Page 1

MITSUBISHI

IPM SPINDLE DRIVE SYSTEM

SJ-PM Series

MDS-B-SPM Series

SPECIFICATION MANUAL

BFN-15979B

Page 2

MITSUBISHI ELECTRIC CO.

(

)

p

NC SERVO SYSTEM ENGINEERING

1. Outline

This procedure is to inform about the “Setting and Attention item” regarding Mitsubishi’s IPM

(Internal Permanent Magnet) type Spindle Motor and Drive Unit.

For the general items that are not mentioned in this book, please refer to our "Built-In AC Spindle

Drive Specification Manual (BFN-14118-04-A)" and "AC Servo and Spindle Drive Unit MDS-A/B series

Specification Manual (BNP-B3759B)".

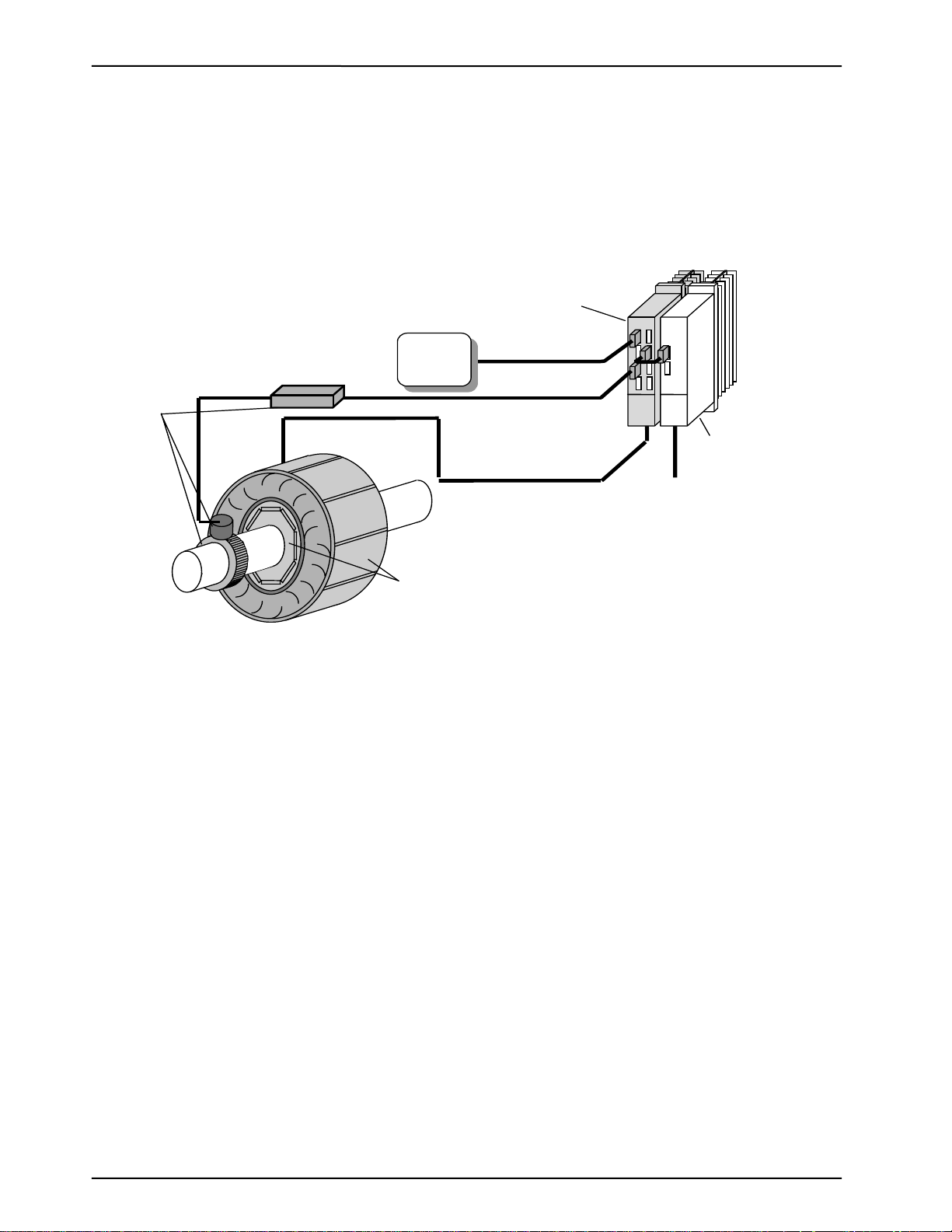

2. System configuration

Pre-Am

.

CNC

IPM Spindle Drive Unit

(MDS-B-SPM)

PLG

3. Amplifier

Fee d B a c k C a b le (A,B,Z )

Power Supply Unit

MDS-B-CV

Pow e r C a ble (U ,V,W) AC 20 0 [V]

IPM Spindle Motor

(SJ-PM)

3-1. Wiring

Wiring and connections are the same as Spindle Drive Unit "MDS-B-SP".

3-2. Parameter setting

<Related Parameters which are now used>

SP205(ZCHS) ・・・・・・・・・ Effective during "Automatic Z-Phase PLG Adjustment Function "

(0 : Invalid / 1 : Effective). 1 is set at normal operation.

SP245(PGHS) ・・・・・・・・・ Effective during "Automatic PLG Adjustment Function "

(0 : Invalid / 1 : Effective).

3-3. Automatic Z-Phase PLG Adjustment

This adjustment must be performed anytime spindle hardware is replaced.

(Spindle Amp, Motor, PLG, etc.)

"Automatic Z-Phase PLG Adjustment" is used to adjust the relative position of the motors

magnetic poles and the Z-Phase pulse signal. This data is then memorized in the MDS-B-SPM.

The purpose of this function is to improve the output torque to achieve a more precise calculation.

After this process has been completed during the first installation, it will be required to do again using

the following procedure when any spindle hardware is replaced.

<Notice>

