HARDWARE TECHNICAL REFERENCE

LS Pro

apricot

MITSUBISHI ELECTRIC

HARDWARE TECHNICAL REFERENCE

386 and 387 are trademarks of Intel Corporation.

SCAMP is a trademark of VLSI Technology Inc.

Cyrix is a trademark of Cyrix Corporation.

National Semiconductor is a registered trademark of National Semiconductor Corporation.

Cirrus Logic is a registered trademark of Cirrus Logic Inc.

Information contained in this document is subject to change without notice and does not represent a commitment on the part of

Apricot Computers Limited. The software described in this manual is furnished under a license agreement. The software may be used

or copied only in accordance with the terms of this agreement.

It is against the law to copy any disk supplied for any purpose other than the

purchaser’s personal use.

All rights reserved; no use or disclosure without written consent.

Copyright © Apricot Computers Limited 1993

Published by

Apricot Computers Limited

3500 Parkside

Birmingham Business Park

Birmingham B37 7YS

MITSUBISHI ELECTRIC

Printed in the United Kingdom

Part no. 15050131

Preface

The Apricot LS Pro Technical Reference Manual is intended for:

Programmers and engineers involved in hardware and software design for LS Pro

computers.

Contents

Preface

Service personnel involved in fault diagnosis and repair.

All computers in the Apricot LS Pro range are covered.

The manual is divided into a number of sections and appendices as described below:

1. Introduction This is a brief overview of the Apricot LS Pro which describes the options and major

components of the system.

2. System Unit This section describes the system unit: it also includes disassembly instructions for

servicing and replacing major components of the system. It includes pinouts of the

connectors which appear on the rear of the system unit.

3. System Board This section provides an overview of the function of the system board and more

detailed descriptions of the processor and interface circuitry. Sub-sections provide a

description of each area of the board.

4. Peripheral This section describes each of the system components which attach to either the

Items system board e.g. floppy disk drive, or system unit e.g. keyboard. Also included is brief

information on the KeyLOC card. Sub-sections describe each component.

5. Memory and This section provides information on the usage of Memory and I/O space by

I/O space the LS Pro system board, and programming information for each part of the system.

Chapter 1

Chapter 2

Chapter 3

Appendices Three appendices are included:

Appendix A

This contains specifications for each component of Apricot LS Pro computers.

Appendix B

This appendix describes the differences between the revision C system board and the

revision D system board described in section 3.

Appendix C

A list of error beep codes.

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 1

Preface

Associated Publications

Preface

ContentsChapter 1

Chapter 2

The following publication may be of general use to engineers and programmers.

IBM Personal Computer AT Technical Reference Manual.

The following manufacturers data sheets give information on specific devices:

Intel 80386SX

80387SX

8042 Keyboard controller

82077 Floppy disk controller

8237 DMA controller

8254 System timers

8259 Interrupt controllers

82596 Ethernet coprocessor

VLSI VL82C311 (SCAMP) AT chipset

Cyrix 486SLC

Cirrus CL-GD542X video controller

National Semiconductor NS16450 Serial communications controller

Chapter 3

Chapter 5Chapter 6

Hitachi MC146818 Real time clock

2 LS PRO HARDWARE TECHNICAL REFERENCE

CONTENTS

Contents

Contents

1 INTRODUCTION

General....................................... 1/2

Variants....................................... 1/2

System unit ................................ 1/3

Keyboard.................................... 1/3

Monitors..................................... 1/4

Expansion ................................... 1/4

2 SYSTEM UNIT

Introduction............................... 2/2

External layout.......................... 2/2

Internal layout ........................... 2/3

Servicing level............................ 2/3

Dismantling and re-assembly . 2/3

Installing add-ons ....................2/16

System unit connectors ........2/20

3 SYSTEM BOARD

3.1 Introduction ........................... 3/2

General....................................... 3/2

Description ................................ 3/4

3.2 Processor system ................ 3/5

Address and data bus

structure..................................... 3/5

Software compatibility.............3/5

Modes of operation ................. 3/5

3.3 SCAMP ..................................... 3/6

Interrupt structure................... 3/6

Direct Memory Access ........... 3/8

System timers............................ 3/9

3.4 System memory.................3/10

General.....................................3/10

Read only memory (ROM)...3/10

Random access memory

(RAM) ....................................... 3/10

Real time clock (RTC) RAM 3/11

3.5 Video adapter......................3/14

General.....................................3/14

3.6 Floppy disk controller .....3/15

General.....................................3/15

Drive formats..........................3/15

3.7 Hard disk interface ...........3/16

General.....................................3/16

Interface signal descriptions.3/16

3.8 Peripherals controller .....3/17

Serial ports...............................3/17

Parallel port ............................. 3/18

3.9 Keyboard/mouse

controller...............................3/18

General.....................................3/18

Keyboard password security3/18

3.10 LOC Technology ...............3/19

3.11 Ethernet port ...................... 3/19

General.....................................3/19

3.12 Apricot Business Audio ..3/21

3.13 System board

connectors ............................3/21

Hard disk drive connectors .3/21

Floppy drive connector.........3/22

System board power

connector.................................3/22

Battery jumper........................3/22

4 PERIPHERAL ITEMS

4.1 Power supply ......................... 4/2

Description ................................ 4/2

Connector ................................. 4/3

4.2 Monitors ................................... 4/3

Introduction............................... 4/3

Maintenance............................... 4/4

Video signal................................ 4/4

Apricot SVGA colour

monitor....................................... 4/4

External controls...................... 4/4

HiVision Low Emission 14"

colour.......................................... 4/6

HiVision Low Emission 17"

colour.......................................... 4/7

VGA connector ........................ 4/9

4.3 Hard disk drives ................... 4/9

Introduction............................... 4/9

Quantum ProDrive ELS .......... 4/9

Maxtor 7213A.........................4/11

Quantum ProDrive

LPS240AT.................................4/12

Quantum ProDrive

LPS525AT.................................4/13

IDE interface............................4/14

Chapter 1

Contents

Contents

Chapter 2

Chapter 3

Chapter 3

Chapter 5

LS PRO HARDWARE TECHNICAL REFERENCE 1

Contents

Contents

Contents

Chapter 1

Chapter 2

Chapter 3

4.4 Floppy drive .........................4/16

Description ..............................4/16

Interface....................................4/17

4.5 Keyboard ...............................4/18

Introduction.............................4/18

Operation.................................4/19

Scan codes ...............................4/22

4.6 KeyLOC card .......................4/29

5 MEMORY AND I/O USAGE

5.1 Introduction ........................... 5/2

5.2 Memory usage.......................5/2

5.3 I/O space .................................. 5/4

DMA I/O address map............ 5/5

Interrupt controllers ............... 5/6

System timers............................ 5/6

Keyboard controller................ 5/6

Port B.......................................... 5/8

RTC RAM/NMI mask .............. 5/9

SCAMP registers ....................5/10

Apricot ports...........................5/11

Hard disk drive controller

registers.................................... 5/14

Serial port controller

registers.................................... 5/14

Ethernet controller................ 5/15

Business audio......................... 5/17

Floppy disk controller ...........5/17

Parallel port controller .........5/18

Video DAC ..............................5/19

VGA registers .........................5/20

CL-GD542X Extension

registers.................................... 5/25

Chapter 5 Chapter 3

2 LS PRO HARDWARE TECHNICAL REFERENCE

APPENDICES

A: Specifications

B: Revision C system board

C: Error beep codes

INDEX

INTRODUCTION

Chapter 1

Contents

1 INTRODUCTION

General........................................1/2

Variants........................................1/2

System unit .................................1/3

Introduction

Keyboard.....................................1/3

Monitors......................................1/3

Expansion ....................................1/4

Contents

Chapter 1

Chapter 1

Chapter 3

Chapter 3

Chapter 5

LS PRO HARDWARE TECHNICAL REFERENCE 1/1

Chapter 6

Introduction

General

Contents

Chapter 1

Chapter 1

The Apricot LS Pro family is a range of ultra-compact IBM compatible computers which

can be used as a personal computer, a network workstation or a high resolution

graphics workstation.

The main features of the system are:

• 80386SX or 486SLC microprocessor operating at up to 33MHz.

• 2 to 16 Mbytes of on-board RAM.

• IBM compatible serial port.

• IBM compatible parallel port.

• Ethernet port.

• Token-Ring port (optional).

• PS/2 compatible mouse port.

• Floppy disk controller on system board.

• Hard disk connector on system board.

Chapter 3

Variants

Chapter 5Chapter 6 Chapter 3

• Full IBM functional compatibility.

• On-board VGA.

• On-board high resolution video.

• Internal power supply.

• LOC Technology security sub-system.

• Socket for 80387SX.

• Windows 3.1 compatible Business Audio subsystem.

The basic system unit may be fitted with:

• 2 to 16 Mbytes of RAM.

• 80, 120, 170, 240 or 540 Mbyte hard disk drive.

• 3.5 inch floppy disk drive.

• 80387SX coprocessor.

A VGA monitor will be required. To take advantage of the high resolution video modes

a suitable SVGA or EVGA monitor will be required.

1/2 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

Introduction

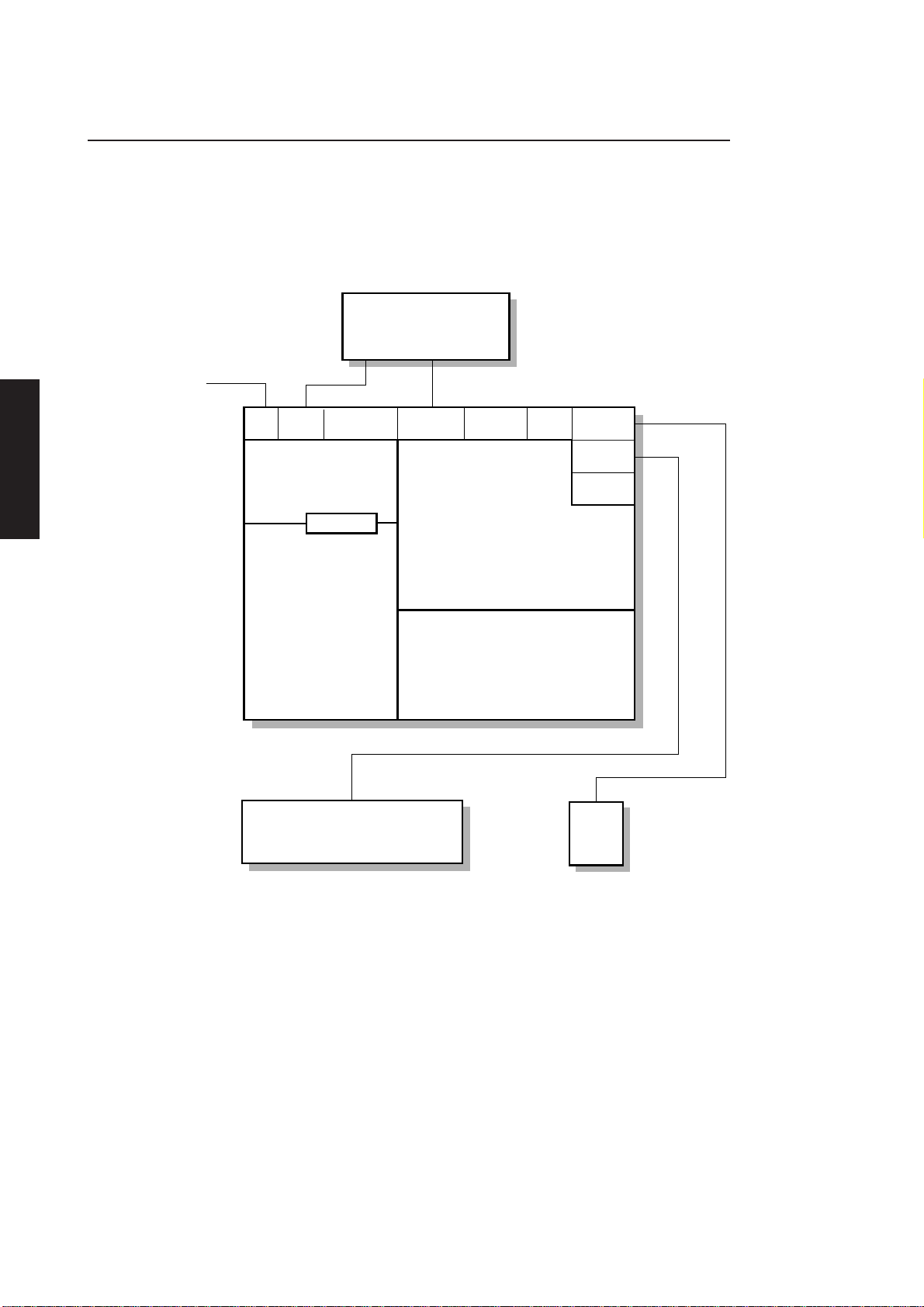

The system unit contains: the processor(s), the system memory, disk drives, power

supply, security circuitry and interfaces to keyboard, monitor and peripherals. All the

interface circuitry except the Token-Ring network interface is on the system board.

Contents

Keyboard

Monitors

Dedicated connectors are provided on the system board for a Token-Ring module.

A block diagram of the system unit is shown at the end of this section. It shows the

components of the system and identifies functions implemented on the system board.

The keyboard is a full QWERTY typewriter keyboard and numeric keypad together

with editing keys. The layout of the 102 key UK keyboard is compatible with the IBM

AT enhanced keyboard.

The keyboard is fitted with a PS/2 style miniature DIN connector and any fully

compatible keyboard can be plugged into the system unit.

The system board is fitted, with a VGA video interface which will drive any suitable

monochrome or colour analogue monitor.

The on-board VGA controller also supports high resolution video modes. To take

advantage of the higher resolution video modes an SVGA or EVGA monitor must be

used. Video drivers for popular software packages are available.

Chapter 1

Chapter 1

Chapter 3

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 1/3

Introduction

Expansion

System RAM may be expanded to 16 Mbytes by fitting SIMMs.

Contents

Chapter 1

Chapter 1

A socket for an 80387SX coprocessor is fitted on the system board.

