Page 1

GRAPHIC OPERATION TERMINAL

Mitsubishi Electric Automation, Inc.

MODEL

GT1055-QSBD

GT1050-QBBD

QUICK START MANUAL

Page 2

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

1. INTRODUCTION .................................................................3

1.1 CAUTION

1.2 CERTIFICATION

1.3 INCLUDED ITEMS

...........................................................................3

................................................................4

...........................................................5

2. SPECIFICATIONS..............................................................5

2.1 MODEL NAME EXPLANATION

2.2 GENERAL SPECIFICATIONS

2.3 PERFORMANCE SPECIFICATIONS

2.4 POWER SUPPLY SPECIFICATIONS

........................................5

...........................................5

................................5

................................6

3. HARDWARE SPECIFICATIONS ...................................6

4. EXTERNAL DIMENSIONS .............................................7

5. RATING PLATE ..................................................................7

6. INSTALLATION AND REMOVAL .................................7

6.1 CONTROL PANEL INSIDE DIMENSIONS FOR

MOUNTING GOT

6.2 PANEL CUTTING DIMENSIONS

6.3 MOUNTING POSITION

6.4 CONTROL PANEL INSIDE TEMPERATURE

AND MOUNTING ANGLE

6.5 INSTALLATION PROCEDURE

..............................................................7

......................................8

....................................................8

.................................................8

..........................................8

7. WIRING ...................................................................................9

7.1 POWER SUPPLY WIRING

7.2 WIRING INSIDE AND OUTSIDE THE PANEL

................................................10

................... 11

8. OPERATION SETTINGS ............................................... 11

8.1. BATTERY

8.2 UTILITY FUNCTION

8.3 UTILITY DISPLAY

8.4 COMMUNICATION INTERFACE SETTING

8.5 DATA TRANSFER

8.6 COMMUNICATION MONITOR

8.7 DISPLAY SETTINGS

8.8 OPERATION SETTING

8.9 CLOCK SETTINGS AND BATTERY STATUS DISPLAY

........................................................................ 11

....................................................... 11

...........................................................12

....................13

...........................................................16

........................................16

......................................................17

..................................................19

.20

9. MAINTENANCE AND INSPECTION .........................21

9.1 DAILY INSPECTION

9.2 PERIODIC INSPECTION

9.3 CLEANING METHOD

.......................................................21

................................................22

.....................................................22

10. WARRANTY .....................................................................23

2

Page 3

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

1. INTRODUCTION

This manual describes the specifications of the product. Before use,

read this manual and manuals of relevant products fully to acquire

proficiency in handling and operating the product. Make sure to learn

all the product information, safety information, and precautions. And,

store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

Registration

The company name and the product name to be described in this

manual are the Registered trademarks or trademarks of each

company.

Effective April 2015

Specifications are subject to change without notice.

© 2008 MITSUBISHI ELECTRIC CORPORATION

1.1 CAUTION

Safety Precaution (Read these precautions before use.) This manual

classifies the safety precautions into two categories: DANGER and

CAUTION.

DANGER Indicates that incorrect handling may cause

hazardous conditions, resulting in death or severe injury.

CAUTION Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or slight personal injury

or physical damage.

Depending on the circumstances, procedures indicated by CAUTION

may also cause severe injury. It is important to follow all precautions for

personal safety.

DANGER DESIGN PRECAUTIONS

• Some failures of the GOT or cable may keep the outputs on or off.

An external monitoring circuit should be provided to check for output

signals which may lead to a serious accident. Not doing so can

cause an accident due to false output or malfunction.

• If a communication fault (including cable disconnection) occurs

during monitoring on the GOT, communication between the GOT

and PLC CPU is suspended and the GOT becomes inoperative. A

system where the GOT is used should be configured to perform any

significant operation to the system by using the switches of a device

other than the GOT on the assumption that a GOT communication

fault will occur. Not doing so can cause an accident due to false

output or malfunction.

• Do not use the GOT as the warning device that may cause a serious

accident. An independent and redundant hardware or mechanical

interlock is required to configure the device that displays and outputs

serious warning. Failure to observe this instruction may result in an

accident due to incorrect output or malfunction.

• Incorrect operation of the touch switch(s) may lead to a serious

accident if the GOT backlight is gone out. When the GOT backlight

goes out, causes the monitor screen to appear blank, while the input

of the touch switch(s) remains active. This may confuse an operator

in thinking that the GOT is in “screensaver” mode, who then tries

to release the GOT from this mode by touching the display section,

which may cause a touch switch to operate.

CAUTION DESIGN PRECAUTIONS

• Do not bundle the control and communication cables with maincircuit, power or other wiring. Run the above cables separately from

such wiring and keep them a minimum of 100mm (3.94 in.) apart.

Not doing so noise can cause a malfunction.

• Do not press the GOT display section with a pointed material as

a pen or driver. Doing so can result in a damage or failure of the

display section.

• Before connecting to GOT, turn ON the controller to enable the

communication. When the communication of controller is not

available, a communication error may occur in GOT.

DANGER MOUNTING PRECAUTIONS

• Be sure to shut off all phases of the external power supply used by

the system before mounting or removing the GOT to/from the panel.

Not doing so can cause the unit to fail or malfunction.

• When installing the battery wear an earth band etc. to avoid the

static electricity. The static electricity can cause the unit to fail or

malfunction.

CAUTION MOUNTING PRECAUTIONS

• Use the GOT in the environment that satisfies the general

specifications described in this manual. Not doing so can cause an

electric shock, fire, malfunction or product damage or deterioration.

• When mounting the GOT to the control panel, tighten the mounting

screws in the specified torque range. Undertightening can cause

the GOT to drop, short circuit or malfunction, and deteriorate the

waterproof effect and oilproof effect.

• Overtightening can cause a drop, short circuit or malfunction

due to the damage of the screws or the GOT, and deteriorate the

waterproof effect and oilproof effect due to distortion of the protective

cover for oil, GOT or panel.

• When using the GOT in the environment of oil or chemicals, use

the protective cover for oil. Failure to do so may cause failure or

malfunction due to the oil or chemical entering into the GOT.

DANGER WIRING PRECAUTIONS

• Be sure to shut off all phases of the external power supply used by

the system before wiring. Failure to do so may result in an electric

shock, product damage or malfunctions.

• Please make sure to ground FG terminal of the GOT power supply

section by applying 100 or less which is used exclusively for the

GOT. Not doing so may cause an electric shock or malfunction.

• Correctly wire the GOT power supply section after confirming the

rated voltage and terminal arrangement of the product. Not doing so

can cause a fire or failure.

• Tighten the terminal screws of the GOT power supply section in the

specified torque range. Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction

due to the damage of the screws or the GOT.

• Exercise care to avoid foreign matter such as chips and wire

offcuts entering the GOT. Not doing so can cause a fire, failure or

malfunction.

CAUTION WIRING PRECAUTIONS

• Plug the communication cable into the connector of the connected

unit and tighten the mounting and terminal screws in the specified

torque range. Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction

due to the damage of the screws or unit

DANGER TEST OPERATION PRECAUTIONS

• Before performing the test operations of the user creation monitor

screen (such as turning ON or OFF bit device, changing the word

device current value, changing the settings or current values of

3

Page 4

GT105_ QUICK START MANUAL

100mm250mm

140mm

GT01-C30R4-8P

Comes equipped

GOT units

Programmable

controller

Added by user

(9.84inch)

(3.93inch)

(5.51inch)

Ex.1

F = Ferrite core

Ex. NEC TOKIN - ESD-R-17S or similar

F F F

Mitsubishi Electric Automation, Inc.

the timer or counter), read through the manual carefully and make

yourself familiar with the operation method. During test operation,

never change the data of the devices which are used to perform

significant operation for the system. False output or malfunction can

cause an accident..

DANGER STARTUP/MAINTENANCE PRECAUTIONS

• When power is on, do not touch the terminals. Doing so can cause

an electric shock or malfunction.

• Connect the battery correctly. Do not discharge, disassemble, heat,

short, solder or throw the battery into the fire. Incorrect handling may

cause the battery to generate heat, burst or take fire, resulting in

injuries or fires.

• Before starting cleaning or terminal screw retightening, always switch

off the power externally in all phases. Not switching the power off in

all phases can cause a unit failure or malfunction. Undertightening

can cause a short circuit or malfunction. Overtightening can cause a

short circuit or malfunction due to the damage of the screws or unit.

CAUTION STARTUP/MAINTENANCE PRECAUTIONS

• Do not drop or apply any impact to the battery. If any impact has

been applied, discard the battery and never use it. The battery may

be damaged by the drop or impact.

• Before touching the unit, always touch grounded metal, etc. to

discharge static electricity from human body, etc. Not doing so can

cause the unit to fail malfunction.

• Replace battery with GT11-50BAT by Mitsubishi electric Co. only. Use

of another battery may present a risk of fire or explosion.

• Dispose of used battery promptly. Keep away from children. Do not

disassemble and do not dispose of in fire..

CAUTION DISPOSAL PRECAUTIONS

• When disposing of the product, handle it as industrial waste.

• When disposing of batteries, separate them from other wastes

according to the local regulations.

CAUTION TOUCH PANEL PRECAUTIONS

• For the analog-resistive film type touch panels, normally the

adjustment is not required. However, the difference between a

touched position and the object position may occur as the period of

use elapses. When any difference between a touched position and

the object position occurs, execute the touch panel calibration.

• When any difference between a touched position and the object

position occurs, other object may be activated. This may cause an

unexpected operation due to incorrect output or malfunction.

CAUTION TRANSPORTATION PRECAUTIONS

• When transporting lithium batteries, make sure to treat them based

on the transport regulations. (Refer to User’s Manual for details of

the regurated models.)

• Before transporting the GOT, turn the GOT power on and check that

the battery voltage status is normal on the Time setting & display

screen (utilities screen). In addition, confirm that the adequate

battery life remains on the rating plate. Transporting the GOT with

the low battery voltage or the battery the reached battery life may

unstabilize the backup data unstable during transportation.

• Make sure to transport the GOT main unit and/or relevant unit(s) in

the manner they will not be exposed to the impact exceeding the

impact resistance described in the general specifications of this

manual, as they are precision devices. Failure to do so may cause

the unit to fail.

• Check if the unit operates correctly after transportation.

4

1.2 CERTIFICATION

Compliance with EC directive (CE Marking)

This note does not guarantee that an entire mechanical module

produced in accordance with the contents of this note will comply with

the following standards. Compliance to EMC directive for the entire

mechanical module should be checked by the user/manufacturer. For

more details please contact the local Mitsubishi Electric sales site.

• This product is designed for use in industrial applications.

• Authorized Representative in the European Community:

Mitsubishi Electric Europe B.V.

Gothaer Str. 8, 40880 Ratingen, Germany

Requirement for Compliance with EMC directive

The following products have shown compliance through direct testing

(to the identified standards) and design analysis (forming a technical

construction file) to the European Directive for Electromagnetic

Compatibility (2004/108/EC) when used as directed by the appropriate

documentation. Type :Programmable Controller (Open Type

Equipment)

Standard Remark

EN61131-2 : 2007

Programmable controllersEquipment, requirement

and tests

EMI

EMS

Compliance with all relevant aspects of the

standard. (Radiated Emissions)

Compliance with all relevant aspects of the

standard. (ESD, RF electromagnetic field,

EFTB, Surge, RF conducted disturbances

and Power frequency magnetic field)

Notes for compliance to EMC regulation

Any device which utilizes a data communication function is susceptible

to the wider effects of local EMC noise. Therefore, when installing any

communication cables care should always be taken with the routing

and location of those cables. The GOT units identified on the previous

chapter are compliant with the EMC requirement when the following

communication cables are used.

