Mitsubishi GT1275-VNBA, GT1265-VNBA, GT1275-VNBD, GT1265-VNBD User Manual

GT12

DANGER

CAUTION

DANGER

CAUTION

DANGER

CAUTION

DANGER

CAUTION

DANGER

DANGER

CAUTION

CAUTION

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

GOT Rear Face

2) 3)

1)

14)

4)5)

6)

7)

12)

15)

9)

10)

11)

8)

13)

14)

Example:

GT1275

User’s Manual (1/2)

GT1275-VNBA, GT1275-VNBD

Thank you for purchasing the GOT1000 Series.

Prior to use, please read both this manual and the

detailed manual thoroughly to fully understand the

product.

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant

manuals introduced in this manual carefully and pay full attention to

safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "DANGER" and

"CAUTION".

Note that the CAUTION level may lead to a serious accident

according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and

always forward it to the end user.

[MOUNTING PRECAUTIONS]

Be sure to shut off all phases of the external power supply used by the

system before mounting or removing the GOT main un it to/from the panel.

Not doing so can cause the unit to fail or malfunction.

When connecting the battery, wear an earth band to avoid damage caused

by static electricity.

GT1265-VNBA, GT1265-VNBD

MODEL GT12-U(SHO)-E

Model

code

SH(NA)-080977ENG-B(1104)MEE

SAFETY PRECAUTIONS

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or

severe injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or

slight personal injury or physical damage.

1D7ME1

[MOUNTING PRECAUTIONS]

1

2

3

4

Use the GOT in the environment that satisfies the general speci fications

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

described in this manual.

Not doing so can cause an electric shock, fire, mal function or product

damage or deterioration.

When mounting the GOT to the control panel, tighten the mounting screws in

the specified torque range.

Undertightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malf unction due to the

damage of the screws or the GOT.

When inserting a CF card into the GOT, push it into the insertion slot until the

CF card eject button pops out.

If not properly inserted, a bad connection may caus e a malfunction.

When inserting/removing a CF card into/from the GOT, turn the CF card

access switch off in advance.

Failure to do so may corrupt data within the CF card

When removing a CF card from the GOT, make sure to support the CF card

by hand, as it may pop out.

Failure to do so may cause the CF card to drop from the GOT and break.

Remove the protective film of the GOT.

When the user continues using the GOT with the protective film, the film may

not be removed.

Operate and store the GOT in environments without direct sunlight, h igh

temperature, dust, humidity, and vibrations.

[DESIGN PRECAUTIONS]

Some failures of the GOT, communication unit or cable may keep the outputs

on or off.

An external monitoring circuit should be provided to check for output signals

which may lead to a serious accident.

Not doing so can cause an accident due to false outp ut or malfunction.

If a communication fault (including cable disconnection) occ urs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative.

A system where the GOT is used should be confi gured to perform any

significant operation to the system by using the sw itches of a device other

than the GOT on the assumption that a GOT communi cation fault will occur.

Not doing so can cause an accident due to false outp ut or malfunction.

Do not use the GOT as the warning device that may cause a seriou s

accident.

An independent and redundant hardware or mechanic al interlock is required

to configure the device that displays and outputs se rious warning.

Failure to observe this instruction may resul t in an accident due to incorrect

output or malfunction.

Incorrect operation of the touch switch(s) may lead to a serious accident if the

GOT backlight is gone out.

When the GOT backlight goes out, the POWER LED flic kers (green/orange)

and the display section turns black and causes the mo nitor screen to appear

blank, while the input of the touch switch(s) remains a ctive.

This may confuse an operator in thinking that the GOT is in "screensaver"

mode, who then tries to release the GOT from this mode by touching the

display section, which may cause a tou ch switch to operate.

Note that the following occurs on the GOT when the b acklight goes out.

• The POWER LED flickers (green/orange) and the moni tor screen appears

blank

The display section of the GT12 is an analog-resistive t ype touch panel.

If you touch the display section simultaneously in 2 points or mor e, the switch

that is located around the center of the touched poin t, if any, may operate.

Do not touch the display section in 2 points or more simultaneously.

Doing so may cause an accident due to incorrect o utput or malfunction.

When programs or parameters of the controller (such as a PLC) that is

monitored by the GOT are changed, be sure to reset the GOT or shut off the

power of the GOT at the same time.

Not doing so can cause an accident due to false outp ut or malfunction.

Do not bundle the control and communication cables with main-circui t, power

or other wiring.

Run the above cables separately from such wiring and kee p them a minimum

of 100mm apart.

Not doing so noise can cause a malfunction.

Do not press the GOT display section with a pointed material a s a pen or

driver.

Doing so can result in a damage or failure of the dis play section.

[WIRING PRECAUTIONS]

Be sure to shut off all phases of the external power supply used by the

system before wiring.

Failure to do so may result in an electric shock, p roduct damage or

malfunctions.

[WIRING PRECAUTIONS]

Always ground the FG terminal, LG terminal, and protective ground term inal

of the GOT power to the protective ground conductors dedicated to the GOT.

Not doing so may cause an electric shock or malfunction.Terminal screws

which are not to be used must be tightened always at torque 0.5 to 0.8 N•m.

Otherwise there will be a danger of short circuit agai nst the solderless

terminals.

Use applicable solderless terminals and tighten them with the specified

torque.

If any solderless spade terminal is used, it may be disconnected

when the terminal screw comes loose, resulting in failu re.

