Page 1

Models

PWFY-P100VM-E-BU

PWFY-P100, P200VM-E-AU

Service Handbook

Page 2

Contents

1 Read Before Servicing ................................................................ 7

[1] Items to Be Checked .............................................................. 7

[2] Necessary Tools and Materials .............................................. 8

[3] Piping Materials ...................................................................... 9

[4] Storage of Piping .................................................................... 11

[5] Piping Processing .................................................................. 11

[6] Brazing.................................................................................... 12

[7]

Air tightness Test

...................................................................... 13

[8] Vacuum Drying (Evacuation) .................................................. 14

[9] Refrigerant Charging .............................................................. 15

[10] Remedies to be taken in case of a Refrigerant Leak ............ 15

[11]

Characteristics of the Conventional and the New Refrigerants

.. 16

[12] Notes on Refrigerating Machine Oil........................................ 17

2 Restrictions .................................................................................. 18

[1] Types and Maximum allowable Length of Cables .................. 18

[2] Types of Switch Setting and Address Setting ........................ 19

[3] Examples of system connection ............................................ 20

[4] Restrictions on piping length .................................................. 20

3 Components of the Unit .............................................................. 21

[1] Appearance of the Components and Refrigerant Circuit........ 21

[2] Control Box ............................................................................ 22

[3] Circuit Board .......................................................................... 23

4 Remote Controller........................................................................ 26

[1]

Functions and Specifications of MA Remote Controller

.................. 26

[2]

Interlocking Setting via the MA Remote Controller

........................ 27

5 Electrical Wiring Diagram ............................................................ 29

[1] PWFY-P100VM-E-BU ............................................................ 29

[2] PWFY-P100, 200VM-E-AU .................................................... 30

6 Refrigerant Circuit ........................................................................ 31

[1] Refrigerant Circuit Diagram .................................................... 31

[2] Functions of Principal Parts.................................................... 32

7 Control.......................................................................................... 34

[1] Dip Switch Functions and Their Factory Settings .................. 34

8 Test Run ...................................................................................... 37

[1] Check Items before Test Run.................................................. 37

[2] Test Run Method .................................................................... 37

[3] Refrigerant .............................................................................. 37

[4] Symptoms that do not Signify Problems ................................ 38

[5] Standard operation data ........................................................ 38

9 Troubleshooting............................................................................ 39

[1] Check Code List .................................................................... 39

[2] Responding to Error Display on the Remote Controller ........ 40

[3] Troubleshooting Principal Parts .............................................. 56

[4] Maintenance .......................................................................... 70

0 LED display.................................................................................. 74

[1] LED Monitor Display .............................................................. 74

Page 3

Page 4

Do not use steel pipes as water pipes.

Copper pipes are recommended.

The water circuit should be a closed circuit.

Do not touch the refrigerant pipes and Water

pipes.

Improper handling may result in injury.

Safety Precautions

Before installing the unit, thoroughly read the following safety precautions.

Observe these safety precautions for your safety.

WARNING

This symbol is intended to alert the user to the presence of important instructions that must be followed to avoid

the risk of serious injury or death.

CAUTION

This symbol is intended to alert the user to the presence of important instructions that must be followed to avoid

the risk of serious injury or damage to the unit.

After reading this manual, give it to the user to retain for future reference.

Keep this manual for easy reference. When the unit is moved or repaired, give this manual to those who provide these

services.

When the user changes, make sure that the new user receives this manual.

WARNING

Ask your dealer or a qualified technician to install the

unit.

Improper installation by the user may result in water leakage, electric shock, smoke, and/or fire.

Properly install the unit on a surface that can withstand the weight of the unit.

Unit installed on an unstable surface may fall and cause injury.

Only use specified cables. Securely connect each cable so that the terminals do not carry the weight of the

cable.

Improperly connected or fixed cables may produce heat

and start a fire.

Take appropriate safety measures against strong

winds and earthquakes to prevent the unit from falling.

If the unit is not installed properly, the unit may fall and

cause serious injury to the person or damage to the unit.

Do not make any modifications or alterations to the

unit. Consult your dealer for repair.

Improper repair may result in water leakage, electric shock,

smoke, and/or fire.

In the event of a refrigerant leak, thoroughly ventilate

the room.

If refrigerant gas leaks and comes in contact with an open

flame, poisonous gases will be produced.

Properly install the unit according to the instructions

in the installation manual.

Improper installation may result in water leakage, electric

shock, smoke, and/or fire.

Have all electrical work performed by an authorized

electrician according to the local regulations and instructions in this manual, and a dedicated circuit must

be used.

Insufficient capacity of the power supply circuit or improper

installation may result in malfunctions of the unit, electric

shock, smoke, and/or fire.

- 1 -

Page 5

WARNING

Securely attach the terminal block cover (panel) to the

unit.

If the terminal block cover (panel) is not installed properly,

dust and/or water may infiltrate and pose a risk of electric

shock, smoke, and/or fire.

Only use the type of refrigerant that is indicated on the

unit when installing or reinstalling the unit.

Infiltration of any other type of refrigerant or air into the unit

may adversely affect the refrigerant cycle and may cause

the pipes to burst or explode.

When installing the unit in a small room, exercise caution and take measures against leaked refrigerant

reaching the limiting concentration.

Consult your dealer with any questions regarding limiting

concentrations and for precautionary measures before installing the unit. Leaked refrigerant gas exceeding the limiting concentration causes oxygen deficiency.

Consult your dealer or a specialist when moving or reinstalling the unit.

Improper installation may result in water leakage, electric

shock, and/or fire.

After completing the service work, check for a gas

leak.

If leaked refrigerant is exposed to a heat source, such as a

fan heater, stove, or electric grill, poisonous gases may be

produced.

Do not try to defeat the safety features of the unit.

Forced operation of the pressure switch or the temperature

switch by defeating the safety features of these devices, or

the use of accessories other than the ones that are recommended by MITSUBISHI may result in smoke, fire, and/or

explosion.

Only use accessories recommended by MITSUBISHI.

Ask a qualified technician to install the unit. Improper installation by the user may result in water leakage, electric

shock, smoke, and/or fire.

Control box houses high-voltage parts.

When opening or closing the front panel of the control box,

do not let it come into contact with any of the internal components. Before inspecting the inside of the control box,

turn off the power, keep the unit off for at least 10 minutes,

and confirm that the voltage between FT-P and FT-N on

INV Board has dropped to DC20V or less. (It takes about

10 minutes to discharge electricity after the power supply is

turned off.)

- 2 -

Page 6

Precautions for handling units for use with R410A

CAUTION

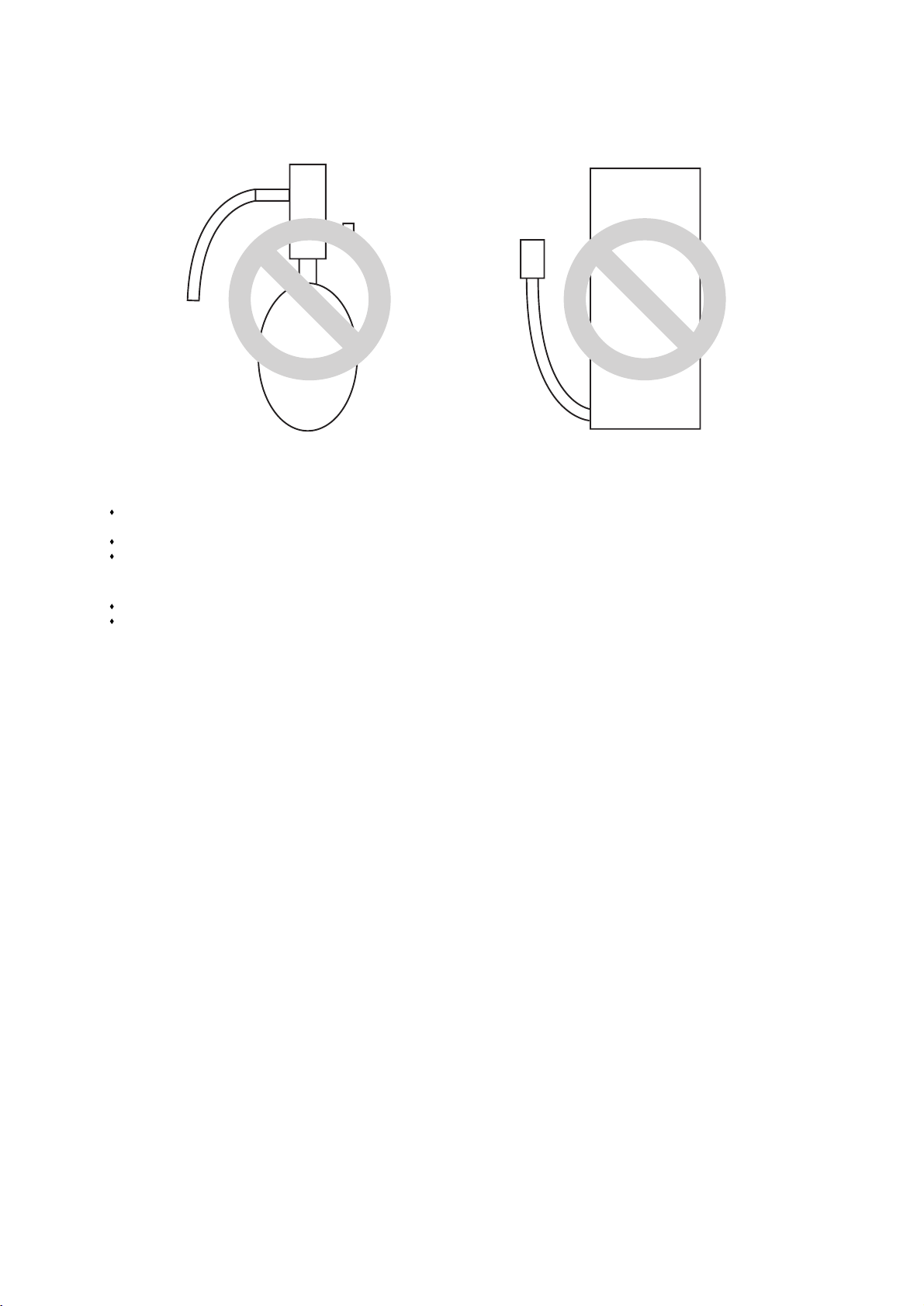

Do not use the existing refrigerant piping.

A large amount of chlorine that may be contained in the residual refrigerant and refrigerating machine oil in the existing piping may cause the refrigerating machine oil in the

new unit to deteriorate.

R410A is a high-pressure refrigerant and can cause the

existing pipes to burst.

Use refrigerant pipes made of phosphorus deoxidized

copper. Keep the inner and outer surfaces of the pipes

clean and free of such contaminants as sulfur, oxides,

dust, dirt, shaving particles, oil, and water.

These types of contaminants inside the refrigerant pipes

may cause the refrigerant oil to deteriorate.

Store the pipes to be installed indoors, and keep both

ends of the pipes sealed until immediately before brazing. (Keep elbows and other joints wrapped in plastic.)

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate or

cause the unit to malfunction.

Use a small amount of ester oil, ether oil, or alkylbenzene to coat flares and flanges.

Infiltration of a large amount of mineral oil may cause the refrigerating machine oil to deteriorate.

Charge liquid refrigerant (as opposed to gaseous refrigerant) into the system.

If gaseous refrigerant is charged into the system, the composition of the refrigerant in the cylinder will change and

may result in performance loss.

Use a vacuum pump with a reverse-flow check valve.

If a vacuum pump that is not equipped with a reverse-flow

check valve is used, the vacuum pump oil may flow into the

refrigerant cycle and cause the refrigerating machine oil to

deteriorate.

Prepare tools for exclusive use with R410A. Do not use

the following tools if they have been used with the conventional refrigerant (gauge manifold, charging hose,

gas leak detector, reverse-flow check valve, refrigerant

charge base, vacuum gauge, and refrigerant recovery

equipment.).

If the refrigerant or the refrigerating machine oil left on

these tools are mixed in with R410A, it may cause the refrigerating machine oil to deteriorate.

Infiltration of water may cause the refrigerating machine

oil to deteriorate.

Gas leak detectors for conventional refrigerants will not

detect an R410A leak because R410A is free of chlorine.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the refrigerant will change, and the unit may experience power loss.

Exercise special care when handling the tools for use

with R410A.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate.

Only use refrigerant R410A.

The use of other types of refrigerant that contain chlorine

(i.e. R22) may cause the refrigerating machine oil to deteriorate.

- 3 -

Page 7

Before installing the unit

WARNING

Do not install the unit where a gas leak may occur.

If gaseous refrigerant leaks and piles up around the unit, it

may be ignited.

Do not use the unit to keep food items, animals, plants,

artifacts, or for other special purposes.

The unit is not designed to preserve food products.

Do not use the unit in an unusual environment.

Do not install the unit where a large amount of oil or steam

is present or where acidic or alkaline solutions or chemical

sprays are used frequently. Doing so may lead to a remarkable drop in performance, electric shock, malfunctions, smoke, and/or fire.

The presence of organic solvents or corrosive gas (i.e.

ammonia, sulfur compounds, and acid) may cause gas

leakage or water leakage.

When installing the unit in a hospital, take appropriate

measures to reduce noise interference.

High-frequency medical equipment may interfere with the

normal operation of the air conditioner or vice versa.

Do not install the unit on or over things that cannot get

wet.

When the humidity level exceeds 80% or if the drainage

system is clogged, the indoor unit may drip water. Drain water is also discharged from the outdoor unit. Install a centralized drainage system if necessary.

- 4 -

Page 8

Before installing the unit (moving and reinstalling the unit) and performing

electrical work

CAUTION

Properly ground the unit.

Do not connect the grounding wire to a gas pipe, water pipe,

lightning rod, or grounding wire from a telephone pole. Improper grounding may result in electric shock, smoke, fire,

and/or malfunction due to noise interference.

Do not put tension on the power supply wires.

If tension is put on the wires, they may break and result in

excessive heat, smoke, and/or fire.

Install an earth leakage breaker to avoid the risk of

electric shock.

Failure to install an earth leakage breaker may result in

electric shock, smoke, and/or fire.

Use the kind of power supply wires that are specified

in the installation manual.

The use of wrong kind of power supply wires may result in

current leak, electric shock, and/or fire.

Use breakers and fuses (current breaker, remote

switch <switch + Type-B fuse>, moulded case circuit

breaker) with the proper current capacity.

The use of wrong capacity fuses, steel wires, or copper

wires may result in malfunctions, smoke, and/or fire.

Do not spray water on the unit or immerse the air

conditioner in water.

Otherwise, electric shock and/or fire may result.

When handling units, always wear protective gloves to

protect your hands from metal parts and high-temperature parts.

Periodically check the installation base for damage.

If the unit is left on a damaged platform, it may fall and

cause injury.

Properly install the drain pipes according to the instructions in the installation manual. Keep them insulated to avoid dew condensation.

Improper plumbing work may result in water leakage and

damage to the furnishings.

Exercise caution when transporting products.

Products weighing more than 20 kg should not be carried

alone.

Do not carry the product by the PP bands that are used on

some products.

Properly dispose of the packing materials.

Nails and wood pieces in the package may pose a risk of

injury.

Plastic bags may pose a risk of choking hazard to children. Tear plastic bags into pieces before disposing of

them.

- 5 -

Page 9

Before the test run

CAUTION

Turn on the unit at least 12 hours before the test run.

Keep the unit turned on throughout the season. If the unit is

turned off in the middle of a season, it may result in malfunctions.

To avoid the risk of electric shock or malfunction of the

unit, do not operate switches with wet hands.

Do not touch the refrigerant pipes with bare hands during and immediately after operation.

During or immediately after operation, certain parts of the

unit such as pipes and compressor may be either very cold

or hot, depending on the state of the refrigerant in the unit

at the time. To reduce the risk of frost bites and burns, do

not touch these parts with bare hands.

