FUEL

CONTENTS

GASOLINE DIRECT INJECTION (GDI) <4G6> 13A...........................

GASOLINE DIRECT INJECTION (GDI) <4G9> 13B...........................

13A-1

FUEL SUPPLY 13C.........................................................

13A-2

GASOLINE DIRECT

INJECTION (GDI)

<4G6>

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 7.................

SEALANT 7..................................

SPECIAL TOOLS 8..........................

TROUBLESHOOTING 9.......................

ON-VEHICLE SERVICE 97...................

Throttle Body (Throttle Valve Area) Cleaning 97..

Throttle Position Sensor Adjustment 97..........

Accelerator Pedal Position Switch and Accelerator

Pedal Position Sensor Adjustment 98............

Fuel Pressure Test 99..........................

Fuel Leak Check 103...........................

Fuel Pump Connector Disconnection (How to

Reduce the Fuel Pressure) 103.................

Fuel Pump Operation Check 104................

Component Location 105........................

Engine Control Relay, Fuel Pump Relay, Injector

Driver Control Relay and Throttle Valve Control

Servo Relay Continuity Check 106...............

Intake Air Temperature Sensor Check 106.......

Engine Coolant Temperature Sensor Check 106..

Throttle Position Sensor Check 107..............

Accelerator Pedal Position Sensor (1st channel)

Check 108.....................................

Accelerator Pedal Position Sensor (2nd channel)

Check 108.....................................

Accelerator Pedal Position Switch Check 109.....

Oxygen Sensor Check 109......................

Injector Check 111.............................

Throttle V alve Control Servo Check 111..........

Clutch Switch Check 111.......................

Purge Control Solenoid Valve Check 112.........

EGR Valve Check 112..........................

FUEL PUMP (HIGH PRESSURE) AND FUEL

PRESSURE REGULATOR (HIGH

PRESSURE) 113............................

INJECTOR 117.............................

THROTTLE BODY 120.......................

INJECTOR DRIVER 123.....................

THROTTLE VALVE CONTROLLER 124.......

GDI <4G6> -

GENERAL INFORMATION

General Information

13A-3

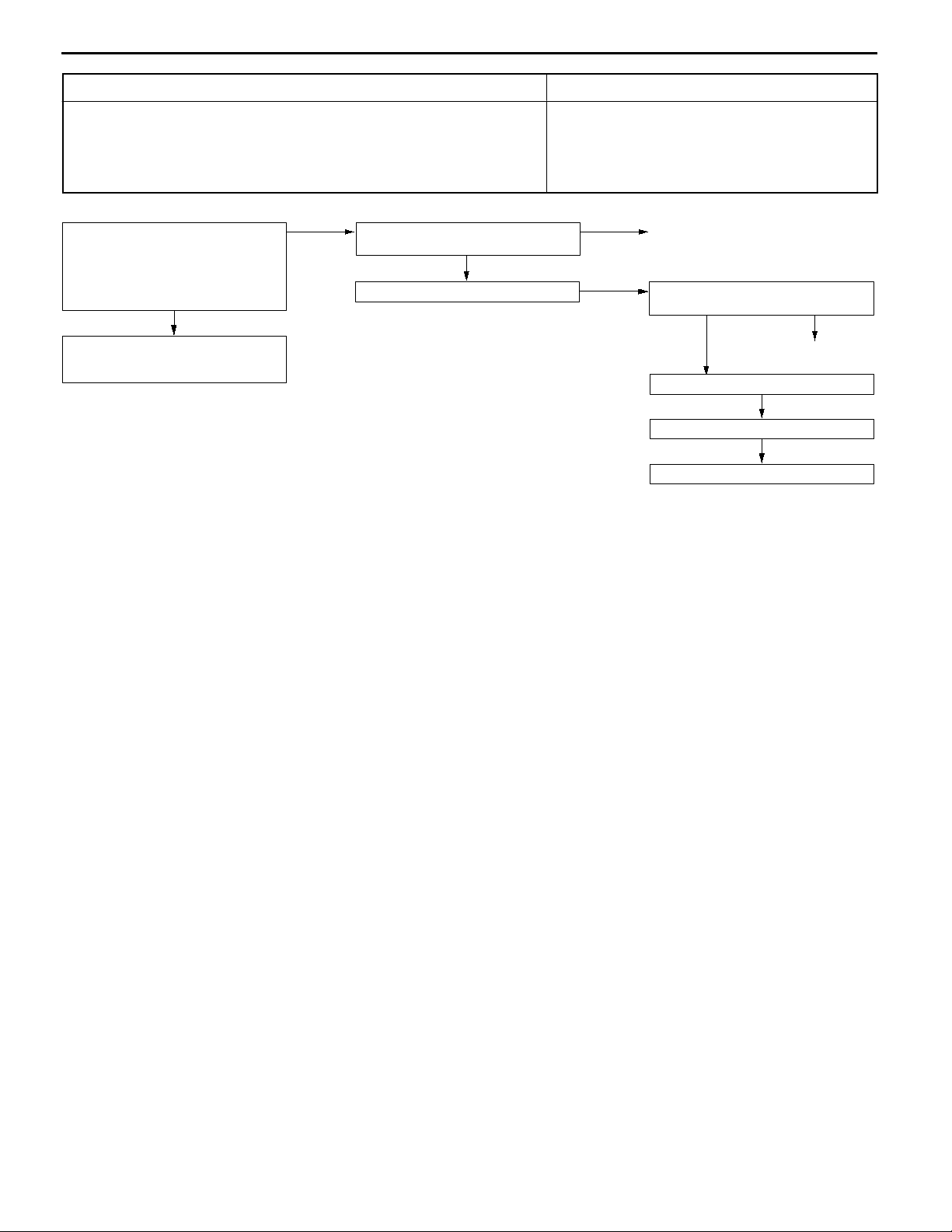

The Gasoline Direct Injection System consists

of sensors which detect the engine conditions,

the engine-ECU which controls the system

based on signals from these sensors, and

actuators which operate under the control of

the engine-ECU. The engine-ECU carries out

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation conditions.

A single injector for each cylinder is mounted

at the cylinder head. The fuel is sent under

pressure from the fuel tank to the fuel pressure

regulator (low pressure) by the fuel pump (low

pressure). The pressure is regulated by the

fuel pressure regulator (low pressure) and the

fuel regulated is then sent to the fuel pump

(high pressure). The fuel under increased

pressure generated by the fuel pump (high

pressure) is then regulated by the fuel pressure

regulator (high pressure) and is then distributed

to each of the injectors via the delivery pipes.

activities such as fuel injection control, idle

speed control and ignition timing control. In

addition, the engine-ECU is equipped with

several diagnosis modes which simplify

troubleshooting when a problem develops.

Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is 1-3-4-2. This is

called sequential fuel injection.

When the engine is cold or under a severe

load, the “open-loop” control keeps the air/fuel

ratio at a richer than usual level to maintain

driveability. When the engine is under low or

medium loads, the air/fuel ratio becomes leaner

to reduce fuel consumption. When the engine

is running at medium or high loads after having

warmed up, the “closed-loop” control uses the

signal from the oxygen sensor to keep the

air/fuel ratio at the optimum theoretical level.

THROTTLE VALVE OPENING ANGLE CONTROL

This system controls throttle valve opening

angle electronically. The engine-ECU determines how deeply the accelerator pedal is

depressed by means of the accelerator position

sensor (APS). Then the engine-ECU sends a

IDLE SPEED CONTROL

This system maintains engine idle speed at

a predetermined condition by controlling the

air flow that passes through the throttle valve

according to engine idling condition and engine

loads at idling.

IGNITION TIMING CONTROL

The power transistor located in the ignition

primary circuit turns ON and OFF to control

the primary current flow to the ignition coil. This

controls the ignition timing in order to provide

the optimum ignition timing with respect to the

engine operating conditions. The ignition timing

target value of the throttle valve opening angle

to the throttle valve controller. The throttle valve

control servo operates the throttle valve so that

it reaches the target opening angle.

The engine-ECU operates the throttle valve

control servo so that engine speed is

maintained within a map value. The map value

is predetermined according to engine coolant

temperature and air-conditioning load.

is determined by the engine-ECU from the

engine speed, intake air volume, engine coolant

temperature, atmospheric pressure and

injection timing (intake stroke or compression

stroke).

13A-4

GDI <4G6> -

SELF-DIAGNOSIS FUNCTION

D When an abnormality is detected in one

of t h e sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates as a

warning to the driver.

D When an abnormality is detected in one

of the sensors or actuators, a diagnosis

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.

3. Fan Motor Control

The revolutions of the radiator fan and

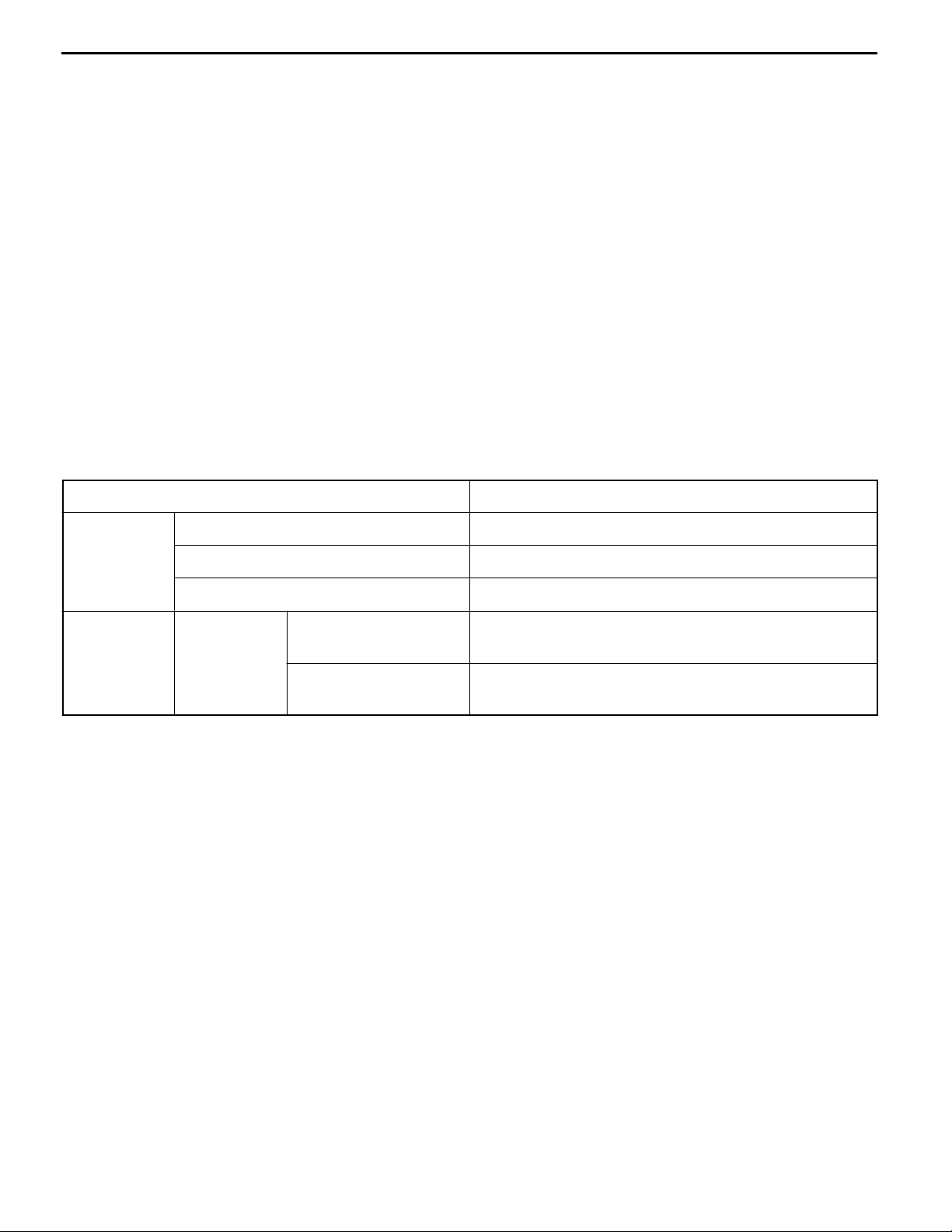

GENERAL SPECIFICATIONS

General Information

code corresponding to the abnormality is

output.

D The RAM data inside the engine-ECU that

is related to the sensors and actuators can

be read by means of the MUT-II. In addition,

the actuators can be force-driven under

certain circumstances.

condenser fan are controlled in response

to the engine coolant temperature and

vehicle speed.

4. Purge Control Solenoid Valve Control

Refer to GROUP 17.

5. EGR valve Control

Refer to GROUP 17.

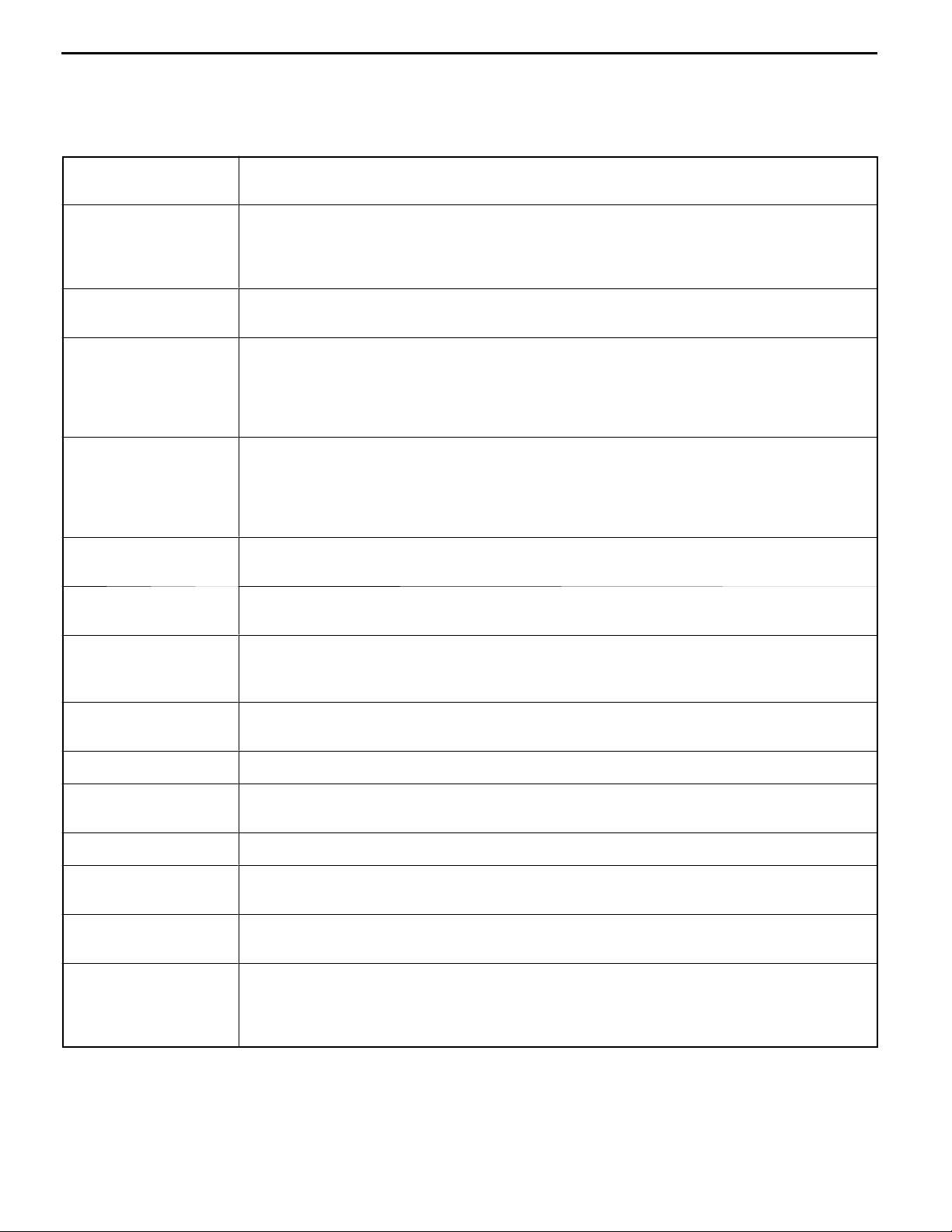

Items Specifications

Throttle body Throttle bore mm 65

Throttle position sensor Variable resistor type

Throttle valve control servo Torque motor type

Engine-ECU Identification

model No.