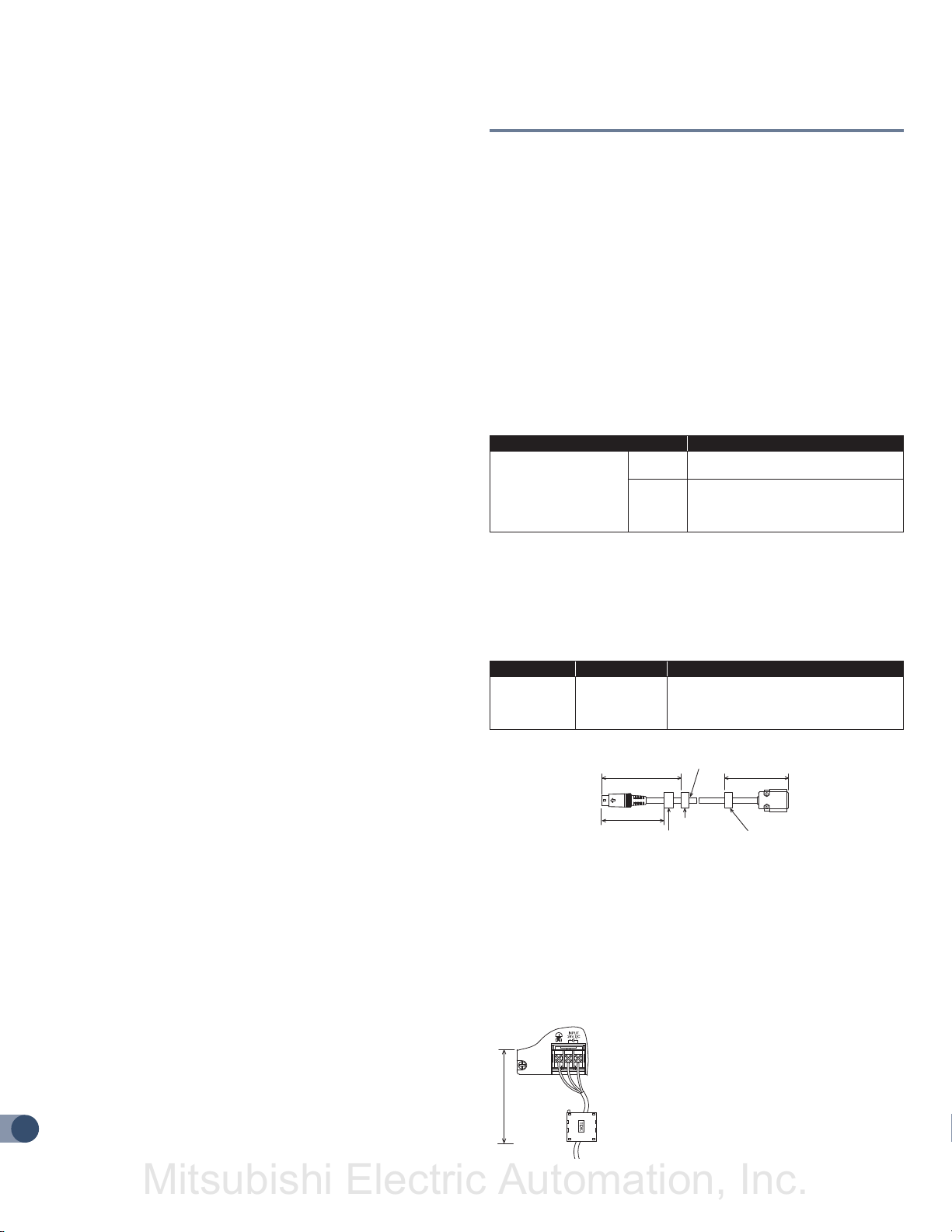

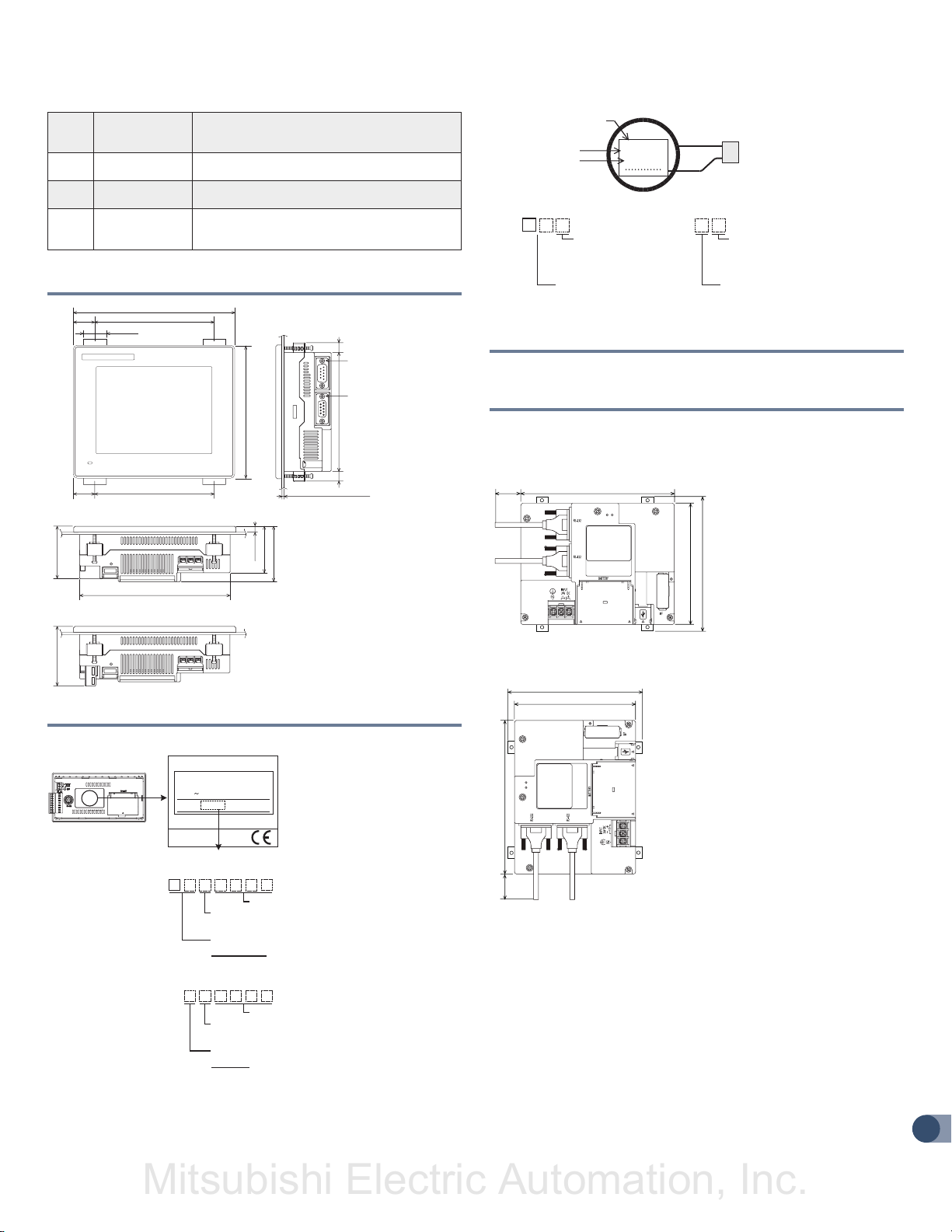

GOT Unit Existing Cables User Made Cables

GT1055-QSBD

and

GT1050-QBBD

Ex.1

F = Ferrite core

Ex. NEC TOKIN - ESD-R-17S or similar

GT01-C30R48P modified as

shown in EX.1

Programmable

controller

140mm

(5.51inch)

Those cables need to be independently tested

by the user to demonstrate EMC compatibility

when they are used with Mitsubishi GOT unit

and FX3U Programmable Controllers.

GT01-C30R4-8P

(9.84inch)

F F F

Comes equipped

100mm250mm

(3.93inch)

Added by user

GOT units

General notes on Power supply

The GT1055-QSBD and GT1050-QBBD unit requires an additional

ferrite filter to be attached to the 24V DC power supply cables. The filter

should be attached in a similar manner as shown in the figure opposite,

i.e. the power cables are wrapped around the filter. However, as with all

EMC situations the more correctly applied precautions the better the

systems Electro-magnetic Compatibility. The ferrite recommended is a

TDK ZCAT3035-1330 or similar. The ferrite should be placed as near

to the 24VDC terminals of the GT1055-QSBD and GT1050-QBBD as

possible (which should be within 75mm of the GOT terminal).

Up to

75mm

(2.95inch)

Page 5

GT105_ QUICK START MANUAL

GT10 5 0 -

Mitsubishi Electric Automation, Inc.

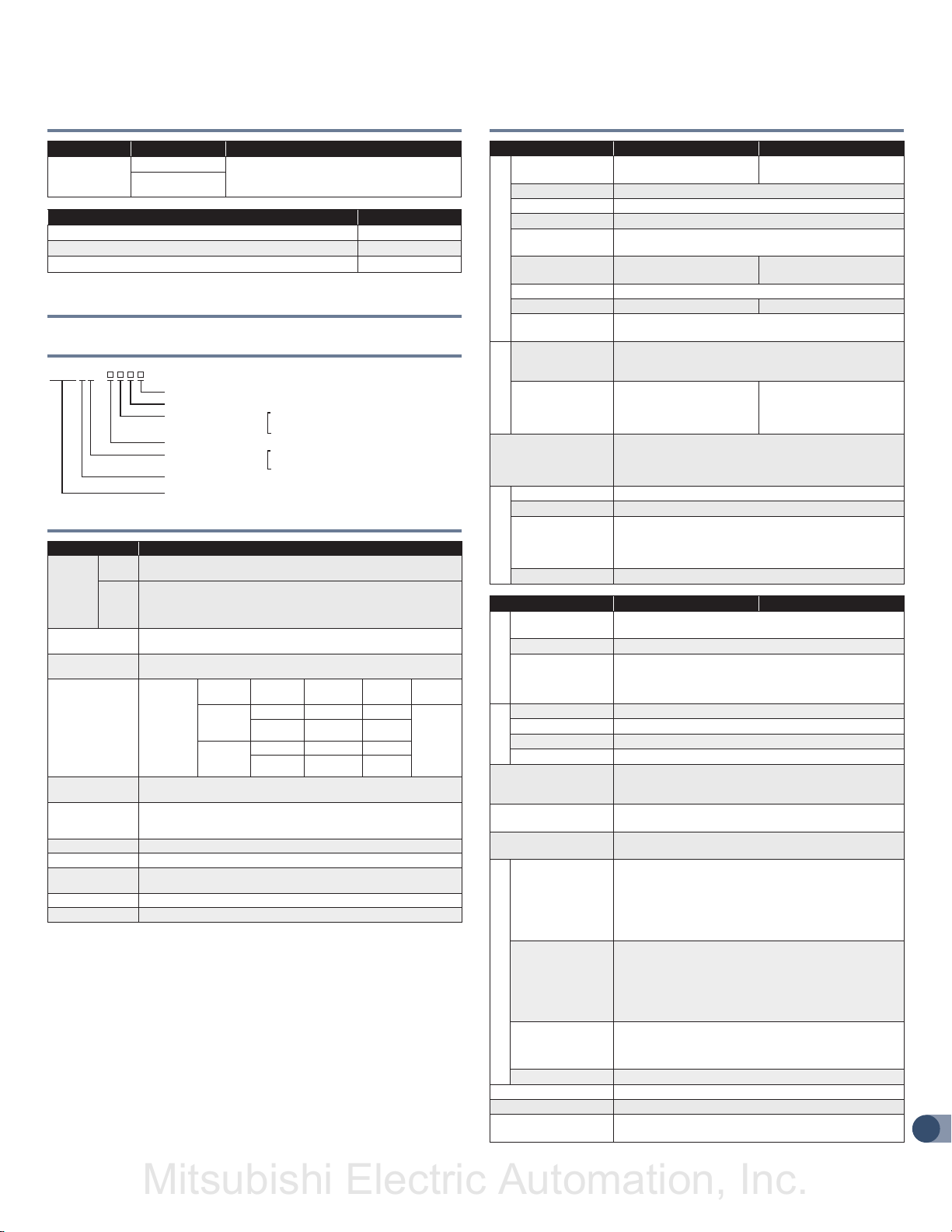

1.3 INCLUDED ITEMS

Product Name Model Name Specifications

GT1055-QSBD GOT main unit

GOT

GT1050-QBBD

(The maintenance supplies below are packed

with the product.)

