Page 1

INDUSTRIAL

MODEL

LS2-1130

classes

High-Speed

Single-Needle

SEWING

MACHINE

Lockstitch

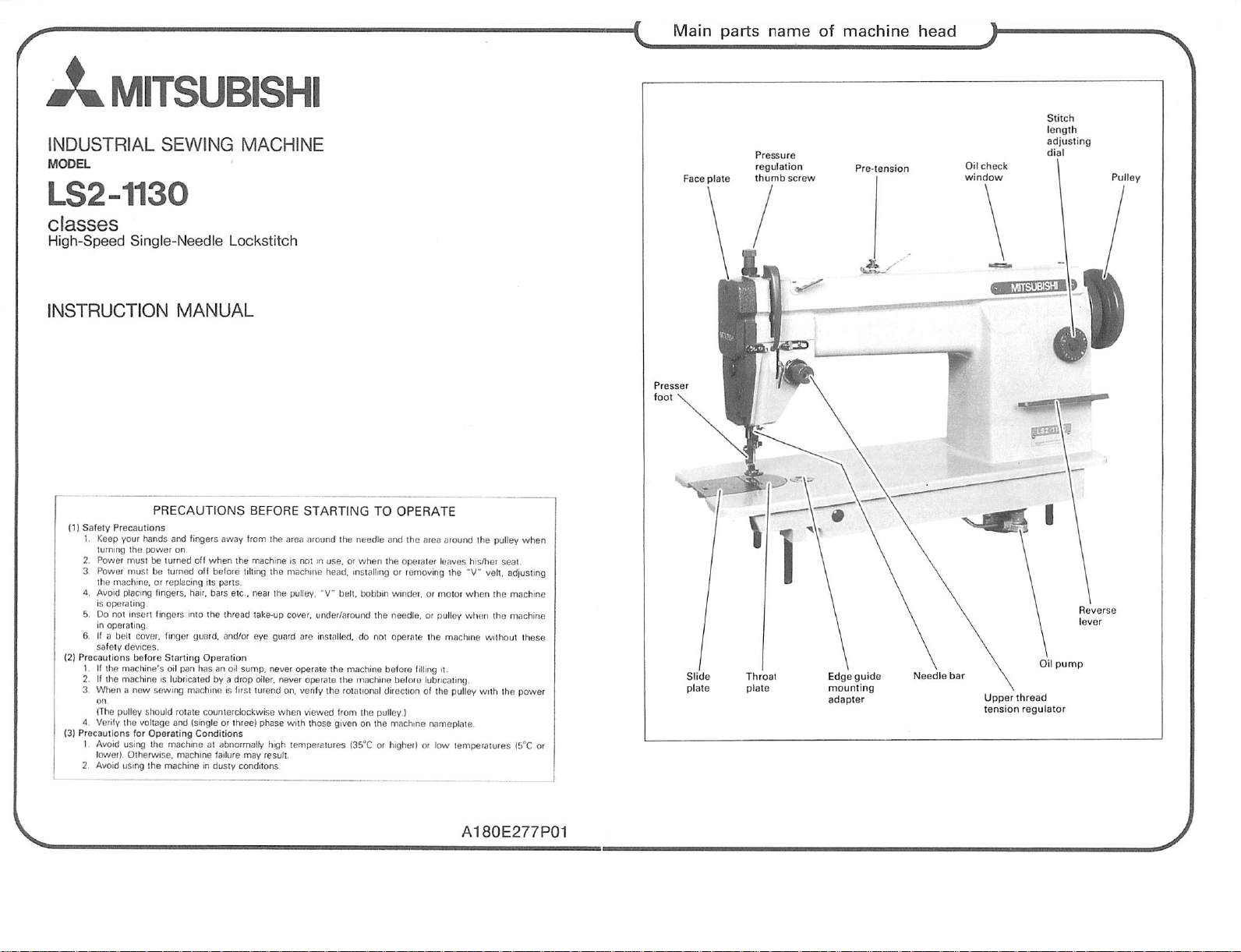

Main

Face

plate

parts

name

Pressure

regulation

thutnb

screw

of

machine

head

Oil

window

check

Stitch

length

adjusting

dial

INSTRUCTION

(1)

Safety

Precautions

1 Keep your hands and fingers away from the area around the needle and Ihe area around the pulley when

turning

the

2. Power must be turned off when the machine is not in use, or when the operaier leaves his/her seal.

3. Power must be turnedoff before

the

machine,

4. Avoid placing fingers, hair,

is

operating.

5. Do not insert fingers into the thread take-up cover, under/around the needle, or pulley when the machine

in operating,

6. If a belt cover, finger guard, and/or eye guard are installed, do not operate the machine wilfwut

safety

(21

(3) Precautions for OperatingCorKlitions

devices.

