Page 1

MELSEC iQ-R Ethernet

User's Manual (Application)

-RJ71EN71

-R00CPU

-R01CPU

-R02CPU

-R04CPU

-R04ENCPU

-R08CPU

-R08ENCPU

-R08PCPU

-R08PSFCPU

-R08SFCPU

-R16CPU

-R16ENCPU

-R16PCPU

-R16PSFCPU

-R16SFCPU

-R32CPU

-R32ENCPU

-R32PCPU

-R32PSFCPU

-R32SFCPU

-R120CPU

-R120ENCPU

-R120PCPU

-R120PSFCPU

-R120SFCPU

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the programmable

controller system, refer to the MELSEC iQ-R Module Configuration Manual.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

1

Page 4

[Design Precautions]

WARNING

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

2

Page 5

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM undefined. The values need to be set in the

buffer memory and written to the flash ROM again. Doing so also may cause malfunction or failure of

the module.

● When changing the operating status of the CPU module from external devices (such as the remote

RUN/STOP functions), select "Do Not Open by Program" for "Opening Method" of "Module

Parameter". If "Open by Program" is selected, an execution of the remote STOP function causes the

communication line to close. Consequently, the CPU module cannot reopen the line, and external

devices cannot execute the remote RUN function.

3

Page 6

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette or a battery-less option cassette into the cassette

connector of the CPU module. After insertion, close the cassette cover and check that the cassette is

inserted completely. Poor contact may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, battery-less option cassette, or connector. Doing so can cause

malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach a blank cover module (RG60) to each empty slot and an included

extension connector protective cover to the unused extension cable connector before powering on the

system for operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cables may swing or inadvertently be pulled,

resulting in malfunction or damage to modules or cables.

In addition, the weight of the cables may put stress on modules in an environment of strong vibrations

and shocks.

Do not clamp the extension cables with the jacket stripped. Doing so may change the characteristics

of the cables, resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

5

Page 8

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not perform each of the following operations more than 50 times

(IEC 61131-2/JIS B 3502 compliant):

Exceeding the limit may cause malfunction.

• Mounting/removing the module to/from the base unit

• Inserting/removing the extended SRAM cassette or battery-less option cassette to/from the

CPU module

• Mounting/removing the terminal block to/from the module

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette or a batteryless option cassette. Doing so may cause malfunction or failure of the module.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM undefined. The values need to be set in the buffer memory and written to the flash ROM

again. Doing so can cause malfunction or failure of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

7

Page 10

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the functions, programming, and troubleshooting of the relevant products listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RJ71EN71, CPU module

8

Unless otherwise specified, the buffer memory addresses in this manual are for when the P1 connecter of the

RJ71EN71 or RnENCPU is used.

Check the corresponding buffer memory addresses in the list and use the correct addresses when using the

following: (Page 336 Buffer Memory)

• CPU module (built-in Ethernet port part)

• P2 connector of the RJ71EN71

• RJ71EN71 (network type: Q-compatible Ethernet)

Page 11

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CHAPTER 1 FUNCTIONS 17

1.1 Connection with MELSOFT Product and GOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connection via a hub. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Direct connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.2 SLMP Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Communication structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Data communication procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

List of valid commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

1.3 Communications Using the Predefined Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Applicable connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Data communication procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Protocol communication type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Packet elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Execution conditions of predefined protocol communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Example of predefined protocol communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

1.4 Socket Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Applicable dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Applicable connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Communication structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Communications using TCP/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Communications using UDP/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Broadcast communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

1.5 Communications Using the Fixed Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Differences between the "Procedure Exist" and "No Procedure" control methods . . . . . . . . . . . . . . . . . . . . . . . 68

Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Applicable dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Applicable connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Communication structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Send procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Receive procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Pairing open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Broadcast communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Example of communications using the fixed buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1.6 Communications Using the Random Access Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Communication structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Procedure for reading from external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

CONTENTS

9

Page 12

Procedure for writing from external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Physical address and logical address of random access buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Example of communications with random access buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

1.7 Communications Using MODBUS/TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Automatic response function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

MODBUS device assignment function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

List of MODBUS standard functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

1.8 Link Dedicated Instruction Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Applicable dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Data communication procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

1.9 File Transfer Function (FTP server) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Data communication procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Files that can be transferred with FTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

FTP command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

1.10 File Transfer Function (FTP Client) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Transferable files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Procedure for executing the file transfer function (FTP client) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

1.11 Time Setting Function (SNTP Client). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

1.12 Web Server Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

JavaScript objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

CGI object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Error message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1.13 Security Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

IP filter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Remote password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

1.14 Simple CPU Communication Function (CPU Module (Built-in Ethernet Port Part)) . . . . . . . . . . . . . . . . . 181

Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Checking the simple CPU communication status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

1.15 Simple CPU Communication Function (RJ71EN71, RnENCPU (Network Part)) . . . . . . . . . . . . . . . . . . . .193

Setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Checking the simple CPU communication status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

1.16 IP Address Change Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

IP address of the Ethernet-equipped module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Usage methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Checking the IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Checking the operating status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

1.17 Redundant System Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

System configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

System switching operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

System switching request to the control system CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Redundant group setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Communication path bypass function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Both systems identical IP address setting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Functions restricted in a redundant system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .229

10

Page 13

Setting example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

CHAPTER 2 PARAMETER SETTINGS 241

2.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

2.2 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

Own Node Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

External Device Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

2.3 Application Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Frame Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Communication Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

FTP Server Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

FTP Client Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

DNS Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

MODBUS/TCP Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Simple CPU Communication Setting (RJ71EN71, RnENCPU (Network Part)). . . . . . . . . . . . . . . . . . . . . . . . .256

Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

Timer Settings for Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

Gateway Parameter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Network/Station No. <-> IP information setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Interrupt Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

IP Packet Transfer Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Network Dynamic Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Module Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Redundant System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Simple CPU Communication Setting (CPU Module (Built-in Ethernet Port Part)). . . . . . . . . . . . . . . . . . . . . . .278

CONTENTS

CHAPTER 3 TROUBLESHOOTING 280

3.1 Checking with LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

3.2 Checking the Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

3.3 Checking the Network Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Ethernet diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

Simple CPU communication diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

3.4 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

3.5 List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .310

3.6 List of Parameter Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .327

3.7 Event List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

3.8 End Codes Returned to an External Device During Data Communications . . . . . . . . . . . . . . . . . . . . . . . 331

APPENDICES 333

Appendix 1 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Appendix 2 I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

List of I/O signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Appendix 3 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

Details of buffer memory addresses (RJ71EN71, RnENCPU (network part)). . . . . . . . . . . . . . . . . . . . . . . . . . 355

Details of buffer memory addresses (CPU module (built-in Ethernet port part)). . . . . . . . . . . . . . . . . . . . . . . . 370

Appendix 4 Dedicated Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

Precautions for dedicated instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Appendix 5 TCP/IP Communications, UDP/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

11

Page 14

TCP/IP communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

UDP/IP communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .383

Appendix 6 Communications with Different Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .385

Appendix 7 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .388

Performance list of simple CPU communication function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

Appendix 8 When Connecting the Module to a Remote Head Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Restricted functions and specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .393

Appendix 9 Port Numbers Used by Ethernet-equipped Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .394

Appendix 10Operation Image and Data Structure of Predefined Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Operation image of each communication type of protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Verification operation of receive packet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Example of packet element data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Appendix 11Example of External Device Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Appendix 12How to Turn Off ERR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Appendix 13Added and Enhanced Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

