Mitsubishi Electric RD62P2E, RD62D2, iQ-R, RD62P2 User Manual

MELSEC iQ-R High-Speed Counter Module

User's Manual (Application)

-RD62P2

-RD62P2E

-RD62D2

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the programmable

controller system, refer to the MELSEC iQ-R Module Configuration Manual.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

2

[Design Precautions]

WARNING

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Outputs may remain on or off due to a failure of a transistor for external output. Configure an external

circuit for monitoring output signals that could cause a serious accident.

[Design Precautions]

CAUTION

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written. Doing so will make the data in the flash ROM undefined. The values

need to be set in the buffer memory and written to the flash ROM again. Doing so also can cause

malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as the remote

RUN/STOP functions), select "Do Not OPEN in Program" for "Open Method Setting" in the module

parameters. If "OPEN in Program" is selected, an execution of the remote STOP function causes the

communication line to close. Consequently, the CPU module cannot reopen the line, and external

devices cannot execute the remote RUN function.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 150mm or more between them. Failure to do so may result in malfunction

due to noise.

3

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so can cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 150mm or more between them. Failure to do so may result in malfunction

due to noise.

● Ground the shield cable on the encoder side (relay box) with a ground resistance of 100 ohm or less.

Failure to do so may cause malfunction.

5

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

6

[Startup and Maintenance Precautions]

CAUTION

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM undefined. The values need to be set in the buffer memory and written to the flash ROM

again. Doing so can cause malfunction or failure of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the functions, parameter settings, and troubleshooting of the relevant products listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RD62P2, RD62P2E, RD62D2

8

MEMO

9

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CHAPTER 1 FUNCTIONS 13

1.1 Pulse Input Modes and Counting Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Types of pulse input modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Setting a counting method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reading the present value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.2 Selecting a Counter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Linear counter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Ring counter function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Coincidence Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Coincidence detection interrupt function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.4 Preset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1.5 Counter Function Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Count error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Count disable function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Latch counter function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sampling counter function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Cycle pulse counter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.6 Pulse Measurement Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

1.7 PWM Output Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CHAPTER 2 PARAMETER SETTINGS 39

2.1 Parameter Setting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

2.2 Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

2.3 Application Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.4 Interrupt Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2.5 Refresh Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Refresh processing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.6 Preset Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

CHAPTER 3 TROUBLESHOOTING 47

3.1 Procedure for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.2 Checking Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.3 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

When the count operation does not start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

When the count operation is not normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

When the coincidence output function does not operate normally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

When a coincidence detection interrupt does not occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

When the preset cannot be executed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

When the pulse measurement does not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

When the pulses are not measured correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

When the PWM output is not correct. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

When the inter-module synchronization function does not operate correctly . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10

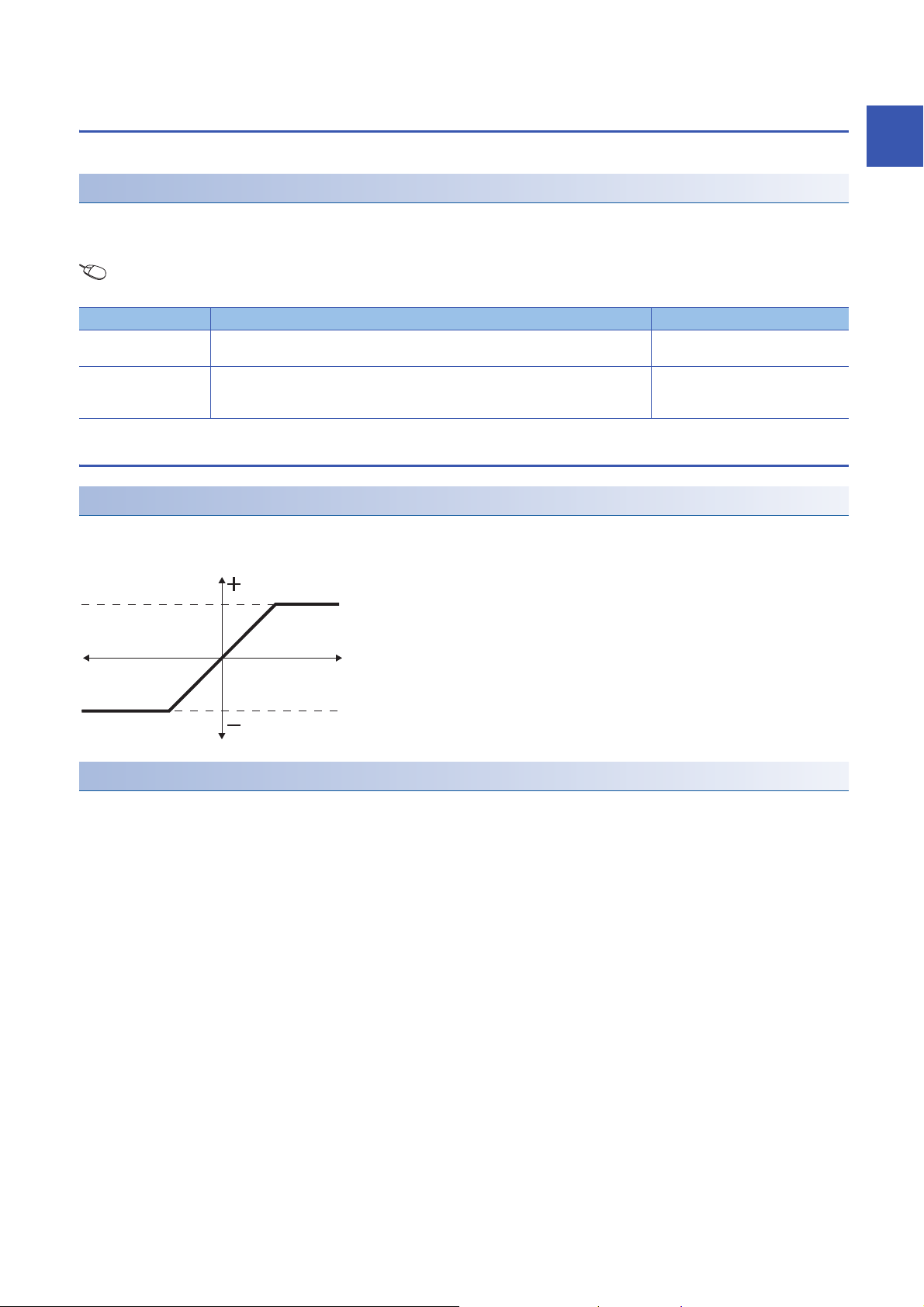

Pulse waveform shaping method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

APPENDICES 52

Appendix 1 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Appendix 2 I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

List of I/O signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Appendix 3 Buffer Memory Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Details of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Appendix 4 Operation Examples of When the Remote Head Module Is Mounted . . . . . . . . . . . . . . . . . . . . . . . . . 69

System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Setting in the master station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Setting in the intelligent device station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Checking the network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Program examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Appendix 5 Added or Changed Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

INDEX 84

CONTENTS

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

11

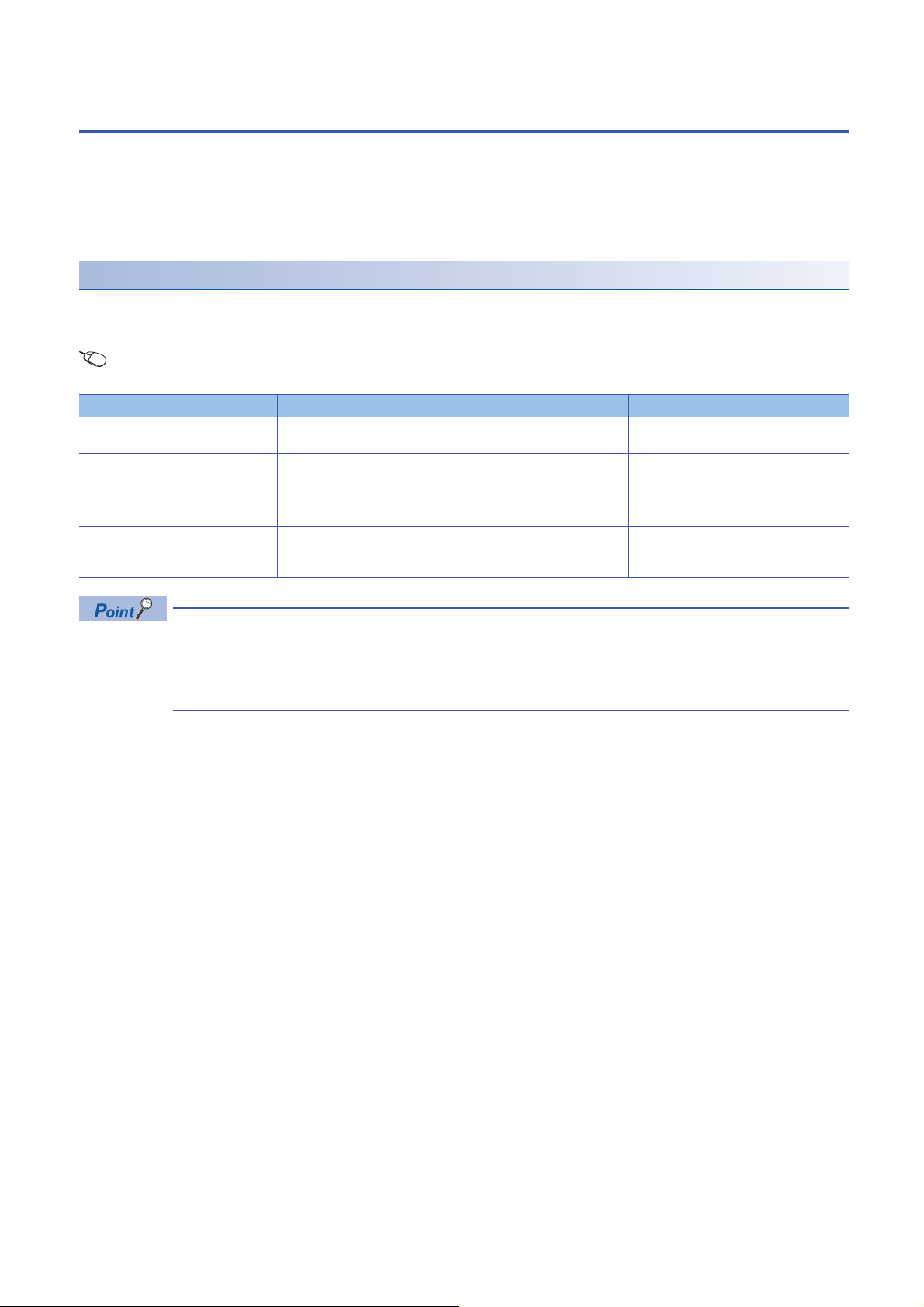

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R High-Speed Counter Module User's Manual

