Mitsubishi FX1N-60MR-ES/UL, FX1N-14MT-ESS/UL, FX1N-14MR-DS, FX1N-14MT-DSS, FX1N-24MR-DS Hardware Manual

...

FX

HARDWARE MANUAL

1N

SERIES PROGRAMMABLE CONTROLLERS

FX1N Series Programmable Controllers

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the correct installation

and operation of the FX

attempting to install or use the unit.

• Further information can be found in the FX Series Programming Manual II.

1N

Series Programmable Controllers. It should be read and understood before

• If in doubt at any stage of the installation of an FX

professional electrical engineer who is qualified and trained to the local and national standards which apply to

the installation site.

• If in doubt about the operation or use of FX1N Series Programmable Controller please consult the nearest

Mitsubishi Electric distributor.

• This manual is subject to change without notice.

1N

Series Programmable Controller always consult a

FX1N SERIES PROGRAMMING CAUTION

Thank you for buying The Mitsubishi FX1N series controller.

Please note the following.

Notes: Block Move instruction

Applicable PLC: FX1N Ver 1.00-2.10

Applicable instructions: BMOV, BMOVP(FNC15)

If the file register parameter setting and the registers D8000-D8225 are used as the

destination devices for the BMOV(BMOVP) instruction, program steps or file register data may

be lost or damaged. All other data registers can be used safely for BMOV(BMOVP) instruction

destination registers.

Program example

Problem OK

M8002

(S·) (D·) n

BMOV D8140 K2

D D

M8002

(S·) (D·)

DMOV D8140

FX1N Series Programmable Controllers

FX

Series Programmable Controllers

1N

Hardware Manual

Manual number : JY992D89301

Manual revision : L

Date :

May 2006

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial

property rights which may occur as a result of using the contents noted in this manual.

i

FX1N Series Programmable Controllers

Guidelines for the safety of the user and protection of the FX1N.

This manual provides information for the installation and use of the FX1N. The manual has

been written to be used by trained and competent personnel. The definition of such a person

or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, (trained and qualified to the local and national standards required to fulfill that

role). These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see Note) should be trained to use that

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the operation of the

completed equipment.

Note :

The term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

ii

FX1N Series Programmable Controllers

Note’s on the symbols used in this manual

At various times through out this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

the equipment. Whenever any of the following symbols are encountered, its associated note

must be read and understood. Each of the symbols used will now be listed with a brief

description of its meaning.

Hardware warnings

1) Indicates that the identified danger

WILL

2) Indicates that the identified danger could

cause physical and property damage.

POSSIBLY

cause physical and property damage.

3) Indicates a point of further interest or further explanation.

Software warning

1) Indicates special care must be taken when using this element of software.

2) Indicates a special point which the user of the associate software element should be aware

of.

3) Indicates a point of interest or further explanation.

iii

FX1N Series Programmable Controllers

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to understanding the

text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual use of the

product based on these illustrative examples.

• Please contact a Mitsubishi Electric distributor for more information concerning applications in life

critical situations or high reliability.

iv

FX1N Series Programmable Controllers

No

te Concerning

the CE Marking

This document does not guarantee that a mechanical system including this product will comply

with the following standards. Compliance to EMC directive and LVD directive of the entire

mechanical system should be checked by the user / manufacturer.

For more details please contact the local Mitsubishi Electric sales site.

EMC

The following products have shown compliance through direct testing (of the identified

standards below) and design analysis (through the creation of a technical construction file) to

the European Directive for Electromagnetic Compatibility (89/336/EEC) when used as directed

by the appropriate documentation.

Refer to a manual or related material of each product other than the following.

Type : Programmable Controller (Open Type Equipment)

Models : MELSEC FX

from March 1st, 2000 FX

from June 1st, 2000 FX

from December 1st, 2000 FX

1N

series manufactured

1N

-232-BD FX1N-485-BD FX1N-422-BD

FX1N-8AV-BD FX1N-CNV-IF FX1N-5DM

FX1N-EEPROM-8L

1N

-

1N

-

Where

MR-ES/UL

MR-DS FX1N-

indicates:14,24,40,60

MT-DSS

v

FX1N Series Programmable Controllers

from June 1st, 2001 FX1N-4EX-BD FX1N-2EYT-BD FX1N-2AD-BD

from July 1st, 2001 FX

FX

1N

-1DA-BD

1N

-

MT-ESS/UL Where

indicates:14,24,40,60

Models : MELSEC FX

from November 1st, 1995 FX

from February 1st, 1996 FX

from April 1st, 1996 FX

from May 1st, 1996 FX

from July 1st, 1996 Harmonized Products

Models : MELSEC FX

0N

series manufactured

0N

-40ER-ES, FX0N-8EX-ES, FX0N-8EYR-ES,

0N

FX

FX

FX

FX

FX

-8EYT-ESS

0N

-8ER-ES, FX0N-16EX-ES, FX0N-16EYR-ES,

0N

-16EYT-ESS

0N

-8ER-ES/UL, FX0N-16EX-ES/UL,FX0N-16EYR-ES/UL,

0N

-16EYT-ESS/UL

0N

-40ER-DS, FX0N-40ET-DSS

0N

-232ADP, FX0N-485ADP

0N

-40ER-ES/UL, FX0N-8EX-ES/UL,FX0N-8EYR-ES/UL,

FX0N-8EYT-ESS/UL

2NC

series manufactured

from October 1st, 2002 FX

2NC

-232ADP FX

2NC

-485ADP

vi

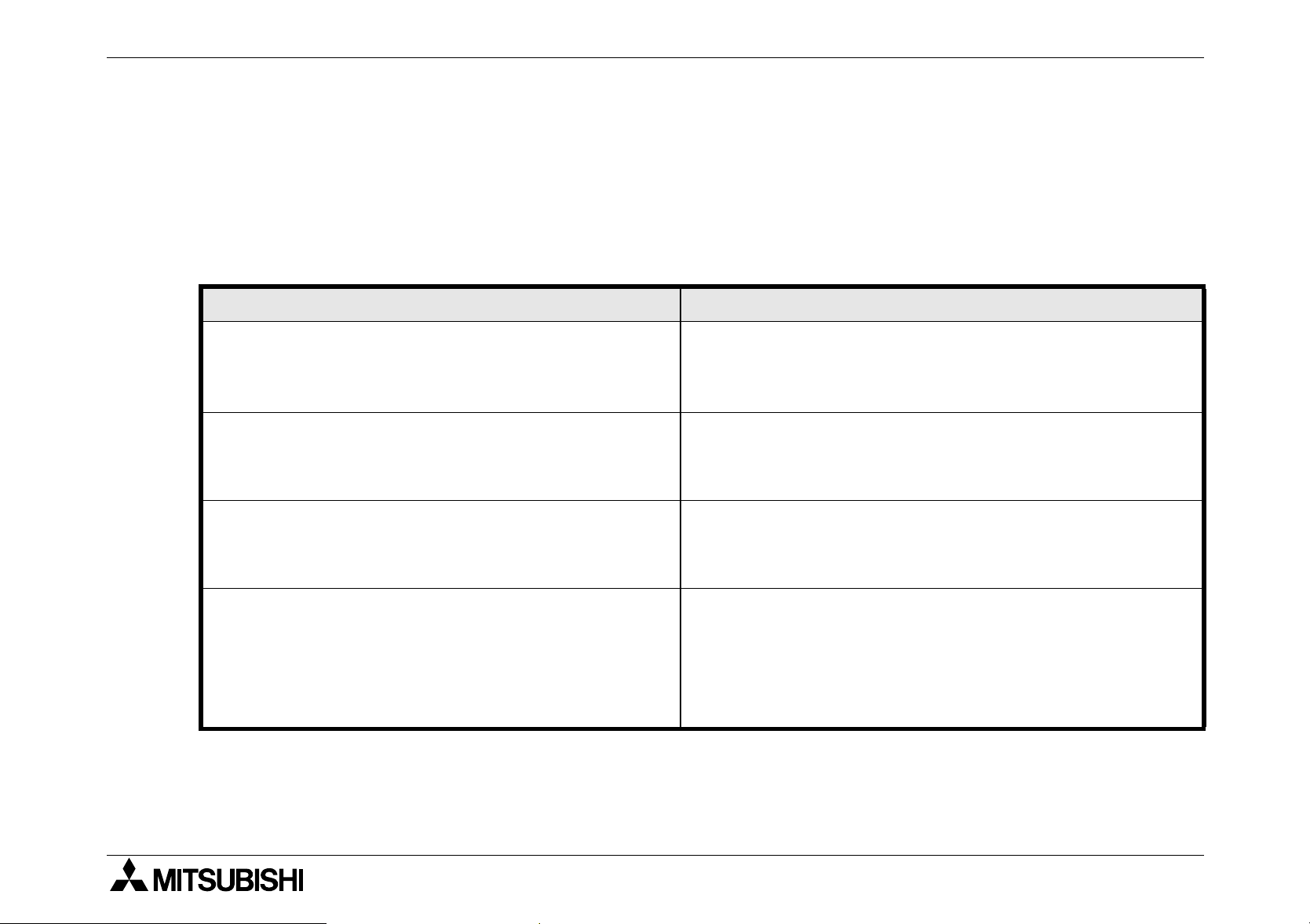

FX1N Series Programmable Controllers

Standard Remark

EN50081-2:1993 Electromagnetic compatibility

EN61000-6-4:2001 - Generic emission standard

Industrial environment

EN61000-6-2:2001 Electromagnetic compatibility

- Generic immunity standard

Industrial environment

Models : MELSEC FX2N series manufactured

from July 1st, 1997 FX

2N

-

ËË

Where

ER-ES/UL FX2N-

indicates:32,48

ËË

FX2N-16EX-ES/UL FX2N-16EYR-ES/UL

2N

FX

from April 1st, 1998 FX

-16EYT-ESS/UL

2N

-48ER-DS FX2N-48ET-DSS

Compliance with all relevant aspects of the

standard.

(Radiated Emissions and Mains Terminal Voltage

Emissions)

Compliance with all relevant aspects of the

standard.

(RF immunity, Fast Transients, ESD, Conducted,

Surge, Power magnetic fields, Voltage dips and

Voltage interruptions)

ET-ESS/UL

ËË

from August 1st, 1998 FX

from August 1st, 2005 FX

FX

2N

-48ER-UA1/UL

2N

-8ER-ES/UL FX2N-8EX-ES/UL

2N

-8EYR-ES/UL FX2N-8EYT-ESS/UL

vii

FX1N Series Programmable Controllers

For the products shown on the previous page, PLCs manufactured

before March 31st, 2002 are compliant with EN50081-2 (EN61000-6-4) and

EN50082-2

from April 1st, 2002 to April 30th, 2006 are compliant with EN50081-2 (EN61000-6-

4) and EN61131-2:1994+A11:1996+A12:2000

after May 1st, 2006 are compliant with EN61131-2:2003

Standard Remark

EN50081-2:1993 Electromagnetic compatibility

EN61000-6-4 - Generic emission standard

:2001 Industrial environment

EN50082-2:1995 Electromagnetic compatibility

- Generic immunity standard

Industrial environment

EN61131-2:1994 Programmable controllers

/A11:1996 - Equipment requirements and

/A12:2000 tests

EN61131-2:2003 Programmable controllers

- Equipment requirements and

tests

Compliance with all relevant aspects of the standard.

(Radiated Emissions and Mains Terminal Voltage

Emissions)

Compliance with all relevant aspects of the standard.

(RF immunity, Fast Transients, ESD, Conducted,

and Power magnetic fields)

Compliance with all relevant aspects of the standard.

(RF Immunity, Fast Transients, ESD and Damped

oscillatory wave)

Compliance with all relevant aspects of the standard.

(Radeiated Emissions, Mains Terminal Voltage

Emissions, RF immunity, Fast Transients, ESD,

Surge, Voltage drops and interruptions, Conducted

and Power magnetic fields)

viii

FX1N Series Programmable Controllers

Notes when using the FX0N-40ER-ES.

This unit may be used as supplied and will be in compliance with the previously identified

standards / directives.However, it is recommended as an additional precaution to reduce

conducted mains terminal voltage emissions when power sources are shared, that an external

mains filter is used. Mitsubishi have tested and would like to recommend the following filters (or

user selected filters which are manufactured / designed/used in a similar manner to those

identified here):

Filter #1: Manufacturer Filter #2: Manufacturer Filter #3: Manufacturer

Volgen TDK Roxburgh Electronics

Unit - VFB-05B Unit -ZHG2203-11S Unit - DRF1, DRF3 range of filters

For the most effective use of any filtering system the following configuration should be adopted,

always remembering to keep the filter as close to the power input port as possible. For

example only:

Ex.

(3 inches)

75mm

AC mains input

-

FX

0N

☆☆

Various extension blocks

MR-ES/UL FX0N-40ER-ES/UL

ix

FX1N Series Programmable Controllers

LV D

The following products have shown compliance through direct testing (of the identified

standards below) and design analysis (through the creation of a technical construction file) to

the European Directive for Low Voltage (73/23/EEC) when used as directed by the appropriate

documentation.

Refer to a manual or related material of each product other than the following.

Type : Programmable Controller (Open Type Equipment)

Models : MELSEC FX

from June 1st, 2000 FX

from December 1st, 2000 FX

from July 1st, 2001 FX

EN61010-1:2001 Safety requirements for electrical

equipment for measurement,

control, and laboratory use

- General requirements

1N

series manufactured

1N

-

1N

-

1N

-

Where

Standard Remark

MR-ES/UL

MR-DS

MT-ESS/UL

indicates:14,24,40,60

The equipment has been assessed as a

component for fitting in a suitable enclosure

which meets the requirements of

EN61010-1:2001

x

FX1N Series Programmable Controllers

Models : MELSEC FX0N series manufactured

FX

0N

-40ER-ES, FX0N-8EX-ES, FX0N-8EYR-ES,

0N

-8EYT-ESS

0N

-8ER-ES, FX0N-16EX-ES, FX0N-16EYR-ES,

from November 1st, 1995 FX

from February 1st, 1996 FX

FX0N-16EYT-ESS

from April 1st, 1996 FX

0N

-8ER-ES/UL, FX0N-16EX-ES/UL, FX0N-16EYR-ES/UL,

FX0N-16EYT-ESS/UL

from May 1st, 1996 FX

0N

-40ER-DS, FX0N-40ET-DSS

from July 1st, 1996 Harmonized Products

0N

FX

FX

Standard Remark

IEC1010-1:1990 Safety requirements for

/A1:1992 electrical equipment for

/A2:1995 measurement, control,

BSEN61010-1 :1993 * and laboratory use

/A2:1995

-40ER-ES/UL, FX0N-8EX-ES/UL, FX0N-8EYR-ES/UL,

0N

-8EYT-ESS/UL

The equipment has been assessed as a

component for fitting in a suitable enclosure which

meets the requirements of IEC 1010-1:1990,

A1:1992 and A2:1995(BSEN61010-1 :1993 and

A2:1995)

* Compliance to BSEN61010-1 and Amendment2 is claimed through virtue of direct

compliance to IEC1010-1, Amendment 1 and Amendment 2.

xi

FX1N Series Programmable Controllers

Models : MELSEC FX2N series manufactured

from July 1st, 1997 FX

from April 1st, 1998 FX

from August 1st, 1998 FX

from August 1st, 2005 FX

For the products above, PLCs manufactured

before March 31st, 2002 are compliant with IEC1010-1

from April 1st, 2002 to April 30th, 2006 are compliant with EN61131-2:1994+A11:1996+

