads 9

Balance of

10

Needle

11

Adjustment of presser foot pressure 9

12

Timing between rotating hook motion and needle motion 10, 11

13

Adjustment of feed dog height 12

14

Relationship between rotating hook motion and take-up lever motion 13

15

Relationship between hook motion and opener motion 13

16

Relationship between needle motion and feed dog motion 14

17

Installationofmovable

thread

thread

tension

tension

knife

Adjustment of thread trimmer cam 16

Adjustment of thread tension regulator 17

Adjustmentof

meshing

pressureof movableknife and fixed knife 18

Sharpening of fixed knife 18

Adjustment for change of needle gage 19

Wiper

adjustment

1

2

5

6

6

7

7

8

9

9

15

20

ADJUSTMENT

m

"1-2

m Pedal

m Adjusting

AND

POSITION"

operation

the

pedaling forces

OPERATION

select

switch

OF

CONTROL

operations

UNIT

21,24

21,24

21,24

m Adjustingthe stitchingspeed 22,25

fSl Optional functions 23, 26, 27

CAUTION

28

Page 4

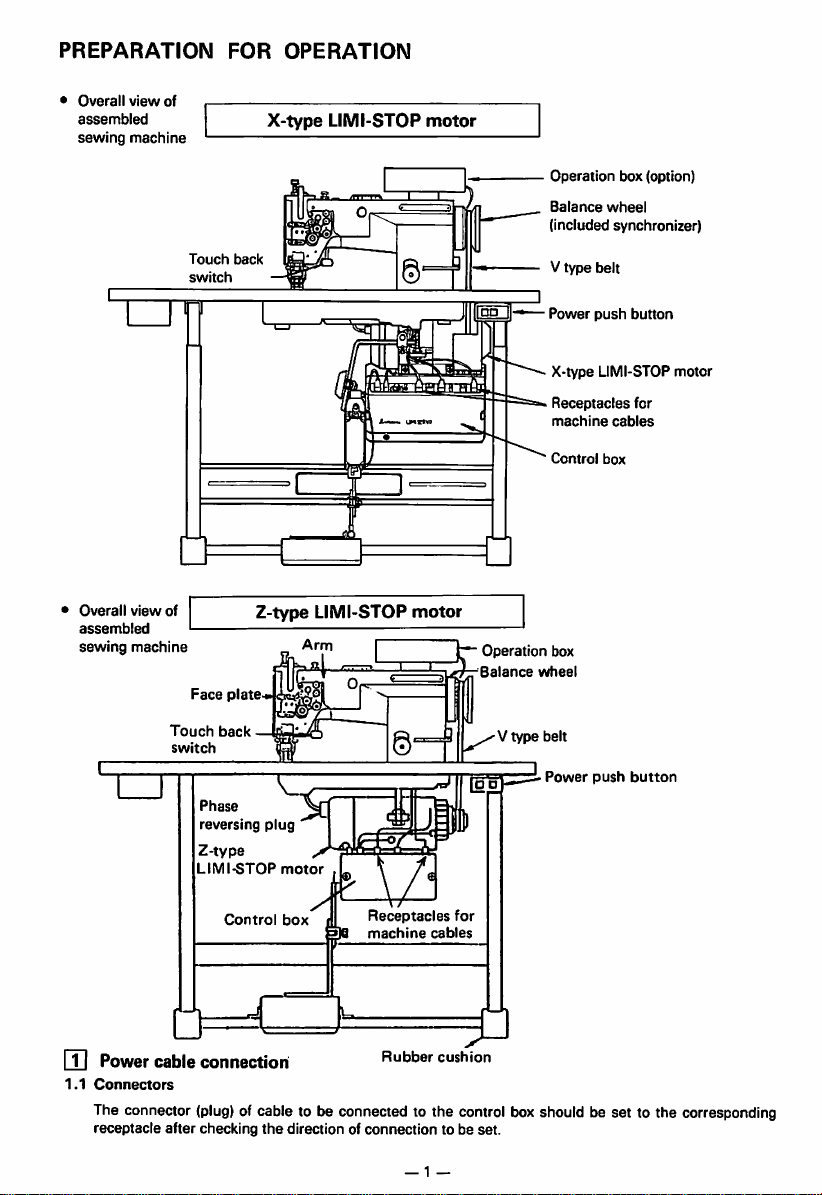

PREPARATION

•

Overall

view

assembled

sewing

of

machine

FOR

OPERATION

X-type

LIMI-STOP

motor

•

Overall

assembled

sewing

view

of

machine

Touch

Touch

switch

Face

switch

back

plate

back

Phase

reversing

Z-type

LIMI-STOP

Control

Z-type

plug

motor

box

LIMI-STOP

Arm

motor

13

Receptacles

machine

for

cables

Operation box

Balance

^^vtype

Operation

Balance

box (option)

wheel

(included synchronizer)

V type belt

Power

push

button

X-type LIMI-STOPmotor

Receptacles

machine

Control

wheel

Power

box

push

for

cables

button

rn

Powercable connection

1.1

Connectors

The connector

receptacle

(plug)

after

Rubber

cushion

of cable to be connected to the control boxshould be set to the corresponding

checking

the

direction of

connection

— 1 —

to be

set.

Page 5

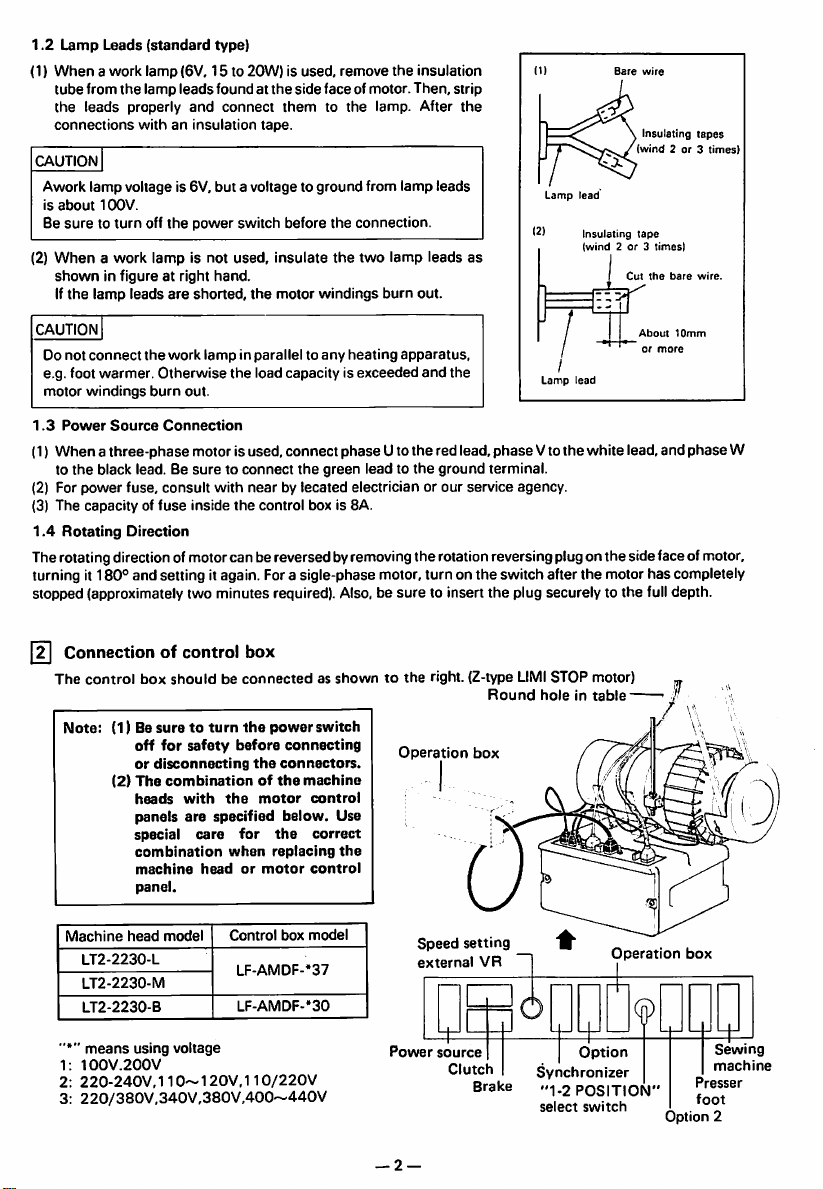

1.2

Lamp

(1)

Whenawork

tube

the

connections

CAUTION

Awork

is

about

Be

suretoturn

(2)

When

shown

If

the

Leads

(standard

lamp

from

the

lamp

leads

properly

withaninsulation

lamp

voltage is 6V, but a voltage to

10OV.

off

(6\/, 15 to

leads

and

the

power

type)

found at

a work lamp is not used,

in figure at right

lamp

leads

are

hand.

shorted,

20W)isused,

connect

tape.

switch

the

remove

from

connection.

the

two

the

lamp. After

lamp

lamp leads

burn

the

sideface ofmotor. Then,strip

themtothe

ground

before

the

insulate

motor

windings

insulation

the

leads

out.

