Mitsubishi GT1150-QLBD, GT1155-QSBD User Manual

Safety Precaution

(Read these precautions before using.)

Before using this product, please read this manual and the relevant manuals

introduced in this manual carefully and pay full attention to safety to handle the

product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "DANGER" and "CAUTION".

Depending on circumstances, procedures indicated by "CAUTION" may also be

linked to serious results.

In any case, it is important to follow the directions for usage.

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury

or physical damage.

DESIGN PRECAUTIONS

• Some failures of the GOT or cable may keep the outputs on or off.

An external monitoring circuit sho uld be provided to check for output signals

which may lead to a serious accident.

Not doing so can cause an accident due to false output or malfunction.

• If a communication fault (including cable disconnection) occurs during

monitoring on th e GOT, communication between t he GOT and PLC CPU is

suspended and the GOT becomes inoperative.

A system where the GOT is used should be configured to perform any

significant operation to the system by using the switches of a device other

than the GOT on the assumption that a GOT communication fault will occur.

Not doing so can cause an accident due to false output or malfunction.

• Do not use the GOT as the warning device that may cause a serious

accident.

An independent and redundant hardware or mecha nical interlock is required

to configure the device that displays and outputs serious warning.

Failure to observe this instruction may result in an accident due to incorrect

output or malfunction.

• Incorrect operation of the touch switch(s) may lead to a serious accident if the

GOT backlight is gone out.

When the GOT backlight goes out, the POWER LED flickers (green/orange)

and the display section turns black and causes the monitor screen to appear

blank, while the input of the touch switch(s) remains active.

This may confuse an operator in thinking that the GOT is in "screensaver"

mode, who then tries to release the GOT from this mode by touching the

display section, which may cause a touch switch to operate.

Note that the following occurs on the GOT when the backlight goes out.

- The POWER LED flickers (green/orange) and the monitor screen appears

blank

DESIGN PRECAUTIONS

• Do not bundle the control and communication cables with main-circuit, power

or other wiring.

Run the above cables separately from such wiring and keep them a minimum

of 100mm (3.94in.) apart.Not doing so noise can cause a malfunction.

MOUNTING PRECAUTIONS

• Be sure to shut off all phases of the external power supply used by the system

before mounting or removing the GOT to/from the panel.

Not doing so can cause the unit to fail or malfunction.

• Be sure to shut off all phases of the external power supply used by the system

before mounting or removing the option function board on to/from the GOT. Not

doing so can cause the unit to fail or malfunction.

MOUNTING PRECAUTIONS

• Use the GOT in the environment that satisfies the general specifications

described in this ma nual. Not doing so can cause an elect ric shock, fire,

malfunction or product damage or deterioration.

• When mounting the GOT to the control panel, tighten the mounting screws in the

specified torque range. Undertightening can cause the GOT to drop, short circuit

or malfunction. Overtightening can cause a drop, shor t circuit or malfunction due

to the damage of the screws or the GOT.

• Securely connect the option function board to the connector provided for the

board.

• When inserting/removing a CF card into/from the GOT, turn the CF card access

switch off in advance. Failure to do so may corrupt data within the CF card.

• When inserting a CF card into the GOT, push it into the insertion slot until the CF

card eject button will pop out. Failure to do so may cause a malfunction due to

poor contact.

• When removing a CF card from the GOT, make sure to support the CF card by

hand, as it may pop out. Failure to do so may cause the CF card to drop from the

GOT and break.

WIRING PRECAUTIONS

• Be sure to shut off all phases of the external power supply used by the system

before wiring. Failure to do so may result in an electric shock, product damage or

malfunctions.

• Please make sure to ground FG terminal of the GOT power supply section by

applying 100 or less which is used exclusively for the GOT. Not doing so may

cause an electric shock or malfunction.

• Correctly wire the GOT power supply section after confirming the rated voltage

and terminal arrangement of the product. Not doing so can cause a fire or failure.

• Tighten the terminal screws of the GOT power supply section in the specified

torque range. Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the

screws or the GOT.

• Exercise care to avoid foreign matter such as chips and wire offcuts entering the

GOT. Not doing so can cause a fire, failure or malfunction.

WIRING PRECAUTIONS

• Plug the communication cable into the connector of the connected unit and

tighten the mounting and terminal screws in the specified torque range.