Item Quantity

Panel Mounting Bracket (with M4 X 20 screws) 4

Panel Mounting Packing 1

GT10 General Description Manual 1

2. SPECIFICATIONS

2.1 MODEL NAME EXPLANATION

Power type

Panel color type

Display device type

Resolution Q:320 × 240(QVGA)

Display color type

Screen size type

GOT1000 series GT10

2.2 GENERAL SPECIFICATIONS

Item Specifications

Operating

Ambient

Temp.

Storage Ambient

Temperature

Operating/Storage

ambient humidity

Vibration

Resistance

Shock Resistance

Operating

Atmosphere

Operating Altitude *1 2000m (6562 ft.) max.

Installation Location Inside control panel

Overvoltage

Category *2

Pollution Degree *3 2 or less

Cooling Method Self-cooling

1. Do not use or store the GOT under pressure higher than the atmospheric pressure of altitude 0m

2. This indicates the section of the power supply to which the equipment is assumed to be

3. *his index indicates the degree to which conductive material is generated in the environment

Display

0 to 50°C

Section

Other

Than

0 to 55°C (When mounted horizontally), 0 to 50°C (When mounted vertically)

Display

Section

-20 to 60°C

10 to 90% RH, non-condensing

(The wet bulb temperature is 39°C or less.)

Conforms

to JIS

B3502 and

IEC61131-2

Conforms to JIS B3502, IEC 61131-2 (147 m/s², 11 ms, Sine half-wave pulse,

3 times each in the X, Y, and Z directions.)

Must be free of lamp black, corrosive gas, flammable gas, or excessive amount

of electro conductive dust particles and must be no direct sunlight. (Same as

for saving)

II or less

(0ft.). Failure to observe this instruction may cause a malfunction. When the air inside the control

panel is purged by pressurization, the surface sheet may be lifted by high pressure. As a result,

the touch panel may be difficult to press, and the sheet may be peeled off.

connected between the public electrical power distribution network and the machinery within

the premises. Category II applies to equipment for which electrical power is supplied from fixed

facilities. The surge voltage withstand level for up to the raged voltage of 300 V is 2500 V.

where the equipment is used. In pollution degree 2, only non-conductive pollution occurs but

temporary conductivity may be produced due to condensation where the equipment is used.

In pollution degree 2, only non-conductive pollution occurs but temporary conductivity may be

produced due to condensation.

Under

intermittent

vibration

Under

continuous

vibration

D:24VDC

B:Black

S:STN color

monochrome(blue/white)

B:STN

5:256 colors supported

0:Monochrome(black/white)

5:5.7"

Frequency Acceleration

5 to 9Hz - 3.5mm

9 to 150Hz 9.8m/s² -

5 to 9Hz - 1.75mm

9 to 150Hz 4.9m/s² -

Halfamplitude

Sweep

Count

10 times

each in X,

Y and Z

directions

2.3 PERFORMANCE SPECIFICATIONS

Item GT1055-QSBD GT1050-QBBD

Type STN color liquid crystal

Screen Size 5.7"

Resolution 320 x 240 dots

Display Size (WxH) 115 x 86 (4.53 x 3.39) mm (inch) (Horizontal format)

Display Character

Display Color 256 colors

Display Section *1

Contrast Adjust. 16-level adjustment

Intensity of LCD Only 380 [cd/m

Life

Type

Life

Backlight

LED (POWER LED)

No. of touch keys Maximum 50 keys/screen (Matrix resistive film touch panel)

Key size Minimum 16 x 16 dots (per key)

Simultaneous

pressing of two (or

more) areas (2-point

Touch Panel

press)

Life 1 million times or more (operating force 0.98N max.)

Item GT1055-QSBD GT1050-QBBD

C Drive *3

Life 100,000 (Number of write times)

Memory

D Drive

Model GT11-50BAT lithium battery

Type Magnesium maganese dioxide lithium primary battery

Backup Target Clock data, alarm history and recipe data

Battery

Life Approx. 5 years (Operating ambient temperature of 25°C)

Buzzer Output (a buzzer

that sounds when touch

keys are pressed)

Environmental Protective

Structure *4

External Dimensions

W x H x D mm (inch)

RS-422/485

RS-232

Built-in Interface

USB

GT10-50FMB For connecting GT10-50FMB memory board

Panel Cutting Dimensions (W x H) 153 x 121 (6.03 x 4.77) mm (inch) (Horizontal format)

Weight 0.7kg (Excluding mounting fixtures)

Compatible Software

Package

16-dot standard font: 20 characters x 15 lines, 12-dot standard

font: 53 characters x 20 lines (Horizontal Format)

²

Approx. 50,000h. (Time for display intensity to become 1/5 at

operating ambient temperature of 25°C)

Cold cathode fluorescent tube (irreplaceable by a user)

backlight shutoff detection function is included. Backlight off/

screen saving time can be set.

Approx. 75,000h or longer

(Time for display intensity

reaches 50% at the operating

ambient temperature of 25°C)

Green light : Power is supplied

Orange light : Screen saving

Green / Orange flashing : Blown backlight bulb

POWER LED is not lit : Power is not supplied

Enable

Flash memory ROM (Internal), for storing project data

(3M bytes or less) and OS

SRAM (Internal), for storing alarm history, recipe data and time

action setting value

Single tone (LONG/ SHORT/ OFF adjustable)

Equivalent to IP67 (JEM1030) (front section)

164 x 135 x 56 (6.46 x 5.32 x 2.21)

(Excluding mounting fixtures) (Horizontal format)

Conforming to serial RS-422/485 standard, 1ch

Transmission speed: 115,200/57,600/38,400/19,200/9,600/

4,800bps

Connector shape: D-sub 9-pin (Female)

Application: PLC communication

Terminating resistor *5: Open/110Ω/330Ω (Switched by

terminating resistor selector switch) (At factory shipment: 330Ω)

Conforming to serial RS-232 standard, 1ch

Transmission speed: 115,200/57,600/38,400/19,200/9,600/4,8

00bps

Connector shape: D-sub 9-pin (Male)

Application: PLC communication, bar code reader connection,

PC communication (Project data upload/download, OS

installation, transparent function)

Conforming to serial USB (Full Speed 12Mbps), device, 1ch

Connector shape: Mini-B

Application: PC communication (Project data upload/download,

OS installation, transparent function)

GT Designer2 Version 2.90U or later/GT Designer3 Version

1.01B or later

] 260 [cd/m²]

STN monochrome (white/blue)

liquid crystal

Monochrome (white/blue), 16

scales

Approx. 54,000h or longer

(Time for display intensity

reaches 50% at the operating

ambient temperature of 25°C)

5

Page 6

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

1. Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel. It is

impossible to completely avoid this symptom, as the liquid crystal display comprises of a great

number of display elements. Flickers may be observed depending on the display color. Please

note that these dots appear due to its characteristic and are not caused by product defect.

• Flickers and partial discoloration may be generated on the liquid crystal display panel due to

the display contents or the contrast adjustment. However, please note that these phenomena

appear due to its characteristic and are not caused by product defect.

• There is a difference in the display brightness and the color tones between liquid crystal

display panels. When using multiple liquid crystal display panels, please note that there is an

individual difference between them.

• • A crosstalk (shadow as an extension of the display) may appear on the liquid crystal display

panel. Please note that it appears due to its characteristic.

• When the display section is seen from the outside of the display angle, the display color

seems like it has changed. Please note that it is due to its characteristic.

• Please note that the response time, brightness and color of the liquid crystal display

panel may vary depending on the usage environmental temperature. Especially in the low

temperature environment, the display response becomes slow due to the characteristics of

the STN liquid crystal. Please check the display response in advance for using this product.

• When the same screen is displayed for a long time, an incidental color or partial discoloration

is generated on the screen due to heat damage, and it may not disappear. To prevent heat

damage, the screen saver function is effective. F

2. Using the GOT Backlight OFF function can prolong the life of the backlight.

3. ROM in which new data can be written without deleting the written data.

4. Note that this does not guarantee all users’ operation environment. In addition, the product may

not be used in environments under exposition of oil or chemicals for a long period of time, or in

environments filled with oil-mist.

5. Set the terminating resistor selector switch of the GOT in accordance with the connection type

when adopting GOT multidrop connection. Gradation inversion is a characteristic of liquid crystal

displays. Please be forewarned that depending on the displayed color, the visualization may be

difficult even within the described view angle. Using the GOT Backlight OFF function can prolong

the life of the backlight. The touch panel is analog resistive film-type. If you touch the panel

simultaneously in 2 points or more, the switch that is located around the center of the touched

point, if any, may operate. Do not touch the panel in 2 points or more simultaneously. Do not

press the GOT display section with a pointed material as a pen or driver. Doing so can result

in a damage or failure of the display section. For the analog-resistive film type touch panels,

normally the adjustment is not required. However, the difference between a touched position

and the object position may occur as the period of use elapses. When any difference between

a touched position and the object position occurs, execute the touch panel calibration. When

any difference between a touched position and the object position occurs, other object may be

activated. This may cause an unexpected operation due to incorrect output or malfunction. ROM

in which new data can be written without deleting the written data. Set the terminating resistor

selector switch of the GOT in accordance with the connection type when adopting GOT multidrop

connection. Compliant with IP67 when the USB environmental protection cover is attached. Not

compliant when a USB cable is connected. Note that this does not guarantee all users’ operation

environment. The protection is not applied when the interface environment protection cover is

removed. In addition, the product may not be used in environments under exposition of oil or

chemicals for a long period of time, or in environments filled with oil-mist.

Appearance

White stripe patterns may appear on the surface of the resin molded part of the product. Please note

that these phenomena appear due to the characteristics of the material used in the product and are

not caused by product defect.