Insulating

(wind

Lamp

lead

12)

Insulating

tape

as

(wind2or3times)

Cut

tapes

2 or 3

times)

the

bare

wire.

CAUTION

Do

not

connect

e.g. foot

warmer.

motor

windings

1.3

Power

Source

(1)

Whenathree-phase

to

the

(2) For

(3)

1.4

black lead. Be

power

The

capacityoffuse

Rotating

fuse,

Direction

the

work

lampinparalleltoany

Otherwise

burn

out.

Connection

motor is used, connect

suretoconnect

consult

with

inside

heating

the

load capacity is

phase

the

green

by lecated electrician or our service agency.

box is 8A.

the

near

control

apparatus,

exceeded

Uto the red lead,

lead to

the

and

ground

the

phase

terminal.

Lamp

Vto

/

lead

the

About

or

more

white lead, and

10mm

phase

Therotating directionof motorcan bereversed byremovingthe rotation reversing plugon the side faceof motor,

turning it

stopped (approximately two minutes required). Also, be

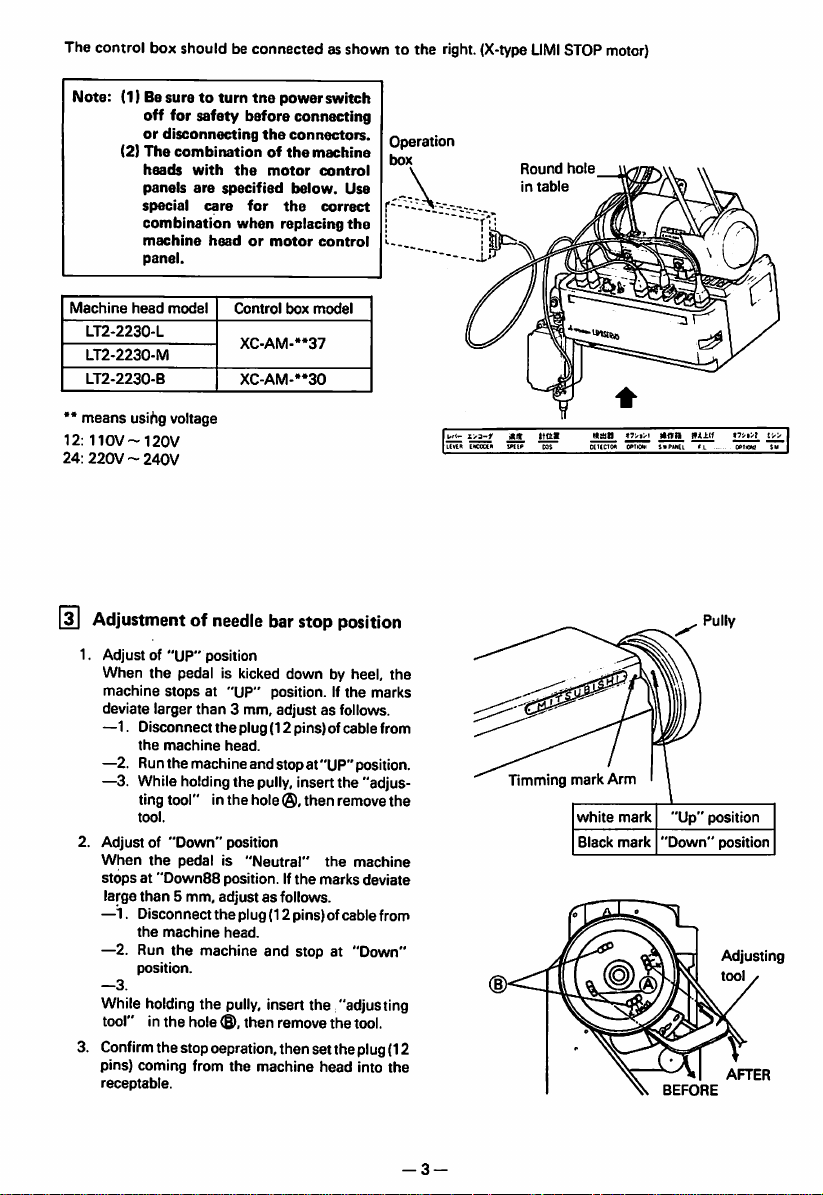

[n

180°

and setting itagain. Fora sigle-phase motor, turn on the switch after the motor has completely

Connection of control box

The

control

box

shouldbeconnectedasshowntothe

Note:

(1) Be

suretoturn

off

for

safety

or

disconnecting

(2)

The

combinationofthe

heads

panels

special

combination

machine

panel.

before

with

the

are

specified

care

for

when

headormotor

the

the

motor

power

connecting

connectors.

machine

control

below.

the

correct

replacing

control

switch

Use

the

sure

to insert

the

plug securely to the fulldepth.

right. (Z-type LIMISTOP motor)

Round

holeintable-

Operation

box

W

Machine

1;

2:

3:

head

model

LT2-2230-L

LT2-2230-M

LT2-2230-B

means

using

100V.200V

220-240V,110~120V,110/220V

220/380V,340V,380V,400~440V

Control

LF-AMDF-*37

LF-AMDF-'30

voltage

box

model

Power

— 2 —

Speed

external

source

setting

Clutch

VR

Brake

Option

Synchronizer

"1-2

POSITION"

select

switch

Operation

box

Option

Sewing

machine

Presser

foot

2

Page 6

The control box should be connectedasshown to the right.

(X-type

LIMI

STOP

motor)

Note: (1) Besuretoturn

off

for

or

disconnecting

(2)

The

combinationofthe

heads

with

panels

are

special

combination

machine

panel.

Machine

••

12:

24:

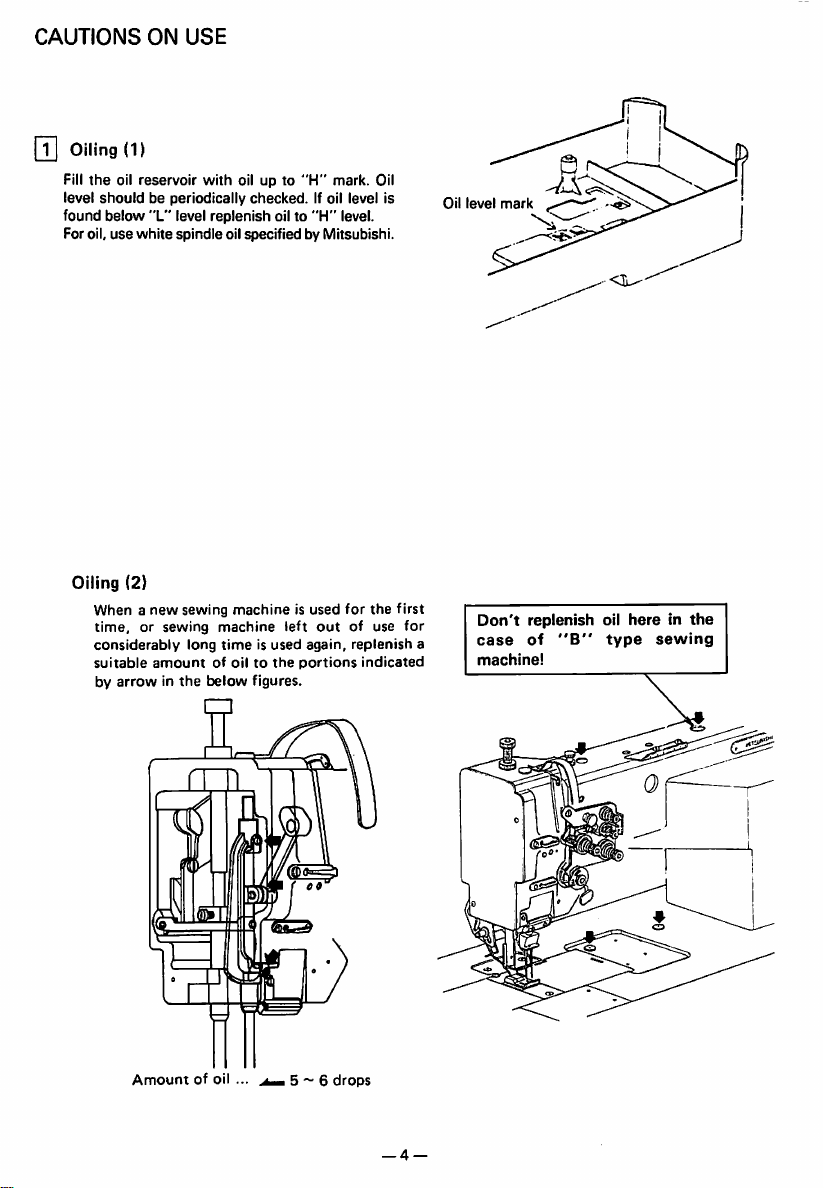

[3]

head

model

LT2-2230-L

LT2-2230-M

LT2-2230-B

means

usihg voltage

110V--120V

220V~240V

Adjustmentofneedle

tne

safety

before

the

the

specified

care

for

when

headormotor

Control

XC-AM-»*37

XC-AM-**30

power switch

connecting

connectors.

motor

below.

the

replacing

box

bar

stop

1. Adjust of "UP" position

When

the

machine

deviate larger

—1. Disconnect

pedal is kicked down by heel,

stopsat"UP"

the

machine

than

position. If

3 mm, adjust as follows.

the

plug (12 pins) ofcable from

head.

