Page 1

PROGRAMMING MANUAL

THE FX SERIES OF PROGR AMM ABLE CONTROLLER

(FX0, F X0S, F X0N, F X , F X

2C, FX2N, FX2NC

)

Page 2

Page 3

FX Series Programmable Controllers

g

g

g

y

g

y

j

FX Series Programmable Controllers

Programming Manual

Manual number : JY992D48301

Manual revision : J

Date : November 1999

Foreword

• This manual contains text, dia

the correct pro

• Before attemptin

understood.

• If in doubt at an

electrical en

which appl

• If in doubt about the operation or use of the PLC please consult the nearest

Mitsubishi Electric distributor.

• This manual is sub

ramming and operation of the PLC.

to install or use the PLC this manual should be read and

stage of the installation of the PLC always consult a professional

ineer who is qualified and trained to the local and national standards

to the installation site.

ect to change without notice.

rams and explanations which will guide the reader in

i

Page 4

FX Series Programmable Controllers

ii

Page 5

y

y

y

g

g

y

y

y

g

y

y

y

y

y

y

g y

y

y y

y

y

FX Series Programmable Controllers

FAX BACK - Combined Programming Manual (J)

Mitsubishi has a worl d wide rep utation fo r its eff orts i n continual l

the frontiers of industrial automation. What is sometimes overlooked b

and attention to detail that is taken with the documentation. However,to continue this process

of improvement, the comments of the Mitsubishi users are alwa

been desi

ward to hearin

Please tick the box of

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your compan

Australia (02) 638-7072 .....................................................................

German

South Africa (0111) 444-8304 .................... ................................. ................

United Kin

What condition did the manual arrive in?

Will

ned for you,the reader ,t o fill in your comments and fax them back to us. W e look fo r-

from you.

our choice;

(0 21 02) 4 86-1 12 Your location: ...............................................

dom (01707) 278-695

Good

ou be using a folder to store the manual?

developing and pushing back

the user is the care

s welcomed. This page has

..............................................

Minor damage

Yes

Unusable

No

What do

Are the explanations understandable?

Which explanation was most difficult to understand:..................................................................

....................................................................................................................................................

Are there an

If so,which:..................................................................................................................................

What do

If there one thin

....................................................................................................................................................

....................................................................................................................................................

Could

ble please identif

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Do

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

ou think to the manual presentation?

Yes

diagrams which are not clear?

ou think to the manual layout?

ou would like to see improved,what is it?......................................................

ou find the information you required easily using the index and/or the contents,if possi-

our experience: ...........................................................................................

ou have any comments in general about the Mitsubishi manuals?.....................................

Good

Tid

Not too bad

Yes

Not too bad

Un-friendl

Unusable

No

Un-helpful

Thank

and this manual easy to use.

ou for taking the time to fill out this questionnaire. W e hope you found both the

product

iii

Page 6

FX Series Programmable Controllers

iv

Page 7

FX Series Programmable Controllers

y

y

g

g

y

j

g

y

y

y

g

y

y

y

g

g

g

y

g

Guidelines for the Safety of the User and Protection of the Programmable

Controller (PLC)

This manual provides information for the use of the FX family of PLC’s. The manual has been

written to be used b

persons is as follows;

trained and competent personnel. The definition of such a person or

a) An

engineer who is responsible for the planning, design and construction of automatic

equipment usin

the product associated with this manual should b e of a competent

nature, trained and qua lified to the local an d national standa rds required to fulfill tha t

role. These en

ineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) An

commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national stand ards required to fulfill that

ob. These engineers

should also be trained in the use and maintenance of the completed product. This

includes bein

completely familiar with all associat ed documentation for the said

product. All maintenance should be carried out in acc ordance with established safet

practices.

c) All operators of the completed equipment should be trained to use that product in a safe

and coordinated manner in compliance to established safet

practices. The operators

should also be familiar with documentation which is connected with the actual operation

of the completed equipment.

Note :

the term ‘completed equipment’ refers to a third part

constructed device which

contains or uses the product associated with this manual.

Note’s on the Symbols used in this Manual

At various times throu

information which are intended to ensure the users personal safet

equipment. Whenever an

be read and understood. Each of the s

its meanin

.

h out this manual certain symbols will be used to highlight points of

and protect the integrity of

of the following symbols are encountered its associated note must

mbols used will now be listed with a brief descript ion of

Hardware Warnings

1) Indicates t hat the identified dan

2) Indicates that the identified dan

damage.

3) Indicates a point of further interest or further explanation.

Software Warning s

4) Indicates special care must be taken when usin

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

WILL

er

er could

cause physical and property damage.

POSSIBLY

cause physical and propert

this element of software.

v

Page 8

FX Series Programmable Controllers

vi

Page 9

g

g

g

g

g

g

g

g

g

FX Series Programmable Controllers

Contents

1. Introduction............................................................................................1-1

1.1 Overview..............................................................................................................1-1

1.2 What is a Pro

rammable Controller? ..................................................................1-2

1.3 What do You Need to Pro

1.4 CPU version numbers .........................................................................................1-3

1.4.1 FX0N CPU versions...................................................................................................1-3

1.4.2 FX and FX

2C

1.5 Special considerations for programming equipment ....... .. ... ............... .. ... ...........1-4

1.5.1 FX CPU version 3.07 or later and FX2C ................................................................... 1-4

1.5.2 FX

2N

(C) CPU all versions ........................................................................................1-5

2. Basic Program Instructions ...................................................................2-1

2.1 What is a Program?.... .. ... .. .. .. ... .. .. .... ... .. .. .. .. ... .. .. .. .. ..... .. .. .. ... .. .. .. ... .. .. .... ... .. .. .. .. ...2-1

2.2 Outline of Basic Devices Used in Pro

2.3 How to Read Ladder Lo

2.4 Load, Load Inverse ..............................................................................................2-3

2.5 Out.......................................................................................................................2 -4

2.5.1 Timer and Counter Variations ...................................................................................2-4

2.5.2 Double Coil Desi

2.6 And, And Inverse.................................................................................................2-6

2.7 Or, Or Inverse......................................................................................................2-7

2.8 Load Pulse, Load Trailin

2.9 And Pulse, And Trailin

2.10 Or Pulse, Or Trailin

2.11 Or Block.............................................................................................................2-11

2.12 And Block ..........................................................................................................2-12

2.13 MPS, MRD and MPP......................................... .. .. .. ..........................................2-13

2.14 Master Control and Reset................................................... ...............................2-15

2.15 Set and Reset................. ................................. ................................. .................2-17

2.16 Timer, Counter (Out & Reset)................................... .. .. .. .. .. ...............................2-18

2.16.1 Basic Timers, Retentive Timers And Counters........................................................2-18

2.16.2 Normal 32 bit Counters ...........................................................................................2-19

2.16.3 Hi

2.17 Leading and Trailing Pulse................................................................................2-20

2.18 Inverse...............................................................................................................2-21

2.19 No Operatio n . .. .. ............................... ... .. ............................... .. .. .........................2-22

2.20 End ....... .. ............................................... .. .. ............................... .. ... ............... .. .. .2 -23

h Speed Counters ..............................................................................................2-19

ram a PLC? ..............................................................1-2

CPU versions.......................................................................................1-3

ramming..................................................2-1

ic..................................................................................2-2

nation..... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...2-5

Pulse. .. .. ................ .. .. ............... ... .. .............................2-8

Pulse.............................................................................2-9

Pulse................................................................................2-10

i

Page 10

g

g

g

g

g

g

g

g

g

g

y

y

g

g

y

y

g

g

y

FX Series Programmable Controllers

3. STL Programming.................................................................................3-1

3.1 What is STL, SFC And IEC1131 Part 3?.............................................................3-1

3.2 How STL Operates..............................................................................................3-2

3.2.1 Each step is a program .............................................................................................3-2

3.3 How To Start And End An STL Program.............................................................3-3

3.3.1 Embedded STL programs .........................................................................................3-3

3.3.2 Activatin

3.3.3 Terminatin

3.4 Moving Between STL Steps................................................................................3-5

3.4.1 Using SET to drive an STL coil .................................................................................3-5

3.4.2 Usin

3.5 Rules and Techniques For STL programs...........................................................3-7

3.5.1 Basic Notes On The Behavior Of STL programs.......................................................3-7

3.5.2 Sin

3.6 Restrictions Of Some Instructions When Used With STL..................................3-10

3.7 Usin

3.8 Usin

STL To Select The Most Appropriate Program .......................................3-11

STL To Activate Multiple Flows Simultaneously......................................3-12

3.9 General Rules For Successful STL Branchin

3.10 General Precautions When Usin

3.11 Pro

3.11.1 A Simple STL Flow..................................................................................................3-16

3.11.2 A Selective Branch/ First State Mer

ramming Examples ....................................................................................3-16

3.12 Advanced STL Use............................................................................................3-20

new states.................................................................................................3-3

an STL Program....................................................................................3-4

OUT to drive an STL coil.................... ...... ...... ....... ...... ....... ...... ....... ...... ....... ... 3-6

le Signal Step Control ........................................................................................3-9

..................................................3-14

The FX-PCS/AT-EE Software.....................3-15

e Example Program...................................... .3-18

4. Devices in Detail....................................................................................4-1

4.1 Inputs...................................................................................................................4-1

4.2 Outputs ................................................................................................................4-2

4.3 Auxiliar

4.3.1 General Stable State Auxiliary Relays ......................................................................4-3

4.3.2 Batter

4.3.3 Special Dia

4.3.4 Special Sin

4.4 State Relays ........................................................................................................4-6

4.4.1 General Stable State - State Relays .........................................................................4-6

4.4.2 Batter

4.4.3 STL Step Rela

4.4.4 Annunciator Fla

4.5 Pointers .............................................................................................................4-10

4.6 Interru p t Po in te r s ............. ............... .. ... .............................. ... .. ...........................4-11

