Page 1

HAND DRYER

HAND BOOK

(For HONG KONG)

Model: JT-SB216DS-W-AUS

Notice:

The term of validity is one year from the issued date.

FOR DEALERS

Nameplate

Repair work should be performed by

the manufacturer, its service agent or

similarly qualified person in order to

avoid a hazard.

April 2006 No. U122

Page 2

Contents

Safety precautions.....................................................................3-4

1. Features................................................................................. 4

2. Names and functions of the hand dryer's components.......... 5

2-1 Configuration diagram and appearance diagram ............. 5

2-2 Operating procedure......................................................... 5

3. Specifications......................................................................... 6

4. Dimensions............................................................................ 6

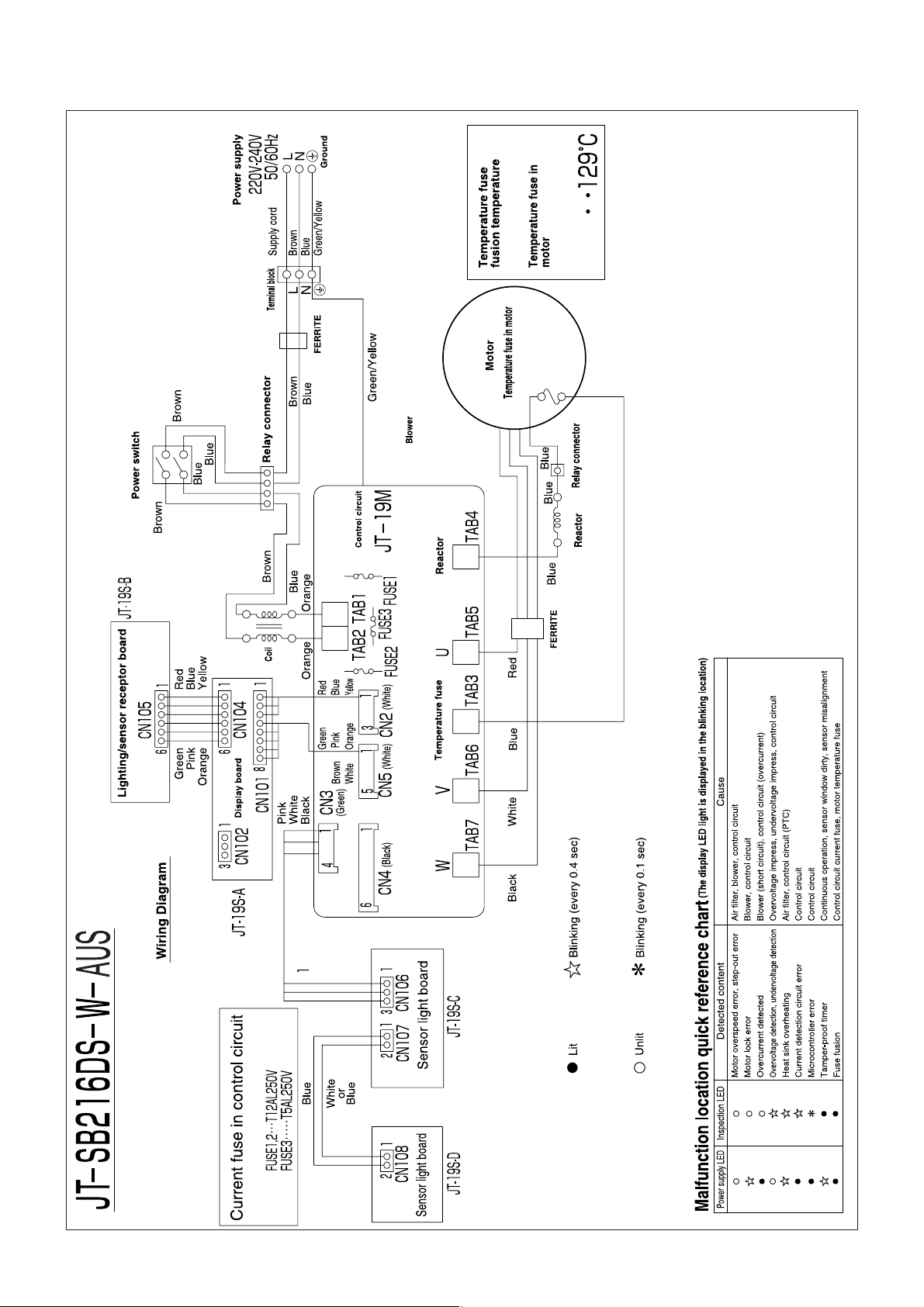

5. Wiring diagrams..................................................................... 7

6. Troubleshooting................................................................ 8-12

7. How to call ........................................................................... 13

8. Technical notes.................................................................... 14

9. Overhaul procedure........................................................ 14-20

10. Sequence timing chart......................................................... 21

11. Description of circuit operation ....................................... 21-22

12. Circuit diagram and items to check ................................ 23-24

13. Board diagram and items to check ...................................... 25

14. Parts list.......................................................................... 26-34

Page 3

Safety precautions

●Please read the following items carefully before using this product, and perform the maintenance and repair work

of the product correctly and safely.

●The types and levels of the dangers from mishandling this product are categorized and indicated by the signs

shown below.

Items that may cause death or serious injury if the product is mishandled.

Warning

Caution for electric shock

If it is absolutely necessary to inspect the circuitry

while turning on electricity, exercise caution not to touch live parts.

(Touching live parts may cause electric

shock.)

Caution for

electric shock

Modification prohibited

Never modify the product.

(Modifying may cause electric shock, fire,

and/or injury.)

Prohibited

Conduct electric work correctly

• Use the designated electric wires, and conduct

electric work according to the Electrical Equipment

Technical Standard, Internal Wiring Regulation, and

Installation Work Guide.

• Be sure to check whether the terminals

and fixed wiring are securely connected.

(Improper connection or installation may

cause electric shock and/or fire.)

Implement by always

g instructions

followin

Scratches and deterioration

Be sure to replace scratched and/or

deteriorated fixed wiring and lead wires.

(They may cause electric shock and/or fire.)

Implement by always

following instructions

Turn off the power

• Be sure to turn off the ground fault circuit interrupter

and the power switch of the product's main body

prior to starting repair work. (The charge voltage in

the circuitry remains for another minute or so, even

after the power is turned off and the LED is unlit;

therefore, wait for at least 1 minute

before disassembling the product.)

(Not turning off the power may cause electric

shock.)

Implement by always

following instructions

Use proper parts and tools

Use the parts listed in the service parts list of the subject model with appropriate tools when

repairing.

(Using improper parts and tools may cause

electric shock, fire, and/or injury.)

Implement by always

following instructions

Check insulation

Upon completing repair work, always measure an

insulation resistance. Verify that it is at

least 1 MΩ, and then turn on the power.

(Inadequate insulation may cause electric

shock.)

Implement by always

following instructions

Avoid misuse

• This appliance is not intended for use by young children or infirm persons unless they are adequately

supervised by a responsible person to ensure that

they can use the appliance safely.

• Young children should be supervised

to ensure that they do not play with the

appliance.

Implement by always

following instructions

Caution

Wear gloves

Always wear a pair of gloves during

inspection or repair work.

(Not wearing gloves may cause injury.)

Items that may cause injury and/or damage to buildings

and/or fixtures if the product is mishandled.

