Page 1

MELSEC iQ-R Simple Motion Module

User's Manual (Startup)

-RD77MS2 -RD77GF4

-RD77MS4 -RD77GF8

-RD77MS8 -RD77GF16

-RD77MS16 -RD77GF32

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. Refer to the MELSEC iQ-R Module Configuration

Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

1

Page 4

[Design Precautions]

WARNING

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Machine home position return is controlled by two kinds of data: a home position return direction

and a home position return speed. Deceleration starts when the proximity dog signal turns on. If

an incorrect home position return direction is set, motion control may continue without

deceleration. To prevent machine damage caused by this, configure an interlock circuit external to

the programmable controller.

(2) When the module detects an error, the motion slows down and stops or the motion rapidly stops,

depending on the stop group setting in parameter. Set the parameter to meet the specifications of

a positioning control system. In addition, set the home position return parameter and positioning

data within the specified setting range.

(3) Outputs may remain on or off, or become undefined due to a failure of a component such as an

insulation element and transistor in an output circuit, where the module cannot detect any error. In

a system that the incorrect output could cause a serious accident, configure an external circuit for

monitoring output signals.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, servo amplifier

and servomotor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or servo amplifier if the abnormal operation of the

module or servo amplifier differs from the safety directive operation in the system.

2

Page 5

[Design Precautions]

WARNING

● Do not remove the SSCNET cable while turning on the control circuit power supply of the module

and servo amplifier. Do not see directly the light generated from SSCNET connector of the module

or servo amplifier and the end of SSCNET cable. When the light gets into eyes, you may feel

something wrong with eyes. (The light source of SSCNET complies with class1 defined in JISC6802

or IEC60825-1.)

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM and SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM and SD memory card again. Doing

so also may cause malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as the remote

RUN/STOP functions), select "Do Not Open by Program" for "Opening Method" of "Module

Parameter". If "Open by Program" is selected, an execution of the remote STOP function causes the

communication line to close. Consequently, the CPU module cannot reopen the line, and external

devices cannot execute the remote RUN function.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

Page 6

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● To mount a module with no module fixing hook, place the concave part(s) located at the bottom onto

the guide(s) of the base unit, push in the module, and fix it with screw(s). Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so can cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach a blank cover module (RG60) to each empty slot and an included

extension connector protective cover to the unused extension cable connector before powering on the

system for operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use a solderless terminal with an insulation sleeve for terminal block wiring. Note that up to two

solderless terminals can be connected per terminal block.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● When an overcurrent caused by an error of an external device or a failure of a module flows for a long

time, it may cause smoke and fire. To prevent this, configure an external safety circuit, such as a fuse.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● When disconnecting the communication cable or power cable from the module, do not pull the cable

by the cable part. For the cable connected to the terminal block, loosen the terminal screws. Pulling

the cable connected to the module may result in malfunction or damage to the module or cable.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● Tighten the terminal block mounting screws, terminal screws, and module fixing screws within each

specified torque range. Undertightening of the terminal block mounting screws and terminal screws

can cause short circuit, fire, or malfunction. Overtightening of them can damage the screw and/or

module, resulting in drop, short circuit, or malfunction. Undertightening of the module fixing screws

can cause drop of the screw. Overtightening of them can damage the screw and/or module, resulting

in drop.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

5

Page 8

[Wiring Precautions]

CAUTION

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in this

manual. If not, normal data transmission is not guaranteed.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25 cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation, set a low speed value for the speed limit parameter so that the operation

can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable movements

may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or absolute

position motor has been replaced, always perform a home position return.

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the absolute

position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install electric

equipment.

7

Page 10

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM and SD memory card undefined. The values need to be set in the buffer memory and

written to the flash ROM and SD memory card again. Doing so also may cause malfunction or failure

of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of the

partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing so

may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the specifications, procedures before operation and wiring of the relevant products listed below. Before

using this product, please read this manual and the relevant manuals carefully and develop familiarity with the functions and

performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RD77MS2, RD77MS4, RD77MS8, RD77MS16

RD77GF4, RD77GF8, RD77GF16, RD77GF32

Symbols used in this manual are shown below.

A serial No. is inserted in the "**" mark.

• [Pr.**]: Symbols indicating positioning parameter or home position return parameter items

• [Da.**]: Symbols indicating positioning data or block start data items

• [Md.**]: Symbols indicating monitor data items

• [Cd.**]: Symbols indicating control data items

• [RD77MS]: Symbols indicating that it corresponds to only RD77MS

• [RD77GF]: Symbols indicating that it corresponds to only RD77GF

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

10

Page 13

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

CHAPTER 1 PART NAMES 18

1.1 LED Display Specifications of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 LED Display Specifications of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 2 SPECIFICATIONS 22

2.1 Performance Specifications of the RD77MS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2 Performance Specifications of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3 Specifications of Interfaces with External Devices of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Electrical specifications of input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2.4 External Circuit Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

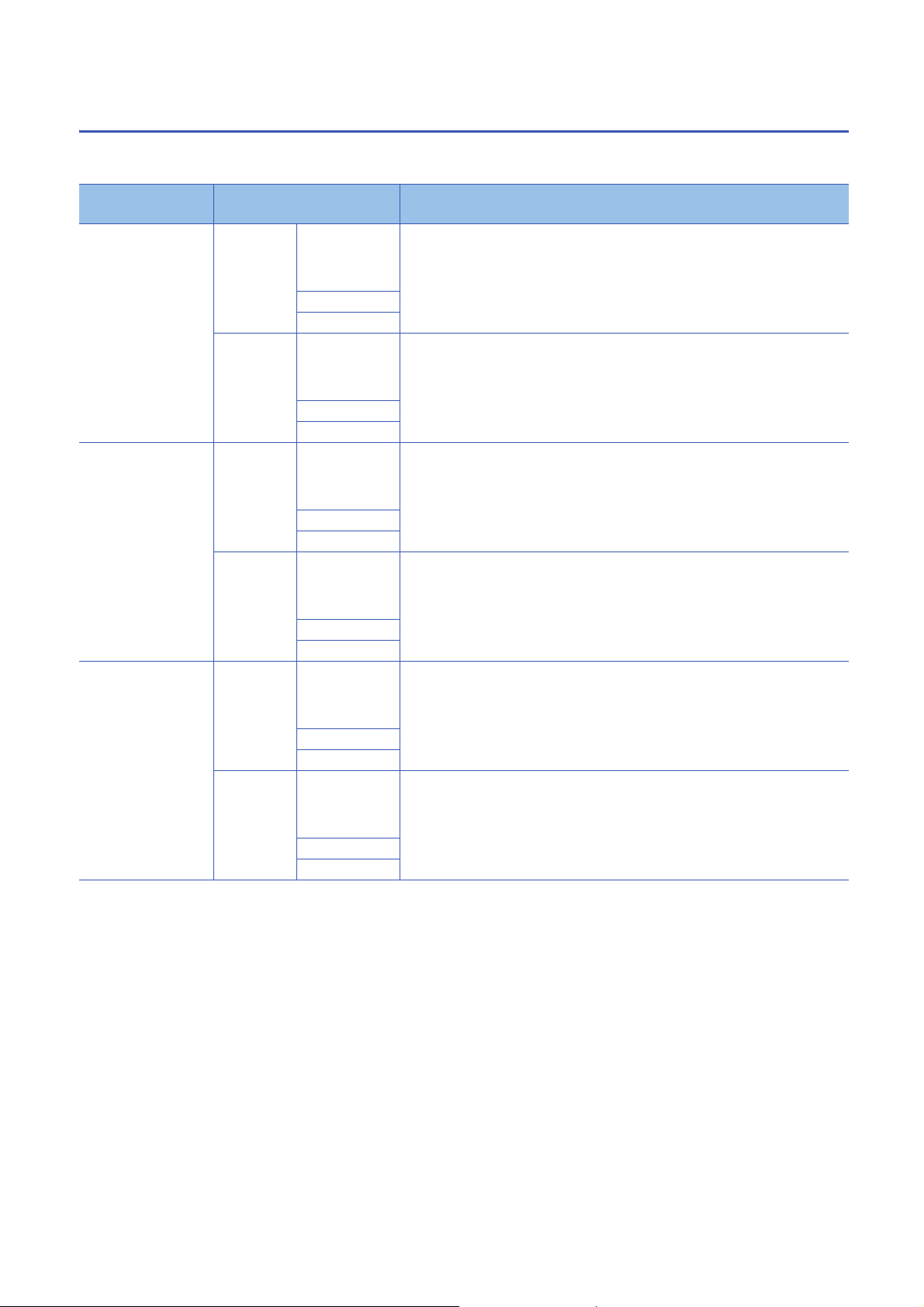

CHAPTER 3 FUNCTION LIST 31

3.1 Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Main functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Sub functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Common functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

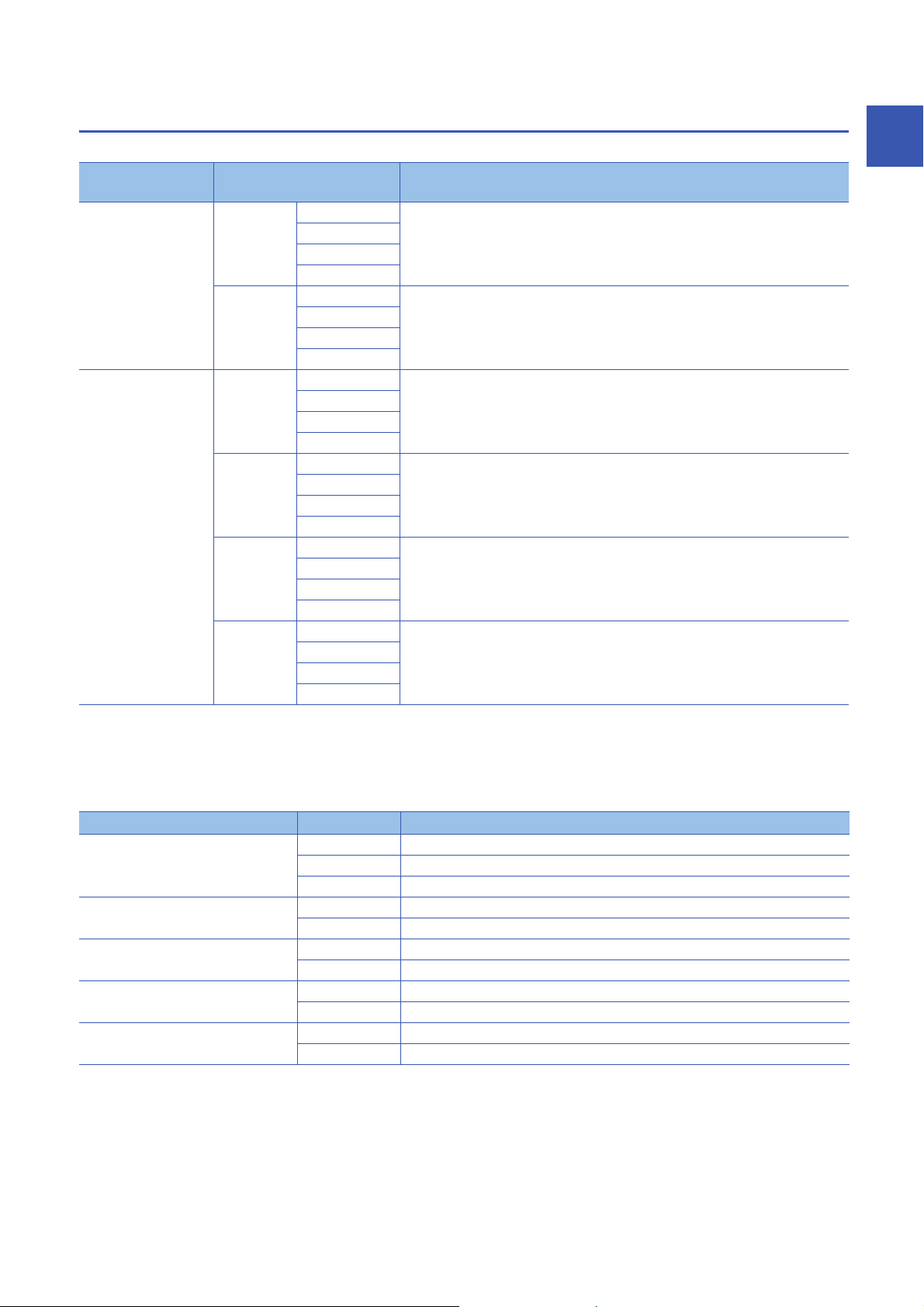

3.2 Combination of Main Functions and Sub Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3 List of RD77GF Network Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Function list of CC-Link IE Field Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