MONITOR

AC

INLETACOUTLET

POWER

SUPPLY

HARD DISK DRIVE

NETWORK

PORTS

FAN

VIDEO

PORT

PROCESSOR; MEMORY; VIDEO ADAPTER

ETHERNET CONTROLLER; SERIAL PORT

PARALLEL

PORT

SYSTEM BOARD

PARALLEL PORT;

LOC TECHNOLOGY SECURITY

FLOPPY DISK CONTROLLER;

HARD DISK CONNECTOR;

KEYBOARD AND MOUSE PORTS;

BUSINESS AUDIO.

FLOPPY DISK DRIVE

PORTS

including:

SERIAL

MOUSE

PORT

KEYBOARD

PORT

AUDIO

PORTS

Chapter 3

Chapter 5Chapter 6 Chapter 3

KEYBOARD

MOUSE

1/4 LS PRO HARDWARE TECHNICAL REFERENCE

SYSTEM UNIT

Chapter 2

Contents

2 SYSTEM UNIT

Introduction................................2/2

External layout...........................2/2

Internal layout ............................2/3

Servicing level.............................2/3

Dismantling and re-assembly . 2/3

Warnings and cautions........ 2/3

Antistatic precautions.......... 2/4

Equipment required ............. 2/4

System board connectors... 2/4

Removing the system unit top

cover ........................................2/5

Removing the system board

metalwork...............................2/6

Removing the floppy drive.. 2/7

Removing the power supply

metalwork...............................2/8

Removing the hard disk

drive..........................................2/9

Removing the fan................ 2/10

Removing the power

supply .................................... 2/11

Removing a Token-Ring

module .................................. 2/11

System unit

Removing a parallel port

cable ...................................... 2/13

Removing a thick wireEthernet

assembly ............................... 2/13

Removing the system

board ..................................... 2/13

Removing an escutcheon

plate....................................... 2/14

Removing the power switch

linkage ................................... 2/14

RFI screening tray and

insulation sheet ................... 2/15

Installing add-ons .................... 2/16

Memory upgrades............... 2/16

Installing an 80387SX......... 2/19

System unit connectors ........ 2/20

VGA....................................... 2/20

Ethernet................................ 2/20

Serial port............................. 2/21

Parallel port ......................... 2/22

Keyboard/mouse

connectors ........................... 2/22

Contents

Chapter 2

Chapter 2

Chapter 2

LS PRO HARDWARE TECHNICAL REFERENCE 2/1

Chapter 5

Chapter 6

System unit

Introduction

The main components of the system unit are:

Contents

Chapter 2

External layout

Chapter 2

• base

• top cover

• system board

• disk drives

• power supply

The top cover is easily removed without any tools.

The system board contains all the processing and interface circuitry and the system

RAM. 2 or 4 Mbytes of RAM is soldered to the board and SIMMs can be fitted to increase

the total amount of system RAM to a maximum of 16 Mbytes.

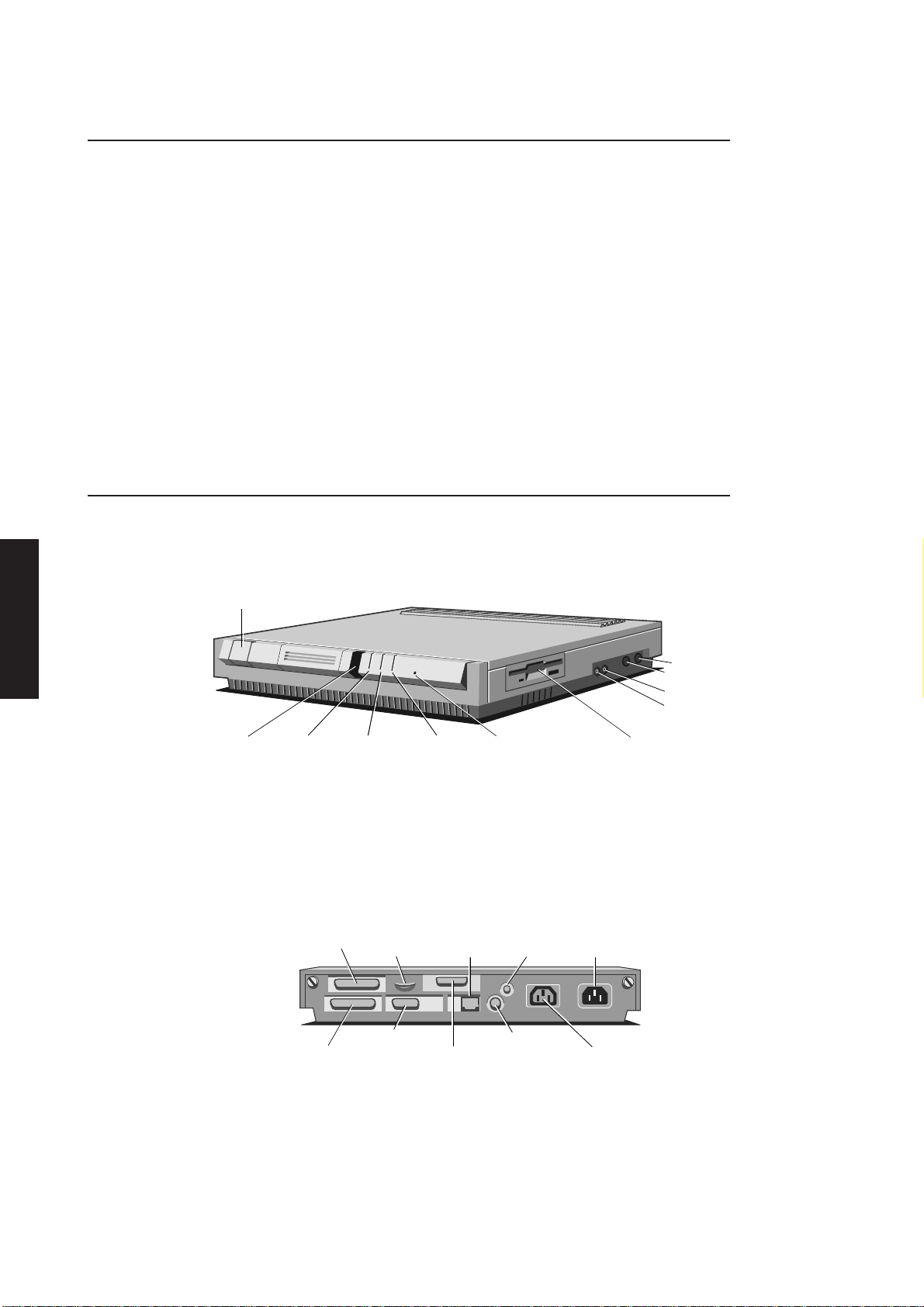

The front panel of the system unit contains: the power switch and slots for four LEDs

and the IR detector for the security card. The right side panel contains the keyboard

and mouse ports, and the audio input and output sockets.

POWER SWITCH

Chapter 2

Chapter 5

Chapter 6 Chapter 3

MOUSE

KEYBOARD

AUDIO IN

AUDIO OUT

INFRARED

SENSOR

LAN

INDICATOR

FLOPPY DISK

INDICATOR

HARD DISK

INDICATOR

POWER

INDICATOR

FLOPPY

DISK DRIVE

The floppy drive bezel is on the right side of the system unit.

The rear panel contains the following connectors: mains power input; auxiliary power

outlet; monitor; Ethernet ports; serial port; parallel port.

The layout of the rear panel is shown in the illustration below.

PARALLEL

PORT

SERIAL

PORT

SECURITY

LOOP

VIDEO

PORT

TWISTED

PAIR ETHERNET

THICK

ETHERNET/

TOKEN RING

PORT

COVER

LOCK

THIN

ETHERNET

PORT

POWER

OUT

POWER

IN

Illustrations and pinouts of the connectors on the rear panel are given at the rear of

this section.

2/2 LS PRO HARDWARE TECHNICAL REFERENCE

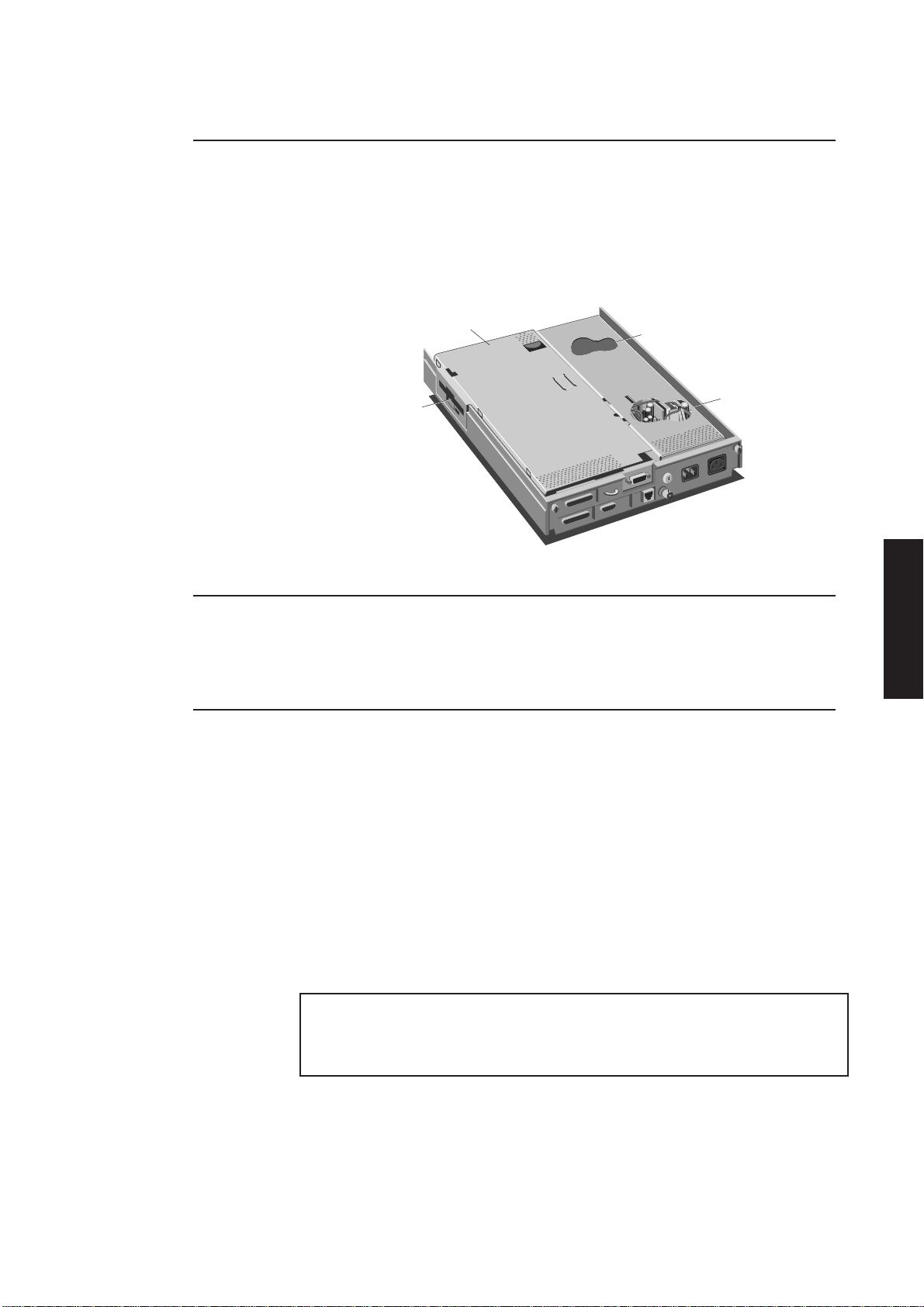

Internal layout

SYSTEM BOARD

METALWORK

FLOPPY

DRIVE

HARD DISK

DRIVE

POWER

SUPPLY

System unit

The layout of the inside of the system unit is shown in the illustration below. At the front

left of the system unit is the hard disk drive. Behind the hard disk drive is the power

supply unit. Both the power supply and the hard disk drive are beneath a metal cover.

Contents

Servicing level

The floppy drive is at the front right of the system unit attached to a metal plate which

extends the full length of the system board.

The level of information in this section is intended to enable suitably qualified personnel

to remove and replace major components of the system unit and to access components

to install add-ons.

Chapter 2

Chapter 2

Chapter 2

Dismantling and re-assembly

The LS Pro range has been designed to meet international EMI and safety standards.

Warnings and To ensure safety and continued compliance with these standards, observe the

cautions following precautions.

• It is recommended that modifications are carried out by an authorized dealer.

Unqualified users should not normally dismantle the equipment.

• Replacement parts should be of the type and rating specified by the manufacturer.

• All earth connections must be maintained to the original specification.

• Ensure that all personnel concerned are familiar with the action to be taken in

the event of electric shock.

Warning

Never carry out any work on the equipment with power applied. Always switch off at the mains

and remove the power lead from the equipment before starting work.

Note

Any reference to left or right during dismantling and re-assembly assumes that the reader is

viewing the unit from the front, unless otherwise stated.

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/3

Contents

System unit

Antistatic All electronic components and equipments are sensitive to static electricity. Even

precautions small electrostatic discharges can render components useless or severely shorten

their working life, therefore preventive measures should always be taken.