A12:2000

after May 1st, 2006 are compliant with EN61131-2:2003

Standard Remark

2N

-

ËË

Where

2N

FX

FX

-16EYR-ES/UL

2N

-48ER-DS

2N

-48ER-UA1/UL

2N

-8ER-ES/UL FX2N-8EX-ES/UL

2N

-8EYR-ES/UL FX2N-8EYT-ESS/UL

ER-ES/UL FX2N-

indicates:32,48

ËË

ET-ESS/UL

ËË

IEC1010-1:1990 Safety requirements for

/A1:1992 electrical equipment for

measurement, control, and

laboratory use

- General requirements

EN61131-2:1994 Programmable controllers

/A11:1996 - Equipment requirements and

/A12:2000 tests

EN61131-2:2003 Programmable controllers

- Equipment requirements and

tests

The equipment has been assessed as a component

for fitting in a suitable enclosure which meets the

requirements of IEC 1010-1:1990+A1:1992

The equipment has been assessed as a component

for fitting in a suitable enclosure which meets the

requirements of EN61131-2:1994+A11:1996

+A12:2000

The equipment has been assessed as a component

for fitting in a suitable enclosure which meets the

requirements of EN61131-2:2003

xii

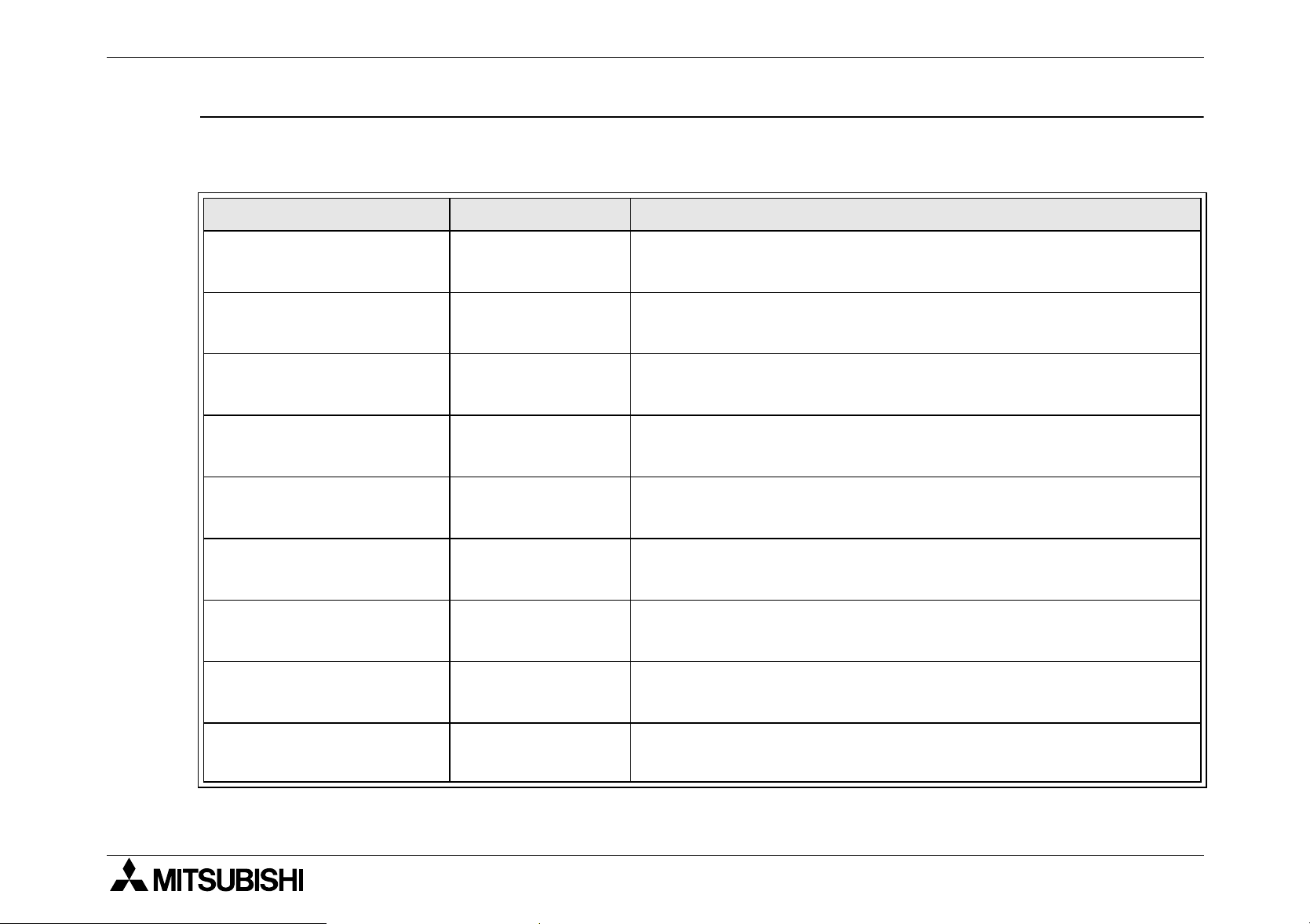

FX1N Series Programmable Controllers

Associated Manuals

The following manuals are recommended as essential reference material for the correct operation of a

FX

series Programmable controller

1N

Manual Name Manual Number Description

FX

Programming Manual II

FX Communication

User’s Manual

1N

FX

-5DM

User’s Manual

FX-10DM-E

User’s Manual

1N

FX

-422-BD

Users Manual

1N

FX

-485-BD

Users Manual

1N

FX

-232-BD

Users Manual

.

JY992D88101

JY992D69901

JY992D84901

JY992D86401

JY992D84101

JY992D84201

JY992D84401

1S

This manual contains instruction explanation about FX

FX

1N

, FX2N and FX

2NC

Series PLC.

,

This manual contains explanation for N:N network,

parallel link, no protocol communication and computer link

This manual contains hardware explanation for

installation, specification and operation.

This manual contains hardware explanation for

installation, specification and operation.

This manual contains hardware explanation for

installation and specification.

This manual contains hardware explanation for

installation and specification.

This manual contains hardware explanation for

installation and specification.

1N

FX

-4EX-BD

Users Manual

1N

FX

-2EYT-BD

Users Manual

JY992D95001

This manual contains explanation for installation,

specification and special auxiliary relay allocation.

This manual contains explanation for installation,

JY992D95201

specification and special auxiliary relay allocation.

xiii

FX1N Series Programmable Controllers

Manual Name Manual Number Description

FX1N-2AD-BD

Users Manual

1N

FX

-1DA-BD

Users Manual

1N

FX

FX

FX

-8AV-BD JY992D84601

1N

-CNV-BD JY992D84701 This manual contains explanation for installation.

0N

-3A

User’s Manual

2N

FX

-5A

User’s Manual

2N

FX

-2DA

User’s Manual

2N

FX

-2AD

User’s Manual

JY992D96201

This manual contains explanation for installation,

specification and special auxiliary relay allocation.

This manual contains explanation for installation,

JY992D96401

specification and special auxiliary relay allocation.

This manual contains hardware explanation for

installation and specification.

This manual contains explanation for wiring, installation,

JY992D49001

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY997D11401

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D74901

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D74701

specification and BFM allocation.

2N

FX

-4DA

User’s Manual

2N

FX

-4AD

User’s Manual

2N

FX

-4AD-PT

User’s Manual

2N

FX

-4AD-TC

User’s Manual

JY992D65901

This manual contains explanation for wiring, installation,

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D65201

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D65601

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D65501

specification and BFM allocation.

xiv

FX1N Series Programmable Controllers

Manual Name Manual Number Description

FX2N-8AD User’s

Manual

2N

FX

-2LC User’s

Manual

2N

FX

-16LNK-M

MELSEC I/O Link

Master User’s Manual

2N

FX

-16CCL-M

CC-Link System Master

User’s Manual

2N

FX

-32CCL

CC-Link System

Interface User’s Manual

2N

FX

-64CL-M

CC-Link System Master

User’s Manual

JY992D86001

This manual contains explanation for wiring, installation,

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D85801

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D73701

setting, specification and I/O allocation.

This manual contains explanation for wiring, installation,

JY992D93101

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY992D71801

specification and BFM allocation.

This manual contains explanation for wiring, installation,

JY997D08501

specification and BFM allocation.

2N

FX

-32ASI-M

AS-interface Master

User’s Manual

JY992D76901

This manual contains explanation for wiring, installation,

specification and BFM allocation.

xv

FX1N Series Programmable Controllers

MEMO

xvi

FX1N Series Programmable Controllers

Table of Contents

Guideline ..............................................................................................ii

Associated Manuals .......................................................................... xiii

1. Introduction............................................................................................1-1

1.1 World Specification. ............................................................................................. 1-7

1.2 Model Name ....................................................................................................... 1-8

1.3 Serial Numbers ................................................................................................... 1-9

1.4 Configuration ..................................................................................................... 1-10

1.4.1 Schematic system ................................................................................................... 1-10

1.4.2 Note for Using Expansion Board ............................................................................. 1-13

1.4.3 Input/Output Points and Current Consumption ....................................................... 1-14

1.4.4 Rules of Expansion ................................................................................................. 1-18

1.5 Back up Data ..................................................................................................... 1-20

1.5.1 EEPROM backup ....................................................................................................1-20

1.5.2 Capacitor backup .................................................................................................... 1-20

2. Terminal layouts ....................................................................................2-1

2.1 AC Powered Main Units ...................................................................................... 2-1

2.2 DC Powered Main Units ...................................................................................... 2-4

0N

2.3 FX

2.4 FX2N Extension blocks ....................................................................................... 2-8

, FX2N-8E Extension blocks .......................................................................2-7

xvii

FX1N Series Programmable Controllers

3. Installation Notes...................................................................................3-1

3.1 Product Outline .................................................................................................... 3-2

3.2 FX1N RUN/STOP Control ....................................................................................3-4

3.3 General Specifications......................................................................................... 3-5

3.4 PLC Mounting Arrangements .............................................................................. 3-7

3.5 DIN Rail Mounting ............................................................................................. 3-10

3.6 Direct Mounting ................................................................................................. 3-10

3.7 Termination at Screw Terminals........................................................................ 3-14

3.8 Installing Optional Units ..................................................................................... 3-16

3.8.1 Expansion Boards ................................................................................................... 3-16

1N

3.8.2 FX

3.8.3 Extension I/O module and Special Function module............................................... 3-19

-5DM Display Module...................................................................................... 3-18

4. Power Supply ........................................................................................4-1

4.1 Wiring Techniques ...............................................................................................4-1

4.2 Wiring Cautions ................................................................................................... 4-1

4.3 Power Supply ...................................................................................................... 4-2

4.4 Power Requirements ........................................................................................... 4-3

4.5 Example Wiring ................................................................................................... 4-4

4.5.1 AC Power supply....................................................................................................... 4-4

4.5.2 24V DC Power supply ...............................................................................................4-6

4.5.3 12V DC Power Supply............................................................................................... 4-8

4.6 Service Power supply .......................................................................................... 4-9

4.7 Earthing / Grounding ........................................................................................... 4-9

xviii

FX1N Series Programmable Controllers

5. Inputs.....................................................................................................5-1

5.1 24V DC input Specifications ................................................................................5-1

5.1.1 Typical Wiring ............................................................................................................ 5-2

5.1.2 Input Circuit Connection ............................................................................................ 5-3

5.1.3 Diodes and Inputs Connected in Series .................................................................... 5-4

5.1.4 Resistors and Inputs Connected in Parallel ..............................................................5-4

5.2 AC110V Input Extension Block............................................................................5-5

5.2.1 Input Circuit Connection ............................................................................................ 5-5

5.2.2 Programming Caution ............................................................................................... 5-6

6. Outputs..................................................................................................6-1

6.1 Output Specifications........................................................................................... 6-1

6.2 Relay Output Example......................................................................................... 6-2

6.2.1 Reliability Tests ......................................................................................................... 6-3

6.3 Transistor Output Example..................................................................................6-4

6.3.1 Transistor Output Writing Diagram (Source Type) .................................................... 6-4

6.3.2 Japanese Model Transistor Output (SInk Type)........................................................ 6-4

6.3.3 Response Times ....................................................................................................... 6-5

6.4 Applying Safe Loads............................................................................................6-6

xix

FX1N Series Programmable Controllers

7. Diagnostics............................................................................................7-1

7.1 Preliminary Checks..............................................................................................7-1

7.2 ERROR LED ON (CPU ERROR) ........................................................................7-2

7.3 Common Errors ...................................................................................................7-3

7.4 Maintenance ........................................................................................................ 7-3

7.5 Operation and Error Flags ...................................................................................7-4

7.6 PLC Status Registers .........................................................................................7-5

7.7 Error Registers .................................................................................................... 7-6

7.8 Error Codes ......................................................................................................... 7-7

7.9 Instruction List ..................................................................................................... 7-8

7.10 Device List ........................................................................................................ 7-11

xx

FX1N Series Programmable Controllers

1 INTRODUCTION

2 TERMINAL LAYOUTS

3 INSTALLATION NOTES

4 POWER SUPPLY

5 INPUTS

1

2

3

4

5

6OUTPUTS

7 DIAGNOSTICS

6

7

FX1N Series Programmable Controllers

1 INTRODUCTION

2 TERMINAL LAYOUTS

3 INSTALLATION NOTES

4 POWER SUPPLY

5 INPUTS

6OUTPUTS

7 DIAGNOSTICS

FX1N Series Programmable Controllers

1. Introduction

Introduction 1.

This manual covers hardware installation instructions for the FX1N Series PLC.

1N

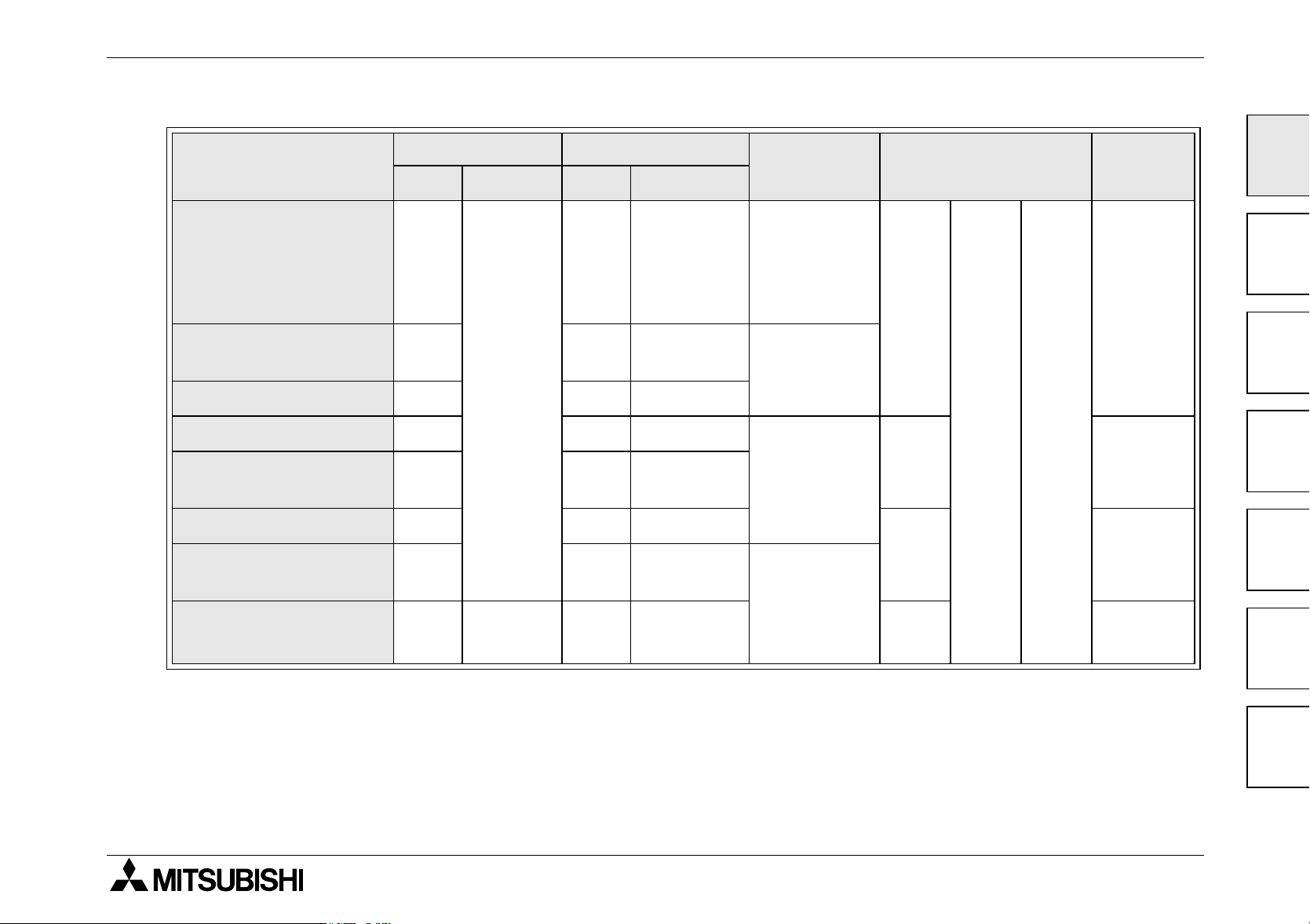

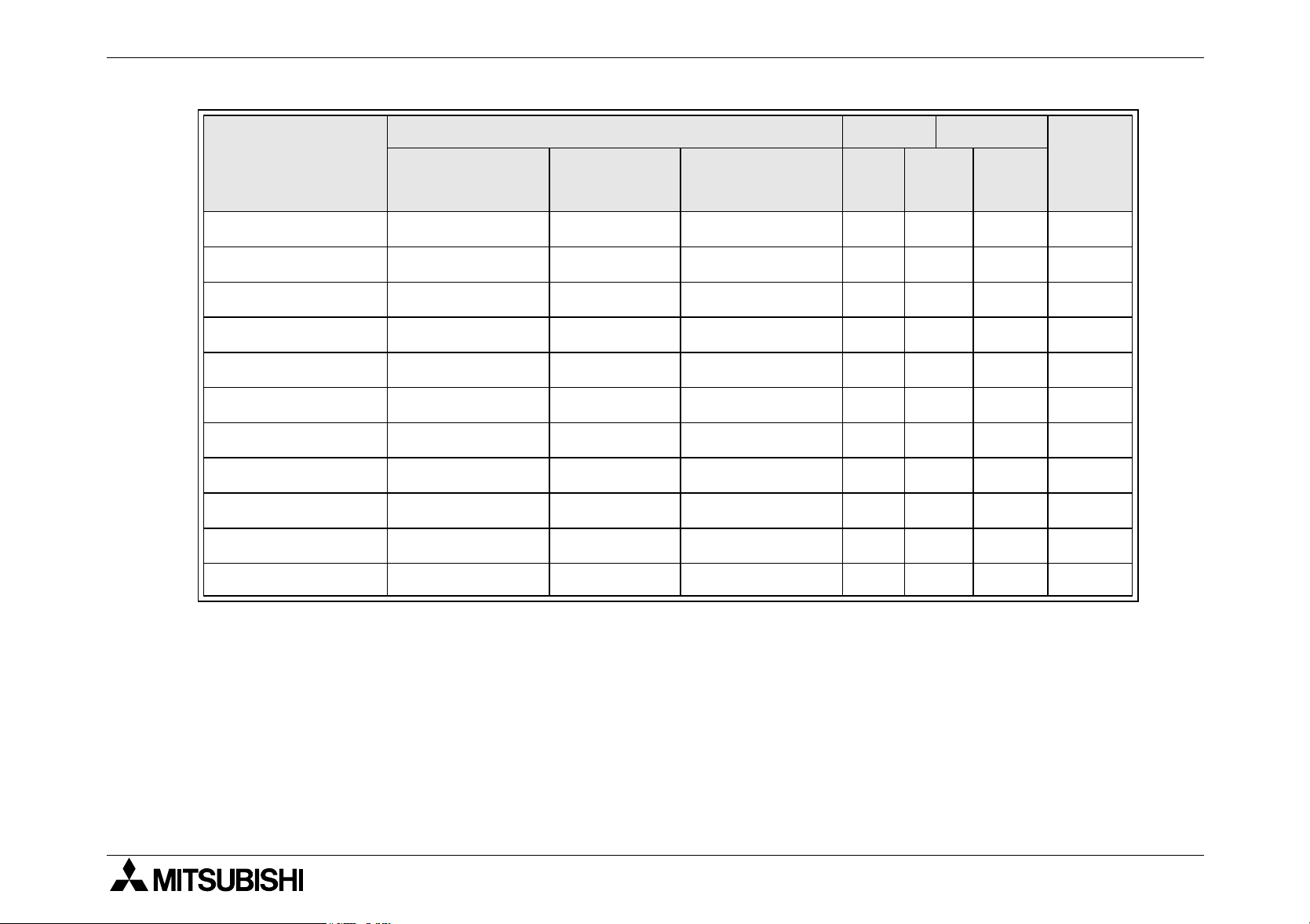

Table 1.1: FX

MODEL

FX1N-14MR-ES/UL

FX1N-14MT-ESS/UL

FX1N-24MR-ES/UL

FX1N-24MT-ESS/UL

FX1N-40MR-ES/UL

FX1N-40MT-ESS/UL

FX1N-60MR-ES/UL

FX1N-60MT-ESS/UL

FX1N-14MR-DS

FX1N-14MT-DSS Transistor

Main Modules

INPUT OUTPUT

QTY TYPE QTY TYPE

8

14

(16)

