Page 1

f

Echelon

®

, LON®, LONWORKS®, Neuron®, 3150®and the Echelon logo are trademarks o

Echelon Corporation registered in the United States and other countries.

TM

LonMaker

and the Lon Users logo are trademarks of Echelon Corporation.

Page 2

Page 3

1

Page 4

Contents

1. Introduction ..........................................................................................................................2

1.1 Purpose of this manual ............................................................................................................................ 2

1.2 Terminology used in this manual.............................................................................................................. 2

2. Product Outline

2.1 Outline and features ................................................................................................................................. 3

2.2 List of products ......................................................................................................................................... 4

2.3 Function ................................................................................................................................................... 4

2.4 Specification ............................................................................................................................................. 5

3. System Design Flow

4. Designing the LMAP03U .........................................................................................................8

4.1 Selecting the air conditioners................................................................................................................... 8

4.2 Selecting the function ............................................................................................................................. 10

4.3 Selecting the system control parts ......................................................................................................... 12

4.4 Object ..................................................................................................................................................... 14

4.5 Restrictions on system configuration ..................................................................................................... 16

5. Design and Operation of LONWORKS System

5-1 Constructing the LONWORKS network................................................................................................. 18

5.2 Function relating to installing ................................................................................................................. 19

5.3 Operation at power recovery.................................................................................................................. 20

5.4 Response restrictions on Poll (Fetch) demand ...................................................................................... 24

5.5 Operation/setting of air conditioner ........................................................................................................ 25

5.6 State monitoring ..................................................................................................................................... 27

5.7 Measurement (Analog value)................................................................................................................. 29

5.8 Trouble/alarm monitoring ....................................................................................................................... 30

5.9 Emergency stop ..................................................................................................................................... 31

APPENDIX 1. Outline of Functions – Network Variables

APPENDIX 2. Outline of Functions – Configuration Properties ..........................................................53

.....................................................................................................................3

..............................................................................................................7

..........................................................................18

..................................................................32

1

Page 5

1. Introduction

1.1 Purpose of this manual

This manual provides design information and restrictions required by the system designing in constructing

the LONWORKS ® network system using LM ADAPTER. For the items not described here, please refer to the

literatures shown below.

LM ADAPTER installation work : "Installation Manual of LM ADAPTER"

M-NET wiring and designing : DATA BOOK of air conditioner and the like

Network variable specification : "Network Variables Specification" of LM ADAPTER

1.2 Terminology used in this manual

This manual uses abbreviations for product names and unit classification partially. The main abbreviations

are given below. For the terminology relating to the LONWORKS, please see the Appendix of this manual.

LMAP : LM ADAPTER

BMS : Building management system

SC : System controller

IC : Indoor unit

OC : Outdoor unit

RC : Local remote controller

<MA remote controller (PAR-20MAU, etc.)>

<ME remote controller (PAR-F27MEA-US, etc)>

MA : Local remote controller <MA remote controller (PAR-20MAU, etc.)>

ME : Local remote controller <ME remote controller (PAR-F27MEA-US, etc)>

TR : Central controller

2

Page 6

2. Product Outline

r

r

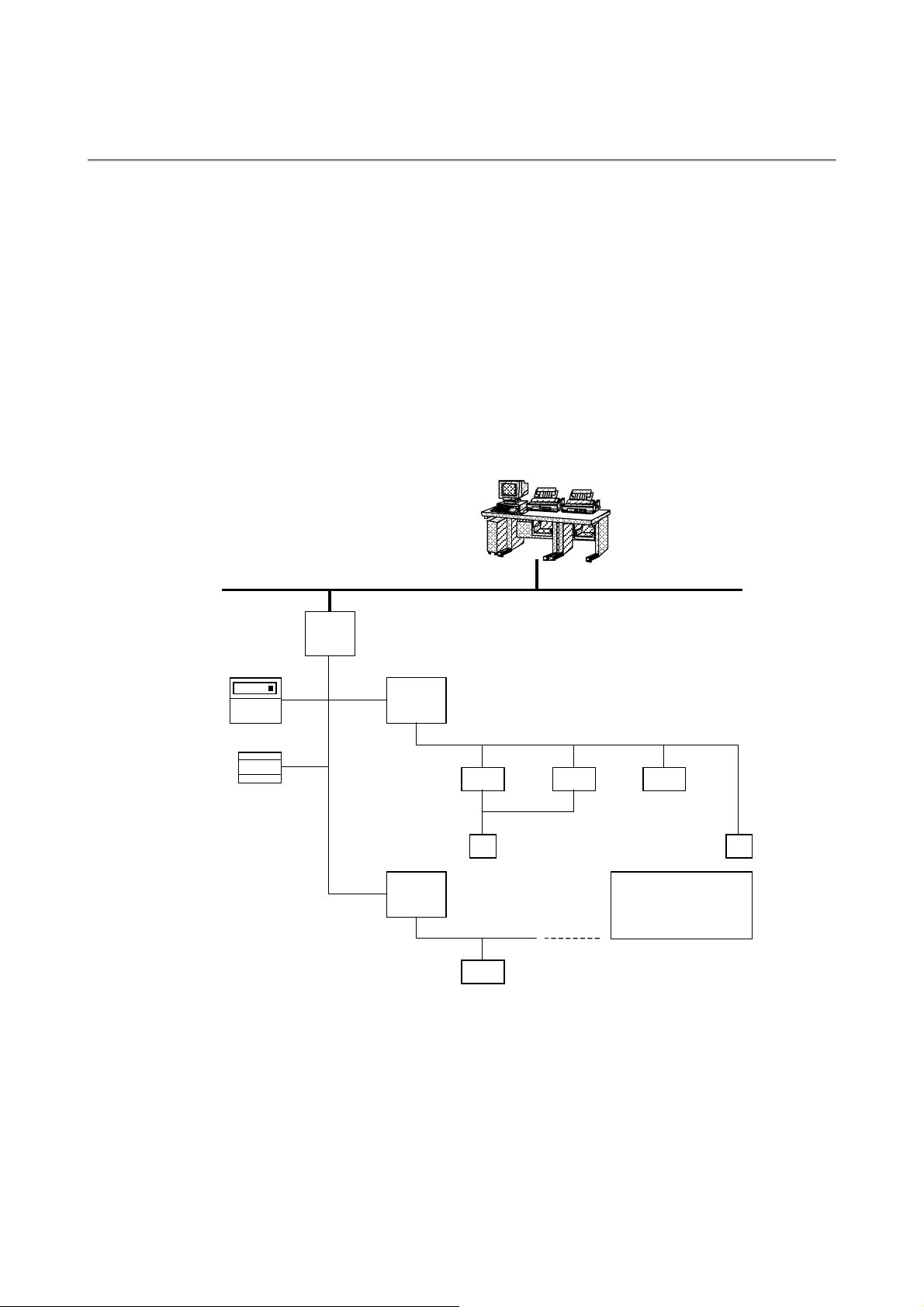

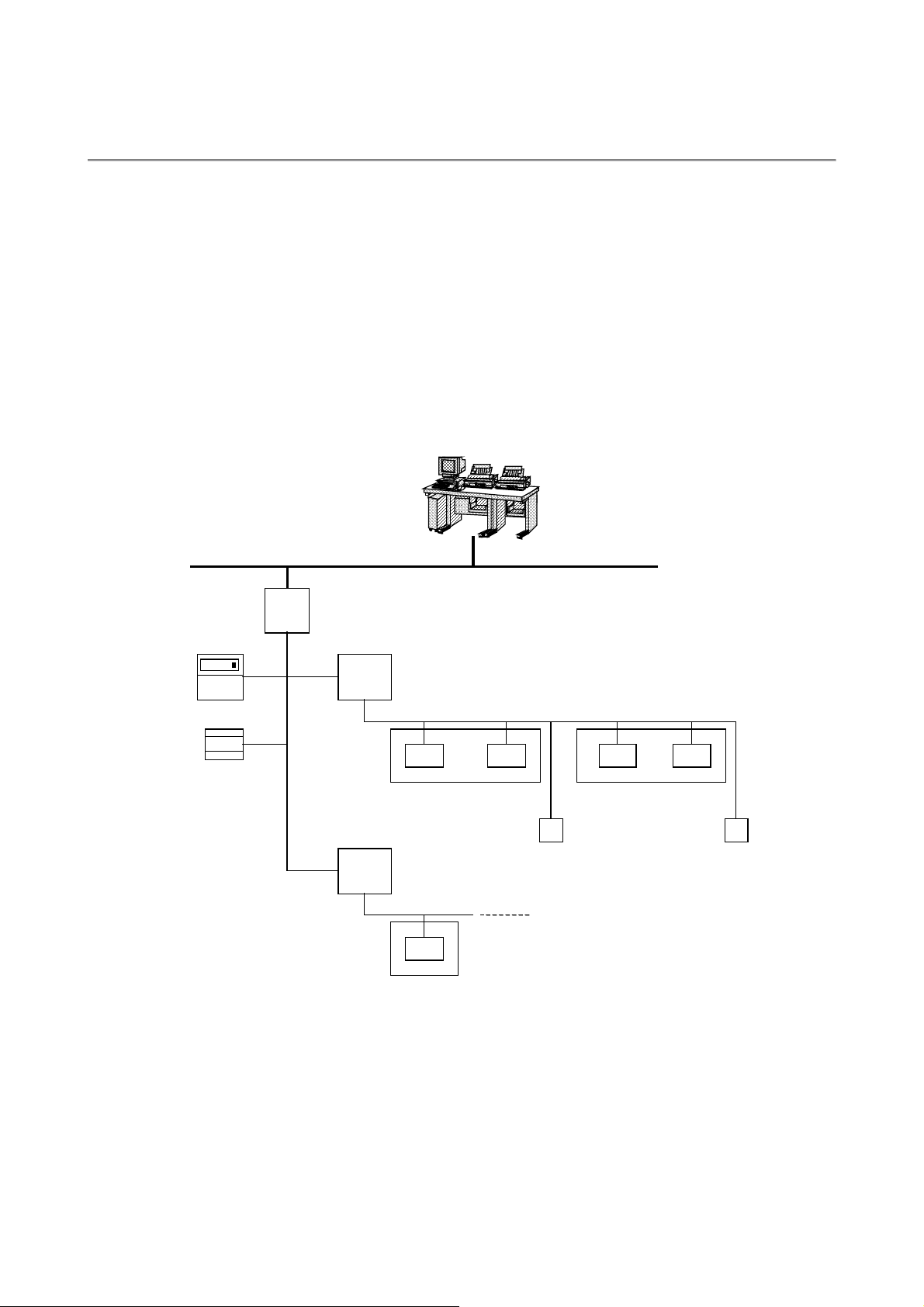

2.1 Outline and features

The LM ADAPTER is a communication interface to connect the Mitsubishi Electric made products for M-NET

use with the LONWORKS network. Only one LM ADAPTER can control and monitor indoor units up to 50

sets.

Since the LONWORKS network is an open protocol, connection with the Building management system

(BMS) and other products usable with LONWORKS can be performed easily thus allowing construction of

various systems including "Schedule operation," "Interlocked operation" and "Energy saving control".

<Features>

- Maximum 50 sets indoor units connectable with one LM ADAPTER

- Operation/monitoring with local remote controllers

- Standard Network Variables Type (SNVT) and enriched function (network variables)

- Various Configuration Properties (CP) essential for network construction

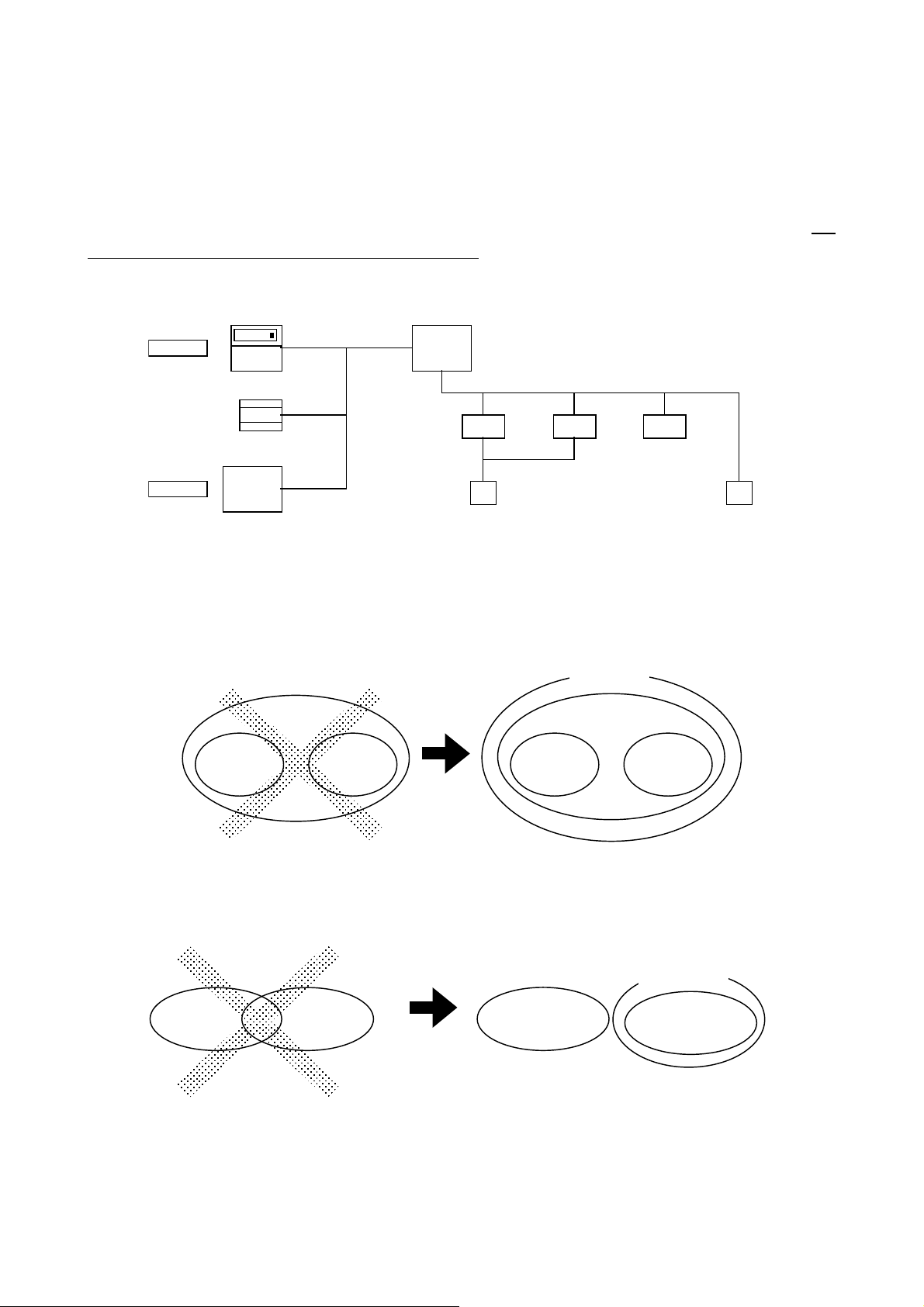

LONWORKS network

LMAP

IC

M-NET indoor-outdoor

transmission line

IC IC

System remote

controller

Power supply unit

OC

M-NET centralized control

Transmission line

MA

OC

IC

*Make sure to install the local remote

controller or system controller.