INDEX 408

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .410

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .411

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .412

12

Page 15

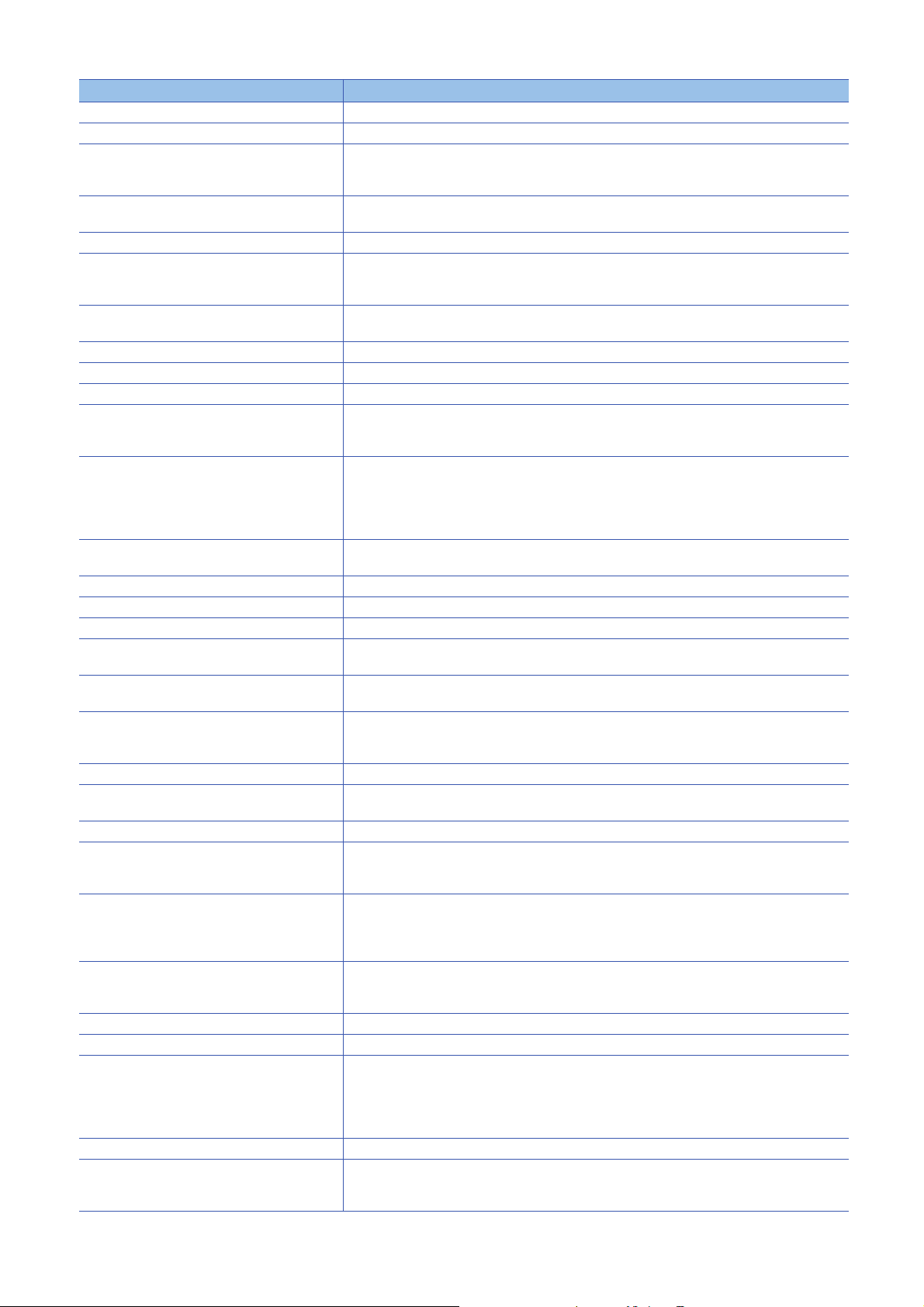

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R Ethernet User's Manual (Application)

[SH-081257ENG] (this manual)

MELSEC iQ-R Ethernet/CC-Link IE User's Manual (Startup)

[SH-081256ENG]

MELSEC iQ-R CPU Module User's Manual (Startup)

[SH-081263ENG]

MELSEC iQ-R Programming Manual (CPU Module Instructions,

Standard Functions/Function Blocks)

[SH-081266ENG]

MELSEC iQ-R Programming Manual (Module Dedicated

Instructions)

[SH-081976ENG]

MELSEC iQ-R MODBUS/TCP Reference Manual

[BCN-P5999-1060-A]

SLMP Reference Manual

[SH-080956ENG]

iQ Sensor Solution Reference Manual

[SH-081133ENG]

This manual does not include information on the module function blocks.

For details, refer to the Function Block Reference for the module used.

Functions, parameter settings, programming, troubleshooting, I/O

signals, and buffer memory of Ethernet

Specifications, procedures before operation, system configuration,

wiring, and communication examples of Ethernet, CC-Link IE

Controller Network, and CC-Link IE Field Network

Performance specifications, procedures before operation, and

troubleshooting of the CPU module

Instructions for the CPU module and standard functions/function

blocks

Dedicated instructions for the intelligent function modules e-Manual

The protocol (MODBUS/TCP) used for data reading or writing from

an external device to the Ethernet-equipped module.

The protocol (SLMP) used for data reading or writing from an

external device to the Ethernet-equipped module.