Correctly wire the GOT power supply section after confirming the rated

voltage and terminal arrangement of the product.

Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section i n the specified

torque range. Undertightening can cause a short ci rcuit or malfunction.

Overtightening can cause a short circuit or mal function due to the damage of

the screws or the GOT.

Exercise care to avoid foreign matter such as chips and wire offcuts entering

the GOT. Not doing so can cause a fire, failure or malfunction.

The module has an ingress prevention label on its top to preven t foreign

matter, such as wire offcuts, from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat

dissipation.

Plug the communication cable into the connector of the connected unit and

tighten the mounting and terminal screws in the specified torque range.

Undertightening can cause a short circuit or ma lfunction.

Overtightening can cause a short circuit or mal function due to the damage of

the screws or unit.

[TEST OPERATION PRECAUTIONS]

Before performing the test operations of the user creation monito r screen

(such as turning ON or OFF bit device, changing the word device current

value, changing the settings or current values of the timer or counter, and

changing the buffer memory current value), read through th e manual

carefully and make yourself familiar with the oper ation method.

During test operation, never change the data of the devices which are used to

perform significant operation for the system.

False output or malfunction can cause an accident.

[STARTUP/MAINTENANCE PRECAUTIONS]

When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfuncti on.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, sold er, or throw the battery

into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in

injury and fire.

Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases.

Not switching the power off in all phases can cause a uni t failure or

malfunction.

Undertightening can cause a short circuit or ma lfunction.

Overtightening can cause a short circuit or mal function due to the damage of

the screws or unit.

Do not disassemble or modify the unit.

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the unit directly.

Doing so can cause a unit malfunction or failure.

The cables connected to the unit must be run in ducts or clamped.

Not doing so can cause the unit or cable to be damaged due to the dangling,

motion or accidental pulling of the cables or can cause a malfunct ion due to a

cable connection fault.

When unplugging the cable connected to the unit, do not hold and pul l from

the cable portion.

Doing so can cause the unit or cable to be damaged o r can cause a

malfunction due to a cable connection fault.

Do not drop the module or subject it to strong shock. A module damage ma y

result.

[STARTUP/MAINTENANCE PRECAUTIONS]

Do not drop or give an impact to the battery mounted to the unit.

Doing so may damage the battery, causing the battery fluid to leak inside the

battery.

If the battery is dropped or given an impact, dispose of it without using.

Before touching the unit, always touch grounded metals, etc. to dis charge

static electricity from human body, etc.

Not doing so can cause the unit to fail or malfunction.

Replace battery with GT11-50BAT by Mitsubishi electric Co.only.

Use of another battery may present a risk of fire or exp losion.

Dispose of used battery promptly.

Keep away from children.Do not disassemble and do not dispose of in fire.

[TOUCH PANEL PRECAUTIONS]

For the analog-resistive film type touch panels, normally the adjustment is not

required.

However, the difference between a touched position and the object position

may occur as the period of use elapses.

When any difference between a touched position and the object position

occurs, execute the touch panel calibration.

When any difference between a touched position and the object pos ition

occurs, other object may be activated.

This may cause an unexpected operation due to incorrect output or

malfunction.

[BACKLIGHT REPLACEMENT PRECAUTIONS]

Before replacing the backlight, be sure to switch off the GOT power supply

externally for all phases and remove the GOT un it from the control panel.

Not switching the power off in all phases may cau se an electric shock.

Not removing the unit from the control panel can cause in jury due to a drop.

When replacing the backlight, use the gloves.

Otherwise, it may cause you to be injur ed.

Start changing the backlight more than 5 minutes after switching the GOT

power off.

Not doing so can cause a burn due to the heat of the back light.

[DISPOSAL PRECAUTIONS]

When disposing of this product, treat it as industrial waste .

When disposing of batteries, separate them from other wastes according to

the local regulations.

(Refer to the User's Manual of the GOT to be used f or details of the battery

directive in the EU member states.)

[TRANSPORTATION PRECAUTIONS]

When transporting lithium batteries, make sure to treat them based on the

transport regulations.

(Refer to the User's Manual of the GOT to be used for details of the regurated

models.)

Make sure to transport the GOT main unit and/or relevant unit(s ) in the

manner they will not be exposed to the impact exceedin g the impact

resistance described in the general specificat ions of the User's Manual of the

GOT to be used, as they are precision devices.

Failure to do so may cause the unit to fail.

Check if the unit operates correctly after transportation.

Manuals

The following shows manuals relevant to this product.

Relevant Manual

Manual name

GT16 User's Manual (Hardware)

GT16 User's Manual (Basic Utility)

GT11 User's Manual

GT Designer3 Version1 Screen Design

Manual (Fundamentals)

GT Designer3 Version1 Screen Design

Manual (Functions) 1/2, 2/2

GOT1000 Series Connection Manual

(Mitsubishi Products) for GT Works3

GOT1000 Series Connection Manual

(Non-Mitsubishi Products 1) for GT Works3

GOT1000 Series Connection Manual

(Non-Mitsubishi Products 2) for GT Works3

GOT1000 Series Connection Manual

(Microcomputer, MODBUS Products,

Peripherals) for GT Works3

GOT1000 Series Gateway Functions Manual

for GT Works3

GT Simulator3 Version1 Operating Manual

for GT Works3

GOT1000 Series User's Manual (Extended

Functions, Option Functions) for GT Works3

GT12 Supplementary Description

GT12 General Description

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Sold separately)

(Included with GOT)

*1 It is stored as a PDF on the GT Works3 CD-ROM.