Implement by always

following instructions

—3—

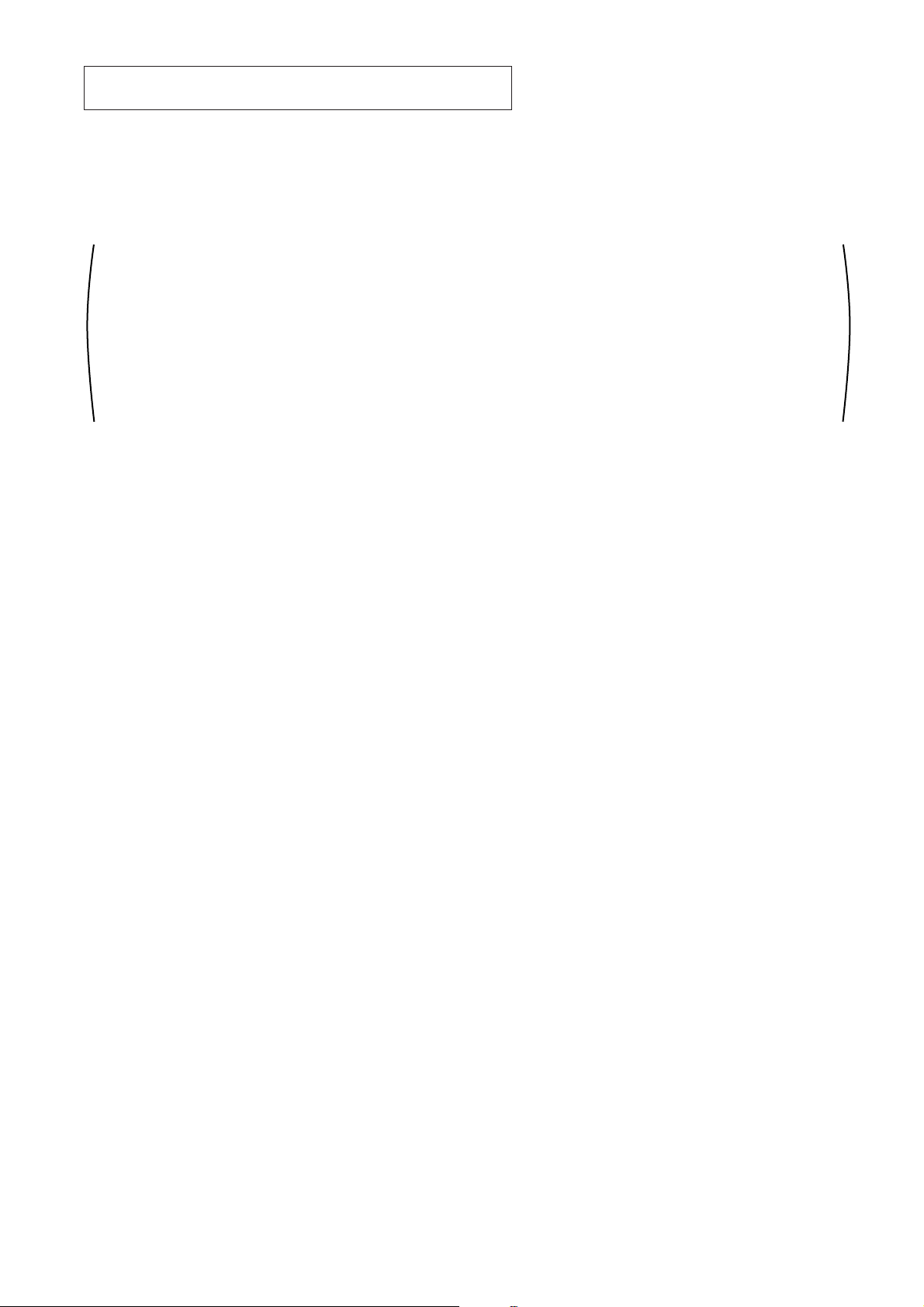

Page 4

—4—

1. Features

1 Speed drying

Equipped with a turbo fan, the hand dryer blows away drops of water on the hands with a high-speed jet air

from a large air volume, high-speed rotary DC brush-less blower, thus quickly draying the hands.

2 Easy to use

The rubbing of the hands is no longer necessary. With the hand dryer, you can dry both hands by just inserting and then removing them slowly.

3 Hygienic

• The hand dryer is automatically started by a sensor. Thus, there is no need to touch the hand dryer with

your wet hands. It is very hygienic.

4 Antibacterial

• The hand dryer uses a silver inorganic substance; thus, maintaining an antibacterial effect for an extended

period of time.

• The hand dryer meets the antibacterial effect standard defined by the Society of Industrial Technology for

Antimicrobial Articles (SIAA).

5 Easy maintenance

The hand dryer does not require a paper or cloth towel, thus eliminating the dumping of paper waste and the

exchanging of towels. Also, the hand dryer is easy to clean.

6 Highly safe with mischievous use prevention timer

To prevent continuous operations of the hand dryer by mischievous use or malfunction, it has a built-in timer

that automatically stops drying upon reaching a specific period of time.

7 Economical

The monthly electricity expense is the only expense the hand dryer requires. Thus, it is extremely economical for use over an extended period of time.

• Inspect the condition of the earth. Correct it if improperly grounded. Also, check to see if a ground fault circuit

interrupter is being installed. If not, install one.

• Check to see whether or not the air filter and the drain tank are installed securely in place.

• Do not leave a towel or other object in the hand-drying area.

• Never place any object on the main body nor cover it.

• Make sure that the product is not being used in any of the following locations:

Locations where the temperature can exceed 0°C to 40°C.

Locations where the humidity can exceed 5%RH to 95%RH.

Locations where the unit may come into direct contact with water.

Locations where the unit is under direct or strong sunlight. (May cause sensor to malfunction.)

Locations where there is a lot of condensation.

Do not use with chemicals (detergents, etc.) on your hands. (This may reduce the productive life of the unit.)

Do not use in locations where corrosive, neutral, or reductive gases are present.

(This may reduce the productive life of the unit and/or cause malfunctions.)

Locations where solt damage may occur.

Places lower than -20m or higher than 2000m above sea level.

Items to check during repair work

●Upon completing repair work, verify that the product operates normally. Clean the product's main body and surrounding area, and notify the customer of the completion of the repair work.

