Mitsubishi JT-SB216DS-W-CE HAND BOOK

HAND DRYER

HAND BOOK

(For HONG KONG)

Issued February 2005 No. U-113

Model: JT-SB216DS-W-CE

Notice:

The term of validity is for a year from the issued date.

MITSUBISHI ELECTRIC CORPORATION

FOR DEALERS

Model name

Repair work should be performed by

the manufacturer, its service agent or

similarly qualified person in order to

avoid a hazard.

Contents

Safety precautions.....................................................................3-4

1. Features................................................................................. 4

2. Names and functions of the hand dryer's components.......... 5

2-1 Configuration diagram and appearance diagram............. 5

2-2 Operating procedure......................................................... 5

3. Specifications......................................................................... 6

4. Dimensions............................................................................ 6

5. Wiring diagrams..................................................................... 7

6. Troubleshooting............................................................... 8-11

7. How to call........................................................................... 12

8. Technical notes.................................................................... 13

9. Overhaul procedure........................................................ 13-19

10. Sequence timing chart......................................................... 20

11. Description of circuit operation ....................................... 20-21

12. Circuit diagram and items to check ................................ 22-23

13. Board diagram and items to check...................................... 24

14. Parts list.......................................................................... 25-33

—3—

Caution for electric shock

If it is absolutely necessary to inspect the circuitry

while turning on electricity, exercise caution not to touch live parts.

(Touching live parts may cause electric

shock.)

Modification prohibited

Never modify the product.

(Modifying may cause electric shock, fire,

and/or injury.)

Conduct electric work correctly

• Use the designated electric wires, and conduct

electric work according to the Electrical Equipment

Technical Standard, Internal Wiring Regulation, and

Installation Work Guide.

• Be sure to check whether the terminals

and fixed wiring are securely connected.

(Improper connection or installation may

cause electric shock and/or fire.)

Scratches and deterioration

Be sure to replace scratched and/or

deteriorated fixed wiring and lead wires.

(They may cause electric shock and/or fire.)

Turn off the power

• Be sure to turn off the ground fault circuit interrupter

and the power switch of the product's main body

prior to starting repair work. (The charge voltage in

the circuitry remains for another minute or so, even

after the power is turned off and the LED is unlit;

therefore, wait for at least 1 minute

before disassembling the product.)

(Not turning off the power may cause electric

shock.)

Use proper parts and tools

Use the parts listed in the service parts list of the subject model with appropriate tools when

repairing.

(Using improper parts and tools may cause

electric shock, fire, and/or injury.)

Check insulation

Upon completing repair work, always measure an

insulation resistance. Verify that it is at

least 1 MΩ, and then turn on the power.

(Inadequate insulation may cause electric

shock.)

Wear gloves

Always wear a pair of gloves during

inspection or repair work.

(Not wearing gloves may cause injury.)

Safety precautions

●Please read the following items carefully before using this product, and perform the maintenance and repair work

of the product correctly and safely.

●The types and levels of the dangers from mishandling this product are categorized and indicated by the signs

shown below.

Items that may cause death or serious injury if the product is mishandled.

g

Items that may cause injury and/or damage to buildings

and/or fixtures if the product is mishandled.

Warning

Caution for

electric shock

Prohibited

Implement by always

instructions

followin

Implement by always

following instructions

Implement by always

following instructions

Implement by always

following instructions

Caution

Implement by always

following instructions

Implement by always

following instructions

—4—

1. Features

1 Speed drying

Equipped with a turbo fan, the hand dryer blows away drops of water on the hands with a high-speed jet air

from a large air volume, high-speed rotary DC brush-less blower, thus quickly draying the hands.

2 Easy to use

The rubbing of the hands is no longer necessary. With the hand dryer, you can dry both hands by just inserting and then removing them slowly.

3 Hygienic

• The hand dryer is automatically started by a sensor. Thus, there is no need to touch the hand dryer with

your wet hands. It is very hygienic.

4 Antibacterial

• The hand dryer uses a silver inorganic substance; thus, maintaining an antibacterial effect for an extended

period of time.

• The hand dryer meets the antibacterial effect standard defined by the Society of Industrial Technology for

Antimicrobial Articles (SIAA).

5 Easy maintenance

The hand dryer does not require a paper or cloth towel, thus eliminating the dumping of paper waste and the

exchanging of towels. Also, the hand dryer is easy to clean.

6 Highly safe with mischievous use prevention timer

To prevent continuous operations of the hand dryer by mischievous use or malfunction, it has a built-in timer

that automatically stops drying upon reaching a specific period of time.

7 Economical

The monthly electricity expense is the only expense the hand dryer requires. Thus, it is extremely economical for use over an extended period of time.

• Inspect the condition of the earth. Correct it if improperly grounded. Also, check to see if a ground fault circuit

interrupter is being installed. If not, install one.

• Check to see whether or not the air filter and the drain tank are installed securely in place.

• Do not leave a towel or other object in the hand-drying area.

• Never place any object on the main body nor cover it.

• Make sure that the product is not being used in any of the following locations:

Locations where the temperature can exceed 0°C to 40°C.

Locations where the humidity can exceed 5%RH to 95%RH.

Locations where the unit may come into direct contact with water.