© 2011 MITSUBISHI ELECTRIC CORPORATION

*Before using the GOT, connect the GOT connector with the battery connector for

the battery purchased by the customer.

Refer to the GT11 User's Manual for the connection method.

*For details on the GT12 wiring, maintenance and ins pection, methods for

checking the version and the compatible standards, and othe rs, refer to the GT11

User's Manual.

Packing List

The GOT product package includes the following:

Model Description Quantity

GT1275-VNBA

GT1275-VNBD

GT1265-VNBA

GT1265-VNBD

GOT 1

Installation fitting 4

GT12 General Description 1

Manual number

SH-080928ENG

*1

SH-080929ENG

*1

JY997D17501A

*1

SH-080866ENG

*1

SH-080867ENG

*1

SH-080868ENG

*1

SH-080869ENG

*1

SH-080870ENG

*1

SH-080871ENG

*1

SH-080858ENG

*1

SH-080861ENG

*1

SH-080863ENG

*1

SH-080864ENG

*1

IB-0800448ENG

(Model code)

(1D7MD3)

(1D7MD4)

(09R815)

(1D7MB9)

(1D7MC1)

(1D7MC2)

(1D7MC3)

(1D7MC4)

(1D7MC5)

(1D7MA7)

(1D7MB1)

(1D7MB3)

(1D7MB7)

(1D7MB4)

1. OVERVIEW

This manual describes different functions between the GT1275VNBA, GT1275-VNBD, GT1265-VNBA, GT1265-VNBD (hereinafter

referred to as GT12) and the GT1155-QSBD, GT1155-QLBD

(hereinafter referred to as GT11).

For details of the installation method, wiring method, and utility

function, refer to description of the GT16 and the GT11 in each

manual.

The GT12 model only has the standard functions available.

The following shows defferences between the GT11 and the GT12.

(For details of the differences, refer to 7.SPECIFICATION

FUNCTION COMPARISON FOR GT12 AND GT11

(1) Option functions available on the standard

No option function board is required for using the option functions.

(2) Large model line up

For screen sizes, there is a 10.4 type (for the GT1675) and an 8.4

type (for the GT1665) available for large models.

(3) Expanding user memory

On the GT11, the capacity for the user memory is 3MB, whereas it

is possible to use 9MB on the GT12 for user memory.

2. FEATURES

(1) Improved monitoring performance and connectivity to FA devices

• Provides multi-language display function based on Unicode2.1

True Type font and produces clear, beautiful text through high

grade font.

• Provides high speed monitoring through high speed

communication at maximum of 115.2kbps for the serial

communication and 100Mbps for the Ethernet communication.

• Provides high speed display and high speed touch switch

response.

• The operation performance is improved by the analog touch

panel.

(2) More efficient GOT operation s including screen desi gn, startup,

adjustment, management and maintenance works

• 9MB user memory is included as standard.

(There is a storage limit of 6M bytes for project data.)

• The RS-232 interface is included as standard.

• The RS-422/485 interface is included as standard.

• The CF card interface is included as standard.

• The Ethernet interface is included as standard.

• The USB interface equipped as standard enables the system

startup to be performed more efficiently by using the FA

transparent function (FA equipment setup tool). It also reduces

the indirect work (replacing cables, cable rewiring) to further

improve work efficiency.

• The blown backlight bulb can be confirmed even during screen

saving, indicated by the POWER LED blinking with backlight

shutoff detection.

3. PART NAMES AND SETTINGS

The following shows the part names for GT1275 and GT1265.

WWW.NNC.IR

No. Name Description

1) POWER LED

2) Display screen Displays the Utility and user creation screen

3) Touch key

4) Power terminal Power input terminal, LG terminal, FG terminal

5) RS-232 interface

6) RS-422/485 interface

7) Ethernet interface

8) USB interface (Device)

9) CF card interface For installing a CF card

10) CF card acce ss LED

11) CF card acce ss switch

12) Battery holder Houses the battery

Terminating resistor

13)

setting switch

(Inside cover)

Hole for unit

14)

installation fitting

15) Installation switch Used for OS installations at the GOT startup

Lit in green : Power is correctly supplied

Lit in orange : Screen saving

Blinks orange / green : Blown backlight bulb

Not lit : Power is not supplied

For operating touch switches in the Utility and the user

creation screen

For communicating with a co ntroller or connecting a

personal computer (Conn ector type: D sub 9-pin (male))

For communicating with a controller (Connector type: D sub

9-pin (female))

For communicating with a controller or using the FTP server

function (Connector ty pe: RJ-45 (modular jack))

For connecting a personal comp uter (Connector type: MINIB)

Lit : CF card accessed

Not lit : CF card not accessed

Used for accepting or stopping the access to the CF card

before removing the CF card from the GOT

ON : CF card being accessed (CF card re moval prohibited)

OFF : CF card not accessed (CF ca rd removal possible)

For switching on and off of the terminating resistor for the

RS-422/485 communication port

Hole for inserting the unit installation fitting

4. SPECIFICATIONS

4.1 General Specifications

Item Specifications

Display

0 to 50

section

Operating

Other

ambient

than the

temperature

Storage ambient

temperature

Operating ambient

humidity

Storage ambient

humidity

Vibration resistance

Shock resistance

Operating

atmosphere

Operating altitude

Installation location Inside control panel

Overvoltage

category

Pollution degree*32 or less

Cooling method Self-cooling

Grounding

*1: Do not use or store the GOT under pr essure higher than the atmospheric

pressure of altitude 0m (0ft.).