2.4 POWER SUPPLY SPECIFICATIONS

GT1055-QSBD GT1050-QBBD

Input power supply

voltage

Fuse (built-in, not

exchangeable)

Power Consumption (At

backlight off)

Inrush current 15A or less (26.4VDC) 2ms

Permissible

instantaneous power

failure time *1

Noise immunity

Dielectric withstand

voltage

Insulation resistance

Grounding

*1 The GOT continues to operate even upon 5ms or shorter instantaneous power

failure. The GOT stops operating if there is extended power failure or voltage drop,

while it automatically resumes operation as soon as the power is restored.

6

24VDC (+10% -15%)

1.0A

9.84W (410mA/24VDC)

or less,

(4.32W (180mA/24VDC)

or less)

9.36W (390mA/24VDC)

or less,

(4.32W (180mA/24VDC)

or less)

Within 5ms

Noise voltage: 1000Vp-p, Noise width: 1µs (by noise

simulator of 30 to 100Hz noise frequency)

500VAC for 1 minute (across power supply terminals

and earth)

10MΩ or larger by insulation resistance tester (across

power supply terminals and earth)

Class D grounding (100Ω or less). To be connected

to the panel when grounding is not possible

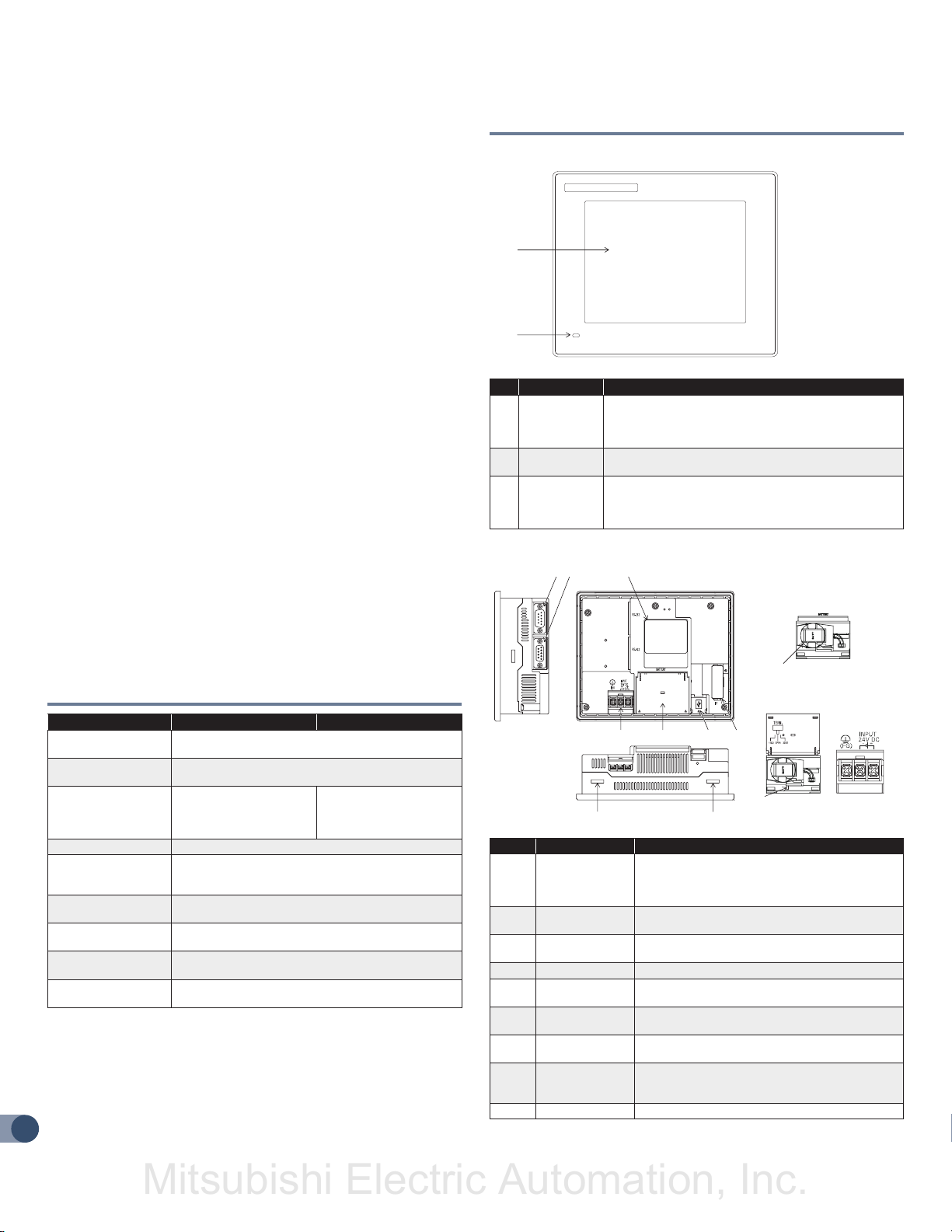

3. HARDWARE SPECIFICATIONS

FRONT PANEL

1) 2)

3)

No. Name Description

Displays the utility screen and the user creation screen.

(1) Display section

(2) Touch panel

(3) POWER LED

BACK PANEL

No. Name Description

(1)

(2)

(3) USB interface

(4) USB cover Open or close when using the USB interface

(5) Power terminal

(6)

(7)

(8)

(9) Battery cover Open or close when replacing the battery.

PLC connection

interface (RS-232)

PLC connection

interface (RS-422)

Power terminal

cover

Rating plate

(nameplate)

Hole for unit

installation fitting

GT1055-QSBD : 320 240 dots, STN color liquid crystal

GT1050-QBBD : 320 240 dots, STN monochrome (white/

blue) liquid crystal

For operating the touch switches in the utility screen and the

user creation screen

Green light: Power is supplied

Orange light: Screen saving (At backlight off)

Green / Orange flashing: Blown backlight bulb

POWER LED is not lit: Power is not supplied

7))1 )2

Battery cover opened

(Hardware version A to B)

10)

(Hardware version

C or later)

5) 6) 3) 4) 11) 12)9)

13)

8) 8)

For communicating with controller (PLC,

microcomputer board, bar code reader, etc) or

personal computer (OS installation, project data

download, transparent) (D-sub 9-pin male)

For communicating with controller (PLC,

microcomputer board, etc) (D-sub 9-pin female)

For PC connection (OS installation, project data

download, transparent) (Mini-B)

Power terminal and FG terminal (for power supply

(24VDC) to GOT and grounding)

Open or close when connecting a power terminal.

(Color: transparent) (Hardware version B or later)

-

Hole for the inserting installation fittings (accessory)

during the GOT installation to the panel (4 holes at top

and bottom)

Power supply

terminal layout

Page 7

GT105_ QUICK START MANUAL

62(2.44")

(1.19")

Mitsubishi Electric Automation, Inc.

(10) Battery

history, recipe data and time action setting value (The

project data is stored in the built-in flash memory.)

GT11-50BAT battery for storing clock data, alarm

Memory board

(11)

(12)

(13)

cover

Memory board

interface

Terminating

resistor selector

switch (TERM.)

Remove when using the memory board.

Interface for mounting the memory board to the GOT.

Terminating resistor selector of RS422/485

(330Ω /OPEN/110Ω) (At factory shipment: 330Ω)

4. EXTERNAL DIMENSIONS

164(6.46")

23(0.91")

120(4.73")

120(4.73")

152(5.99")

135(5.32")

6(0.24")

47(1.86")

56(2.21")

53(2.09")

22

(0.87")

22

(0.87")

10

(0.4")

#4-40UNC

(Inch screw type)

M2.6

(Metric screw type)

120

(4.73")

10

Panel thickness: 5mm(0.2") or less

(0.4")

Nameplate

Model name

LOT.

<Jan., 2010 or later>

3-digit

1 0 1

Year (example: 2010)

Last two digit of year

GT11-50BAT

LOT.101

Month

(example:Jan.)

1 (Jan.) to 9 (Sep.),

X (Oct.), Y (Nov.), Z (Dec.)

Connector

<Dec., 2009 or before>

2-digit

8

X

Month

(example: Oct.)

1 (Jan.) to 9 (Sep.),

X (Oct.), Y (Nov.), Z (Dec.

Year (example: 2008)

Last digit of year

6. INSTALLATION AND REMOVAL

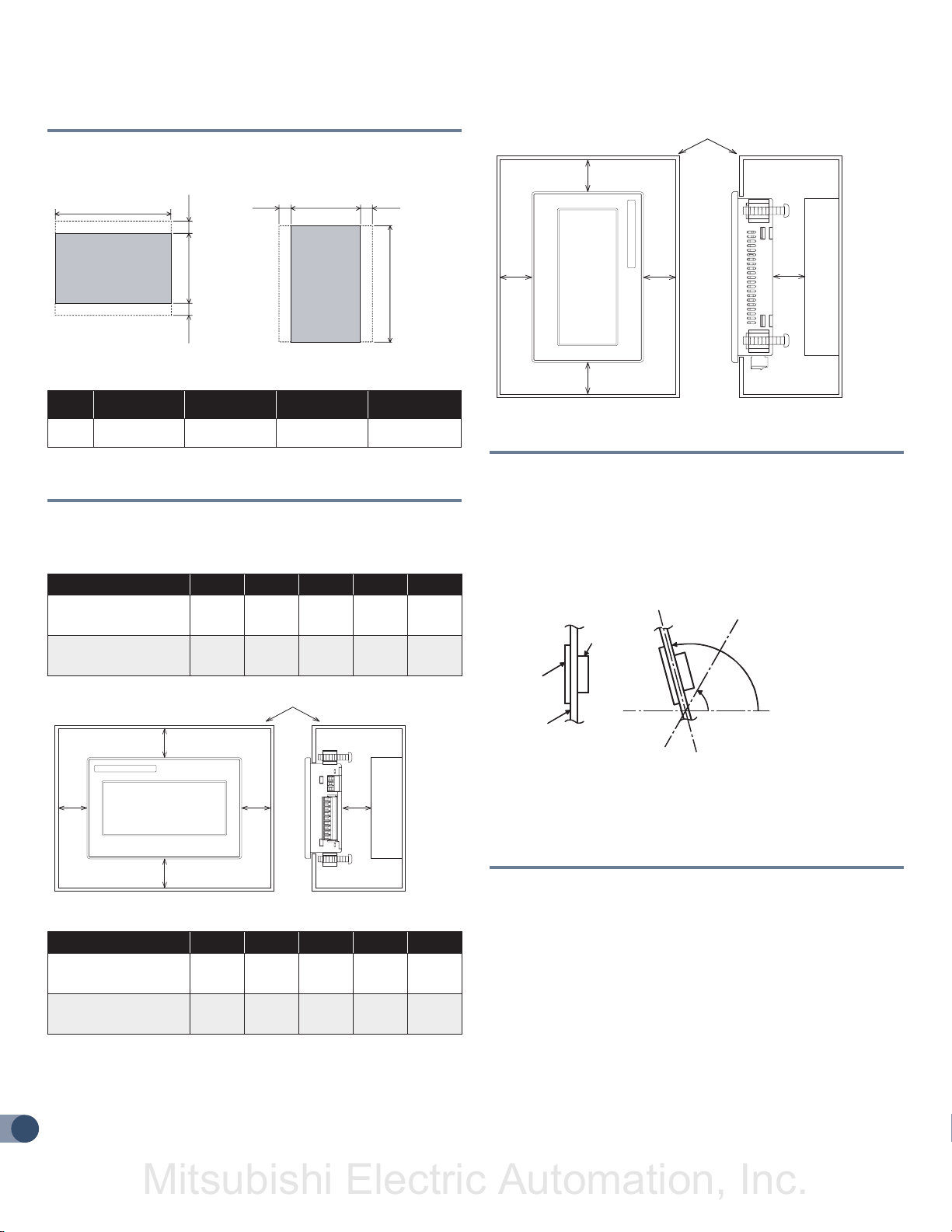

6.1 CONTROL PANEL INSIDE DIMENSIONS FOR MOUNTING GOT

Mount the GOT onto the control panel while considering the following

control panel inside dimensions.

