Page 1

MITSUBISHI

Industrial Sewing Machine

TECHNICAL INFORMATION

Automatic

Model

LS2-

Undertrimmer,

1 1

80

Single-Needle

Lookstitch

ET-035

• MITSUBISHI

"ELECTRIC

..

Page 2

CONTENTS

1.

SPECIFICATIONS ............................................................................................................................................. 2

2.

THREAD TRIMMER SYSTEM ...................................................................................................................

3-5

2.1

2.2

2.3

3.

3.1 Installation

3.2

4.

4.1

4.2 Thread

Electric Section ............................................................................................................................................ 3

Machine

Machine

PREPARATIONS

Adjustment

3.2.1

3.2.2

3.2.3

Head Section

Head Section

of

of

Adjust

Adjust

Comfirm

into

of

of

the

(1

) .......................................................................................................................... 4

(2)

.......................................................................................................................... 5

BEFORE

Sewing

Machine

"UP"

"DOWN"

the

receptacle ............................................................................................................................ 7

OPERATION ...................................................................................................

Machine and

Stop

Position ...................................................................................................... 7

position

position

stop operation then

Motor.

................................................................................................................... 7

............................................................................................................ 7

............................................................................................. 6

the

plug

(12 pins)

coming

from

the

machine

ADJUSTMENTS ......................................................................................................................................

How

to

Adjust

Trimmer

Timing

between Needle and Hook .................................................................................. 7

Mechanism ..................................................................................................................... 8

4.2.1 Construction ...................................................................................................................................... 8

4.2.2 Cautions on

4.2.3 Installation

4.2.4 Connection

Knife

4.2.5

driving

4.2.6 Installation

4.2.7 Installation

4.2.8

Adjustment

4.2.9

Adjustment

4.3

4.4 Cautions on Installation

4.5

4.6

4.7

4.8

4.9

4.10 Hook,

Adjustment

Touch-Back Pushbutton ........................................................................................................................... 12

Wiper

.......................................................................................................................................................... 13

Height

4.6.1

Wiper

4.6.2

Adjustment

Adjustment

Timing

of

Feed .......................................................................................................................................... 14

Bobbin

adjustment

of

knife base and

of

knife base and knife

shaft and related parts .............................................................................................. 9

of

thread

of

thread

of

knife

of

needle thread tension releasing

of

Needle Thread Remaining Length .................................................................................

of

wiper

............................................................................................................................... 13

operation

of

Forward and Reverse Stitch Lengths ............................................................................ 13

of

Feed Dog Inclination ....................................................................................................... 13

Case, and Bobbin ............................................................................................................. 14

position

................................................................................................................... 8

fixed

blade bracket unit.. ............................................................... 8

trimmer

trimmer

engagement

of

Touch-Back

............................................................................................................... 13

driving

solenoid

cam ............................................................................................... 10

..................................................................................................

Solenoid

crank ......................................................................... 9

unit

................................................................................ 10

amount

................................................................................. 12

............................................................

6-7

head

7-14

11

12

12

5.

TROUBLESHOOTING ....................................................................................................................................

