Mitsubishi Electric JT-SB216JSH2-W-NE, JT-SB216JSH2-H-NE, JT-SB216JSH2-S-NE, JT-SB216KSN2-W-NE User Manual

Page 1

HAND DRYER

HANDBOOK

MODELS

JT-SB216JSH2-W-NE

JT-SB216JSH2-H-NE

JT-SB216JSH2-S-NE

November 2015 No. U208

JT-SB216KSN2-W-NE

Nameplate

Warning:

Repair work must be performed by the manufacturer, its service

agent or a similarly qualified person in order to avoid hazards.

Page 2

Contents

1. Safety precautions

2. Features

3. Names and functions of components

4. Specifications

5. Outside dimensions

6. Electrical wiring diagrams

7. Circuit board diagrams

8. Principles of operation

9. Troubleshooting

10. How to call

11. Service inspection list

12. Overhauling procedures

13. Parts catalog

JT-SB216JSH2-W-NE

.......................................................................................

..................................................................................

.........................................................................

....................................................................

..............................................................................

.....................................................................

............................................................

............................................................

................................................................

.....................................................................

.................................................................

........................................................

.....................................................

3-4

..........................................

8-10

12-15

17-24

25-57

26-33

4

5

6

6

7

11

16

16

JT-SB216JSH2-H-NE

JT-SB216JSH2-S-NE

JT-SB216KSN2-W-NE

.....................................................

......................................................

....................................................

34-41

42-49

50-57

Page 3

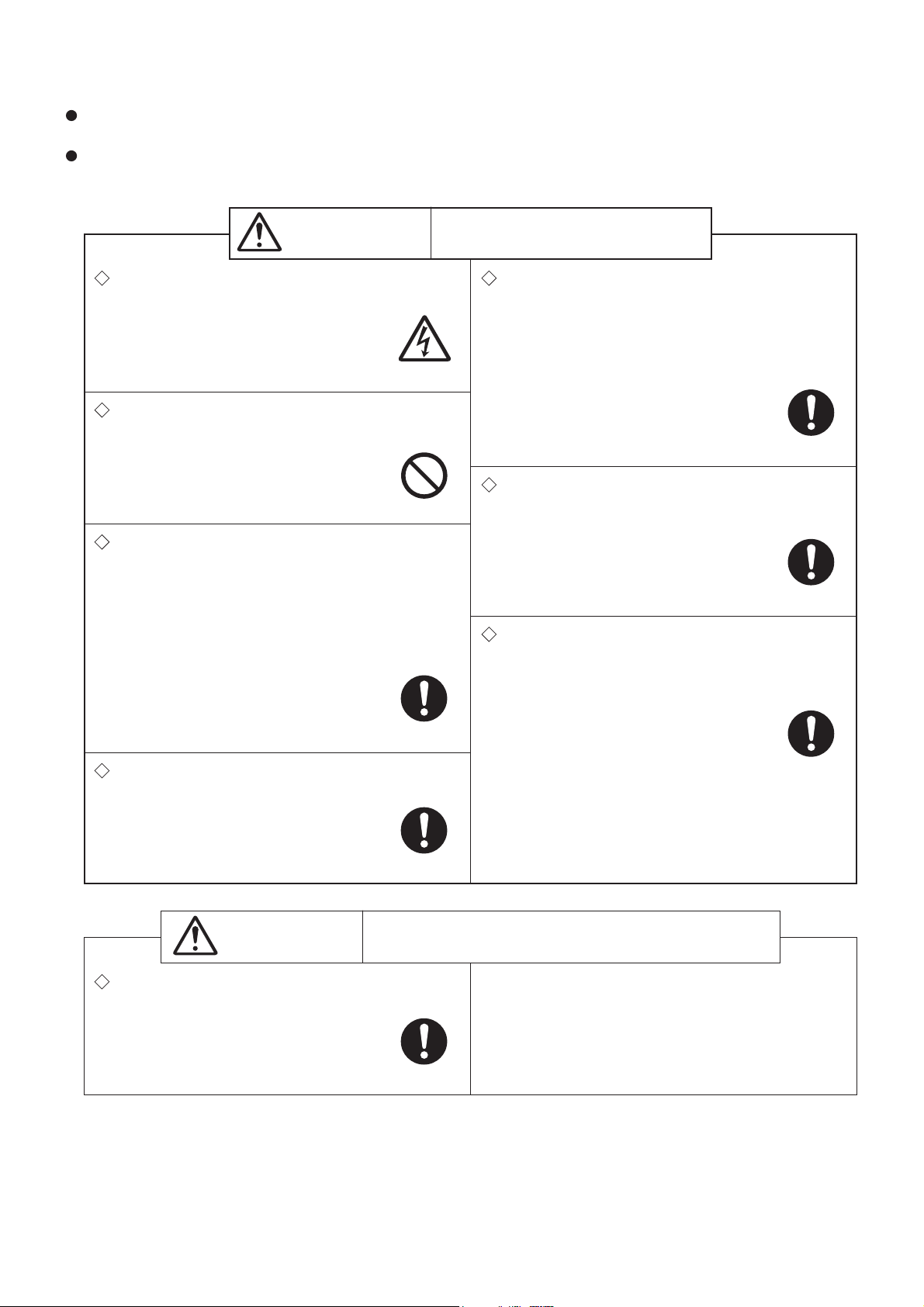

1. Safety precautions

Read the following precautions thoroughly before the maintenance, and then inspect and repair the product in a

safe manner.

The types and levels of danger that may arise if the product is handled incorrectly are described with the warning

symbols shown below.

Incorrect handling of the product may

Warning

result in serious injury or death.

Electric shock

If you must inspect the circuitry while the power is

on, do not touch the live parts.

(Failure to heed this warning may result

in electric shock.)

Caution against

electric shock

Modification is prohibited

Do not modify the unit.

(Failure to heed this warning may result

in electric shock, fire and/or injury.)

Prohibited

Proper electric work

• Use the electric wires designated for electric work,

and conduct electric work in accordance with the

"Electric Installation Engineering Standard", the

"Indoor Wiring Regulations" and the installation

instructions.

• Make sure that the terminals and fixed wiring are

securely connected.

(Improper connection or wiring installation

may result in electric shock and/or fire.)

Be sure to follow

this instruction.

Scratches and deterioration

Make sure to replace scratched and/or deteriorated

wiring and lead wires.

Turn off the power

Make sure to turn off the earth leakage breaker

prior to starting repair work. (The charge voltage in

the circuitry remains for another 40 seconds or so,

even after the power is turned off and the lamp is

unlit; therefore, wait for at least 40 seconds before

disassembling the product.)

(Failure to heed this warning may result

in electric shock.)

Be sure to follow

this instruction.

Use proper parts and tools

For repair, be sure to use the parts listed in the parts

catalog of the applicable model and use the proper

tools.

(Failure to heed this warning may result in

electric shock, fire and/or injury.)

Be sure to follow

this instruction.

Check insulation

Upon completing repair work, always measure the

insulation resistance. Verify that it is at least 10 MΩ

(with a 500-V DC insulation resistance tester), and

then turn on the power.

(Inadequate insulation may result in

electric shock.)

Be sure to follow

this instruction.

(Failure to heed this warning may result

in electric shock and/or fire.)

Be sure to follow

this instruction.

Incorrect handling of the product may result in injury or

Caution

damage to properties including buildings and equipment.

Wear gloves

Always wear a pair of gloves during inspection or

repair work.

(Failure to heed this caution may result in

injury.)

Be sure to follow

this instruction.

─ 3 ─

Page 4

Request for repair

●

Before repairs, take the product off the wall.

●

Inspect the earth condition, and repair it if it is incomplete. Make sure that an earth leakage breaker or an over-

load protection device is installed, if it is not installed, recommend the dealer to install one.

●

Check whether the air filter, side cover, and the drain tank are installed securely in place.

●

Do not leave a towel or other object in the hand-drying area.

●

Never place any object on the main body nor cover it.

●

Make sure that the product is not being used in any of the following locations:

• Outdoors

• Locations where the temperature could be lower than 0ºC

• Locations where the temperature could be higher than 40ºC

• Locations where there is a lot of dust

• Locations where there is a lot of condensation

• Locations where salt damage could occur

• Vehicles (including ships and airplanes)

• Locations where corrosive, neutral, or reductive gases are present

• Near food or tableware

• Kitchens

•

Locations where the product may come into direct contact with water (Where there is a risk of water splashing)

• Locations where the product is in direct sunlight or strong light (It may cause sensor malfunction)

• Rooms that have a sterilization basin, swimming pools, or bathrooms

Make sure that the product operates properly upon completion of repair. Clean the product and the surrounding

area, and then notify the customer of the completion of repair.

2. Features

• The silent wave nozzle has reduced operating sound by 2 dB.

• The newly added "High air speed" (for the heater-less type: JT-SB216KSN2-W-NE) has improved the drying

performance.

• Power control section has been removed to prevent misuses.

• Cleanable drain ditch

• Exteriors can be cleaned by wiping with alcohol.

• The square design matches various lavatories.

─ 4 ─

Page 5

3. Names and functions of components

*Shaded areas in the figure indicate antibacterial material.

Hand drying area

Blow panel f assy

(Panel (front))

Black wall area

Main unit

Sensor

The blue indicator does not have a sterilizing

effect.

Do not look directly into the blue indicator.

Side panel R (right side, not in view)

Front panel

Side panel L

Side cover

Tank cover

Drain tank

Blow panel bm assy

(Panel (back))