Page 5

—5—

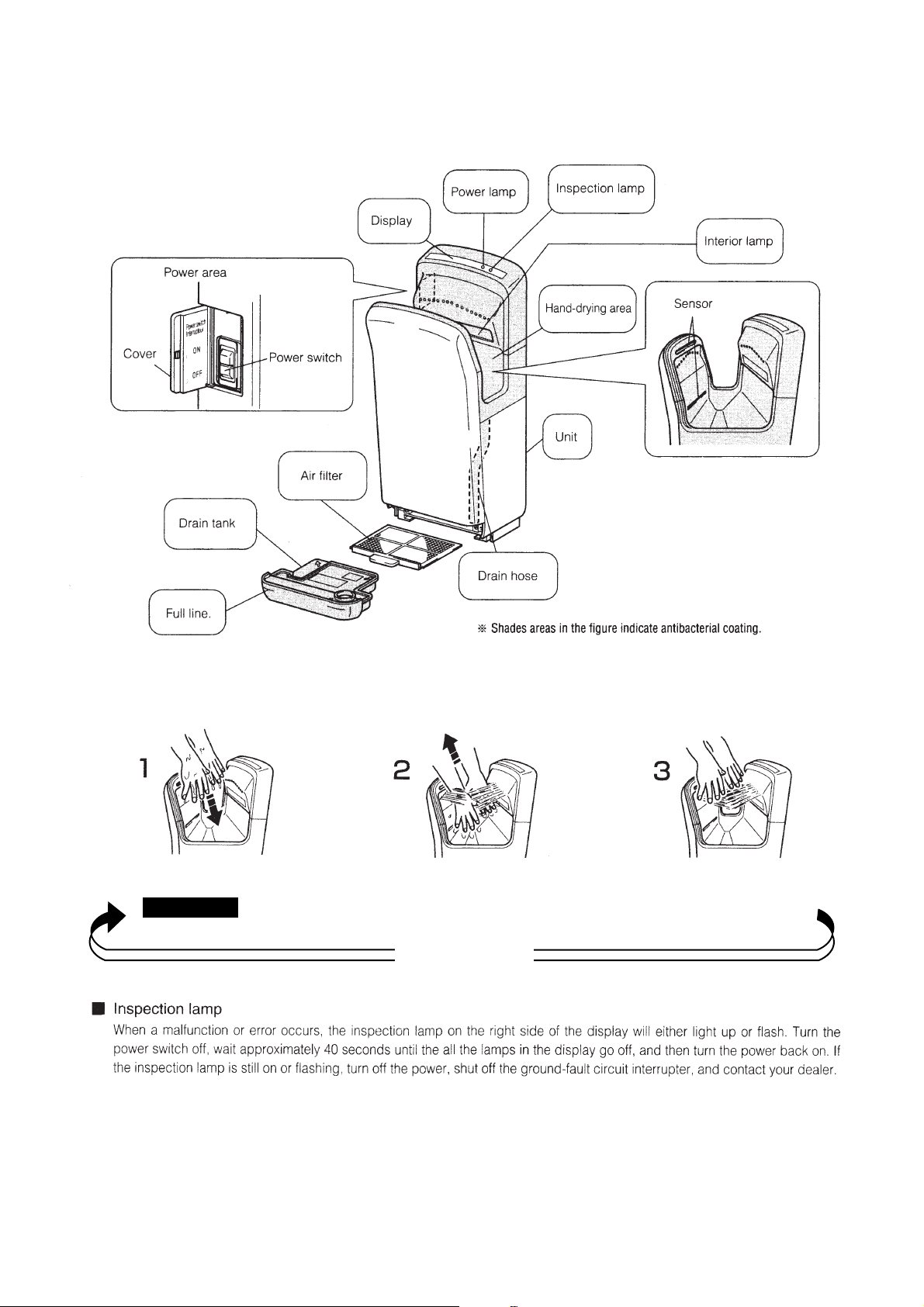

2. Names and functions of the hand dryer's components

2-1 Configuration diagram and appearance diagram

2-2 Operating procedure

With both hands open, insert them

all the way in.

The unit will come on automatically.

Pull them out slowly,

letting the air blow the

water off.

Pull hands all the way

out.

Repeat until dry

Page 6

—6—

Voltage

(Vac)

220-240

Model

JT-SB216DS-W-AUS

Frequency

(Hz)

50-60

Phase

single-phase

Power consumption

(W)

650

Current

(A)

4

Weight

(kg)

11

Dimensions (W ✕ D ✕ H)

(mm)

300 ✕ 220 ✕ 687

The drain tank capacity is 0.8 .

3. Specifications

4. Dimensions

Unit (mm)

