Mitsubishi HS-U449 Service Manual

SPECIFICATIONS

Tape Format

Power Source

Power Consumption

Video Signal System

Video Recording System

Luminance

Color Signal

Hi-Fi Audio

Recording System

Linear Audio Track

Tape Speed

Record/Playback Time

Record/Playback System

Video

Hi-Fi Audio

Monaural Audio Control

Erase

Video Input

Audio Input

Video Output

Audio Output

Tuner VHF

UHF

CATV

Operating Temperature

Relative Humidity

RF Channel Output

Weight

Dimensions

Timer Program Capacity

Deck

: VHS 1/2” high-density video

cassette tape

: 120 V AC ; 60 Hz

: Approx. 20 W (STBY 3 W)

: EIA standard ; NTSC color

: VHS standard

: Frequency modulation recording

: Low frequency conversion

sub-carrier phase shift recording

: VHS standard

Azimuth helical scanning system

: 1 track

: 1-5/16 i.p.s (standard play)

7/16 i.p.s (extended play)

:

120 min. with T-120 video cassette

(SP mode)

360 min. with T-120 video cassette

(EP mode)

: 4 heads

: 2 heads

: 1 head

: 1 head

:

0.5 - 2.0 V(p-p), 75 Ω unbalanced

RCA Pin Jack

:

346 mV(rms), 47 kΩ unbalanced

RCA Pin Jack

: 1.0 V(p-p), 75 Ω unbalanced

RCA Pin Jack

: 346 mV(rms), 1 kΩ unbalanced

RCA Pin Jack

: 54 - 88 MHz, 174 - 216 MHz

: 470 - 806 MHz

: 54 - 88 MHz, 90 - 804 MHz

: 41 - 104°F

: 30 - 80%

: Channel 3 or 4 switchable

: Approx. 8.0 lbs. (3.6 kg)

: 16.7”(W) × 3.7”(H) × 11.9”(D)

425 (W) × 93 (H) × 302 (D) mm

: 1 month programmable

/ 8 programs

: α Deck

• Weight and dimensions shown are approximate.

• Design and specifications are subject to change without notice.

Only cassettes marked VHS can be used with this video cassette recorder.

2003

VIDEO CASSETTE RECORDER

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Ave. Irvine, California 92618 U.S.A.

Copyright C 2003 Mitsubishi Digital Electronics America, Inc. All Rights Reserved.

MODEL

HS-U449

-2-

CONTENTS

- FILE "COVERPGE" -

SPECIFICATIONS ...........................................................1

CONTENTS......................................................................2

GLOSSARY OF ABBREVIATIONS .................................4

- FILE "DISASSY" -

SAFETY PRECAUTIONS ................................................1

CONNECTION .................................................................3

DISASSEMBLY................................................................4

HOW TO EXECUTE CIRCUIT BOARD SERVICE...........7

CHIP PARTS REPLACEMENT........................................9

- FILE "ELCTADJ" -

HOW TO INITIALIZE THE E2PROM................................1

WHEN REPLACING IC5A0 .............................................1

ELECTRICAL ADJUSTMENTS.......................................1

Servo circuit..................................................................2

- FILE "MECHAADJ" -

MECHANICAL ADJUSTMENT

AND REPLACEMENT...............................1

1. DECK Cleaning...................................................1

1-1 VIDEO HEAD .................................................1

1-2 Tape Running System ....................................1

1-3 REEL DISK Drive System ..............................1

2. Replacement of Major Parts ..............................2

2-1 CLEANING ARM ...........................................2

2-2 STAY PLATE..................................................2

2-3 BOTTOM ASSY .............................................3

2-4 INSERT GUIDE (TU).....................................4

2-5 INSERT GUIDE (SP).....................................4

2-6 REC HOLDER, REC LEVER,

REC SPRING ................................................5

2-7 F/L ARM ASSY, F/L BEARING......................5

2-8 A/C HEAD UNIT ............................................6

2-9 F/E HEAD UNIT.............................................6

2-10 SENSOR COVER (TU)..................................7

2-11 SENSOR COVER (SP)..................................7

2-12 REV UNIT (TU),

REV UNIT (SP)..............................................8

2-13 MODE POSITION UNIT ................................8

2-14 REEL BELT, PULLEY BUSH,

THRUST WASHER,

BELT PULLEY, SHIFT SLIDER,

PULLEY GEAR ASSY, SLIP GEAR,

SLIP SPRING, SLIP WASHER,

THRUST WASHER, SLIP ADJUSTER,

IDLER 2 UNIT................................................9

2-15. CAPSTAN BRAKE SPRING,

CAPSTAN BRAKE ASSY ............................11

2-16 FC HOLDER, MOTOR HOLDER,

LOADING WORM,

LOADING MOTOR ASSY,

WORM WHEEL ...........................................12

2-17 PINCH ARM CAP, PINCH UNIT ..................13

2-18 F/L PLATE, DOOR ARM..............................13

2-19 BRAKE CAM PLATE ...................................14

2-20 GUIDE LAMP ..............................................15

2-21 MAIN CAM, GUIDE ARM (TU),

BRAKE LEVER,LB PIN ...............................16

2-22 L/D LOCK LEVER .......................................17

2-23 BRAKE BELT (SP), BELT HOLDER............17

2-24 BELT LEVER, BELT ADJUSTER.................18

2-25 TENSION ARM, TENSION LEVER,

TENSION SPRING, TENS AXIS HOLDER,

REEL DISK (SP side) ..................................18

2-26 BRAKE BELT (TU).......................................19

2-27 BRAKE (TU), REEL DISK (TU side)............19

2-28 SHIFT LEVER .............................................20

2-29 CHARGE SPRING, SWING LEVER,

CHARGE ASSY...........................................21

2-30 LOADING ARM ASSY (SP),

LOADING ARM ASSY (TU).........................21

2-31 A/L LEVER ..................................................22

2-32 TAPE GUIDE ASSY (SP),

TAPE GUIDE ASSY (TU) ............................24

2-33 DRUM CLAMPER, DRUM ASSY ................25

2-34 DRUM MOTOR STATOR, BRUSH SPRING,

SPACER, ROTOR CASE, END RING,

BRUSH, UPPER DRUM ASSY ...................26

2-35 CAPSTAN MOTOR......................................27

3. Interchangeability Adjustment

of the Mechanism.............................................29

3-1 Adjustment of BACK TENSION and

TENSION POLE's Position..........................29

3-2 Check and Adjustment of

the FM Envelope..........................................30

3-2-1 GUIDE ROLLER Adjustment Check............30

3-2-2 Height Adjustment of

GUIDE ROLLER (SP)..................................30

3-2-3 Height Adjustment of

GUIDE ROLLER (TU)..................................30

3-2-4 Coarse Adjustment of Phase.......................31

3-2-5 Flatness Check of FM Waveform.................31

-3-

CONTENTS

3-2-6 Tape Running Condition

at the GUIDE ROLLERs (Check1) ...............32

3-2-7 Tape Running Condition

at the GUIDE ROLLERs (Check 2) ..............32

3-3 A/C HEAD Adjustment .................................33

3-3-1 Slant Adjustment of A/C HEAD ....................33

3-3-2 Azimuth and Height Adjustment of

A/C HEAD ....................................................33

3-4 Phase Adjustment ........................................34

3-5 Tape wrinkle check.......................................34

4. Servicing Tape Jam

during the Loading Process .........................35

SERVICE CAN BE EXECUTED

WITH THE EE PICTURE DISPLAYED ..........................36

DECK OPERATION CHECK .........................................36

- FILE "PARTSLST" -

Parts List .........................................................................1

1. CABINET ASSEMBLY ........................................2

1. CABINET ASSEMBLY LIST................................3

2. PACKING PARTS................................................4

2. PACKING PARTS LIST .......................................5

3. ELECTRICAL PARTS .........................................6

- FILE "DECKASSY" -

DECK ASSEMBLY-1.........................................................1

DECK ASSEMBLY-1 LIST ................................................2

DECK ASSEMBLY-2.........................................................4

DECK ASSEMBLY-2 LIST ................................................5

- FILE "SCHEMATC" -

BLOCK DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED CIRCUIT BOARD PARTS LAYOUT

-4-

GLOSSARY OF ABBREVIATIONS

JSTCLK

LIN-IN

LIN-OUT

LMUTE

LP

MOD

MOTORV

NL

OSC

PB

PC

PCB

PG

PLL

PRT

PSAVE

PSLED

PSYNC

PWSV

PWV

QH

QV

REC

REC2

RECPBC

RES

RESPCM

REW

RIS

RMSDET

RS

RXD

SAPIND

SCLK

SCR

SI

SLD

SP

SS

SSVSYNC

STRB

SU-SENS

TSREC

TSSW

TU-SENS

V-REF

VBUSY

VCA

VCO

VENV

VSETCLK

VSETCS

YNR

: Just Clock

: Linear Audio In

: Linear Audio Out

: Linear Mute

: Long Play

: Modulator

: Motor Voltage

: Non Linear

: Oscillator

: Play Back

: Position Control

: Printed Circuit Board

: Pulse Generator

: Phase Locked Loop

: Protect

: Power Save

: Power Save Light Emitting Diode

: Pretened Vartical Synchronizing Signal

: Power Save

: ON/OFF Command to supply B + Power

: Cue Horizontal Signal

: Cue Vertical Signal

: Recording

: Record Command for the PB/REC Control Circuit

: Record/Play Back Chroma Signal

: Reset

: Reset Pulse Code Modulation

: Rewind

: Record Inhibit Switch

: Root Mean Square Detector

: Reverse Search

: Read X Data

: SAP carrier detect Indicator

: Serial Clock

: Scramble

: Serial control data Input

: Side Lock Detector

: Standard Play

: Start Sensor

: Speed Search Vertical Synchronizing Signal

: Strobe

: Supply Reel Sensor

: Tape Simulate Recording

: Tape Simulator Switch

: Take Up Reel Sensor

: Voltage Reference

: VSET Busy

: Voltage Control Amplifier

: Voltage Controlled Oscillator

: Video Envelope

: VSET Clock

: VSET Chip Select

: Y(Luminance) Signal Noise Reduction

: Audio/Control

: Audio Play Back

: Audio Recording

: Audio Erase

: Audio Envelope

: Automatic Frequency Control

: Audio Flip Flop

: Auto Fine Tuning Voltage

: Automatic Level Control

: Audio Mode

: Amplifier Alternating Current Ground

: Automatic Phase Control

: Auto Fine

: Attenuator

: Blue Back Mute

: Carrier/Noise Ratio

: Charge Coupled Device

: Character Generator-Chip Slect

: Channel Switch

: Clock Select

: Counter

: Comparator

: Converter Switch

: Capstan-Frequency Generator

: Capstan-Reverse

: Capstan Motor Voltage

: Chroma Rotation

: Composite Synchronizing Signal

: Control

: Detail Enhancer

: Drum Flip Flop

: Demodulator

: Detector

: Delay

: Drop Out Compensator

: Drop Out Control Stop

: Drum-Frequency Generator

: Drum Control Out

: Drum-Phase Generator

: Electronic-Electronic

: Emphasis

: Extended Play

: Equalizer

: End Sensor

: Feed Back Clamp

: Full Erase

: Fast Forward

: Frequency Generator

: Fluorescent Tube Driver Chip Slect

: Frequency Modulation

: Forward Search

: Frequency of Color Subcarrier

: Ground

: Head Amplifier Switch

: Hi-Fast Forward/Reverse Speed Search 400

: Hi-Fast Forward/Reverse Speed Search

: Horizontal Synchronizing Signal

: I(Current)-Limitter

A/C

A-PB

A-REC

AE

AENV

AFC

AFF

AFTV

ALC

AMODE

AMPC

APC

ATFN

ATT

BLMUTE

C/N

CCD

CG-CS

CHSW

CLKSEL

CNTR

COM

CONV SW

CP-FG

CP-REV

CPMOTORV

CROT

CSYNC

CTL

D.E.

D-FF

DEMOD

DET

DLY

DOC

DOCSTOP

DR-FG

DR-OUT

DR-PG

EE

EMPH

EP

EQ

ES

FBC

FE

FF

FG

FLDCS

FM

FS

FSC

G

HASW

HFR400

HFRSS

HSYNC

I-LIMIT

-1-

INTRODUCTION

This manual provides service information for the adjustments

of mechanical and electrical operations.

Due to design modifications, the servicing procedures and

data given in this manual are subject to possible change

without prior notice.

SAFETY PRECAUTIONS

WARNING : Many of the programs broadcast by television

stations are protected by copyright and Federal law

imposes strict penalties for copyright infringement. Some

motion picture companies have taken the position that

home recording for non-commercial purposes is an

infringement of their copyrights. Until the courts have ruled

on the proper interpretation of the law as applied to home

video recording, this equipment, if used to record

copyrighted material, should be operated at the user’s own

risk.

WARNING :

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This video cassette recorder should be used with AC

120V, 60Hz only.

SAFETY NOTICE

Before returning VCR to the customer a safety check of the

entire VCR should be made. The service technician must be

sure that no protective device built into the instrument by the

manufacturer has become defective or inadvertently

damaged during servicing. Observe all caution and safety

related notes located on or inside the VCR cabinet.