Except vehicles for

Germany

Vehicles for Germany E2T72575 <M/T>

E2T72571 <M/T>

E2T72574 <A/T>

E2T73576 <A/T>

GDI <4G6> -

Items Specifications

Sensors Air flow sensor Karman vortex type

Barometric pressure sensor Semiconductor type

Intake air temperature sensor Thermistor type

Engine coolant temperature sensor Thermistor type

Oxygen sensor Zirconia type

General Information

13A-5

Accelerator pedal position sensor (1st

and 2nd channels)

Accelerator pedal position switch Rotary contact type, within accelerator pedal position

Vehicle speed sensor Magnetic resistive element type

Inhibitor switch Contact switch type

Camshaft position sensor Hall element type

Crank angle sensor Hall element type

Detonation sensor Piezoelectric type

Fuel pressure sensor Metallic membrane type

Power steering fluid pressure switch Contact switch type

Actuators Engine control relay type Contact switch type

Fuel pump relay type Contact switch type

Injector driver control relay Contact switch type

Injector type and number Electromagnetic type, 4

Variable resistor type

sensor (1st channel)

Fuel pressure

regulator (low

pressure)

Fuel pressure

regulator

(high pressure)

Injector identification mark DIM 1100G

Throttle valve control servo relay Contact switch type

Throttle valve control servo Torque motor type

EGR valve Stepper motor type

Purge control solenoid valve Duty cycle type solenoid valve

Regulator pressure kPa 324

Regulator pressure MPa 5.5

13A-6

GDI <4G6> -

General Information

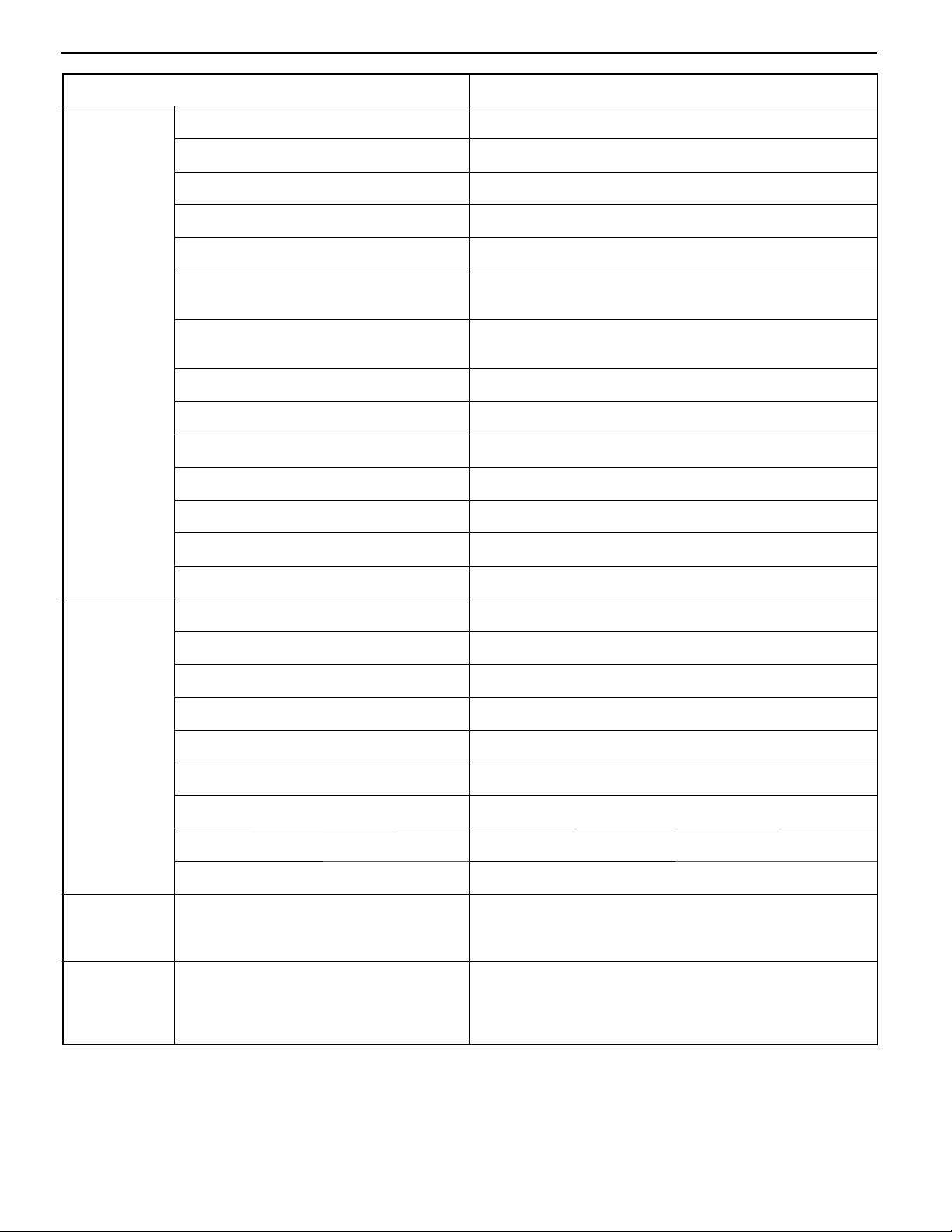

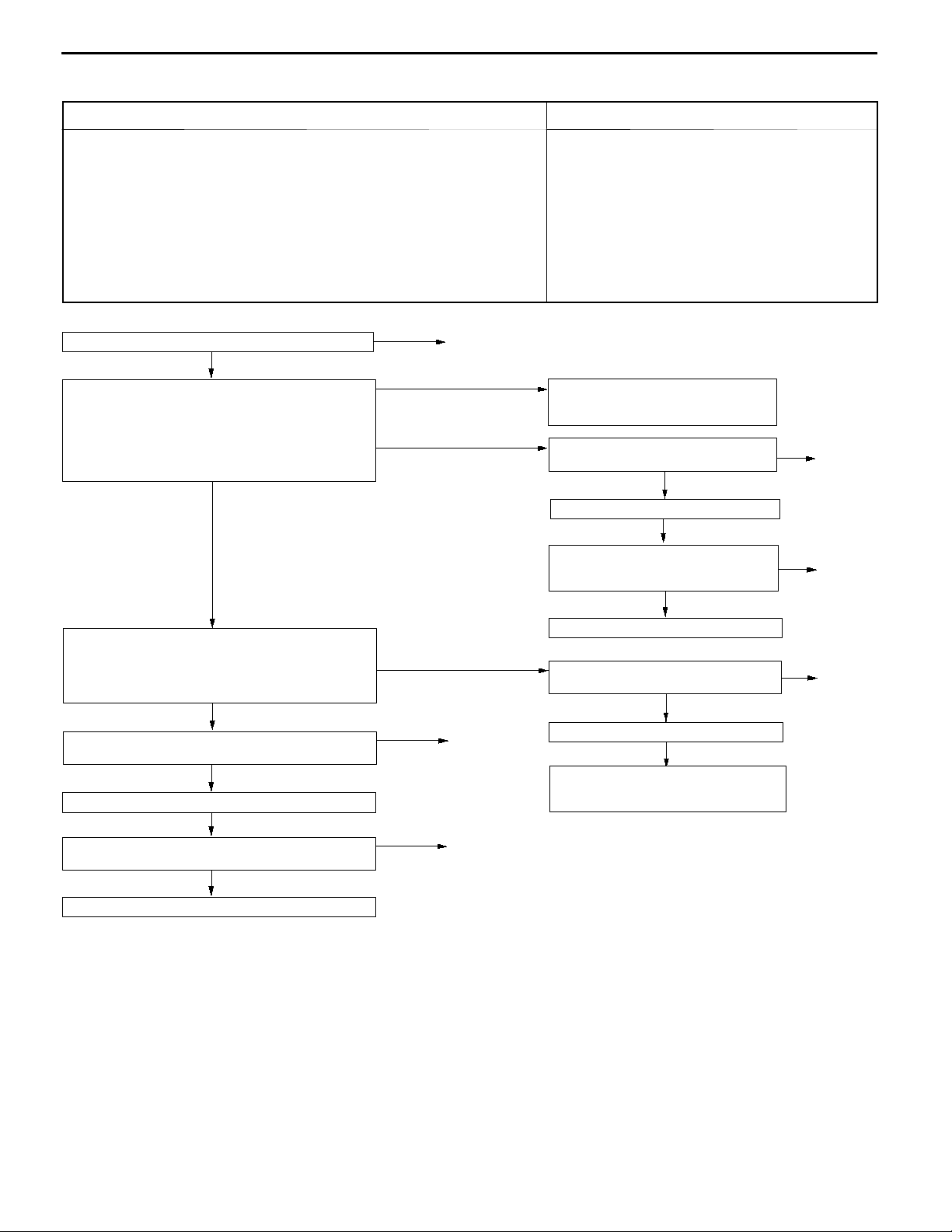

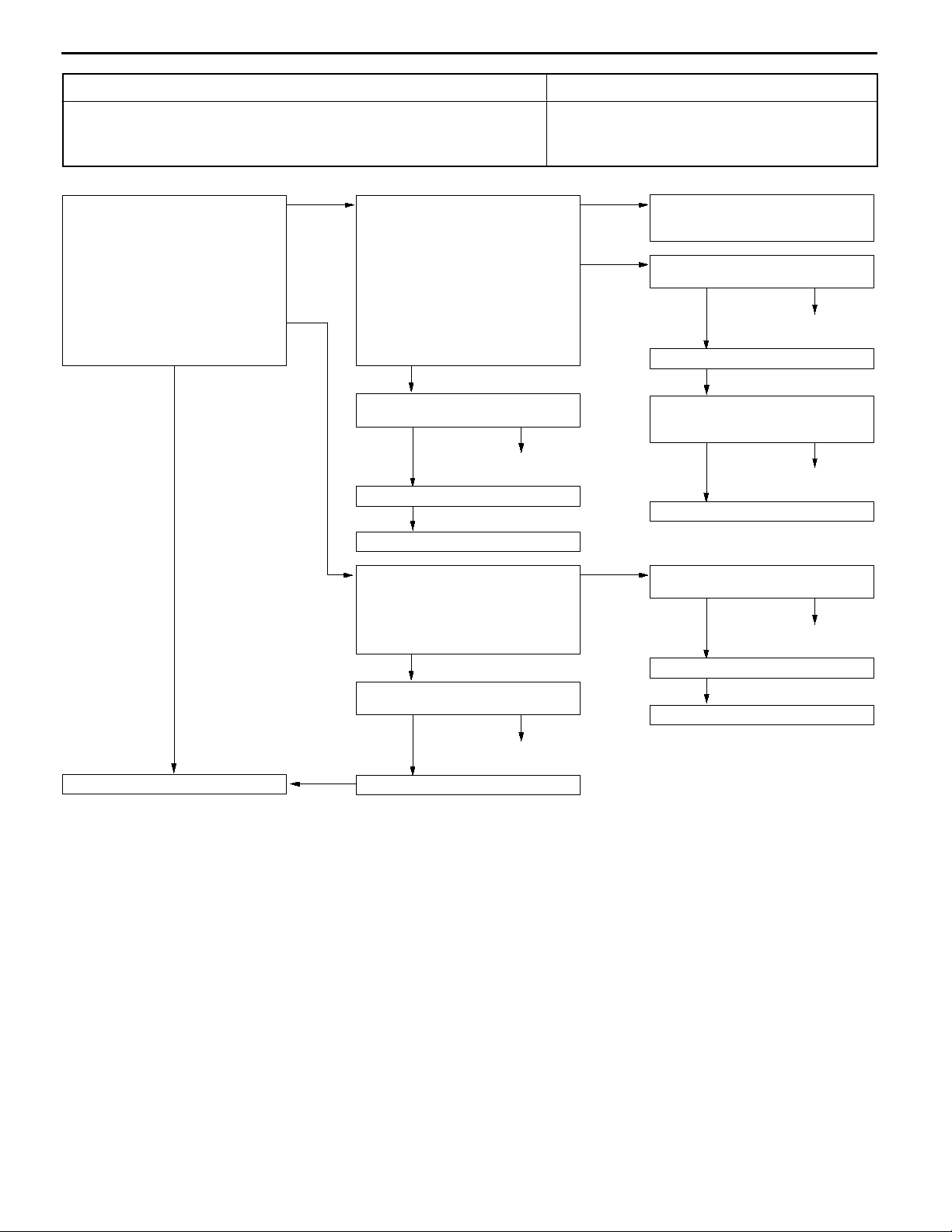

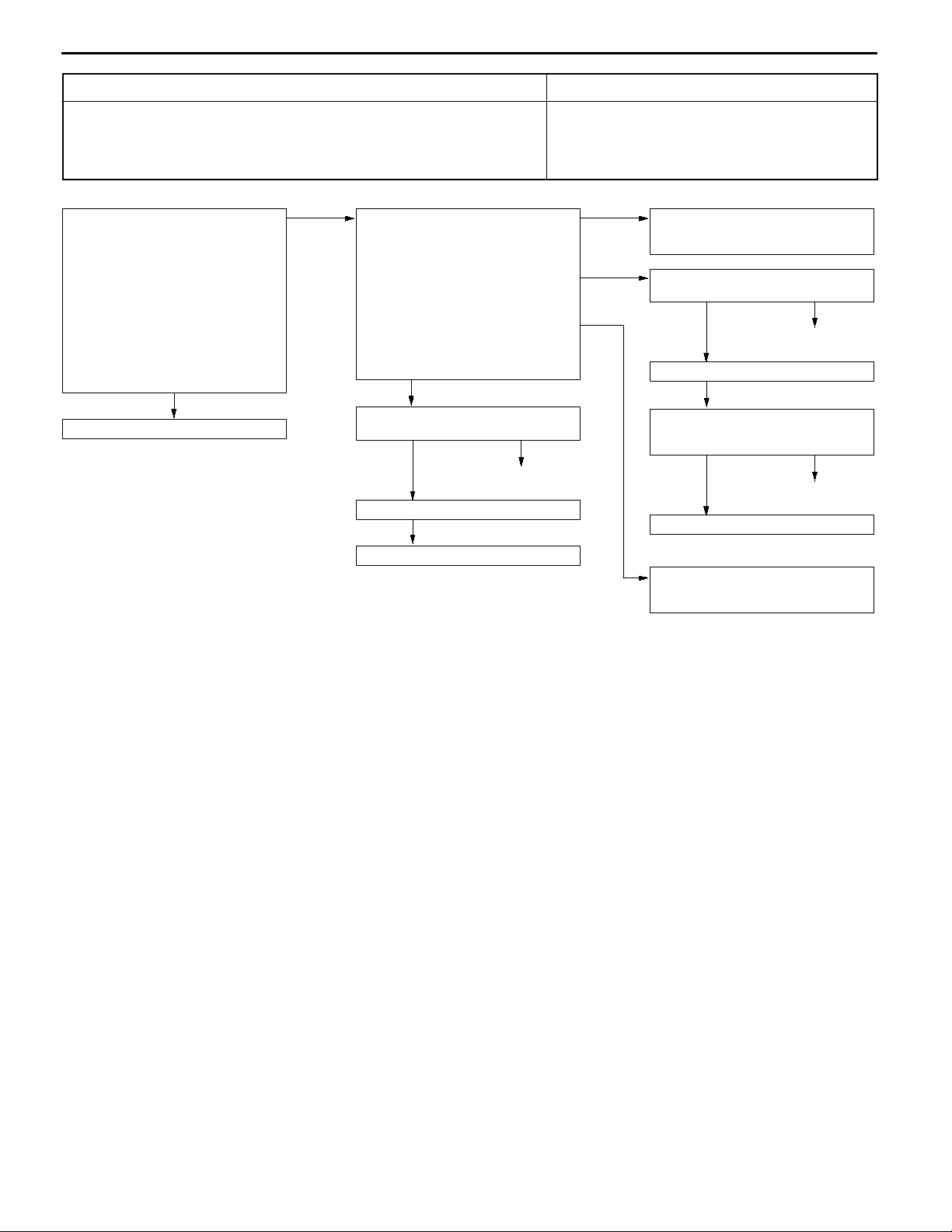

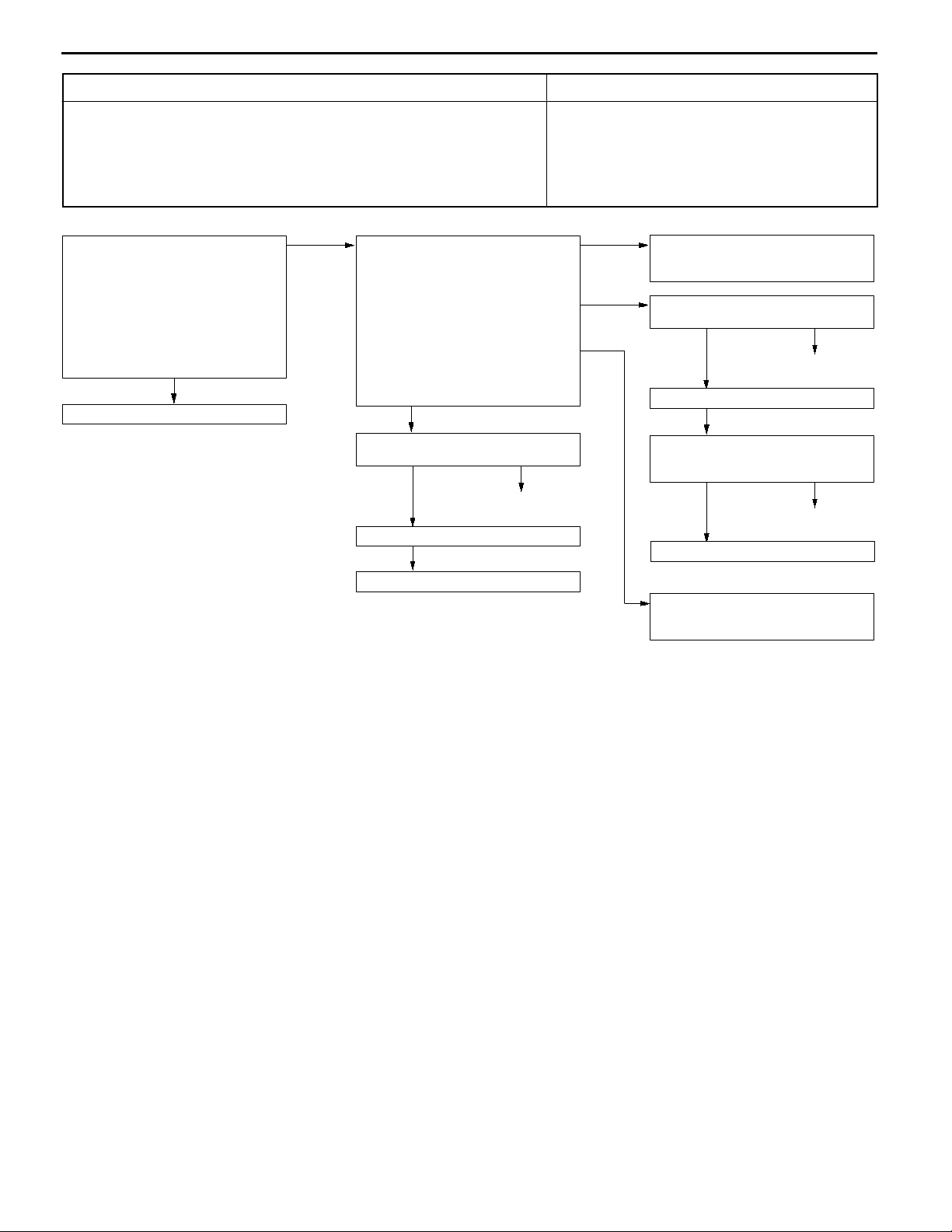

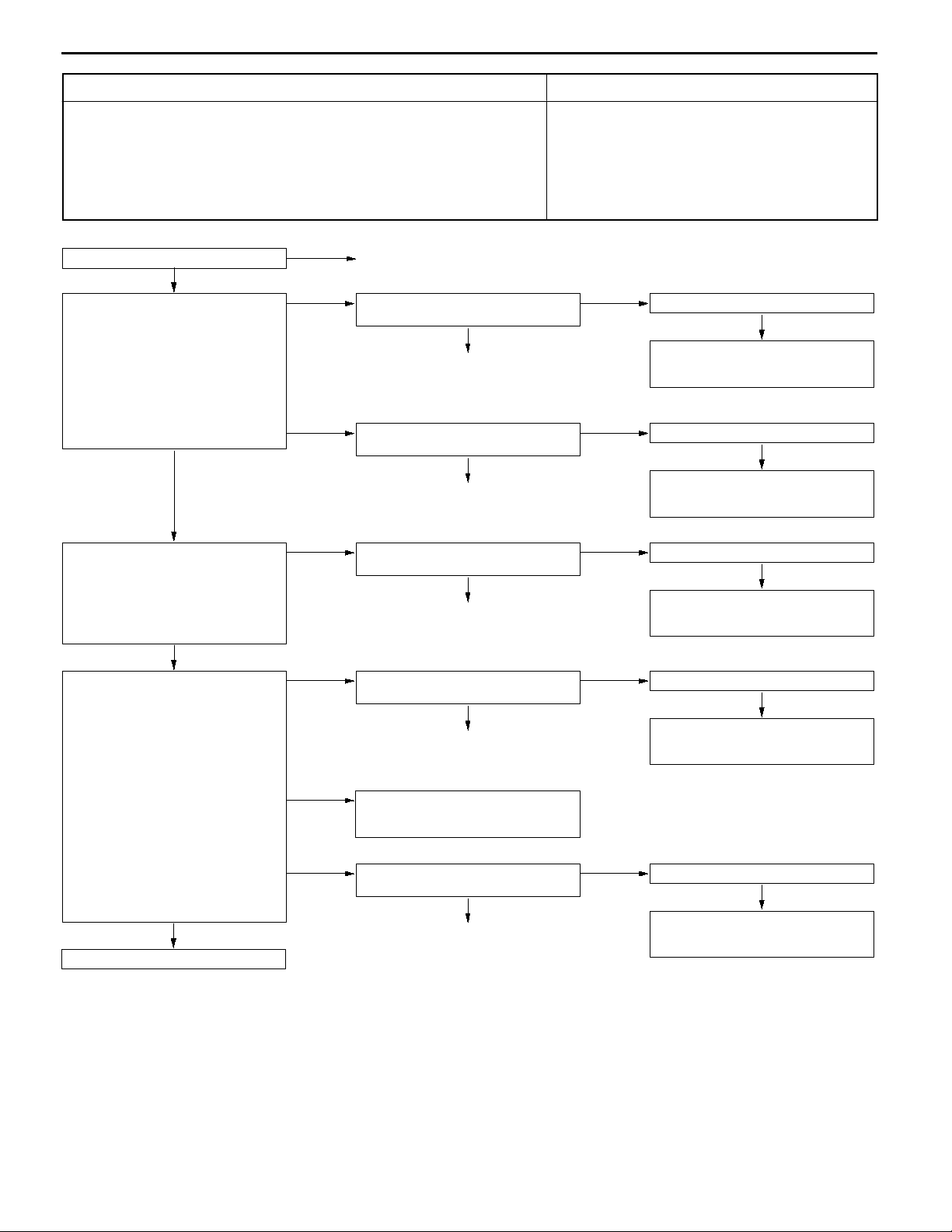

GASOLINE DIRECT INJECTION SYSTEM DIAGRAM

*1 Oxygen sensor

(front)

*2 Air flow sensor

*3 Intake air tempera-

ture senor

*4 Throttle position

sensor (2nd chan-

nel)

*5 Camshaft position

sensor

*6 Crank angle sen-

sor

*7 Barometric pres-

sure sensor

*8 Engine coolant

temperature sen-

sor

*9 Detonation sensor

*10 Fuel pressure sen-

sor

*11 Oxygen Sensor

(rear)

*12 Throttle position

sensor 1

D Power supply

D Ignition switch - IG

D Ignition switch - ST

D Accelerator pedal posi-

tion sensor (1st

channel)

D Accelerator pedal posi-

tion switch

D Vehicle speed sensor

D A/C switch (1st channel)

D A/C switch (2nd chan-

nel)

D M/T oil temperature

sensor

D Inhibitor switch

D Power steering fluid

pressure switch

D Alternator FR terminal

D Stop lamp switch

D Small lamp switch

D Clutch switch

D Brake vacuum sensor

D Injector wire open circuit

check signal

D Throttle valve controller

D A/T-ECU

D Power supply

D Ignition switch - IG

D Accelerator pedal posi-

tion sensor 2

D Engine-ECU

Engine-

ECU

Throttle

valve

control-

ler

z1 Injector driver (In-

jector)

z2 EGR valve (Step-

per motor)

z3 Purge control sole-

noid valve

z4 Throttle valve con-

trol servo

D Engine control relay

D Fuel pump relay

D Injector driver relay