1

15

Page 3

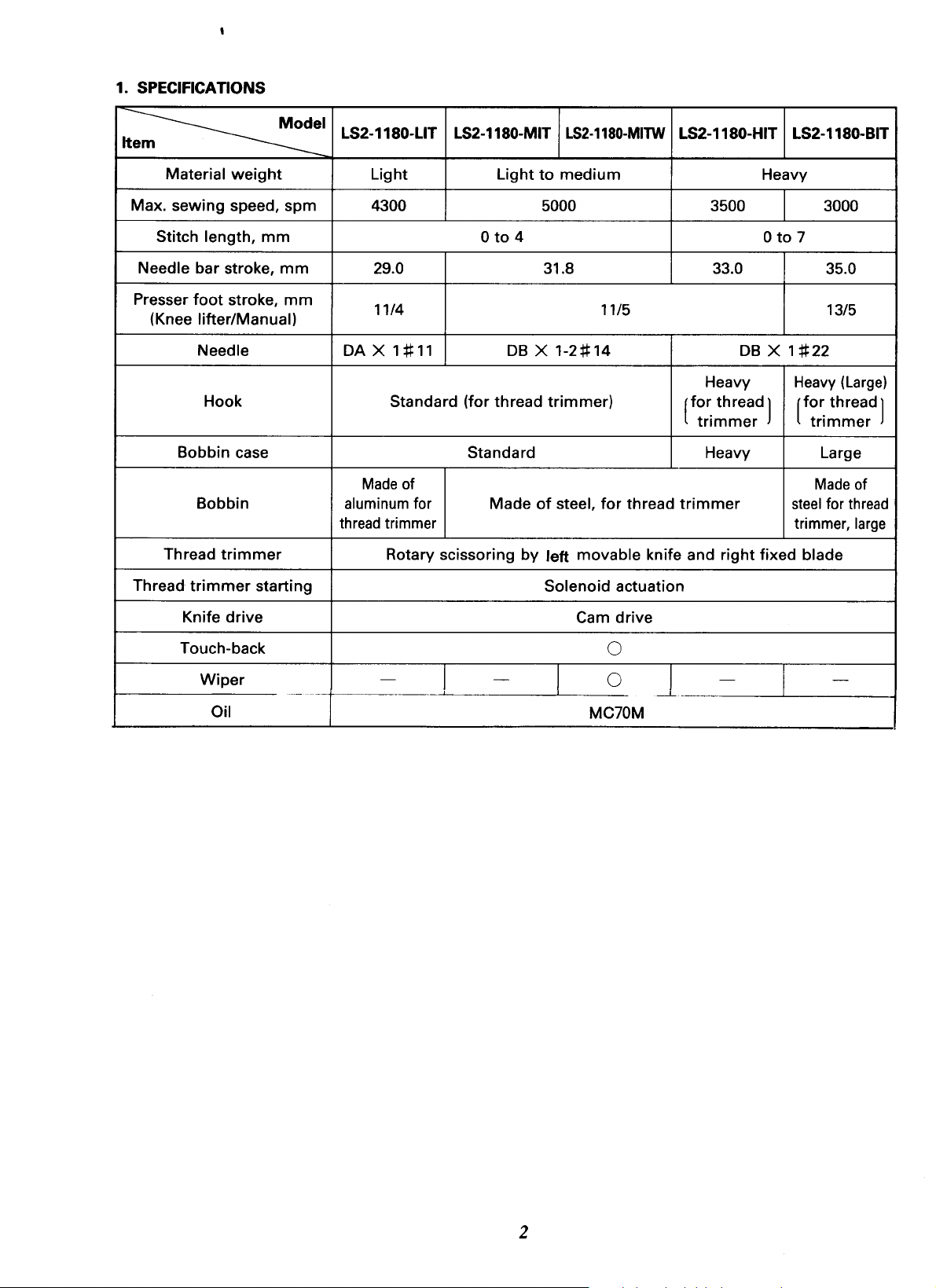

1. SPECIFICATIONS

~I

It

Material

Max. sewing speed,

Stitch

Needle bar stroke,

Presser

(Knee lifter/Manual)

Bobbin case

Thread

Thread

weight

length,

foot

stroke,

Needle

Hook Standard (for thread

Bobbin

trimmer

trimmer

spm

mm

mm

mm

starting

LS2-1180-LIT LS2-1180-MIT

Light

4300 5000

29.0

11/4 11/5 13/5

DA X 1

aluminum for

thread

#11

Made

of

trimmer

Rotary scissoring

Light

0

to

4

DB X 1-2#14

Standard Heavy Large

Made

LS2-1180-MITW

to

medium

31.8 33.0 35.0

trimmer)

of

steel,

for

thread

by

left

movable

Solenoid actuation

LS2-1180-HIT LS2-1180-BIT

Heavy

3500 3000

0

to

DB

X 1

Heavy

[fo~

thread]

tnmmer

trimmer

knife and

right

fixed blade

7

#22

Heavy

[

fo~

thread]

tnmmer

Made

steel

for

trimmer,

(Large)