Blue indicator

Display

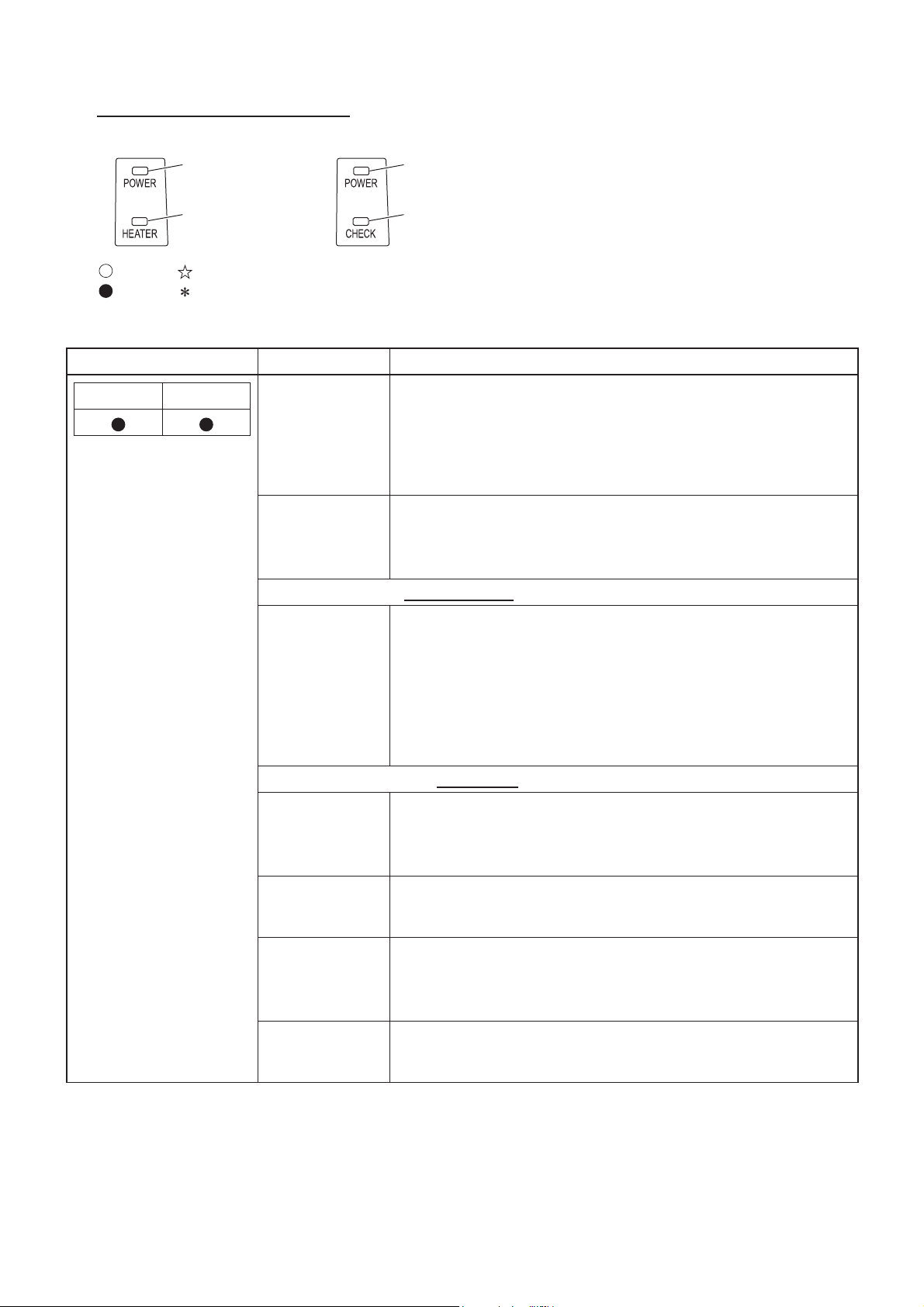

Heater type

(JT-SB216JSH2-W/H/S-NE)

HEATER

ON HIGH AIR SPEED

OFF STANDARD

AIR SPEED

Settings

HEATER

AIR SPEED

OFF / ON

STANDARD / HIGH

Heater type

(JT-SB216JSH2-W/H/S-NE)

Power lamp

Heater lamp

Heater-less type

(JT-SB216KSN2-W-NE)

HIGH

STANDARD

Settings

AIR SPEED

STANDARD / HIGH

$LU¿OWHU

Heater-less type

(JT-SB216KSN2-W-NE)

Power lamp

Check lamp

Note: JT-SB216KSN2-W-NE is not equipped with the HEATER switch.

─ 5 ─

Page 6

4. Specifications

Model

Rated

voltage

(V)

Rated

frequency

(Hz)

Heater

Motor

speed

Rated

current

(A)

Power con-

sumption

(W)

Air

speed

(m/s)

Noise

(dB)

Weight

(kg)

Drain tank

capacity

(ℓ)

High 5.7-6.2 1240 106 59

JT-SB216JSH2-W-NE

ON

Standard

4.9-5.3 1070 98 56

JT-SB216JSH2-H-NE

JT-SB216JSH2-S-NE

220-240

Single phase

50-60

OFF

High 3.9-4.2 720 106 59

Standard

3.0-3.2 550 98 56

11 0.8

High 3.9-4.2 720 106 59

JT-SB216KSN2-W-NE ―

Standard

3.0-3.2 550 98 56

• Air speed is calculated from the static pressure measured by the pitot tube (at the nozzle).

• Noise is the A range value measured in an anechoic room.

(Average of the three points: 2 m from the front and both sides of the unit.)

• The heater is turned off automatically when ambient temperature reaches 32°C or more. (Applicable models: JTSB216JSH2-W/H/S-NE)

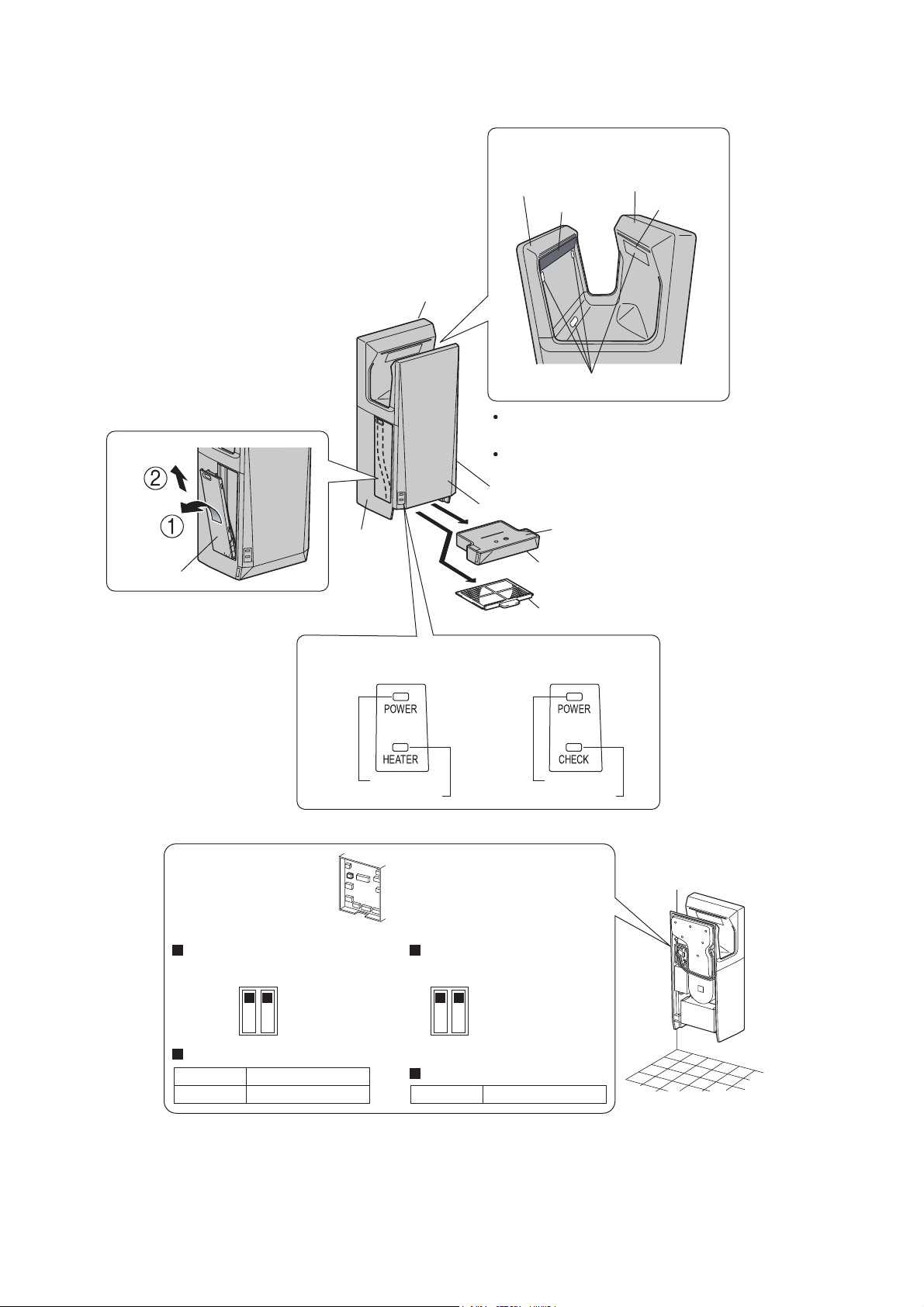

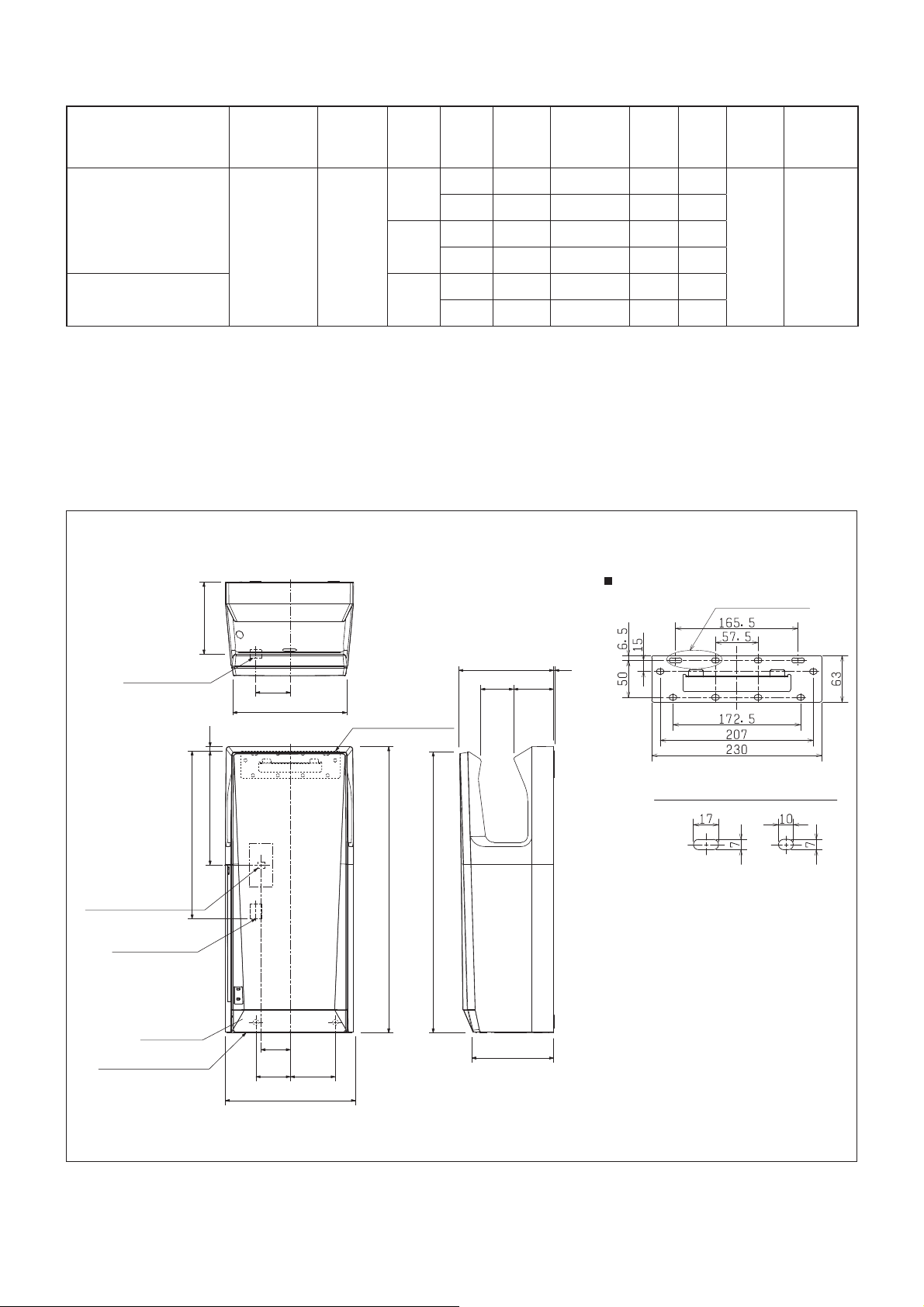

5. Outside dimensions

JT-SB216JSH2-W-NE, JT-SB216JSH2-H-NE, JT-SB216JSH2-S-NE, JT-SB216KSN2-W-NE

Terminal block

Power cable hole

(rear)