Operation methods of the online functions for iQ Sensor Solution Print book

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual

PDF

PDF

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual

PDF

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

13

Page 16

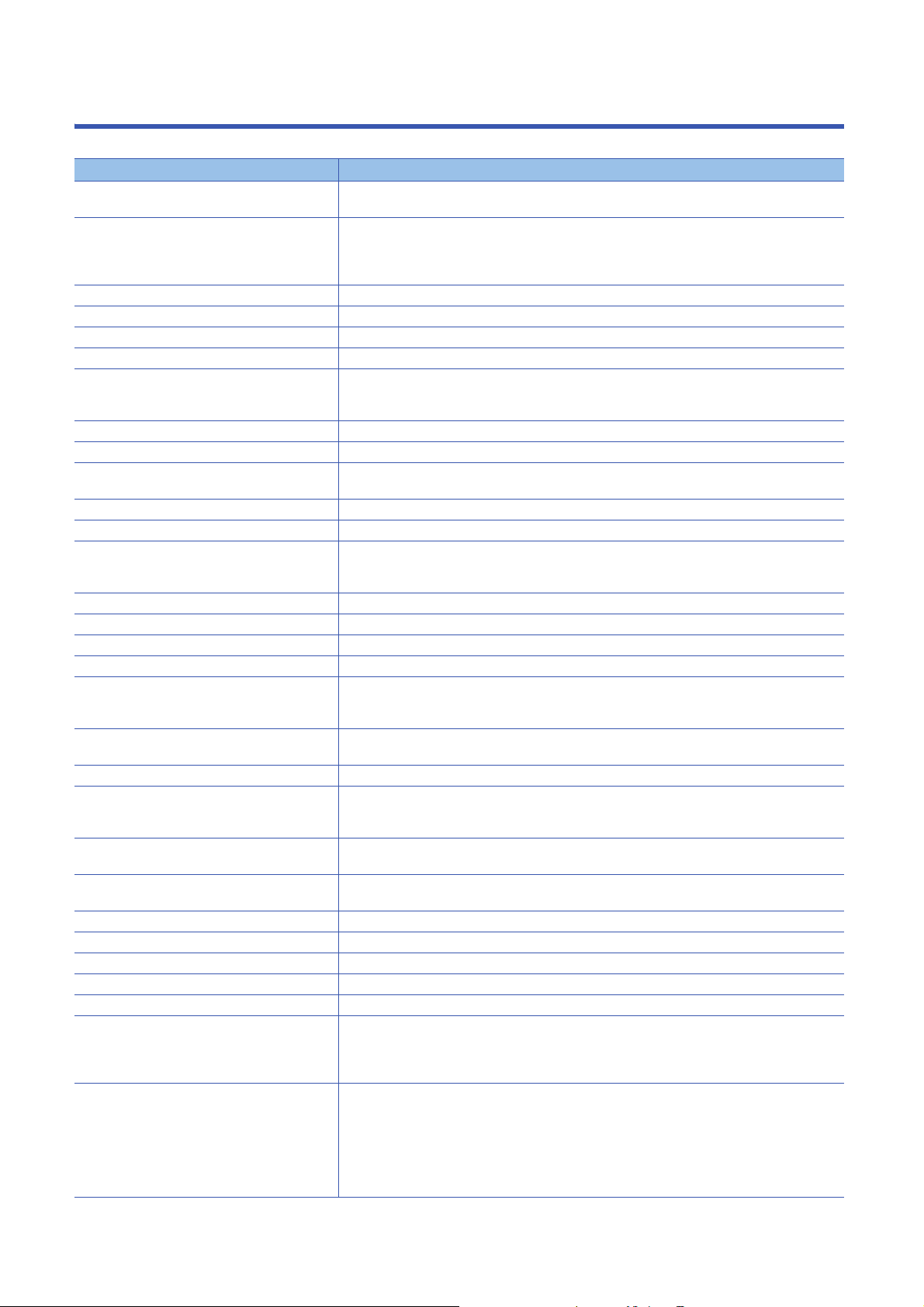

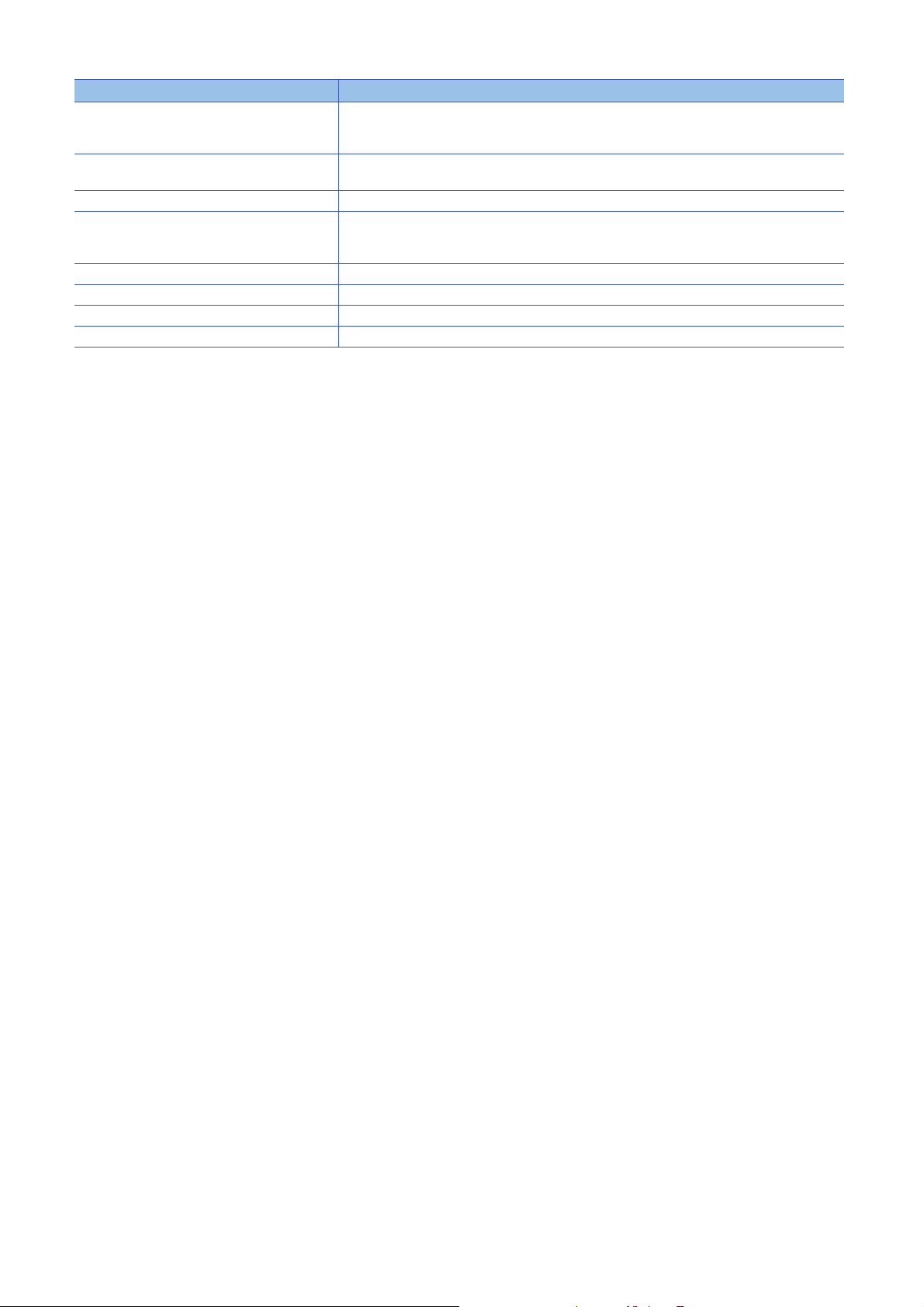

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

ARP The abbreviation for Address Resolution Protocol. This protocol is used to obtain the MAC address of

Buffer memory Memory in an intelligent function module for storing data such as setting values and monitored values.

BUFRCV A generic term for the GP.BUFRCV and ZP.BUFRCV

BUFRCVS A generic term for the G.BUFRCVS and Z.BUFRCVS

BUFSND A generic term for the GP.BUFSND and ZP.BUFSND

CLOSE A generic term for the GP.CLOSE and ZP.CLOSE

Control CPU A CPU module that controls connected I/O modules and intelligent function modules.

Control system A system that takes control and performs network communications in a redundant system.

CPU module A generic term for the MELSEC iQ-R series CPU modules

CPU module (built-in Ethernet port part) A built-in Ethernet port part of the CPU module (CPU part for the RnENCPU) ( MELSEC iQ-R

Dedicated instruction An instruction for using the functions of a module

Device A device (X, Y, M, D, or others) in a CPU module

Device supporting iQSS A generic term for a device which supports iQ Sensor Solution.

Engineering tool Another term for the software package for the MELSEC programmable controllers

ERRCLEAR A generic term for the GP.ERRCLEAR and ZP.ERRCLEAR

ERRRD A generic term for the GP.ERRRD and ZP.ERRRD

Ethernet device A generic term for the devices supporting IP communication (such as personal computers)

Ethernet-equipped module A generic term for the following modules when the Ethernet function is used:

External device A generic term for the personal computer and other Ethernet-equipped modules connected over

FTP The abbreviation for File Transfer Protocol. This protocol is used to transfer data files over a network.

Global label A label that is valid for all the program data when multiple program data are created in the project.

ICMP The abbreviation for Internet Control Message Protocol. This protocol is used to exchange messages of

Intelligent function module A module that has functions other than input and output, such as an A/D converter module and D/A

Label A label that represents a device in a given character string

MELSECNET/10 The abbreviation for the MELSECNET/10 network system

MELSECNET/H The abbreviation for the MELSECNET/H network system

MODBUS device Devices used for communications using the MODBUS protocol.

MODBUS/TCP A generic term for the protocols for using MODBUS protocol messages on a TCP/IP network.

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to each

Network module A generic term for the following modules:

Ethernet from an IP address.

When integrated into the CPU module, this memory refers to a memory for storing data such as setting

values and monitored values of the Ethernet function, and data used for data communication of the

multiple CPU system function.

The multiple CPU system allows the user to assign this control to any CPU module on a module-bymodule basis.

Ethernet/CC-Link IE User's Manual (Startup))

For details on iQ Sensor Solution, refer to the following.

iQ Sensor Solution Reference Manual

• RJ71EN71

• CPU module

Ethernet for data communications.

There are two types of global label: a module specific label (module label), which is generated

automatically by GX Works3, and an optional label, which can be created for any specified device.

errors in an IP network or other information related to an Ethernet network.

converter module.

module in a given character string.

For the module used, GX Works3 automatically generates this label, which can be used as a global

label.

• Ethernet interface module

• CC-Link IE Controller Network module

• Module on CC-Link IE Field Network

• MELSECNET/H network module

• MELSECNET/10 network module

• RnENCPU (network part)

14

Page 17

Ter m Description

New control system A system that has switched to control system from standby system after system switching.

OPEN A generic term for the GP.OPEN and ZP.OPEN

OPS A generic term for the partner products with built-in EZSocket that supports a redundant system. For

Predefined protocol support function A function of GX Works3.