4.6.1 Input Interrupts ........................................................................................................4-12

4.6.2 Timer Interrupts.......................................................................................................4-12

4.6.3 Disablin

4.6.4 Counter Interrupts ...................................................................................................4-13

4.7 Constant K.........................................................................................................4-14

4.8 Constant H.........................................................................................................4-14

4.9 Timers................................................................................................................4-15

4.9.1 General timer operation...........................................................................................4-16

4.9.2 Selectable Timers.................................. ............................................. ....... ...... ....... .4-16

4.9.3 Retentive Timers .....................................................................................................4-17

4.9.4 Timers Used in Interrupt and ‘CALL’ Subroutines ...................................................4-18

4.9.5 Timer Accurac

4.10 Counters............................................................................................................4-19

4.10.1 General/ Latched 16bit UP Counters ......................................................................4-20

4.10.2 General/ Latched 32bit Bi-directional Counters.......................................................4-21

Relays....................................... ............................... .............................4-3

Backed/ Latched Auxiliary Relays.................................................................4-4

nostic Auxiliary Relays ...................................... ....... ...... ....... ...... ....... ... 4-5

le Operation Pulse Relays.....................................................................4-5

Backed/ Latched State Relays............... ...... ....... ...... ....... ...... ....... ...... ....... ...4-7

s .......................................................................................................4-8

s .....................................................................................................4-9

Individual Interrupts .................................................................................4-13

.......................................................................................................4-18

ii

Page 11

y

y

y

)

g

y

g

g

y

g

g

g

y

FX Series Programmable Controllers

4.11 High Speed Counters........................................................................................4-22

4.11.1 Basic High Speed Counter Operation .....................................................................4-23

4.11.2 Availabilit

4.11.3 Availabilit

4.11.4 Availabilit

4.11.5 1 Phase Counters - User Start and Reset (C235 - C240) .......................................4-29

4.11.6 1 Phase Counters - Assi

4.11.7 2 Phase Bi-directional Counters (C246 to C250) ....................................................4-31

4.11.8 A/B Phase Counters (C252 to C255) ......................................................................4-32

of High Speed Counters on FX0, FX0S and FX0N PLC’s......................4-24

of High Speed Counters on FX, FX2C PLC’s........................................4-25

of High Speed Counters on FX

4.12 Data Registers...................................................................................................4-33

4.12.1 General Use Registers............................................................................................4-34

4.12.2 Batter

4.12.3 Special Dia

4.12.4 File Re

4.12.5Externall

Backed/ Latched Registers.................... ...... ....... ...... ....... ...... ....... ..............4-35

nostic Registers...................................................................................4-35

isters ..........................................................................................................4-36

Adjusted Registers...................................................................................4-37

4.13 Index Registers............. ... .. .. .. ... .. .. .. ..... .. .. .. .. ... .. .. .. .. ... .... .. .. ... .. .. .. ... .. .. .. ..... .. .. .. .. .4-38

4.13.1 Modifying a Constant...............................................................................................4-39

4.13.2 Misuse of the Modifiers ...........................................................................................4-39

4.13.3 Usin

Multiple Index Registers................................................................................4-39

4.14 Bits, Words, BCD and Hexadecimal..................................................................4-40

4.14.1 Bit Devices, Individual and Grouped .......................................................................4-40

4.14.2 Word Devices..........................................................................................................4-42

4.14.3 Interpretin

4.14.4 Two’s Compliment...................................................................................................4-45

Word Data............................................................................................4-42

4.15 Floating Point And Scientific Notation ...............................................................4-46

4.15.1 Scientific Notation....................................................................................................4-47

4.15.2 Floatin

4.15.3 Summar

Point Format..............................................................................................4-48

Of The Scientific Notation and Floating Point Numbers..........................4-49

2N(C

PLC’s ..........................................4-28

ned Start and Reset (C241 to C245)..............................4-30

iii

Page 12

FX Series Programmable Controllers

5. Applied Instructions...............................................................................5-1

5.1 Program Flow-Functions00 to 09 ........................................................................5-4

5.1.1 CJ (FNC 00) ..............................................................................................................5-5

5.1.2 CALL (FNC 01)..........................................................................................................5-7

5.1.3 SRET (FNC 02).........................................................................................................5-8

5.1.4 IRET, EI, DI (FNC 03, 04, 05) ...................................................................................5-9

5.1.5 FEND (FNC 06).......................................................................................................5-11

5.1.6 WDT (FNC 07) ........................................................................................................5-12

5.1.7 FOR, NEXT (FNC 08, 09) .......................................................................................5-13

5.2 Move And Compare - Functions 10 to 19..........................................................5-16

5.2.1 CMP (FNC 10).........................................................................................................5-17

5.2.2 ZCP (FNC 11) .........................................................................................................5-17

5.2.3 MOV (FNC 12) ........................................................................................................5-18

5.2.4 SMOV (FNC 13)......................................................................................................5-18

5.2.5 CML (FNC 14)................................. ...... ....... ...... ...... ....... ...... ..................................5-19

5.2.6 BMOV (FNC 15) .....................................................................................................5-20

5.2.7 FMOV (FNC 16) ......................................................................................................5-21

5.2.8 XCH (FNC 17).............................................................................. ...... ....... ...... ....... . 5 -21

5.2.9 BCD (FNC18)........................... ............................................. ....... ...... ....... ...... ....... .5-22

5.2.10 BIN (FNC 19) .. ....... .......................................................................................... ....... .5-22

5.3 Arithmetic And Logical Operations -Functions 20 to 29 ....................................5-24

5.3.1 ADD (FNC 20).............................................................................. ...... ....... ...... ....... . 5 -25

5.3.2 SUB (FNC 21) ........................................................................................................5-26

5.3.3 MUL (FNC 22)................................. ...... ....... ...... ...... ....... ...... ....... ...... ....... ..............5-27

5.3.4 DIV (FNC 23).. ....... ...... ........................................................................................... .5-2 8

5.3.5 INC (FNC 24) .........................................................................................................5-29

5.3.6 DEC (FNC 24) ...................................... ............................................. ....... ...... ....... .5-29

5.3.7 WAND (FNC 26)......................................................................................................5-30

5.3.8 WOR (FNC 27)........................................................................................................5-30

5.3.9 WXOR (FNC 28) .....................................................................................................5-31

5.3.10NEG (FNC 29) .........................................................................................................5-31

5.4 Rotation And Shift - Functions 30 to 39.............................................................5-34

5.4.1 ROR (FNC 30).........................................................................................................5-35

5.4.2 ROL (FNC 31) .........................................................................................................5-35

5.4.3 RCR (FNC 32)......................................................................................................... 5-36

5.4.4 RCL (FNC 33) .........................................................................................................5-36

5.4.5 SFTR (FNC 34) .......................................................................................................5-37

5.4.6 SFTL (FNC 35)........................................................................................................5-37

5.4.7 WSFR (FNC 36)......................................................................................................5-38

5.4.8 WSFL (FNC 37).......................................................................................................5-38

5.4.9 SFWR (FNC 38)......................................................................................................5-39

5.4.10 SFRD (FNC 39).......................................................................................................5-40

5.5 Data Operation - Functions 40 to 49 ....................................................... ..........5-42

5.5.1 ZRST (FNC 40) .......................................................................................................5-43

5.5.2 DECO (FNC 41) ......................................................................................................5-43

5.5.3 ENCO (FNC 42) ......................................................................................................5-44

5.5.4 SUM (FNC 43).........................................................................................................5-45

5.5.5 BON (FNC 44).........................................................................................................5-45

5.5.6 MEAN (FNC 45) ......................................................................................................5-46

5.5.7 ANS (FNC 46) .........................................................................................................5-47

5.5.8 ANR (FNC 47).............................................................................. ...... ....... ...... ....... . 5 -47

5.5.9 SQR (FNC 48).........................................................................................................5-48

5.5.10 FLT (FNC 49) ..........................................................................................................5-49

iv

Page 13

FX Series Programmable Controllers

5.6 High Speed Processing - Functions 50 to 59 ....................................................5-52

5.6.1 REF (FNC 50) .........................................................................................................5-53

5.6.2 REFF (FNC 51) .......................................................................................................5-53

5.6.3 MTR (FNC 52)......................................................................................................... 5-54

5.6.4 HSCS (FNC 53).......................................................................................................5-55

5.6.5 HSCR (FNC 54) .......... ....... ............................................. ...... ....... ...... ....... ...... ....... .5-56

5.6.6 HSZ (FNC 55) .........................................................................................................5-57

5.6.7 SPD (FNC 56) .........................................................................................................5-60

5.6.8 PLSY (FNC 57) ..... ...... ....... ...... ....... ...... ....... ...... ...... ....... ........................................5-61

5.6.9 PWM (FNC 58)........................................................................................................5-62

5.6.10 PLSR (FNC 59) .......................................................................................................5-63

5.7 Handy Instructions - Functions 60 to 69............................................................5-66

5.7.1 IST (FNC 60)...........................................................................................................5-67

5.7.2 SER (FNC 61) .........................................................................................................5-69

5.7.3 ABSD (FNC 62).......................................................................................................5-70

5.7.4 INCD (FNC 63)........................................................................................................5-71

5.7.5 TTMR (FNC 64).......................................................................................................5-72

5.7.6 STMR (FNC 65) .......... ....... ...... ....... ...... ....... ...... ............................................. ....... .5-72

5.7.7 ALT (FNC 66)..........................................................................................................5-73

5.7.8 RAMP (FNC 67) ......................................................................................................5-73

5.7.9 ROTC (FNC 68) .......... ....... ...... ....... ............................................. ...... ....... ...... ....... .5-75

5.7.10 SORT (FNC 69).......................................................................................................5-77

5.8 External FX I/O Devices - Functions 70 to 79 ...................................................5-80

5.8.1 TKY (FNC 70)..........................................................................................................5-81