Terminal block

393

168

10

267

80

263

Installation panel

(Fix plate)

670

658

77

219

93

Installation panel

(Fix plate)

2

Detailed view of installation holes

Installation holes

Drain tank

Air ¿ lter (air intake)

68

(79.5)

300*

189

(103.5)

* Maximum width of main unit

Unit: mm

─ 6 ─

Page 7

6. Electrical wiring diagrams

JT-SB216JSH2-W-NE, JT-SB216JSH2-H-NE, JT-SB216JSH2-S-NE

JT-SB216KSN2-W-NE

─ 7 ─

Page 8

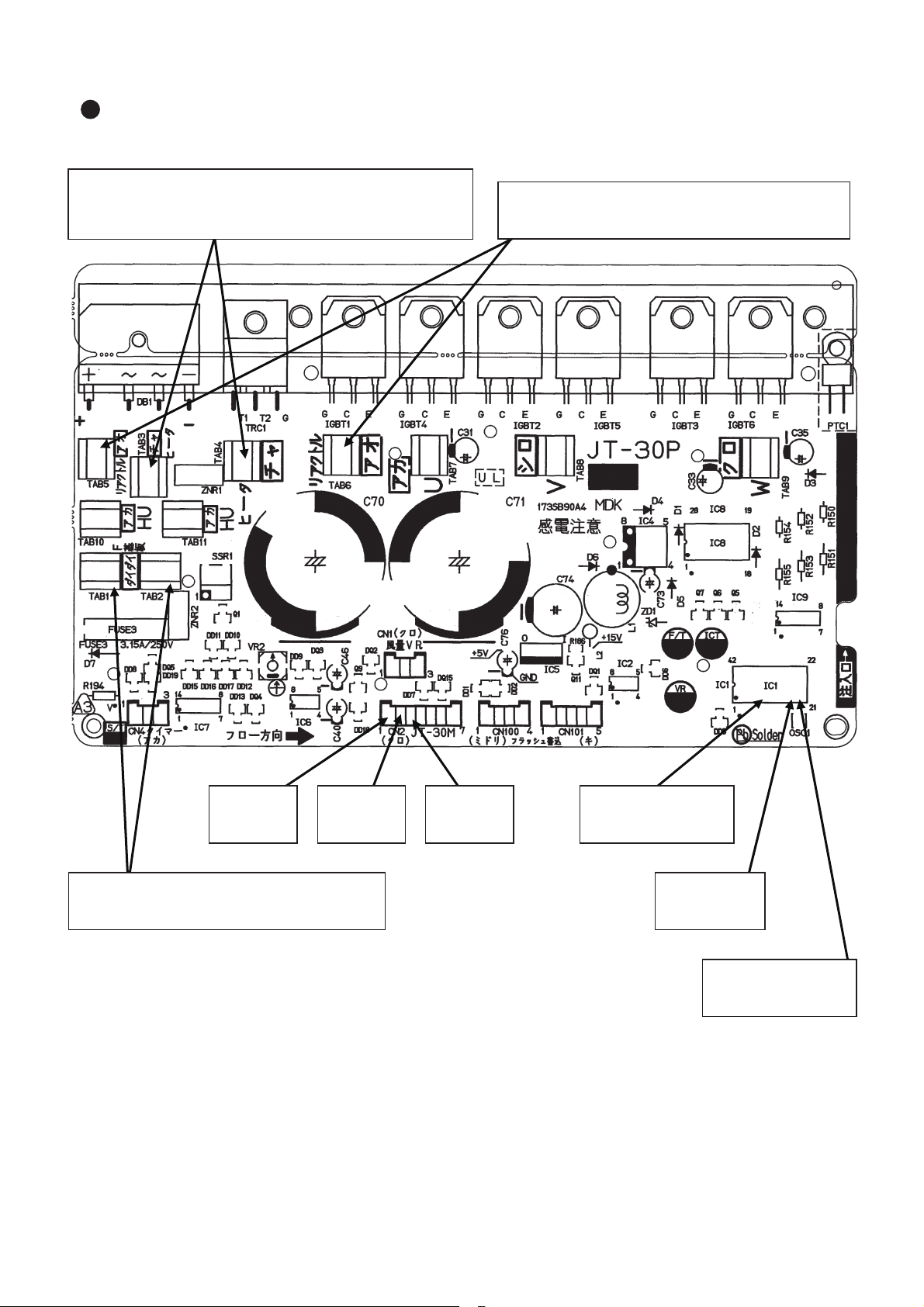

7. Circuit board diagrams

Circuit board diagrams and check points

1 Power circuit board (JT-30P8H)

<JT-SB216JSH2-W/H/S-NE>

Heater power supply (With heater ON): 220 V AC, 230 V AC, 240 V AC

(Between TAB3 and TAB4)

Bus voltage (Being stopped): 310 V DC, 324 V DC, 338 V DC

(Between TAB5 and 0 V or between TAB6 and 0 V)

15 V

(CN2 1P)

Power supply voltage: 220 V AC, 230 V AC, 240 V AC

(Between TAB1 and TAB2)

5 V

(CN2 2P)

0 V

(CN2 3P)

Carrier frequency 15 kHz

(IC1 8P)

Reset input 5 V

(IC1 18P)

Clock frequency 12 MHz

(IC1 19P)

─ 8 ─

Page 9

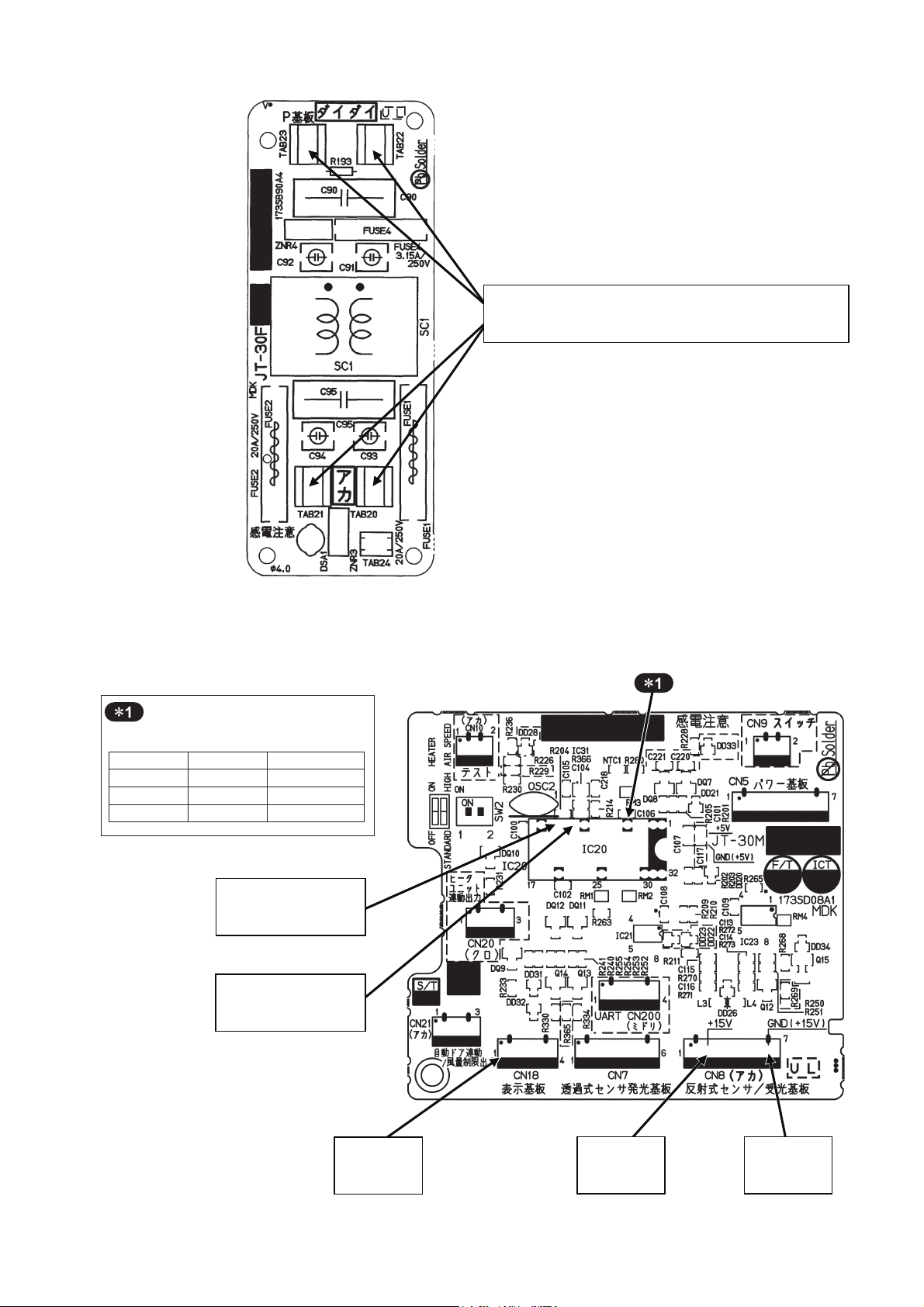

2 Filter circuit board (JT-30F8)

Power supply voltage: 220 V AC, 230 V AC, 240 V AC

(Between TAB20 and TAB21, and between TAB22 and TAB23)

3 Control circuit board

(JT-30M8A [JT-SB216JSH2-W-NE] /JT-30M8 [JT-SB216JSH2-H/S-NE] /JT-30M9A [JT-SB216KSN2-W-NE])

Circuit thermostat characteristics

(IC20 5P)

Temperature Resistance IC20 5P Voltage

20°C 59.3 kΩ 3.44 V

30°C 37.6 kΩ 2.91 V

40°C 24.5 kΩ 2.38 V

Clock frequency 8 MHz

(IC20 14P)

Reset input 5 V

(IC20 11P)

5 V

(CN18 1P)

─ 9 ─

15 V

(CN8 2P)

0 V

(CN8 7P)