D Throttle valve control

servo relay

D A/C relay

D Ignition coil

D Fan controller

D Engine warning lamp

D Diagnosis output

D Alternator G terminal

D Throttle valve controller

D A/T-ECU

D Engine-ECU

From fuel pump

(low pressure)

To fuel tank

High-pressure fuel

regulator assembly

[integrated in fuel

pressure regulator

(high pressure)]

Fuel pump

(high pressure)

*10 Fuel pressure

sensor

*5 Camshaft position

sensor

*4 Throttle position sensor 2

*12 Throttle position sensor 1

z2 EGR valve

Injector

*8 Engine coolant

temperature sensor

*9 Detonation sensor

*1 Oxygen sensor (front)

z4 Throttle valve

control servo

z1 Injector

driver

z3 Purge control

*3 Intake air temperature

sensor

*2 Air flow sensor

*7 Barometric

pressure sensor

Canister

solenoid valve

*6 Crank angle sensor

*11 Oxygen sensor (rear)

GDI <4G6> -

Service Specifications/Sealant

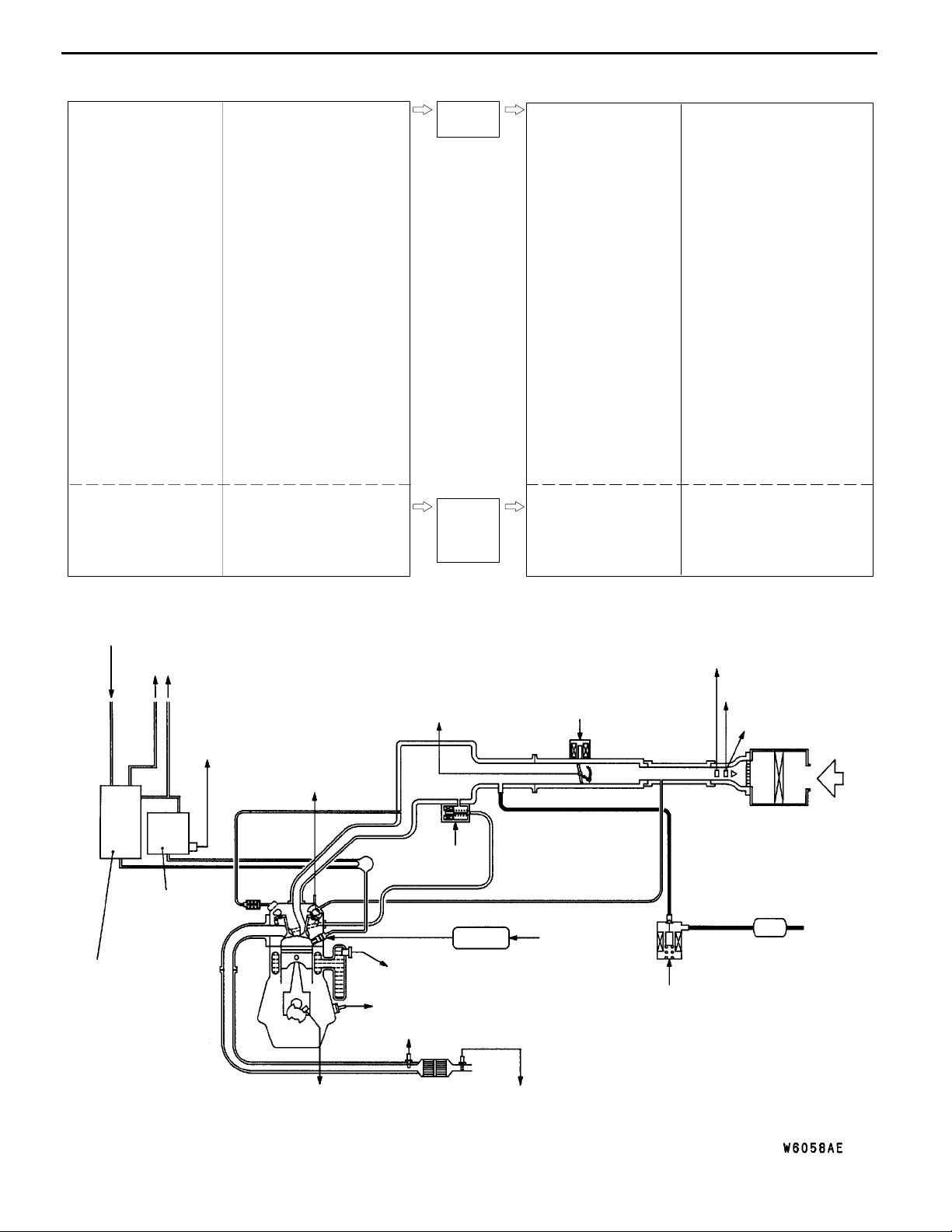

SERVICE SPECIFICATIONS

Item Standard value

13A-7

Adjustment voltage of throttle position sensor

(1st channel) V

Adjustment voltage of throttle position sensor

(2nd channel) V

Resistance of throttle position sensor kW 1.7 - 3.8

Adjustment voltages (1) and (2) of accelerator pedal position

sensor V

Resistance (1) and (2) of throttle position sensor kW 3.5 - 6.5

Intake air temperature sensor at 20_C 2.3 - 3.0

resistance kW

at 80_C 0.30 - 0.42

Engine coolant temperature at 20_C 2.1 - 2.7

sensor resistance kW

at 80_C 0.26 - 0.36

Fuel pressure High-pressure side MPa 4 - 7.5

Low-pressure side kPa Approximately 324

Injector coil resistance W 0.9 - 1.1

Oxygen sensor output voltage V 0.6 - 1.0

0.4 - 0.6

4.2 - 4.8

0.4 - 1.0

Oxygen sensor heater resistance W 11 - 18

Throttle valve control servo resistance W 1.35 - 1.65

SEALANT

Item Specified sealant Remark

Engine coolant temperature sensor

threaded portion

3M Nut Locking Part No. 4171 or equivalent Drying sealant

13A-8

GDI <4G6> -

Special Tools

SPECIAL TOOLS

Tool Number Name Use

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

MB991502 MUT-II sub

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: Probe

assembly

D Fuel gauge simple inspection

A: Connector pin contact pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

D Reading diagnosis code

D GDI system inspection

MB991348,

MB991658

MB991709 Test harness

MB991519 Alternator harness

MD998478 Test harness

Test harness set D Measurement of voltage during trouble-

connector

(3-pin, triangle)

shooting

D Inspection using an analyzer

Measurement of voltage during

troubleshooting

D Measurement of voltage during trouble-

shooting

D Inspection using an analyzer

MD998464 Test harness

(4-pin, square)

Inspection of oxygen sensor

GDI <4G6> -

Tool UseNameNumber

Special Tools/Troubleshooting

13A-9

MB991529 Diagnosis code

check harness

MD998709 Adaptor hose Measurement of fuel pressure

MD998742 Hose adaptor

MB991637 Fuel pressure

gauge set

Reading diagnosis code

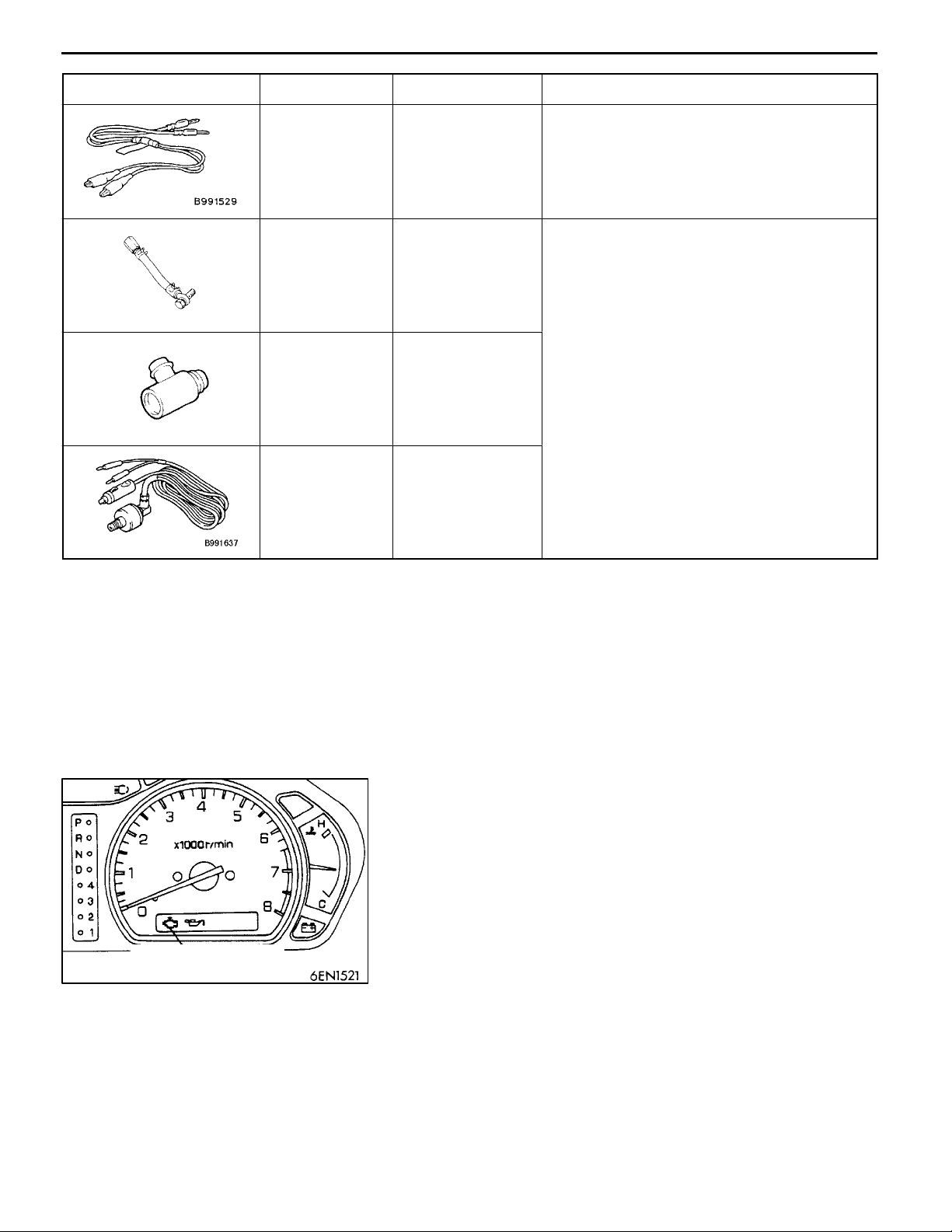

Engine warning lamp

(check engine lamp)