WARNING : Alterations of the design or circuitry of this VCR

should not be made. Any design alterations or additions,

such as circuit modifications, auxiliary speaker jacks,

switches, grounding, active or passive circuitry, etc., or use of

unauthorized camera, cables, accessories, etc. may alter the

safety characteristics of this VCR and potentially create a

hazardous situation for the user. Any design alterations or

unauthorized additions will invalidate the manufacturer’s

warranty and will further relieve the manufacturer of

responsibility for personal injury or property damage resulting

from them. Do not lubricate any motors. When reassembling

the VCR, always be certain that all the protective devices are

put back in place, such as non-metallic control knobs, shield

plates, etc. When service is required, observe the original

lead dress. Components that show evidence of overheating

or other electrical or mechanical damage should be replaced.

WARNING : Replace with same type 1.6A, 125V FUSE.

LEAKAGE CURRENT CHECK

Before returning the VCR to the customer, it is recommended

the leakage current be measured by the following methods.

1. Cold Check

With the AC plug removed from the 120V AC source,

place a jumper across the two AC plug prongs. Turn the

AC switch on. Using an ohmmeter, connect one lead to

the AC plug with the jumper and touch the other lead to

each exposed metal part (metal cabinet, screwheads,

metal overlays, control shafts, etc.), particularly any

exposed metal part having a return path to the chassis.

Exposed metal parts having a return path to the chassis

should have a minimum resistance reading of 1 MΩ. Any

resistance below this value indicates an abnormality

which requires corrective action. Exposed metal parts not

having a return path to the chassis will indicate an open

circuit.

-2-

2. Hot Check

The test sequence, with reference to the measuring

circuit in the figure is as follows:

(1) With switch S1 open, connect the VCR to the measuring

circuit. Immediately after connection, measure the

leakage current using both positions of switch S2 and

with the switching devices in the VCR in all of their

operating positions.

(2) Close switch S1, energizing the VCR, and immediately

after closing the switch, measure leakage current using

both positions of switch S2, and with the switching

devices in the VCR in all of their operating positions.

Repeat the current measurements of items (1) and (2)

after the VCR has reached thermal stabilization. The

leakage current should not be more than 0.5 mA.

AC Leakage Test

Avoid shock hazards. Do not connect this VCR to a TV

antenna, cable or accessory that exhibits excessive leakage

currents. If available, the television instrument or cable to

which this VCR is connected should have the antenna cold

check and leakage current hot check performed.

PRECAUTIONS

Handling and storage

• Avoid using the VCR in the following places:

- extremely hot, cold or humid places,

- dusty places,

- near appliances generating strong magnetic fields,

- places subject to vibration,

- poorly ventilated areas.

• Be careful of moisture condensation.

• If you pour a cold liquid into a glass, water vapor in the air

will condense on the surface of the glass. This is called

moisture condensation.

• Moisture condensation on the head drum, one of the

most critical parts of the VCR, will cause damage to the

tape.

• The VCR is equipped with a moisture condensation

prevention circuit. This circuit operates only when the unit

is attached to an AC outlet.

• Handle the VCR carefully.

• Do not block the ventilation openings.

• Do not place anything heavy on the recorder.

• Do not place liquids on the top cover of the recorder.

• Use the Recorder in horizontal (flat) position only.

• Avoid violent shocks to the recorder during packing and

transportation.

• Before packing, be sure to remove the cassette from the

recorder.

120V

S1

GH

(GROUNDING)

OPEN

VCR

GROUNDING SUPPLY CONDUCTOR

B

A

AC MILLIAMMETER

INSULATING

TABLE

S2

-3-

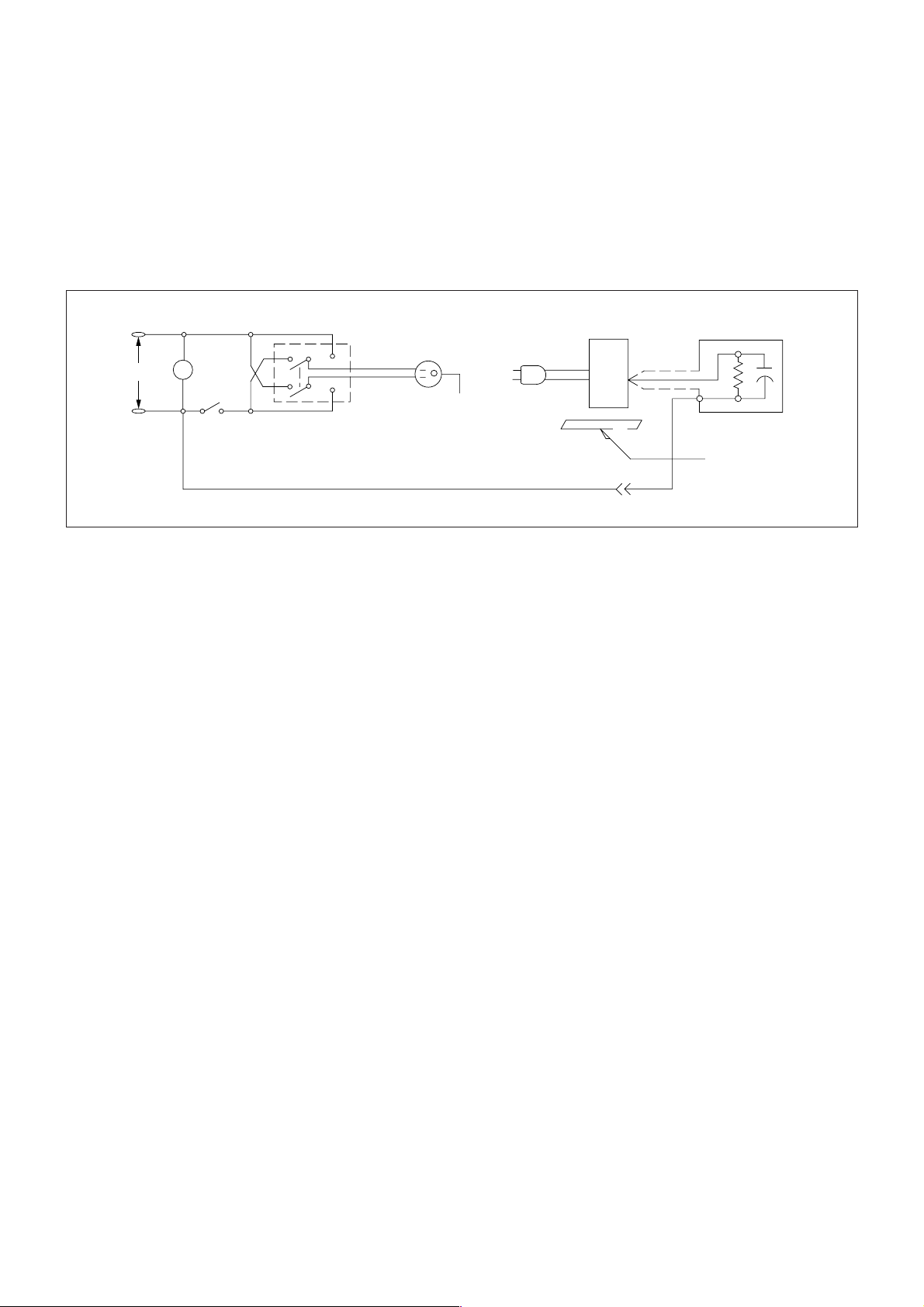

Connecting separate antennas (UHF/VHF)

Connecting the Television

To connect separate UHF/VHF antennas to the VCR:

1. Disconnect the antennas from the back of your TV.

2. Connect the antenna leads to the combiner.

3. Screw or push the combiner onto the ANTENNA terminal

on the VCR labeled ANTENNA IN.

4. When you are finished, refer to “Connecting

the Television” to complete your connections.

CONNECTION

Connecting a regular TV to the VCR

Before connecting the VCR to the TV, complete the cable or

antenna connections to the VCR. (If you have not already

done so.)

To connect a regular TV to the VCR:

1. Take the black cable that is supplied with your VCR

(called a coaxial cable) and connect it to the ANTENNA

terminal on the VCR labeled ANTENNA OUT.

2. Connect the other end of this cable to the terminal on

your TV labeled ANTENNA IN. (This terminal may also

be labeled VHF IN.) If you have an older TV without this

kind of terminal, you will have to use a splitter and then

connect the splitter to the television.

Now that you’ve completed the antenna connections to your

VCR, you’re ready to connect the VCR to the TV.

Because every television is different (especially older model

TVs), your VCR may need to be connected in a variety of

ways. See the Owner’s Manual for Instruction Information

ON:

• Determining if you need a splitter,

• Connecting TVs with audio and video inputs.

ANTENNA

IN

OUT

ANTENNA OUT ANTENNA IN

ANTENNA IN

TV ANTENNA TERMINAL

VCR ANTENNA TERMINAL

TV without ANTENNA IN terminal (single antenna terminal for VHF and UHF)

Connect to

UHF IN on TV.

UHF/VHF Splitter

Connect to

VHF IN on

TV.

From ANTENNA OUT

on VCR

▲▲

▲▲

▲▲

▲▲

▲▲

▲▲

Connect to

UHF IN on TV.

UHF/VHF Splitter

Connect to

VHF IN on TV.