(Application)

[SH-081241ENG] (this manual)

MELSEC iQ-R High-Speed Counter Module User's Manual

(Startup)

[SH-081239ENG]

Functions, parameter settings, troubleshooting, I/O

signals, and buffer memory of the high-speed counter

module

Performance specifications, procedures before

operation, wiring, and operation examples of the highspeed counter module

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual refers to the Mitsubishi FA electronic book manuals that can be browsed using a dedicated tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

GX Works3 The product name of the software package for the MELSEC programmable controllers

Engineering tool Another term for GX Works3

Global label A label that is valid for all the program data when multiple program data are created in the project.

High-speed counter module The abbreviation for the MELSEC iQ-R series high-speed counter module

Buffer memory A memory in an intelligent module for storing data (such as setting values and monitored values)

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to

Remote head module The abbreviation for the RJ72GF15-T2 CC-Link IE Field Network remote head module

The global label has two types: a module specific label (module label), which is generated

automatically by GX Works3, and an optional label, which can be created for any specified

device.

to be transferred to the CPU module

each module in a given character string. For the module used, GX Works3 automatically

generates this label, which can be used as a global label.

12

1 FUNCTIONS

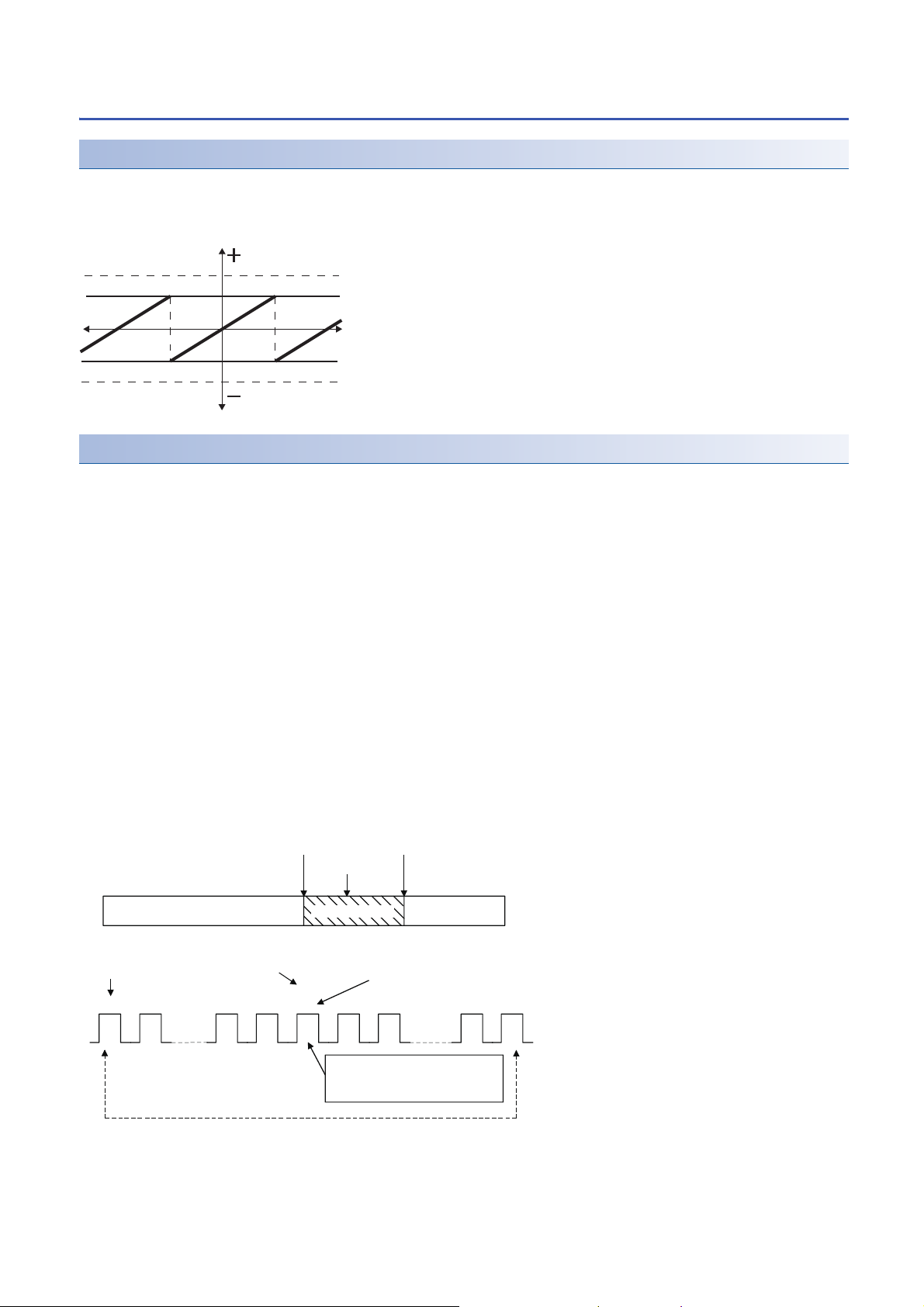

φA

φB and

CH1 Down

count command

(Y3)

φA

φB or

CH1 Down

count command

(Y3)

φA

φB

This chapter describes the functions for the high-speed counter module and the setting methods. For details on I/O signals

and buffer memory areas, refer to the following.

• Page 55 Input signals

• Page 57 Output signals

• Page 62 Details of buffer memory addresses

This chapter describes the I/O numbers (X/Y), buffer memory addresses, and external I/O terminals for CH1.

To check the I/O numbers (X/Y) for CH2, refer to the following.

Page 54 List of I/O signals

To check the buffer memory addresses for CH2, refer to the following.

Page 60 List of buffer memory addresses

1.1 Pulse Input Modes and Counting Methods

This section describes the pulse input modes and the counting methods.

Types of pulse input modes

The following six pulse input modes are prepared: 1-phase pulse input (1 multiple/2 multiples), CW/CCW pulse input, and 2-

phase pulse input (1 multiple/2 multiples/4 multiples).