CHAPTER 4 PROCEDURES BEFORE OPERATIONS 45

4.1 Procedures before Operation of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2 Procedures before Operation of the RD77GF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CHAPTER 5 NETWORK CONFIGURATION OF RD77GF 49

CONTENTS

5.1 CC-Link IE Field Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.2 Precautions for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

CHAPTER 6 WIRING 54

6.1 Wiring of the RD77MS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.2 External Input Connection Connector of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Signal layout for external input connection connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

List of input signal details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Interface internal circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3 Wiring of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

CHAPTER 7 OPERATION EXAMPLES 68

11

Page 14

7.1 Operation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

7.2 Communication Examples of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

APPENDICES 88

Appendix 1 Component List of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Reference product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Appendix 2 Component List of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Reference product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Recommended product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Appendix 3 Connection with External Devices of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

External input signal cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix 4 External Dimensions of the RD77MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix 5 External Dimensions of the RD77GF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

INDEX 108

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12

Page 15

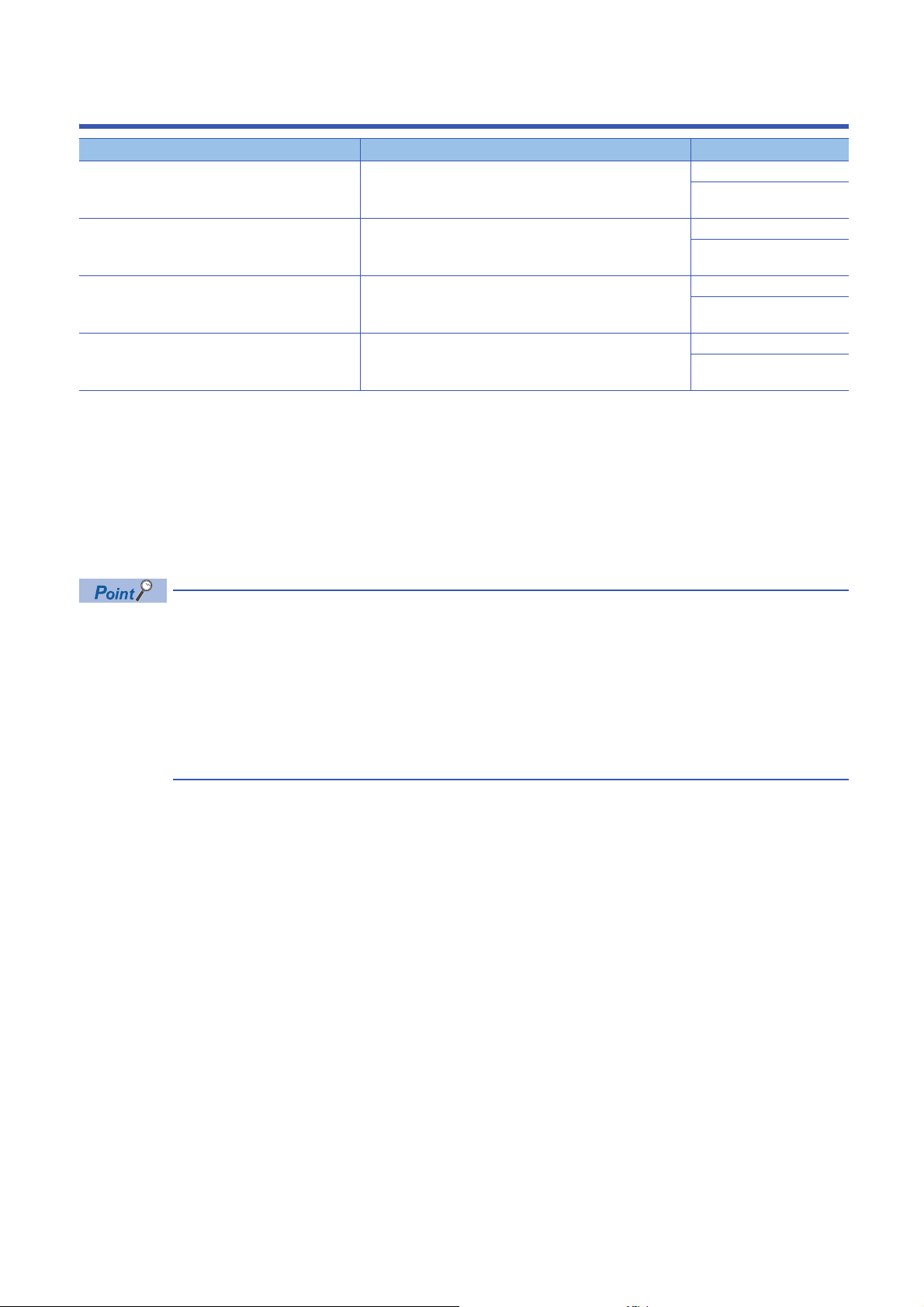

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R Simple Motion Module User's Manual

(Startup)

[IB-0300245ENG] (This manual)

MELSEC iQ-R Simple Motion Module User's Manual

(Application)

[IB-0300247ENG]

MELSEC iQ-R Simple Motion Module User's Manual

(Advanced Synchronous Control)

[IB-0300249ENG]

MELSEC iQ-R Simple Motion Module User's Manual

(Network)

[IB-0300307ENG]

This manual does not include detailed information on the followings:

• General specifications

• Available CPU modules and the number of mountable modules

• Installation

For details, refer to the following.

MELSEC iQ-R Module Configuration Manual

This manual does not include information on the module function blocks.For details, refer to the Function Block Reference for

the module used.

Specifications, procedures before operation, system configuration,

wiring, and operation examples of the Simple Motion module

Functions, input/output signals, buffer memory, parameter

settings, programming, and troubleshooting of the Simple Motion

module

Functions and programming for the synchronous control of the

Simple Motion module

Functions, parameter settings, troubleshooting, and buffer

memory of CC-Link IE Field Network

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

13

Page 16

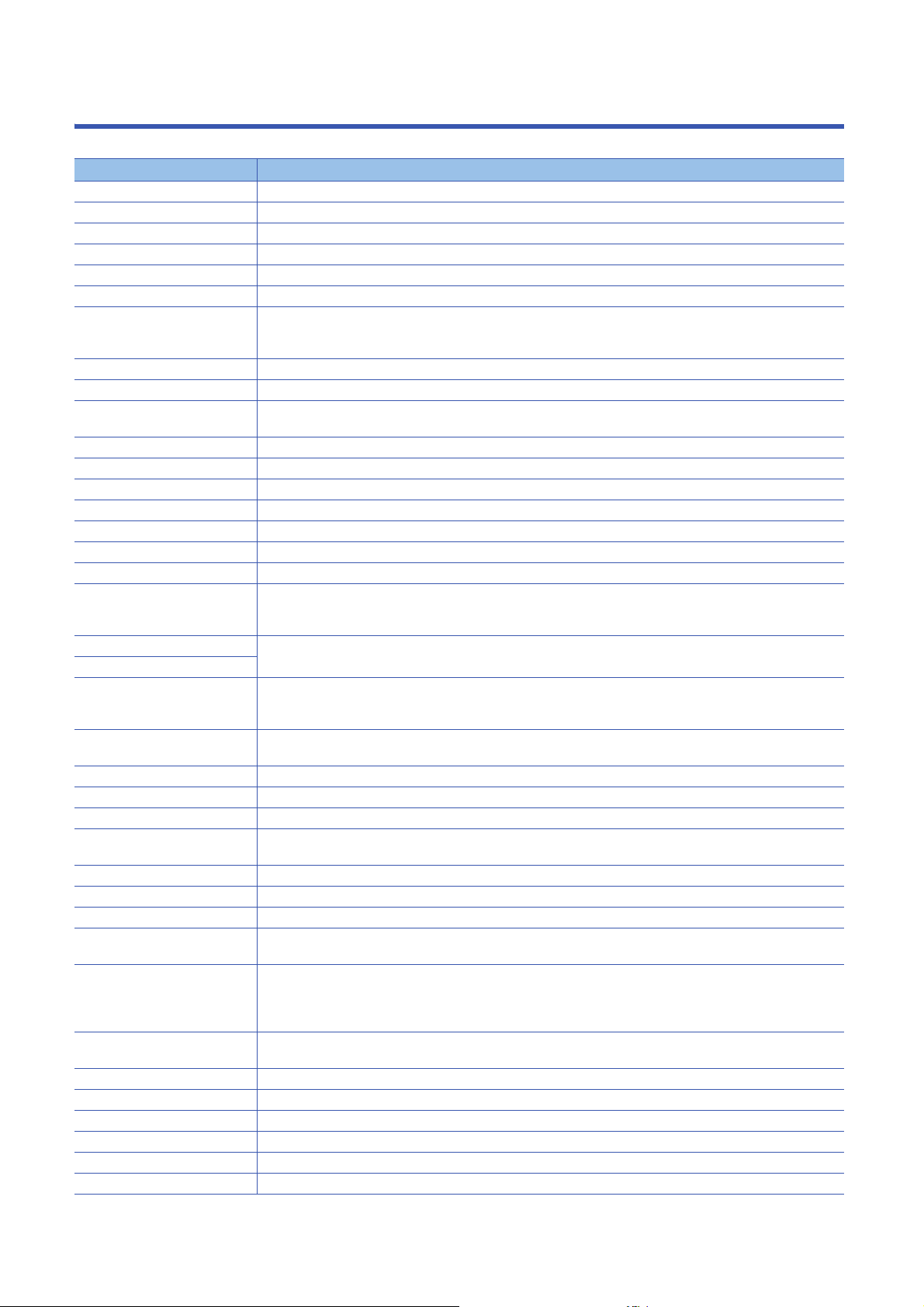

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

2-axis module A generic term for RD77MS2

4-axis module A generic term for RD77MS4 and RD77GF4

8-axis module A generic term for RD77MS8 and RD77GF8

16-axis module A generic term for RD77MS16 and RD77GF16

32-axis module A generic term for RD77GF32

Axis Another term for a servo amplifier

Buffer memory A memory in an intelligent function module, where data (such as setting values and monitoring values) are stored. When

CC-Link IE Field Network A high-speed and large-capacity open field network that is based on Ethernet (1000BASE-T)

CPU module The abbreviation for the MELSEC iQ-R series CPU module

CPU module (built-in Ethernet port

part)

Cyclic transmission A function by which data are periodically exchanged among stations on the network using link devices

Data link A generic term for cyclic transmission and transient transmission

Dedicated instruction An instruction for using functions of the module

Device A device (X, Y, M, D, or others) in a CPU module

Disconnection A process of stopping data link if a data link error occurs

Engineering tool A generic term for GX Works2, GX Works3, and MR Configurator2

Ethernet device A generic term for the devices supporting IP communication (such as personal computers)

Global label A label that is enabled for all program data when creating multiple program data in the project. There are two types of

GX Works2 The product name of the software package for the MELSEC programmable controllers

GX Works3

Intelligent device station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission. This

Intelligent function module A MELSEC iQ-R series module that has functions other than input and output, such as an A/D converter module and D/

Label A label that represents a device in a given character string

Link device A device (RX, RY, RWr, or RWw) in a module on CC-Link IE Field Network

Link refresh Automatic data transfer between a link device of the Simple Motion module and a device in a CPU module

Link scan (link scan time) Time required for all the stations on the network to transmit data. The link scan time depends on data volume and the

Link special register (SW) Word data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Link special relay (SB) Bit data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Local station A station that performs cyclic transmission and transient transmission with the master station and other local stations

Master station A station that controls the entire network. This station can perform cyclic transmission and transient transmission with all

Master/local module A generic term for the following modules when the CC-Link IE Field Network function is used:

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to each module in a given

MR Configurator2 The product name of the setup software for the servo amplifier

MR-J3(W)-B MR-J3-_B_(-RJ)/MR-J3W-_B Servo amplifier series

MR-J4(W)-B MR-J4-_B_(-RJ)/MR-J4W_-_B Servo amplifier series

MR-J4-B-RJ MR-J4-_B_-RJ Servo amplifier series

MR-J4-GF MR-J4-_GF_(-RJ) Servo amplifier series

MR-JE-B(F) MR-JE-_B/MR-JE-_BF Servo amplifier series

using the CPU module, the memory is indicated for storing data (such as setting values and monitored values) of the

Ethernet function and data used for data communication of the multiple CPU function.

