Page 1

AIR-COOLED SPLIT-TYPE DUCTED AIR CONDITIONERS

Series : PEH,PUH

HEAT PUMP

: Model

PEH-5,6,8,10,12,16,20MYC

PUH-5,6,8,10,12MYG

DATA BOOK

Page 2

- 1 -

Before conducting installation work, please read this ''SAFETY FOR USE'' carefully

for

correct installation.

Since the caution items shown here contain important description relative to safety, please

observe them without fail.

After reading, please keep it with you together the Instruction Manual, and read it again at the

movement of the unit.

The unit should not be installed by the user.

If the unit is installed improperly, explosion, water

leakage, electric shock or fire may be result.

Consult your dealer or specialist subcontractor for

repair and movement.

For installation, conduct the work correctly by

following the Installation Manual.

Improper installation may cause a fire, electrical shock

or water leakage.

Install the unit on a spot sufficiently durable against

the unit weight.

Insufficient durability can cause an injury by the falling

down of unit.

All electric work must be performed by licensed

technician, according to local regulations and the

instructions given in this manual.

The units should be powered by dedicated power lines.

Power lines with insufficient capacity or improper

electrical work may result in electric shock or fire.

Use only the specified cables for wiring. The

connections must be made secured without

tension the terminals.

Improper connection or fastening can cause a fire or

electrical shock.

The unit should be installed according to the

instructions in order to minimize the risk of damage

from earthquakes, typhoons or strong winds.

Improper installation work can cause an injury by the

falling down of the unit.

The outdoor unit must be installed on stable, level

surface, in a place where there is no accumulation

of snow , leaves or rubbish.

The outdoor unit should be installed in a location

where air and noise emitted by the unit will not

disturb the neighbors. The indoor unit should be

securely installed.

When installing or relocating the unit, make sure that

no substance other than the specified refrigerant

enters the refrigerant circuit.

Any presence of foreign substance such as air can

cause abnormal pressure rise or explosion.

If the unit is loosely mounted, it may fall, and cause injury.

Never repair the unit, remodel or transfer it to

another site by yourself.

If they are performed improperly, water leakage, electric

shock or fire may result. If you need to have the unit

repaired or moved, consult your dealer.

Use only the specified refrigerant (R-22) to charge

the refrigerant circuit.

Do not mix it with any other refrigerant and do not

allow air to remain in the circuit.

Air enclosed in the circuit can cause high pressure resulting

in a rupture and other hazards.

Ventilate the room if refrigerant leaks during

Installation.

The refrigerant heated generates poisonous gas by

decomposition which can cause poisoning.

After completing installation work, make sure that

refrigerant gas has not leaked.

If refrigerant gas has leaked and exposed to fan heater,

stove, oven and so on, it may generate noxious gases.

Take a proper measure to suppress the critical

concentration of refrigerant if leaked when

installing the unit in a small room.

The limit density is made not to be exceeded even if the

refrigerant leaks by any chance.

You are necessary to ventilation measures to prevent

the accident. If the refrigerant leaks, hypoxia accident

may caused.

For the countermeasure to be taken, consult your

dealer.

The terminal block cover of unit must be firmly

attached to prevent entry of dust and moisture.

Improper mounting of the cover cause electric shock or

fire.

Use only optional parts authorised by Mitsubishi

Electric.

If the accessories are installed improperly, water

leakage, electric shock or fire may result.

Ask your dealer or an authorised company to install

them.

Erroneous handling gives a high possibility to induce serious results such as

death or heavy injury.

Erroneous handling may induce serious injury depending on the situation.

Warning

Warning

Caution

SAFETY FOR USE

Page 3

Never install on the place where a combustible gas

might leak.

The gas may ignite or explode when the gas leaks and

collects in surrounding of the unit.

When the unit is installed at telecommunication

centers or hospitals, take a proper provision

against noise.

The erroneous operation of air conditioner may be

induced by inverter equipment, independent power

device, medical equipment or communication

equipment.

While the erroneous operation of medical equipment or

communication equipment may caused by the air

conditioner.

For special use as for foods, animals/plants,

precision equipment or art objects, the applicability

should be confirmed beforehand.

As the use for the applications other than that

designed originally may result in the deterioration of the

quality. Consult your dealer in this regard.

Do not use the unit under a special atmosphere.

Installing the unit at the following places may cause a

trouble, a place where much machine oil, salt sonnet,

humidity or dust, spa district, a place full of sulfur gas,

volatile gas, or corrosive gas, a place near high

frequency processing machine.

Thermal insulation of the drain pipes is necessary

prevent dew condensation.

If the drain pipes are not properly insulated,

condensation will result and drip on ceiling, floor or other

possessions.

The drain piping must process by surely,and insulate

the drain piping not to be dewy.

When the room humidity exceeds 80% or when the

drain pipe is clogged, water may drip from the indoor

unit. The outdoor unit produces condensation during the

heating operation.

Make sure to provide drainage around the outdoor unit if

such condensation is likely to cause damage.

Install drain piping according to this Installation

Manual to ensure proper drainage.

Place thermal insulation on the pipes to prevent

condensation.

Improper drain piping may cause water leakage and

damage to furniture or other possessions.

The unit must be properly earth connected.

Do not connect the earth wire to gas pipe, city water

pipe, lightning rod or telephone earth wire.

Improper earth connection may cause electrical shock.

When installing at a watery place, provide an

electric leak breaker.

Failure to mount the electric leak breaker may cause

electrical shock.

Make sure that there is a main power switch.

Use breaker or fuse with proper capacity.

Using a wire or a copper wire instead of proper capacity

of fuse can cause fire or trouble.

Other appliances connected to the same line could cause

an overload.

For the power lines, use standard cables of

sufficient current capacity.

Otherwise, current leakage, overheating or fire may

occur.

When installing the power lines, do not apply

tension to the cables.

The tighten or loosen the connections may cause generate

heat and cause fire.

Arrange the configuration of wiring not to bring up

the panel and terminal cover, and fasten the panel

and terminal cover securely.

The poor mounting of the panel or terminal cover may

cause the heat generation of the terminal connection,

a fire or electrical shock.

Do not wash the unit with water.

If washed with water, electrical shock may be caused.

Do not handle the switch with wet hands.

Otherwise electrical shock can be resulted.

Be very careful on handling the unit.

When carrying in outdoor unit, be sure to support it at

four points.

Carrying in and lifting with 3-point support may make

outdoor unit unstable, resulting in a fall of it.

The unit should not be carried by only one person if it is

more than 20kg.

Some units use PP bands for packing.

Do not use any PP band for delivery purpose.

Do not touch the heat exchanger fins with your bear

hands.

Doing so may cut your hands.

Be sure to safely dispose the packaging materials.

Packaging materials, such as catches and other metal

or wooden parts, may cause stabs or other injuries.

Tear off and discard plastic packing bags so that

children will not play any of them.

If children play with a plastic bag which was not torn off,

it may cause a risk of suffocation.

Do not leave the mounting base being damaged.

The damaged base may cause the falling down of

the unit which may give injury.

Turn on the main power switch more than 6 hours

before starting operation.

Do not turn the main power switch OFF during seasons

of heavy use, doing so can result in failure.

Do not touch the compressor or refrigerant piping

without wearing glove on your hands.

Touching directly such part can cause a burn or

frostbite as it becomes high or low temperature

according to the refrigerant state.

Do not touch the metal edges inside the unit

without wearing glove on your hands.

Touching directly it may injure your hands.

Do not remove the panel or the fan guard from

the outdoor unit when it is running.

You could be injured if you touch rotating, hot or highvoltage parts.

Do not operate the air conditioner without the air

filter set place.

Dust may accumulate, and cause a failure.

At emergency (if you smell something burning), stop

operation and turn the power source switch off.

Continuing the operation without eliminating the

emergency state may cause a machine trouble, fire, or

electrical shock.

After stopping operation, be sure to wait for five

minutes before turning off the main power switch.

Otherwise, water leakage or unit failure may occur.

Remote controller is not pushed with the thing

sharpening ahead.

It occasionally causes the electric shock and the

breakdown.

Do not connect the unit in the reverse phase

sequence.

If connected in the reverse phase sequence, the indoor

unit will not be able to provide sufficient cooling air. (8 - 20HP)

The fan on the outdoor unit that is connected in the reverse

phase sequence will turn in the wrong direction and makes

the compressor rattle, and it will result in compressor damage.

Remote controller is not installed for the place

where direct sunshine strikes.

Caution

- 2 -

Page 4

- 3 -

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. <Color: yellow>

Warning:

Carefully read the labels affixed to the unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an filter and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• Do not touch the heat exchanger fins and metal edges.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water ma y enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge the it with a refrigerant different from the refrigerant (R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Following standards may be applicable if local regulation are not available.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is heavier than the air.

• The appliance is not intended for use by young children or infirm persons without supervision.

• Young children should be supervised to ensure that they do not play

with the appliance.

• Never operate in open phase condition.

Control box may be broken.

1.2. Before Installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit. P erform collective drainage work

together with the outdoor unit, as required.

1.3. Before Installation (moved) - electrical

work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• The reverse phase of L lines (L

1, L2, L3) can be detected (Error cord: 4103),

but the reverse phase of L lines and N line can be not be detected.

- Some electric parts should be damaged when power is supplied under the

miss wiring.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands f or a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

SAFETY PRECAUTIONS

Page 5

• Remote controller is not allowed to install for the place where direct

sunshine strikes.

1.4. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be

hot and may be cold, depending on the condition of the refrigerant flowing

through the refrigerant piping, compressor, and other refrigerant cycle parts.

Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards remo ved.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

• Do not operate the air conditioner without the air filter set place.

- Dust may accumulate, and cause a failure.

• At emergency (if you smell something b urning), stop operation and turn

the power source switch off.

- Continuing the operation without eliminating the emergency state may cause

a machine trouble, fire, or electric shock.

• Remote controller should be pushed with finger.

- It occasionally causes the electric shock and the breakdown.

- 4 -

Page 6

- 5 -

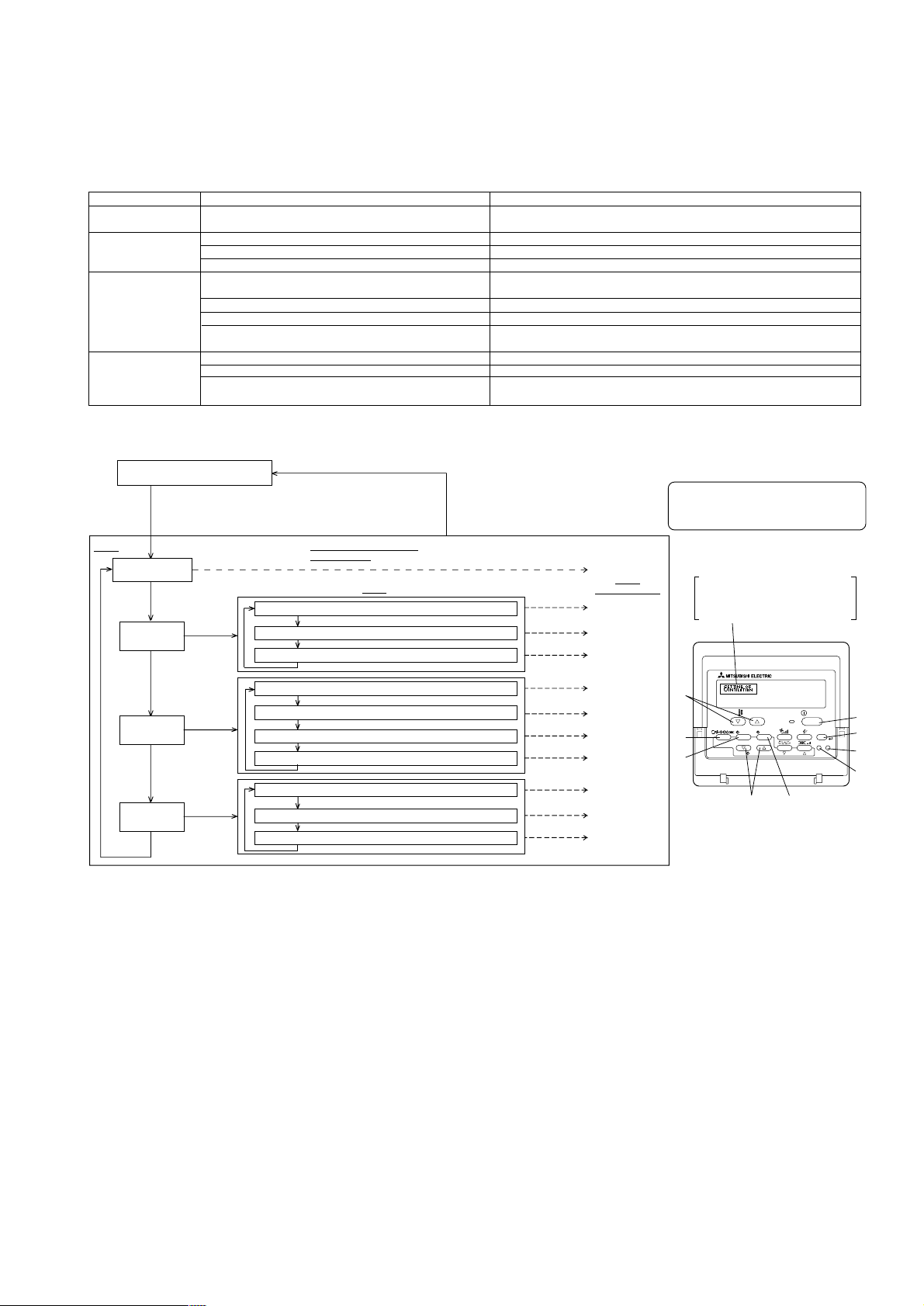

11

. Model general descriptions

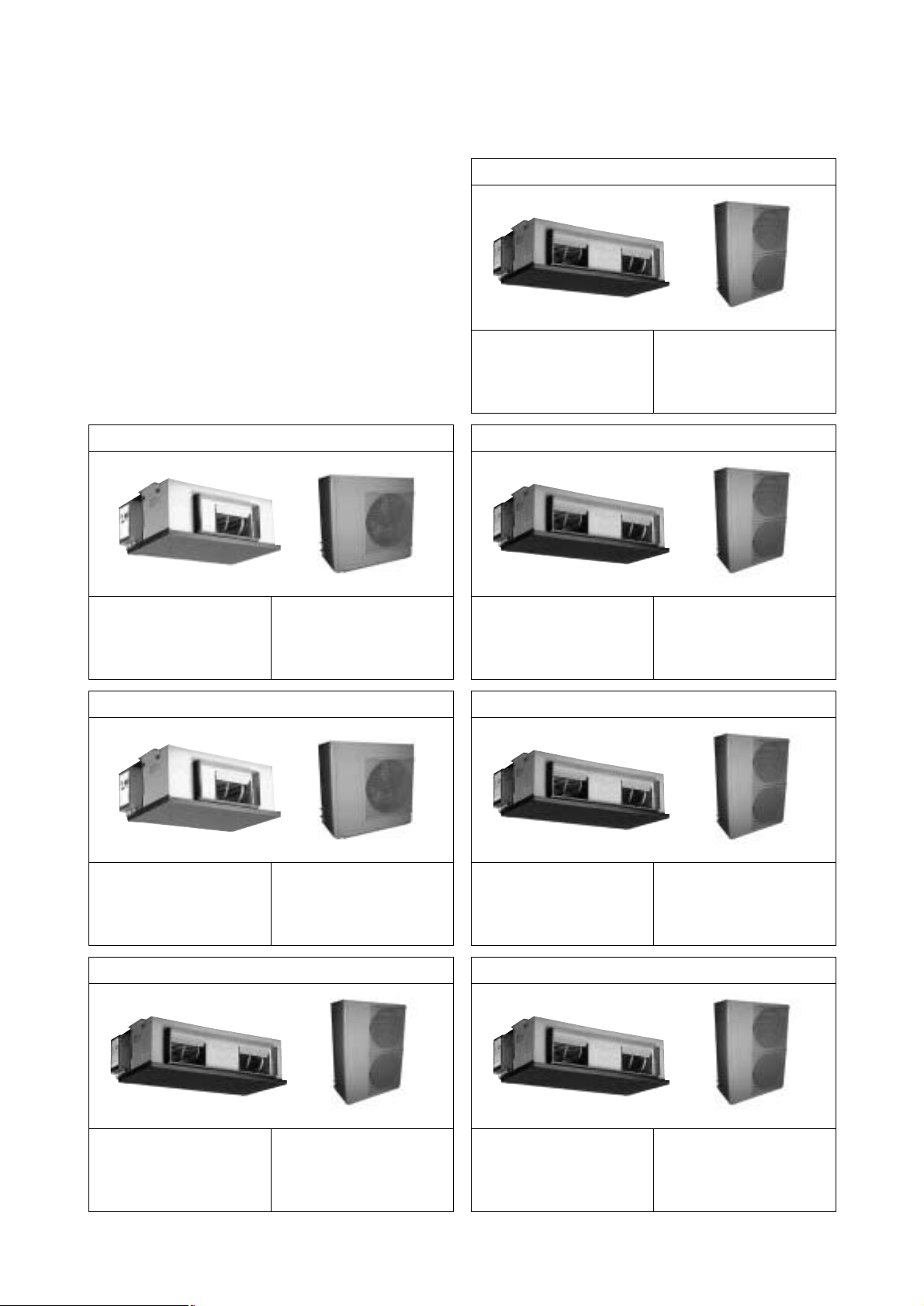

1. A Complete Line Up

Model PEH-8

PUH-8

Cooling capacity(GROSS) (50Hz)

20,100kcal/h

80,000Btu/h

23.4kW

Heating capacity(NET) (50Hz)

21,100kcal/h

84,000Btu/h

24.6kW

Model PEH-6

PUH-6

Cooling capacity(GROSS) (50Hz)

15,000kcal/h

60,000Btu/h

17.5kW

Heating capacity(NET) (50Hz)

15,900kcal/h

63,000Btu/h

18.5kW

Model PEH-5

PUH-5

Cooling capacity(GROSS) (50Hz)

12,500kcal/h

50.000Btu/h

14.6kW

Heating capacity(NET) (50Hz)

13,200kcal/h

52,500Btu/h

15.3kW

Model PEH-20

PUH-10 x 2

Cooling capacity(GROSS) (50Hz)

50,300kcal/h

200,000Btu/h

58.6kW

Heating capacity(NET) (50Hz)

52,800kcal/h

210,000Btu/h

61.4kW

Model PEH-16

PUH-8 x 2

Cooling capacity(GROSS) (50Hz)

40,200kcal/h

160,000Btu/h

46.8kW

Heating capacity(NET) (50Hz)

42,200kcal/h

168,000Btu/h

49.2kW

Model PEH-12

PUH-12

Cooling capacity(GROSS) (50Hz)

28,800kcal/h

114,500Btu/h

33.5kW

Heating capacity(NET) (50Hz)

30,100kcal/h

120,000Btu/h

35.1kW

Model PEH-10

PUH-10

Cooling capacity(GROSS) (50Hz)

25,100kcal/h

100,000Btu/h

29.3kW

Heating capacity(NET) (50Hz)

26,400kcal/h

105,000Btu/h

30.7kW

Page 7

- 6 -

2. FEATURES

High sensible cooling capacity.

The sensible cooling capacity has been significantly improved through balanced optimized heat

exchanger design.

Highly efficient operation.

The EER(Energy Efficiency Ratio) on these models

is greatly improved by adopting scroll compressor

and revised design specifications and by being

manufactured stringently to Mitsubishi Electric high

quality standards.