—2. Runthemachineandstop at"UP"position.

—3. Whileholdingthe

ting tool" in

tool.

2. Adjust of

When

stops

large

—1. Disconnect

—2. Run

—3.

"Down"

the

pedalis"Neutral"

at "DownSBposition. If

than

5 mm,

the

machine

the

position.

pully,

the

insertthe "adjus

hole®,then

position

the

adjustasfollows.

the

plug (12 pins) ofcable from

head.

machine and stop at "Down"

While holdingthe pully, insert the "adjusting

tool" in

the

hole

<B),

then

remove

3.

Confirm

thestopoepration, then setthe plug(12

pins)

coming

from

the

receptable.

machine

machine

control

Use

correct

the

control

model

position

the

remove

the

marks

the

head

Operation

box

the

marks

the

machine

deviate

tool.

into

the

Round

hole

in

table

a-f

Alt

UvlR

ENCOCCM

ttal

iPtlfi

Pully

Timming mark Arm

white

mark

"Up"

position

"Down"

BEFORE

position

Adjusting

tool

AFTER

Black

mark

— 3 —

Page 7

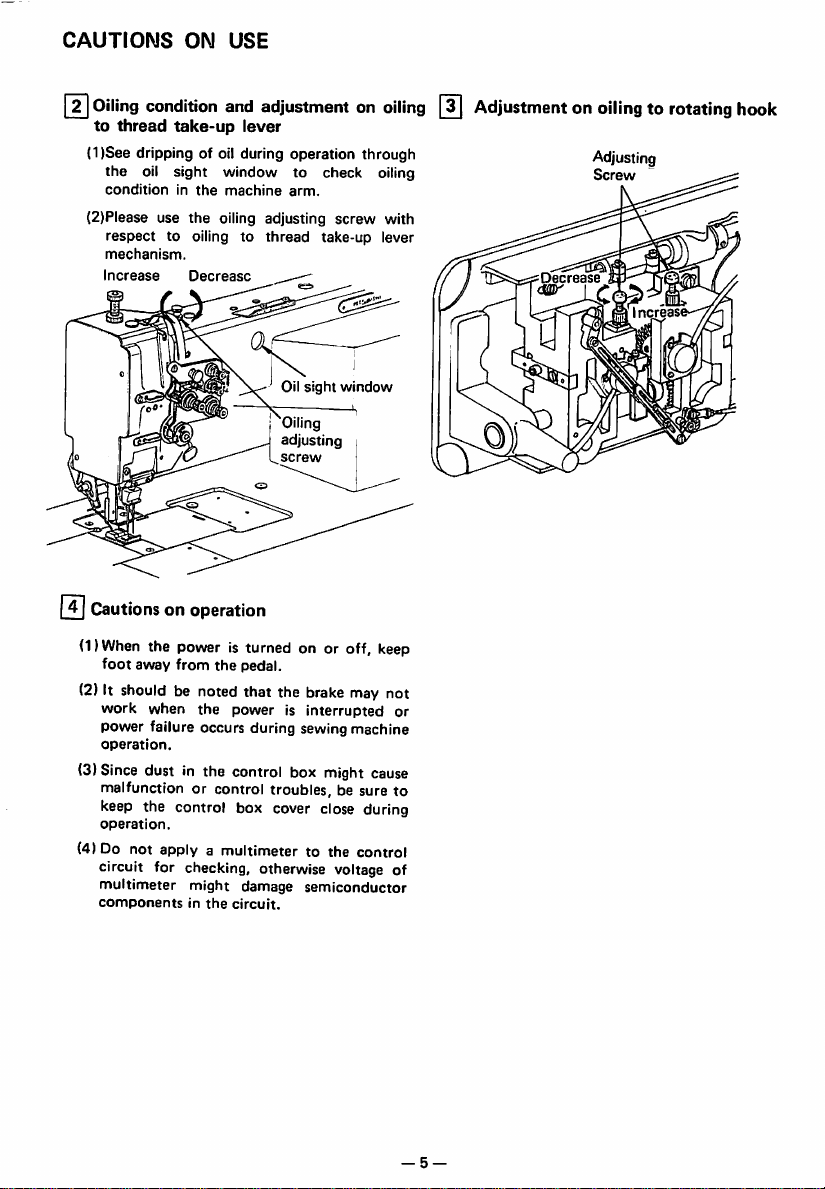

CAUTIONS

rn

Oiling

Fill

level

found below "L" level replenish oilto "H" level.

For oil,

the

oil reservoir

should

use

ON

USE

(1)

with

be periodically

white

spindleoil specified by Mitsubishi.

oil up to

checked.

Oiling (2)

When a

new

sewing

time,

or sewing

considerably

suitable

amountofoiltothe

by

arrowinthe

machineisused

machine

long

timeisused

below

left

figures.

"H"

mark. Oil

If oil level is

for

out

again,

portions

the

of use

replenish

indicated

first

for

Oil

level

Don't

replenish

case

a

of

machine!

"B"

oil

hereinthe

type

sewing

Amount

of oil ... 5 ~ 6

drops

— 4 —

Page 8

CAUTIONS

[Tl

Oiling

to

thread

ON

condition

take-up

USE

and

adjustmentonoiling

lever

(1)See dripping of oil during operation through

the

oil sight window to check oiling

conditioninthe

(2)Please use

respect

mechanism.

Increase

@

Cautionsonoperation

machine

the

oiling adjusting

to oiling to

Decrease

arm.

thread

Oil

Oiling

adjusting

screw

screw

take-up lever

sight

window

with

Adjustmentonoilingtorotating

Adjusting

Screw

ecrease

Increas

hook

(DWhen the power is turned on or off, keep

foot

away

from

the

pedal.

(2) It should be noted that the brake may not

work

when

the

power is interrupted or

power failure occurs during sewing machine

operation.

(3)Since dust in the control box might cause

malfunction or control troubles, be sure to

keep the control box cover close during

operation.

(4) Do not apply a multimeter to the control

circuit for checking, otherwise voltage of

multimeter might damage semiconductor

components

in

the

circuit.