Figure 1-1. System configuration diagram (Example)

Building management

system (BMS)

OC:Outdoor unit

IC :Indoor unit

MA:MA remote controlle

ME:ME remote controlle

ME

3

Page 7

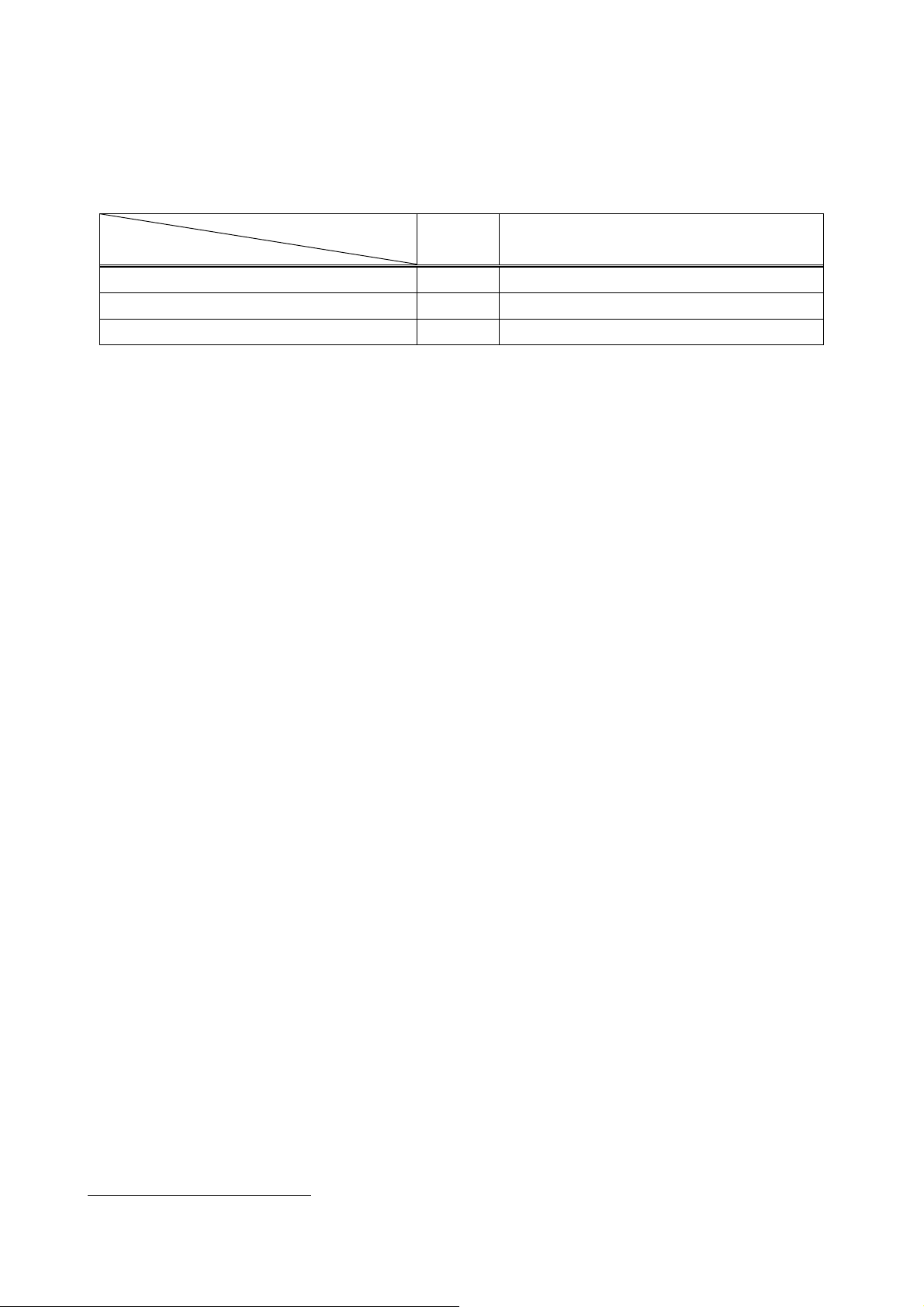

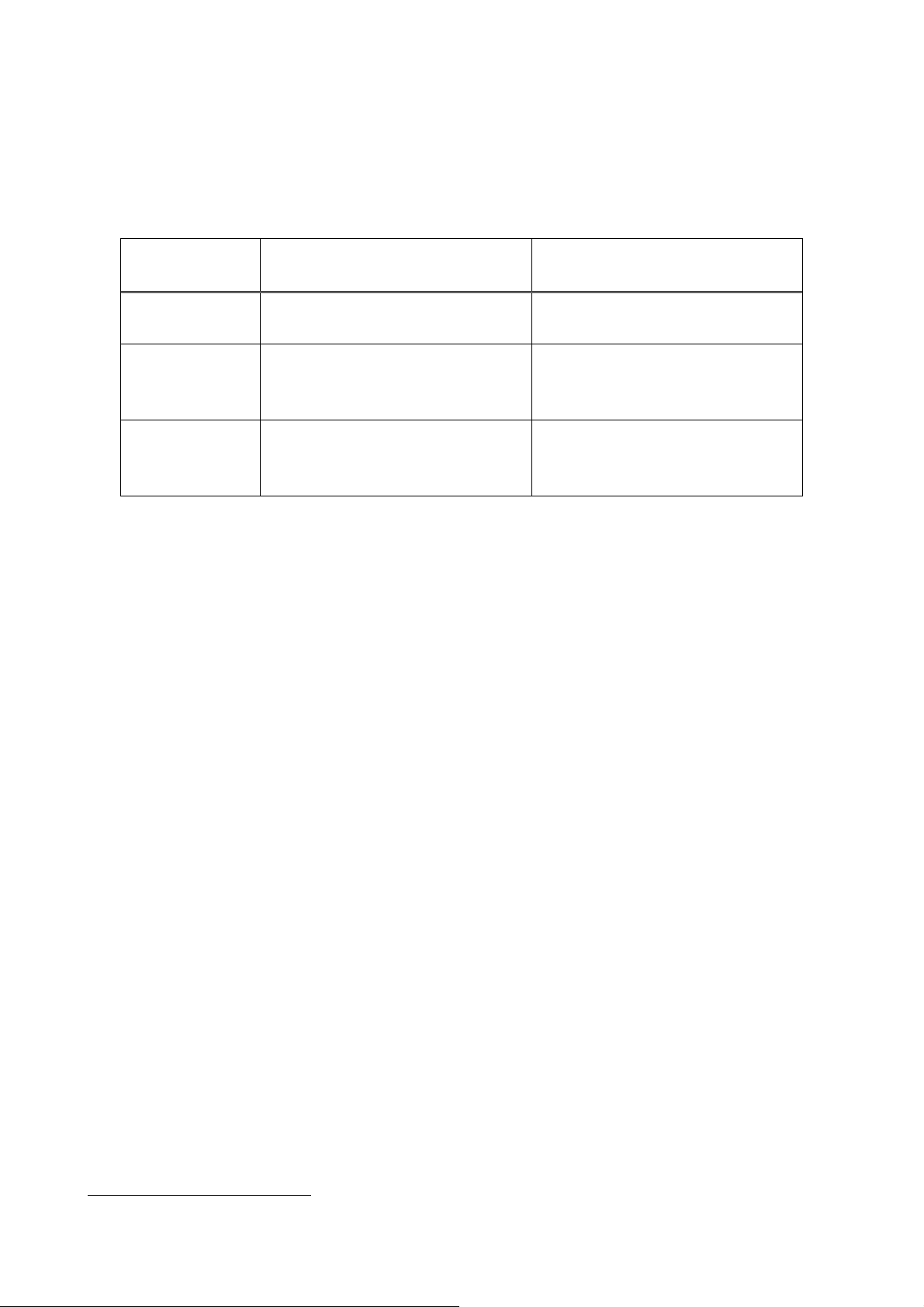

2.2 List of products

The air conditioners controllable with LM ADAPTER are shown below.

Model name Objective models for control

LMAP03U 1 CITY MULTI, LOSSNAY

2.3 Function

The basic functions of LM ADAPTER are outlined as below.

2

Items

Details

Emergency stop Stopping all air conditioners. Not prohibiting local remote controller operation.

ON/OFF Operating/monitoring ON/OFF state.

Mode Operating/monitoring the operation mode set for air conditioners & LOSSNAYs.

SetPoint Operating/monitoring the temperature set of air conditioners.

Fanspeed Operating/monitoring the fan airflow rate setting.

Local remote controller prohibit

Forced thermostat OFF Operating/monitoring the forced thermostat OFF of air conditioners.

Filter sign/Run time for filter Resetting/monitoring the integrated data of filter operation time.

Local remote controller setting

Defrosting state Outputting the defrosting status of all air conditioners.

Failure/alarm Outputting the failure of air conditioners, control panels and humidifiers.

LM ADAPTER

abnormal communication state

Air conditioner (charging) information

(thermostat status)

Air conditioner (charging) information

(capacity code)

Space temperature status Outputting the outlet and inlet temperature of each air conditioner.

Operating/monitoring the operation prohibit of local remote controllers.

(ON/OFF, operation mode, temperature setting, batch)

Setting the local remote controller.

(Time, temperature setting range, simplified locking, actual operation mode display, room

temperature display)

Outputting the communication error if existed between LM ADAPTER and air conditioners.

Outputting each state of the operation/thermostat/auxiliary heater of air conditioners.

Outputting the capacity code of air conditioners.

1

North America model

2

The applicable function differs depending on the objective models for control.

4

Page 8

2.4 Specification

(1) Product specification

Dimension 340mm(Height) x 360mm(Width) x 59.6mm(Depth)

Weight 3.4 kg / 7 ½ lb

Power source

Power consumption 10 W

Data holding Memorizing binding information, address information on air conditioners

Environmental

condition

Installation method Mountable in horizontal or vertical direction

External finish Galvanized steel plate

Alias 100 pieces

Explicit message Not applicable yet

Neuron ID Indicated on the seal attached to circuit board (differs by product)

Program ID Indicated on the seal attached to circuit board (differs by product)

Neuron chip

Network transceiver FTT-10A (Free topology 78kbps) 1 piece

Items 1 Specification

13 7/16(Height) x 14 3/16(Width) x 2 3/8(Depth) in

~ 208 – 230V (60Hz)

and set values in nonvolatile memory. Input/output variables are not

held.

Temperature

Humidity 30 to 95 %RH (No condensation allowed)

Operating

Non operating

- 15 to 43 ℃ / 5 to 109 °F

- 20 to 60 ℃ / - 4 to 140 °F

For vertical installation, locate in the direction of the pasted seal.

TMPN3150(10MHz) 1 piece

(2) Performance

Mean communication capacity 2.5 input / second

Peak communication capacity 50 input / second (for 1 second)

Response capacity for poll demand 15 demand / second

Items 2 3 Specification

1

For the detail specification of the LONWORKS network, see the data published by Echelon. "FTT-10A Free Topology Transceiver User's Guide"

2

Transmitting with an interval time exceeding the capacity hinders normal receiving. Please take a sufficient interval.

3

The Ack Service is recommended for your network service.