Hi/Lo fan speed

PEH-5,6,8,10,12 have Hi/Lo fan speed and enable

to further reduce the operating sound.

Compact size

Low height design permits installation of the unit

even in a narrow ceiling space. PEH-5,6,8,10 is

400mm low height.

Labour saving installation.

The unit operation can commence immediately

after connecting to the power supply, refrigerant

piping, drain piping, ducting and control system.

Upgrade designed outdoor unit

Matched with hi-class restaurant, shop,office.

Employ A-control

Two choice is available.Local mechanical controller

& MA remote controller

<PAR-21MAA:Accessory>

3. DESCRIPTIONS

MITSUBISHI ELECTRIC Split-type Air Conditioners

consist of a Series PEH (Indoor unit) installed

indoors, and a Model PUH (Outdoor unit) installed

outdoors.These units are connected with refrigerant piping and wiring as a complete air conditioners for connection in the field.

The heat pump unit is equipped with a heat

exchanger, a fan, a fan motor and capillary tube in

an enclosed cabinet with an air supply duct connection.

Deluxe Remote Controller

PAR-21MAA

Page 8

- 7 -

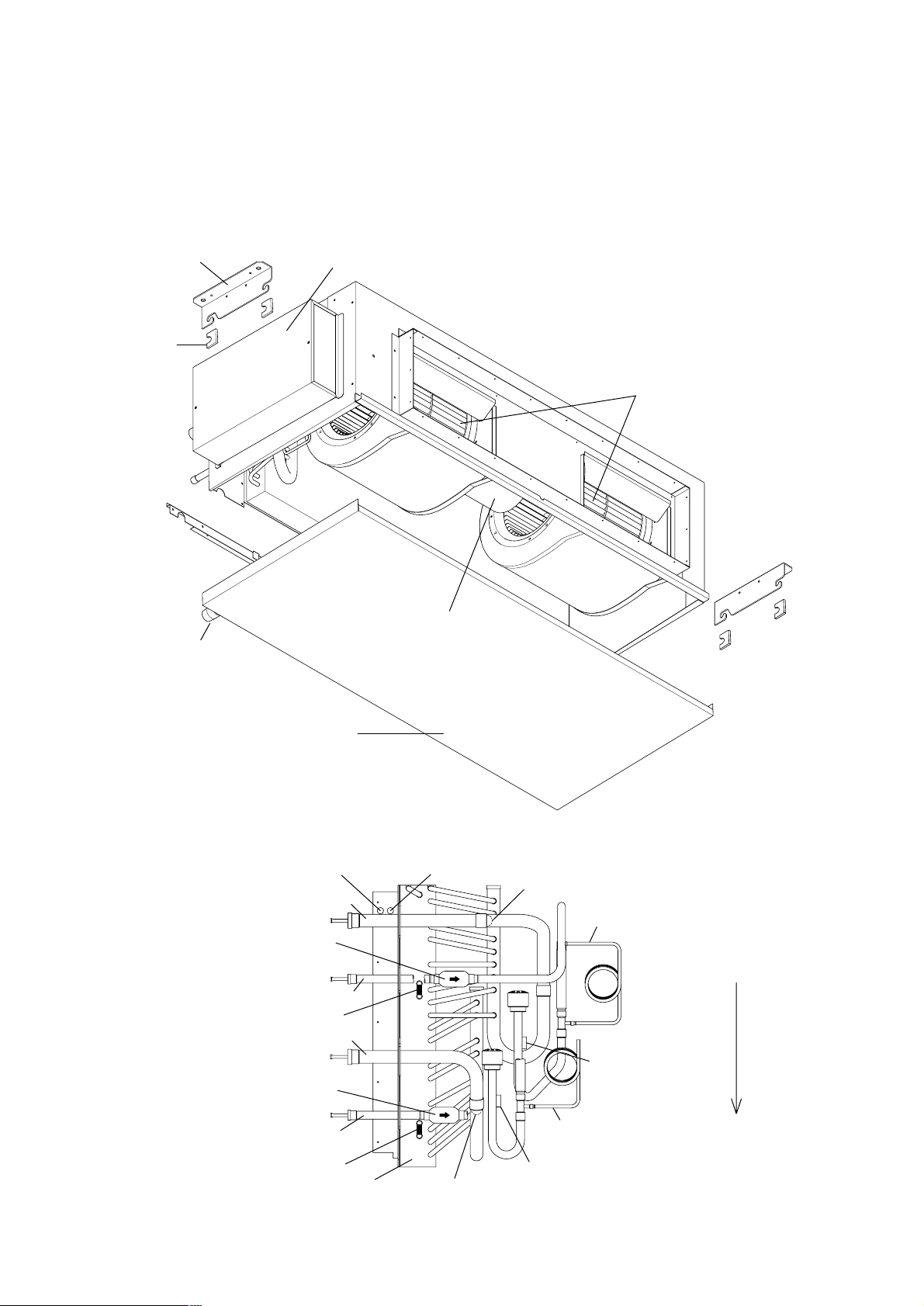

4. MECHANICAL SPECIFICATIONS

1. General

2. Indoor Units

All units consist of a ceiling-concealed indoor unit, an outdoor unit and are factory-assembled.They are

also tested and checked under a strict quality control system in the factory. The units can be easily connected together with refrigerant pipe and the control switch can be wired in the field.They are designed

to operate at outdoor ambient temperature as high as 46˚CDB (114˚F).

Casing

All panels are made of 1mm thick galvanized steel

and are insulated by 10mm thick, polyethylene.

Drain Pan

Each unit has a 1mm thick steel drain pan coated

with epoxy resin enamel and is insulated with

10mm thick polyethylene.

Indoor Coil

Coils are made of 9.52mm OD and 0.35mm thick

seamless copper tubing mechanically bonded to

0.12mm thick aluminium fins and are factory leak

tested at a pressure of 3.3MPa.They are provided

with strainers attached to the capillary tubes to further ensure a clean system.

Indoor Fan Motor

Single phasecage induction motor (PEH-5,6) and

three phasecage induction motor (PEH8,10,12,16,20) are used to drive the evaporator

fans.PEH-5,6,8,10,12 have Hi-notch Lo-notch.

(Type PEH)

Indoor Fan

Direct-driven, forward curved, centrifugal-type fans

made of galvanized steel or plastic are used to

deliver an accurate air flow at a low noise level.

Fan-driving components are mounted on rubber

pad isolators to reduce noise and vibration.

(Type PEH)

3. Outdoor Units

Casing

All condensing unit casing is 0.8mm thick steel

with exterior surfaces coated with ivory-white

acrylic resin.

Compressor

All condensing units have high efficiency type, hermetic, line-starting scroll compressors.

Compressors are equipped with an internal thermostat, overcurrent relay, and high and low pressure switches.All models also have a crankcase

heater.

Outdoor Coil

Condenser Coils are made of 9.52mm OD,

0.35mm thick seamless copper tubes mechanically bonded to 0.12mm thick aluminium plate fins.

Each coil is leak-tested at a pressure of 3.3MPa at

the factory.

Outdoor Fan

This is a light plastic propeller fan designed to

reduce energy requirement and ensure quiet operation.

Outdoor Fan Motor

A weatherproof squirrel-cage induction motor is

used to drive the condenser fan.

Page 9

PUH

PEH

PEH

PEH

PUH

PEH

- 8 -

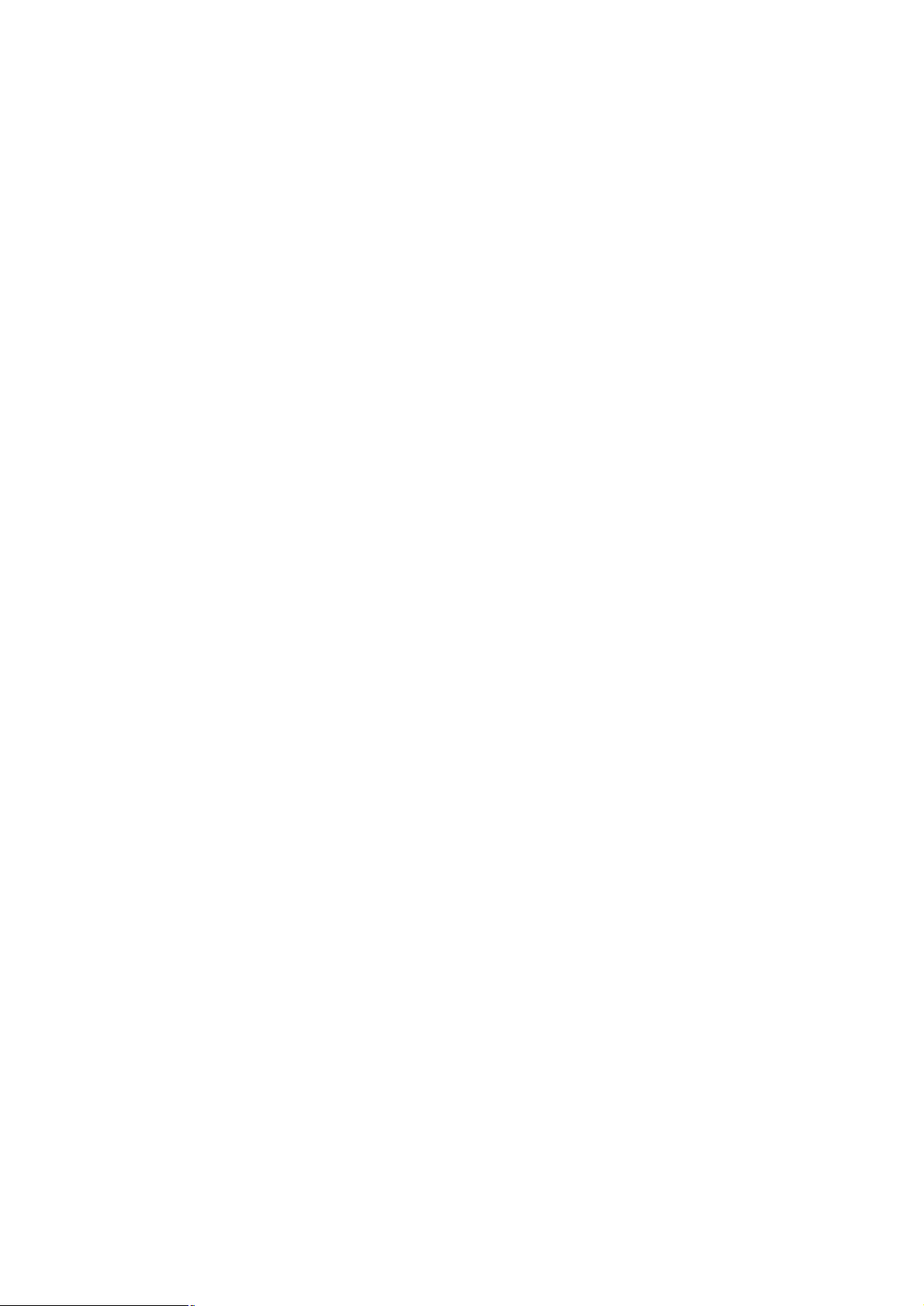

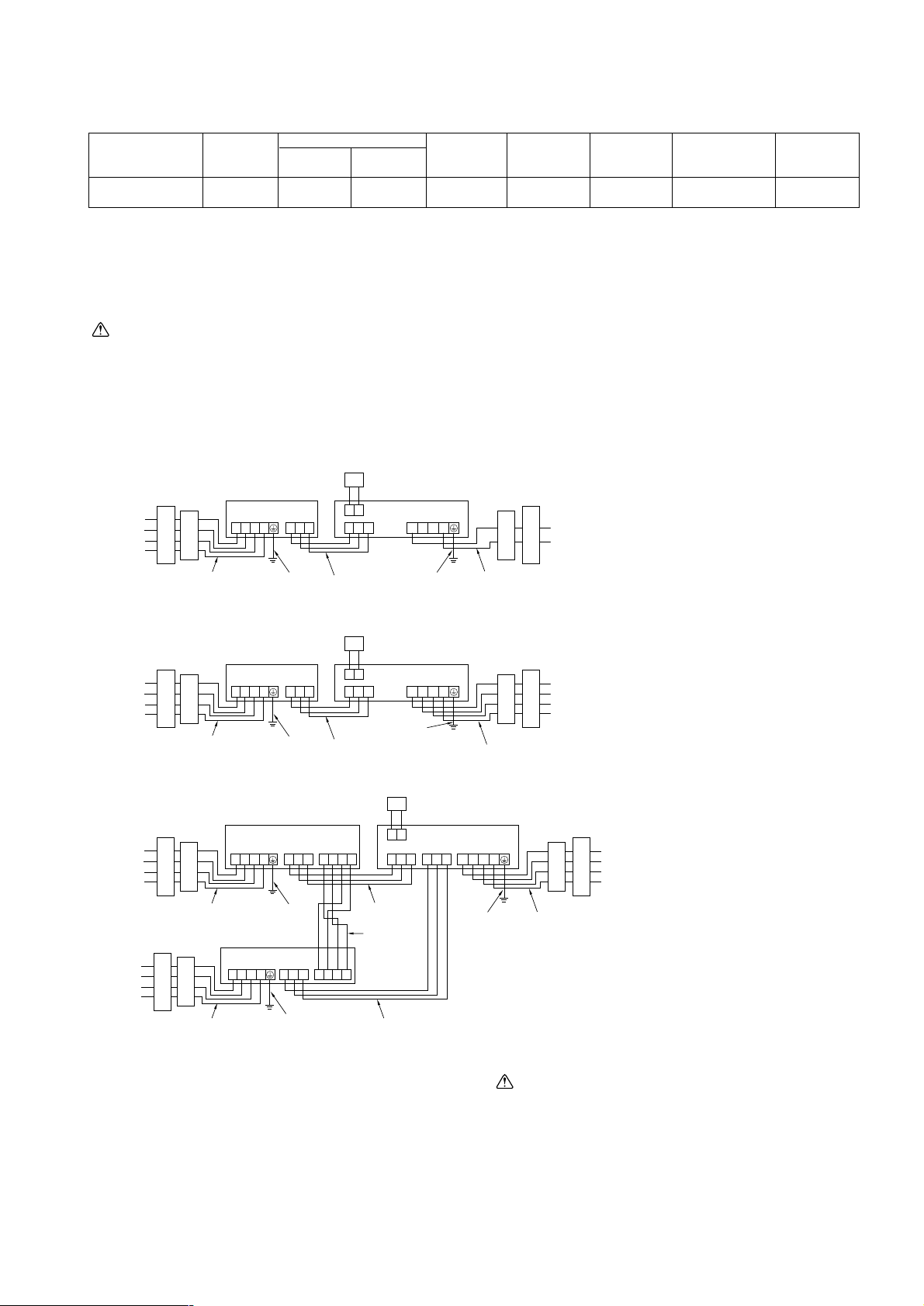

5.TYPICAL INSTALLATION EXAMPLE

6. MODEL-DESIGNATION BREAKDOWN

PUH-5MYG

Product sequence

Voltage series:3N~/380,400V415V

Made in Malaysia

Capacity Horsepower

5=5HP

6=6HP

8=8HP

10=10HP

12=12HP

16=16HP

20=20HP

Series Number

PEH=Indoor unit

PUH=Outdoor unit

Page 10

PUH-OOMYG

1PEH

5HP 8HP 10HP 12HP

PEH-OOMYC

1No. of outdoor units

No. of outdoor units

Wired remote controller

Accessory (PAR-21MAA)

111

No1 5 8 10 12

No2

6HP

5HPCapacity 8HP 10HP 12HP

5 8 10 12

6HP

6

5 8 10 126

1

-----

6

16HP 20HP

PEH-OOMYC

Model

Model

Model 16 20

22

No1

Connected

outdoor unit

Connected

outdoor unit

810

No2 8 10

Capacity

Capacity

• Air inlet : Return the indoor unit.

• Filter : Air filter is not provided with in the unit.

However, simple filter is available as

optional part to remove visible dust and dirt.

If air purification is one of the conditions required

for use, consult with your dealer.

• Air outlet: Blows the cooled / warmed air into the room.

- 9 -

7. System Components

8. PART NAMES AND FUNCTIONS

(1) Outdoor unit

(2) Indoor unit

(1) Indoor unit

(3) Remote controller

Air inlet

Filter

Air outlet

Page 11

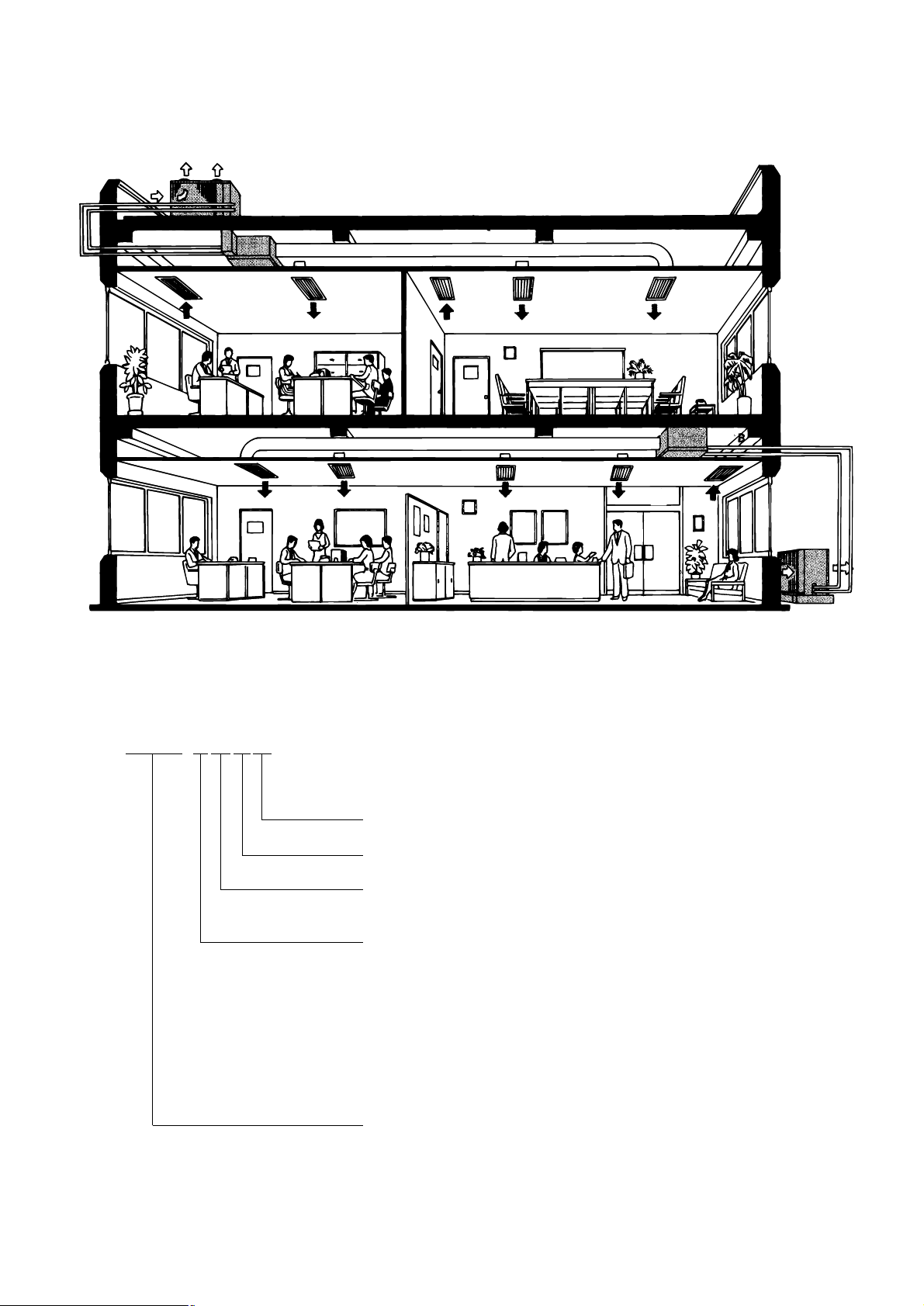

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

1

45 67

8

9

0

A

B

C

2

3

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

A

C

D

E

FGHIJKLM

N

O

P

B

Set T emperature buttons

Down

Up

Timer Menu button (Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button (Set Day button)

Louver button (

Operation button)

To preceding operation number.