1

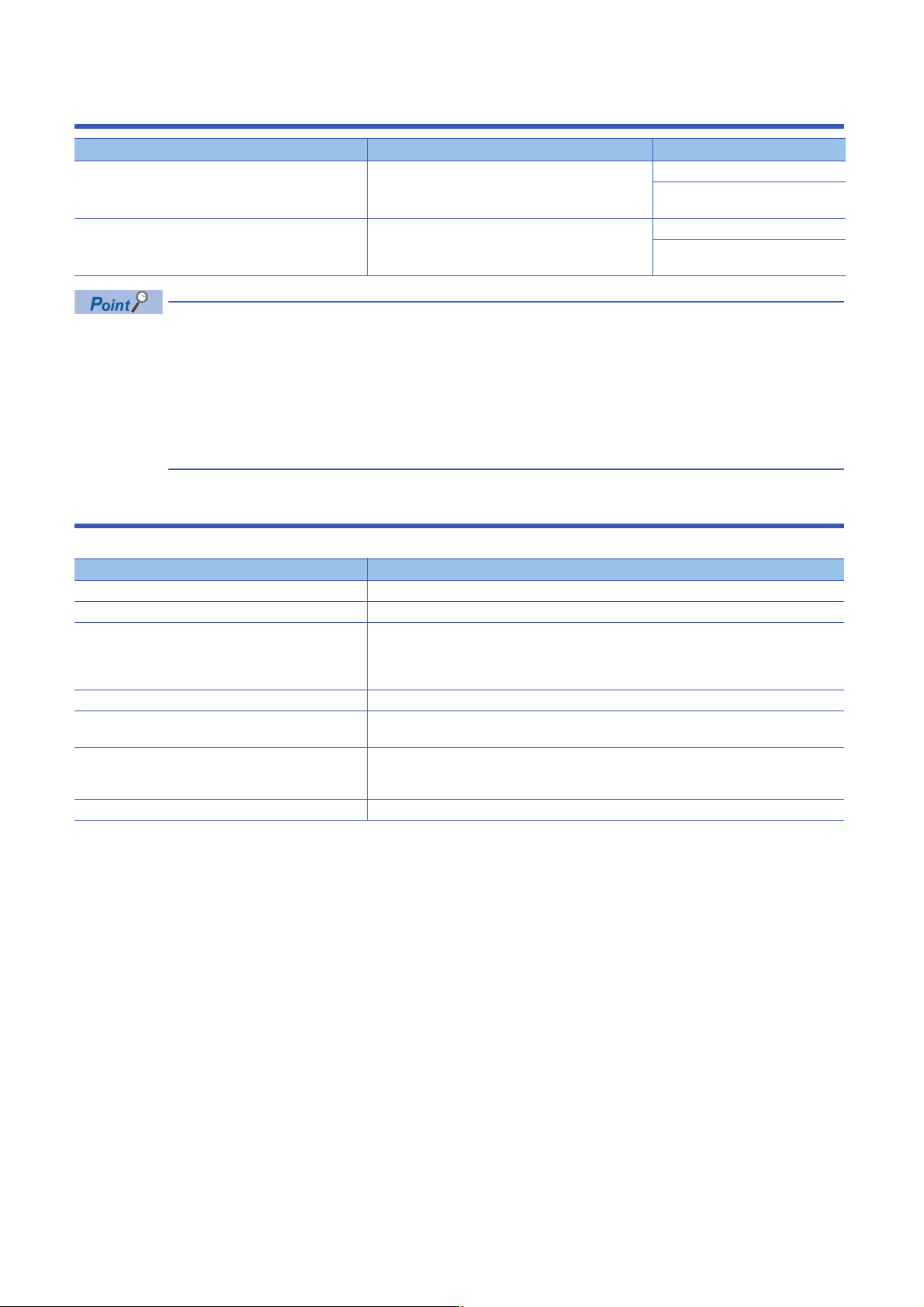

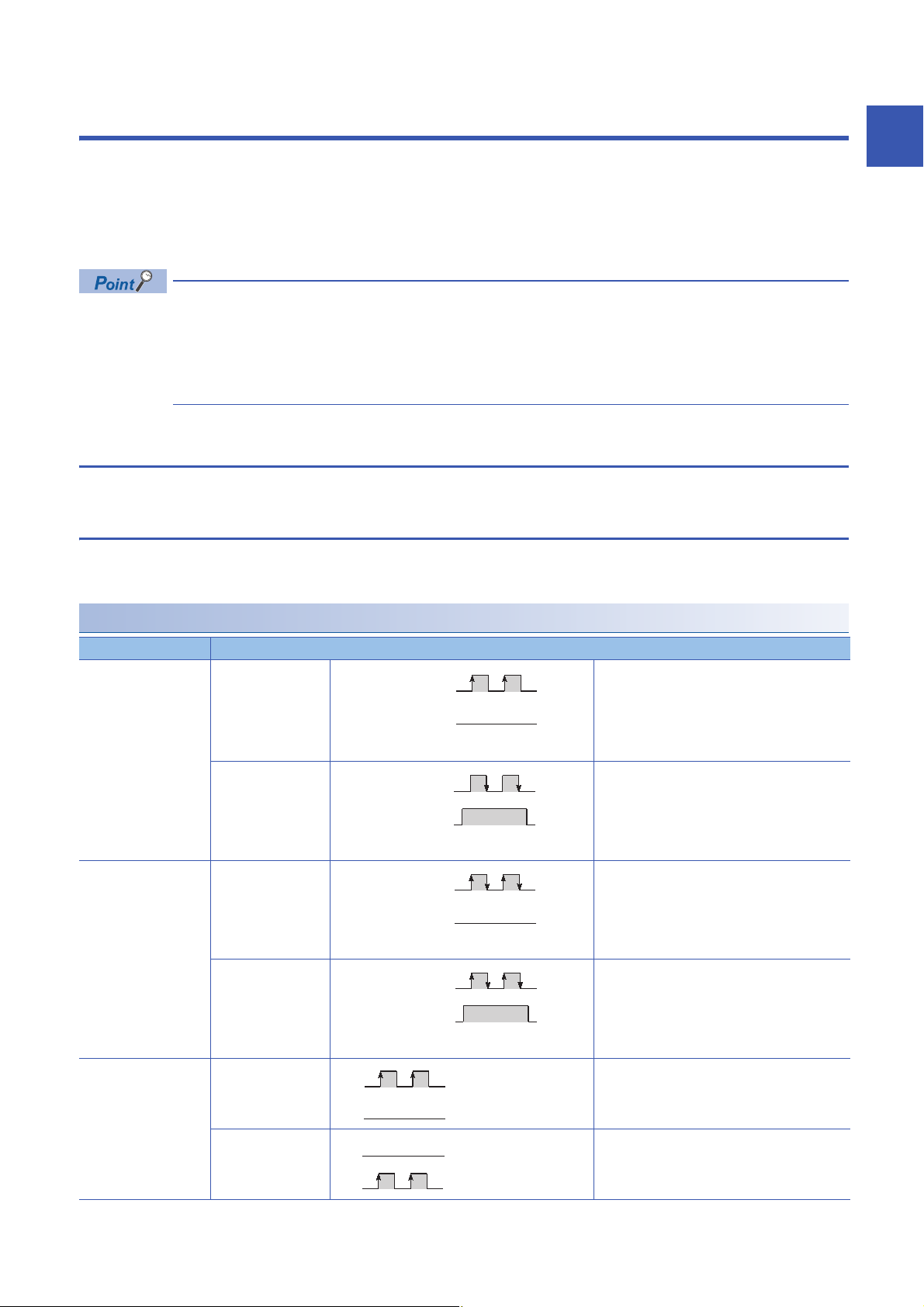

Pulse input modes and count timing

Pulse input mode Count timing

1-phase multiple of 1 For counting up Counts on the rising edge () of A.

count command

For counting down Counts on the falling edge () of A.

count command

1-phase multiple of 2 For counting up Counts on the rising edge () and the falling edge

For counting down Counts on the rising edge () and the falling edge

CW/CCW For counting up Counts on the rising edge () of A.

φB and

CH1 Down

(Y3)

φA

φB or

CH1 Down

(Y3)

φA

B and CH1 Down count command (Y3) are off.

B or CH1 Down count command (Y3) is on.

() of A.

B and CH1 Down count command (Y3) are off.

() of A.

B or CH1 Down count command (Y3) is on.

B is off.

For counting down A is off.

φA

φB

Counts on the rising edge () of B.

1.1 Pulse Input Modes and Counting Methods

1 FUNCTIONS

13

Pulse input mode Count timing

φA

φB

φA

φB

φA

φB

φA

φB

φA

φB

2-phase multiple of 1 For counting up Counts on the rising edge () of A while B is off.

For counting down Counts on the falling edge () of A while B is off.

2-phase multiple of 2 For counting up Counts on the rising edge () of A while B is off.

For counting down Counts on the rising edge () of A while B is on.

2-phase multiple of 4 For counting up Counts on the rising edge () of A while B is off.

For counting down Counts on the rising edge () of A while B is on.

φA

φB

Counts on the falling edge () of A while B is on.

Counts on the falling edge () of A while B is off.

Counts on the falling edge () of A while B is on.

Counts on the rising edge () of B while A is o n.

Counts on the falling edge () of B while A is off.

Counts on the falling edge () of A while B is off.

Counts on the rising edge () of B while A is off.

Counts on the falling edge () of B while A is on .

For the 1-phase pulse input and counting up pulses, check that the B phase pulse input and CH1 Down count

command (Y3) are off before performing the A phase pulse input. If at least one of the B phase pulse input

and CH1 Down count command (Y3) is on, pulses are counted down in the A phase pulse input.