Do not operate the unit without panels and safety

guards.

Rotating, high-temperature, or high-voltage parts on the unit

pose a risk of burns and/or electric shock.

Do not turn off the power immediately after stopping

the operation.

Keep the unit on for at least five minutes before turning off

the power to prevent water leakage or malfunction.

Do not operate the unit without the air filter.

Dust particles may build up in the system and cause malfunctions.

- 6 -

Page 10

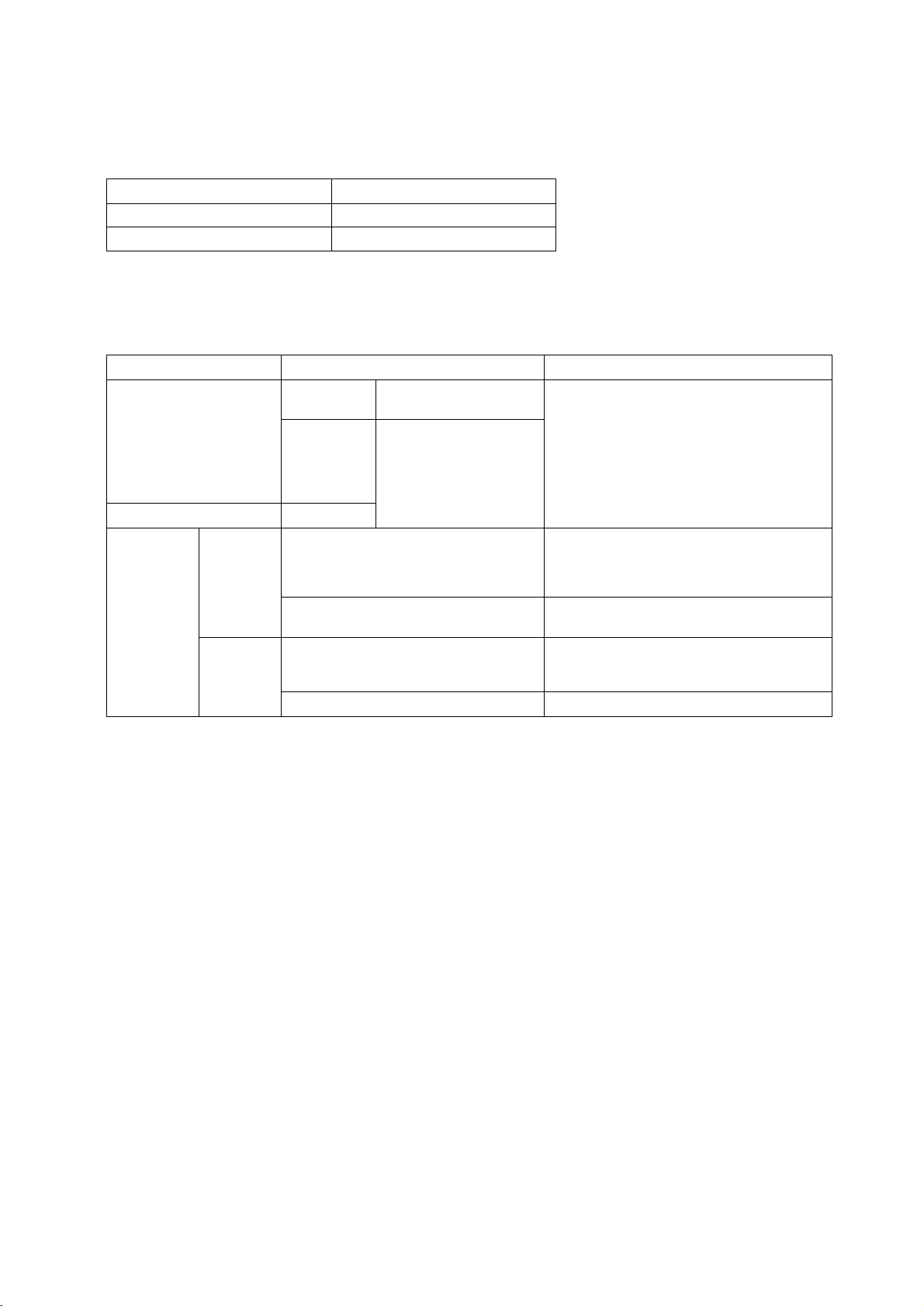

1. Check the type of refrigerant used in the system to be serviced.

Refrigerant Type

Between unit and BC controller

PWFY-P100VM-E-BU

Inside the unit

R410A

-

PWFY-P100, 200VM-E-AU

2. Check the symptoms exhibited by the unit to be serviced.

Refer to this service handbook for symptoms relating to the refrigerant cycle.

3. Thoroughly read the safety precautions at the beginning of this manual.

4. Preparing necessary tools: Prepare a set of tools to be used exclusively with each type of refrigerant.

Refer to "Necessary Tools and Materials" for information on the use of tools.(page 8)

5. Verification of the connecting pipes: Verify the type of refrigerant used for the unit to be moved or replaced.

Use refrigerant pipes made of phosphorus deoxidized copper. Keep the inner and outer surfaces of the pipes clean and free

of such contaminants as sulfur, oxides, dust, dirt, shaving particles, oil, and water.

These types of contaminants inside the refrigerant pipes may cause the refrigerant oil to deteriorate.

6. If there is a leak of gaseous refrigerant and the remaining refrigerant is exposed to an open flame, a poisonous gas

hydrofluoric acid may form. Keep workplace well ventilated.

CAUTION

Install new pipes immediately after removing old ones to keep moisture out of the refrigerant circuit.

The use of refrigerant that contains chloride, such as R22, will cause the refrigerating machine oil to deteriorate.

R410A

R134A

- 7 -

¡¡

Read Before Servicing

Page 11

[2] Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

To ols for use with R410A (Adaptability of tools that are for use with R22 or R407C)

1. To be used exclusively with R410A (not to be used if used with R22 or R407C)

2. Tools and materials that may be used with R410A with some restrictions

3. Tools and materials that are used with R22 or R407C that may also be used with R410A

4. Tools and materials that must not be used with R410A

Tools for R410A must be handled with special care to keep moisture and dust from infiltrating the cycle.

setoNesUslairetaM/slooT

c tnaregirfer dna noitaucavEdlofinaM eguaG harging Higher than 5.09MPa[738psi] on the

high-pressure side

igrahc tnaregirfer dna noitaucavEesoH gnigrahC ng The hose diameter is larger than the

conventional model.

Refrigerant Recovery Cylinder Refrigerant recovery

hTgnigrahc tnaregirfeRrednilyC tnaregirfeR e refrigerant type is indicated. The

cylinder is pink.

Charging Port on the Refrigerant Cylinder Refrigerant chargingThe charge port diameter is larger

than that of the current port.

tiw tinu eht fo noitcennoCtuN eralFh the pipes Use Type-2 Flare nuts.

setoNesUslairetaM/slooT

noitceted kael saGrotceteD kaeL saG The ones for use with HFC refrigerant

may be used.

retpada evlav kcehc a fi desu eb yaMgniyrd muucaVpmuP muucaV

is attached.

eht rof snoisnemid gnissecorp eralFgnissecorp eralFlooT eralF

piping in the system using the new refrigerant differ from those of R22. Refer to next page.

Refrigerant Recovery Equipment Refrigerant recovery

May be used if compatible with R410A

or R134a

setoNesUslairetaM/slooT

Vacuum Pump with a Check Valve Vacuum drying

sepip gnidneBredneB

snoisnemid gnissecorp eralf eht ylnOstun eralf gninethgiThcnerW euqroT

for pipes that have a diameter of

ø12.70 (1/2") and ø15.88 (5/8") have

been changed.

sepip gnittuCrettuC epiP

Welder and Nitrogen Cylinder Welding pipes

Refrigerant Charging Meter Refrigerant charging

kcehc level muucaVeguaG muucaV

setoNesUslairetaM/slooT

esu ot detibihorPgnigrahc tnaregirfeRrednilyC gnigrahC

- 8 -

Page 12

[3] Piping Materials

1. Copper pipe materials

The distinction between O-materials (Annealed) and 1/2H-materials (Drawn) is made based on the strength of the pipes them-

selves.

O-materials (Annealed) can easily be bent with hands.

1/2H-materials (Drawn) are considerably stronger than O-material (Annealed) at the same thickness.

2. Types of copper pipes

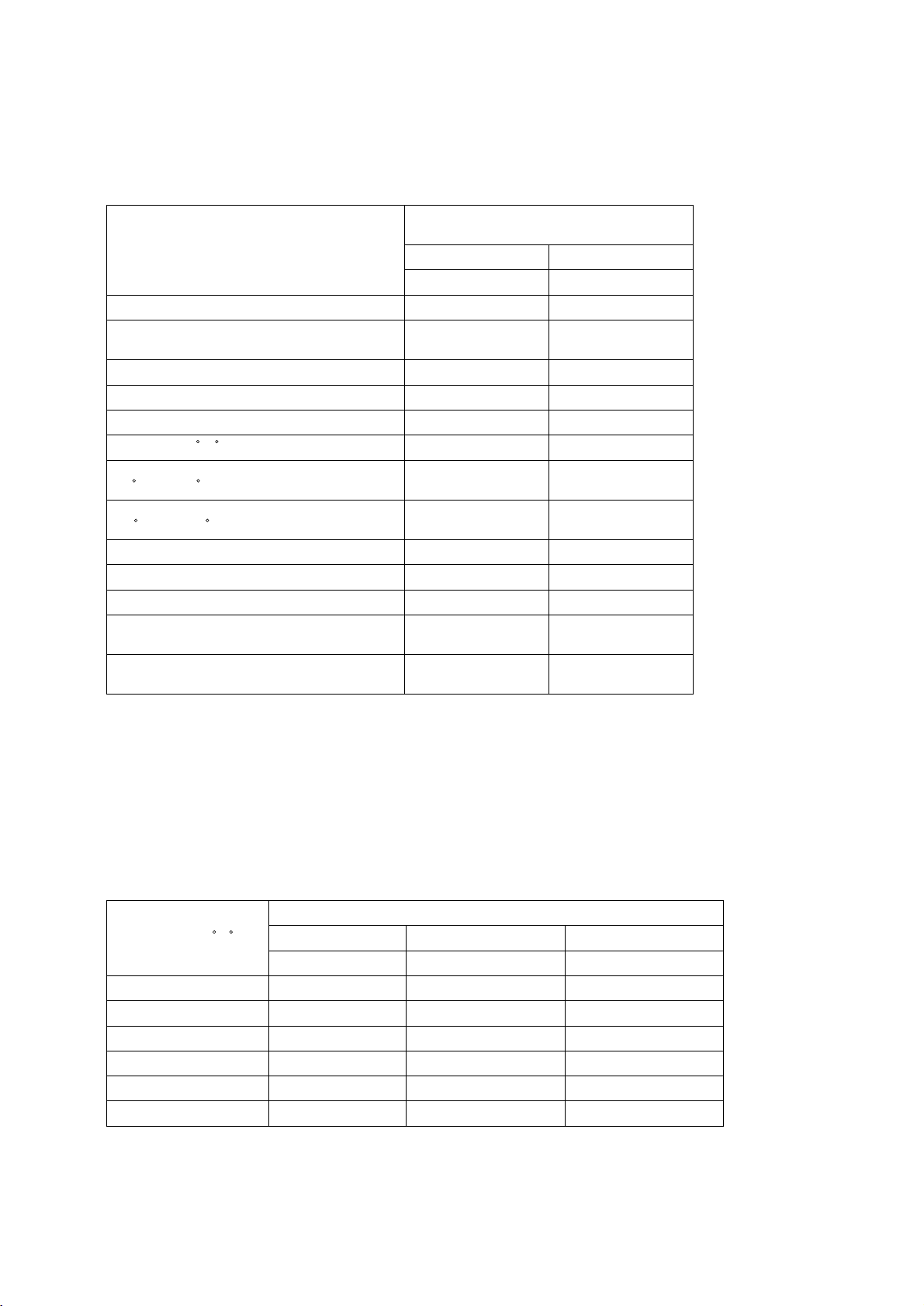

3. Piping materials/Radial thickness

Use refrigerant pipes made of phosphorus deoxidized copper.

The operation pressure of the units that use R410A is higher than that of the units that use R22.

Use pipes that have at least the radial thickness specified in the chart below.

(Pipes with a radial thickness of 0.7 mm or less may not be used.)

The pipes in the system that uses the refrigerant currently on the market are made with O-material (Annealed), even if the

pipe diameter is less than ø19.05 (3/4"). For a system that uses R410A, use pipes that are made with 1/2H-material (Drawn)

unless the pipe diameter is at least ø19.05 (3/4") and the radial thickness is at least 1.2t.

The figures in the radial thickness column are based on the Japanese standards and provided only as a reference. Use pipes

that meet the local standards.

O-material (Annealed) Soft copper pipes (annealed copper pipes). They can easily be bent with hands.

1/2H-material (Drawn) Hard copper pipes (straight pipes). They are stronger than the O-material (Annealed)

at the same radial thickness.

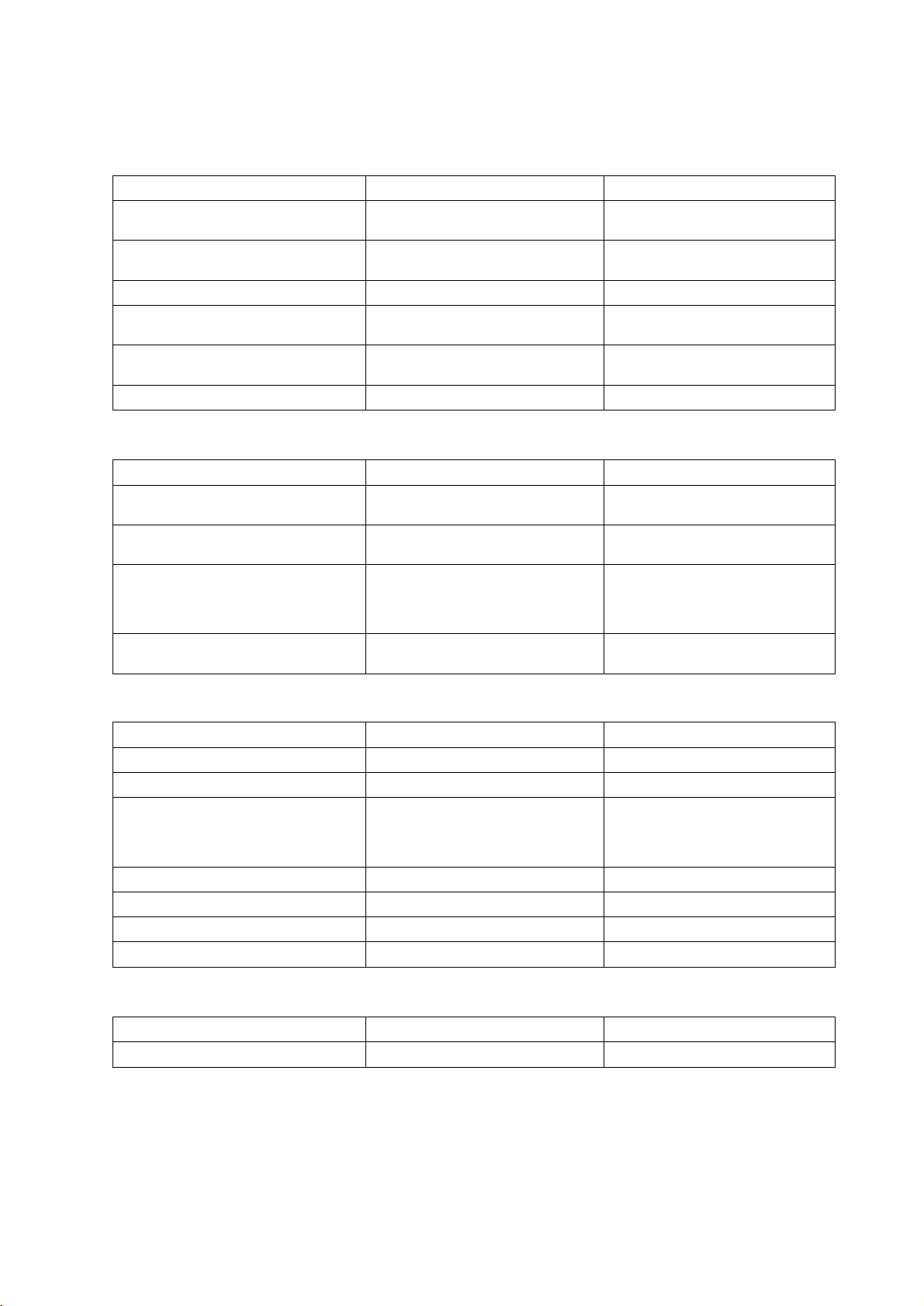

Maximum working pressure Refrigerant type

4.30 MPa [624psi] R410A and R134a

Pipe size (mm[in]) Radial thickness (mm) Type

ø6.35 [1/4"] 0.8t

O-material (Annealed)

ø9.52 [3/8"] 0.8t

ø12.7 [1/2"] 0.8t

ø15.88 [5/8"] 1.0t

ø19.05 [3/4"] 1.0t

1/2H-material,

H-material (Drawn)

ø22.2 [7/8"] 1.0t

ø25.4 [1"] 1.0t

ø28.58 [1-1/8"] 1.0t

ø31.75 [1-1/4"] 1.1t

ø34.93 [1-3/8"] 1.1t

ø41.28 [1-5/8"] 1.2t

Do not use the existing piping!