Ventilation button (

Operation button)

To next operation number.

ON/OFF button

F

1

2

3

4

5

6

7

8

9 an Speed button

Opening the door.

0 Filter button (<Enter> button)

A Test Run button

B Check button (Clear button)

C Airflow Up/Down button

Notes:

• If you press a button for a feature that is not installed at the indoor unit,

the remote controller will display the “Not Available” message.

• If you are using the remote controller to drive multiple indoor units, this

message will appear only if the feature is not present at the parent unit.

• Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

• Never place any obstacle around the lower right-hand section of the remote controller. Doing so can result in the erroneous measurement of

room temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off timer is set.

If the simple or Auto Off timer is set, shows the time remaining.

“Sensor” indication

Displayed when the remote controller sensor is used.

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is supported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a main controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Up/Down Air Direction indicator

The indicator

shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to weak and downward during COOL or DR Y mode. (Oper

ation varies according to model.)

The indicator goes off after one hour, at which time the airflow direction also changes

.

Louver display

Indicates the action of the swing louver. Does not appear if the louver is stationary.

Room T

A

B

C

D

E

F

G

H

I

J emperature display

Shows the room temperature.

K

(Power On indicator)

Indicates that the power is on.

L Ventilation indicator

Appears when the unit is running in V entilation mode.

M Fan Speed indicator

Shows the selected fan speed.

N “Locked” indicator

Indicates that remote controller buttons have been locked.

O “Clean The Filter” indicator

Comes on when it is time to clean the filter.

P Timer indicators

The indicator comes on if the corresponding timer is set.

Note:

• For purposes of this explanation, all parts of the display are shown as lit.

During actual operation, only the relevant items will be lit.

Remote controller-Button

Remote controller-Display

- 10 -

(2) Remote controller (PAR-21MAA)

Page 12

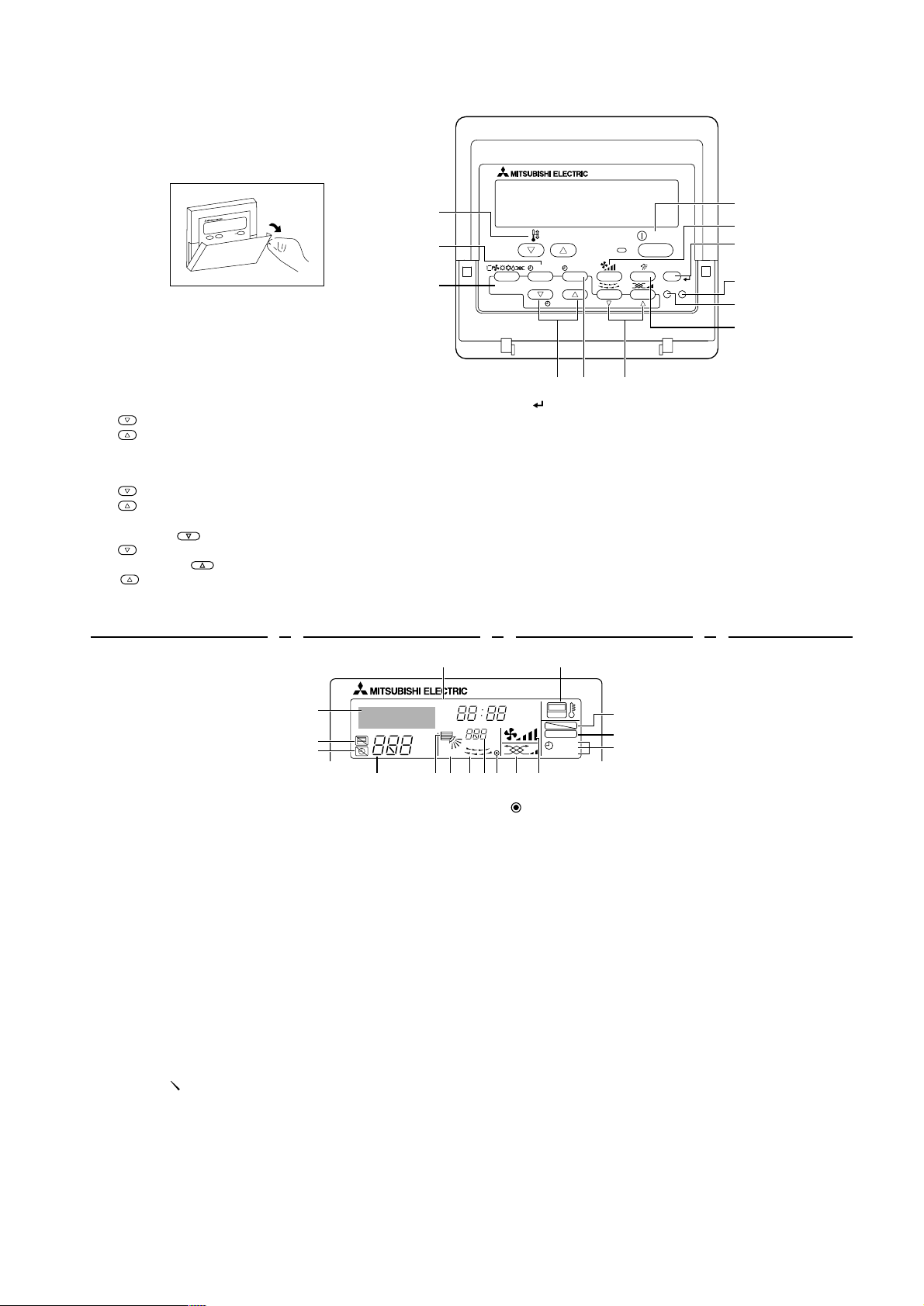

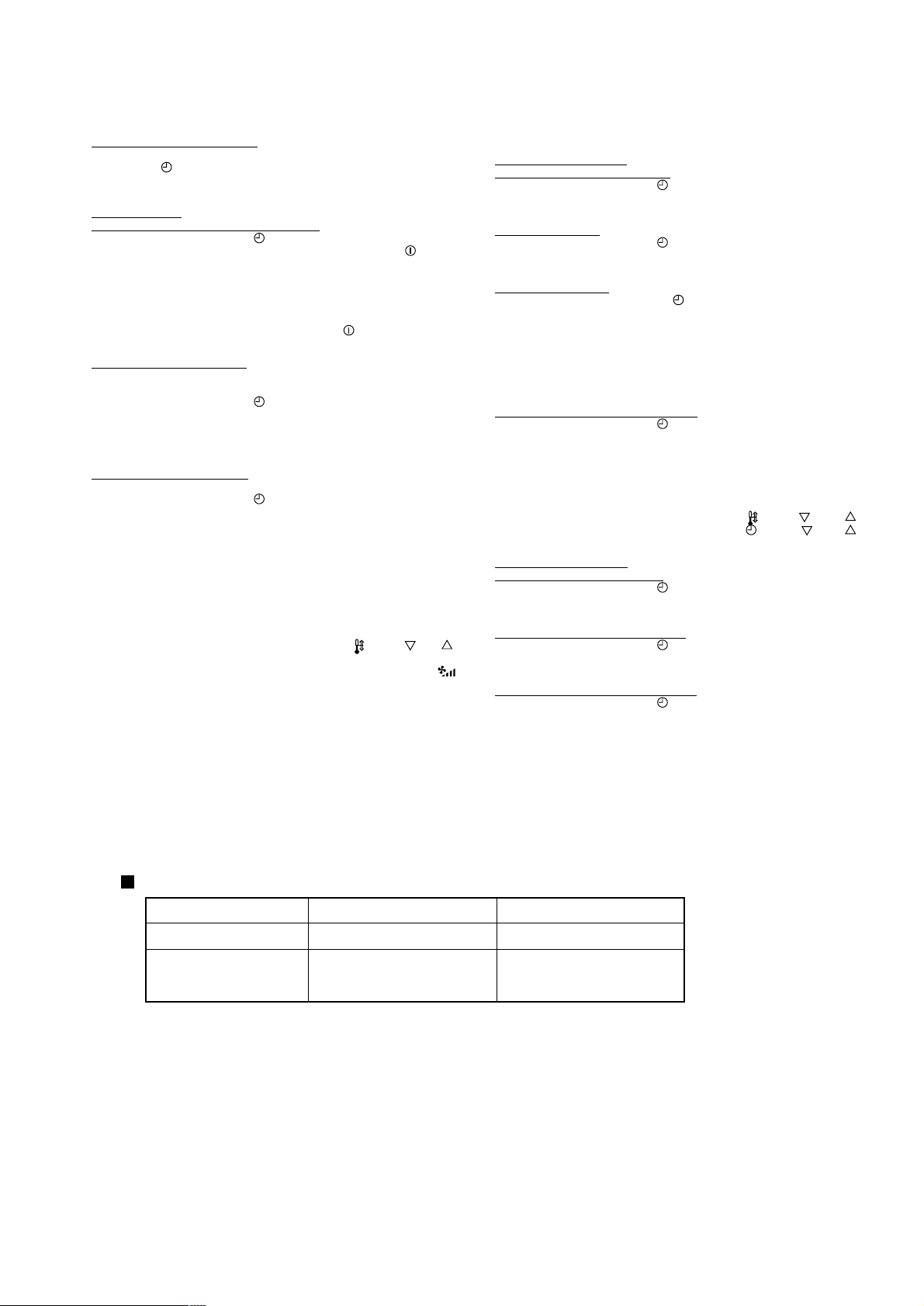

[Function selection flowchart]

[1] Stop the air conditioner to start remote controller function selection mode.

→ [2] Select from item1. → [3] Select from item2. → [4] Make the setting. (Details

are specified in item3)

→ [5] Setting completed. → [6] Change the display to the normal one. (End)

Function selection

<Wired remote controller type>

(1) Function selection of remote controller

The setting of the following remote controller functions can be changed using the remote controller function selection mode. Change the setting when needed.

Item 1

1.Change Language

(“CHANGE LANGUAGE”)

2.Function limit

(“FUNCTION

SELECTION”)

3.Mode selection

(“MODE SELECTION”)

4.Display change

(“DISP MODE SETTING”)

Item 3 (Setting content)

• Display in multiple languages is possible.

• Setting the range of operation limit (operation lock)

• Setting the use or non-use of “automatic” operation mode

• Setting the temperature adjustable range (maximum, minimum)

• Selecting main or sub remote controller

*

When two remote controllers are connected to one group, one controller must be set to sub.

• Setting the use or non-use of clock function

• Setting the timer type

• Contact number display in case of error

• Setting the telephone number

• Setting the temperature unit (

˚C or ˚F) to display

• Setting the use or non-use of the display of indoor (suction) air temperature

• Setting the use or non-use of the display of “Cooling” or “Heating” displa y during

operation with automatic mode

Item 2

Language setting to display

(1)

Operation function limit setting (operation lock) (“LOCKING FUNCTION”)

(2) Use of automatic mode setting (“SELECT AUTO MODE”)

(3) Temperature range limit setting (“LIMIT TEMP FUNCTION”)

(1) Remote controller main/sub setting (“CONTROLLER MAIN/SUB”)

(2) Use of clock setting (“CLOCK”)

(3) Timer function setting (“WEEKL Y TIMER”)

(4) Contact number setting for error situation (“CALL.”)

(1) Temperature display

˚C/˚

F setting (“TEMP MODE ˚C/˚F ”)

(2)

Suction air temperature display setting (“ROOM TEMP DISP SELECT”)

(3)

Automatic cooling/heating display setting (“A UT O MODE DISP C/H”)

(Hold down the E button and press the D button for two

seconds.)

*The display cannot be changed during the unit function

selection, the test run and the self diagnosis.

(Hold down the E button and press

the D button for two seconds.)

* The remote controller records the

setting that is made in this way.

Press the

G button.

See [4]-1

Item 3

(Setting content)

Item 1

Remote Controller Function

Selection Mode

Item 2

Mode selection

(“MODE

SELECTION”)

Normal display (Display when the

air condition is not running)

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

F

G

C

D

B

I

A

H

E

Change Language

(“CHANGE LANGUAGE”)

Function limit

(“FUNCTION

SELECTION”)

Display change

(“DISP MODE

SETTING”)

NOTE

Timer operation stops when the display for

remote controller function selection is changed

to the normal one.

Press the G button.

Press the E

button.

Press the

E button.

Press the

E button.

Press the

E button.

Press the

G button.

Press the

G button.

See [4]-2. (1)

See [4]-2. (2)

See [4]-2. (3)

See [4]-3. (1)

See [4]-3. (2)

See [4]-3. (3)

See [4]-3. (4)

See [4]-4. (1)

See [4]-4. (2)

See [4]-4. (3)

Dot display

The language that is selected in

CHANGE LANGUAGE mode

appears on this display. English is set

in this manual.

Press the D

button.

Press the D

button.

Press the D

button.

Operation function limit setting (“LOCKING FUNCTION”)

Press the G button.

Temperature range limit setting (“LIMIT TEMP FUNCTION”)

Use of automatic mode setting (“SELECT AUTO MODE”)

Temperature display ˚C/˚F setting (“TEMP MODE ˚C/˚F”)

Press the G button.

Automatic cooling/heating display setting (“AUTO MODE DISP C/H”)

Suction air temperature display setting (“ROOM TEMP DISP SELECT”)

Remote controller main/sub setting (“CONTROLLER MAIN/SUB”)

Press the G button.

Timer function setting (“WEEKL Y TIMER”)

Use of clock setting (“CLOCK”)

Contact number setting for error situation (“CALL.”)

- 11 -

Page 13

[Detailed setting]

[4] -1. CHANGE LANGUAGE setting

The language that appears on the dot display can be selected.

• Press the [

MENU] button to change the language.

1 Japanese (JP), 2 English (GB), 3 German (D), 4 Spanish (E), 5 Russian

(RU), 6 Italian (I), 7 Chinese (CH), 8 French (F)

[4] -2. Function limit

(1) Operation function limit setting (operation lock)

• To switch the setting, press the [

ON/OFF] button.

1 no1: Operation lock setting is made on all buttons other than the [

ON/OFF]

button.

2 no2: Operation lock setting is made on all buttons.

3 OFF (Initial setting value):

Operation lock setting is not made.

* To make the operation lock setting valid on the normal screen, it is necessary to

press buttons (Press and hold down the [FIL TER] and [

ON/OFF] buttons at the

same time for two seconds.) on the normal screen after the above setting is made .

(2) Use of automatic mode setting

When the remote controller is connected to the unit that has automatic operation

mode, the following settings can be made.

• To switch the setting, press the [

ON/OFF] button.

1 ON (Initial setting value):

The automatic mode is displayed when the operation mode is selected.

2 OFF:

The automatic mode is not displayed when the operation mode is selected.

(3) Temperature range limit setting

After this setting is made, the temperature can be changed within the set range.

• To switch the setting, press the [

ON/OFF] button.

1 LIMIT TEMP COOL MODE:

The temperature range can be changed on cooling/dry mode.

2 LIMIT TEMP HEAT MODE:

The temperature range can be changed on heating mode.

3 LIMIT TEMP AUTO MODE:

The temperature range can be changed on automatic mode.

4 OFF (initial setting): The temperature range limit is not active.

* When the setting, other than OFF, is made, the temperature range limit setting

on cooling, heating and automatic mode is made at the same time. Howe v er , the

range cannot be limited when the set temperature range has not changed.

• To increase or decrease the temperature, press the [

TEMP ( ) or ( )]

button.

• To switch the upper limit setting and the lower limit setting, press the [

]

button. The selected setting will flash and the temperature can be set.

• Settab le range

Cooling/Dry mode: Lower limit: 19

˚C ~ 30 ˚C Upper limit: 30 ˚C ~ 19 ˚C

Heating mode: Lower limit: 17˚C ~ 28 ˚C Upper limit: 28 ˚C ~ 17 ˚C

Automatic mode: Lower limit: 19˚C ~ 28 ˚C Upper limit: 28 ˚C ~ 19 ˚C

* The settable range varies depending on the unit to connect (Mr . Slim units, F ree-

plan units, and intermediate temperature units)

[4] -3. Mode selection setting

(1) Remote controller main/sub setting

• To switch the setting, press the [

ON/OFF] button.

1 Main: The controller will be the main controller.

2 Sub: The controller will be the sub controller.

(2) Use of clock setting

• To switch the setting, press the [

ON/OFF] button.

1 ON: The clock function can be used.

2 OFF: The clock function cannot be used.

(3) Timer function setting

• To switch the setting, press the [

ON/OFF] button (Choose one of the

followings.).

1 WEEKLY TIMER (Initial setting value):

The weekly timer can be used.

2 AUTO OFF TIMER: The auto off timer can be used.

3 SIMPLE TIMER: The simple timer can be used.

4 TIMER MODE OFF: The timer mode cannot be used.

* When the use of clock setting is OFF, the “WEEKLY TIMER” cannot be used.

(4) Contact number setting for error situation

• To switch the setting, press the [

ON/OFF] button.

1 CALL OFF: The set contact numbers are not displayed in case of error.

2 CALL **** *** ****: The set contact numbers are displayed in case of error.

CALL_: The contact number can be set when the display is as sho wn

on the left.

• Setting the contact numbers

To set the contact numbers, follow the following procedures.

Move the flashing cursor to set numbers. Press the [

TEMP. ( ) and ( )]

button to move the cursor to the right (left). Press the [

CLOCK ( ) and ( )]

button to set the numbers.

[4] -4. Display change setting

(1) T emperature display

˚C/˚F setting

• To switch the setting, press the [ ON/OFF] button.

1

˚C:The temperature unit ˚C is used.

2 ˚F: The temperature unit ˚F is used.

(2) Suction air temperature display setting

• To switch the setting, press the [ ON/OFF] button.

1 ON: The suction air temperature is displayed.

2 OFF: The suction air temperature is not displayed.

(3) Automatic cooling/heating display setting

• To switch the setting, press the [

ON/OFF] button.

1 ON: One of “Automatic cooling” and “Automatic heating” is displayed under the

automatic mode is running.