From ANTENNA OUT

on VCR

12

x

x

UHF

VHF

x

x

Combiner

300 Ohm Transformer

Antenna VHF

75 Ohm

Coaxial Cable

300 Ohm

Flat Twin Lead

Antenna UHF

300 Ohm Flat

Twin Lead

2

3

-4-

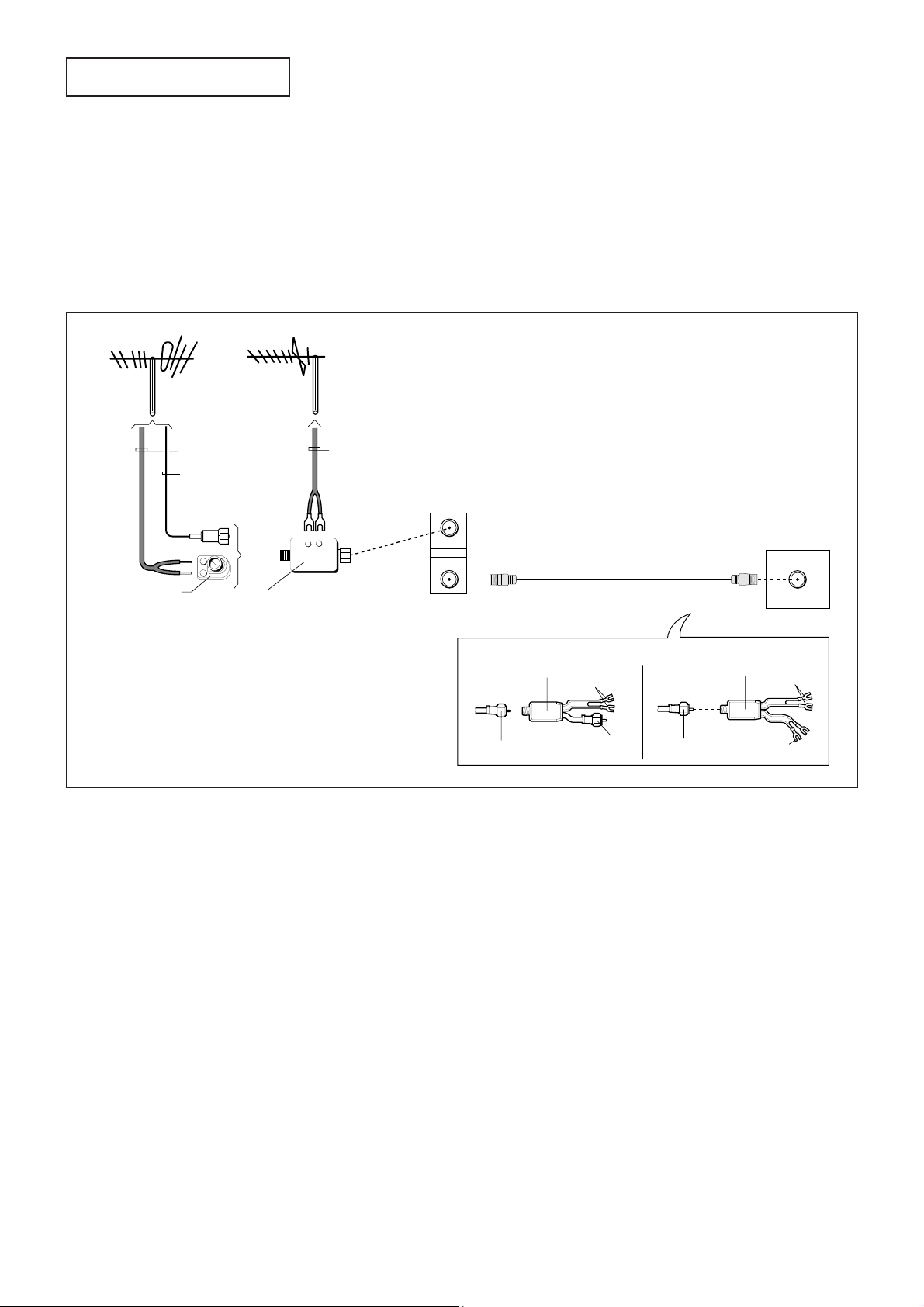

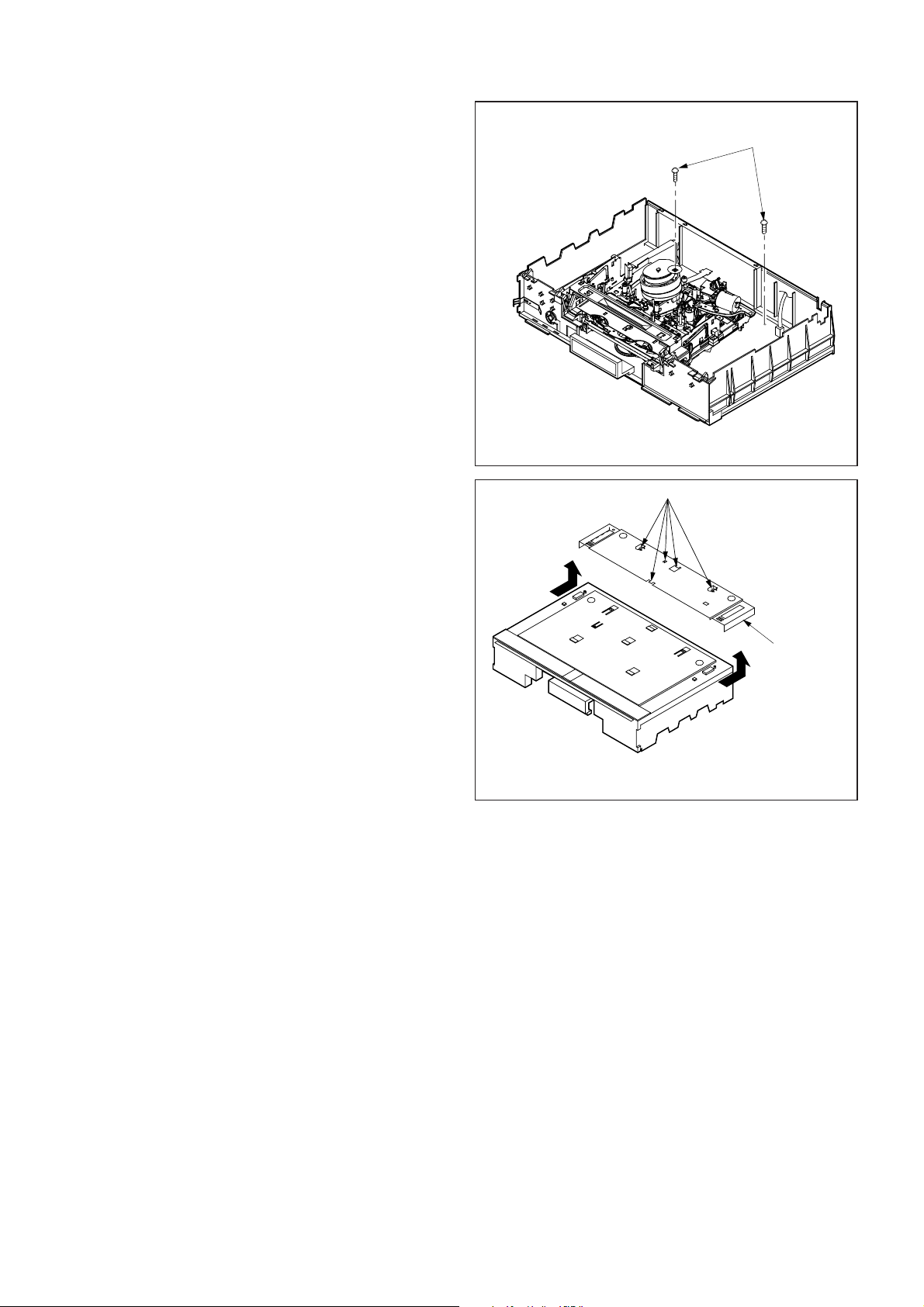

1. Removal of Top Cover

1. Remove the two Top Cover fastening screws (a) shown

in Fig. 1 and remove the Top Cover in the direction shown

by arrow.

2. Removal of Front Panel

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Unfasten the seven catches (

b) shown in Fig. 1 and

remove the Front Panel in the direction shown by arrows.

DISASSEMBLY

Top Cover

a

a

Front Panel

b

b

b

Fig. 1

-5-

a

3. Removal of Bottom Panel

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the two fastening screws (a) shown in Fig. 2.

3. Turn the set upside down as shown in Fig. 3.

4. Slide and lift the Bottom Panel in the direction of the

arrows paying attention to the five catches (b) to remove

it.

Fig. 2

b

Bottom Panel

Fig. 3

-6-

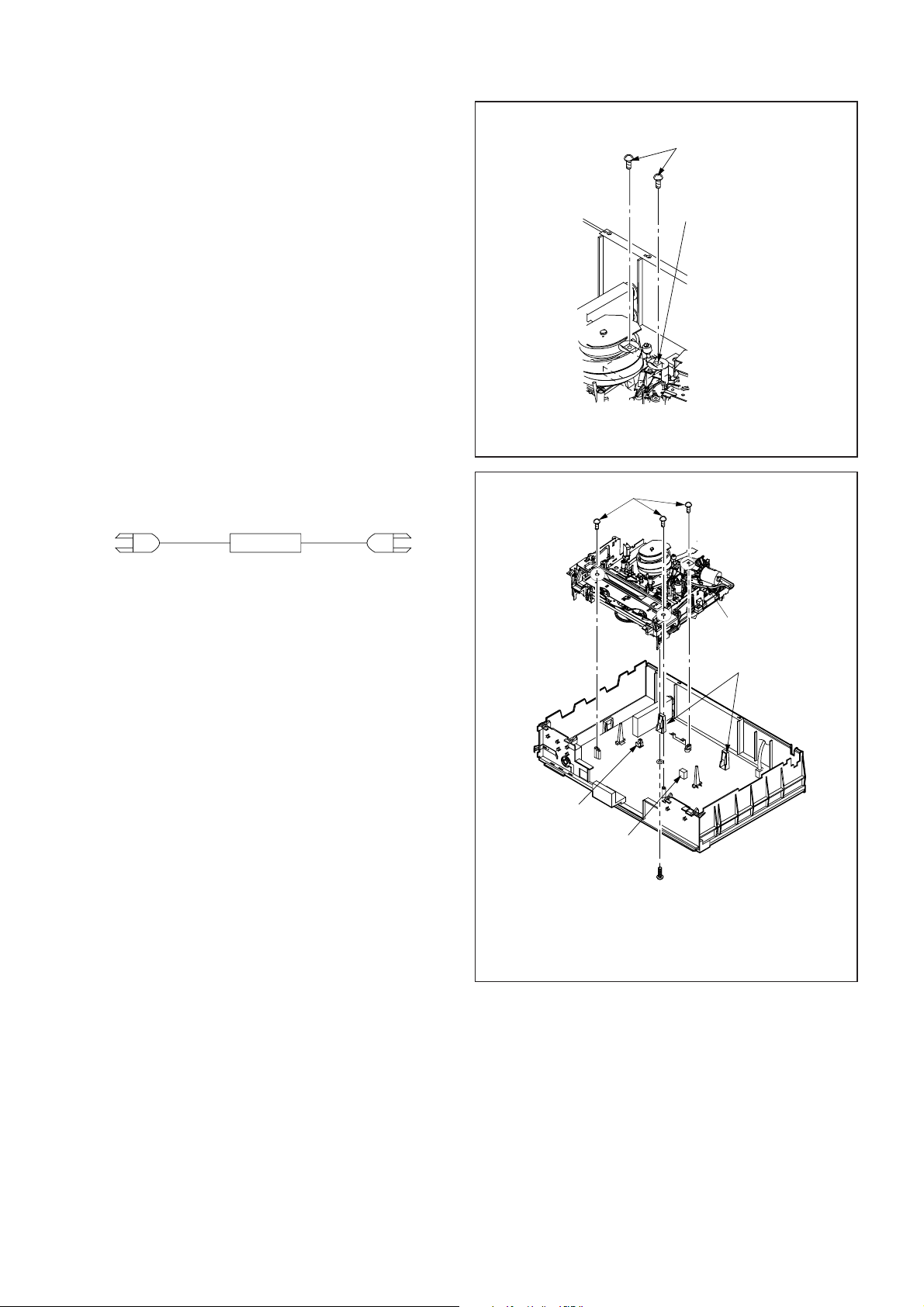

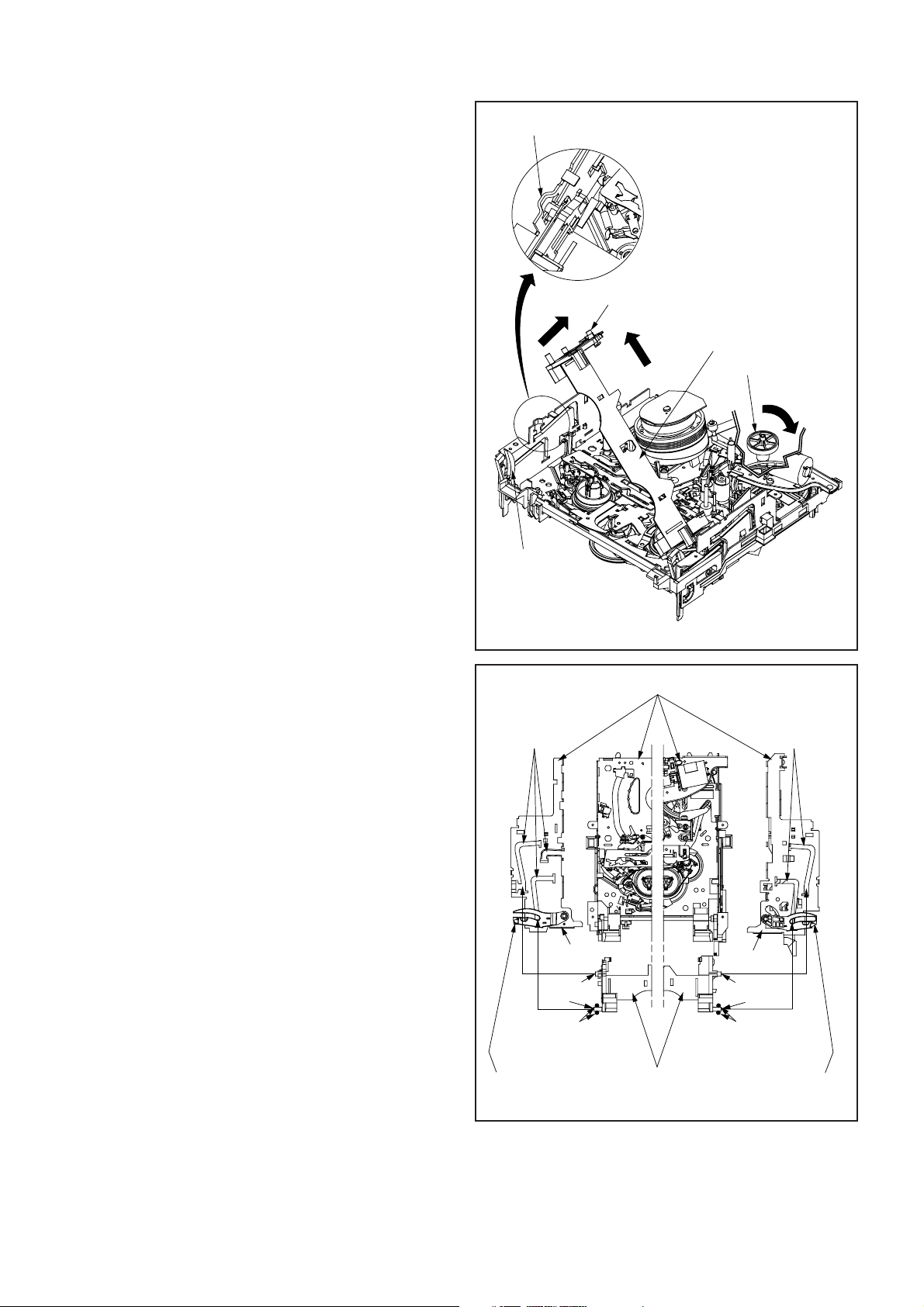

4. Removal of DECK ASSY

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Short-circuit the cathode side of D927 and the GND of

the DECK ASSY using the jig shown below.

Note: The CAPSTAN MOTOR may be damaged without

above short circuit.

4. Remove the two screws (

a) shown in Fig. 4.

5. Remove the four screws (

b) shown in Fig. 5.

6. Disconnect the Connectors MA, MD, MH and ML.

7. Release the two catches (

c) shown in Fig.5 and raise

the DECK ASSY to remove it.

Note1:Remove the DECK ASSY paying attention to the

Connectors MC and MF under it.