Horizontal format.

30

(1.19")

152 (5.99")

120 (4.73")

140 (5.52")

Memory board connected

5. RATING PLATE

Example nameplate (manufacture's serial number 1010001)

GRAPHIC OPERATION TERMINAL

MODEL

IN 20.4

S/N

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

<Jan., 2010 or later>

7-digit

0 1 10 0 0

<Dec., 2009 or before>

6-digit

9 X 0 0 0

Unit: mm(inch)

GT1055-QSBD

POWER 2.2W MAX

26.4VDC

1010001 AA

Actual product nameplate differs

*

from the example shown above.

1

Control number

Month (example: Jan.). 1 to 9: Jan. to Sep.,

X: Oct., Y: Nov., Z: Dec.

Year (example: 2010)

Last two digit of year

1

Control number

Month (example: Oct.). 1 to 9: Jan. to Sep.,

X: Oct., Y: Nov., Z: Dec.

Year (example: 2009)

Last digit of year

Unit:mm(inch)

Vertical format.

140 (5.52")

120 (4.73")

152 (5.99")

30

Unit:mm(inch)

Applicable cable

Some cables may need to be longer than the specified dimensions

when connecting to the GOT. Therefore, consider the connector

dimensions and bending radius of the cable as well for installation.

How to confirm production year and month

The production date of the optional replacement battery can be

confirmed by the lot No. marked on the nameplate (label) affixed on the

battery.

7

Page 8

GT105_ QUICK START MANUAL

• Horizontal format • Vertical format

Mitsubishi Electric Automation, Inc.

6.2 PANEL CUTTING DIMENSIONS

Cut holes in the following dimensions on the panel. A space of top and

bottom is required to allow for the attachment of mounting fixtures.

A

B CC

Unit: mm(inch)

GOT A B C

GT105

153 (6.03")

(+2 (0.07"), 0 (0))

121 (4.77")

(+2 (0.07"), 0 (0))

B

10 (0.39") or

more

CC

A

Unit: mm(inch)

Panel Thickness

mm (inch)

Within 2 (0.07")

to 5 (0.19")

6.3 MOUNTING POSITION

When mounting the GOT, the following clearances must be maintained

from other structures and devices.

Horizontal position

Installation Environment A B C D E

In the presence of radiatednoise or heat-generating

equipment nearby

In the absence of radiatednoise or heat-generating

equipment nearby

B

50 mm

(1.97")

or more

20 mm

(0.79") or

more

80 mm

(3.14") or

more *1

20 mm

(0.79") or

more

Other device or control panel

50 mm

(1.97") or

more*2

20 mm

(0.79") or

more

50 mm

(1.97")

or more

20 mm

(0.79") or

more

100 mm

(3.93") or

more

20 mm

(0.79") or

more

Other device or control panel

B

C

ED

A

6.4 CONTROL PANEL INSIDE TEMPERATURE AND MOUNTING ANGLE

When mounting the main unit to a control panel or similar fixture, set

the GOT display section as shown below.

Horizontal installation

When the temperature inside the control panel is 40° to 55°, the

mounting angle should be in the range from 60 to 105 degrees.

Vertical installation

When the temperature inside the control panel is 40° to 50°, the

mounting angle should be in the range from 60 to 105 degrees.

GOT

back

GOT

display

section

panel

105°

60°

Control

panel, etc.

The GOT will have a longer lifetime if used within the mounting angles

C

D E

shown above. Ideally, the temperature inside the control panel should

not exceed 0 to 40°C

6.5 INSTALLATION PROCEDURE

A

The GOT is designed to be embedded into a panel. Mount the GOT by

following the procedure below.

Vertical position

Installation Environment A B C D E

In the presence of radiatednoise or heat-generating

equipment nearby

In the absence of radiatednoise or heat-generating

equipment nearby

50 mm

(1.97")

or more

20 mm

(0.79") or

more

50 mm

(1.97")

or more

20 mm

(0.79") or

more

80 mm

(3.14") or

more *1

20 mm

(0.79") or

more

50 mm

(1.97")

or more

20 mm

(0.79") or

more

100 mm

(3.93") or

more

20 mm

(0.79") or

more

Cautions on the installation panel

Make sure that the panel surface is free from warpage, flaws and

irregularities. Warpage, flaws and irregularities may disable the

waterproof effect. Select proper panel thickness under consideration

of the panel strength. (For example, the panel strength may be

insufficient depending on the panel material and dimensions even

if the panel thickness is acceptable. Insufficient panel strength may

cause warpage depending on the installation positions of the GOT and

other equipment.) Installing the packing Install packing to the packing

installation groove on the back panel of the GOT. While referring to

the cross sectional view of the packing shown right, push the thinner

side into the packing groove. (Drawing below is the example of lateral

8

format.)

Page 9

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

For GT105

While referring to the cross sectional view of the packing shown right,

push the thinner side into the packing groove. (Drawing below is the

example of lateral format.)

Packing

Magnified

illustration

Packing

Packing

installation groove

Packing cross

sectional view

Inserting

direction

Inserting into the panel face

Insert the GOT from the front side of the panel. (Drawing below is the

example of lateral format.)

Mounting hole

Fixing the GOT

1. Insert the hooks on the mounting fittings (supplied) into the mounting

holes on the GOT unit.

2. Slide the mounting fittings to the back end.

3. Slide them to the left to lock them in place, and then fix them with

the mounting screws (supplied).

The GOT will be fixed in 4 upper/lower parts.

Magnified illustration

Mounting fitting

Mounting screw

For GT105

Cautions on installation

Tighten the mounting screw with the specified torque. Undertightening

of mounting screws can cause a drop, and deteriorate the waterproof

effect and oilproof effect. Failure to do so may damage the unit, or

distort the panel and make a surface waviness on the display area,

leading to deterioration of the visibility or incorrect input from the touch

panel. In addition, the waterproof effect and oilproof effect may not be

available due to the “distortion” of GOT or panel.

GOT GT105

Tightening torque 0.3 to 0.5 N•m

A protection film is attached on the display section of GOT prior to

shipment. Remove the film when the installation is completed.

7. WIRING

DANGER WIRING PRECAUTIONS

• Be sure to shut off all phases of the external power supply used by

the system before wiring. Failure to do so may result in an electric

shock, product damage or malfunctions.

• Please make sure to ground FG terminal of the GOT power supply

section by applying 100 or less which is used exclusively for the

GOT. Not doing so may cause an electric shock or malfunction.

• Correctly wire the GOT power supply section after confirming the

rated voltage and terminal arrangement of the product. Not doing so

can cause a fire or failure.

• Tighten the terminal screws of the GOT power supply section in the

specified torque range. Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction

due to the damage of the screws or the GOT.

• Exercise care to avoid foreign matter such as chips and wire

offcuts entering the GOT. Not doing so can cause a fire, failure or

malfunction.

CAUTION WIRING PRECAUTIONS

• Plug the communication cable into the connector of the connected

unit and tighten the mounting and terminal screws in the specified

torque range. Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction

due to the damage of the screws or unit.

GENERAL PREVENTIVE MEASURES AGAINST NOISE

There are two kinds of noises: Radiated noise that is transmitted

into the air and conductive noise that is directly transmitted along

connected lines. Countermeasures must be taken considering both

kinds of noises and referring to the following 3 points.

1. Protecting against noise

Keep signal lines away from noise sources such as a power cable

or a high power drive circuit.

Shield the signal lines.

2. Reducing generated noise

Use a noise filter, etc. to reduce the level of the noise generated

due to a source such as a high-power motor drive circuit.

Attach surge killers to the terminals on the no fuse breakers

(NFB), electromagnetic contactors, relays, solenoid valves, and

generators to suppress noise interference.

3. Releasing noise to the ground

Make sure to connect the ground cable to the ground.

Use a short and thick cable to lower its ground resistance.

Ground the power system and the control system separately.

9

Page 10

GT105_ QUICK START MANUAL

Terminal

Solderless

Mitsubishi Electric Automation, Inc.

7.1 POWER SUPPLY WIRING

Connect the power supply to the power terminals on the back panel

of the GOT. Use a specified size power supply wire to prevent voltage

drop, and tighten the terminal screws firmly to a specified torque. Do

not exceed the number of wires that are allowed to be connected.

Use 0.75mm² or thicker cables to avoid voltage drop and tighten the

terminal screw with the specified torque securely. Terminal screws

should be tightened to between 0.5 to 0.8 N•m. Terminal screws must

be secured to prevent a loose connection thus avoiding a malfunction.

Failure to do so may cause equipment failures or malfunctions.

Electrical wire size, recommended terminal shape

Solderless

6.2mm

or less

6.2mm

or less

3.2

3.2

When wiring one cable to When wiring two cables to

Terminal

screw

terminal

screw

terminal

Cable Size For Power Supply: 0.75mm² min. For Grounding: 2mm² min.

M3 solderless terminal:

Solderless

terminal

Recommended applicable solderless terminal

JST Part No. FV0.5-3, Pressure Bonding Tool YHT-2622

JST Part No. FV1.25-B3A, Pressure Bonding Tool YNT-2216

JST Part No. FV2-MS3, Pressure Bonding Tool YNT-1614

Wiring example GT105

noise, which may result in malfunctions. Keeping the GOT’s ground

cable and power line away from each other will help minimize noise

interference.

FG

Power supply for power equipment

Good: Wiring the ground cable away

from the power cable

Power supply for power equipment

Bad: Bundling the ground cable and

the power cable

Connecting the ground cable from the panel that houses control

equipment to the panel to which the GOT is grounded.

When running a single ground cable from the panel that houses such

piece of control equipment as a sequencer to the panel to which the

GOT is grounded, the ground cable may have to be directly connected

to the terminal on the GOT.

Connection cable

FG

Ground cable from

the panel that houses

control equipment

INPUT

24V DC

+10%

DC24V

Class D

grounding

-15%

Tightening torque for the power terminals 0.5 to 0.8 N•m

Grounding the GOT and other devices

Make sure to carry out the followings for grounding.

• Carry out the independent grounding if possible. Provide class D

(class 3) grounding. (Ground resistance must be 100Ω or less.)

• If the independent grounding is impossible, carry out the shared

grounding as shown in fig. 2) below.

Grounding

(100 or less)

Other

device

GOT

(1) Independent ground

...... Best condition

GOT

(2) Shared grounding

...... Good condition

Grounding

(100 or less)

Other

device

GOT

(3) Common grounding

...... Not allowed

• Set the grounding point closer to the GOT to make the grounding

cable short as possible. Provide grounding using a single grounding

wire. Below to shows the proper size grounding wire.

• Ground wire size: 2mm² or more.