No work should be carried on any item unless it is in a Special Handling Area (SHA)

as defined in BS CECC 00015:Part 1. In general this involves:

• a common earth point

• an earthed bench or bench mat

• an earthed wrist strap

Chapter 2

Chapter 2

Chapter 2

Equipment The following tools are required to dismantle the system unit.

required

• Philips screwdriver

• Flat-bladed screwdriver

• Nut spanner set

• thin nosed pliers

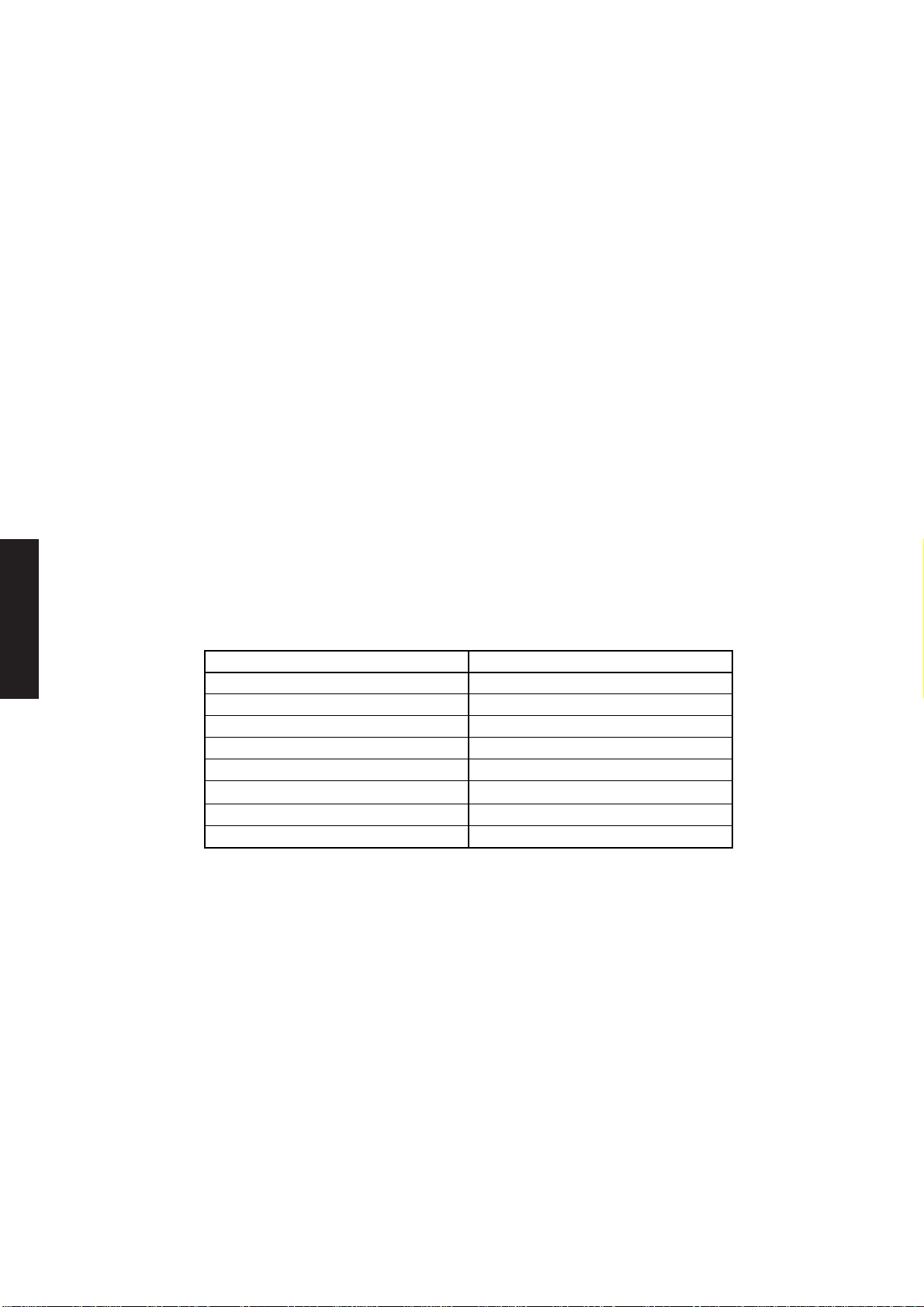

System board Many of the dismantling/reassembly procedures which follow involve the

connectors disconnection and reconnection of system board plugs and sockets. The following

table gives, for each socket, the connector number which identifies it. This number

is printed on the system board next to each connector.

Connector Label

Parallel port PL8

Token ring module PL9 and PL16

Hard disk drive power PL12

Thick Ethernet PL13

System board power PL15

Hard disk drive control PL17

Floppy disk drive PL18

Loudspeaker PL40

Chapter 5

Chapter 6 Chapter 3

2/4 LS PRO HARDWARE TECHNICAL REFERENCE

THICK

ETHERNET

ASSEMBLY

TOKEN RING

MODULE

SW 1

BATTERY

POWER

JUMPER

POWER

TOKEN RING

MODULE

System unit

PARALLEL

PORT

CABLE

Contents

Chapter 2

Chapter 2

HARD DISK

SIGNAL

FLOPPY

DISK

HARD DISK

POWER

LOUDSPEAKER

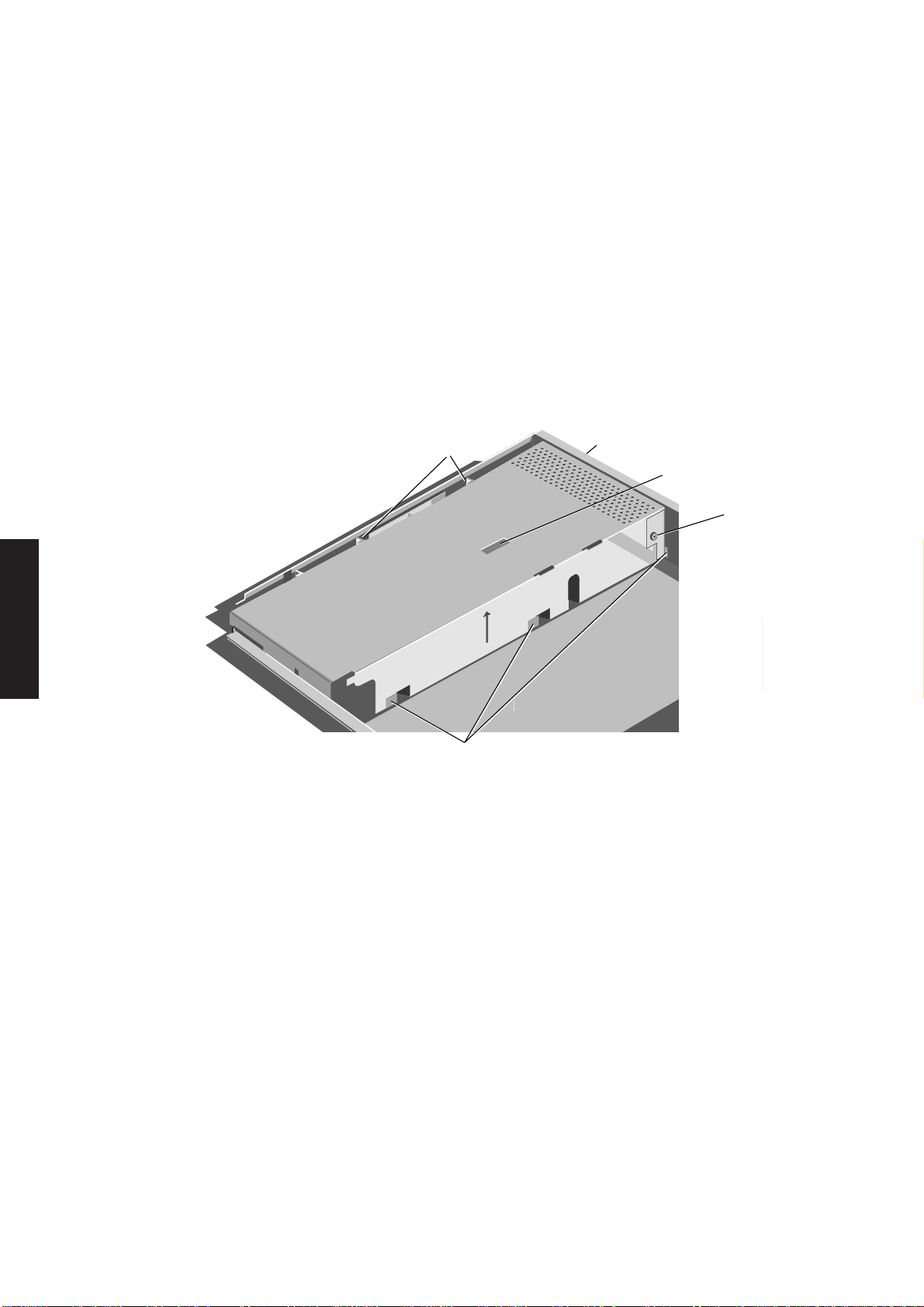

Removing the A keylock on the rear panel of the system unit locks the top cover in place. The

system unit cover cannot be removed unless this is unlocked. The cover is located by a ledge at

top cover the front and lugs on the sides and at the rear. Two thumbscrews in the rear panel

secure the cover.

Chapter 2

Chapter 5

LS PRO HARDWARE TECHNICAL REFERENCE 2/5

Chapter 6

System unit

The following illustration shows the thumbscrews and keylock.

Contents

Chapter 2

Chapter 2

CASING

SCREWS

COVER

LOCK

CASING

SCREWS

1. Check that the system unit power switch and mains supply are switched off and

disconnect the mains supply.

2. Ensure that the keylock on the rear panel is unlocked.

3. Loosen the two thumbscrews at the top of the rear panel. If they have been done

up tightly it may be necessary to use a screwdriver to loosen them.

4. Slide the top cover forward a few millimetres and lift it clear.

5. Replacing the top cover is simply the reverse of removal. Check that the keylock

is in the unlocked position. Make sure that the top cover is properly aligned

during replacement and do not force it into position.

Note

It is not necessary to remove cables (other than the mains power cable) to remove the system

unit top cover. However, in order to remove some of the internal components external cabling

must be removed.

Chapter 2

Chapter 5

Removing the The system board metalwork is secured to the power supply metalwork by lugs, and

system board by clips to the system unit base.

metalwork

SECURING

LUGS

SECURING

CLIPS

1. Remove the system unit top cover.

2. Release the two retaining latches. On releasing the latches, the system board

metalwork will spring up slightly.

Chapter 6 Chapter 3

2/6 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

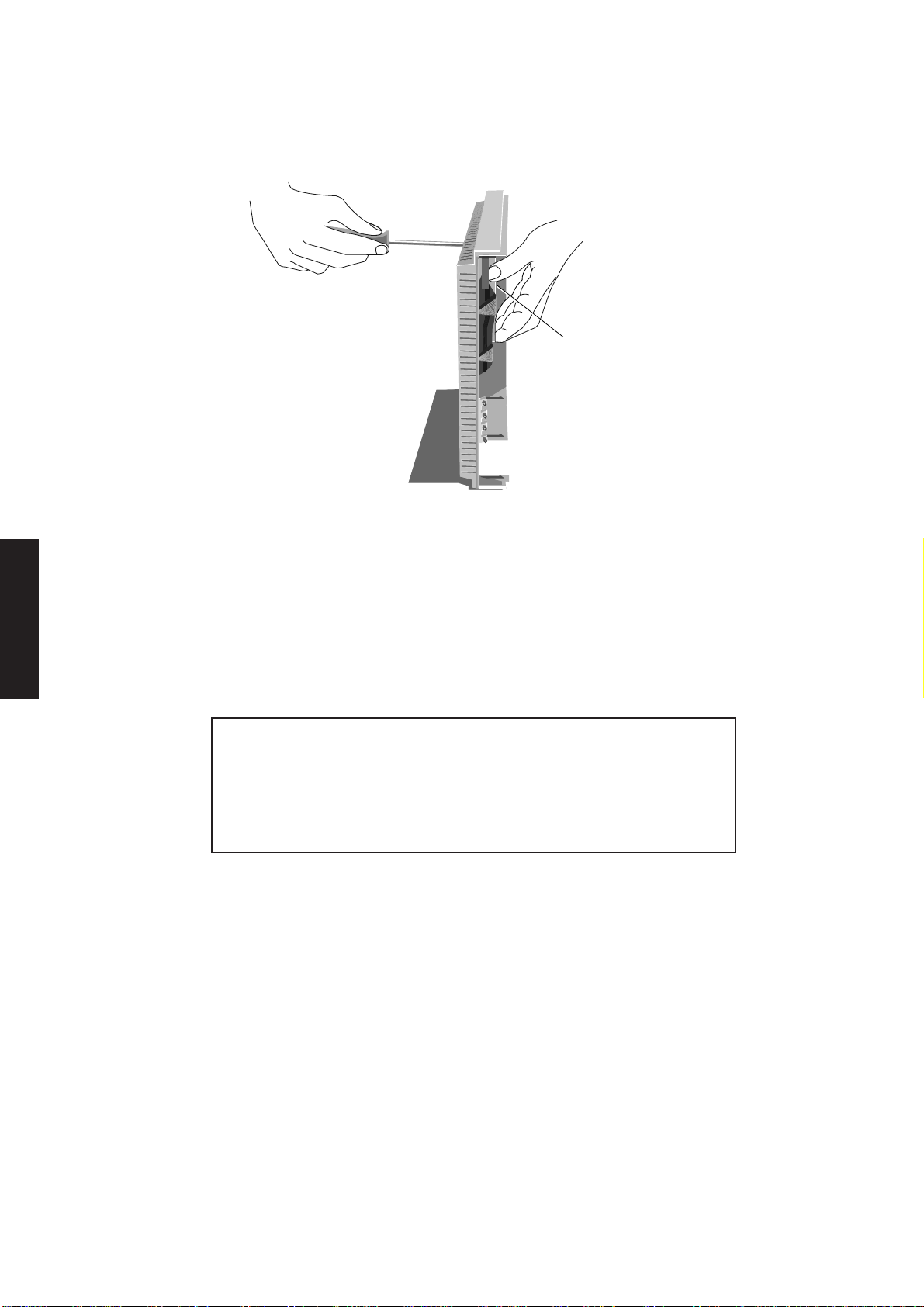

3. Hinge the system board metalwork to the vertical as shown below:

4. Disconnect the loudspeaker cable from the system board.

5. If your system is fitted with a floppy disk drive disconnect the ribbon cable at the

system board taking care not to strain the cable or its connectors.

Contents

Chapter 2

Chapter 2

Chapter 2

6. Lift the system board metalwork clear of the computer.

7. Invert the system board metalwork, and rest it on a flat surface.

8. Replacement is simply the reverse of removal. Take care to ensure that the

metalwork engages correctly. Do not use undue force. Route the loudspeaker

cable between the front of the system unit and the LEDs.

Removing the The floppy drive is mounted in the metalwork above the system board.

floppy drive

Two variants of metalwork have been used, they are both shown in the illustration

below.

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/7

System unit

1. Remove the system board metalwork.

2. Remove the four screws which secure the floppy drive and remove the drive.

Contents

Chapter 2

Chapter 2

3. Replacing the floppy drive is simply the reversal of removal. If the drive being

installed is a replacement ensure that the drive select switch on the side of the

drive is in the same position as that on the old drive.

Removing the The power supply metalwork covers the top of the power supply and divides the

power supply system unit, it applies gentle pressure to the top of the system unit fan. The system

metalwork board metalwork uses the power supply metalwork for location.

The power supply metalwork is secured by two screws and a number of lugs.