Page 7

—7—

5. Wiring diagrams

Page 8

—8—

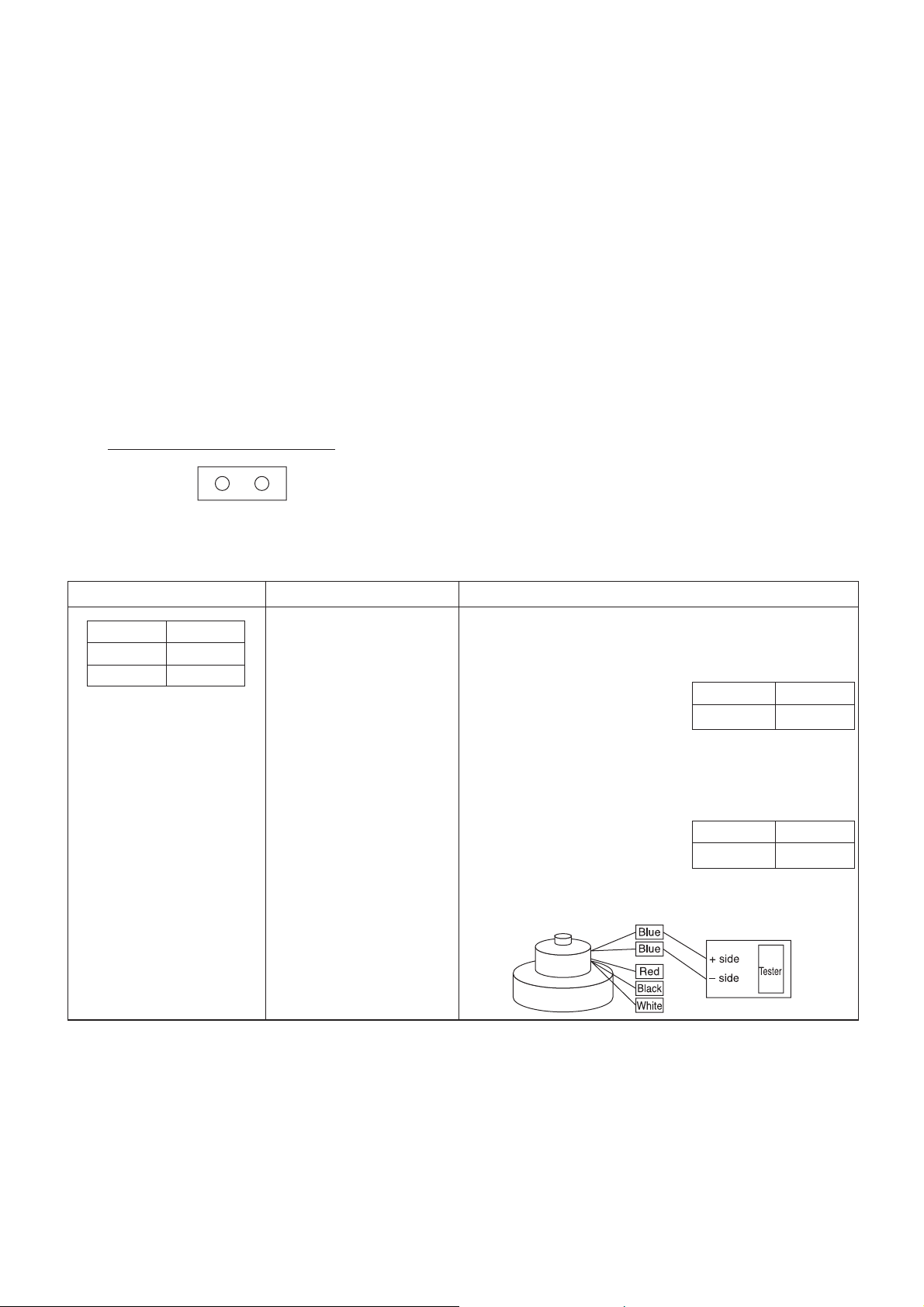

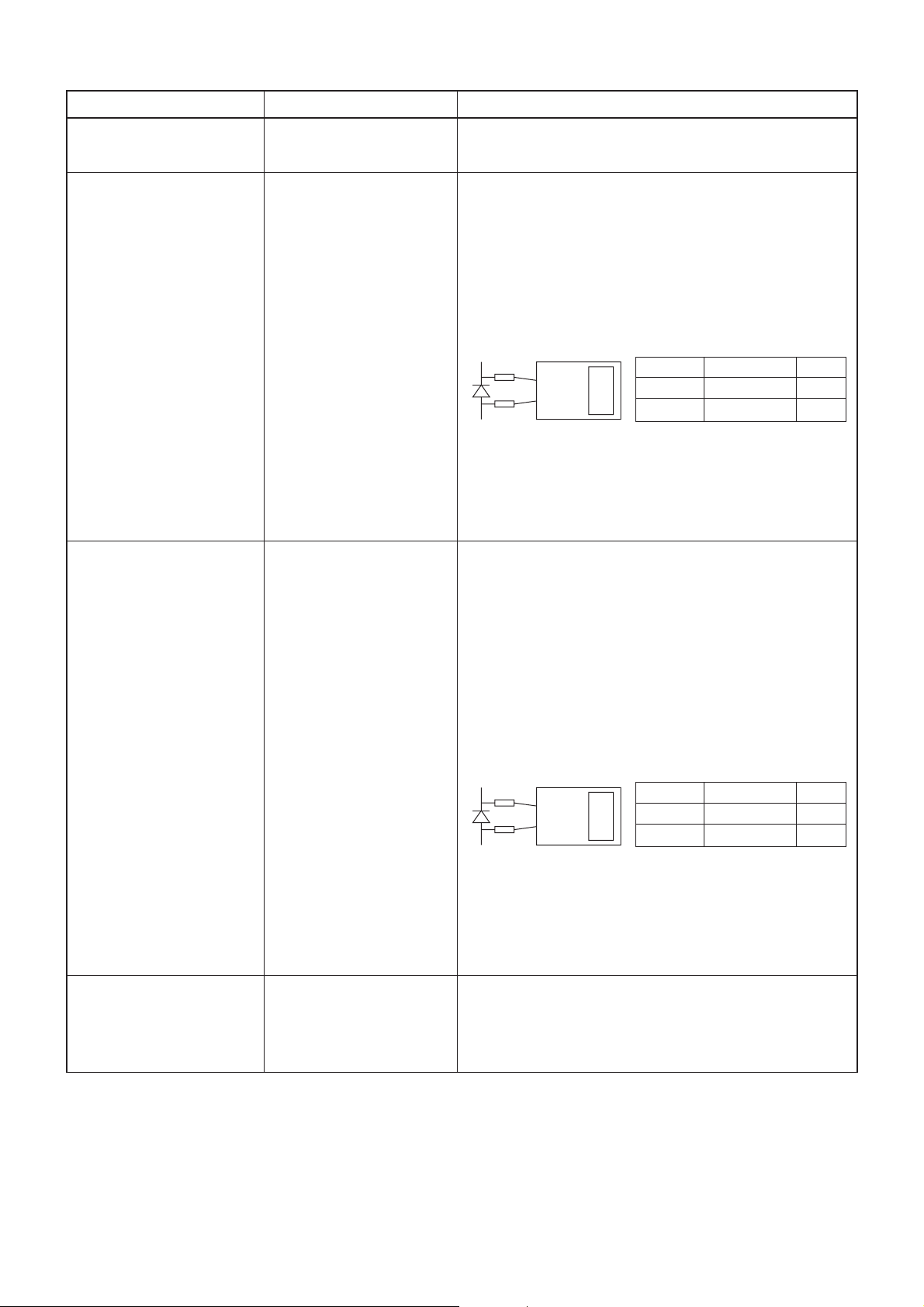

• Is the power supply connected?

• Is the power switch on?

• Measure the resistance between the current fuses on

the control board.

* Replace the control board

if the measured resistance value is other than the

normal value shown in the table at right.

• Is the motor's lead wire connector connected?

• Measure the resistance between the motor's two

"blue" lead wires.

* Replace the motor if the

measured resistance value is other than the normal

value shown in the table at right.

6. Troubleshooting

Precautions when diagnosing malfunctions:

● When servicing, be sure to recreate the malfunction 2 to 3 times before initiating repairs.

● When servicing, always keep proper footing.

● When servicing, make sure that the cord is pulled out of the outlet, or the breaker is off if no mains connector is

built in the product, so as no electrical shock or injury to occur. Pay sufficient attention when working on the

product.

● Always connect the power wire properly.

● When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force to

the surface mounted parts.

● When removing the circuit board, be careful of the metal edges on the board.

● When inserting or extracting pin connectors on the circuit board, hold the entire housing. Do not pull on the lead

wires.

● If a malfunction of the printed circuit board is suspected, check for any broken copper-printed pattern, burnt or

discolored parts.

● Be sure to restore same settings as those on the one just replaced.

* The names of the parts indicated are compatible with those listed under the "Name of part" in the chapter

"Parts list".

Description of error modes below

LED2LED1

[●] Lit [✩] Blinking (0.4 sec on/0.4 sec off)

[●] Unlit [✻] Fast blinking (0.1 sec on/0.1 sec off)

Error mode display Cause Check procedure and action to take

LED1 LED2

Power Inspection

●●

Measured value Decision/action

0Ω Normal

Measured value Decision/action

0Ω Normal

(No display, no operation)