Locations where the unit is under direct or strong sunlight. (May cause sensor to malfunction.)

Locations where there is a lot of condensation.

Do not use with chemicals (detergents, etc.) on your hands. (This may reduce the productive life of the unit.)

Do not use in locations where corrosive, neutral, or reductive gases are present.

(This may reduce the productive life of the unit and/or cause malfunctions.)

Locations where solt damage may occur.

Places lower than -20m or higher than 2000m above sea level.

Items to check during repair work

●Upon completing repair work, verify that the product operates normally. Clean the product's main body and surrounding area, and notify the customer of the completion of the repair work.

—5—

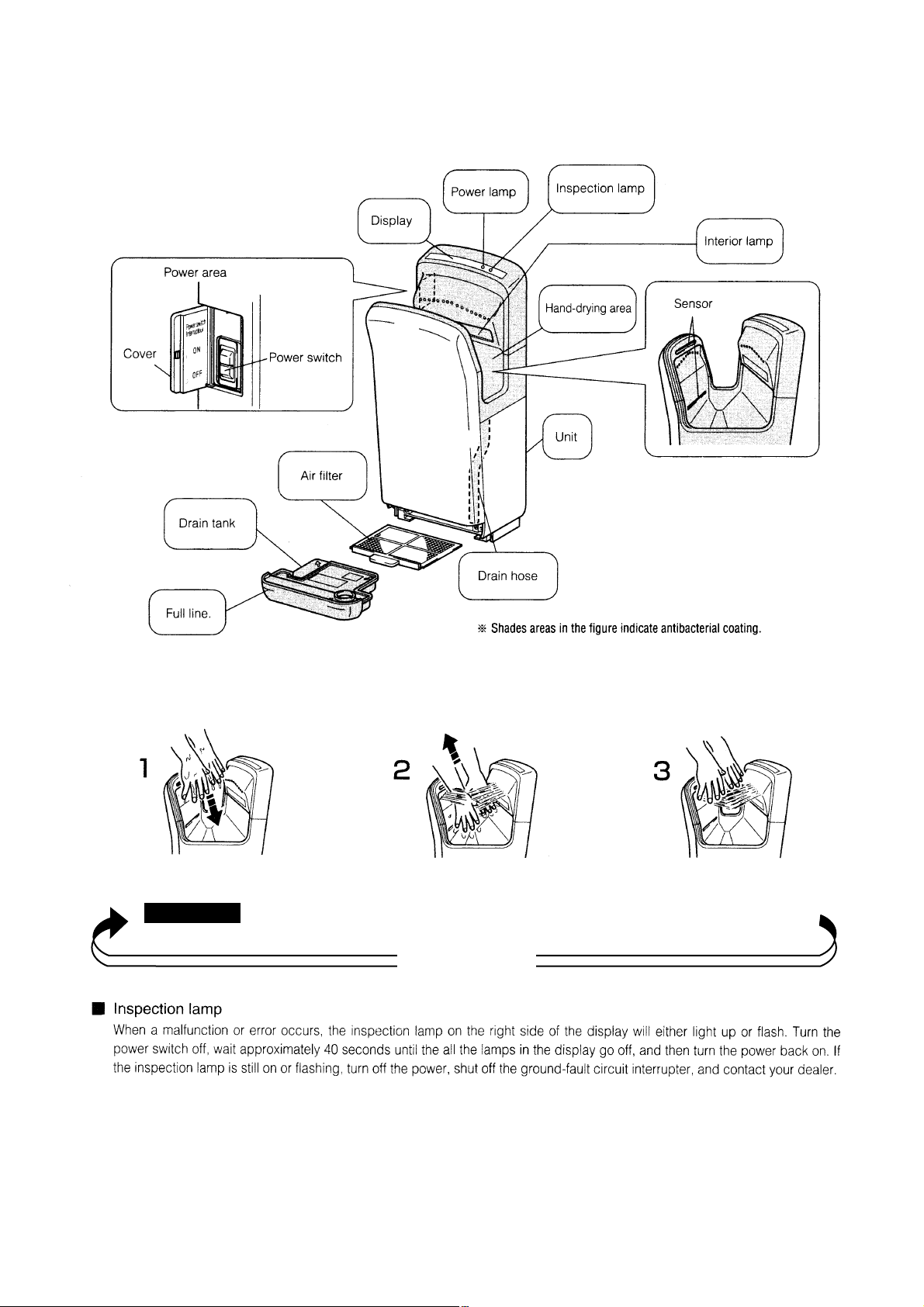

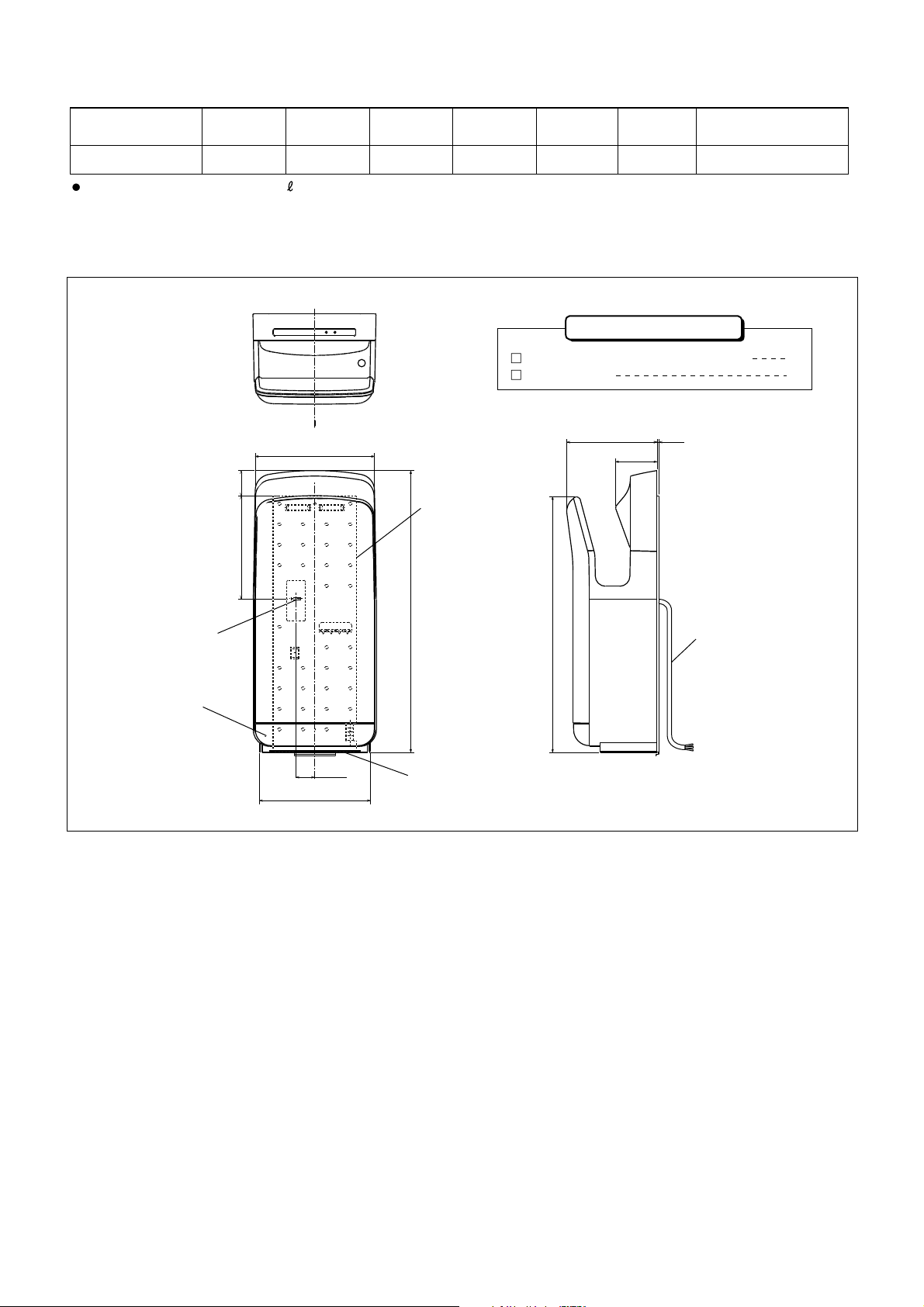

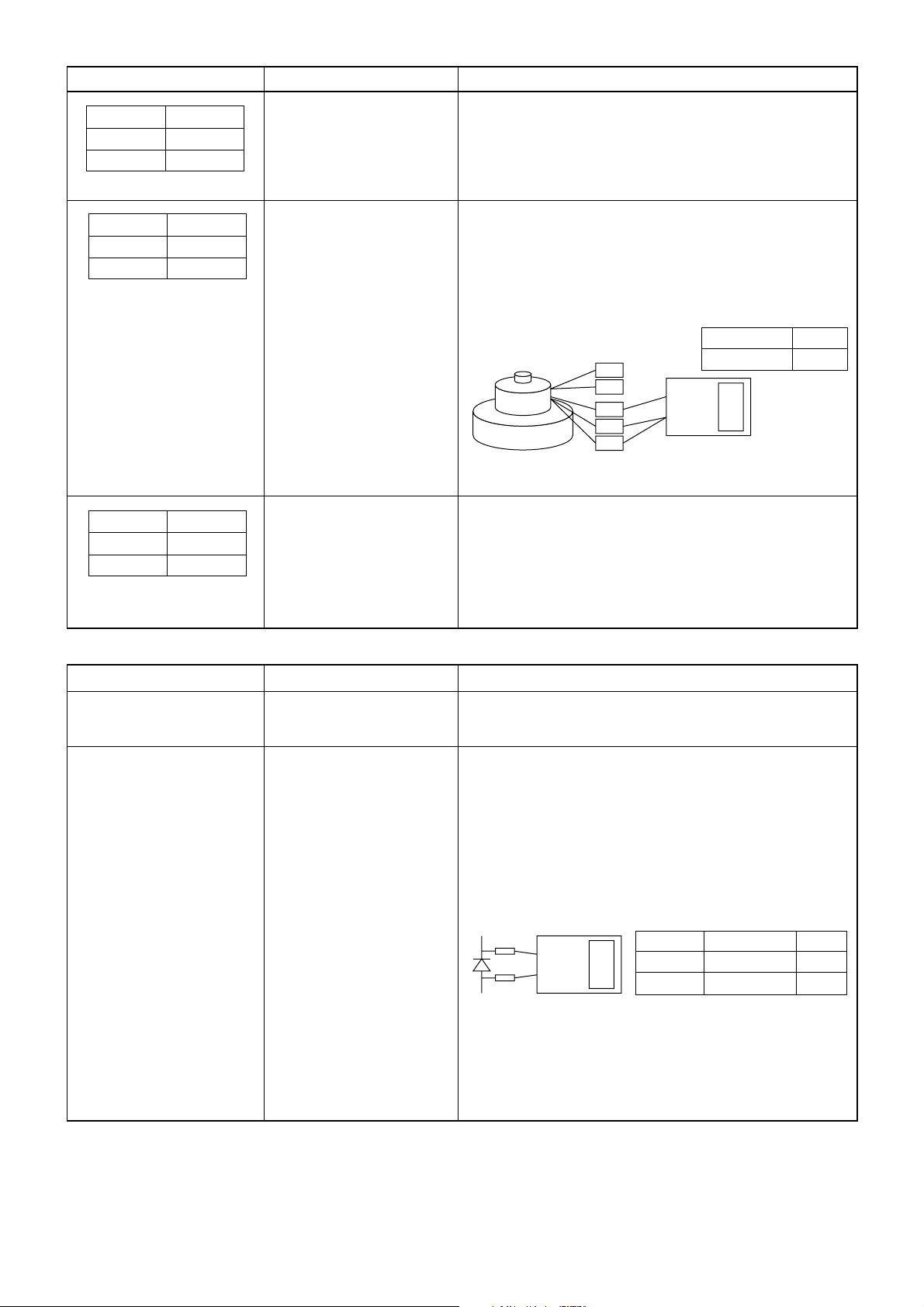

2. Names and functions of the hand dryer's components

2-1 Configuration diagram and appearance diagram

2-2 Operating procedure

With both hands open, insert them

all the way in.

The unit will come on automatically.

Pull them out slowly,

letting the air blow the

water off.

Pull hands all the way

out.

Repeat until dry

—6—

Voltage

(Vac)

220-240

Model

JT-SB216DS-W-CE

Frequency

(Hz)

50-60

Phase

single-phase

Power consumption

(W)

650

Current

(A)

4

Weight

(kg)

11

Dimensions (W ✕ D ✕ H)

(mm)

300 ✕ 220 ✕ 687

The drain tank capacity is 0.8 .

3. Specifications

4. Dimensions

Installation panel screws (5x30 self-tapping) 6

Installation panel 1

Accessories

Supply cord hole (rear)

Drain tank

Air filter

Installation panel

Supply cord

(Approx 1.5m)

623

220

2

101

250 62

687

300

270

46

Unit (mm)