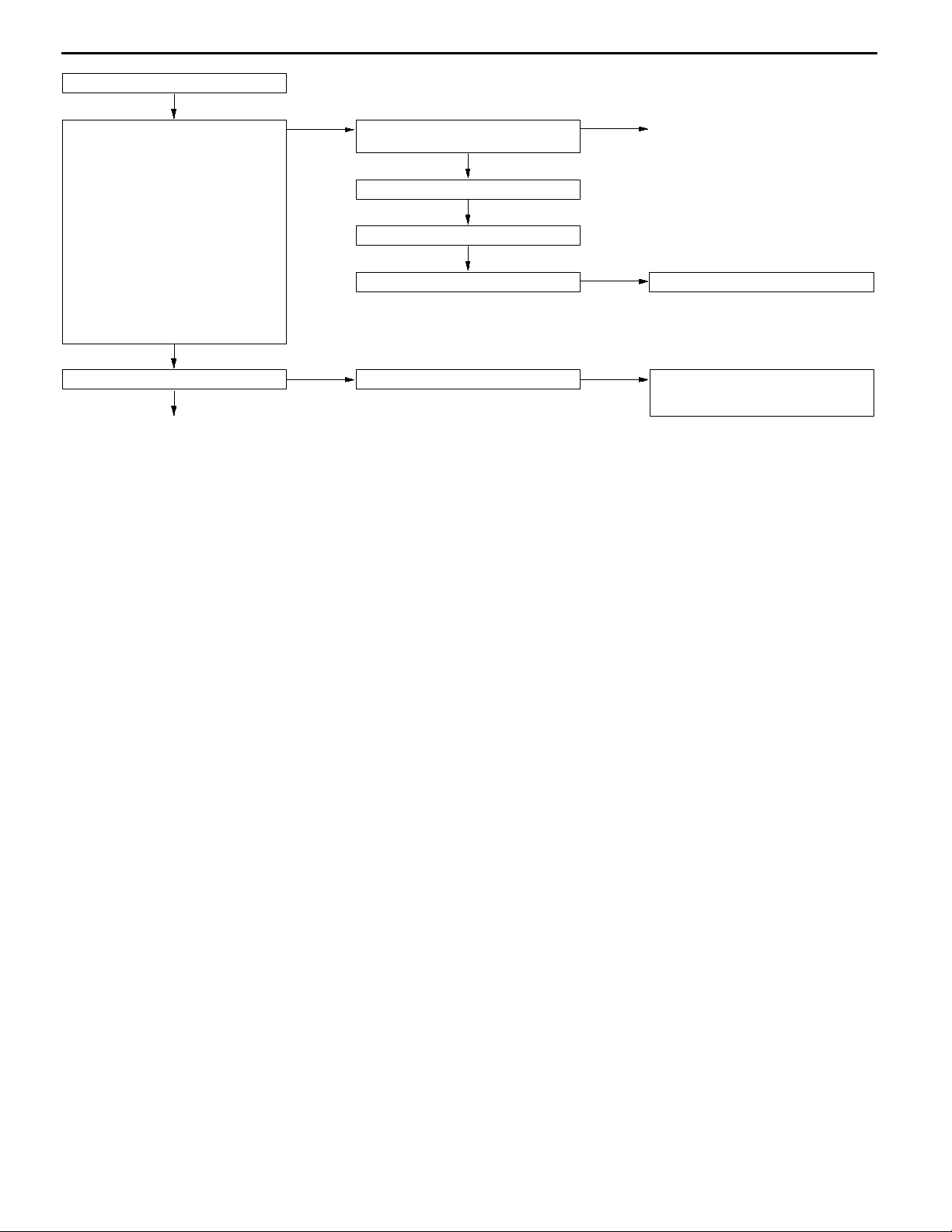

TROUBLESHOOTING

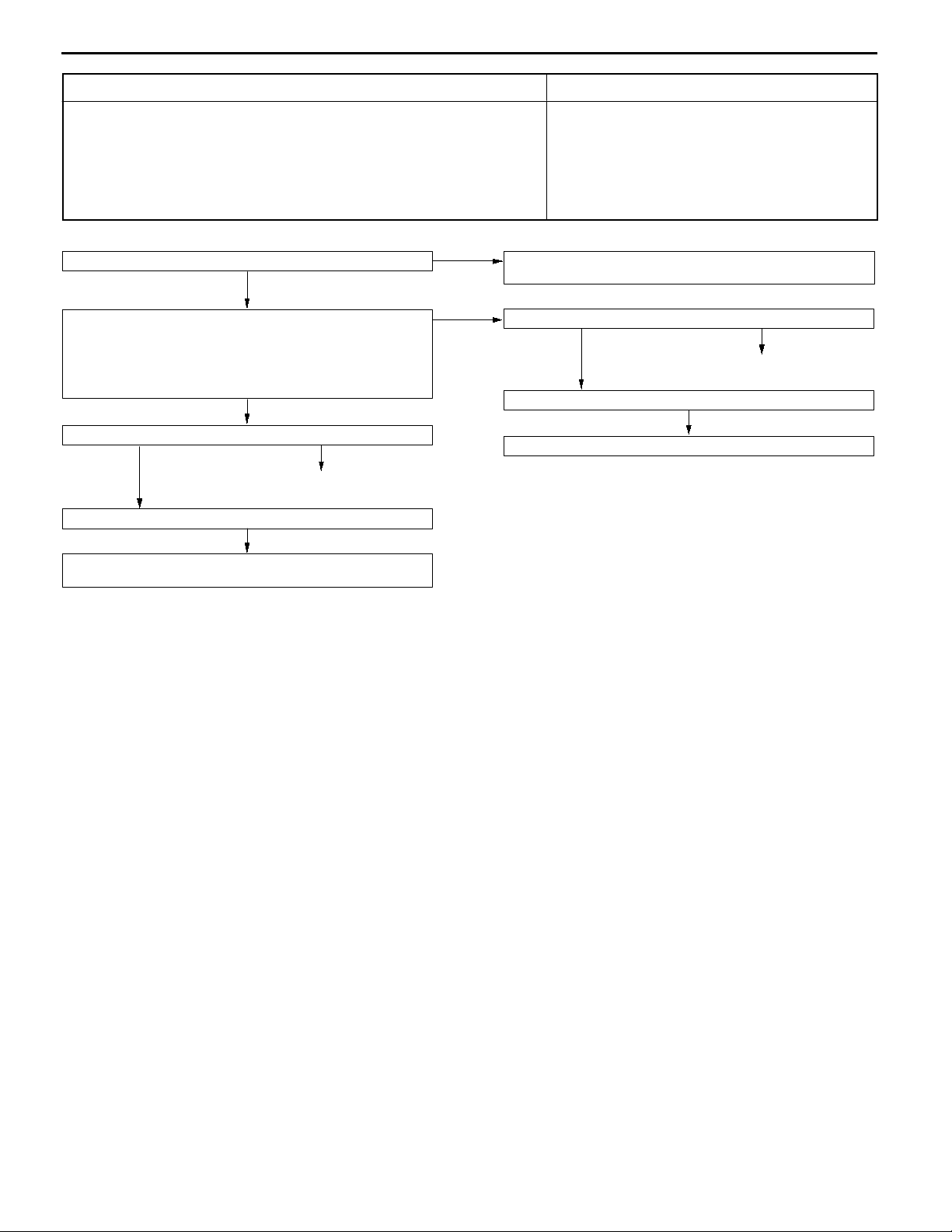

DIAGNOSIS TROUBLESHOOTING FLOW

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

NOTE

If the engine-ECU is replaced, the steering lock cylinder a nd

ignition key should be replaced together with it.

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the Gasoline Direct Injection (GDI) system, the engine

warning lamp will illuminate.

If the lamp remains illuminated or if the lamp illuminates while

the engine is running, check the diagnosis code output.

13A-10

GDI <4G6> -

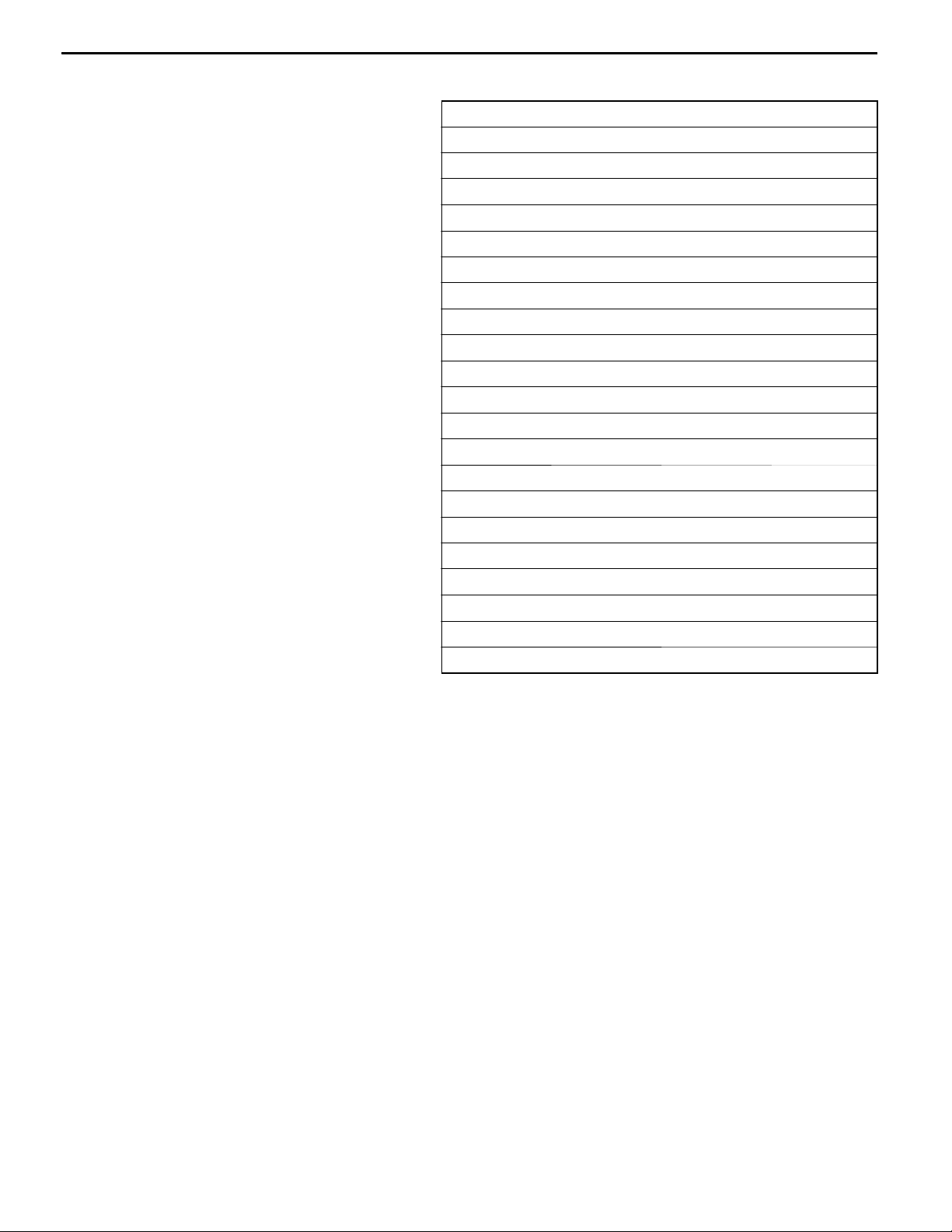

Engine warning lamp inspection items

Troubleshooting

Engine-ECU

Oxygen sensor

Air flow sensor

Intake air temperature sensor

Throttle position sensor (1st channel)

Throttle position sensor (2nd channel)

Engine coolant temperature sensor

Crank angle sensor

Camshaft position sensor

Barometric pressure sensor

Detonation sensor

Injector

Abnormal combustion

Immobilizer system

Abnormal fuel pressure

Brake vacuum sensor

Fuel system malfunction

Accelerator pedal position sensor (1st channel)

Accelerator pedal position sensor (2nd channel)

Electronic-controlled throttle valve system

Throttle valve control servo

Throttle valve controller

METHOD OF READING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING MUT-IIDATA LIST AND

ACTUATOR TESTING

1. Carry out inspection by means of the data list and the

actuator test function.

If there is an abnormality, check and repair the chassis

harnesses and components.

2. After repairing, re-check using the MUT-IIand check that

the abnormal input and output have returned to normal

as a result of th e repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II.

5. Start the engine again and carry out a road test to confirm

that the problem has disappeared.

GDI <4G6> -

Troubleshooting

13A-11

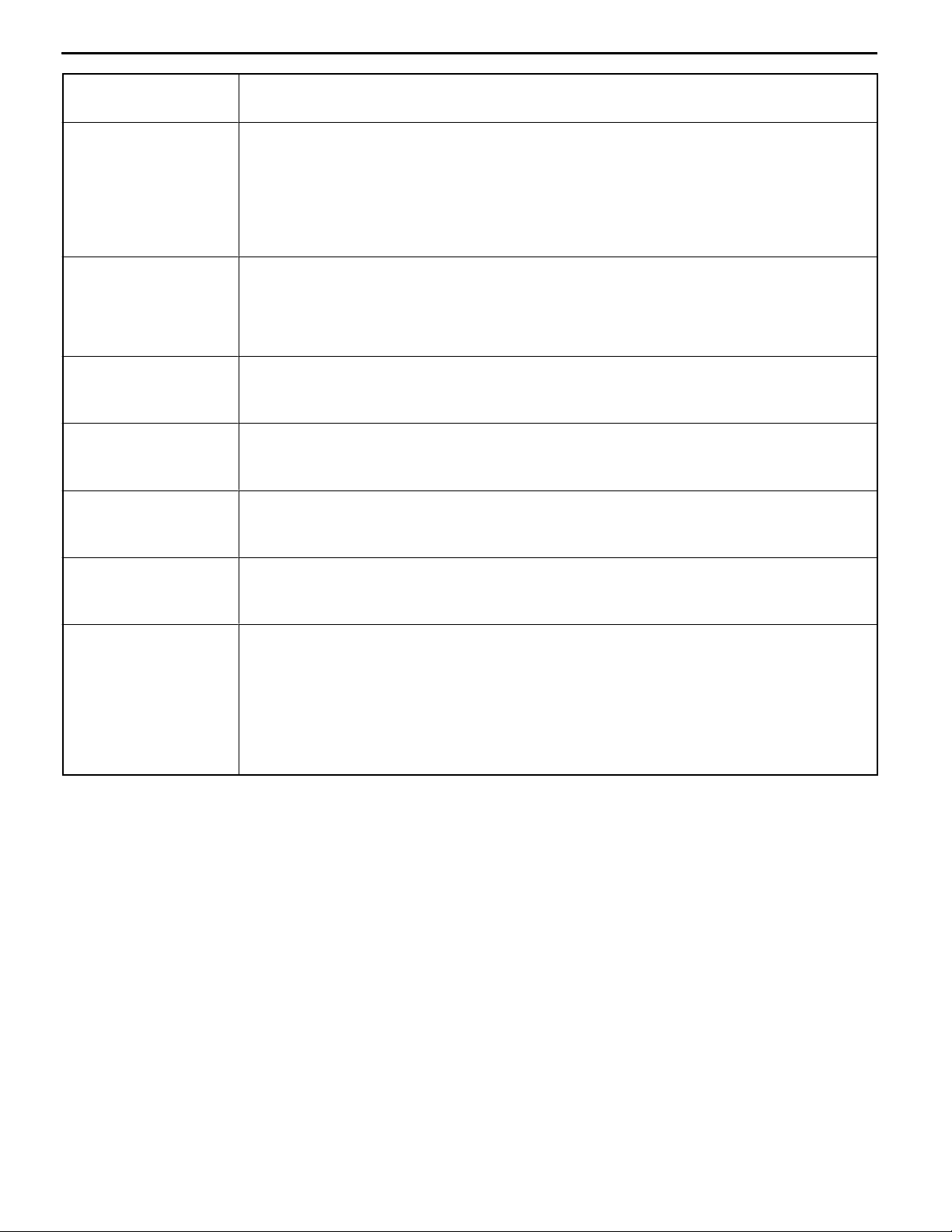

FAIL-SAFE FUNCTION REFERENCE TABLE

If the diagnosis system detects any sensor malfunction, the vehicle can be driven safely by using a

default control logic instead of the faulty sensors.

Defective part or

function

Air flow sensor (1) Disables lean-mixture combustion.