of

thread

large

Knife

drive

Touch-back

Wiper

Oil

Cam

drive

0

-~·-

------·

--

-

-

0

MC70M

j_

-

-

2

Page 4

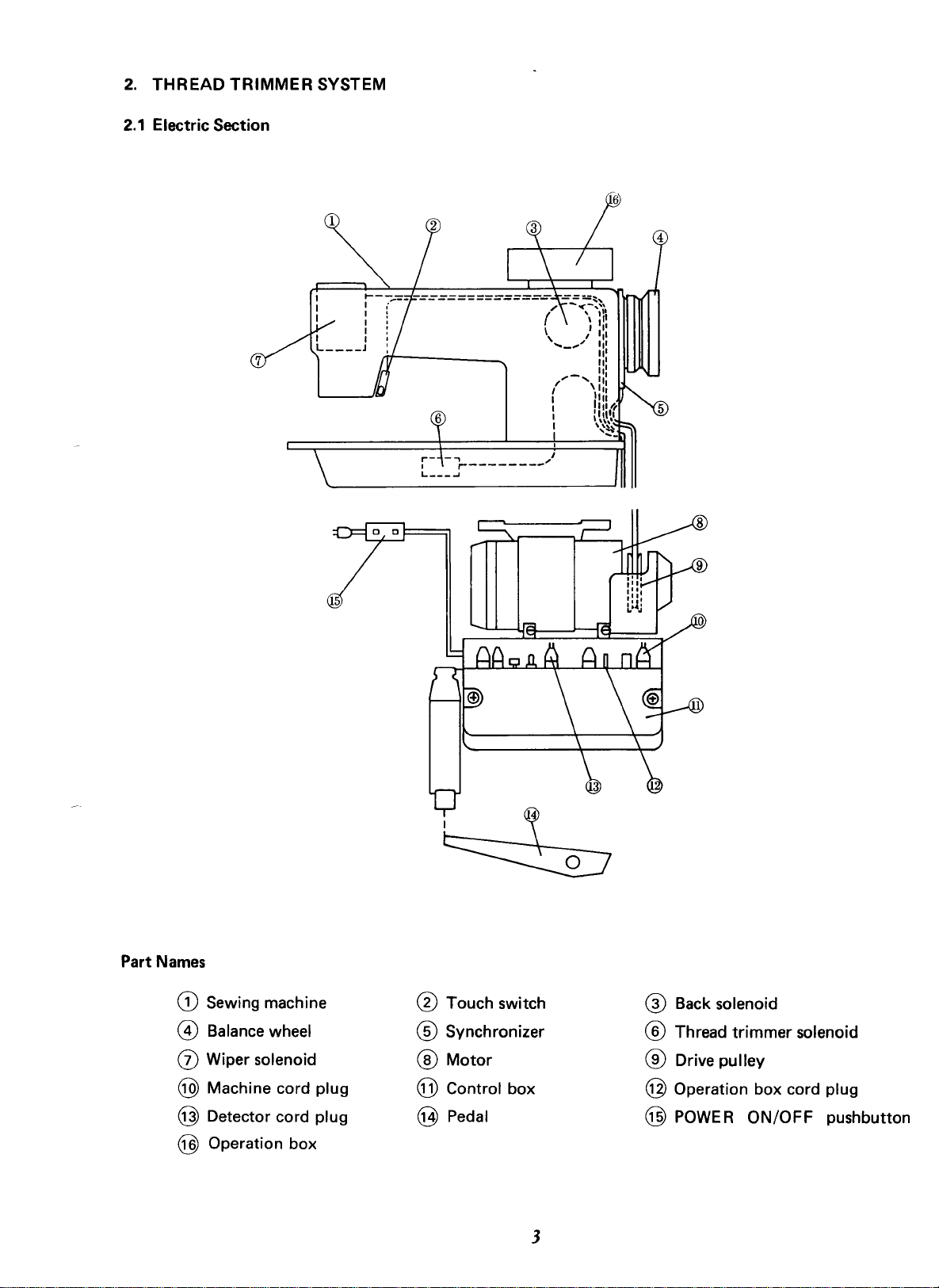

2.