5.8.2 HKY (FNC 71) .........................................................................................................5-82

5.8.3 DSW (FNC 72) ........................................................................................................5-83

5.8.4 SEGD (FNC 73) ......................................................................................................5-84

5.8.5 SEGL (FNC 74).......................................................................................................5-85

5.8.6 ARWS (FNC 75).......... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...........................5-87

5.8.7 ASC (FNC 76) .........................................................................................................5-88

5.8.8 PR (FNC 77)............................................................................................................5-89

5.8.9 FROM (FNC 78)......................................................................................................5-90

5.8.10 TO (FNC 77)............................................................................................................5-91

5.9 External FX Serial Devices - Functions 80 to 89...............................................5-94

5.9.1 RS (FNC 80)............................................................................................................5-96

5.9.2 RUN (FNC 81)......................................................................................................... 5-97

5.9.3 ASCI (FNC 82) ........................................................................................................5-99

5.9.4 HEX (FNC 83) .......................................................................................................5-100

5.9.5 CCD (FNC 84)....................................................................................................... 5-101

5.9.6 VRRD (FNC 85) .......... ....... ...... ....... ...... ....... ...... ............................................. ...... 5-102

5.9.7 VRSD (FNC 86).....................................................................................................5-102

5.9.8 PID (FNC 88).. ....... ...... ....... ...... ....... ...... ....... .........................................................5-103

5.10 External F2 Units - Functions 90 to 99 ............................................................5-111

5.10.1 MNET (FNC 90) .... ...... ............................................. ....... ...... ....... ...... ....... ...... ...... 5-11 2

5.10.2 ANRD (FNC 91) .... ...... ....... ............................................. ...... ....... ...... ....... ...... ...... 5-11 2

5.10.3 ANWR (FNC 92)....................................................................................................5-113

5.10.4 RMST (FNC 93) .... ...... ............................................. ....... ...... ....... ...... ....... ...... ...... 5-11 3

5.10.5 RMMR (FNC 94) ...................................................................................................5-114

5.10.6 RMRD (FNC 95)....................................................................................................5-115

5.10.7 RMMN (FNC 96) ...................................................................................................5-115

5.10.8 BLK (FNC 97)........................................................................................................5-116

5.10.9 MCDE (FNC 98).................................................................................................... 5-117

v

Page 14

g

g

g

g

g

g

FX Series Programmable Controllers

5.11 Floating Point 1 & 2 - Functions 110 to 129 ....................................................5-119

5.11.1 ECMP (FNC 110) ..................................................................................................5-121

5.11.2 EZCP (FNC 111) ...................................................................................................5-121

5.11.3 EBCD (FNC 118)...................................................................................................5-122

5.11.4 EBIN (FNC 119) ....................................................................................................5-122

5.11.5 EADD (FNC 120)...................................................................................................5-123

5.11.6 EAUB (FNC 121)...................................................................................................5-124

5.11.7 EMUL (FNC 122)...................................................................................................5-124

5.11.8 EDIV (FNC 123) ....................................................................................................5-125

5.11.9 ESQR (FNC 127) ..................................................................................................5-125

5.11.10INT (FNC 129) ......................................................................................................5-126

5.12 Trigonometry - FNC 130 to FNC 139 ..............................................................5-128

5.12.1 SIN (FNC 130) ....... ...... ....... ...... .............................................................................5-129

5.12.2 COS (FNC 131).....................................................................................................5-130

5.12.3 TAN (FNC 132) .....................................................................................................5-130

5.13 Data Operations 2 - FNC 140 to FNC 149 ............................................. .........5-132

5.13.1 SWAP (FNC 147) ..................................................................................................5-133

5.14 Real Time Clock Control - FNC 160 to FNC 169.............................................5-136

5.14.1 TCMP (FNC 160) ............................................... ...... ....... ...... ....... ...... ....... ...... ...... 5-13 7

5.14.2 TZCP (FNC 161) ...................................................................................................5-138

5.14.3 TADD (FNC 162)...................................................................................................5-139

5.14.4 TSUB (FNC 163) ...................................................................................................5-140

5.14.5 TRD (FNC 166) .....................................................................................................5-141

5.14.6 TWR (FNC 167) ....................................................................................................5-142

5.15 Gray Codes - FNC 170 to FNC 179 .................... .. .. ........................................5-144

5.15.1 GRY (FNC 170).....................................................................................................5-145

5.15.2 GBIN (FNC 171)....................................................................................................5-145

5.16 Inline Comparisons - FNC 220 to FNC 249.....................................................5-148

5.16.1 LD compare (FNC 224 to 230) .............................................................................. 5-149

5.16.2 AND compare (FNC 232 to 238)...........................................................................5-150

5.16.3 OR compare (FNC 240 to 246) .............................................................................5-151

6. Diagnostic Devices................................................................................6-1

6.1 PLC Status (M8000 to M8009 and D8000 to D8009)..........................................6-2

6.2 Clock Devices (M8010 to M8019 and D8010 to D8019) ...................................6-3

6.3 Operation Fla

6.4 PLC Operation Mode (M8030 to M8039 and D8030 to D8039) .........................6-5

6.5 Step Ladder (STL) Fla

6.6 Interrupt Control Fla

6.7 Error Detection Devices (M8060 to M8069 and D8060 to D6069) .....................6-8

6.8 Link And Special Operation Devices (M8070 to M8099 and D8070 to D8099) ..6-9

6.9 Miscellaneous Devices (M8100 to M8119 and D8100 to D8119) .....................6-10

6.10 Communication Adapter Devices, i.e. 232ADP, 485ADP ................................6-10

6.11 Hi

h Speed Zone Compare Table Comparison Flags . .. .. ................ .. .. ............6-11

6.12 Miscellaneous Devices (M8160 to M8199) .......................................................6-12

6.13 Index Re

6.14 Up/Down Counter Control (M8200 to M8234 and M8200 to D8234) ..... ..........6-14

6.15 Hi

h Speed Counter Control (M8235 to M8255 and D8235 to D8255) ............6-14

6.16 Error Code Tables.............................. ................................. ..............................6-15

s...................................................................................................6-4

s (M8040 to M8049 and D8040 to D8049) ...................6-6

s (M8050 to M8059 and D8050 to D8059) ......................6-7

isters (D8180 to D8199) ................. ................................. .................6-13

vi

Page 15

g

g

y

g

g

g

g

g

g

g

g

g

g

g

g

y

g

g

FX Series Programmable Controllers

7. Execution Times And Instructional Hierarchy........................................7-1

7.1 Basic Instructions ................................................................................................7-1

7.2 Applied Instructions ............................................................................................7-3

7.3 Hierarchical Relationships Of Basic Pro

7.4 Batch Processin

7.5 Summar

of Device Memory Allocations...........................................................7-14

7.6 Limits Of Instruction Usa

7.6.1 Instructions Which Can Only Be Used Once In The Main Program Area ...............7-16

7.6.2 Instructions Which Are Not Suitable For Use With 110V AC Input Units ................7-16

8. PLC Device Tables................................................................................8-1

8.1 Performance Specification Of The FX0 And FX0S ............................................. 8-1

8.2 Performance Specification Of The FX

8.3 Performance Specification Of The FX (CPU versions 2.0 to 3.06) .....................8-4

8.4 Performance Specification Of The FX

(CPU versions from 3.07) And FX

8.5 Performance Specification Of The FX

9. Assigning System Devices....................................................................9-1

9.1 Addressing Extension Modules...........................................................................9-1

9.2 Usin

9.2.1 Using the FX2-24EI With A F-16NP/NT ....................................................................9-3

9.2.2 Usin

9.2.3 Usin

9.2.4 Usin

9.3 Parallel Link Adapters..........................................................................................9-6

9.4 Real Time Clock Function ...................................................................................9-7

9.4.1 Setting the real time clock .........................................................................................9-8

The FX2-24EI With F Series Special Function Blocks .............................. 9-2

the FX2-24EI With A F2-6A.............................................................................9-4

the FX2-24EI With A F2-32RM .......................................................................9-4

the FX2-24EI With A F2-30GM .......................................................................9-5

ram Instruction s .................. .. ............7-12

...............................................................................................7-14

e ...............................................................................7-16

0N

............................................................8-2

2C

(all versions) ......................................8-6

2N(C)

.......................................................8-8

10.Points Of Technique...........................................................................10-1

10.1 Adva nced Programming Points.... ............... ... .. ............... .. ... .............................10-1

10.2 Users of DC Powered FX Units.........................................................................10-1

10.3 Usin

10.3.1 A RUN/STOP push button configuration.................................................................10-2

10.3.2 Remote RUN/STOP control ....................................................................................10-3

10.4 Constant Scan Mode.........................................................................................10-4

10.5 Alternatin

10.6 Usin

10.7 Indexin

10.8 Readin

10.9 Measurin

10.9.1 A 1 msec timer pulse measurement........................................................................10-6

10.9.2 A 0.1 msec timer pulse measurement.....................................................................10-7

10.10Using The Execution Complete Flag, M8029 ...................................................10-7

10.11Creatin

10.12An Example S

10.13Usin

10.14Communication Format...................................................................................10-18

10.14.1Specification of the communication parameters:..................................................10-18

10.14.2Header and Terminator Characters...................................................................... 10-19

10.14.3Timin

10.14.48 bit or 16 bit communications..............................................................................10-23

The Forced RUN/STOP Flags.................................................................10-2

ON/OFF States................................................................................10-4

Battery Backed Devices For Maximum Advantage.................................10-5

Through Multiple Display Data Values................................................10-5

And Manipulating Thumbwheel Data ............... .. .................................10-6

a High Speed Pulse Input.................................. .. .. .. .. ......................10-6

a User Defined MTR Instruction........................................ .................10-8

stem Application Using STL And IST Program Control............10-8

The PWM Instruction For Motor Control...............................................10-15

diagrams for communications:..................................................................10-20

vii

Page 16

g

g

g

FX Series Programmable Controllers

10.15PID Programming Techniques........................................................................10-24