5

Page 9

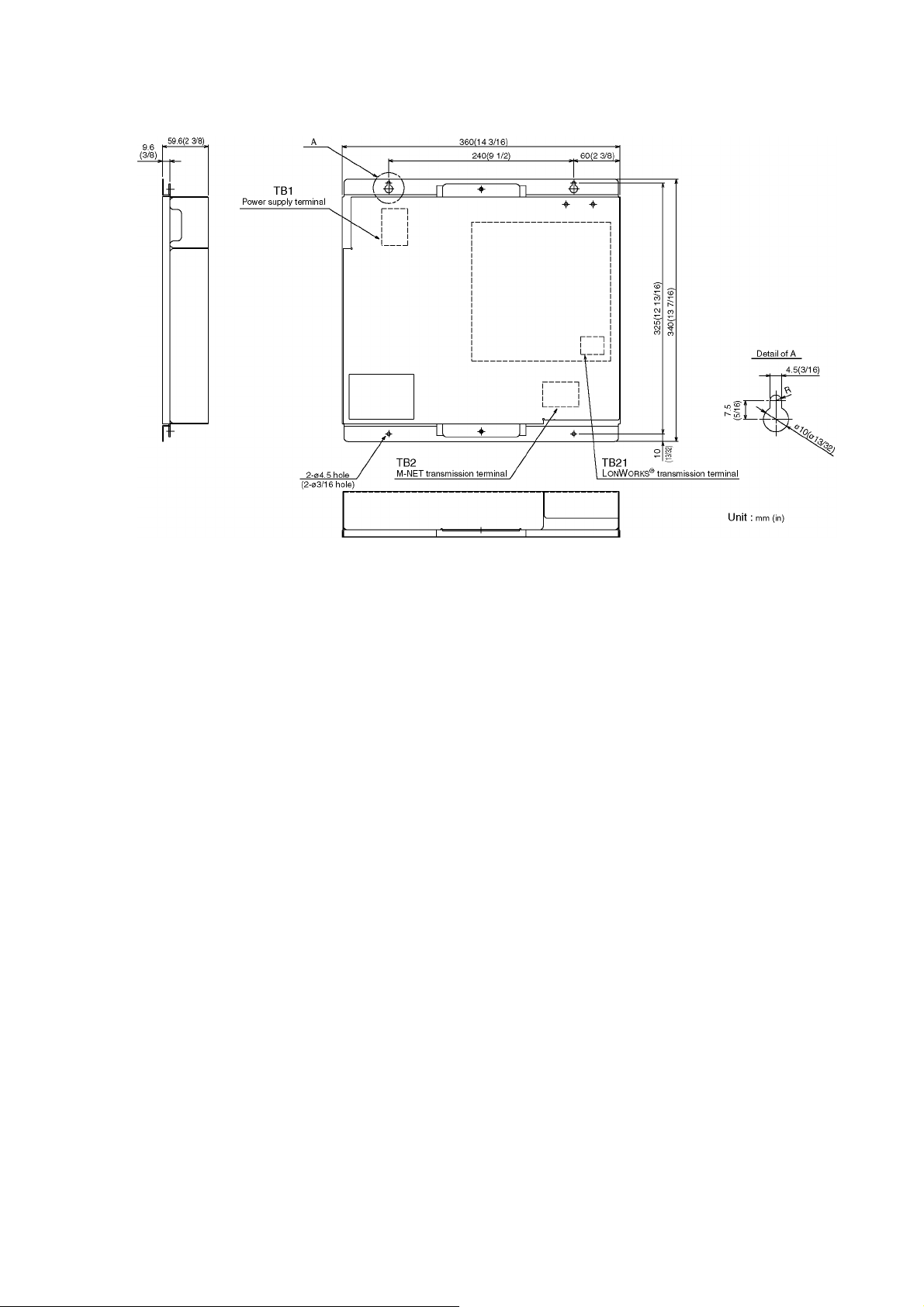

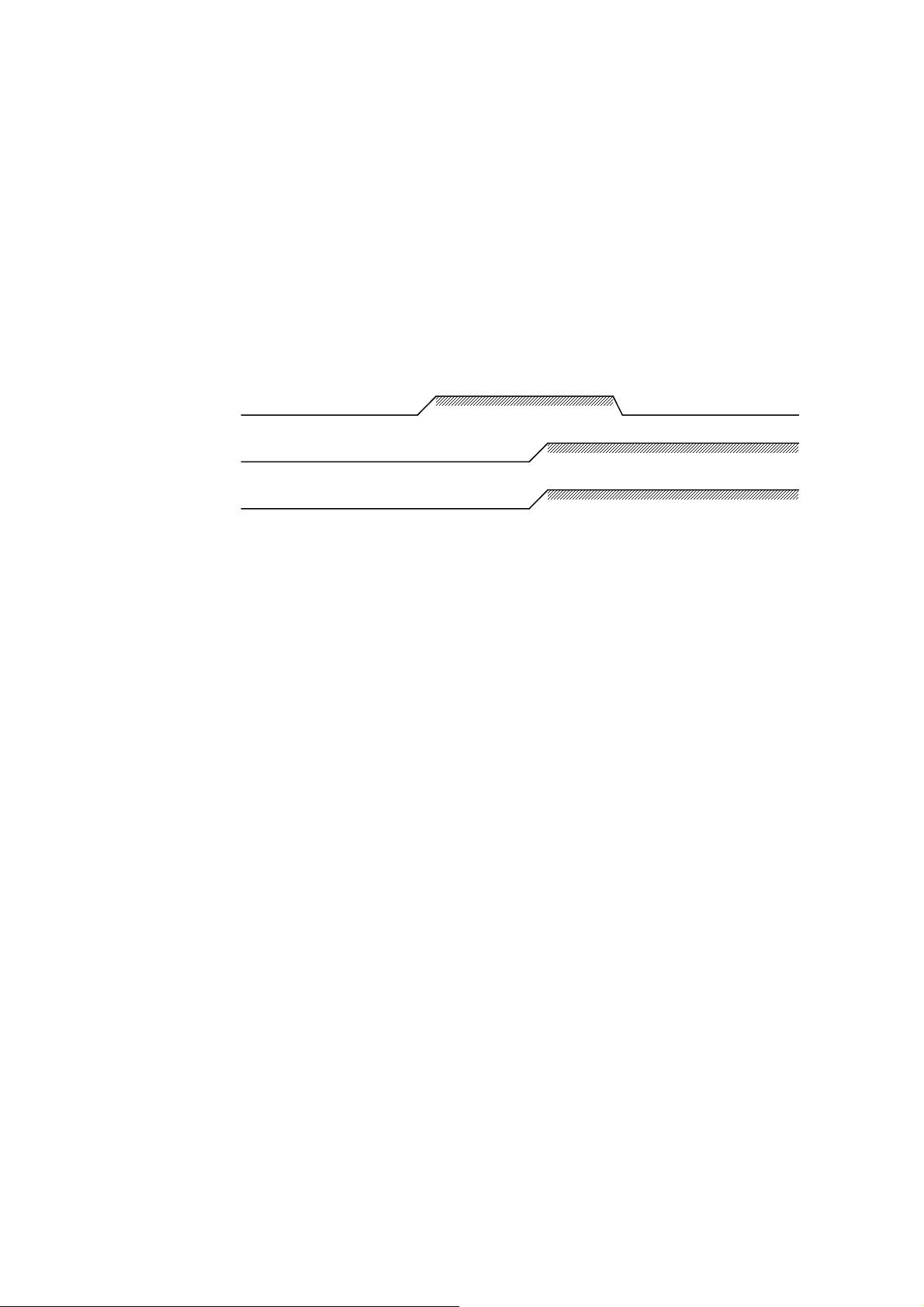

(3) External dimension

6

Page 10

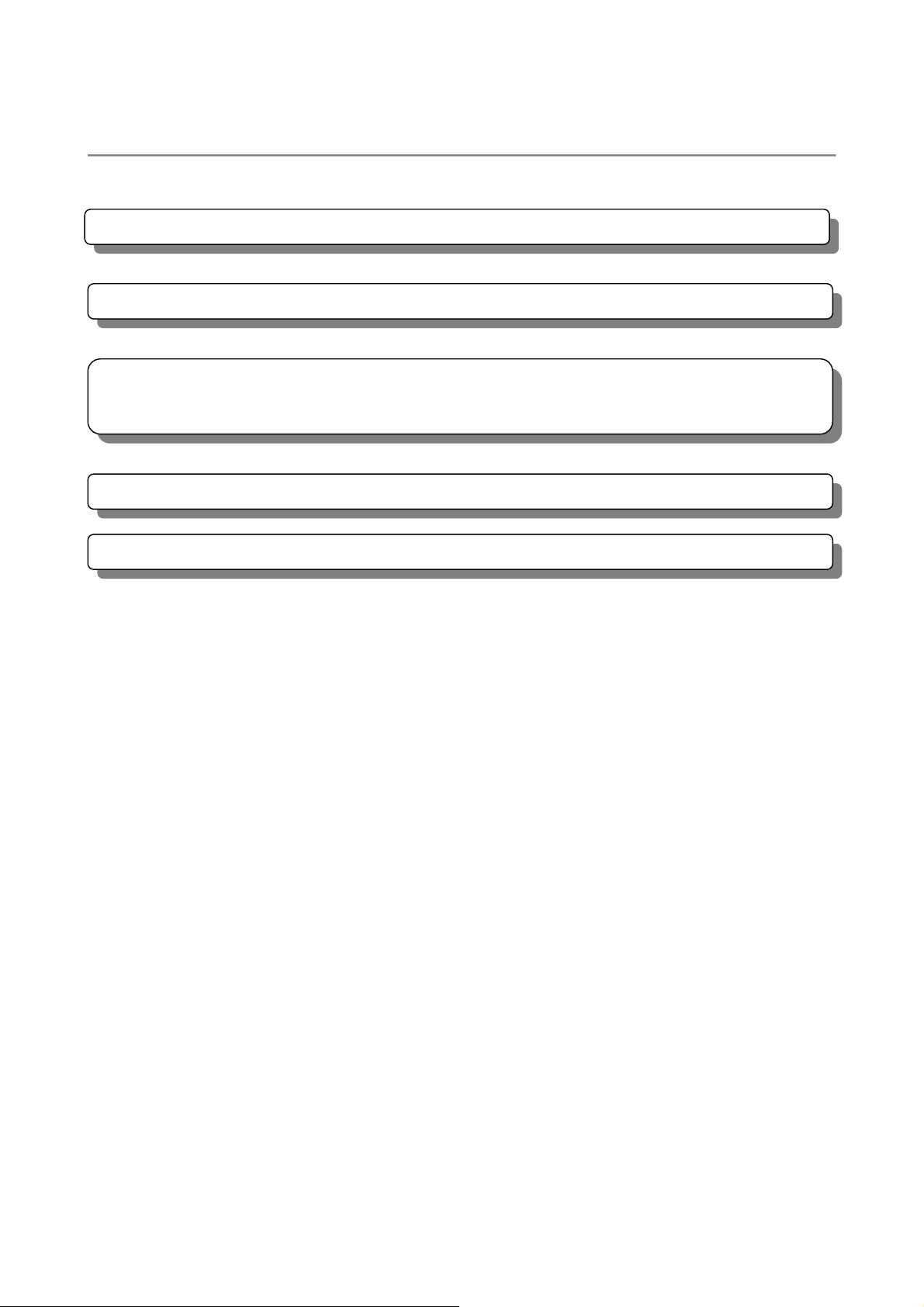

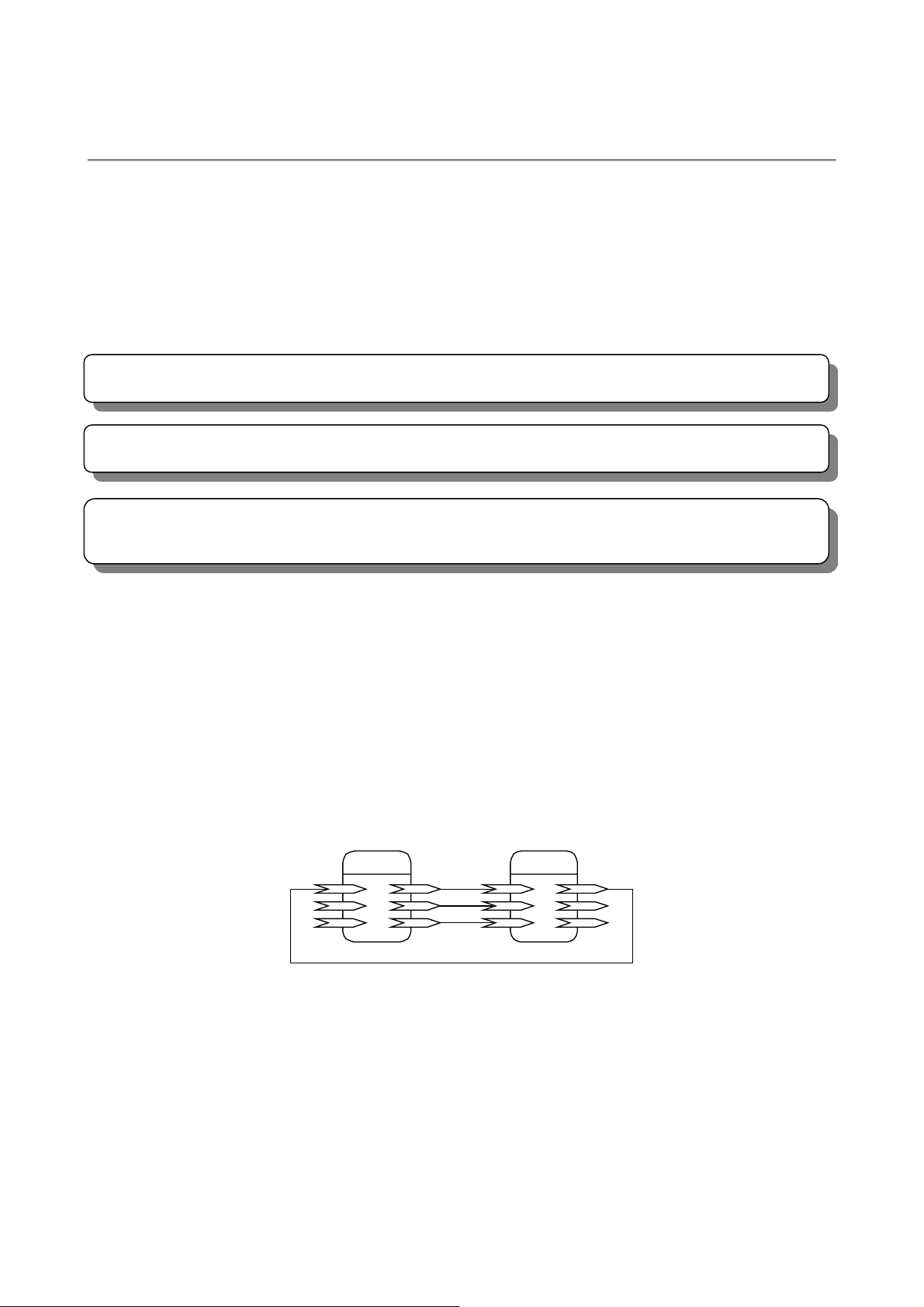

3. System Design Flow

The following indicates design flow to construct the system of the LONWORKS network by LM ADAPTER.

Step 1: Selecting the air conditioners (objective equipment for control, restrictions, etc.).

Step 3: Selecting the system control parts

(Quantity of LM ADAPTER, other system controllers, etc.).

Step 4: Determining the air conditioner addresses.

Step 5: Constructing the LONWORKS system.

7

Page 11

4. Designing the LMAP03U

r

r

This section summarizes the air conditioners controllable with LM ADAPTER and various restrictions to be

applied. For the details of air conditioning equipment, please refer to the manual of each air conditioner.

4.1 Selecting the air conditioners

4.1.1 Controllable quantity

One LM ADAPTER can control indoor units up to 50 sets. The number of LOSSNAY (including ventilation

units) is to be included in this figure.

4.1.2 Range of group control

When using other SC in combination, the control can be performed within the group range set by the SC.

When not using other SC in combination, group control cannot be performed.