24 16

36

(40)

8

24V DC

Source

Sink/

6

(8)

10

(16)

24

6

(8)

Relay

Transistor

Relay

Transistor

Relay

Transistor

Relay

Transistor

Relay

POWER

SUPPLY

100-240 VAC

+10%

-15%

50/60Hz

DIMENSIONS

mm (inches)

90

(3.55)

90

(3.55)

130

(5.12)

175

(6.89)

90

(3.55)

90

(3.55)75(2.96)

WEIGHT

kg (lbs)

0.45

(0.99)

0.45

(0.99)

0.65

(1.43)

0.80

(1.76)

0.45

(0.99)

1

2

3

4

5

FX1N-24MR-DS

FX1N-24MT-DSS Transistor

FX1N-40MR-DS

FX1N-40MT-DSS Transistor

FX1N-60MR-DS

FX1N-60MT-DSS Transistor

14

(16)

24 16

36

(40)

24V DC

Sink/

Source

(16)

10

24

Relay

Relay

Relay

12V DC

-15%

to

24V DC

+20%

Note: Occupied points are shown in brackets for input and outputs.

90

(3.55)

130

(5.12)

175

(6.89)

90

(3.55)75(2.96)

1-1

0.45

(0.99)

0.65

(1.43)

0.80

(1.76)

6

7

FX1N Series Programmable Controllers Introduction 1.

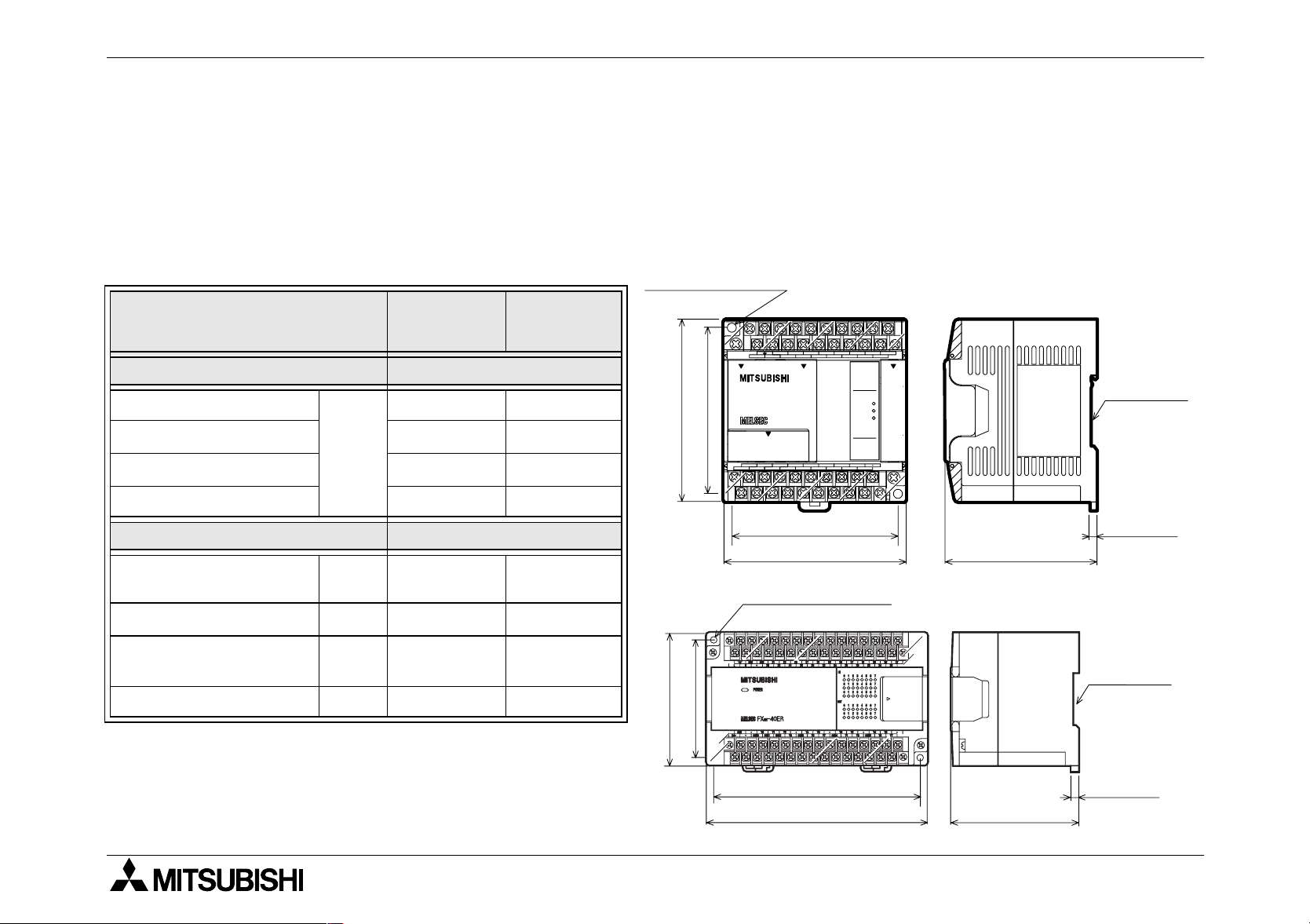

Figure 1.1 :Main unit outline

2 - φ4.5 (0.17'')

82 (3.23'')

90 (3.55'')

24V

L

0V

COM0 COM1

X1

S/S

N

Y0

Y1

X0 X2

COM2

X3 X5

Y2

Y3

COM3

X7

COM4

X11

X6

X10

0123

4567

14 15

FX1N-24MR

0123

4567

Y10Y5

Y6

Y7

X4

Y4

POWER

RUN

ERROR

1110

X15

X1

X12

X14

131110 12

IN

OUT

Y11

W - 8 (0.32'')

W

75 (2.96'')

Please see the previous page for each units width measurement.

UNITS: mm (inches)

27.3(1.08")

DIN rail

mounting

slot

27.3(1.08")

8 (0.32'')

1-2

FX1N Series Programmable Controllers Introduction 1.

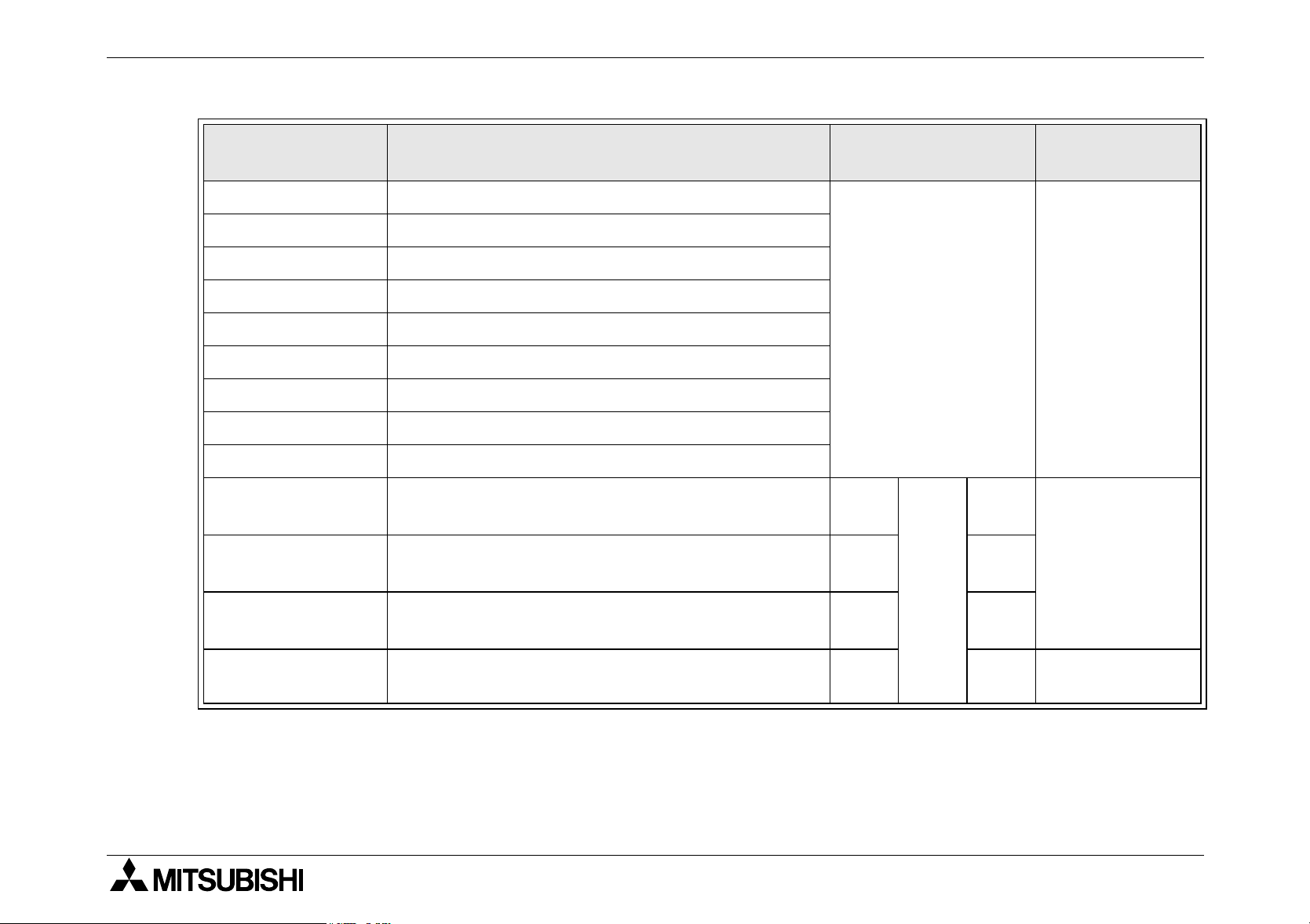

Table 1.2: Powered Extension Units

MODEL

FX0N-40ER-ES/UL

FX0N-40ET-DSS

FX0N-40ER-DS

FX2N-32ER-ES/UL

FX2N-32ET-ESS/UL

FX2N-48ER-ES/UL

FX2N-48ET-ESS/UL

FX2N-48ER-UA1/UL

INPUT OUTPUT

QTY TYPE QTY DEVICE

24

24 16

24V DC

24 16 Relay

16 16 Relay

16 16

24 24 Relay

24 24

24 110VAC 24 Relay

Sink/

Source

16 Relay

Transistor

(Source)

Transistor

(Source)

Transistor

(Source)

POWER

SUPPLY

100-

240VAC

+10%,

-15%

50/60Hz

24VDC

+20%

-15%

100-

240VAC

+10%,

-15%

50/60Hz

100-

240VAC

+10%,

-15%

50/60Hz

DIMENSIONS

mm (inches)

150

(5.91)

90

150

(5.91)

182

(7.17)

220

(8.67)

(3.55)87(3.43)

WEIGHT

kg (lbs)

0.75

(1.65)

0.65

(1.43)

0.85

(1.87)

1.00

(2.2)

1

2

3

4

5

6

1-3

7

FX1N Series Programmable Controllers Introduction 1.

Table 1.3: Extension blocks

MASS

(WEIGHT)

kg (lbs)

MODEL

INPUT OUTPUT

QTY TYPE QTY DEVICE TYPE

DIMENSIONS

mm (inches)

FX0N-8EX-UA1/UL

110V

FX

2N

-8EX-UA1/UL

8

AC

-- -

inputs

FX0N-8EX-ES/UL

FX

2N

-8EX-ES/UL

8

24V DC

-- -

Sink/

FX0N-8ER-ES/UL

2N

FX

-8ER-ES/UL

44

Source

-

Relay

FX0N-8EYR-ES/UL

--8 -

2N

FX

-8EYR-ES/UL

FX0N-8EYT-ESS/UL

- - 8 Transistor Source

2N

FX

-8EYT-ESS/UL

24V DC

FX0N-16EX-ES/UL 16

Sink/

-- -

Source

FX0N-16EYR-ES/UL - - 16 Relay FX0N-16EYT-ESS/UL - - 16 Transistor Source

43

(1.70)

70

(2.76)

0.2

(0.44)

90

(3.55)87(3.43)

0.3

(0.66)

24V DC

FX2N-16EX-ES/UL 16

Sink/

-- -

Source

FX2N-16EYR-ES/UL - - 16 Relay FX2N-16EYT-ESS/UL - - 16 Transistor Source

40

(1.58)90(3.55)87(3.43)

0.3

(0.66)

1-4

FX1N Series Programmable Controllers Introduction 1.

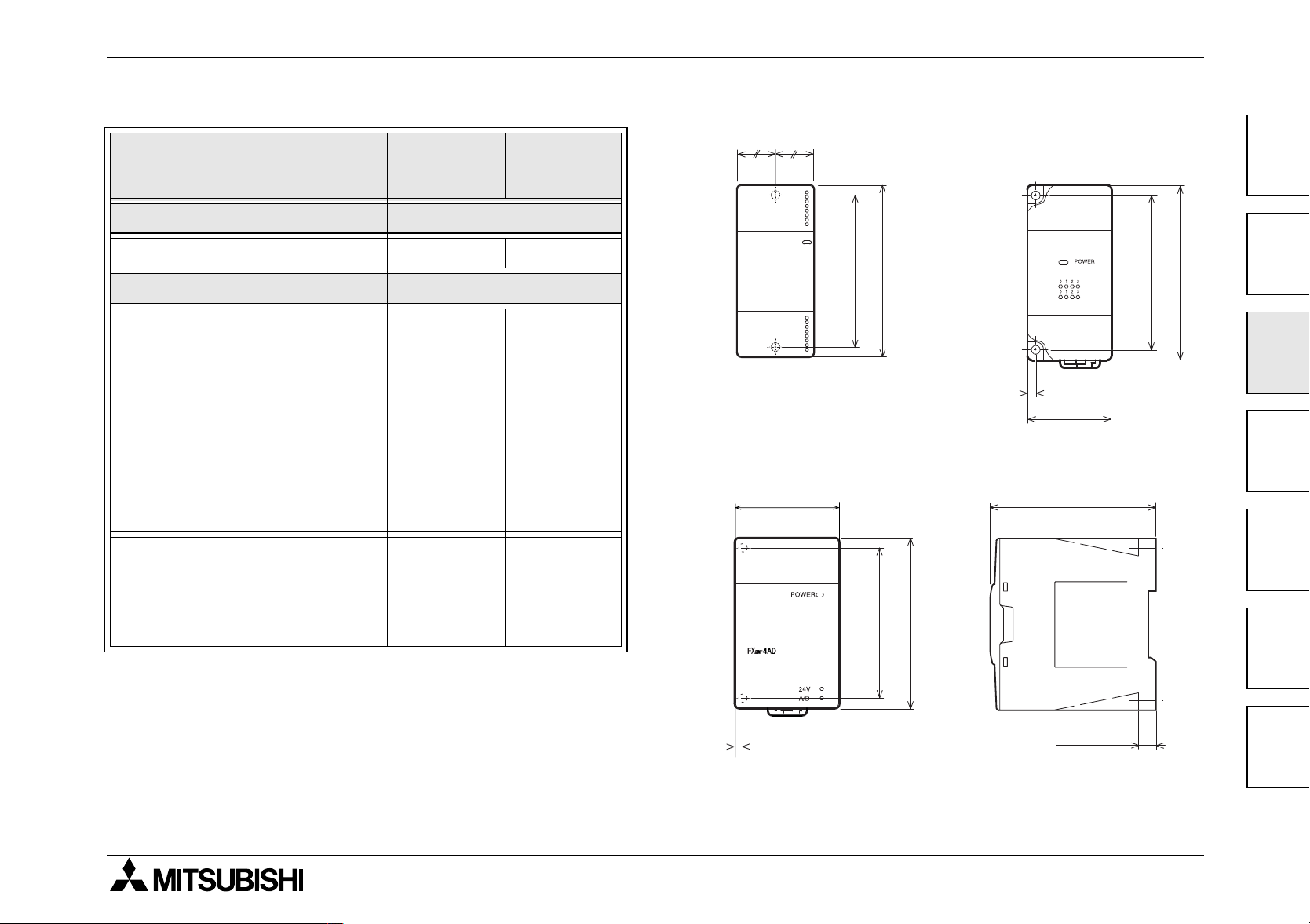

Table 1.4: Special function blocks

MODEL DESCRIPTION

FX0N-3A Analog / Digital converter 43 (1.70)

FX2N-5A Analog / Digital converter 55 (2.17) 0.3 (0.66)

FX2N-2DA Digital to analog converter

43 (1.70) 0.2 (0.44)

FX2N-2AD Analog to digital converter

FX2N-4DA Digital to analog converter

FX2N-4AD Analog to digital converter

55 (2.17)

FX2N-4AD-PT PT 100 probe interface

FX2N-4AD-TC Thermo-couple interface

FX2N-8AD Analog input interface 75 (2.96) 75 (2.96)

FX2N-2LC Temperature Control 55 (2.17)

FX2N-16LNK-M

FX2N-16CCL-M CC-Link master 0.4 (0.88)

MELSEC I/O LINK

Remote I/O system master

43 (1.70)

DIMENSIONS

mm (inches)

87 (3.43)

90 (3.5)

87 (3.43)

MASS

kg (lbs)

0.2 (0.44)

0.3 (0.66)

0.5 (1.1)

(WEIGHT)

1

2

3

4

5

FX2N-32CCL CC-Link interface 0.2 (0.44)

FX2N-64CL-M CC-Link/LT master 0.15 (0.33)

FX2N-32ASI-M AS-interface master 55 (2.17) 0.2 (0.44)

1-5

6

7

FX1N Series Programmable Controllers Introduction 1.