10.15.1Keeping MV within a set range.............................................................................10-24

10.15.2Manual/Automatic chan

10.15.3Usin

10.15.4Other tips for PID pro

the PID alarm signals .............................. ...... ....... ...... ....... ...... ....... ...... ...... 10 -2 5

10.16Additional PID functions..................................................................................10-26

10.16.1Output Value range control (S3+1 b5)..................................................................10-26

10.17Pre-tuning operation ............................................................. ..........................10-27

10.17.1Variable Constants ............................................................................................... 10-27

10.18Example Autotuning Program.........................................................................10-28

11.Index...................................................................................................11-1

11.1 Index..................................................................................................................11-1

11.2 ASCII Character Codes.....................................................................................11-9

11.3 Applied Instruction List ....................................................................................11-10

e over................... ...... ...... ....... ...... ....... ...... ....... ...... ...... 10 -2 4

ramming............................................................................10-25

viii

Page 17

FX Series Programmable Controllers Introduction 1

1 Introduction

2 Basic Program Instructions

3 STL Programming

4 Devices in Detail

5 Applied Instructions

6 Diagnostic Devices

7 Instruction Execution Times

8 PLC Device Tables

9 Assigning System Devices

10 Points of Technique

11 Index

Page 18

FX Series Programmable Controllers Introduction 1

g

g

Chapter Contents

1. Introduction............................................................................................1-1

1.1 Overview..............................................................................................................1-1

1.2 What is a Pro

1.3 What do You Need to Pro

1.4 CPU version numbers .........................................................................................1-3

1.4.1 FX0N CPU versions...................................................................................................1-3

1.4.2 FX and FX

1.5 Special considerations for programming equipment ....... .. ... ............... .. ... ...........1-4

1.5.1 FX CPU version 3.07 or later and FX2C ................................................................... 1-4

1.5.2 FX

2N

rammableCo ntro l le r? ......... .. ... .. .. .. .. ... .. .. .... ... .. .. .. ... .. .. .. .. ... .... .. .. ... 1-2

ram a PC? ................................................................1-2

2C

CPU versions.......................................................................................1-3

CPU all versions .............................................................................................1-5

Page 19

1. Introduction

g

g

g

y

y

y

y

ying

g

g

FX

0(S)

FX

0N

FX FX

(2C)

FX

2N(C)

1.1 Overview

1) Scope of this manual

This manual

0S

, FX

0, FX2N

FX

the PLC hardware and installation, refer to the appropriate manual supplied with the unit.

2) How to use this manual

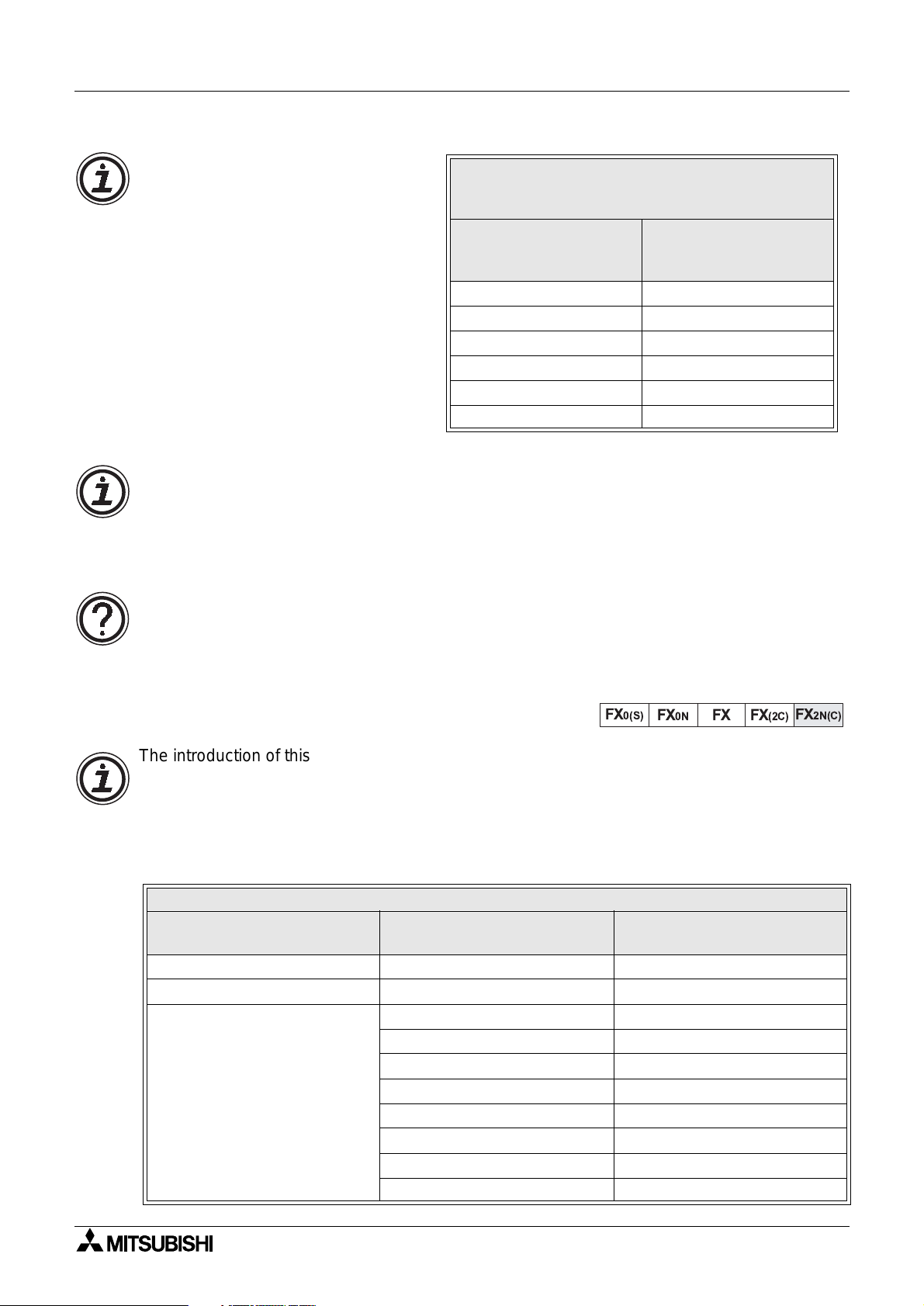

This manual covers all the functions of the hi

Controller (PLC). For this reason, the followin

to show which PLCs that section applies to;

Introduction 1

ives details on all aspects of operation and programming for FX, FX2C, FX0N,

and FX

2NC

programmable controllers (PLCs). For all information relating to

hest specification Programmable (Logic)

indicator is included in relevant section titles

FX

0(S)

- “FX

- “FX

0(S)

0N

FX FX

” - All FX0 and FX0S PLCs

” - All FX0N PLCs

(2C)

FX

0N

- “FX” - All FX and FX

- “FX

- - All FX

- “FX

(2C)

” - All FX and FX2 PLCs (CPU versions 3.07 or later)

2C

PLCs (see page 1-4)

2N(C)

” - All FX2N and FX

FX

2N(C)

2

PLCs (CPU ver 2.30 or earlier)

2NC

Shaded boxes indicate

the applicable PLC t

PLCs

pe

If an indicator box is half shaded, as shown to the

FX

0(S)FX0N

FX FX

(2C)

FX

2N(C)

left, this means that not all the functions described in

the current section appl

to that PLC. The text

explains in further detail or makes an independent

reference.

If there are no indicator boxes then assume the section applies to all PLC t

pes unless

otherwise stated.

3) FX famil

This is a generic term which is often used to describe all Programmable Controllers without

identif

4) CPU version numbers and pro

As Mitsubishi up

individual types or model names.

ramming support

rades each model different versions have different capabilities.

- Please refer to section 1.4 for details about version numbers and capabil it ies.

- Please refer to section 1.5 for details about peripheral support for each model.

1-1

Page 20

1.2 What is a Programmable Controller?

g

y

gg

g

y

g

gy

g

y

g

y

g

g

g

g

y

g

FX

0(S)

FX0N FX FX(2C)

FX2N(C)

FX

0(S)

FX0N FX FX(2C)

FX2N(C)

A Programmable Logic Controller (PLC or programmable controller) is a device that a user can

pro

ram to perform a series or sequence of events. These events are triggered by stimuli

(usuall

counted occur-rences. Once an ev ent tri

or OFF electronic control

will continuall

outputs at the programmed specific times.

called inputs) received at the PLC or through delayed actions such as time delays or

ear or the physical actuation of devices. A programmable controller

‘loop’ through its internal ‘user defined’ program waiting for inputs and givin

Introduction 1

ers, it actuates in the outside world by switching ON

Note on termin o lo

The term pro

control s

‘Pro

rammable Logic Controller ’, ‘PLC’ or ‘programmable controller ’ to de scribe the same

control s

stem under one descriptive na me. Sometimes engineers use the term

stem.

The construction of a pro

element where the pro

Processin

Unit or MPU. Other terms commonly heard to describe this device are ‘base unit’,

:

rammable controller is a generic word used to bring all the elements making the

rammable controller can be broken down into component parts. The

ram is loaded, s tored and pr ocessed is often known as th e Main

‘controller’ and ‘CPU’. The term CPU is a little misleadin

ma

contain local CPU devices. A Main CPU (or more correctly a Main Processing Unit)

controls these local CPUs throu

h a communication network or bus.