2 OFF: Only “Automatic” is displayed under the automatic mode.

- 12 -

Cooling

Indoor suction temp. 15~24˚CWB

Outdoor suction temp. -5~46˚CDB

Heating

15~27˚CDB

-15~15˚CWB

PEH

9. Operating T emperature Range

Page 14

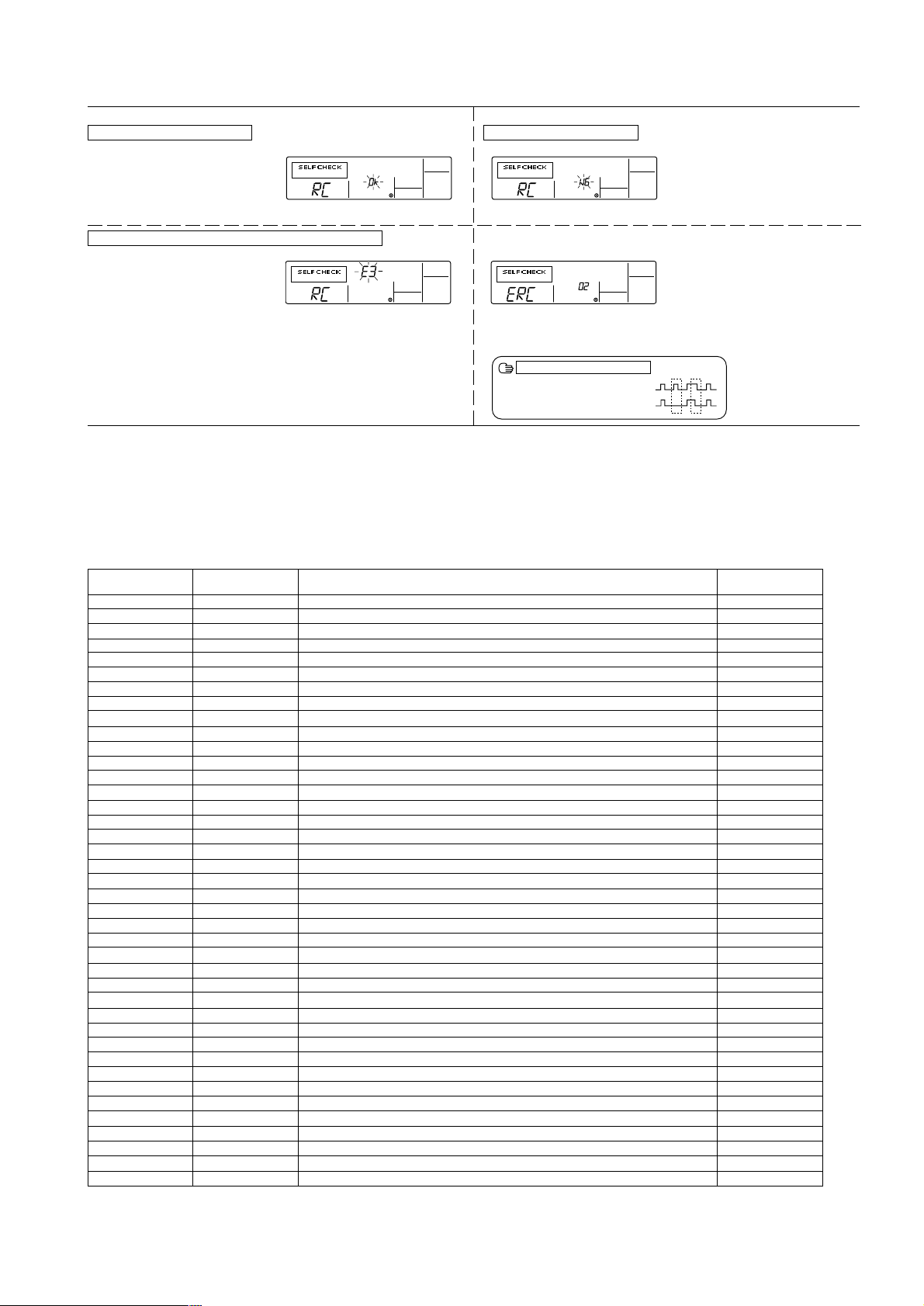

Notes Remedies

Since air conditioners use microcomputer inside, the small

amount of noise interference is come from the power

supply, transmission line and air conditioning units. When

air conditioners are installed near the equipment, which

uses subtle electric signals (eg. wireless microphones,

medical equipment), malfunctions may occur among the

equipment due to noise interference. When air

conditioners are installed near the equipment that

discharge strong noise (Electrical discharge machine),

malfunctions may occur among air conditioners. If these

cases are concerned, refer to the following.

Place the equipment, which is easy to get influenced by noise

interference (eg. recivers of wireless microphones, antennas)

far from the air conditioners.

Separate the power supply of the equipment which discharges

strong noise from the air conditioners' power supply. Install

transmission line, power supply line, and air conditioner apart

from each other.

Notes Remedies

When outdoor air temperature is low (6

˚CWB or lower),

the outdoor unit capacity may drop due to the frost on the

heat exchanger, and the defrost operation may start.

(This is normal.)

The longer it takes to defrost due to over cooled gas pipes

(due to too much frost on the heat exchanger, or outdoor

unit exposed directly to outdoor air), the longer it takes for

the outdoor unit to return to the normal operation.

(It takes maximum 10~20 minutes.)

Estimate the load, according to the capacity correction

described in the section [1. The characteristics of

cooling/heating capacity] in [3Product data].

Take the following correction factors into account when

calculating heating capacity requirement: temperature, piping

length, and defrosting.

Take appropriate measures against wind and snow.

(Refer to Chapter 4-1.)

Notes Remedies

The noise level, which is described in the outdoor unit

specification is measured in an anechoic room.

Therefore, the environment and sound echo at the

installation site must be taken into account.

Do not install outdoor units next to each other in the

residential areas.

If outdoor unit noise is concerned, please ask us for

installation environment.

- 13 -

10. Notes on Unit Selection

(1) Noise interference

(2) Outdoor unit noise

(3) Influence on heating capacity during defrost

(4) Cleaning the main parts in the indoor unit

Clean the main parts (eg. filter, heat exchanger, fans) of indoor unit regularly, when indoor unit is used

in a place where there is much dust or oil mist.

Page 15

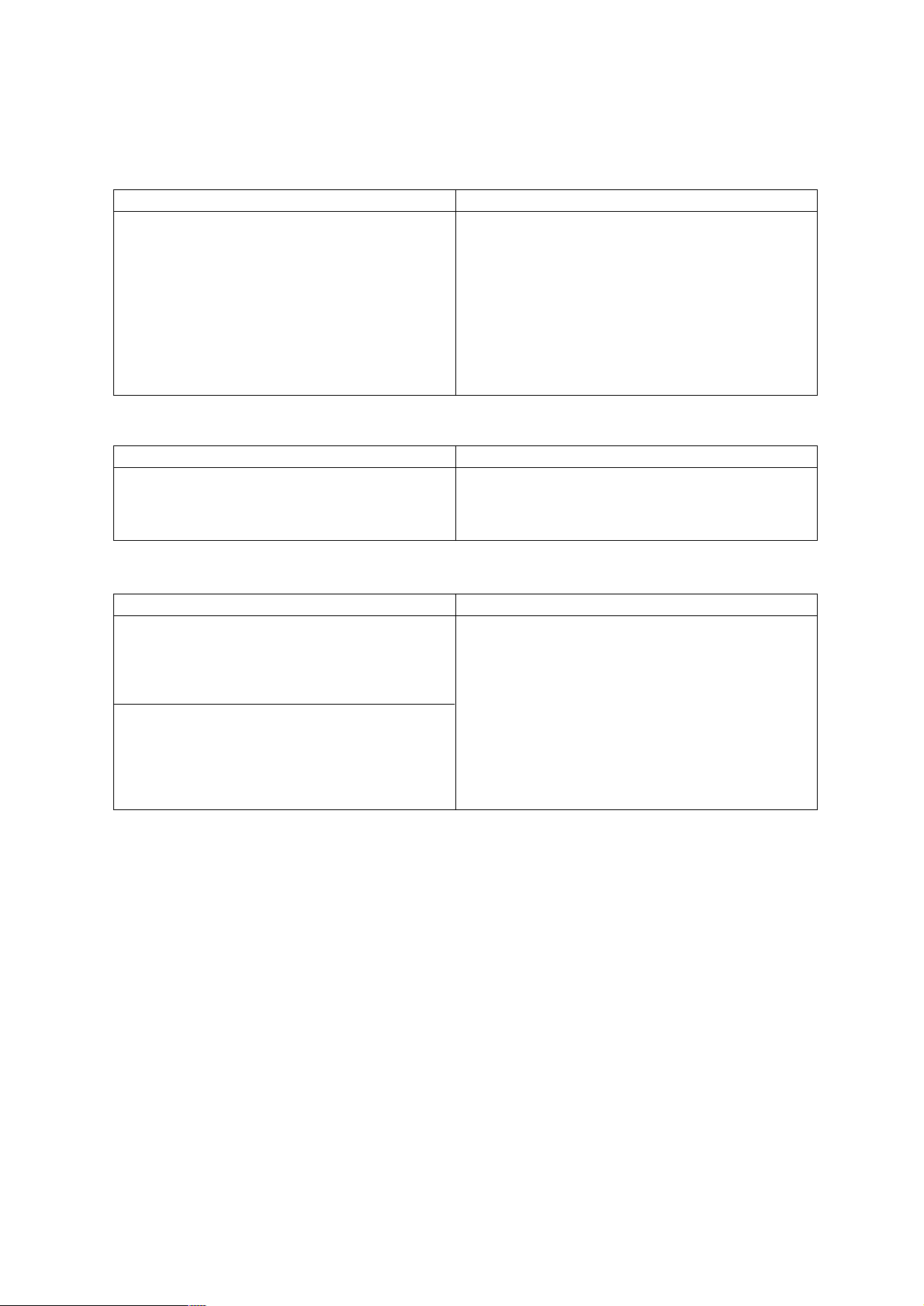

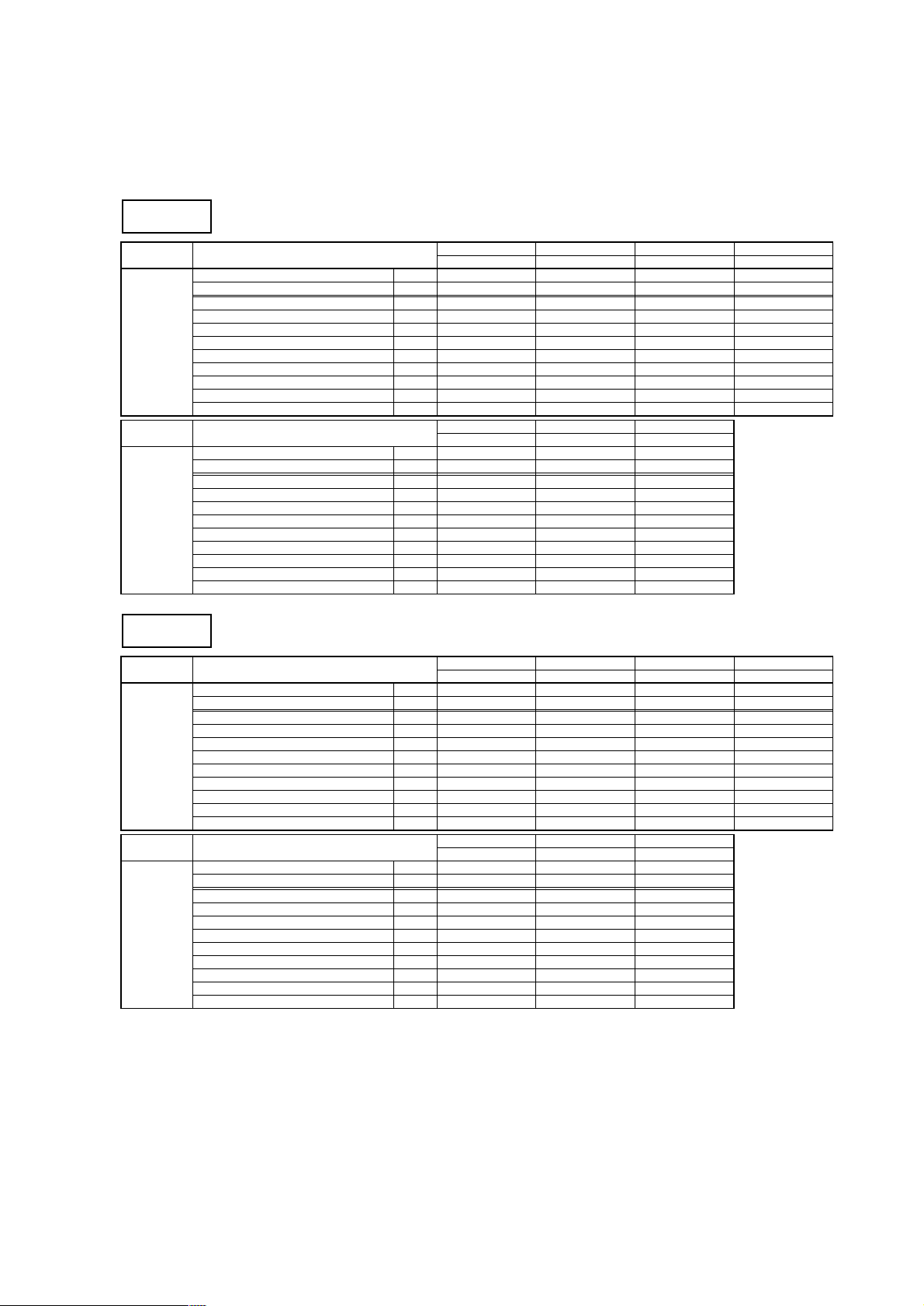

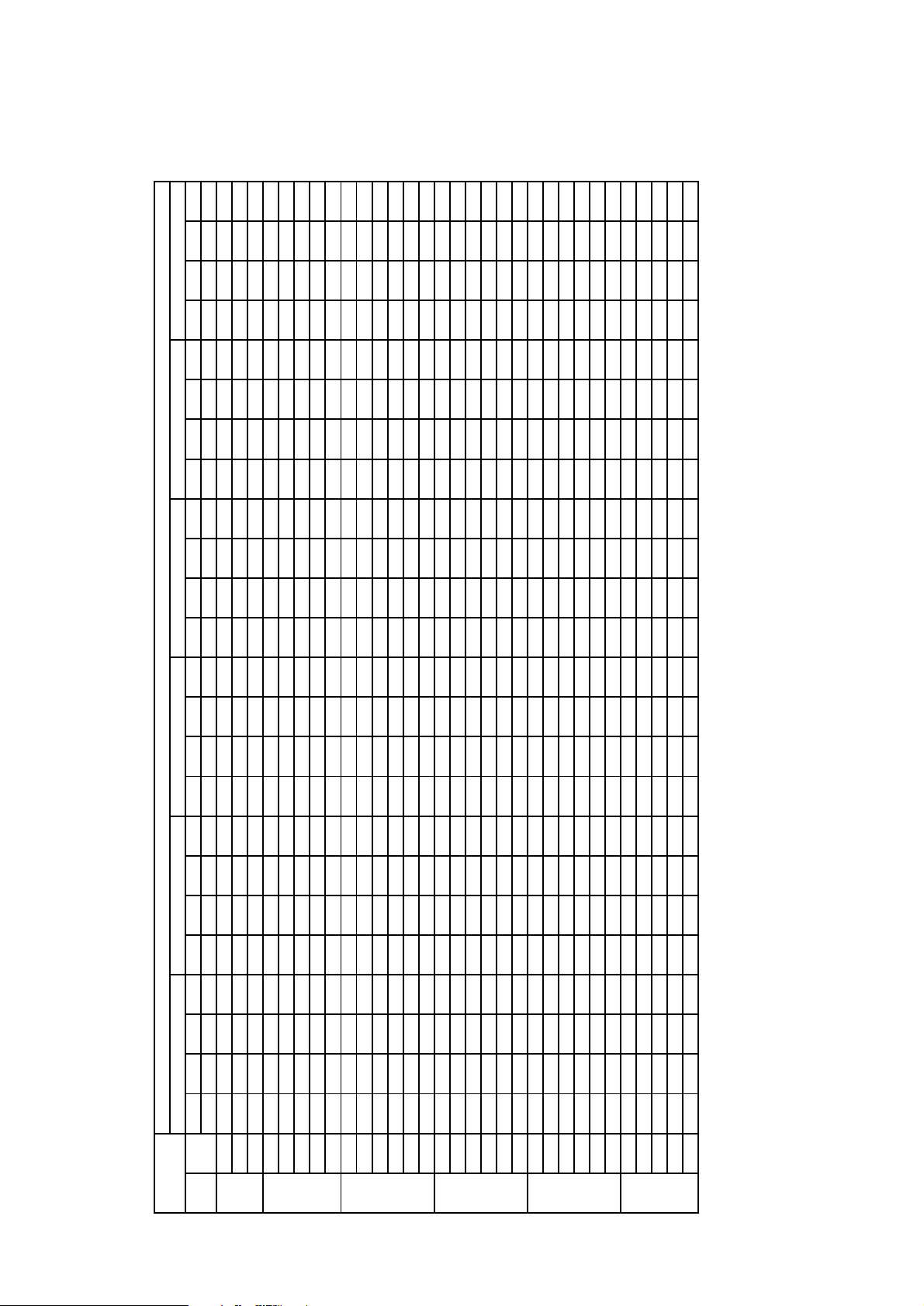

Model name PEH-5MYC PEH-6MYC PEH-8MYC PEH-10MYC PEH-12MYC PEH-16MYC PEH-20MYC

indoor

outdoor

kW 14.6 17.5 23.4 29.3 33.5 46.8 58.6

BTU/h 50,000 60,000 80,000 100,000 114,500 160,000 200,000

kcal/h 12,500 15,000 20,100 25,100 28,800 40,200 50,300

kW 11.21 13.58 17.27 21.83 24.96 32.48 40.32

BTU/h 38,200 46,300 58,900 74,500 85,200 110,800 137,600

kcal/h 9,600 11,700 14,800 18,800 21,500 27,900 34,700

kW 13.8 16.7 22.5 28.4 32.2 45.5 56.1

BTU/h 47,100 57,000 76,800 96,900 109,900 155,200 191,400

kcal/h 11,900 14,400 19,300 24,400 27,700 39,100 48,200

kW 15.3 18.5 24.6 30.7 35.1 49.2 61.5

BTU/h 52,500 63,000 84,000 105,000 120,000 168,000 210,000

kcal/h 13,160 15,900 21,100 26,400 30,100 42,300 52,800

%

kg 6 7.5 9 9 10 9X2 9X2

PEH-5MYC PEH-6MYC PEH-8MYC PEH-10MYC PEH-12MYC PEH-16MYC PEH-20MYC

Height mm 428

Width mm 1400 1600 1580

Depth mm 650

kg 56 59 70 77 82 130 133

kW 0.46 0.46 0.75 0.75 1.2 1.3 1.8

CMM

50 55 65 80 95 120 160

CFM

1,770 1,940 2,300 2,830 3,360 4,240 5,650

L/S

833 917 1,083 1,333 1,583 2,000 2,667

CMM

40 44 52 64 76

CFM

1,410 1,550 1,840 2,260 2,680

L/S

667 733 867 1,067 1,267

mmAq

Pa

Hi dB(A)

46 49 49 50 50 52 53

Lo dB(A)

42 45 45 46 48 - -

--

--

--

mm

PUH-5MYG PUH-6MYG PUH-8MYG PUH-10MYG PUH-12MYG PUH-8MYG X 2 PUH-10MYG X 2

Height mm

Width mm 1047 1247 1447

Depth mm

kg 147 154 203 211 238 203 X 2 211 X 2

kW

1 X 3.75 1 X 4.5 1 X 5.6 1 X 7.5 1 X 8.6 2 X 5.6 2 X 7.5

W

1 X 150 1 X 150 2 X 150 2 X 150 2 X 150 2 X (2 X 150) 2 X (2 X 150)

CMM 70 75 140 140 150 140 / unit 140 / unit

CFM 2,472 2,649 4,945 4,945 5,298 4,945 / unit 4,945 / unit

L/S 1,167 1,250 2,333 2,333 2,500 2,333 / unit 2,333 / unit

dB(A) 58/59 59/60 61/63 61/63 61/63 61/63 / unit 61/63 / unit

Propellar -direct drive

Squirrel cage induction motor

High&Low pressure switch,Overcurrent relay(Compressor),Internal thermostat (Compressor, Evaporator and Condenser fan motor)

Anti-short cycle timer, Freeze protector,Fuse

1047 1047

Cross fin coil

Sound pressure level

25.4

Polyester resin coating

Munsell 5Y 8/1

1480

Hi

100 150

1000

Indoor fan air flow

Lo

Sound pressure level(cool/heat)

Protection devices

Net weight

Compressor

No. X Motor output

Outdoor coil

Outdoor fan

Outdoor fan motor

No. X Motor output

Dimension

Outdoor fan air flow

Drain connection

External finish

Color

Outdoor unit

Model name

547

Hermetic line start Scroll

Cross fin coil

Centrifugal (Plastic)-Direct drive Centrifugal (Steel)-Direct drive

15

Three phasecage induction motor

Refrigerant control

External finish

Model name

Indoor unit

Power supply

Total cooling capacity

(Gross)

Sensible cooling capacity

(Gross)

Net weight

Total cooling capacity

(Net)

Total heating capacity

(Net)

Dimension

Capacity step

Refrigerant

Refrigerant charge

~ 220-240V 50Hz

3N~ 380-415V 50Hz

3N~ 380-415V 50Hz

0-100 0-50-100

595

1947

764

R-22

Capillary tube

Galvanized steel

400

External static pressure

Single phasecage induction motor(Hi/Lo)

Three phasecage induction motor(Hi/Lo)

1180

634

10

Indoor coil

Indoor fan

Indoor fan motor

Motor output

Note 1. Cooling and heating capacitiies are based on the following conditions.