THREAD

2.1

Electric Section

TRIMMER

SYSTEM

i-

L----'

-.,_

________

./

Part Names

G) Sewing machine

@ Balance wheel

(j) Wiper solenoid

5

® Touch switch

® Synchronizer

®Motor

® Back solenoid

® Thread

trimmer

® Drive pulley

solenoid

@ Machine cord plug

@ Detector cord plug

@ Control box

@Pedal

@ Operation box

3

@ Operation box cord plug

@

POWER

ON/OFF

pushbutton

Page 5

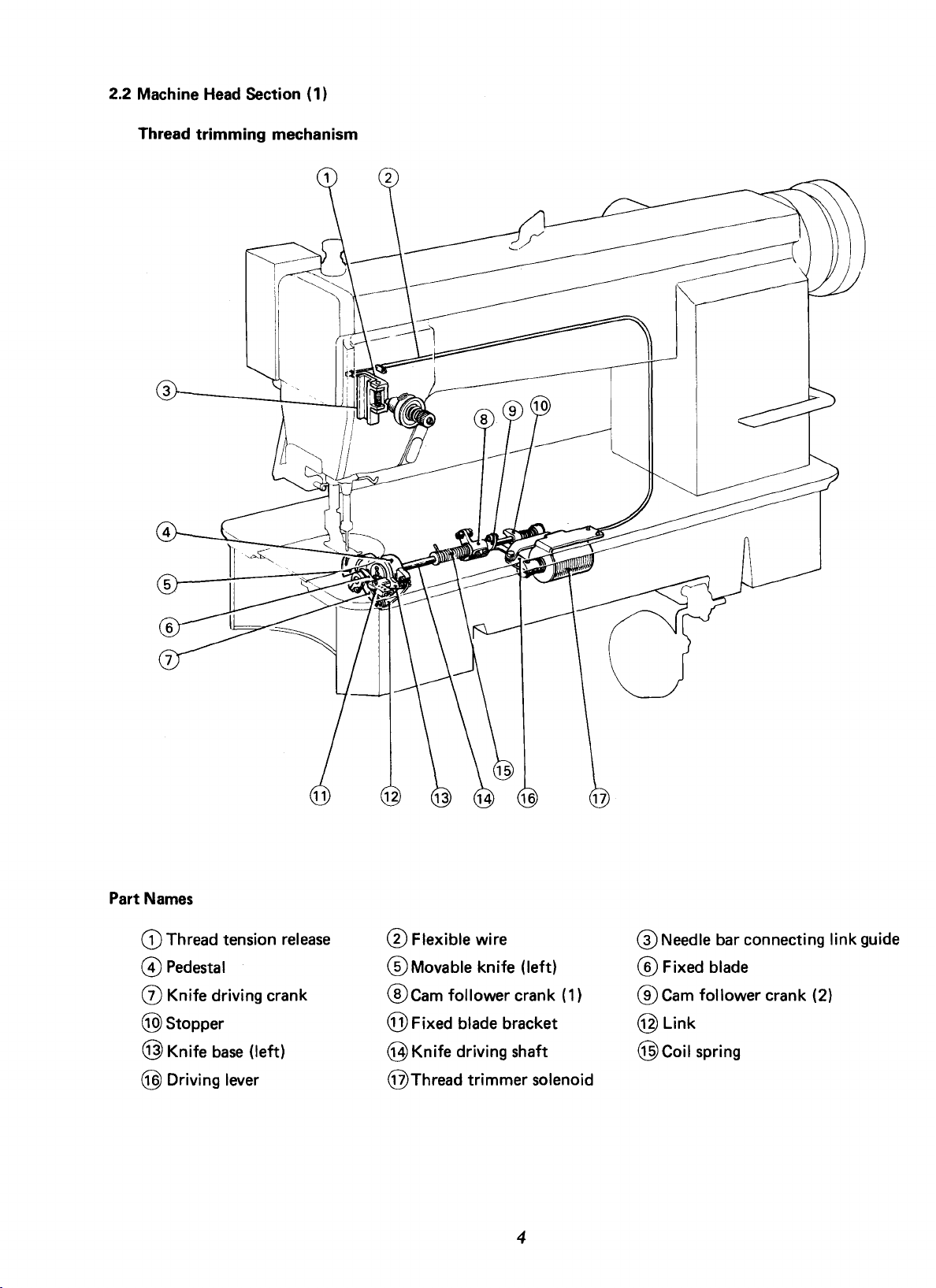

2.2 Machine

Head

Section ( 1)

Thread

trimming

mechanism

Names

Part

CD

Thread tension

@Pedestal

(j)

Knife driving crank

@stopper

@Knife

base

@ Driving lever

(left)

release

®Flexible

®Movable

®cam

wire

knife (left)

follower crank (1)