Table 1.5 :Expansion Board and Communication Adapter

MODEL DESCRIPTION DIMENSIONS

FX

-4EX-BD Four point special input

1N

FX

-2EYT-BD Two point special output

1N

-2AD-BD Two channel special analog to digital converter

FX

1N

-1DA-BD One channel special digital to analog converter

FX

1N

-232-BD RS-232C communication interface

FX

1N

-422-BD RS-422 communication interface

FX

1N

-485-BD RS-485 communication interface

FX

1N

-8AV-BD Analog potentionmeter

FX

1N

-CNV-BD Communication adapter connection interface

FX

1N

FX

FX

FX

-232ADP

2NC

-232ADP

0N

-485ADP

2NC

*1

*1

*1

RS-232C commuication adapter

RS-232C commuication adapter

RS-485 commuication adapter

Mounts directly into

top of PLC

19.1

(0.76)

43

(1.70)

19.1

(0.76)

90

(3.55)

85

(3.35)

68

(2.68)

78

(3.08)

MASS (WEIGHT)

kg (lbs)

Mounts directly

into top of PLC

0.1 (0.22)

FX

-485ADP

0N

*1

RS-485 commuication adapter

43

(1.70)

87

(3.43)

0.3 (0.66)

*1 The communication adapter needs to connect via an FX1N-CNV-BD to the FX1N Series

PLC.

1-6

FX1N Series Programmable Controllers Introduction 1.

1.1 World Specification.

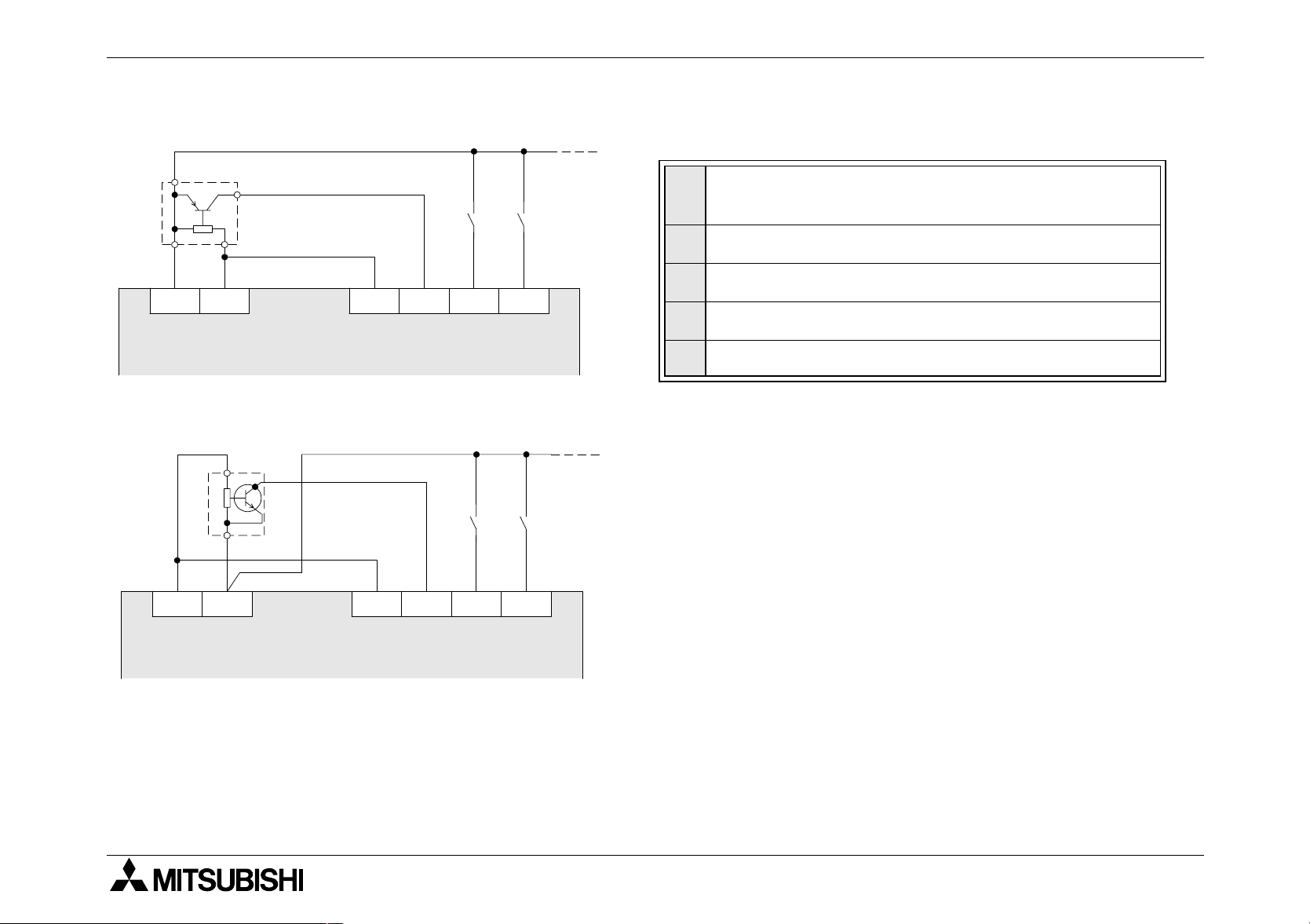

Table 1.6: World Specification

Input

Sink / Source

Outputs

Transistor

World spec models : SINK / SOURCE.

Japanese models : ALWAYS SINK.

World spec models : ALWAYS SOURCE.

Japanese models : ALWAYS SINK.

1

2

3

4

5

1-7

6

7

FX1N Series Programmable Controllers Introduction 1.

1.2 Model Name

FX

A)

B)

C)

-24MR-DS /

1N

F)

E)

D)

Table 1.7 :Notes on model name

Ref. Description Ref. Description

A)

B)

C)

PLC type: FX

Total number of I / O channels

Unit type

M MPU - main unit DS DC World spec, CE & UL registered.

E Powered extension unit DSS DC World spec, DC source transistor, CE & UL registered.

EX Extension block, input E AC, Japanese spec.

EY Extension block, output ES AC, World spec, CE registered.

Output type

1N

Features

Omit AC, Japanese spec.

D DC Japanese spec.

E)

ESS AC World spec, DC source transistor, CE registered.

D)

RRelay UA1 AC Power Supply, AC inputs, CE registered.

TTransistor

STriac (SSR)

*1. The FX

40ET-DSS and FX

0N-

F)

40ER-DSS FX0N series extension units do not have UL certi-

0N-

UL UL registered

fication.

1-8

FX1N Series Programmable Controllers Introduction 1.

1.3 Serial Numbers

SERIAL NO.: 0 6 3267

1)

e.g.

0=2000

1=2001

Table 1.8 : Notes on serial numbers

1)

2)

3)

2)

1 - 9 = Jan - Sept

X= Oct

Y= Nov

Z= Dec

Production year

Production month

Production serial number

1

3)

2

3

4

5

1-9

6

7

FX1N Series Programmable Controllers Introduction 1.

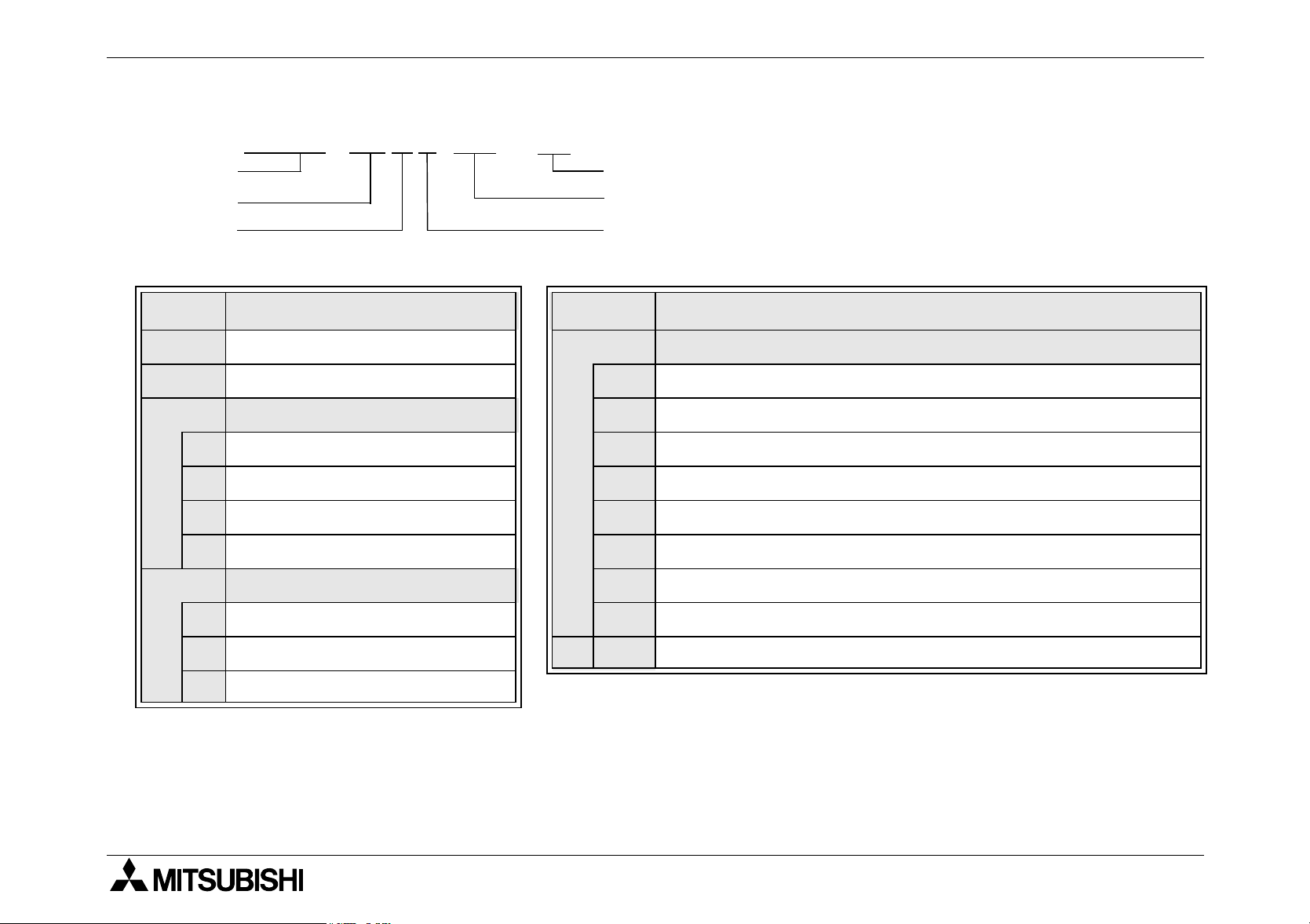

1.4 Configuration

1.4.1 Schematic system

FX1N-2AD-BD*1 FX1N-1DA-BD

FX1N-4EX-BD*1 FX1N-2EYT-BD

FX1N-232-BD FX1N-422-BD

-485-BD

FX

1N

-8AV-BD

FX

1N

-CNV-BD + FX

FX

1N

-CNV-BD + FX0N-232ADP

FX

1N

-CNV-BD + FX

FX

1N

-CNV-BD + FX0N-485ADP

FX

1N

-232ADP

2NC

-485ADP

2NC

1

FX1N-5DM

-EEPROM-8L

FX

1N

*2

GX Developer

FX-PCS/WIN-E

GX IEC Developer

FX-PCS/AT-EE

MELSEC MEDOC

RS-232C/RS-422 Converter

FX-232AW FX-232AWC

FX-232AWC-H

*1

B

*1

C

D

FX1N-14MR-ES/UL

-24MR-ES/UL

FX

1N

-40MR-ES/UL

FX

1N

-60MR-ES/UL

FX

1N

-14MT-ESS/UL

FX

1N

-24MT-ESS/UL

FX

1

1'

1N

-40MT-ESS/UL

FX

1N

-60MT-ESS/UL

FX

1N

-14MR-DS

FX

1N

-24MR-DS

FX

1N

-40MR-DS

FX

1N

-60MR-DS

FX

1N

-14MT-DSS

FX

1N

-24MT-DSS

FX

1N

-40MT-DSS

FX

1N

-60MT-DSS

FX

1N

1" 2

A

FX2N-32ER-ES/UL

-40ER-ES/UL

FX

0N

-48ER-ES/UL

FX

2N

-32ET-ESS/UL

FX

2N

-48ET-ESS/UL

FX

2N

-40ER-DS

FX

0N

-40ET-DSS

FX

0N

-48ER-UA1/UL

FX

2N

3

GOT-900 Series

FX-10DM-E

FX-10DU-E

*3

H

FX-50DU-TKS-E

E

FX-40DU-TK-ES

FX-40DU-ES

FX-30DU-E

FX-20P-E (-SET0)

F

FX-10P-E

G

FX-25DU-E

FX-20DU-E

H'

FX0N-8EX-UA1/UL

FX0N-8EX-ES/UL

FX0N-8ER-ES/UL

FX0N-8EYR-ES/UL

-8EYT-ESS/UL

FX

0N

FX2N-8EX-UA1/UL

FX2N-8EX-ES/UL

FX2N-8ER-ES/UL

2N

-8EYR-ES/UL

FX

FX2N-8EYT-ESS/UL

K

FX0N-16EX-ES/UL

-16EYR-ES/UL

FX

0N

FX0N-16EYT-ESS/UL

FX2N-16EX-ES/UL

FX2N-16EYR-ES/UL

-16EYT-ESS/UL

FX

2N

FX0N-3A

FX2N-2DA FX2N-2AD

-4DA FX2N-4AD

FX

2N

FX2N-4AD-PT

FX2N-4AD-TC

FX2N-8AD FX2N-5A

-2LC

FX

2N

FX2N-16LNK-M

FX2N-64CL-M

FX2N-16CCL-M

-32CCL

FX

2N

FX2N-32ASI-M

J

I

1-10

FX1N Series Programmable Controllers Introduction 1.

*1 Available for use with FX1N version 2.00 or later.

*2 When using the FX

1N

-EEPROM-8L with an expansion board in group C, only the loader

function (transfer program) can be used. Remove it from the PLC after operating the

loader function and attach the top cover into the PLC.

*3 GOT-F900 Series can connect via an FX

*4 When supplying 24V DC power source to the FX

1N

-232-BD to the FX1N PLC.

1N

main unit, only the FX0N series

powered extension unit (DC power supply type) can connect.

1N

When supplying 12V DC power source to the FX

main unit, the powered extension unit

and special function blocks cannot connect to it.

*5 FX

1N

series PLC cannot connect together with an FX2N-32ASI-M and FX2N-16CCL-M.

An FX2N-32ASI-M module cannot be attached to an FX1N series PLC that is using an

2N

FX

-16CCL-M module. Only one FX2N-32ASI-M module can be connected to the PLC.

1

2

3

4

5

1-11

6

7

FX1N Series Programmable Controllers Introduction 1.