Failure to observe this instruction may c ause a malfunction.

When an air purge is made inside the control panel by adding pressure, there

may be a clearance between the surface sheet and the screen making it difficult

to use the touch panel, or the sheet may come off.

*2: This indicates the section of the power supply to which the equipment is

assumed to be connected between the public electric al power distribution

network and the machinery within the premises.

Category II applies to equipment for which electrical powe r is supplied from

fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

*3: This index indicates the degree to which conductive material is generated in the

environment where the equipment is used.

In pollution degree 2, only non-conductive pollu tion occurs but temporary

conductivity may be produced due to condensa tion.

Point

Refer to GT12 Supplementary Description for details on the performance specifications of

each GOT.

0 to 55

display

section

-20 to 60

10 to 90% RH, non-condensing

10 to 90% RH, non-condensing

Under

intermittent

vibration

Under

continuous

vibration

Frequency

5 to 9Hz

9 to 150Hz

5 to 9Hz

9 to 150Hz

Compliant

with JIS B

3502 and

IEC

61131-2

Compliant with JIS B 35 02 and IEC 61131-2 (147 m/s

in X, Y and Z directions)

No greasy fumes, corrosive gas, flammable gas, excessive

conductive dust, and dire ct sunlight (Same as storage atmosphere)

*1

2000 m (6562 ft) max.

II or less

*2

D type grounding with a resis tance of 100 or less, ground to panel

when grounding is not possi ble

Acceleration

9.8m/s

4.9m/s

Sweep

Half-

count

amplitude

10 times

3.5mm

-

2

-

2

1.75mm

each in X,

Y and Z

-

directions

-

2

, 3 times each

-

4.2 Power Supply Specifications

The following indicates the power supply specifications for GT12.

4.2.1For GOTs powered from the 100 to 240VAC power supply

4.2.2For GOTs powered from the 24VDC power supply

Note

Operation at momentary failure

• If an instantaneous power failure occurs in the power supply and continues for more

than the permissible period, the GOT will be reset.

• Make sure to power on the unit more than 5 seconds after power-off.

4.2.1 For GOTs powered from the 100 to 240VAC

power supply

Item

Input power supply voltage AC100 to 240VAC (+10%, -15%)

Input frequency 50/60Hz 5%

Input max. apparent power 44VA (maximum load)

Power consumption 18W or less

When backlight is not lit 15W or less

Inrush current 40A or less (4ms) (maximum load)

Allowable momentary power

failure time

Noise immunity

Dielectric withstand v oltage 1500VAC for 1 mi nute across power terminals and earth

Insulation resistance

Applicable wire size 0.75 to 2[mm

Applicable solderless

terminal

Applicable tightening torque

(Terminal block terminal

screw)

20 ms or less (AC 100VAC or more)

1,500Vp-p noise voltage, 1 s noise width (when measuring

with a noise simulator under 25 to 60Hz noise frequency)

10M or more across power terminals and earth by a 500V

DC insulation resistance tester

Solderless terminal for M3 screw RAV1.25-3, V2-S3.3, V2N3A, FV2-N3A

0.5 to 0.8[N•m]

Specifications

GT1275-VNBA, GT1265-VNBA

2

]

4.2.2 For GOTs powered from the 24VDC power

supply

Item

Input power supply voltage DC24V (+25%, -20%)

Power consumption 11W or less

When backlight is not lit 6W or less

Inrush current 29A or less (10ms) (maximum load)

Allowable momentary power

failure time

Noise immunity

Dielectric withstand voltage

Insulation resistance

Applicable wire size 0.75 to 2[mm

Applicable solderless

terminal

Applicable tightening torque

(Terminal block terminal

screw)

*1: In this product, the surge absorber is connected between the power supply an d

the ground to avoid a malfunction due to noise caused by the application of

lightning surge.

The values of the dielectric withstand volta ge and insulation resistance are

recorded when the surge absorber is not connec ted.

