Page 1

SPECIFICATIONS

Tape Format

Power Source

Power Consumption

Video Signal System

Video Recording System

Luminance

Color Signal

Hi-Fi Audio

Recording System

Linear Audio Track

Maximum Recording Time

D-VHS

VHS

Record/Playback System

Video

Audio

Digital

Rewind Time

Video Input

Audio Input

Video Output

Audio Output

Digital Interface

Input/Output

Tuner VHF

UHF

CATV

Operating Temperature

Relative Humidity

RF Channel Output

Weight

Dimensions

Timer Program Capacity

Memory Backup Time

Deck

: VHS NTSC standard with Hi-Fi

audio and D-VHS standard

: 120 V AC ; 60 Hz

: Approx. 25 W (standby 6.0 W)

:

EIA standard ;

NTSC color

: VHS standard/D-VHS standard

: Frequency modulation recording

: Low frequency conversion

sub-carrier phase shift recording

: VHS standard

Azimuth helical scanning system

: 1 track

:

150 min. with DF-300 video cassette (HS)

300 min. with DF-300 video cassette (STD)

:

120 min. with T-120 video cassette (SP)

360 min. with T-120 video cassette (EP)

: 4 heads

:

2 Hi-Fi channels and 1 monoral audio control

: HS 4 heads

STD 2 heads

:

Approx. 43 seconds for T-120 cassette

: 0.5 to 2.0 V(p-p), 75 Ω

unbalanced RCA pin Jack

: 346 mV(rms), 47 kΩ

unbalanced RCA pin Jack

: 1.0 V(p-p), 75 Ω unbalanced

RCA pin Jack

: 346 mV(rms), 1 kΩ unbalanced

RCA pin Jack

:

based on IEEE 1394 digital

interface, 4 pin, corresponds to S400

: 54 to 88 MHz, 174 to 216 MHz

: 470 to 806 MHz

: 54 to 88 MHz, 90 to 804 MHz

: 41 °F to 104 °F

: 30 % to 80 %

: Channel 3 or 4 switchable

: Approx. 9.5 lbs (4.3 kg)

: 16.7”(W) × 3.7”(H) × 12.0”(D)

: 1 month programmable

/ 16 programs

: Approx. 30 minutes

: α Deck

• Weight and dimensions shown are approximate.

• Design and specifications are subject to change without notice.

Only cassettes marked D-VHS or VHS can be used with this video cassette recorder.

MITSUBISHI

2002

VIDEO CASSETTE RECORDER

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Ave. Irvine, California 92618 U.S.A.

Copyright C 2002 Mitsubishi Digital Electronics America, Inc. All Rights Reserved.

MODEL

HS-HD1100U

Page 2

-

2

-

CONTENTS

SPECIFICATIONS ...........................................................1

CONTENTS......................................................................2

GLOSSARY OF ABBREVIATIONS ................................4

SAFETY PRECAUTIONS ................................................1

CONNECTION .................................................................3

WARNING........................................................................3

DISASSEMBLY ...............................................................4

HOW TO EXECUTE CIRCUIT BOARD SERVICE ..........7

CHIP PARTS REPLACEMENT .....................................11

HOW TO INITIALIZE THE E

2

PROM ................................1

WHEN REPLACING IC5A0 .............................................1

ELECTRICAL ADJUSTMENTS.......................................1

Servo circuit Adjustment...............................................3

D-VHS signal circuit Adjustment ..................................4

MECHANICAL ADJUSTMENT

AND REPLACEMENT ..............................1

1. DECK Cleaning...................................................1

1-1 VIDEO HEAD .................................................1

1-2 Tape Running System....................................1

1-3 REEL DISK Drive System ..............................1

2. Replacement of Major Parts ..............................2

2-1 CLEANING ARM, FELT RING ......................2

2-2 STAY PLATE.................................................2

2-3 BOTTOM ASSY.............................................3

2-4 INSERT GUIDE (TU).....................................4

2-5 INSERT GUIDE (SP).....................................4

2-6 REC HOLDER, REC LEVER,

REC SPRING ................................................5

2-7 F/L ARM ASSY, F/L BEARING .....................5

2-8 A/C HEAD UNIT ............................................6

2-9 F/E HEAD UNIT.............................................6

2-10 SENSOR COVER (TU) .................................7

2-11 SENSOR COVER (SP) .................................7

2-12 REV UNIT (TU),

REV UNIT (SP)..............................................8

2-13 MODE POSITION UNIT ................................8

2-14 REEL BELT, PULLEY BUSH,

THRUST WASHER,

BELT PULLEY, SHIFT SLIDER,

PULLEY GEAR ASSY, SLIP GEAR,

SLIP SPRING, THRUST WASHER,

SLIP WASHER, SLIP ADJUSTER,

IDLER 2 UNIT................................................9

2-15. CAPSTAN BRAKE SPRING,

CAPSTAN BRAKE ASSY............................11

2-16 FC HOLDER, MOTOR HOLDER,

LOADING WORM,

LOADING MOTOR ASSY,

WORM WHEEL ...........................................12

2-17 PINCH ARM CAP, PINCH UNIT .................13

2-18 F/L PLATE, DOOR ARM .............................13

2-19 BRAKE CAM PLATE ...................................14

2-20 GUIDE LAMP ..............................................15

2-21 MAIN CAM, GUIDE ARM (TU),

BRAKE LEVER............................................16

2-22 L/D LOCK LEVER .......................................17

2-23 BRAKE BELT (SP), BELT HOLDER ...........17

2-24 BELT LEVER, BELT ADJUSTER................18

2-25 TENSION ARM, TENSION LEVER,

TENSION SPRING, TENS AXIS HOLDER,

REEL DISK (SP side) ..................................18

2-26 BRAKE BELT (TU) ......................................19

2-27 BRAKE (TU), REEL DISK (TU side)............19

2-28 SHIFT LEVER .............................................20

2-29 CHARGE SPRING, SWING LEVER,

CHARGE ASSY...........................................21

2-30 LOADING ARM ASSY (SP),

LOADING ARM ASSY (TU).........................21

2-31 A/L LEVER ..................................................22

2-32 TAPE GUIDE ASSY (SP),

TAPE GUIDE ASSY (TU) ............................24

2-33 DRUM CLAMPER, DRUM ASSY ................25

2-34 DRUM MOTOR STATOR, BRUSH SPRING,

SPACER, ROTOR CASE, END RING,

BRUSH, UPPER DRUM ASSY ...................26

2-35 CAPSTAN MOTOR .....................................27

2-36 SSW HOLDER, SSW SLIDER.....................29

3. Interchangeability Adjustment

of the Mechanism.............................................30

3-1 Adjustment of BACK TENSION and

TENSION POLE's Position ..........................30

Page 3

-

3

-

CONTENTS

3-2 Check and Adjustment of

FM Envelope ................................................31

3-2-1 GUIDE ROLLER Adjustment Check ............31

3-2-2 Height Adjustment of

GUIDE ROLLER (SP) ..................................31

3-2-3 Height Adjustment of

GUIDE ROLLER (TU) ..................................31

3-2-4 Coarse Adjustment of Phase .......................32

3-2-5 Flatness Check of FM Waveform.................32

3-2-6 Tape Running Condition

at the GUIDE ROLLERs (Check1) ...............33

3-2-7 Tape Running Condition

at the GUIDE ROLLERs (Check 2) ..............33

3-3 A/C HEAD Adjustment .................................34

3-3-1 Slant Adjustment of A/C HEAD....................34

3-3-2 Azimuth and Height Adjustment of

A/C HEAD ....................................................34

3-4 Phase Adjustment ........................................35

3-5 Tape wrinkle check ......................................35

4. Servicing for Tape Jam

during the Loading Process..................................36

SERVICE CAN BE EXECUTED

WITH THE EE PICTURE DISPLAYED........................37

DECK OPERATION CHECK .........................................37

PARTS LIST ....................................................................1

1. CABINET ASSEMBLY........................................1

2. PACKING PARTS...............................................3

3. ELECTRICAL PARTS.........................................5

DECK ASSEMBLY-1........................................................1

DECK ASSEMBLY-1 P/L ................................................2

DECK ASSEMBLY-2........................................................4

DECK ASSEMBLY-2 P/L ................................................5

BLOCK DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED CIRCUIT BOARD PARTS LAYOUT

Page 4

-

4

-

JSTCLK

LIN-IN

LIN-OUT

LMUTE

LP

MOD

MOTORV

NL

OSC

PB

PC

PCB

PG

PLL

PRT

PSAVE

PSLED

PSYNC

PWSV

PWV

QH

QV

REC

REC2

RECPBC

RES

RESPCM

REW

RIS

RMSDET

RXD

SAPIND

SCLK

SCR

SI

SLD

SP

SS

SSVSYNC

STRB

SU-SENS

TSREC

TSSW

TU-SENS

V-REF

VBUSY

VCA

VCO

VENV

VSETCLK

VSETCS

YNR

: Just Clock

: Linear Audio In

: Linear Audio Out

: Linear Mute

: Long Play

: Modulator

: Motor Voltage

: Non Linear

: Oscillator

: Play Back

: Position Control

: Printed Circuit Board

: Pulse Generator

: Phase Locked Loop

: Protect

: Power Save

: Power Save Light Emitting Diode

: Pretened Vartical Synchronizing Signal

: Power Save

: ON/OFF Command to supply B + Power

: Cue Horizontal Signal

: Cue Vertical Signal

: Recording

: Record Command for the PB/REC Control Circuit

: Record/Play Back Chroma Signal

: Reset

: Reset Pulse Code Modulation

: Rewind

: Record Inhibit Switch

: Root Mean Square Detector

: Read X Data

: SAP carrier detect Indicator

: Serial Clock

: Scramble

: Serial control data Input

: Side Lock Detector

: Standard Play

: Start Sensor

: Speed Search Vertical Synchronizing Signal

: Strobe

: Supply Reel Sensor

: Tape Simulate Recording

: Tape Simulator Switch

: Take Up Reel Sensor

: Voltage Referrence

: VSET Busy

: Voltage Control Amplifier

: Voltage Controlled Oscillator

: Video Envelope

: VSET Clock

: VSET Chip Select

: Y(Luminance) Signal Noise Reduction

: Audio/Control

: Audio Play Back

: Audio Recording

: Audio Erase

: Audio Envelope

: Automatic Frequency Control

: Audio Flip Flop

: Auto Fine Tuning Voltage

: Automatic Level Control

: Audio Mode

: Amplifier Alternating Current Ground

: Automatic Phase Control

: Auto Fine

: Attenuator

: Blue Back Mute

: Carrier/Noise Ratio

: Charge Coupled Device

: Character Generator-Chip Slect

: Channel Switch

: Clock Select

: Counter

: Comparator

: Converter Switch

: Capstan-Frequency Generator

: Capstan-Reverse

: Capstan Motor Voltage

: Chroma Rotation

: Composite Synchronizing Signal

: Control

: Detail Enhancer

: Drum Flip Flop

: Demodulator

: Detector

: Delay

: Drop Out Compensator

: Drop Out Control Stop

: Drum-Frequency Generator

: Drum Control Out

: Drum-Phase Generator

: Electronic-Electronic

: Emphasis

: Extended Play

: Equalizer

: End Sensor

: Feed Back Clamp

: Full Erase

: Fast Forward

: Frequency Generator

: Fluorescent Tube Driver Chip Slect

: Frequency Modulation

: Frequency of Color Subcarrier

: Ground

: Head Amplifier Switch

: Hi-Fast Forward/Rewind 400

: Hi-Fast Forward/Reverse Speed Search

: Horizontal Synchronizing Signal

: I(Current)-Limitter

A/C

A-PB

A-REC

AE

AENV

AFC

AFF

AFTV

ALC

AMODE

AMPC

APC

ATFN

ATT

BLMUTE

C/N

CCD

CG-CS

CHSW

CLKSEL

CNTR

COM

CONV SW

CP-FG

CP-REV

CPMOTORV

CROT

CSYNC

CTL

D.E.

D-FF

DEMOD

DET

DLY

DOC

DOCSTOP

DR-FG

DR-OUT

DR-PG

EE

EMPH

EP

EQ

ES

FBC

FE

FF

FG

FLDCS

FM

FSC

G

HASW

HFR400

HFRSS

HSYNC

I-LIMIT

GLOSSARY OF ABBREVIATIONS

Page 5

-

1

-

INTRODUCTION

This manual provides service information for the adjustments

of mechanical and electrical operations.

Due to design modifications, the servicing procedures and

data given in this manual are subject to possible change

without prior notice.

SAFETY PRECAUTIONS

WARNING : Many of the programs broadcast by television

stations are protected by copyright and Federal law

imposes strict penalties for copyright infringement. Some

motion picture companies have taken the position that

home recording for noncommercial purposes is an

infringement of their copyrights. Until the courts have ruled

on the proper interpretation of the law as applied to home

video recording, this equipment, if used to record

copyrighted material, should be operated at the user’s own

risk.

WARNING :

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This video cassette recorder should be used with AC

120V, 60Hz only.

SAFETY NOTICE

Before returning VCR to the customer a safety check of the

entire VCR should be made. The service technician must be

sure that no protective device built into the instrument by the

manufacturer has become defective or inadvertently

damaged during servicing. Observe all caution and safety

related notes located on or inside the VCR cabinet.

WARNING : Alterations of the design or circuitry of this VCR

should not be made. Any design alterations or additions,

such as circuit modifications, auxiliary speaker jacks,

switches, grounding, active or passive circuitry, etc., or use of

unauthorized camera, cables, accessories, etc. may alter the

safety characteristics of this VCR and potentially create a

hazardous situation for the user. Any design alterations or

unauthorized additions will invalidate the manufacturer’s

warranty and will further relieve the manufacturer of

responsibility for personal injury or property damage resulting

from them. Do not lubricate any motors. When reassembling

the VCR, always be certain that all the protective devices are

put back in place, such as non-metallic control knobs, shield

plates, etc. When service is required, observe the original

lead dress. Components that show evidence of overheating

or other electrical or mechanical damage should be replaced.

WARNING : Replace with same type 1.6A, 125V FUSE.

LEAKAGE CURRENT CHECK

Before returning the VCR to the customer, it is recommended

the leakage current be measured by the following methods.

1. Cold Check

With the AC plug removed from the 120V AC source,

place a jumper across the two AC plug prongs. Turn the

AC switch on. Using an ohmmeter, connect one lead to

the jumpered AC plug and touch the other lead to each

exposed metal part (metal cabinet, screwheads, metal

overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis. Exposed

metal parts having a return path to the chassis should

have a minimum resistance reading of 1 MΩ. Any

resistance below this value indicates an abnormality

which requires corrective action. Exposed metal parts not

having a return path to the chassis will indicate an open

circuit.

Page 6

-

2

-

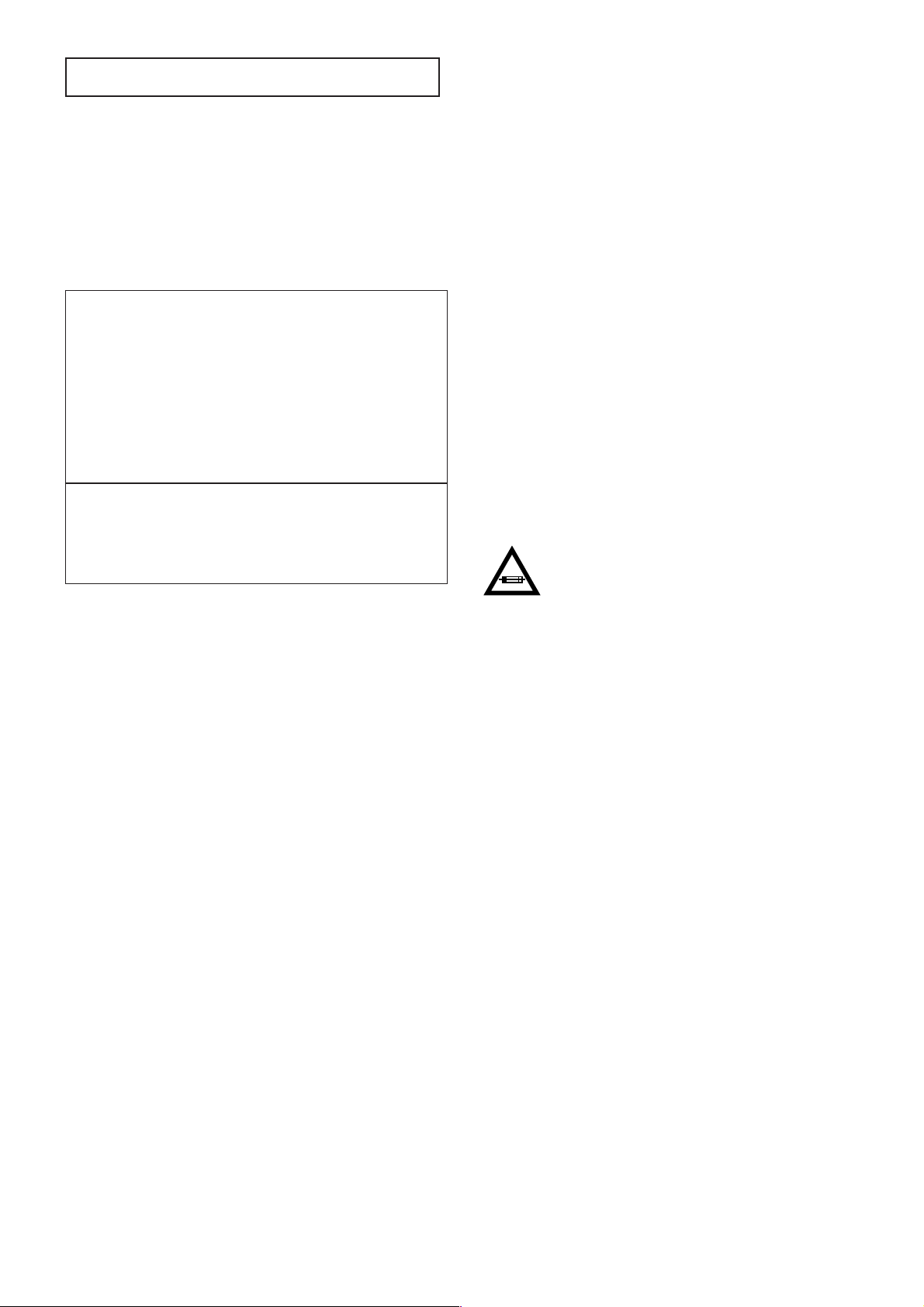

2. Hot Check

The test sequence, with reference to the measuring

circuit in the figure is as follows:

(1) With switch S1 open, connect the VCR to the measuring

circuit. Immediately after connection, measure the

leakage current using both positions of switch S2 and

with the switching devices in the VCR in all of their

operating positions.

(2) Close switch S1, energizing the VCR, and immediately

after closing the switch, measure leakage current using

both positions of switch S2, and with the switching

devices in the VCR in all of their operating positions.

Repeat the current measurements of items (1) and (2)

after the VCR has reached thermal stabilization. The

leakage current should not be more than 0.5 mA.

AC Leakage Test

Avoid shock hazards. Do not connect this VCR to a TV

antenna, cable or accessory that exhibits excessive leakage

currents. If available, the television instrument or cable to

which this VCR is connected should have the antenna cold

check and leakage current hot check performed.

PRECAUTIONS

Handling and storage

• Avoid using the VCR in the following places:

- extremely hot, cold or humid places,

- dusty places,

- near appliances generating strong magnetic fields,

- places subject to vibration,

- poorly ventilated areas.

• Be careful of moisture condensation.

• If you pour a cold liquid into a glass, water vapor in the air

will condense on the surface of the glass. This is called

moisture condensation.