A built-in Ethernet port part of the CPU module (CPU part for the RnENCPU) (MELSEC iQ-R Ethernet/CC-Link IE

User's Manual (Startup))

global labels: module label that is automatically generated by GX Works2 and GX Works3 and label that can be created

for the any of the specified devices.

station responds to a transient transmission request from another station and also issues a transient transmission

request to another station.

A converter module

number of transient transmission requests.

stations. Only one master station can be used in a network.

• RJ71GF11-T2

• RJ71EN71

• RnENCPU

character string. GX Works2 and GX Works3 automatically generate this label, which can be used as a global label.

14

Page 17

Ter m Description

Network module A generic term for the following modules:

RAS The abbreviation for Reliability, Availability, and Serviceability. This term refers to usability of automated equipment.

RD77GF Another term for the MELSEC iQ-R series Simple Motion module (compatible with CC-Link IE Field Network)

RD77MS Another term for the MELSEC iQ-R series Simple Motion module (compatible with SSCNET/H)

Relay station A station that includes two or more network modules. Data are passed through this station to stations on other networks

Remote device station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission. This

Remote I/O station A station that exchanges I/O signals (bit data) with the master station by cyclic transmission

Remote input (RX) Bit data input from a slave station to the master station (For some areas in a local station, data are input in the opposite

Remote output (RY) Bit data output from the master station to a slave station (For some areas in a local station, data are output in the

Remote register (RWr) Word data input from a slave station to the master station (For some areas in a local station, data are input in the

Remote register (RWw) Word data output from the master station to a slave station (For some areas in a local station, data are output in the

Reserved station A station reserved for future use. This station is not actually connected, but counted as a connected station.

Return A process of restarting data link when a station recovers from an error

RnENCPU A generic term for the R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, and R120ENCPU

Safety communications A function to exchange safety data between safety stations on the same network

Safety connection A connection established for safety communications

Safety CPU A generic term for the R08SFCPU, R16SFCPU, R32SFCPU, and R120SFCPU

Safety data Data exchanged through safety communications

Safety station A generic term for a station that performs safety communications and standard communications

Servo amplifier A generic term for a drive unit

Simple Motion module The abbreviation for the MELSEC iQ-R series Simple Motion module

Slave station A generic term for a local station, remote I/O station, remote device station, and intelligent device station

SSCNET

SSCNET/H

Transient transmission A function of communication with another station, which is used when requested by a dedicated instruction or the

*1

*1

• Ethernet interface module

• CC-Link IE Controller Network module

• Module on CC-Link IE Field Network

• MELSECNET/H network module

• MELSECNET/10 network module

• RnENCPU (network part)

station responds to a transient transmission request from another station.

direction.)

opposite direction.)

opposite direction.)

opposite direction.)

Unless specified in particular, indicates the motor driver unit of the sequential command method which is controlled by

the Simple Motion module (belonging to own station).

High speed synchronous communication network between RD77MS and servo amplifier

engineering tool

*1 SSCNET: Servo System Controller NETwork

15

Page 18

PERIPHERALS

RD77MS4

ERRRUN

AX

3

4

2

1

AX

SSCNET

µ

cable

External input

signal cable

Synchronous encoder via servo amplifier:

Q171ENC-W8 (Up to 4 modules via

MR-J4-B-RJ), etc.

RD77MS

• Upper stroke limit

• Lower stroke limit

• Proximity dog

External input signals of servo amplifier

Manual pulse generator/

Incremental synchronous encoder

× 1

Assigning the external input signals

for 20 points to any of the following

signals.

•

External command signal/Switching

signal

•

Upper stroke limit

•

Lower stroke limit

• Proximity dog

signal

•

Stop signal

Forced stop input (24 V DC)

Servo

motor

Servo

motor

Servo

motor

MR-J4(W)-B servo amplifier

MR-J3(W)-B servo amplifier

MR-JE-B(F) servo amplifier

Optical hub unit MR-MV200

Inverter FR-A700 series/FR-A800 series

Stepping motor driver AlphaStep/5-phase

manufactured by ORIENTAL MOTOR Co., Ltd.

Servo driver VC´ series/VPH series

manufactured by CKD NIKKI DENSO CO., LTD.

IAI electric actuator controller

manufactured by IAI Corporation

RD77MS2: Up to 2 axes

RD77MS4: Up to 4 axes

RD77MS8: Up to 8 axes

RD77MS16: Up to 16 axes

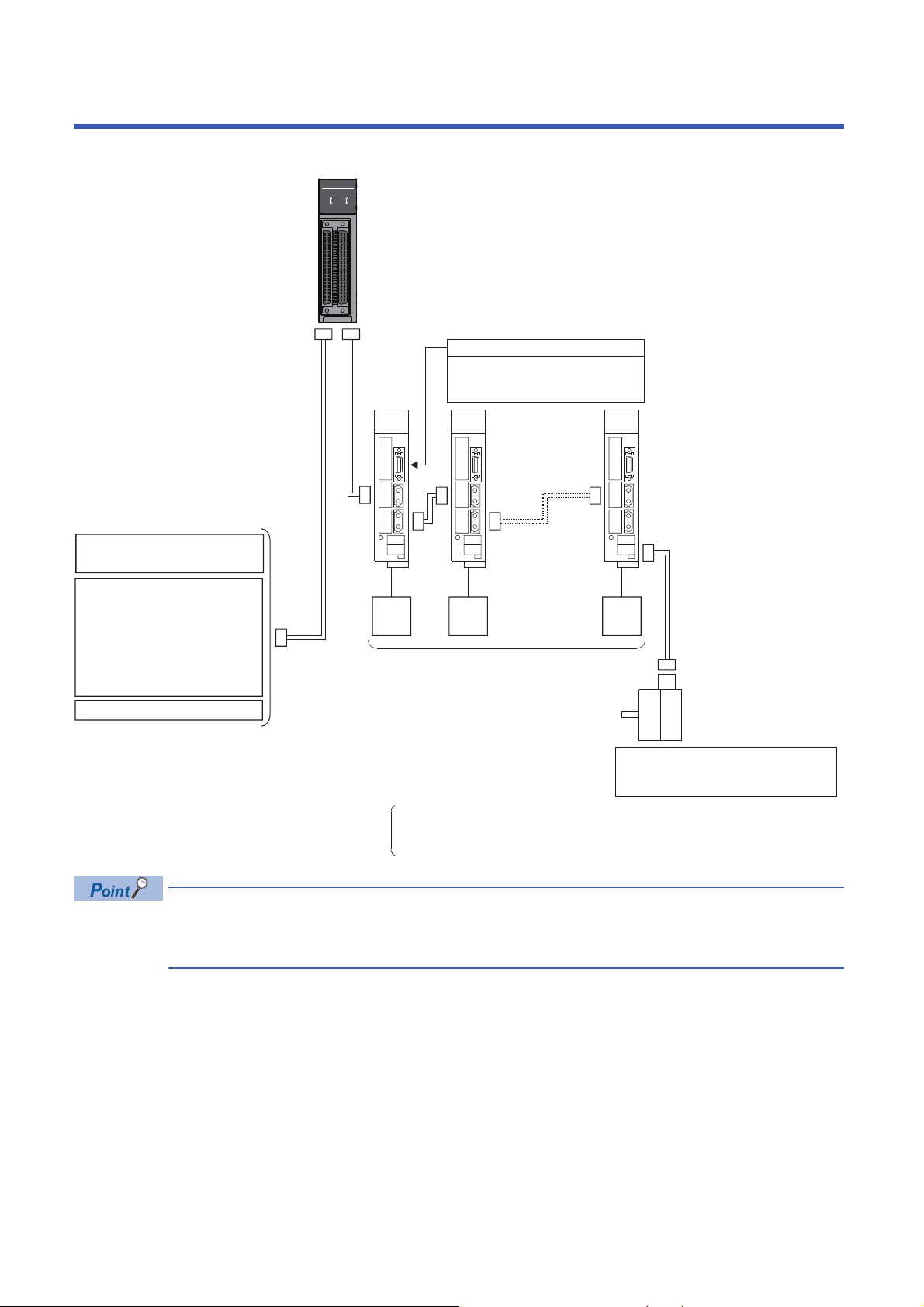

The following figure shows the peripherals when the RD77MS is used.

16

• The external input signal cannot be used depending on the connected device. Confirm the specification of

the connected device.

• When using RD77MS2, the external input signals that can be assigned are for 10 points.