Undertightening can cause a shor t circuit or malfunction. Overtightening can

cause a short circuit or malfunction due to the damage of the screws or unit.

TEST OPERATION

PRECAUTIONS

• Before performing the test operations of the user creation monitor screen (such as

turning ON or OFF bit device, ch anging the word device current value, changing

the settings or current values of the timer or counter, and changing the buffer

memory current value), read through the manual carefully and make yourself

familiar with the operation method.

During test operation, never change the data of the devices which are used to

perform significant operation for the system. False output or malfunction can

cause an accident.

STARTUP/MAINTENANCE

PRECAUTIONS

• When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

• Connect the battery correctly. Do not discharge, disassemble, heat, short, solder

or throw the battery into the fire. Incorrect handling may cause the battery to

generate heat, burst or take fire, resulting in injuries or fires.

• Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases. Not switching the power off in all phases can cause

a unit failure or malfunction. Under tightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction due to the

damage of the screws or unit.

Associated Manuals

The following manuals are relevant to this product. When these loose manuals are required, please consult with our local distributor.

*1 Stored in the GT Works 2/GT Designer2 in PDF format.

For details of a PLC to be connected, refer to the PLC user's manual respectively.

Bundled Items

1. Features

1) Improved monitoring performance and connectivity to FA devices

- High speed monitoring through high speed communication at maximum of 115.2kbps.

- Multiple languages are displayed using the Unicode2.1-compatible fonts and beautiful characters are drawn using the TrueType and high quality fonts.

- High speed display and high speed touch switch response.

2) More efficient GOT operations including screen design, startup, adjustment, management and maintenance works

- The 3MB user memory is included as standard.

- Font installation is available to increase the system fonts.

3) Enhanced support of FA setup tools

- Transferring or monitoring the sequence programs using the personal computer connected to GOT, during direct connection to Q, QnA, A, or FX series PLC CPU, or

computer link connection to QnA or Q series (FA Transparent function).

- The USB connector is positioned on the GOT front. This enables the system startup to be performed more efficiently using FA device setup tool, and eliminates the

indirect works (opening and closing the control panel, cable replacement, cable rewiring) in order to improve the working efficiency.

STARTUP/MAINTENANCE

PRECAUTIONS

• Do not disassemble or modify the unit.

Doing so can cause a failure, malfunction, injury or fire.

• Do not touch the conductive and electronic parts of the unit directly.

Doing so can cause a unit malfunction or failure.

• The cables connected to the unit must be run in ducts or clamped.

Not doing so can cause the unit or cable to be damaged due to the dangling,

motion or accidental pulling of the cables or can cause a malfunction due to a

cable connection fault.

• When unplugging the cable connected to the unit, do not hold and pull the cable

portion. Doing so can cause the unit or cable to be damaged or can cause a

malfunction due to a cable connection fault.

DISPOSAL PRECAUTIONS

• When disposing of the product, handle it as industrial waste.

TRANSPORTATION

PRECAUTIONS

• When transporting lithium batteries, make sure to treat them based on the

transport regulations.

• Before transporting the GOT, turn the GOT power on and check that the battery

voltage status is normal on the Time setting & display screen (utilities screen).

In addition, confirm that the adequate battery life remains on the rating plate.

Transporting the GOT with the low battery voltage or the battery the reached

battery life may unstabilize the backup data unstable during transportation.

• Make sure to transport the GOT main unit and/or relevant unit(s) in the manner

they will not be exposed to the impact exceeding the impact resistance

described in the general specifications of this manual, as they are precision

devices. Failure to do so may cause the unit to fail.

Check if the unit operates correctly after transportation.

Manual name Contents

Manual Number

(Model Code)

GT11 User's Manual

(sold separately)

Describes the GT11 hardwar e-relevant content such as part names, external dimens ions,

mounting, power supply wiring, specifications, and introduction to option devices.