Intake air temperature

sensor

Throttle position

sensor (1st channel)

Throttle position

sensor (2nd channel)

Engine coolant

temperature sensor

Camshaft position

sensor

What to do when a sensor is defective

(2) Determines injector basic operating time and basic ignition timing according to map

value, which has been predetermined by throttle position sensor and crank angle

sensor signals.

Controls as the intake air temperature is 25_C.

(1) Disables lean-mixture combustion.

(2) Controls throttle valve opening angle by closed loop control by using the throttle

position sensor (2nd channel) signal.

(3) Disables the throttle valve opening angle control when the throttle position sensor

(2nd channel) signal is also defective.

(1) Disables lean-mixture combustion.

(2) Controls throttle valve opening angle by closed loop control by using the throttle

position sensor (1st channel) signal.

(3) Disables the throttle valve opening angle control when the throttle position sensor

(1st channel) signal is also defective.

Controls as if the engine coolant temperature is 80_C. (Note that this control will continue

until the ignition switch is turned off even if the sensor signal return to normal.)

Controls according to the conditions before a failure is detected.

Vehicle speed sensor (1) Disables lean-mixture combustion. However, if a predetermined time elapses at an

engine speed of 1,500 r/min or more, the lean-mixture combustion will return to normal.

(2) Disables lean-mixture combustion during engine idling.

Barometric pressure

sensor

Detonation sensor Holds the ignition timing at that for regular gasoline.

Injector (1) Disables lean-mixture combustion.

Abnormal combustion Disables lean-mixture combustion.

Communication line

with A/T-ECU

Alternator FR terminal Disables inhibition control of the alternator output according to electrical load (treats the

Fuel pressure sensor (1) Controls as if the fuel pressure is 5.5 MPa (if there is open or short circuit).

Controls as if the barometric pressure is 101 kPa.

(2) Shuts down exhaust gas recirculation.

Disables ignition timing retard control (engine and transmission total control) during shift

change.

alternator as if it is conventional one).

(2) Turns off the fuel pump relay (if the fuel pressure is excessively high).

(3) Shuts off the fuel injection (If an excessively low pressure is detected or the engine

speed exceeds 3,000 r/min).

13A-12

GDI <4G6> -

Troubleshooting

Defective part or

function

Accelerator pedal

position sensor (1st

channel)

Accelerator pedal

position sensor (2nd

channel)

Electronic-controlled

throttle valve system

Throttle valve position

feedback

Throttle valve control

servo motor malfunction (1st phase)

What to do when a sensor is defective

(1) Disables lean-mixture combustion.

(2) Controls the throttle valve position by using the accelerator pedal position sensor

(2nd channel) signal.

(3) Disables the electronic-controlled throttle valve system if the accelerator pedal position

sensor (2nd channel) signal is also defective, and holds the throttle valve at a

predetermined angle where the vehicle can be driven safely although its performance

is reduced.

(1) Disables lean-mixture combustion.

(2) Controls the throttle valve position by using the accelerator pedal position sensor

(1st channel) signal.

(3) Disables the electronic-controlled throttle valve system if the accelerator pedal position

sensor (1st channel) signal is also defective.

(1) Disables the electronic-controlled throttle valve system.

(2) Disables lean-mixture combustion.

(3) Disables idle engine speed feedback control.

(1) Disables the electronic-controlled throttle valve system.

(2) Disables lean-mixture combustion.

(3) Disables idle engine speed feedback control.

Disables lean-mixture combustion.

Throttle valve control

servo motor malfunction (2nd phase)

Communication line

with the throttle valve

controller

(1) Disables the electronic-controlled throttle valve system.

(2) Disables lean-mixture combustion.

(3) Disables idle engine speed feedback control.

(1) Error in communication between the throttle valve controller and engine-ECU

D Disables lean-mixture combustion.

D Shuts off fuel supply when engine speed exceeds 3,000 r/min.

(1) Error in communication between the throttle valve controller and engine-ECU

D Disables lean-mixture combustion.

D Shuts off fuel supply when engine speed exceeds 3,000 r/min.

D The throttle valve controller controls the throttle valve opening angle by using

the accelerator pedal position sensor (2nd channel) signal.

GDI <4G6> -

Troubleshooting

13A-13

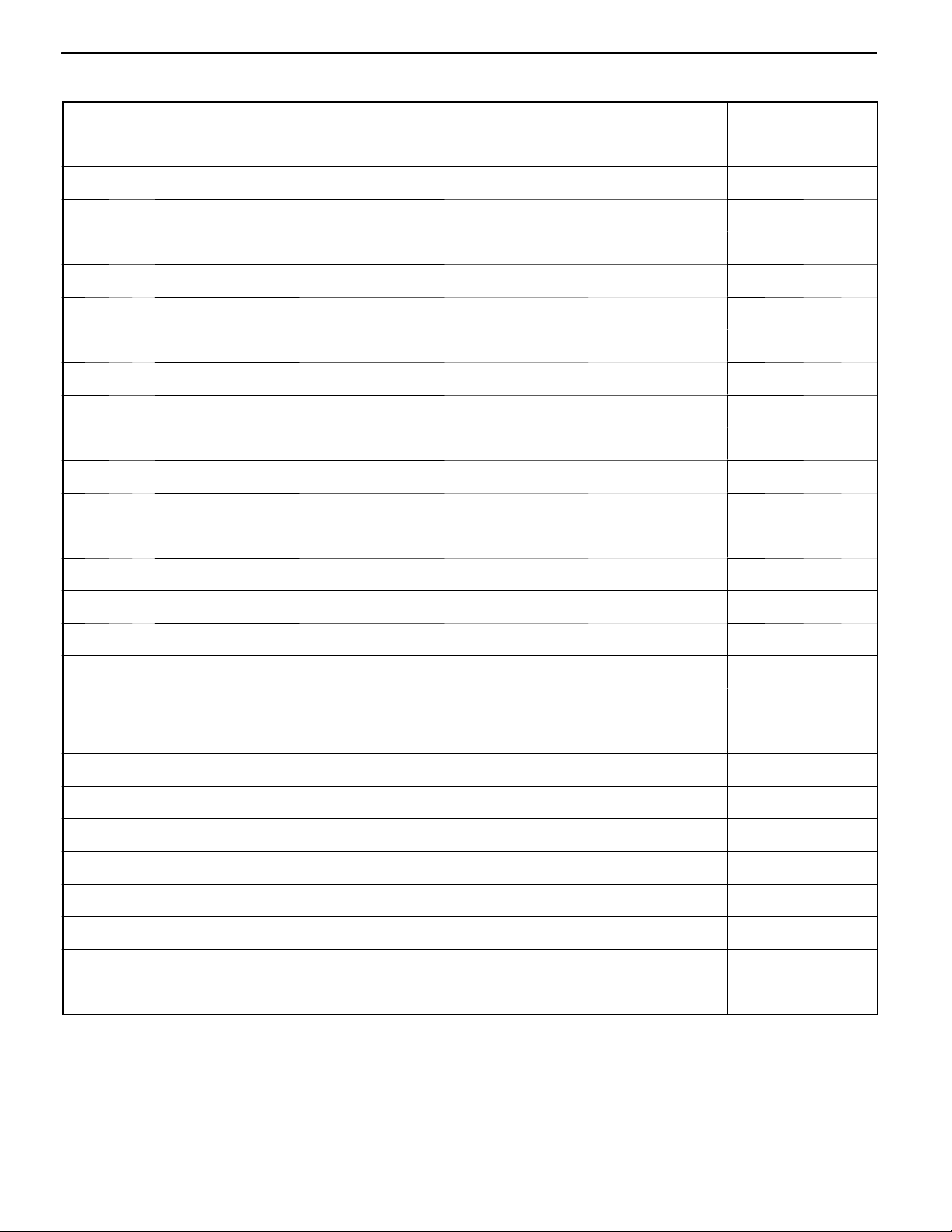

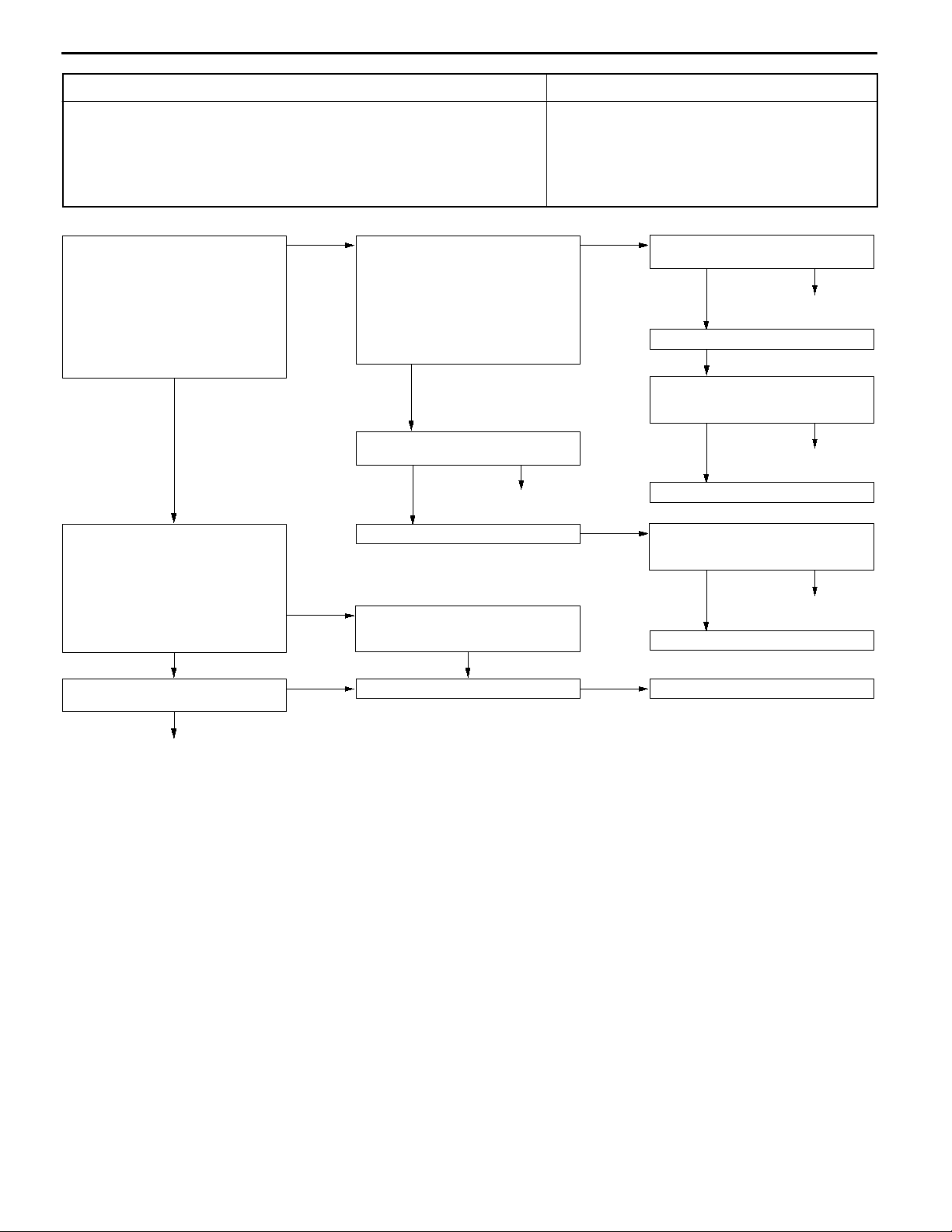

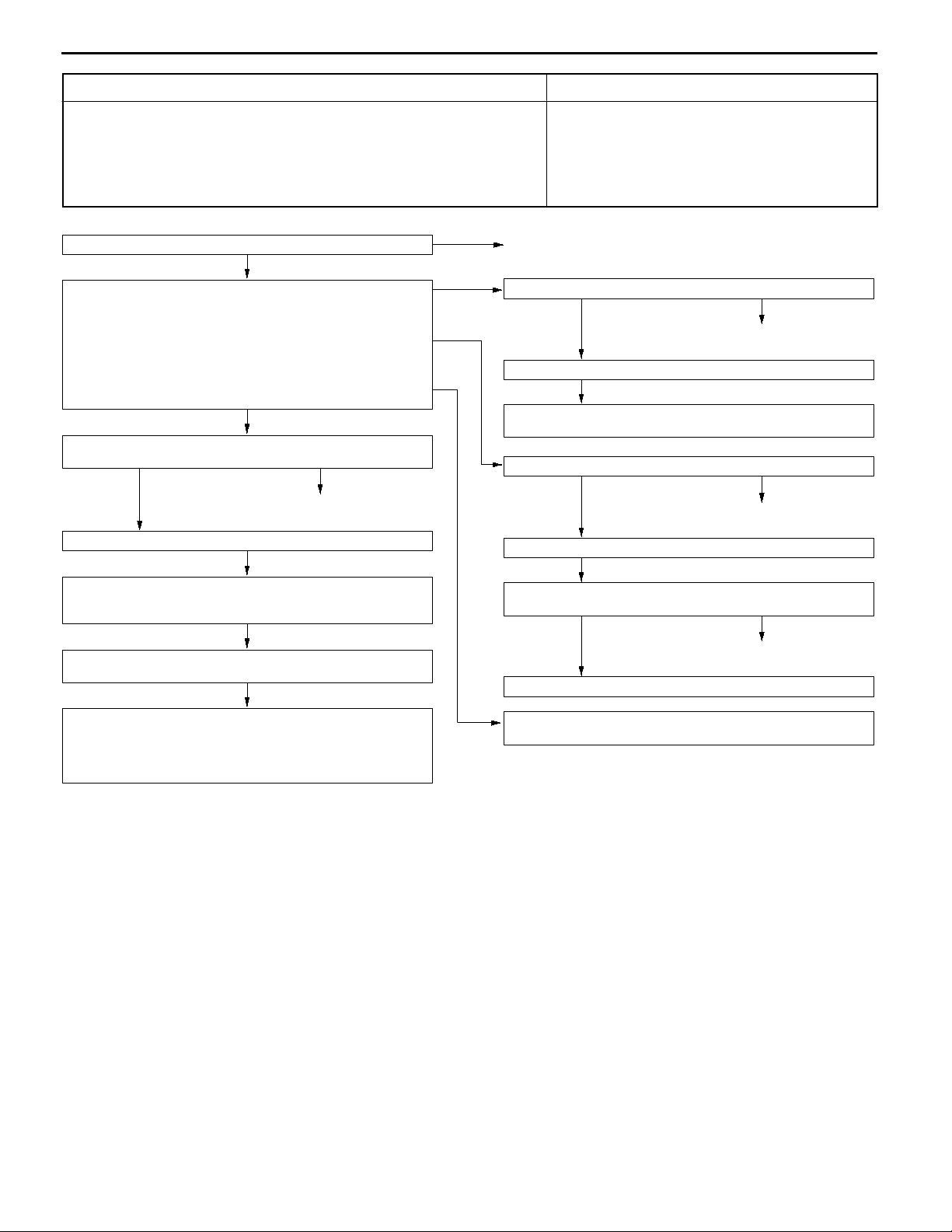

INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference page

11 Oxygen sensor (front) system 13A-14

12 Air flow sensor system 13A-15

13 Intake air temperature sensor system 13A-16

14 Throttle position sensor (2nd channel) system 13A-17

21 Engine coolant temperature sensor system 13A-18

22 Crank angle sensor system 13A-19

23 Camshaft position sensor system 13A-20

24 Vehicle speed sensor system 13A-21

25 Barometric pressure sensor system 13A-22

31 Detonation sensor system 13A-23

41 Injector system 13A-24

44 Abnormal combustion 13A-26

54 Immobilizer system 13A-27

56 Abnormal fuel pressure system 13A-28

59 Oxygen sensor (rear) system 13A-30

61 Communication line with A/T-ECU system 13A-31

64 Alternator FR terminal system 13A-31

66 Brake vacuum sensor system 13A-32

77 Accelerator pedal position sensor (2nd channel) system 13A-33

78 Accelerator pedal position sensor (1st channel) system 13A-34

79 Throttle position sensor (1st channel) system 13A-35

89 Abnormality in fuel pressure system 13A-36

91 Electronic-controlled throttle valve system 13A-36

92 Throttle valve position feedback system 13A-37

94 Communication line system with throttle valve controller 13A-37

95 Malfunction in throttle valve control servo motor system (1st phase) 13A-38

99 Malfunction in throttle valve control servo motor system (2nd phase) 13A-38

NOTE

Code No. 56 may be also output when air is sucked in high-pressure fuel line due to no fuel supply.