—7—

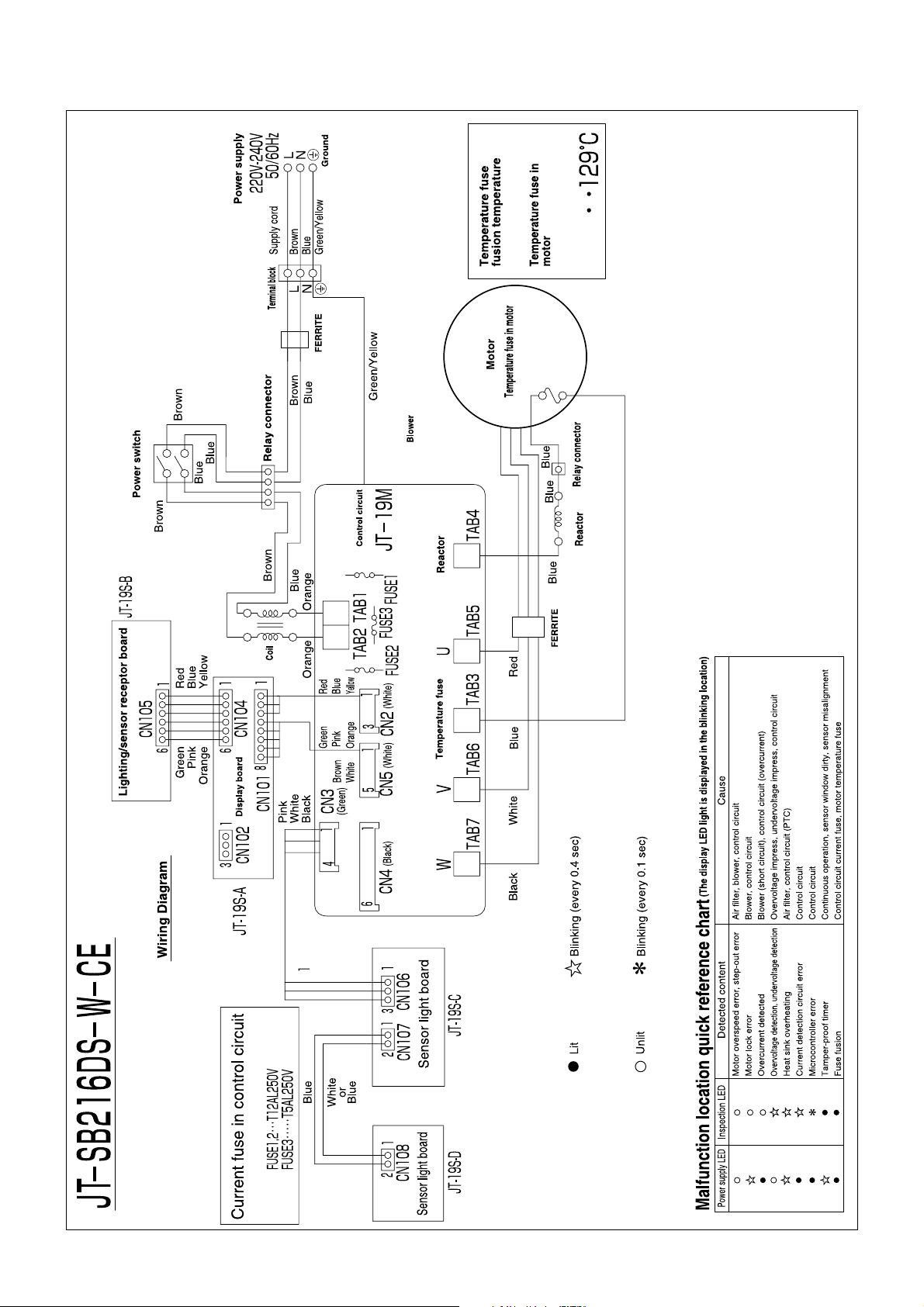

5. Wiring diagrams

—8—

• Is the power supply connected?

• Is the power switch on?

• Measure the resistance between the current fuses on

the control board.

*Replace the control board

if the measured resistance value is other than the

normal value shown in the table at right.

• Is the motor's lead wire connector connected?

• Measure the resistance between the motor's two

"blue" lead wires.

*Replace the motor if the

measured resistance value is other than the normal

value shown in the table at right.

• Unplug the relay connector, and measure the

resistance at two places between each pair of the

power switch's "brown" and "blue" lead wires.

• Replace the control circuit if other than above.

• Is the sensor's lead wire connector (CN2) connected?

• Unplug the control circuit's CN2 (3-pin connector),

measure the voltage between pins 1 and 2 as well as

pins 1 and 3 of the CN2 by diode check (measure on

the lead wire side).

• Replace the control circuit if other than above.