-5

—

Page 9

OPERATION

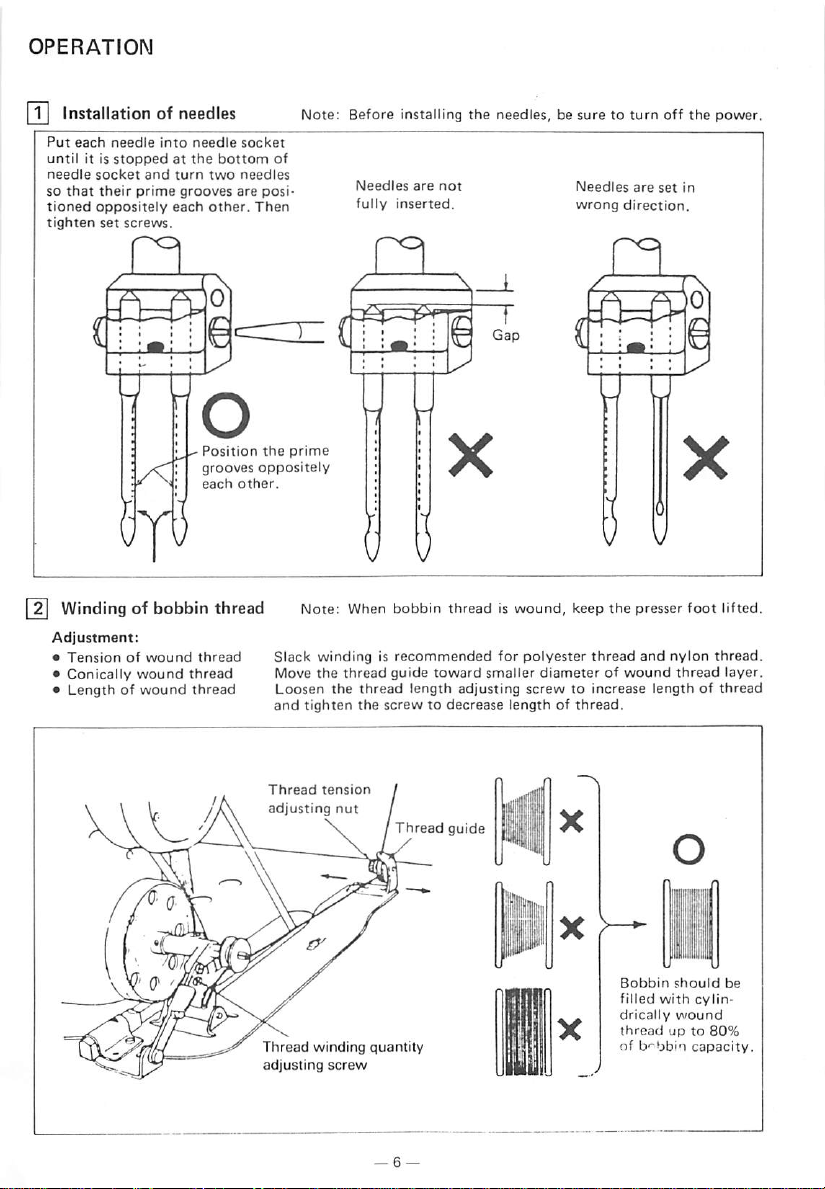

pn

Installationofneedles

Put

each

that

it is

socket

oppositely

needle

stoppedatthe

and

their

prime

set

screws.

until

needle

so

tioned

tighten

into

each

needle

turn

grooves

bottom

two

other.

socket

needles

are

Then

posi

Note:

Before

installing

of

Needles

fully

inserted.

the

needles,besuretoturn

are

not

Needles

wrong

are

set

direction.

off

the

power.

in

n

Windingofbobbin

Adjustment:

•

Tensionofwound

•

Conically

•

Lengthofwound

wound

O

Position

grooves

each

thread

thread

thread

other.

thread

n

the

prime

oppositely

Note: When bobbin thread is wound, keep the presser foot lifted.

Slack

windingisrecommended

Move

the

the

tighten

tension

thread

nut

thread

the

Loosen

and

Thread

adjusting

guide

toward

length

screwtodecrease

Thread

adjusting

guide

for

polyester

smaller

diameterofwound

screwtoincrease

lengthofthread.

thread

and

lengthofthread

nylon

thread

thread.

layer,

m

Thread

adjusting

winding

screw

quantity

Bobbin

should

filled

with

drically

wound

threadupto

of b-^bbin

be

cylin-

80%

capacity.

Page 10

OPERATION

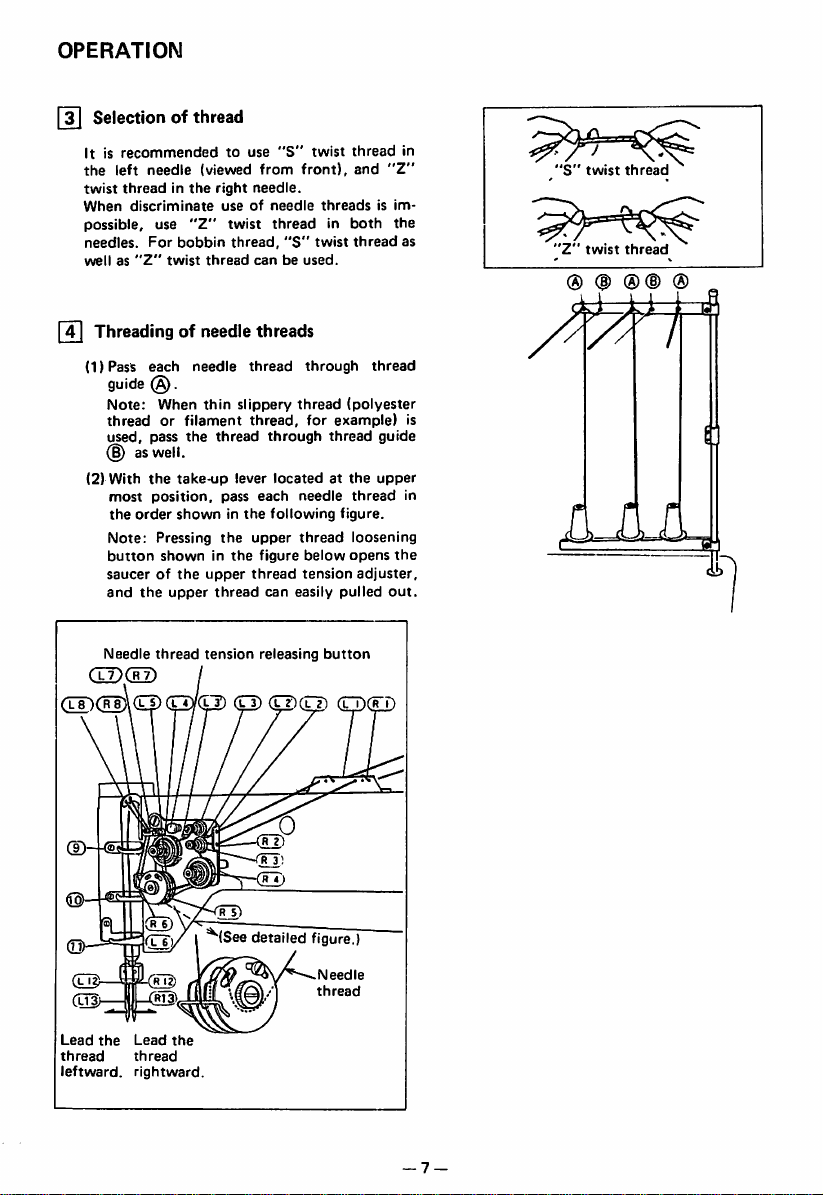

[3] Selection of thread

It is

recommendedtouse

the

left

needle

use

"Z"

For

bobbin

twist

each

needle

@.

When

pass

the

the

take-up

position,

showninthe

Pressing

showninthe

the

upper

(viewed

right

useofneedle

twist

thread

thin

thread

pass

the

upper

thread

twist

threadinthe

When

discriminate

possible,

needles.

wellas"Z"

[T]

Threadingofneedle

(1)

Pass

guide

Note:

threadorfilament

used,

(J)aswell.

(2)

With

most

the

order

Note:

button

saucerofthe

and

"S"

from

needle.

threadinboth

thread,

"S"

canbeused.

threads

thread

slippery

thread,

through

lever

locatedatthe

each

following

upper

figure

thread

can

twist

front),

threadsisim

twist

through

thread

for

example)

thread

needle

figure.

thread

below

tension

easily

pulled

thread

and

"Z"

the

thread

thread

(polyester

guide

upper

thread

loosening

opens

the

adjuster,

out.

in

as

S

twist

Z '

twist

® (1)

thread

thread

®(D

®

is

in

Needle

GDdD

(IT)(rJ)\(0)

Lead

the

thread

leftward,

Lead

thread

rightward.

thread

Ck

the

tension

releasing

kD

(kD

(0)(0)

^(Seedetailed

button

figure.)

Needle

thread

— 7 —

Page 11

OPERATION

Adjustment

reversing

Note:

the

feed

setting

dialtoa

(touch

To

make

reverse

Stitch

setting

of

stitch

back)

stitch

lever

desired

length

dial

Feed

lever

[6! Setting ofbobbin

(1) Pull

out

5 cm

thread

(2)

Hold

the

bobbinsothat

in right direction

and

tail

put

length

length

and

set

position.

reverse

from

the

bobbin

it into

smaller,

the

^

the

bobbin.

threadiswould

the

hook.

and

stitch

stitch

depress

length

•

Touch-back

canbereversedbydepressing

Stitching

buttonisheld

direction

goes

when

Thread

button

on in

down,

the

buttonisreleased.

tail

. . .

reversed

Directionofstitching

this

button.

direction

and

returnstoforward

Touch-back

while

^ button

the

Ft]

Adjusting,of

Please

adjust

tensioner

Thread

guide

position

Materials

Needle

thread

supply

needle

needle

The

standard

More

Left

thicker

than

thread

accordingtosewing

thread

guide

of n'.^edle

condition.