• Moisture condensation on the head drum, one of the

most critical parts of the VCR, will cause damage to the

tape.

• The VCR is equipped with a moisture condensation

prevention circuit. This circuit operates only when the unit

is attached to an AC outlet.

• Handle the VCR carefully.

• Do not block the ventilation openings.

• Do not place anything heavy on the recorder.

• Do not place liquids on the top cover of the recorder.

• Use the Recorder in horizontal (flat) position only.

• Avoid violent shocks to the recorder during packing and

transportation.

• Before packing, be sure to remove the cassette from the

recorder.

120V

S1

GH

(GROUNDING)

OPEN

VCR

GROUNDING SUPPLY CONDUCTOR

B

A

AC MILLIAMMETER

INSULATING

TABLE

S2

Page 7

-

3

-

Connecting separate antennas (UHF/VHF)

Connecting the Television

To connect separate UHF/VHF antennas to the VCR:

1. Disconnect the antennas from the back of your TV.

2. Connect the antenna leads to the combiner.

3. Screw or push the combiner onto the ANTENNA terminal

on the VCR labeled ANTENNA IN.

4. When you are finished, refer to “Connecting

the Television” to complete your connections.

CONNECTION

Connecting a regular TV to the VCR

Before connecting the VCR to the TV, complete the cable or

antenna connections to the VCR. (If you have not already

done so.)

To connect a regular TV to the VCR:

1. Take the black cable that is supplied with your VCR

(called a coaxial cable) and connect it to the ANTENNA

terminal on the VCR labeled ANTENNA OUT.

2. Connect the other end of this cable to the terminal on

your TV labeled ANTENNA IN. (This terminal may also

be labeled VHF IN.) If you have an older TV without this

kind of terminal, you will have to use a splitter and then

connect the splitter to the television.

Now that you’ve completed the antenna connections to your

VCR, you’re ready to connect the VCR to the TV.

Because every television is different (especially older model

TVs), your VCR may need to be connected in a variety of

ways. See the Owner’s Manual for Instruction Information

ON:

• Determining if you need a splitter,

• Connecting TVs with audio and video inputs.

ANTENNA

IN

OUT

ANTENNA OUT ANTENNA IN

ANTENNA IN

TV ANTENNA TERMINAL

VCR ANTENNA TERMINAL

TV without ANTENNA IN terminal (single antenna terminal for VHF and UHF)

Connect to

UHF IN on TV.

UHF/VHF Splitter

Connect to

VHF IN on

TV.

From ANTENNA OUT

on VCR

▲▲

▲▲

▲▲

▲▲

▲▲

▲▲

Connect to

UHF IN on TV.

UHF/VHF Splitter

Connect to

VHF IN on TV.

From ANTENNA OUT

on VCR

12

ANTENNA

IN

OUT

x

x

UHF

VHF

x

x

Combiner

300 Ohm Transformer

Antenna VHF

75 Ohm

Coaxial Cable

300 Ohm

Flat Twin Lead

Antenna UHF

300 Ohm Flat

Twin Lead

2

3

WARNING

Use the specified batteries.

Batteries of wrong type can lead to explosion.

Be sure to replace with batteries of the same type or

equivalent batteries. Use the parts specified in the circuit

diagram or parts list.

Confirm that the batteries are placed with their positive (+)

and negative (-) in the correct position.

Page 8

-

4

-

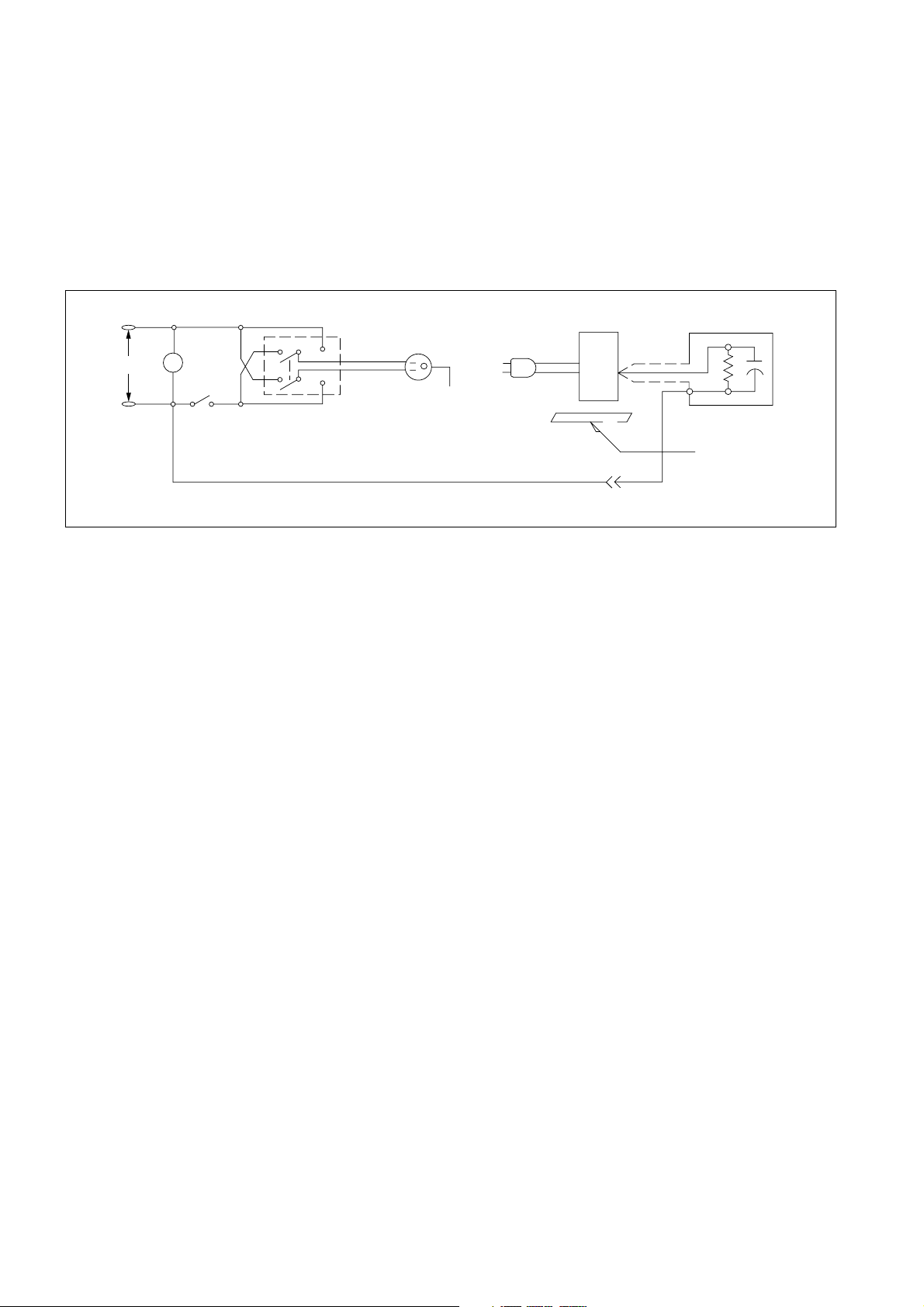

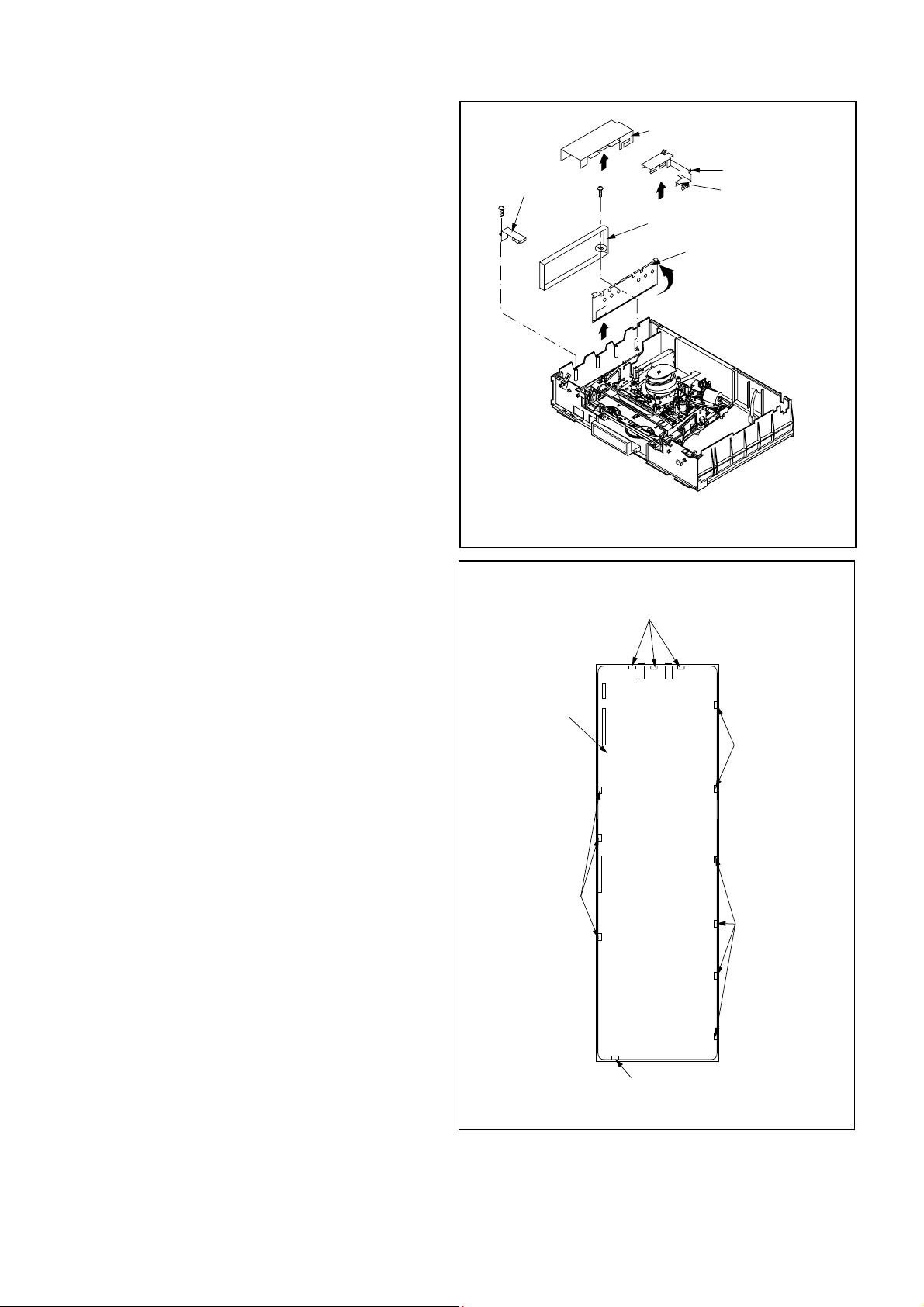

1. Removal of Top Cover

1. Remove the two Top Cover fastening screws (a) shown

in Fig. 1 and remove the Top Cover in the direction

shown by arrow.

2. Removal of Front Panel

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Jog Dial and the Shuttle Ring.

3. Unfasten the seven catches (b) shown in Fig. 1 and

remove the Front Panel in the direction shown by arrows.

4. Disconnect the Connector OG inFig.1.

DISASSEMBLY

Fig. 1

a

a

Top Cover

b

b

Connector OG

b

Front Panel

b

Shuttle Ring

Jog Dial

Page 9

-

5

-

a

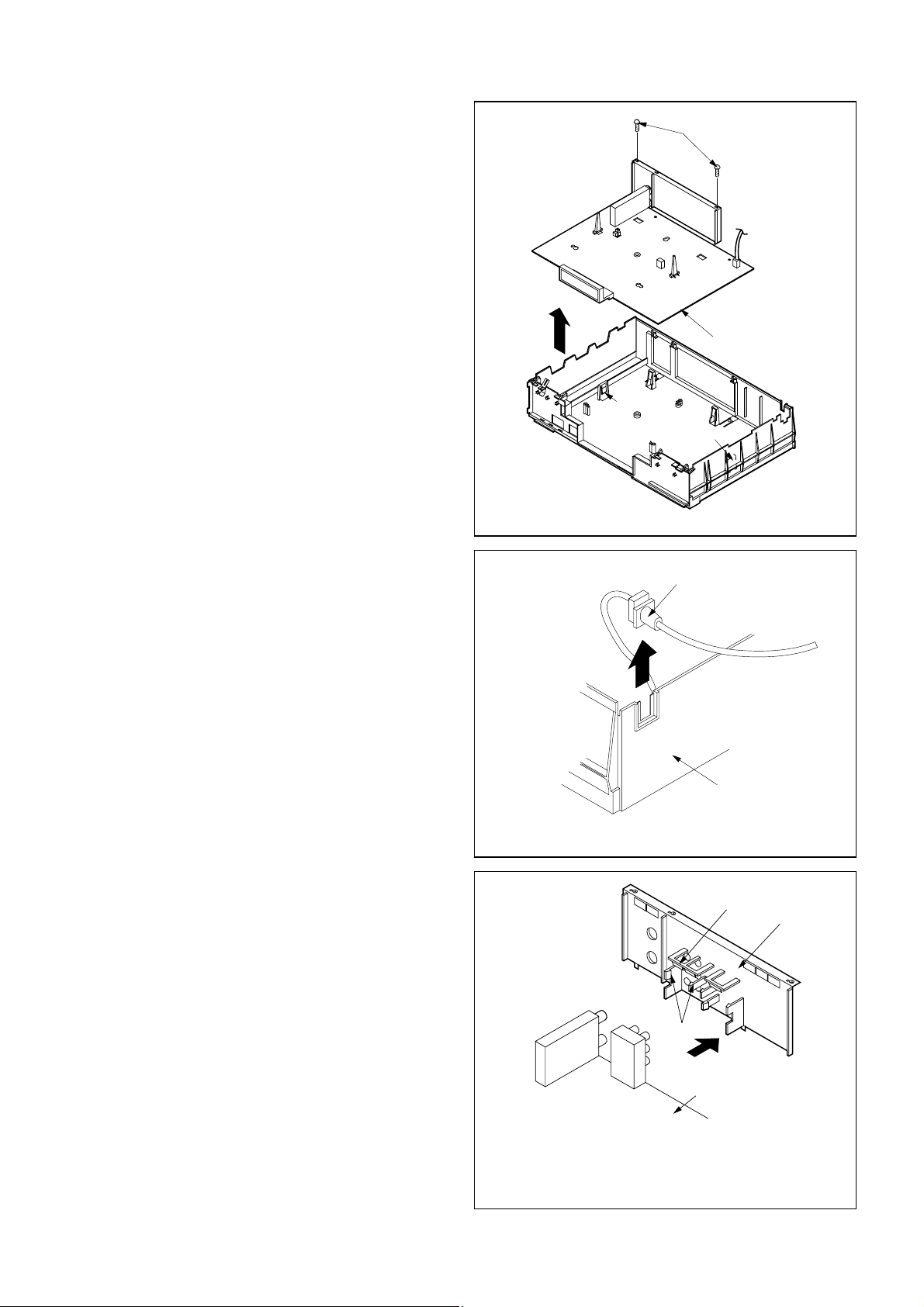

3. Removal of Bottom Panel

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the two fastening screws (a) shown in Fig. 2.

3. Turn the set upside down as shown in Fig. 3.

4. Slide and lift the Bottom Panel in the direction of the

arrows paying attention to the four catches (b) to remove

it.

Fig. 2

b

Bottom Panel

Fig. 3

Page 10

-

6

-

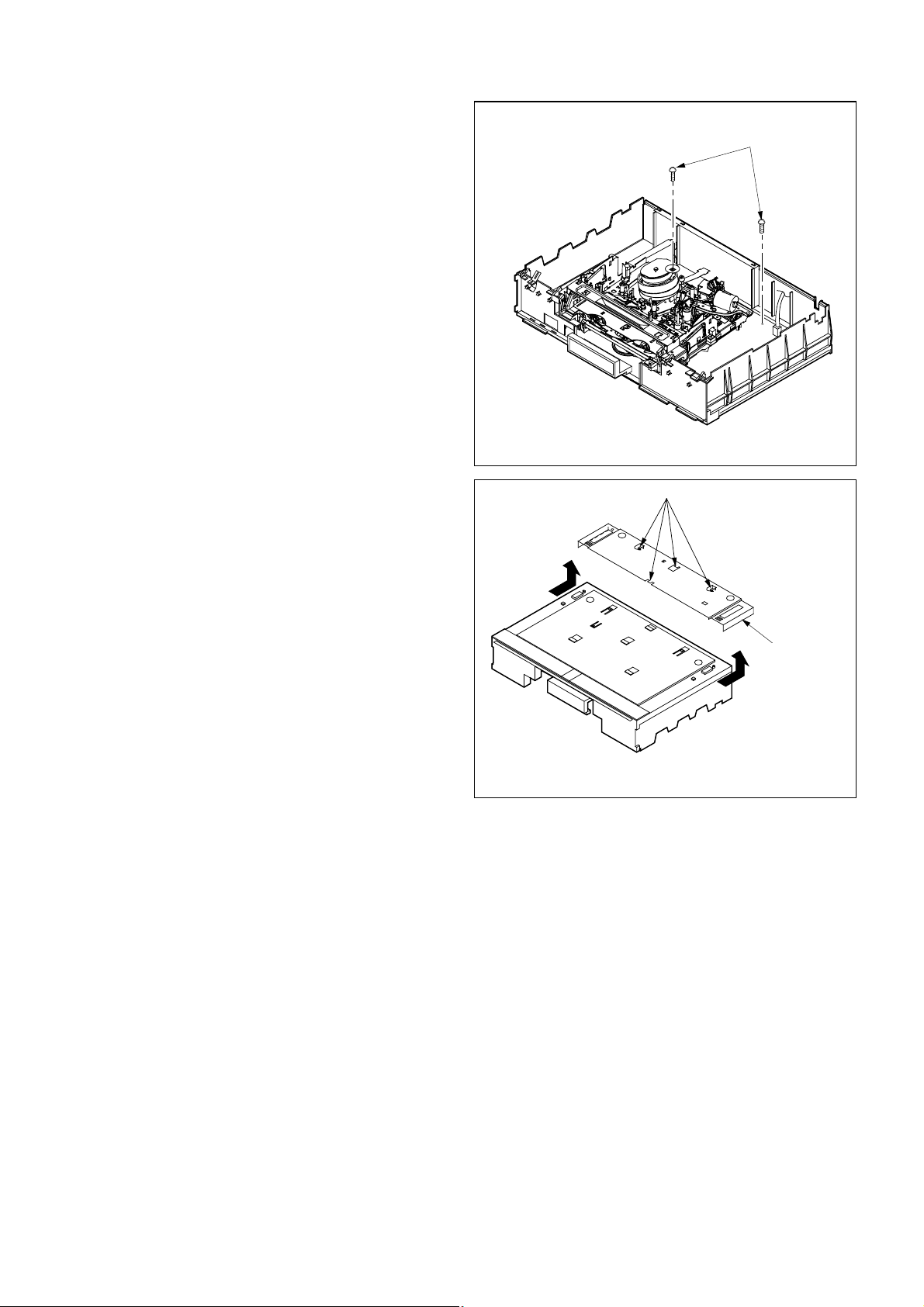

4. Removal of DECK ASSY

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Short-circuit the cathode side of D927 and the GND of

the DECK ASSY using the jig shown below.

Note: The CAPSTAN MOTOR may be damaged without

above short circuit.

4. Remove the one screw (a) and remove PCB HA Holder.

5. Disconnect the Connectors HH and HK on PCB-HEAD

AMP.

6. Remove the two screws (b) shown in Fig. 4 and raise

the PCB-HEAD AMP to remove it.