- 9 -

Page 13

- 10 -

4. Thickness and refrigerant type indicated on the piping materials

Ask the pipe manufacturer for the symbols indicated on the piping material for new refrigerant.

5. Flare processing (O-material (Annealed) and OL-material only)

The flare processing dimensions for the pipes that are used in the R410A system are larger than those in the R22 system.

If a clutch-type flare tool is used to flare the pipes in the system using R410A, the length of the pipes must be between 1.0

and 1.5 mm. For margin adjustment, a copper pipe gauge is necessary.

6. Flare nut

The flare nut type has been changed to increase the strength. The size of some of the flare nuts have also been changed.

The figures in the radial thickness column are based on the Japanese standards and provided only as a reference. Use pipes

that meet the local standards.

Flare processing dimensions (mm[in])

Pipe size (mm[in]) A dimension (mm)

ø6.35 [1/4"] 9.1

ø9.52 [3/8"] 13.2

ø12.7 [1/2"] 16.6

ø15.88 [5/8"] 19.7

ø19.05 [3/4"] 24.0

Flare nut dimensions (mm[in])

Pipe size (mm[in]) B dimension (mm)

ø6.35 [1/4"] 17.0

ø9.52 [3/8"] 22.0

ø12.7 [1/2"] 26.0

ø15.88 [5/8"] 29.0

ø19.05 [3/4"] 36.0

Dimension A

Dimension B

Page 14

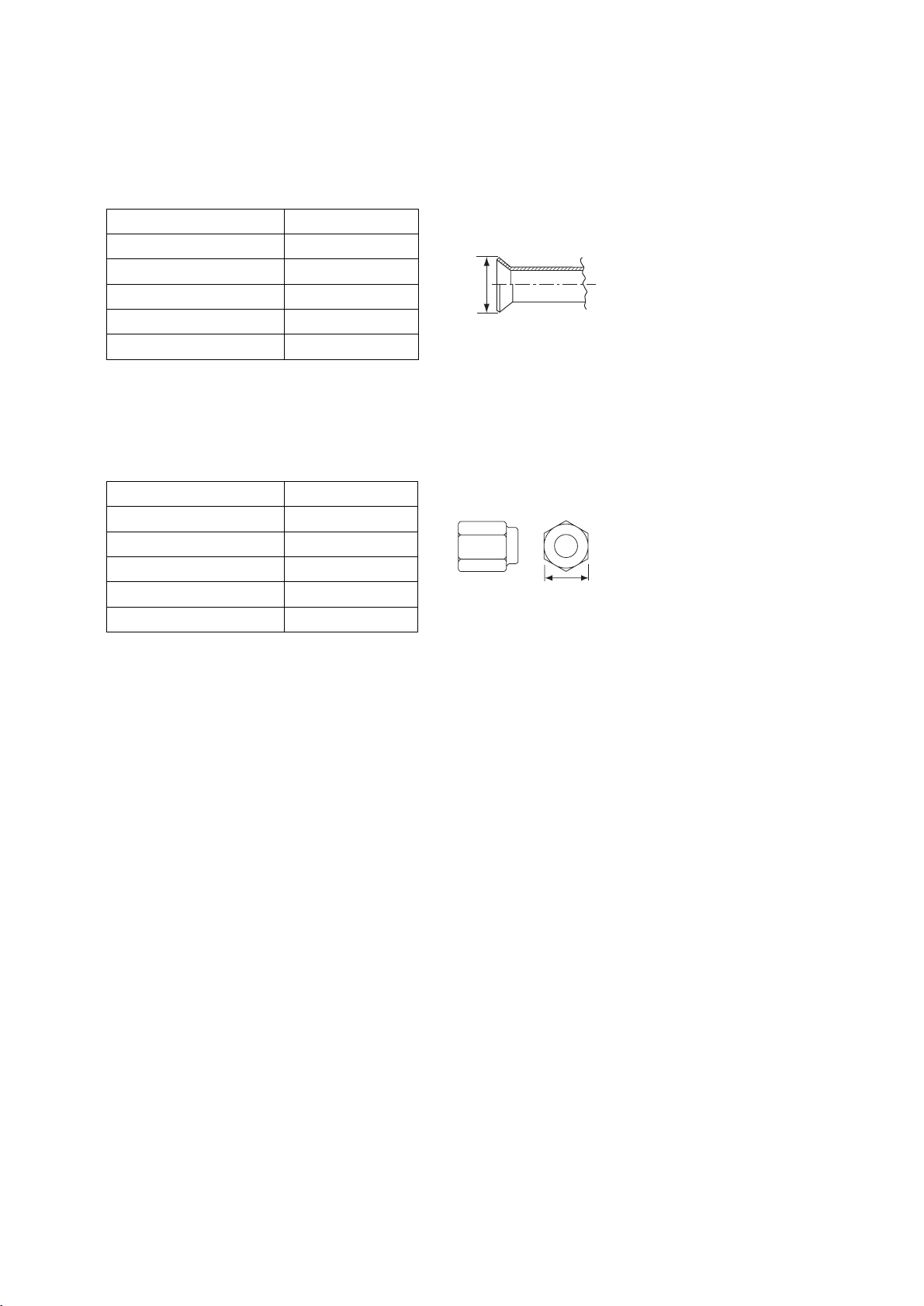

[4] Storage of Piping

1. Storage location

Store the pipes to be used indoors. (Warehouse at site or owner's warehouse)

If they are left outdoors, dust, dirt, or moisture may infiltrate and contaminate the pipe.

2. Sealing the pipe ends

Both ends of the pipes should be sealed until just before brazing.

Keep elbow pipes and T-joints in plastic bags.

The new refrigerator oil is 10 times as hygroscopic as the conventional refrigerating machine oil (such as Suniso) and, if not

handled with care, could easily introduce moisture into the system. Keep moisture out of the pipes, for it will cause the oil to

deteriorate and cause a compressor failure.

[5] Pipe Processing

Use a small amount of ester oil, ether oil, or alkylbenzene to coat flares and flanges.

Use a minimum amount of oil.

Use only ester oil, ether oil, and alkylbenzene.

- 11 -

Page 15

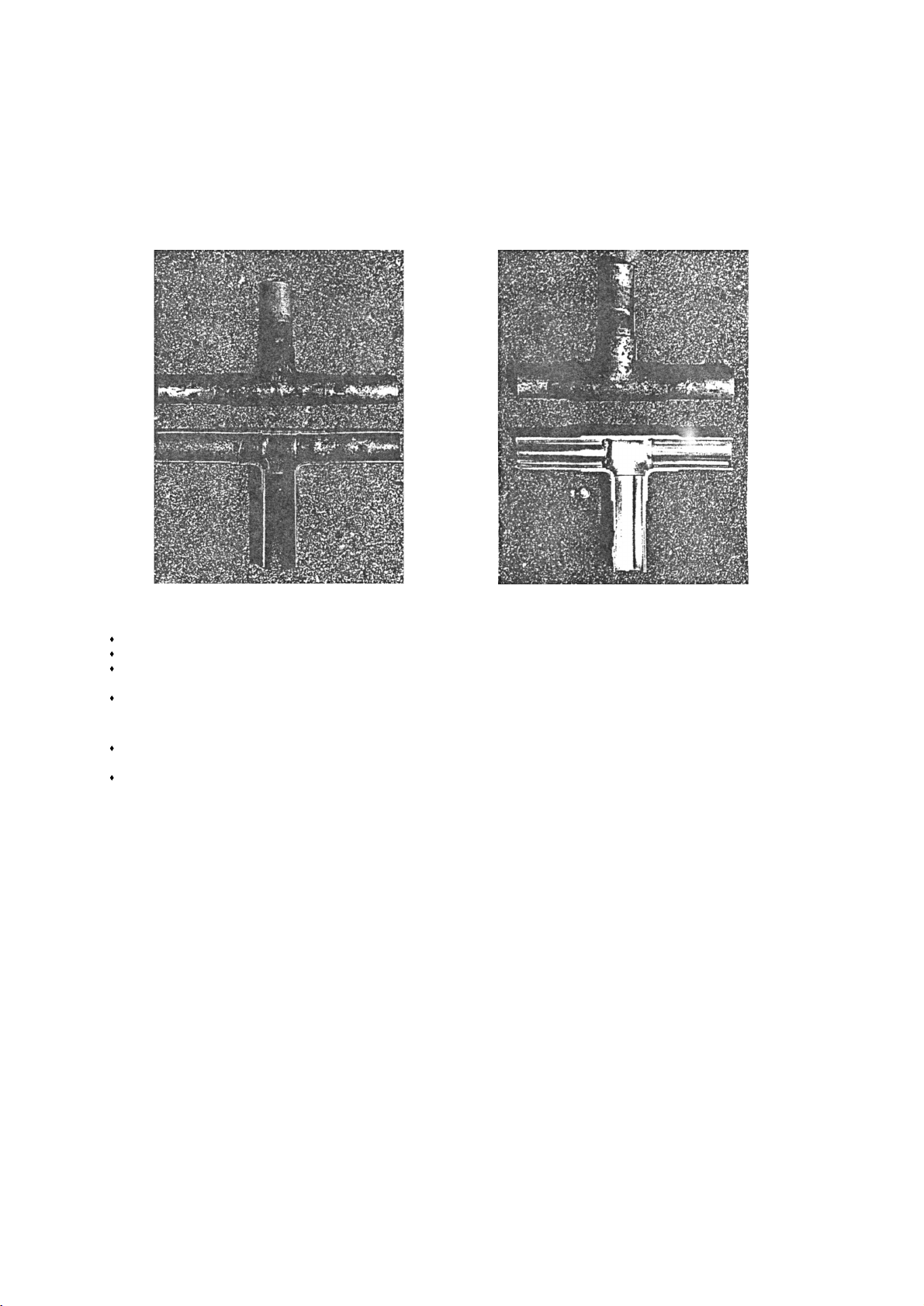

[6] Brazing

No changes have been made in the brazing procedures. Perform brazing with special care to keep foreign objects (such as oxide

scale, water, and dust) out of the refrigerant system.

Example: Inside the brazed connection

1. Items to be strictly observed

Do not conduct refrigerant piping work outdoors if raining.

Use non-oxidized solder.

Use a brazing material (BCuP-3) that requires no flux when brazing between copper pipes or between a copper pipe and

copper coupling.

If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends.

2. Reasons

The new refrigerating machine oil is 10 times as hygroscopic as the conventional oil and is more likely to cause unit failure if

water infiltrates into the system.

Flux generally contains chloride. Residual flux in the refrigerant circuit will cause sludge to form.

3. Notes

Do not use commercially available antioxidants because they may cause the pipes to corrode or refrigerating machine oil to

deteriorate.

esUgnizarb rof redlos dezidixo fo esU of non-oxidized solder for brazing

- 12 -

Page 16

[7] Air T ightness Test

No changes have been made in the detection method. Note that a refrigerant leak detector for R22 will not detect an R410A leak.

1. Items to be strictly observed

Pressurize the equipment with nitrogen up to the design pressure (4.15MPa[601psi]), and then judge the equipment's air tightness, taking temperature variations into account.

When using refrigerant instead of a leak detector to find the location of a leak, use R410A.

Refrigerant R410A must be charged in its liquid state (vs. gaseous state).

2. Reasons

Oxygen, if used for an air tightness test, poses a risk of explosion. (Only use nitrogen to check air tightness.)

Refrigerant R410A must be charged in its liquid state. If gaseous refrigerant in the cylinder is drawn out first, the composition

of the remaining refrigerant in the cylinder will change and become unsuitable for use.

3. Notes

Procure a leak detector that is specifically designed to detect an HFC leak. A leak detector for R22 will not detect an

HFC(R410A, R407C) leak.

rotceted egakael 22Rhcrot edilaH

- 13 -

Page 17

[8] Vacuum Drying (Evacuation)

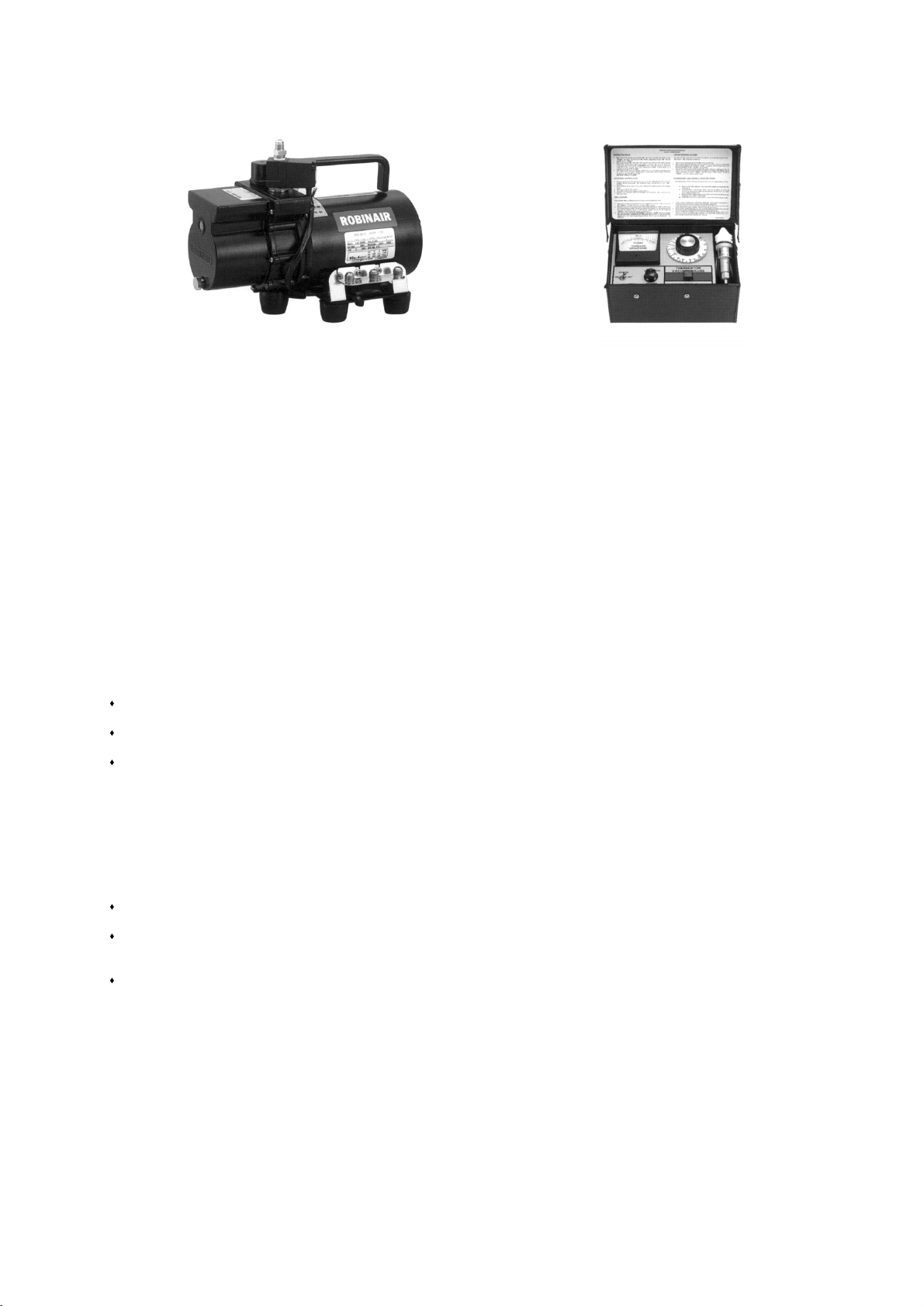

1. Vacuum pump with a reverse-flow check valve (Photo1)

To prevent the vacuum pump oil from flowing into the refrigerant circuit during power OFF or power failure, use a vacuum

pump with a reverse-flow check valve.