Middle

Standard

guide

The

ner

standard

thread

Right

thin

than

Less

— 8

Page 12

OPERATION

[si

Threadingofbobbin

(1)

Put

bobbin

the lug (2) and extend it below the bed.

(2) While

hand,

hand.

showninthe

lifted.

shouldbealigned

thread

Thread

holding

rotate

the

the

By

pullingupthe

figure,

Bothofbobbin

threads

into the slit (j},

Opener

two

needle

handwheel

and

the

thread

led

one

needle

bobbin

backward.

pass

Thread

threadsbyleft

turnbyright

threads,

threads

and

needle

under

will be

thread

ITil

*

Needle

referencetobobbin

as

•Toadjust

sion

Needle

special

and

Balanceofthread

AO

BX

CX

Needle

threadtension

thread

tension

needle

adjusting

thread

fabric

strokeofthread

nut.

tension

and

thread

tension

Balanced

tension

po-i-r^

Tight

needleorloose

bobbin

tension

Loose

needleortight

bobbin

tension

shouldbeadjusted

thread

tension.

tension,

canbealso

threadbychanging

takeupspring.

Tighten

turn

adjusted

each

ten

intensity

in

for

Tension

Tension

screw

adjusmtnet

adjusting

of

bobbin

threads

Loosen

Tighten

12

Adjustmentofpresser

Pressuretofabric(s)

pressure

-9-

adjusting

Weaken

..

Thread

adjusting

foot

pressure

canbeadjustedbyturning

screw.

Tighten

tension

nut

the

Page 13

OPERATION

Timing between rotatina hook motion

and

needle

motion

(DSet

stitch length on

dial

shown

(2)

When

lowest position, the following positional relation

ship

—The

1.0

—The

centerofneedle

—Gap

faceofneedle

table.

needleislifted@shown

should

be maintained.

upper edge of needle eye should be

~ 1.6 mm

hook point should be located at the

between the hook point and the side

(3) Needle/rotating hook position can be ad

justedasfollows.

(For easy adjustment, it is recommended

that the presser foot, throat plate and feed

dog assemblies are removed.)

•

Position

adjustmentofhook

Adjust the hook point so that it comes to the

centerofneedle

ID Lean

(2) Turn the balance wheel and stop when the

the

three

machine

set screws of hook

needleislifted

lowest

(3)

(4) Move the

position.

Rotate

the

hook

pointtothe

ward and position it so that gap between the

hook

hook point and side face of needle is 0.05

mm.

For

this

and

two

of

the

stitch length setting

below

the

hook point.

axis.

shouldbe0.05mm.

axis.

head

backward

shaft

(§)mmshown

hookbyhand

center

of needle axis.

bracket

adjustment,

shouldbeloosened.

leftward or right-

each

table,

point

and

gear (small).

table

to position

screws

from

loosen

from

(§)

the

the

,(§)

the

--—.....^Cla^

Set

the

stitch

length

Needle

lift

Gap®

Clearance

©

Hook

Set screw of

shaft gear (small)

2.0

point

hook

-L

2

mm

-M

3

2.2

1.0~1.6

0.05

mm

mm

mm

-B

4.5

2.4

mm

Note:Inthe

adjustment,donot

excessively

loosen set screws©and alwaysmaintain mesh

ing of

hook

shaft

gear

and

lower

shaft

gear.

(5)Tighten the set screws inthe following order:

(j)

While

pressing

the

lower

shaft

gear

against the side face of hook bracket,

(large)

tighten the set screws(£)first.

@

After

(D

and the

Then

checking

tighten

gap

hook,

tighten

thesetscrews®.

between

theset

the

needle

screws@^

—10—

Set

screwoflower

shaft gear (large)

Set

screw

Set

screw

Q)

Set

screw

(B

Set

screw

Set

screw

\

®

Page 14

OPERATION

•

Position

adjustmentofneedle

point

Adjust needle position so that gap between the

upperedgeof needleeyeand the hookpointis(§)

mmwhen the needleIs

lowest positionshown Inbefore page.

(1)

Remove

of

bartoadjust.

(2)

After

needle

the

the

bar

adjustment,

face

bracket

lifted

plate,

loosen

and

vertically

tighten

by@ mm

the

the

set

from

set

move

screw.

screw

the

Its

0

-Needle

-Needle

bracket

Set

screw

bar

bar

—11

—

Page 15

OPERATION

55

Adjustmentoffeed

Height of feed dog

shouldbeadjusted

following

cautions:

♦

Fabric

will be

too

high,orpressureofpresser

♦

Even

stitch

dogistoo

small.

♦

Feed

point

length

loworpressureofpresser

dog

height

where

dog

height

and

pressure of presser

for

individual

damagedifthe

fabric(s)

feed

footistoo

cannot

be assured if

shouldbemeasuredatthe

the

needleisat

the

with

dog

extends

the

footistoo

top

position.

foot

the

large.

feed

2ZZ

TSi

22ZZr

!

0.8mm

1.0mm

For

light

For

usual

For

heavy

Adjustment

(1)

Lean

(2)

Turn

the

feed

(3)

Loosen

(4)

Vertically

tion

adjustitto

(5)

After

set

screw.

The

feed

1

mm.

fabrics

fabrics

fabrics

procedure

the

machine

the

handwheelbyhand

dog

the

move

indicated

adequate

the

adjustment,

dog

Approx.

throat

Approx.

.

throat

.

Approx.

throat

head

risestothe

feed

bar

set

the

by

arrowinthe

heightisfactory-adjusted

backward.

screw.

feed

height.

tighten

0.8mm

plate

1.0mm

plate

1.2mm

plate

and

maximum

bar

(in

the

stop

height.

the

figure)

feed

from

from

from

when

direc

bar

1.2mm

to

Set

Feed

screw

bar

to

—12—

Page 16

OPERATION

Relationship between rotating

motion

and

take-up

lever

motion

hook

When the timing belt (cog belt) was removed for

its replacement, for example, the relationship

between rotating

motion

shouldbeadjustedasfollows:

(1)Turn

take-up

(2)

Lean

the

sure

the

timing

the

bossofhook

(3) If

the

black

stallitagaintoadjust.

]

Relationship

opener

the

balance wheel

lever is

machine

arrow

belt

is in

timing

line,

remove

motion

hook

motion

liftedtoits

head

(timing

line

with

shaft

markisnot

the

between

and

top

backward

mark)

the

bearing.

in line

timing

hook

and

take-up lever

stop

postion.

and

putonthe

black

belt

motion

when

line

with

and

make

on

the

in

and

the

Black

hook

lineonboss

shaft

bearing

Timing

belt

ill

Timing

mark

Timing

belt

sprocket

of

(1)Turn

when

remotely

(2) Make

and

(3) If

the

opener

the

the

balance

the

from

sure

the

openerisapproximately

gap is

set

opener.

wheelbyhand

opener

the

throat

gap

between

too

largeorsmall, loosen

screw@and

holderislocated

plate.

the

bobbin

0.2

adjust

position

and

case

mm,

stop

most

the

of

—13—

Approx.

0.2mm

Opener Screw®

Opener

holder

Page 17

OPERATION

[T^

Relationship

feed

dog

oThe

needle

at

the

(1)Set

(2)

(3)

(4) Lower

(5)

(6)

(7) If

(8)

between

motion

feed

dog

can plunge

centerofthe

stitch

setting

dial.

Lean

the

machine

Loosen

the

and(^

the

Adjust

the

bar

and

the

tentatively

of

the

feed

Check

that

nected

with

in

Figure.

the

connectionisnot

move

the

and

move

arrow

directiontoadjust.

After

the

tighten

the

needle

shouldboadjustedsothat

into

the

hole.

lengthto"0"on

head

feed

shaft

needletothe

distance

needle

tighten

the

the

needle

the

crank.

right

feed

linkatright

cover,

(§), (§)

shaft

back

the

completionofadjustment,

screws

motion

feed dog needle hole

the

stitch

backward.

crank

set

screw

lowest position.

between

bartobe

bar

"the

13.5,

screws

(§)

shaft

crankiscon

angle,asshown

.at right angle, re

loosen

the

screw

rocking

rodinthe

and

©.

and

the

length

pressure

and

and

©

fully

(b)

Screw

Screw

Feed

crank

shaft

(middle)

Feed

crank(right)

shaft

'Needle

rocking

bar

rod

Needle

bar-

n..'5

Pressure

bar

Feed

crank

—14—

shaft

(right)

Screw®

Screw

Needle

rocking

©

bar

rod

Page 18

OPERATION

Installationofmovable

1.