14

1 FUNCTIONS

1.1 Pulse Input Modes and Counting Methods

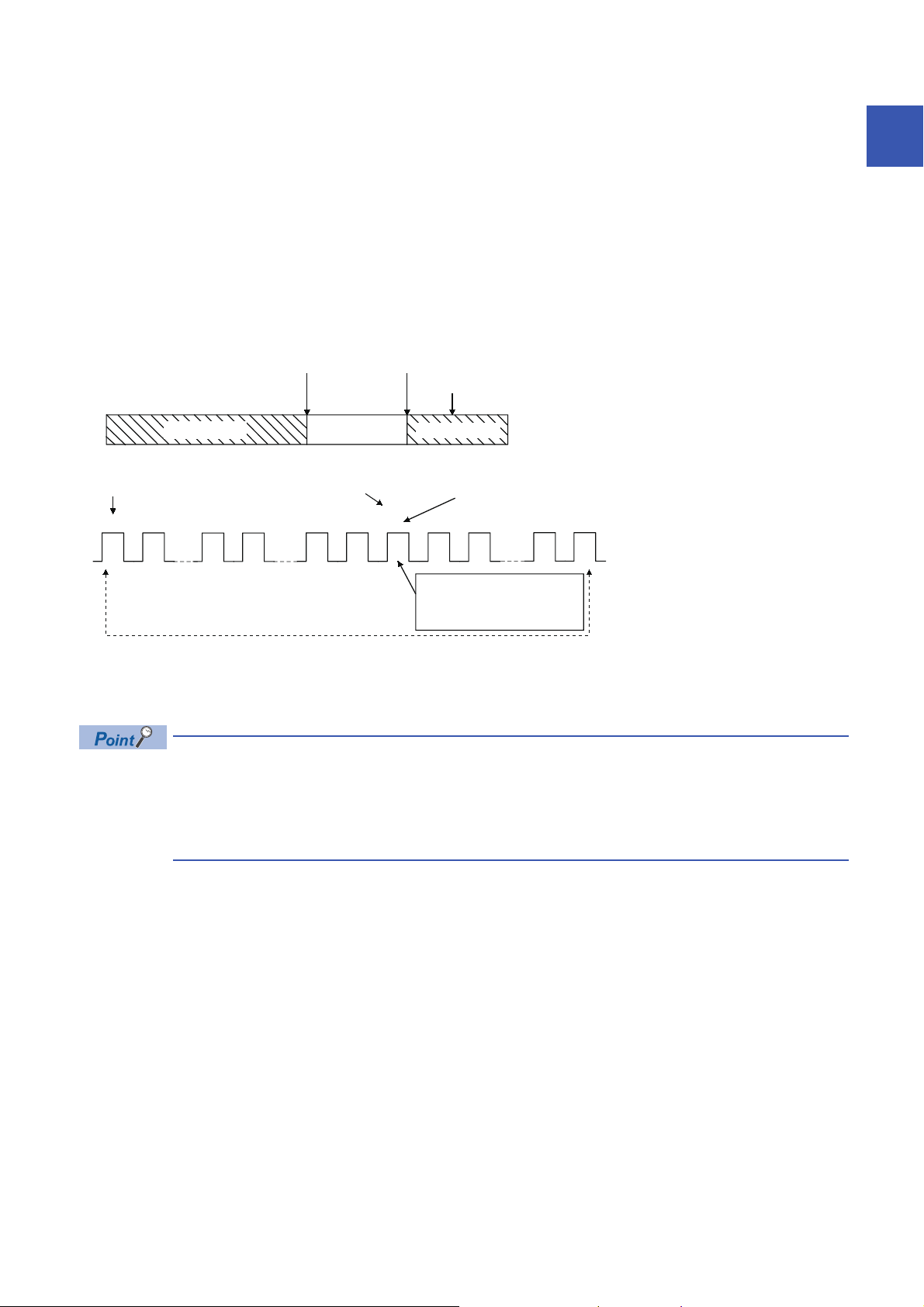

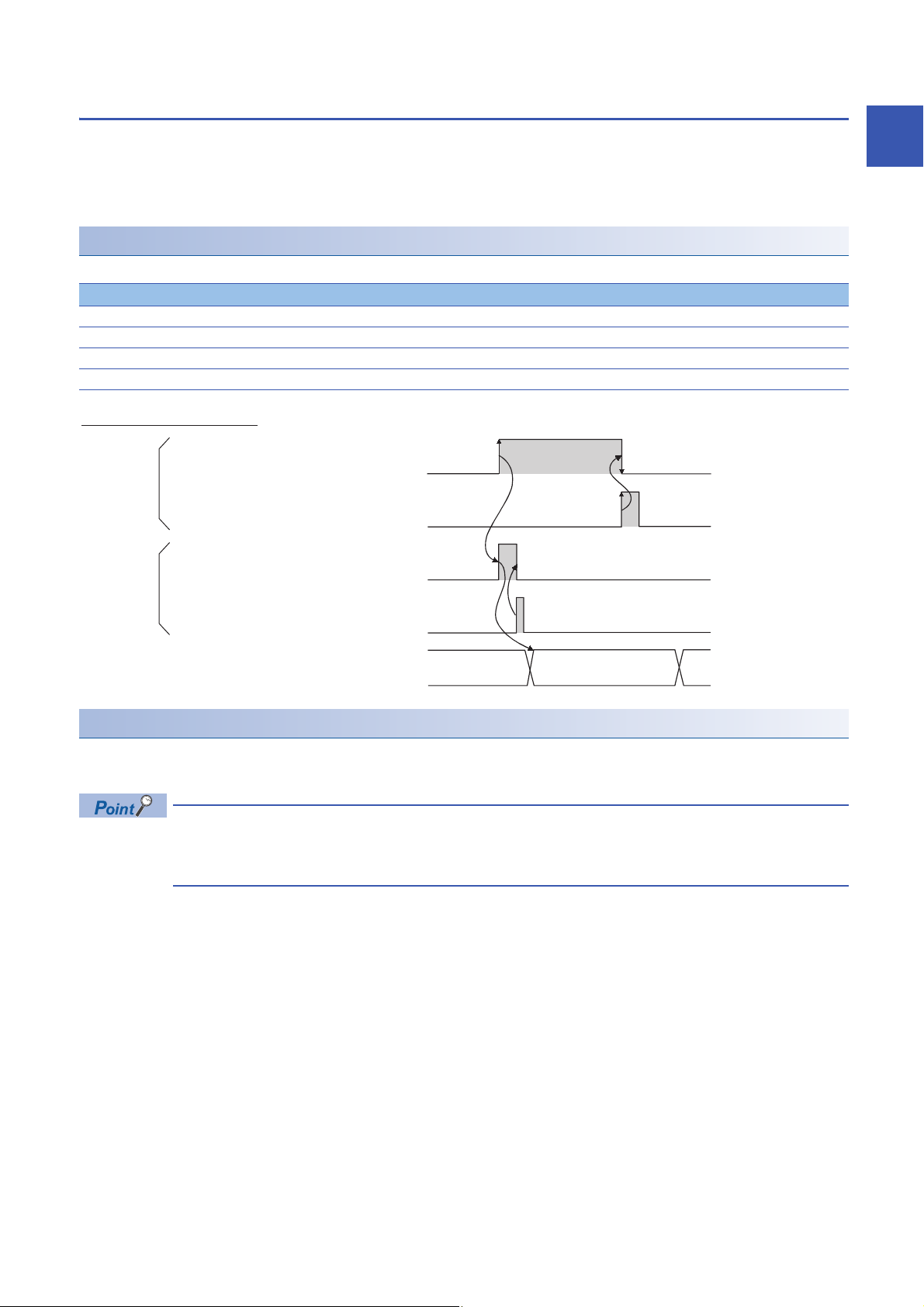

■1-phase pulse input

φA

φB

Pulse input

Encoder

High-speed counter module

φB or CH1 Down count command

(Y3)

φA

φB

Count-up pulse input

Count-down pulse input

Encoder

Encoder

High-speed counter module

φA

φB

Phase A pulse input

Phase B pulse input

Encoder

High-speed counter module

The count method can be selected from 1 multiple and 2 multiples. The following figure shows the relationship between the A

phase pulse input and B phase pulse input or CH1 Down count command (Y3).

■CW/CCW pulse input

Pulses can be counted up with the A phase pulse input and counted down with the B phase pulse input. The following figure

shows the relationship between the A phase pulse input and B phase pulse input.

1

■2-phase pulse input

The count method can be selected from 1 multiple, 2 multiples, and 4 multiples. The phase difference between the A phase

pulse and B phase pulse determines whether the pulses are counted up or down. The following figure shows the relationship

between the A phase pulse input and B phase pulse input.

1 FUNCTIONS

1.1 Pulse Input Modes and Counting Methods

15

Setting a counting method

Set a counting method in "Basic setting" For details on the setting method, refer to the following.

Page 39 Basic Setting

Reading the present value

This section describes the details on the present value stored in the buffer memory and the count values selected from the

counter function selection, and their reading method.

When the refresh setting is used

By configuring the refresh setting, writing and reading data can be performed without creating a communication program for

the high-speed counter module. For details on the setting method, refer to the following.

Page 43 Refresh Setting

When the refresh setting is not used

■Storage location of the count value

The present value is always stored in CH1 Present value (Un\G2 to Un\G3) regardless of the counter function used.

When the latch counter function, sampling counter function, or cycle pulse counter function is performed, the counter function

selection count value is stored in the corresponding buffer memory addresses listed in the following table besides CH1

Present value (Un\G2 to Un\G3).