Note2:Short-circuit the cathode side of D927 and the Shield

Plate using the jig shown below before attaching the

DECK ASSY.

a

Shield Plate

Fig. 4

b

b

c

DECK ASSY

Connector MC

Connector MF

Fig. 5

Jig (Part No. : 859C548O10)

3W 330Ω

-7-

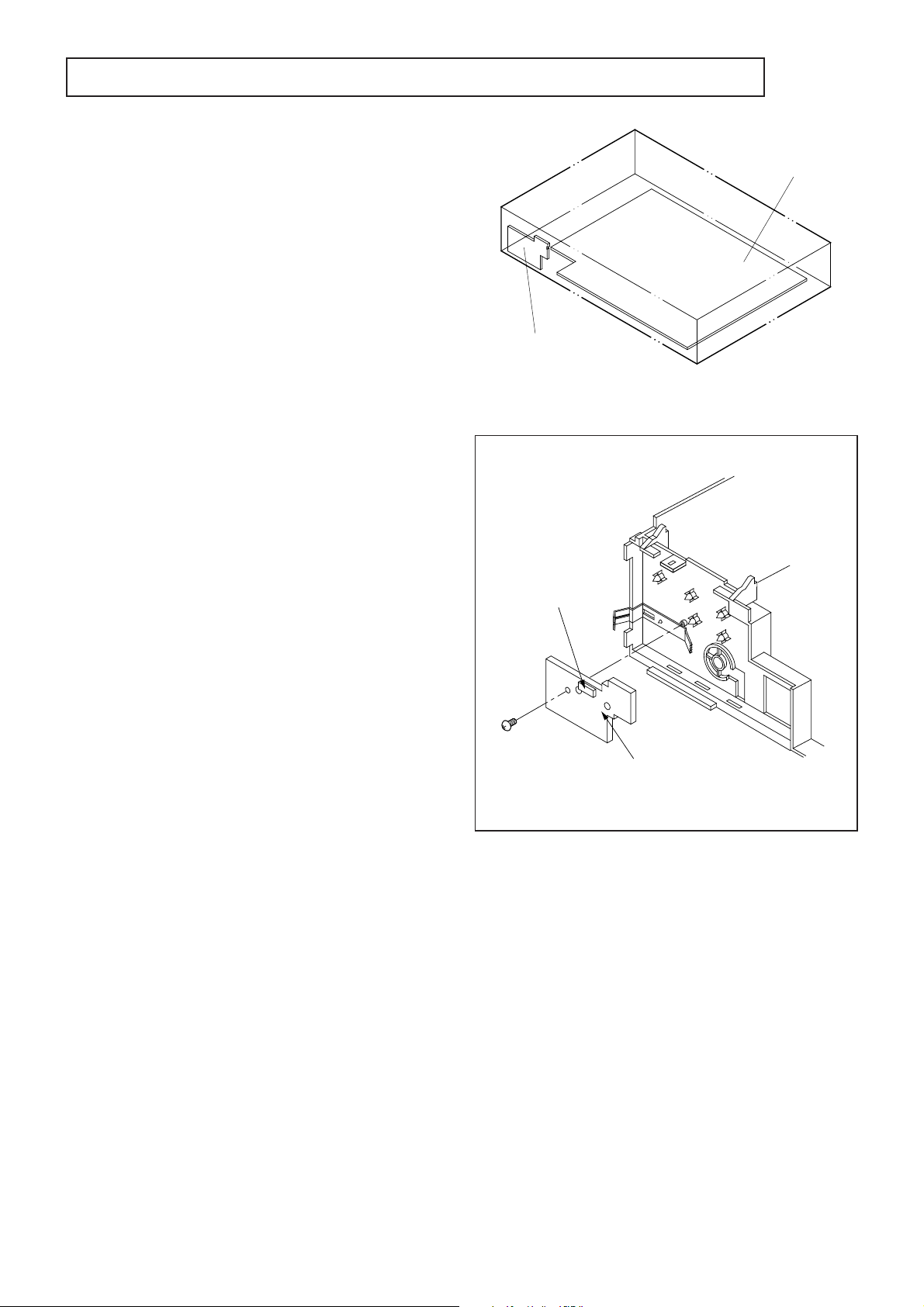

CAUTION: BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE A.C. SOURCE.

LOCATION OF PRINT

CIRCUIT BOARDS

Note :

• Take caution when removing flat cables to prevent any

contact problem.

• Connect and disconnect the flat cables at right angles to

the connector and make sure that it is completely

secured.

• After servicing the PCB, restore the flat cable and leads

to their former state.

PCB - OPE

PCB - MAIN

HOW TO EXECUTE CIRCUIT BOARD SERVICE

Fig. 6

a

Connector OS

PCB-OPE

Fig. 7

1. PCB-OPE

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Remove the Connector OS.

4. Remove the screw (

a) shown in Fig. 7 to remove the

PCB-OPE.

-8-

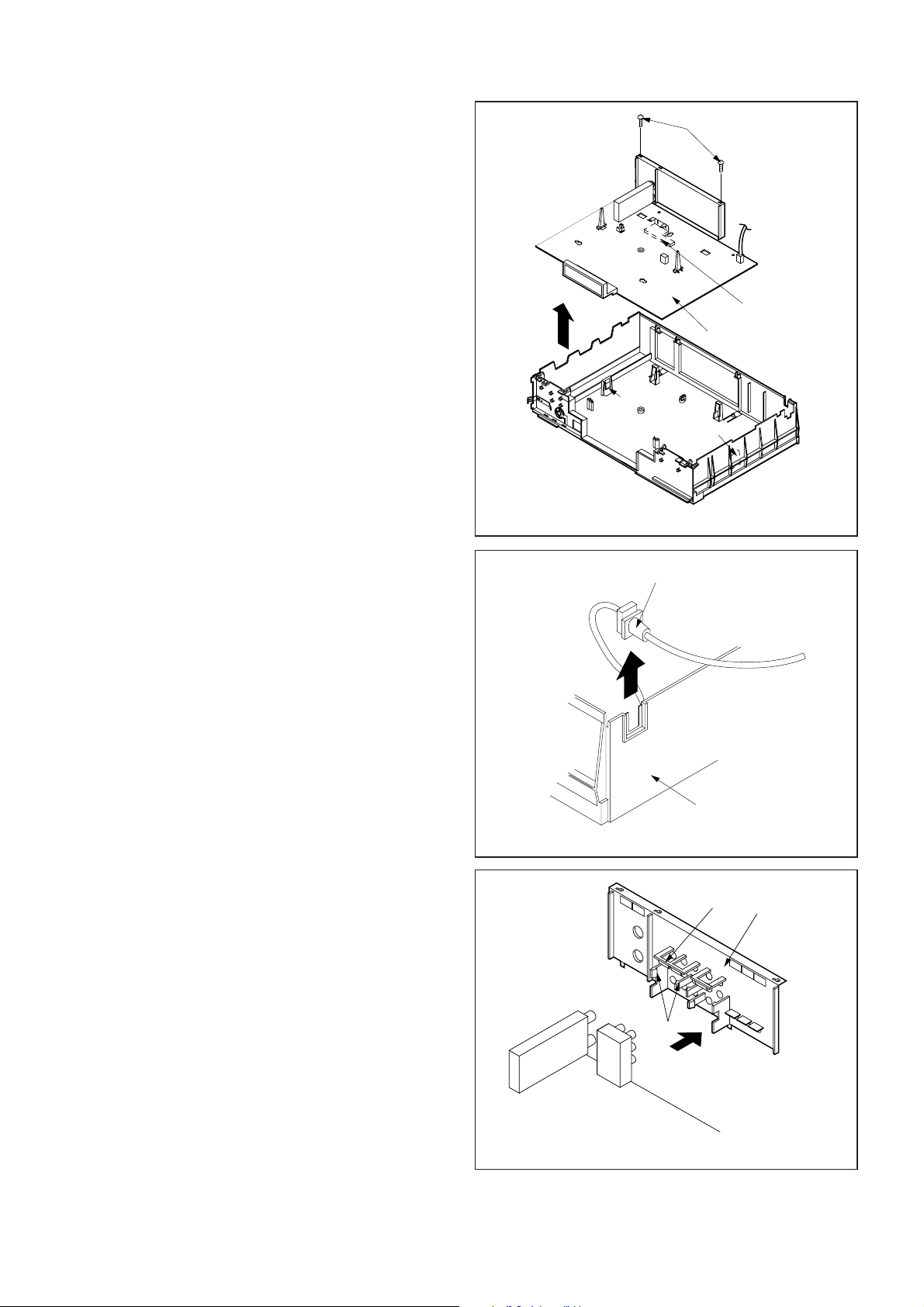

2. PCB-MAIN

1. Remove the Bottom Panel.

(Refer to Para. 3 of the DISASSEMBLY.)

2. Remove the DECK ASSY.

(Refer to Para. 4 of the DISASSEMBLY.)

3. Remove the two screws (a) shown in Fig. 8.

4. Remove the Holder for the AC Power Cord from the Base

Chassis shown in Fig. 9.

5. Remove the PCB-OPE.

(Refer to Para. 1 of the HOW TO EXECUTE CIRCUIT

BOARD SERVICE.)

6. Release the two fastening catches (b) shown in

Fig. 8. Raise the PCB-MAIN to remove it.

7. Release the three catches (C) shown in Fig. 10 and

remove the Antenna Cover.

JJ

Service of PCB

• Head Amp block

1. Unsolder the four soldering points of the Shield Plate

shown in Fig. 8 and remove it.

Note: Before checking the operation, mount the Shield Case

and the Shield Plate on the original position. If not

provided, beat or picture disturbance may appear.

a

b

b

Shield Plate

PCB-MAIN

Fig. 8

Base chassis

Holder for the AC Power Cord

Fig. 9

c

c

Antenna Cover

Fig. 10

-9-

Soldering Pencil

Tweezers

Solder

Chip

Pattern

CHIP PARTS REPLACEMENT

Some resistors, shorting jumpers (0Ω resistor), ceramic

capacitors, transistors and diodes are chip parts.

When replacing these parts, note the following cautions.

Cautions :

A. Use fine tipped, well insulated soldering pencil (iron),

about 30 watts, and tweezers.

B. Melt the solder and remove the Chip Parts carefully

not to tear off the copper foil of the printed circuit

board.

C. Discard removed chips ; do not reuse them.

D. Do not apply heat for more than 3 seconds to new

Chip Parts.

E. Avoid using a rubbing stroke when soldering.

F. Take care not to scratch, or damage the Chip Parts

when soldering.

G. Supplementary cementing is not required.

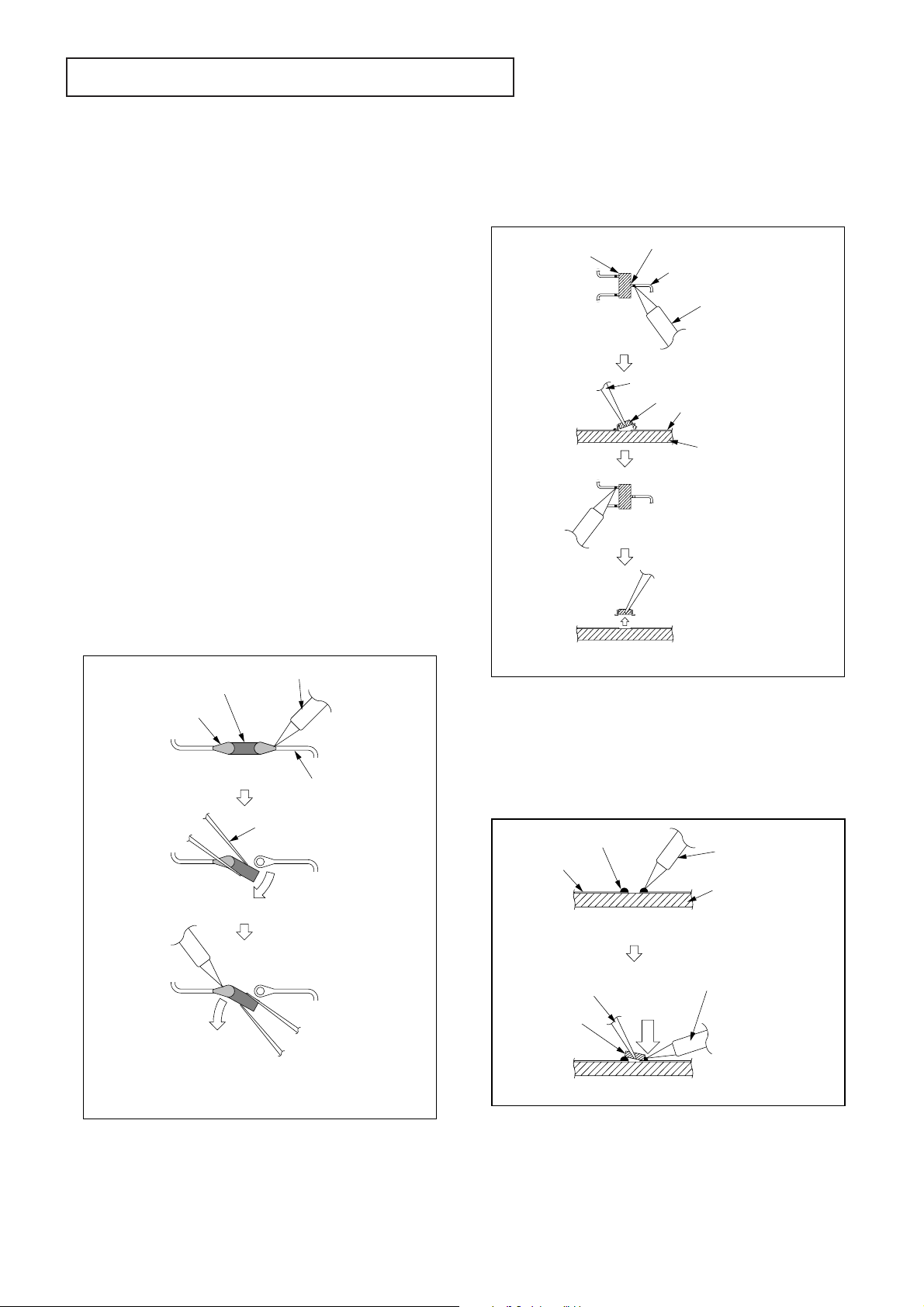

1. Removal of Chip Parts

(Resistors, capacitors, etc.)