Page 10

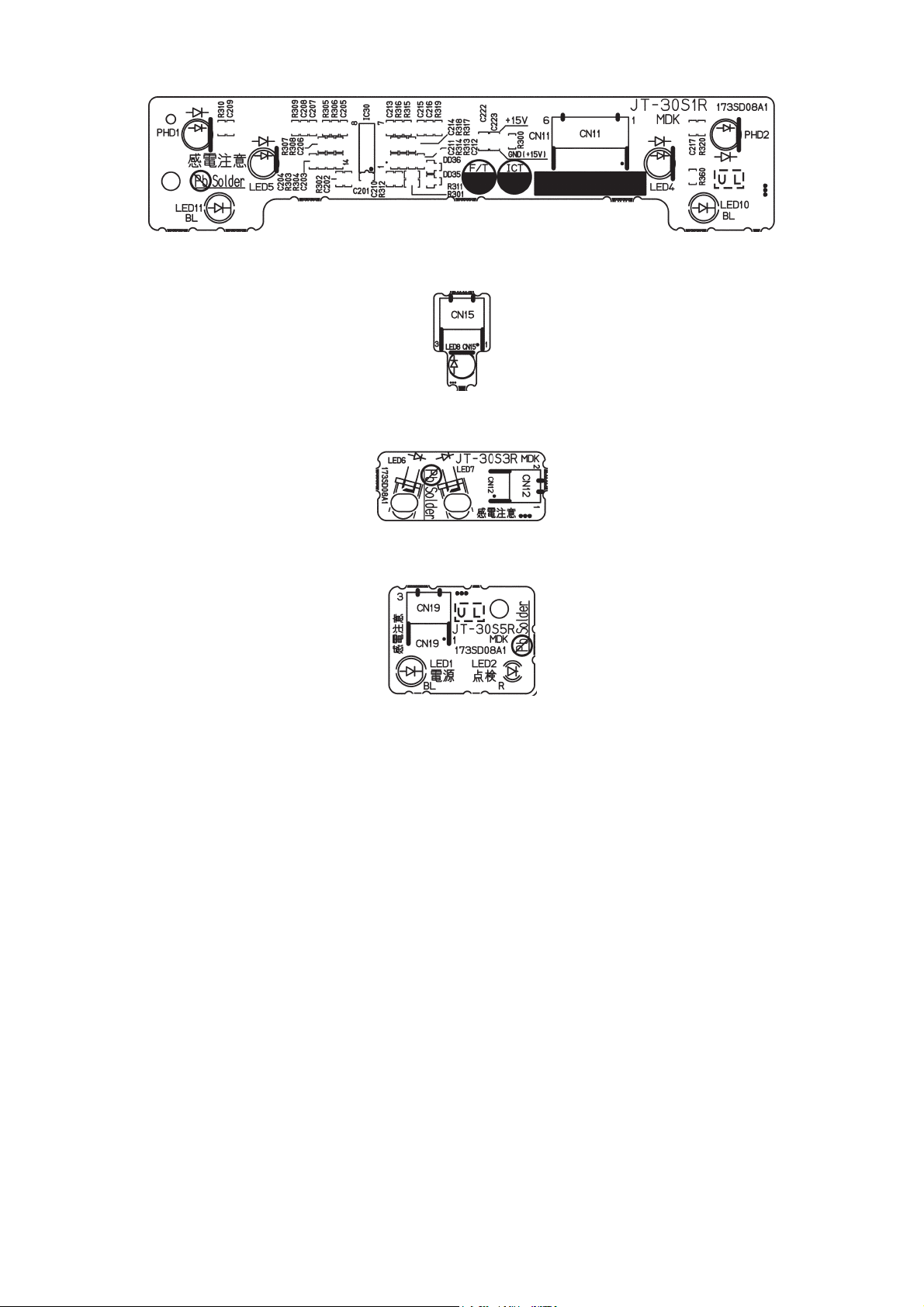

4 Light receiving circuit board (JT-30S1R) (Upper sensor)

5 Sensor circuit board (JT-30S2R) (Middle sensor)

6 Sensor circuit board (JT-30S3R) (Lower sensor)

7 Display circuit board (JT-30S5R)

─ 10 ─

Page 11

8. Principles of operation

Descriptions of circuit operation

(1)

Notes for turning the power “ON / OFF”

1 When the power is turned “ON”, the power lamp (LED1), the heater lamp (LED2) (JT-SB216JSH2-W/H/S-

NE only, with the heater switch ON), and blue indicators (LED10, 11) turn on after 1.5 seconds

hand dryer becomes ready for operation.

• Before the power lamp turns on, the hand dryer will not operate even if hands are inserted in the hand drying area. In the meantime, the microcomputer (IC20) of the main unit performs the initial settings, including the setting of the hand detection sensor sensitivity.

• In order to set the sensitivity of the hand detection sensor correctly, do not insert hands in the hand drying

area until the power lamp is turned on.

• Even if the hand dryer has started immediately (within 15 seconds or less) after turning the power “ON”, it

is normal though the motor input may become slightly lower because of the initial setting.

*1: If the power is turned ON again 30 to 120 seconds after turning the power OFF, it may take 3 seconds

before the operation is enabled.

2 When the power is turned “OFF”, the power lamp and blue indicators turn off and operation stops.

• The circuitry takes about 40 seconds to discharge the voltage retained in it. Wait until the discharging time

elapses before plugging in or out the connectors, replacing the circuit boards, or doing other maintenance.

• Even when any error is occurred, the error display will go off if the power has been turned off. Only when a

microcomputer error is occurred, the error display persists till the voltage retained in the circuitry has been

discharged (till the microcomputer has been reset).

(*1)

, and the

(2)

Hand detection and operation

1 The hand detection sensors are infrared sensors containing the light emitting sensor (infrared LED) and

light receiving sensor (photo-diode), etc. and consist of the upper sensor, the middle sensors, and the lower

sensor.

2 Reflection type upper sensor:

This sensor detects the change in the reflected amount of infrared light when hands are inserted.

Transmission type middle and lower sensors:

These sensors detect that the infrared light is shielded when hands are inserted.

3 When the lower or middle sensors detect hands, the blower motor turns on and the hand dryer starts to

operate.

4 Once operation has started, it continues as long as any of the upper, middle, or lower sensors detects

hands.

5 If 1.5 to 3 seconds elapse without detecting hands by any of the sensors, the blower motor turns off and

operation stops.

6 The hand dryer continuously operates for up to 30 seconds.

• Once 30 seconds have elapsed, the hand dryer stops operating even if hands are detected.

• Since this is a function to assume the presence of a foreign object, the operation will resume if hands are

pulled out and reinserted.

(3)

Control of the heater (Applicable models: JT-SB216JSH2-W/H/S-NE)

1 The heater turns ON simultaneously with the blower motor turns ON. (The heater lamp turns on.)

2 The heater does not turn ON in the following occasions:

• When the heater switch is turned “OFF”

• When a temperature detected by the circuit thermostat on the control circuit board (JT-30M8A/JT-30M8)

is 32°C or higher

─ 11 ─

Page 12

9. Troubleshooting

Work precautions

• When servicing, be sure to recreate the malfunction two or three times before starting repairs.

• When servicing, always take care to keep proper footing.

• Before starting the service, always unplug the power cord from the outlet, or turn off the earth leakage

breaker when no power cord plug is provided. Sufficient care must be taken to avoid electric shock or injury.

• Make sure to connect the power supply wires correctly.

• When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force

to the surface mounted parts.

• When removing the circuit board, be careful of the metal edges on the board.

• When removing or inserting the connectors for the circuit board, hold the entire housing section. Never pull

on the lead wires.

• When circuit board failure is considered to be a cause, check closely for any broken section on the copper

foil patterns, burning or discoloration of parts.

• After replacing a circuit board, make sure to restore the same settings as before the replacement.

(1) Table of the safety devices

Purpose Device

Overcurrent protection Current fuse

Protection against an excessive temperature rise of the heater parts

Protection against an excessive temperature rise of the blower parts

Motor lock protection • Current detection circuit

Thermal fuse

Thermal fuse

( Detects abnormal current caused by the motor lock, and stops

the power to the motor.)

• Current fuse

─ 12 ─

Page 13

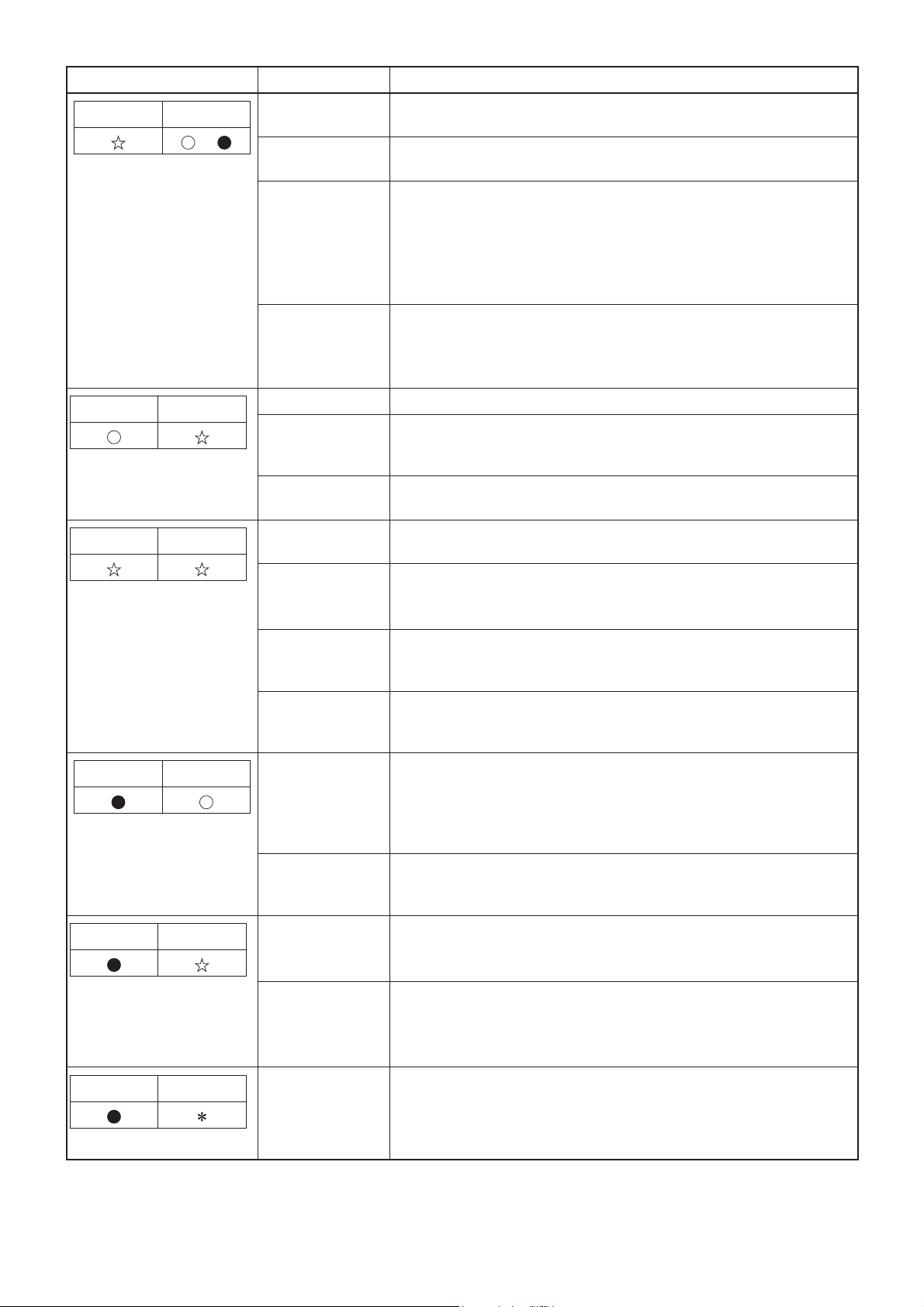

(2) Troubleshooting

Description of the error mode display

<JT-SB216JSH2-W/H/S-NE> <JT-SB216KSN2-W-NE>

Power lamp

Heater lamp

: ON : Slow blinking (ON for 0.4 seconds/ OFF for 0.4 seconds)

: OFF : Fast blinking (ON for 0.1 second/ OFF for 0.1 second)

Troubles with error display

Error Mode Display Checkpoint Check Method and Remedy

Power

(Lamps do not light.)

Heater/Check

Power supply

voltage

Power supply

voltage on the

power circuit

board (JT-30P8H)

●If 220 to 240 V AC is not supplied, check the following points.

Power supply

voltage on the

filter circuit board

(JT-30F8)

Power lamp

Check lamp

Check that approx. 220 to 240 V AC is supplied at both ends of the

power cord connections on the terminal block.