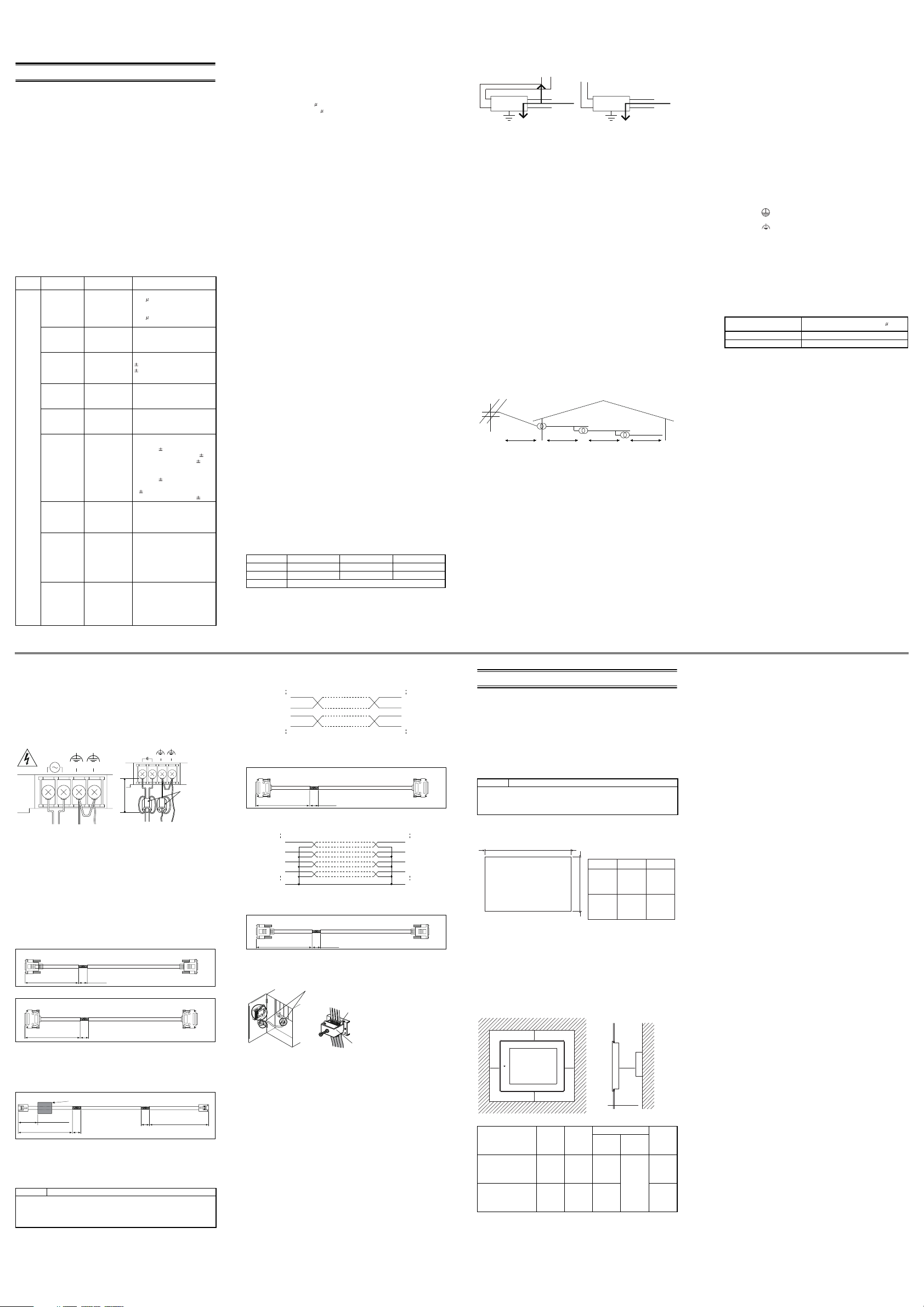

4.3 External Dimensions

GT1275-VNBA, GT1275-V NBD GT1265-VNBA, GT1265-VNB D

10

(0.39) (0.39)

199 (7.83)

214 (8.43)

10

6

53 (2.09)

10 ms or less

500Vp-p noise voltage, 1 s noise wi dth (when measuring

with a noise simulator under 25 to 60Hz noise frequency)

*1

500VDC for 1 minute across pow er terminals and earth

10M or more across power terminals and earth by a 500V

*1

DC insulation resistance tester

Solderless terminal for M3 screw RAV1.25-3, V2-S3.3, V2N3A, FV2-N3A

0.5 to 0.8[N•m]

303 (11.93)

252 (9.92)

222 (8.74)

(0.24)

288 (11.34)

Unit : mm (inch)

Specifications

GT1275-VNBD, GT1265-VNBD

2

]

10

190 (7.48)

175 (6.89)

10

6

(0.39) (0.39)

51 (2.01)

52 (2.05)

175.5 (6.91)

175.5 (6.91)

(0.24)

241 (9.49)

226 (8.90)

Unit : mm (inch)

58 (2.28)

5. EMC AND LOW VOLTAGE DIRECTIVE

230 or less (9.06)

40 (1.57)

Unit : mm (inch)

GOT side PLC side

For the products sold in European countries, the conformance to the EMC

Directive, which is one of the European Directives, has been a legal

obligation since 1996. Also, conformance to the Low Voltage.

Directive, another European Directives, has been a legal obligation since

1997.

Manufacturers who recognize their products must conform to the EMC and

Low Voltage Directive are required to declare that their products conform to

these Directives and put a "CE mark" on their products.

• Authorized representative in Europe

Authorized representative in Europe is shown below.

Name :Mitsubishi Electric Europe BV

Address :Gothaer strase 8, 40880 Ratingen, Germany

5.1 Requirements to Meet EMC Directive

EMC Directives are those which require "any strong electromagnetic force

is not output to the external.:Emission (electromagnetic interference)" and

"It is not influenced by the electromagnetic wave from the external.:

Immunity (electromagnetic sensitivity)".

Items5.1.1 through5.4.3 summarize the precautions to use GOT and

configure the mechanical unit in order to match the EMC directives.

Though the data described herein are produced with our best on the basis

of the requirement items and standards of the restrictions gathered by

Mitsubishi, they do not completely guaranteed that all mechanical unit

manufactured according to the data do not always match the above

directives. The manufacturer itself which manufactures the mechanical unit

must finally judge the method and others to match the EMC directives.

5.1.1 EMC directive

The standards of the EMC Directive are shown below.