A reverse-flow check valve may also be added to the vacuum pump currently in use.

2. Standard of vacuum degree (Photo 2)

Use a vacuum pump that attains 0.5Torr(6 5Pa) or lower degree of vacuum after 5 minutes of operation, and connect it directly

to the vacuum gauge. Use a pump well-maintained with an appropriate lubricant. A poorly maintained vacuum pump may not

be able to attain the desired degree of vacuum.

3. Required precision of vacuum gauge

Use a vacuum gauge that registers a vacuum degree of 5Torr(650Pa) and measures at intervals of 1Torr(130Pa). (A recommended vacuum gauge is shown in Photo2.)

Do not use a commonly used gauge manifold because it cannot register a vacuum degree of 5Torr(650Pa).

4. Evacuation time

After the degree of vacuum has reached 5Torr(650Pa), evacuate for an additional 1 hour. (A thorough vacuum drying removes moisture in the pipes.)

Verify that the vacuum degree has not risen by more than 1Torr(130Pa) 1hour after evacuation. A rise by less than

1Torr(130Pa) is acceptable.

If the vacuum is lost by more than 1Torr(130Pa), conduct evacuation, following the instructions in section 6. Special vacuum

drying.

5. Procedures for stopping vacuum pump

To prevent the reverse flow of vacuum pump oil, open the relief valve on the vacuum pump side, or draw in air by loosening

the charge hose, and then stop the operation.

The same procedures should be followed when stopping a vacuum pump with a reverse-flow check valve.

6. Special vacuum drying

When 5Torr(650Pa) or lower degree of vacuum cannot be attained after 3 hours of evacuation, it is likely that water has penetrated the system or that there is a leak.

If water infiltrates the system, break the vacuum with nitrogen. Pressurize the system with nitrogen gas to

0.5kgf/cm

2

G(0.05MPa) and evacuate again. Repeat this cycle of pressurizing and evacuation either until the degree of vac-

uum below 5Torr(650Pa) is attained or until the pressure stops rising.

Only use nitrogen gas for vacuum breaking. (The use of oxygen may result in an explosion.)

01041 )2otohP(H01051 )1otohP(

Recommended vacuum gauge:

ROBINAIR 14010 Thermistor Vacuum Gauge

- 14 -

Page 18

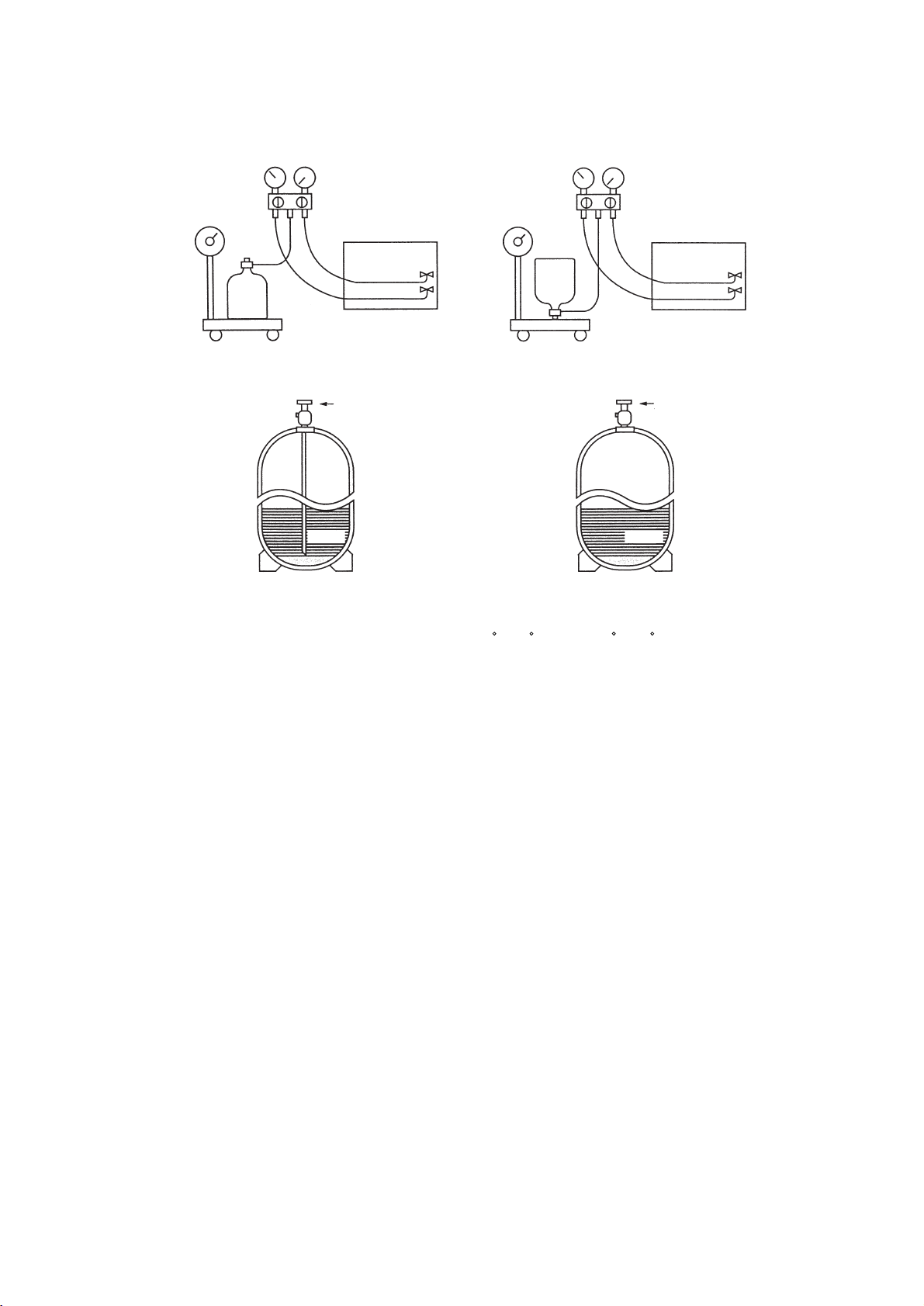

[9] Refrigerant Charging

1. Reasons

R410A is a pseudo-azeotropic HFC blend (boiling point R32=-52 C[-62 F], R125=-49 C [-52 F]) and can almost be handled

the same way as a single refrigerant, such as R22. To be safe, however, draw out the refrigerant from the cylinder in the liquid

phase. If the refrigerant in the gaseous phase is drawn out, the composition of the remaining refrigerant will change and become unsuitable for use.

2. Notes

When using a cylinder with a siphon, refrigerant is charged in the liquid state without the need for turning it upside down. Check

the type of the cylinder on the label before use.

[10] Remedies to be taken in case of a Refrigerant Leak

If the refrigerant leaks out, it may be replenished. The entire refrigerant does not need to be replaced. (Charge refrigerant in the

liquid state.)

Cylinder with a siphon

etats diuqil eht ni gnigrahc tnaregirfeR.knip si A014R roloc rednilyC

Cylinder

liquid

evlaVevlaV

liquid

Cylinder

Cylinder without a siphon

- 15 -

Page 19

[11] Characteristics of the Conventional and the New Refrigerants

1. Chemical property

As with R22, refrigerants R410A and R134A are low in toxicity and chemically stable nonflammable refrigerants.

However, because the specific gravity of vapor refrigerant is greater than that of air, leaked refrigerant in a closed room will

accumulate at the bottom of the room and may cause hypoxia.

If exposed to an open flame, refrigerant will generate poisonous gases. Do not perform installation or service work in a confined area.

*1 When CFC11 is used as a reference

*2 When CO

2

is used as a reference

2. Refrigerant composition

R410A is a pseudo-azeotropic HFC blend and can almost be handled the same way as a single refrigerant, such as R22. To

be safe, however, draw out the refrigerant from the cylinder in the liquid phase. If the refrigerant in the gaseous phase is drawn

out, the composition of the remaining refrigerant will change and become unsuitable for use.

If the refrigerant leaks out, it may be replenished. The entire refrigerant does not need to be replaced.

3. Pressure characteristics

R410A has slightly higher operating pressure compared with R22.

New Refrigerant (HFC type)

R410A

R32/R125

)05/05()%tw( noitisopmoC

ciportoeza-oduesPtnaregirfeR fo epyT

Refrigerant

dedulcni toNedirolhC

1A/1AssalC ytefaS

6.27thgieW raluceloM

-/4.15-)F/C( tnioP gnilioB 60.5

Steam Pressure

(25 C,MPa/77 F,psi) (gauge)

1.557/226

Saturated Steam Density

(25 C,kg/m

3

/77 F, psi)

64.0

elbammalfnoNytilibammalF

Ozone Depletion Coefficient (ODP)

*1

0

Global Warming Coefficient (GWP)

*2

1730

Refrigerant Charging Method Refrigerant charging in

the liquid state

Replenishment of Refrigerant after a Refrigerant

Leak

Available

Temperature ( C/ F )

Pressure (gauge)

R410A R134a R22

MPa/psi MPa/psi MPa/psi

-20/-4 0.30/44 0.13/19 0.14/20

0/32 0.70/102 0.29/42 0.40/58

20/68 1.34/194 0.57/83 0.81/117

40/104 2.31/335 1.02/148 1.44/209

60/140 3.73/541 1.68/244 2.33/338

65/149 4.17/605 1.89/274 2.60/377

R134a

R134a

(100)

Single-

Refrigerant

Not contained

A1/A1

102.0

-26.1/-15.0

0.67/97

32.3

Non-flammable

0

1300

Liquid charging

Possible

- 16 -

Page 20

- 17 -

[12] Notes on Refrigerating Machine Oil

1. Refrigerating machine oil in the HFC refrigerant system

HFC type refrigerants use a refrigerating machine oil different from that used in the R22 system.

Note that the ester oil used in the system has properties that are different from commercially available ester oil.

2. Effects of contaminants

*1

Refrigerating machine oil used in the HFC system must be handled with special care to keep contaminants out.

The table below shows the effect of contaminants in the refrigerating machine oil on the refrigeration cycle.

3. The effects of contaminants in the refrigerating machine oil on the refrigeration cycle.

Refrigerant Refrigerating machine oil

HAB

Ester oil

R134a

R410A

*1.Contaminants is defined as moisture, air, processing oil, dust/dirt, wrong types of refrigerant, and refrigerating machine oil.

stceffEsmotpmySesuaC on the refrigerant cycle

evlav noisnapxe nezorFnoitartlifni retaW

and capillary tubes

Clogged expansion valve and capillary tubes

Poor cooling performance

Compressor overheat

Motor insulation failure

Burnt motor

Coppering of the orbiting scroll

Lock

Burn-in on the orbiting scroll

Hydrolysis

Sludge formation and adhesion

Acid generation

Oxidization

Oil degradation

Air infiltration Oxidization

Infiltration of

contaminants

Dust, dirt

Adhesion to expansion valve and capillary

tubes

Clogged expansion valve, capillary tubes, and

drier

Poor cooling performance

Compressor overheat

Infiltration of contaminants into the compressor

Burn-in on the orbiting scroll

Mineral oil

etc.

Sludge formation and adhesion Clogged expansion valve and capillary tubes

Poor cooling performance

Compressor overheat

llorcs gnitibro eht no ni-nruBnoitadarged liO

Page 21

Unit Unit

Unit

Remote

BC controller

controller

2-core cable

2-core cable

Remote

controller

Unit

Multiple-

core cable

BC controller

PWFY-P100VM-E-BU

Type of cable

Cable diameter

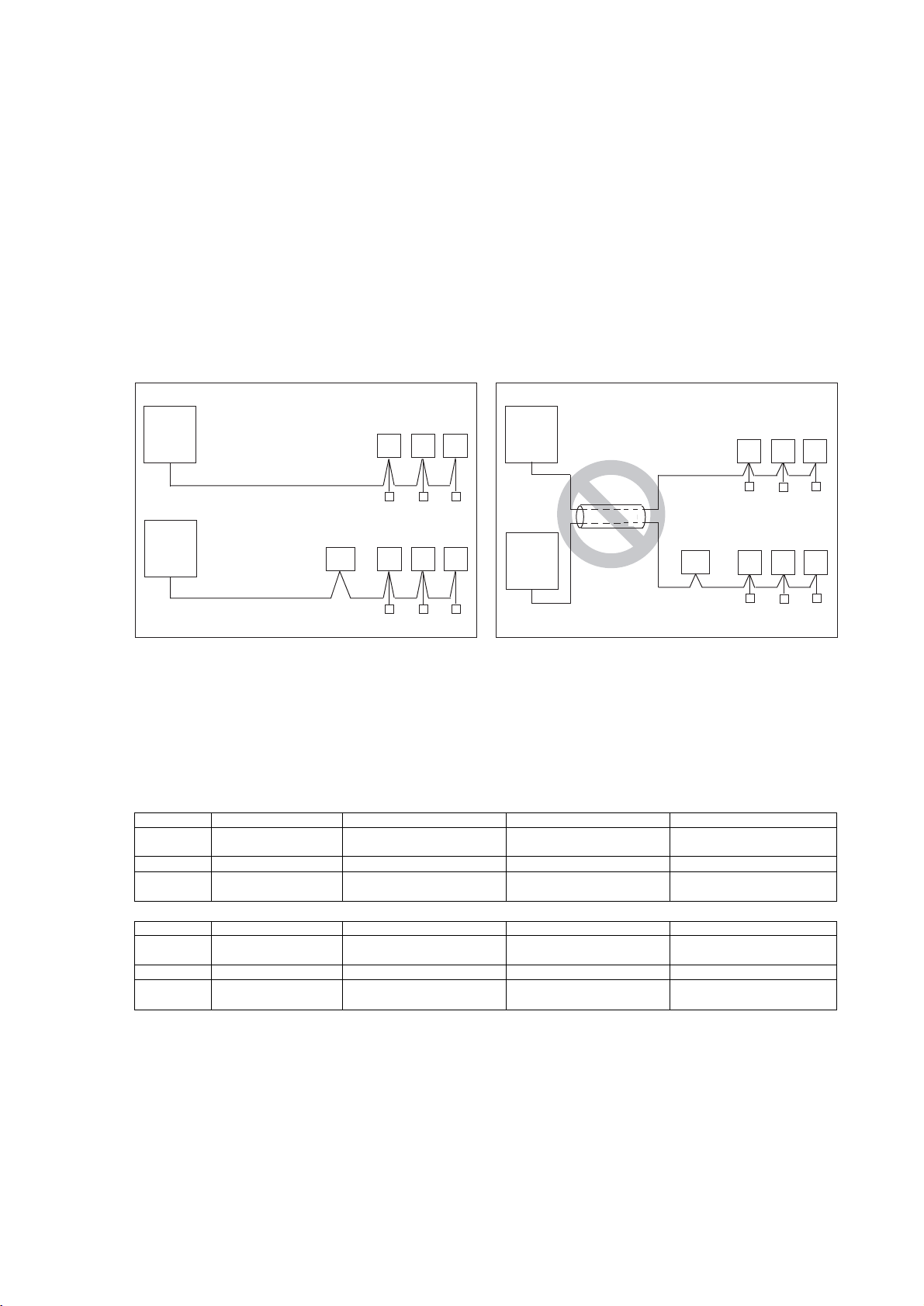

Remarks

Transmission cables

Shielding wire (2-core)