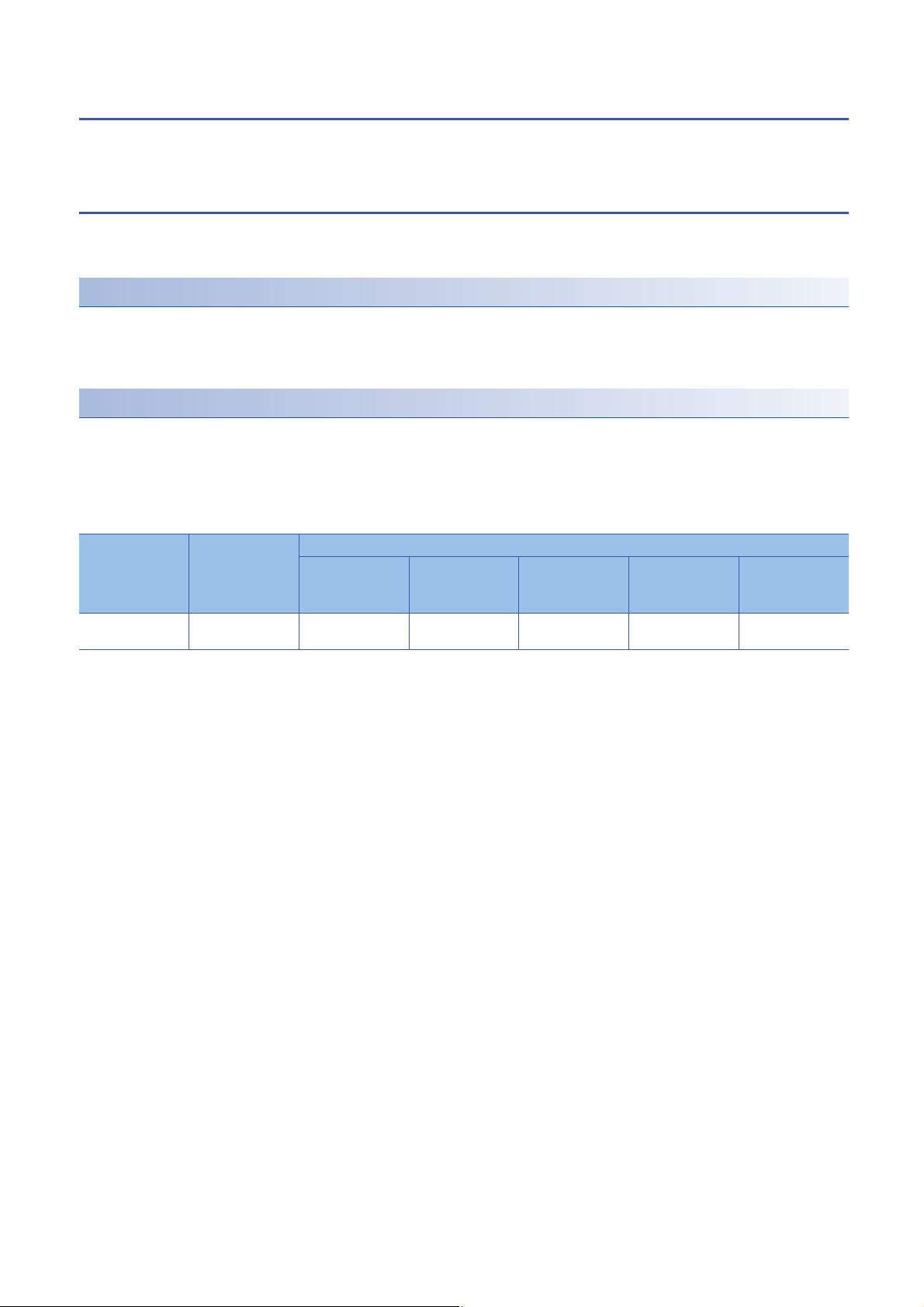

Description Present value Counter function selection count value

Buffer memory

address

Latch count

value

Un\G2 to Un\G3 Un\G12 to Un\G13 Un\G14 to Un\G15 Un\G16 to Un\G17 Un\G18 to Un\G19 Un\G24 to Un\G27

Sampling count

value

Cycle pulse

count previous

value

Cycle pulse

count current

value

Cycle pulse

count difference

value

■Stored data

The present value and the counter function selection count values are stored in the buffer memory in 32-bit signed binary.

However, only the cycle pulse count difference value is stored in the buffer memory in 64-bit signed binary. The values in the

buffer memory are automatically updated depending on the count operation.

16

1 FUNCTIONS

1.1 Pulse Input Modes and Counting Methods

1.2 Selecting a Counter Type

+2147483647

-2147483648

Present counter value

Overflow

Overflow

Counting upCounting down

0

Select a counter type in "Counter type" of "Basic setting".

Setting method

1. Set "Counter operation mode" to "Pulse count mode".

2. Set "Counter type" to "Linear counter" or "Ring counter".

Navigation window [Parameter] [Module Information] Module model name [Module Parameter] [Basic

setting]

Item Description Reference

Linear counter This function counts pulses between -2147483648 (lower limit value) and 2147483647

(upper limit value). If a count exceeds the range, the overflow is detected.

Ring counter This function counts pulses repeatedly between the values stored in CH1 Ring counter

lower limit value setting (Un\G20 to Un\G21) and CH1 Ring counter upper limit value

setting (Un\G22 to Un\G23).

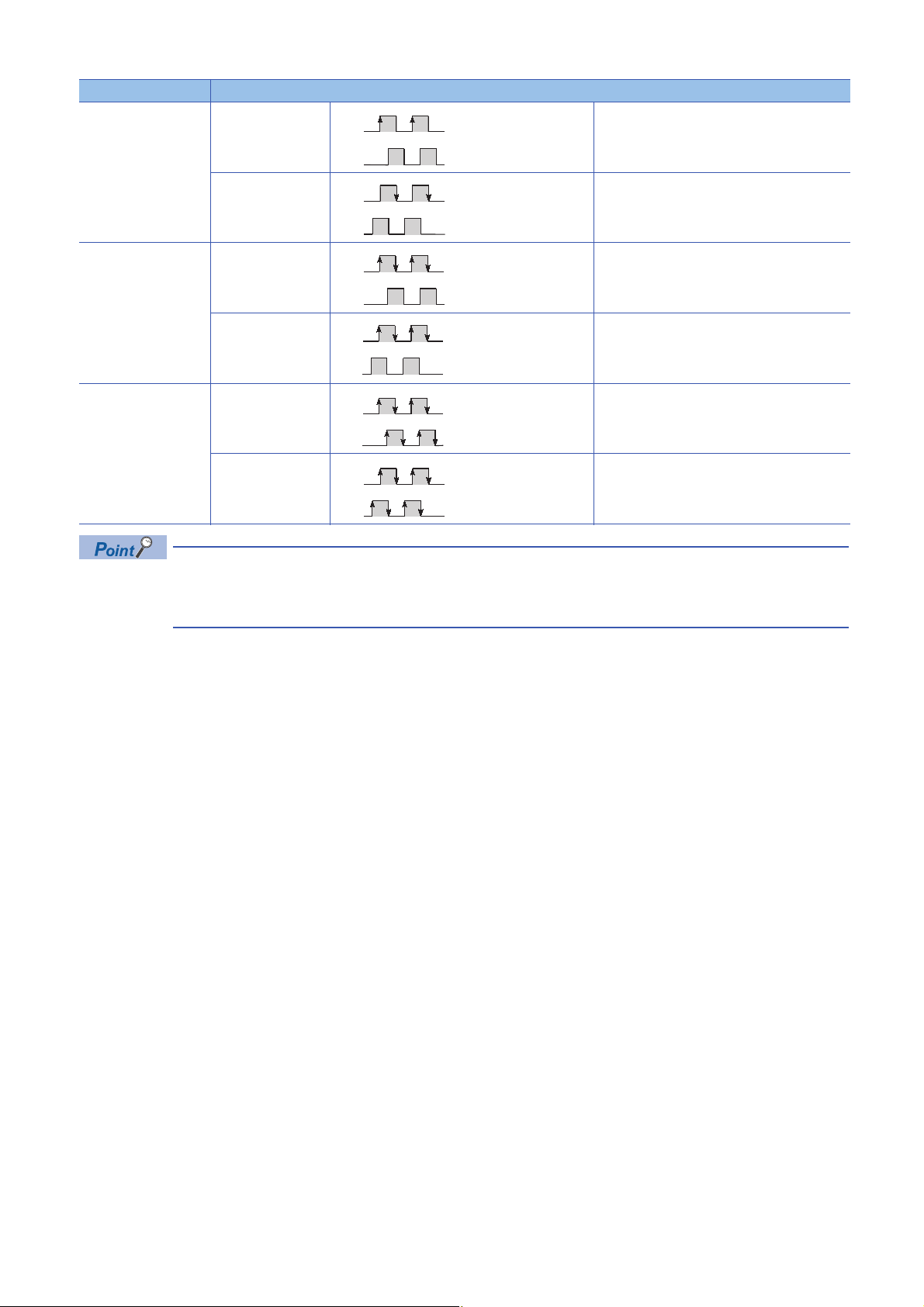

Linear counter function

Operation of the linear counter

• This function counts pulses between -2147483648 (lower limit value) and 2147483647 (upper limit value).

• The preset function and coincidence output function can be used with this function.

Page 17 Linear counter function

Page 18 Ring counter function

1

Overflow error

• When the counter type is the linear counter, an overflow error occurs if the value in CH1 Present value (Un\G2 to Un\G3)

• If an overflow error occurs, 1 is stored in CH1 Overflow detection (Un\G8) and the counting operation stops. The present

• The overflow error can be cleared by performing the preset function.

• When the preset function is performed, 0 is stored in CH1 Overflow detection (Un\G8) and the counting operation restarts.

falls below -2147483648 (lower limit value) at the subtraction or exceeds 2147483647 (upper limit value) at the addition.

value does not change from -2147483648 or 2147483647 even if pulses are input.

1 FUNCTIONS

1.2 Selecting a Counter Type

17

Ring counter function

+2147483647

-2147483648

0

CH1

Ring counter upper limit (Un\G22 to Un\G23)

CH1

Ring counter lower limit (Un\G20 to Un\G21)

Present counter value

Counting up

Counting down

-2147483648

0

500

2000

2147483647

(2000)

500 501 1998 1999 0 1 2 498 499

Ring counter

lower limit value

Present value

Ring counter

upper limit value

Ring counter

lower limit value

to to

Ring counter upper

limit value

The ring counter upper limit value,

2000, is not stored in CH1 Present

value (Un\G2 to Un\G3).

Present value

Counting range

Operation of the ring counter

This function repeatedly counts pulses between the values stored in CH1 Ring counter lower limit value setting (Un\G20 to

Un\G21) and CH1 Ring counter upper limit value setting (Un\G22 to Un\G23). When the ring counter function is selected, an

overflow error does not occur. The preset function and coincidence output function can be used with this function.

Count range of the ring counter

The count range is determined by the relationship between the ring counter lower limit value or ring counter upper limit value

and the value in CH1 Present value (Un\G2 to Un\G3) when CH1 Count enable command (Y4) is turned on or when the

preset function is performed. Normally, the count range is Ring counter lower limit value Present value Ring counter upper

limit value.

■When the count range is Ring counter lower limit value Present value Ring counter upper

limit value (normally used)

• When pulses are counted up, the ring counter lower limit value is automatically stored in CH1 Present value (Un\G2 to

Un\G3) when the present value reaches the ring counter upper limit value.