Applied

Test standard Test details Standard val ue

standard

EN

61131-2

: 2007

EN55011

Radiated noise

EN55011

Conducted

*1

noise

EN61000-4-2

Electrostatic

*1

immunity

EN61000-4-3

Radiated electromagnetic field AM

modulation

EN61000-4-4

Fast transient

*1

burst noise

EN61000-4-5

Surge immunity

EN61000-4-6

Conducted RF

*1

immunity

EN61000-4-8

Power supply

frequency

magnetic field

immunity

EN61000-4-11

Instantaneous

power failure and

voltage dips

immunity

Electromagnetic

emissions from the

*1

product are

measured.

Electromagnetic

emissions from the

product to the power

line is measured.

Immunity test in

which static

electricity is applied

to the cabinet of the

equipment.

Immunity test in

which field is

irradiated to the

product.

Immunity test in

which burst noise is

applied to the powe r

line and signal lines.

Immunity test in

which lightening

*1

surge is applied to

the product.

Immunity test in

which a noise

inducted on the

power and signal

lines is applied.

Test for checking

normal operations

under the circumstance exposed to

the ferromagnetic

field noise of the

power supply frequency (50/60Hz).

Test for checking

normal operations

at instantaneous

power failure.

30M-230MHz QP:

30dB V/m (30m in measurement

*2, *3

range)

230M-1000MHz QP:

37dB V/m(30m in measurement

*2, *3

range)

150k-500kHz QP:79dB,

*2

Mean: 66dB

500k-30MHz QP:73dB,

*2

Mean: 60dB

4kV Contact discharge

8kV Aerial discharge

80-1000MHz:10V/m

1.4-2GHz:3V/m

2.0-2.7GHz:1V/m

80%AM modulation@1kHz

Power line:2kV

Digital I/O(24V or higher): 1kV

(Digital I/O(24V or less))> 250V

(Analog I/O, signal lines)> 250V

AC power type

Power line (between line and

ground): 2kV

Power line (between lines): 1kV

Data communication port: 1kV

DC power type

Power line (between line and

ground): 0.5kV

Power line (between lines):

0.5kV

Data communication port: 1kV

Power line: 10V

Data communication port: 10V

30 A/m

AC power type

0.5 cycle 0% (interval 1 to 10 s)

250/300 cycle 0%

10/12 cycle 40%

25/30 cycle 70%

DC power type

10ms (interval 1 to 10s)

(Continue to next page)

*1: The GOT is an open type device (device ins talled to another device) and must

be installed in a conductive control panel.

The above test items are conducted in the condition where the GOT is installed

on the conductive control panel and combined with the Mitsubishi PLC.

*2: QP (Quasi-Peak): Quasi-peak value, Mean: Average value

*3: The above test items are conducted in the foll owing conditions.

30M-230MHz QP : 40dB V/m (10m in measurement range)

230M-1000MHz QP : 47dB V/m (10m in measurement range)

5.1.2 Control panel

The GOT is an open type device (device installed to another device) and

must be installed in a conductive control panel.

It not only assure the safety but also has a large effect to shut down the

noise generated from GOT, on the control panel.

(1) Control Panel

(a) The control panel must be conductive.

(b) When fixing a top or bottom plate of the control panel wit h bolts,

do not coat the plate and bolt surfaces so that they will come into

contact.

And connect the door and box using a thick grounding cable in

order to ensure the low impedance under high frequency.

(c) When using an inner plate to ensure electric conductivity with the

control panel, do not coat the fixing bolt area of the inner plate

and control panel to ensure conductivity in the largest area as

possible.

(d) Ground the control panel using a thick grounding cable in order to

ensure the low impedance under high frequency.

(e) The diameter of cable holes in the control panel must be 10cm

(3.94in.). In order to reduce the chance of radio waves leaking

out, ensure that the space between the control panel and its door

is small as possible.

Paste the EMI gasket directly on the painted surface to seal the

space so that the leak of electric wave can be suppressed.

Our test has been carried out on a panel having the damping

characteristics of 37dB max. and 30dB mean (measured by 3m

method with 30 to 300MHz).

(2) Connection of power and ground wires

Ground and power supply wires for the GOT must be connected as

described below.

(a) Provide a grounding point near the GOT. Short-circuit the LG and

FG terminals of the GOT (LG: line ground, FG: frame ground)

and ground them with the thickest and shortest wire possible

(The wire length must be 30cm (11.81in.) or shorter.)

The LG and FG terminals function is to pass the noise generated

in the PC system to the ground, so an impedance that is as low

as possible must be ensured. As the wires are used to relieve the

noise, the wire itself carries a large noise content and thus short

wiring means that the wire is prevented from acting as an

antenna.

Note) A long conductor will become a more efficient antenna at

high frequency.

(b) The earth wire led from the earthing point must be twisted with

the power supply wires.

By twisting with the earthing wire, noise flowing from the power

supply wires can be relieved to the earthing. However, if a filter is

installed on the power supply wires, the wires and the earthing

wire may not need to be twisted.

5.1.3 Noise filter (power supply line filter)

The noise filter (power supply line filter) is a device effective to reduce

conducted noise. Except some models, installation of a noise filter onto

the power supply lines is not necessary. However conducted noise can

be reduced if it is installed. (The noise filter is generally effective for

reducing conducted noise in the band of 10MHz or less.) Usage of the

following filters is recommended.