Process CPU A generic term for the R08PCPU, R16PCPU, R32PCPU, and R120PCPU

Process CPU (redundant mode) A Process CPU operating in redundant mode.

Programmable controller CPU A generic term for the R00CPU, R01CPU, R02CPU, R04CPU, R04ENCPU, R08CPU, R08ENCPU,

READ A generic term for the JP.READ and GP.READ

RECV A generic term for the JP.RECV and GP.RECV

RECVS A generic term for the G.RECVS and Z.RECVS

Redundant function module Another term for the R6RFM

Redundant system A system consisting of two systems that have same configuration (CPU module, power supply module,

Relay station A station that includes two or more network modules. Transient transmission is performed through this

Remote head module The abbreviation for the RJ72GF15-T2 CC-Link IE Field Network remote head module

REQ A generic term for the J.REQ, JP.REQ, G.REQ, and GP.REQ

RnENCPU A generic term for the R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, and R120ENCPU

RnENCPU (CPU part) A module on the left-hand side of the RnENCPU ( MELSEC iQ-R Ethernet/CC-Link IE User's

RnENCPU (network part) A module on the right-hand side of the RnENCPU ( MELSEC iQ-R Ethernet/CC-Link IE User's

Routing A process of selecting paths for communication with other networks. There are two types of routing:

Safety CPU A generic term for the R08SFCPU, R16SFCPU, R32SFCPU, and R120SFCPU

Seamless communication Communication that allows users to access a different kind of networks without having to consider the

SEND A generic term for the JP.SEND and GP.SEND

SIL2 function module Another name for the R6PSFM.

SIL2 Process CPU A generic term for the R08PSFCPU, R16PSFCPU, R32PSFCPU, and R120PSFCPU

SLMP The abbreviation for Seamless Message Protocol.

SREAD A generic term for the JP.SREAD and GP.SREAD

Standby system A backup system in a redundant system

Subnet mask A number used to logically divide one network into multiple subnetworks and manage them easily. The

SWRITE A generic term for the JP.SWRITE and GP.SWRITE

System A A system that is set as system A to distinguish two systems, which are connected with two tracking

communications with an OPS, use "OPS Connection Module" of "Module List" in "External Device

Configuration" under "Basic Settings".

This function sets protocols appropriate to each external device and reads/writes protocol setting data.

A redundant system is configured with this CPU module. Process control FBs and the online module

change function can be executed even in this mode.

R16CPU, R16ENCPU, R32CPU, R32ENCPU, R120CPU, R120ENCPU

This module is used with the Process CPU (redundant mode) or SIL2 Process CPU as a pair and

configures a redundant system.

network module, and other modules). Even after an error occurs in one of the two system, the other

system takes over the control of the entire system. For details, refer to "Redundant system" of the

following manual.

MELSEC iQ-R Module Configuration Manual

station to stations on other networks

Manual (Startup))

Manual (Startup))

dynamic routing that auto-selects the communication routes, and static routing where communication

routes are arbitrarily set.

differences as if data were exchanged within one single network.

This module is used with the SIL2 Process CPU as a pair and performs safety control. The module can

only be paired with the SIL2 Process CPU.

This module is used with a SIL2 function module as a pair, and performs both standard control and

safety control. This module is also used with a redundant function module as a pair and configures a

redundant system.

This protocol is used to access an SLMP-compatible device or a programmable controller connected to

an SLMP-compatible device from an external device.

following Ethernet network systems can be configured:

• A small-scale Ethernet network system in which multiple network devices are connected.

• A medium- or large-scale network system in which multiple small-scale network systems are

connected via routers or other network communication devices.

cables. When the two systems start up at the same time, this system will be a control system. System

switching does not affect the system A/B setting.

15

Page 18

Term Description

System B A system that is set as system B to distinguish two systems, which are connected with two tracking

System switching A function which switches the systems between the control system and the standby system to continue

Tracking cable An optical fiber cable used to connect two redundant function modules in a redundant system.

Transient transmission group number Number that is assigned for transient transmission to any given stations.

UINI A generic term for the G.UINI, GP.UINI, Z.UINI, and ZP.UINI

WRITE A generic term for the JP.WRITE and GP.WRITE

ZNRD A generic term for the J.ZNRD and JP.ZNRD

ZNWR A generic term for the J.ZNWR and JP.ZNWR

cables. When the two systems start up at the same time, this system will be a standby system. System

switching does not affect the system A/B setting.

operation of the redundant system when a failure or an error occurs in the control system.

By specifying a group of stations as transient transmission target, data can be sent to the stations of the

same group number.

16

Page 19

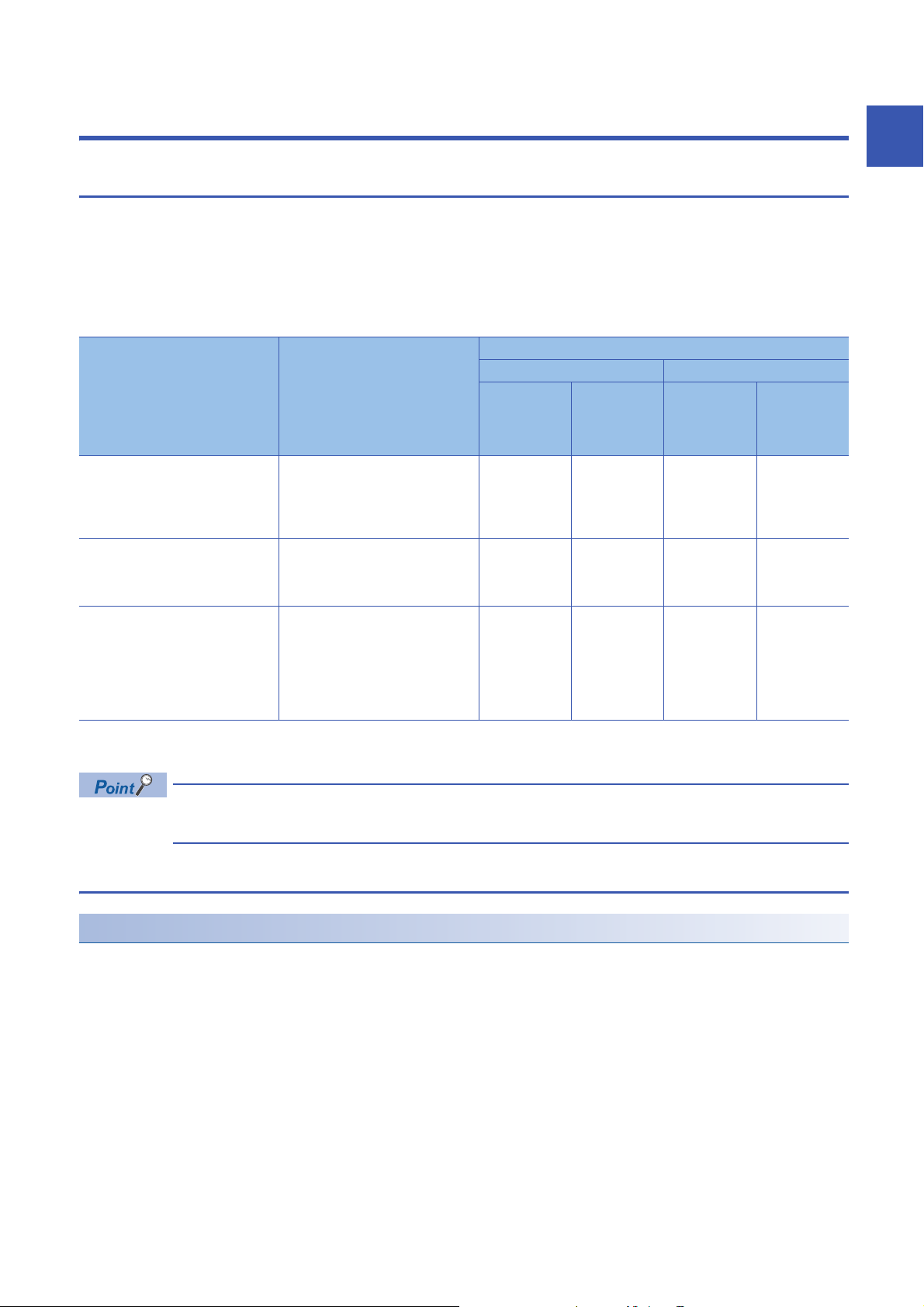

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Programming and monitoring of the programmable controller with the engineering tool, and monitoring and testing of the

programmable controller from the GOT can be performed via Ethernet. This function enables remote operations using

Ethernet's long-distance connection and high-speed communication.