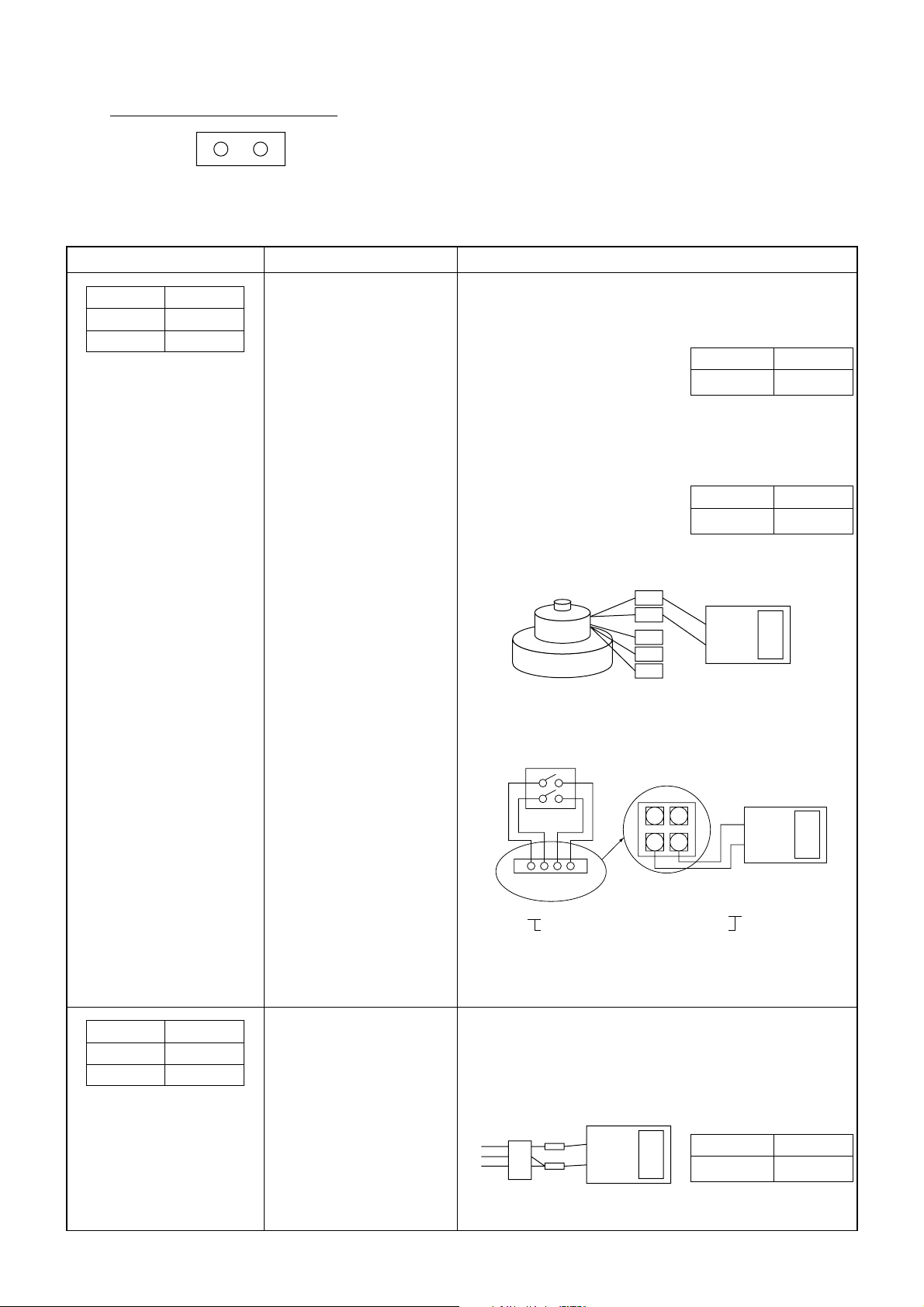

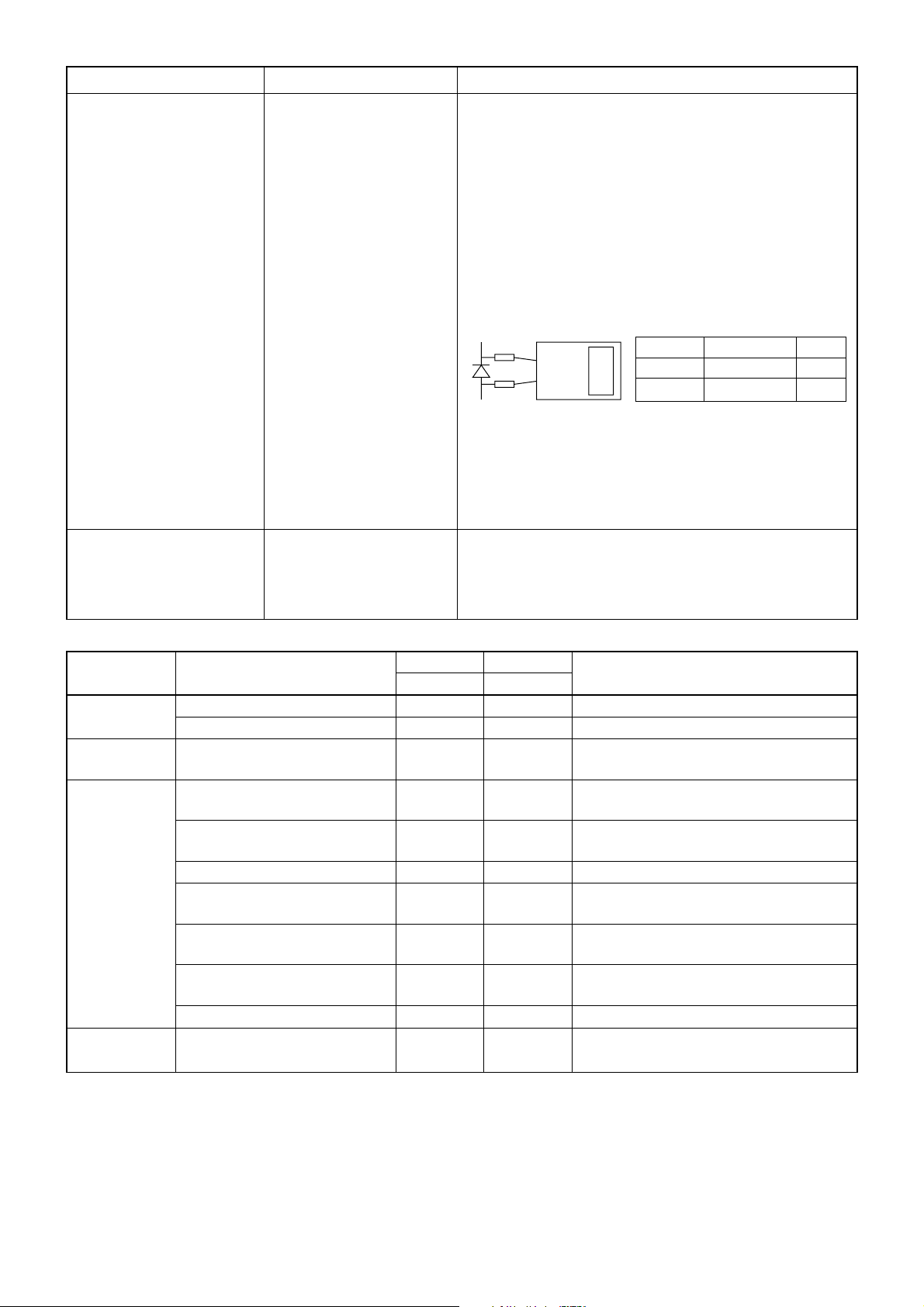

6. Troubleshooting

Description of error modes below

LED2LED1

[●●] Lit [✩] Blinking (0.4 sec on/0.4 sec off)