Cooling : Indoor:27°CDB, 19°CWB ; Outdoor:35°CDB.

Heating : Indoor:20°CDB, ; Outdoor:7°CDB, 6°CWB.

Cooling and heating capacities are based 7.5m pipe length.

2. Refergirant charge volumes are factory charged (at 7.5m piping length).

Refrigerant is enclosed with the outdoor unit.

3. The measuring point of the sound pressure level is,

4. Specification subject to change without notice.

For Indoor : 1.5m from the unit

For Outdoor : 1m from the unit

- 14 -

22

. Product Specifications

1. SPECIFICATIONS

PEH-5,6,8,10,12,16,20MYC

Page 16

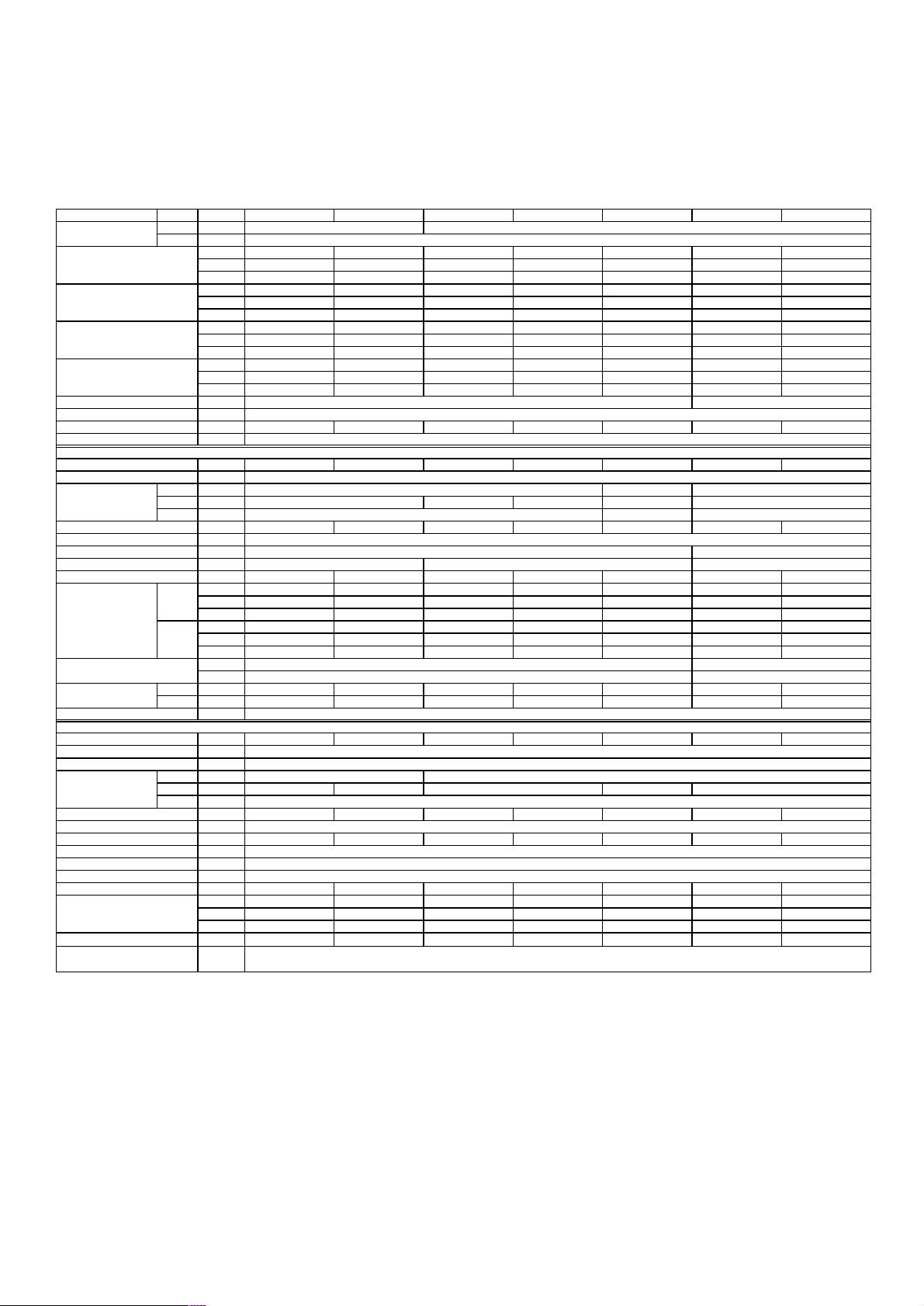

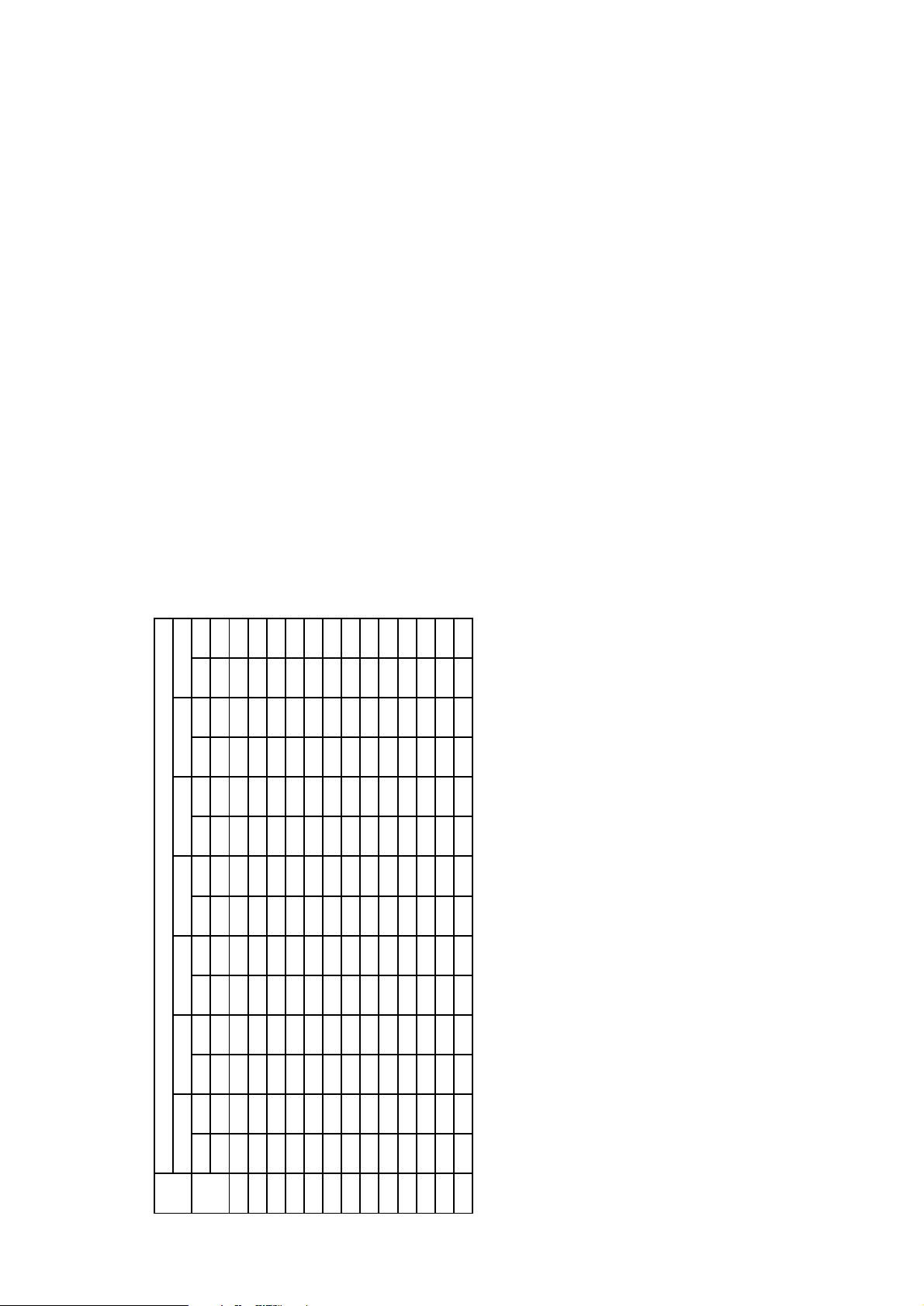

Cooling

TOTAL INPUT

TOTAL RUN CURRENT

COMPRESSOR INPUT

RUN CURRENT

STARTING CURRENT

O/D FAN INPUT

RUN CURRENT

STARTING CURRENT

I/D FAN INPUT

RUN CURRENT

STARTING CURRENT

PEH-5,6

220-240V

PEH-8,10

PUH-5~10

380-415V

VOLT ITEM

kW

A

kW

A

A

kW

A

A

kW

A

A

5.45

10.8

4.42

8.12

65.5

0.23

0.58

1.5

0.80

3.7

6.4

PEH-5MYC

PUH-5MYG

6.19

11.0

5.16

8.32

74.0

0.23

0.58

1.5

0.80

3.7

6.4

PEH-6MYC

PUH-6MYG

7.81

14.6

6.45

11.94

95.0

0.46

1.16

3.0

0.90

1.5

5

PEH-8MYC

PUH-8MYG

9.80

18.1

8.44

15.44

125.0

0.46

1.16

3.0

0.90

1.5

5

PEH-10MYC

PUH-10MYG

TOTAL INPUT

TOTAL RUN CURRENT

COMPRESSOR INPUT

RUN CURRENT

STARTING CURRENT

O/D FAN INPUT

RUN CURRENT

STARTING CURRENT

I/D FAN INPUT

RUN CURRENT

STARTING CURRENT

PEH-12~20

PUH-8~12

380-415V

VOLT ITEM

kW

A

kW

A

A

kW

A

A

kW

A

A

10.80

19.5

9.01

16.04

118.0

0.46

1.16

3.0

1.33

2.3

9

PEH-12MYC

PUH-12MYG

15.12

29.4

12.9

23.88

106.9

0.92

2.32

4.2

1.30

3.2

8.5

PEH-16MYC

PUH-8MYG X 2

20.27

38.3

16.88

30.88

140.4

0.92

2.32

4.2

2.47

5.1

10

PEH-20MYC

PUH-10MYG X 2

Heating

TOTAL INPUT

TOTAL RUN CURRENT

COMPRESSOR INPUT

RUN CURRENT

STARTING CURRENT

O/D FAN INPUT

RUN CURRENT

STARTING CURRENT

I/D FAN INPUT

RUN CURRENT

STARTING CURRENT

PEH-5,6

220-240V

PEH-8,10

PUH-5~10

380-415V

VOLT ITEM

kW

A

kW

A

A

kW

A

A

kW

A

A

4.67

9.1

3.64

6.42

65.5

0.23

0.58

1.5

0.8

3.7

6.4

PEH-5MYC

PUH-5MYG

5.22

9.9

4.19

7.22

74.0

0.23

0.58

1.5

0.8

3.7

6.4

PEH-6MYC

PUH-6MYG

7.03

13.4

5.67

10.74

95.0

0.46

1.16

3

0.9

1.5

5

PEH-8MYC

PUH-8MYG

9.12

16.8

7.76

14.14

125.0

0.46

1.16

3

0.9

1.5

5

PEH-10MYC

PUH-10MYG

TOTAL INPUT

TOTAL RUN CURRENT

COMPRESSOR INPUT

RUN CURRENT

STARTING CURRENT

O/D FAN INPUT

RUN CURRENT

STARTING CURRENT

I/D FAN INPUT

RUN CURRENT

STARTING CURRENT

PEH-12~20

PUH-8~12

380-415V

VOLT ITEM

kW

A

kW

A

A

kW

A

A

kW

A

A

9.71

17.7

7.92

14.24

118.0

0.46

1.16

3

1.33

2.3

9

PEH-12MYC

PUH-12MYG

13.56

27.0

11.34

21.48

105.7

0.92

2.32

4.16

1.3

3.2

8.5

PEH-16MYC

PUH-8MYG X 2

18.91

35.7

15.52

28.28

139.1

0.92

2.32

4.16

2.47

5.1

10

PEH-20MYC

PUH-10MYG X 2

- 15 -

2. ELECTRICAL DATA

PEH-5,6,8,10,12,16,20MYC

Page 17

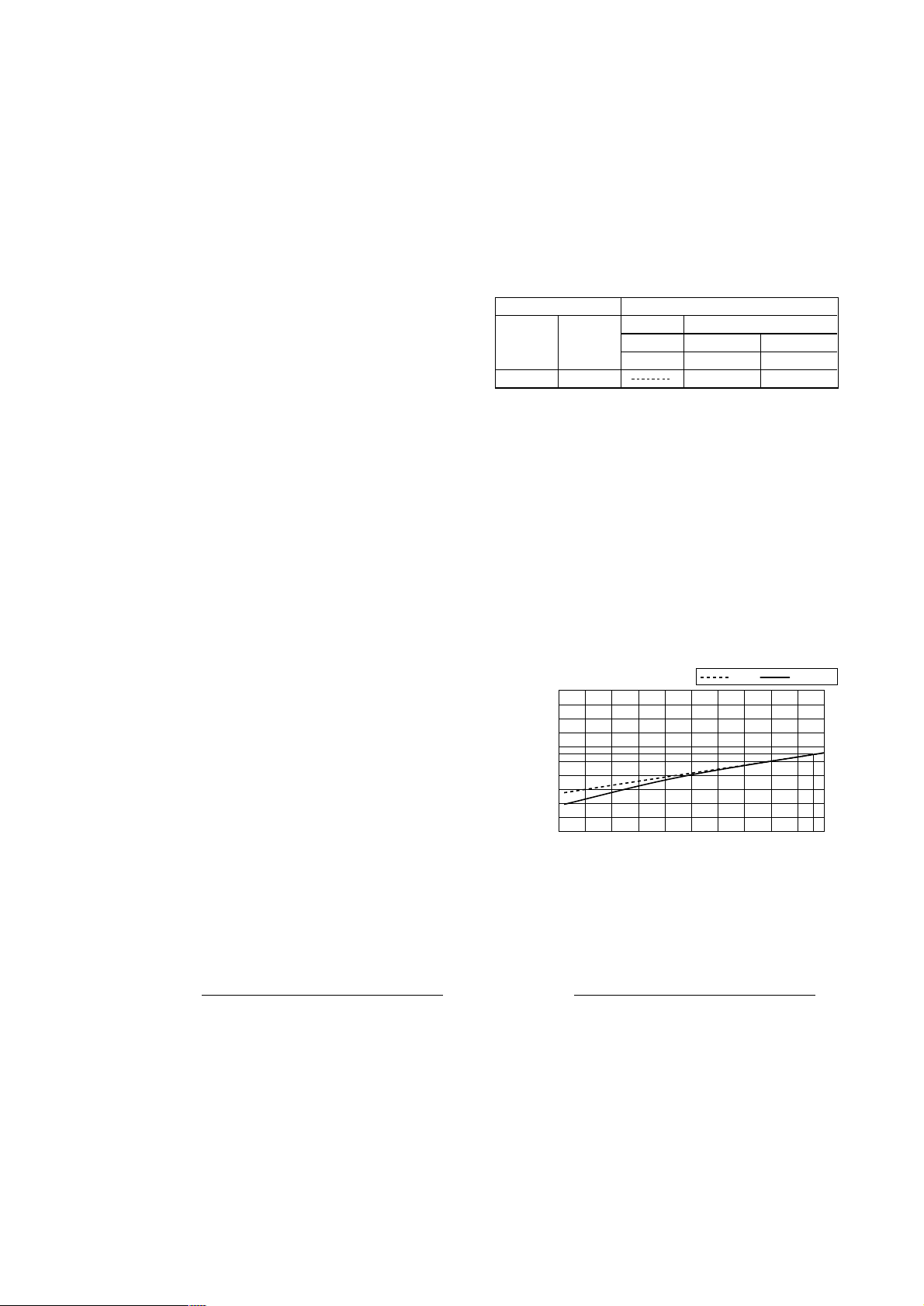

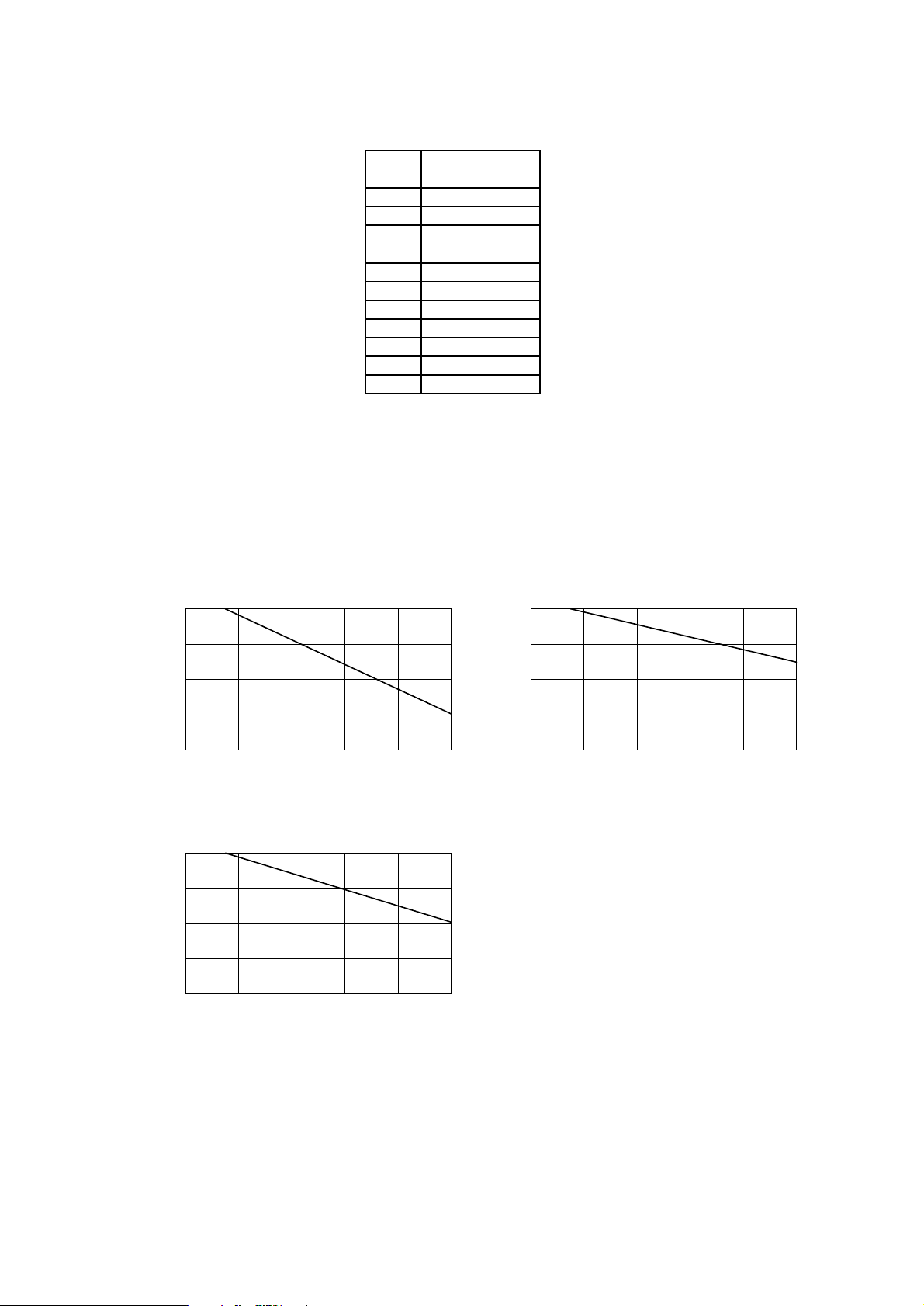

3. SELECTION PROCEDURE

1. Model Selection (With actual examples)

First step, to select the approximate model:

Based on the cooling load and the cooling capacity listed in the performance table, select the applicable

model.