CVVS, CPEVS or MVVS

More than 1.25 mm

2

-

MA Remote controller cables

Sheathed 2-core cable (shielded)

CVVS

0.3 ~ 1.25 mm2 (0.75 ~ 1.25 mm2)*1

Max.length: 200 m

External input

Sheathed multi-core cable (shielded)

CVVS or MVVS

0.3 ~ 0.5 mm

2

Max.length: 100 m

External output

Sheathed multi-core cable (unshielded)

CVV or MVV

0.3 ~ 1.25 mm

2

Rated voltage: L1-N: 220 ~

240 V

Rated load: 0.6 A

PWFY-P100/200VM-E-AU

Type of cable

Cable diameter

Remarks

Transmission cables

Shielding wire (2-core)

CVVS, CPEVS or MVVS

More than 1.25 mm

2

-

MA Remote controller cables

Sheathed 2-core cable

CVV (unshielded)

0.3 ~ 1.25 mm2 (0.75 ~ 1.25 mm2)*1

Max.length: 200 m

External input

Sheathed multi-core cable

CVV or MVV (unshielded)

0.3 ~ 0.5 mm

2

Max.length: 100 m

External output

Sheathed multi-core cable (unshielded)

CVV or MVV

0.3 ~ 1.25 mm

2

Rated voltage: L1-N: 220 ~

240 V

Rated load: 0.6 A

*1 Connected with simple remote controller. CVVS, MVVS: PVC insulated PVC jacketed shielded control cable

CVV, MVV

: PVC insulated PVC sheathed control cable

CPEVS :

PE insulated PVC jacketed shielded communication cable

[1] Types and Maximum allowable Length of Cables

1. Wiring work

(1) Notes

1) Have all electrical work performed by an authorized electrician according to the local regulations and instructions in this manual.

2) Install external transmission cables at least 5cm [1-31/32"] away from the power supply cable to avoid noise interference.

(Donot put the control cable and power supply cable in the same conduit tube.)

3) Provide grounding for the outdoor unit as required.

4) Run the cable from the electric box of the indoor or outdoor unit in such way that the box is accessible for servicing.

5) Do not connect power supply wiring to the terminal block for transmission line. Doing so will damage the electronic components on the terminal block.

6) Use 2-core shielded cables as transmission cables.

Use a separate 2-core control cable for each refrigerant system. Do not use a single multiple-core cable to connect indoor

units that belong to different refrigerant systems. The use of a multiple-core cable may result in signal transmission errors and

malfunctions.

(2) Control wiring

Types and maximum allowable length of cables

Control lines are categorized into 2 types: transmission line and remote controller line.

Use the appropriate type of cables and observe the maximum allowable length specified for a given system. If a given system

has a long transmission line or if a noise source is located near the unit, place the unit away from the noise source to reduce

noise interference.

- 18 -

™™

Restrictions

Page 22

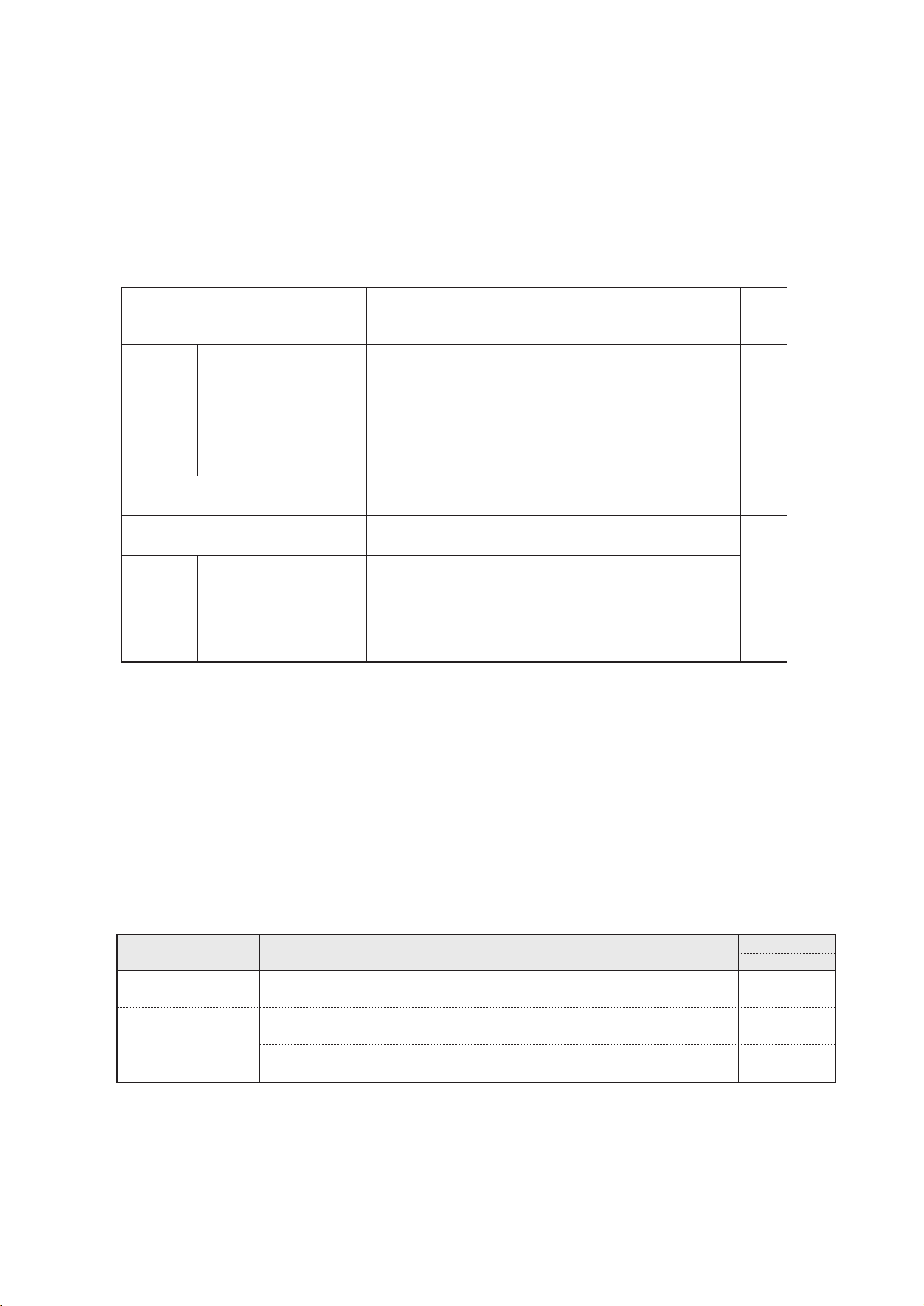

00

Main

00

Address (1) setting varies depending on the system configuration. See “[3] Examples of system connection”

section for details.

Unit or controller

Address

Setting method

setting range

Unit Main/sub units

MA remote controller

Outdoor unit

0, 01~50

(Note 1)

0, 51~100

(Note 1, 2, 3)

52~100

(Note 2, 3)

Factory

setting

Type and method of switch setting

Switch setting vary depending on the system configuration. Make sure to read “[3] Examples of system connection”

before conducting electrical work. Turn off the power before setting the switch. Operating the switch while the unit is

being powered will not change the setting, and the unit will not properly function.

Notes:

1. Address setting is not required for a single refrigerant system (with a few exception).

2. When setting the unit and outdoor auxiliary unit address to “100,” make it “50.”

3. When an address in a system overlapped with the heat source unit or BC controller (Main) address of other refrigerant system,

choose an another address within the set range that is not in use (with a few exceptions).

4. BC controller is found only in the R2 systems.

Use the address that equals the sum of the smallest indoor

unit address in the same refrigerant system and 50.

Use the address that equals the sum of the smallest

address of the indoor unit out of all the indoor units

that are connected to the BC controller and 50.

When a sub BC controller is connected, the automatic

start up function will not be available.

Auxiliary

units

BC controller (Sub)

Use the address that equals the sum of the address of the

heat source unit in the same refrigerant system and 1.

BC controller (Main)

Assign the smallest address to the indoor unit to

become the main unit within the same group, and

then use sequential numbers to assign an address

to all the indoor units in the group.

If applicable, set the sub BC controllers in an R2

system in the following order:

(1)

Indoor unit to be connected to the main BC controller

(2)

Indoor unit to be connected to No.1 sub BC controller

(3)

Indoor unit to be connected to No.2 sub BC controller

Set the address so that (1) < (2) < (3)

No address setting required. (When operating with 2 remote controllers,

the main/sub selector switch must be set.

Various start-stop controls (Unit settings)

Each unit (or group of units) can be controlled individually by setting SW 1-3 and 1-4.

(3)

Unit port switch setting (R2 series (Factory Setting: “0”))

Make the settings for the port switch that corresponds to the connected BC (Main/Sub) controller.

When more than two ports are used, make the setting on the port with a smaller port number.

(2)

Operation of the indoor unit when the operation is resumed after the unit was stopped

Function

Setting (SW1) (Note 2)

Power ON/OFF by the

plug (Note 1)

Unit will go into operation regardless of its operation status before power off

(power failure). (In approx. 5 minutes)

Unit will remain stopped regardless of its operation status before power off

(power failure).

Unit will go into operation if it was in operation when the power was turned off

(or cut off due to power failure). (In approx. 5 minutes)

34

OFF OFF

ON ON

OFF ON

(Note 1) Do not cut off power to the outdoor unit.

Cutting off the power supply to the outdoor unit will cut off the power supply to the crankcase heater and may cause the

compressor to malfunction when the unit is put back into operation.

(Note 2) Requires that the dipswitch settings for all the units in the group be made.

Automatic restoration

after power failure

- 19 -

[2] Types of Switch Setting and Address Setting

1. Switch setting

2. Address setting

Page 23

• Connect the “1” and “2” on unit TB15 to a MA remote controller. (Non-polarized 2-wire)

MA Remote controller

TB02

TB15

earth cable

(shielded)

TB5

SM1M2 SM1M2

TB3

M1M2

(A) (B) (C)

(D)

(E)

(E)

1 2S

TB15TB5

SM1M2 1 2

(shielding wire)

(A) Outdoor unit

(B) BC controller

(C) PWFY-P100VM-E-BU

(D) PWFY-P100, 200VM-E-AU

(E) MA remote controller

• DC 10 to 13 V between 1 and 2 (MA remote controller)

• The MA remote controller cannot be used at the same time or interchangeably.

Note:

Ensure that the wiring is not pinched when fitting the terminal box cover. Pinching the wiring may cut it.

Caution:

• Use wire with supplemental insulation.

• Input to TB142A, TB142B, and TB142C should not carry voltage.

• Cables from equipment connected to external input/output should have supplemental insulation.

• Use a single multiple-core cable for external input/output to allow for connection to the PG screw.

Caution:

Wire the power supply so that no tension is imparted. Otherwise disconnection, heating or fire result.

(B)

(A)

S

2

1

L

N

DC10~13V

12

AB

(C)

S

M2

M1

(D)

(E)

2

S

M2

M1

(A)

(B)

(D)

(E)

1

L

N

DC10~13V

AB

12

(C)

(A) Non-polarized

(B) TB15 (MA remote controller cables)

(C) MA remote Controller

(D) TB5 (Transmission cables)

(E) TB2 (Power supply wiring)

PWFY- P100VM-E-BU PWFY- P100, 200VM-E-AU

- 20 -

[3] Examples of system connection

1. Connecting remote controller, indoor and outdoor transmission cabls

• Connect unit TB5 and outdoor unit TB3. (Non-polarized 2-wire (shield))

The “S” on unit TB5 is a shielding wire connection. For specifications about the connecting cables, refer to

the outdoor unit installation manual.

• Install a remote controller following the manual supplied with the remote controller.

2. System using MA remote controller

(1) In the case of single refrigerant system (Automatic address set-up)

[4] Restrictions on piping length

The same piping length restrictions apply as the ones that apply to the conventional indoor units.

Refer to the Service Manual that came with the outdoor unit for restrictions on piping length.

Design the water piping system so that the total amount of water held in the system is 100 liter or less.

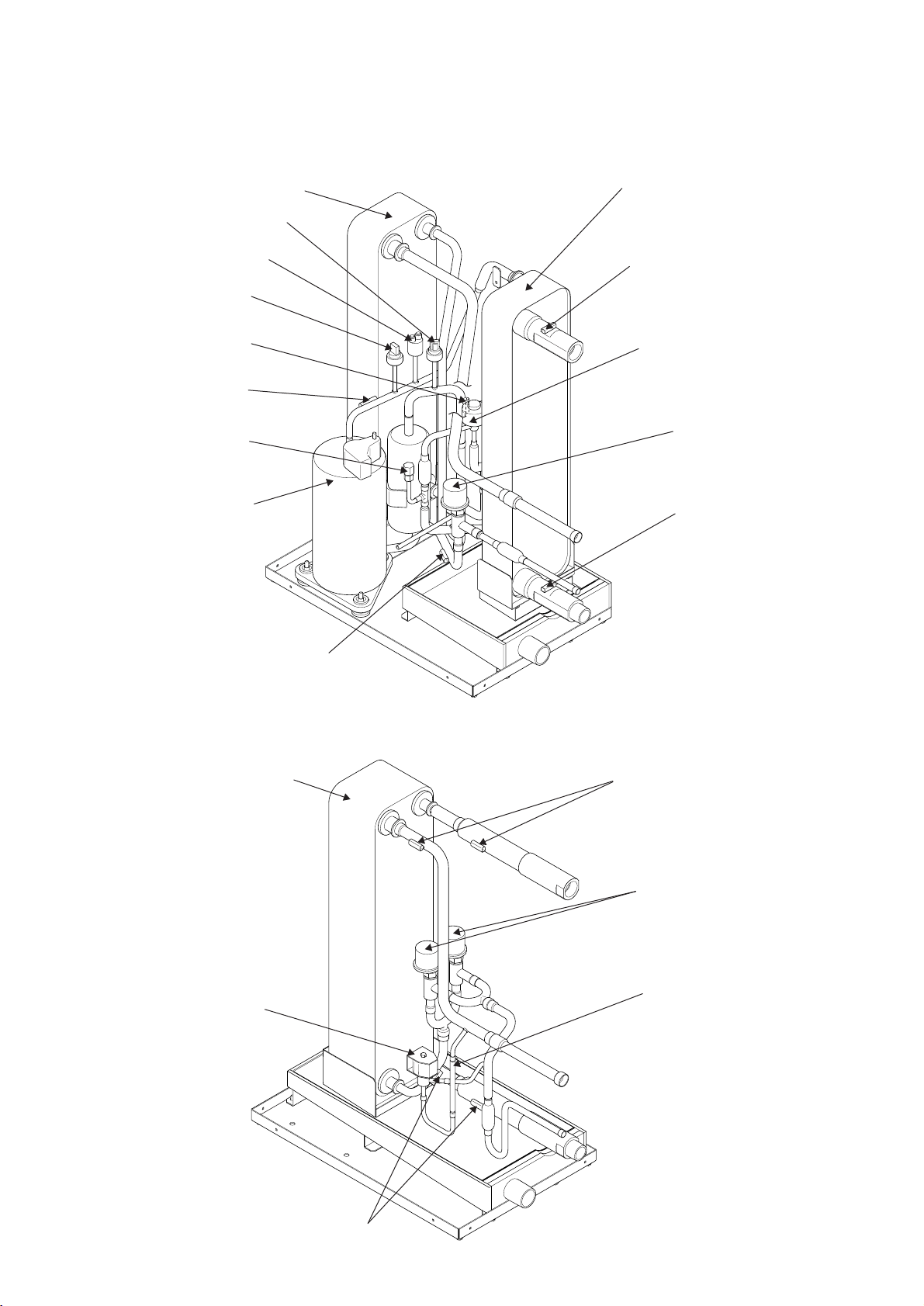

Page 24

Heat exchanger assy

Pressure sensor (63LS)