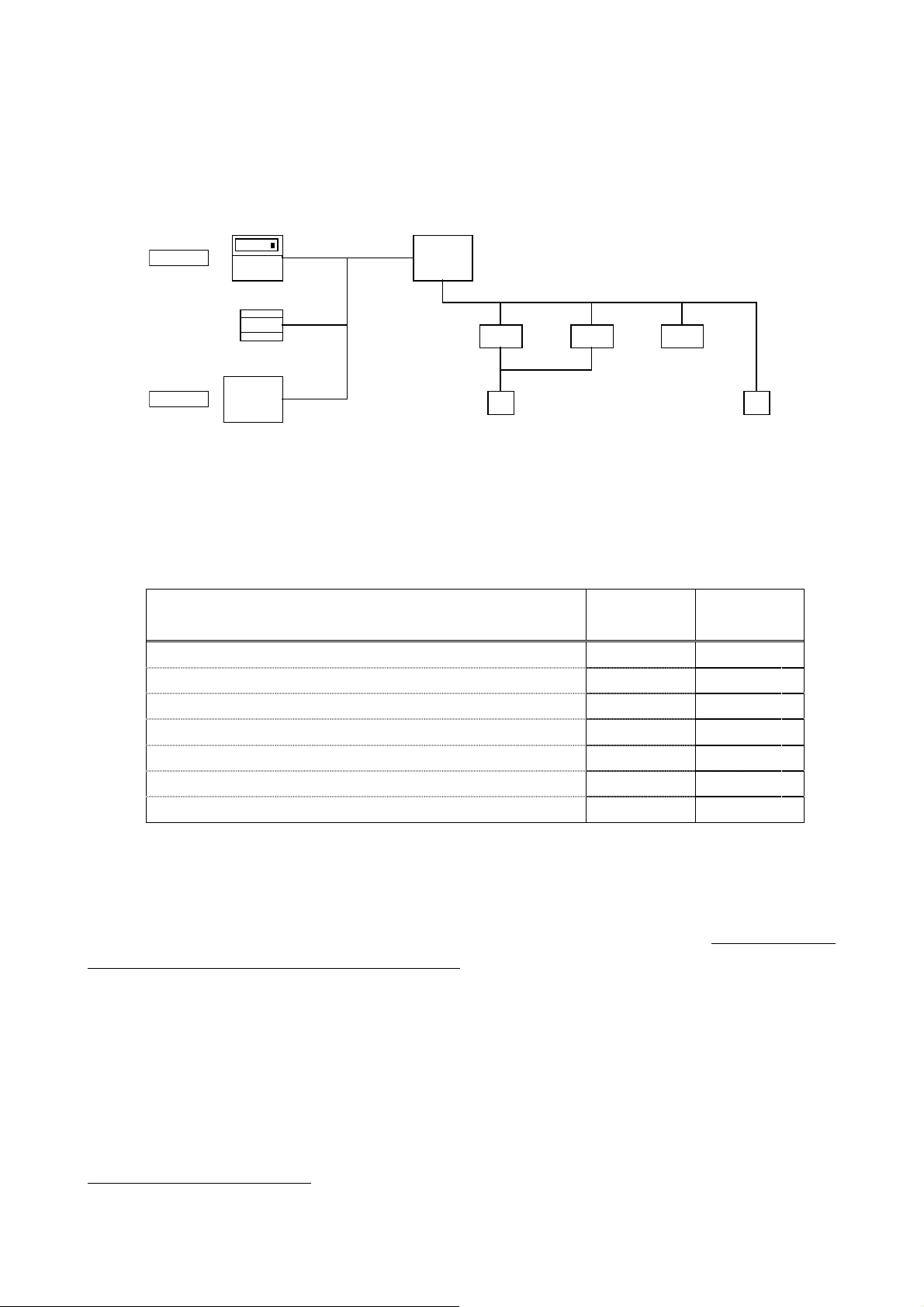

BMS

LONWORKS network

System remote

controlle

Po wer su pply u nit

LMAP

transmission line

M-NET centralize control

OC

OC

M-NET indoo

transmission line

IC IC IC

Group1 Group2

IC

Group3

Figure 4-1. System configuration (Example)

-outdoor

IC

ME

*Make sure to install a local remote

controller or system controller.

ME

8

Page 12

4.1.3 Objective equipment for control

The following table lists the objective air conditioners for control.

Some indoor units own the plural M-NET addresses. For counting the connected numbers, refer to the table

below.

O : Controllable x : Uncontrollable △ : Controllable depending on connected models

Function

LMAP03U Counting method of connected quantity

Models

CITY MULTI

PAC for general purpose/industrial application

K-control unit 1

○

×

× -

Quantity of indoor unit

4.1.4 Connecting location

Connect LM ADAPTER to the centralized system transmission line of air conditioners.

4.1.5 Restriction on M-NET transmission wiring

As the M-NET transmission line has restrictions on its wiring length, wire materials, etc. in accordance with

the system configuration, the design should be conducted taking the transmission lines of air conditioners and

control equipment into your consideration. For detail, please refer to the manuals such as the "DATA BOOK"

of each air conditioner.

1

Unable to control/monitor even by connecting the K-transmission converter.

9

Page 13

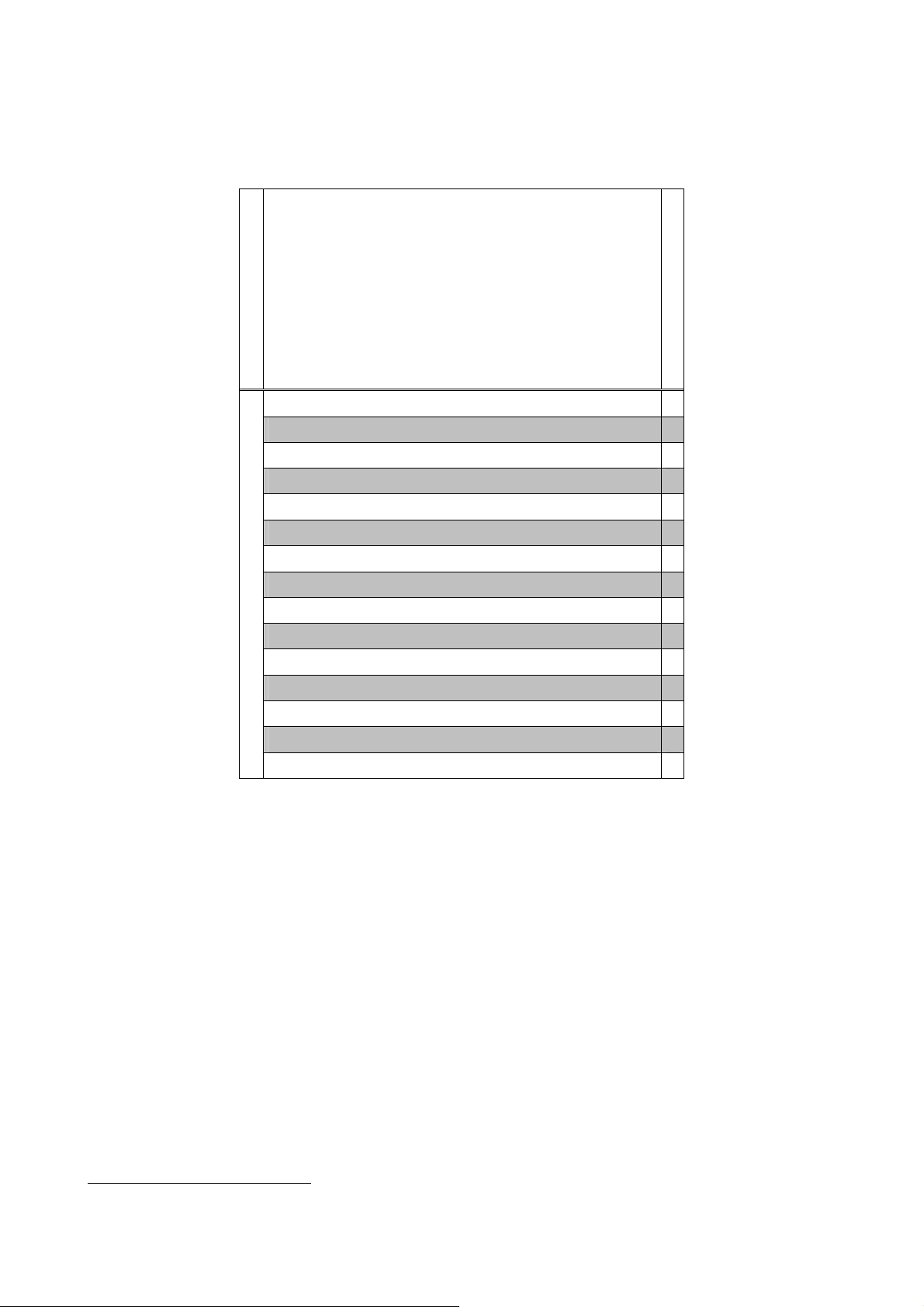

4.2 Selecting the function

The list below shows the operation/monitor function of LM ADAPTER.

(1) Operation/Setting

◎: With function ●: Individual -: Without function

Function

CITY MULTI

Request All OFF (Emergency stop)

Request On/Off

Request Mode

SetPoint

Request LOSSNAY Mode

Operation/Setting

Request Fanspeed

Request Local Prohibit On/Off 1

Request Local Prohibit Mode 1

Request Local Prohibit SetPoint 1

Request Collective Operation Prohibit 1

Request Forced Thermostat OFF

Filter Sign Reset

Time Stamp 2

Request Limit Temperature Setting Range 2

Request Simplified Locking 2

●

●

●

●

-

●

●

●

●

●

●

●

●

●

●

1

Applicable only at using of MA remote controller (PAR-20MAA) for a local remote controller.

2

Applicable only at using of ME remote controller (PAR-F27MEA) for a local remote controller.

10

Page 14

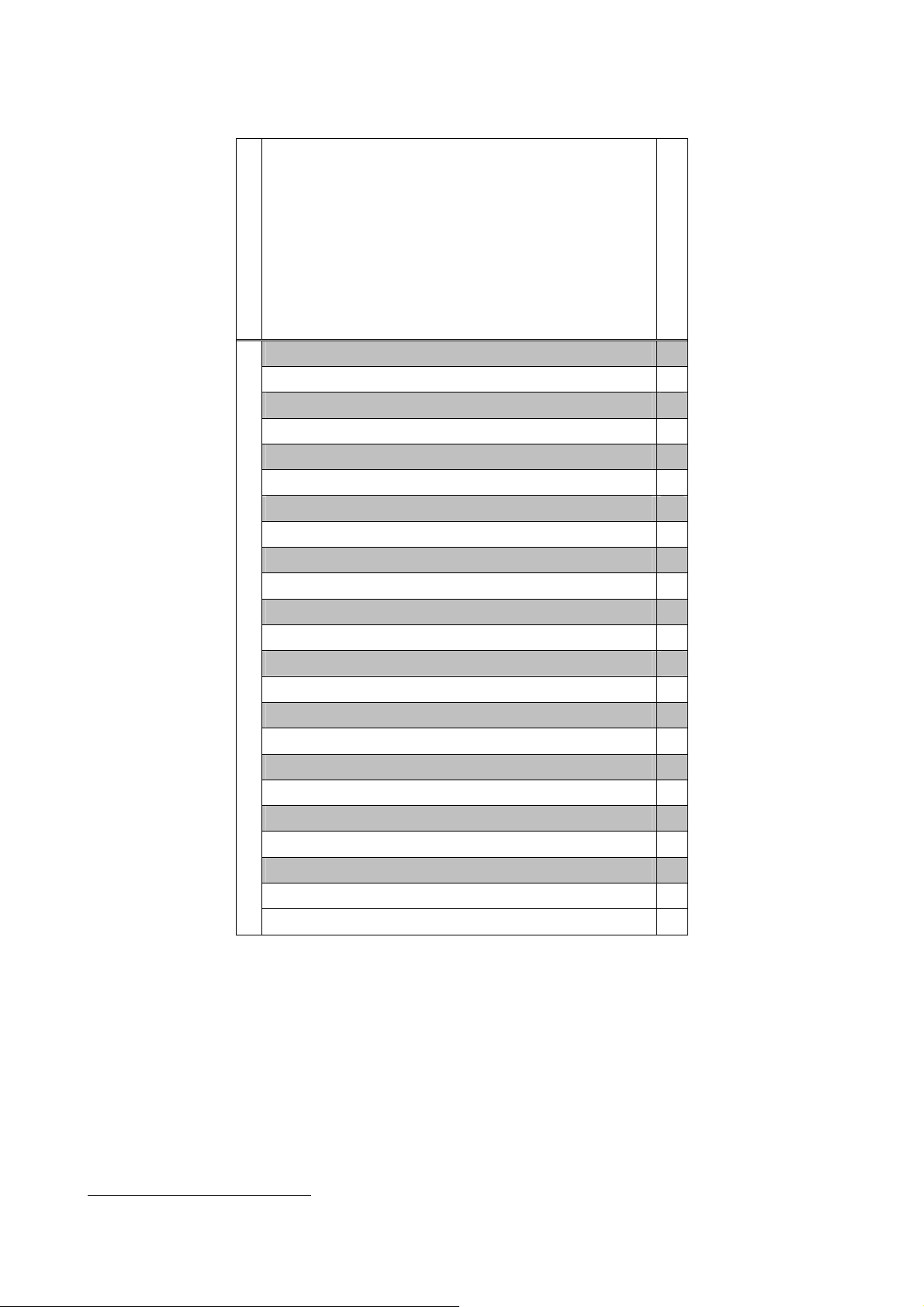

(2) Monitoring/Measuring

◎: With function ●: Individual -: Without function

CITY MULTI

Function

Emergency state

On/Off run state

Collective On/Off state

Mode state

SetPoint state

LOSSNAY Mode state

Fanspeed state

Local Prohibit On/Off state 1

Local Prohibit Mode state 1

Measuring/Monitoring

Local Prohibit SetPoint state 1

Collective Local Prohibit state 1

Forced Thermostat OFF state

Filter Run Time

Space Temperature

Alarm state

Collective Alarm for Indoor Unit

Collective Alarm for LM ADAPTER

Error Code

Error Unit Address

Thermostat On/Off state_1

Thermostat On/Off state_2

Model Code

Defrost state

●

●

●

●

●

-

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

1

Applicable only at using of MA remote controller (PAR-20MAA) for a local remote controller.

11

Page 15

4.3 Selecting the system control parts

g

g

g

rang

Using the system controller (SC) together other than LM ADAPTER allows connecting operation. Some

rules to be observed for this purpose are introduced below.

4.3.1 Master controller and slave controller

When LM ADAPTER is used together with other system controller inside a system under own control, it is

essential to set a slave SC(requiring a DIP-SW change). In this case, set it so that the control range of LM

ADAPTER is included within the control range of the system controller (air conditioner) which is to be the

master SC.