■

If 220 to 240 V AC is not supplied, check the following points.

1 Check that the earth leakage breaker is turned ON.

2 Check that the power cord is connected securely to the terminal

block.

Check that approx. 220 to 240 V AC is supplied between TAB1 and

TAB2 (orange) on the power circuit board (JT-30P8H).

Check that approx. 220 to 240 V AC is supplied to the following

points in the order of 1 and 2.

1 Between TAB20 and TAB21 (red)

If approx. 220 to 240 V AC is not supplied, check the power

supply voltage of the earth leakage breaker.

2 Between TAB22 and TAB23 (orange)

If approx. 220 to 240 V AC is not supplied, replace the filter

circuit board (JT-30F8).

●When 220 to 240 V AC is supplied, check the following points.

Connector disconnection for

the display circuit

board (JT-30S5)

Connector disconnection between

the circuit boards

Malfunction of the

control circuit board

(JT-30M8A/JT30M8/JT-30M9A)

Malfunction of

the power circuit

board (JT-30P8H)

Check if the connector CN19 on the display circuit board (JT30S5R) or CN18 on the control circuit board (JT-30M8A/JT-30M8/

JT-30M9A) is disconnected.

Check if the connector CN2 on the power circuit board (JT-30P8H)

or CN5 on the control circuit board (JT-30M8A/JT-30M8/JT-30M9A)

is disconnected.

If no error is found after checking the above, replace the control

circuit board (JT-30M8A/JT-30M8/JT-30M9A).

If the hand dryer does not operate even after replacing the control

circuit board (JT-30M8A/JT-30M8/JT-30M9A), replace the power

circuit board (JT-30P8H).

─ 13 ─

Page 14

Error Mode Display Checkpoint Check Method and Remedy

Power

Heater/Check

or

(Tamper-proof timer)

Dirty sensor

window

Remaining foreign

object

Connector disconnection for the

sensors

Dirt may shield the sensors. Wipe the dirt off the sensor window.

Check for any objects left over and shielding the sensor in the hand

drying area.

Check if the following connectors are disconnected.

1 Sensor circuit board (JT-30S3R) connector CN12

2 Sensor circuit board (JT-30S2R) (2 locations) connectors CN15

3 Light receiving circuit board (JT-30S1R) connector CN11

4 Control circuit board (JT-30M8A/JT-30M8/JT-30M9A) connec-

tors CN7 and CN8

Malfunction of the

control circuit board

If no error is found after checking the above, replace the control

circuit board (JT-30M8A/JT-30M8/JT-30M9A).

(JT-30M8A/JT30M8/JT-30M9A)

Power

Heater/Check

(Motor start error)

(Motor lock)

(Motor over-revolution)

Power

Heater/Check

(Motor overcurrent error)

( Current detection circuit

error)

Power

Heater/Check

( Motor power error)

Power

Heater/Check

( Motor signal error)

Power

Heater/Check

(Microcomputer error)

Motor malfunction Check that the motor is not locked and turns smoothly by hand.

Malfunction of

the power circuit

If no error is found after checking the above, replace the power

circuit board (JT-30P8H).

board (JT-30P8H)

Blower (assembly) malfunction

If the error display persists after replacing the power circuit board

(JT-30P8H), replace the blower (assembly).

Motor overload Check for causes of motor overload. (Too much higher power sup-

ply voltage, any object disturbing the motor revolution, etc.)

Connector disconnection for the

Check if the motor lead wire connectors (black, white, and red) are

disconnected.

motor

Blown thermal

fuse of the motor

Measure the resistance between Red and White and between Red

and Black of the motor lead wires. If it is ∞ Ω, replace the blower

(assembly).

Malfunction of

the power circuit

board (JT-30P8H)

Abnormal power

supply voltage

If no error is found after checking the above, or if the error display

persists after replacing the blower (assembly), replace the power

circuit board (JT-30P8H).

Check that correct power supply voltage is applied.

• The error will occur if the power supply voltage is approx. 359 V

AC or over, or approx. 127 V AC or under.

*Note: If 359 V AC or over is applied, a current fuse on the power

circuit board (JT-30P8H) may blow.

Malfunction of

the power circuit

If no error is found after checking the above, replace the power

circuit board (JT-30P8H).

board (JT-30P8H)

Connector disconnection

Check if the connector CN5 on the control circuit board (JT-30M8A/

JT-30M8/JT-30M9A) or CN2 on the power circuit board (JT-30P8H)

is disconnected.

Malfunction of the

control circuit board

If no error is found after checking the above, replace the control

circuit board (JT-30M8A/JT-30M8/JT-30M9A).

(JT-30M8A/JT30M8/JT-30M9A)

Malfunction of the

Replace the control circuit board (JT-30M8A/JT-30M8/JT-30M9A).

control circuit board

(JT-30M8A/JT30M8/JT-30M9A)

─ 14 ─

Page 15

Troubles without error display

Symptom Cause Check Method and Remedy

Warm air does not blow.

( JT-SB216JSH2-W/H/S-

NE)

Heater switch Check that the heater switch is turned ON.

(Heater lamp lights with the heater switch ON.)

Connector disconnection for the

Check if the connectors TAB3 and TAB4 on the power circuit board

(JT-30P8H) are disconnected.

heater

Blown thermal

fuse of the heater

Measure the resistance between the connectors TAB3 and TAB4

on the power circuit board (JT-30P8H).

At a heater temperature of 0°C or over: 100 Ω or under

If the fuse is blown, the resistance will be ∞ Ω.

In this case, replace the heater (PTC) and the power circuit board

(JT-30P8H).

The hand dryer operates

by itself.

The hand dryer does not

stop operation.

Air speed switch does not

change the air volume.

The hand dryer makes

abnormal noises.

Air blow is weak.

Malfunction of

the power circuit

board (JT-30P8H)

Check that approx. 220 to 240 V AC is output at both ends of the

connectors TAB3 and TAB4 on the power circuit board (JT-30P8H).

If it is not output, replace the power circuit board (JT-30P8H).

*Note: Approx. 220 to 240 V AC is output during operation, and it is

not output during standby.

Heater malfunction

Connector disconnection for the

sensors

If no error is found after checking the above, replace the heater

(PTC).

Check if the following connectors are disconnected.

1 Sensor circuit board (JT-30S3R) connector CN12

2 Sensor circuit board (JT-30S2R) (2 locations) connectors CN15

3 Light receiving circuit board (JT-30S1R) connector CN11

4 Control circuit board (JT-30M8A/JT-30M8/JT-30M9A) connec-

tors CN7 and CN8

Malfunction of

the sensor circuit boards (JT30S1/2/3R)

Visually check the sensor circuit boards for a defect such as a

crack, corrosion, or a cold solder joint.

If the error persists after replacing the control circuit board (JT30M8A/JT-30M8/JT-30M9A) in the next procedure, replace the

damaged sensor circuit boards (JT-30S1/2/3R).

Malfunction of the

control circuit board

If no error is found after checking the above, replace the control

circuit board (JT-30M8A/JT-30M8/JT-30M9A).

(JT-30M8A/JT30M8/JT-30M9A)

Connector disconnection

Check if the connector CN21 on the control circuit board (JT30M8A/JT-30M8/JT-30M9A) or CN4 on the power circuit board

(JT-30P8H) is disconnected.

Malfunction of

the power circuit

If no error is found after checking the above, replace the power

circuit board (JT-30P8H).

board (JT-30P8H)

Sucking of foreign

matter

Check for any foreign matter sticking to the blower (assembly)

vanes.

Clogged filter Check the filter for clogging with dust, etc.

Incorrect wiring Check if the motor lead wires of the blower (assembly) (red to

TAB7, white to TAB8, black to TAB9) are connected to incorrect

TABs on the power circuit board (JT-30P8H).

( If they are connected incorrectly, the motor turns in the reverse

direction.)

Malfunction of

the power circuit

If no error is found after checking the above, replace the power

circuit board (JT-30P8H).

board (JT-30P8H)

─ 15 ─

Page 16

10. How to call

Symptom Remedy

Air blow is too weak to dry hands

quickly.

Water leaks from the product.

Air does not blow immediately after

turning on the power and inserting

hands.

Warm air does not blow.

(JT-SB216JSH2-W/H/S-NE)

The product has an abnormal odor.

1 Check if the filter is clogged.

2 Isn’t the air speed switch set at the STANDARD position?

1 Check if the drain tank is filled up. (Empty the drain tank.)

*Note: Drain water will overflow onto the floor when the drain tank is

2 Is the drain tank installed properly?

Initial setting takes 1.5 seconds after turning on the power. Operation

is disabled in the meantime.

1 Is the heater switch turned ON?

2 Is the room temperature lower than 32°C?

1 Check if the drain tank is filled up. (Empty the drain tank.)

Check the inside of the drain tank for any foreign matter. (Remove it.)

2

3 Is the inside of the side cover cleaned up?

11. Service inspection list

Location Inspection Item Check Result

Electric wiring

Are lead wire connectors connected securely?

filled up beyond its capacity.

Is the wiring correct?

Lamps Do the power lamp (LED1), the heater lamp (LED2) (JT-

SB216JSH2-W/H/S-NE only, with the heater switch ON), and

blue indicators (LED10, 11) come on?

Operation Does it operate properly?

Isn’t there any abnormal noise, vibration, etc?

Heater

(JT-SB216JSH2-W/H/S-NE)

Wall installation Isn’t there clearance between the product and the back wall?

Is warm air blown?

─ 16 ─

Page 17

12. Overhauling procedures

Work precautions

• Before replacing parts, follow the instructions described in the troubleshooting.

• When servicing, always take care to keep proper footing.

• Before starting the service, always unplug the power cord from the outlet, or turn off the earth leakage

breaker when no power cord plug is provided. Sufficient care must be taken to avoid electric shock or injury.

• Make sure to connect the power supply wires correctly.

• After completing repairs, check that the unit operates properly.

Always wear gloves when servicing.

(1)

Turn off the power supply.