JY997D17501

(09R815)

GOT1000 Series Connection Manual

(sold separately)

*1

Describes system configurations of the connection method applicable to GOT1000 series

and cable creation method

SH-080532ENG

(1D7M26)

GT Designer2 Version2 Basic Operation/Data Transfer

Manual (For GOT1000 Series)

(sold separately)

*1

Describes methods of the GT De signer2 installation operation, basic operation for drawing

and transmitting data to GOT1000 series

SH-080529ENG

(1D7M24)

GT Designer2 Version2 Screen Design Manual (For

GOT1000 Series) 1/2, 2/2

(sold separately)

*1

Describes specifications and settings of the object functions used in GT Designer2

SH-080530ENG

SH-080531ENG

(1D7M25)

Product Name Model Name Specifications

GOT

GT1155-QSBD 5.7" diagonal [320 × 240 dots], STN color LCD (256 colors), built-in battery and backlight

GT1150-QLBD 5.7" diagonal [320 × 240 dots], STN monochrome LCD (black/white, 16 scales), built-in battery and backlight

Bundled item Quantity Bundled item Quantity

Mounting brackets 4 Dust-/Water-proof packing 1

Mounting screws: M4 x 35mm (1.38") 4 GT11 General Description (This manual) 1

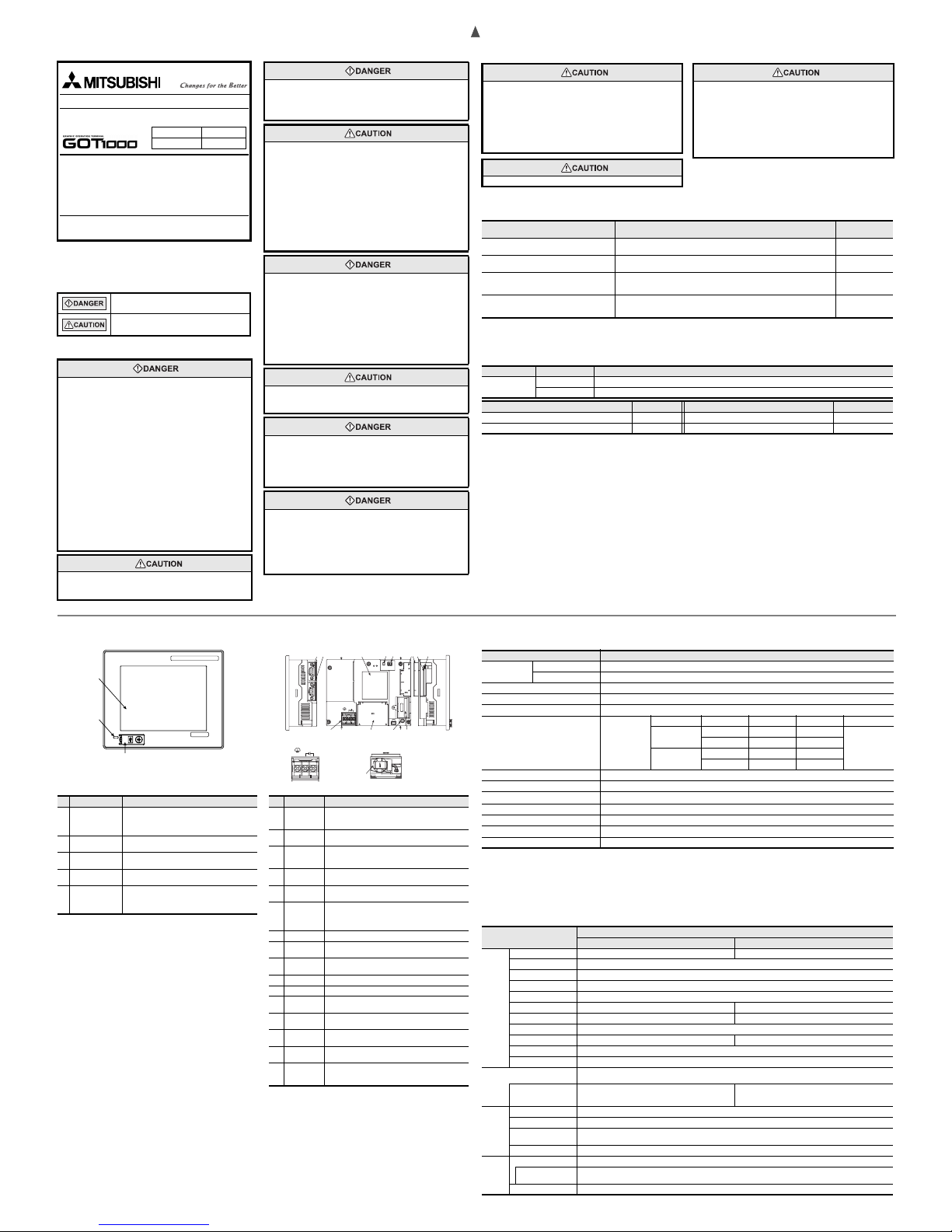

2. Part Name

2.1 Front Panel

For the PC connection, refer to the following.