Page 19

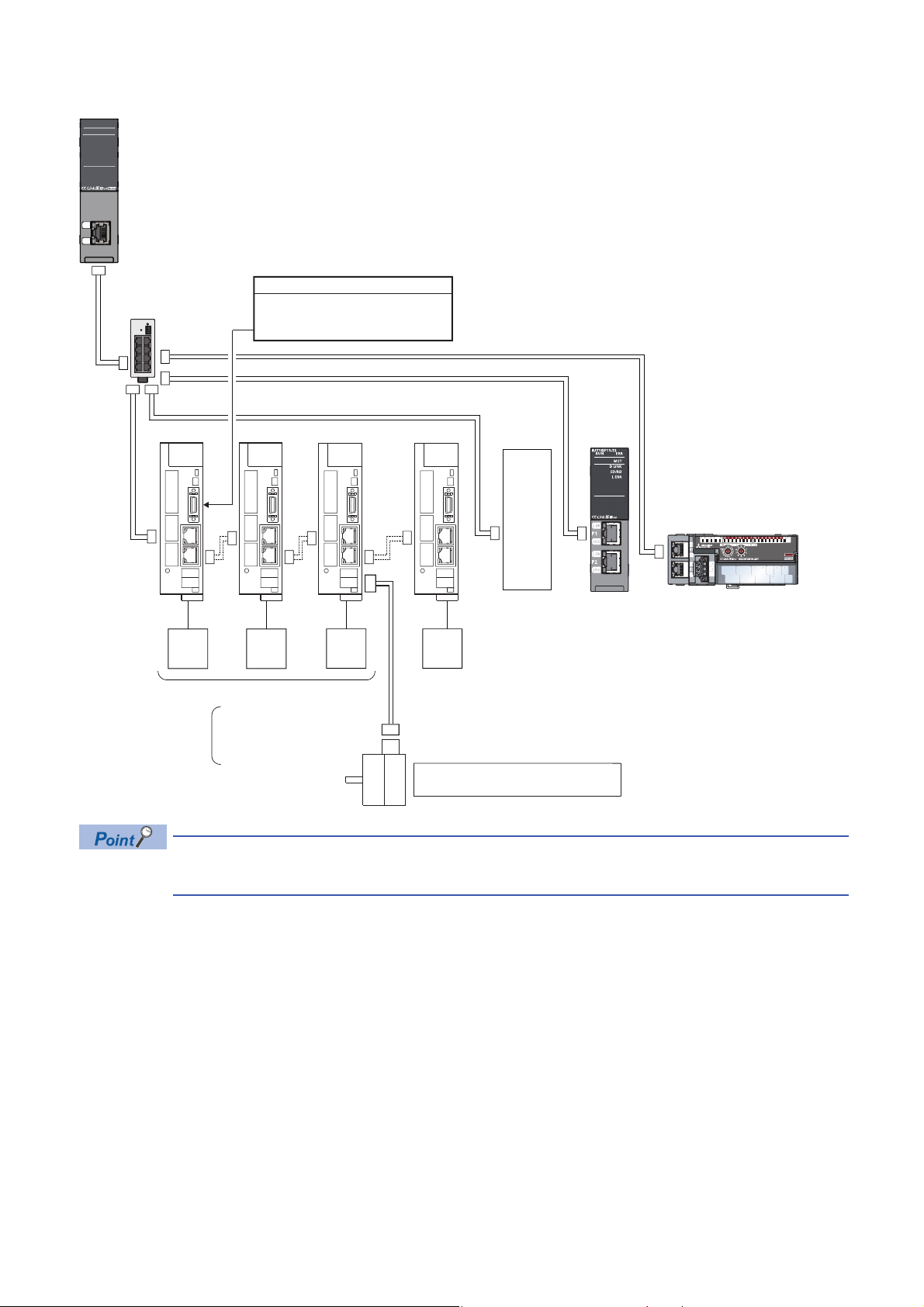

The following figure shows the peripherals when the RD77GF is used.

RD77GF4

ERRRUN

AX1-4

D LINK

SD/RD

L ERR

L ER

LINK

RD77GF4: Up to 4 axes

RD77GF8: Up to 8 axes

RD77GF16: Up to 16 axes

RD77GF32: Up to 32 axes

MR-J4-GF servo amplifier (Motion mode)

Servo

motor

Servo

motor

Servo

motor

MR-J4-GF

servo amplifier

(I/O mode)

Servo

motor

Another brand

drive unit

Remote I/OLocal station

CC-Link IE Field

Network cable

RD77GF

Switching hub

• Upper stroke limit

• Lower stroke limit

• Proximity dog

External input signals of servo amplifier

Synchronous encoder via servo amplifier:

Q171ENC-W8 (via MR-J4-_GF_-RJ)

• The external input signal cannot be used depending on the connected device. Confirm the specification of

the connected device.

17

Page 20

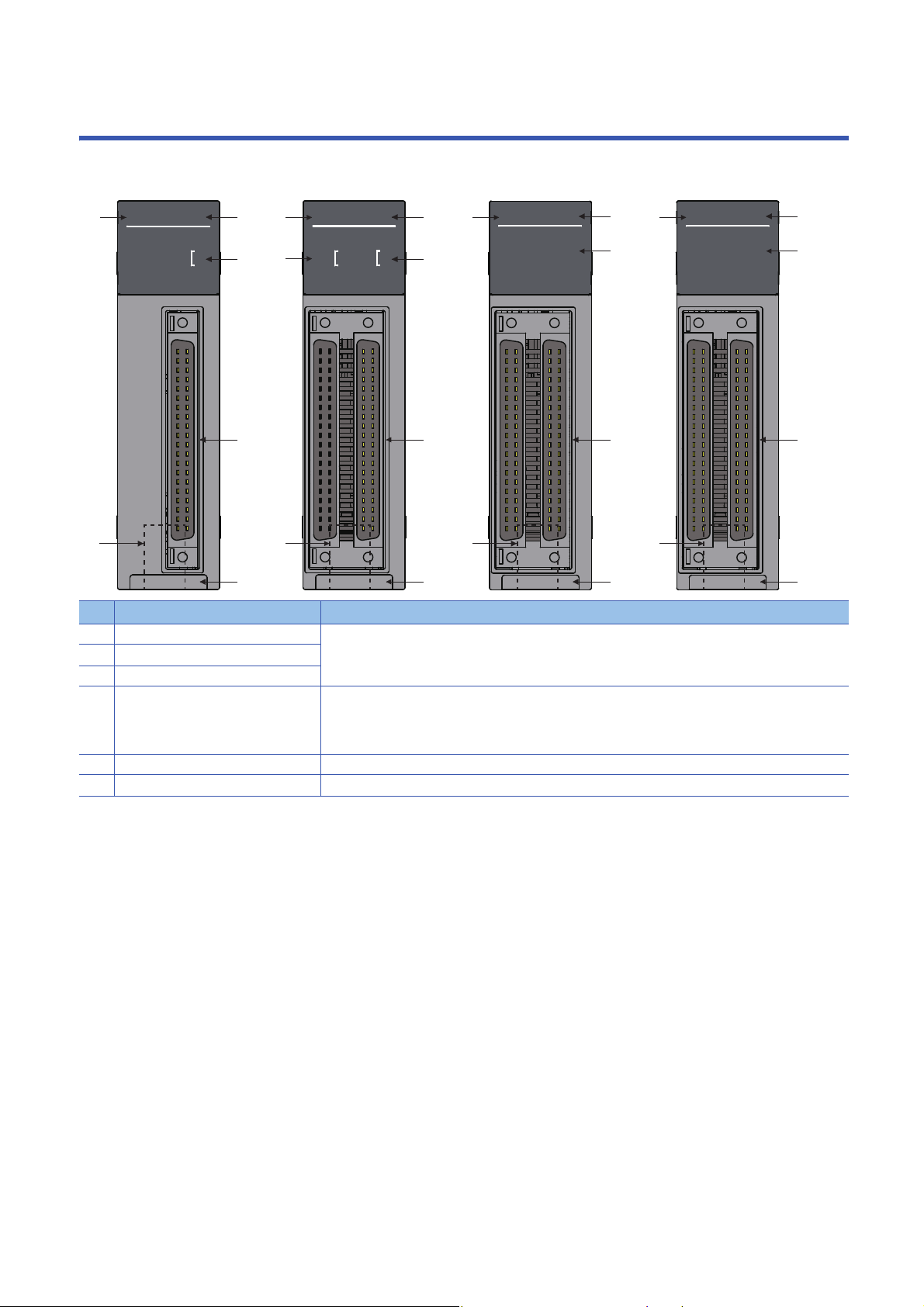

1 PART NAMES

RD77MS16

ERRRUN

AX1-16

RD77MS8

ERRRUN

AX1-8

RD77MS4

ERRRUN

AX

3

4

2

1

AX

RD77MS2

ERRRUN

2

1

AX

(6)

(4)

(5)

(1)

(2)

(3)

(2)

(3)

(1)

(4)

(6)

(5)

(6)

(5)

(4)

(2)

(3)

(1)

(3)

(2)

(3)

(1)

(4)

(6)

(5)

RD77MS2 RD77MS4 RD77MS8 RD77MS16

This chapter describes the part names of the Simple Motion module.

No. Name Description

(1) RUN LED For details, refer to the following.

(2) ERR LED

(3) Axis display LED

(4) External input connection connector Connects to a mechanical system input, manual pulse generator/incremental synchronous encoder, or

(5) SSCNET cable connector Connects to a servo amplifier.

(6) Serial No. marking Shows the serial No. printed on the rating plate.

Page 20 LED Display Specifications of the RD77MS

forced stop input.

For the signal layout, refer to the following.

Page 26 Specifications of Interfaces with External Devices of the RD77MS

18

1 PART NAMES

Page 21

No. Name Description

RD77GF4

ERRRUN

AX1-4

D LINK

SD/RD

L ERR

L ER

LINK

RD77GF8

ERRRUN

AX1-8

D LINK

SD/RD

L ERR

L ER

LINK

RD77GF16

ERRRUN

AX1-16

D LINK

SD/RD

L ERR

L ER

LINK

RD77GF32

ERRRUN

AX1-32

D LINK

SD/RD

L ERR

L ER

LINK

RD77GF4 RD77GF8 RD77GF16

(2)

(3)

(4)

(8)

(7)

(1)

(5)

(6)

(9)

(2)

(3)

(4)

(8)

(7)

(1)

(5)

(6)

(9)

(2)

(3)

(4)

(8)

(7)

(1)

(5)

(6)

(9)

RD77GF32

(2)

(3)

(4)

(8)

(7)

(1)

(5)

(6)

(9)

(1) RUN LED For details, refer to the following.

(2) ERR LED

(3) Axis display LED

(4) D LINK LED

(5) SD/RD LED

(6) L ERR LED

(7) LEDs for CC-Link IE Field connector

(8) Connector for CC-Link IE Field Network

cable

(9) Serial No. marking Shows the serial No. printed on the rating plate.

Page 21 LED Display Specifications of the RD77GF

Connects to a slave station.

In the following manual, this connector is referred to as "PORT2", "P2", or "Port 2".

MELSEC iQ-R Simple Motion Module User's Manual (Network)

1

1 PART NAMES

19

Page 22

1.1 LED Display Specifications of the RD77MS

This section lists the LED display specifications of the RD77MS.

: OFF, : ON, ●: Flashing

Simple Motion

module status

Normal operation RUN

Operation failure RUN

Online module change RUN ●

LED display Description

ERR

RUN

ERR

ERR

RUN

ERR ●

ERR

RUN

ERR

AX1

AX2

AX3

AX4

AX1-8

AX1-16

AX1

AX2

AX3

AX4

AX1-8

AX1-16

AX1 ●

AX2

AX3

AX4

AX1-8 ●

AX1-16 ●

AX1

AX2

AX3

AX4

AX1-8

AX1-16

AX1

AX2

AX3

AX4

AX1-8

AX1-16

AX1

AX2

AX3

AX4

AX1-8

AX1-16

*1

*1

*2

*2

*3

*3

The axes stopped

The axes on standby

The axis in operation

Minor error

Moderate error

Watchdog timer error

Module remove selection in operation

Module change in operation

*1 When all axes are stopped or on standby, the AX LED turns OFF.

*2 When any of the axes is in operation, the AX LED turns ON.

*3 When an error occurs in any of the axes, the AX LED is flashing.

1 PART NAMES

20

1.1 LED Display Specifications of the RD77MS

Page 23

1.2 LED Display Specifications of the RD77GF

This section lists the LED display specifications of the RD77GF.

Simple Motion

module status

Normal operation RUN

Operation failure RUN

LED display Description

*1

ERR

RUN

ERR

ERR

RUN

ERR

RUN

ERR ●

RUN

ERR

AX1-4

*1

AX1-8

AX1-16

AX1-32

AX1-4

AX1-8

AX1-16

AX1-32

AX1-4 ●

AX1-8 ●

AX1-16 ●

AX1-32 ●

AX1-4

AX1-8

AX1-16

AX1-32

AX1-4 Flashing (500 ms interval): A data link faulty station detected

AX1-8

AX1-16

AX1-32

AX1-4 Major error

AX1-8

AX1-16

AX1-32

*1

*1

*2

*2

*2

*2

*3

*3

*3

*3

*4

*4

*4

*4

The axes stopped

The axes on standby

The axis in operation

Minor error (related to axis)

Minor error (general)

Flashing (200 ms interval): Moderate error

1

: OFF, : ON, ●: Flashing

*1 When all axes are stopped or on standby, the AX LED turns OFF.

*2 When any of the axes is in operation, the AX LED turns ON.