Initial

positionofmovable

{1)

Turn

the

balance

(2)

Push

the

cam

(3)

Turn

the

balance

wheel.

the

cam

coming

the

the

fixed

knife,asshowninFigure

14)

(5)

balance

Set

roller

Adjust

the

Loosen

follower

follower

out

thread

movable

Bolt{g)

knife

wheel

and

cranksothat

wheel

crankatthis

from

the

trimmer

knifesothat

knife

lower

until

cam

rocking

Thread

rocking

the

groove.

trimmer

the

black

crank

the

and

crank

needle

the

cam

position

movable

tighten

bartothe

roller

mark

pointonthe

withascrewdriver

clamp

bolts@and

knife

the

lowest

enters

into

arm

end

slant

bolts@and

0 ~

0.5mm

position.

the

thread

meets

@.

portion

(§)

trimmer

the

white

temporarily

protrudes

.

Movable

mark

preventing

knife

cam

groove.

pointonthe

0 —

0.5mmfrom

Fixed

the

knife

cam

2.

Gap

hoider

(1)

(2)

(3)

between

Turn

reaches

With

press

wheel

extremityofits

Manually

tion

gap

ner

screws

for

movable

stopper

the

balance

the

the

cam

until

indicatedbyarrowinFigure

between

hook

@

this

adjustment).

wheel by

lowest

position.

needleatfhe

follower

rotate

crank,

the

movable

stroke.

the

inner

the

movable knife and

stoppertoabout

and

@

Thread

rocking

knife

and

bobbin

hand

until

lowest

position,

turn

the

0.2

balance

reaches

and

mm

knife

hookinthe

shouldbeloosened

trimmer

crank

case

needle

direc

adjust

the

(the

Bolt(D

de

the

in

—15

knife-

0.2

mm

^—-Screw

Screw

inner

hook

Movable

Hook positioner

Approx.

—

Page 19

OPERATION

|l^

Adjustment ofthreadtrimmer cam

(1)

Turn

the

balance wheel by

(2)

Maintaining

grooveofthread

(3)

Turning

starts

pointonthe

To

adjust,

Cam

groove

the

moving

loosen

the

balance

when

arm.

needle

position,

trimmer

wheelbyhand,

the

two

thread

cam.

green

hand

mark

trimmer

until

the

depress

adjust

pointonthe

cam

Cam

crank

Cam

Screw

needles reach

the

cam

the

clamp

follower

roller

@

follower

thread

balance

screws

the

lowest

crank

trimmer

wheel

@

position.

and

camsothat

comes

Green

mark

Black

point

put

in line

the

point

mark

cam

the

with

roller

movable

the

black

Balance

into

knife

mark

wheel

the

Thread

trimmer

cam

—16—

Page 20

OPERATION

|20|

Adjustmentofthead

(1)

Turn

the

(2)

Maintaining

grooveofthread

(3)

Turning

close when the white mark point on the balance wheel comes in line with the black mark point

on

the

arm.

To

adjust,

(4)

Opening

the convexed portion of thread release cam, as shown in Fig.

Toadjust,

(5)

Make

fine

Thread

tension

release

lever

Screw

@

Roller

Thread

release

cam

Threadtrimmer ^

cam

tension

balance

wheel

the

needle

trimmer

the

balance

wheelbyhand,

loosen

two

degreeoftension

loosen

the

byhand

position,

cam.

tension

disc

screws

© anddrawthe

regulator

release

adjustmentbyloosening

(D

(D

Screw

until

the

needles

reach

depress

the

cam

adjust

the

thread

cam

clamp

screws

shouldbeadjusted

wire.

the

nut

© .

Cam

follower

crank

Cam

roller

the

follower

tension

@.

with

the

lowest

position.

crank

and put thecam

release

tension

White mark point

cam

sothat the

release

Blackmark

point

roller

roller

tension

(g)

mounted

Balance

intothe

disc

on

wheel

-17-

Page 21

OPERATION

[21I

Adjustment of

(1)

Loosen

(2)

Turn

socket

Note;

(3)

Move

Hexagon socket head

cap

meshing

the

fixed

knife

the

vertical

cap

excess

movable

Fixed

bracket

(g)

position

screw

knife

knife

head

Since

failure, adjust itso

the

screw

pressure of

bracket

adjusting

®.

pressure

that

and

movable

clamp

hexagon

screw(§)to

causes

large

thread can be trimmed with minimum pressure.

check

that

the

knife

socket

adjust

torquetothe

thread

canbesharply

head

meshing

and

cap

thread

fixed

screw

pressure

trimming

trimmed.

knife

@.

and

thenrighten

mechanism

the

and

hexagon

trimming

Vertical position

]

Sharpeningoffixed

When

the

Since It is very difficult to sharpen the movable knife, replace it

knives

dull,

the

knife

fixed

Fixed

knife

shouldbesharpenedasillustratedinFig.

roii'e

adjusting

--

—18—

screw

with

a new one when it dulls

Oil

stone

Page 22

OPERATION

23

Adjustment

for

changeofneedle

gage

(1) Replace

(2)

(3)

(4)

(5)

(6)

(7)

(Since

the

suretouse

Lean

the

Loosen

two

Remove

Loosen

hook.

When

the

Contact

link

clamp

the

throat

throat

those

machine

connecting

the

spring

the hook

needles

the

rocldng

bolt(^.

plate,

feed

plate

specifiedbyus.)

head

dog

and

feed

backward.

link

clamp

(@).

bracket

clamp

and

hooks

have

cranks@and

and

dog

bolts

screws

been

needle

are

special

(^.

@ and

adjusted,

to

clamp.

the

parts

designed

(B)

and

install

the

spring

stopper

pins®and and

adjust

for

thread

gap

(^.

(8) Turn the balance wheel by hand until the needles reach the lowest position.

(9) Loosenthe nuts (g) and (H).

(10)

Depress

the

cam

smoothly

(11)

Adjustmentofthe

(a) Push

(b)Turn

(c) Push

the

groove

trimmer

follower

enter

the

cam follower crank so

the

connecting

surface

the

cam

cam

groove

Thread

trimmer

rocking

crank

Connecting

link

Hook

bracket

crank®and

grooveofthread

cam

groove

rod(pand

and

trimmer

the

cam

that

adjust

(R)assmallaspossible,

follower

crank

smoothly.

Screw®

again

Stopper

adjust

the

connecting

cam.

Then

tighten

roller

the cam roller enters into

the

and

and

pin

clearance

tighten

check

Screw

Hook

the

that

Cam

@

Spring

Cam

bracket

between

nuts

the

roller

groove

rod(psothatthe

the

nuts

the

cam groove.

the

(g)

and

cam

roller

trimming

between

(§)

cam

(H)

.

enters

Cam

follower

crank

Thread

cam

Cam

crank

Camroler

each

tighten

and

(p.

roller

into

trimmer

Lower

shaft

follower

(

machine,

needle

the

cam

and the

the

be

and

connecint

roller

can

cam

thread

Bolt Stopper pin .

Thread

rocking

trimmer

crank

-19-

Connecting

Nut

^5)

Thread

trimmer

cam

Page 23

OPERATION

24

Wiper

adjustment

1.

Run

the

machine

then

2. Loosenthe screw ©, then adjust the base blocksothat the line ® and the line

stopat"Up"

tighten the screw

©.

position.

(6)

are the same plane, then

3. Loosenthe screw©,then adjust the wipermoveso as the © clearance is2 mm,then tightenthe screw

©.

Connecting

rod

Base

Lower

of

Base

block

Lower

of

Arm

© 2

plane

mm

Screw

©

screw

-20

—

Page 24

ADJUSTMENT

rn

"1-2

POSITION"

Needle

stop

(FOR

position

AND

Z-type

can be

OPERATION

LIMI-STOP

select

switch

selected

OF

CONTROL

motor)

between"1-POSITION"

UNIT

and

"2—POSITION".

^mark

_»

l_mark

"2-POSITION"

"1-POSITION"

When the switch set at "1 POSITION", thread istrimmed in one turn of the sewing machine when the

pedaliskicked

I2 I

Pedal

backbyheel.

operation

The pedal operation and resultant motion (stitching, thread trimming and needle motion) are as

follows;

\

\

"1-2

switch

Pedal

1

2

operation

POSITION"

setting

POSITION

POSITION

operation

Pedal

Stop

with

"UP"

Stop

with

"DOWN"

Toe

Neutral

needle

position

needle

position

down

I

at

at

Neutral (stitching

Neutral

4

Light

heeling

Presser foot goes Presser

up

Presser foot goes Presser foot goes UP

up

1

Toe

Down

start

turn

(needle

trimming

position)

Neutral

Full

foot

goes UP

and

thread

DOWNtoUP)

—T

'[

'Heeling

Neutral

heeling

trimming

after

after

Notes; 1. Stitching speed can be changedby changingdegree of pressingdown of the pedal.