Table 1.9 : Configuration Notes

A

FX

B

FX

C

FX

D

Memory Cassette or Display Module

E

Programming Software

F

RS-232C/RS-422 Converter for PC

G

Dedicated Programming Tools

Series Main Unit

1N

Expansion Boards for Analog I/O

1N

Expansion Boards without Analog I/O

1N

Table 1.10: Connection Ports

1

Left hand side port

Left hand side port + FX

or

Left hand side port + FX

+ FX

2NC

-232ADP

1'

or

Left hand side port + FX

0N

+ FX

-232ADP

1N

1N

1N

-232-BD

-CNV-BD

-CNV-BD

H

H’

I

J

K

1"

2

3

HMI Devices

(GOT-F900/ GOT-A900/ DM/ DU)

<GOT: Graphic Operation Terminal,

DM: Display Module,

DU: Data access Unit>

DU Series

(Discontinued since Sept. 2002)

Powered Extension Units

Extension Blocks

Special Function Blocks

1N

Left hand side port + FX

-422-BD

Programming Port

Extension Bus Port

1-12

FX1N Series Programmable Controllers Introduction 1.

1.4.2 Note for Using Expansion Board

1S

The following conditions cannot be accomplished with an FX

-FX

-FX

-FX-10DM + FX

- Connect two Programming tools (FX-10P-E, FX-20P-E, Programming software, etc.)

- The use of Special function Blocks

1N

-422-BD + FX-2PIF

1N

-5DM + FX1N-422-BD + FX-10DM

1N

-422-BD + FX-10DM

PLC.

Caution

Connect a programming tool (such as an FX-10P-E, FX-20P-E and personal computer) to

either the connector built in to the PLC or the connector on the FX1N-422-BD or FX1N-232BD. If a programming tool is connected to both connectors, the program stored in the PLC

may not match the program stored in the programming tool. If the program is changed or the

set value of timers or counters are changed with this configuration, the program may be partially overwritten and the PLC may malfunction.

1

2

3

4

5

1-13

6

7

FX1N Series Programmable Controllers Introduction 1.

1.4.3 Input/Output Points and Current Consumption

0N

The following tables show the input/output points of various types of FX

and FX2N series

extension blocks, and special function blocks, along with the special function block current

consumption.

Table 1.11: Extension blocks

FX

FX

FX

FX

FX

FX

FX

FX

MODEL

0N

-8ER-ES/UL

2N

-8ER-ES/UL

0N

-8EX-ES/UL

2N

-8EX-ES/UL

0N

-8EX-UA1/UL

2N

-8EX-UA1/UL

0N

-8EYR-ES/UL

2N

-8EYR-ES/UL

*1 8 points are used for actual input/output, however, this block should occupy 16 input/

output points.

INPUTXOUTPUT

Y

4(8) 4(8)

TOTAL MODEL

*1

16

8-8

8-8

-88

FX0N-8EYT-ESS/UL

2N

FX

FX

FX

FX

FX

FX

FX

-8EYT-ESS/UL

0N

-16EX-ES/UL 16 - 16

0N

-16EYT-ESS/UL - 16 16

0N

-16EYR-ES/UL - 16 16

2N

-16EX-ES/UL 16 - 16

2N

-16EYR-ES/UL - 16 16

2N

-16EYT-ESS/UL - 16 16

INPUTXOUTPUT

Y

TOTAL

-88

1-14

FX1N Series Programmable Controllers Introduction 1.

Table 1.12: Special function block/Function adapters/Expansion board

CURRENT CONSUMPTION INPUT OUTPUT

FX

FX

FX

FX

FX

FX

FX

FX

MODEL

0N

-3A 30mA 90mA - - 8 - 8

2N

-5A 70mA - 90mA - 8 - 8

2N

-2DA 30mA 85mA - - 8 - 8

2N

-2AD 20mA 50mA - - 8 - 8

2N

-4AD 30mA - 55mA - 8 - 8

2N

-4DA 30mA - 200mA - 8 - 8

2N

-4AD-PT 30mA - 50mA - 8 - 8

2N

-4AD-TC 30mA - 50mA - 8 - 8

INTERNAL 5V

DC

INTERNAL

24V DC

EXTERNAL

24V DC

X X/Y Y

TOTAL

1

2

3

4

FX

FX

FX

FX

FX

FX

FX

FX

FX

2N

-8AD 50mA - 80mA - 8 - 8

2N

-2LC 70mA - 55mA - 8 - 8

*1

2N

-16CCL-M

2N

-32CCL 130mA - 50mA - 8 - 8

2N

-64CL-M 190mA - 25mA

2N

-16LNK-M 200mA - 90mA *4 *4

2N

-32ASI-M

0N

-232ADP 200mA - - - - - -

0N

-485ADP 30mA - 50mA - - - -

*1

Self supplied - 150mA *2 *2

150mA - 70mA

*3

*5

*3 *3

*6 *6

5

6

7

1-15

FX1N Series Programmable Controllers Introduction 1.

Table 1.12: Special function block/Function adapters/Expansion board

CURRENT CONSUMPTION INPUT OUTPUT

FX

FX

FX

FX

FX

FX

FX

FX

FX

FX

FX

MODEL

2NC

-232ADP 100mA - - - - - -

2NC

-485ADP 150mA - - - - - -

1N

-4EX-BD - - 25mA - - - -

1N

-2EYT-BD - - - - - - -

1N

-2AD-BD - - - - - - -

1N

-1DA-BD-------

1N

-232-BD 20mA - - - - - -

1N

-422-BD 120~220mA - - - - - -

1N

-485-BD 60mA - - - - - -

1N

-8AV-BD - - - - - - -

1N

-CNV-BD-------

INTERNAL 5V

DC

INTERNAL

24V DC

EXTERNAL

24V DC

X X/Y Y

TOTAL

*1 FX1N series PLC cannot connect together with an FX2N-32ASI-M and FX2N-16CCL-M.

An FX2N-32ASI-M module cannot be attached to an FX1N series PLC that is using an

2N

FX

-16CCL-M module. Only one FX2N-32ASI-M module can be connected to the PLC.

1-16

FX1N Series Programmable Controllers Introduction 1.

*2 Maximum number of I/O points per system Connection is allowed as far as the following

condition is satisfied:

(Actual number of I/O points of PLC) + (Number of points occupied by special extension

2N

blocks) + (Number of points occupied by FX

O modules) ≤ 128

Moreover, if connecting two or more FX

connect to the “remote I/O modules” and “remote device modules” but subsequent

modules only connect to “remote device modules”.

*3 For details, refer to FX

*4 The value depends on the switch setting (16, 32, 48, 64, 96 or 128 points).

*5 FX

*6 The I/O control points of both the FX

2N

-32ASI-M must be supplied 70mA (at Typical 30.5V) from the AS-interface power

supply.

points. Therefore, there is a limitation in the number of units (number of slaves) which

can be controlled according to the I/O points recognized by the PLC's CPU (occupation).

Occupation I/O points: Each AS- i slave station occupies 4 CPU I/ O points.

2N

-64CL-M User’s Manual.

2N

-32ASI-M and PLC CPU must not exceed 128

-16CCL-M: 8) + (32 x Number of remote I/

2N

-16CCL-M, the first master module can

1

2

3

4

5

1-17

6

7

FX1N Series Programmable Controllers Introduction 1.

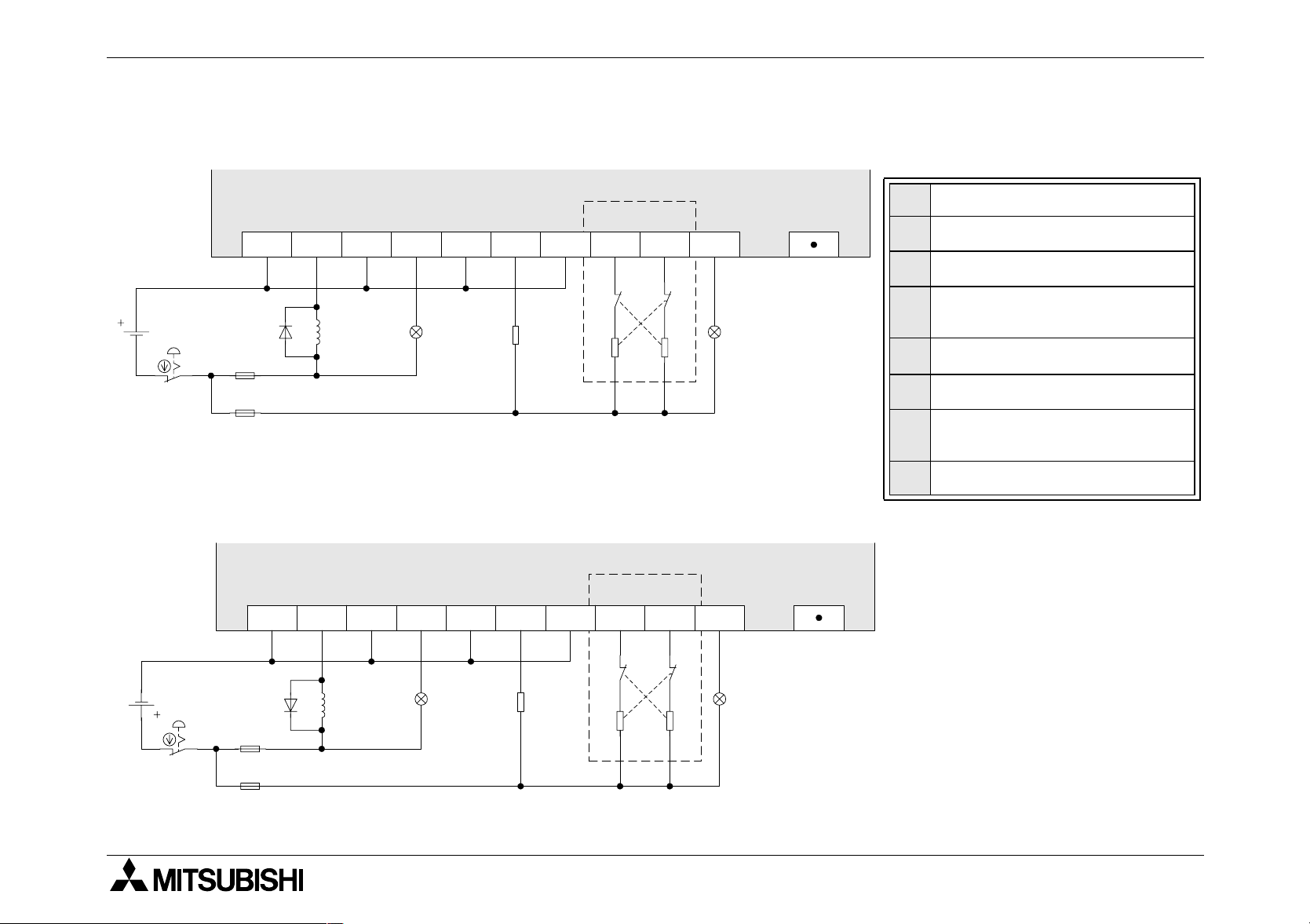

1.4.4 Rules of Expansion

1N

The maximum I/O for an FX

system is 128 I/O points and 8 special function blocks.

The FX1N Series can be expanded as follows when used independently.

- 2 special function blocks

- 1 special function block and up to 16 I/O points

- Up to 32 I/O points

It can also be expanded to 4 special function blocks when used in conjunction with an FX

extension unit (2+2). An AC powered FX1N can be expanded by 8 special function blocks when

used in conjunction with an FX2N extension unit (2+6).

X000~X043 X050~X057

FX0N-232ADP

POWER

RD

SD

Y000

FX0N-232ADP FX1N-60MR-ES/UL FX0N-16EX-ES/UL

X070

X1

COM

X3 X5X4X7X6X11 X15

X0 X2

LN

Y1

Y0

COM

24+

COM0

COM Y0Y1Y2 Y4Y6 Y0Y2 Y4Y6

Y4

Y2

COM2

COM3

COM1

Y5

Y3

Y027

~

X117

~

X1

X5 X7X6X1

COM COM X1

X0 X2X3X4

N X0 X2 X4 X6L

POWER

-40ER

FX

0N

X17

X13 X43

X21

X22

X14 X16

X20

Y14

Y10

Y12

Y11

COM4

Y15

Y13 COM5

X5 X7

X6

IN

01234567

01234567

01234567

OUT

07654321

01234567

Y6

X10

Y7

X0 X2X3X4

X23 X25

Y16

X27

X31

X33

X35

X37

X41

X32

0123

10 11 12 13 14 15 16 17

30 31 32 33

40 41 42 43

0123

Y22

Y23 Y25

X42X12

X34

X36

X40

4567

272524 2620 21 22 23

373534 36

IN

POWER

RUN

ERROR

FX1N-60MR

OUT

4567

1716

14 1510 11 12 13

272624 2520 21 22 23

Y26

Y24

COM7

Y27

FX0N-8EYR

OUT

4765

POWER

3210

X060

24+X1X3X5X7

X0 X2 X4 X6

FX0N-16EX

POWER

60

770IN11223344556

X0X1X2 X4 X6

X3 X5 X7

~

X067

X26

X30

X24

Y20

Y17

Y21

COM6

X7X3 X5

Y7COM0 COM1 COM2 Y3 COM3 Y5 Y7 COM4 Y1 Y3 COM5 Y524+

1N

•FX

series PLC cannot connect together with

an FX2N-32ASI-M and FX2N-16CCL-M.

2N

An FX

-32ASI-M module cannot be attached to

an FX1N series PLC that is using an FX2N16CCL-M module.

2N

Only one FX

-32ASI-M module can be

connected to the PLC.

2N

• If connecting two or more FX

-16CCL-M, the

first master module can connect to the “remote I/

O modules” and “remote device modules” but

subsequent modules only connect to “remote

0N

Y030

Y047

~

FX0N-40ER-ES/UL

Y050

~

Y057

device modules”.

FX0N-8EYR-ES/UL

1-18

FX1N Series Programmable Controllers Introduction 1.

• If a DC powered main unit is used with a power supply of less than 24VDC -15% (20.4V DC

or less), then it

extension units.

It can accommodate a maximum of an additional 32 I/O points.

• If an FX

above, as it utilizes special M coils for its operation and therefore does not contribute to the

maximum 128 I/O point count. Only one special function board can be used at any time.

See section 3.9.1 for more details.

expansion board is being used, it does not alter the rules of expansion outlined

1N

cannot

be fully expanded by using special function blocks or powered

1

2

3

4

5

1-19

6

7

FX1N Series Programmable Controllers Introduction 1.

1.5 Back up Data

1.5.1 EEPROM backup

Data includes the Program, Comment, File Registers (D1000 ~ D7999), and parameter data.

This will be stored as long as the EEPROM is not damaged. Mitsubishi Electric has

guaranteed a life cycle time of 10,000 writes to the EEPROM memory. Users may experience

operational writes to the EEPROM in excess of 10,000; however, due to temperature effects a

quantitative estimation cannot be given.

If the PLC has been powered on for five minutes or more, the following device data will be

saved in the EEPROM at powerdown:

S0 ~ S127, M384 ~ M511, C16 ~ C31, C235 ~ C255, and D128 ~ D255.

1.5.2 Capacitor backup

The capacitor backed memory includes M512 ~ M1535, S128 ~ S999, T246 ~ T255,

C32 ~ C199, C220 ~ C234, D256 ~ D7999 and the RTC.

The capacitor backed memory will retain data for a maximum of 10 days (Ambient

temperature: 25 °C), and requires 30 minutes to recharge upon power up.

1N

Note

: The FX

does not have battery backup, if a system requires backup of more than 10

days (Ambient temperature: 25 °C), a peripheral backup power source must be provided.

1-20

FX1N Series Programmable Controllers Introduction 1.