13A-14

GDI <4G6> -

Troubleshooting

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

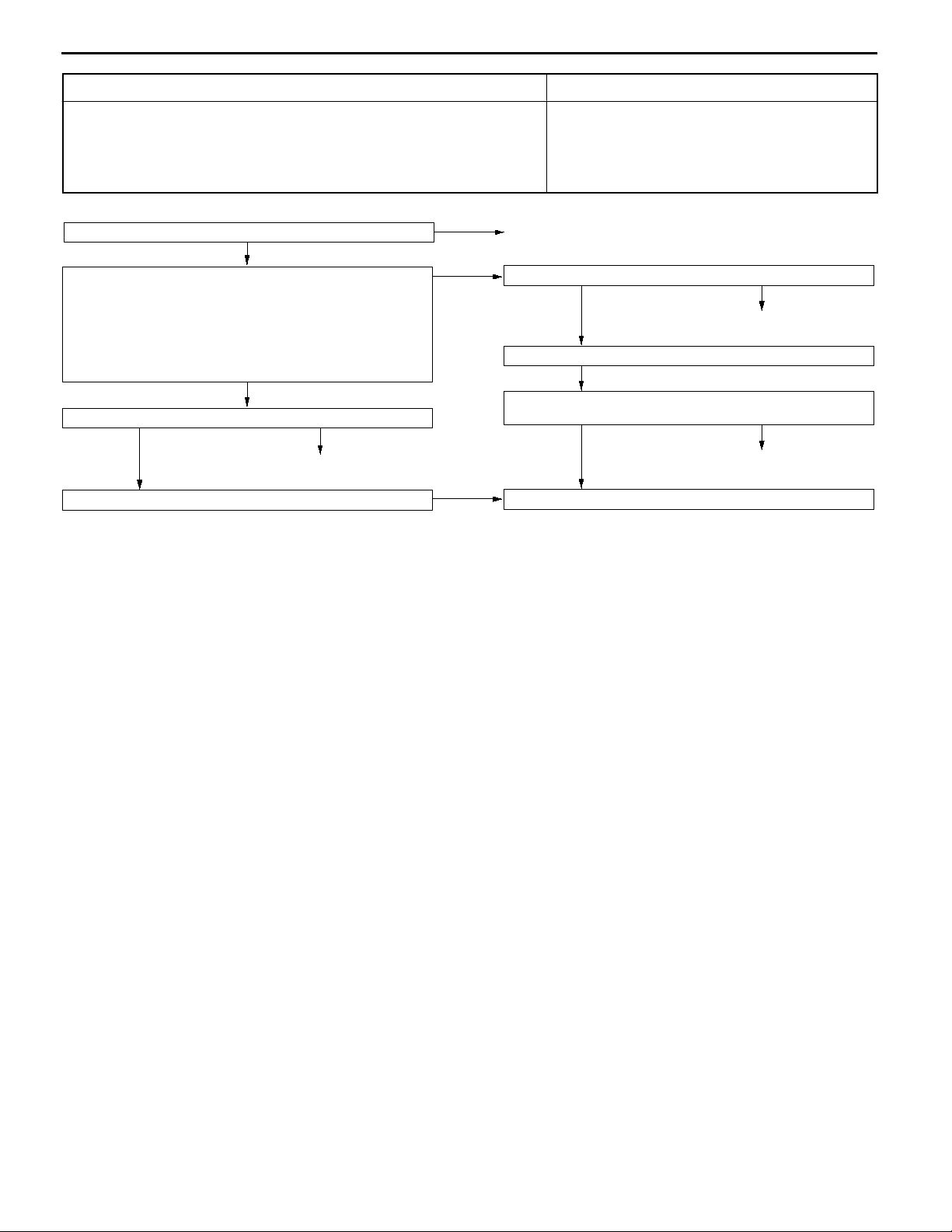

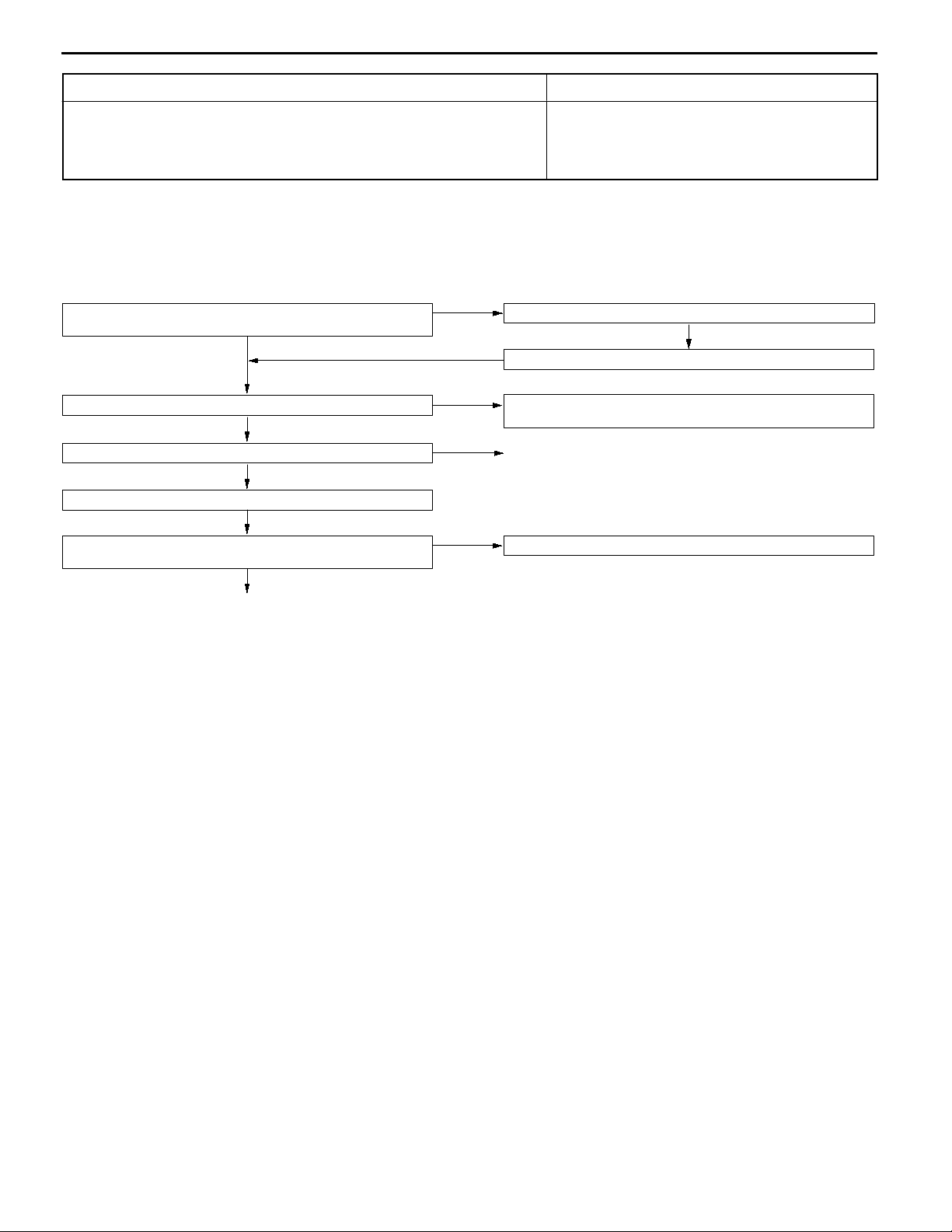

Code No. 11 Oxygen sensor (front) system Probable cause

Range of check

D 3 minutes have passed after engine was started.

D Engine coolant temperature is approx. 80_C or more.

D Intake air temperature is 20- 50_C.

D Engine speed is approx. 2,000 - 3,000 r/min

D Vehicle is moving at constant speed on a flat, level road surface

Set conditions

D The oxygen sensor output voltage is around 0.6 V for 30 seconds (does not cross

0.6 V for 30 seconds).

D When the range of check operations given above which accompany starting of

the engine are carried out four time in succession, a problem is detected after

each operation.

D Malfunction of the oxygen sensor (front)

D Improper connector contact, open circuit or

short-circuited harness wire

D Malfunction of the engine-ECU

Check the oxygen sensor (front). (Refer to P.13A-109.)

OK

Measure at the oxygen sensor (front) connector B-17.

D Disconnect the connector, and measure at the

harness side.

(1) Voltage between 2 and earth (Ignition switch: ON)

OK:

(2) Continuity between 4 and earth

Measure at the engine-ECU connector B-54.

D Disconnect the connector, and measure at the

D Voltage between 6 and earth (Ignition switch: ON)

Check the following connector:

Check trouble symptom.

Check the harness wire between the engine-ECU and

the oxygen sensor (front) connector.

Replace the engine-ECU.

System voltage

OK:

Continuity

harness side.

OK:

System voltage

OK

OK

B-54

OK

NG

OK

NG

(1) NG

(2) NG

NG

NG

NG

Replace

Repair

Repair

Check the harness wire between the oxygen sensor (front) and the engine control

relay connector, and repair if necessary.

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and the oxygen sensor connector.

OK

Replace the engine-ECU.

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and the oxygen sensor (front)

connector, and repair if necessary.

B-54

B-17

NG

NG

NG

Repair

Repair

Repair

GDI <4G6> -

Troubleshooting

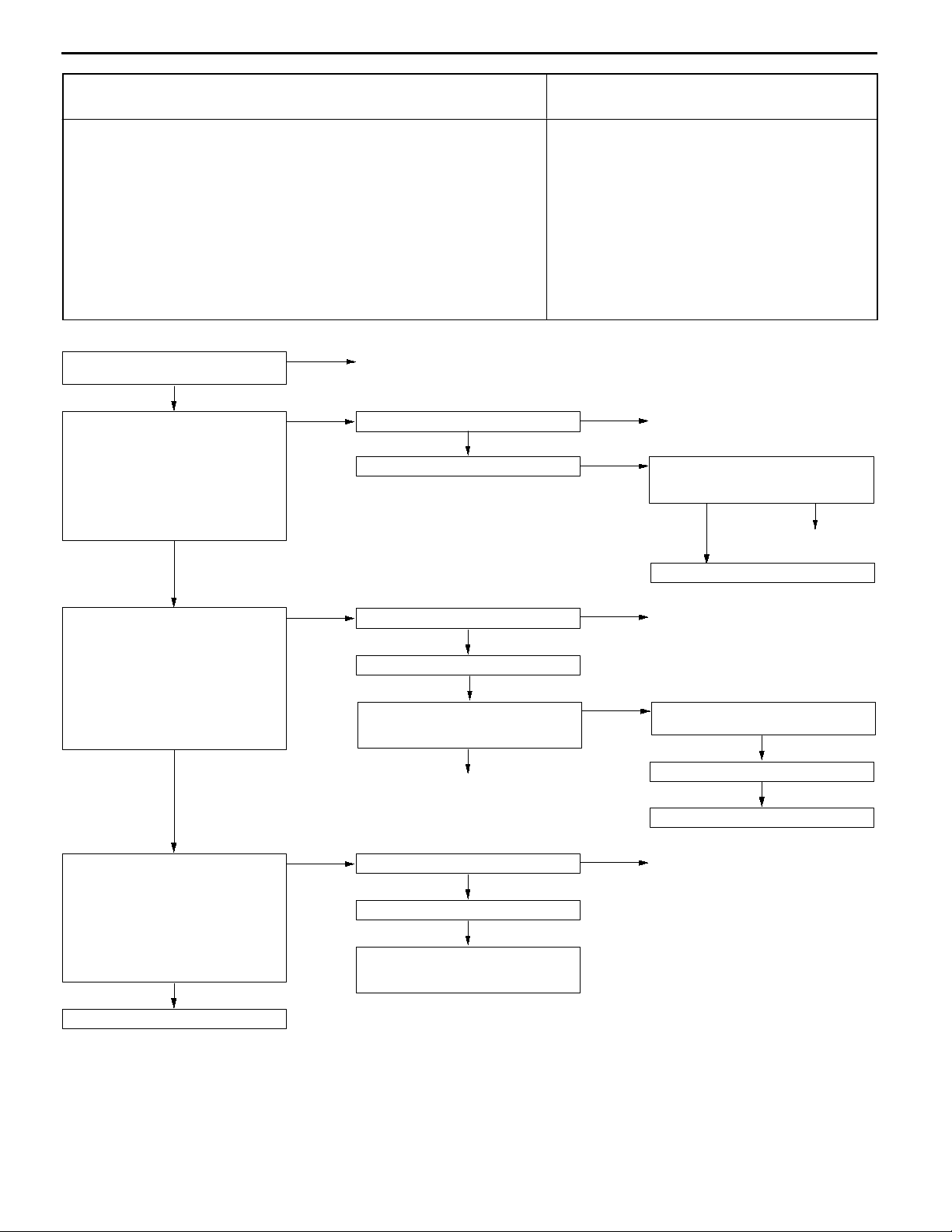

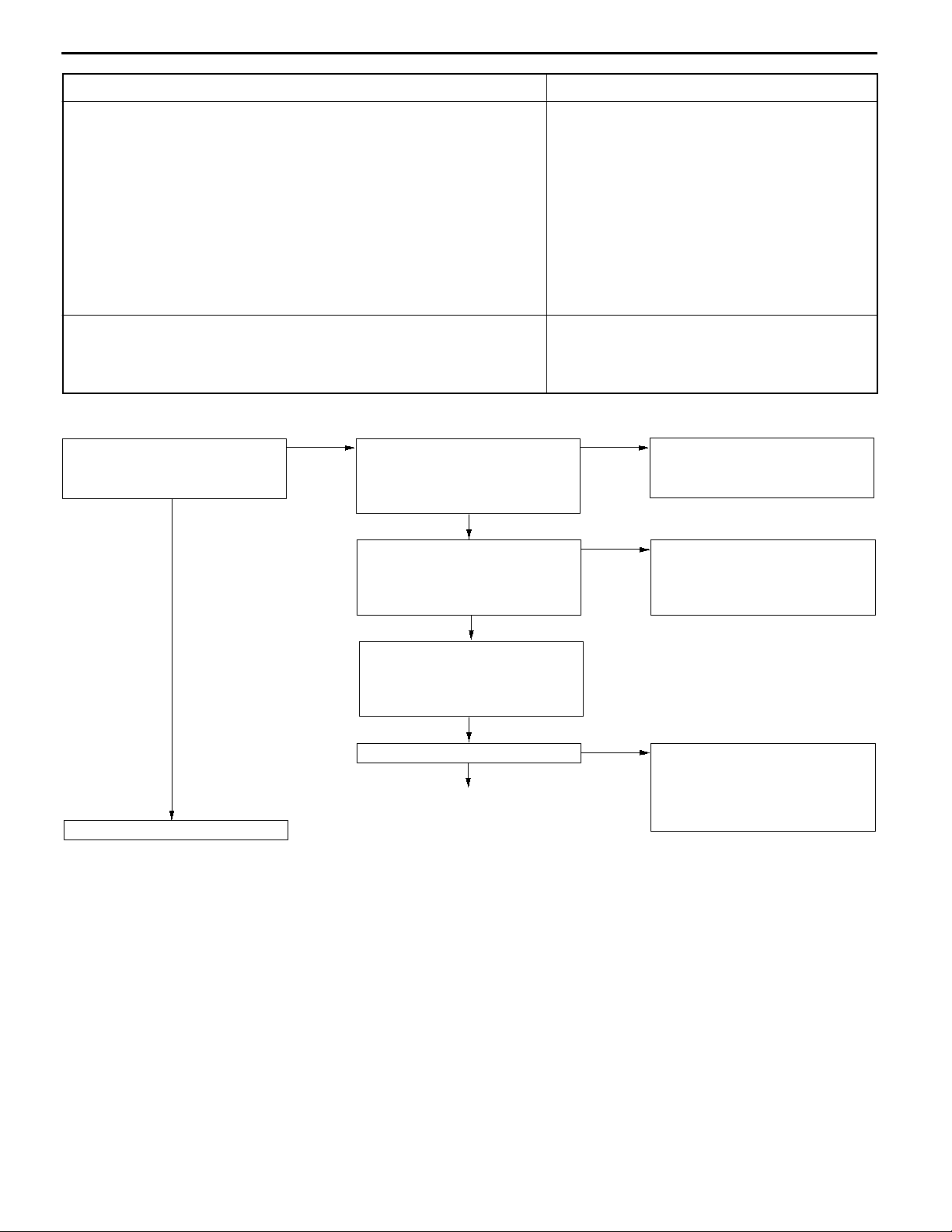

Code No.12 Air flow sensor system Probable cause

Range of check

D Engine speed is 500 r/min or more.

Set conditions

D Sensor output frequency is 3.3 Hz or less for 4 seconds.

D Malfunction of the air flow sensor

D Open circuit or short-circuited harness wire of air

flow sensor circuit

D Malfunction of the engine-ECU

13A-15

Measure at the air flow sensor connector

A-07.

D Connect the connector

(Use the test harness MB991709)

(1) Voltage between 3 and earth

(Engine: Idling)

OK:

(2) Voltage between 7 and earth

Replace the engine-ECU.

2.2 - 3.2 V

OK:

0 - 0.1 V

(Engine: Idling)

OK:

6-9V

(Engine speed: 4,000 r/min)

OK

(1) NG

(2) NG

NG

Measure at the air flow sensor connector

A-07.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between 4 and earth

(Ignition switch: ON)

OK:

(2) Voltage between 3 and earth

(3) Continuity between 5 and earth

Check the following connector:

A-07

Check trouble symptom.

Replace the air flow sensor.

Measure at the engine-ECU connector

B-54.

D Connect the connector

D Voltage between 19 and earth

Check the following connector:

B-54

Check trouble symptom.