THE CAUSE OF MALFUNCTIONS RELATED WIRING/REMEDY

Grounding of the GOT may cause electric potential difference and

noise interference, which may result in GOT malfunctions. These

problems may be resolved by taking the following measures.

• Wiring path of the GOT’s ground cable and power line Bundling the

10

GOT’s ground cable and power line together can cause interference

Other

device

If electric potential difference between the ground points created by

it causes malfunctions, lowering the voltage as shown in Remedy 1

below may solve the problem.

Remedy 1 (Refer to the figures Remedy 1-1 and 1-2 below.)

If the electric potential difference between the ground cable and the

panel that houses the GOT is creating problems, connect the ground

cable to the panel also. If the wiring method as shown in Remedy 1-1 is

not feasible, follow Remedy 1-2.

Connection cable

Ground cable from

the panel that houses

control equipment

Use the thickest

cable possible.

FG

Panel

grounding

Remedy1-1

Connection cable

Ground cable from

the panel that houses

control equipment

Use the thickest

cable possible.

FG

Panel

grounding

Remedy1-2

If taking Remedy 1 worsens noise interference, taking Remedy 2 may

alleviate it.

Remedy 2 (Refer to the figures Remedy 2-1 and 2-2 below.)

Attach a ferrite core to the cable if noise from the GOT panel has

adverse effects on the GOT when Remedy 1 is taken. Wind the wire

around the ferrite core several times (approx. 3 times), if a ferrite core

is used. If the wiring method as shown in Remedy 2-1 is not feasible,

follow Remedy 2-2.

Connection cable

Ground cable from

the panel that houses

control equipment

Use the thickest

cable possible.

FG

Ferrite core

Panel

grounding

Remedy2-1

Connection cable

Ground cable from

the panel that houses

control equipment

Use the thickest

cable possible.

FG

Ferrite core

Panel

grounding

Remedy2-2

Page 11

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

7.2 WIRING INSIDE AND OUTSIDE THE PANEL

Wiring inside

Run power lines, servo amplifier drive wires, and communication

cables so that they do not cross each other. Noise interference that is

generated by cables that cross each other may cause malfunctions.

Surge suppressors are an effective way to filter out surge noise that is

generated from no fuse breakers (NFB), electromagnetic contactors

(MC), relays (RA), solenoid valves, and induction motors.

Power

cable

Uncrossed power lines and

communication cables

GOT connection cable

NFB

MC

PLC

PLC I/O wire

MC RA RA

Drive control wire

Terminal block Terminal block

Power

cable

NFB

MC

Crossing power lines and

communication cables

PLC

PLC

I/O wire

MC RA RA

Drive control wire

GOT connection cable

Outside the panel

To pull the power line and communication cable out of the panel, make

two pullout holes away from each other and pull the cables through.

Putting both cables through the same pullout hole will increase noise

interference.

Connection

cable

Power line

Pullout hole Pullout hole

Power line

Connection

cable

Keep the power line and communication cable inside the duct at least

100 mm away from each other. If that is not possible, the use of a

metal separator inside the duct can reduce noise interference.

Power line

Wiring duct Separator

Remedy for DC inductive load

Keep the ground cable and

communication cable away

from each other.

Output

Output equipment

such as PLC output unit

D

DC

L: Load

Place the surge killer

near the load.

8. OPERATION SETTINGS

8.1. BATTERY

The battery backs up clock data, alarm history and recipe data. At

factory shipment, a battery is built in the GT105.

Applicable battery

Model Name Description

GT11-50BAT

Battery specifications

Item Description

Type Magnesium manganese dioxide lithium primary battery

Initial Voltage 3.0V

Storage Life Approx. 5 years (Operating ambient temperature of 25°C )

Application

Replace battery periodically at intervals of 4 to 5 years as reference.

1. Turn the GOT power off.

2. Open the back cover of the GOT.

3. Remove the old battery from the holder.

Battery for backup of clock data, alarm history, recipe data and

time action setting value

For backup of clock data, alarm history, recipe data and time action

setting value

Back cover

100mm or more

Signal line

Signal linePower line

Attaching surge killers to control equipment

If communication errors happen in sync with the on/off signals from

certain control equipment (referred to as “load” hereafter) such as no

fuse breakers, electromagnetic contactors, relays, solenoid valves, and

induction motors, surge noise interference is suspected. If this problem

happens, keep the ground cable and communication cable away from

the load. If that is not possible, an installation of a surge killer will help

reduce noise interference. Place the surge killer as close to the load as

possible.

Remedy for AC inductive load

Keep the ground cable and

communication cable away

from each other.

AC

C

R

L: Load

Place the surge killer

near the load.

Output

Output equipment

such as PLC output unit

Holder

Connector

4. Disconnect the old battery connector and insert the new battery

connector within 30s.

5. Insert the new battery into the holder and close the back cover.

r

Back cove

Holder

Connector

6.Turn the GOT power on.

7. Check if the battery condition is normal with the utility.

8.2 UTILITY FUNCTION

The utility functions allow the user to confirm the settings for

communication interface, screen display, operation methods, and

clock data as well as OS information. GT10 is factory-installed with

the Standard monitor OS and BootOS. (An installation of the Standard

monitor OS or BootOS is not required to use the utility functions.)

11

Page 12

GT105_ QUICK START MANUAL

Menu call key

Mitsubishi Electric Automation, Inc.

Utility Function List

The items in the following list can be set/operated on the utility

screens.

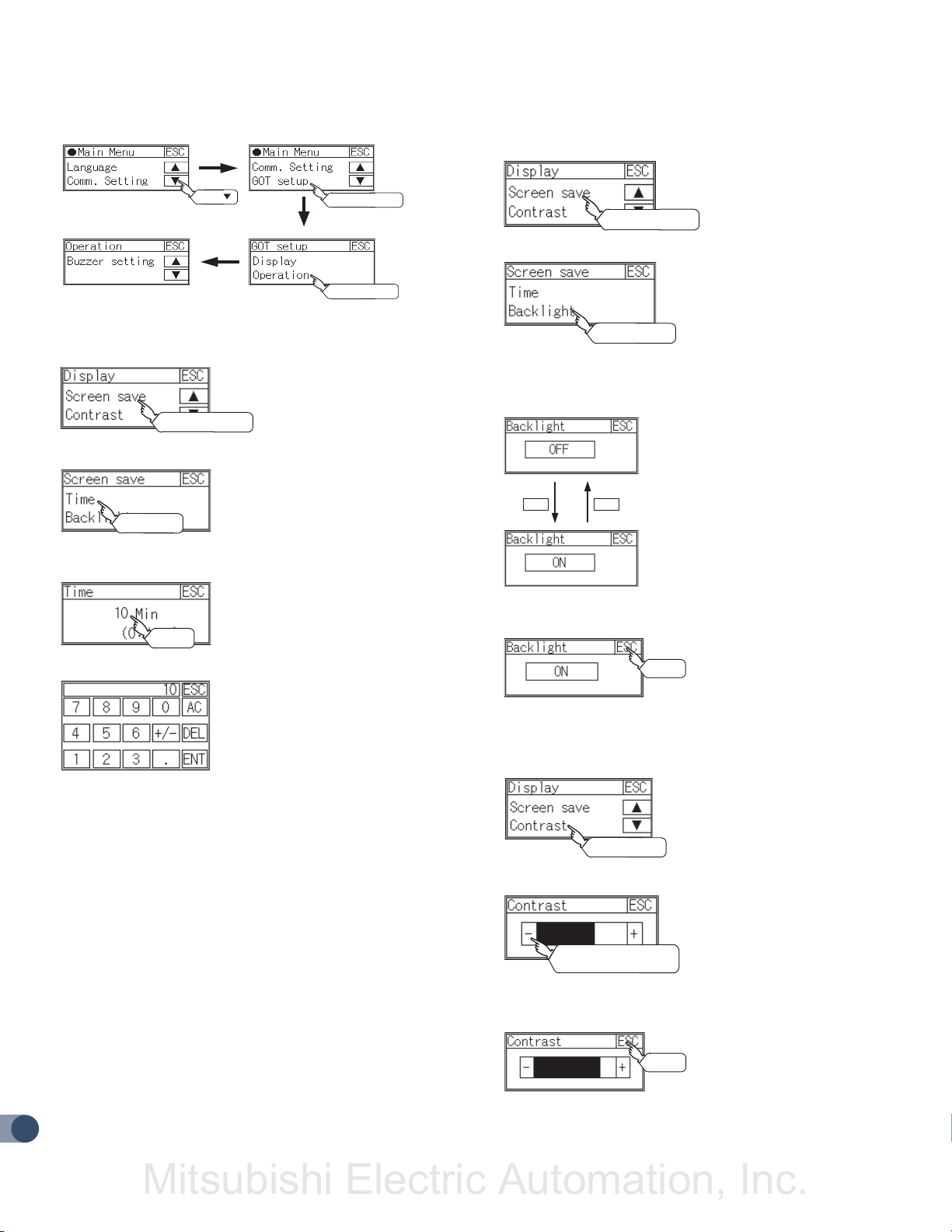

Item GT105

Language

Standard I/F

Data Transfer

Communication Monitor

Keyword Sets a keyword of the FX series PLC.

Time

Screen

Save

Backlight

Contrast

Brightness -

Opening time

Buzzer Volume

Buzzer

Setting

Window Move

Buzzer

Calibration -

Security *1

Utility Call Setting of the menu call key

Key Reaction Display of key reaction speed

Clock Setting

Time setting

OS Information

Data

Clear Data Clears the project data and resource data on the GOT

GT10-50FMB Datas are transferred between the memory boards.

Device Monitor Device monitor of PLC of intelligent module

FX List Editor The sequence program of FX PLC can be list edited

FX3U-

Debug

ENETADP

Communication

Setting Function

Clean Display the screen to clean the display section

*1: It is necessary to set the security level with drawing software.

Switches the display language for the utility functions

(Japanese/English)

Displays the detailed information about the

communication method and communication driver

Displays the screen for transferring project data between

the PC and GOT (If any device other than the PC is

allocated to the interface for communication with PC, the

GOT will not be able to communicate with the PC, except

when the Data transfer window is on the screen.)

Displays the communication status of each

communication port

Sets the screensaver activation time (from the last time

the screen was touched) Setting range: 0 to 60 min.

(Screensaver is disabled when it is set to 0 minute.)

Default: 0 min.

This setting is used to decide whether to turn the

backlight on or off when the screensaver comes on

Default: OFF

Adjusts the contrast on the liquid crystal display

(16 level adjustment, 0 to 15)

The title display period at the main unit boot can be set.

(0 to 60 sec) Default: 5 sec

Changes the buzzer settings (OFF/SHORT/LONG)

Default: SHORT

Whether turn ON/OFF buzzer when move window can be

selected Default: ON

Security level change (security password input of each

object)

Setup the method to adjust the time between GOT clock

data and clock data of PLC CPU connected with GOT

Sets the clock (clock data) on the PLC,

Display of battery status

Displays the OS (Standard monitor OS, BootOS) and

communication driver versions

The communication set value of the FX3U-ENET-ADP

stored in the CPU can be changed.

8.3 UTILITY DISPLAY

GOT power on

Touch the OK button

When touching menu call key

If you touch the menu call key while a user-created screen is displayed,

the main menu is displayed. The menu call key can be set with the

GOT utility screen or drawing software. (At factory shipment, menu call

key is set to “Simultaneous 2 - point presses on GOT screen upper right and upper - left corners” on the GT105.)