[●] Unlit [✻] Fast blinking (0.1 sec on/0.1 sec off)

Error mode display Cause Check procedure and action to take

LED1 LED2

Power Inspection

●●

Measured value Decision/action

0Ω Normal

Measured value Decision/action

0Ω Normal

Measured value Decision/action

1.5 to 1.8V Normal

(No display, no operation)

LED1 LED2

Power Inspection

●●

(Operates, but no display)

1.Power off

2.Current fuse

3.Motor temperature fuse

4.Power switch

5.Control circuit

1.Display board

2.Control circuit

+ side

– side

Blue

Blue

Red

Black

White

Tester

+ side

– side

Tester

Power switch

Relay connector

Relay connector

Blue Blue

Brown

Blue

Brown

Blue

BrownBrown

Resistance

value

Power switch ON

Power switch OFF

Replace the power

switch if the measured

resistance values are

other than those at left.

: Approx. 0 Ω

: Approx. ∞ Ω

+ side

– side

Tester

C

N

2

—9—

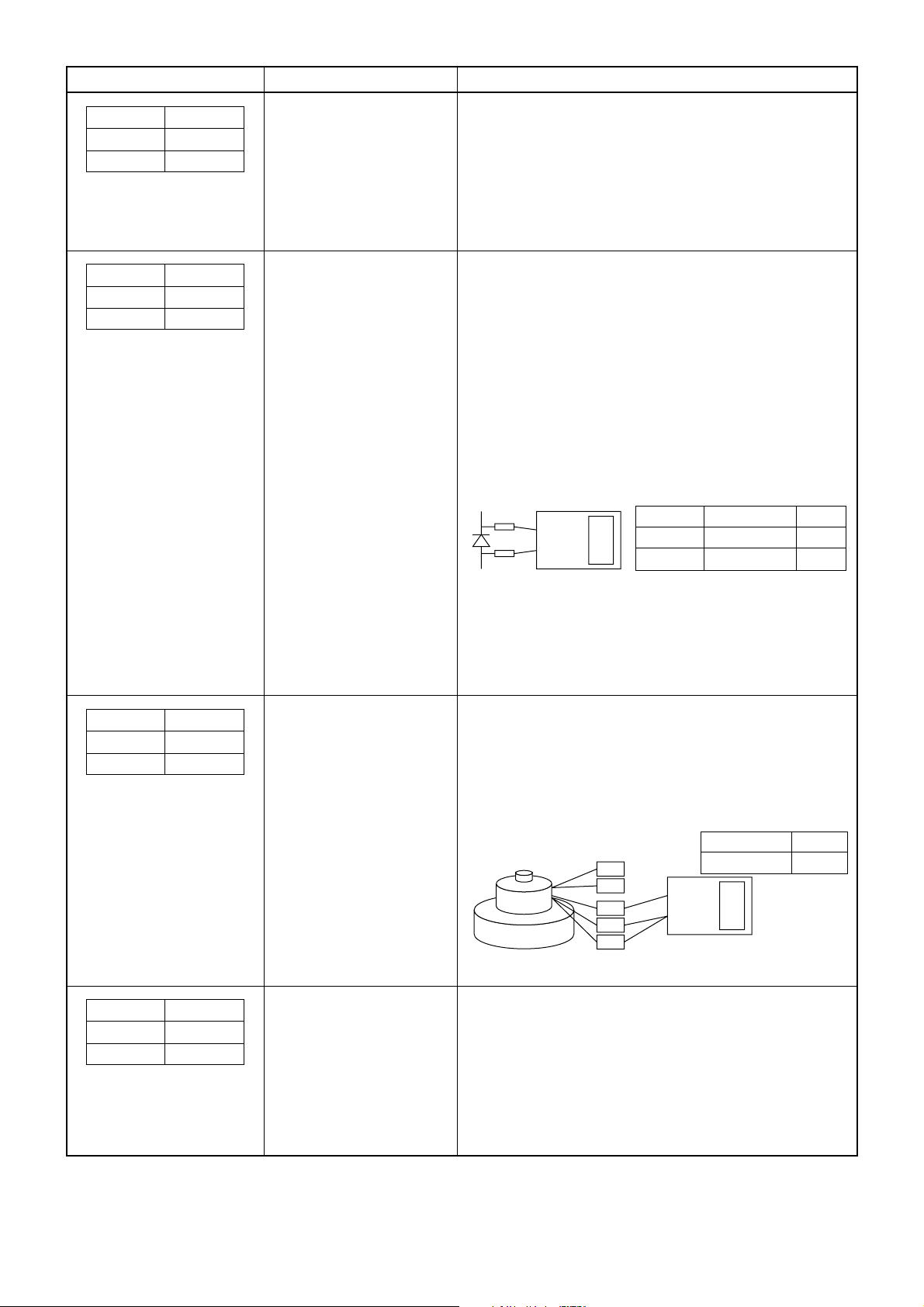

• Is the filter clogged with dust and the like? → If so,

clean the filter.

• Are the temperatures of the control circuit and

electronic parts too high? → If so, turn OFF the power

switch and lower the temperatures to normal

temperatures (40 ˚C or less).

• Replace the control circuit if other than above.