System voltage

(Ignition switch: ON)

OK:

4.8 - 5.2 V

OK:

Continuity

OK

OK

NG

(Ignition switch: ON)

OK:

6-9V

OK

OK

NG

Repair

NG

Repair

(1) NG

(2), (3) NG

NG

Check the harness wire between the

air flow sensor and the engine control

relay, and repair if necessary.

Check the following connectors:

B-51, B-52

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the air flow sensor,

and repair if necessary.

OK

Replace the engine-ECU.

Check the following connector:

A-07

OK

Check trouble symptom.

NG

Replace the air flow sensor.

NG

Repair

NG

Repair

NG

Repair

13A-16

GDI <4G6> -

Troubleshooting

Code No.13 Intake air temperature sensor system Probable cause

Range of check

D After 60 seconds have passed since the engine have started

Set conditions

D Sensor resistance is 0.14 kW or less for 4 seconds.

or

D Sensor resistance is 50 kW or more for 4 seconds.

D Malfunction of the intake air temperature sensor

D Open circuit or short-circuited harness wire of the

intake air temperature sensor circuit

D Malfunction of the engine-ECU

Check the intake air temperature sensor. (Refer to P.13A-106.)

OK

Measure at the air flow sensor connector A-07.

D Disconnect the connector, and measure at the harness

side.

D Voltage between 6 and earth

(Ignition switch: ON)

OK:

OK:

4.8 - 5.2 V

Continuity

OK

OK

A-07

NG

Repair

D Continuity between 5 and earth

Check the following connector:

Check trouble symptom.

NG

NG

NG

Replace

Check the following connectors:

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and the intake

air temperature sensor.

OK

Replace the engine-ECU.

B-51, B-52

NG

Repair

NG

Repair

GDI <4G6> -

Troubleshooting

13A-17

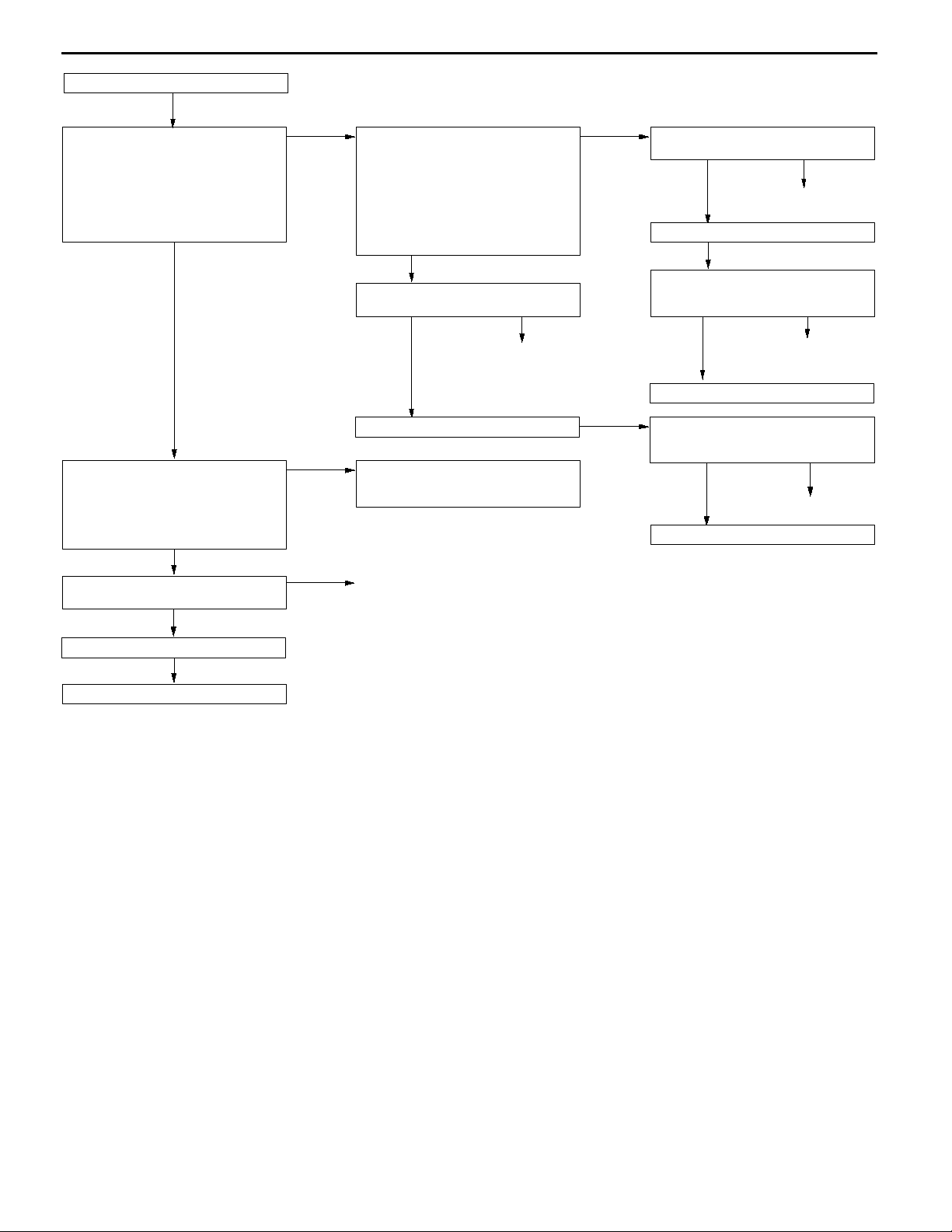

Code No.14 Throttle position sensor system (2nd

channel)

The throttle valve controller determines whether a failure is present or not, and sends

a signal indicating its result to the engine-ECU.

Range of check

D Ignition switch: ON

D Throttle position sensor (1st channel) is normal

Set conditions

D The throttle position sensor (1st channel) output voltage is 1.24 V or more, and

the (2nd channel) output voltage is 4.6 V or more for one second.

or

D The throttle position sensor (1st channel) output voltage is 3.53 V or less, and

the (2nd channel) output voltage is 0.2 V or less for one second.

or

D Throttle position sensor (1st and 2nd channels) output voltages are outside 4

to 6 V.

Check the throttle position sensor. (Refer to P.13A-107.)

OK

Measure at throttle position sensor connector A-73.

D Disconnect the connector, and

measure at the harness side.

D Voltage 1 and earth

(Ignition switch: ON)

OK:

OK:

4.8 - 5.2 V

Continuity

OK

D Continuity between 3 and earth

NG

NG

Replace

Check the following connector:

OK

Check trouble symptom.

Probable cause

D Malfunction of throttle position sensor (2nd channel)

D Open circuit or short-circuited harness wire in throttle

position sensor (2nd channel) or poor connector

contact

D Faulty throttle valve controller

D Malfunction of the engine-ECU

B-50

NG

NG

Repair

Check the harness wire between the

throttle position sensor and throttle valve

controller.

OK

Replace the throttle valve controller.

NG

Repair

Measure at engine-ECU connector

B-51.

D Connect the connector.

D Disconnect the throttle control servo

connector (Close the throttle valve

fully by finger).

D Voltage between terminal 84 and

earth

(Ignition switch: ON)

OK:

4.2 - 4.8 V

OK

Measure at throttle valve controller connector B-50.

D Connect the connector.

D Disconnect the throttle control servo

connector (Close the throttle valve

fully by finger).

D Voltage between 7 and earth

(Ignition switch: ON)

OK:

0.4 - 0.6 V

OK

Replace the throttle valve controller.

NG

NG

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and throttle position sensor.

NG

Repair

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the

throttle valve controller and throttle position sensor, and repair if necessary.

A-73

A-73

NG

OK

NG

Repair

Adjust the throttle position sensor. (Refer

to P.13A-97.)

Check trouble symptom.

NG

Replace the engine-ECU.

Repair

13A-18

GDI <4G6> -

Troubleshooting

Code No.21 Engine coolant temperature sensor system Probable cause

Range of check

D After 60 seconds have passed since the engine have started

Set conditions

D Sensor resistance is 50 W or less for 4 seconds.

or

D Sensor resistance is 72 kW or more for 4 seconds.

Range of check

D After engine starts

Set conditions

D After 5 minutes or more have passed since the engine coolant temperature

after filtering has dropped from 40_C or more to less than this temperature

D Malfunction of the engine coolant temperature

sensor

D Open circuit or short-circuited harness wire of the

engine coolant temperature sensor circuit

D Malfunction of the engine-ECU

Check the engine coolant temperature sensor.(Refer to P.13A-106.)

OK

Measure at the engine coolant temperature sensor connector A-80.

D Disconnect the connector, and measure st the harness

side.

D Voltage between 1 and earth

(Ignition switch: ON)

OK:

OK:

4.8 - 5.2 V

Continuity

OK

OK

A-80

NG

Repair

D Continuity between 2 and earth

Check the following connector:

Check trouble symptom.

NG

NG

NG

Replace

Check the following connectors:

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and the engine

coolant temperature sensor.

OK

Replace the engine-ECU.

B-51, B-52

NG

Repair

NG

Repair

GDI <4G6> -

Troubleshooting

Code No.22 Crank angle sensor system Probable cause

Range of check

D Engine: During cranking

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal is

being input).

D Malfunction of the crank angle sensor

D Open circuit or short-circuited harness wire of the

crank angle sensor circuit

D Malfunction of the engine-ECU

13A-19

Measure at the crank angle sensor connector A-71.

D Connect the connector

(Use the test harness

MD998478)

D V oltage between 2 (black clip)

and earth

(Engine: Cranking)

OK:

D V oltage between 2 (black clip)

Replace the engine-ECU.

0 - 4.0 V

and earth

(Engine: Idling)

OK:

1.5 - 2.5 V

OK

NG

Measure at the crank angle sensor connector A-71.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

(2) Voltage between 2 and earth

(3) Continuity between 1 and earth

Check the following connector:

A-71

Check trouble symptom.

Replace the crank angle sensor.

System voltage

(Ignition switch: ON)

OK:

4.8 - 5.2 V

OK:

Continuity

OK

OK

NG

NG

Repair

(1) NG

(2) NG

(3) NG

Check the harness wire between the

crank angle sensor and the engine control relay, and repair if necessary.

Check the following connector:

B-51

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the crank angle sensor.

OK

Replace the engine-ECU.

Check the harness wire between the

crank angle sensor and the earth, and

repair if necessary.

NG

Repair

NG

Repair

13A-20

GDI <4G6> -

Troubleshooting

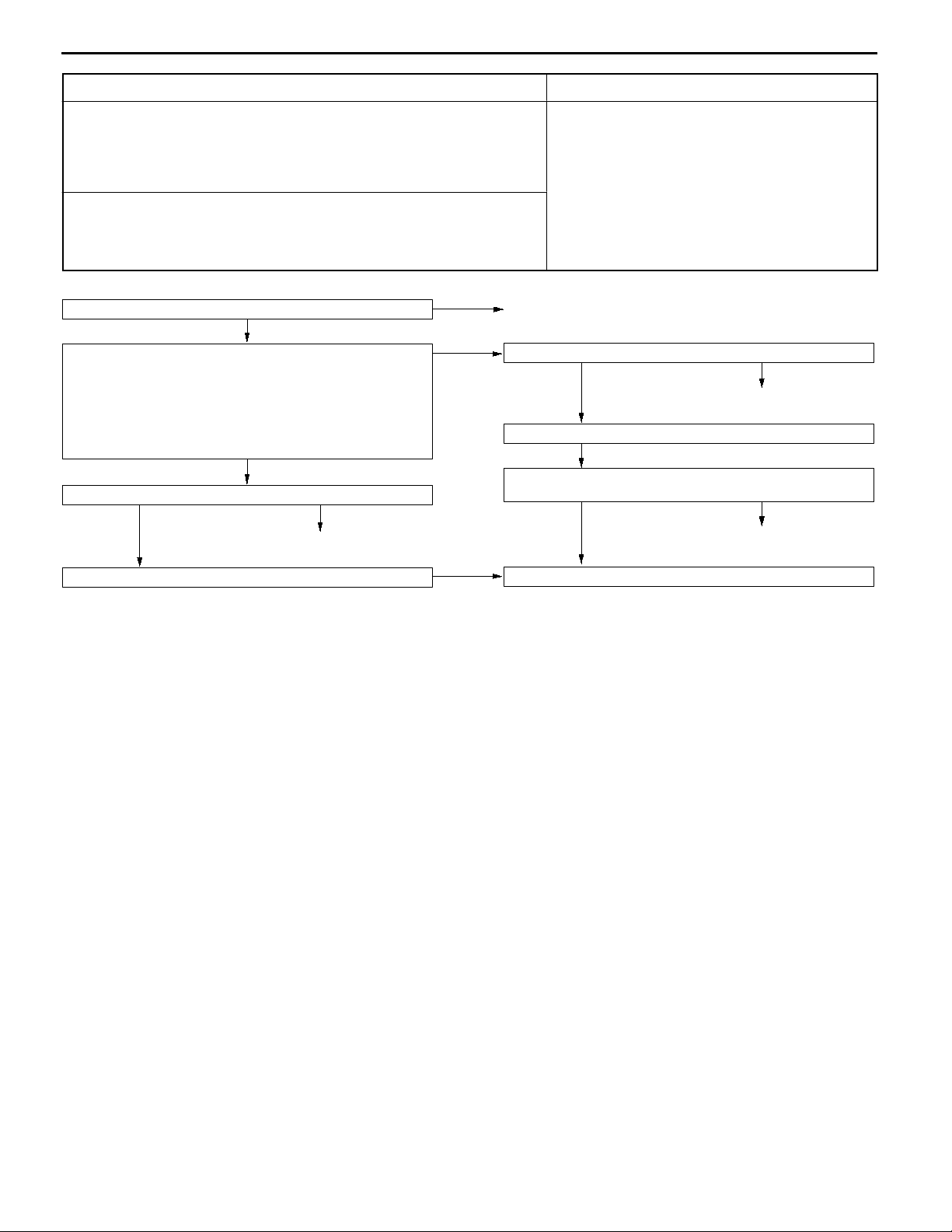

Code No.23 Camshaft position sensor system Probable cause

Range of check

D While engine is cranking or running

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal is

being input).

or

D Abnormal pulse signal pattern is output.

D Malfunction of the camshaft position sensor

D Open circuit or short-circuited harness wire of the

camshaft position sensor

D Malfunction of the engine-ECU

Measure at the camshaft position sensor connector A-78.

D Connect the connector (Use the

test harness MB991709)

D Voltage between 2 and earth

(Engine: Cranking)

OK:

D Voltage between 2 and earth

Replace the engine-ECU.

0 - 4.0 V

(Engine: Idling)

OK:

0.5 - 2.0 V

OK

NG

Measure at the camshaft position sensor connector A-78.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

(2) Voltage between 2 and earth

(3) Continuity between 1 and earth

Check the following connector:

A-78

Check trouble symptom.

Replace the camshaft position sensor.

System voltage

(Ignition switch: ON)

OK:

4.8 - 5.2 V

OK:

Continuity

OK

OK

NG

NG

Repair

(1) NG

(2) NG

(3) NG

Check the harness wire between the

camshaft position sensor and the engine

control relay, and repair if necessary.

Check the following connector:

B-51

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the camshaft position

sensor.

OK

Replace the engine-ECU.

Check the harness wire between the

camshaft position sensor and the earth,

and repair if necessary.

NG

Repair

NG

Repair

GDI <4G6> -

Troubleshooting

Code No. 24 Vehicles speed sensor system Probable cause

Range of check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

D Engine speed is 3,000 r/min or more.

D Driving under high engine load conditions.

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal input).

D Malfunction of the vehicle speed sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the vehicle speed

sensor circuit

D Malfunction of the engine-ECU

13A-21

Does the speedometer operate normally?

Yes

Measure at engine-ECU connector B-51.

D Connect the connector.

D Voltage between terminal 86 and earth

(Ignition switch: ON)

OK:

If the vehicle is moved forward without starting the engine,

0 V and system voltage alternates.

NG

Check the following connectors:

OK

Check trouble symptom.

Check the harness wire between the vehicle speed sensor and

engine-ECU.

A-81, A-85, A-86

NG

Repair

NG

No

OK

Check the vehicle speed sensor circuit. (Refer to GROUP 54 Combination Meter.)

Check the following connector:

OK

Check trouble symptom.

Replace the engine-ECU.

B-51

NG

Repair

NG

13A-22

GDI <4G6> -

Troubleshooting

Code No.25 Barometric pressure sensor system Probable cause

Range of check

D After 60 seconds have passed since the engine have started

D Battery voltage is 8 V or more.

Set conditions

D Sensor output voltage is 0.2 V or less for 4 seconds.

or

D Sensor output voltage is 4.5 V or more for 4 seconds.

D Malfunction of the barometric pressure sensor

D Open circuit or short-circuited harness wire of the

barometric pressure sensor

D Malfunction of the engine-ECU

Measure at the air flow sensor connector

A-07.

D Connect the connector. (Use test

harness MB991709)

D Voltage between 2 and earth

(Ignition switch: ON)

OK:

3.9 - 4.1 V

(at altitude of 0 m)

3.3 - 3.6 V

(at altitude of 1,200 m)

OK

Measure at the engine-ECU connector

B-51.