Second step, to select the model:

To select the model, the following conditions must be known:

(1) Power source frequency

(2) Total cooling load or sensible cooling load

(3) Indoor conditioned temperature (WB*1, DB)

(4) Designed outdoor temperature (DB)*2

(5) Designed air flow

(6) Designed external static pressure (= Wind pressure loss of air duct)*3

Notes:

*1.The correct WB is required since it has a serious effect on the capacity.

*2.The cooling capacity decreases as the outdoor temperature increases.Therefore, the estimated highest tem-

perature during an air conditioning time frame is the "designed outdoor temperature". However, it is recommended that the abnormal outdoor temperature which may occur once or twice a year be excluded from the

calculation to avoid selection of an excessively large capacity model.

*3.The wind pressure loss of an air duct should be calculated correctly. If a value having an excessive allowance

is used, an excessively large model will be selected.Moreover, an excessively high air flow will be induced

during actual operation causing the generation of high operating sounds and carry-over of condensed water.

(Step-1) Confirmation of operation range

Confirm that the conditions given above for the model to be selected are within the operation range listed on Page 12 or 94.

(Step-2) Calculation of actual air flow, external static pressure, and fan motor input

Based on the designed air flow and external static pressure, obtain the actual air flow,

actual external static pressure, and fan motor power input from the fan performance table

for the model selected. For an explanation of how to use the fan performance table, see

the following examples.

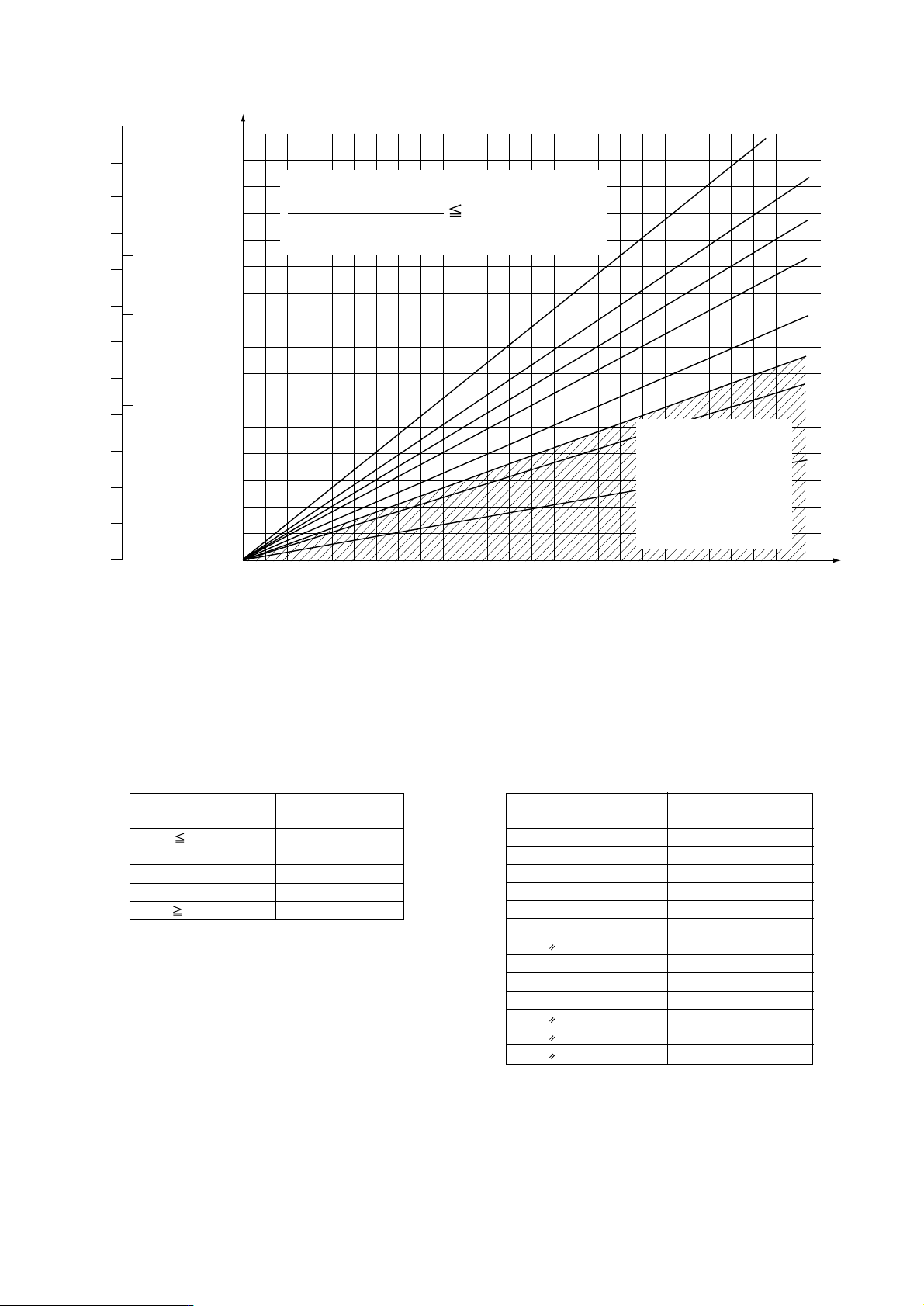

Example: PEH-8, 50Hz

Example 1. (To operate with values near to the designed air flow and external static pressure.)

Condition : Designed air flow 65CMM

Designed external static pressure 60Pa

Calculation :The designed point is A. Therefore, duct resistance line passing A is

dotted line.

Therefore, actual point is B for Hi

Actual air flow = 69CMM

Actual external static pressure = 70Pa

Notes: Duct resistance line is secondary cur ve.

- 16 -

PEH-8

Fan Performance Curve

(Pa)

250

200

150

100

External Static Pressure

50

Recommended range

o

Hi

B

A

0

40.0 50.0 60.0 70.06980.0 90.0

Air flow

(CMM)

Page 18

- 17 -

(Step-3) Calculation of net capacity

Based on the indoor conditioned temperature (WB,DB), designed outdoor temperature

(DB), and the actual air flow obtained in Step-2, obtain the gross capacity from the gross

capacity tables (pages 13~26).Then, calculate the net capacity from the formula below by

using the fan motor input obtained in Step-2.

Net capacity (kW) = Gross capacity (kW) - Fan motor input (kW)

Example: PEH-8, 50Hz

Condition:

Indoor conditioned temp.: 24˚CDB, 17˚CWB

Designed outdoor temp.: 40˚CDB

Actual air flow : 69CMM

Fan motor input :0.90kW (See P.15)

Calculation :

The sections of the gross capacity table

applicable for the above conditions are

shown right.

At 17˚C of ID, Q = 20.6, T/I = 8.24

Therefore, when AF is 69(CMM)

Q = 20.6 x 1.01* = 20.81

T/I = 8.24 x 1.01 = 8.32

Therfore, the net capacity is,

Net total cooling capacity = 20.81 (kW) - 0.90(kW)

= 19.91(kW)

Note * : Refer to the right figure.

• Refrigerant cycle energy efficiency

(1) COP =

Notes: 1. COP : Coefficient of performance

2. Temperature condition of COP

Indoor entering air temp. : 80˚FDB (=27˚CDB), 66.2˚FWB(=19˚CWB)

Outdoor entering air temp. : 95˚FDB (=35˚CDB)

3. Total input = Compressor input + Indoor fan motor input + Outdoor fan motor input (page 15).

Gross total cooling capacity (kW)

Total input (kW)

Indoor

DB

˚C

Indoor

WB

˚C

T/I

kW

8.24

Q

40

Outdoor DB

˚C

kW

20.624 17

2. Efficiency Calculation

• System energy efficiency

(1) COP =

Net cooling capacity (kW)

Total input (kW)

1kW = 3412Btu/h

PEH-8MYC

input Capacity

0.9

1.0

1.01

1.1

45 50 55 60 65 7069

Air flow rate (m

3

/min)

Capacity/ input factor

Page 19

<Accessory>

·Conduit mouting plate

(Painted the same color as the unit body)

a) ø27····················································1pc.

b) ø34····················································1pc.

·Tapping screw 4✕12·································4pcs.

Note 1.It is possible to change to ø27 or ø34 by

selecting the conduit mounting plate a,b.

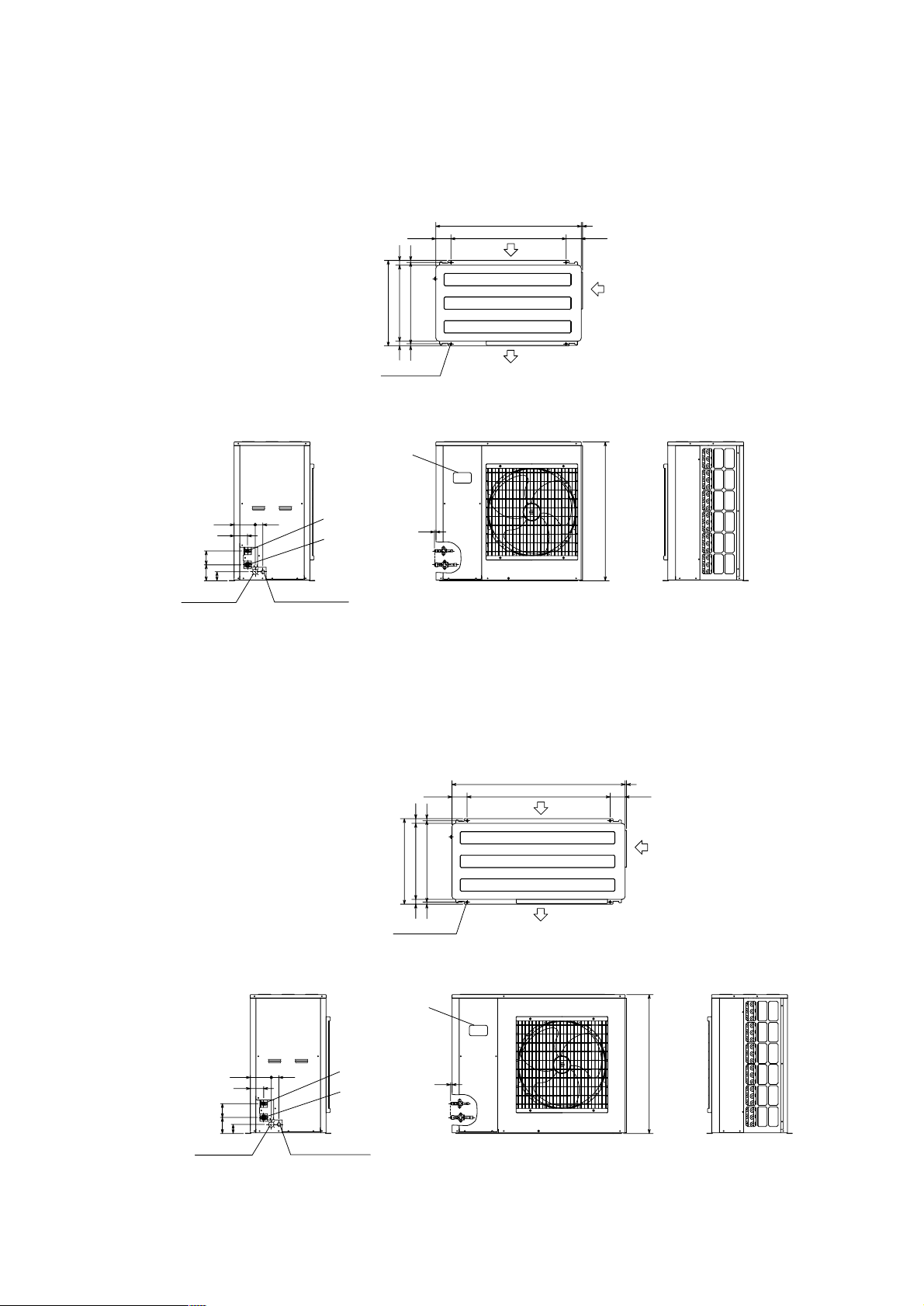

615

54734 34

58515 15

108.5 830

1047

108.5

9

Air inlet

Air outlet

Top view

Air inlet

4-10X20 Holes

<For mounting

anchor bolt M8>

[Field supply]

Right side viewFront view

10

1000

Knock out hole

Pressure gauge

(For option)

Refrigerant pipe

ø12.7(1/2 flare)

Refrigerant pipe

ø19.05 (3/4 flare)

152 55

97

100115

65

ø27 Hole

<For the indoor unit

connection wiring>

Left side view

<For the power

supply wiring>

Note 1

ø40 Hole

<Accessory>

·Conduit mouting plate

(Painted the same color as the unit body)

a) ø27····················································1pc.

b) ø34····················································1pc.

·Tapping screw 4✕12·································4pcs.

Note 1.It is possible to change to ø27 or ø34 by

selecting the conduit mounting plate a,b.

615

54734

58515 15

34

108.5

4-10✕20 Holes

<For mounting

anchor bolt M8>

[Field supply]

Top view

Air outlet

Air inlet

1030 108.5

1247 9

Air inlet

Right side viewFront view

1000

Knock out hole

Pressure gauge

(For option)

10

Refrigerant pipe

ø12.7(1/2 flare)

Refrigerant pipe

ø19.05 (3/4 flare)