7. Remove the four screws (c) shown in Fig. 5.

8. Disconnect the Connectors MA, MD and ML on PCBMAIN.

9. Release the two catches (d) shown in Fig.5 and raise

the DECK ASSY to remove it.

Note1:Remove the DECK ASSY paying attention to the

Connectors MC and MF under it.

Note2:Short-circuit the cathode side of D927 and the Shield

Plate using the jig shown below before attaching the

DECK ASSY.

b

a

PCB-HEAD AMP

PCB HA Holder

HK

HH

Fig. 4

c

c

d

DECK ASSY

Connector MC

Connector MF

Fig. 5

Jig (Part No. : 859C548O10)

3W 330Ω

Page 11

a

c

b

Connector OS

PCB-OPE L

-

7

-

CAUTION: BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE A.C. SOURCE.

LOCATION OF PRINT

CIRCUIT BOARDS

Note :

• Take caution when removing flat cables to prevent any

contact problem.

• Connect and disconnect the flat cables at right angles to

the connector and make sure that it is completely

secured.

• After servicing the PCB, restore the flat cable and leads

to their former state.

PCB-OPE L

PCB-MAIN

PCB-OPE R

PCB-JOG

PCB-HEAD AMP

PCB-1394/D-VHS

HOW TO EXECUTE CIRCUIT BOARD SERVICE

Fig. 6

Fig. 7

a

c

b

Connector OJ

PCB-OPE R

Fig. 8

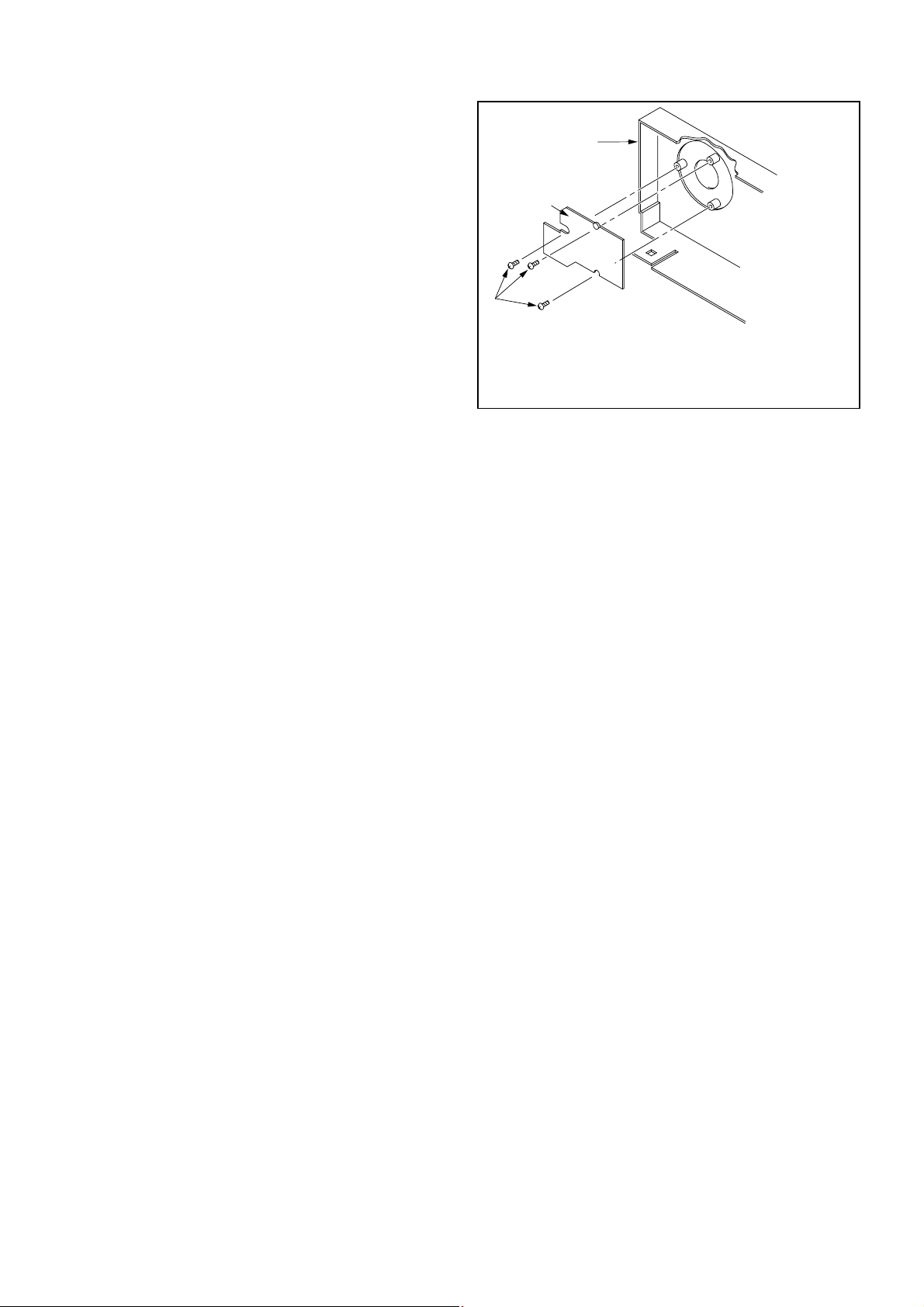

2. PCB-OPE R

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Remove the Connector OJ.

4. Unfasten the two catchs (a) shown in Fig. 8 and rotate

the PCB-OPE R in the direction shown by arrow (b) and

remove it in the direction shown by arrow (c).

1. PCB-OPE L

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Remove the Connector OS.

4. Unfasten the two catchs (a) shown in Fig. 7 and rotate

the PCB-OPE L in the direction shown by arrow (b) and

remove it in the direction shown by arrow (c).

Page 12

-

8

-

3. PCB-JOG

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Unfasten the three screws (a) shown in Fig. 9 and

remove the PCB-JOG.

a

PCB-JOG

Front Panel

Fig. 9

Page 13

-

9

-

b

ASSY PCB-1394/D-VHS

Shield Cover

Spring Earth EMC

Part A

A

Cover D VHS

a

PCB HOLDER

Fig. 10

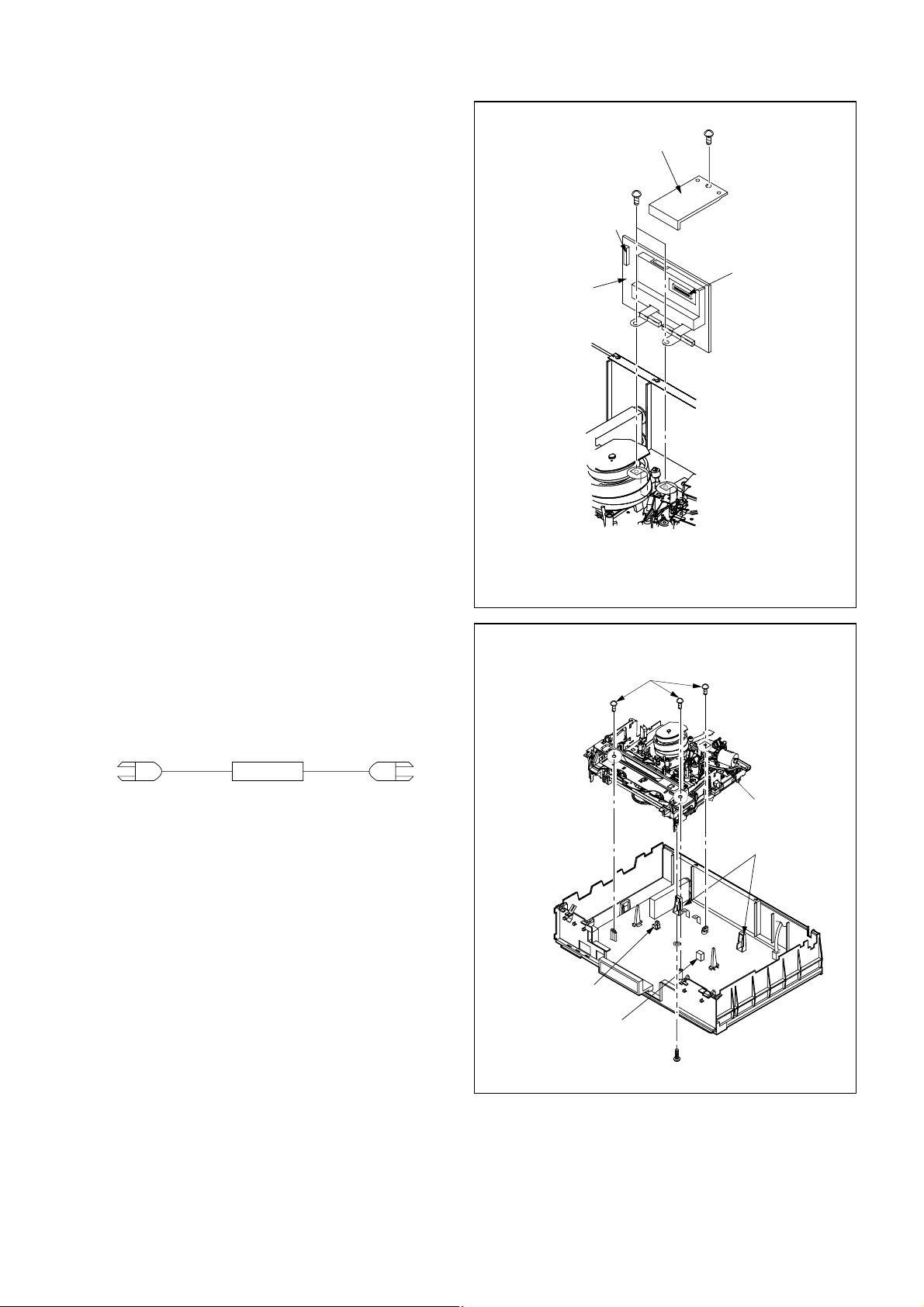

4. PCB-1394/D-VHS

1. Remove the Top Cover.

(Refer to Para. 1 of the DISASSEMBLY.)

2. Lift and remove the Cover D VHS as shown in Fig.10.

3. Remove the one screw (a) and remove the PCB

HOLDER shown in fig. 10.

4. Disconnect the connectors EE ,EK and EX on the PCB1394/D-VHS .

5. Pull out the Part A,lift and remove the Spring Earth

EMC as shown in Fig. 10.

6. Unfasten the one screws (b) shown in Fig. 10 and

remove the ASSY PCB-1394/D-VHS.

7. Separate the bottom of the Shield Cover from the ASSY

PCB-1394/D-VHS first. Remove the Shield Cover

moving the bottom in the direction shown by the arrow

(A) as shown in Fig. 10.

8. Disconnect thirteen soldering connections and remove

the PCB-1394/D-VHS as shown in Fig. 11.

PCB-1394/D-VHS

Soldered part

Soldered part

Soldered part

Soldered part

Soldered part

Fig. 11

Page 14

-

10

-

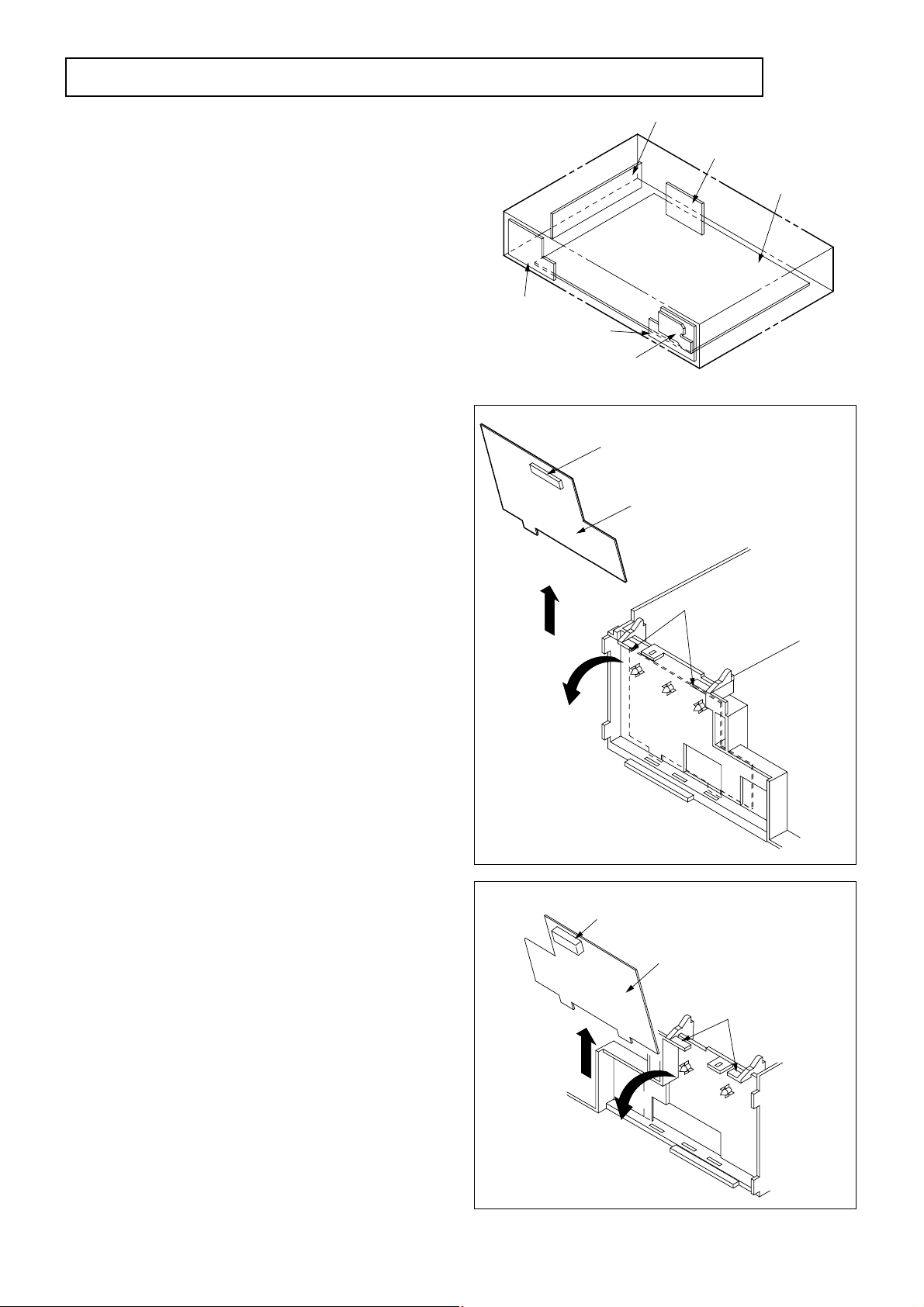

5. PCB-MAIN

1. Carry out steps 1 and 2 of “3.Removal of Bottom Panel”

of “DISASSEMBLY”

2. Remove the Front Panel.

(Refer to Para. 2 of the DISASSEMBLY.)

3. Remove the DECK ASSY.

(Refer to Para. 4 of the DISASSEMBLY.)

4. Lift and remove the Cover D VHS as shown in Fig.10.

5. Disconnect the connectors EE and EX on the PCB1394/D-VHS .

6. Pull out the Part A,lift and remove the Spring Earth EMC

as shown in Fig. 10.

(Refer to Para. 4 of the HOW TO EXECUT CIRCUIT

BOARD SERVICE.)

7. Remove the two screws (a) shown in Fig. 12.

8. Remove the Holder for the AC Power Cord from the Base

Chassis shown in Fig. 13.

9. Disconnect the connectors ME,MJ and MS on the PCBMAIN .

10. Release the two fastening catches (b) shown in

Fig. 12. Raise the PCB-MAIN to remove it.

11. Release the three fastening catches (c) and remove the

Antenna Cover shown in Fig. 14.

a

b

b

PCB-MAIN

Fig. 12

Holder for the AC Power Cord

Base chassis

Fig. 13

c

c

Antenna Cover

PCB-MAIN

Fig. 14

Page 15

-

11

-

Soldering Pencil

Tweezers

Solder

Chip

Pattern

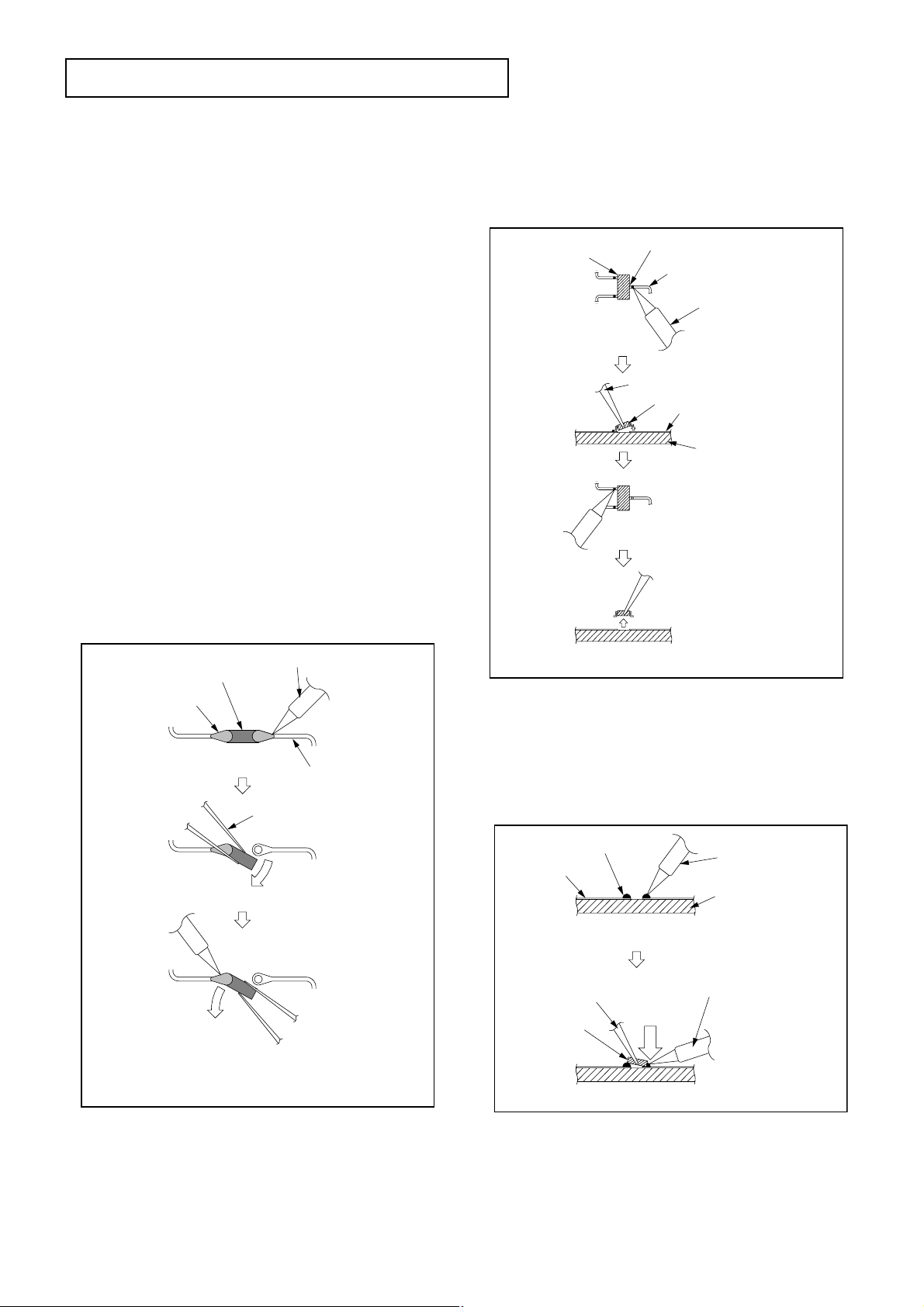

CHIP PARTS REPLACEMENT

Some resistors, shorting jumpers (0Ω resistor), ceramic

capacitors, transistors and diodes are chip parts.