D Connect the connector.

D Voltage between 85 and earth

(Ignition switch: ON)

OK:

3.9 - 4.1 V

(at altitude of 0 m)

3.3 - 3.6 V

(at altitude of 1,200 m)

OK

Check the following connector:

B-51

NG

Repair

NG

NG

OK

Measure at the air flow sensor connector

A-07.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between 1 and earth

(Ignition switch: ON)

OK:

OK:

4.8 - 5.2 V

Continuity

OK

OK

NG

Repair

OK

(2) Continuity between 5 and earth

Check the following connector:

A-07

Check trouble symptom.

Check the harness wire between the

engine-ECU and the barometric pressure sensor, and repair if necessary.

Check trouble symptom.

NG

NG

NG

Check the following connector:

B-51

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the barometric pressure sensor.

OK

Replace the engine-ECU.

Check the harness wire between the

engine-ECU and the barometric pressure sensor.

OK

Replace the air flow sensor.

Replace the engine-ECU.

NG

Repair

NG

Repair

NG

Repair

GDI <4G6> -

Troubleshooting

Code No.31 Detonation sensor system Probable cause

Range of check

D After 60 seconds have passed since the engine have started

Set conditions

D Amount of change in the sensor output voltage (detonation sensor peak

voltage for each half rotation of the crankshaft) is 0.06 V or less for 200

continuous times.

D Malfunction of the detonation sensor

D Open circuit or short-circuited harness wire of the

detonation sensor

D Malfunction of the engine-ECU

13A-23

Measure at the detonation sensor connector A-79.

D Disconnect the connector, and

measure at the harness side.

D Continuity between 2 and earth

OK:

Continuity

NG

Check the harness wire between the

detonation sensor and the earth, and

repair if necessary.

OK

Check the following connector:

B-51

OK

Check trouble symptom.

NG

NG

Repair

Check the harness wire between the

engine-ECU and the detonation sensor.

OK

Replace the detonation sensor.

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Repair

13A-24

GDI <4G6> -

Troubleshooting

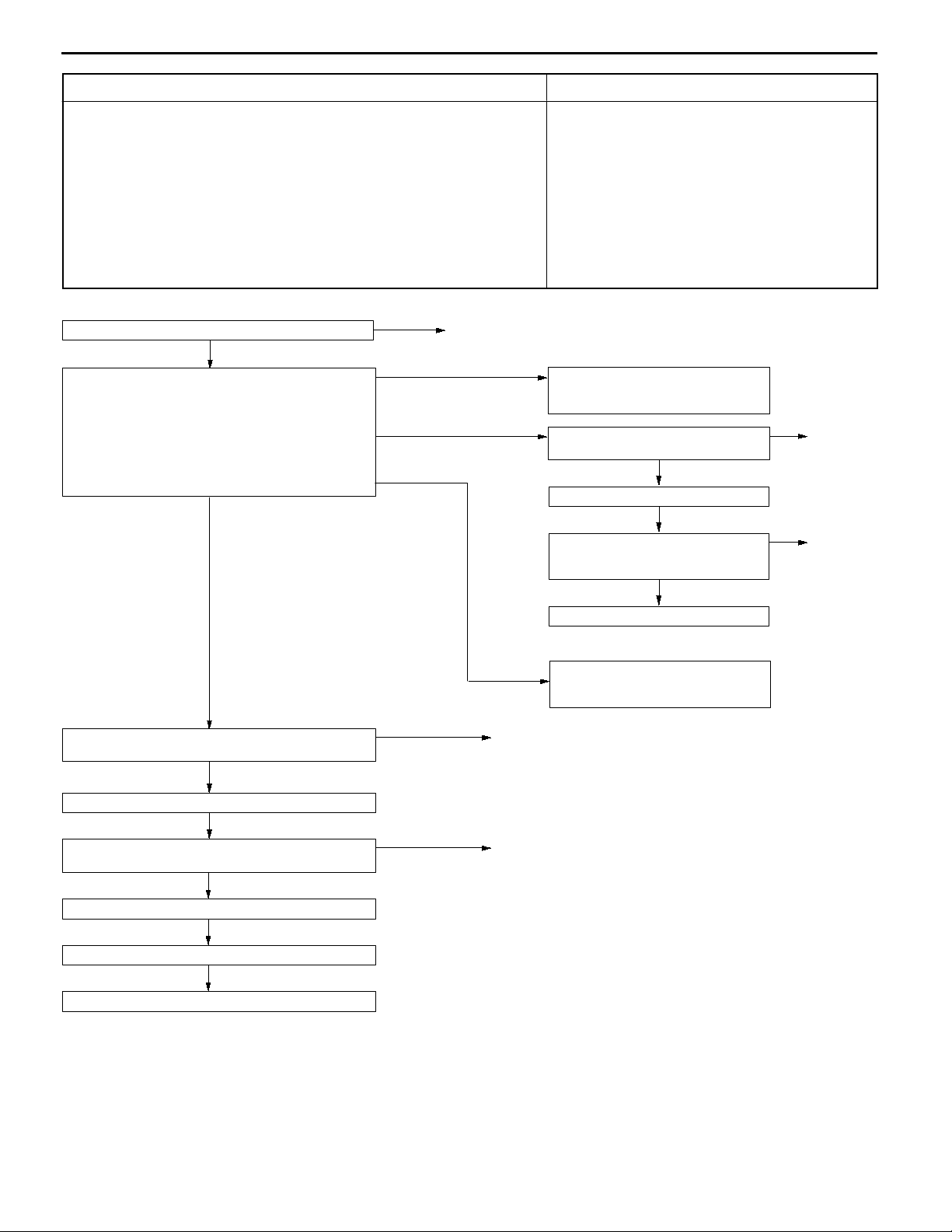

Code No.41 Injector system Probable cause

Range of check

D Engine: while cranking, or running

D Engine speed: 4,000 r/min or less

D System voltage: 10 V or more

D Fuel shut off, or while forcible activating of injector (actuator test) is in operation.

Set conditions

D Injector open circuit check signal is not output from the injector predetermined

time(s).

D Malfunction of the injector

D Faulty injector driver relay

D Faulty injector driver

D Open circuit or short-circuited harness wire in the

injector drive circuit, or poor connector contact

D Malfunction of the engine-ECU

Check the injector. (Refer to P.13A-111.)

OK

Measure at injector driver relay connector A-13X.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between terminal 4 and

earth

(Ignition switch: ON)

OK:

(2) Voltage between terminal 3 and

Measure at engine-ECU connector

B-54.

D Disconnect the connector, and

D Voltage between terminal 20 and

Measure at injector driver connector

A-08.

D Disconnect the connector, and

(1) Voltage between 12, 21 and earth

(2) Voltage between 13, 22 and earth

(3) Resistance between terminals 14

To the next page

System voltage

earth

OK:

System voltage

OK

measure at the harness side.

earth (Ignition switch: ON)

OK:

System voltage

OK

measure at the harness side.

(Ignition switch: ON)

OK:

System voltage

OK:

System voltage

and 23

Resistance between terminals 15

and 24

Resistance between terminals 16

and 25

Resistance between terminals 17

and 26

OK:

0.9 - 1.1 W

OK

NG

(1) NG

(2) NG

NG

(1) NG

(2) NG

(3) NG

Replace

Check the following connectors:

B-28, B-89, B-103

NG

Repair

Check the following connector:

A-28

NG

Repair

Check the following connector:

A-13X

NG

Repair

Check the following connector:

A-13X

NG

Repair

Check the harness wire between the

injector driver and earth, and repair if

necessary.

Check the following connectors:

A-02, A-03, A-04, A-05, A-06

NG

Repair

OK

OK

OK

OK

OK

Check trouble symptom.

NG

Check the harness wire between the

injector driver relay and ignition switch,

and repair if necessary.

Check trouble symptom.

NG

Check the harness wire between the

injector driver relay and battery, and repair if necessary.

Check trouble symptom.

NG

Check the harness wire between the

injector driver relay and engine-ECU,

and repair if necessary.

Check trouble symptom.

NG

Check the harness wire between the

injector driver and injector driver relay,

and repair if necessary.

Check trouble symptom.

NG

Check the harness wire between the

injector driver and injector, and repair

if necessary.

From the previous page

OK

Measure at engine-ECU connector

B-52.

D Connect the connector.

D Voltage between terminal 51 and

earth (Ignition switch: ON)

OK:

D Voltage between terminal 1 and

Check the following connector:

4.0 - 5.2 V

earth

Voltage between terminal 2 and

earth

Voltage between terminal 14 and

earth

Voltage between terminal 15 and

earth

(Ignition switch: ON)

OK:

8-11V

NG

A-08

NG

Repair

GDI <4G6> -

OK

OK

Check the following connectors:

B-52, B-54

Check trouble symptom.

Replace the injector driver.

Check trouble symptom.

Check trouble symptom.

Troubleshooting

NG

OK

NG

NG

NG

13A-25

Repair

Replace the engine-ECU.

Check the harness wire between the

injector driver and engine-ECU, and repair if necessary.

13A-26

GDI <4G6> -

Troubleshooting

Code No.44 Abnormal combustion Probable cause

Range of check

D While engine is running during lean fuel combustion

Set conditions

D Abnormal engine speed due to mis-firing is detected by the crank angle

sensor

D Malfunction of the ignition coil

D Malfunction of the spark plug

D Malfunction of the EGR valve

D Open circuit or short-circuit in ignition primary

circuit

D Malfunction of the injector system

D Malfunction of the engine-ECU

Check the ignition coil (Refer to GROUP 16 - Ignition System).

OK

Measure at the ignition coil connectors A-74, A-94, A-97, A-98.

D Disconnect the connector, and measure at the harness

side.

(1) Voltage between 1 and earth (Ignition switch: ON)

OK:

(2) Voltage between 3 and earth (Engine: Cranking)

(3) Continuity between 2 and earth

Check the following connectors:

A-74, A-94, A-97, A-98

Check trouble symptom.

Check the following items in the order given.

D Spark plugs

D Compression pressure

Check the injector system (Refer to P.13A-24, INSPECTION PROCEDURE FOR DIAGNOSIS CODE No.41)

Check for air leaking into the air intake system.

D Damaged intake manifold gasket

D Damaged vacuum hose

D Damaged air intake hose

D Check the EGR valve.

System voltage

OK:

0.5 - 4.0 V

OK:

Continuity

OK

OK

NG

Repair

NG

OK

OK

NG

(1) NG

(2) NG

(3) NG

Replace

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the ignition coil and the ignition

switch, and repair if necessary.

Check the following connector:

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and the ignition

coil.

OK

Replace the engine-ECU.

Check the harness wire between the ignition coil and the

earth, and repair if necessary.

B-28, B-89, B-103

NG

Repair

B-54

NG

Repair

NG

Repair

GDI <4G6> -

Troubleshooting

13A-27

Code No.54 Immobilizer system Probable cause

Range of Check

D Ignition switch: ON

Set Conditions

D Improper communication between the engine-ECU and immobilizer-ECU

D Radio interference of encrypted codes

D Incorrect encrypted code

D Malfunction of harness or connector

D Malfunction of immobilizer-ECU

D Malfunction of engine-ECU

NOTE

(1) If the ignition switches are close each other when starting the engine, radio interference may cause

this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

Is there another ignition key near the ignition key that is inserted

in the ignition switch?

No

Is a diagnosis code output from the immobilizer-ECU?

No

Check the following connector:

Check trouble symptom.

Check the harness wire between the engine-ECU and the immobilizer-ECU.

B-51

OK

NG

NG

Repair

Yes

Yes

NG

OK

Remove the extra ignition key.

NG

Check trouble symptom.

Check the immobilizer system. (Refer to GROUP 54 - Ignition

Switch and Immobilizer System.)

Repair

Replace the engine-ECU and immobilizer-ECU.

13A-28

GDI <4G6> -

Troubleshooting

Code No.56 Abnormal fuel pressure Probable cause

Range of check

D Ignition switch: ON

Set conditions

D Sensor output voltage is 4.8 V or more for four seconds.

or

D Sensor output voltage is 0.2 V or less for four seconds.

Range of check

D After the engine is started, the following condition has been detected:

(1) Engine speed: 1,000 r/min or more

(2) Fuel pressure: 2 MPa or more

D While engine is running

Set conditions

D Fuel pressure is 6.9 MPa or more for four seconds.

or

D Fuel pressure is 2 MPa or less for four seconds.

This diagnosis code is also output when air is sucked in high-pressure fuel line

due to no fuel supply.

In this case, air can be bled by letting the engine run at 2,000 r/min for at least

fifteen seconds. After the air bleeding, the diagnosis code must be erased by the

MUT-II.

D Malfunction of the fuel pressure sensor

D Open circuit or short-circuited harness wire of the

fuel pressure sensor

D Malfunction of the engine-ECU

D Malfunction of the fuel pump (high pressure)

D Malfunction of the fuel pressure regulator (high

pressure)

D Clogged high-pressure fuel line

D Air sucking due to no fuel supply

MUT-IIData list

74 Fuel pressure sensor

D Ignition switch: ON

OK:

0 - 8 MPa

NG

To the next page

OK

MUT-IIData list

74 Fuel pressure sensor

D Maintain the engine speed at 2,000

r/min for at least fifteen seconds.

OK:

6.9 MPa or less

OK

MUT-IIData list

74 Fuel pressure sensor

D Engine: Idle running for at least three

minutes

OK:

4 MPa or more

OK

Erase diagnosis code No.56. (This diagnosis code has been output due to air

sucking into high-pressure fuel line. But

that problem has been resolved by revving the engine at 2,000 r/min.)

Check trouble symptom.

OK

Normal

NG

NG

NG

D Replace the high-pressure fuel

regulator (seized regulator).

D Replace the high-pressure return

pipe (seized pipe).

D Replace the fuel pump (high

pressure) (poor pump discharge

pressure)

D Replace the high-pressure regulator

(fuel leakage at the return side).

Check if input voltage from the fuel

pressure sensor to engine-ECU

changes suddenly by performing an

intermittent malfunction simulation test.

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

From the previos page

GDI <4G6> -

Troubleshooting

13A-29

Measure at the fuel pressure sensor

connector A-77.

D Connect the connector. (Use test

harness MB991348)

D Voltage between 2 and earth

OK:

3 V or less

(Engine: Cranking)

0.3 - 4.7 V (Engine: Idling)

OK

Measure at the engine-ECU connector

B-51.

D Connect the connector.

D Voltage between 74 and earth

(Engine: idling)

OK:

0.3 - 4.7 V

OK

Check the following connectors:

A-77, B-51

OK

NG

NG

NG

Measure at the fuel pressure sensor

connector A-77.

D Disconnect the connector, and

measure at the harness side.

D Voltage between 1 and earth

(Ignition switch: ON)

OK:

OK:

4.8 - 5.2 V

Continuity

OK

OK

NG

Repair

D Continuity between 3 and earth

Check the following connectors:

A-77, B-51

Check trouble symptom.

Check the harness wire between the

engine-ECU and the fuel pressure sensor, and repair if necessary.

Repair

NG

NG

Check the following connector:

B-51

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the fuel pressure sensor.

OK

Replace the engine-ECU.

Check the harness wire between the

engine-ECU and the fuel pressure sensor.

OK

Replace the fuel pressure sensor.

NG

Repair

NG

Repair

NG

Repair

Check trouble symptom.

NG

Replace the engine-ECU.

13A-30

GDI <4G6> -

Troubleshooting

Code No. 59 Oxygen sensor (rear) system Probable cause

Range of Check

D 3 minutes have passed after engine was started.

D Engine coolant temperature is approx. 80_C or more.

D Idle position switch: OFF

D The throttle position sensor output voltage is 4.1 V or more.

D Open loop control in operation

D 20 seconds have passed after deceleration finished.

Set conditions

D The oxygen sensor (rear) output voltage is 0.1 V or less.

D The difference in the maximum and minimum values for the oxygen sensor (rear)

output voltage is 0.08 V or less.

D The oxygen sensor (rear) output voltage is 0.5 V or more.

D The above conditions continue for a continuous period of 5 seconds.

D Malfunction of the oxygen sensor (rear)

D Improper connector contact, open circuit or

short-circuited harness wire

D Malfunction of the engine-ECU

Check the oxygen sensor (rear). (Refer to P.13A-109.)

OK

Measure at the oxygen sensor (rear) connector C-29.

D Disconnect the connector, and measure at the

harness side.

(1) Voltage between 3 and earth (Ignition switch: ON)

OK:

(2) Continuity between 2 and earth

(3) Continuity between 4 and earth

Check the following connectors:

B-52, C-29

System voltage

OK:

Continuity

OK:

Continuity

OK

OK

NG

(1) NG

(2) NG

(3) NG

NG

Replace

Repair

Check the harness wire between the

oxygen sensor and the control relay

connector, and repair if necessary.

Check the following connector:

B-52

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the oxygen sensor

connector.

OK

Replace the engine-ECU.

Check the harness wire between the

oxygen sensor connector and the earth,

and repair if necessary.

NG

NG

Repair

Repair

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and

the oxygen sensor connector.

OK

Replace the oxygen sensor (rear).

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Repair

Loading...

Loading...