Precautions

1. Ifthe machine's oilpan has an oil sump, never operate the machine before

2. Ifthe machine is lubricated bya dropoiler,never operate the machinebefore

3. Whena new sewing machine is first turend on, verifythe rotational direction of the pulley with the power

on

(Trve

pulley should rotate counterclockwise when viewed from the pulley.)

Verify

Ihe voltage and {singleor three) phase with those given on the machine nnmeplate.

4.

1.

Avoid

using the machine at

lower).

Otherwise,

2. Avoid using the machine in

MANUAL

PRECAUTIONS

power

on.

or replacing its

before

Starting

machine

parts.

bars

etc.,

Operation

attfiormally

failure

dusiy

BEFORE

tilling

the

machine

near tlie pufiey, "V"

high temperatures

may

result.

conditons

STARTING

head,

belt,

TO

OPERATE

installingorremoving

bobbin

winder,ormotor

filling

lubricating

I35°Corhigher)

or low temperatures

the "V"velt,

it.

when

the

adjusting

machine

these

{5"C

'T\'

(I

Slide

piste plate

or

Throat

\ \ \

Edge

guide

mounting

adapter Upperthread

Needle

bar \

tension

\

regulator

Oil

pump

A180E277P01

Page 2

How

to

use

the

machine

Note:

Before

making

the

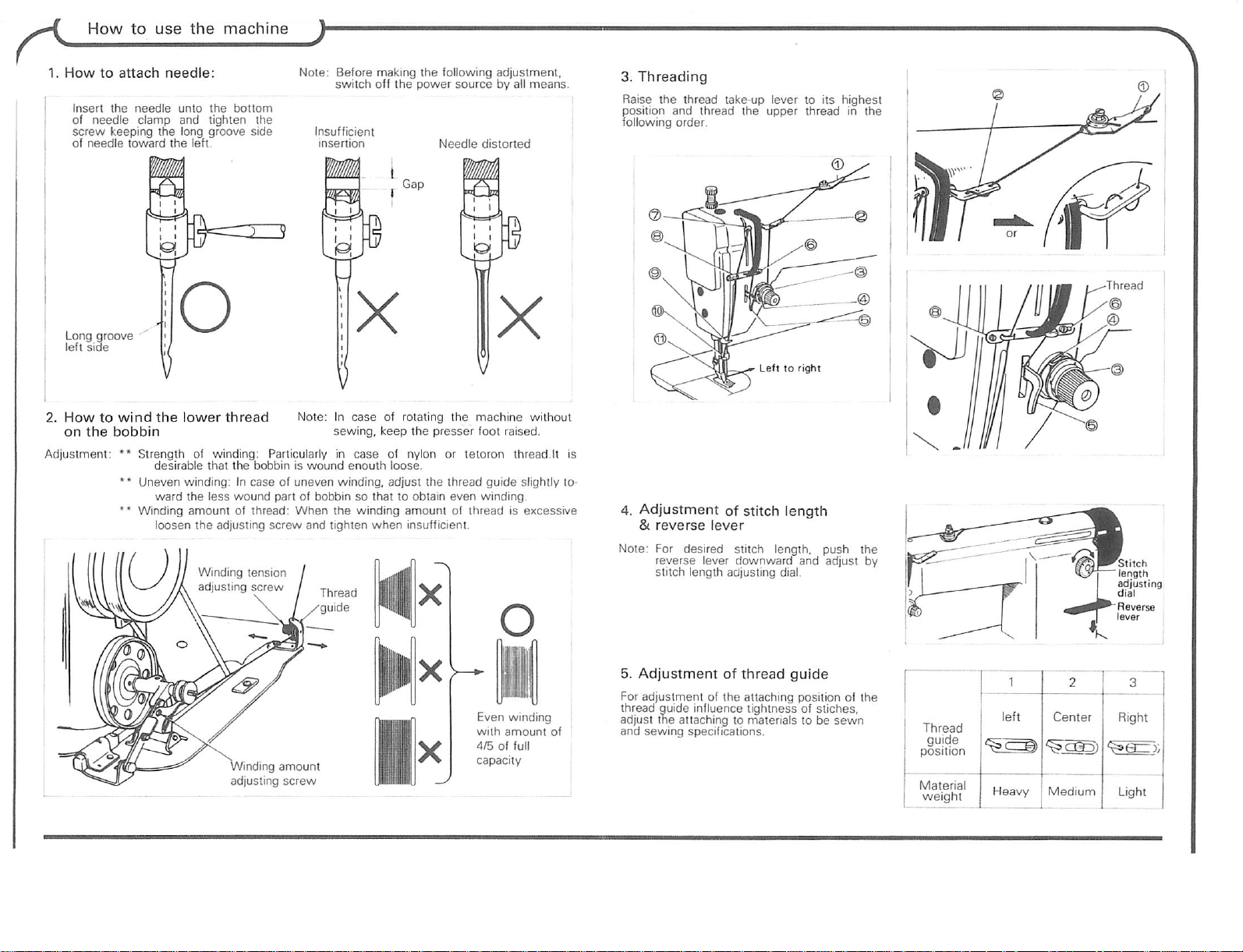

1.