→

→ →

→ GT Designer2 Version Basic Operation/Data Transfer Manual

2.2 Back Panel

For the connection to the PLC, microcomputer board or PC, refer to the following.

→

→ →

→ GOT 1000 Series Connection Manual

No Name Specifications

1) Display screen

Displays the utility screen and the user creation screen.

GT1155-QSBD:320×240 dots, STN color liquid crystal

GT1150-QLBD:320×240 dots, STN monochrome

(white/black) liquid crystal, 16 scales

2) Touch key

For operating the touch switches in the utility screen

and the user creation screen

3) USB interface

USB interface for connecting a personal computer

(OS installation, project data download, transparent)

4)

USB environmental

protection cover

Opens/Closes when the UBS interface is used.

5) POWER LED

Lit in green : Power is correctly supplied

Lit in orange : Screen saving

Blinking in orange/green : Blown backlight bulb

Not lit : Power is not supplied

1) 2)

3) 4)

5)

GRAPHIC OPERATION TERMINAL

GOT

1000

MITSUBISHI

No. Name Specifications

1)

RS-232

interface

For communicating with PLCs, connecting a bar code

reader or personal computer (OS installation, project data

download, transparent) (D-sub 9-pin male)

2)

RS-422

interface

For communicating with PLCs (D-sub 9-pin female)

3)

Hole for unit

installation

fitting

Hole for the inserting installation fittings (accessory) during

the GOT installation to the panel (4 holes at top and

bottom)

4)

Rating plate

(nameplate)

--

5)

CF card

access LED

Lit: CF card accessed Not lit: CF card not accessed

6)

CF card

access switch

Switch for prohibiting access to CF card before removing

the CF card from the GOT

ON: CF card being accessed (CF card removal prohibited)

OFF:No access to CF card (CF card removal possible)

7) CF card cover Open or close when inserting or removing the CF card.

8)

Option function

board (option)

Connect when using optional functions.

9)

Option function

board cover

Remove when using the option function board.

10) Reset switch Hardware reset switch (Use an isolated rod to operate.)

11) Battery cover Open or close when replacing the battery.

12) Power terminal

Power terminal and FG terminal

(for power supply (24VDC) to GOT and grounding)

13)

Power terminal

cover

Open or close when connecting a power terminal. (Color:

transparent)

14)

CF card

interface

Interface for installing the CF card to GOT

15)

CF card eject

button

Button for removing the CF card

16) Battery

GT11-50BAT battery for storing clock data, alarm history

and recipe data

(The project data is stored in the built-in flash memory.)

1)

2)

5)4)

3)

10)11)12)13)

Power supply terminal layout

Battery cover opened

CF card cover

opened

16)

6)

7)

8)9)

15)

14)

RS-232

CF CARD

I/F

ACCESS

BATTERY

24V DC

INPUT

RESEET

+-

(FG)

CF

CARD

OFF ON

RS-422

(FG)

24V DC

INPUT

+-

3)

3)

3)

3. Specifications

3.1 General Specifications

*1 The wet bulb temperature is 39°C or less.

*2 Do not use or store the GOT under pressure higher than the atmospheric pressure of altitude 0m (0ft.). Failure to observe this instruction may cause a malfunction.

*3 This indicates the section of the power supply to which the equipment is assumed to be connected between the public electrical power distribution network and the

machinery within the premises.

Category II applies to equipment for which electrical power is supplied from fixed facilities.

The surge voltage withstand level for up to the raged voltage of 300 V is 2500 V.

*4 This index indicates the degree to which conductive material is generated in the environment where the equipment is used.

In pollution degree 2, only non-conductive pollution occurs but temporary conductivity may be produced due to condensation.