• When pulses are counted down, even when the present value reaches the ring counter lower limit value, the ring counter

lower limit value is held as the lower limit, and the value of Ring counter upper limit value - 1 is stored in CH1 Present value

(Un\G2 to Un\G3) at the next count-down pulse input.

Both when pulses are counted up and when pulses are counted down, the ring counter upper limit value is not stored in CH1

Present value (Un\G2 to Un\G3). For example, when the count enable command is valid while the ring counter lower limit

value is 0, the ring counter upper limit value is 2000, and the present value is 500, the count range and the present value will

change as follows.

18

1 FUNCTIONS

1.2 Selecting a Counter Type

■When the count range is Present value < Ring counter lower limit value or Ring counter upper

-2147483648

0

2000

3000 3001 2001-2 -1 0 2002 29982147483647 -2147483648 2999

(2000)

3000

2147483647

Ring counter

lower limit value

Present value

Ring counter

upper limit value

Ring counter

lower limit value

Ring counter

upper limit valuePresent value

to toto

The ring counter upper limit

value, 2000, is not stored in CH1

Present value (Un\G2 to Un\G3).

Counting range Counting range

limit value < Present value

• When pulses are counted up, even when the present value reaches the ring counter lower limit value, the ring counter

lower limit value is held as the lower limit, and the value of Ring counter upper limit value + 1 is stored in CH1 Present value

(Un\G2 to Un\G3) at the next count-up pulse input.

• When pulses are counted down, the ring counter lower limit value is automatically stored in CH1 Present value (Un\G2 to

Un\G3) when the present value reaches the ring counter upper limit value.

Both when pulses are counted up and when pulses are counted down, the ring counter upper limit value is not stored in CH1

Present value (Un\G2 to Un\G3). For example, when the count enable command is valid while the ring counter lower limit

value is 0, the ring counter upper limit value is 2000, and the present value is 3000, the count range and the present value will

change as follows.

1

■When the count range is Ring counter lower limit value = Ring counter upper limit value

When this condition is established, a value that can be expressed in 32-bit signed binary (-2147483648 to 2147483647) will

be the count range, regardless or the present value.

• While CH1 Count enable command (Y4) is on, even if CH1 Ring counter lower limit value setting (Un\G20 to

Un\G21) and CH1 Ring counter upper limit value setting (Un\G22 to Un\G23) are changed, the high-speed

counter module does not operate with the changed value. Turn off CH1 Count enable command (Y4) before

changing the ring counter upper limit value or ring counter lower limit value.

• Turn off CH1 Count enable command (Y4) before changing the count range using the preset function.

1 FUNCTIONS

1.2 Selecting a Counter Type

19

1.3 Coincidence Output Function

This function compares the present count value with the preset count value, and outputs a signal when they match.

Setting method

1. Set "Counter operation mode" to "Pulse count mode".

2. Set a count value for "Coincidence output point No.1 setting" or "Coincidence output point No.2 setting".

Navigation window [Parameter] [Module Information] Module model name [Module Parameter] [Basic

setting]

Item Setting range

Coincidence output point No.1 -2147483648 to 2147483647

Coincidence output point No.2

Up to two coincidence outputs can be set for each channel.

When the external output of the coincidence signal is used, turn on CH1 Coincidence signal enable command (Y2)

beforehand.

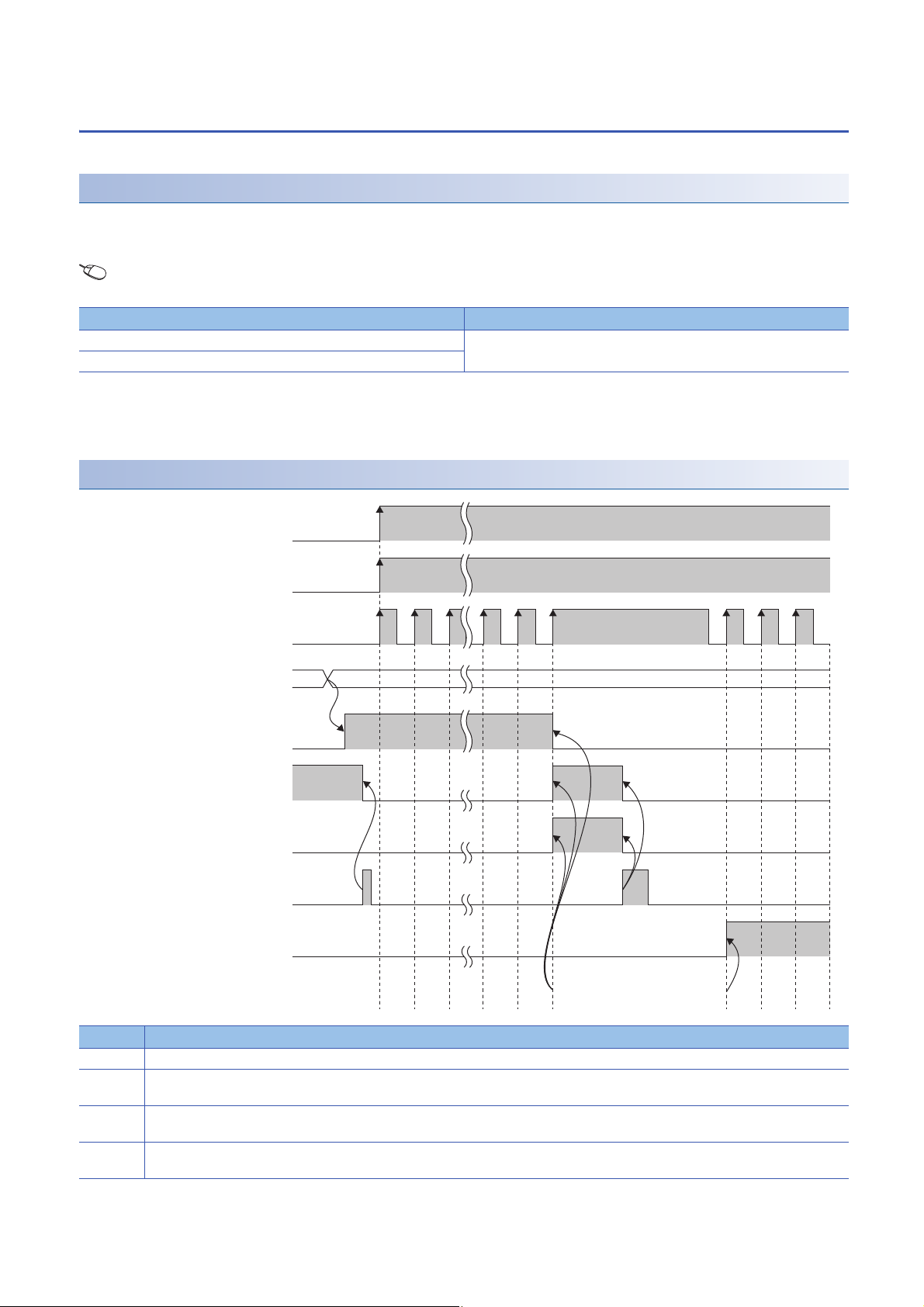

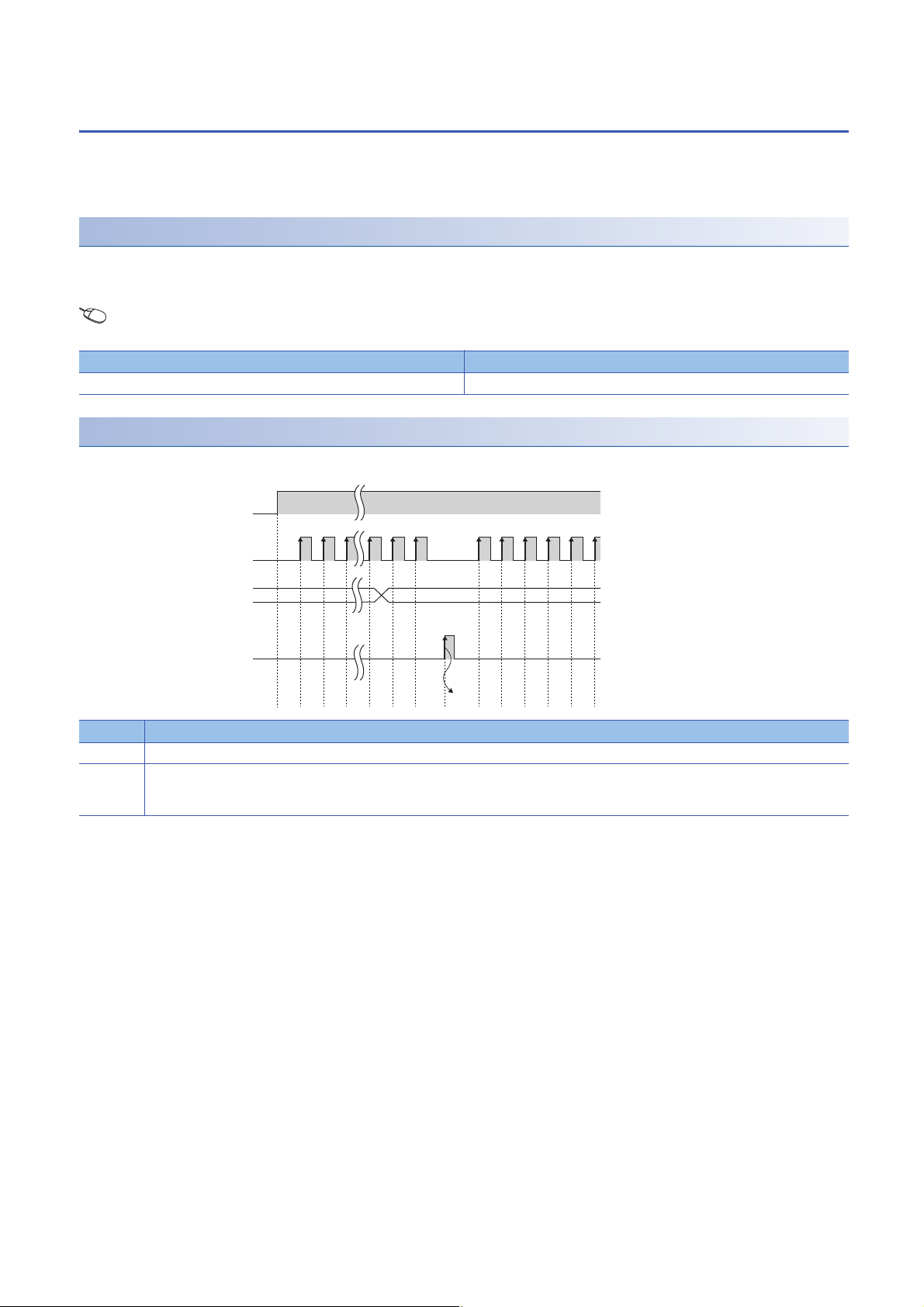

Operation of the coincidence output

CH1 Count enable command (Y4)