M-NET centralized control

Mas t er S C

System remote

controller

transmission line

OC

M-NET indoor-outdoor

transmission line

IC IC IC

MA

ME

Slave SC

Power supply unit

LMAP

Figure 4-2. System configuration of system controller

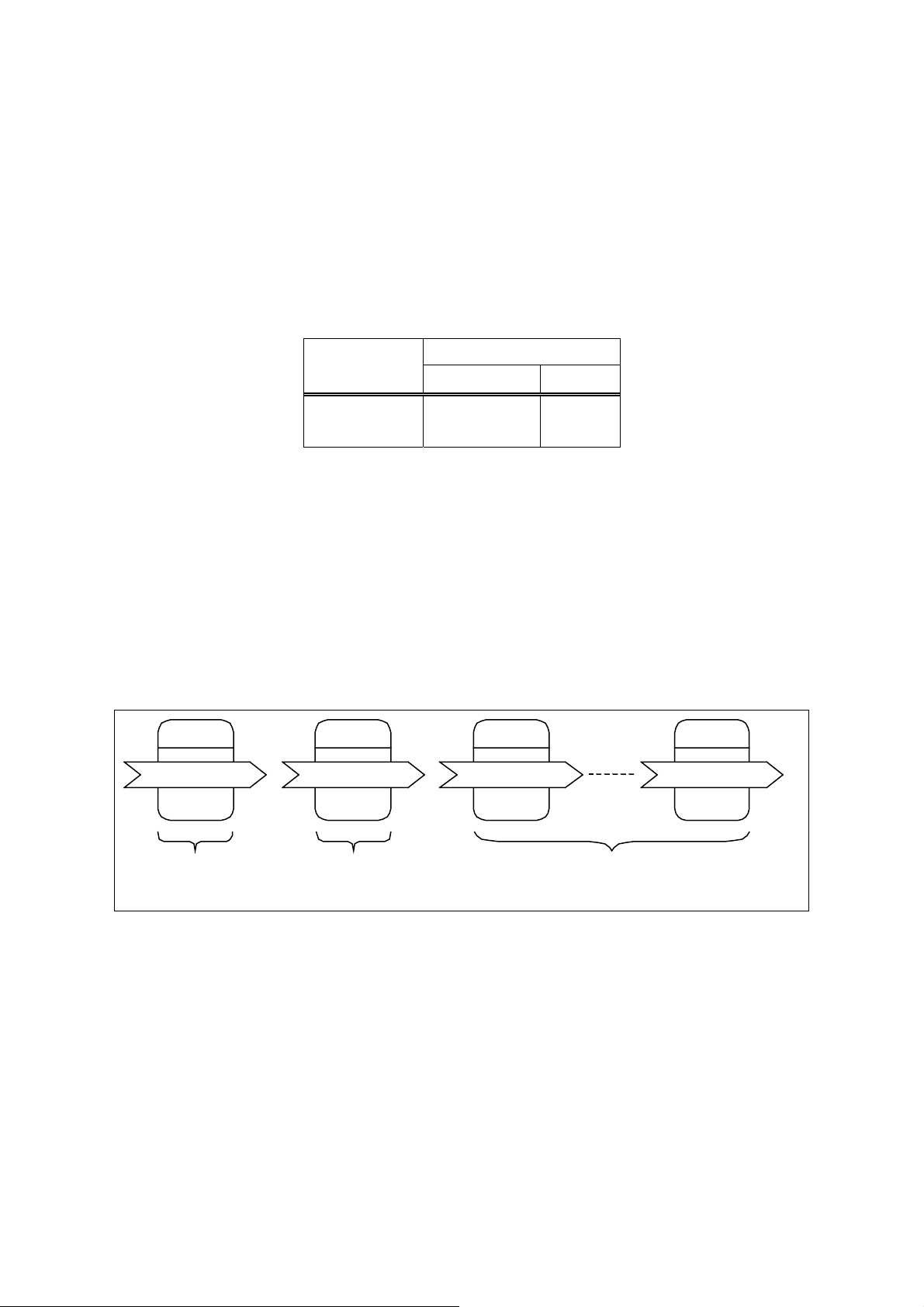

(1) In the case when the control range of the LM ADAPTER is covering that of plural system controllers, make

sure to install the Master system controller that covers the LM ADAPTER control range.

SC1

control

ran

Master SC

LM ADAPTER

control range

e

SC2

control

e

SC1

control

ran

LM ADAPTER

control range

e

SC2

control

e

ran

(2) In the case when the LM ADAPTER control range is covering the control range of the system controller

partially, install the system controller so that it covers the entire control range of LM ADAPTER.

SC2

control range

SC1

control range

LM ADAPTER

control range

SC1

control range

LM ADAPTER

control range

12

Page 16

4.3.2 Local remote controller

r

The local remote controller includes ME remote controller (PAR-F27MEA, etc.) to be connected to the

M-NET indoor-outdoor transmission line of air conditioners and MA remote controller (PAR-20MAA, etc.) to be

connected to each indoor unit. Each remote controller provides a different function usable by LM ADAPTER

and a different system construction method.

M-NET centralized control

Mas t er S C

System remote

contoller

transmission line

OC

M-NET indoo

transmission line

-outdoor

IC IC IC

MA

ME

Slave SC

Power supply unit

LMAP

Figure 4-3. System configuration of local remote controller

(1) Comparison of function by local remote controllers

The usable function (network variables) by LM ADAPTER differs depending on the model of the local remote

controllers (MA remote controller/ME remote controller).

Function (NV names)

Request Local Prohibit (ON/OFF , Mode , SetPoint)

Local Prohibit State (ON/OFF , Mode , SetPoint)

Request Collective Local Prohibit

Collective Local Prohibit State

Time Stamp

Request Limit Temperature Setting Range

Request Simplified Locking

MA remote

controller

○ △

○ △

○ △

○ △

× △

× △

× △

ME remote

controller

1

1

1

1

2

2

2

○ : With function △ : Possible with limitation ×: Without function

(2) Caution on a system without using remote controller

The following problems will be incurred when the operation/monitoring is done only from the BMS

(centralized monitoring system) without using the local remote controller. Therefore, please be sure to install a

local remote controller or system controller without fail.

① Test run can not be applied to air conditioners until the BMS has started up.

② Air conditioners can not be operated or monitored when trouble is generated on the BMS and

LM ADAPTER.

③ The detail of the trouble i.e. the stopping of indoor units can not be clarified.

④ The operation/setting of the items other than that controlled by the BMS cannot be performed.

⑤ Interlocked setting of LOSSNAY and air conditioners can not be performed.

1

Applicable to some model of CITY MULTI air conditioners ( manufactured after January 2003 ) even when using ME remote controller.

2

Applicable when only using ME remote controller for the standard models except the medium temperature models.

13

Page 17

4.3.3 External contact input/output

g

y

The external contact input/output function is not provided to LM ADAPTER.

4.3.4 Power supply to M-NET transmission line

The M-NET centralized system controller line should be powered. For the system using other system

controller or that with LOSSNAY only, the power supply unit for transmission line is required. In accordance

with the system configuration, the setting of LM ADAPTER and outdoor units should partially be changed.

Please conduct the setting operation by referring to the "Installation Manual" of LM ADAPTER. For the power

supply capacity of the power supply unit and the selection of the unit, please refer to the manuals (like DATA

BOOK) of each air conditioner.

Installation of power supply unit

Individual With SC

LMAP02-E

LMAP03U

Not required Required

4.4 Object

4.4.1 Network variables and objects

The network variables provided allows the LA ADAPTER to operate/monitor plural equipment (indoor unit,

LOSSNAY, etc.) The functional profile (object) represents the network variables collected for each objective

equipment to be controlled. Here the objects and network variables are outlined, and the relationship with air

conditioners is explained. For the detail of each object and the specification of the network variables, please

refer to the "Network Variables Specification" of each product.

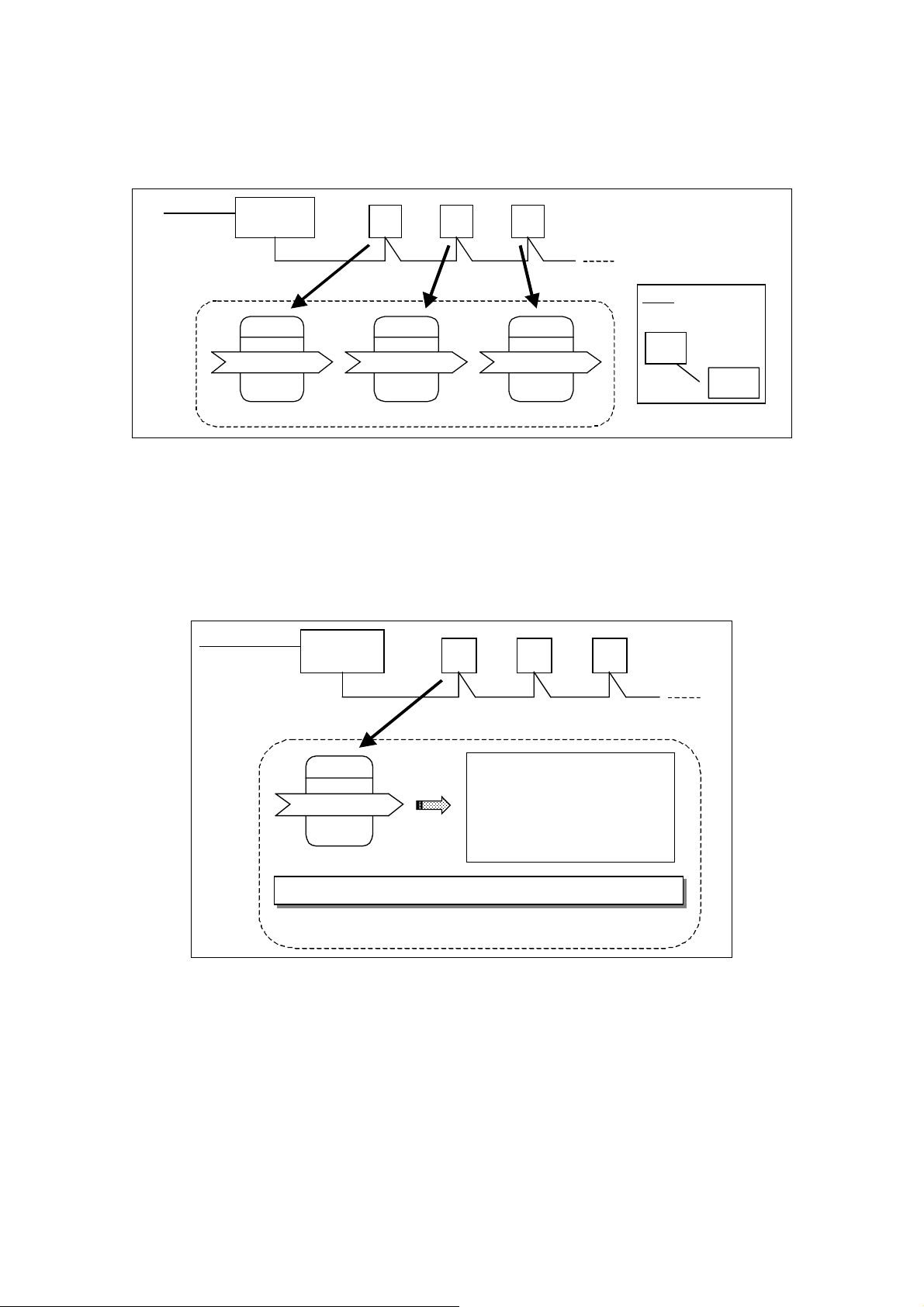

(1) Object configuration of LM ADAPTER

Node

Object

Indoor [0]

Indoor [1]

Indoor [50]

For node object

For collective variables

and confi

uration propert

For indoor unit

14

Page 18

(2) Object and equipment address

transmissio

e

r

p

The object for indoor units is individually related with the objective equipment for control. The object (Indoor

[1] ~ Indoor [50]) corresponds to the indoor unit (LOSSNAY, ventilation unit, Mr. SLIM) with the M-NET

address of 01 ~ 50 being set to each equipment.

Outdoor unit

M-NET centralized

control transmission line

Indoor [1]

051

IC

001

Indoor [2]

Object of LM ADAPTER

IC

002

IC

003

M-NET Indoor-outdoor

n lin

Indoor [3]

Legend

OC:Outdoor unit

IC:Indoor unit

IC

05

M-NET

address

4.4.2 Network variables and air conditioner address

LM ADAPTER owns the network variables for each air conditioner. The network variables include

set/monitor of an air conditioner individually and to set/monitor of all air conditioners collectively.

Please set so that the M-NET address of the objective air conditioner for control will agree to the name of the

variable.

Outdoor unit

051

IC

001

IC

002

IC

003

M-NET centralized

control transmission line

Indoor [1]

For No.1 indoor unit

Network variable name →Function name + M-NET address (3-digit display)

Relationshi

Request On/Off:

On/Off run state

SetPoint

between M-NET address and Network variables

SetPoint state :nvoSetP_001

:

:

:

M-NET Indoo

transmission line

nviOnOff_001

:

nvoOnOff_001

:

nviSetP_001

:

:

:

-outdoor

15

Page 19

4.5 Restrictions on system configuration

The restrictions in constructing the system by LM ADAPTER are outlined here.

4.5.1 Restrictions by system configuration

(1) Group control

In the case when the group setting of indoor units are carried out by the local remote controller or system

controller, the operation from the BMS is performed as follows.

Group setting Operation Monitoring

No setting

(individual)

Setting by the local

remote controller

Setting by the system

controller

Required to issue a same command to all

Principal 1 unit in the same group

When using “Forced Thermostat OFF” is

required to request into indoor units individual

every unit every unit

every unit

every unit

indoor units

every unit

4.5.2 Restrictions by control items

(1) Operation prohibit

① When using together the system controller that can set to prohibit the local remote controller operation,

make the controller for setting of operation prohibit one unit, either LM ADAPTER (BMS) or the system

controller.

② Operation prohibit can not be applied to other system controllers by LM ADAPTER (from BMS)

③ Although

they can be operated by LM ADAPTER (BMS) or other system controllers.

air conditioners can not be operated by the local remote controller of which operation is being prohibited,

1

At the unit of lowest address in the same group

16

Page 20

(2) Emergency stop

The emergency stopping of LM ADAPTER stops all air conditioners together, however it does not set the

operation prohibit of the local remote controller allowing the operation from other system controller or local

remote controller. To prohibit operation from the local remote controller, therefore, set it by entering

[Request Collective Local Prohibit] (collective).

*Operating to run during emergency stopping only results in immediate stopping.

(3) Operation mode

In the case of cooling/heating selectable models of CITY MULTI, the operation mode will be determined by

the principle of the "Priority for former pressing." Under the circumstance, a same command should be

issued to all indoor units within a same refrigerant system to change the operation mode.

Indoor unit 1

Indoor unit 2

Outdoor unit

Coo l

Coo l

Coo l

Heat (Inoperable)

Cool (Inoperable)

Hea t

Hea t

17

Page 21

5. Design and Operation of LONWORKS System

This section introduces the mechanism, function and operating method of LM ADAPTER in configuring the

system of LONWORKS network by LM ADAPTER. As the operating method shown here represents just one

of the examples, you are kindly requested to carry out your designing to meet the system configuration or

operation in the actual system.

5-1 Constructing the LONWORKS network

The flow of installation procedure for LONWORKS network is shown below.

Step 1: Addressing (to determine the address of each node)

Step 2: Binding (to connect network variables)

Step 3: Configuration (for optimum service of each connection, adjustment of

re-transmission frequency and interval)

(1) Addressing

An address is assigned to each node (equipment applicable to LONWORKS) on the LONWORKS network.

Set this address by using the install tool. Setting by using LM ADAPTER is not necessary.

(2) Binding

The network variables between each node should be related with the exclusive tool like LonMaker for

Windows ® or the like.

(3) Configuration

For the configuration property of LM ADAPTER, the initial value was set at factory shipment. The set value

may be changed depending on the configuration or operation of the network.

=

BMS Indoor [1]

Binding of network variables

=

18

Page 22

5.2 Function relating to installing

(1) Service pin (Service switch)

The service pin is used at the installation of LONW ORKS network.

Pressing the service pin sends out the service pin-message (control message including Neuron ID and

Program ID) to the network.

(2) Service LED

The service ID indicates the present state of the product.