2. For automatic presser foot lift, use optional unit,

(DC

24V).

3.

For

tackstitching,

I 3 I

Adjusting

1.

Adjusting

The

justedbychanging

the

It

notbestoppedatpositionifthe

the

pedaling

the

pedal

pedal

toe

coil

springtothe

shouldbenoted

down

use

optional

control

box,

forces B A

toe

down

force

force

lever,

that

canbead-

position

the

lever may

force

of

is

hooking

LE-FM-1

LD-C2,04or

or LE-FM-2,or solenoid valve

06.

and

one

holf

thread

2.

Adjusting

To

After

(see figure at right hand). Coil sorina Lever

the

pedal

adjust,

loosen

the

adjustment,

heeling

nut

"A"

tighten

force

and

turn

nut

bolt

"A"

Coilspring

—21-

® ^

/^^OREASE-rirMCnOAC^-

/DECREASE

Adjusting

the

—^

pedal

INOREASE\ ,

pressing

down

Lever

force

Page 25

ADJUSTMENT

I4 I

Adjusting

1. Adjusting

1) Adjustmentof

the

Twovariableresistors are avilableforadjustment of the maximum speed: one is located inthe control

boxandthe other ison thecontrolboxfrontpanel.Thevariableresistoronthe controlboxfront(external

VR)

permits adjustment of speed within the range from the low (minumum) speed to the maximum

speed

setbythe

The internal variable resistor H is factory-set as shown in the followingtable:

AND

the

stitching

maximum

OPERATION

stitching

maximum

internal

OF

CONTROL

speed

speed

speed (Speedachieved by

variable

resistor

H.

UNIT

fully

depressing the pedal)

Internal Variable Resistor H

3700

rpm (LT2-2230-L, M)

3000

rpm (LT2-2230-B)

Setting

External Variable Resistor Adjustable Range

Maximum

speedto200

spm

Forspeed setting out ofthe adjustable range ofthe external variableresistor, the setting of internal

variable resistor H

For fine

CAUTION

speed

mustbechanged.

adjustment,

useaspeed

meter.

Evenifa larger motorpulleywith a muc largerdiameter is used, the speed set bythe twovariableresistors

cannotbeincreased.

2) Adjustmentof lowspeed (Speed achievedbyslightlydepressing the pedal)

The low

speed

Speed increases

counterclockwise.

when

The adjustable range is 160 to

Internal

variable

resistors

L P T H H

can be adjusted by

the

for

the

internal variable resistor L.

internal variable resistor Lis turned clockwise, and

320

spm. (Factory-set to 200 spm.)

speed

setting

^ ^

Speed

setting

external

"1-2

variable

resistor

decreases

POSITION"

when

. . ,

select

o„

SPEED

L(Low

speed)

P (Positioning speed)

T (Thread trimming speed)

H (High

speed)

M

(Medium

3) Positioning

The positioning

Clockwise turn increases

to

320

speed

spm.

(Factory-set to

speed)

speedisadjustable

the

speed

250

spm.)

Adjustment

with

the

ofSpeeds

internal variable resistor P.

and counterclockwiseturn decreases. The adjustable range is

turned

switch

160

4)

Adjustmentofthread

The

internal variable resistor T

when

the

(Factory-setto175

Since

sewing

5)

Adjustmentofbacktacking

When

adjustedbythe

maximum speed. It should be noted

backtacking

internal

thread

machine

an control

speed,

trimming

variable

resistor

spm.)

trimming

speed

of consult our service agency for

switch

panel

internal variable resistor M. Adjust

the

set

speed

permits

T is

may differ

speed

(option) is

backtacking

the

adjustmentofthread

turned

clockwise,

dependingonnachines,

used

for backtacking, backtacking

thatifthe

speed

will vary.

-22-

and

readjustmentofthread

the

maximum

trimming

decreases

backtacking

speedisadjusted

when

refer to

speed

speed.

The

speed

turned

counterclockwise.

the

instruction

trimming speed.

speed

(medium

after

the

after

the

increases

manualifthe

speed)

can

adjustment

adjustment

be

of

of

Page 26

ADJUSTMENT

AND

I 5 I Optionalfunctions

By

(1)

connecting

internal

For

details,

Internal

DIP

consult

Dip

external

switch,

switches

various

with

OPERATION

(optional)

our

optional

service

control

functions

agency.

OF

signal to

canbeused.

CONTROL

the

option

UNIT

connector,

and

setting

the

correspond

COCO

• For UDS, SoC, A, SH,

BR

functions,

CO s — . . _ ^

2

3-1567

refertothe

5q-

—+ ooii.mm

12

3 4 5 6 7

on"

;W3I

POS,

US, TB, CRH, P, IL,+1, SL, FL, BL, BM, S3L, FUM, ES,

instruction

Internal

manual

ISW411111

Switches

LF-AMDF

• • S4L : High-speed operation signal (S4) inhibit switch

• •

S4/S2

• • SH/CKD ; One-shot

• •

S4/S3

• Functions for reverse operation of

• Rl : Reverse

• • G :

Internal

(2)

Model

LF-AMDF

delay in

oftime after

the

sewing

These resistors

: High-speed operation signal

signal/needle

S4/pedal

DOWNposition outputselect switch

: High-speed operation signal/pedal light heeling signal outputselect switch

sewing

machine

setting

switch

setat"ON")

variable

Gain

resistors

operation

switch

(to be

is incorporated with time delay variable resistors, as shown in Fig., which allow time

the

range from

the

machine

0.05

to 1.5 seconds.These variable resistors

input ofthread trimmer prioritystop PSUor DOWNpositoin prioritystop PSDwhich stops

at UP or DOWN position after fabric

are

factory-set to full counterclockwise (minimum) position.

Variable

resistors

for

time

delay

PSU

PSD

Operation

WIOIW

L

DELAY

5£SSaigoQ.a»

1 2 3 4 5 6 7

OMkBKH|i|K|

M11l.<twsl

control

full heelingsignal

after

thread

end

detection using a photolectric switch, etc.

Tojlf

00MCO

toStoS

ONI

S6,

box

functions.

output

trimming

are

activated a predetermined period

Delay

time

K, D, PIT,VEL,S,

select

switch

Internal

Variable

-23-

Resistors

Page 27

ADJUSTMENT

(FOR

n~l

Setting

the1-2

AND

OPERATION

X-type

POSITION

LIMI-STOP

Switch

OF

CONTROL

motor)

UNIT

Thestop

Whenthe switchis set to 1

and

I2 I

trim

Pedal

position

ofthe sewing machinecan bedeterminedbythe select switchon the panel.

mark

mark

the

thread.

2

POSITION

1

POSITION

POSITION,

fully

heelingthe pedalcauses the sewingmachinetorotate one turn

Operation

Thetwo-steppedal heelingmechanismallowsthe threadto betrimmedandthe presser foottoautomatically

go

up.

Pedal

Position

1-2

POSITION

1

2

Pedal

Settin&\

POSITION

POSITION

operation

Note: 1. The stitching

For

automatic

valve

(24V

Toe

down

—

Neutral

Stopatneedle

UP position

Stopatneedle

DOWNposition

\

\

\f7^^

511-"""^'"^

speed

can be varied bychanging the

presser

DC).

foot lifting,

'-II

/

!)

Note3Light

Neutral

use

the

Neutral

Presser

goes

Presser

goes

up.

up.

—

foot

foot

Light Heeling

Neutral —Full Heeling

Sewing

machine

and

trims

up.

thread,

up.

thread,

machine

then

H f.'

goes

Sewing

from DOWN to UP

trims

goes

rotates

then

rotates

down

(stitching

start)

pedal

optionalLE-FM-1, LE-FM-2 orLE-FA lifter or a

Neutral

toeing degree.

one

presser

half

position

presser

turn

foot

turn

and

foot

solenoid

I3 [

Adjusting

Pressures

The

lever

stepsbychanging

ponding

unit spring

spring

the

Pedal

Toeing

pressureisadjustableinthree

the

pressure

position of

adjust

knob.

and

Heeling

the

corres

Heeling

adjust

Toeing

adjust

spring

knob

spring

knob

pressure

pressure

| •

Tl

Page 28

I 4 I

Adjusting

1 Adjusting the maximum speed {speed available with the pedal fullytoed)

Twovariable resistorsare available for adjustment ofthe maximum speed; one Islocated in the control box

and the other on the control boxpanel. The external variable resistor

low

Is

the

Operating

speed

and

the

factory-setasfollows:

maximum

Speeds

speed

(knob)

set

by the Internal variable resistor H.The Internal variableresistor H

allows adjustment between

Internal Variable Resistor HSetting

3700spm

3000

Toset to any speed outside the aboverange, adjustthe internal variable resistor H, usinga speed meter.