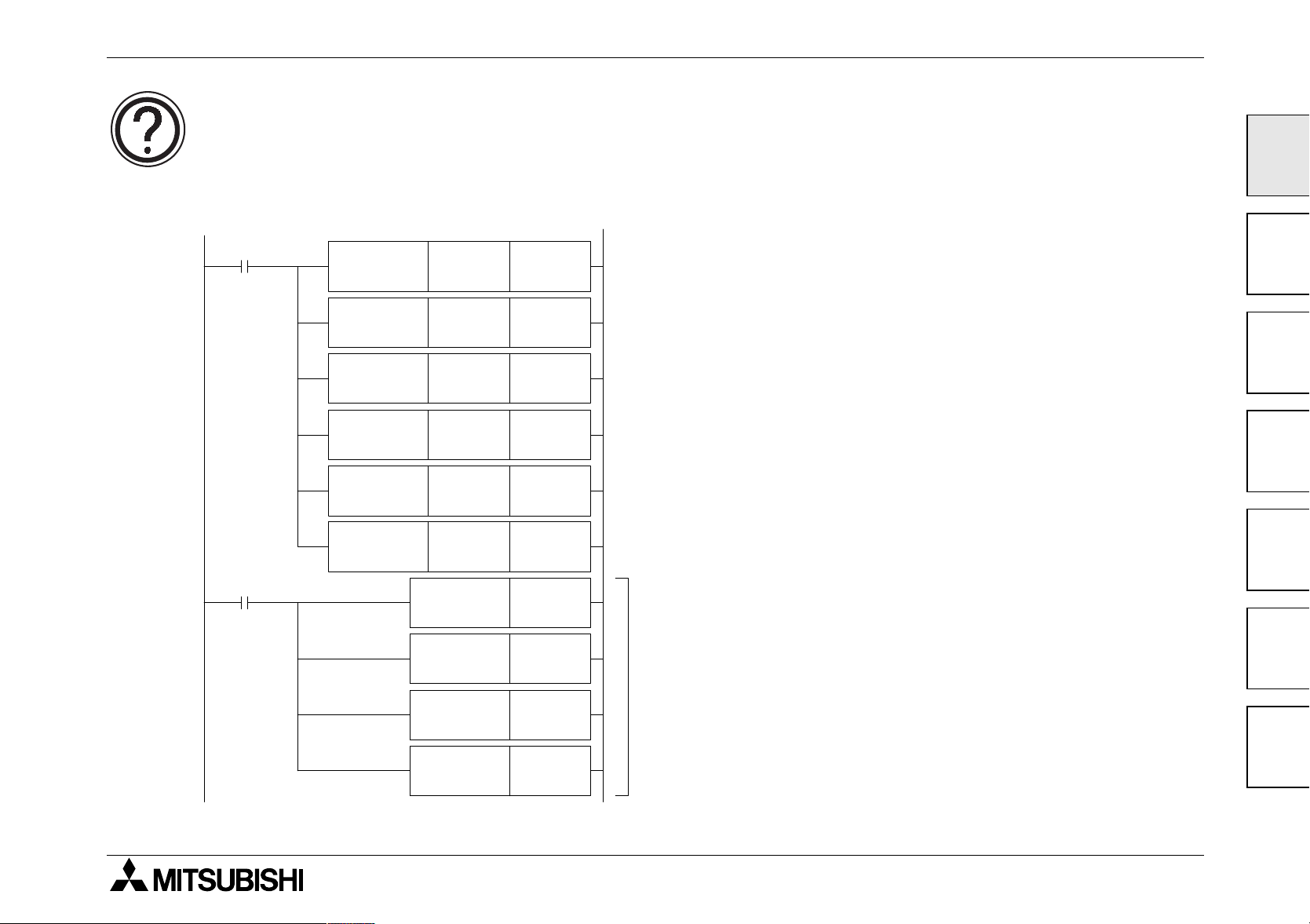

Warning

If the PLC will be intentionally powered down for a duration exceeding 10days (Ambient

temperature: 25 °C), then please include the following code into the user program as the

supercapcitor backed area of memory will be unfixed.

The device data held by the

M8002

M8001

FNC 40

ZRST

FNC 40

ZRST

FNC 40

ZRST

FNC 40

ZRST

FNC 40

ZRST

FNC 40

ZRST

D256 D7999

M512 M1535

S128 S999

T246 T255

C32 C199

C220 C234

RST T246

supercapcitor will not be reset to 0

as there is NO internal hardware

reset function.

However, initialization method by

the ZRST instruction, for capacitor

backed devices (T246 ~ T255,

C32 ~ C199, C220 ~ C234) can

not be initialized. In order to

initialize the condition of the reset

coil, execute in OFF the RST

instruction of the corresponding

device currently used into the user

program as shown in the example

1

2

3

4

5

RST T247

RST C32

RST C33

The capacitor

backed device

currently used

into the user

program.

program on the left.

6

7

1-21

FX1N Series Programmable Controllers Introduction 1.

MEMO

1-22

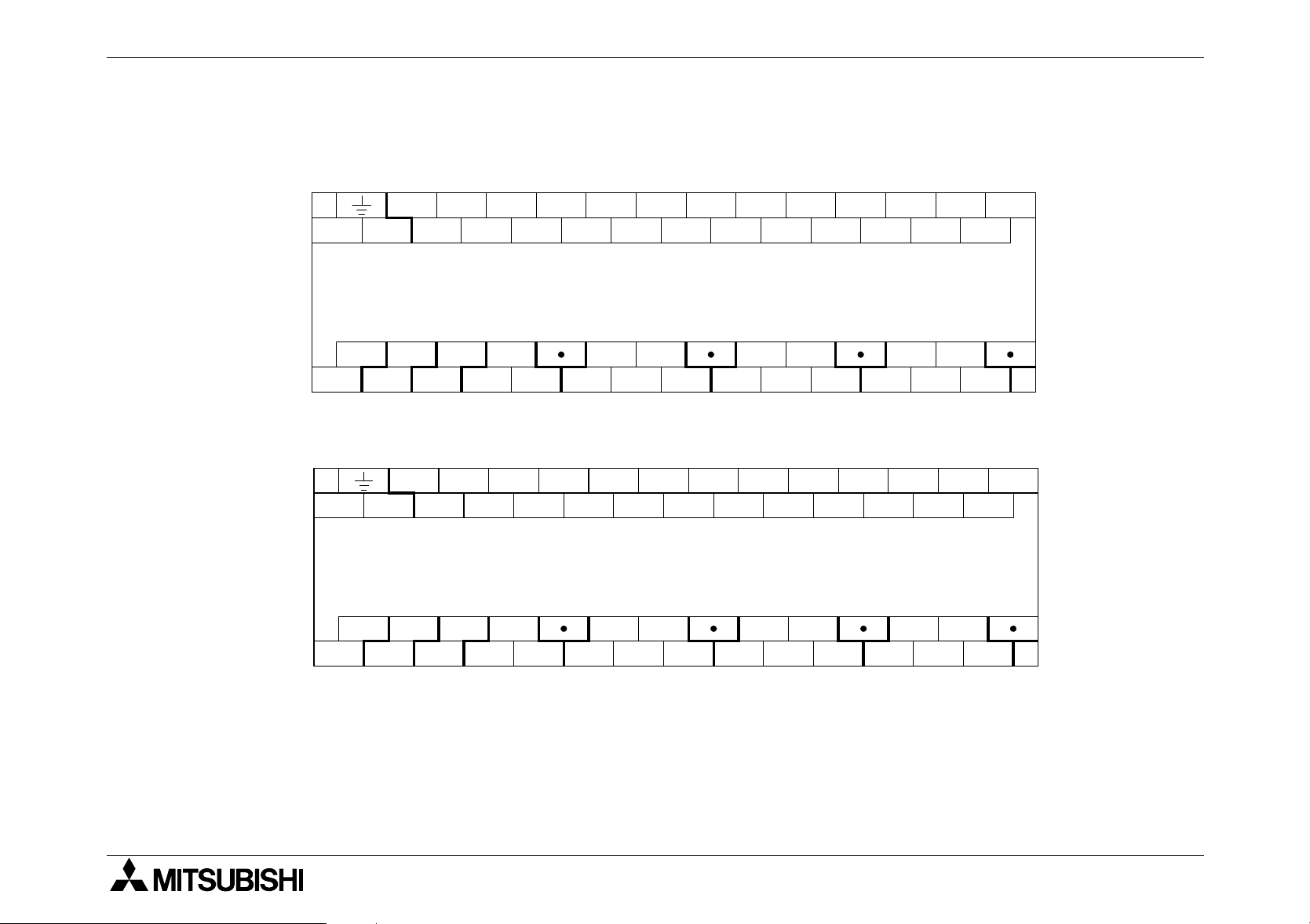

FX1N Series Programmable Controllers

2. Terminal layouts

The following selection of terminal layouts are taken from the FX1N product range.

Note: All layouts are schematic only and are intended to aid the creation of wiring diagrams.

Terminal layouts 2.

1

2.1 AC Powered Main Units

S/S X1

L

N X0 X4

X2

FX1N-14MR-ES/UL

0V Y0 Y1 Y2 Y3

COM0 COM1 COM3COM2

24V

S/S

X0 X4

NL

X1

X3

X2

FX1N-14MT-ESS/UL

X3

X5

X5

X7

X6

Y4

COM4 COM5

X7

X6

Y5

S/S X1

L

N X0 X4

X3

X2

FX1N-24M R-ES/UL

0V Y0 Y1 Y2 Y3

COM0 COM1 COM3COM2

24V

S/S X1

L

X0 X4

N

X3

X2

FX1N-24MT-ESS/UL

X5

X5

X6

X6

X7

Y5

COM4

X7

X10

Y6Y4Y10

X10

X13X11

X12

X12

X14

Y7 Y11

X13X11

X14

2

X15

3

4

5

X15

6

24V

0V

Y0 Y1 Y2 Y3

+V0 +V1 +V3+V2

Y4

+V4 +V5

Y5

0V Y0 Y1 Y2 Y3

24V

Y5

Y6 Y10

Y7 Y11+V0 +V1 +V2 +V3 Y4 +V4

2-1

7

FX1N Series Programmable Controllers Terminal layouts 2.

S/S X1

L

N X0 X4

FX1N-40MR-ES/UL

0V Y0 Y1 Y2

COM0 COM1 COM3COM2

24V

S/S X1

L

X0 X4

N

FX1N-40MT-ESS/UL

0V Y0 Y1 Y2

24V

X2

X2

X3

X3

Y3

X5

X5

X6

X6

X7

X7

X13X11

X10

X12

Y6Y4 Y14

Y5

X10

Y5

Y7 Y11

X12

Y6Y4 Y14

Y7 Y11

X14

COM4

X13X11

X14

X15

X16

X20

Y10 Y12

Y13

X15

X16

Y10 Y12

X21X17

X21X17

X20

Y13

X23

X22 X24

COM5

X22 X24

Y15 Y17

X23

Y15 Y17+V0 +V1 +V2 +V3 +V4 +V5Y3

X25

X26

Y16

X25

Y16

X27

X27

X26

2-2

FX1N Series Programmable Controllers Terminal layouts 2.

1

S/S X1

L

24V

24V

N X0 X4

0V

L

Y0 Y1 Y2

COM0 COM1 COM3COM2

S/S X1

N

0V

Y0 Y1 Y2

+V0 +V1 +V2 +V3 +V4 +V5 +V6 +V7

X3

X2

X5

X7

X6

FX1N-60MR-ES/UL

Y3

X3

X0 X4

X2

X5

X7

X6

FX1N-60MT-ESS/UL

Y3

X13X11

X10

X12

Y6Y4 Y14

Y5

X10

Y7 Y11

X12

Y6Y4 Y14

Y5

Y7 Y11

X14

COM4

X13X11

X14

X15

X16

Y10 Y12

X15

X16

Y10 Y12

X21X17

X20

Y13

X21X17

X20

Y13

X23

X22 X24

COM5

Y15 Y17

X23

X22 X24

Y15 Y17

X25

X26

Y16

X25

Y16

X27

X27

X26

X31

X30 X32

Y20 Y22

COM6

Y21 Y23

X31

X30 X32

Y20 Y22

Y21 Y23

X33

X33

X35

X34

X34

X36

COM7

X35

X36

X37

Y24 Y26

X41

X40

Y25 Y27

X37

Y24 Y26

X41

X40

Y25 Y27

X43

X42

2

3

4

X43

X42

5

6

2-3

7

FX1N Series Programmable Controllers Terminal layouts 2.

2.2 DC Powered Main Units

+

S/S X1

-

X0 X4

X3

X2

FX1N-14MR-DS

0V Y0 Y1 Y2 Y3

COM0 COM1 COM3COM2

24V

+

S/S

-

X1

X0 X4

X3

X2

FX1N-14MT-DSS

0V

24V

Y0 Y1 Y2 Y3

+V0 +V1 +V3+V2

X5

X5

X7

X6

Y4

COM4 COM5

X7

X6

Y4

+V4 +V5

Y5

Y5

S/S X1

-

+

X0 X4

X2

FX1N-24MR-DS

0V Y0 Y1 Y2 Y3

COM0 COM1 COM3COM2

24V

S/S X1

-

+

X0 X4

X2

FX1N-24MT-DSS

0V Y0 Y1 Y2 Y3

24V

X3

X3

X5

X5

X6

X6

X7

X10

Y5

COM4

X7

X10

Y5

X13X11

X12

Y6Y4Y10

Y7 Y11

X13X11

X12

Y6 Y10

Y7 Y11+V0 +V1 +V2 +V3 Y4 +V4

X15

X14

X15

X14

2-4

FX1N Series Programmable Controllers Terminal layouts 2.

1

S/S X1

X0 X4

+

-

FX1N-40MR-DS

0V Y0 Y1 Y2

COM0 COM1 COM3COM2

24V

S/S X1

-

+

X0 X4

FX1N-40MT-DSS

0V Y0 Y1 Y2

24V

X2

X2

X3

X3

Y3

X5

X5

X6

X6

X7

X10

Y5

X7

X10

Y5

X13X11

X12

Y6Y4 Y14

Y7 Y11

X13X11

X12

Y6Y4 Y14

Y7 Y11

X15

X14

Y10 Y12

COM4

X15

X14

Y10 Y12

X16

X16

X21X17

X20

Y13

X21X17

X20

Y13

X23

X22 X24

COM5

X22 X24

Y15 Y17

X23

Y15 Y17+V0 +V1 +V2 +V3 +V4 +V5Y3

X25

Y16

X25

Y16

X27

X26

2

3

4

X27

X26

5

6

2-5

7

FX1N Series Programmable Controllers Terminal layouts 2.

+

24V

+

24V

S/S X1

-

X0 X4

X3

X2

X5

X6

X7

X10

X12

X13X11

X14

X15

X16

X20

X21X17

X22 X24

X23

X25

X26

X27

X30 X32

X31

X33

X35

X34

FX1N-60MR-DS

0V

Y0 Y1 Y2

COM0 COM1 COM3COM2

S/S X1

-

X0 X4

X2

X3

Y3

X5

X7

X6

Y6Y4 Y14

Y5

Y7 Y11

X13X11

X10

X12

Y10 Y12

COM4

X15

X14

X16

Y13

X21X17

X20

COM5

Y15 Y17

X23

X22 X24

Y16

X25

X26

Y20 Y22

COM6

X27

X31

X30 X32

Y21 Y23

X33

X34

X35

FX1N-60MT-DSS

0V

Y0 Y1 Y2

+V0 +V1 +V2 +V3 +V4 +V5 +V6 +V7

Y3

Y6Y4 Y14

Y5

Y7 Y11

Y10 Y12

Y13

Y16

Y15 Y17

Y20 Y22

Y21 Y23

X37

X36

Y24 Y26

COM7

X37

X36

Y24 Y26

X41

X40

X42

Y25 Y27

X41

X40

X42

Y25 Y27

X43

X43

2-6

FX1N Series Programmable Controllers Terminal layouts 2.

2.3 FX0N, FX2N-8E Extension blocks

S/S X1 X3

X0 X2

FX

2N

-8EX-ES/UL

FX

0N

-8EX-ES/UL

FX

2N

-8EYR-ES/UL

X4 X6

X5 X7

S/S X1 X3

X0 X2 X4 X6

Y0 Y2

FX

0N

-8EYR-ES/UL

Y4 Y6

X5 X7

COM1

Y1 Y3

COM2

Y5 Y7

FX

2N

-8EYT-ESS/UL

FX

0N

-8EYT-ESS/UL

+V0 +V1

Y0 Y2

Y1 Y3

Y4 Y6

Y5 Y7

COM1

FX

FX

0N

2N

-8ER-ES/UL

-8ER-ES/UL

Y1 Y3

S/S

X0 X2

X1 X3

COM1

Y0 Y2

Y1 Y3

COM2

Y0 Y2 Y4 Y6

X0 X2

FX

FX

0N

2N

-8EX-UA1/UL

-8EX-UA1/UL

X4 X6

Y5 Y7

COM1

X1 X3

X5 X7

+V0 Y1 Y3

Y0 Y2 Y4 Y6

+V1

1

2

3

4

5

Y5 Y7

FX0N-16EX-ES/UL

X0 X2 X4 X6

X1 X3 X5 X7

FX0N-16EYR -ES/UL

Y0 Y2 Y4 Y6

COM3

Y1 Y3 Y5 Y7

COM4

FX0N-16EYT-E SS/UL

Y0 Y2 Y4 Y6

+V2 Y1 Y3 Y5 Y7+V3

6

7

2-7

FX1N Series Programmable Controllers Terminal layouts 2.