1.Power off

2.Current fuse

3.Motor temperature fuse

Page 9

—9—

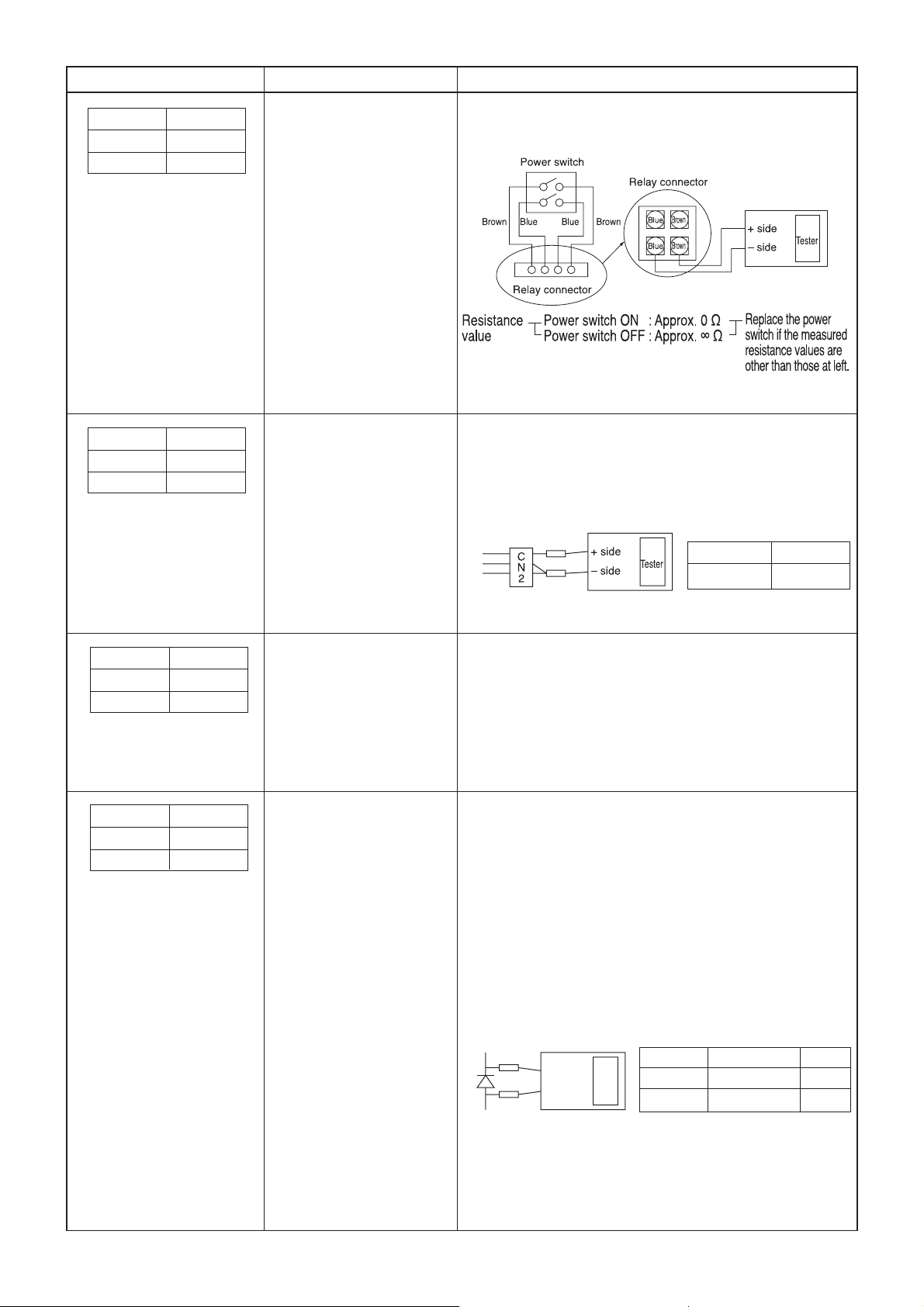

• Unplug the relay connector, and measure the

resistance at two places between each pair of the

power switch's "brown" and "blue" lead wires.

• Replace the control circuit if other than above.

• Is the sensor's lead wire connector (CN2) connected?

• Unplug the control circuit's CN2 (3-pin connector),

measure the voltage between pins 1 and 2 as well as

pins 1 and 3 of the CN2 by diode check (measure on

the lead wire side).

• Replace the control circuit if other than above.

Error mode display Cause Check procedure and action to take

LED1 LED2

Power Inspection

●●

Measured value Decision/action

1.5 to 1.8V Normal

(No display, no operation)

LED1 LED2

Power Inspection

●●

(Operates, but no display)

4.Power switch

5.Control circuit

1.Display board

2.Control circuit

• Is the filter clogged with dust and the like? → If so,

clean the filter.

• Are the temperatures of the control circuit and

electronic parts too high? → If so, turn OFF the power

switch and lower the temperatures to normal

temperatures (40 ˚C or less).

• Replace the control circuit if other than above.

• When the operation time exceeds 30 seconds, the

operation stops by the activated mischievous use

prevention timer.

• Are the sensor's three windows stained?

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced (top/bottom

light emitting boards, light receiving board)?

• Measure the forward voltages of the LEDs on the

top/bottom light emitting boards and the photo diode

(PHD) on the light receiving board with a measuring

device that has a diode check function.

* Replace the top/bottom light emitting boards and the

light receiving board if the measured values are

other than the normal values shown in the table

above.

• Replace the control circuit if other than above.

LED1 LED2

Power Inspection

✩✩

1.Filter clogged with dust

2.PTC operation (control

circuit)

3.Control circuit

1.Continuous operation

2.Stained sensor's

windows

3.Disengaged sensor

4.Displaced sensor's

board positions

5.Sensor light

emitting/receiving

diode failure

6.Control circuit

(Heat sink overheat)

LED1 LED2

Power Inspection

✩

●

(Mischievous use

prevention timer)

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

Page 10

—10—

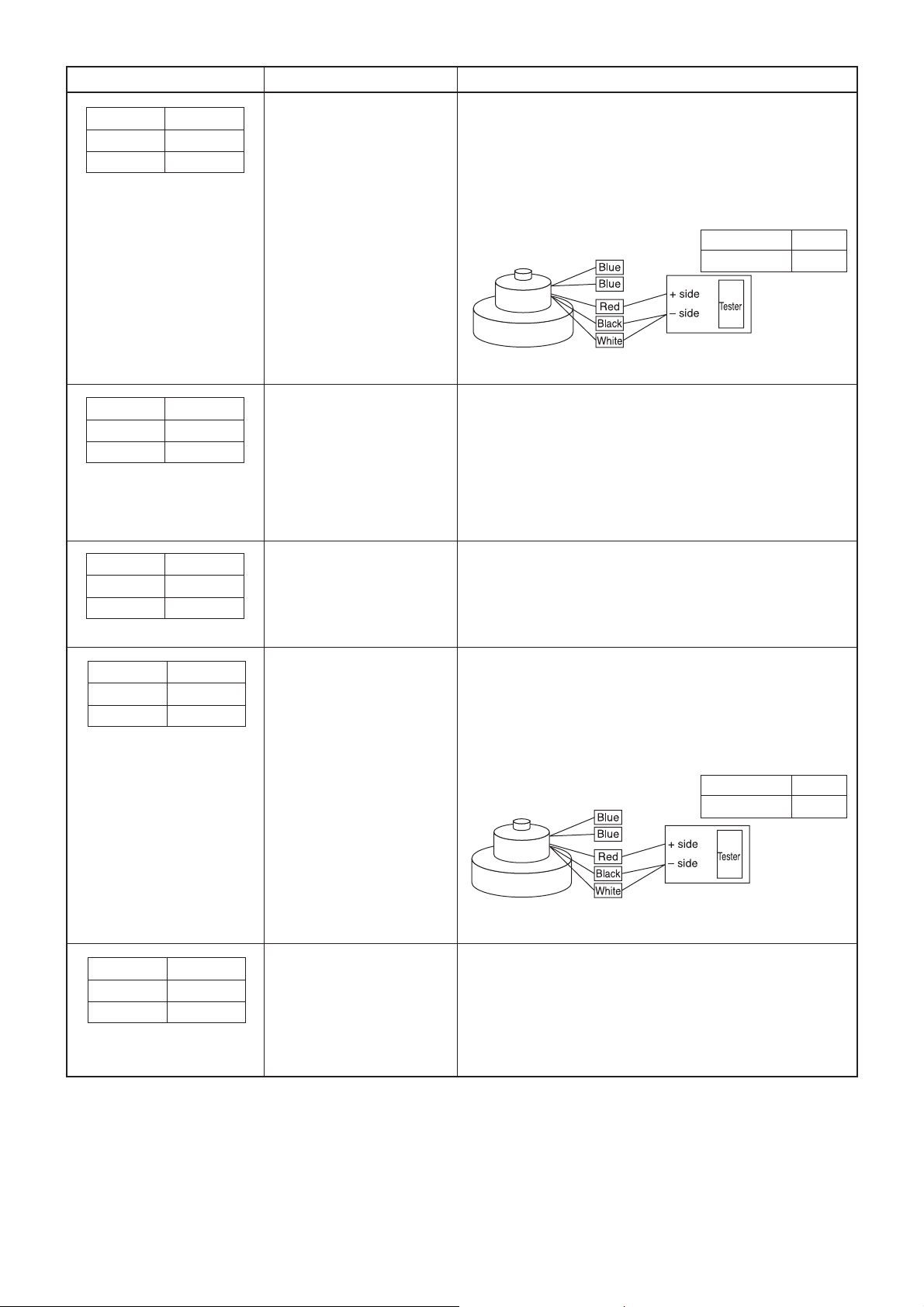

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

* Replace the motor if the measured values are other

than the normal value shown in

the table at right.