CH1 Coincidence signal enable

command (Y2)

Counter input pulse

CH1 Coincidence output point

No.1 setting (Un\G4 to Un\G5)

CH1 Counter value smaller

(point No.1) (X3)

CH1 Counter value coincident

(point No.1) (X2)

Coincidence output point No.1

terminal (EQU1)

CH1 Coincidence signal No.1

reset command (Y0)

CH1 Counter value larger

(point No.1) (X1)

ON

OFF

ON

OFF

H

L

0 100

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

(4)

(1)

(2)

(3)

(5)

(5)

(5)

(6) (7)

(8)

CH1 Present value

(Un\G2 to Un\G3)

0 1 2 98 99 100 101 102 103

·

No. Description

(1) The comparison operation starts with the value set to CH1 Coincidence output point No.1 setting (Un\G4 to Un\G5).

(2) When CH1 Present value (Un\G2 to Un\G3) becomes less than CH1 Coincidence output point No.1 setting (Un\G4 to Un\G5), CH1 Counter

(3) When CH1 Coincidence signal No.1 reset command (Y0) is turned on, CH1 Counter value coincident (point No.1) (X2) and the coincidence

(4) If a coincidence output from the coincidence output point No.1 terminal (EQU1) is required, turn on CH1 Coincidence signal enable command

value smaller (point No.1) (X3) turns on.

output point No.1 terminal (EQU1) turns off.

(Y2).

1 FUNCTIONS

20

1.3 Coincidence Output Function

No. Description

(5) When CH1 Present value (Un\G2 to Un\G3) equals to CH1 Coincidence output point No.1 setting (Un\G4 to Un\G5), CH1 Counter value

coincident (point No.1) (X2) and the coincidence output point No.1 terminal (EQU1) turn on.

Also, CH1 Counter value smaller (point No.1) (X3) turns off.

(6) When CH1 Coincidence signal No.1 reset command (Y0) is turned on while the values match, CH1 Counter value coincident (point No.1) (X2)

and the coincidence output point No.1 terminal (EQU1) turn off.

(7) Even though CH1 Coincidence signal No.1 reset command (Y0) is turned off while the values match, CH1 Counter value coincident (point No.1)

(X2) and the coincidence output point No.1 terminal (EQU1) do not turn on.

(8) When CH1 Present value (Un\G2 to Un\G3) becomes greater than CH1 Coincidence output point No.1 setting (Un\G4 to Un\G5), CH1 Counter

value larger (point No.1) (X1) turns on.

1

1 FUNCTIONS

1.3 Coincidence Output Function

21

Precautions for using the coincidence output function

When CH1 Coincidence signal enable command (Y2) is turned on before the count is started or while the coincidence output

point setting value and the current value match, the coincidence output is performed. To avoid this status, perform one of the

following operations before turning on CH1 Coincidence signal enable command (Y2).

■Setting different values to the coincidence output point setting value and the current value

Set different values to the coincidence output point setting value and the current value by one of the following methods.

• Changing the coincidence output point setting value

• Changing the current value using the preset function

• Changing the current value by inputting a pulse

■Turning off the counter value coincidence signal

Turn on and off CH1 Coincidence signal No.1 reset command (Y0).

• Since CH1 Present value (Un\G2 to Un\G3) and CH1 Coincidence output point No.1 (Un\G4 to Un\G5) are

0 after the CPU module is powered on or is reset, CH1 Counter value coincident (point No.1) (X2) turns on.

• When CH1 Coincidence signal enable command (Y2) is turned on while CH1 Counter value coincident

(point No.1) (X2) is on, the coincidence output is performed to outside the module. To avoid an incorrect

coincidence output, turn on and off CH1 Coincidence signal No.1 reset command (Y0) before turning on

CH1 Coincidence signal enable command (Y2), and turn off CH1 Counter value coincident (point No.1)

(X2).

Precautions for mounting a remote head module

When a high-speed counter module has been mounted with a remote head module, whether to hold or clear the Y signal at a

disconnection of own station can be set with “CPU error output mode setting” in the module parameter. According to this

setting, whether to continue counting and operate the coincidence output, or to stop counting and not to operate the

coincidence output can be specified.

Setting methods when the parameter is set with “CPU error output mode setting” are described as follows.

• Enable the station-based block data assurance for cyclic data in the sending side.

• To hold the PWM output at a disconnection, select “Hold” for “CPU error output mode setting” in the module parameter.

• To stop the PWM output at a disconnection, select “Clear” for “CPU error output mode setting” in the module parameter.

This setting is valid in module units. The parameter cannot be set in each channel.