When replacing these parts, note the following cautions.

Cautions :

A. Use fine tipped, well insulated soldering pencil (iron),

about 30 watts, and tweezers.

B. Melt the solder and remove the Chip Parts carefully

not to tear off the copper foil of the printed circuit

board.

C. Discard removed chips ; do not reuse them.

D. Do not apply heat for more than 3 seconds to new

Chip Parts.

E. Avoid using a rubbing stroke when soldering.

F. Take care not to scratch, or damage the Chip Parts

when soldering.

G. Supplementary cementing is not required.

1. Removal of Chip Parts

(Resistors, capacitors, etc.)

A. Grasp the part with tweezers. Melt the solder at both

sides alternately, remove one side of the part with a

twisting motion.

B. Melt the solder at the other side and remove the part.

2. Removal of Chip Parts (Transistors)

A. Melt the solder of one lead. Lift the side of that lead

upward.

B. Simultaneously melt the solder of the two remaining

leads and lift the part from the PCB.

PCB

Chip

Pattern

Tweezers

Soldering Pencil

Lead

Chip

Pattern

3. Replacement

A. Presolder the contact points of the circuit pattern.

B. Press the part downward with tweezers and apply the

soldering pencil as shown in Fig. 3.

PCB

Solder

Pattern

Chip

Tweezers

Soldering Pencil

Soldering Pencil

Fig. 1

Fig. 3

Fig. 2

CHIP PARTS REPLACEMENT

Page 16

-1-

Lightly apply the cloth

on the UPPER DRUM

ASSY. Do not move the

cloth.

Video Head

Cleaning

Cloth

!1

!2

w

uy

!0

e

r

q

t

i

o

Fig. 1-1

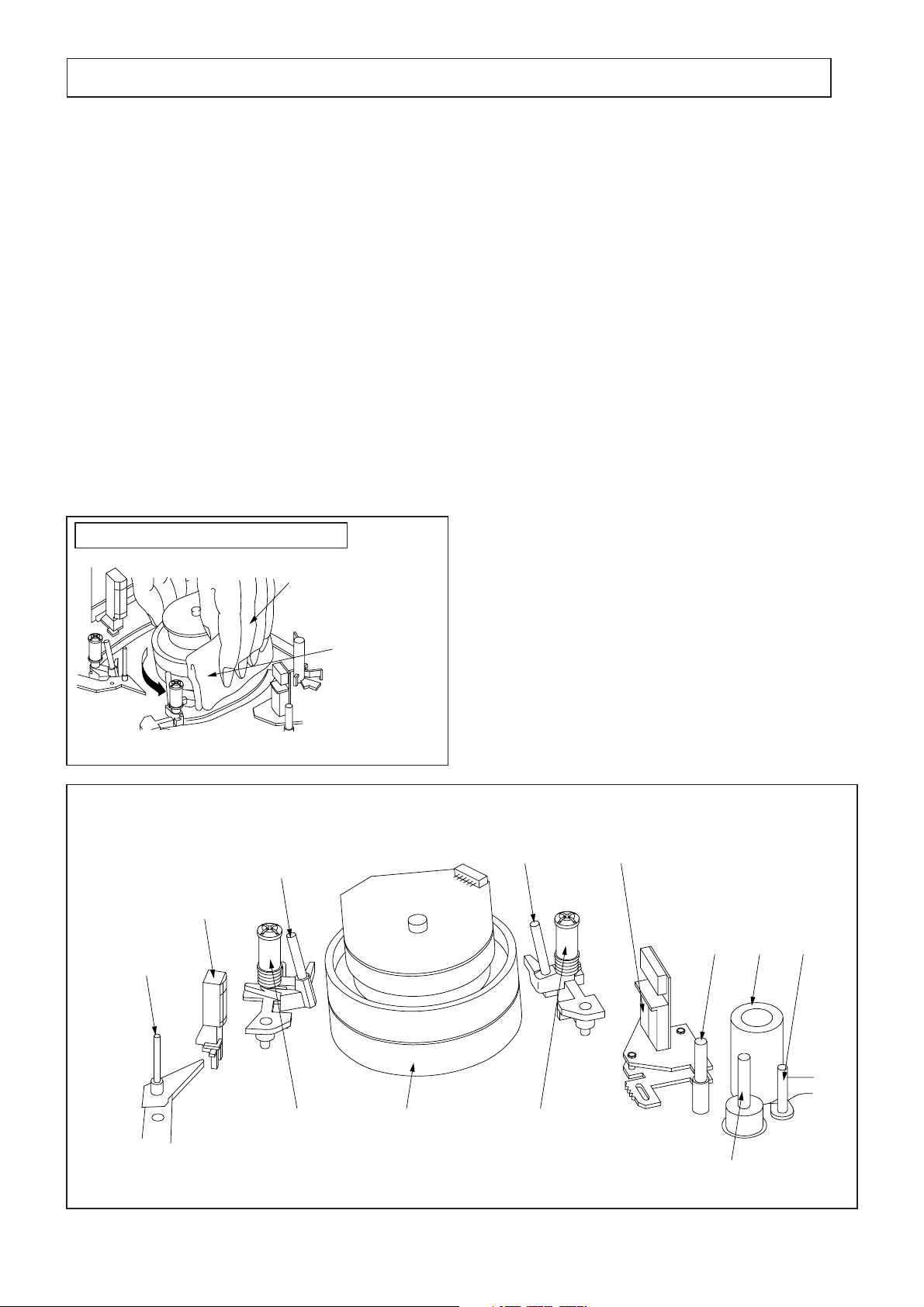

1. DECK Cleaning

The following Parts require cleaning whenever serviced in

order to maintain satisfactory performance.

1-1. VIDEO HEAD

1. Clean the VIDEO HEAD according to the following

method. Dust and other foreign objects on the VIDEO

HEAD disturb the normal PLAYBACK picture. To

clean the VIDEO HEAD, hold a VIDEO HEAD

cleaning cloth dampened with alcohol against the

DRUM and slowly turn the DRUM counter-clockwise.

Note : Do not directly touch the HEADS installed to the

UPPER DRUM ASSY. The HEADS are very hard

but brittle to shock (especially to shock in the

vertical direction) and easily breakable.

Never apply force to it in the vertical direction.

2. Allow the residual alcohol to dry thoroughly before

running a tape. The residual alcohol on the HEADs

may damage the tape if not dried completely.

MECHANICAL ADJUSTMENT AND REPLACEMENT

1-2. Tape Running System

Clean the following Parts of the Tape Running System.

1. TENSION PIN

2. F/E HEAD

3. SLANT POLE (SP)

4. SLANT POLE (TU)

5. A/C HEAD

6. GUIDE POLE (TU)

7. PINCH ROLLER

8. GUIDE PIN (TU)

9. GUIDE ROLLER (SP)

10. UPPER / LOWER DRUM ASSY

11. GUIDE ROLLER (TU)

12. CAPSTAN SHAFT

1. Clean the Tape Running System, using a piece of

gauze dampened with alcohol, except for the GUIDE

ROLLER (SP), GUIDE ROLLER (TU), and PINCH

ROLLER which require to be cleaned with a piece of

dry gauze.

2. Allow the residual alcohol to dry thoroughly before

running the tape. The residual alcohol on the

SYSTEM may damage the tape if not dried

completely.

1-3. REEL DISK Drive System

1. Clean the BRAKE side and REEL BELT of the REEL

DISK Drive System.

2. Clean the REEL DISK Drive System, using a piece of

gauze dampened with alcohol, except for the REEL

BELT which requires cleaning with a piece of dry

gauze.

3. Allow the residual alcohol to dry thoroughly before

operation.

Fig. 1-2

UPPER DRUM ASSY cleaning

Page 17

-2-

a

a

b

b

FELT RING

CLEANING

ARM

Fig. 2-1

a

a

STAY PLATE

Fig. 2-2

2. Replacement of Major Parts

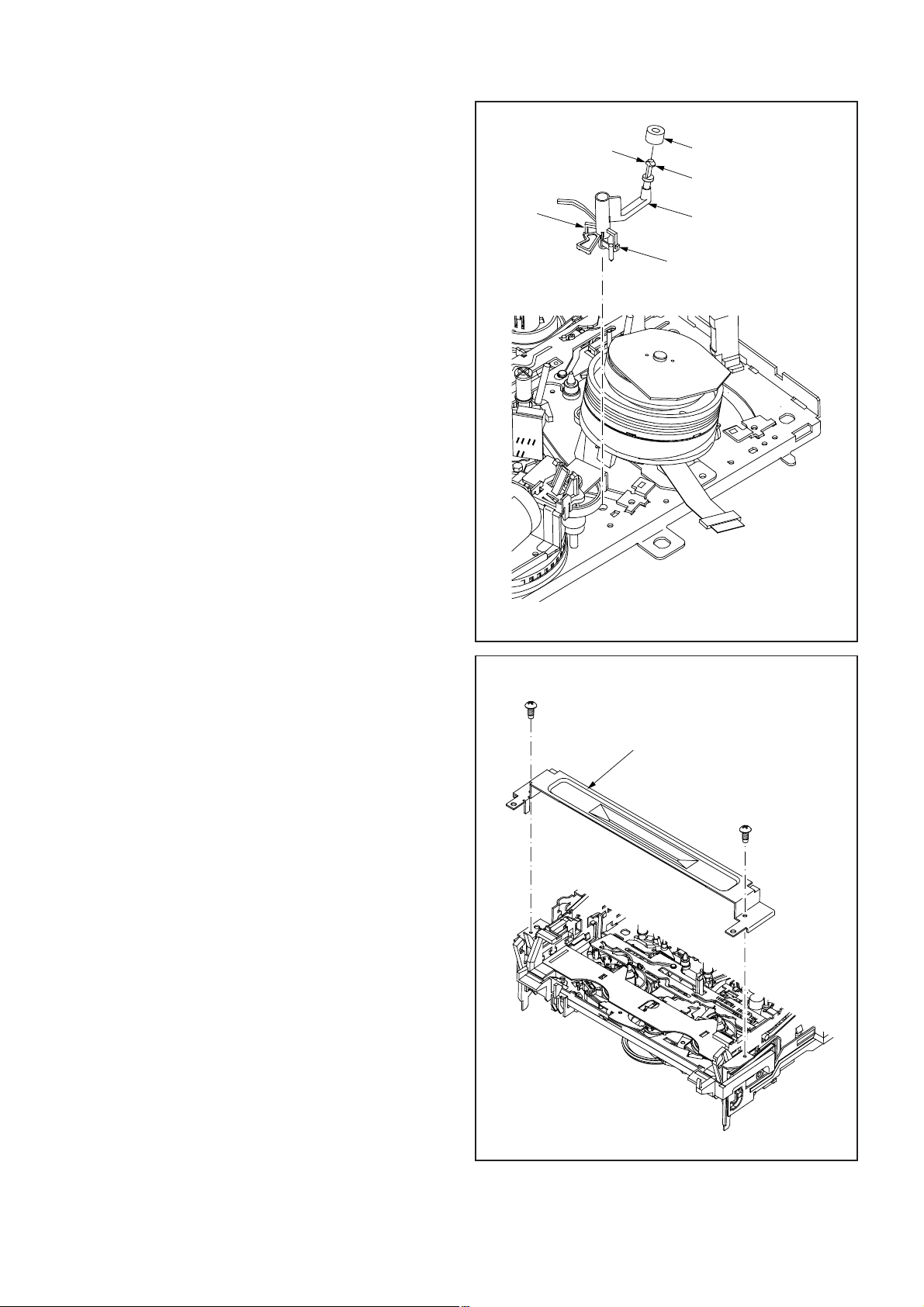

2-1. CLEANING ARM, FELT RING

SET POSITION : Normal

(Removal)

1. Release the two catches (a) of the CLEANING ARM

shown in the Fig. 2-1 to remove the CLEANING ARM.

2. Release the two catches (b) of the CLEANING ARM

shown in the Fig. 2-1 to remove the FELT RING.

(Installation)

1. Install the FELT RING shown in the Fig. 2-1 to the

CLEANING ARM.

2. Install the CLEANING ARM shown in the Fig. 2-1.

2-2. STAY PLATE

SET POSITION : Normal

(Removal)

1. Remove the two screws (a) fastening the STAY

PLATE shown in the Fig. 2-2 to remove the STAY

PLATE.

(Installation)

1. Install the STAY PLATE shown in the Fig. 2-2.

Page 18

-3-

B

A

C

a

Hole in MAIN PLATE ASSY

BOTTOM ASSY

WORM WHEEL

ARM (SP)

Lift

Pull out

Fig. 2-3-1

b

c

d

e

MAIN PLATE ASSY

Groove of MAIN

PLATE ASSY

Side View

GREASE

(MULTEMP AC-DM)

BOTTOM ASSY

ARM (SP)

ARM (TU)

Groove of MAIN

PLATE ASSY

GREASE

(MULTEMP AC-DM)

Side View

Fig. 2-3-2

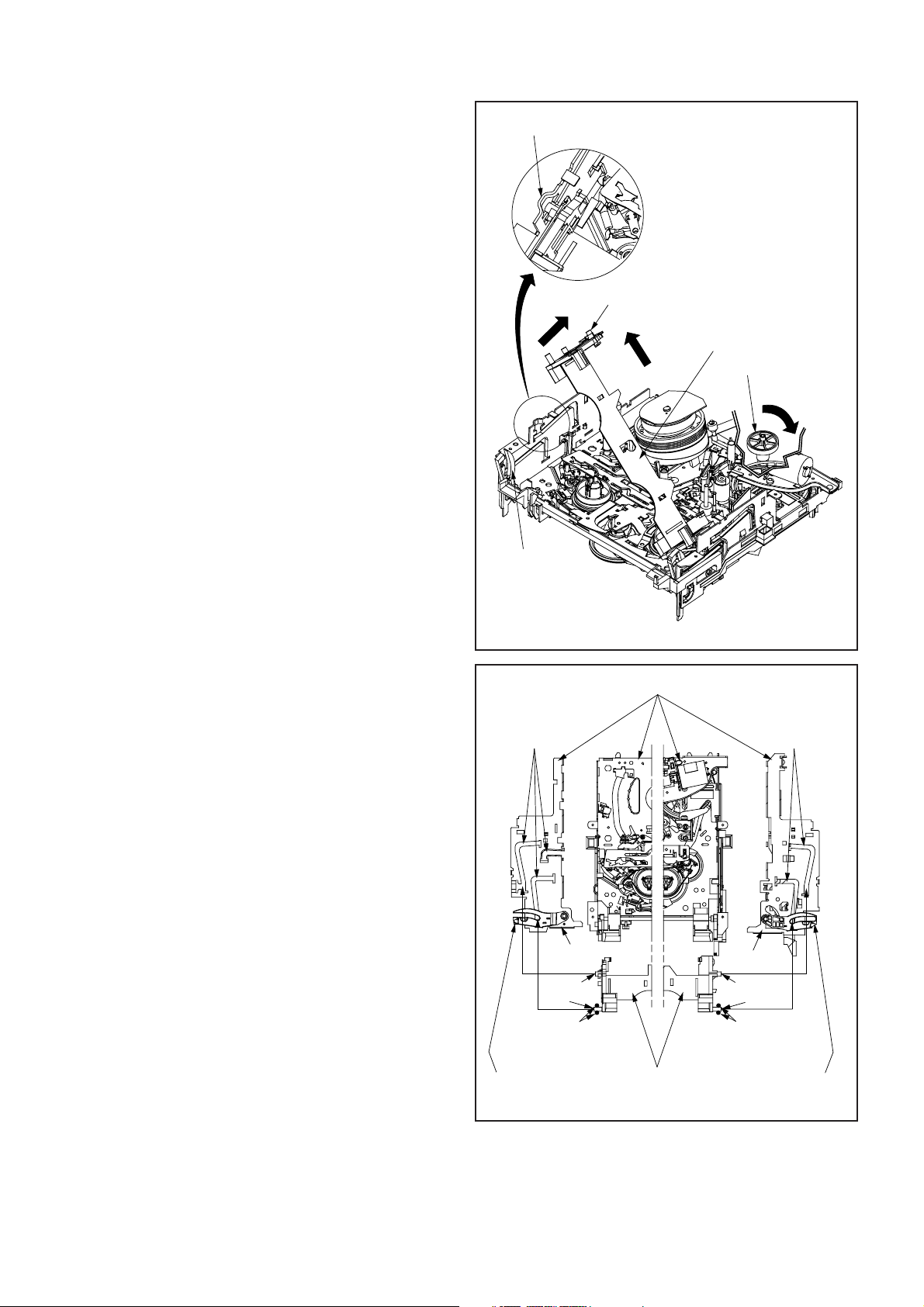

2-3. BOTTOM ASSY

SET POSITION : Normal

Remove the following part before replacing the BOTTOM

ASSY. Refer to the corresponding item to install it.

• STAY PLATE (Item 2-2)

(Removal)

1. Move the WORM WHEEL in the Fig. 2-3-1 in the

direction shown by the arrow A. And match the Boss

a of the BOTTOM ASSY with the Hole in the MAIN

PLATE ASSY.

2. Lift the BOTTOM ASSY in the Fig. 2-3-1 in the

direction shown by the arrow B and pull it out in the

direction shown by the arrow C.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the Grooves of the MAIN PLATE ASSY shown in the

Fig. 2-3-2.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the Bosses of the BOTTOM ASSY shown in the Fig.

2-3-2.

3. Rotate the WORM WHEEL shown in the Fig. 2-3-1 so

that the ARM (SP) stands vertically.

4. Insert the Boss b of the BOTTOM ASSY shown in

the Fig. 2-3-2 in the Upper Groove of the MAIN

PLATE and the Boss c in the Lower Groove.

5. Insert the Boss d of the BOTTOM ASSY to the Upper

Groove through the Hole in the MAIN PLATE ASSY

shown in the Fig. 2-3-1 and the Boss e to the Lower

Groove through the slot in the ARM (SP).

Page 19

-4-

a

INSERT GUIDE (TU)

Fig. 2-4

a

INSERT GUIDE (SP)

Fig. 2-5

2-4. INSERT GUIDE (TU)

SET POSITION : Normal

Remove the following parts before replacing the INSERT

GUIDE (TU). Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Remove the screw (a) fastening the INSERT GUIDE

(TU) shown in the Fig. 2-4 to remove the INSERT

GUIDE (TU).

(Installation)

1. Install the INSERT GUIDE (TU) shown in the Fig. 2-4.

2-5. INSERT GUIDE (SP)

SET POSITION : Normal

Remove the following parts before replacing the INSERT

GUIDE (SP). Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Remove the screw (a) fastening the INSERT GUIDE

(SP) shown in the Fig. 2-5 to remove the INSERT

GUIDE (SP).