(1-point touch on GOT screen upper-right corner)

Menu call key

(Simultaneous 2-point touch)

When the utility call key is set to the zero point

Even when the utility call key is set to the zero point, you can display

the main menu using either of the following two operations:

• Pressing the special function switch set on the user-created screen

• Selecting [Utility] from the “Select mode” screen

When touching special function switch

If you touch the special function switch (utility) while user-created

screen is displayed, the main menu is displayed. The special function

switch (utility) can be set as a touch switch that is displayed on a

user-created screen by drawing software. (When the utilities menu is

assigned to the special function switch, the main menu appears when

the switch is touched.)

Special function switch (Utility)

When selecting the start mode

The “Select mode” screen appears when you power ON the GOT while

touching the upper left corner of the screen. If you touch [Utility] on the

“Select mode” screen, the main menu is displayed.

Turn the GOT power

on with the upper left

corner touched.

Touch [Utility].

Display operation of main menu

The following four types of operation can display the main menu. (The

utility function windows appear in the horizontal format, and this format

cannot be changed.)

When project data is not downloaded

After the GOT is turned on, a dialog box for notifying of absence of

project data is displayed. After the dialog box is displayed, touch the

[OK] button to display the main menu.

Lock the utility display by password

When a password is set on the GOT using drawing software, a

password dialog box is displayed when trying to access the main menu

of the utility display. (The password setting option in drawing software

is located in the common menu.) Enter the password that has been

12

set.

Page 13

GT105_ QUICK START MANUAL

Scroll button

Main item

Mitsubishi Electric Automation, Inc.

Input operation of password

1. Input the password after touching [0] to [9], [A] to [F] key.

2. Define the password by touching [ENTER] key, after inputting

password.

3. To correct the input character, touch [DEL] key to delete the

correcting character and then reinput/retype the new character.

Password input cancel operation

1. When [ESC] button is touched, the screen returns to the monitor

screen.

If an invalid password is entered

If an invalid password is entered, the error message will appear.

Touching the [OK] button will take the screen back to the monitor

screen.

When starting the GOT without selecting any language (At factory

shipment) The following screen will be displayed at the initial startup of

GOT. Touching the button of a desired language restarts the GOT and

the language is switched to the selected one.

Utility basic configuration

1. The menu items that can be selected from the GOT utility are

displayed Use the [p], [q] buttons to select an item from the menu.

2. Touching a menu item in the main menu will display the setting

screen or following selection screen for the item.

3. Touching the [ESC] button will take the screen back to the user

screen.

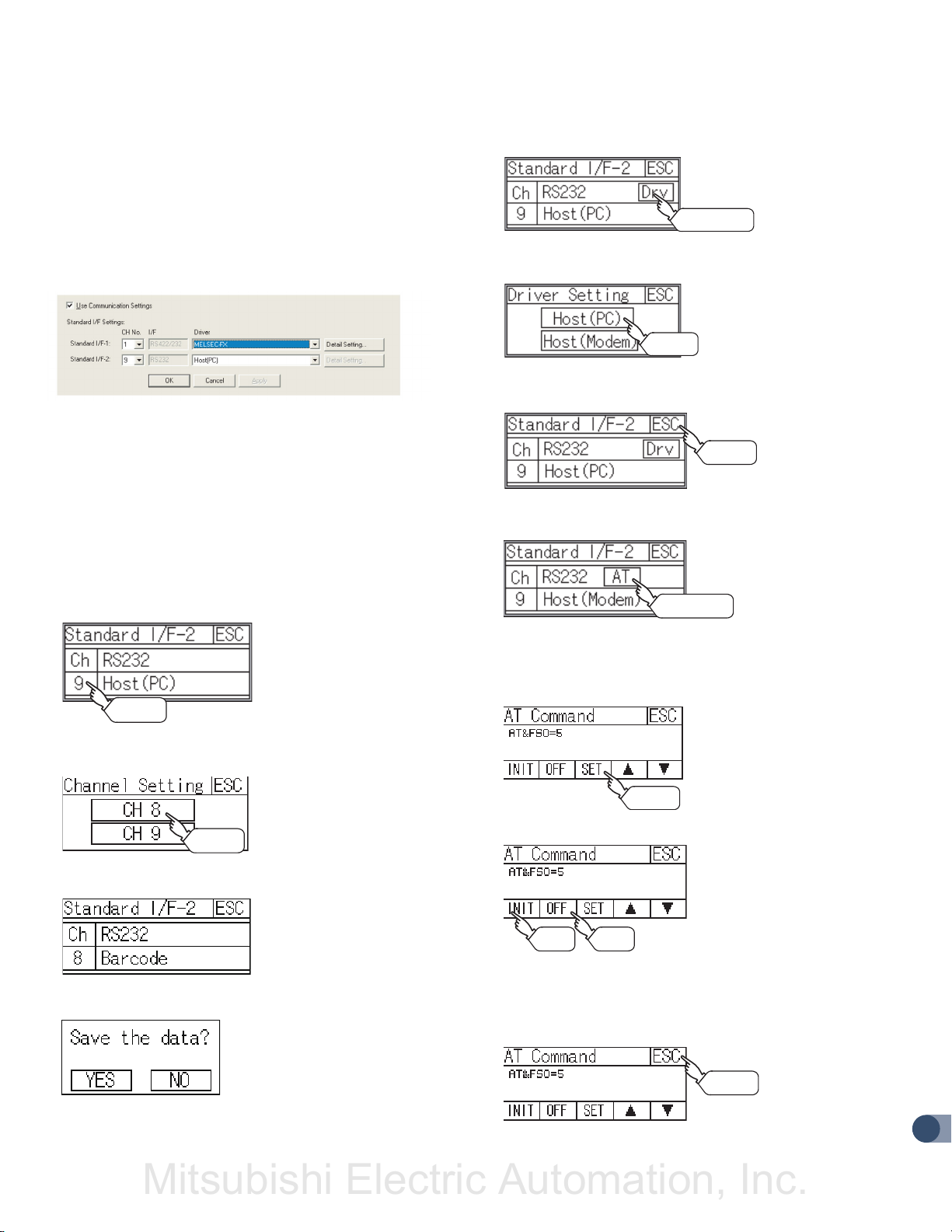

8.4 COMMUNICATION INTERFACE SETTING

The [Communication Setting] menu has the [Standard I/F], [Data

Transfer], [Communication Monitor], and [Keyword] menus. The

[Standard I/F] menu sets the information about the channel numbers,

controller name, and detailed settings of the communication

parameters that are allocated to the communication interfaces by

drawing software.

The [Data Transfer] menu displays the screen for transferring project

data between the PC and GOT. The [Communication Monitor] menu

displays the communication status of each communication port. The

[Keyword] menu registers, deletes, clears, and protects a keyword of

the FX series PLC.

Standard I/F functions

Function Contents

Channel no. display

Communication driver

display

Communication parameters

display

Displays the channel number (CH No) that has been

assigned by drawing software

Displays the communication driver that has been

assigned by drawing software

Displays the communication parameters of the

controllers that has been assigned by drawing

software

n STANDARD I/F DISPLAY OPERATION

Main Menu

Touch [Comm. Setting].

Standard I/F

Touch [Standard I/F].

Title display

The screen title name is displayed in title display part.

Close/Return button

When a middle screen of the layers is displayed, if the [ESC] (Close/

return) button in the right corner of screen is touched, returns to the

previous screen. If this button is touched when directly displayed from

monitor screen, the screen is closed and returns to monitor screen.

Scroll button

For screens in which the content does not fit on one screen page,

there is a right or down scroll button on the screen. [p], [q] Scroll one

line/window

Close/Return buttonTitle display

Described below are the display items on the standard I/F setting menu

and their functions.

1. Display item column

Channel No.

specification menu BOX

Standard interface display BOX

Driver display BOX

button

Drv

AT

button

Standard interface display BOX

The standard interface includes the following three types.

• Standard I/F-1 (RS-422): For communication with PLC,

microcomputer and other equipment

• Standard I/F-2 (RS-232): For communication with PLC, PC

(drawing software), modem, other equipment, bar code reader and

transparent

• Standard I/F-3 (USB): For communication with PC (drawing

software) and transparent

13

Page 14

GT105_ QUICK START MANUAL

Standard I/F-1 (RS-422)

[GOT back panel]

Standard I/F-2 (RS-232)

Standard I/F-3 (USB)

Mitsubishi Electric Automation, Inc.

Channel No. specification menu BOX

0: Set when the communication interface is not used.

1: Set when connecting to PLC or microcomputer.

(For GT105_, either of standard I/F-1 or standard I/F2 can be set.)

Set when connecting to bar code reader.

Set when connecting to PC (drawing software), modem. (For

standard I/F-2 and standard I/F-3, the simultaneous setting is

possible. However, when either interface is communicating, the

communication is not allowed for another interface.)

• Setting is not allowed for 2 to 7, *.

• Fixed to 9 for the USB interface.

Driver display BOX

The name of the communication driver for which a channel number is

assigned is displayed. “None” is displayed in the driver display box in

the following cases :

The communication driver is not installed.

“0” is set in the channel number specification menu box.

• [*****] will appear when the communication driver that was installed

on the GOT from drawing software and the controller setting that

was downloaded on to the GOT from drawing software do not match.

• When setting the channel number to “9”, the communication driver

“Host (PC)” is automatically assigned.

• When the driver display box is touched, the screen jumps to

the detail information screen and the communication parameter

appears.

• [DRV] button

Displays the driver setting screen.

Select the driver to use on the driver setting screen.

• [DRV] button is displayed in the following cases.

When setting the “ch9” to standard I/F-2.

• [AT] button

Displays the AT command setting screen.

Set the AT command to use for initializing the modem on the AT

command setting screen.

• [AT] button is displayed in the following case.

When “ch9 Host (Modem)” is set to standard I/F-2.

1. Touch Standard I/F-1 driver display box in the Standard I/F setting

window.

2. The screen jumps to the detailed information screen and the

communication parameter will appear. Use the [p], [q] buttons

to toggle through the items when there are multiple items to be

set. (The [p], [q] buttons will not work when no other items are

available.)

3. Touch the numerical values of baud rate to switch them repeatedly.

Ex. 4800bps 9600bps 19200bps

The numerical values are set using the ten-key depending on the

setting

“0” to “9”: Use these keys to enter numerical values. Enter “0” to

disable the screensaver function

“ESC” : Closes the ten-key window without saving any value

entered

“AC” : Deletes the entire string of numerical characters that are

being entered

“DEL” : Deletes a digit from a string of numerical characters that

are being entered

“ENT” : Enters the value for the clock that has been entered and

closes the ten-key pad window

“+ / -” : Switches between positive and negative values (Only

positive values are valid for the clock setting.)

“ . ” : Invalid key (not used)

When the [ESC] button is touched, the settings are fixed and the

window returns to the previous one. Therefore, touch the [ESC] button.

Touch the [ESC] button to display the window confirming whether to

save the settings.

Touch the [YES] button to save the settings and restart. Touch the [NO]

button to discard the changes.

n DETAIL INFORMATION SETTING OPERATION

The types of items that are in the communication parameter setting

menu depend on the type of communication driver that is installed on

Touch [Driver display BOX].

the GOT in use. Refer to the section below for the setting contents of

various drivers.