The section describes the methods of connecting the Ethernet-equipped module, MELSOFT product (such as engineering

tool and MX Component), and GOT.

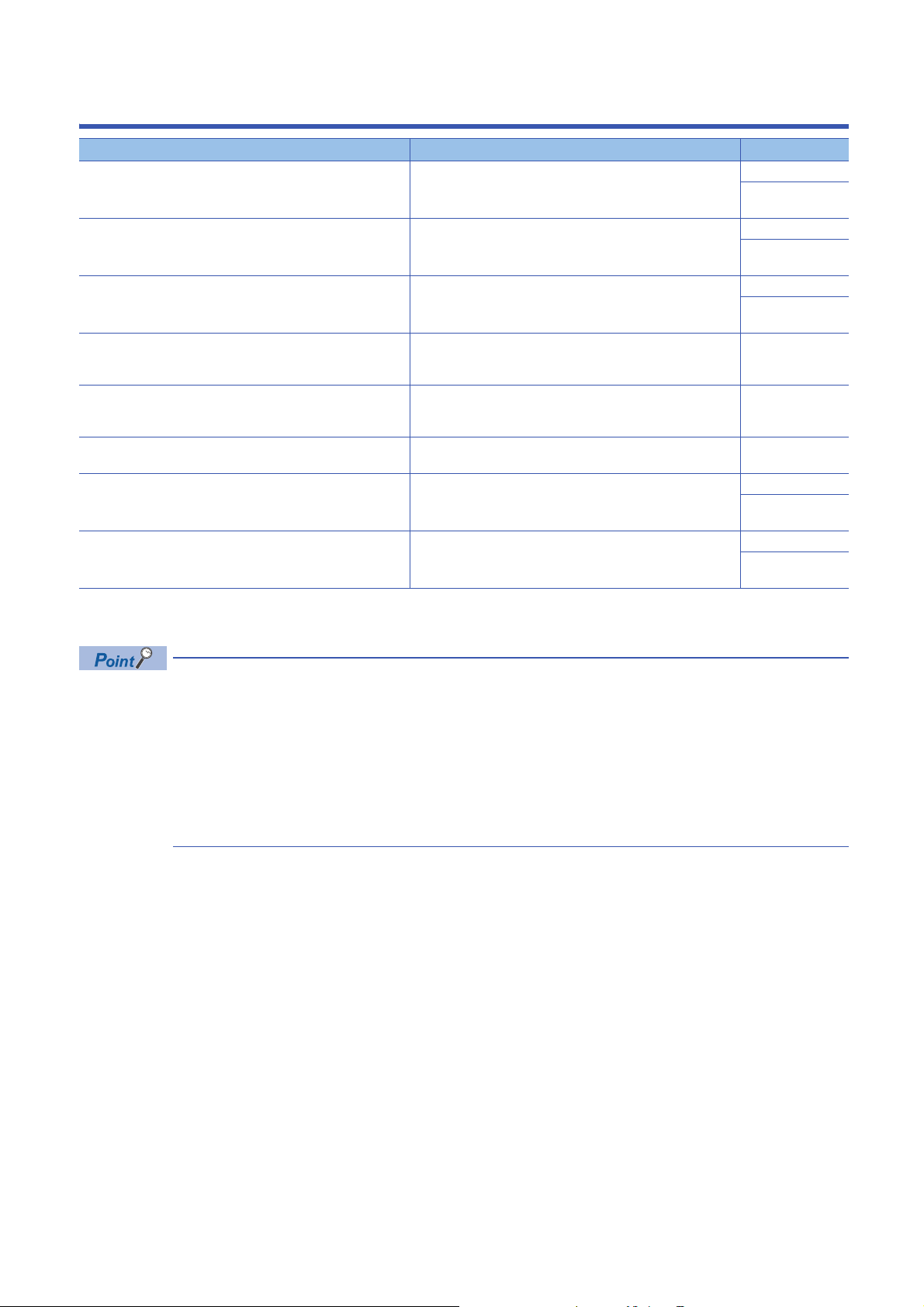

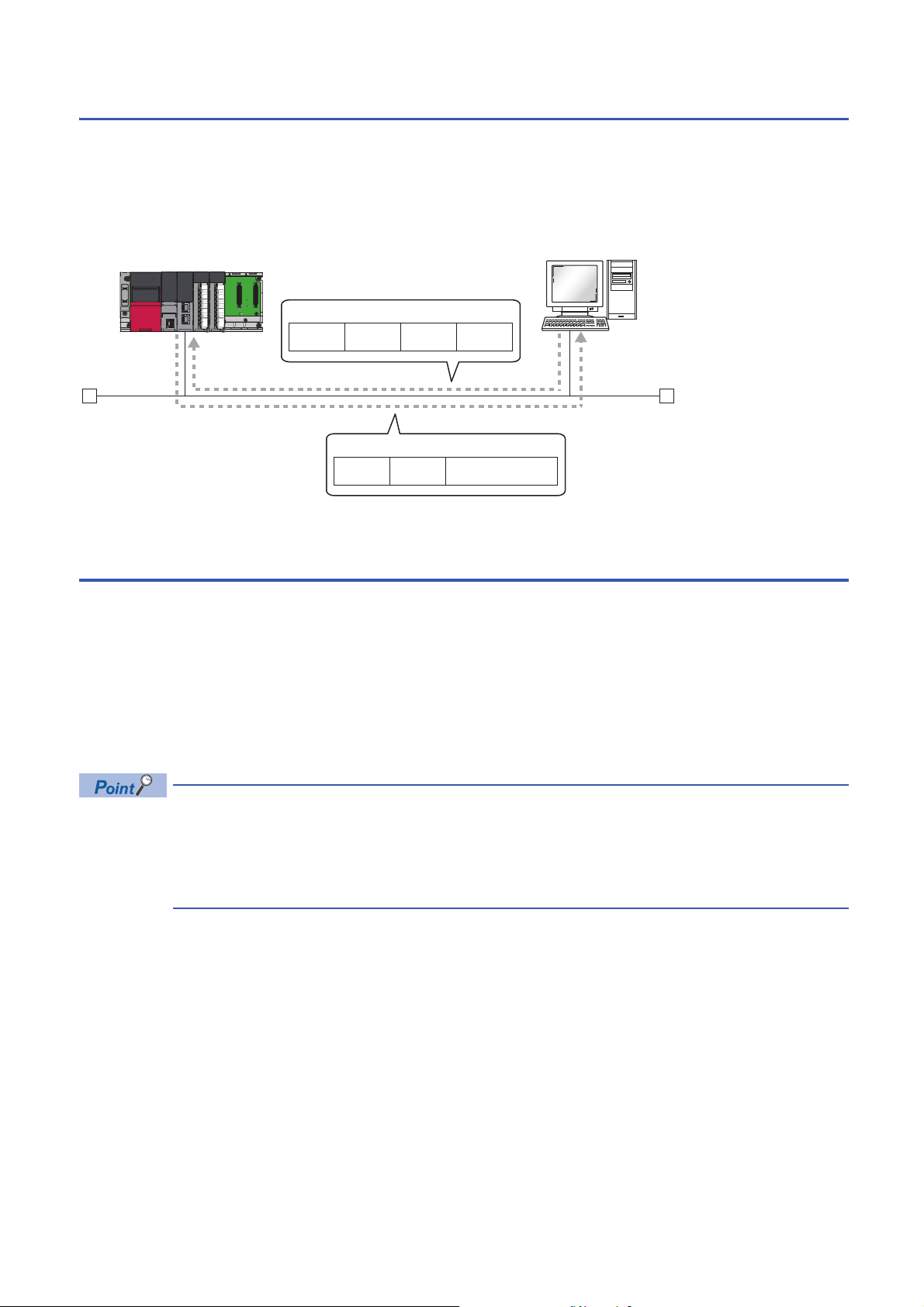

: Connection available, : Connection not available

Connection method Purpose Availability

MELSOFT products GOT

Connection via a hub

(Connection by specifying the IP

address)