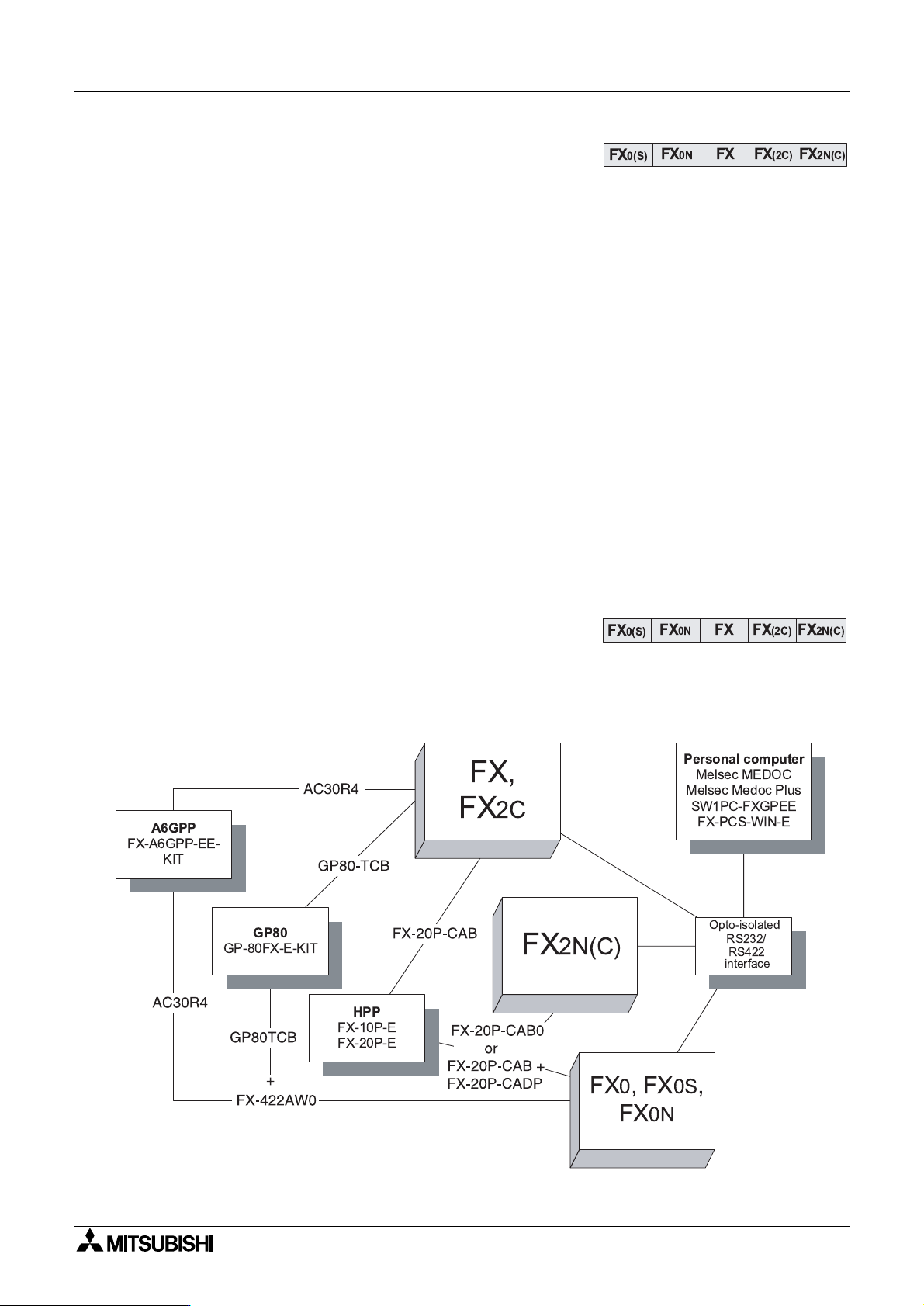

1.3 What do You Need to Program a PLC?

A variety of tools are available to program the Mitsubishi FX family of PLCs. Each of these

tools can use and access the instructions and devices listed in this manual for the identified

PLC.

FX

A6GPP

FX-A6GPP-EE-

KIT

FX,

2C

as todays more advanced products

Personal computer

Melsec MEDOC

Melsec Medoc Plus

SW1PC-FXGPEE

FX-PCS-WIN-E

GP80

GP-80FX-E-KIT

HPP

FX-10P-E

FX-20P-E

FX

2N(C)

Opto-isolated

RS232/

RS422

interface

FX0,FX0S,

FX

0N

1-2

Page 21

1.4 CPU version numbers

g

g

y

g

g

g

g

y

g

g

FX0(S) FX0N FX FX(2C) FX2N(C)

Over time Mitsubishi adds newer and better features to develop and enhance the products.

Because of the nature of PLCs, that can be likened to ‘industrial computers’, chan

sometimes occur within the units main CPU (Central Processin

similar to those experienced b

processor. The followin

functions and features added.

Introduction 1

es

Unit). These changes are

office and home computer users, that is, going to a version up

lists identify the CPU versions that had significant upgrades or new

1.4.1 FX

0N

CPU versions

CPU Ver 1.20

CPU Ver 1.40

1.4.2 FX and FX

CPU Ver 3.07

The followin

features were added:

Software control for protocol 1 and 4 communications with the FX

1:N network.

The followin

Software control for communications usin

features were added:

the FX0N-485ADP, peer to peer

(N:N) network.

2C

CPU versions

The following instructions were added:

ASCI (FNC82), CCD (FNC84), FLT (FNC49), HEX (FNC83), RS (FNC80),

SER (FNC61), SORT (FNC69), SQR (FNC48)

The following instructions were upgraded:

EI (FNC04), BMOV (FNC15), HSCS (FNC53), PLSY (FNC57),

FMOV (FNC16), MEAN (FNC45), ABSD (FNC62), DSW (FNC72),SEGL (74),

PR (FNC 77)

The following device ranges were added:

Input and output devices are independently addressable upto 256 points in

software. Total combined input and output points (hardware or software) is

256.

Auxiliar

Data re

Optional RAM File Re

relays increased to 1536 points (M0-M1535)

isters increased to 1000 points (D0-D999)

isters added, 2000 points (D6000 -D7999)

Pointers increased to 128 points (P0 - P127)

0N

-485ADP,

CPU Ver 3.11

CPU Ver 3.2

CPU Ver 3.30

The following instructions were added:

PID (FNC88)

The following features were added:

Software control for protocol 4 communications with th e FX-485ADP, 1:N

network.

The following features were added:

Software control for protocol 1 communications with th e FX-485ADP, 1:N

network.

The following instructions were phased out (removed):

ANRD (FNC91), ANWR (FNC92), BLK (FNC97), MCDE (FNC98), MNET

(FNC90)

1-3

Page 22

1.5 Special considerations for programming equipment

y

y

ying

y

g

g

g

FX

0(S)

FX0N FX FX(2C)

FX

2N(C)

g

g

y

Introduction 1

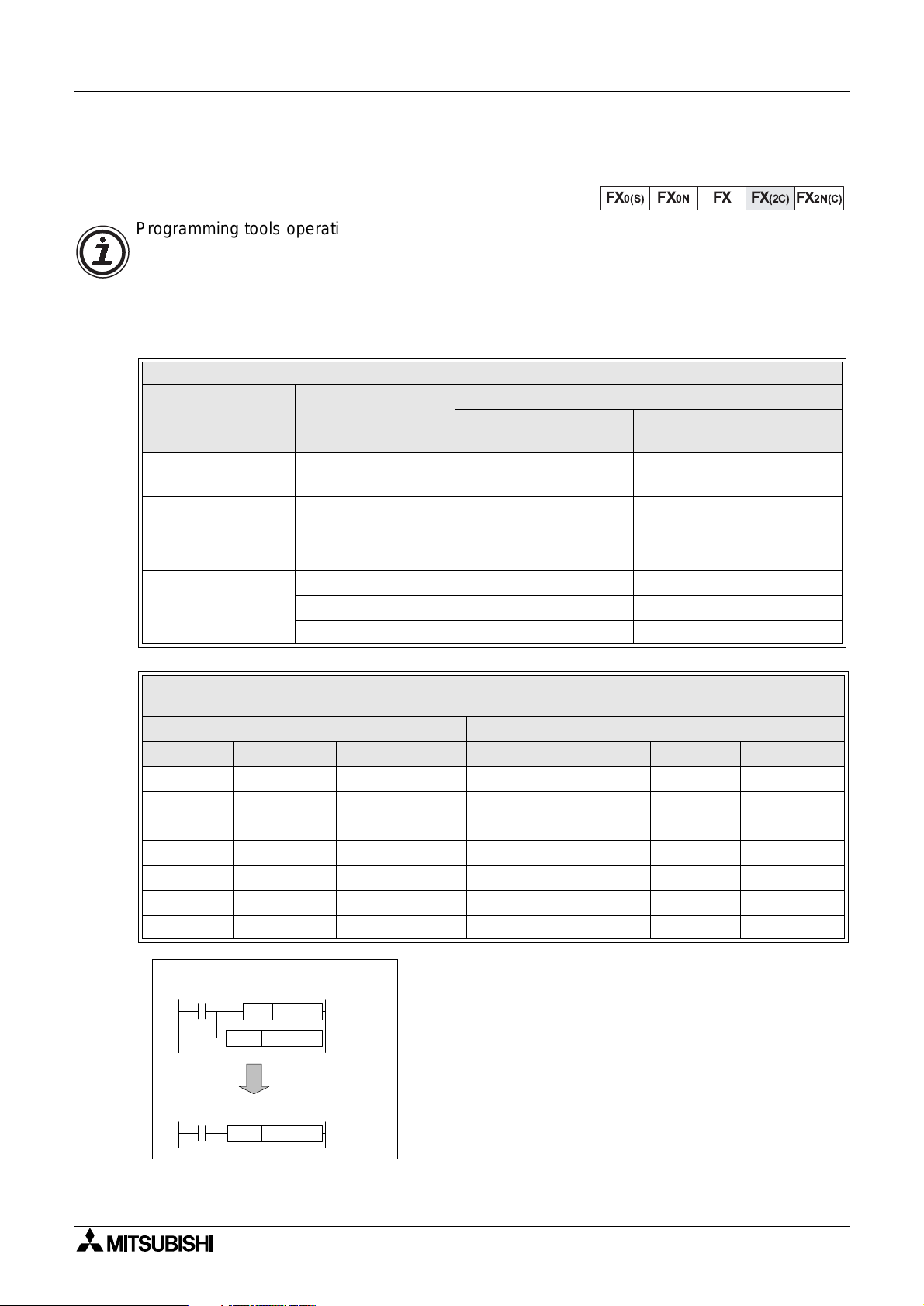

1.5.1 FX CPU version 3.07 or later and FX

Programming tools operating old system software can not access the new featur es added to

the FX CPU from version 3.07 (and available on all FX

certain ‘standard’ applied instructions in conjunction with special auxiliary coils (M coils) can

achieve the same ’effective instruction’ as the new instructions. The followin

which version of peripheral software will work directly with all of the ’new’ features and which

peripheral software versions require use of modified instructions.