3.2 Performance Specifications

Item Specifications

Operating ambient

temperature

Display section 0 to 50°C

Other than display section 0 to 55°C

Storage ambient temperature -20 to 60°C

Operating ambient humidity

*1

10 to 90% RH, non-condensing

Storage ambient humidity

*1

10 to 90% RH, non-condensing

Vibrationresistance

Conforms to JIS

B3502 and

IEC61131-2

Frequency Acceleration Half-amplitude Sweep Count

Under intermittent

vibration

5 to 9Hz -- 3.5mm

10 times each in X,

Y and Z directions

9 to 150Hz 9.8m/s

2

--

Under continuous

vibration

5 to 9Hz -- 1.75mm

9 to 150Hz 4.9m/s

2

--

Shock resistance

Conforms to JIS B3502, IEC 61131-2 (147 m/s

2

, 3 times each in X, Y and Zdirections)

Operating atmosphere No corrosive gas

Operating altitude

*2

2000 m (6562 ft) max.

Installation location Inside control panel

Overvoltage category

*3

II or less

Pollution degree

*4

2 or less

Cooling method Self-cooling

Item

Specifications

GT1155-QSBD GT1150-QLBD

Display

section

*1

Type STN color liquid crystal STN monochrome (white/black) liquid crystal

Screen size 5.7"

Resolution 320 × 240 dots

Display size W115(4.53) × H86(3.39)[mm](inch)

Display character 16-dot standard font: 20 characters × 15 lines, 12-dot standard font: 26 characters × 20 lines

Display color 256 colors Monochrome (white/black), 16 scales

Display angle Left/Right: 50 degrees, Top: 50 degrees, Bottom: 60 degrees Left/Right: 45 degrees, Top: 20 degrees, Bottom: 40 degrees

Contrast adjustment 16-level adjustment

Intensity of LCD only 280 to 350[cd/m

2

](Adjustable in 8 levels) 160 to 220[cd/m2](Adjustable in 8 levels)

Intensity adjustment 8-level adjustment

Life

*2

Approx. 50,000h. Guaranteed: 1 year (Time for display intensity to become 1/5 at operating ambient temperature of 25°C)

Backlight

Cold cathode fluorescent tube (irreplaceable by a user) backlight shutoff detection function is included.

Backlight off/screen saving time can be set.

Life

Approx. 75,000h or longer, Guaranteed: 1 year (Time for display

intensity reaches 50% at the operating ambient temperature of

25°C)

Approx. 54,000h or longer, Guaranteed: 1 year (Time for display

intensity reaches 50% at the operating ambient temperature of

25°C)

Tou c h

panel

Number of touch keys 300 keys/screen (Matrix structure of 15 lines × 20 columns)

Key size Minimum 16 × 16 dots (per key)

Number of points touched

simultaneously

Maximum of 2 points

Life 1 million times or more (operating force 0.98N max.)

Memory

C drive

*3

Flash memory (Internal), for storing project data (3Mbytes) and OS

Life

(Number of write times)

100,000 times

D drive SRAM (Internal), 512kbyes (battery backup)

GT1155-QSBD, GT1150-QLBD

GT11 General Description

This manual describes the part names, dimensions, mounting, and

specifications of the product. Before use, read this manual and manuals of

relevant products fully to acquire proficiency in handling and operating the

product. Make sure to learn all the product information, safety information, and

precautions.

And, store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

Registration

The company name and the product name to be described in this manual are

the registered trademarks or trademarks of each company.

Effective April 2005

Specifications are subject to change without notice.

2005 Mitsubishi Electric Corporation

Manual Number JY997D17401A

Date Apr il. 2005

This manual confers no industrial property rights or any rights of any other kind,

nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be

the cause of Mitsubishi; machine damage or lost profits caused by faults in the

Mitsubishi products; damage, secondary damage, accident compensation

caused by special factors unpredictable by Mitsubishi; damages to products

other than Mitsubishi products; and to other duties.

For safe use

This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in

a device or system used in purposes related to human life.

Before using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi.

This product has been manufactured under strict quality control. However

when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

•

•

•

HEAD OFFICE

HIMEJI WORKS

: MITSUBISHI DENKI BLDG MARUNOUTI TOKYO 100-8310

: 840, CHIYODA CHO, HIMEJI, JAPAN

*1 Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel. It is impos sible to completely avoid this symptom, as the liquid crystal display

comprises of a great number of display elements. Flickers may be observed depending on the display color.