Connection via a hub

(Connection by specifying the network

number and station number)

Direct connection

(Connection without specifying the IP

address, network number, or station

*1

number)

• To connect to an Ethernet-equipped

module that has no network number

and station number

• To connect multiple MELSOFT

products

• To connect by using network number

and station number

• To connect multiple MELSOFT

products and GOTs

• To connect without hub using one

Ethernet cable for one-on-one

communication with the external

device

• To connect to an Ethernet-equipped

module whose IP address in

unknown

RJ71EN71,

RnENCPU

(network

part)

CPU module

(built-in

Ethernet port

part)

*2

RJ71EN71,

RnENCPU

(network

part)

CPU module

(built-in

Ethernet port

part)

*2

1

*1 This connection method is not available when the RJ71EN71 network type is set to "Q Compatible Ethernet".

*2 Before the connection, check the firmware version of the CPU module. (Page 406 Added and Enhanced Functions)

For the procedures to connect the Ethernet-equipped module and GOT, refer to the following.

Manual for the GOT used

Connection via a hub

Setting procedure

■Setting in the Ethernet-equipped module side

Set the IP address of the Ethernet-equipped module in "Own Node Settings" under "Basic Settings". ( Page 242 Own

Node Settings)

When connecting by specifying the network number and station number, set the network number and station number in "Own

Node Settings" under "Basic Settings".

Even if "External Device Configuration" is not set under "Basic Settings", the Ethernet-equipped module can be connected to

the MELSOFT product and GOT using the system dedicated connection.

*1 When using a TCP/IP connection with the system dedicated connection, up to ((maximum number of connected modules in "External

Device Configuration") - (set number) + 1) modules can be connected.

When using a UDP/IP connection, up to the maximum number of connectable modules can be connected.

* 1

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

17

Page 20

When connecting multiple MELSOFT products with TCP/IP, drag "MELSOFT Connection Module" from the

"Module List" to "List of devices" or "Device map area" in "External Device Configuration" under "Basic

Settings". ( Page 244 External Device Configuration)

18

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Page 21

■Settings on the engineering tool side

Set in the "Specify Connection Destination Connection" window.

[Online] [Current Connection Destination]

1

1. Set "PC side I/F" to "Ethernet Board".

2. Double-click "Ethernet Board", and open the "PC side I/

F Detailed Setting of Ethernet Board" window.

3. Set the network number, station number, and protocol of

the personal computer. (Set the network number and

protocol according to the settings for the Ethernetequipped module. Set the station number so that it is not

the same as a station number assigned to other

Ethernet devices.)