In the case of LM ADAPTER under the shipment state (Non-configured state), the service LED is blinking.

(3) WINK

Upon receipt of the WINK message from the LONWORKS network, LM ADAPTER blinks the maintenance

LED 001 for about 10 seconds.

(4) Commission

After completing the binding, the set detail is reflected on the node. Doing this way allows communication

between the nodes on the LONWORKS network.

(5) XIF

To design the LONWORKS network, the configuration information of each node, interface (network

variables), etc. are required. When the product is already in your hand, such information can be obtained from

the LONWORKS network. Without the product, however, you may get it from XIF (eXternal Interface File)

locating the interface information of the product.

19

Page 23

5.3 Operation at power recovery

5.3.1 Outline of LM ADAPTER operation

After the power source is applied (the same as the power recovery after instantaneous power stop/power

failure), LM ADAPTER requires a time for initialization to collect the connection and operation state of air

conditioners up to 50 sets to be controlled. As the operation timing differs depending on the setting of

configuration property, you are kindly requested to carry out designing to meet the system operation.

LMAP

power source

Neuron chip

operating state

Event output

Relating configuration property

- Send Start Time

- Send Heartbeat Start Time( nciStartHrtBt

Communication

Timing

(

nciSet_1)

Send Heartbeat Start Time

(nciStartHrtBt)

(A) (B) (C)

- Initialize Start Time( nciInitStartTm)

(

nciStartOutTm)

)

(A) (B) (C)

Operation/setting from BMS Not applicable Applicable Applicable

Monitoring by Poll (Fetch) from BMS Not applicable Applicable Applicable

Output from LM-AP at changing Not applicable Not applicable Applicable

20

Page 24

5.3.2 Setting relating to operation after power recovery

(1) Setting of Neuron Chip communication start time

The communication start timing of NC can be set through “Communication Timing 【nciSet_1】”.

① "initialize"

Upon completion of the connection between LM ADAPTER and air conditioner, NCstartsoperation. Up to

this time, NC will not reply (even without returning of Ack).

This operation is specifically used to acquire the state of air conditioners by Poll (Fetch)demand.

② "setting time"

Synchronized with the shortest time among the set times of the configuration property below, NC starts

operation. Up to this time, NC will not reply (even without returning of Ack).

This operation is specially used to acquire the state of air conditioners by event (at changing) output.

- Send Start Time 【nciStartOutTm】

- Send Heartbeat Start Time 【nciStartHrtBt】

- Initialize Start Time 【nciInitStartTm】

LMAP power source

NC operation

[ initia liz e ]

Related configuration property

[ setting time ]

Set time

Completed initialization

between LM ADAPTER

and air conditioner

- Send Start Time ( nciStartOutTm )

- Send Heartbeat Start Time

- Initialize Start Time( nciInitStartTm)

(

nciStartHrtBt)

(2) Setting of start time relating to event output

The start timing of event output after power recovery can be set by the configuration property shown in the

table below.

Items Set detail and operation

Send Start Time

【nciStartOutTm】

Send Heartbeat Start Time

【nciStartHrtBt】

Initialize Start Time

【nciInitStartTm】

The timing to start output at changing is set.

Up to the time passing the set time after power recovery, LM ADAPTER does not

output the variables even when the status of the air conditioner changes. During this

time, the air conditioner can be operated/set.

The timing to start the automatic updating (periodical status notice) from LM

ADAPTER is set.

The timing to start the initial output is set.

To match the image of the operation information on air conditioners held by BMS and

that of the actual operation status, LM ADAPTER automatically outputs the status of

the air conditioners after power recovery.

21

Page 25

(3) Setting to match images

The state of an air conditioner before power failure and after power recovery may differ sometimes

1

. In

such case, the operation state of the air conditioner held by the BMS differs from the actual operation state of

the air conditioner. In order to match the image after power recovery, LM ADAPTER can be set enabling the

initial output to match the image at a time when a certain time has elapsed after power recovery.

∇Relating configuration property

Items Set detail and operation

Initialize Start Time

【nciInitStartTm】

Initialize Send Time_1

【nciInitOutTm_1】

Initialize Send Time_2

【nciInitOutTm_2】

Explained before

The transmission interval of each air conditioner is set respectively.

The variable firstly output by each air conditioner (operation state output) keeps the set

interval for output.

The transmission interval of each variable is set respectively.

Each variable of each air conditioner is output keeping this set interval.

① Outline of operation

When “Initialize Start Time 【nciInitStartTm】” has passed, the state variable of air conditioners will be output

from No.1 unit in order. The transmission interval of each variable will be that being set by the configuration

property. When the initial output time per each unit exceeds “Initialize Send Time_1【nciInitOutTm_1】”, the

variable of the next indoor unit will be output after completing the output of the variable of the indoor unit

immediately before.

Power ON

LMAP

pow er source

BMS

State of

No.1 unit

State of

No.2 unit

Start of

No.3 unit

LMAP

Init ializ e St ar t Time

Output image in a unit of air

conditioner (Status of No.2 unit)

Initizalize

Send Time_2

Run Cool 25℃ Low

Standard of set time

Initialize Send Time_1(Sec) = Initialize Send Time_2

* N value (To be determined by a number of the objective variables)

N = 12

Initizalize

Send Time_2

Initialize Send

Time_1

Initizalize

Send Time_2

(Sec)×

Initialize Send

Time_1

N

1

Through the setting of air conditioners, the operation after power recovery ( Power ON/OFF, / Automatic recover / Normal <Stop> ) can be set.

22

Page 26

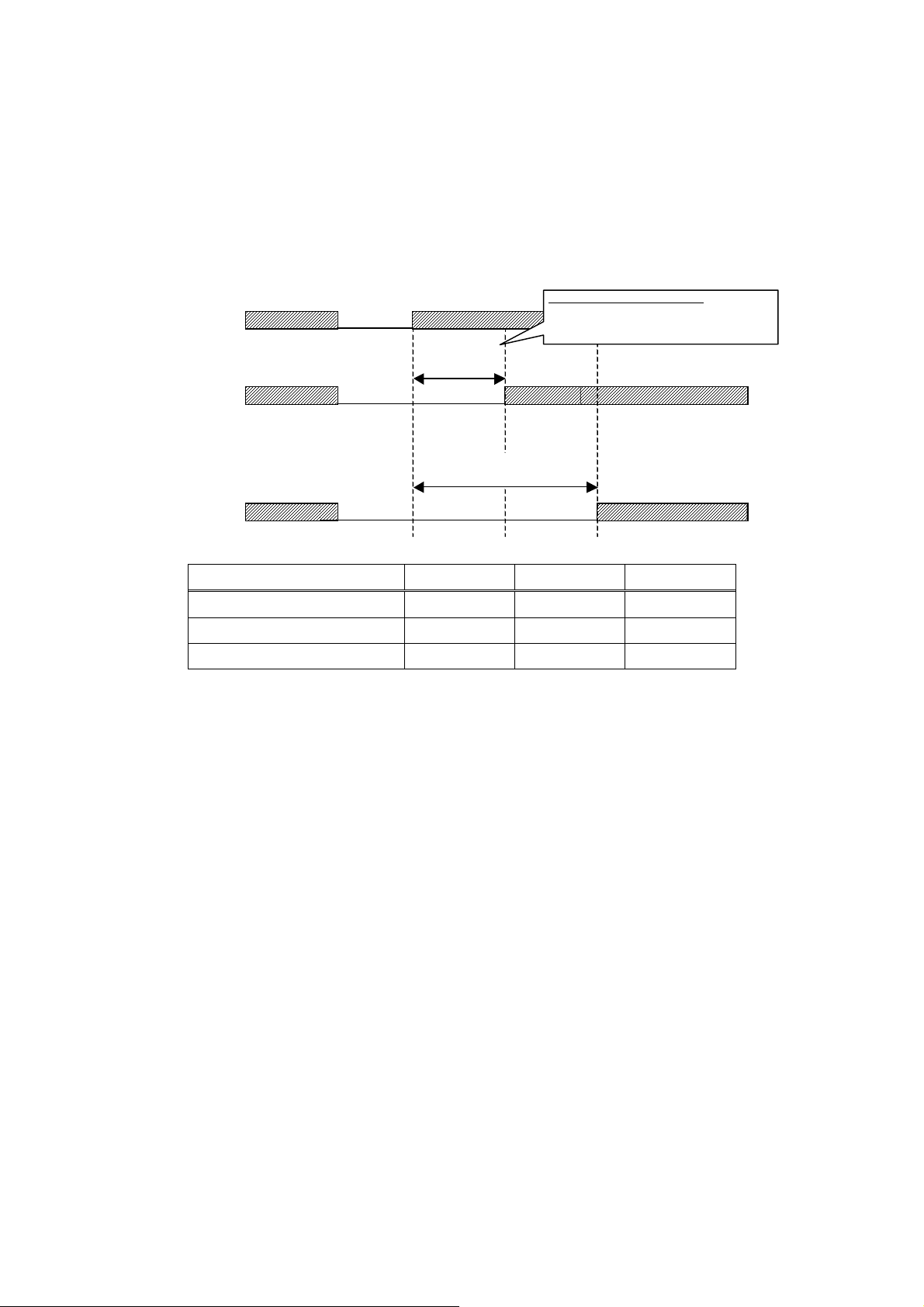

② Setting for plural unit installation

When conducting initial output by installing plural LM ADAPTERs on a same system, stagger the start time of

the initial output in setting to avoid the concentration of each output.

Power ON

LMAP

power source

BMS

LMAP_001

LMAP_002

LMAP_003

Standard of set time (for LMAP_002)

Initialize Start Time(LMAP_002) = Initialize Start Time(LMAP_001) + Ti ×m

Maximum control address value of LMAP_001:m(1 to 50)

Initialize Send Time_2 of LMAP_001:Ti

Init ial iz e Start Ti me

Init ial iz e Star t Ti me

Init ial iz e Start Time

23

Page 27

5.4 Response restrictions on Poll (Fetch) demand

Upon receipt of Poll (Fetch) demand from the BMS, LM ADAPTER responses with the latest value of the

corresponding variable.

As the operation status being held will be responded at power shutdown due to air conditioner inspection or

communication error caused by the disconnection of M-NET transmission line, the error cannot be judged by

the BMS.

When the present data being held is uncertain as is in such case, LM ADAPTER can be set so that error

generation can be judged easily by suppressing the response against Poll (Fetch) demand.

①Suppressing the response of unconnected indoor units.

②Suppressing the response of indoor units unable to communicate.

This setting is to follow the configuration property below.

Effective PollFetch【nciPollFetch】

LM

ADAPTER

Indoor unit

Mo ni to r

transmission

Responding with

holding latest state

Communication

error

Status

change

Event driben system

Poll (Fetch)

system

Suppressing

Poll response

BMS

Mo ni to r

transmission

Monitor de mand

Monitor respons e

Monitor de mand

24

Page 28

5.5 Operation/setting of air conditioner

conditioners

5.5.1 Operation/setting method

BMS

For the operation/setting of air conditioners, please renew

nvi

nvo

the value of the input variable of LM ADAPTER.

Renewal of input

variable

Operating/setting method of air

5.5.2 Function requiring periodical renewal (Receive Heartbeat, Effective Time)

When setting cannot be cancelled by the local side at the communication error caused by some reason from

the BMS side, a function is available to cancel the setting when the communication from the BMS side pauses

for a certain time. To continue the setting, it is required to update the input variable again within the set time.

∇Relating configuration property

Items Set detail and operation

LM

ADAPTER

Indoor [1]

nvi1

nvi2 nvo1

Receive Heartbeat_1 (Local Prohibit)

【nciRcvHrtBt_1】

Receive Heartbeat_2 (Forced Thermostat OFF)

【nciRcvHrtBt_2】

Effective Time_1 (Emergency Stop)

【nciEffectTm_1】

Effective Time_2 (Collective Local Prohibit)

【nciEffectTm_2】

LONWORKS network

LMAP

OC

Error

occurred

Continue operation

prohibit

Operation prohibit

The setting is cancelled when the set time is passed after previous

receiving.

The setting is cancelled when the set time is passed after previous

receiving.

Effective request is continued over the set time.

The setting cannot be cancelled until the effective time is over.

Effective request is continued over the set time.

Building

Management

system

The setting cannot be cancelled until the effective time is over.

Set time passed

LONWORKS network

LMAP

OC

Error

continues

Cancel operation

prohibit

Operation permit

Building

Management

system

ON

IC

IC

Disable to

change setting

IC

25

OFF

IC

MA

IC

Enable to

change setting

IC

Page 29

5.5.3 Function allowing operating/setting at local side

When using a remote controller together to operate air conditioners locally by user, the same function can be

operated/set at both the master system side and the local side. In this case, the "Priority is given to the later

pressing" is a principle. Please carry out to configure the LONWORKS system taking the following into

consideration.

(1) Disagreement of state

Problem Disagreement of state may occasionally be detected when setting is changed by the local

side including the local remote controller after operating/setting of the BMS.

Measure taken by BMS side Avoid detecting for the disagreement of the state.

BMS

LONWORKS network

LMAP

OC

Request:[Stop]

State:[Stop]

State

disagreed

[Run] state

After operated for [Stop] from Building

management sys tem, [Run] is requested

from local side.

IC IC IC

[Run] request

MA

(2) Periodical transmission from master system

Problem When receiving run request from equipment (like PLC) with the function of periodical transmission

(Send Heartbeat), the setting of the local side like remote controllers may not be reflected (or seems

to be not reflected) on the air conditioners.

Measure taken by BMS

side

Try to transmit (renew) a request only at a time of changing.

<Example actions>

- Make the periodical transmission (Send Heartbeat) invalid.

- Fetch it once by the BMS, and renew the variable of LM ADAPTER.

LMAP

O C

Stop

↓↑

Run

[Run] request

Int e rl oc k ed

w ith ligh ting

LONWORKS network

[Stop] request

IC IC IC

MA

[Run]s but [Stop]s soon

26

Transmits

periodically

Lighting

BMS

PLC

OFF

Page 30

5.6 State monitoring

5.6.1 State monitoring method

The method to monitor the operation state of air conditioners from the BMS via LM ADAPTER can roughly

be classified into two systems, namely (1) Event driven system and (2) Polling system. The configuration

property for setting differs depending on the systems.

Event driven system Polling system

Operation

outline

State change

State is automatically output from LM ADAPTER at the

change of air conditioner status (event generation).

At state change of air conditioner At Poll (Fetch) demand

output timing

Condition Each variable of both BMS and LM ADAPTER should

be bound.

Communication

image

BMS LM -AP

Stat e: st op

stop

Stat e: ru n

Air

condi ti oner

Stop

Run

Regardless of air conditioner state changes, the

variable is directly acquired through polling or

fetching from the BMS at any time.