Description Model Number

Hand held

pro

rammer (HHP)

HHP cassette FX-20P-MFXA-E V 1.20 from V 2.00

rammin

Pro

software

Data access units

FX-10P-E V 1.10 from V 2.00

FX-PCS/AT-E-KIT V 1.01 from V 2.00

FX-A6GPP-E-KIT V 1.00 from V 2.00

FX-10DU-E V 1.10 from V 2.00

FX-20DU-E V 1.10 from V 2.00

Other DU units from V 1.00

2C

Peripherals Table

System software version which will.......

....require the use of

auxiliary M coils

2C

units). However, programmin

tables identif

....program all instructions

directly

Existing Instruction And Special M Coil Combination To Mimic The Operation Of The

Identified Instruction

Existing FX instruction used to mimic the operation of......

Mnemonic FNC number Modifying M coil Mimicked instruction Mnemonic FNC Number

MOV 12 M8190 Square root SQR 48

MOV 12 M8191 Float FLT 49

RAMP 67 M8193 Data search SER 61

RAMP 67 M8194 RS232 instruction RS 80

FMOV 16 M8196 Hex to ASCII conversion ASCI 82

FMOV 16 M8197 ASCII to Hex conversion HEX 83

FMOV 16 M8195 Sum check CCD 84

Example usage

Using existing FX functions......

SET

M8190

D10

K36

MOV

to mimic......

This format is ver

correctl

.The user must program the ’mimic’ instruction

with the modif

before the instruction to be modified.

important for the instruction to operate

M coil in a SET instruction immediatel

SQR

K36

D10

1-4

Page 23

Introduction 1

y

y

g

g

g

g

g

g

g

g

g

g

g

FX

0(S)

FX0N FX FX(2C)

FX

2N(C)

g

y

g

Using the new Interrupt Pointers:

To pro

throu

instruction with older pro

ram new Interrupt Pointer s I010

h I060 in to the HSCS (FNC 53)

rammin

equipment, substitute the followin

special M codes for the appropriate

Interrupt Pointer; see the table ri

ht.

Existing Instruction And Special M Coil

Combination To Mimic The Operation

Of The Identified Interrupt pointer

Existing Auxiliary Coil

used to replace the ident i-

fied Interrupt Pointer

M8181 I010

M8182 I020

M8183 I030

M8184 I040

M8185 I050

M8186 I060

Interrupt Pointer

Using M8198 with the BMOV instruction:

With old software and peripherals, file re

BMOV (FNC 15) instruction. To BMOV data into file re

isters can not be used as a destination device in the

isters with old equipment set special M

coil M8198 on. This switches the source and destination parameters; i.e., the source is then

treated as the destination and the destination becomes the source.

General note:

I

pro

sections, will apply.

1.5.2 FX

The introduction of this CPU provides the FX user with many new devices and instructions. To

use the full features of the FX

pro

However, because of the downward compatibilit

existin

CPU ver 3.30 units.

nore the special programming techniques identified in this section if using updated

ramming software or peripherals; then normal operation, as identifiedin the followin

2N(C)

CPU all versions

2N(C)

units the user must upgrade older software and hardware

ramming tools.

of the FX

programming tools for use with FX

Description Model Number

Hand held programmer (HHP) FX-10P-E from V 3.00

HHP cassette FX-20P-MFXA-E from V 3.00

FX-10DU-E from V 4.00

FX-20DU-E Supports up to FX devices onl

FX-25DU-E from V 2.00

FX-30DU-E from V 3.00

Data access units

FX-40DU-E(S) Supports up to FX devices onl

FX-40DU-TK-ES from V 3.00

FX-50DU-TK(S)-E from V 2.10

F940GOT-SWD(LWD)-E All versions

2N(C)

units up to the equivalent functionality of FX

Peripherals Table

2N(C)

, it is not necessary to upgrade

System software version with

full support for FX

2N(c)

1-5

Page 24

MEMO

Introduction 1

1-6

Page 25

FX Series Programmable Controllers Basic Program Instructions 2

1 Introduction

2 Basic Program Instructions

3 STL Programming

4 Devices in Detail

5 Applied Instructions

6 Diagnostic Devices

7 Instruction Execution Times

8 PLC Device Tables

9 Assigning System Devices

10 Points of Technique

11 Index

Page 26

FX Series Programmable Controllers Basic Program Instructions 2

g

g

g

g

g

g

g

g

Chapter Contents

2. Basic Pro

ram Instructions ...................................................................2-1

2.1 What is a Program?.... .. ... .. .. .. ... .. .. .... ... .. .. .. .. ... .. .. .. .. ..... .. .. .. ... .. .. .. ... .. .. .... ... .. .. .. .. ...2-1

2.2 Outline of Basic Devices Used in Pro

2.3 How to Read Ladder Lo

ic..................................................................................2-2

ramming..................................................2-1

2.4 Load, Load Inverse ..............................................................................................2-3

2.5 Out.......................................................................................................................2 -4

2.5.1 Timer and Counter Variations ...................................................................................2-4

2.5.2 Double Coil Desi

nation..... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...2-5

2.6 And, And Inverse.................................................................................................2-6

2.7 Or, Or Inverse......................................................................................................2-7

2.8 Load Pulse, Load Trailin

2.9 And Pulse, And Trailin

2.10 Or Pulse, Or Trailin

Pulse. .. .. ................ .. .. ............... ... .. .............................2-8

Pulse.............................................................................2-9

Pulse................................................................................2-10

2.11 Or Block.............................................................................................................2-11

2.12 And Block ..........................................................................................................2-12

2.13 MPS, MRD and MPP......................................... .. .. .. ..........................................2-13

2.14 Master Control and Reset................................................... ...............................2-15

2.15 Set and Reset................. ................................. ................................. .................2-17

2.16 Timer, Counter(Out & Reset)................................................... ..........................2-18

2.16.1 Basic Timers, Retentive Timers And Counters........................................................2-18

2.16.2 Normal 32 bit Counters ...........................................................................................2-19

2.16.3 Hi

h Speed Counters ..............................................................................................2-19

2.17 Leading and Trailing Pulse................................................................................2-20

2.18 Inverse...............................................................................................................2-21

2.19 No Operatio n . .. .. ............................... ... .. ............................... .. .. .........................2-22

2.20 End ....... .. ............................................... .. .. ............................... .. ... ............... .. .. .2 -23

Page 27

g

g

g

g

g

y

y

y

y

y

g

g

FX Series Programmable Controllers

2. Basic Program Instructions

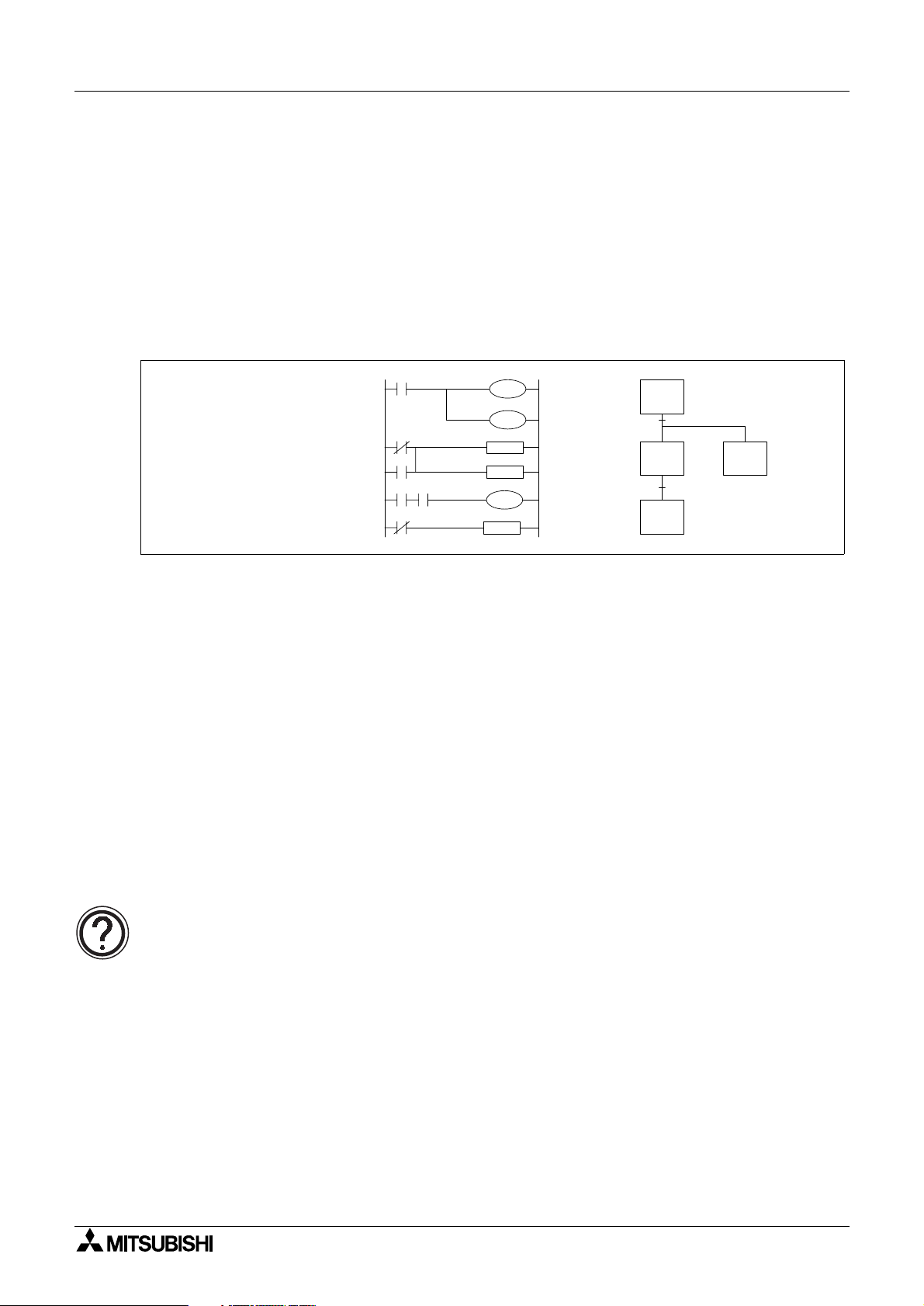

2.1 What is a Program?

A program is a connected series of instructions written in a language that the PLC can