*3 When an error occurs in any of the axes, the AX LED is flashing.

*4 The AX LED does not turn OFF when the axis is in operation or a minor error (related to axis) has occurred.

Status LED display Description

Indicates the data link status. D LINK

D LINK ●

D LINK

Indicates the data sending/receiving

status.

Indicates the receive data and line error

status.

Indicates the port status. L ER Abnormal data received

Indicates the link status. LINK Link-up

SD/RD Data being sent or received

SD/RD Data not sent nor received

L ERR Abnormal data received

L ERR Normal data received

L ER Normal data received

LINK Link-down

*1

*1

*1

Data link (cyclic transmission being performed)

Data link (cyclic transmission stopped)

Data link not performed (disconnection)

: OFF, : ON, ●: Flashing

*1 The LED is always OFF in offline mode.

1 PART NAMES

1.2 LED Display Specifications of the RD77GF

21

Page 24

2 SPECIFICATIONS

This chapter describes the performance specifications of the RD77MS and the RD77GF.

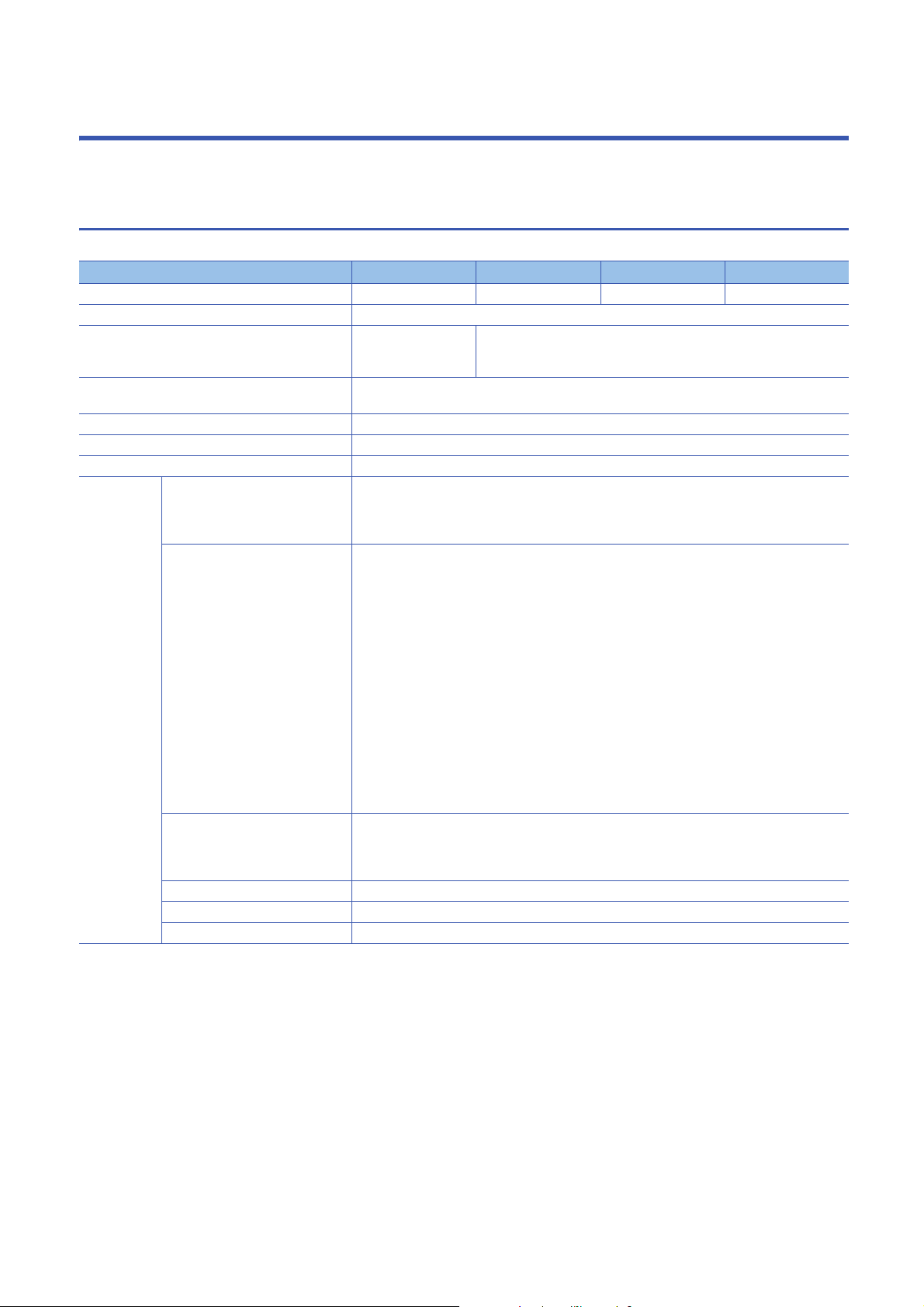

2.1 Performance Specifications of the RD77MS

This section lists the performance specifications of the RD77MS.

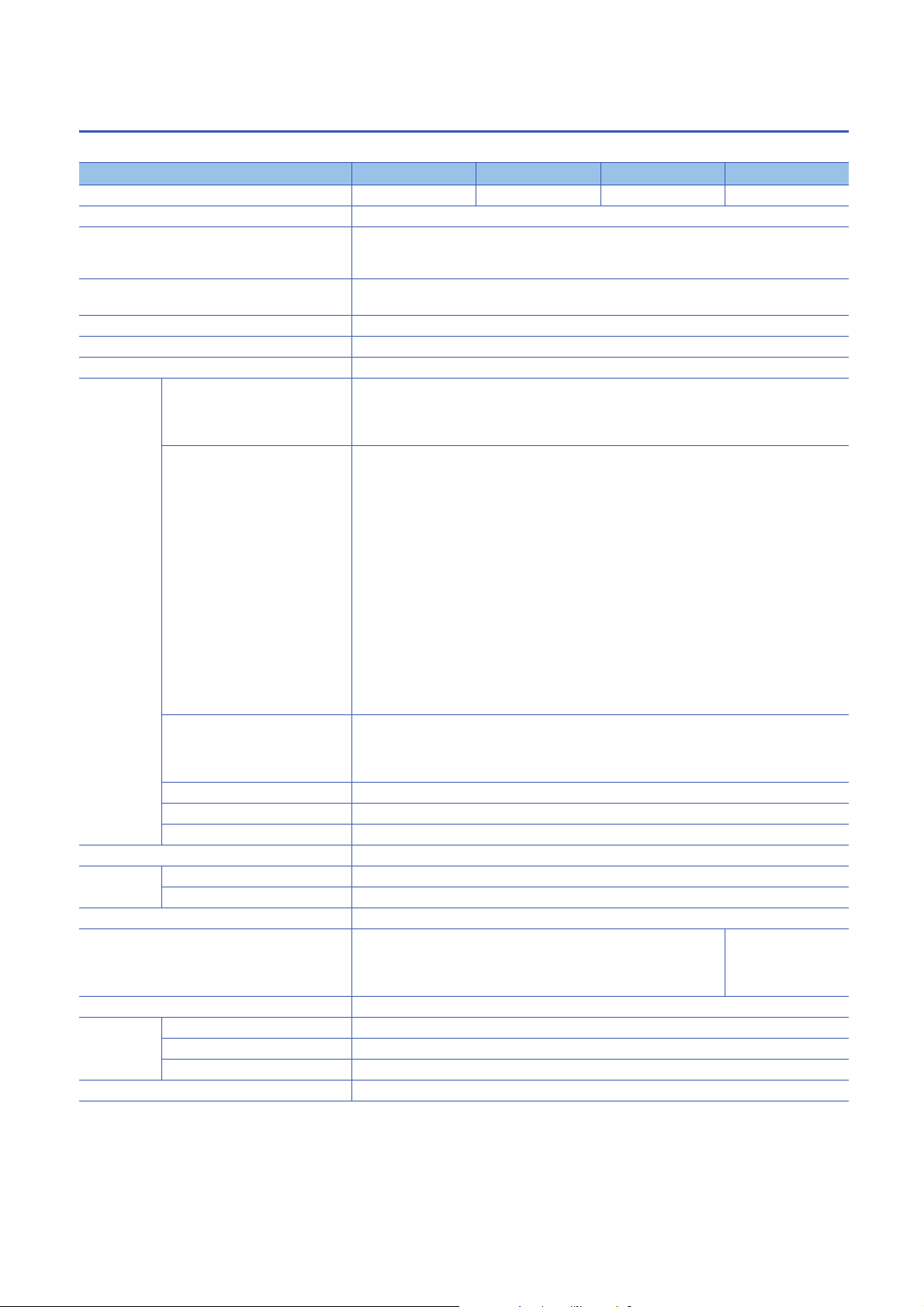

Item RD77MS2 RD77MS4 RD77MS8 RD77MS16

Number of controlled axes 2 axes 4 axes 8 axes 16 axes

Operation cycle 0.444 ms/0.888 ms/1.777 ms/3.555 ms

Interpolation function 2-axis linear

interpolation, 2-axis

circular interpolation

Control method PTP (Point To Point) control, path control (linear, arc, and helix can be set), speed control, speed-

position switching control, position-speed switching control, speed-torque control

Control unit mm, inch, degree, pulse

Positioning data 600 data/axis (The 101st data to the 600th data can be set only with the engineering tool.)

Execution data backup function Parameters, positioning data, and block start data can be saved on flash ROM. (battery-less backup)

Positioning Positioning system PTP control: Incremental system/absolute system

Speed-position switching control: Incremental system/absolute system

Position-speed switching control: Incremental system

Path control: Incremental system/absolute system

Positioning range In absolute system

• -214748364.8 to 214748364.7 (m)

• -21474.83648 to 21474.83647 (inch)

• 0 to 359.99999 (degree)

• -2147483648 to 2147483647 (pulse)

In incremental system

• -214748364.8 to 214748364.7 (m)

• -21474.83648 to 21474.83647 (inch)

• -21474.83648 to 21474.83647 (degree)

• -2147483648 to 2147483647 (pulse)

In speed-position switching control (INC mode)/position-speed switching control

• 0 to 214748364.7 (m)

• 0 to 21474.83647 (inch)

• 0 to 21474.83647 (degree)

• 0 to 2147483647 (pulse)

In speed-position switching control (ABS mode)

0 to 359.99999 (degree)

Speed command 0.01 to 20000000.00 (mm/min)

0.001 to 2000000.000 (inch/min)

0.001 to 2000000.000 (degree/min)

1 to 1000000000 (pulse/s)

Acceleration/deceleration process Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration

Acceleration/deceleration time 1 to 8388608 (ms) (Four patterns can be set for each of acceleration time and deceleration time.)