@ Fixed blade bracket

@Knife

@Thread

driving shaft

trimmer

solenoid

4

@Needle

®Fixed

®Cam

@Link

@Coil

follower crank (2)

spring

bar connecting link guide

blade

Page 6

2.3

Machine

Touch back mechanism

Head

Section (2)

Part Names

G) cover

@Coil

0Pin

spring

@ Micro switch

@Side

@Bushing

@Reverse sewing crank

@Spring

cover

bracket

@Switch

@Link

@Wiper

@Pushbutton

@Plunger

@Feed

@

@Solenoid

regulator

Reverse

sewing lever

mounting bracket

cam

5

®Wiper

®Wiper

@Switch

solenoid

bracket

bracket

@ Back solenoid

@Link

@Spring

@For

bracket

reverse

sewing

Page 7

3.

PREPARATIONS BEFORE OPERATION

3.1

Installation

of

Sewing Machine and

Motor

Operation

Operation

Receptacles

~l

box

(option)

box

(option)

for

machine cords

hole

Round

------

Passing the Machine cords

in table

~

Wiring between sewing machine and control box

Note:

Before plugging

Pass

two

cables

plugs

into

the respective

or

unplugging, be sure to

from

the sewing machine through the

plug

receptacles.

turn

[[oop

off

the POWER

Operation

Detector

Connectors location on

•

the

control

'·DoD

I "

External knob 1-2 position select switch

round

ON/OFF

hole

pushbutton.

in the table

and

connect the

Machine

box

box

0

oo]j

two

6

Page 8

3.2

Adjustment

of

Machine

Stop

Position

Adjust

3.2.1

When

machine

deviate

(1) Disconnect

(2) Run

(3)

3.2.2

Adjust

When

"DOWN"

than 3

(1) Disconnect

(2)

of

"UP"

the

stops at

larger than 3

the

machine

the

While

tool"

holding

in

of

"DOWN"

the

pedal is Newtral

position.

mm

the

machine

Run the

tion.

position

pedal is kicked

"UP"

the

mm

plug

position.

adjust

(12 pins)

head.

machine

the

the

hole

and

stop

pully

@,then

position

If

the

adjust

the

as

follows.

plug

(12 pins)

head.

machine

and stop at

down

insert

the

by

heel,

If

the

marks

as

follows.

of

cable

from

at

"UP"

position.

the

"adjusting

remove

the

tool.

machine stops as

the

marks deviate larger

of

cable

from

"DOWN"

posi-

3rd

mark

Pully

(3)

3.2.3

While

tool"

Comfirm

pins)

holding

in

the

coming

receptacle.

4. ADJUSTMENTS

4.1

How

to

Adjust

The standard

~lass

Item

Needle lift-up

lowest position

Distance between

needle hole and hook

Distance between needle

hook point

Distance between

needle plate setting base, in highest

position

of

needle bar

the

hole@,

stop

from

the

timing

quantity

upper

needle

the

pully

insert

the

then

remove

operation

the

Timing

then

machine

between

head

Needle and

between needle and

·L

point

from@

side

point

of

and©

1.8 2.0 1.8 1.8

@

0-0.2

0.05 0.05 0.05 0.05

and

17.3 18.8

"adjusting

the

tool.

the

plug

(12

into

the

hook

is

·M

- - -

18.8

Hook

following

·B

(mm)

·H

20.6

the

table.

®

' '

H

' I

I :

' '

'.'

(/:0

\ty

"Up"

"Down"

position

position

7

Fig.1

Page 9

4.2 Thread

Trimmer

Mechanism

4.2.1 Construction

Knife

driving

4.2.2 Cautions on

adjustment

A hook shaft cam system

sewing machine,

if

the sewing machine

operating state (the roller

knife

state

makes

only

contact

with

during a normal thread

Knife

driving

shaft

Cam

follower

the thread

is

rotated one

crank (2)

Fig.

trimmer

is

engaged

is

of

crank

utilized

cam

follower

for

the needle, resulting in damage.

trimming

cycle (Needle DOWN position

crank

2 Cam

turn

Be

Thread

(1)

Driving

follower

trimmer

crank

solenoid

Flexible

=~,.

lever

(2)

Stopper

wire

,p,;ng

drive. Therefore, during the adjustment

with

with

sure

the thread

the thread

to

bring the solenoid

to

trimmer

trimmer

UP

position).

solenoid in the

cam), the movable

into

the operating

of

4.2.3

Installation

4.2.3.1 Knife base

(1)

As

shown in Fig.

hook shaft bushing

of

knife base and fixed blade bracket

unit

3,

fit

(left) and

@.