How

to

attach

Insert

of

screw

of

needle

the

needle

keeping

needle

clamp

toward

needle:

the

the

unto

and

long

left.

the

tighten

groove

bottom

the

side

switch

Insufficient

insertion

off

the

power

following

Needle

source

adjustment,

by all

distorted

means.

3.

Threading

Raise

position

Tollowing

the

thread take-up lever to its

and

thread

the

order.

upper

highest

threadinthe

Long

groove

left

side

2.

Howtowind

on

the

o

the

lower

bobbin

Strength of winding: Particularly in

desirable

Uneven

ward

Winding

loosen

thread

that

the

bobbiniswound

winding;Incaseofuneven

the

less

wound

amountofthread:

the

adjusting

Winding

adjusting

part of bobbinsothattoobtain

screw

tension

screw

Winding

adjusting

amount

screw

Note: In

When

and

X X

case

sewing,

case

enouth

winding,

the

tighten

of rotating

keep

winding

when

of nylon or

loose-

adjust

the

the

presser

tetoron

the

thread

even

amountofthreadisexcessive

insufficient.

machine

foot raised.

without

thread,It is

guide

slightly

winding.

Even winding

with

amount

4/5offull

capacity

Lefttoright

to

4.

Adjustment

&

reverse

Note: For desired stitch length, push

reverse

stitch length adjusting dial,

5.

Adjustment

For

adjustmentofthe

thread quide influence

adjust

the

and

of

sewing

of stitch

lever

lever

downward

of

thread

attaching

attachingtomaterials

specifications.

tightnessofstiches,

length

and

guide

position of

to be

adjust

sewn

the

the

by

Thread

guide

position

left

CenterIRight

Stitch

length

adjusting

dial

Reverse

lever

Heavy fvledium Light

Page 3

6.

Adjustmentofpressure

presser

Pressureonthe

in

accordance

7.

Adjustment

OWell

I

8.

Upper

"•*

Upper thread is

lower

• •

Upper

regulating

For

special

the

desired

adjusting

thread take-up spring.

9.

Lower

r

Thread

spring

10.

Adjustmentofhook

foot

presser

with

balanced

stitch ^

thread

thread

tension.

thread

thumb

fabric

tension

the

strenghth

thread

tension

Strengthen

^ / Lowerthread tension

/ can be

I

foot

materialstobe

of

thread

tension:

adjusted

tensionisadjustedbytension

nut.

sewing withspecial thread,

canbeobtained

and operating

tension:

Weaken

cnrpw

on

is tobeadjusted

sewn.

tension:

V

In

is

threadistoo

according to

by

range

^justed

(®

by

oil

lubrication:

Adjustment is made by rotatingscrew ®.

For

weight

material

(weaken)

caseofupper

too

strongorlower

the

of

In

caseofcotton

#

60,

tension

as the

andifthe

slowly,

is

obtained.

light

thread

weak.

the

canbechecked

pulled

the

regular

out thread,

bobbin

proper

Pressure

3 ^

X

thread

thread

case

tension

regulating

For

heavy

material

In

caseofupper

too

weakorlower

is

too

strong.

fall

thumb

weight

(tighten)

Weaken

screw

thread

thread

Thread

tension

nut

trengthen

Rotation

of

bobbin

11.

Adjustmentofoil

For

the

regular

the

adjustment

speed operation, if

check window on the machine arm is reduced,

close

the

12.

Adjustmentoftimingtoopen

upper

is

Adjust timing

ing to

open

for

the

clearance

of

presser

1. Remove

screw

2.

Move

the

Positionedtothe

Positionedtothe

3.

Tighten

condition

been

• It is

same

of

the

beneath

sewing,

of oil

oil

bypass

thread

with

the

tension disc can be adjusted

(within

foot.

the

rubber plug and loosen the

(S>

the

thread

right or

the

the screw ® after the opening

of

the

checked.

convenienttooperate

thickness

pressure

the

presser

pump:

it is not

pump,

oil

flow

hole

tension

the

following knackastim

tension

left.

left....

thread

of plateasthe

foot

necessary

butincaseoflow

amount for

of oil

pump.

regulator

the

limits of

releasing

right... quick

slow

tension

by fitting

you

intendtoloosen

foot.