55152

97

100115

65

ø27 Hole

<For the indoor unit

connection wiring>

Left side view

<For the power

supply wiring>

Note 1

ø40 Hole

- 18 -

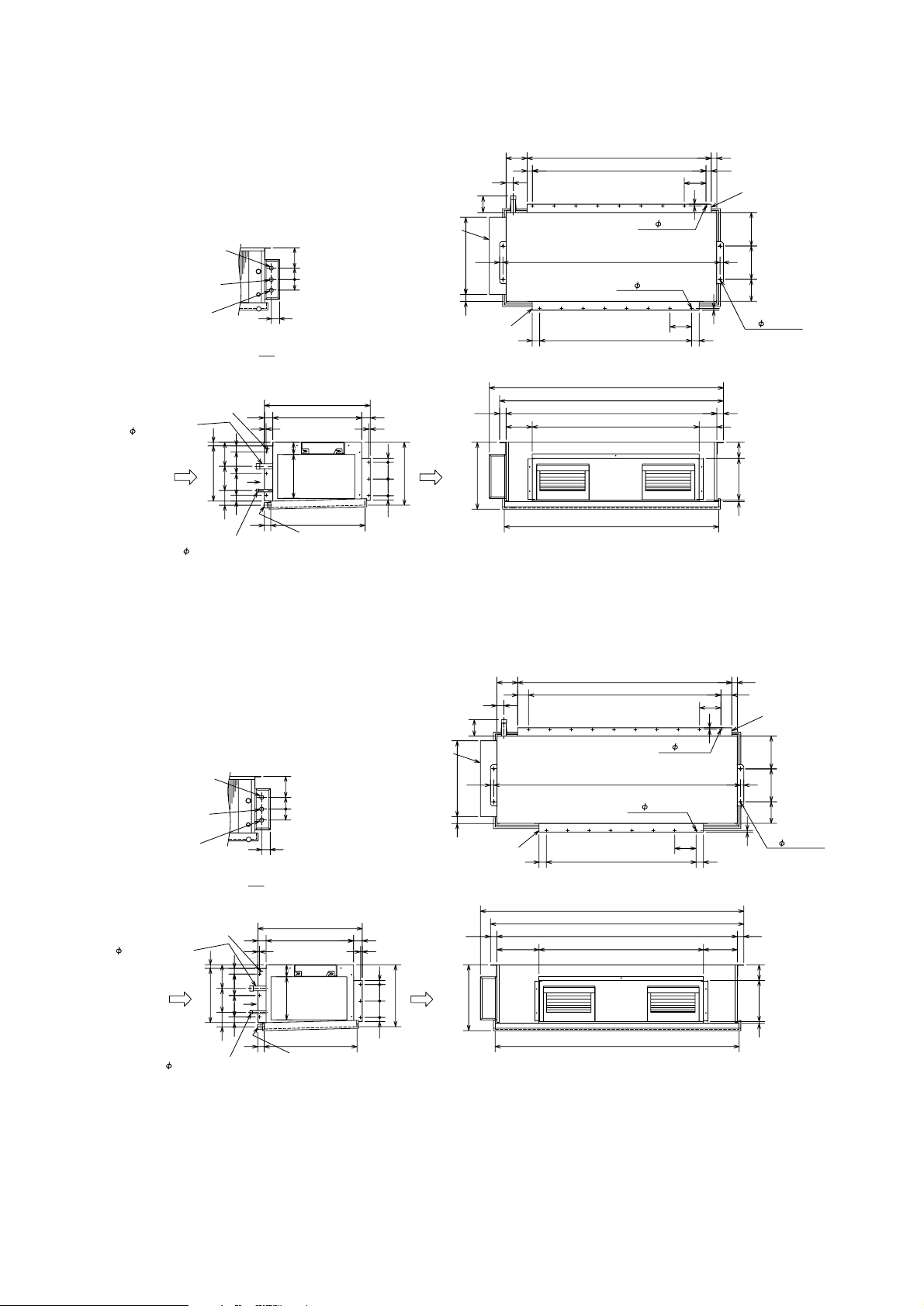

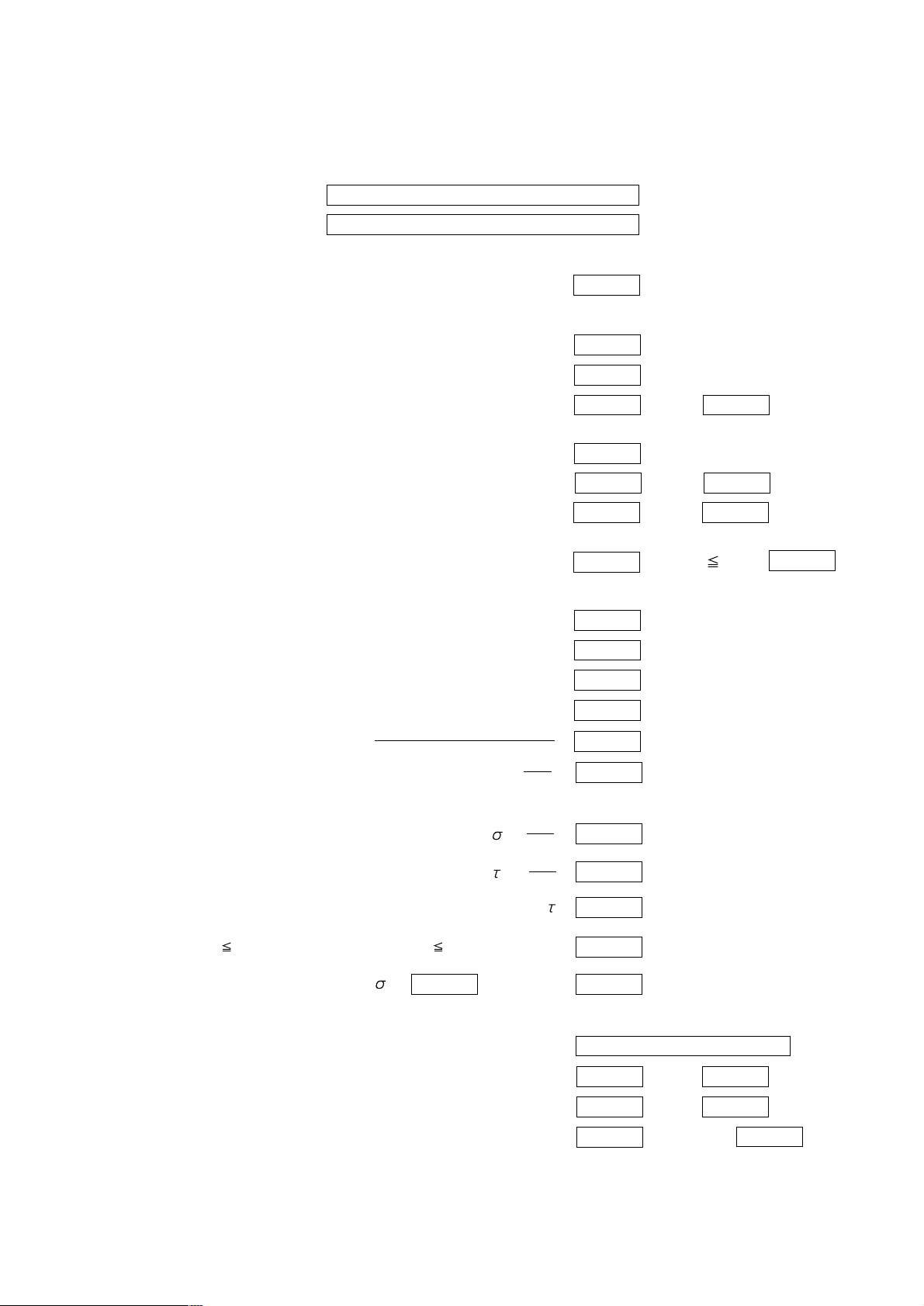

4. Outline Dimensions

(1) Outdoor unit

(i) PUH-5MYG

(ii) PUH-6MYG

Page 20

<Accessory>

·Conduit mouting plate

(Painted the same color as the unit body)

a)ø27····················································1pc.

b)ø34····················································1pc.

·Tapping screw 4✕12·······························4pcs.

·Connection pipe······································1pc.

Note 1.It is possible to change to ø27 or ø34 by

selecting the conduit mounting plate a,b.

Air inlet

Air outlet

Top view

4-10✕20 Holes

<For mounting anchor bolt M8>

[Field supply]

Air inlet

Note 1

ø40 Hole

<For the power

supply wiring>

<For the indoor unit

connection wiring>

ø27 Hole

Refrigerant pipe

ø15.88(5/8 flare)

Refrigerant pipe

ø28.6 (1-1/8 flange)

Connection pipe

(Accessory)

Knock out hole

Pressure gauge

(For option)

Front view Right side viewLeft side view

58515 15

54734 34

615

108.51230

1447 9

108.5

152 55

97

100115

65

10

103

1480

<Accessory>

·Conduit mouting plate

(Painted the same color as the unit body)

a) ø27····················································1pc.

b) ø34····················································1pc.

·Tapping screw 4✕12································4pcs.

·Connection pipe·······································1pc.

Note 1.It is possible to change to ø27 or ø34 by

selecting the conduit mounting plate a,b.

615

547 3434

585 1515

Air inlet

Air outlet

Top view

4-10✕20 Holes

<For mounting

anchor bolt M8>

[Field supply]

108.5830108.5

91047

Air inlet

Right side viewFront view

1480

Knock out hole

Pressure gauge

(For option)

10

103

Connection pipe

(Accessory)

Refrigerant pipe

PUH-8MYG :

ø

25.4 (1 flange)

PUH-10MYG :

ø

28.6 (1-1/8 flange)

Refrigerant pipe

ø15.88(5/8 flare)

Left side view

ø27 Hole

<For the indoor unit

connection wiring>

Note 1

ø40 Hole

<For the power

supply wiring>

55152

97

100115

65

- 19 -

(iii) PUH-8,10MYG

(iv) PUH-12MYG

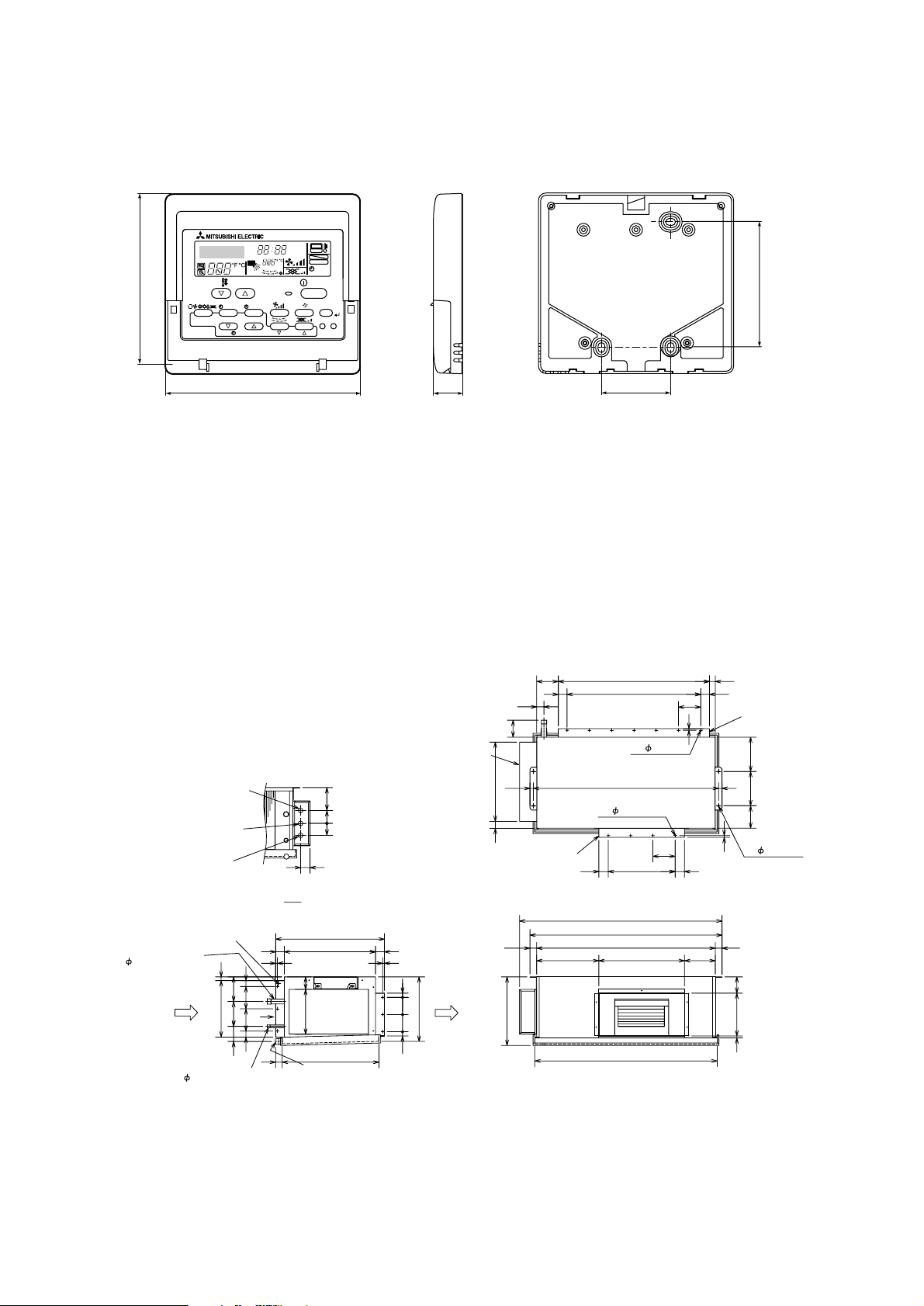

Page 21

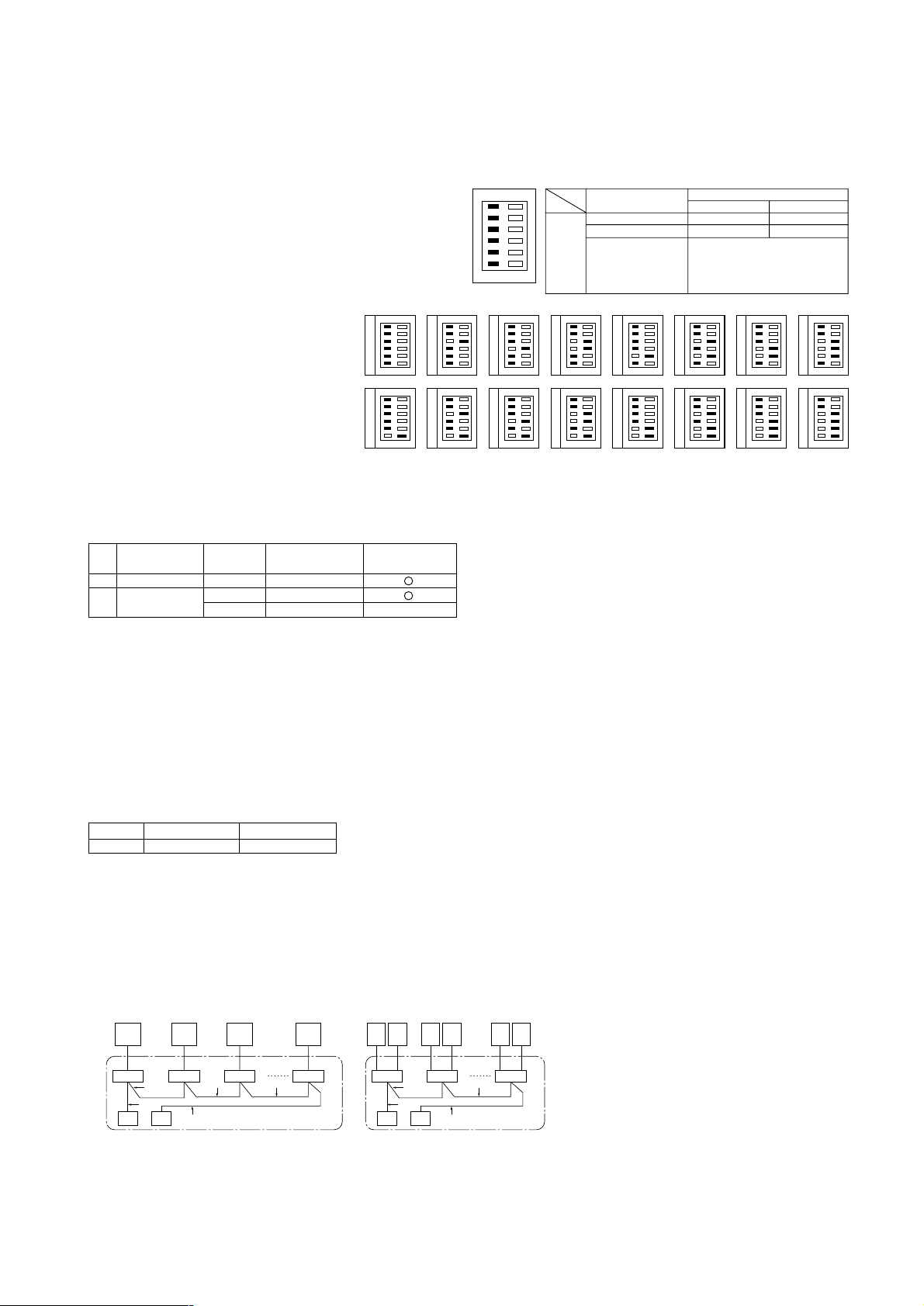

120

130

19

46

83.5

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFFHrAFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

(Front view) (Side view) (Rear view)

- 20 -

(2) Remote Controller

• Models PAR-21MAA

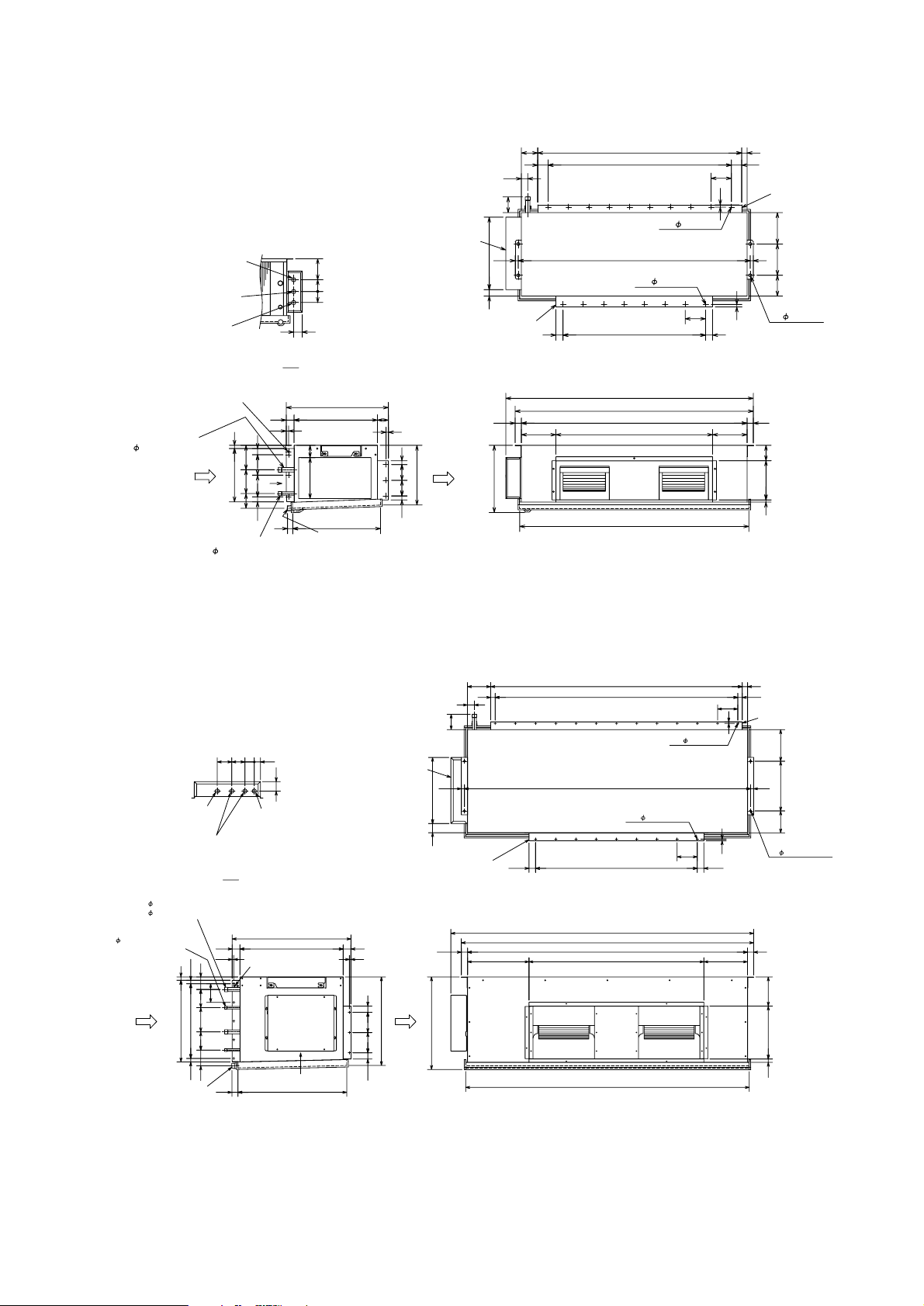

(3) Indoor unit

(i) PEH-5,6MYC

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

75

55

12970

A

A

4- 12 Holes

Drain R1

Front view

Supply air

Left side view

Return air

<Accessory>

.

Pipe cover....................................... 2pcs.

(For dew condensation prevention of

.

Remote controller............................ 1pcs.

local piping and unit connection.)

Refrigerant pipe

19.05 (3/4 braze)

Refrigerant pipe

12.7 (1/2 braze)

Return air

sensor

20- 3 Holes

14- 3.1 Holes

<For hanging bolt M10>

[Field supply]

Supply air

duct flange

Return air

duct flange

Control box

Top view

400

124

42

34

530

50

131

9525011

10

179500361

1180

55 3X130(=390)

130

55

882

51 6X130(=780)

25 100 100 25

376

10

54

10

73262

634

35

130

130

35

89

145

330 22

39 565

1120

40104040

1064

144

462

20

40

100

199

20

1080

10

200

51

130

Page 22

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

75

55

12970

Return air

sensor

A

A

4- 12 Holes

Drain R1

Top view

Control box

Return air

duct flange

Supply air

duct flange

<For hanging bolt M10>

[Field supply]

22- 3.1 Holes

24- 3 Holes

Refrigerant pipe

15.88 (5/8 braze)

Refrigerant pipe

25.4 (1 braze)

<Accessory>

.

Pipe cover.......................................... 2pcs.

(For dew condensation prevention of

local piping and unit connection.)

.

Remote controller............................... 1pcs.

Return air

Left side view

Supply air

Front view

42

124 34

131

530

50

9525011

7x130(=910)

10

130

130

45

45

31 31

1102

200

10

8x130(=1040)

1300

20

199

100

40

20

462

144

1284

400

155 1000 105

40 1260 40

1340

1400

56539

22330

145

89

35

130

130

35

634

262 73

10

54

10

376

2510010025

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

75

55

70 129

A

A

4- 12 Holes

Drain R1

Top view

Control box

22- 3.1 Holes

<For hanging bolt M10>

[Field supply]

Return air

duct flange

Supply air

duct flange

26- 3 Holes

Left side view

Supply air

Return air

Front view

Return air

sensor

<Accessory>

.

Pipe cover..........................................2pcs.

(For dew condensation prevention of

.

Remote controller.............................. 1pcs.

local piping and unit connection.)