4.2.3.2 Fixed blade bracket

(

1)

As shown in Fig.

unit

with

fix

then

with

4,

install the fixed blade bracket

the

hook

positioner dismounted, and

the screws ® .

the

unit

knife

fix

base

with

unit

to

the

the screws

unit

Fig.

3

8

Fig.

4

Page 10

4.2.3.3 Relation between fixed blade and movable knife (left)

edge

(

1)

Fig. 5 shows the standard state.

If

(2)

the dimension indicated in Fig. 5

three-thread breakage

will occur, leading

is

too

to

thread cast-off, etc. after the thread trimming.

Reversely,

the dimension

is

too

small, thread

if

trimming error may result. Therefore, caution must

be

exercised.

(3) Make the adjustment in (2) in the

procedure

installation procedure

4.2.4 Connection

(1) Make connection

use

care

of

fixed blade bracket

of

fixed blade.

of

knife

base

as

shown in Fig.

for

the position

and knife driving crank

of

link

installation

unit

or

6.

At

this time,

depends on the

sewing machine model.

large,

needle

in the

(Knife

Fixed

edge)

blade

LS2-1180-LIT

LS2-1180-MIT

LS2-1180-HIT

0.3mm

0

0

Fig. 5

LS2-1180-BIT

4.2.5 Knife driving shaft and related parts

Cam

follower

90.5mm

(BIT:

87.5

mm)

(1) Fig. 7 shows the standard setting position.

(2) During assembling,

(3) Fix the

(4)

Fix

cam

the stopper

be

follower

to

the

sure

to

crank (1)

recess

pass

the knife driving shaft through the knife driving crank first.

to

the

recess

so

that

the knife driving shaft

axial direction.

crank

(1)

Cam

follower

Knife

Fig. 7

of

knife driving shaft at the position shown in Fig.

driving

crank

shaft

(2)

can

rotate smoothly

without

7.

play in the

9

Page 11

4.2.6 Installation

of

thread

trimmer

solenoid

unit

(1) Operation stroke

CD

Standard operation stroke

of

thread

@ Adjust the operation stroke

(2) Installation

CD

Install the

Fig.

@ Install the

provided between the driving lever and cam

crank (2)

the solenoid.

@

When

clearance

follower cranks (1)

is

by moving the

arrow direction in Fig. 8

of

unit

unit

with

8.

unit

so

with

the stopper

the solenoid

of

is

0.5 mm

and

the standard installation status. Make adjustment

solenoid mounting bracket in the

trimmer

the

screws@

that

solenoid

is

6.0 mm.

by

use

of

the

nut

and©

shown in

approximately 1 mm

@.

is

follower

nut

® in contact

with

energized under this condition,

is

provided between the

(2)

as

shown in Fig.

9.

cam

This

Fig. 8

Fig. 9

4.2.7

Installation

(1)

Align the second timing mark ® on the pulley

of

thread

trimmer

cam

matching mark on the arm.

Set the thread

(2)

turn the thread

cam

makes contact

the operation

cam

(3)

the

When

and the

clearance between the

Thread

trimmer

trimmer

trimmer

of

follower

cam

_,.

solenoid

cam

with

the roller,

thread

trimmer

crank (2)

cam

and roller end

to

the operation state and

forward.

At

fix

the cam.

solenoid

has

returned, the standard

is

the

0.5

point

has

to

with

where

been

reset

1.0 mm.

the

Thread

trimmer

cam

0.5

to

1.0

mm

Fig. 10

10

Page 12

The

Note:

4.2.8 Adjustment

(

1)

Positions

CD

Fig.

standard

to

the operation

position

the stopper plate, make adjustment

screw (Fig.

of

movable knife (left) and fixed blade

12

shows the standard state.

position

is

has

been changed,

7)

and

then make adjustment in (1) to (3).

of

knife engagement

of

cam

follower

shown in Fig.

for

example,

crank (2)

11.

When

by

removing

with

the adjust

prior

this

Cam

Movable

LS2-1180-BIT

'~~~.