*1

4. Set the "PLC side I/F" to the module to be connected.

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

19

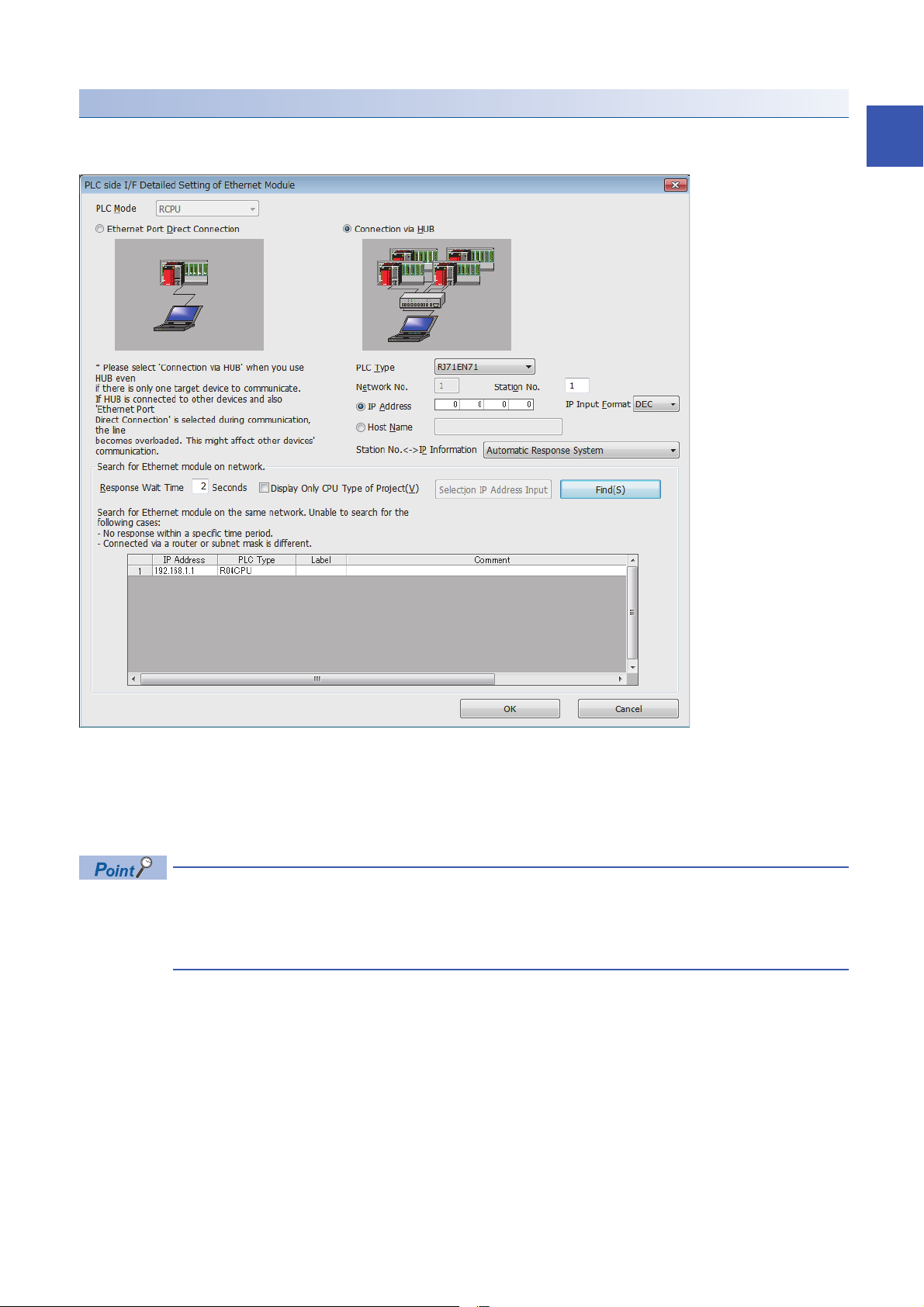

Page 22

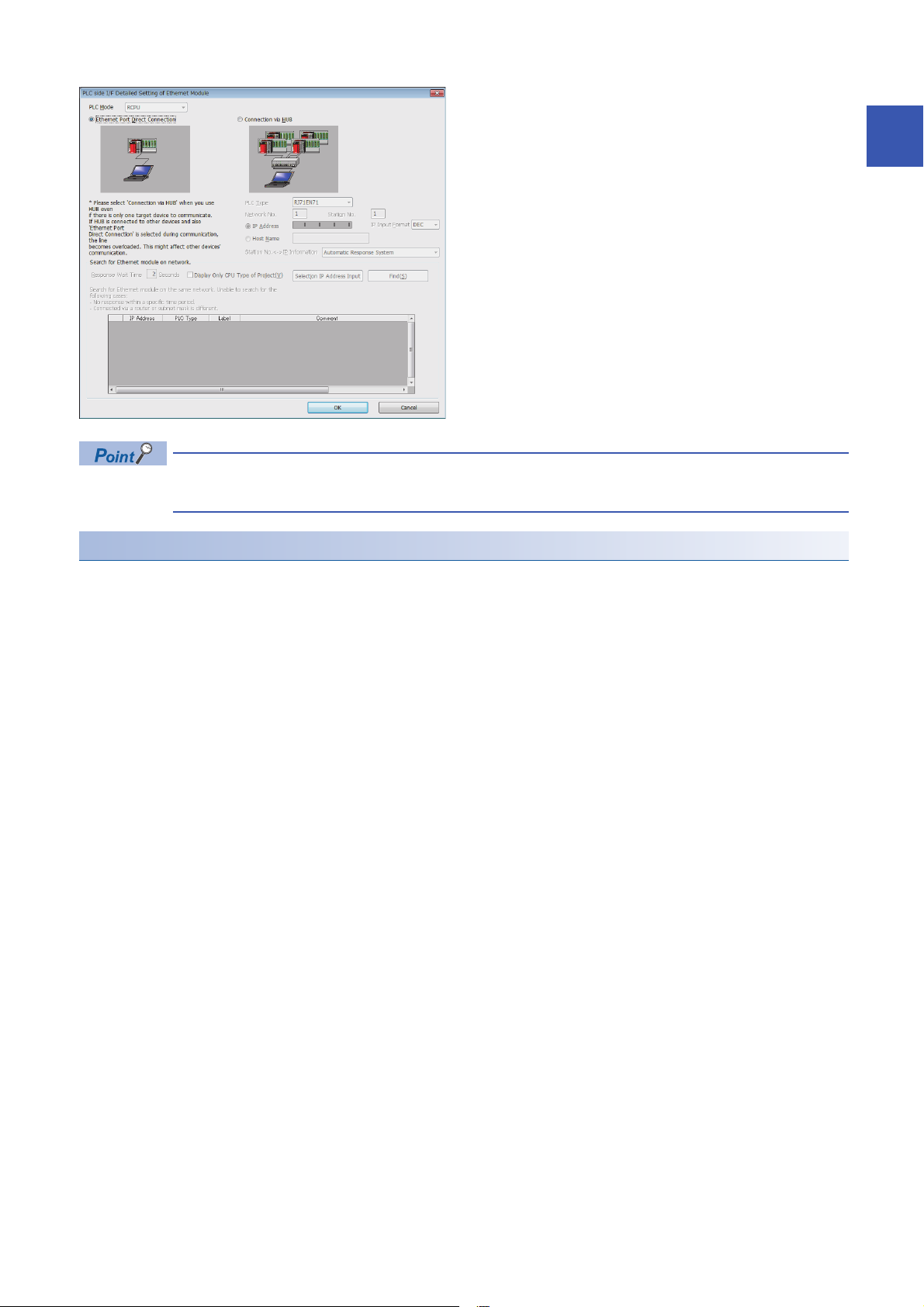

5. Double-click the icon set in step 4, and open the

detailed setting window.

6. Select "Connection via HUB" for the connection method,

and enter the station number and IP address or host

name for the Ethernet-equipped module. Select

"RJ71EN71" to connect the RnENCPU (network part).

7. Set "Other Station Setting" or "Network Communication

*1 The network number and station number do not need to be set when connecting with the CPU module (built-in Ethernet port part).

Route" if necessary.

20

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Page 23

Searching modules on the network

When connecting with a hub, a list of modules that can be searched for will appear by clicking the [Find] button on the detailed

setting window.

1

■Search target modules

• The control CPU of the RJ71EN71 or the CPU module connected to the same hub as the engineering tool

• The control CPU of the RJ71EN71 or the CPU module connected to cascade-connected hub

• The remote head module that controls the RJ71EN71 connected to the same hub as the engineering tool

• The remote head module that controls the RJ71EN71 connected to a cascade-connected hub

• By setting "Do Not Respond to CPU Module Search" in "Security" under "Application Settings" to "Do Not

Respond", the modules will not be listed even if a search is performed.

• Only the MELSEC iQ-R Series Ethernet-equipped modules are searched.

• The RJ71EN71 in which the network type is set to "Q Compatible Ethernet" cannot be searched.

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

21

Page 24

■When module does not appear after search

If a connected Ethernet-equipped module does not appear in the list after searching the modules on the network, check the

following items.

• Search cannot be performed if it is disabled with the IP filter function.

• Modules connected via a router cannot be searched.

• If the module is connected via a wireless LAN, packet loss can prevent the Ethernet communication from stabilizing, and

may inhibit the module search.

• If there are modules with the same IP address in the list, review the IP address parameter settings for the Ethernetequipped module.

• If the service processing load of the search-target CPU module is high, it may not be possible to search for the

corresponding module. If the search cannot be performed, increase the response wait time in the search dialog, and

perform the search again.

Precautions

■Remote operation

If remote STOP or remote PAUSE has been executed from the engineering tool to the CPU module on another station when

the CPU module (built-in Ethernet port part) and engineering tool are connected with an Ethernet cable, perform the following

before turning the power off or resetting the CPU module.

• Remote RUN

• Remote RESET

■Functions incompatible with connection via a hub

The following functions cannot be used for connection via a hub. To use the following functions, connect the CPU module

(built-in Ethernet port part) directly or with a USB cable.

• Ethernet Diagnostics

• CC-Link IE Field Diagnostics

• CC-Link IE Control Diagnostics

22

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Page 25

■Communications by network number/station number by using the CPU module (built-in

USB

(1)

Ethernet Ethernet

USB

(2)(3)

Ethernet module controlled by CPU No.2

Ethernet Ethernet

Ethernet port part)

• The UDP/IP protocol is used for the connection and data is always exchanged as binary codes.

• When accessing another station, set the network number for the CPU module (built-in Ethernet port part) so that it is unique

among the network numbers of the other network. Also, set the station number that is unique among the station numbers

set for the other modules on the same network.

• When configuring the target station or relay station as a multiple CPU system, ensure that the CPU modules listed below

have the firmware supporting the communications by network number/station number.

• Target station

• CPU modules working as the relay path

• CPU module that controls the Ethernet module working as the relay path

When communicating with CPU module shown as (1), ensure that all CPU modules have the firmware of the version supporting the communications by network

number/station number. Also, set the network number and station number to all CPU modules.

1

When communicating with CPU module shown as (2), ensure also that all CPU modules have the firmware of the version supporting the communications by

network number/station number. Note, however, that the communication is possible even when the network number and station number are not set to CPU

module shown as (3) of the CPU No. 2.

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

23

Page 26

Direct connection

The Ethernet-equipped module and engineering tool can be directly connected with one Ethernet cable without using a hub.

When direct connection is made, communication is possible without setting the IP address or host name in the "Specify

Connection Destination Connection" window. (Communicate using broadcast communications)

• To prohibit direct connection with the Ethernet, set "Disable" for "Disable Direct Connection with MELSOFT"

in "Security" under the "Application Settings".

• A direct connection is not possible when the RJ71EN71 network type is set to "Q Compatible Ethernet".

Set in the "Specify Connection Destination Connection" window.

[Online] [Current Connection Destination]

24

1. Set "PC side I/F" to "Ethernet Board".

2. Double-click "Ethernet Board", and open the "PC side I/

F Detailed Setting of Ethernet Board" window.

3. Set the network number, station number, and protocol of

the personal computer. (Set the network number and

protocol according to the settings for the Ethernetequipped module. Set the station number so that it is not

the same as a station number assigned to other

Ethernet devices.)

4. Set the "PLC side I/F" to the module to be connected.

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Page 27

5. Double-click the icon set in step 4, and open the

detailed setting window.

6. Select "Ethernet Port Direct Connection" for the

connection method.

When connecting directly with the CPU module (built-in Ethernet port part), setting is also possible by clicking

the [CPU Module Direct Coupled Setting] button of the "Specify Connection Destination Connection" window.

1

Precautions

■Connection with LAN line

Do not connect with a LAN line and set direct connection. Data will be sent to all external devices on the LAN line, so this

setting will cause the line load to increase and will affect communication with other external devices.