1 Stop the operation.

2 Turn off the earth leakage breaker on the distribution board.

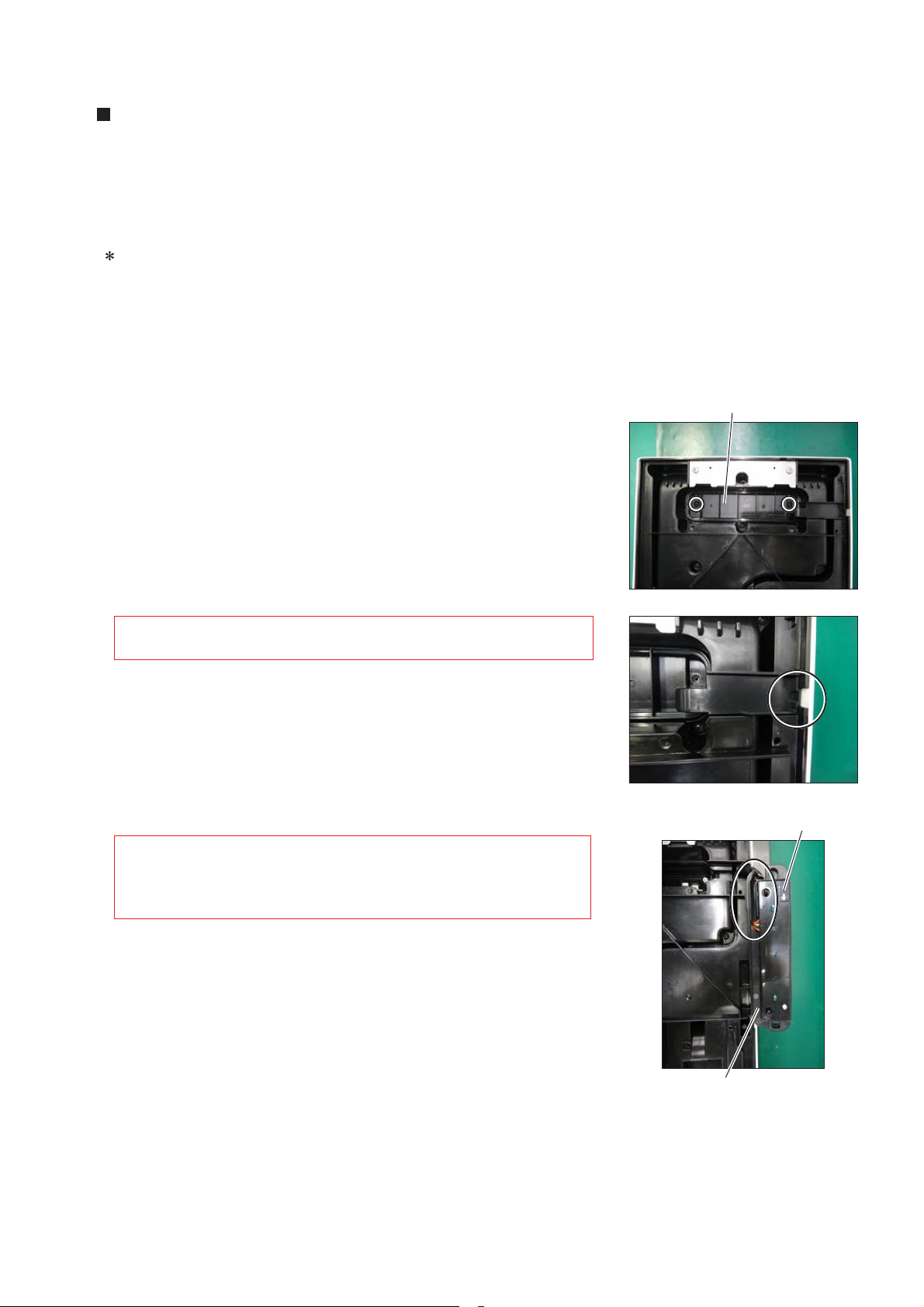

(2) Light receiving circuit board (JT-30S1R)

1 Unscrew the clamping screws, and remove the maintenance (maint.)

cover.

(Two special (spl) screws 4 x 16, indicated by )

Assembly precaution

Insert the maint. cover into the groove of the base. (Indicated by )

2 Remove the fix plate.

Assembly precautions

• Run the lead wires through the groove of the maint. cover.

(Indicated by )

• Take care not to pinch the lead wires.

Maint. cover

Fix plate

─ 17 ─

Maint. cover

Page 18

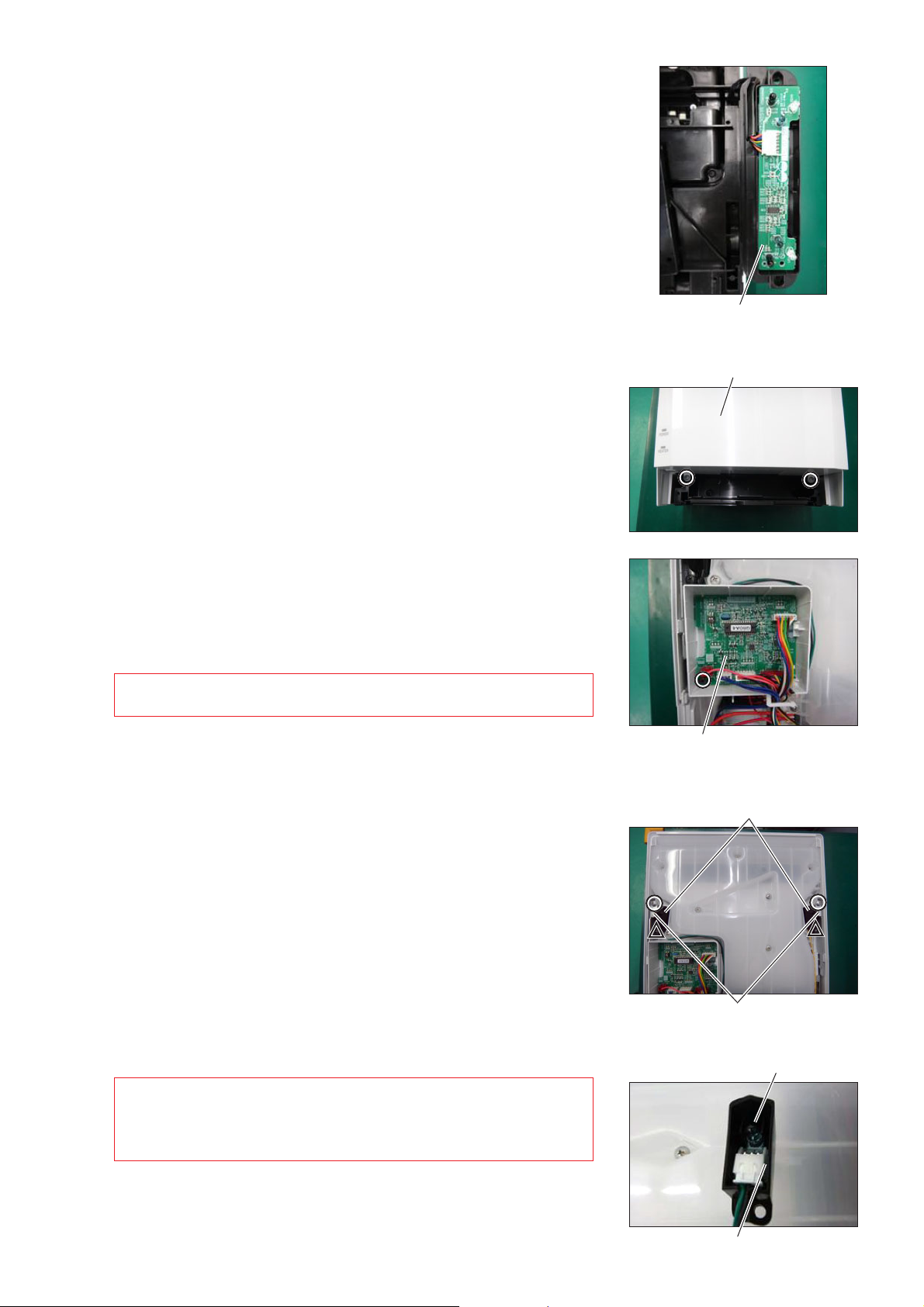

3 Remove the light receiving circuit board (JT-30S1R).

Light receiving circuit board (JT-30S1R)

(3) Control circuit board (JT-30M8A/JT-30M8/JT-30M9A)

1 Draw out the drain tank (Tank assembly).

2 Unscrew the clamping screws, and remove the front panel.

(Two spl screws 4×16, indicated by )

3 Disconnect the lead wires from the control circuit board (JT-30M8A/

JT-30M8/JT-30M9A).

4 Unscrew the clamping screw, and remove the control circuit board

(JT-30M8A/JT-30M8/JT-30M9A).

(One spl screw 4×12, indicated by )

Assembly precaution

Take care not to pinch the lead wires.

(4) Sensor circuit board (JT-30S2R)

Front panel

Control circuit board

(JT-30M8A/JT-30M8/JT-30M9A)

Fix piece

1 Remove the front panel. → See (3) 1 to 2.

2

Unscrew the clamping screws for the panel holders (left (L) and right (R)).

(Two PTT screws 4×16, indicated by )

3 Unscrew the clamping screws

(Two spl screws 4×12, indicated by )

4 Slightly push aside the panel holders to

locations)

5 Remove the sensor circuit boards (JT-30S2R)

Assembly precautions

• Insert the sensor circuit board between the claws of the fix piece.

• Take care not to pinch the lead wires.

•

After installing the circuit board, make sure that the LED is upright.

for the

fix pieces.

take out the fix pieces. (Two

from the fix pieces.

─ 18 ─

Panel holder (L, R)

Fix piece

Sensor circuit board (JT-30S2R)

Page 19

(5) Power circuit board (JT-30P8H)

1 Unscrew the clamping screws, and remove the circuit board (PCB)

cover.

(Two PTT screws 4×16, indicated by )

2 Disconnect the lead wires from the power circuit board (JT-30P8H),

and remove the power circuit board.

Assembly precautions

• Take care not to pinch the lead wires.

• Connect the lead wires as printed on the power circuit board.

PCB cover

Power circuit board

(JT-30P8H)

(6) Filter circuit board (JT-30F8)

1 Unscrew the clamping screw, and remove the terminal block (TB)

cover.

(One PTT screw 4×6, indicated by )

2 Unscrew the clamping screw, and take out the PCB box.

(One PTT screw 4×16, indicated by )

TB cover

PCB box

3 Unscrew the clamping screw, and remove the cover.

(One PTT screw 4×6, indicated by )

Assembly precaution

Install the cover over the PCB box.

─ 19 ─

Cover

Page 20

4 Disconnect the lead wires from the filter circuit board (JT-30F8).

5 Remove the spacers (four locations, indicated by

move the filter circuit board (JT-30F8).

(Pinch the spacers from the back for easier removal.)

Assembly precaution

Run the lead wires through the cord bush. (Indicated by )

), and then re-

(7) Display circuit board (JT-30S5R)

Filter circuit board (JT-30F8)

1 Remove the PCB cover for the power circuit board.

→ See (5) 1.

2 Unhook the claw of the LED holder, and slide the LED holder in the

direction of the arrow, and remove it.

3 Remove the display circuit board (JT-30S5R) from the LED holder.

Assembly precautions

• Take care not to pinch the lead wires.

• After installing the circuit board, make sure that the LEDs can be

seen through the holes of the LED holder.

Claw LED holder

─ 20 ─

Display circuit board (JT-30S5R)

Page 21

(8) Terminal block (with a thermal fuse)

1 Unscrew the clamping screw, and remove the terminal block.

(One PPT screw 4×30, indicated by )

2 Remove the lead wires from the filter circuit board (JT-30F8).

→ See (6) 1 to 5.

3 Remove the lead wires from the terminal block.

Assembly precaution

When running the lead wire through the groove of the terminal plate,

set the thermal fuse right under the terminal block.

Terminal block

Terminal plate Thermal fuse

For JT-SB216JSH2-W/H/S-NE

(9) Heater (PTC)

1 Unscrew the side panel (left (L) and right (R)) clamping screws.

(Two PTT screws 4×16, indicated by )

2 Remove the side panel L in the direction of the arrow.

Assembly precautions

• Install the side panel L after installing the PCB cover for the power

circuit board.

• T

ake care not to pinch the lead wires.

•

Fit the side panel L into the groove of the panel (back) and the base.

Side panel L

Panel (back) Base

3 Remove the side panel R in the direction of the arrow.

Assembly precaution

Fit the side panel R into the groove of the panel (back) and the base.