/g~haft

follower

crank

.(q/

t.l._,.

(2)

1 -

knife

Roller

Knife

driving

shaft

(left)

7mm

(BIT:

7.5

mm)

Fig.

I

J

•

I

2.5

LS2-1180-LIT

LS2-1180-M IT

LS2-1180-HIT

1

·~;

)u.~

'-

r

·,,/

11

Fixed

blade

m

(2) Adjustment

CD

Set the solenoid

sewing machine. Then, the

by the thread

has

amount

of

moved

is

knife engagement amount

to

the operation state and rotate the

trimmer

to

the maximum, the standard engagement

1.5

to

2.0 mm.

cam.

See

® Make adjustment by the installation

(3) Adjustment

CD

The standard knife engaging pressure

movable knife (left) and fixed blade start making contact

with

®

When

thread, a slight increase

produces

of

knife engagement pressure

each

other at the position shown in Fig.

cutting action

an

effect.

is

poor especially

movable knife (left)

When

the movable knife (left)

Fig.

13.

of

knife driving crank.

is

obtained when the

14.

because

of

the engagement pressure

is

rotated

of

thick

Knife

Movable

driving

knife

1.5

to

(left)

crank

Fig. 12

2.0

mm

Fig. 13

Fixed

blade

®

To

adjust the engagement pressure, loosen the lock

in Fig.

11

and adjust

with

the adjust screw @.

nut@

11

Fig.

14

Page 13

4.2.9

Adjustment

of

needle thread tension releasing

amount

Thread

trimmer

solenoid

(

1)

Make adjustment

operated, the tension discs

approximately 1 mm.

(2) To make adjustment, loosen the nuts ® and move the flexible

wire.

CAUTION

If

the opening

thread

thread cast-off. Reversely,

too

leading

4.3

Adjustment

(

1)

Adjust

pretension adjust

Clockwise

wise

will

large, the tension discs

to

loose stitches.

the

turn

turn

increases the length.

so

that

when the thread

of

thread tension regulator open

of

tension discs

be

trimmed

of

Needle Thread Remaining Length

remaining length

nut

reduces the remaining length. Counterclock-

at

short length, leading

if

@.

is

too

the opening

are

left

of

needle thread

trimmer

small, the needle

to

of

tension discs

opened continuously,

by

solenoid

needle

is

use

of

the

is

...

Fig. 15

4.4 Cautions on Installation

Adjust

that

twisted, and make sure

smoothly in the vertical direction.

mounting

4.5 Touch-Back Pushbutton

The

(

1)

the position

the plunger

screws.

function

Normally,

Fig.

pushbutton

of

18.

of

of

solenoid and the

See

pushbutton

this pushbutton

When the sewing machine

is

pressed, reverse stitching

of

Touch-Back Solenoid

solenoid in the longitudinal direction

that

the

Fig.

17.

can

be

eliminated

is

used

link

(for

connection) are

reverse

sewing lever moves

After

at

that, tighten the

as

required.

the position shown in

is

operated

is

performed.

after

so

not

the

Fig. 16

@

@rr,

~

--

-::::.=-=

--

==:

Feed regulating lever

Fig. 17

)

(2) When the pushbutton

the broken line in Fig.

it

is

pressed.

is

moved

18,

the switch does

to

the position indicated

not

function

even

12

by

if

Fig. 18

Page 14

4.6 Wiper

4.6.1

Height

1)

The standard height

(

which

of

is

stopped at the

wiper

of

wiper

UP

position.

is

2 mm below the

tip

of

needle

(2) Make adjustment after

loosening the

4.6.2 Wiper operation position

(

1)

The standard operation position

of

the center

fully

To

(2)

pushed (when the solenoid

make adjustment, loosen the

needle when the plunger

adjust the mounting position

of

4.7 Adjustment

Forward and

screw@.

of

wiper

is

energized).

screws

of

solenoid unit.

Reverse

Stitch Lengths

is 0 to

of

2 mm from

wiper solenoid

is

@ and © and then

Fig. 19

(

1)

Loosen the screw @ and make adjustment by turning the

eccentric

length and

wise

reverse

4.8 Adjustment

(1) To adjust the inclination

turn the eccentric pin

tilt.

turn

shaft@.

increases

increases

Clockwise turn reduces the forward stitch

the

the forward stitch length and

stitch length.

of

Feed

Dog Inclination

of

@.