Rapid stop deceleration time 1 to 8388608 (ms)

2-, 3-, or 4-axis linear interpolation, 2-axis circular interpolation, 3-axis

helical interpolation

*1

*2

22

2 SPECIFICATIONS

2.1 Performance Specifications of the RD77MS

Page 25

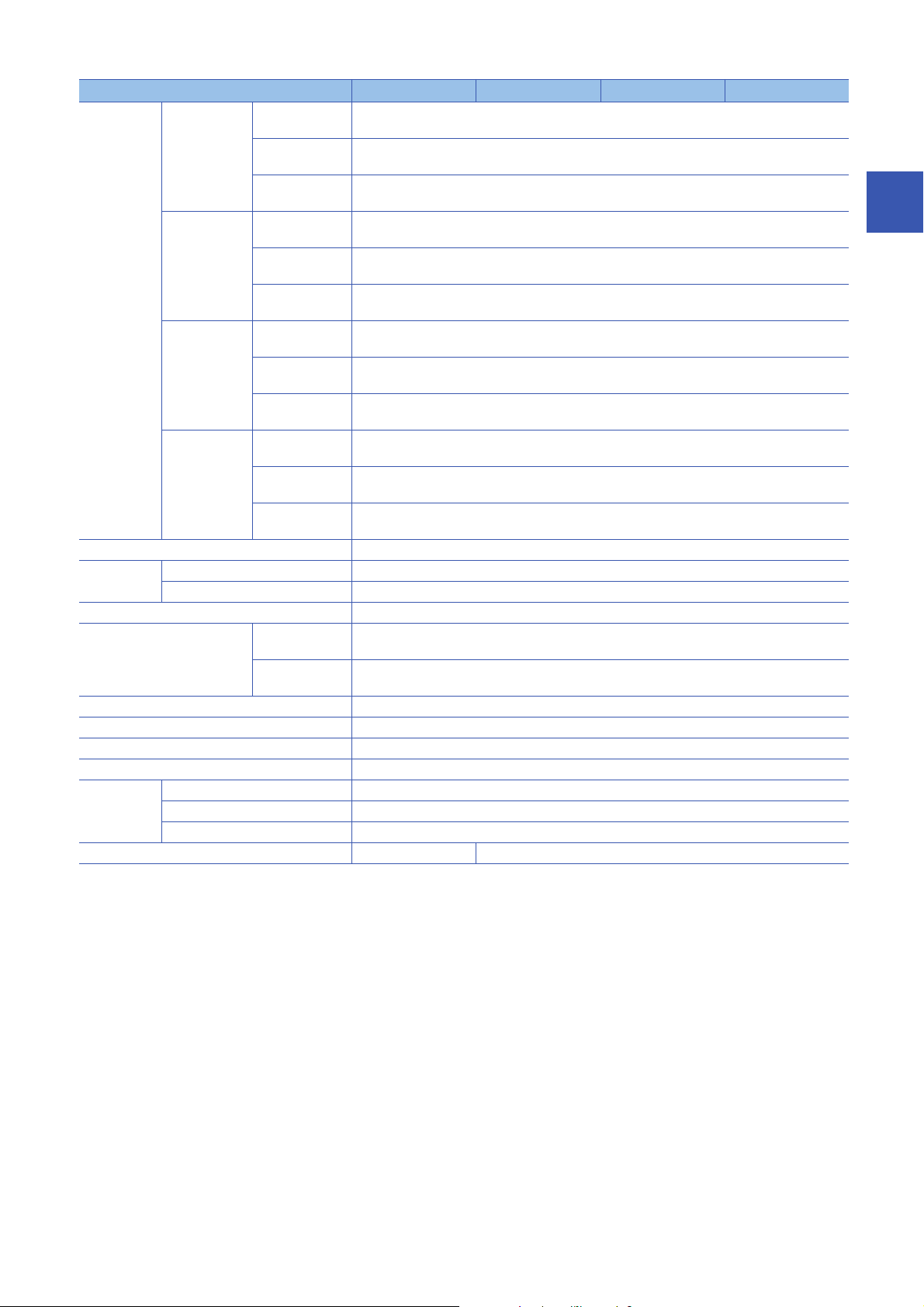

Item RD77MS2 RD77MS4 RD77MS8 RD77MS16

Starting time*3Operation cycle

External wiring connection system 40-pin connector

Applicable

wire size

External input wiring connector A6CON1, A6CON2, A6CON4 (sold separately)

Manual pulse generator/

Incremental synchronous

encoder input maximum

frequency

Manual pulse generator 1 pulse input magnification 1 to 10000 times

Flash ROM write count Max. 100000 times

Number of occupied I/O points 32 points (I/O assignment: Intelligent function module 32 points)

Internal current consumption (5 V DC) 1.0 A

External

dimensions

Mass 0.22 kg 0.23 kg

0.444 ms

Operation cycle

0.888 ms

Operation cycle

1.777 ms

Operation cycle

3.555 ms

When A6CON1 or A6CON4 is used 0.088 to 0.3 mm2 (AWG28 to AWG22) stranded wire

*4

When A6CON2 is used 0.088 to 0.24 mm

Height 106 mm (4.17 inch)

Width 27.8mm (1.09inch)

Depth 110 mm (4.33 inch)

Maximum number

of axes: 1 axis

Maximum number

of axes: 2 axes

Maximum number

of axes: 4 axes

Maximum number

of axes: 4 axes

Maximum number

of axes: 8 axes

Maximum number

of axes: 12 axes

Maximum number

of axes: 8 axes

Maximum number

of axes: 12 axes

Maximum number

of axes: 16 axes

Maximum number

of axes: 8 axes

Maximum number

of axes: 12 axes

Maximum number

of axes: 16 axes

Differential-output

type

Open-collector

type

0.7 ms

0.7 ms

0.74 ms

1.1 ms

1.32 ms

1.46 ms

1.1 ms

1.46 ms

1.59 ms

0.92 ms

1.12 ms

1.52 ms

Up to 1 Mpulses/s

Up to 200 kpulses/s

2

(AWG28 to AWG24) stranded wire

*1 The speed-position switching control (ABS mode) can be used only when the control unit is "degree".

*2 When "Speed control 10 multiplier setting for degree axis function" is valid, the setting range is 0.01 to 20000000.00 (degree/min).

*3 Time from accepting the positioning start signal until BUSY signal turns ON.

*4 Use cables with outside diameter of 1.3 mm (0.05 inch) or shorter to connect 40 cables to the connector. In addition, consider the

amount of current to be used and select appropriate cables.

2

2 SPECIFICATIONS

2.1 Performance Specifications of the RD77MS

23

Page 26

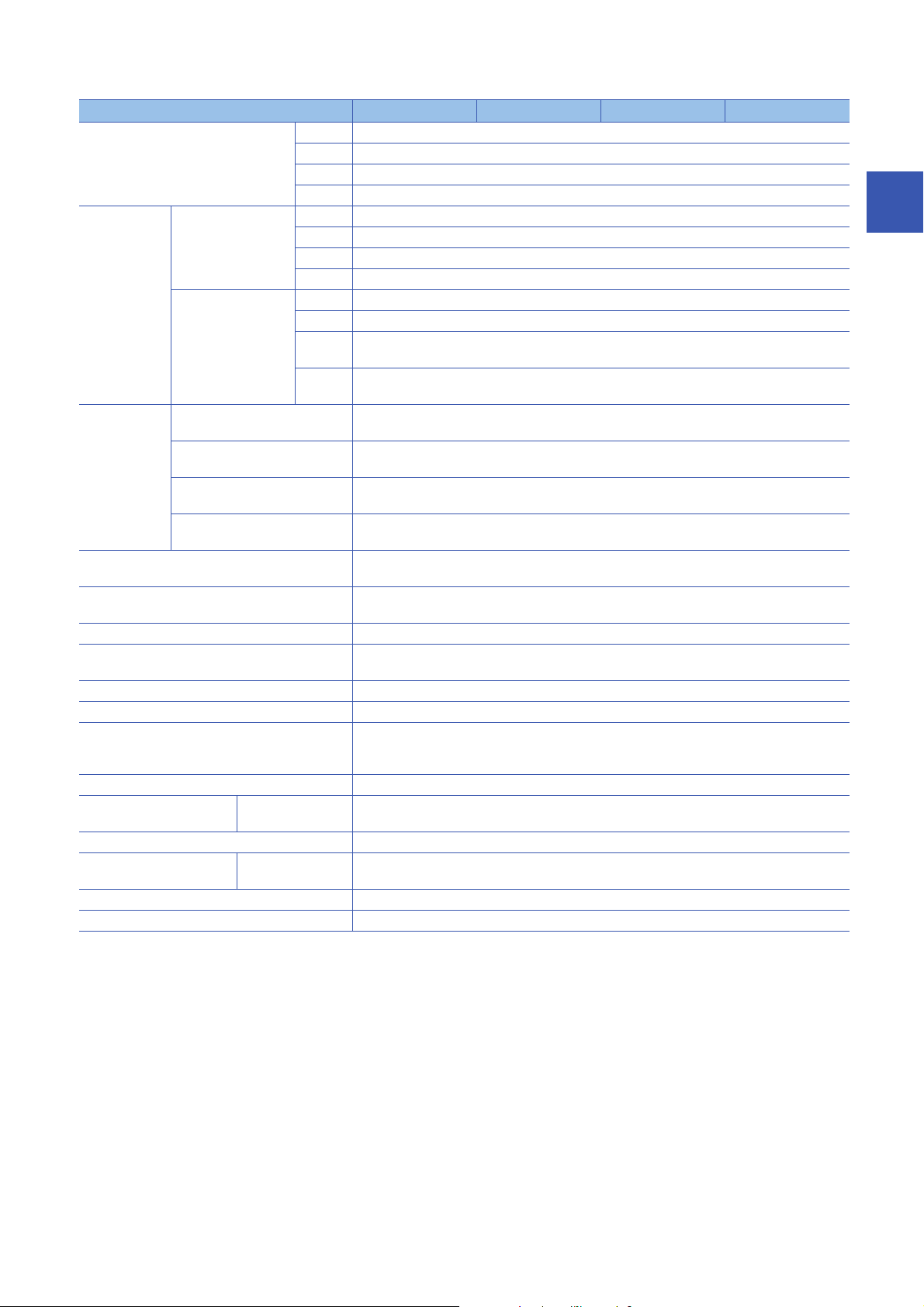

2.2 Performance Specifications of the RD77GF

This section lists the performance specifications of the RD77GF.

Item RD77GF4 RD77GF8 RD77GF16 RD77GF32

Number of controlled axes 4 axes 8 axes 16 axes 32 axes

Operation cycle 0.50 ms/1.00 ms/2.00 ms/4.00 ms

Interpolation function 2-, 3-, or 4-axis linear interpolation

2-axis circular interpolation

3-axis helical interpolation

Control method PTP (Point To Point) control, path control (linear, and arc can be set), speed control, speed-position

Control unit mm, inch, degree, pulse

Positioning data 600 data/axis (All the data points can be set with the buffer memory.)

Execution data backup function Parameters, positioning data, and block start data can be saved on flash ROM. (battery-less backup)

Positioning Positioning system PTP control: Incremental system/absolute system

Positioning range In absolute system

Speed command 0.01 to 20000000.00 (mm/min)

Acceleration/deceleration process Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration

Acceleration/deceleration time 1 to 8388608 (ms) (Four patterns can be set for each of acceleration time and deceleration time.)

Rapid stop deceleration time 1 to 8388608 (ms)

Starting time 0.2 ms to 5.0 ms

Manual pulse

generator

Flash ROM write count Max. 100000 times

Number of occupied I/O points 32 points (I/O assignment: Intelligent function module 32 points) 64 points (I/O

Internal current consumption (5 V DC) 1.1 A

External

dimensions

Mass 0.23 kg

Signal input form Link device

1 pulse input magnification 1 to 10000 times

Height 106 mm (4.17 inch)

Width 27.8 mm (1.09 inch)

Depth 110 mm (4.33 inch)

switching control, position-speed switching control, speed-torque control

Speed-position switching control: Incremental system/absolute system

Position-speed switching control: Incremental system

Path control: Incremental system/absolute system

• -214748364.8 to 214748364.7 (m)

• -21474.83648 to 21474.83647 (inch)

• 0 to 359.99999 (degree)

• -2147483648 to 2147483647 (pulse)

In incremental system

• -214748364.8 to 214748364.7 (m)

• -21474.83648 to 21474.83647 (inch)

• -21474.83648 to 21474.83647 (degree)

• -2147483648 to 2147483647 (pulse)

In speed-position switching control (INC mode)/position-speed switching control

• 0 to 214748364.7 (m)

• 0 to 21474.83647 (inch)

• 0 to 21474.83647 (degree)

• 0 to 2147483647 (pulse)

In speed-position switching control (ABS mode)

0 to 359.99999 (degree)

0.001 to 2000000.000 (inch/min)

0.001 to 2000000.000 (degree/min)

1 to 1000000000 (pulse/s)

*2

*1

assignment: Intelligent

function module 64

points)

*1 The speed-position switching control (ABS mode) can be used only when the control unit is "degree".