Please note that these dots appear due to its characteristic and are not caused by product defect.

*2 The GOT screen saving/backlight off function prevents images from becoming permanently etched on the display screen and increases the backlight life.

*3 ROM in which new data can be written without deleting the written data.

*4 Compliant with IP67 when the USB environmental protection cover is attached. Not compliant when a USB cable is connected. Note that this does not guarantee all

users' operation environment.

3.3 Power Supply Specifications

*1 The GOT continues to operate even upon 5ms or shorter instantaneous power failure.

The GOT stops operating if there is extended power failure or voltage drop, while it automatically resumes operation as soon as the power is restored.

Battery GT11-50BAT lithium battery

Backup target Clock data, alarm history and recipe data

Life Approx. 5 years (Operating ambient temperature of 25°C), Guaranteed: 1 year

Built-in

interface

RS-422

Conforming to serial RS422 standard, 1ch

Transmission speed: 115,200/57,600/38,400/19,200/9,600/4,800bps

Connector shape : D-sub 9-pin (Female)

Application : PLC communication

RS-232

Conforming to serial RS232 standard, 1ch

Transmission speed : 115,200/57,600/38,400/19,200/9,600/4,800bps

Connector shape : D-sub 9-pin (Male)

Application : PLC communication, bar code reader connection, PC communication

(Project data upload/download, OS installation, transparent function)

USB

Conforming to serial USB (Full Speed 12Mbps), device, 1ch

Application: PC communication (Project data upload/download, OS installation, transparent function)

CF card

Conforming to PCMCIA, compact flash slot, 1ch

Connector shape : Dedicated for TYPE I

Application : Data transfer, data storage

Option function board For installing option function board, 1ch

Buzzer output Single tone (tone length adjustable)

Environmental protective structure

*4

Equivalent to IP67 (JEM1030) (front section) when the USB environmental protective cover is attached

External dimensions W164(6.46) × H135(5.32) × D56(2.21)[mm](inch)(Excluding USB environmental protective cover)

Panel cutting dimensions W153 (6.03) × H121(4.77)[mm] (inch)

Weight 0.7kg (Excluding mounting fixtures)

Compatible software package GT Designer2 Version2 or later

Item

Specifications

GT1155-QSBD GT1150-QLBD

Input power supply voltage 24VDC (+10% -15%), ripple voltage 200mV or less

Fuse (built-in, not exchangeable) 1.0A

Power consumption 9.84W (410mA/24VDC) or less 9.36W (390mA/24VDC) or less

At backlight off 4.32W (180mA/24VDC) or less

Inrush current 15A or less (26.4V) 2ms

Permissible instantaneous power

failure time

*1

Within 5ms

Noise immunity Noise voltage: 1000Vp-p, Noise width: 1µs (by noise simulator of 30 to 100Hz noise frequency)

Dielectric withstand voltage 500VAC for 1 minute (across power supply terminals and earth)

Insulation resistance 10MΩ or larger by insulation resistance tester (across power supply terminals and earth)

Applicable wire size

0.75 to 2[mm

2

]

Applicable solderless terminal Solderless ter minal for M3 screw RAV1.25-3, V2-N3A, FV2-N3A

Applicable tightening torque

(Terminal block terminal screw)

0.5 to 0.8[N

•

m]

Item

Specifications

GT1155-QSBD GT1150-QLBD

3.4 External Dimensions

4. Installation

4.1 Control Panel Inside D imensions for Mounting GOT

Mount the GOT onto the control panel while considering the following control panel

inside dimensions.

Applicable cable

Some cables may need to be longer than the specified dimensions when connecting

to the GOT. Therefore, consider the connector dimensions and bending radius of the

cable as well for installation.

4.2 Panel Cutting D imensions

Make holes in the panel according to the dimensions list below.

Also, ensure 10mm spaces in upper and lower parts of the panel for mounting

fixtures.