※1 Before starting, check and or adjust the mechanical alignment between the detector gear and

sensor for proper gap setting.

※2 Before starting, remove any load (GD

it as much as possible (max. 5 times motor GD

2

)or friction that may be applied to the Spindle, or reduce

2

).

- 1 -

Page 3

MITSUBISHI ELECTRIC CO.

NC SERVO SYSTEM ENGINEERING

※3 During the Automatic Z-Phase PLG adjustment, the motor will turn automatically at the

adjustment RPM.

※ 4 If the system is started without implementing this procedure, the protection function is

activated and Alarm 16 will occur.

※ 5 Make sure to properly adjust the A & B phase zero volt offset and the 3 volts P-P levels with

an oscilloscope using the adjustment potentiometers BEFORE starting the auto adjustment

procedure. Also, make sure you have the Z phase marker pulse by a visual on the oscilloscope.

(1) Change the parameter : SP205 from 1 to 0, cycle power then set SP205 from 0 to1 and proceed to

step 2. If already set to 0, change to 1 and cycle power.

(2) Start spindle at approx. 200RPM (CW direction).

(3) The Spindle motor turns automatically at the speed for the adjustment.

(4) The adjustment result is computed within about 90 seconds after starting (time depends on

starting position). Spindle stops automatically when completed.

(5) After the spindle stops, cycle the power once more.

If it is required to do the Automatic Z-Phase PLG adjustment once again, Set 0 into parameter

SP205 and implement once again from 3-3 ※1. There is only one chance to do the Automatic Z-Phase

PLG Adjustment after parameter SP205 is changed. Process can be performed repeatedly after the

parameter is changed and power is cycled.

Never touch the Motor Shaft or anywhere near the Motor

.

3-4. Automatic PLG Adjustment for the MDS-B-SPM

This adjustment must be performed anytime spindle hardware is replaced.

(Spindle Amp, Motor, PLG, etc.)