─ 21 ─

Side panel R

Base Panel (back)

Page 22

4 Unscrew the clamping screws, and remove the exhaust duct.

(Nine PTT screws 4×16, indicated by )

Assembly precautions

• Replace the packing used in the disassembled section with a new

one.

• Take care not to twist the packing when installing it.

5 Unscrew the clamping screws, and remove the blower cover.

(Four PTT screws 4×16, indicated by )

Precaution

• Since the blower (assembly) may drop off the blower case, remove

the lead wires first, and then slowly remove the blower cover.

Assembly precautions

•

Replace the packing used in the disassembled section with a new

one.

• Take care not to twist the packing when installing it.

• When replacing the heater, attach the included fixing piece to the

position, indicated by , with a screw (one PTT screw 4×16) to

prevent the blower from dropping off.

Exhaust duct

Blower cover

6 Unscrew the clamping screws, and remove the heater (PTC).

(Two PTT screws 4×16, indicated by )

Assembly precaution

When installing the heater, set the heater as the lead wire comes

out from the right side.

Assembly precautions

•

Hook the lead wire into the rib of the blower cover. (Indicated by )

• Run the lead wires through the grooves of the blower cover.

(Indicated by )

Make sure to match the size of the grooves and lead wires.

• Take care not to pinch the lead wires.

Blower (assembly)

Heater (PTC)

Upper groove (Bigger)

Lower groove (Smaller)

Lead wire

─ 22 ─

Page 23

(10) Blower (assembly)

1 Remove the blower cover. → See (6) 1 to 2, and (9) 1 (Remove

the side panel R clamping screw only), 4 to 5.

Precaution

• Since the blower (assembly) may drop off the blower case, remove

the lead wires first, and then slowly remove the blower cover.

Assembly precautions

• When replacing the blower (assembly), attach the included fixing

piece to the position, indicated by , with a screw (one PTT screw

4×16).

• Set the blower (assembly) as the lead wire outlet comes to the

position indicated by .

• The part of the lead wires covered by the white code tube must

pass through the code bush. (Indicated by )

2 Remove the blower (assembly).

(11) Sensor circuit board (JT-30S3R)

1 Remove the blower (assembly). → See (4) 1 to 2, (5) 1, and (10)

1 to 2.

2 Unscrew the clamping screws, and remove the blower case.

(Three PTT screws 4×16, indicated by )

Set the blower horizontally.

Blower (assembly)

3 Unscrew the panel (front) and panel holder clamping screws, and

remove the panel holders (L and R).

(Five PTT screws 4×16, indicated by )

4 Tilt the panel (front) in the direction of the arrow, and remove it.

Blower case

Panel (front)

Panel holder L Panel holder R

─ 23 ─

Panel (front)

Page 24

5 Remove the sensor holder.

Assembly precaution

Take care not to pinch the lead wires.

Sensor holder

6 Unhook the claw of the sensor holder (one location, indicated by ),

and remove the sensor circuit board (JT-30S3R).

When reassembling

Reassemble the unit in the reverse order of disassembly.

After reassembly, always make a test run to be sure that the unit oper-

ates properly.

Sensor holder

Sensor circuit board (JT-30S3R)

─ 24 ─

Page 25

13. Parts catalog

Please note the following when using the parts catalog.

1. When ordering parts, always indicate the part number, part name, and the number of

parts required.

2. Parts are not always available, and it may take time for you to receive them.

3. There may be specification improvements.

4. Parts marked are critical for safety. To maintain safety and performance, always

replace these parts with the parts prescribed.

Description of screw abbreviations

Screw

Abbreviation Description

PC screw Cross recess fl at head machine screw

PRC screw Cross recess oval head machine screw

PP screw Cross recess pan head machine screw

SW · PP screw Cross recess pan head screw with spring washer

PPT screw Cross recess tapping screw

PCT screw Cross recess fl at head tapping screw

PTT screw Cross recess truss head tapping screw

PT screw Cross recess truss head machine screw

SET screw Slotted head stop screw

SQ · SET screw Square head stop screw

P · SET screw Pan head stop screw

PMT screw Primer truss head screw

HS · SET screw Hexagon head stop screw

P · R · W screw Cross recess round wood screw

4

Screw diameter Length

×

16

P · C · W screw Cross recess fl at head wood screw

P · R · C · W screw Cross recess round and fl at wood screw

R · W screw Slotted round wood screw

PW · PP screw Cross recess pan head screw with small washer

SW-PW · PP screw Cross recess pan head machine screw with spring washer and fl at washer

─ 25 ─

Page 26

13

4

5

6

17

7

18

15

1

2

8

9

10

11

12

3

19

16

14

a

a

a

a

a

a

a

a

a

Special

screw 5x30

20

a (7 pcs.

)

(

2 pcs.

)

(

9 pcs.

)

6 pcs.

1 pc.

1 pc.

Cord clip

a

JT-SB216JSH2-W-NE

JT-SB216JSH2-W-NE

─ 26 ─

<Standard screws>

Symbol Screw name

a PTT screw 4x16

shows accessory parts.

Page 27

JT-SB216JSH2-W-NE

No. Name of part Parts No.

1 Side cover Y45 631 806 1

2 Side panel L Y45 636 806 1

3 Exhaust duct M45 697 804 1

4 Panel holder L M45 684 824 1

5 Panel holder R M45 684 825 1

6 Panel (front) Y45 636 816 1 With packing

7 Panel (back) Y45 636 802 1 With packing

8 Base M45 697 814 1

9 Spl screw 4×16 H00 631 018 11

10 Hook (upper) M45 684 805 1

11 Spl screw 4×16 M45 632 047 2

12 Fix plate M45 697 802 1

13 Spl screw 4×16 M45 632 045 2

14 Indicator plate Y45 636 809 1

15 Front panel Y45 636 800 1

16 Wiring diagram Y45 636 358 1

17 Side panel R Y45 631 809 1

18 Filter M45 665 806 1

19 Cover M45 684 804 1

20 Parts in bag Y45 636 049 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─27─

Page 28

42

43

44

45

31

38

39

40

41

32

33

34

46

47

49

50

51

52

53

54

48

32

32

32

46

46

48

49

b

c

a

a

b

a

a

35

36

37

(

4 pcs.

)

9

a

<Standard screws>

Symbol Screw name

a PTT screw 4x16

b PTT screw 4x6

c PPT screw 4x30

JT-SB216JSH2-W-NE

─ 28 ─

Page 29

JT-SB216JSH2-W-NE

No. Name of part Parts No.

31 TB cover M45 684 826 1

32 Cord bush M45 649 226 5

33 Terminal block Y45 636 220 1 With a fuse

34 Terminal plate Y45 630 806 1

35 LED holder Y45 636 808 1

36 Circuit board Y45 636 176 1 JT-30S5R

37 Insulator sheet M45 684 823 1

38 PCB box M45 697 808 1 With a cover

39 Cord bush M45 640 226 1

40 Insulator sheet M45 684 821 1

41 Spacer M45 617 095 4 PCB-3L(V-0)

42 Circuit board Y45 636 171 1 JT-30F8

43 Circuit board Y45 636 173 1 JT-30S1R

44 Fix plate M45 684 831 1

45 Maint. cover M45 684 828 1

46 Spl screw 4×12 M34 869 018 3

47 Circuit board Y45 636 172 1 JT-30M8A

48 Circuit board Y45 636 174 2 JT-30S2R

49 Fix piece M45 684 829 2

50 Circuit board Y45 636 175 1 JT-30S3R

51 Sensor holder M45 684 830 1

52 Reactor (assy) Y45 622 803 1

53 PCB cover M45 684 827 1

54 Circuit board Y45 636 804 1 JT-30P8H

Q'ty

pcs/unit

Critical

for

safety

Remarks

─29─

Page 30

64

a

(

2 pcs.

65

)

(

3 pcs.

)

a

68

67

66

(

4 pcs.

)

a

61

JT-SB216JSH2-W-NE

62

63

69

<Standard screws>

Symbol Screw name

a PTT screw 4x16

─ 30 ─

Page 31

JT-SB216JSH2-W-NE

No. Name of part Parts No.

61 Blower cover M45 697 823 1 With packing

62 Blower stopper M45 673 227 1

63 Blower (assy) M45 689 400 1

64 Floating rubber M45 664 227 1

65 Heater (PTC) Y45 636 801 1 With a fuse

66 Blower case M45 684 833 1 With packing

67 Cord bush M45 684 225 1

68 Tank cover Y45 636 807 1

69 Tank assy Y45 636 803 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─31─

Page 32

81

82

86

85

83

84

JT-SB216JSH2-W-NE

─ 32 ─

Page 33

JT-SB216JSH2-W-NE

No. Name of part Parts No.

81 Lead wire Y45 636 223 1 CN18-CN19

82 Lead wire Y45 636 221 1 CN7-CN12・CN15

83 Lead wire Y45 636 222 1 CN8-CN11

84 Lead wire Y45 631 219 1 With a ferrite core

85 Lead wire (M-P) Y45 636 219 1 CN2-CN5、 CN4-CN21

86 Ferrite core Y45 622 179 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─33─

Page 34

JT-SB216JSH2-H-NE

13

4

5

6

17

7

18

15

1

2

8

9

10

11

3

19

16

14

a

a

a

a

a

a

a

a

a

Special

screw 5x30

20

a (7 pcs.

)

(

2 pcs.

)

(

9 pcs.

)

6 pcs.

1 pc.

1 pc.

Cord clip

a

12

JT-SB216JSH2-H-NE

─ 34 ─

<Standard screws>

Symbol Screw name

a PTT screw 4x16

shows accessory parts.

Page 35

JT-SB216JSH2-H-NE

No. Name of part Parts No.

1 Side cover Y45 631 812 1 Gray

2 Side panel L Y45 636 812 1

3 Exhaust duct M45 697 804 1

4 Panel holder L M45 684 824 1

5 Panel holder R M45 684 825 1

6 Panel (front) M45 697 803 1 With packing

7 Panel (back) Y45 636 811 1 With packing

8 Base M45 697 814 1

9 Spl screw 4×16 H00 631 018 11

10 Hook (upper) M45 684 805 1

11 Spl screw 4×16 M45 632 047 2

12 Fix plate M45 697 802 1

13 Spl screw 4×16 M45 632 045 2

14 Indicator plate Y45 636 810 1

15 Front panel Y45 636 805 1

16 Wiring diagram Y45 636 358 1

17 Side panel R Y45 631 815 1 Gray

18 Filter M45 665 806 1

19 Cover M45 684 804 1

20 Parts in bag Y45 636 049 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─35─

Page 36

42

43

44

45

31

38

39

40

41

32

33

34

46

47

49

50

51

52

53

54

48

32

32

32

46

46

48

49

b

c

a

a

b

a

a

35

36

37

(

4 pcs.

)

9

a

<Standard screws>

Symbol Screw name

a PTT screw 4x16

b PTT screw 4x6

c PPT screw 4x30

JT-SB216JSH2-H-NE

─ 36 ─

Page 37

JT-SB216JSH2-H-NE

No. Name of part Parts No.