164(6.46")

23(0.91")

22

(0.87")

120(4.73")

135(5.32")

47(1.86")

56(2.21")

22

(0.87")

120(4.73")

152(5.99")

120(4.73")10

(0.4")

10(0.4")

Unit: mm (inch)

GRAPHIC OPERATION TERMINAL

GOT

1000

MITSUBISHI

#4-40UNC

(Inch screw type)

M2.6

(Metric screw type)

Panel thickness: 5mm(0.2") or less

53(2.09")

5

4

(0.2")

(0.16")

No Name

1) PLC connection cable/PC connection cable

1)

152(5.99")

120(4.73")

30

(1.19")

140(5.52")

CF CARD

I/F

24V DC

INPUT

+-

Unit: mm (inch)

153

+2

-0

10(0.4") or more

10(0.4") or more

Unit: mm (inch)

121

+2

-0

(6.03" )

+0.08"

-0

(4.77" )

+0.08"

-0

4.3 Mounting Position

When mounting the GOT, the

clearances shown on the right must

be left from a structure or the other

device.

Secure 50mm (1.97") or more on

the left, right and bottom sides of

the GOT to structures or other

devices.

Secure 80mm (3.15") or more on

the top of the GOT from structures

or other devices to allow good

ventilation.

If devices (such as a contactor)

generating radiated noise or those

generating heat are arranged

around the GOT, secure 100mm

(3.94") or more on the back panel.

When using the CF card, secure a sufficient distance on the left side to allow

installation and removal of the CF card.

[Securing 100mm (3.94") or more is recommended.]

4.4 Control Panel Inside Temperature an d Mounting Angle

When mounting the main unit to a control panel or similar, set the display section

as shown below.

When the temperature inside the control panel is 40 to 55°C or less, the mounting

angle should be in the range 60° to 105° degrees.

• The GOT will be

deteriorated earlier if it is

used at the mounting angle

other than the above.

Therefore, the temperature

inside the control panel

should be within 40°C.

4.5 Installation Procedure

The GOT is designed to be embedded into a panel. Mount the GOT by following

the procedure below. For panel cutting dimensions, refer to Section 4.2. Note that

the panel thickness should be within 5mm.

1) Installing the packing

Install packing to the packing

installation groove on the back panel

of the GOT.

While referring to the cross sect ional

view of the packing shown right, push

the thinner side into the packing

groove.

2) Inserting into the panel face

Insert the GOT from the front side of

the panel.

3) Fixing the GOT

Engage the hook of the mounting

fitting (accessory) to the unit fixing

hole of the GOT and tig hten the

screw until the GOT is fixed w ith the

mounting bolt (accessory).

The GOT will be fixed in 4 upper/

lower parts.

Tighten the mounting screw with the

specified torque.

(Failure to do so may distor t the

panel and make a surface waviness

on the protective sheet.)

4) A protection film is attached on the display section of GOT prior to shipment.

Remove the film when the installation is completed.

50mm

(1.97")

or

more

80mm (3.15") or more

50mm (1.97") or more

*1 To use the CF card, leave sufficient

distances for removal and installation

of the CF card.

50mm

(1.97")

or

more

*1

GOT

back

panel

GOT

display

section

Control

panel,

etc.

105°

60°

Packing cross

sectional view

Inserting

direction

Packing

Packing

installation groove

Packing

Magnified

illustration

Mounting hole

Mounting

fitting

Mounting

screw

Magnified illustration

5. Wiring

5.1 Power Supply Wiring

Connect the power supply to the power terminals on the back panel of the GOT.

Use 0.75mm

2

or thicker cables to avoid voltage drop and tighten the terminal screw

with the specified torque securely.

• Carry out the independent grounding if possible.

• If the independent grounding is impossible, carry out the shared grounding as

shown in fig.2) below.

• Use the cable of 2mm

2

or more for grounding.

Set the grounding point closer to the GOT to make the grounding cable short as

possible.

1) Recommended terminal shape

6. Maintenance and In spection

The GOT does not include consumable components that will cause the shorten life.

However, note that battery life is 5 years and LCD life is 50,000 hours. The life of

backlight in GT1155-QSBD is 75,000 hours and that in GT1150-QLBD is 54,000 hours.

It is recommended to replace the battery periodically. (For the replacement of the liquid

crystal screen and backlight, please consult your nearest sales office or FA Center.)

6.1 Daily Inspection

Daily inspection items

Applicable solderless terminal RAV 1.25-3, V2-N3A and FV2-N3A

No. Inspection Item

Inspection

Method

Criterion Action

1 GOT mounting status

Check for

loose mounting

screws.