2.4 FX2N Extension blocks

FX

2N

-16EX-ES/UL

S/S

X7

X3X1X0X5 X6X3X1

X5 X7

X4X2X0 X6X4X2

FX

2N

-16EYR-ES/UL

COM1

Y7

Y5 Y7Y3Y1Y0Y5 Y6Y3Y1

Y4Y2Y0 Y6Y4Y2

COM2

FX

2N

-16EYT-ESS/UL

+V0

Y4Y2Y0 Y6Y4Y2

Y7

Y5 Y7Y3Y1Y0Y5 Y6Y3Y1

+V1

2-8

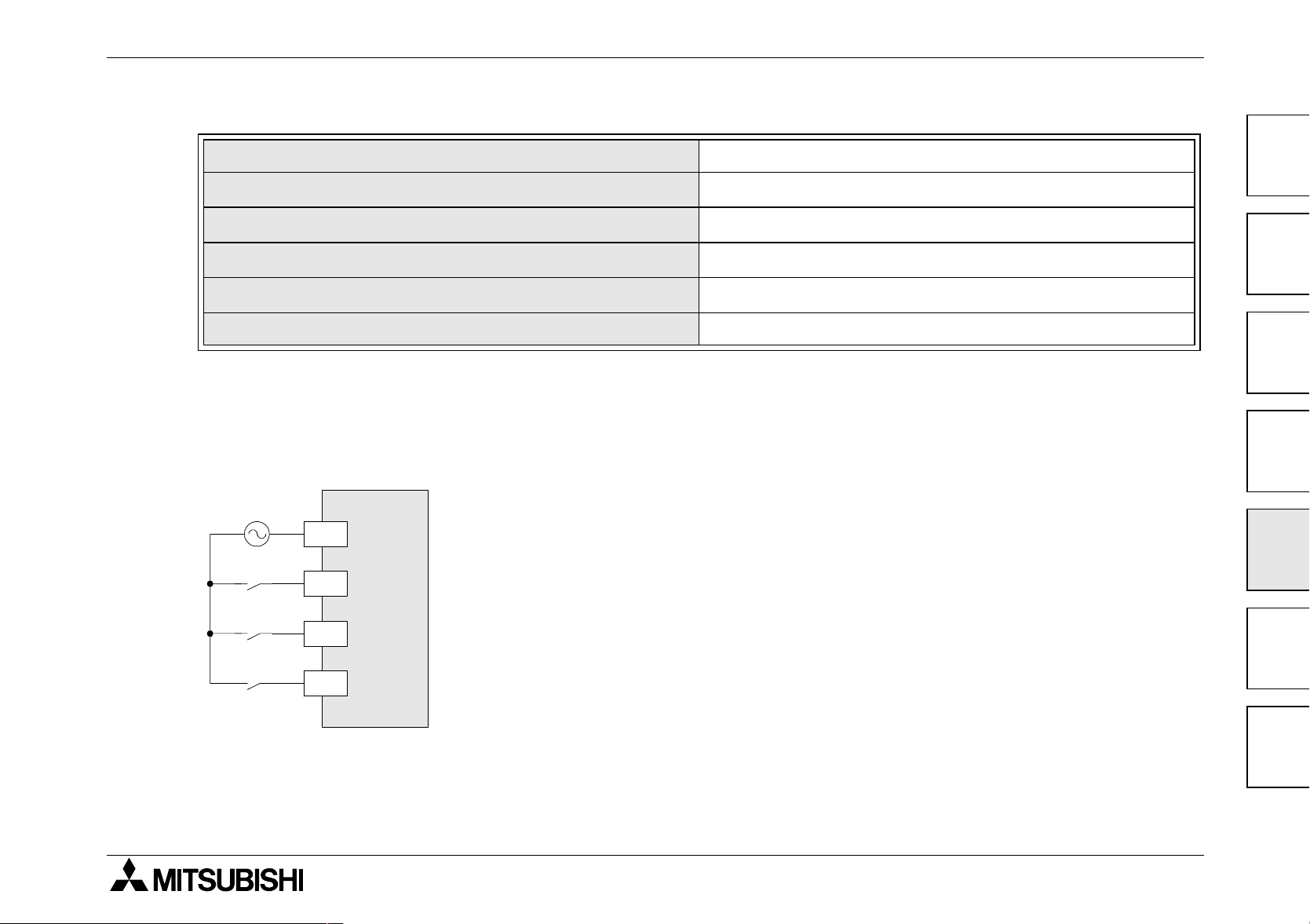

FX1N Series Programmable Controllers

3. Installation Notes

The installation of FX1N products has been designed to be safe and easy. When the products

associated with this manual are used as a system or individually, they must be installed in a

suitable enclosure. The enclosure should be selected and installed in accordance to the local

and national standards.

Installation Notes 3.

1

2

3

4

3-1

5

6

7

FX1N Series Programmable Controllers Installation Notes 3.

3.1 Product Outline

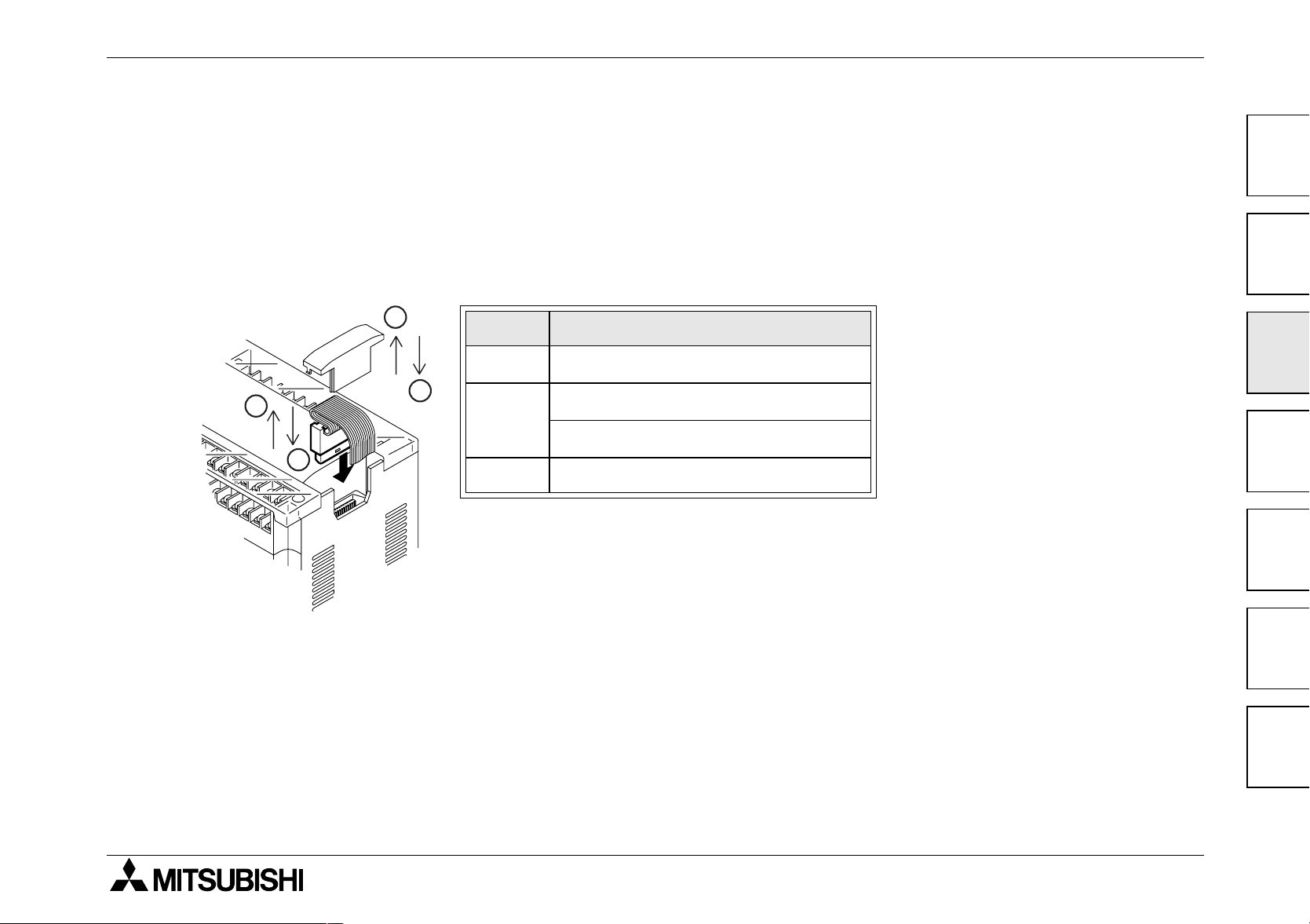

Figure 3.1:Features of the FX

➁

➀

24V

➂

0V

S/S X13

L

N

Y0Y2Y1

COM0

COM1

X0 X2

COM2

X1 X3

COM3

Y3

➃

Y4

X5X4X7X6X11

X10

Y5

Y6

COM4

Y7

0123

4567

14 15

POWER

RUN

ERROR

FX

1N

0123

4567

1110

Y10

➂

➉

➈

X12

-24MR

Y11

1N

X14

131110 12

IN

OUT

➂

PLC

➂

X15

➄

➅

➆

➇

➁

11

15

14

Top cover removed

X1 X3

24V

LN

0V

COM0

Y0Y2Y1

COM1

S/S

X0 X2

COM2

COM3

Y3

Y4

X5X4X7X6X11

X10

Y5

Y6

COM4

Y7

X12

0123

4567

14 15

POWER

RUN

ERROR

FX1N-24MR

0123

4567

1110

Y10

Y11

X13

X15

X14

131110 12

IN

OUT

12

13

3-2

FX1N Series Programmable Controllers Installation Notes 3.

Table 3.1 : Features table

1

2

3

4

5

6

7

8

9

10

11

12

13

Top cover

Direct mounting holes (4.5 mm <0.17"> diameter)

I/O terminal block securing screws

Input terminals (24V DC) and power supply terminals

Input LED status indicators

Expansion port cover

PLC status indicators (POWER, RUN, ERROR)

Output LED status indicators

DIN rail mounting clip

Output terminals and power supply source terminals

Optional equipment connector

Expansion port

Run/Stop switch

1

2

3

4

5

14

15

Programming port

Variable analog potentiometers. Upper pot, D8030 read from VR1. Lower pot D8031

read from VR2

3-3

6

7

FX1N Series Programmable Controllers Installation Notes 3.

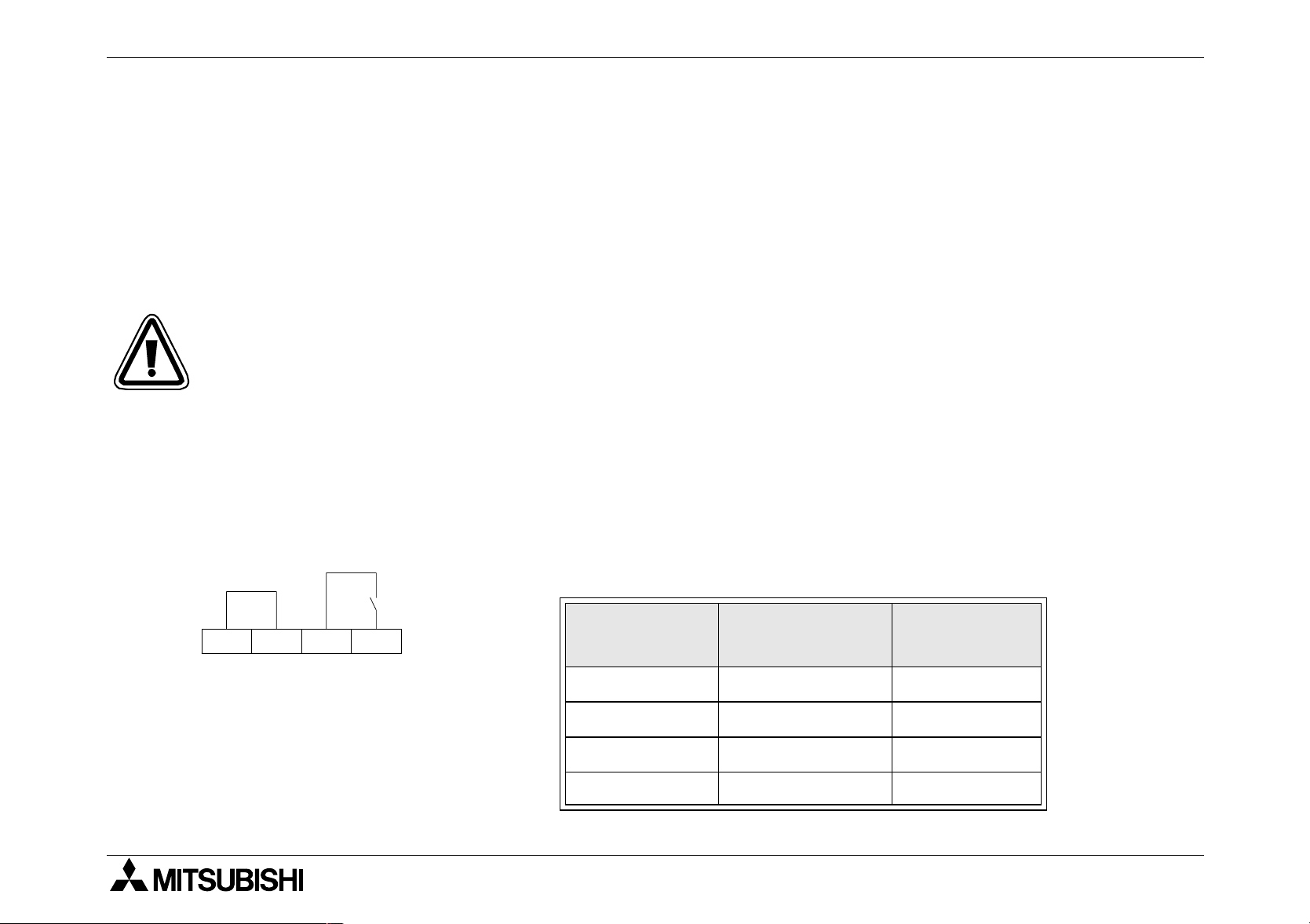

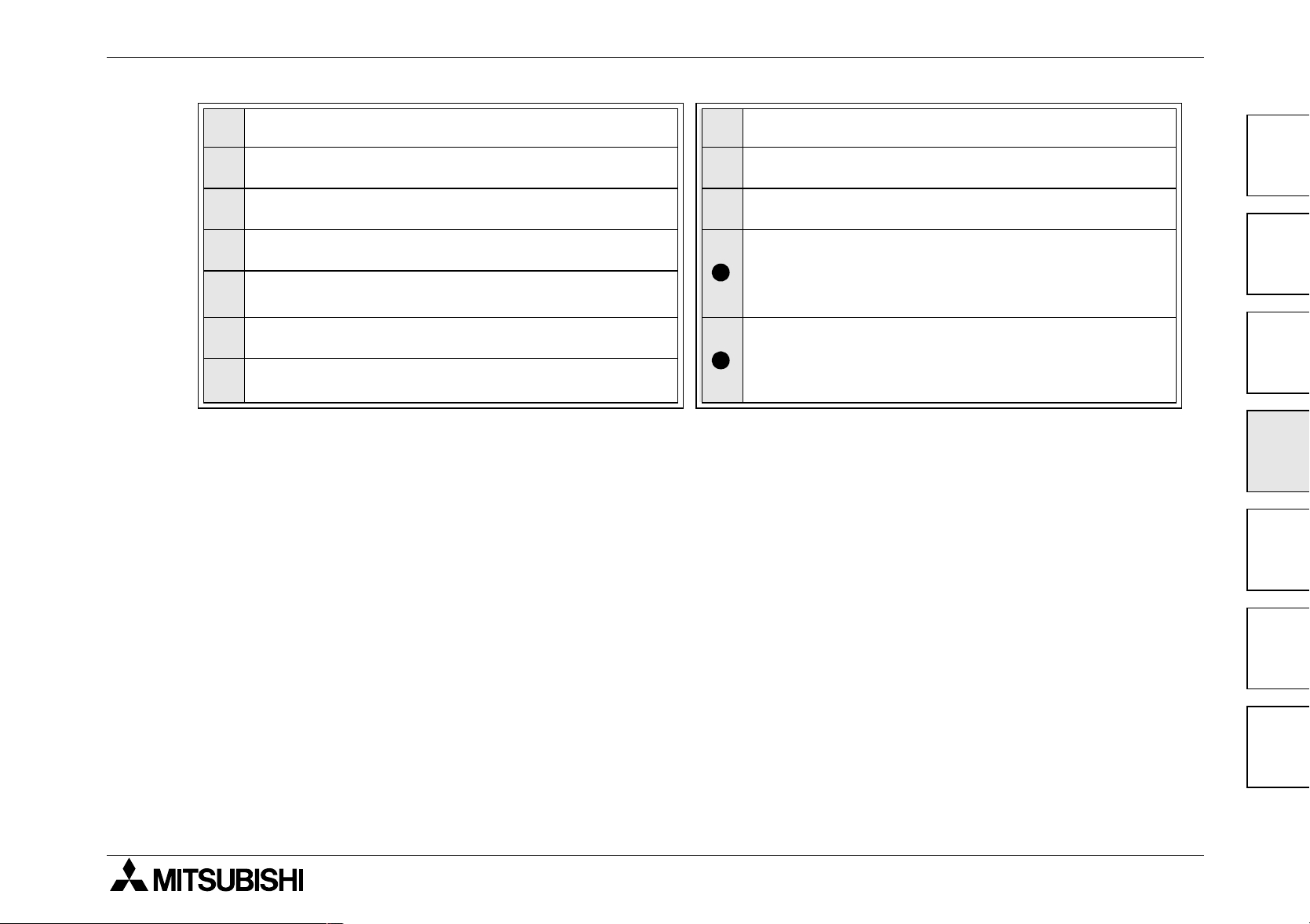

3.2 FX1N RUN/STOP Control

RUN or STOP of the FX1N can be controlled by:

The RUN/STOP switch mounted next to the programming port.

n

A standard input (X0 to X17) defined by the system parameters.

o

Remotely from a personal computer or other programming peripheral.

p

Note

:The FX

1N

RUN/STOP switch works in parallel with the RUN-input terminal. Please

refer to the table below.

During remote operation the FX

recently operated control.

E.g. If the RUN/STOP switch is in RUN and a remote STOP is made from a personal

computer the RUN/STOP switch must be switched to STOP then back to RUN to

switch the MPU back to RUN mode.

Figure 3.2:RUN input terminal

RUN

➊

S/S 0V 24V X0

1N

RUN/STOP status is determined by the most

Table 3.2 : RUN/STOP selection

RUN/STOP

SWITCH

✔✔

✔✘

✘✘

RUN INPUT

➊

TERMINAL

FX1N MPU

STATUS

RUN

RUN

STOP

✘✔

RUN

3-4

FX1N Series Programmable Controllers Installation Notes 3.