A. Grasp the part with tweezers. Melt the solder at both

sides alternately, remove one side of the part with a

twisting motion.

B. Melt the solder at the other side and remove the part.

2. Removal of Chip Parts (Transistors)

A. Melt the solder of one lead. Lift the side of that lead

upward.

B. Simultaneously melt the solder of the two remaining

leads and lift the part from the PCB.

PCB

Chip

Pattern

Tweezers

Soldering Pencil

Lead

Chip

Pattern

3. Replacement

A. Presolder the contact points of the circuit pattern.

B. Press the part downward with tweezers and apply the

soldering pencil as shown in Fig. 3.

PCB

Solder

Pattern

Chip

Tweezers

Soldering Pencil

Soldering Pencil

Fig. 1

Fig. 3

Fig. 2

CHIP PARTS REPLACEMENT

-1-

Lightly apply the cloth

on the UPPER DRUM

ASSY. Do not move the

cloth.

Video Head

Cleaning

Cloth

!1

!2

w

uy

!0

e

r

q

t

i

o

Fig. 1-1

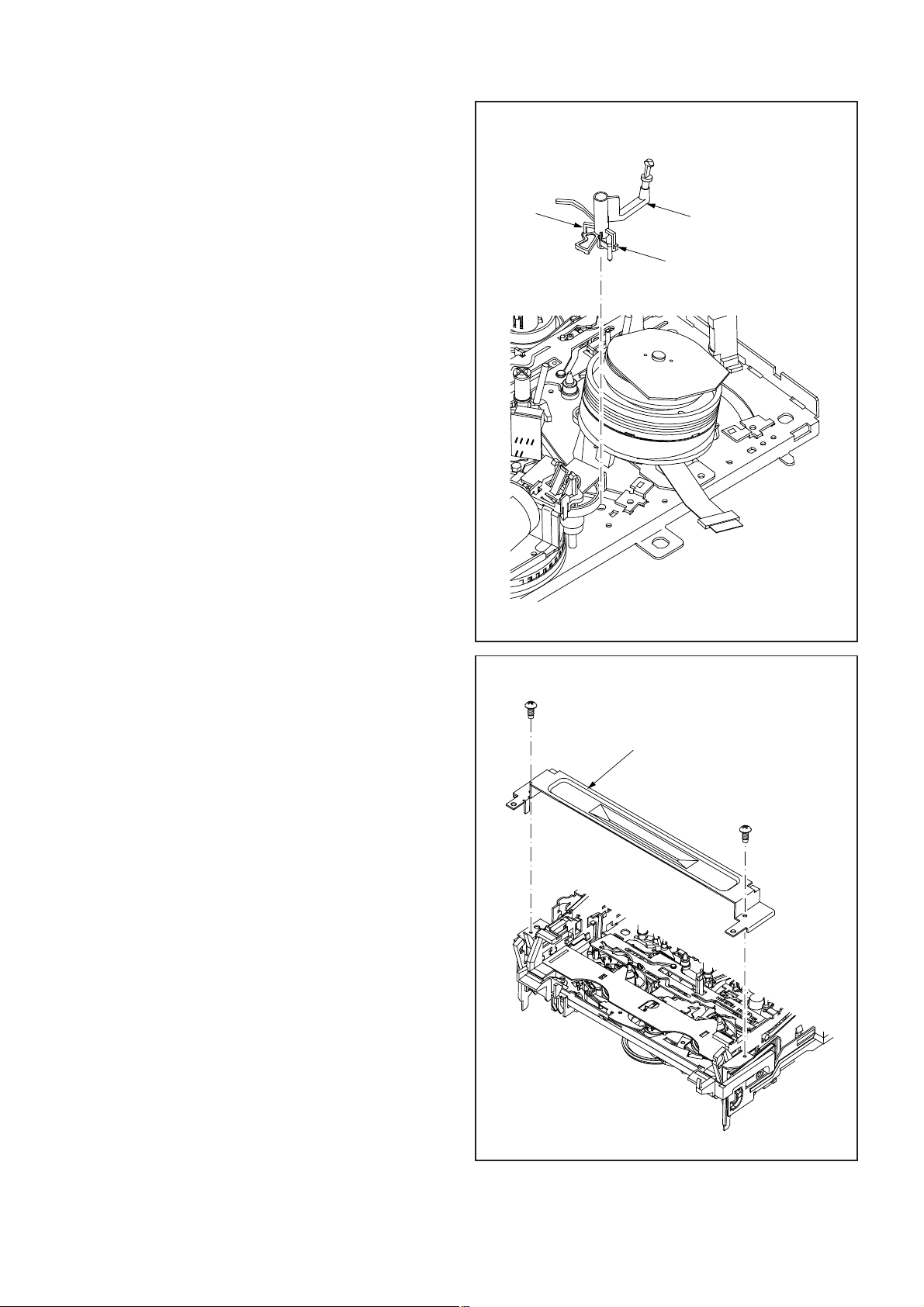

1. DECK Cleaning

The following parts require cleaning whenever serviced in

order to maintain satisfactory performance.

1-1. VIDEO HEAD

1. Clean the VIDEO HEAD according to the following

method. Dust and other foreign objects on the VIDEO

HEAD disturb the normal PLAYBACK picture. To

clean the VIDEO HEAD, hold a VIDEO HEAD cleaning

cloth dampened with alcohol against the DRUM and

slowly turn the DRUM counter-clockwise.

Note : Do not directly touch the HEADS attached to the

UPPER DRUM ASSY. The HEADS are very hard

but brittle to shock (especially to shock in the

vertical direction) and are easily broken.

Never apply force to it in the vertical direction.

2. Allow the residual alcohol to dry thoroughly before

running a tape. The residual alcohol on the HEADs

may damage the tape if not dried completely.

MECHANICAL ADJUSTMENT AND REPLACEMENT

1-2. Tape Running System

Clean the following parts of the Tape Running System.

1. TENSION PIN

2. F/E HEAD

3. SLANT POLE (SP)

4. SLANT POLE (TU)

5. A/C HEAD

6. GUIDE POLE (TU)

7. PINCH ROLLER

8. GUIDE PIN (TU)

9. GUIDE ROLLER (SP)

10. UPPER / LOWER DRUM ASSY

11. GUIDE ROLLER (TU)

12. CAPSTAN SHAFT

1. Clean the Tape Running System using a piece of

gauze dampened with alcohol except for the GUIDE

ROLLER (SP), GUIDE ROLLER (TU), and PINCH

ROLLER which require to be cleaned with a piece of

dry gauze.

2. Allow the residual alcohol to dry thoroughly before

running the tape. The residual alcohol on the

SYSTEM may damage the tape if not dried

completely.

1-3. REEL DISK Drive System

1. Clean the BRAKE side and the REEL BELT of the

REEL DISK Drive System.

2. Clean the REEL DISK Drive System using a piece of

gauze dampened with alcohol except for the REEL

BELT which requires cleaning with a piece of dry

gauze.

3. Allow the residual alcohol to dry thoroughly before

operation.