SECURING

SECURING

LUGS

SCREW

FAN LOCATION

SLOT

EARTH

BOND

SCREW

Chapter 2

Chapter 5Chapter 6 Chapter 3

SECURING

LUGS

1. Remove the system board metalwork.

2. Remove the earth bond screw which secures the system board escutcheon plate

to the power supply metalwork.

3. Remove the screw in the rear panel between the mains inlet and outlet which

secures the power supply metalwork.

4. Slide the power supply metalwork forward by approximately 6mm to free the

lugs.

5. An earth cable connects the power supply to the metalwork. Gently lift the

metalwork and carefully turn it over.

6. Remove the screw which secures the cable to the metalwork and lift the

metalwork clear.

2/8 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

7. Replacement is the reverse of removal. However care must be taken to note the

following:

Warning

Contents

Remember to reconnect the power supply earth cable to the metalwork.

• The metalwork must be behind the switch operating lever of the power switch

linkage.

• A metal RFI screening tray is fitted in the base of the system unit. During the

replacement of the power supply metalwork the front edge of the tray can be

damaged.

In order to prevent damage occurring use a piece of card to hold down the

fingers at the front edge of the metalwork while the metalwork is replaced.

Once the metalwork is in place gently remove the card.

• Take care to ensure that the lugs on the bottom right of the metalwork are

properly engaged and that the metalwork does not foul on the fan.

The fan rests on a flexible foam pad which is compressed when the power

supply metalwork is in place. A slot is provided in the metalwork to allow a

small blunt instrument (flat bladed screwdriver) to push the fan down during

the replacement of the metalwork. Do not force the power supply metalwork

into position.

Removing the The hard disk drive is attached to the system unit base by four screws on the

hard disk drive underside of the system unit. The following illustration identifies the screws which

hold the hard disk drive in place.

Chapter 2

Chapter 2

Chapter 2

Chapter 3

HARD DISK

DRIVE

SECURING

SCREWS

1. Remove the system unit top cover, system board metalwork and power supply

metalwork.

2. Disconnect the hard disk drive power and signal cables from the system board.

Warning

Do not attempt to disconnect the cables from the drive with the drive still in the system

unit. Attempting to do so will damage the drive circuit board.

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/9

System unit

Contents

Chapter 2

3. Holding the hard disk drive firmly in position carefully turn the system unit onto

one side and remove the four screws which secure it.

HARD DISK

DRIVE

Chapter 2

Chapter 2

Removing the fan The cooling fan rests on a flexible foam pad and is located in the base of the system unit

4. Still holding the disk drive, carefully turn the system unit back and rest it on the

work surface.

5. Slide the hard disk drive to the right to clear the power supply metalwork and

lift the hard disk drive out of the system unit complete with the power and signal

cables.

6. Replacing the hard disk drive is simply the reverse of removal. If the drive being

installed is a replacement ensure that the drive select jumpers are in the same

positions as those on the old drive.

Warning

1. Reconnect the power and signal cables to the drive before putting the drive in

position.

2. Ensure that the screws which you use to secure the drive are the ones which you

removed. If you use longer screws you will damage the drive.

by small ribs. Gentle pressure from the power supply metalwork ensures that the fan

is held in place.

1. Remove the power supply metalwork.

Chapter 5Chapter 6 Chapter 3

2/10 LS PRO HARDWARE TECHNICAL REFERENCE

2. Disconnect the fan power connector from the PSU.

3. Remove the fan.

4. Replacement is simply the reverse of removal. Make sure that you replace the

fan in the same orientation as it was before removal, and that the fan power cable

is secured to the fan with a cable tie.

System unit

SECURING

SCREWS

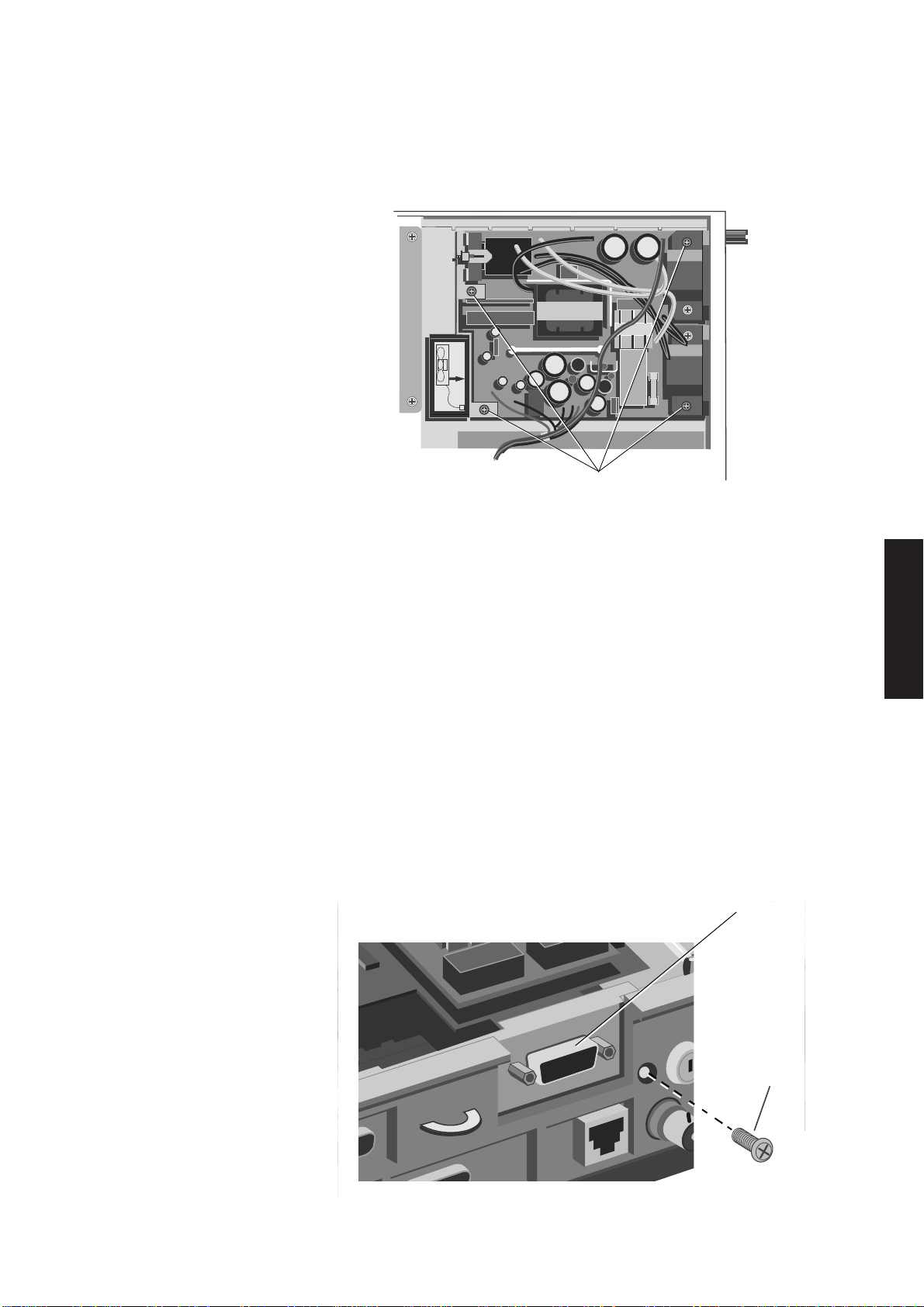

Removing the The power supply is secured to the bottom of the system unit by four screws. The

power supply following illustration identifies the screws that must be removed and the connectors

that must be disconnected in order to remove the power supply.

1. Remove the power supply metalwork.

Contents

Chapter 2

Chapter 2

2. Disconnect the system board and fan power connectors.

3. Lift out the fan.

4. Remove the four screws securing the power supply.

5. Lift the power supply clear of the system unit.

6. Replacement is simply the reverse of removal. Ensure that the voltage range

selection jumper is in the correct position for the mains supply available. The

jumper is identified in section 4 of this manual.

Removing a The Token-Ring module is secured to three standoff pillars inside the system unit,

Token-Ring and to the escutcheon plate at the rear of the system unit. To remove the module

module follow the instructions below:

1. Remove the system board metalwork.

2. Remove the screw in the rear panel of the system unit, to the right of the TokenRing connector.

TOKEN RING

CONNECTOR

Chapter 2

Chapter 3

Chapter 5

SECURING

SCREW

LS PRO HARDWARE TECHNICAL REFERENCE 2/11

Chapter 6

System unit

3. Remove the screws and nuts which secure the module to the standoff pillars.

Contents

Chapter 2

Chapter 2

SECURING

NUTS

4. Gently remove the module.

Note

Care must be taken to ensure that the module is removed vertically. Any horizontal

movement will damage the connectors.

SECURING

SCREW

Chapter 2

Chapter 5Chapter 6 Chapter 3

Read the following paragraphs before replacing the module.

The Token-Ring module connectors have three components: the connectors on the

system board, the connectors on the Token-Ring module, and the pin assemblies which

connect them. When you remove the Token-Ring module the pin assemblies will

probably come out with the Token-Ring module, although they may remain in the

system board.

When the Token-Ring module is in position the plate that surrounds the Token-Ring

connector is between the system unit base and the escutcheon plate. The two standoff

pillars by the connector nearest the power supply, protrude through corresponding

holes in the Token-Ring module.

It is vital that during replacement the Token-Ring module is correctly aligned. Any

misalignment will damage the connectors and/or the module. When replacing the

module make sure that the plate is inserted correctly and that the standoff pillars are

correctly aligned. Check that the connectors are correctly aligned, then gently insert

the module.

Warning

Take care not to exert undue pressure when inserting the module.

2/12 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

Removing a The parallel port cable is secured to the escutcheon plate by the two D-type

parallel port connector screwlocks. To remove the cable:

cable

1. Remove the system board metalwork.

Contents

2. Remove the two screwlocks in the parallel port connector.

3. Unplug the cable from the socket on the system board and lift the cable clear.

4. Replacement is simply the reverse of removal.

Removing a thick The thick wire Ethernet assembly is secured to the escutcheon plate at the rear of

wire Ethernet the system unit. To remove the assembly follow the instructions below:

assembly

1. Remove the system board metalwork.

2. Remove the screw that secures the thick wire Ethernet assembly to the

escutcheon plate, unplug the assembly cable from the system board, and lift the

assembly clear of the system unit.

3. Replacement is simply the reverse of removal.

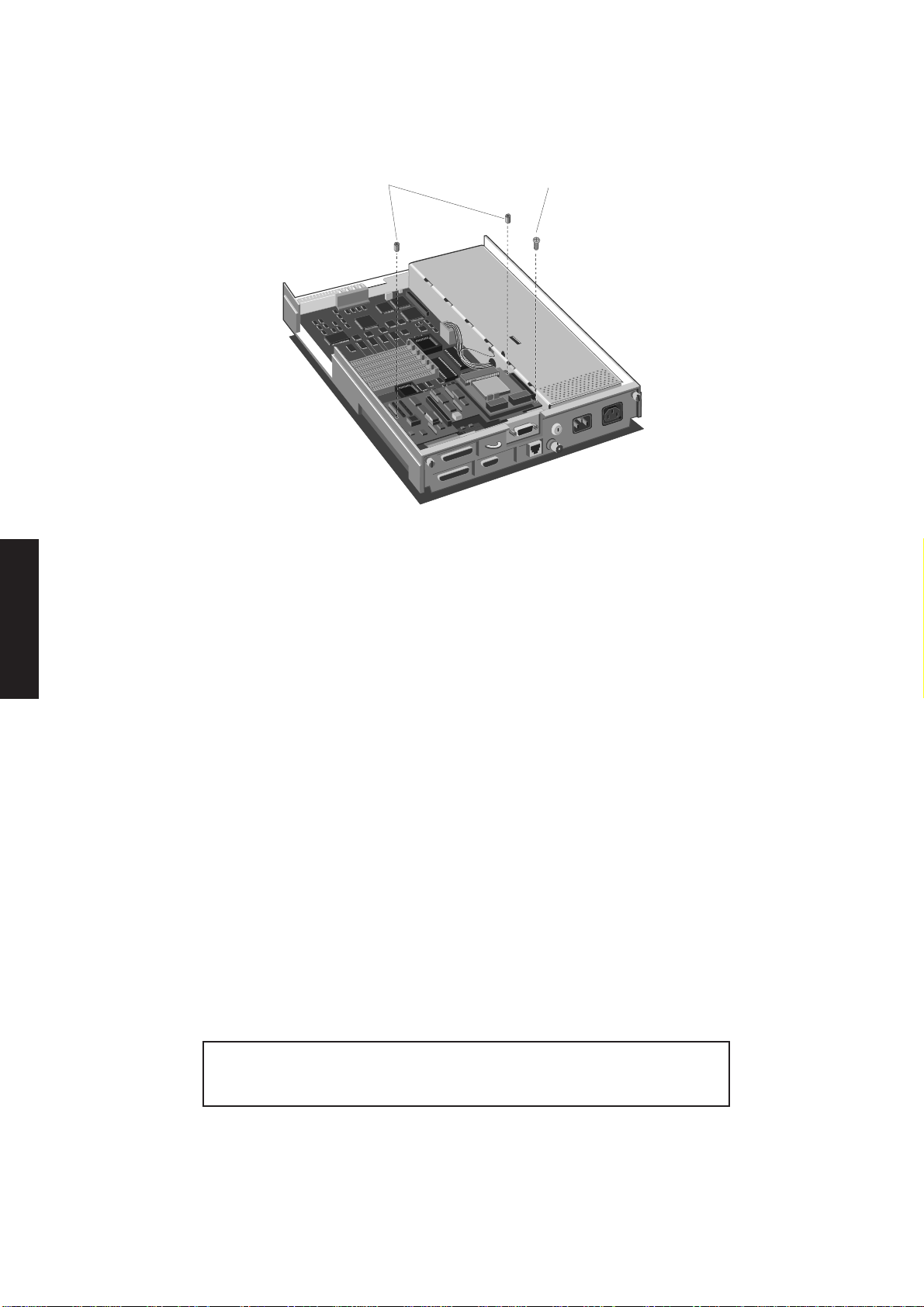

Removing the The system board is secured to the base of the system unit by seven screws through

system board the system board and four screwlocks through the escutcheon plate. The following

illustration identifies the positions of the system board screws.