Model name FN343-3/01 FN660-6/06 ZHC2203-11

Manufacturer SCHAFFNER SCHAFFNER TDK

Rated current 3A 6A 3A

Rated voltage 250V

The precautions required when installing a noise filter are described

below.

(1) Do not install the input and output cables of the noise filter together

to prevent the output side noise will be inducted into the input side

cable where noise has been eliminated by the noise filer.

Input side

(power supply side)

Filter

• Instal ling the input and output cables

together will cause noise induction.

(2) Connect the noise filter's ground terminal to the control panel with

the shortest cable as possible (approx. 10cm (3.94 in.) or less).

Induction

Output side

(device side)

Input side

(power supply side)

Filter

Output side

• Separate the input cable from the output

cable.

(device side)

5.2 Requirements for Compliance with the Low Voltage Directive

The Low Voltage Directive requires each device which operates with

power supply ranging from 50VAC to 1000V and 75VDC to 1500V to

satisfy necessary safety items.

In the Sections from

the GOT to conform to the Low Voltage Directive requires are described.

We have put the maximum effort to develop this material based on the

requirements and standards of the Directive that we have collected.

However, compatibility of the devices which are fabricated according to

the contents of this manual to the above Directive is not guaranteed.

Each manufacturer who fabricates such device should make the final

judgement about the application method of the Low Voltage Directive

and the product compatibility.

5.2.1 to 5.2.5, cautions on installation and wiring of

5.2.1 Standard subject to GOT

Standard applied to GOT : EN61131-2 Programmable controllers - Equ ipment

requirements and tests

EN60950-1 Safety of In formation Technology Equipment

5.2.2 Power supply

The insulation specification of the GOT was designed assuming

installation category II. Be sure to use the installation category II power

supply to the GOT.

The installation category indicates the durability level against surge

voltage generated by lightning strike.

Category I has the lowest durability; category IV has the highest

durability.

Category II indicates a power supply whose voltage has been reduced

by two or more levels of isolating transformers from the public power

distribution.

Installation category

Category ICategory IICategory IIICategory IV

5.2.3 Control panel

Because the GOT is open type equipment (device designed to be stored

within another device), be sure to use it only when installed in a control

panel.

(1) Shock Protection

In order to prevent those who are unfamiliar with power facility,

e.g., an operator, from getting a shock, make sure to take the

following measures on the control panel.

(a) Store the GOT within the control panel locked, and allow only

those who are familiar with power facility to unlock the panel.

(b)Build the structure in order that the power supply will be shut off

when the control panel is opened.

(2) Dustproof and waterproof features

The control panel also provides protection from dust, water and

other substances. Insufficient ingression protection may lower the

insulation withstand voltage, resulting in insulation destruction.

The insulation in the GOT is designed to cope with the pollution

level 2, so use in an environment with pollustion level 2 or better.

Pollution level 1: An env ironment where the air is dry and conductive

Pollution level 2: An env ironment where conductive dust does not

Pollution level 3: An environment where co nductive dust exits and

Pollution level 4: Continuo us conductivity may occur due to rain, snow,

dust does not exist.

usually exist, but occasional temporary conducti vity

occurs due to the accumulated dust.

Generally, this is the level for inside the control panel

equivalent a control room or on the floor of a typical

factory.

conductivity may be generated due to the accumulated

dust.

An environment for a typical factory floor.

etc. An outdoor environment.

5.2.4 Grounding

The following are applicable ground terminals. Use them in the grounded

state.

Be sure to ground the GOT for ensuring the safety and complying with

the EMC Directive.

Protective grounding : Ensures the safety of the GOT and improves the nois e

Functional grounding : Improves the noise resistance.

resistance.

5.2.5 External wiring

(1) External devices

When a device with a hazardous voltage circuit is externally

connected to the GOT, select a model which complies with the

Low Voltage Directive's requirements for isolation between the

primary and secondary circuits.

(2) Insulation requirements

Dielectric withstand voltages are shown in the following table.

Reinforced Insulation Withstand Voltage

(Installation Category II, source : IEC664)

Rated voltage of hazardous

voltage area

150 VAC or below 2500V

300 VAC or below 4000V

Surge withstand voltage (1.2/50 s)

5.3 EMC Directive-Compliant System Configuration

5.3.1 GOT

Use any of the GOTs with which CE mark logo is printed on the rating plate.

All GT12 models support the EMC Directive.

5.3.2 Cables

Modify the cables (including user-produced cable) to ensure

compliance with the EMC Directive.

For details, refer to Section 5.4.2.

In addition, refer to the GOT1000 Series Connection Manual regarding

cables to be used.

5.4 EMC Directive-Compliant System Configuration

Wire and connect GOT1000 series equipments as instructed below.

For the GOT with the 24VDC power supply, attach a ferrite core

(RFC-H13 manufactured by KITAGAWA INDUSTRIES CO.,LTD.)

within the range shown below.

If the GOT1000 series equipments are configured in a way differ ent

from the following instructions, the system may not comply with EMC

directives.

5.4.1 Power and ground wires wiring method

(1) Power and ground wires wiring method

Connect the power wire and connection cable as shown in the

illustration.

Lead the power wire and ground wire as shown in Section 5.1.2

(2).

Be sure to ground the LG cable, FG cable, and protective ground

cable.