Fig. 1-2

UPPER DRUM ASSY cleaning

-2-

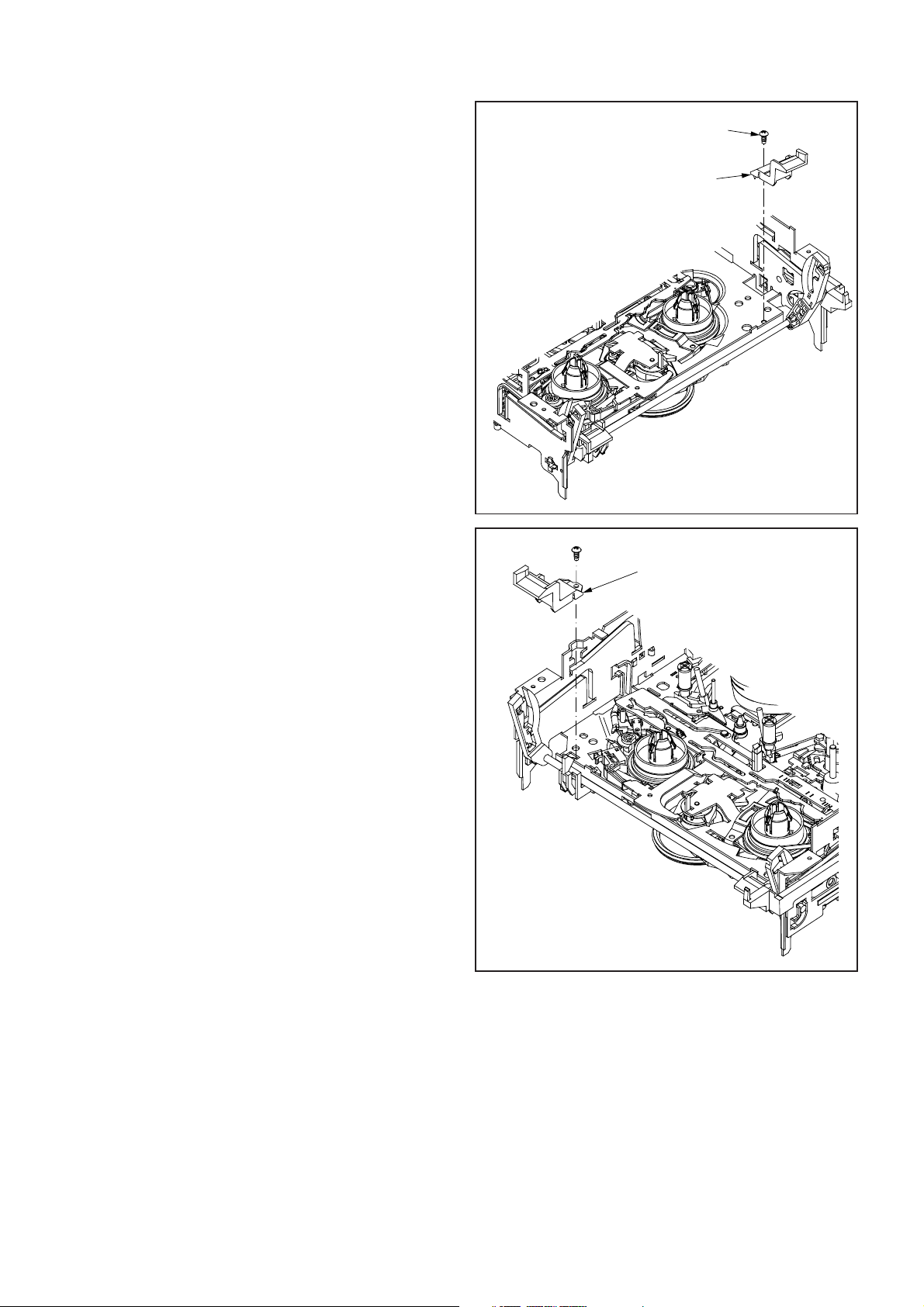

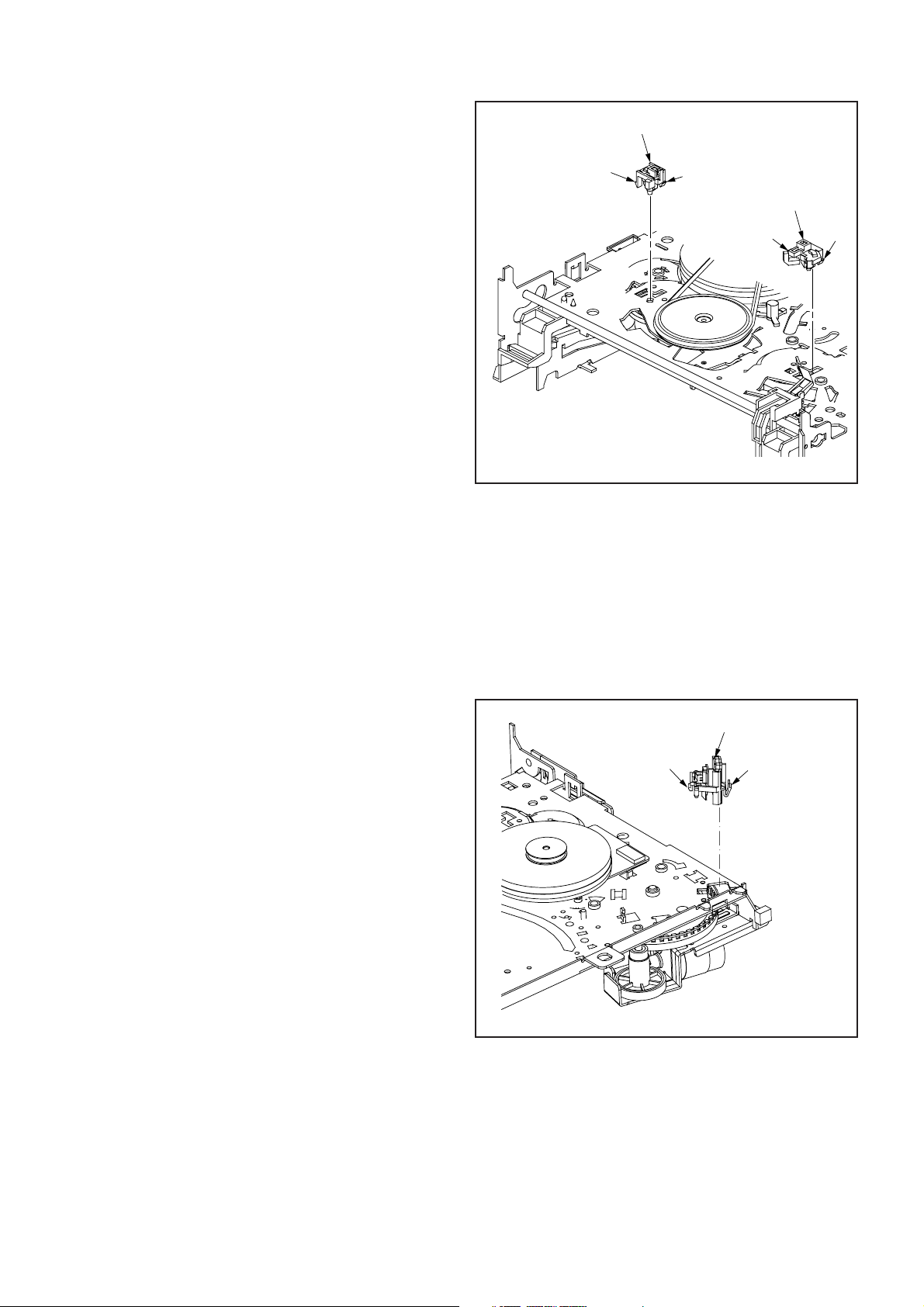

a

a

CLEANING

ARM

Fig. 2-1

a

a

STAY PLATE

Fig. 2-2

2. Replacement of Major Parts

2-1. CLEANING ARM, FELT RING

SET POSITION : Normal

(Removal)

1. Release the two catches (a) of the CLEANING ARM

shown in Fig. 2-1 to remove the CLEANING ARM.

(Installation)

1. Install the CLEANING ARM shown in Fig. 2-1.

2-2. STAY PLATE

SET POSITION : Normal

(Removal)

1. Remove the two screws (a) fastening the STAY

PLATE shown in Fig. 2-2 to remove the STAY PLATE.

(Installation)

1. Install the STAY PLATE shown in Fig. 2-2.

-3-

B

A

C

a

Hole in MAIN PLATE ASSY

BOTTOM ASSY

WORM WHEEL

ARM (SP)

Lift

Pull out

Fig. 2-3-1

b

c

d

e

MAIN PLATE ASSY

Groove of MAIN

PLATE ASSY

Side View

GREASE

(MULTEMP AC-DM)

BOTTOM ASSY

ARM (SP)

ARM (TU)

Groove of MAIN

PLATE ASSY

GREASE

(MULTEMP AC-DM)

Side View

Fig. 2-3-2

2-3. BOTTOM ASSY

SET POSITION : Normal

Remove the following part before replacing the BOTTOM

ASSY. Refer to the corresponding item to install it.

• STAY PLATE (Item 2-2)

(Removal)

1. Move the WORM WHEEL in Fig. 2-3-1 in the direction

shown by arrow A. And match the boss (a) of the

BOTTOM ASSY with the hole in the MAIN PLATE

ASSY.

2. Lift the BOTTOM ASSY in Fig. 2-3-1 in the direction

shown by arrow B and remove in the direction shown

by arrow C.

(Installation)

1. Apply grease (MULTEMP AC-DM)[859D055O90] to

the grooves of the MAIN PLATE ASSY shown in Fig.

2-3-2.

2. Apply grease (MULTEMP AC-DM)[859D055O90] to

the bosses of the BOTTOM ASSY shown in Fig. 2-3-

2.

3. Rotate the WORM WHEEL shown in Fig. 2-3-1 so that

the ARM (SP) stands vertically.

4. Insert the boss (b) of the BOTTOM ASSY shown in

Fig. 2-3-2 in the upper groove of the MAIN PLATE and

the boss (c) in the lower groove.

5. Insert the boss (d) of the BOTTOM ASSY to the

upper groove through the hole in the MAIN PLATE

ASSY shown in Fig. 2-3-1 and the boss (e) to the

lower groove through the slot in the ARM (SP).

-4-

a

INSERT GUIDE (TU)

Fig. 2-4

a

INSERT GUIDE (SP)

Fig. 2-5

2-4. INSERT GUIDE (TU)

DECK POSITION : Normal

Remove the following parts before replacing the INSERT

GUIDE (TU). Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Remove the screw (a) fastening the INSERT GUIDE

(TU) shown in Fig. 2-4 to remove the INSERT GUIDE

(TU).

(Installation)

1. Install the INSERT GUIDE (TU) shown in Fig. 2-4.

2-5. INSERT GUIDE (SP)

DECK POSITION : Normal

Remove the following parts before replacing the INSERT

GUIDE (SP). Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Remove the screw (a) fastening the INSERT GUIDE

(SP) shown in Fig. 2-5 to remove the INSERT GUIDE

(SP).

(Installation)

1. Install the INSERT GUIDE (SP) shown in Fig. 2-5.

-5-

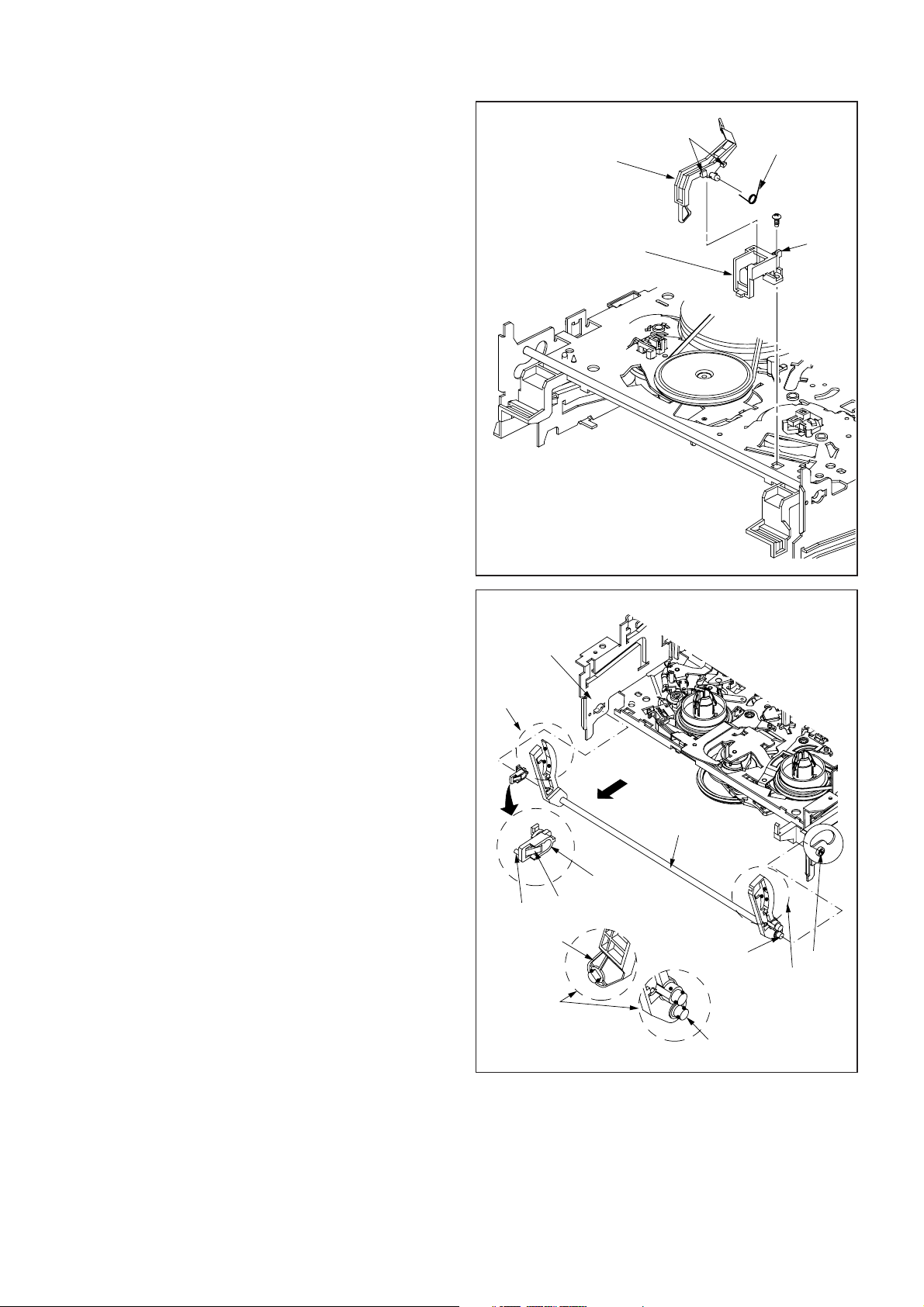

c

d

a

b

A

MAIN PLATE

ASSY

F/L ARM ASSY

F/L

BEARING

GREASE

(MULTEMP AC-DM)

ARM (SP)

ARM (TU)

GREASE

(MULTEMP AC-DM)

GREASE

(MULTEMP

AC-DM)

a

c

b

REC LEVER

REC

SPRING

REC HOLDER

Fig. 2-6

Fig. 2-7

2-6. REC HOLDER, REC LEVER,

REC SPRING

DECK POSITION : Upside down

(Removal)

1. Remove the screw (a) fastening the REC HOLDER

shown in Fig. 2-6 to remove the REC HOLDER.

2. Release the REC SPRING shown in Fig. 2-6 from the

catch (b) of the REC HOLDER to remove the REC

LEVER.

3. Release the two catches (c) of the REC LEVER

shown in Fig. 2-6 to remove the REC SPRING.

(Installation)

1. Install the REC SPRING shown in Fig. 2-6 to the REC

LEVER and hook the REC SPRING to the catches

(c).

2. Install the REC LEVER shown in Fig. 2-6 to the REC

HOLDER.

3. Hook the REC SPRING shown in Fig. 2-6 to the catch

(b).

4. Install the REC HOLDER shown in Fig. 2-6.

2-7. F/L ARM ASSY, F/L BEARING

DECK POSITION : Normal

Remove the following parts before replacing the F/L ARM

ASSY and F/L BEARING. Refer to the corresponding

items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• INSERT GUIDE (TU) (Item 2-4)

• INSERT GUIDE (SP) (Item 2-5)

• REC HOLDER (Item 2-6)

(Removal)

1. Release the catch (a) of the F/L BEARING shown in

Fig. 2-7 and pull out the F/L ARM ASSY in the

direction shown by arrow A.

Note : Do not pull the F/L ARM by force because it may

break the catch (a) of the F/L BEARING.

2. Release the catch (b) of the F/L BEARING shown in

Fig. 2-7 and rotate the F/L BEARING 90 degrees to

remove it.

(Installation)

1. Apply grease (MULTEMP AC-DM)[859D055O90] to

the groove of the MAIN PLATE ASSY shown in Fig. 2-

7.

2. Apply grease (MULTEMP AC-DM)[859D055O90] to

the boss of the ARM (SP) shown in Fig. 2-7.

3. Apply grease (MULTEMP AC-DM)[859D055O90] to

the bosses of the ARM (TU) shown in Fig. 2-7.

4. Install the F/L BEARING shown in Fig. 2-7.

5. Insert the boss (c) of the F/L ARM ASSY shown in

Fig. 2-7 into the groove (d) of the MAIN PLATE ASSY

to install the F/L ARM ASSY.