for

oil

tension

2~7mm)

cam

disc

has

the

clearance

Standard

0.5-1.0

By-pass

disc

to

Rubber

hole

of

Driver

\ II

(

VLef_^^

plu

gap

/ ^

Right

Adjusting

Thread

releasing

Pin

plate

tension

cam

Screw®

Presser

bar

lifter

tension

Presser

Upper thread

regulator

foot

Specifications

MODEL

LS2-1130-MOB

LS2-1t30HO8

LS2-1130-BOB

MATERIAL

WEIGHT

Standard

heavy

heavy

4500

3500

3500

SPEED

Max

spm

spm

spm

ROTARY

HOCK

Lub/Aut

Standard

heavy

Large

size

heavy

NEEDLE

DBX1

DBX1

DBX1

FEED

3

3

3

Pieces

type

Pieces

type

Pieces

type

DOG

STITCH

LENGTH

0—5mm

0~7mm

0~7mm

PRESSER

STROKE

KNEEAW>JD

13/6mm

13/6mm

13/6mm

BAR

NEEDLE

BAR

STROKE

30.5mm

33.0mm

35.0mm

Decrease

Increase

MITSUBISHI

ELECTRIC

CORPORATION

Page 4

TftJUduiiun

ueiufB

siaruny

lu

uperaie

1

lUUUtB

0(

nB|Jclll

1.

Lubrication-1

Before

startingtooperate

sion

(A)

of oil tank. While

questedtocheck

andincase

the position

(A).

Use

2.

Lubrication-2

When starting to

idlefor a longtime withoutusinq it is essential

to

oil

ber

plug.

3.

Condition

While operating

to

check

through

4. Periodical

'

Remove

clean

MC70M

enough

the

the

oil

volume

(B)

replenish oil up to the position

oil

specified

through

of

the

the

condition

oil

check

cleaning•Remove

the

throat

feed

dog.

pour

oil up

the

operating

oil

volume

would

periodically,

come

you

by Mitsubishi.

sew

initialy

and after kept

the oilholes in the rub

oil

lubrication

machine

window.

plate and

of

it is

and

neccessary

oil

clean

'

Law

and

the

posi-

are

less

than

lubrication

the

throat

the

down

clean

re

feed

the

the

plate

dog.

machine

hook.

Oil

check

head

Knee lift pin

Rubber

plug

window

' Lay

Oil removing

dowm

and

clean

screen.

the

the

screw

machine

oil

pump

head

Skip

irregular

stitch

Thread

stiching

cuts

1)

Needle

•

Bent

•

Not

suited

thread

needle

deposit

deposit

with

attached

not

distorted

with

side

thread

too

take-up

too

weak

thread

too

bent

attached

size

thread

too

tension

case

thread

inserted

into

bobbin

weak

weak

strong

in

thread

21

Wrong

needle

•

Insertion

enough

•

Needle

Attached

opposite

1)

Upper

tension

2)

Thread

spring

3)

Lower

tension

11

Poor

2)

Needle

*

Needle

* Wrong

needle

* Thread too big for

the

3)

Upper

tension

*

Dust

between

discs.

*

Excissiveoruneven

windingoflower

tfireadonthe

bobbin.

'

Dust

bobbin

' Damaged

tensiononbobbin

Wrong

bobbin

Repairing

Change the

Replace with proper one accoding to the thicknessol thread.

Insert

Attach the needle as its hole faces side ways. (But. using the nylon

or

ing of

its

Correct the attaching side.attach the needle keeping its groove side

toward the left, arxfconcave

Turn the upper thread tension regulator thumb nut to the

strengthen.

Turn the tension

Turn

!Change the thread with

Change

See

needle

with

properlyasper

polyester

thread,

loop

finish.)

stud

the

bobbin

case

the

needle

No.2 of skip stiching.

with

new

one.

instruction

distance

manual.

the

needle

side

toward the right.

the right to strertgthen.

tension

screwtothe

better

quality one.

new

one.

hole

somewhat,

right to strertgthen.

Either change with proper size thread or with proper needle.

'

Turn

the

tension

regulator

nuttothe

Remove

the

tension

discs and clean by brush.

Rewinding correctly with the winding amount of 4/5 of its full

capacity.

: Remove the bobbin

Change

witt>

' Replace the bobbin correctly, so that to

when

the

thread

new

one,

is pulled-out.

case

and clean by brush.

lefttoweaken.

rotate

the

after

check

right

bobbin clockwise

to

Feed

dog

base

Oil

screen

pump

Feed

dog

Puckering

f)

Needle&thread

too

big

2)

Thread

(upperorlower

thread)

3)

Pressure

presser

for

tension

of

foot

fabric

Change with proper size needle and thread for fabric.

Adjust the thread tension by regulator thumb nut, take-up spring,

adjusting

screw

Weaken by

on the bobbin

turnir^g

the regulatii^g

case.

thumb

screw

to the left.

Loading...

Loading...