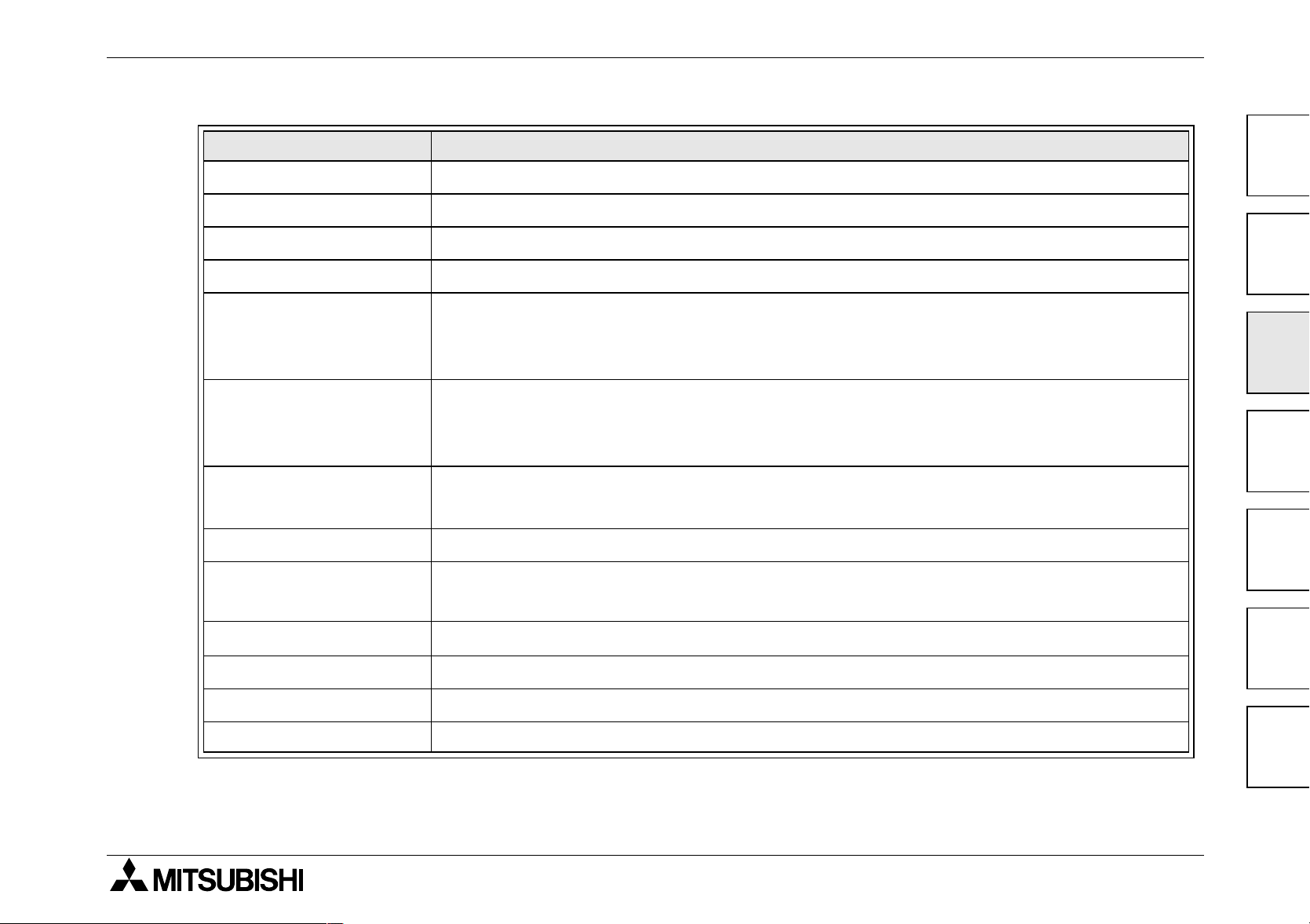

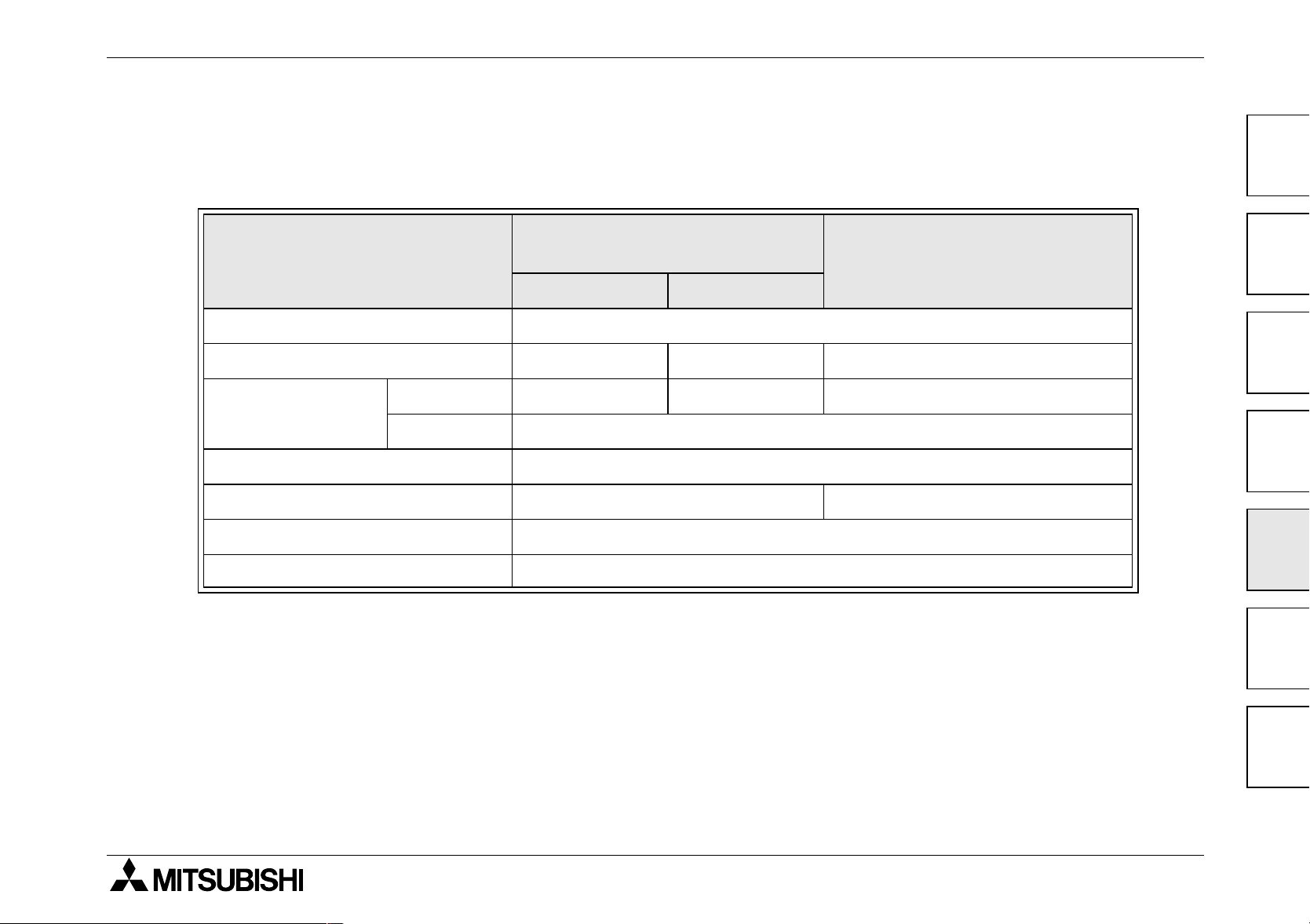

3.3 General Specifications

Item Description

Operating Temperature 0 to 55 °C (32 to 131 °F)

Storage Temperature -20 to 70 °C (-4 to 158 °F)

Operating Humidity 35 to 85% Relative Humidity, No condensation

storage Humidity 35 to 90% Relative Humidity, No condensation

Vibration Resistance

- Direct Mounting

Vibration Resistance

- DIN rail Mounting

Shock Resistance

Noise Immunity 1000 Vp-p, 1microsecond, 30 - 100 Hz, tested by noise simulator

Dielectric Withstand

Voltage

Conforms to EN 68-2-6; 10 - 57 Hz: 0.075 mm Half Amplitude

2

57 - 150 Hz: 9.8 m/s

Sweep Count for X, Y, Z: 10 times (80 min in each direction)

Conforms to EN 68-2-6; 10 - 57 Hz: 0.035 mm Half Amplitude

57 -150 Hz: 4.9 m/s

Sweep Count for X, Y, Z: 10 times (80 min in each direction)

Conforms to EN 68-2-27: 147m/s

3 times in each direction X, Y, and Z

AC PSU: 1500 V AC > 1 min., tested between each terminal with ground terminal

DC PSU: 500 V AC > 1 min., tested between each terminal with ground terminal

2

Acceleration, Action Time: 11 ms

Acceleration

2

Acceleration

1

2

3

4

5

*1

*1

Insulation Resistance

Ground Grounding resistance 100 Ω or less

Certification UL/cUL (UL508)

EC Directive EMC (EN61000-6-2, EN50081-2), LVD (EN61010-1)

5 MΩ > at 500 V DC, tested between each terminal with ground terminal

*1

*1 Perform dielectric withstand voltage and insulation resistance tests at the stated voltage

between each terminal and the main unit’s ground terminal.

3-5

6

7

FX1N Series Programmable Controllers Installation Notes 3.

Between terminals

Between power supply terminal and ground terminal

Between 24V DC service

power supply connected to

input terminal (24V DC) and

ground terminal

Between input terminal (100V

AC) and ground terminal

Between output terminal

(relay) and ground terminal

Between output terminal (transistor) and ground terminal

Dielectric strength

AC Power Supply Units DC Power Supply Units

1.5kV AC for 1 min

500V AC for 1 min

500V AC for 1 min

1.5kV AC for 1 min

1.5kV AC for 1 min

500V AC for 1 min

Insulation

resistance

5MΩ or

more on

500V DC

Megger

Remarks

−

−

−

−

−

3-6

FX1N Series Programmable Controllers Installation Notes 3.

FX

1N

CPU

Function block

Function block

A

A

A

FX0N,FX

2N

Extension

blocks

A

A

A

> 50mm (1.97 inches)

A

A

3.4 PLC Mounting Arrangements

To prevent a rise in temperature, mount the units to walls. Never mount them to the floor or

1

ceiling of an enclosure.

Below (left)Single row arrangement

Below (right)Double row arrangement using extension cable FX

0N

-65EC

2

(650mm (25.59”); supplied separately).

3

A

1N

FX

CPU

Function block

A

> 50mm (1.97 inches)

A

AA

Function block

4

5

6

7

3-7

FX1N Series Programmable Controllers Installation Notes 3.

Caution

• Units should not be installed in areas subject to the following conditions: excessive or

conductive dust, corrosive gas (salt air, Cl2, H2S, SO2, NO2, etc.) or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration.

• Take special care not to allow debris to fall inside the unit during installation e.g. cut

wires, shavings etc. Once installation is complete remove the protective paper band, to

prevent overheating.

• Always ensure that mounted units and blocks are kept as far away as possible from

high-voltage cables, high-voltage equipment and power equipment.

• Do not lay signal cables near high voltage power cabling or cabinet housing along the

same trunking duct. Effects of noise or surge induction may occur. Keep signal cables of

more than 100 mm (3.94") away from these power cables.

• Install necessary power supply cut off precautions to the enclosure of the final system.

Attach a warning label (hazard symbol 417-IEC-5036) concerning electric shock to the

enclosure.

1N

•Use the FX

series PLC with consideration for electrical noise in an environment that

does not exceed conditions provided by EN50081-2 and EN61000-6-2.

• Cut off all phases from the power source before installation or performing wiring work to

avoid electric shock. Incorrect operation can lead to serious damage to the product.

• Cut off all phases from the power source before installing/removing extension or

communication cables to modules to avoid electric shock, incorrect operation or serious

damage to the product.

3-8

FX1N Series Programmable Controllers Installation Notes 3.

• Replace the terminal cover provided, after installation or wiring work is completed, and

before supplying power and operating the unit to avoid electric shock.

• After reading the manual's safety instructions, initiate the operation for making program

changes while the PLC is in RUN mode, forcing ON/OFF and switching RUN/STOP.

• The power supply of the extension units/blocks and the special function units/blocks

1N

should be started at the same time or earlier than the FX

• DO NOT use the “●” terminal in PLC.

• When using an incorrect power source or performing incorrect operation, serious

damage will occur regardless of the level of the voltage and frequency.

• When performing incorrect wiring or operation, serious damage will occur.

• The “L” and “N” terminals are not reversible.

If the “L” and “N” terminals are reversed, the units/blocks may be seriously damaged.

• The “24V” and “0V” terminals are not reversible.

If the “24V” and “0V” terminals are reversed, the units/blocks may be seriously damaged.

• During transportation avoid any impact as the PLC is a precision instrument.

Series main unit.

1

2

3

4

5

It is necessary to check the operation of PLC after transportation, in case of any impact

damage.

• When storing the PLC, conform to the environmental conditions specified by the general

specification.

3-9

6

7

FX1N Series Programmable Controllers Installation Notes 3.

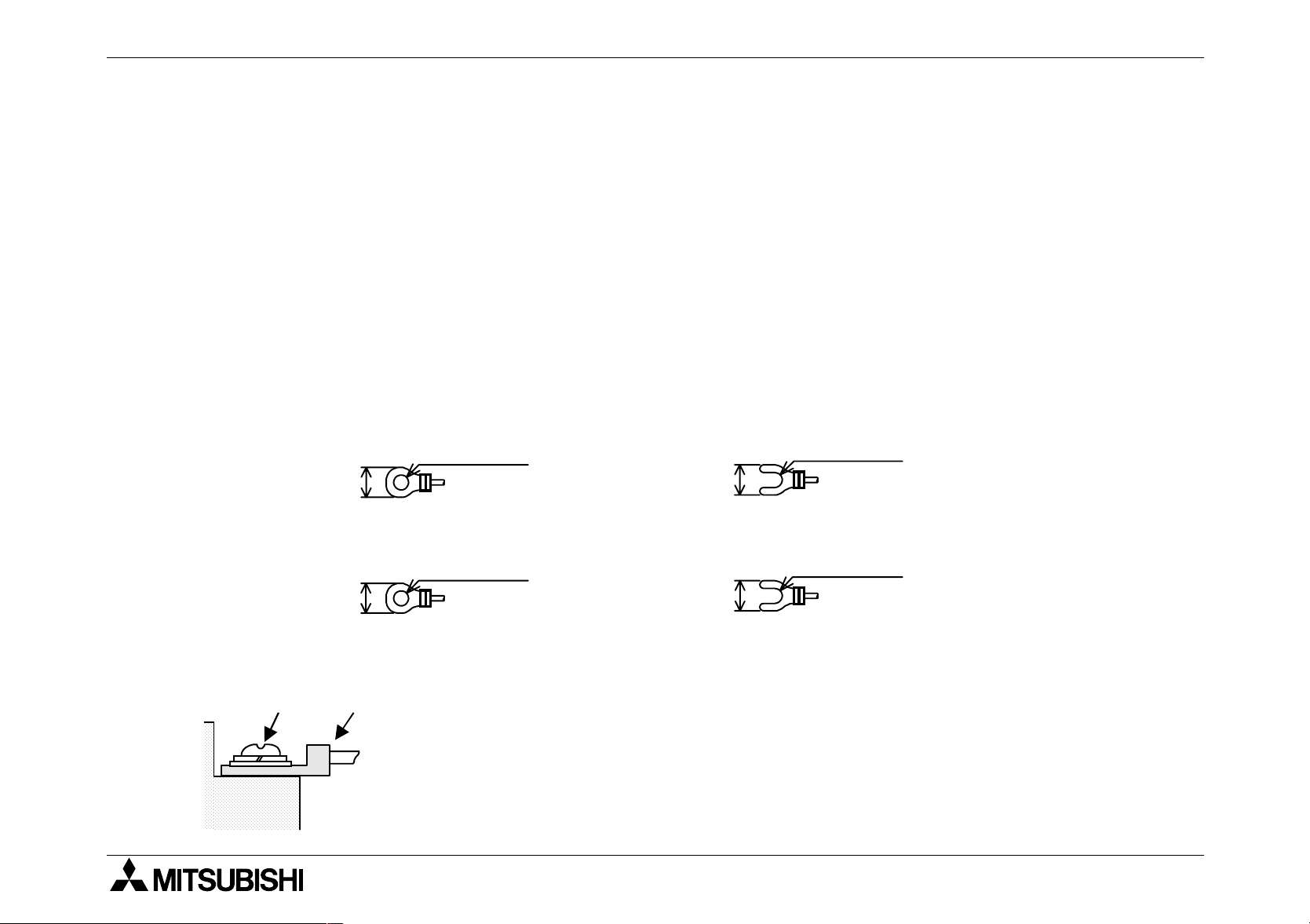

3.5 DIN Rail Mounting

Units can be snap mounted to 35mm (1.37") DIN rail (DIN EN 50022). To release, pull the

spring loaded clips away from the rail and slide the unit up and off.

3.6 Direct Mounting

Table 3.3 :Hole positions

UNIT

A = W-8mm (0.32")

1N

FX

FX

FX

FX

FX

FX

FX

FX

1N

1N

1N

-14M

-24M

-40M

-60M

✩

✩

✩

✩

∅

2-

( → )

B = W-10mm (0.40")

∅

0N

-40E

✩