100-240VAC GOT power section 24VDC GOT power section

90mm or less

INPUT

24VDC

+−

(LG) (FG)

Ferrite core

(RFC-H13)

INPUT

100-240VAC

(LG) (FG)

5.4.2 Processing connection cables

Process the cable used with the GOT with the following method.

When processing the cable, ferrite core and cable clamp are required.

The cable clamp used by Mitsubishi Electric for the EMC specification

compatibility test is shown be low.

• TDK corporation brand ZCAT3035-1330 Ferrite Core

• Mitsubishi Electric Model AD75CK cable clamp

• Japan Zipper Tubing Co., Ltd. Zipper tube SHNJ type

(1) CPU direct connection and computer link connection

• Strip the outer insulation layer of the prepared cable by the

length shown below to expose the braided shield for

grounding. (For grounding with cable clamps. (Refer to

Section 5.4.3.))

(a) For RS-232 cable

GOT side PLC side

230 or less(9.06)

(b) For RS-422 cable

GOT side PLC side

40 (1.57)

Unit : mm (inch)

(a) For RS-422/485 c able

• Each signal wire (excluding SG and FG) should be made

into a two power wires and connected, then twisted.

SDA

SDB

RDA

RDB

• Make the SG wire more than two wires and connect.

• Strip the outer insulation layer of the prepared cable by the

length shown below to expose the braided shield for

grounding. (For grounding with cable clamps. (Refer to

Section 5.4.3.))

(b) For RS-232 cable

Use a twisted pair style for each signal wire (except SG, FG)

with SG.

RD

SD

DTR

DSR

SG

• Strip the outer insulation layer of the prepared cable by the

length shown below to expose the braided shield for

grounding. (For grounding with cable clamps. (Refer to

Section 5.4.3.))

RDA

RDB

SDA

SDB

SD

RD

DSR

DTR

SG

GOT side PLC side

230 or less (9.06)

40 (1.57)

Unit : mm (inch)

5.4.3 Grounding the cable

Ground the cable and grounding wire to the control panel where the

GOT and base unit are installed.

1) Ground the braided shield portion of the

cable to the control panel with the cable

clamp (AD75CK).

Braided shield

6. INSTALLATION

6.1 Control Panel Inside Dimensions for Mounting GOT

Install the GOT on the control panel out of the way for the equipment

inside the control panel. Do not install the GOT and the unit in

prohibited areas for the installation.

When mounting the GOT to the control panel, place the mounting

fixtures (included with GOT) on the mounting fixt ure attaching part of

the GOT, and fix them by tightening in the torque range of 0.36 to

0.48N•m.

Point

Applicable cable

Some cables may need to be longer than the spec ified dimensions when

connecting to the GOT. Therefore, consider the connector dimensions and

bending radius of the cable as well for installation.

6.2 Panel Cutting Dimensions

A

6.3 Mounting Position

When mounting the GOT, the following clearances must be

maintained from other structures and devices.

Some cables may need to be longer than the specified dimensions

when connecting to the GOT.

Therefore, consider the connector dimensions and bending radius of

the cable as well for installation.

For the lead-in allowance for cables at the bottom of the GOT, refer

to the following.

*Panel thickness : 2 to 4 mm

or less

GOT A

289

(11.38)

GT1275

B

GT1265

+2(0.08)

0(0)

227

(8.94)

+2(0.08)

0(0)

Unit : mm (inch)

B

200

(7.87)

+2(0.08)

0(0)

176

(6.93)

+2(0.08)

0(0)

230 or less (9.06)

(2)Ethernet connection

Strip the outer insulation layer at both ends of the cable by the

length shown below to expose the braided shield for grounding.

(For grounding with cable clamps. (refer to Section 5.4.3.))

Attach the ferrite core to the cable in the position as illustrated

below.

GOT side

120 or less (4.72)

230 or less (9.06)

(3) When connecting to PLC (manufactured by other company),

microcomputer, temperature controller, inverter, servo amplifier,

CNC, MODBUS(R)/RTU or MODBUS(R)/TCP connection.

Produce the cable (RS-232 cable, RS-422 cable) for connecting

the GOT to a controller with reference to the GOT1000 Series

Connection Manual.

Point

Configure the system to me et the EMC Directive specifications for the c onnected device

when connecting the GOT to a controller.

The following gives the instructions to ensure the machinery comply with the EMC

Directive. However, the manufacturer of th e machinery must finally determine how to make

it comply with the EMC Directives: if it is actually compliant with the EMC Directives.

40 (1.57)

Ferrite Core (ZCAT3035-1330)

40

40

(1.57)

(1.57)

Unit : mm (inch)

400 or less (15.75)

Unit : mm (inch)

PLC side

2) Do not arrange the cable clamp adjacent to

other cables which do not clamp.

Noise from the control panel may access

the GOT from the cable clamp and cause

adverse effects.

Cable clamps

WWW.NNC.IR

C

Installation

Environment

In the presence of

radiated-noise or

heat-generating

equipment nearby

In the absence of

radiated-noise or

heat-generating

equipment nearby

B

A

50(1.97)

or more

20(0.79)

or more

DE

Panel thickness: 2 to 4mm

(0.08 to 0.16inch)

C

When the

A,D B

80(3.15)

or more

20(0.79)

or more

CF card is

not used

50(1.97)

or more

20(0.79)

or more

When the

CF card is

used

100(3.94)

or more

Unit : mm(inch)

E

100(3.94)

or more

20(0.79)

or more

Loading...

Loading...