understand. There are three forms of pro

pro

ramming tools can work in all programming forms. Generally hand held programmin

panels only work with instruction format while most graphic programming tools will work with

both instruction and ladder format. Specialist pro

pro

ramming.

Basic Program Instructions 2

ram format; instruction, ladder and SFC/STL. Not all

ramming software will also allow SFC style

LD

OUT

AND

SET

LD

OUT

X10

Y7

M38

S5

X21

T01

K40

Instruction format Ladder Format SFC Format

2.2 Outline of Basic Devices Used in Programming

There are six basic programming devices. Each device has its own unique use. To enable

quick and eas

- X: This is used to identif

- Y: This is used to identif

- T: This is used to identif

- C: This is used to identif

- M and S: These are used as internal operation fla

identification each device is assigned a single reference letter;

all direct, physical inputs to the PLC.

all direct, physical outputs from the PLC.

a timing device which is contained within the PLC.

a counting device which is contained within the PLC.

s within the PLC.

All of the devices mentioned above are known as ‘bit devices’. This is a descriptive title tellin

the user that these devices only have two states; ON or OFF, 1 or 0.

Detailed device information:

• Chapter 4 contains this information in detail. However, the above is all that is

required for the rest of this chapter.

2-1

Page 28

FX Series Programmable Controllers Basic Program Instructions 2

g

g

y

y

g

g

g

y

y

y

g

g

g

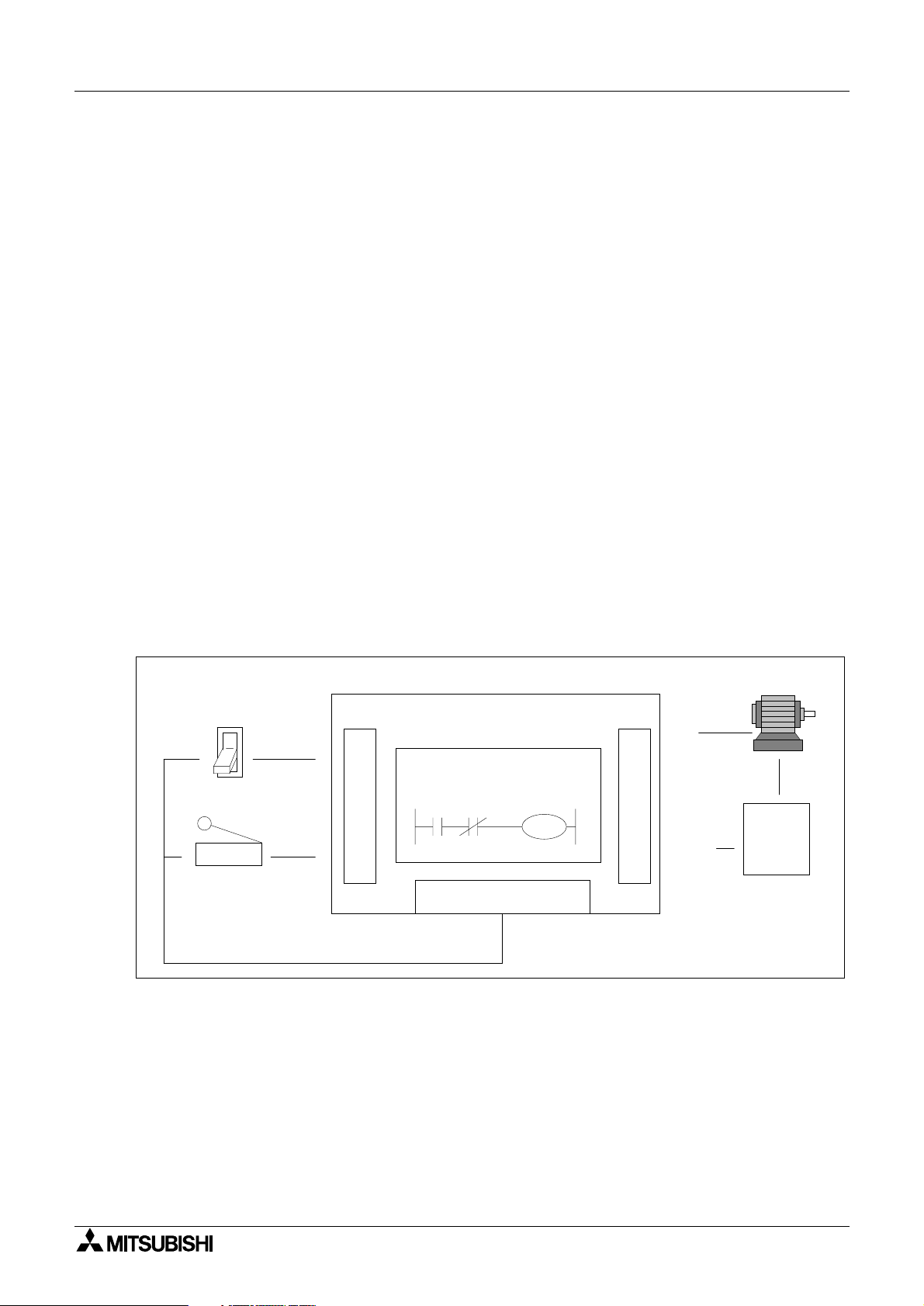

2.3 How to Read Ladder Logic

Ladder logic is very closely associated to basic relay logic. There are both contacts and coils

that can be loaded and driven in different confi

the same.

A coil drives direct outputs of the PLC (ex. a Y device) or drives internal timers, counters or

s (ex. T, C, M and S devices). Each coil has associated contacts. These contacts are

fla

available in both “normall

open” (NO) and “normally closed” (NC) configurations.

urations. However, the basic principle remains

The term “normal(l

)” refers to the status of the contacts when the coil is not energized. Usin

a relay analogy, when the coil is OFF, a NO contact would have no current flow, that is, a load

bein

supplied through a NO contact w ould not o perate. Ho wever, a NC contact w ould allo w

current to flow, hence the connected load would be active.

Activatin

the coil reverses the contact status , that is, the current would flow in a NO contac t

and a NC contact would inhibit the flow.

Ph

sical inputs to the PLC (X devi ces) have n o programmable coil. These devices may only be

used in a contact format (NO and NC t

pes are available).

Example:

Because of the close rela

association, ladder logic programs can be read as current flowin

from the left ve rtical line to the right vertical line. This current must pass through a series of

contact representations such as X0 and X1 in order to switch the output coil Y0 ON. Therefore,

in the example shown, switchin

X0 ON causes the output Y0 to also switch ON. If however,

the limit switch X1 is activa tes, the output Y0 turns OFF. This is because the con nection

between the left and the ri

Toggle switch

X0

X1

Limit switch

ht vertical lines breaks so there is no current flow.

Programmable Controller

Y0

I

N

P

U

T

PC Program

X0 X1

Y0

DC Power Supply

O

U

T

P

U

COM

T

(Y0)