■Connections that are not direct connections

• Do not use a configuration in which the Ethernet-equipped module and external device are connected with a hub. A direct

connection is not established when the devices are connected with a hub.

• When creating a network connection on the personal computer side, communication with a direct connection is not possible

if two or more Ethernet ports are set to "Enable". Review the personal computer settings so that only the Ethernet port for

the direct connection is set to "Enable", and the other Ethernet ports are set to "Disable".

■Settings incompatible with direct connection

When using the RJ71EN71 or the RnENCPU (network part), a direct connection cannot be established if the following setting

is made in the "Specify Connection Destination Connection" window of the engineering tool.

• When "Other Station (Co-existence Network)" is selected for "Other Station Setting"

• When "Other Station (Single Network)" is selected for "Other Station Setting", and "Other station in the same loop or access

to multilevel system" is selected in the "Network Communication Route Detailed Setting of Ethernet" window

■Functions incompatible with direct connection

The following functions cannot be used when the RJ71EN71 or the RnENCPU (network part) is directly connected. To use the

following functions, connect the CPU module (built-in Ethernet port part) directly or connect the CPU module with a USB

cable.

• CC-Link IE Field Diagnostics

• CC-Link IE Control Diagnostics

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

25

Page 28

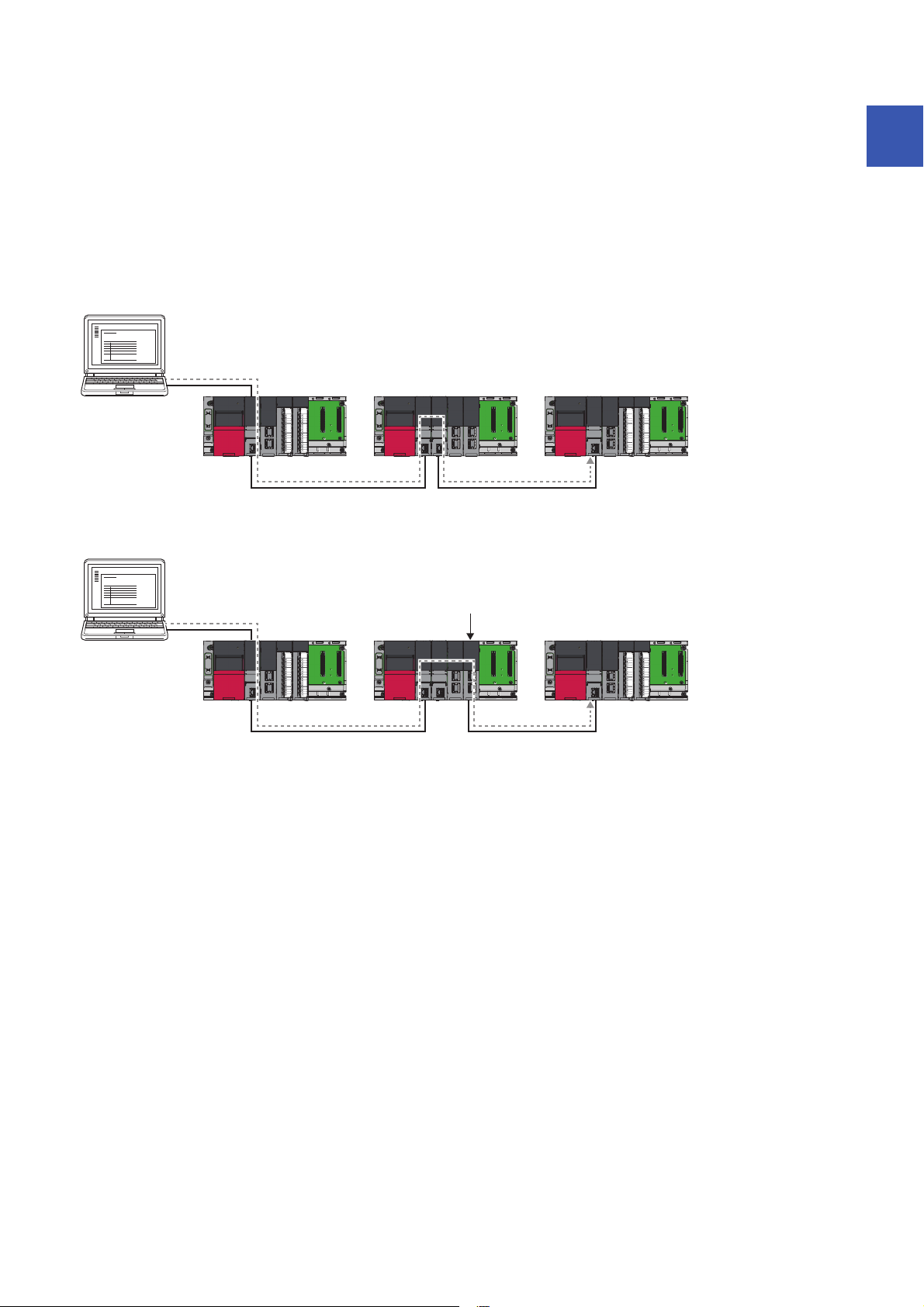

■Conditions that cannot communicate with direct connection

Ex.

Ex.

Communication with a direct connection may be disabled if the following conditions apply. If connection is not possible, review

the settings for the Ethernet-equipped module and personal computer.

• When all bits of the IP address for the Ethernet-equipped module that correspond with the 0 section of the subnet mask for

the personal computer are on or off

IP address for the Ethernet-equipped module: 64.64.255.255

IP address for the personal computer: 64.64.1.1

Subnet mask for the personal computer: 255.255.0.0

• When all bits of the IP address for the Ethernet-equipped module that correspond with the host address of each class in the

IP address for the personal computer are on or off

IP address for the personal computer: 192.168.0.1 192.x.x.x., class C and the host address is the fourth octet.

Subnet mask for the personal computer: 255.0.0.0

IP address for the Ethernet-equipped module: 64.64.255.255 each bit turns on because of the fourth octet is 255

The IP address for each class are as follow.

• Class A: 0.x.x.x to 127.x.x.x

• Class B: 128.x.x.x to 191.x.x.x

• Class C: 192.x.x.x to 223.x.x.x

The host address for each class is the 0 section shown below.

• Class A: 255.0.0.0

• Class B: 255.255.0.0

• Class C: 255.255.255.0

26

1 FUNCTIONS

1.1 Connection with MELSOFT Product and GOT

Page 29

1.2 SLMP Communications

SLMP is a protocol used by external devices to access SLMP-compatible devices via the Ethernet.

SLMP communications are available among devices that can receive/send messages with the SLMP control procedure.

The Ethernet-equipped module processes and transfers data following instructions (command) from the external device, so

the programmable controller only needs the open/close processing and does not require a program for data communication.

For SLMP communications, refer to the following.

SLMP Reference Manual

Applications

This section describes the applications of SLMP communications.

Data read/write

Data read/write can be executed for the following data. With this, the external device can monitor the operation of the

Ethernet-equipped module, analyze data, and control production.

• Device or global label of the CPU module connected with the RJ71EN71 (When the Ethernet function of the RJ71EN71 or

the RnENCPU (network part) is used)

• Device or global label of the CPU module (When the Ethernet function of the CPU module (CPU part for the RnENCPU) is

used)

• Buffer memory of the intelligent function module

1

File read/write

Files such as parameter files stored in a CPU module can be read/written. Files in a CPU module can be managed on an

external device.

Remote control of a CPU module

A CPU module can be remotely controlled from the external device using remote operations.

Remote password lock/unlock

The remote password can be locked and unlocked from the external device.

Access to the programmable controller on another station via other network

In systems with CC-Link IE Controller Network, CC-Link IE Field Network, MELSECNET/H, MELSECNET/10 or Ethernet, the

programmable controller on another station can be accessed from the external device via the network. However, when

connecting the external device to the CPU module (built-in Ethernet port part), other stations cannot be accessed via network

such as CC-Link IE Controller Network and CC-Link IE Field Network.