-6-

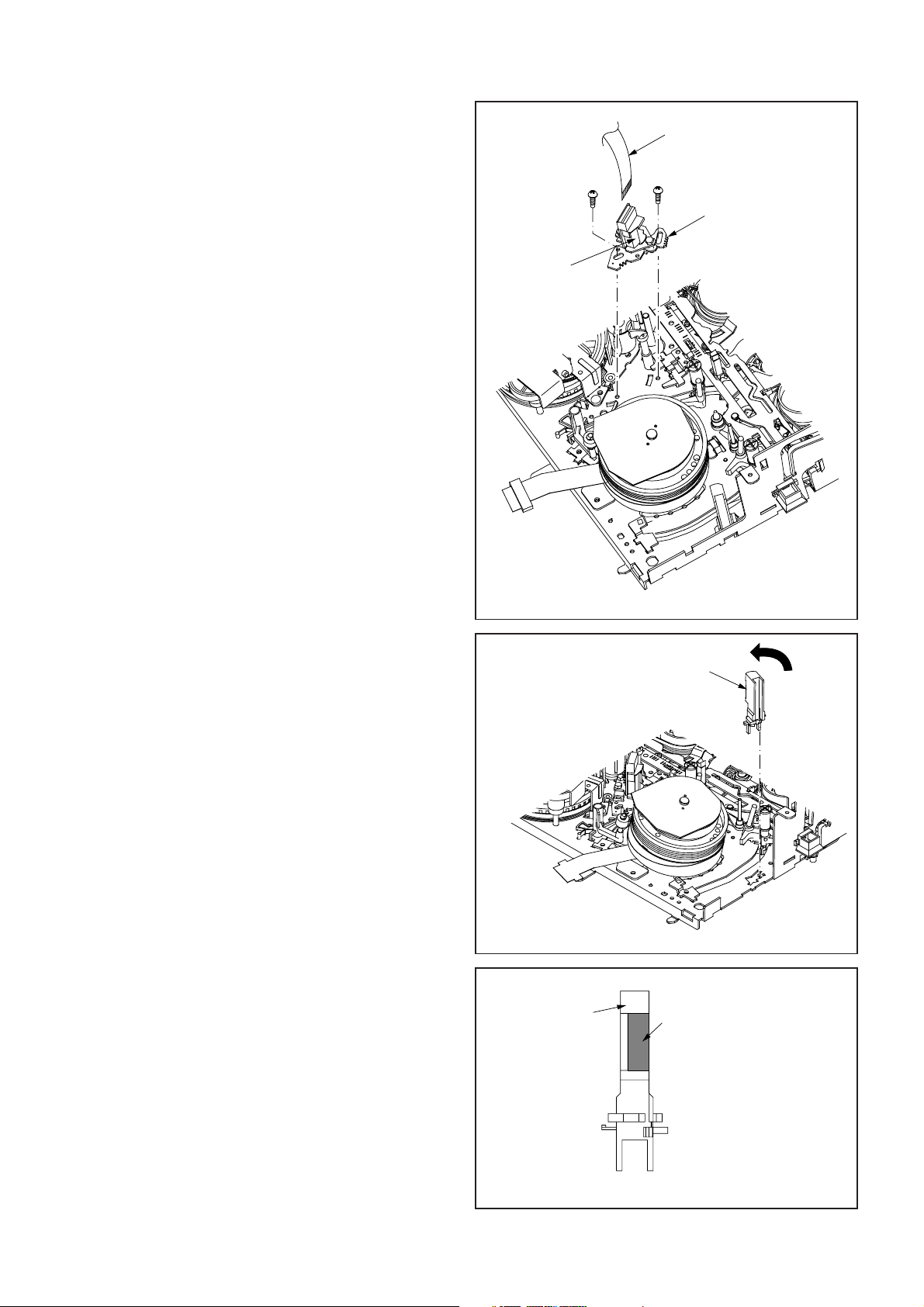

a

a

LEAD CONNECTOR

A/C HEAD UNIT

Head

Fig. 2-8

2-8. A/C HEAD UNIT

DECK POSITION : Normal

(Removal)

1. Remove the LEAD CONNECTOR of the A/C HEAD

UNIT shown in Fig. 2-8.

2. Remove the two screws (a) fastening the A/C HEAD

UNIT shown in Fig. 2-8 to remove the A/C HEAD

UNIT.

(Installation)

1. Install the A/C HEAD UNIT shown in Fig. 2-8.

Note : Never touch the head of the A/C HEAD UNIT

shown in Fig. 2-8. Clean dirt on the head with

alcohol, if necessary.

2. Install the LEAD CONNECTOR of the A/C HEAD

UNIT shown in Fig. 2-8.

3. Perform “3-3. A/C HEAD Adjustment” and “3-4. Phase

Adjustment” of “3. Interchangeability Adjustment of

the Mechanism.”

2-9. F/E HEAD

DECK POSITION : Normal

(Removal)

1. Lift the F/E HEAD shown in Fig. 2-9-1 in the direction

shown by arrow A to remove it.

Note : Be sure to replace the removed F/E HEAD with a

new one.

(Installation)

1. Install the F/E HEAD shown in Fig. 2-9-1.

Note : Never touch the head shown in Fig. 2-9-2. Clean

it with alcohol, if necessary.

F/E HEAD

Head Part

Never touch the Head Part.

A

F/E HEAD

Counterclockwise

Fig. 2-9-1

Fig. 2-9-2

-7-

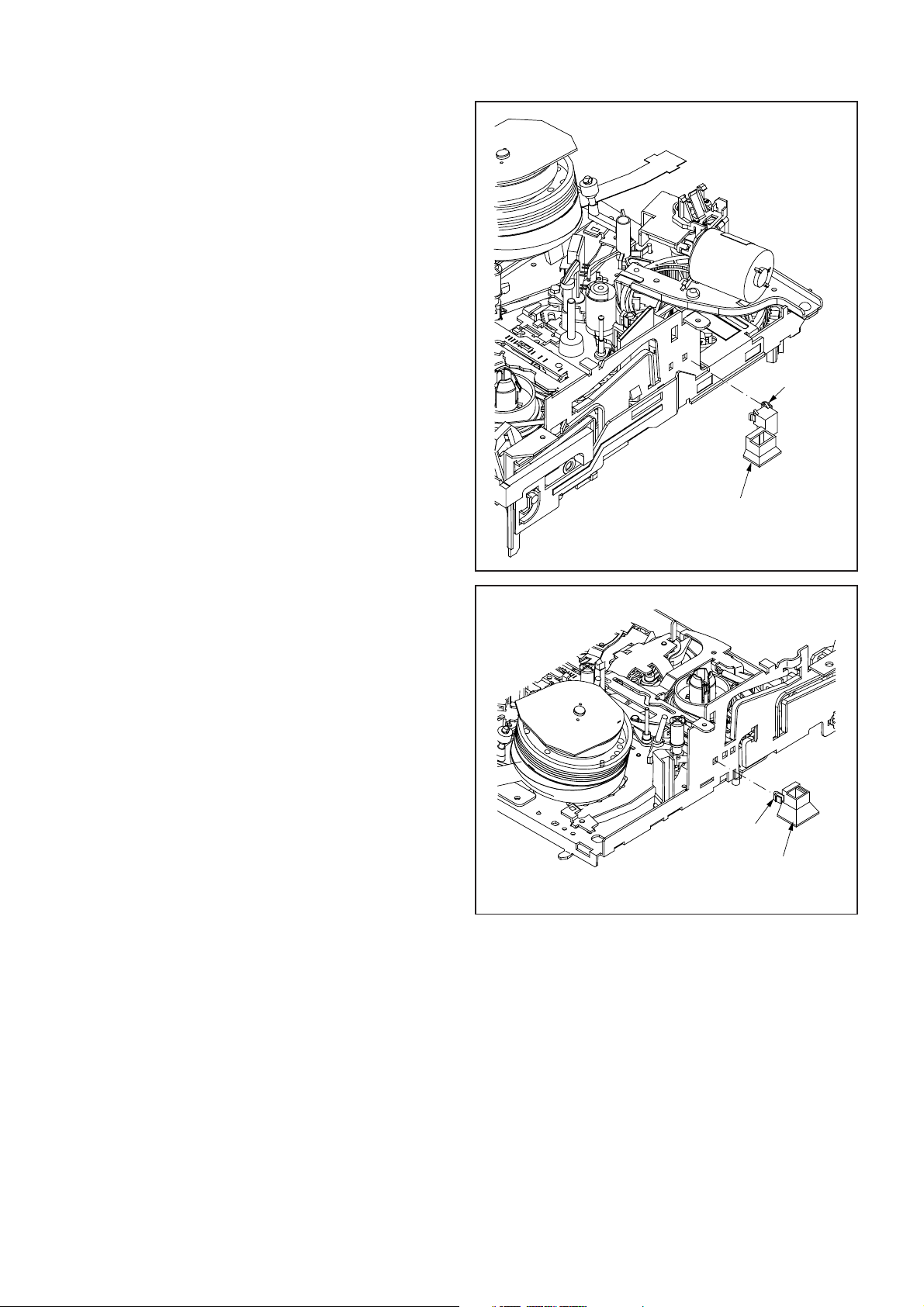

2-10.SENSOR COVER (TU)

DECK POSITION : Normal

(Removal)

1. Release the catch (a) of the SENSOR COVER (TU)

shown in Fig. 2-10 to remove the SENSOR COVER

(TU).

(Installation)

1. Install the SENSOR COVER (TU) shown in Fig. 2-10.

2-11.SENSOR COVER (SP)

DECK POSITION : Normal

(Removal)

1. Remove the catch (a) of the SENSOR COVER (SP)

shown in Fig. 2-11 to remove the SENSOR COVER

(SP).

(Installation)

1. Install the SENSOR COVER (SP) shown in Fig. 2-11.

a

SENSOR COVER (TU)

Fig. 2-10

a

SENSOR COVER (SP)

Fig. 2-11

-8-

2-12.REV UNIT (TU),

REV UNIT (SP)

DECK POSITION : Upside down

(Removal)

1. Release the two catches (a) of the REV UNIT (TU)

shown in Fig. 2-12 to remove the REV UNIT (TU).

2. Release the two catches (b) of the REV UNIT (SP)

shown in Fig. 2-12 to remove the REV UNIT (SP).

(Installation)

1. Clean dirt on the transparent part of the REV UNIT

(TU) with a VIDEO HEAD cleaning cloth.

Note : Never use solvent such as alcohol to clean the

REV UNIT (TU).

2. Install the REV UNIT (TU) shown in Fig. 2-12.

3. Clean dirt on the transparent part of the REV UNIT

(SP) with a VIDEO HEAD cleaning cloth.

Note : Never use solvent such as alcohol to clean the

REV UNIT (SP).

4. Install the REV UNIT (SP) shown in Fig. 2-12.

2-13.MODE POSITION UNIT

DECK POSITION: Upside down

(Removal)

1. Release the two catches (a and b) of the MODE

POSITION UNIT shown in Fig. 2-13 to remove the

MODE POSITION UNIT.

(Installation)

1. Install the catch (b) of the MODE POSITION UNIT

shown in Fig. 2-13.

2. Install the catch (a) of the MODE POSITION UNIT

shown in Fig. 2-13.

a

a

b

b

REV UNIT (TU)

REV UNIT (SP)