SECURING SCREWS

Chapter 2

Chapter 2

Chapter 2

SECURING SCREWS

1. Remove the system unit top cover and put the system cover lock in the locked

position.

2. Remove the system board metalwork and disconnect all system board connectors.

3. Remove the parallel port cable and thick cable Ethernet assembly or Token-Ring

module (if fitted).

4. Remove the seven screws which secure the system board.

5. Remove the screwlocks that secure the video and serial port connectors.

6. Remove the lock nut on the thin Ethernet connector.

7. Carefully lift the system board clear of the system unit.

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/13

System unit

Contents

Chapter 2

escutcheon plate the rear of the system unit base. To remove the escutcheon plate:

Notes

1. If the system cover lock is not in the locked position the system board will foul during

removal.

2. During removal the audio connector may foul on the RFI isolation tray. If so, press

the isolation tray against the side of the system unit base to allow the connectors

clearance.

7. Replacement is simply the reverse of removal.

Ensure that all the switches and jumpers on a replacement board are in the correct

position.

Removing an The escutcheon plate at the rear of the system unit is secured by three screws to

1. Remove the system board metalwork.

2. Remove the system board.

Chapter 2

Chapter 2

3. Remove the screw that secures the escutcheon plate to the power supply

metalwork.

4. Remove the three screws that secure the escutcheon plate to the system unit,

and lift the escutcheon plate clear.

5. Replacement is simply the reverse of removal.

Removing the The power switch linkage mechanically links the system ON/OFF switch on the front

power switch of the system unit to the power supply ON/OFF switch. It is located in two slots in the

linkage system unit base plastics. The linkage must clear a rib on the side of the base plastics

during removal, and another during replacement. To remove the linkage:

REAR

SLOT

POWER SWITCH

LINKAGE

Chapter 5Chapter 6 Chapter 3

2/14 LS PRO HARDWARE TECHNICAL REFERENCE

FRONT

SLOT

SPRING

RIB

OPERATING

LEVER

1. Remove the system unit top cover, system board metalwork, hard disk drive,

power supply metalwork, fan, power supply and system board.

Warning

During the following instructions do not apply excessive pressure or the linkage may

be deformed or the plastics break.

System unit

2. Using a pair of thin nosed pliers, disconnect the spring and put it somewhere safe.

3. Exerting gentle inward pressure on the operating lever, slide the power switch

linkage forward past the rear of the two ribs, far enough to free the back of the

linkage from the rear slot.

Contents

4. Slide the linkage back bending it gently to allow it to pass to the right of the rear

slot and push it as far back as it will travel.

REAR

SLOT

OUTWARD

POWER SWITCH

LINKAGE

INWARD

SPRING

FRONT

SLOT

RIB

OPERATING

LEVER

5. With the 90° bend at the front of the linkage against the front of the two slots

swing the rear of the linkage into the centre of the system unit.

Chapter 2

Chapter 2

Chapter 2

Note

There should be no resistance to this movement. If there is resistance you have not

pushed the linkage far enough back.

6. Slide the linkage back through the slot and lift it clear.

7. Replacement is simply the reverse of removal except that gentle inward pressure

must be exerted to the front of the linkage to allow it to pass the front rib. Do

not force the linkage into place.

RFI screening tray The LS Pro system unit base is fitted with a metal RFI screening tray and a plastic

and insulation insulation sheet during manufacture. The metal tray reduces RFI emissions from the

sheet system unit and ensures compliance with international regulations.

The plastic sheet insulates components inside the system unit from the RFI

tray. Both components are essential.

There should never be any need to remove the tray or the screening sheet.

However if you do need to remove them you must ensure that they are

replaced correctly when you reassemble the system.

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/15

Contents

System unit

Insulation sheet

The plastic insulation sheet rests on the isolation tray and is not secured until the other

system unit components are installed. Correct positioning of the sheet can be ensured

by checking that the screw holes in the sheet align with those in the RFI tray, and the

system unit base.

RFI screening tray

The RFI screening tray sits in the system unit base, it is only secured by double sided

tape at the front left of the system unit, in front of the hard disk drive.

Chapter 2

Installing add-ons

Chapter 2

Chapter 2

Chapter 5Chapter 6 Chapter 3

Since the tray includes cut-outs for all the system unit connectors, the correct

orientation should be obvious. Ensure that the connector cut-outs and the screwholes

in the base of the tray are all correctly aligned with the system unit base. Then secure

the front left edge of the tray with the double-sided tape.

Memory During manufacture 2 or 4 Mbytes of RAM can be soldered to the system board.

upgrades System board memory can be expanded to a maximum capacity of 16 Mbytes by

fitting SIMMs in sockets provided on the system board.

When 4 Mbytes of RAM is installed during manufacture four SIMM sockets are fitted.

When 2 Mbytes of RAM is installed six SIMM sockets are fitted.

SIMMs must be installed in pairs, upgrades of 2 and 8 Mbytes are available. The 2 Mbyte

upgrade contains two 60nS 1Mx9 SIMMs, the 8 Mbyte upgrade contains two 60nS 4Mx9

SIMMs.

The following table identifies the valid upgrade combinations.

System board Upgrade

(Mbytes) (Mbytes)

2 4 2 - 2 6 2 2 2 8 2 2 2 1

2 12 2 8 2 16 - 8 8 2

4 6 N/A 2 4 8 N/A 2 2 1

4 12 N/A 8 4 16 N/A 8 8 2

1 2 3

Bank

Notecapacity to

Notes

1. For both system board RAM capacities an alternative method of achieving 8 Mbytes

of RAM is to install an 8 Mbyte upgrade in bank 2 and leave the other bank (or banks)

empty. This configuration disables the RAM soldered to the system board.

2. When banks 2 and 3 are both occupied by 8 Mbyte upgrades the RAM soldered to the

system board is disabled.

2/16 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

The SIMM connectors are located on the right side of the system board just behind the

floppy drive bezel as shown in the following illustration.

SIMM SOCKETS

Note

Contents

Chapter 2

Chapter 2

When removing and installing SIMMs it is easiest to work with the rear of the system unit

towards you. As a result the following instructions assume that you are viewing the system unit

from the rear.

Removing SIMMs

If you wish to install an upgrade in a pair of SIMM sockets which are already occupied

you must first remove the existing SIMMs. Starting with the SIMM nearest the rear of

the system unit and working towards the front:

1. Lever the metal clips on each side of the socket gently away from the SIMM using

your thumbnails. When the clips are far enough apart the top edge of the SIMM

will move backwards until the SIMM is at an angle of about 15°.

Chapter 2

Chapter 3

Chapter 5

2. Taking care to avoid touching any of the components on the SIMM grip the top

corners of the SIMM between thumb and first finger and carefully pull the SIMM

out of the socket.

3. Repeat steps 1 and 2 for the other SIMM(s) affected.

LS PRO HARDWARE TECHNICAL REFERENCE 2/17

Chapter 6

System unit

Contents

Chapter 2

Chapter 2

Inserting SIMMs

From the illustrations showing the possible SIMM combinations decide which SIMM

capacity will be installed in each bank. Then, working from the socket nearest the front

of the system unit towards the rear, install the SIMMs.

To fit a SIMM:

1. Hold the SIMM so that the memory chips are facing the front of the system unit

with the metal connector strip nearest the system board.

2. Position the SIMM above the socket at an angle of about 15°.

Chapter 2

Chapter 5Chapter 6 Chapter 3

3. Lower the SIMM towards the socket. The right edge of the SIMM will be

prevented from reaching the connector by the securing clip.

4. Allow the left edge of the SIMM to drop into the connector.

5. Push the SIMM gently to the right and lower the right edge into the connector.

6. Ensure that the SIMM is properly located in the connector.

7. Rotate the SIMM into the vertical position by pushing gently on the top corners.

8. If the SIMM is properly located the SIMM should remain in position held by the

securing clips, and with a small plastic lug through the holes on either side of the

SIMM.

2/18 LS PRO HARDWARE TECHNICAL REFERENCE

Installing an 1. Remove the system unit top cover.

80387SX

2. Remove the system board metalwork.

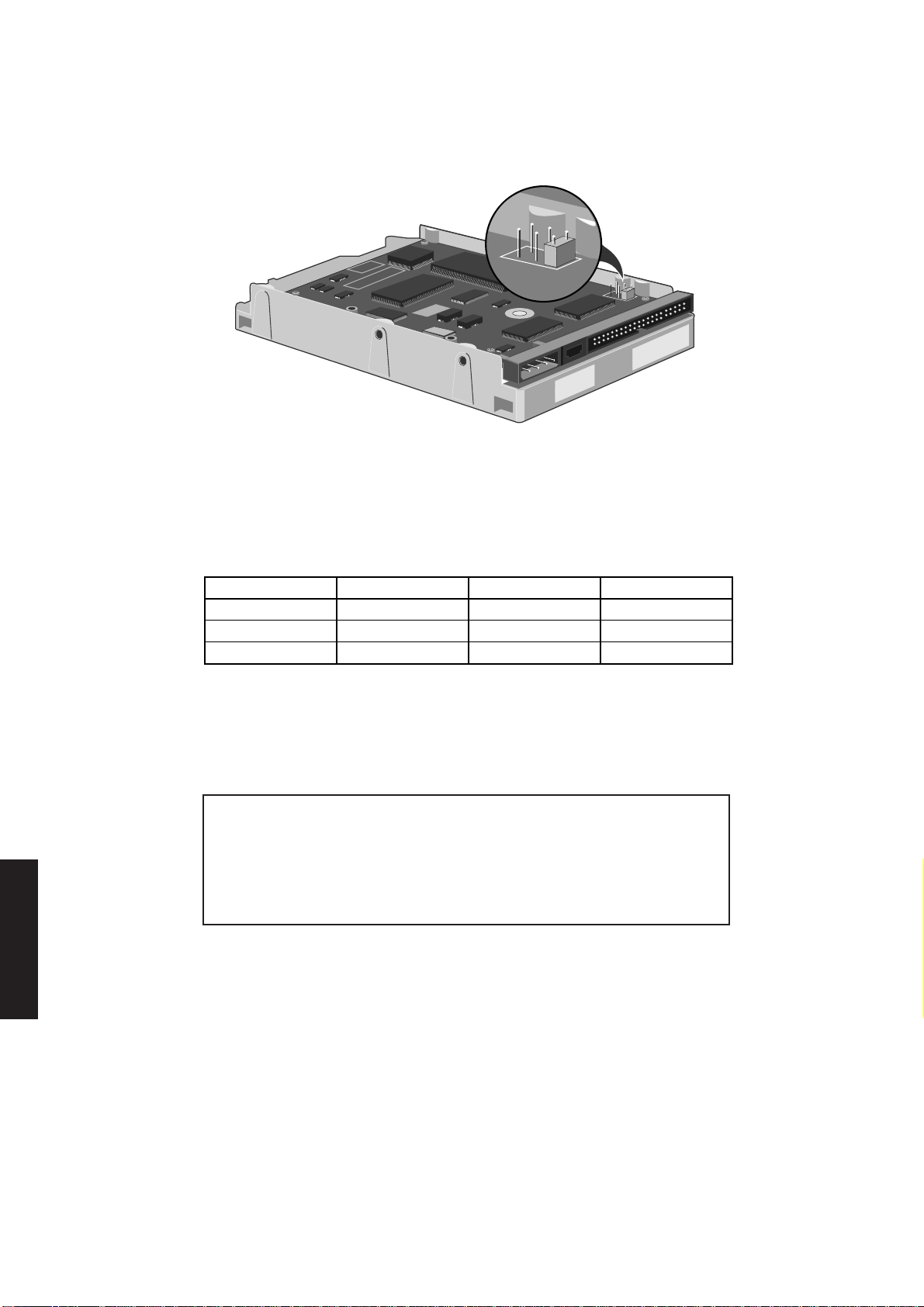

3. Locate the 80387SX socket from the following illustration.

PIN 1

80387SX

SOCKET

4. The 80387SX has a positioning guide in the form of a circular recess. Insert the

80387SX in the socket with the positioning guide at pin 1 making sure that you

do not bend or otherwise damage the pins.

System unit

Contents

Chapter 2

Chapter 2

Chapter 2

Note

The 80387SX only fits in one orientation. Do not use excessive force or damage may

occur.

5. Reassemble the system.

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 2/19

Contents

System unit

System unit connectors

The following illustrations and tables show the layout, pin numbering and pinout of each

of the connectors on the rear panel of the system unit.

5

1

Chapter 2

Chapter 2

Chapter 2

VGA The VGA display connector is a 15-pin D-shell.

Pin I/O Output Mono Colour

1 O Red No pin Red

2 O Green Mono Green

3 O Blue No pin Blue

4 NA Reserved No pin No pin

5 NA Digital Gnd Self Test Self Test

6 NA Red rtn Key pin Red rtn

7 NA Green rtn Mono rtn Green rtn

8 NA Blue rtn No pin Blue rtn

9 NA Plug No pin No pin

10 NA Digital Gnd Digital Gnd Digital Gnd

11 NA Reserved No pin Digital Gnd

12 NA Reserved Digital Gnd No pin

13 O Hsync Hsync Hsync

14 O Vsync Vsync Vsync

15 NA Reserved No pin No pin

10

6

1115

Chapter 5Chapter 6 Chapter 3

Ethernet Thick

The thick Ethernet connector is a 15-pin female D-shell

which uses a slide to hold the male and female connectors

together.

Pin I/O Signal

1 NA Collision presence shield

2 I Collision presence (+ve)

3 O Transmit (+ve)

4 NA Receive shield

5 I Receive (+ve)

6 NA Power return

7 NA Reserved (+ve)

8 NA Reserved shield

9 I Collision presence (-ve)

10 O Transmit (-ve)

11 NA Transmit shield

12 I Receive (-ve)

13 NA Power

14 NA Power shield

15 NA Reserved (-ve)

8

15

1

9

2/20 LS PRO HARDWARE TECHNICAL REFERENCE

System unit

Thin

The thin Ethernet connector is a BNC socket.

Core Signal

Shield Return

Twisted pair (TPE)

The unshielded twisted-pair Ethernet port is an RJ45 connector.