"Automatic PLG Adjustment” is used to adjust the Offset and Gain for the A and B phase sine wave

signal of the PLG. This data is then memorized in the MDS-B-SPM.

The purpose of this function is to improve the position data to achieve a precise calculation. After

this process has been completed during the first installation, it will be required to do again using the

following procedure when any spindle hardware is replaced.

<Notice>

※1 Before starting, check and or adjust the mechanical alignment between the detector gear and

sensor for proper gap setting.

※2 Before starting, remove any load (GD

it as much as possible (max. 5 times motor GD

※3 During the Automatic Z-Phase PLG adjustment, the motor will turn automatically at the

adjustment RPM.

※4 If the system is started without implementing this procedure, the protection function is

activated and Alarm 16 will occur.

(1) Change the parameter : SP245 from 1 to 0, cycle power then set SP245 from 0 to1 and proceed to

step 2. If already set to 0, change to 1 and cycle power.

(2) Start spindle at approx. 200RPM (CW direction).

(3) The Spindle motor turns automatically at the speed for the adjustment.

(4) The adjustment result is computed within about 50 seconds after the starting. Spindle stops

automatically when completed

(5) After the spindle stops, cycle the power once more.

If it is required to do the Automatic PLG adjustment once again, Set 0 into parameter SP245 and

implement once again from 3-4 ※1. There is only one chance to do the Automatic PLG adjustment after

parameter SP245 is changed. Process can be performed repeatedly after the parameter is changed and

power is cycled.

2

)or friction that may be applied to the Spindle, or reduce

2

).

Never touch the Motor Shaft or anywhere near the Motor

.

- 2 -

Page 4

MITSUBISHI ELECTRIC CO.

NC SERVO SYSTEM ENGINEERING

3-5. Alarm

<Alarm which was occurred in Automatic Adjustment>

AL16 :Magnetic Pole Position detection malfunction. (Similar to servo alarm #16)

( It occurs when starting without Automatic Z-Phase Adjustment.)

AL42 :Feed back Signal malfunction

( It occurs when detecting incorrect Z-Phase Pulse signal.)

AL3F : Rotation error detection function alarm.

( This alarm was added to prevent motor damage due to missing or bad speed FB

signal during adjustment)

Perform the outlined adjustments above in 3-3 and 3-4 to remove the alarm condition.

4. Motor

4-1. Safekeeping

Store the motor in the packaging material until ready for installation.

< Warning>

(1) The rotor used for this motor is a powerful permanent magnet.

(2) Especially in case of the built in type motor, the material is one that produces a very strong

magnetic field and will influence the magnetic pull onto the nearby substances. Damage will

result to the compositions that are affected by the magnetism such as clocks, magnetic storage

media, etc.

4-2.Construction (Built-in type)

(1) The rotor is a powerful permanent magnet.

Caution needs to be exercised when inserting the rotor shaft into rotor or when installing the motor

into the machine giving particular attention to clear hands and fingers.

(2) Do not drop or impact the stator and rotor.

When an impact is made to the stator, the insulation material can be damaged resulting in the

windings becoming damaged or burnt under loaded conditions.

When an impact is made to the rotor, the magnetic capacity is reduced and damage to the material

can occur.

(3) When installing the shaft into the rotor, do not allow the rotors temperature to exceed 130°C,

which is the upper limit of the rotors heating temperature.

If the rotors temperature rises above this limit, demagnetization will occur.

- 3 -

Page 5

MITSUBISHI

IPM SPINDLE DRIVE SYSTEM

SJ-PM Series

MDS-B-SPM Series

SPECIFICATION MANUAL(BFN-15979B)

Background of revision

Version Date Contents

* Sept.04.1998 beginning

A Feb.07.2000 AL42 was added in 3-5.Alerm.

B Nov.14.2001 AL3F was added and doc was revised for better understanding

MITSUBISHI ELECTRIC CO.

NC SERVO SYSTEM ENGINEERING

- 4 -

Loading...

Loading...