Securely

mounted

Retighten screws

within the

specified torque

range

2

Connection status

Loose terminal

screws

Retighten

screws with

screwdriver

Not loose

Retighten

terminal screws

Proximate

solderless terminals

Visual check

Proper

intervals

Correct

Loose connectors Visual check Not loose

Retighten

connector fixing

screws

Grounding

(100Ω or less)

24VDC

power supply

-

+

CF CARD

I/F

24V DC

INPUT

+-

24V DC

INPUT

+-

PC and external

device connection

cables

Power supply terminal

GO GO GO

Other

device

Other

device

Other

device

Grounding

(100Ω or less)

Grounding

(100Ω or less)

(1) Independent ground

...... Best condition

(2) Shared grounding

...... Good condition

(3) Common grounding

...... Not allowed

Terminal

screw

Solderless

terminal

Terminal

screw

6.2mm

or less

3.2

3.2

6.2mm

or less

When wiring one cable to

one terminal

When wiring two cables to

one terminal

Solderless

terminal

Refer to the following for the model names of the protection sheet or the replacement

procedure.

→

→ →

→ GT11 User’s Manual

6.2 Periodic Inspection

Yearly or half-yearly inspection items

The following inspection should also be performed when equipment has been moved

or modified or the wiring changed.

6.3 Battery Replacement

The battery backs up clock data, alarm history and recipe data.

Screen data is stored in the flash memory and data is retained even if the battery is

dead.

• Battery model name

GT11 is shipped with the following battery.

• Battery replacement procedure

1) Turn the GOT power off.

2) Open the back cover of the GOT.

3) Remove the old battery from the

holder.

4) Disconnect the old battery connector

and insert the new battery connector

within 30s.

(Clock data, alarm history, and recipe

data is retained by the GOT condenser

for 30 seconds.)

5) Insert the new battery into the holder

and close the back cover.

3

Usage status

Dirt on protection

sheet

Visual check

Not

outstanding

Replace with new

one

Foreign material

attachment

Visual check

No foreign

matter sticking

Remove clean

No. Inspection Item

Inspection

Method

Criterion Action

1

Surrounding

environment

Ambient

temperature

Make

measurement

with

thermometer or

hygrometer

Measure

corrosive gas

Display

section

0 to

50°C

For use in control

panel,

temperature

inside control

panel is ambient

temperature

Other

portions

0 to

55°C

Ambient

humidity

10 to 90%RH

Atmosphere

No corrosive

gas

2

Power supply voltage

check

24VDC

Measure

voltage across

terminals.

20.4 to

26.4VDC

Change supply

power

3

Connection

status

Loose

terminal

screws

Retighten

screws with

screwdriver

Not loose

Retighten

terminal screws

Proximate

solderless

terminals

Visual check

Proper

intervals

Correct

Loose

connectors

Visual check Not loose

Retighten

connector fixing

screws

Product name Model name

Battery GT11-50BAT

No. Inspection Item

Inspection

Method

Criterion Action

Back cover

Holder

Connector

Back cover

Holder

Connector

• How to confirm production year and month

The production year and month of the batter y built in the purchased GOT can

be confirmed by the production No. (serial No.) marked on the GOT main unit.

• Battery life

Approximate battery life:

5 years (ambient temperature: 25°C) [Guaranteed for 1 year]

Battery replacement: In 4 to 5 years

Approximate life is 5 years, but life may be shor ter depending on the ambient

temperature, therefore, note that the battery must be repl aced in 4 to 5 years.

Make sure to purchase a new battery as needed as it self-discharges.

Battery status can be confirmed on a GOT utility screen.

For details of battery status or how to output alarm, refer to the following:

→

→ →

→ GT11 User’s Manual

GRAPHIC OPERATION TERMINAL

MODEL

IN 20.4

SERIAL

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

80M1 IND. CONT. EQ

US LISTED

JY550D26101A

540001 BC

26.4VDC

POWER 9.54W MAX

GT1155-QSBD

5 4 0 0 0

Control number

Year (example: 2005)

last digit

1

Month (example: Jun.). 1 to 9: Jan. to Sep.,

X: Oct., Y: Nov., Z: Dec.

CF CARD

I/F

24V DC

INPUT

+-

Loading...

Loading...