Pin Function

1 Transmit data +

2 Transmit data 3 Receive data +

4 Not used

5 Not used

6 Receive data 7 Not used

8 Not used

1 2 3

1

Contents

Chapter 2

4

5

6

7

8

Chapter 2

Chapter 2

13

Serial The serial port uses a male 25-pin D-shell

connector.

Pin I/O Signal name

2 O Transmit data (COM1)

3 I Receive data (COM1)

4 O Request to send (COM1)

5 I Clear to send (COM1)

6 I Data set ready (COM1)

7 NA Signal ground

8 I Data carrier detect (COM1)

12 I Data carrier detect (COM2)

13 I Clear to send (COM2)

14 O Transmit data (COM2)

16 I Receive data (COM2)

19 O Request to send (COM2)

20 O Data terminal ready (COM1)

22 I Ring indicate(COM1)

All other pins are not connected.

Note

14

25

Chapter 3

Chapter 5

Chapter 6

The Rev C system board does not provide the COM2 signals.

LS PRO HARDWARE TECHNICAL REFERENCE 2/21

System unit

Contents

Chapter 2

Chapter 2

Parallel port The parallel port uses a female 25-pin D-shell

connector.

Pin I/O Signal name Pin I/O Signal name

1 I/O Strobe 14 O Autofeed XT2 I/O Data bit 0 15 I Error3 I/O Data bit 1 16 O Init4 I/O Data bit 2 17 O Slct In5 I/O Data bit 3 18 NA Ground

6 I/O Data bit 4 19 NA Ground

7 I/O Data bit 5 20 NA Ground

8 I/O Data bit 6 21 NA Ground

9 I/O Data bit 7 22 NA Ground

10 I Ack- 23 NA Ground

11 I Busy 24 NA Ground

12 I PE 25 NA Ground

13 I SLCT

13 1

25

14

Keyboard/mouse The keyboard and mouse connectors are miniature 6-pin

Chapter 2

Chapter 5Chapter 6 Chapter 3

connectors DIN connectors.

Pin I/O Signal name

1 I/O Data

2 NA Reserved

3 NA Ground

4 NA +5Vdc

5 I/O Clock

6 NA Reserved

6

5

4

3

2 1

2/22 LS PRO HARDWARE TECHNICAL REFERENCE

SYSTEM BOARD

Chapter 3

Contents

3 SYSTEM BOARD

System Board

Contents

3.1 Introduction ............................3/2

General...................................... 3/2

System Identification Number

(SIN).......................................3/2

Major components............3/2

Description.............................. 3/4

Coprocessor.......................3/4

System reset........................3/4

3.2 Processor system ................3/5

80386SX processor features.3/5

486SLC processor features.3/5

Address and data bus

structure................................... 3/5

Software compatibility ........3/5

Modes of operation..............3/5

3.3 SCAMP ...................................3/6

Memory controller........... 3/6

System control port B.....3/6

Interrupt structure ...............3/6

List of hardware interrupts 3/7

Non-Maskable Interrupts3/8

Direct Memory Access.......3/8

Address generation ..........3/8

System timers .........................3/9

Operation.............................3/9

3.4 System memory .................3/10

General................................... 3/10

Read only memory (ROM) .. 3/10

Random access memory

(RAM)..................................... 3/10

Real time clock (RTC)RAM. 3/11

Contents of RTC RAM.... 3/11

3.5 Video adapter .....................3/14

General................................... 3/14

Video controllers ........... 3/15

3.6 Floppy disk controller .......3/15

General................................... 3/15

Drive formats ...................... 3/15

3.7 Hard disk interface ............3/16

General................................... 3/16

Interface signal descriptions 3/16

3.8 Peripherals controller .......3/17

Serial ports............................ 3/17

Programmable baud-rate

generator........................... 3/17

Parallel port.......................... 3/18

3.9 Keyboard/mouse

controller ............................3/18

General................................... 3/18

Keyboard password security. 3/18

3.10 LOC Technology ................3/19

3.11 Ethernet port .......................3/19

General................................... 3/19

82596 LAN coprocessor.. 3/20

82C503 dual serial

transceiver ........................ 3/20

7997..................................... 3/20

3.12 Apricot Business Audio ....3/21

3.13 System board connectors..3/21

Hard disk drive connectors. 3/21

Control Connector....... 3/21

Power connector ........... 3/22

Floppy drive connector ... 3/22

System board power

connector.............................. 3/22

Battery jumper .................... 3/22

Chapter 1

Chapter 2

Chapter 3

Chapter 3

Chapter 5

LS PRO HARDWARE TECHNICAL REFERENCE 3/1

Chapter 6

System Board

3.1 INTRODUCTION

General

ContentsChapter 1

This section describes the LS Pro system board and the operation of its processing

system and interface circuits.

The LS Pro range uses a highly integrated, IBM AT compatible system board. In addition

to standard features, the LS Pro system board provides: Ethernet interface, business

audio subsystem, LOC Technology security subsystem and a mouse port.

System Each system board fitted with the LOC Technology subsystem is identified by its own

Identification System Identification Number (SIN). During normal operation the SIN will never be

Number (SIN) required. Under certain circumstances the system may display a prompt asking for the

SIN to be entered. If this happens refer to the Owner's Handbook and associated

documentation. If Apricot’s LOC Technology software is in use refer to the

documentation supplied with the software.

Chapter 2

Chapter 3

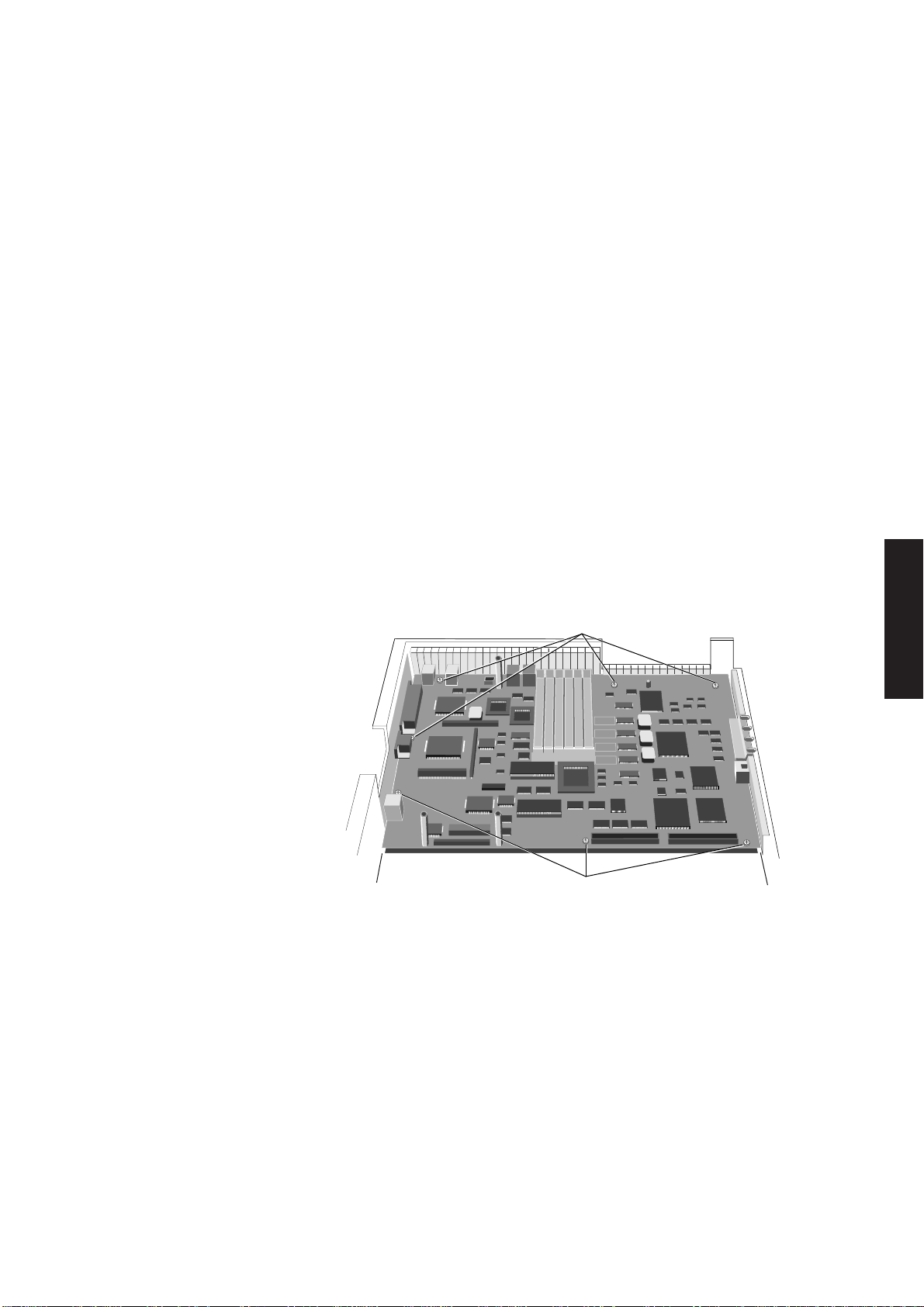

Major The following list of major components on the system board identifies the custom chips

components and briefly details their function:

1. Processor: 80386SX

486SLC

2. 4 Mbytes of RAM

3. 128 Kbyte ROM

4. VL82C311 (SCAMP) AT chipset

5. 8042 keyboard and mouse interface

6. CL-GD542X video controller with 1Mbyte of video RAM

7. 82596SX based Ethernet interface

8. 8051 based LOC Technology security feature

9. ATA compatible hard disk interface

10.82077 based floppy drive interface

11.16C452 based serial and parallel ports

12.Four SIMM sockets for memory expansion

Chapter 5Chapter 6 Chapter 3

3/2 LS PRO HARDWARE TECHNICAL REFERENCE

13.146818A Real Time Clock

14.Yamaha YMZ263 based business audio subsystem

System Board

TOKEN RING

MODULE

CONNECTOR

PARALLEL

PORT

SOCKET

PERIPHERALS

CONTROLLER

KEYBOARD

CONTROLLER

TOKEN RING

MODULE

CONNECTOR

THICK

ETHERNET

SOCKET

POWER

CONNECTOR

SIMM

SOCKETS

R A M

80387SX

SOCKET

ETHERNET

CONTROLLER

SCAMP

AUDIO

PROCESSOR

FLOPPY

CONTROLLER

HARD DISK DRIVE

CONNECTOR

FLOPPY

CONNECTOR

ROM BIOS

BATTERY

VIDEO

CONTROLLER

The major components are identified in the following illustration.

Contents

Chapter 1

Chapter 2

Chapter 3

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 3/3

System Board

Description

ContentsChapter 1

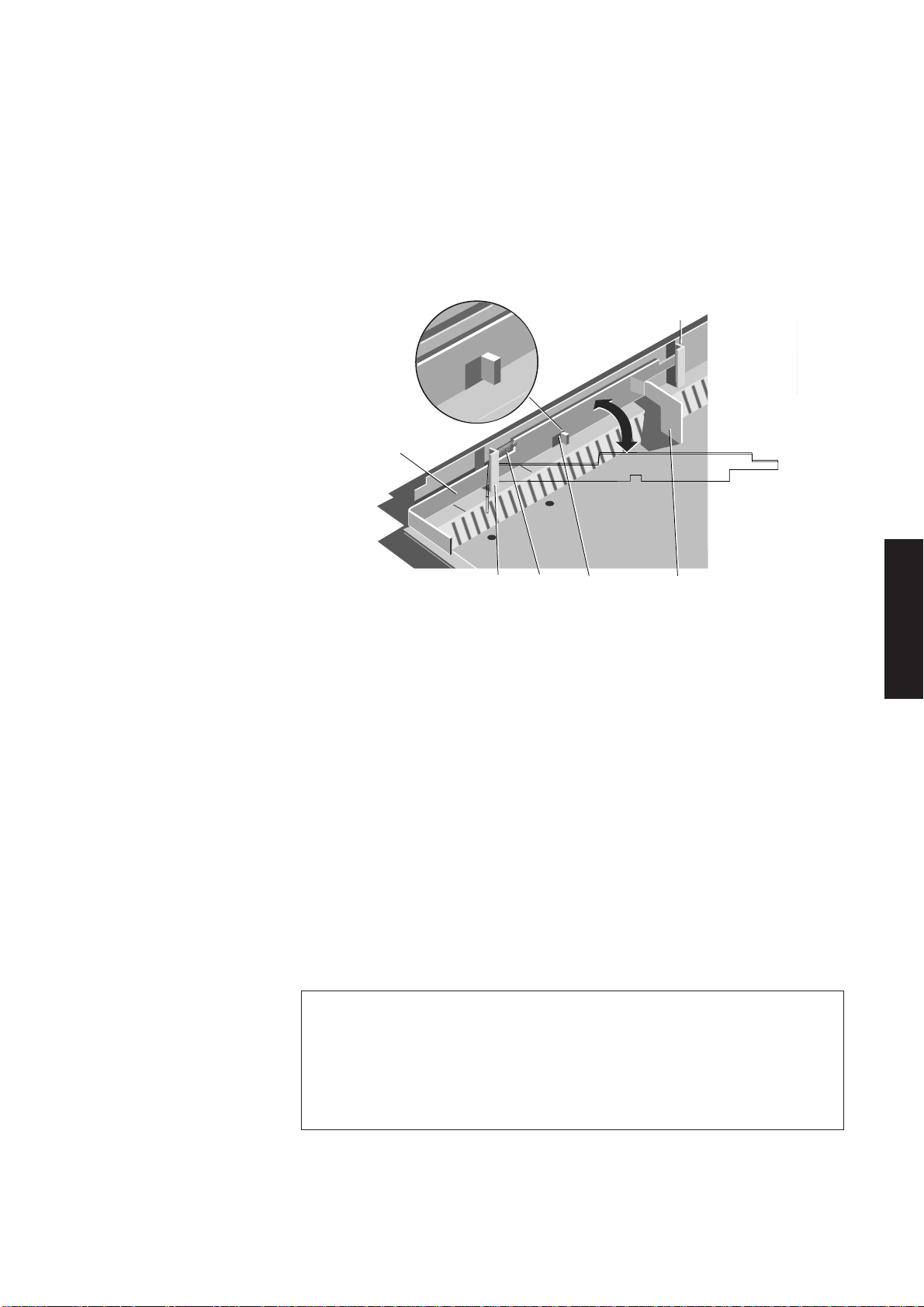

The following description of the system board should be read in conjunction with the

block diagram below. The diagram shows the peripheral areas of circuitry which are

connected to the CPU. For clarity, timing and control signals are omitted.