*2 When "Speed control 10 multiplier setting for degree axis function" is valid, the setting range is 0.01 to 20000000.00 (degree/min).

2 SPECIFICATIONS

24

2.2 Performance Specifications of the RD77GF

Page 27

The performance specifications of CC-Link IE Field Network is shown below.

Item RD77GF4 RD77GF8 RD77GF16 RD77GF32

Maximum number of link points per

network

Maximum

number of link

points per

station

Safety

communications

Inter-module synchronization cycle

synchronization communication)

Transient transmission 1: N communication (such as monitor, program upload/download)

Transient transmission capacity 1920 bytes maximum

Maximum number of transient transmissions per link

scan

Communication speed 1 Gbps

Network topology Line topology, star topology

Communication cable • Ethernet cable which satisfies 1000BASE-T standard:

Maximum station-to-station distance 100 m (conforms to ANSI/TIA/EIA-568-B (Category 5e))

Overall cable distance Single master

Number of cascade connections 4 levels maximum

Maximum number of

connectable stations

Maximum number of networks 239

Communication method Token passing

Master station RX 16K points (16384 points, 2K bytes)

Local station

Maximum number of safety

connectable stations per network

Maximum number of safety

connections per network

Maximum number of safety

connections per station

Maximum number of link points per

safety connection

*1

*2

configuration

Single master

configuration

RX 16K points (16384 points, 2K bytes)

RY 16K points (16384 points, 2K bytes)

RWr 8K points (8192 points, 16K bytes)

RWw 8K points (8192 points, 16K bytes)

RY 16K points (16384 points, 2K bytes)

RWr 8K points (8192 points, 16K bytes)

RWw 8K points (8192 points, 16K bytes)

RX 2K points (2048 points, 256 bytes)

RY 2K points (2048 points, 256 bytes)

RWr 1K points (1024 points, 2K bytes)

RWw 1K points (1024 points, 2K bytes)

(with

256 points when communication mode is "High-Speed"

256 points when communication mode is "High-Speed"

121 stations

1814 connections

120 connections

8 words (input: 8 words, output: 8 words)

0.50 ms/1.00 ms/2.00 ms/4.00 ms

Dedicated instructions from sequence programs

4

Category 5e or higher, straight cable (double shielded, STP)

• RJ45 connector

Line topology: 12000 m (when 121 stations are connected)

Star topology: Depends on the system configuration.

121 stations (master station: 1, slave station: 120)

*3

2

*1 The maximum number of points that a master station can assign to one station. A local station can receive the range assigned to other

stations using the cyclic transmission function.

*2 The cycle that each module performs the synchronous control via a network using the synchronous communication function.

*3 A switching hub supporting synchronous communication is required for the star topology.

2 SPECIFICATIONS

2.2 Performance Specifications of the RD77GF

25

Page 28

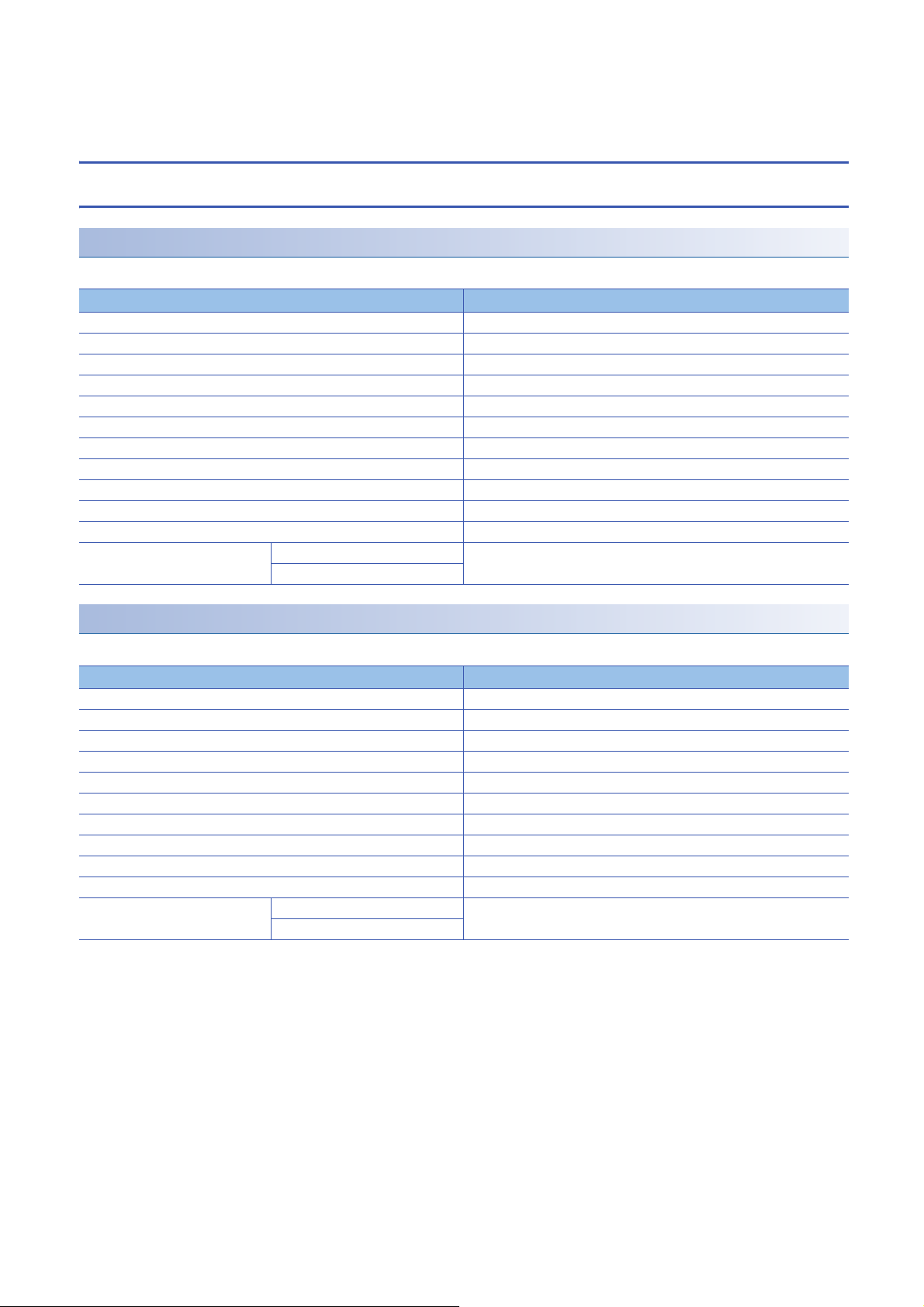

2.3 Specifications of Interfaces with External Devices

of the RD77MS

Electrical specifications of input signals

External input signal

■Specifications of external input signal

Item Specifications

Signal name Input signal (SIN)

Number of input points RD77MS2: 10 points, RD77MS4/RD77MS8/RD77MS16: 20 points

Input method Positive common/Negative common shared

Common terminal arrangement 4 points/common (Common contact: COM)

Isolation method Photocoupler

Rated input voltage 24 V DC

Rated input current (I

Operating voltage range 19.2 to 26.4 V DC (24 V DC+10/-20%, ripple ratio 5% or less)

ON voltage/current 17.5 V DC or more/3.5 mA or more

OFF voltage/current 7 V DC or less/1 mA or less

Input resistance Approx. 6.8 kΩ

Response time OFF ON 1 ms or less

) Approx. 5 mA

IN

ON OFF

Forced stop input

■Specifications of forced stop input signal

Item Specifications

Number of input points 1 point

Input method Positive common/Negative common shared

Common terminal arrangement 1 point/common (Common contact: EMI.COM)

Isolation method Photocoupler

Rated input voltage 24 V DC

Rated input current (I

Operating voltage range 19.2 to 26.4 V DC (24 V DC+10/-20%, ripple ratio 5% or less)

ON voltage/current 17.5 V DC or more/3.5 mA or more

OFF voltage/current 7 V DC or less/1 mA or less

Input resistance Approx. 6.8 kΩ

Response time OFF ON 4 ms or less

) Approx. 5 mA

IN

ON OFF

26

2 SPECIFICATIONS

2.3 Specifications of Interfaces with External Devices of the RD77MS

Page 29

Manual pulse generator/Incremental synchronous encoder input

A-phase

0.5 μs or more

1 μs or more

B-phase

0.25 μs

or less

0.25 μs

or less

0.5 μs or more

0.25 μs

or more

(Note): Duty ratio 50%

A-phase

2.5 μs or more

5 μs or more

B-phase

1.2 μs

or less

1.2 μs

or less

2.5 μs or more

1.2 μs

or more

(Note): Duty ratio 50%

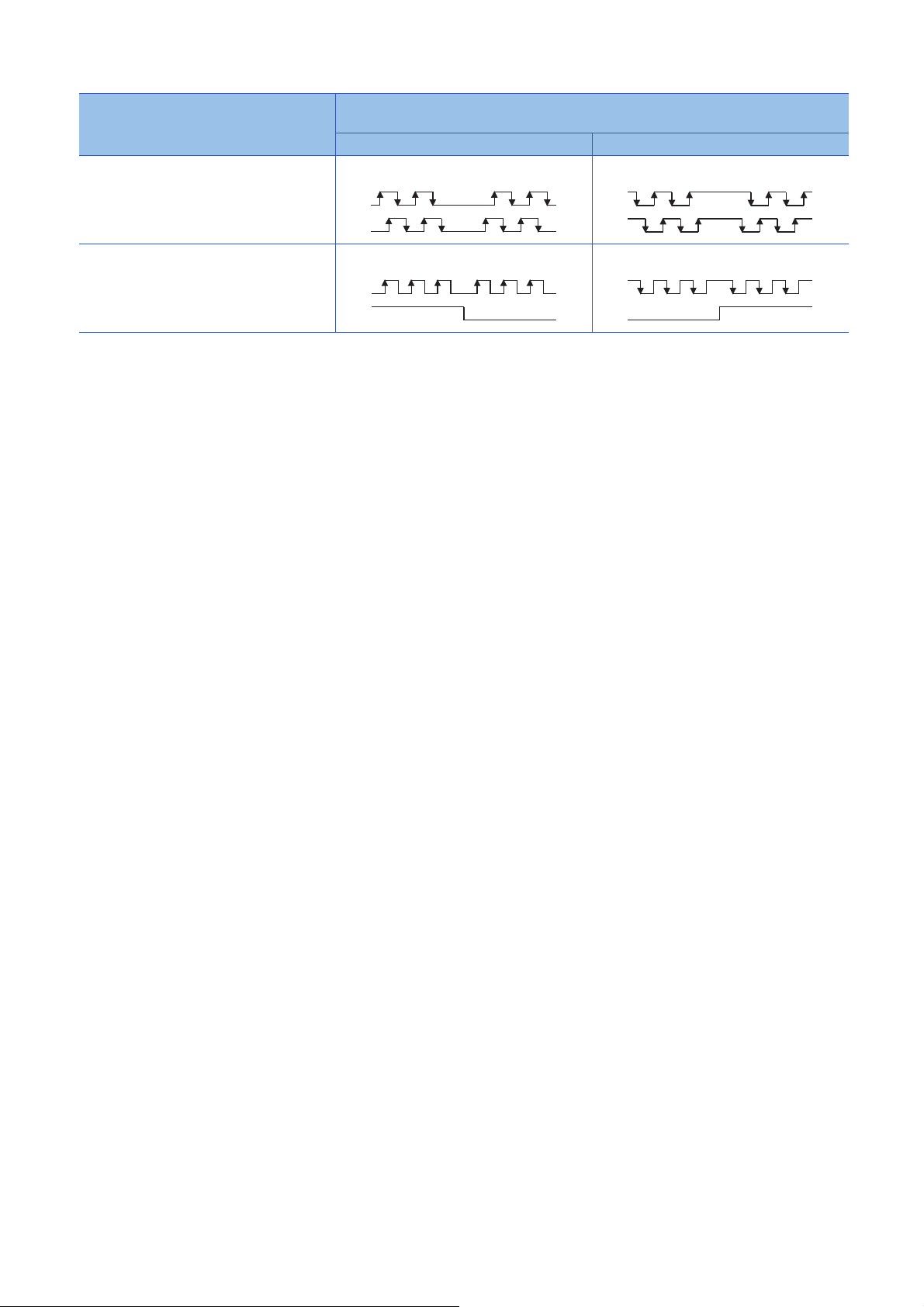

■Specifications of manual pulse generator/incremental synchronous encoder

Item Specifications

Signal input form

Differential-output type

(26LS31 or equivalent)

*1

Maximum input pulse frequency 1 Mpulses/s (After magnification by 4, up to 4 Mpulses/s)

Pulse width 1 s or more

Leading edge/trailing edge time 0.25 s or less

Phase difference 0.25 s or more

Rated input voltage 5.5 V DC or less

High-voltage 2.0 to 5.25 V DC

Low-voltage 0 to 0.8 V DC

Differential voltage 0.2 V

Cable length Up to 30 m (98.43 ft.)