22

1 FUNCTIONS

1.3 Coincidence Output Function

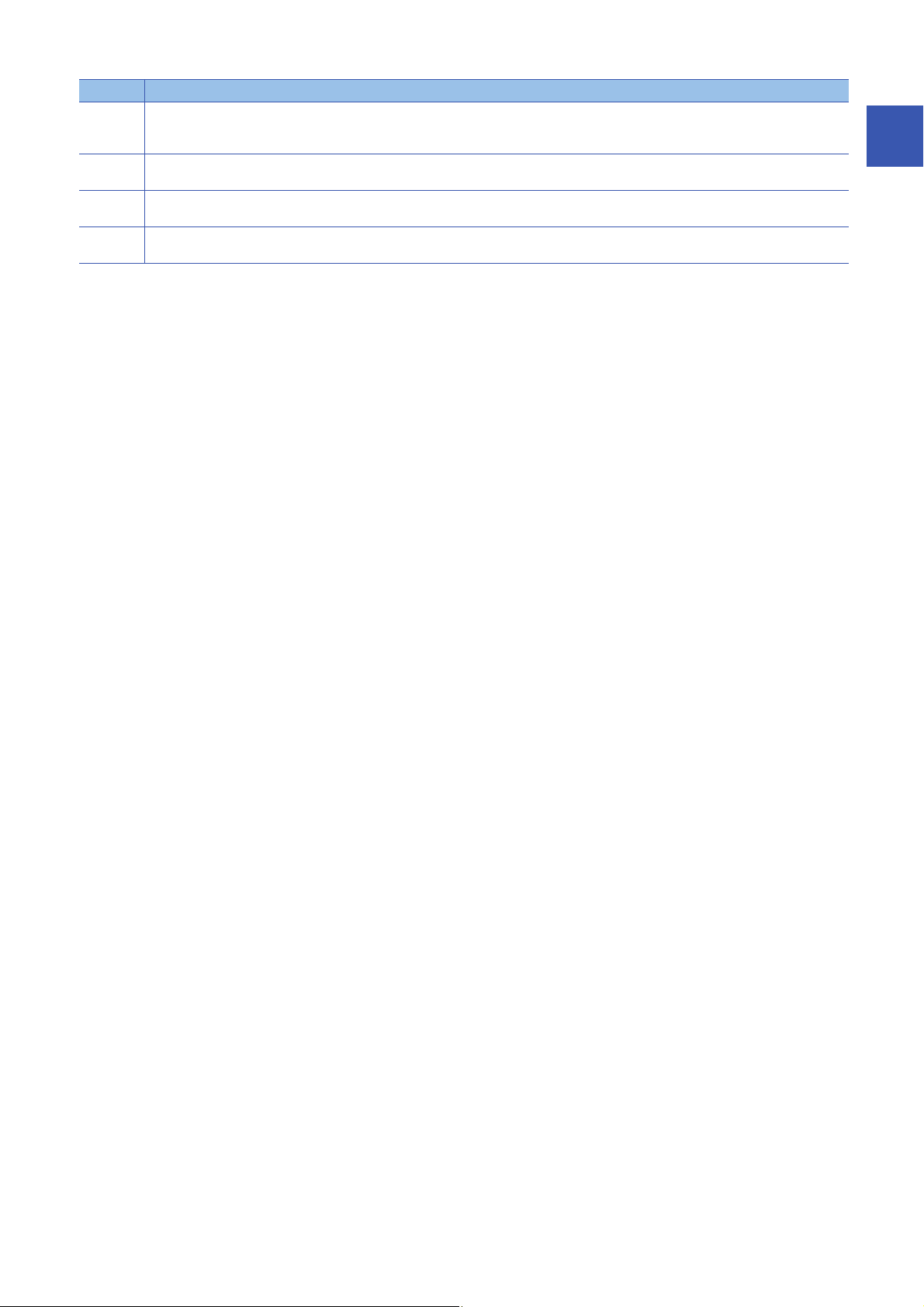

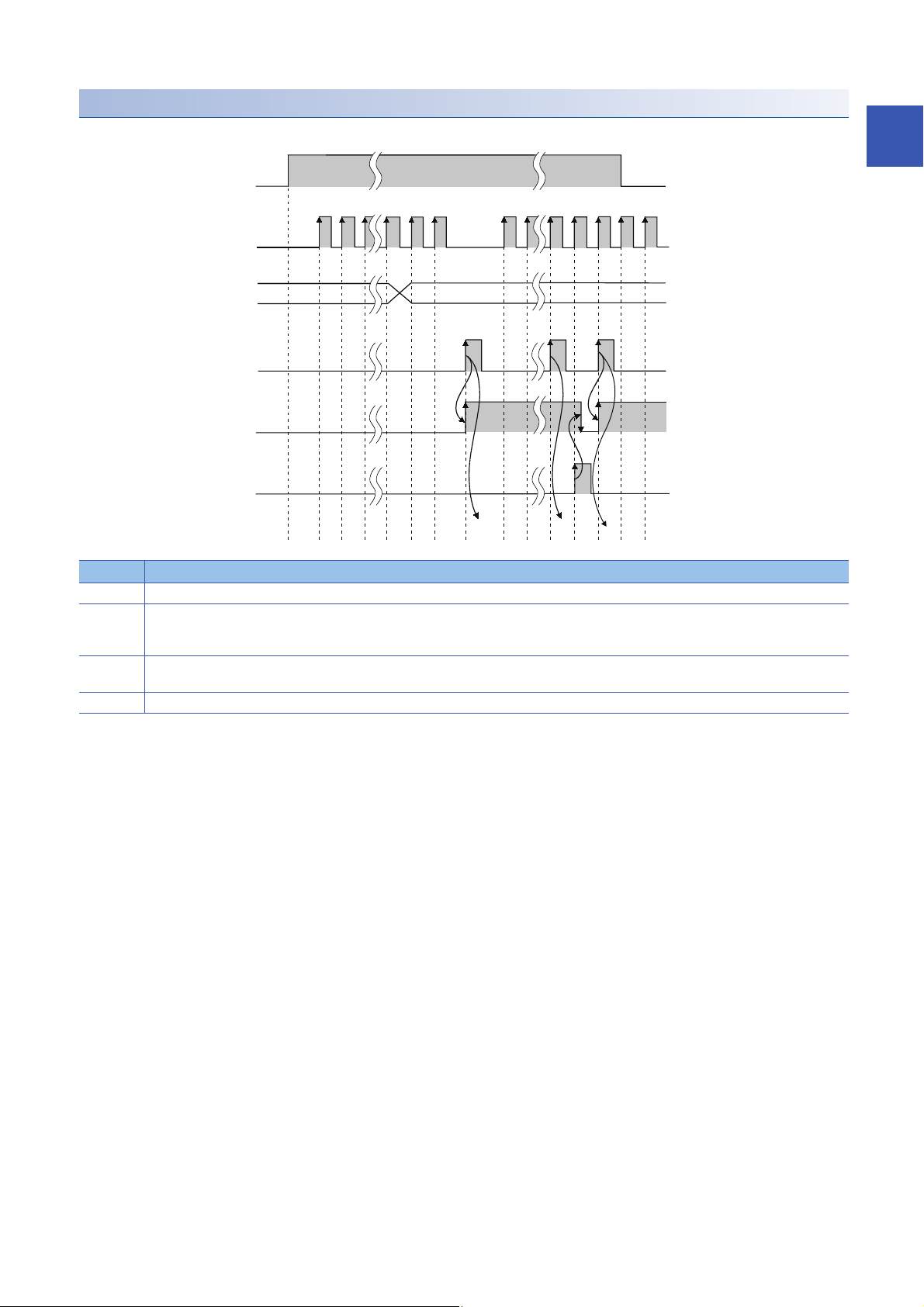

Coincidence detection interrupt function

Interrupt program execution timing

I/O signals

Interrupt request

Interrupt request clear

Interrupt program

Internal

processing of

CPU module

CH1 Counter value coincident (point No.1) (X2)

CH1 Counter value coincident (point No.2) (X6)

CH1 Coincidence signal No.1 reset command (Y0)

CH1 Coincidence signal No.2 reset command (Y7)

Program in CPU module

This function outputs an interrupt request to the CPU module and starts an interrupt program when the present counter value

matches with the preset coincidence output point setting value.

For details on the interrupt program, refer to the following.

MELSEC iQ-R CPU Module User's Manual (Application)

Interrupt factor

The high-speed counter module has interrupt factors of 4 points for each coincidence output point.

Interrupt factor

Turning on CH1 Counter value coincident (point No.1) (X2)

Turning on CH1 Counter value coincident (point No.2) (X6)

Turning on CH2 Counter value coincident (point No.1) (X9)

Turning on CH2 Counter value coincident (point No.2) (XD)

1

Setting interrupt pointers

Set interrupt pointers in the parameter settings. For details on the setting method, refer to the following.

Page 42 Interrupt Setting

• A coincidence detection interrupt occurs on the rising edge of the counter value coincidence signal (When

the signal is turned off and on). Therefore, the next interrupt will not be requested unless the coincidence

signal is reset and the counter value coincidence signal is turned off.

1 FUNCTIONS

1.3 Coincidence Output Function

23

1.4 Preset Function

ON

OFF

ON

OFF

101100676665210

1000

(1)

(2)

102 103 104 105

Counter input pulse

CH1 Count enable command

(Y4)

CH1 Preset command

(Y1)

CH1 Present value

(Un\G2 to Un\G3)

CH1 Preset value

(Un\G0 to Un\G1)

to

This function overwrites the present counter value with the set numerical value. The set value is referred to as a preset value.

This function can be used to start counting pulses from the preset value. The function can be performed using a program or

an external control signal.

Setting method

1. Set "Counter operation mode" to "Pulse count mode".

2. Set a preset value to "Preset value setting".

Navigation window [Parameter] [Module Information] Module model name [Module Parameter] [Basic

setting]

Item Setting range

Preset value setting -2147483648 to 2147483647

Performing the preset function using a program

Perform the preset function by turning on CH1 Preset command (Y1) using a program.

No. Description

(1) Write a value into CH1 Preset value setting (Un\G0 to Un\G1) in 32-bit signed binary.

(2) On the rising edge (off and on) of CH1 Preset command (Y1), the value in CH1 Present value (Un\G2 to Un\G3) is replaced with the value in CH1

Preset value setting (Un\G0 to Un\G1).

The preset function can be performed regardless of the on/off status of CH1 Count enable command (Y4).

24

1 FUNCTIONS

1.4 Preset Function

Performing the preset function using an external control signal

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1016665210 130 131 100 10110067

0 100

(1)

(2) (2)

(4)

(3)

toto

CH1 Count enable command

(Y4)

CH1 Preset value

(Un\G0 to Un\G1)

Preset command

(preset input terminal)

CH1 External preset

request detection

(X4)

CH1 External preset

detection reset command

(Y5)

CH1 Present value

(Un\G2 to Un\G3)

Counter input pulse

Perform the preset function by applying an ON voltage to the preset input terminal for external input.

1

No. Description

(1) Write a value into CH1 Preset value setting (Un\G0 to Un\G1) in 32-bit signed binary.

(2) On the rising edge (off and on) of the preset command (A voltage is applied to the preset input terminal), the value in CH1 Present value (Un\G2

(3) Even though a voltage is applied to the preset input terminal while CH1 External preset request detection (X4) is on, the value in CH1 Present

(4) CH1 External preset request detection (X4) is turned off by turning on CH1 External preset detection reset command (Y5).

to Un\G3) is replaced with the value in CH1 Preset value setting (Un\G0 to Un\G1). The preset function can be performed regardless of the on/off

status of CH1 Count enable command (Y4).

value (Un\G2 to Un\G3) is not replaced with the preset value.

1 FUNCTIONS

1.4 Preset Function

25

1.5 Counter Function Selection

The count disable function, latch counter function, sampling counter function, or cycle pulse counter function can be used by

selecting each item in the counter function selection setting of the "Counter function selection setting". The selected counter

function is performed by the counter function selection start command (when CH1 Counter function selection start command

(Y6) is turned on using a program or a voltage is applied to the function start input terminal).

Only one of the four counter functions can be selected from the counter function selection.

Setting method

1. Set "Counter operation mode" to "Pulse count mode".

2. Set the function to be used in "Counter function selection setting".

Navigation window [Parameter] [Module Information] Module model name [Module Parameter] [Application

setting]

Item Description Reference

Count disable function This function stops counting pulses while CH1 Count enable command

(Y4) is on.

Latch counter function This function latches the present counter value when Counter function

selection start command is input.

Sampling counter function This function counts pulses input during the specified sampling time (T)

and stores the count value in the buffer memory.

Cycle pulse counter function This function stores the current value, previous value, and difference

value of the counter in the buffer memory at every specified cycle time

(T).

Page 28 Count disable function

Page 29 Latch counter function

Page 30 Sampling counter function

Page 31 Cycle pulse counter function

• Change the counter function while CH1 Counter function selection start command (Y6) is off.

• The selected counter function can be performed by turning on CH1 Counter function selection start

command (Y6) or applying a voltage to the function start input terminal. A signal that is input first takes

priority.

26

1 FUNCTIONS

1.5 Counter Function Selection

Loading...

Loading...