CAUTION

Thespeed set bythe internal

motor

pulleyIsused.

2.

Adjusting

the lowspeed(speed

Thelowspeed isadjustablewith the

(LT2-2230-L, -M)

spm

{LT2-2230-B)

variable

available

Internal

resistor Hand external

withthe pedal

variable

slightly

resistorL.Clockwise

External Knob Adjustable Range

Low

speedtomaximum

knob

cannot be exceededifa larger

speed.

toed)

turn Increasesthe lowspeed

and counterclockwise turn decreases. The speed isadjustable between 160 and 320spm (factor-set to

250spm).

Speed

setting Internal variable resistors

P T H M

L (Low

speed)

P (Positioning speed)

T (Thread trimming speed)

H (High

speed)

M (Medium speed)

External

Control box

knob

panel

1-2 POSITION

I I

select

ii

switch

3. Positioning

The

clockwisetoincrease

4. Adjusting the thread trimming speed

The threadtrimming speed can be adjusted bythe internal variable resistor T.Turn Itclockwise to Increase

and

sewing

contact

5. Adjusting

Whenanyon the

speed)

4000spm).

speed

positioning

speedcan beadjusted bythe

counterclockwise

machine

the

service

the

backtacking

used.

agency.

control

isadjustable withthe

and

counterclockwise

todecrease,the

When

adjusting

speed

switch

panels

internal

Internal

todecrease, the

trimming

variable

speedis

factory-setto200spm

adjustable

this speed, refer to the sewing

(option)

variable

Isusedfor

resistorMwhichIsfactory-set

—25—

backtacking,

resistorP

(factory-setto250spm).

rangeis 160to

machine

the

backtacking

320spm.

andmay

adjusting

depend

speed

to1400spm(at

manual

high

Turn

onthe

(medium

speedof

it

of

Page 29

I 5 I

Option•Functions

Bysetting

the

internal switches and connecting external switches to

the

option connectors as required, each

control box can be used with various sewing machines with underbed trimmer and allows the sewing

machine

service

1.

to be

usedasa

agency.

Internal

switches

Set

the

switchesinaccordance

lowing specifications

switches

Mitsubishi

internal

tions.

For

functions.

A:

are

switches

the

SH, BL, SqC,

factory-set

machine

are

SW1

Standing-work

high-speed

(Not

SL, +1;

US:

PCS:

IB:

SSL:

Slow

Needle

switch

1-2

POSITION

Back

Presser

required

start

UP

tack

foot lifting

RU: Reverser

Used to

stop

after

S6/TL:

Thread

thread

trimming

Usedtoswitch

safety S6

IL:

Thread

Used to

to

restart

trimmer

cancel

BM: Backtacking

Usedtoset

standing-work

and

with

Fig. 12 All internal

to OFF.

table

setisused,

factory-settothe

PSU/ES,

G1, G2

sewing

switch

for

the

switch

external

controlbyback

switch

solenoidatthread

cancel

needle

lifting

the

switch

sewing

trimming.

safety/thread

the

thread

stitch

the

sewing

trimming cancel TLfunctions.

interlock

the

operation

after

change

back

tack

and

operation

machineoran

the

fol

When

the

the

posi

automatic

Rg.12XC-AM Internal

and

FUM functions,

machine

knob)

tack

trimmer

switch by light heeling

machine

interlock

machine

cancel

trimming

switch

restart

near

disable

time

the

needle

cancel

connector

commandatthe

has

passed.

switch

solenoid

operation

timing to

machine.

Switches

see

SL

+1

bar

select

5 - 6

the

top

switch

match

OFF

OFF

dead

signal

time of

For

further

XC-AN

0 1

center

between

thread

the

length

details,

contact

and

XC-AFL control box

stitch

2

stitches

ON

OFF

by reversing

the

thread

trimming.

ON

ON

the

Set

of backtacking stitch.

the

motor

trimming

to ON

BM

OFF

ON

UP

DN-

~LJ

N-2

N-1

i_r

T_r

Backtack solenoid operation timing ON or OFF

ON

1

?5N OFF

—

26—

i_r

i_r

\0i-\-

Page 30

UDS: Needle UP/DOWN control by back tack

Allows a half stitch to be

D:

machine

Start

backtacking

Allows

accordance

P: Pfaff type

has

start

with

thread

stoped.

speed

backtacking

the

trimmer

pedal

sewn

varying

speed

toeing

switch

by turning on

switch

to be

degree.

(Model

switch

changed

463)

the

back tack switchS7when

(between

low

and

backtacking

the

speeds)

sewing

in

2. Option

Option

1

Option

2

DOWN

UP

position

connectors

Lever

Encoder

Run (high speed)

Run (low speed)

+12V

Correction stitching

UP/DOWN

control

Variable-speed signal

Thread

trimmer

Run

(medium

speed)

OV

One-shot

UP position signal

position prioritystop

Power supply

priority

stop/emergency

OV

stop

Speed

@)

/ \

LOW

signal

HIGH

9

8

7

6

5

4

3

2

1

6

5

4

3

2

1

Position

—

(5)!

1—

VC1

>CpR

—OXI—1

VC2

—

OV

—CK

♦12V

MAX

—40mA

P^ES

OV

Detector

1

1 L

,

Option

External

AAA

(D (D (3)

<!}<D(D

knob

AAA

Presser

toot

Option

up

Control

switch

1

panel

10k

n

Sewing

mashme

Presser

foot

UP

OV

Presser foot UPsignal

PresserfootUPoutput+

Presser

footUPoutput-

Sewing

machine

1

2

3

4

Thread

trimming

Thread trimmer

Back tack

output

+30V

OV

Back tack signal

+30V

—

safety/thread

OV

output

+30V

Wiper

output

Ground

trimming

cancel

12

11

10

9

8

7

6

5

4

3

2

1

~®-(

SG/TL

-(wH

"I

Sewing machine

—27—

Page 31

CAUTION:

When a

around

commendedtouse

Threading

needleofsmall

needle

and

then

stepped

for

gauge

passed

light

(below

needle.

fabric

through

stitching

#11)isused,

needle

eye,asshown

each

needle

thread

below,toassure

shouldbewound

neat

stitches.

about

3/4

It is re

turn

—28—

Page 32

SPECIFICATIONS

SpecificationsofLT2-2230

Spec.

.

Application

Stitching

Stitch length

Needle

n X . • 1

Presser

Needle

Rotating hook

(for

Bobbin

Thread

Lubrication

Automatic

Bed

Needle

gauge

thread

trimming

size

speed

bar

foot

stroke

stroke

trimmer

back

Standard

Option

(Max.)

use)

method

Knee

..

Hand

Model

—

^

LT2-2230-LIT

Light fabric

LT2-2230-MITW

Light ~ Midium-heavy,

fabric

4CXX)spm

0 ~ 4

mm

33.4

mm

9

lifter

lifter

DP

X 5

#11

mm

7

mm

DPx5#14

, full-rotation, automatic lubarication, horizontal type hook, equipped

with racing prevention spring

2.4,4,

Aluminum

Combinationoffixed

5.6, 8,

bobbin

Automatic

517X178

3.2,

9.5,12.7,15.9,

for

thread

trimmer

knife

and

movable

lubrication

Touch-back

mm

4.8,

6.4

mm

19, 25.4, 28.5, 31.8, 38.1 mm

LT2-2230BIT

midium-heavy

fabric

300spm

0 ~ 7

35

13

7

DP

X 5

use

knife

mm

mm

mm

mm

#18

Notes:

• Needle

gauges

of-L class machine, applicate

3.2,4,4.8,5.6,6.4,8,9.5

mm

• Some materials, gauge sizes, and/or sewing conditions may require specifications other

than

those

listed

above.

• Feed

dog,

timmer.

throat plate,

rotating

hook,

bobbin

case and

bobbin

shouldbe those designedforthread

• Bobbin should be of high quality free from deformation.

• This specification is subject to change for machine improvement.

A

MITSUBISHI

HEAD

OtFiCE

MITSUBISHI

OENXI

ELECTRIC

BlOG

MaRunOUCmi

Tokyo

CORPORATION

iQO

TClE*

J2«532

CABLE

MElCO

TOkyQ

A180E128P02

PrintedinPapan

Loading...

Loading...