• Replace the control circuit if other than above.

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a power supply frequency 50 or 60 Hz?

• Replace the control circuit if other than the above.

Error mode display Cause Check procedure and action to take

1.Motor

2.Control circuit

1.Excess voltage applied

2.Low voltage

3.No power supply

frequency

4.Control circuit

• Replace the control circuit.

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

* Replace the motor if the measured values are other

than the normal value shown

in the table at right.

• Replace the control circuit if other than above.

• Replace the control circuit.

LED1 LED2

Power Inspection

●

✩

1.Control circuit

1.Motor

2.Control circuit

1.Control circuit

(Current detection circuit

abnormality)

LED1 LED2

Power Inspection

✩

●

(Motor lock)

LED1 LED2

Power Inspection

●

✩

(Overvoltage, low voltage,

power supply frequency

detection)

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

LED1 LED2

Power Inspection

● ●

(Overcurrent detection)

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

LED1 LED2

Power Inspection

●✻

(Microcomputer RAM abnormality)

Page 11

—11—

• Replace the light receiving board.

• Replace the control board if other than above.

• Are the sensor's three windows stained?

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced (bottom

light emitting boards, light receiving board)?

• Measure the forward voltages of the LEDs on the

bottom light emitting boards and the photo diode

(PHD) on the light receiving board with a measuring

device that has a diode check function.

* Replace the bottom light emitting boards and the light

receiving board if the measured values are other than

the normal values shown in the table above.

• Replace the display board or the control circuit if other

than above.

1.Lighting board

2.Control circuit

1.Stained sensor's windows

2.Disengaged sensor

3.Displaced sensor's

board positions

4.Sensor light

emitting/receiving

diode failure

5.Control circuit

Phenomenon Cause Check procedure and action to take

Phenomena of problems other than error mode display

Lighting does not turn on.

The hand dryer starts

drying as soon as the

power switch is turned

ON.

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

• Are the sensor's three windows stained? → Clean the

windows if stained.

• Is the sensor's lead wire connector connected?

• Are the sensor's board positions displaced? → Install

the sensor light boards in their proper positions if

displaced (top light emitting boards, light receiving

board).

• Measure the forward voltages of the LEDs on the top

light emitting boards and the photo diode (PHD) on

the light receiving board with a measuring device that

has a diode check function.

* Replace the top light emitting boards and the light

receiving board if the measured values are other

than the normal values shown in the table above.

• Replace the display board or the control circuit if other

than above.

• Are foreign particles being attached to the motor's

fins?

• Is the filter clogged with dust?

1.Stained sensor's

windows

2.Disengaged sensor

3.Displaced sensor's

board positions

4.Sensor light

emitting/receiving

diode failure

5.Control circuit

1.Suction of foreign

particles

2.Filter clogged with dust

The hand dryer does not

stop after removing the

hands.

Abnormal noise is

generated.

Item name Measured value Decision

LED 0.9 to 1.2V Normal

Photo diode 0.5 to 0.8V Normal

– side

+ side

Tester

Page 12

—12—

[Reference data] LED display list

Description

LED1 LED2

Power Inspection

Main cause of occurrence

When normal

Abnormal 1

Abnormal 2

Abnormal 3

Power switch OFF

Power switch ON

Mischievous use prevention

timer

Motor rotating excessively, out

of step

Motor startup error, locked

Overcurrent

Overvoltage, low voltage, no

power supply frequency

Fin overheating

Current detection circuit

abnormality

Microcomputer abnormality

Blown fuse

●

●

✩

●

✩

●

●

✩

●

●

●

●

●

●

●

●

●

✩

✩

✩

✻

●

Continuous operation, sensor

stained/disengaged

Main circuit, motor demagnetized

Main circuit, motor's wire

open/disconnected

Main circuit, motor short-circuited

Main circuit, power supply, 5A-fuse

blown out (excess voltage applied)

Main circuit, no fin, operated at high

temperature

Main circuit

Main circuit

Current fuse, temperature fuse, power

supply

[●] Lit [✩] Blinking (0.4 sec on/0.4 sec off)

[●] Unlit [✻] Fast blinking (0.1 sec on/0.1 sec off)

Page 13

—13—

7. How to call

Phenomenon 1 Phenomenon 2 Action to take

1.No air comes out after

inserting the hands.

2.The airflow is too low to dry

the hands quickly.

3.Water leaks from the hand

dryer.

4.Air does not come out

immediately after turning

on the power and inserting

the hands.

5.Odor emanates from the

hand dryer.

• The indicator lamps on the

display are not lit.

• The right indicator lamp on

the display is blinking.

• Turn ON the power switch.

• Because the hand dryer was operated over 30

seconds, the safety device was activated, thus

automatically stopping the unit.

• Are foreign particles and/or stains attached to

the sensor part?

• Is the hand dryer exposed to direct sunlight?

* Change the installation location, or block

sunlight with sunshade so that the sensor part

is not exposed to direct sunlight.

• Is the filter closed with dust?

(Clean the filter as often as once a week.)

• Is the drain tank full with water? (If so, drain

water.)

* If the hand dryer is operated with the drain

tank full, water may soak into the main body.

To prevent this, an overflow hole is provided in

the drain tank.

• Is the drain tank installed properly?

• After the power switched is turned on, the hand

dryer needs one second to charge the control

circuit. Therefore, the hand dryer does not blow

air during this period.

• Is the drain tank full with water? (If so, drain

water.)

• Is there any foreign particle inside the drain

tank? (Remove the foreign particle.)

Page 14

—14—

8. Technical notes

• By employing a mono-form design, the hand dryer blends into various shapes of architectural spaces.

• By using an angular nozzle, the hand dryer reduces air blow back, making it more comfortable to use.

• The joint of the hand insertion section has been reduced by half. It minimizes the clogging of dust in the joint,

making cleaning much easier.

• The hand insertion section, drain tank and drain hose are treated by an antimicrobial process, improving

hygiene.

9. Overhaul procedure

Precautions when overhauling the unit:

● Before replacing parts, take steps in accordance with the instructions listed in the chapter "Troubleshooting".

● When servicing, always keep proper footing.

● When servicing, make sure that the cord is pulled out of the outlet, or the breaker is off if no mains connector

is built in the product, so as no electrical shock or injury to occur. Pay sufficient attention when workingon the

product.

● Always connect the power wire properly.

● Make sure that the proper functioning of the unit is restored when the repair is complete.

* The names of the parts indicated are compatible with those listed under the "Name of part" in the chapter

"Parts list".

(1) Turning power off

1Shutdown the unit.

2Turn off the breaker on the distribution board.

(2) Power switch

1Pull out the drain tank, and then remove the front panel

clamping screws (two special silver screws 4 x 16, indicated by ●).

2Remove the connector cover clamping screw (one PTT

screw 4 x 16, indicated by ●).

3Remove the relay connector (indicated by ●).

Page 15

—15—

4Remove the maintenance cover clamping screws (marked

by ▼) (five special black screws 4 x 16, indicated by ●).

5Pull out the maintenance cover, and then remove the switch

cover clamping screw (one PTT screw 4 x 16, indicated by ●).