Motor

AC

Power

Supply

2-2

Page 29

FX Series Programmable Controllers Basic Program Instructions 2

y

g

g

y

y

g

y

y

g

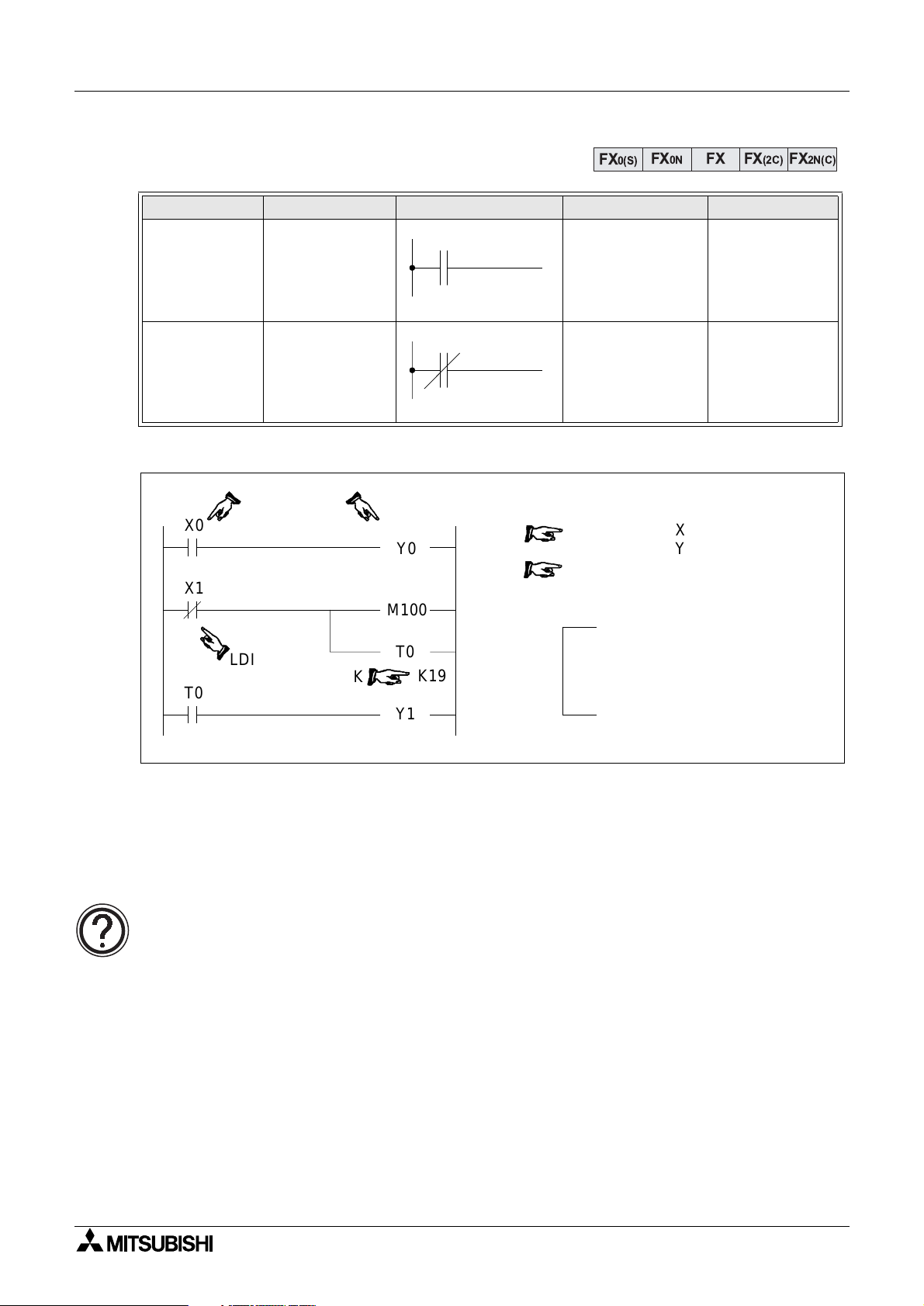

2.4 Load, Load Inverse

Mnemonic Function Format Devices Program steps

Initial lo

LD

(LoaD)

LDI

(LoaD Inverse)

Program example:

X0

X1

T0

operation contact

t

pe NO

(normall

Initial lo

operation contact

t

pe NC

(normall

LDI

ical

open)

ical

closed)

K

Y0

M100

T0

Y1

K19

FX

X, Y, M, S, T, C 1

X, Y, M, S, T, C 1

0

1

2

3

4

7

8

FX0N FX FX(2C)

0(S)

LD

OUT

LDI

OUT

OUT

SP

LD

OUT

X

Y

X

M

T

K

T

Y

100

0

0

1

0

19

0

1

When using hand held

programmers, the space key

needs to be pressed to enable

the constant to be entered.

FX2N(C)

Basic points to remember:

- Connect the LD and LDI instructions directl

- Or use LD and LDI instructions to define a new block of pro

to the left hand bus bar.

ram when using the ORB

and ANB instructions (see later sections).

The OUT instruction:

• For details of the OUT instruction (including basic timer and counter variations)

please see over the followin

page.

2-3

Page 30

FX Series Programmable Controllers Basic Program Instructions 2

y

y

g

g

y

g

y

gg

g

g

y

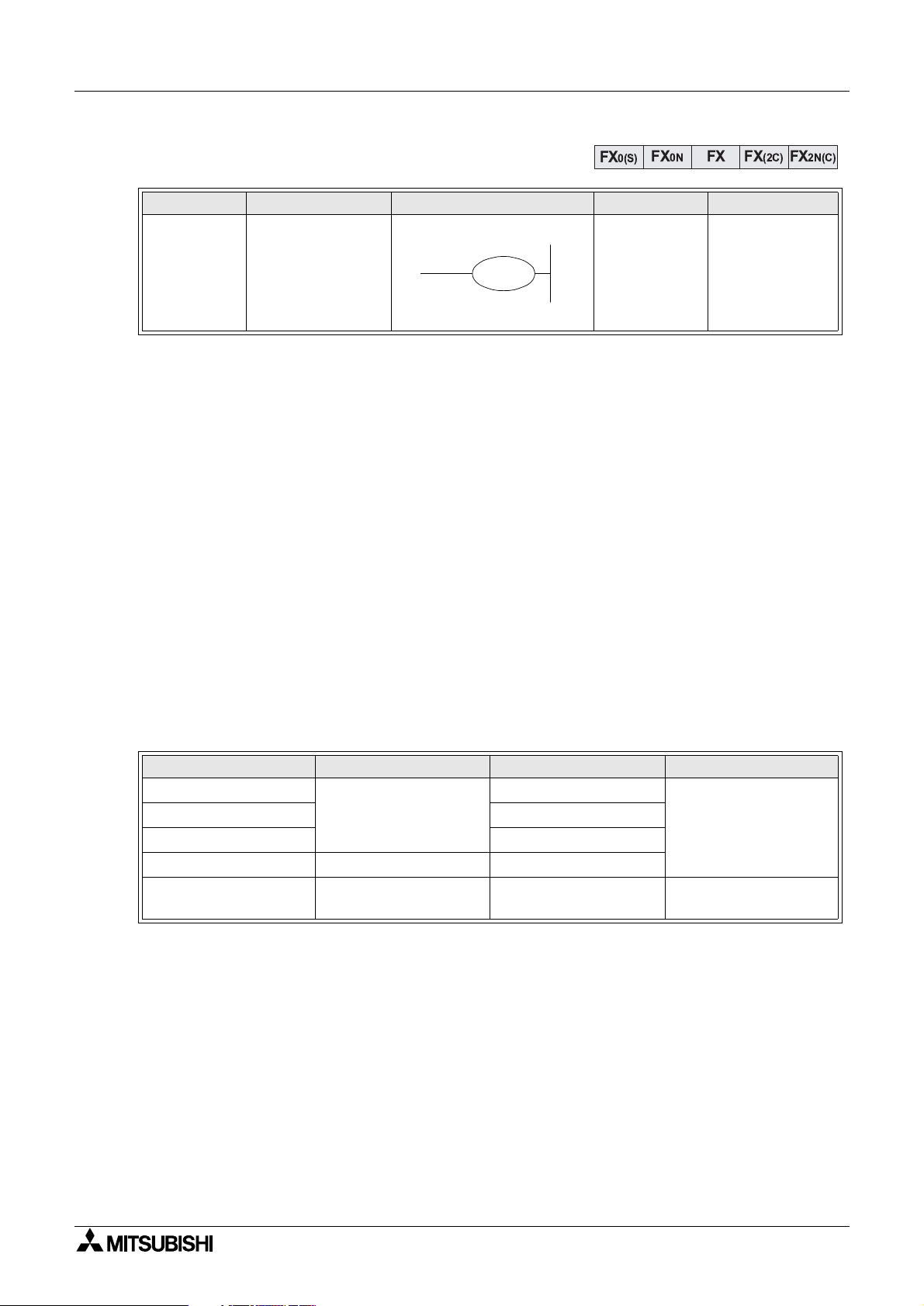

2.5 Out

Mnemonic Function Format Devices Program steps

OUT

(OUT)

Final lo

operation t

drive

Basic points to remember:

- Connect the OUT instruction directl

- It is not possible to use the OUT instruction to drive ‘X’ t

- It is possible to connect multiple OUT instructions in parallel (for example see the

previous pa

2.5.1 Timer and Counter Variations

When confi

uring the OUT instruction for u se as either a timer (T) or counte r (C) a consta nt

must also be entered. The constant is identified b

pa

e; T0 K19).

In the case of a timer, the constant “K” holds the duration data for the timer to operate, i.e. if a

100 msec timer has a constant o f “K100” it will be (100 5 100 msec) 10 s econds before the

timer coil activates.

With counters, the constant identifi es how ma n

before the counter coil activates. For example, a counter with a constant of “8” must be

tri

ered 8 times before the counter coil finally energizes.

The followin

table identifies some basic parameter data for various timers and counters;

ical

pe coil

e; M100/T0 configuration)

FX

Y, M, S, T, C

FX0N FX FX(2C)

0(S)

Y, M:1

S, special M

coils: 2

T:3

C (16 bit): 3

C (32 bit): 5

to the right hand bus bar.

pe input devices.

the letter “K” (for example see previous

times the counter must be pulsed or triggered

FX2N(C)

Timer/Counter Setting constant K Actual setting Program steps

1 msec Timer

10 msec Timer 0.01 to 327.67 sec

100 msec Timer 0.1 to 3276.7 sec

16 bit Counter 1 to 32,767 1 to 32,767

32 bit Counter

1 to 32,767

-2,147,483,648 to

2,147,483,647

0.001 to 32.767 sec

-2,147,483,648 to

2,147,483,647

3

5

2-4

Page 31

FX Series Programmable Controllers Basic Program Instructions 2

g

g

g

g

g

g

g

g

g

g

y

g

y

g

g

g

g

g

g

g

g

g

g

g

2.5.2 Double Coil Designation

X1

1.

Y3

Double or dual coilin

practice. Usin

same device can cause the pro

operation to become unreliable. The example

pro

ram shown opposite identifies a double

is not a recommended

multiple output coils of the

ram

coil situation; there are two Y3 outputs. The

Y3

Y4

followin

sequence of events will occur when

inputs X1 = ON and X2 = OFF;

2.