Pressure switch (63H1)

Pressure sensor (63HS)

Thermistor (TH11)

Check joint

Compressor

Heat exchanger assy

Linear expansion valve

Linear expansion valve coil

(LEV2W)

Linear expansion valve

(LEV1W)

Thermistor (TH8)

Thermistor (TH6)

Thermistor (TH22)

Thermistor (TH13)

- 21 -

££

Components of the Unit

[1] Appearance of the Components and Refrigerant Circuit

< PWFY-P100VM-E-BU >

Heat exchanger assy

Solenoid valve

Solenoid valve coil (SV)

Thermistor (TH6,TH22)

Check valve

Linear expansion valve

(LEV1Wa,b)

Thermistor (TH8,TH23)

< PWFY-P100, 200VM-E-AU >

Page 25

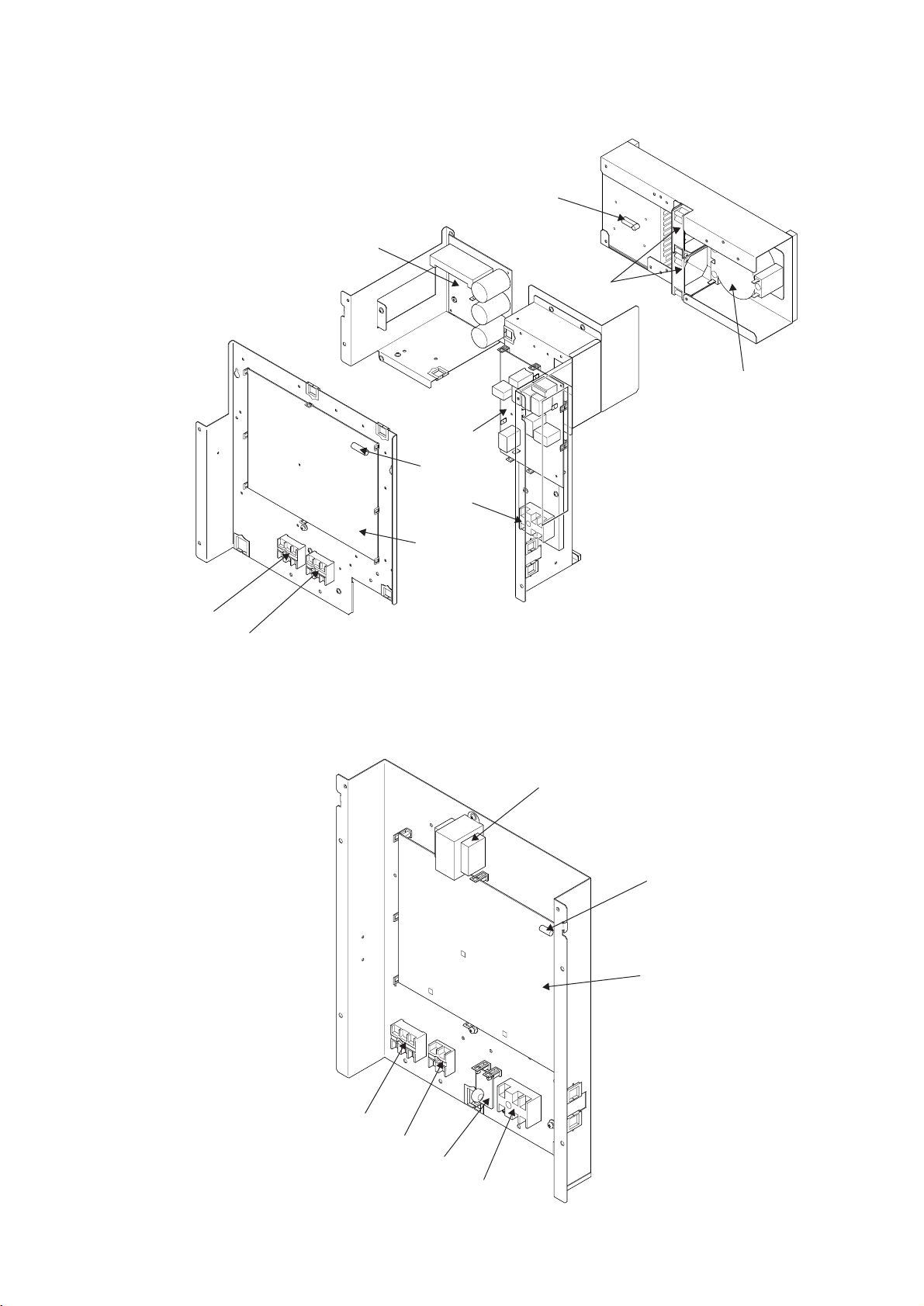

- 22 -

Thermistor (THHS)

INV board

Fan

Noise filter

Te r minal block

(TB2)

Te r minal block

(TB5)

Te r minal block (TB15)

Control board

Fuse

Reactor

Tr ansformer

Fuse

Control board

Te r minal block assy (TB5)

Te r minal block assy (TB15)

DSA board

Te r minal block assy

(TB2)

[2] Control Box

< PWFY-P100VM-E-BU >

< PWFY-P100, 200VM-E-AU >

Page 26

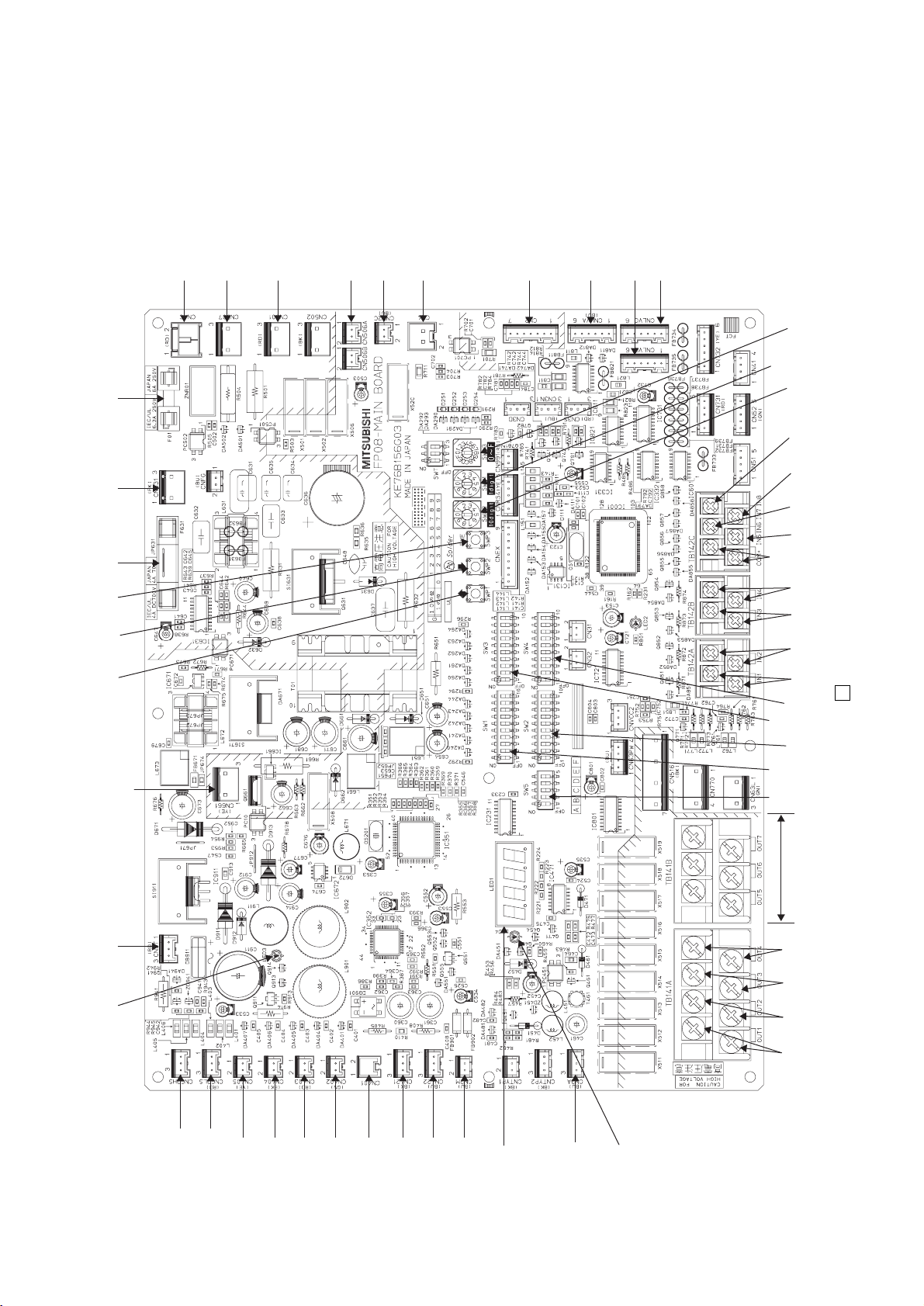

- 23 -

TB141A

(OUT1)

TB141A, TB142A, TB142B, TB142C : Refer to 5 Electrical Wiring Diagram

TB142A

(IN1)

TB142A

(IN2)

TB142B

(IN3)

TB142B

(IN4)

TB142C

(IN5)

TB142C

(IN6)

TB142C

(IN7)

TB142C

(IN8)

TB142C

(COM

+

)

TB141B

SW5 SW1 SW3

SW2 SW4

SWU1

SWU2

CNLVC

CNLVB

CNLVA

CN2

CN4

CN52C

CN506A,B

CN501

CN507

CNAC

F01CN631CN661

(63H1)

F631SWP3SWP2SWP1CN3TLED3

LED4

LED1

CN2M

CN422

CN421

CN401

CN402

CN403

CN404

CN405

CN63LS

CN63HS

CN3A

SWU3

TB141A

(OUT2)

TB141A

(OUT3)

TB141A

(OUT4)