(Installation)

1. Install the INSERT GUIDE (SP) shown in the Fig. 2-5.

Page 20

-5-

c

d

a

b

A

MAIN PLATE

ASSY

F/L ARM ASSY

F/L

BEARING

GREASE

(MULTEMP AC-DM)

ARM (SP)

ARM (TU)

GREASE

(MULTEMP AC-DM)

a

c

b

REC LEVER

REC

SPRING

REC HOLDER

Fig. 2-6

Fig. 2-7

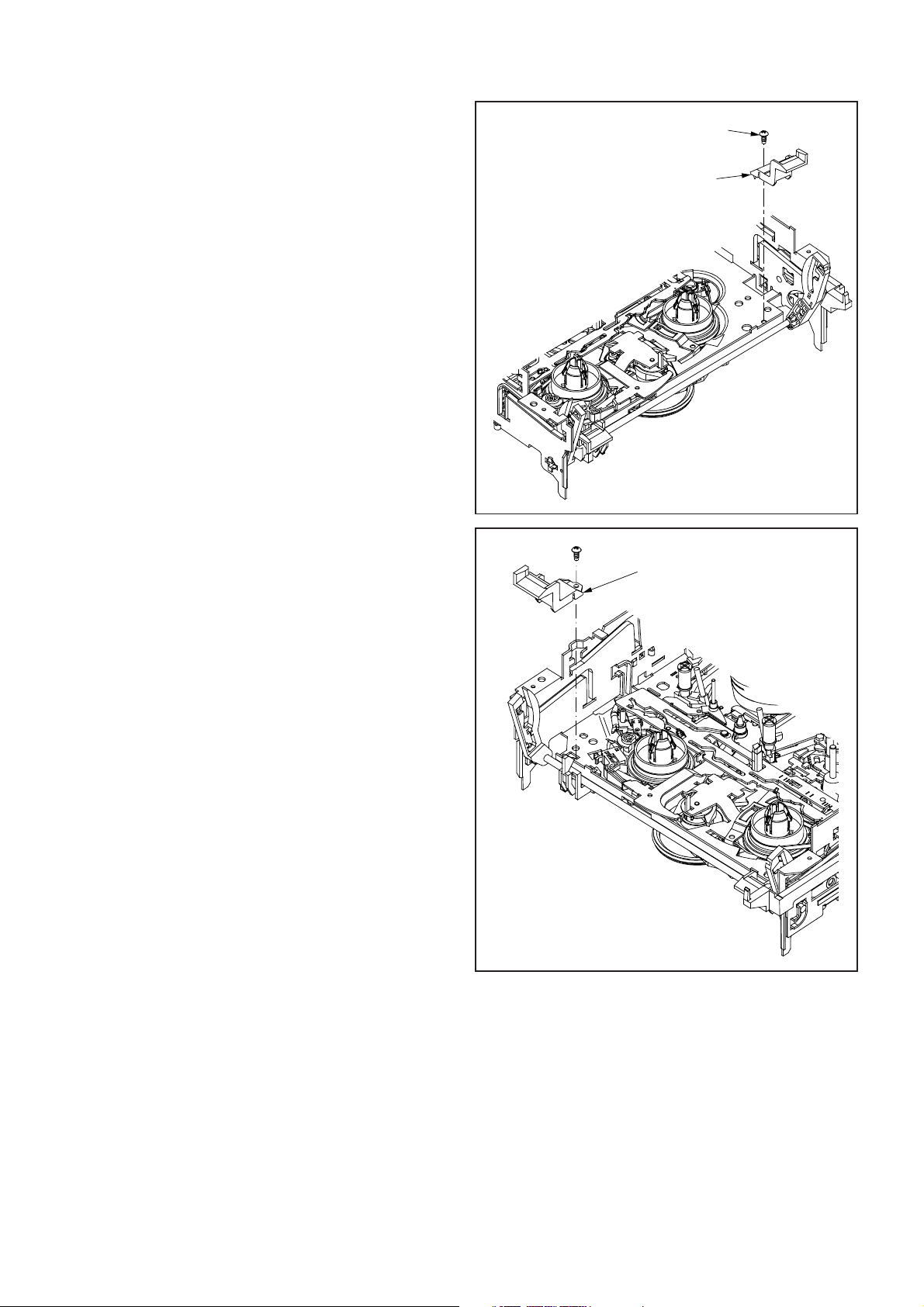

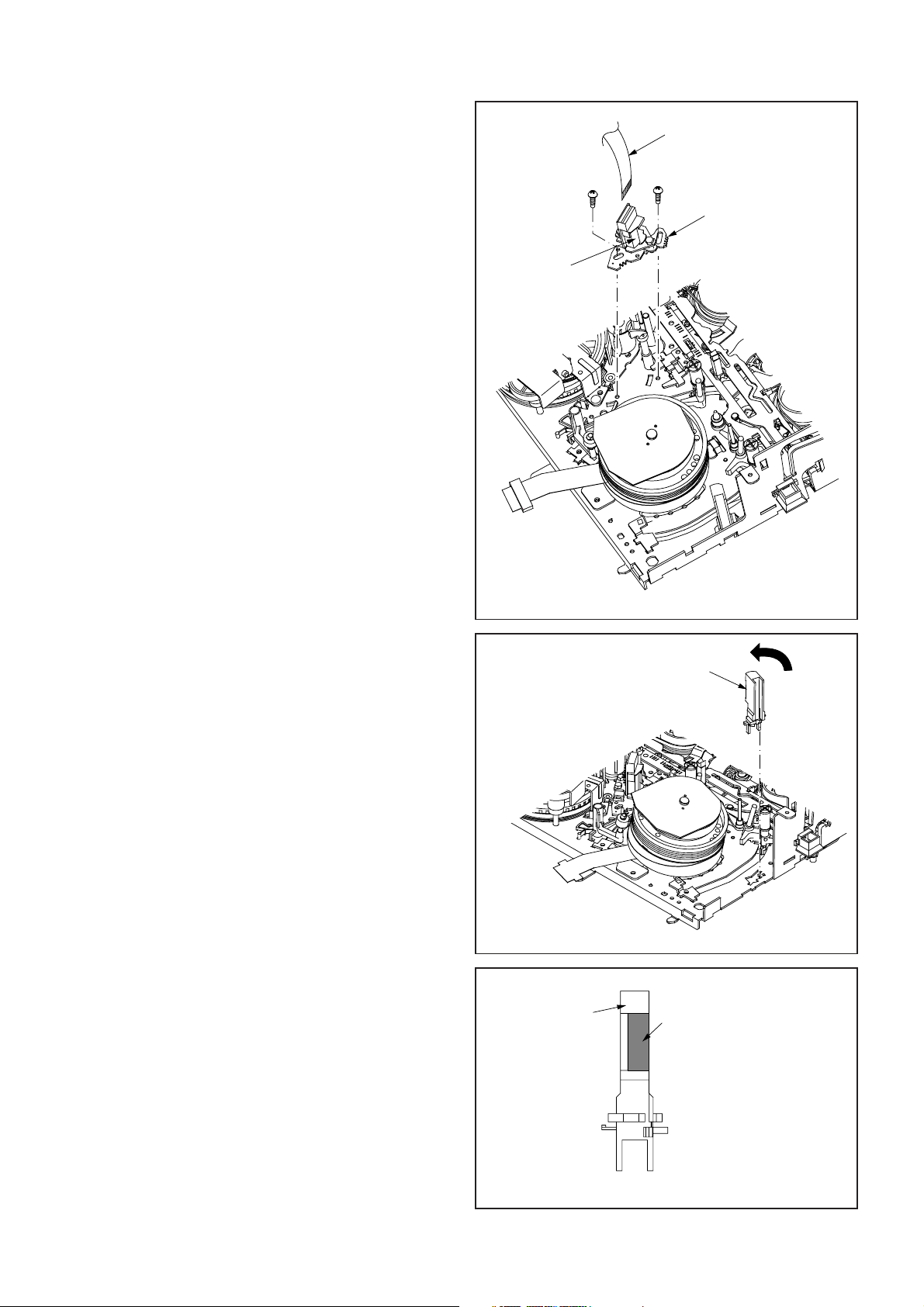

2-6. REC HOLDER, REC LEVER,

REC SPRING

SET POSITION : Upside down

(Removal)

1. Remove the screw (a) fastening the REC HOLDER

shown in the Fig. 2-6 to remove the REC HOLDER.

2. Release the REC SPRING shown in the Fig. 2-6 from

the catch (b) of the REC HOLDER to remove the

REC LEVER.

3. Release the two catches (c) of the REC LEVER

shown in the Fig. 2-6 to remove the REC SPRING.

(Installation)

1. Install the REC SPRING shown in the Fig. 2-6 to the

REC LEVER and hook the REC SPRING to the

catches (c).

2. Install the REC LEVER shown in the Fig. 2-6 to the

REC HOLDER.

3. Hook the REC SPRING shown in the Fig. 2-6 to the

catch (b).

4. Install the REC HOLDER shown in the Fig. 2-6.

2-7. F/L ARM ASSY, F/L BEARING

SET POSITION : Normal

Remove the following parts before replacing the F/L ARM

ASSY, F/L BEARING. Refer to the corresponding items

to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• INSERT GUIDE (TU) (Item 2-4)

• INSERT GUIDE (SP) (Item 2-5)

• REC HOLDER (Item 2-5)

(Removal)

1. Release the catch (a) of the F/L BEARING shown in

the Fig. 2-7 and pull out the F/L ARM ASSY in the

direction shown by the arrow A.

Note : Do not pull the F/L ARM by force because it may

break the catch (a) of the F/L BEARING.

2. Release the catch (b) of the F/L BEARING shown in

the Fig. 2-7 and rotate the F/L BEARING by 90

degrees to remove it.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the Groove of the MAIN PLATE ASSY shown in the

Fig. 2-7.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the Boss of the ARM (SP) shown in the Fig. 2-7.

3. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the Bosses of the ARM (TU) shown in the Fig. 2-7.

4. Install the F/L BEARING shown in the Fig. 2-7.

5. Insert the Boss c of the F/L ARM ASSY shown in the

Fig. 2-7 into the Groove d of the MAIN PLATE ASSY

to install the F/L ARM ASSY.

Page 21

-6-

a

a

LEAD CONNECTOR

A/C HEAD UNIT

Head

Fig. 2-8

2-8. A/C HEAD UNIT

SET POSITION : Normal

(Removal)

1. Remove the LEAD CONNECTOR of the A/C HEAD

UNIT shown in the Fig. 2-8.

2. Remove the two screws (a) fastening the A/C HEAD

UNIT shown in the Fig. 2-8 to remove the A/C HEAD

UNIT.

(Installation)

1. Install the A/C HEAD UNIT shown in the Fig. 2-8.

Note : Never touch the Head of the A/C HEAD UNIT

shown in the Fig. 2-8. Clean the dirt on the Head

with alcohol if necessary.

2. Install the LEAD CONNECTOR of the A/C HEAD

UNIT shown in the Fig. 2-8.

3. Perform the Item 3-3. "A/C HEAD Adjustment" and

Item 3-4. "Phase Adjustment" of the

"Interchangeability Adjustment of the Mechanism".

2-9. F/E HEAD

SET POSITION : Normal

(Removal)

1. Lift the F/E HEAD shown in the Fig. 2-9-1 in the

direction by the arrow A to remove it.

Note : Be sure to replace the removed F/E HEAD with a

new one.

(Installation)

1. Install the F/E HEAD shown in the Fig. 2-9-1.

Note : Never touch the Head shown in the Fig. 2-9-2.

Clean it with alcohol if necessary.

F/E HEAD

Head Part

Never touch the Head Part.

A

F/E HEAD

Counterclockwise

Fig. 2-9-1

Fig. 2-9-2

Page 22

-7-

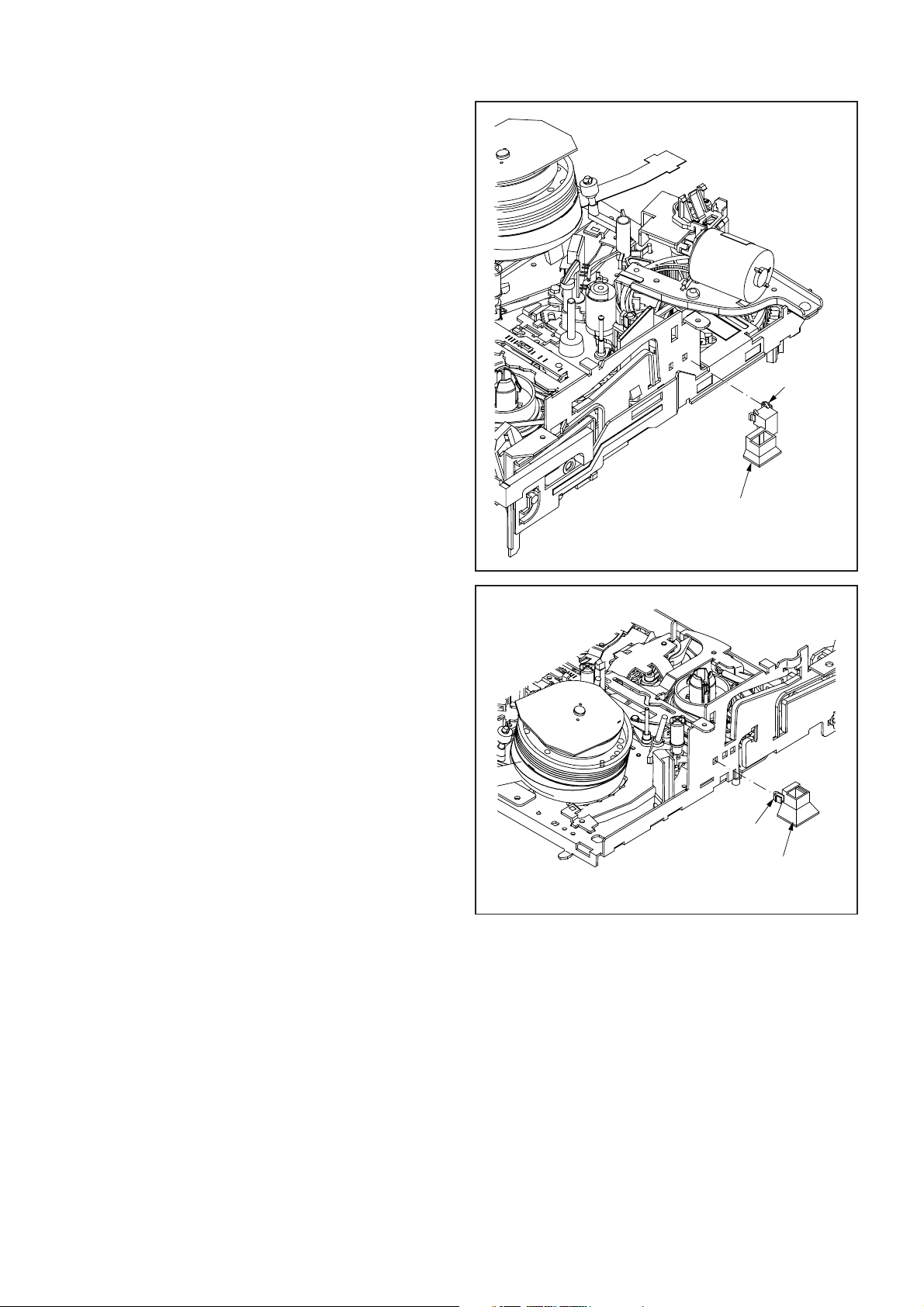

2-10.SENSOR COVER (TU)

SET POSITION : Normal

(Removal)

1. Release the catch (a) of the SENSOR COVER (TU)

shown in the Fig. 2-10 to remove the SENSOR

COVER (TU).

(Installation)

1. Install the SENSOR COVER (TU) shown in the Fig. 2-

10.

2-11.SENSOR COVER (SP)

SET POSITION : Normal

(Removal)

1. Remove the catch (a) of the SENSOR COVER (SP)

shown in the Fig. 2-11 to remove the SENSOR

COVER (SP).

(Installation)

1. Install the SENSOR COVER (SP) shown in the Fig. 2-

11.

a

SENSOR COVER (TU)

Fig. 2-10

a

SENSOR COVER (SP)

Fig. 2-11

Page 23

-8-

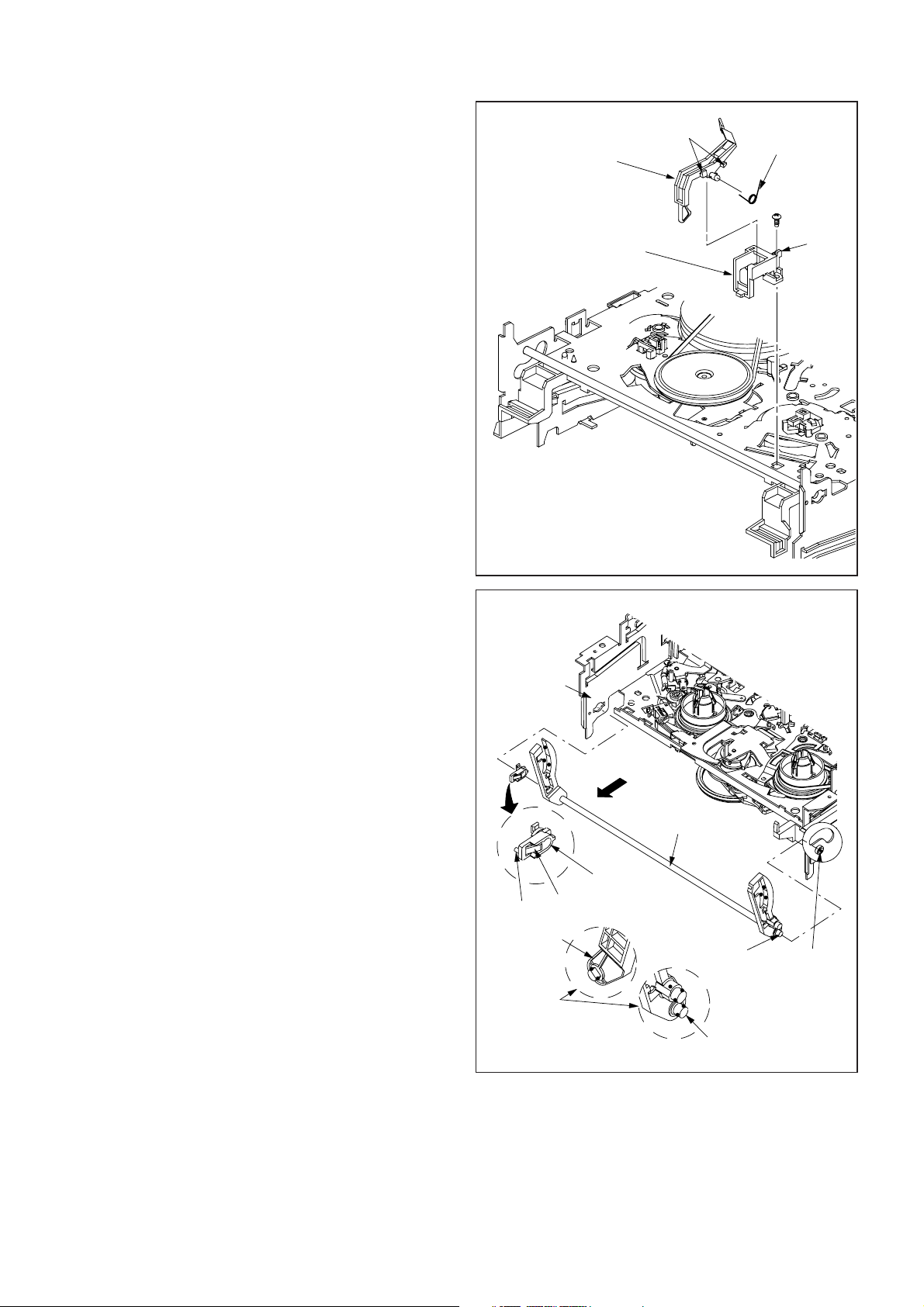

2-12.REV UNIT (TU),

REV UNIT (SP)

SET POSITION : Upside down

(Removal)

1. Release the two catches (a) of the REV UNIT (TU)

shown in the Fig. 2-12 to remove the REV UNIT (TU).

2. Release the two catches (b) of the REV UNIT (SP)

shown in the Fig. 2-12 to remove the REV UNIT (SP).