Example of waveform

A-phase/B-phase (Magnification by 4/Magnification by 2/Magnification by 1),

PULSE/SIGN

*2

2

Voltage-output type/Open-collector

type (5 V DC)

Maximum input pulse frequency 200 kpulses/s (After magnification by 4, up to 800 kpulses/s)

Pulse width 5 s or more

Leading edge/trailing edge time 1.2 s or less

Phase difference 1.2 s or more

Rated input voltage 5.5 V DC or less

High-voltage 3.0 to 5.25 V DC/2 mA or less

Low-voltage 0 to 1.0 V DC/5 mA or more

Cable length Up to 10 m (32.81 ft.)

Example of waveform

*1 Set the signal input form in "[Pr.24] Manual pulse generator/Incremental synchronous encoder input selection".

*2

2 SPECIFICATIONS

2.3 Specifications of Interfaces with External Devices of the RD77MS

27

Page 30

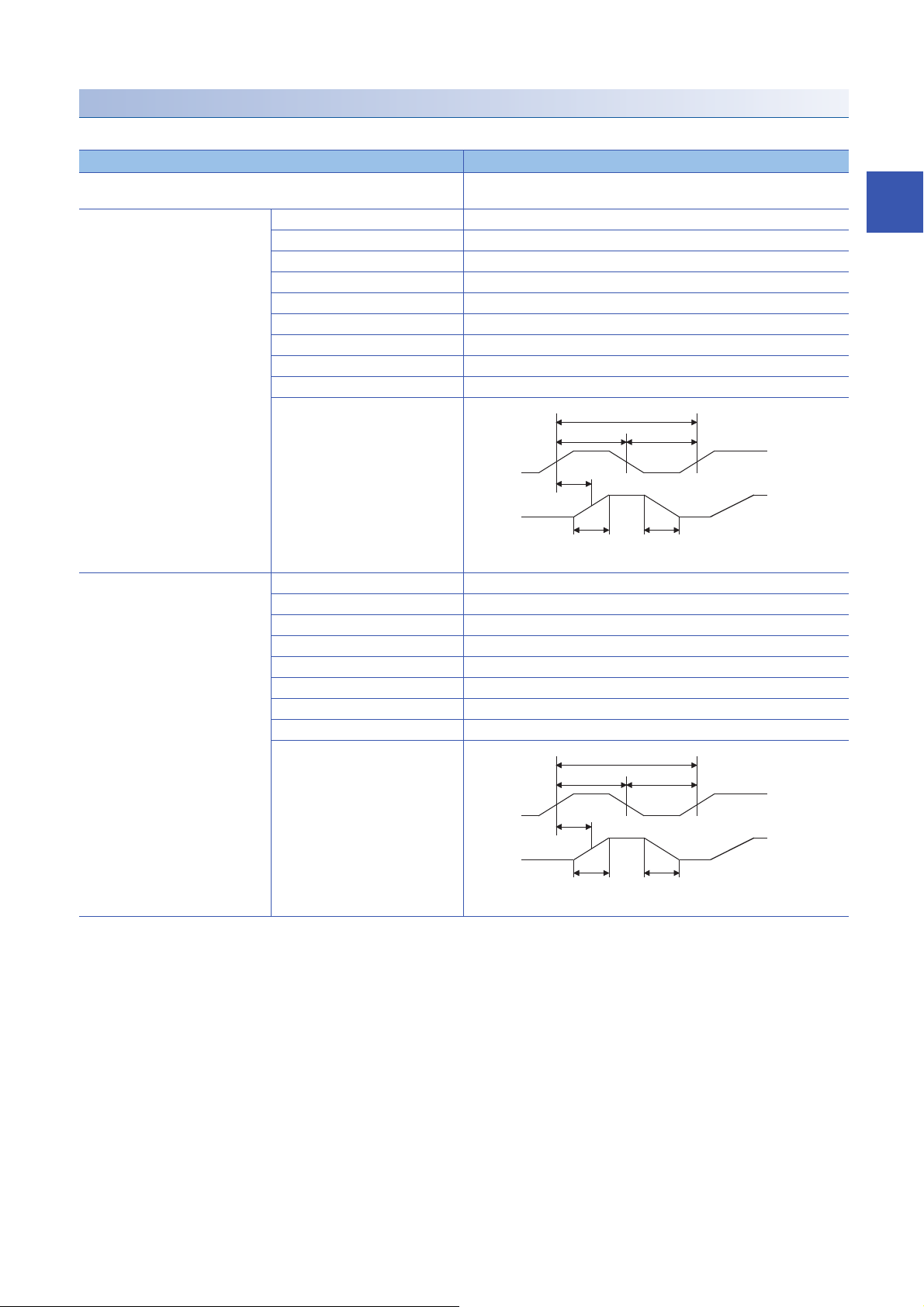

[Pr.24]

Manual pulse generator/Incremental

synchronous encoder input selection

A-phase/B-phase

[Pr.151] Manual pulse generator/Incremental synchronous encoder input logic

selection

Positive logic Negative logic

Forward run Reverse run Forward run Reverse run

PULSE/SIGN

*2 Maximum input pulse frequency is magnified by 4, when "A-phase/B-phase Magnification by 4" is set in "[Pr.24] Manual pulse generator/

Incremental synchronous encoder input selection".

Forward run Reverse run

HIGH LOW

Forward run Reverse run

HIGHLOW

28

2 SPECIFICATIONS

2.3 Specifications of Interfaces with External Devices of the RD77MS

Page 31

2.4 External Circuit Design

Forced stop

EMI

EMI.

COM

R61P RD77MSRnCPU

24 V DC

Forced stop circuit

The forced stop of all servo amplifiers is possible in a lump by using the forced stop input of Simple Motion module. After

forced stop, the forced stop factor is removed and the forced stop canceled. (The servo error detection signal does not turn on

with the forced stop.)

[RD77MS]

A wiring example which uses a Simple Motion module for the forced stop input is shown below. Set "[Pr.82] Forced stop valid/

invalid selection" to "0: Valid (External input signal)".

2

2 SPECIFICATIONS

2.4 External Circuit Design

29

Page 32

[RD77GF]

FG

1

2

3

X01

X12

X23

X34

X45

X56

7

X78

X89

X910

XA11

XB12

XC13

XD14

XE15

XF16

COM17

COM18

+24V

24G

X6

1

2

3

R61P RD77GFRnCPU

Remote input

module

CC-Link IE

Field Network

X0

COM

Forced stop24 V DC

<Remote input module NZ2GF2B1(N)-16D>

Signal name

Pin

No.

Not insulated

UNIT POWER

CABLE

Input terminal block

Module power supply/

FG terminal block

*1

Module power

supply

Forced stop

24 V DC

A wiring example which uses a remote input module (NZ2GF2B1(N)-16D) for the forced stop input is shown below. Set

"[Pr.82] Forced stop valid/invalid selection" to "3: Valid (Link device)", and set forced stop signals (EMI) ([Pr.900] to [Pr.903])

according to the input modules.

*1 Only one wire can be connected to a terminal of the terminal block for module power supply and FG. Multiple wires cannot be connected

to a terminal. Connecting two or more wires may cause a poor contact.

It is also possible to use the forced stop signal of the servo amplifier. Operation status of the emergency stop, servo amplifier

forced stop and the Motion controller forced stop are as follows.

Item Operation when the

signal is turned on

Emergency stop Servo OFF The power supply of the servo amplifier is shut off by external circuit, and the servomotor stops.

Servo amplifier

forced stop

Motion controller

forced stop

Shut-off the main circuit power supply of a servo amplifier when an emergency stop, alarm, servo amplifier forced stop, or

motion controller forced stop occurs. Make sure to use molded-case circuit breakers (MCCB) for input wires of a servo

amplifier power supply. For details, refer to the servo amplifier instruction manual.

30

2 SPECIFICATIONS

2.4 External Circuit Design

Remarks

A stop command from the external circuit to the servo amplifier is output, and the servo amplifier stops the

servomotor.

A stop command from the Simple Motion module to the servo amplifier is output, and the servo amplifier

stops the servomotor.

Page 33

3 FUNCTION LIST

There are restrictions in the function that can be used by the software of the Simple Motion module and the version of

engineering tool. Refer to the following for details.

MELSEC iQ-R Simple Motion Module User's Manual (Application)

3.1 Control Functions

The Simple Motion module has several functions. Refer to the following for details on each function.

MELSEC iQ-R Simple Motion Module User's Manual (Application)

In this manual, the Simple Motion module functions are categorized and explained as follows.

Main functions

Home position return control

"Home position return control" is a function that established the start point for carrying out positioning control (Machine home

position return), and carries out positioning toward that start point (Fast home position return). This is used to return a

workpiece, located at a position other than the home position when the power is turned ON or after positioning stop, to the

home position. The "home position return control" is pre-registered in the Simple Motion module as the "Positioning start data

No. 9001 (Machine home position return)", and "Positioning start data No. 9002 (Fast home position return)".

3

Major positioning control

This control is carried out using the "Positioning data" stored in the Simple Motion module. Positioning control, such as

position control and speed control, is executed by setting the required items in this "positioning data" and starting that

positioning data. An "operation pattern" can be set in this "positioning data", and with this whether to carry out control with

continuous positioning data (ex.: positioning data No. 1, No. 2, No. 3, etc.) can be set.

High-level positioning control

This control executes the "positioning data" stored in the Simple Motion module using the "block start data". The following

types of applied positioning control can be carried out.

• Random blocks, handling several continuing positioning data items as "blocks", can be executed in the designated order.

• "Condition judgment" can be added to position control and speed control.

• The operation of the positioning data that is set for multiple axes can be started simultaneously. (Command is output

simultaneously to multiple servo amplifiers.)

• The designated positioning data can be executed repeatedly,

etc.

Manual control

The Simple Motion module executes the random positioning operation by inputting a signal into the Simple Motion module

from an external device.

Use this manual control to move the workpiece to a random position (JOG operation), and to finely adjust the positioning

(inching operation, manual pulse generator operation), etc.

Expansion control

The following controls other than the positioning control can be executed.

• Speed control and torque control not including position loop for the command to servo amplifier (Speed-torque control).