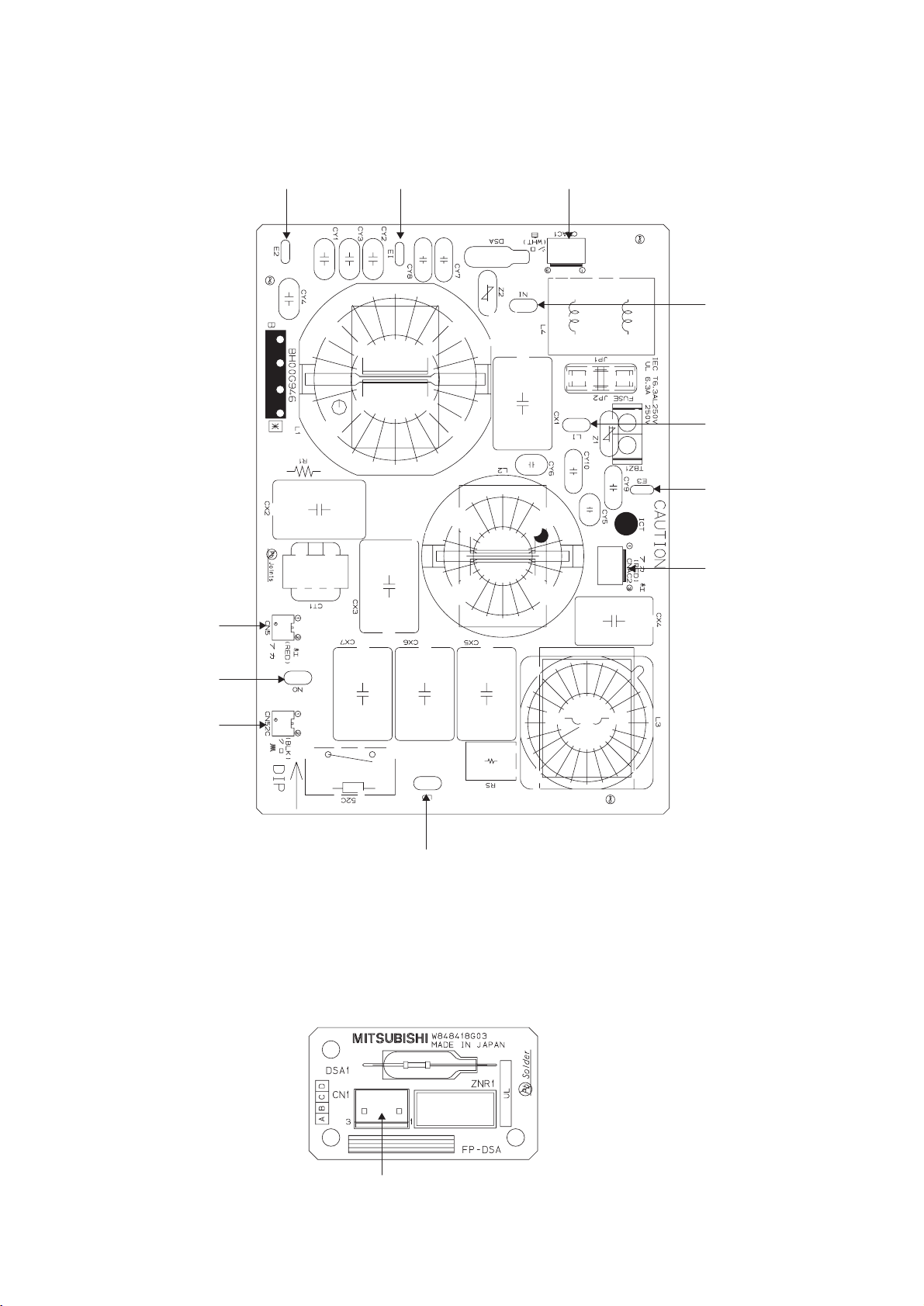

[3] Circuit Board

1. Main board

< PWFY-P100VM-E-BU, PWFY-P100, 200VM-E-AU >

Page 27

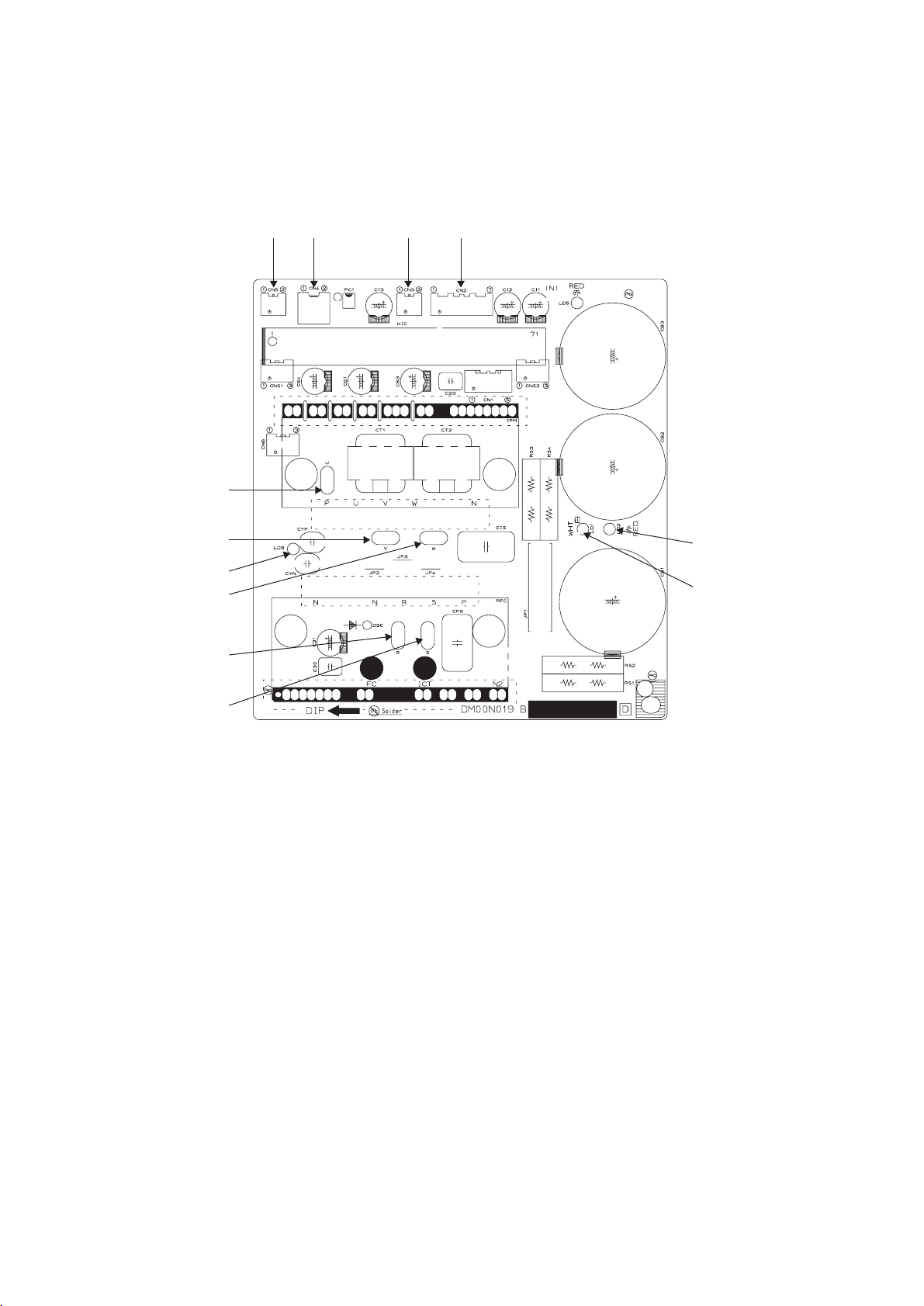

- 24 -

CN5

U

V

LD9

LD2

LD1

W

R

S

CN4 CN3 CN2

2. Power board

< PWFY-P100VM-E-BU >

Page 28

- 25 -

CN5

CN52C

LO

CNAC2

E3

LI

NI

E2 E1 CNAC1

NO

3. Noise filter

CN1

4. DSA

< PWFY-P100VM-E-BU >

< PWFY-P100,200VM-E-AU >

Page 29

- 26 -

Function/specification

Remote controller address setting Not required

Indoor/outdoor unit address setting Not required (required only by a system with one outdoor unit)

Wiring method Non-polar 2 wires

✻ Daisy-chain the units with non-polar 2 wires when running

a group operation.

Installation location of remote controller Connectable to any unit in the group

Making group changes MA remote controller wires between units require rewiring.

MA remote controller

¢¢

Remote Controller

[1] Functions and Specifications of MA Remote Controller

MA remote controller is connected to each unit.

Page 30

- 27 -

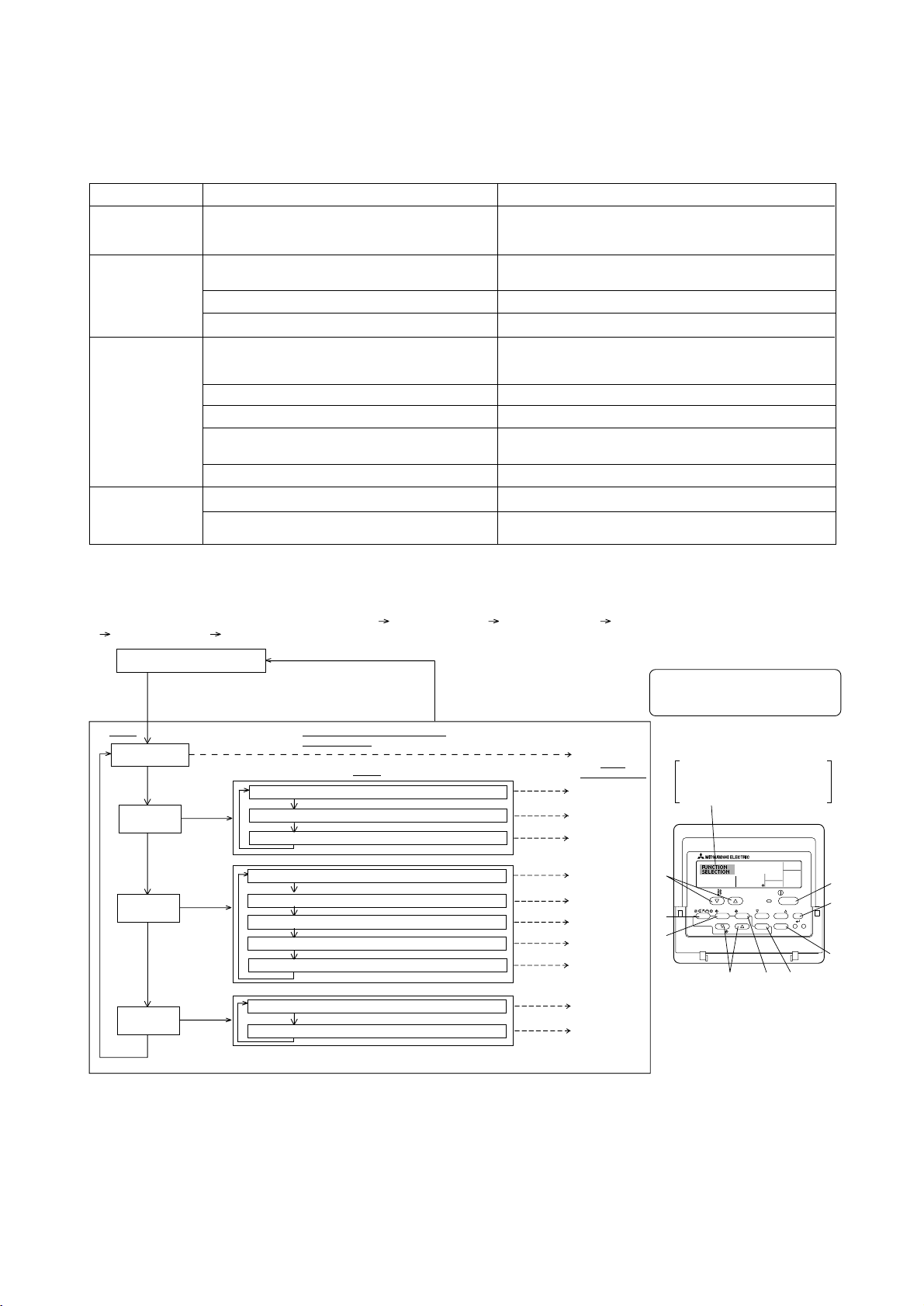

[2] Interlocking Setting via the MA Remote Controller

1. Remote controller function selection via the MA remote controller

Item 3 (Setting content)

• Display in multiple languages is possible

• Setting the range of operation limit (operation lock)

• Setting the use or non-use of each operation mode

• Setting the temperature adjustable range (maximum, minimum)

• Selecting main or sub remote controller

* When two remote controllers are connected to one group, one

controller must be set to sub.

• Setting the use or non-use of clock function

• Setting the timer type

• Contact number display in case of error

• Setting the telephone number

• Setting the use or non-use of setback amount setting

• Setting the temperature unit (

˚C or ˚ F) to display

• Setting the use or non-use of the display of water temperature

Function selection of remote controller

The setting of the following remote controller functions can be changed using the remote controller function selection mode. Change the setting when needed.

Item 1

1. Change Language

(“CHANGE

LANGUAGE”)

2. Function limit

(“FUNCTION

SELECTION”)

3. Mode selection

(“MODE SELECTION”)

4. Display change

(“DISP MODE

SETTING”)

Item 2

Language setting to display

(1) Operation function limit setting (operation lock) (“LOCKING

FUNCTION”)

(2) Operation mode skip setting (“SELECT MODE”)

(3) Temperature range limit setting (“LIMIT TEMP FUNCTION”)

(1) Remote controller main/sub setting (“CONTROLLER MAIN/

SUB”)

(2) Use of clock setting (“CLOCK”)

(3) Timer function setting (“WEEKLY TIMER”)

(4) Contact number setting for error situation (“CALL.”)

(5) Temp off set setting (“TEMP OFF SET FUNCTION”)

(1) Temperature display

˚C/˚ F setting (“TEMP MODE ˚C/˚ F”)

(2) Water temperature display setting (“WATER TEMP DISP

SELECT”)

(Hold down the E button and press the D button for two

seconds.)

* The display cannot be changed during the test run and

the self diagnosis.

(Hold down the E button and press

the D button for two seconds.)

* The remote controller records the

setting that is made in this way.

Press the

G button.

See [3]–1

Item 3

(Setting content)

See [3]–2. (1)

See [3]–2. (2)

See [3]–2. (3)

See [3]–3. (1)

See [3]–3. (2)

See [3]–3. (3)

See [3]–3. (4)

See [3]–3. (5)

See [3]–4. (1)

See [3]–4. (2)

Item 1 Remote Controller Function

Selection Mode

Item 2

Normal display (Display when

the unit is not running)

Change Language

(“CHANGE LANGUAGE”)

Function limit

(“FUNCTION

SELECTION”)

NOTE

Timer operation stops when the display for

remote controller function selection is

changed to the normal one.

Press the G button.

Press the

E button.

Press the

D button.

Operation function limit setting (“LOCKING FUNCTION”)

Press the G button.

Temperature range limit setting (“LIMIT TEMP FUNCTION”)

Dot display

The language that is selected in

CHANGE LANGUAGE mode appears on this display. English is

set in this manual.

Mode selection

(“MODE

SELECTION”)

Display change

(“DISP MODE

SETTING”)

Press the

E button.

Press the

E button.

Press the

E button.

Press the

G button.

Press the

G button.

Operation mode skip setting (“SELECT MODE”)

Press the

D button.

Temperature display ˚C/˚F setting (“TEMP MODE ˚C/˚F”)

Press the G button.

Water temperature display setting (“WATER TEMP DISP SELECT”)

Press the

D button.

Remote controller main/sub setting (“CONTROLLER MAIN/SUB”)

Press the G button.

Timer function setting (“WEEKLY TIMER”)

Use of clock setting (“CLOCK”)

Temp off set setting (“TEMP OFF SET FUNCTION”)

Contact number setting for error situation (“CALL.”)

Function selection flowchart

[1] Stop the unit to start remote controller function selection mode. [2] Select from item 1. [3] Select from item 2. [4] Make the setting. (Details are specified in item

3) [5] Setting completed. [6] Change the display to the normal one. (End)

F

TEMP.

MENU

ON/OFF

E

BACK DAY

PAR-W21MAA

G

MONITOR/SET

CLOCK CLEAR

C

INITIAL SETTING

CHECK TEST

D

ON/OFF

CIR.WATER

H

I

A

B

Page 31

- 28 -

Detailed setting

[3]–1. CHANGE LANGUAGE setting

The language that appears on the dot display can be selected.

• Press the [

MENU] button to change the language.

1 English (GB), 2 German (D), 3 Spanish (E), 4 Russian (RU),

5 Italian (I), 6 French (F), 7 Swedish

[3]–2. Function limit

(1) Operation function limit setting (operation lock)

• To switch the setting, press the [

ON/OFF] button.

1 no1 : Operation lock setting is made on all buttons other than the

[

ON/OFF] button.

2 no2 : Operation lock setting is made on all buttons.

3 OFF (Initial setting value) : Operation lock setting is not made.

* To make the operation lock setting valid on the normal screen, it is necessary to

press buttons (Press and hold down the [CIR.WATER] and [

ON/OFF] buttons

at the same time for two seconds.) on the normal screen after the above setting

is made.

(2) Operation mode skip setting

After setting is changed, the operation mode can not be changed within the changed

range.

• To switch the following settings, press the [

ON/OFF] button.

1 Heating mode : Sets the use or non-use of the Heating mode.

2 Heating ECO mode : Sets the use or non-use of the Heating ECO

mode.

3 Hot Water mode : Sets the use or non-use of the Hot Water mode.

4 Anti-freeze mode : Sets the use or non-use of the Anti-freeze

mode.

5 Cooling mode : Sets the use or non-use of the Cooling mode.

6 OFF (Initial setting value) : Operation mode skip is not executed.

* When the setting, other than OFF, is made, the skip settings of the Heating,

Heating ECO, Hot Water, Anti-freeze, and Cooling modes are executed at the

same time.

*A mode that is not available on the unit to connect cannot be used even if the

setting is “AVAILABLE.”

(3) Temperature range limit setting

After this setting is made, the temperature can be changed within the set range.

• To switch the setting, press the [

ON/OFF] button.

1 LIMIT TEMP HEATING MODE:

The temperature range can be changed on heating mode.

2 LIMIT TEMP HOT WATER MODE:

The temperature range can be changed on heating/hot water mode.

3 LIMIT TEMP ANTI-FREEZE MODE:

The temperature range can be changed on anti-freeze mode.

4 LIMIT TEMP COOLING MODE:

The temperature range can be changed on cooling mode.

5 OFF (Initial setting) : The temperature range limit is not active.

* When the setting, other than OFF, is made, the temperature range limit setting

on hot water, anti-freeze and cooling mode is made at the same time. However,

the range cannot be limited when the set temperature range has not changed.

• To increase or decrease the temperature, press the [

TEMP. or ]

button.

• Settable range

Hot Water mode : Lower limit: 30 ~70

˚C (87 ~158 ˚F)

Upper limit: 70 ~30

˚C (158 ~ 87 ˚ F)

Heating mode : Lower limit: 30 ~45

˚C (87 ~113 ˚F)

Upper limit: 45 ~30

˚C (113 ~ 87 ˚ F)

Cooling mode : Lower limit: 10 ~30

˚C (50 ~ 87 ˚F)

Upper limit: 30 ~10

˚C (87 ~ 50 ˚F)

* The settable range varies depending on the unit to connect.

[3]–3. Mode selection setting

(1) Remote controller main/sub setting

• To switch the setting, press the [

ON/OFF] button D.

1 Main : The controller will be the main controller.

2 Sub : The controller will be the sub controller.

(2) Use of clock setting

• To switch the setting, press the [

ON/OFF] button D.

1 ON : The clock function can be used.

2 OFF : The clock function cannot be used.

(3) Timer function setting

• To switch the setting, press the [

ON/OFF] button D (Choose one of the

followings.).

1 WEEKLY TIMER (Initial setting value): The weekly timer can be used.

2 AUTO OFF TIMER : The auto off timer can be used.

3 SIMPLE TIMER : The simple timer can be used.

4 TIMER MODE OFF : The timer mode cannot be used.

* When the use of clock setting is OFF, the “WEEKLY TIMER” cannot be used.

(4) Contact number setting for error situation

• To switch the setting, press the [

ON/OFF] button D.

1 CALL OFF : The set contact numbers are not displayed in case of error.

2 CALL **** *** **** : The set contact numbers are displayed in case of error.

CALL_ : The contact number can be set when the display is as

shown on the left.