(Installation)

1. Clean the dirt on the transparent part of the REV

UNIT (TU) with a VIDEO HEAD cleaning cloth.

Note : Never use solvent such as alcohol to clean the

REV UNIT (TU).

2. Install the REV UNIT (TU) shown in the Fig. 2-12.

3. Clean the dirt on the transparent part of the REV

UNIT (SP) with a VIDEO HEAD cleaning cloth.

Note : Never use solvent such as alcohol to clean the

REV UNIT (SP).

4. Install the REV UNIT (SP) shown in the Fig. 2-12.

2-13.MODE POSITION UNIT

SET POSITION: Upside down

(Removal)

1. Release the two catches (a, b) of the MODE

POSITION UNIT shown in the Fig. 2-13 to remove the

MODE POSITION UNIT.

(Installation)

1. Install the catch (b) of the MODE POSITION UNIT

shown in the Fig. 2-13.

2. Install the catch (a) of the MODE POSITION UNIT

shown in the Fig. 2-13.

a

a

b

b

REV UNIT (TU)

REV UNIT (SP)

Fig. 2-12

a

b

MODE POSITION UNIT

Fig. 2-13

Page 24

-9-

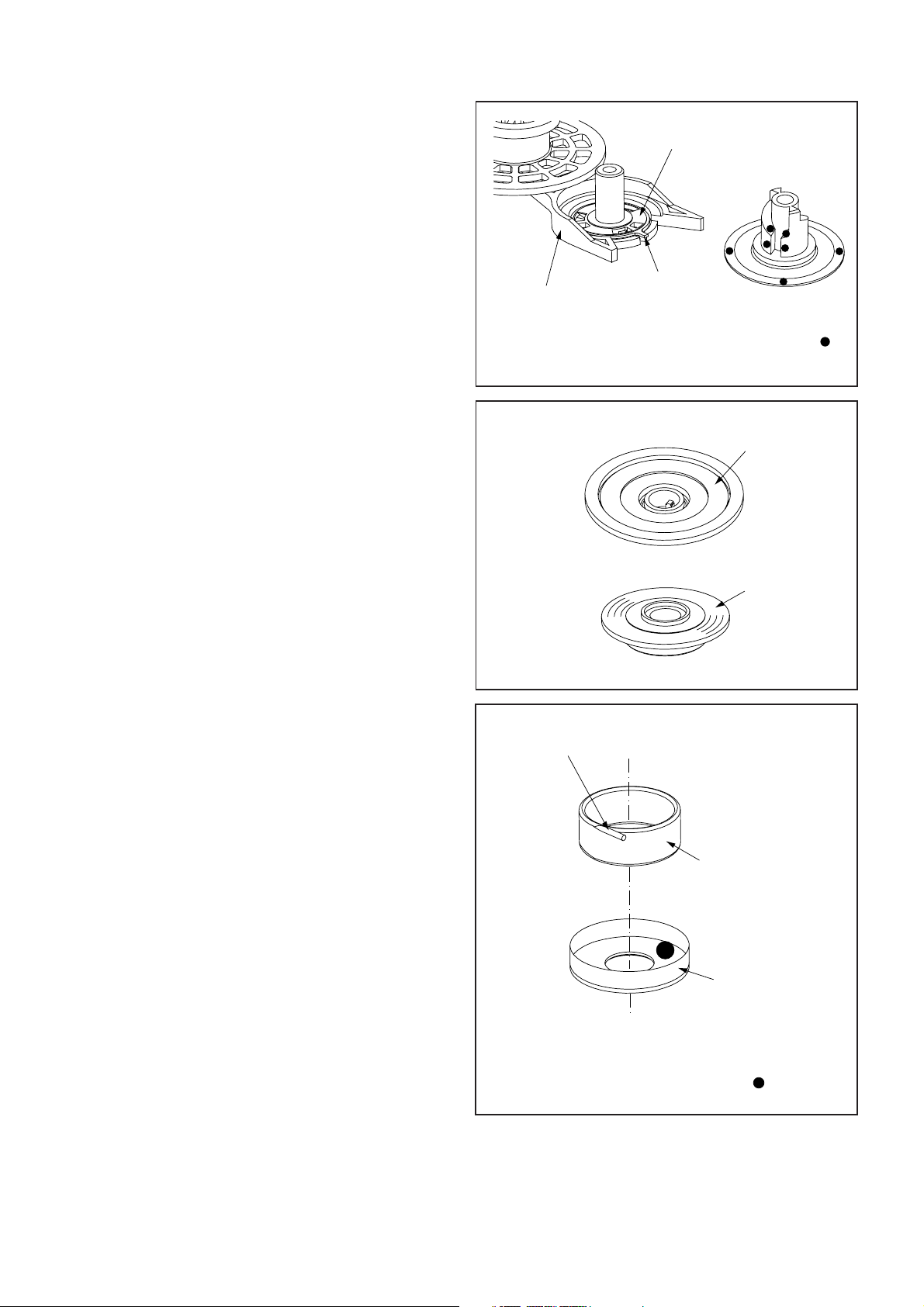

a

A

REEL BELT

PULLEY BUSH

THRUST WASHER

BELT PULLEY

Pull in the direction

of the Arrow (A) to

remove it from the

SHIFT LEVER.

SHIFT SLIDER

PULLEY GEAR ASSY

SLIP GEAR

SLIP SPRING

SLIP WASHER

THRUST WASHER

SLIP ADJUSTER

IDLER 2 UNIT

OIL (FLOIL 948P)

GREASE (PG-641)

GREASE (MULTEMP AC-DM)

SHIFT LEVER

GREASE

(PG-641)

Fig. 2-14-1

SLIP ADJUSTER

SHIFT SLIDER

Apply GREASE (PG-641) to the parts .

Fig. 2-14-2

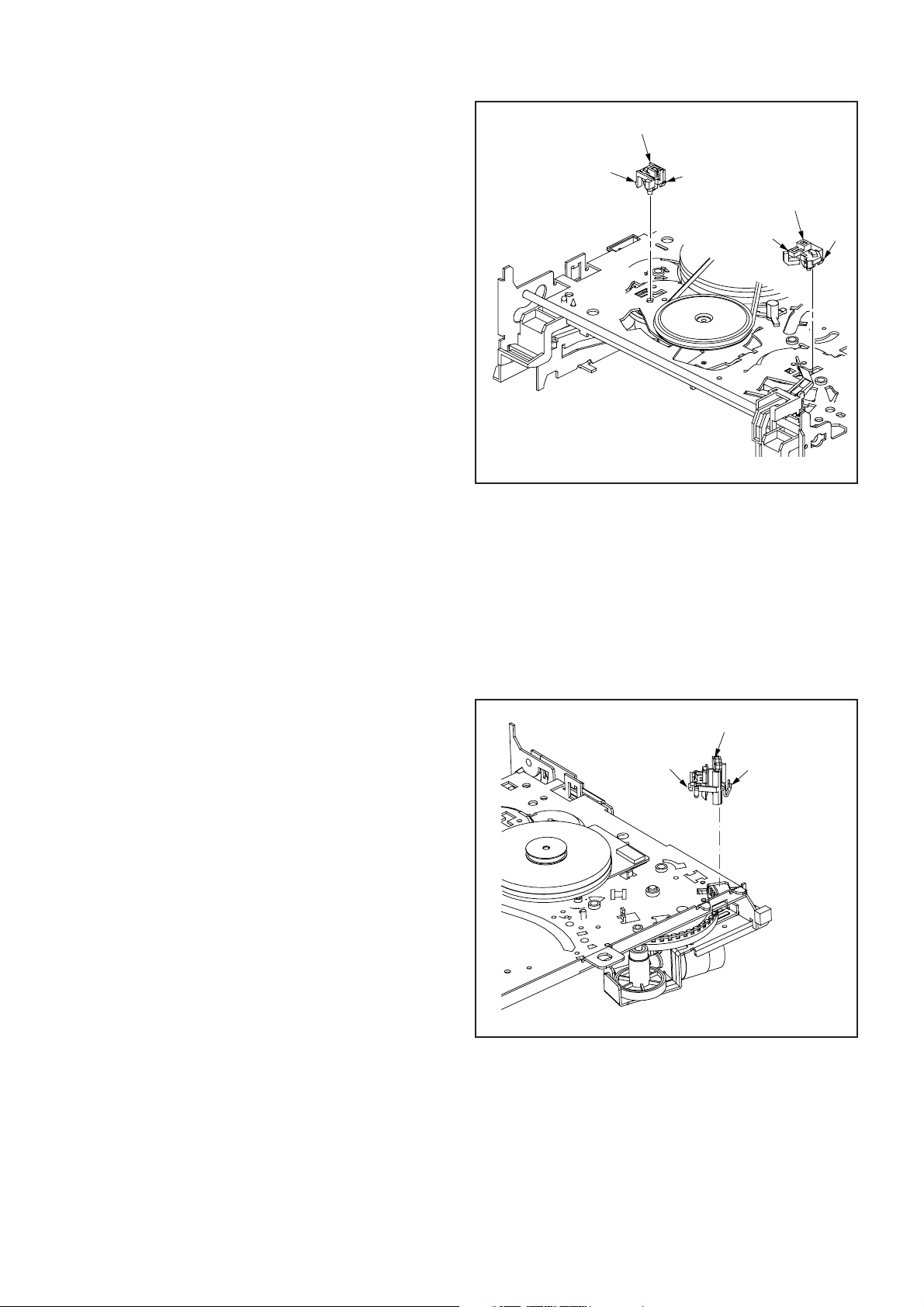

2-14.REEL BELT, PULLEY BUSH, THRUST

WASHER, BELT PULLEY,

SHIFT

SLIDER, PULLEY GEAR ASSY,

SLIP

GEAR, SLIP SPRING, SLIP WASHER,

THRUST WASHER, SLIP ADJUSTER,

IDLER 2 UNIT

SET POSITION : Upside down

(Removal)

1. Remove the REEL BELT shown in the Fig. 2-14-1.

2. Move the SHIFT SLIDER in the Fig. 2-14-1 in the

direction shown of the arrow A to remove the SHIFT

SLIDER from the SHIFT LEVER.

3. Release the two catches (a) of the PULLEY BUSH

shown in the Fig. 2-14-1 to remove the PULLEY

BUSH.

Note : Be sure to replace the removed PULLEY BUSH

with a new one.

4. Remove the units from the THRUST WASHER to

IDLER 2 UNIT shown in the Fig. 2-14-1.

(Installation)

Note : Be careful so that GREASE and OIL does not

adhere on the Felt Side of the PULLEY GEAR

ASSY or the Grooved Side of the SLIP GEAR

shown in the Fig. 2-14-4.

1. Apply OIL (FLOIL 948P) [859D154O20] to the SHAFT

for the IDLER 2 UNIT shown in the Fig. 2-14-1.

2. Apply GREASE (PG-641) [859D055O30] to the parts

on the IDLER 2 UNIT specified in the Fig. 2-14-1.

3. Apply GREASE (MULTEMP AC-DM) [859D055O90]

to the parts on the MAIN PLATE ASSY specified in

the Fig. 2-14-1.

4. Apply GREASE (PG-641) [859D055O30] to the parts

on the new SHIFT SLIDER specified in the Fig. 2-14-

2.

5. Apply GREASE (PG-641) [859D055O30] to the parts

on the new SLIP ADJUSTER specified in the Fig. 214-2.

6. Apply GREASE (PG-641) [859D055O30] to the parts

on the new BELT PULLEY specified in the Fig. 2-14-3.

7. Install the IDLER 2 UNIT shown in the Fig. 2-14-1.

8. Install the SLIP ADJUSTER shown in the Fig. 2-14-3,

matching the Lug of the SLIP ADJUSTER with the

Center Notch of the IDLER 2 UNIT.

Page 25

-10-

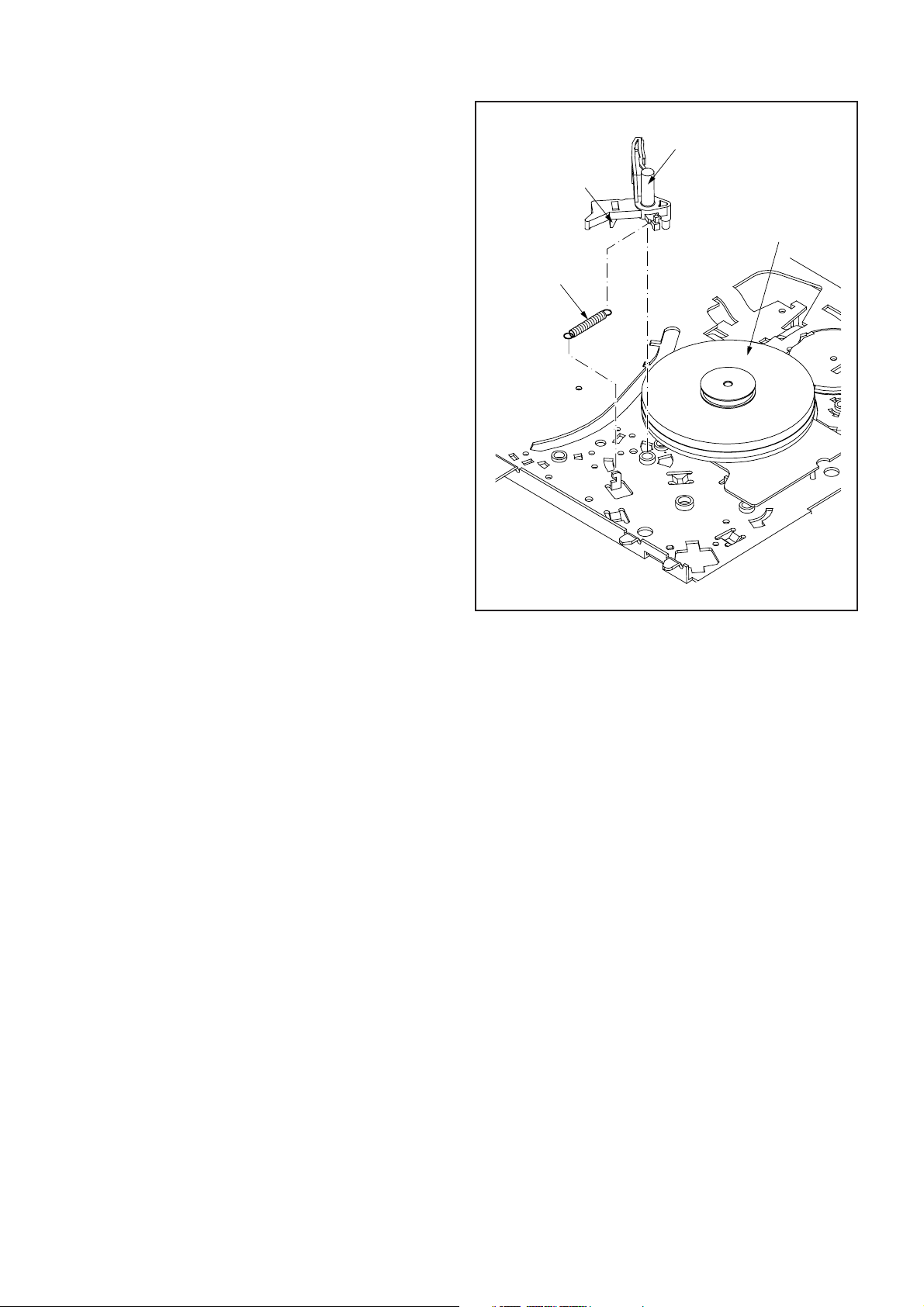

SLIP ADJUSTER

Center of the

BELT PULLEY

IDLER UNIT

Match the Lug of the

SLIP ADJUSTER with

the Center Notch of

the IDLER UNIT.

Apply GREASE

(PG-641)

to the parts .

Fig. 2-14-4

Fig. 2-14-3

Apply GREASE (PG-641) to the parts .

SLIP SPRING

SLIP WASHER

[SLIP GEAR side]

[THRUST WASHER side]

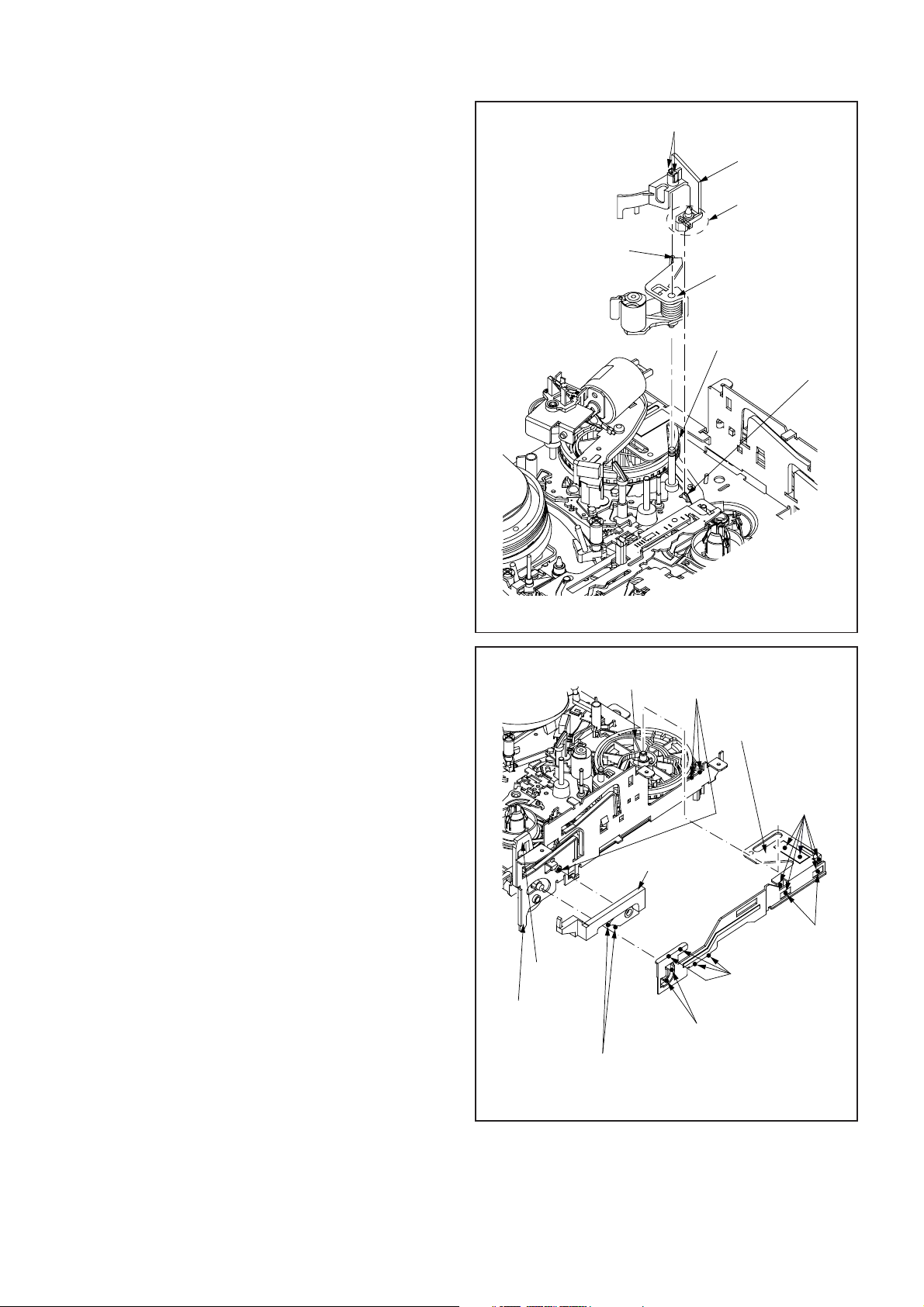

Straight end

Fig. 2-14-5

9. Install the units from the SLIP WASHER to REEL

BELT shown in the Fig. 2-14-1.