Chapter 2

Chapter 3

80387SX

TOKEN RING

MODULE

CONNECTORS

PROCESSOR

IDE

CONNECTOR

LOCAL DATA 0-15

LOCAL ADDRESS 0-23

KEYBOARD

MOUSE

CONTROL

ETHERNET MEMORY

FLOPPY

CONTROL

PERIPHERAL

CONTROL

REAL

TIME

CLOCK

AUDIO

MA

SCAMP

82C311

LA

SYSTEM ADDRESS 0-23

VGA

LD

BUFFER

BIOS

ROM

SA

EXPANSION

ROM

SYSTEM DATA 0-15

BUFFER

The block diagram is a functional description of the system board and does not identify

specific chips.

The LS Pro system board uses highly integrated components, reducing the chip count

and the system board area, and increasing reliability. The VLSI SCAMP chipset

integrates much of the standard AT system board peripheral logic onto a single chip.

SD

Chapter 5Chapter 6 Chapter 3

The processor and coprocessor are connected to a 16-bit local bus running at 33MHz.

Control logic for the local bus is integrated in SCAMP.

Memory addresses are generated by SCAMP and are routed to system memory on a

dedicated memory address bus. Memory data uses the local data bus.

The 82596 based Ethernet interface connects directly to the local bus allowing fast

transfers to and from system memory.

The BIOS ROM is addressed from the system bus and places its data on the local bus.

All other peripheral circuitry is connected to the system bus.

Coprocessor The system board includes a socket for an 80387SX coprocessor. This is a high

performance numeric coprocessor which further improves the performance of the

processing system in applications which perform many floating point arithmetic

operations.

The coprocessor has two I/O ports 00F0h and 00F1h which are used to control reset

and error latching. The coprocessor interface control logic is integrated in SCAMP.

If a coprocessor is fitted on the system board it should always be reset at the same time

as the processor.

System reset The system is automatically reset on power up. No external hardware reset facility is

provided. Some operating systems provide a software reset e.g. MS-DOS resets the

machine if CTRL, ALT and DEL are pressed at the same time.

3/4 LS PRO HARDWARE TECHNICAL REFERENCE

3.2 PROCESSOR SYSTEM

The processor system uses either an 80386SX or a 486SLC microprocessor, these are

described below.

System Board

Contents

80386SX The 80386SX is a high performance microprocessor which features:

processor

features • 24-bit address and 16-bit data busses.

• compatibility with software written for less powerful members of the 80X86

microprocessor family - the 8086, 8088 and 80286.

• high speed.

• enhanced modes of operation - real, protected and virtual 8086 mode.

• on board memory management unit.

486SLC The 486SLC incorporates all the features of the 80386SX listed above. In addition

processor it offers:

features

• 1 Kbyte of cache RAM.

• 80486SX instruction set compatibility.

Address and data bus structure

The system board utilises all address and data lines available on the processor. This

allows up to 16 Mbytes of physical memory to be addressed.

Chapter 1

Chapter 2

Chapter 3

The total addressable I/O space of the processor is 64 Kbytes. Section 5 shows how

it is used and details the I/O ports used by various devices.

Software compatibility

Existing software which has been written for the 8086/8088/80286 will be executed at

greater speed on the 80386SX/486SLC, even higher performance will be achieved with

new software which takes advantage of the 80386SX or 486SLC architecture and

enhanced instruction set.

Modes of operation

The processor enters real mode at power up or when it is reset. In this mode it provides

fast execution in an unprotected mode like that of the 8086 or 80286 in real mode. The

main difference between the 80386SX/486SLC, and the 80286/8086 in this mode is

speed.

In the protected mode the 80386SX/486SLC has all the advanced architectural features

of the 80286: memory management and protection mechanisms, task management, and

virtual memory support. In addition it operates with greater speed and supports 32bit registers and instructions.

In the virtual 8086 mode the 80386SX/486SLC creates one or more 8086 environments

within its protected multitask environment. This allows multiple 8086 tasks or a

mixture of 8086 and 80286/80386 tasks to be executed concurrently.

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 3/5

System Board

3.3 SCAMP

ContentsChapter 1

The LS Pro system board is based on a VLSI VL82C311 single chip AT

compatible chipset. The VL82C311 integrates the following standard AT

system board peripheral logic in a single QFP package:

• two 8237A DMA controllers

• two 82C59A interrupt controllers

• 82C54 system timer

• 74LS612 memory mapper

• 82284 clock generator and ready interface

• 82288 bus controller

In addition to the logic listed above the VL82C311 also includes:

• memory controller

Chapter 2

Chapter 3

Interrupt structure

• bus steering logic

• parity generation and checking logic

• Port B and NMI logic

Memory The memory controller integrated in the VL82C311 can access the full 16Mbyte

controller address range of the processor. Memory is addressed in up to four banks of 2 or 8

Mbytes. Page mode operation and interleaving maximise system performance.

Full LIM 4.0 support is included with 36 mapping registers. ROM shadowing is

supported from 640k to 1M.

System control Port B is located at I/O location 0061h. The port may be used for: gate timer 2 (speaker);

port B speaker data; RAM parity check enable; enable I/O channel check; refresh detect; timer

2 out; I/O channel check; RAM parity check. The detailed function of each bit is

described in section 5.

The system board supports 16 levels of edge sensitive, maskable hardware

interrupts, including Non-Maskable Interrupts (NMI).

Chapter 5Chapter 6 Chapter 3

3/6 LS PRO HARDWARE TECHNICAL REFERENCE

The interrupt control circuitry is functionally equivalent to two 8259A

programmable interrupt controllers. Each controller has eight interrupt inputs;

one interrupt input is used to cascade the controllers together. This leaves

fifteen inputs available for the processing system to use.

The output from the controllers goes to the INTR input on the processor. All

of the interrupts may be masked using the processor CLI instruction.

System Board

The following illustration shows the maskable interrupt structure.

Contents

IRQ0

IRQ1

IRQ3

IRQ4

IRQ5

IRQ6

IRQ7

IRQ8

IRQ9

IRQ10

IRQ11

IRQ12

IRQ13

IRQ14

IRQ15

0

INTA

1

2

3

D0 to D7

4

5

6

RD,WR

7

MASTER

CONTROLLER

0

INTA

1

2

D0 to D7

3

RD,WR

4

5

6

7

SLAVE

CONTROLLER

INT

XD0 to XD7

A0

INT

A0

IOR, IOW

SA0

INTR

INTA

8-BIT

DATA

BUS

ADDRESS

BUS

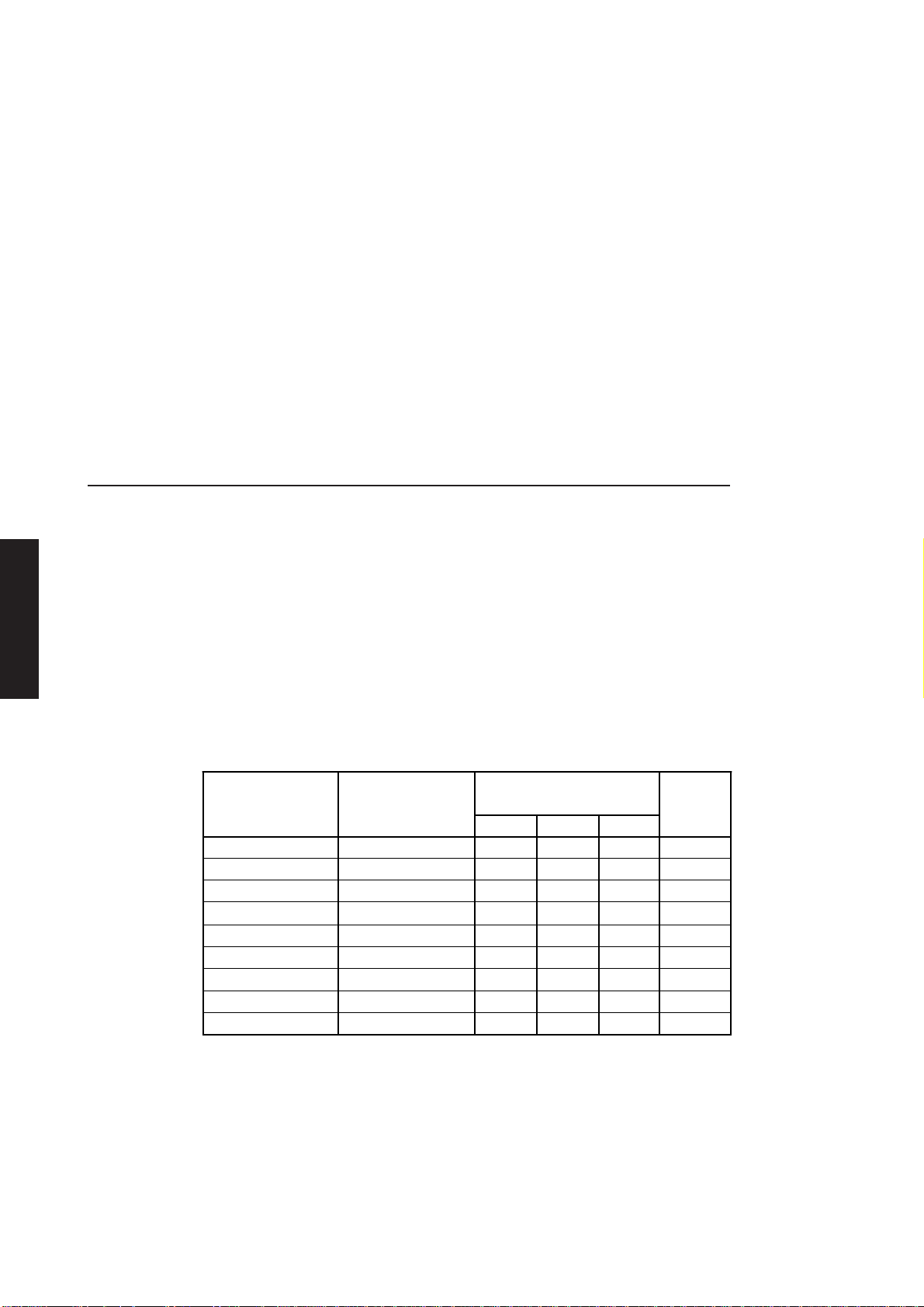

List of hardware The interrupts are allocated to hardware functions in the priorities shown in the

interrupts following table. IRQ0 is the highest priority.

Chapter 1

Chapter 2

Chapter 3

Interrupt level Function

IRQ0 Timer

IRQ1 Keyboard

IRQ2 Slave controller input

IRQ8 Real time clock

IRQ9 Token ring module

IRQ10 Ethernet port

IRQ11 Security

IRQ12 Mouse

IRQ13 Coprocessor exception

IRQ14 Hard disk controller

IRQ15 Digital audio

IRQ3 Reserved

IRQ4 Serial port

IRQ5 Reserved

IRQ6 Floppy disk controller

IRQ7 Parallel port

Note

Chapter 3

Chapter 5

Chapter 6

IRQ0 and IRQ13 are both used inside the SCAMP chip. Neither emerges for use on the system

board.

LS PRO HARDWARE TECHNICAL REFERENCE 3/7

System Board

ContentsChapter 1

Direct Memory Access

Chapter 2

Non-Maskable A non-maskable interrupt (NMI) is generated in the event of a parity or I/O error.

Interrupts Reading Port B indicates the source of the NMI. NMI may be disabled by writing to

I/O address 0070h.

On power up, and after a reset the NMI bit of port 0070h is set to 1 (NMI

disabled). Before NMI is enabled after a power up the I/O channel check state

is initialized by POST.

Note

I/O port 0070h is also used to access the Real Time Clock CMOS RAM, as a result port 0071h

must be read immediately after port 0070h has been written to enabling or disabling NMI.

If this is not done the successful operation of the Real Time Clock and its CMOS RAM cannot

be guaranteed.

Direct Memory Access (DMA) allows data to be transferred to or from system

memory without interrupting the system processor. The DMA controller is

functionally equivalent to two 8237A DMA controllers.

Chapter 3

Chapter 5Chapter 6 Chapter 3

The DMA controller may be programmed by the system microprocessor. The

DMA registers are programmed or read by the system processor addressing

the DMA controller in the ranges shown below.

• hex 0000 to 001F

• hex 0081 to 008F

• hex 00C0 to 00DF

Details on the effect and usage of these addresses is given in section 5.

The two 8237A compatible controllers are cascaded with the DREQ and

DACK signals of channel 0 on one controller connected to the HRQ and HLDA

signals of the other controller. This arrangement results in four 8-bit DMA

channels (DMA1) and three 16-bit channels (DMA2).

The table below shows which DMA channels are allocated which functions.

DMA channels 0 and 1 support memory-to-memory transfers.

DMA channel Function

1 Audio

2 Floppy drive interface

3 Audio

Address In order to access the full 16Mbyte address space of the processor the DMA controller

generation must generate a 24-bit address. The bits 0-7 are taken directly from the 8237A address

outputs, bits 8-15 are latched from the 8237A data outputs while bits 16-24 are from

the appropriate DMA page register.

3/8 LS PRO HARDWARE TECHNICAL REFERENCE

System timers

System Board

The SCAMP chip provides a three channel 82C54 compatible system timer.

The counters are:

Contents

counter 0 system timer

counter 1 refresh request

counter 2 sound output

Full details on the operation of 8254 counters are given in the manufacturers

data sheets and are not repeated here.

The system timers are programmed by accessing the four I/O ports recognised

by the timers. The counters provide six modes of operation. The four I/O ports

which are used to program the counters are organised as one count register

for each counter and one control byte (I/O ports 0040h to 0043h). The function

of each port is given in section 5.

Operation The clock input to the timer is 1.193 MHz. This is obtained by dividing the14.31818 MHz

system oscillator (OSC) by twelve. The output frequency of each timer is then

separately programmed by loading the associated count register.

System timer

BIOS loads the counter 0 registers with a value of 65536 which results in a

system timer frequency of approximately 18.2Hz. The output of counter 0

generates a hardware interrupt, IRQ0, which is used to maintain a time of day

clock based on the number of “ticks” since midnight.