Precautions for communication between GOT and connected devices

14

1. Installing [Communication driver] and downloading [Communication

Settings] To perform communication with the connected device, the

Page 15

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

following actions are necessary.

a. Installing [Communication driver] (Up to 1, OS installation)

The driver for [MELSEC-FX] is factory-installed. Install the

communication driver to connect a controller other than a

MELSEC-FX.

b. Assigning channel number and communication driver to

communication interface (Communication Setting)

c. Downloading [Communication Settings] (project data) assigned in

step 2)

Perform a), b) and c) with drawing software.

• To change the communication parameter setting after downloading

project data, change the setting at drawing software again.

• When [Communication Settings] has not been downloaded using

drawing software

2. When [Communication Settings] has not been downloaded, the

GOT automatically assigns the installed communication driver as

the standard I/F-1. When assigning the communication driver to

Standard GT105_, make the setting in the communication settings of

drawing software or in the communication settings of the utility.

n CHANNEL NUMBER SETTING OPERATION

1. Touch the channel No. specification menu box to be set.

n DRIVER SETTING OPERATION

1. Touch [Drv] button to bring up the driver setting window.

Touch [Drv]

2. The available driver names are displayed on the driver setting

screen. Select the driver to use.

Touch

3. When the driver is selected, the display returns to the standard IF

setting screen. Touch [ESC] button.

Touch

n AT COMMAND OPERATION

1. Touch [AT] button to bring up the AT command setting window.

Touch [AT]

Touch

2. When the channel setting window appears, select the channel

number.

Touch

3. When the channel number is selected, the settings are fixed and the

window returns to the previous one. Therefore, touch the [ESC] button.

4. Touch the [ESC] button to display the window confirming whether to

save the settings.

2. The AT command, set in the drawing software or in the utility of the

main unit, is displayed. When editing the AT command, touch [SET]

button to display the ASCII window. Input the AT command in the

ASCII window.

Touch

3. Touch following buttons as necessary.

Touch Touch

[INIT] button: Outputs the AT command to the modem.

[OFF] button: Disconnects the line.

4. After settings are completed, touch [ESC] button to close the setting

screen.

Touch

5. Touch the [YES] button to save the settings and restart. Touch the

[NO] button to discard the changes.

15

Page 16

GT105_ QUICK START MANUAL

Main Menu

Mitsubishi Electric Automation, Inc.

n INSTALLING OF COMMUNICATION DRIVER

GT10 is factory-installed with the driver for MELSEC-FX. An installation

of the communication driver is required when connected to a controller

other than a MELSEC-FX. When installing the communication driver,

first bring up the OS installation screen on the GOT, and then install

the communication driver from drawing software.

Bringing up the OS installation screen

Turn the GOT power

on with the lower right

corner touched.

About the OS installation screen

The OS can be transferred from GT Designer2 or GT Designer3

without displaying the OS installation screen depending on the

combination of the GOT and the standard monitor OS.

Model BootOS Version

GT105_ From the first version

Standard

Monitor OS

GT Designer2 GT Designer3

Version2.90U or

later

From the first

version

Checking method of BootOS, Standard monitor OS version

1. 1. Check the version of BootOS or Standard monitor OS installed in

GOT at [OS information] of the utility.

When the Boot OS version

GRAPHIC OPERATION TERMINAL

GT1030-LBD

MODEL

IN 20.4

S/N

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

26.4VDC

710001 AA

POWER 2.2W MAX

AA

BootOS Version

is 2 digits, only the lower

digit is printed.

Example H/W version: H

Boot OS version: AD

Rating plate: HD

2. Check the version of BootOS installed in GOT at product shipment

on the rating plate on GOT rear face.

[Data Transfer] appears at the startup. In the [Normal], an initial screen

appears when the monitor screen has been created, and the utility

main menu appears when the monitor screen has not been created.

[Data Transfer] screen appears in the [Data Transfer]. Standard I/F-2 is

used in the communication mode to the PC.

Bringing up the select mode screen

Turn the GOT power

on with the upper left

corner touched.

DATA TRANSFER DISPLAY

[Waiting] on the data transfer screen will change to [Transferring...]

when project data are transferred from drawing software. At the

completion of data transfer, the user-created screen will appear.

Transfer of project data

from drawing software

Completion of data transfer

User-created screen

Transfer of project data

If [ESC] button on the display screen is pushed during transfer of

project data, transmission of project data is stopped. In that case,

project data are transfered from drawing software again.

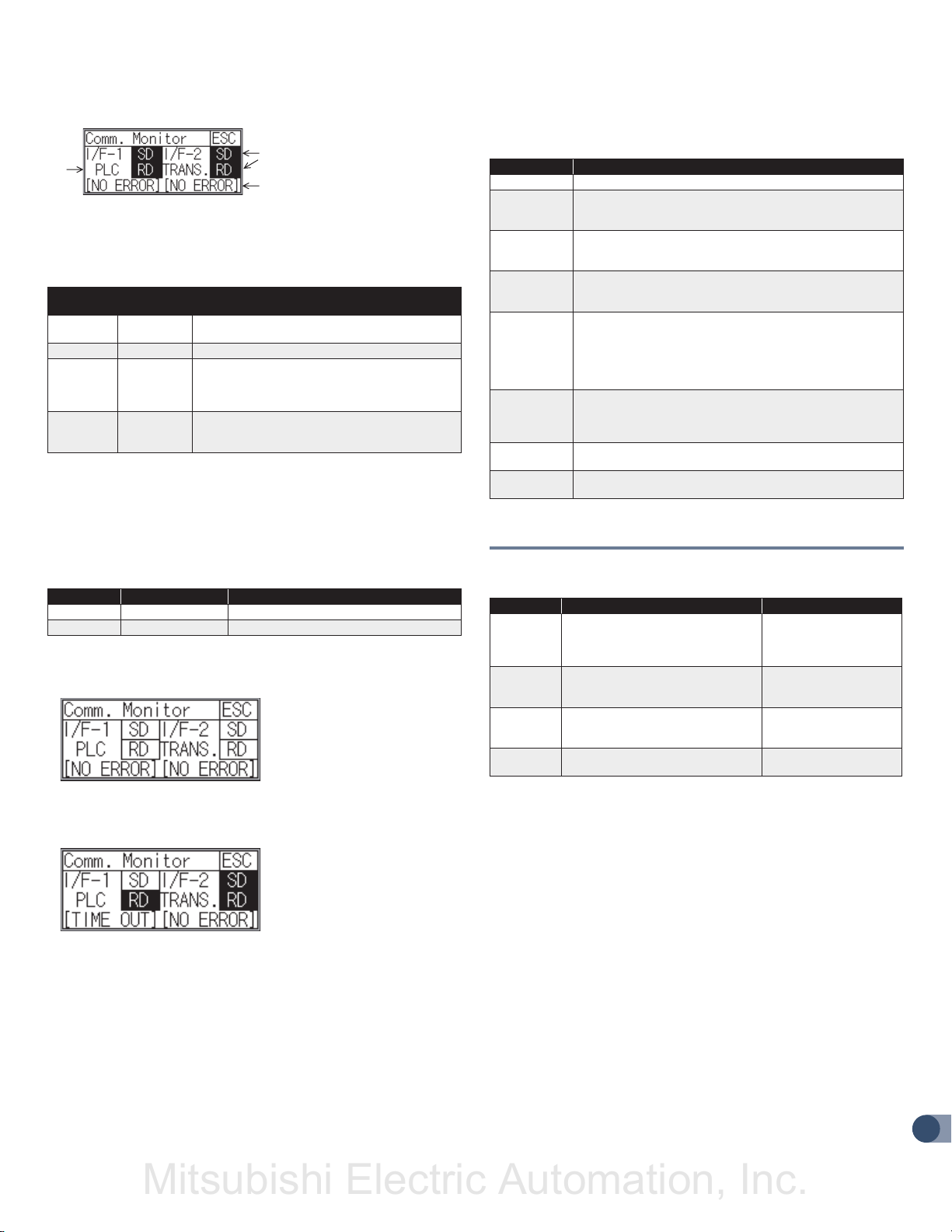

8.6 COMMUNICATION MONITOR

8.5 DATA TRANSFER

Function Contents

Displays the screen for transferring project data between the

Data transfer

screen display

PC and GOT. If any device other than the PC is allocated to the

interface for communication with PC, the GOT will not be able to

communicate with the PC, except when the Data transfer window

is on the screen.

Display from the utility main menu

Main Menu

Touch [Comm. Setting].

Data Transfer

Touch [Data Transfer].

Display from the select mode

If data transfer screen cannot be displayed on the user-created screen,

power ON to perform select mode while pressing and holding the

upper left corner of the screen. The selection screen of [Normal] or

16

Function Contents

Communication port-selection

status display

Communication status display

Communication error status

display

Displays the connection status of Standard I/F-1

and I/F-2

Displays the communication status (SD: send,

RD: receive)

Displays an error message when a communication

error occurs

Communication Monitor display operation

Touch [Comm. Setting].

Communication Monitor

Touch [Comm. Monitor].

Communication Monitor

(When bar code is connected)

Touch .

Page 17

GT105_ QUICK START MANUAL

Mitsubishi Electric Automation, Inc.

Screen display content

1)

2)

3)

Connection status of the communication ports

Indicates the connection status of Standard I/F-1 and I/F-2. Listed in

the table below are display items and the connection status (channel

number).

Display

Item

PLC Ch1

BCR Ch8 “BCR” appears when connected to a bar code reader

TRANS. Ch9

PC Ch9

Channel

Number

Remarks

“PLC” appears when connected to a controller (PLC

or microcomputer)

“TRANS.” appears when the controller that is allocated

to one of the communication ports supports the

transparent mode “TRANS.” automatically changes to

“PC” when communicating with drawing software

“PC” appears when the controller that is allocated to

one of the communication ports does not support the

transparent mode

Communication status

Communication status of each communication port is displayed on this

screen. The [SD] and [RD] symbols appear in black on white while data

are being sent or received, and in white on black at other times. They

may appear lit depending on the communication status.

The SD and RD symbols on the screen indicate normal communication

or cable disconnection.

Port Channel Number Controller Type

I/F-1 Ch1 MELSEC-FX

IF-2 Ch8, Ch9 −

[During normal communication (with connection to a device that

supports the transparent mode)]

Communication error status

Communication error status of each port is displayed on this screen.

The table below summarizes the types and nature of the errors.

Display Item Action

NO ERROR Communication is executed normally.

ERR Ovr.

ERR Frm.

ERR Prt.

ERR Text

TIME OUT

ERR Line

ERR Cmd.

The receive data is sent continuously with a short interval. Let the

baud rate (communication speed) be equivalent between the GOT

and counterpart equipment.

The communication frames of GOT and PLC are inconsistent.

Confirm the communication settings of GOT and PLC, such as

data length, stop bit and baud rate.

The parity check conditions of GOT and PLC are inconsistent.

Let the parity check condition (odd or even) of GOT and PLC be

consistent.

The sum data is inconsistent. Or the contents of the receive data

are not consistent with the send command from the GOT. Let

the communication settings and contents of data be consistent

between the GOT and counterpart equipment. (If NAK is received

while the GOT is connected to the microcomputer board, a text

error occurs.)

Though receiving is started, receive data is not sent. Check the