Note1 : Be sure to replace the removed PULLEY BUSH

with a new one.

Note2 : Attach the SLIP SPRING with its straight end

facing the SLIP GEAR side.

Note3 : Attach the SLIP WASHER with its position set as

shown in the Fig. 2-14-5.

Note4 : Apply GREASE (PG-641) [859D055O30] to the

part on the SLIP WASHER specified in the Fig. 214-5.

10. Install the SHIFT SLIDER to the SHIFT LEVER shown

in the Fig. 2-14-1.

PULLEY GEAR ASSY

Felt Side

SLIP GEAR

Grooved Side

Page 26

-11-

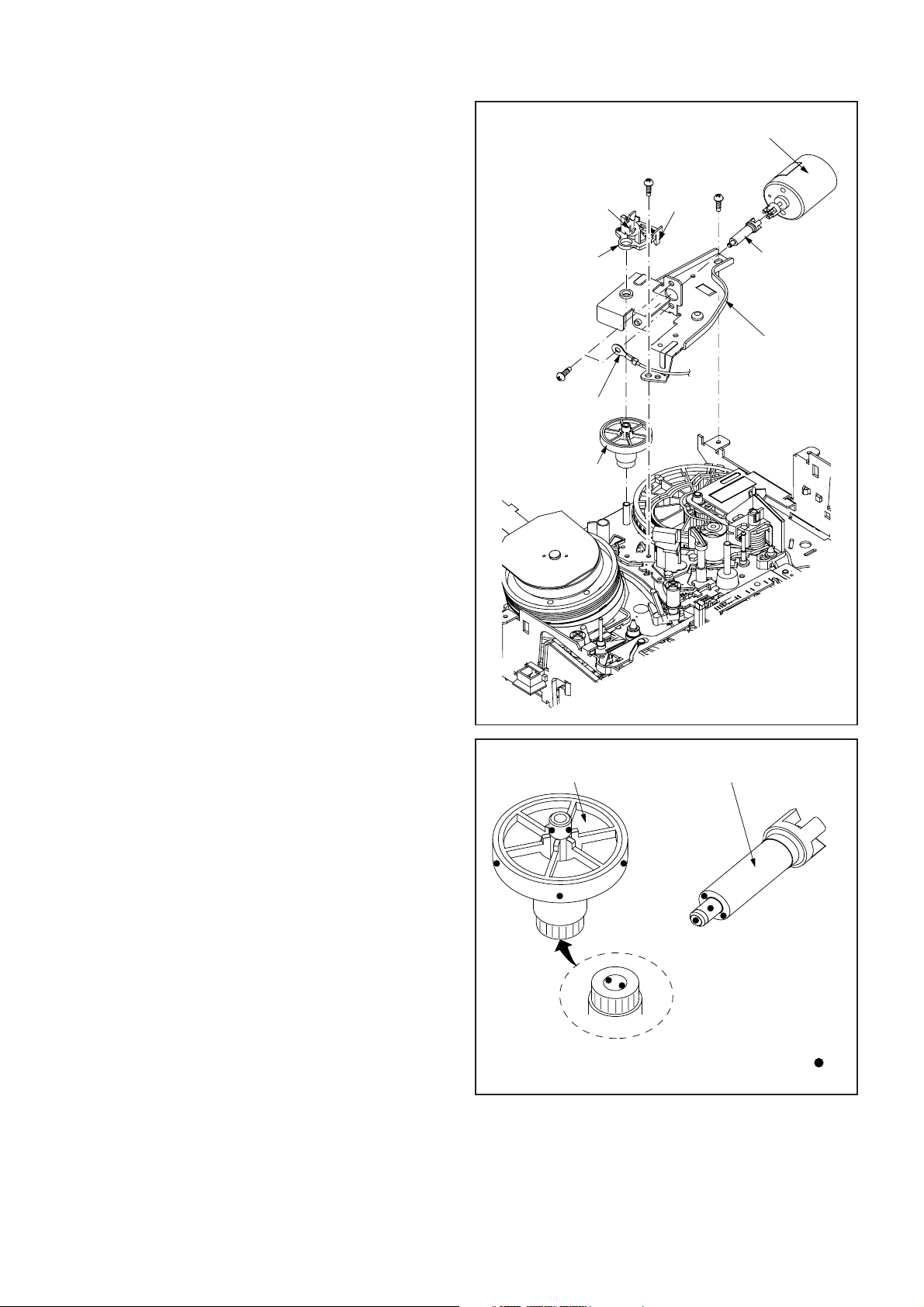

2-15.CAPSTAN BRAKE SPRING, CAPSTAN

BRAKE ASSY

SET POSITION : Upside down

(Removal)

1. Remove the CAPSTAN BRAKE SPRING shown in the

Fig. 2-15.

2. Remove the catch (a) of the CAPSTAN BRAKE

ASSY shown in the Fig. 2-15 to remove the CAPSTAN

BRAKE ASSY.

(Installation)

1. Install the CAPSTAN BRAKE ASSY shown in the Fig.

2-15.

2. Install the CAPSTAN BRAKE SPRING shown in the

Fig. 2-15.

a

CAPSTAN BRAKE ASSY

CAPSTAN

BRAKE SPRING

CAPSTAN MOTOR

Fig. 2-15

Page 27

-12-

b

b

c

a

a

LOADING MOTOR ASSY

FC HOLDER

LOADING

WORM

MOTOR

HOLDER

LUG TERMINAL

WORM WHEEL

Fig. 2-16-1

WORM WHEEL LOADING WORM

Apply GREASE (MULTEMP AC-DM) to the parts .

Fig. 2-16-2

2-16.FC HOLDER, MOTOR HOLDER,

LOADING WORM, LOADING MOTOR

ASSY, WORM WHEEL

SET POSITION : Normal

(Removal)

1. Release the two catches (a) of the FC HOLDER

shown in the Fig. 2-16-1 to remove the FC HOLDER.

2. Remove the two screws (b) fastening the MOTOR

HOLDER shown in the Fig. 2-16-1 to remove the

MOTOR HOLDER.

3. Remove the two screws (c) fastening the LOADING

MOTOR ASSY shown in the Fig. 2-16-1 to remove the

LOADING MOTOR ASSY and LOADING WORM.

4. Remove the WORM WHEEL.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the LOADING WORM shown in the Fig. 2-16-2.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the WORM WHEEL shown in the Fig. 2-16-2.

3. Install the WORM WHEEL.

4. Install the LOADING WORM, LOADING MOTOR

ASSY to the MOTOR HOLDER.

Note : Tighten the screw (c) shown in the Fig. 2-16-1

after putting the LUG TERMINAL on the screw.

5. Install the MOTOR HOLDER.

6. Install the FC HOLDER.

Page 28

-13-

a

PINCH ARM

CAP

Part

Part

PINCH ASSY

MAIN CAM

Rib

A

B

Fig. 2-17

GREASE

(MULTEMP AC-DM)

F/L PLATE

DOOR ARM

ARM (TU)

MAIN CAM

GREASE

(MOLYKOTE

G PASTE)

MAIN PLATE

ASSY

GREASE

(MULTEMP AC-DM)

Back

GREASE

(MOLYKOTE

G PASTE)

GREASE

(MULTEMP AC-DM)

Fig. 2-18-1

2-17.PINCH ARM CAP, PINCH UNIT

SET POSITION : Normal

(Removal)

1. Release the two catches (a) of the PINCH ARM CAP

shown in the Fig. 2-17 to remove the PINCH ARM

CAP.

2. Remove the PINCH UNIT shown in the Fig. 2-17.

(Installation)

1. Insert Part A of the PINCH UNIT shown in the Fig. 2-

17 in the most external groove of the MAIN CAM.

2. Install the PINCH ARM CAP matching the Part B of

the PINCH ARM CAP with the Rib of the MAIN PLATE

ASSY.

2-18.F/L PLATE, DOOR ARM

SET POSITION : Normal

Remove the following parts before replacing the F/L

PLATE, DOOR ARM. Refer to the corresponding items to

install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• SENSOR COVER (TU) (Item 2-10)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

(Removal)

1. Slightly lift the back of the F/L PLATE (MAIN CAM

side) shown in the Fig. 2-18-1 to remove the F/L

PLATE.

2. Remove the DOOR ARM.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the points on the new F/L PLATE specified in the Fig.

2-18-1.

2. Apply GREASE (MOLYKOTE G PASTE)

[859D055O50] to the points on the new F/L PLATE

specified in the Fig. 2-18-1.

Page 29

-14-

Hole

MAIN CAM

F/L PLATE

Boss

Fig. 2-18-2

B

A

b

b

a

a

a

b

b

BRAKE CAM PLATE

MAIN CAM

Fig. 2-19-1

70mm

40mm

130mm

99mm

BRAKE CAM PLATE

Back

Apply GREASE (MOLYKOTE G PASTE) to the points .

Back

Back

Back

Fig. 2-19-2

3. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the points on the MAIN PLATE ASSY specified in the

Fig. 2-18-1.

4. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the points on the DOOR ARM specified in the Fig. 2-

18-1.

5. Install the DOOR ARM.

6. Match the Hole in the MAIN CAM with the Hole in the

MAIN PLATE ASSY shown in the Fig. 2-18-2.

7. Install the F/L PLATE shown in the Fig. 2-18-1 from

the front side (ARM (TU) side).

8. Insert the Boss of the F/L PLATE shown in the Fig. 2-

18-2 into the Groove of the MAIN CAM.

2-19.BRAKE CAM PLATE

SET POSITION : Normal

Remove the following parts before replacing the BRAKE

CAM PLATE. Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

(Removal)

1. Rotate the MAIN CAM in the Fig. 2-19-1 in the

direction shown by the arrow A. And move the

BRAKE CAM PLATE so that the three catches (a) of

the MAIN PLATE ASSY can be released.

2. Remove the BRAKE CAM PLATE.

(Installation)

1. Apply GREASE (MOLYKOTE G PASTE)

[859D055O50] to the points on the BRAKE CAM

PLATE specified in the Fig. 2-19-2.

2. Hook the BRAKE SPRING shown in the Fig. 2-19-3 to

the catch of the BRAKE (TU).

3. Install the BRAKE CAM PLATE, inserting the six

Guide Pins (b) shown in the Fig. 2-19-1 into the slits

of the BRAKE CAM PLATE.

4. Move the BRAKE SPRING in the Fig. 2-19-3 in the

direction of the arrow C to release the Catch of the

BRAKE (TU) and insert the BRAKE SPRING under

the Catch.

5. Rotate the MAIN CAM shown in the Fig. 2-19-1 in the

direction shown of the arrow B. And move the

BRAKE CAM PLATE to hook it to the three catches

(a) of the MAIN PLATE ASSY.

Page 30

-15-

a

b

c

AB

MAIN PLATE ASSY

GUIDE LAMP

Removing Direction Installing Direction

Fig. 2-20

C

BRAKE SPRING

Catch

Insert the BRAKE SPRING

under the Catch.

BRAKE (TU)

Fig. 2-19-3

2-20.GUIDE LAMP

SET POSITION : Normal

Remove the following parts before replacing the GUIDE

LAMP. Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

(Removal)

1. Release the catch (a) of the GUIDE LAMP shown in

the Fig. 2-20.

2. Rotate the GUIDE LAMP in the direction shown by the

arrow A (counterclockwise, when viewed from the

bottom) to match the longest slit (c) of the MAIN

PLATE ASSY with the longest arm (b) of the GUIDE

LAMP shown in the Fig. 2-20. Pull it out downward to

remove it.

(Installation)

1. Clean the dirt on the GUIDE LAMP with a VIDEO

HEAD cleaning cloth.

Note: Never use solvent such as alcohol to clean the

GUIDE LAMP.

2. Insert the GUIDE LAMP in the Fig. 2-20, matching the

longest arm (b) of the GUIDE LAMP with the longest

slit (c) of the MAIN PLATE ASSY.

3. Rotate the GUIDE LAMP in the direction shown by the

arrow B (clockwise, when viewed from the bottom) to

match the arm (a) of the GUIDE LAMP shown in the

Fig. 2-20 with the longest slit (c) of the MAIN PLATE

ASSY.

Note : Clean the dirt on the GUIDE LAMP with a VIDEO

HEAD cleaning cloth if necessary.

Page 31

-16-

A

a

MAIN CAM

BRAKE LEVER

GREASE

(MULTEMP AC-DM)

GUIDE ARM (TU)

Back

GREASE

(MULTEMP AC-DM)

MAIN PLATE ASSY

LB PIN

B

Fig. 2-21-1

Fig. 2-21-2

MAIN CAM

Apply GREASE (MULTEMP AC-DM) to the parts .

Front Back

Wall

Fig. 2-21-3

2-21.MAIN CAM, GUIDE ARM (TU),

BRAKE LEVER

SET POSITION : Normal

Remove the following parts before replacing the MAIN

CAM, GUIDE ARM (TU), BRAKE LEVER. Refer to the

corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• SENSOR COVER (TU) (Item 2-10)

• MOTOR HOLDER (Item 2-16)

• WORM WHEEL (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• F/L PLATE (Item 2-18)

(Removal)

1. Remove the MAIN CAM shown in the Fig. 2-21-1.

2. Remove the GUIDE ARM (TU) shown in the Fig. 2-21-

1.

3. Move the BRAKE LEVER in the Fig. 2-21-1 in the

direction shown by the arrow A and release the catch

(a) to remove the BRAKE LEVER.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the points on the new GUIDE ARM (TU) specified in

the Fig. 2-21-1.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the points on the MAIN PLATE ASSY specified in the

Fig. 2-21-1.

3. Install the GUIDE ARM (TU), matching the Hole in the

GUIDE ARM (TU) shown in the Fig. 2-21-2 with the

Hole in the MAIN PLATE ASSY.

Note : Install the GUIDE ARM (TU) so that the Part

specified with the Oblique Lines of the GUIDE

ARM (TU) will be under the SHAFT FLANGE of

the PINCH UNIT.

4. Install the BRAKE LEVER shown in the Fig. 2-21-2 so

that the Hole in the BRAKE LEVER overlaps the Hole

in the MAIN PLATE ASSY.

5.

Apply GREASE (MULTEMP AC-DM)[859D055O90] to the

points on the new MAIN CAM specified in the Fig. 2-21-3.

6. Install the MAIN CAM so that the Hole in the MAIN

CAM shown in the Fig. 2-21-2 overlaps with the Hole

in the MAIN PLATE ASSY.

Note : Install the MAIN CAM inserting the Pins of the

CAPSTAN BRAKE ASSY, GUIDE ARM (TU),

BRAKE LEVER into the Grooves on the back of

the MAIN CAM for sure.

Set the Main Cam while pulling the Guide Pin (on

the CAPSTAN BRAKE ASSY) in the direction

indicated by the arrow B (toward the deck front)

using tweezers as shown in Fig. 2-21-1.

Be careful that GREASE does not adhere on the

Wall when applying GREASE to the most external

circle on the back of the MAIN CAM (4 parts)

shown in the Fig. 2-21-3.

MAIN PLATE ASSY

MAIN CAM

GUIDE ARM (TU)

Part with

Oblique Lines

Hole

BRAKE

LEVER

Hole

SHAFT

FLANGE

of the

PINCH

ASSY

Page 32

-17-

L/D LOCK LEVER

Fig. 2-22

b

a

c

BELT HOLDER

BRAKE BELT (SP)

BELT LEVER

REEL DISK (SP side)

Fig. 2-23

2-22.L/D LOCK LEVER

SET POSITION : Normal

Remove the following parts before replacing the L/D

LOCK LEVER. Refer to the corresponding items to install

them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

(Removal)

1. Remove the L/D LOCK LEVER shown in the Fig. 2-

22.

(Installation)

1. Install the L/D LOCK LEVER shown in Fig. 2-22.

2-23.BRAKE BELT (SP), BELT HOLDER

SET POSITION : Normal

Remove the following parts before replacing the BRAKE

BELT (SP), BELT HOLDER. Refer to the corresponding

items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Lift the BRAKE BELT (SP) shown in the Fig. 2-23 to

remove it from the REEL DISK (SP side).

2. Release the BRAKE BELT (SP) from the catch (a) of

the BELT LEVER shown in the Fig. 2-23.

3. Release the two catches (b) of the BELT HOLDER

shown in the Fig. 2-23 and separate the BELT

HOLDER from the BRAKE BELT (SP).

4. Release the catch (c) of the BELT HOLDER shown

in the Fig. 2-23 to remove the BRAKE BELT (SP).

(Installation)

Note : Install the BRAKE BELT (SP) so that its Felt Side

touches the REEL DISK (SP side). GREASE

applied to the BRAKE CAM PLATE and MAIN

PLATE ASSY should not adhere on the Felt Side

of the BRAKE BELT (SP).

1. Install the BRAKE BELT (SP) shown in the Fig. 2-23

to the catch (c) of the BELT HOLDER.

2. Install the BELT HOLDER shown in the Fig. 2-23.

3. Install the BRAKE BELT (SP) shown in the Fig. 2-23

to the catch (a) of the BELT LEVER.

4. Hook the BRAKE BELT (SP) shown in the Fig. 2-23 to

the REEL DISK (SP side).

Page 33

-18-

a

b

A

TENSION ARM

REEL DISK (SP side)

TENSION

SPRING

TENS

AXIS

HOLDER

MAIN PLATE ASSY

THRAUST

WASHER

TENSION

LEVER

GREASE

(MULTEMP

AC-DM)

a

BELT LEVER

BELT ADJUSTER

Fig. 2-24

Fig. 2-25

2-24. BELT LEVER, BELT ADJUSTER

SET POSITION : Normal

Remove the following parts before replacing the BELT

LEVER, BELT ADJUSTER. Refer to the corresponding

items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

• BRAKE BELT (SP) (Item 2-23)

• BELT HOLDER (Item 2-23)

(Removal)

1. Release the catch (a) of the BELT LEVER shown in

the Fig. 2-24 to remove the BELT LEVER.

2. Remove the BELT ADJUSTER shown in the Fig. 2-24.

(Installation)

1. Install the BELT ADJUSTER shown in the Fig. 2-24.

2. Install the BELT LEVER shown in the Fig. 2-24.

2-25 TENSION ARM, TENSION LEVER,

TENSION SPRING, TENS AXIS

HOLDER, REEL DISK (SP side)

SET POSITION : Normal

Remove the following parts before performing this Item.

Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

• BRAKE BELT (SP) (Item 2-23)

• BELT HOLDER (Item 2-23)

• BELT LEVER (Item 2-24)

(Removal)

1. Remove the TENSION SPRING shown in the Fig. 2-

25.

2. Release the catch (a) of the TENS AXIS HOLDER

shown in the Fig. 2-25 to remove the TENSION ARM.

3. Remove the TENSION LEVER shown in the Fig. 2-25.

4. Release the catch (b) of the TENS AXIS HOLDER

shown in the Fig. 2-25. Move the TENS AXIS

HOLDER in the direction shown by the arrow A to

remove it.

5. Remove the REEL DISK (SP side).

Page 34

-19-

a

a

BRAKE BELT (TU)

BRAKE (TU)

REEL DISK (TU side)

Fig. 2-26

(Installation)

1. Apply GREASE (MULTEMP AC-DM) [859D055O90]

to the parts on the MAIN PLATE ASSY specified in

the Fig. 2-25.

2. Install the REEL DISK (SP side).

3. Install the TENS AXIS HOLDER.

Note : Install the TENS AXIS HOLDER so that the catch

(a) for the TENSION ARM will be positioned on

the front (F/L ARM ASSY side).

4. Install the TENSION LEVER.

5. Install the TENSION ARM.

6. Install the TENSION SPRING.

Note : Install the longer hook of the TENSION SPRING

to the TENSION ARM.