• When the operation time exceeds 30 seconds, the

operation stops by the activated mischievous use

prevention timer.

• Are the sensor's three windows stained?

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced (top/bottom

light emitting boards, light receiving board)?

• Measure the forward voltages of the LEDs on the

top/bottom light emitting boards and the photo diode

(PHD) on the light receiving board with a measuring

device that has a diode check function.

*Replace the top/bottom light emitting boards and the

light receiving board if the measured values are

other than the normal values shown in the table

above.

• Replace the control circuit if other than above.

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

*Replace the motor if the measured values are other

than the normal value shown in

the table at right.

• Replace the control circuit if other than above.

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a power supply frequency 50 or 60 Hz?

• Replace the control circuit if other than the above.

Error mode display Cause Check procedure and action to take

LED1 LED2

Power Inspection

✩✩

1.Filter clogged with dust

2.PTC operation (control

circuit)

3.Control circuit

1.Continuous operation

2.Stained sensor's

windows

3.Disengaged sensor

4.Displaced sensor's

board positions

5.Sensor light

emitting/receiving

diode failure

6.Control circuit

1.Motor

2.Control circuit

1.Excess voltage applied

2.Low voltage

3.No power supply

frequency

4.Control circuit

(Heat sink overheat)

LED1 LED2

Power Inspection

✩

●

(Mischievous use

prevention timer)

LED1 LED2

Power Inspection

✩

●●

(Motor lock)

LED1 LED2

Power Inspection

●●

✩

(Overvoltage, low voltage,

power supply frequency

detection)

+ side

– side

Blue

Blue

Red

Black

White

Tester

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

—10—

• Replace the control circuit.

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

*Replace the motor if the measured values are other

than the normal value shown

in the table at right.

• Replace the control circuit if other than above.

• Replace the control circuit.

Error mode display Cause Check procedure and action to take

LED1 LED2

Power Inspection

●

✩

1.Control circuit

1.Motor

2.Control circuit

1.Control circuit

(Current detection circuit

abnormality)

LED1 LED2

Power Inspection

● ●●

(Overcurrent detection)

+ side

– side

Blue

Blue

Red

Black

White

Tester

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

• Replace the light receiving board.

• Replace the control board if other than above.

• Are the sensor's three windows stained?

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced (bottom

light emitting boards, light receiving board)?

• Measure the forward voltages of the LEDs on the

bottom light emitting boards and the photo diode

(PHD) on the light receiving board with a measuring

device that has a diode check function.

*Replace the bottom light emitting boards and the light

receiving board if the measured values are other than

the normal values shown in the table above.

• Replace the display board or the control circuit if other

than above.

1.Lighting board

2.Control circuit

1.Stained sensor's windows

2.Disengaged sensor

3.Displaced sensor's

board positions

4.Sensor light

emitting/receiving

diode failure

5.Control circuit

Phenomenon Cause Check procedure and action to take

Phenomena of problems other than error mode display

Lighting does not turn on.

The hand dryer starts

drying as soon as the

power switch is turned

ON.

LED1 LED2

Power Inspection

●✻

(Microcomputer RAM abnormality)

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

—11—

[Reference data] LED display list

Description

LED1 LED2

Power Inspection

Main cause of occurrence

When normal

Abnormal 1

Abnormal 2

Abnormal 3

Power switch OFF

Power switch ON

Mischievous use prevention

timer

Motor rotating excessively, out

of step

Motor startup error, locked

Overcurrent

Overvoltage, low voltage, no

power supply frequency

Fin overheating

Current detection circuit

abnormality

Microcomputer abnormality

Blown fuse

●

●●

✩

●●

✩

●

●●

✩

●

●

●

●

●

●

●●

●●

●●

✩

✩

✩

✻

●

Continuous operation, sensor

stained/disengaged

Main circuit, motor demagnetized

Main circuit, motor's wire

open/disconnected

Main circuit, motor short-circuited

Main circuit, power supply, 5A-fuse

blown out (excess voltage applied)

Main circuit, no fin, operated at high

temperature

Main circuit

Main circuit

Current fuse, temperature fuse, power

supply

[●●] Lit [✩] Blinking (0.4 sec on/0.4 sec off)

[●] Unlit [✻] Fast blinking (0.1 sec on/0.1 sec off)

• Are the sensor's three windows stained? → Clean the

windows if stained.

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced? → Install

the sensor light boards in their proper positions if

displaced (top light emitting boards, light receiving

board).

• Measure the forward voltages of the LEDs on the top

light emitting boards and the photo diode (PHD) on

the light receiving board with a measuring device that

has a diode check function.

*Replace the top light emitting boards and the light

receiving board if the measured values are other

than the normal values shown in the table above.

• Replace the display board or the control circuit if other

than above.

• Are foreign particles being attached to the motor's

fins?

• Is the filter clogged with dust?

1.Stained sensor's

windows

2.Disengaged sensor

3.Displaced sensor's

board positions

4.Sensor light

emitting/receiving

diode failure

5.Control circuit

1.Suction of foreign

particles

2.Filter clogged with dust

The hand dryer does not

stop after removing the

hands.

Abnormal noise is

generated.

Phenomenon Cause Check procedure and action to take

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

Loading...

Loading...