Chapter 1

Chapter 2

Chapter 3

Chapter 3

Refresh request

The BIOS loads the counter 1 registers with a value of 18 which generates a

refresh request rate of 66.278kHz (one refresh request every 15.08 µseconds).

A refresh request puts the processor into hold and accesses memory via a DMA

type operation.

Sound output

The sound output may be set to give the output frequency required. To enable

the output bit 0 of Port B (I/O 0061h) must be set to 1.

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 3/9

System Board

3.4 SYSTEM MEMORY

General

ContentsChapter 1

Read only memory (ROM)

Chapter 2

Random access memory (RAM)

Chapter 3

The system board contains:

• 128 Kbytes of ROM.

• system RAM.

• 50 byte battery backed Real-time clock CMOS RAM.

• expansion ROM socket (optional).

The system ROM contains the BIOS and the system board Setup utility. It

consists of a 1 Mbit EPROM arranged as 128 Kbytes of memory. It is addressed

at the top of the first and last Megabyte of the processor address space and is

not parity checked.

The lower 64 Kbytes of the ROM contains code which is used only during the

boot process. If shadow RAM is enabled this lower 64 Kbyte address space

(E0000-EFFFF) is available for use as RAM. If shadowing is disabled the top 128

Kbytes of the first and last Mbytes are used by the system ROM.

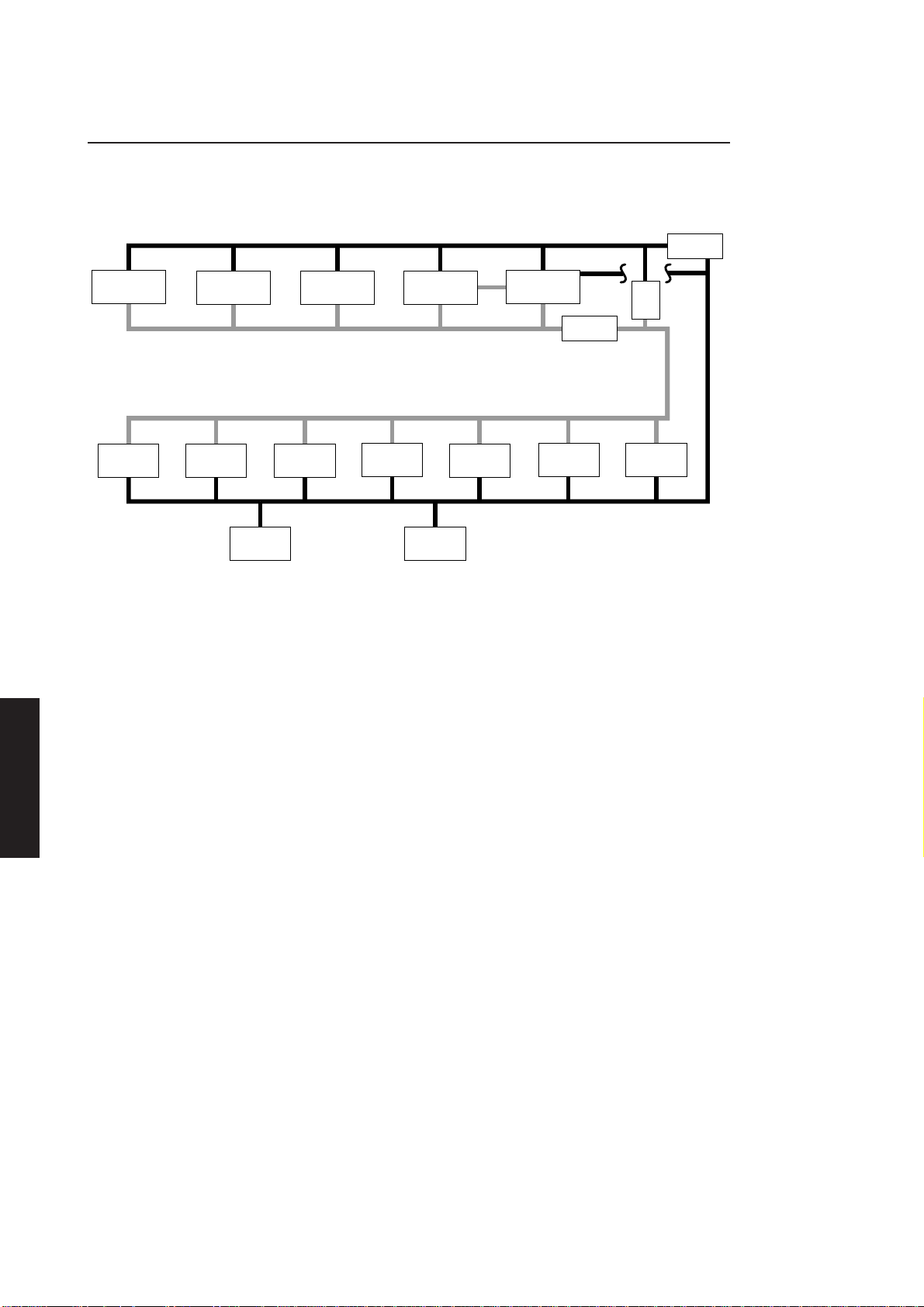

Four Megabytes of RAM are soldered directly to the system board. Additional

RAM is plugged into SIMM sockets on the system board. Upgrades are in pairs

of 1 or 4 Mbyte SIMMs giving upgrade capacities of 2 and 8 Mbytes. The

following table gives the permissible upgrade combinations and the total system

RAM available with each.

Chapter 5Chapter 6 Chapter 3

System board

capacity (Mbytes)

4 6 N/A 2 4 8 N/A 2 2

4 12 N/A 8 -

4 16 N/A 8 8

Note

When banks 2 and 3 are both occupied by 8 Mbyte upgrades the RAM soldered to the system

board is disabled.

Upgrade to

(Mbytes)

1 2 3

Bank

(Mbytes)

3/10 LS PRO HARDWARE TECHNICAL REFERENCE

Real time clock (RTC) RAM

The real time clock and its associated battery backed RAM is an MC146818. The RTC

RAM is accessed via I/O ports 0070h and 0071h. The first fourteen bytes are used to

store real time clock information, the remainder are used for system configuration

data.

The RTC is normally powered from the system +5V supply. However when the

computer is not switched on power is supplied by a rechargeable battery on

the system board. This maintains the correct time and configuration information.

If the battery becomes discharged the time and date will need to be reset and

the system will need to be reconfigured using the SETUP utility.

System Board

Contents

Chapter 1

Contents of The contents of the RTC RAM are listed below.

RTC RAM

Address Function Address Function

Real time clock data 16 Base memory (high byte)

00h seconds 17

01h alarm seconds 18

02h minutes 19 Drive type for hard drive 0

03h alarm minutes 1A-1E Reserved

04h hours 1F shadow BIOS

05h alarm hours 20-27 Reserved

06h day of week 28 Apricot sound volume

07h date 29 Apricot options

08h month 2A Apricot boot type

09h year 2B

0Ah status register A 2C-2D Reserved

0Bh status register B 2E High byte checksum for 10-2D

Chapter 2

Expected expanded memory

(low byte)

Expected expanded memory

(high byte)

Chapter 3

Chapter 3

Apricot cache disable

(see also byte 34h)

0Ch status register C 2F Low byte checksum for 10-2D

0Dh status register D 30

0E Diagnostic Status 31

0F Shutdown code 32 Century in BCD

Configuration data 33

10 Diskette drive type 34

11 Reserved 35 Apricot access rights

12 Fixed disk drive type 36 Floppy/Token-Ring autodetect

13 Power on password 37 Hard disk autodetect

14 Equipment byte 38-3E Power on password

15 Base memory (low byte) 3F Byte checksum of bytes 38-3E

LS PRO HARDWARE TECHNICAL REFERENCE 3/11

Actual expanded memory

(low byte)

Actual expanded memory

(high byte)

Memory exceeds 512K/387

presence

486SLC cache control

(see also Apricot byte 2Bh)

Chapter 5

Chapter 6

System Board

The contents of each of the RTC RAM locations which requires further explanation

is described in the following table.

ContentsChapter 1

Chapter 2

Chapter 3

Chapter 5Chapter 6 Chapter 3

Location/Title Bit(s) Function

0E 7 1 = Real time clock lost power

Diagnostic 6 1 = CMOS checksum bad

status 5 1 = Invalid configuration at POST

4 1 = Memory size error at POST

3 1 = Fixed disk fails initialization

2 1 = CMOS time found invalid

1, 0 Reserved

0F 7-0 00h = Normal execution of POST

Shutdown 01h = Chipset initialization for real mode re-entry.

code 05h = Issue an EOI and JMP to 40:67h

06h = JMP to 40:67h without an EOI

07h = Return to INT 15h function AH=87h block move

08h = Return to POST memory test

09h = Return to INT 15h function AH=87h block move

0Ah = JMP to 40:67h without an EOI

10 7-4 Drive type of diskette drive 0

Diskette 0000 = No drive

drive type 0001 = Not used (360k)

0010 = Not used (1.2MB)

0011 = Not used (720k)

0100 = 1.44MB

0101-1111 are Reserved

3-0 Reserved (no second drive)

12 7-4 Drive type for drive 0 (0-14) if 15 look at byte 19h

Fixed disk 3-0 Reserved

drive type

13 7-1 Reserved

Power on 0 1 = Power on password enabled

password

14 7-6 Diskette drives installed

Equipment 00h = 1

byte 01-03h Reserved

5-4 Primary display adapter

00h = VGA

01h = Not used (40 column colour)

02h = Not used (80 column colour)

03h = Not used (Monochrome)

3-2 Reserved

1 1 = 80387 installed

0 1 = Diskette drive available for boot

3/12 LS PRO HARDWARE TECHNICAL REFERENCE

System Board

Location/Title Bit(s) Function

1F 7-4 Reserved

Shadow BIOS 3 1 = shadow BIOS

2-0 Reserved

28 7-0 Sound volume 0 = minimum, FF = maximum

Sound volume

29 7 1 = Power on sound enabled

Options 6 1 = Quiet boot (No text output)

5 1 = Fast boot

4-3 Reserved

2 1 = Graphical boot

1-0 Monitor type

00 = VGA

01 = HiVision 14"

10 = HiVision Low Emission

11 = Reserved

2A 7 Token-Ring Bus width (see 36h bit 1)

Boot type 1 = 16-bit, 0 = 8-bit

6 Token-Ring data rate

0 = 16 Mbits/sec, 1 = 4 Mbits/sec

5 1 = Token-Ring present

4-3 Reserved

2-0 Remote Boot type

000 = None

001 = Ethernet RPL

010 = Token-Ring RPL

100 = Optional ROM at C000

2B 7-0 00h = Cache enabled

Cache disable CDh = Cache disabled (see 34h)

33 7 1 = memory exceeds 512K

RAM exceeds 6-5 Reserved

512K/387 status 4 Save 387 status

1 = present, 0 = not present

3-0 Reserved

34 7-6 Reserved

486SLC cache 5 1 = cache enabled (see 2Bh)

4-0 Reserved

35 7-2 Reserved

Access rights 1 1 = Setup access right enabled

0 1 = Floppy boot right enabled

36 7-2 Reserved

Floppy/ 1 1 = Token-Ring present

Token-Ring 0 1 = Floppy drive present

autodetect

Contents

Chapter 1

Chapter 2

Chapter 3

Chapter 3

Chapter 5

Chapter 6

LS PRO HARDWARE TECHNICAL REFERENCE 3/13

System Board

3.5 VIDEO ADAPTER

General

ContentsChapter 1

Chapter 2

Chapter 3

Chapter 5Chapter 6 Chapter 3

The video adapter on the LS Pro system board is based on either a Cirrus Logic

CL-GD5422 or 5426 chip. These chips contain all the elements of a VGA controller,

except display memory, providing 100% compatibility with the IBM VGA standard.

The video controller consists of the GD542X, 1 Mbyte of display memory and a 7.6mA

current reference. Video dot clocks vary from 25 to 65 MHz depending on video mode.

Software support is provided by a video BIOS included in the system BIOS.

In addition to full compatibility with the VGA standard the video controllers support

a range of enhanced video modes.

The video modes available are given in the following table:

Mode Type Colours

0, 1 Text 16/256K 40x25 9x16 360x400

2, 3 Text 16/256K 80x25 9x16 720x400

4, 5 Graphics 4/256K 40x25 8x8 320x200

6 Graphics 2/256K 80x25 8x8 640x200

7 Text - 80x25 9x16 720x400

D Graphics 16/256K 40x25 8x8 320x200

E Graphics 16/256K 80x25 8x8 640x200

F Graphics - 80x25 8x14 640x350

10 Graphics 16/256K 80x25 8x14 640x350

11 Graphics 2/256K 80x30 8x16 640x480

12 Graphics 16/256K 80x30 8x16 640x480

13 Graphics 256/256K 40x25 8x8 320x200

58 Graphics 16/256K 100x37 8x16 800x600

5C Graphics 256/256K 100x37 8x16 800x600

5D Graphics 16/256K 128x48 8x16 1024x768

5F Graphics 256/256K 80x30 8x16 640x480

60 Graphics 256/256K 128x48 8x16 1024x768

64 Graphics 64K - - 640x480

65 Graphics 64K - - 800x600

66 Graphics 32K - - 640x480

67 Graphics 32K - - 800x600

6C Graphics 16/256K 160x64 8x16 1280x1024

6F Graphics 64K 40x25 8x8 320x200

70 Graphics 16M 40x25 8x8 320x200

71 Graphics 16M 80x30 8x16 640x480

Displayed

Chars

Character

Cell

Pixels

Note

Mode 6C is interlaced only.

Sync signals output to the monitor are at TTL levels while the analogue video

outputs are at 0 to 0.7 volts.

3/14 LS PRO HARDWARE TECHNICAL REFERENCE

System Board

Video controllers The video controllers implement all the control and data registers, and all the data

manipulation capabilities and data paths of the standard VGA controller. In addition

they can generate high-resolution display modes (those supported in BIOS are

listed in the table above), and uses several enhancements to improve on the

performance of the standard VGA implementation.

These enhancements include a pair of FIFOs. One isolates the processor from

display memory, allowing zero wait state writes from processor to display

memory, provided the FIFO is not full. Reads also occur with zero wait states

provided the data required is held in the FIFO. The second allows the use of

fast page mode cycles to fetch data from display memory, increasing the time