Fig. 2-12

a

b

MODE POSITION UNIT

Fig. 2-13

-9-

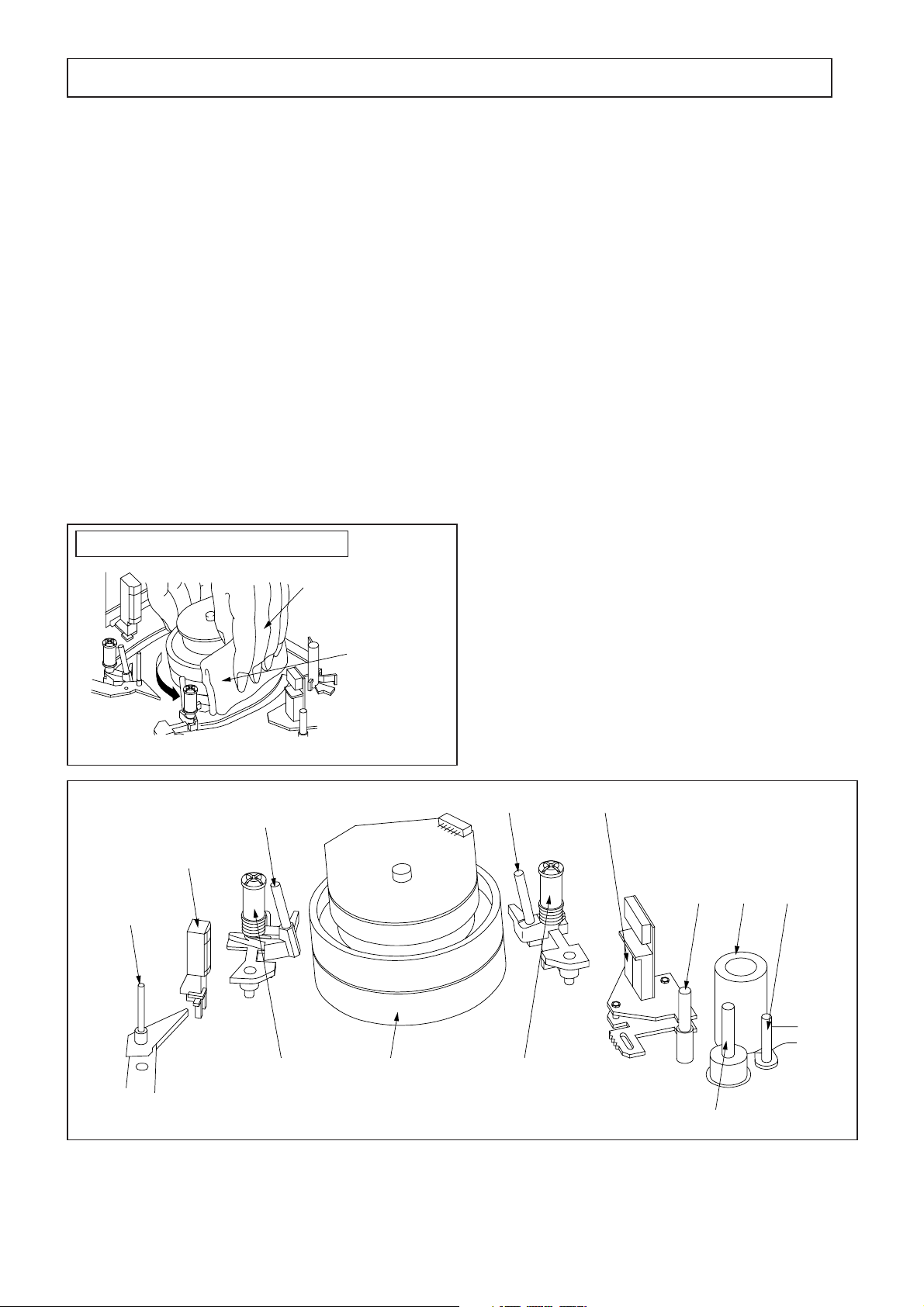

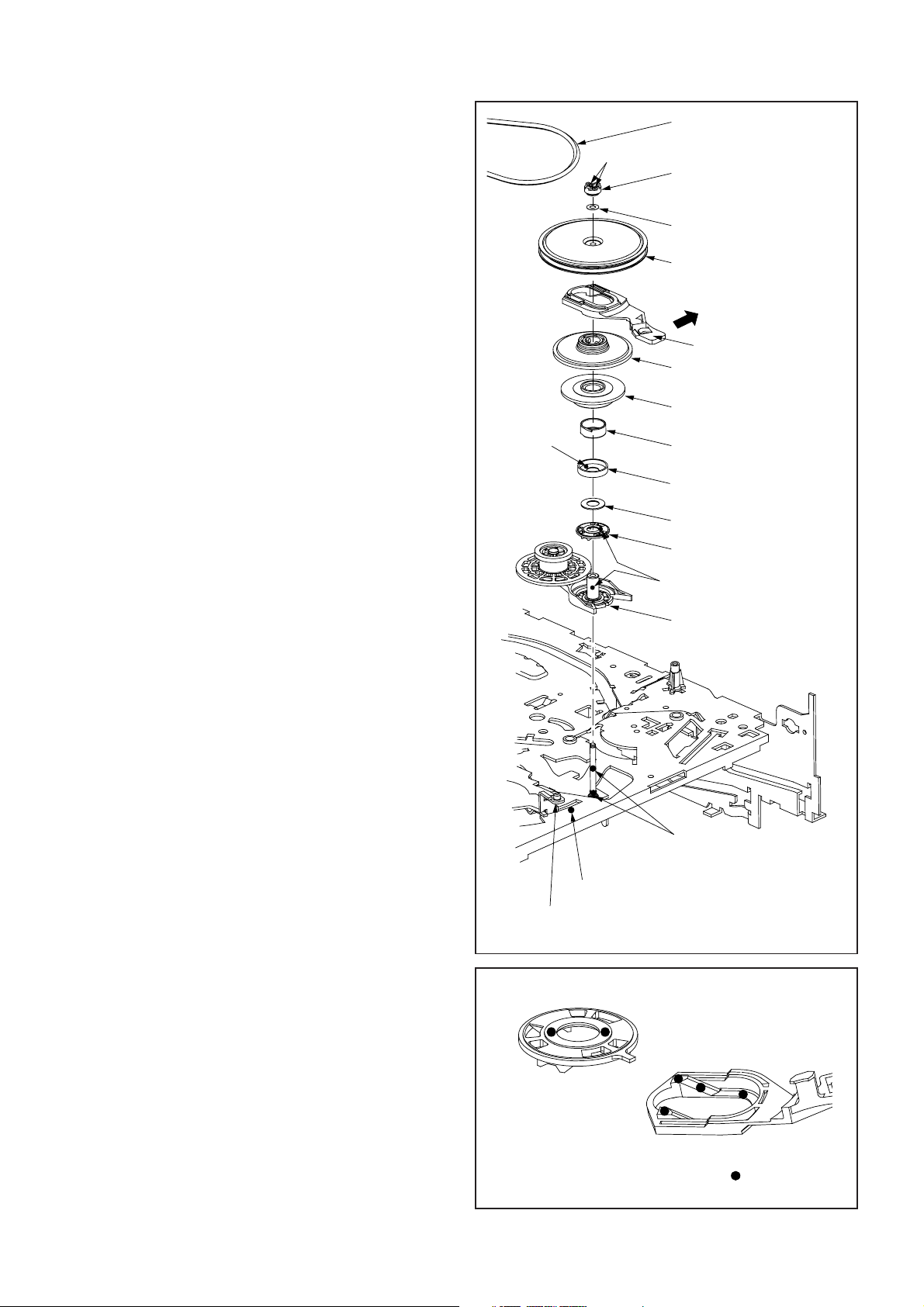

a

A

REEL BELT

PULLEY BUSH

THRUST WASHER

BELT PULLEY

Pull in the direction

of arrow to

remove it from the

SHIFT LEVER.

SHIFT SLIDER

PULLEY GEAR ASSY

SLIP GEAR

SLIP SPRING

SLIP WASHER

THRUST WASHER

SLIP ADJUSTER

IDLER 2 UNIT

OIL (FLOIL 948P)

GREASE (PG-641)

GREASE (MULTEMP AC-DM)

SHIFT LEVER

GREASE

(PG-641)

A

Fig. 2-14-1

SLIP ADJUSTER

SHIFT SLIDER

Apply grease (PG-641)

to the parts marked by .

Fig. 2-14-2

2-14.REEL BELT, PULLEY BUSH, THRUST

WASHER, BELT PULLEY,

SHIFT

SLIDER, PULLEY GEAR ASSY,

SLIP

GEAR, SLIP SPRING, SLIP WASHER,

THRUST WASHER, SLIP ADJUSTER,

IDLER 2 UNIT

DECK POSITION : Upside down

(Removal)

1. Remove the REEL BELT shown in Fig. 2-14-1.

2. Move the SHIFT SLIDER in Fig. 2-14-1 in the

direction shown by arrow A to remove the SHIFT

SLIDER from the SHIFT LEVER.

3. Release the two catches (a) of the PULLEY BUSH

shown in Fig. 2-14-1 to remove the PULLEY BUSH.

Note : Be sure to replace the removed PULLEY BUSH

with a new one.

4. Remove the units from the THRUST WASHER to the

IDLER 2 UNIT shown in Fig. 2-14-1.

(Installation)

Note : Be careful not to apply grease and oil to the felt

side of the PULLEY GEAR ASSY or the grooved

side of the SLIP GEAR shown in Fig. 2-14-4.

1. Apply oil (FLOIL 948P) [859D154O20] to the SHAFT

for the IDLER 2 UNIT shown in Fig. 2-14-1.

2. Apply grease (PG-641) [859D055O30] to the specified

parts on the IDLER 2 UNIT in Fig. 2-14-1.

3. Apply grease (MULTEMP AC-DM) [859D055O90] to

the specified parts on the MAIN PLATE ASSY in Fig.

2-14-1.

4.

Apply grease (PG-641) [859D055O30] to the specified

parts on the new SHIFT SLIDER in Fig. 2-14-2.

5. Apply grease (PG-641) [859D055O30] to the specified

parts on the new SLIP ADJUSTER in Fig. 2-14-2.

6. Apply grease (PG-641) [859D055O30] to the specified

parts on the new BELT PULLEY in Fig. 2-14-3.

7. Install the IDLER 2 UNIT shown in Fig. 2-14-1.

8. Install the SLIP ADJUSTER shown in Fig. 2-14-3,

aligning the lug of the SLIP ADJUSTER with the

center notch of the IDLER 2 UNIT.

-10-

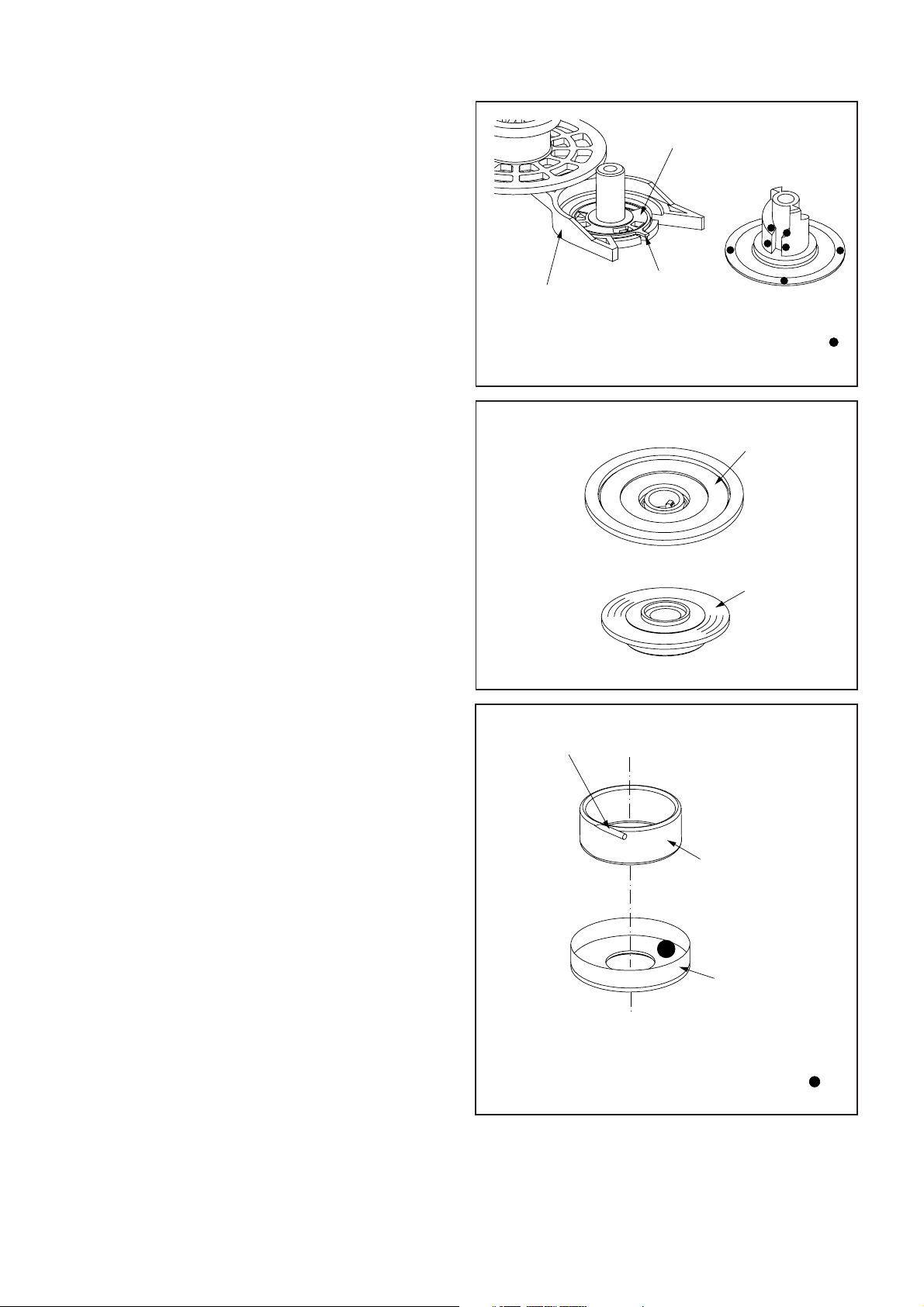

SLIP ADJUSTER

Center of the

BELT PULLEY

IDLER UNIT

Align the Lug of the

SLIP ADJUSTER with

the Center Notch of

the IDLER UNIT.

Apply grease

(PG-641) to the

parts marked by .

Fig. 2-14-4

Fig. 2-14-3

Apply grease (PG-641) to the parts marked by .

SLIP SPRING

SLIP WASHER

[SLIP GEAR side]

[THRUST WASHER side]

Straight end

Fig. 2-14-5

9. Install the units from the SLIP WASHER to the REEL

BELT shown in Fig. 2-14-1.

Note1 : Be sure to replace the removed PULLEY BUSH

with a new one.

Note2 : Attach the SLIP SPRING with its straight end

facing the SLIP GEAR side.

Note3 : Attach the SLIP WASHER in the orientation

shown in Fig. 2-14-5.

Note4 : Apply grease (PG-641) [859D055O30] to the

specified part on the SLIP WASHER in Fig. 2-14-

5.

10. Install the SHIFT SLIDER to the SHIFT LEVER shown

in Fig. 2-14-1.

PULLEY GEAR ASSY

Felt Side

SLIP GEAR

Grooved Side

Loading...

Loading...