2-26.BRAKE BELT (TU)

SET POSITION : Normal

Remove the following parts before replacing the BRAKE

BELT. Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

(Removal)

1. Lift the BRAKE BELT (TU) shown in the Fig. 2-26 to

remove it from the REEL DISK (TU side).

2. Release the two catches (a) of the BRAKE (TU)

shown in the Fig. 2-26 to remove the BRAKE BELT

(TU).

(Installation)

1. Install the BRAKE BELT (TU) shown in the Fig. 2-26

to the BRAKE (TU).

2. Hook the BRAKE BELT (TU) shown in the Fig. 2-26 to

the REEL DISK (TU side).

Note : Install the BRAKE BELT (TU) so that its Felt Side

touches the REEL DISK (TU side).

2-27.BRAKE (TU), REEL DISK (TU side)

SET POSITION : Normal

Remove the following parts before replacing the BRAKE

(TU), REEL DISK (TU side). Refer to the corresponding

items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

(Removal)

1. Move the BRAKE (TU) in the Fig. 2-27 in the direction

shown by the arrow A to remove it.

2. Remove the BRAKE BELT (TU) from the BRAKE

(TU).

3. Remove the REEL DISK (TU).

A

BRAKE BELT (TU)

REEL DISK (TU side)

WASHER

BRAKE (TU)

MAIN PLATE

ASSY

GREASE

(MULTEMP AC-DM)

Fig. 2-27

Page 35

-20-

(Installation)

Note : Install the BRAKE BELT (TU) so that its Felt Side

touches the REEL DISK (TU side).

The GREASE applied to the BRAKE CAM PLATE

and the MAIN PLATE ASSY should not adhere on

the Felt Side of the BRAKE BELT (SP).

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the MAIN PLATE ASSY specified in the

Fig. 2-27.

2. Install the REEL DISK (TU side).

3. Install the BRAKE BELT (TU) to the BRAKE (TU).

4. Install the BRAKE (TU).

5. Hook the BRAKE BELT (TU) to the REEL DISK (TU

side).

2-28.SHIFT LEVER

SET POSITION : Normal

Remove the following parts before replacing the SHIFT

LEVER. Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

• BRAKE (TU) (Item 2-27)

• REEL DISK (TU side) (Item 2-27)

(Removal)

1. Move the SHIFT SLIDER in the Fig. 2-28 in the

direction shown by the arrow A to release it from the

SHIFT LEVER.

2. Move the SHIFT LEVER in the Fig. 2-28 in the

direction shown by the arrow B to remove it.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the new SHIFT LEVER specified in the

Fig. 2-28.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the MAIN PLATE ASSY specified in the

Fig. 2-28.

3. Install the SHIFT LEVER so that its Part (a) shown in

the Fig. 2-28 will be positioned under the MAIN

PLATE ASSY.

4. Install the SHIFT SLIDER to the SHIFT LEVER.

a

B

A

Back

SHIFT LEVER

SHIFT SLIDER

MAIN PLATE ASSY

Apply GREASE (MULTEMP AC-DM) to the parts .

Back

Back

Fig. 2-28

Page 36

-21-

CHARGE SPRING

CHARGE ASSY

SWING LEVER

REEL DISK (SP side)

Both Sides

(Front/Back)

MAIN PLATE ASSY

a

b

c

Back

Front

Fig. 2-29

2-29.CHARGE SPRING, SWING LEVER,

CHARGE ASSY

SET POSITION : Normal

Remove the following parts before replacing the

CHARGE SPRING, SWING LEVER, CHARGE ASSY.

Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

(Removal)

1. Remove the CHARGE SPRING shown in the Fig. 2-

29 from the SWING LEVER.

2. Remove the SWING LEVER shown in the Fig. 2-29.

3. Release the Part a of the CHARGE ASSY shown in

the Fig. 2-29 from the Part b of the MAIN PLATE

ASSY to remove the CHARGE ASSY.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the MAIN PLATE ASSY specified in the

Fig. 2-29.

2. Install the CHARGE ASSY.

3. Install the SWING LEVER inserting the Part c of the

SWING LEVER in the Fig. 2-29 into the groove in the

MAIN PLATE ASSY.

4. Install the CHARGE SPRING to the SWING LEVER.

2-30.LOADING ARM ASSY (SP), LOADING

ARM ASSY (TU)

SET POSITION : Upside down

(Removal)

1. Release the catch (a) of the LOADING ARM ASSY

(SP) shown in the Fig. 2-30-1 to remove the

LOADING ARM ASSY (SP).

Note : Be sure to replace the removed LOADING ARM

ASSY (SP) with a new one.

2. Remove the screw (b) fastening the SPACER PLATE

shown in the Fig. 2-30-1 to remove the SPACER

PLATE.

3. Remove the LOADING ARM ASSY (TU) shown in the

Fig. 2-30-1.

a

b

SPACER PLATE

LOADING

ARM ASSY (TU)

LOADING ARM

ASSY (SP)

MAIN PLATE ASSY

GREASE (MULTEMP AC-DM)

Fig. 2-30-1

Page 37

-22-

LOADING ARM

ASSY (TU)

Mark

LOADING ARM

ASSY (SP)

Fig. 2-30-3

Fig. 2-30-2

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the MAIN PLATE ASSY specified in the

Fig. 2-30-1.

2. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the LOADING ARM ASSY (TU) specified

in the Fig. 2-30-2.

3. Install the LOADING ARM ASSY (SP) and LOADING

ARM ASSY (TU) so that the Marks on the both UNITs

face each other, as shown in the Fig. 2-30-3.

Note : Be sure to replace the removed LOADING ARM

ASSY (SP) with a new one.

2-31.A/L LEVER

SET POSITION: Upside down

Remove the following parts before replacing the A/L

LEVER. Refer to the corresponding items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

• LOADING ARM ASSY (SP) (Item 2-30)

• LOADING ARM ASSY (TU) (Item 2-30)

(Removal)

1. Remove the CUT WASHER and WASHER shown in

the Fig. 2-31-1. Then, remove the A/L LEVER.

CUT WASHER

A/L LEVER

WASHER

MAIN PLATE ASSY

GREASE (MOLYKOTE G PASTE)

Fig. 2-31-1

LOADING ARM ASSY (TU)

Apply GREASE (MULTEMP AC-DM) to the parts .

Page 38

-23-

A/L LEVER

Boss

FLANGE of

LOADING ARM ASSY (SP)

Mark

Part with

Oblique Lines

Fig. 2-31-2

Fig. 2-31-3

(Installation)

Note : Install the LOADING ARM ASSY (TU) and

LOADING ARM ASSY (SP), according to the

following procedure, after installing the A/L

LEVER.

1. Apply GREASE (MOLYKOTE G PASTE)

[859D055O50] to the parts on the MAIN PLATE ASSY

specified in the Fig. 2-31-1.

2. Apply GREASE (MOLYKOTE G PASTE)

[859D055O50] to the parts on the A/L LEVER

specified in the Fig. 2-31-2.

3. Install the A/L LEVER so that the Mark on the A/L

LEVER faces to the FLANGE of the LOADING ARM

ASSY (SP), as shown in the Fig. 2-31-3.

Note : The Part specified with Oblique Lines on the A/L

LEVER should be under the FLANGE of the

LOADING ARM ASSY (SP).

4. Install the LOADING ARM ASSY (TU) so that the

Marks on the LOADING ARM ASSY (TU) and on the

A/L LEVER will face each other, as shown in the Fig.

2-31-4.

5. Install the LOADING ARM ASSY (SP) so that the

mark on the LOADING ARM ASSY (SP) and the

Reinforcement Rib of the LOADING ARM ASSY (TU)

will face each other, as shown in the Fig. 2-31-4.

Note : Be sure to replace the removed LOADING ARM

ASSY (SP) with a new one.

LOADING ARM

ASSY (TU)

LOADING ARM

ASSY (SP)

Reinforcement Rib

MarkA/L LEVER

Mark

Fig. 2-31-4

A/L LEVER

Back

Apply GREASE (MOLYKOTE G PASTE) to the parts .

Page 39

-24-

TAPE GUIDE ASSY (SP)

TAPE GUIDE ASSY (TU)

Fig. 2-32-1

GUIDE CATCHER (SP)

GUIDE CATCHER (TU)

Front of

MAIN PLATE ASSY

Back of

MAIN PLATE ASSY

Apply GREASE (MULTEMP AC-DM) to the parts .

Fig. 2-32-2

2-32.TAPE GUIDE ASSY (SP),

TAPE GUIDE ASSY (TU)

SET POSITION : Normal

Remove the following parts before replacing the TAPE

GUIDE ASSY (SP), (TU). Refer to the corresponding

items to install them.

• STAY PLATE (Item 2-2)

• BOTTOM ASSY (Item 2-3)

• MOTOR HOLDER (Item 2-16)

• PINCH ARM CAP (Item 2-17)

• PINCH UNIT (Item 2-17)

• BRAKE CAM PLATE (Item 2-19)

• BRAKE BELT (SP) (Item 2-23)

• BELT HOLDER (Item 2-23)

• BELT LEVER (Item 2-24)

• TENSION ARM (Item 2-25)

(Removal)

1. Loosen the TAPE GUIDE ASSY (SP) shown in the

Fig. 2-32-1 (turn it fully in the Unloading direction) to

remove it.

2. Loosen the TAPE GUIDE ASSY (TU) shown in the

Fig. 2-32-1 (turn it fully in the Unloading direction) to

remove it.

(Installation)

1. Apply GREASE (MULTEMP AC-DM)[859D055O90] to

the parts on the MAIN PLATE ASSY specified in the

Fig. 2-32-2.

2. Install the TAPE GUIDE ASSY (SP) shown in the Fig.

2-32-1.

3. Install the TAPE GUIDE ASSY (TU) shown in the Fig.

2-32-1.

4. Perform the Item 3-2-1. "GUIDE ROLLER Check" to

the Item 3-2-5. "Flatness Check of FM Waveform" of

the "Interchangeability Adjustment of the Mechanism".

Page 40

-25-

B

A

DRUM CLAMPER

Hook here to attach

DRUM CLAMPER

to DRUM ASSY.

DRUM ASSY

Removing

Direction

Installing

Direction

a

b

DRUM ASSY with

DRUM CLAMPER

LEAD CONNECTOR

MAIN PLATE ASSY

Fig. 2-33-2

Fig. 2-33-1

2-33.DRUM CLAMPER, DRUM ASSY

SET POSITION : Normal

(Removal)

1. Disconnect the LEAD CONNECTOR of the DRUM

ASSY shown in the Fig. 2-33-1.

2. Remove the two screws (a, b) fastening the DRUM

CLAMPER shown in the Fig. 2-33-1 to remove the

DRUM ASSY with the DRUM CLAMPER.

3. Rotate the DRUM CLAMPER in the Fig. 2-33-2 in the

direction shown by the arrow A to remove it from the

DRUM ASSY.

(Installation)

1. Install the DRUM CLAMPER in the Fig. 2-33-2 to the

DRUM ASSY by rotating it in the direction shown of

the arrow B.

2. Hook the Catch of the DRUM CLAMPER shown in the

Fig. 2-33-3 to the Reference Pin.

3. Fasten the screw (b) while pushing the Part A in the

direction shown by the arrow C (clockwise when

viewed from the top) as shown in the Fig. 2-33-3.

Note : Confirm at this time that the Catch of the DRUM

CLAMPER touches the side of the Reference Pin.

4. Fasten the screw (a) shown in the Fig. 2-33-3.

Note : Confirm at this time that the Catch of the DRUM

CLAMPER touches the side of the Reference Pin.

5. Connect the LEAD CONNECTOR of the DRUM ASSY

with the DRUM CLAMPER shown in the Fig. 2-33-1.

6. Connect the LEAD CONNECTOR of the DRUM ASSY

shown in the Fig. 2-33-1.

7. Perform the Item "PLAYBACK Switching Point" of the

"Circuit Adjustment" in this service manual.

8. Perform the Item "Interchangeability Adjustment of the

Mechanism".

9. Clean the DRUM ASSY shown in the Fig. 2-33-1 with

alcohol.

Page 41

-26-

a

b

b

c

DRUM MOTOR

STATOR

ROTOR CASE

Side View of END RING

This side down.

LEAD

CONNECTOR

BRUSH

SPRING

BRUSH

END RING

UPPER

DRUM ASSY

SPACER

LOWER

DRUM ASSY

Mark using a pen, etc.

for convenience

in attachment.

Fig. 2-34-1

a

b

C

Reference

Pin

Catch

Reference Pin and

Catch have to

touch each other.

Part A

Fig. 2-33-3

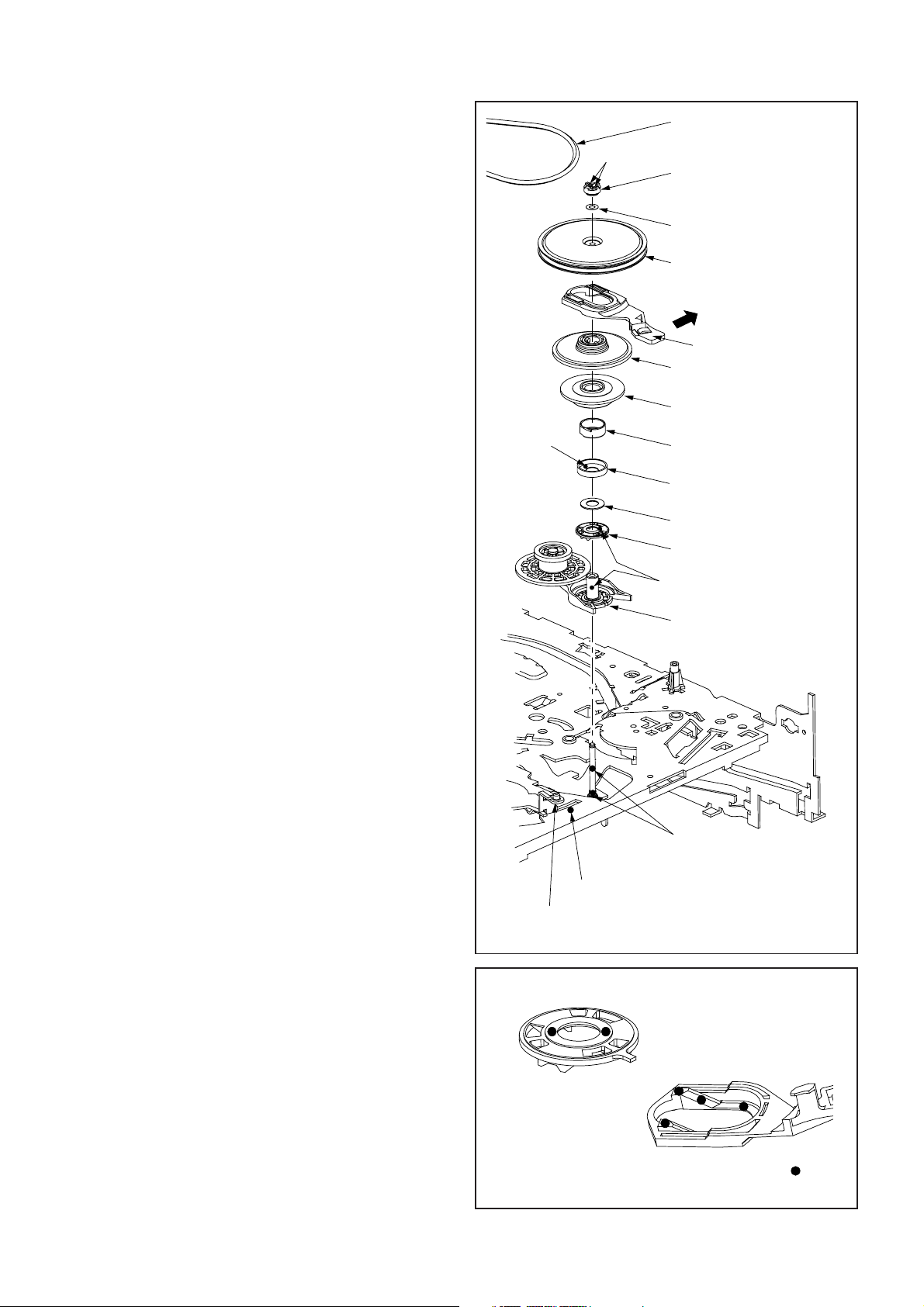

2-34.DRUM MOTOR STATOR, BRUSH

SPRING, SPACER, ROTOR CASE,

END RING, BRUSH, UPPER DRUM

ASSY

SET POSITION : Normal

(Removal)

1. Disconnect the LEAD CONNECTOR of the DRUM

ASSY shown in the Fig. 2-34-1.

2. Remove the two screws (a) fastening the DRUM

MOTOR STATOR shown in the Fig. 2-34-1 to remove

the DRUM MOTOR STATOR.

3. Remove the two screws (b) fastening the ROTOR

CASE shown in the Fig. 2-34-1 to remove the ROTOR

CASE.

Note : Mark on the END RING and UPPER DRUM ASSY

shown in the Fig. 2-34-1 using a pen, etc. for

convenience in installing them.

4. Loosen the hexagon screw (c) fastening the END

RING shown in the Fig. 2-34-1 to remove the END

RING.

5. Remove the BRUSH SPRING shown in the Fig. 2-34-

1.

6. Remove the BRUSH shown in the Fig. 2-34-1.

7. Remove the UPPER DRUM ASSY shown in the Fig.

2-34-1.

8. Remove the SPACER shown in the Fig. 2-34-1.

Page 42

-27-

B

ROTOR CASE

UPPER DRUM

ASSY

Fig. 2-34-3

A

Lock

STAY PLATE

WORM

WHEEL

Hook of

BOTTOM ASSY

Lock

Fig. 2-35-1

A

END RING

Rear Line of MAIN PLATE ASSY

Fig. 2-34-2

(Installation)

1. Install the SPACER shown in the Fig. 2-34-1.

Note : Be sure to use the new SPACER packed with the

new UPPER DRUM ASSY.

2. Install the UPPER DRUM ASSY shown in the Fig. 2-

34-1.

3. Install the END RING so that the reference hole (A)

of the END RING shown in the Fig. 2-34-2 will be

placed in parallel with the Rear Line of the MAIN

PLATE ASSY. (The reference hole (A) should be on

the right when viewed from the bottom.)

4. Apply the screw-sealing agent to the hexagon screw

(c) fastening the END RING shown in the Fig. 2-34-

1.

5. Install the ROTOR CASE shown in the Fig. 2-34-3,

matching its Holes with the three reference holes (B)

of the UPPER DRUM ASSY.

6. Install the BRUSH shown in the Fig. 2-34-1.

7. Install the BRUSH SPRING shown in the Fig. 2-34-1.

8. Install the DRUM MOTOR STATOR shown in the Fig.

2-34-1.

9. Connect the LEAD CONNECTOR of the DRUM ASSY

shown in the Fig. 2-34-1.

10. Perform the Item "PLAYBACK Switching Point"

adjustment.

11. Perform the Item "Interchangeability Adjustment of the

Mechanism".

12. Clean the DRUM ASSY with alcohol.

2-35.CAPSTAN MOTOR

SET POSITION : Normal

Remove the following part before replacing the CAPSTAN

MOTOR. Refer to the corresponding item to install it.

• REEL BELT (Item 2-14.)

(Removal)

1. Rotate the WORM WHEEL in the Fig. 2-35-1 in the

direction shown by the arrow A to release the Hooks

of the BOTTOM ASSY from the Locks of the STAY

PLATE.

2. Rotate the WORM WHEEL in the Fig. 2-35-2 in the

direction shown by the arrow A so that the GUIDE

ARM (TU) moves in the direction of arrow B and