31 TB cover M45 684 826 1

32 Cord bush M45 649 226 5

33 Terminal block Y45 636 220 1 With a fuse

34 Terminal plate Y45 630 806 1

35 LED holder Y45 636 808 1

36 Circuit board Y45 636 176 1 JT-30S5R

37 Insulator sheet M45 684 823 1

38 PCB box M45 697 808 1 With a cover

39 Cord bush M45 640 226 1

40 Insulator sheet M45 684 821 1

41 Spacer M45 617 095 4 PCB-3L(V-0)

42 Circuit board Y45 636 171 1 JT-30F8

43 Circuit board Y45 636 173 1 JT-30S1R

44 Fix plate M45 684 831 1

45 Maint. cover M45 684 828 1

46 Spl screw 4×12 M34 869 018 3

47 Circuit board Y45 636 177 1 JT-30M8

48 Circuit board Y45 636 174 2 JT-30S2R

49 Fix piece M45 684 829 2

50 Circuit board Y45 636 175 1 JT-30S3R

51 Sensor holder M45 684 830 1

52 Reactor (assy) Y45 622 803 1

53 PCB cover M45 684 827 1

54 Circuit board Y45 636 804 1 JT-30P8H

Q'ty

pcs/unit

Critical

for

safety

Remarks

─37─

Page 38

64

a

(

2 pcs.

65

)

(

3 pcs.

)

a

68

67

66

(

4 pcs.

)

a

61

JT-SB216JSH2-H-NE

62

63

69

<Standard screws>

Symbol Screw name

a PTT screw 4x16

─ 38 ─

Page 39

JT-SB216JSH2-H-NE

No. Name of part Parts No.

61 Blower cover M45 697 823 1 With packing

62 Blower stopper M45 673 227 1

63 Blower (assy) M45 689 400 1

64 Floating rubber M45 664 227 1

65 Heater (PTC) Y45 636 801 1 With a fuse

66 Blower case M45 684 833 1 With packing

67 Cord bush M45 684 225 1

68 Tank cover Y45 636 807 1

69 Tank assy Y45 636 813 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─39─

Page 40

81

82

86

85

83

84

JT-SB216JSH2-H-NE

─ 40 ─

Page 41

JT-SB216JSH2-H-NE

No. Name of part Parts No.

81 Lead wire Y45 636 223 1 CN18-CN19

82 Lead wire Y45 636 221 1 CN7-CN12・CN15

83 Lead wire Y45 636 222 1 CN8-CN11

84 Lead wire Y45 631 219 1 With a ferrite core

85 Lead wire (M-P) Y45 636 219 1 CN2-CN5、 CN4-CN21

86 Ferrite core Y45 622 179 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─41─

Page 42

JT-SB216JSH2-S-NE

13

4

5

6

17

7

18

15

1

2

8

9

10

11

3

19

16

14

a

a

a

a

a

a

a

a

a

Special

screw 5x30

20

a (7 pcs.

)

(

2 pcs.

)

(

9 pcs.

)

6 pcs.

1 pc.

1 pc.

Cord clip

a

12

JT-SB216JSH2-S-NE

─ 42 ─

<Standard screws>

Symbol Screw name

a PTT screw 4x16

shows accessory parts.

Page 43

JT-SB216JSH2-S-NE

No. Name of part Parts No.

1 Side cover Y45 631 812 1 Gray

2 Side panel L Y45 636 812 1

3 Exhaust duct M45 697 804 1

4 Panel holder L M45 684 824 1

5 Panel holder R M45 684 825 1

6 Panel (front) M45 697 803 1 With packing

7 Panel (back) Y45 636 811 1 With packing

8 Base M45 697 814 1

9 Spl screw 4×16 H00 631 018 11

10 Hook (upper) M45 684 805 1

11 Spl screw 4×16 M45 632 047 2

12 Fix plate M45 697 802 1

13 Spl screw 4×16 M45 632 045 2

14 Indicator plate Y45 636 815 1

15 Front panel Y45 636 814 1

16 Wiring diagram Y45 636 358 1

17 Side panel R Y45 631 815 1 Gray

18 Filter M45 665 806 1

19 Cover M45 684 804 1

20 Parts in bag Y45 636 049 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─43─

Page 44

42

43

44

45

31

38

39

40

41

32

33

34

46

47

49

50

51

52

53

54

48

32

32

32

46

46

48

49

b

c

a

a

b

a

a

35

36

37

(

4 pcs.

)

9

a

<Standard screws>

Symbol Screw name

a PTT screw 4x16

b PTT screw 4x6

c PPT screw 4x30

JT-SB216JSH2-S-NE

─ 44 ─

Page 45

JT-SB216JSH2-S-NE

No. Name of part Parts No.

31 TB cover M45 684 826 1

32 Cord bush M45 649 226 5

33 Terminal block Y45 636 220 1 With a fuse

34 Terminal plate Y45 630 806 1

35 LED holder Y45 636 808 1

36 Circuit board Y45 636 176 1 JT-30S5R

37 Insulator sheet M45 684 823 1

38 PCB box M45 697 808 1 With a cover

39 Cord bush M45 640 226 1

40 Insulator sheet M45 684 821 1

41 Spacer M45 617 095 4 PCB-3L(V-0)

42 Circuit board Y45 636 171 1 JT-30F8

43 Circuit board Y45 636 173 1 JT-30S1R

44 Fix plate M45 684 831 1

45 Maint. cover M45 684 828 1

46 Spl screw 4×12 M34 869 018 3

47 Circuit board Y45 636 177 1 JT-30M8

48 Circuit board Y45 636 174 2 JT-30S2R

49 Fix piece M45 684 829 2

50 Circuit board Y45 636 175 1 JT-30S3R

51 Sensor holder M45 684 830 1

52 Reactor (assy) Y45 622 803 1

53 PCB cover M45 684 827 1

54 Circuit board Y45 636 804 1 JT-30P8H

Q'ty

pcs/unit

Critical

for

safety

Remarks

─45─

Page 46

64

a

(

2 pcs.

65

)

(

3 pcs.

)

a

68

67

66

(

4 pcs.

)

a

61

JT-SB216JSH2-S-NE

62

63

69

<Standard screws>

Symbol Screw name

a PTT screw 4x16

─ 46 ─

Page 47

JT-SB216JSH2-S-NE

No. Name of part Parts No.

61 Blower cover M45 697 823 1 With packing

62 Blower stopper M45 673 227 1

63 Blower (assy) M45 689 400 1

64 Floating rubber M45 664 227 1

65 Heater (PTC) Y45 636 801 1 With a fuse

66 Blower case M45 684 833 1 With packing

67 Cord bush M45 684 225 1

68 Tank cover Y45 636 807 1

69 Tank assy Y45 636 813 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─47─

Page 48

81

82

86

85

83

84

JT-SB216JSH2-S-NE

─ 48 ─

Page 49

JT-SB216JSH2-S-NE

No. Name of part Parts No.

81 Lead wire Y45 636 223 1 CN18-CN19

82 Lead wire Y45 636 221 1 CN7-CN12・CN15

83 Lead wire Y45 636 222 1 CN8-CN11

84 Lead wire Y45 631 219 1 With a ferrite core

85 Lead wire (M-P) Y45 636 219 1 CN2-CN5、 CN4-CN21

86 Ferrite core Y45 622 179 2

Q'ty

pcs/unit

Critical

for

safety

Remarks

─49─

Page 50

JT-SB216KSN2-W-NE

13

4

5

6

17

7

18

15

1

2

8

9

10

11

3

19

16

14

a

a

a

a

a

a

a

a

a

Special

screw 5x30

20

a (7 pcs.

)

(

2 pcs.

)

(

9 pcs.

)

6 pcs.

1 pc.

1 pc.

Cord clip

a

12

JT-SB216KSN2-W-NE

─ 50 ─

<Standard screws>

Symbol Screw name

a PTT screw 4x16

shows accessory parts.

Page 51

JT-SB216KSN2-W-NE

No. Name of part Parts No.

1 Side cover Y45 631 806 1

2 Side panel L Y45 636 806 1

3 Exhaust duct M45 697 804 1

4 Panel holder L M45 684 824 1

5 Panel holder R M45 684 825 1

6 Panel (front) Y45 636 816 1 With packing

7 Panel (back) Y45 636 802 1 With packing

8 Base M45 697 814 1

9 Spl screw 4×16 H00 631 018 11

10 Hook (upper) M45 684 805 1

11 Spl screw 4×16 M45 632 047 2

12 Fix plate M45 697 802 1

13 Spl screw 4×16 M45 632 045 2

14 Indicator plate Y45 637 809 1

15 Front panel Y45 637 800 1

16 Wiring diagram Y45 636 358 1

17 Side panel R Y45 631 809 1

18 Filter M45 665 806 1

19 Cover M45 684 804 1

20 Parts in bag Y45 636 049 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─51─

Page 52

42

43

44

45

31

38

39

40

41

32

33

34

46

47

49

50

51

52

53

54

48

32

32

32

46

46

48

49

b

c

a

a

b

a

a

35

36

37

(

4 pcs.

)

9

a

<Standard screws>

Symbol Screw name

a PTT screw 4x16

b PTT screw 4x6

c PPT screw 4x30

JT-SB216KSN2-W-NE

─ 52 ─

Page 53

JT-SB216KSN2-W-NE

No. Name of part Parts No.

31 TB cover M45 684 826 1

32 Cord bush M45 649 226 5

33 Terminal block Y45 636 220 1 With a fuse

34 Terminal plate Y45 630 806 1

35 LED holder Y45 636 808 1

36 Circuit board Y45 636 176 1 JT-30S5R

37 Insulator sheet M45 684 823 1

38 PCB box M45 697 808 1 With a cover

39 Cord bush M45 640 226 1

40 Insulator sheet M45 684 821 1

41 Spacer M45 617 095 4 PCB-3L(V-0)

42 Circuit board Y45 636 171 1 JT-30F8

43 Circuit board Y45 636 173 1 JT-30S1R

44 Fix plate M45 684 831 1

45 Maint. cover M45 684 828 1

46 Spl screw 4×12 M34 869 018 3

47 Circuit board Y45 637 171 1 JT-30M9A

48 Circuit board Y45 636 174 2 JT-30S2R

49 Fix piece M45 684 829 2

50 Circuit board Y45 636 175 1 JT-30S3R

51 Sensor holder M45 684 830 1

52 Reactor (assy) Y45 622 803 1

53 PCB cover M45 684 827 1

54 Circuit board Y45 636 804 1 JT-30P8H

Q'ty

pcs/unit

Critical

for

safety

Remarks

─53─

Page 54

a

(

4 pcs.

(

3 pcs.

)

a

67

66

65

64

63

62

)

68

61

<Standard screws>

Symbol Screw name

JT-SB216KSN2-W-NE

a PTT screw 4x16

─ 54 ─

Page 55

JT-SB216KSN2-W-NE

No. Name of part Parts No.

61 Blower cover M45 697 823 1 With packing

62 Blower stopper M45 673 227 1

63 Blower (assy) M45 689 400 1

64 Floating rubber M45 664 227 1

65 Blower case M45 684 833 1 With packing

66 Cord bush M45 684 225 1

67 Tank cover Y45 636 807 1

68 Tank assy Y45 636 803 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─55─

Page 56

81

82

86

85

83

84

JT-SB216KSN2-W-NE

─ 56 ─

Page 57

JT-SB216KSN2-W-NE

No. Name of part Parts No.

81 Lead wire Y45 636 223 1 CN18-CN19

82 Lead wire Y45 636 221 1 CN7-CN12・CN15

83 Lead wire Y45 636 222 1 CN8-CN11

84 Lead wire Y45 631 219 1 With a ferrite core

85 Lead wire (M-P) Y45 636 219 1 CN2-CN5、 CN4-CN21

86 Ferrite core Y45 622 179 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─57─

Loading...

Loading...