Polling cycle is determined taking the following into

consideration.

①Communication traffic of whole LONWORKS

network

②Response performance of LM ADAPTER

BMS LM -AP

Poll

cycle

Poll

cycle

Poll d emand

stop

Poll d emand

stop

Stat e: st op

Stat e: ru n

Air

condition er

Stop

Run

Relating nci

run

nciStartOutTm【Send Start Time】

nciStartHrtBt【Send Heartbeat Start Time】

nciMinOutTm【Minimum Send Time】

nciSndHrtBt_1【Send Heartbeat_1】

nciSndHrtBt_2【Send Heartbeat_2】

nciInitStartTm【Initialize Start Time】

nciInitOutTm_1【Initialize Send Time_1】

nciInitOutTm_2【Initialize Send Time_2】

nciSet_1【Communication Timing】

Poll d emand

Poll

cycle

run

nciPollFetch【Effective PollFetch】

nciOffline【Effective Offline Mode】

nciSet_1【Comminication Timing】

27

Page 31

5.6.2 Setting of periodical state notification (Send Heartbeat)

Purpose In the case of the event driven system, there is no chance to renew the state until facing the next event

generation if an unexpected omitting was incurred carelessly. During this time, the air conditioner status

being held by the BMS and that of the actual are different.

Countermeasure Set to conduct the periodical state notification

(Transmission heartbeat: Send Heartbeat).

Setting nci

nciSndHrtBt_1【Send Heartbeat_1】

nciStartHrtBt 【Send Heartbeat Start Time】

BMS

Poll response:[Run] state

Run

LMAP

Transmits

periodically

OC

LONWORKS network

Run

IC IC IC

MA

28

Page 32

5.7 Measurement (Analog value)

5.7.1 Measuring method

The same as the state output of air conditioners, the state will be informed from LM ADAPTER at state

change or periodically.

5.7.2 Condition setting for state output

Condition setting of output at changing Setting of periodic state notification

Purpose As the analog value such as the room temperature

varies continually, frequent outputs are presented at

changing. To suppress this, set to provide the event

output only at the occurrence of a certain change.

Countermeasure Set the variation range of analog value.

The variation range below the set value will not be

applied with the event output.

Communication

image

Setting nci

BMS LM-AP

22.5℃

+1.1℃

23.6℃

-1.2℃

22.4℃

In case of variation range = 10 ℃

nciAnalogWidth 【Spacetemp Width】

con ditioner

22.5℃

22.9℃

23.6℃

23.4℃

23.1℃

22.4℃

22.2℃

Air

periodical monitoring

inte rval

10 minutes

10 minutes

10 minutes

nciAnlgMonTm 【Monitoring Time)

The variation range of the room temperature

decreases as the temperature is stabilized. For this

reason, set to provide the state notification

periodically as the measurement can not be

performed only by the output at changing.

Set the transmission interval.

As the set time elapsed, the present value is

automatically output.

Air

conditioner

22.5℃

22.6℃

22.7℃

22.6℃

22.6℃

22.4℃

22.2℃

10 minu tes

10 minu tes

10 minu tes

Event driven

output

Heartbeat

output

Heartbeat

output

BMS

0.2℃

0.1℃

In case of variation range = 1.0 ℃

LM-AP

22.5℃

22.7℃

22.4℃

nciSndHrtBt_2 【Send Heartbeat_2】

nciStartHrtBt 【Send Heartbeat Start Time】

29

Page 33

5.8 Trouble/alarm monitoring

BMS

The trouble/alarm that can be monitored with LM

ADAPTER can mainly be classified as follows.

⑤

(Note: It differs depending on the types of LM ADAPTER)

① Trouble of equipment such as air conditioners and

remote controllers

② Network fault of M-NET

③ Alarm due to improper air conditioning

④ Trouble of LM ADAPTER

④

②

LMAP

M-NET centralized control

system transmission line

OC

M-NET indoor-outdoor

tra nsmis sion lin e

⑤ Fault of LON network

IC IC IC

MA

Section in trouble Symptom Monitoring method Relating nci

①③

Air conditioning equipment

② M-NET communication

④ LM-AP

⑤ LON communication

Trouble of relating equipment such as air

conditioner/remote controller

Unable to communicate between

LM ADAPTER and objective equipment

for control

Trouble of LM ADAPTER itself 1) Node object

Unable to perform the communication of

LONWORKS network

1) Network variable (Error) 1) None

1) Network variable (Error)

2) Presence of Poll response

2) Presence of response

(including Ack)

1) Node object

2) Presence of response

(including Ack)

LONWORKS network

①、③

1) None

2) nciPollFetch

(Effective PollFetch)

1) & 2) nciSet_1

(Communication

Timing)

1) & 2) nciSet_1

(Communication

Timing)

5.8.1 Trouble/alarm monitoring by network variables

(1) Trouble and alarm of air conditioner - - - ①,③

Air conditioning equipment in trouble will be informed to the BMS by the network variables via LM ADAPTER.

In case when the local remote controller or system controller is installed, the detail of the trouble will be

displayed.

Detecting method of trouble

- Trouble of indoor unit : Error output from individual indoor unit

- Trouble of outdoor unit : Error output from all indoor units within a same refrigerant system

(2) Communication fault of M-NET (including power failure) - - - ②

When the communication (M-NET) between LM ADAPTER and air conditioner is disabled, LM ADAPTER

monitors the communication with the air conditioner for a certain time, and informs you about a

communication error if abnormality is detected.

Detecting method of M-NET communication error

- Network variables (collective for all indoor units) exclusive for communication error

- Response to Polling (by “Effective PollFetch 【nciPollFetch】”)

30

Page 34

(3) Resetting of trouble/alarm

The resetting method differs depending on the equipment generating trouble/alarm.

Trouble of indoor unit

Switches over the indoor unit in trouble from [Run] to [Stop].

Trouble of outdoor unit

Switchovers all indoor units in the refrigerant system from [Run] to [Stop].

5.8.2 Health check of LM ADAPTER - - - ④,⑤

Several factors can be considered as the cause to disable the communication of the master system with LM

ADAPTER. Depending on the function of the BMS or the system configuration, conduct health check (to judge

the life) by combining each detecting method.

(1) Detection by Node Object

The Node Object is an exclusive variable to conduct health check (to judge the life) on LM ADAPTER. This is

effective when the application of LM ADAPTER is crashed under the condition allowing LON communication,

or to detect the recovery timing of power failure.

The node object uses the input variable 【nviRequest】 and output variable 【nvoStatus】 in a pair. The

output variable returns the value corresponding to the requested value when only the input variable is

renewed. The response can be performed if the application is working regardless of the status of the local

side (M-NET).

(2) Detection by effectuation of communication

When Ackd is used as the communication service of LON communication, the fault of LON communication

can be monitored by the presence of Ack. However for the generating spot of the communication error, it is

required to judge comprehensively taking the communication status of other node into consideration.

5.9 Emergency stop

In the case when air conditioners are stopped (emergency stop) collectively, it is considered that the

communication with the master system may not be performed after stopping. For this reason, the present

status will be maintained until “Effective Time_1【nciEffectTm_1】” has passed once emergency stop was

received. Even after releasing the emergency stop, the air conditioner will continue to stop unless receiving

the run request.

31

Page 35

APPENDIX 1. Outline of Functions – Network Variables

- Models

LMAP03U

- Functions

「ON/OFF」

「Mode」

「Thermostat ON/OFF state」

「Filter Sign Reset / Run Time for Filter」

「LOSSNAY Mode」

「Error state」

「Collective Alarm」

「Collective ON/OFF」

「Local Prohibit」

「Collective Local Prohibit」

「Local Remote Controller Setting」

「Space Temperature」

「Set Point」

「Fan Speed」

「Forced Thermostat OFF」

「Emergency Stop」

「Model Code」

「Collective Alarm for LM ADAPTER」

「Defrost state」

「Group Number」

32

Page 36

Function - [ ON/OFF ]

Function [Request On/Off] [On/Off run state]

Description The run/stop operation and state of indoor units or ventilation units (individual operation without interlocking) are

monitored.

In the case of the ventilation unit interlocked with the indoor unit, the operation will run/stop interlocking with the

indoor unit being registered for interlocking.

Using NV 【nviOnOff_n】【nvoOnOff_n】

Control unit Indoor unit

Outline of

operation

Communication Image

① Operation from BMS

"Indoor unit" will run/stop for each unit individually.

"Ventilation unit (individual)" will run/stop for each unit individually.

"Ventilation unit (interlocked)" will run/stop interlocking with the unit being registered for interlocking. There is no

need to control the operation and to monitor the state.

BMS

LM-AP

[Run] operation

[Run] operation

IC

LMAP03U

state [Run]

state [Stop]

state [Run]

state [Stop]

② Operation from local

remote controller

Restrictions

- Operation control during emergency stopping (LMAP03U only)

During the emergency stopping in valid, the operation control by the LonWorks network will be invalid.

33

Page 37

Function - [Mode]

Function

Description

Using NV

Control unit

Outline of

operation

Communication Image

① Operation from BMS

[Request Mode] [Mode state]

The operation mode control and state of the indoor unit are monitored.

【nviMode_n】 【nvoMode_n】

Indoor unit

"Cooling only unit", "Heat Pump (Y unit)"

Within a same refrigerant system, the mixed

operation of cooling and heating can not be

performed. "Priority is given to the former

pressing."

"Heat Pump (R2 unit)"

Within a same refrigerant system, cooling

and heating operation can be mixed. "Priority

is given to the later pressing."

BMS

[Cool] operation

state [Cool]

state [Heat]

LM-AP

LMAP03U

Within a same refrigerant system, mode

operation can be mixed.

Cooling only unit Y unit R2 unit

Auto -- -- All

Cool/Dry Fan Fan All

Heat -- Fan All

Fan Cool Cool/Heat All

IC

[Cool] operation

state [Cool]

state [Heat]

② Operation from local

remote controller

Restrictions

- How to determine the operation mode

In the case of CITY MULTI air conditioners (models exclusive for cooling and that for cooling/heating selectable), priority is given to

the operation mode (Cooling-Dry/Heating) formerly adapted to the indoor unit within a same refrigerant system. ("Priority is given to

the former pressing.") To change the operation mode, therefore, change the operation mode of all indoor units within a same

refrigerant system simultaneously.

For the models of cooling/heating simultaneous operation, the indoor unit operating for cooling (drying) and that for heating can be

mixed in a same refrigerant system. ("Priority is given to the later pressing.")

34

Page 38

Function – [Thermostat ON/OFF state]

Function [Thermo On/Off state_1] [Thermo On/Off_2]

Description Monitoring the thermostat state of indoor units, run/stop state, and the state of auxiliary heater for heating.

Using NV LMAP02-E:【nvoThermo_n】

LMAP03U:【nvoThermoSt_n】【nvoThermo_n】

Control unit Indoor unit

Outline of

operation

Communication Image

The thermostat status of each indoor unit is monitored. In the case of CITY MULTI, the compressor of the

outdoor unit turns off if the thermostat of all indoor units within a same refrigerant system turn off. (It depends on

the operating condition.)

*While the thermostat is turned off forcibly, the thermostat OFF will be output. (LMAP03U only)

BMS

state [Thermostat ON]

state [Thermostat OFF]

LM-AP

state [Thermostat ON]

state [Thermostat OFF]

IC

Thermostat [ON]

→ Thermostat [OFF]

LMAP03U

35

Page 39

Function – [Filter Sign Reset / Run Time for Filter]

Function [Filter Sign Reset] [Run Time for Filter]

Description Monitoring the integrated operation time of the filter. Resetting the filter sign information also.

Using NV 【nviFiltReset_n】 【nvoOnTime_n】

Control unit Indoor unit

Outline of

operation

Communication

① Operation from BMS

Restrictions

- The Run Time for filter.

The filter cleaning period cumulative time and maximum value differ with model (Indoor unit, ventilation, etc...).

- Continuous reset operation

When reset operation is continuously carried out by local remote control or BMS, Run Time is reset each time.

The filter sign resetting clears the filter sign and the filter operating integrated time.

The filter sign of the local remote controller or the like will also be reset.

The filter sign can be reset with the local remote controller or system controller.

BMS

LM-AP

[Reset] operation

[Reset] operation

Run Time [0h]

Run Time [0h]

Run Time [0h]

Run Time [0h]

IC

② Operation from local

remote controller

Resetting the run time

of the filter

LMAP03U

36

Page 40

c

Function – [LOSSNAY Mode]

Function

Description Switching over and monitoring the operation and state of the ventilation unit individually operated (not

Using NV

Control unit

Outline of

operation

Communication Image

① Operation from BMS

[Request LOSSNAY Mode] [LOSSNAY Mode State]

interlocked with indoor unit).

【nviLCMode_n】 【nvoLCMode_n】

Indoor unit

The operation mode (LOSSNAY ventilation/bypass ventilation/automatic) is selected for each ventilation unit.

However, the ventilation unit that used the LOSSNAY adapter can not be changed over to the automatic mode.

The operation mode of the ventilation unit interlocked with indoor unit is determined by the operating condition of

the indoor unit.

BMS

[LOSSNAY ventilation]

operation

[LOSSNAY ventilation]

[Bypass ventilation]

state

state

LM-AP

[LOSSNAY ventilation]

operation

state

[LOSSNAY ventilation]

state

[Bypass ventilation]

Ventilation

② Operation from local

remote controller

LMAP03U

Restrictions

-The operation mode of the ventilation unit interlocked with indoor unit can not be changed over.

-Determining measure of operation mode of ventilation unit interlocked with indoor unit

- Operation from the Building management system, system controller, and remote controller is disabled. It is fixed to the automati

mode.

However, the ventilation unit that the LOSSNAY adapter, operation mode is fixed to the LOSSNAY ventilation mode.

37

Page 41

Function – [Error state]

Function [Alarm State]

Description Monitoring the error of the indoor unit or ventilation unit if any.

Using NV 【nvoAlarm_n】

Control unit Indoor unit

Outline of

operation

Function [Error Code] [Error Address]

Description Outputting the error detail (error code, generating source address) of the indoor unit or ventilation unit.

Using NV 【nvoErrCode_n】 【nvoErrAdrs_n】

Control unit Indoor unit

Outline of

operation

The error of the indoor unit and ventilation unit if any is output for each unit.

The error of the outdoor unit if any is output by all indoor units within a same refrigerant system.

For the error of the indoor unit and ventilation unit, the error code and generating source address are output for

each unit.

For the error of the outdoor unit, the error code and generating source address of the outdoor unit are output

from all indoor units within a same refrigerant system.

On the local remote controller or system controller controlling the unit generating an error, the error code and

generating source address are displayed.