6Open the lid of the switch cover, and then remove the switch

clamping screw (one PPT screw 3 x 10, indicated by ●).

(3) Display board

1Perform the same work as in steps 1 through 4 of (2) above.

2Pull out the maintenance cover, and then remove the display

board lead wires (indicated by ●).

3Remove the display board from the mounting spacers

(indicated by ●).

Page 16

—16—

(4) Control board

1Perform the same work as in steps 1 through 3 of (2) above.

2Remove the control board clamping screw (one PTT screw

4 x 16, indicated by ●).

3Remove the cord clip clamping screw (one PTT screw

4 x 16, indicated by ▲).

4Remove the line filter clamping screw (one PTT screw

4 x 16, indicated by ).

7Pull out the control board, and then remove the control

board cover clamping screw (one PTT screw 4 x 6,

indicated by ●).

8Remove the control board lead wires, and then remove

the bushing (indicated by ●).

5Remove the terminal cover clamping screw (one PTT screw

4 x 16, indicated by ●).

6Remove the earth lead wire (green / yellow) from the

terminal.

Page 17

—17—

6Remove the blower.

*Replace the packing of the disassembled part with a new

one.

* When replacing the packing, be careful not to twist it.

5Remove the blower cover clamping screws (four PTT

screws 4 x 16, indicated by ●).

* When installing the blower cover, be sure to securely inlay

the part indicated by .

* Once the blower cover is installed, slide the line filter

(indicated by ▲) over the lead wires (red, white and

black) of the blower.

(6) Light emitting board (top)

1Perform the same work as in step 1 of (2) above.

2Remove the cover clamping screws for light emitting board

(top) (two PTT screws 4 x 16, indicated by ●), and disconnect

the lead wires of the light emitting board.

(5) Blower

1Perform the same work as in steps 1 through 8 of (4) above.

2Remove the drain hose clamping screw (one PTT screw 4 x

16, indicated by ●).

3Remove the bushing (indicated by ▲).

*When installing the bushing, be sure to securely inlay it all the

way to the base.

4Remove the relay connector (indicated by ●).

Page 18

—18—

7Remove the left reinforcing plate clamping screws (four PTT

screws 4 x 16, indicated by ●; one PPT screw 4 x 16, indicated

by ▲).

8Remove the right reinforcing plate clamping screws (four PTT

screws 4 x 16, indicated by ●; one PPT screw 4 x 16, indicated

by ▲).

9Remove the panel (front) clamping screws (five PTT screws

4 x 16, indicated by ●).

0Remove the cord clamping screw (one PTT screw 4 x 16,

indicated by ▲).

(7) Light emitting board (bottom)

1Perform the same work as in steps 1 through 6 of (5) above.

2Perform the same work as in steps 1 and 2 of (6) above.

3Remove the right side panel clamping screws (two PTT

screws 4 x 16, indicated by ●).

4Remove the left side panel clamping screws (two PTT

screws 4 x 16, indicated by ●).

5Remove the reactor clamping screw (one PTT screw 4 x16,

indicated by ▲).

6Remove the reactor (indicated by ).

Page 19

—19—

(8) Light receiving board

1Perform the same work as in steps 1 through B of (7) above.

2Reverse the main body, remove the clamping screws (twelve

special black screws 4 x 16, indicated by ●) from the rear surface,

and then reverse the main body back to the original position again.

ARemove the board fixing plate clamping screws (two PTT

screws 4 x 16, indicated by ●).

BRemove the light emitting board (bottom) from the board

fixing plate, and disconnect the lead wires.

3Remove the panel (center).

4Remove the duct (T-shaped) clamping screws (three PTT

screws 4 x 16, indicated by ●).

Page 20

—20—

5Remove the panel (rear).

* Be careful not to drop the water immersion protective rubber

(indicated by ●).

* Replace the packing of the disassembled part with a new one.

* When replacing the packing, be careful not to twist it.

6Remove the light receiving board holder clamping screws

(two PTT screws 4 x 16, indicated by ●).

* Replace the packing of the disassembled part with a new

one.

* When replacing the packing, be careful not to twist it.

7Remove the light receiving board from the holder. Remove

the two claws (indicated by ●).

* Replace the packing of the disassembled part with a new one.

* When replacing the packing, be careful not to twist it.

Cautions:

● Reverse the order to replace the Product.

● Make sure that the proper functioning of the unit is restored when

the repair is complete.

*Precautions when replacing Product

Page 21

—21—

10. Sequence timing chart

11. Description of circuit operation

(1) Precautions for turning ON/OFF the power switch

1When the power switch is turned ON, the power indicator lamp (LED1) and lighting lamps (LED3 to LED6)

are lit after one second, and the hand dryer can then be operated.

• If the power switch is turned OFF (or if power failure occurs) while the blower motor is rotating, in order to

protect the circuitry, the hand dryer will not operate for five seconds the next time the power switch is

turned ON (or power failure is recovered) when the hands are inserted.

• The hand dryer does not operate when the hands are inserted while the power indicator lamp and

lighting indicator lamps are unlit. The microcomputer (IC1) performs initial settings such as determining

the power supply frequency and setting the hand detection sensor's sensitivity.

2When the power switch is turned OFF, the power indicator lamp and lighting lamps are unlit, and the

operation of the hand dryer is disabled.

• It requires approximately 60 seconds for the voltage in the circuitry to discharge. Therefore, wait at least

60 seconds before plugging/unplugging the connector or replacing the circuitry.

• If an abnormality occurs

, the hand dryer continues to show error display until electric power in the

circuitry finishes discharging (i.e., until the microcomputer resets) even after the power switch is turned

OFF.

3In regions where the power supply voltage is either 220 VAC or 230 VAC, the air volume and power

consumption in the initial operation after the power switch is turned ON may be lower than those in the

second and succeeding operations, although it is within the normal ranges.

• The hand dryer detects the power supply voltage and sets the blower motor output so that the rated air

volume and power consumption are used with each power supply voltage of 220 VAC, 230 VAC or 240

VAC.

• The hand dryer determines the power supply voltage and sets the blower motor output in the following

cases:

- When 15 seconds have elapsed after the power switch is turned ON

- When the blower motor has stopped in the event the hand dryer was operated within 15 seconds

• Immediately after the power switch is turned ON, the hand dryer cannot detect an accurate power supply

voltage because of the effect of the rush current. Therefore, the blower motor output is temporarily set at

240 VAC.

• When the hand dryer is operated within 15 seconds of turning ON the power switch, it is operated at

either 220 VAC or 230 VAC with a setting of 240 VAC in regions where the power supply voltage is either

220 VAC or 230 VAC. Therefore, the air volume and power consumption will slightly decrease.

Page 22

—22—

(2) Hand detection and hand dryer operation

1Each of the top and bottom hand detection sensors is an infrared radiation sensor mainly consisting of a

light emitting sensor (infrared LED) and a light receiving sensor (photodiode).

2The light emitting sensors of the top and bottom hand detection sensors continuously emit pulses.

3When a hand is inserted into the hand-drying area, the lights from the light emitting sensors are blocked;

thus, there will be no output from the light receiving sensors. Through this, the hand dryer detects that a

hand has been inserted into the dryer.

4When the bottom hand detection sensor detects a hand, the blow motor is turned ON and the operation

starts.

5Once the operation has started, it continues as long as either the top or bottom hand detection sensor

detects a hand.

6After that, if one second elapses while both the top and bottom hand detection sensors do not detect a

hand, the blower motor is turned OFF, and the operation stops.