Counterclockwise turn

reverse

stitch length. Counterclock-

feed dog, loosen the

Clockwise turn

sets

to

upward

tilt.

sets

decreases

screw@

to

downward

the

Fig. 20

and

13

Fig.

21

Page 15

4.9

Timing

of

Feed

Needle

1)

The position

(

tip

is

located

needle plate when the feed dog

and the teeth

needle plate.

(2)

Make

adjustment

To install,

ing hole on a

4.10

Hook,

( 1)

Use

the

slit

guide

for

approximately 3 mm

of

See

timing

upper

Bobbin

Case,

undertrimmer

@

as

the standard feed

feed dog align

Fig. 22.

by the

mark on a feed cam is according

shaft,

and Bobbin

shown in Fig.

is

mounting

by

set screw

hook

which

24.

timing

sunk

with

positions

is

where the needle

below the

by

turning

the upper surface

of

as

shown

has

the bobbin thread

top

surface

the

pulley

feed cam.

with

in Fig.

oil-

23.

N~d·s~

of

of

~-~t---.Ll3mm

Feed dog Fig.

Rubber cap

Set screw

Fig.

22

23

Timming

mark

(2)

Use

the

bobbin

@ at the

(3)

For the bobbin, use the attached bobbin. The standard bobbin

of

Model -L sewing machine is made

order

to

prevent the

as

lightly

bottom

as

possible.

case

which

as

shown in Fig. 25.

deformation

has

idel running prevention spring

of

aluminum.

of

bobbin,

wind

the thread

In

Fig.

24

Fig. 25

14

Page 16

5.

TROUBLESHOOTING

Trouble

Thread cannot

me

d.

Neeedle thread comes

out

of

start

the needle

of

stitching.

be

trim-

at

the

Cause

Knife

engagement

Knife engaging pressure

Damage and/or wear

of

movable knife (left). fixed blade

Machine stops

Machine stop position varies largely.

Position

Since the movable knife (left)

operated

cannot

At

thread tension regulator

open.

of

too

be

the time

is

improper.

is

too

of

cutting

too

early.

fixed blade

early, loop spreading

performed

of

is

improper.

by

the knife.

thread trimming,

discs

do

low.

edge

not

Corrective

is

Adjust

Adjust

Change

Adjust

1.

2.

Adjust

Adjust

trimmer

Adjust

releasing.

the engagement amount.

the engaging pressure.

the knife and/or blade.

the stop position.

Check needle thread tension

time

of

thread trimming.

In the

machine, check table specifications

(motor

box G switch

case

pulley diameter, control

the position

the installation

cam.

the needle thread tension

of

ON).

Action

Model

of

at

the

-H

or

-B

fixed blade.

of

thread

Reference

Section

4.1.8

4.1.8

3.2

4.1.9

4.1.3

4.1.7

4.1.9

Skip stitch at the start

stitching

Needle thread

after thread

is

too

long Pretension

trimming.

Thread

Thread

before the

knife

blade.

Needle

the thread.

Pretension

Bobbin thread becomes short due

of

the idle running

thread trimming.

Tension

The remaining length

thread on the needle side

after thread

Thread

Thread movement between the

and the hook positioner

smooth.

trimmer

is

trimmed

cutting

(left)

engage

is

too

is

too

of

bobbin thread

trimming.

is

too

trimmer

timing

by the fixed blade

edge

with

thick

with

strong.

of

weak.

timing

is

too

early.

of

movable

the

fixed

respect

bobbin at the

is

of

is

is

too

too

too

high.

needle

short

late.

hook

is

not

to

to

Adjust

trimmer

Adjust

Adjust

Use

prevention spring.

Adjust

1.

2.

3.

Adjust

Adjust

trimmer

the installation

cam.

the position

the pretension. 4.2

a bobbin

the tension

Adjust

Check the installation

trimmer

Check the thread contact

the pretension. 4.2

case

the pretension.

cam.

the installation

cam.

of

of

fixed blade. 4.1.3

with

idle running

of

bobbin thread.

of

of

thread 4.1.7

4.9

4.2

thread

area.

thread 4.1.7

4.1.7

15

Loading...

Loading...