Refrigerant pipe

15.88 (5/8 braze)

Refrigerant pipe

28.6 (1-1/8 braze)

42

124

131

50 530

34

130

9525011

10

66

1302

1484

7x130(=910)

130

45

45

200

20

100

20

199

40

1500

462

66 9X130(=1170)

10

25 100 100 25

10 10

1540

40146040

255 205

376

1000

1600

73262

400

39 565

54

634

35130

89

145

144

330 22

130

35

- 21 -

(ii) PEH-8MYC

(iii) PEH-10MYC

Page 23

- 22 -

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

1347570

55

66

130

1440

A

A

4- 12 Holes

<For hanging bolt M10>

[Field supply]

26- 3.1 Holes

22- 3.1 Holes

Drain R1

Supply air

duct flange

Control box

Return air

duct flange

Refrigerant pipe

28.6 (1-1/8 braze)

Supply air

Return air

Refrigerant pipe

15.88 (5/8 braze)

Top view

Left side view

Front view

<Accessory>

.Pipe cover......................................... 2pcs.

(For dew condensation prevention of

.

Remote controller.............................. 1pcs.

local piping and unit connection.)

Return air

sensor

15

131 200

56233

1580

262 78

46240

650

428

530 70

25

15

10025 100

50

130

344 20

42

95

382

341302104

66

20 201480

15

40

220

45

130

40

1520

1000220

1464

98250

14

156152

13042

40

100

199

15

7X130(=910)45

9X130(=1170)

Rubber bush

<Remote

controller wiring>

Rubber bush

<Power supply

wiring>

Rubber bush

<Outdoor unit

connection wiring>

4084 60

61

94

*2

*1

*2

*1

Refrigerant pipe

15.88 (5/8 braze)

[2 places (*2 part)]

Refrigerant pipe

PEH-16MYC: 25.4 (1 braze)

PEH-20MYC: 28.6 (1-1/8 braze)

[2 places (*1 part)]

Return air

sensor

(2 places)

Drain R1

24- 3.1 HOLES

36- 3 HOLES

Left side view Front view

Top view

Return air

Supply air

4- 15 HOLES

<For hanging bolt M12>

[Field supply]

Return air

duct flange

Control

box

Supply air

duct flange

A

A

<Accessory>

.

Pipe cover...................................... 4pcs.

(For dew condensation prevention of

.

Remote controller........................... 1pcs.

local piping and unit connection.)

10

20 1840

10

4040 1800

1880

50 664

525 22

81

117156117

102

22.5

120

4X120(=480)22.5

595

1824

50

764

2801125395

340 18822

1947

570

40 130 130 40

10

33

29

130

12X130(=1560)29

149 1618

45

100

42.5

130

8X130(=1040)42.5

10

203320141

20

42559

70039

(iv) PEH-12MYC

(v) PEH-16,20MYC

Page 24

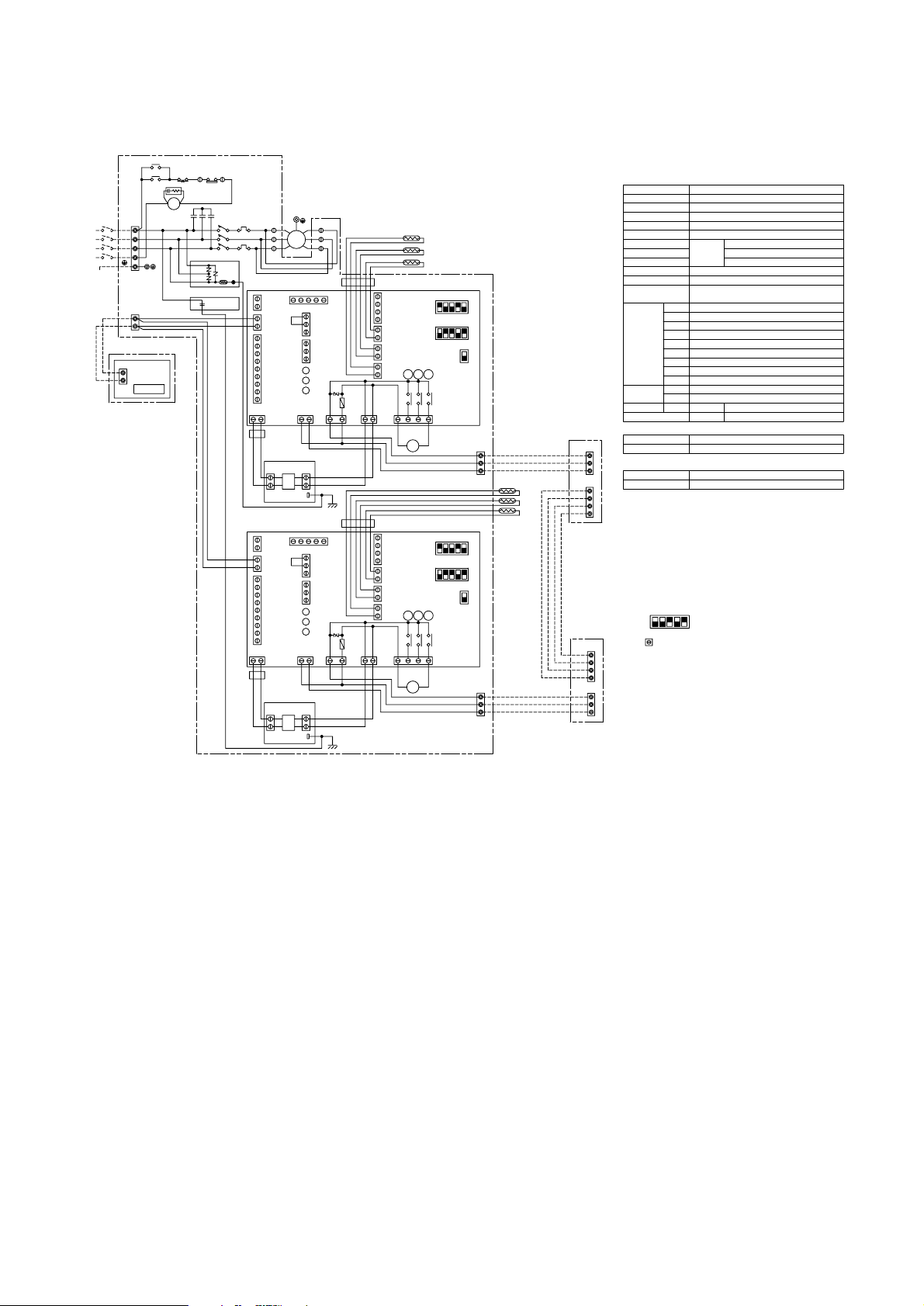

1

C11

1

C12

3

1

C21

3

C22

1

MF2 MF3

TB6

UVWN

C14

SV1

CH 63H1 63L

21S4

X1

3

6

1

6

1

3

5

7

F10

F20

F30

CNOUT1

CNOUT2

1

6

5

11

3

3

1

35

CNIN

CNFC2

CNFAN

F.C.

BOARD

CNPOW

3

1

F2

5

1

F03

LED1

SW4

1

OFF

ON

4

SW3

OFF

ON

1

2

SW5

OFF

ON

1

SW1

6

6

OFF

ON

1

SW2

TH2

CN51

CN28CNS3

CNFG

CN81

63H2

3

CN20

TR

313

CN53

CNMNT CN2

1212

CN312CN4CN40

1

L1

L2

L3

N

N

52C

51C

CN3N

CN27

CN24

CN3S

CNVMNT

CN3D

1

3

L1 L2 L3

3

1

CN34

DC power supply

Transmission

Circuit

F02

F04

CNFC1

X05

X02

X04

X01

X03

MC

CN23

1

3

CN22

CN21

3

5

3

CN26

3

CN25

CN52

1

52C

52C

1

2

1

TH1

F1

1

3

F01

1

1

1

7

PE

51C

X1

OUT OUT

IN

IN

N.F.BOARD

Blue

Black

White

Red

Black

White

Red

Green/Yellow

TO INDOOR UNIT

CONNECTING WIRES (*2)

(POLER)

S3S2S1

MAIN BOARD

INDOOR UNIT

OUTDOOR UNIT CONTROL BOX

(*1)(*1)

TB8

TB3

TB1

POWER SUPPLY

3N~PE

380/400/415V

50HZ

PUH-12MYG : 60A

CIRCUIT BREAKER

PUH-8MYG : 50A

(FIELD SUPPLY)

PUH-10MYG : 50A

OUTDOOR UNIT

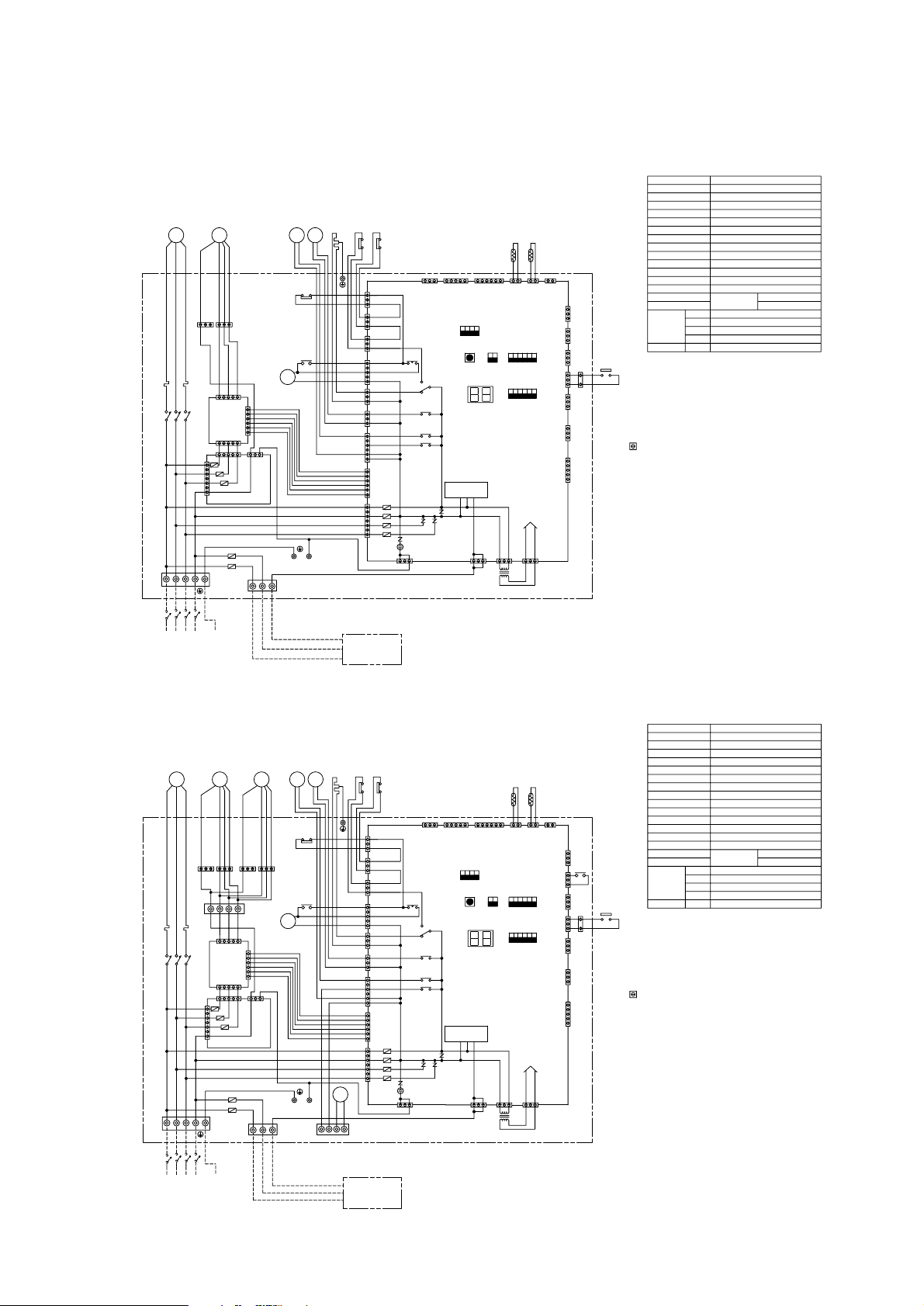

TR TRANSFORMER

FAN MOTOR (OUTDOOR)MF2,MF3

SYMBOL NAME

F1,F2 FUSE (15A 250VAC CLASS T)

51C

52C

63L

63H1

63H2

MC COMPRESSOR MOTOR

LIQUID PIPE TEMP

OVER CURRENT RELAY (COMPRESSOR)

21S4

SV1

CH

TB1,3,6,8

TH1

TH2

MAGNETIC CONTACTOR (COMPRESSOR)

PRESSURE SWITCH (LOW PRESSURE)

4-WAY VALVE

X1 AUXILIARY RELAY

SOLENOID VALVE

CRANK CASE HEATER (COMPRESSOR)

TERMINAL BLOCK

PRESSURE SWITCH (HIGH PRESSURE)

PRESSURE SWITCH (FOR CONTROL)

THERMISTOR

DISCHARGE TEMP

F01-F04

FUSE (6.3A 250VAC CLASS F)

X01-X05

LED1

SW1-5 SWITCH

AUXILIARY RELAY

LED (FOR SERVICE)

OUTDOOR

MAIN

BOARD

N.F.BOARD

F10-F30

FUSE (6.3A 250VAC CLASS F)

Caution,

1.To protect compressor from abnormal current,

over current relays is installed. Therefore, do not

change factory set value of over current relays.

6. mark is connector.

Note:1.The dotted lines show field wiring.

2.Color of earth wire is yellow and green twisting.

3.Specification subject to change without notice.

4.This motor(*1) includes auto reset type internal thermostat.

5.Indoor and outdoor connecting wires (*2) are made with

polarities, make sure matching wiring and terminal.

OUTDOOR UNIT

C14

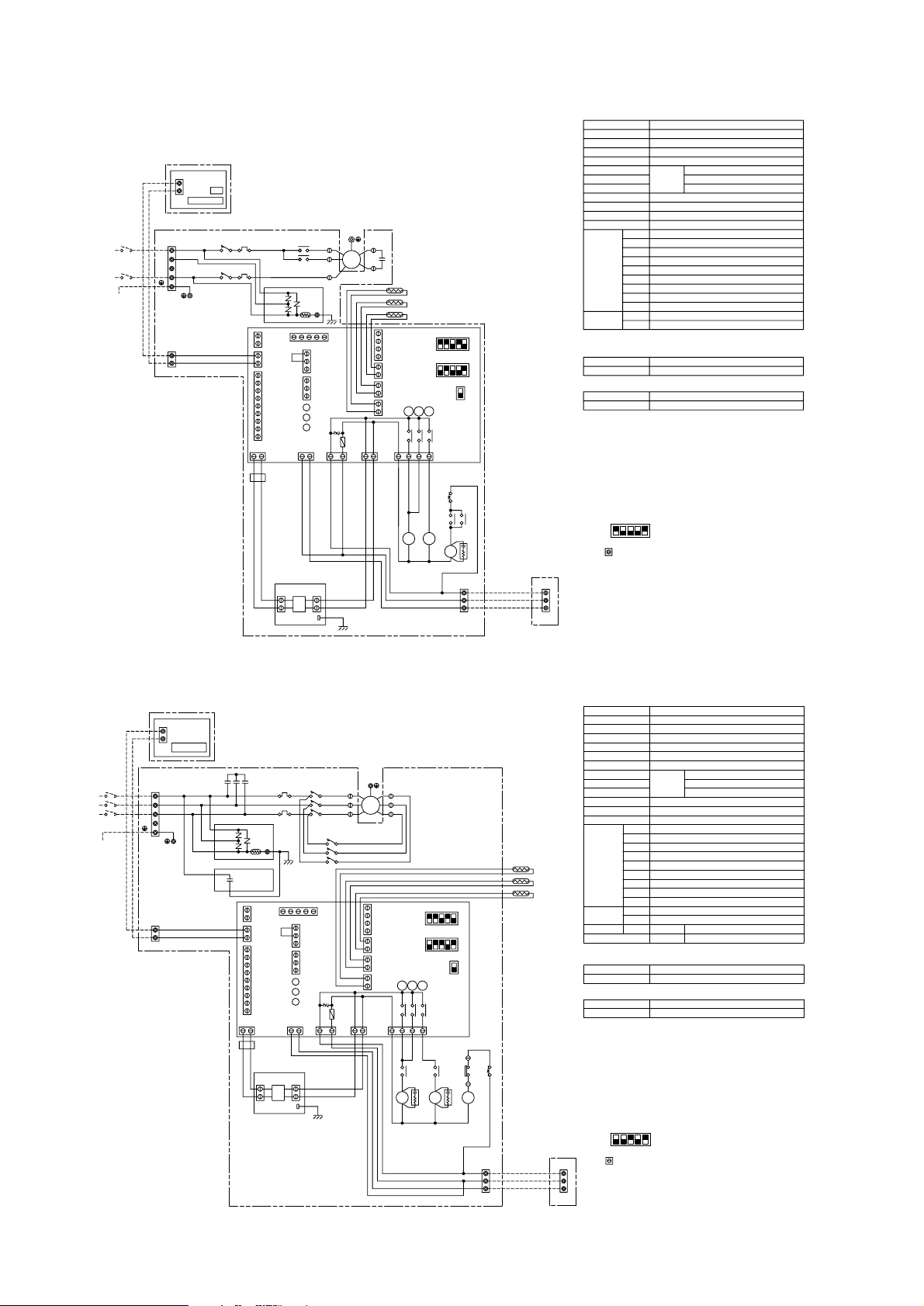

TR TRANSFORMER

FAN MOTOR (OUTDOOR)MF2

SYMBOL NAME

F1,F2 FUSE (15A 250VAC CLASS T)

51C

52C

63L

63H1

63H2

MC COMPRESSOR MOTOR

LIQUID PIPE TEMP

OVER CURRENT RELAY (COMPRESSOR)

21S4

SV1

CH

TB1,3

TH1

TH2

MAGNETIC CONTACTOR (COMPRESSOR)

PRESSURE SWITCH (LOW PRESSURE)

4-WAY VALVE

SOLENOID VALVE

CRANK CASE HEATER (COMPRESSOR)

TERMINAL BLOCK

PRESSURE SWITCH (HIGH PRESSURE)

PRESSURE SWITCH (FOR CONTROL)

THERMISTOR

DISCHARGE TEMP

1

C11

1

C12

3

MF2

3

1

CN51

CN81

63H2

1

2

F01-F04

FUSE (6.3A 250VAC CLASS F)

X01-X05

LED1

SW1-5 SWITCH

AUXILIARY RELAY

LED (FOR SERVICE)

OUTDOOR

MAIN

BOARD

SV1

CH

63H1

63L

21S4

1

6

1

3

5

7

F10

F20

F30

CNOUT1

CNOUT2

1

6

5

11

3

3

1

35

CNIN

CNFC2

CNFAN

F.C.

BOARD

CNPOW

3

1

F2

5

1

F03

LED1

SW4

1

OFF

ON

4

SW3

OFF

ON

1

2

SW5

OFF

ON

OFF

ON

1

SW1

661

SW2

TH2

CN28

CNS3

CNFG

CN20

TR

313

CN53

CNMNT

CN2

121

2

CN3

1

2

CN4CN40

1

L1

L2

L3

N

N

52C

51C

CN3N

CN27

CN24

CN3S

CNVMNT

CN3D

1

3

L1 L2 L3

3

1

CN34

DC power supply

Transmission

Circuit

F02

F04

CNFC1

X05

X02

X04

X01

X03

MC

CN23

1

3