7The hand dryer continuously operates up to 30 seconds.

• Once 30 seconds have elapsed, the hand dryer stops operating even if the top or bottom hand detection

sensor detects a hand.

• This is a feature that assumes the presence of a foreign matter in the hand-drying area. The hand dryer

will resume its operation when a hand is removed once and then inserted again.

(3) Control of the blower motor

1A DC brushless motor is used as a blower motor. It does not have a Hall sensor that detects the position of

the rotor. Instead, it is driven by determining the position of the rotor and the direction of rotation by the

back electromotive force (voltage) of the motor winding.

2The microcomputer (IC1) drives the blower motor by controlling the MOSFET (driving transistor) at a

power stage via the drive IC (IC2).

Page 23

—24——23—

12. Circuit diagram and items to check

0V (CN5 4P) 15V (CN5 2P) 5V (CN2 1P)

DC311V to 339V

(stopping) (DB1 +)

AC220V to 240V

(TAB1–TAB2)

Clock frequency 8MHz (lC1 19P)

Reset input 5V (lC1 18P) Carrier frequency 16.7kHz (lC1 8P)

Page 24

—25—

13. Board diagram and items to check

Page 25

—26—

14. Parts list

Please note the following when using the parts list.

1. When ordering parts, always indicate the part number, part name, and number of parts

required.

2. Parts are not always available, and it may take time for you to receive them.

3. There may be specification improvements or prices changes.

4. Specifications and prices are as of April 2006.

5. Parts marked are critical for safety. To maintain safety and performance, always

replace these parts with the parts prescribed.

6. The numbers that are circled in the exploded view are the same as the reference

number for the part being indicated.

Description of screw abbreviations

Screw

4 × 16

Abbreviation

PC screw

PRC screw

PP screw

SW · PP screw

PPT screw

PCT screw

PTT screw

PT screw

SET screw

SQ · SET screw

P · SET screw

PMT screw

HS · SET screw

P · R · W screw

P · C · W screw

P · R · C · W screw

R · W screw

PW · PP screw

SW-PW · PP screw

Description

Cross recess flat head machine screw

Cross recess oval head machine screw

Cross recess pan head machine screw

Cross recess pan head screw with spring washer

Cross recess tapping screw

Cross recess flat head tapping screw

Cross recess truss head tapping screw

Cross recess truss head machine screw

Slotted head stop screw

Square head stop screw

Pan head stop screw

Primer truss head screw

Hexagon head stop screw

Cross recess round wood screw

Cross recess flat head wood screw

Cross recess round and flat wood screw

Slotted round wood screw

Cross recess pan head screw with small washer

Cross recess pan head machine screw with spring washer and flat washer

Screw diameter Length

Page 26

Model JT-SB216DS-W-AUS

No. Parts No. Name of part Critical Remarks Price

1. M45 632 853 Tube 1

2. M45 632 829 Switch door 1

3. Y45 610 806 Panel(back) 1

4. M45 632 828 Sensor fix plate 1 Lighting

5. M45 632 173 Light/sensor board 1 JT-19S-B

6. M45 632 851 Packing 1 Black

7. M45 632 827 Sensor holder 1

8. M45 632 836 Side panel(left) 1

9. M45 632 800 Front panel 1

10. Y45 610 368 Wiring diagram 1

11. M45 632 822 Panel holder(left) 1

12. M45 641 810 Protect plate 1

13. M45 632 045 Special screw 4×16 2

14. H00 231 005 PPT screw 4×16 2

15. M45 225 224 Cord clip 2

16. M45 632 176 Sensor light board 1 JT-19S-D

17. M45 632 823 Panel holder(right) 1

18. D40 038 344 Cord clip 2

19. H00 163 007 PTT screw 4×16 42

20. M45 632 832 Air supply duct 1

21. M45 632 837 Side plate(right) 1

22. Y45 609 802 Panel(front) 1

23. M45 632 831 Sensor fix plate 1 Light

24. M45 606 018 Special screw 5×30 6

25. M45 632 174 Sensor light board 1 JT-19S-C

26. Y45 609 803 Panel(under) 1

Q'ty

pcs/unit

for safety

27

Page 27

—28—

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

19

6

19

19

19

19

19

19

19

6

19

Page 28

Model JT-SB216DS-W-AUS

No. Parts No. Name of part Critical Remarks Price

31. M45 632 815 Drain tank 1

32. M45 632 816 Tank cover 1

33. Y45 606 802 Base 1

34. M45 632 803 Hook(upper) 1

35. Y45 606 258 Switch 1

36. M45 632 810 Switch cover 1

37. X40 256 228 Cord band 1

38. Y45 610 800 Maintenance cover 1

39. M45 606 095 Spacer 3

40. M45 632 172 Display board 1 JT-19S-A

41. M45 632 802 Installation panel 1

42. D41 233 018 Special screw 4×16 18

43. M45 632 834 Filter 1

44. M45 632 809 Tank base 1

45. M45 632 805 Support piece(front) 2

46. M45 632 808 Filter rail 2

47. M45 632 137 Rivet 2

48. M45 632 806 Support piece(back) 2

49. M45 632 047 Special screw 4×16 13

50. M45 632 804 Hook(under) 1

51. Y45 610 220 Cord 1

Q'ty

pcs/unit

for safety

29

Page 29

—30—

31 32 33 34 35 36 37 38 39 40 41

42 43 44 45 46 47 48 49 50 51

19

49

49

49

48

49

49

49

45

47

46

42

15

Page 30

Model JT-SB216DS-W-AUS

No. Parts No. Name of part Critical Remarks Price

61. M45 632 813 Blower cover 1

62. D41 006 363 Lead band 2

63. M45 632 225 Cord bush 1

64. Y45 606 225 Cord bush 1

65. M45 632 839 Protect cover 1

66. M45 632 817 Drain pipe 1

67. M45 632 046 Special screw 4×50 1

68. M45 632 852 Packing 1 Grey

69. M45 632 833 Air exhaust duct 1

70. M45 632 229 O ring 1

71. M45 608 227 Blower stopper 1

72. M45 632 812 Blower case 1

73. Y45 606 400 Blower 1

74. M45 632 230 Floating rubber 1

75. M45 632 814 Air supply cover 1

Q'ty

pcs/unit

for safety

31

Page 31

—32—

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

19

68

68

68

19

19

19

19

62

42

42

18

Page 32

Model JT-SB216DS-W-AUS

No. Parts No. Name of part Critical Remarks Price

81. H00 000 487 PTT screw 4×8 3

82. M45 632 819 Cover 1

83. Y45 606 179 Reactor 1

84. M45 632 821 Insulation sheet 1

85. M34 981 225 Cord bush 1

86. M45 632 818 Box(reactor) 1

87. K81 481 236 Terminal block 1 3P

88. H00 141 005 PPT screw 4×20 1

89. Y45 606 219 Noise filter assy 1

90. M45 632 835 Terminal cover 1

91. M45 632 226 Cord bush 1

92. H00 312 007 PTT screw 4×6 1

93. Y45 606 220 Lead wier(set) 1

94. M45 632 825 Board cover 1

95. M45 632 228 Cord bush 1

96. M45 632 227 Cord bush 1

97. Y45 606 171 Circuit board 1 JT-19M3

98. Y45 606 180 Line filter 1 ESD-R-25D-B

Q'ty

pcs/unit

for safety

33

Page 33

—34—

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

81

19

19

19

19

Page 34

Printed in Japan

April, 2006

35 <MEE>

Loading...

Loading...