LMAP03U

Communication

BMS

LM-AP

IC

state [Alarm]

state [Error]

Error

occurred

Error Code [xxxx]

Error Address [xxx]

Restrictions

- Error output during stopping (All of the alarm, error code and error generating source)

Under the stopping of air conditioner, ventilation unit, etc., error output from LM ADAPTER is disabled.

- Output of maintenance error

The output of maintenance error (including intermittent fault checking) will not be done.

- For some ventilation units, the error (including all alarms, error codes and error generating source addresses) is disabled to output.

38

Page 42

A

A

Function – [Collective Alarm]

Function [Collective Alarm for Indoor Unit]

Description Monitoring the possible error of all units controlled by LM ADAPTER collectively.

Using NV 【nvoAllAlarm】

Control unit All of indoor units controlled by LM ADAPTER

Outline of

operation

Communication

The error will be output even if 1 set of indoor units or ventilation units being controlled by LM ADAPTER

generates an error.

The error will be output at the error of the outdoor unit.

On the local remote controller or system controller controlling the unit with an error generated, the error code

and generating source address are displayed.

BMS

state [Alarm]

LM-AP

state [Error]

from error unit

LMAP03U

IC

Error

occurred

Restrictions

- Error output during stopping

s the error judgment of air conditioners, LOSSNAY, etc. can not be applied during their stopping; the error output from LM

DAPTER is disabled accordingly.

- Output of maintenance error

The output of maintenance error (including intermittent fault checking) will not be done.

- For some ventilation units, the output of the error (including all alarms, error codes and error generating source addresses) is

disabled.

39

Page 43

Function – [Collective ON/OFF]

Function [Collective On/Off State]

Description Monitoring the operation status of all units controlled by LM ADAPTER collectively.

Using NV 【nvoAllOnOff】

Control unit All of indoor units controlled by LM ADAPTER

Outline of

operation

Communication Image

① Operation from BMS

The "Run" will be output even if 1 set of indoor units or ventilation units being controlled by LM ADAPTER is

operating.

The "Stop" will be output at the stopping of all units.

BMS

[Run] operation

state [Run]

state [Stop]

LM-AP

[Run] operation

state [Run]

state [Stop]

LMAP03U

IC

② Operation from local

remote controller

Restrictions

- State output of ventilation unit interlocked with indoor unit

When operating only the ventilation unit interlocked with indoor unit by using the local remote controller, "Collective stopping" will be

output to the Building management system unless other indoor unit or individually operating ventilation unit is not being operated.

40

Page 44

t

f

y

f

Function – [Local Prohibit]

Function [Request Local Prohibit] [Local Prohibit State]

Description Monitoring and setting the prohibit/permit of operation of the remote controller to be connected with indoors unit

and ventilation unit.

Using NV ON/OFF: 【nviProOnOff_n】 【nvoProOnOff_n】

Mode : 【nviProMode_n】 【nvoProMode_n】

SetPoint: 【nviProSetP_n】 【nvoProSetP_n】

Control unit Indoor unit

Outline of

operation

Communication

Setting the prohibit/permit of each operation for each unit.

When operation is prohibited, the operation can not be done from the local remote controller, however, it can be

carried out from LM ADAPTER.

If other system controllers are used together, LM ADAPTER can not prohibit their operation.

LMAP03U

① Operation from BMS

Effective Time(*1)

BMS

[Prohibit] operation

state [Prohibit]

LM-AP

[Prohibit] operation

state [Prohibit]

IC

“CENTRALLY CONTROLLED”

Remote controller buttons

are locked.

[Permit] operation

“CENTRALLY CONTROLLED”

Remote controller buttons

are unlocked.

state [Permit]

state [Permit]

displa

goes of

*1: Setting by Receive Heartbeat_1 【nciRcvHrtBt_1】

Restrictions

- Types of local remote controller

This function is effective to use MA remote controller and ME remote controller for the local remote controller.

- Prohibit/permit of local remote controller for ventilation units

The prohibit/permit setting for the local remote controller of LOSSNAY individually operating is only possible when OA processing uni

is controlled with MA remote controller. In this case, turn on the function setting switch (SW1-1) of LMAP.

- Effective time of operation prohibit for local remote controller (LMAP03U only)

The operation prohibit setting of the local remote controller will automatically be the operation permit of the local remote controller, i

the effective time passes without set value renewal or poll/fetch demand within the effective time being set by the “Receive

Heartbeat_1 【nciRevHrtBT_1】”.

41

Page 45

f

Function – [Collective Local Prohibit]

Function [Request Collective Local Prohibit] [Collective Local Prohibit state]

Description Setting and monitoring the operation for prohibit/permit of all local remote controllers to be connected with the

indoor units and ventilation units individually operated (without interlocking).

Using NV 【nviAllPro】 【nvoAllPro】

Control unit All of local remote controllers

Outline of

operation

Communication

The operation of all local remote controllers to be connected with indoor units and ventilation units is set

collectively for the prohibit/permit.

When operation is being set to prohibit, the operation by the local remote controller is disabled, however, it can

be done by LM ADAPTER.

If other system controllers are used together, LM ADAPTER can not prohibit their operation.

LMAP03U

BMS

LM-AP

IC (All)

① Setting from BMS

Effective Time(*1)

[Prohibit] operation

state [Prohibit]

[Prohibit] operation

state [Prohibit]

“CENTRALLY CONTROLLED”

Restricted operations are

shown below.

- ON/OFF

- Operation mode

- Set temperature

[Permit] operation

state [Permit]

state [Permit]

“CENTRALLY CONTROLLED”

Remote controller buttons

are unlocked.

*1: Setting by Effective Time_2【nciEffect_2】

display

goes of

Restrictions

- Type of local remote controllers

This function is only effective to use MA remote controller (PAR-20MAA) for the local remote controller.

- Prohibit/permit of local remote controller for ventilation units

The prohibit/permit setting for the local remote controller of LOSSNAY individually operating is only possible when OA processing

unit is controlled with MA remote controller. In this case, turn on the function setting switch (SW1-1) of LMAP.

- Effective time of operation prohibit for local remote controller

The operation prohibit setting of the local remote controller will automatically be the operation permit of the local remote

controller, if the effective time passes without set value renewal within the effective time being set by the “Effective TIme_2

【nciEffectTm_2】”.

42

Page 46

Function – [Local Remote Controller Setting]

Function [Time Stamp]

Description Setting the time of the local remote controller.

Using NV 【nviRmTime】

Control unit All local remote controllers

Outline of

operation

Function [Request Limit Temperature Setting Range] [Request Simplified Locking]

Description Setting the limit on the temperature range that can be set with the local remote controller and the simplified

Using NV 【nviRmLim】 【nviRmLck】

Control unit All local remote controllers

Outline of

operation

Set the local remote controller’s time.

locking of operation.

"Set temperature range limit" Limits the temperature range that can be set with the local remote controller.

Limited temperature range: Cooling/drying lower limit temperature, heating upper limit temperature

"Simplified locking" Locks simply the operation of local remote controllers.

Operation items to set: All operation or the operation other than ON/OFF

At setting of the set temperature range and simplified locking, the display detail of the local remote controller can

also be set.

Display to be set: Display of actual operation mode under automatic operation and room temperature

Each set value is to be prepared by the configuration property.

LMAP03U

Communication

BMS

LM-AP

RC (All)

① Setting from BMS

[hhmmdd] setting

[hhmmdd] setting

Renewal

Restrictions

- Types of local remote controllers

This function is only effective to use ME remote controller for the local remote controller.

By using ME remote controller, it is also effective to control OA processing unit among the ventilation units individually operated.

(The other models than LOSSNAY can not be controlled with ME remote controller when they are operating individually.)

- Mode selection when temperature set range is limited

When limiting the temperature set range, the automatic mode can not be selected. The operation mode changes to the fan operation

when the setting is changed.

Under the circumstance, please change the operation mode after setting the temperature set range.

43

Page 47

Function – [Space Temperature]

Function [Space Temperature State]

Description The room temperature designed to be measured by the indoor unit will be measured.

Using NV 【nvoSpaceTemp_n】

Control unit Indoor unit

Outline of

operation

Communication Image

Renewal

The output for changes will be

output at the change exceeding a

certain change range.

Renewal

The current value will be output

after a certain time is elapsed.

The room temperature (or inlet temperature) is measured.

Measuring temperature range: -10ºC ~ 50ºC, Temperature unit: 1.0ºC

For the measuring sensor, select the indoor unit inlet or remote controller sensor in the setting of indoor units.

The output for changes will be output at the change exceeding a certain change range.

Even in the case of no change, the current value will be output after a certain time is elapsed.

The value of the changing range is set by the configuration property.

BMS

state [xx℃]

LM-AP

Space temp. demand

state [xx℃]

Update interval(*1)

state [xx℃]

Space temp. demand

state [xx℃]

*1: Setting by Send Heartbeat_2【nciSndHrtBt_2】

LMAP03U

IC

Restrictions

- A difference of the display value of local remote control and BMS

With monitor timing, the display value of local remote control and BMS may change.

- Depending on the connecting number of indoor unit, the monitor interval that can be set is different.

To set a periodical monitor interval below 10 minutes, it is required to change SW1-3 on LM ADAPTER to ON. Please make the

connecting number 30 sets or less.

- The changing range: 0.5 ℃~2.0 ℃, Temperature unit: 0.5 ℃

Operated for 0.49℃ or less (except –0.01 ℃) --- Set to 0.5 ℃

Operated for –0.01℃ --- Set to 1.0 ℃

Operated for 2.01℃ or more --- Set to 2.0℃

44

Page 48

Function – [Set Point]

Function [Setpoint] [Setpoint State]

Description Setting and monitoring the target temperature of indoor units.

Using NV LMAP02-E: 【nviSetPoint_n】 【nvoSetPoint_n】

LMAP03U : 【nviSetP_n】 【nvoSetP_n】

Control unit Indoor unit

Outline of

operation

Communication Image

① Operation from BMS

Restrictions

- To set temperature from the Building management system, set so that it stays within the set temperature range above.

- The action by the setting out of the set temperature range differs depending on the operation mode at that time.

<At cooling/drying mode> Operated for 19ºC or less, or 31ºC or more - - - Set to 19ºC, 30ºC respectively

<At heating mode> Operated for 17ºC or less, or 29ºC or more - - - Set to 17ºC, 28ºC respectively

<At automatic mode> Operated for 19ºC or less, or 29ºC or more - - - Set to 19ºC, 28ºC respectively

The target room temperature for each indoor unit is set and monitored.

In accordance with the operation mode of indoor units, the temperature

range that can be set is different.

Set temperature unit: 1.0ºC

BMS

[xx℃] setting

state [xx℃]

state [xx℃]

LM-AP

[xx℃] setting

state [xx℃]

state [xx℃]

Mode Setting Range

Auto 19 ~28 ℃

Cool 19 ~30 ℃

Heat 17 ~28 ℃

Dry 19 ~30 ℃

Fan Not used

IC

② Operation from local

remote controller

LMAP03U

45

Page 49

LMAP03U

Function – [Fan Speed]

Function [Request FanSpeed] [FanSpeed State]

Description Setting and monitoring the airflow rate of indoor units and individually operating ventilation units (not interlocked

with indoor units).

Using NV 【nviFanSpeed_n】 【nvoFanSpeed_n】

Control unit Indoor unit

Outline of

operation

Communication Image

The airflow rate (High/Med.2/Med.1/Low) for each unit is set and monitored.

BMS

LM-AP

IC

① Operation from BMS

[High] operation

[High] operation

state [High]

state [High]

state [Low]

② Operation from local

remote controller

state [Low]

Restrictions

- Airflow setting value and setting operation by unit types

3-speed model: Setting to Med.2 operates in the Med.1 airflow.

2-speed model: Setting to Med 2 or Med 1 operates in the low airflow rate.

1-speed model: Setting to Med 2, Med 1 or Low operates in the high airflow rate.

46

Page 50

g

Function – [Forced Thermostat OFF]

Function [Request Forced Thermostat OFF] [Forced Thermostat OFF State]

Description Setting the Indoor unit forcibly to thermostat OFF.

Using NV 【nviThermoOff_n】 【nvoThermoOff_n】

Control unit Indoor unit

Outline of

operation

Communication Image

① Operation from BMS

Effective Time(*1)

Indoor unit is forcibly set to thermostat OFF.

The indoor unit being set to thermostat OFF will be in the thermostat OFF status regardless of operating

conditions (i.e. room temperature, set temperature, etc.).

BMS

[Enable] operation

state [Enable]

state [Disable]

LM-AP

[Enable] operation

LMAP03U

IC

state [Enable]

[Disable] operation

state [Disable]

*1: Setting by Receive Heartbeat_2【nciRcvHrtBt_2】

Restrictions

- Effective time of forced thermostat OFF

The thermostat OFF will automatically be cancelled if it is not renewed or poll/fetch demand is not presented during the effective

time bein

set by the “Receive Heartbeat 2【nciRcvHrtBt 2】”.

47

Page 51

Function – [Emergency Stop]

Function [Request All Off] [Emergency State]

Description Applying emergency stop collectively to all units controlled by LM ADAPTER.

Using NV 【nviAllOff】

Control unit All of indoor units controlled by LM ADAPTER

Outline of

operation

Communication

① Operation from BMS

② Operation from BMS during

emergency stop

The indoor units and ventilation units being controlled by LM ADAPTER are stopped collectively.

During the time when emergency stopping is valid, the operation from LM ADAPTER will be invalid. As the

operation from the local remote controller or system controller is valid, the operation may be started, but it stops

soon. (LMAP03U only)

To prohibit operation from the local remote controller or system controller, use the setting for collective operation

prohibit together in combination.

Effective Time(*1)

BMS

[Stop] operation

state [Stop]

[Run] operation

state [Run]

LM-AP

[Stop] operation

state [Stop]

state [Run]

*1: Setting by Effective Time_1【nciEffectTm_1】

LMAP03U

IC (All)

③ Operation from local

remote controller

Restrictions

- Effective time of emergency stop (LMAP03U only)

When conducting emergency stop, the operation control from LonWorks network will be invalid for a certain time.

The effective time mentioned here can be set by the “Effective time_1【nciEffectTm_1】” of the configuration property.

- Operation of air conditioner during emergency stop

The operation from the local remote controller is valid even under emergency stopping.

When the operation from the local remote controller is not desired, use together with the variable of “Request Collective Operation

prohibit【nviAllPro】”.

48

Page 52

Function – [Model Code]

LMAP03U

Function [Mode Code]

Description Outputting the capacity code of indoor unit and OA processing unit.

Using NV 【nvoIcMdlSize_n】

Control unit Indoor unit

Outline of

operation

Communication

The capacity code indicating the capacity of indoor unit and OA processing unit is output.

This is used for the apportioning of charge, etc.

As this variable is not provided by the event output, acquire the data by Polling or Fetching.

BMS

LM-AP

IC

① Polling or Fetching from BMS

Poll demand

demand [Model Code]