• Setting the contact numbers

To set the contact numbers, follow the following procedures.

Move the flashing cursor to set numbers. Press the [

TEMP. or

] button F to move the cursor to the right (left). Press the [ CLOCK

or ] button C to set the numbers.

(5) Temp off see. setting

• To switch the following settings, press the [

ON/OFF] button D.

1 ON : The setback amount setting is displayed under the water temperature

initial setting mode.

2 OFF : The setback amount setting is not displayed under the water tempera-

ture initial setting mode.

[3]–4. Display change setting

(1) Temperature display ˚C/˚ F setting

• To switch the setting, press the [

ON/OFF] button D.

1 ˚C: The temperature unit

˚C is used.

2 ˚F: The temperature unit

˚F is used.

(2) Water temperature display setting

• To switch the setting, press the [

ON/OFF] button D.

1 ON : The water temperature is displayed.

2 OFF : The water temperature is not displayed.

Page 32

- 29 -

∞∞

Electrical Wiring Diagram

[1] PWFY-P100VM-E-BU

M

4-20mA

4-20mA

gray

2

1

gray

black

To outdoor unit/

BC controller

To MA remote

controller

Power Supply

~220/230/240V

50Hz/60Hz

3

2

1

blue

red

yellow/green

bluered

CN4

63LS

CN63HS

1

1

3

2

2

3

THHS

12

CN63LS

123

t∞

TH8

2

1

CN403

red

t∞

TH6

1

2

CN404

black

t∞

31

CT1

Moter

3~

CYN

RS4

MS

RS3

(Compressor)

CN3A

blue

U

t∞

red

yellow

TH22

CN405

IPM

W

V

U

black

1

63HS

7

2

1

3

1

2

CN3

2

1

t∞

CN401

CN2

256

t∞

red

CN5

2

1

TH11

1

2

TH13

2

1

white

CN402

green

red

5

6

RS1

black

2

CN52C

R1

LO

U

CNAC2

red

2

CN5

1

1

2

red

blue

red

LEV2W

M

LI

24V

blue

+

CB3

Z2

1

U

CT1

LEV1W

1

CN2

63H1

6

5

CNAC

2

red

1

CX2

L

CN506A

L3

N

6

5

N

CN-E1

CN631

DSA

pink

E2

3

1

E1

432

1

CY4

P

CY3

31

L4

Z1

NI

CB1

+

1

TB2

CN661

2L23

X506

W

4

CN4

blue

U

CN52C

1

2

+

CX3

INV control

circuit

PFC

E3

1

L1

2

M

ZNR01

ACL

CY1CY2

CT2

Noise

Filter

red

Fan motor

1

3

(DC)

CX5

CYP

CIS

CX6

1

2

7

V

yellow

LED3:Lit when powered

INV Board

Control Board

CB2

(DC)

CY6

S

CX4

R

CNAC1

M

CNLVA

NO

Fan motor

3

1

2

RS2

CY5

P

CNLVB

blue

CX1

CX7

CN506B

CPS

+

RS

F01

AC250V

6.3A

F631

DC700V

4A

Power

Supply circuit

blue

red

TB5

M1 M2

S(SHIELD) S(SHIELD)

TB15

yellow

purple

black

orange

gray

red

black

white

gray

gray

52C

1

2

CN2M

blue

31

*4

IN2

TB141B

TB142B

IN6

COM+

OUT5

TB142C

OUT7

OUT6

X515 X517

X516

IN8

IN5 IN7

TB142A

X514

OUT2

X512

X511 X513

OUT1 OUT3

OUT4

TB141A

*5 *6 *7

IN3 IN4

COM+

LED4:Remote controller

when powered

SWU1

10

SW1

5

ON

OFF

1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

SWP3

SW5

SWP1

SWU3

SWP2

SWU2

OFF

ON

110

SW4

OFF

ON

110

LED1

OFF

ON

1

SW3

OFF

ON

110

SW2

IN1

gray

CN421

black

31

CN422

blue

IN1

IN2

31

CN421

black

31

CN422

blue

2

2

2

2

BC controller/outdoor unit

Booster unit

Linear

expansion valve

LEV1W

LEV2W

IN7 Anti-freeze

IN6 Heating ECO

Symbol

Function

COM+ Common

IN5 Hot water

IN4 Operation ON/OFF

Connection demand

Symbol

IN3

Function

Symbol

Pump interlock

Function

IN1

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

Function

Symbol

OUT1 Operation ON/OFF

OUT2 Defrost

OUT3 Compressor

OUT4 Error signal

<HIGH VOLTAGE WARNING>

Control box houses high-voltage parts.

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes,and confirm that the voltage

CN631 on Control Board has dropped to DC20V or less.

<CAUTION FOR INSTALLATION>

Prior to installation,read the Installation Manual carefully.

*1.Single-dotted lines indicate wiring not supplied with the unit.

*2.Dot-dash lines indicate the control box boundaries.

*3.Faston terminals have a locking function.

Make sure the terminals are securely locked in place after insertion.

Press the tab on the terminals to removed them.

TH8 water outlet temp

TH6 water inlet temp

TH22 liquid pipe temp

TH13 Evaporator outlet temp

Compressor discharge tempTH11 Thermistor

TB15 MA remote controller

TB5 Outdoor unit/BC controller

AC reactor

Pressure

switch

High pressure switch

(High pressure protection for the booster unit)

Discharge pressure

Low pressure

TB2

CT1,CT2

ACL

THHS

Magnetic relay(main circuit)

Current sensor(AC)

Explanation

Ter minal

block

Power supply

IGBT temp

Pressure

sensor

Symbol

63H1

63HS

63LS

52C

<Symbol explanation>

Page 33

- 30 -

[2] PWFY-P100, 200VM-E-AU

gray

red

M

For opening/closing the bypass circuit

Solenoid valve

SV1

IN1

TB5

M1 M2

S(SHIELD)

To outdoor unit/

BC controller/

4-20mA

4-20mA

132

CN421

black

132

CN422

blue

132

CN422

blue

2

black

CN421

13

IN1

234

5

yellow/green

LEV1Wa

LEV1Wb

Linear

expansion valve

BC controller/outdoor unit

BC controller/outdoor unit

Function

Function

Function

black

yellow purple

bluered

NL

IN7

IN8IN6

IN5COM+

IN4IN3

orange

*3.Difference of appliance

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

Model name

Appliance

P100 *3 do not exist

P200 *3 exist

*7*6*5

*4

Cooling

TH23 gas pipe temp

CN502

black

COM+

TH8

TH6

TH23

t∞

t∞

t∞

blue

CN2M

2

1

2

1

CN402

green

2

1

CN403

red

1

2

CN404

black

yellow

CN405

t∞

TH22

1

2

21

To MA remote

controller

Power Supply

~220/230/240V

50Hz/60Hz

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1

TB15

ZNR1

U

DSA1

CN1

1

3

SWU2

SWU1

SWP3

SWP2

SWP1

OFF

ON

110

SW4

OFF

ON

110

SW3

OFF

ON

110

SW1

OFF

ON

110

SW2

LED4:Remote controller

when powered

5

CNLVC

6

1

LEV1Wb

123

4

X502

CN507

3

1

M

5

6

ON

OFF

1

SW5

SWU3

LED3:Lit when powered

Control Board

CNLVB

LEV1Wa

TB2

SV1

*3

DSA Board

CN3T

red

13

T01

ZNR01

3

1

1

2

CNAC

red

U

F01

AC250V

6.3A

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

OUT4

OUT3

OUT2

X514

X513

X512

TB141A

OUT1

X511

31

CN3A

blue

TB142CTB142B

X516

X517X515

OUT6

OUT7OUT5

TB141B

TB142A

IN2

IN8

IN7 Anti-freeze

IN6 Heating ECO

Symbol

COM+ Common

IN5 Heating

IN4 Operation ON/OFF

Connection demand

Symbol

IN3

Symbol

Pump interlockIN1

Function

Symbol

OUT1 Operation ON/OFF

OUT2 Defrost

OUT4 Error signal

<CAUTION FOR INSTALLATION>

Prior to installation,read the Installation Manual carefully.

*1.Single-dotted lines indicate wiring not supplied with the unit.

*2.Dot-dash lines indicate the control box boundaries.

TH8 water outlet temp

TH6 water inlet temp

TH22 liquid pipe temp

Thermistor

TB15 MA remote controller

TB5 Outdoor unit/BC controller

TB2

Explanation

Ter minal

block

Power supply

Symbol

<Symbol explanation>

Page 34

TH11

63H1

63HS

63LS

TH13

TH22

LEV1W

LEV2W

COMP

Water outlet

TH6

TH8

ST3

ST1

ST2

CJ

Brazed

Brazed

screw

screw

Water inlet

Hex

Hex

- 31 -

§§

Refrigerant Circuit

[1] Refrigerant Circuit Diagram

< PWFY-P100VM-E-BU >

< PWFY-P100VM-E-AU >

TH6

TH23

LEV1Wa

TH8

TH22

SV

CV1

ST2

ST3

Water inlet

Water outlet

screw

screw

Brazed

Brazed

< PWFY-P200VM-E-AU >

TH6

TH23

LEV1Wa

TH8

TH22

LEV1Wb

SV

ST2

ST4

CV1

Water inlet

Water outlet

screw

screw

Brazed

Brazed

Page 35

High-pressure shell rotary

compressor

20˚C[68˚F] : 0.583Ω

Pressure

0~3.60 MPa [522psi]

Vout 0.5~3.5V

0.071V/0.098 MPa [14psi]

Pressure [MPa]

=1.38 x Vout [V]-0.69

Pressure [psi]

=(1.38 x Vout [V] - 0.69) x 145

GND (Black)

Vout (White)

Vcc (DC5V) (Red)

Connector

Connector

63HS

1

123

2

3

Pressure

0~1.7 MPa [247psi]

Vout 0.5~3.5V

0.173V/0.098 MPa [14psi]

Pressure [MPa]

=0.566 x Vout [V] - 0.283

Pressure [psi]

=(0.566 x Vout [V] - 0.283) x 145

GND (Black)

Vout (White)

Vcc (DC5V) (Red)

63LS

1

123

2

3

Part

Name

Notes Usage Specifications Check method

Symbols

(functions)

1

273+t

Compressor

High

-pressure

sensor

Pressure

switch

Thermistor

MC1

63HS

R

120=7.465kΩ

R25/120=4057

Rt =

7.465exp{4057( - )}

Resistance value

check

Resistance value

check

1

393

1

273+t

R0=15kΩ

R0/80=3460

Rt =

15exp{3460( - )}

1

273

Adjusts the amount of circulating

refrigerant by adjusting the operating

frequency based on the operating

pressure data

63H1

TH11

(Discharge)

TH8

(Outlet water

temperature)

THHS

Inverter

heat sink

temperature

Heat sink

PWFY-P100,

200VM-E-AU

only

1) Detects high pressure

2) Provides high-pressure protection

1 Detects discharge temperature

2 Protects high pressure

Detects water temperature at the

outlet

TH6

(Inlet water

temperature)

TH13

Detects inlet water temperature

Controls inverter cooling fan, using

THHS temperature.

0˚C : 698kΩ 60˚C : 48kΩ

10˚C : 413kΩ 70˚C : 34kΩ

20˚C : 250kΩ 80˚C : 24kΩ

30˚C : 160kΩ 90˚C : 17.5kΩ

40˚C : 104kΩ 100˚C : 13.0kΩ

50˚C : 70kΩ 110˚C : 9.8kΩ

0˚C : 15kΩ 25˚C : 5.3kΩ

10˚C : 9.7kΩ 30˚C : 4.3kΩ

20˚C : 6.4kΩ 40˚C : 3.1kΩ

1

273+t

R0=17kΩ

R25/120=4170

Rt =

17exp{4170( - )}

1

323

0˚C : 181kΩ 25˚C : 50kΩ

10˚C : 105kΩ 30˚C : 40kΩ

20˚C : 64kΩ 40˚C : 26kΩ

3.60MPa[522psi] OFF setting

1) Detects high pressure

2) Regulates frequency and provides

high-pressure protection

Low

-pressure

sensor

63LS

1) Detects low pressure

2) Provides low-pressure protection

Solenoid

valve

SV1

Bypass

solenoid

valve (defrost)

A refrigerant bypass circuit that

functions to prevent water heat

exchanger from icing up during the

defrost cycle.

AC220~240V

Open when energized

Closed when not energized

Continuity check

with a tester

TH22

TH23

For LEV2 control

Controls compressor suction

superheat based on the difference

with the saturation temperature

yielded from the TH13 and 63LS

values.

Controls LEV1, using TH22, TH23

- 32 -

[2] Functions of Principal Parts

1. Unit

Page 36

DC12V

Opening of a valve driven by a

stepping motor 0-480

pulses

(direct driven type)

Linear

expansion

valve

LEV1

LEV2 PWFY-P100

VM-E-BU

only

1 Adjusts superheat at the unit heat

exchanger outlet during cooling

2 Adjusts subcool at the unit heat

exchanger outlet during hot water

or heating

Adjusts compressor suction

superheat

DC12V

Opening of stepping motor

driving valve 0-(1400) pulses

Refer to the section

on continuity test

with a tester

Continuity between

white-red-orange

Continuity between

yellow-brown-blue

YellowMBlueBrown

White

Red

Orange

Part

Name

Notes Usage Specifications Check method

Symbols

(functions)

- 33 -

Page 37

- 34 -

¶¶

Control

[1] Dip Switch Functions and Their Factory Settings

1. Unit

(1) Main board

Switch Function

Function according to switch setting

Switch setting timing

OFF ON

SW1

1T

Operation after power recovery

*1

Operation after power recovery

H0 thermistor selection Water inlet thermistor TH6 Water outlet thermistor TH8 Before power on

Before power on

Before power on

2- - - -

3

Remains stopped

Depends on the SW1-3 setting

Auto recovery (to the status

before power failure)

Forced to operate

*1 Valid only when SW1-4 is set to OFF

4

5- - - -

6- - - -

7Test-run mode OFF ON Any time

8Error history deleted Normal Deleted Any time

9

Effective only when SW1-7 is

set to ON and only on the AT W

models.

Heating Cooling Any time

10 - - - -

SW2 1-10

For self-diagnosis/operation

monitoring

--Any

t

ime

SW3

1Capacity setting (AT W only) 4HP 8HP (ATW only) Before power on

2Service LED display selection Display in Centigrade Display in Fahrenheit Any time

3- - - -

4- - - -

5

Cumulative compressor operation time is deleted.

Normal Deleted Any time

6- - - -

7- - - -

8- - - -

9- - - -

10 - - - -

SW4

1

2

3

Use to change pr

Do not change from factory setting.

Do not change from factory setting.

eset temperature range for the Heating ECO

mode.

HWS : Ineffective

ATW : Ine ffective

HWS : 30˚C to 50˚ C

ATW : 30 ˚C to 50˚C

Before power on

4

Use to change preset temperature range for the Anti-freeze

mode.

BU : Ineffective

WH : Ineffective

BU : 10˚C to 45 ˚C

WH : 10˚C to 45˚C

Before power on

5- - - -

6- - - -

7- - - -

8- - - -

9- - - -

10 - - - -

SW5

1

Error detection enabled

Enabling/disabling ACCT sensor

error detection

Error detection disable

(No load operation is possible)

Any time

2- - - -

3- - - -

4- - - -

Page 38

- 35 -

Model Frequency/heating Speed

PWFY-P100VM-E-BU 25~100Hz 2Hz/sec.

2. Frequency control

• The following table shows the frequency change of the inverter compressor during normal operation.

(1) Pressure limit

The maximum limit of high pressure (Pd) is set for frequency level. If this limit is exceeded, the frequency will

be reduced every 1 minute.

(2) Discharge temperature limit

• Control is performed 1 min after compressor start-up and every 1 min thereafter.

(3) Periodic frequency control